Patents

Literature

246results about How to "Good for deformation control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

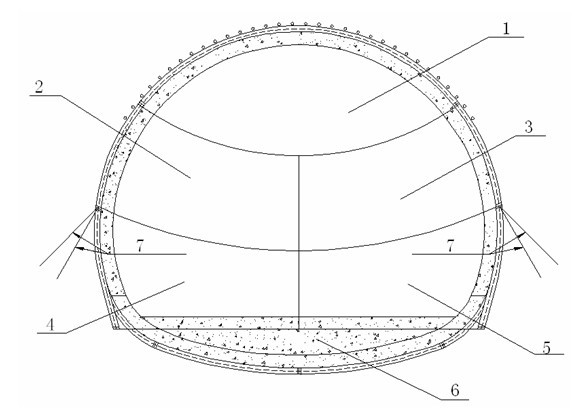

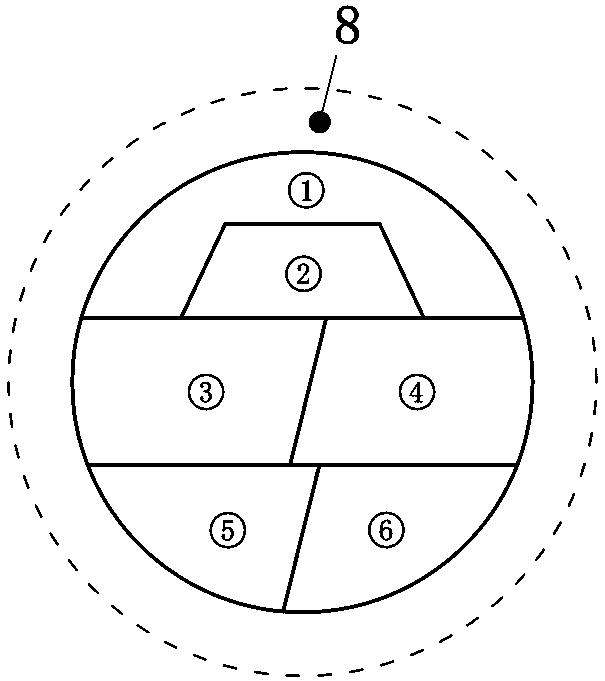

Large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method

ActiveCN102562075AMeet the requirements for enhanced controlsSpeed up early closure timesUnderground chambersTunnel liningShortest distanceRock tunnel

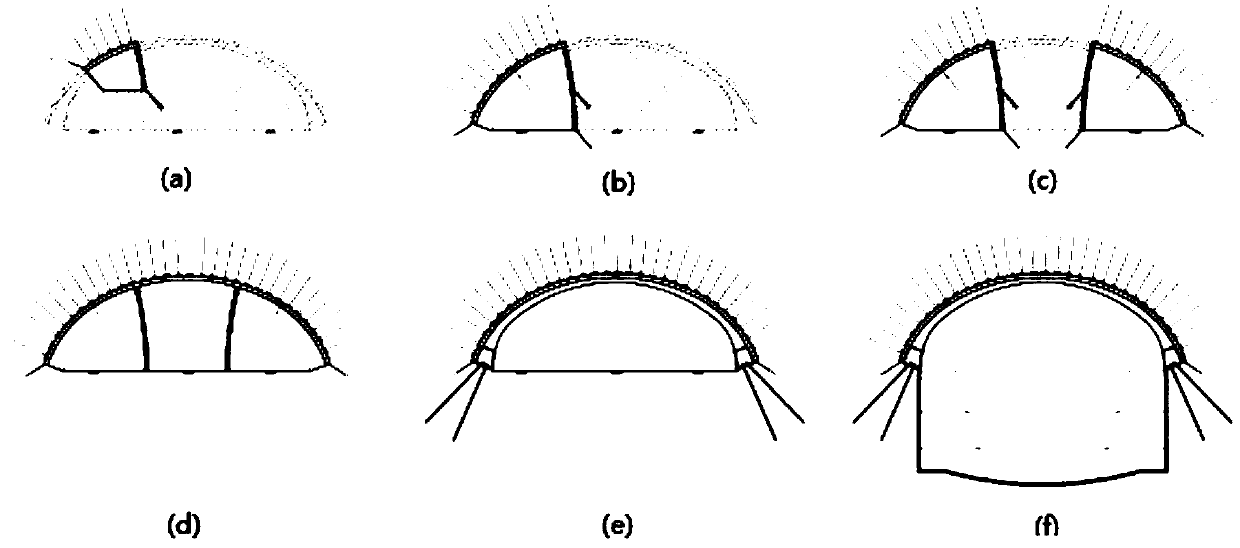

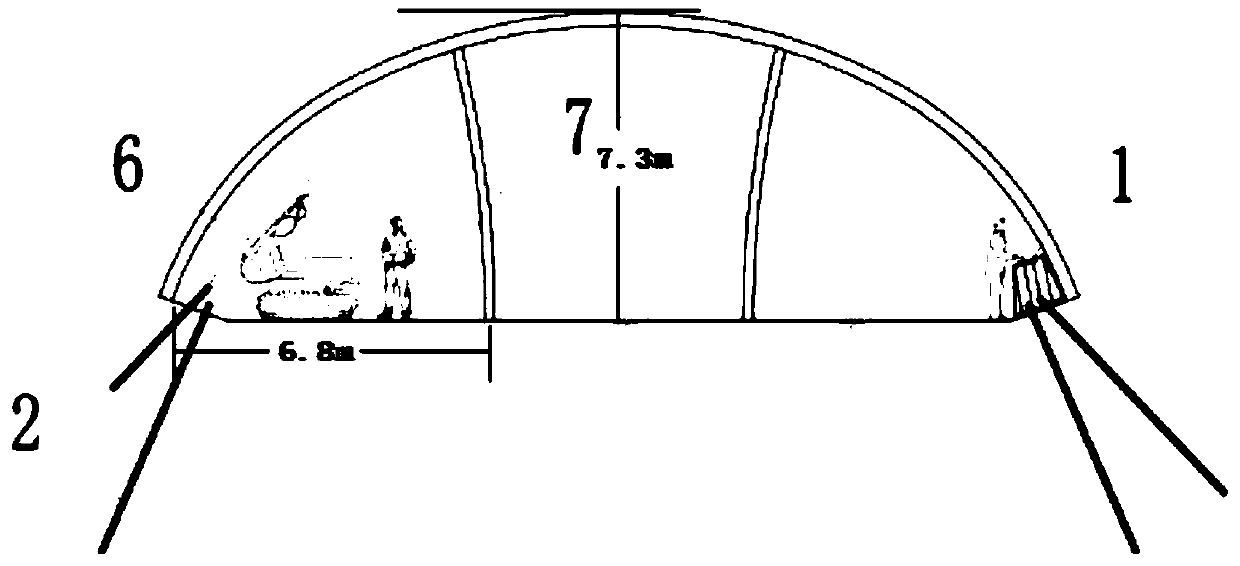

The invention discloses a large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method, which comprises the steps as follows: (1) annularly excavating an upper step of an upper part arc pilot tunnel, transferring excavated earthwork of the upper step to a lower step; (2) excavating a left part of a middle step about 4.5-5 meters behind the upper step, and transferring excavated earthwork to the lower step; (3) excavating a right part of the middle step about 3-4 meters behind the left part of the middle step, and transferring excavated earthwork to the lower step;(4) excavating a left part of the lower step about 6-8 meters behind the left part of the middle step or about 3-4 meters behind the right part of the middle step, and conveying excavated earthwork of the left part of the lower step out of the tunnel; (5) excavating a right part of the lower step about 3-4 meters behind the left part of the lower step, and conveying excavated earthwork of the lower step out of the tunnel; and (6) excavating the rest part of the tunnel bottom about 20-25 meters behind the right part of the lower step, excavating continuously according to the steps in a circulating and interlacing manner, and finally realizing tunnel excavating construction. The method can be used for building a large cross-section tunnel in a safe, rapid and economic manner.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

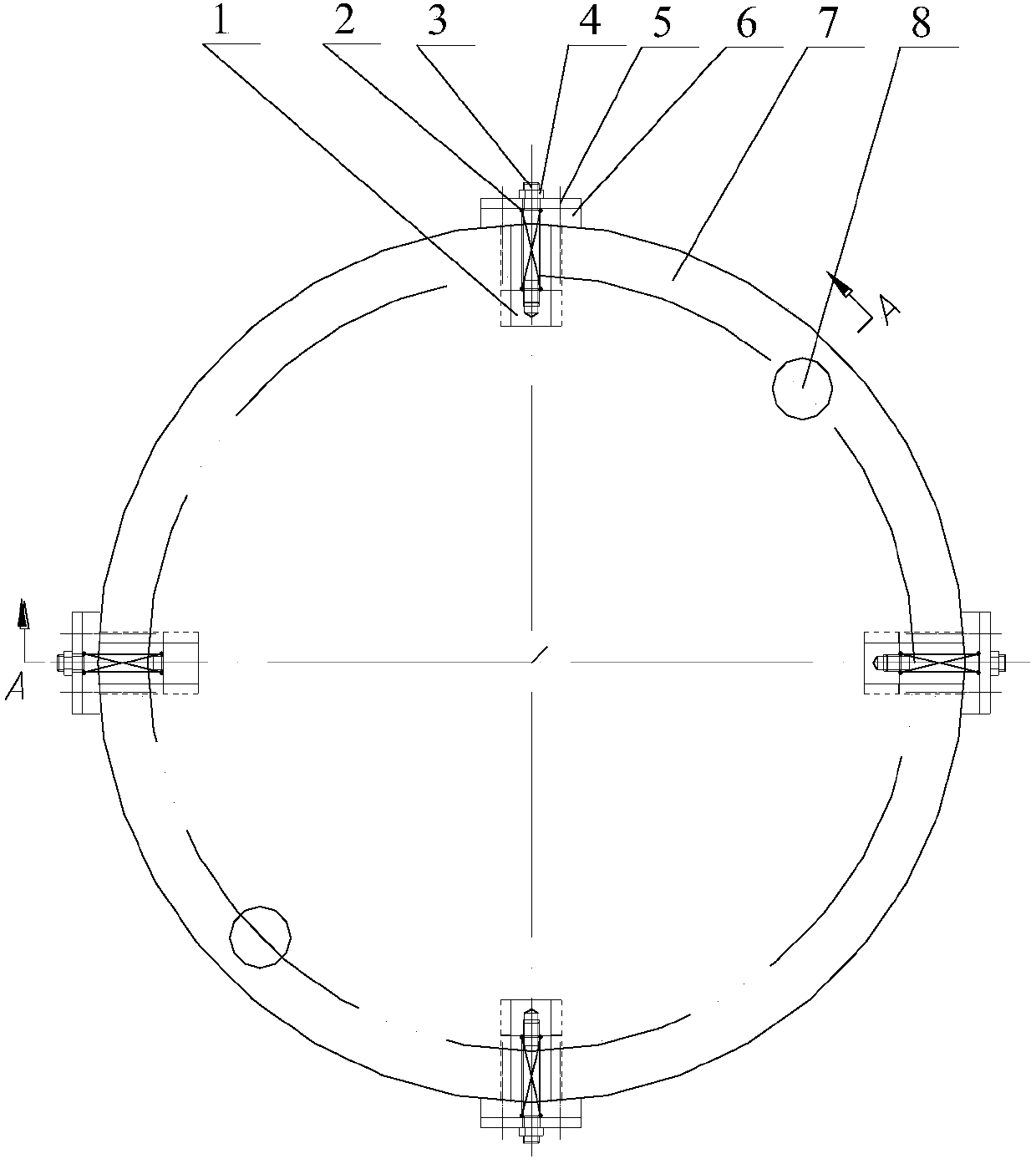

Method for processing split thin-walled parts

ActiveCN103143885AGood for deformation controlSolve the deformationMachining processComputer science

A method for processing split thin-walled parts belongs to the technical field of aero-engines. The method can be used for processing not only components of an aero-engine but also mechanical parts, and enables a processing stress and a residual stress, which are formed in the part processing process, to interact and cancel, so that the problem that the split thin-walled parts are deformed is solved. The method comprises the following steps: selecting a blank which adopts a ring-shaped forged piece for processing two parts; roughing the ring-shaped forged piece before welding; achieving heat treatment to remove the residual stress for roughing; semi-finishing; welding longitudinal mounting edges to enable the longitudinal mounting edges of the two parts to be in crossed distribution; conducting heat treatment to eliminate the welding stress; lathing a datum plane; cutting off to separate the two parts; linearly cutting the longitudinal mounting edges of the two parts; and respectively finishing the two parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

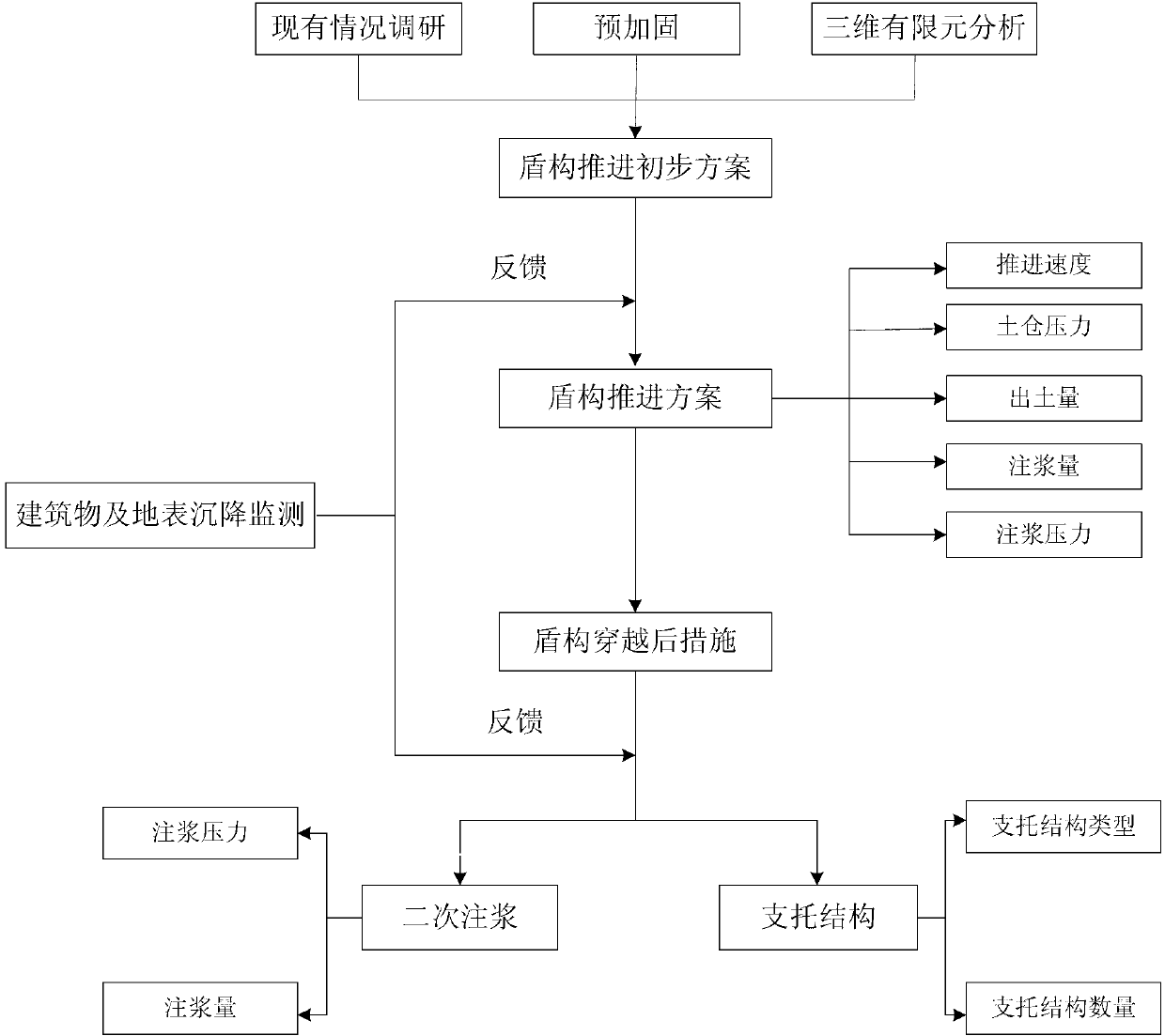

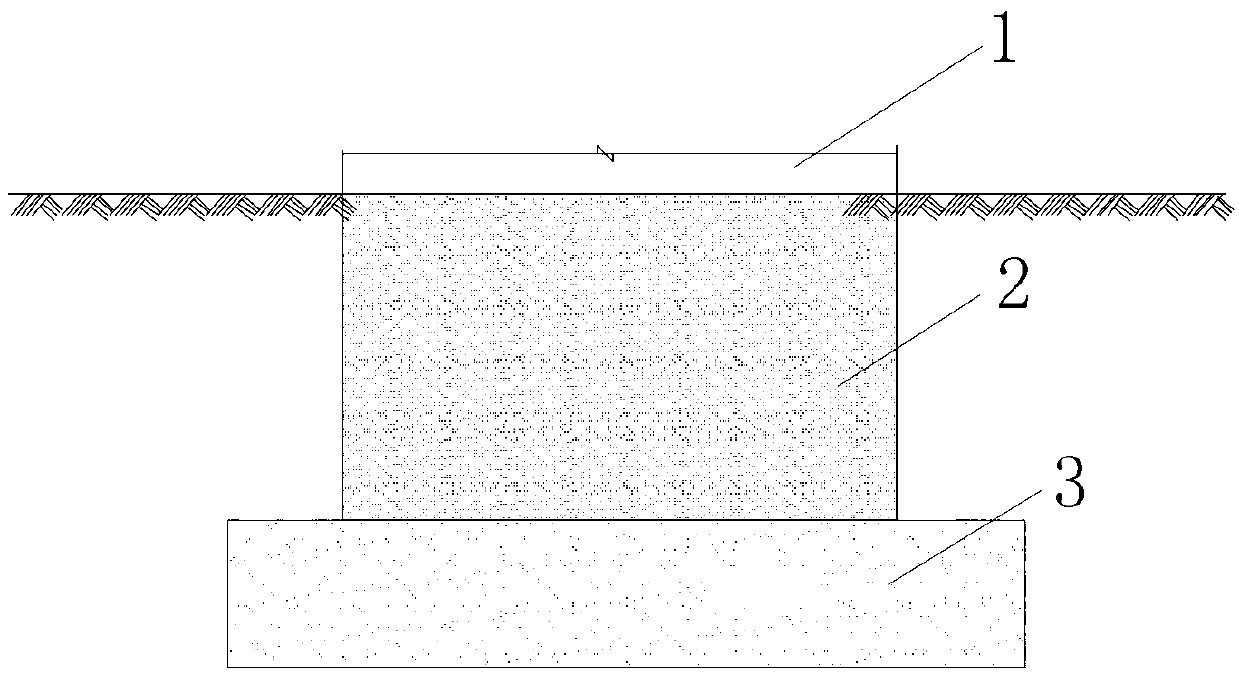

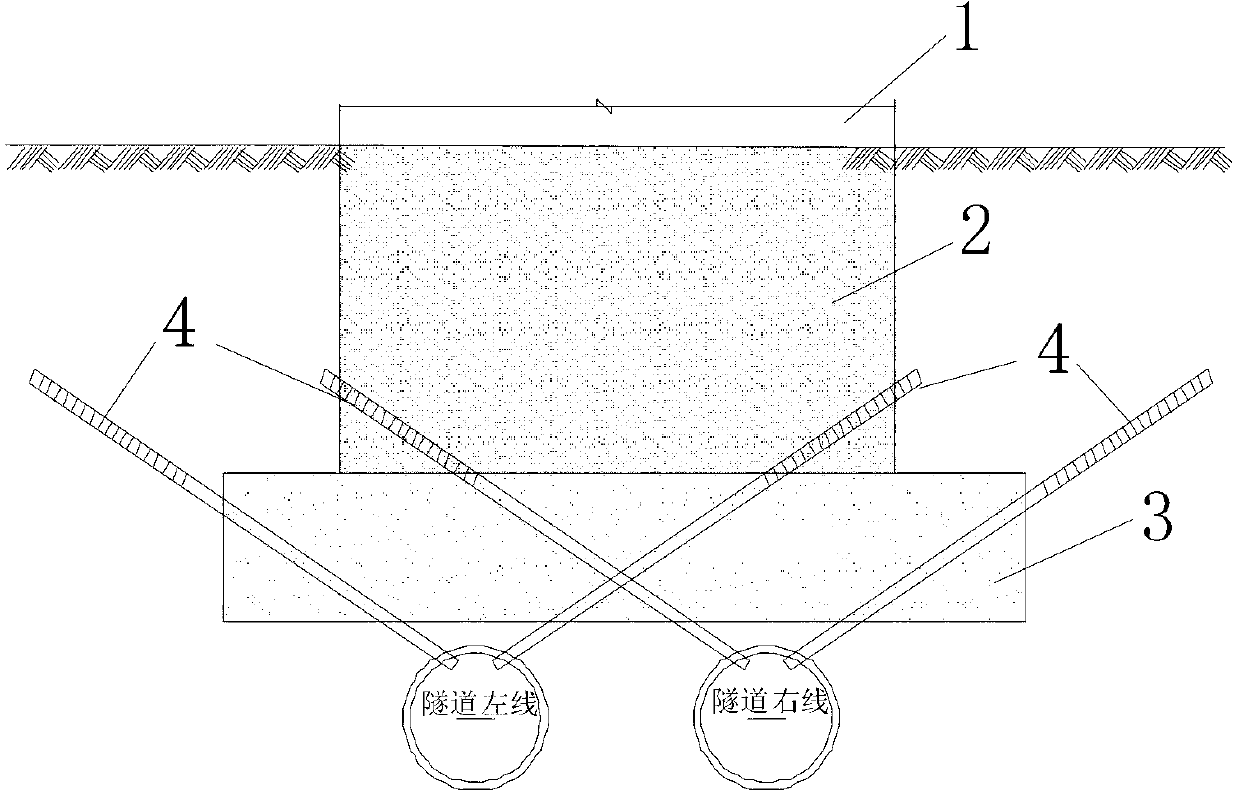

Deformation control method for close-range downward penetration of shield through composite-foundation building

ActiveCN102996136AConstruction safetyGood for deformation controlUnderground chambersTunnel liningArchitectural engineeringDeformation control

The invention provides an effective deformation control method for close-range downward penetration of a shield through a composite-foundation building. The building is researched prior to close-range construction and downward penetration of the shield so as to know specific conditions of the building, the building is pre-protected according to the obtained building conditions (structural features) such as the protection level of the building, the specific form of the foundation and the like, and pre-protection facilities mainly for reinforcement are constructed for the existing building foundation and infrastructure; numerical simulation analysis is performed through three-dimensional finite element software for every construction sequence and method and various conditions during downward penetration of the shield after construction completion of the pre-protection facilities; settlement monitoring is performed for the building and surrounding surface soil prior to downward penetration of the shield through the building; an appropriate progress scheme is adopted according to monitoring data during downward penetration of the shield; and secondary grouting and support structures are adopted for pipe pieces dropped out of the tail part of the shield to ensure that late settlement of the building meets standards.

