Patents

Literature

196 results about "Counterpoint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In music, counterpoint is the relationship between voices that are harmonically interdependent (polyphony) yet independent in rhythm and contour. It has been most commonly identified in the European classical tradition, strongly developing during the Renaissance and in much of the common practice period, especially in the Baroque. The term originates from the Latin punctus contra punctum meaning "point against point", i.e. "note against note".

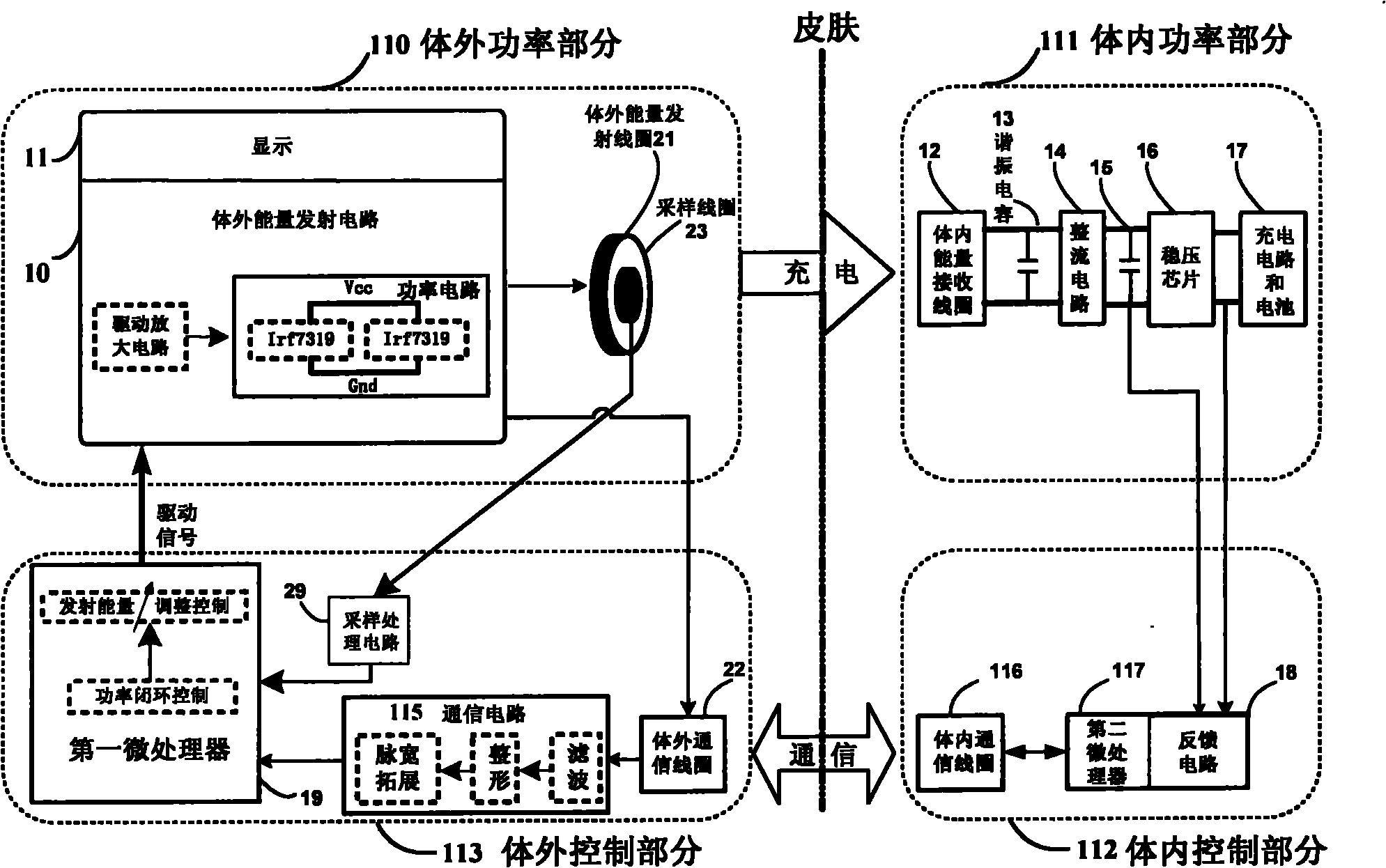

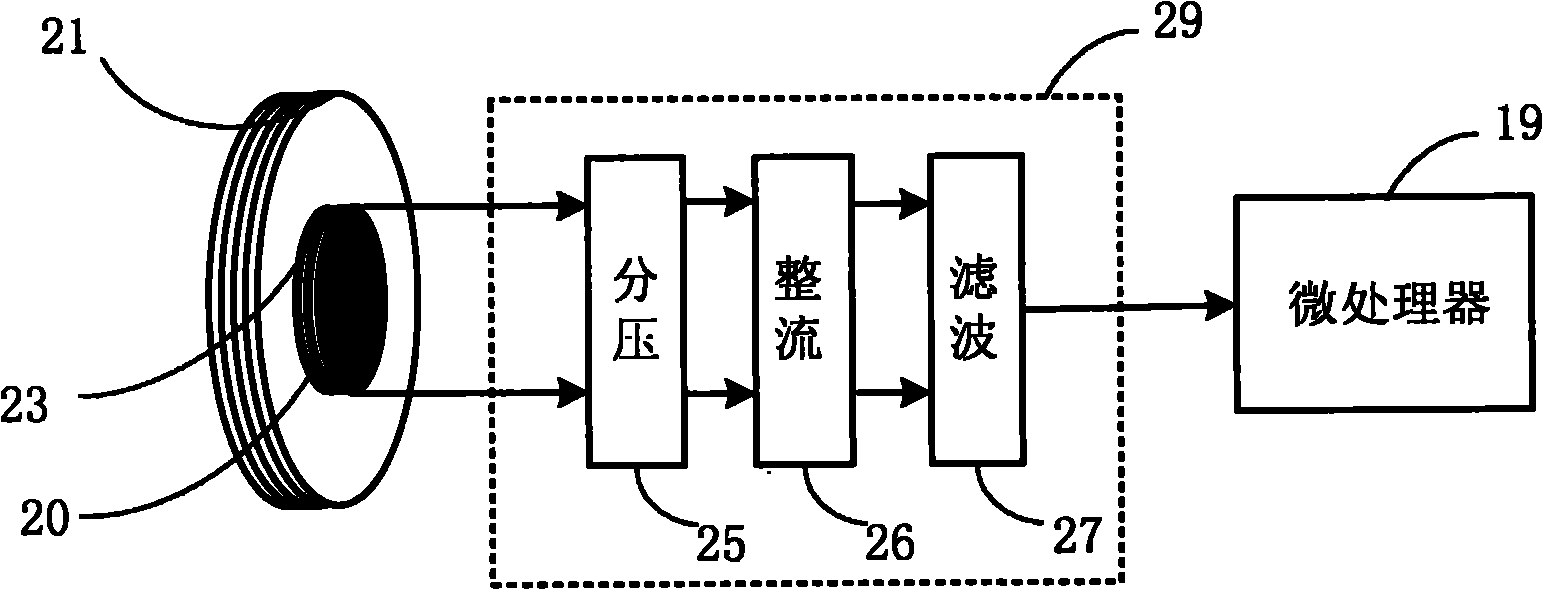

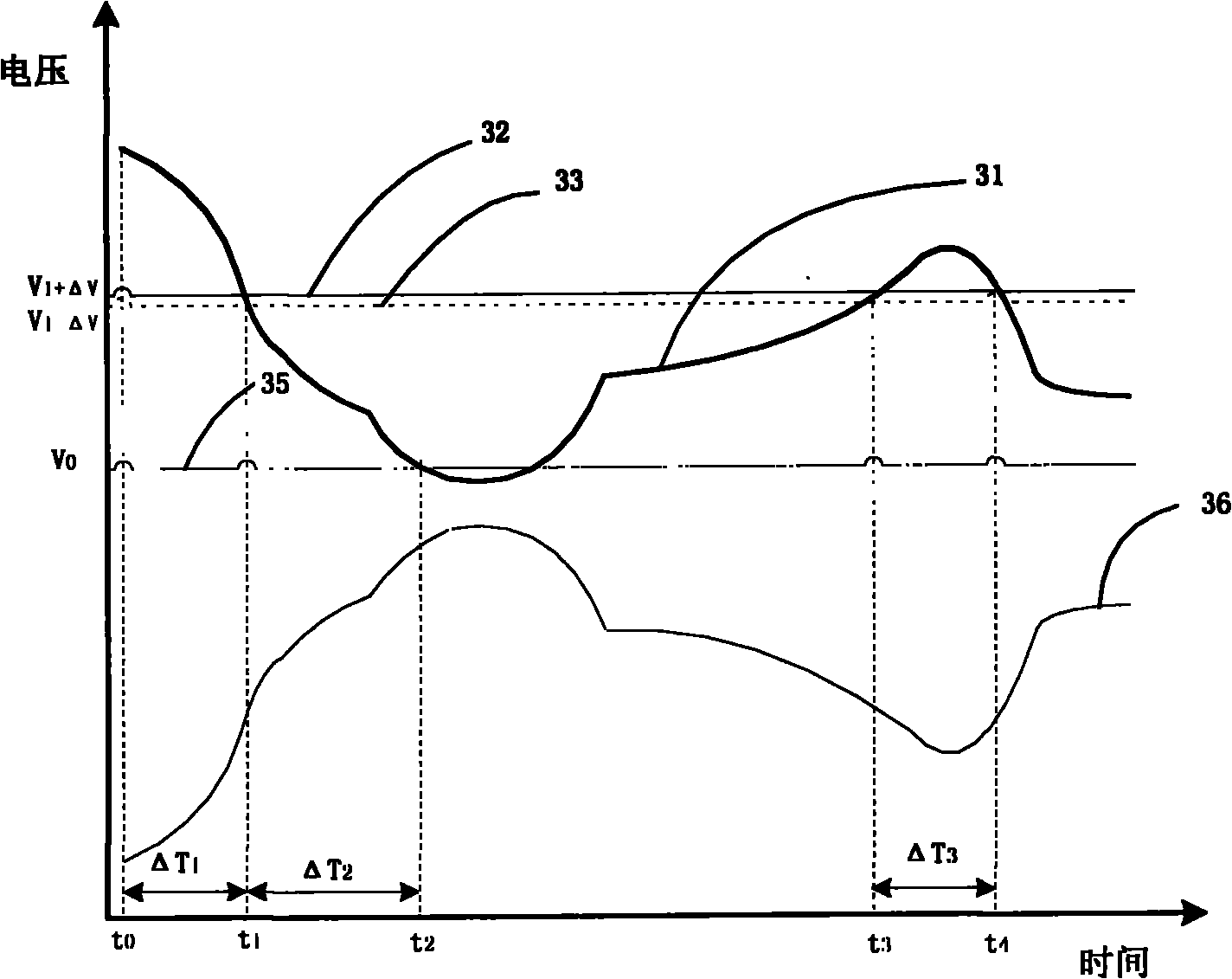

Wireless charging method with counterpoint automatic prompting function for implanted medical instrument

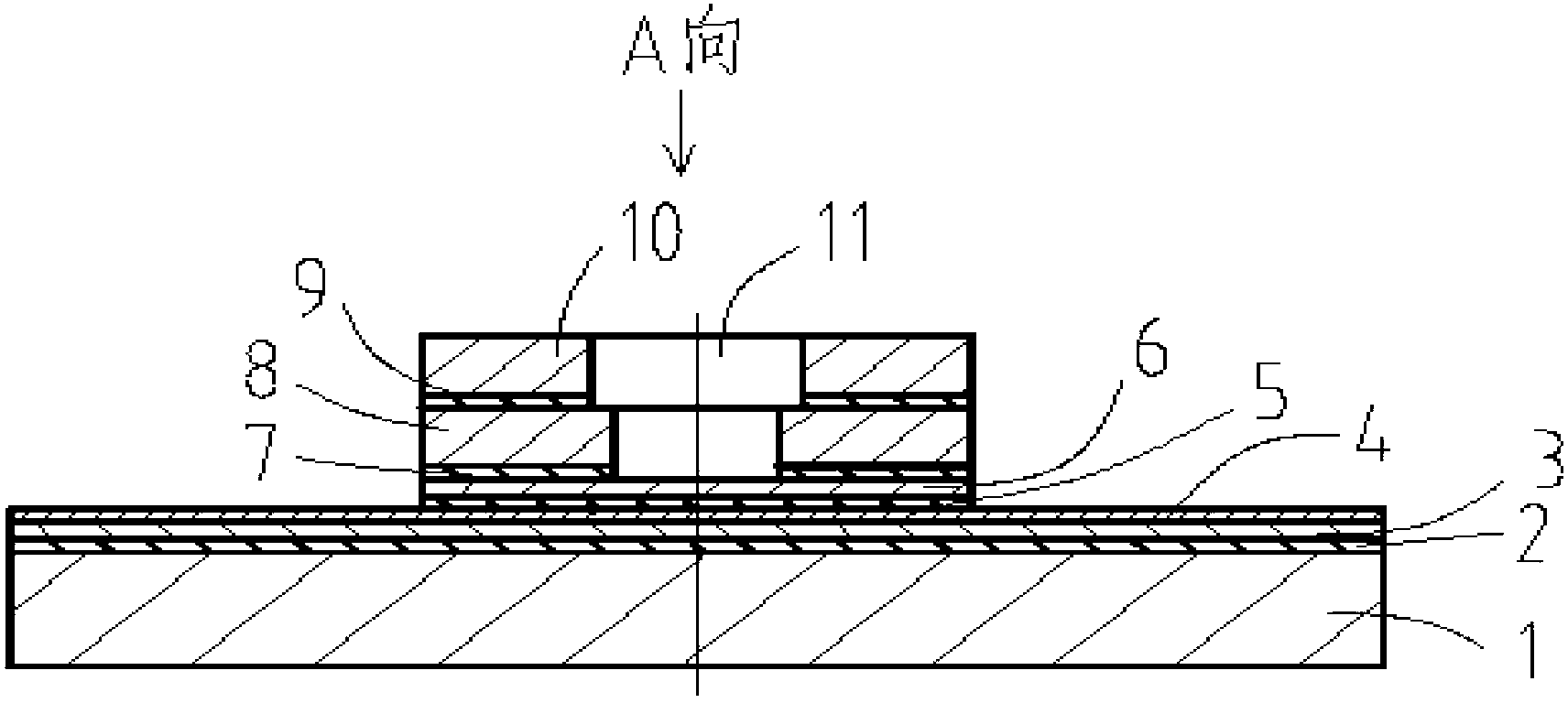

ActiveCN102013717AReduce fever increaseEffective control of feverBatteries circuit arrangementsElectromagnetic wave systemCapacitanceTransmitted power

The invention discloses a wireless charging method with a counterpoint automatic prompting function for an implanted medical instrument, belonging to the field of implanted medical instruments. The wireless charging method is characterized in that after a corresponding device is established, a voltage on a rectifier output capacitance in an in vivo power part is collected by using a first microprocessor in an in vitro charger to serve as feedback quantity, the voltage deviation value between two feedbacks and the rate of change of voltage deviation are calculated, a fuzzy control rule is utilized to determine the variation of in vitro transmitting power, and the variation of the in vitro transmitting power is overlapped on a set transmitting power value for compensating the variation of the voltage on the rectifier output capacitance owing to shifting, charging stage variation and the like. By using the method, the counterpoint situation of in vivo / vitro coils can be automatically prompted in the process of charging, the charging efficiency is improved, the stability is improved and the radiation is reduced. Under the conditions of different counterpoint positions or different charging stages, the in vitro transmitting power is automatically regulated, and the radiation of the in vivo implanted medical instrument is effectively controlled in a reasonable range.

