Patents

Literature

568 results about "Cement composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cementitious composites having wood-like properties and methods of manufacture

InactiveUS20080099122A1Harder to saw, nail or screwLow densityPlastic recyclingLaminationPorosityBuilding product

A method of manufacturing a cementitious composite includes: (1) forming mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) causing or allowing the hydraulic cement to hydrate to form the cementitious composite. Such a process yields a cementitious composite that is suitable for use as a wood substitute. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

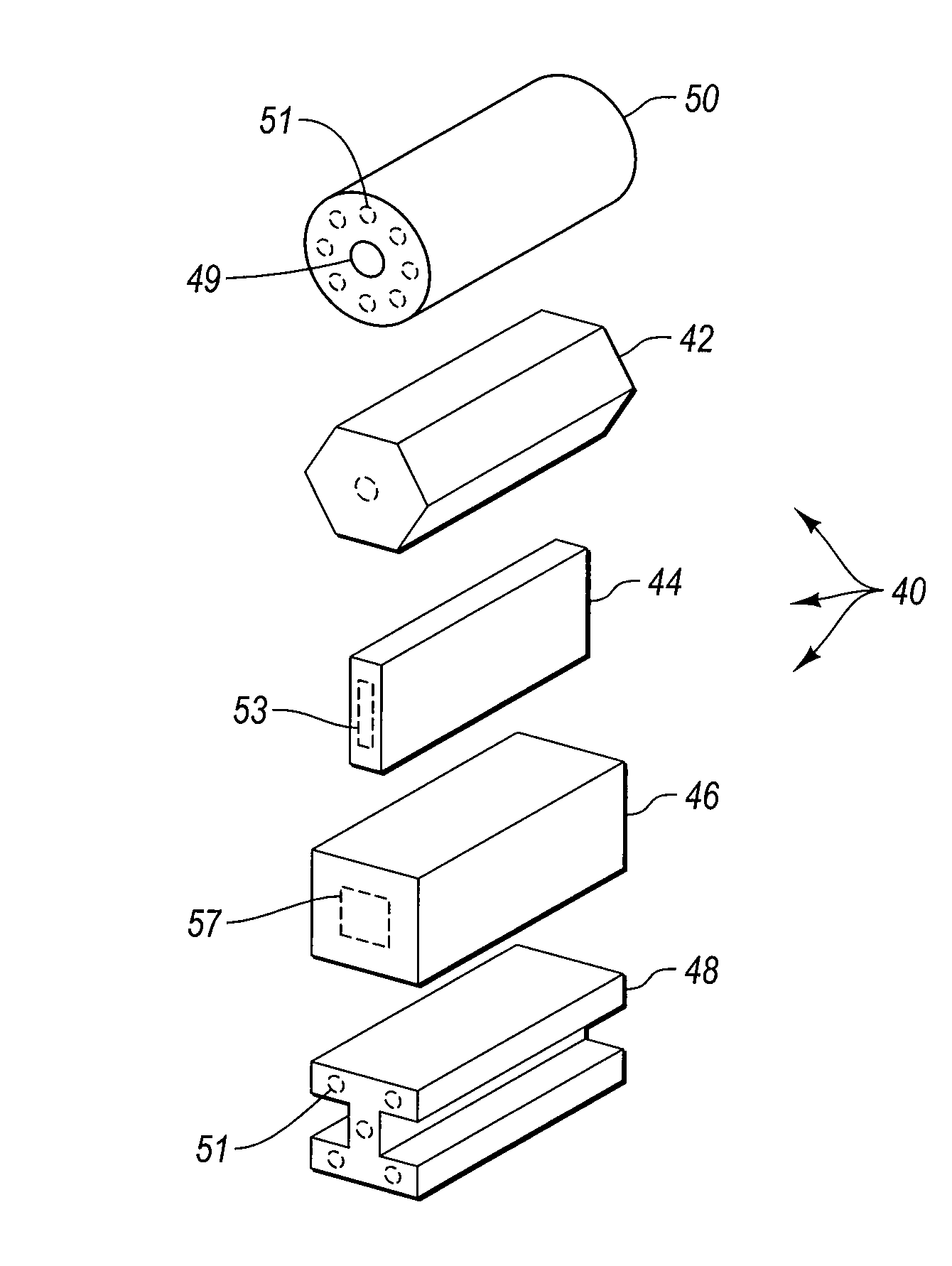

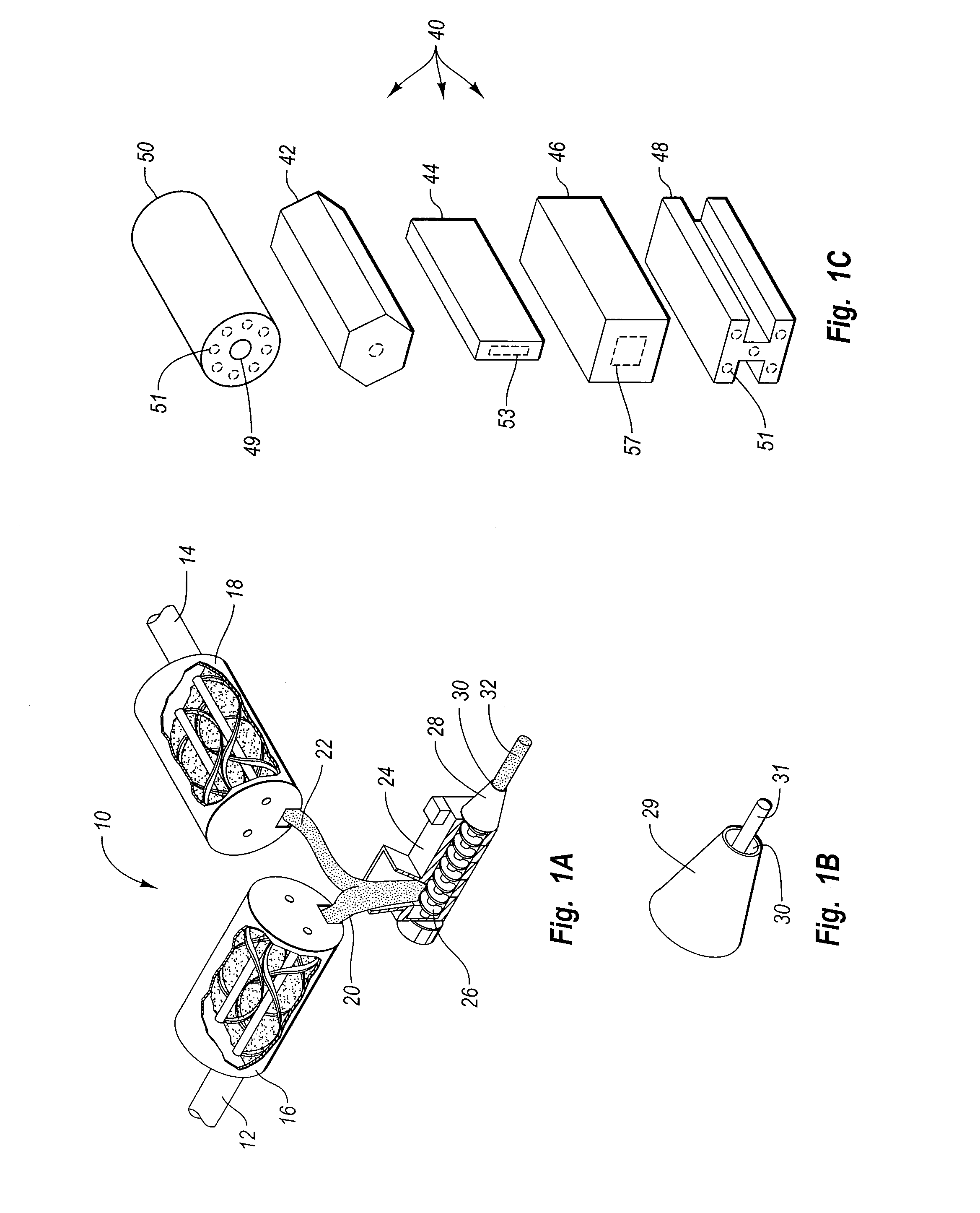

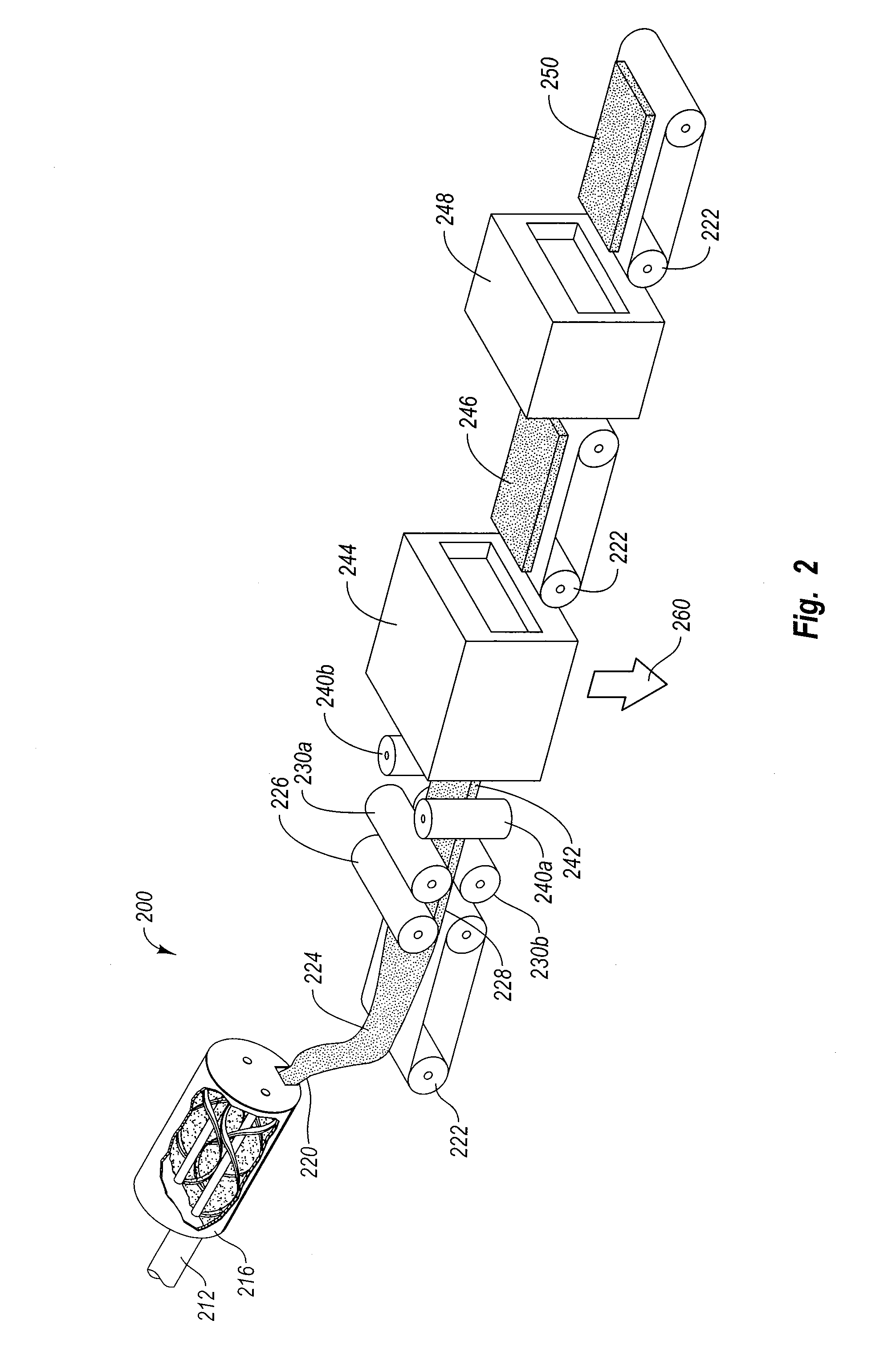

