Patents

Literature

936 results about "Installation Error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Windows installer errors like this are caused by something negatively affecting the Windows installer when you are attempting to run the .msi file. The causes of this can range from a previous version of the RuneScape Client not uninstalling correctly to some conflicting entries in your Windows registry.

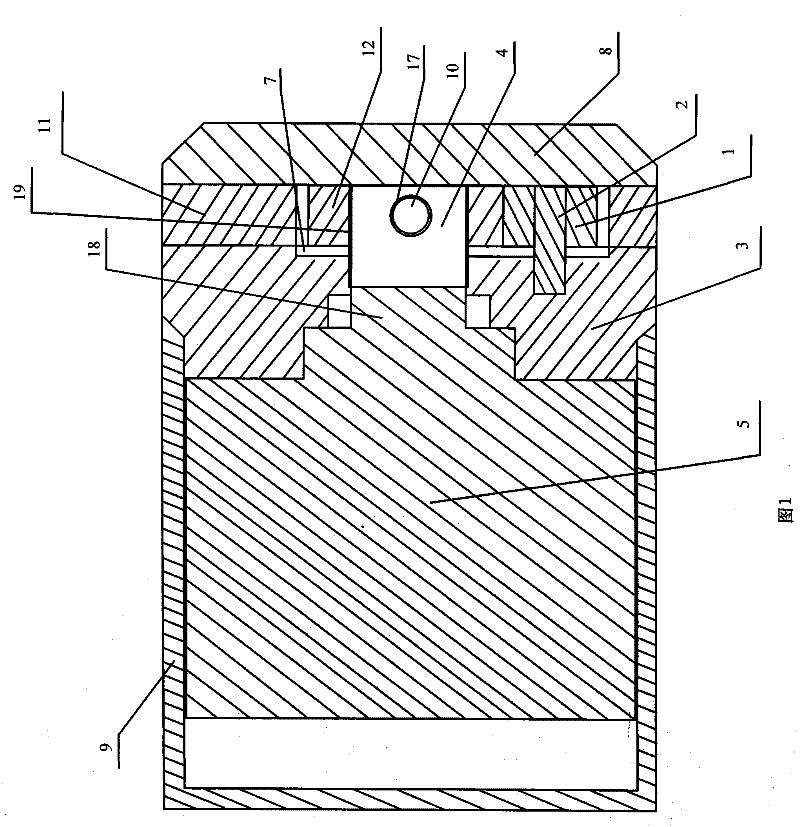

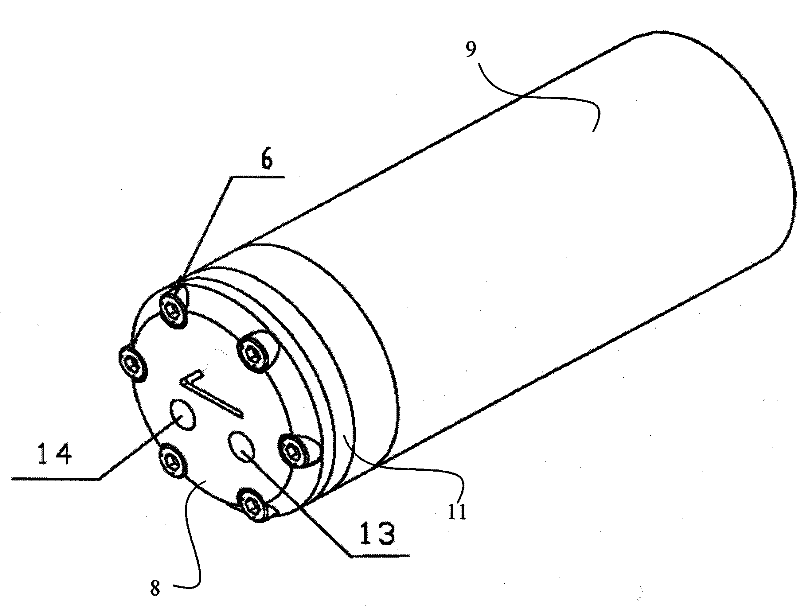

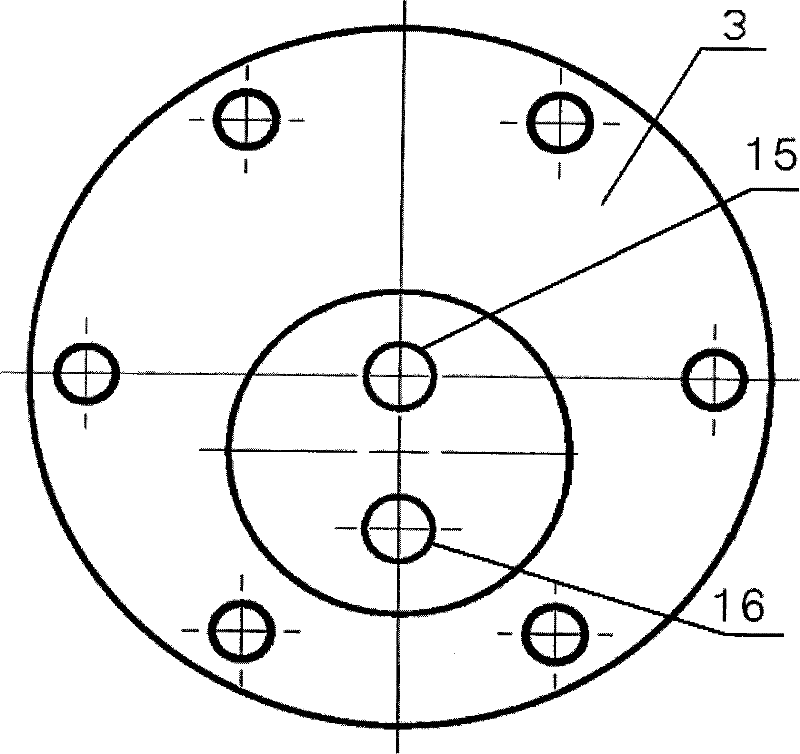

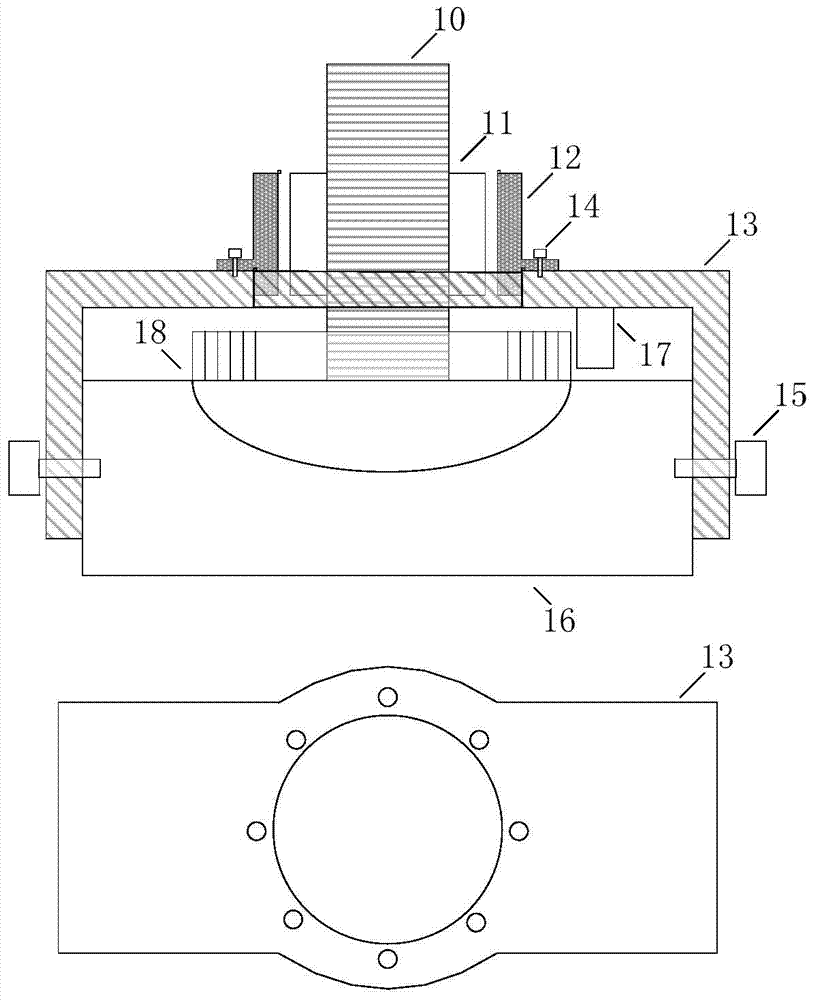

Gear pump for micro-miniature turbojet engine

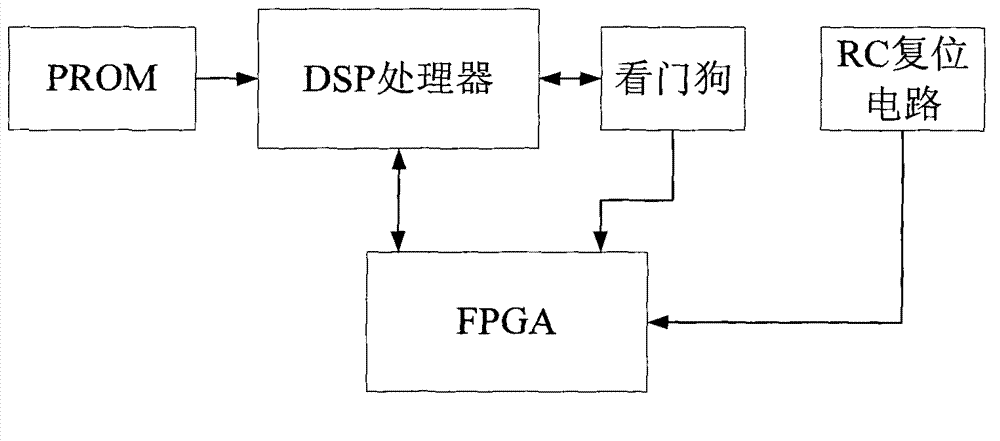

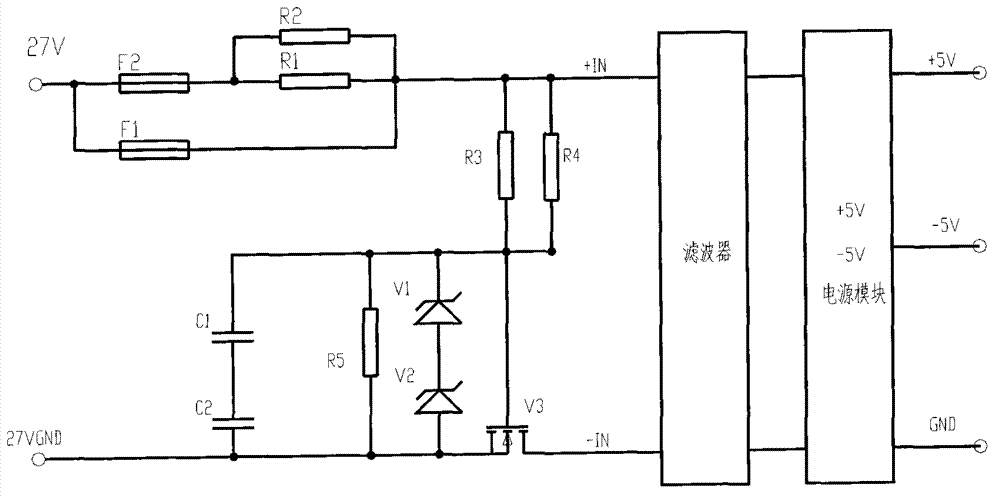

ActiveCN101403382BReduce weightReduce leakageRotary piston pumpsRotary piston liquid enginesMicrocontrollerJet engine

The invention discloses a gear pump used for a microminiature turbo-jet engine, comprising a direct current motor, a pump body, an upper pump cover, a lower pump cover, a shell, a pair of driving and driven gears which are meshed and a driving shaft and a driven shaft. The driving gear is arranged on the driving shaft; the driven gear is arranged on the driven shaft and is aligned and meshed withthe driving gear; the lower pump cover is fixed on the direct current motor, the upper pump cover is connected to the lower pump cover and the plane of the pump body is pressed tightly and sealed so as to lead the structure to be simple; the shell is sleeved at the outside of the lower pump cover; the driving gear and the driving shaft adopt a method of combining clearance fit and a transmission pin to eliminate the installation error of an output shaft of the direct current motor; and an antifriction material is embedded at the positions on the lower pump cover and the upper pump cover corresponding to the driving gear and the driven gear so as to increase the reliability and durability of the gear pump. Most parts of the gear pump adopt aluminium alloy so as to reduce the weight furthest. The gear pump can control the rotating speed of the direct current motor by pulse-width modulation of a single-chip microcontroller and control the flow rate of the gear pump precisely.

Owner:北京领动国创科技有限公司

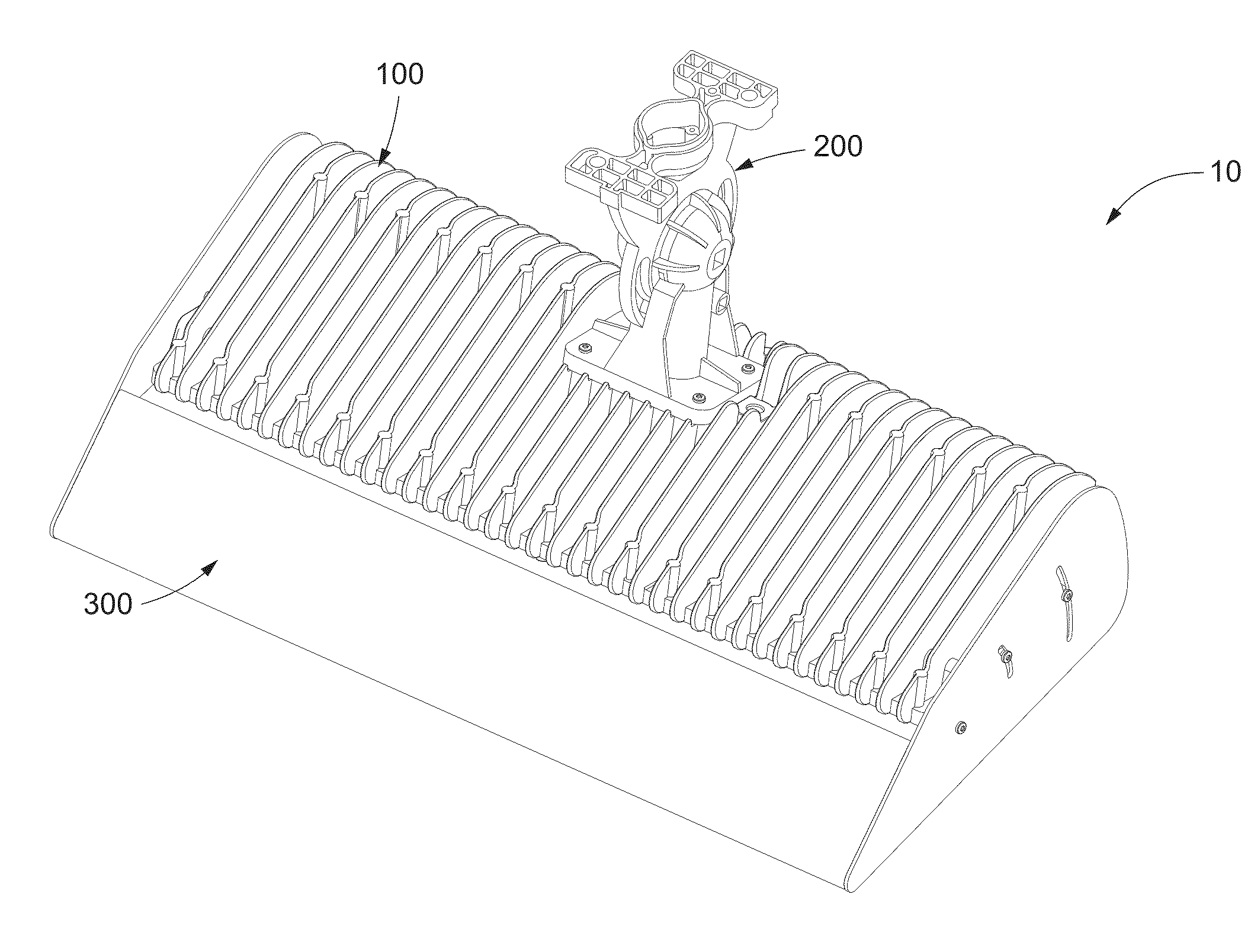

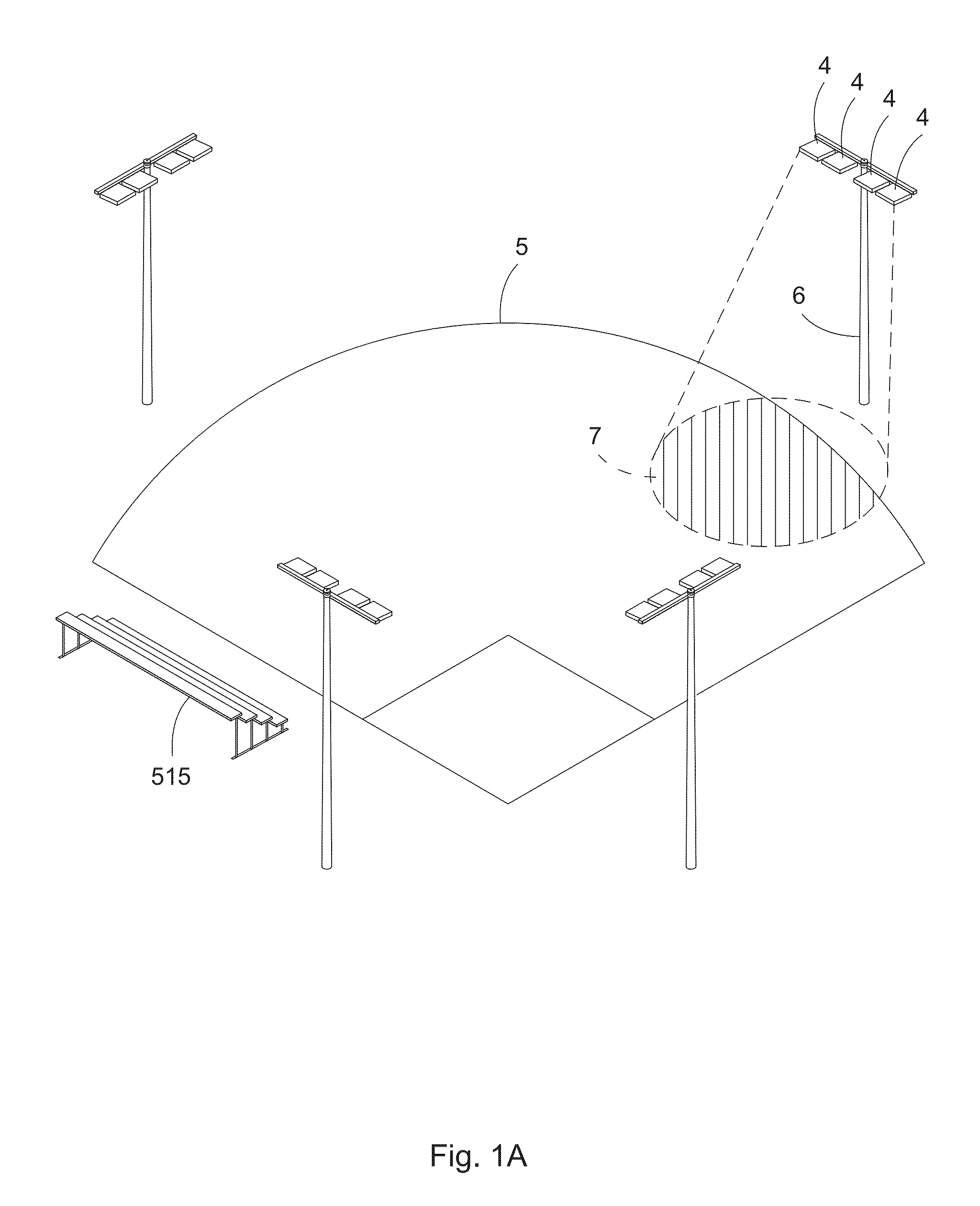

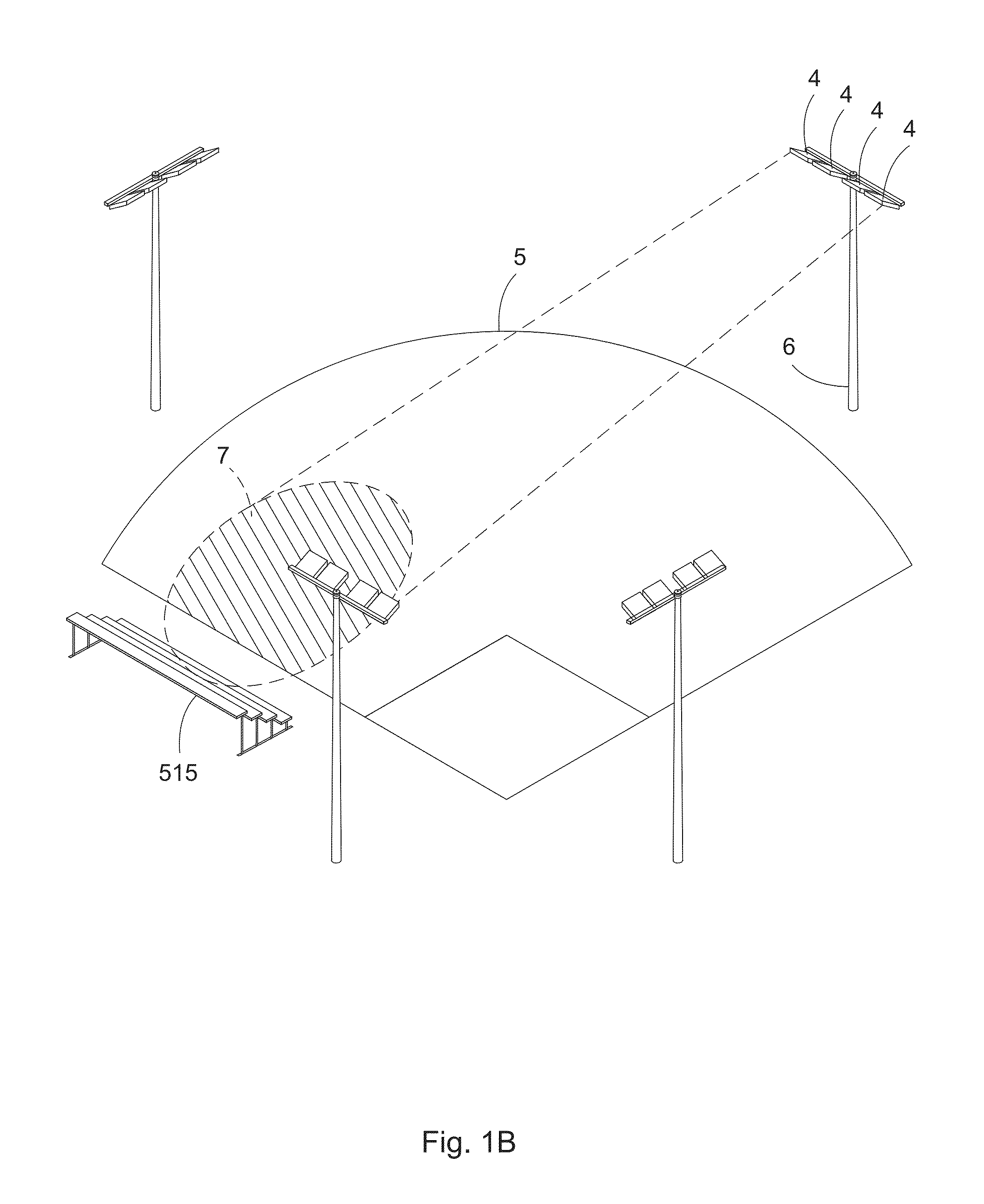

Apparatus, method, and system for independent aiming and cutoff steps in illuminating a target area

ActiveUS20130250556A1Easy to controlReduced EPAMechanical apparatusLighting support devicesProject areaEffect light

Presented is a design of modular LED lighting fixture whereby the steps of light directing and light redirecting are independent, but cooperative, so to promote a compact fixture design with low effective projected area (EPA), good thermal properties, and a selectable degree of glare control. A lighting system employing a plurality of said fixtures is highly customizable yet has the potential to be pre-aimed and pre-assembled prior to shipping, which reduces the potential for installation error while preserving the customized nature of the fixtures.

Owner:MUSCO

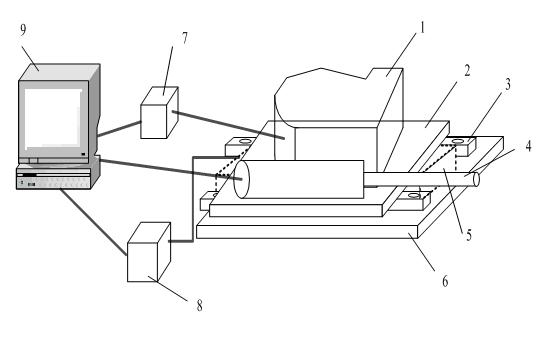

Star sensor calibrator and method for calibrating high-precision star sensor

The invention discloses a star sensor calibrator and a method for calibrating a high-precision star sensor. The star sensor calibrator has the structure that a two-dimensional adjustable plane mirror is arranged on the optical path between a single-star simulator and a star sensor to be calibrated; the position forming an included angle of 90+ / -15 degrees with the two-dimensional adjustable plane mirror is provided with a laser device of a laser angle measuring device; the position 50-200 cm away from the center of the two-dimensional adjustable plane mirror is provided with a high-precision two-dimensional guide rail which can vertically and horizontally move on an optical hover platform; a laser detector of the laser angle measuring device is installed on the high-precision two-dimensional guide rail; after being reflected by the two-dimensional adjustable plane mirror, the laser emitted by the laser device is incident into the laser detector; and a data processing computer is respectively communicated with the star sensor to be calibrated and the laser detector. The invention does not need to rotate the star sensor, increases the tangential distortion and the deflection angle of the installation error, and can meet the requirements for very-high-precision (sub-arcsec) star sensors. The invention has the advantages of simple method and small amount of calculation.

