Patents

Literature

6341 results about "Assembly machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

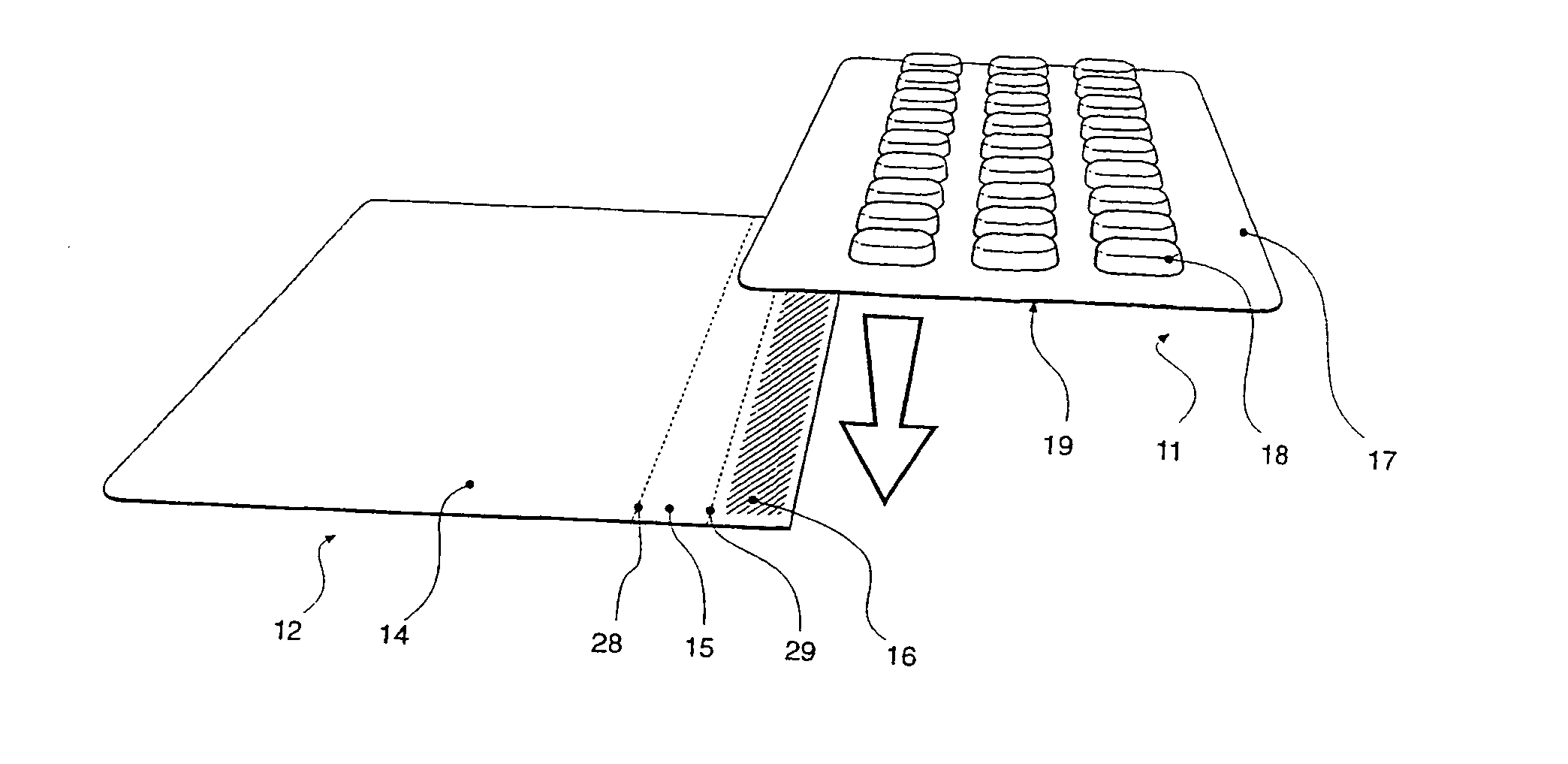

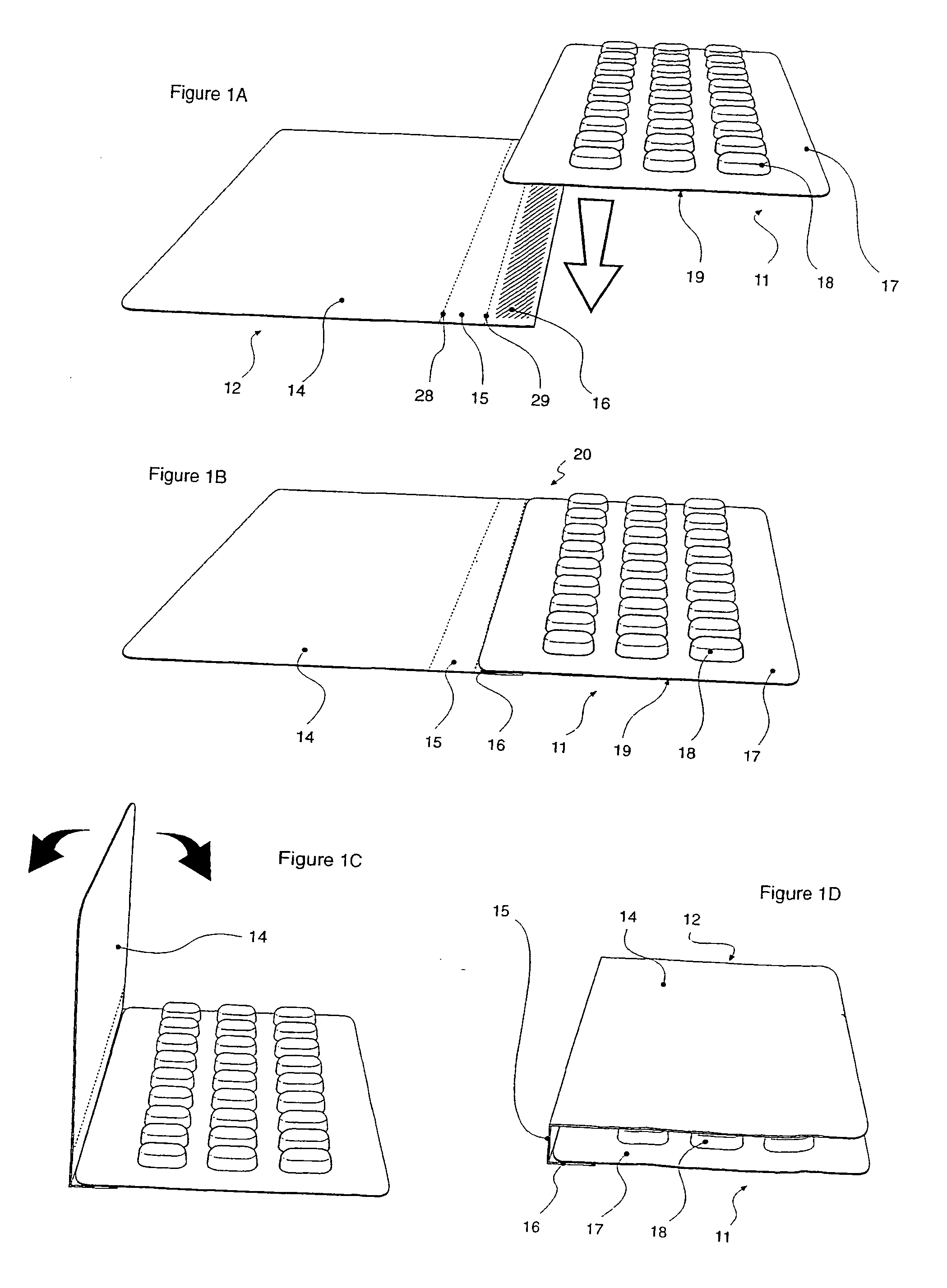

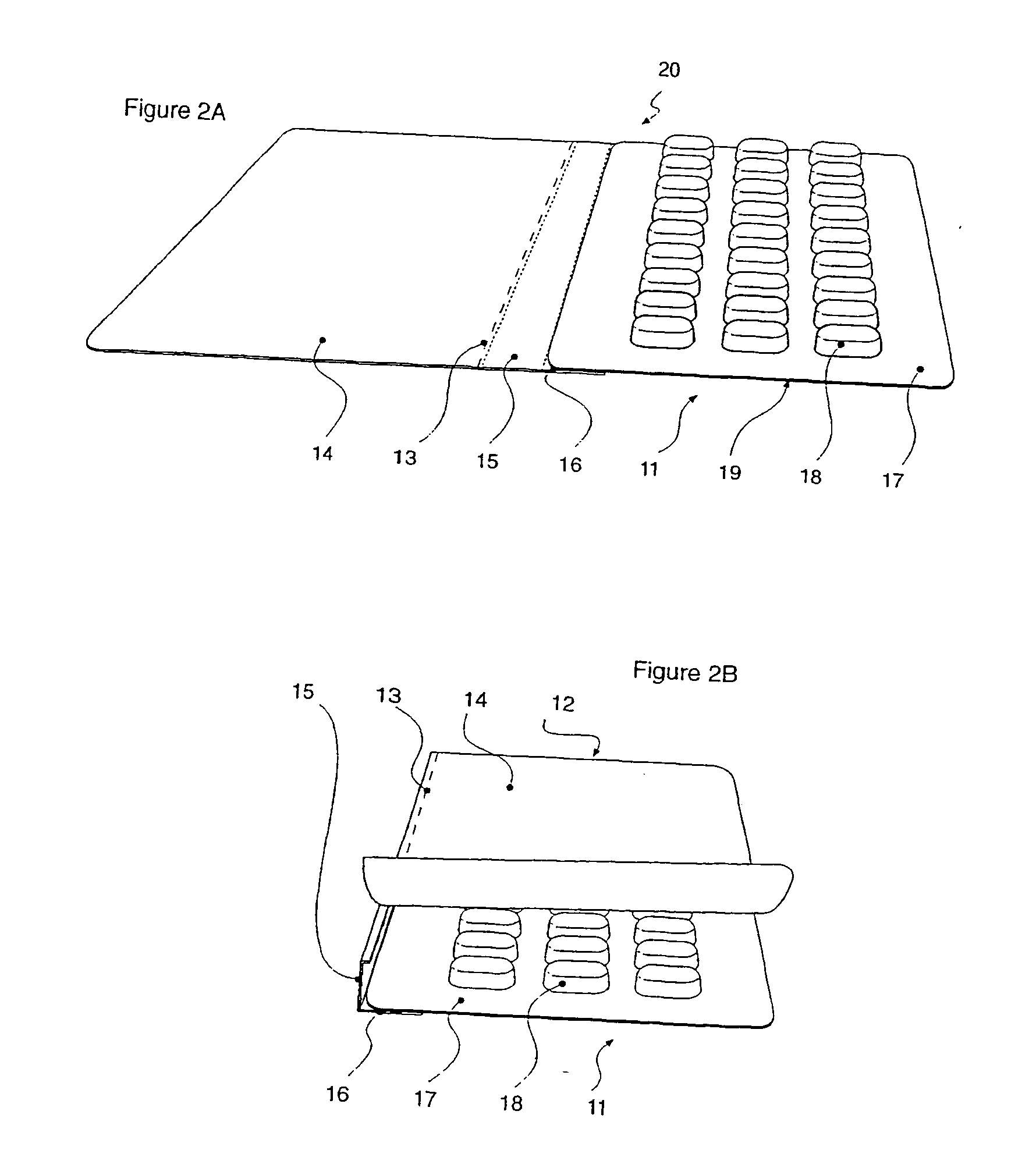

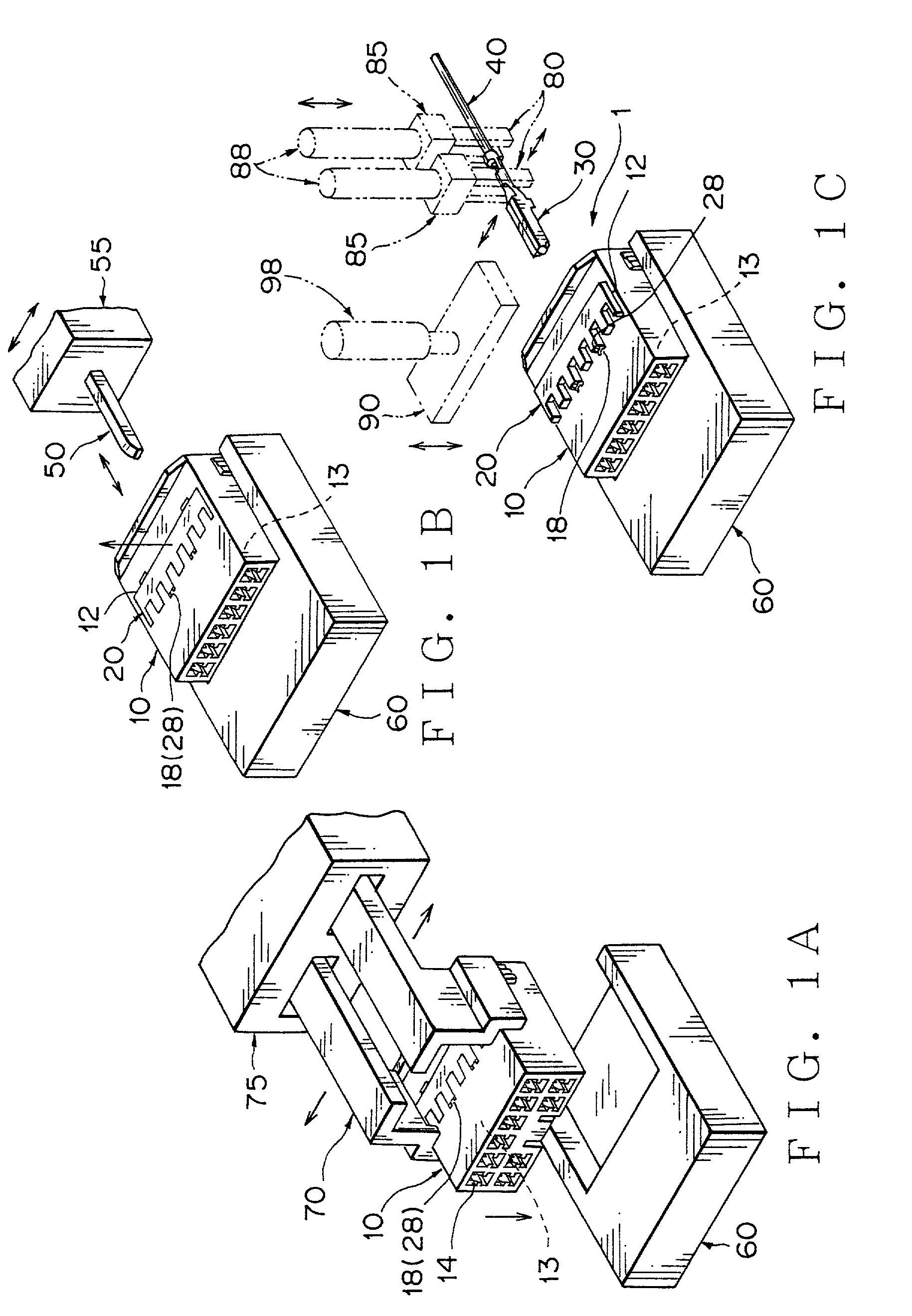

Carded blister pack

InactiveUS20040026293A1Easy to foldSmall article dispensingContainer decorationsBlister packAssembly machine

A blister pack (20) folded wallet has a mounting card (12), with a [hinged] spine segment (15), and an adhesive edge strip (16). Overlaid by a pre-formed blister pack (11), for mutual (edge) entrainment; a dedicated assembly machine entrains mounting cards and blister packs stored in respective magazines. Child resistance is available through cover latching and / or paper reinforced foil laminate (161), with through apertures (166) and perforations (163, 165) for selective localised paper patch (169) removal, over individual blister pockets (168).