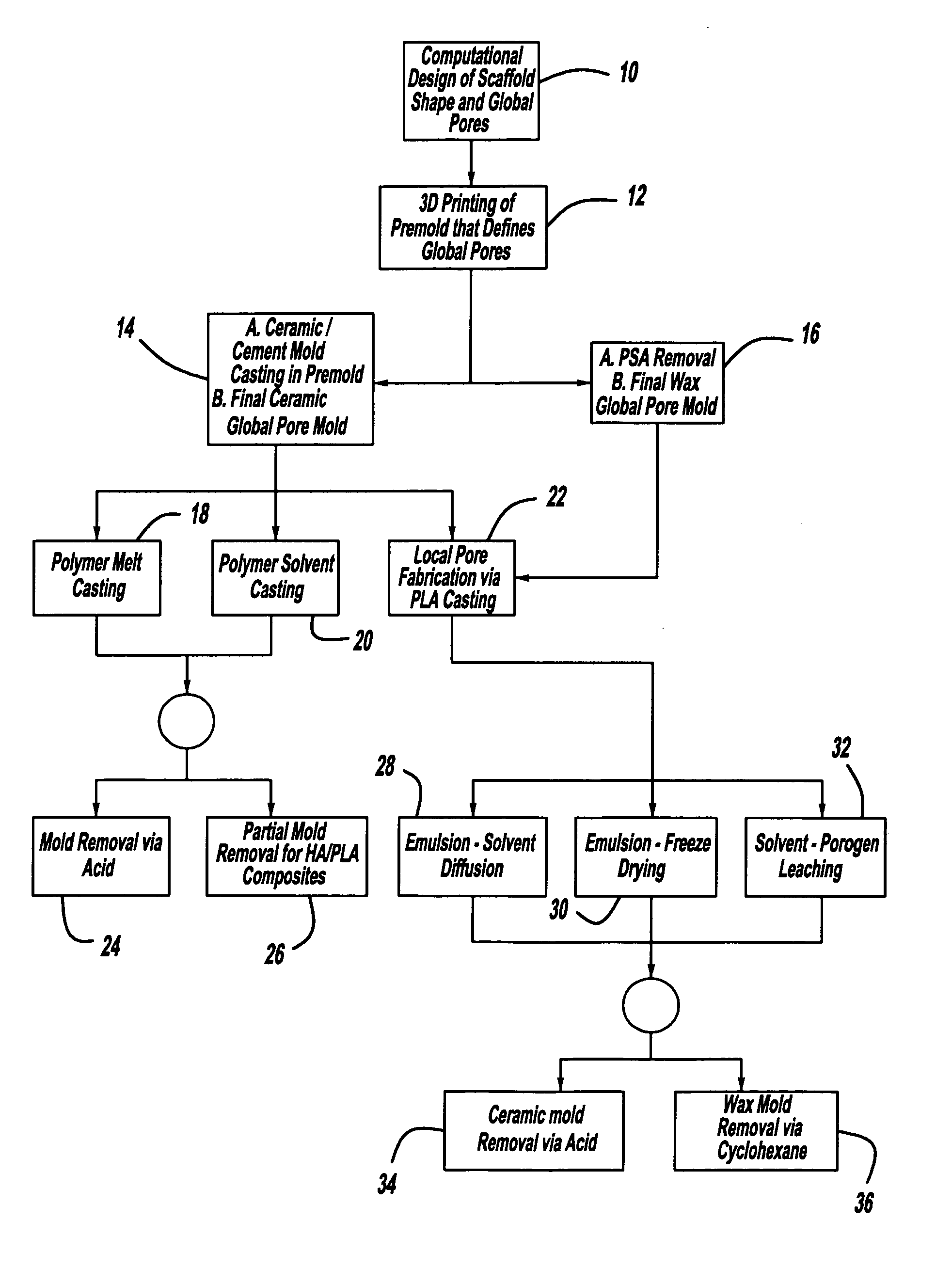

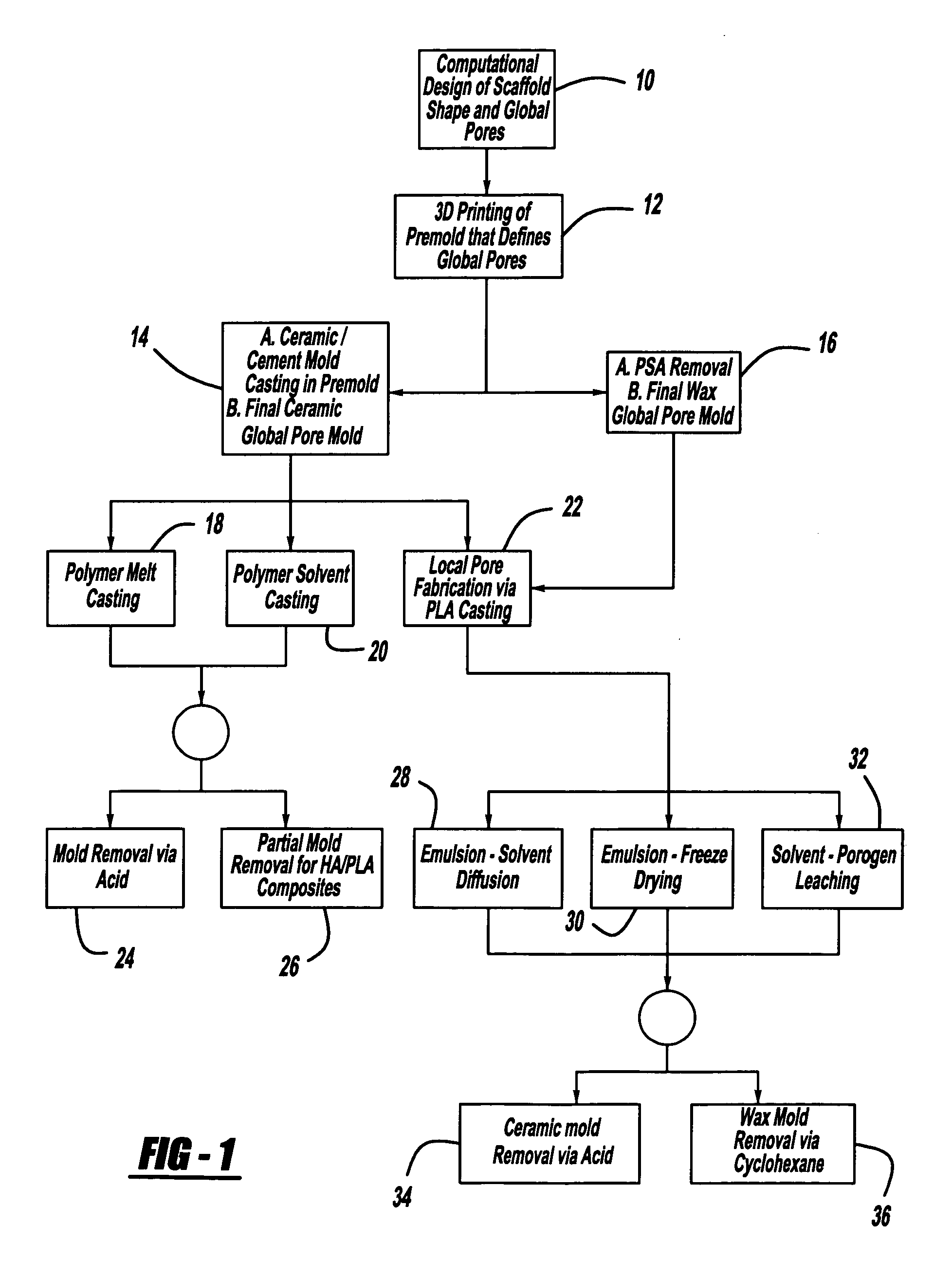

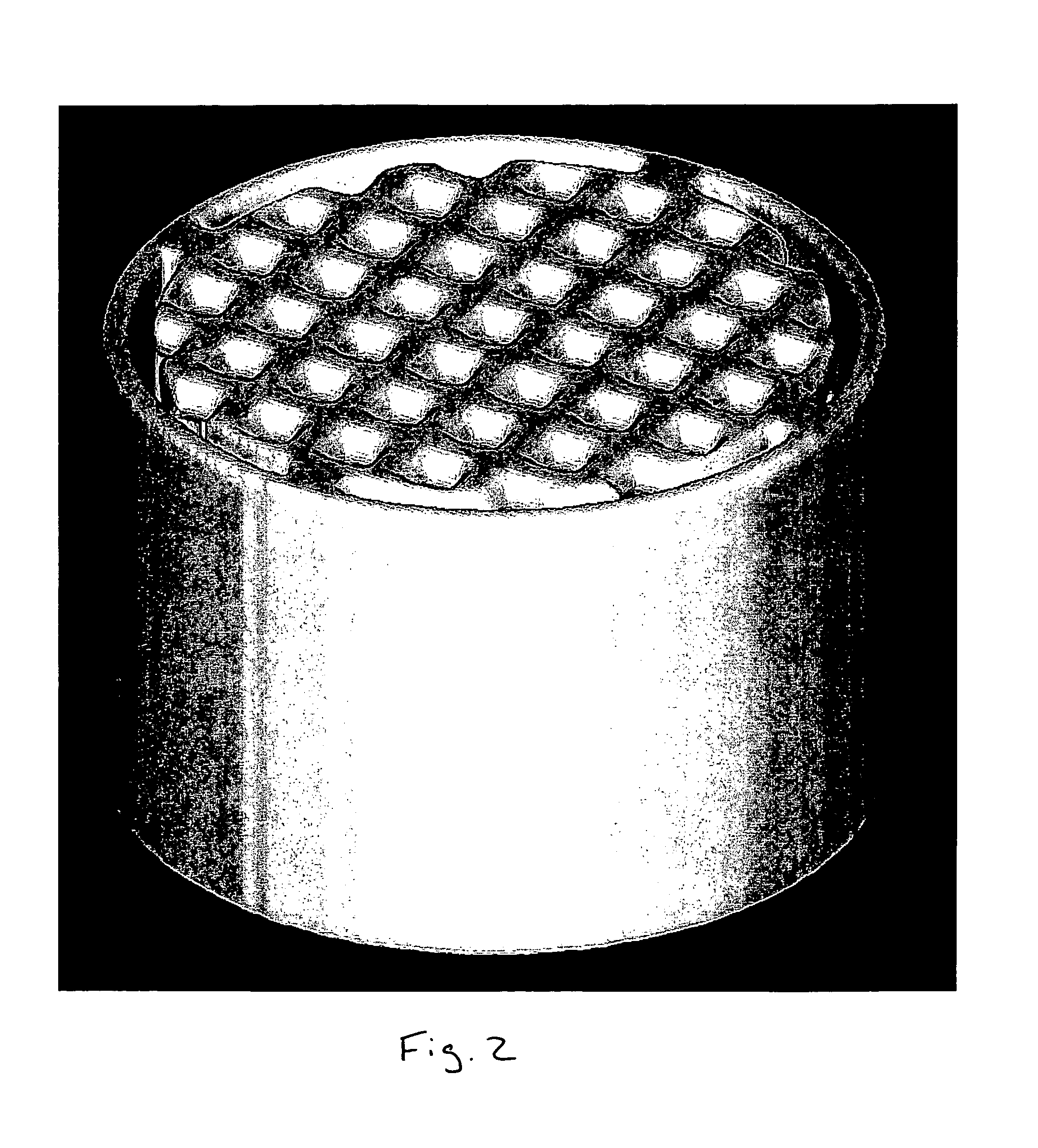

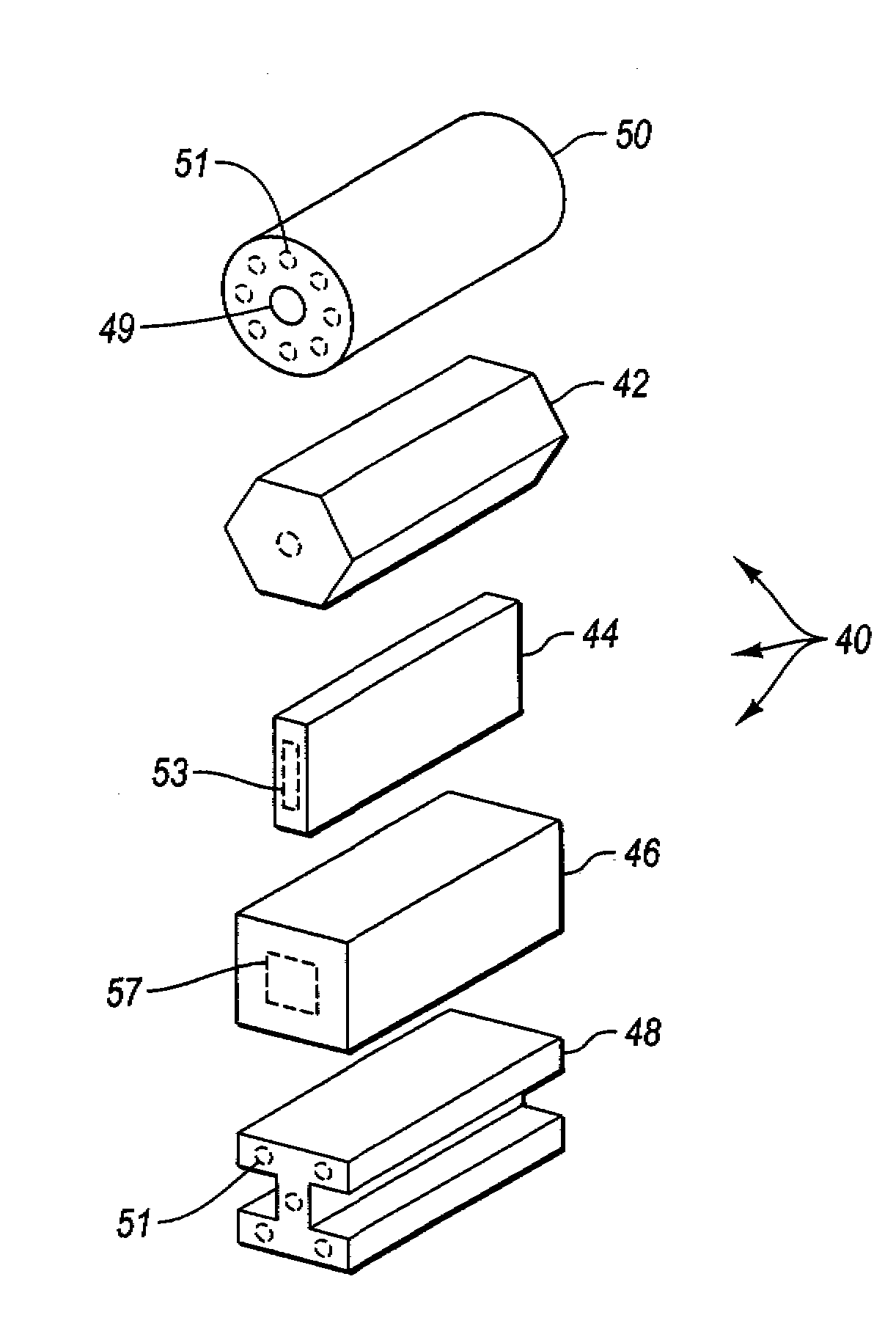

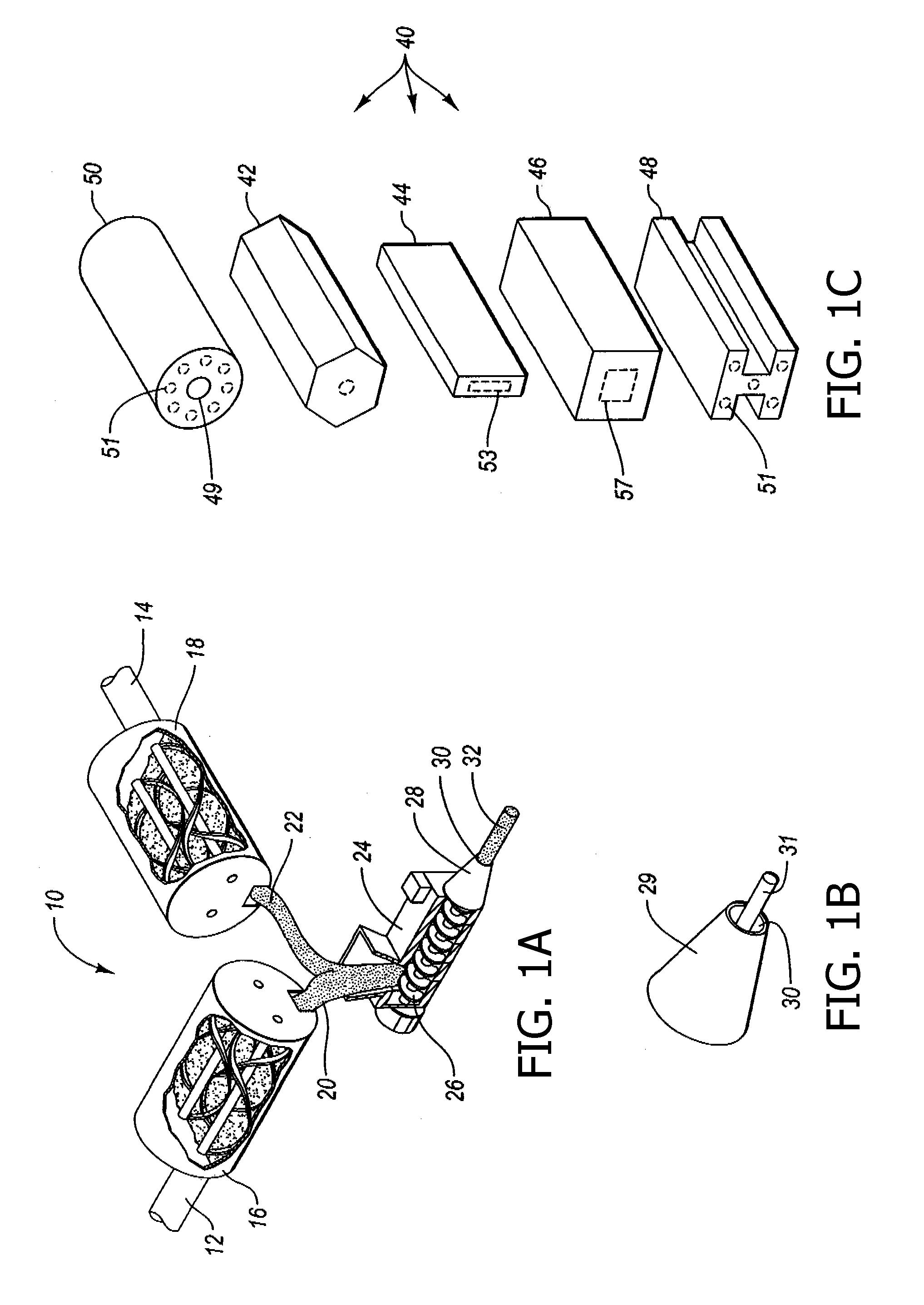

Controlled local/global and micro/macro-porous 3D plastic, polymer and ceramic/cement composite scaffold fabrication and applications thereof

InactiveUS7087200B2Easy to controlImprove interconnectivityMouldsJoint implantsManufacturing technologyFree form

An indirect solid free form scaffold manufacturing technique is provided. More particularly, the present invention provides a set of molds, casting methods, mold removals, and surface modification techniques that are compatible with image-based design methods and with solvent, melt, and slurry casting of polymers and ceramics.