Owner:宏润建设集团上海有限公司

Thermal treatment deformation control method for duplicate spiral bevel gear

ActiveCN104372157ASolve problems with different depthsReasonable technologyFurnace typesHeat treatment furnacesDeformation controlQuenching

The invention relates to a thermal treatment deformation control method for a duplicate spiral bevel gear. By carburizing on a component for twice, a problem that carburizing layers of different parts of the component are different in depth is solved, and the conventional quenching mode is changed; allowance is reserved during machining, and the machining allowance is changed into deformation compensation dosage under the action of quenching pressure of a mould on the top of the bevel gear, so that the carburizing layer precision of the duplicate spiral bevel gear is controlled within 0.1mm, and the + / -10' error control on taper angle at two sides is realized. The thermal treatment deformation control method disclosed by the invention is reasonable in process technology, remarkable in deformation control effect, and capable of providing a novel thought for deformation control of similar products.

Owner:HARBIN DONGAN ENGINE GRP

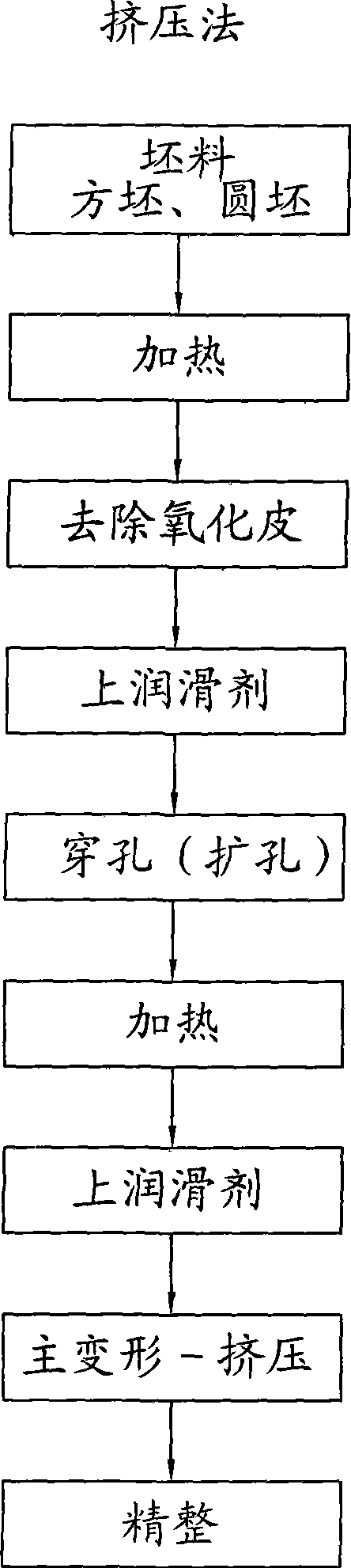

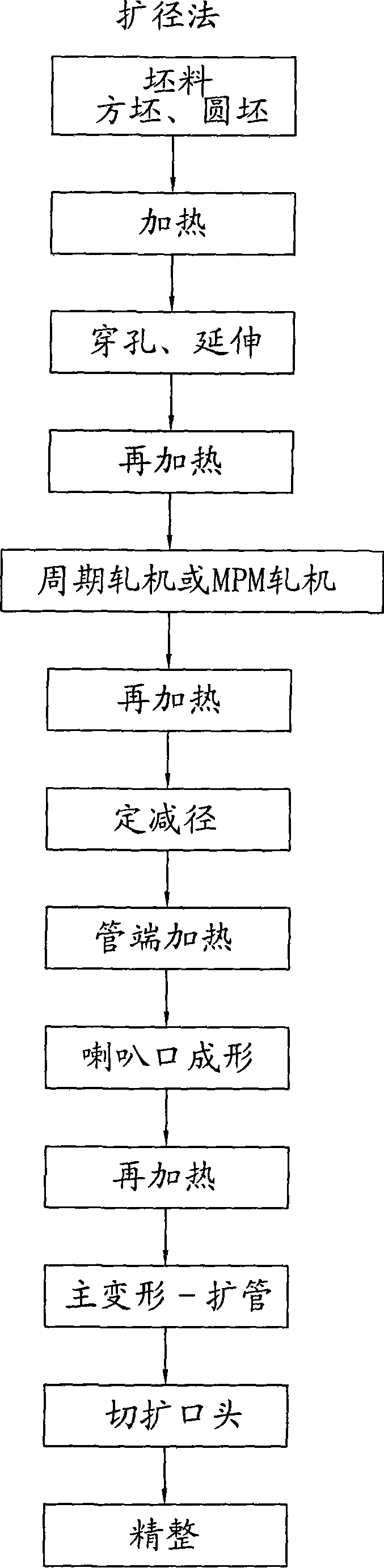

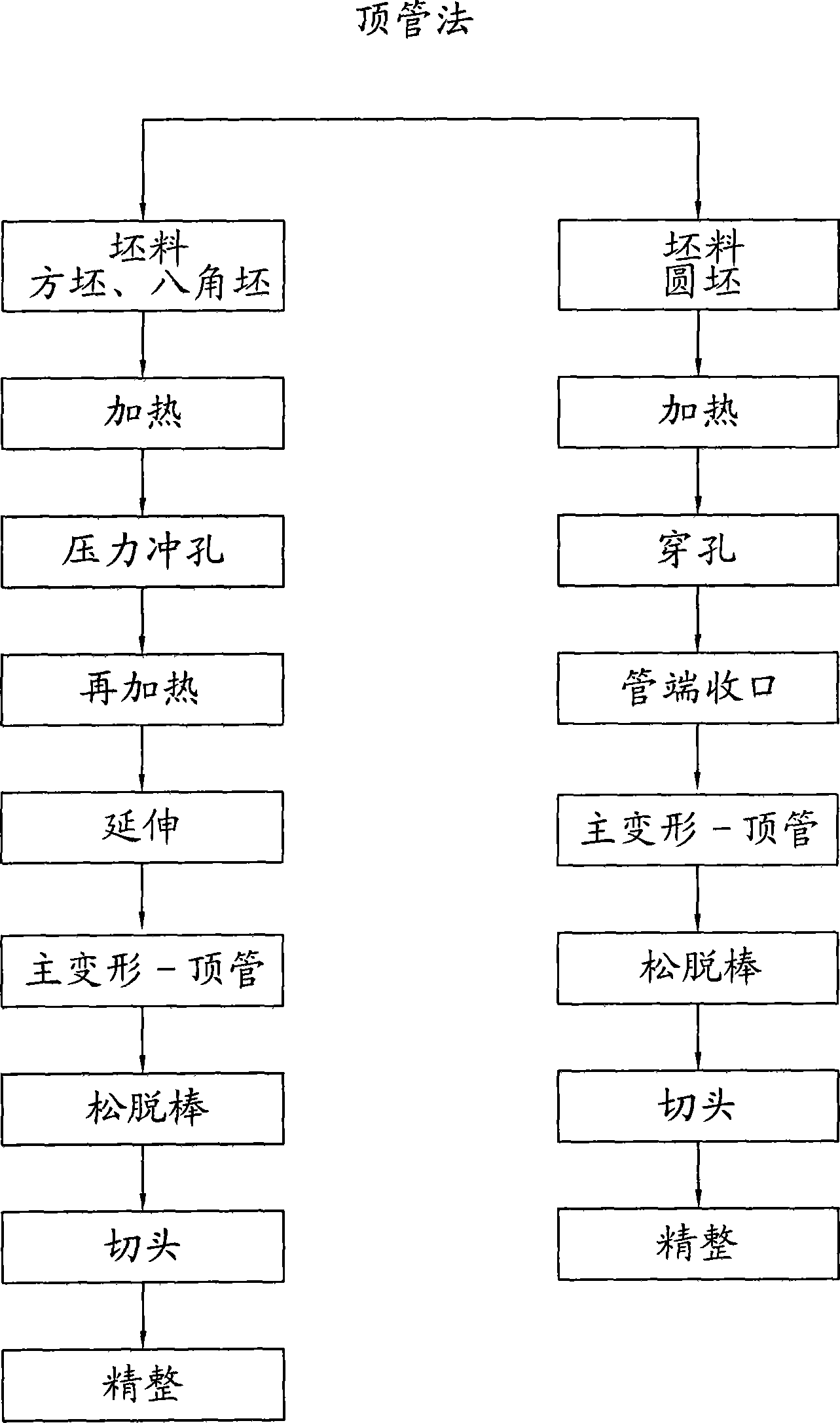

Novel technique for producing seamless steel pipe

InactiveCN101376204AQuality improvementLess centrifugal castingMetal rolling arrangementsElongation control deviceNovel techniquePipe fitting

A new process for producing a seamless steel pipe comprises the following processing steps: firstly, producing a hollow pipe blank, at one end of which an annular cup bottom is arranged, through centrifugal casting; secondly, mechanically processing the inner surface and the outer surface of the hollow pipe blank; thirdly, heating the processed hollow pipe blank; fourthly, performing pipe jacking mill processing to the heated hollow pipe blank, and obtaining pipe fittings meeting the requirements of the wall thickness, the diameter and the length; and fifthly, after bar loosening and bar releasing, performing end cropping and finishing operation to the pipe fittings after the pipe jacking mill processing, and obtaining qualified finished product pipe materials. The invention can produce a high-quality stainless steel and special steel pipe difficult to process, and overcomes the defects in the prior art, so as to form an energy-saving, high-quality and economic new process with the short procedure for producing the seamless steel pipe compared with the traditional method.

Owner:北京蓝海科融新技术有限公司

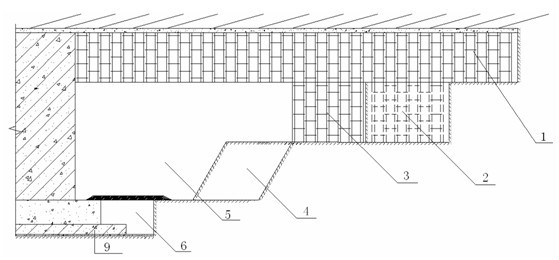

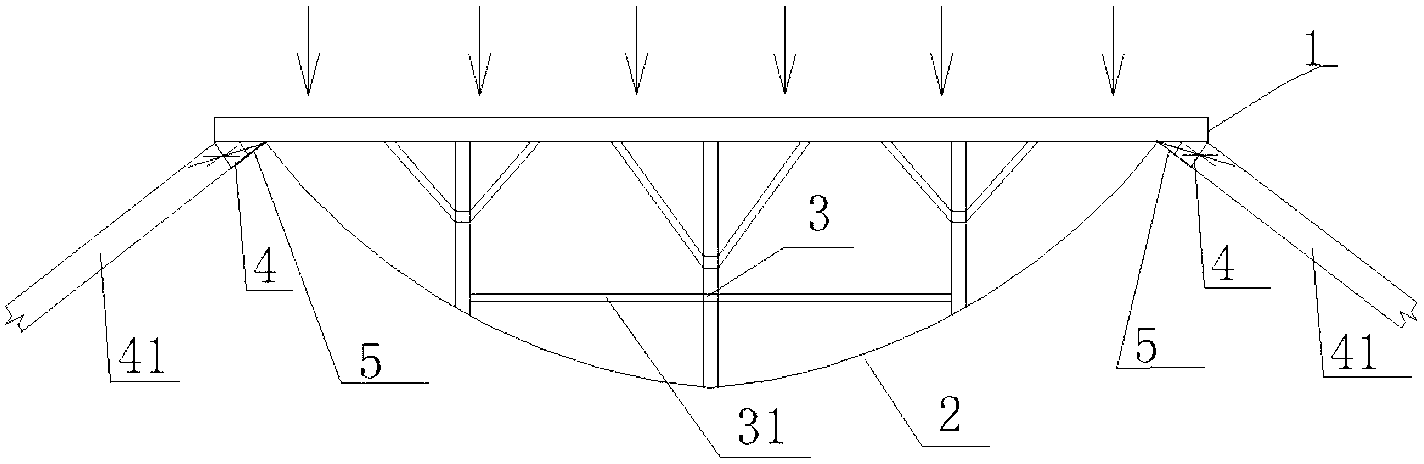

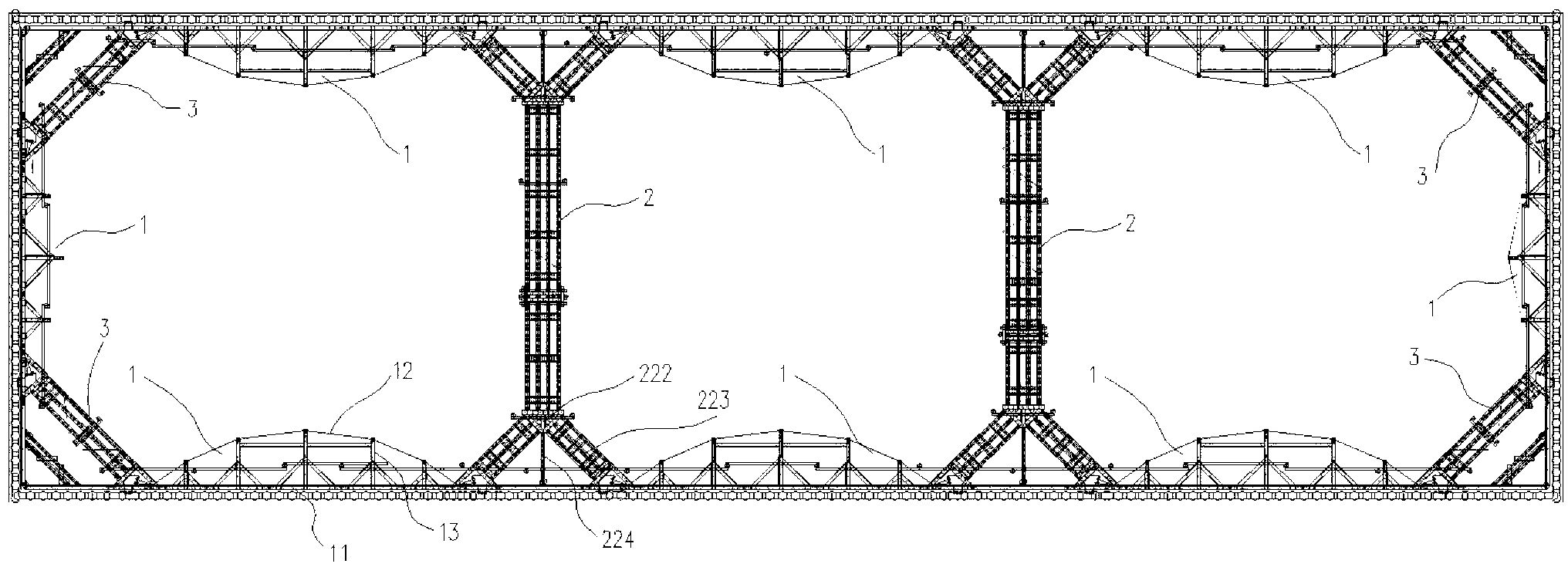

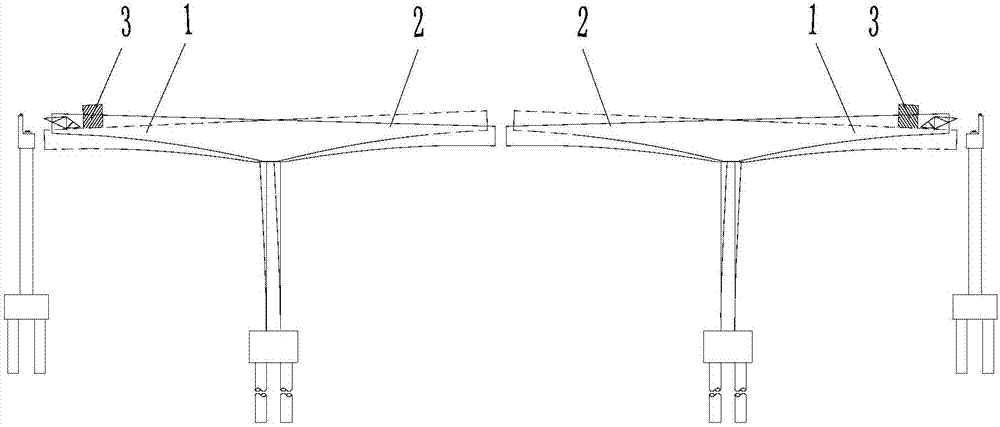

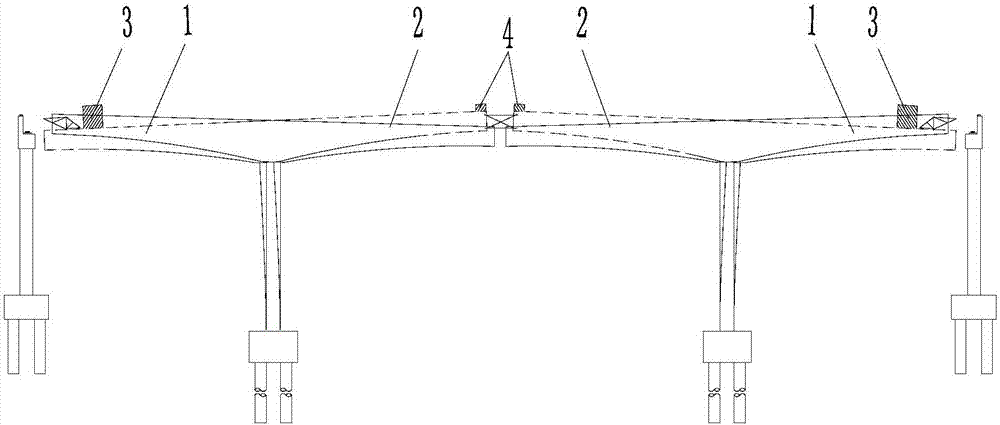

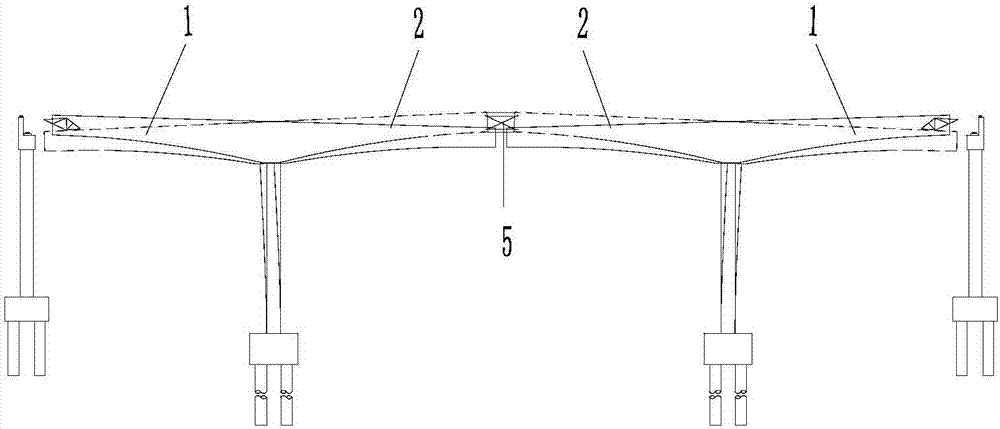

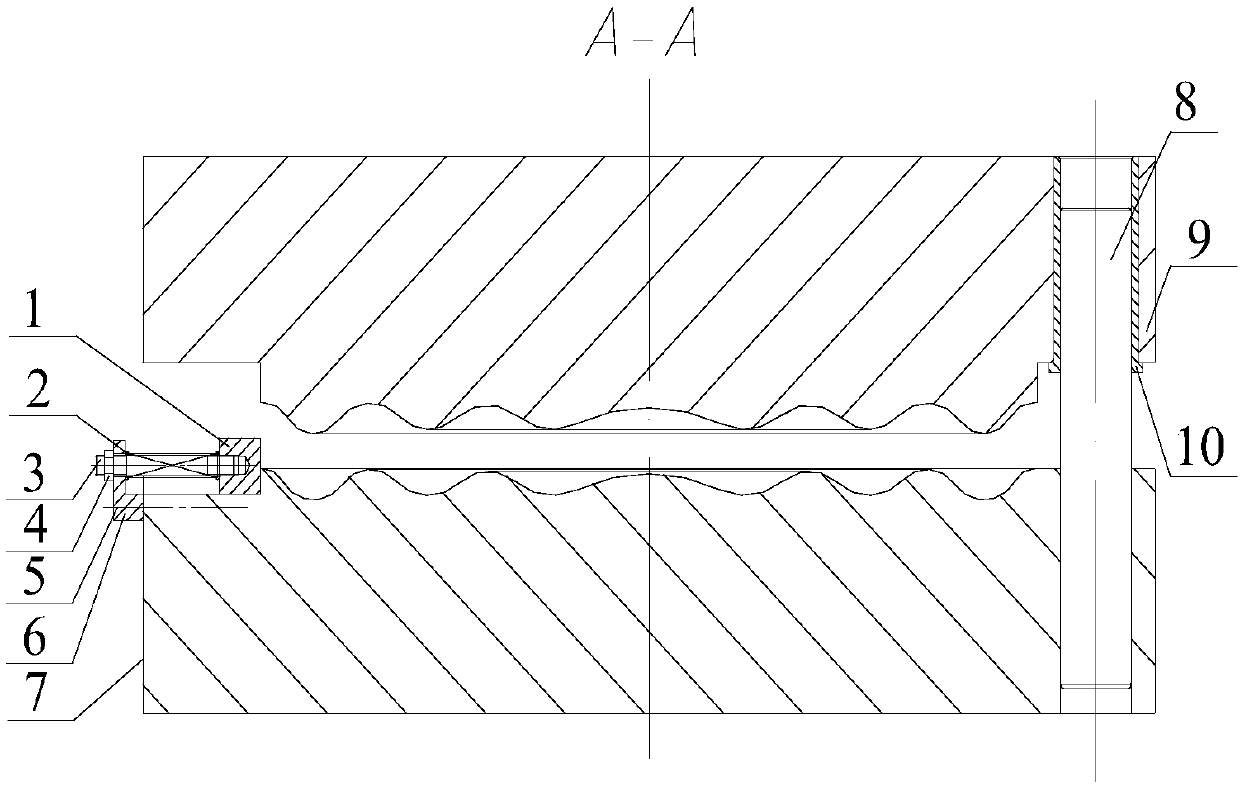

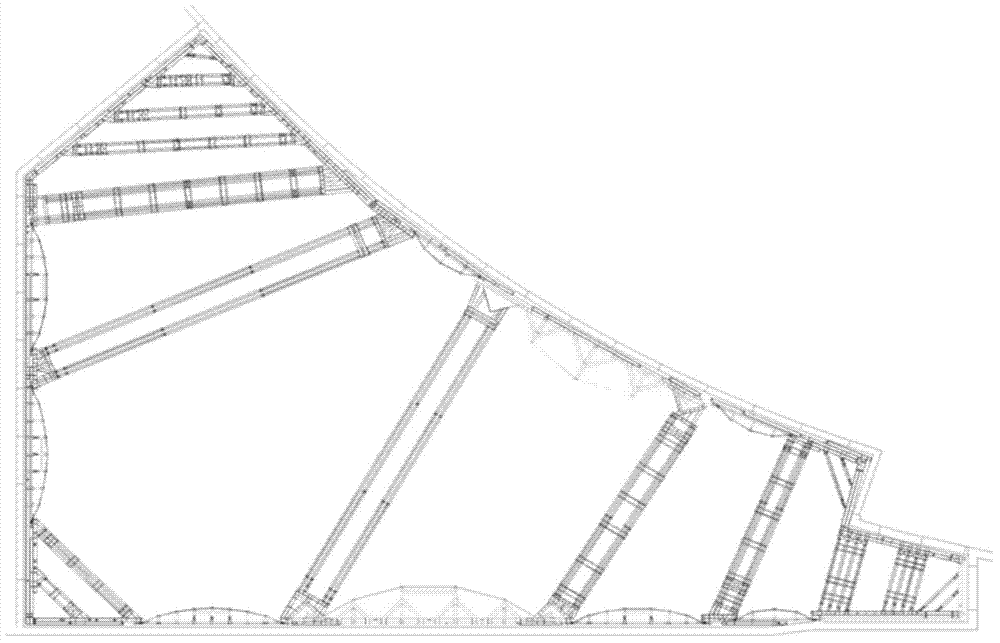

Long-span pre-stress fish belly sill for foundation pit support and mounting method thereof

The invention provides a long-span pre-stress fish belly sill. The long-span pre-stress fish belly sill is used for overcoming the defects of low rigidity, small span and insecure connection with opposite support of an encircling purlin of a supporting structure in the present foundation pit support. The encircling purlin has the advantages of high rigidity, long span, control deformation reliability, convenience in construction, reusability, and the like. The purposes of increasing the degree of safety of the foundation pit support, shortening the construction period and lowering the construction cost are achieved.