Owner:HUGHES DAVID

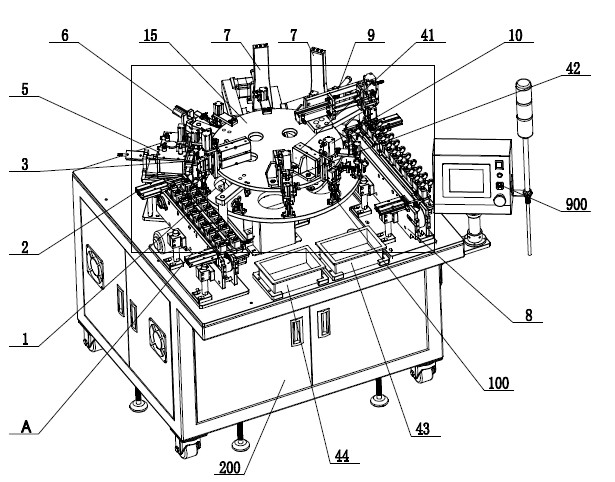

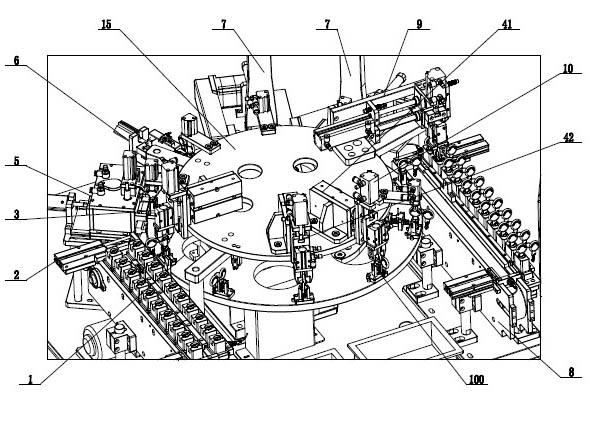

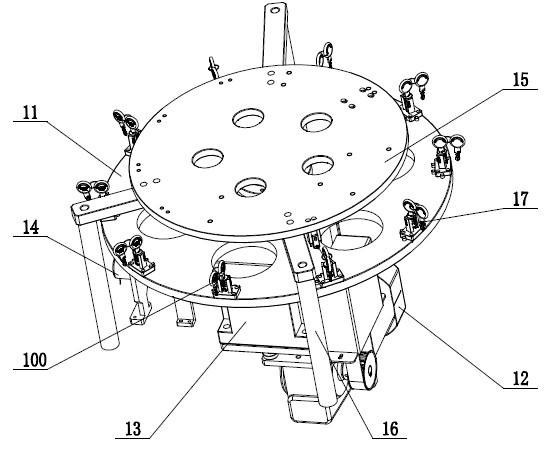

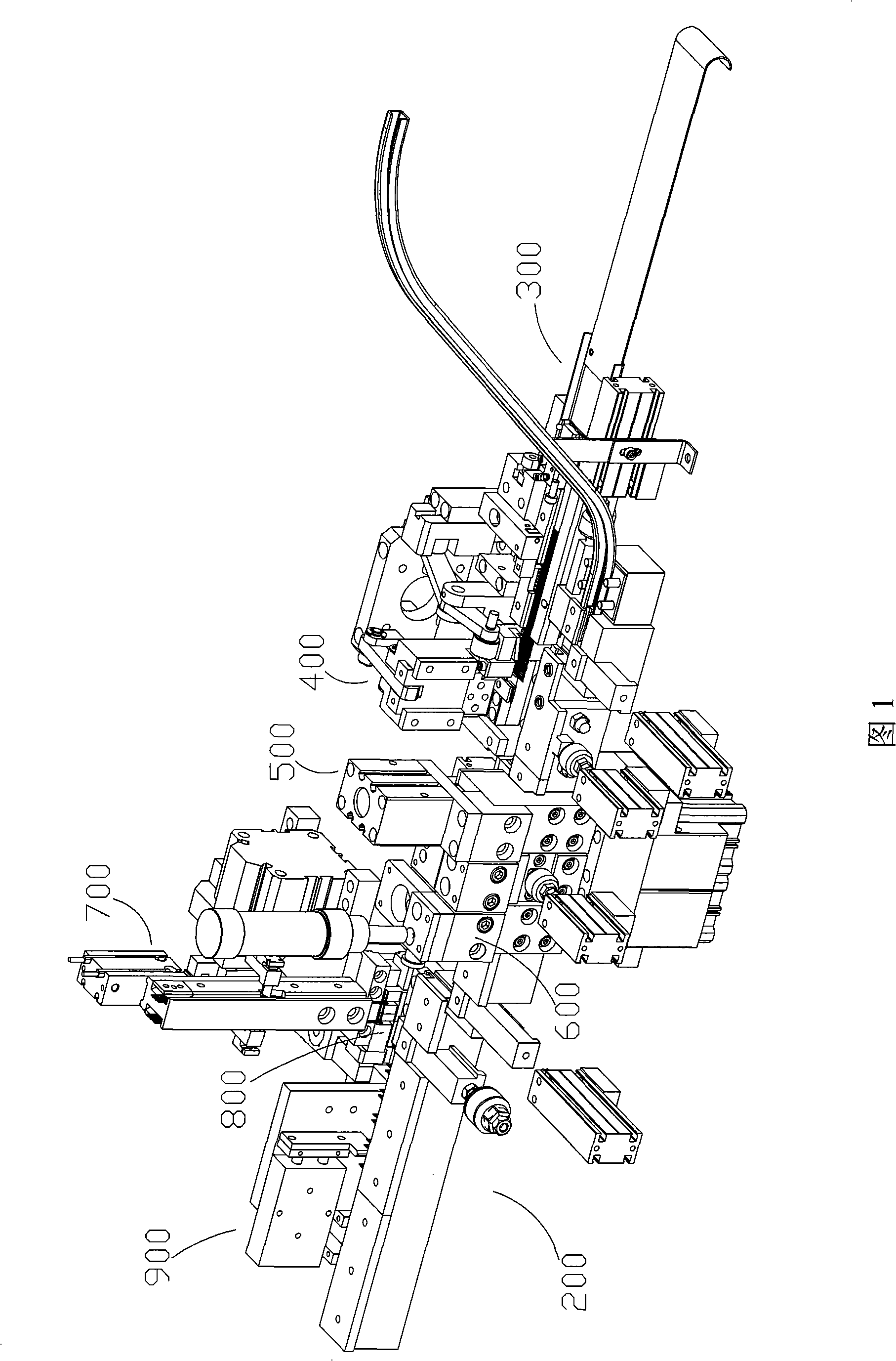

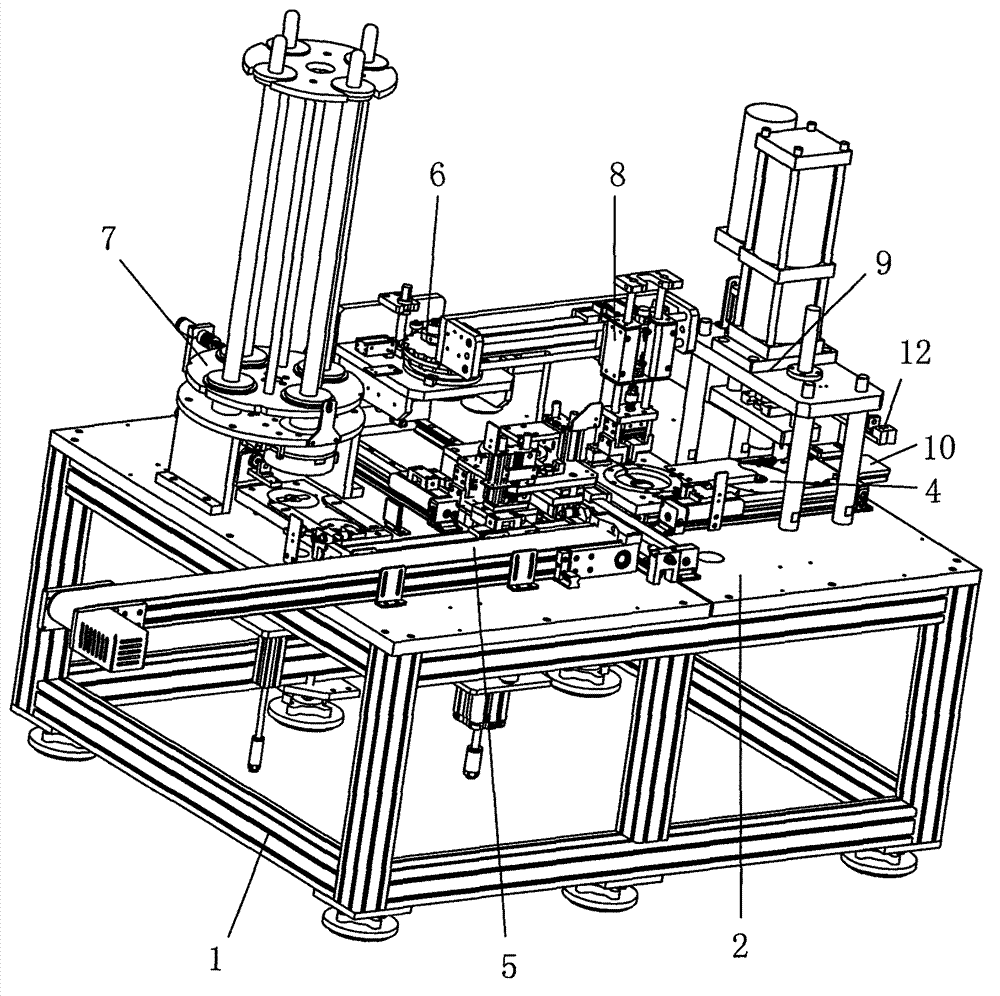

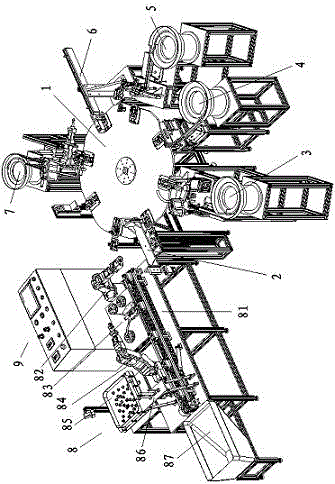

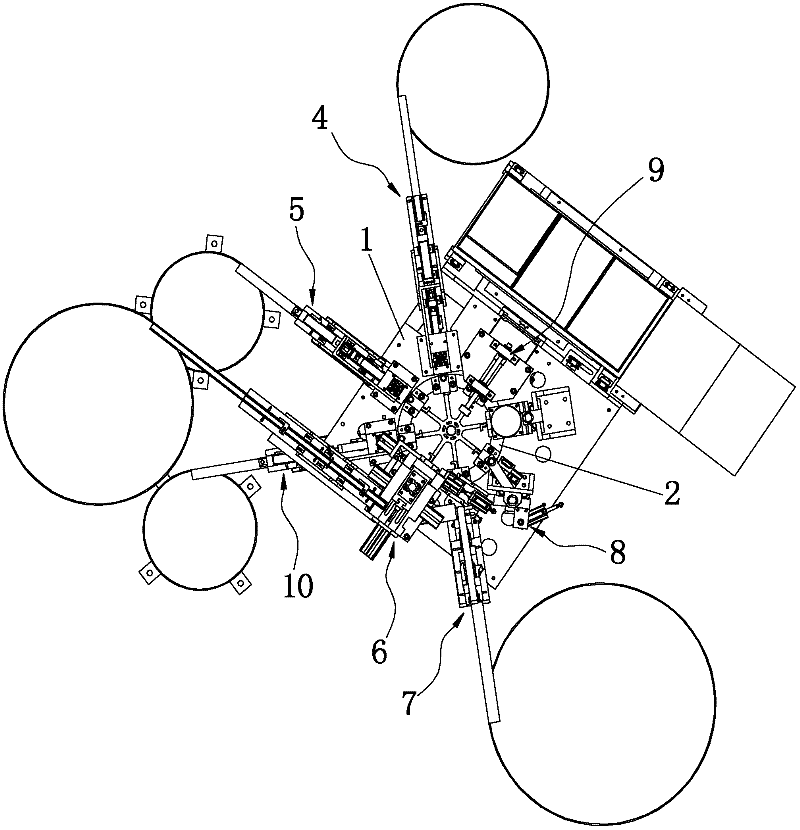

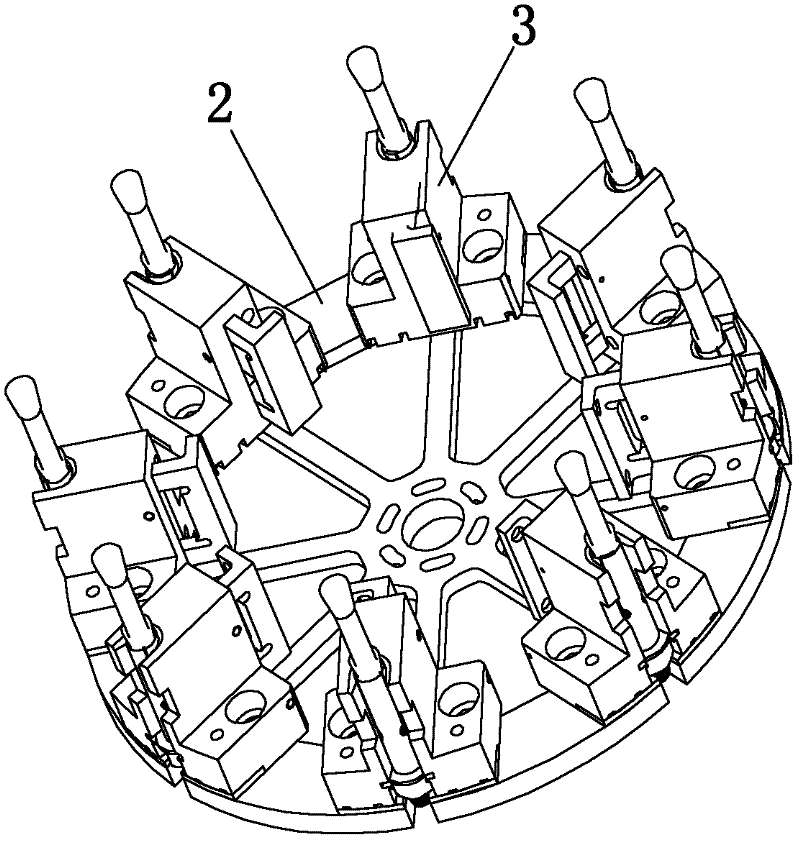

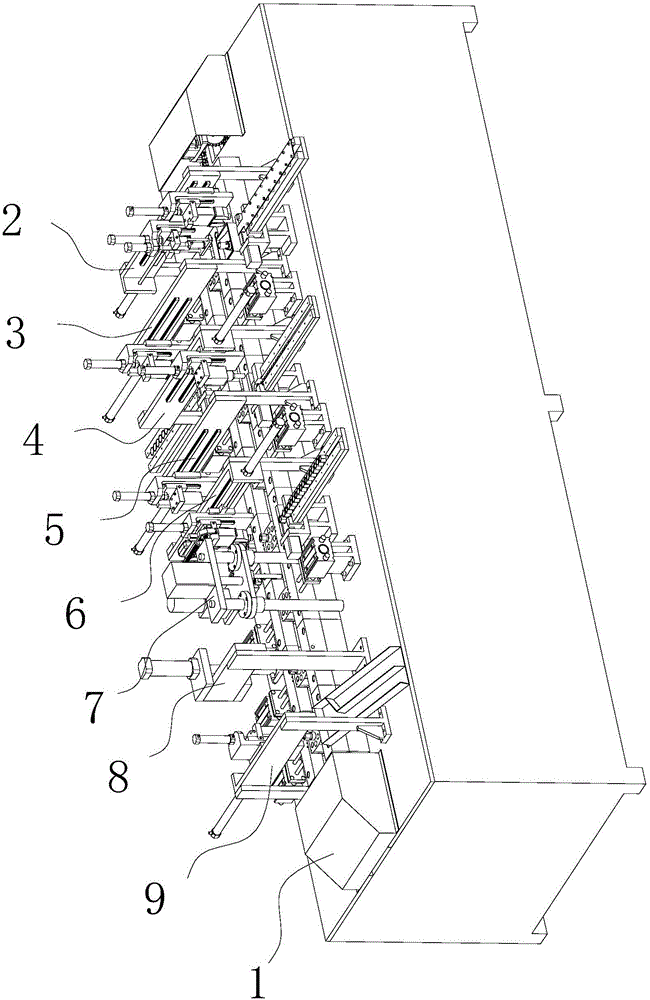

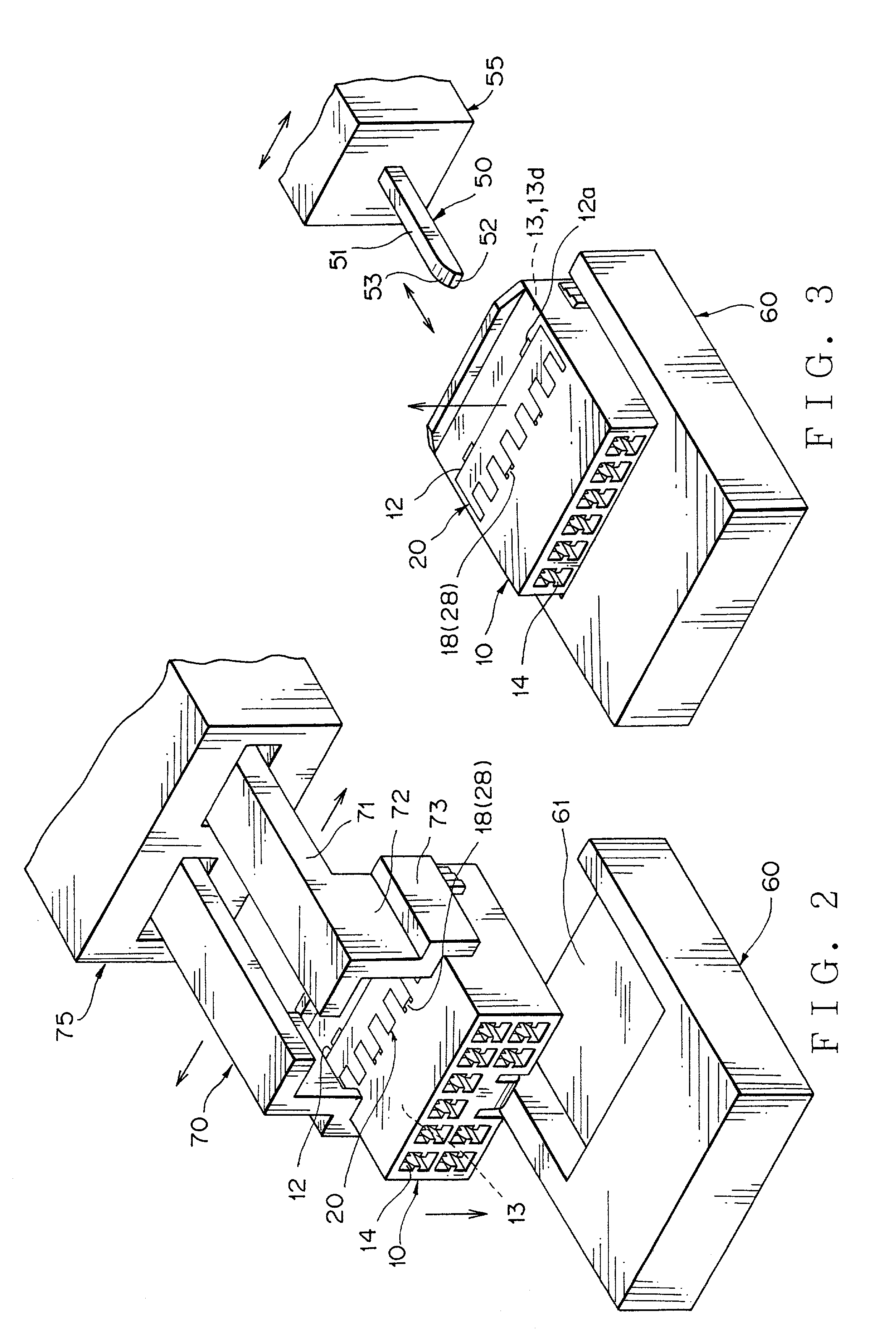

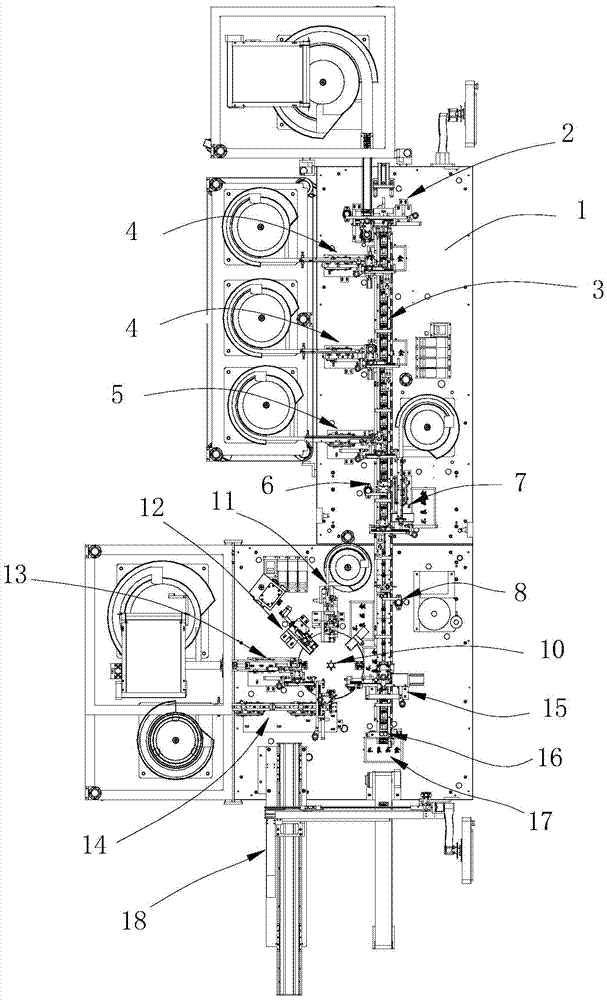

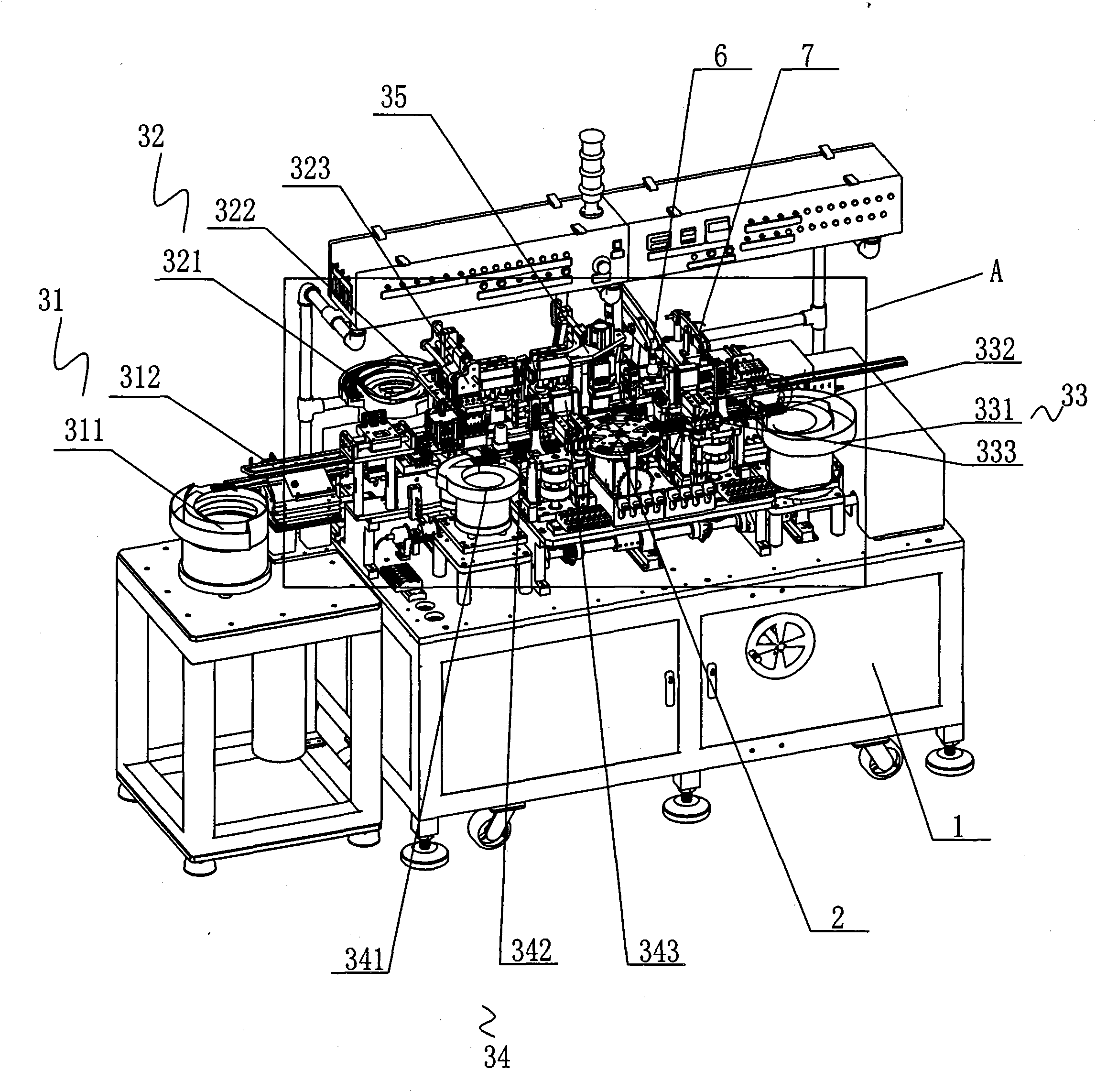

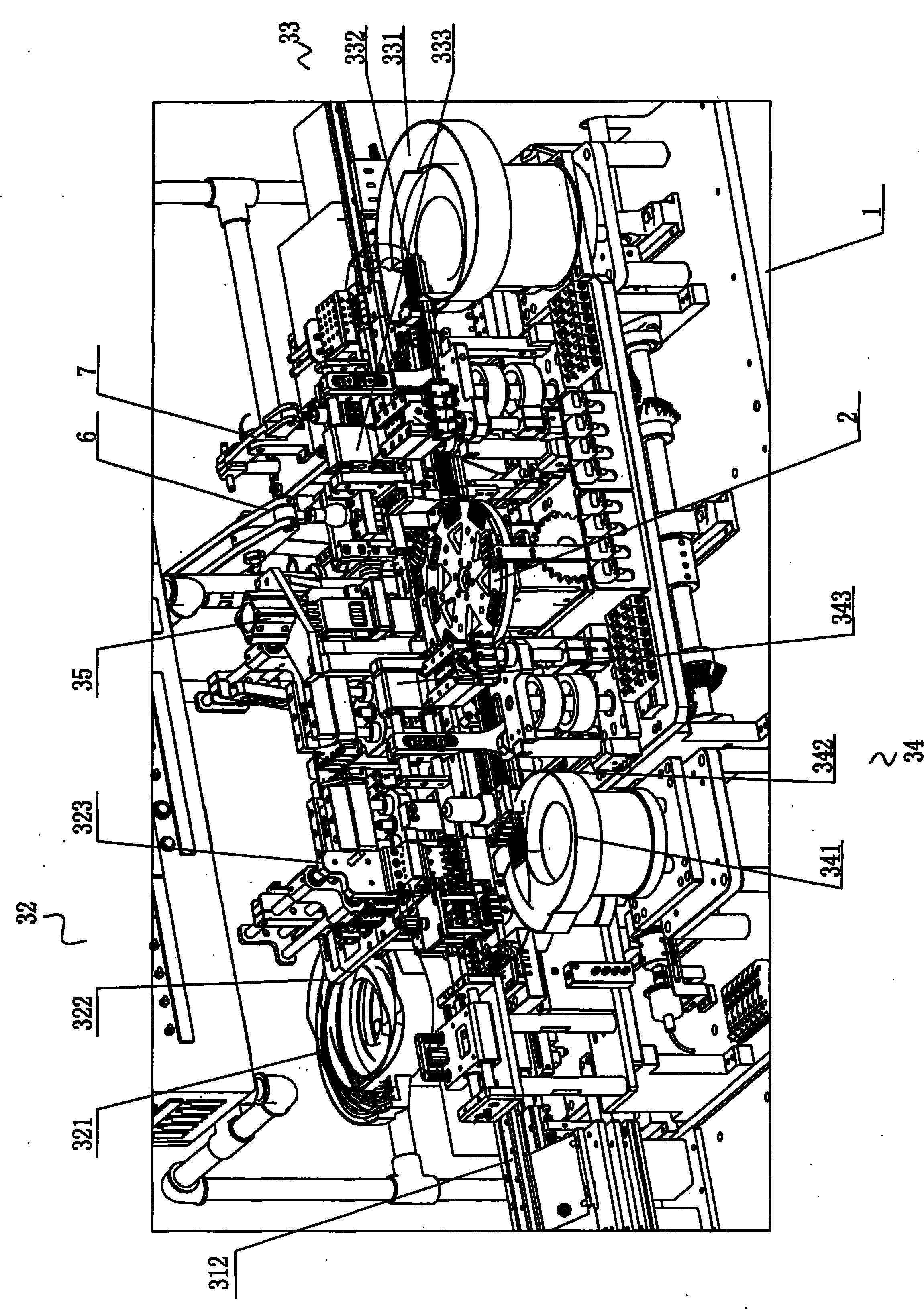

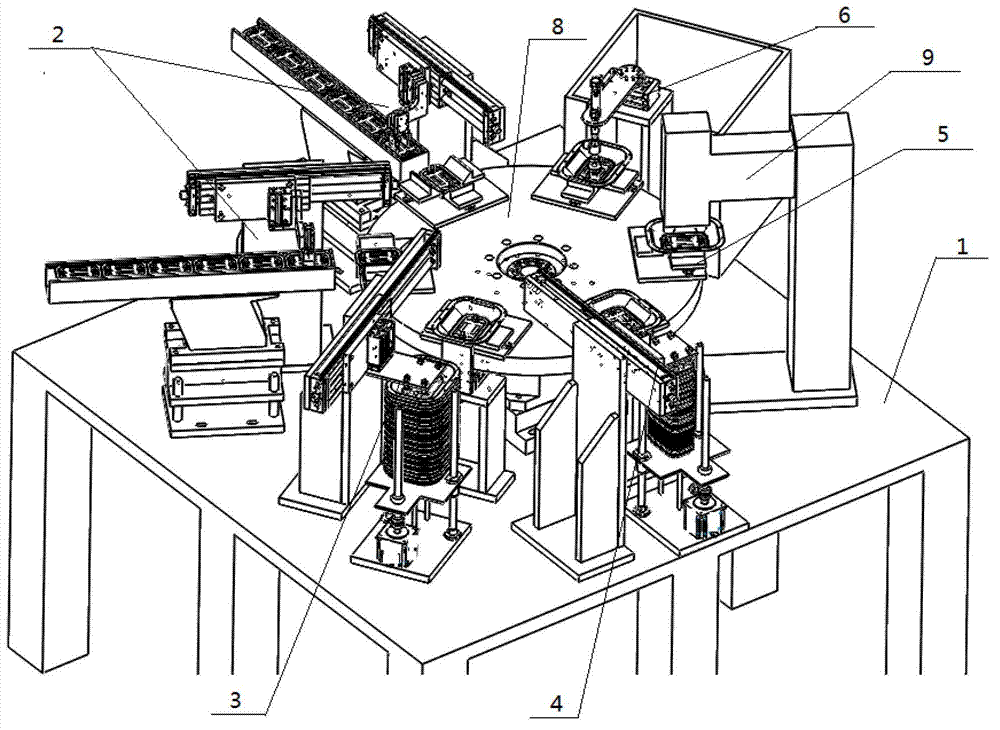

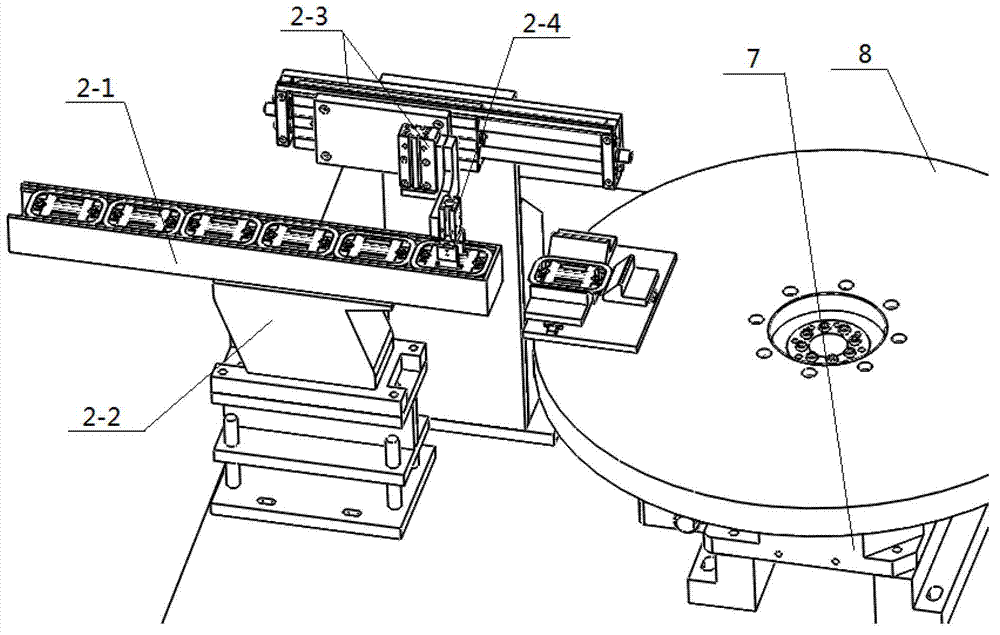

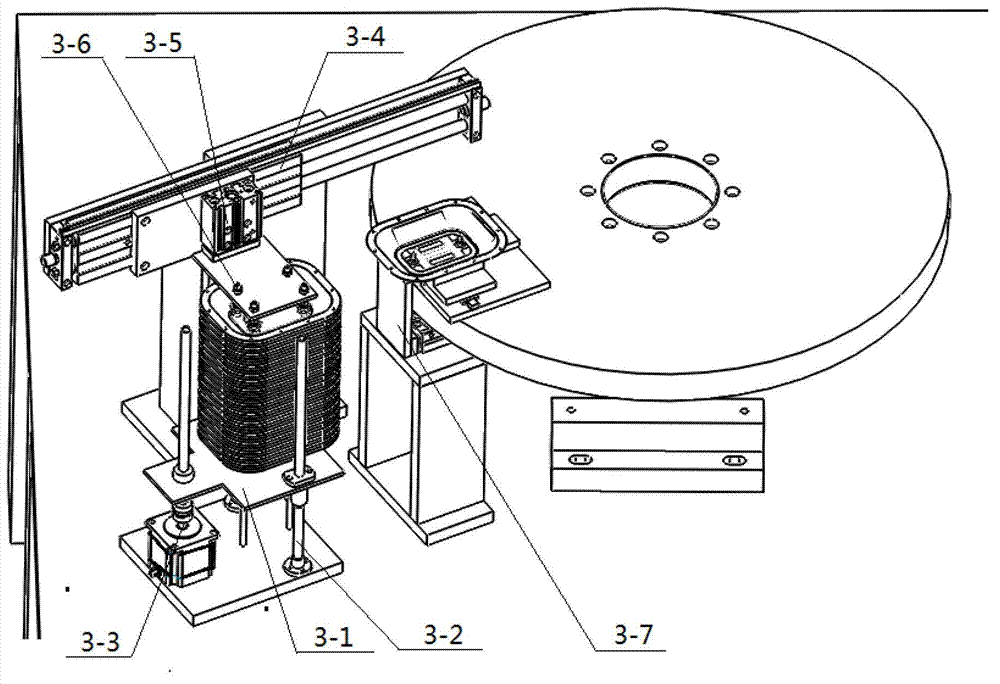

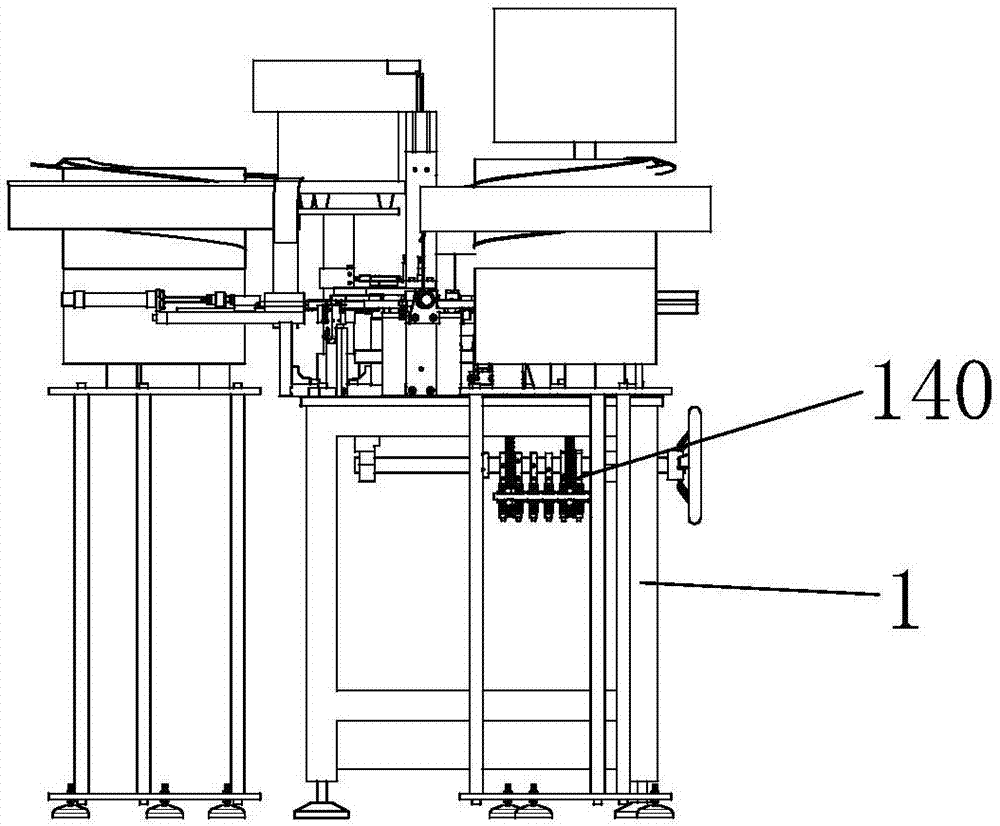

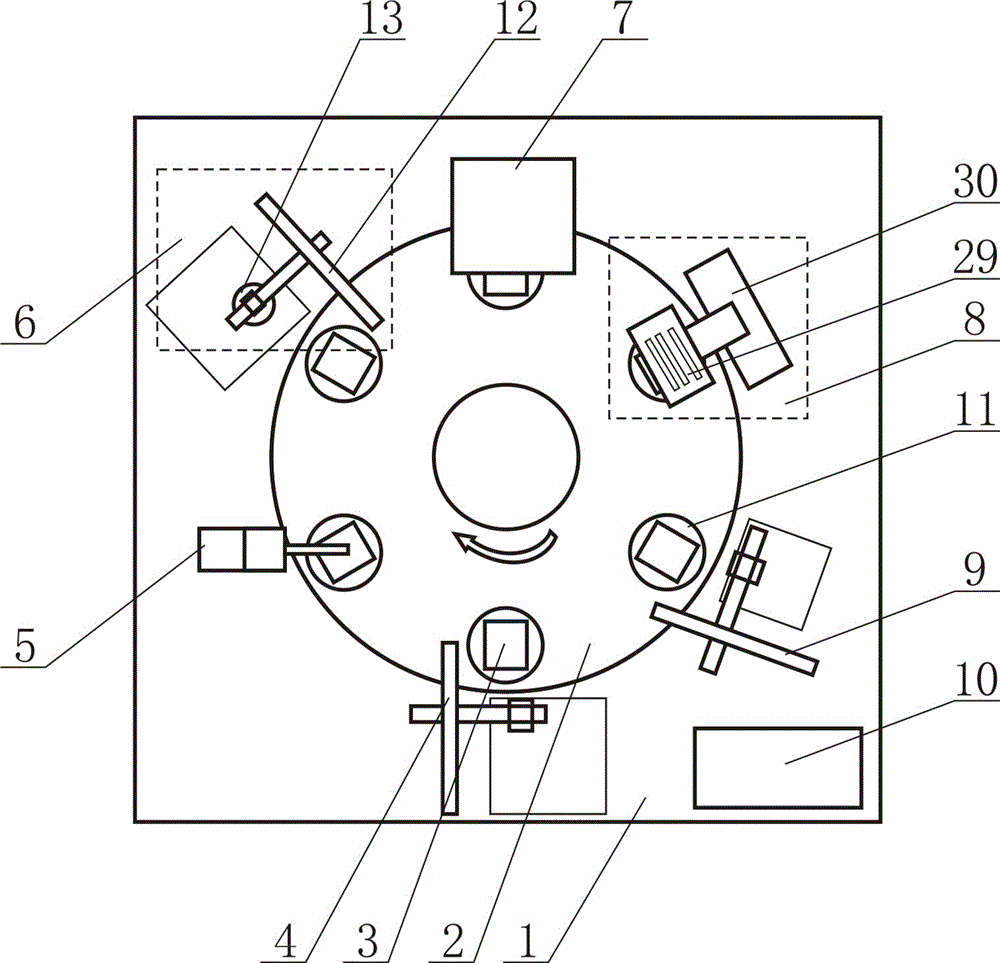

Automatic lock cylinder assembly machine

InactiveCN102009343ASolve the speed problemSolve efficiency problemsAssembly machinesEngineeringControl circuit

The invention discloses an automatic lock cylinder assembly machine which comprises a machine body and a rotating plate assembly with a lock cylinder arranged on the machine body, wherein an upper lock cylinder manipulator assembly, an upper spring assembly, a spring dection assembly, two upper lock plate assemblies, a key inserting manipulator assembly, a lock cylinder detection assembly, and a finish-product grabbing manipulator assembly are successively arranged along the clockwise circumference direction of the rotating plate assembly, wherein the finish-product grabbing manipulator assembly comprises a good product grabbing manipulator assembly and a defective product grabbing manipulator assembly; and the upper lock cylinder manipulator assembly, the key inserting manipulator assembly, the lock cylinder detection assembly, the good product grabbing manipulator assembly and the defective product grabbing manipulator assembly are all arranged on the rotating plate assembly, the rest assemblies are all arranged on the machine body, the machine body is provided with a bracing wire feeding mechanism for conveying the lock cylinder and a key to the corresponding position, and the assemblies are all connected with a master control circuit and are controlled by the master control circuit. The automatic lock cylinder assembly machine provided by the invention not only has the advantages of high production efficiency and low space capacity, but also ensures that the lock cylinder assembling quality is improved.