Owner:RGT UNIV OF MICHIGAN

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

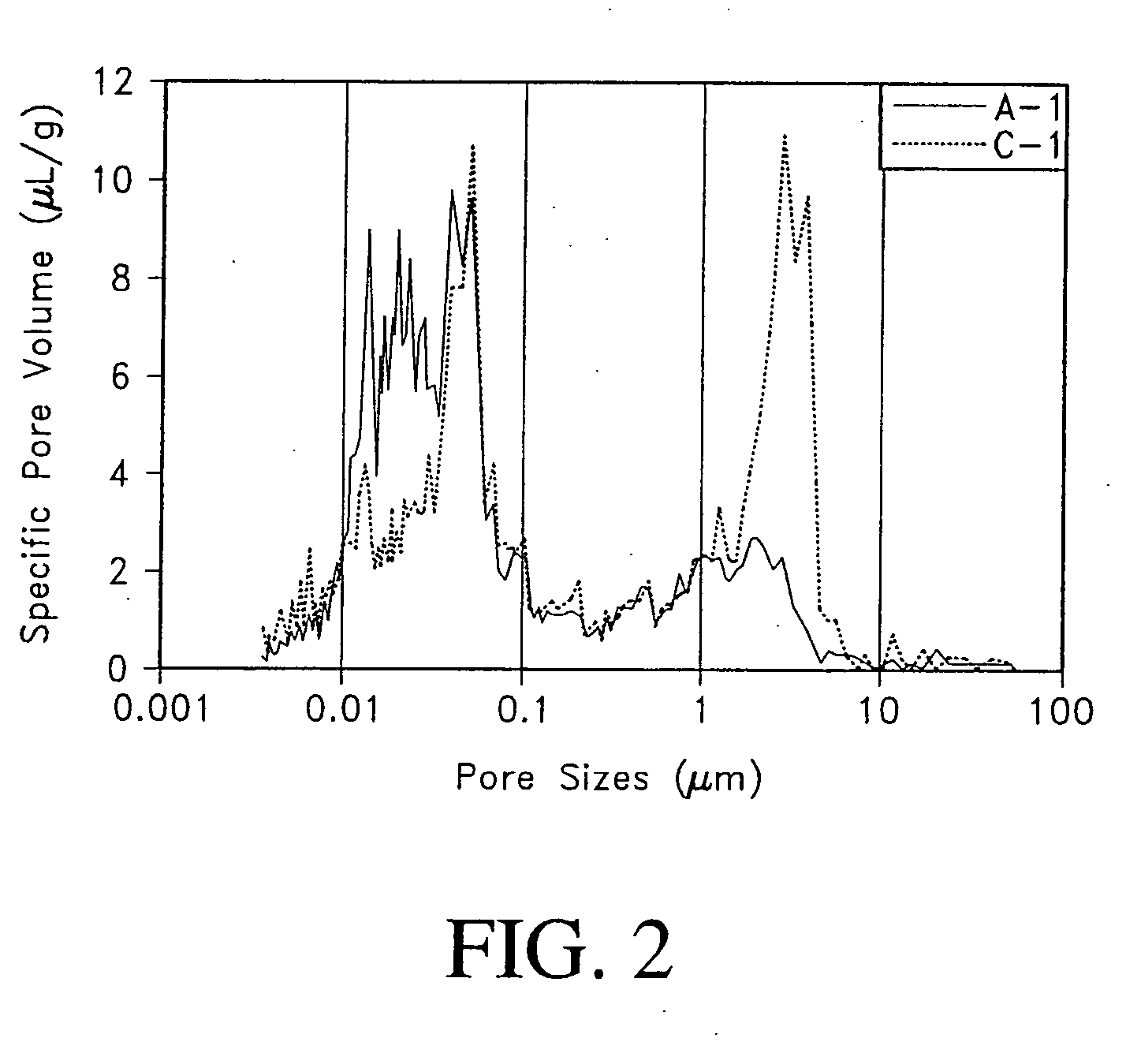

Durable medium-density fibre cement composite

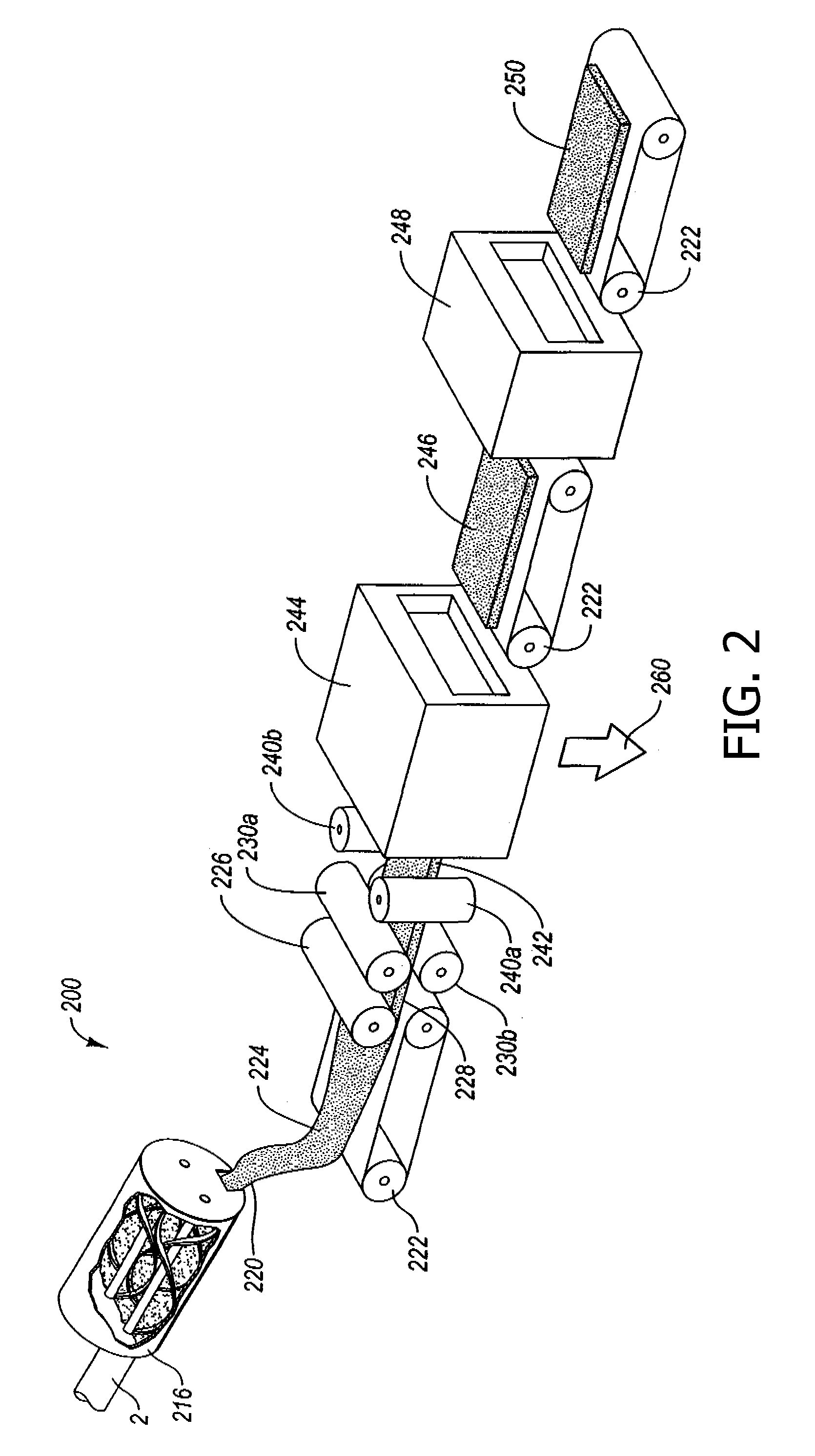

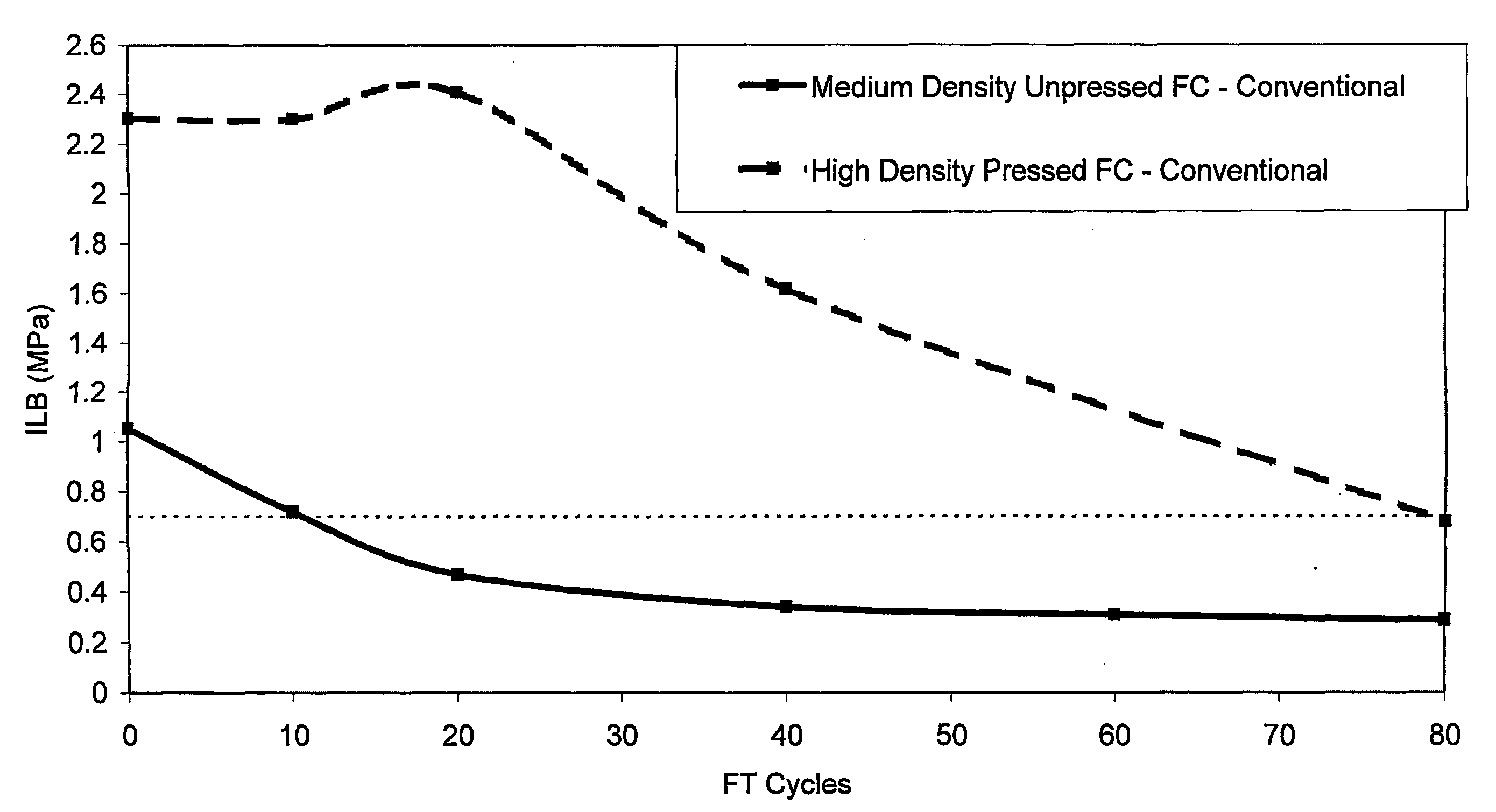

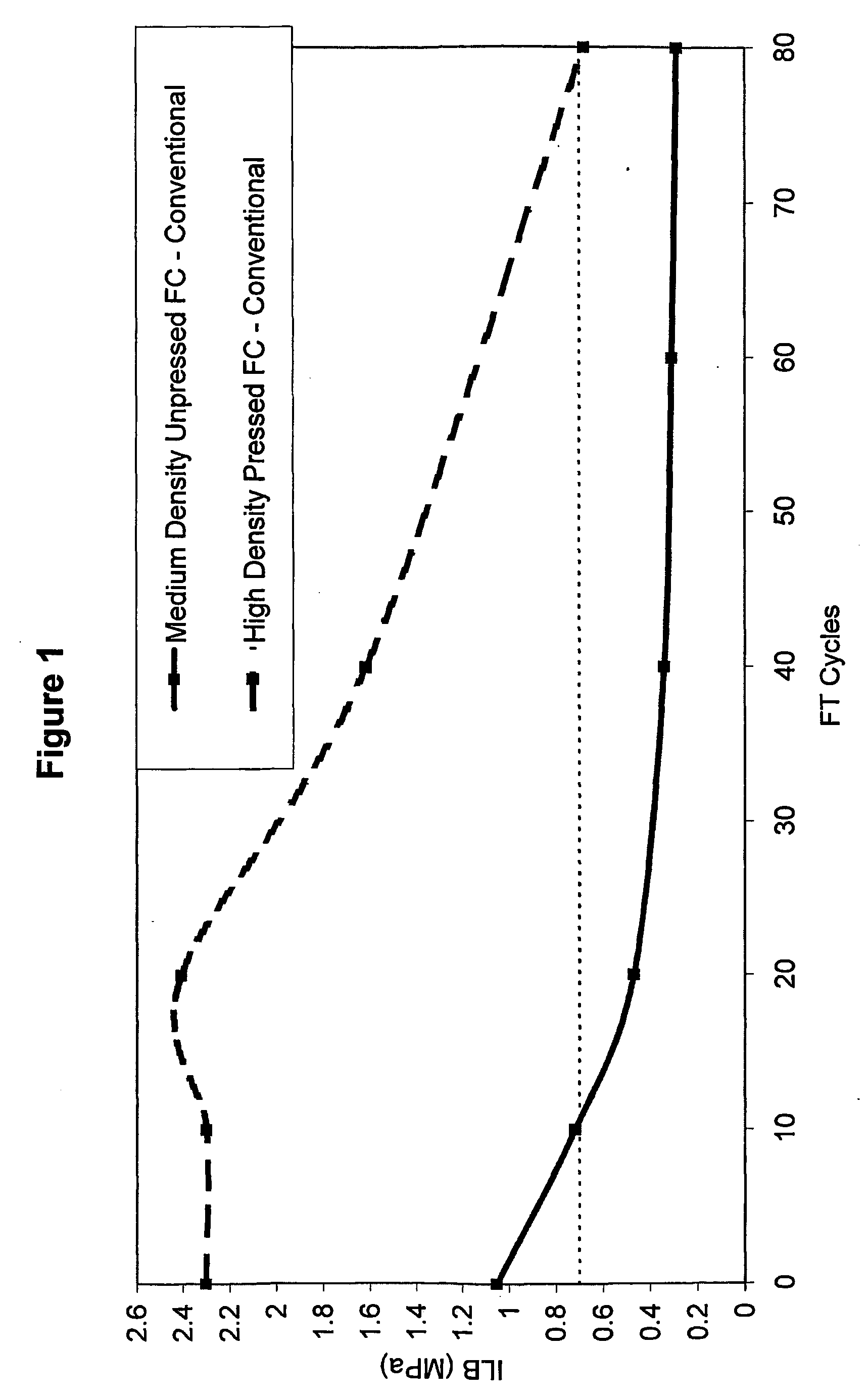

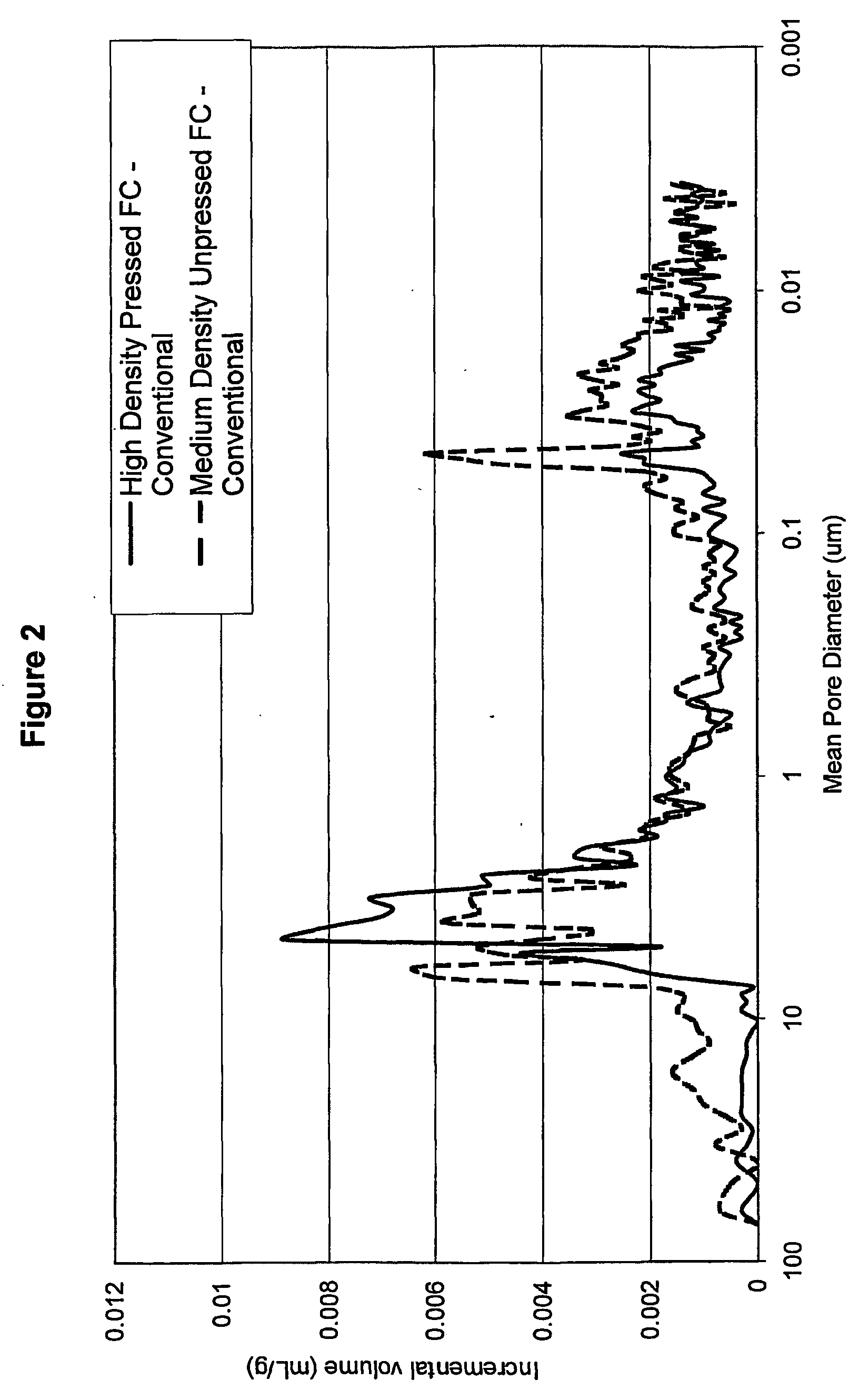

ActiveUS20060288909A1Simple materialIncreased durabilitySolid waste managementCeramic shaping apparatusHigh densityCement composites

A cementitious product and method of modifying the properties of a low or medium density FRC product by providing a predetermined pore size distribution. The pore size distribution is obtained such that in critical zones of the distribution, the pore volume is substantially equivalent to or less than the pore volume in a respective critical zone of a conventional high density FRC product. The resultant material provides improved properties over conventional medium density FRC products, in particular improved freeze / thaw durability and / or improved workability.

