Patents

Literature

593results about How to "Easy to mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

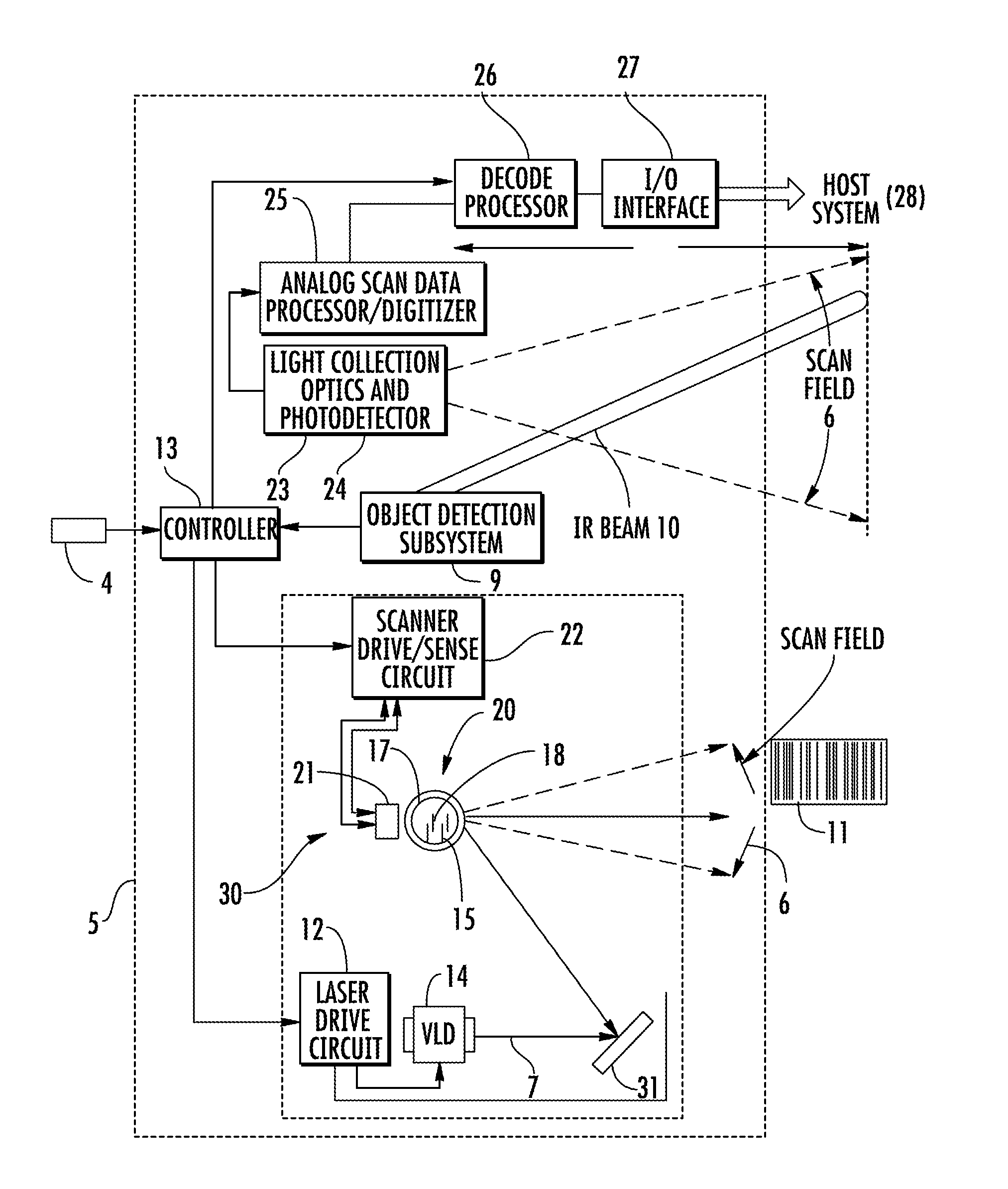

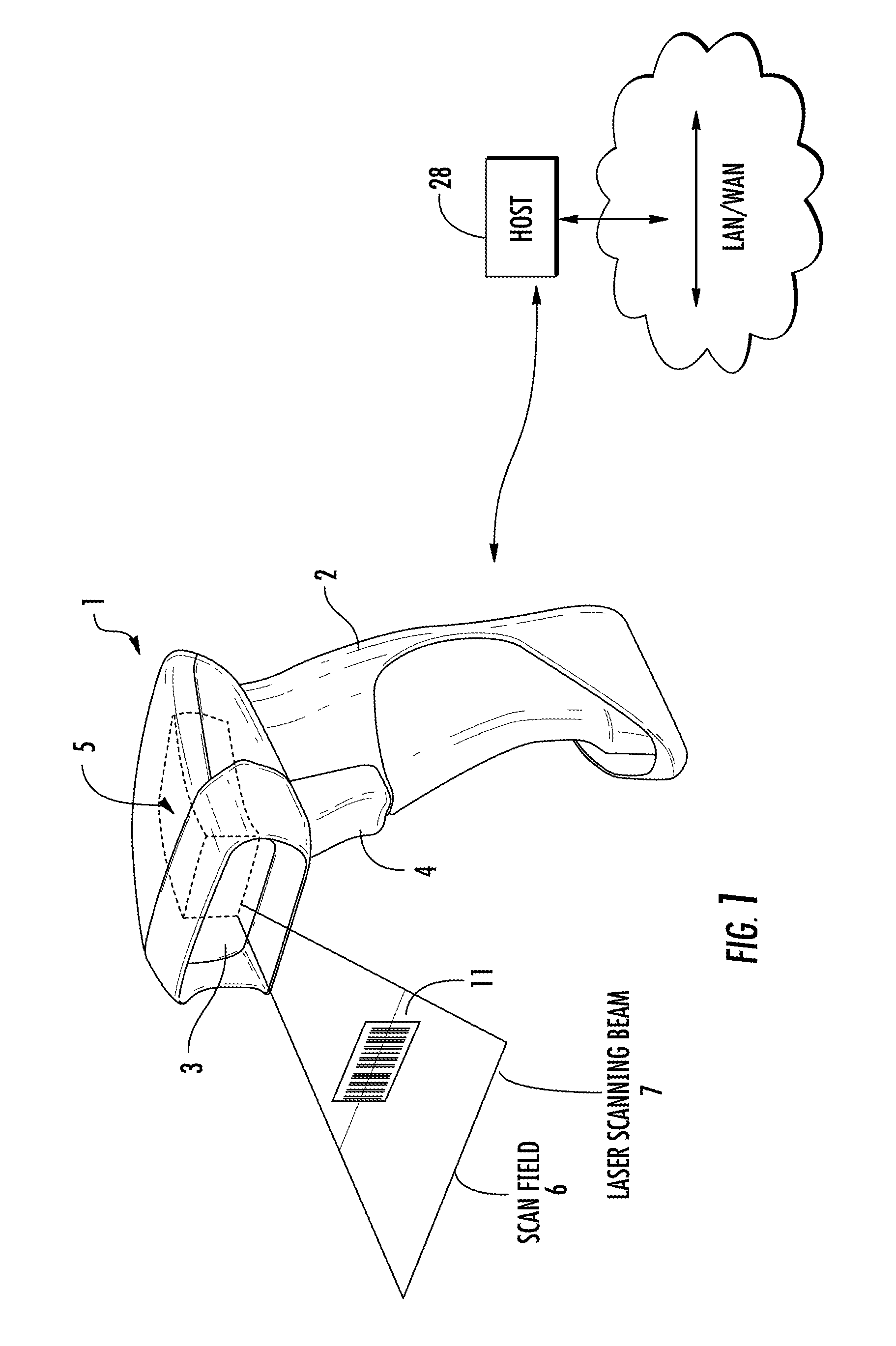

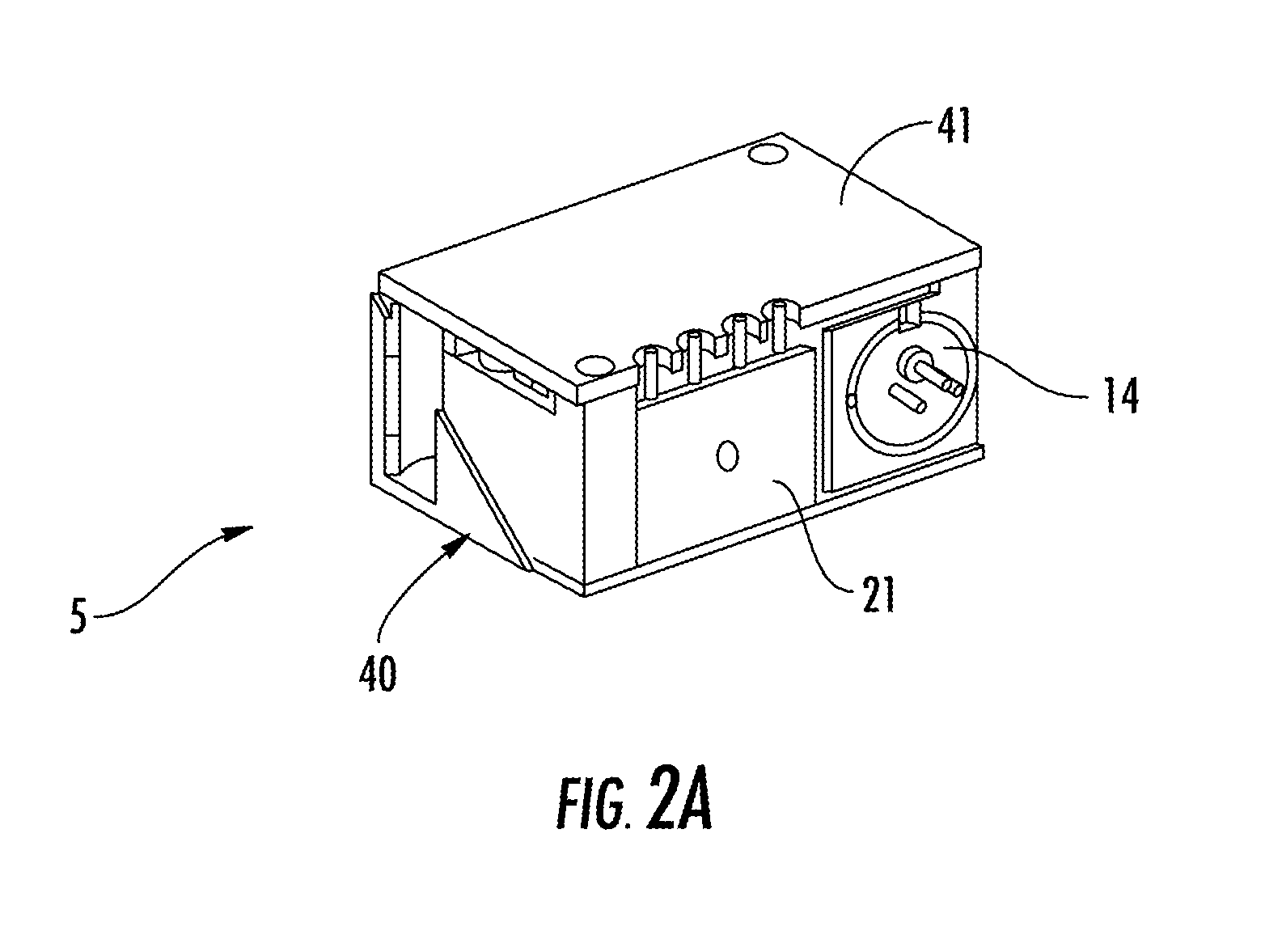

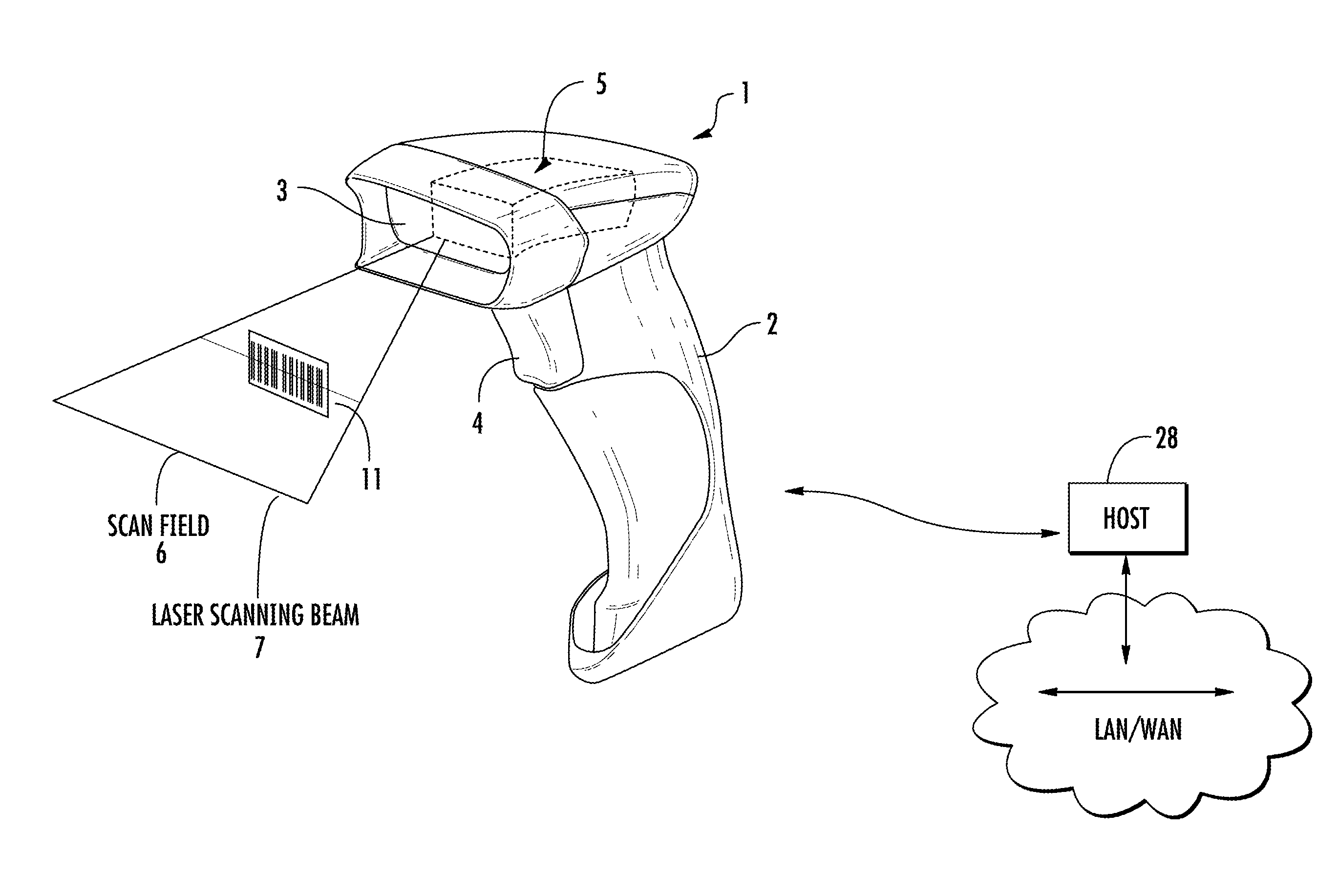

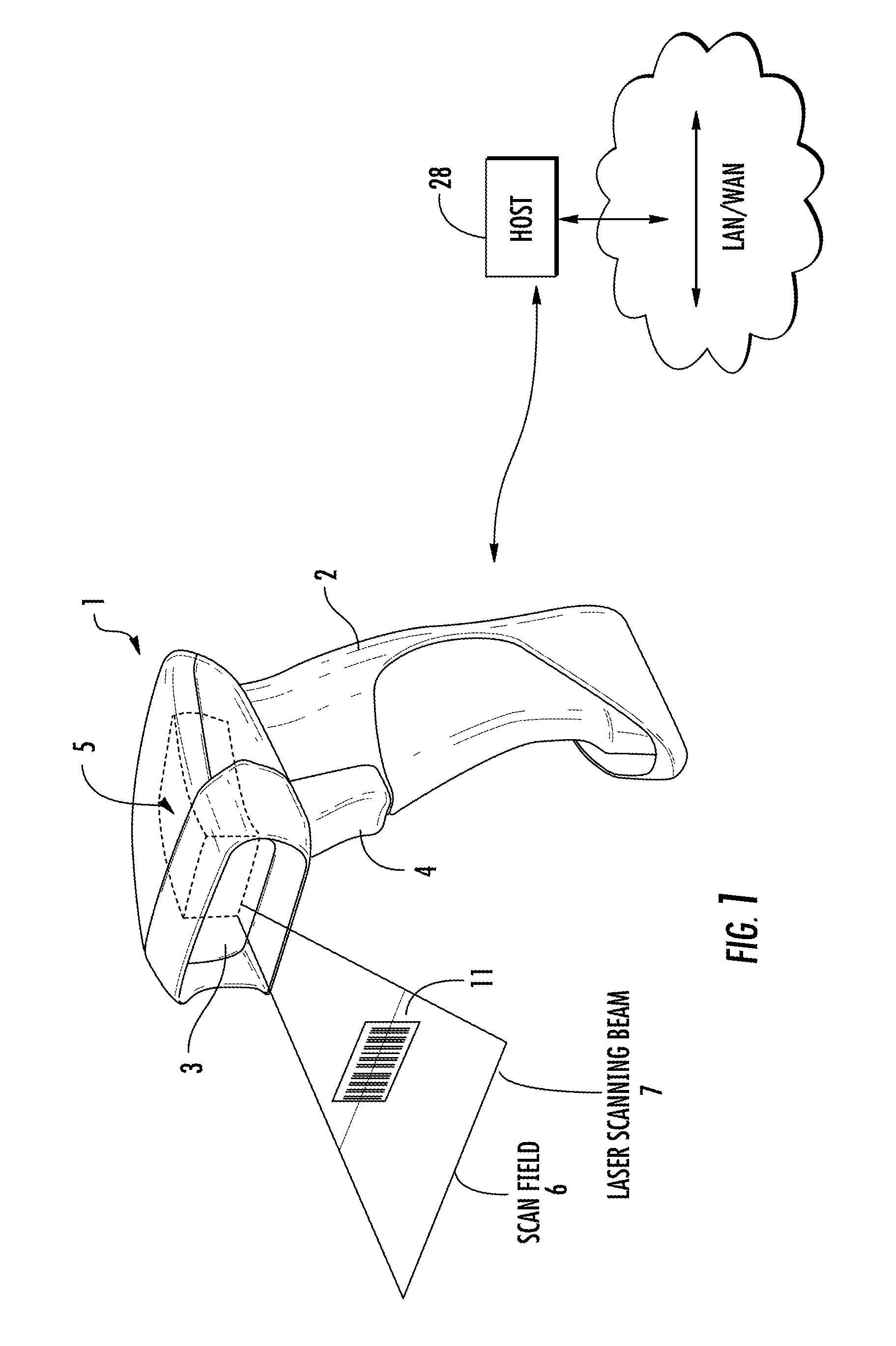

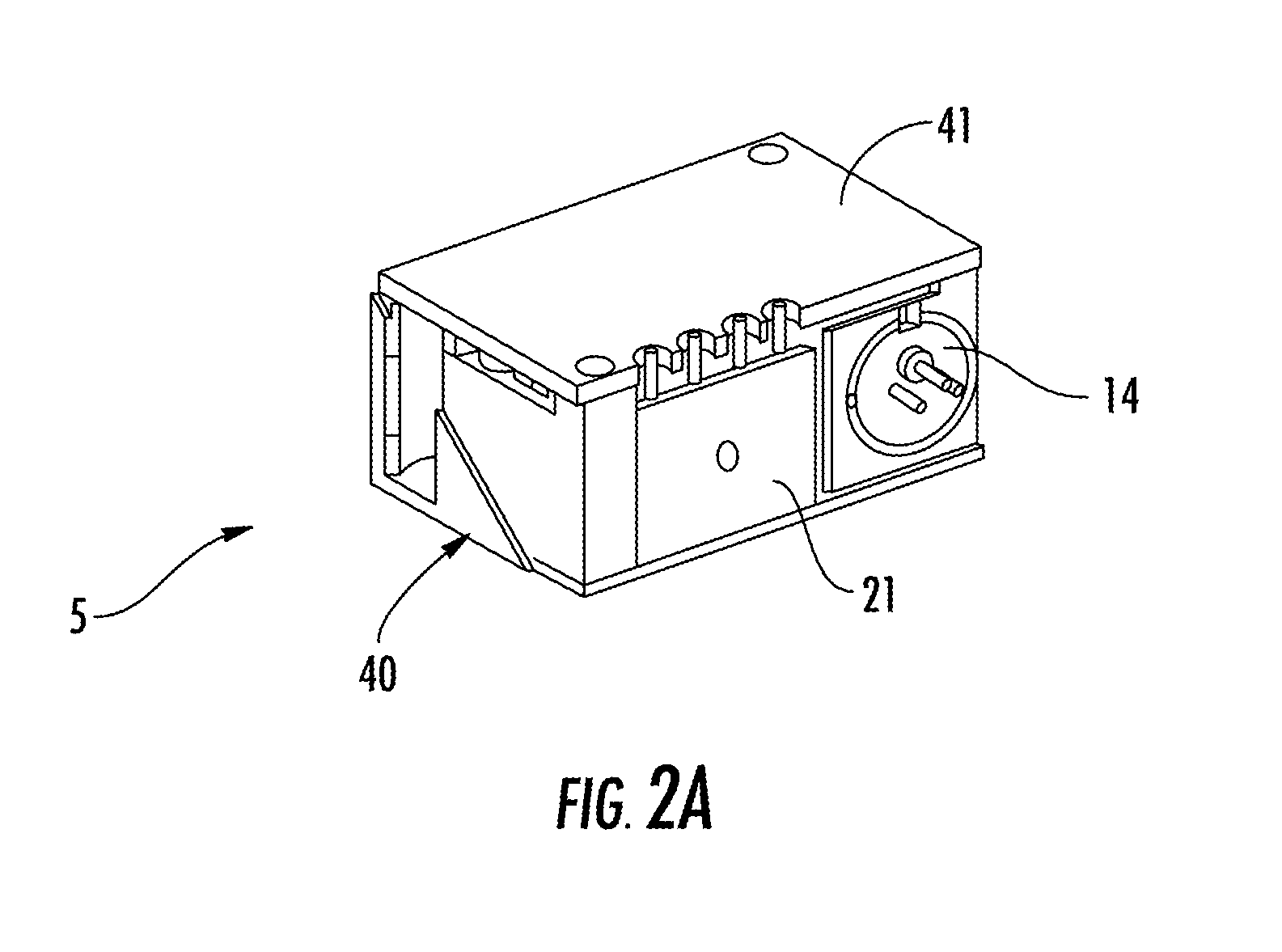

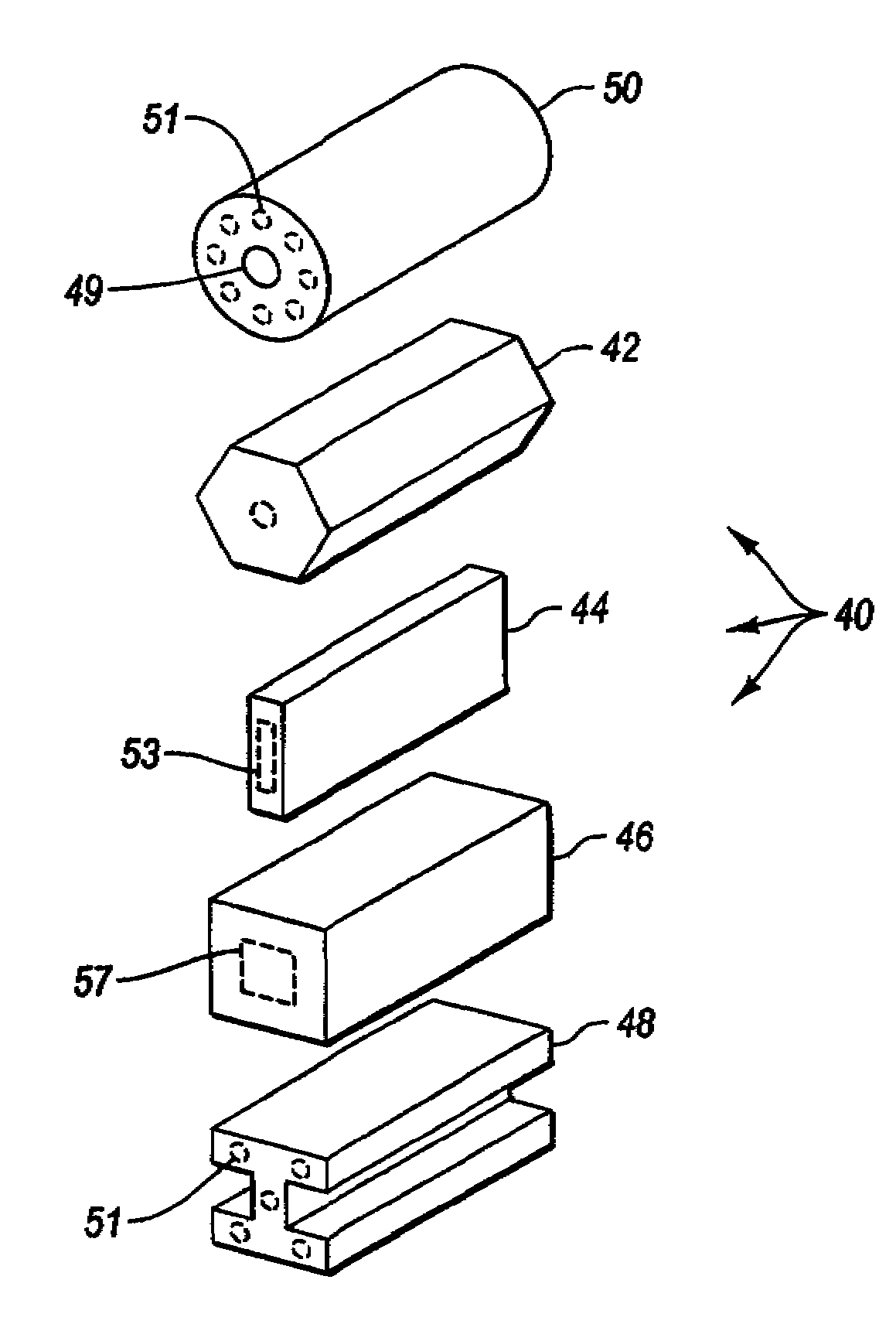

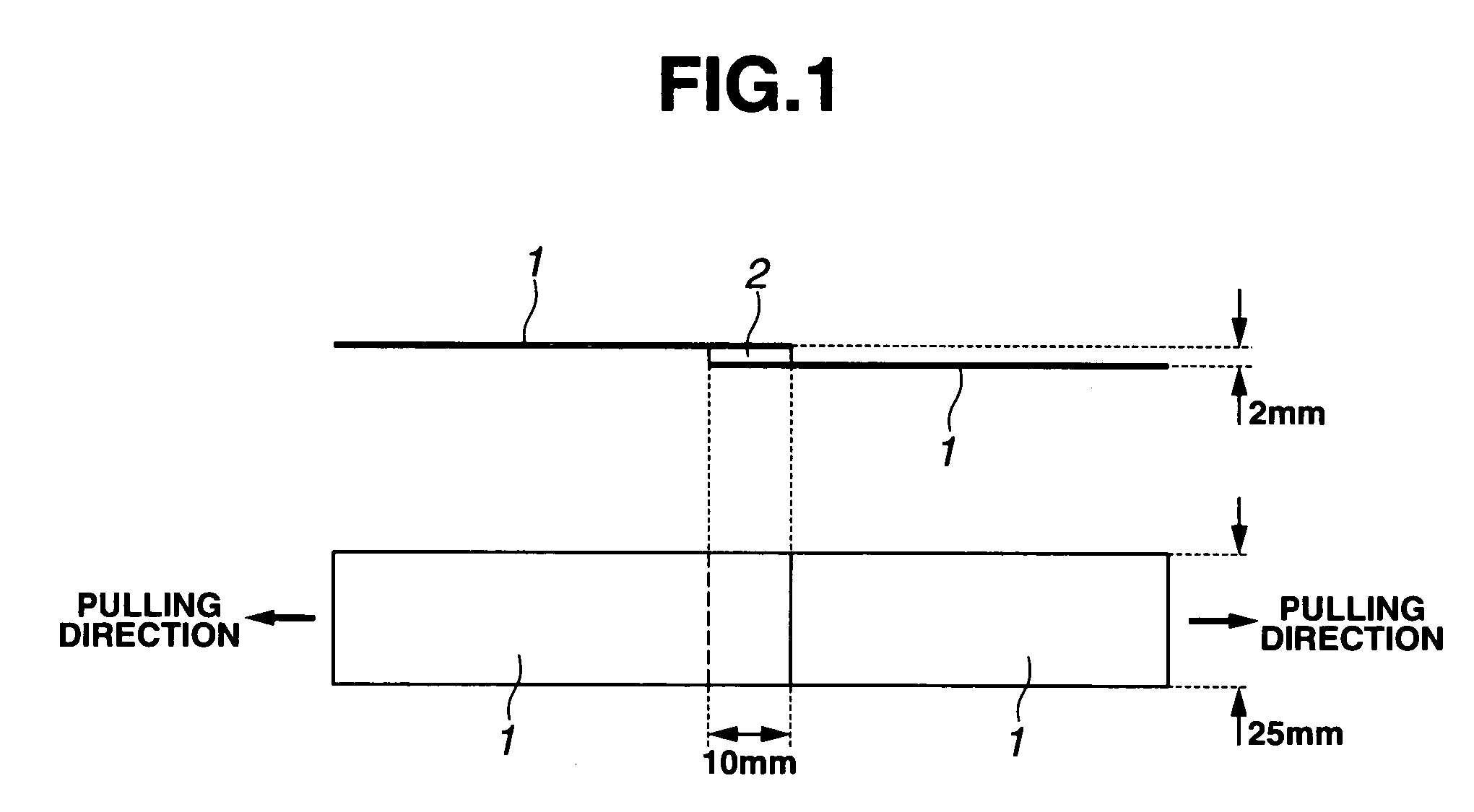

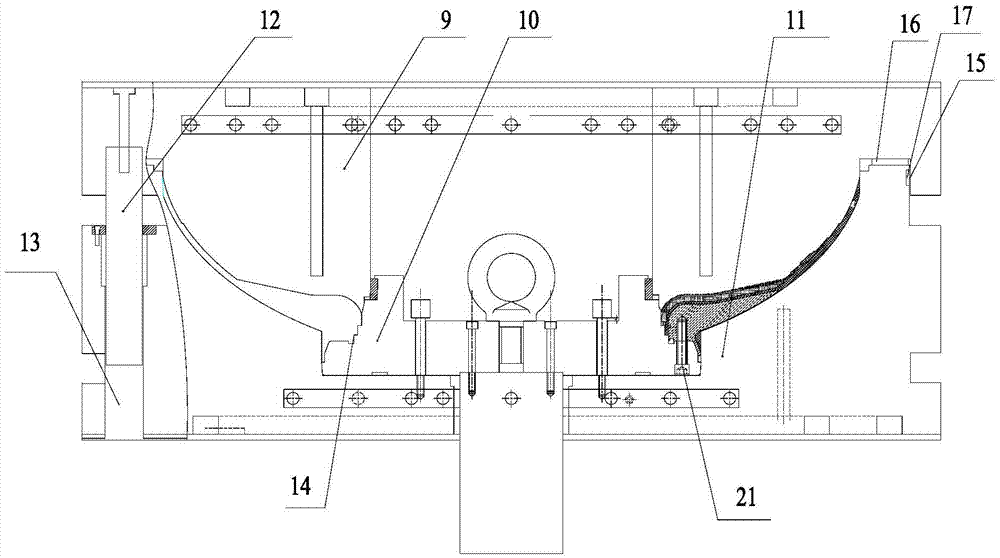

Laser scanning module employing a laser scanning assembly having elastomeric wheel hinges

ActiveUS20140197239A1Less electric powerSpace minimizationSensing by electromagnetic radiationOptical elementsLaser scanningMirror mount

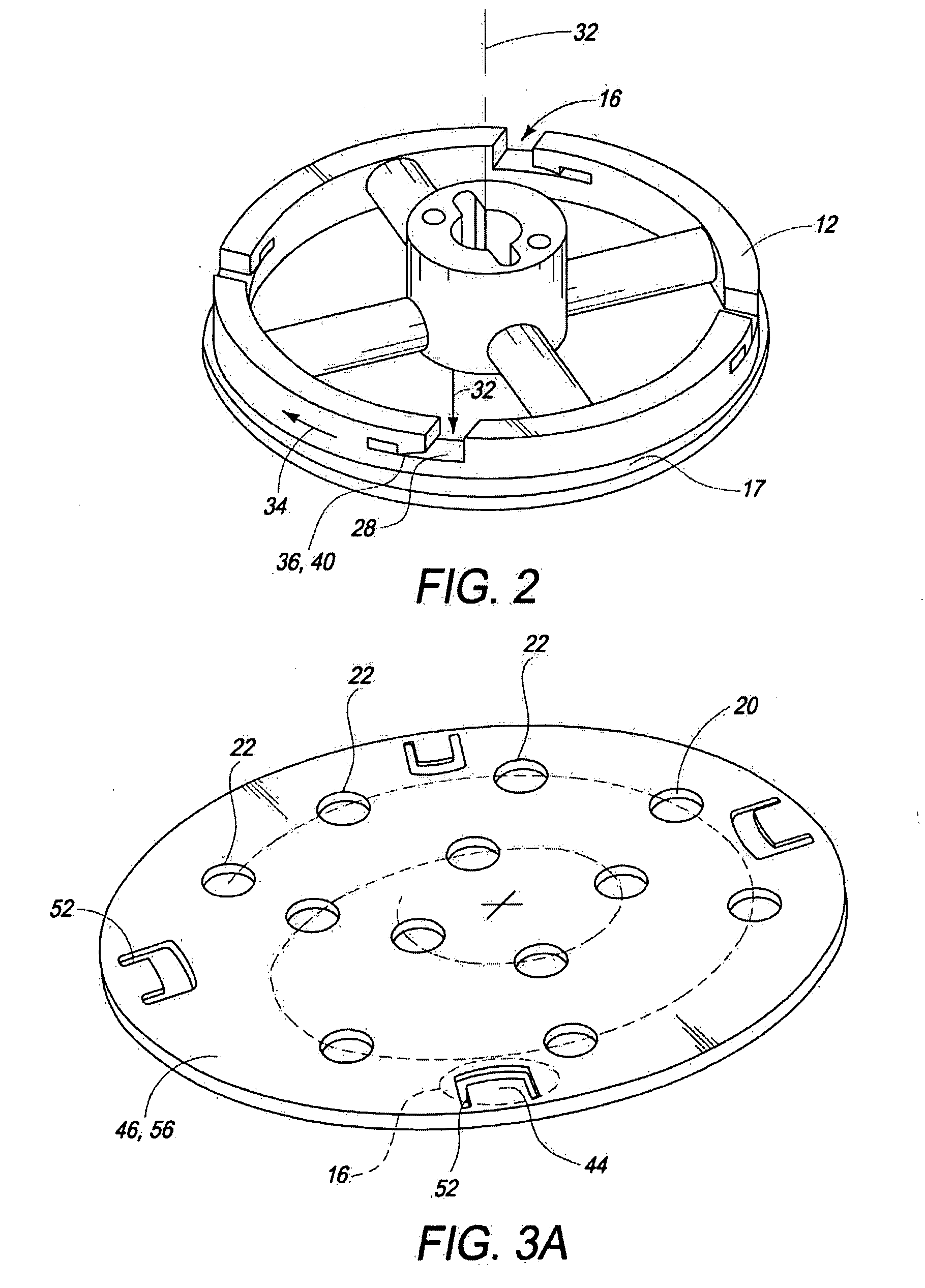

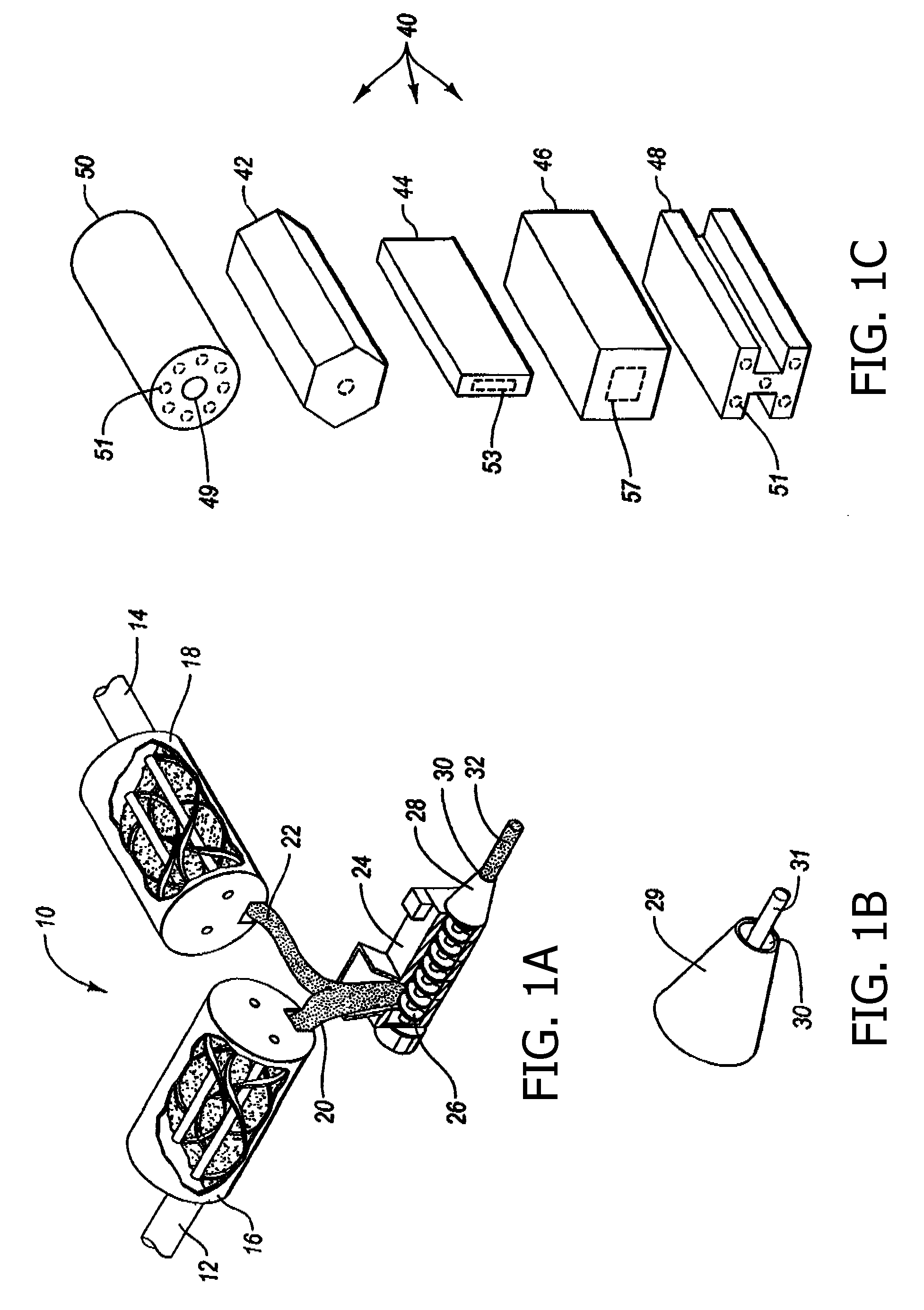

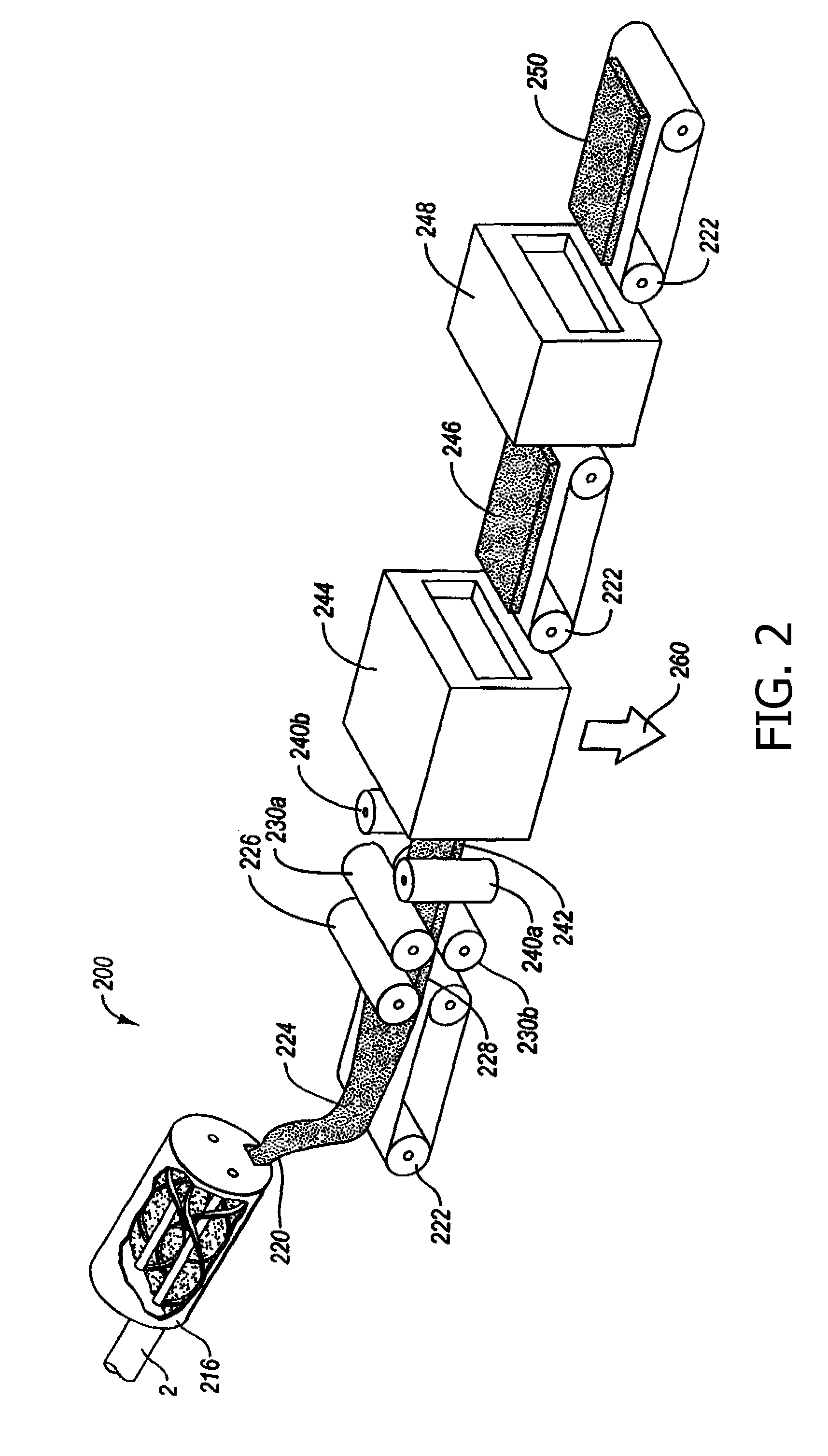

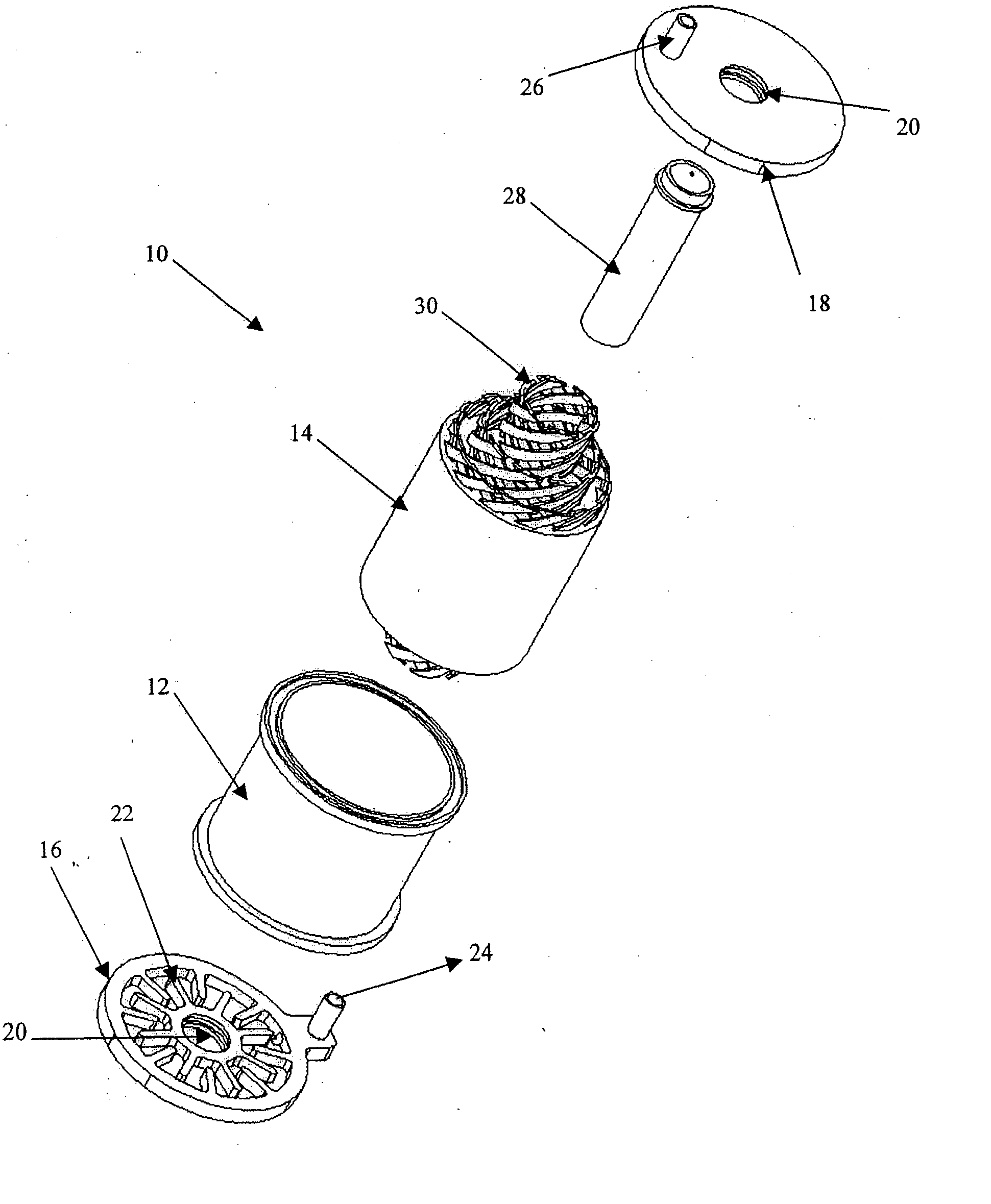

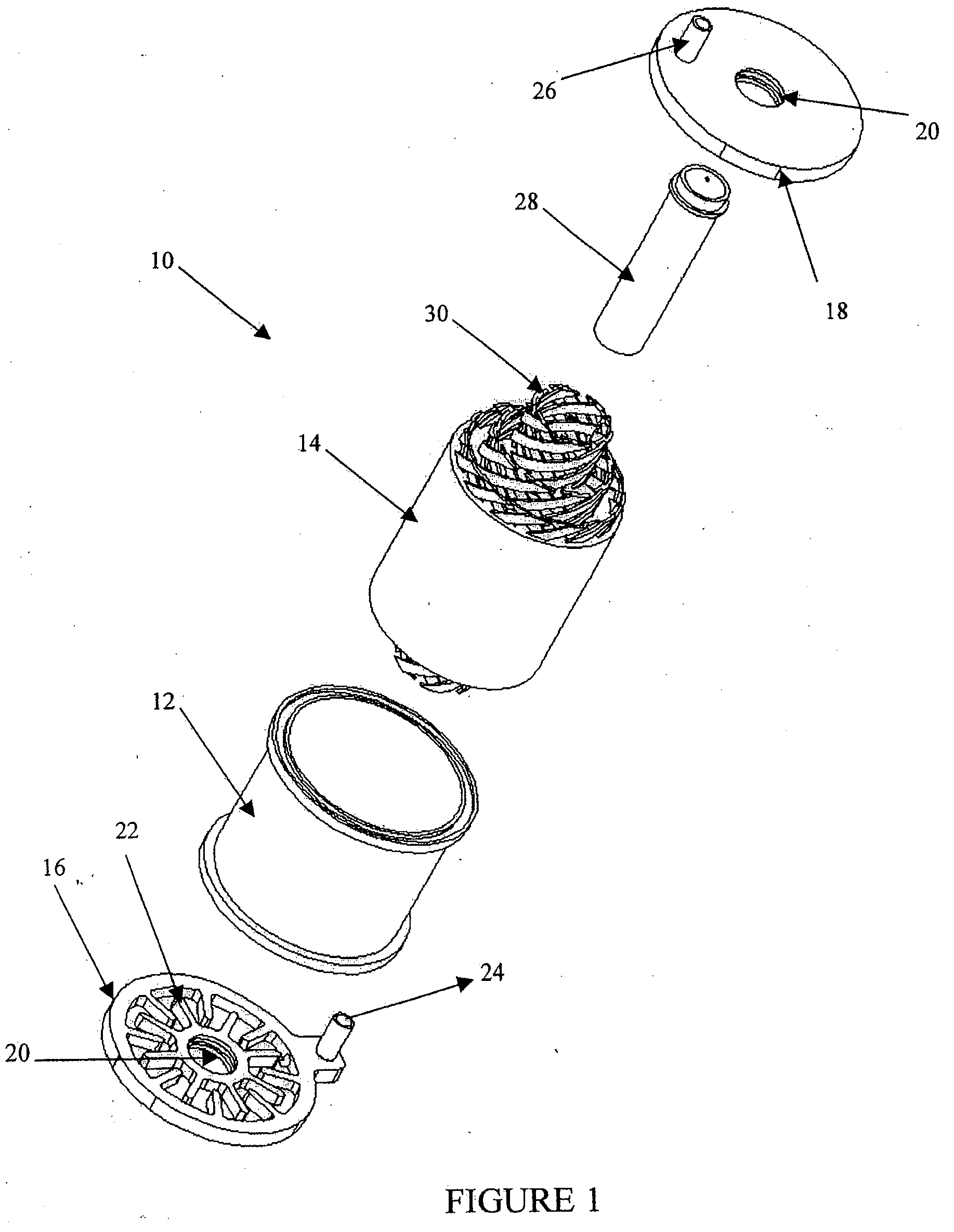

A laser scanning module employs a scan mirror and magnet rotor subassembly supported by a stator structure using a pair of elastomeric wheel hinges. The scan mirror and magnet rotor subassembly includes: a scan mirror and magnet rotor subassembly having a rotor frame having a pair of rotor support posts aligned along a scan axis passing through the rotor frame; a scan mirror mounted on the rotor frame; and a permanent magnet mounted on the rotor frame. The elastomeric wheel hinge includes a central portion having an aperture for passage and fixed attachment of one rotor support post, a plurality of elastomeric spoke portions extending from the central portion and radially extending from the central aperture to a circumferential rim portion connected to the outer end portion of each spoke portion so as to form the elastomeric wheel hinge.

Owner:HAND HELD PRODS

Laser scanning module employing a laser scanning assembly having elastomeric wheel hinges

InactiveUS9092681B2Simple moldingMinimum distanceSensing by electromagnetic radiationLaser scanningMirror mount

A laser scanning module employs a scan mirror and magnet rotor subassembly supported by a stator structure using a pair of elastomeric wheel hinges. The scan mirror and magnet rotor subassembly includes: a scan mirror and magnet rotor subassembly having a rotor frame having a pair of rotor support posts aligned along a scan axis passing through the rotor frame; a scan mirror mounted on the rotor frame; and a permanent magnet mounted on the rotor frame. The elastomeric wheel hinge includes a central portion having an aperture for passage and fixed attachment of one rotor support post, a plurality of elastomeric spoke portions extending from the central portion and radially extending from the central aperture to a circumferential rim portion connected to the outer end portion of each spoke portion so as to form the elastomeric wheel hinge.