Owner:NAT UNIV OF DEFENSE TECH

Method and system for error reporting and correction in transaction-based applications

ActiveUS8978012B1Non-redundant fault processingProgram loading/initiatingError reportingApplication software

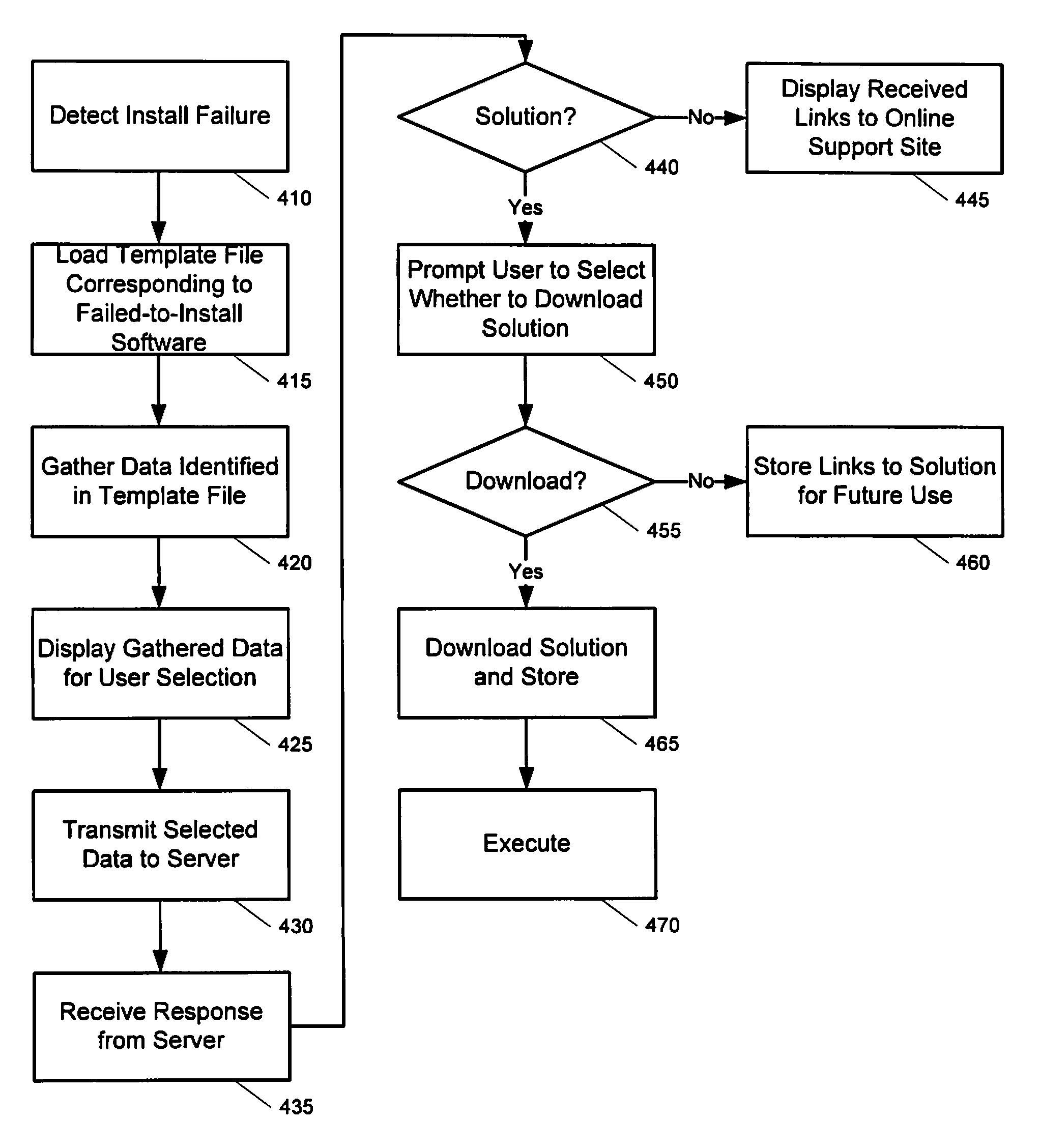

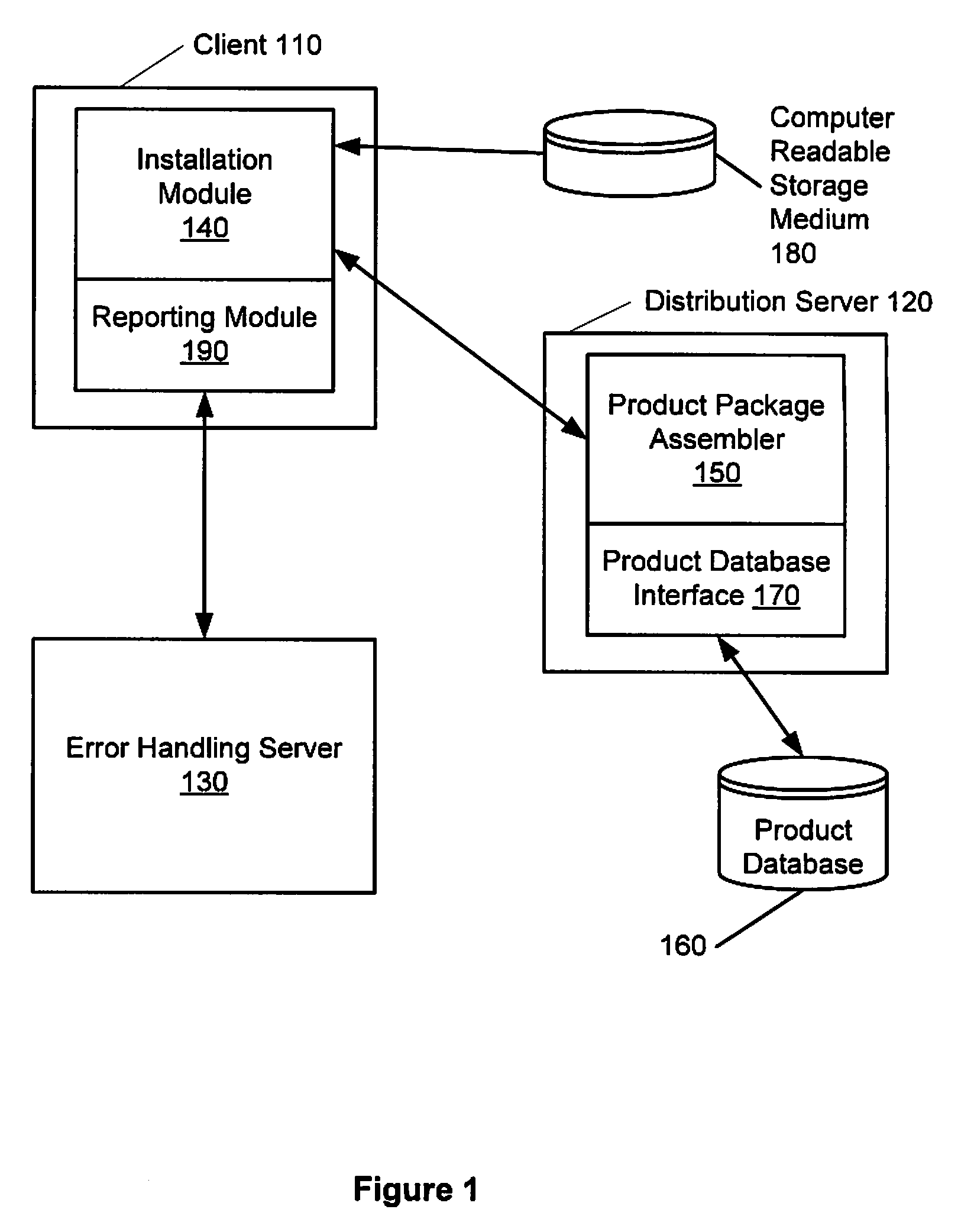

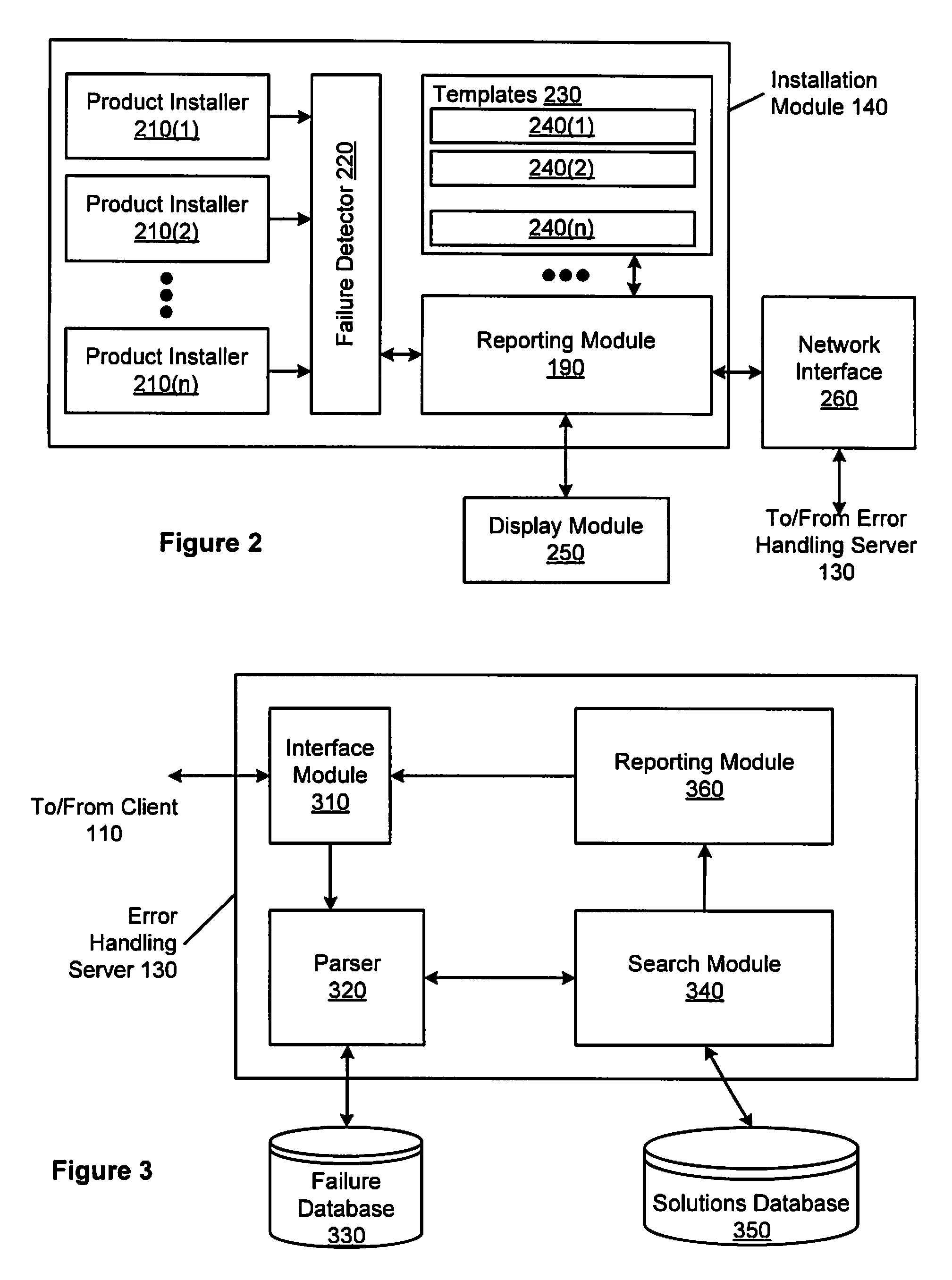

A system, apparatus and method for reporting a failure in execution of a software transaction (e.g., scripts and executables to install software on a computer) to a network resource that can then store the error-related information and automatically provide a previously determined solution to the error or links to resources to which the customer can refer for help in resolving the problem is provided. Automatically searching a database of reported errors and their solutions for a variety of products and providing a found solution to a customer experiencing an error (e.g., an installation error) is further provided. In the event that a solution to a customer-experienced error is not found by the network resource, alternate sites for information such as a customer support website can also be provided.

Owner:CA TECH INC

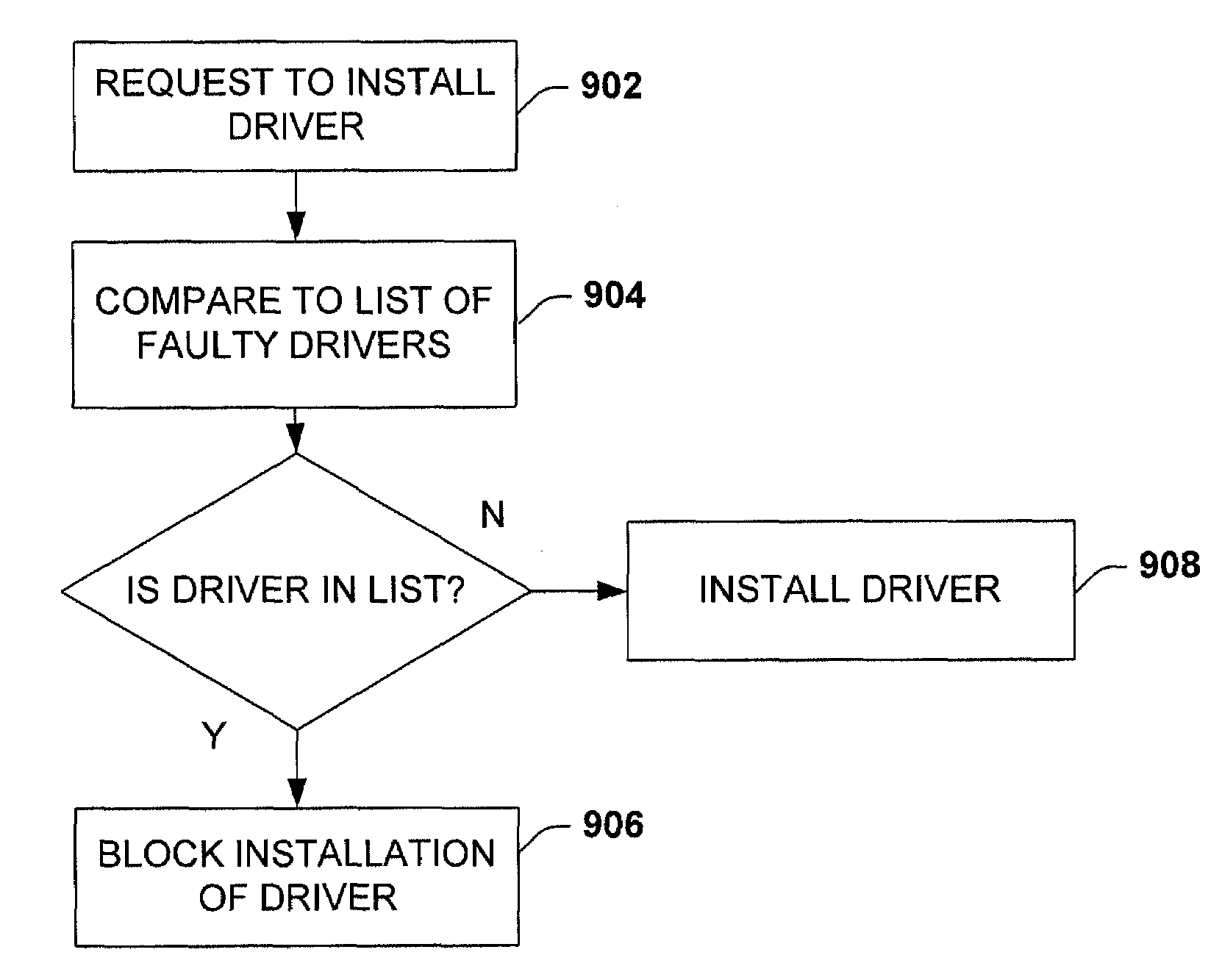

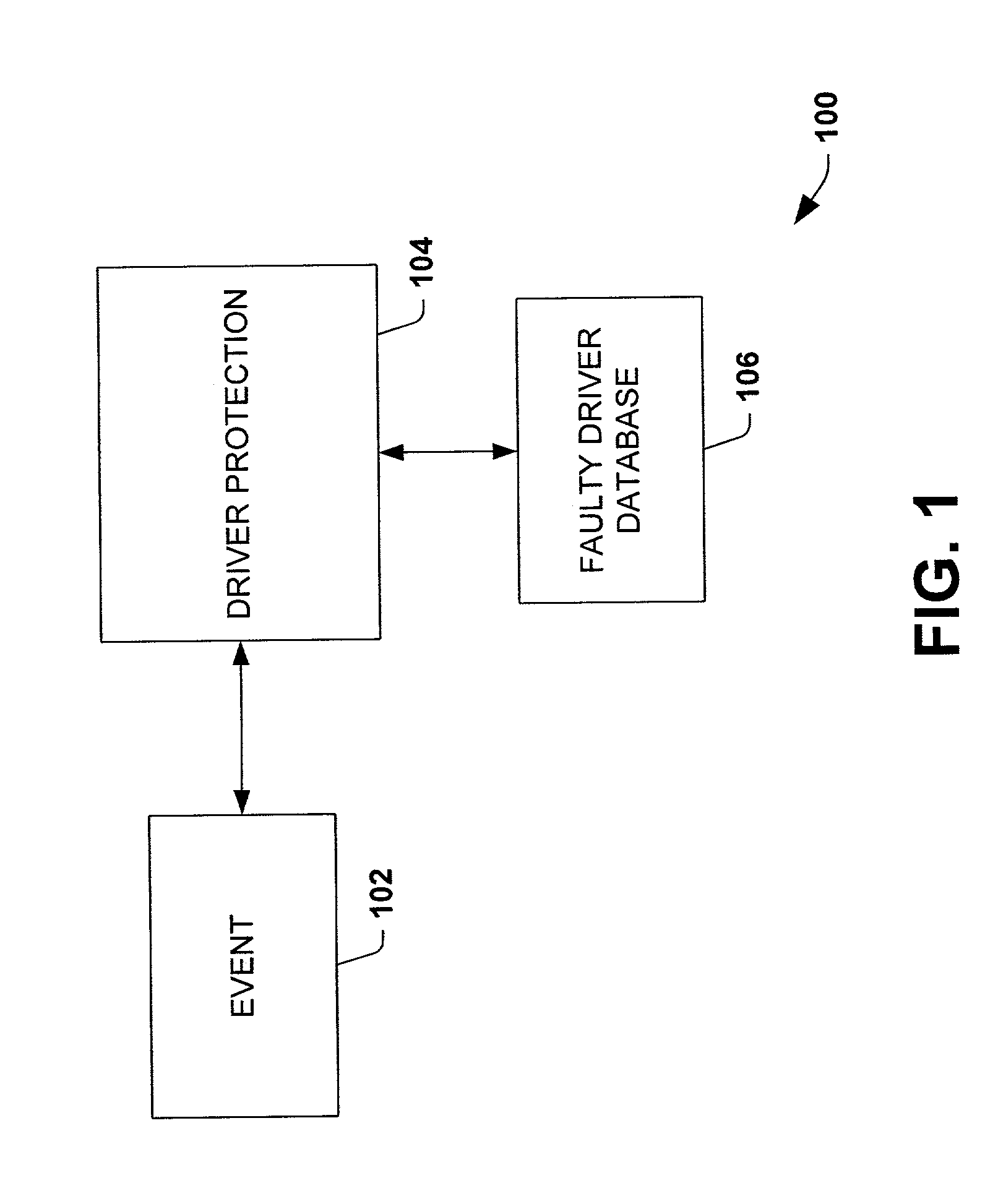

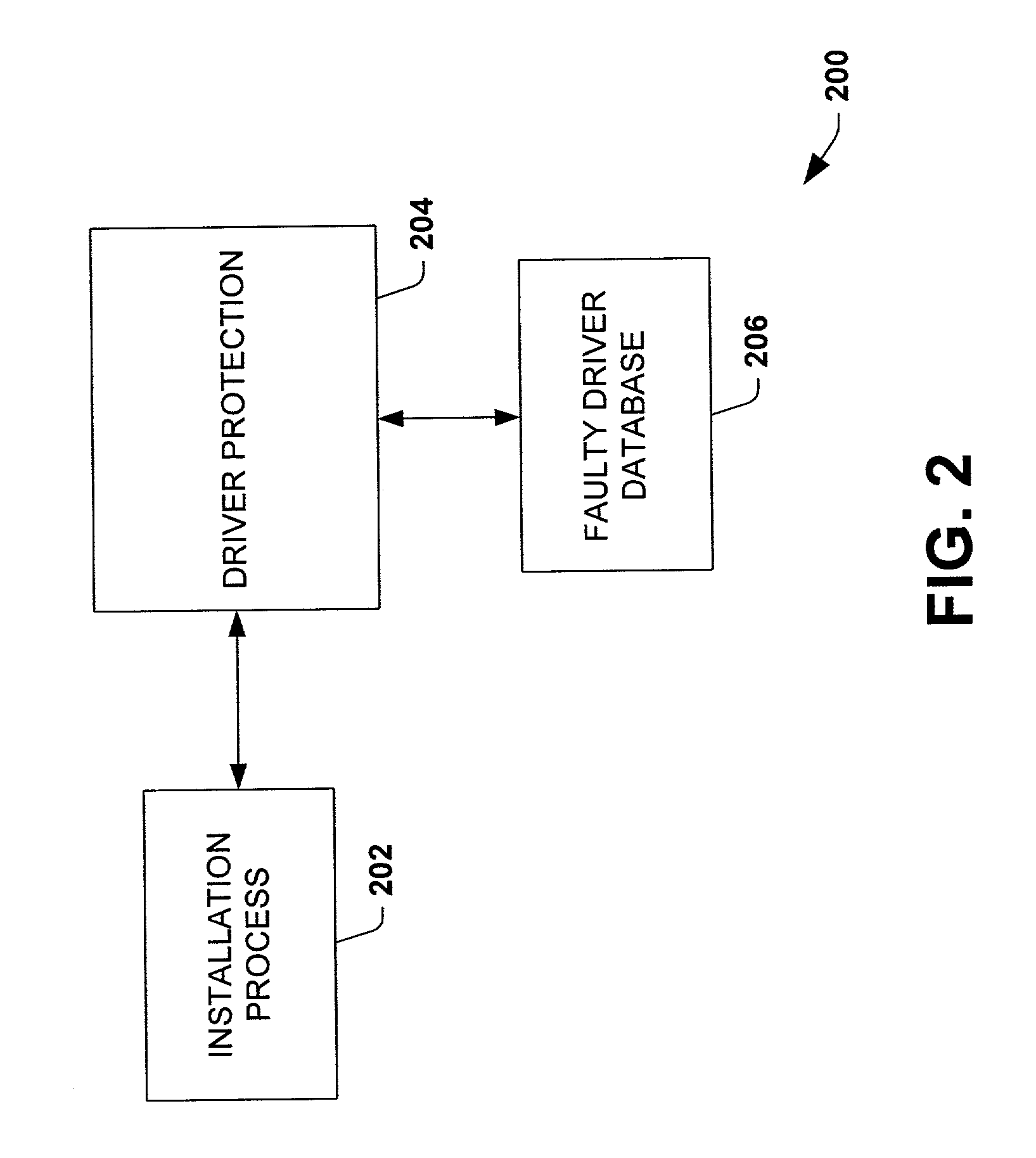

Driver protection

ActiveUS6950964B1Reduce loadPromote system stabilityError avoidanceProgram loading/initiatingInstabilityData Corruption

Systems and methods are provided that prevent faulty drivers from being loaded and / or can prevent faulty drivers from being installed. Thus, instability of a computer system can be mitigated. Additionally, the occurrence of data corruption, system halting and the like can be reduced. A requested driver is compared to a list of faulty drivers from a faulty driver database. If the requested driver is in the list of faulty drivers, the requested driver is deemed faulty or defective, and is prevented from being loaded. Additionally, if the requested driver is in the list of faulty drivers, the requested driver can be prevented from being installed. Otherwise, the requested driver is operable and can be installed and / or loaded.

