Laser displacement sensor position error calibration method

A laser displacement and error calibration technology, applied in the field of robotics, can solve the problems of low calibration accuracy and insufficient utilization, and achieve the effect of high calibration accuracy and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

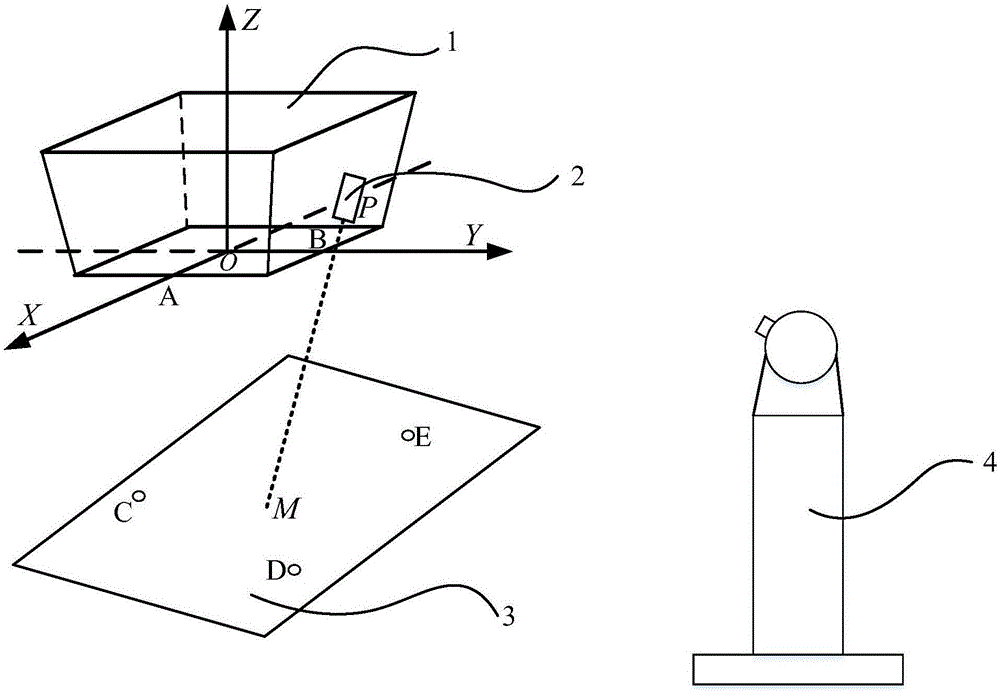

[0022] see figure 1 , The device used in the present invention consists of a mount 1, a laser displacement sensor 2, a flat plate 3 and a laser tracker 4. The laser displacement sensor 2 is installed on the mount 1 .

[0023] The steps of the method of the present invention are described in detail below.

[0024] The specific implementation steps of the inventive method are as follows:

[0025] Step 1: Set up the laser tracker 4 on the ground, so that the mounting base 1 and the panel 3 are included in the measurement range of the laser tracker 4;

[0026] Step 2: Fix the mount 1, and the laser tracker 4 measures the three reference holes A, O and B on the mount 1, and establishes the measurement coordinate system OXYZ, where the hole O is the origin, OA is the X axis, and OB is Y axis, determine the Z axis according to the right-hand rule;

[0027] Step 3: Use the laser tracker 4 to measure the three reference holes C, D and E on the plane plate 3, and then establish the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com