Owner:JAMES HARDIE TECH LTD

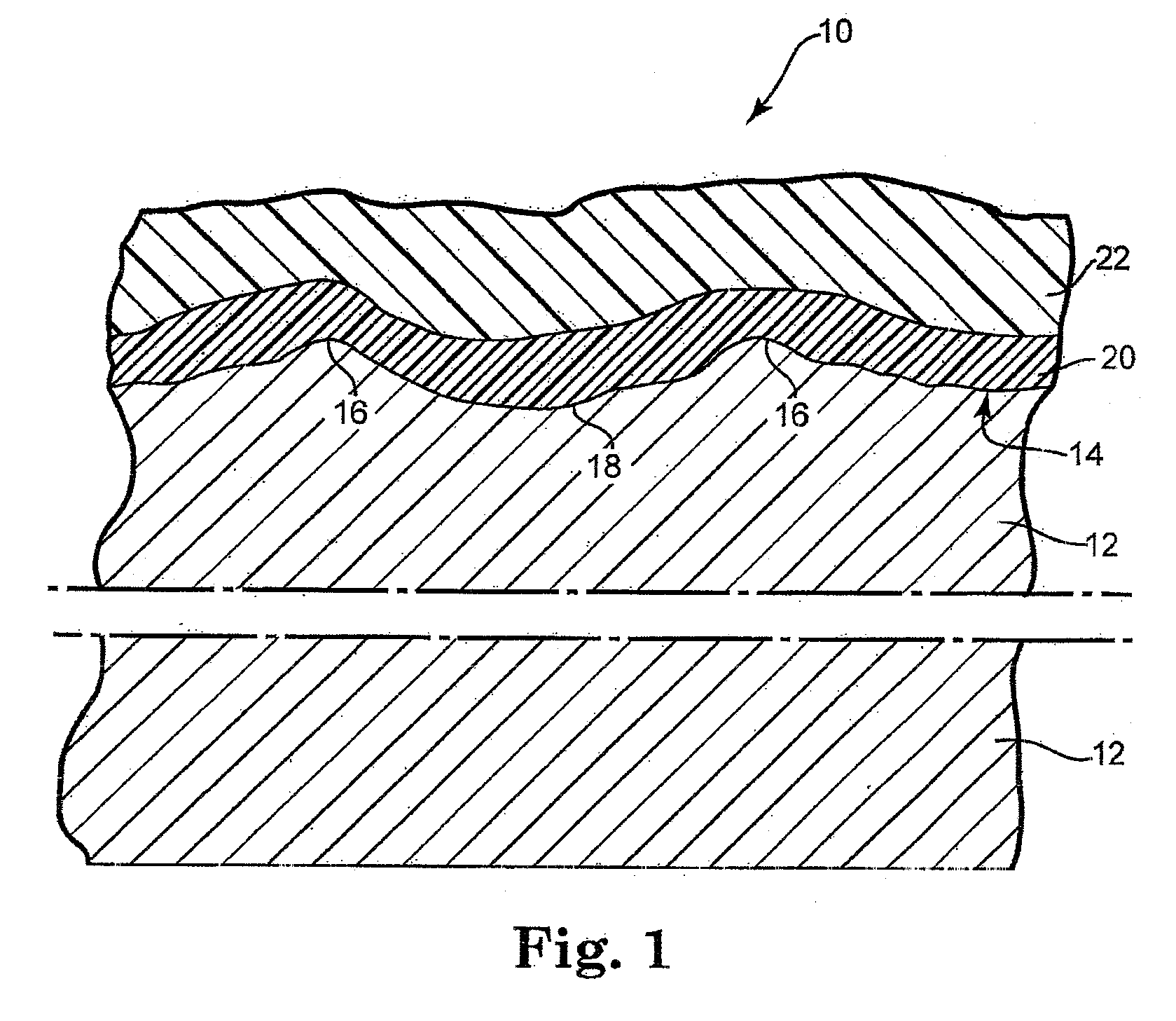

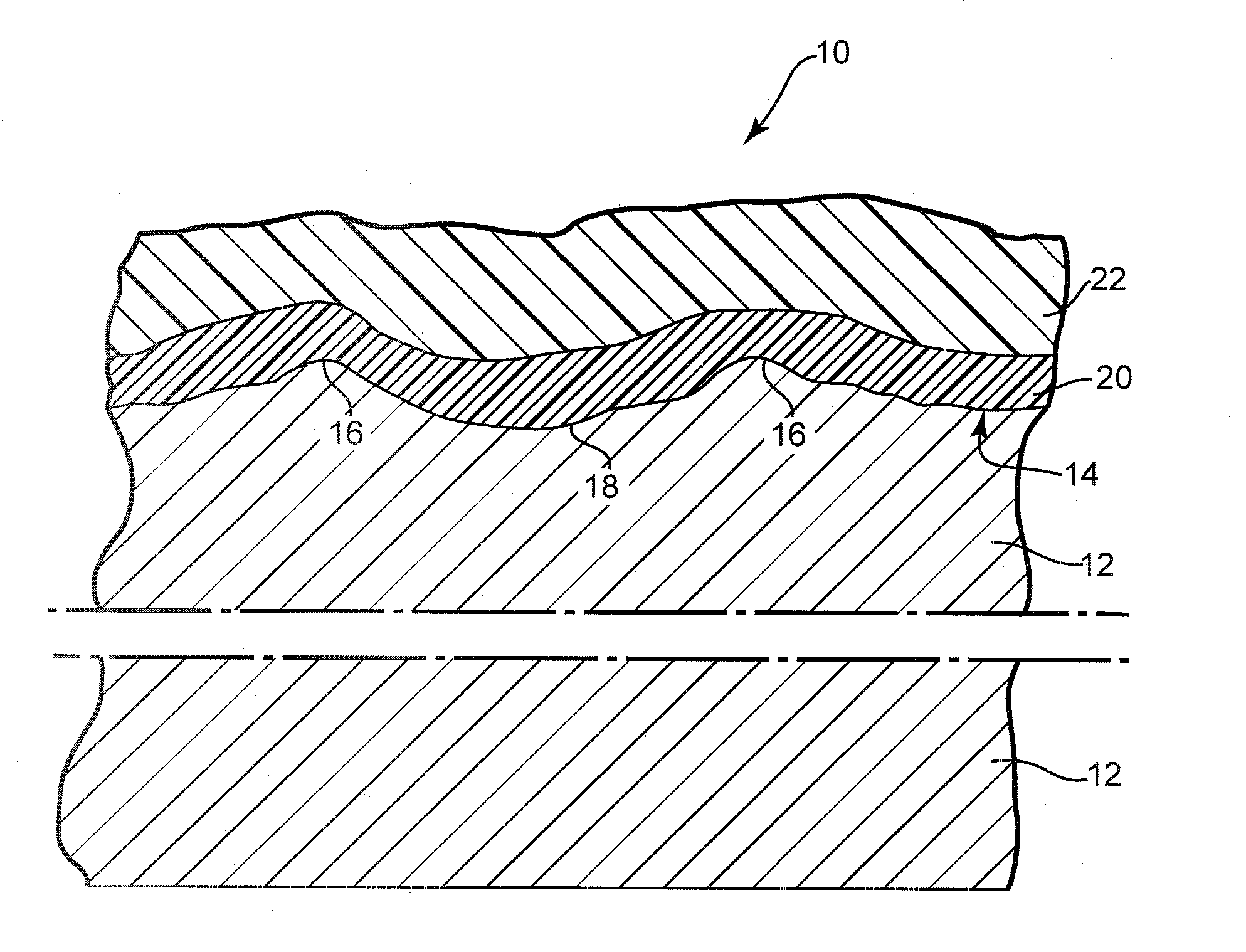

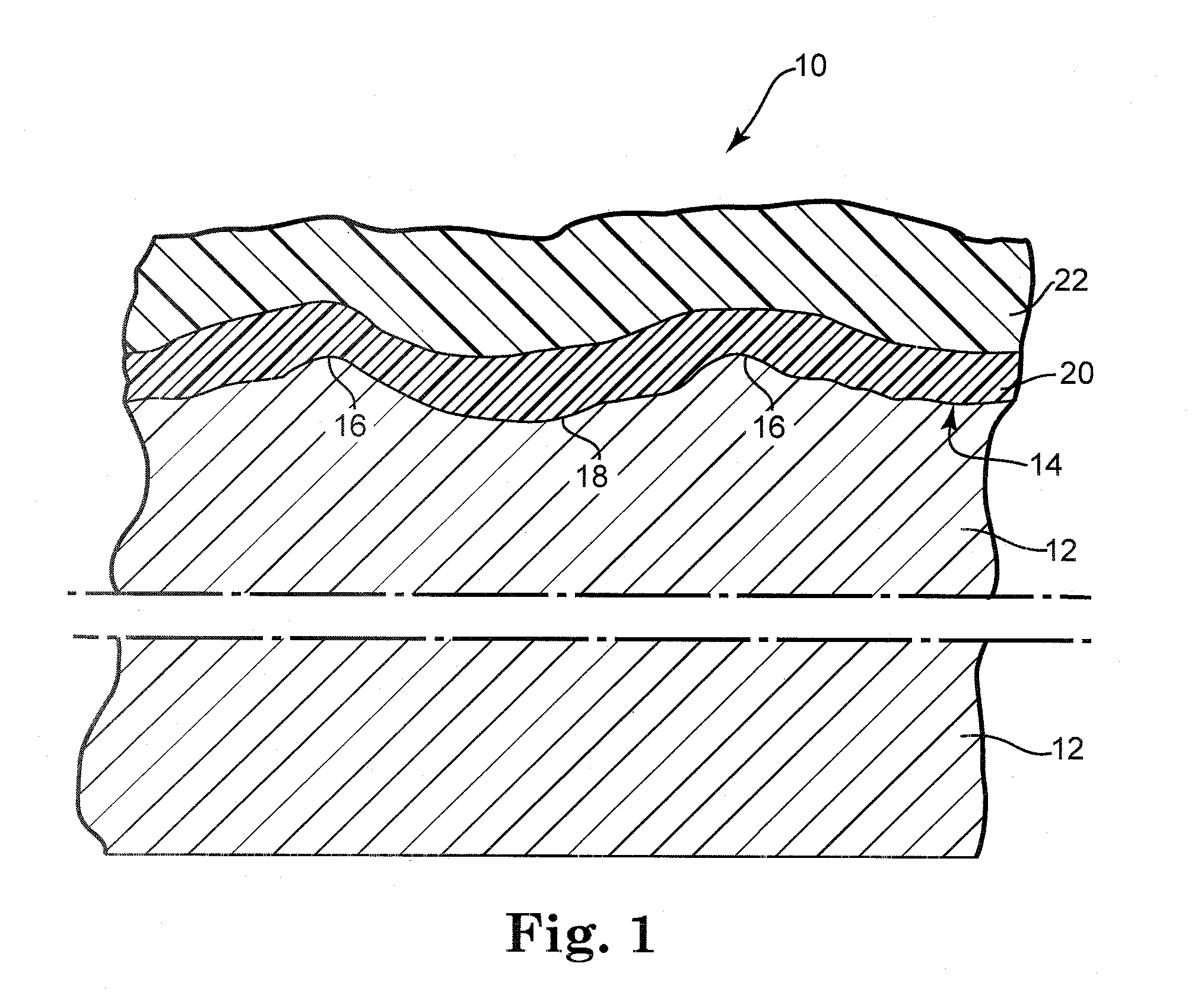

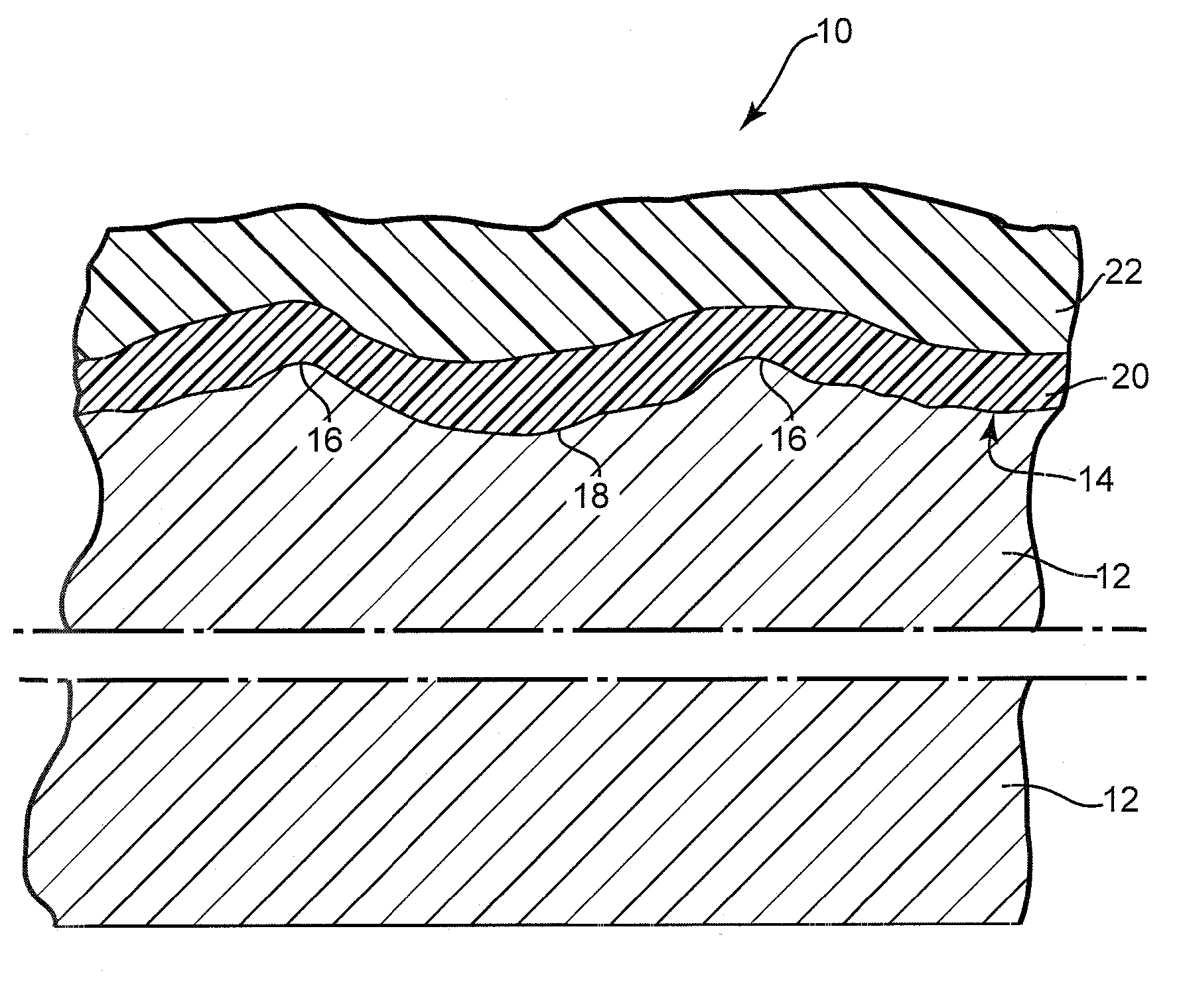

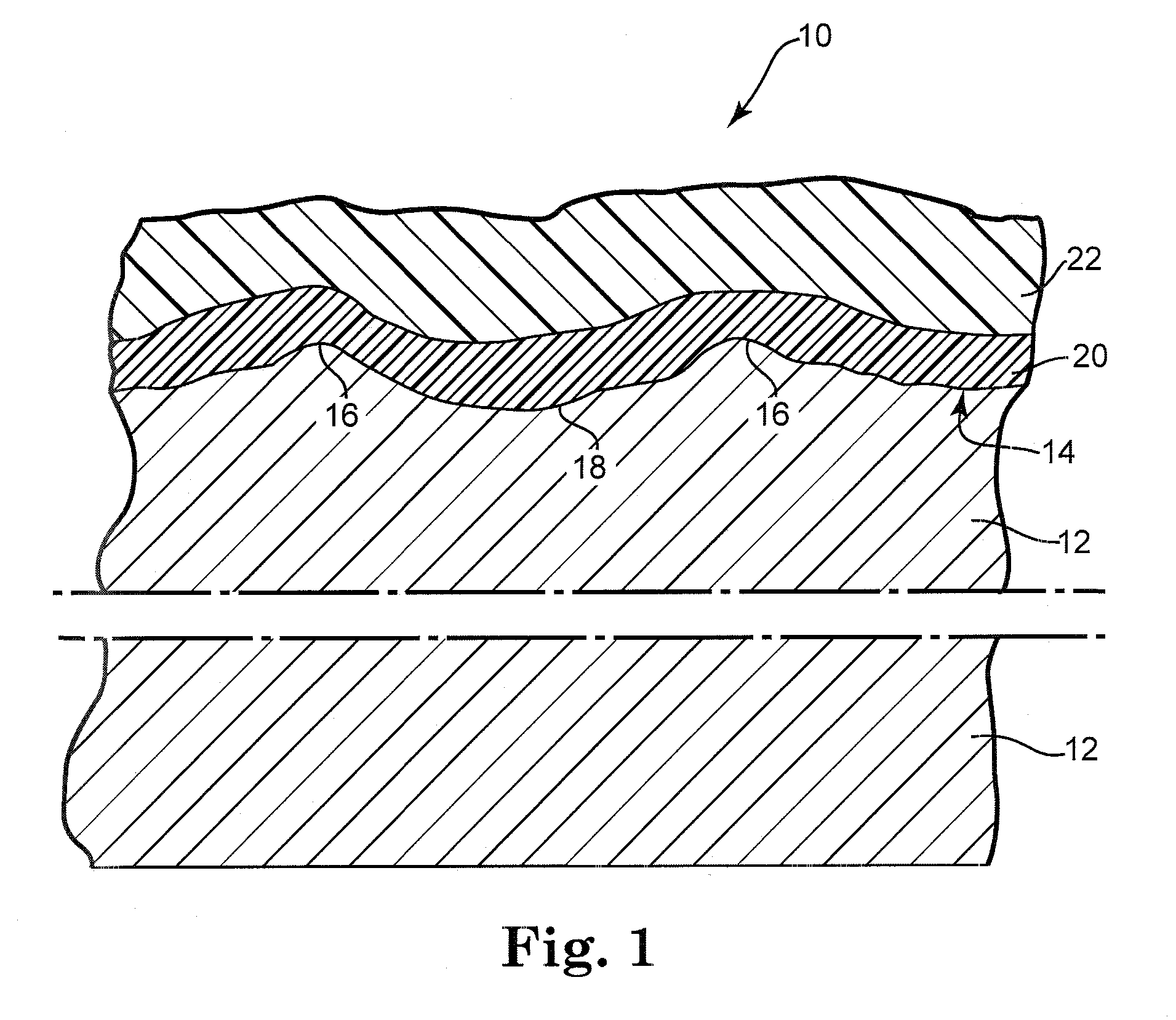

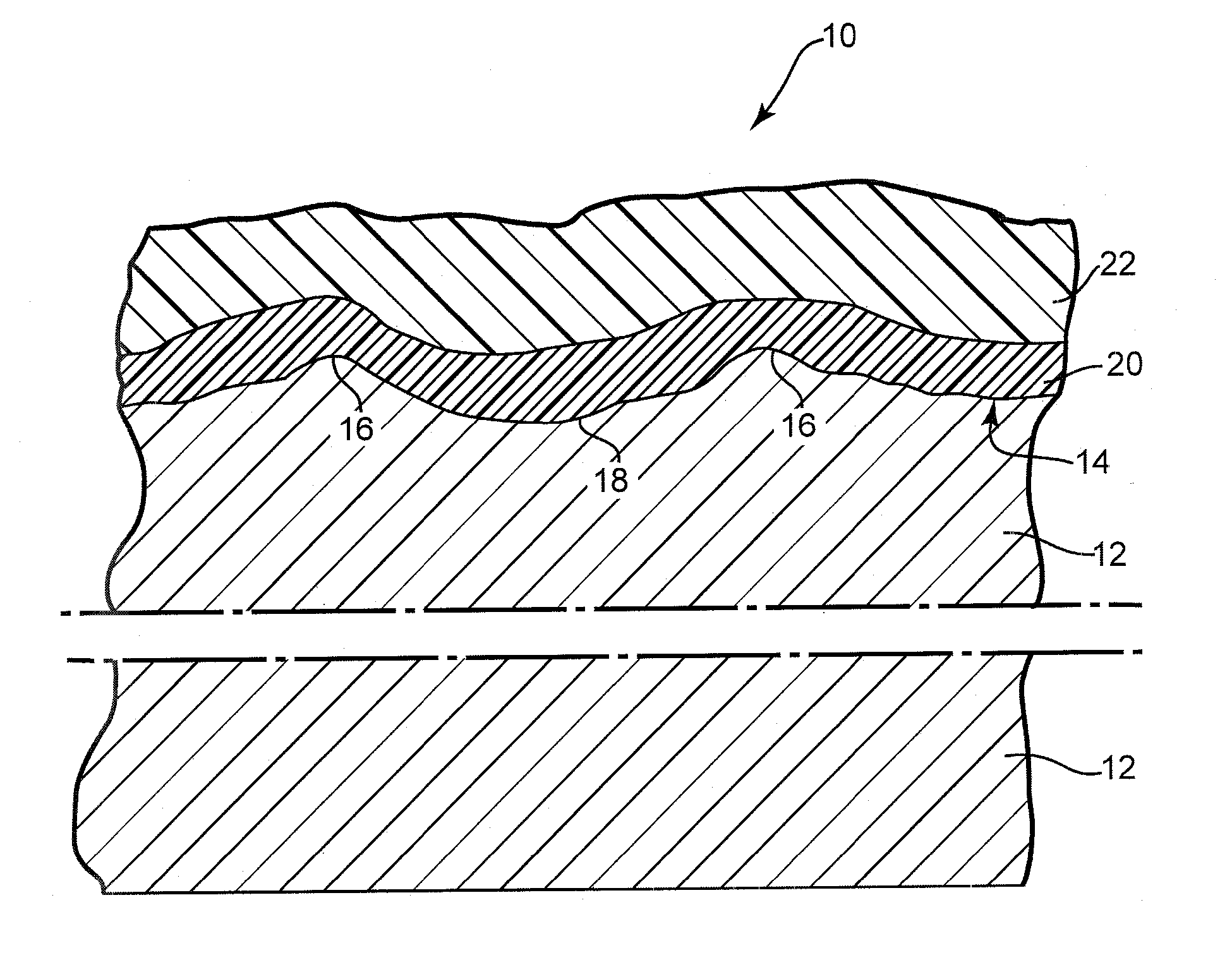

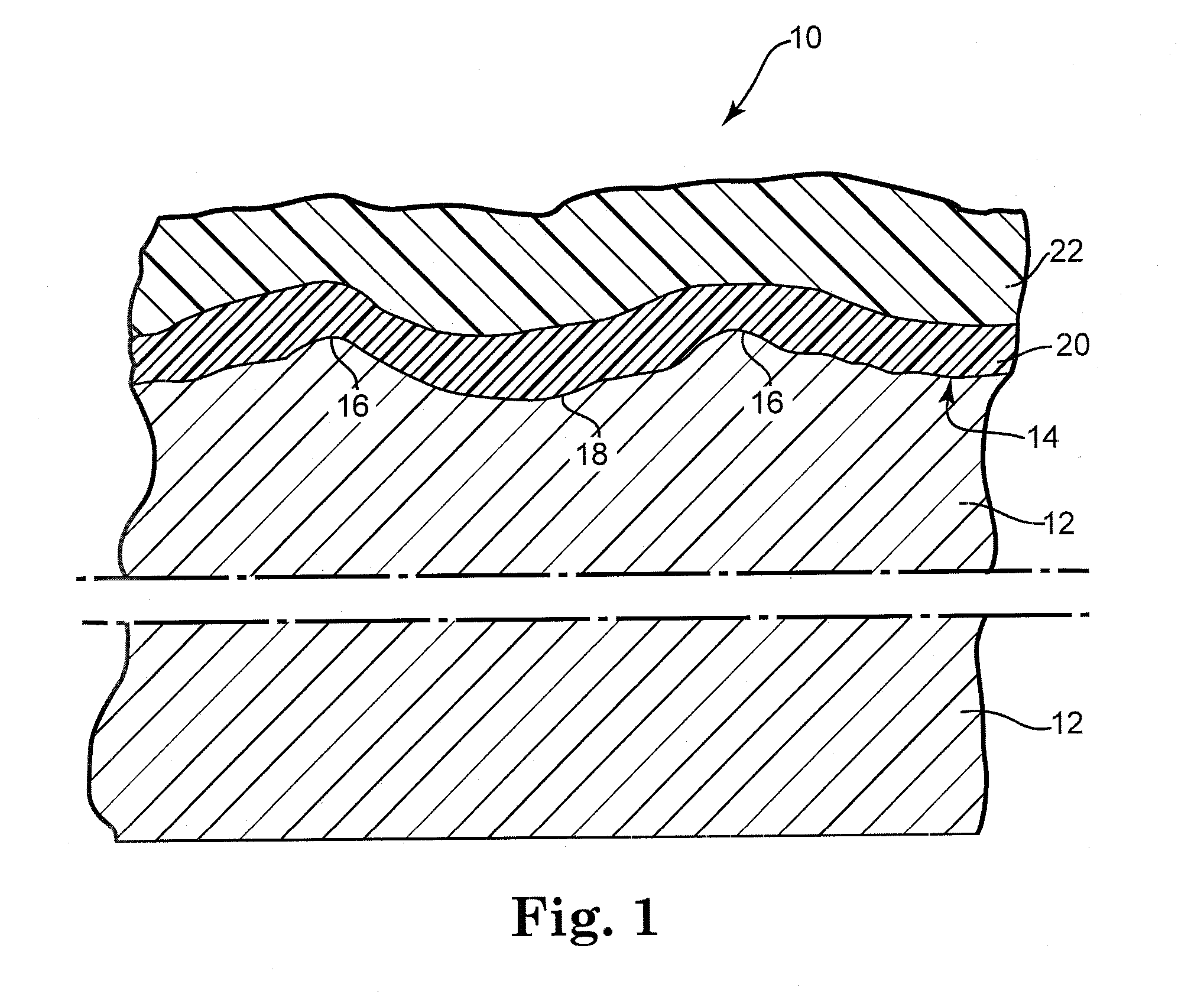

Mat-Faced Cementitious Article and Method for Preparing Same

InactiveUS20100143682A1Solid waste managementSynthetic resin layered productsCement compositesVolumetric Mass Density

A cementitious composite article comprising (a) a cementitious core, (b) a skim coat cementitious layer in contact with the cementitious core having a density greater than the cementitious core, and (c) a fibrous mat comprising (i) microfibers and (ii) continuous fibers having a length of about 0.6 cm or more, wherein the fibrous mat comprises an inner surface in contact with the skim coat cementitious layer; as well as a method for manufacturing same.