Owner:HAND HELD PRODS

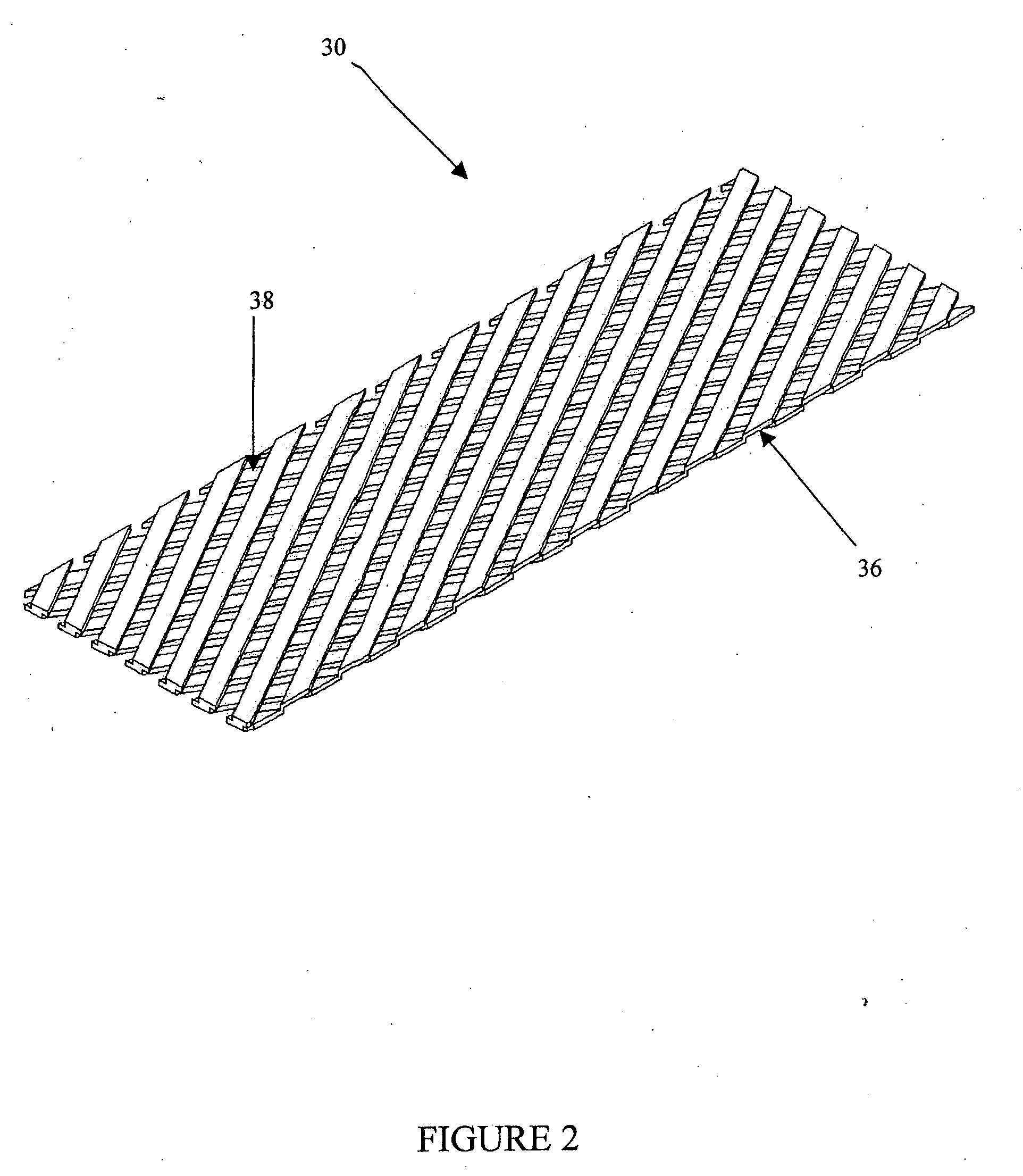

Disposable acetabular reamer from flat stock

ActiveUS20090163921A1Easy to moldMinimizing stress-induced deformationSurgeryStress inducedMetallic materials

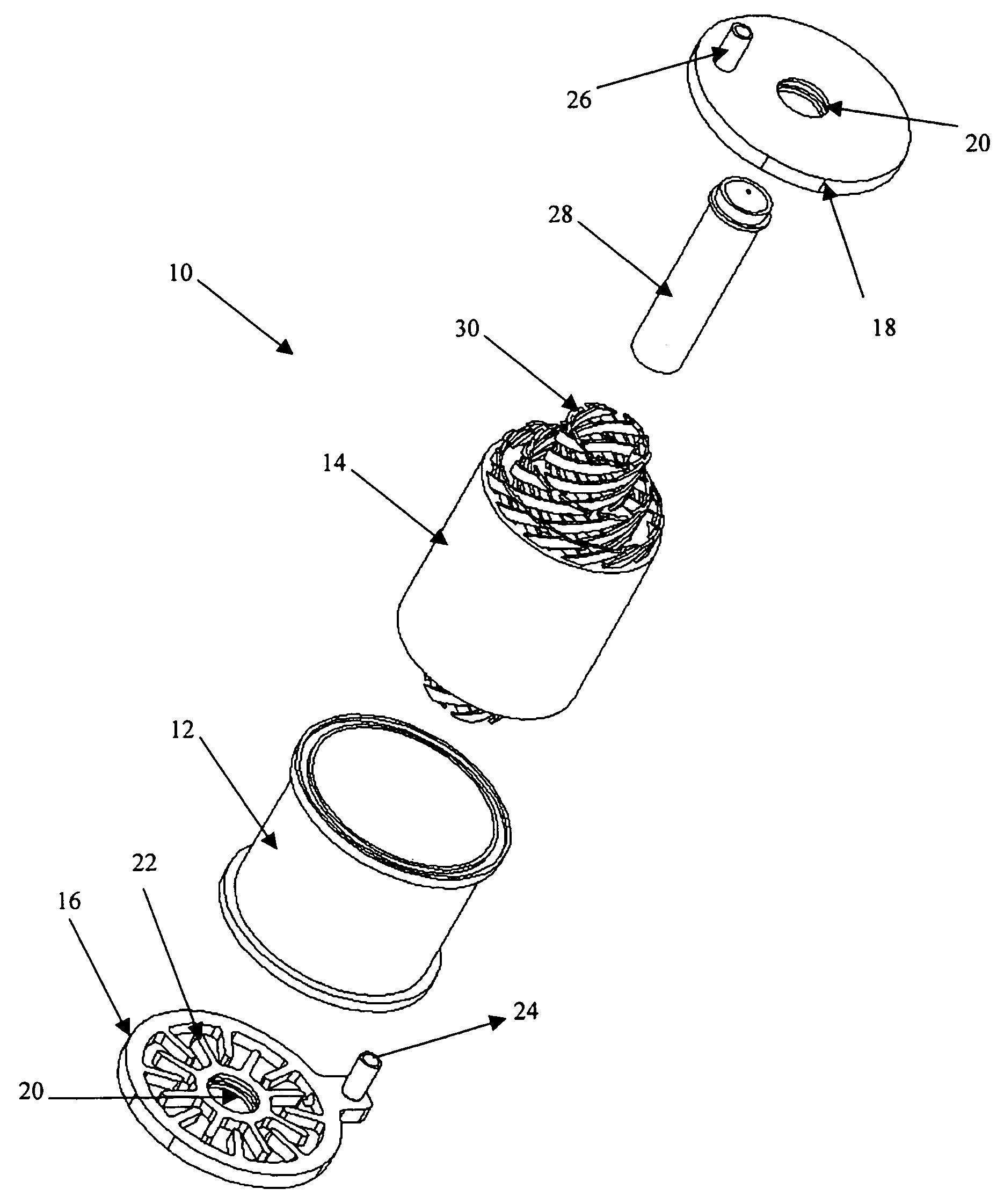

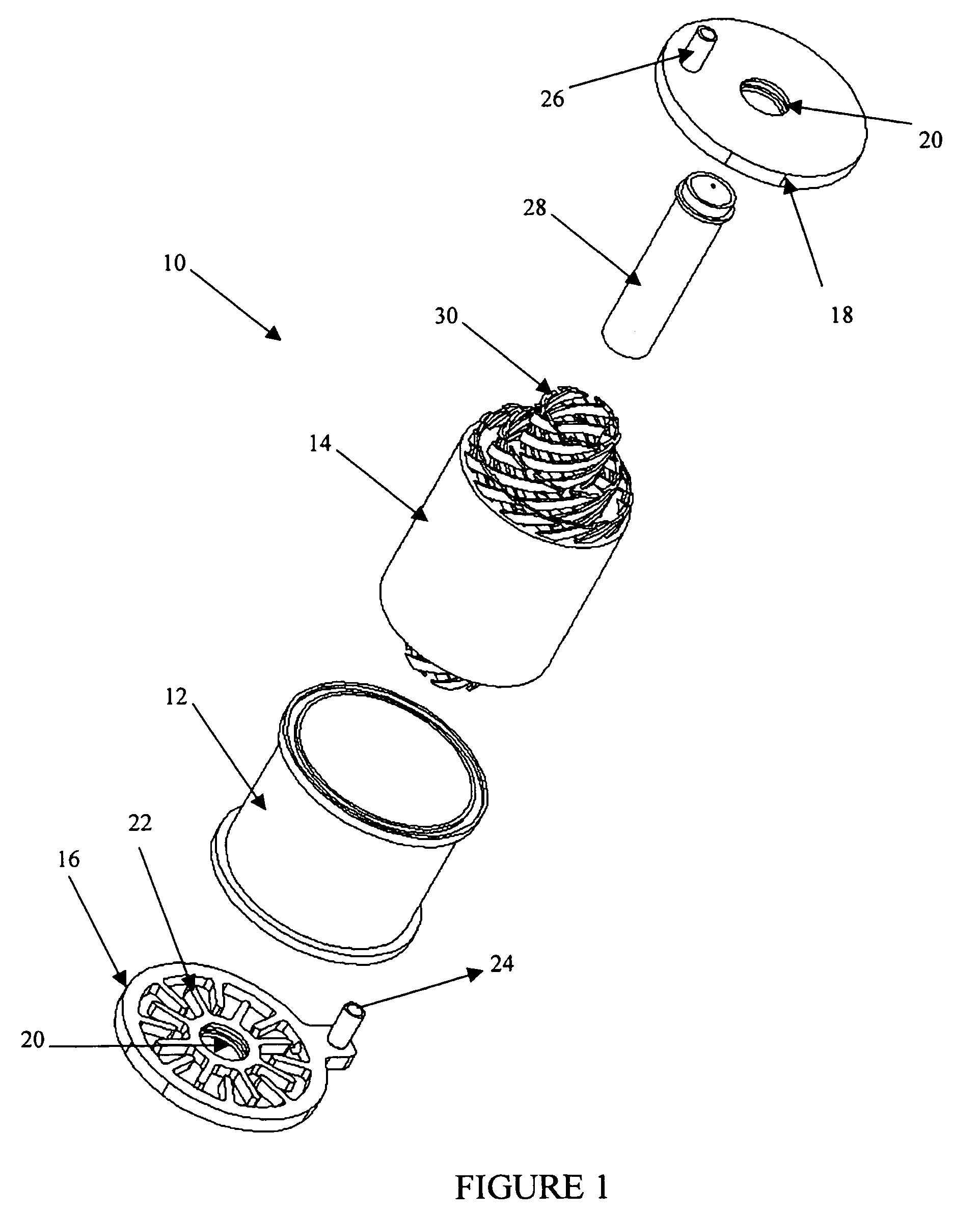

A disposable reamer is provided, made up of a base and a thin-walled, perforated cutting body of flat metal stock affixed thereto. The base and body may be molded together or assembled together in a mechanical manner. The body is optionally formed so as to comprise a plurality of appendages connected at a center so as to improve die forming of the body into a final desired shape while at the same time minimizing stress-induced deformation in the body.

Owner:VIANT AS&O HLDG LLC

Electromagnet having spacer for facilitating cooling and associated cooling method

ActiveUS7088210B2Increase loopImpart different cooling propertyTransformers/inductances coolingTransformers/inductances coils/windings/connectionsNuclear engineeringConductor Coil

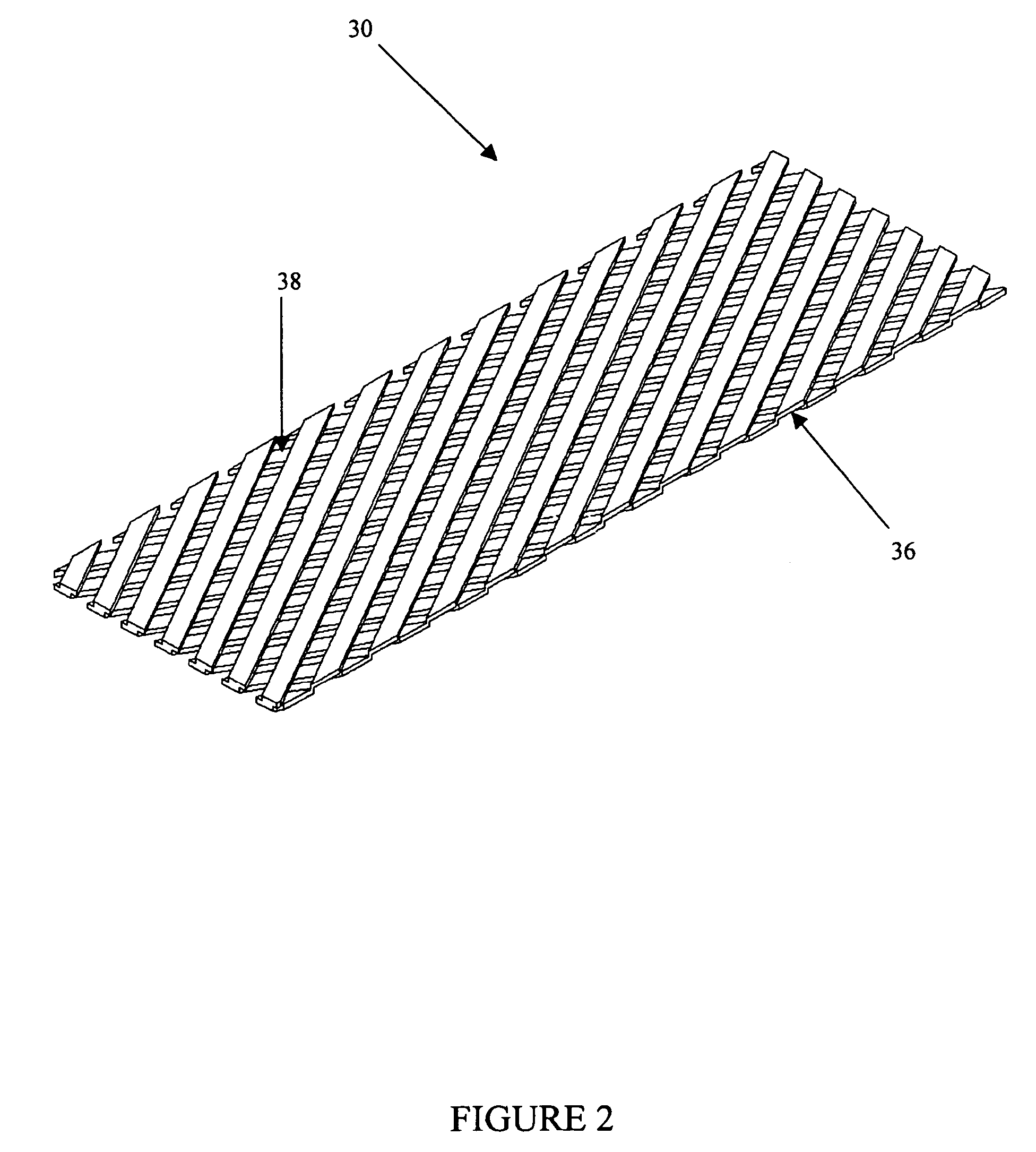

An electromagnet and associated apparatus and method are provided. The electromagnet includes a core and at least one winding disposed circumferentially about the core such that the winding extends at least one revolution around the core. The electromagnet further includes at least one spacer having channels defined therein and disposed circumferentially about the core and adjacent to the at least one winding. The channels facilitate cooling by directing fluid about the windings of the coil as fluid is introduced into the electromagnet.

Owner:THE BOEING CO

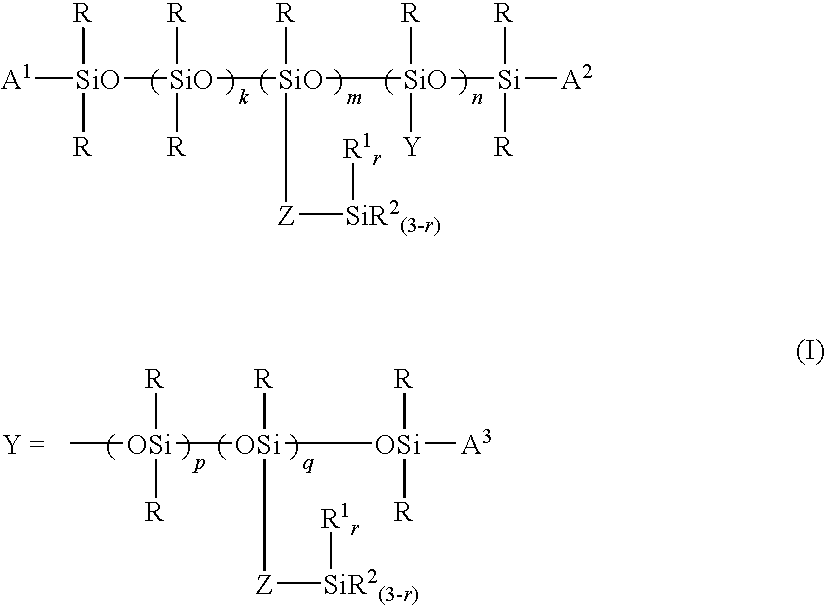

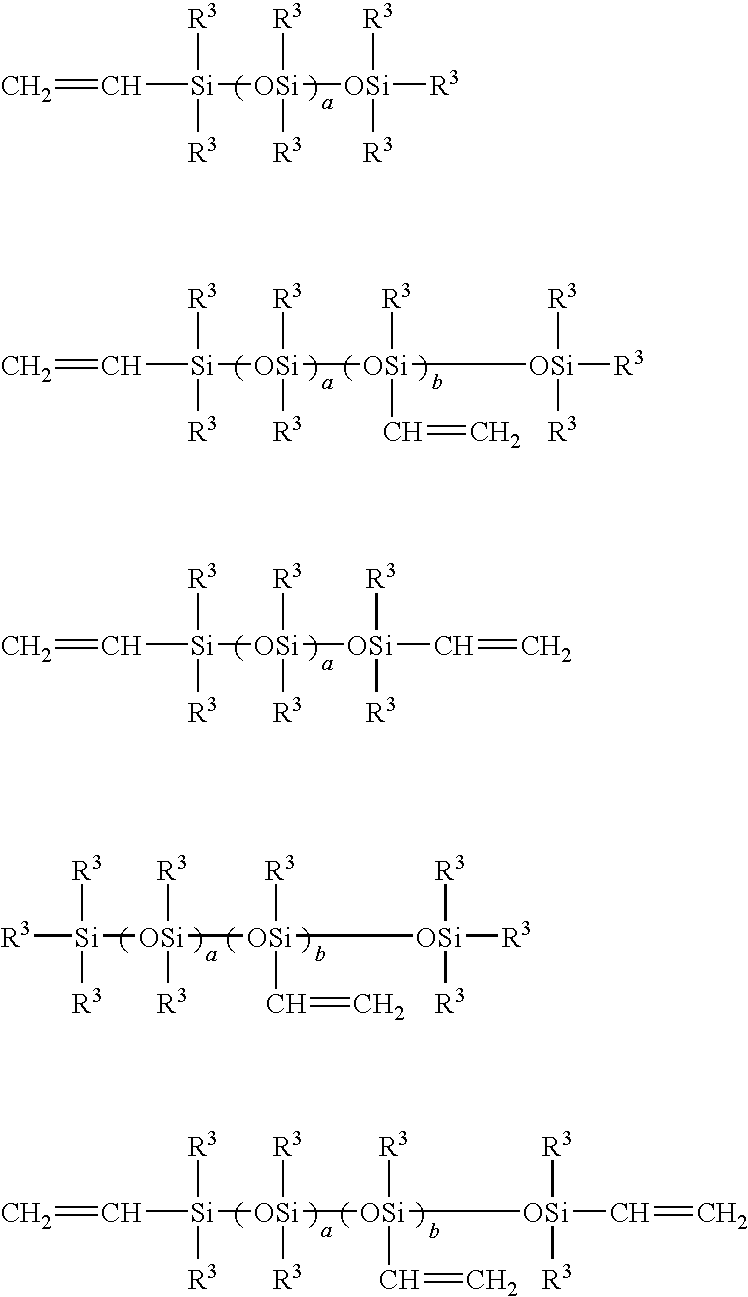

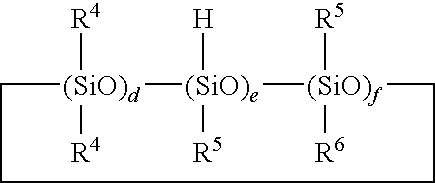

Silicone lens and silicone resin composition for molding lens

ActiveUS20070249790A1Good flexibilityHigh transparencySurgical adhesivesProsthesisPolymer scienceEthyl group

A colorless transparent silicone lens produced by thermally curing a silicone resin composition comprising(A) an organopolysiloxane having a resin structure comprising R1SiO1.5 unit, R22SiO unit, and R3aR4bSiO(4-a-b) / 2 unit wherein R1, R2, and R3 are independently methyl group, ethyl group, propyl group, cyclohexyl group, or phenyl group, R4 is vinyl group or allyl group, a is 0, 1, or 2, b is 1 or 2, and a+b is 2 or 3, and wherein number of repetition of the R22SiO unit is 5 to 300,(B) an organohydrogen polysiloxane having a resin structure comprising R1SiO1.5 unit, R22SiO unit, and R3cHdSiO(4-c-d) / 2 unit wherein c is 0, 1, or 2, d is 1 or 2, and c+d is 2 or 3, and wherein number of repetition of the R22SiO unit is 5 to 300, the component, and(C) a platinum group catalyst.A silicone lens having excellent flexibility, transparency, and moldability as well as reduced surface tackiness is provided.

Owner:SHIN ETSU CHEM IND CO LTD

Extruded fiber reinforced cementitious products having stone-like properties and methods of making the same

InactiveUS20110120349A1Improve flexural strengthHigh tensile strengthConstruction materialSolid waste managementBuilding productCement composites

A cementitious composite product that can function as a substitute for stone and solid surface materials, such as granite, marble, and engineered stone is provided. Furthermore methods for manufacturing the cementitious composite product using an extrudable cementitious composition that can be extruded or otherwise shaped into stone-like building products that can be used as a substitute for many known stone products is disclosed. In one embodiment, the cementitious composite products can be manufactured more cheaply to be as tough or tougher and more durable than stone and solid surface materials.

Owner:E KHASHOGGI INDS

Reclaimed pet resin composition, molded article thereof, and flame-retardant resin composition and molded article thereof

In the present invention, the No. I invention relates to a regenerated PET resin composition which comprises formulating 0.5-100 part by weight of a lactone polymer (B) with 100 parts by weight of a regenerated PET resin (A), in which there is improved a molding processability such as an injection moldability and extruding molding, and relates to a molded article therefrom and, the No. II invention relates to a flame retardant resin composition containing a thermoplastic resin (E) and a flame retardant (F), in which bleeding of the flame retardant is suppressed without a decline of a flame retardancy, and relates to a molded article therefrom.

Owner:DAICEL CHEM IND LTD

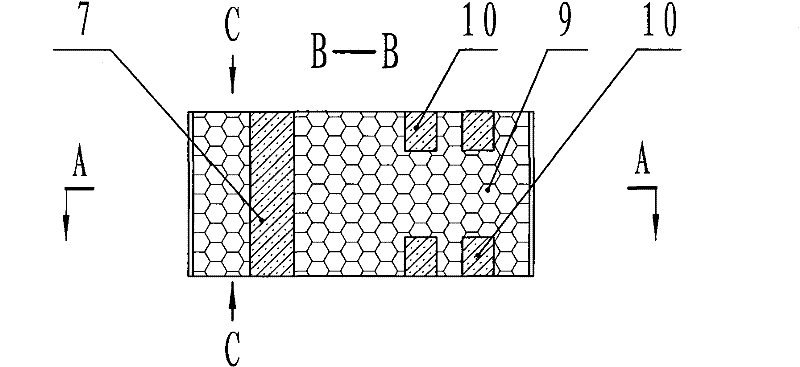

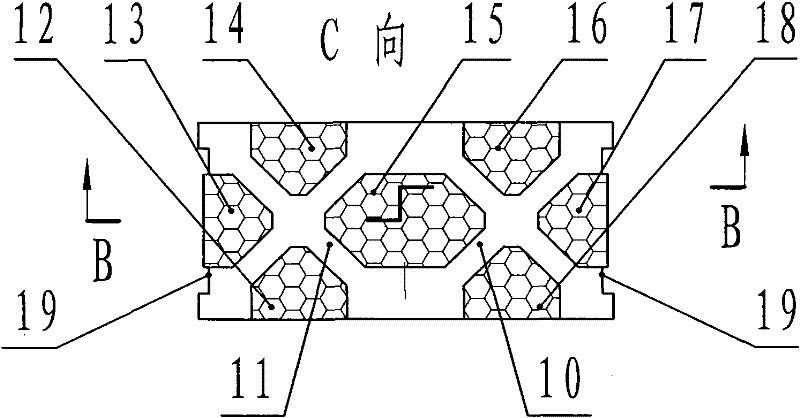

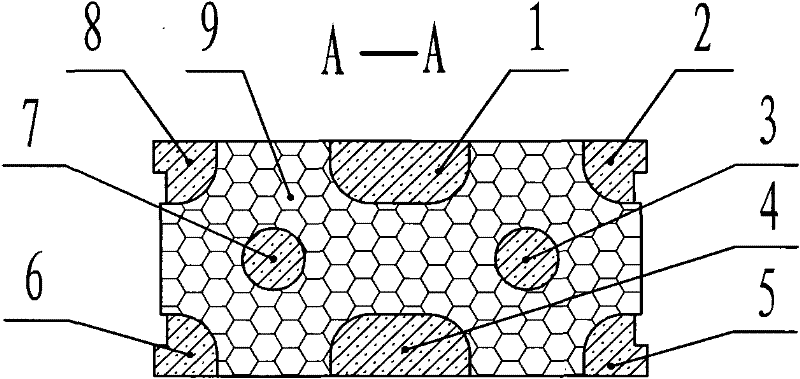

X-shaped self-heat insulating building block

The invention discloses an X-shaped self-heat insulating building block, comprising a column A, a column B, an intermediate column A, a column C, a column D, a column E, an intermediate column B, a column F, an intermediate heat insulating block, an X-shaped lacing wire A, an X-shaped lacing wire B, a top and bottom self-heat insulating block A, a top and bottom self-heat insulating block B, a top and bottom self-heat insulating block C, a top and bottom self-heat insulating block D, a top and bottom self-heat insulating block E, a top and bottom self-heat insulating block F, a top and bottom self-heat insulating block G, and a groove. The X-shaped self-heat insulation building block adopts monolithic self-heat insulating foamed plastic, so that the production and transportation are convenient, and the die-filling is simple; and a concrete structure of X-shaped lacing wires and 8 columns, so that the mechanical properties and high heat insulation performance are optimum, and the energy saving effect is optimum. The X-shaped self-heat insulation building block is a product for replacing a self-heat insulating building block.