Owner:周俊雄

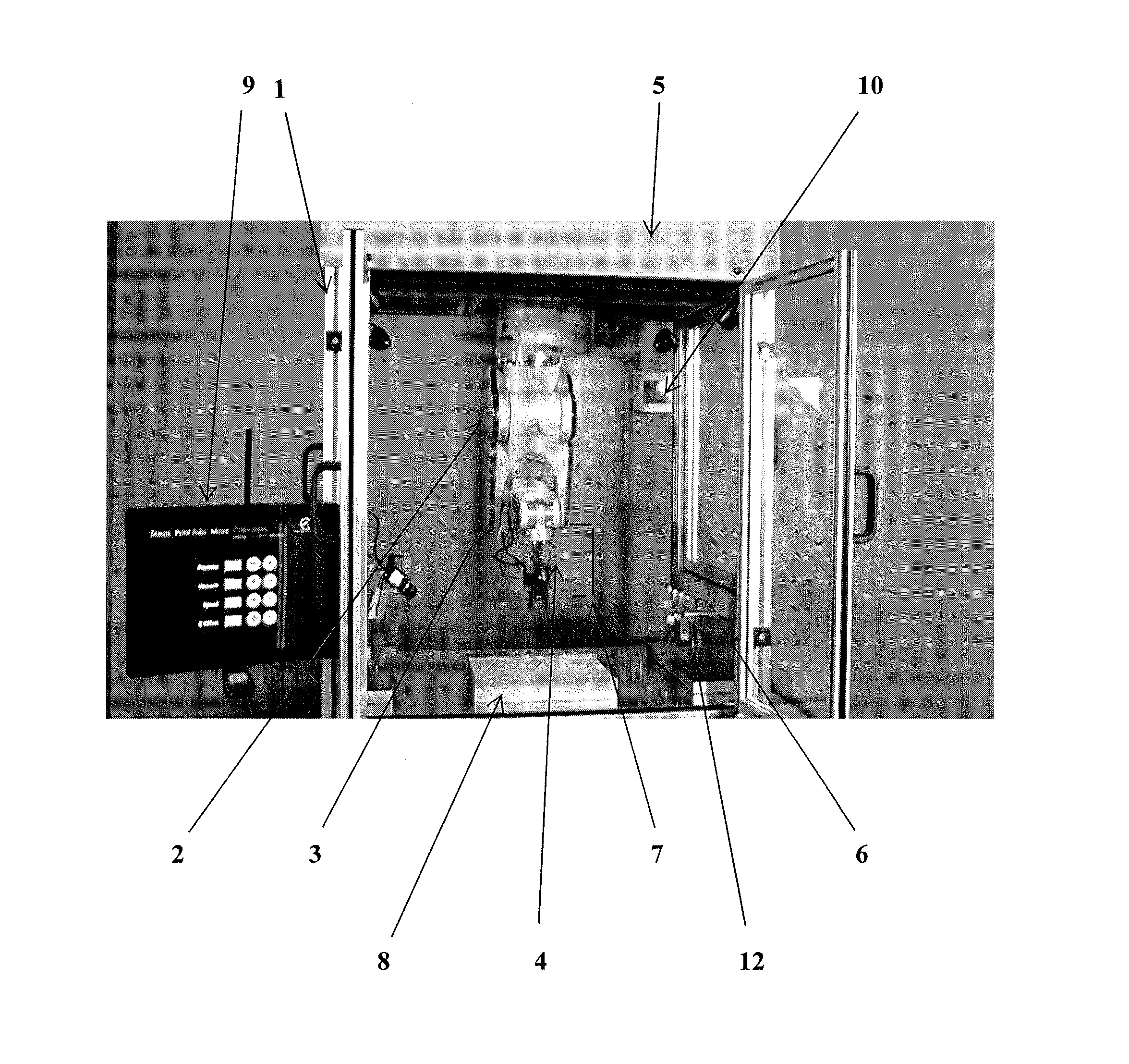

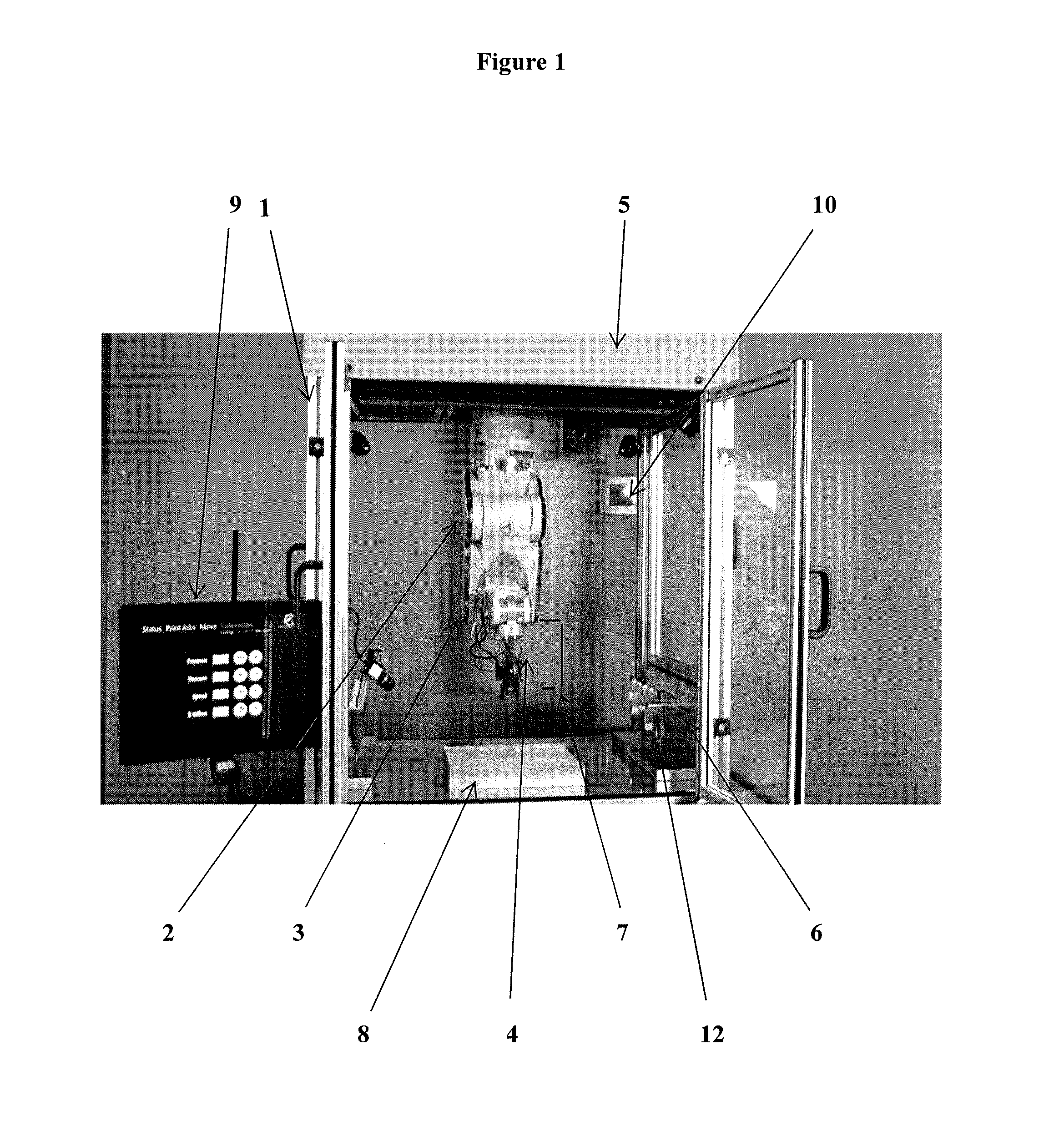

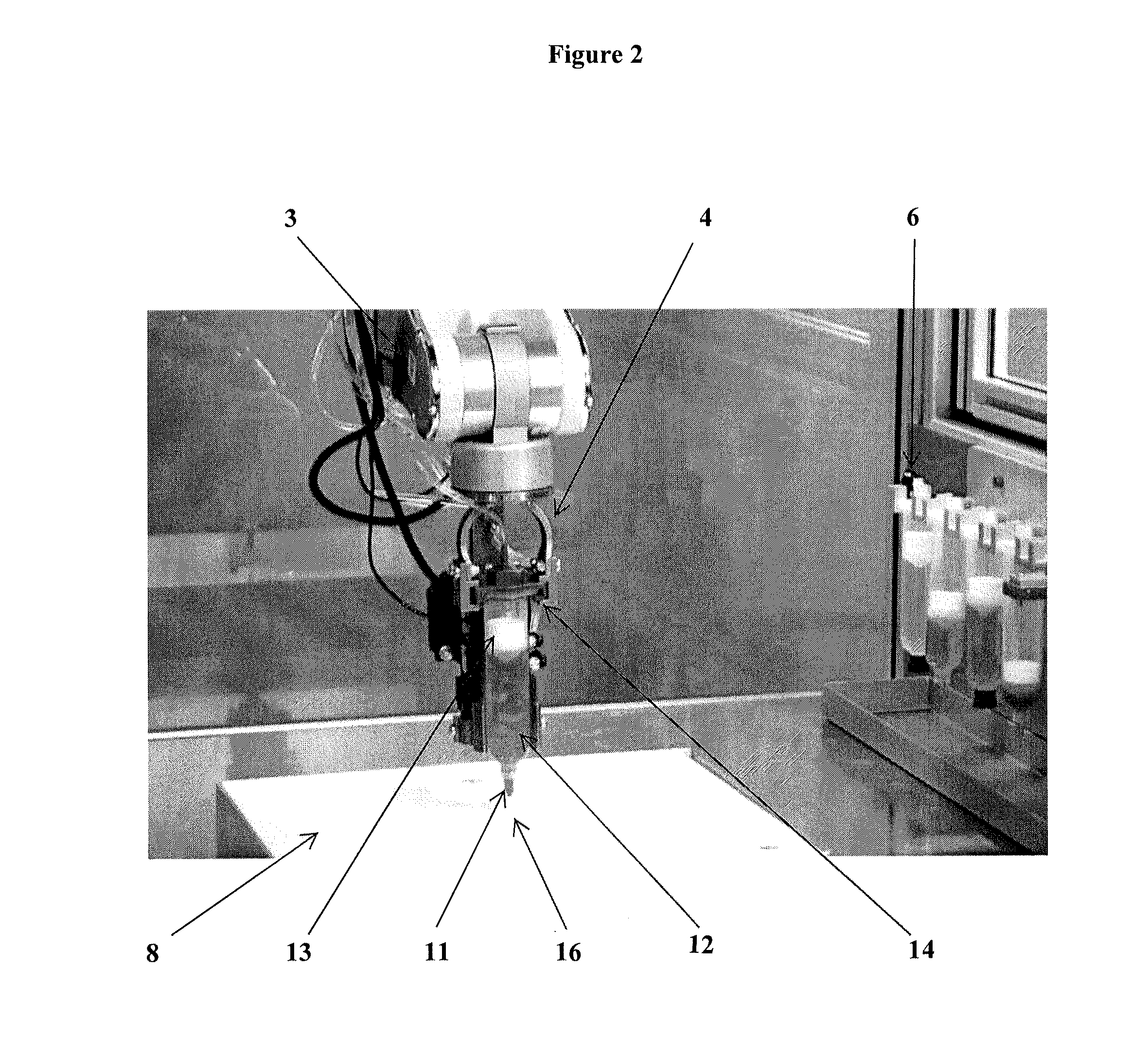

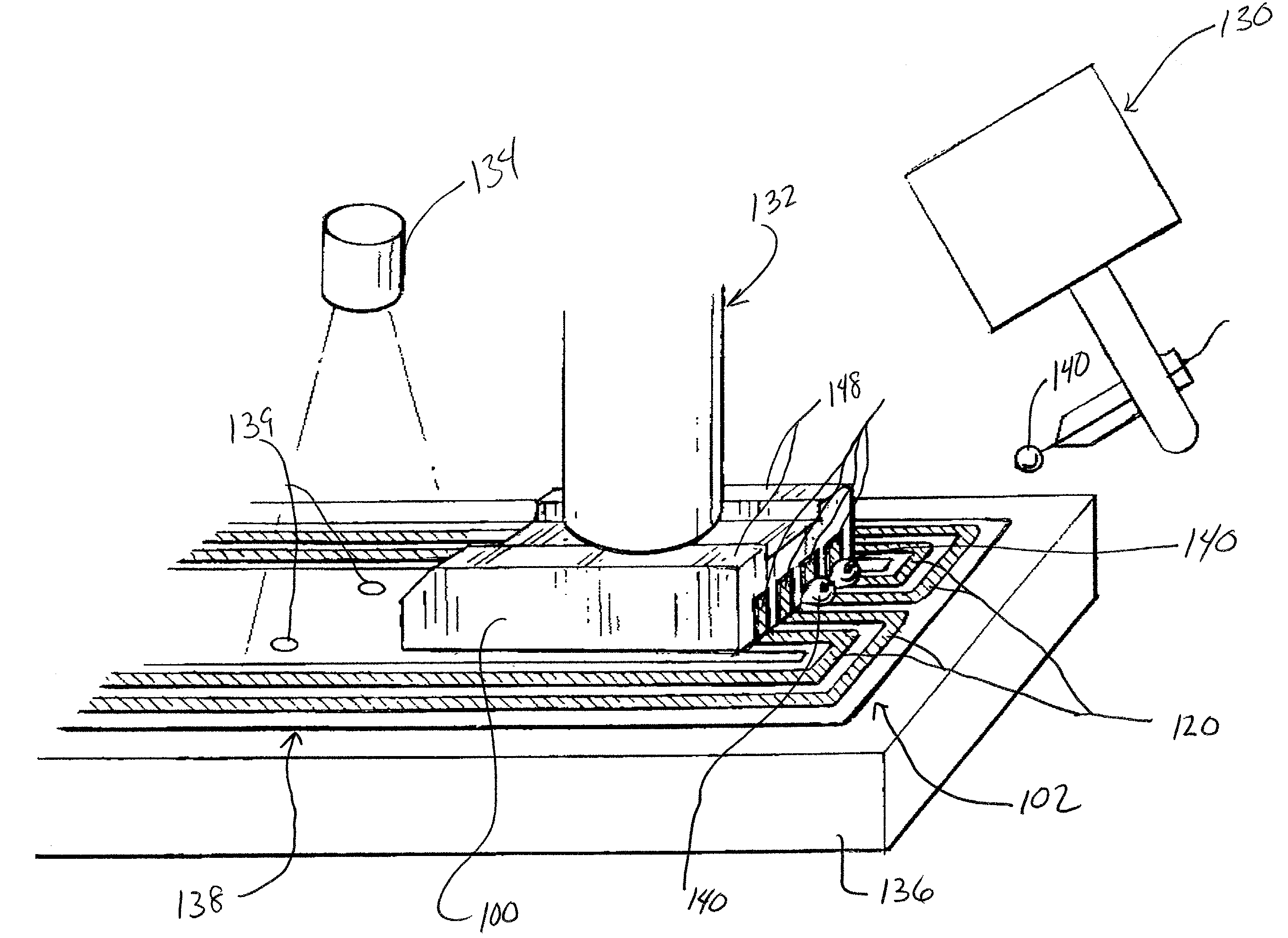

System and workstation for the design, fabrication and assembly of bio-material constructs

ActiveUS20150105891A1Build versatilityProgramme controlManufacturing platforms/substratesComputer Aided DesignModeling software

A bioassembly system having a tissue / object modeling software component fully and seamlessly integrated with a robotic bioassembly workstation component for the computer-assisted design, fabrication and assembly of biological and non-biological constructs. The robotic bioassembly workstation includes a six-axis robot providing the capability for oblique-angle printing, printing by non-sequential planar layering, and printing on print substrates having variable surface topographies, enabling fabrication of more complex bio-constructs including tissues, organs and vascular trees.

Owner:ADVANCED SOLUTIONS LIFE SCI

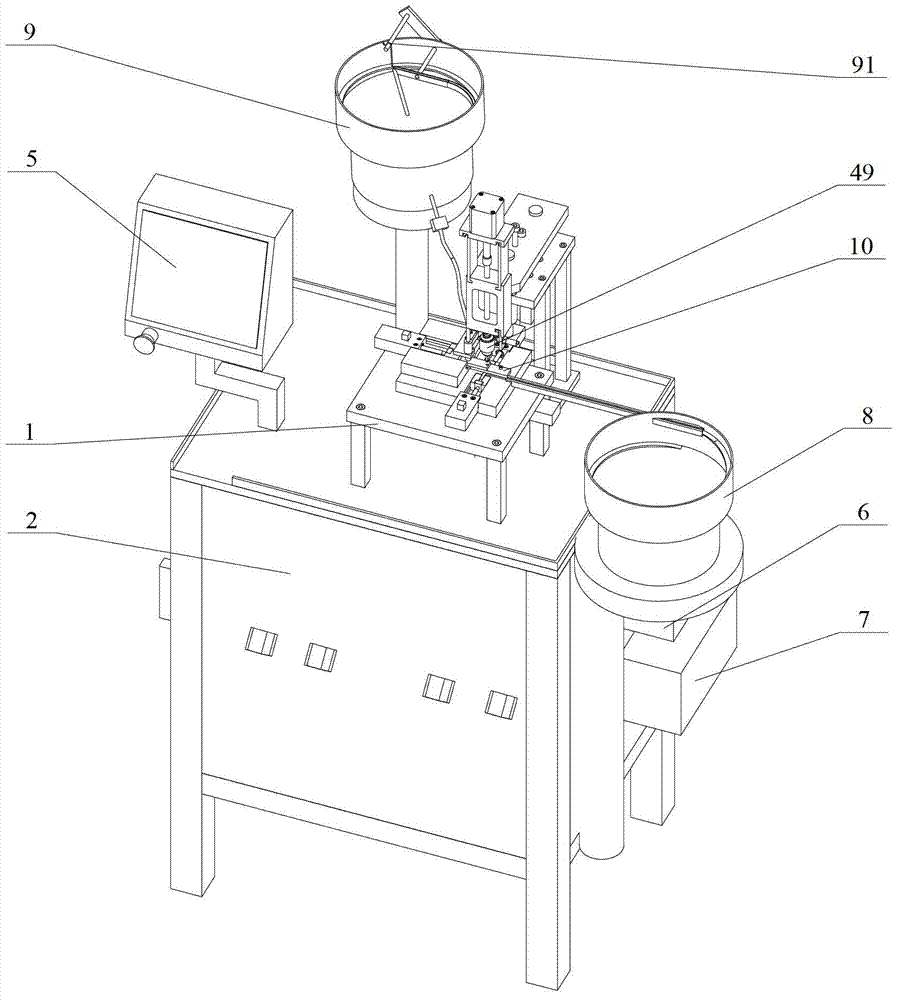

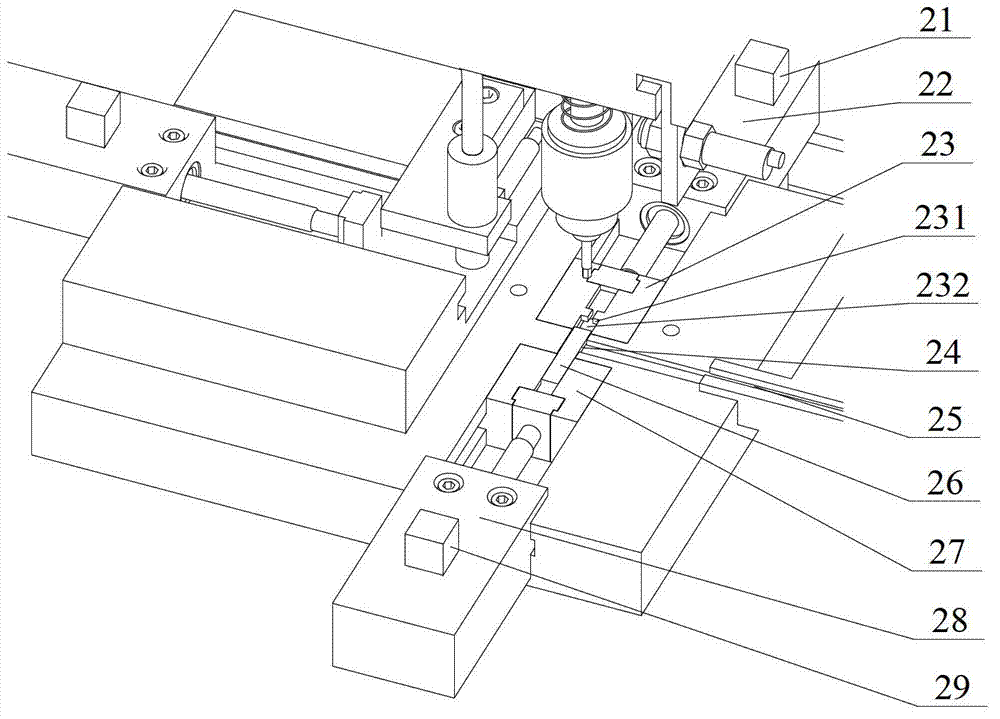

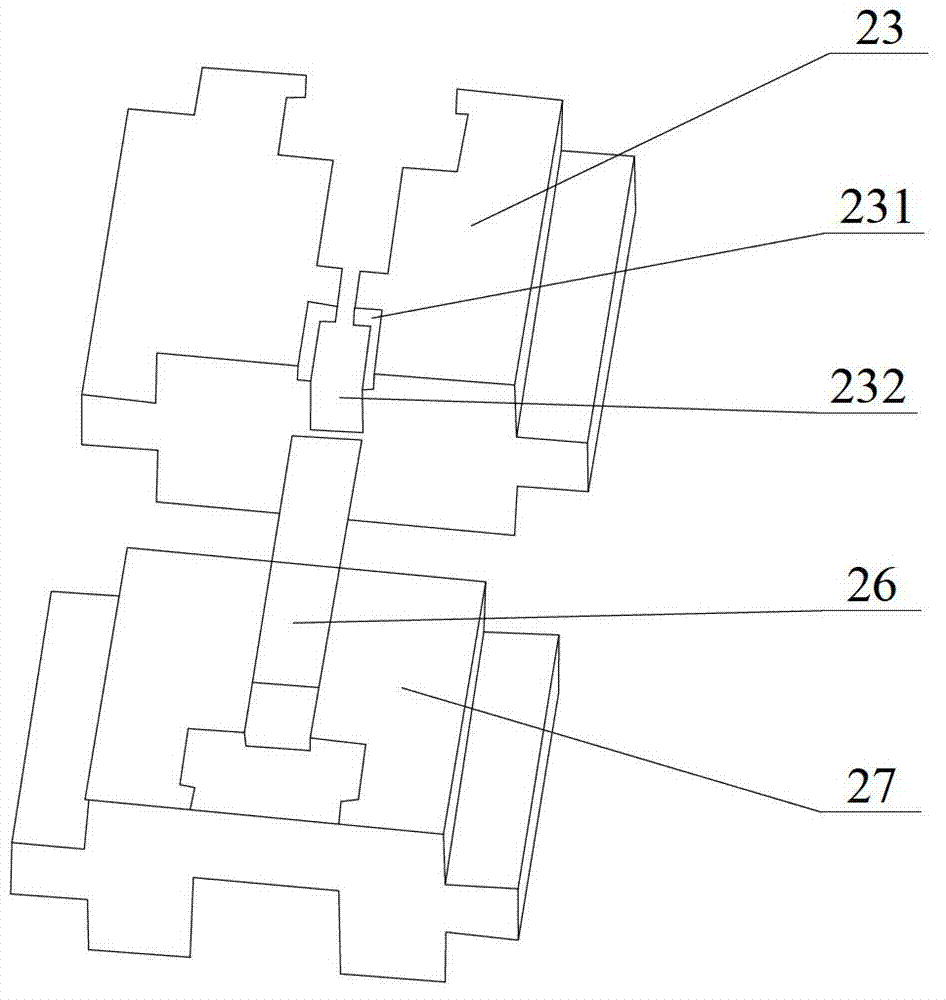

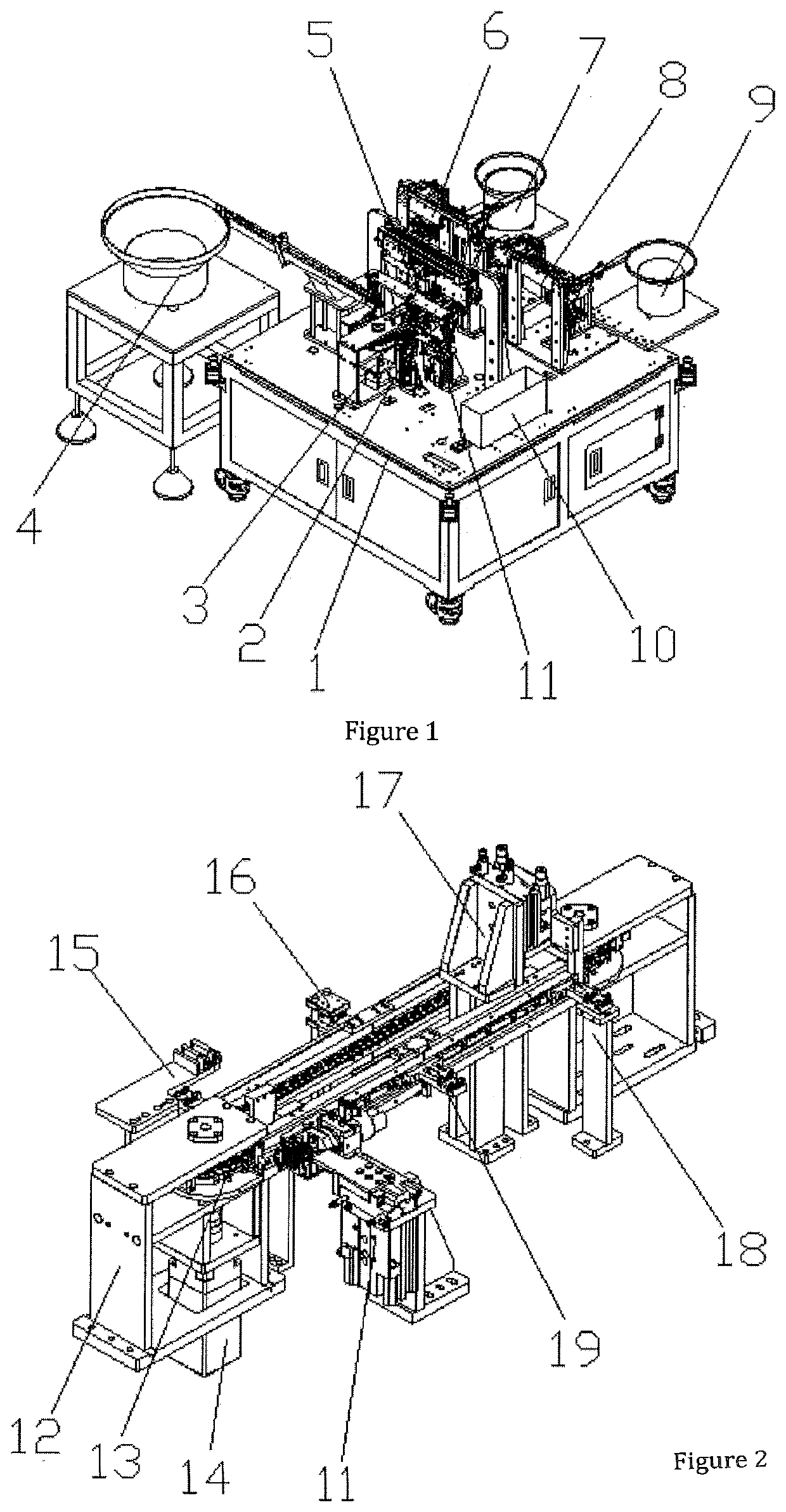

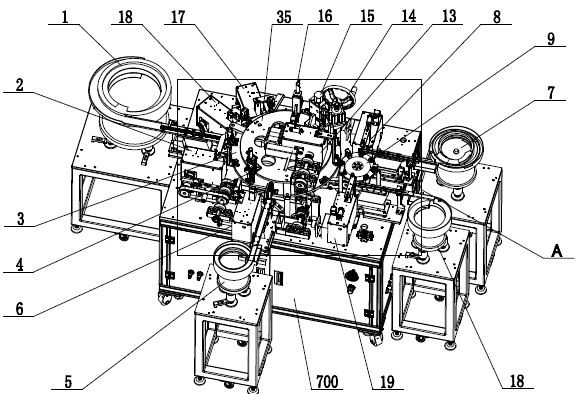

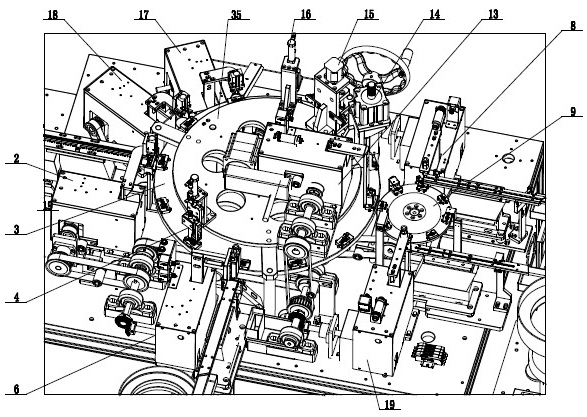

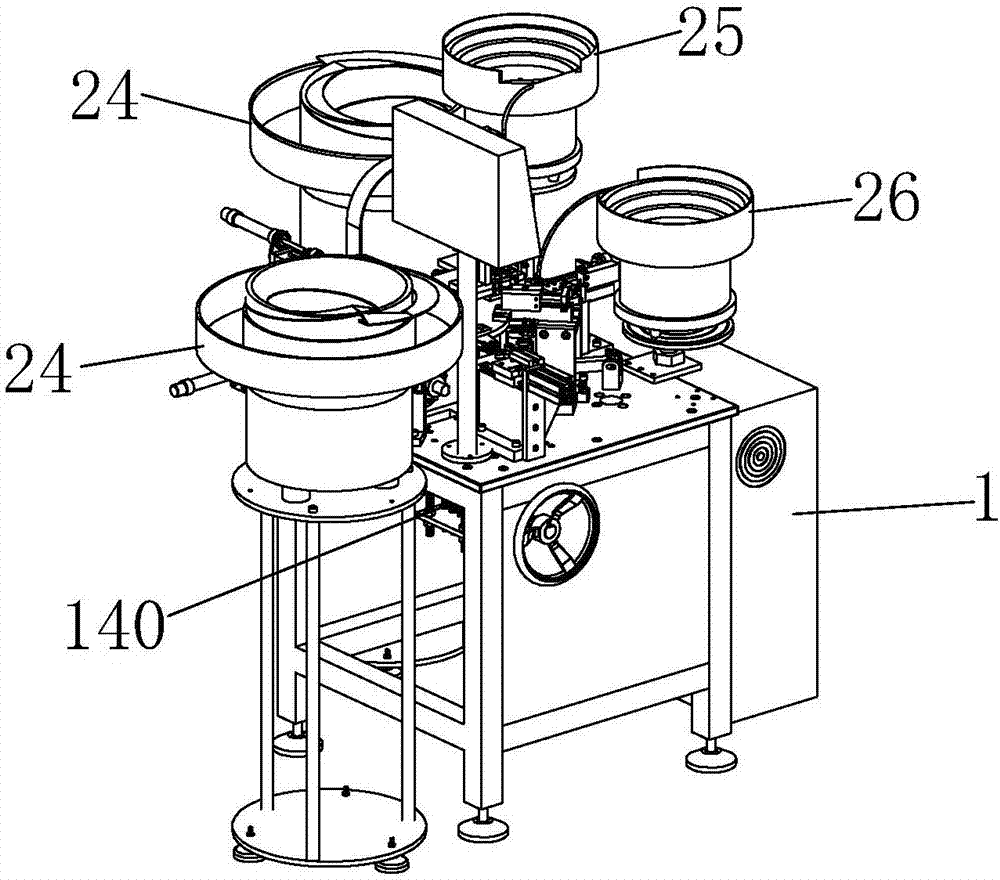

Full-automatic combination assembly machine for adjusting screws and nuts

ActiveCN102729038ARealize automated assemblyRealize sortingMetal working apparatusAssembly machineEngineering

The invention discloses a full-automatic combination assembly machine for adjusting screws and nuts, and the full-automatic combination assembly machine comprises a working table and a nut feeding device, a screw feeding device, a lifting spinning device and a discharge device which are arranged on the working table. A nut feeding vibration plate containing the nuts and a screw feeding vibration plate containing the screws are arranged on the working table; the nuts and the screws are respectively delivered to an assembling position through the nut feeding device and the screw feeding device, are assembled through the lifting spinning device, and finally are sorted out and exported through the discharge device. The full-automatic combination assembly machine realizes the automatic assembly and sorting of the screws and the nuts, so that the production efficiency is greatly improved, and the labor cost is greatly reduced; moreover, the full-automatic combination assembly machine does not injure figures of workers, and the assembled products have uniform appearance and stable quality.

Owner:浙江吉达金属有限公司

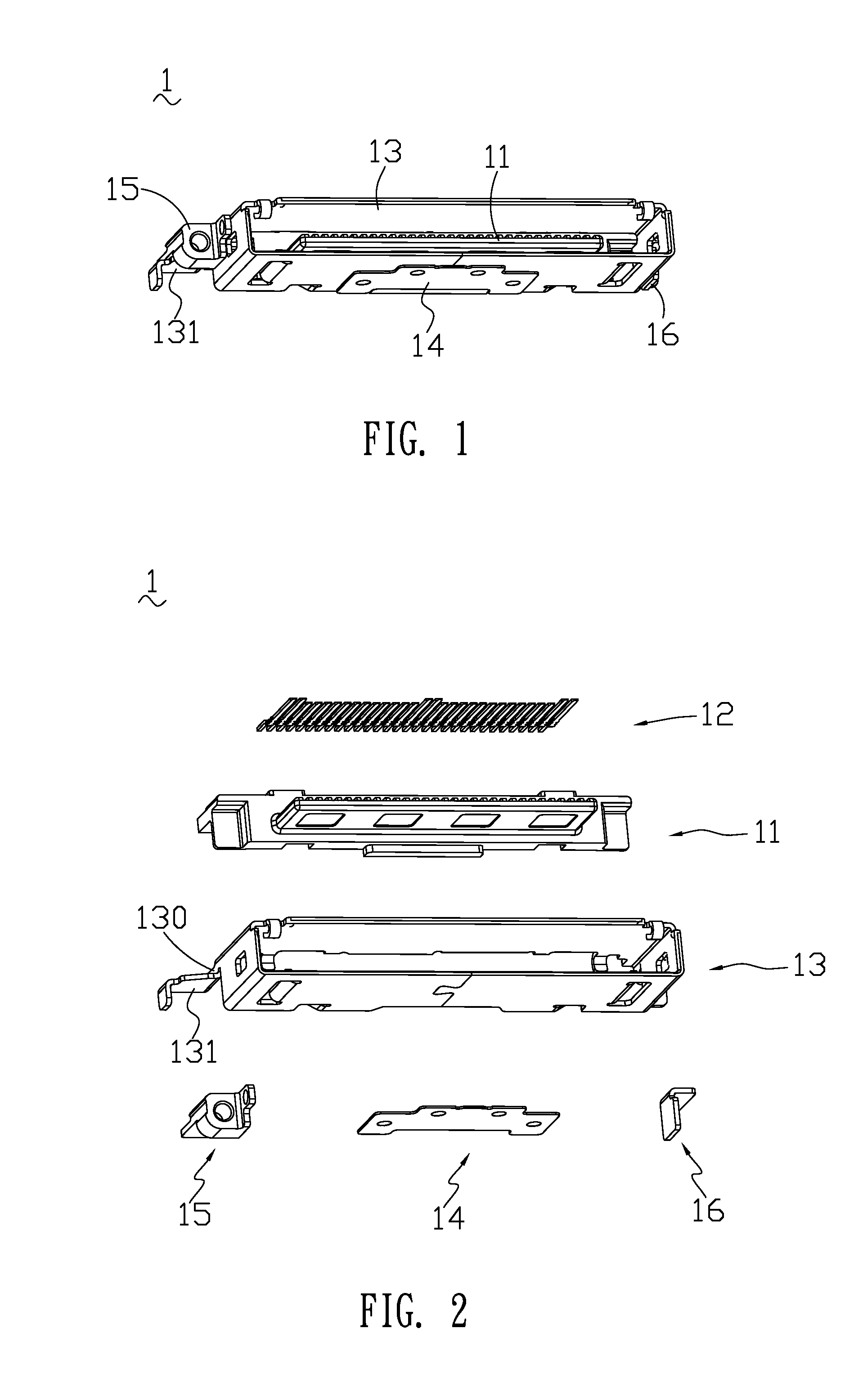

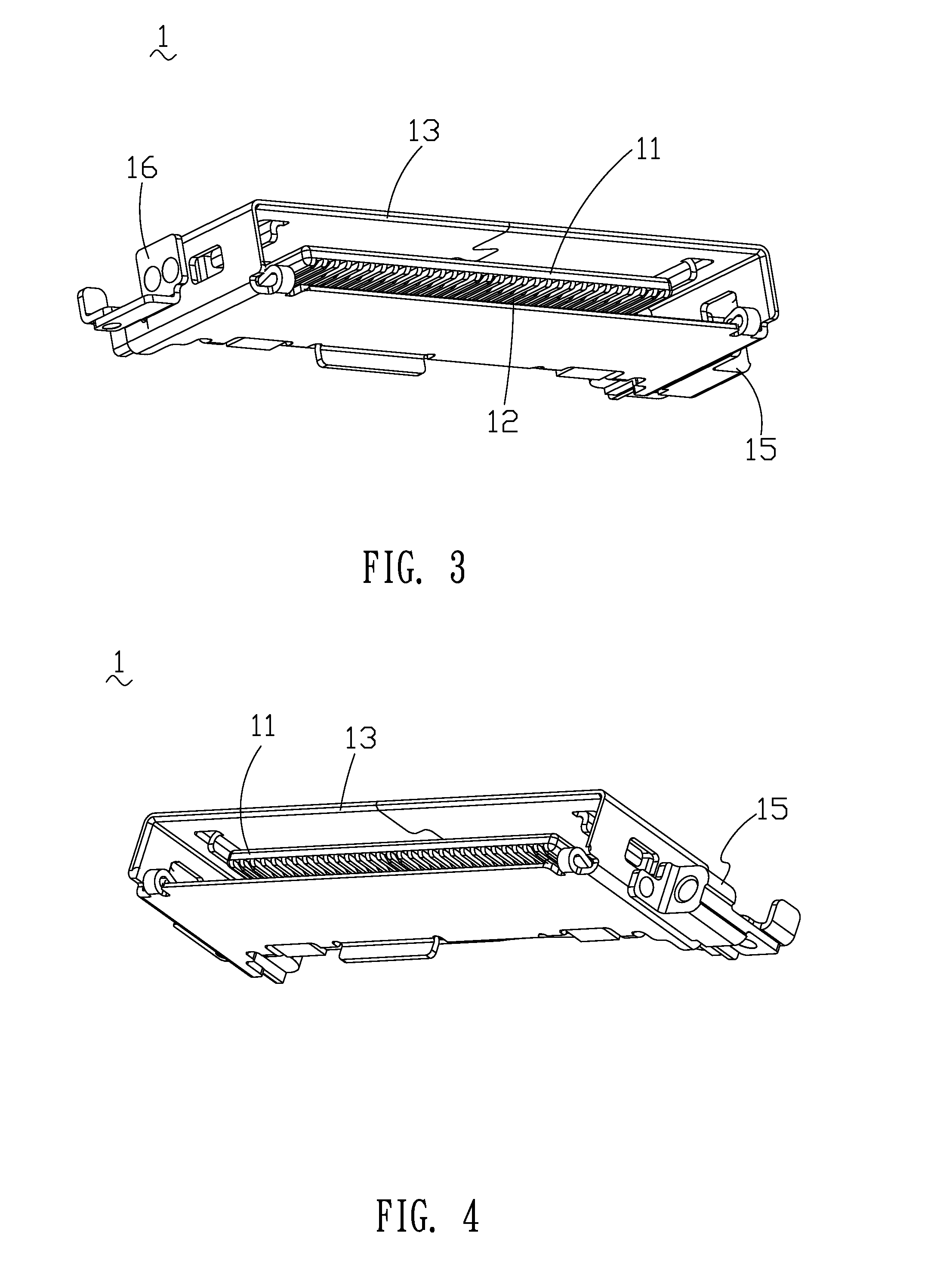

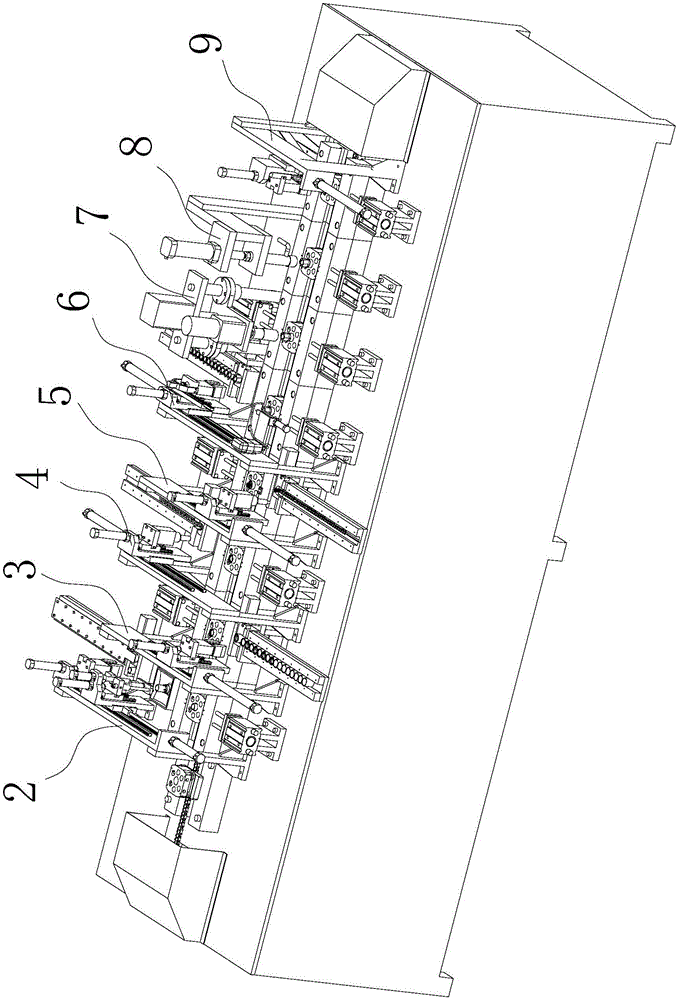

Automatic assembling machine of accurate connector

The invention discloses a precision connector automatic assembly machine which belongs to connector automatic assembly field. The precision connector automatic assembly machine includes: a filtering rubber core working station device and a rubber core flow passage connected with the working station device; a terminal feeding working station device installed on one side of a flow notch facing to the rubber core flow passage on the rubber core flow passage device, an insert end working station is set on adjacent position; a terminal cutting working station device installed on upper side of the rubber core flow passage and adjacent to the insert end working station device position; a case contact feeding working station device installed on one side of the flow notch facing to the rubber core flow passage on the rubber core flow passage device and adjacent to a bending working station device position, a case contact cutting pre-insert working station device is installed on down side; a case contact tearing working station device installed on one side of the flow notch facing to the rubber core flow passage on the rubber core flow passage device and adjacent to the case contact cutting pre-insert working station device; a main control unit controlling coordinated action of each device. The precision connector automatic assembly machine need not hand operation and can increase production efficiency.