Owner:UNITED STATES GYPSUM CO

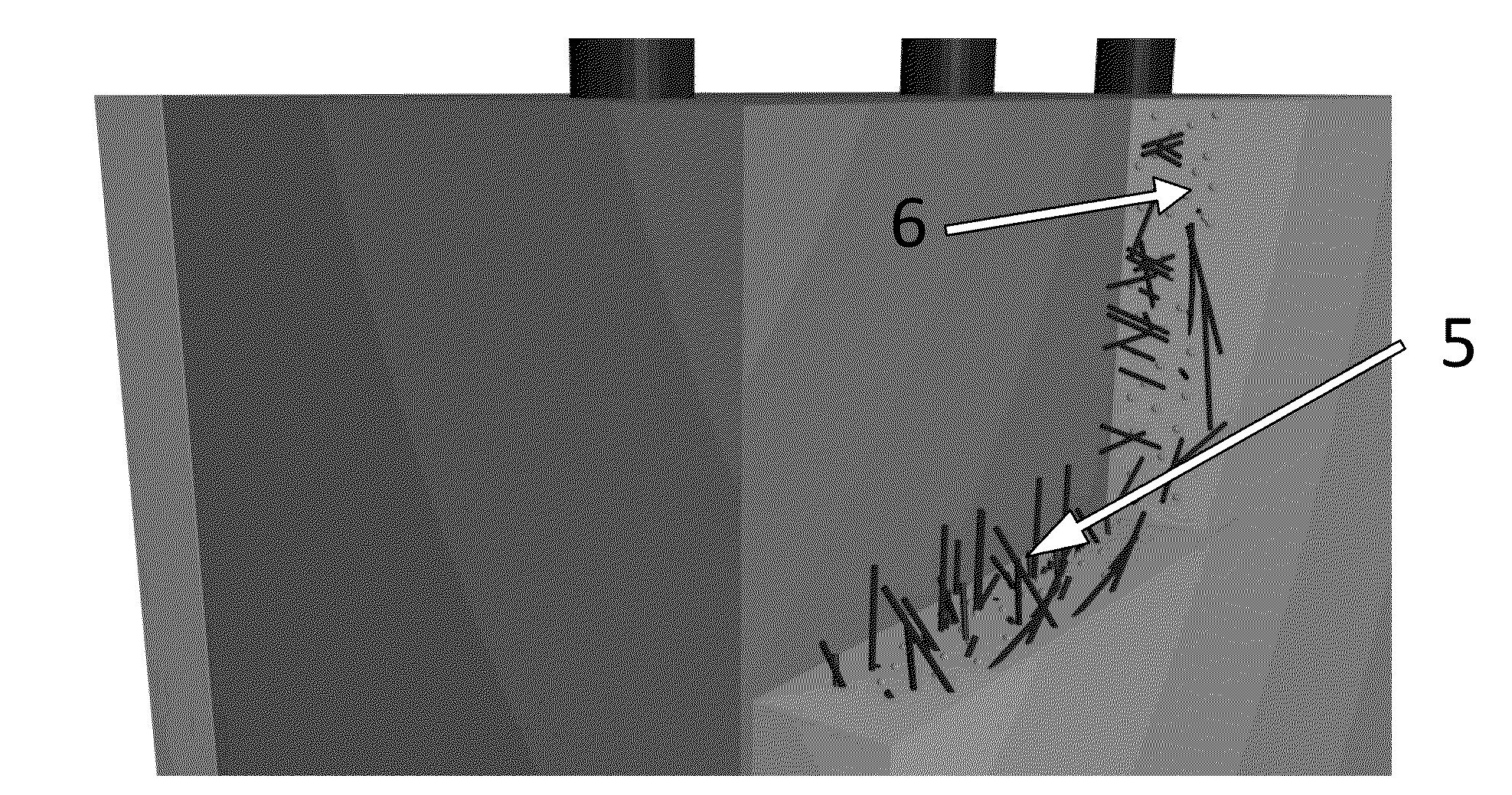

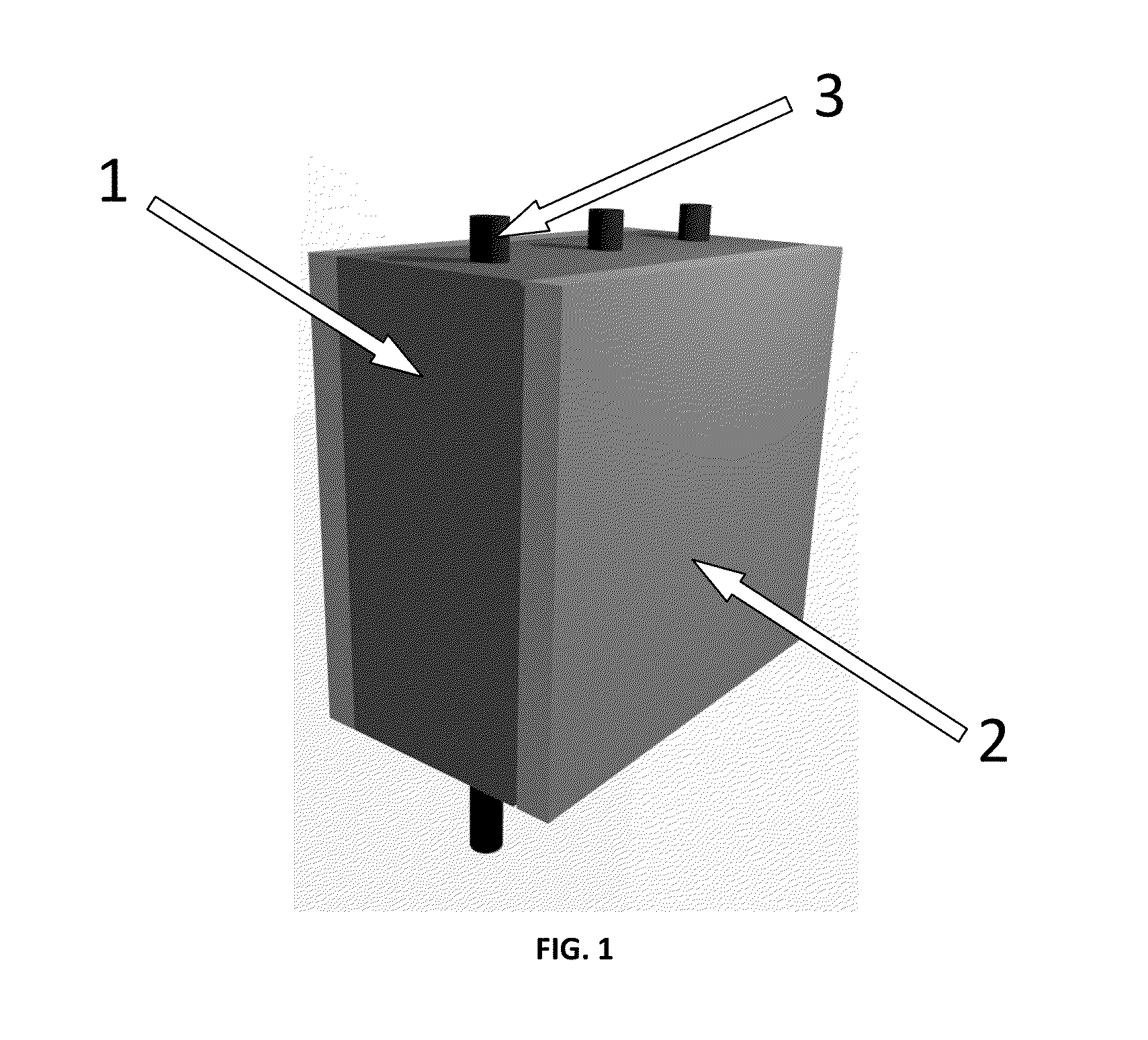

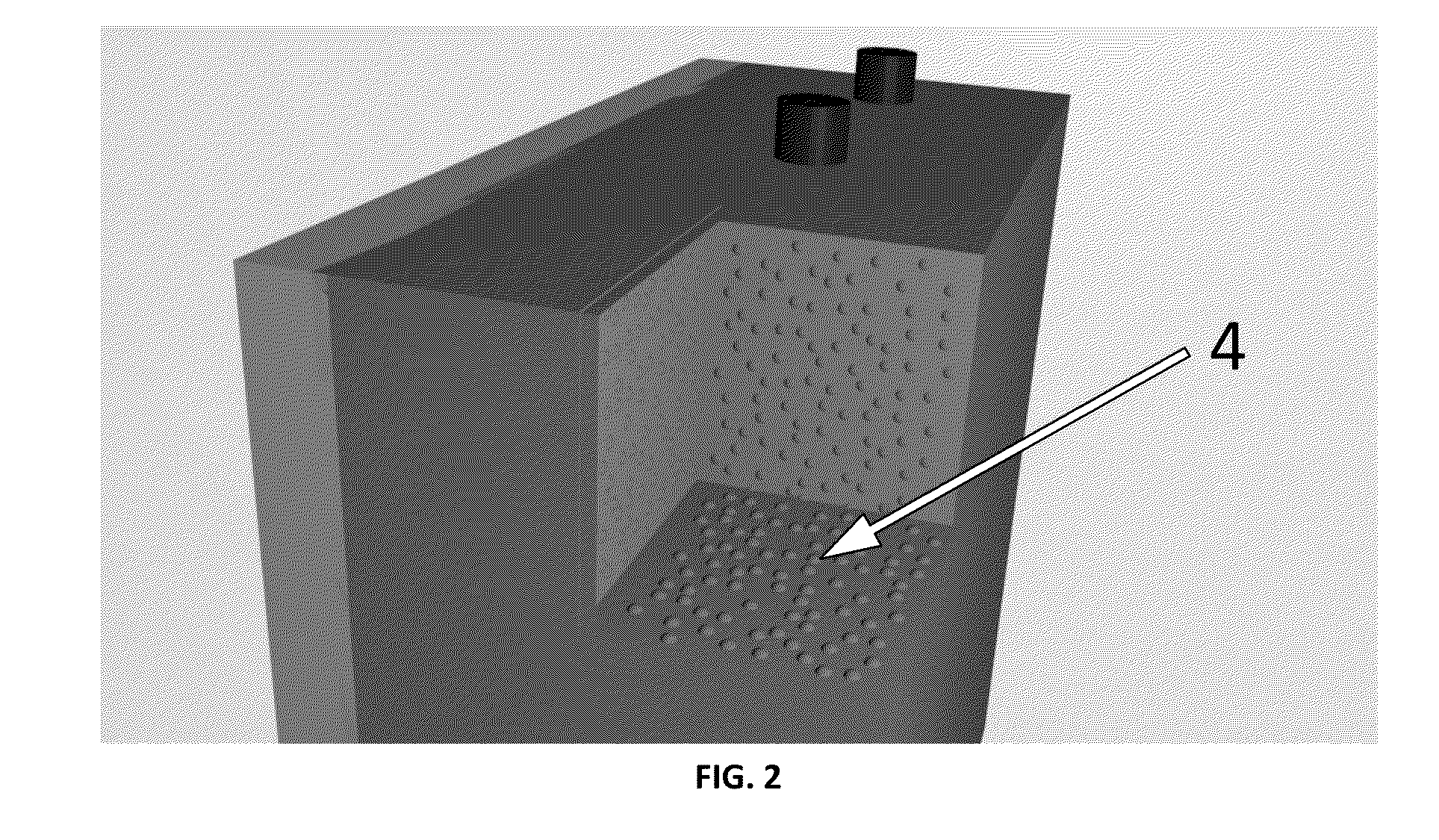

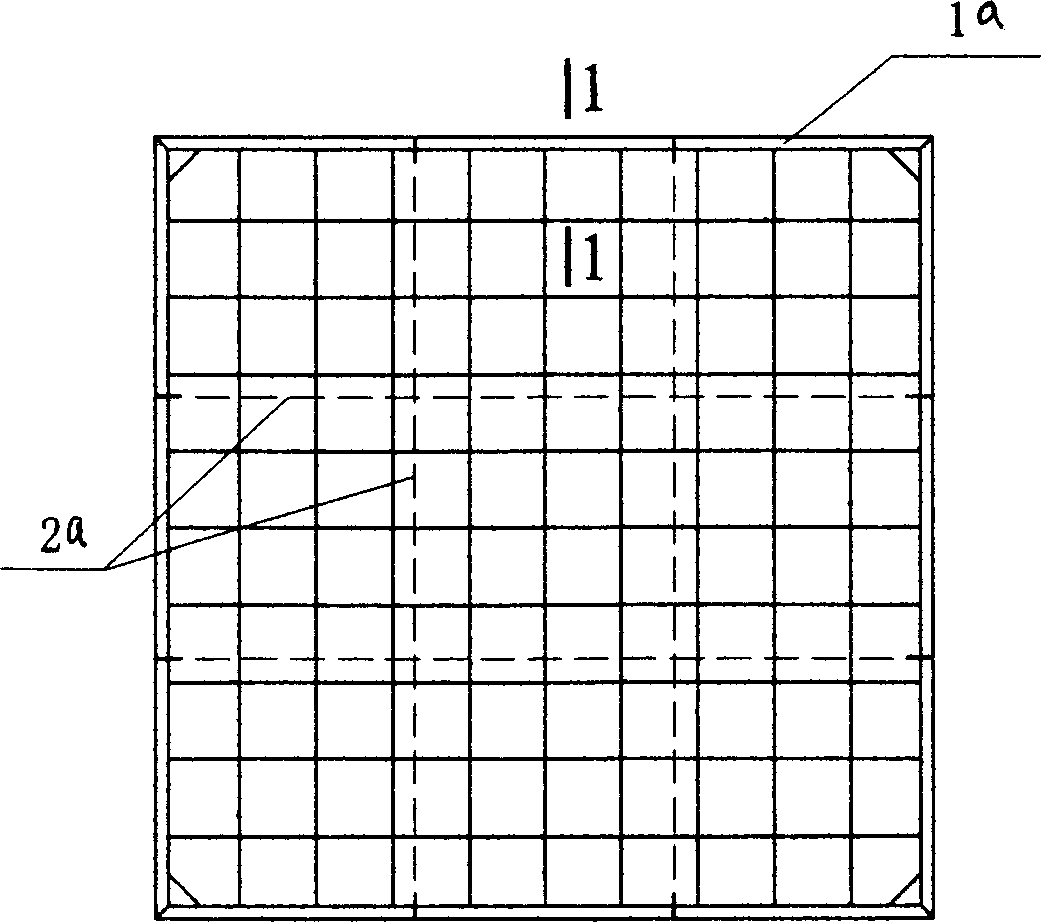

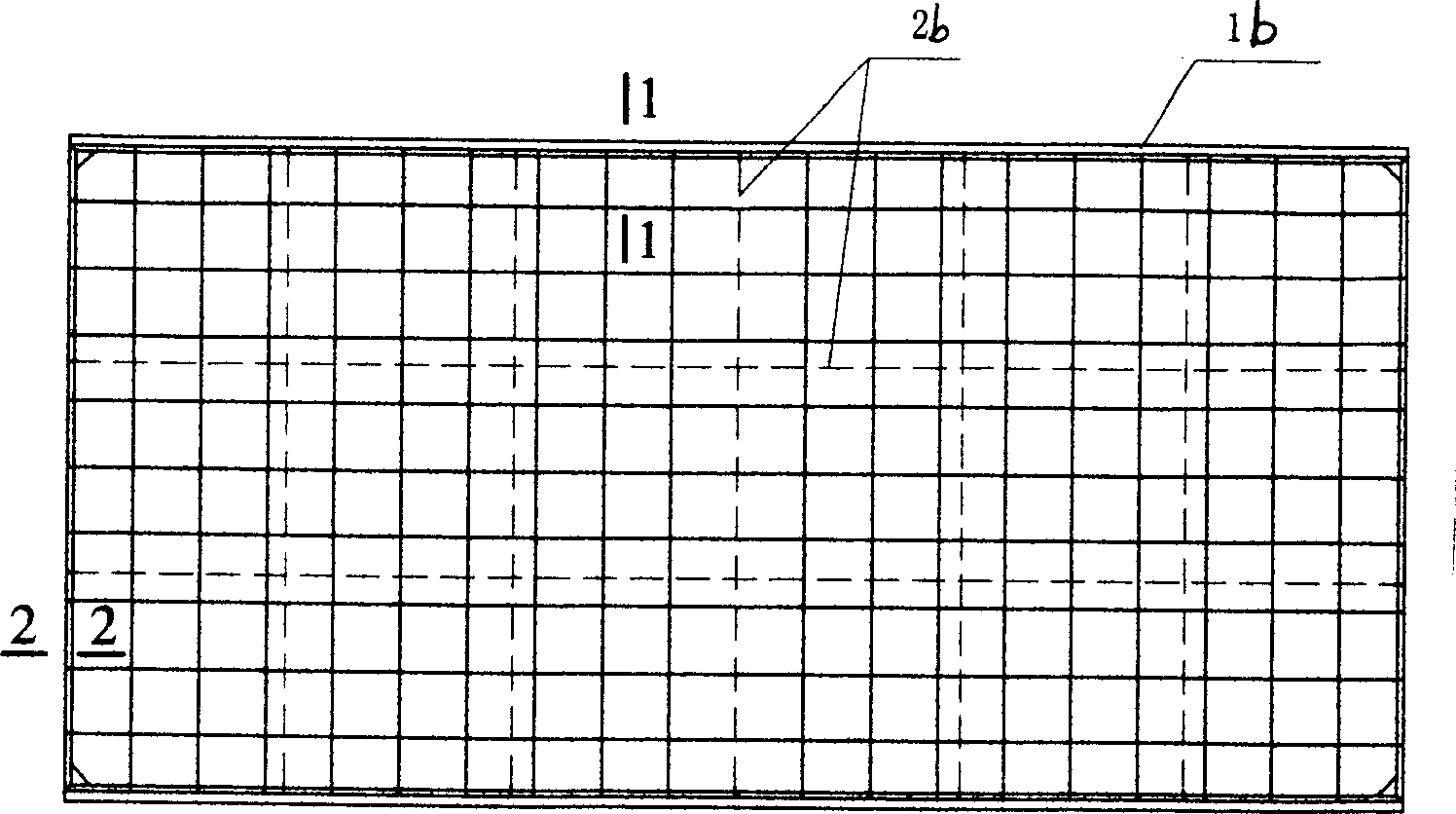

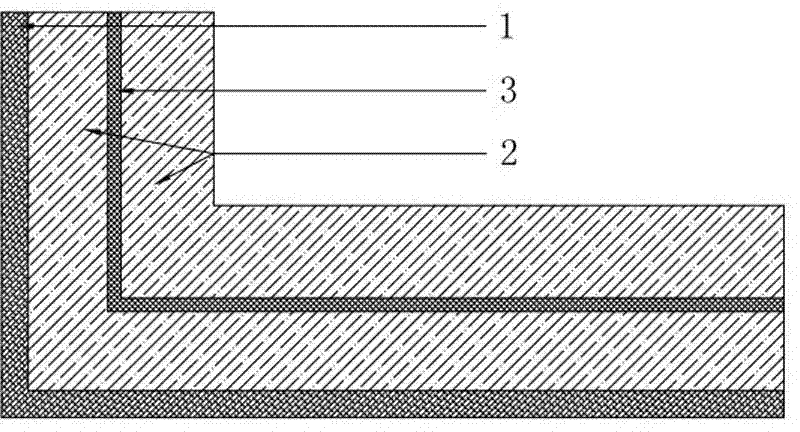

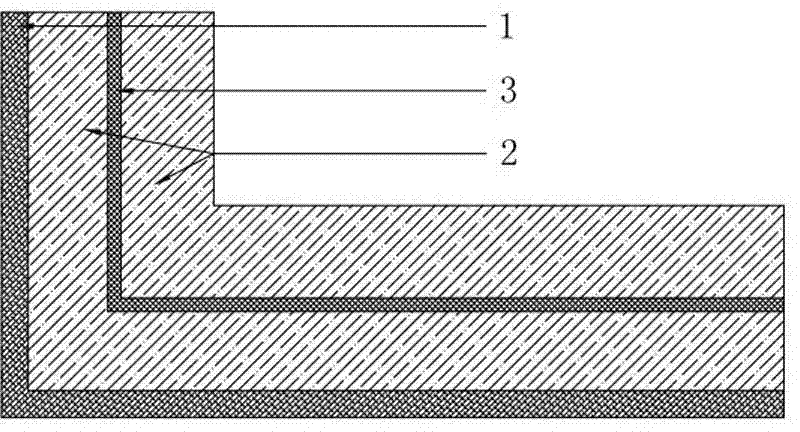

Fiber reinforced cement composite concrete precast construction member and production method thereof

InactiveCN102561584ARealize industrialized prefabrication productionImprove product qualityMouldsClimate change adaptationCement compositesArchitectural engineering

The invention relates to a fiber reinforced cement composite concrete precast construction member (PC-FRC) and a production method thereof, which are suitable for engineering of building exterior wall decoration, building structure containment, and energy conservation and heat preservation, are particularly suitable for prefabricated housing industrialization projects and are suitable for the fields of people's livelihood such as natural disaster prevention and post-disaster reconstruction. The fiber reinforced cement composite concrete precast construction member comprises a decorative finish layer, a fiber reinforced cement layer, a concrete structure layer, a heat preservation layer and a steel reinforcement framework, wherein the fiber reinforced cement layer is composited on the decorative finish layer and is connected with the concrete structure layer; the heat preservation layer is laid in the concrete structure layer and is completely coated by the concrete structure layer; the steel reinforcement framework is laid in the concrete structure layer; and the fiber reinforced cement layer, the heat preservation layer and the concrete structure layer are composited and molded in molds with models. According to the fiber reinforced cement composite concrete precast construction member, the connecting part of the surface of the precast construction member is provided with exposed steel reinforced bars, and the exposed steel reinforced bars are used for connecting precast pieces with building structures during building assembly; and suspension embedded pieces are laid in the concrete structure layer.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

Coating System for Cement Composite Articles

A coated article is provided that includes a cement composite substrate; and a coating system applied to the substrate. The coating system includes an epoxy-functional coating composition applied to the substrate, and a water-based coating composition, distinct from the epoxy-functional coating composition, applied to the epoxy-based coating. between the compositions. A method is also provided that includes the steps of: providing a cement composite substrate; applying an epoxy-functional coating composition to the substrate; and applying a water-based coating composition, distinct from the epoxy-functional coating composition, to the epoxy-based coating. The water-based coating composition used in this method preferably comprises a polymer having one or more functional groups that can react with the epoxy-based coating to promote adhesion between the compositions.