Owner:TSINGHUA UNIV +1

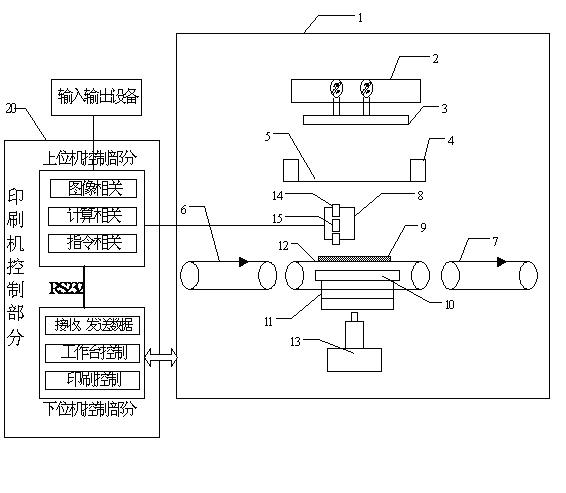

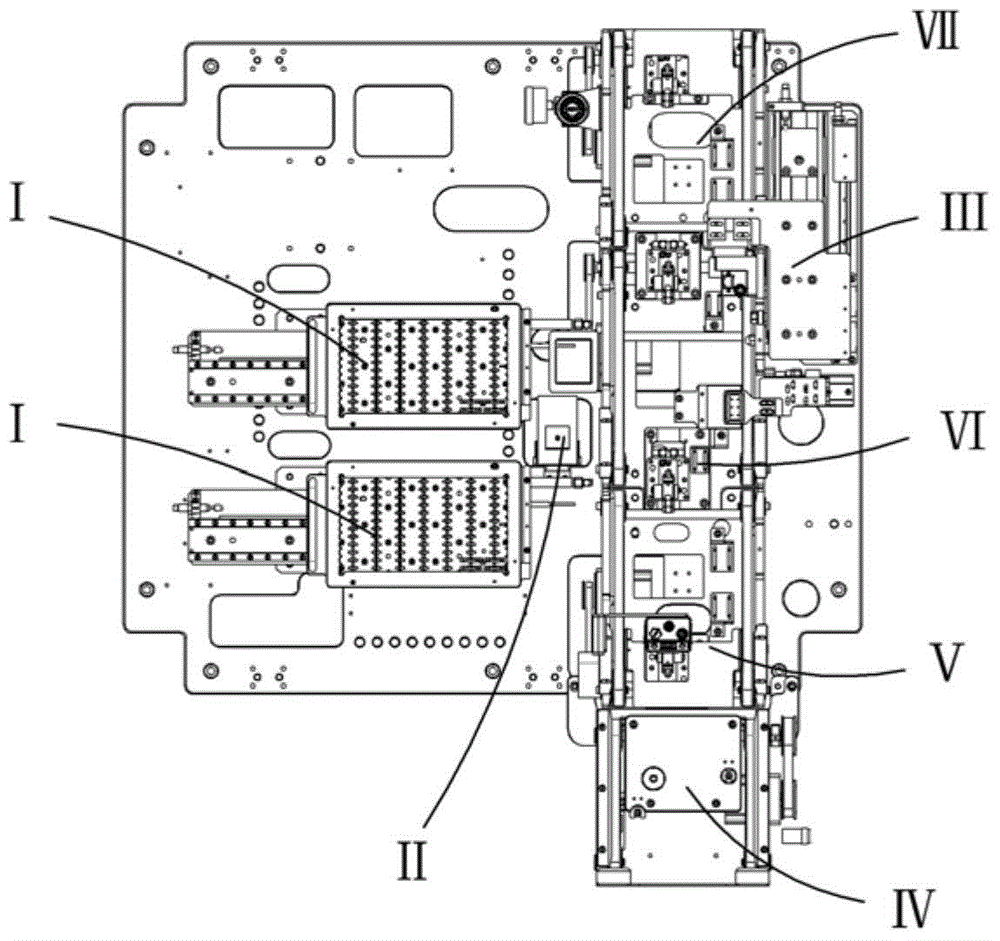

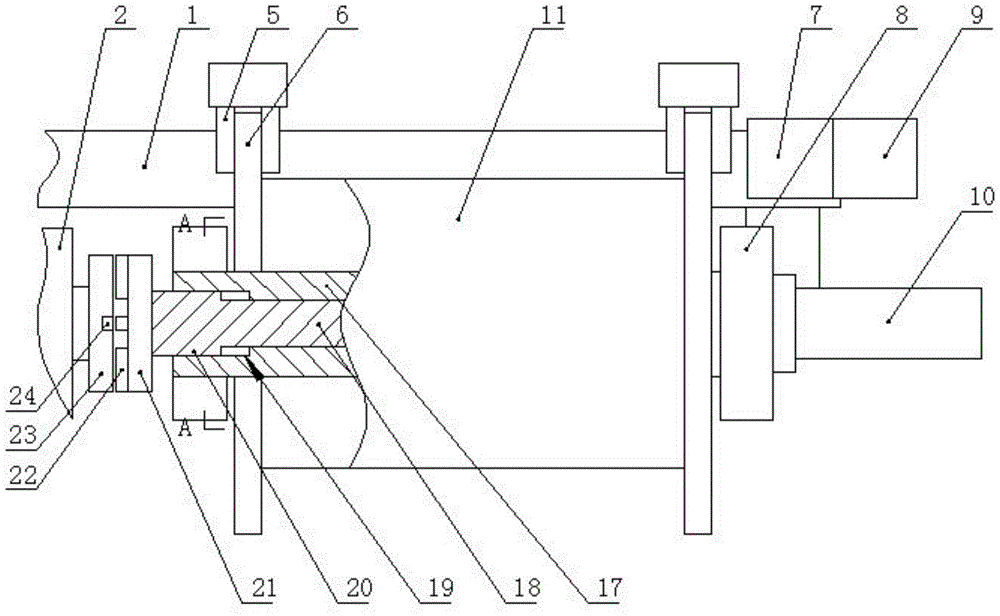

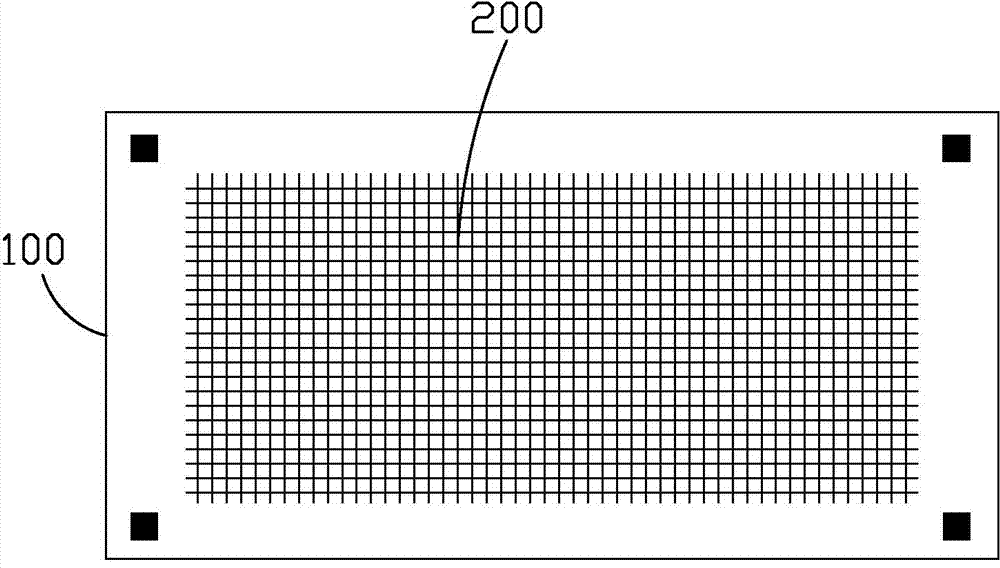

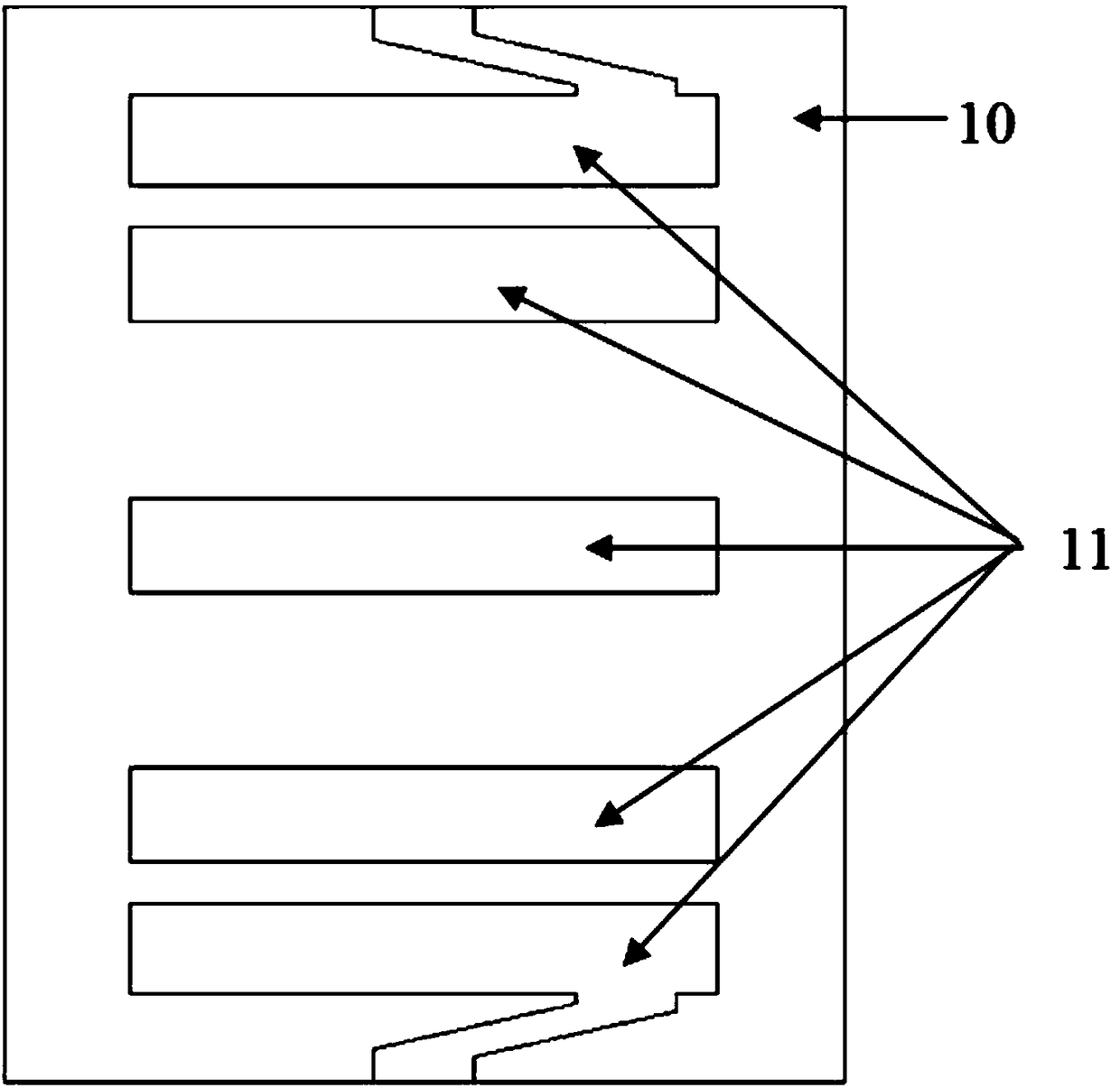

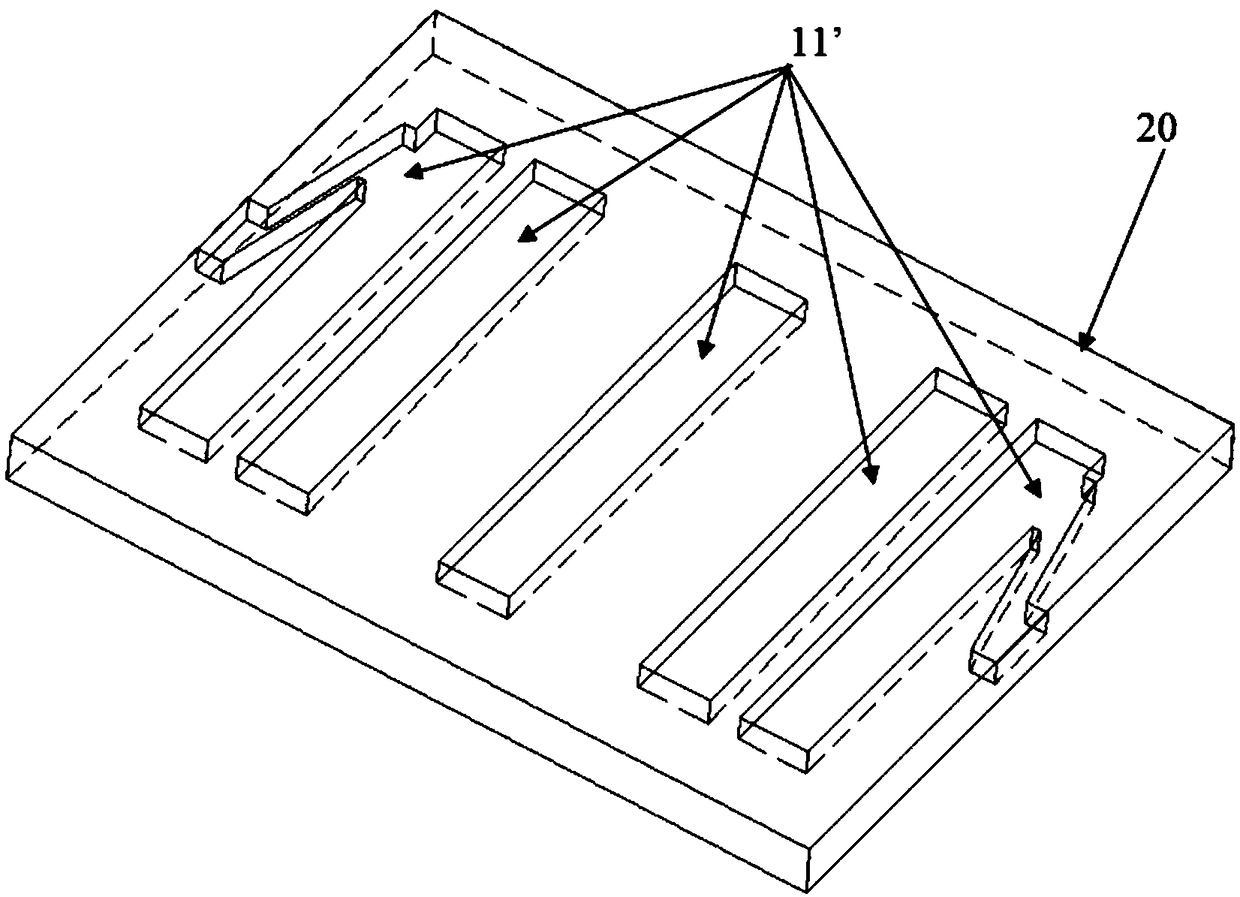

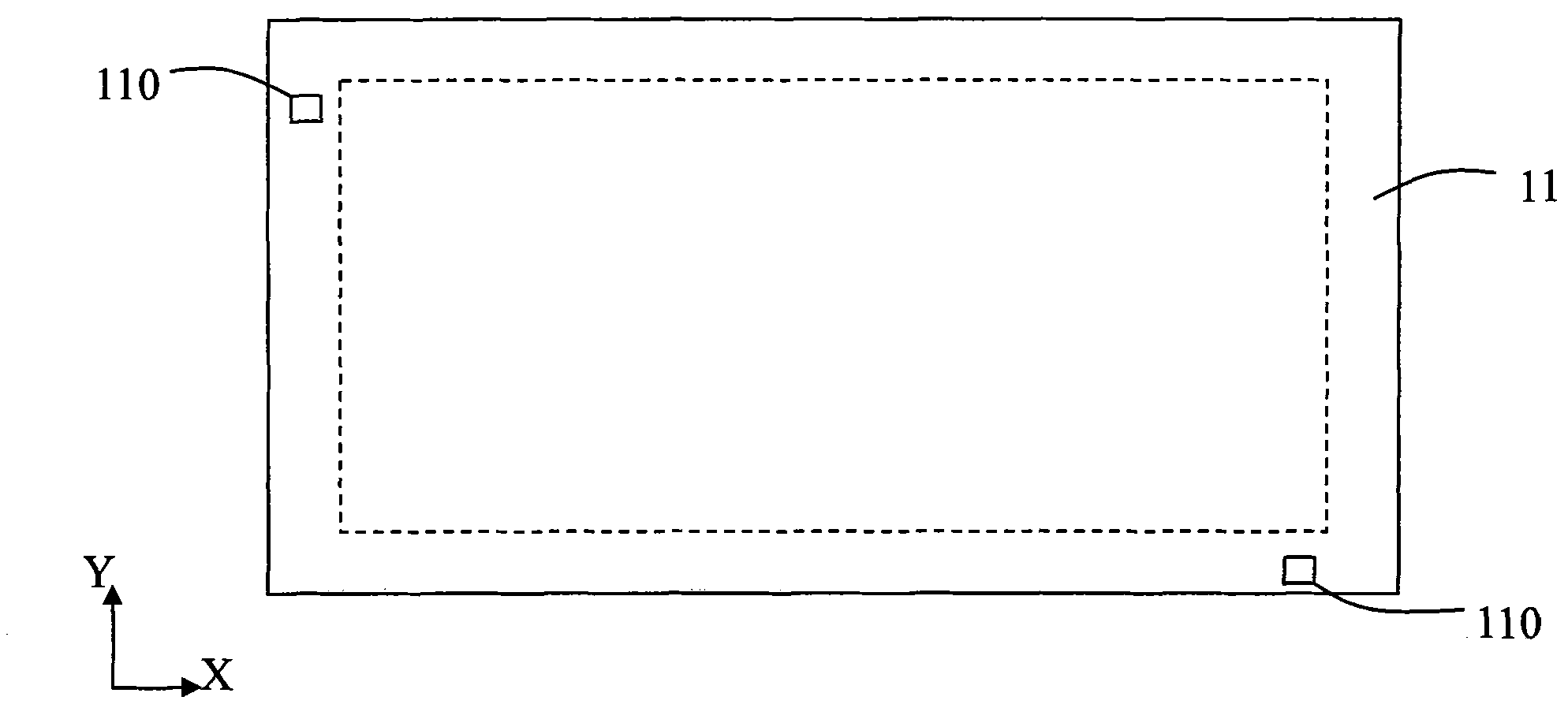

Positioning method in novel silk screen printing CCD (charge coupled device) image identification

InactiveCN102328493AHigh precisionHigh-precision alignment accuracyScreen printersScreen printingAngular deviation

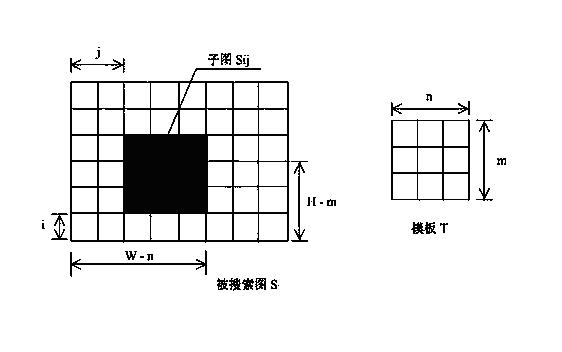

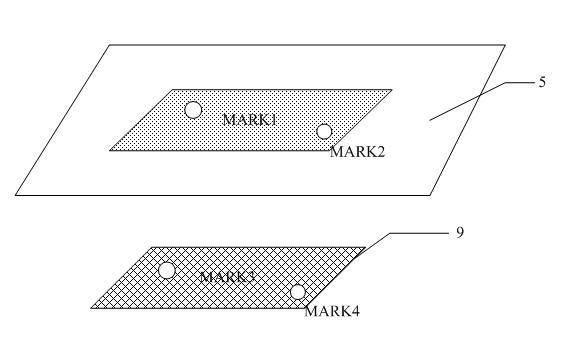

The invention discloses a positioning method in novel silk screen printing CCD (charge coupled device) image identification, comprising the following steps of: (a) conveying PCBs (printed circuit boards) to an operating platform part to be initially positioned and clamped by virtue of an introducing part and an operating platform conveying part; (b) obtaining a CCD positioning identification template by adopting a manually programming method; (c) calculating angular deviation and distance deviation by virtue of the PCBs and MARK points on a silk screen, controlling the operating platform to correspondingly adjust position and angle; and (d) moving an image acquisition device to the position above the PCBs and the MARK points, respectively shooting the PCBs and the MARK points of the silk screen by virtue of a CCD camera, matching the obtained image with the CCD positioning identification template, and carrying out automatic printing after a matching requirement is achieved. The invention provides a whole set of system, the system can automatically detect offset between the center of an object window required to be retrieved by a user and the center of any pattern, the offset is namely correction, the correction is added during counterpoint calculation, and counterpoint actuating quantity is calculated and a counterpoint action is executed. For various patterns used for counterpoint of a base plate, the various patterns can be simply counterpointed without high correction proficiency requirement, and printing counterpoint accuracy can be improved.

Owner:PANDA ELECTRONICS GROUP +1

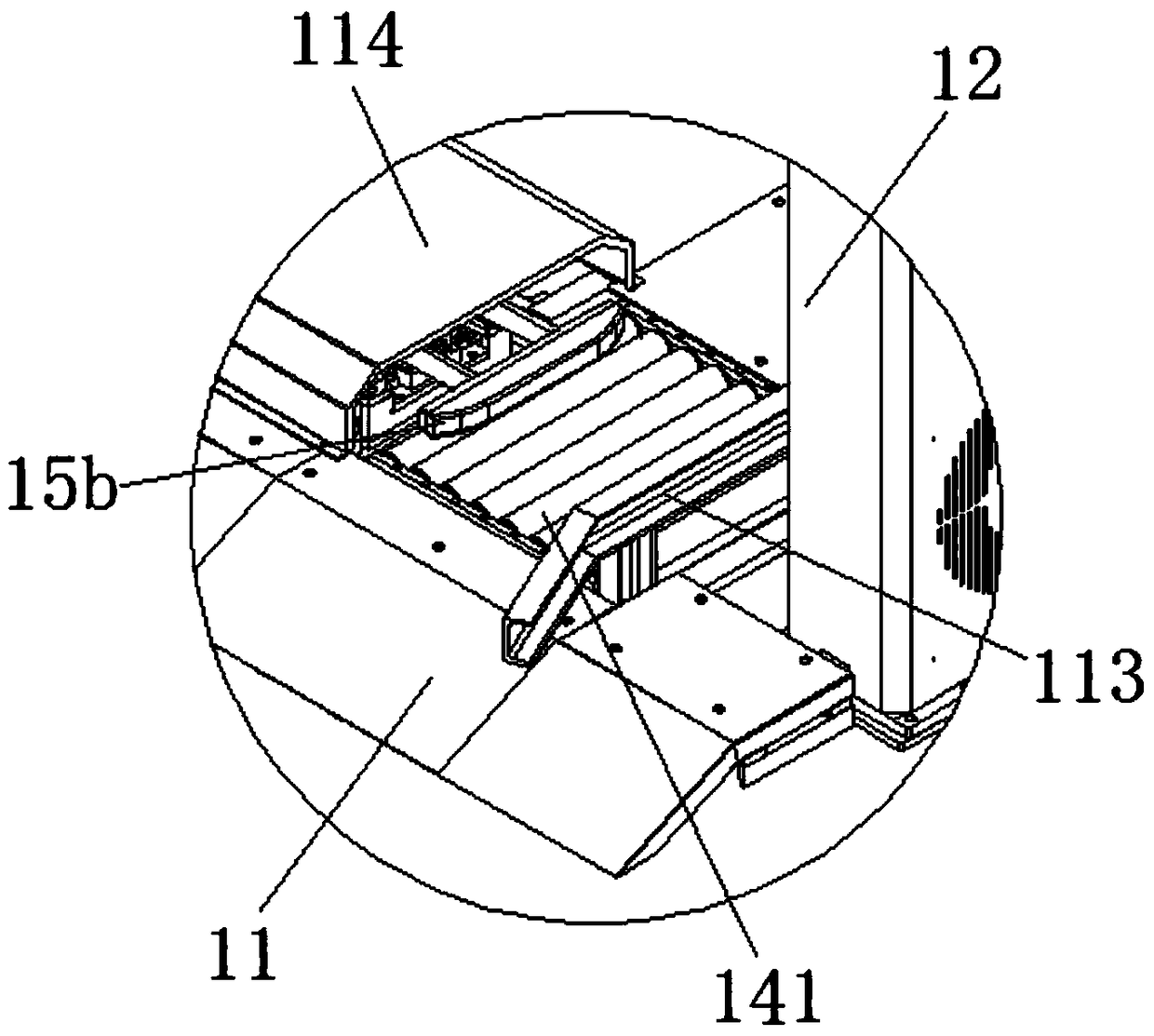

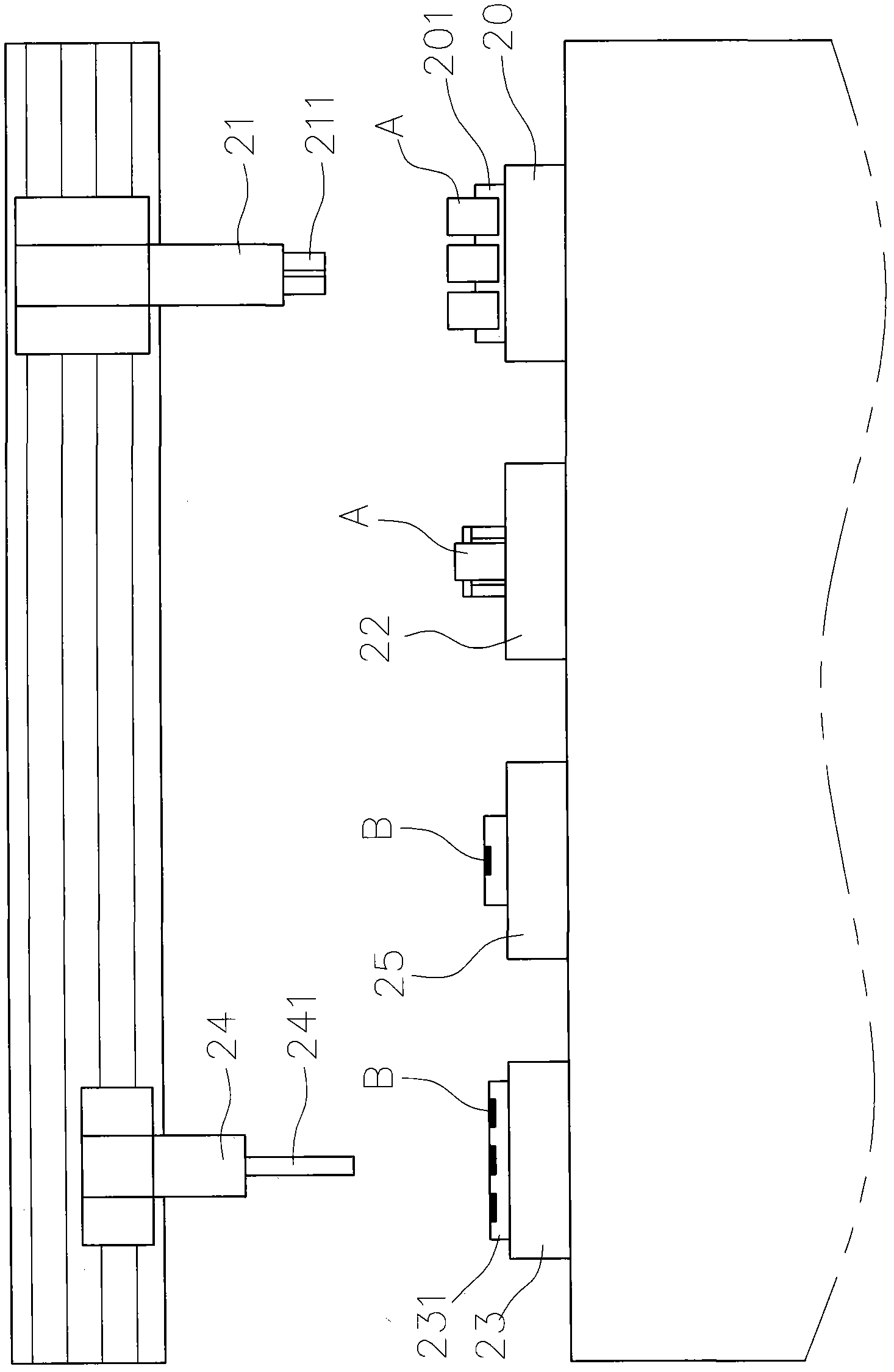

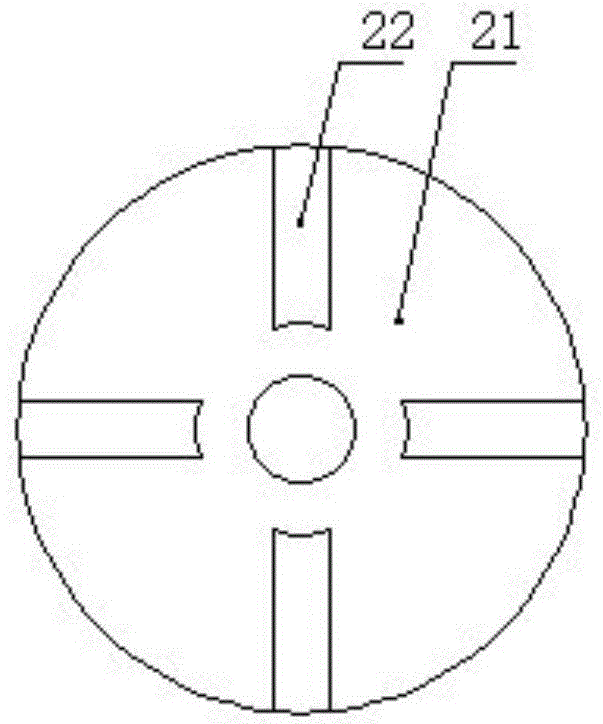

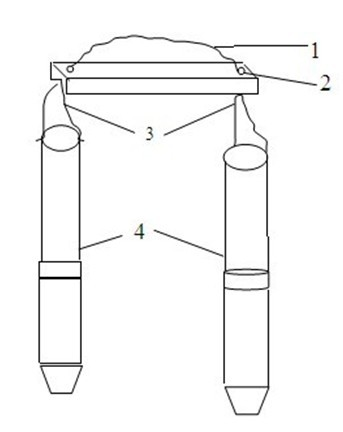

Floating type counterpoint vehicle-mounted storage battery automatic replacing station

ActiveCN108058688AAvoid chimera failureSmooth liftElectric propulsion mountingVehicular energy storageElectric vehiclePositioning system

The invention belongs to the technical field of vehicle maintenance, and relates to a floating type counterpoint vehicle-mounted storage battery automatic replacing station which comprises a vehicle positioning and lifting mechanism for positioning and lifting an electric vehicle and a battery locking and unlocking mechanism for positioning and replacing a vehicle-mounted storage battery. The battery locking and unlocking mechanism comprises an ejecting assembly, a positioning assembly arranged on the ejecting assembly and a plurality of locking and unlocking assemblies arranged on the positioning assembly. The ejecting assembly comprises a lifting table for fixing the positioning assembly. The positioning assembly comprises a floating support, and at least two positioning pins arranged onthe upper side of the floating support. The floating support is hung below a lifting table through four chains. The positioning assembly can float by means of the chains, the position of the vehicle-mounted storage battery can be automatically fine adjusted according to the actual conditions of a chassis when the vehicle-mounted storage battery is arranged on the electric vehicle chassis, and theembedment failure is avoided.

Owner:NIO CO LTD

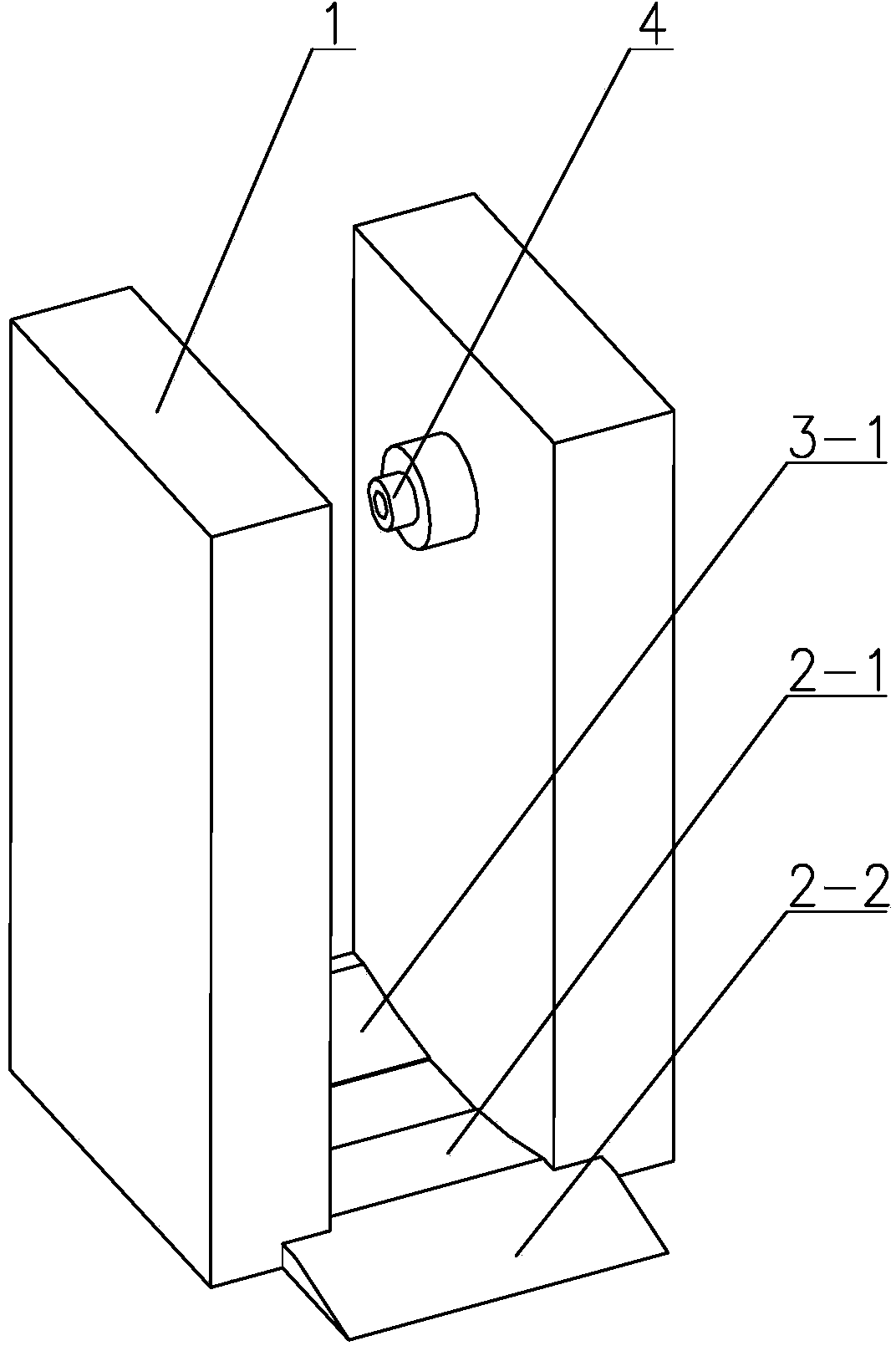

Public bicycle fixed point locking device

ActiveCN103909997AGuaranteed smoothnessAccurate positioningAnti-theft cycle devicesCycle standsMaterial resourcesNoise reduction

The invention provides a public bicycle fixed point locking device. The public bicycle fixed point locking device is used for locking and placing public bicycles. The public bicycle comprises a front wheel, a position-limiting mechanism and two lock tongues, wherein the two ends of a wheel shaft of the front wheel are respectively provided with a lock bar; limiting space is formed and the limiting space is used for positioning the front wheel in the horizontal direction; the two lock tongues are arranged on the position-limiting mechanism. According to the public bicycle fixed point locking device, accurate and stable positioning to the front wheel of the bicycle is achieved through a simple and delicate structure, so that accurate counterpoint of the position of the lock bar and the lock tongues is achieved, locking and placing of the bicycle are convenient and quick, the lock bar is arranged on the wheel shaft so that the lock bar is not prone to being damaged, long term using of the public bicycle is facilitated, initiative in using the public bicycle of users is improved, and popularization of the environment friendly transportation tool is facilitated, therefore contribution to noise reduction and emission reduction and traffic pressure relief is made, and labor investment and material resource investment in daily maintenance of the public bicycle are reduced.

Owner:NANTONG JIANGHUA MASCH CO LTD

Impact piece exploder and manufacture method thereof

The invention discloses an impact piece exploder and a manufacture method thereof. The manufacture method comprises the following steps: using half curing adhesive to axially couple together a reflective sheet, a bridge foil, a flyer and an accelerating chamber in sequence, wherein the reflective sheet, the flyer and the accelerating chamber are made of polyimide; using a first polyimide layer to form a reflective sheet layer; pressurizing and bonding the reflective sheet layer; using a second polyimide layer and a copper foil layer to form a composite film; then, exposing, developing and etching the copper foil layer of the composite film to acquire the bridge foil; using bonding glue to glue a polyimide film on the surface of the bridge foil to serve as the flyer layer; then, processing the accelerating chamber on a third polyimide layer and a fourth polyimide layer; using the half curing adhesive to pressurize and bond the reflective sheet, the bridge foil, the flyer and the accelerating chamber in a counterpoint manner; and finally, blanking the impact piece exploder on a punch. The impact piece exploder is high in reliability, low in material cost, and convenient for automatic mass production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