Owner:深圳市金洋电子股份有限公司

Automatic soldering system

InactiveUS20120055975A1Easy to assembleImprove pass ratePrinted circuit assemblingWelding/cutting auxillary devicesControl systemEngineering

An automatic soldering system includes a conveyance mechanism, a vehicle, a first part assembling mechanism, a first soldering mechanism, a turn-over mechanism, a second part assembling mechanism, a second soldering mechanism, and a control system. The vehicle is conveyed by the conveyor mechanism for carrying a workpiece. The first part assembling mechanism and the first soldering mechanism assemble and solder a first part to the primary workpiece carried by the vehicle. The turn-over mechanism turns the vehicle that is conveyed by the conveyor mechanism and carries the primary workpiece having the first part assembled thereto by a predetermined angle. The second part assembling mechanism and the second soldering mechanism assemble and solder and position a second part to the primary workpiece. The control system is electrically connected to and thus controls the first part and second part assembling mechanisms, the first and second soldering mechanisms, and the turn-over mechanism.

Owner:CHENG UEI PRECISION IND CO LTD

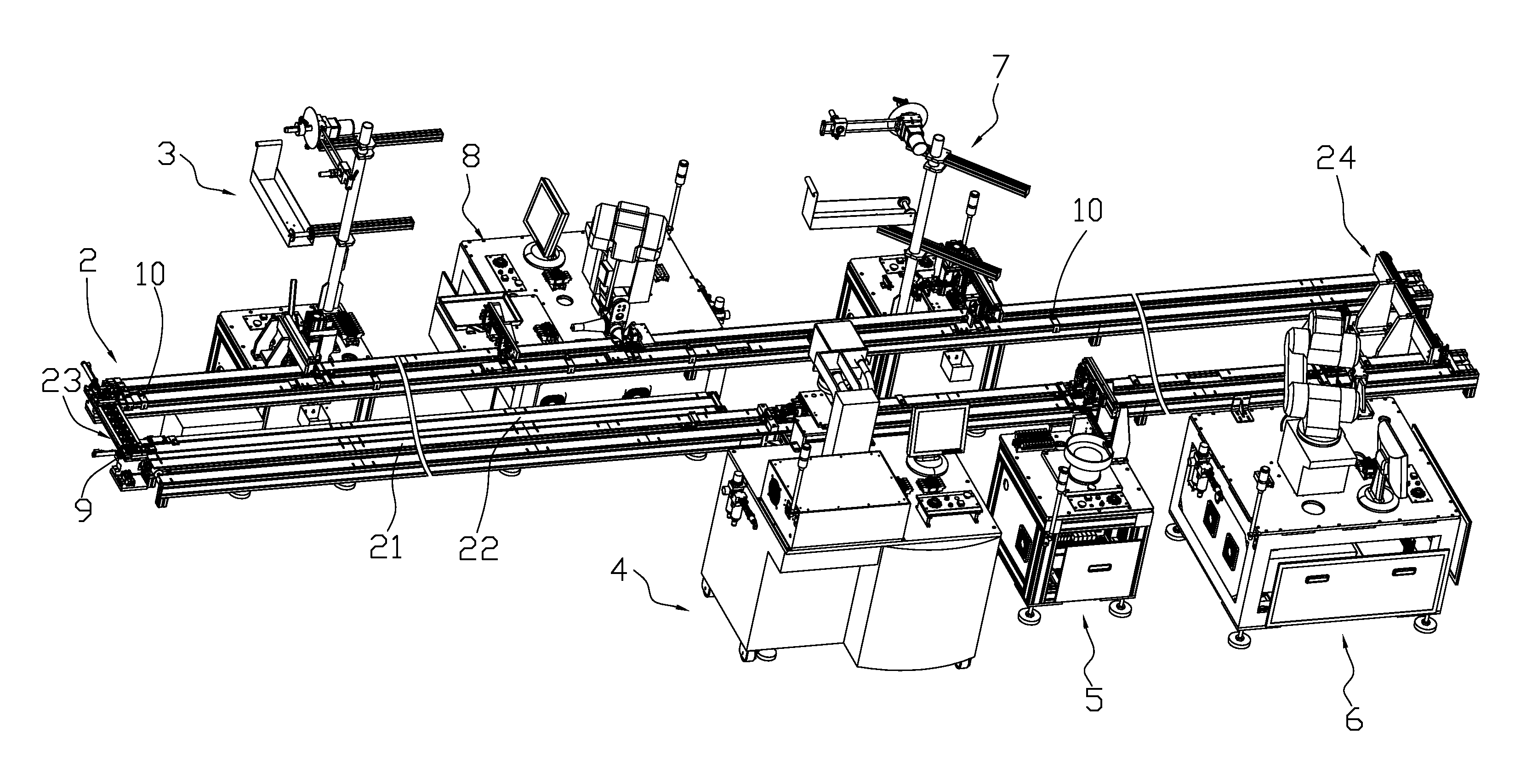

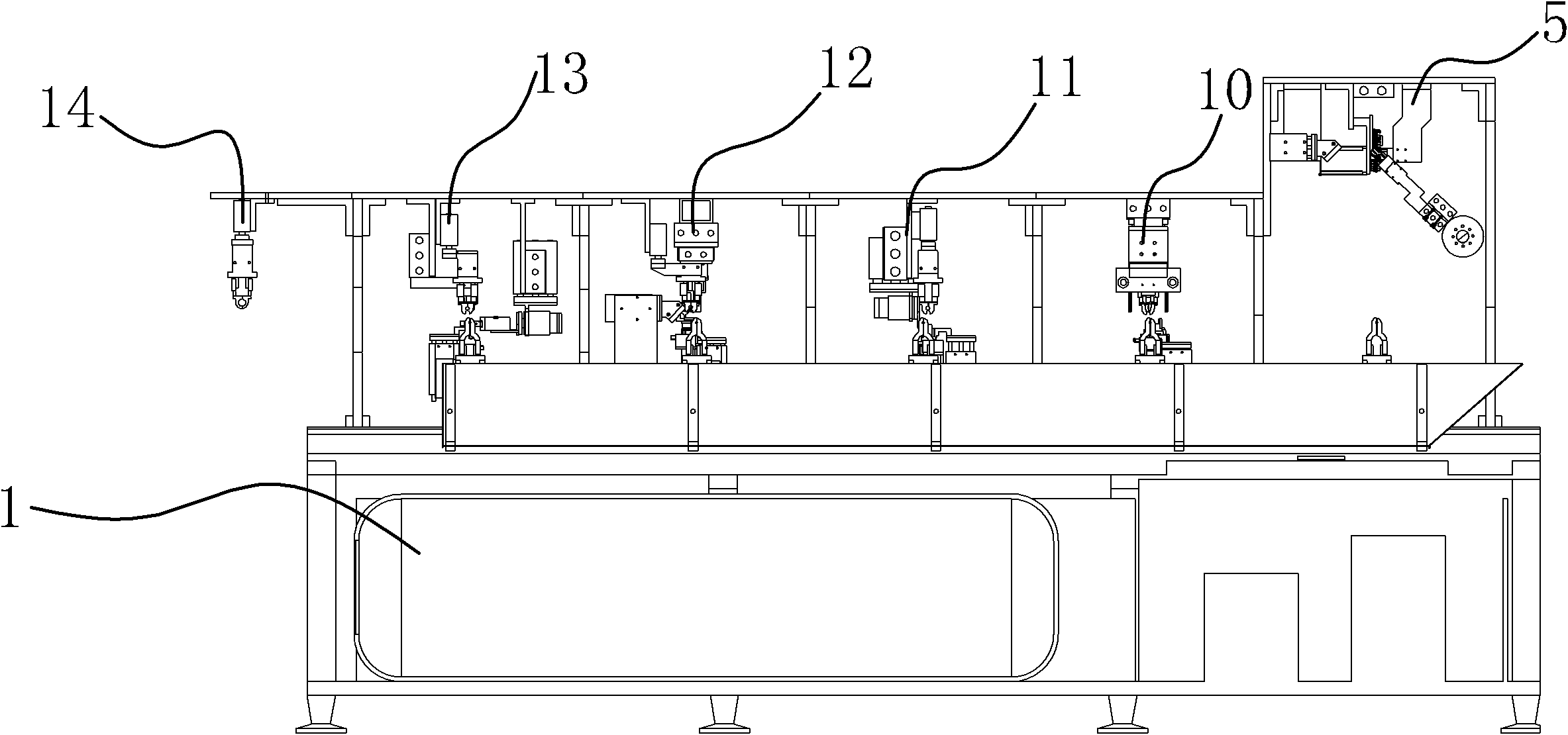

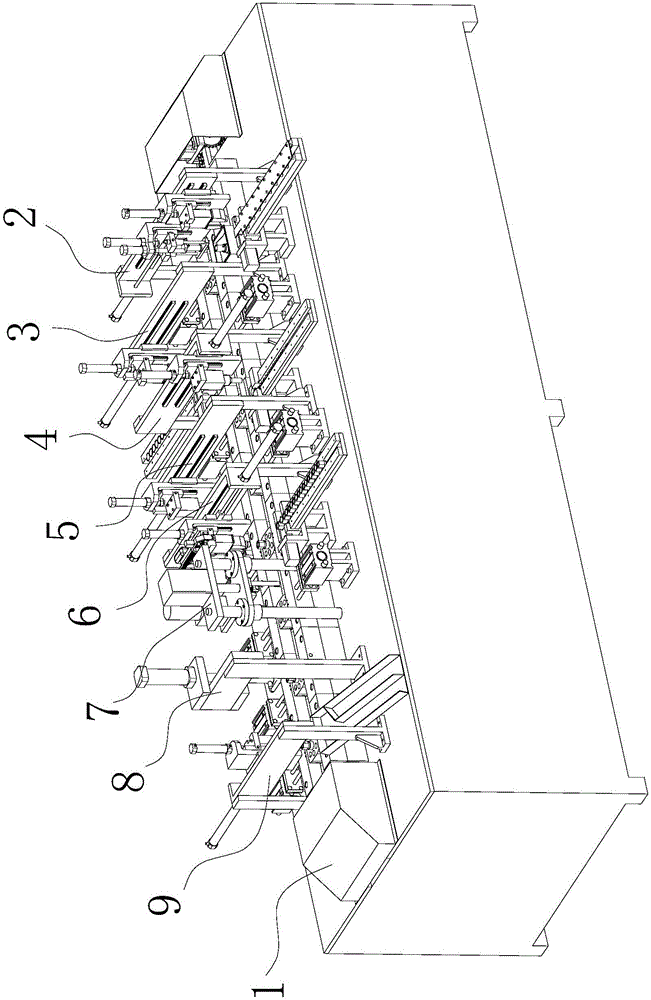

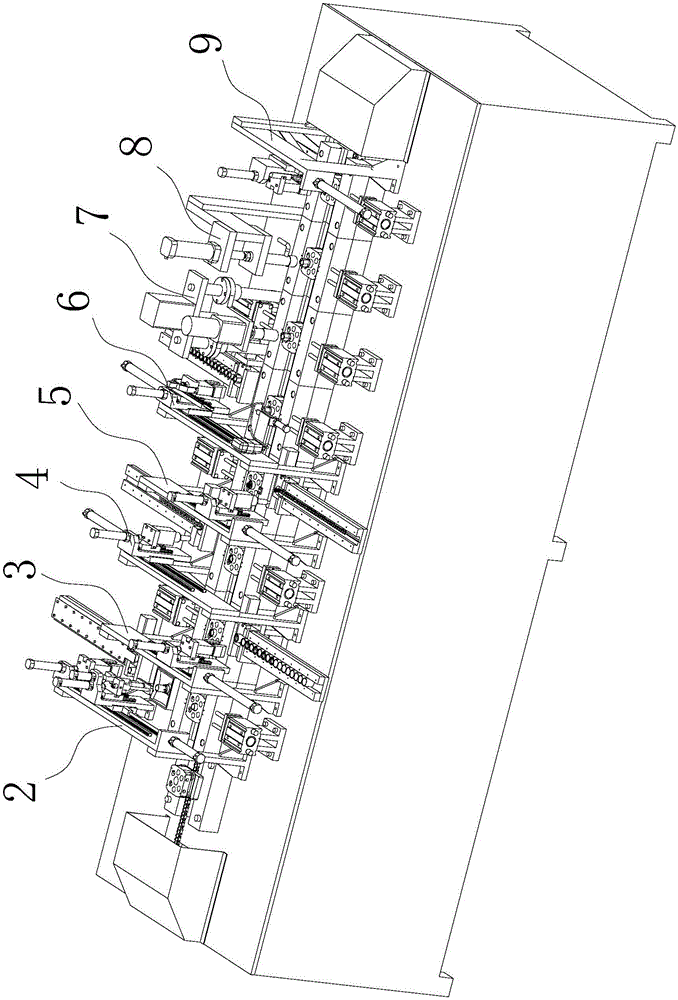

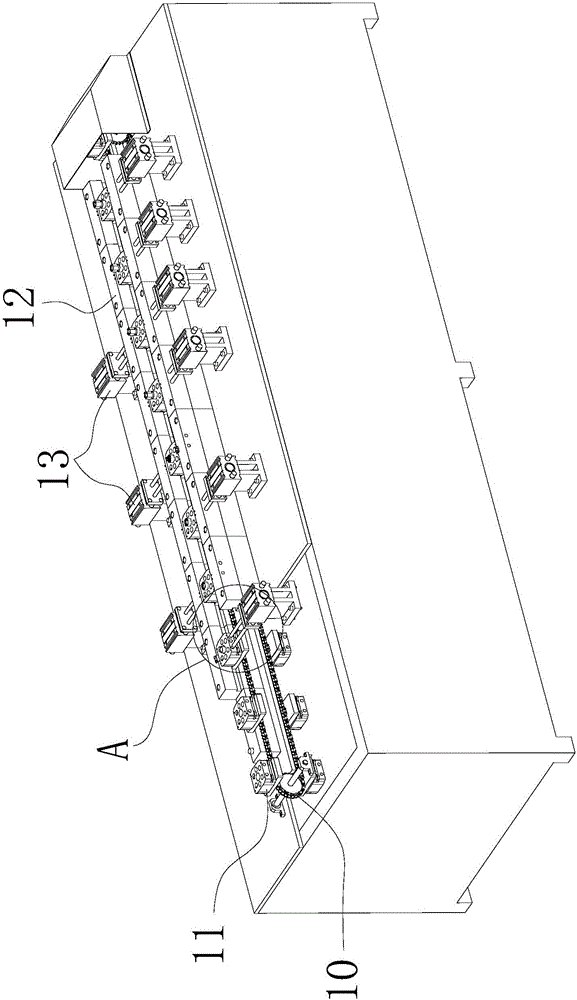

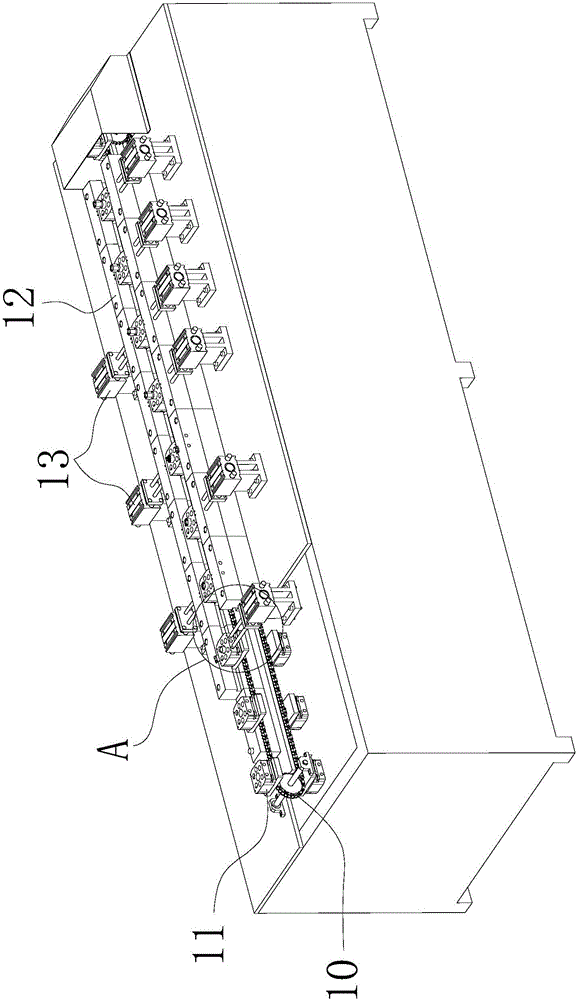

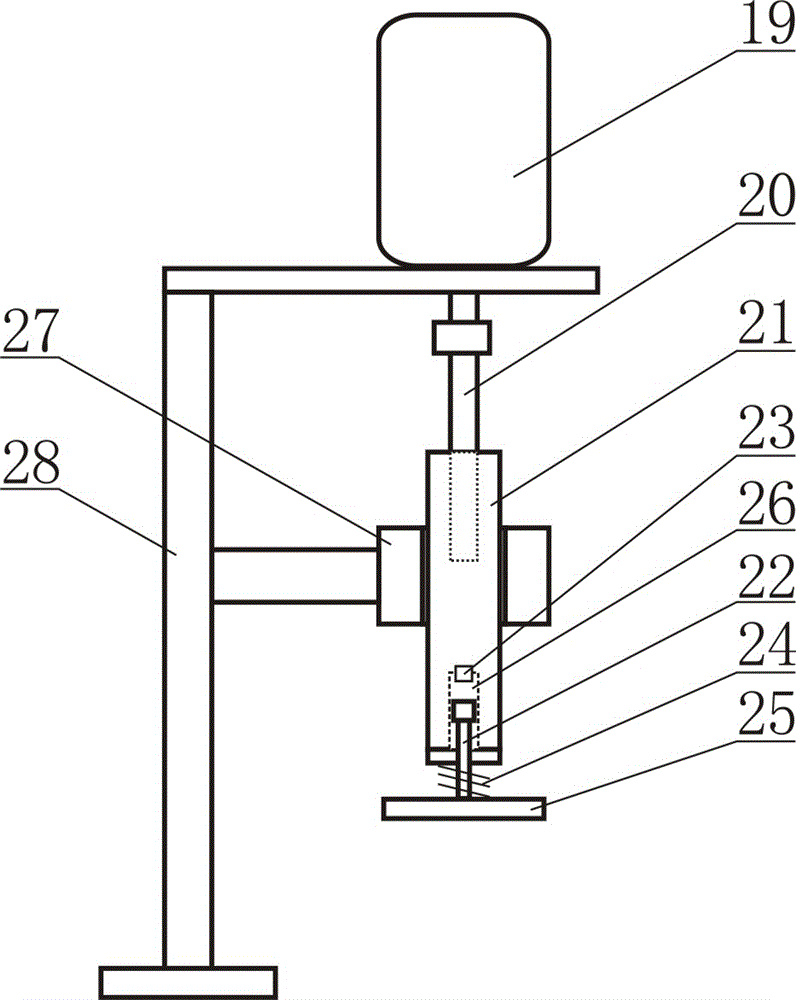

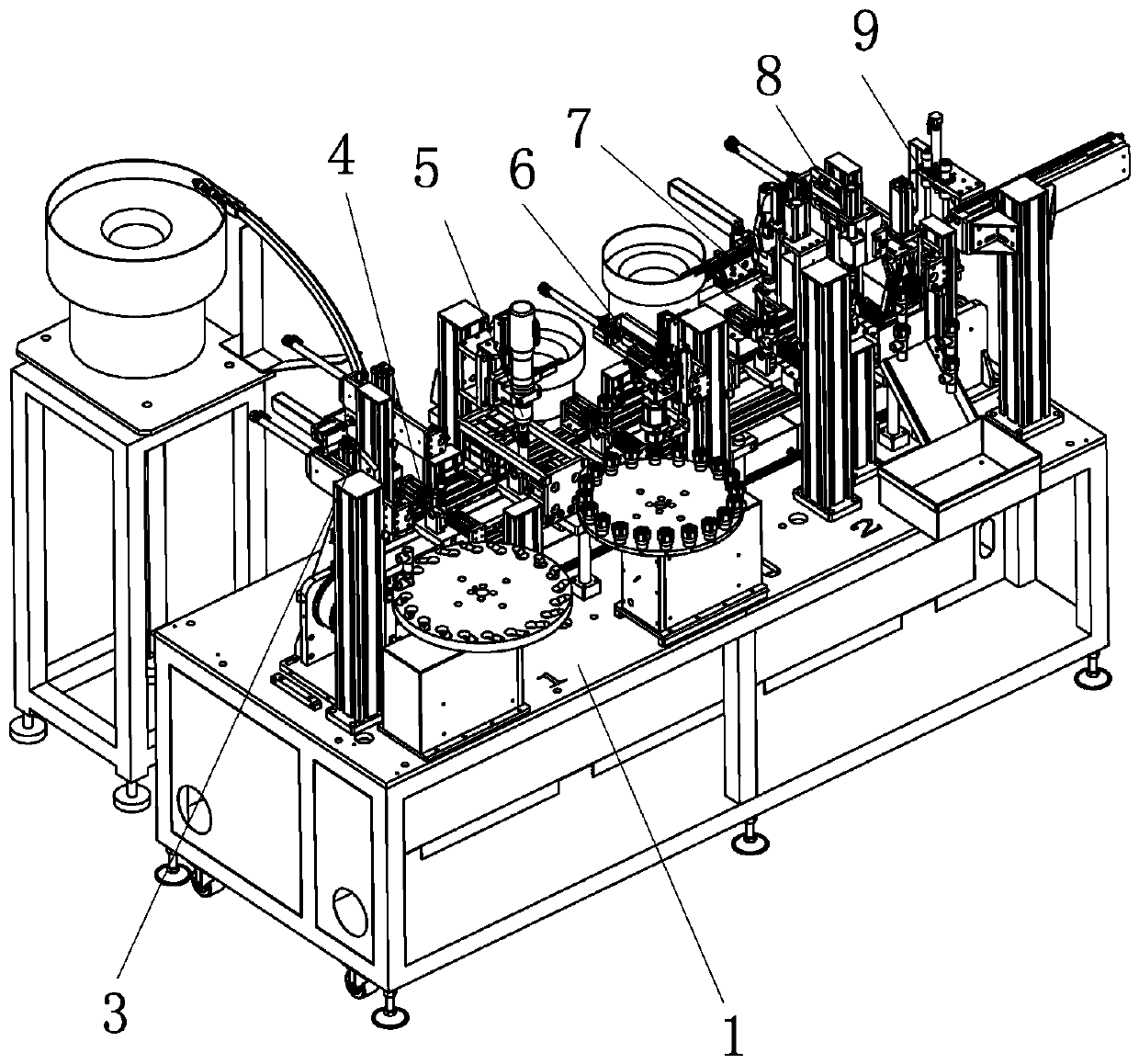

Automatic assembly machine for infusion apparatus

The invention provides an automatic assembly machine for an infusion apparatus, and belongs to the technical field of medicinal instruments. The automatic assembly machine solves the problem of low automation degree of the conventional infusion apparatus assembly machine. The automatic assembly machine for the infusion apparatus comprises a frame, wherein the frame is glidingly connected with a feeding sliding table; a feeding driving mechanism is arranged between the frame and the feeding sliding table; two sides of the feeding sliding table are fixedly provided with a plurality of pairs of clamping stations distributed opposite; the inlet end of the feeding sliding table is provided with an infusion long tube feeding device; one side of the feeding sliding table is sequentially providedwith a flow box assembly device, a switching wheel assembly device, an infusion short tube assembly device and a filter assembly device; the other side of the feeding sliding table is sequentially provided with a dropping bottle assembly device, a two-way tube assembly device, an infusion medium tube assembly device and a bottle inserting needle assembly device; and the outlet end of the feeding sliding table is also provided with an unloading device for taking the assembled infusion apparatus assembly out of the clamping station. The automatic assembly machine for the infusion apparatus has high positioning accuracy, accurate clamping position and high automation degree.

Owner:TAIZHOUSNG JIN AUTOMATION EQUIP MFG

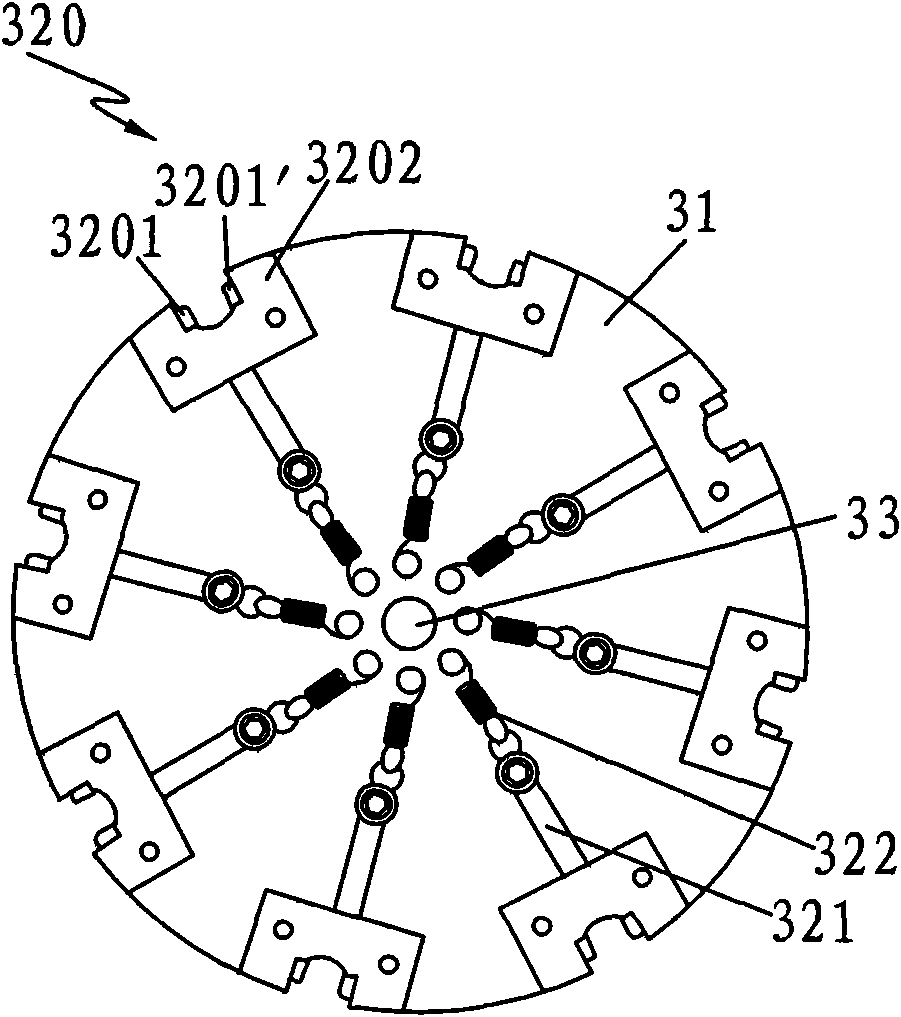

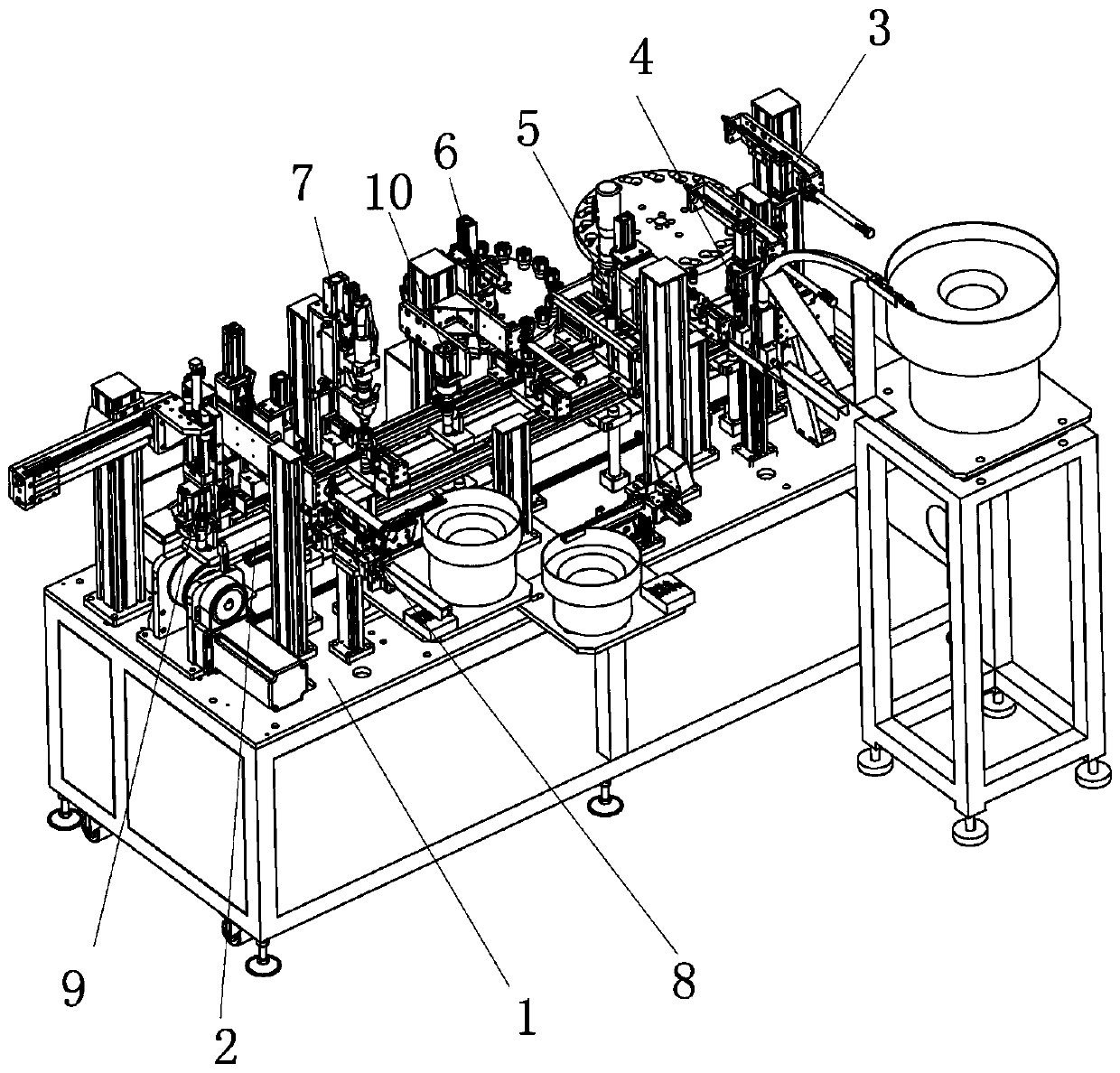

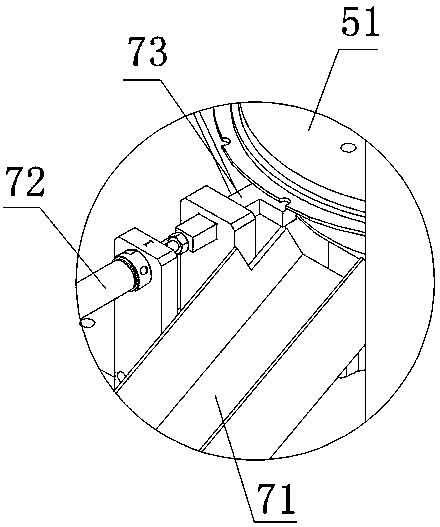

Full-automatic bearing assembly machine

ActiveCN103047300AImprove assembly efficiencyImprove assembly qualityBearing componentsEngineeringTransfer mechanism

The invention discloses a full-automatic bearing assembly machine. The assembly machine comprises a base, a working platform, a assembling station and a press fit station, wherein the assembling station and the press fit station are arranged on the working platform; an inner-ring feeding mechanism is arranged in the front of the assembling station, and a roller assembling mechanism is arranged behind the assembling station; a roller feeding mechanism is arranged behind the roller assembling mechanism; a holder feeding mechanism is arranged on one side of the assembling station; the inner ring of the bearing, the holder and a tapered roller are assembled together to form an inner assembly of the bearing; an assembly transferring mechanism which can convey the inner assembly of the bearing from the assembling station to the press fit station is arranged between the other side of the assembling station and the inner side of the press fit station; a press fit mechanism is arranged on the press fit station; a material discharging passage is arranged outside the press fit station; and a material pushing mechanism is arranged on the material discharging passage. With the adoption of the structure, assemblies of the holder, the tapered roller and the inner ring of the bearing can be performed automatically, and the inner assembly of the bearing is transferred to the press fit station for pressing through the assembly transferring mechanism, so that the assembly efficiency and the assembly quality are improved greatly, and potential safety hazards are eliminated.