Owner:上海新强劲工程技术有限公司

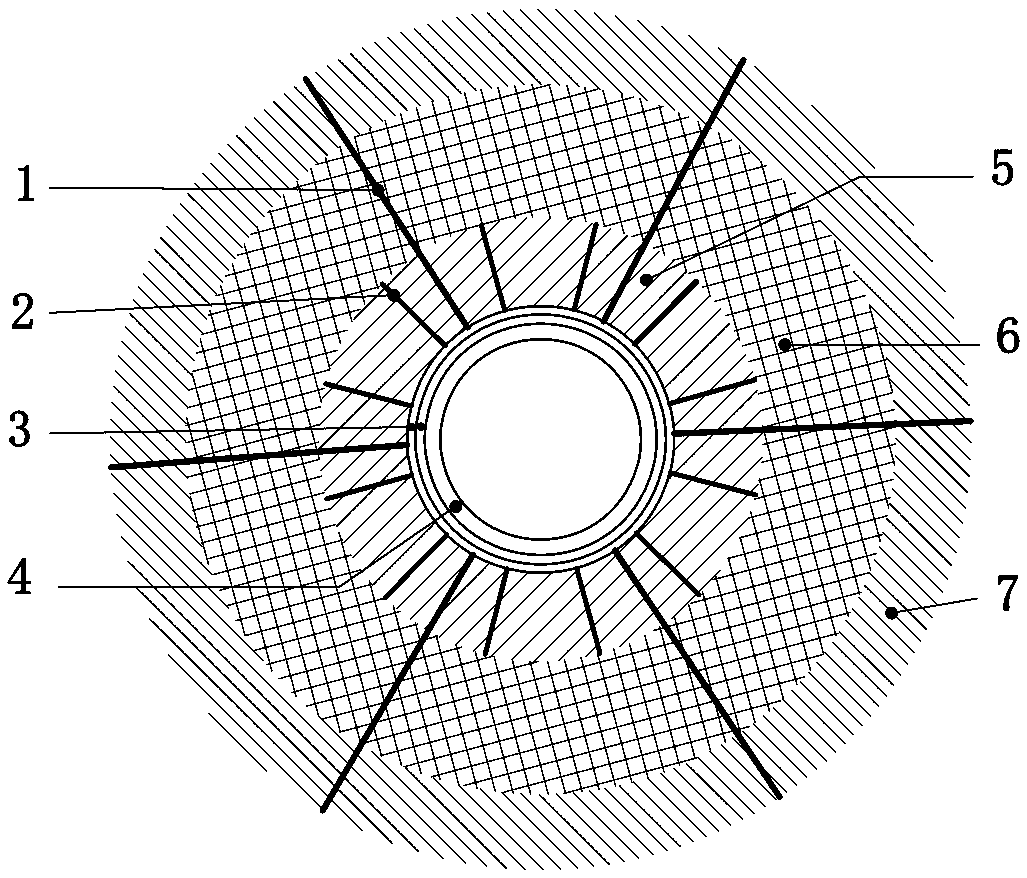

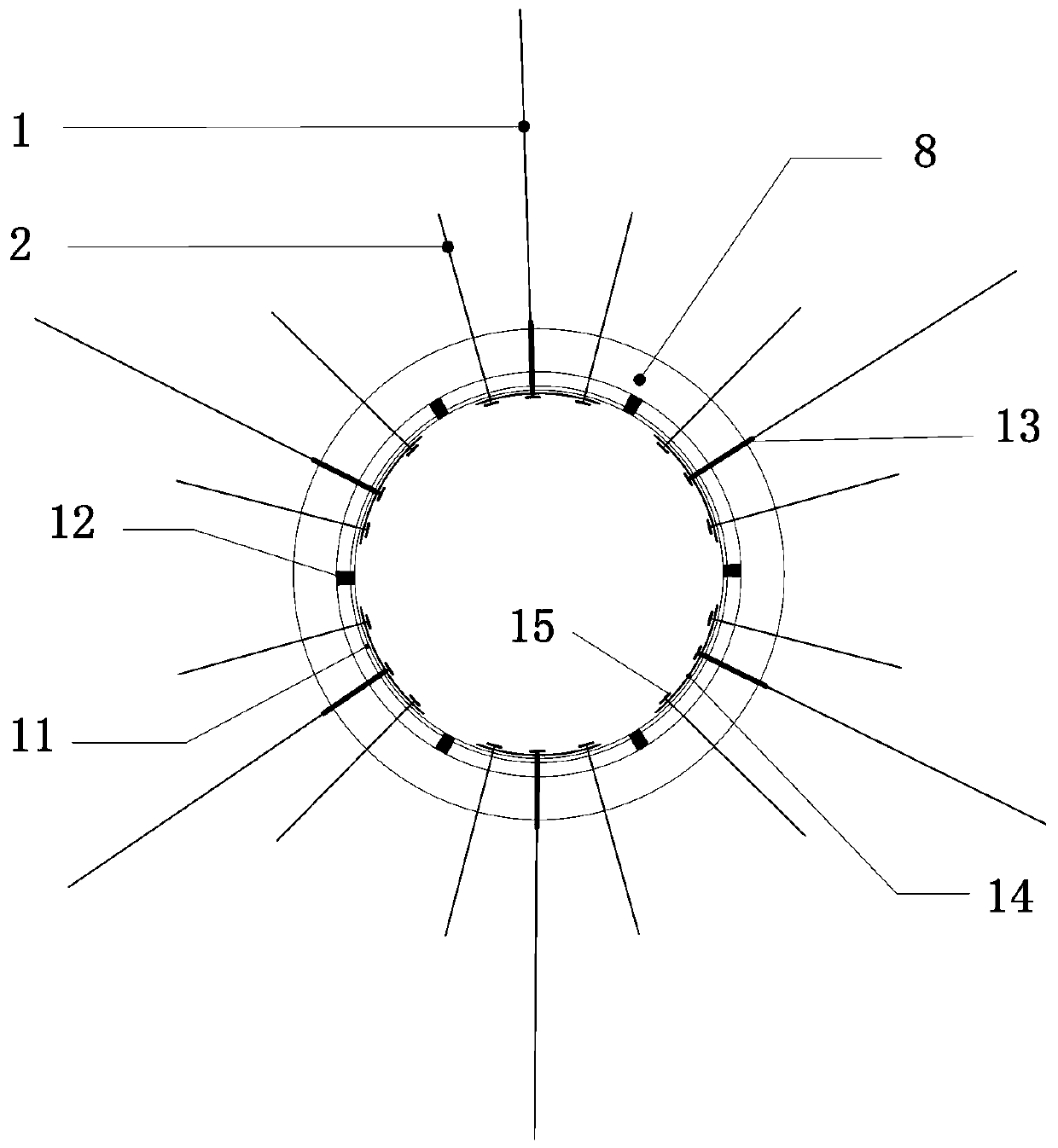

Extremely-high geostress soft rock large-deformation tunnel multistage pressure-yielding and pressure-resisting support structure and construction method thereof

PendingCN110847930AImprove the state of stressThe lining structure is safe and stableUnderground chambersTunnel liningShotcreteReinforced concrete

The invention relates to an extremely-high geostress soft rock large-deformation tunnel multistage pressure-yielding and pressure-resisting support structure and a construction method thereof. The construction method comprises the following steps: excavating a tunnel with a nearly circular section, then driving long anchor cables and short anchor rods into surrounding rock, erecting ring-shaped profile steel frames at tail ends of the long anchor cables and the short anchor rods and spraying concrete, additionally driving reinforcement lengthened or encrypted anchor cables into the surroundingrock, then erecting steel frames and spraying concrete again to form multilayer extension support; constructing a reinforced concrete lining structure on the inner side of the multilayer extension support, and forming the multistage pressure-yielding and pressure-resisting support structure through the long anchor cables, the short anchor rods, multilayer support and the reinforced concrete lining structure. According to the extremely-high geostress soft rock large-deformation tunnel multistage pressure-yielding and pressure-resisting support structure, the pressure is actively released by reserved deformation; the long anchor cables and the short anchor rods are used for anchoring in time with high pre-tightening force, enabling the pressure of the surface surrounding rock to be transferred to the deep part of the surrounding rock and expanding the surrounding rock bearing ring; the pressure-yielding support structure is used for providing high resistance and continuous deformation capacity; the reinforced concrete structure is used for resisting rheomorphism; the deformation of the surrounding rock can be effectively controlled; long-term stability of the structure can be ensured.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

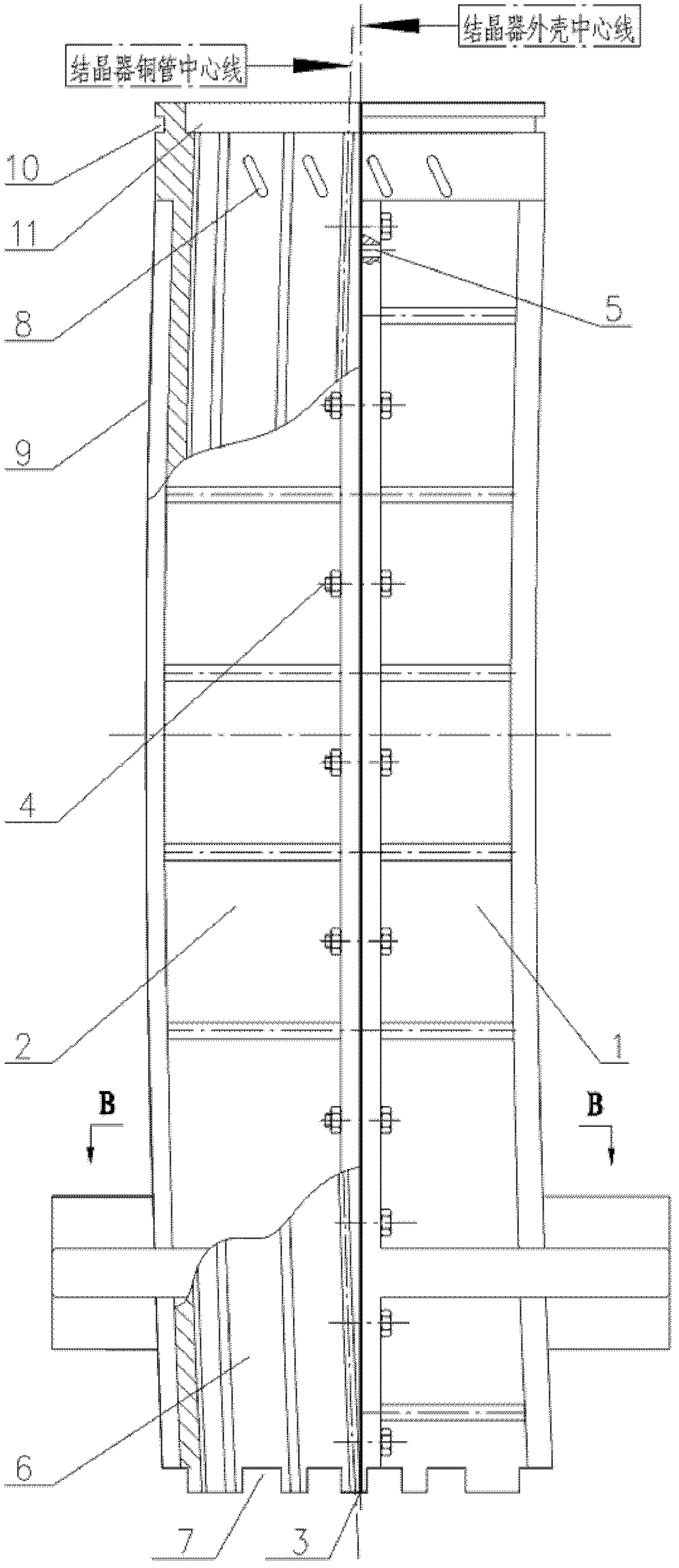

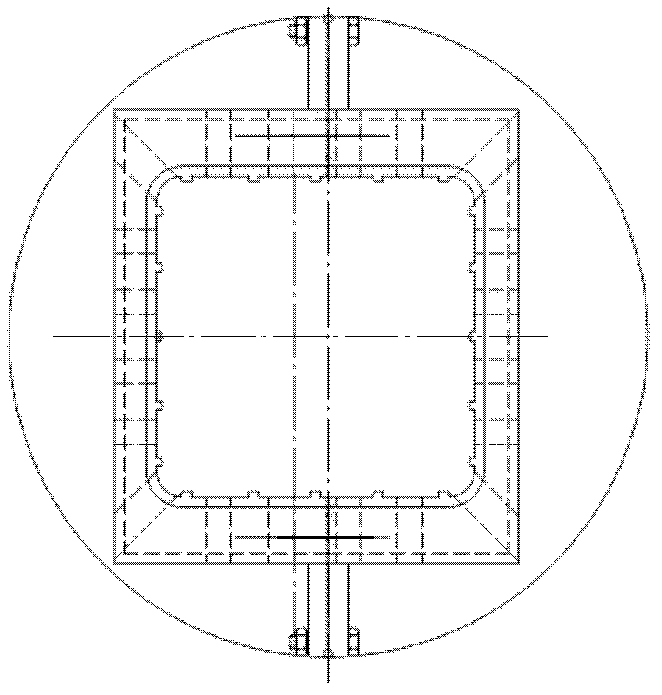

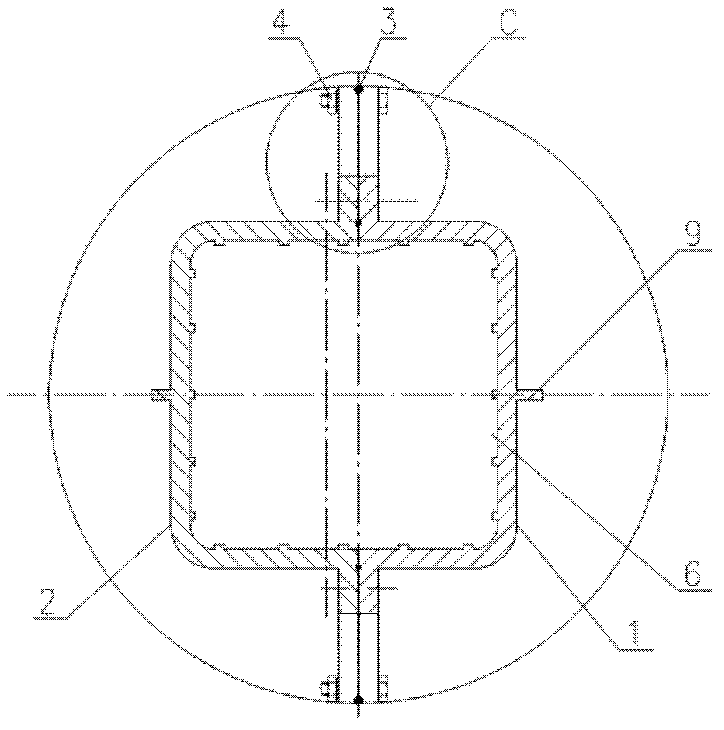

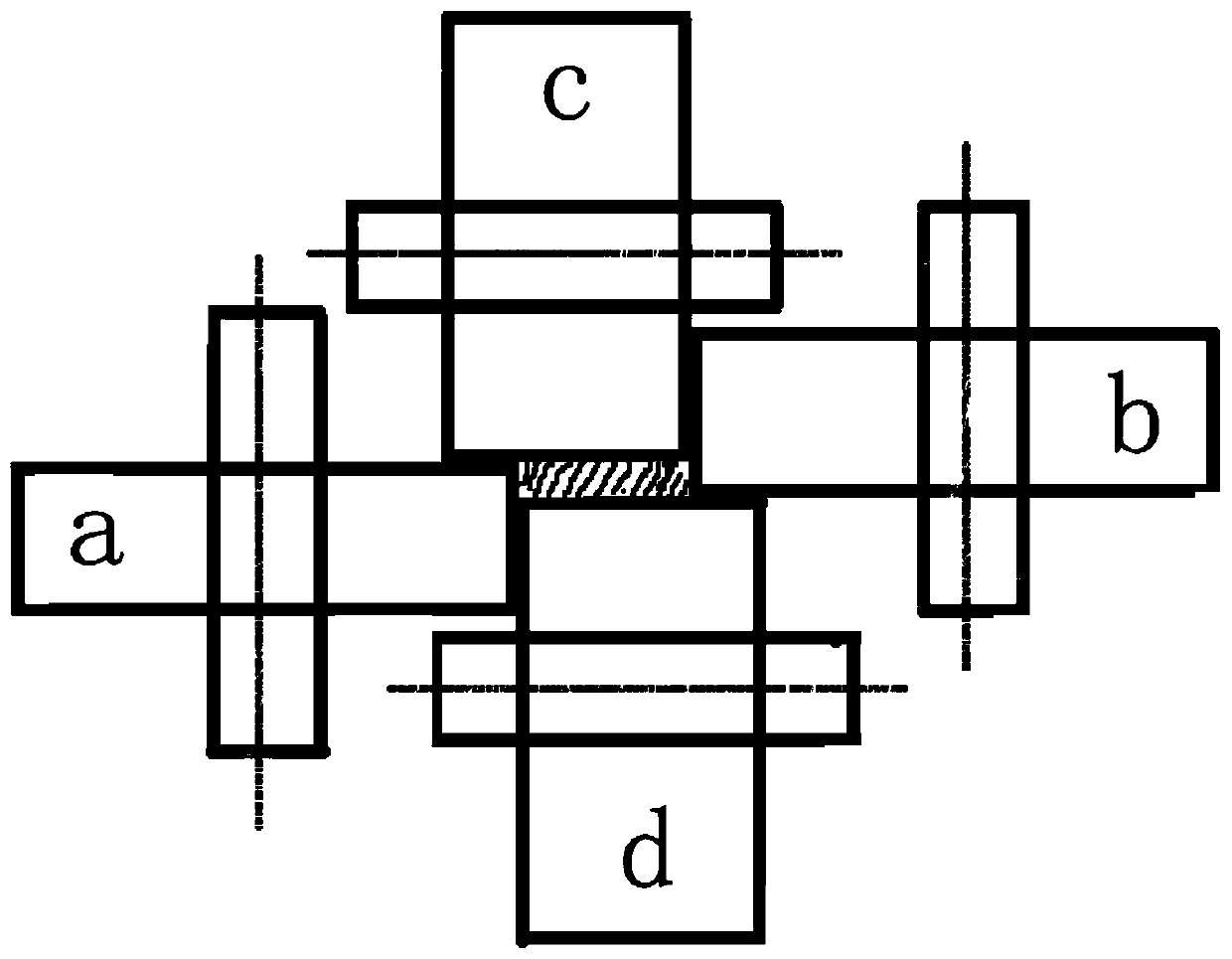

Split type water jacket with diversion water tank and assembly method

The invention provides a split type water jacket with a diversion water tank and an assembly method. The split type water jacket with the diversion water tank comprises an inner arc half water jacket, an outer arc half water jacket, a sealing element, a fastening element and a positioning pin group; wherein the water jacket are two separated bodies by using the centerline of a crystallizer cylinder as a dividing line; an angular water path, a side surface water path and an arc surface water path are arranged in each separated body; an inner cavity of each water jacket is provided with ribs; a diversion water tank is formed between every two adjacent ribs; and crisscross rib plates are distributed at the outer side of the water jackets. When the water sleeves are assembled, the inner arc half water jacket, an outer arc half water jacket are combined according to design dimensions firstly and then are integrally processed; after being processed, the inner arc half water jacket, an outer arc half water jacket are assembled in a crystallizer; combining surfaces are sealed; positioning pins are arranged between the combining surfaces for positioning; and bolts are arranged between the combining surfaces for fastening. According to the split type water jacket, the controllability of cooling water joints is structurally ensured; the deviation between the center of a circle of a copper pipe circular arc and the center of a casting machine can be avoided; the heat exchange effect of the water joints is beneficial for improving; and the production and operation cost is reduced.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Structure for improving rigidity and stability of foundation pit steel support

The invention provides a structure for improving rigidity and stability of a foundation pit steel support; a plurality of fish-belly sill enclosing purlins are arranged on the surrounding of a foundation pit; section steel bracings for connecting the fish-belly sill enclosing purlins are arranged in the middle of the foundation pit; edge corners of the foundation pit are provided with section steel angle braces for connecting the fish-belly sill enclosing purlins; the section steel bracings or the section steel angle braces are formed by more than two parallel section steels; the section steels are connected with each other by bolts in a length direction; the structure is characterized in that transverse and inclined fixed plates are arranged on the parallel section steels in a width direction; the fixed plates connected to the section steels by bolts; and the transverse fixed plates and the inclined fixed plates form triangular stable structures together with the section steels; and the structure for improving the rigidity and the stability of the foundation pit steel support, provided by the invention, has the advantages of large structural rigidity, good stability, small foundation pit deformation, convenience in construction, recyclable material and so on; and purposes of reducing construction period and reducing construction cost are achieved.