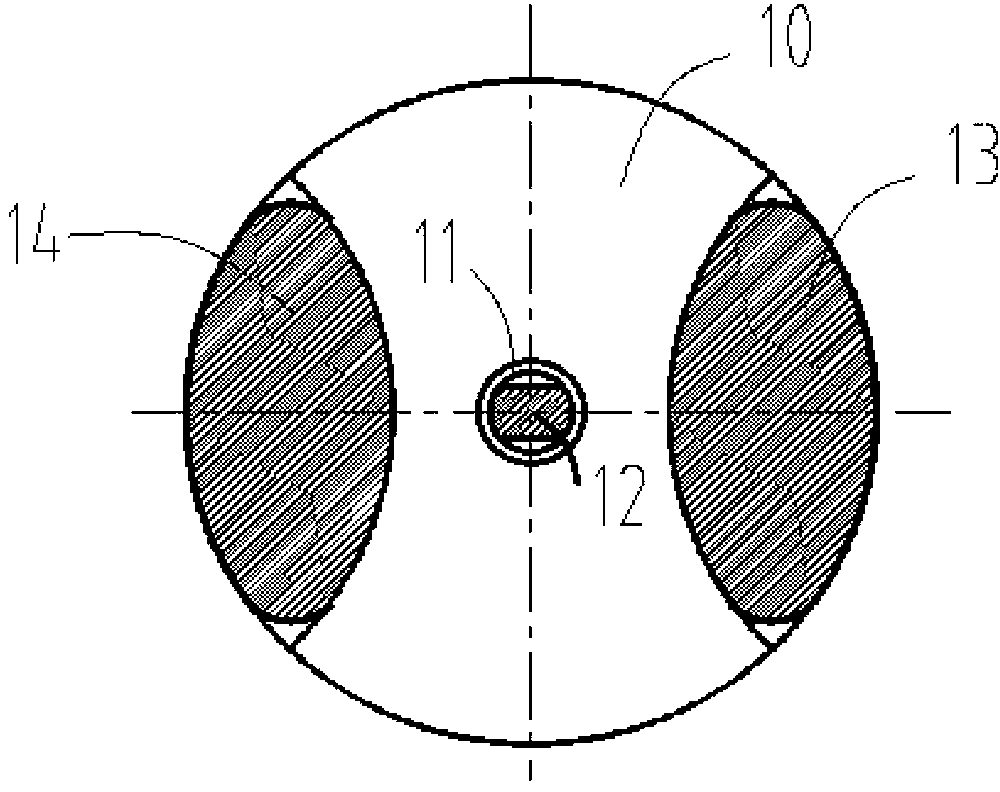

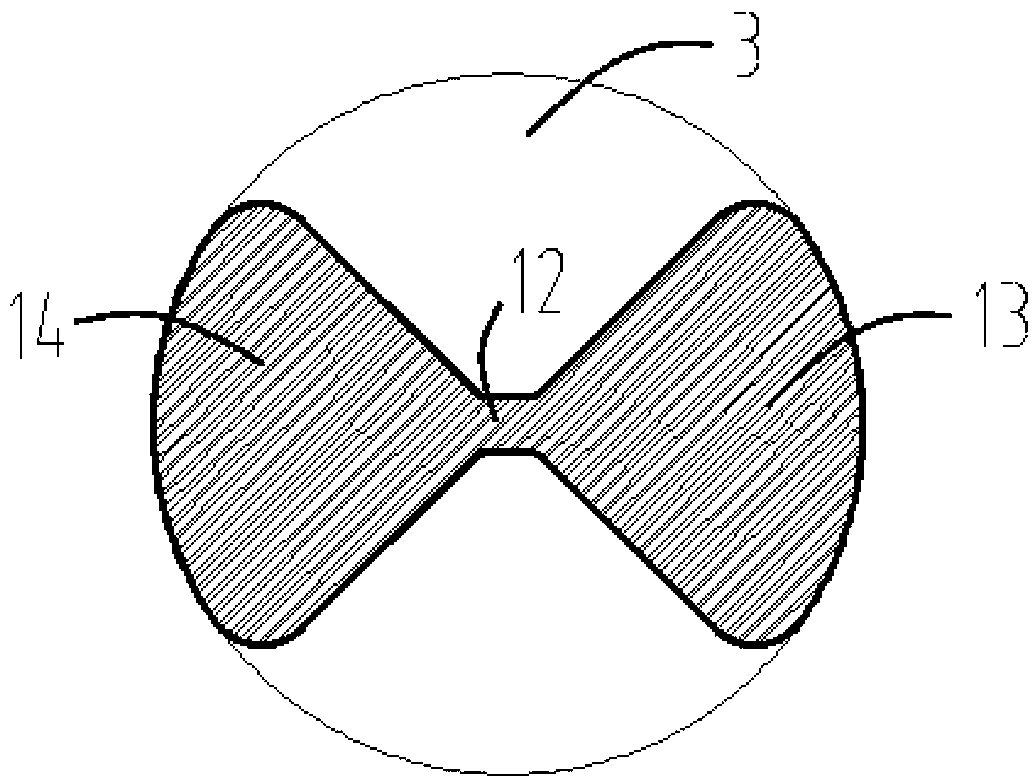

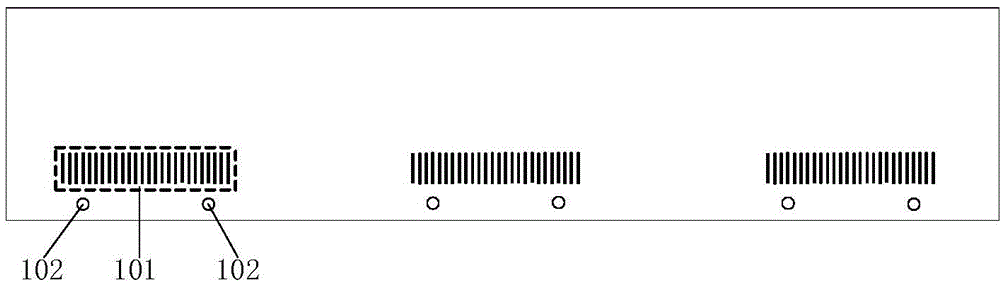

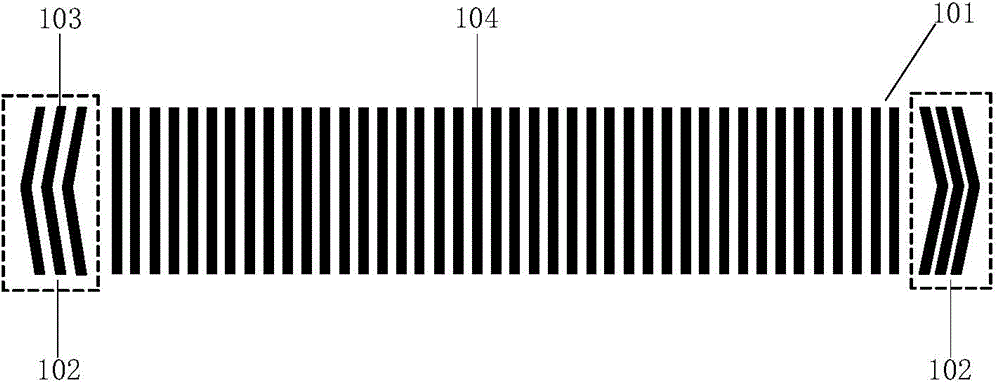

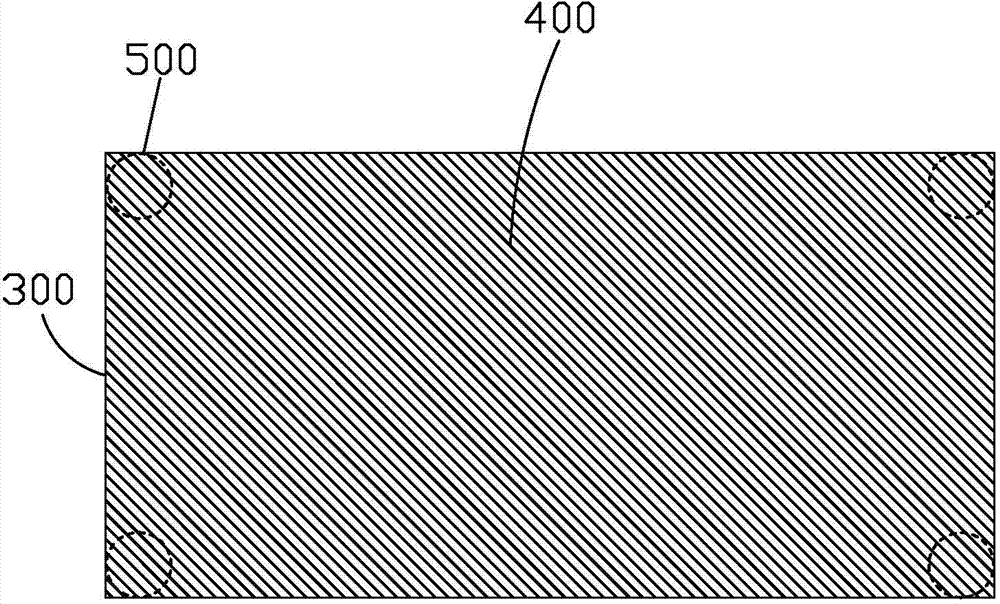

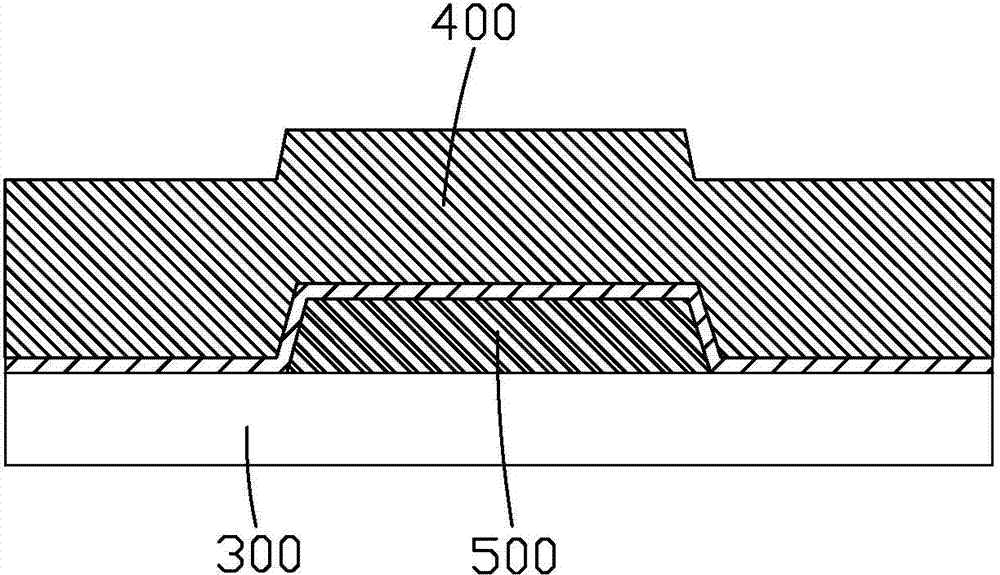

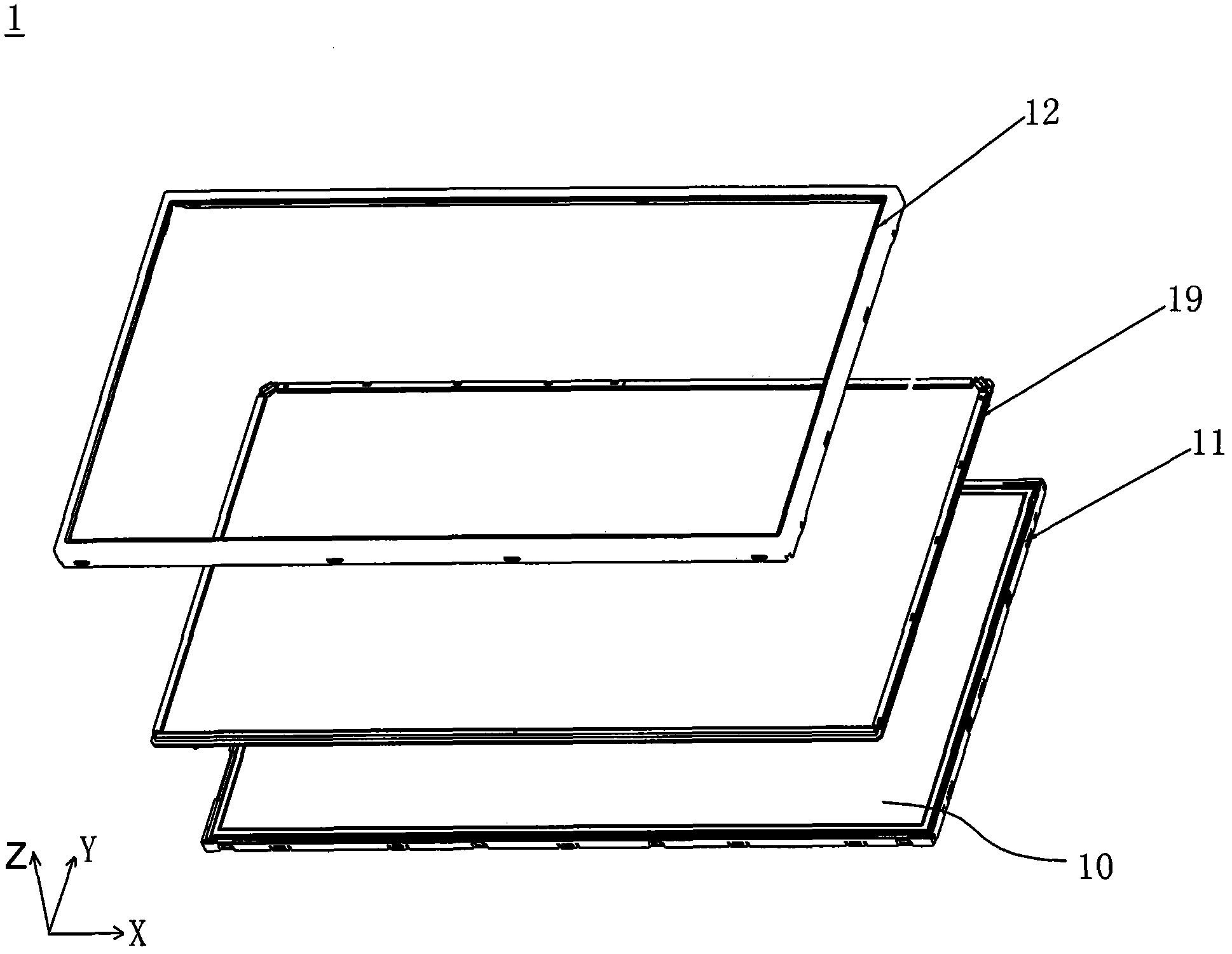

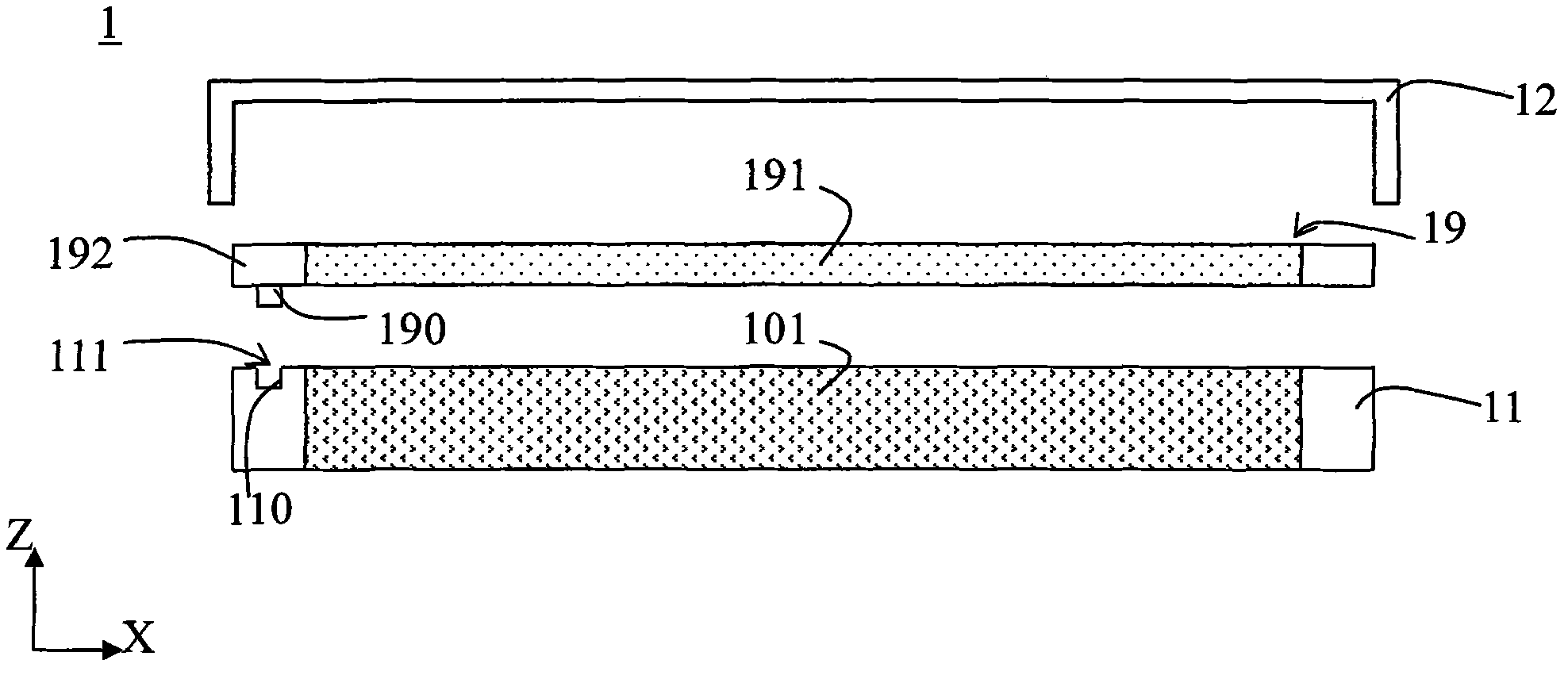

Counterpoint label, circuit board and display device

InactiveCN104661430AIncrease profitMeet the requirements of narrowingFinal product manufactureCasings with display/control unitsDisplay deviceEngineering

Owner:BOE TECH GRP CO LTD

Component height difference detecting device

ActiveCN104567697AImprove supply efficiencyReduce labor intensityUsing optical meansHeight differenceAssembly line

The invention relates to a component height difference detecting device. Material is fed in a material feeding assembly line mechanism, and a first assembly line mechanism is capable of blocking a carrier and scanning a serial number of a component through a bar-code scanner; the component is driven by a manipulator to move to the position of a CCD mechanism and to take a picture, and the component position is calibrated; a second assembly line mechanism is capable of separating the carrier from a conveyer belt and blocking the forward movement of the carrier, and the carrier is capable of maintaining level after the carrier is lifted up; the component is placed on the carrier through the manipulator, a material pressing mechanism is driven by a driving air cylinder and a lifting air cylinder to drive a material pressing plate to press the component after the component is placed, a detecting counterpoint mechanism is driven by the manipulator and is transported to the position above the component, a height difference between the component and the datum on the carrier is detected, and after the height difference is detected, the material pressing mechanism is moved out, a mandril is retreated, and the carrier is continuously transported forward to a material discharging assembly line mechanism for material discharging. The component height difference detecting device is used for detecting the height difference on small components of electronic products, the height difference can be confirmed, and the next step of operation is prepared.

Owner:BOZHON PRECISION IND TECH CO LTD

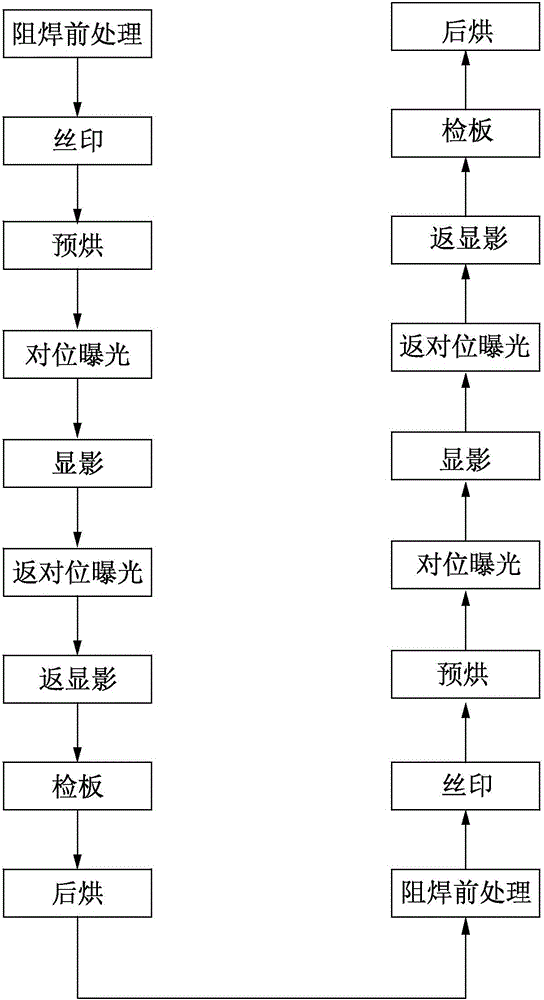

PCB manufacturing method capable of preventing green oil hole plugging

ActiveCN105916302ACoverage is precise and comprehensiveImprove pass rateLithography/patterningResistScreen printing

Provided is a PCB (Printed Circuit Board) manufacturing method capable of preventing green oil hole plugging, comprising the steps of: (1) pre-welding treatment; (2) screen printing: forming a layer of solder resist ink on a copper layer; (3) preliminary baking: performing preheating; (4) counterpoint exposure: performing selective ultraviolet exposure on the solder resist ink covering the area needing solder resist to form a solder resist layer; (5) developing; (6) secondary counterpoint exposure: performing secondary ultraviolet exposure on the area except the function hole of a PCB; (7) secondary developing: employing chemical liquid medicine to perform secondary developing on solder resist ink in the function hole so as to thoroughly remove solder resist ink left in the function hole; (8) board checking; (9) postbaking; and (10) performing pre-welding treatment, screen printing, preliminary baking, counterpoint exposure, developing, secondary counterpoint exposure, secondary developing, board checking and postbaking again on the PCB. The method introduces secondary counterpoint exposure and secondary developing, and effectively solves the problem of hole plugging.

Owner:DONGGUAN MEADVILLE CIRCUITS

A method for improving that alignment between a soft bonding plate layer and a hard bonding plate layer

ActiveCN108990317AHigh precisionImprove lamination qualityMultilayer circuit manufactureEngineeringExposure compensation

The invention discloses a method for improving the alignment between a soft bonding plate layer and a hard bonding plate layer, which comprises the following steps: manufacturing an inner layer circuit on a soft plate core plate; In the finished soft-hard bonding plate, the soft-board core plate comprises a soft-board area and a soft-hard bonding area; The coating film is pressed on the soft platearea of the soft plate core plate, and then the expansion and contraction coefficient of the soft plate core plate is measured. The inner layer circuit is fabricated on the hard board core board, andthe exposure compensation is carried out according to the expansion and contraction coefficient of the soft board core board when the inner layer circuit is fabricated. Using the same OPE punching machine to drill rivet holes at corresponding riveting positions on the soft plate core plate and the hard plate core plate respectively; Flexible and hard core plates are pre-laminated with non-flowingadhesive PP, riveted by rivets, and then compressed to produce plates. The method of the invention solves the deviation problem of the pressing counterpoint holes caused by pressing the covering film, improves the pressing quality of the soft-hard bonding plate, and reduces the deviation scrap rate of the soft-hard bonding plate layer.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

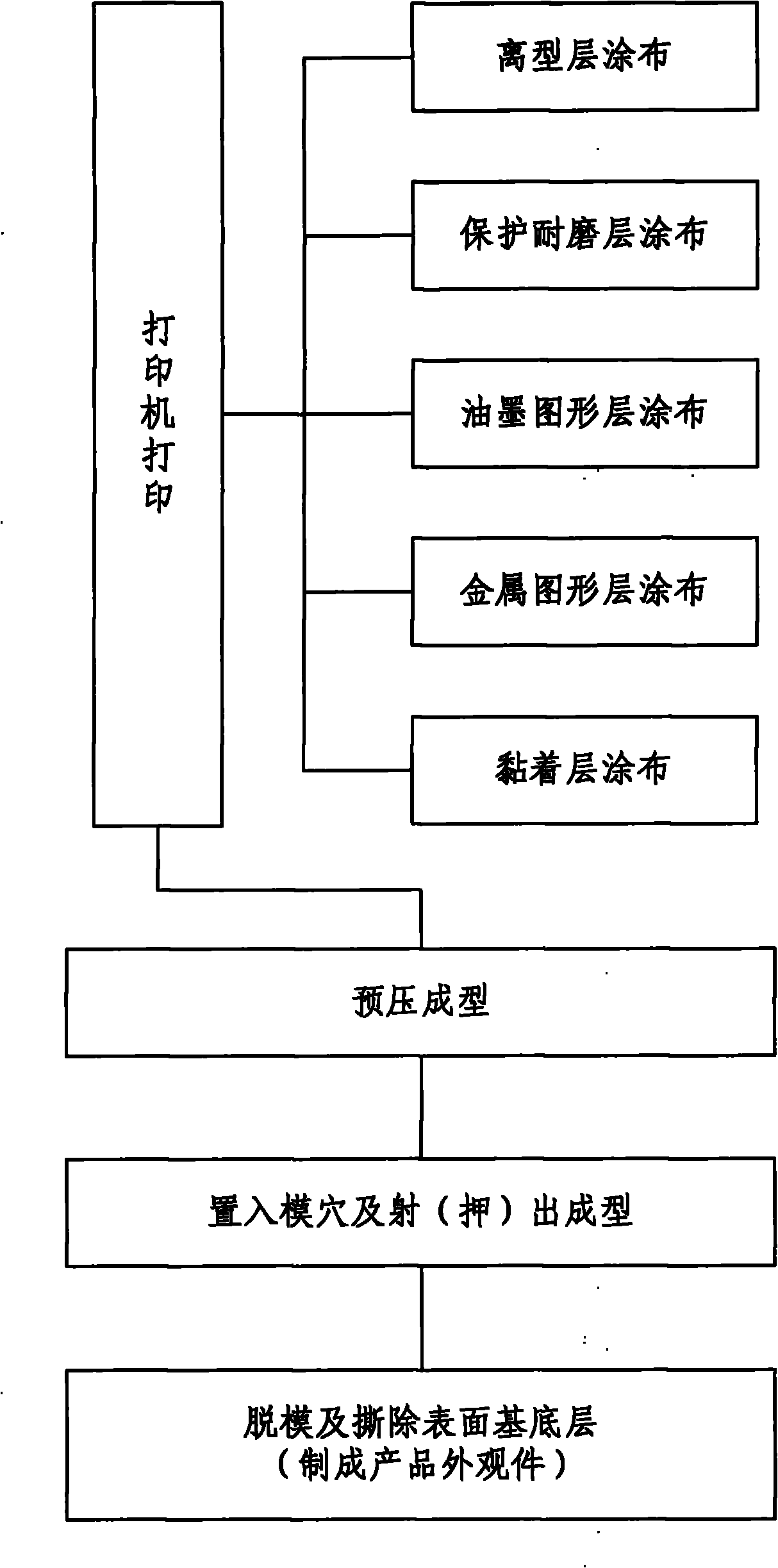

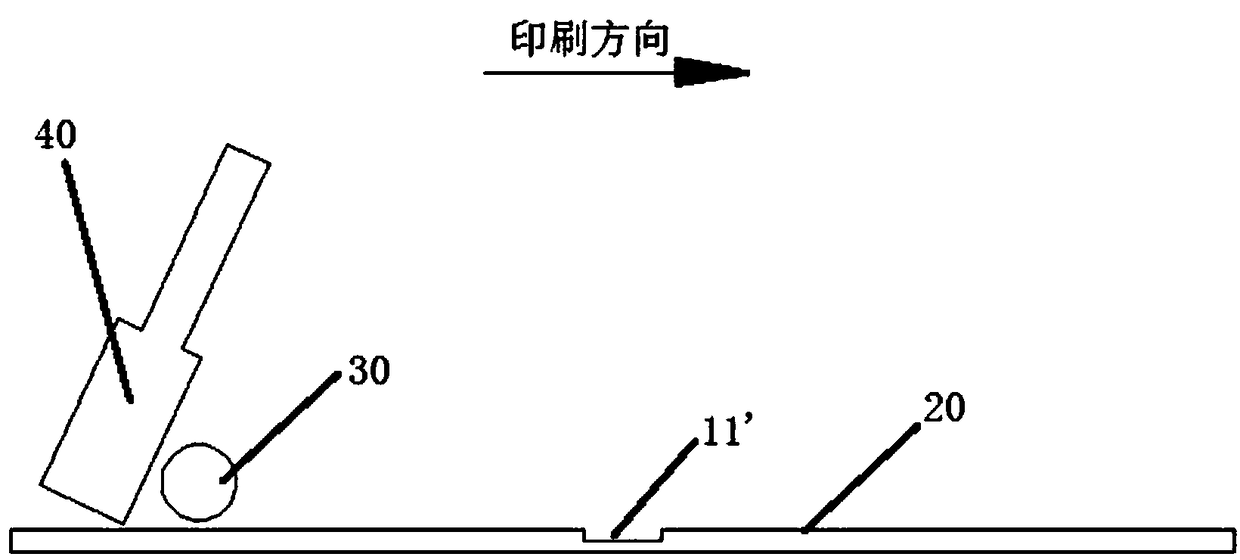

Method for printing prepressing in-mould transfer printing films and in-mould decorative films by using a printer

InactiveCN102152699AAchieve environmental qualityEnvironmentally friendlyDecorative surface effectsPrinting inkEngineering

The invention discloses a method for printing prepressing in-mould transfer printing films and in-mould decorative films by using a printer, which comprises the following steps: carrying out digital printing by using a printer so as to form a release layer, a protective wear-resisting layer, a printing ink pattern layer, a metal pattern layer and an adhesion layer in a counterpoint mode; carrying out prepressing molding on an in-mould transfer printing film according to the shape of an in-mould transfer printing film product by an in-mould transfer printing method, then putting the in-mould transfer printing film subjected to prepressing molding into an injection molding mould or an extrusion molding mould, combining the prepressing in-mould transfer printing film with plastics in the process of injection molding or extrusion molding, and removing an outermost substrate layer after demoulding so as to complete the process of in-mould transfer printing to finally obtain the required product; or putting an in-mould decorative film subjected to prepressing molding on the injection molding mould to carry out injection molding or extrusion molding, then cutting into the shape of an in-mould decorative film product (or cutting before the in-mould decorative film is put into the injection molding mould or the extrusion molding mould), so as to complete the process of preparing the in-mould transfer printing film.

