Patents

Literature

506results about How to "Easy to overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonwoven fabric

InactiveUS20070298671A1Fast transferPoor quick penetration characteristicSynthetic resin layered productsAbsorbent padsWoven fabricEngineering

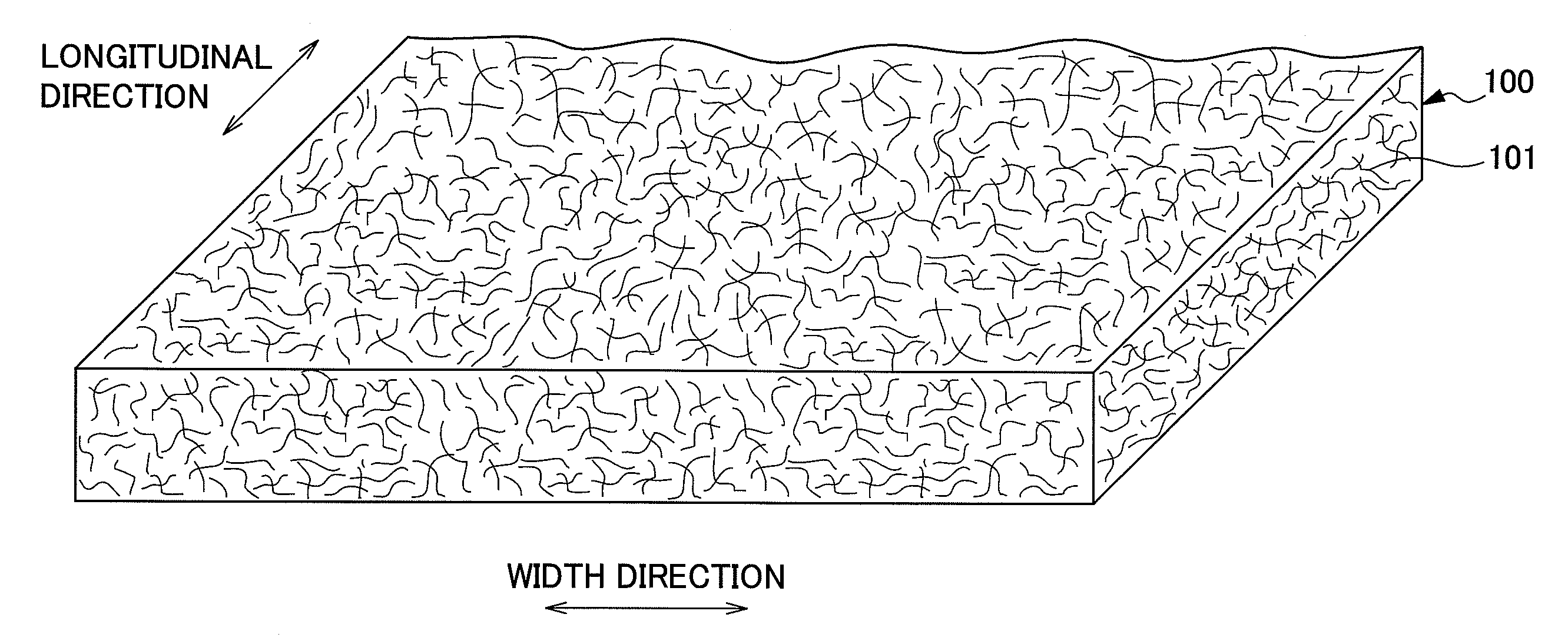

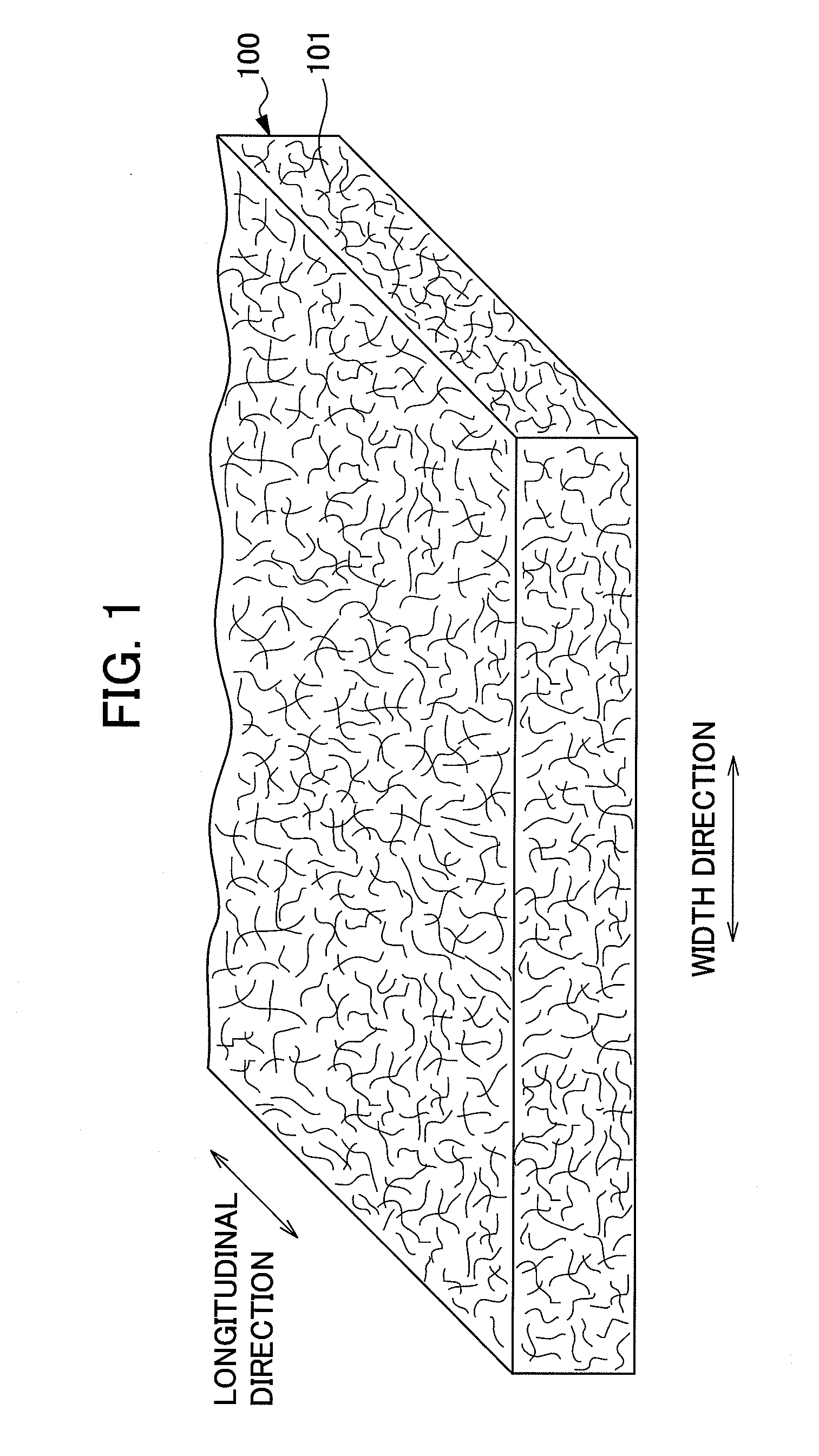

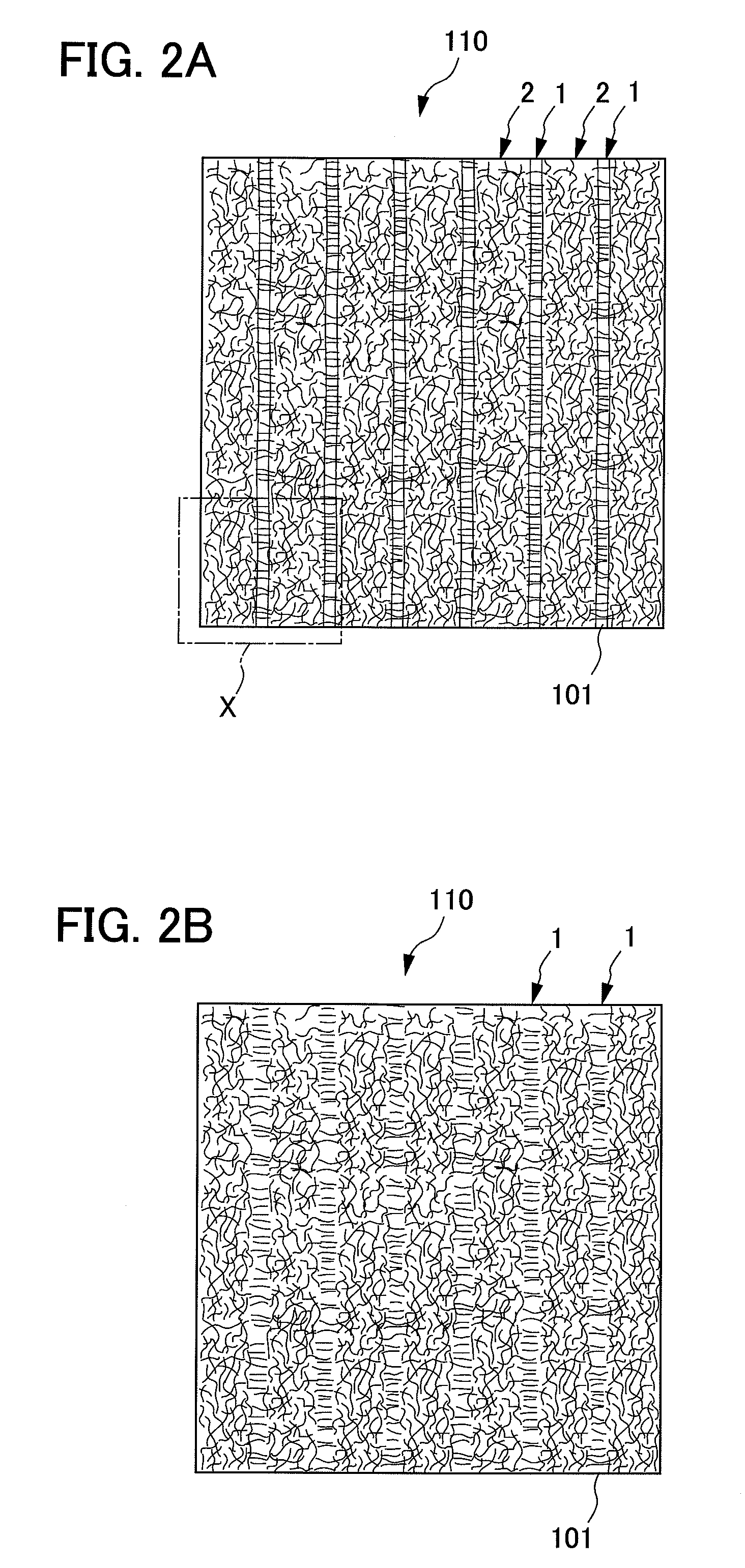

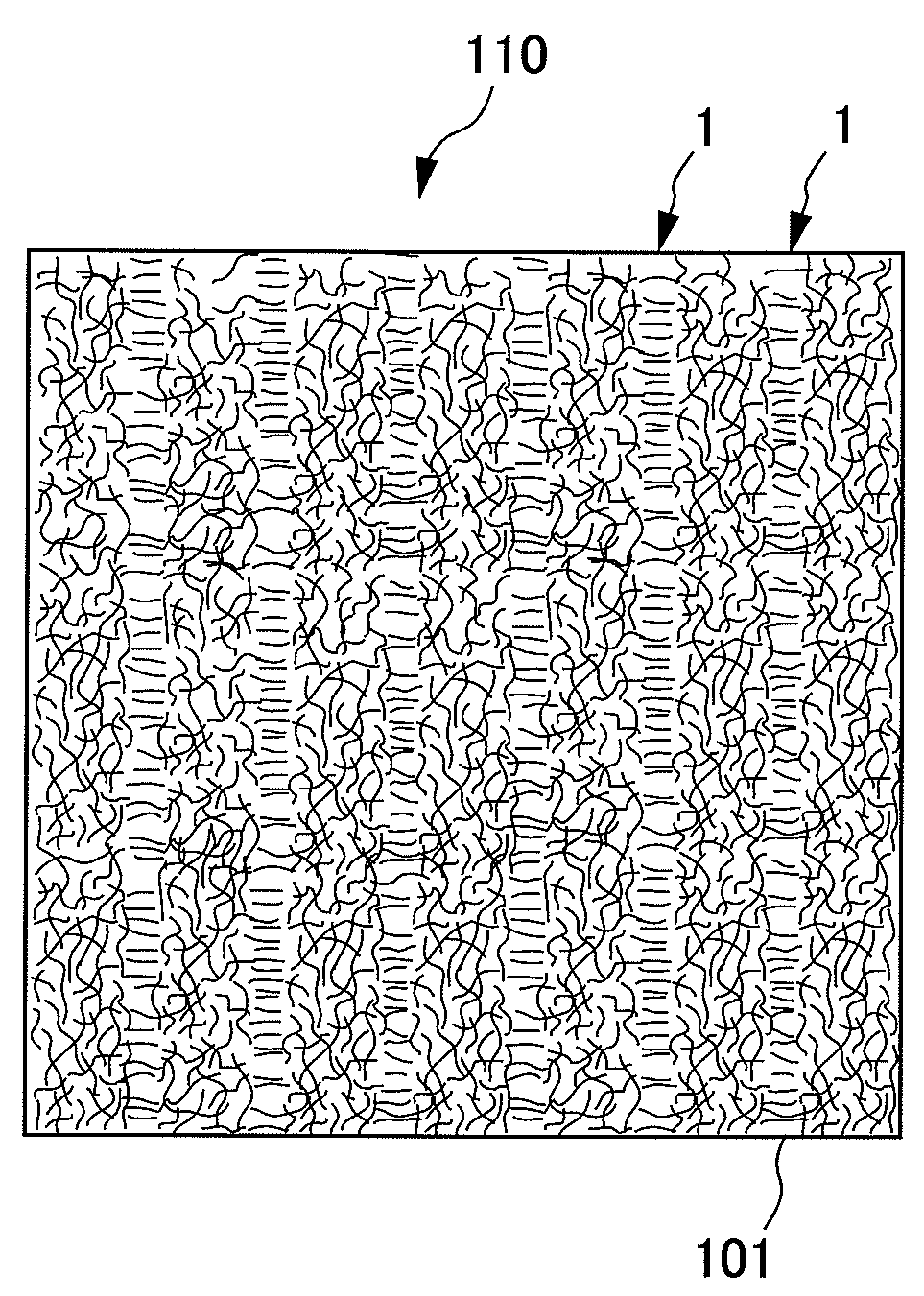

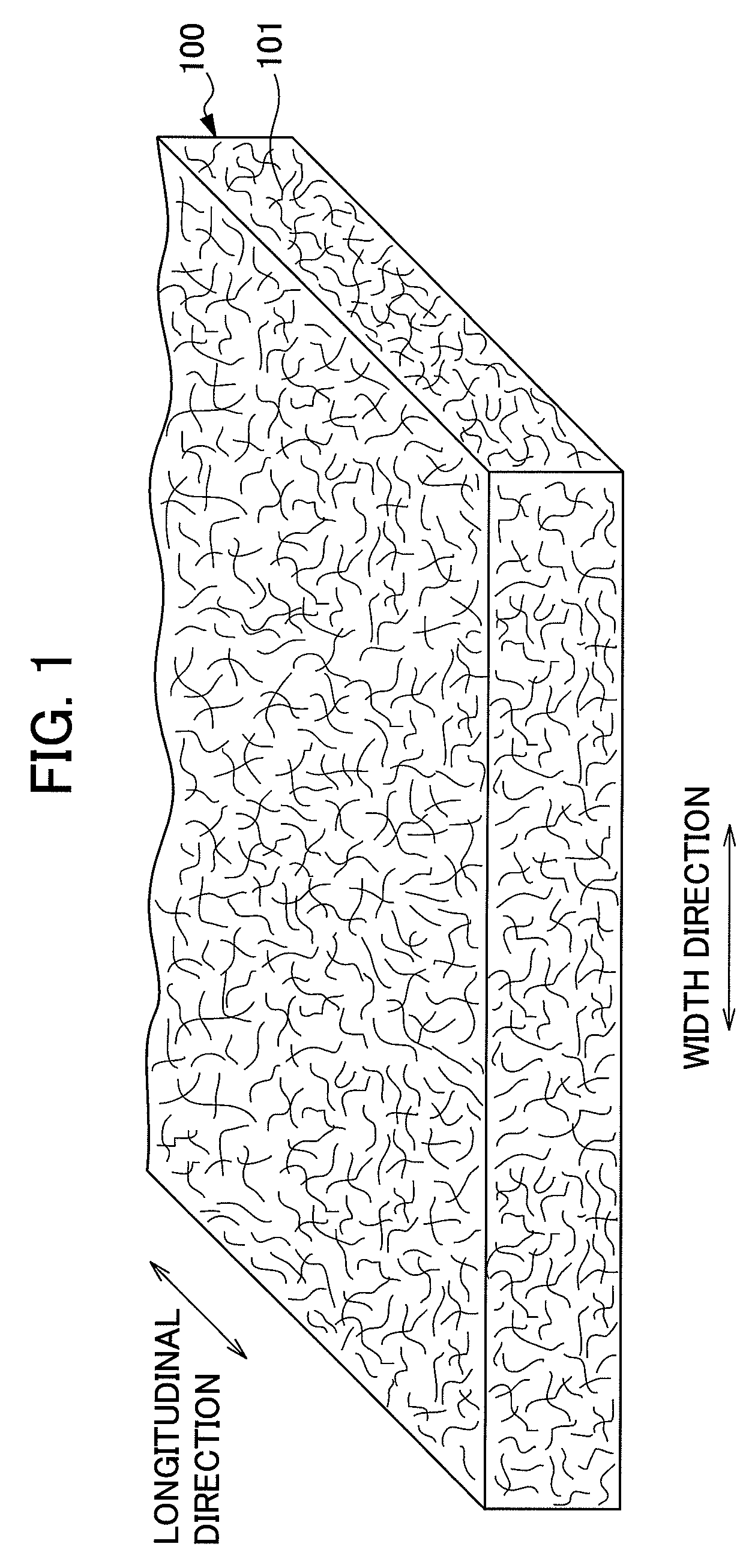

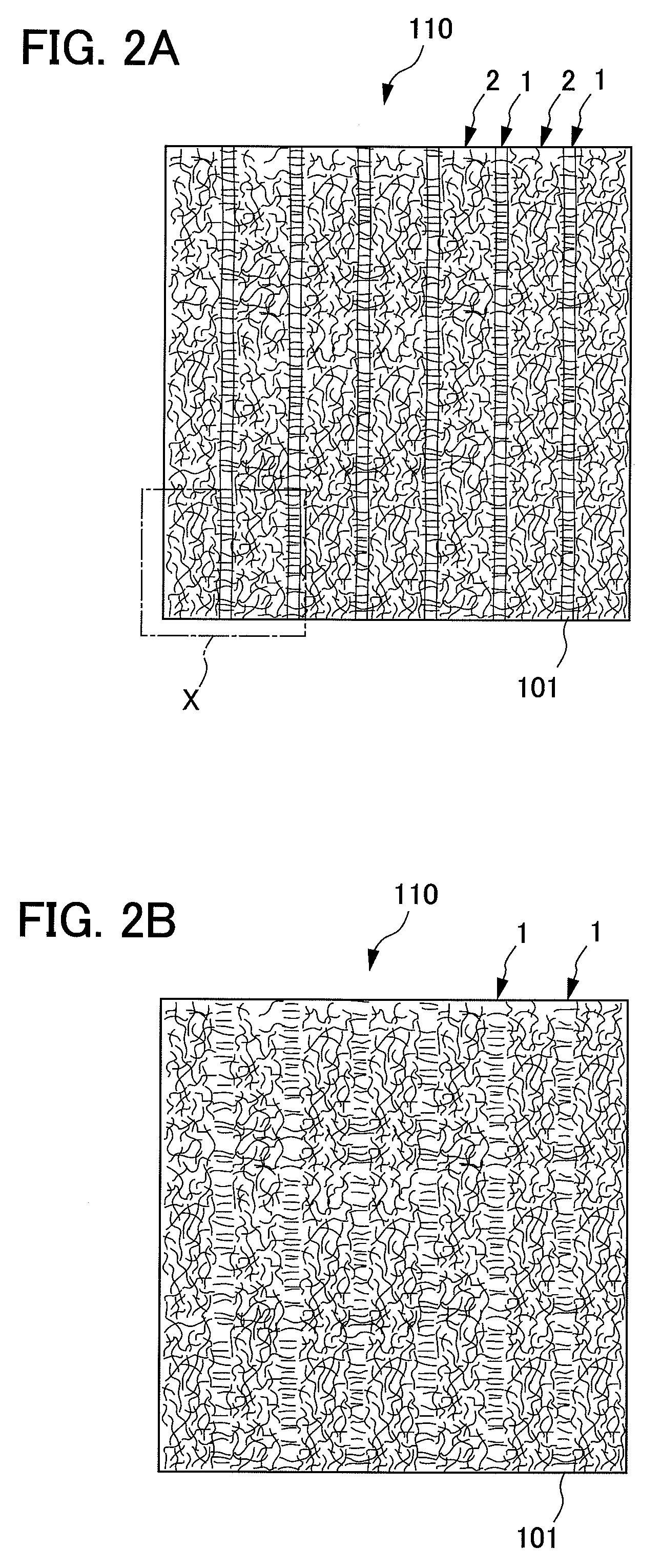

It is an objective of the present invention to provide a nonwoven fabric prepared so as to be able to rapidly transfer a predefined liquid. The nonwoven fabric is formed by jetting a fluid, which consists mainly of gaseous matter, to a fiber web 100 supported from beneath by a predefined breathable support member, from an upper surface side in order to move fibers in the fiber web 100. A number of groove portions 1 and a number of convex portions 2 are formed on a jetted area of the nonwoven fabric in the direction in which the area is extended, and the fiber density of the groove portions 1 is less than the fiber density of the convex portions 2.

Owner:UNI CHARM CORP

Nonwoven fabric

InactiveUS8143177B2Poor quick penetration characteristicHigh densitySynthetic resin layered productsAbsorbent padsEngineeringNonwoven fabric

It is an objective of the present invention to provide a nonwoven fabric prepared so as to be able to rapidly transfer a predefined liquid. The nonwoven fabric is formed by jetting a fluid, which consists mainly of gaseous matter, to a fiber web 100 supported from beneath by a predefined breathable support member, from an upper surface side in order to move fibers in the fiber web 100. A number of groove portions 1 and a number of convex portions 2 are formed on a jetted area of the nonwoven fabric in the direction in which the area is extended, and the fiber density of the groove portions 1 is less than the fiber density of the convex portions 2.