Owner:MICROSOFT TECH LICENSING LLC

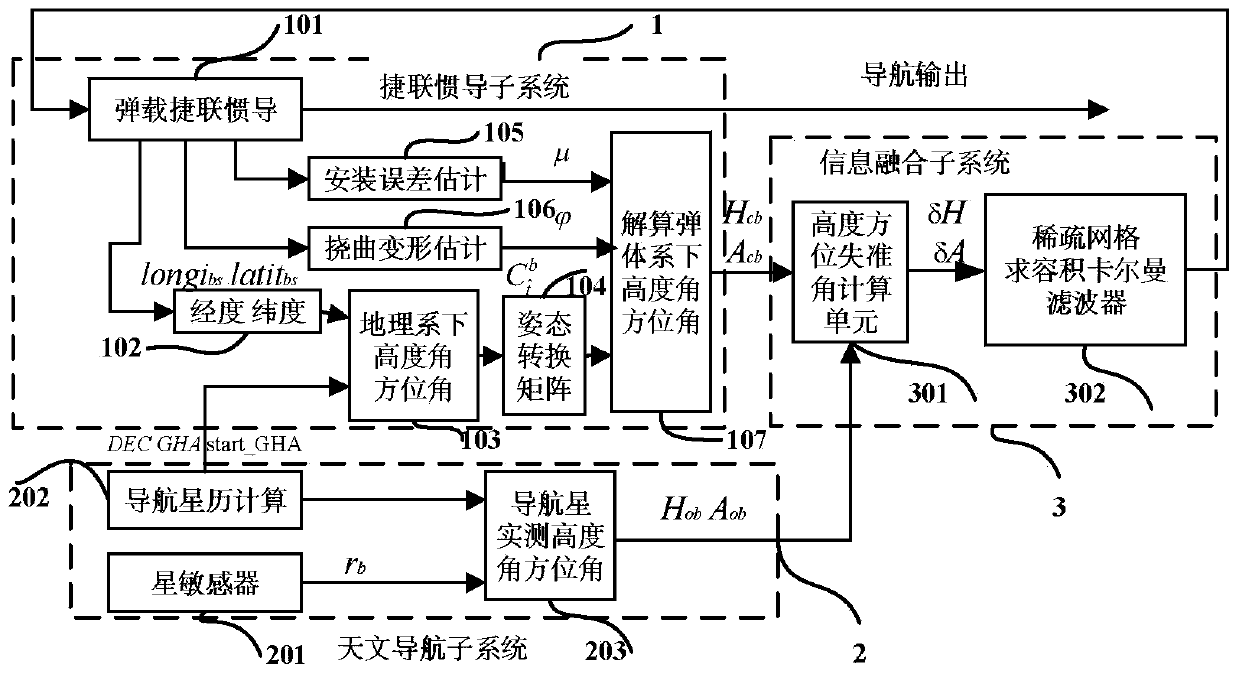

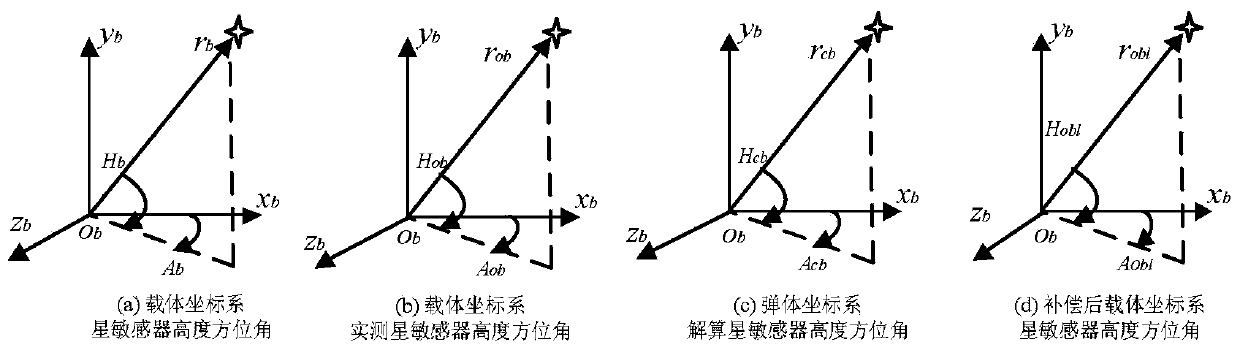

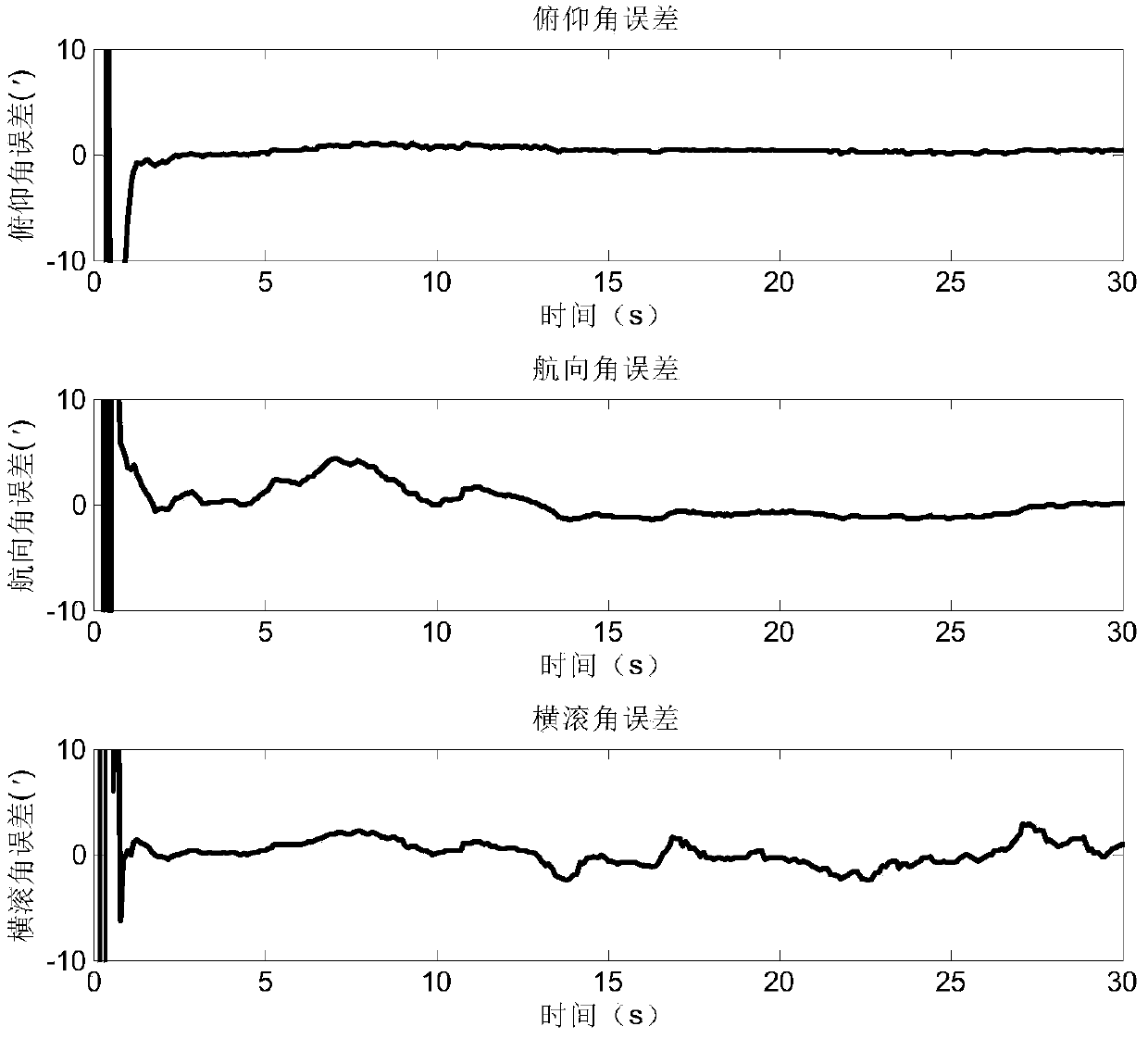

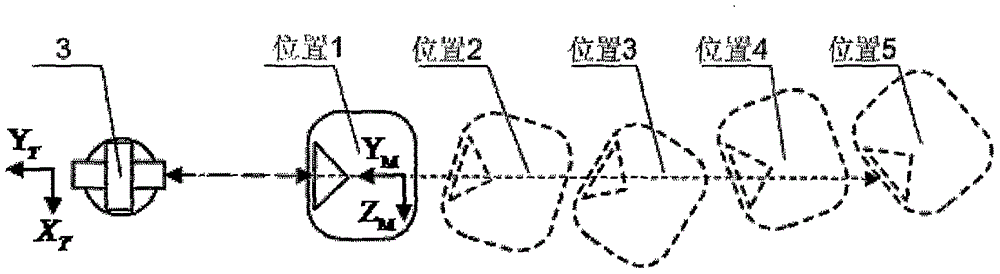

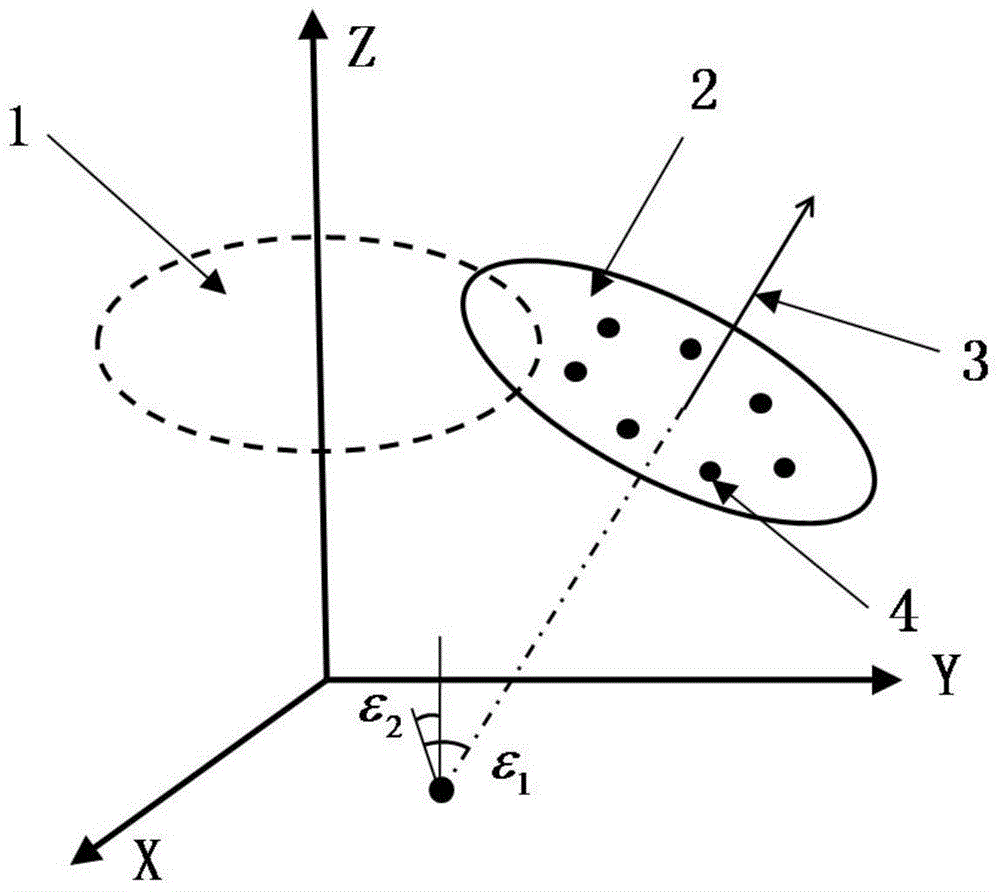

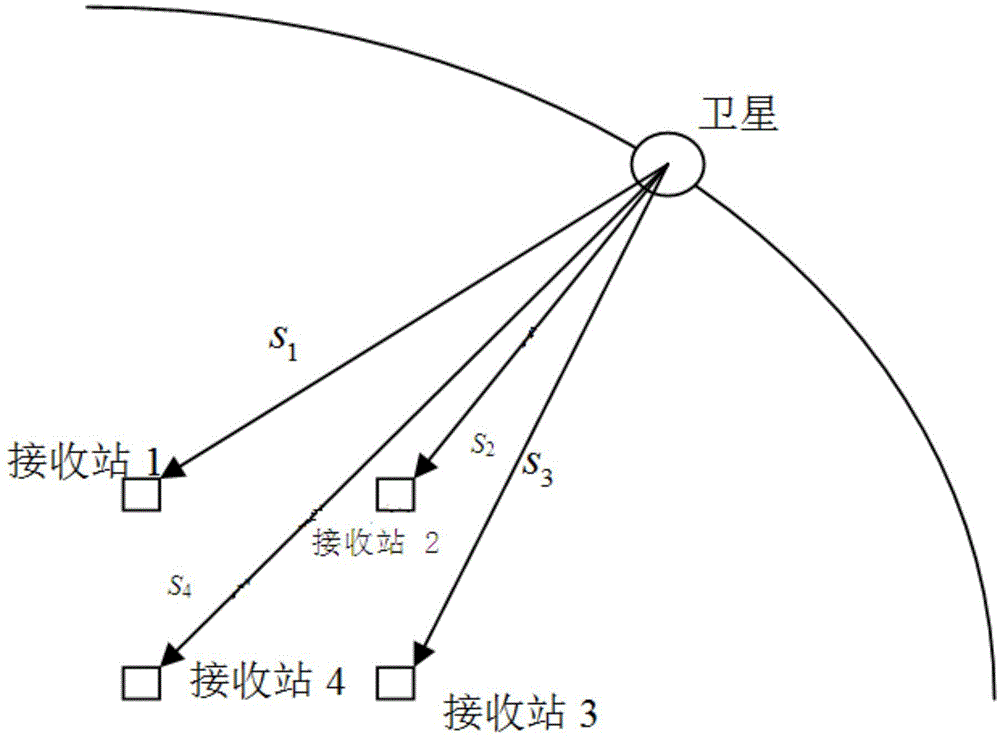

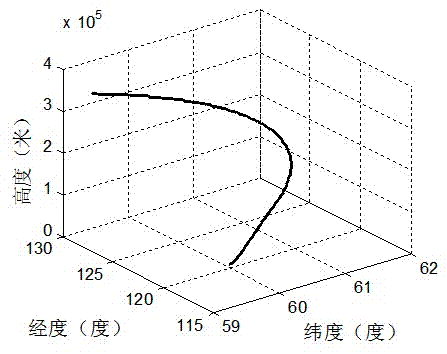

Near-space missile-borne strap-down inertial navigation system transfer alignment method based on star sensor

ActiveCN104165640AAttitude Error Estimation High AccuracyComply with flight altitudeMeasurement devicesInertial coordinate systemInstallation Error

The invention discloses a near-space missile-borne strap-down inertial navigation system transfer alignment method based on a star sensor. The method comprises the following steps: 1) establishing a missile-borne strap-down inertial navigation system transfer alignment state equation by taking an inertial coordinate system (launching point coordinate system for short) on a carrier launching point as a navigation coordinate system and a strap-down inertial navigation system (SINS) on a missile to be launched as sub-inertial navigation; 2) calculating navigation information and observed quantity of the missile-borne strap-down inertial navigation system; 3) establishing a measurement equation; 4) by depending on the state equation and the measurement equation established, estimating a mathematics platform misalignment angle, a speed error, a position error and an installation error of the missile as well as flexural deflection of the carrier through a sparse grid integral kalman filter, and correcting a sub-inertial navigation system, thus finishing a transfer alignment process.

Owner:SOUTHEAST UNIV

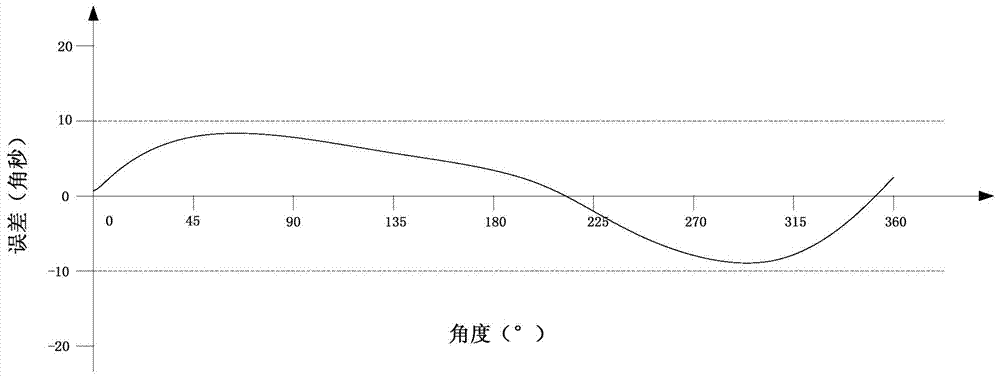

Rotary transformer static and dynamic angle measuring accuracy calibration device and method

InactiveCN103499365ALow costConvenient researchConverting sensor output electrically/magneticallyGratingExternal reference

The invention discloses a rotary transformer static and dynamic angle measuring accuracy calibration device and a rotary transformer static and dynamic angle measuring accuracy calibration method. The method is based on an external reference comparison method. The calibration device mainly comprises a driving turntable, a mechanical shaft system, a metal polygon, a photoelectric auto-collimator, a circular grating and the like. The metal polygon and the photoelectric auto-collimator are utilized for carrying out static angle measuring accuracy calibration on a rotary transformer, in addition, calibration and compensation are carried out on the circular grating, and installation errors are corrected. When the driving turntable drives the shaft system to rotate, the circular grating is utilized for carrying out dynamic angle measuring accuracy calibration on the rotary transformer. The device and the method have the advantages that different external reference characteristics are combined, the same device is utilized for completing the static and dynamic calibration of the rotary transformer, the comprehensive analysis and the error compensation of the angle measuring accuracy of the rotary transformer are realized, the improvement of an angle measuring system is favorably realized, and the angle measuring accuracy is improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Calibration method of inertial unit optical aiming prism installation error

The invention provides a calibration method of inertial unit optical aiming prism installation errors. The calibration method is characterized in that prism lines of the inertial unit optical aiming prism rotate for several positions; a self calibration theodolite and an inertial unit optical aiming prism collimator which are fixed in the one position is used in each position. The relative posture of the inertial unit is provided through inertial navigation solution; the relative posture of the theodolite collimation axis can be obtained through reading and calculation via a dial. According to the initial conditions of the self calibration theodolite and the inertial unit optical aiming prism collimator in each position, a multivariate overdetermined equation including inertial unit optical aiming prism installing error Z0 (deflection quantity) and Y0 (inclination quantity) is built; the installing errors Y0 and Z0 of the inertial unit optical aiming prism can be obtained through solving the multivariate overdetermined equation. The posture in the inertial unit rotationprocess is given through inertial navigation solution; the rotation process can be manually completed on an ordinary platform; the requirements on test equipment is low; the realization is easy; the calibration parameters are comprehensive; high universality is realized.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

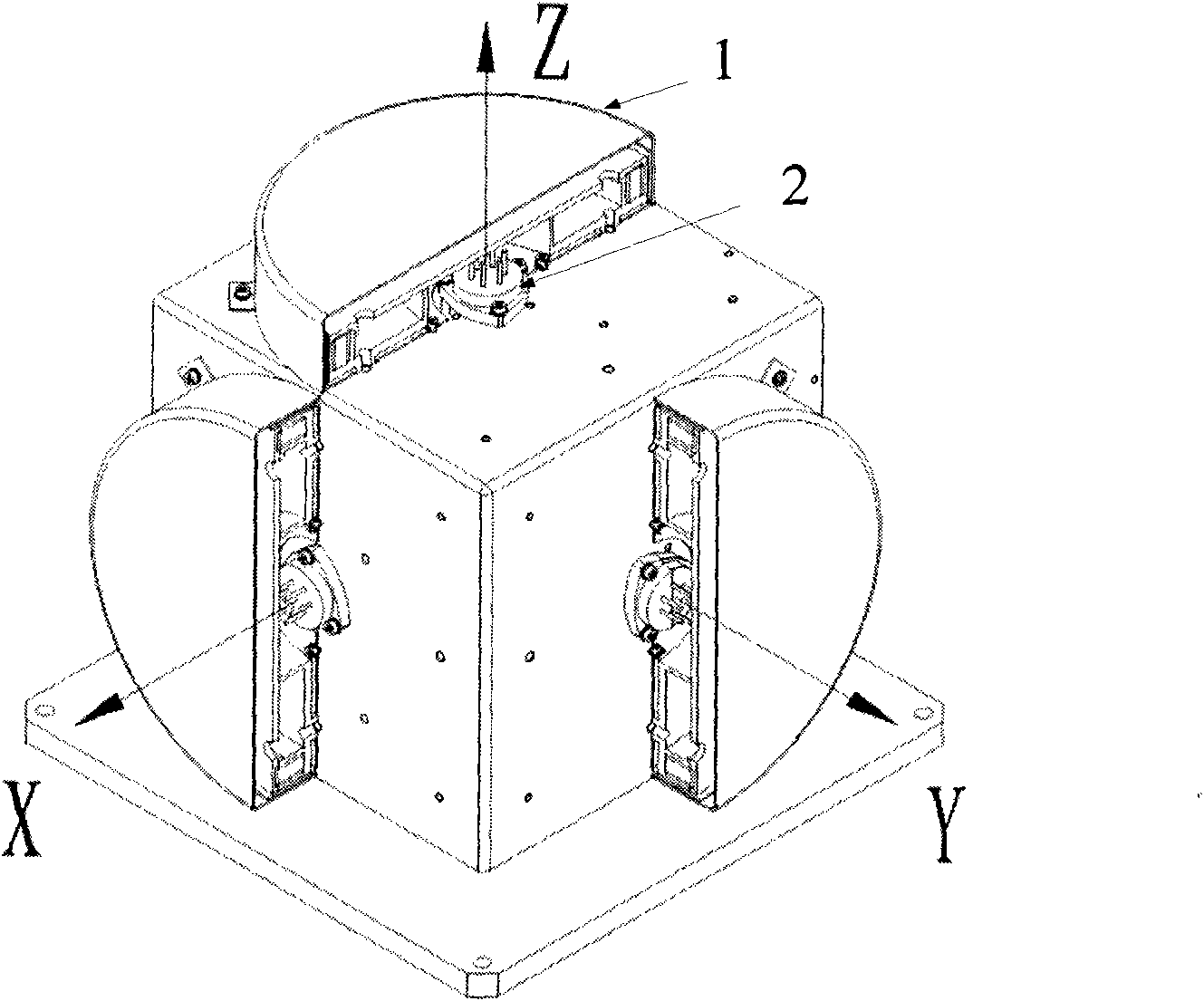

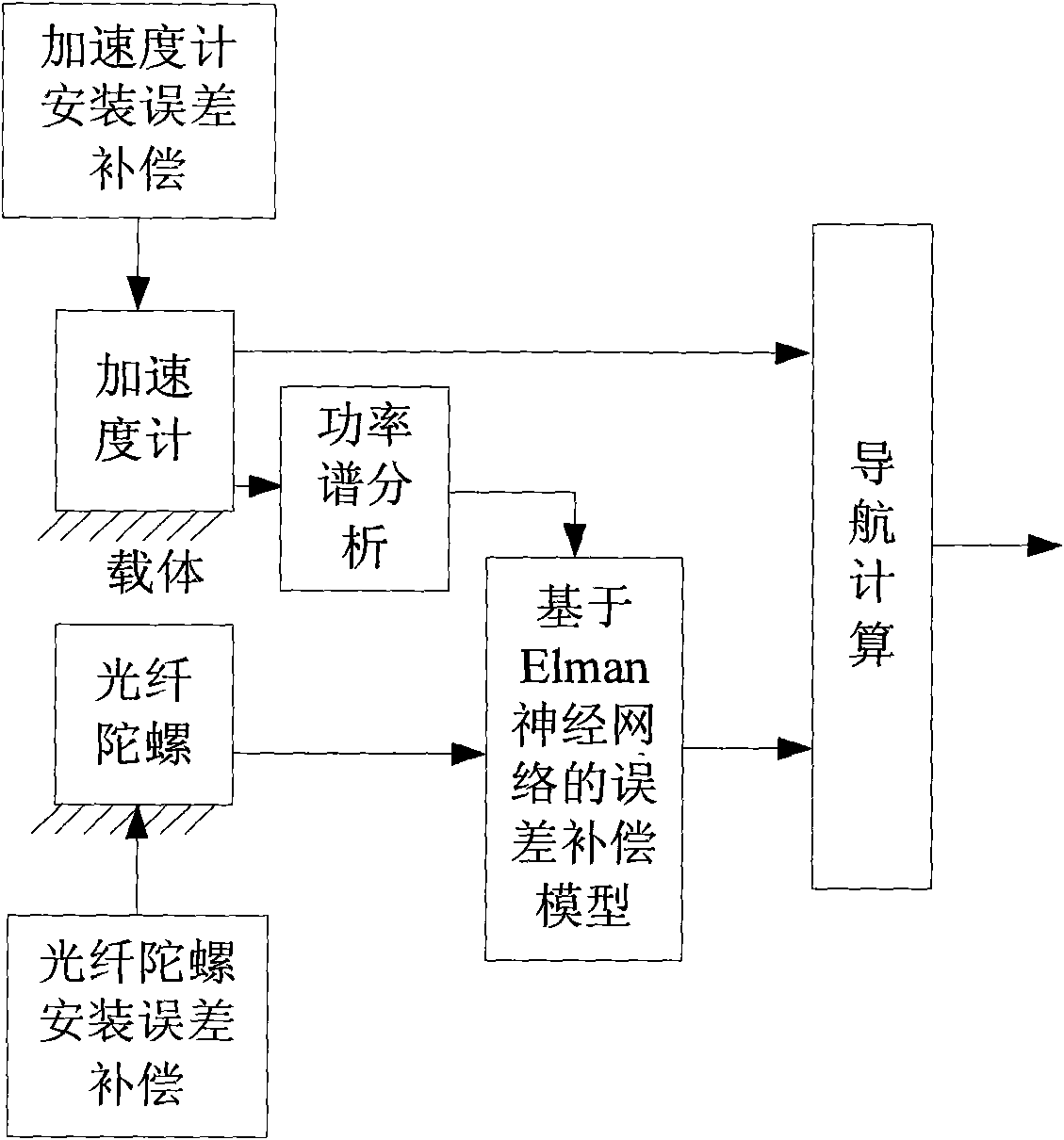

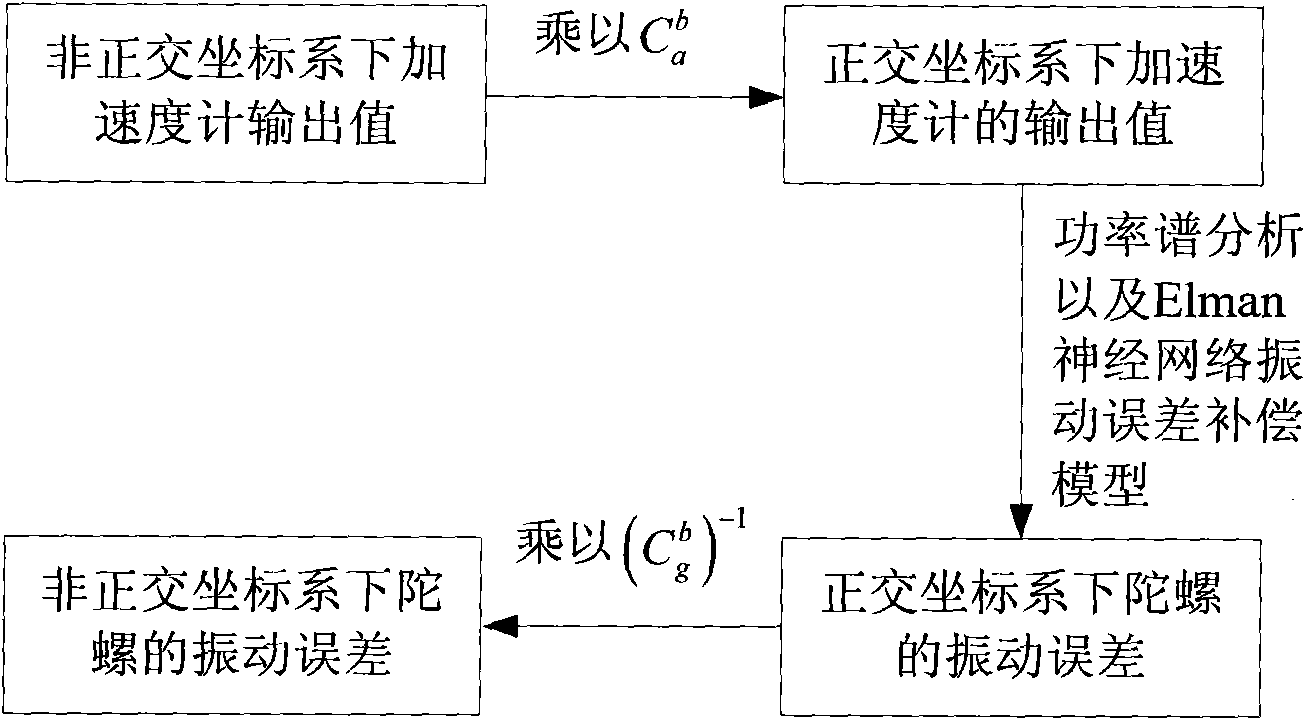

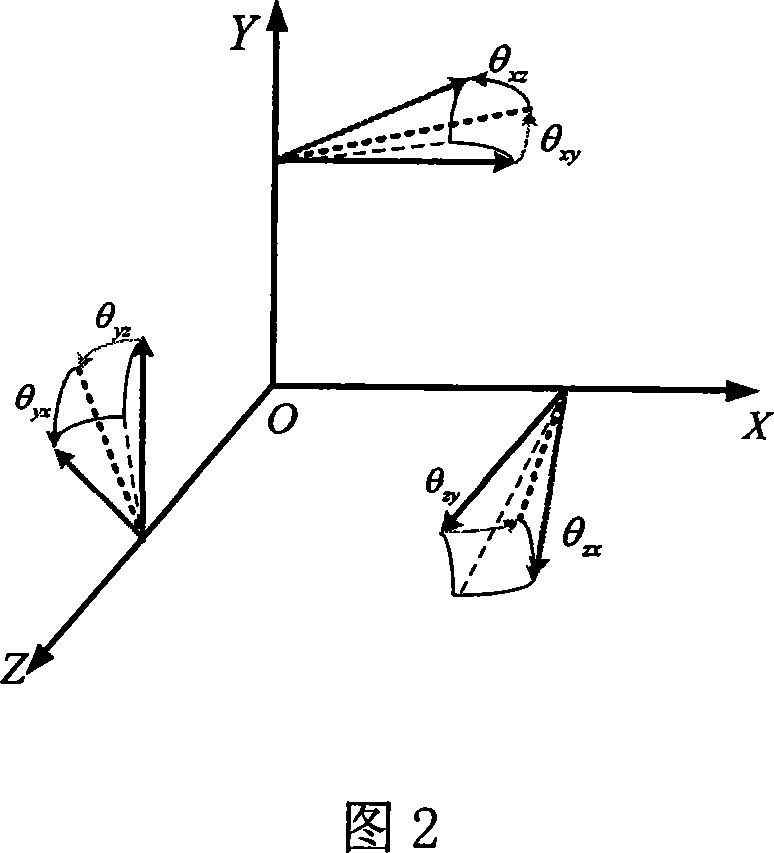

Vibration error compensation method of fiber optic gyro strap-down inertia measurement system

ActiveCN101566483AThe method of error compensation is preciseGood precisionNavigation by speed/acceleration measurementsNeural learning methodsFiberAccelerometer

The invention provides a vibration error compensation method of a fiber optic gyro strap-down inertia measurement system. A vibration experiment is conducted on the fiber optic gyro strap-down inertia measurement system to collect the output data of an inertia measurement element accelerometer and a fiber optic gyro of the fiber optic gyro strap-down inertia measurement system; the installation error of the fiber optic gyro and the accelerometer is considered and is compensated to the output of the gyro and the accelerometer; and power spectral analysis is conducted on the output of the accelerometer after the compensation of installation error to obtain the vibration characteristics of a vibration signal; and an Elman neural network method is used to conduct non-linear compensation to the vibration error output of the fiber optic gyro strap-down inertia measurement system. In the situation of environmental vibration, the method uses a reasonable neural network model to compensate the vibration error and can effectively reduce the effect of the environmental vibration on the precision of the system and maintain favorable precision.