Owner:许西岳 +1

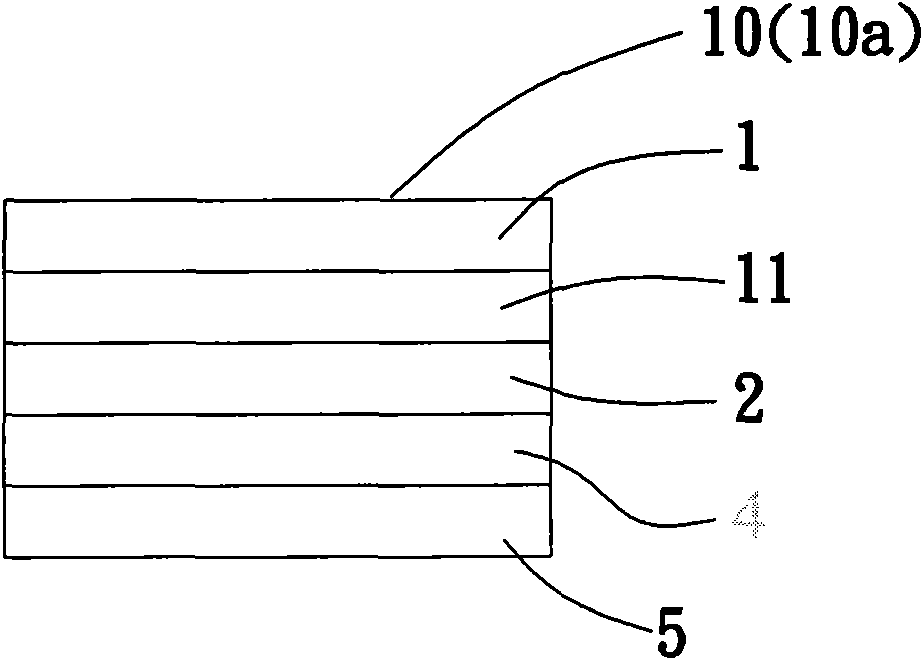

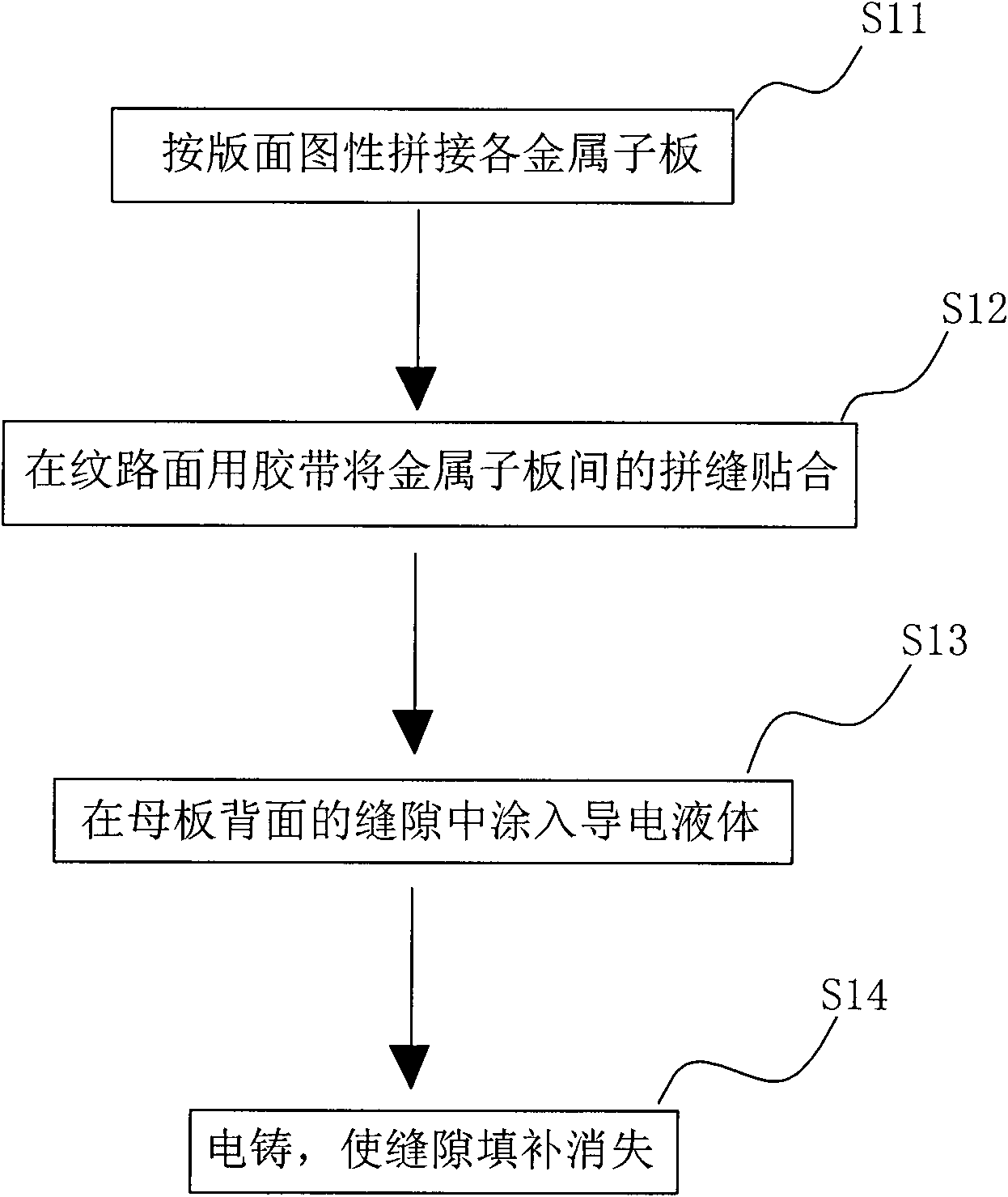

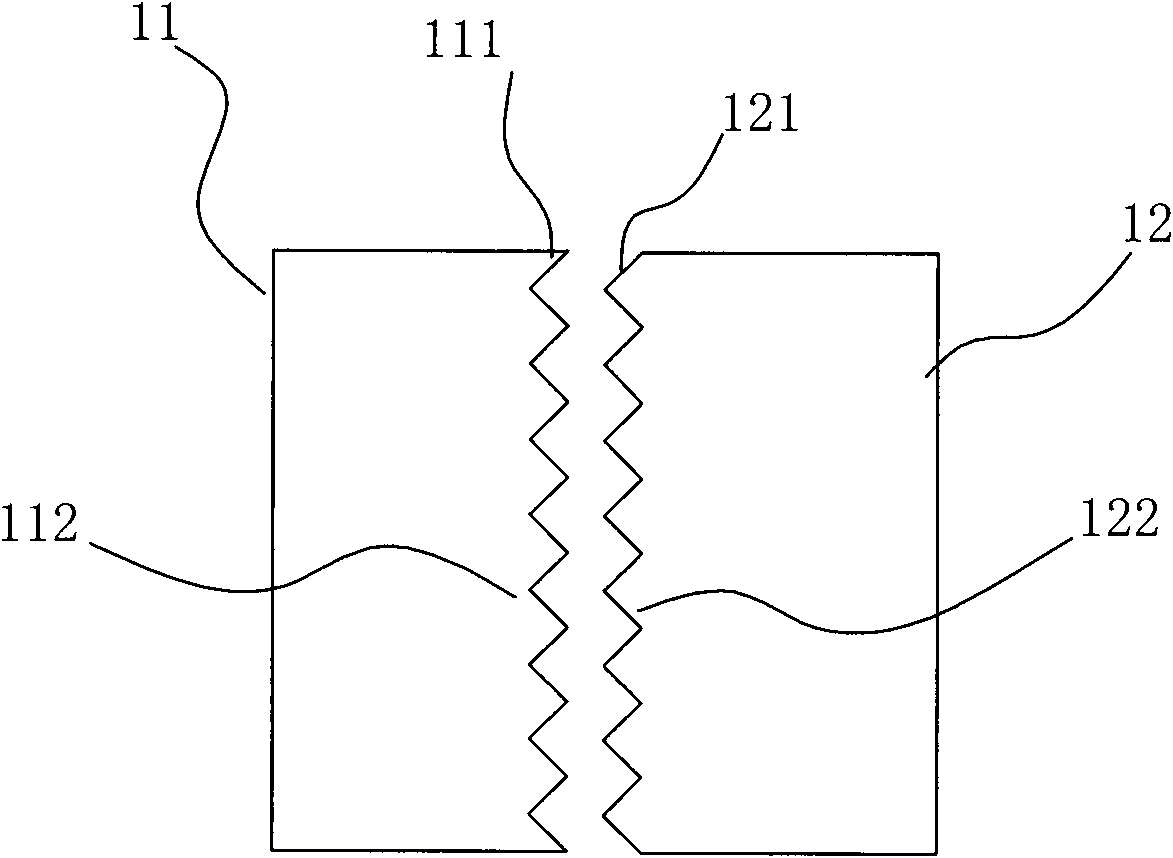

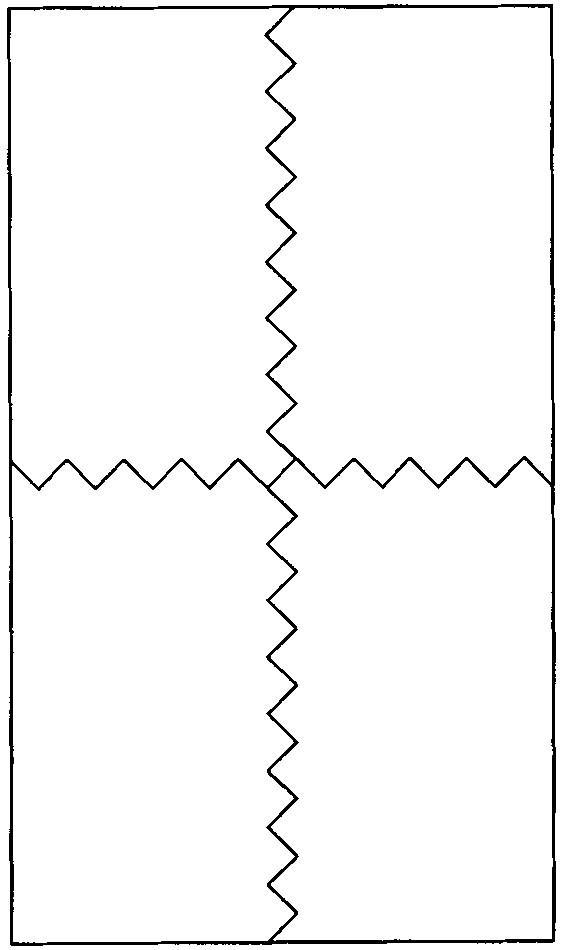

Method for making metal mother board

ActiveCN102009517AIncrease contact surfaceAvoid breakingPrinting formes reproductionConvex structureMetal

The invention relates to a method for making a metal mother board. The metal mother board is made by splicing at least two metal daughter boards together, and each metal daughter board has lines of a laser image. In the method, an abutted seam between the at least two metal daughter boards is stuffed mainly in an electroforming manner, wherein a concave-convex structure is arranged on the abuttededge of each metal daughter board, and the concave-convex structures of adjacent daughter boards are matched with each other. By adopting the concave-convex structures, the electroforming strength among metal daughter boards is increased, simple and accurate counterpoint is also realized, and the quality of the finished product of the metal mother board is improved.

Owner:SVG TECH GRP CO LTD +1

Reverse electric conduction structure of double-surface solar cell based on PERC and manufacturing method

PendingCN108365026AImprove photoelectric conversion efficiencyImprove export performanceFinal product manufacturePhotovoltaic energy generationEngineeringLaser

The invention discloses a reverse electric conduction structure of a double-surface solar cell based on PERC and a manufacturing method. The structure comprises a reverse passivation film layer, a reverse silver main grid electrode is arranged on the reverse passivation film layer, and laser grooving areas are arranged at the two sides of the reverse silver main grid electrode; the widths of the laser grooving areas are gradually narrowed in the direction away from the reverse silver main grid electrode. The manufacturing method comprises the steps that S1, a silver main grid electrode area isreserved on the reverse passivation film layer, and the laser grooving areas and counterpoint embedding points are arranged on the reverse passivation film layer; S2, by using the counterpoint embedding points, aluminum grid lines are printed on the laser grooving areas; S3, by using the counterpoint embedding points, the reverse silver main grid electrode and silver grid lines are printed on analuminum grid layer. The reverse electric conduction structure and the manufacturing method have the advantages that by means of a tapered structure of gradual widening, the capacity of exporting reverse photon-generated carriers along local grid lines is improved, thermal loss and power loss in the exporting process are reduced, and the photoelectric conversion efficiency of front and reverse surfaces of the double-surface solar cell based on PERC is improved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