Owner:UNI CHARM CORP

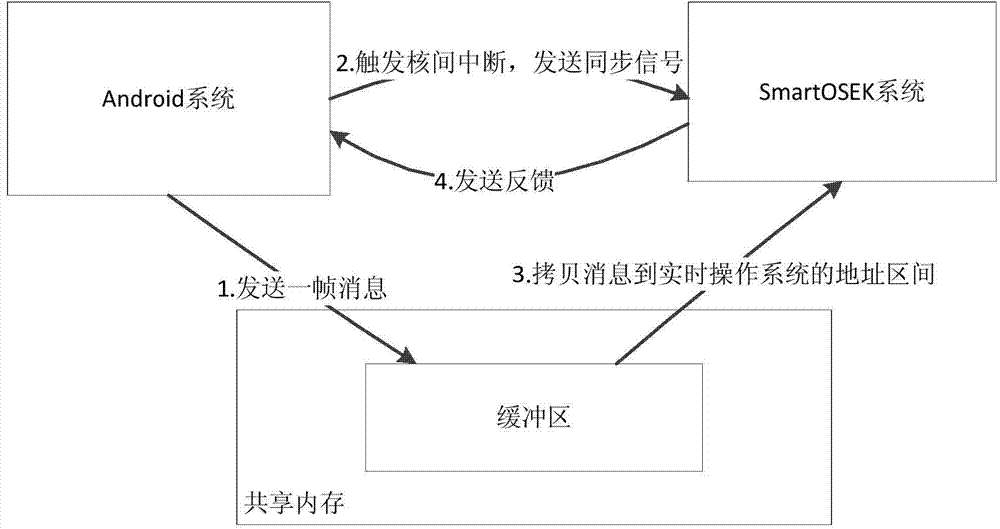

Communication method between real-time operating system and non-real-time operating system on multi-core processor

InactiveCN103942178AReduce system overheadEnsure orderDigital computer detailsElectric digital data processingMulti-core processorComputer science

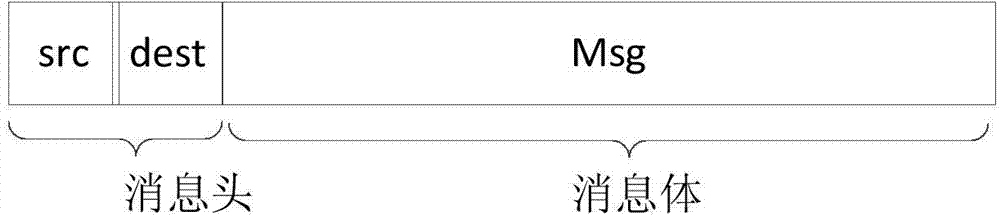

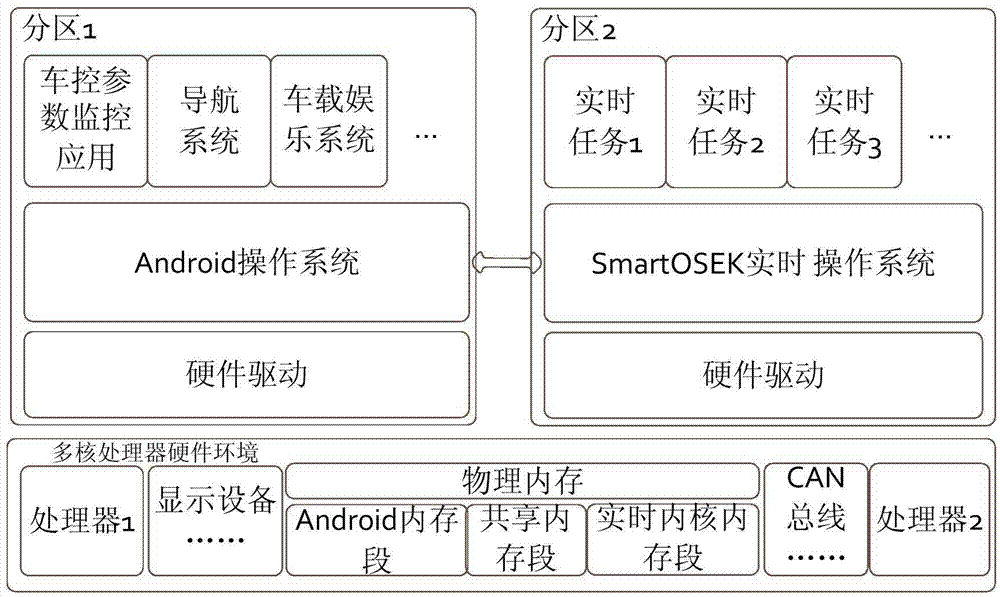

The invention discloses a communication method between a real-time operating system and a non-real-time operating system on a multi-core processor. The method comprises the following steps that firstly, the length of information of each frame and the capacity of the shared memory are statically configured; secondly, the shared memory is divided into a buffer area for synchronous messages and a queue for asynchronous messages, a progress of processing the messages is established for the real-time operating system and the non-real-time operating system, and internuclear interruption is registered on the multi-core processor; thirdly, the operating systems are communicated, the operating system sending the messages stores the messages into the corresponding part in the shared memory, the internuclear interruption is triggered, the operating system receiving the messages responds to the internuclear interruption, the messages are copied from the shared memory, the feedback is sent to the operating system sending the messages, and communication is finished. According to the communication method, the communication mode adopted in the messages is set in advance, a unified mapping table is not needed, and the progress can be managed conveniently.

Owner:ZHEJIANG UNIV

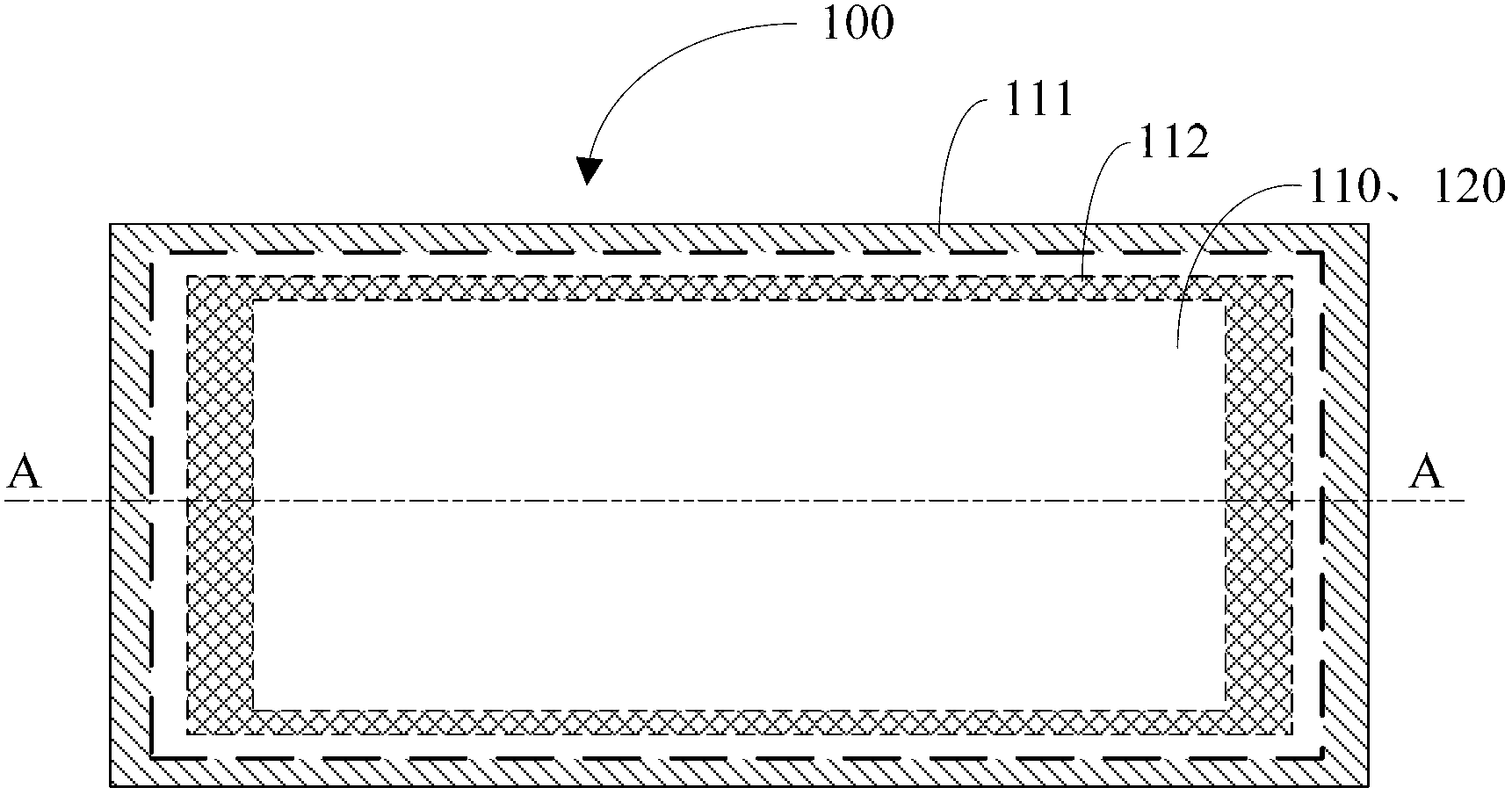

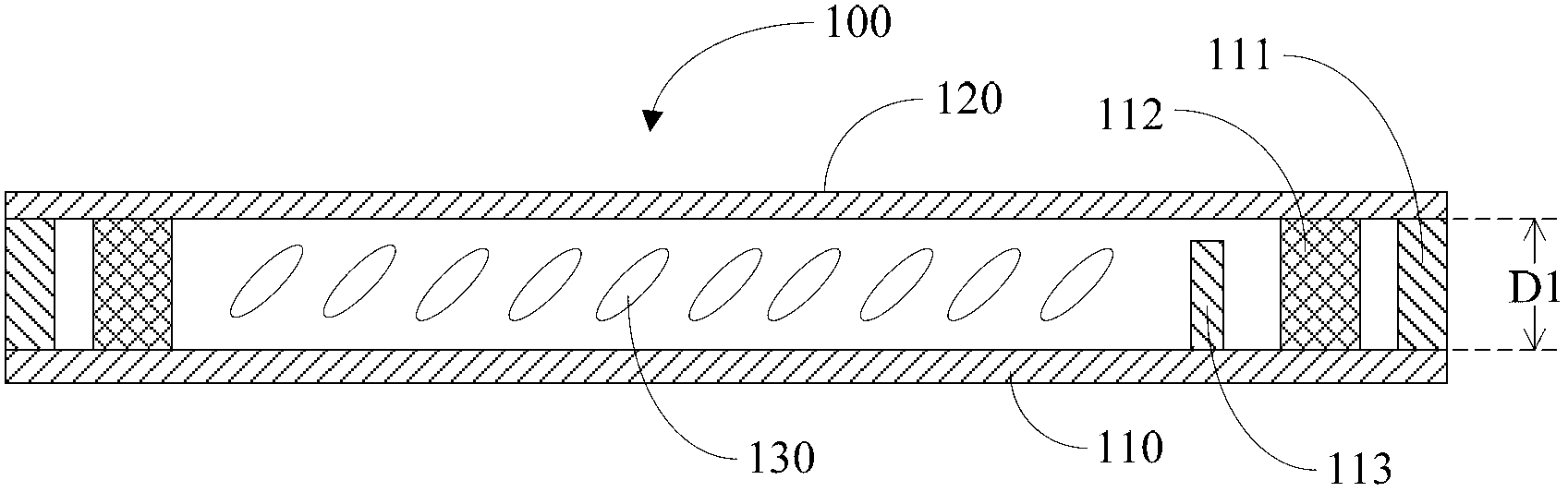

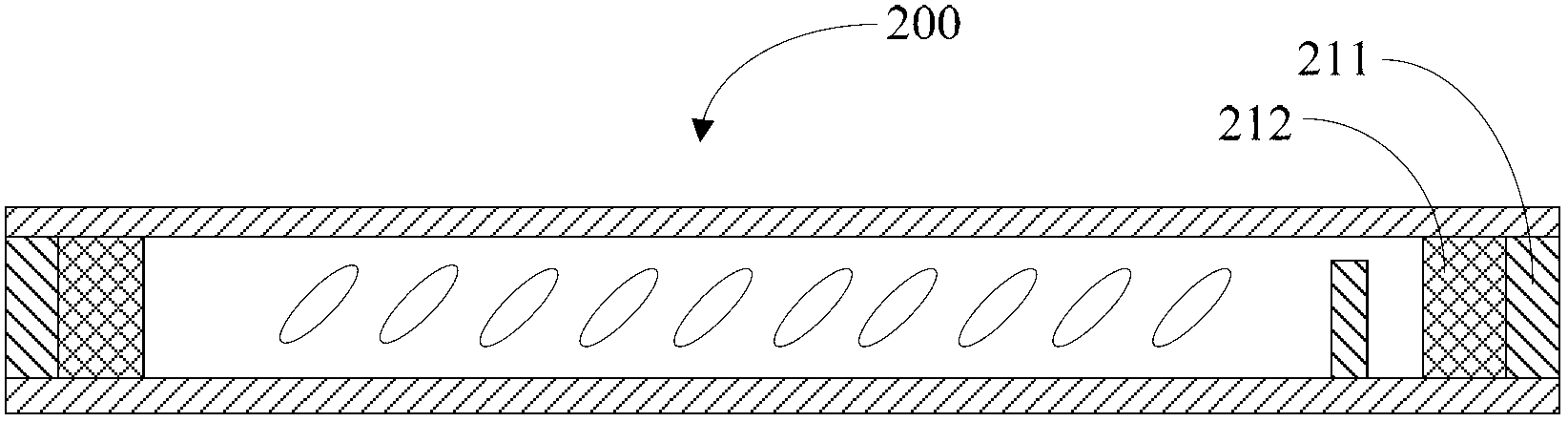

Liquid crystal panel and manufacturing method thereof

ActiveCN102707509AImprove overflowReduce the difficulty of design and the requirements for panel cutting accuracyNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses a liquid crystal panel and a manufacturing method thereof. The liquid crystal panel comprises a first base plate, a second base plate, a frame glue and a retaining wall, wherein the first base plate and the second base plate are oppositely arranged; the frame glue is annularly arranged between the first base plate and the second base plate; the retaining wall is arranged between the first base plate and the second base plate and positioned outside an area surrounded by the frame glue, and the top surface and the bottom surface of the retaining wall respectively closely support against the first base plate and the second base plate. According to the mode, the flush of the frame glue can be avoided and the design difficulty of a narrow frame and the requirement of cutting accuracy can be lowered.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

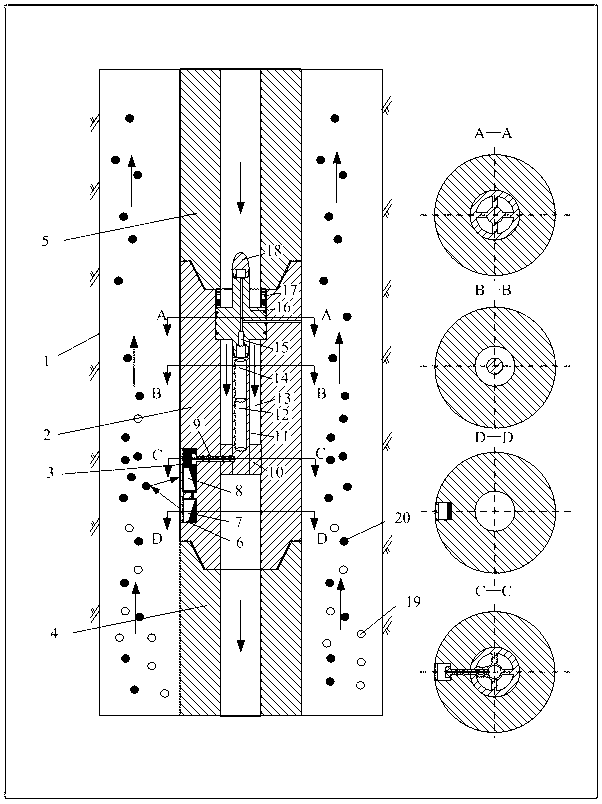

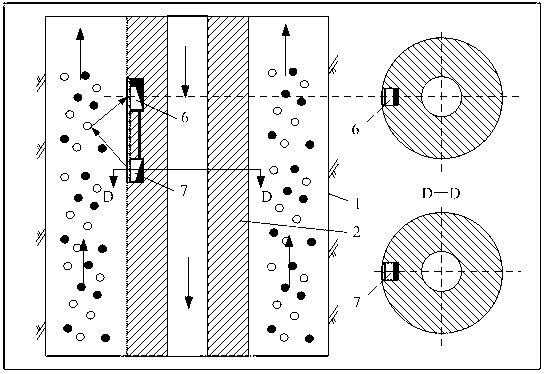

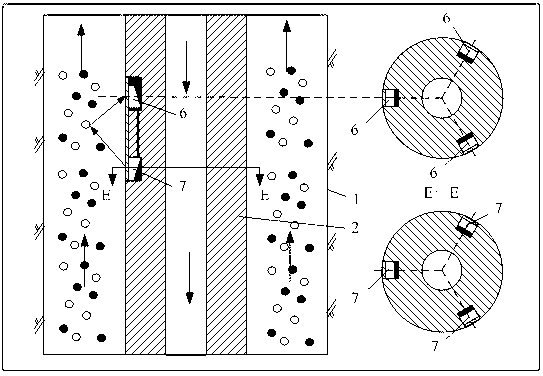

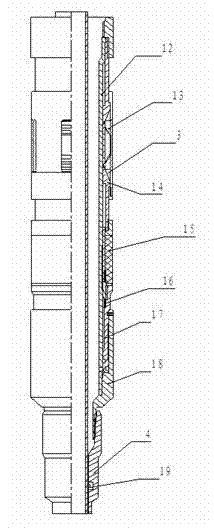

Device for measuring downhole flow while drilling and monitoring early overflow

InactiveCN103061753AAccurate monitoringAccurate monitoring of early floodingSurveyElectricityMeasurement device

Disclosed is a downhole flow measuring while drilling device capable of measuring downhole annular flow, annular pressure and annular temperature and monitoring early overflow while drilling. The measuring device measures downhole annular flow and flow change through an ultrasonic wave sensor mounted at a short section of a drill collar and measures annular pressure and annular temperature through a pressure and temperature sensor mounted inside an annular fluid guiding device, a power source and a circuit board are mounted inside an exploring pipe, physical signals, such as annular flow, pressure and temperature, are converted into electric signals through the sensors, the measuring device records, stores and uploads data through the circuit board, and the measuring device is connected with a MWD (measurement while drilling) through an MWD joint to timely upload actually-measured data to the ground. The device is simple in structure, low in manufacturing cost and long in service life, and working conditions such as downhole overflow can be judged in real time by comprehensively analyzing and processing timely-uploaded downhole data and related data on the ground to achieve the objective of early overflow monitoring, so that safety of well control of well drilling is effectively improved.

Owner:SOUTHWEST PETROLEUM UNIV

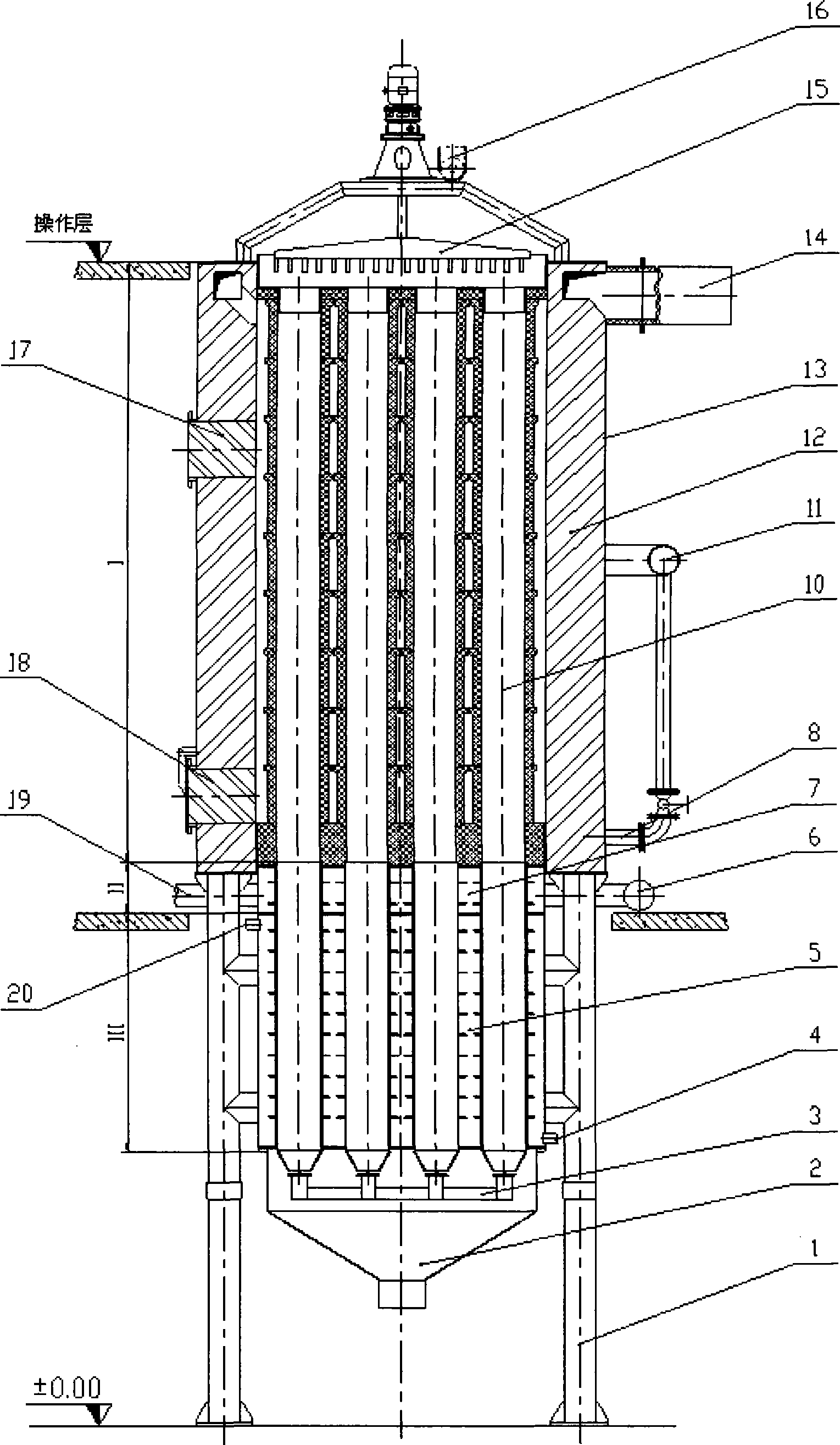

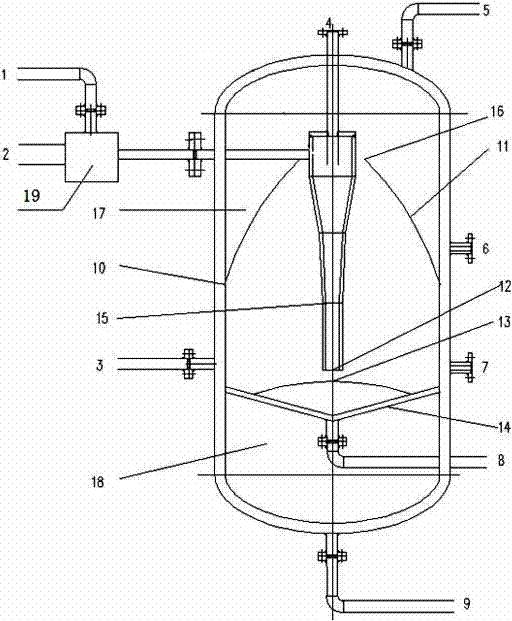

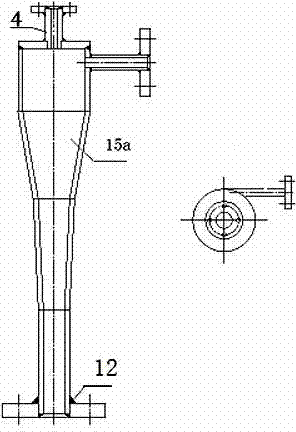

Manganese ore reduction calcination method and apparatus

The invention discloses a method and a device for reducing and roasting manganese dioxide into manganese monoxide in electrolytic manganese industry. The method comprises the following steps: dried manganese dioxide mineral powder is ground, well mixed with reducing powder and conveyed to a feeding bin on the top of a roasting furnace, and then enters hermetic roasting devices; a plurality of burners are arranged among the hermetic roasting devices; fuel is burnt so as to roast manganese dioxide ore; the manganese dioxide ore and the reducing powder are heated and roasted to 900 to 970 DEG C in the hermetic roasting devices with no oxygen supplement; under the circumstance of oxygen-free contact after reaction in the lower ends in the hermetic roasting devices, the temperature of roasted manganese ore is lowered, so as to recover heat and cool the manganese ore; and finally, the manganese ore is discharged out of a furnace by an automatic discharging device and then is subjected to a subsequent process. The method and the device can reduce and roast the high / low-grade manganese dioxide ore, have the advantages of low production cost, simple process and convenient operation, can control the reduction rate of manganese dioxide and other metals through the automatic discharging device, and improve the quality of final products.