Owner:上海新强劲工程技术有限公司

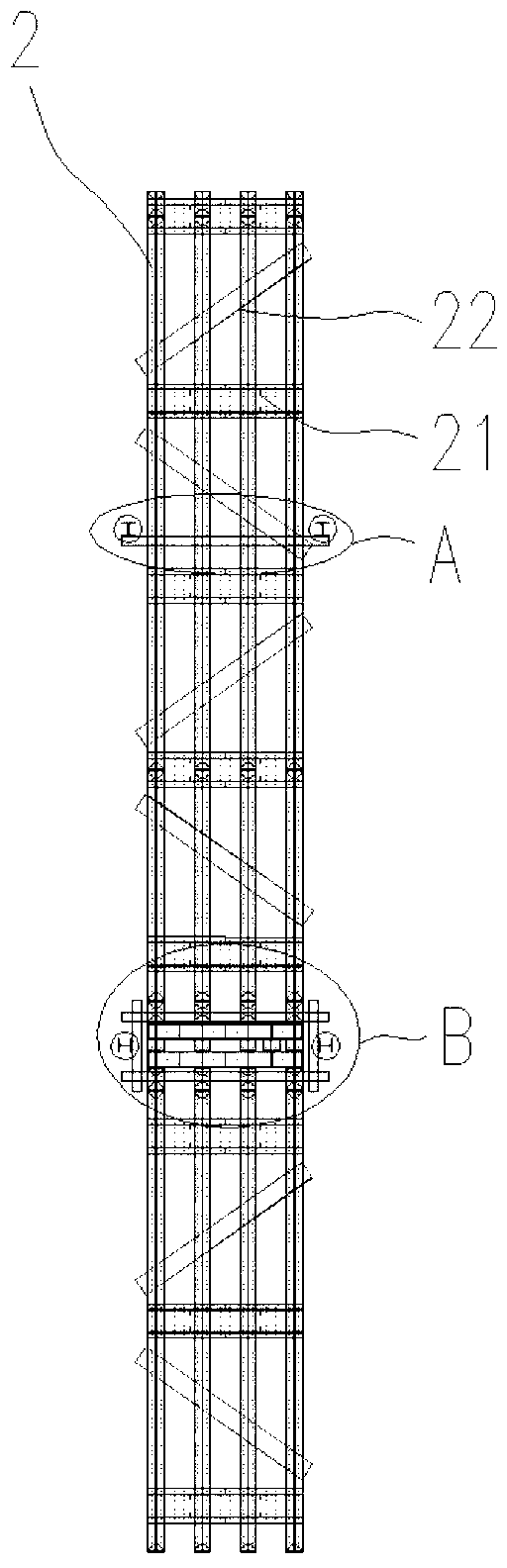

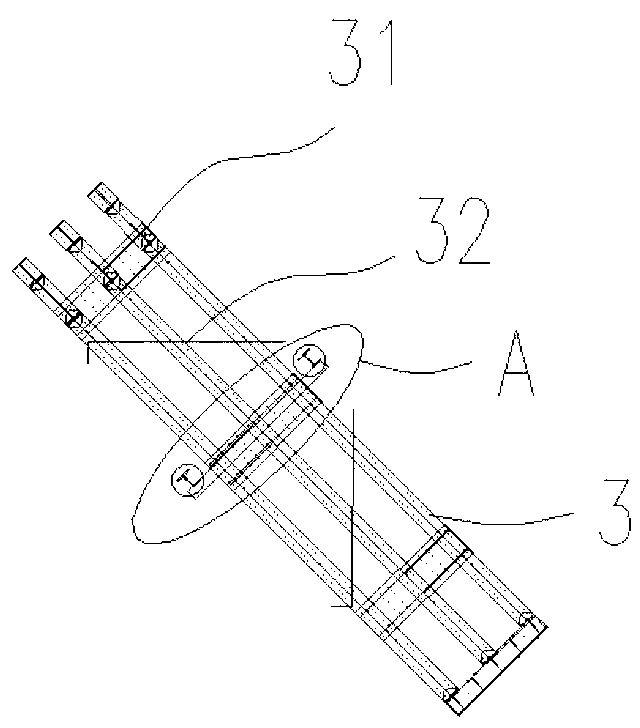

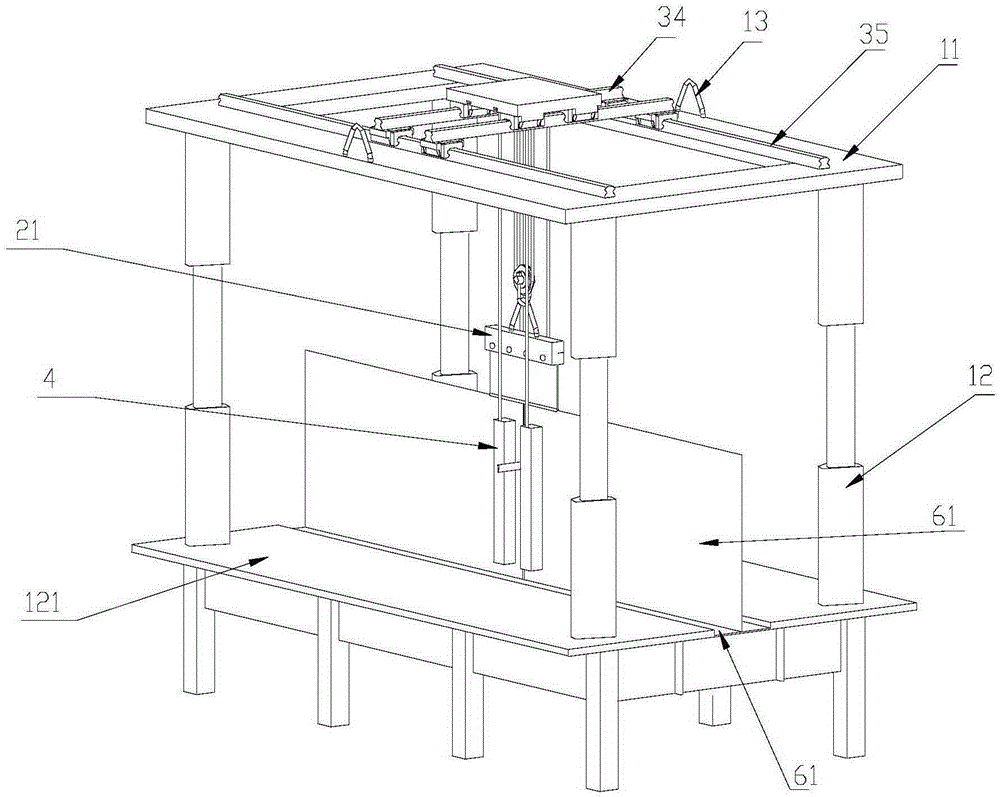

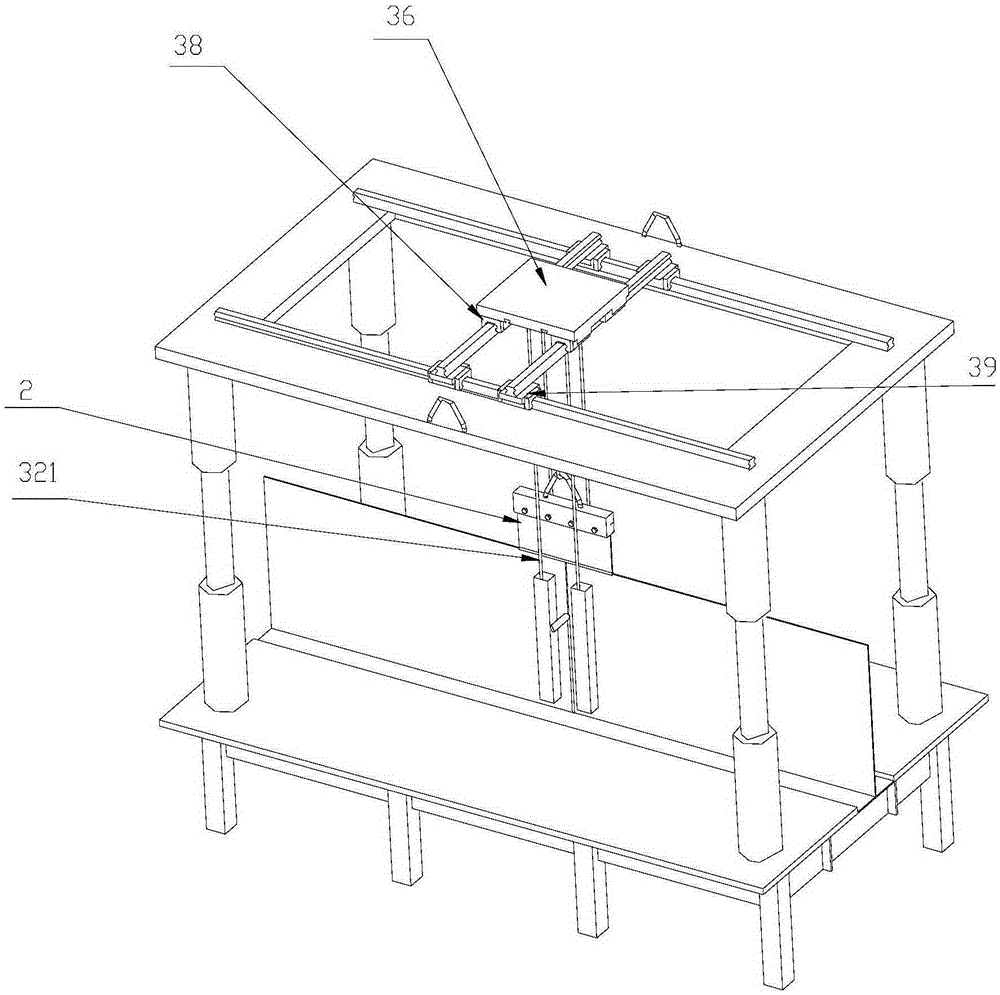

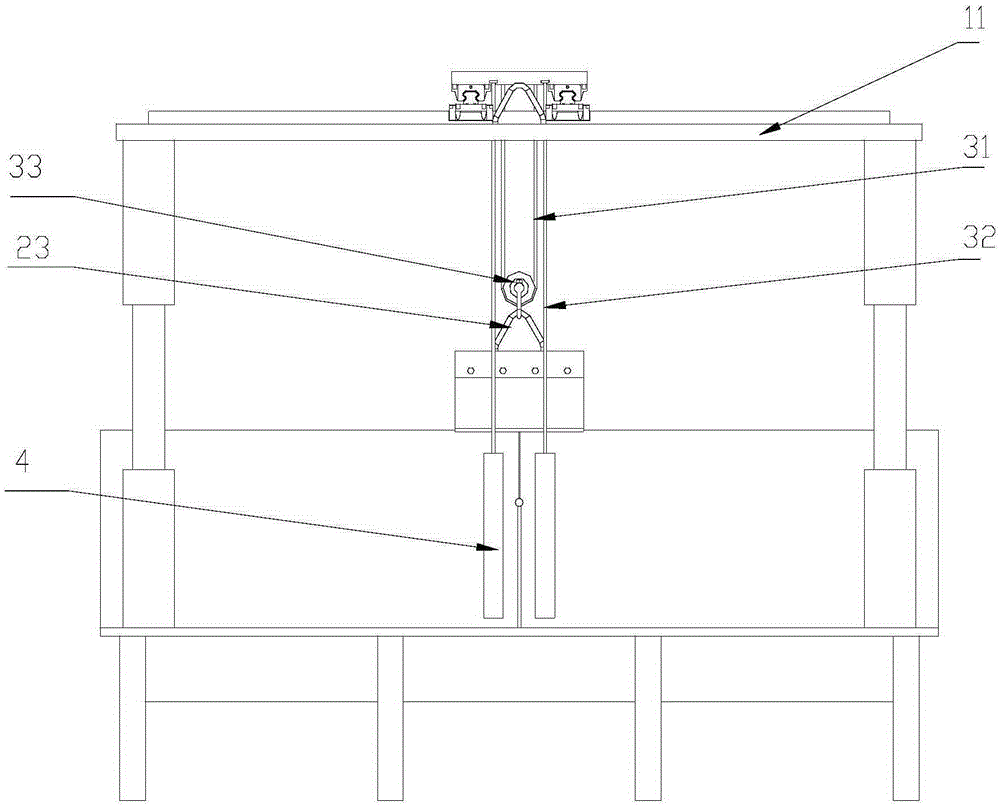

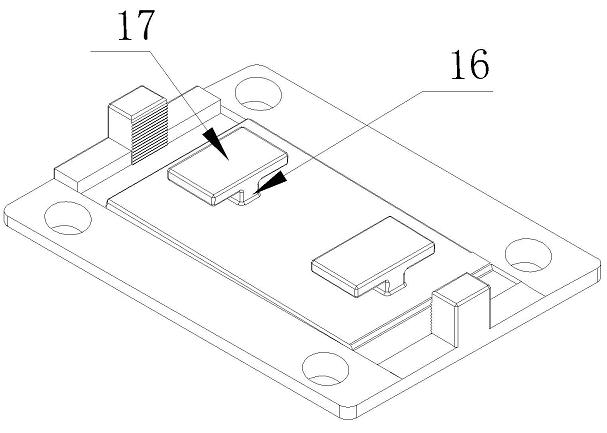

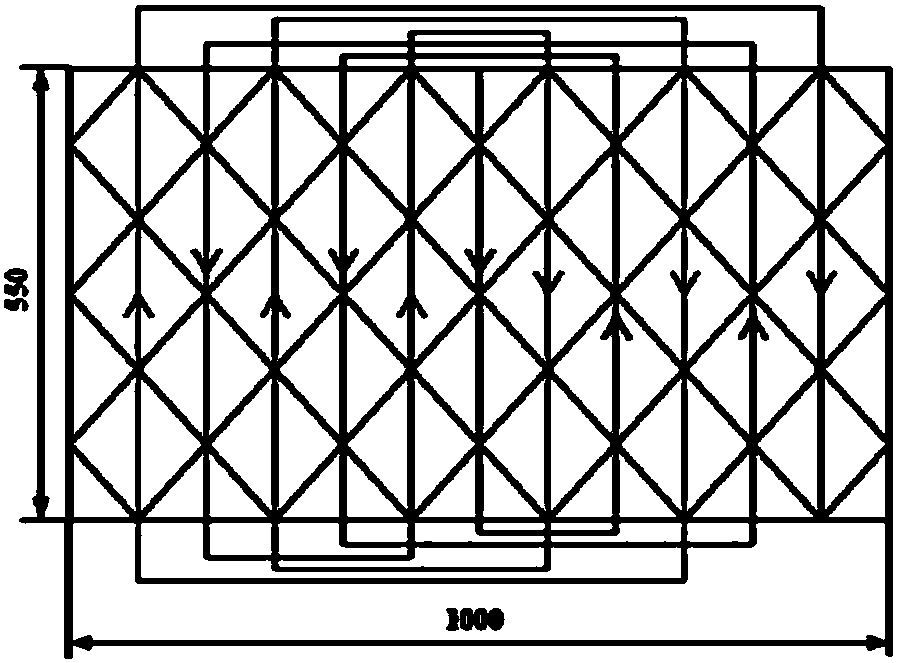

Aluminous thin-wall hull vertical welding seam prestress deformation control method and device

ActiveCN105312740AEasy to controlGood for deformation controlWelding accessoriesButt weldingMarine engineering

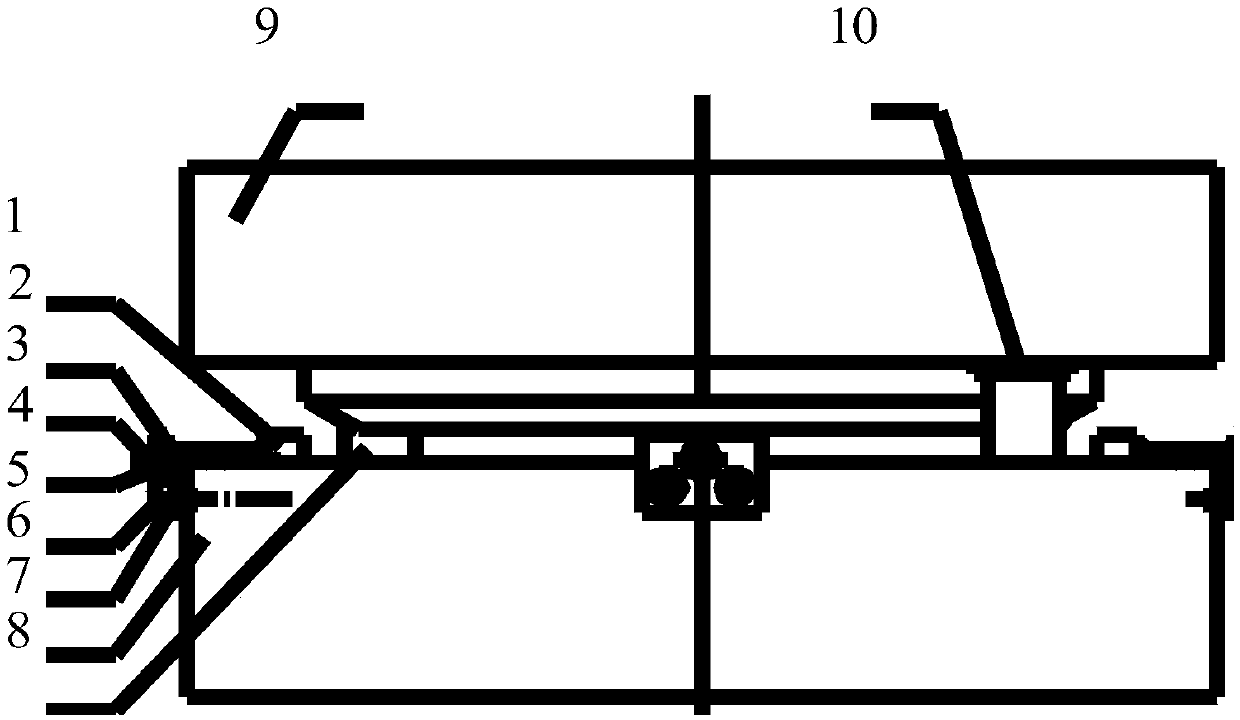

The invention discloses an aluminous thin-wall hull vertical welding seam prestress deformation control method and device. The deformation control device comprises a main body structure and a prestretching stress application structure. The main body structure comprises a top frame, a movable application device and a plurality of upright columns. The movable application device is movably arranged in the middle of the top frame. The movable application device comprises a middle lifting beam and two side lifting beam sets. A movable pulley is arranged under the middle lifting beam. The prestretching stress application structure is arranged below the movable pulley. The prestretching stress application structure comprises a steel clamping plate and a run-off plate which are arranged from top to bottom. The deformation control method conducts deformation control by using the deformation control device. The aluminous thin-wall hull vertical welding seam prestress deformation control method and device are suitable for cabin vertical butt welding seam welding of hull building, and a range of problems that welding deformation is large due to the fact that the hull cabin vertical welding deformation is large and the rigid restraint is insufficient are solved.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

T structure closure pouring method for mountainous-area high-pier large-span continuous rigid-frame bridge

ActiveCN106948273ASave engineeringImprove securityBridge erection/assemblyHanging basketDeformation control

The invention discloses a T structure closure pouring method for a mountainous-area high-pier large-span continuous rigid-frame bridge. Before T structure closure pouring, weights are loaded at the cantilever ends of T structures to enable the cantilever ends of the two sides of T structure mid-span enclose sections to generate large longitudinal horizontal displacement towards to the two side-span directions so as to compensate shrinkage and creep and horizontal displacement generated due to later-period whole temperature reduction; the high-pier large-span characteristics are combined, adverse influence, on the continuous rigid-frame bridge internal force and deflection, of concrete shrinkage, creep and the temperature effect which are caused due to the effect of long-term load is reduced, and mid-span mid span bottom bending caused due to the influence of concrete shrinkage and creep is avoided; and weight bodies can obtain materials from local sources, pushing is not needed, simple and feasible effects are achieved, construction is convenient, safety is high, original side span cast-in-situ sections and enclose sections adopt hanging baskets for pouring till pouring is conducted to supporting seats, supporting engineering is reduced, after mid-span enclosure, in side span cast-in-situ, the whole rigidity is large, deformation control is good, and construction is easy.

Owner:CHONGQING JIAOTONG UNIVERSITY +2

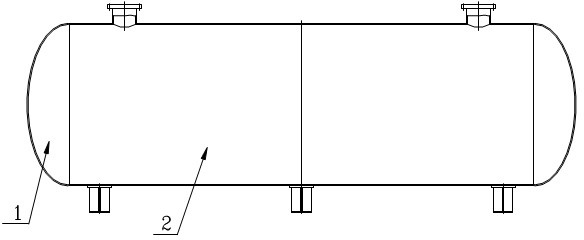

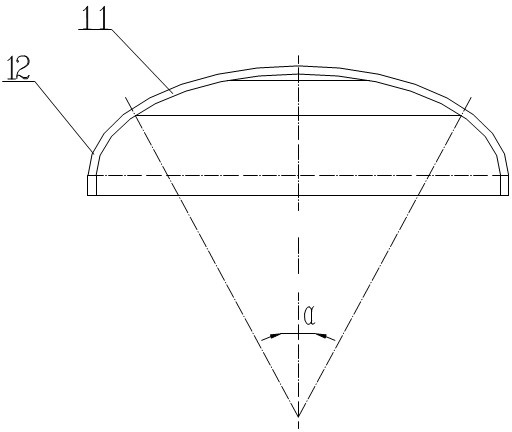

Large recovered oil and gas tank

ActiveCN102491011AReduce the difficulty of suppressionForming quality is easy to guaranteeLarge containersSteel platesWelding deformation

The invention discloses a large recovered oil and gas tank, which comprises a standard elliptic end enclosure and a cylinder assembled and welded with the end enclosure to form the tank, and is characterized in that: the end enclosure is formed by assembling and welding 3 roof round plates and side plates, which are formed by cold pressing molding; the roof round plates are assembled and welded to form the top end part of the standard elliptic end enclosure; the top end part is in a partial spherical shell shape with a sphere center angle between 18 and 28 degrees; the side plates are welded on the edge of the top end part and extend to form a side edge part; 2 to 3 rib plates are welded at the weld joints of the roof round plates and the side plates, which are assembled and welded, to prevent welding deformation; and the cylinder is formed by assembling and welding cylinder joints one by one; and each cylinder joint is formed by using pressing heads of three steel plates, rolling thesteel plates, checking the curve of each steel plate petal and assembling and welding. The entire large recovered oil and gas tank has a reasonable structure, is convenient for transport and on-site processing, and has high molding quality.

