Synchronous dual-light beam laser welding method of crossed joint

A welding method and cross-shaped technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low welding efficiency and poor welding seam quality, so as to improve welding quality, improve welding efficiency, and easily overflow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

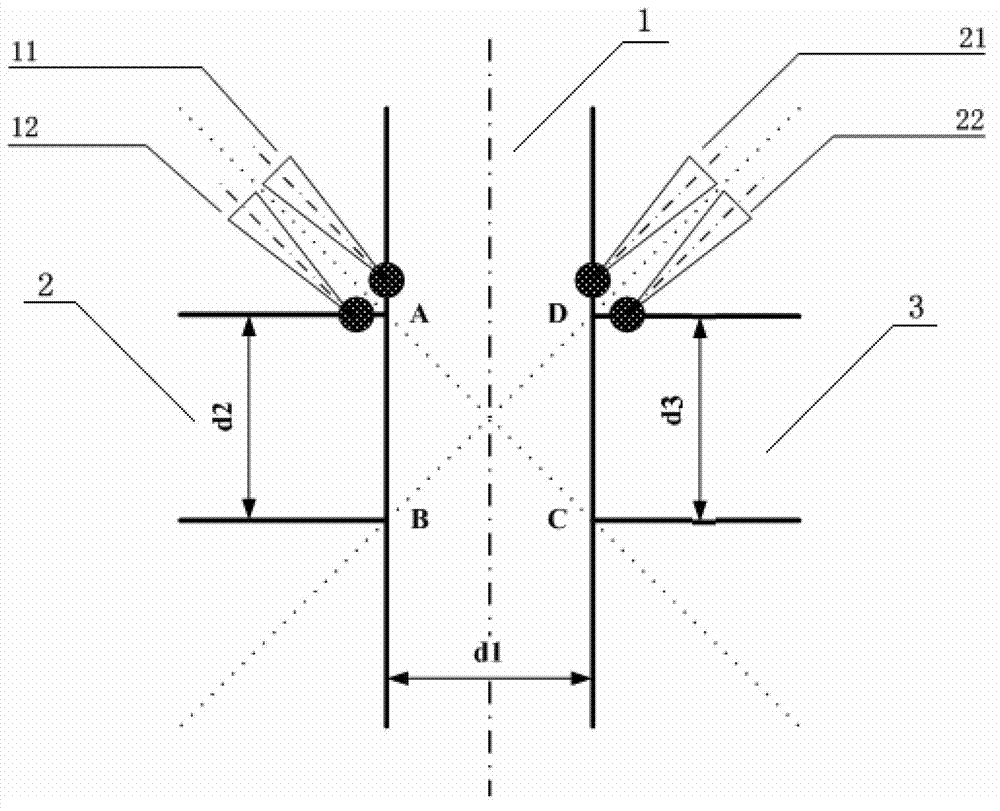

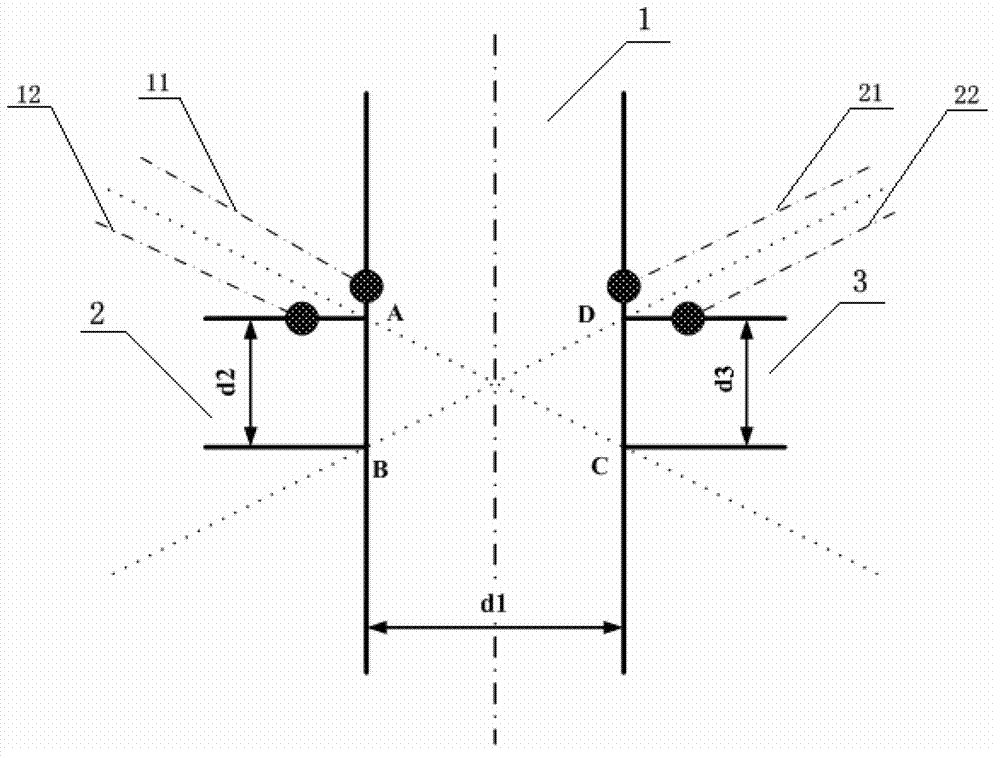

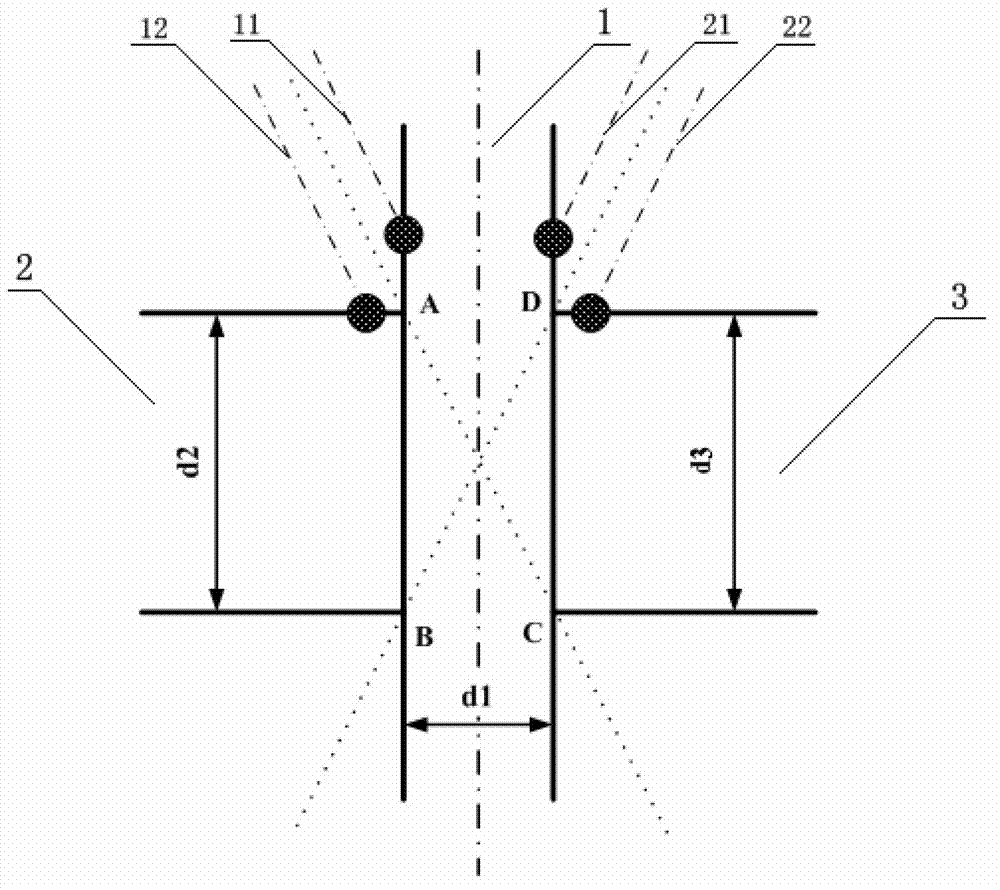

[0015] Specific implementation mode 1: In this implementation mode, the laser synchronous double-beam welding method for cross-shaped joints is carried out according to the following steps:

[0016] Two lasers are used to emit the main beam a and the main beam b respectively. The two lasers are mirrored on both sides of the cross-shaped joint support plate 1, and the main beam a is divided into the welding beam 11 and the welding beam 12. The focusing spot of the welding beam 11 and the The focusing spots of the welding beam 12 are arranged in parallel and act on both sides of the cross-shaped joint diagonal line AC composed of the support plate 1, the support plate 2 and the support plate 3 at equal distances. The optical axis of the welding beam 11 and the welding beam 12 The optical axes are all parallel to the diagonal line AC, the main beam b is divided into a welding beam 21 and a welding beam 22, the focus spot of the welding beam 21 and the focus spot of the welding bea...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the energy of the welding beam 11 is 1 / 2 of the energy of the main beam a. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 in that the energy of the welding beam 12 is 1 / 2 of the energy of the main beam a. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com