Owner:朱军

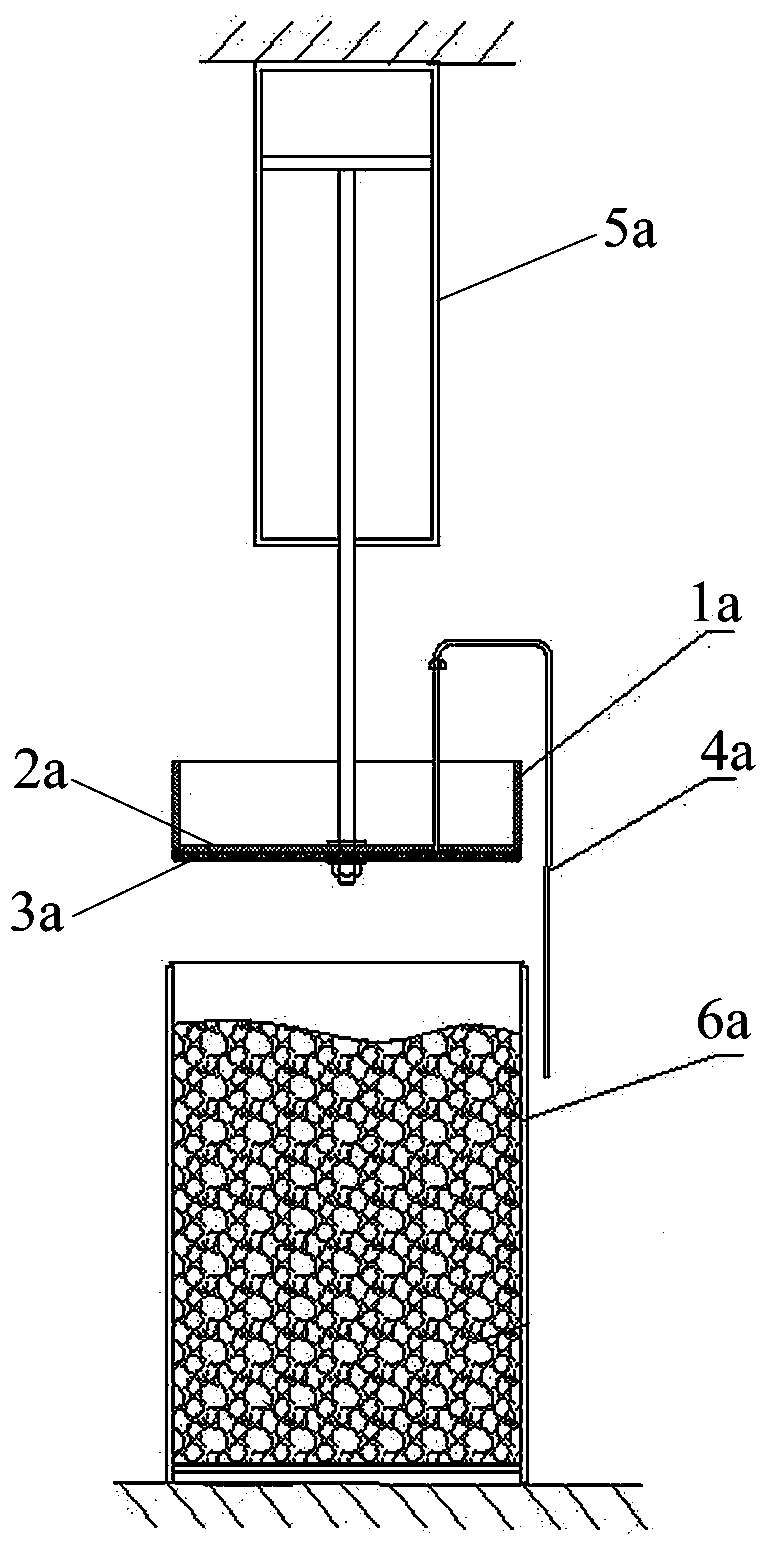

Method for producing mash gas from municipal sludge through dry method anaerobic fermentation

ActiveCN101935139ASmall volumeReduce heating energy consumptionWaste processingWaste based fuelBiomassChemistry

The invention relates to a method for producing mash gas from municipal sludge through dry method anaerobic fermentation, which belongs to the field of solid waste reclamation, and can overcome the difficulties difficult mass transfer, difficult gas overflow and the like caused by dewatered sludge which has high viscosity, no fluidity, no gaps and the like. The method comprises the following steps of: performing biological pre-drying on the dewatered sludge, and stacking the dewatered sludge in an aerobic environment for 2 to 3 days; adding the material after the biological pre-drying into anaerobic granular sludge or biogas residues to perform inoculation, and performing static starting for 6 to 8 days; performing acidogenic fermentation on the material under an aerobic or anaerobic condition, performing spiral band type or anchor type stirring, and adjusting the pH if necessary; performing methanogenesis fermentation on the material after acid production under an anaerobic condition, performing extruding type stirring, keeping the temperature of the material to be 35+ / -1 DEG C, and keeping the pH between 6.6 and 7.5; and performing refluxing inoculation on part of the biogas residues, and performing aerobic compost stabilization on the rest of the biogas residues. The method can be used for beneficial utilization of the municipal sludge and the recovery of biomass energy sources, and compared with wet fermentation, the method can save equipment investment and land occupation.

Owner:TONGJI UNIV

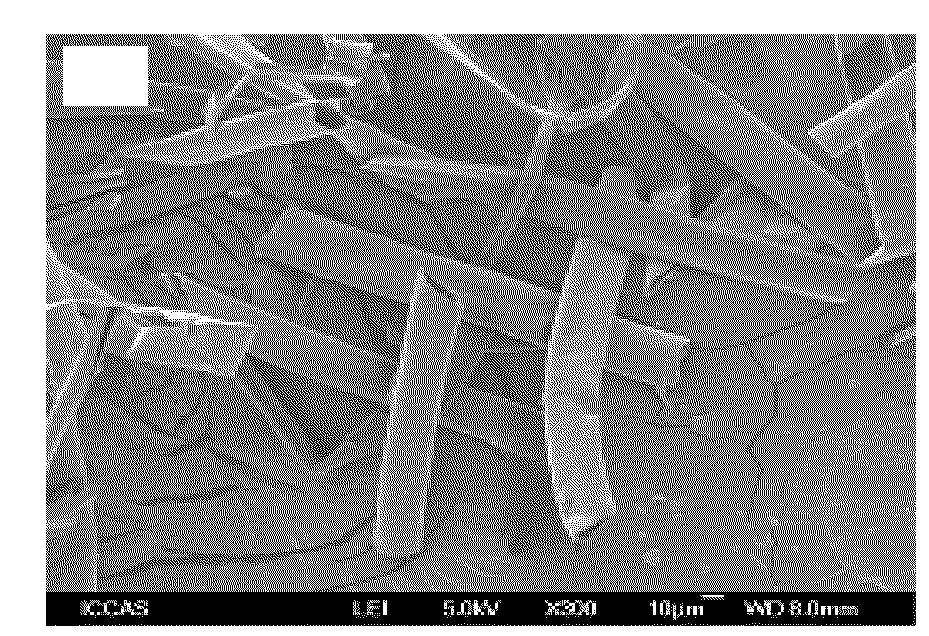

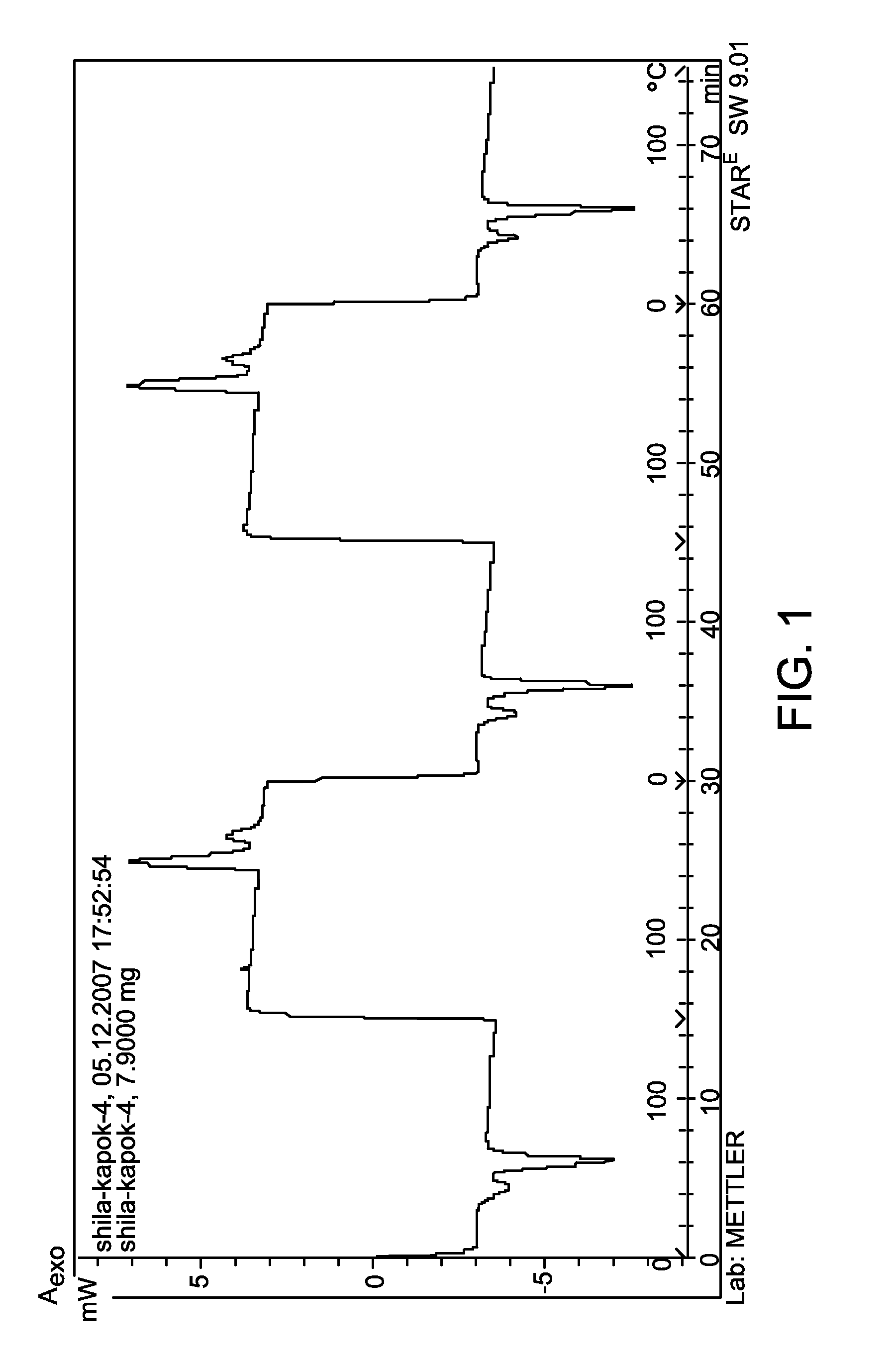

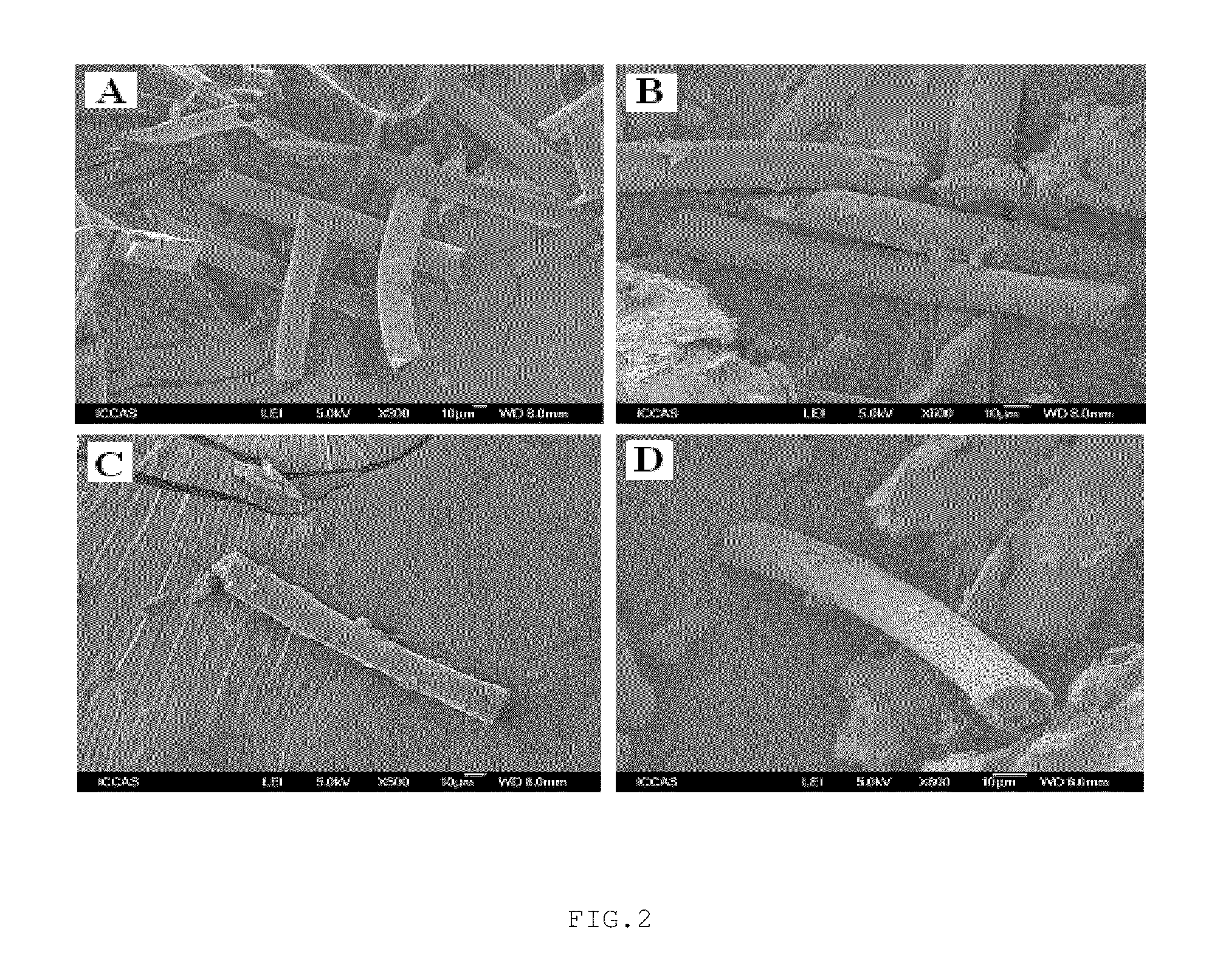

Natural microtubule encapsulated phase-change materials and preparation thereof

InactiveUS20100071882A1Cheap and easily available natural microfibersLarge specific surface areaHeat storage plantsMetal-working apparatusMicrotubulePolymer science

Microtubule encapsulated microcapsules of a phase-change material and preparation thereof are provided. The microcapsules of a phase-change material consist of a phase-change material, truncated microtubules, and a polymer. The truncated microtubules are formed by truncating hollow tubular natural fibers into fiber segments with a length of 0.1 mm-5 cm. The diameter of the hollow tubular natural fiber is 0.1-1000 μm. The phase-change material is encapsulated in the truncated microtubules and the truncated microtubules are covered with the polymer. The microtubules have high energy storage density due to high hollowness, and can transfer energy stably due to the closed structure, transfer heat rapidly due to the very fine micro-tubular structures, and may be used for a long term in view of the heat and chemical stability.

Owner:ETERNAL MATERIALS CO LTD

Metal powder for 3D printing of high-strength aluminum alloy and printing method and application thereof

ActiveCN109128150AImprove performanceShorten the setting timeAdditive manufacturing apparatusTransportation and packagingHigh intensityGraphene

The invention discloses a metal powder for 3D printing of a high-strength aluminum alloy, a printing method for 3D printing of the high-strength aluminum alloy with the metal powder and application ofthe 3D printing method. The metal powder for 3D printing of the high-strength aluminum alloy comprises aluminum alloy micro-particles. The metal powder is characterized in that the surface of the aluminum alloy micro-particles is modified with graphene and nano-reinforced particles from inside to outside; the addition amount of the graphene is 0.3-0.6% of the total mass of the metal powder, and the total addition amount of the nano-reinforced particles is 1-3% of the total mass of the metal powder; the particle size of the aluminum alloy micro-particles is 10[mu]m-60[mu]m; and the particle size of the nano-reinforced particles is 30nm-60nm. The metal powder can be used for printing the high-strength aluminum alloy and is widely applied in the manufacture of aluminum alloy parts.

