Automatic lock cylinder assembly machine

A technology of assembly machines and lock cylinders, applied in the directions of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems that the output and quality cannot meet customer needs, reduce the market competitiveness of enterprises, and difficult to guarantee product quality, and achieve assembly quality. good, space-saving, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples, but the specific examples do not limit the present invention in any way.

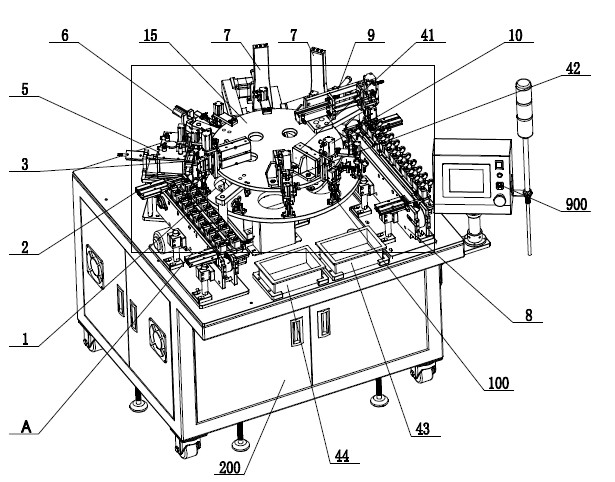

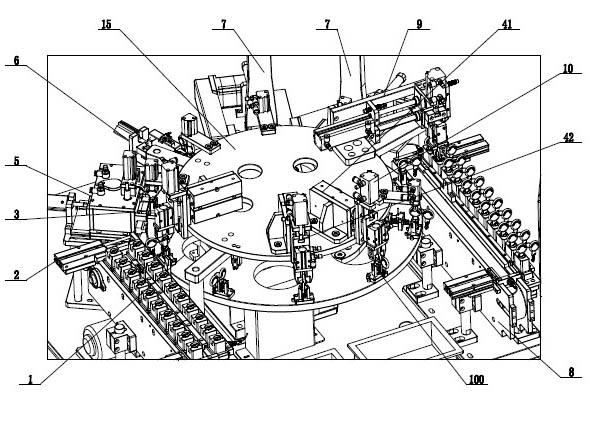

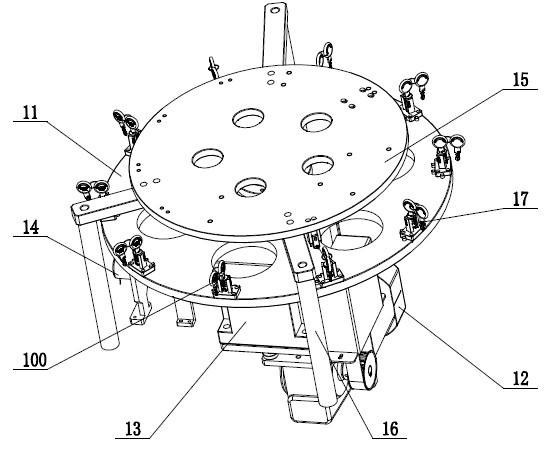

[0031] Such as figure 1 , 2 As shown, the lock cylinder automatic assembly machine in the present invention includes: a body 200 and a rotating disk assembly 1 arranged on the body 200 and a wire feeding mechanism for sending the lock cylinder 100 and the key to the corresponding position. The wire feeding mechanism includes: Lock cylinder feeding mechanism 2 and key feeding mechanism 8. Along the clockwise circumferential direction of the rotating disk assembly 1, there are arranged in sequence: a lock cylinder feeding mechanism 2, an upper lock cylinder manipulator assembly 3, an upper spring assembly 5, a spring detection assembly 6, two upper lock plate assemblies 7, and a key insertion manipulator assembly 9 , a key feeding mechanism 8, a lock cylinder detection assembly 10, and a finished product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com