Owner:李精华

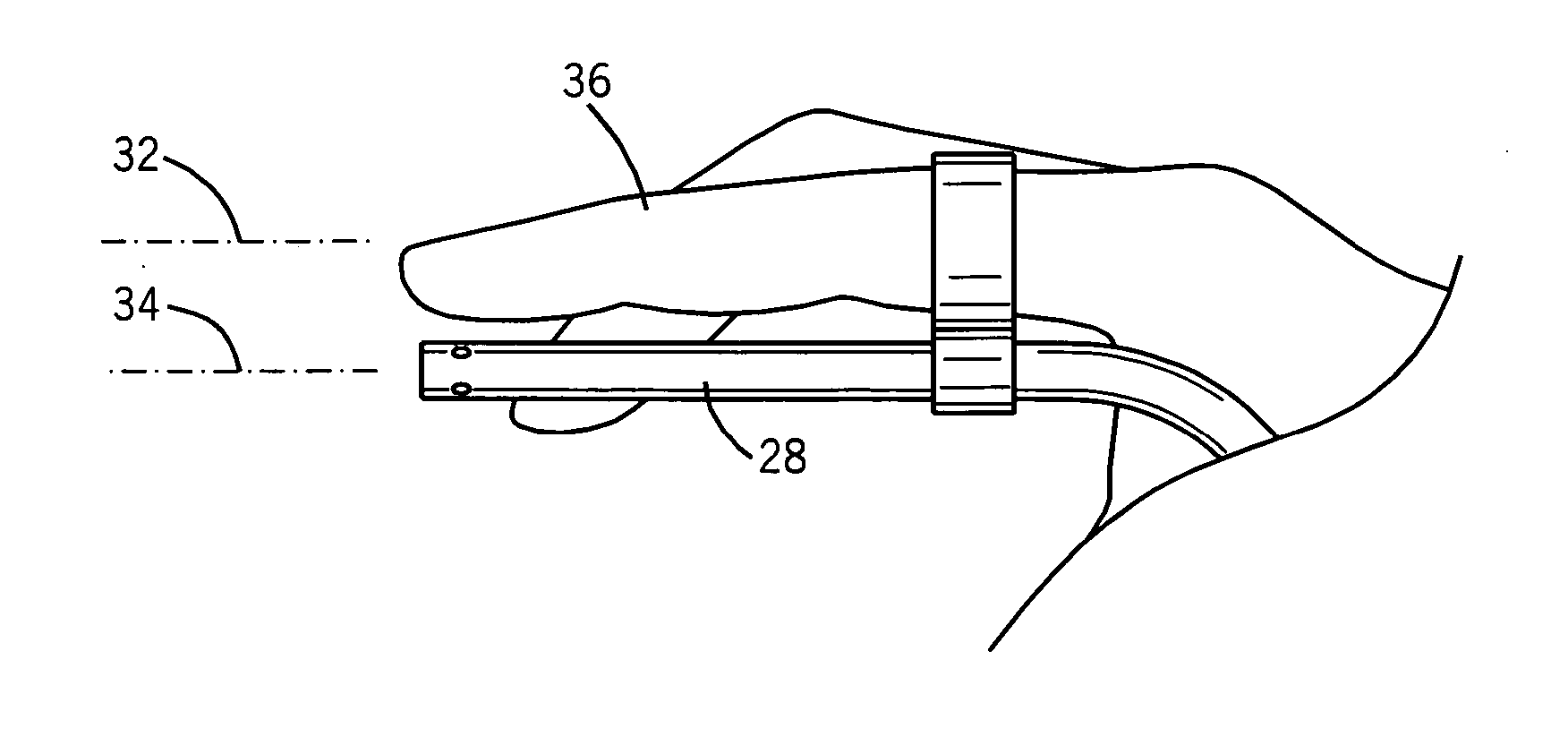

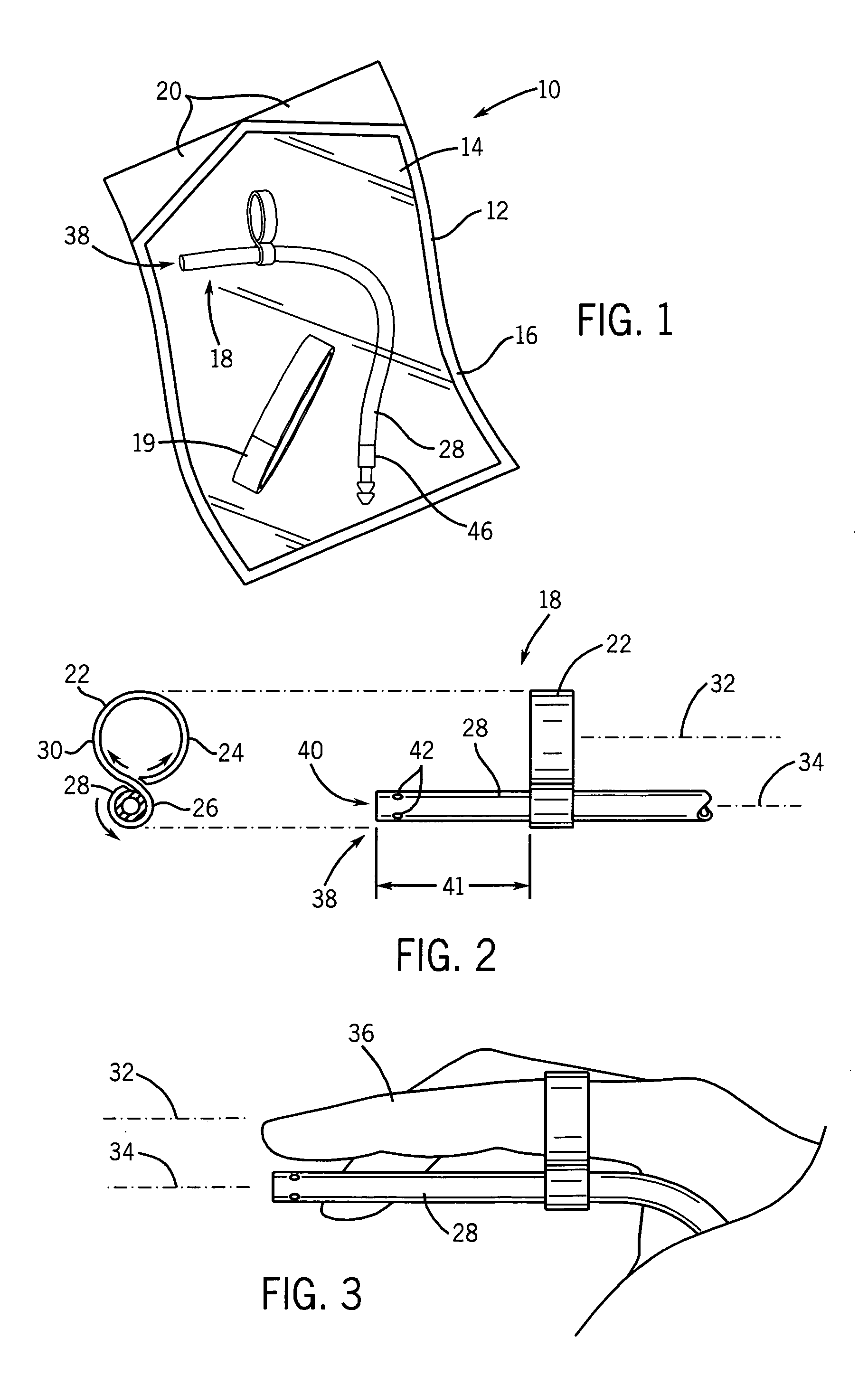

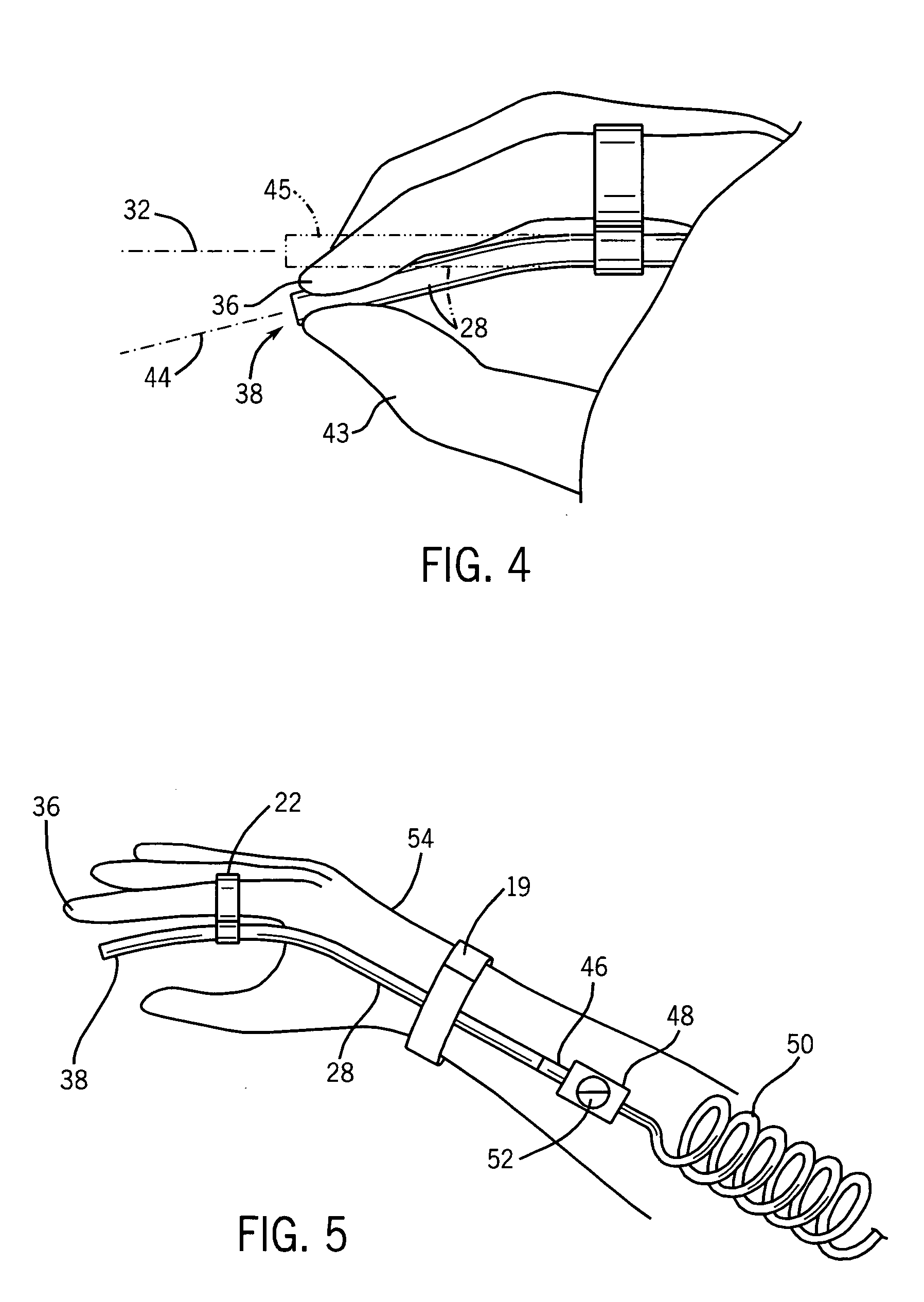

Hand mounted surgical aspiration device

A finger clamp fitting over the proximal phalanx of a surgeon's finger holds a flexible aspiration tube near the tip of the surgeon's finger but away from the gripping plane so as to be easily bent, gripped and released over the course of surgery.

Owner:ABOU KANSOUL HASSAN

NANO particle/polyamide composite material, preparation method therefor, and use thereof

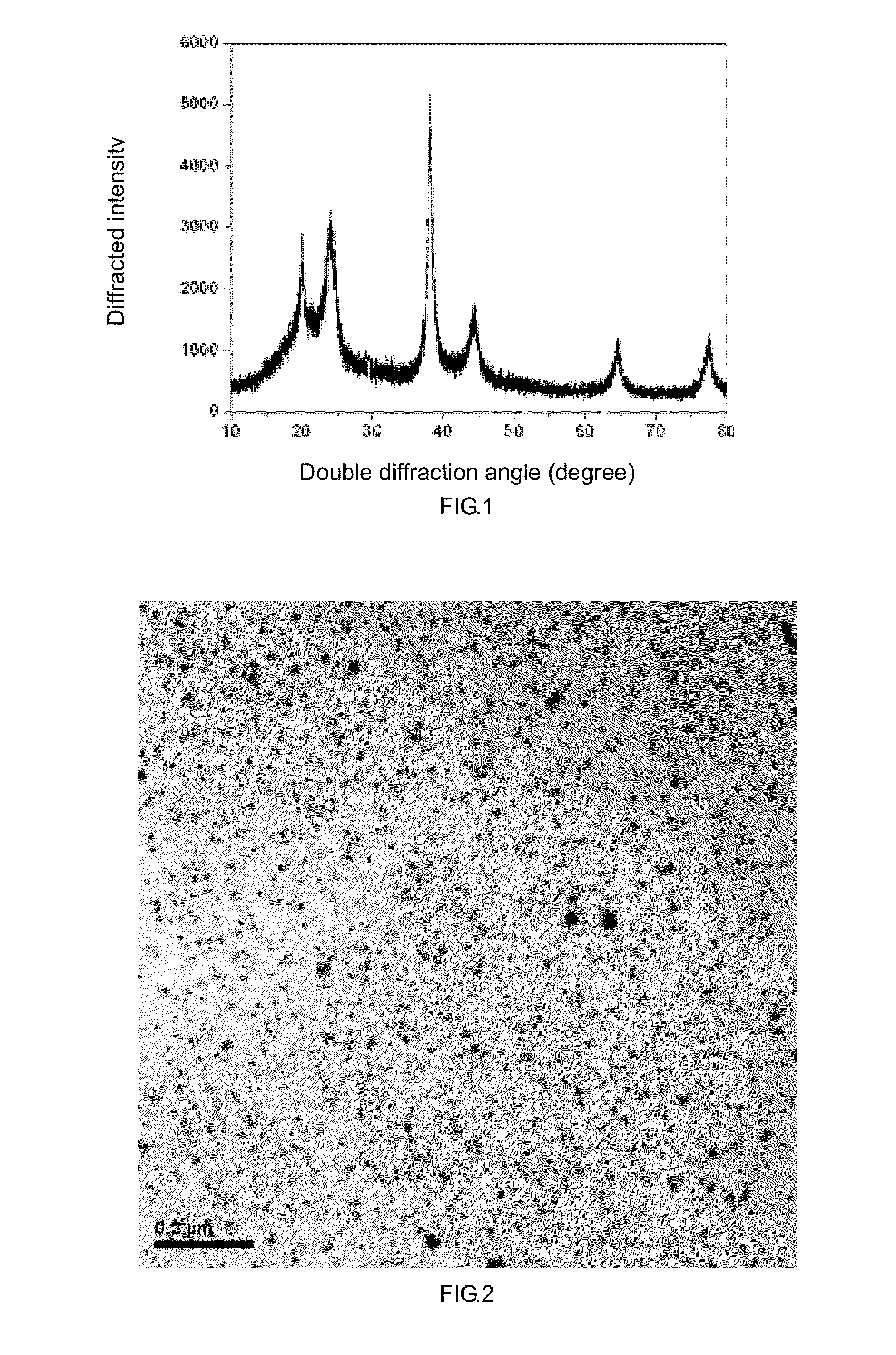

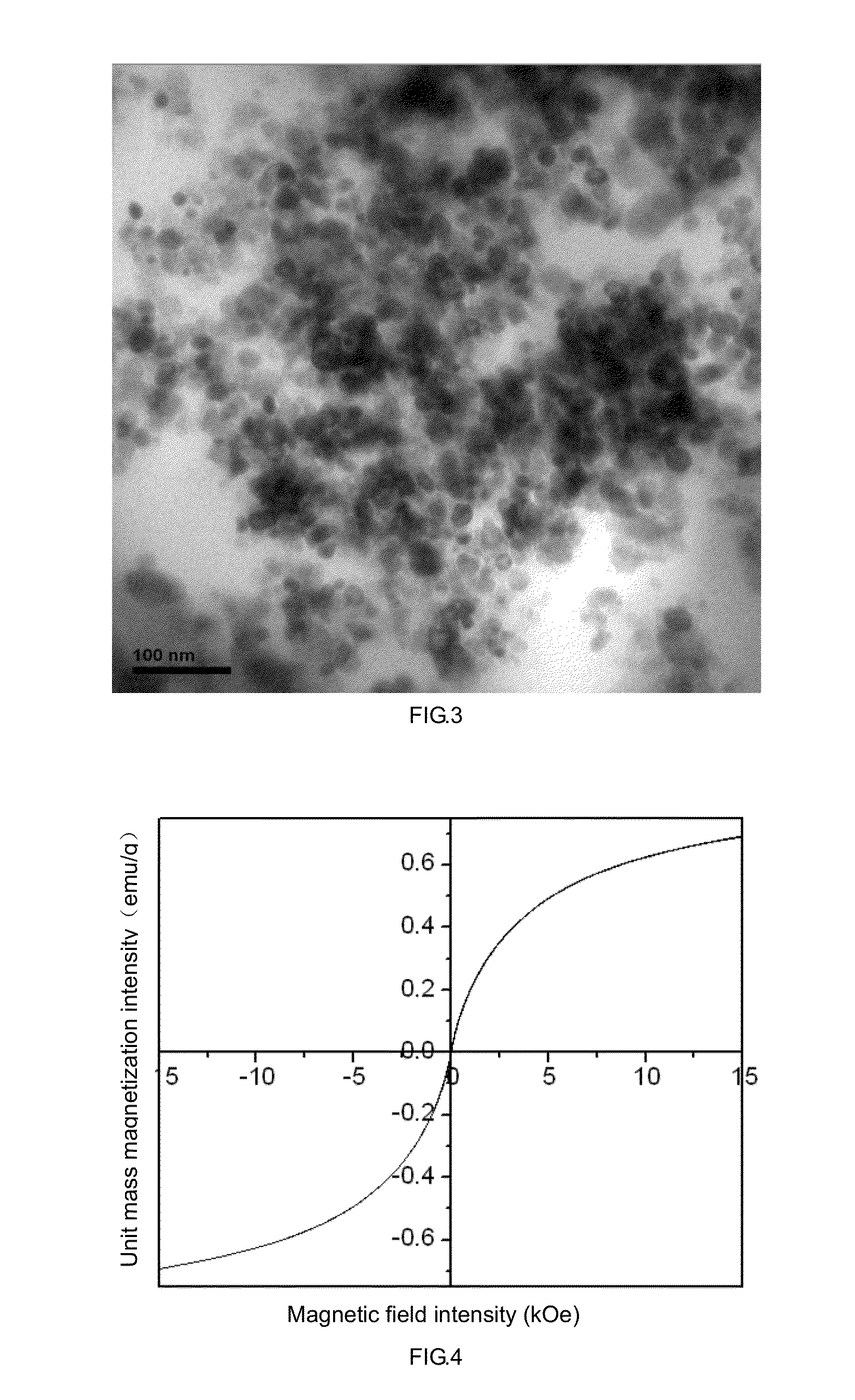

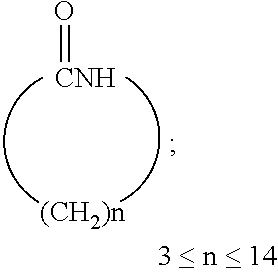

ActiveUS20140048738A1Improve mechanical propertiesEasy to moldNanotechInorganic material magnetismSynthesis methodsPolyamide

The present invention relates to the technical field of polymer composite material, and a nano particle / polyamide composite material, a preparation method therefor and a use thereof are disclosed. The nano particle / polyamide composite material comprises 0.01-99 parts by weight of inorganic nano particles and 1-99.99 parts by weight of a polyamide matrix. The preparation method for the nano particle / polyamide composite material of the present invention comprises hydrolysis polymerization or anionic polymerization. The nano particle / polyamide composite material of the present invention has the particular functions of nano materials, while having the advantages of the polymer matrix such as good mechanical performance and being easy for processing and molding. The nano particle is well dispersed in the polyamide matrix, is physically stable, and has a strong interaction at an interface between the nano particles and the polymer matrix, thus being useful as a structural material, a functional material and a polymer masterbatch. The cost of raw materials used in the synthesis method is low, the production apparatus is simple, and the route is green and environment friendly. Therefore, the method is applicable to large-scale industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

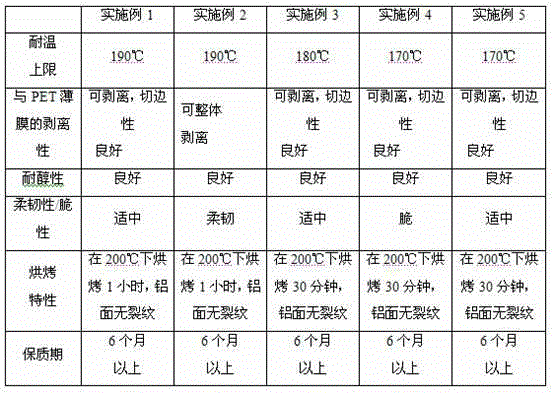

Water-based laser transfer coating for wine bottle glass baking paper, and preparation method thereof

The invention discloses a water-based laser transfer coating for wine bottle glass baking paper, and a preparation method thereof. The coating is prepared by mixing the following components in percentage by mass: 10-30% of water-based acrylic resin, 25-40% of water-based polyurethane resin, 0-8% of cosolvent, 20-45% of deionized water, 0-0.4% of water-based defoaming agent, 0.1-0.4% of base material wetting agent, and 0-0.2% of pH value regulating agent. The water-based laser transfer coating for the wine bottle glass baking paper is an environment-friendly laser transfer coating which meets national VOC detection standard by taking the water-based resin and deionized water as main raw materials. In addition, the composite water-based resin endows a curing film with good temperature resistance, aluminum adherence, strippability, alcohol resistance and the like, thus meeting the index requirement of the wine bottle glass baking paper.

Owner:三友(天津)高分子技术有限公司

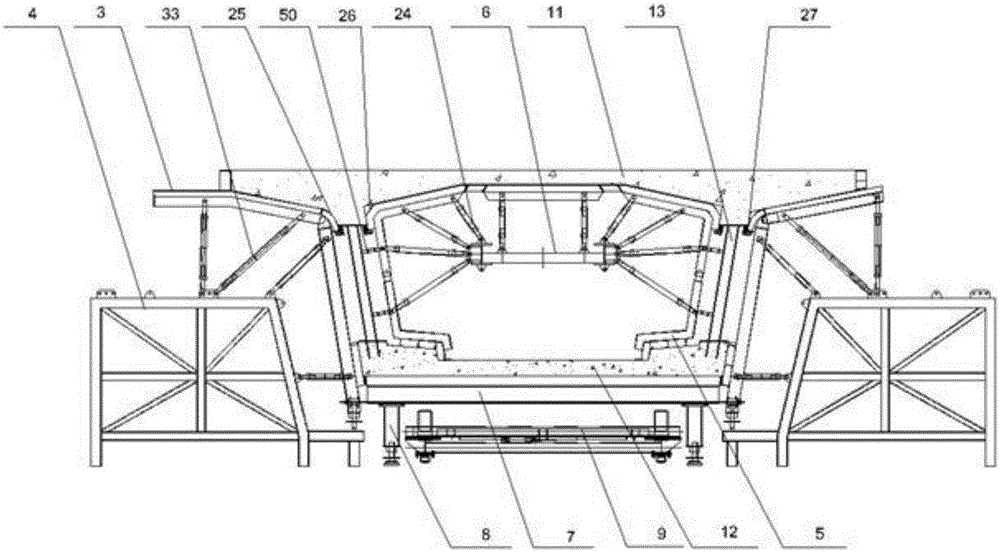

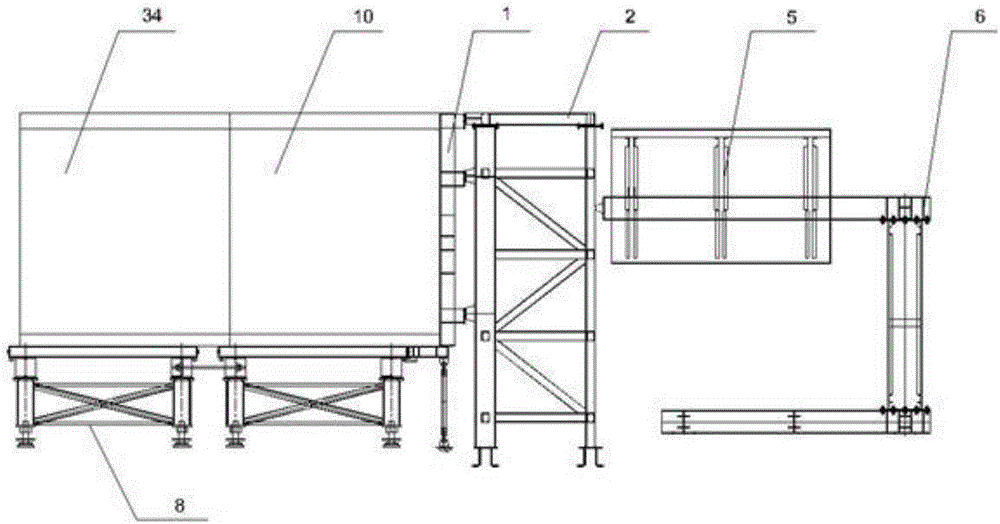

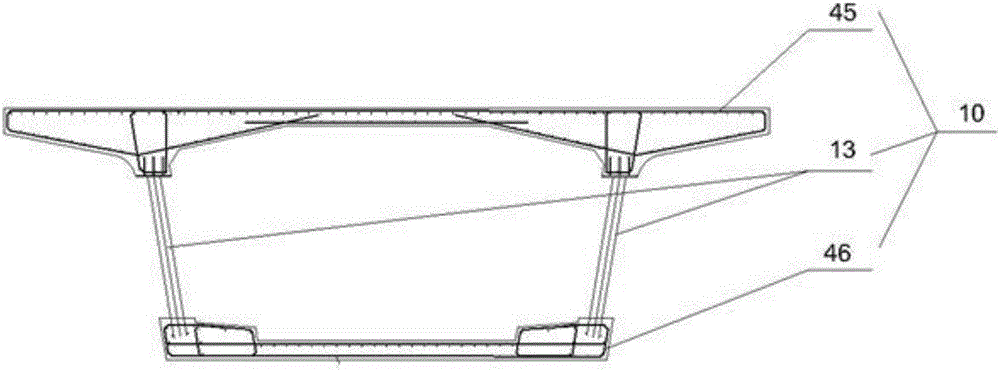

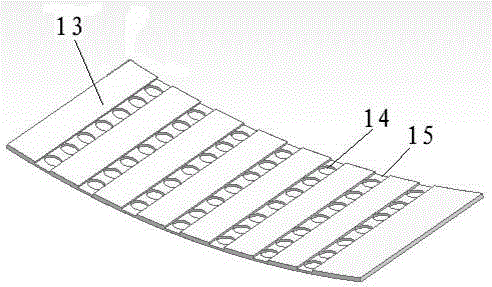

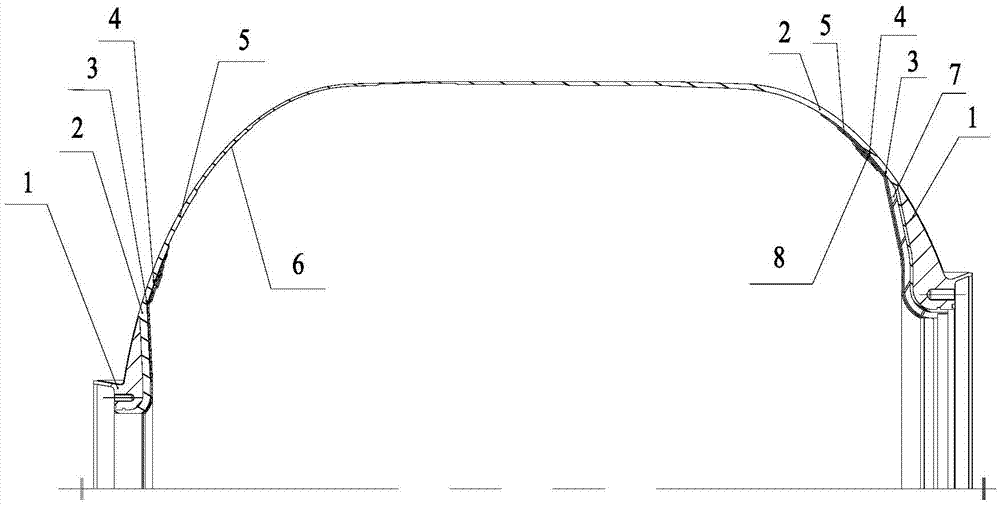

Stub matching prefabricated form system used for corrugated steel web composite structure girder bridge

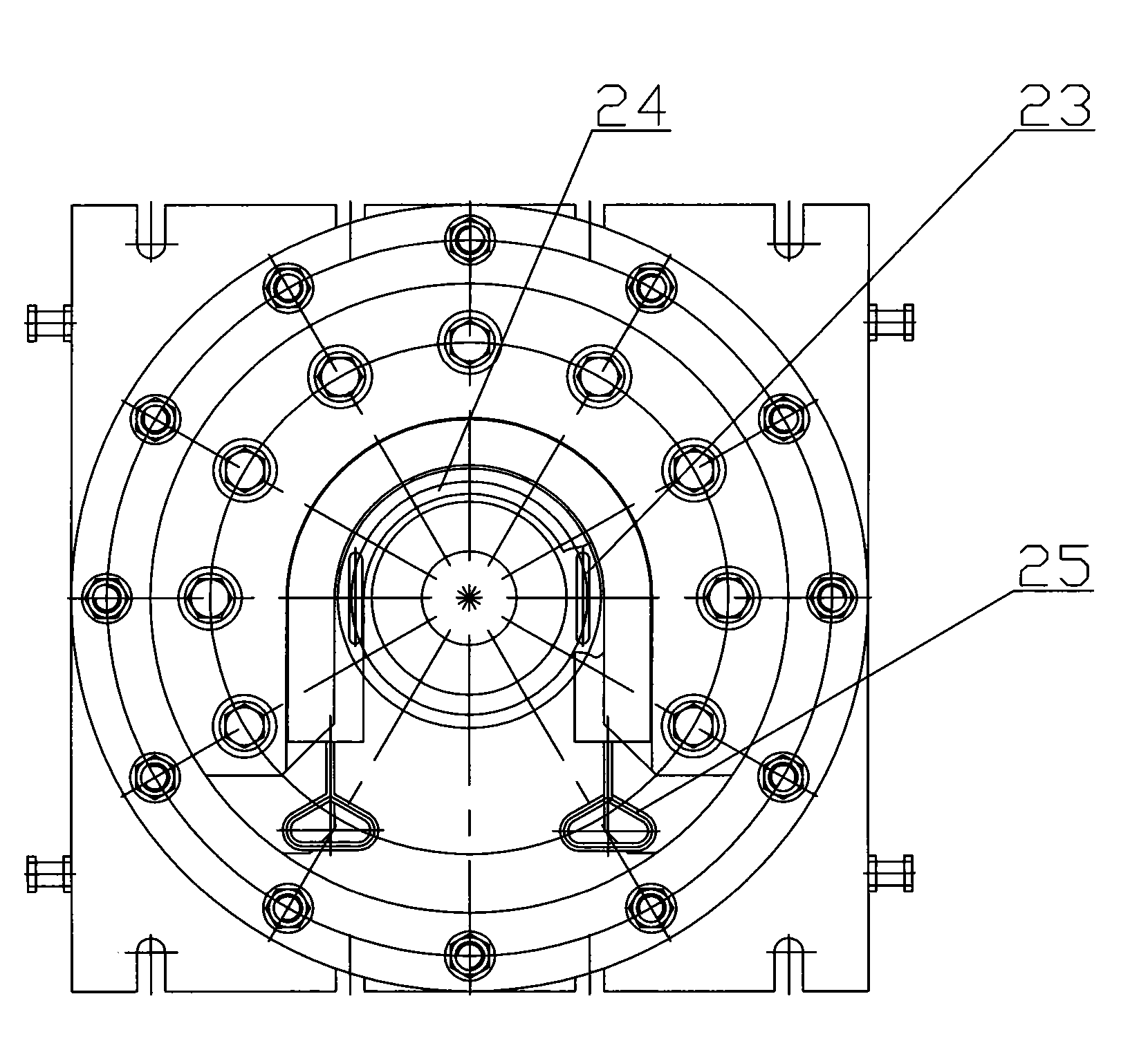

ActiveCN105848839ASolving Die-in DifficultiesEasy to moldMould separation apparatusMouldsGirder bridgePush pull

The invention discloses a stub matching prefabricated form system used for corrugated steel web composite structure girder bridge. The system includes a fixed end mould, a fixed end mould holder, an outer mould, an outer mould holder, an inner mould, an inner mould holder, a bottom mould, a bottom mould holder, a bottom mould trolley, a hydraulic system and the like. The fixed end mould includes an upper part and an under part, and a push-pull moving block which is convenient to enter mould for the corrugated steel web is disposed on the upper part opposite of the corrugated steel web. A three-way position adjustment device is disposed on a girder of the outer mould which accurately positions the space attitude of the corrugated steel web. A sealing device on steel-concrete composite is disposed on the steel-concrete composite area, and the device has the locate function of the corrugated steel web. The parts of the mould are assembled and accurately positioned by the hydraulic system according to the structure size of the girder sections. The system overcomes the problems that the installation accuracy requirement of the corrugated steel web is high and the reinforcement cage integral installation is difficult, and the prefabrication construction of the composite girder sections has high-quality and high-efficient.