Owner:哈尔滨哈船导航技术有限公司

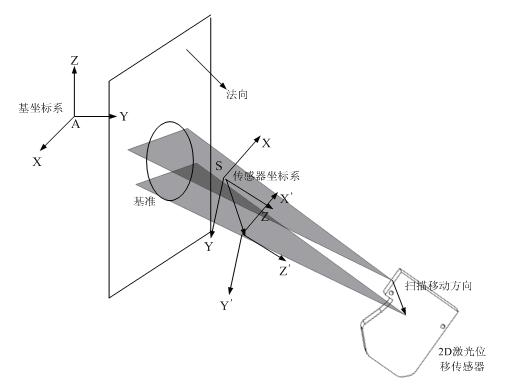

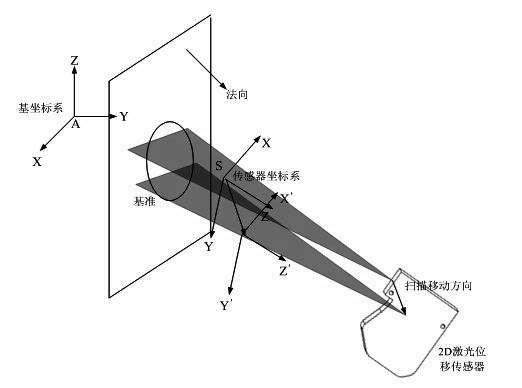

Reference detecting device of automatic drilling and riveting system of airplane components and detecting method thereof

ActiveCN102636110ABenchmark high-precision detectionRealize online detectionUsing optical meansJet aeroplaneComputer vision

The invention relates to a reference detecting device of an automatic drilling and riveting system of airplane components and a detecting method thereof. The detecting method comprises the following steps of: acquiring information of a reference profile by a 2D laser displacement sensor and a distance sensor, establishing a parameter space of a reference hole center coordinate by applying a least square method, then realizing transformation from a reference hole boundary space domain to the reference hole center coordinate by applying generalized Hough transformation, fitting and calculating a reference center position, and realizing detection of an actual position of the reference, thus realizing determination of the actual position for the processing reference of the automatic drilling and riveting system so as to determine the deviation between the theoretical position and the actual position of the reference. The positions of points to be preprocessed on a product are compensated and corrected, so that the manufacture and installation errors are eliminated, and the drilling and riveting accuracy is increased; and the detecting method is simple, the solving speed is high and the online detection of the reference can be realized.

Owner:江苏航鼎智能装备有限公司

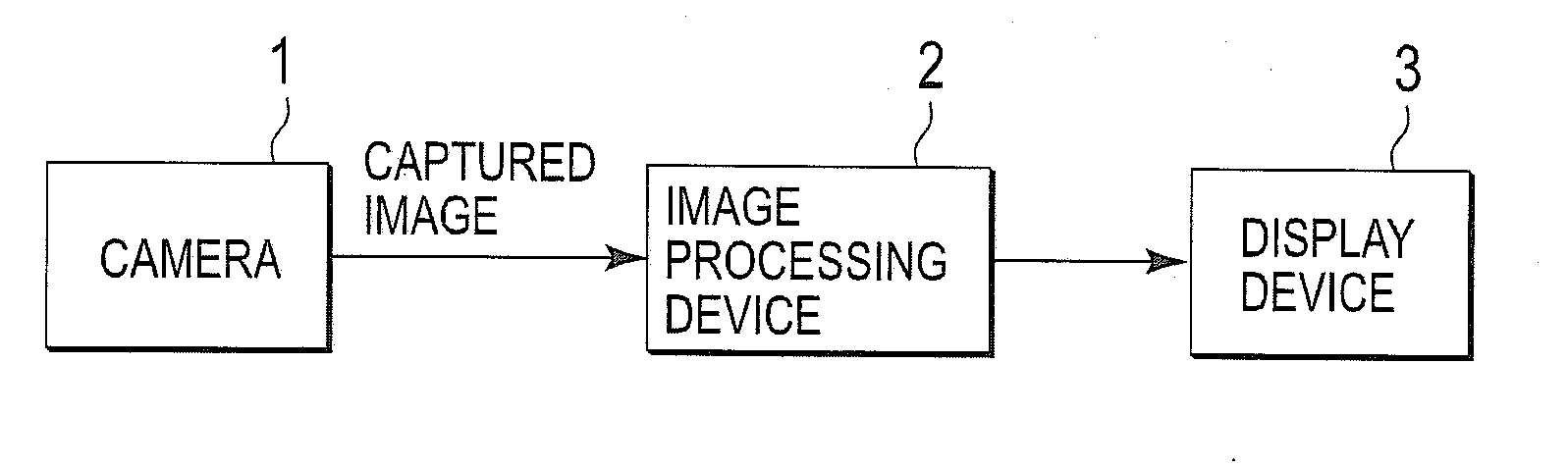

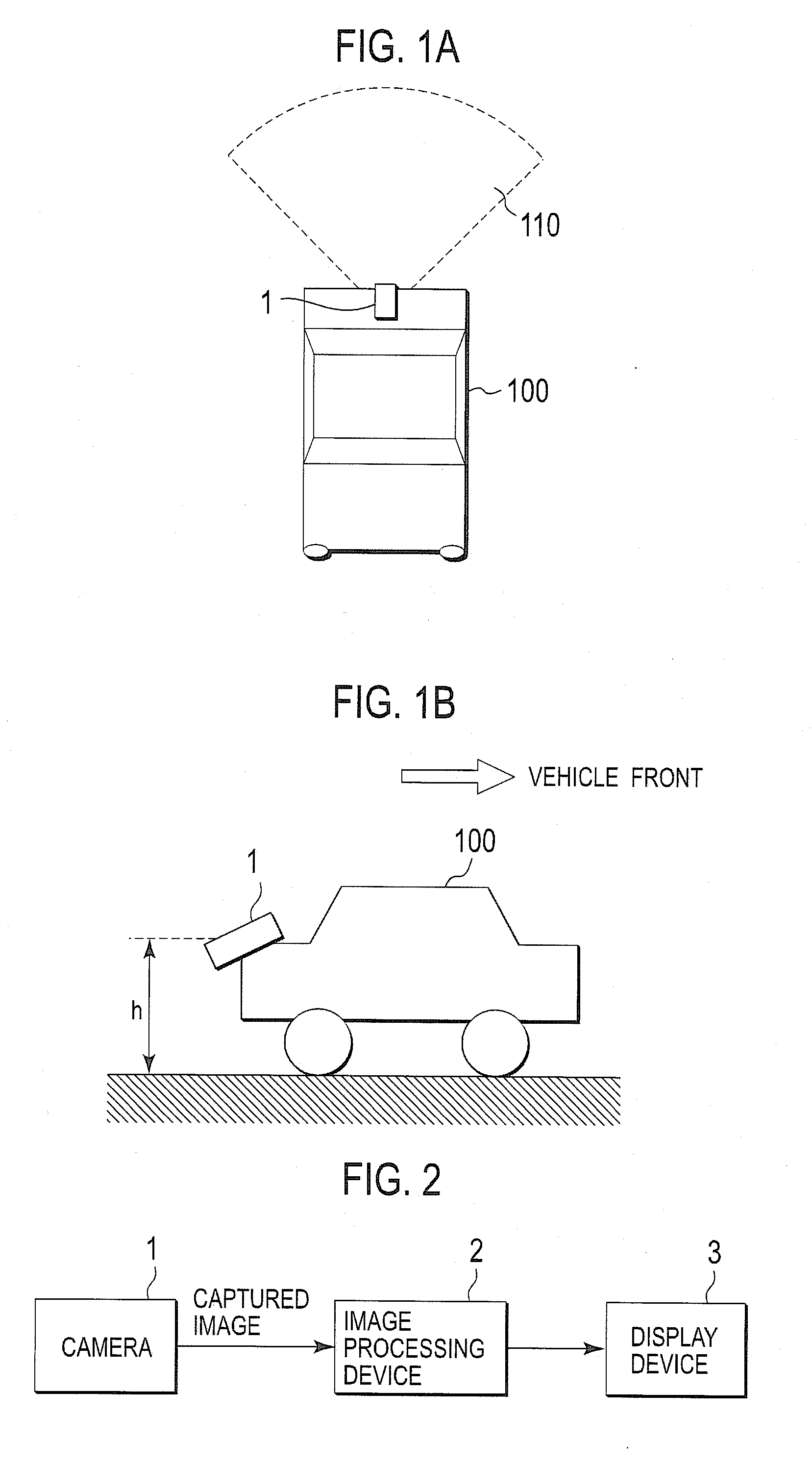

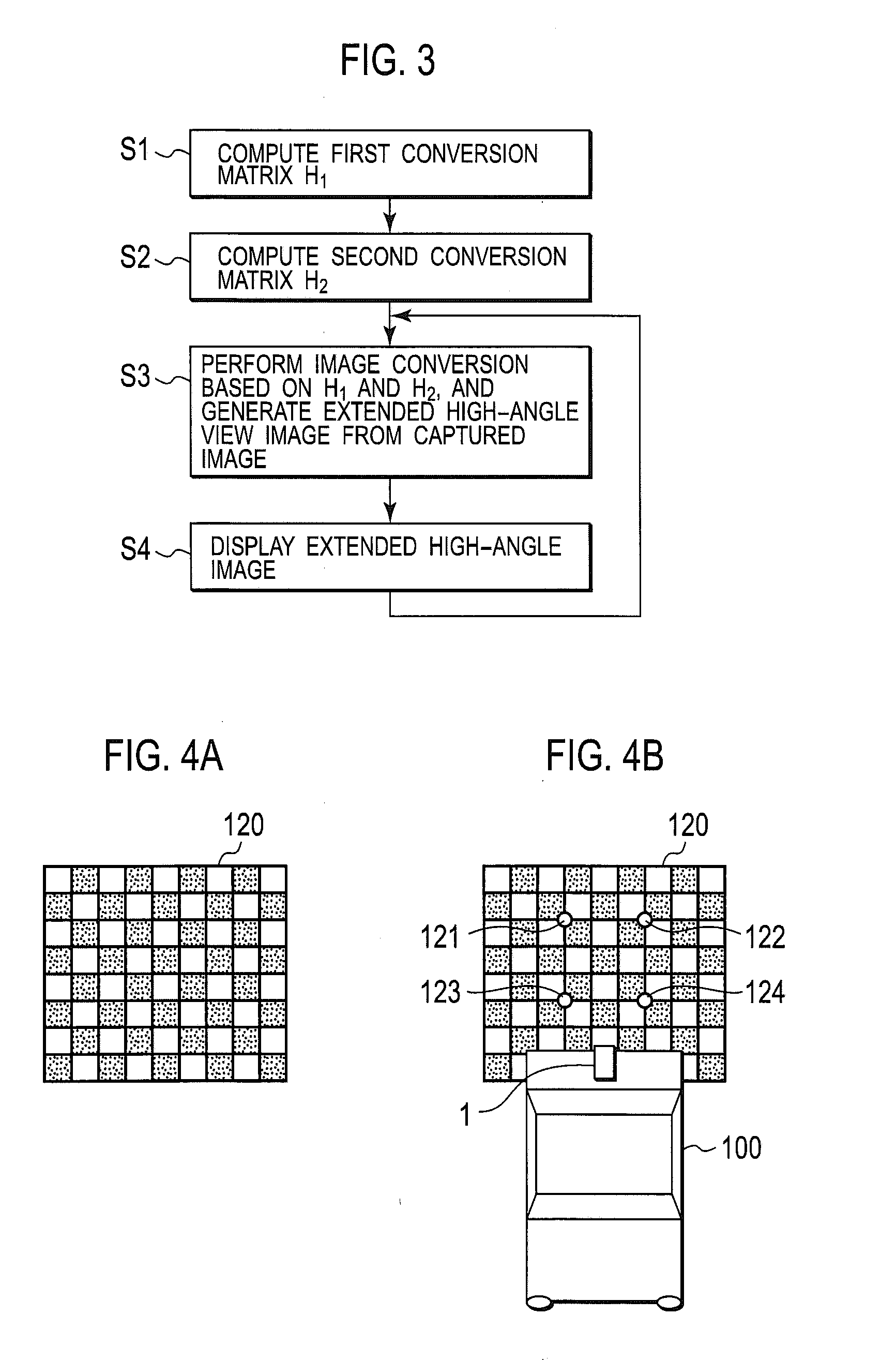

Image Processor, Image Processing Method, And Vehicle Including Image Processor

InactiveUS20090322878A1Less susceptible to camera installation errorWide fieldTelevision system detailsGeometric image transformationVisibilitySupporting system

A visibility support system is provided which displays a wide field of view while absorbing camera installation errors. The visibility support system obtains a first conversion matrix H1 for projecting a captured image onto the ground, while a second conversion matrix H2 for projecting the captured image on a plane different from the ground (e.g. no-conversion unit matrix) is set. An extended high-angle view image is divided into a first region corresponding to the vehicle periphery and a second region corresponding to farther away from the vehicle, and a high-angle view image based on H1 is displayed in the first region, whereas an image based on a weight-added conversion matrix in which H1 and H2 are weight-added is displayed in the second region. Weight for the weight-addition is varied according to a distance from the border of the first and second regions to seamlessly join the images in both regions.

Owner:SANYO ELECTRIC CO LTD

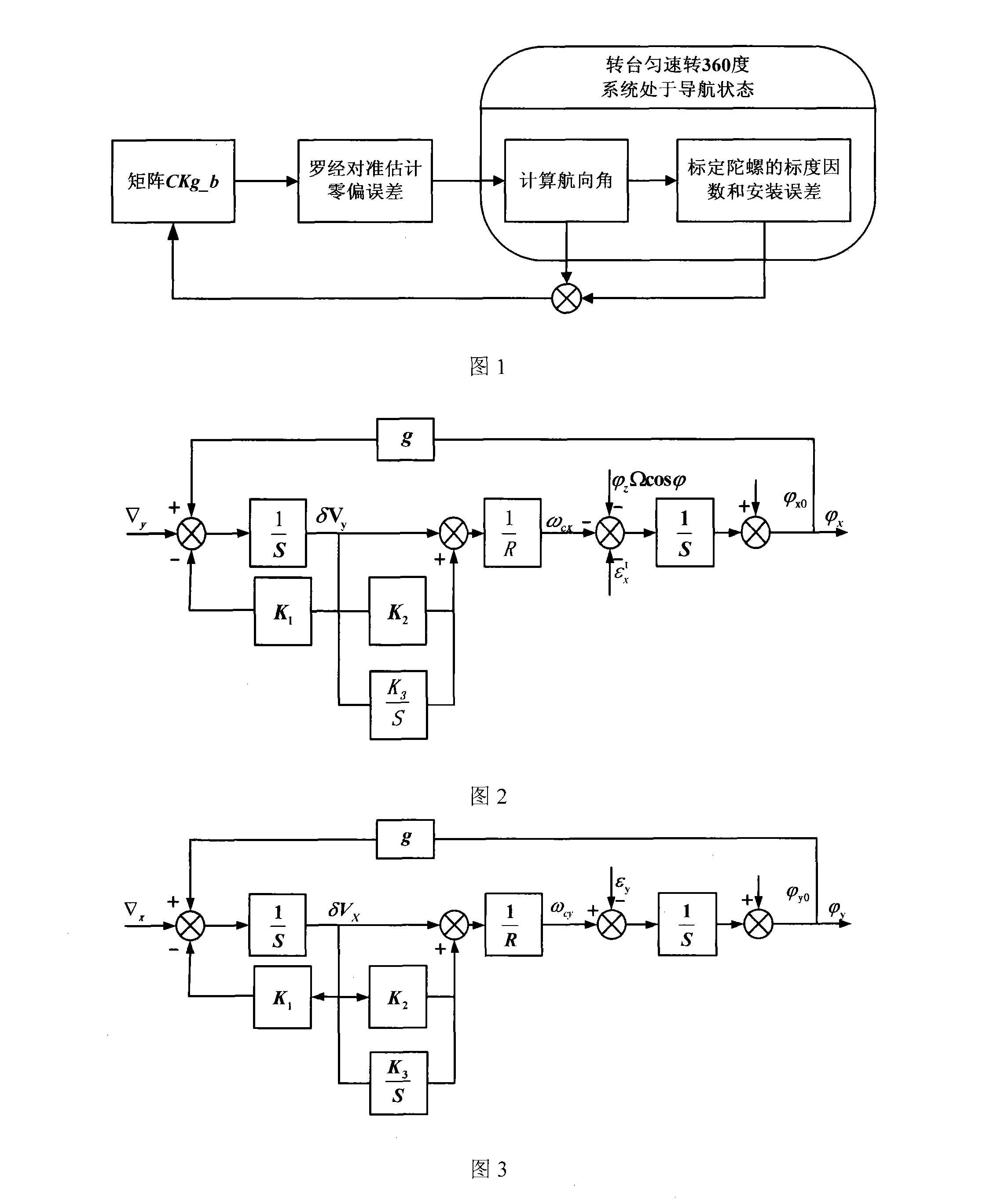

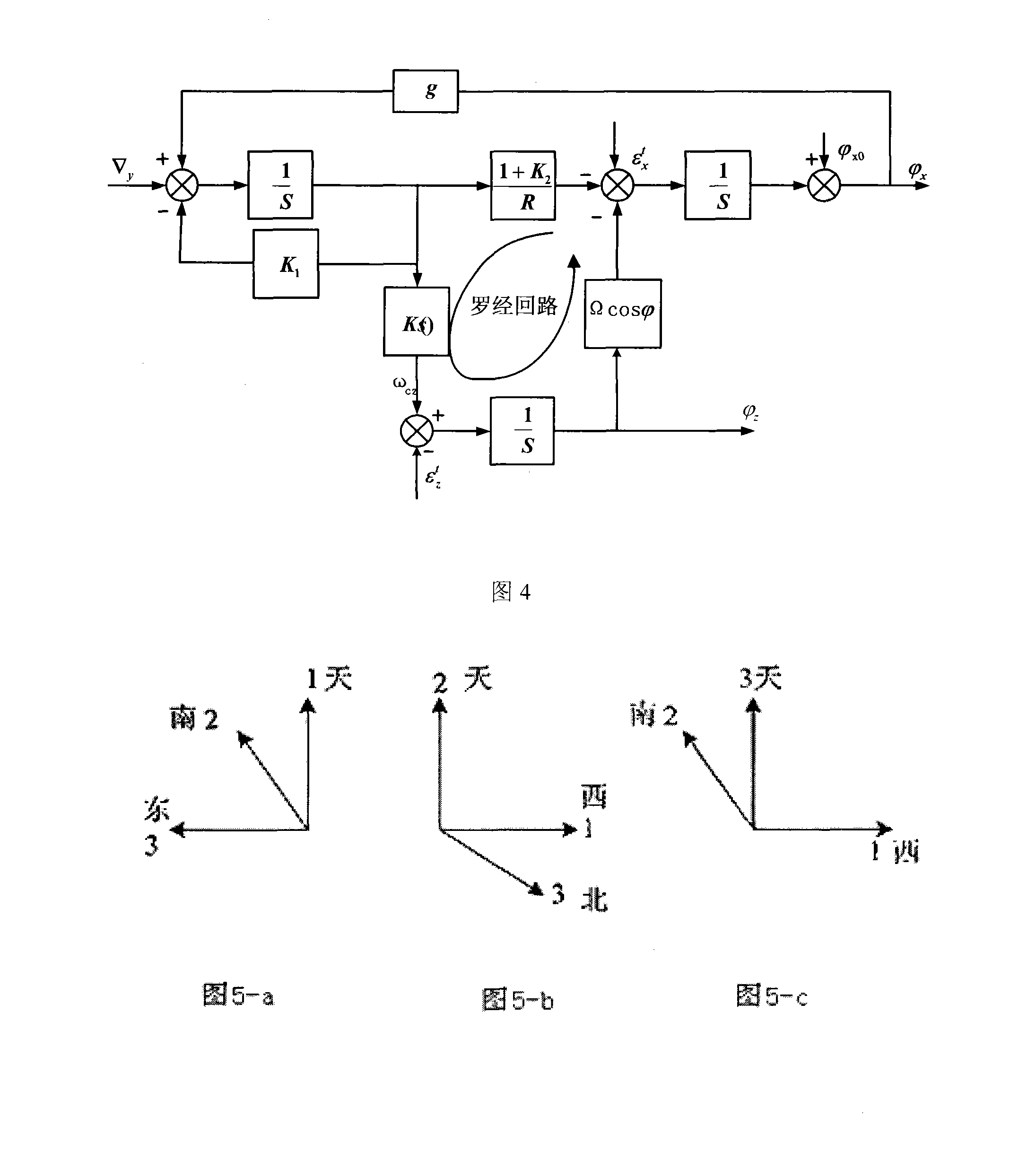

Closed-loop calibration method of micro-mechanical gyroscope inertial measuring component

The invention provides a closed-loop calibration method of a micro-mechanic gyro inertia measuring component, which comprises the following steps: data output by a gyro and an accelerometer is collected; a scale factor of the Y axis is roughly measured; a matrix CKg-b is constructed by using the roughly determined scale factor and an installation error; the alignment of a micro-mechanic strapdown inertial navigation system is implemented according to a compass loop method, and a course angle that is output by system navigation parameters and control angular velocities on each axis of a geographical coordinate system are read after the compass alignment is finished, thus measuring constant drift of the gyro; when the system enters a navigation phase, the scale factor and the installation error angle of the gyro are precisely calibrated; the updated matrix CKg-b and the course angle are written into a navigation computer, and a next round of calibration is implemented, when the difference between the course angles that are obtained from two calibrations is less than a given constant 0.0001 degree, the calibration is finished. By using the calibration method provided by the invention, the system lies in a closed-loop feedback state and can implement the feedback calibration of the calibration error, thus improving calibration precision.

Owner:HARBIN ENG UNIV

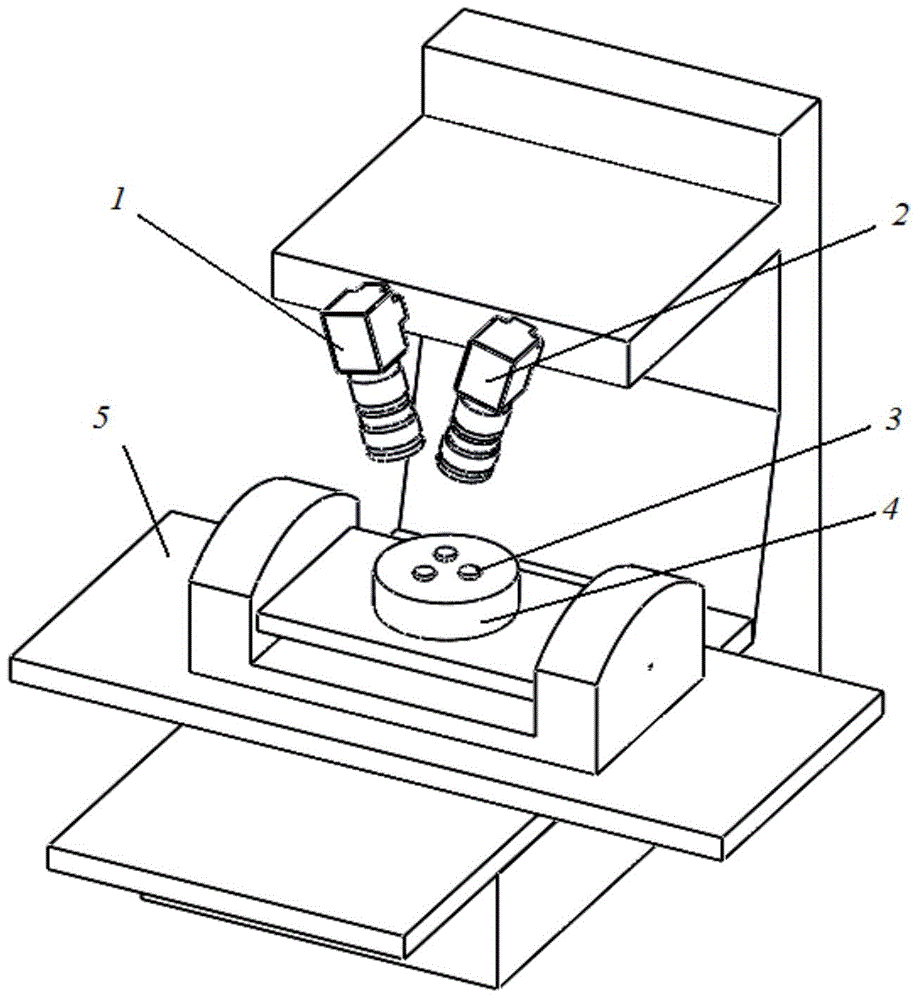

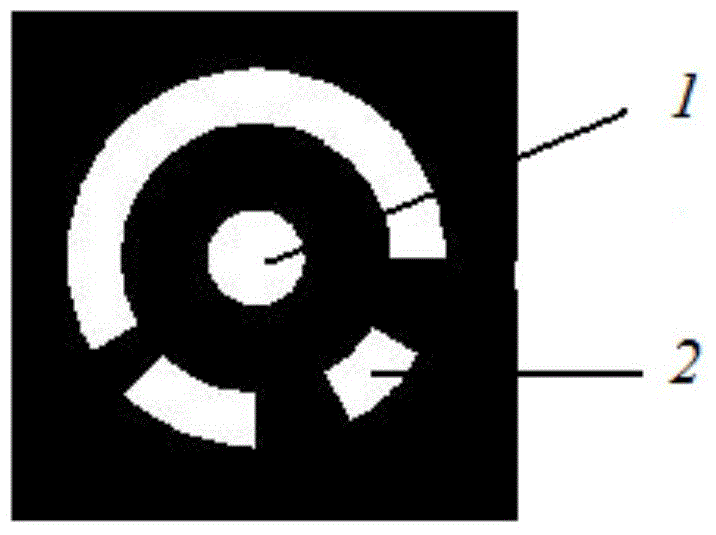

Numerical control machine tool rotating shaft error detection method based on binocular vision

ActiveCN105043259AImprove the efficiency of error detectionFast wayCharacter and pattern recognitionUsing optical meansNumerical controlImage segmentation

The invention discloses a numerical control machine tool rotating shaft error detection method based on binocular vision, belongs to the machine tool precision detection technology field and relates to a double rotating shaft geometry error detection and identification method of a five-axes numerical control machine tool. The method adopts a high-resolution binocular vision system. Position information of a marking point which is pasted on a machine tool rotation table surface is collected. Through camera calibration, image segmentation, marking point extraction and a machine tool rotating shaft error identification model, detection acquisition of a two-position error and a two-angle error of a machine tool rotating shaft is realized. Rapid measurement of a geometrical parameter is completed. A circular marking point is used. An image processing program is simple, feature extraction precision is high, robustness is good and measurement is rapid and convenient. Simultaneously, a problem that numerical control machine tool rotating shaft installation error detection and identification are difficult is solved and a new direction is provided for a machine tool error detection and identification technology.