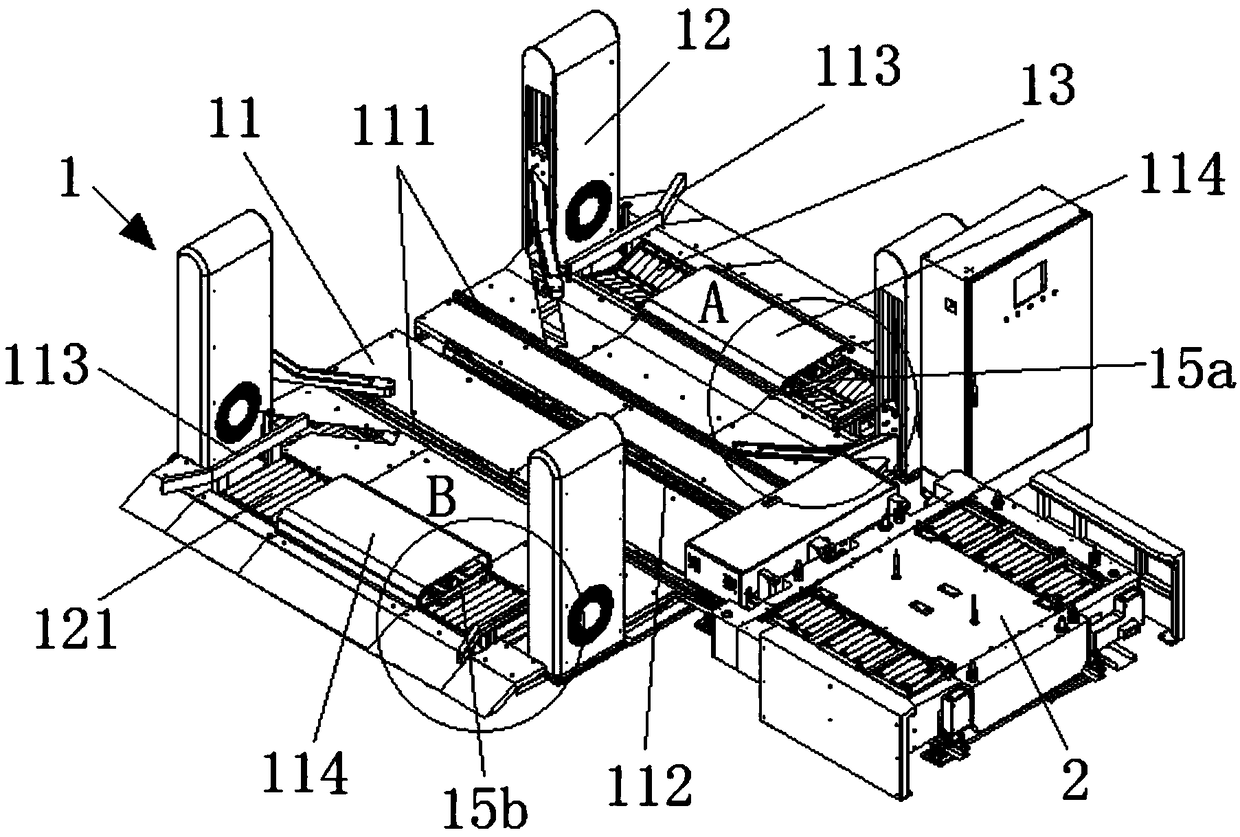

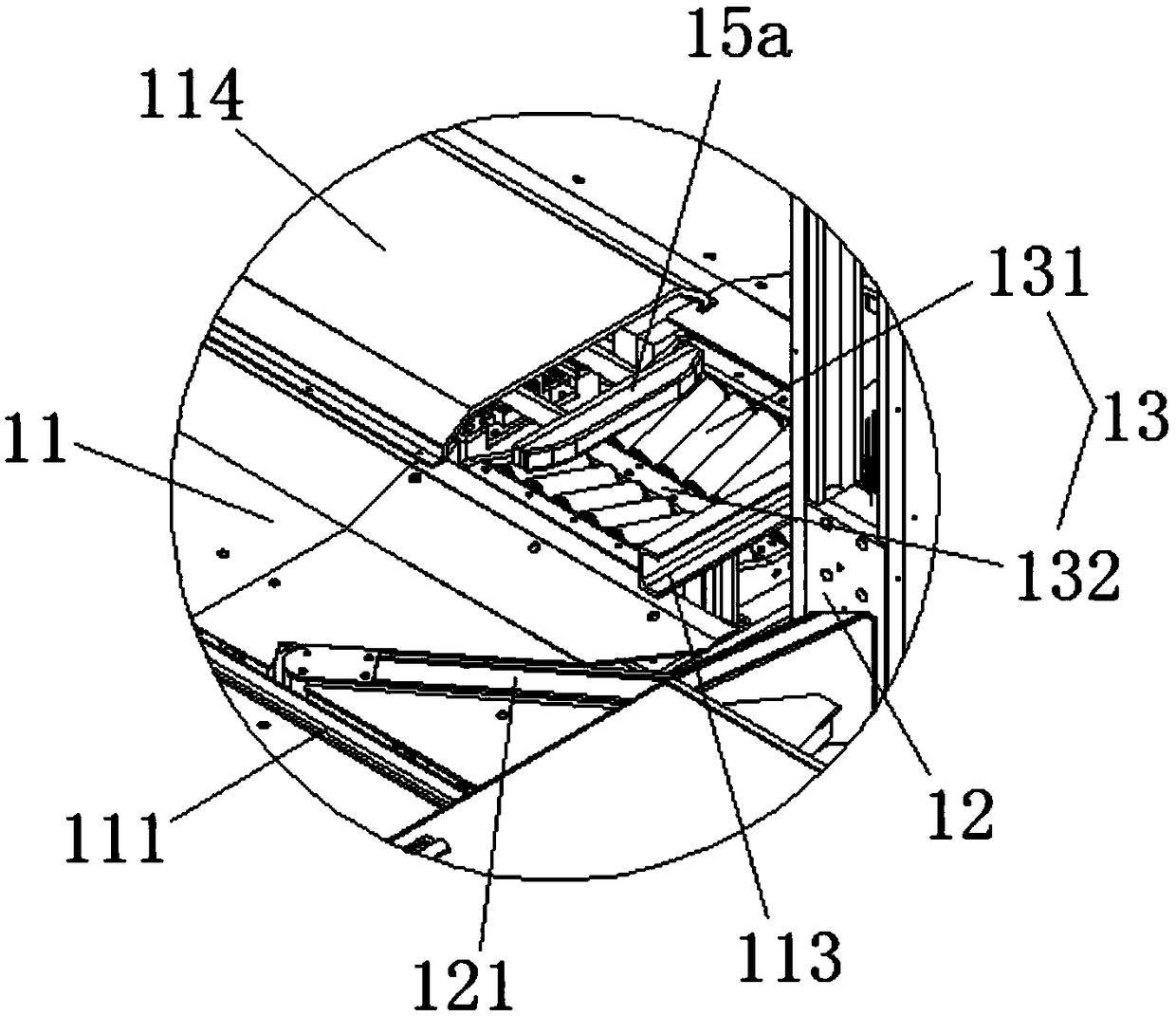

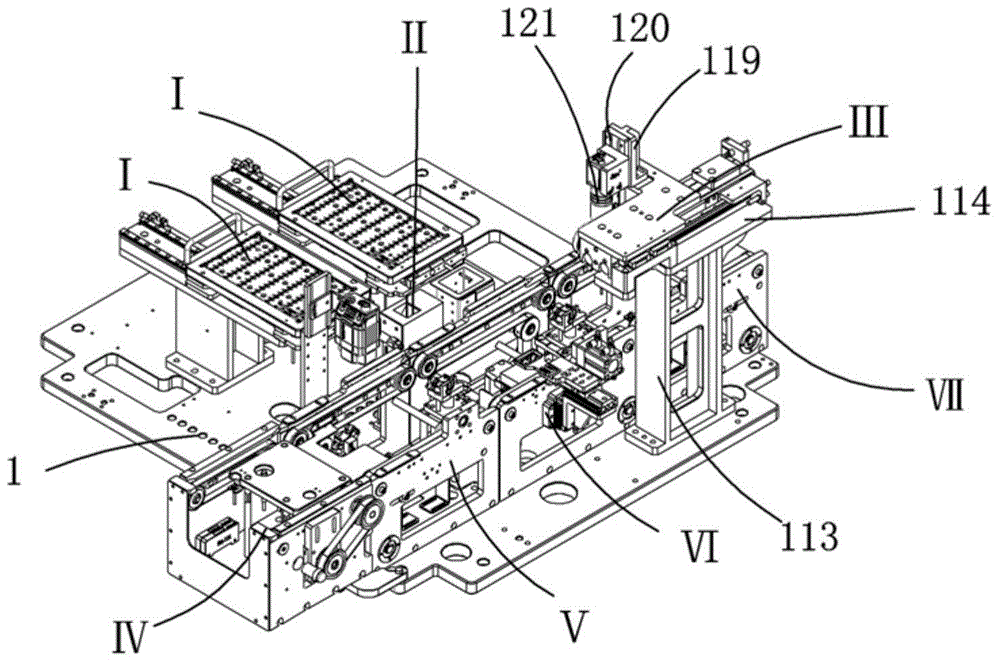

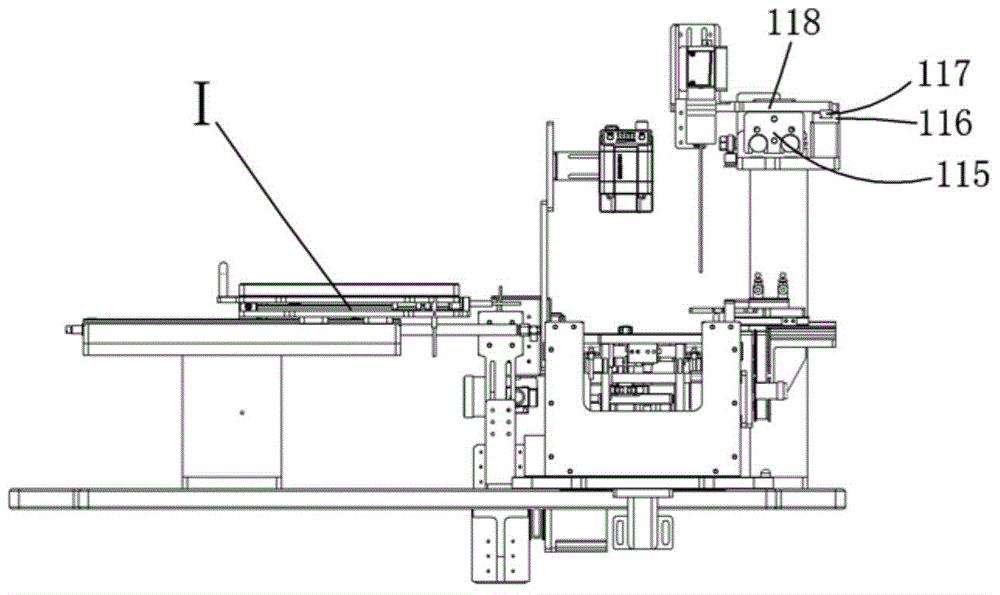

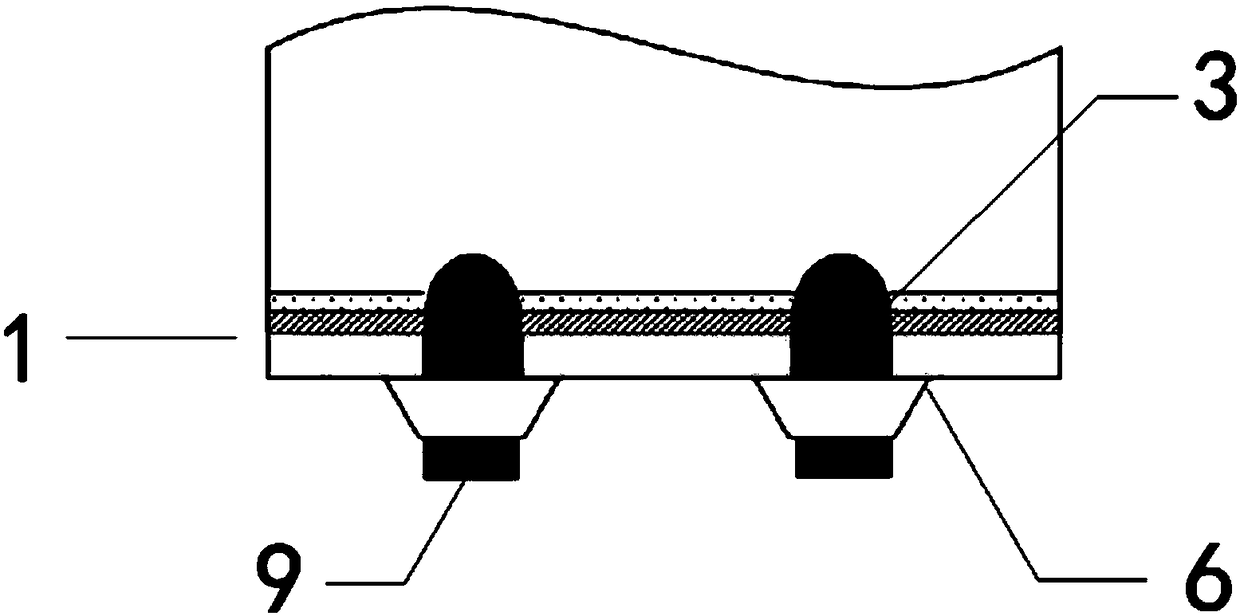

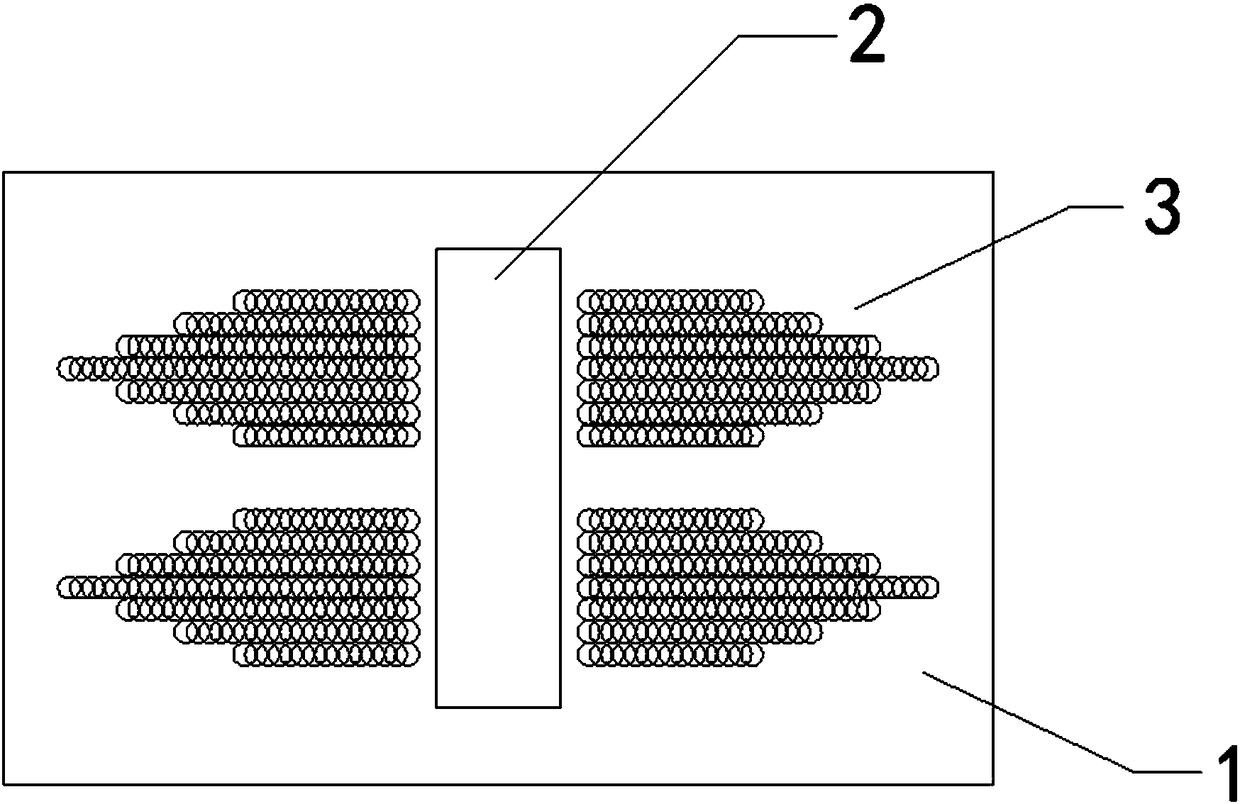

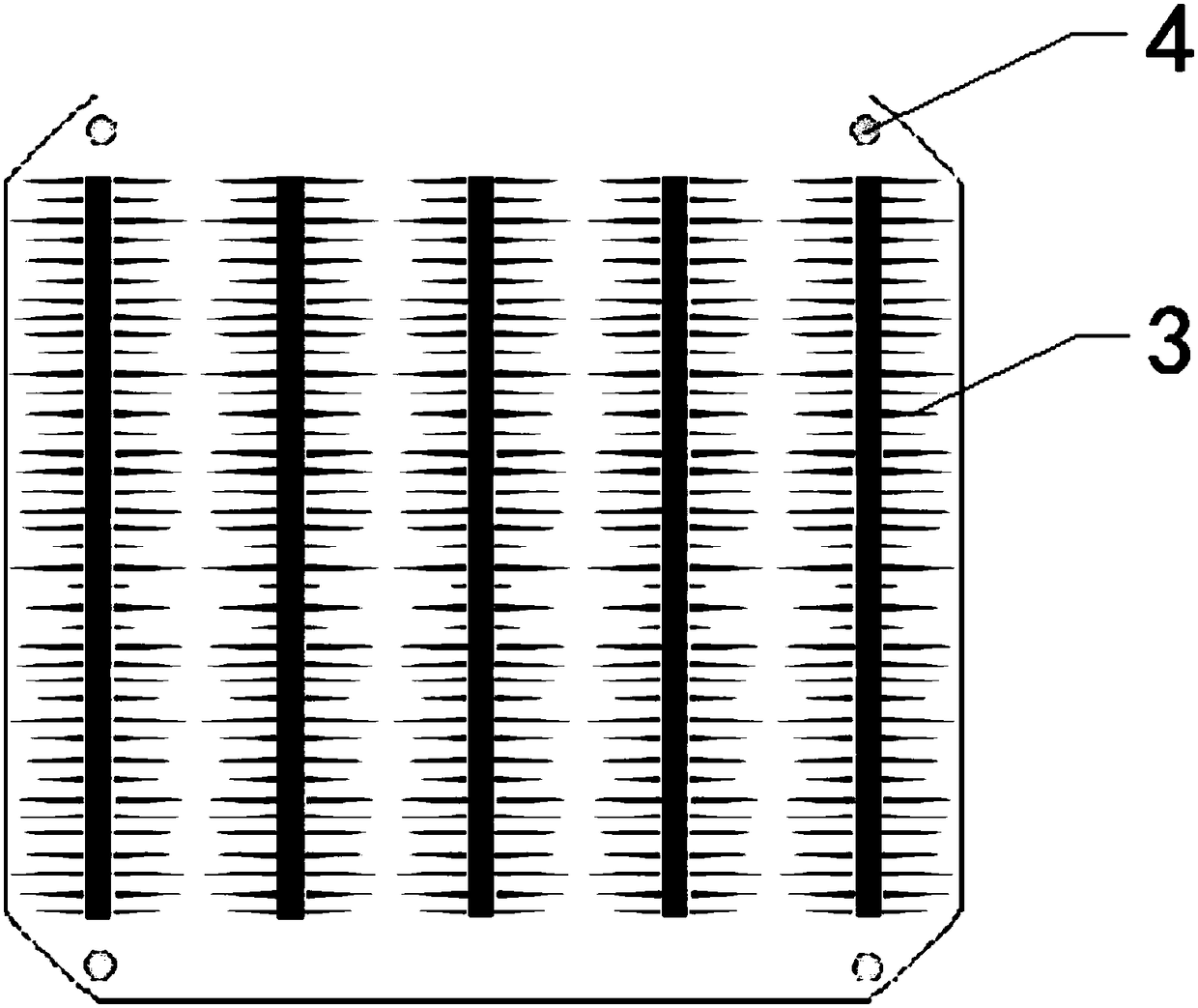

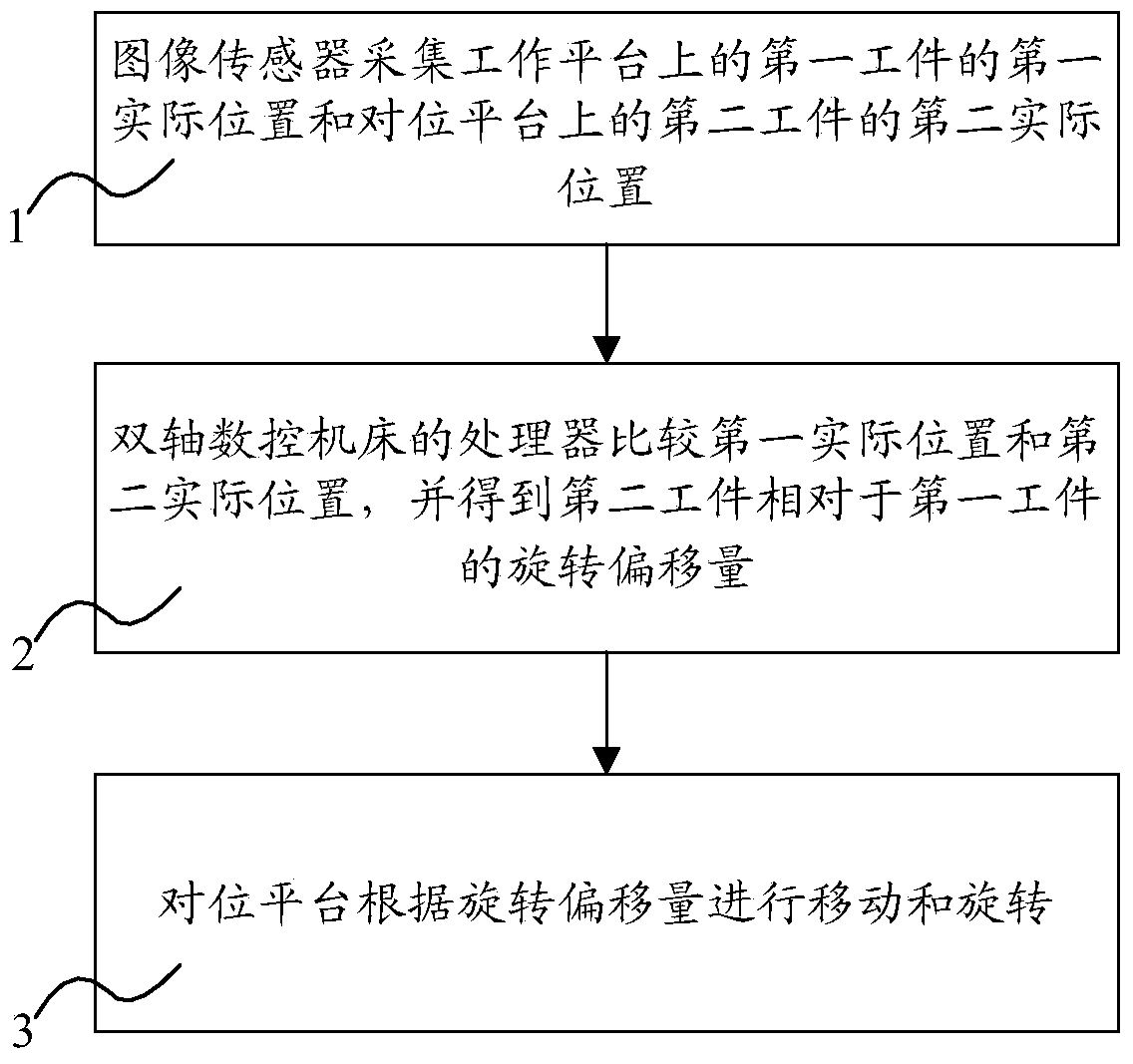

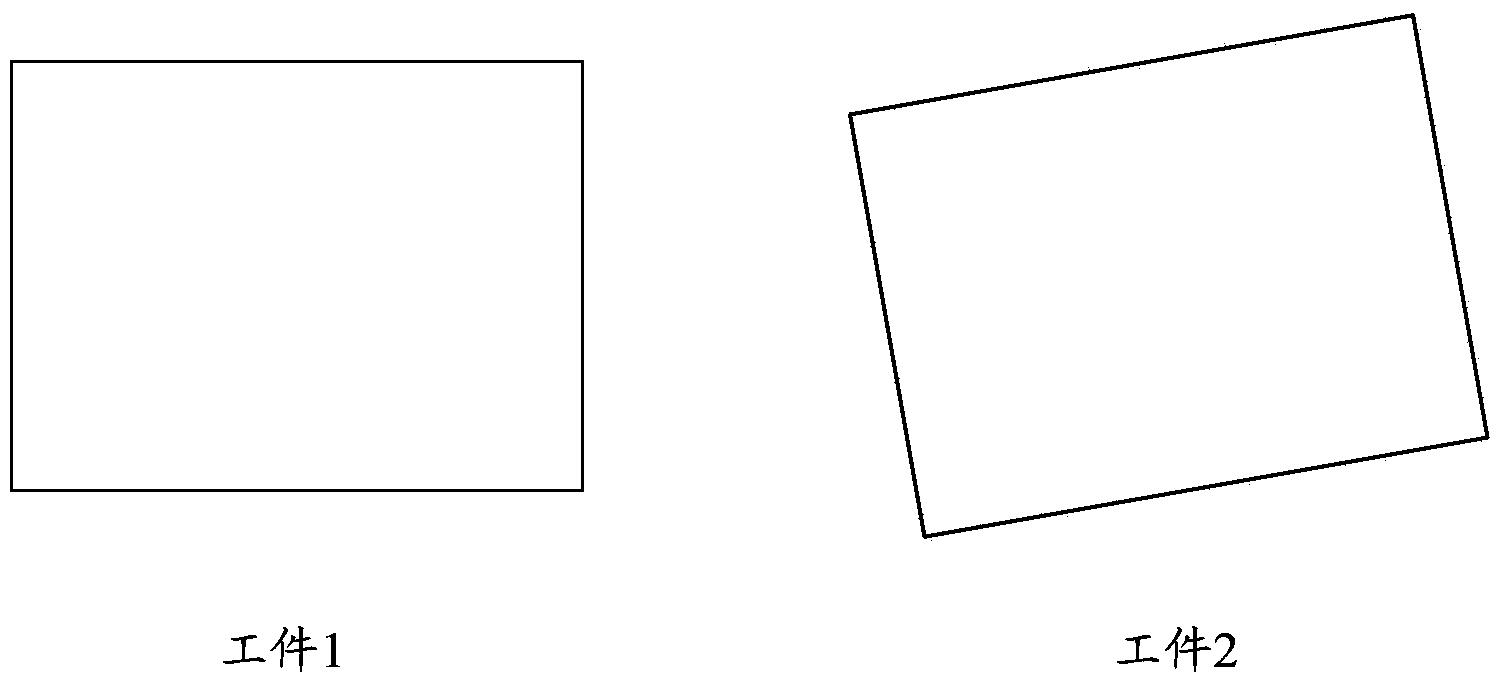

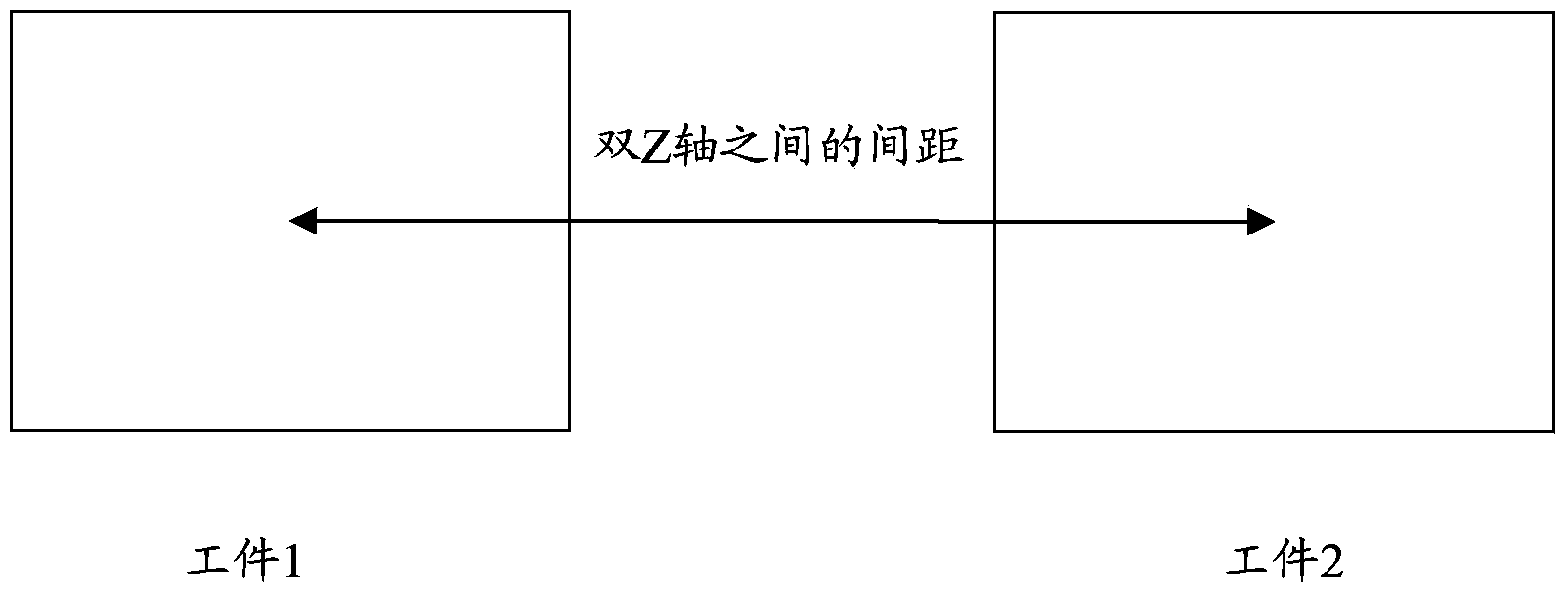

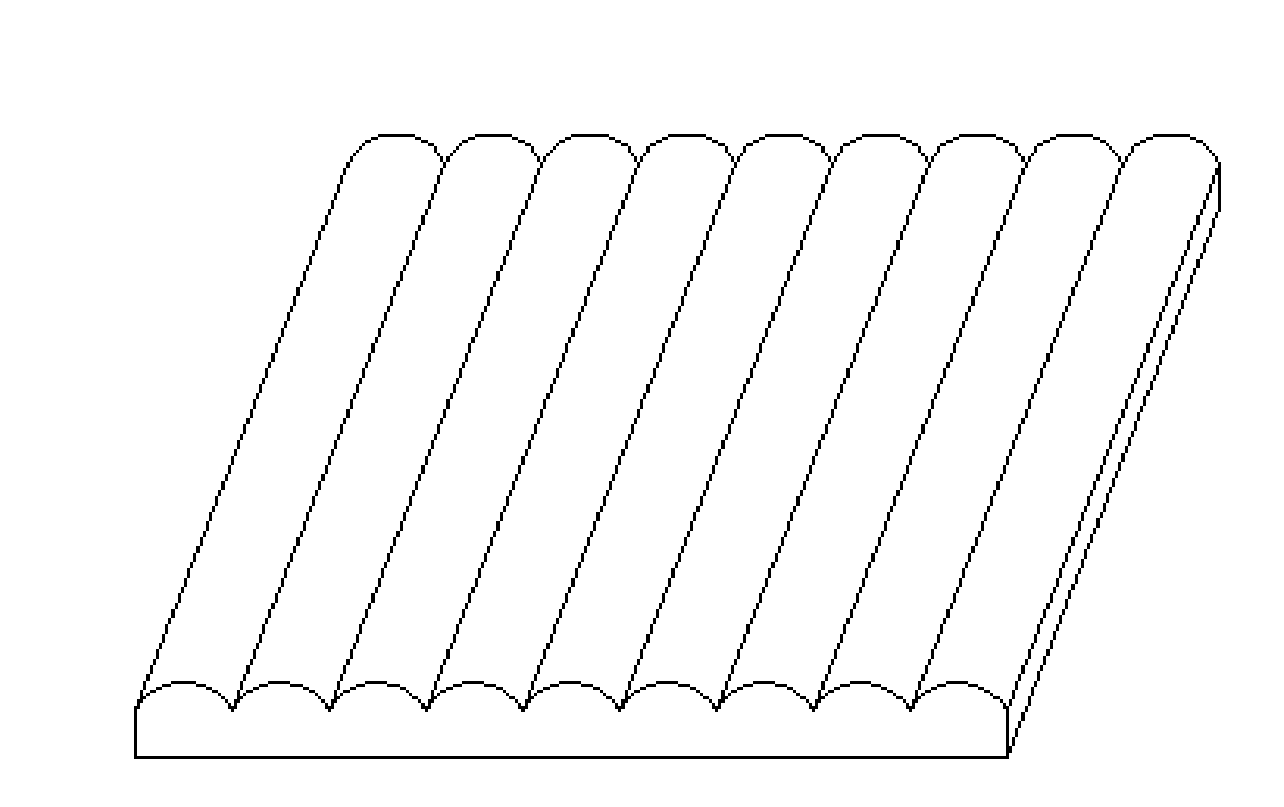

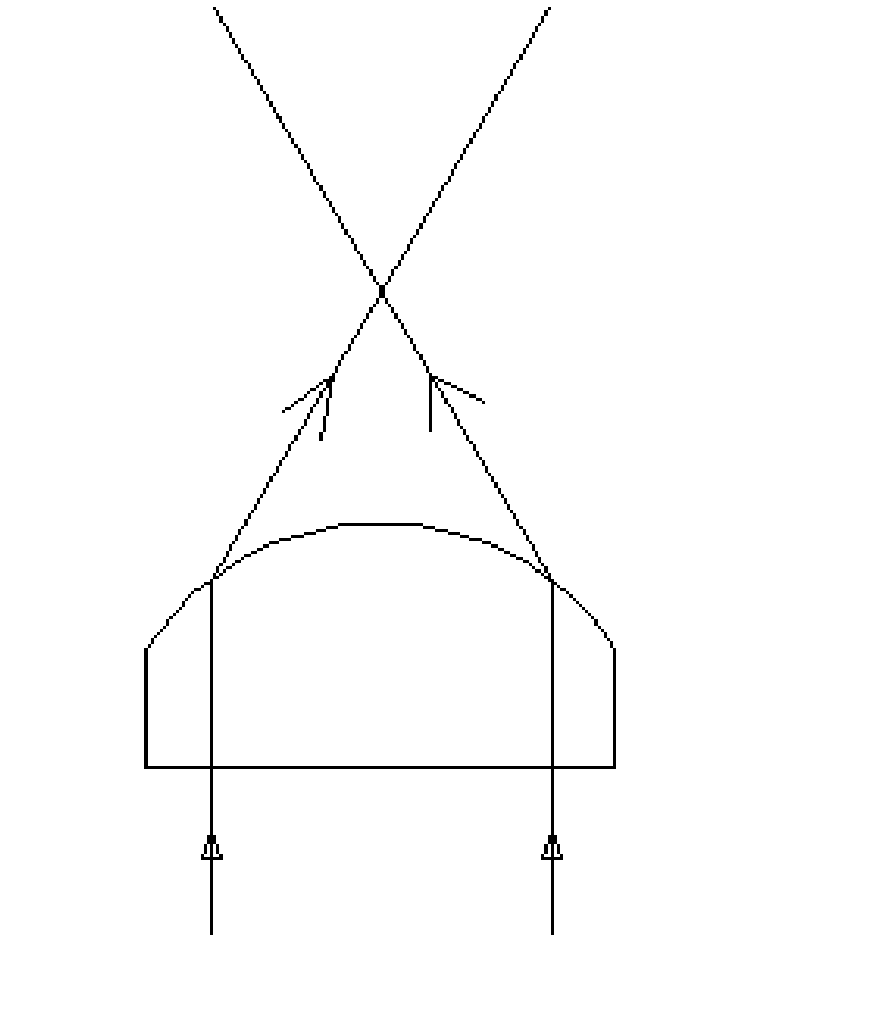

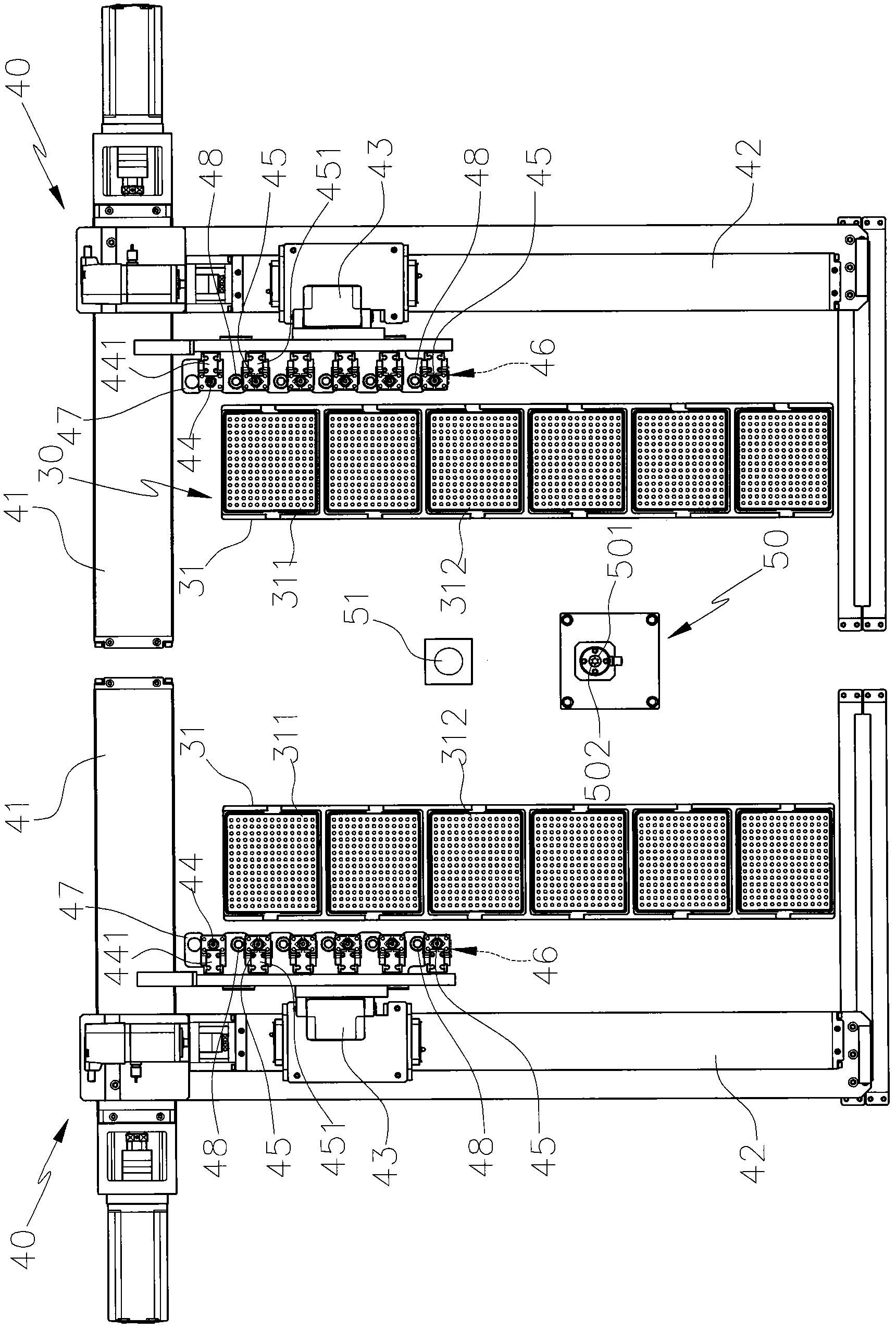

Biaxial numerical control machine tool correction positioning implementation method and system based on counterpoint platform

ActiveCN104181861ADifficulty of Simplifying CorrectionWith linkage functionNumerical controlNumerical controlWork performance

The invention relates to a biaxial numerical control machine tool correction positioning implementation method and system based on a counterpoint platform. The counterpoint platform is arranged on a working platform of a biaxial numerical control machine tool. A first workpiece is arranged on the working platform, and a second workpiece is arranged on the counterpoint platform. The method includes the steps that the first actual position of the first workpiece and the second actual position of the second workpece are collected; the rotating deviation of the second workpiece relative to the first workpiece is worked out through a processor of the biaxial numerical control machine tool; the counterpoint platform conducts moving and rotating according to the rotating deviation. The invention further relates to a biaxial numerical control machine tool correction positioning system based on the counterpoint platform. The system comprises an image collection module, a processing module and the counterpoint platform. By the adoption of the biaxial numerical control machine tool correction positioning achieving method and system based on the counterpoint platform, the difficulty in correcting the two workpieces simultaneously is lowered, processing efficiency and accuracy are improved, and the system is stable in work performance and high in reliability and has the wider application range.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH

Optical grating counterpoint splicing method

An optical grating counterpoint splicing method belongs to the field of optics and aims at solving the problem that errors are large by an existing method that two lenticular lens optical gratings are spliced by the aid of a concave optical grating. The optical grating counterpoint splicing method comprises the steps of jointly placing n optical gratings to be spliced on a testing bar chart, using one of n optical gratings as a standard optical grating, and enabling the testing bar chart to form a standard interference fringe on the standard optical grating, respectively moving and revolving n-1 optical gratings to be spliced to enable the testing bar chart to form splicing interference fringes on the n-1 optical gratings to be spliced, and finishing counterpoint splicing of the n optical gratings when all the splicing interference fringes are identical to the standard optical grating in thickness degree and extended lines of the splicing interference fringes and an extended line of the standard optical grating are located in the same straight line. The optical grating counterpoint splicing method is used for splicing a plurality of optical gratings.

Owner:NINGBO VISION DISPLAY TECH

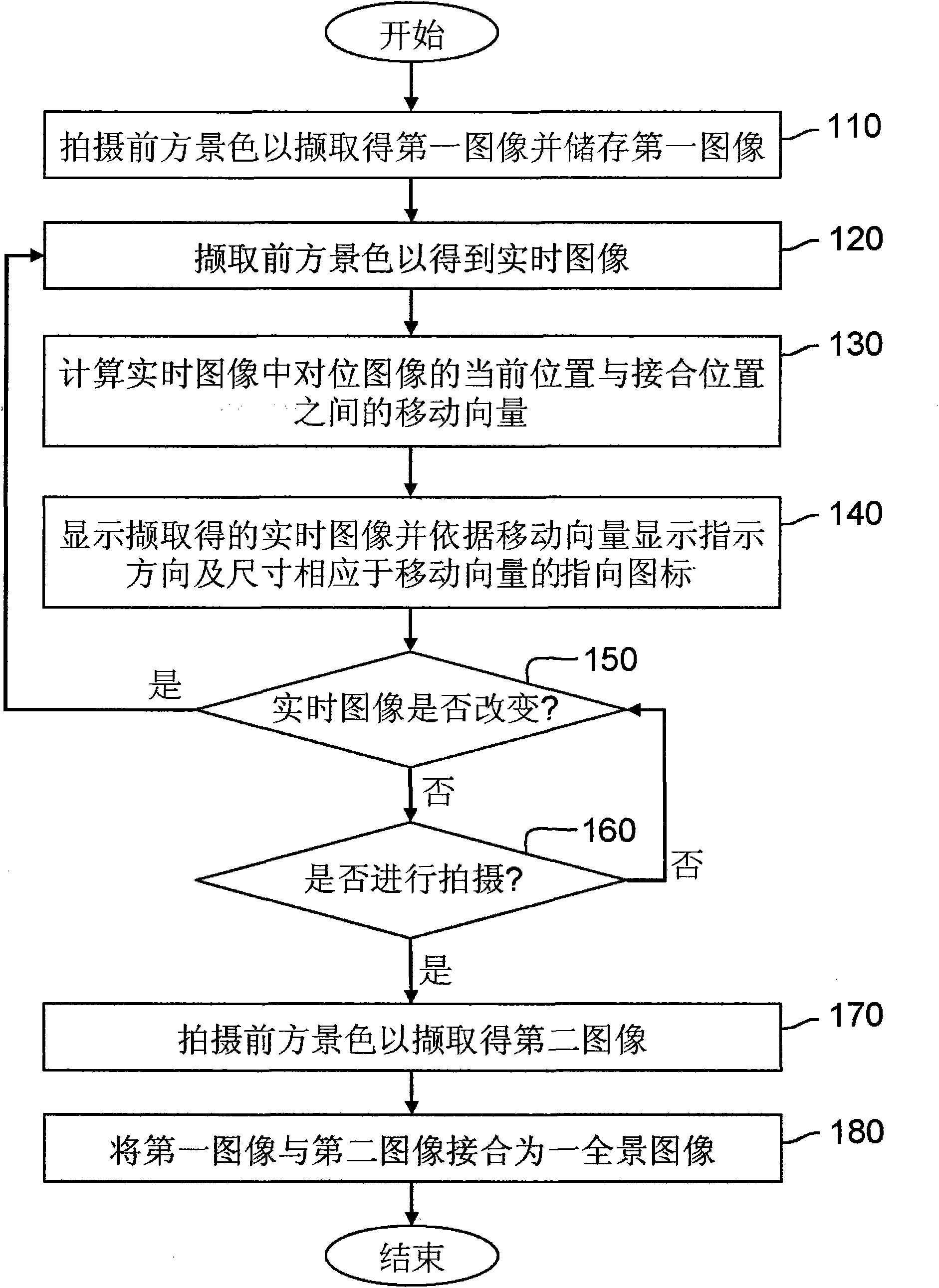

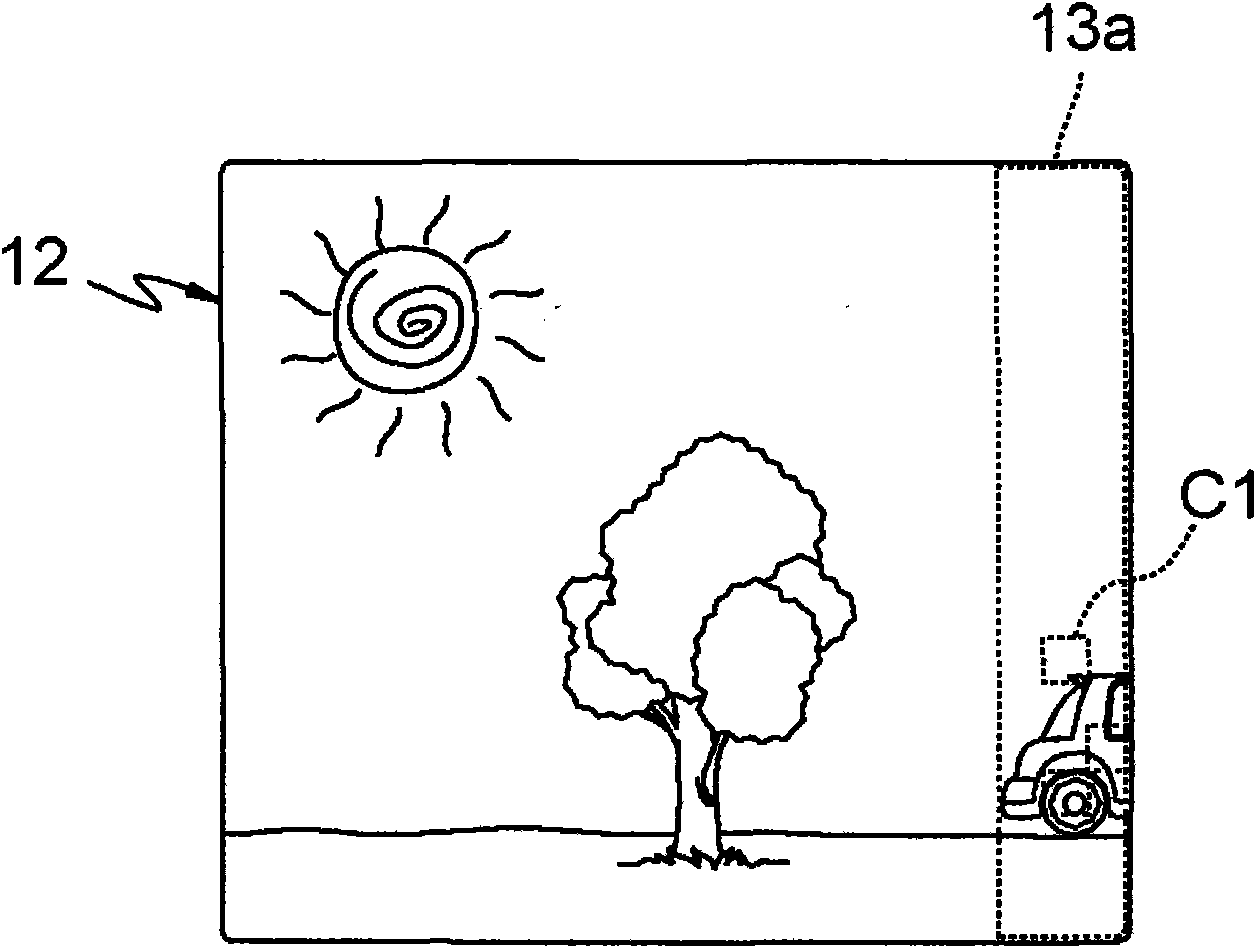

Directed shooting method for panoramic picture

InactiveCN101964869AEasy to shootReduce incidenceTelevision system detailsColor television detailsComputer graphics (images)Motion vector

The invention discloses a directed shooting method for a panoramic picture. A pointing icon corresponding to a motion vector is displayed by calculating the motion vector between the current position and the joint position of a counterpoint image in a real-time image and according to the calculated motion vector, so that when displaying the real-time image, a digital camera device can display the pointing icon to guide the shooting position of the next image of a user at the same time. Therefore, the shooting of the panoramic picture and the failure occurrence of shooting the panoramic picture by the user is greatly reduced.