Owner:CCCC SECOND HARBOR ENG +2

Fire extinguishing composition generating fire extinguishing substance through high-temperature decomposition

InactiveUS20130181158A1Environment friendly and efficientPrevent wrong additionFire rescueFire extinguisherDecompositionEngineering

The present invention relates to a fire extinguishing composition generating fire extinguishing substance through high-temperature decomposition; the fire extinguishing composition includes a fire extinguishing material which can be decomposed to release substance with fire extinguishing properties during the heating process; the content of the fire extinguishing material is at least 80 wt %; a pyrotechnic agent is adopted as a heat source and a power source in a process of fire extinguishing; and the purpose of fire extinguishing is achieved by: igniting the pyrotechnic agent, generating a large quantity of fire substance from the fire extinguishing composition in the use of high temperature produced by burning pyrotechnic agent, and the fire substance sprays out together with the pyrotechnic agent. Compared with the traditional aerosol fire extinguishing systems, the gas fire extinguishing systems and the water type extinguishing systems, the present invention provides a more efficient and safer fire extinguishing composition.

Owner:XIAN J&R FIRE FIGHTING EQUIP

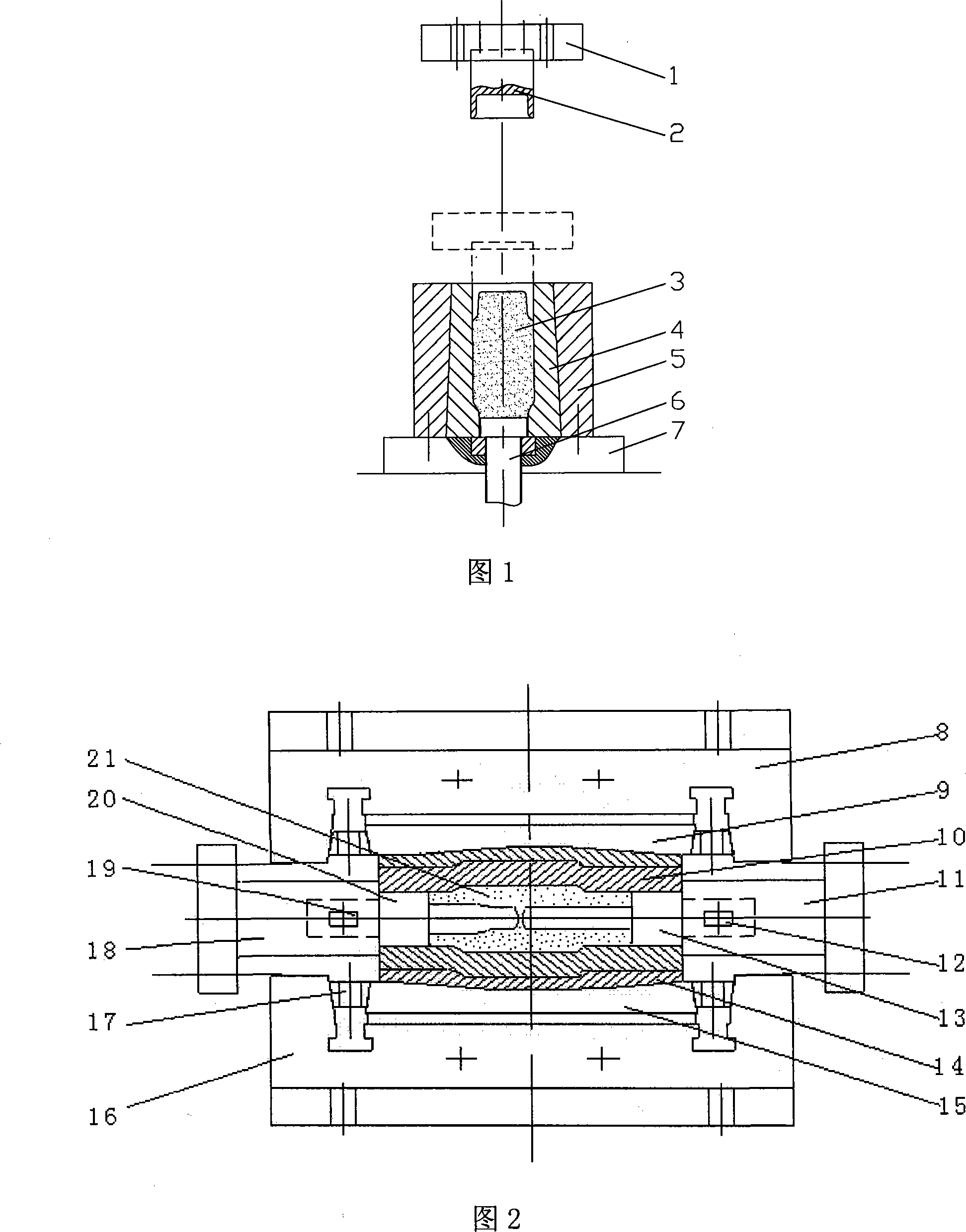

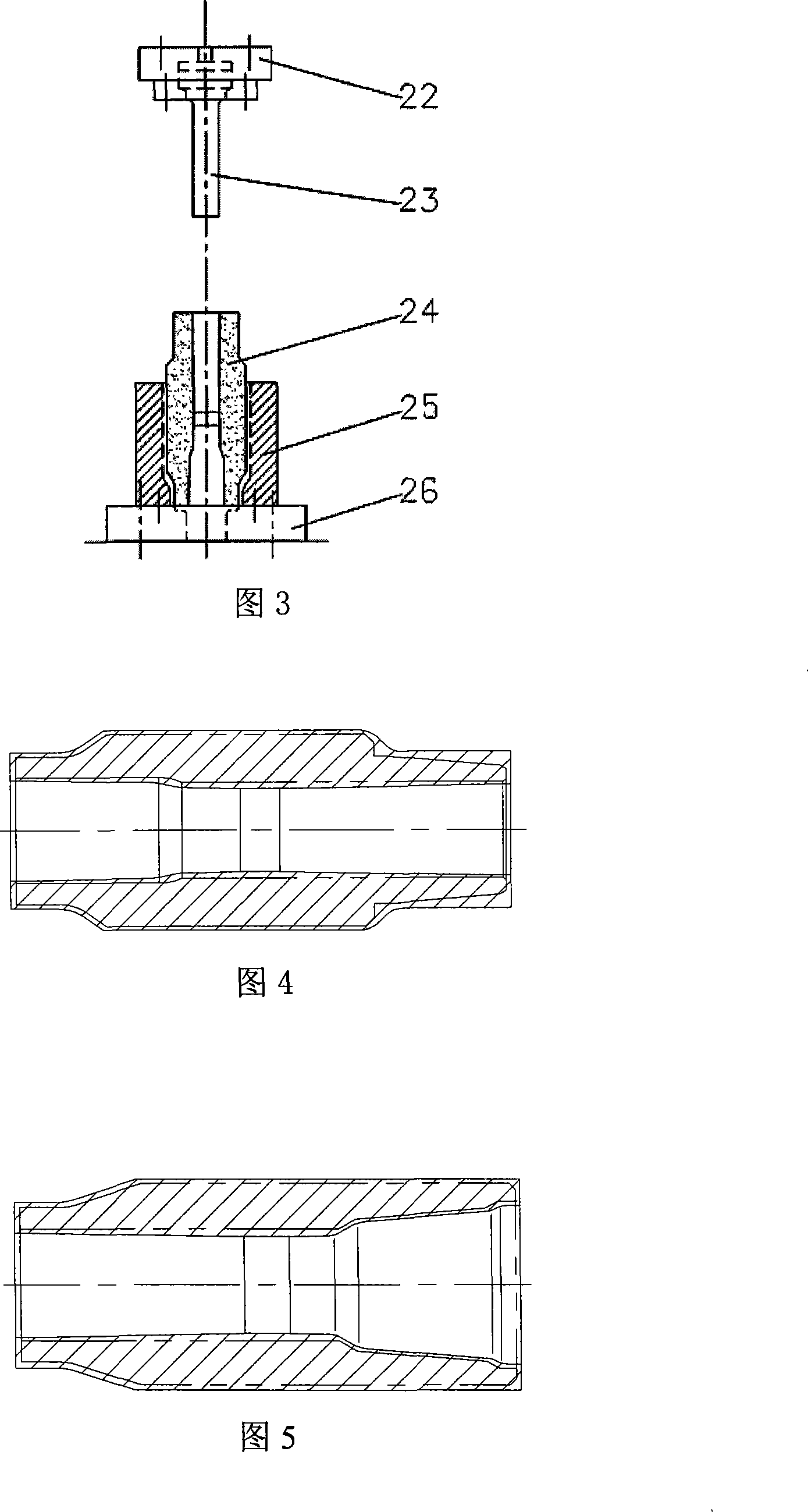

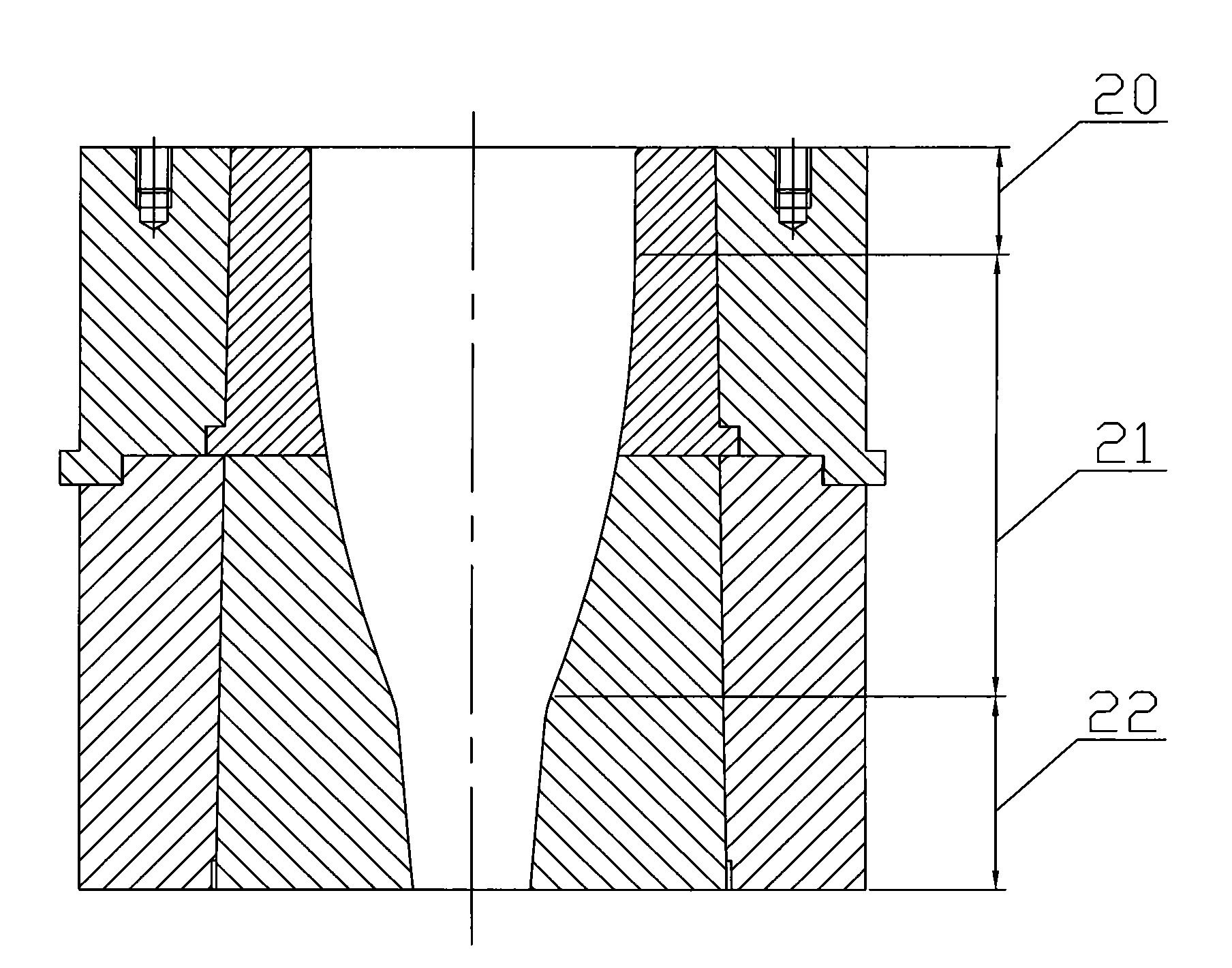

Drill pipe joint precision die forging process

InactiveCN101181730AEasy to moldSmall machining allowanceForging/hammering/pressing machinesMedium frequencyMaterial consumption

The invention discloses a precise die forging technique of a petroleum drill rod connector and is characterized in that: 1) flan material is prepared with a band saw; 2) the flan material is heated quickly at a temperature that is suitable for forging by a medium frequency electric induction furnace; 3) then the flan material is extruded in a close type into a prefabricated flan and a flan makes concave die on a quick flan-making oil hydraulic machine; 4) a molding concave by die level method extrudes and presses the prefabricate flan into a connector die forging piece on the quick flan-making oil hydraulic machine which can implement combination of the upper molding concave die and the lower molding concave die and relative extrusion and pressing from right and left and inner holes of the connector die forging piece is provided with wad; 5) finally a hole punching die punches away the recess inside the inner hole of the forging piece on a special hole punching oil hydraulic machine to obtain the connector forging piece with accurate specifications, excellent structure performance and central through holes. The invention has the advantages of good streamline distribution, material conservation, environmental protection and high production efficiency.