Owner:DALIAN UNIV OF TECH

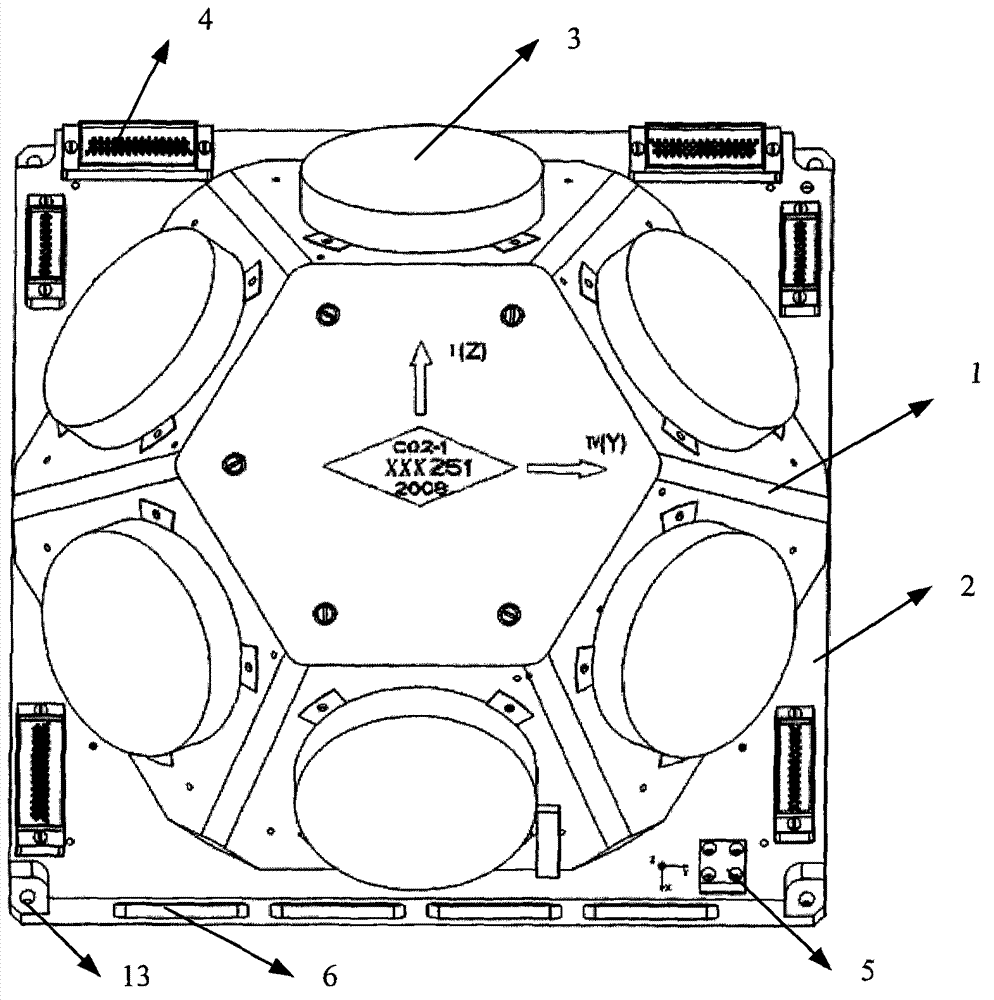

Apparatus for measuring inertia of fiber gyro composite unit and its calibration method

ActiveCN102735232AImprove mechanical propertiesImprove the accuracy of useSagnac effect gyrometersFiberEngineering

The invention relates to an apparatus for measuring inertia of a fiber gyro composite unit and its calibration method, and especially relates to the apparatus for measuring the inertia of the fiber gyro composite unit with miniaturization, high reliability and redundant multi-tables used for navigation, guidance and control of spacecrafts, which belongs to the inertia measurement technical field. The apparatus comprises a hexangular pyramid and a pedestal; six fiber gyroscopes are uniformly distributed on six side surfaces of the hexangular pyramid, six signal processing and interface circuits and six secondary power sources are arranged in the pedestal. According to the invention, the gravity center is positioned at a geometric center as possible, and the anti-mechanical capacity is good; the six fiber gyroscopes are redundant backup with each other; the reliability is high; in the process of in-orbit operation, a triaxial attitude angle speed can be still provided even the fault is generated by no more than three shafts at will, and the fault detection and the isolation can be realized. The calibration method can accurately calibrate zero position, scale factor and installation error, and can effectively enhance the in-orbit usage precision.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

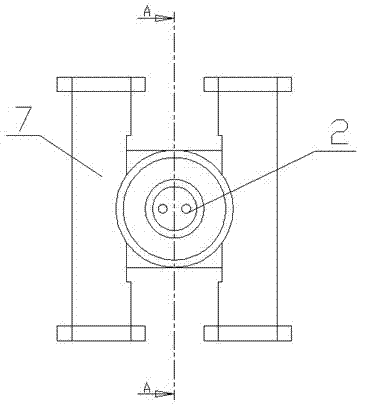

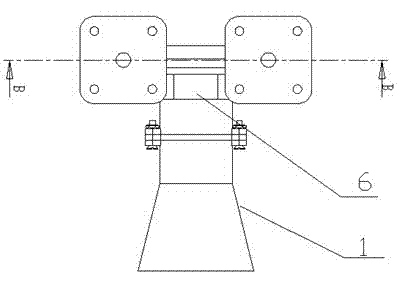

Charging butt joint and separation device for inspection robot and solar charging base station

ActiveCN102904307APrecise dockingThe docking process is simpleBatteries circuit arrangementsCoupling device detailsButt jointInstallation Error

The invention relates to a charging butt joint and separation device for an inspection robot and a solar charging base station. The device comprises a butt joint deviation adaptation mechanism, a charging dock mechanism arranged on the butt joint deviation adaptation mechanism, and a charging head connected with the charging dock mechanism in a matching manner; the device is arranged on the suspension clamp of a high-altitude transmission line; and the charging head is arranged on the mechanical arm of the robot. When the mechanical arm is moved along the transmission line so as to perform butt joint on the charging head and the device, the device can adapt to alignment deviation brought by installation errors of the charging head and the device, downward deformation of the transmission line due to the gravity of the robot and the like, so that the butt joint of the inspection robot and the solar automatic charging base station is realized, the butt joint is simple, efficient, safe and reliable, and the cost is low.

Owner:GUANGDONG KEYSTAR INTELLIGENCE ROBOT CO LTD

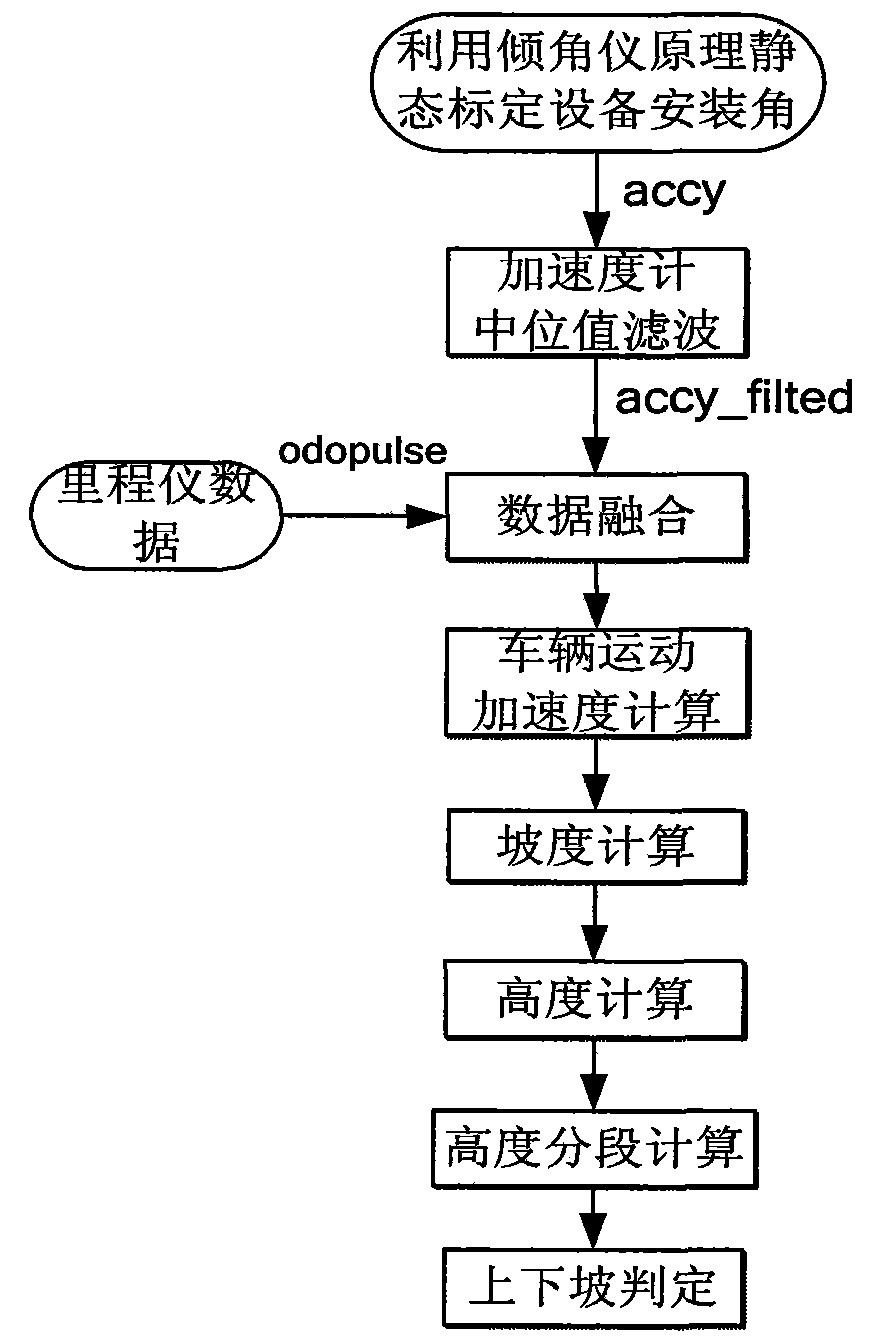

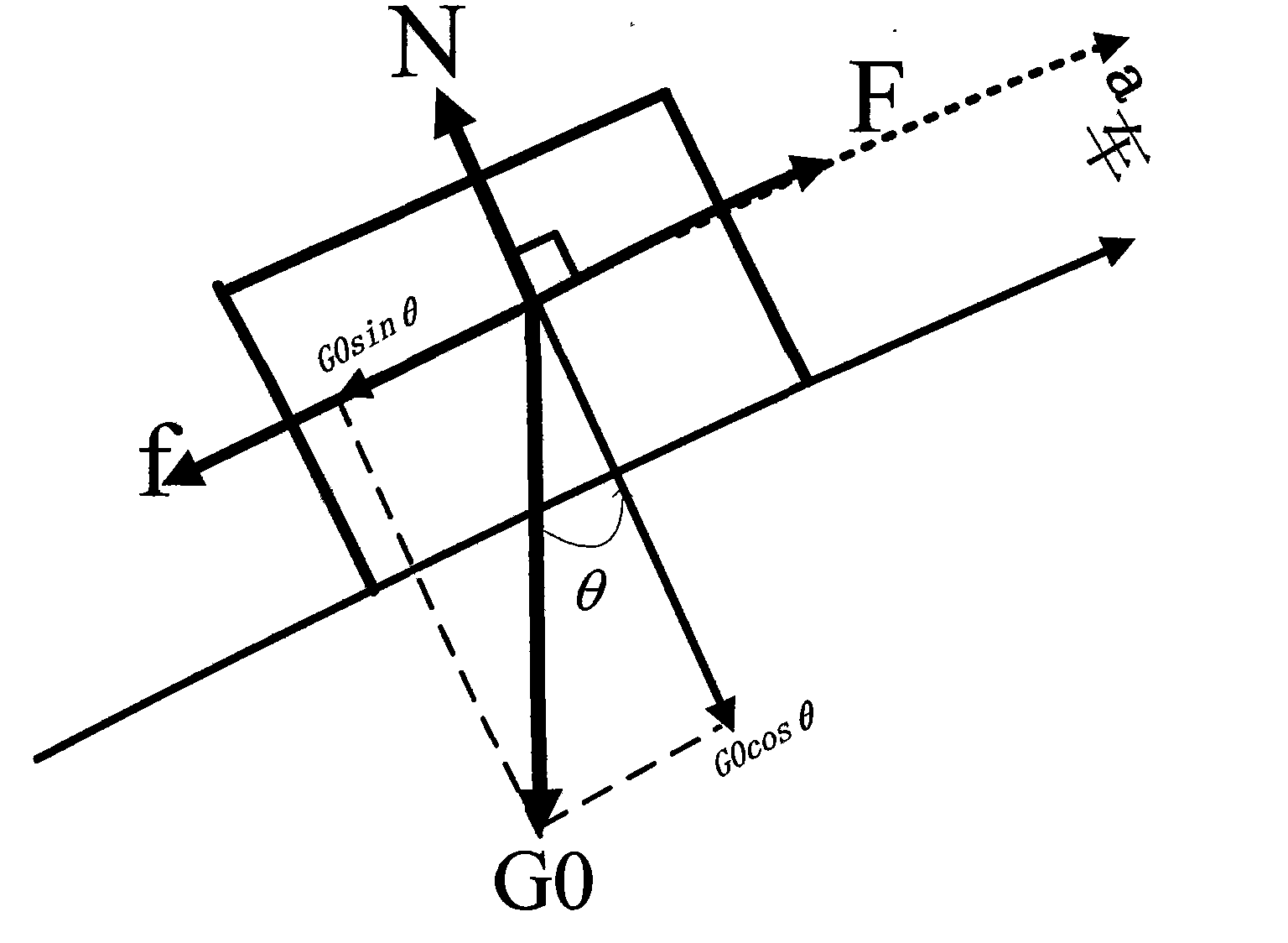

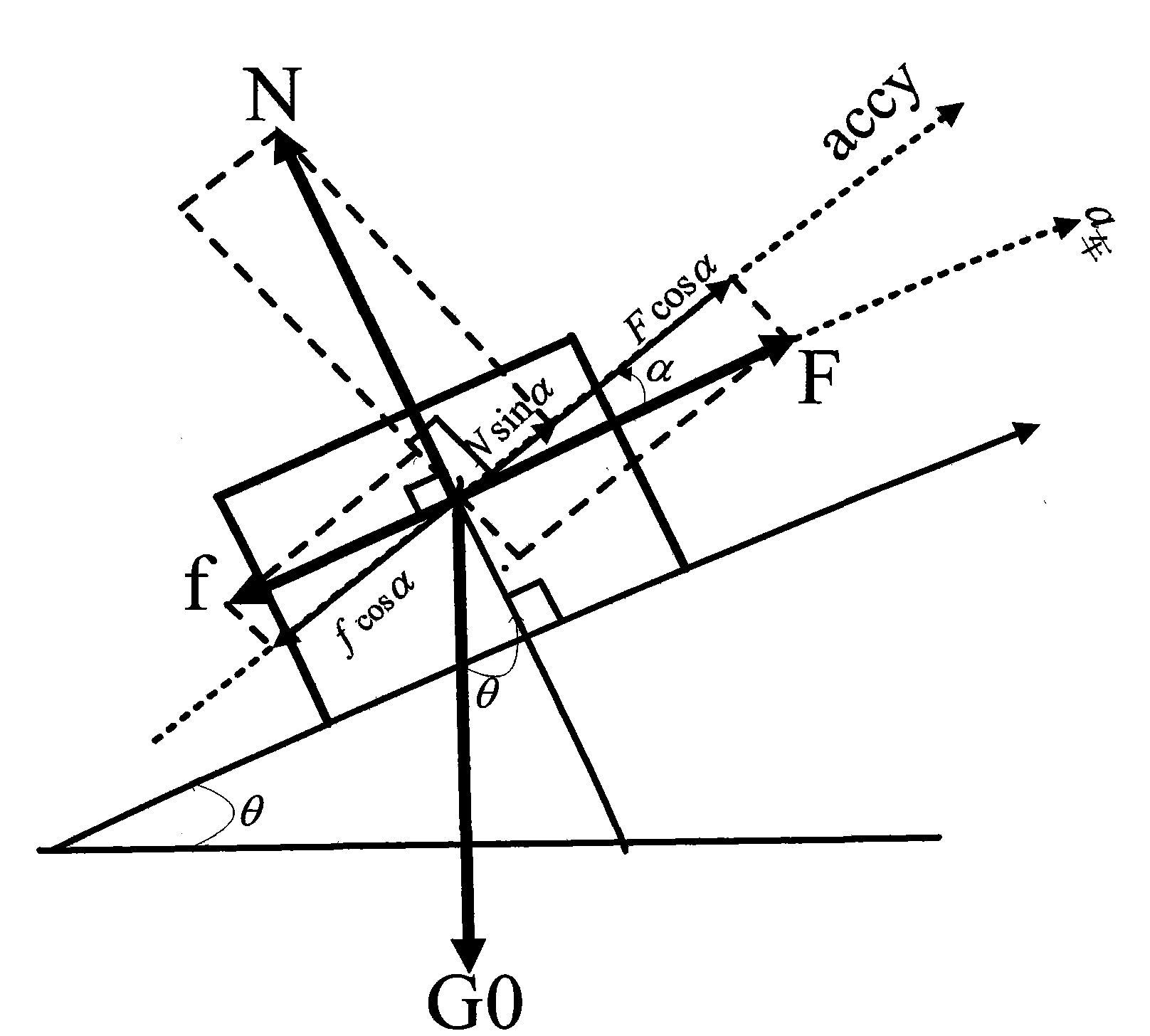

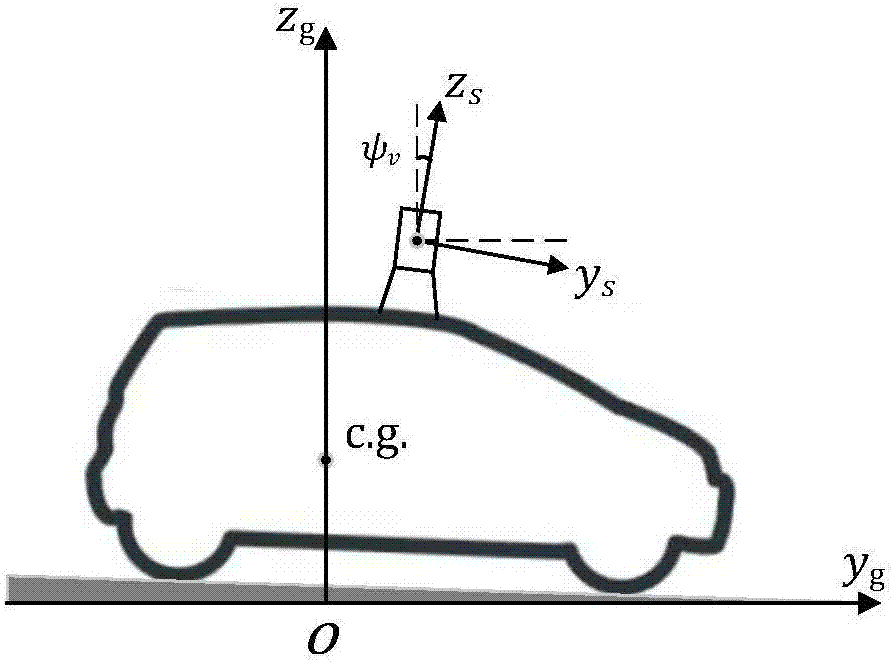

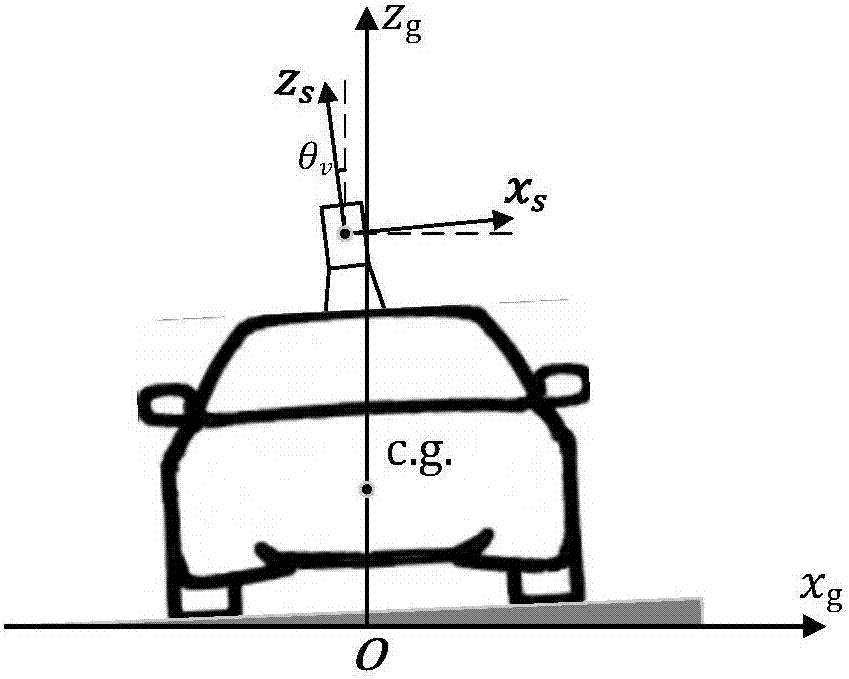

Method for dynamic estimation of vehicle running gradient and relative height

InactiveCN101598549AHigh measurement accuracyAvoid the pitfalls of relying solely on accelerometer sensorsHeight/levelling measurementIncline measurementAccelerometerEngineering

The invention discloses a method for dynamic estimation of vehicle running gradient and relative height. In the method, based on a uniaxial accelerometer and an odometer hardware, an algorithm is used to calculate road grade and vehicle running relative height information, the uniaxial accelerometer is used to measure acceleration accy in the vehicle longitudinal axis direction; the odometer is used to accurately measure vehicle running speed, thus providing the vehicle with vehicle acceleration information a, and according to the geometric relationship between accy and a, gradient value and height change value can be obtained, then whether the vehicle runs upslope and downslope can be identified according to height change and restricting rules. In the process of concrete implementation, installation error of the uniaxial accelerometer, noise processing of acceleration data, alignment of data of two types of sensors and upslope and downslope identification rules are taken into consideration. The method features high measurement accuracy, improvement of stability and reliability of a system, realization of real-time measurement of vehicle running gradient and height, very high sensibility and response speed, small power dissipation, quick startup, simpleness and practicability.