Owner:宁波江宸智能装备股份有限公司

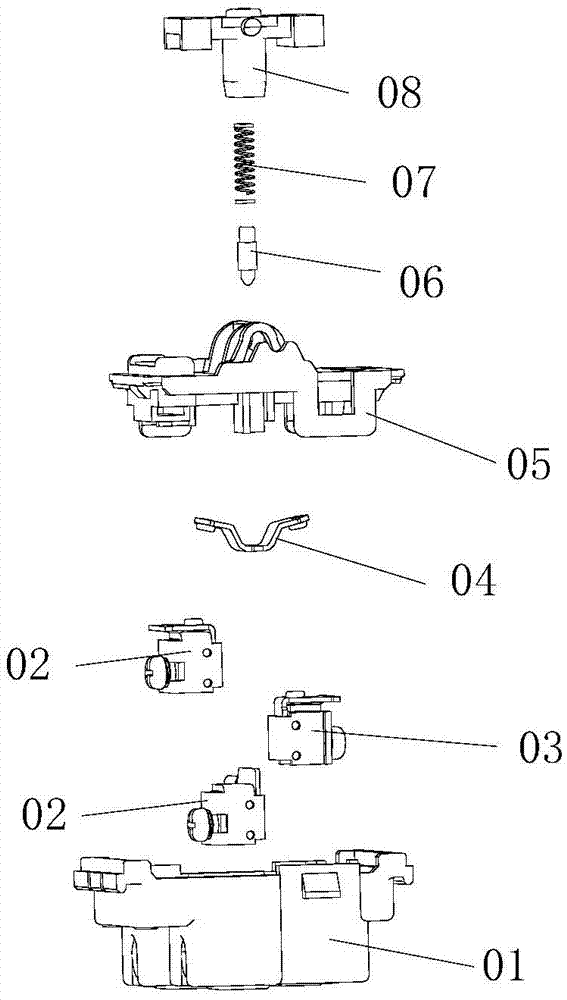

Stroke switch assembly machine

InactiveCN105990053ANeatly assembledLabor savingElectric switchesMetal working apparatusRubber ringAssembly line

The invention discloses a stroke switch assembly machine, which comprises an eight-working position turntable mechanism, a bottom charging manipulator, a waterproof rubber ring charging mechanism, a clasp charging mechanism, a rubber ring protective cover charging mechanism, a contact charging mechanism, a rivet charging mechanism, a labeling assembly line and a main electric control cabinet, wherein the bottom charging manipulator, the waterproof rubber ring charging mechanism, the clasp charging mechanism, the rubber ring protective cover charging mechanism, the contact charging mechanism and the rivet charging mechanism are annularly located around the eight-working position turntable mechanism; the labeling assembly line is arranged at the left rear side of the eight-working position turntable mechanism; and the rear side of the eight-working position turntable mechanism is provided with the main electric control cabinet. Through the above mode, the manual labor can be replaced, assembly of the stroke switches can be completed automatically, high efficiently and tidily, the labor is saved and the production cost is reduced.

Owner:乐清市华田电力科技有限公司

Automatic spring fastener assembly machine

ActiveUS20190337105A1Completed efficientlyCompleted fastContact member assembly/disassemblyAssembly machinesRobot handEngineering

The present invention relates to an automatic spring fastener assembly machine, including a rack and a power control box, and the rack is provided with a circulating conveying device, and a rubber casing feeding device, a fastener feeding device and a spring loading device which are in turn arranged around the circulating conveying device. The rubber casing feeding device includes a rubber casing vibration tray disposed to the left front side of the circulating conveying device, and the rubber casing feeding vibration tray is connected with a rubber casing distributing block through the rubber casing conveying track. The upper side of the circulating conveying device is provided with a rubber casing transportation manipulator, and the right front side thereof is provided with a rubber casing clamping device located below the rubber casing transportation manipulator, and a fastener pushing in device fitting the circulating conveying device is disposed under the rubber casing clamping device. In the present invention, material feeding and conveying is done by the circulating conveying device, and fasteners are fitted into corresponding holes on the rubber casings from a higher position with the fastener pushing in device, which can be completed fast and efficiently, is easy to operate, realize quick assembly of spring fasteners and improve working efficiency.

Owner:DONGGUAN UNIV OF TECH

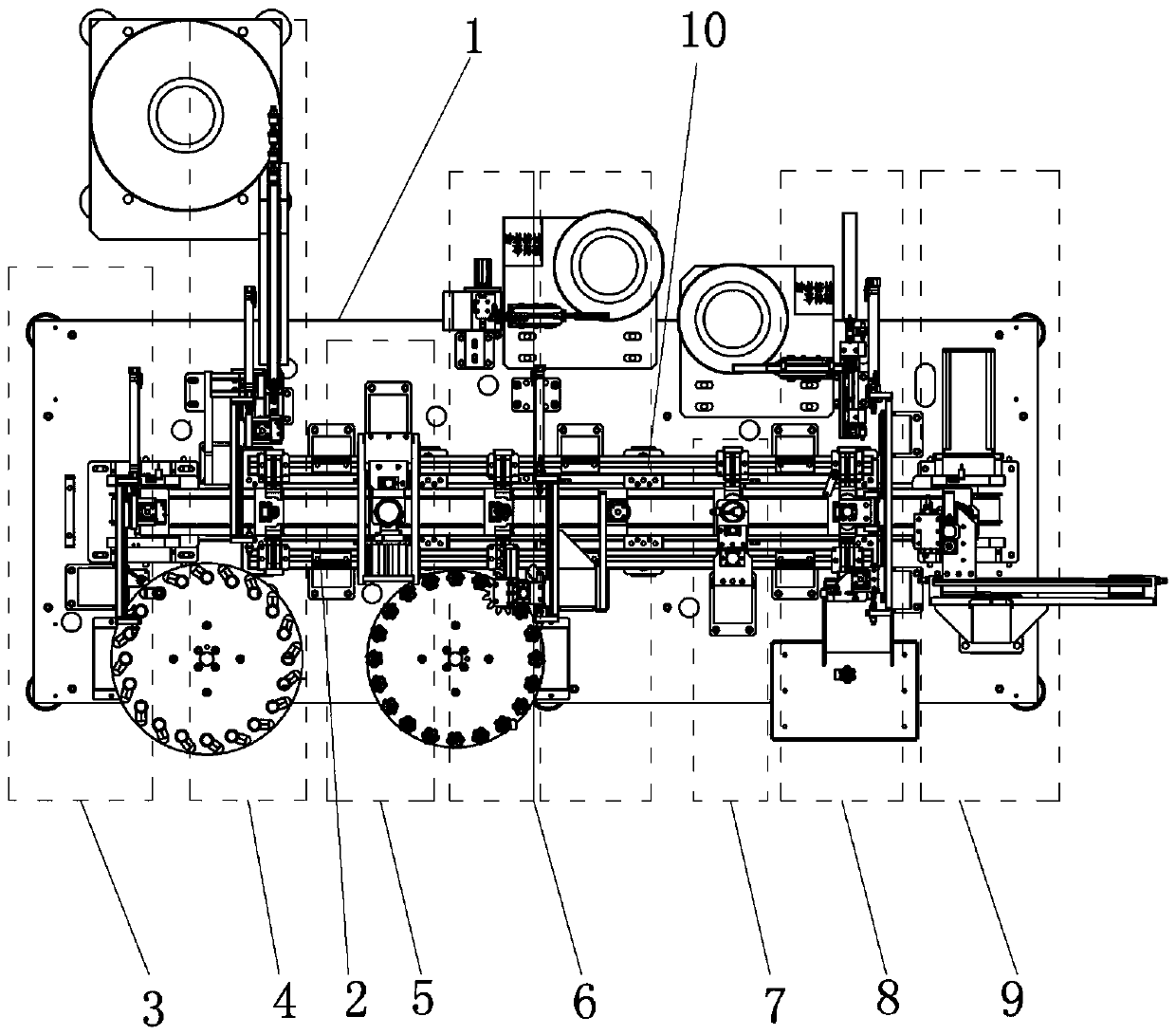

Automatic assembly machine of quick connectors

InactiveCN103273312AAssembly precisionIncrease productivityAssembly machinesForeign matterEngineering

An automatic assembly machine of quick connectors comprises a machine frame, wherein a large turntable and a small turntable are installed on the machine frame. A main-body feeding mechanism, a main-body inner cavity foreign-matter sucking mechanism, a main-body inside foreign-matter detecting machine, a green sealing ring pressing-in mechanism, a green sealing ring detecting machine, a spacer ring assembling mechanism, a spacer ring assembling detecting machine, a blue sealing ring assembling mechanism, a blue sealing ring assembling detecting machine, a safety ring pre-assembling mechanism and a safety ring pressing-in mechanism are installed on the large turntable in sequence. A safety ring detecting machine, a locking spring assembling mechanism, a locking spring assembling detecting machine and an output mechanism are installed on the small turntable in sequence, wherein the output mechanism outputs good products and NG products of the assembled quick connectors after detection. A transition mechanism used for transferring the quick connectors in a rotating mode is installed between the safety ring pressing-in mechanism and the safety ring detecting machine. The automatic assembly machine achieves automatic assembly and detection of the quick connectors, is convenient to operate, accurate in assembly and high in production efficiency, reduces dependence on manpower resources, and saves production cost.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