Owner:JIANGYIN LONGCHENG DRILLING & PRODN MACHINERY MFG

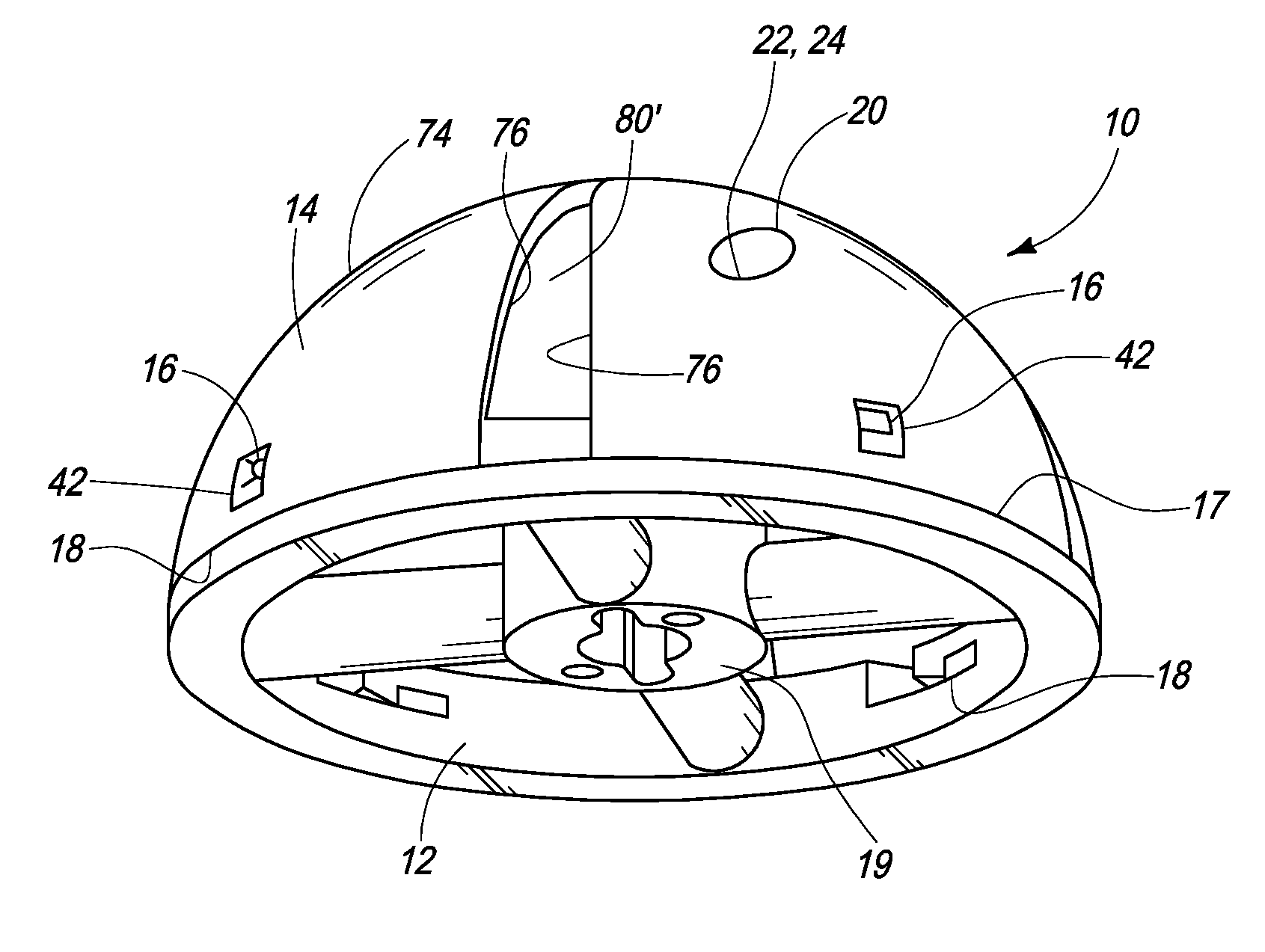

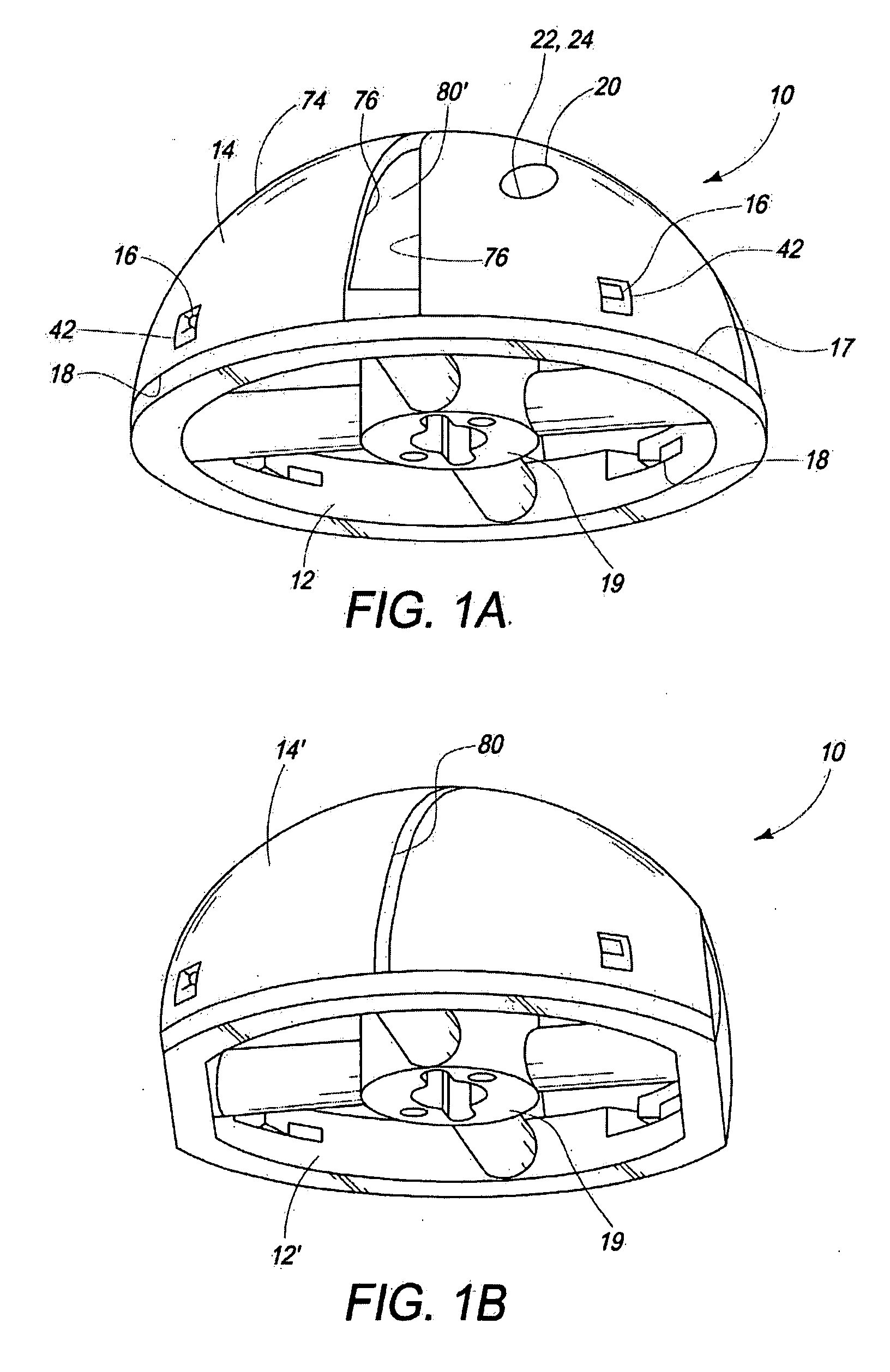

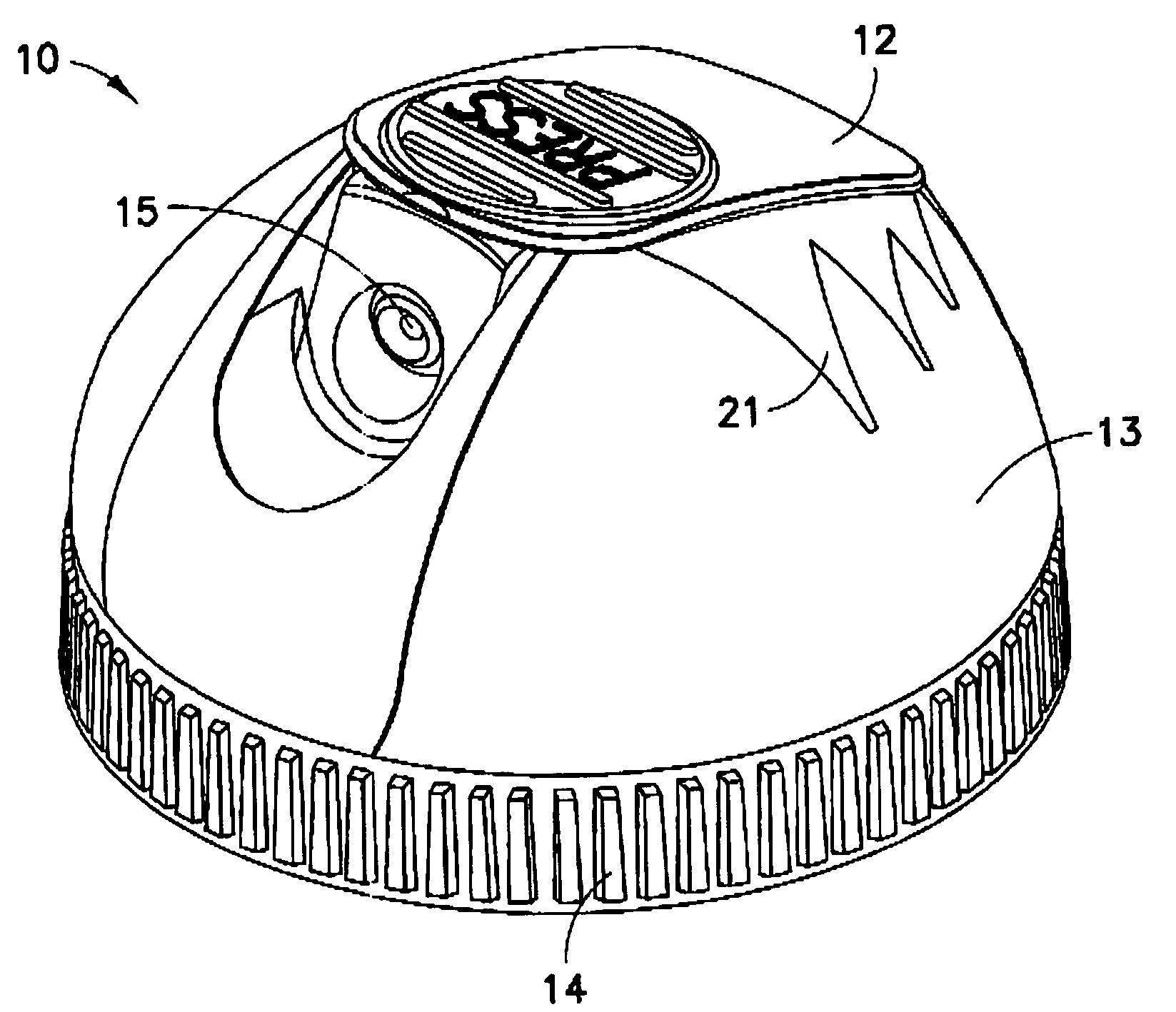

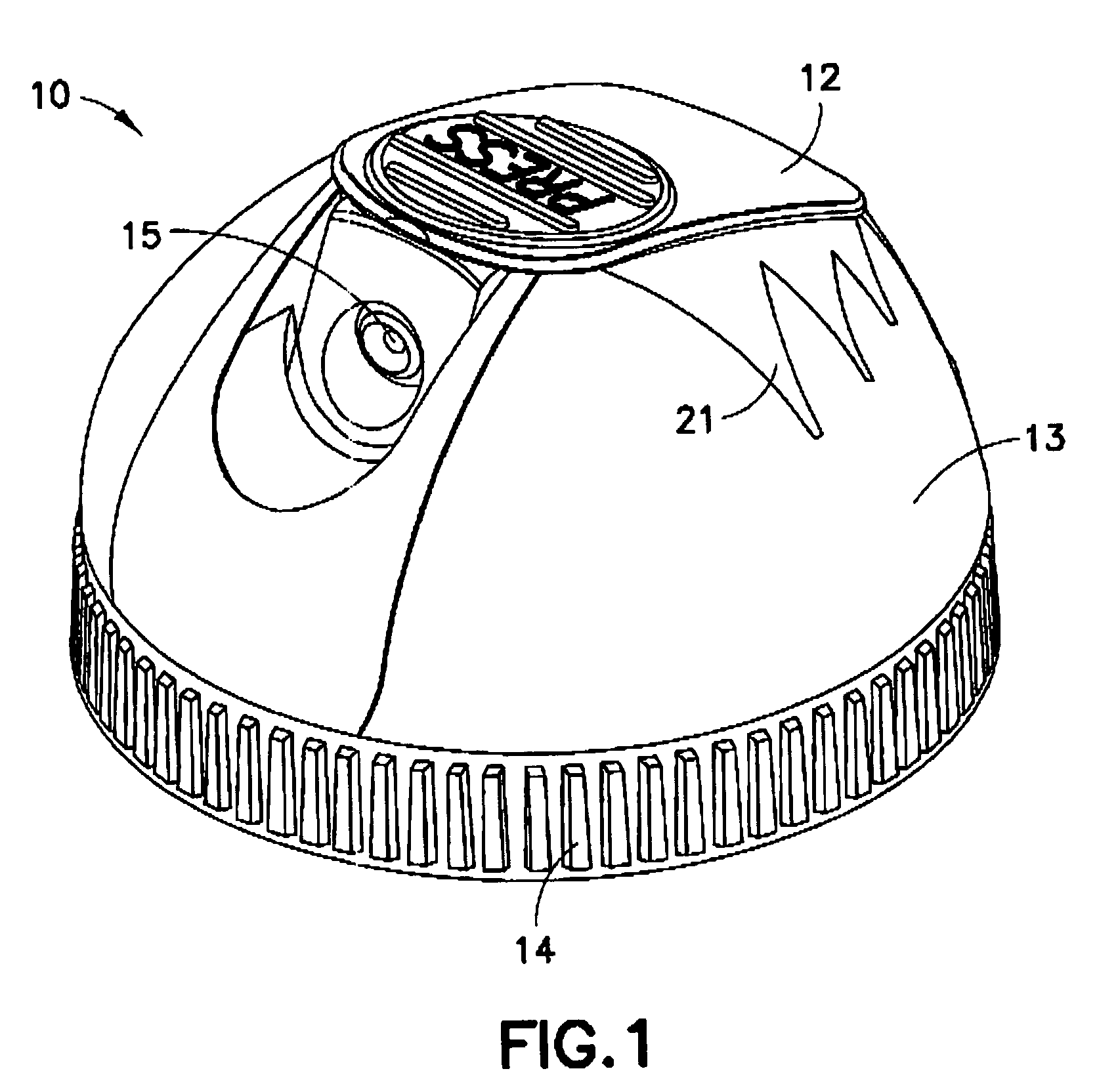

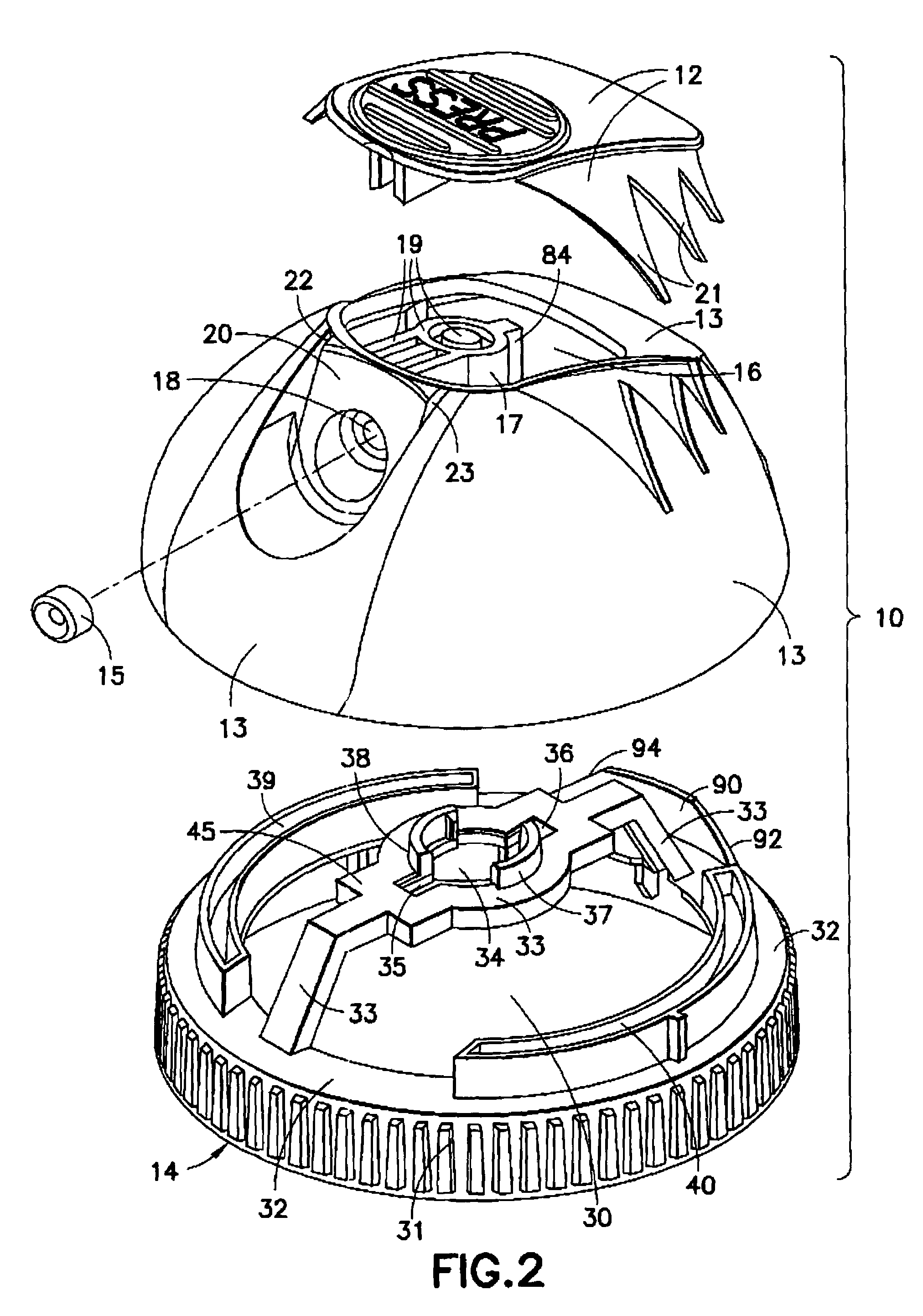

Locking aerosol dispenser

ActiveUS7530476B2Robust constructionEasy to assembleDecorative coversClosure decorative/protective coversEngineeringMechanical engineering

A locking aerosol dispenser with a dome, a top thermoplastic elastomeric button member molded over a dome opening, and a base lock member. The rotatable base lock rotates from locked to unlocked position with respect to the essentially non-rotatable dome. A product channel member in the dome is held by the elastomeric button, and not otherwise attached to the dome. The base lock has an upstanding bridge with unlocking slots within which extend fingers on the product channel member when the dispenser is unlocked and actuated. The base lock is not attached to the aerosol valve mounting cup. The dome is attached to the base lock member and the aerosol valve mounting cup, the dome capturing the base lock member between the dome and aerosol container.

Owner:PRECISION VALVE CORP

Heat conductive silicone rubber composition and molded article

ActiveUS7547743B2Easy to handleEasy to moldConductive materialNon-conductive material with dispersed conductive materialPolymer scienceShell molding

A heat conductive silicone rubber composition comprising (A) an organopolysiloxane containing, on the average, at least 0.1 silicon-bonded alkenyl radical and having a viscosity of 50-100,000 mPa·s at 25° C., (B) an organopolysiloxane containing, on the average, at least 2 SiH radicals and having a viscosity of 1-100,000 mPa·s at 25° C., (C) a heat conductive filler, (D) a platinum catalyst, and (E) a specific organopolysiloxane having a molecular weight of at least 10,000, is easy to handle and mold, and especially smooth in flow, even when heavily loaded with the filler.

Owner:SHIN ETSU CHEM IND CO LTD

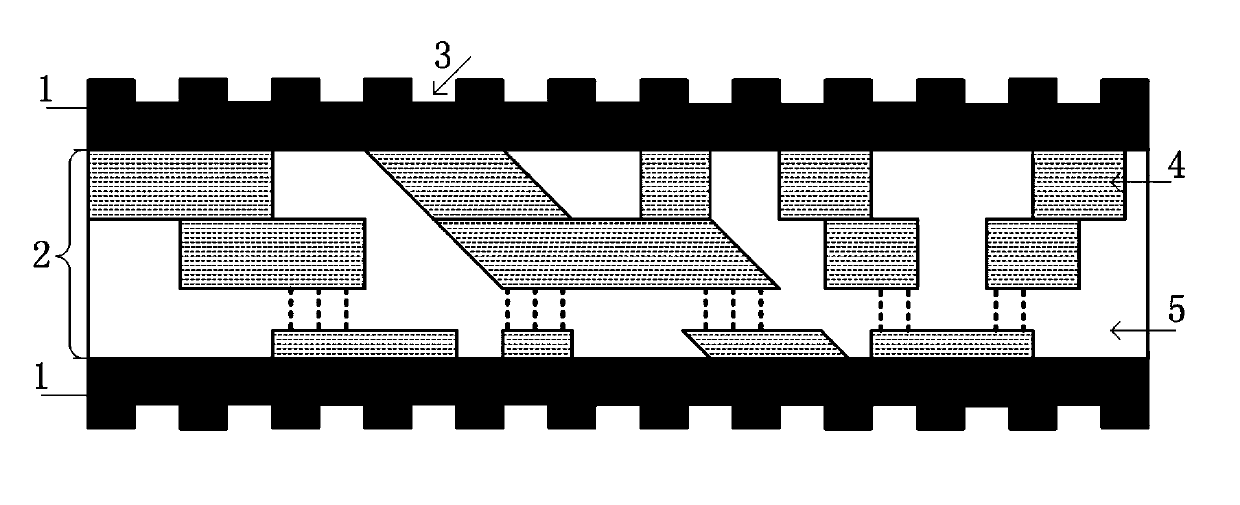

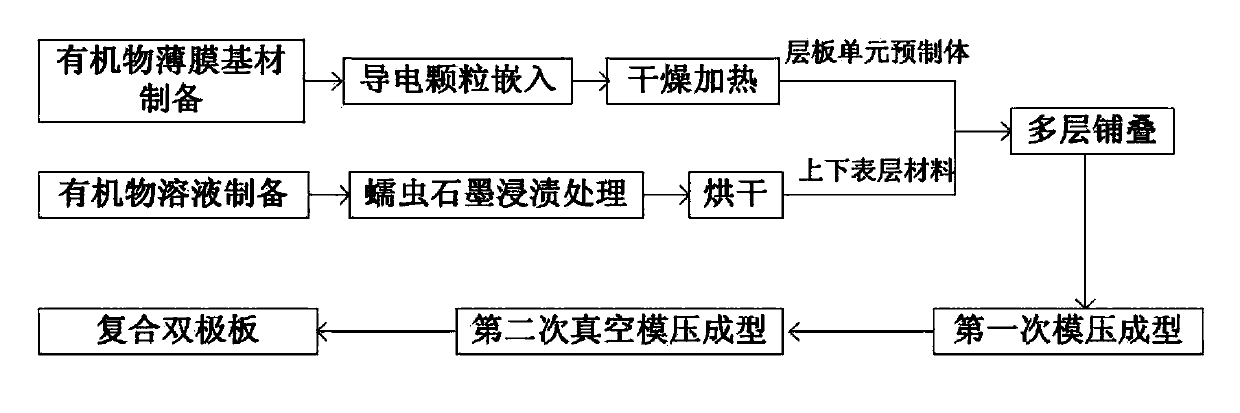

Composite bipolar plate for PEM (proton exchange membrane) fuel battery and preparation method thereof

ActiveCN103746131AGood effectImprove air tightnessFinal product manufactureCell electrodesSurface layerProton

The invention discloses a composite bipolar plate for a PEM (proton exchange membrane) fuel battery and a preparation method thereof. The bipolar plate comprises an upper and lower surface layers prepared by using vermicular graphite as a base material, and a plurality of laminated plate unit preforms prepared by embedding conductive particles in organic substance films, wherein every two adjacent laminated plate unit preforms are provided with one or a plurality of conductive particle overlay areas to form one or a plurality of zigzag conductive paths. The preparation method comprises the following steps: sequentially laying the lower surface layer material, the laminated plate unit preforms and the lower surface layer material in a die, and carrying out die pressing twice to obtain the bipolar plate for a PEM fuel battery. The method enhances the production efficiency of the composite bipolar plate for a PEM fuel battery, and lowers the manufacturing cost; and the composite bipolar plate has the advantages of high bending strength, favorable conductivity and favorable air tightness.

Owner:CHINA THREE GORGES UNIV

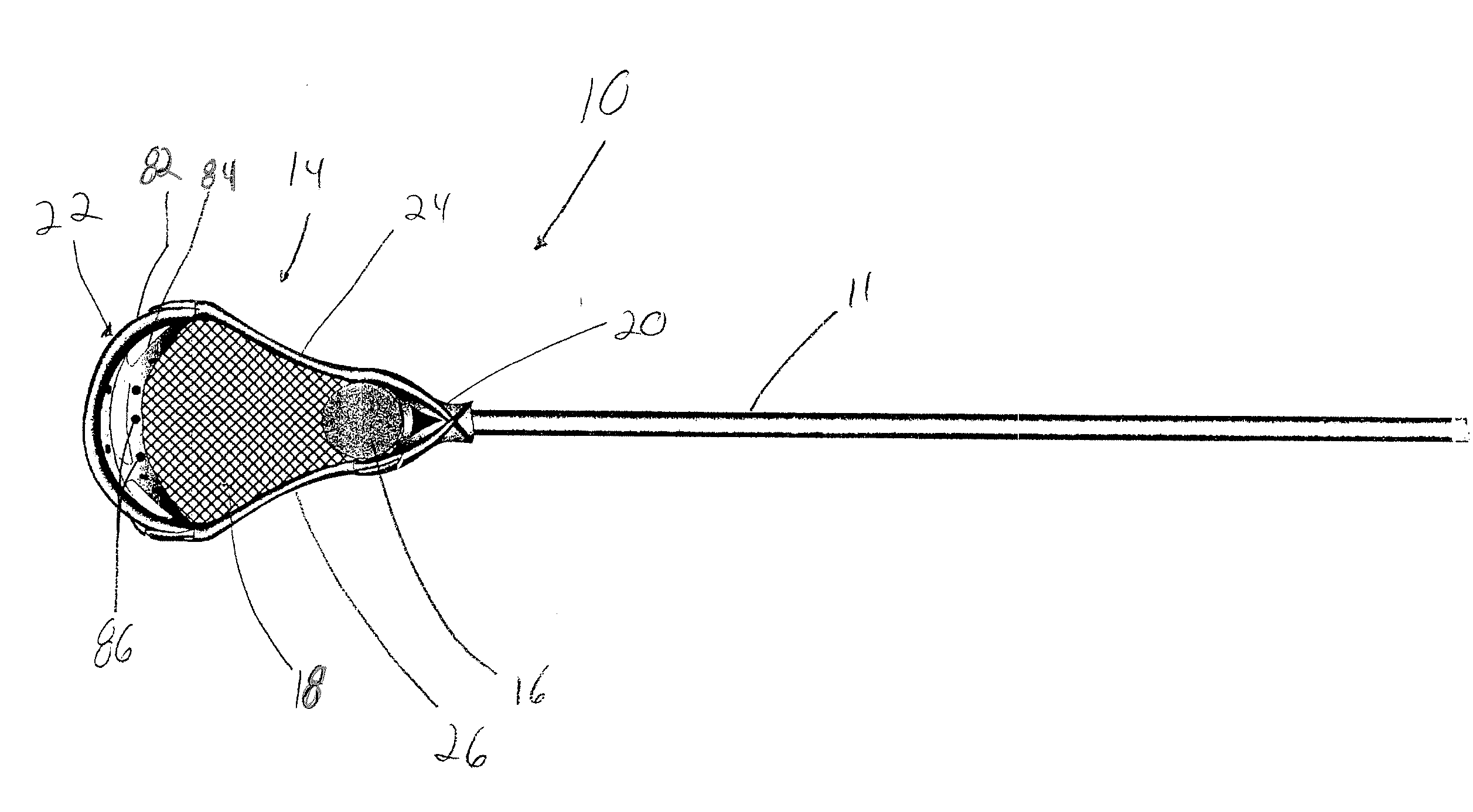

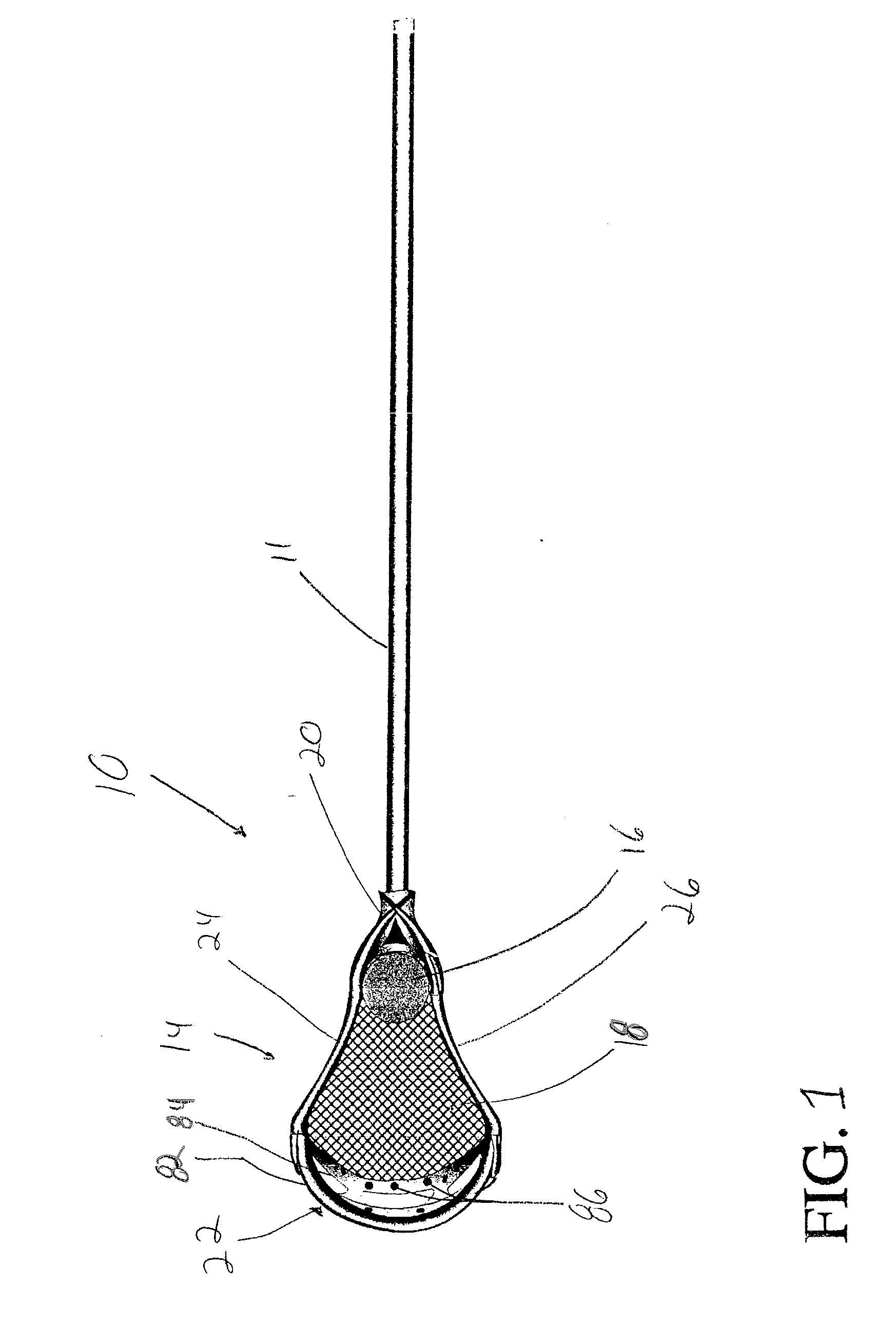

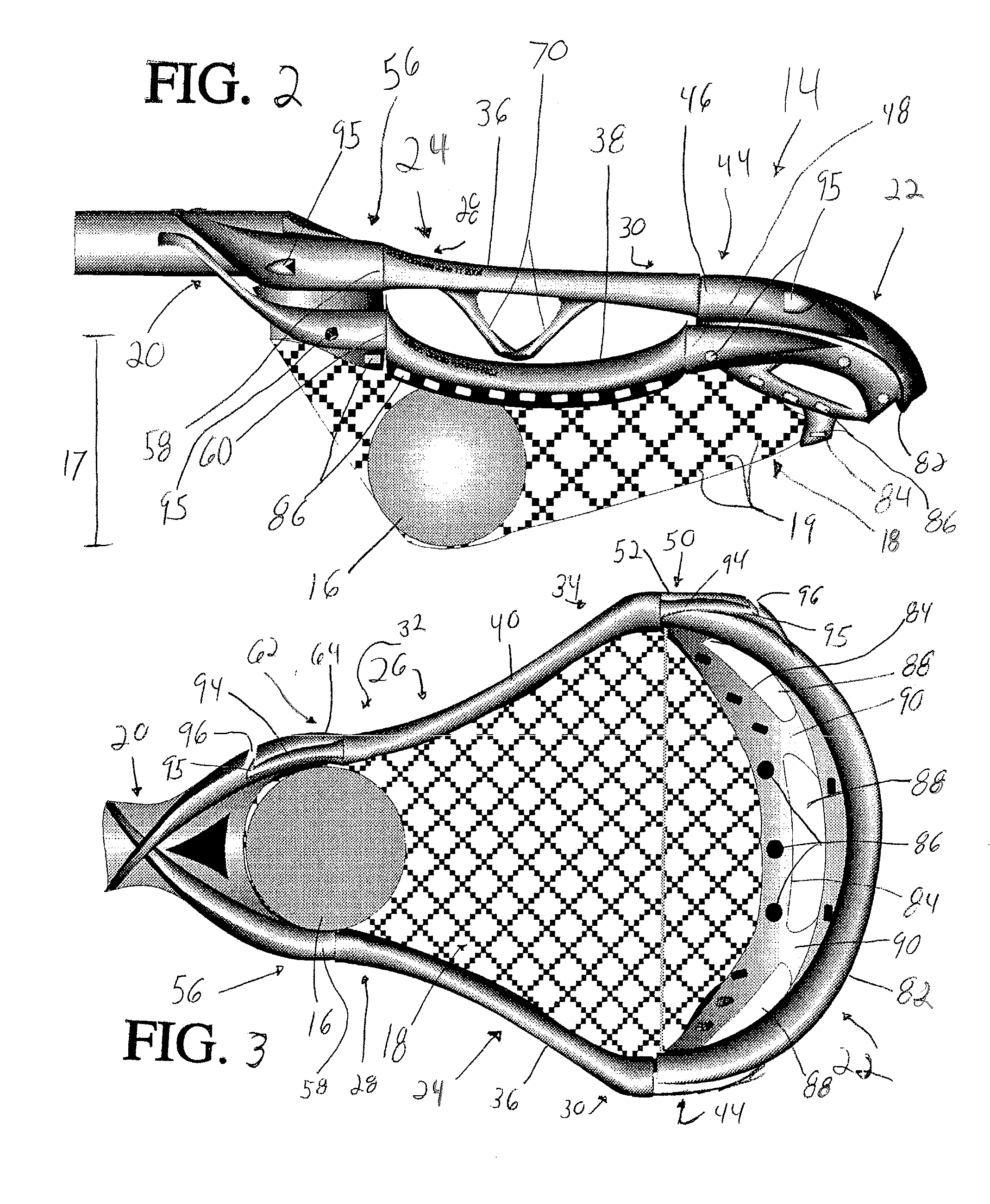

Lacrosse Head With Separable Parts

InactiveUS20080026883A1Easy to replaceEasy to manufactureThrow gamesRacket sportsEngineeringMechanical engineering

A lacrosse stick comprising a lacrosse head and a lacrosse handle. The head comprises a scoop removably attached to a throat. The scoop and the throat can be disassembled from one another to allow replacement of the individual components of the head. The head can comprise a throat, a scoop, and first and second sidewalls connecting the throat to the scoop. Each sidewall can include a top support spaced from a bottom support. A removable stanchion can be spaced between one of the top supports and one of the bottom supports. The scoop can include a molded first armature attached to a second molded armature wherein the second molded armature can be positioned substantially between the first molded armature and the throat. A handle can be integrally connected to the head. The throat can be molded with the handle such that the handle can be inseparable from the throat.