Owner:BEIHANG UNIV

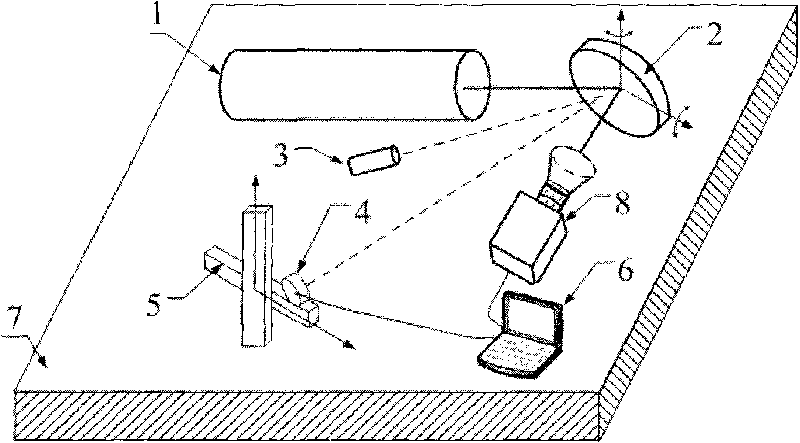

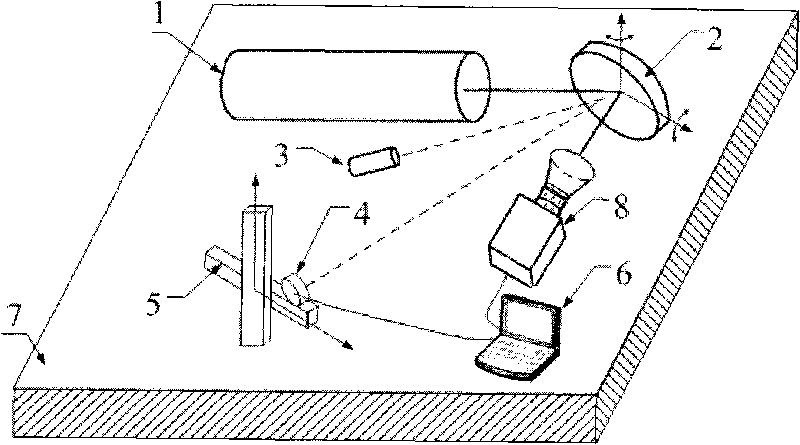

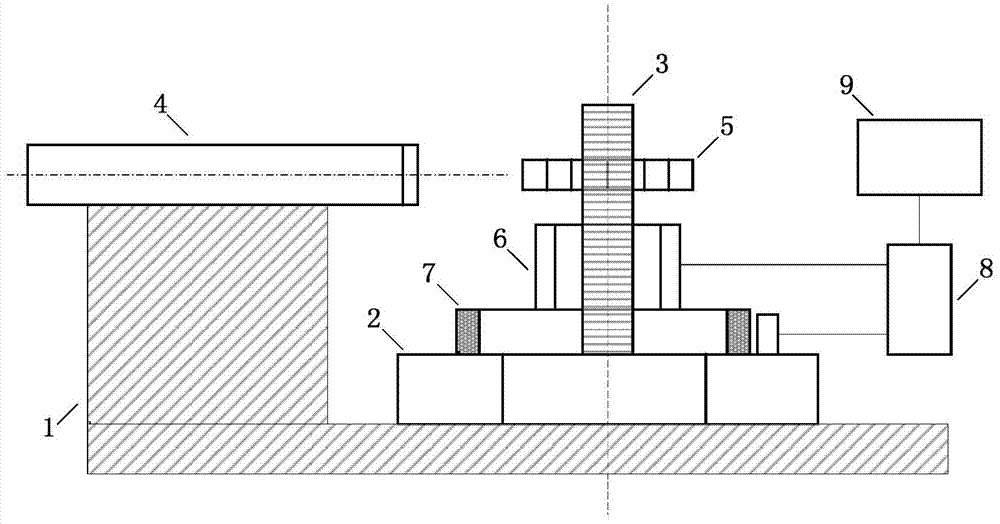

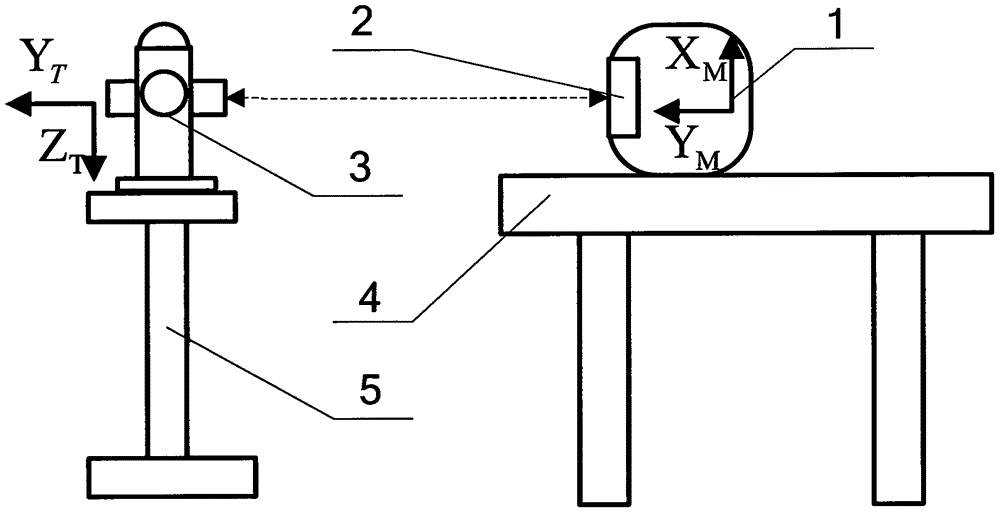

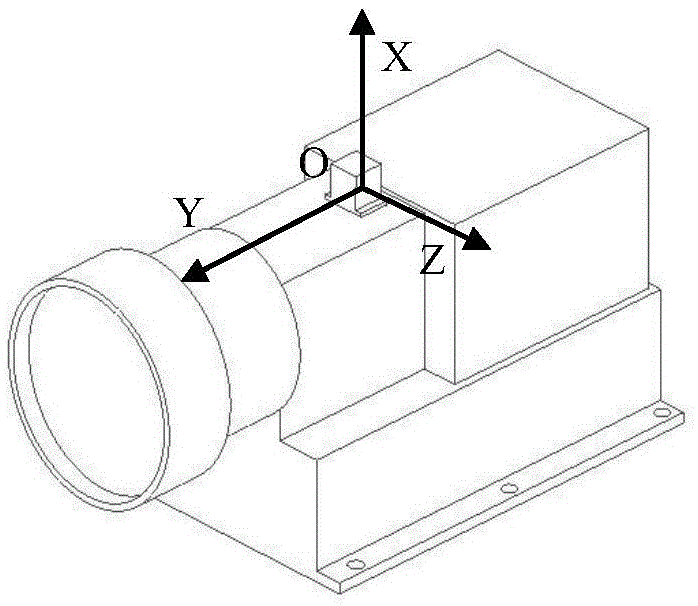

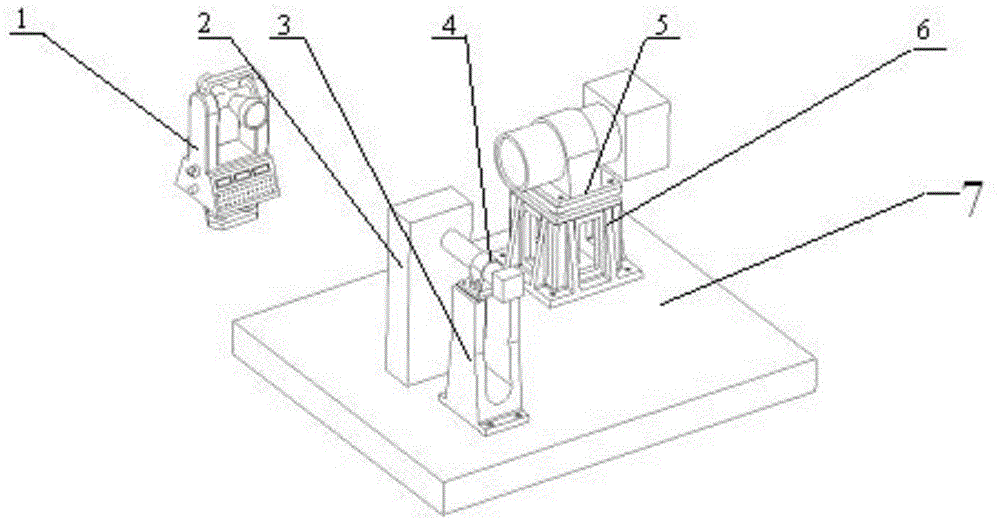

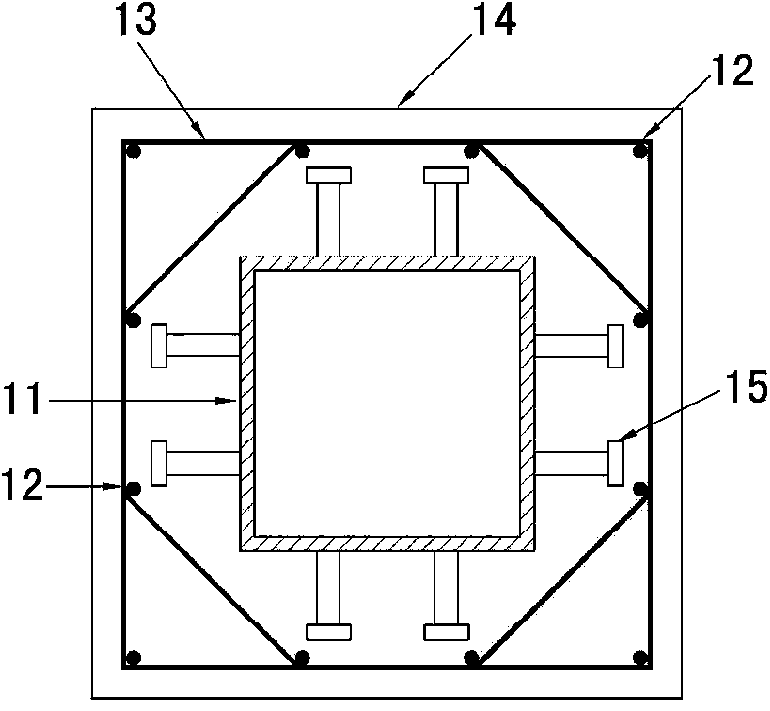

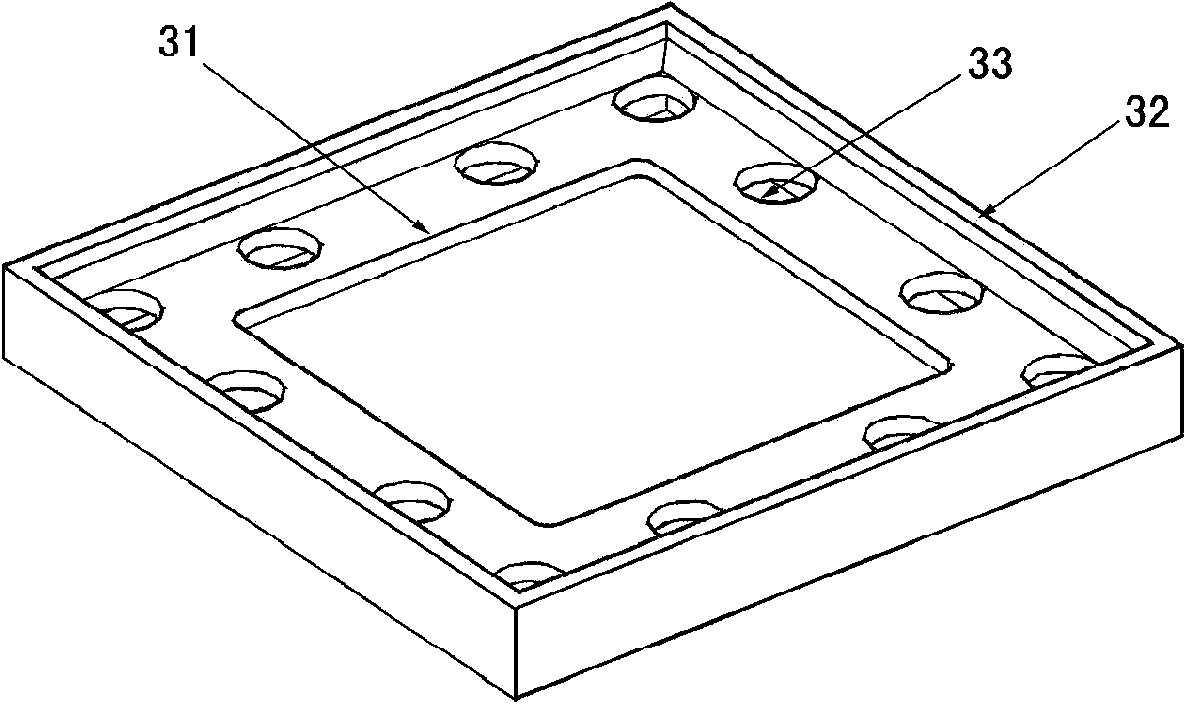

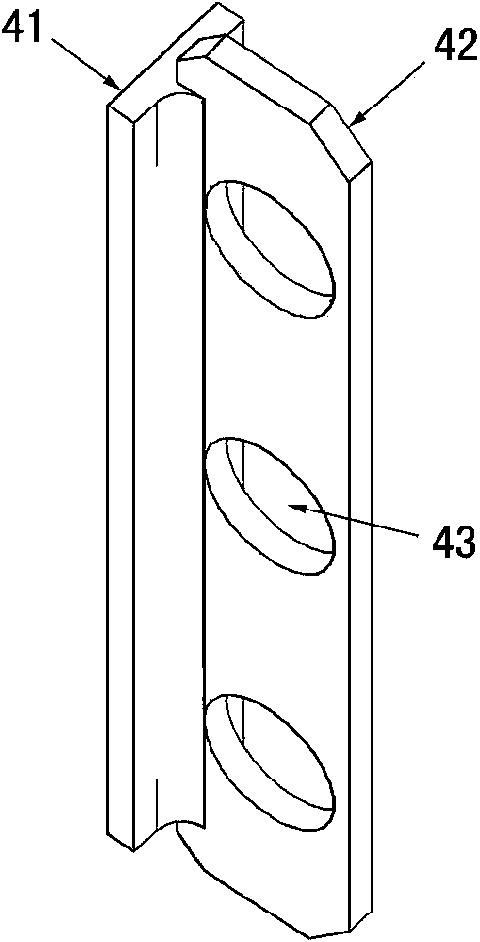

Star sensor reference cube-prism installation error calibration apparatus

ActiveCN105318891AHigh precisionQuick installation error calibrationMeasurement devicesSingle starTheodolite

The present invention belongs to the technical field of optoelectronic equipment calibration, and particularly relates to a star sensor reference cube-prism installation error calibration apparatus. According to the present invention, a photoelectric autocollimator and a single star simulator are respectively placed on two orthogonal axes of a reference plane, a detected star senor is placed at the intersection point position of the two axes so as to make the normal lines of the two orthogonal light reflection surfaces of the detected star senor reference prism be respectively parallel to the two orthogonal axes, the optical axes of the photoelectric autocollimator and the single star simulator are respectively adjusted to parallel to the reference plane through a theodolite, the star sensor is installed on a star sensor three-dimensional adjustment reference base, the input optical axis of the star sensor and the output optical axis of the single star simulator are adjusted to achieve a parallel state through the star sensor three-dimensional adjustment reference base, a detected reference cube-prism is arranged on the upper surface of the housing of the detected star senor, the installation angle error of the reference cube-prism round the X-axis and the Y-axis is measured by using photoelectric autocollimation, the star sensor three-dimensional adjustment reference base rotates 90 DEG, and the installation angle error of the reference cube-prism round the Z-axis is measured.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

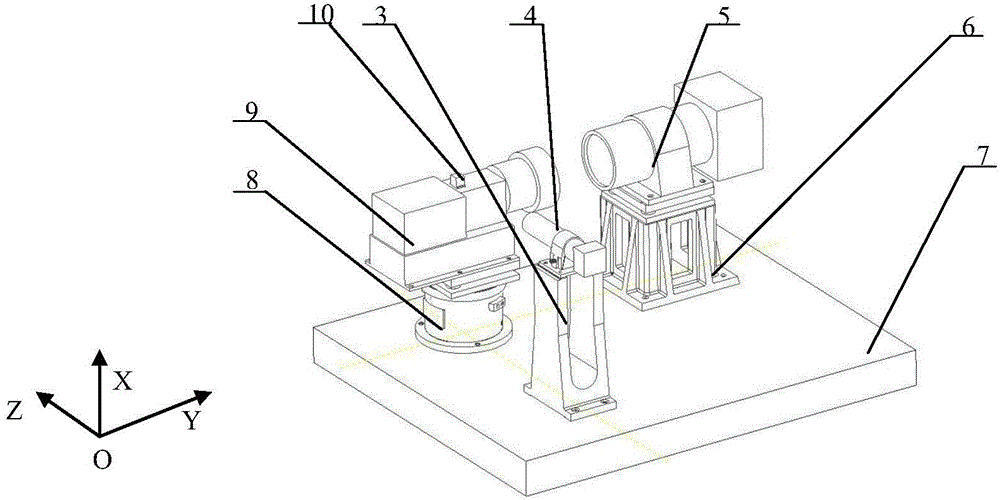

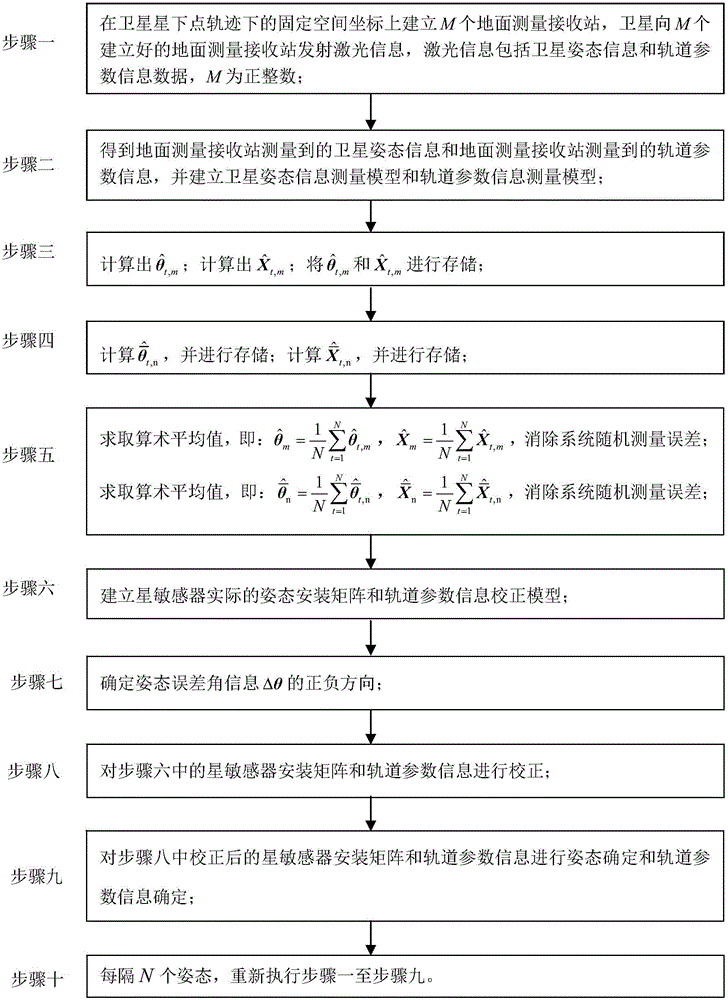

Star sensor installation error matrix and navigation system star-earth combined calibration and correction method

ActiveCN104792340AOvercome the defects of installation errorsHigh precisionMeasurement devicesNavigation systemErrors and residuals

The invention relates to a star sensor installation error matrix and navigation system star-earth combined calibration and correction method, and aims at solving the problem that a conventional star sensor calibration method cannot preferably complete the calibration of an installation error matrix of a star sensor and cannot calibrate and correct the star sensor installation error matrix and navigation system deviation at regular intervals. The method is realized according to the following steps: (1) acquiring information theta<t,m> and X<t,m>; (2) establishing an attitude information and orbital parameter information measurement model; (3) determining values shown in the specification; (4) calculating values shown in the specification; (5) solving an arithmetic mean value; (6) establishing a practical attitude installation matrix and orbital parameter information correction model of the star sensor; (7) determining the direction of delta theta; (8) correcting the (6); (9) determining the attitude and the orbital parameter information; and (10) rerunning every N attitudes. The star sensor installation error matrix and navigation system star-earth combined calibration and correction method is applied to the field of satellite attitude determination technology and satellite navigation technology.

Owner:HARBIN INST OF TECH

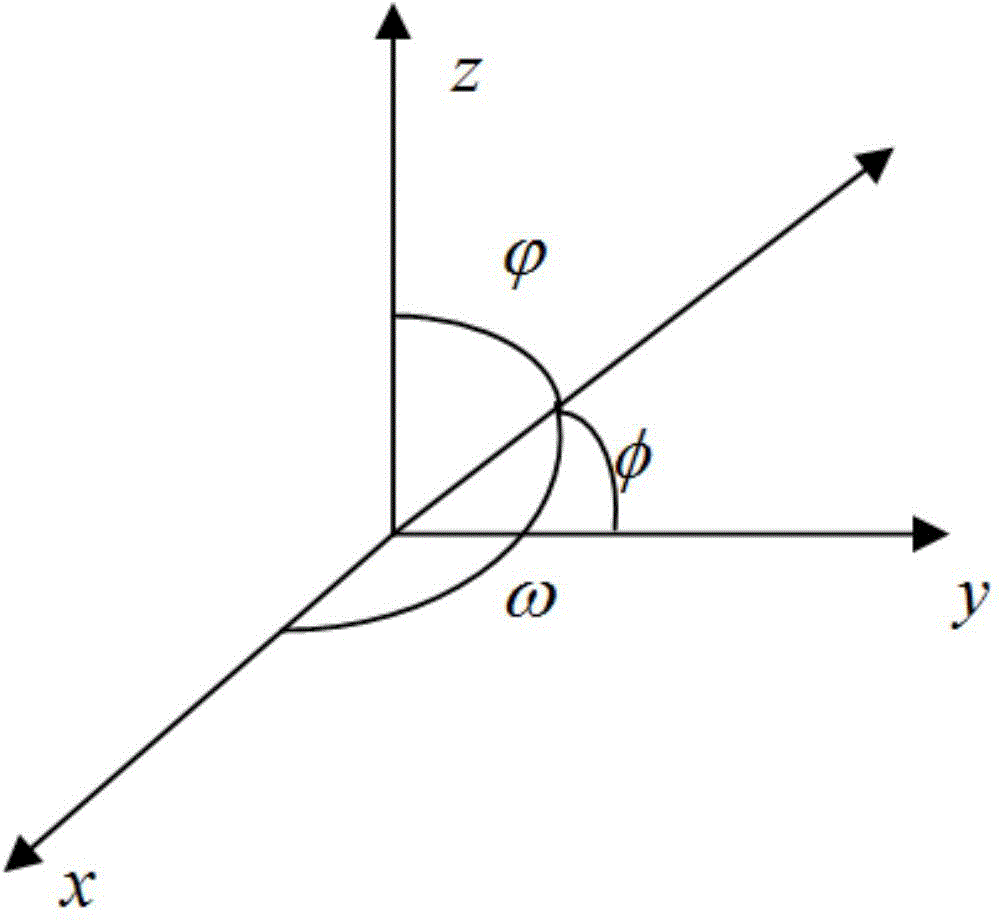

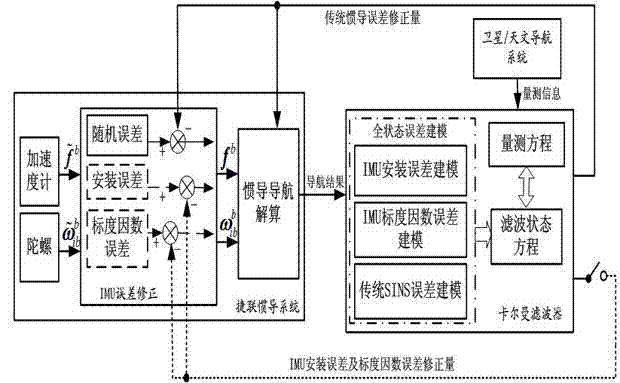

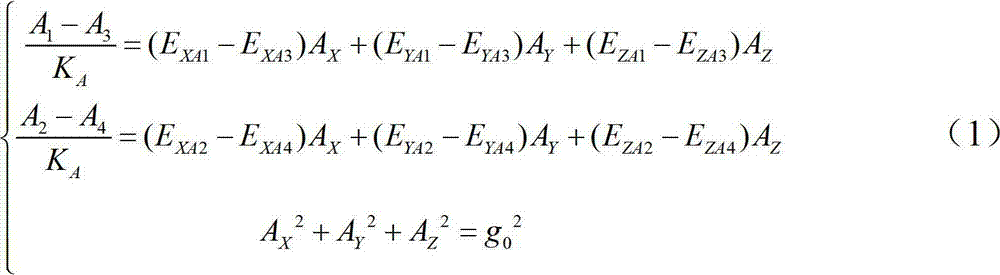

Method for calibrating fixed errors of inertial sensor in inertial navigation system in real time

ActiveCN103245359AReduce mistakesHigh precisionMeasurement devicesInstallation ErrorEquation of state

The invention discloses a method for calibrating fixed errors of an inertial sensor in an inertial navigation system in real time. The method comprises the following steps of: firstly, establishing a fixed error model of the inertial sensor during the dynamic flying process of an aircraft, wherein the fixed errors include installation errors and scale factor errors; secondly, establishing a state equation and a position, speed and attitude linear measurement equation of a filter, with the fixed errors of the inertial sensor included, on the basis of a random error model of a traditional IMU (Inertial Measurement Unit) and the established fixed error model; and finally, carrying out real-time dynamic calibration and correction to the fixed errors of the inertial sensor during the dynamic flying process of the aircraft, so as to obtain the navigation result of the inertial navigation system after the fixed errors of the inertial sensor are compensated and corrected. The method can realize the calibration and correction of installation errors and scale factor errors of the inertial sensor used in the inertial navigation system during the dynamic flying process of the aircraft, effectively enhances the performance of the inertial navigation system, and is suitable for engineering application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