Owner:AXALTA COATING SYST IP CO LLC

Coating systems for cement composite articles

The present invention provides a coating composition, a method of coating a substrate, and a coated substrate (e.g., a coated cement fiberboard article). In preferred embodiments the coating composition includes one or more latex polymers and an aliphatic epoxy resin system. The coating composition can include one or more coating compositions that may be applied in one or more layers. A coated article comprising a cement fiberboard substrate and a coating system applied to the substrate is also provided. The article includes a first coating system applied to the substrate, wherein the first coating system includes an aliphatic epoxy resin system having an aqueous dispersion of polymer particles, optionally a silicate additive, and optionally one or more olefinic compounds and initiator for same. The first coating system preferably includes one or more coating compositions that may be applied in one or more layers. In a preferred embodiment, the first coating system is applied to all the surfaces of the substrate (e.g., the front side, back side and edges of a board). The coated substrate may then be coated with other optional coatings, e.g., decorative or protective topcoats.

Owner:AXALTA COATING SYST IP CO LLC

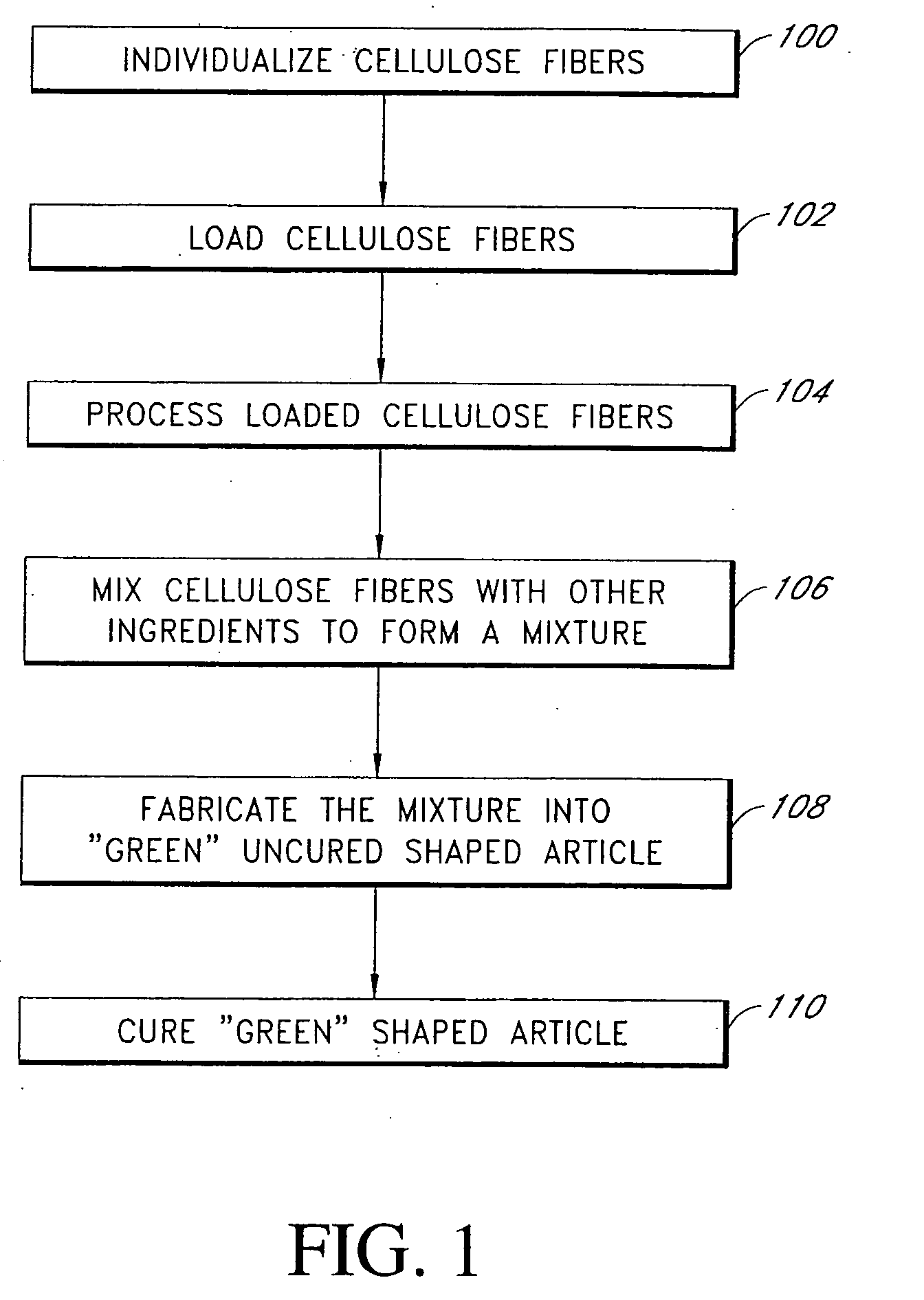

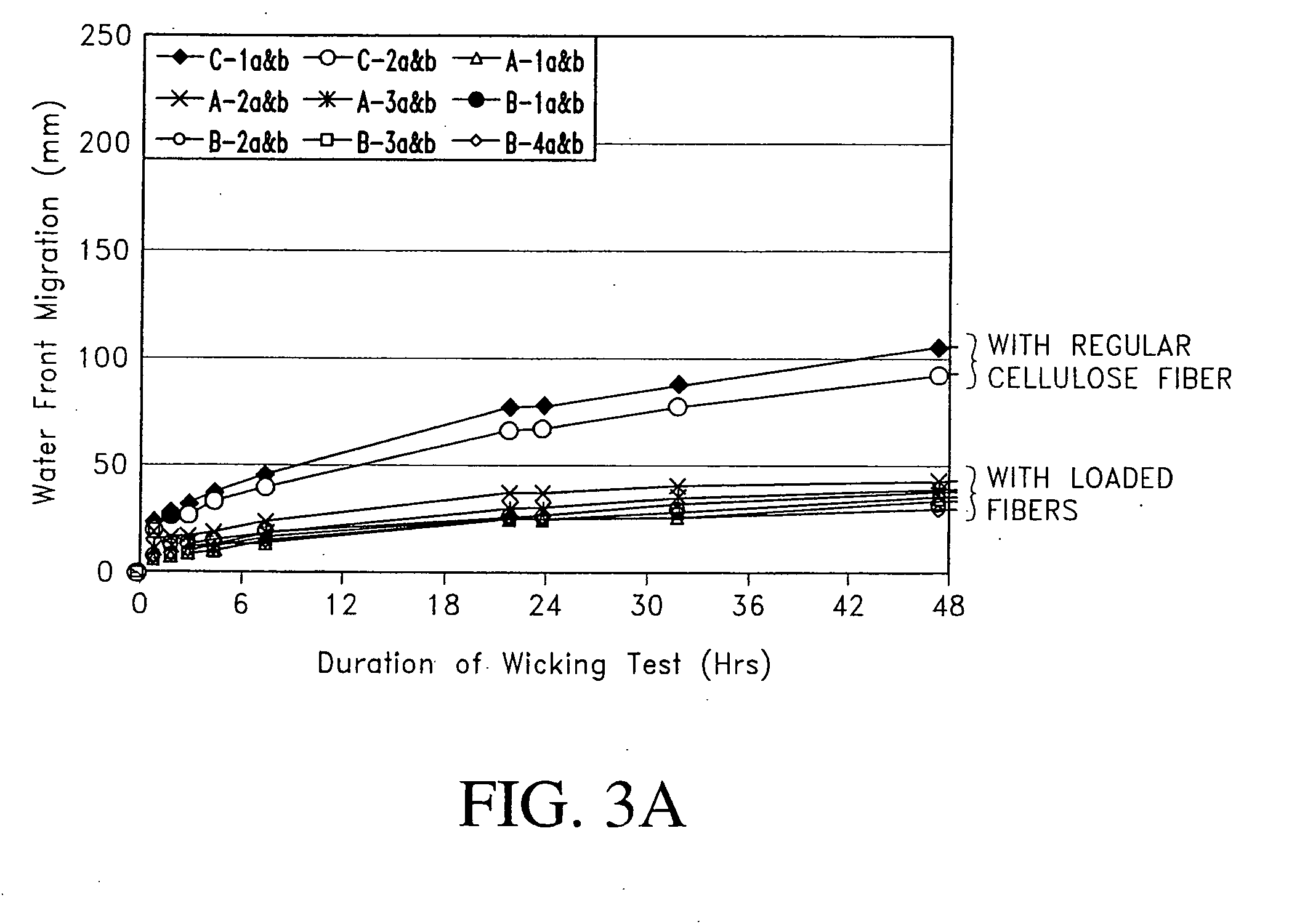

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS20050235883A1Low water absorptionLow water migrationConstruction materialWater-repelling agents additionCement compositesCellulose fiber

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:MERKLEY DONALD J +1

Foaming cement composite vacuum heat insulation plate and preparation method thereof

ActiveCN102979205ASolve the problem of broken air leakageEasy to installClimate change adaptationInsulation improvementCement compositesHigh intensity

The invention relates to a foaming cement composite vacuum heat insulation plate comprising a vacuum heat insulation plate and foaming cement which covers the periphery of the vacuum heat insulation plate. The vacuum heat insulation plate comprises core materials, high strength air resistance film and interface mortar. The high strength air resistance film covers the periphery of the core materials and is encapsulated between core materials through vacuumpumping. A layer of interface mortar covers the periphery of the high strength air resistance film. The thickness of the interface mortar is 2 millimeters to 3 millimeters. The foaming cement composite vacuum heat insulation plate and a preparation method of the foaming cement composite vacuum heat insulation plate have the advantages that problem of damage and air leakage of the vacuum heat insulation plate in a work process is solved, construction and installation are convenient to achieve, heat retaining property, water resisting property, durability and freezing resistance are good, flame class is non-ignitable or fire-retardant and good fireproof performance is achieved.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

Coating system for cement composite articles

A coated article which includes a cement fiberboard substrate and a radiation-curable coating system applied to the substrate. The coating system includes a latex polymer, one or more olefinic compounds and water, and may be provided in the form of one or more coating compositions that may be applied in one or more layers, wherein each of the coating compositions is preferably an aqueous composition, or can be mixed with another composition (e.g., on the substrate) to form an aqueous composition.

Owner:AXALTA COATING SYST IP CO LLC

Coating system for cement composite articles

ActiveUS20070259188A1Liquid surface applicatorsConstruction materialWater dispersibleCement composites

A coated article which includes a cement fiberboard substrate and a radiation-curable coating system applied to the substrate. The coating system includes an aqueous dispersion of water-dispersible polymer particles, one or more olefinic compounds and water, and may be provided in the form of one or more coating compositions that may be applied in one or more layers, wherein each of the coating compositions is preferably an aqueous composition, or can be mixed with another composition (e.g., on the substrate) to form an aqueous composition.

Owner:AXALTA COATING SYST IP CO LLC

Composite wall panel with low thermal conductivity and sufficient strength for structural use

ActiveUS20130216802A1Improve insulation effectImprove barrier propertiesSolid waste managementWallsThermal insulationRebar

The present invention provides a composite wall panel with good thermal insulation and sufficient strength for structural use which is designed for the fabrication of energy efficient building. The composite wall panel of the present invention comprises a foamed concrete core with sufficient compressive strength and low thermal conductivity which is sandwiched between two lightweight ductile fiber reinforced cementitious composite (FRCC) protective layers with low thermal conductivity, good barrier resistance to moisture / chloride ion / gas, multiple cracking as well as certain amount of steel reinforcements. These composite wall panels are useful in a variety of buildings in both cold and hot regions.

Owner:NANO & ADVANCED MATERIALS INST

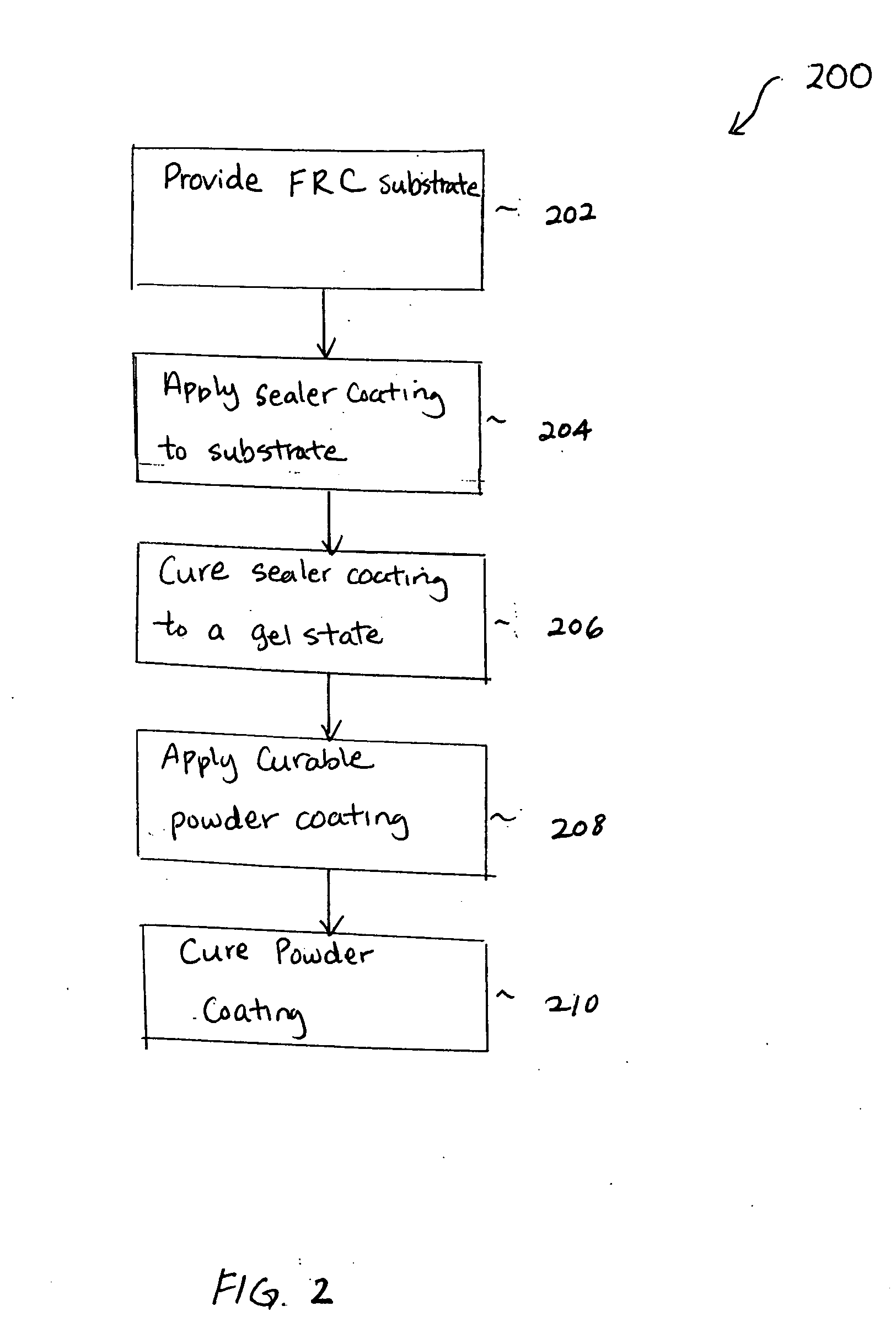

Composite cement article incorporating a powder coating and methods of making same

A cementitious composite article incorporating a powder coating on at least one surface is provided. The composite article includes a surface treatment adapted to facilitate application of the powder coating onto the article. The surface treatment can include modifications to surface porosity, surface, and / or application of a sealer to the surface so as to make the cementitious surface more conducive to powder coating. One method of manufacturing the cementitious composite article includes first applying a sealer coating to a surface of a fiber cement substrate, partially curing the substrate to a gel-like state, applying a powder coating to the article, processing the article to a curing device in which the powder coating and sealer coating are co-cured to form a hardened film.