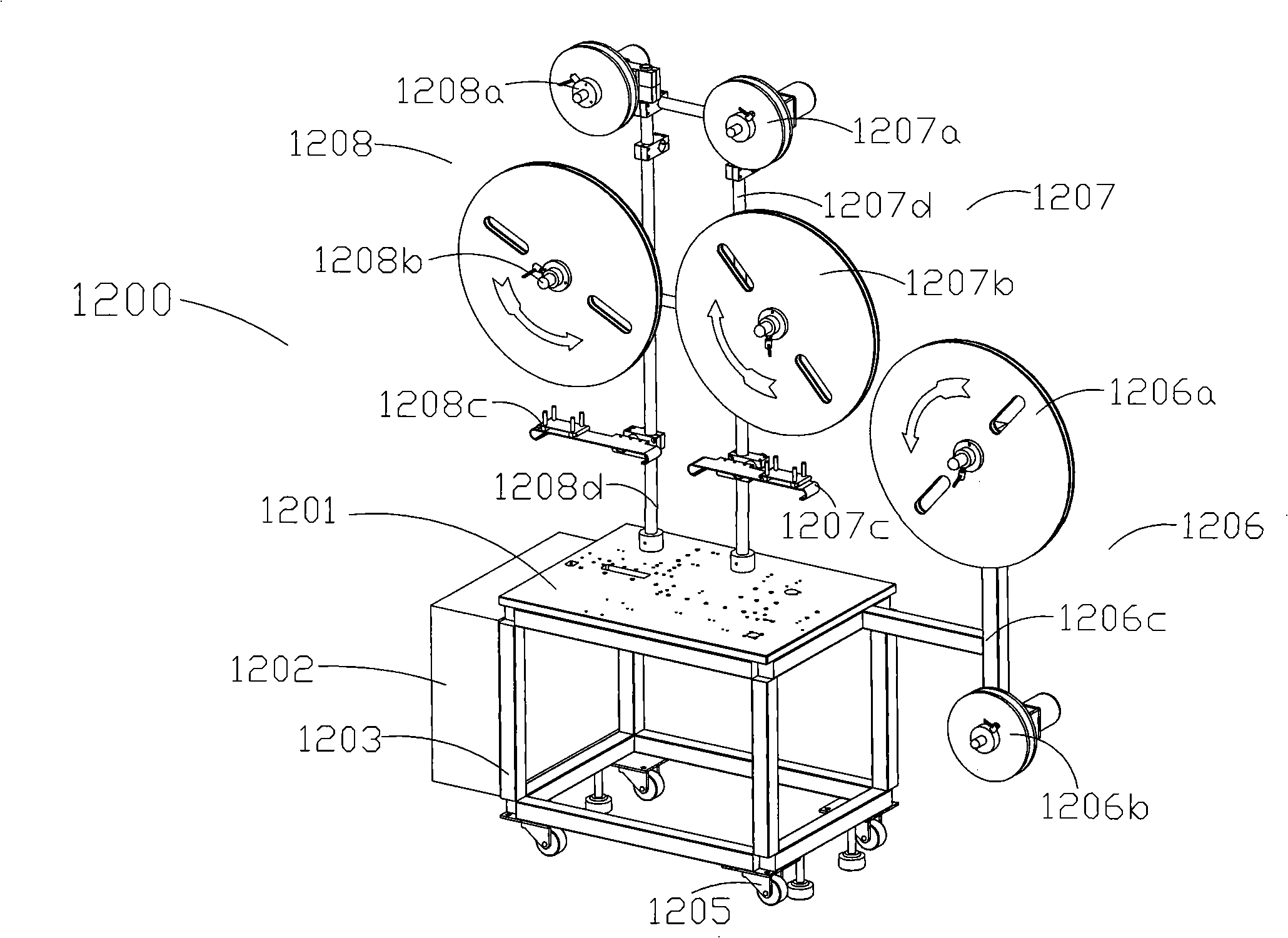

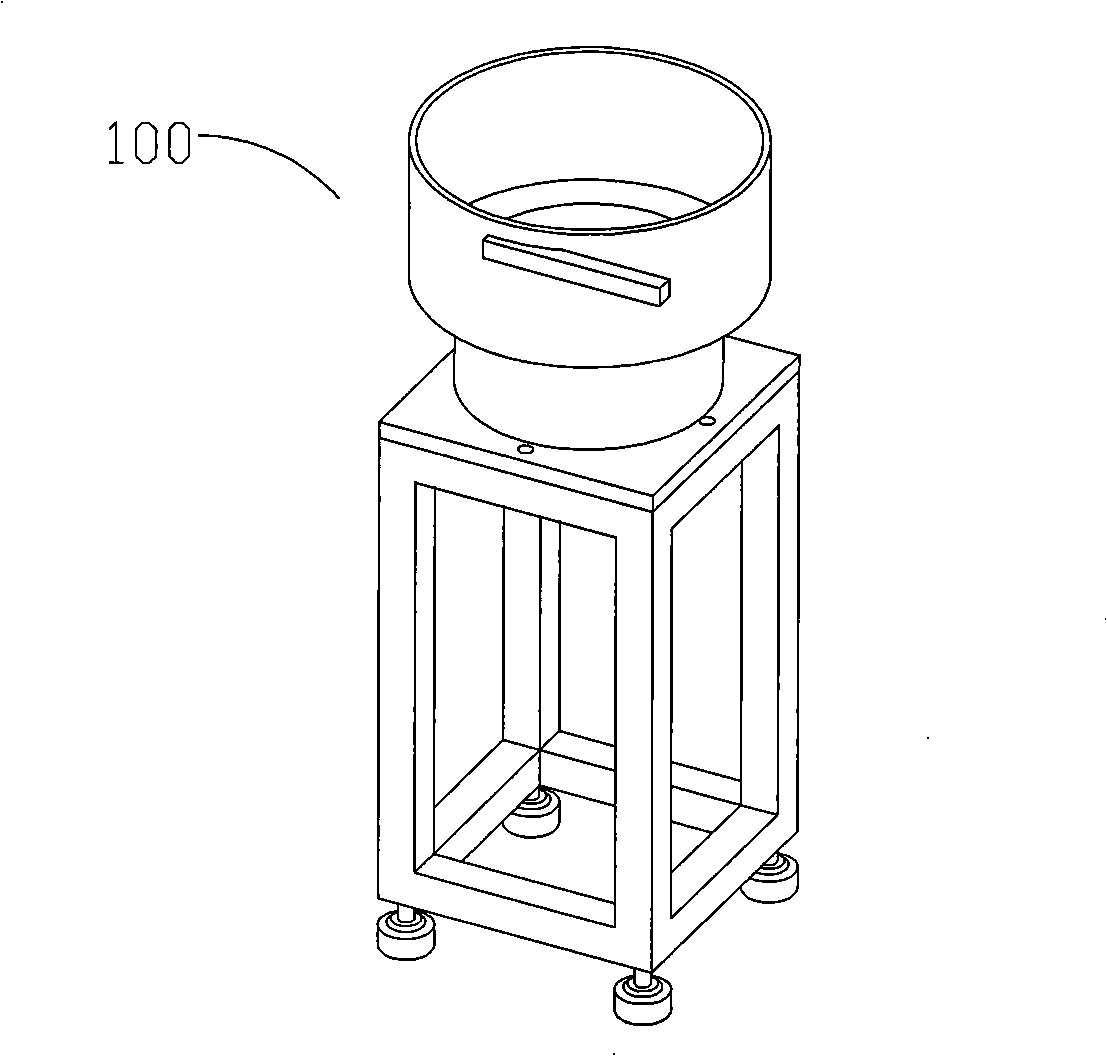

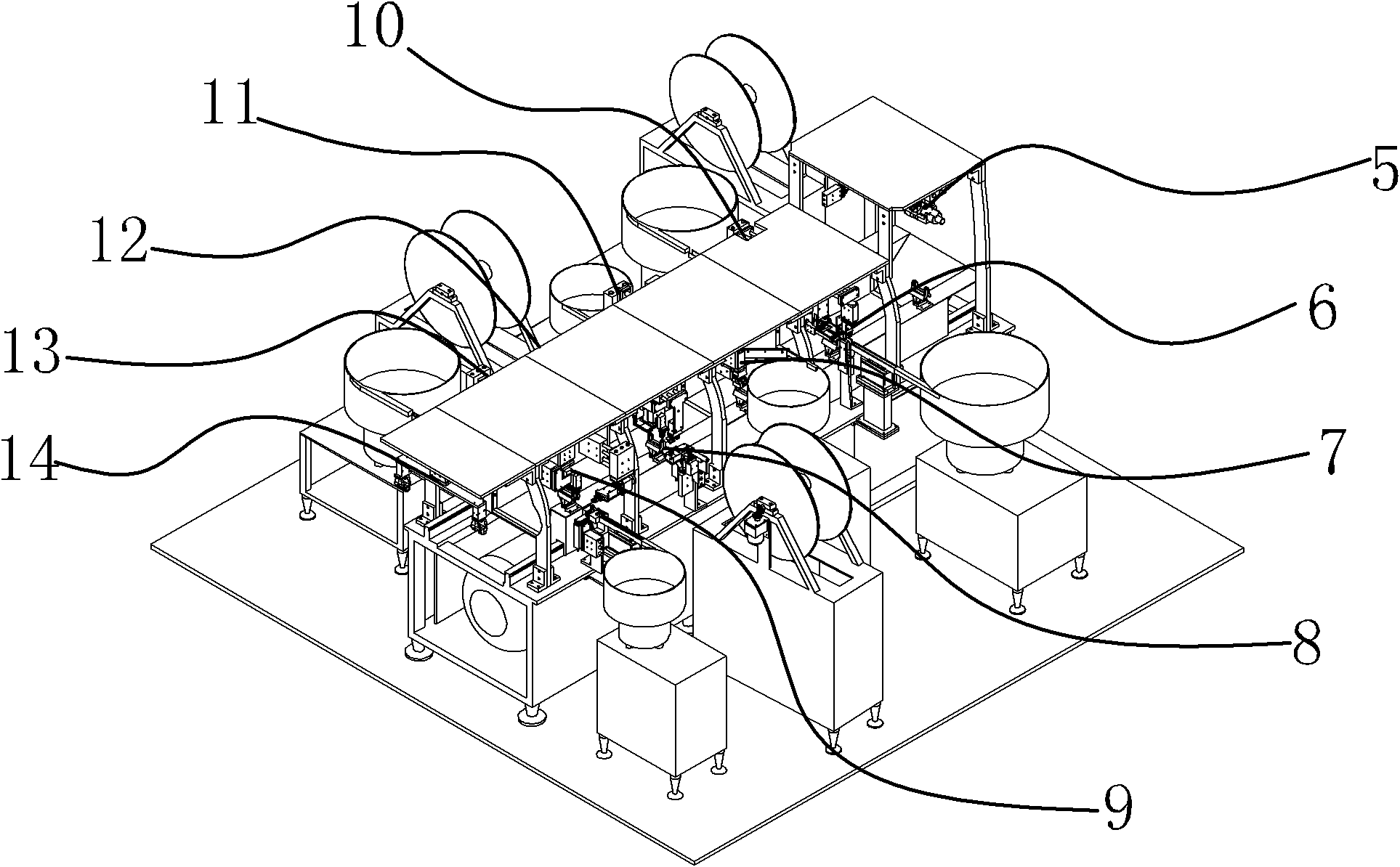

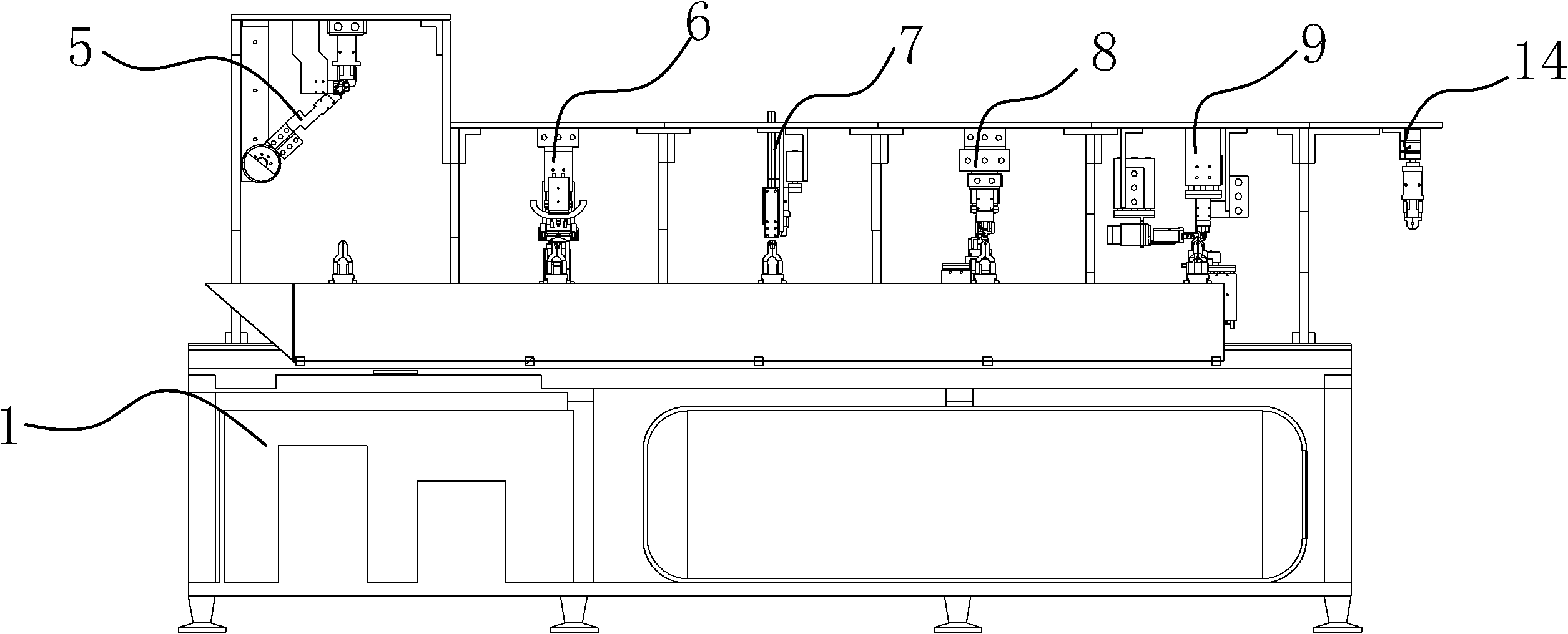

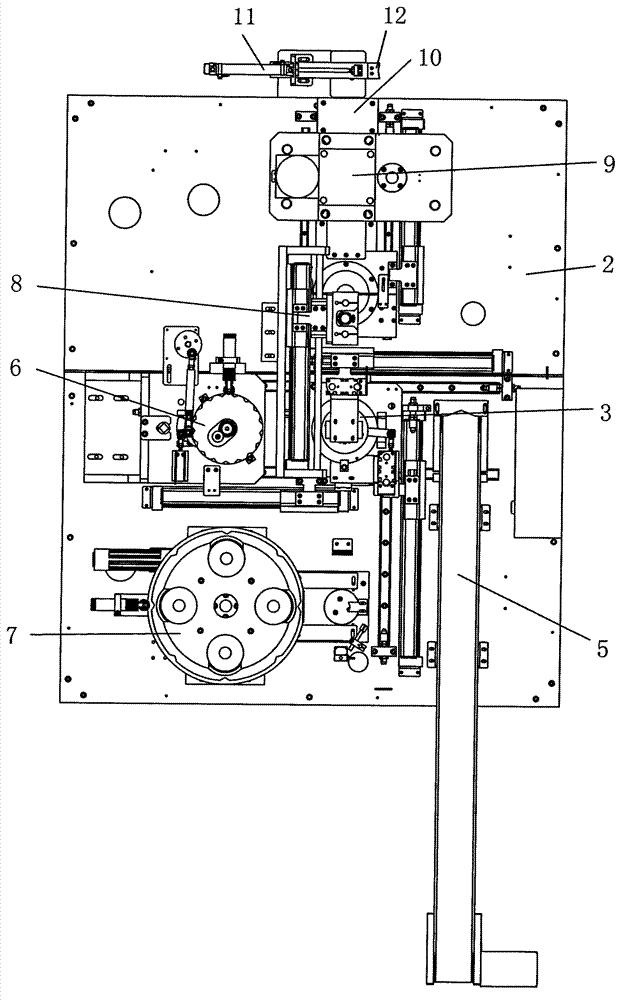

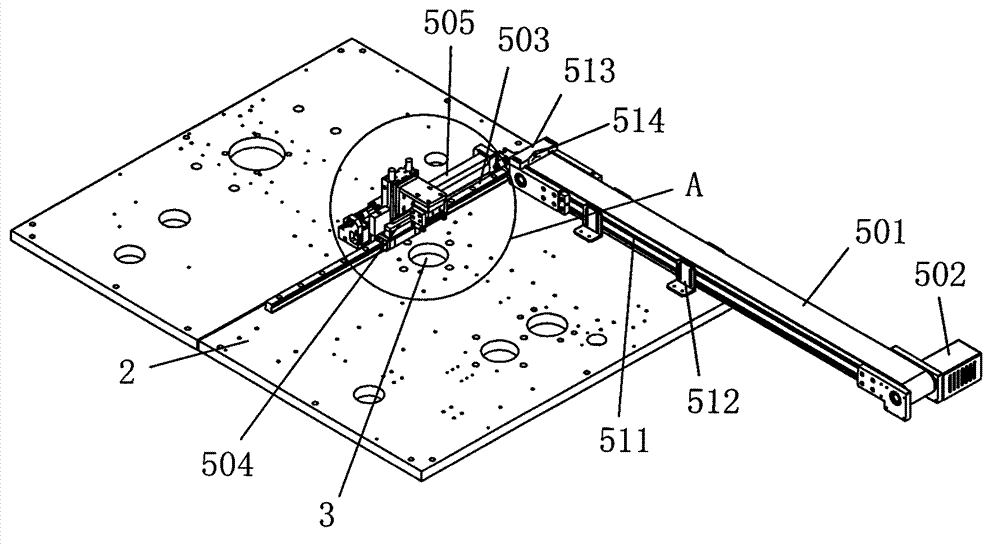

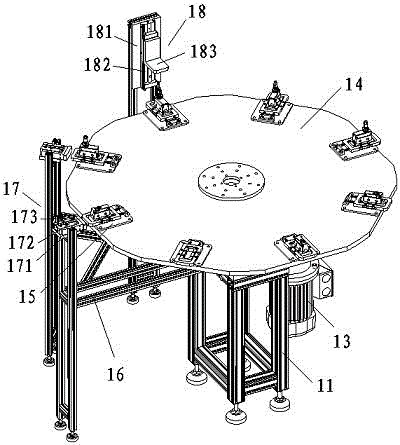

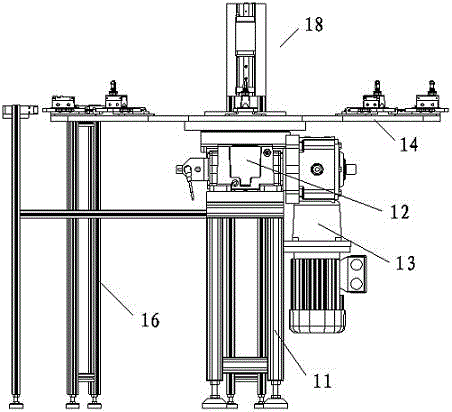

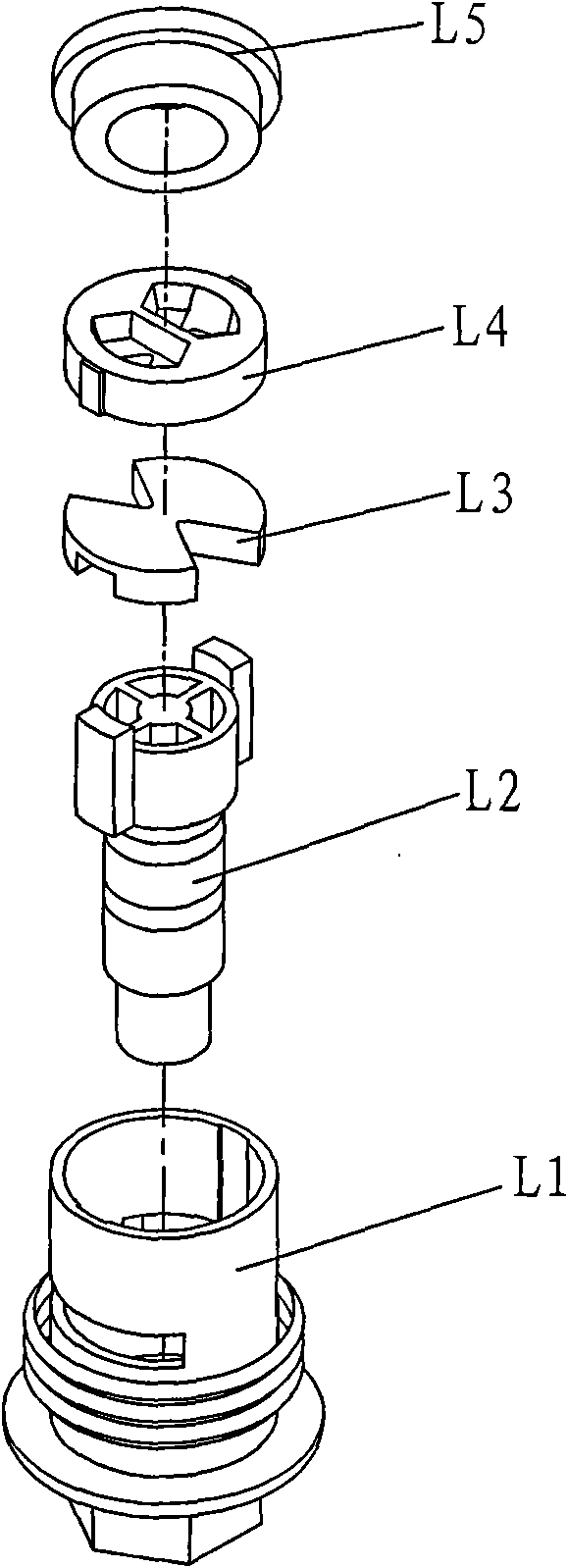

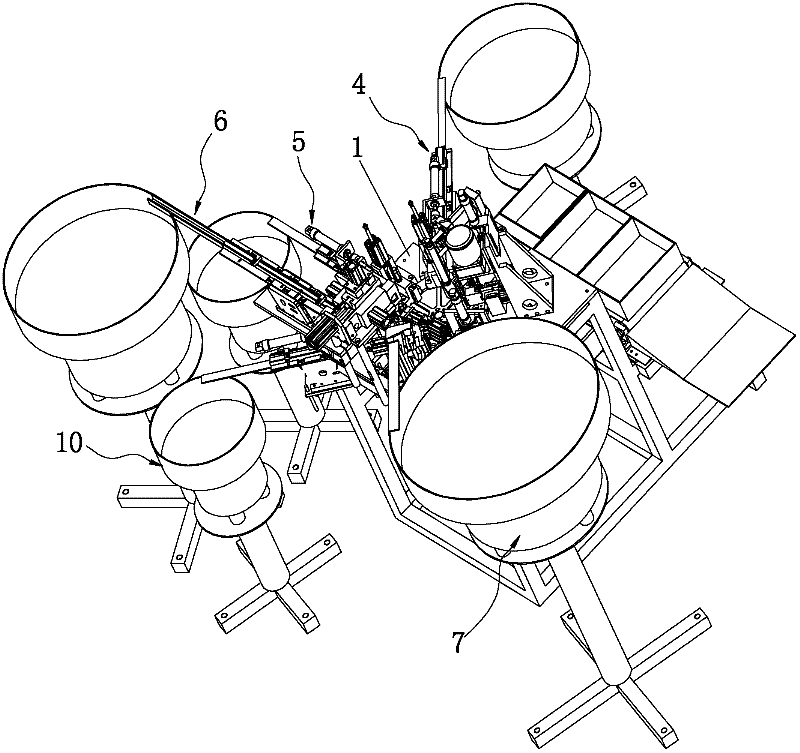

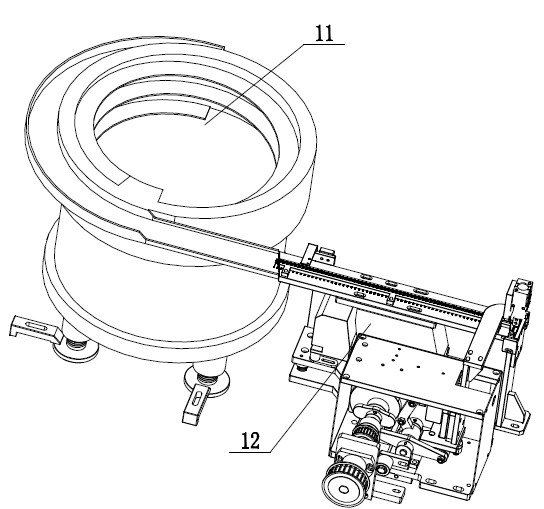

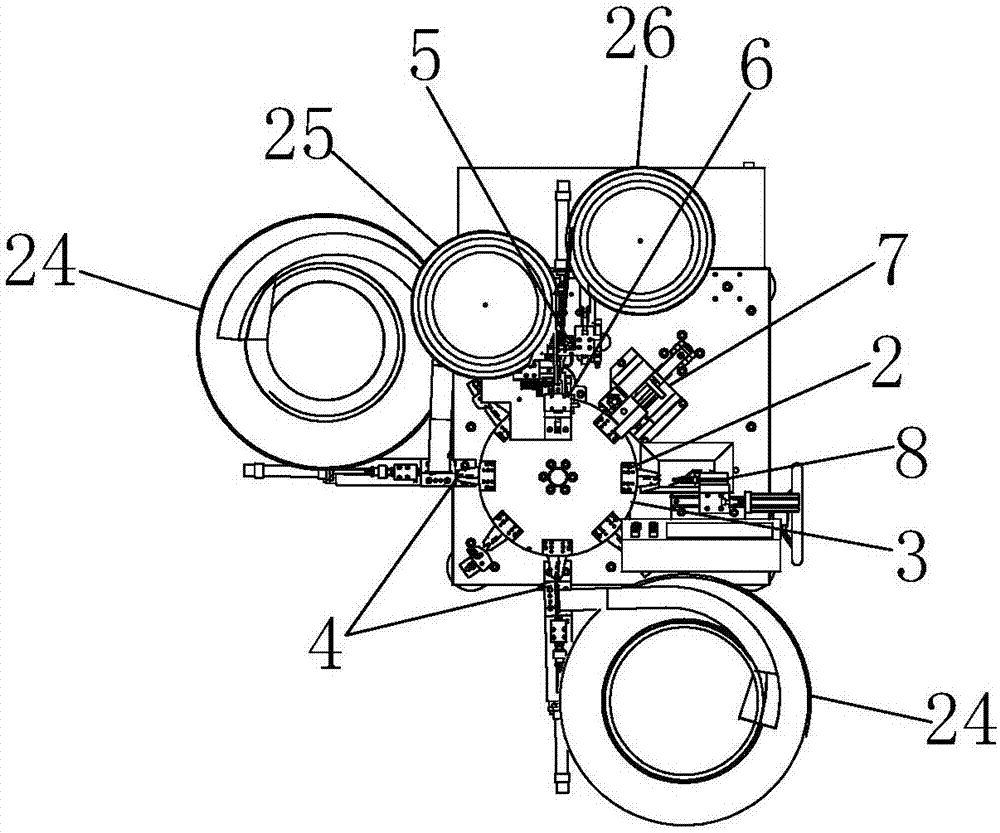

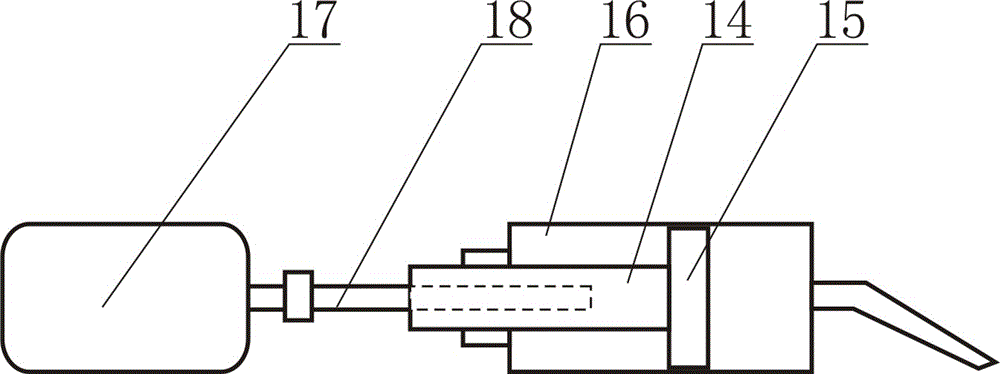

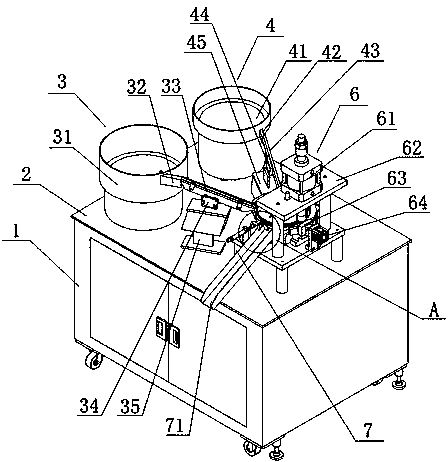

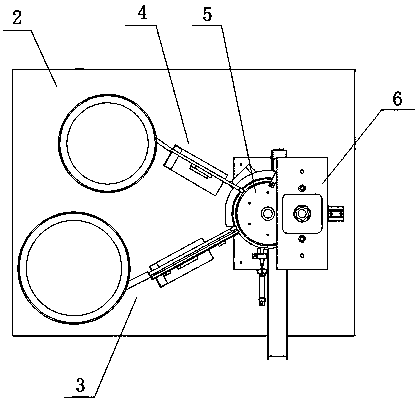

Method for assembling faucet valve core and fully automatic assembly machine

InactiveCN101590595ASmall footprintIncrease productivityAssembly machinesWork holdersEngineeringFully automatic

The invention discloses a method for assembling a faucet valve core and a fully automatic assembly machine. Before the assembly of the valve core, all parts are first sorted by a specially arranged vibration disk, then conveyed to specific positions through conveying pipes, and finally assembled into a whole through the action of a mechanical clamp and the positioning of a worktable. The middle of the fully automatic assembly machine is a working turntable; the periphery of the working turntable is provided with part vibration sorters; and the sorted parts are conveyed to the locking end of the turntable to assemble the core. The fully automatic assembly machine is provided with secondary pressure supplementing and product quality inspecting equipment. The fully automatic assembly machine adopts a circular production turntable to complete the assembly of the valve core, thereby having the advantage of small space occupation; and the working turntable cooperate with mechanical hands at the ends of the part conveying pipes to rotate a certain angle to complete a next assembly step, so the production efficiency is high.

Owner:苏锦波

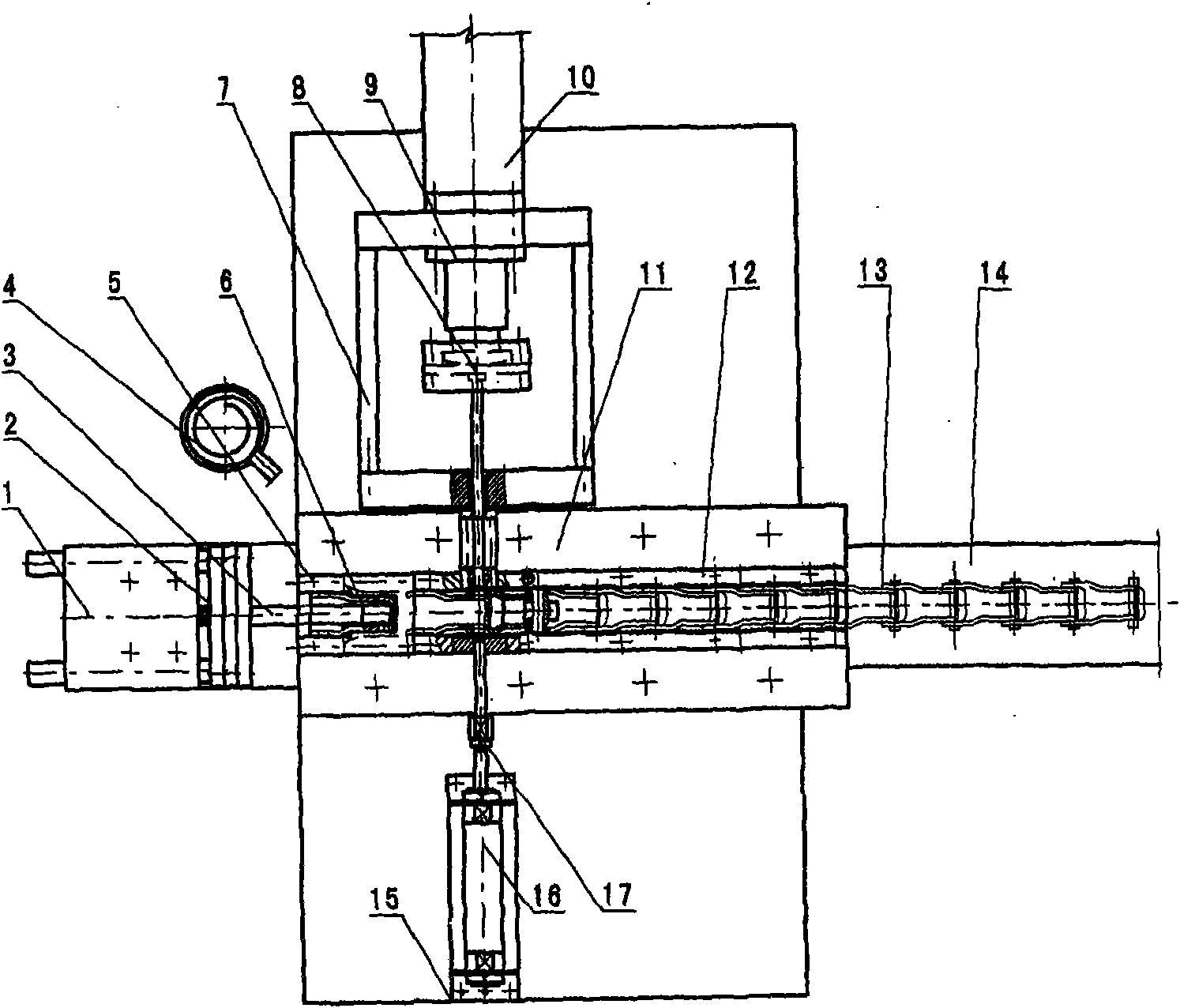

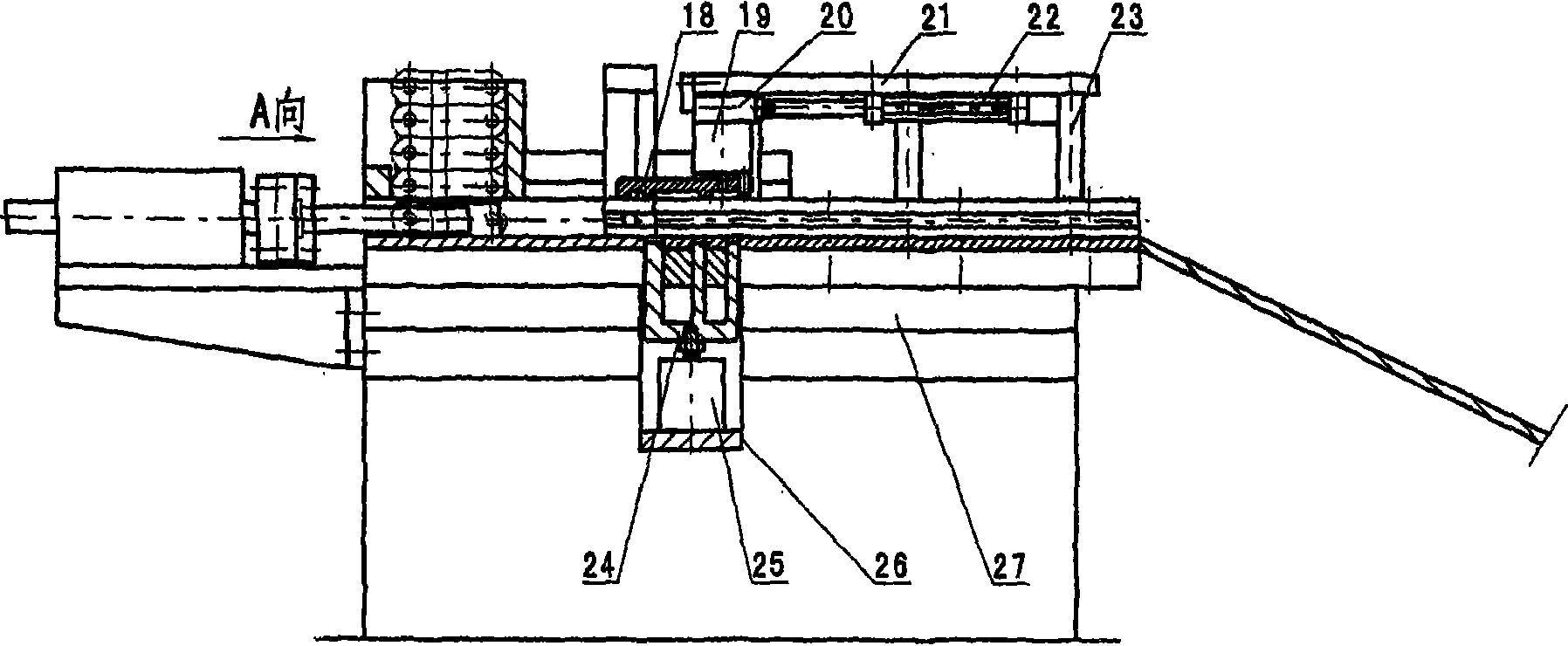

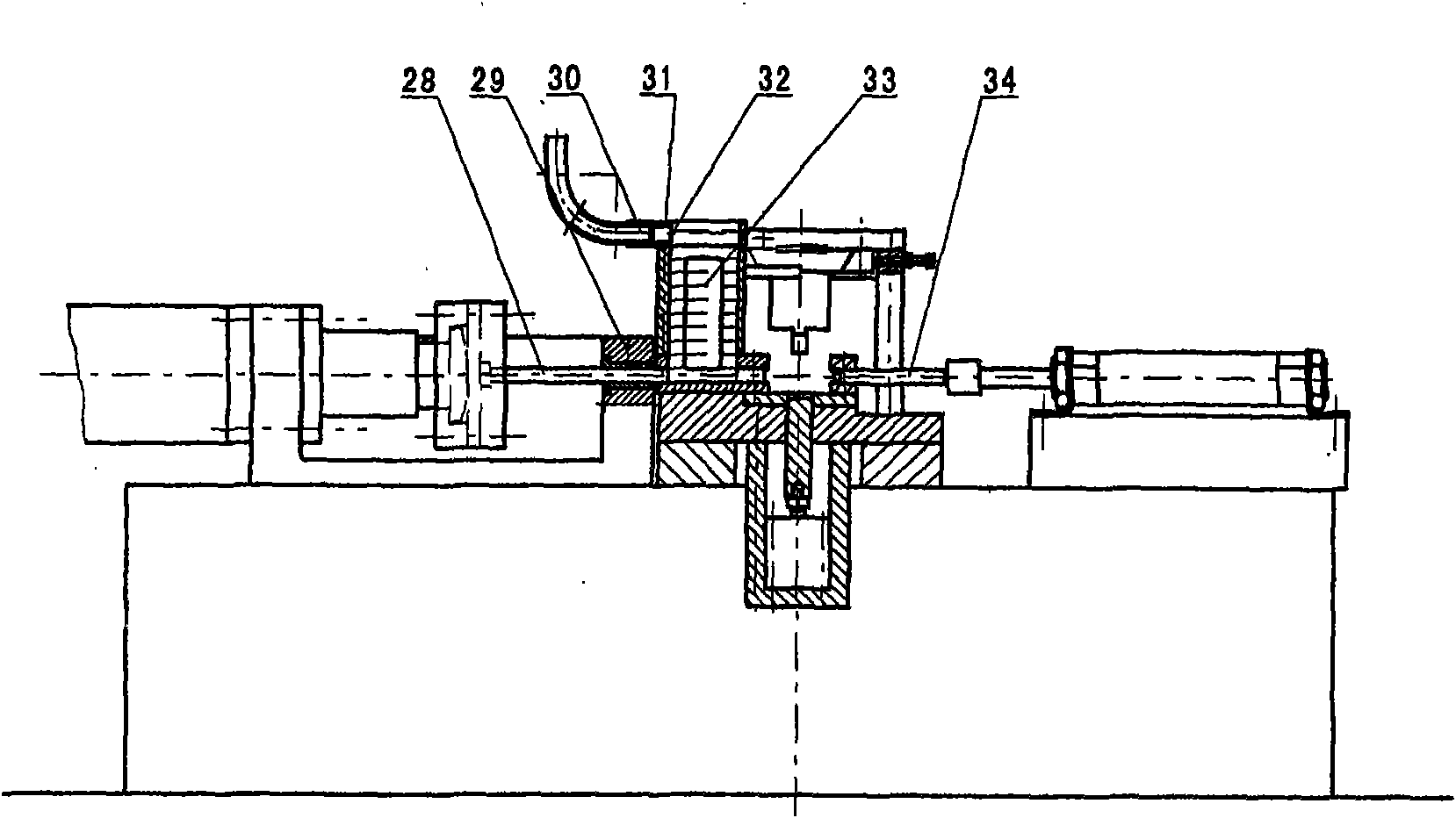

Pintle chain automatic assembly machine

InactiveCN101676049AGood assembly precisionSolve the shortcomings of manual assemblyMetal chainsControl systemEngineering

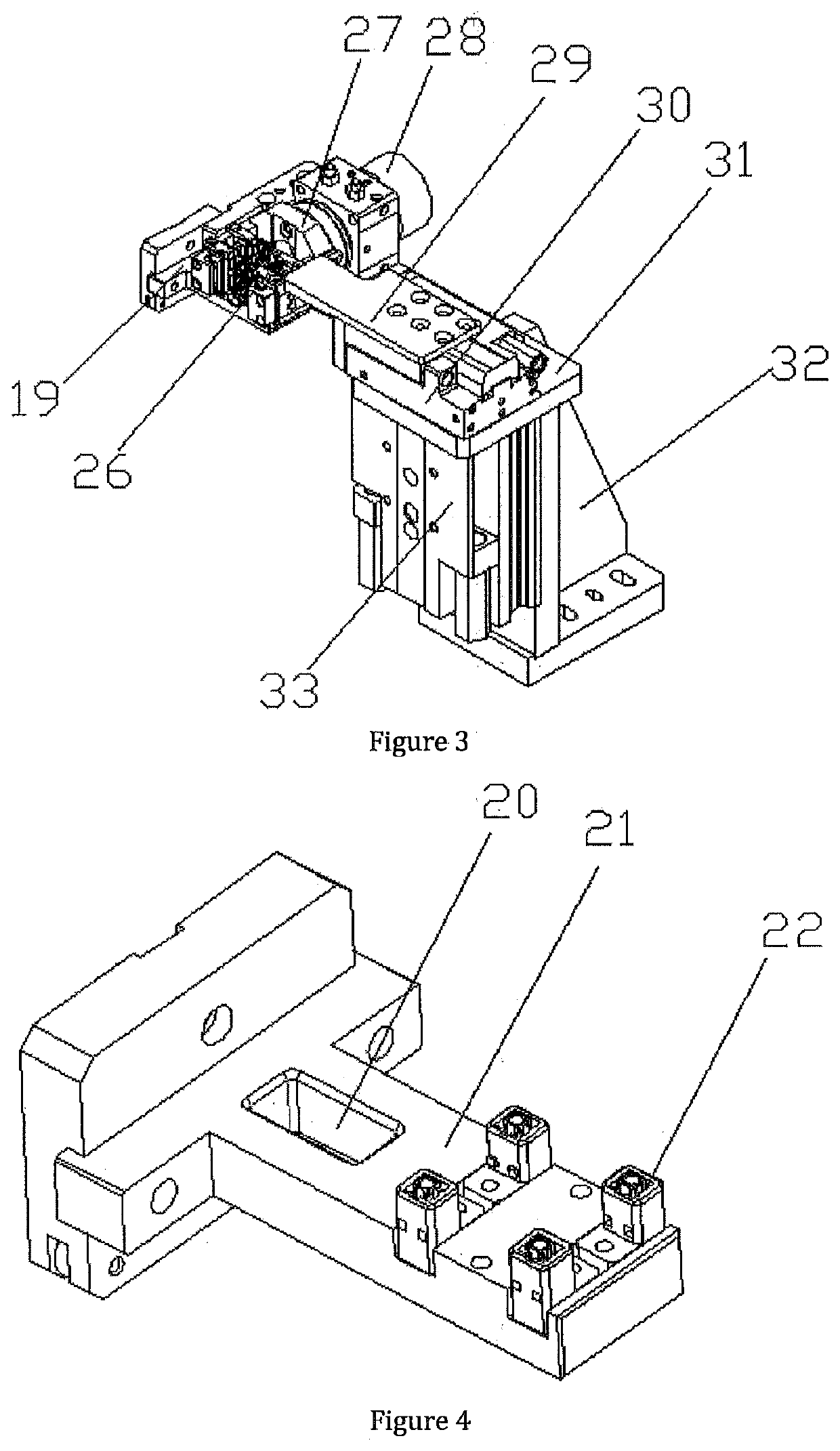

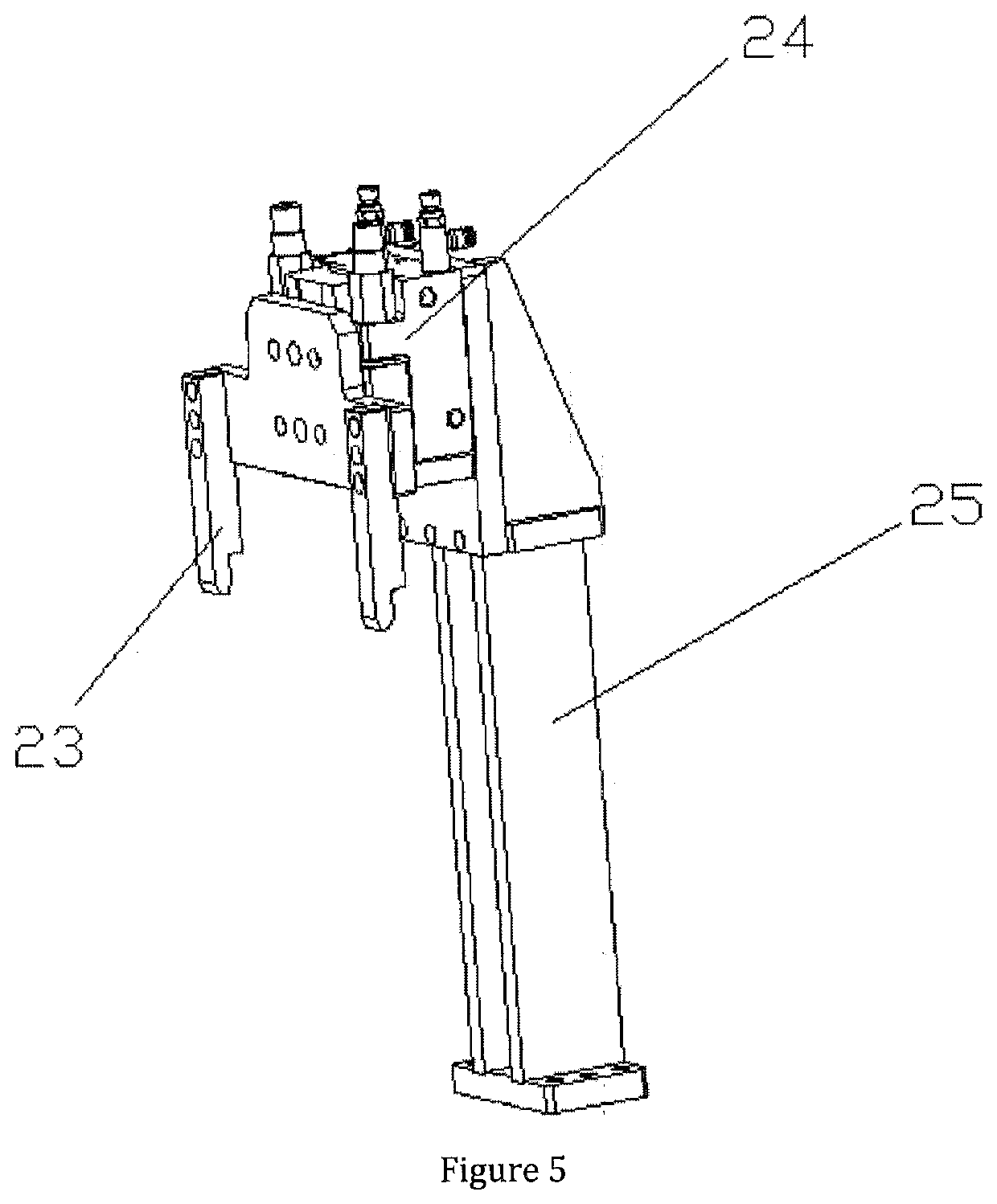

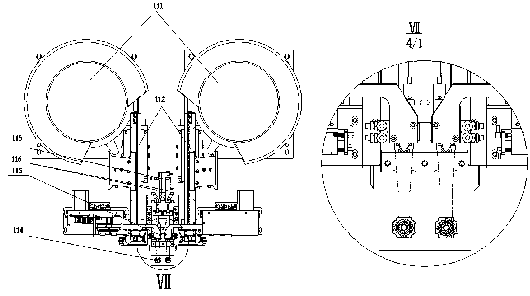

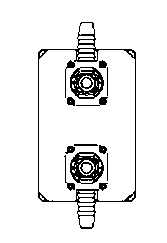

The invention relates to a pintle chain automatic assembly machine, belonging to the technical field of chain manufacturing machinery. The invention aims to provide a pintle chain automatic assembly machine which is suitable for the assembly production process of pintle chains and has good precision control and high production efficiency. The technical key of the pintle chain automatic assembly machine in that the assembly machine comprises a frame, a link plate feeding mechanism, a link plate positioning mechanism, a pin-penetrating mechanism, a chain element moving mechanism, a PLC automaticcontrol system and a discharging plate, wherein the link plate feeding mechanism comprises a double-cylinder feeding air cylinder (1) and a feeding pole (3) which are arranged in the front of the frame (27) and a link plate-feeding box (5); the link plate positioning mechanism comprises a positioning air cylinder (25) and a positioning block (24) which are arranged below the platen of the frame;the chain pin feeding and pin-penetrating mechanism comprises a pin-pressing air cylinder (10) and a pin-introducing air cylinder (16) which are arranged on the two sides of the parallel track of theplaten of the frame and a vibration pin-distributing disk (4), a pin-sending hose (30) and a pin-collecting box (32) which are arranged on the platen of the frame; the chain element moving mechanism comprises a moving air cylinder (22) and a chain element-pressing air cylinder (19) which are arranged above the platen of the frame; the discharging plate (14)is arranged on the backside of the platenof the frame.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

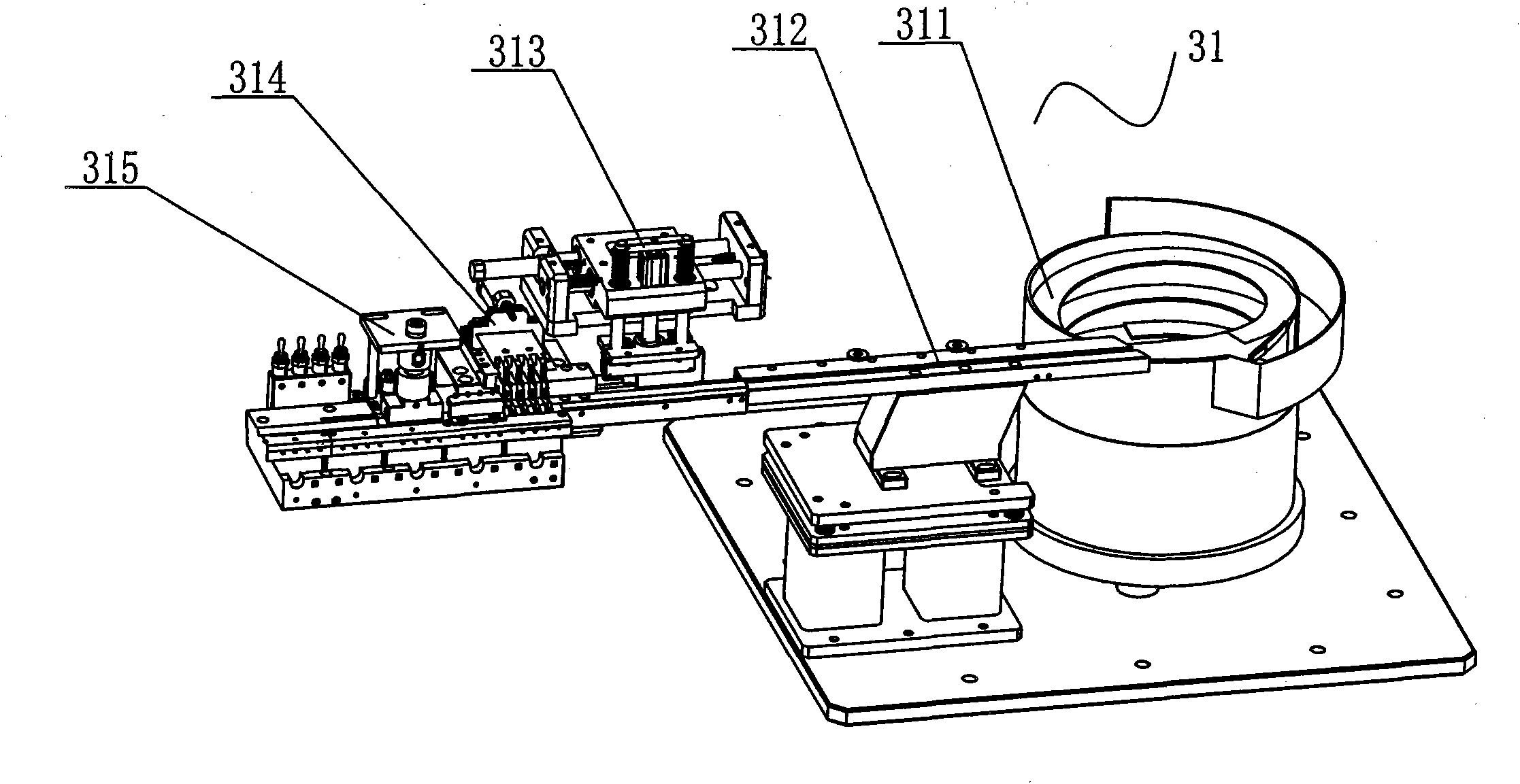

Nut mounting station of quick joint automatic assembly machine

ActiveCN105817873AThe air tightness index is qualifiedImplement step-by-step jobsMetal working apparatusAir tightnessSealant

The invention relates to the technical field of quick joint assembly equipment, in particular to a nut mounting station of a quick joint automatic assembly machine. The nut mounting station comprises a nut feeding pre-screwing station and a nut screwing station which are arranged in the material flow direction of the automatic assembly machine. The nut feeding pre-screwing station comprises a nut feeding mechanism, a nut feeding pre-screwing mechanical arm, a nut gluing mechanism and a nut pre-screwing mechanism. Nut accessories are conveyed to the specified position through the nut feeding pre-screwing mechanical arm. The nut pre-screwing mechanism and the nut gluing mechanism cooperate to firstly complete the action of coating the nut accessories with sealant, and after the sealant coating action is completed, the nut feeding pre-screwing mechanical arm completes the assembly action of the nut accessories in cooperation with the nut pre-screwing mechanism. The nut screwing station is used for locking the pre-screwed nut accessories. Step-by-step work in the nut mounting process is achieved, it is guaranteed that the nut accessories are mounted in place, and it is ensured that the air tightness index of a quick joint is qualified.

Owner:NINGBO SINPPA TOOLS CO LTD

Expansion bolt automatic assembly machine

The invention discloses an automatic expansion bolt assembling machine, comprising a rack and a cam divider rotary table which is arranged on the rack and provided with a plurality of fixtures at intervals. The automatic expansion bolt assembling machine also comprises a nut feeding device, a shim feeding device, an expansion tube feeding device, a bolt feeding device, a rotary assembling device and a finished product discharging device which are all arranged on the rack, wherein the nut feeding device is used for feeding nuts into the fixtures; the shim feeding device is used for feeding shims into the fixtures; the expansion tube feeding device is used for feeding expansion tubes into the fixtures; the bolt feeding device is used for feeding bolts into the fixture; the rotary assemblingdevice is used for assembling the nuts, the shims, the expansion tubes and the bolts which are fed into the fixture; and the finished production discharging device is used for unloading an assembled finished product; and the automatic expansion bolt assembling machine also comprises a spring shim feeding device which is arranged between the shim feeding device and the expansion tube feeding device on the rack and is used for feeding spring shims into the fixtures. Therefore, all the components of an expansion bolt are automatically assembled into the expansion bolt; and the automatic expansion bolt assembling machine has the advantages of high assembling efficiency, stable product quality and the capability of effectively improving the product percent of pass.