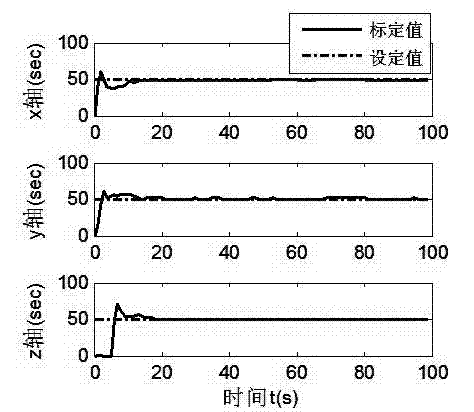

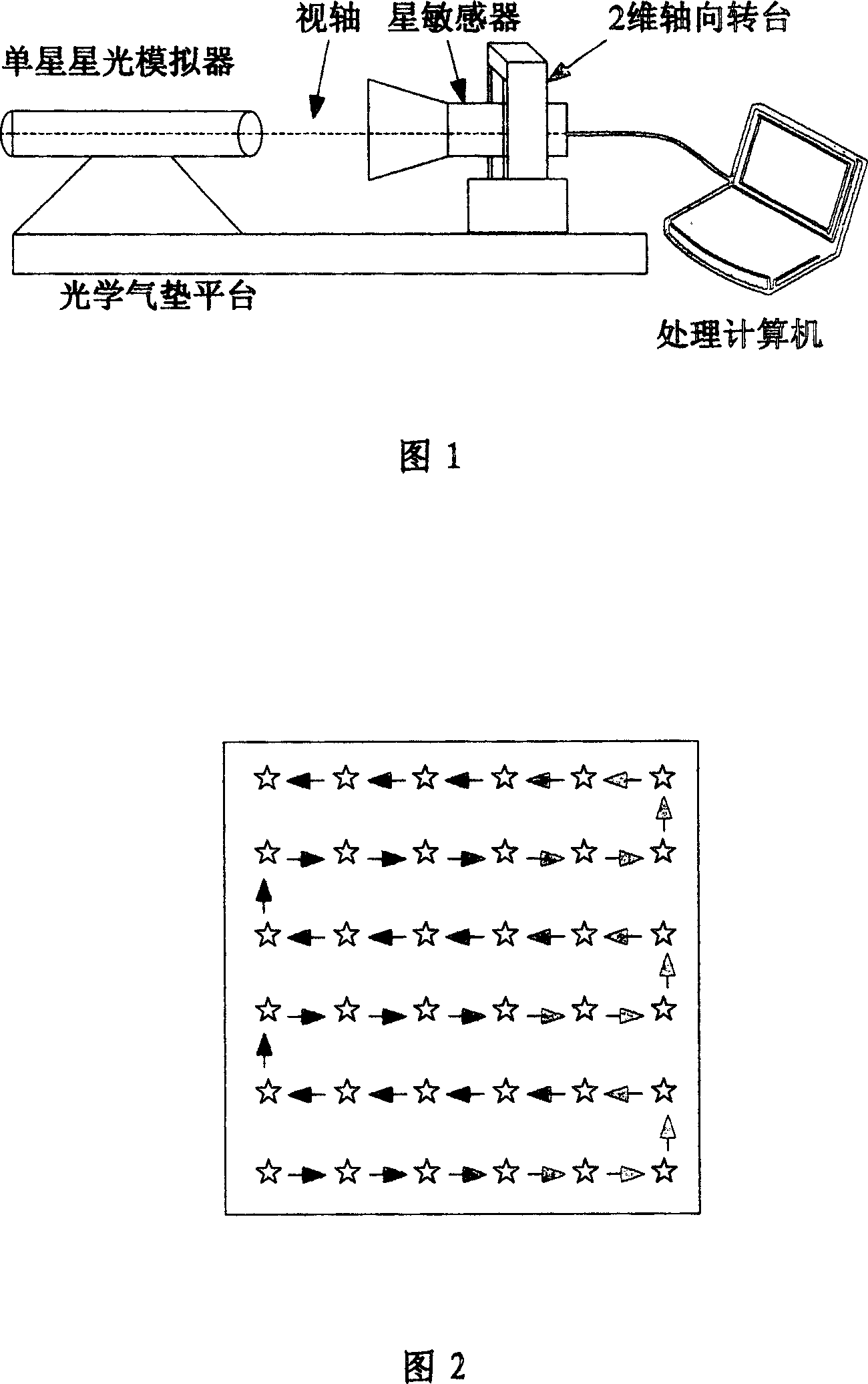

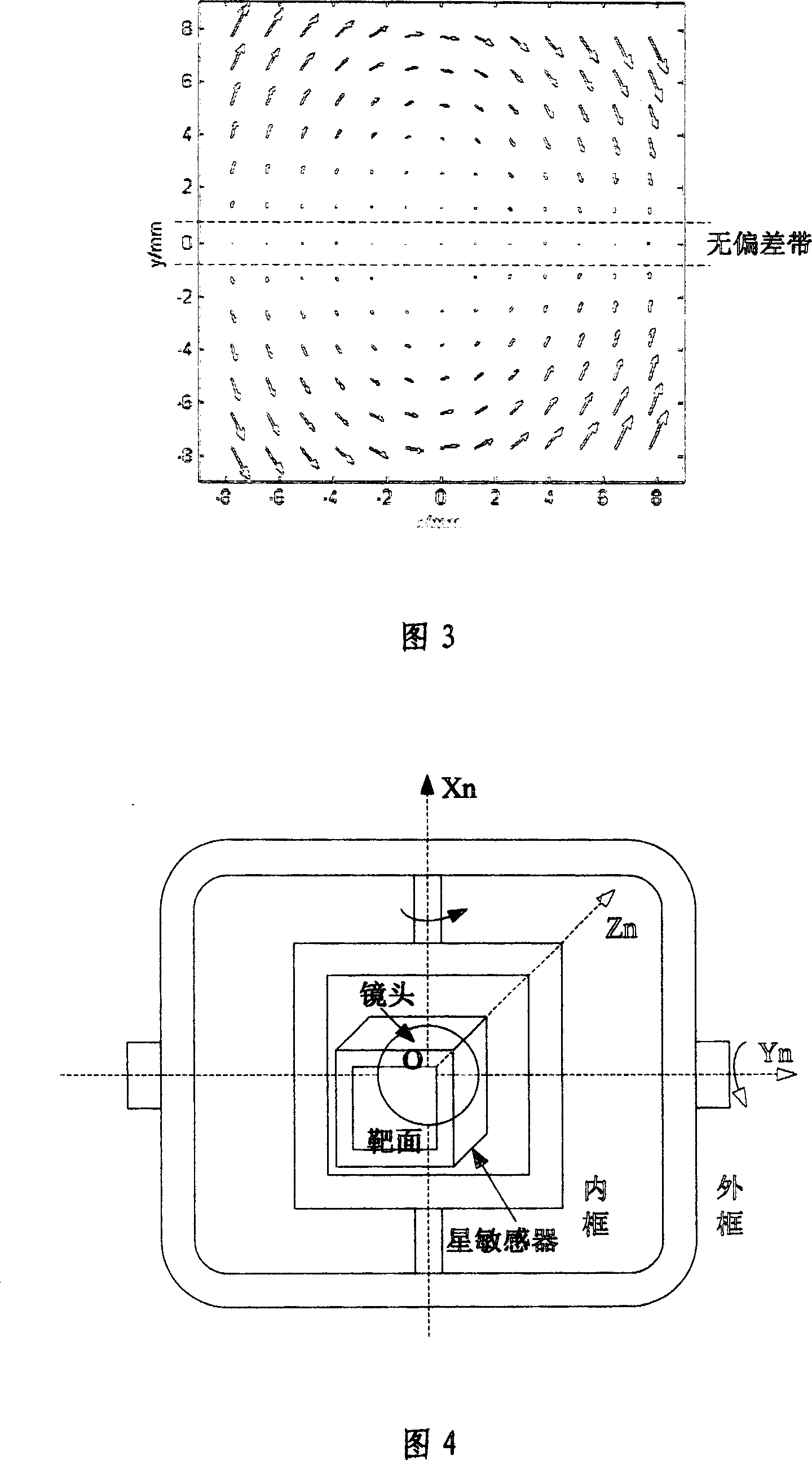

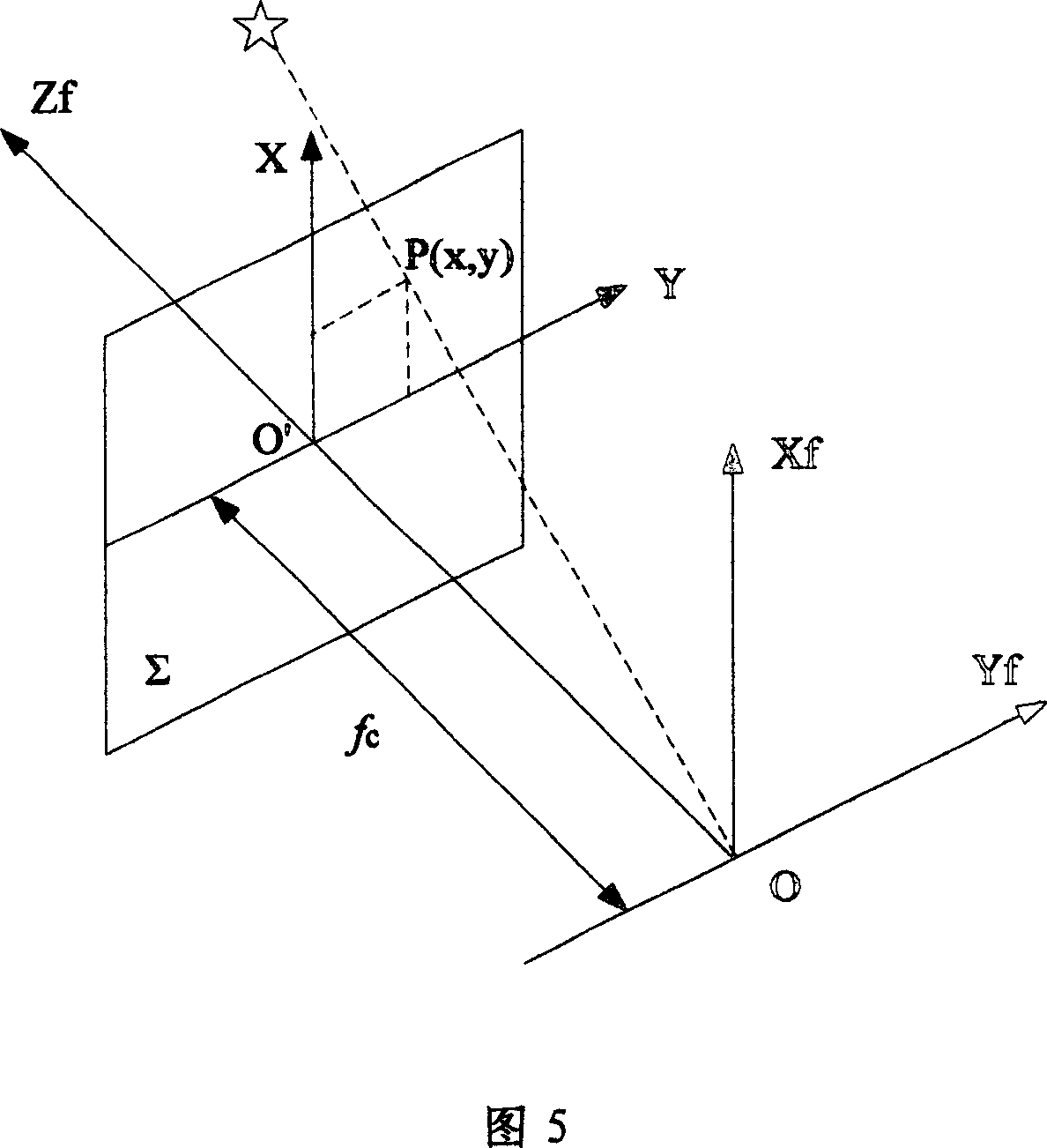

Zero deflection band based star sensor ground surface calibration method

InactiveCN101013033ARemove estimated effectsSmall amount of calculationPhotogrammetry/videogrammetryCosmonautic vehicle trackingSingle starEngineering

The invention is a space measurement technology, involving the improvement to the star sensor calibration method. The invention uses the calibration system which comprising the air cushion platform, single star starlight simulator, star sensor, two-dimensional axial turntable and data processing computer, and its steps are: 1. establish the star sensor imaging model; 2. parameters calibrating. The invention uses no deviation strip to calibration focus and radial distortion coefficient, eliminating the internal parameter estimation effect by the external installation error; the method has simple model and small computing volume, particularly applied to the star sensor calibration based on radial distortion.

Owner:BEIHANG UNIV

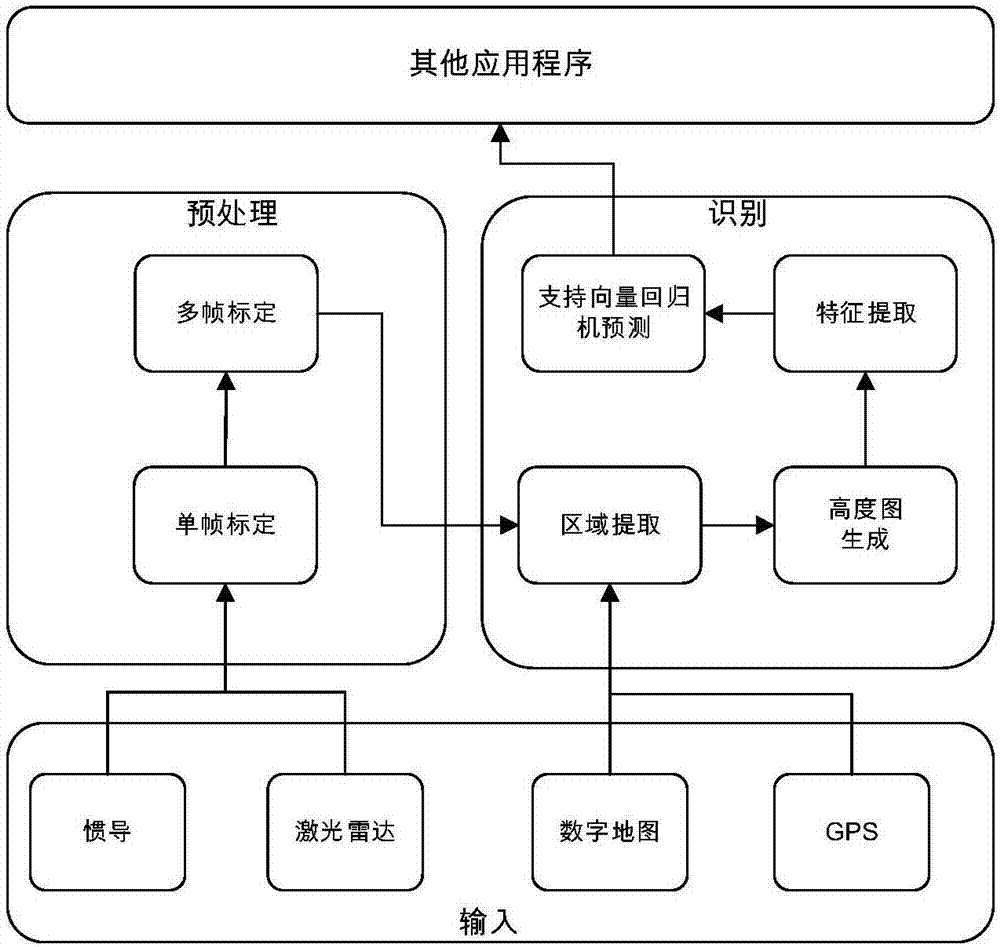

Unmanned vehicle intersection detection method based on three-dimensional laser radar

InactiveCN106896353AEfficient detectionStrong real-timeWave based measurement systemsData acquisitionSupport vector regression machine

The invention relates to an unmanned vehicle intersection detection method based on three-dimensional laser radar. In the traveling process of an unmanned vehicle, the laser radar collects ambient environment data and inputs the data to a support vector regression machine, thereby obtaining front intersection branch information. The training process of the support vector regression machine includes the following steps: S1. a laser radar installation error is corrected; S2. the unmanned vehicle travels along a road, the laser radar performs data collection on ambient environment, point cloud data are obtained, and an intersection node in front of the unmanned vehicle is found; S3. grid division is performed on a region of interest of each branch, thereby obtaining multiple frames of height information map; and S4. a pixel point sequence in the height information map is used as a feature vector, and characteristics of branches are used as output, thereby training the support vector regression machine. Compared with the prior art, a method for modeling different types of intersections is designed, different types of intersections can be effectively detected, and the method is suitable for different types of laser radars, and can achieve the same detection effect.

Owner:TONGJI UNIV

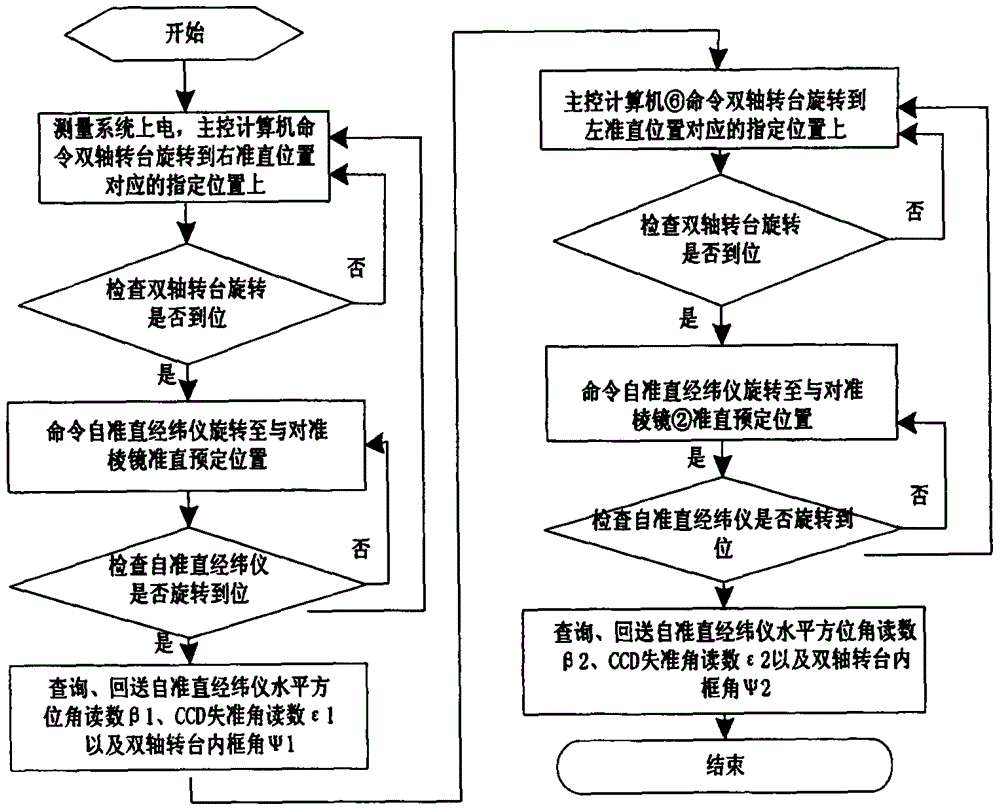

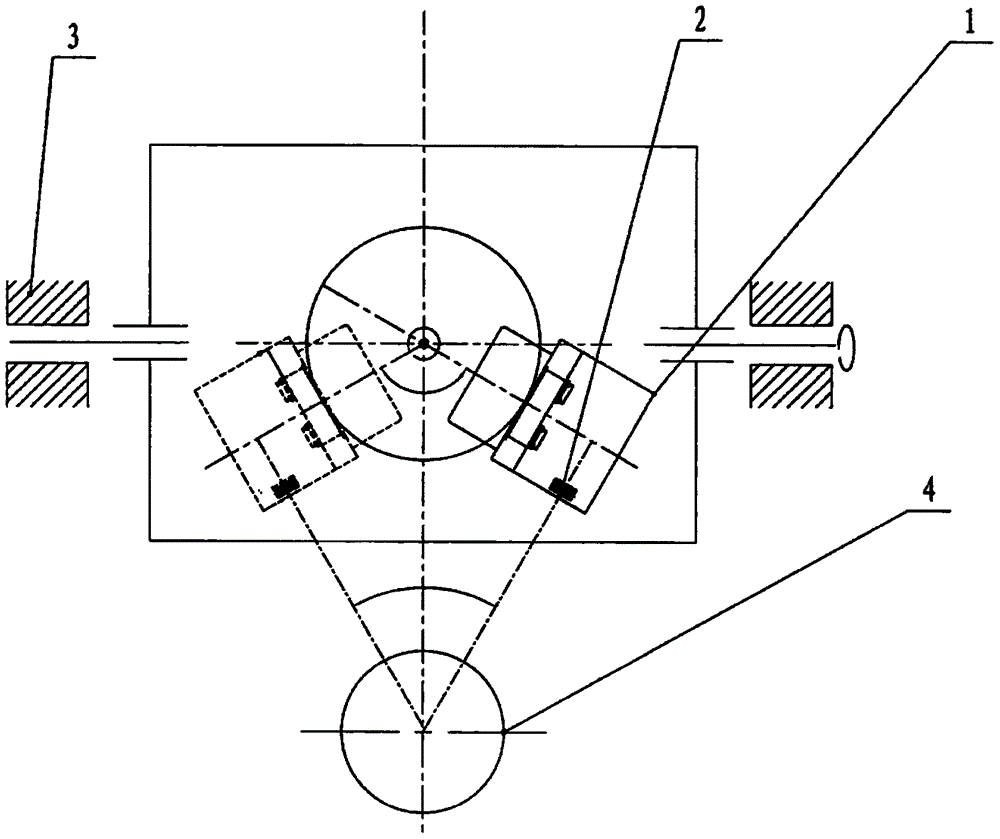

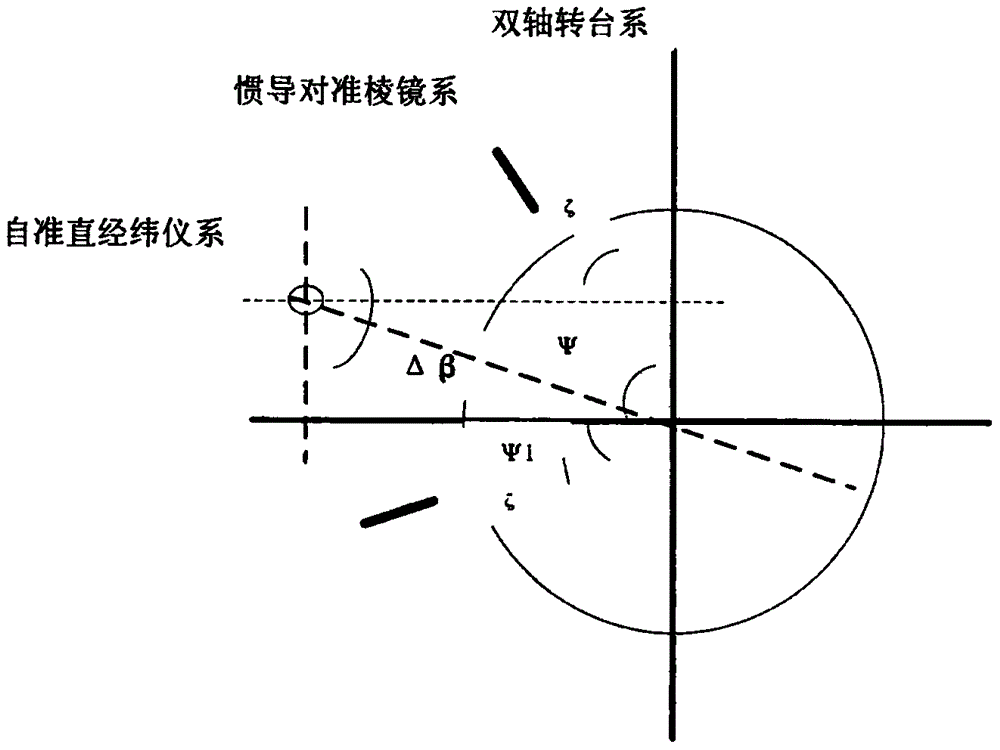

Method for measuring installation error coefficient of strap-down inertial navigation system and alignment prism

The invention provides a method for measuring an installation error coefficient of a strap-down inertial navigation system and an alignment prism. Hardware facilities comprise a two-axis turntable, a strap-down inertial navigation system, an alignment prism, an autocollimation theodolite, a main control computer, a display, a keyboard and the like. The method comprises the following steps: changing collimation positions of the strap-down inertial navigation table, the alignment prism and the autocollimation theodolite by rotating the two-axis turntable twice, recording CCD (Charge Coupled Device) misalignment angle reading and horizontal plate reading beta of the autocollimation theodolite, inside and outside frame coded disc reading alpha of the two-axis turntable and strap-down inertial navigation output parameters twice by the main control computer, and resolving the installation error coefficient between the alignment prism and the inertial navigation system after an initial alignment manner of the alignment prism to the strap-down inertial navigation system is changed into a vertical installation manner.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

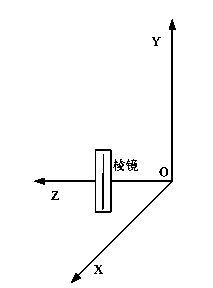

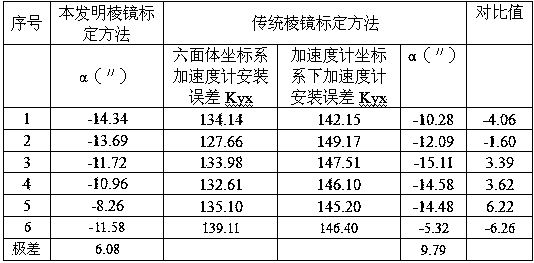

Laser strapdown inertial navigation system prism ridge orientation installation error calibration method

ActiveCN103471619ASolve complex operationsGuaranteed Calibration AccuracyMeasurement devicesAccelerometerTheodolite

The invention discloses a laser strapdown inertial navigation system prism ridge orientation installation error calibration method. The method utilizes calibration equipment such as a marble flat plate or a rotary table and a self-alignment theodolite. Through integrated computation on an inertial navigation product accelerometer leveling angle and a self-alignment theodolite-aimed prism pitching angle, a prism ridge orientation installation error computational formula is derived. The method is simple and practicable, is convenient for operation, and solves the problem that the traditional calibration method for calibration of a laser strapdown inertial navigation system adopting an accelerometer coordinate system as an inertial navigation proprio-coordinate system has high calibration complexity. The method can realize direct calibration of a prism ridge orientation installation error of the laser strapdown inertial navigation system adopting the accelerometer coordinate system as the inertial navigation proprio-coordinate system so that prism orientation installation error calibration is fast.

Owner:HUNAN AEROSPACE ELECTROMECHANICAL EQUIP & SPECIAL MATERIAL INST

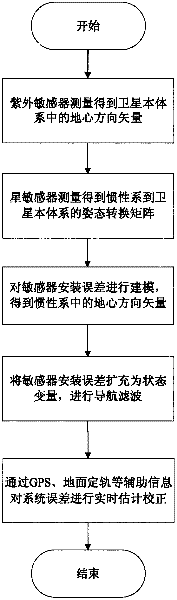

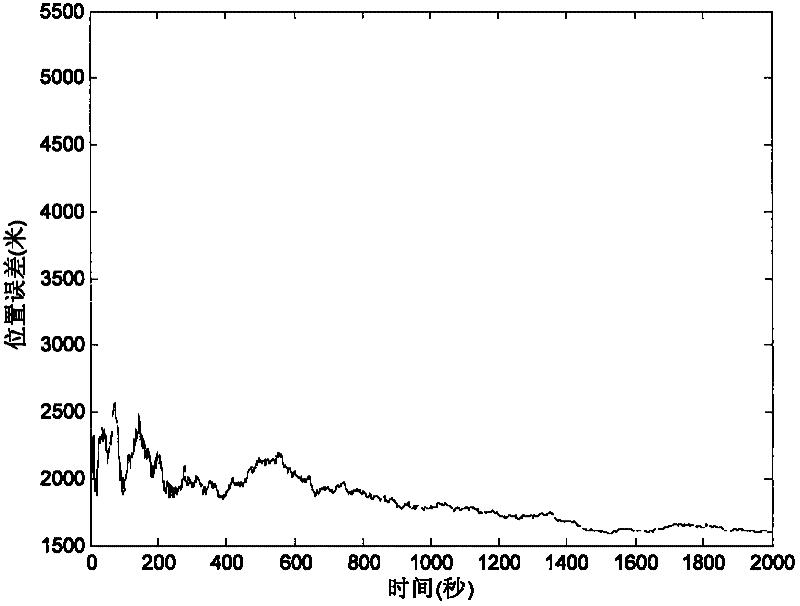

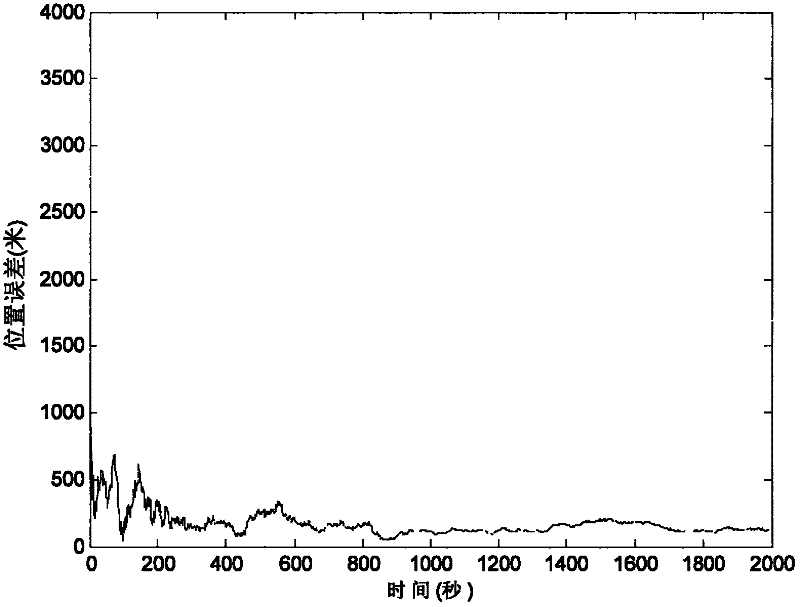

Error correction method of autonomous navigation system

ActiveCN102175260AImprove navigation accuracyMeasurement devicesAutonomous Navigation SystemState variable

The invention discloses an error correction method of an autonomous navigation system. In the autonomous navigation system based on an ultraviolet earth sensor and a star sensor, the ultraviolet earth sensor is used for measuring a geocentric vector in a satellite local system, and the star sensor is used for measuring an attitude transformation matrix of the satellite local system. Since the sensors inevitably have relative installation error, and a filter cannot eliminate the system error, the navigation accuracy becomes poor. In the method provided by the invention, the relative installation error of the ultraviolet earth sensor and the star sensor is modeled, and the installation error is expanded into a state variable so as to perform navigation filtering. Assuming that the satellite can obtain high-accuracy position measurement information by a GPS receiver or ground orbit determination within certain period of time, the system error can be estimated and corrected in time by filtering. The method provided by the invention has simple operation and can obviously improve the navigation accuracy.