Owner:J DEBEER & SON

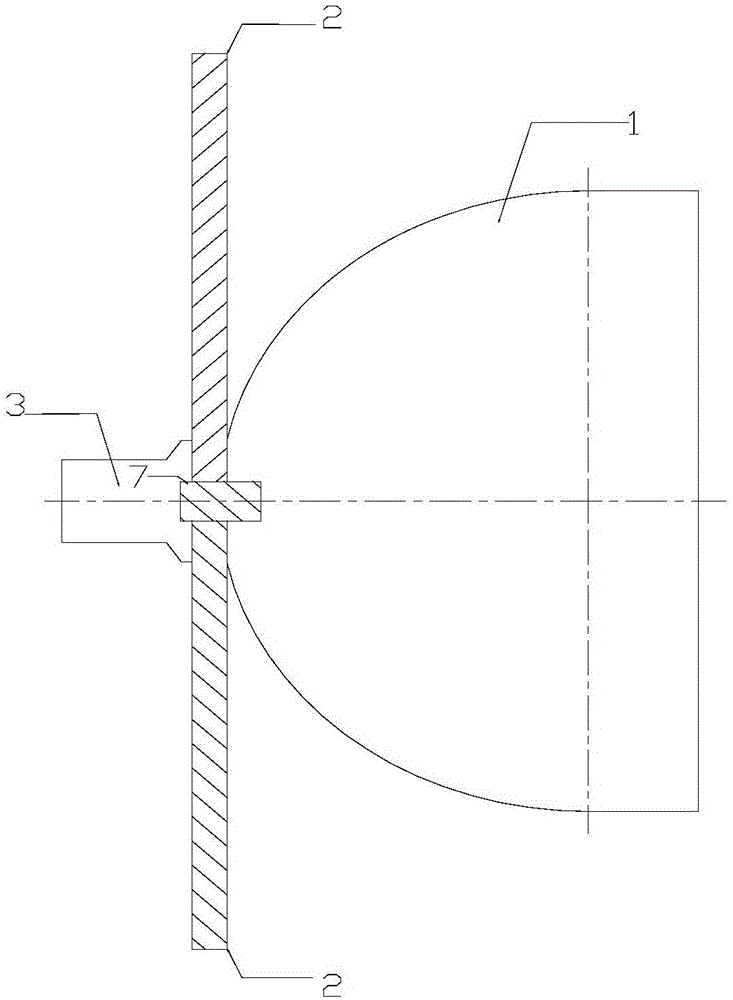

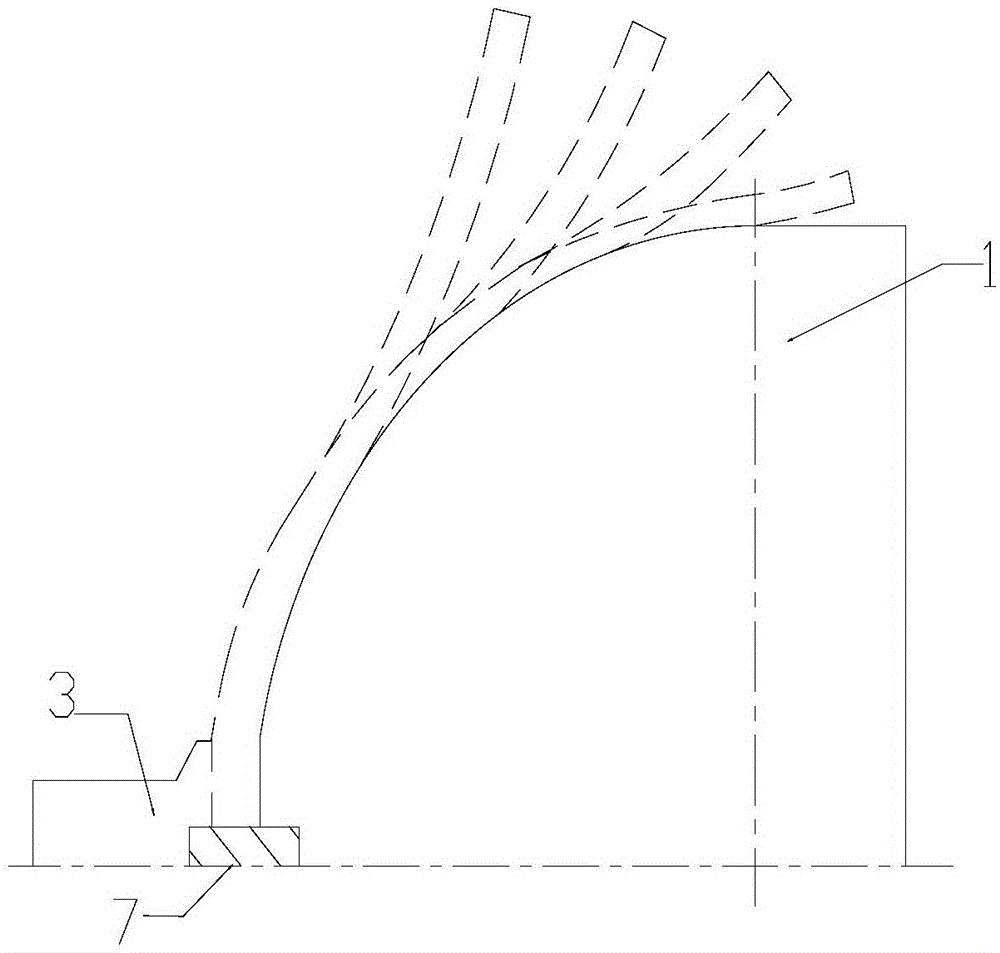

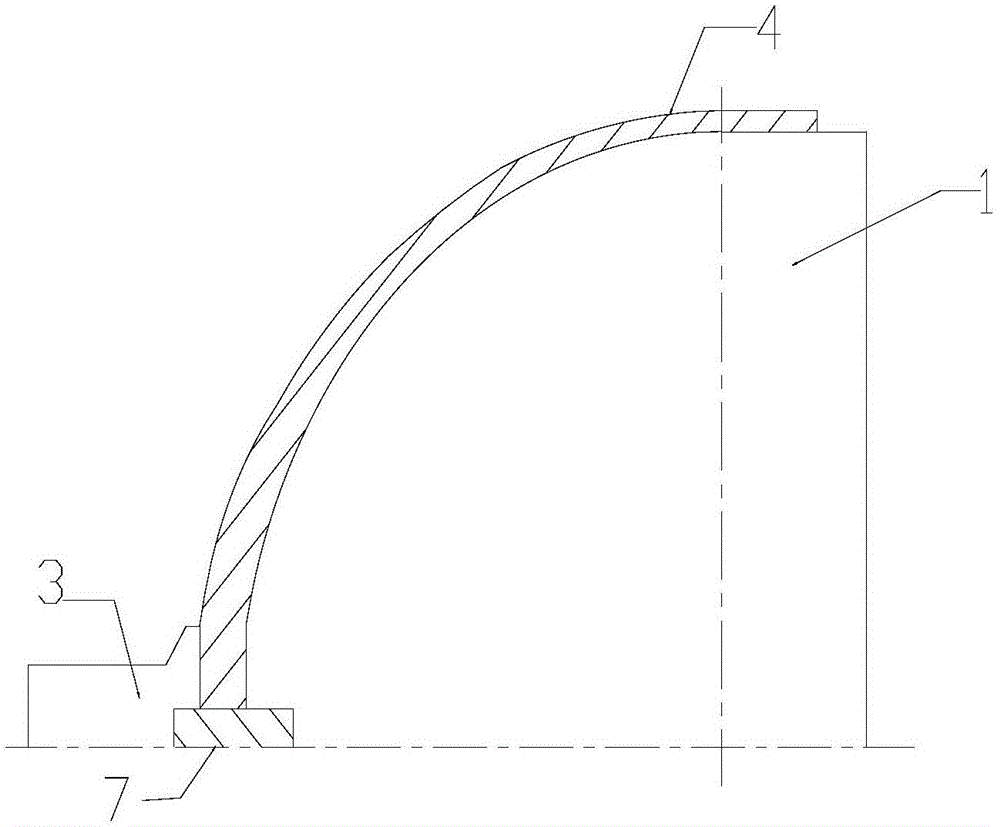

Storage tank hemispherical shell forming method for improving mechanical performance

ActiveCN105107917AHigh strengthHigh yield strengthShaping toolsRoom temperatureUltimate tensile strength

The invention relates to a storage tank hemispherical shell forming method. Aiming at the forming production of an aluminum alloy hemispherical shell capable of being strengthened through heat treatment, an aluminum alloy flat plate is hot spun directly and wholly to form a pre-formed blank, and is quenched to spin at a room temperature to form a final-formed blank; the diameter of the final-formed core mold is smaller than the diameter of the pre-formed blank by 2-4 mm; through setting a reasonable spinning gap value, the deformation is about 5-10%; the ageing treatment is performed after the spinning; a final state can reach a 787 state; and the yield strength and the tensile strength of a shell are improved by 10-20% compared with a T62 state of a traditional process (direct quenching and ageing after spinning). Two sets of molds with different diameters are only needed; spun workpieces are excellent in mold bonding; a formed hemispherical shell is high in strength; the optimal performance state of such thermal-treated strengthened aluminum alloys as 2219 exerts; and the advantages of the thermal-treated strengthened aluminum alloys are fully embodied compared with general aluminum alloys incapable of being strengthened through heat treatment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Dry type manufacturing method of animal specimen

InactiveCN1971663AImprove qualityAdequate perfusionDead animal preservationEducational modelsHigh concentrationGlycerol

The invention relates to a dry type making method for animal specimen that includes six steps: collecting material, reshaping antisepsis fix and tube cavity cast, alcohol dewatering fix, glycerol process, turpentine impregnation and air drying, material repairing tinction preservation or seal up for keeping. Thereinto, in step 1, the animal material is bleed and killed via health quarantine, in step 2, potting it with the formalin with colorless glycerin and phenol or alcohol solution, in step 3, controlling the concentration of every step and fixed time, in step 4, marinating it with glycerol moisture absorption soften liquid, and transfer it from low concentration to high concentration of glycerin, and the time is prolonged gradually, in step 5, treating it with turpentine continually, in step 6, printing it. The invention improves the present technique, the quality of specimen is improved greatly, and that can keep the original state of material, the color and the luster. The dried specimen is sanitation without peculiar smell, and good at handle and quality.

Owner:王荣林

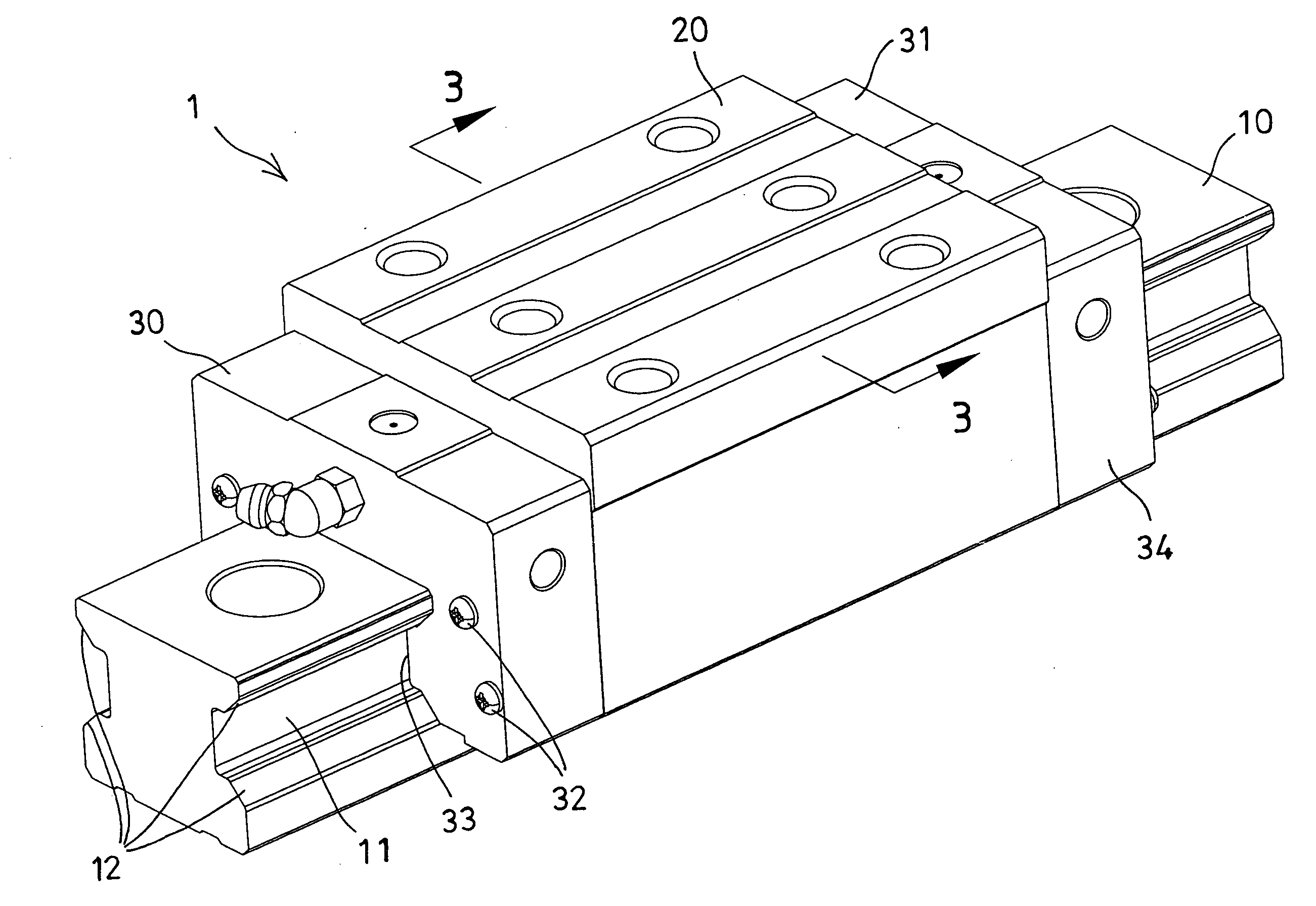

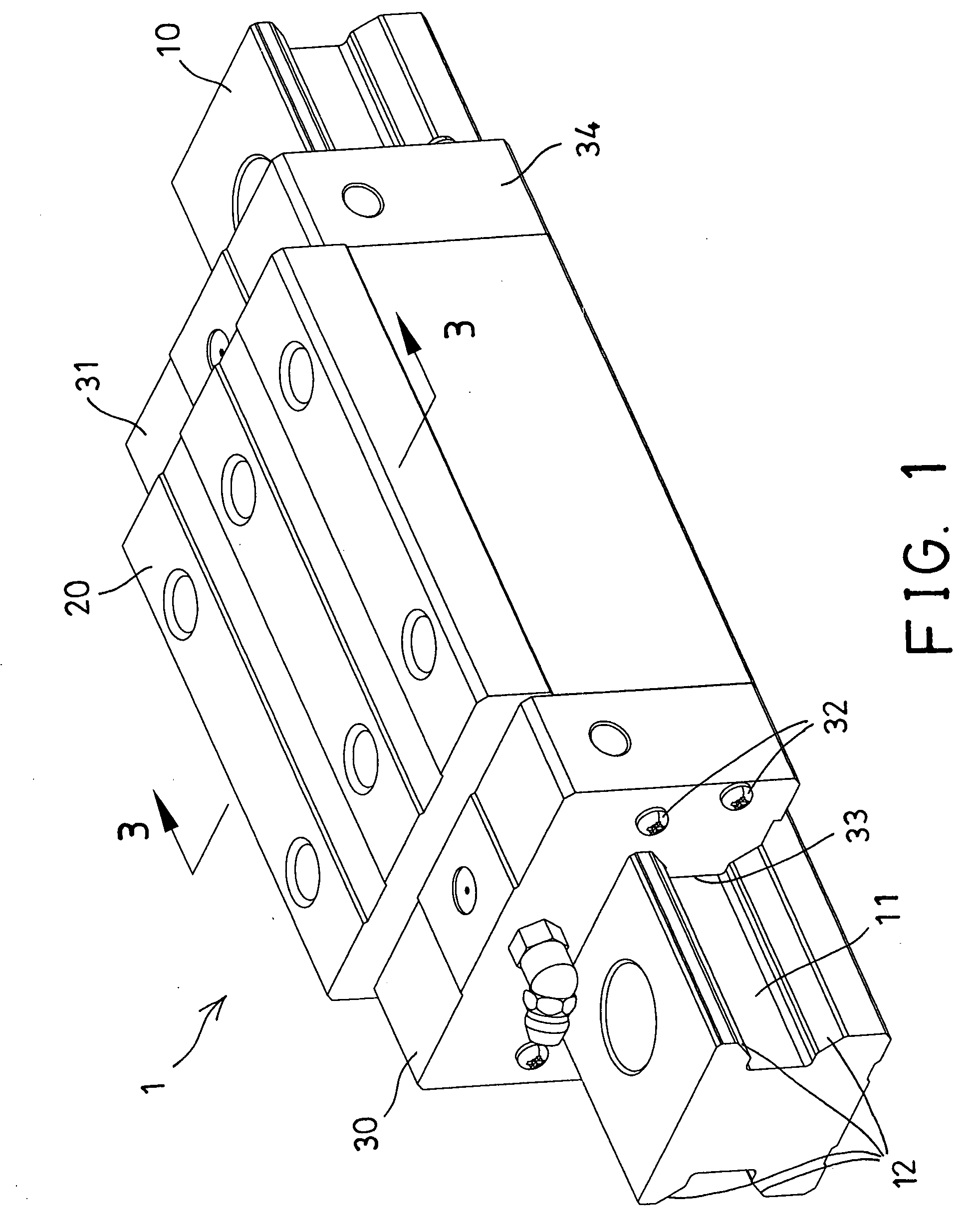

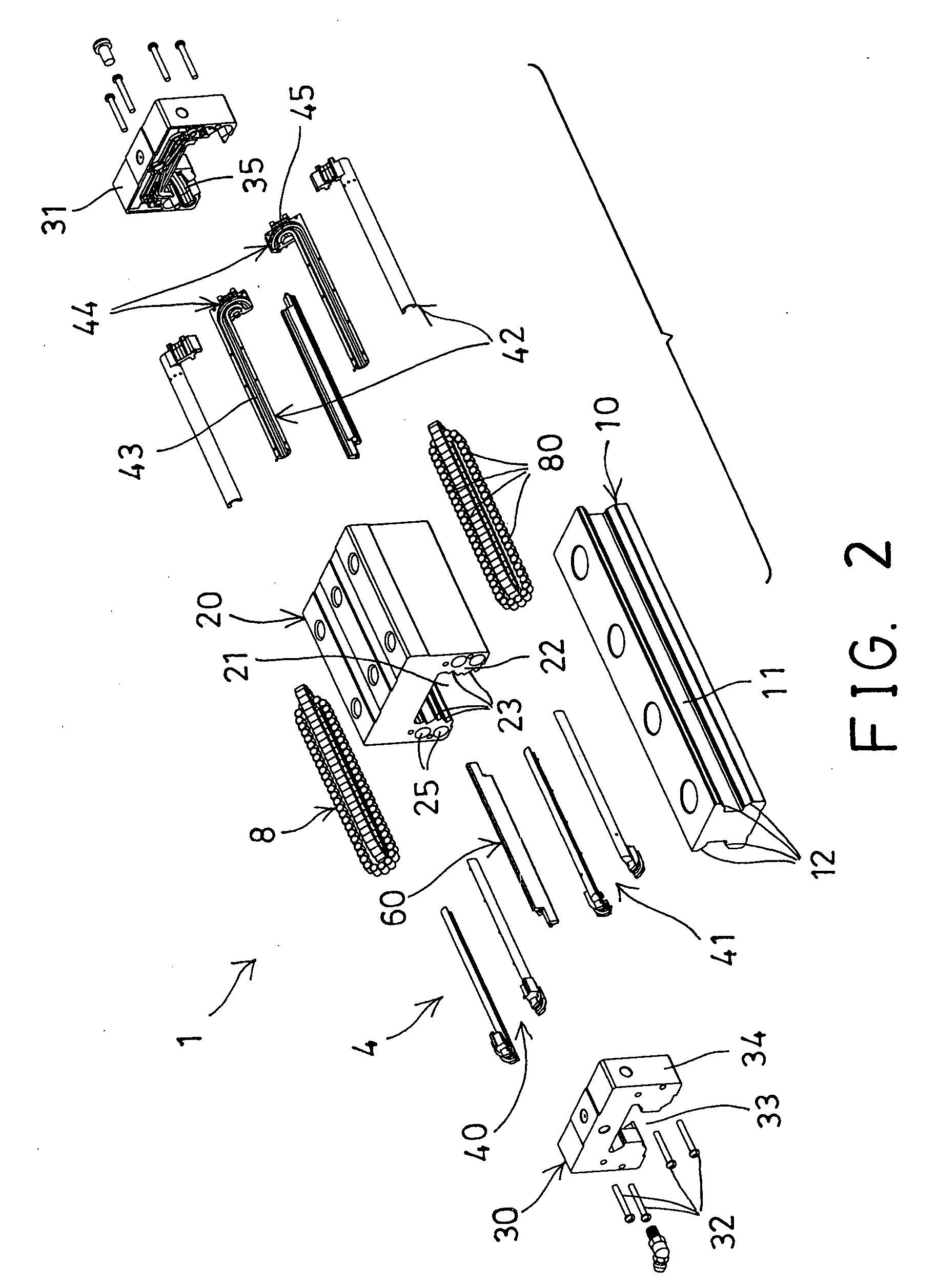

Linear motion guide apparatus

InactiveUS20080292226A1Easy to manufactureEasy to moldLinear bearingsBearing componentsLinear motionEngineering

A linear motion guide device includes a slider and two end caps attached to side portions of the slider, and two holding assemblies attached to two side legs of the slider and the end caps for forming four endless ball guiding channels and for smoothly receiving four chains of rolling members, the holding assemblies each include two L-shaped holding devices and a retaining device attached to the leg of the slider and the end caps, and the holding devices each include two detachable halves for allowing the holding devices to be easily and quickly molded and for allowing the holding devices to be easily disengaged from the mold devices.

Owner:HIWIN TECH

Rubber stopper composition and medical rubber stopper

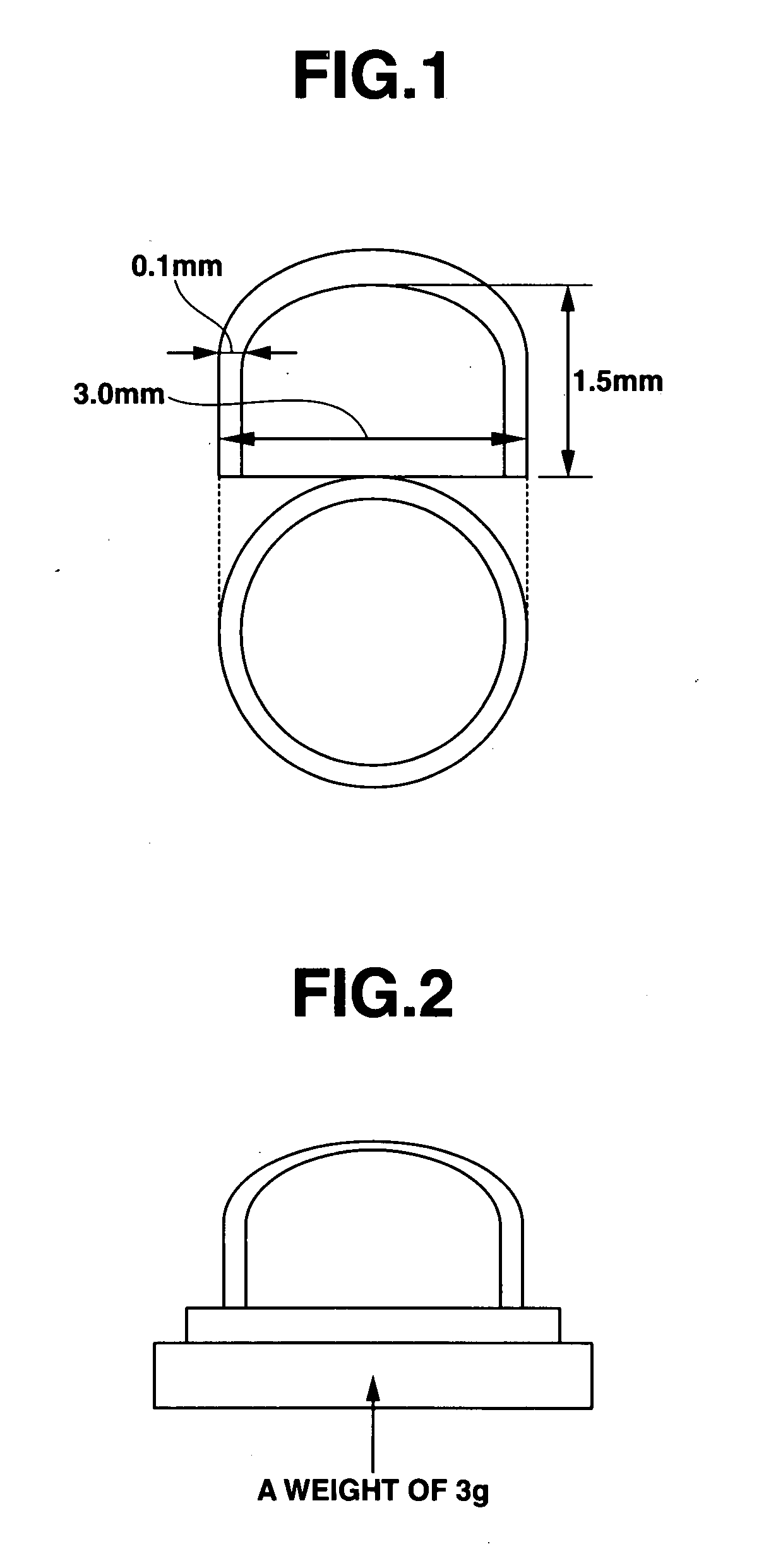

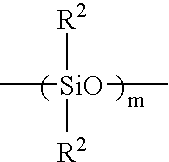

InactiveUS20100249296A1Excellent flexibility and gas barrier propertyGood propertyClosuresPharmaceutical containersIsobutyleneLubricant

It is an object of the present invention to provide: a rubber stopper composition that is easy to mold and process, excellent in sealing properties and gas-barrier properties, low in propensity to elute into the contents, and satisfactory in needle penetration; and a medical rubber stopper made by using the same. The object of the present invention is attained by a composition made up in a predetermined way by dynamically cross-linking an isobutylene-based polymer in the presence of polyolefin with use of a hydrosilyl-group-containing compound and by further adding a softener to the isobutylene-based polymer thus cross-linked, the isobutylene-based polymer having an alkenyl group at a terminal thereof. To the composition of the present invention, a block copolymer consisting of a polymer block (a) composed mainly of an aromatic vinyl-based compound and a polymer block (b) composed mainly of isobutylene or a lubricant can be added.

Owner:KANEKA CORP

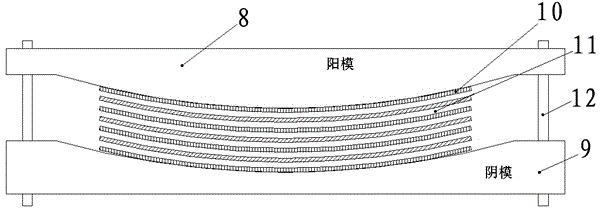

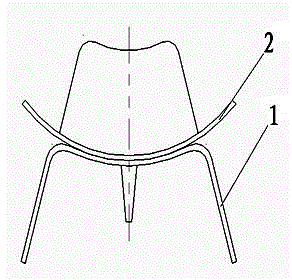

Manufacturing method of bent bamboo furniture and bent bamboo rod pieces

The invention provides a manufacturing method of bent bamboo furniture and bent bamboo rod pieces. The manufacturing method involves manufacturing of the bent bamboo rod pieces and bent bamboo plate pieces. According to the method, bamboo is divided into long-strip-shaped bamboo filaments or bamboo splits after bamboo skin and bamboo pith which can affect the bonding performance are removed; adhesives are arranged on the surfaces of the bamboo filaments or the bamboo splits after the bamboo filaments or the bamboo splits are dried; plate blank is formed in a planar cold press in a cold pressing mode; the plate blank is arranged in a bending forming die in an overlaying mode, pressing is conducted to enable the plate blank to form bent-plate-shaped bent bamboo rod plates, the bent bamboo rod plates and the die are sent into a heating chamber to be heated and cured, after the die is disassembled, according to the requirements of bent bamboo rods, the plates are cut into bent bamboo rods in a sawing mode in the bending direction of the bamboo filaments, and the bent bamboo rod pieces are formed after the surfaces are smoothed; meanwhile, the bamboo is sawed off at fixed length and divided into rectangular bamboo strips, assembly is conducted according to the requirements of the plate blank, the plate blank is arranged in a drying and shaping die to be compressed, and drying, heating and shaping are conducted to form bent bamboo plate piece panels; the surfaces of the panels are coated with adhesives, the panels are laid in a heat curing die, and pressing, heating and curing are conducted to obtain the bent bamboo plate pieces.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Electromagnet having spacer for facilitating cooling and associated cooling method

InactiveUS20060218790A1Increase loopImpart different cooling propertyTransformers/inductances coils/windings/connectionsMetal-working apparatusNuclear engineeringConductor Coil

An electromagnet and associated apparatus and method are provided. The electromagnet includes a core and at least one winding disposed circumferentially about the core such that the winding extends at least one revolution around the core. The electromagnet further includes at least one spacer having channels defined therein and disposed circumferentially about the core and adjacent to the at least one winding. The channels facilitate cooling by directing fluid about the windings of the coil as fluid is introduced into the electromagnet.