Owner:南通市展成商品混凝土有限公司

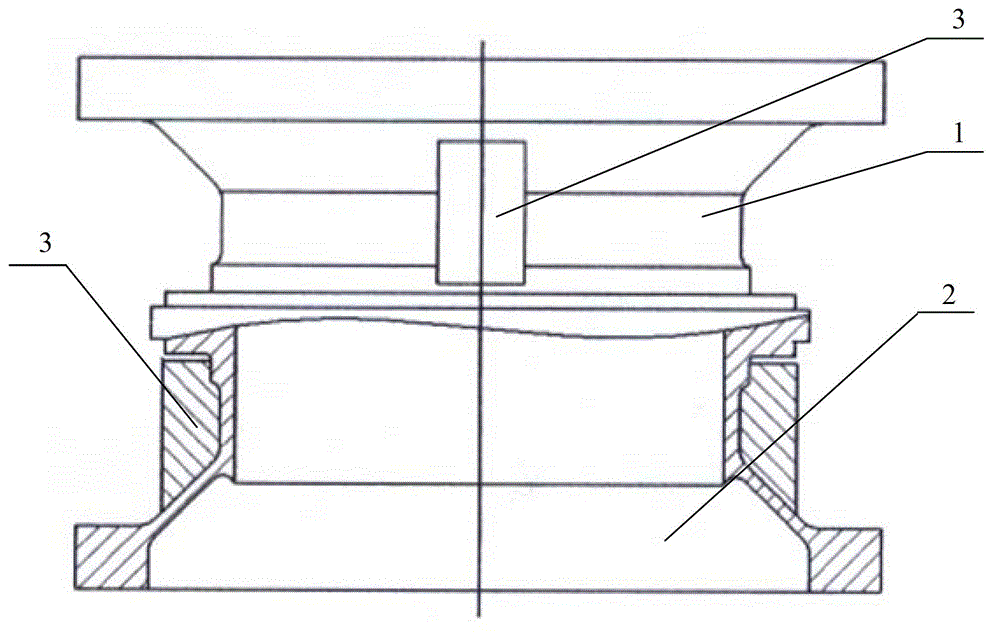

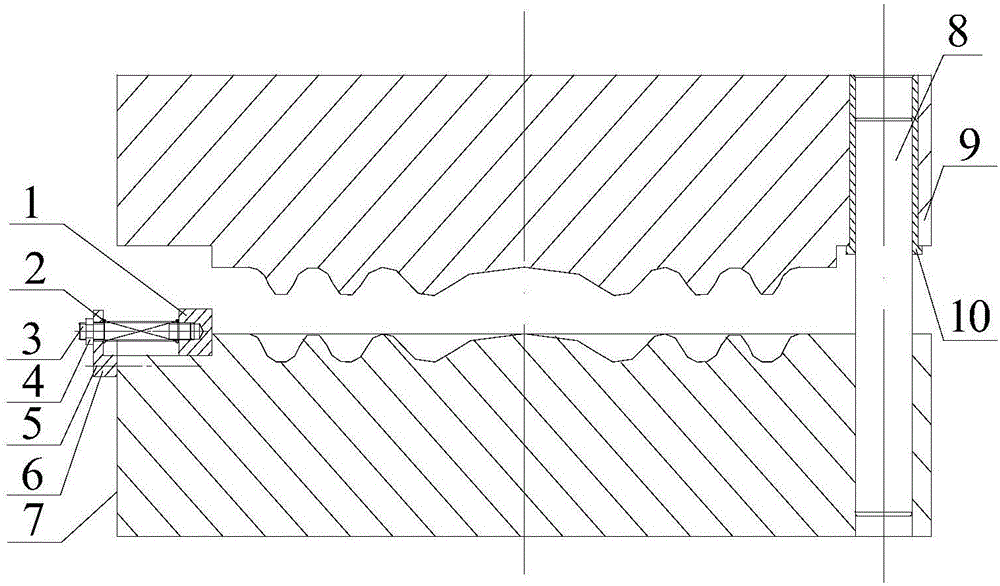

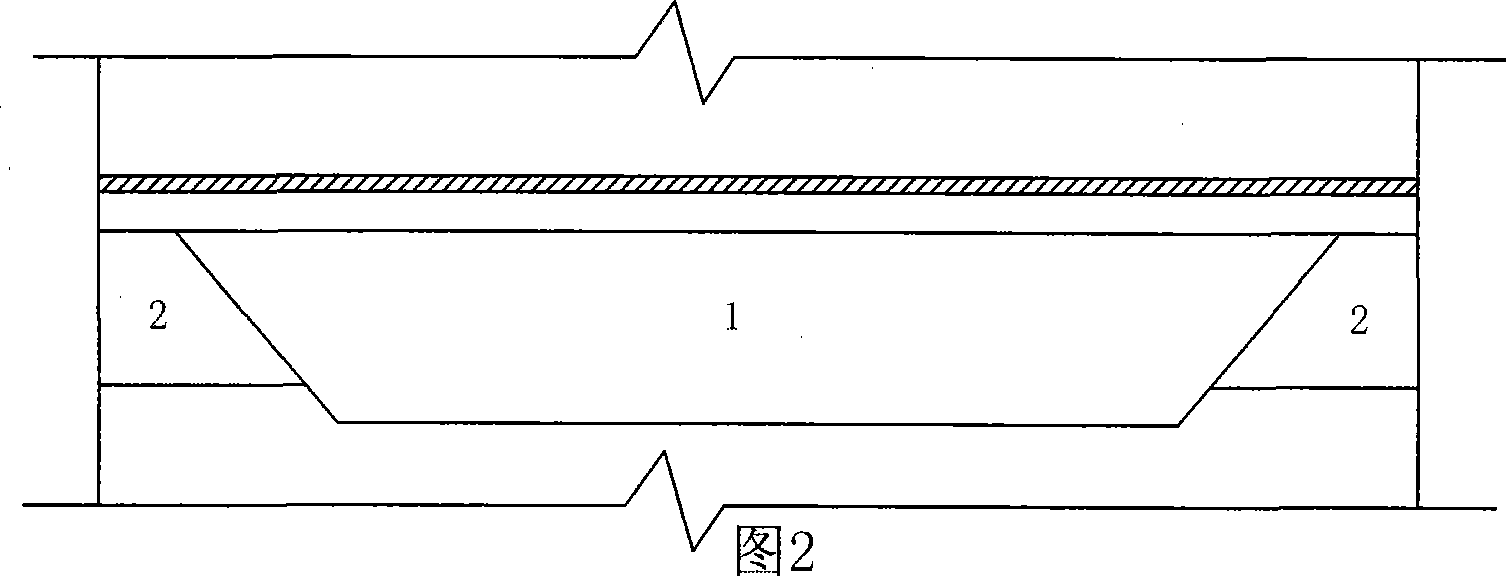

Repeated plate ring wave drawing intense deformation die and technology

InactiveCN106424261AUniform plastic deformationUniform strain distributionShaping toolsMetal-working feeding devicesMicrometerWave shape

The invention discloses a repeated plate ring wave drawing intense deformation die and technology. The die comprises an upper ring wave die body and a lower ring wave die body, wherein the upper surface and the lower surface of the upper ring wave die body are formed by a plurality of circles of concave-convex, continuous, alternative and coincident ring waves, and the upper surface and the lower surface of the lower ring wave die body are formed by a plurality of circles of concave-convex, continuous, alternative and coincident ring waves. The upper ring wave die body is connected with a movable cross beam of a hydraulic machine. The lower ring wave die body is fixed to a working table board. The upper ring wave die body is a movable die, and the lower ring wave die body is a fixed die. Two locating mechanisms arranged symmetrically in the radial direction are arranged at the upper end of the lower ring wave die body and can locate a plate. The upper ring wave die body and the lower ring wave die body are guided through a guide column and a guide sleeve which are arranged symmetrically in the axial direction, and directly participate in formation of the plate. By means of die closing, the plate is drawn to a set ring wave shape. According to the technology, through the die, repeated drawing is carried out for deforming and refining plate grain particles to enable the size of the grain particles to reach the micrometer level or the sub-micrometer level, finally, a flattening die is used for flattening the deformed plate, and a smooth plate is obtained. The die is free of restrictions of the size of the plate, the plate in the large size can be machined, and the comprehensive performance of the aspects such as physics, chemistry and mechanics of the plate are improved greatly.

Owner:河北华杰缝纫机零件有限公司

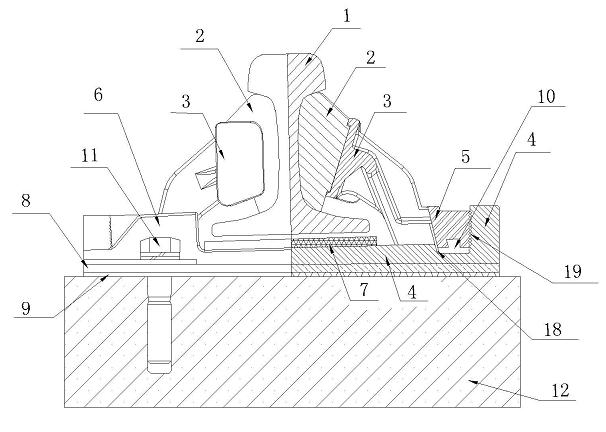

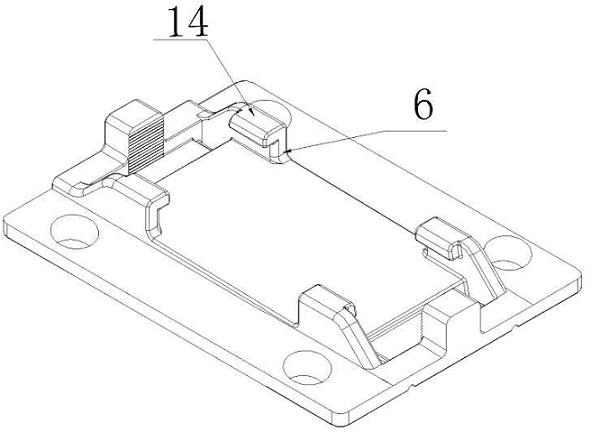

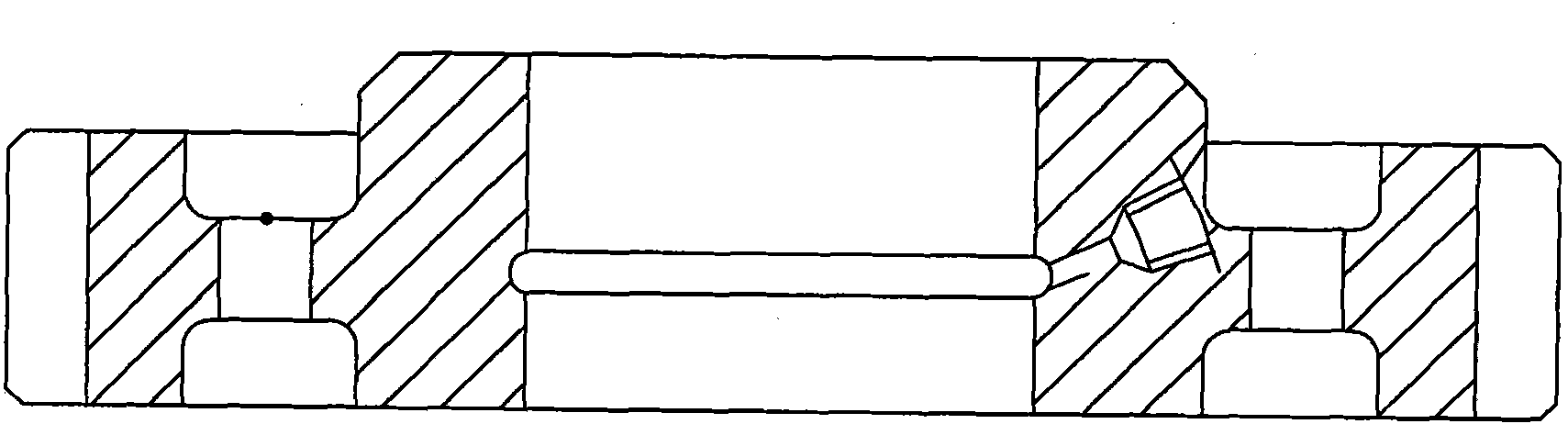

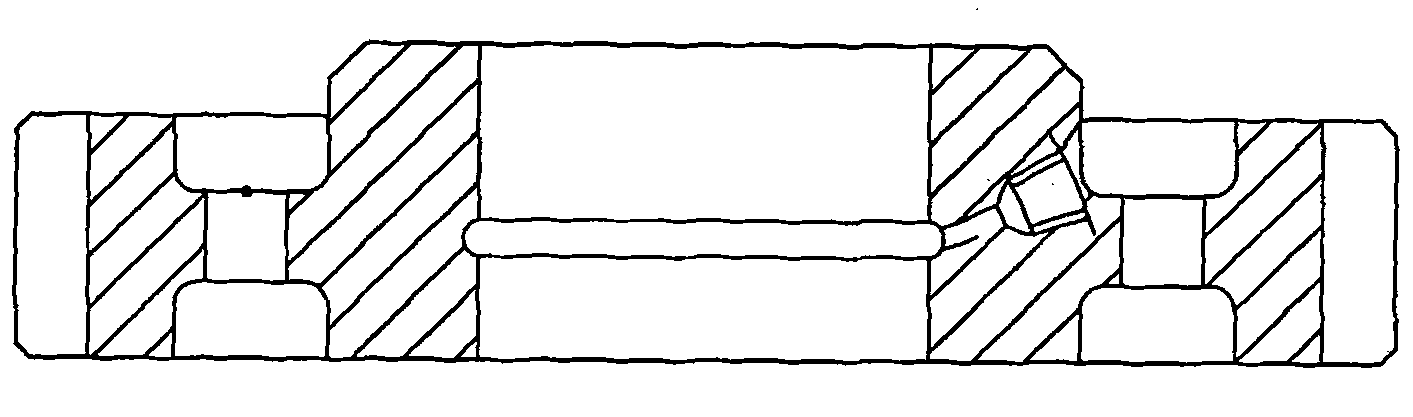

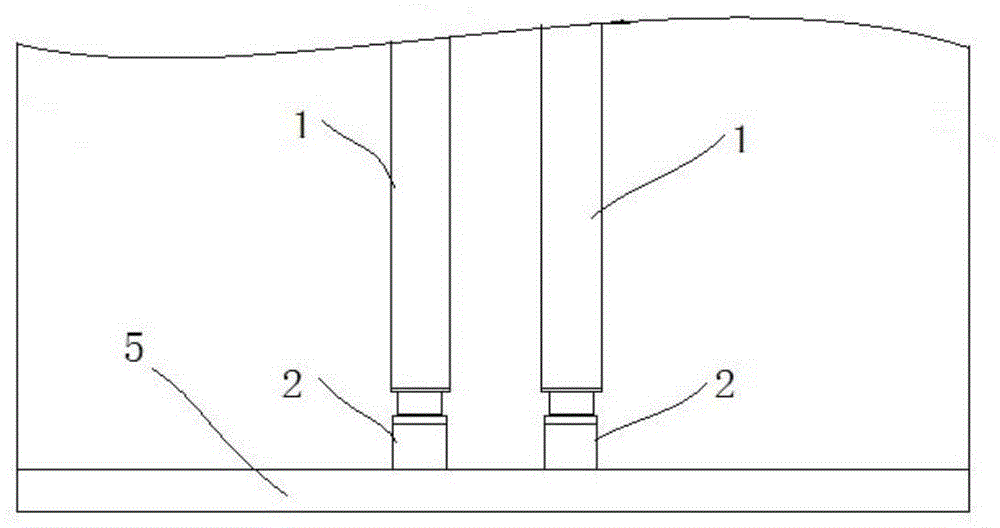

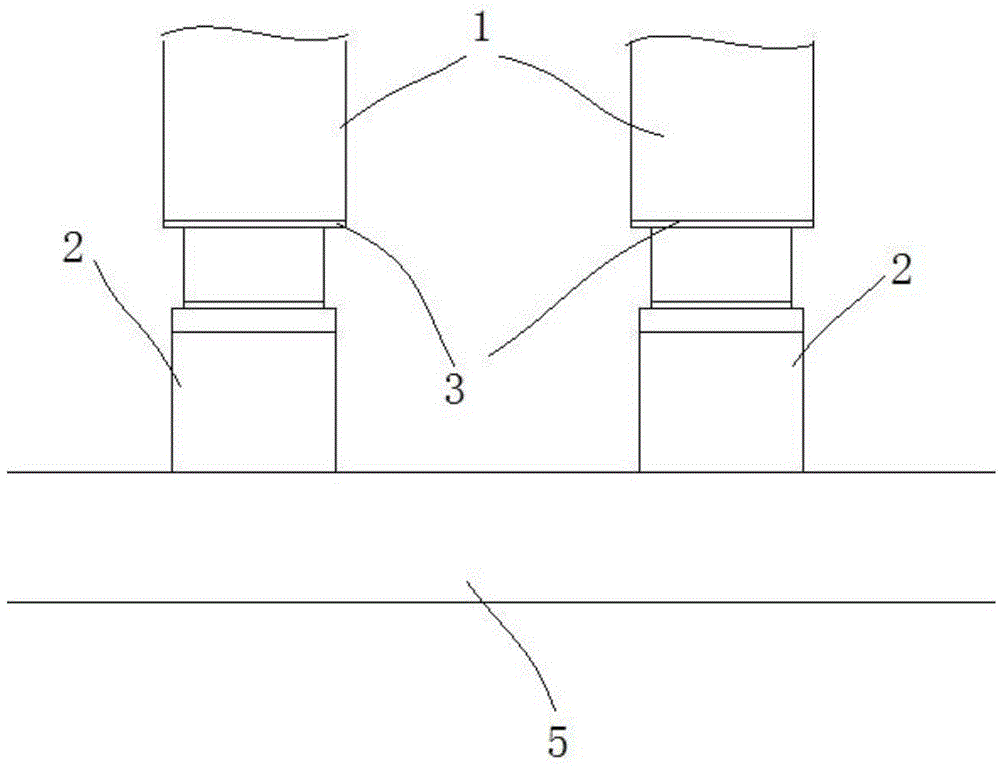

Chute-mounted suspended steel rail vibration reduction fastener

ActiveCN102359036ASmall overall deformationEnsure driving safetyRail fastenersNoise reductionVehicle safety

The invention belongs to the field of rail vibration reduction and noise reduction, and provides a chute-mounted suspended steel rail vibration reduction fastener. A structure for limiting a lateral bracket (3) is arranged at the joint position of a fastener bottom plate (4) and the lateral bracket (3), and the limiting structure is provided with at least one limiting surface I (6) for limiting the lateral bracket (3) to move in the laying direction of a steel rail and at least one limiting surface II (14) for limiting the lateral bracket (3) to move vertically; and a space for allowing the lateral bracket (3) to horizontally move in the direction vertical to the laying direction of the steel rail (1) is formed between the limiting surface I (6) and the limiting surface II (14). Through the fastener, movement of the lateral bracket (3) in the vertical direction and the laying direction of the steel rail (1) can be effectively controlled, torsion of the lateral bracket (3) due to torsion of the steel rail (1) can be effectively controlled, the stability of the lateral bracket (3) structure is effectively enhanced, and the safety of a vehicle is ensured.

Owner:洛阳双瑞橡塑科技有限公司

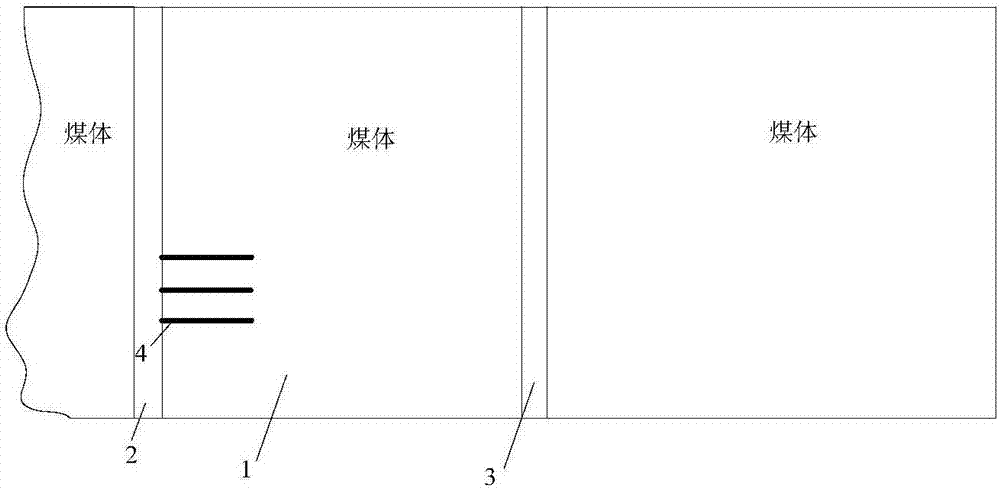

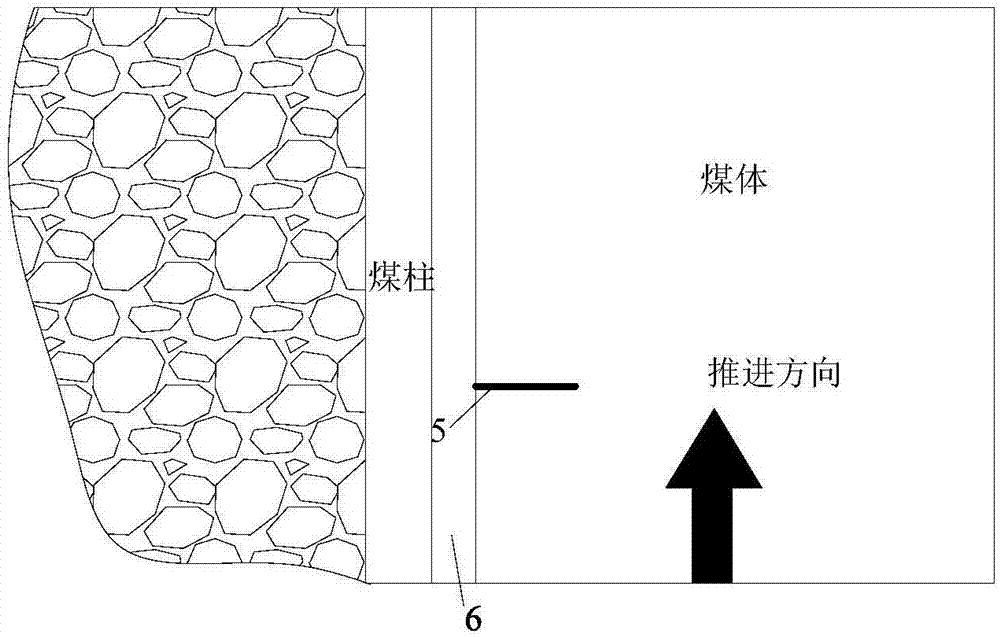

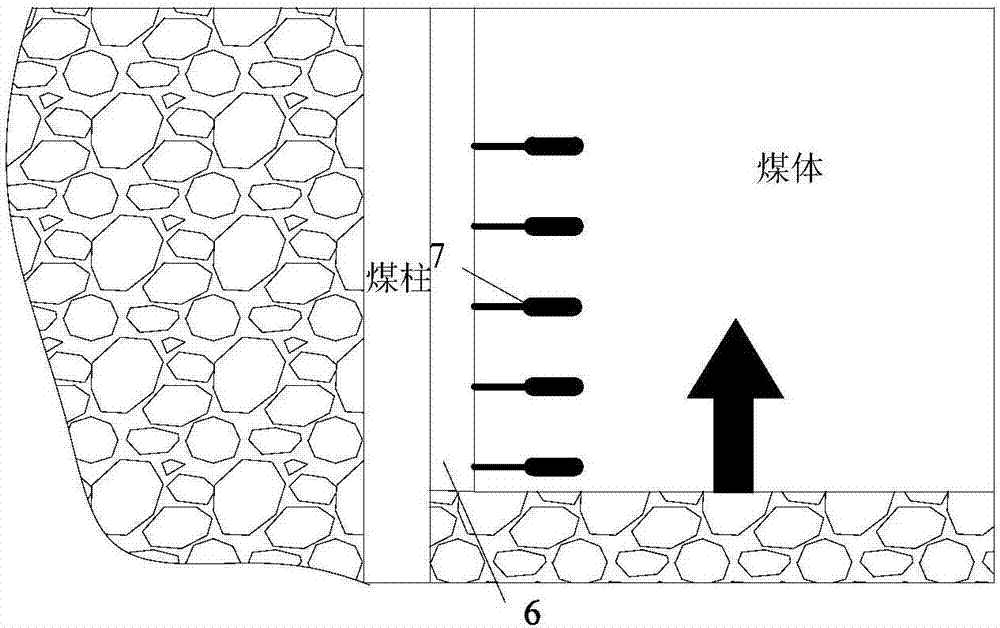

Construction method for drilling depressurization hole in gob-side mining roadway

ActiveCN106930691AReduce construction difficultyShort construction periodDrilling machines and methodsGeomorphologyOperability

The invention discloses a construction method for drilling a depressurization hole in a gob-side mining roadway. The construction method comprises the main steps that (1), drilling sampling is conducted in a coal side where a haulage gate of a first coal mining face is not influenced by mining; (2), drilling sampling is conducted on the side, close to a coal mining face and away from a base plate by 1.5 m in height, of the next coal mining face gob-side mining roadway; (3) according to the two drilling sampling processes, the corresponding rule of the drilling depth and the pulverized coal quality value is found out, and the lateral bearing pressure distribution rule of the side, close to the coal mining face, of the gob-side mining roadway is obtained; (4), the stepped depressurization hole is drilled in an area from the front side of the coal mining face to a stopping line along the roadway by reference to the obtained lateral bearing pressure distribution rule; and (5), construction in the next coal mining face gob-side mining roadway is continuously conducted, and the construction steps are repeated till construction is completed. The construction method for drilling the depressurization hole in the gob-side mining roadway has the characteristics of being small in disturbance on the gob-side mining roadway, good in depressurization effect, small in construction difficulty, high in operability, short in construction period, low in construction cost and the like.