Owner:BEIJING INST OF CONTROL ENG

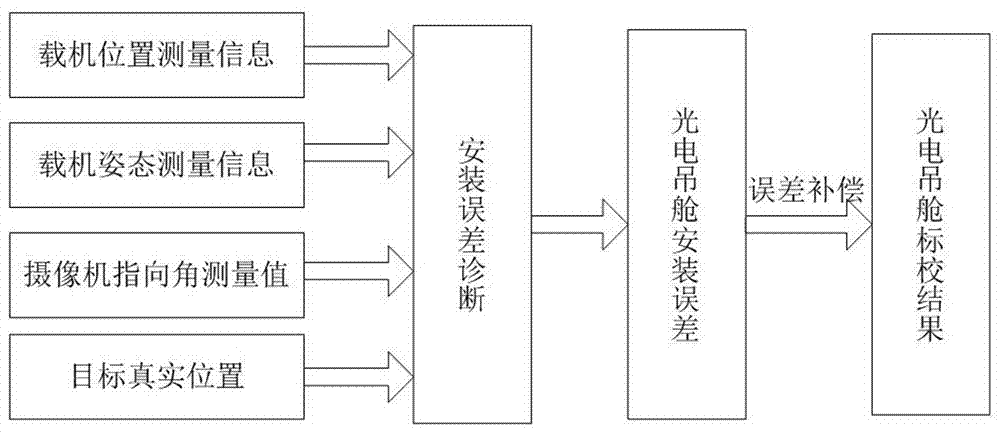

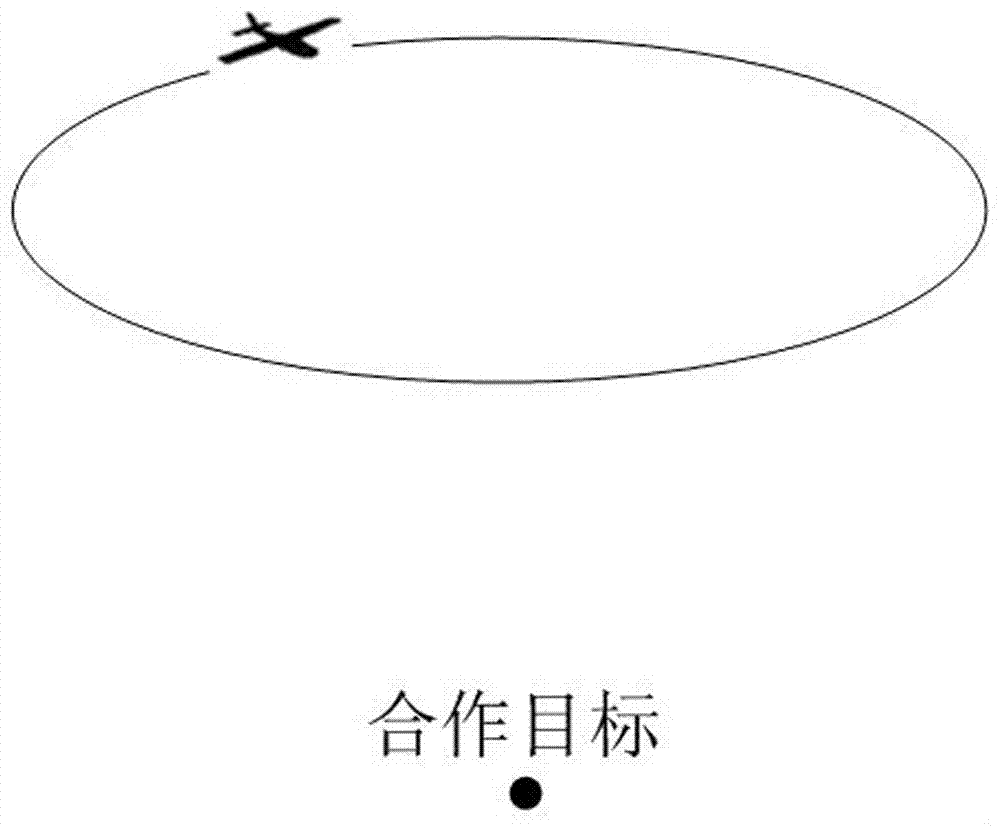

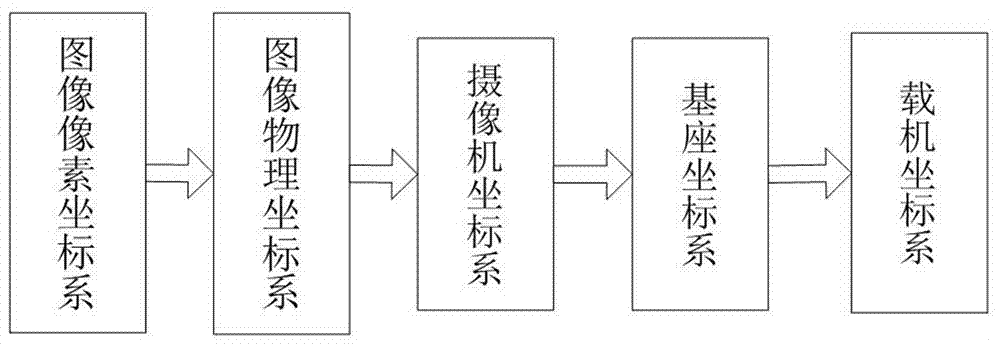

Method for calibrating installation error of optoelectronic pod of unmanned aerial vehicle

ActiveCN106871927AReduce installation errorsImprove efficiencyMeasurement devicesUncrewed vehicleLongitude

The invention discloses a method for calibrating the installation error of an optoelectronic pod of an unmanned aerial vehicle. The method comprises the following concrete steps: 1, firstly, determining a ground cooperation target point, and using a high precision differential global positioning system (GPS) to acquire longitude, latitude and elevation of the target point; 2, determining a flight alignment route of the unmanned aerial vehicle according to the cooperation target point; observing the cooperation target point, acquiring and recording image point coordinates of the cooperation target point, and carrying out coordinate transformation; 3, establishing an installation error diagnosis model; 4, identifying unknown parameters in the installation error diagnosis model and compensating for the installation error of the optoelectronic pod during a subsequent positioning process. According to the method, the installation angle error of the optoelectronic pod is obtained mainly by analyzing flight alignment data, and correction is performed during coordinate transformation, so that the problems that at present, the installation error calibration of the optoelectronic pod of an existing unmanned aerial vehicle is complicated to implement and inefficient are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

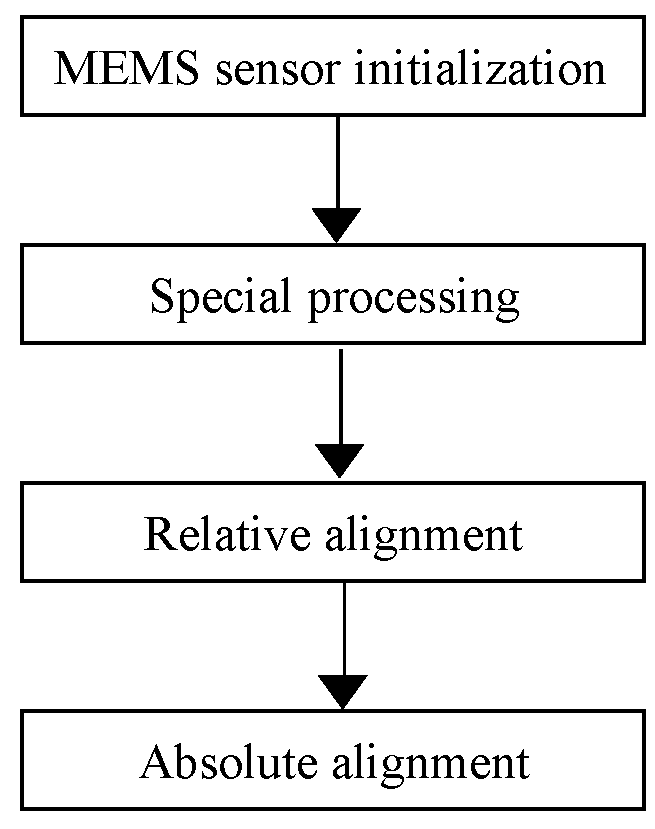

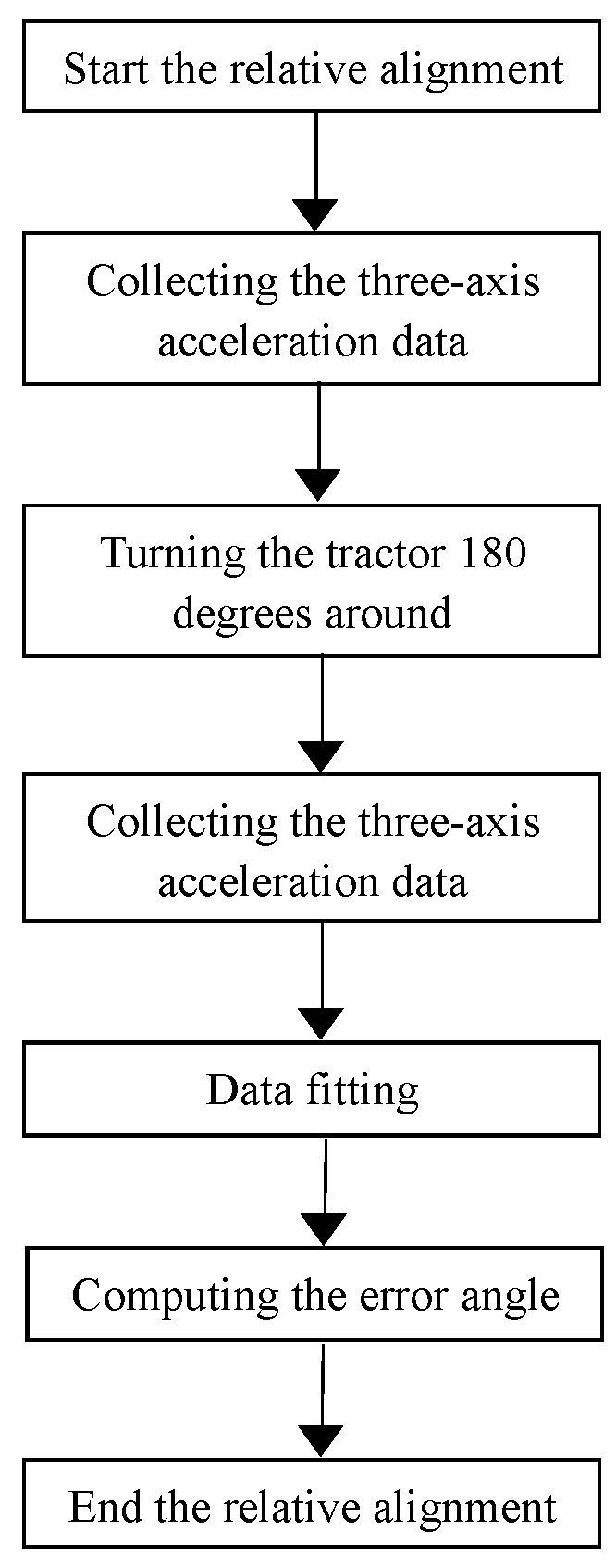

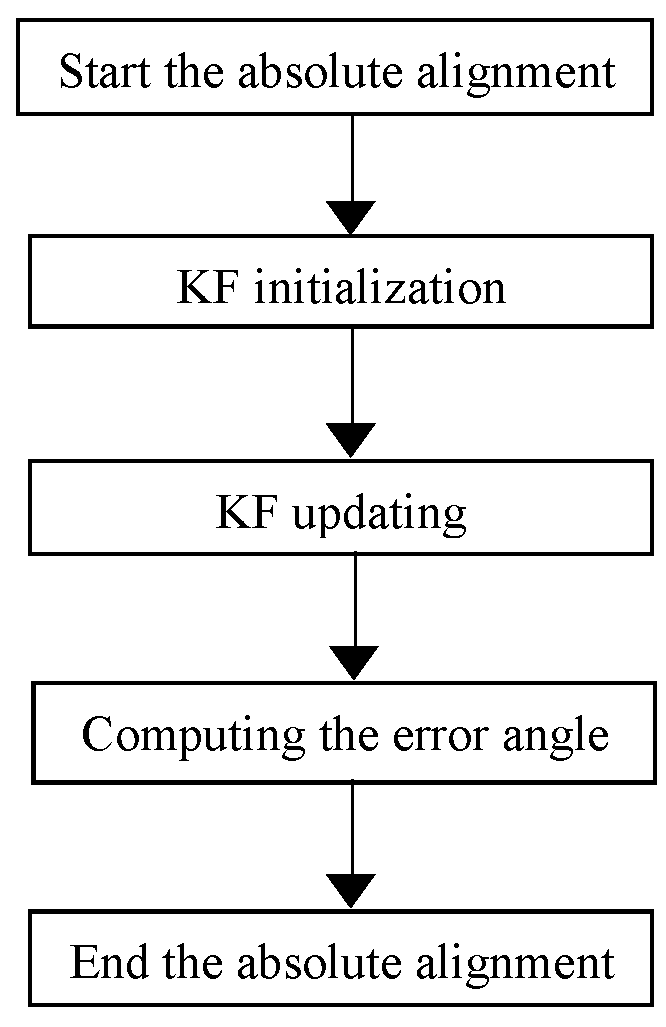

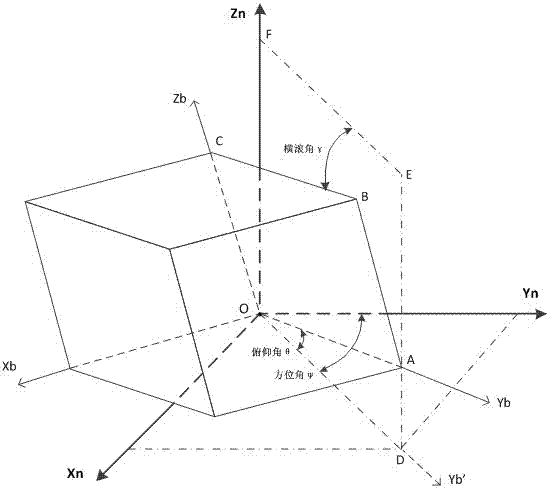

A method for initial alignment of an inertial navigation apparatus

ActiveUS20180274940A1Convergence can be speededImprove accuracyNavigation by speed/acceleration measurementsKaiman filterComputer vision

A method for initial alignment of an inertial navigation apparatus, comprising the following steps: providing an apparatus loaded with a sensor, and preprocessing the sensor; carrying out relative alignment to calculate an installation error angle of the sensor; carrying out absolute alignment to calculate an installation attitude angle error of the sensor to increase an accuracy of an error attitude angle calculated during the relative alignment. The relative alignment process calculates a relative error attitude angle, the relative error attitude angle being used as the initial value for attitude error in a stat vector in the absolute alignment process, thereby accelerating convergence of the Kalman filter. Alignment precision is further enhanced by the absolute alignment process.

Owner:SHANGHAI HUACE NAVIGATION TECH

Connecting joint of prefabricated hollow steel-reinforced concrete column and steel beam and construction method

InactiveCN103437425AReliable power transmissionImprove working conditionsBuilding material handlingReinforced concrete columnEngineering

The invention discloses a connecting joint of a prefabricated hollow steel-reinforced concrete column and a steel beam and a construction method. The connecting joint comprises the prefabricated hollow steel-reinforced concrete column, the H-type steel beam, a horizontal connecting disc and a connecting piece. In the construction process, the horizontal connecting disc and the connecting piece are attached to a central steel tube to be manufactured with the hollow steel-reinforced concrete column in a factory, and prefabricated hollow steel-reinforced concrete column splicing and steel beam installation are carried out at the construction site. The connecting joint is simple in structure and reliable in force transmission. The steel beam and the hollow steel-reinforced concrete column are manufactured in the factory, therefore, the operation condition can be improved, and the quality is easily guaranteed. The construction method for connecting the steel beam with the prefabricated hollow steel-reinforced concrete column is easy and convenient to achieve, and influences of installation errors on stress in a joint area are fewer. After concrete is poured, two materials including steel and the concrete are mutually limited and jointly stressed, and the improvements of the bearing capacity, the rigidity and the ductility of the joint are facilitated.

Owner:SHAANXI JIANKE XINGYE STEEL STRUCTURE

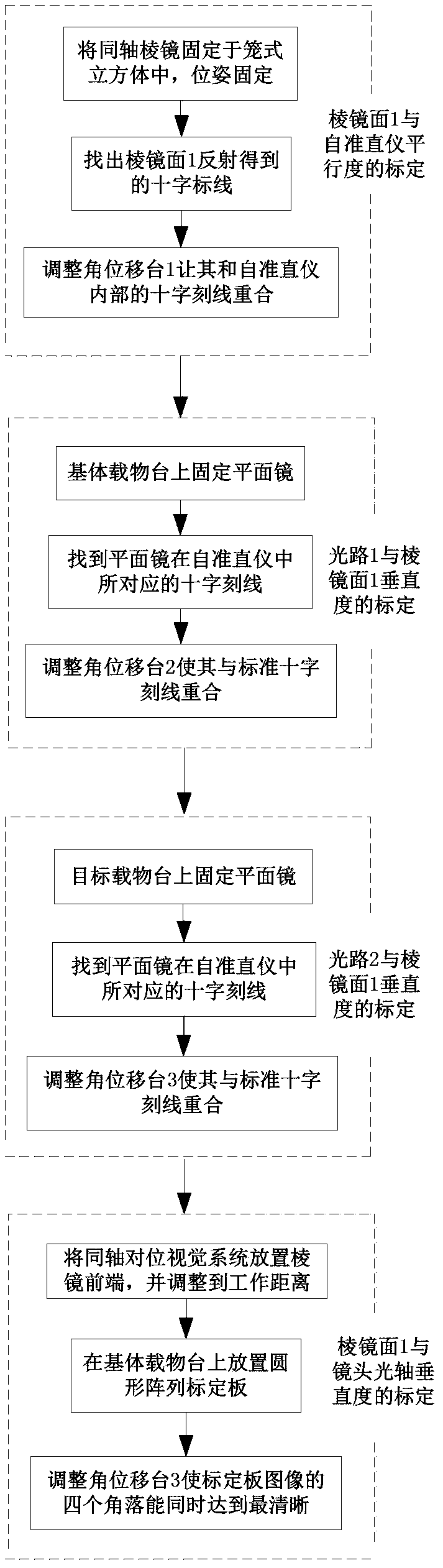

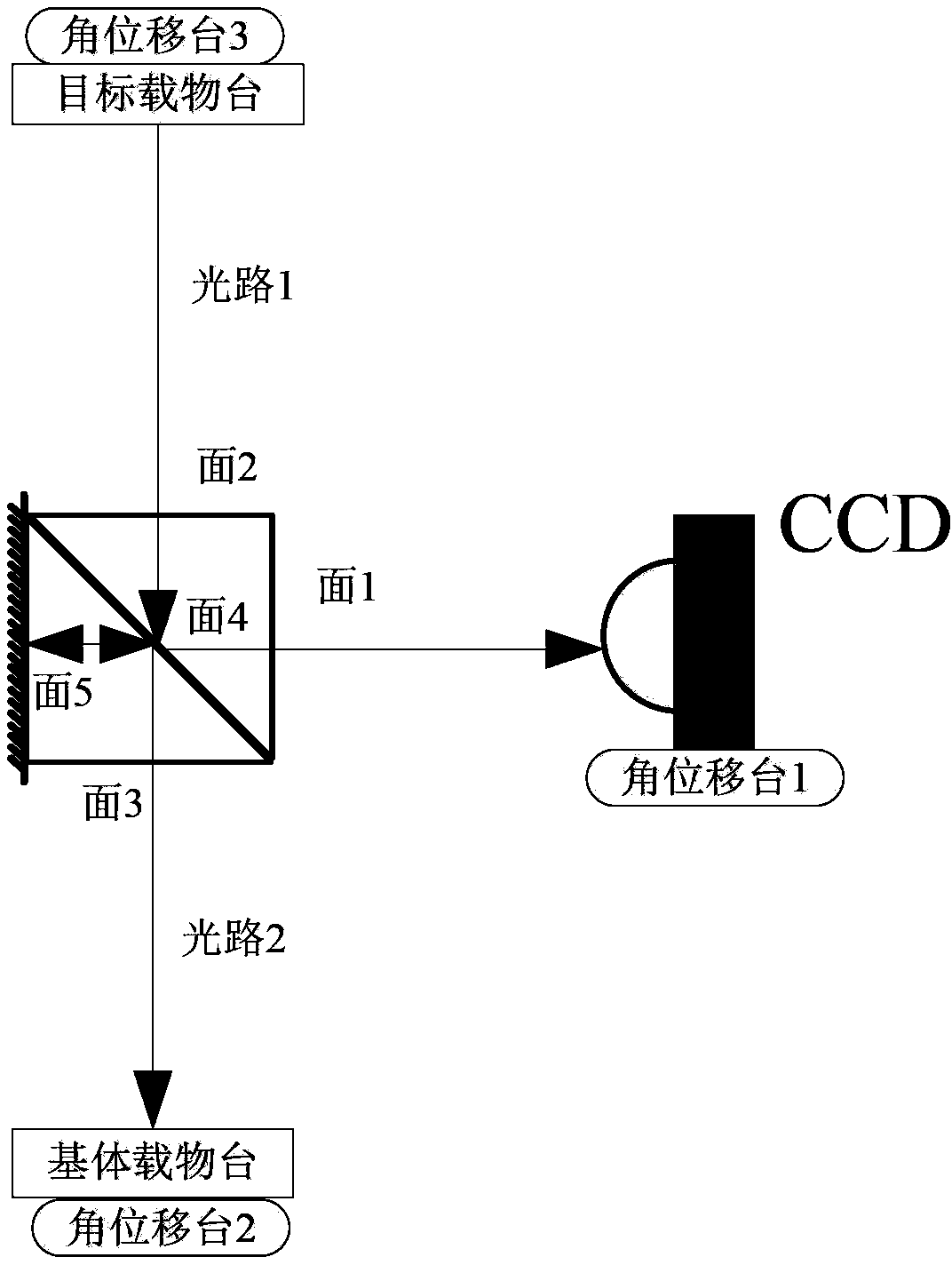

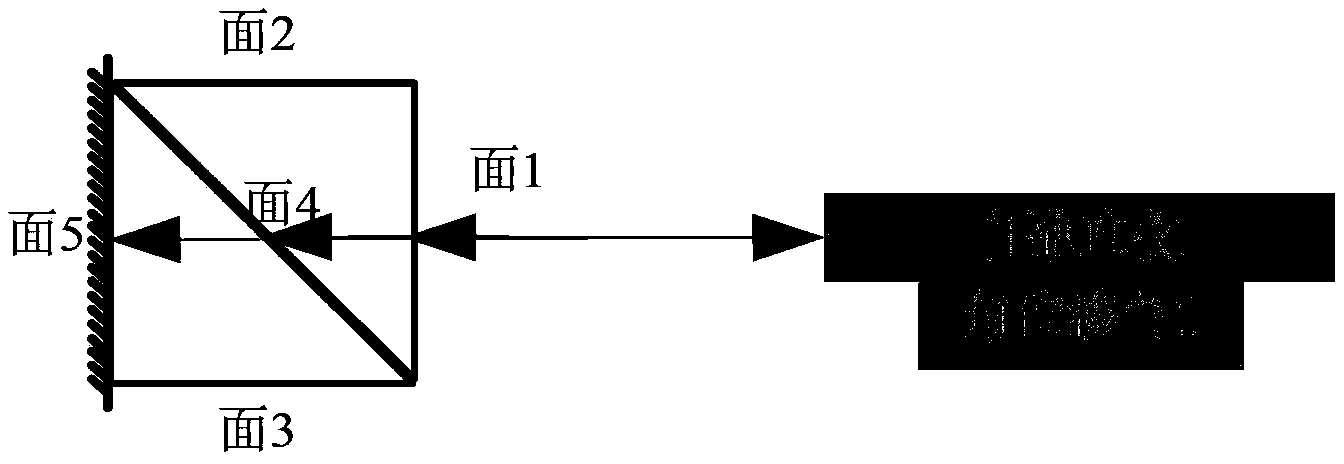

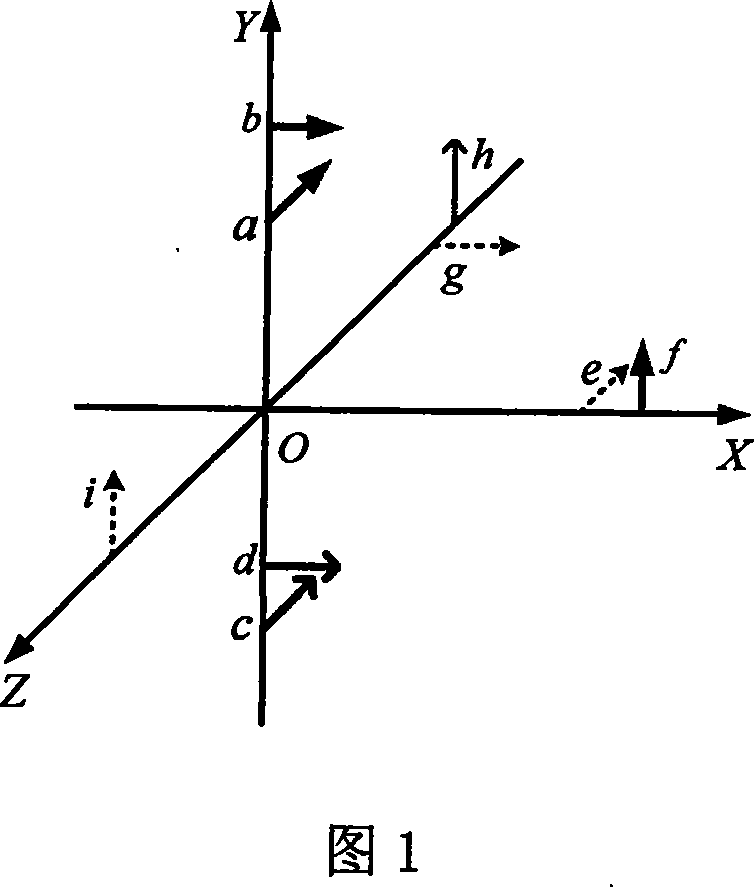

Calibration method oriented towards coaxial counterpoint micro-assembly system

The invention relates to a calibration method oriented towards a coaxial counterpoint micro-assembly system, and belongs to the technical field of micro detection and micro assembly. An autocollimator is adopted. The calibration method oriented towards the coaxial counterpoint micro-assembly system comprises the steps of (1) calibrating the parallelism between a prism face and an imaging face of the autocollimator, (2) calibrating the perpendicularity between a reflected light path of a base body object stage and the imaging face of the autocollimator, and (3) calibrating the perpendicularity between reflected light rays of a target object stage and the imaging face of the autocollimator, (4) installing a CCD and a microscope lens after the autocollimator is disassembled, and carrying out fine adjustment to eliminate installation errors. The purpose that a CCD camera and the optical axis of a prism are perpendicular to the prism face is achieved, the calibration work of relative poses of components, including the prism, the target object stage, the base body object stage and the microscope lens, of the coaxial counterpoint micro-assembly system is accomplished, the assembly accuracy of the coaxial counterpoint micro-assembly system is greatly improved, and the calibration method oriented towards the coaxial counterpoint micro-assembly system is simple and easy to implement.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Vector correcting method for non-gyro accelerometer array mounting error

ActiveCN101067628AHigh precisionSmall amount of calculationAcceleration measurementTesting/calibration of speed/acceleration/shock measurement devicesObservational errorAccelerometer

The invention relates to a measurement error correcting method, concretely a vector correcting method for gyro-free acceleration meter array installation error, offsetting the installation position error and installation azimuth error one by one to offset the acceleration meter array installation error, and as compared with the existing techniques, it has features of less calculation quantity, accurate results, and being able to raise data accuracy by at least one order of magnitude.

Owner:ZHONGBEI UNIV

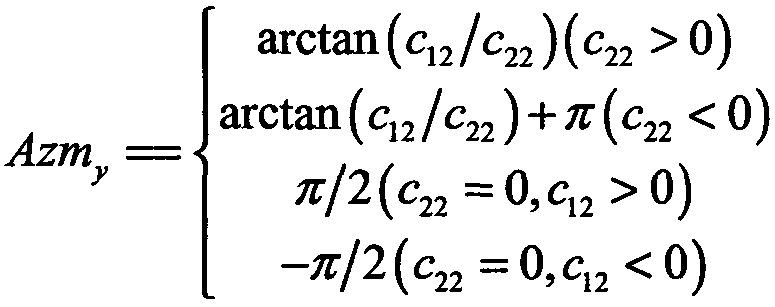

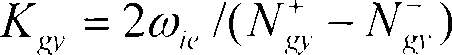

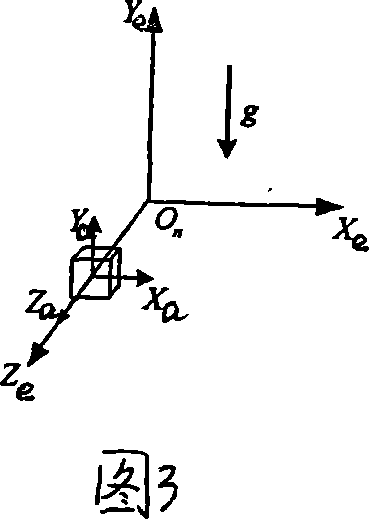

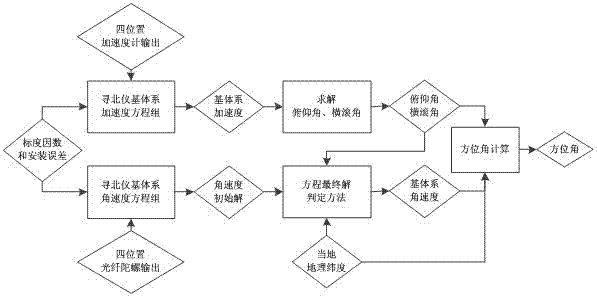

Method for improving precision of fiber optic gyroscope (FOG) north-seeker

InactiveCN102735231AEliminate North Seeking ErrorsReduce processing requirementsNavigation by speed/acceleration measurementsSagnac effect gyrometersFiberGyroscope

The invention discloses a method for improving precision of a fiber optic gyroscope (FOG) north-seeker, comprising the following steps of: calibrating the north-seeker to obtain calibration factor and installation error of FOG and an accelerometer; carrying out four-position data acquisition and pretreatment based on system installation error calibration, and then calculating axial acceleration of a base system to obtain pitch angle and roll angle of the north-seeker; and calculating and determining axial angular velocity of the base system to finally obtain azimuth angle of the north-seeker. By the adoption of the method, north-seeking errors caused by rotating errors and rotating shaft orientation errors of an indexing mechanism are eliminated; north-seeking errors caused by installation errors of FOG and the accelerometer are eliminated; technological requirements of the north-seeker are reduced; there is no need to eliminate installation errors from the aspect of technology; it is unnecessary for the four positions rotated by the indexing mechanism to be strictly orthogonal each other; and the north-seeking precision of the FOG north-seeker under all-attitude state is improved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com