Owner:THE BOEING CO

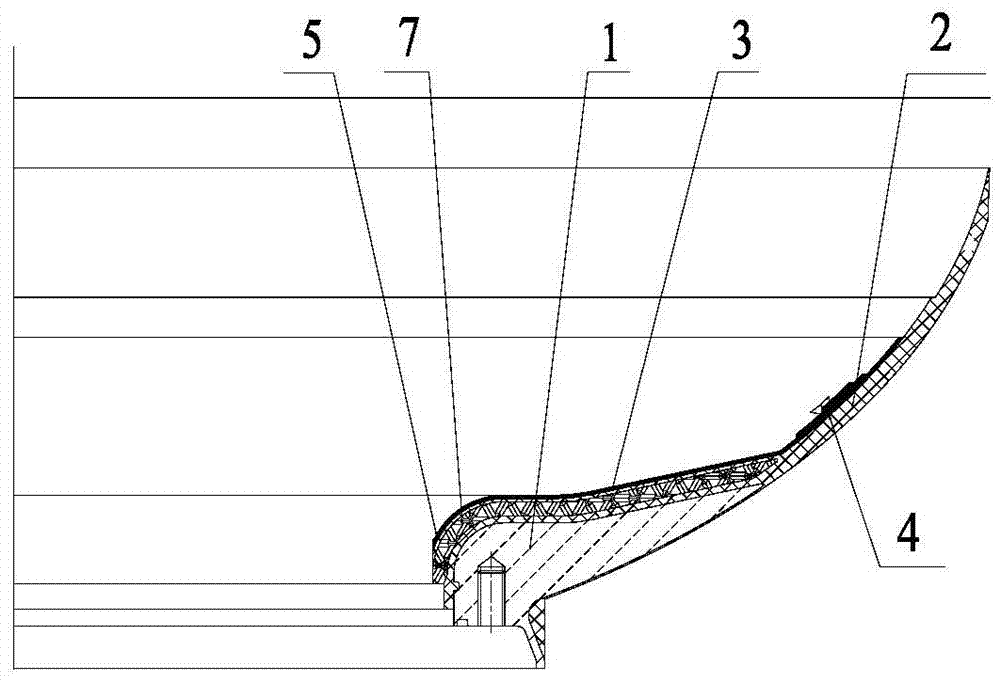

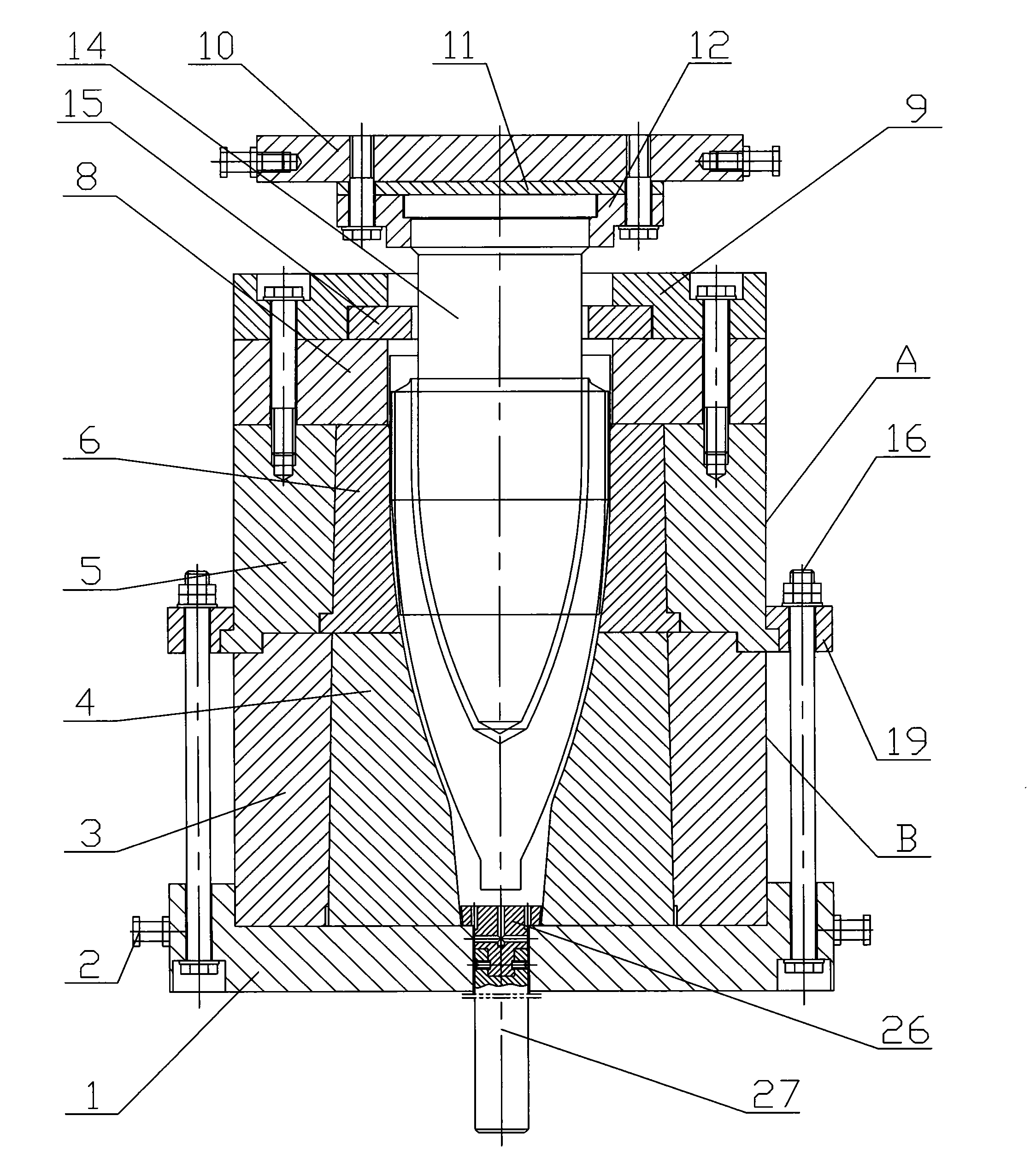

Seal head heat insulating layer forming method and mold of filament winding engine heat insulating structure

ActiveCN105437521AOvercome stabilityOvercome the defect of low bonding strengthDomestic articlesVulcanizationEngineering

The invention discloses a seal head heat insulating layer forming method of a filament winding engine heat insulating structure. A cover layer and a bottom layer of a seal head heat insulating layer are firstly and independently formed in a vulcanization and compression manner and then overall formed in a vulcanization and compression manner, and the defect that the forming quality stability and consistency of manual SMT technology products are low is overcome. A release agent is sprayed or release cloth is pasted in the direction with the decreasing diameter at the crack arrest point, a proper tackiness agent is adopted in other lining layers, and the releasing effect of the cover layer and the bottom layer of the manufactured seal head heat insulating layer is good. In addition, when the seal head heat insulating layer is a rear seal head heat insulating layer, an EPDM heat insulating material wrapping structure is adopted in a T-1 anti-elation layer, and therefore the seal head heat insulating layer is isolated from a high-strength aluminum alloy connector. According to a provided integral forming mold, two sets of tools of the integral forming mold and a bottom layer forming mold can be achieved only by replacing an upper integral mold and an upper bottom layer mold, the structure is simple, and cost is low. Meanwhile, locating and mold releasing can be achieved well, and mold stripping of products is facilitated.

Owner:湖北三江航天江北机械工程有限公司

Controlled release antimicrobial polymer compositions

InactiveUS20060062850A1Long period of timeEasy to usePowder deliveryHeavy metal active ingredientsControlled releaseOrganic acid

Antimicrobial polymers that are able to release antimicrobial agents at a controlled rate over a predetermined period of time are provided. The antimicrobial polymers comprise an acid copolymer, an antimicrobial agent, and optionally, an organic acid. The acid copolymer and the organic acid, if present, may be at least partially neutralized. Also provided are methods of manufacturing the antimicrobial polymers of the invention, and articles made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

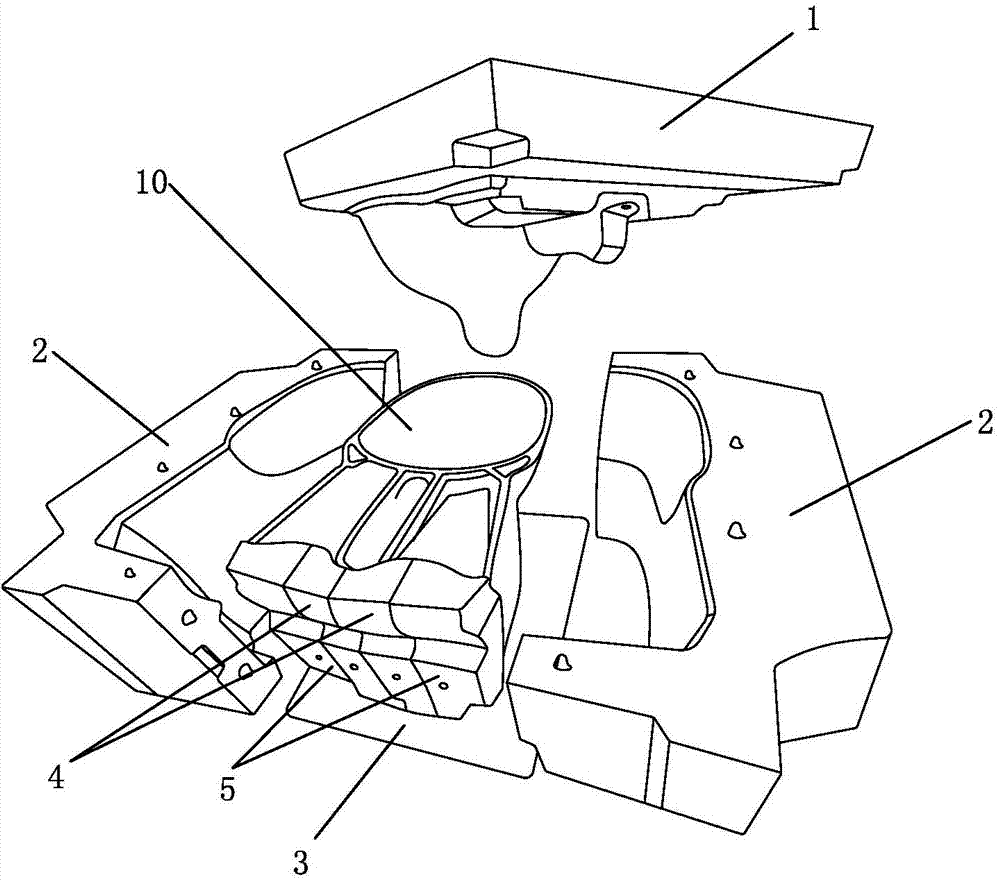

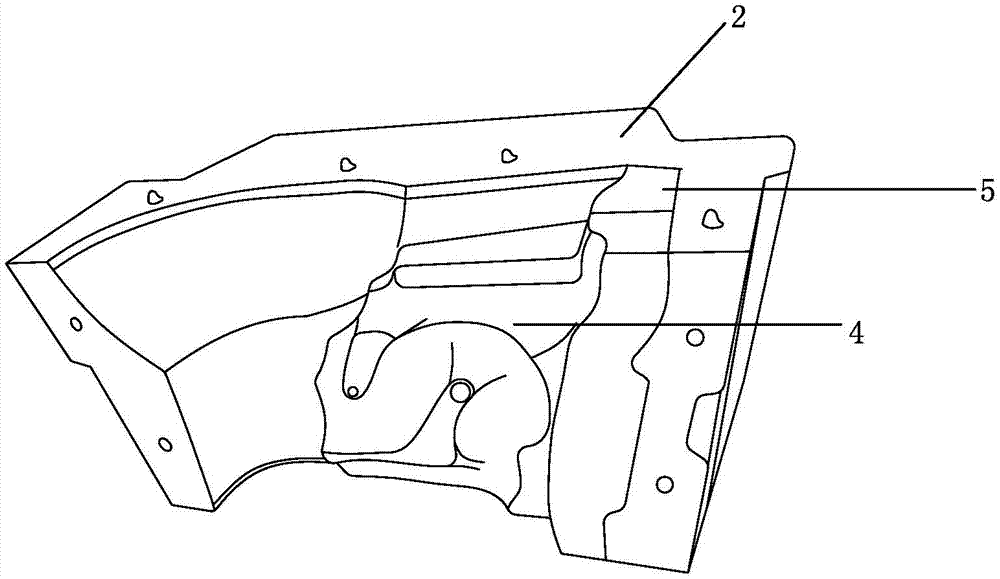

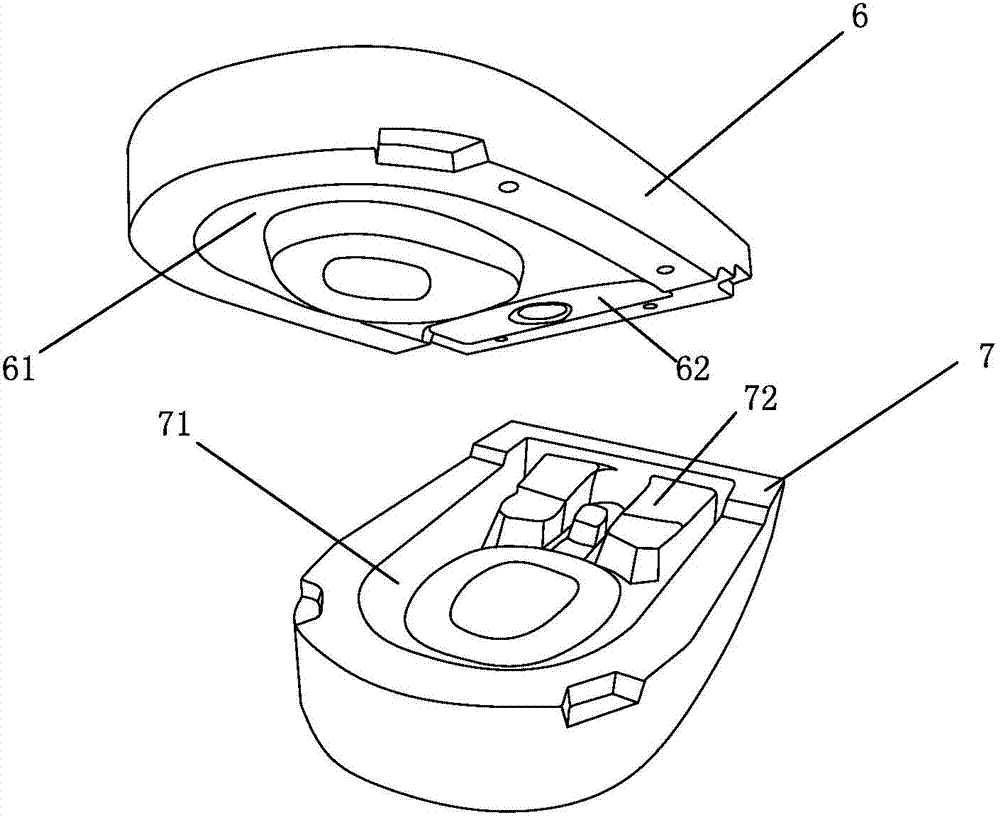

Pedestal pan mold, and mold splitting technology and pedestal pan thereof

InactiveCN103770202AEasy to moldConvenient mold opening operationWater closetsMould separation apparatusSewage treatmentMaterials science

The invention discloses a pedestal pan mold, and a mold splitting technology and a pedestal pan of the pedestal pan mold. The mold comprises a mold body and a seat ring mold, wherein the seat ring mold comprises an upper seat ring mold and a lower seat ring mold, an upper concave ditch is formed in the upper seat ring mold, a lower concave ditch is formed in the lower seat ring mold, and the seat ring mold is used for producing a seat ring with the complete water guide ring. The mold splitting technology comprises the steps that the pedestal pan is split into a pedestal pan body, the mold body and the seat ring mold, and the mold body and the seat ring mold are independently developed from the seat ring; the seat ring mold is divided into the upper seat ring mold and the lower seat ring mold, and is used for producing the seat ring with the complete water guide ring. The pedestal pan comprises a pedestal pan body at least provided with a bed pan, a sewage disposal pipeline and a jetting water way and a seat ring, the pedestal pan body and the seat ring are independently formed, the seat ring is provided with the water guide ring, and the seat ring is stuck to the top end of the pedestal pan body. According to the pedestal pan mold, and the mold splitting technology and the pedestal pan of the pedestal pan mold, the production efficiency can be greatly improved, the labor intensity of workers is reduced, and the production cost is reduced.

Owner:JOMOO KITCHEN & BATHROOM

Extrusion die and method for extrusion molding inside and outside reduction blank by same

The invention provides an extrusion die and a method for extrusion molding inside and outside reduction blank by the same, which relate to a die and a method for extrusion molding blanks by the die, and are aimed to solve the problems that the adoption of the common blank extrusion molding die and method cannot mold a workpiece with an external shape of one end of a larger diameter and the other end of a smaller diameter, and the workpiece with an internal hole end of a larger diameter, a bottom part of a smaller internal diameter and a long axial length. The die is characterized in that a second assembly is arranged on a lower die seat; a first assembly is arranged on a second assembly; the die holes of a first lower die and a second lower die are combined to form into a lower die cavity; a cushion block and a discharging plate are detachably connected with a first pre-stressed ring; a convex die is arranged in the lower die cavity; the connection part of the convex die is arranged in a stepped through hole of a fixing plate of the convex die; and the fixing plate of the convex die is detachably connected with the cushion block and an upper die seat. The method comprises the following steps of blanking, turning, heating, extruding and annealing treatments, wherein the heating temperature is between 1100 DEG C and 1150 DEG C. With the adoption of the extrusion die and the method provided by the invention, the extrusion molding of inside and outside reduction blanks can be realized.

Owner:HARBIN JIANCHENG GRP

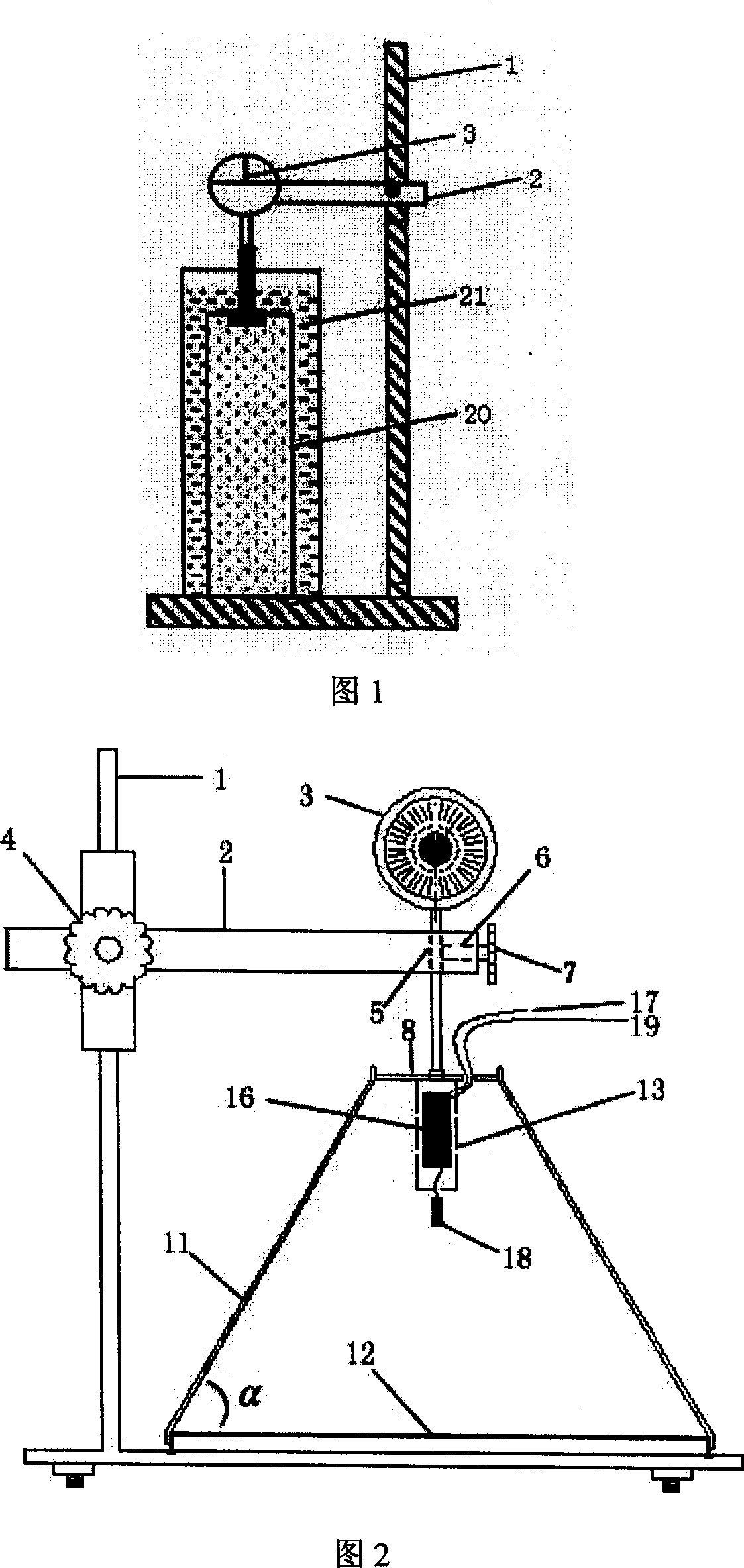

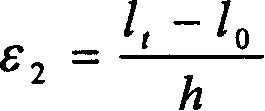

Measuring apparatus for rate of self-contraction of cement concrete

InactiveCN1963503AReduce resistanceEasy to moldElectrical/magnetic solid deformation measurementMaterial thermal analysisAutomatic controlData acquisition

Owner:BEIJING UNIV OF TECH

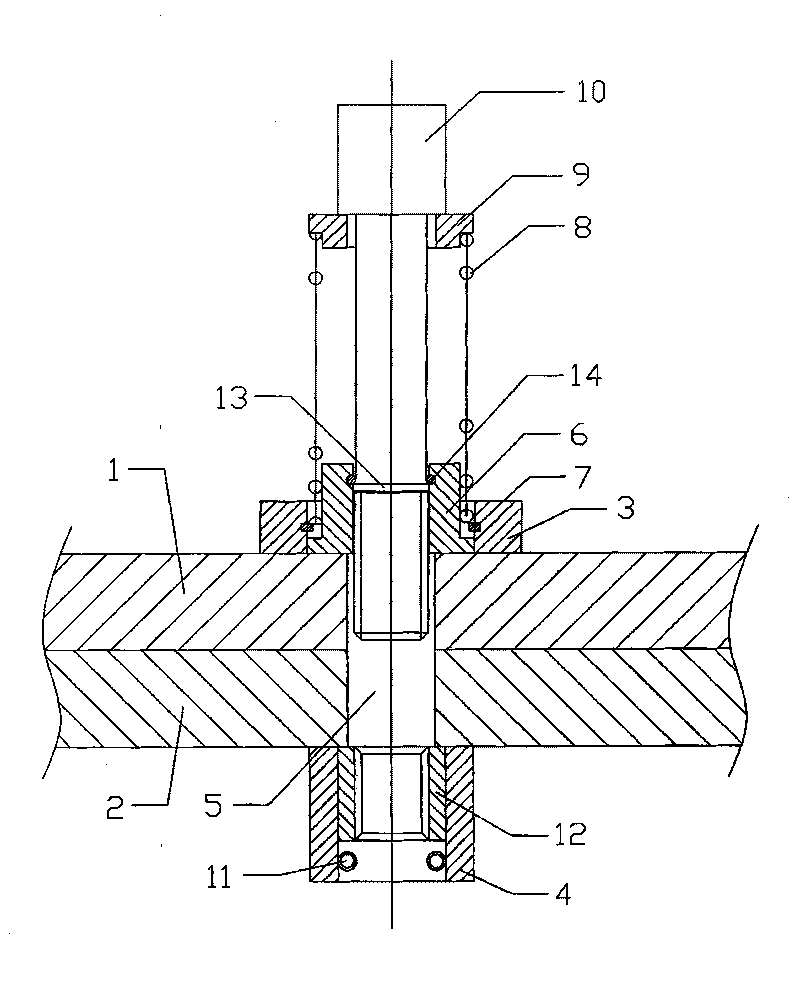

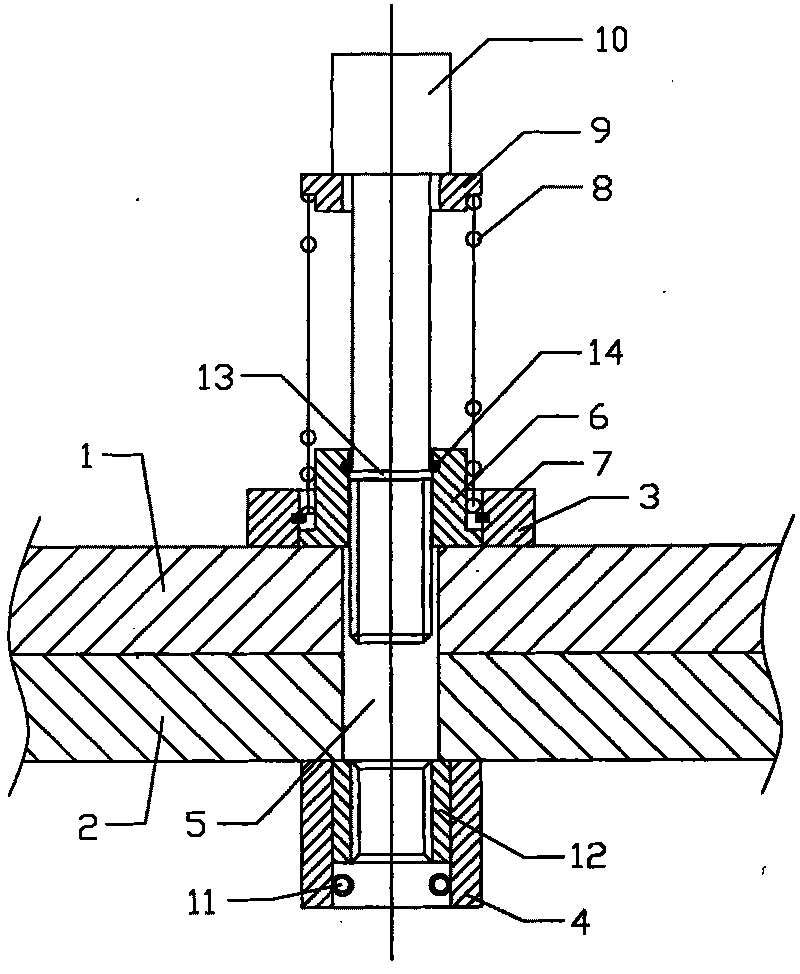

Tubular pile die screw

The invention discloses a tubular pile die screw, which comprises an upper die and a lower die, wherein the edges of the upper die and the lower die are correspondingly fixedly provided with a plurality of upper seats and lower seats, bolt fixing holes run through the upper seats, the upper die, the lower die and the lower seats, a lower spring pad is arranged in the upper seat, the lower spring pad is clamped in the upper seat via a clamp spring, a spring is sleeved between the lower spring pad and the upper seat, the upper end of the spring is sleeved with an upper spring pad, a bolt penetrates through the upper spring pad, the spring, the lower spring pad, the bolt fixing hole and the lower seat from top to bottom, a nut used for locking the bolt is clamped in the lower seat via an inserted pin, the lower part of the bolt is fixedly provided with a convex ring, the inner side of the lower spring pad is fixedly provided with an inner clamping ring used for clamping the convex ring and preventing the bolt from dropping, and after the nut is unscrewed, the spring jacks up the bolt and makes the bolt separated from the lower die. The die clamping screw arranged on the upper die can not loose, the die clamping is convenient, the die can be clamped well by directly screwing the bolt, and the production efficiency is high.

Owner:GUANGDONG SANHE PILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com