Owner:ALTEK CORP

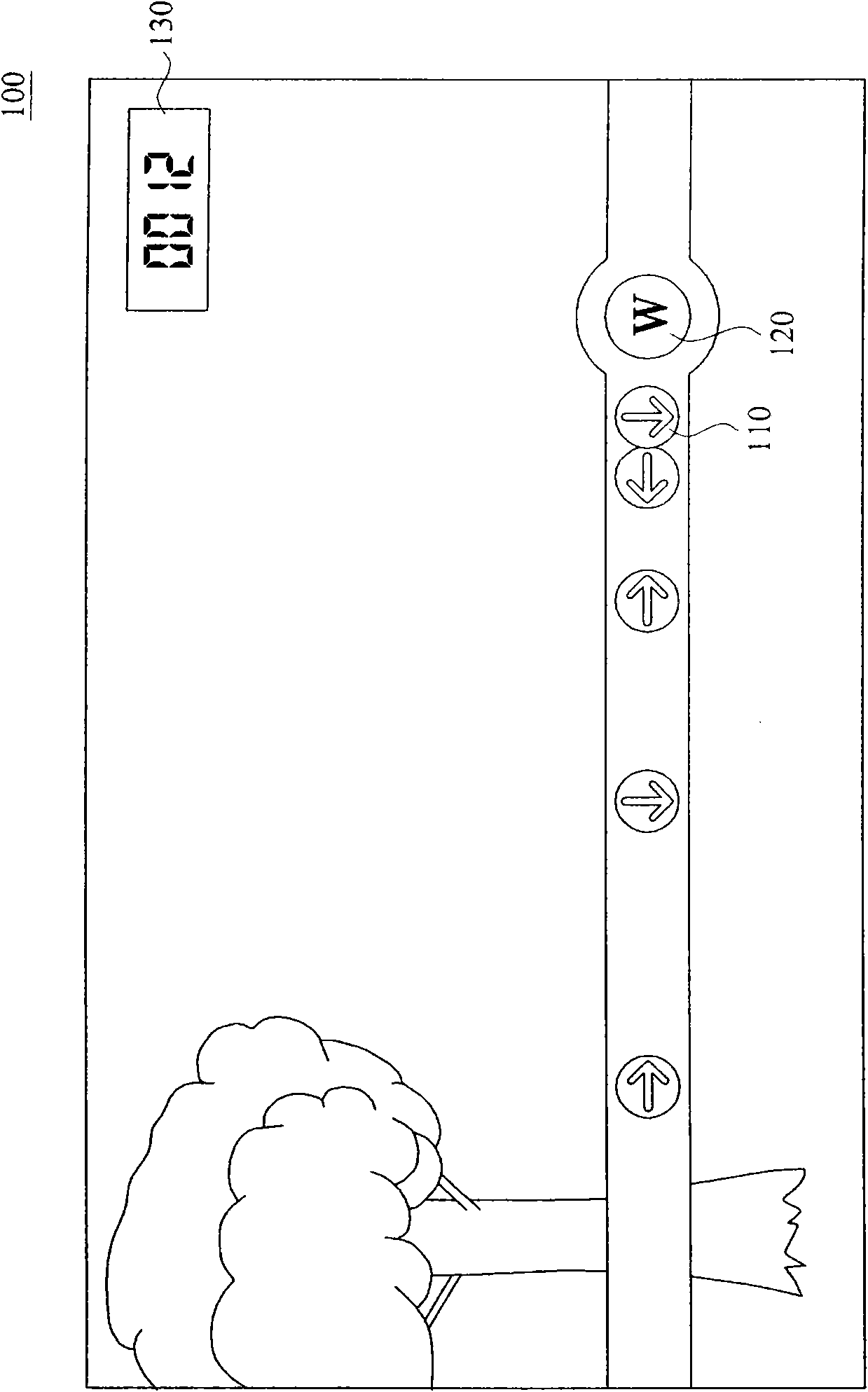

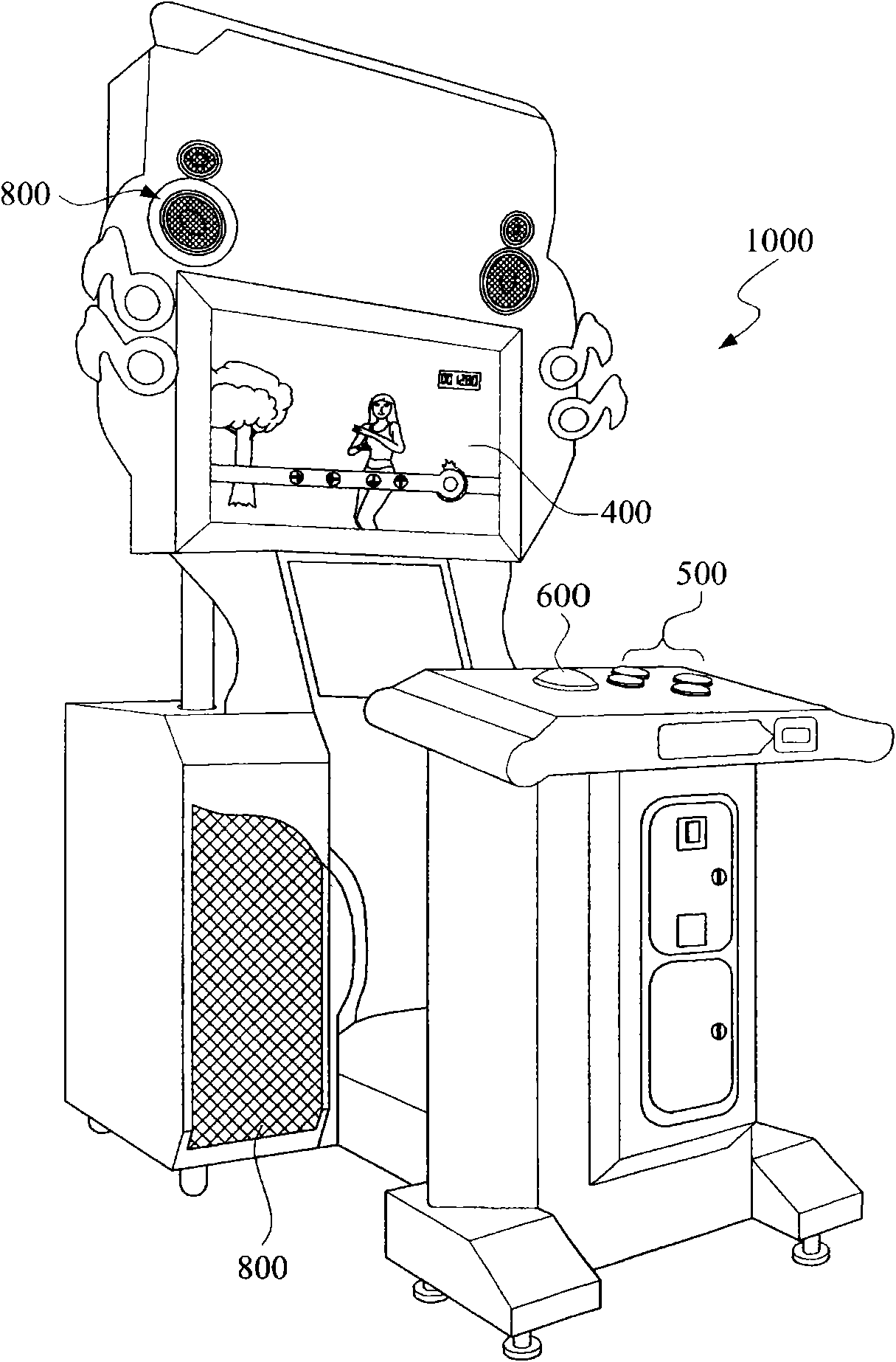

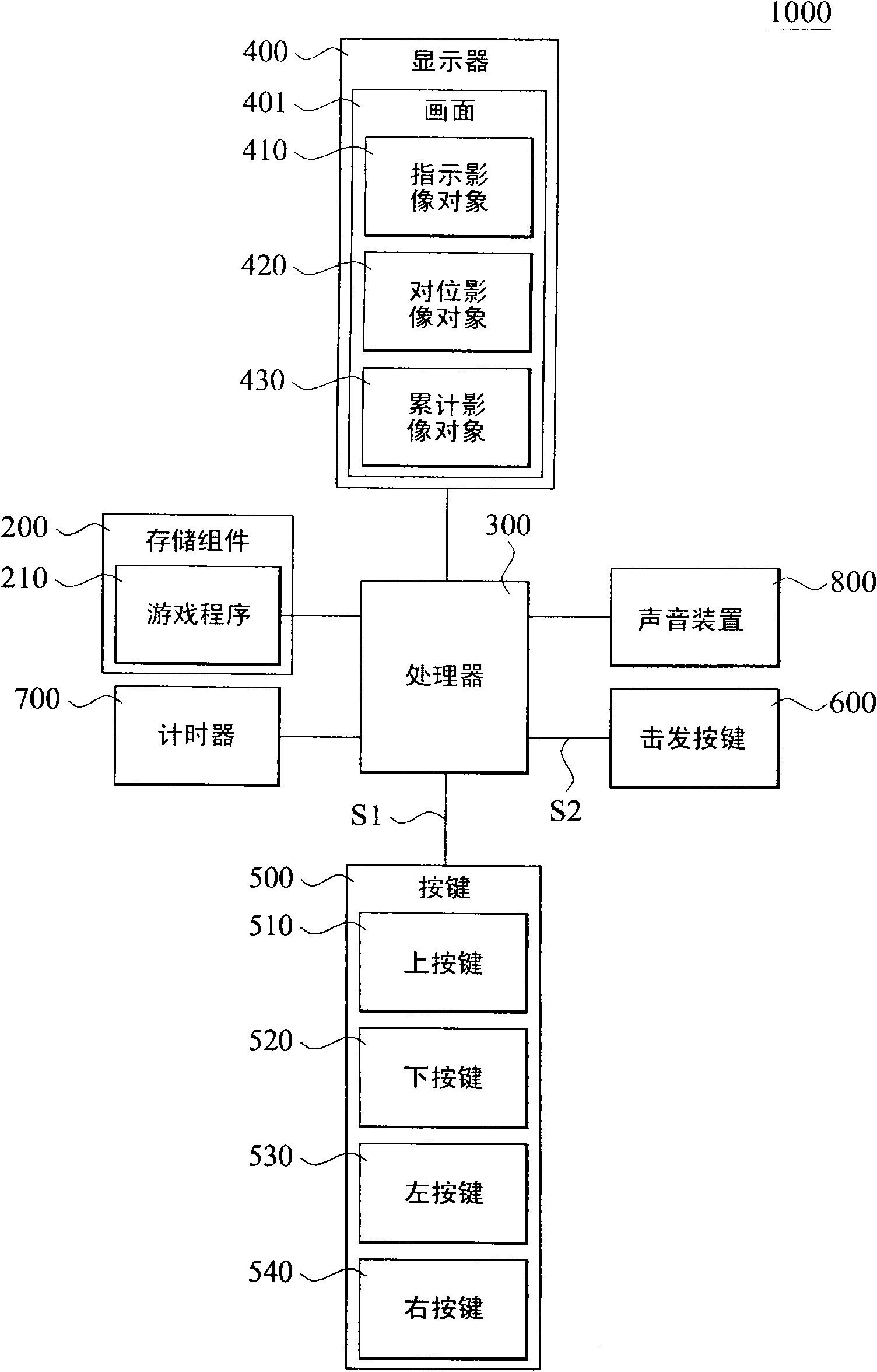

Execution system for rhythm training and method thereof

InactiveCN101648074AIncrease the difficultyIncrease irritationRegistering/indicating time of eventsVideo gamesComputer graphics (images)Rhythm

The invention relates to an execution system for rhythm training, which is used for executing the rhythm training, such as dancing machines, drum machines and the like. A picture of the rhythm training comprises a plurality of pointing image objects, a counterpoint image object and an accumulating image object, wherein the pointing image objects move in the picture and pass through the counterpoint image object. When the pointing image objects superpose the counterpoint image object, the image object can be accumulated by pressing a key corresponding to the pointing image objects; and when theaccumulating image object accumulates to reach a standard, a processor enables the pointing image objects to produce a display change, such as rotation, reverse display, invisible display, acceleration during moving or deceleration during moving generated while the pointing image objects move in the picture.

Owner:INTERNATIONAL GAMES SYSTEM

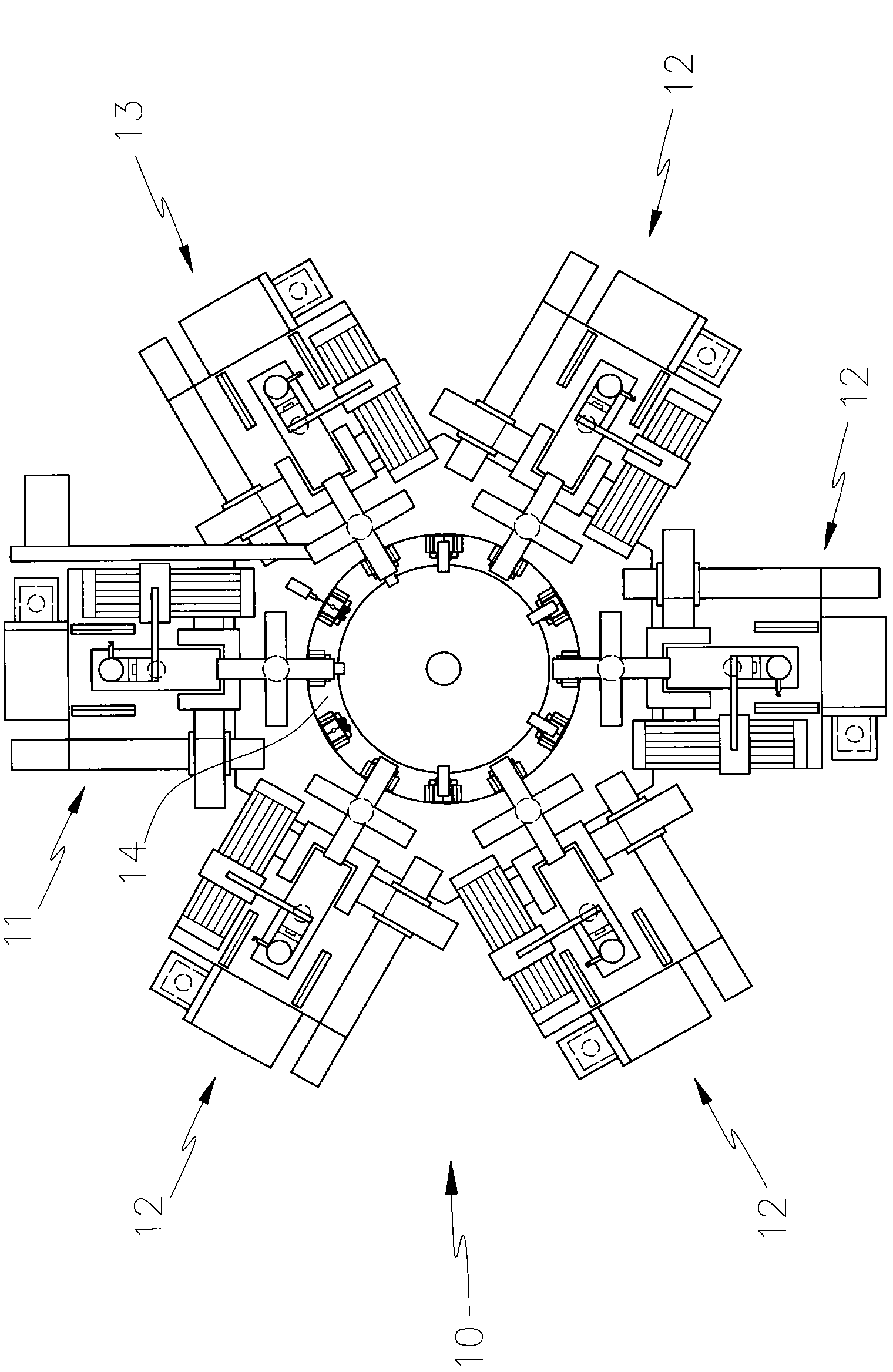

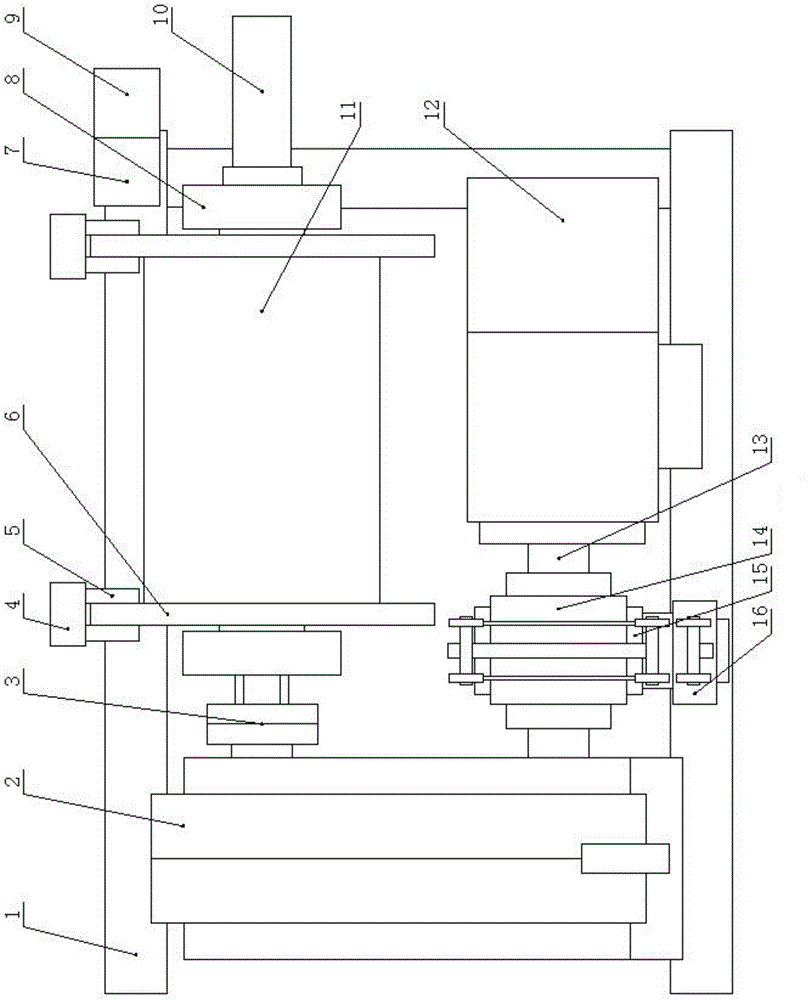

Automatic lens assembly machine

An automatic lens assembly machine mainly comprises a material feeding and receiving device, at least two moving and loading devices and an assembly station seat, wherein the material feeding and receiving device is used for supporting and placing a plurality of kinds of lens components, the at least two moving and loading devices are respectively provided with a plurality of taking and placing devices for moving and loading the lens components and can drive the taking and placing devices to make displacement along three axial directions, moreover, counterpoint mechanisms are respectively and correspondingly arranged on the taking and placing devices, so that the central positions of the lens components can be respectively corrected, and the moving and loading devices are used for sequentially grabbing, moving and loading the lens components on the material feeding and receiving device; in the process of moving and loading, the central positions of the lens components can be corrected by the counterpoint mechanisms, and then the lens components are sequentially moved and loaded on the assembly station seat for carrying out the assembly operation of the lens; the timing collocated moving, loading and assembling are carried out by using the moving and loading devices, during the moving and loading, the central positions of the lens components can be corrected at the same time, therefore, the automatic lens assembly machine is suitable for different assembly types, and can carry out the assembly operation quickly and accurately so as to achieve the practical benefit of greatly improving the production efficiency.

Owner:SYNERGY AUTOMATION CORP

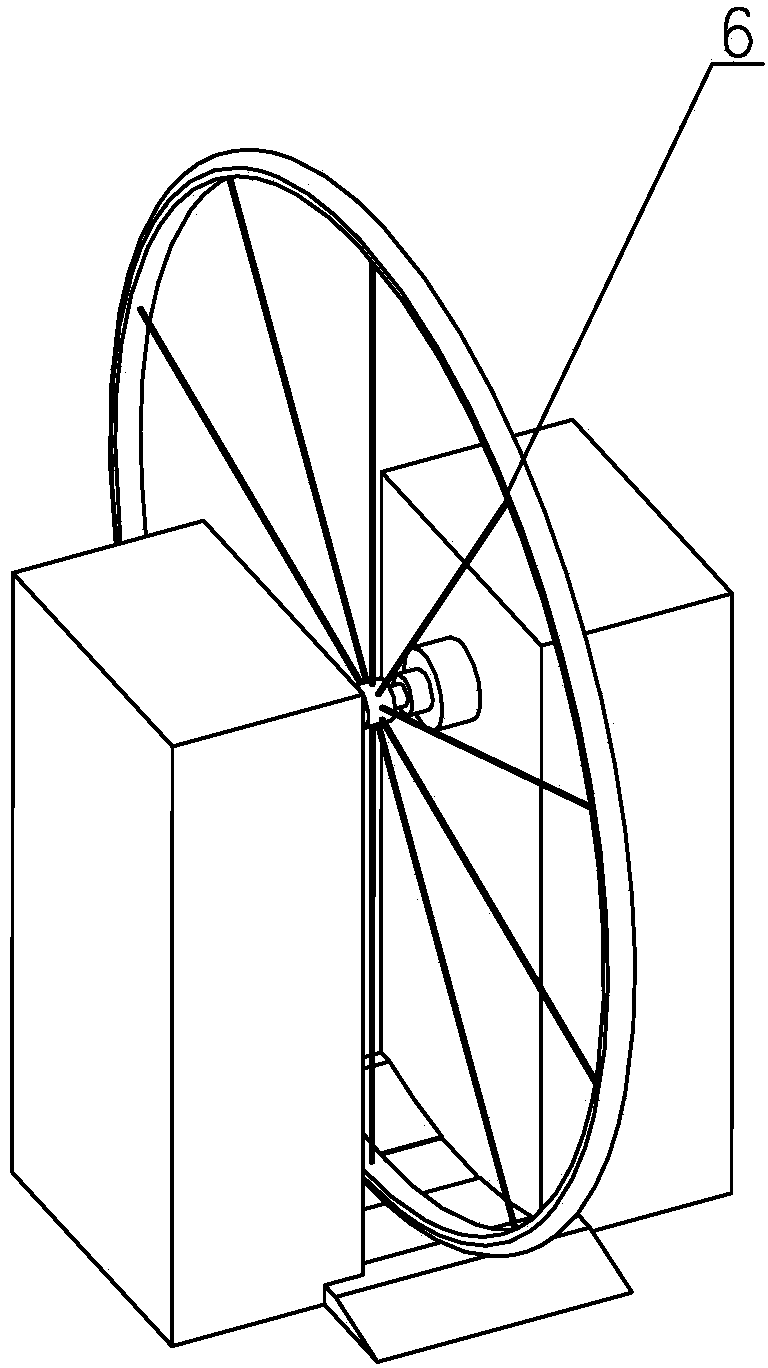

Durable winching lifting device

InactiveCN106144928ASafe and reliable workReduce friction lossWinding mechanismsFriction lossCalipers

The invention relates to a durable winching lifting device. The output end of a reduction box is connected with the rotary shaft of a winding drum through a clutch; a brake disc is mounted at each of two ends of the winding drum; a pair of pneumatic calipers is mounted on each brake disc in a counterpoint manner; and the two pairs of pneumatic calipers are connected with an air pump through an electromagnetic valve. According to the invention, brake wheels only need to brake for a while, so that friction loss is reduced; a motor is not in a driven braking state on the long-term basis; and in addition, due to the function of the pneumatic calipers, the winding drum is high in braking speed, the height of a weight is accurate, the overall work is safer, and the efficiency is higher.

Owner:天津中科恒达数控机床制造有限公司

Manufacturing method of black matrix

ActiveCN104765190ARealize the shading functionEasy to identifyPhotomechanical apparatusNon-linear opticsOptoelectronicsMetal particle

The invention provides a manufacturing method of a black matrix. A black matrix light resistance system which comprises negative photoresist and metal halide is arranged on a substrate in a coating mode, a light resistance layer is formed, the metal halide is materials with low optical density values when exposure is not carried out, so that the light resistance layer is in a transparent state, and identification on marks is convenient. After exposure, the metal halide can be decomposed into metal particles, the metal particles appear to be black due to the size is small, so that the light resistance layer appears to be black, accordingly, the light blocking function of the black matrix is achieved, and the feature that the negative photoresist can be dissolved in developing liquid when exposure is not carried out, and after exposure, the negative photoresist cannot be dissolved in the developing liquid is used for solving the problem that during a BOA manufacturing process, after black matrix light resistance system coating, counterpoint marks cannot be recognized easily.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

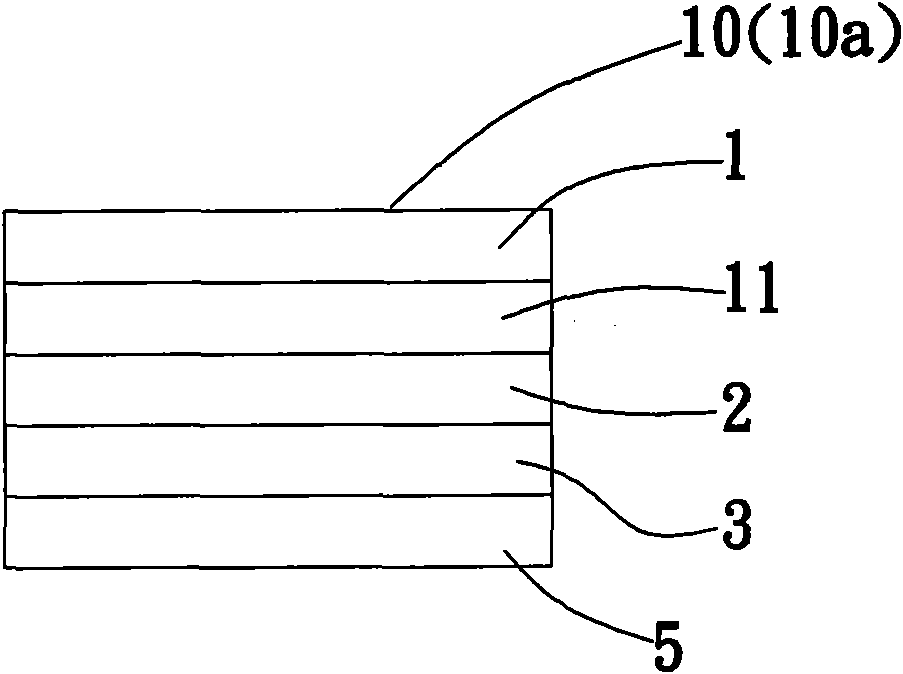

Laminated element and producing method thereof

The invention discloses a laminated element and a producing method thereof. The producing method comprises a step of producing an inner electrode. A method for producing the inner electrode comprisesthe following steps: 1) producing electrode patterns, namely cutting inner electrode pattern through holes in a first crude ceramic piece; 2) performing lamination, namely laminating a second uncut crude ceramic piece with the first crude ceramic piece under preset pressure so as to obtain a laminated body with inner electrode pattern grooves; 3) performing inner electrode printing, namely performing counterpoint printing on the inner electrode pattern grooves in the laminated body by using conductive slurry, thereby printing the inner electrode, wherein the inner electrode pattern grooves arefilled with the conductive slurry at least. The laminated element is provided with the inner electrode produced through the steps, and the thickness is 20-100 [mu]m.

Owner:SHENZHEN SUNLORD ELECTRONICS

Dry and dense resonance method for reinforcing soft soil foundation of new hydraulic-fill sand

InactiveCN102465523AImprove reinforcement effectIntensified settlementSoil preservationSludgeWater table

The invention relates to a dry and dense resonance method for reinforcing a soft soil foundation of new hydraulic-fill sand. The method is suitable for reinforcing the soft soil foundation of the new large-area hydraulic-fill sand quickly. The method comprises the following steps of: 1, establishing resonance equipment; 2, distributing points in a constructional area; 3, dewatering in the constructional area, namely dewatering in a mode of combining light well-point dewatering with the water pumping of a vibrator, and performing resonance by using the vibrator after the water level of underground water is reduced to a certain range; 4, performing vibration retention for the first time, namely performing the vibration retention after the vibrator reaches the required depth; 5, performing the vibration retention stage by stage, namely lifting the vibrator by 0.4 to 0.6 meter to perform the vibration retention for the second time after the reinforced depth is reached and the first-time vibration retention is performed, and performing the vibration retention stage by stage in a mode of lifting the vibrator by 0.4 to 0.6 meter until the vibrator is lifted to the ground surface; and 6, performing counterpoint on resonance points, namely during resonance, after a group of double-end or three-end resonance is completed, guiding double-end or three-end resonance equipment to the other group of point positions which need to be resonated by using a crane to perform the next group of resonance. The dry and dense resonance method has a good sealing effect, and the problem of performingresonant construction on sludge interlayers is solved.

Owner:葛辉 +2

Three-dimensional (3D) printing method

The invention discloses a three-dimensional (3D) printing method. A 3D printer appeared in the middle of 90 years in 20th century. In practice, the 3D printer is a fast molding device by the adoption of technologies of photocuring, paper stacking and the like. An operating principle of the 3D printer is basically same as that of a normal printer. 'Materials for printing' are arranged in the printer. The 'materials for printing' are liquid or powder and the like. After the printer is connected with the computer, the 'materials for printing' are stacked layer by layer through a computer controlling, and at last a blueprint of the computer is changed into a material object. Fast molding technologies in the market are divided into a 3DP technique, an FDM melting lamination molding technique, an SLA three-dimensional planographic printing technique, an SLS precinct laser sintering, a DLP laser molding technique, an ultraviolet (UV) ray molding technique and the like. At present, the 3D printing method is used in a motor industry, a medical treatment die processing industry and the like. A printing coverage is coated on a polymer clay sheet, an image printing is carried out on the coverage by a normal color printer, the printed image is carried out on counterpoint superposition and stretching to form a 3D image.