Owner:JAMES HARDIE TECH LTD

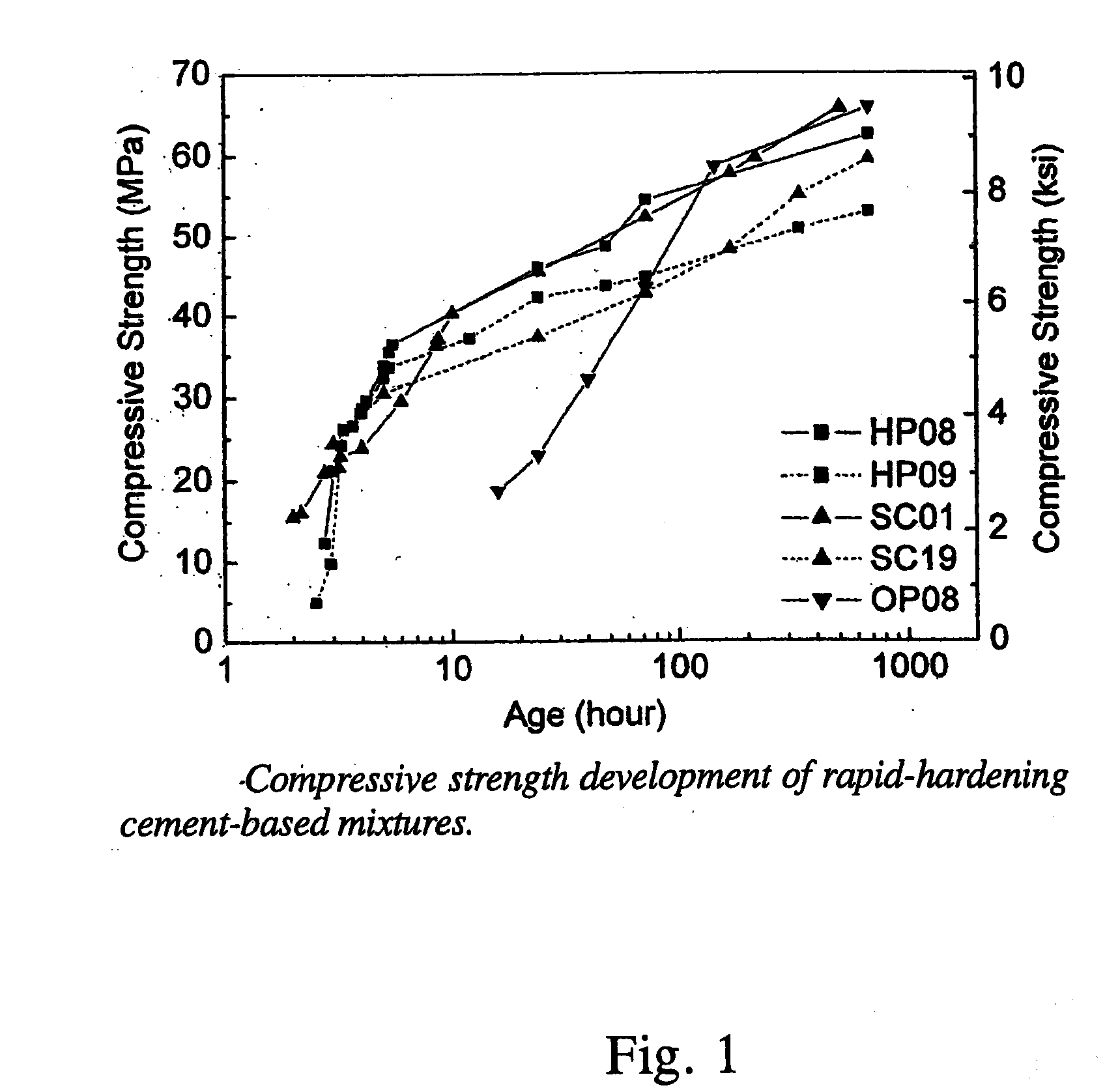

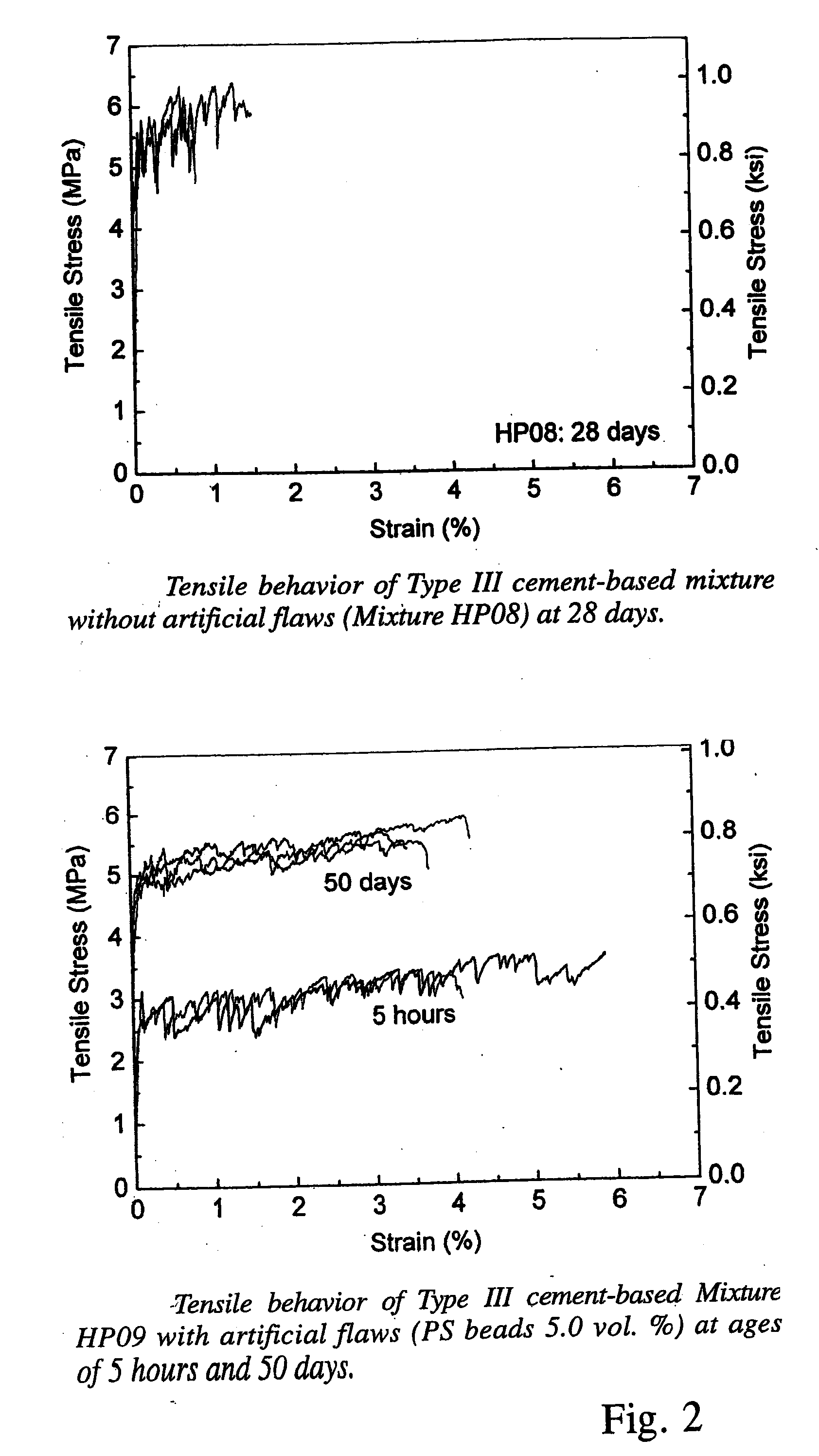

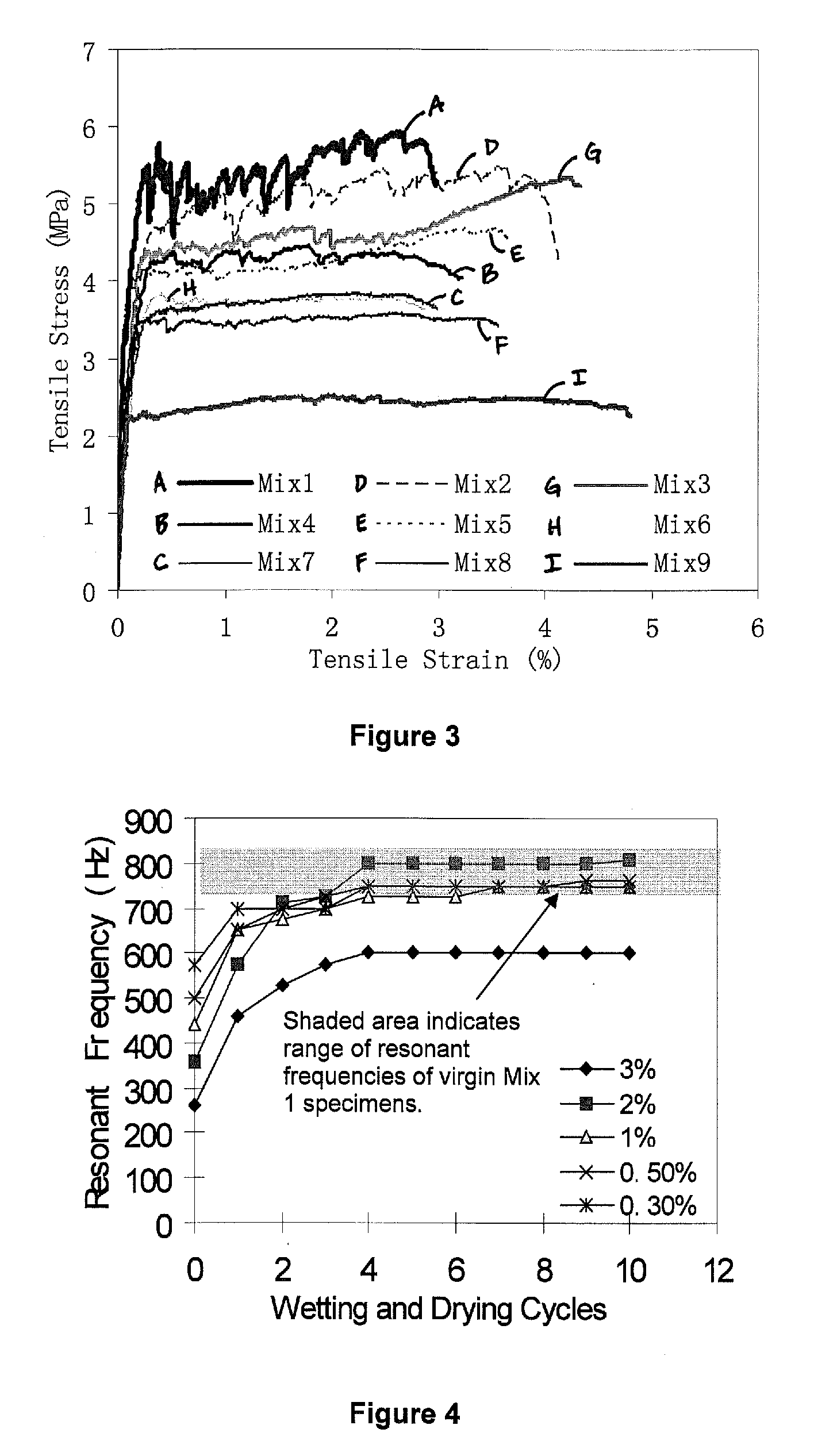

High Early Strength Engineered Cementitious Composites

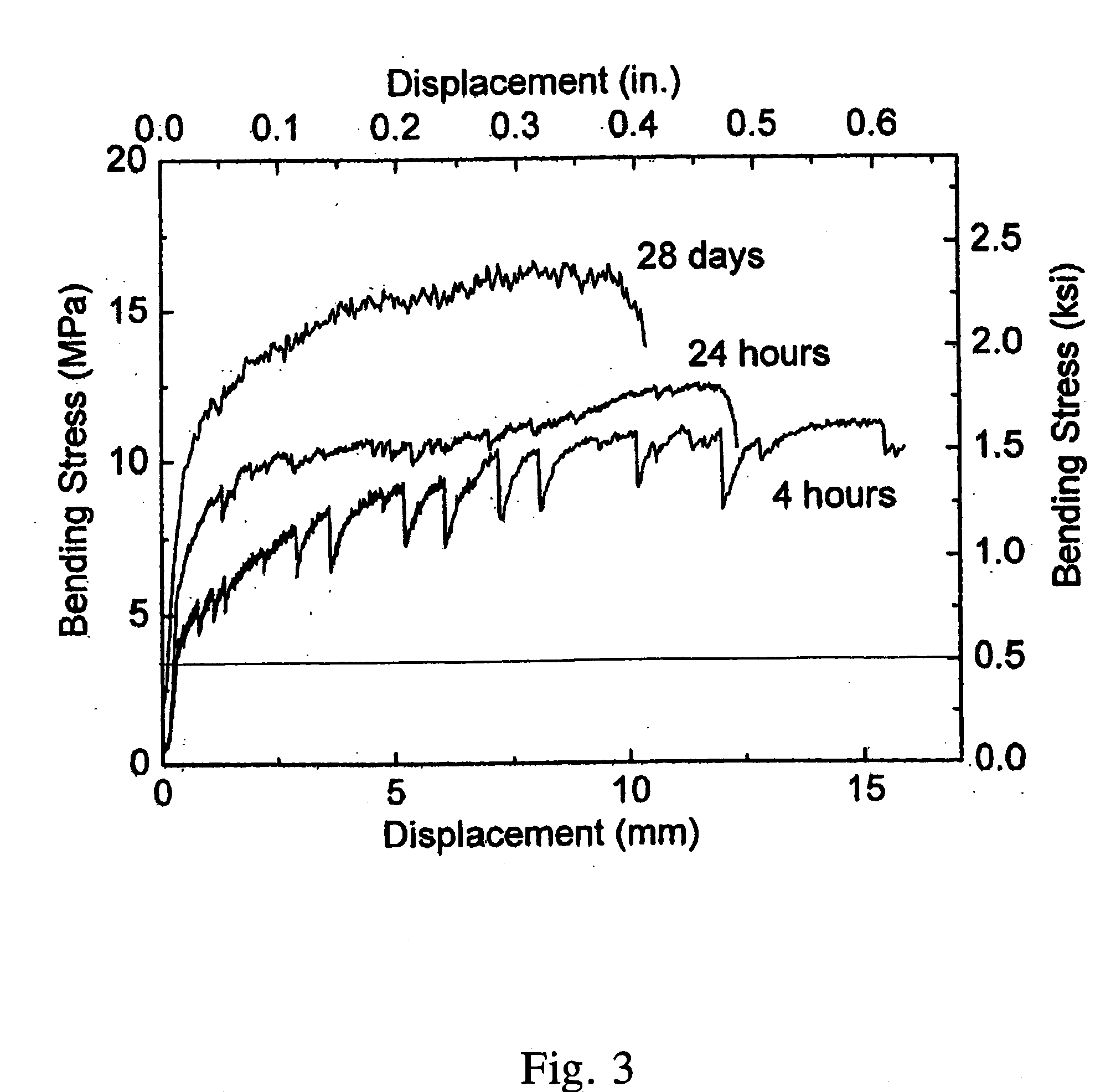

ActiveUS20070181040A1High early-strengthLarge capacitySolid waste managementClimate change adaptationTensile strainCement composites

Rapid repair and retrofit of existing infrastructures demand durable high early strength materials that not only deliver sufficient strength within a few hours of placement but also significantly prolong the maintenance interval. The invention comprises a class of newly developed polyvinyl alcohol (PVA) fiber-reinforced high early strength engineered cementitious composites (ECC) materials featuring extraordinary ductility. The tailoring of preexisting flaw size distribution through non-matrix interactive crack initiators in the composite matrix results in high tensile ductility. The resulting high early strength ECC materials are capable of delivering a compressive strength of 21 MPa (3.0 ksi) within 4 hours after placement and retaining long-term tensile strain capacity above 2%.