Owner:SOUTHWEST JIAOTONG UNIV

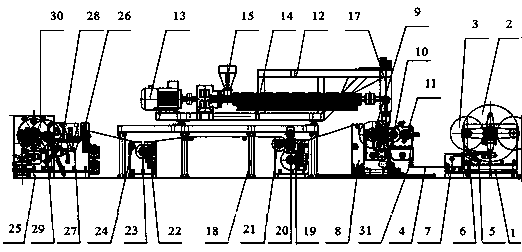

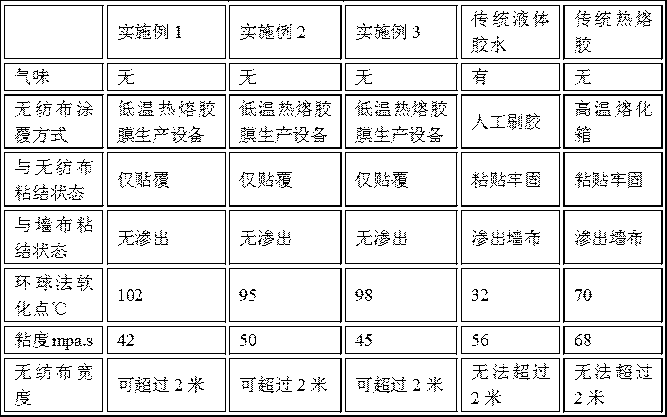

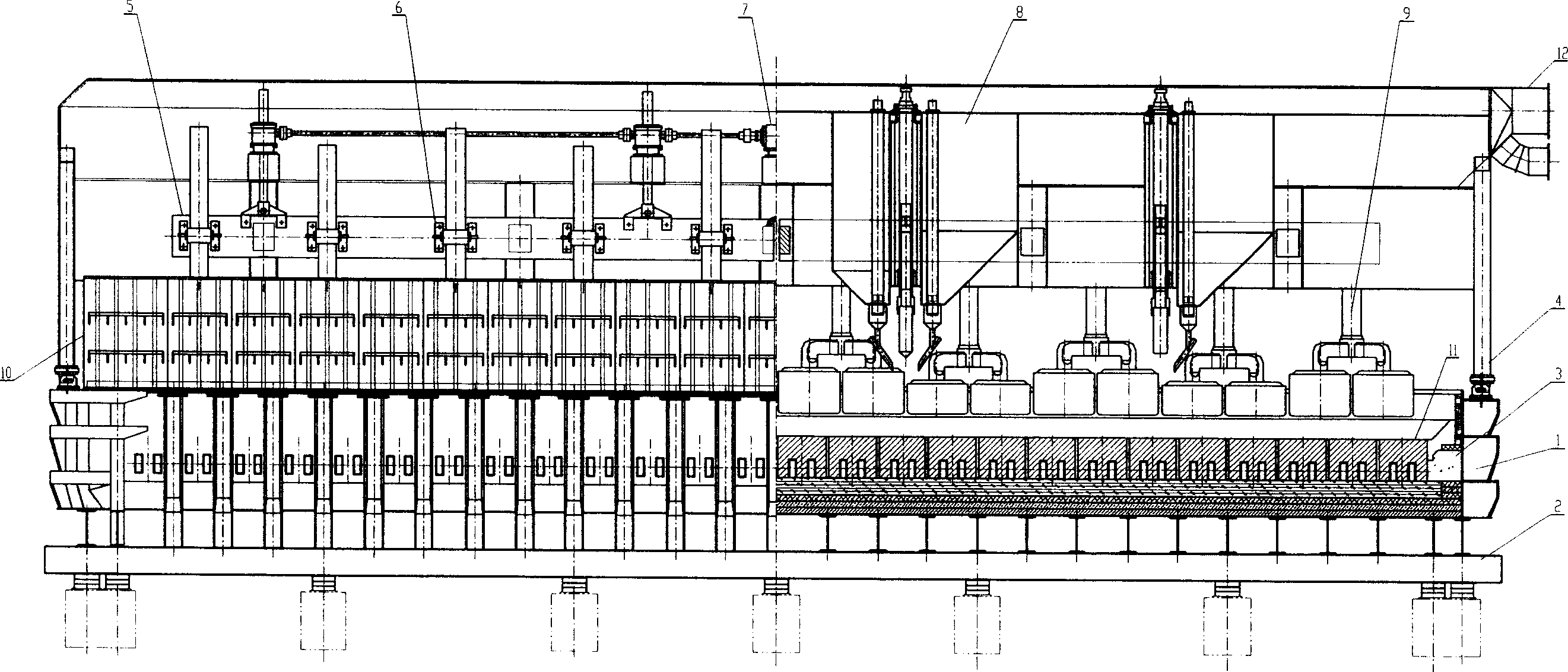

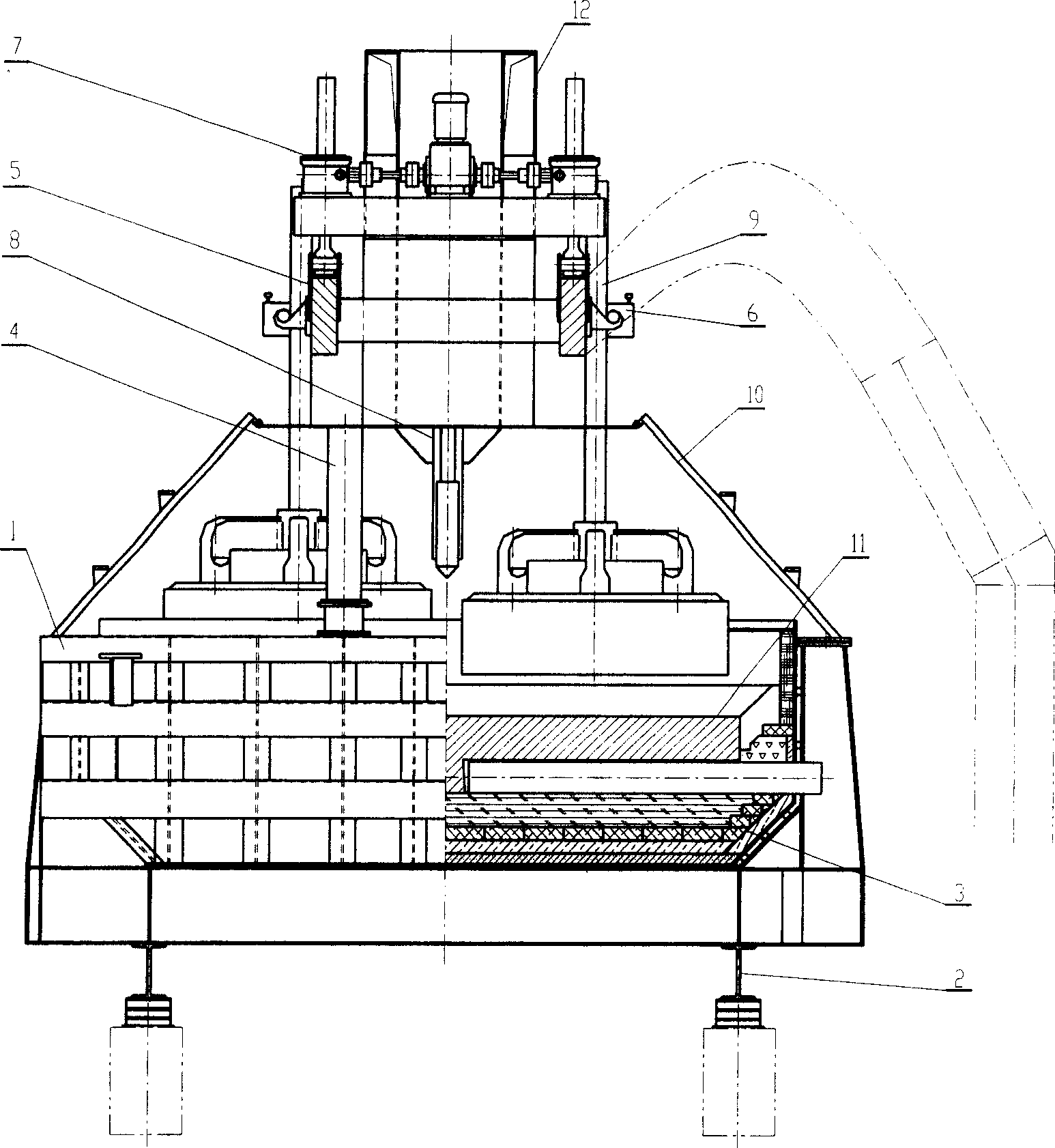

Non-woven fabric coated with hot melt glue and hot gluing process of non-woven fabric

ActiveCN107663783AGuaranteed viscosityModerate viscosityLaminationLamination apparatusMetallurgyPlasticizer

The invention discloses a non-woven fabric coated with a hot melt glue and a hot gluing process of the non-woven fabric. The hot melt glue is pasted and covered on the surface of the non-woven fabric;a raw material of the hot melt glue is EVA (Ethylene-Vinyl Acetate) particles; the EVA particles are prepared from the following components in parts by weight: 50 to 60 parts of ethylene-vinyl acetate (EVA), 30 to 60 parts of modified EVA, 15 to 20 parts of tackifying resin, 5 to 10 parts of plasticizer, and 0.1 to 5 parts of function additive. The hot gluing process of the non-woven fabric coated with the hot melt glue comprises the following concrete steps of (1) building low-temperature hot melt glue membrane production equipment; (2) preparing the EVA particles; (3) running the non-wovenfabric on production equipment; (4) laying off the EVA particles; (5) casting, extruding, pressing, covering and sizing; (6) cooling and rolling. The non-woven fabric coated with the hot melt glue andthe hot gluing process of the non-woven fabric provided by the invention have the following advantages that the time and the labor are saved, the environmental protection property is improved, the width of a hot melt glue membrane is ensured to exceed 2m, and the product stability and the precision of the thickness uniformity are improved.

Owner:江苏和和新材料股份有限公司

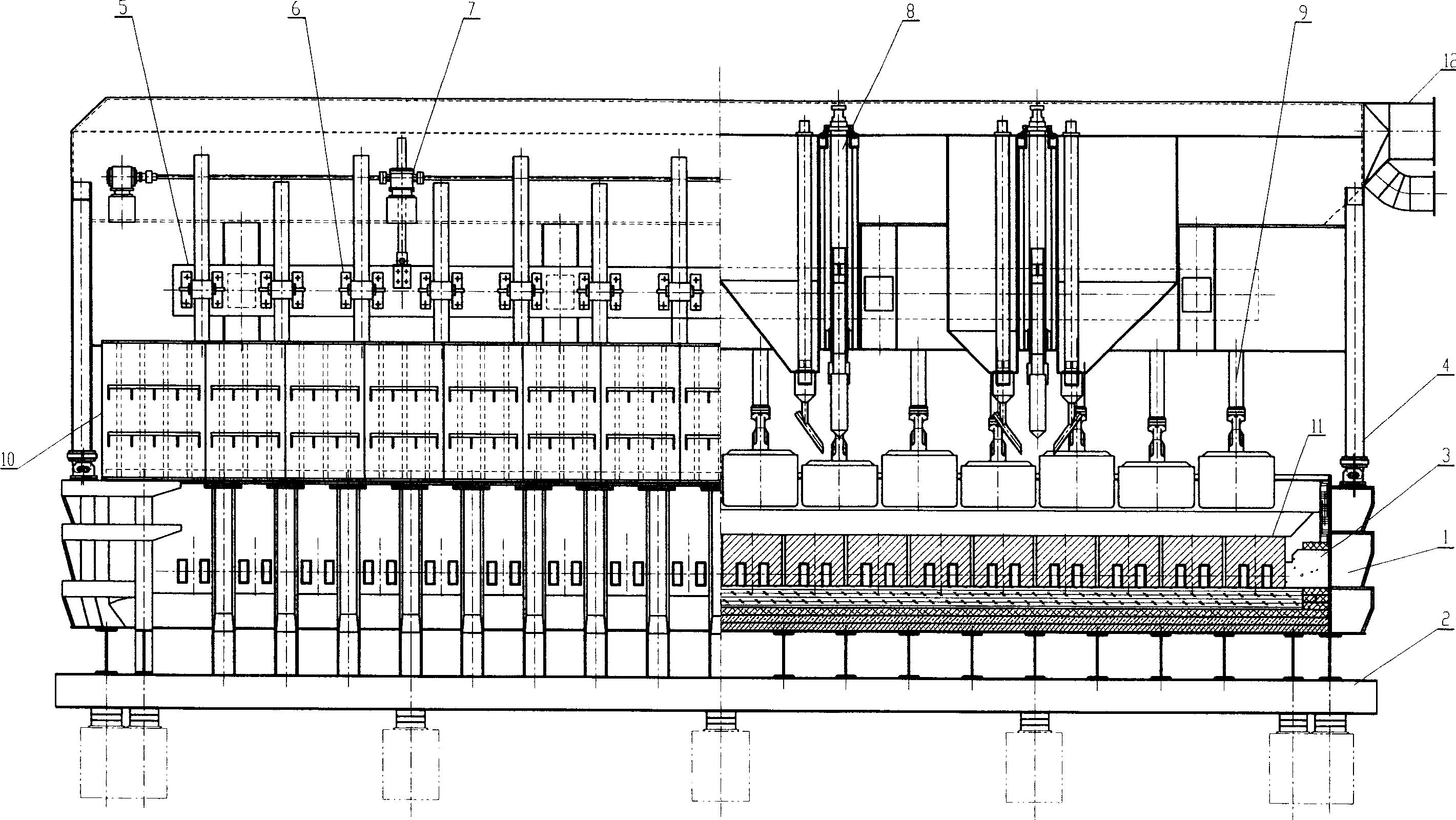

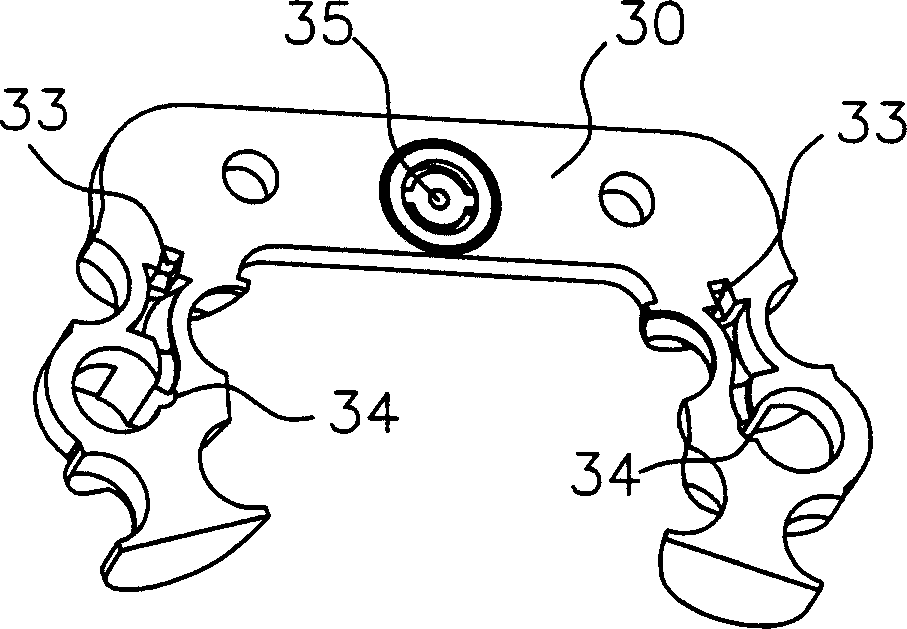

Large-scale aluminium electrolysis pre-baking tank

The large aluminum electrolyzing pre-roasting tank includes anode carbon block combination, anode bus, breaking and feeding unit, anode elevating mechanism, crossbeam and portal upright, tank sealing air exhaust system, tank casing, cathode structure and bottom heat insulating structure. It features the double anode structure comprising two anode carbon blocks assembled through aluminum rod and steel pawl; the elevator installed below the top surface of the crossbeam; the tank sealing air exhaust system set inside the crossbeam; and the cathode with surround casing, carbon block with bottom composite heat insulating layer, side silicon nitride to combine silicon carbide blocks and surrounding cast material. The present invention has improved structure resulting in raised fume collecting efficiency, reasonable gas flow distribution and smooth aluminum electrolyzing process.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