Owner:陈绪国

Display module integrating touch panel and assembling method thereof

InactiveCN102096502AEasy to assembleReduce manufacturing costNon-linear opticsInput/output processes for data processingHuman–computer interactionTouch panel

The invention provides a display module integrating a touch panel and an assembling method thereof. The display module comprises a display panel, a first frame, a touch panel and a second frame; the display panel is arranged in the first frame, the touch panel comprises a touch region and an edge region around the touch region; the first frame is provided with a counterpoint part and used for enabling the touch region of the touch panel to correspond to a display region of the display panel; and the second frame is sleeved on the touch panel and the first frame and used for positioning the touch panel in a direction vertical to the display panel. According to the invention, the display module integrating the touch panel can be conveniently assembled and the product quality can be improved.

Owner:QISDA SUZHOU +1

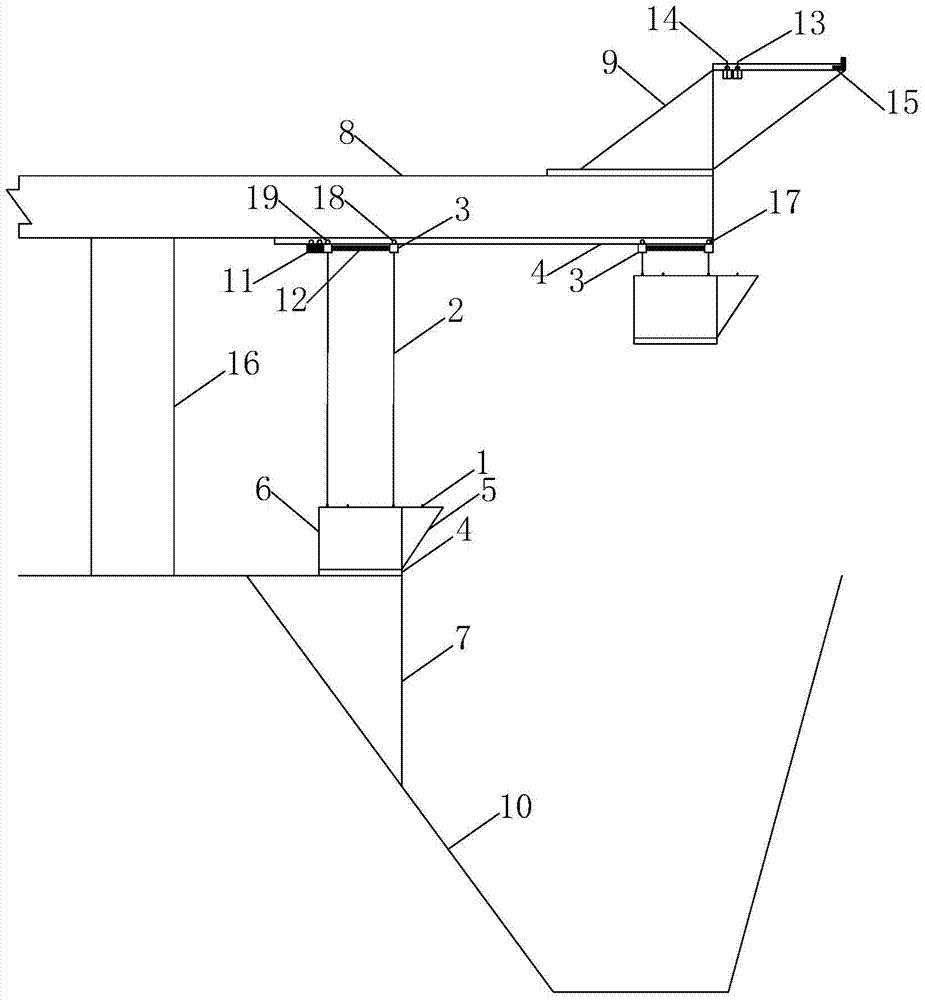

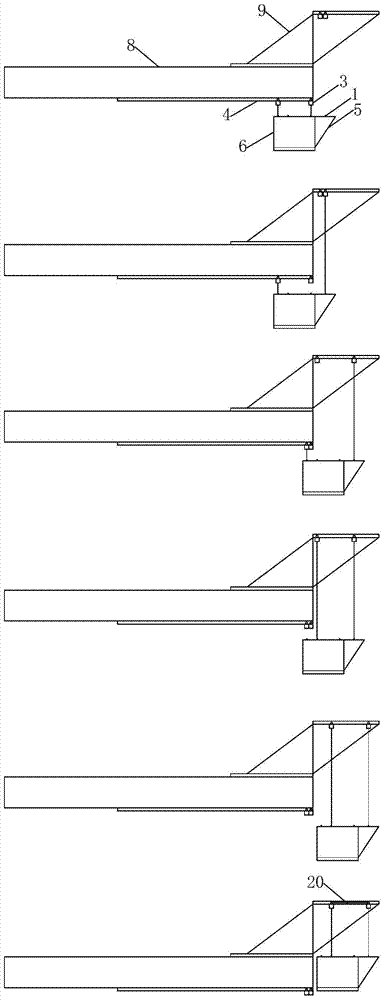

Bridge segment lifting device and method

InactiveCN104762882ARealize hoistingAvoid complicated aerial workBridge erection/assemblyStructural engineeringEngineering

The invention relates to a bridge segment lifting device and method. A beam top lifting device placed at the top of an erected beam segment and a beam bottom lifting device placed at the bottom of the erected beam segment are included. The beam bottom lifting device comprises a lower walking track. A front wheel pair and a back wheel pair are arranged on the lower walking track. A between-track-front-wheel-pair-and-back-wheel-pair rigid connecting piece is arranged between the front wheel pair and the back wheel pair. Lifting devices are arranged on the front wheel pair and the back wheel pair. A power group which can move along the track is arranged on the back wheel pair. The beam top lifting device comprises a segment lifting state converting and lifting counterpoint mechanism arranged at the top of the erected beam segment. A front horizontal beam and a back horizontal beam are arranged on the mechanism. Lifting devices are arranged on the front horizontal beam and the back horizontal beam. A between-front-horizontal-beam-and-back-horizontal-beam rigid connecting piece is arranged between the front horizontal beam and the back horizontal beam. A pulling pressing jack is arranged at the front end of the top of the mechanism. The bridge segment lifting device and method have the advantages that the field application range of bridge segment lifting and splicing working can be expanded.

Owner:TIANJIN CHENGJIAN UNIV

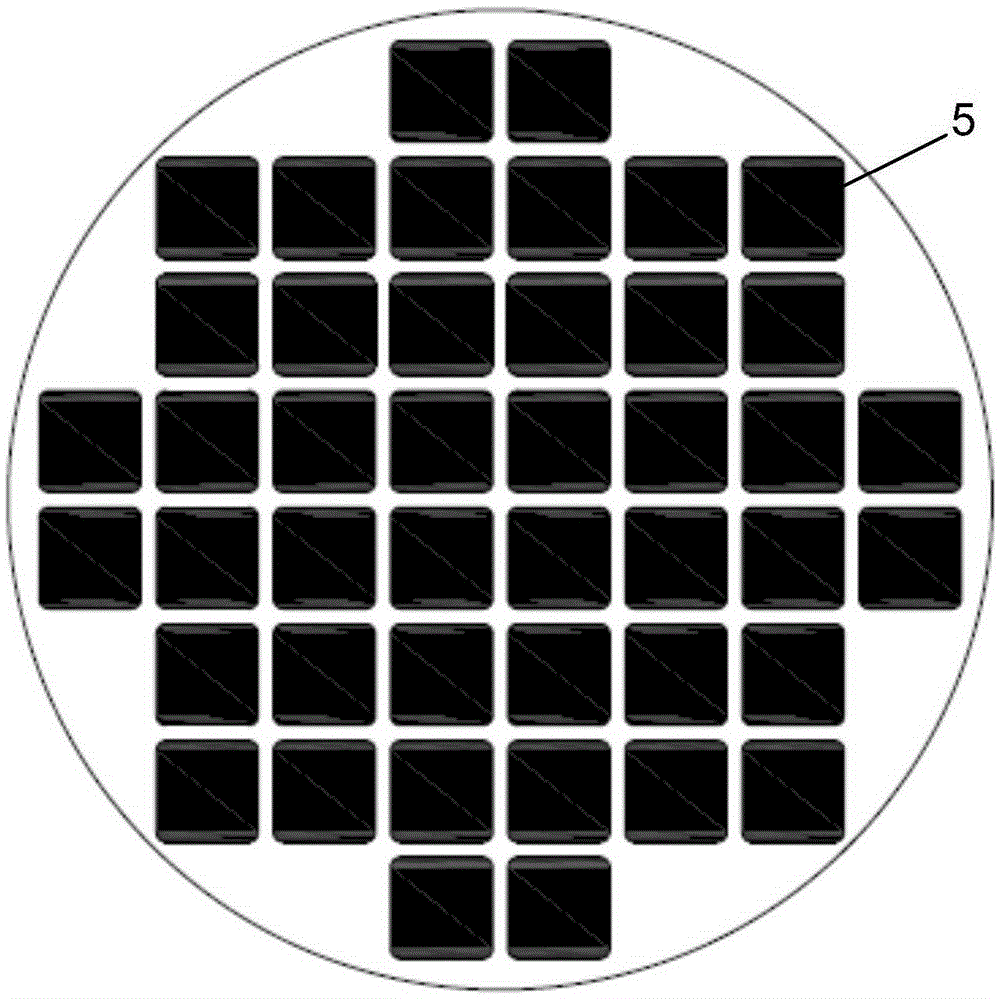

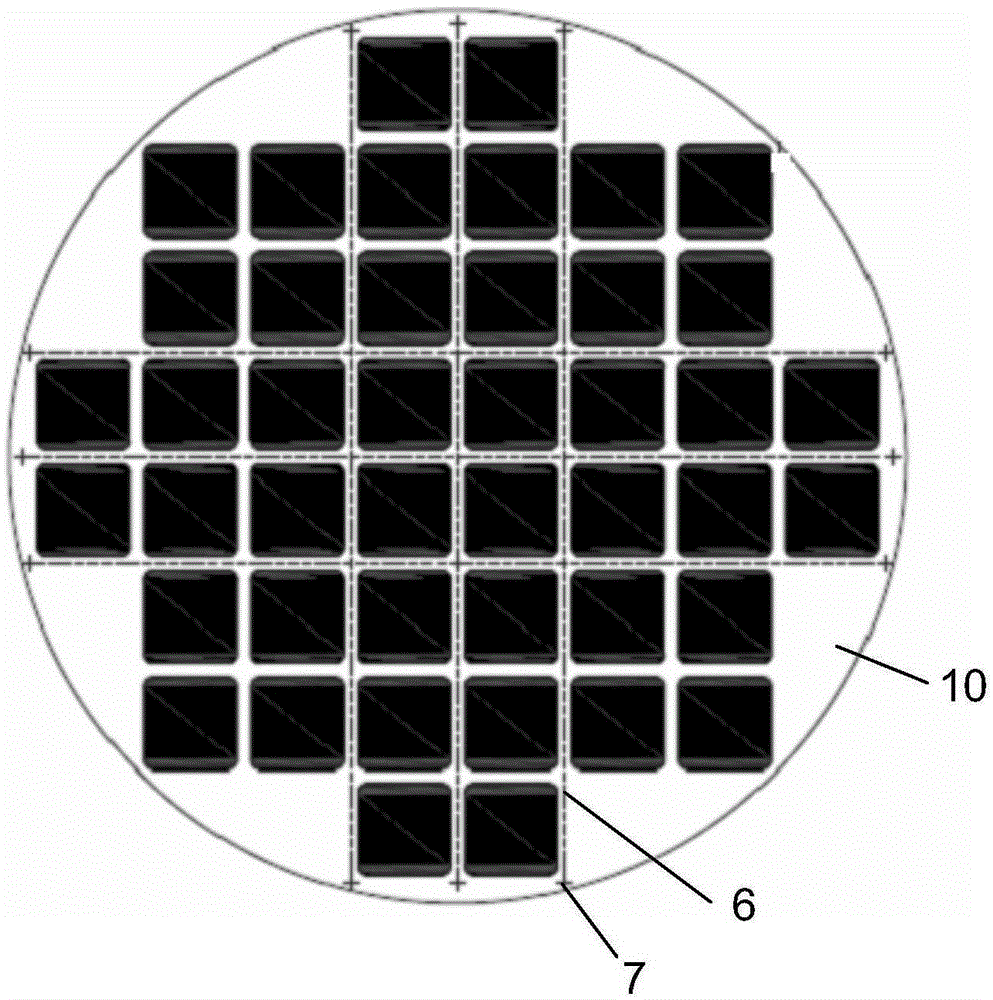

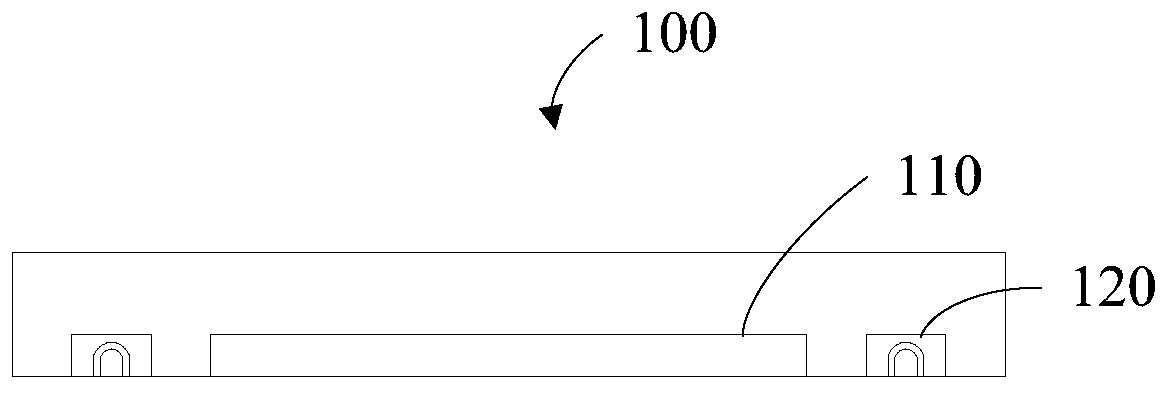

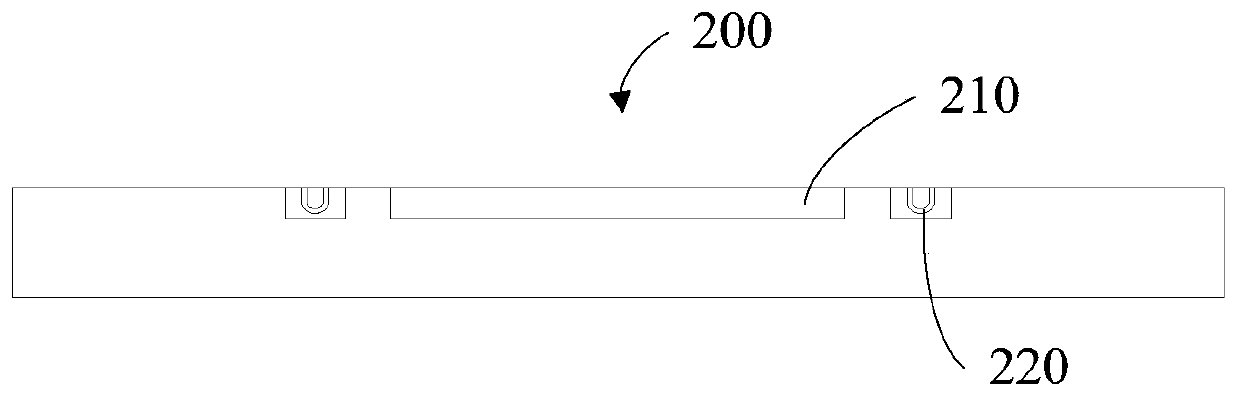

Production method and equipment for back-surface cutting counterpoint line of glass passivation silicon wafer

ActiveCN106531689AImprove manufacturing precisionReduce manufacturing costSemiconductor/solid-state device manufacturingEngineeringFlow time

The invention discloses production method and equipment for a back-surface cutting counterpoint line of a glass passivation silicon wafer. The production method and equipment is used for making a back-surface cutting positioning mark of a single-table diode, a cutting mark corresponding to a front-surface groove is made on a back surface of the glass passivation silicon wafer by a laser vertical penetrating mode, and the mark can be used for back-surface positioning cutting during back-surface cutting of the silicon wafer. Therefore, a conventional complicated secondary photoetching process is not needed to make the back-surface positioning cutting mark, the accuracy of a positioning line is improved, and the process flow time is shortened; and by comparison with actual production, compared with an original double-sided photoetching process, the production method has the advantages that the positioning accuracy is improved to + / -1 micrometer from original + / -30 micrometers, the production time is substantially shortened, the material and the labor consumed by multi-step double-sided photoetching are reduced, and the production method has quite remarkable economic value.

Owner:SHANGHAI MICRO SEMI WORLD

Wireless charging method and related device

ActiveCN110474437AHigh power transmission efficiencyImprove charging efficiencyCircuit arrangementsTerminal equipmentComputer terminal

The invention provides a wireless charging method and a related device. The method comprises the following steps of if a terminal device successfully shakes hands with an external charging device, making a first magnet work at first power, wherein the first magnet working at the first power is used for carrying out adsorption and counterpoint on the terminal device and the charging device, and a position of the charging device, which corresponds to the first magnet, is provided with a second magnet; and after the adsorption and counterpoint of the terminal device and the charging device, receiving electric energy transmitted by the charging device through a first charging coil so as to charge the terminal device. Through the adsorption and counterpoint of the first magnet on the terminal device and the second magnet on the charging device, a first charging coil on the terminal device is aligned with a second charging coil on the charging device so as to improve power transmission efficiency of the charging device to the terminal device and further increase charging efficiency of the terminal device.

Owner:VIVO MOBILE COMM CO LTD

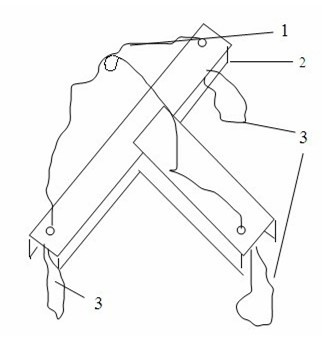

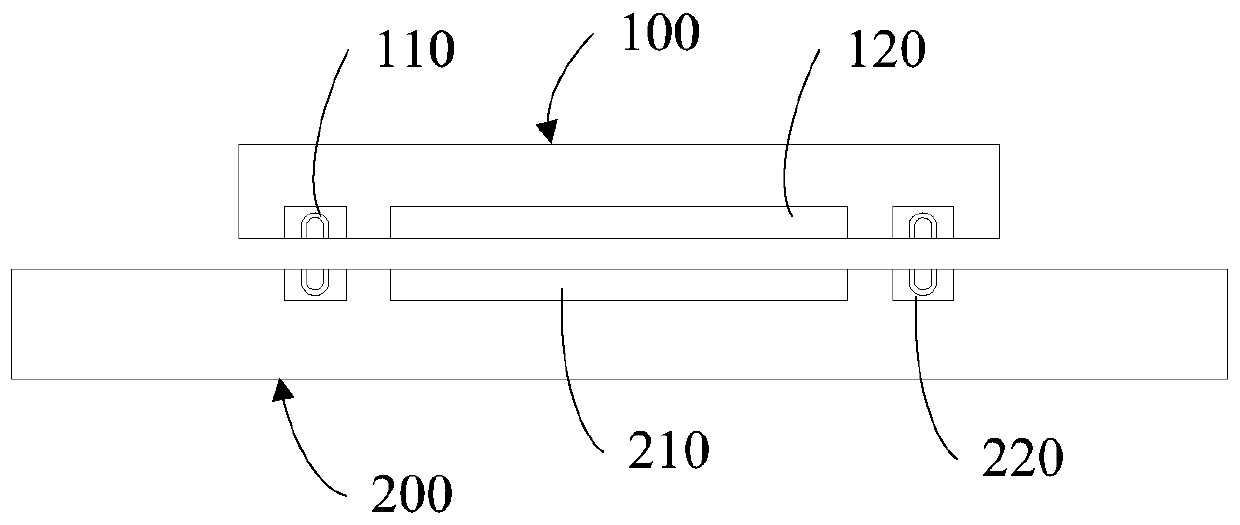

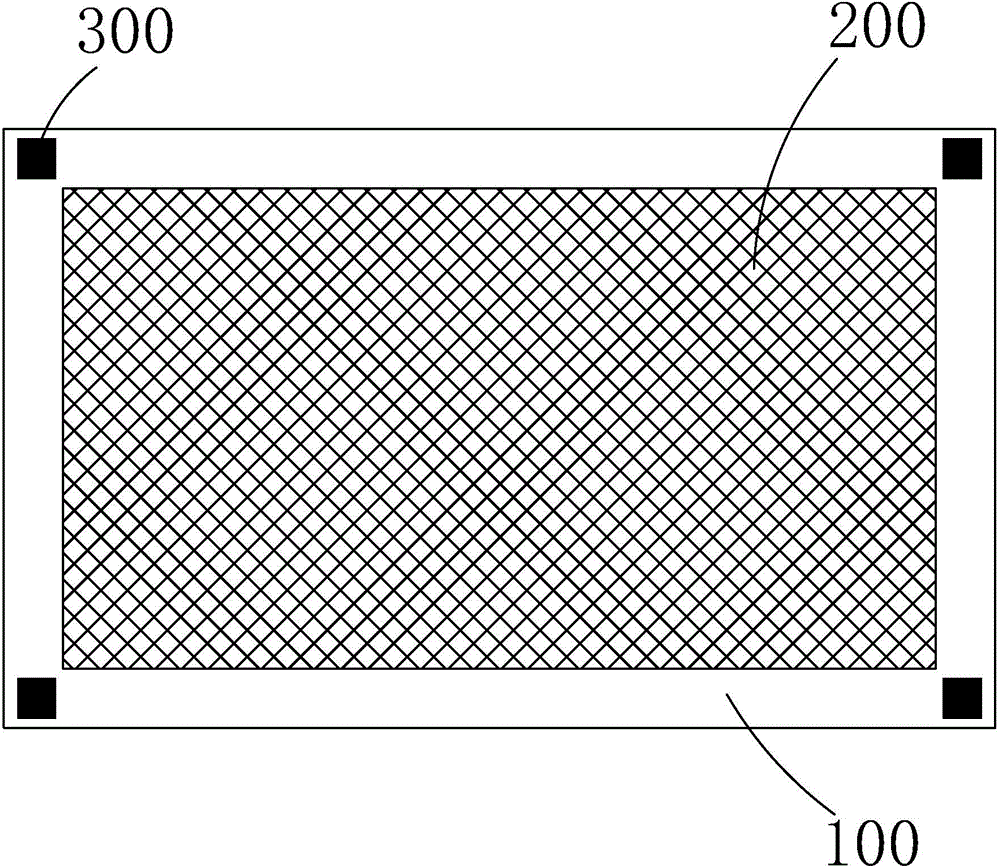

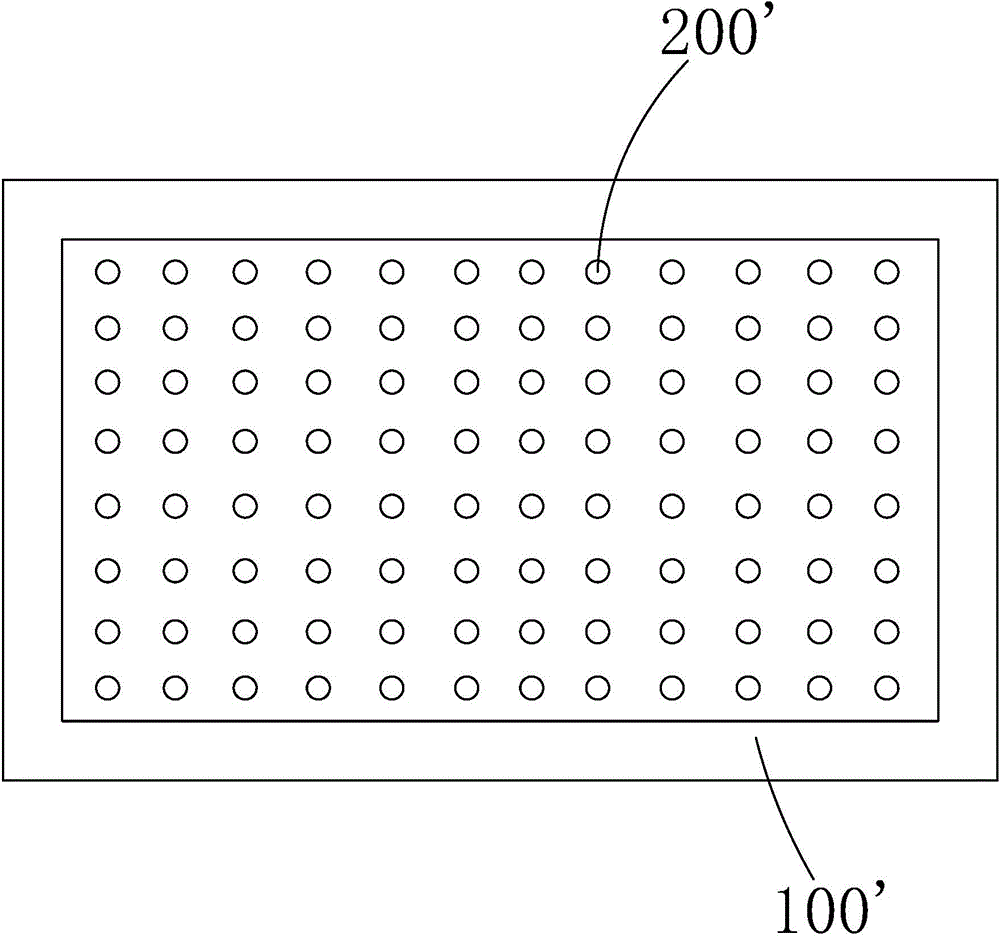

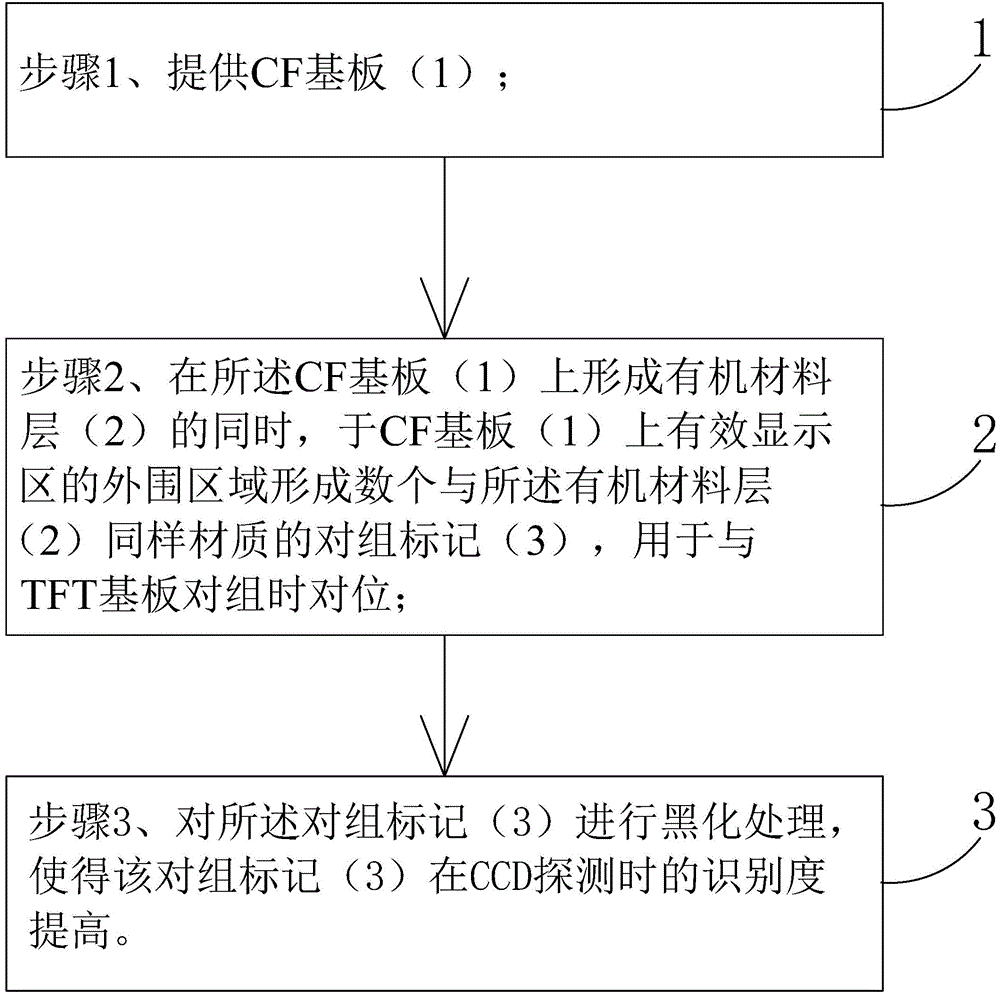

Method for manufacturing pairing marks of CF substrate

The invention provides a method for manufacturing pairing marks of a CF substrate. The method comprises the steps that step 1, the CF substrate (1) is provided; step 2, while an organic material layer (2) is formed on the CF substrate (1), multiple pairing marks (3) are formed on the peripheral area of an effective display area of the CF substrate (1) and made of the same material as the organic material layer (2), and the pairing marks (3) are used for achieving counterpoint when the CF substrate is paired with a TFT substrate; step 3, the pairing marks (3) are blackened, so that the recognition degree of the pairing marks (3) in CCD detection is improved. The method can improve the recognition degree of the pairing marks (3) in CCD detection, so that the pairing marks provide precise counterpoint reference for subsequent processing.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