Owner:SHANDONG UNIV OF SCI & TECH

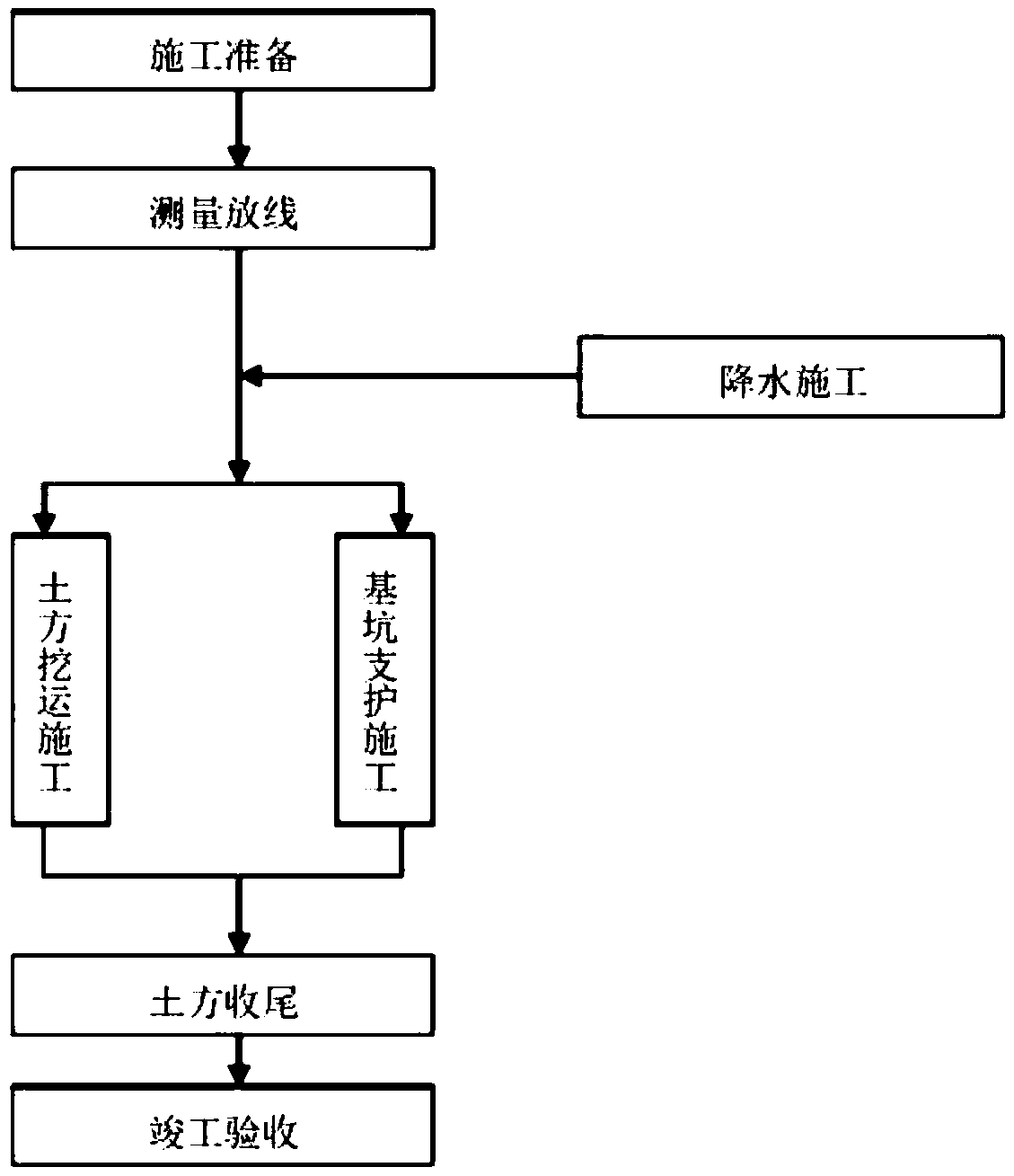

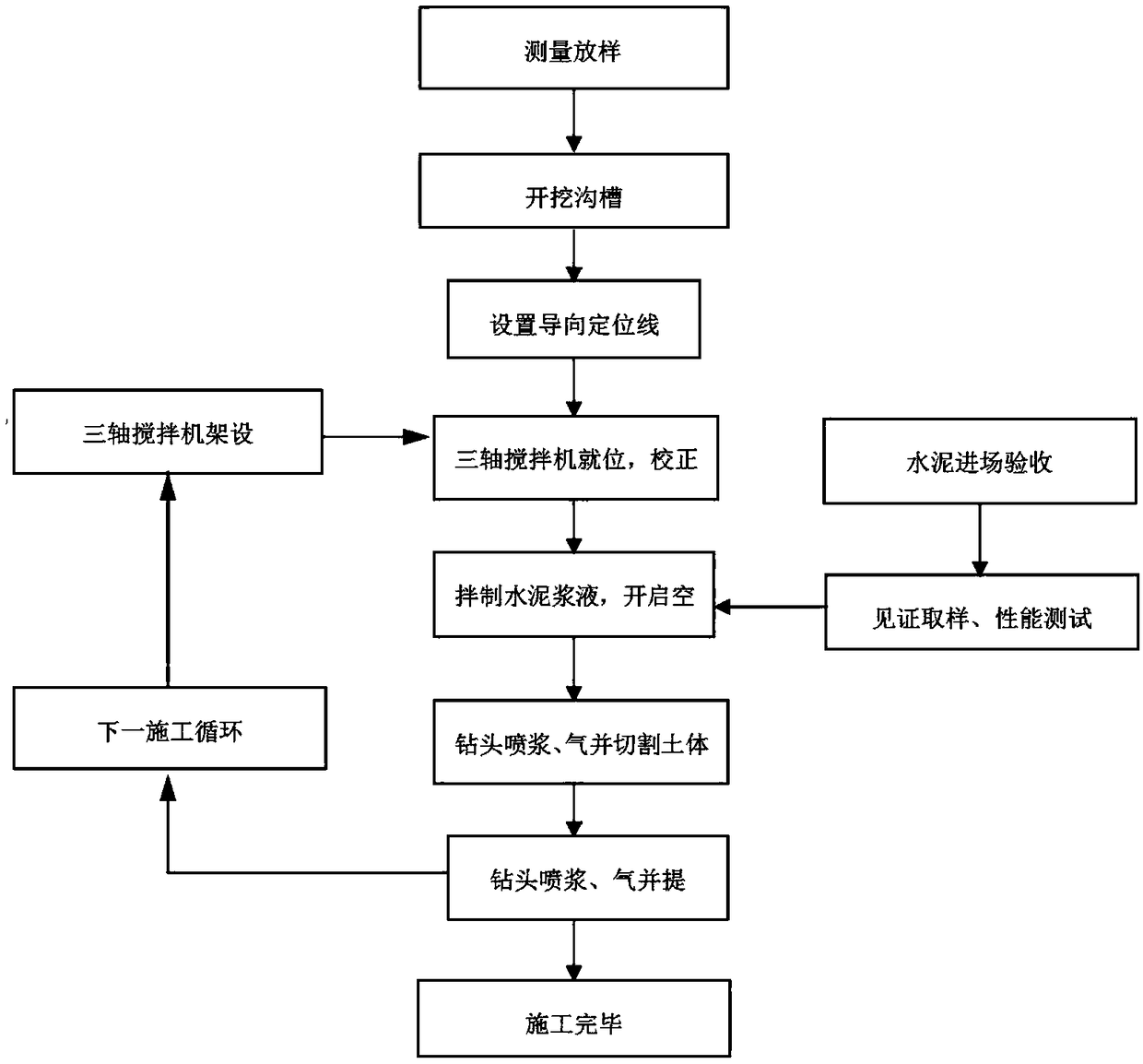

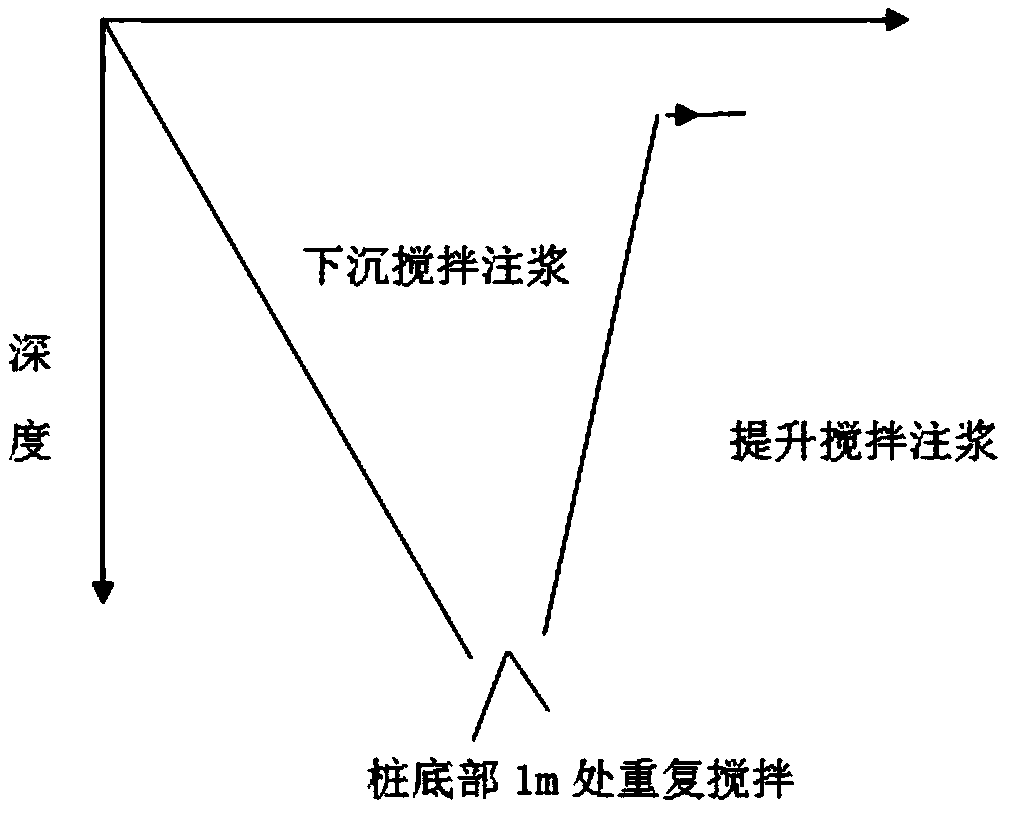

Construction process for prestress support in deep foundation pit

InactiveCN108797598AGood for deformation controlEnsure safetyExcavationsBulkheads/pilesPre stressProcess efficiency

The invention relates to a construction process for a prestress support in a deep foundation pit. The construction process specifically comprises the following steps: (1) cleaning a site and constructing and paying off; (2) construction preparation; and (3) constructing enclosure engineering: a prestress is applied in an enclosure mode by means of triaxial stirring pile water sealing, a cast-in-situ bored pile, a biaxial stirring pile, a stiffening anchor rod pile, anchor spraying and a semi-detached waist rail, wherein the step (3) specifically comprises the following steps: sequentially joining and alternately performing triaxial stirring pile water sealing, cast-in-situ bored pile enclosing and biaxial stirring pile matched with earthwork excavation and transportation; firstly, performing construction of the cast-in-situ bored pile, wherein two stirring pile drivers move in opposite directions to reduce construction cold joints, and 3-5 days after construction of the biaxial stirring piles, following up and inputting the mixture into a drilling machine for performing construction of the cast-in-situ bored pile; after construction of the cast-in-situ bored pile, excavating earthwork, and then continuously excavating earthwork after constructing the stiffening anchor rod pile, and performing anchor spraying and the semi-detached waist rail; and repeating the construction flowsin the steps till integral construction of a to-be-constructed super deep foundation pit is finished. The construction process efficiency is high, the safety of the foundation pit is ensured, and theconstruction period is shortened.

Owner:江苏地基工程有限公司

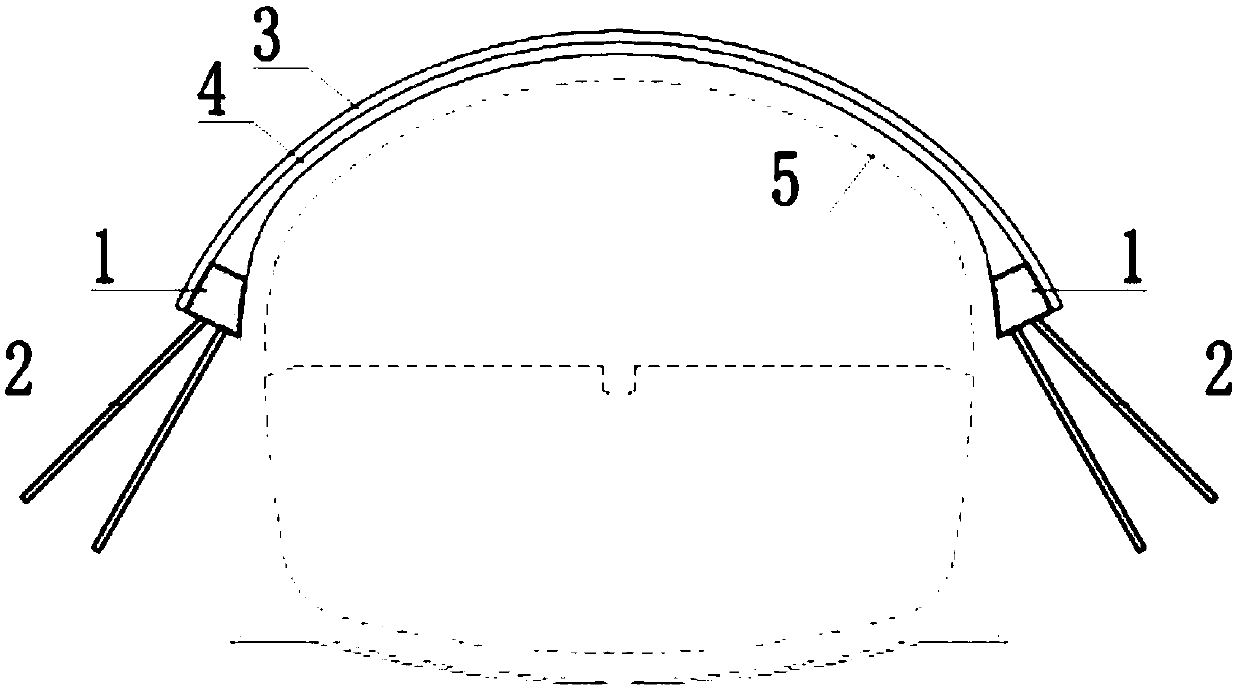

Reinforcement structure for arch-covering-method underground excavation subway station arch feet and construction method

PendingCN109538246AEasy to controlIncrease stiffnessUnderground chambersTunnel liningSubway stationStructural integrity

The invention discloses a reinforcement structure for arch-covering-method underground excavation subway station arch feet and a construction method. The reinforcement structure for the arch feet comprises two layers of arch cover supports, arch foot piles distributed at the arch feet of the left and right sides of subway station arch cover bodies and arch foot longitudinal beams, the arch foot longitudinal beams and the arch foot piles are integrally connected, and pile bodies of the arch foot piles are distributed along the tangent line of the arch feet; each arch foot pile is composed of asection steel framework and fine aggregate concrete which is poured into the section steel framework and pile holes. The reinforcement structure is a reinforcement system combining the arch foot pileswith the longitudinal beams, the longitudinal beams are connected with the arch foot piles and the first and second layers of arch cover supports, the structural integrity is good, the capacity of resisting local stress and deformation is high, and deep and thick smashed surrounding rock at the arch feet can be effectively reinforced and protected; in addition, according to the construction method of the reinforcement structure for the arch feet, the reinforcement range and implementation objects are flexibly selected, rock layers of the arch feet for supporting arch covers are smashed, the integrity influence cannot be caused, and the advantages of an arch-cover method in the aspects such as project cost, construction working period, implementation efficiency and mechanical operation cannot be influenced.