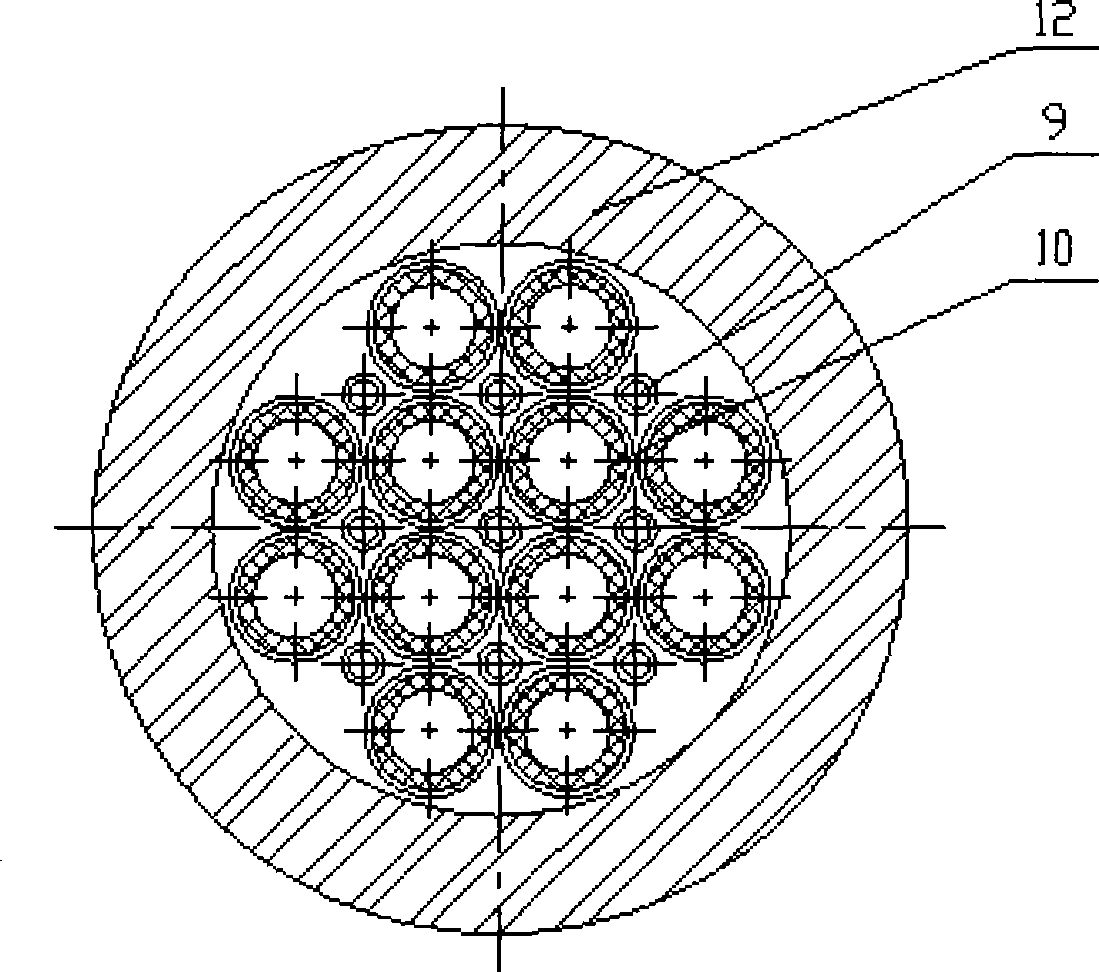

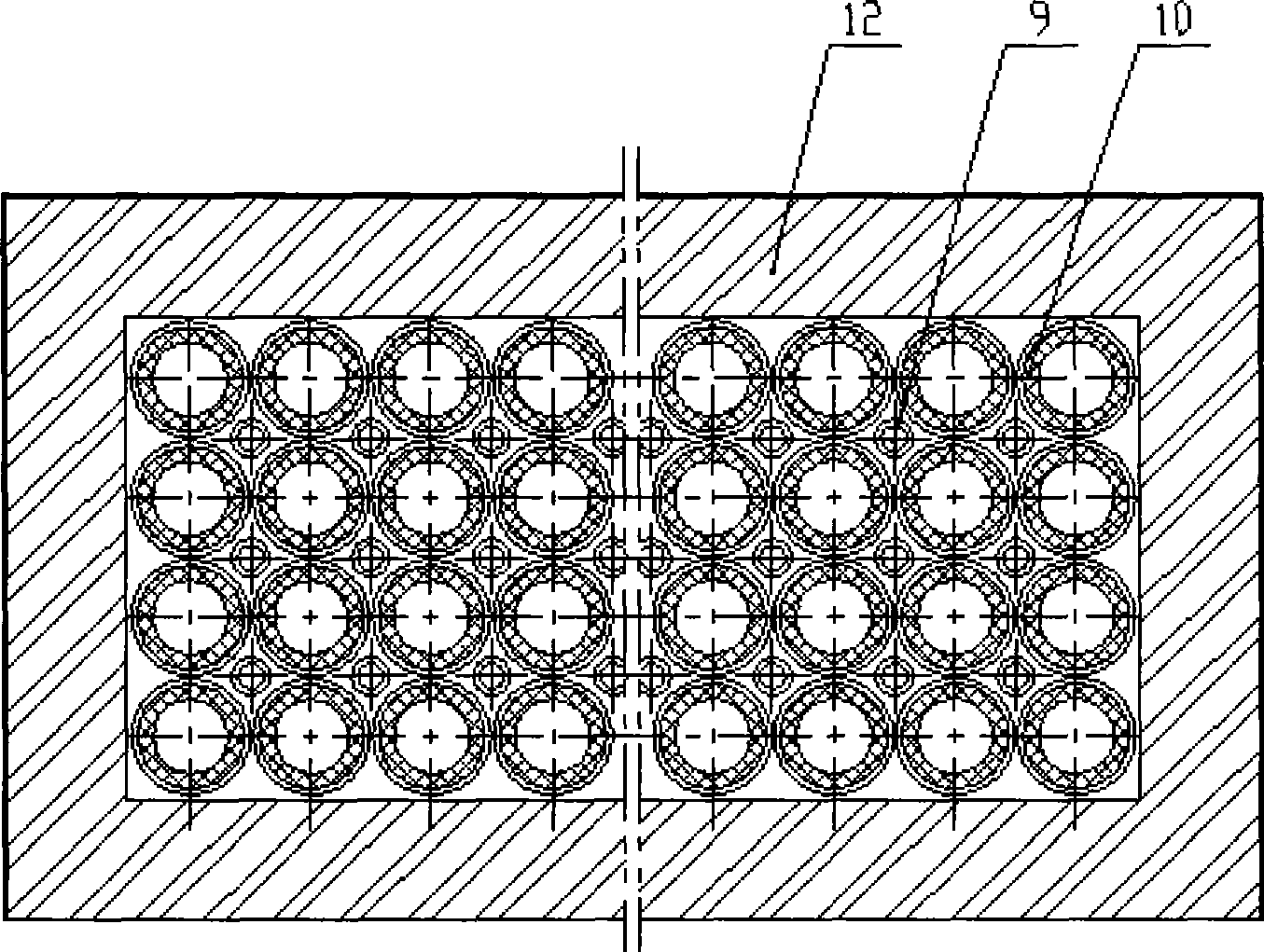

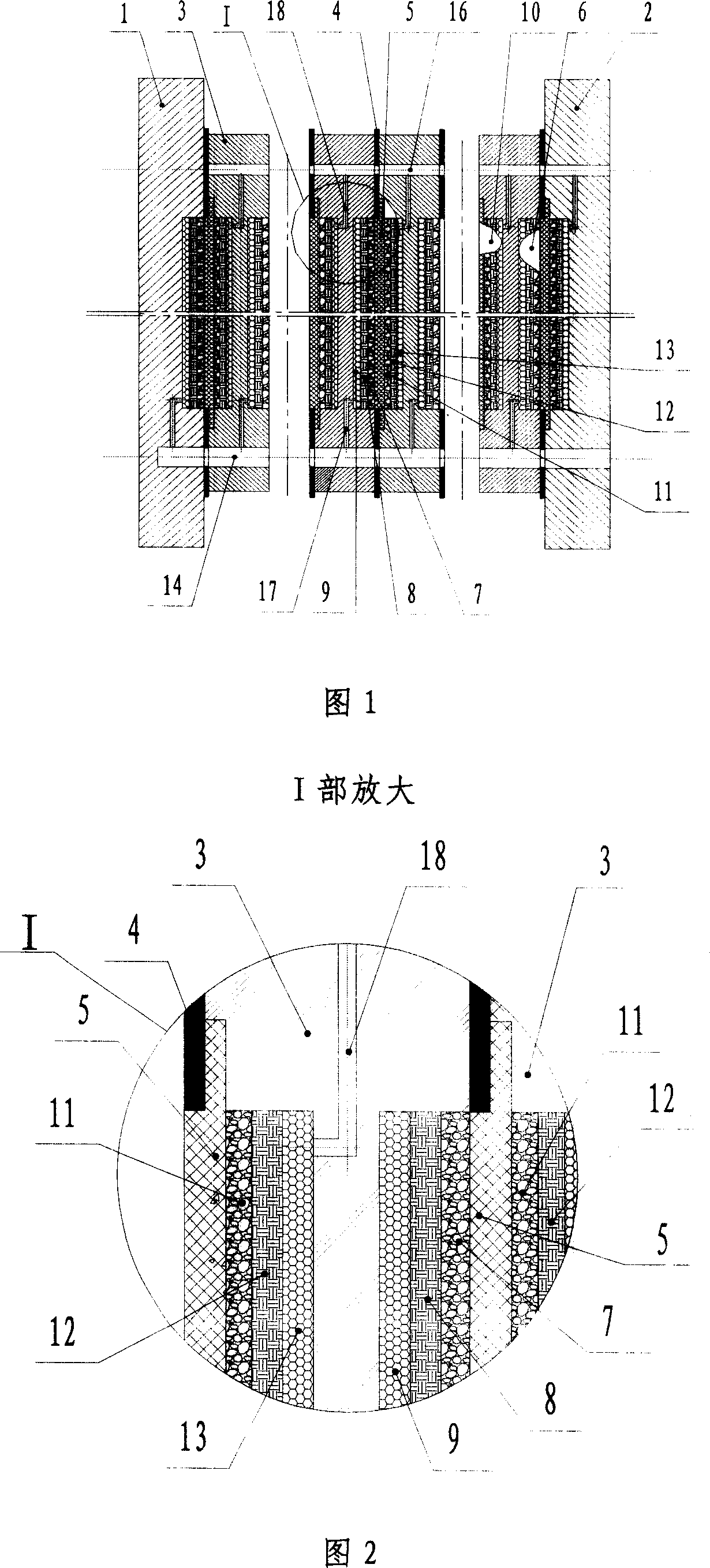

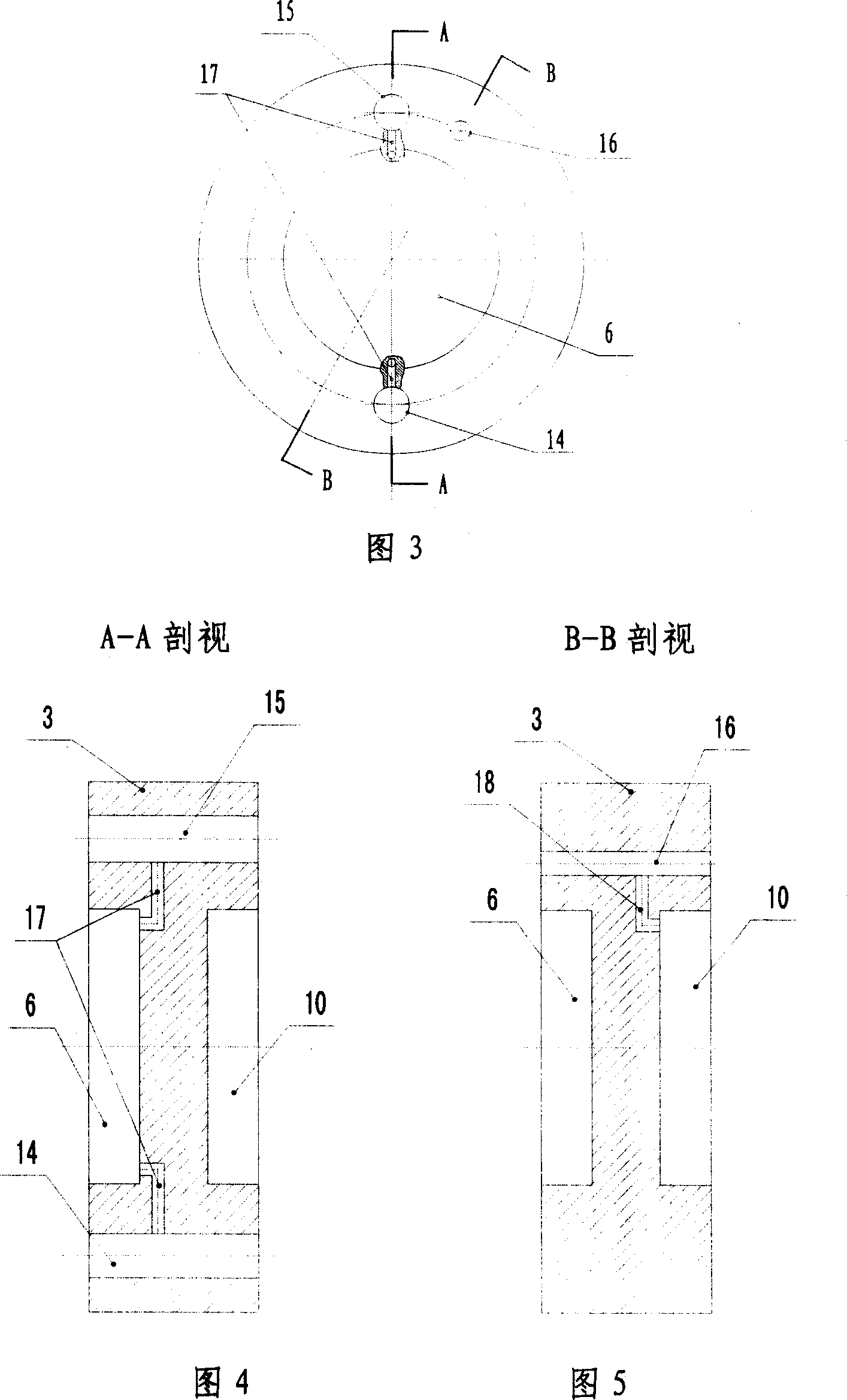

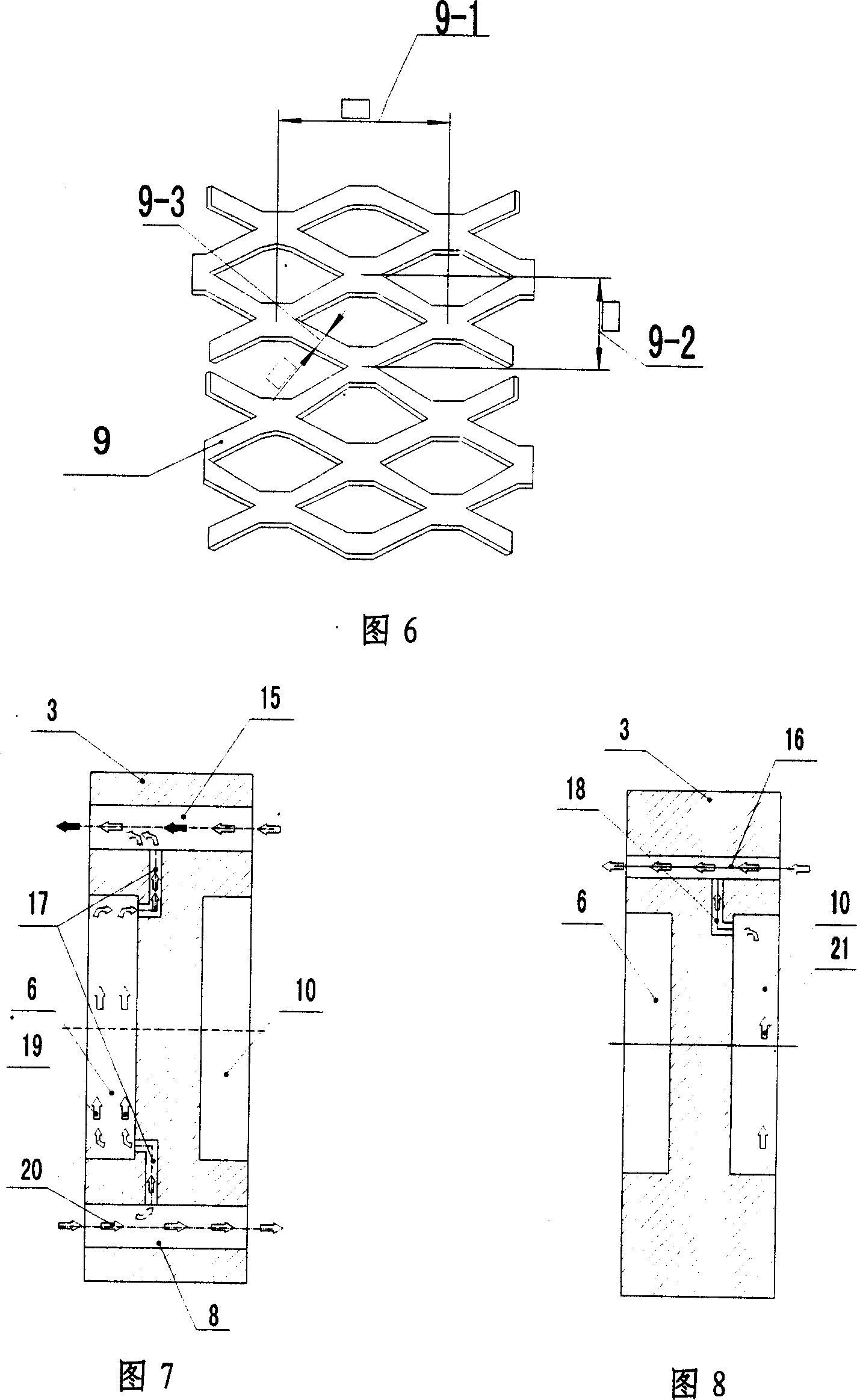

Filter-press type water electrolyzer

The invention belongs to an electrolysis device for producing hydrogen, in particular to a filter-pressing water electrolyser tank applied in the industry of hydrogen production with water electrolysis. Flexible metal or a netty main anode 7 knitted with metal wire, a netty auxiliary anode 8 and an anode support component 9 which is provided with a vented mesh to allow the passing of liquid and the function of elastic expansion are arranged in the anode room 6 of anode half groove 1 and bipolar unit groove 3; and flexible metal or a netty main cathode 11 knitted with metal wire, a netty auxiliary cathode 12 and an cathode support component 13 which has a vented mesh to allow the passing of liquid and the function of elastic expansion are arranged in the cathode room 10 of anode half groove 2 and bipolar unit groove 3; and the main anode 7 and the main cathode 11 are mounted in a film-type pole distance. The invention has a simple structure, convenient manufacture and maintenance, high hydrogen purity, small size and light weight; the voltage in the unit groove is 1.9 to 2.2v, the current efficiency is above 99 percent, the consumption of direct current is 4.5 to 5.0KW.h / Nm3H2 and the purity of hydrogen is 99.99 to 99.999 percent.

Owner:李士宏

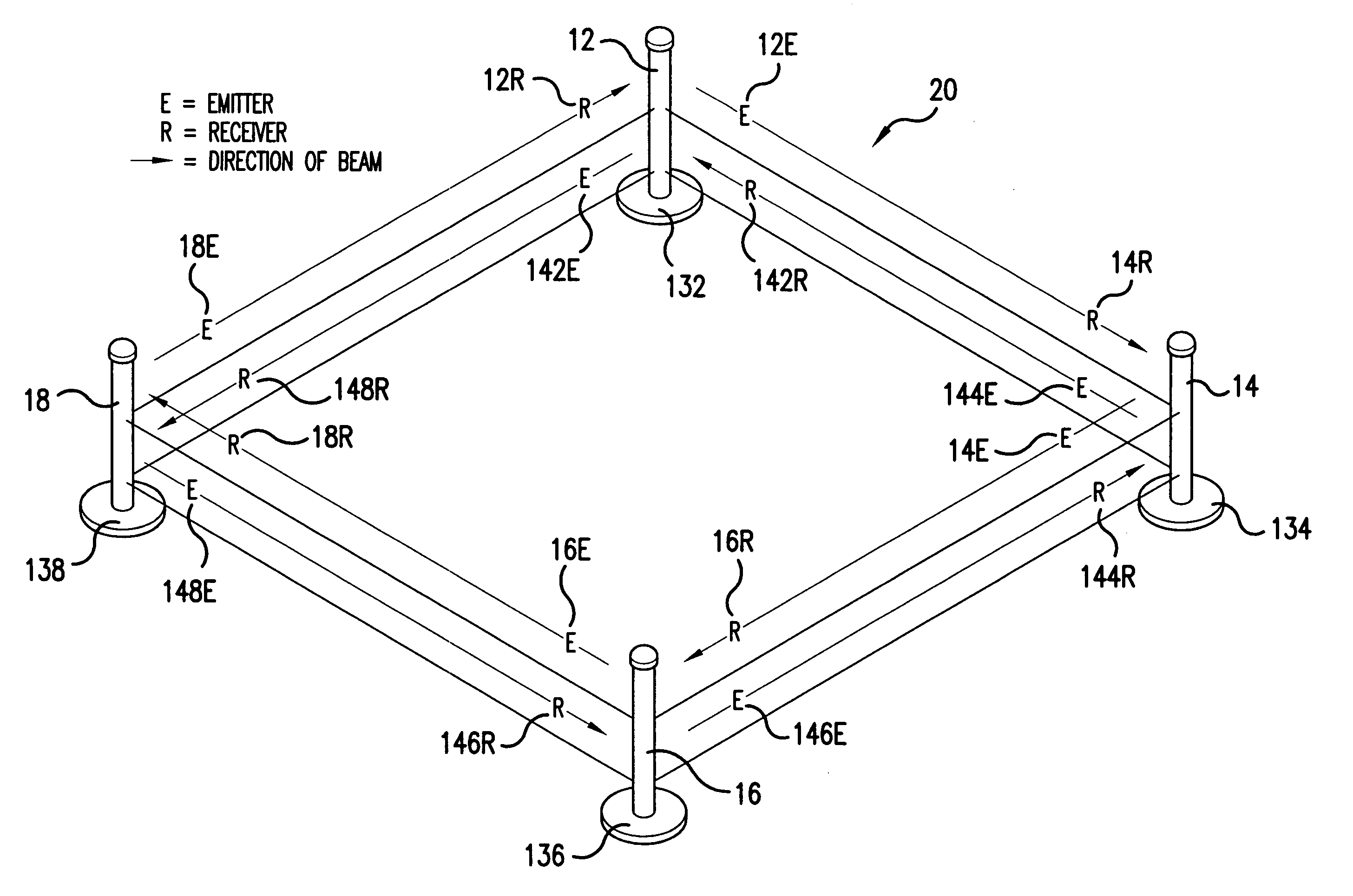

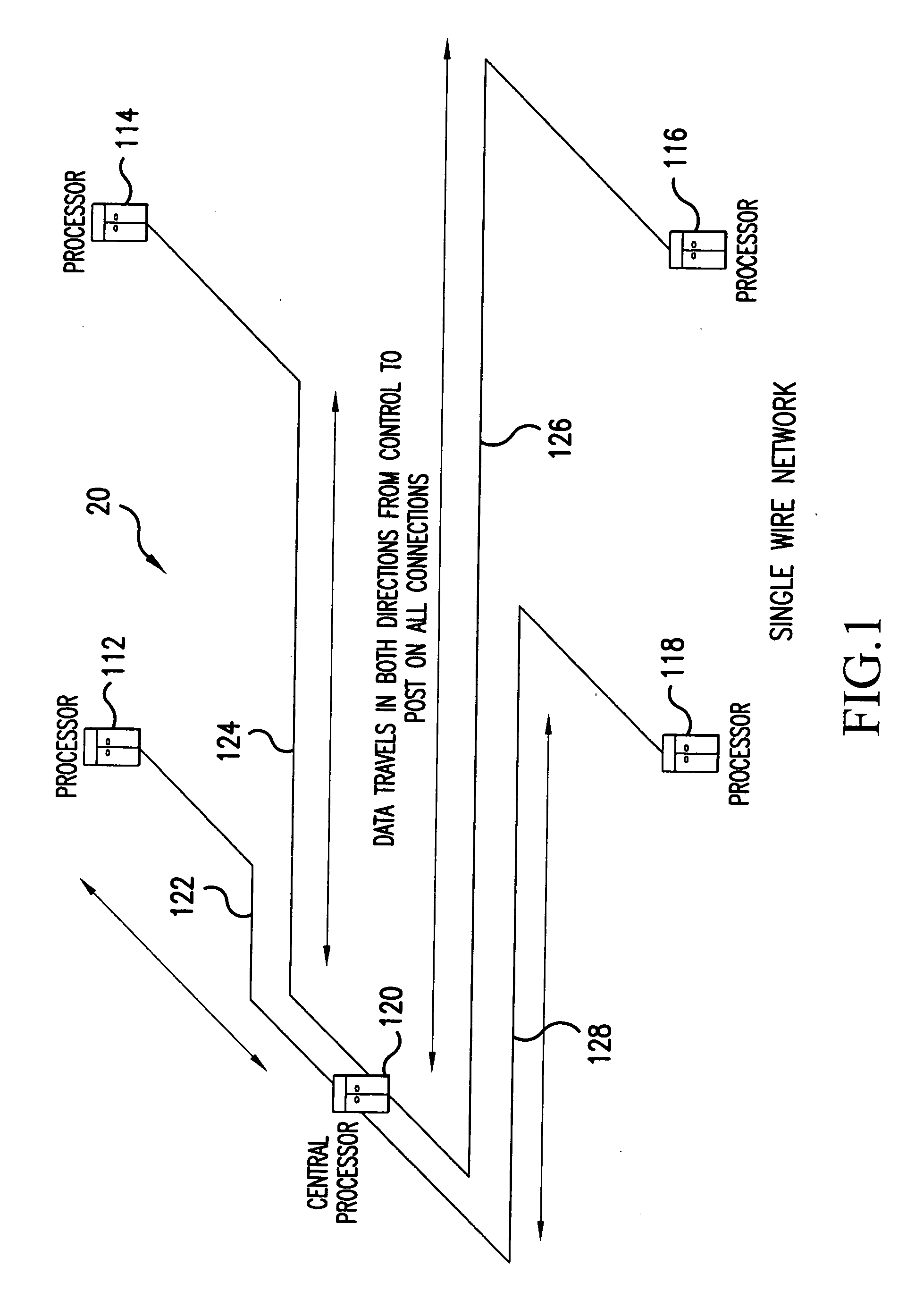

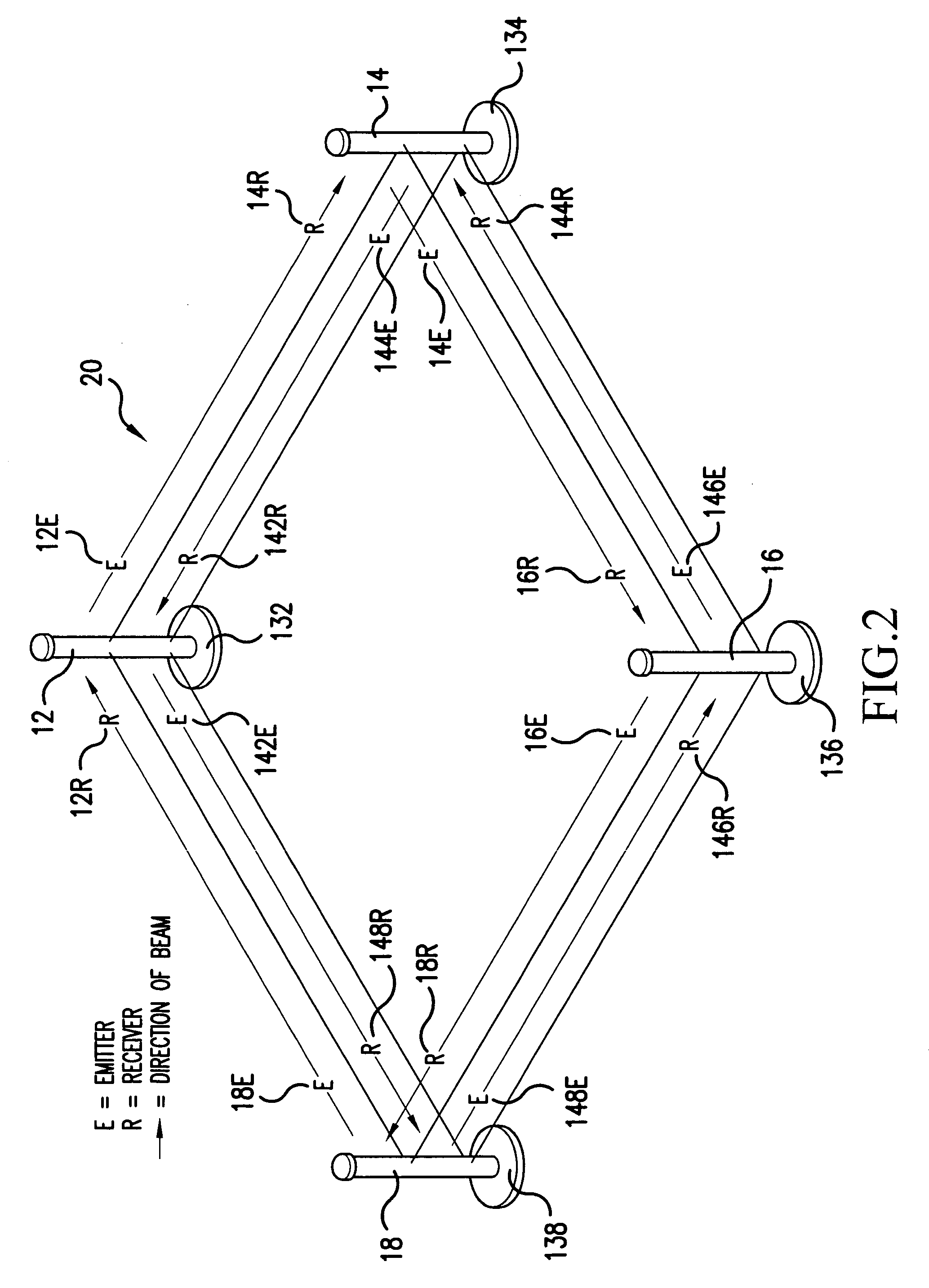

Virtual electronic perimeter fence with solar powered lights

A virtual electronic perimeter fence includes at least a first, second and third fence post each including an emitter for emitting a beam of infrared light at a predetermined frequency. The first, second and third fence posts include a receiver for receiving the predetermined frequency of infrared light emitted from a designated fence post. A beam of infrared light of a first frequency is emitted from the first fence post to the second fence post and a beam of infrared light of a second frequency is emitted from the second fence post to the third fence post and infrared light of a third frequency is emitted from the third fence post to the first fence post for providing a virtual electronic perimeter fence that provides an alarm if an interruption occurs in the beam of infrared light while eliminating cross-signals therebetween. A light, sound and video system may be provided.

Owner:SMARTPOOL

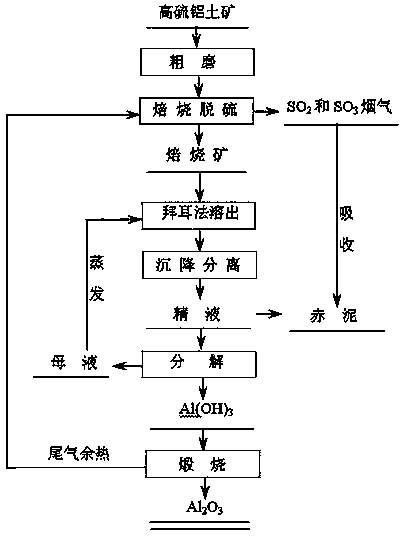

Method for producing alumina by use of high sulfur bauxite

InactiveCN103833056APromote dissolutionReduce energy consumptionAluminium oxides/hydroxidesEnergy consumptionMaterials science

The invention discloses a method for producing alumina by use of high sulfur bauxite, and the method comprises the following steps: carrying out coarse grinding on crushed high sulfur bauxite, roasting the crushed high sulfur bauxite to enable the sulfur content of the ore to be smaller than 0.7%, and then, directly entering an alumina production flow by use of a Bayer process. After the pre-roasting treatment, the leaching performance of the ore is perfected, a better leaching effect can be obtained without fine grinding, and the energy consumption in a fine grinding process of the ore is reduced, so that the method is beneficial to equipment selection in the roasting process and suitable for treating the high sulfur bauxite. The ore in the invention is roasted at a rough particle size, thus helping the overflow of the generated SO2 (or SO3) gas and ensuring a good roasting desulfurization effect; in addition, by adopting the method disclosed by the invention, the energy consumption in the fine grinding process of the ore is reduced, the over burning and dust pollution problems caused by superfine particle size are avoided, the cyclic utilization of energy source is achieved and the desulfurization cost is reduced.