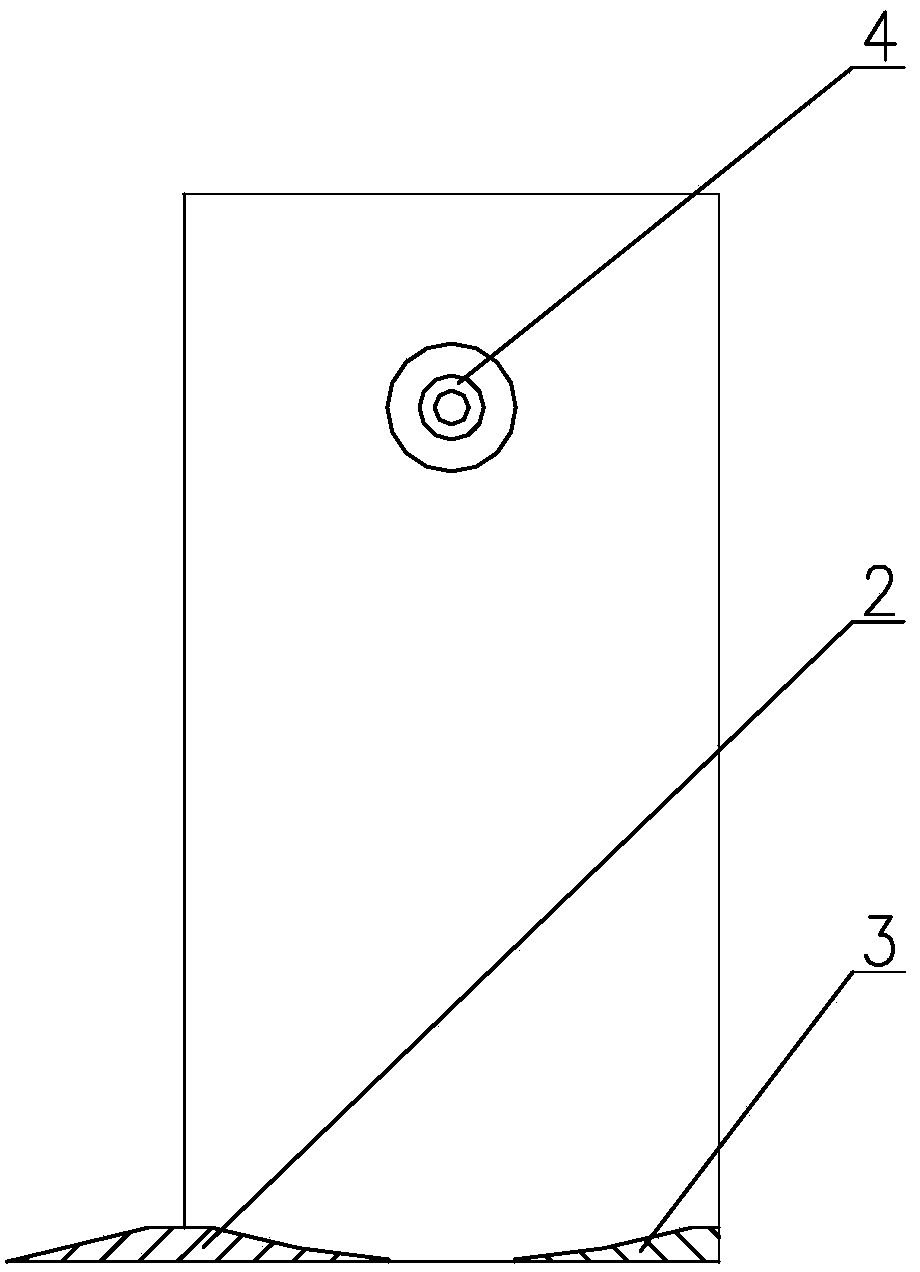

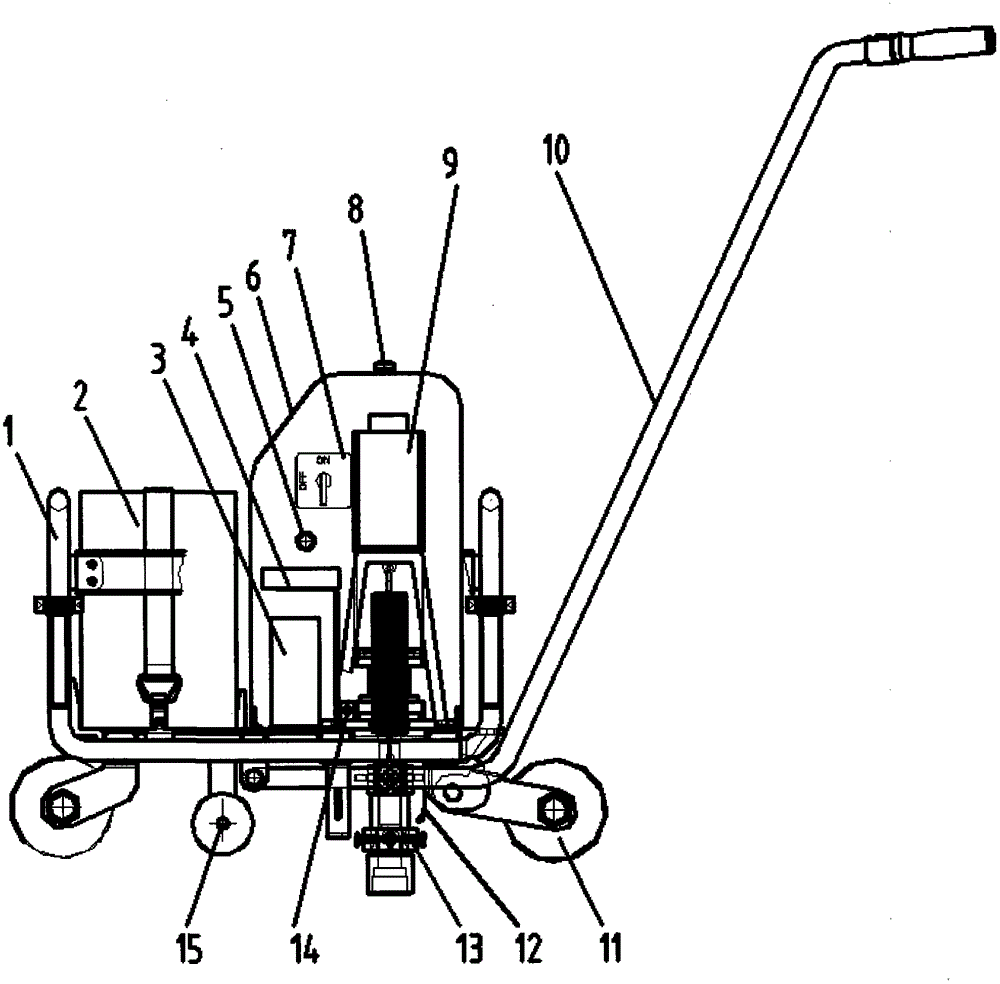

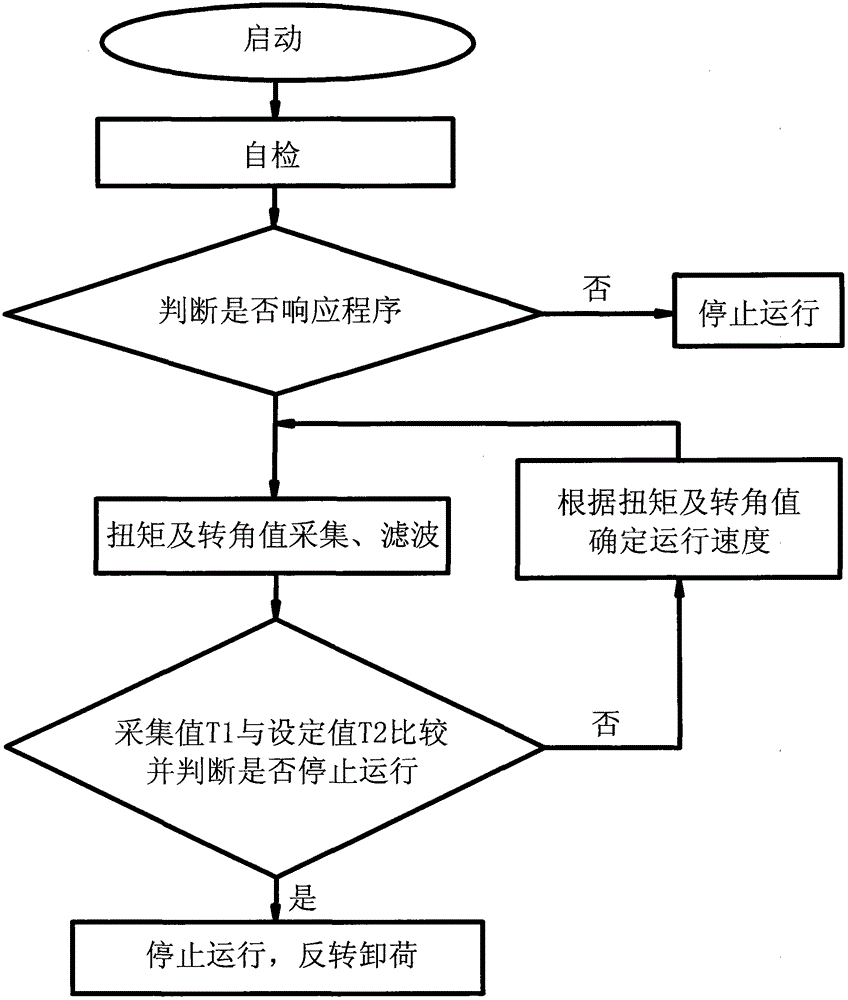

Railway track bolt tightening device and method thereof

ActiveCN102720104AAbility to workImprove practicalityRailway track constructionEngineeringUltimate tensile strength

The invention provides a railway track bolt tightening device and a method thereof. The railway track bolt tightening device comprises a frame, wherein a power source, a main control device, a lifting counterpoint device, a walking device, a lighting device and a displacement device are arranged on the frame, the displacement device is connected with a shaft control device, the shaft control device is connected with a tightening shaft, the tightening shaft is connected with a lifting counterpoint device, and the lifting counterpoint device is connected with a torque output mechanism; and the main control device is respectively connected with a power source, the shaft control device, the walking device, the lighting device and the displacement device. The railway track bolt tightening device provided by the utility model has a simple structure and is convenient to operate, can meet the task for demounting various center distance lower bolt nuts such as common tracks, high-speed rail passenger tracks and the like, has strong versatility, can accomplish railway track pavage and maintenance tasks in a way of high efficiency, high precision and high quality, the labor intensity is lowered greatly, can get rid of distance limitation of a wired AC power supply within a certain range, has a wider operation coverage, and has the operation capability in gloomy ray environment such as at night or in a tunnel and the like.

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

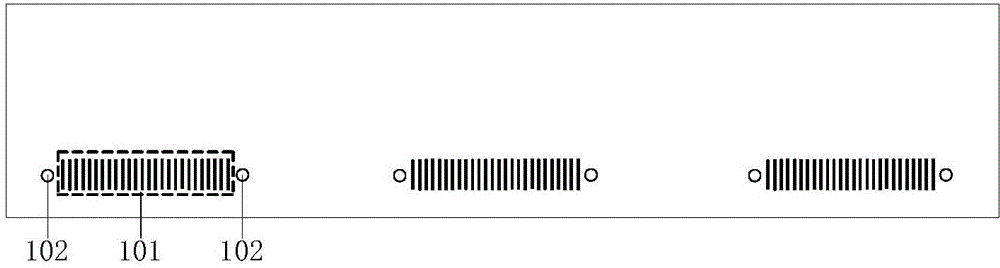

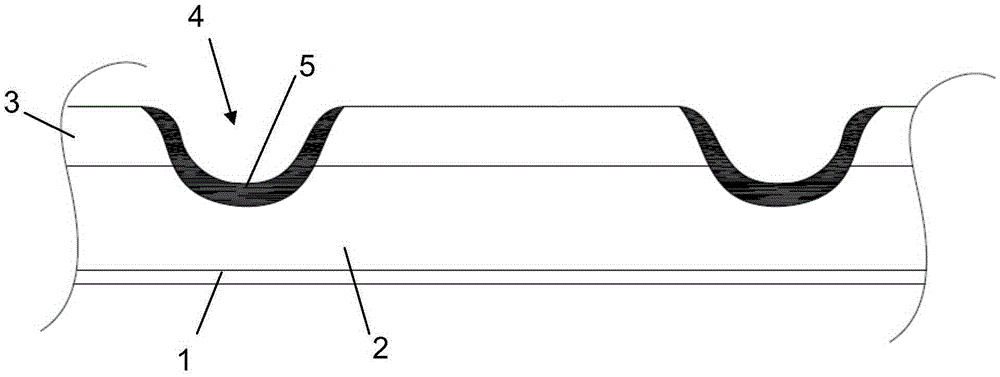

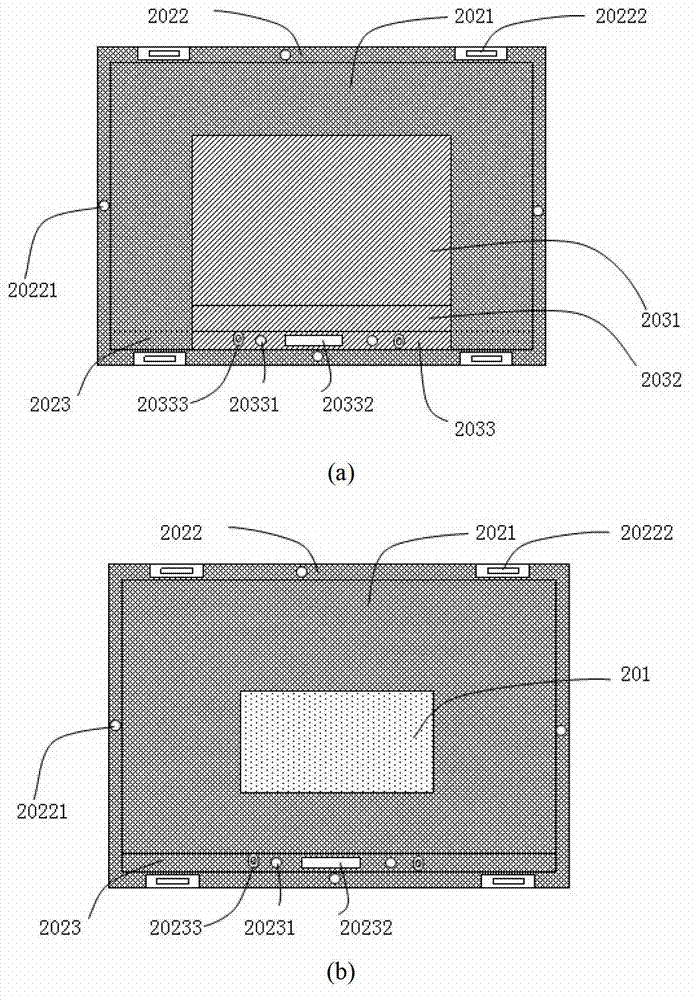

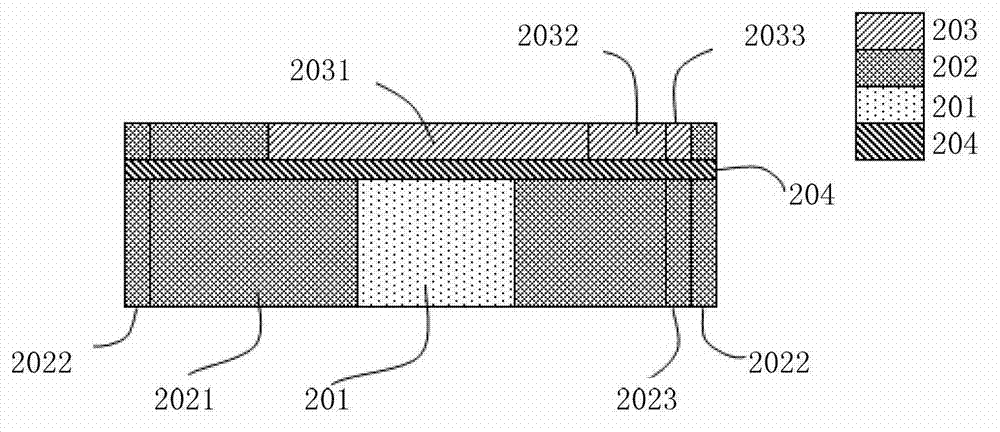

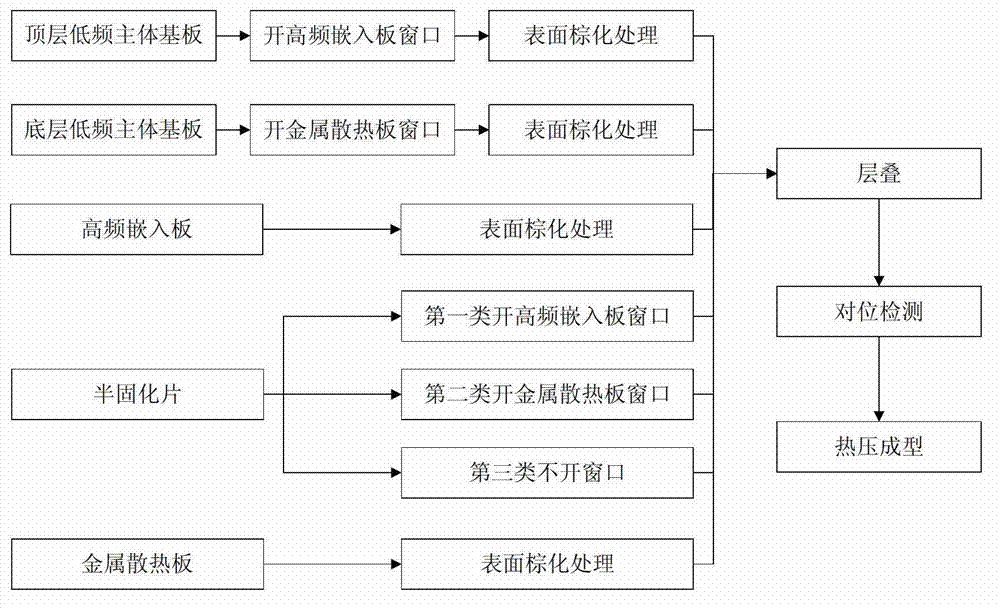

Preparation method of high-low frequency hybrid-voltage printed circuit board

InactiveCN102811560AReduce destructive detectionEasy alignmentPrinted circuit manufactureEngineeringPrinted circuit board

The invention discloses a preparation method of a high-low frequency hybrid-voltage printed circuit board, belonging to the technical field of printed circuit board manufacturing. The method comprises the step of adding counterpoint edges 2023 and 2033 on a low-frequency main body substrate 202 and a high frequency embedding board 203, wherein acounterpoint detecting holes and alignment testing rectangular windows are respectively formed at the added counterpoint edges. The alignment of the low frequency main body substrate with the high frequency embedding board is improved greatly, the destructive detection to the low frequency main body substrate and the high frequency embedding board after being laminated is reduced, and meanwhile the material quantity of the high frequency embedding board is reduced.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

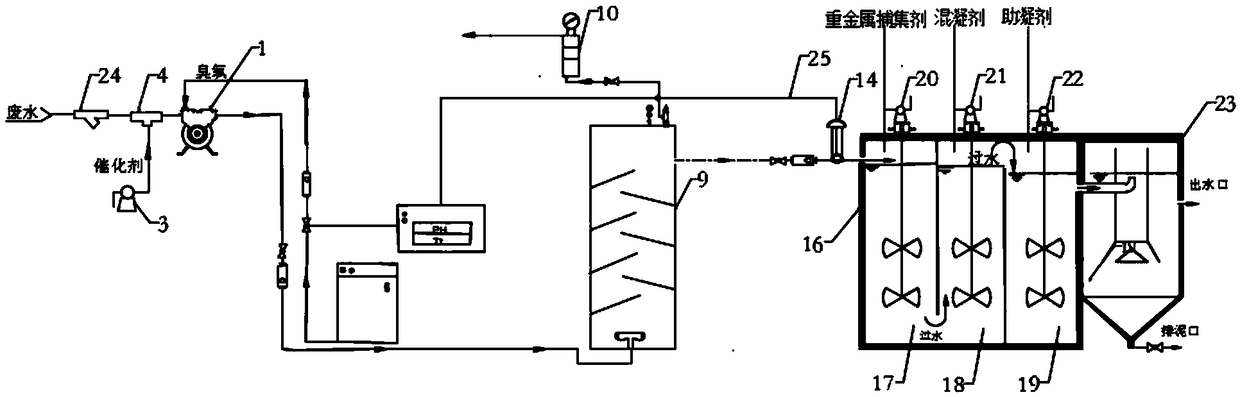

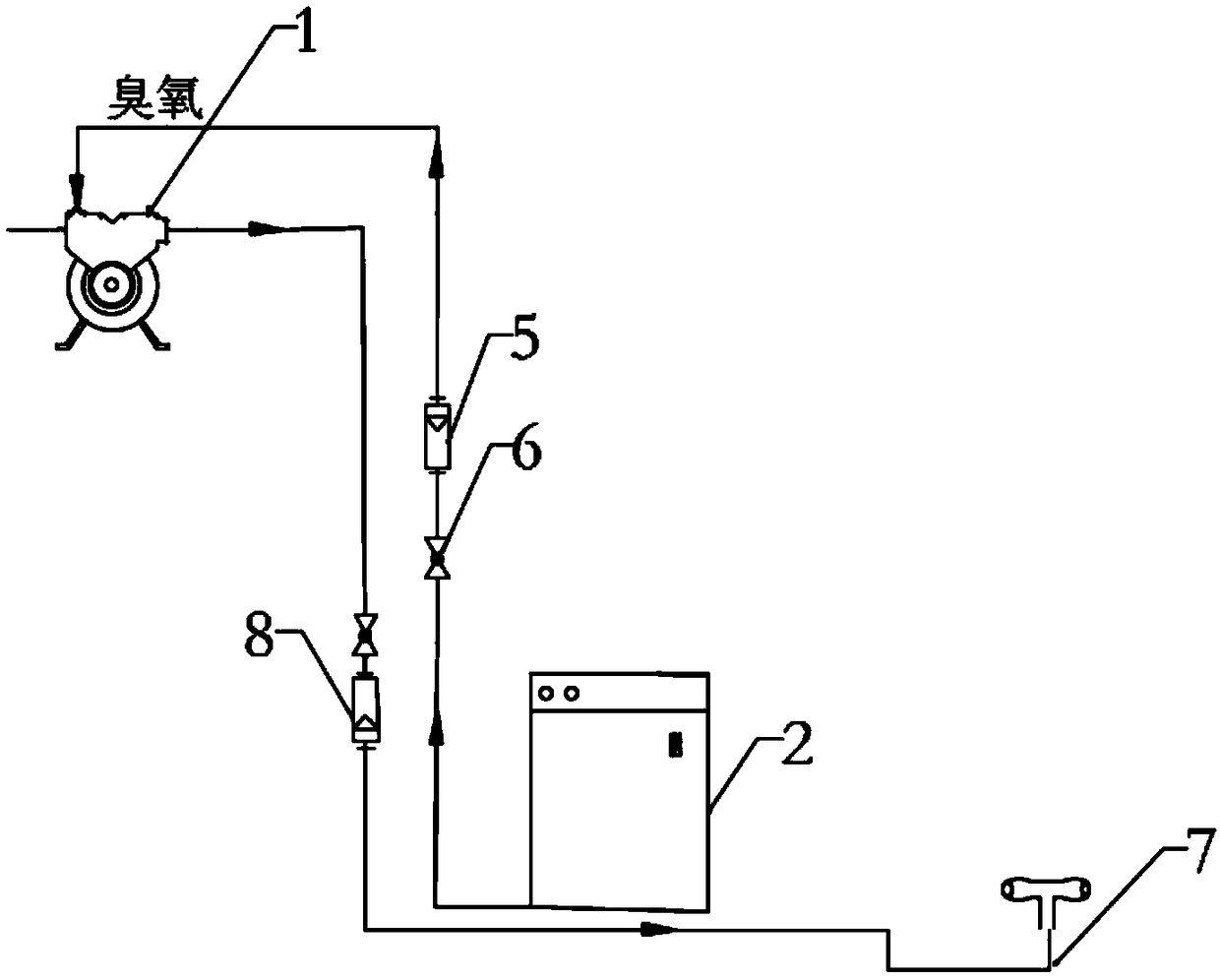

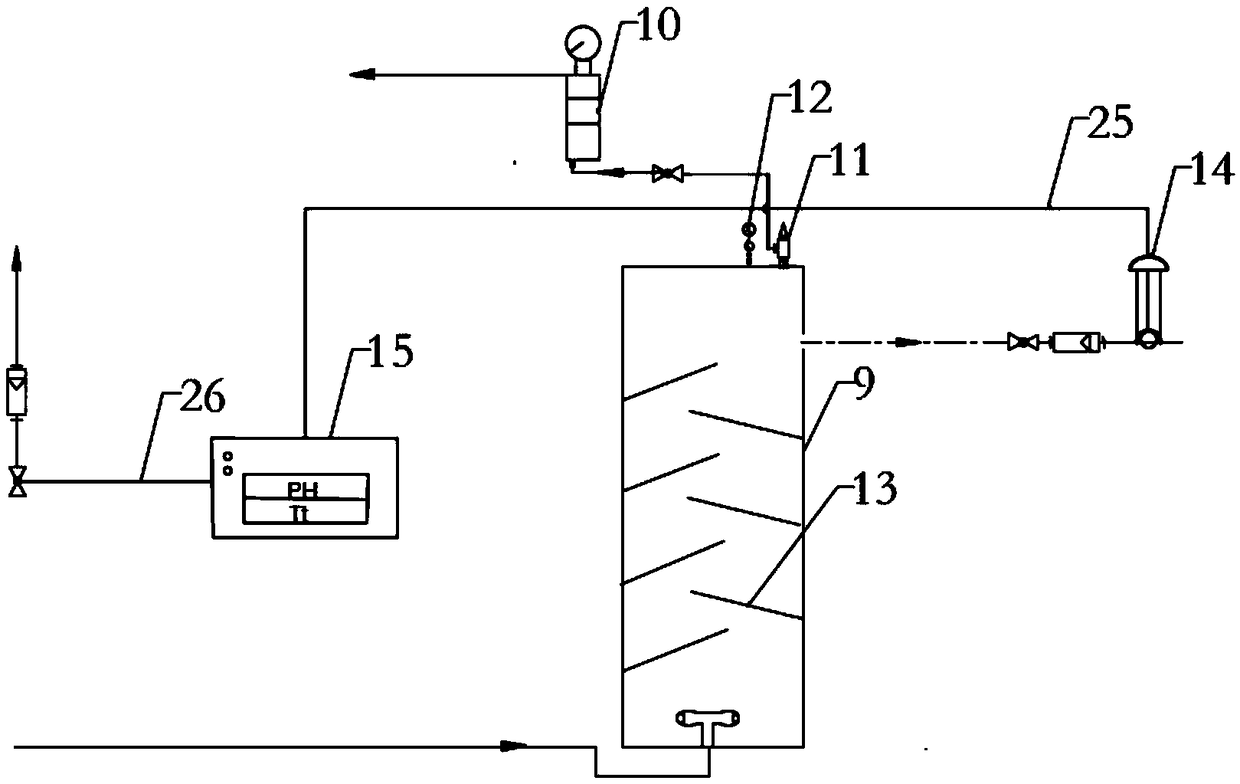

Copper-containing wastewater treatment technology and application

ActiveCN109502809AImprove dissolution efficiencyIncrease generation baseWater treatment parameter controlWater contaminantsMicro nanoFlocculation

The invention belongs to the technical field of industrial wastewater treatment and relates to a copper-containing wastewater treatment technology and application. The copper-containing wastewater treatment technology comprises the following steps: S1, adding a catalyst into copper-containing wastewater, utilizing a micro-nano bubble aerating device to fully mix the copper-containing wastewater with ozone, spraying into a folded plate type catalyzed ozonation reactor and performing oxidization complexation breaking pretreatment; S2, detecting the pretreated wastewater through a pH online monitoring joint control device, sending the pretreated wastewater into a reaction tank and sequentially adding a heavy metal capturing agent, a coagulant and a coagulant aid to perform counterpoint competition chelation reaction, agglomeration reaction and flocculation reaction; S3, sending the reacted wastewater into a solid-liquid separation device to perform solid-liquid separation to obtain the heavy metal copper removed wastewater. The copper-containing wastewater treatment technology disclosed by the invention can effectively reduce the copper content in the wastewater, can ensure that the heavy metal copper concentration in effluent continuously and stably reach the discharge standard and the total copper content of the effluent is lower than 0.3 mg / L and has the advantages of simple technology, low operation cost and strong adaptability.

Owner:GUANGDONG UNIV OF TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com