Owner:DONGGUAN YIXIN AUTOMATION EQUIP

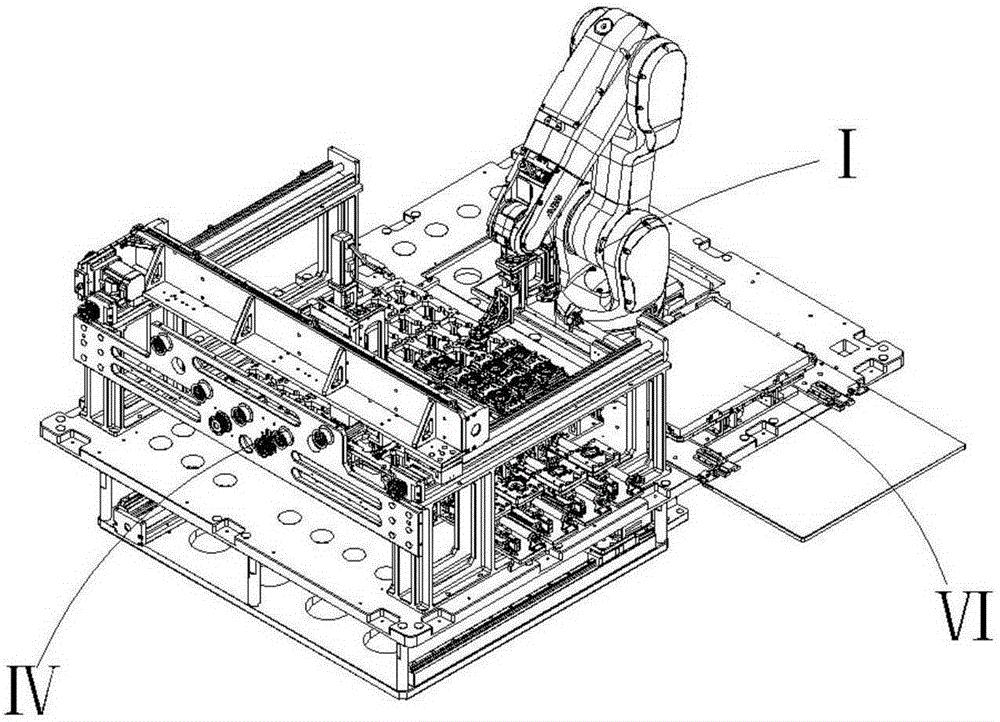

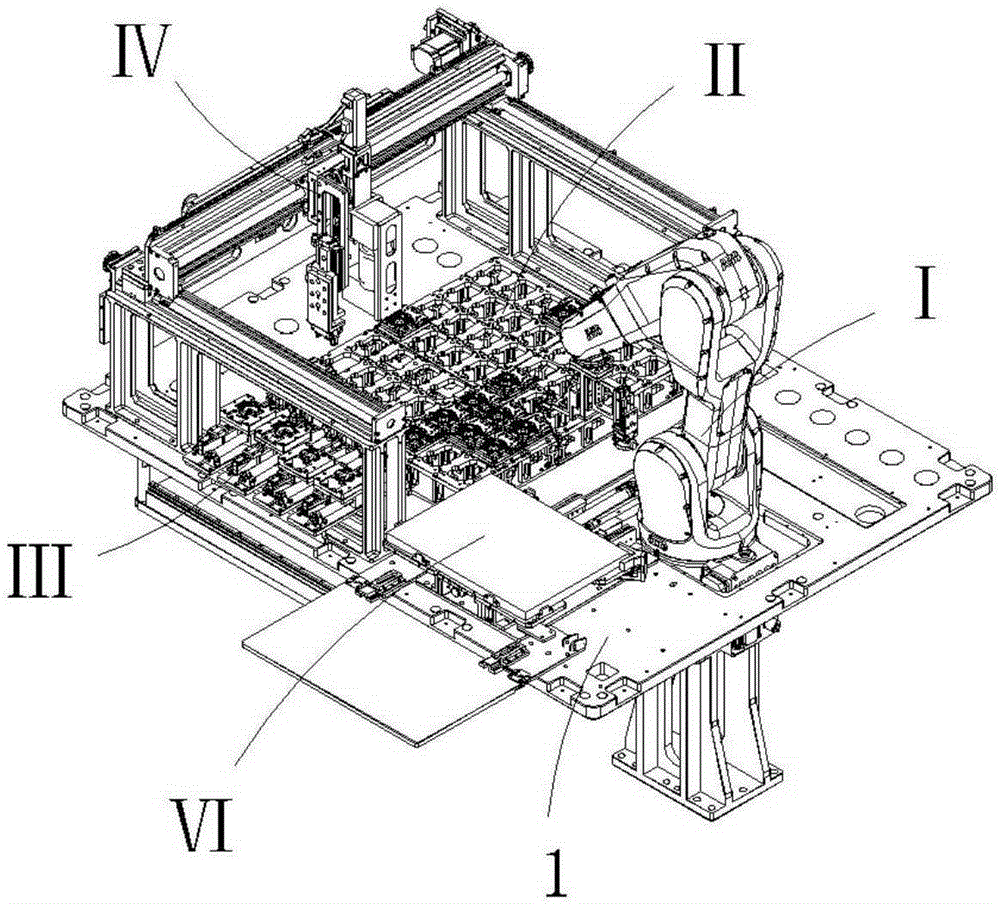

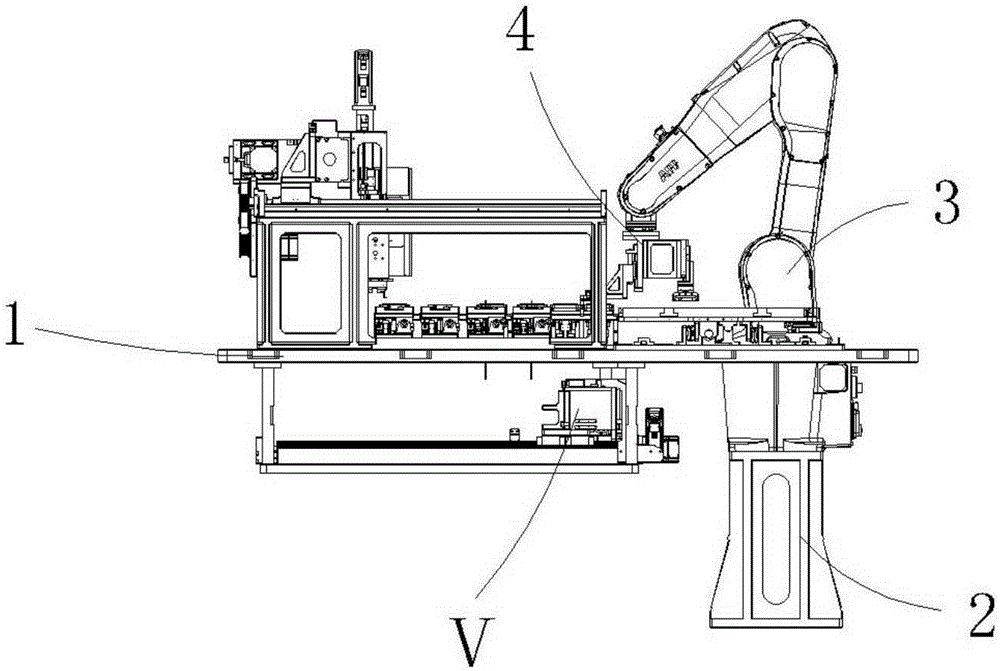

Multi-station automatic assembly machine for quick coupler

ActiveCN105834711AImprove assembly efficiencyAvoid mixingAssembly machinesMetal working apparatusAir tightnessAssembly machine

The invention relates to the technical field of quick coupler assembly equipment, in particular to a multi-station automatic assembly machine for a quick coupler. The multi-station automatic assembly machine comprises a workpiece transport mechanism which is driven by a step motor to realize step type motion, wherein a central loading station, an outer loading station, a sealing pad loading station, a valve element loading station, a nut loading and pre-twisting station, a nut locking station, an air tightness detecting station and a delivery station are sequentially arranged in a transport direction of the workpiece transport mechanism. The multi-station automatic assembly machine realizes quick assembly, air tightness online monitoring and unqualified product automatic sorting of the quick coupler, so that the assembly efficiency of the quick coupler is improved, the defective rate is reduced, and the unqualified products are effectively prevented from being mixed in a qualified product batch.

Owner:NINGBO SINPPA TOOLS CO LTD

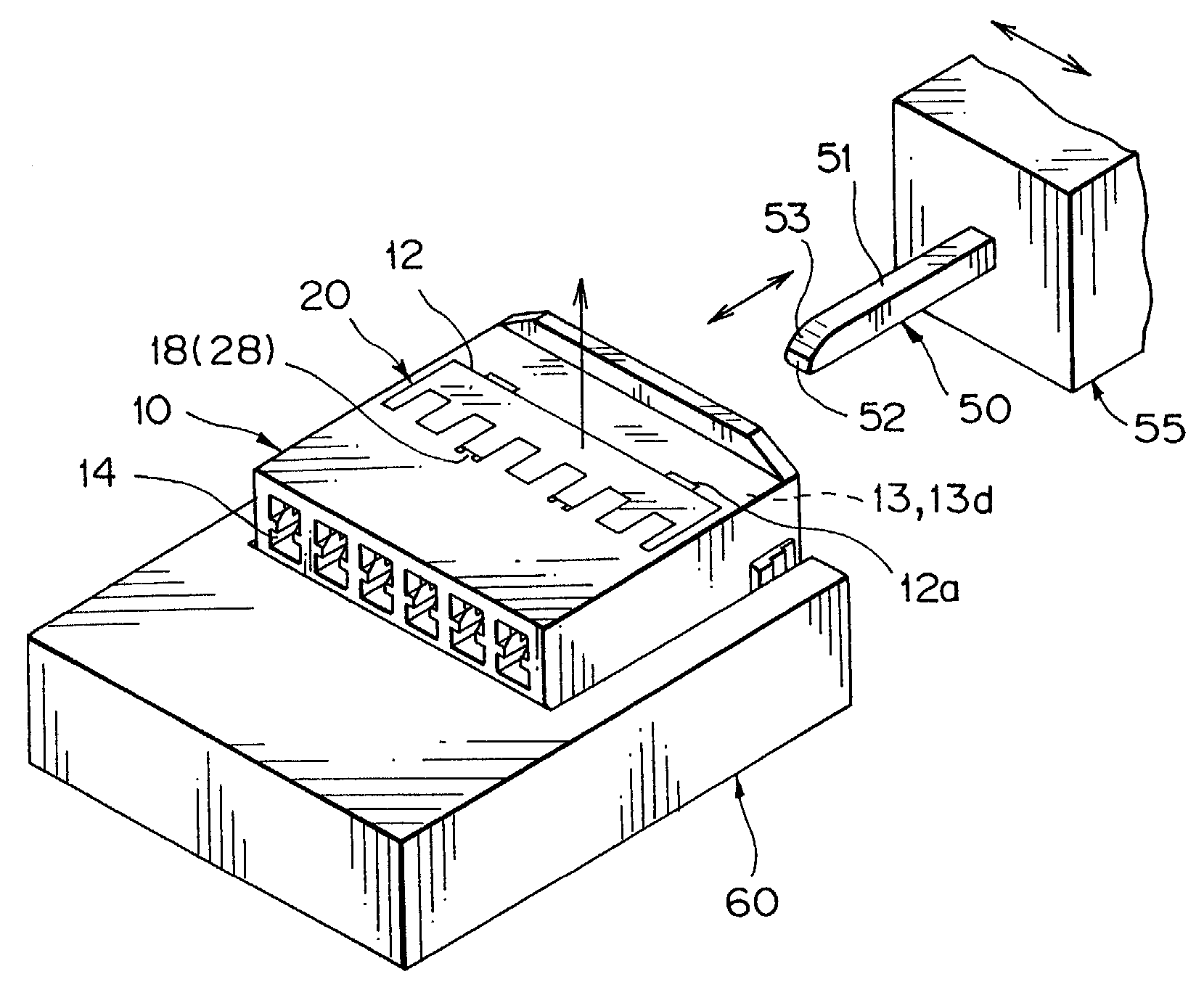

Process for assembling connector

InactiveUS7124506B2Increase productivityPromote recoveryContact member manufacturingContact member assembly/disassemblyAssembly machineElectrical and Electronics engineering

A process for assembling a connector is provided, by which the production efficiency can be improved by preventing the problem of insertion error from occurring in a step of terminal insertion into a connector housing in the manufacturing process of the wiring harness by using an automatic assembly machine or in a step of the operation by the human hands. The process includes the steps of: provisionally locking the spacer in the connector housing; inserting ajig rod into the connector housing before inserting the terminal into the connector housing, the jig rod being for releasing the locking of the spacer which is completely locked in the connector housing; pulling the jig rod out from the connector housing; and inserting the terminal into the connector housing.

Owner:YAZAKI CORP

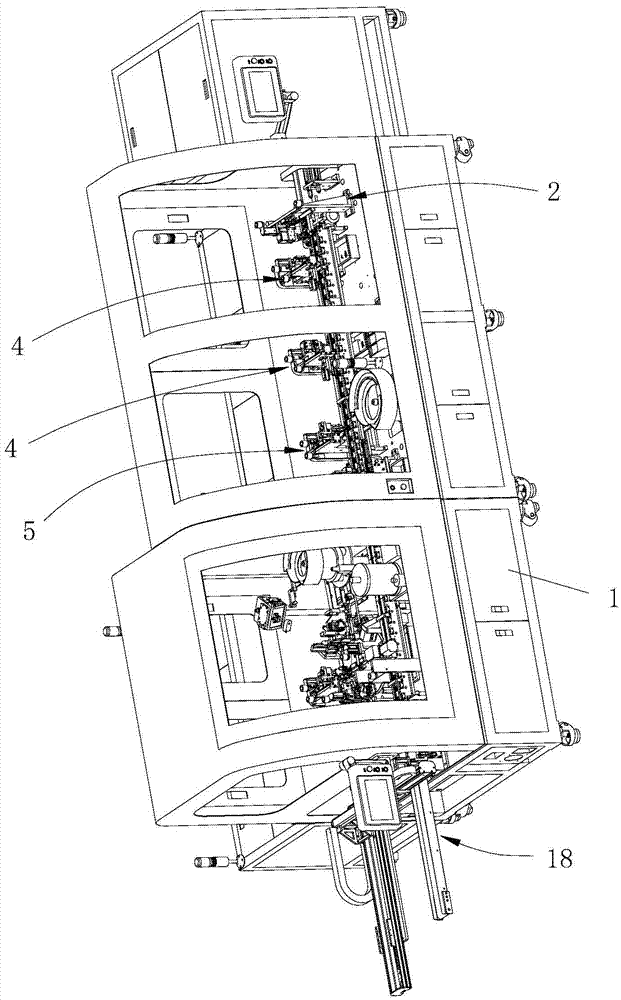

Automatic assembly machine for wall control switch

ActiveCN105448562AHigh degree of automationImprove assembly efficiencyAssembly machinesElectric switchesEngineeringControl switch

The invention discloses an automatic assembly machine for a wall control switch. The automatic assembly machine comprises a rack, a trough conveyer device, a base feeding mechanism, a side terminal feeding assembly mechanism, a medium terminal feeding assembly mechanism, a terminal missing detection mechanism, a wane feeding assembly mechanism, an oil adding mechanism, a rotary plate mechanism, a bullet feeding mechanism, a spring feeding assembly mechanism, a pressure plate feeding assembly mechanism, a transition part feeding assembly mechanism, a transition part component assembly mechanism, a switch conduction detection mechanism, a defective product discharge mechanism and a finished product discharge mechanism, wherein the trough conveyer device, the base feeding mechanism, the side terminal feeding assembly mechanism, the medium terminal feeding assembly mechanism, the terminal missing detection mechanism, the wane feeding assembly mechanism, the oil adding mechanism, the rotary plate mechanism, the bullet feeding mechanism, the spring feeding assembly mechanism, the pressure plate feeding assembly mechanism, the transition part feeding assembly mechanism, the transition part component assembly mechanism, the switch conduction detection mechanism, the defective product discharge mechanism and the finished product discharge mechanism are arranged on the rack. According to the automatic assembly machine for the wall control switch, various components of the wall control switch can be automatically assembled into a finished product of the wall control switch; the automatic degree and the assembly efficiency are high; the quality of the product is stable; and the qualified rate of the product can be effectively improved.

Owner:DONGGUAN YI CHENG AUTOMATIC EQUIP

Novel tact switch assembling machine

InactiveCN102097237ARealize automatic assemblyEasy to cycleElectric switchesManipulatorControl circuit

The invention discloses a novel tact switch assembling machine which comprises a machine body, a manipulator assembly and a feeding assembly, wherein the manipulator assembly and the feeding assembly are arranged on the machine body. The novel tact switch assembling machine also comprises a large turntable assembly and a small turntable assembly, which are sequentially arranged on the machine body; a compaction assembly is also arranged on the large turntable assembly; the manipulator assembly is used for sequentially placing a body and an elastic sheet on the feeding assembly at corresponding positions on the large turntable assembly, sequentially placing a button and an iron sheet on the feeding assembly at corresponding positions on the small turntable assembly and sequentially assembling a button and an iron sheet on the small turntable onto the elastic sheet of the large turntable; the compaction assembly is used for sequentially compacting the body, the elastic sheet, the buttonand the iron sheet on the large turntable assembly; and all assemblies are connected with and controlled by a master control circuit. Through the novel tact switch assembling machine of the invention, the automatic assembling of a tact switch can be realized, the occupied space is small, the running efficiency is high and the assembling can be realized rapidly.

Owner:周俊雄

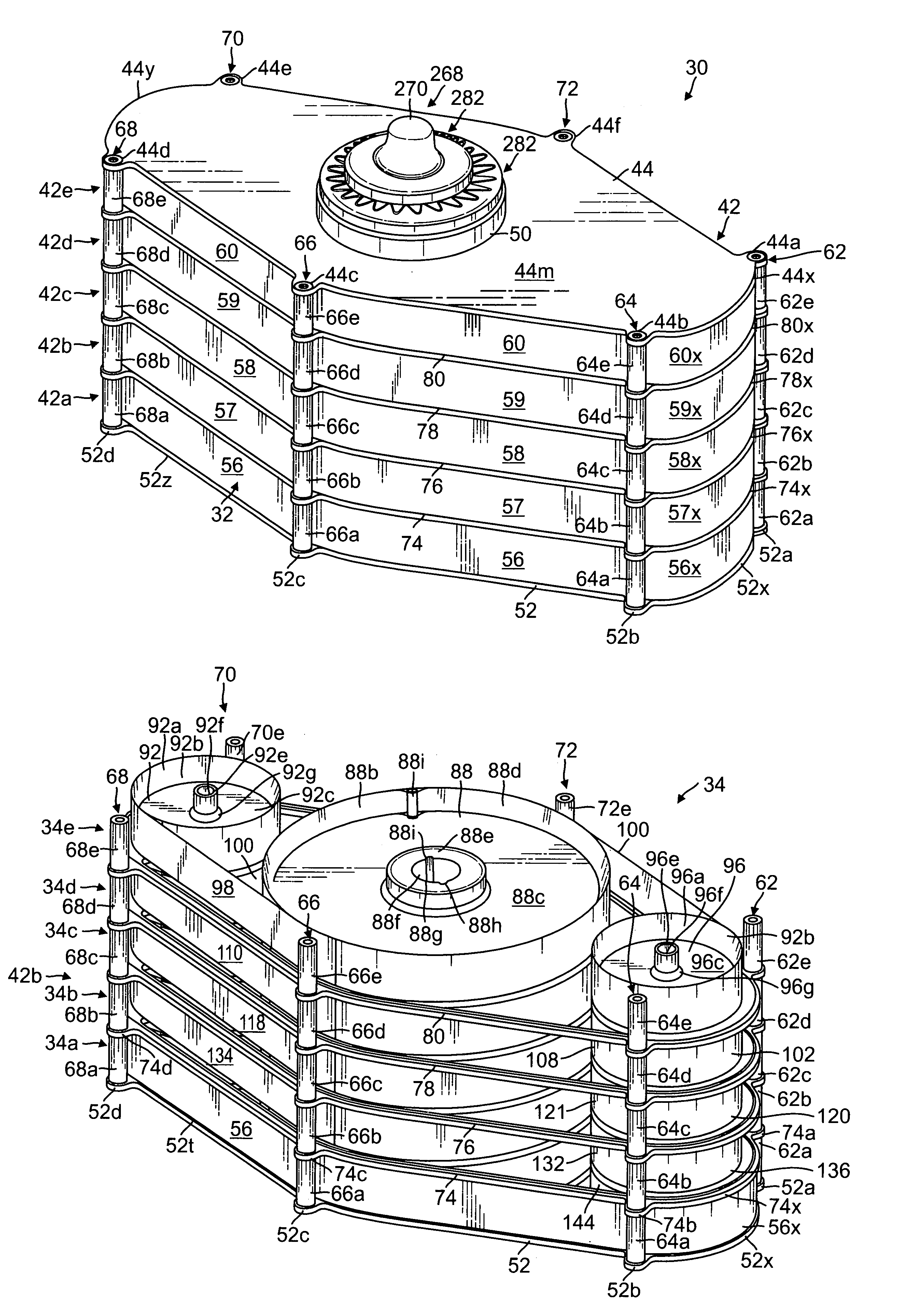

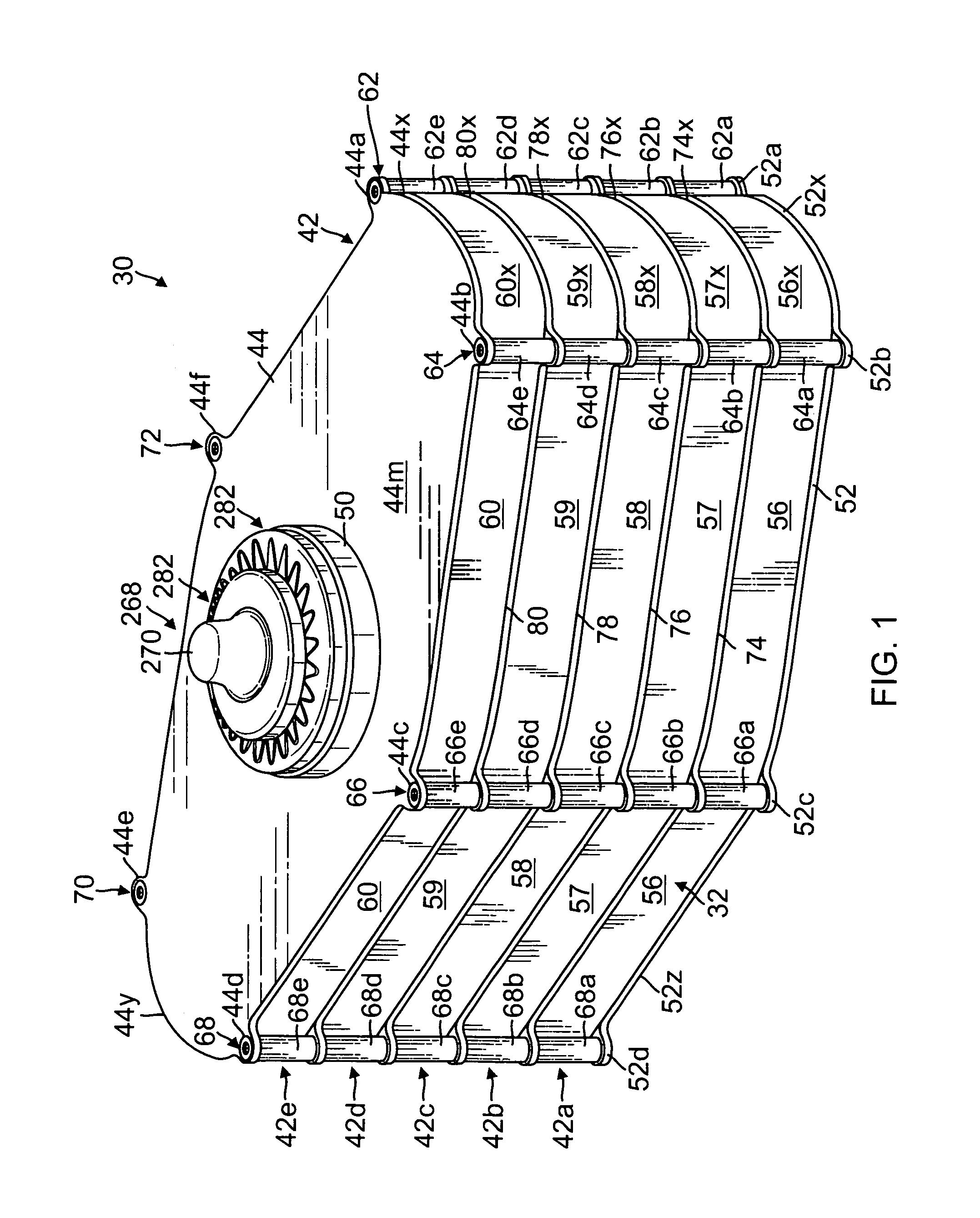

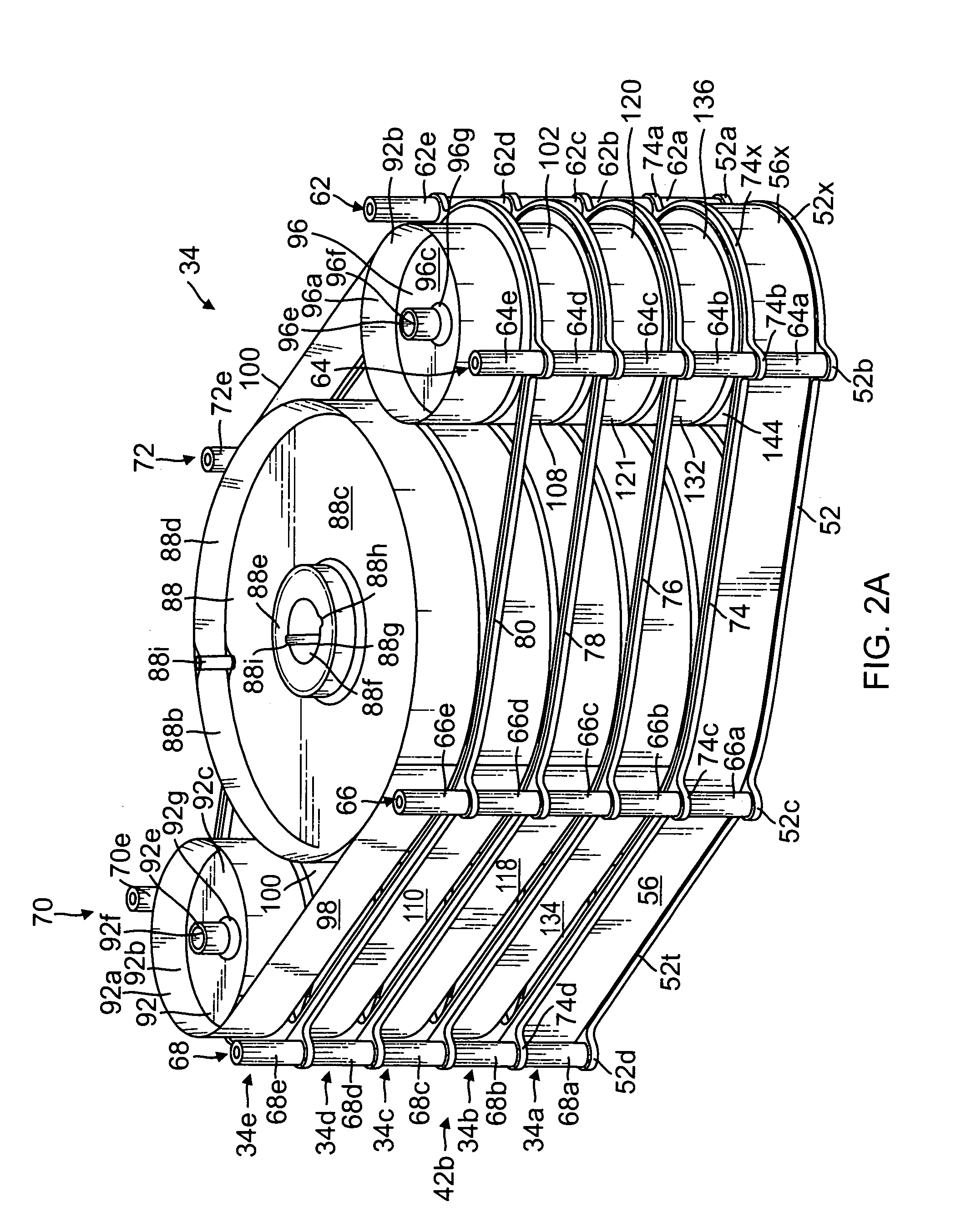

Integrated resistance spring force machine

An integrated resistance spring force assembly machine which is incorporated into an exercise machine and having a plurality of internal transverse sections with each section having respective constant force springs to output a respective magnitude of a spring resistance force, which serves as the respective force loads when in use, and a force selection mechanism which can be used to selectively activate the respective springs so that the respective force loads can be output to a combined level of resistance for an exercise routine.