Owner:中铁科学研究院有限公司

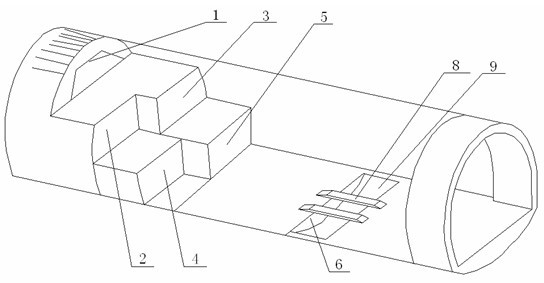

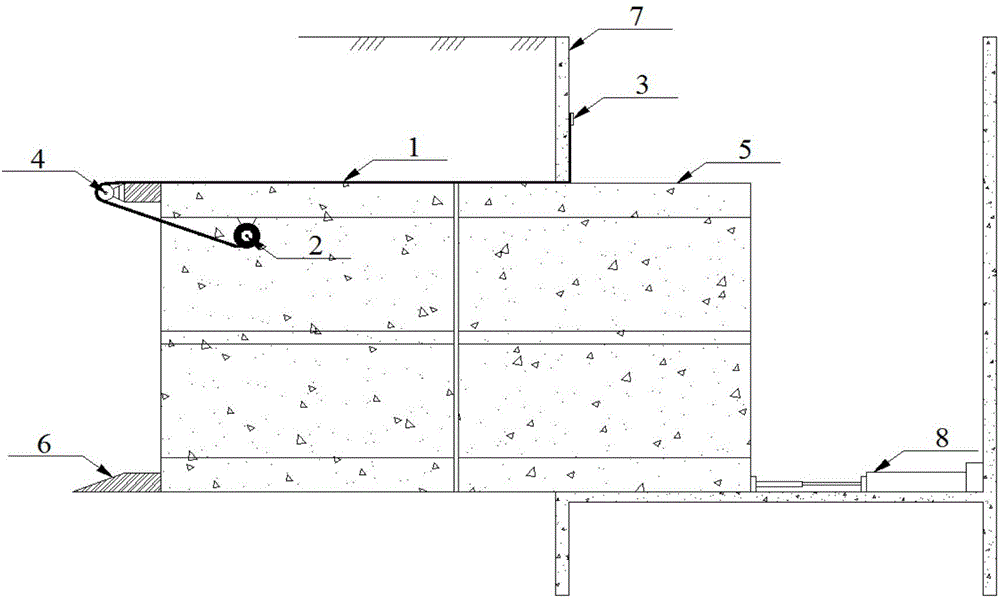

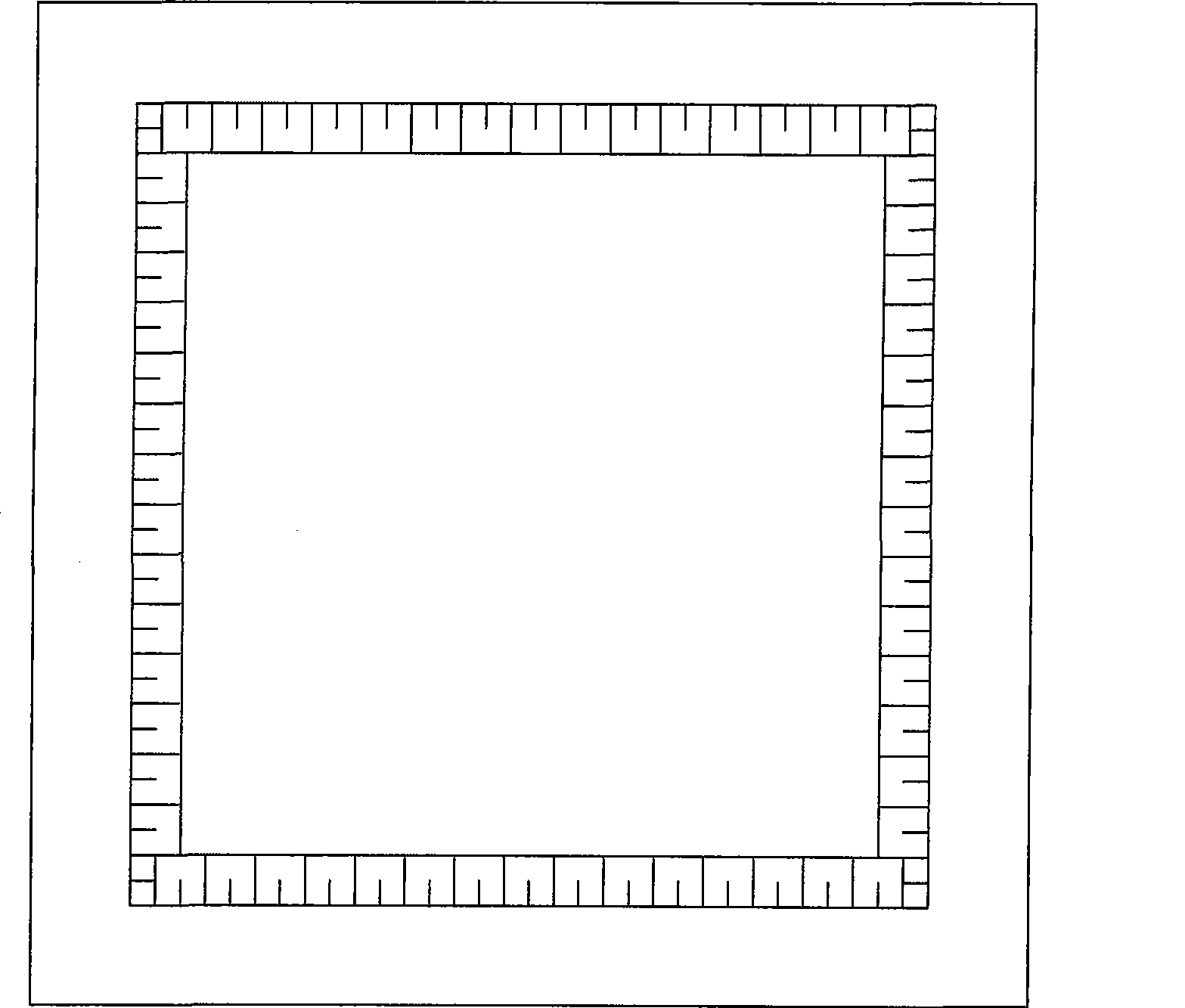

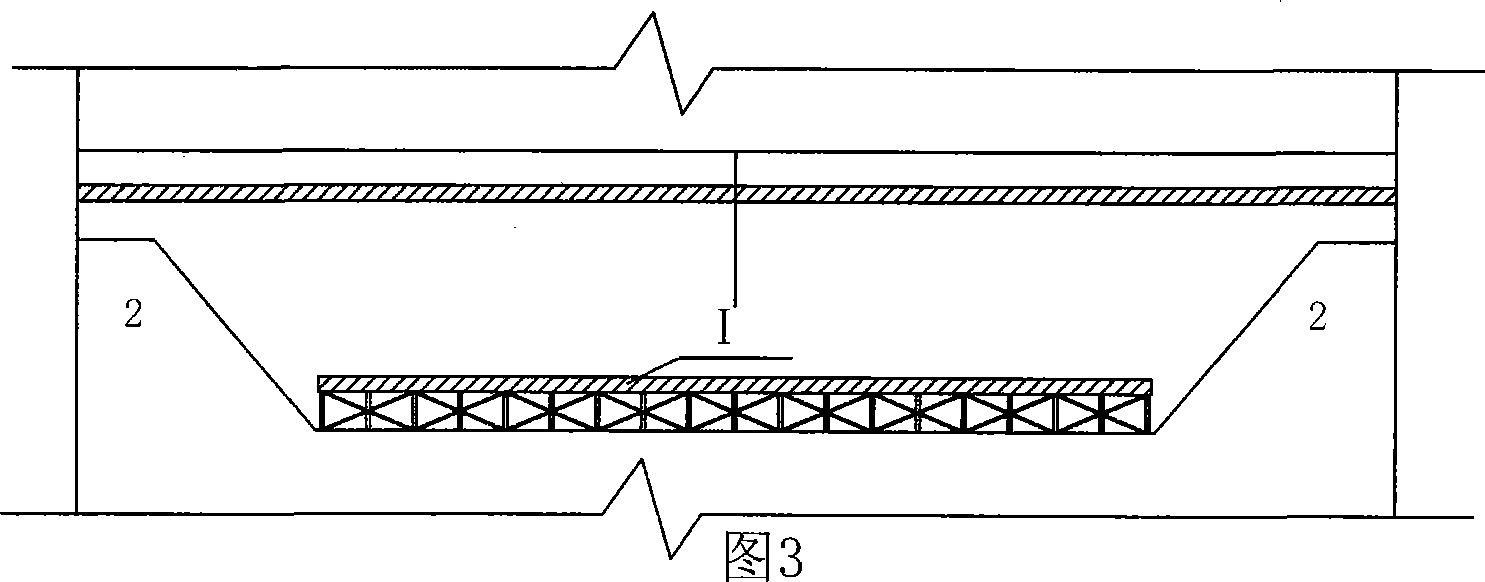

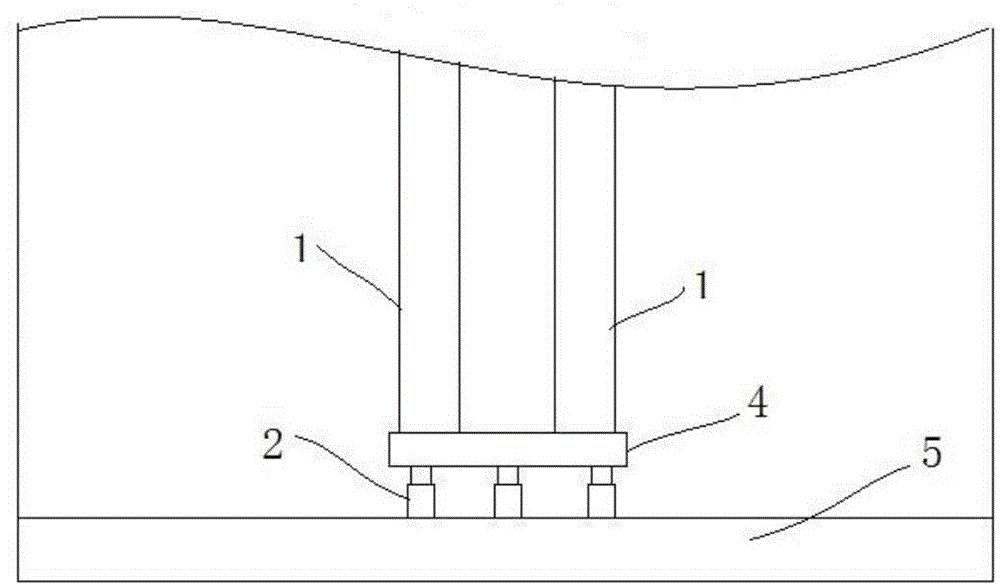

Reverse towing device capable of reducing longitudinal deformation of soil when box culvert is jacked in

InactiveCN104100273AAvoid late consolidation settlementLow costUnderground chambersTunnel liningLongitudinal deformationLocal pressure

The invention relates to a reverse towing device capable of reducing longitudinal deformation of soil when a box culvert is jacked in. The reverse towing device comprises a towing plate, a storage component inside a towing sleeve, an anchoring component outside the towing sleeve and an anti-drag pulley. The towing plate is of thin-plate coiled materials and pulled out from the front end of the box culvert when the box culvert is jacked in to separate the box culvert and soil layers. The storage component inside the towing sleeve is arranged in the box culvert and used for accommodating the towing plate and synchronously releasing the same when the box culvert is further jacked in. The anchoring component outside the towing sleeve is arranged in a box culvert starting well and used for fixing the outer end of the towing plate. By the anti-drag pulley which is arranged at the front end of a box body, sliding friction is replaced by rolling friction, thus the towing plate is low in frictional resistance when pulled out of the front end and is protected from damage caused by large local pressure of a bezel. Compared with the prior art, the reverse towing device is mainly applied to the top of the box culvert to be a substitute for a pipe curtain method and thixotropic mud, and is used for separating the soil and the box culvert so as to control disturbance to the soil and to avoid deformation of strata above the box culvert.

Owner:TONGJI UNIV

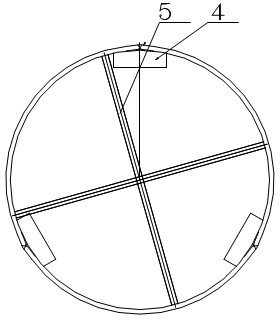

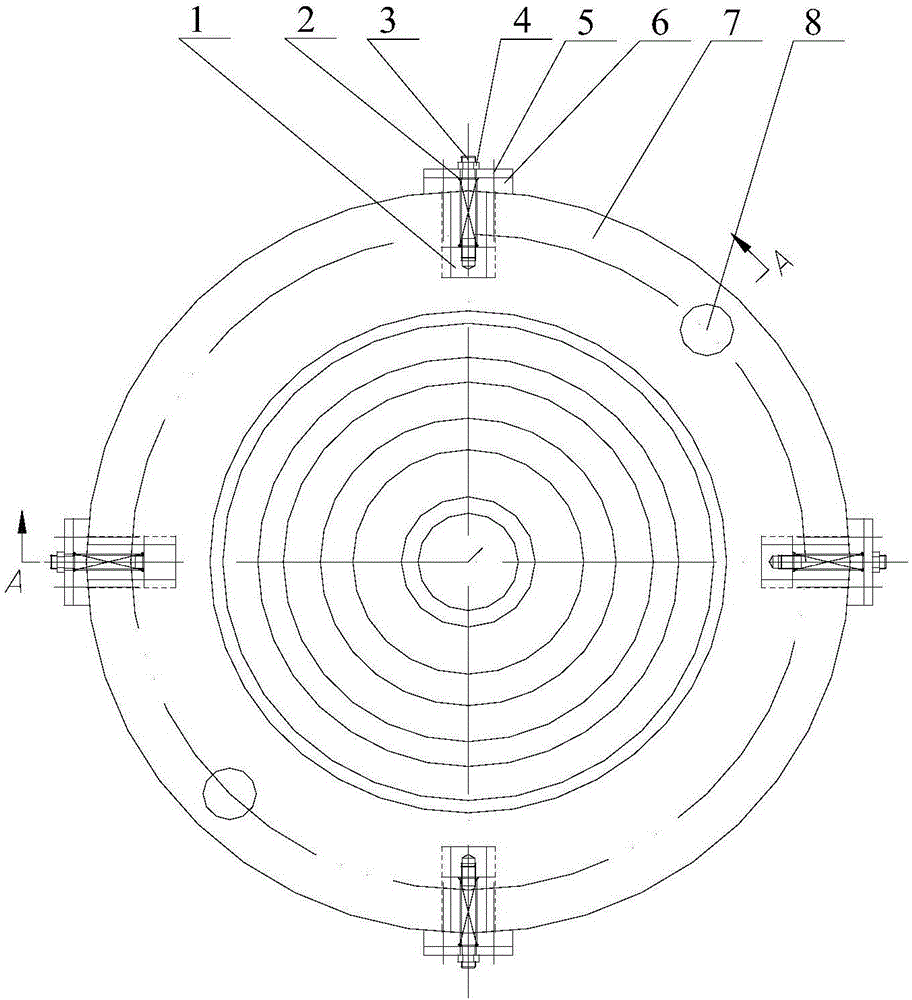

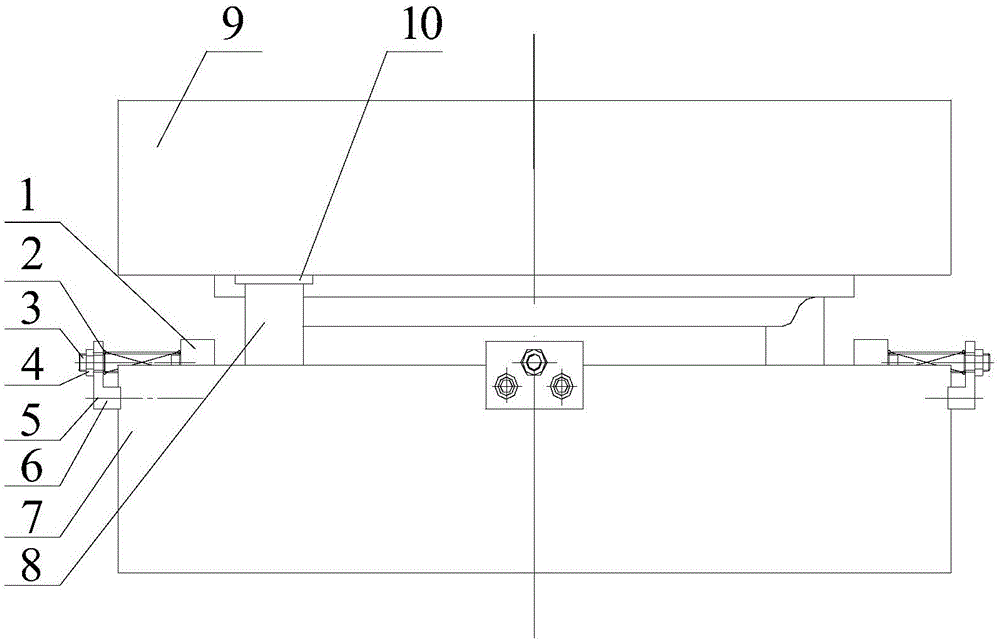

Ring-wave repeated drawing high deformation mold for plate and machining method

InactiveCN107716668AUniform plastic deformationUniform strain distributionGeometric CADShaping toolsWave shapeLarge size

The invention discloses a ring-wave repeated drawing high deformation mold and technology for a plate. The mold comprises two ring-wave mold bodies including the ring-wave mold body A and the ring-wave mold body B, wherein the two ring-wave mold bodies are both of an axially-symmetrical cylindrical structure, the upper surfaces and the lower surfaces of the ring-wave mold bodies are each composedof a plurality rings of convex-concave continuous alternate matchable ring waves, the ring wave radian and length of the axial center are large, the wave height of the axial center is small, and the ring wave radian and length are decreased ring by ring and the wave height is increased ring by ring from the axial center to the exterior. Ring-wave upper mold bodies are movable mold bodies, ring-wave lower mold bodies are fixed mold bodies, and two groups of positioning mechanisms which are radially and symmetrically arranged are arranged at the upper end of each ring-wave lower mold body; and the plate is drawn to be in a set ring wave shape by the ring-wave upper mold bodies and the ring-wave lower mold bodies through mold closing. According to the technology, crystal grains of the plate can be repeatedly drawn, deformed and refined through the mold, and then the size of the crystal grains reaches the micron grade or the submicron grade. The ring-wave repeated drawing high deformationmold is not limited by the plate size, a large-size plate can be machined, and the comprehensive properties of the plate on the physical aspect, the chemical aspect, the mechanical aspect and the likecan be greatly improved.

Owner:YANSHAN UNIV

Middle plate construction method of wide pit top-down construction

The invention relates to underground construction, in particular to a construction method for a median plate under the condition of construction of a wide foundation pit by the reverse construction method. The method comprises the following steps: an earthwork in the middle is excavated first, and tables are preserved near an enclosing structure to control deformation of the enclosing structure; when concrete slabs are subjected to placing, a reinforced concrete slab in the middle is constructed first and tables on both sides are excavated after subdividing when the reinforced concrete slab in the middle reaches the strength; and concrete slabs on both sides near the enclosing structure are symmetrically constructed after subdividing. The construction method has reasonable excavating and placing sequence, is favorable for controlling deformation of the foundation pit, saves the construction period, and is convenient to construct.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

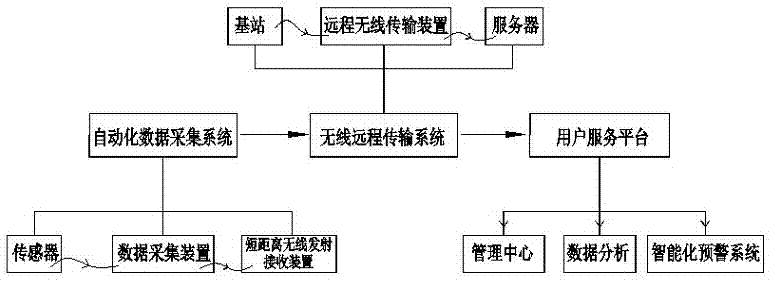

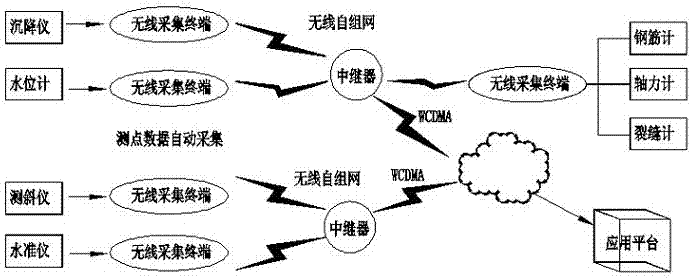

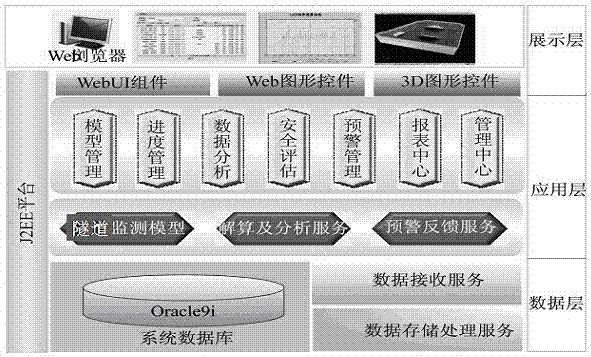

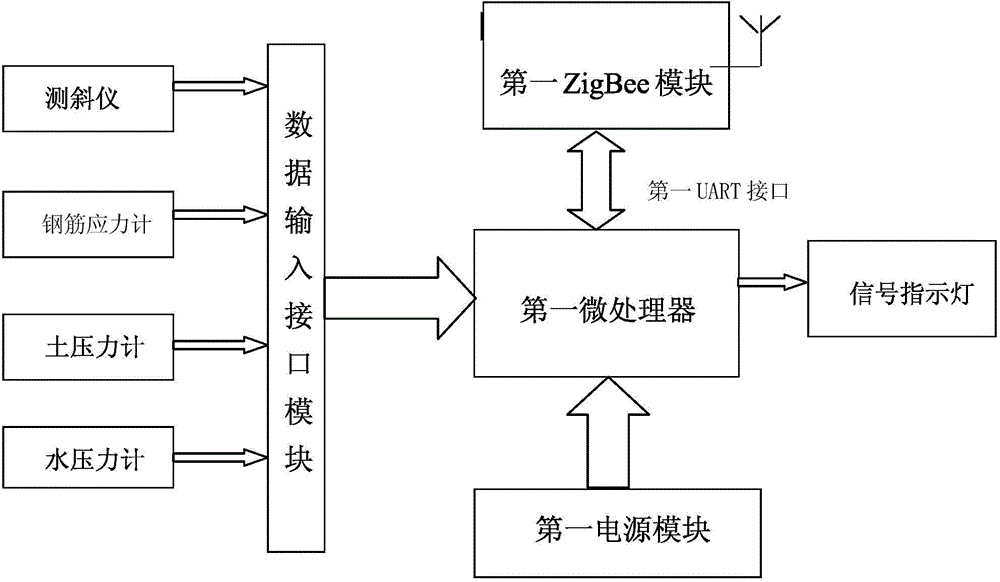

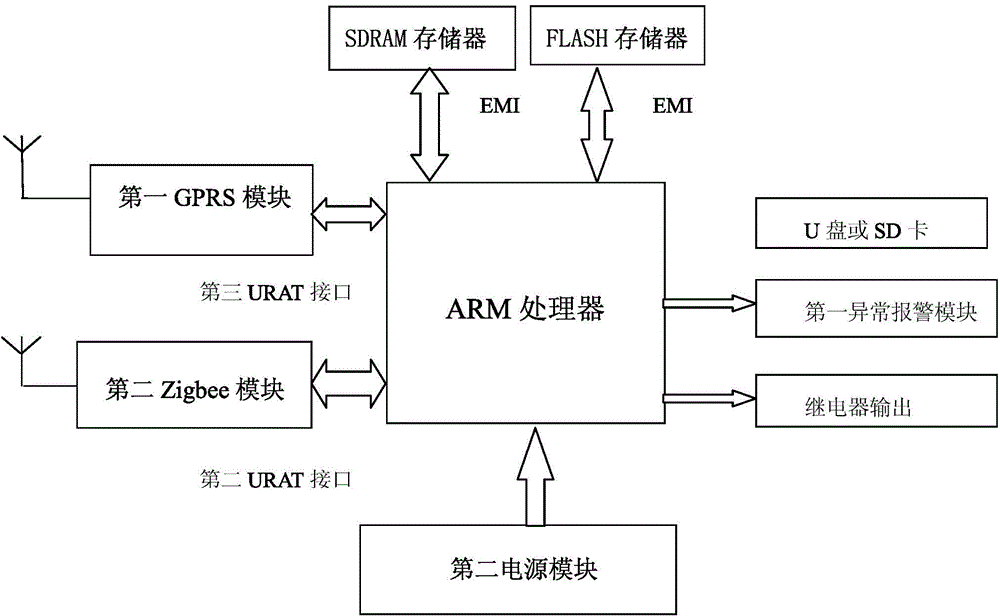

ZigBee-based tunnel automatic monitoring system and monitoring method thereof

InactiveCN107067690AReduce usageAvoid destructionTransmission systemsShort range wirelessTreatment system

The invention discloses a ZigBee-based tunnel automatic monitoring system and a monitoring method thereof. The system comprises an automatic data acquisition system, a wireless remote transmission system and a user service platform, wherein the automatic data acquisition system comprises a sensor, a data acquisition system and a short distance wireless transmitting and receiving device; the wireless remote transmission system comprises a base station, a remote wireless transmission device and a server; and the user service platform comprises treatment systems, such as a data analyzing and processing system, an intelligent early warning system and a management center. The monitoring system and monitoring method which are disclosed by the invention have the advantages that a wireless communication technology is adopted, fewer cables are used, damage caused by tunnel construction on the cables is avoided, a large-scale network is adopted for carrying out large-scale point distribution, and a tunnel structure can be monitored, early-warned and evaluated more detailedly and more accurately.

Owner:SUN YAT SEN UNIV

Simple method for deformation control during carburizing and quenching of large-diameter heavy-duty gears

InactiveCN102010973AEasy to operateGood deformation controlSolid state diffusion coatingFurnace typesDeformation controlHeavy duty

The invention relates to the technical field of carburizing and quenching as well as deformation control of steel work-pieces, and particularly relates to a simple method for deformation control during the carburizing and quenching of large-diameter heavy-duty gears. In the method, the deformation control can be carried out on the carburizing and quenching of the steel work-pieces by adopting simple facilities under simple operation conditions, so as to reach the expected effect and improve the product quality. The method comprises the following steps of: normalizing of steel work-piece, carburization of the steel work-pieces placed in a direction A, normalization of the steel work-pieces placed in a direction B, quenching of the steel work-pieces placed in the direction B in a static oil, and tempering. The method has the significances of breaking through the situation that the deformation control of the carburizing and quenching of the large-diameter complicated heavy-duty face gears can be controlled only by adopting complicated facilities and complicated technological operations, and simultaneously developing a simple and practical way for the deformation control during the carburizing and quenching of the large-diameter complicated heavy-duty face gears.

Owner:CRRC QISHUYAN CO LTD

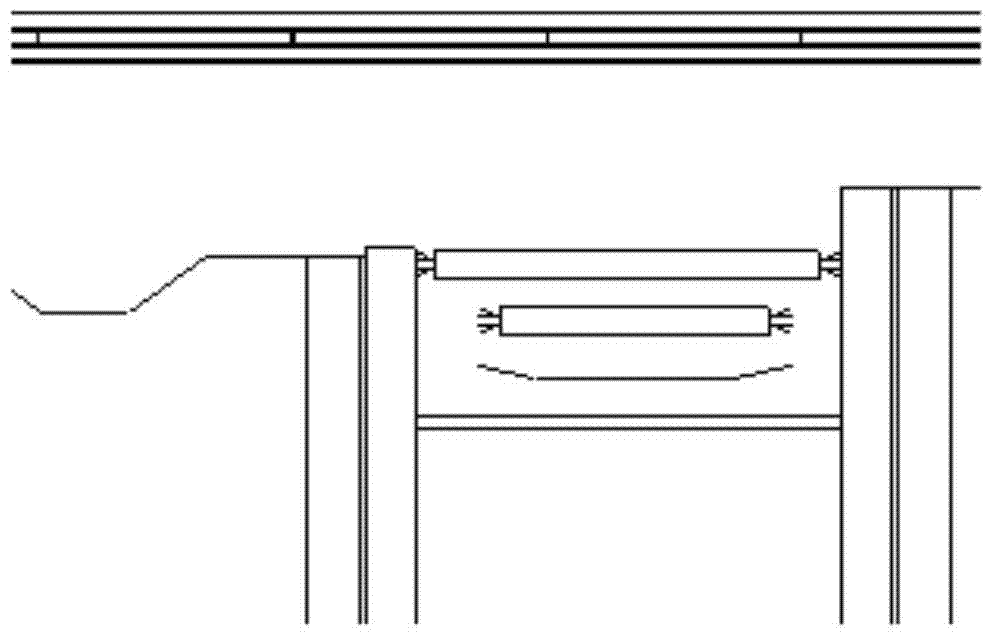

Reinforced concrete inner support with pre-stressed loaders for supporting foundation pit

ActiveCN102979101AGood for deformation controlImprove support stiffnessExcavationsReinforced concretePre stress

The invention provides a reinforced concrete inner support with pre-stressed loaders for supporting a foundation pit. The reinforced concrete inner support comprises reinforced concrete supporting beams and reinforced concrete enclosing purlins, which are arranged in the foundation pit, wherein a plurality of pre-stressed loaders are arranged between the reinforced concrete supporting beams and the reinforced concrete enclosing purlins. The inner support is high in supporting rigidity and controllable in foundation pit deformation. The prestress applied to the reinforced concrete support can be adjusted at any time when the soil pressure of the side wall of the foundation pit is changed, so that the soil pressure of the side wall of the foundation pit is counteracted.