Owner:GUIZHOU UNIV

Powder evanescent mode casting paint and application method and application thereof

InactiveCN106694798AGood bonding performance at room temperatureImprove breathabilityFoundry mouldsFoundry coresPhosphatePolyvinyl alcohol

The invention discloses powder evanescent mode casting paint and an application method thereof. The powder paint comprises the following components in percentage by weight: 88.9-89.7% of refractory aggregate, 3.7-4.5% of sodium base bentonite, 0.78-1.23% of polyethyl alcohol, 0.82-1.85% of aluminum dihydrogen phosphate, 0.32-0.44% of sodium carboxymethylcellulose, and 3.8-4.8% of expanded graphite. During preparing, all powder is added in a mixer for dry mixing to reach an uniform state to obtain the finished powder evanescent mode casting paint. Water by 23.5-37 weight% of the powder paint is firstly added in the mixer; the mixer is started; the powder paint is slowly added in the mixer; after materials are added, the stirring is continued by 1-2 hours; and then, an evanescent mode can be coated by the paint. The paint can achieve the effect of long-time storage without deteriorating by adding no formaldehyde in the raw materials; no surface active agent is added in the raw materials to prevent the trouble of adding a defoaming agent to defoam in subsequent use; the finished product is higher in strength at normal temperature or high temperature; and the paint is excellent in permeability, and cannot release poisonous substances.

Owner:HUBEI UNIV OF TECH

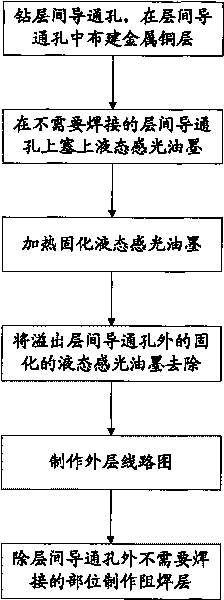

Processing technology of printed circuit board

ActiveCN101765298AProduction does not affectGood removal effectMultilayer circuit manufactureNon-metallic protective coating applicationSolder maskCopper

The invention discloses a processing technology of a printed circuit board, sequentially comprising the following steps of: drilling a conducting hole and establishing a metal copper layer in the conducting hole; stuffing a solder mask in the conducting hole with no need for welding; heating and solidifying the solder mask in the conducting hole; removing the solidified solder mask overflowing out of the conducting hole; and making a solder mask layer in the positions of the printed circuit board except for the conducting hole with no need for welding. The invention solves the processing problem that the solder mask overflows and covers plate faces without being covered by the solder mask to be inconvenient to remove when the conducting hole is near to a windowing part with the need for welding or when the conducting hole needs single-face windowing. The processing technology of the printed circuit board can be used for accurately making the conducting hole and the solder mask layer with low cost without affecting the making effect of the solder mask layers of other parts.

Owner:SHENNAN CIRCUITS

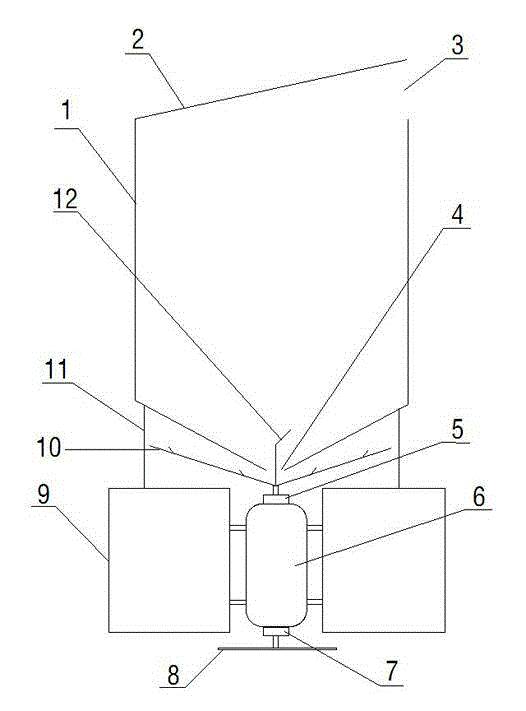

Floating type aerating and feeding dual-purpose machine

InactiveCN105432534ALow costReduce energy consumptionPisciculture and aquariaRemote controlElectric machine

The invention relates to a floating type aerating and feeding dual-purpose machine. The floating type aerating and feeding dual-purpose machine comprises a feed box, a feed box cover, a feed inlet, a feed outlet, a remote control clutch I, a motor, a remote control clutch II, a revolving paddle, pontoons, a feeding tray, a fixing rack, a drainage connecting rod and a remote controller, wherein the motor is fixedly connected with the pontoons; the pontoons are connected with the feed box; the remote control clutch I and the remote control clutch II are separately fixed at the two ends of the motor; and the feeding tray and the drainage connecting rod are mounted on an output shaft at the upper end of the motor, and the revolving paddle is mounted on an output shaft at the lower end of the motor. According to the floating type aerating and feeding dual-purpose machine, the revolving paddle or feeding tray is conducted and driven to rotate by making full use of power of the output shafts at the two ends of the motor, so that the water surface is stirred to aerate water, or feed in the feed box is thrown out by using a centrifugal force, and the dual purposes of aerating, feeding and saving electric energy and equipment are achieved; and the utilization ratio of the equipment is increased, the cost is reduced, and the energy consumption is lowered. According to the floating type aerating and feeding dual-purpose machine, a feeding machine can float on the water surface by using the pontoons, the former sector-shaped feed throw-out is changed into circular throw-out, the area of feeding is enlarged, and the food intake for fishes is facilitated.

Owner:李福海

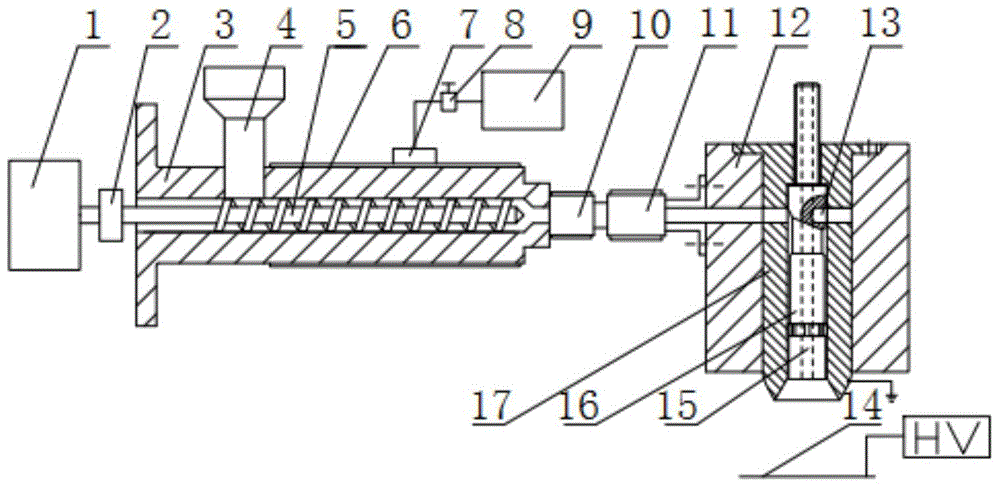

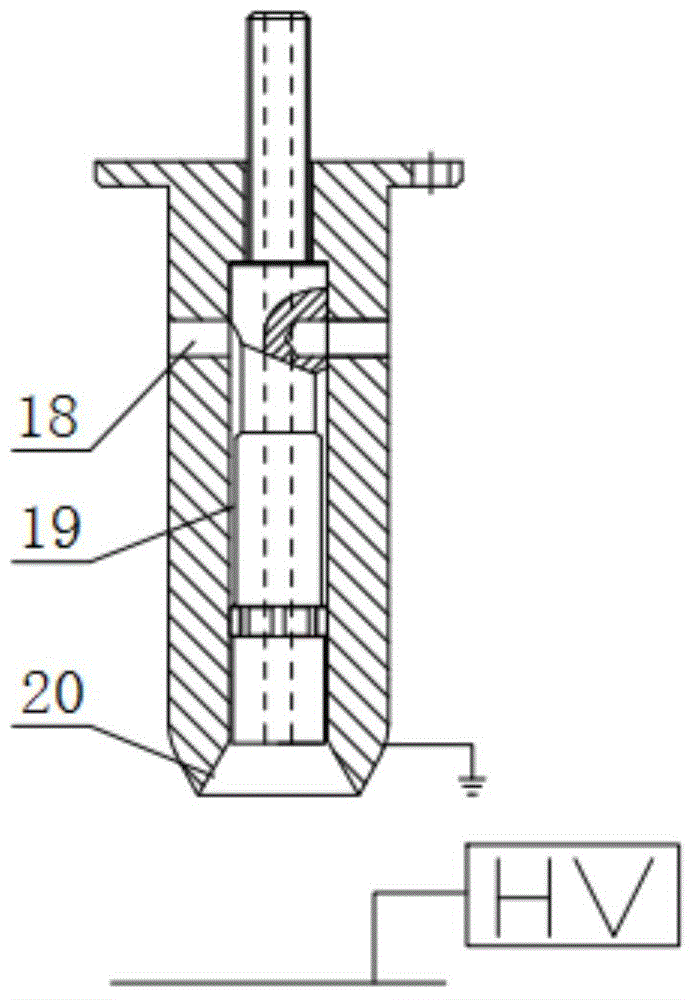

Melt electro-spinning device and technology capable of mixing supercritical gas

InactiveCN104894664AImprove uniformitySmooth feedingFilament forming substance formingArtificial thread manufacturing machinesFiberMolten state

The invention relates to a melt electro-spinning device and technology capable of mixing supercritical gas. The device comprises a power device, an extruding device, a supercritical gas generator and a melt electro-spinning device body. The technology comprises the steps that polymer is firstly added into a charging barrel, heated to a melt state, and mixed with supercritical gas conveyed by the supercritical gas generator; the mixture is conveyed to a static mixer, and the polymer and the supercritical gas form a gas / polymer homogeneous system through the static mixer; the mixture is fed to the melt electro-spinning device body, the polymer is blown, pulled and thinned under the action of high-speed hot gas flow input in an electric field between a spray nozzle and a receiving device and a gas flow channel, and finally the mixture is deposited on the receiving device to obtain fibers. According to the melt electro-spinning device and technology capable of mixing supercritical gas, the extruding device and the melt electro-spinning device body are combined, and therefore nanofibers with good uniformity can be prepared continuously and stably.

Owner:NINGBO GMF TECH

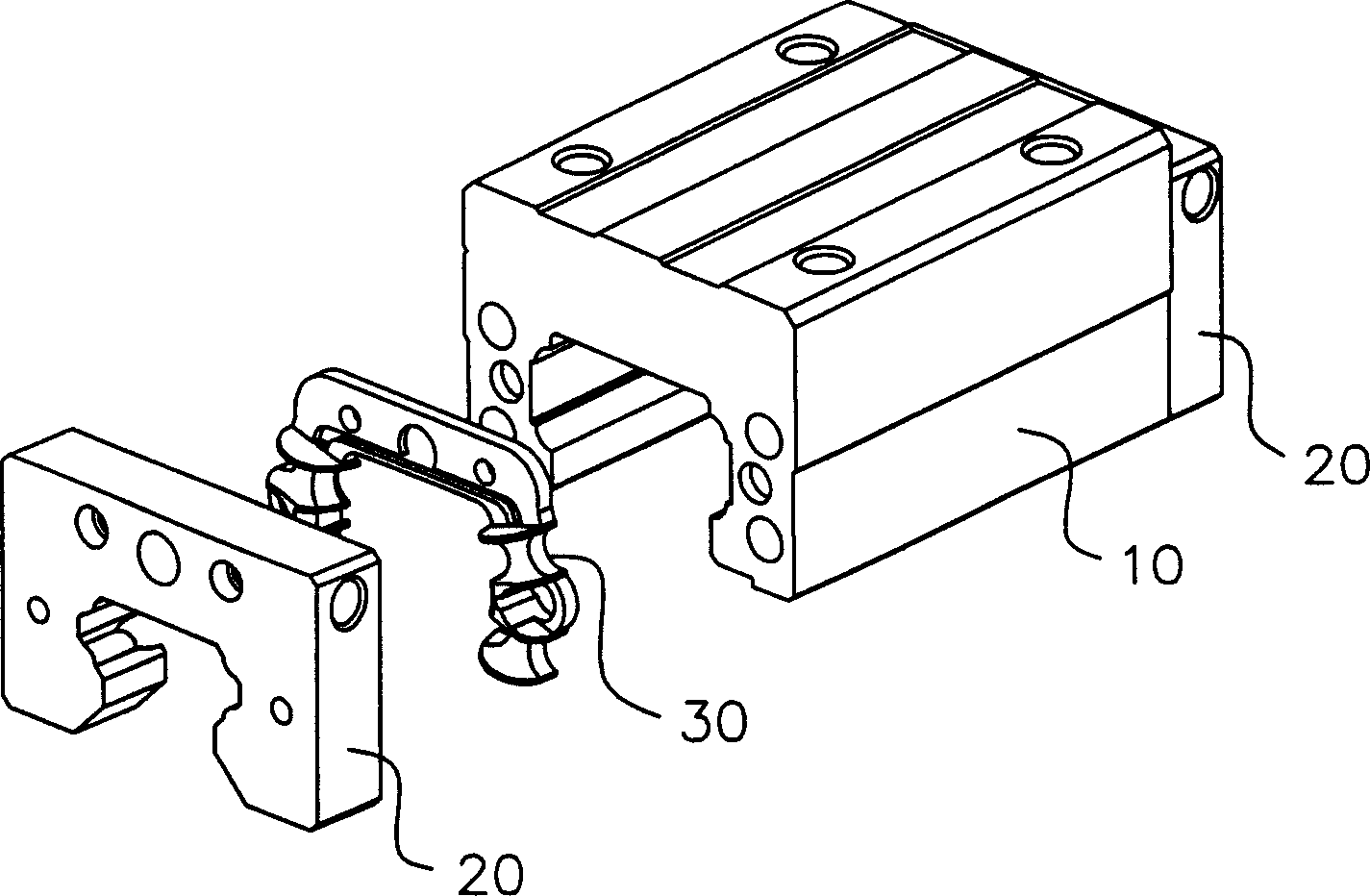

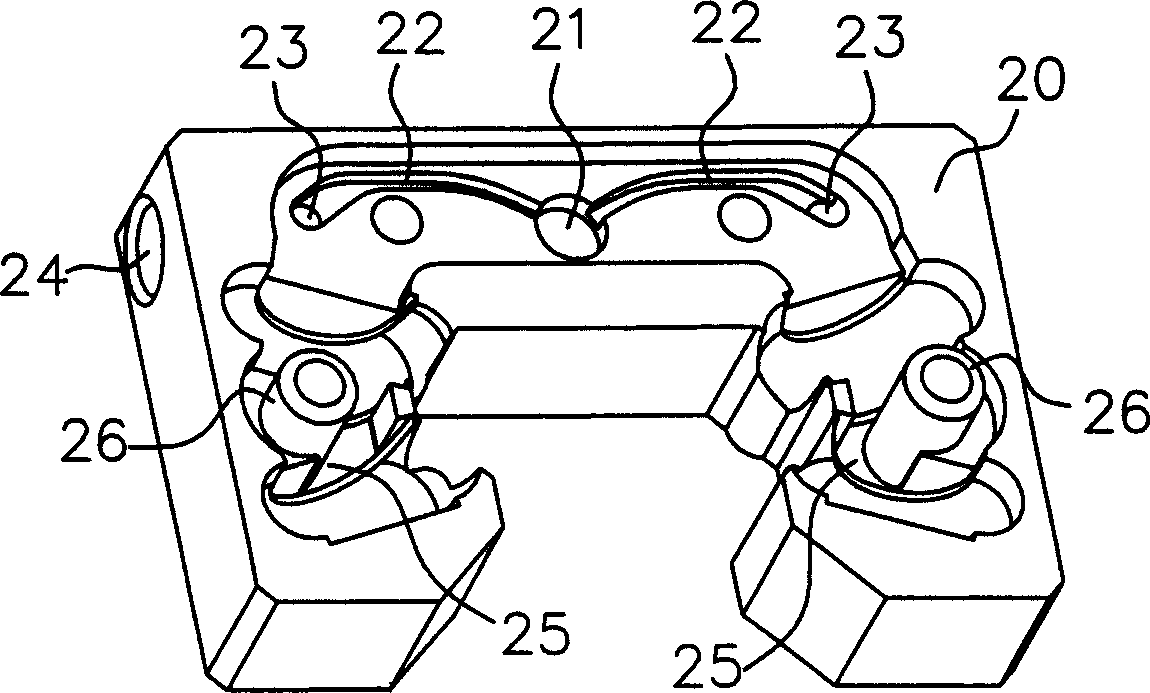

Linear sliding rail lubricating system

ActiveCN1641256AEasy to overflowImproved situationLinear bearingsEngine lubricationCounter flowEngineering

The invention is a structural design about a type of lubricative system of a linear slide-rail. It redesighs the oilway of lubricating oil--ameliorate planar oilway used to be known of linear slide-rail for tridimensional oilway,which makes lubricating oil circulate tridimensionally to interspace of counter-flow vat of above and below balls so that the lubricating oil can contribute to each counter-flow vat to lubricate balls. In addition, it sets up the lubricating location on the matching surface of end cap and cover board, but the slide block, in pairs or groups so that it can also prevent lubricating oil over falling from the matching surface of the end cap and the cover board to a certain degree to advance the leakproofness of oilway.