Owner:EHRLICH MICHAEL J +2

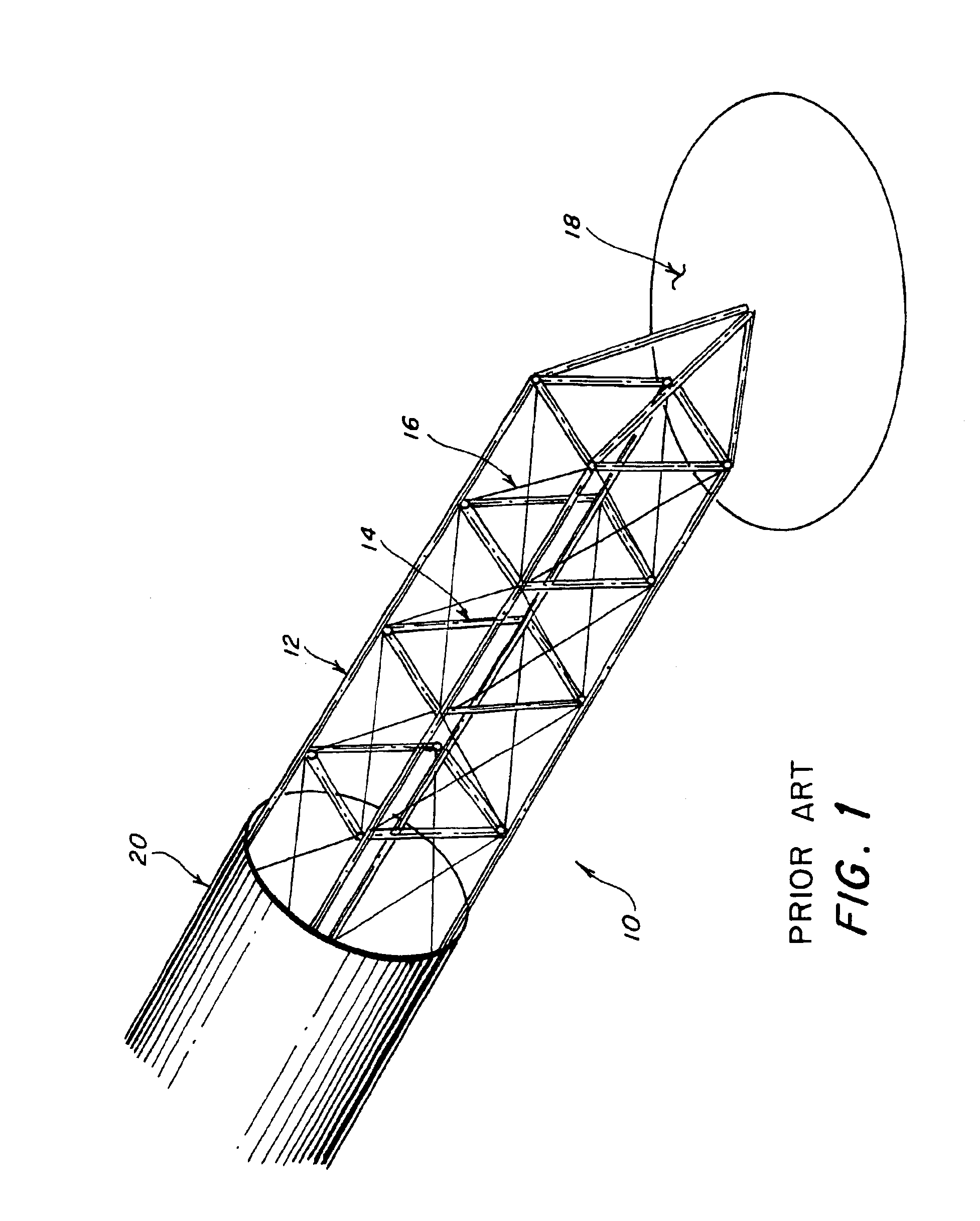

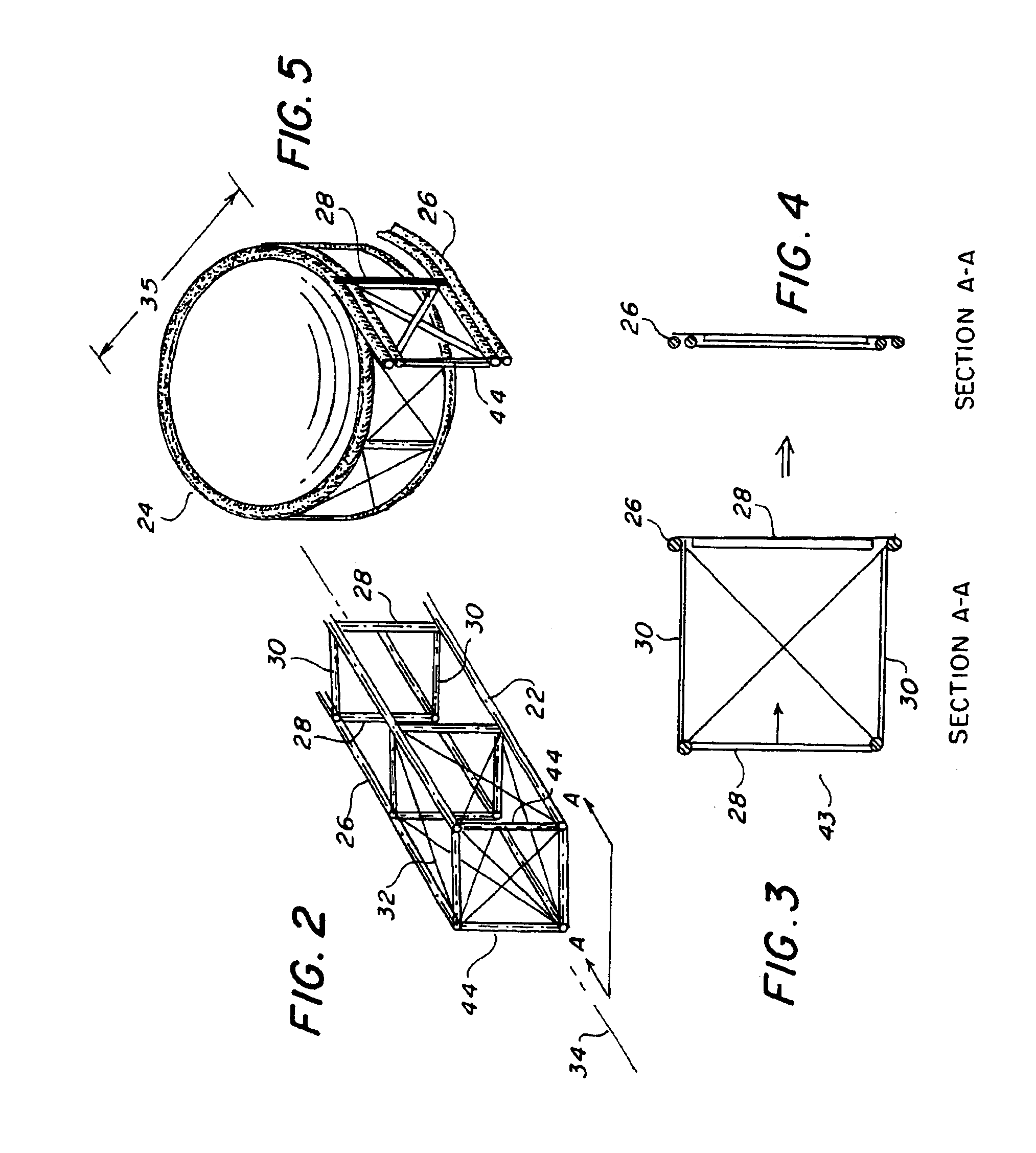

Elongated truss boom structures for space applications

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Automatic assembly machine for touch switch

InactiveCN101777448AAssembled preciselyRealize automatic assemblyElectric switchesEngineeringTransfer mechanism

The invention discloses an automatic assembly machine for a touch switch, which comprises a machine body. The machine body is provided with an assembly rotary disc and a feeding mechanism which feeds a body, an elastic sheet, a button and a cover plate assembly of the touch switch into assembly stations respectively. The automatic assembly machine also comprises a main conveying track for bearing the body, wherein a transferring mechanism which clamps the body and does regular vertical or horizontal feed movement is arranged below the main conveying track; a body feeding mechanism is arranged at the input end of the main conveying track; an elastic sheet feeding mechanism, a button feeding mechanism and a cover plate feeding mechanism are orderly arranged along the main conveying track; the assembly rotary disc is arranged between the button feeding mechanism and the cover plate feeding mechanism for assembling the button and the cover plate integrally; a third assembling mechanism is arranged on one side of the assembly rotary disc for assembling the touch switch assembly; and the mechanisms are connected with a main control circuit and is controlled by the main control circuit. The automatic assembly machine accurately and efficiently assemblies the touch switch through automatic assembling so as to save the production cost.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Full-automatic alignment and assembly machine

ActiveCN105196032ASimple structureEasy to useGripping headsMetal working apparatusWatch glassAdhesive

Owner:BOZHON PRECISION IND TECH CO LTD

Assembly machine for gas surface membrane component

InactiveCN102814650AExpand the scope of workImprove qualityAssembly machinesDrive motorSurface membrane

An assembly machine for a gas surface membrane component comprises a rack and a turntable indexing drive device, wherein the turntable indexing drive device is fixed on the rack, and comprises a turntable, a drive motor and a divider for converting the continuous rotation of the drive motor into indexing rotation, the drive motor is connected with the divider, and the turntable is fixed on an output flange of the divider; and six groups of adjustable clamps are uniformly distributed on the turntable, and six station working areas are uniformly distributed arranged at the outer part of the turntable indexing drive device, and are sequentially a plastic clamping box assembling station, a membrane assembling station, an aluminum clamping box assembling station, a hot weld station and an unloading station. According to assembly machine for the gas surface membrane component disclosed by the invention, the assembling efficiency can be greatly increased, the employment requirement is lowered, the production cost of an enterprise is reduced, and the production quality of a product is ensured.

Owner:ZHEJIANG UNIV

Automatic assembly machine of clamps

The invention belongs to the technical field of clamp assembly machines, and particularly relates to an automatic assembly machine of clamps. The automatic assembly machine comprises a rack, and a rotary disc, clamping piece mounting mechanisms, a spring mounting mechanism, a dowel mounting mechanism, a dowel pressing mechanism and a taking mechanism are arranged on the rack; the rotary disc is connected with a rotating driving device; clamping seats are mounted on the rotary disc; the clamping piece mounting mechanisms are connected with clamping piece input mechanisms; the spring mounting mechanism is connected with a spring input mechanism; the dowel pressing mechanism is connected with a dowel input mechanism; the dowel mounting mechanism comprises a dowel feeding seat and a dowel pushing rod; the dowel pushing rod is connected with a fourth driving device; and a first channel is formed in the dowel feeding seat. The automatic assembly machine is characterized in that a dowel clamping device is further arranged on the dowel feeding seat. The automatic assembly machine has the advantages that the dowel clamping device presses dowels, the dowels and the clamps on the clamping seats are accurately aligned, and accuracy of insertion of the dowels is improved.

Owner:浙江宏日自动化科技有限公司

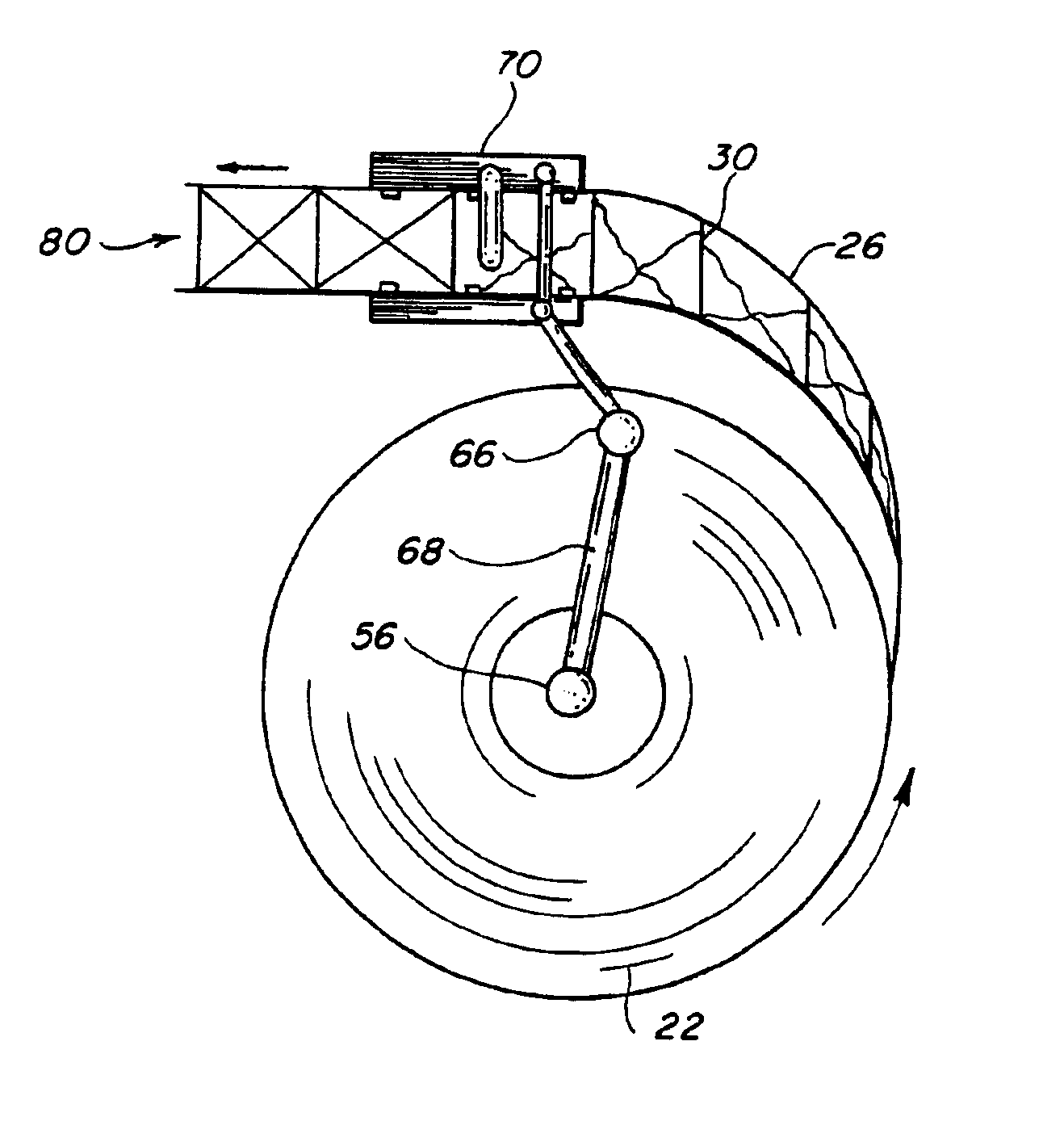

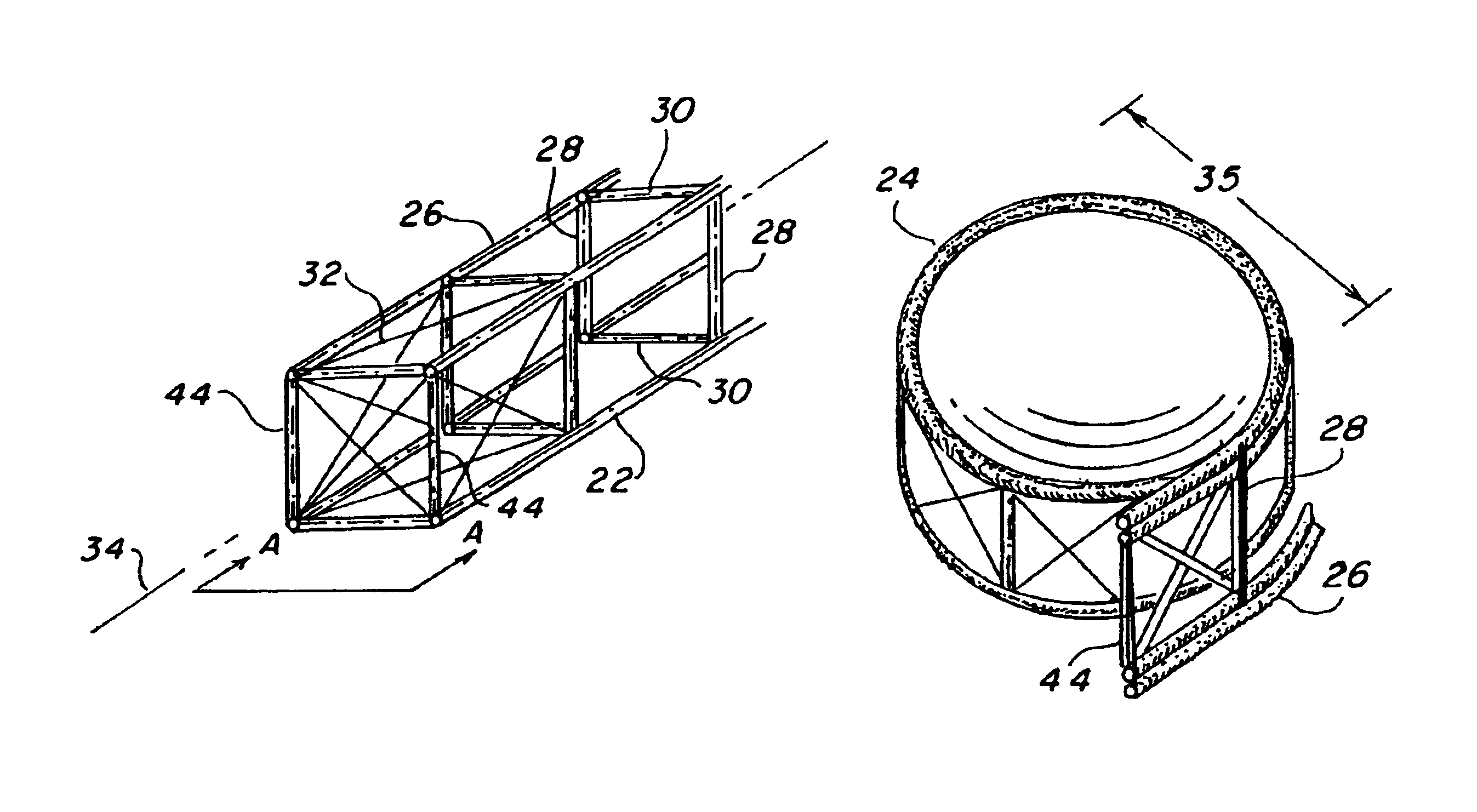

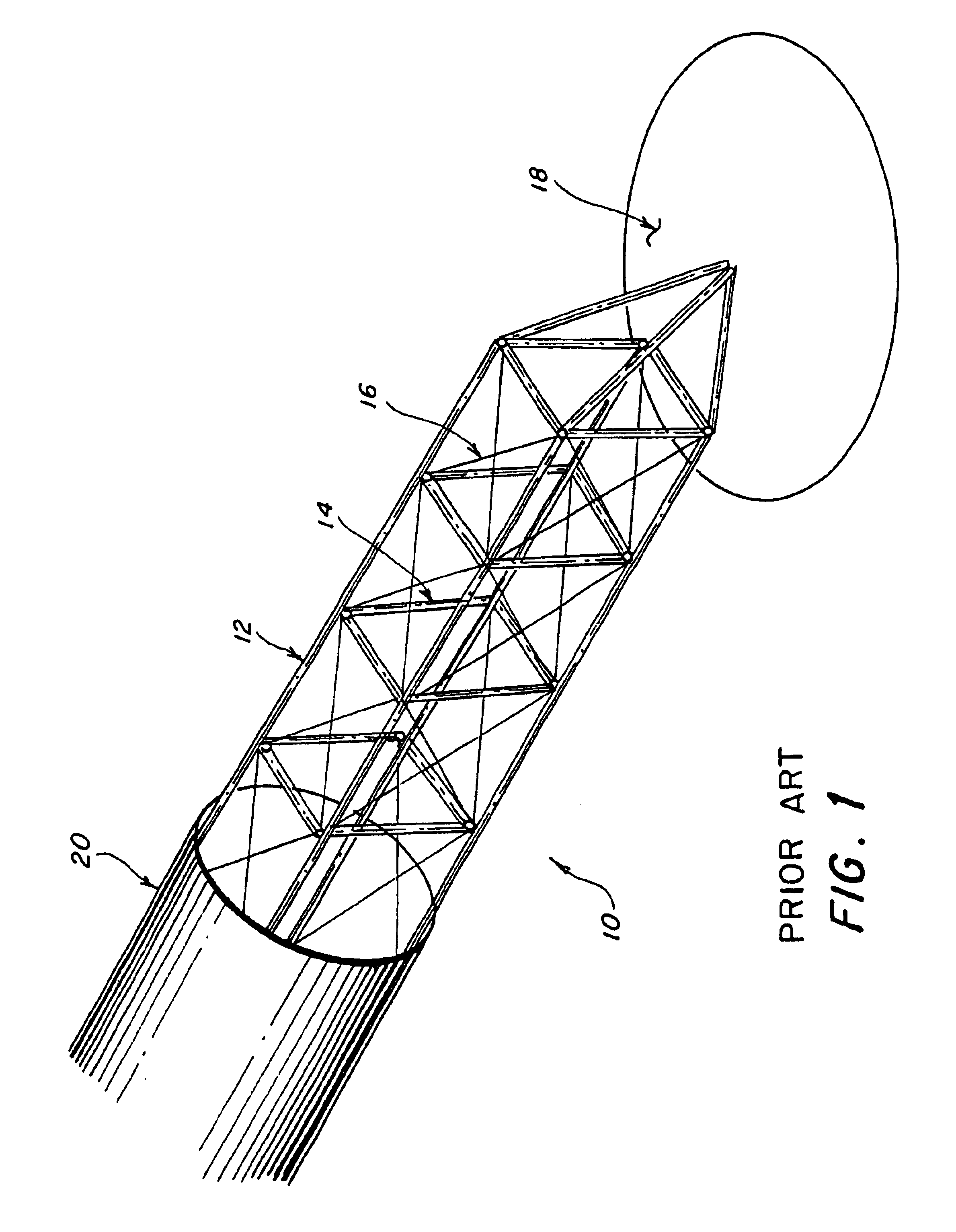

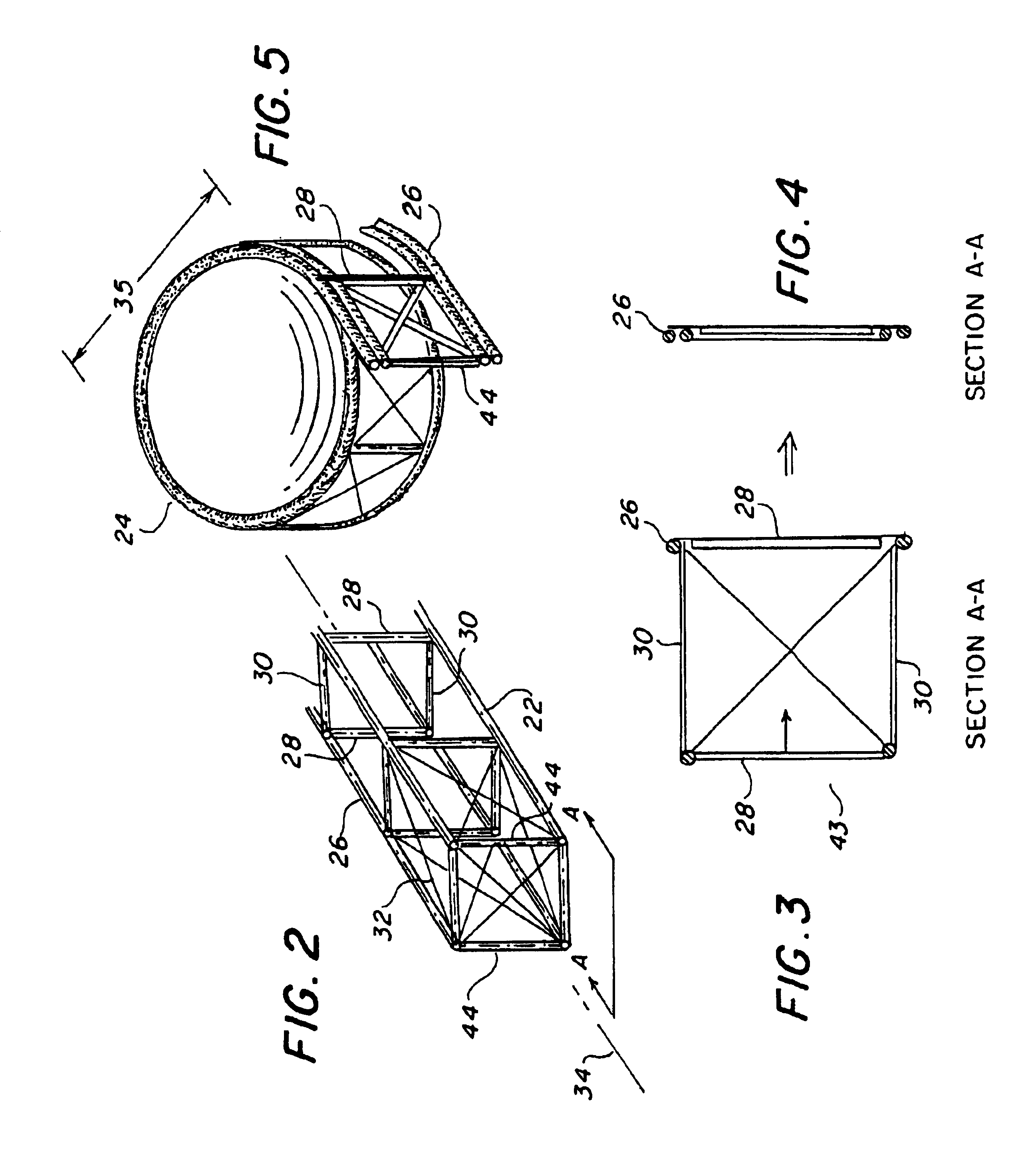

Elongated truss boom structures for space applications

An elongated truss boom structure is adapted to be flattened and coiled to a stowed configuration. The truss boom includes longerons, battens, and diagonals. A fixed ladder shaped structure is formed by a plurality of fixedly coupled battens which interconnect two adjacent longerons. The truss boom is flattened for stowage by arranging all of the longerons coplanar to the plane of the fixed ladder shaped structure. The longerons preferably have a corrugated cross section. For stowage the longeron is heated and compressed into a ribbon shaped cross section, and upon deployment the longeron is heated to restore its corrugated cross section. A mechanical assembly machine includes a drum, a stowed flattened truss boom rolled into a coil around the drum, a device for unrolling the coil, an actuating and locking mechanism, and a control arm which connects the actuating and locking mechanism to the drum.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Optical module automatic chip mounting and assembling machine

InactiveCN106239902AHigh precisionIncrease productivityMaterial gluingOptical articlesUV curingOptical Module

The invention discloses an optical module automatic chip mounting and assembling machine. The optical module automatic chip mounting and assembling machine comprises a worktable and an intermittent rotary plate arranged on the worktable. Six tool clamps are evenly distributed along the periphery of the intermittent rotary plate at intervals. A glass prism feeding manipulator, a glue dispensing device, an optical filter feeding device, a chip mounting press-fitting device, a UV curing device, a finished product taking manipulator and a controller which correspond to the tool clamps are sequentially arranged on the worktable and around the intermittent rotary plate. Linkage of all the processes is realized through the intermittent rotary plate with six stations, glass prism feeding, glue dispensing, optical filter feeding, chip mounting press-fitting, UV curing and finished product taking are carried out in sequence, and automatic operation of all the procedures is realized. Automatic batch production is realized through various sensors and electric element control machines and mechanisms, and the production efficiency, and reliability and consistency of novel products are improved. As the glue outlet amount can be controlled accurately, the accuracy of chip mounting and assembling is greatly improved, and product quality is improved.

Owner:OPTIMAL COATECH GUANGZHOU CO LTD

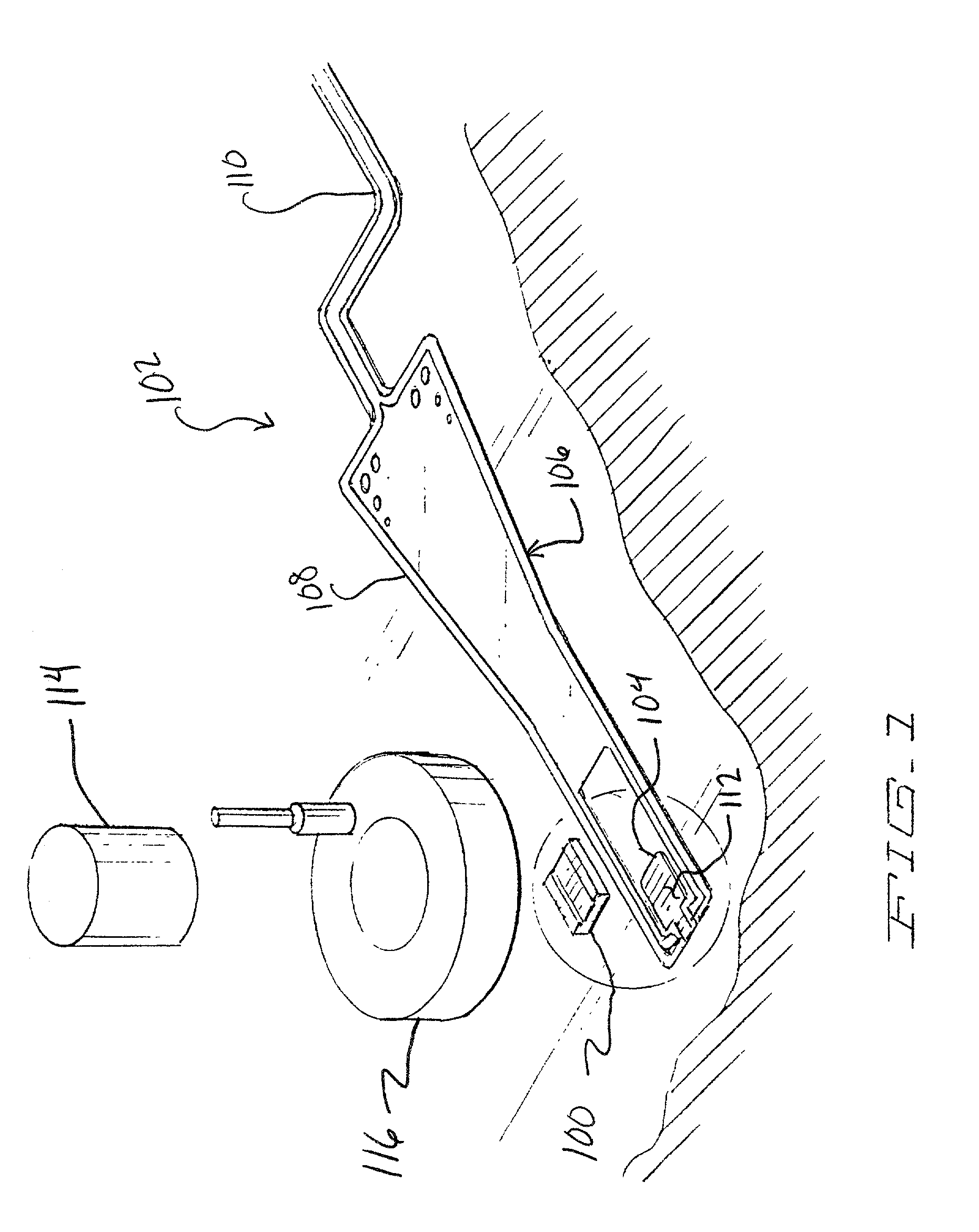

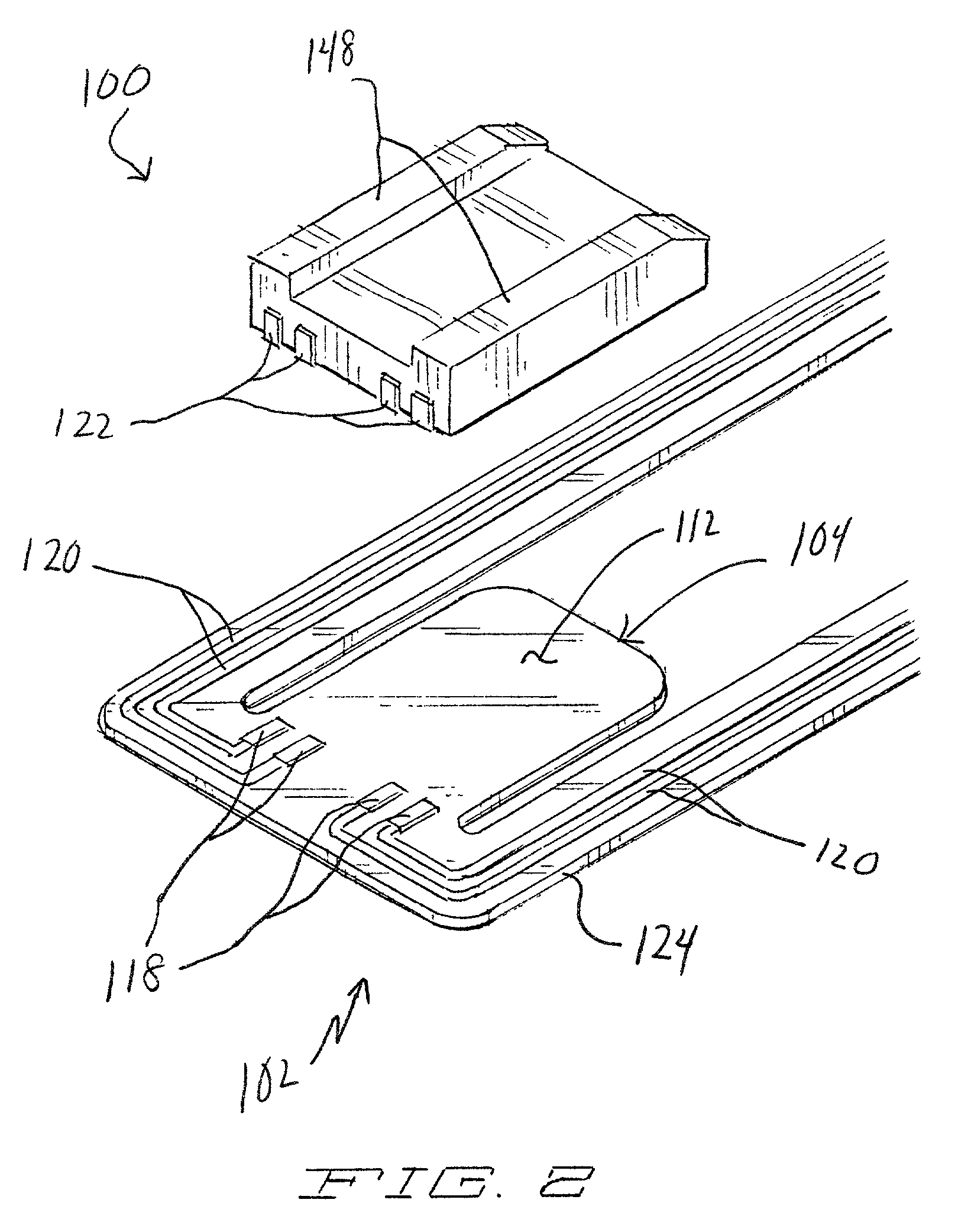

Head gimbal assembly method

InactiveUS7127799B2Free from damageEasy alignmentPrinted circuit assemblingElectrical transducersHard disc driveEngineering

The present invention provides a method for assembling a head gimbal assembly useful in a hard disk drive and for testing such an assembly. In a method in accord with the present invention a head / slider is mounted to a circuited gimbal in an automated assembly machine. Following this step the head / slider circuited gimbal assembly will be subjected a dynamic electrical test with those head / slider circuited gimbal assemblies not passing being sorted from the lot. Following this step the head / slider circuited assembly will be attached to a suspension.

Owner:APPLIED KINETICS

Full automatic angle valve assembly machine

PendingCN108015536ASimple structureReduce manufacturing costAssembly machinesMetal working apparatusLocking mechanismEngineering

The invention discloses a full automatic angle valve assembly machine which is characterized in that the full automatic angle valve assembly machine comprises a main frame and a material shifting andlocating mechanism arranged above the main frame; a valve body charging mechanism, a valve core charging mechanism, a valve core tightening mechanism, a handle charging mechanism, a screw locking mechanism, a valve cap assembly mechanism and a finished product taking mechanism are sequentially arranged above the material shifting and locating mechanism, wherein the material shifting and locating mechanism comprises a synchronous belt and a plurality of locating seats arranged on the synchronous belt; the synchronous belt is driven to rotate by a servo motor and then drives the locating seats to sequentially enter the various assembly mechanisms; locating rods are arranged above and below the synchronous belt; and guide grooves in the bottoms of the locating seats are located in the surfaces of the locating rods to slide. The full automatic angle valve assembly machin has the beneficial effects that by employing the multiple assembly mechanisms, automatic charging and assembly of various fittings of an angle valve are realized, and when full automatic assembly is realized, the assembly quality of products can be ensured since a standardized flow and operation sequences are adopted.

Owner:FOSHAN SUCCEED AUTOMATIC TECH

Automatic assembling machine for screws and gaskets

The invention relates to an automatic assembling machine for screws and gaskets. The automatic assembling machine comprises a rack, a working tabletop is arranged on the rack, and a diving plate mechanism is arranged on the working tabletop. A screw vibration disc mechanism and a gasket vibration disc mechanism are arranged beside the diving plate mechanism. A punching mechanism is arranged on the index plate mechanism. A discharging mechanism is arranged beside the index plate mechanism. The index plate mechanism comprises an index rotating disc, multiple stations are arranged on the index rotating disc, and an index air cylinder is arranged below the index rotating disc and used for driving the index rotating disc to rotate. A damper is arranged on the index rotating disc. The task of conveying the screws is automatically finished through the screw vibration disc mechanism, the task of conveying the gaskets is automatically finished through the gasket vibration disc mechanism, and the screws and the gaskets are assembled in place through the index disc mechanism and then punched through the punching mechanism. According to the whole machine, the necessary stations are connected in series through the index disc mechanism to achieve automatic operation, labor is reduced, production efficiency can be improved, production cost can be reduced, and safety performance can be improved.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com