Owner:SHANGHAI STRONG FOUND ENG

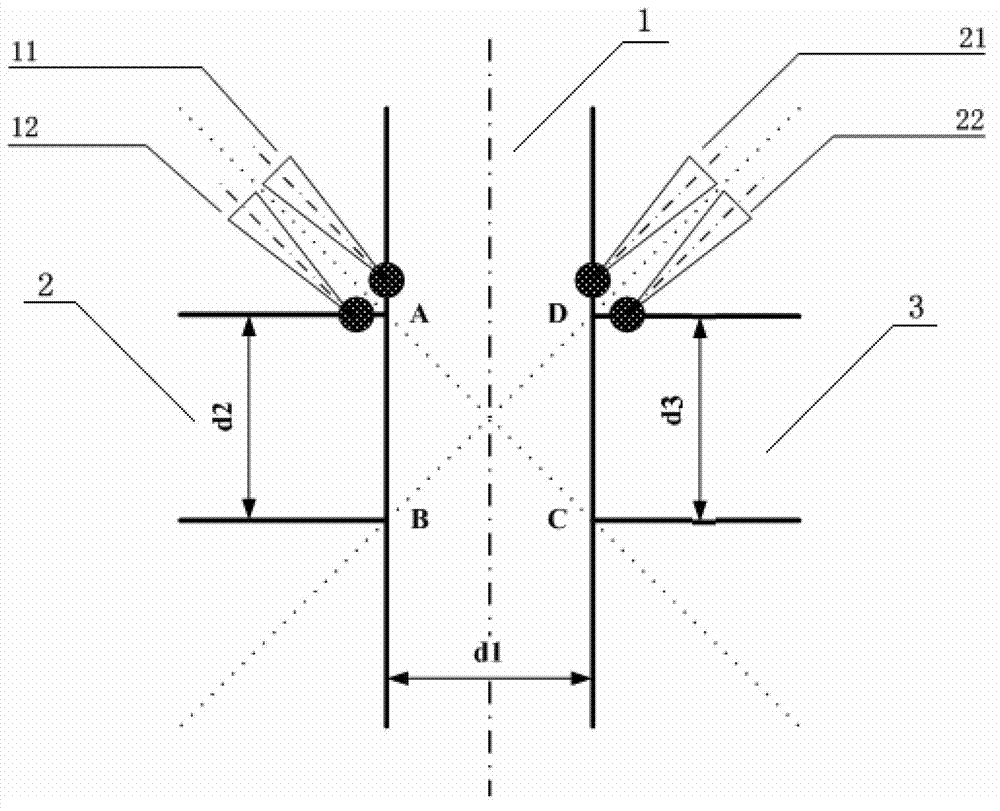

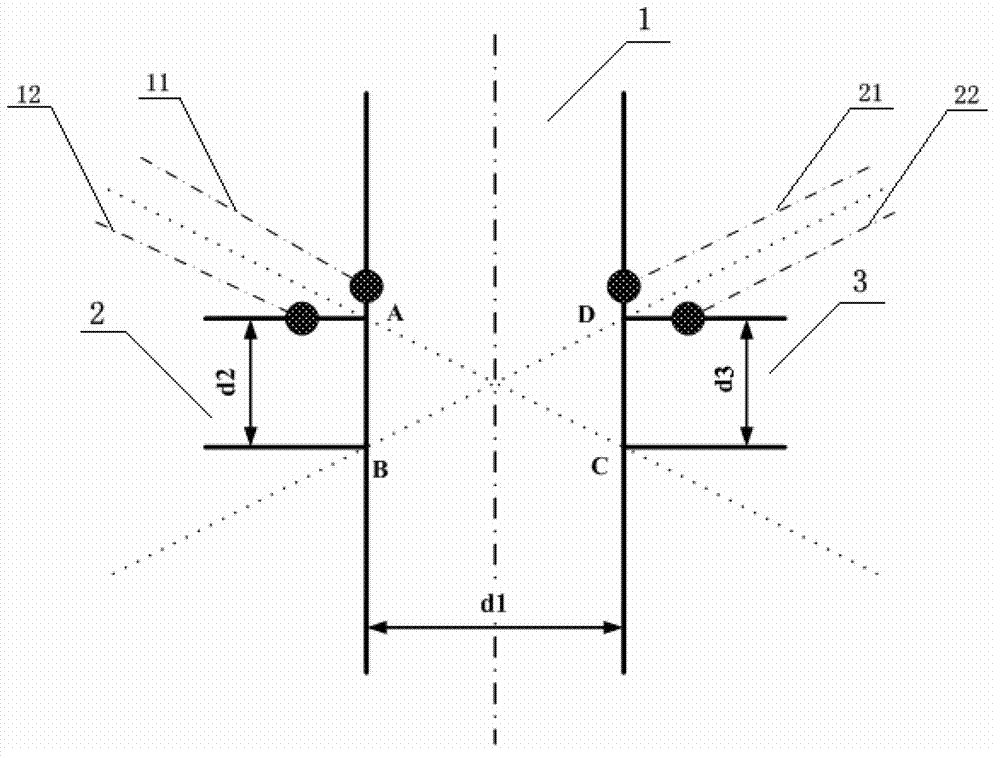

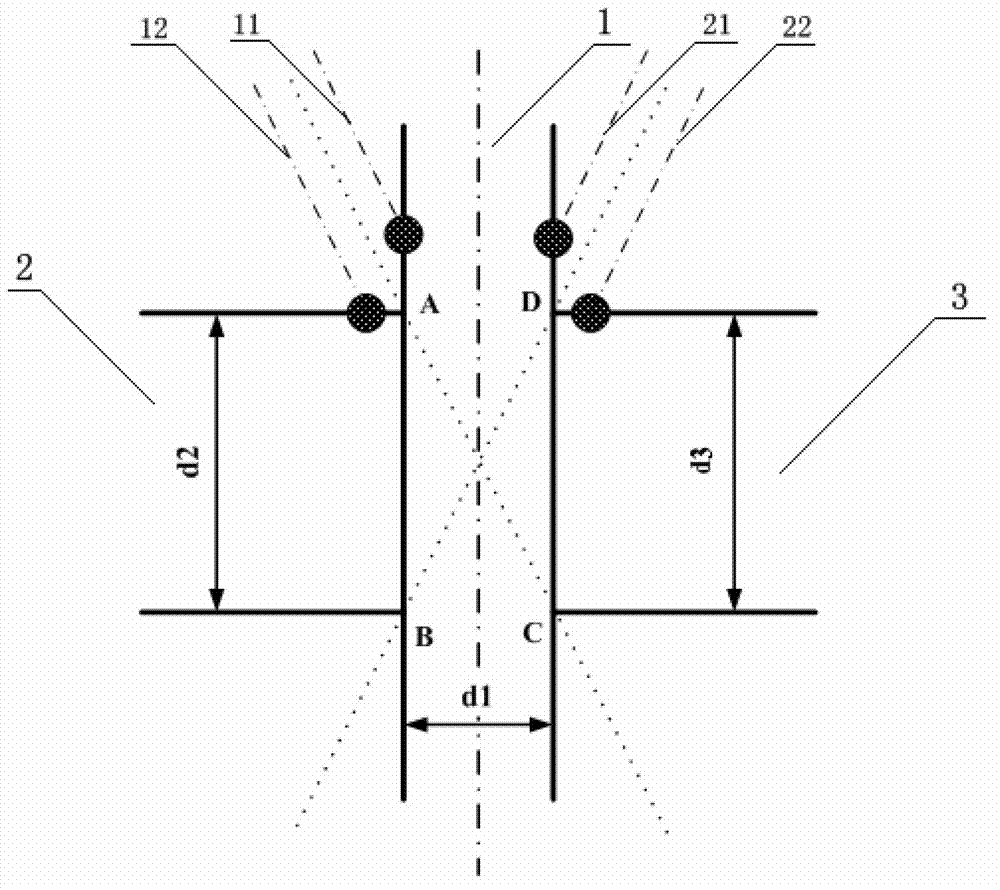

Synchronous dual-light beam laser welding method of crossed joint

ActiveCN102922135AImprove performanceEasy to overflowLaser beam welding apparatusLight beamOptoelectronics

The invention provides a synchronous dual-light beam laser welding method of a crossed joint and relates to a welding method. The invention solves the technical problem of low welding efficiency and poor weld quality existing in the existing single-light beam laser welding method. The welding method comprises the following steps: respectively emitting a main light beam a and a main light beam b by applying two lasers, arranging the two lasers on the two sides of a crossed joint supporting plate in an imaging manner, dividing the main light beam a into a welding light beam 11 and a welding light beam 12, dividing the main light beam b into a welding light beam 21 and a welding light beam 22 and synchronously welding the welding light beam 11, the welding light beam 21 and the welding light beam 12. The synchronous dual-light beam laser welding method has the beneficial effect that aiming at the weld characteristics and the quality requirements of the crossed joint, the problems of uneasiness in stress deformation control, poor weld quality and low welding efficiency existing in the current crossed joint welding process are solved.

Owner:HARBIN INST OF TECH

Milling method for controlling wall thickness uniformity of a thin-wall structural member

ActiveCN109840337AAvoid being too rigidGood for deformation controlMilling equipment detailsSpecial data processing applicationsFinite element analysis softwareMachining deformation

The invention discloses a wall thickness uniformity control milling method for a thin-wall structural part. A workpiece model and J C constitutive model are imported into ABAQUS finite element analysis software. milling path simulation is carried out according to the optimal milling process parameters determined by the high-speed milling test; According to a simulation result, a combination scheme of different overall feeding modes and feeding paths in a cavity is formulated, and finally, an optimal feeding path scheme is determined through a wallboard milling test, so that workpiece deformation is most beneficial to keeping of wall thickness uniformity in the milling process, and wall thickness uniformity control is achieved. The whole feeding path is bilaterally symmetrical, a compositefeeding mode combining spiral feeding and cycloid feeding is adopted in a single cavity, the machining time is short, and the stability of the machining process is improved; The machining deformationof the wallboard structural part is reduced by 40%, the machining efficiency is improved, the service life of a cutter is prolonged, and the machining cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

High-performance iron-based superconducting strip and preparation process thereof

InactiveCN109949999AHigh densityImprove current carrying capacitySuperconductors/hyperconductorsSuperconductor devicesSingle-coreHeat treated

The invention discloses a high-performance iron-based superconducting strip and a preparation process thereof. The process in particular comprises steps of preparing an iron-based superconductor precursor powder; injecting the precursor powder into a metal pipe to obtain a pipe-loaded composite body, and obtaining a single-core wire by extruding and drawing; cutting the single-core wire into a plurality of equal-length single-core wires, loading the equal-length single-core wires into the metal pipe to form a multi-core composite pipe, and obtaining multi-core wires by extruding and drawing; performing four-roller rolling on the single-core wires or multi-core wires to obtain a single-core strip or multi-core strip; and obtaining the high-performance iron-based superconducting strip afterthe heat treatment of the single-core strip or the multi-core strip. The multi-core strip is prepared by four-roll rolling, is subjected to the uniform pressing force in four directions, which obviously increases the density of the superconducting strip, and obtains high textured degree and density while ensuring the superconducting core of the strip. Thus, the current carrying property of the strip is improved, and the critical transfer current and the critical engineering current density of the superconducting strip are improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

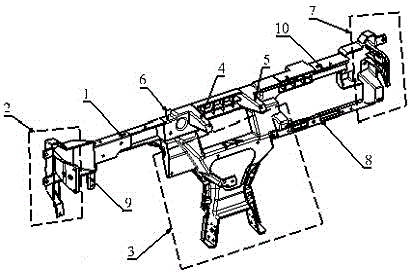

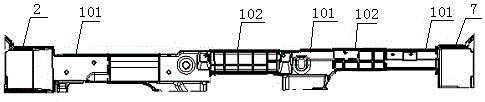

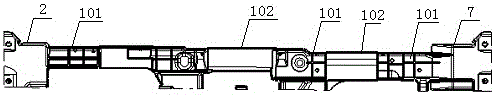

Automobile steering support beam assembly

ActiveCN105857406AEasy to moldGuaranteed accuracySuperstructure subunitsSteering columnsEngineeringUltimate tensile strength

The invention discloses an automobile steering support beam assembly which comprises a main steering support beam, left and right mounting assemblies for steering support, a central support assembly and left and right DVD brackets, and the like, wherein the left and right mounting assemblies for steering support are integrated at left and right ends of the main steering support beam; the central support assembly is integrated with the middle part of the main steering support beam; a PAB mounting bracket and a glove box bracket are integrated on the right section of the main steering support beam; the main steering support beam has a groove structure and is formed by successively and adjacently arranging outward opening first groove structure and inward opening second groove structure in sections; criss-cross reinforcing ribs are arranged in the first and second grooves. The automobile steering support beam assembly can realize the integration and light weight of the steering support beam assembly under the condition of ensuring the rigidity and strength of the steering support beam assembly.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Concrete support and fish-belly sill combined supporting system of special-shaped foundation pit and construction method

The invention relates to a concrete support and fish-belly sill combined supporting system of a special-shaped foundation pit. The system comprises concrete supports, assembled fish-belly sills, section steel diagonal supports, corner supports and middle stand columns, wherein the first pass and the third pass of supports of the foundation pit adopt the concrete supports, and the second pass and the fourth pass of supports adopt the fish-belly sill supports; and the concrete supports and the fish-belly sill supports are vertically connected through steel stand columns in the foundation pit to form a space system. The invention additionally discloses a construction method for the concrete support and fish-belly sill combined supporting system of the special-shaped foundation pit. The construction method comprises the steps of constructing the first pass of concrete supports, roadway slabs and trestle slabs after foundation pit enclosure and stand column piling are completed; after the strength meets the requirement, downwards excavating the foundation pit to the position of the second pass of supports, i.e. the fish-belly sill supports, sequentially installing corbels, brackets, purlins, the corner supports and the fish-belly sills, and finally installing the diagonal supports. The concrete support and fish-belly sill combined supporting system of the special-shaped foundation pit and the construction method provided by the invention have the advantages that the foundation pit is ensured to be safely and quickly constructed; a larger operating space can provided, the speed of installing and removing the supports is fast and the deformation control of the foundation pit is facilitated.

Owner:中铁建大桥工程局集团第三工程有限公司

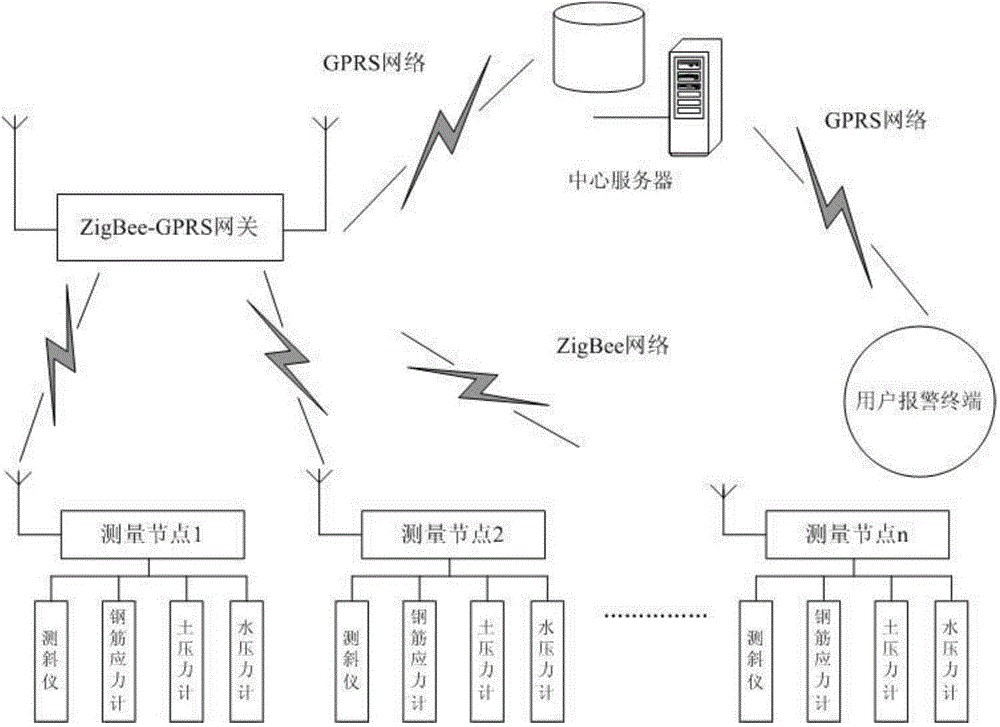

Wireless monitoring and early warning system for deep foundation pit comprehensive parameters

InactiveCN104088306AGet parameter data in real timeGrasp the law of dynamic changeTransmission systemsFoundation testingSensing dataEarly warning system

The invention discloses a wireless monitoring and early warning system for deep foundation pit comprehensive parameters. The wireless monitoring and early warning system comprises at least one measurement node arranged in a deep foundation pit, a Zigbee-GPRS gateway, a central server and a user warning terminal. The measurement nodes transmit measured data to the Zigbee-GPRS gateway through a Zigbee network. The Zigbee-GPRS gateway receives the data transmitted by all the measurement nodes and transmits the data to the central server through a GPRS network. The central server processes the data and judges the data through a database inside the central server. If data abnormity is found, an alarm instruction is generated and sent to the user warning terminal through the GPRS network, so that an alarm is given. According to the wireless monitoring and early warning system, automatic monitoring and early warning are conducted on the deep foundation pit parameters such as the inclination degree, the reinforcement stress, the soil pressure and the water pressure through the wireless sensing data communication network and through combination with the advanced computer information technology.

Owner:SUZHOU UNIV OF SCI & TECH

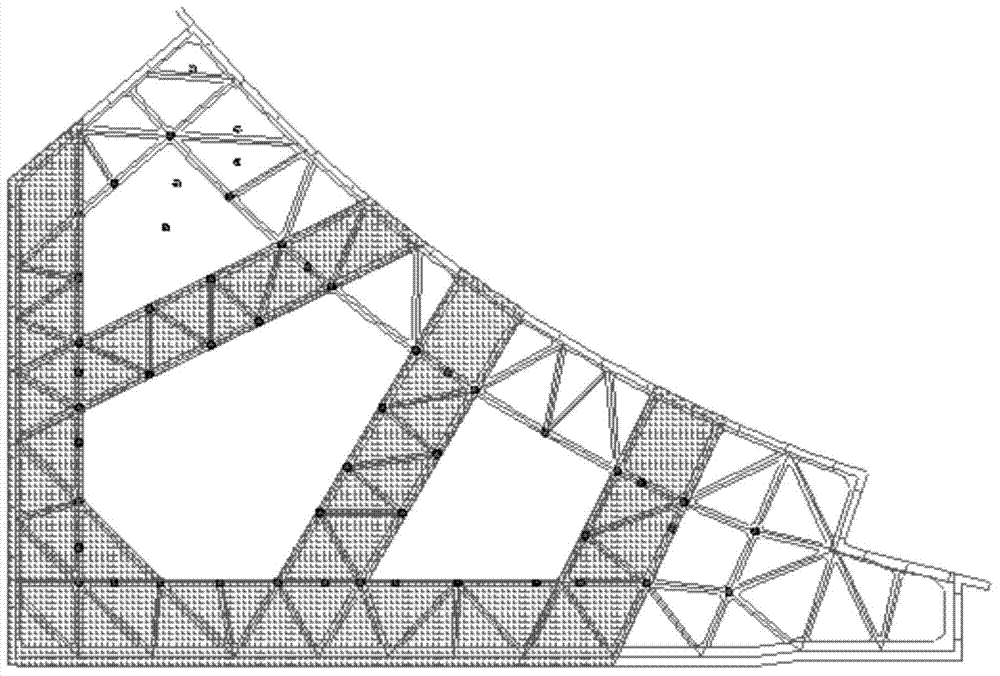

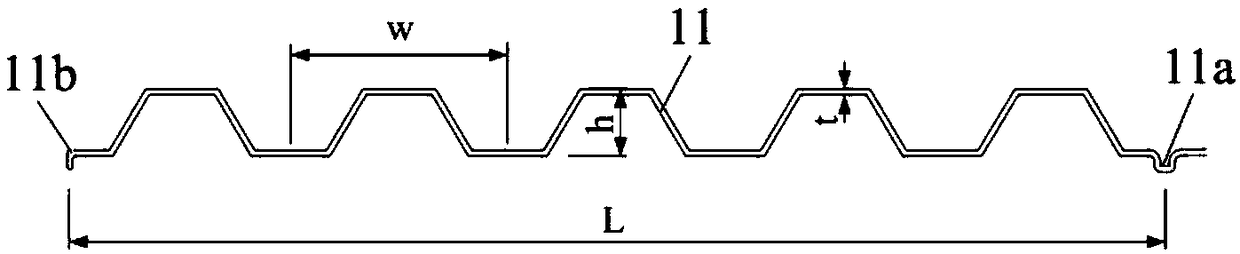

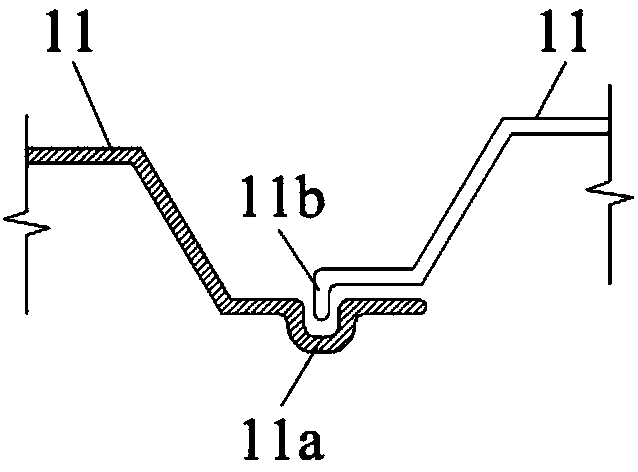

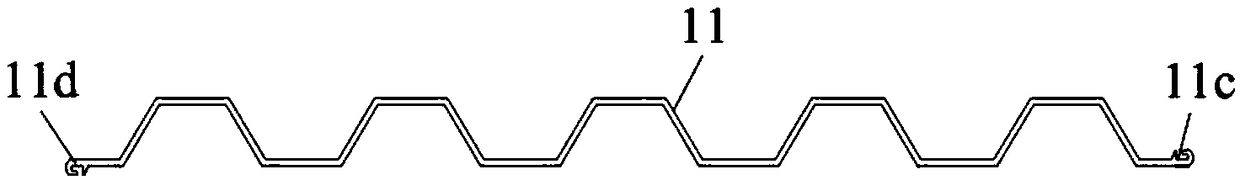

Ladder waveform steel plate and steel truss combined assembled envelop enclosure structure and construction method thereof

ActiveCN108239984AReduce deformation effectsIncrease stiffnessExcavationsBulkheads/pilesEngineeringStructural engineering

The invention discloses a ladder waveform steel plate and steel truss combined assembled envelop enclosure structure and a construction method thereof, relates to the technical field of foundation pitengineering, and solves the problems of low rigidity, high environmental influence, difficult quality control and incapability of recycling in a traditional foundation pit envelop enclosure structure. The assembled envelop enclosure structure is formed by continuously assembling multiple envelop enclosure structure units arranged along the edge lengths of a foundation pit; each envelop enclosurestructure unit comprises two ladder waveform steel plates, multiple steel trusses connected between the two ladder waveform steel plates n the height directions, and multiple connecting rods connectedbetween the ladder waveform steel plates and the steel trusses; the ends of the two adjacent ladder waveform steel plates are joined or engaged; and the steel trusses are of plane truss structures consisting of two parallel chord rods and multiple web rods connected between the two chord rods. The envelop enclosure structure units are inserted in a unit overall manner or a component insertion manner; and the adjacent envelop enclosure structure units are in joined or engaged connection to form the continuously complete assembled envelop enclosure structure capable of retaining soil and stopping water at the same time.

Owner:SHANGHAI CONSTRUCTION GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com