Owner:HIWIN TECH

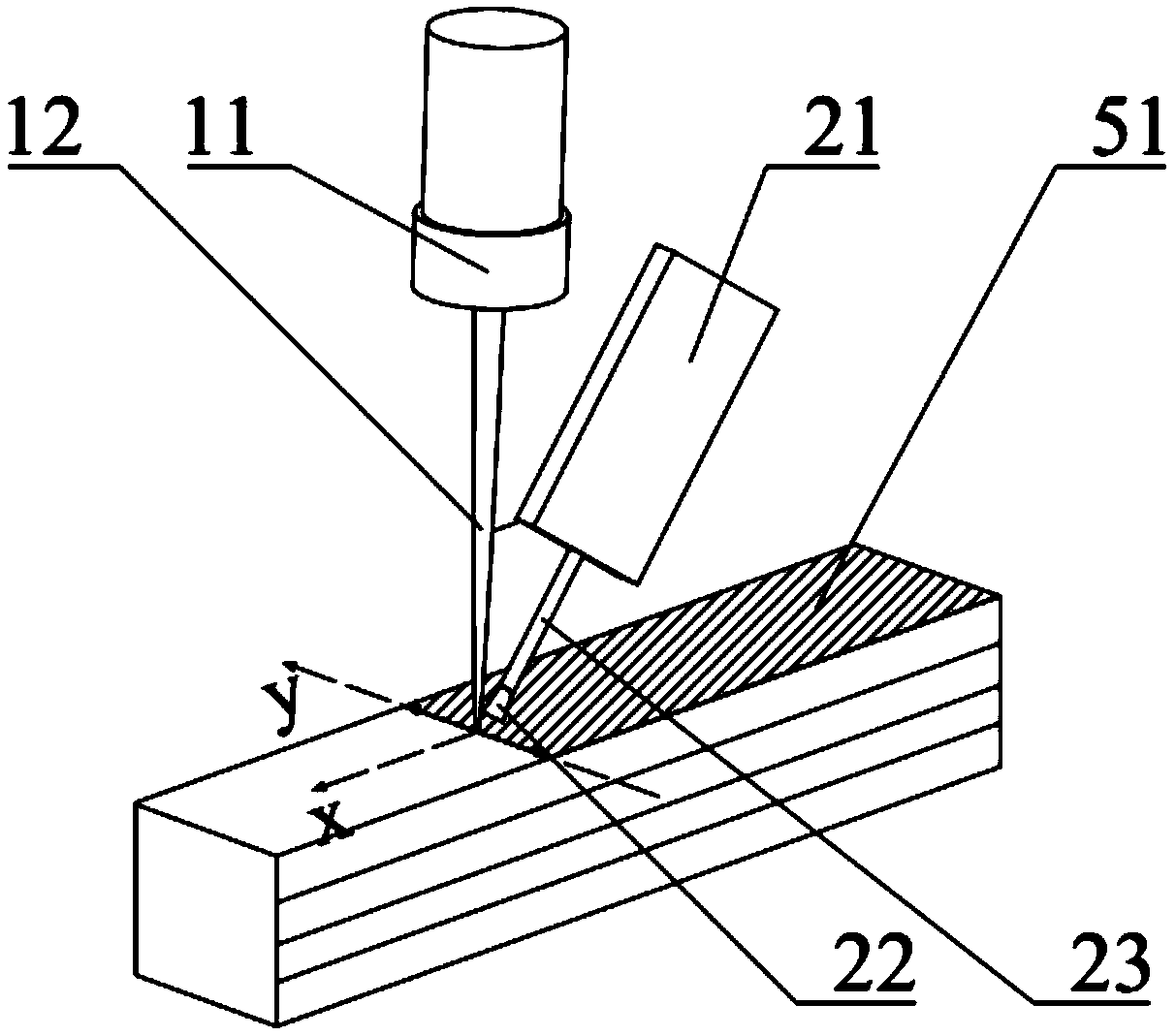

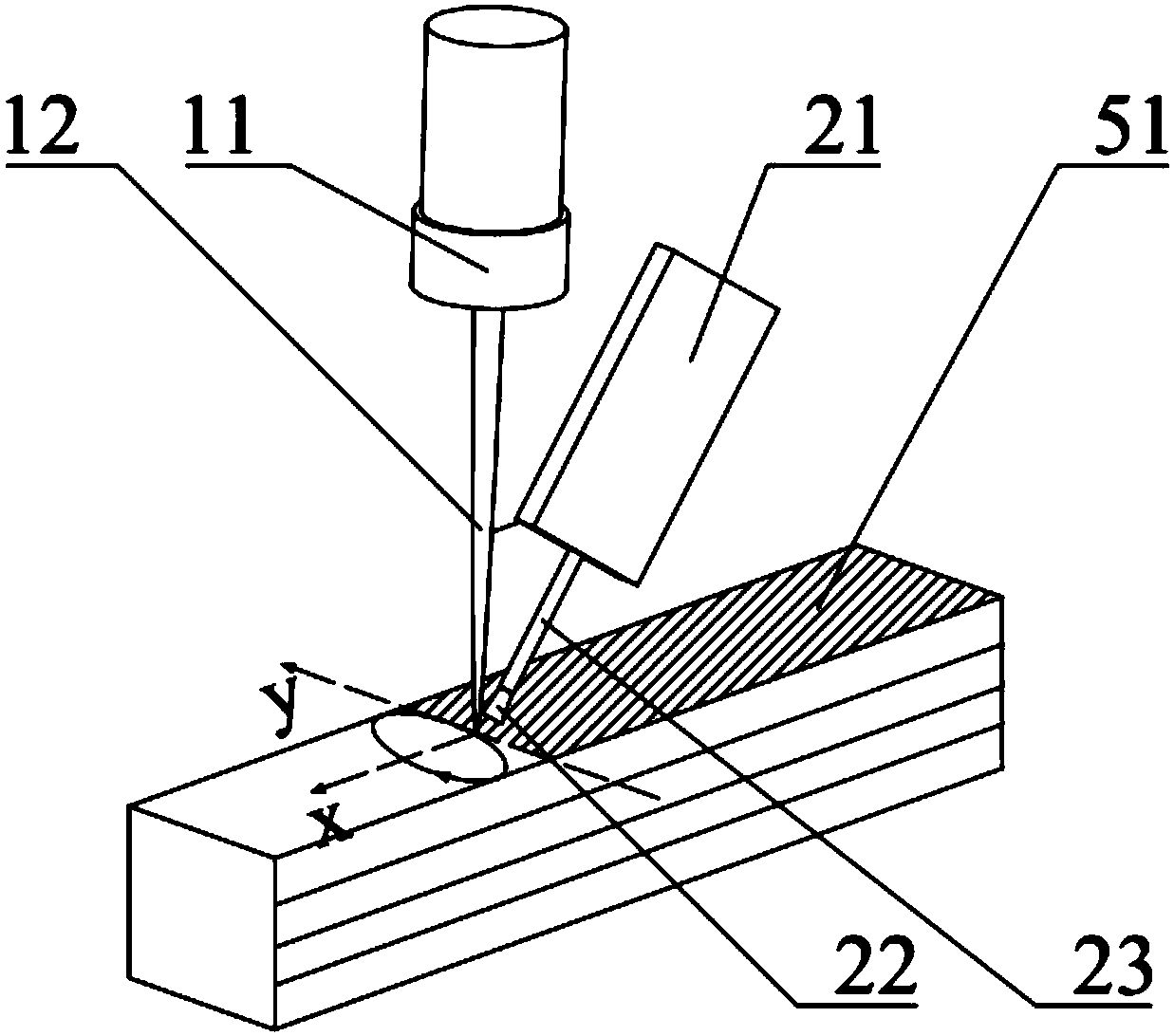

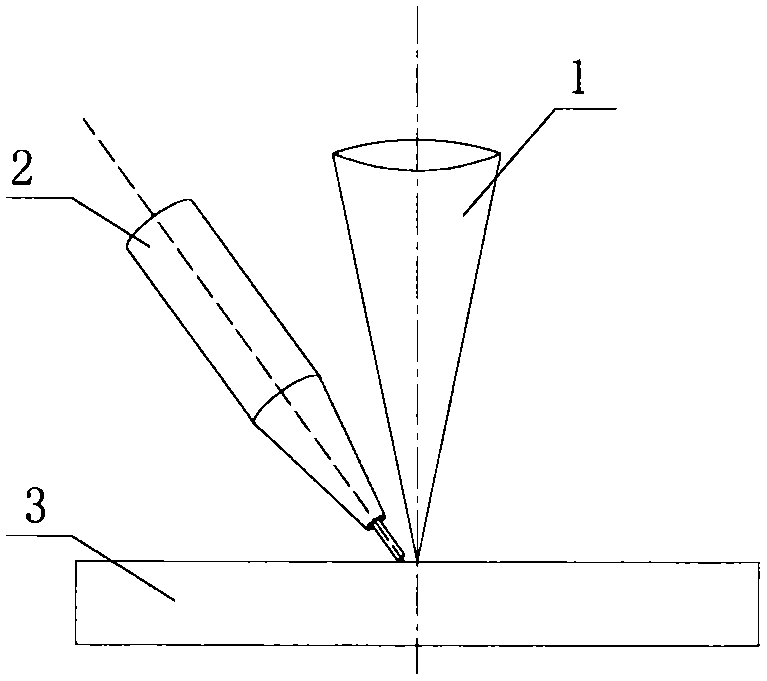

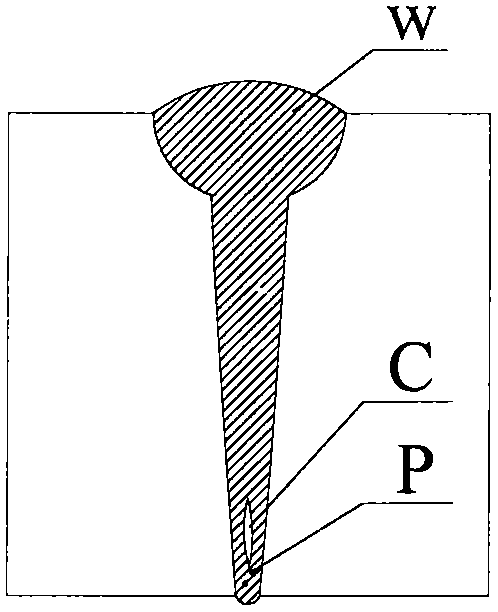

Laser-double side arc compound welding method for thick plate

ActiveCN105127595AGood fluidityConducive to overflowWelding/soldering/cutting articlesMetal working apparatusElectric arcOptical axis

The invention provides a laser-double side arc compound welding method for a thick plate, and solves the problems of welding line root defect, low laser energy utilization rate, complicated operation, time consumption, high equipment cost and the like during thick plate welding of the existing welding method. The laser-double side arc compound welding method comprises the following steps: 1, processing a groove in a part to be welded according to the form of a welding joint; 2, fixing a workpiece, and cleaning the groove; 3, arranging a laser bundle and a first welding gun on one side of the joint, wherein a first included angle of 30-45 degrees is formed between the optical axis of the laser bundle and the middle axial line of the first welding gun, and a preset gap is formed between the incidence point of the laser bundle and the tail end of a welding wire of the welding gun; arranging a second welding gun on the other side of the joint in a mirror image manner; 4, forming a double-side penetrating melting pond at the joint in a welding process by energy matching, wherein an electric arc plasma generated by the first welding gun is in contact with a laser-induced plasma generated by the laser bundle, thus diluting the laser-induced plasma.

Owner:上海临仕激光科技有限公司

Raw bamboo protective agent and processing technology thereof

InactiveCN102687729APlay a role in long-term protectionMoth proofBiocidePest repellentsPunchingMethyl carbamate

The invention discloses an insect-resistant, corrosion-resistant, and mildew-resistant raw bamboo protective agent which comprises the following components: ammoniacal copper quaternary, N-2-benzimidazolyl methyl carbamate, and a penetrating agent, and also discloses processing technology of the raw bamboo protective agent, which comprises the following steps: performing bamboo joint punching processing of a fresh felled raw bamboo, naturally drying; putting the raw bamboo into a pressure impregnation tank, closing the tank door, turning on a vacuum pump to vacuumizing the impregnation tank; adding the raw bamboo protective agent till the impregnation tank is filled up with the vacuum pump being turned on; turning off the vacuum pump, turning on a pressure pump till the raw bamboo protective agent becomes saturated in the raw bamboo; releasing the pressure, discharging the protective agent in the impregnation tank. The purpose of the invention is to provide the raw bamboo protective agent which can simultaneously provide insect-resistant, corrosion-resistant, and mildew-resistant effects for raw bamboos, and also to provide the processing technology of the raw bamboo protective agent, which allows the protective agent to completely penetrate into the raw bamboo and thus to reach the effect of long-term raw bamboo protection without environment problems.

Owner:SOUTHWEST FORESTRY UNIVERSITY +1

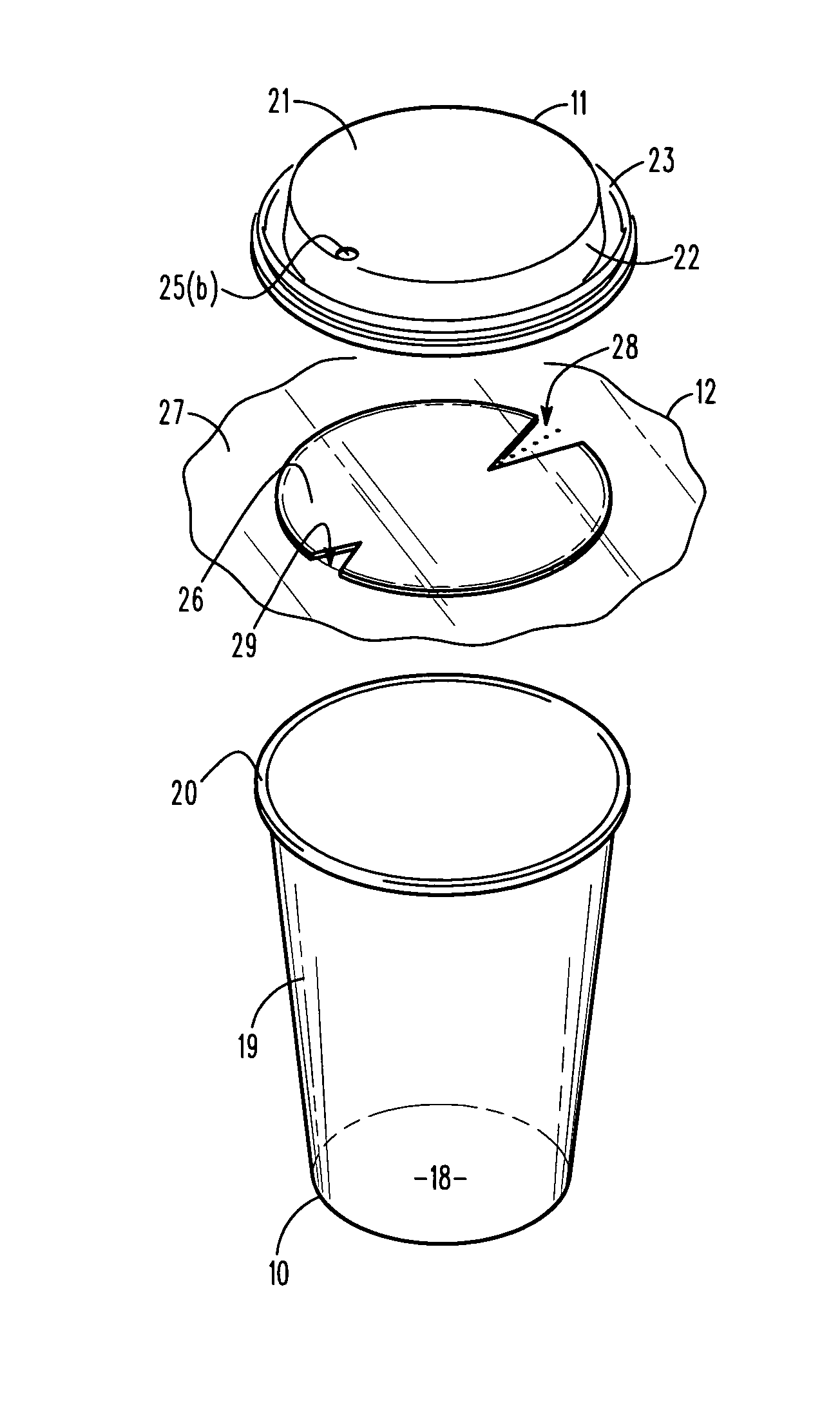

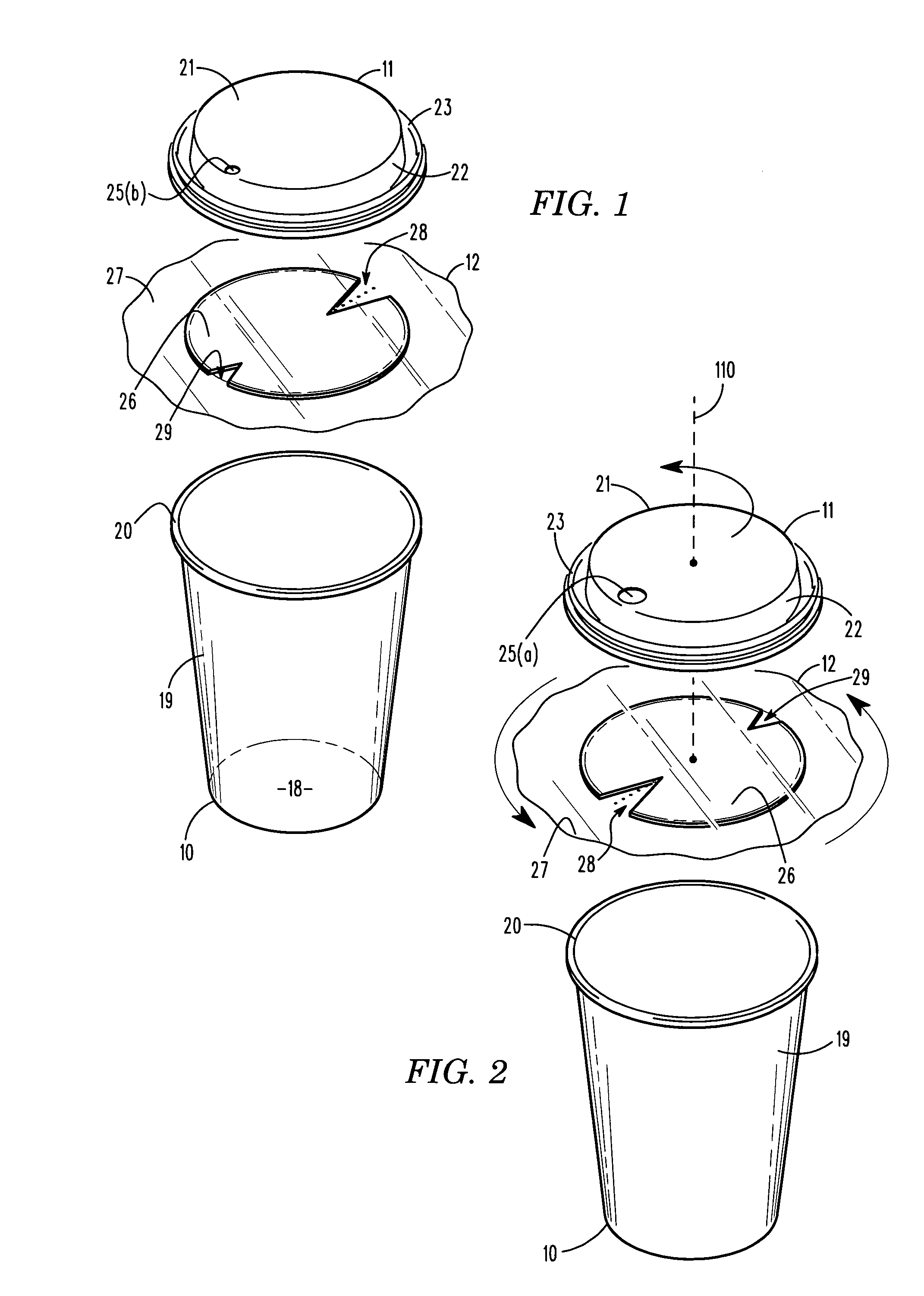

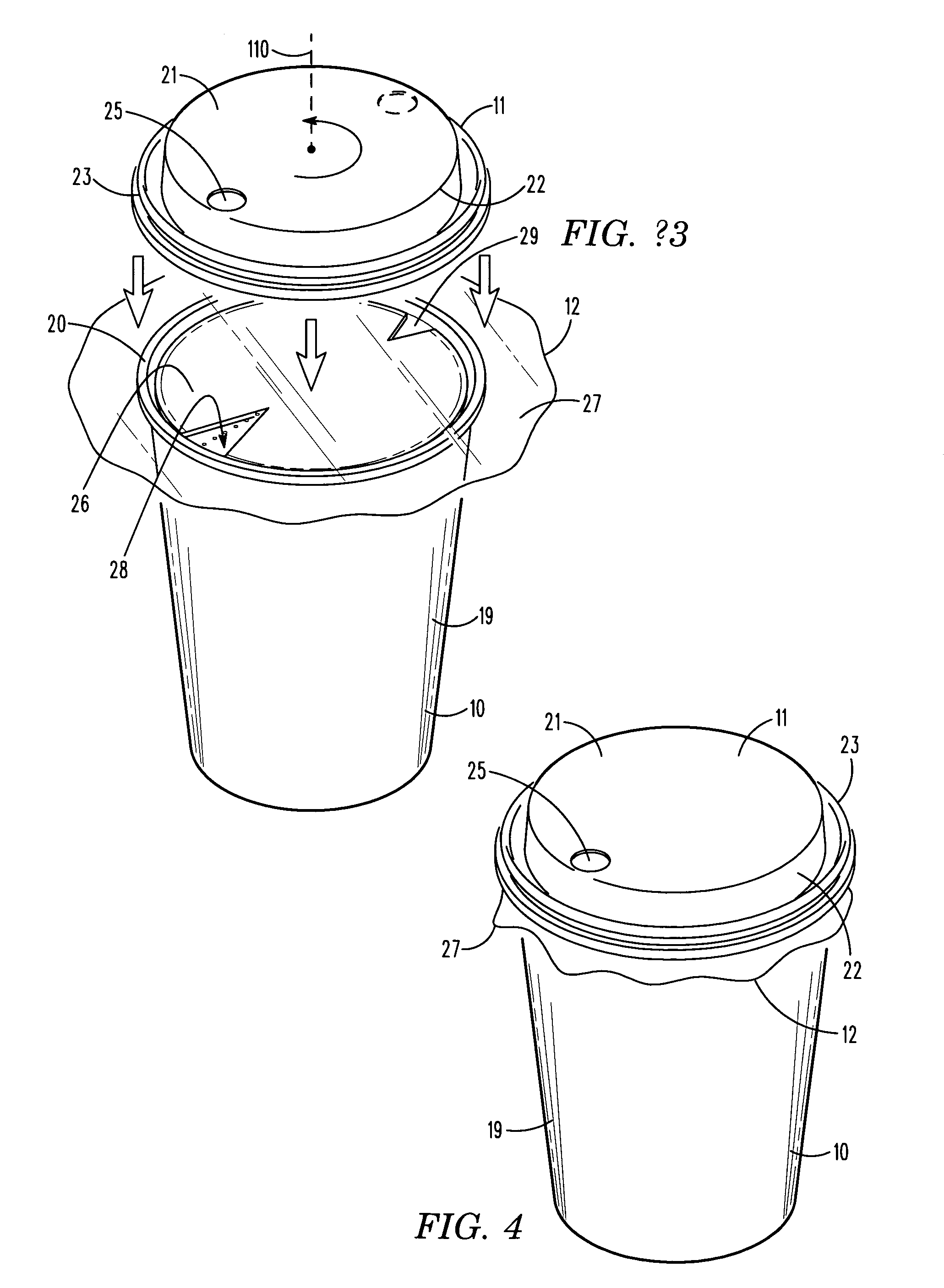

Hot beverage container assembly, insert, and methods

ActiveUS20120205384A1Efficient heatingAvoid spendingClosuresDomestic cooling apparatusEngineeringMechanical engineering

An insert assembly is outfitted upon a lidded beverage container for enabling the user to transfer heat from a relatively hot assembly-contained beverage so as to prevent scalding prior to consumption. The insert assembly comprises a damming structure and a rim-engaging structure. The damming structure is formed from a semi-rigid material and is sized and shaped for receipt within the upper rim perimeter of a container structure. The rim-engaging structure is formed from a flexible material and extends outwardly from the beverage-damming structure. The rim-engaging structure is received intermediate the upper container rim and a lid for defining beverage-containing and beverage-cooling compartments. The insert structure comprises first and second apertures for outletting beverage and inletting air intermediate the beverage-containing and beverage-cooling compartments. The beverage-cooling compartment receives heat from the beverage received therewithin and thereby enables the beverage to cool before being outlet via a primary outlet of a lid.

Owner:LEA SAVENOK 2003 TRUST

Making method of lotus leaf and Radix Puerariae tea

The invention discloses a making method of a lotus leaf and Radix Puerariae tea. The method comprises the procedures of cleaning, slicing, sun-drying, baking, mixing and packaging, and concretely comprises the following steps: cleaning lotus leaves, slicing, sun-drying, stir-frying with slow fire, and spreading after a baking fragrance appears to prepare a lotus leaf tea; cleaning Radix Puerariae, slicing, sun-drying, baking, spreading to prepare a Radix Puerariae tea; and mixing the lotus leaf tea with the Radix Puerariae tea according to a weight ratio, uniformly stirring, and packaging according to 15g each bag. The lotus leaf and Radix Puerariae tea is simple to make; the stir-fried lotus leaf tea has a baking fragrance; compared with a non-stir-fried lotus leaf tea, the stir-fried lotus leaf tea has the advantages of easy dissolution of nutritional components, and fragrant mouthfeel after immersion; the lotus leaf and Radix Puerariae tea made by mixing the lotus leaf tea with the lotus leaf and Radix Puerariae tea according to a weight ratio of 1:1.5-2 can eliminate the smooth and greasy feeling of Radix Puerariae powder, does not influence respective efficacies, is in favor of the human healthcare, and is in favor of the utilization and sale of the lotus leaf and the Radix Puerariae after immersion. The lotus leaf and Radix Puerariae resources are abundant.

Owner:ZHENJIANG GAOGUAN FOOD

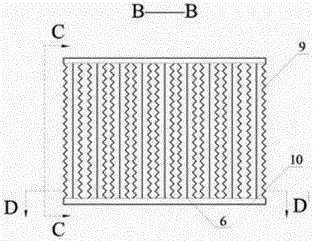

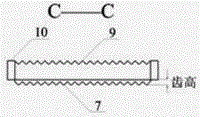

Uniform overflow type liquid distributor

InactiveCN104307192AAvoid effusionEasy to overflowEvaporator accessoriesEvaporators with horizontal tubesButt jointEngineering

The invention relates to a liquid distribution device, and particularly relates to a uniform overflow type liquid distributor used for uniformly distributing liquid on a horizontal heat exchange pipe. The liquid distributor comprises a flange, a feeding pipe, a horizontal branch pipe, a spray pipe, a folded-plate type overflow groove, a connecting channel and liquid distributing teeth, wherein the flange is arranged at a feeding opening; one end of the feeding pipe is connected with the flange, and the other end of the feeding pipe is connected with horizontal branch pipe; the spray pipe and the horizontal branch pipe are not in central butt joint, and occurrence of liquid accumulation in the spray pipe can be avoided; liquid in the overflow groove slowly increases by using the spray pipe, so that liquid overflows stably and has small fluctuation.

Owner:SHENYANG AEROSPACE UNIVERSITY

Preparation method for instant tremella

InactiveCN102669647AKeep appearanceEasy to overflowClimate change adaptationFood preparationBiotechnologyTremella

The invention relates to a preparation method for instant tremella. The method comprises the steps as follows: steeping tremella in cleaning water, breaking up tremella cells with ultrasonic waves, uniformly spreading, placing on a reticular plate coated with Teflon or a plate with water filtering function, curing with high-temperature steam, and then drying to obtain finished instant tremella. By adoption of the method, the instant tremella retains all the natural elements of tremella and has the advantages of quickness in rehydration, good condition, stability in production, high efficiency, low cost and easiness in automatized mass production.

Owner:CHONGQING UNIV

Novel rotational-flow air-floatation sewage treatment device

InactiveCN102874964AEasy to separateMeet the requirements of cleaner productionFatty/oily/floating substances removal devicesMultistage water/sewage treatmentThree stageFiltration

The invention relates to a novel rotational-flow air-floatation sewage treatment device. The novel rotational-flow air-floatation sewage treatment device comprises a vertical barrel body and is characterized by also comprising a hydrocyclone, a static mixer, a cover plate and a boss of a parabolic plane. Compared with the conventional like products, the novel rotational-flow air-floatation sewage treatment device has the advantages that the equipment has a small size and occupies small area; many technologies of rotational flow, air floatation, filtration and the like are combined, so that a three-stage separation effect is achieved and oil and water can be separated completely; and the equipment has a wide application range and can meet the requirements of petroleum and chemical enterprises on cleaning production.

Owner:MORIMATSU (JIANGSU) HEAVY IND CO LTD

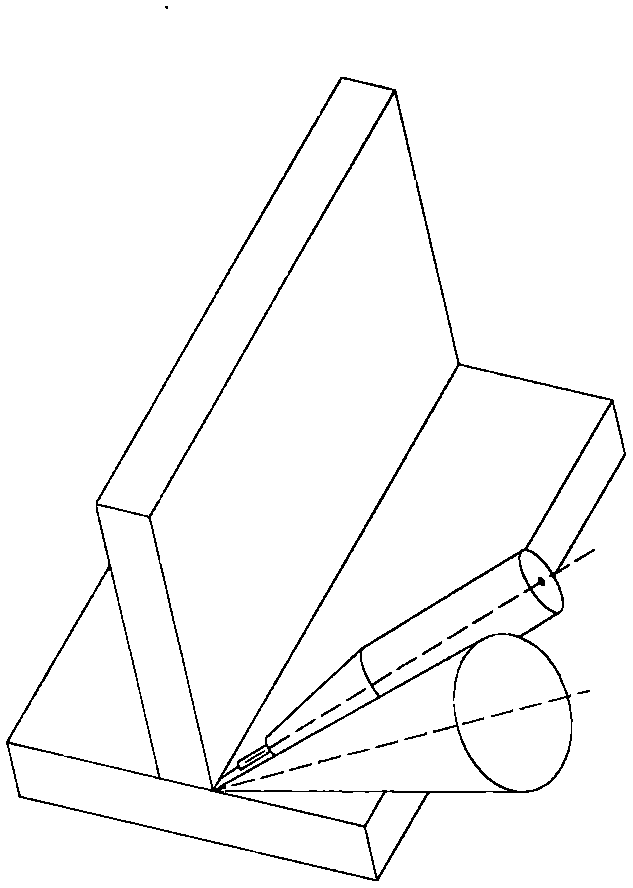

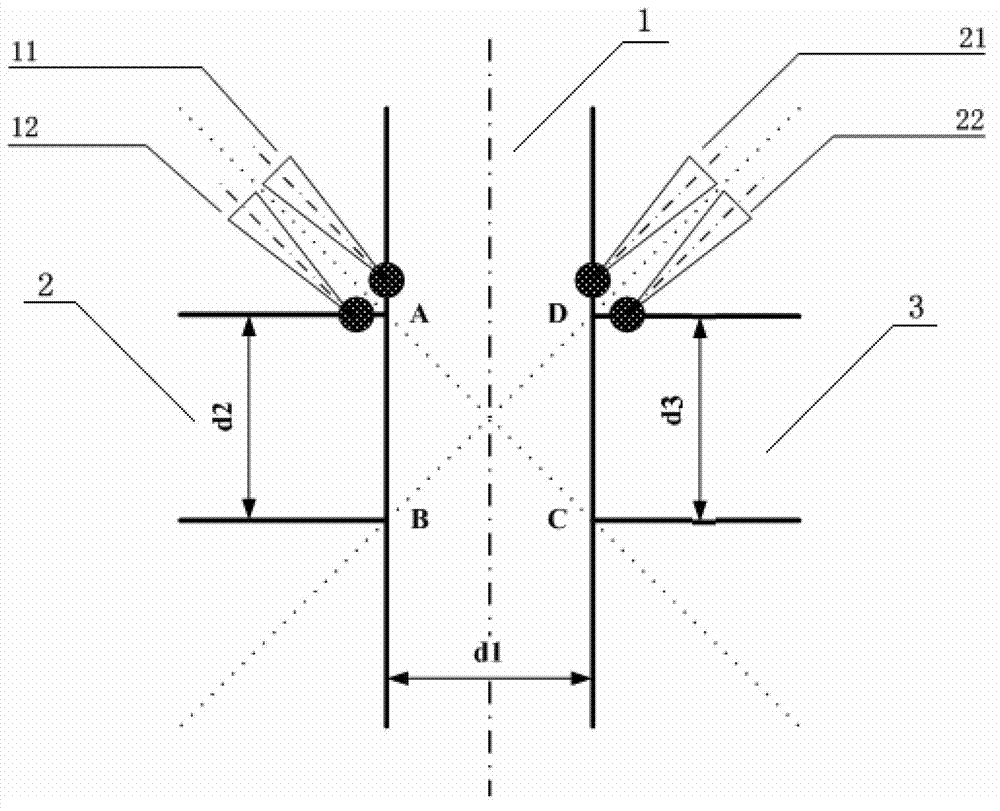

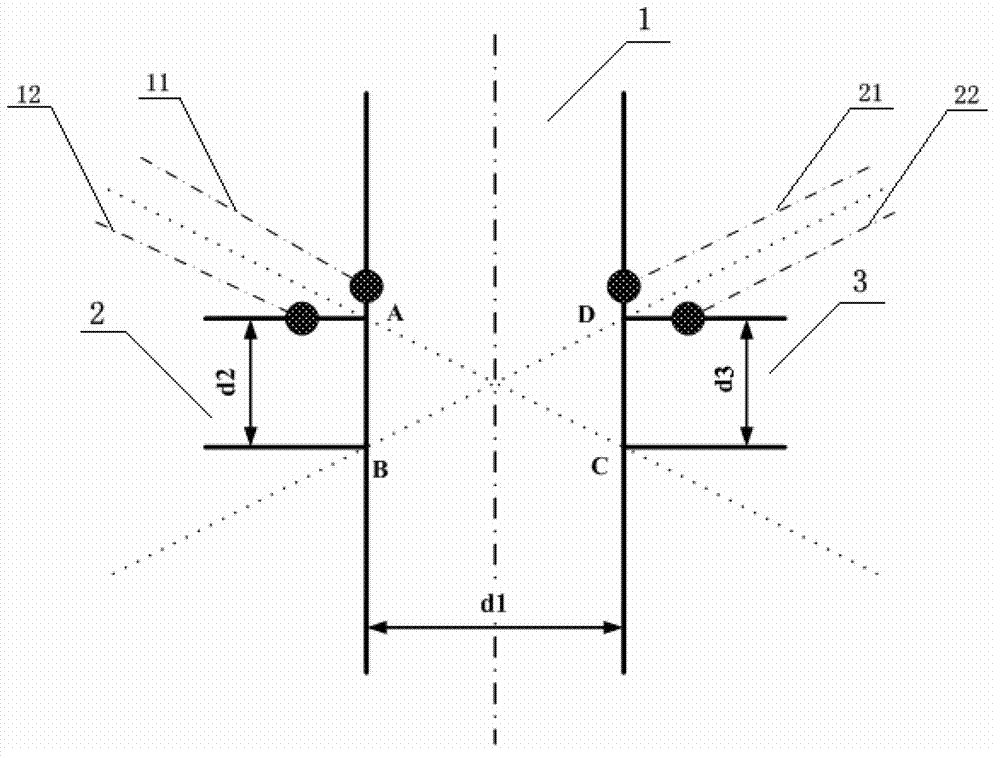

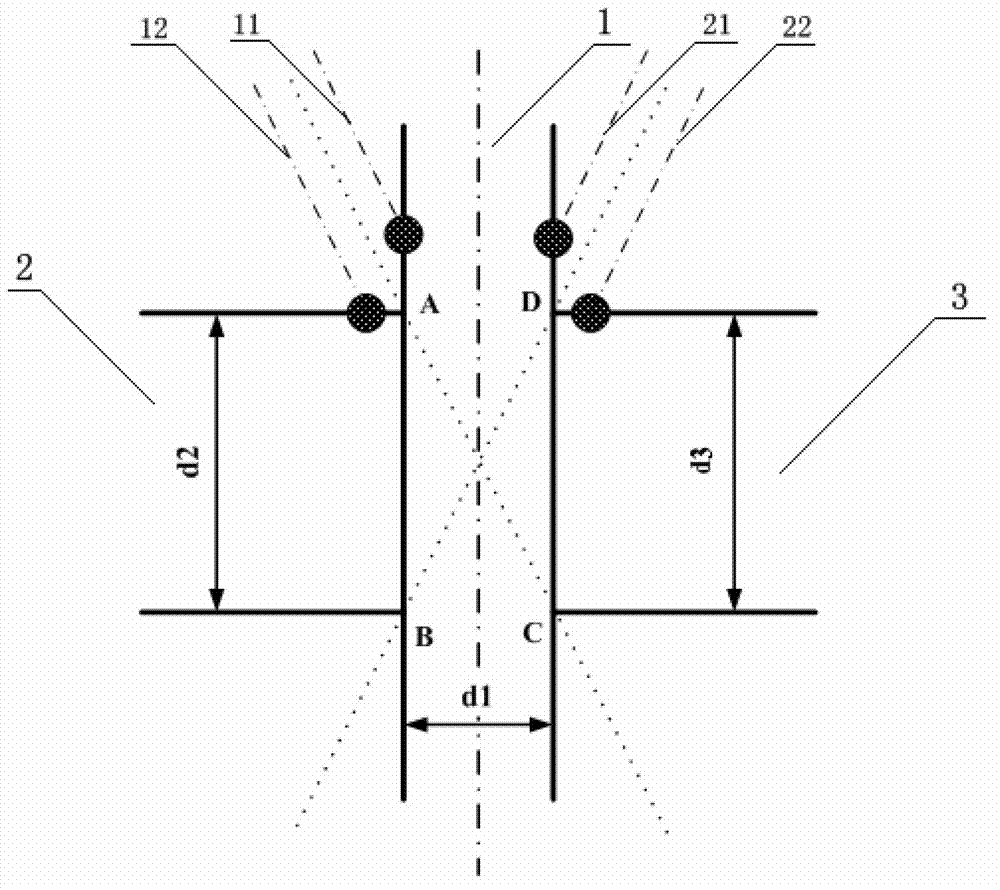

Synchronous dual-light beam laser welding method of crossed joint

ActiveCN102922135AImprove performanceEasy to overflowLaser beam welding apparatusLight beamOptoelectronics

The invention provides a synchronous dual-light beam laser welding method of a crossed joint and relates to a welding method. The invention solves the technical problem of low welding efficiency and poor weld quality existing in the existing single-light beam laser welding method. The welding method comprises the following steps: respectively emitting a main light beam a and a main light beam b by applying two lasers, arranging the two lasers on the two sides of a crossed joint supporting plate in an imaging manner, dividing the main light beam a into a welding light beam 11 and a welding light beam 12, dividing the main light beam b into a welding light beam 21 and a welding light beam 22 and synchronously welding the welding light beam 11, the welding light beam 21 and the welding light beam 12. The synchronous dual-light beam laser welding method has the beneficial effect that aiming at the weld characteristics and the quality requirements of the crossed joint, the problems of uneasiness in stress deformation control, poor weld quality and low welding efficiency existing in the current crossed joint welding process are solved.

Owner:HARBIN INST OF TECH

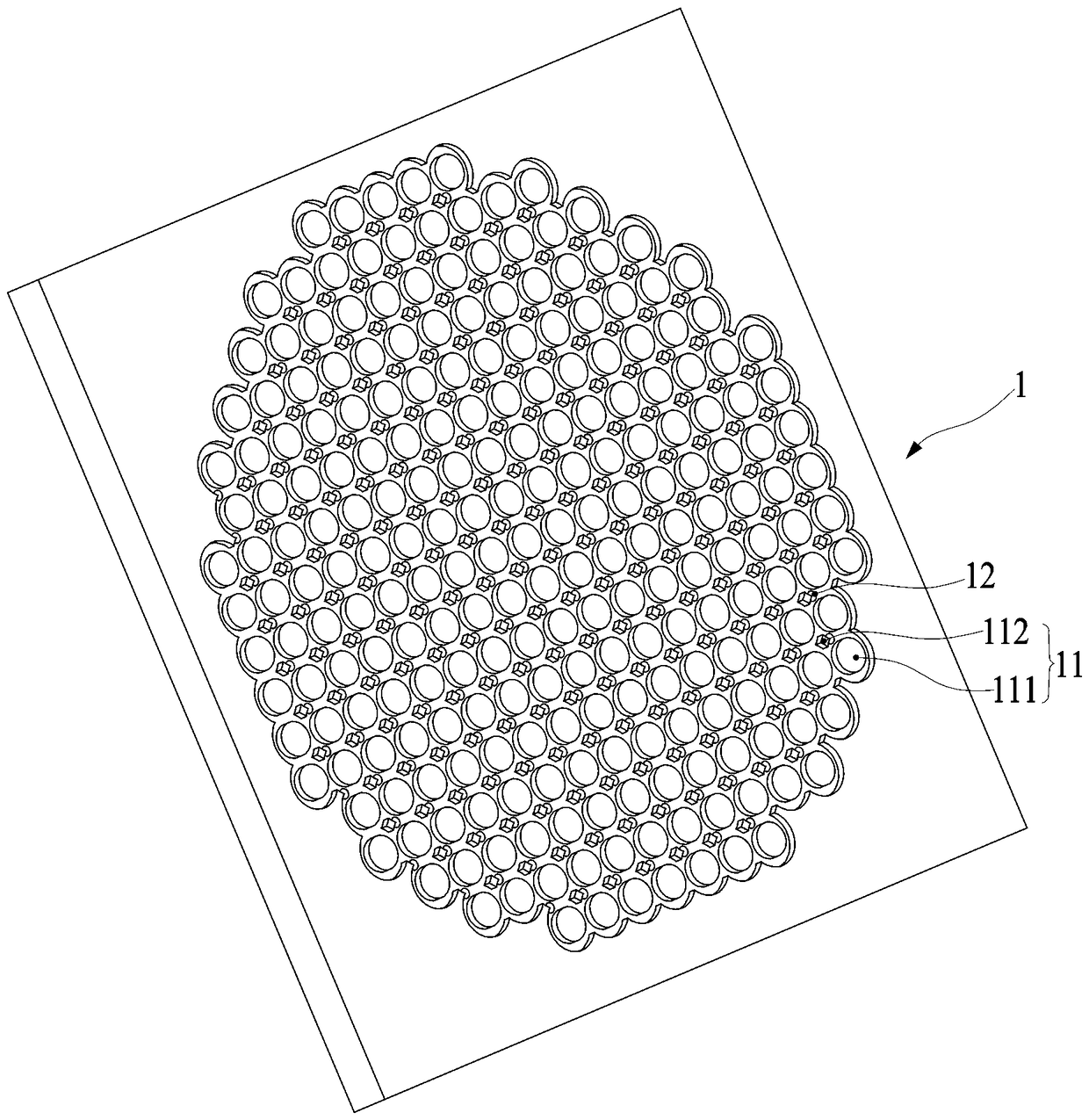

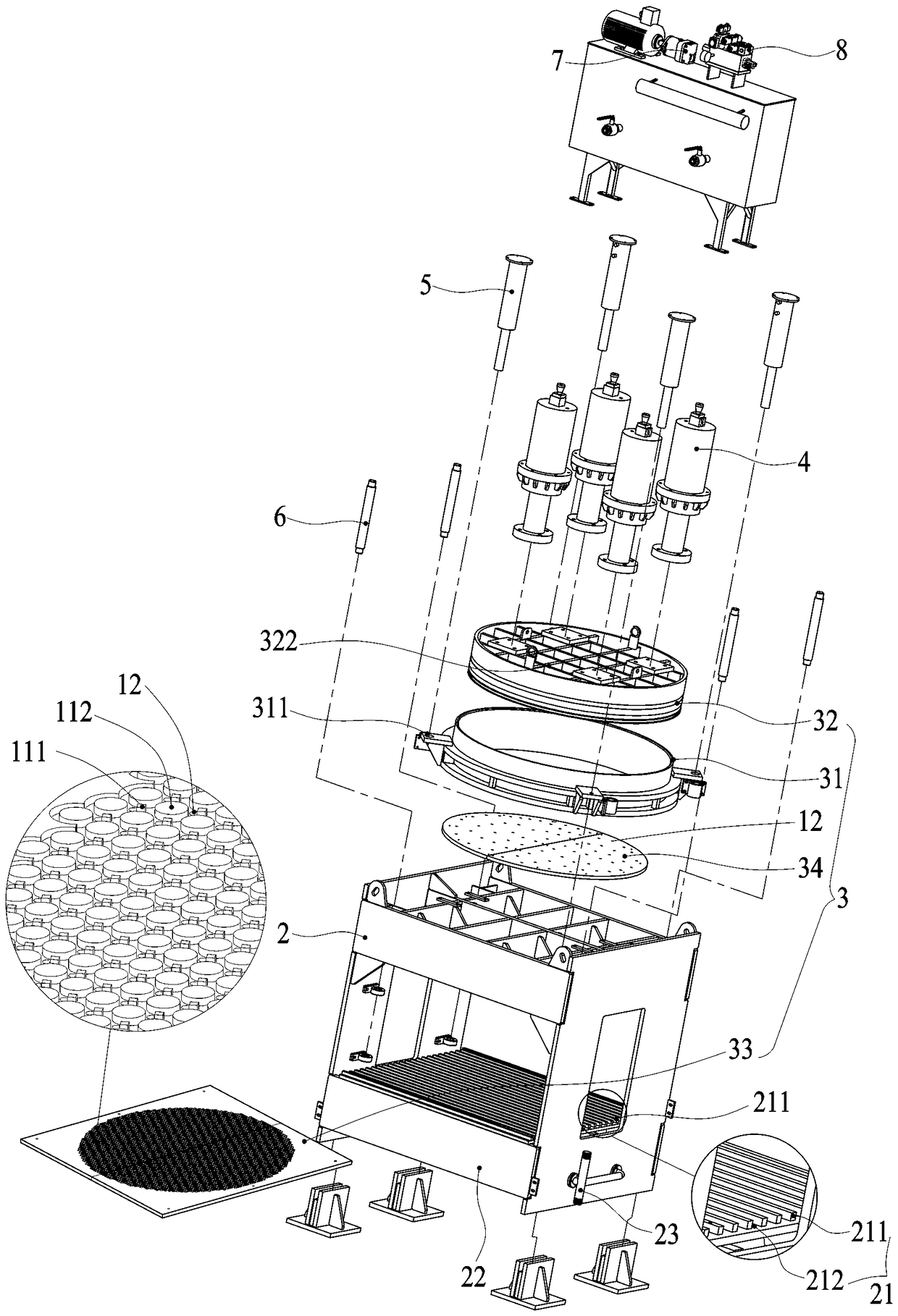

Filter plate and high-pressure piston type solid-liquid separation device made of same

PendingCN108859213AIncrease contact areaIncrease the number ofSludge treatment by de-watering/drying/thickeningPressesControl systemEngineering

The invention discloses a filter plate and high-pressure piston type solid-liquid separation device made of the same. Vertical and horizontal staggered projecting particles are arranged on the surfaceof the filter plate facing filtered objects, and water passing through holes penetrate the filter plate and are formed among the projecting particles. The high-pressure piston type solid-liquid separation device comprises a frame, a filter component, a piston oil cylinder, a lifting oil cylinder, a guide rod, an oil pump and a control system, the lifting oil cylinder drives a filter cylinder to vertically move along the guide rod, the piston oil cylinder drives a piston to vertically move along the filter cylinder, a first filter plate body and a second filter plate body are provided with thefilter plate, and the projecting particle surfaces of the first filter plate body and a second filter plate body are oppositely arranged. By the aid of the scheme, the extruding surface of the filterplate is provided with point-like distributed projecting particles, the contact areas among the filter plate and the filtered objects are greatly increased, more moisture can be extruded by the filter plate under the same extruding force, and solid-liquid separation effects are good.

Owner:厦门厦工重工有限公司

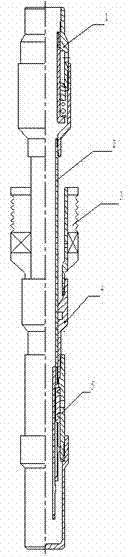

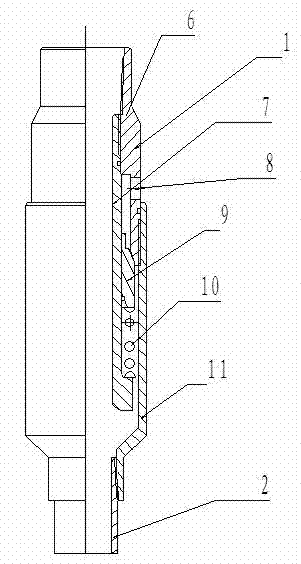

Down-hole steam injection string of thick-oil thermal production well

The invention discloses a down-hole steam injection string of a thick-oil thermal production well. The down-hole steam injection string is capable of protecting a casing in a steam injected well, improving the dryness of steam at the bottom of the well, and improving the steam injection heat efficiency and the steam injection effect. The steam injection string comprises a heat insulation pipe and a wall-hook packer; the heat insulation pipe, a backwashing valve and a sealed telescopic pipe are orderly connected to form an internal steam injection string; the wall-hook packer is orderly connected with a sealing sleeve and a switch assembly to form an external steam injection string; the wall-hook packer of the external steam injection string is down and sealed and hung on the inner wall of the casing; the sealed telescopic pipe of the internal steam injection string is inserted in the switch assembly of the external steam injection string and is capable of sliding in the sealing sleeve. The down-hole steam injection string of the thick-oil thermal production well can be reused after being put down once; the steam injection quality is obviously improved, the oil-steam ratio is increased, and an obvious oil increasing effect is achieved. The down-hole steam injection string of the thick-oil thermal production well is simple in structure and reliable in working; besides, the swept volume of the steam and multi-turn steam injection efficiency are improved, the energy source is thoroughly saved, the casing is effectively protected, and the defect of leakage at the wellhead casing head of the existing steam injection string is eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing refined level lactide from recovered polylactic acid

ActiveCN102746270ASimplify production stepsReduce environmental pollutionOrganic chemistryPolylactic acidCrusher

The invention relates to a method for preparing refined level lactide from recovered polylactic acid. The method includes the following steps of: A. crushing a recovered polylactic acid material by a crusher; B. conducting melting: subjecting the crushed recovered polylactic acid material to melt extrusion in a double-screw extruder, putting the obtained melt into a predepolymerization kettle, thus obtaining a polylactic acid melt; C. at a temperature of 180-250DEG C and in the presence of a catalyst, subjecting the polylactic acid melt to a chain breakage reaction to cause breakage of a melt molecular chain and decline of the number average molecular weight of the melt to less than 5000; D. bringing the chain broken polylactic acid melt to a depolymerization reaction under the conditions of a temperature of 150-250DEG C and a vacuum degree ranging from -0.1 to -0.09MPa to generate a lactide crude product; and E. subjecting the lactide crude product to melt crystallization for separation so as to obtain refined lactide. Detected by a conventional method, the refined level lactide produced by the invention has content up to more than 99.5% and optical purity up to over 99.9%.

Owner:XIAOGAN ESUN NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com