Owner:RGT UNIV OF MICHIGAN

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

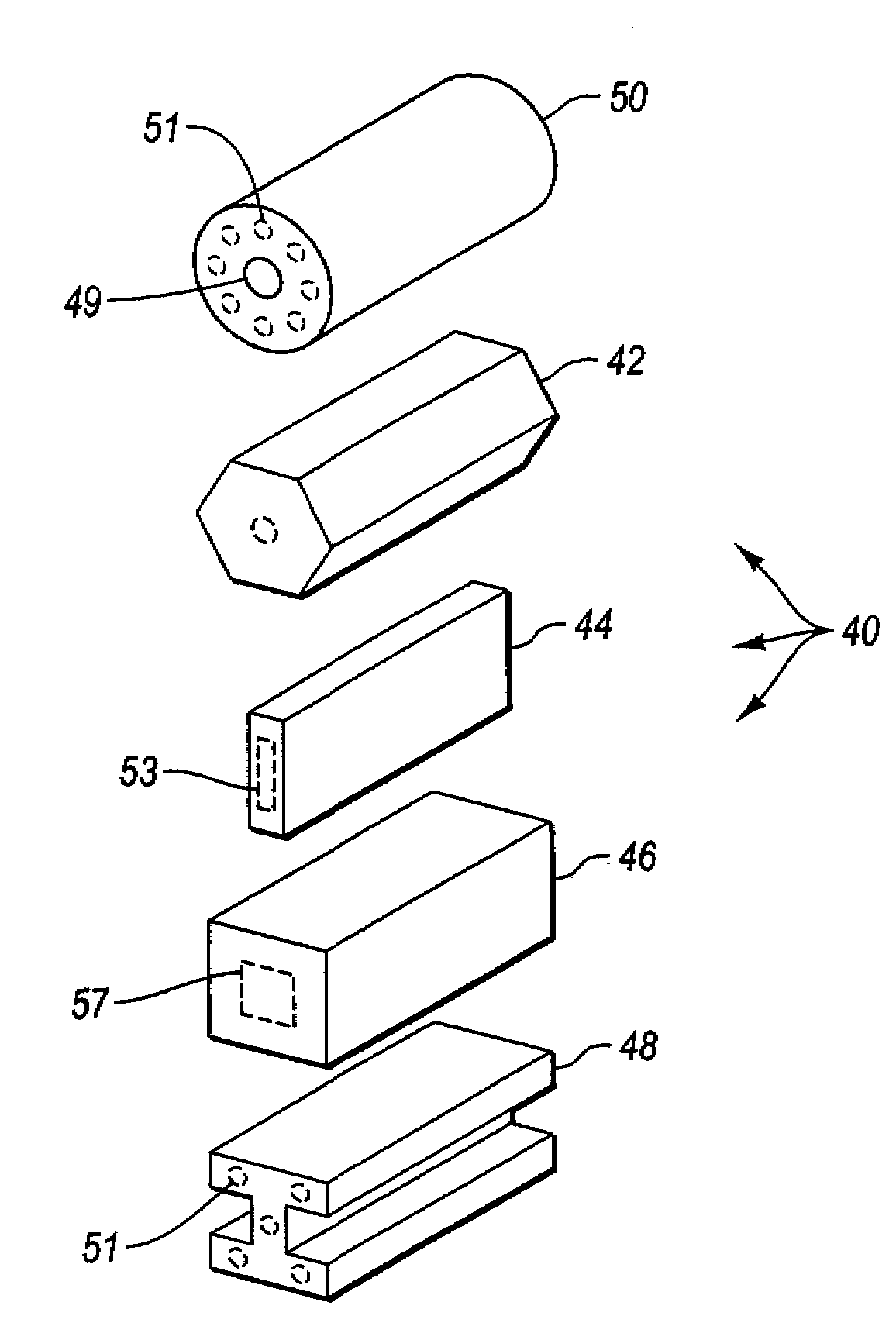

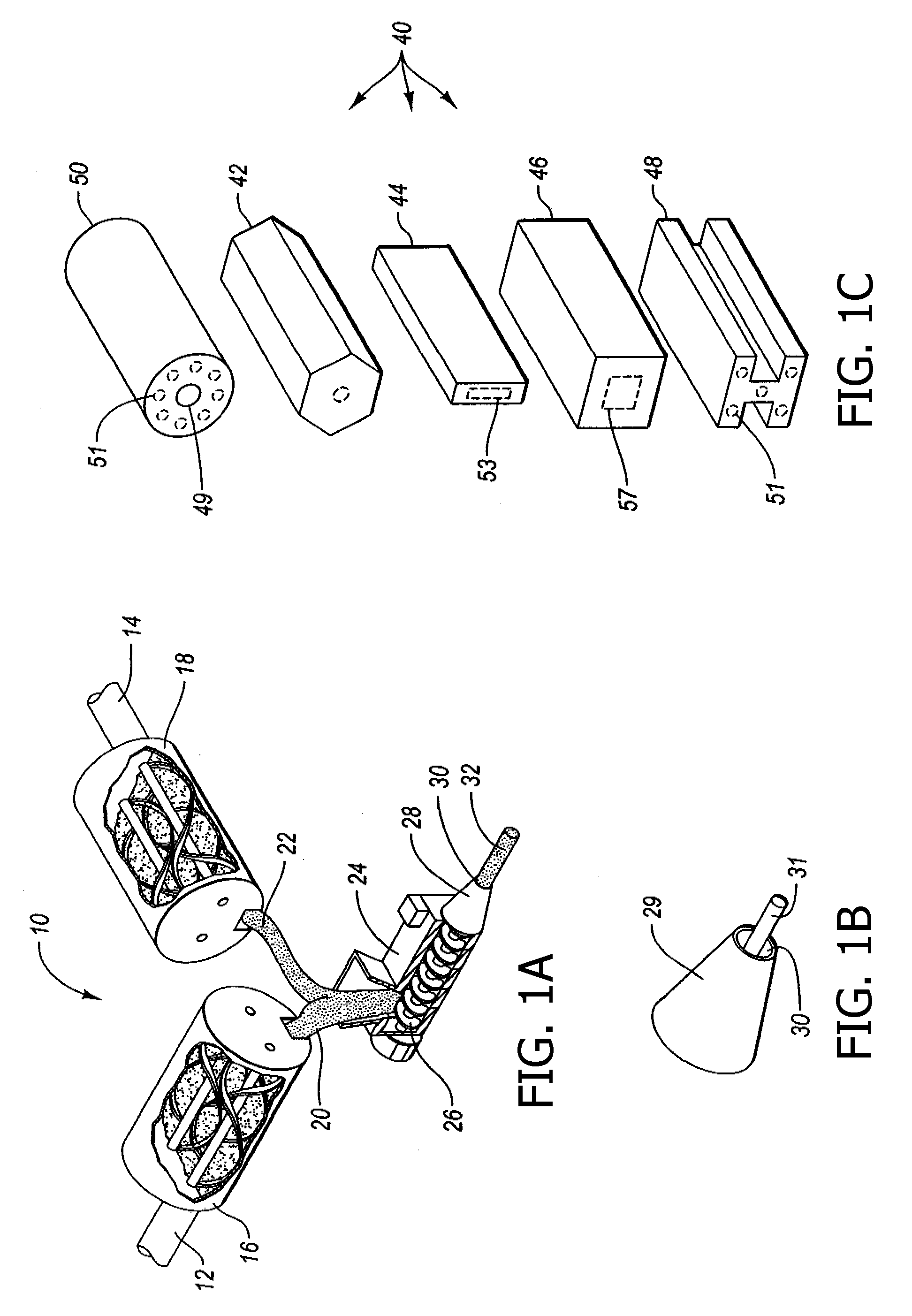

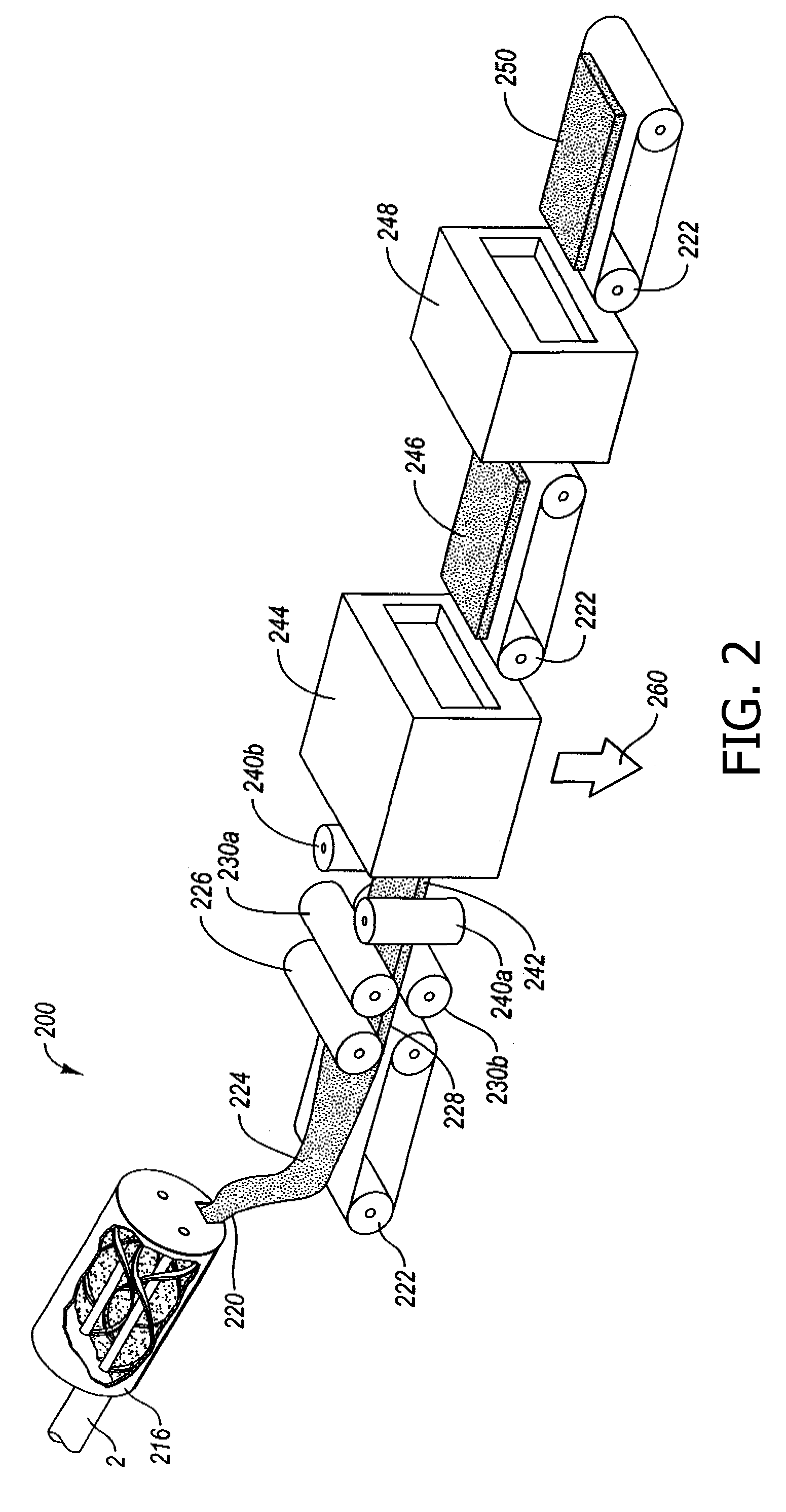

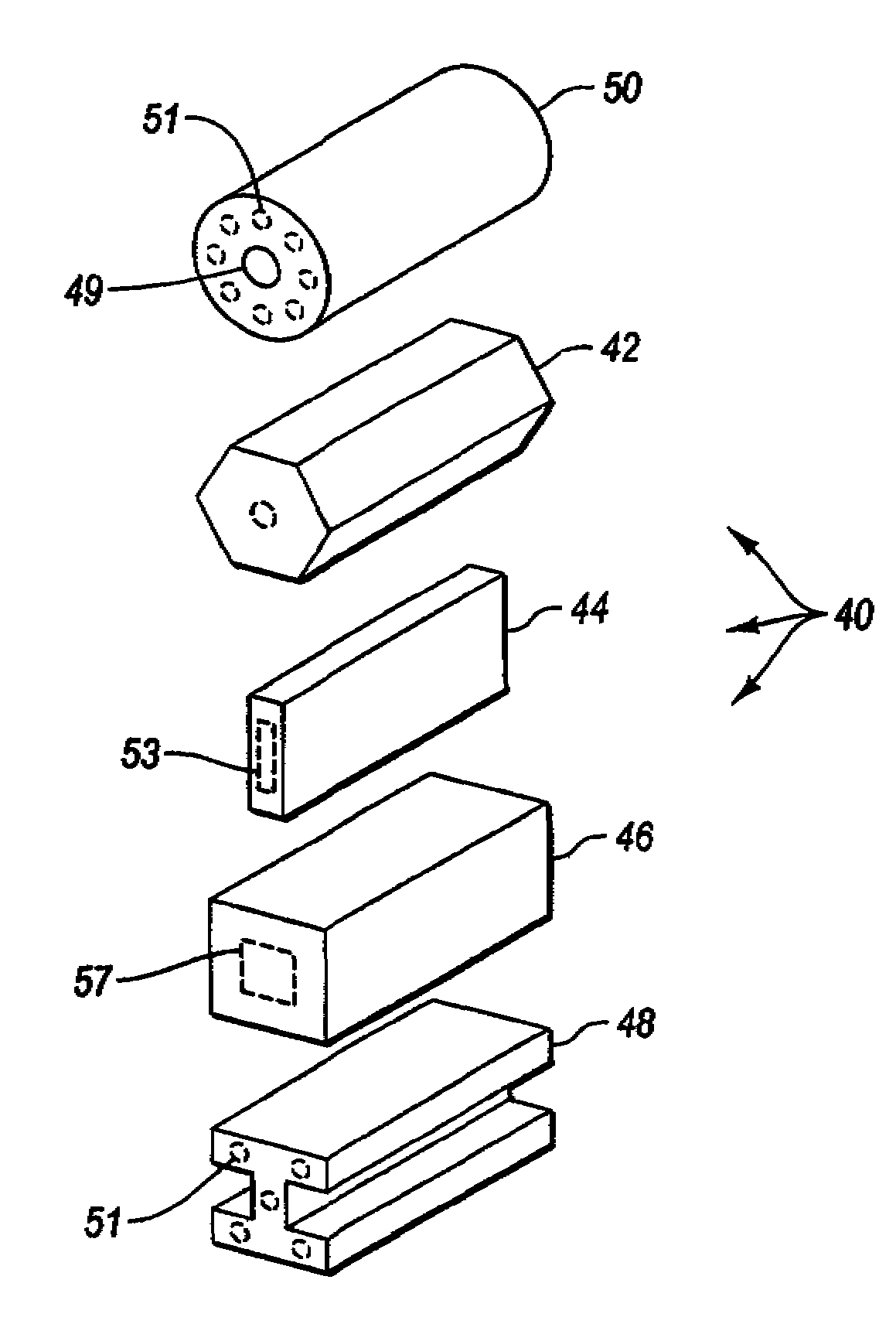

InactiveUS20120276310A1Low densityReduce hardnessEnvelopes/bags making machineryCeramic extrusion diesPorosityBuilding product

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Extruded fiber reinforced cementitious products having stone-like properties and methods of making the same

InactiveUS20110120349A1Improve flexural strengthHigh tensile strengthConstruction materialSolid waste managementBuilding productCement composites

A cementitious composite product that can function as a substitute for stone and solid surface materials, such as granite, marble, and engineered stone is provided. Furthermore methods for manufacturing the cementitious composite product using an extrudable cementitious composition that can be extruded or otherwise shaped into stone-like building products that can be used as a substitute for many known stone products is disclosed. In one embodiment, the cementitious composite products can be manufactured more cheaply to be as tough or tougher and more durable than stone and solid surface materials.

Owner:E KHASHOGGI INDS

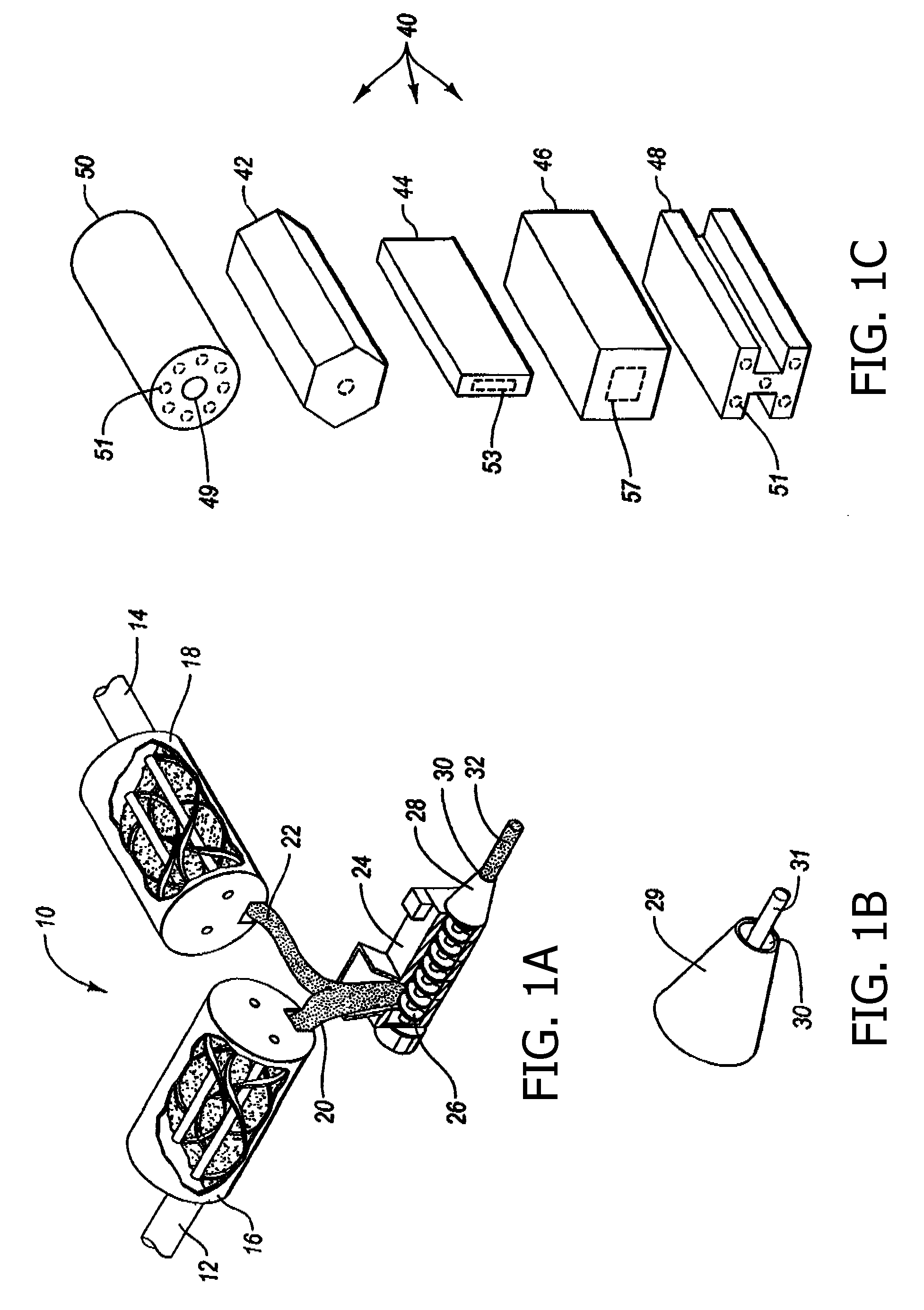

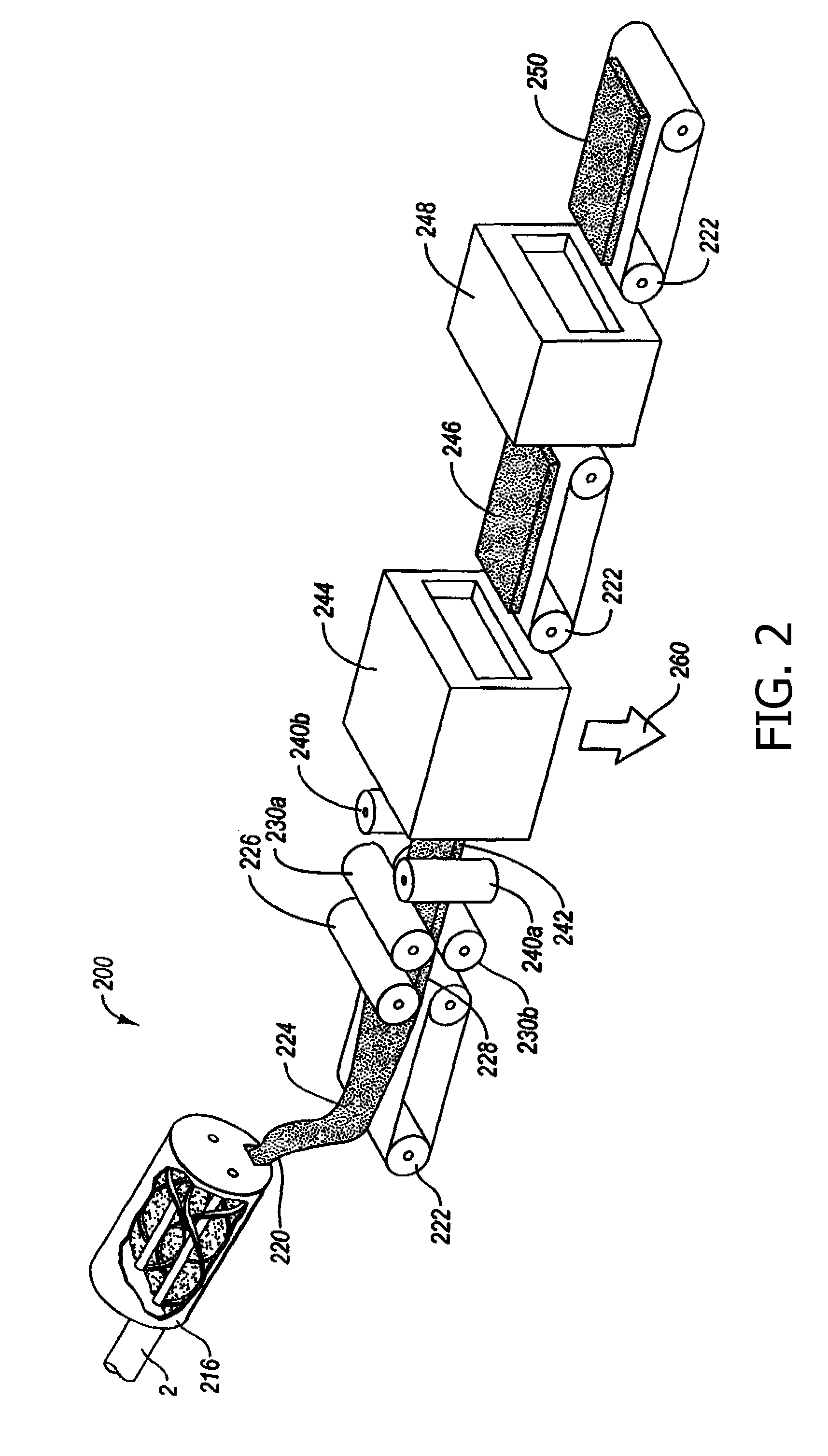

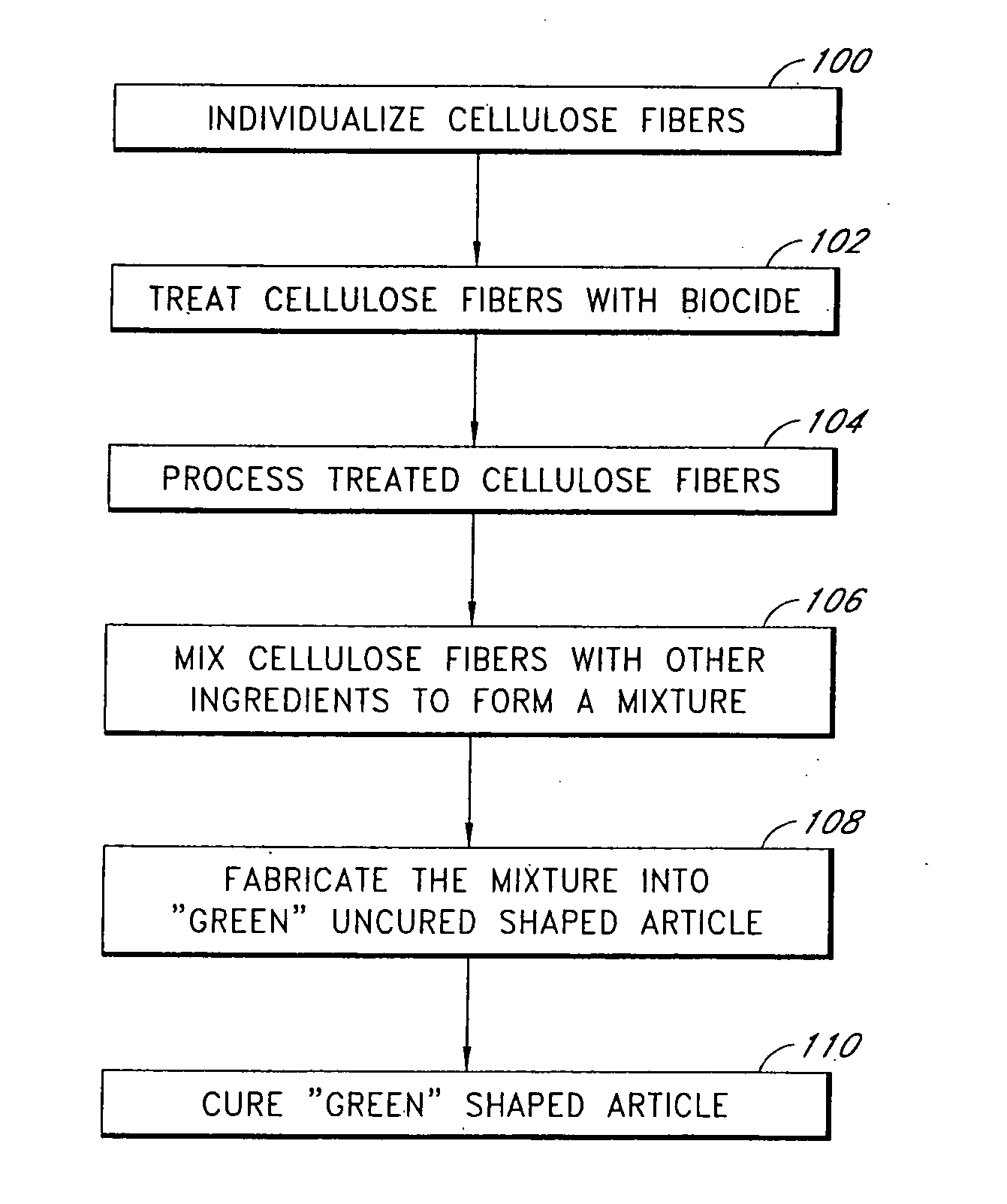

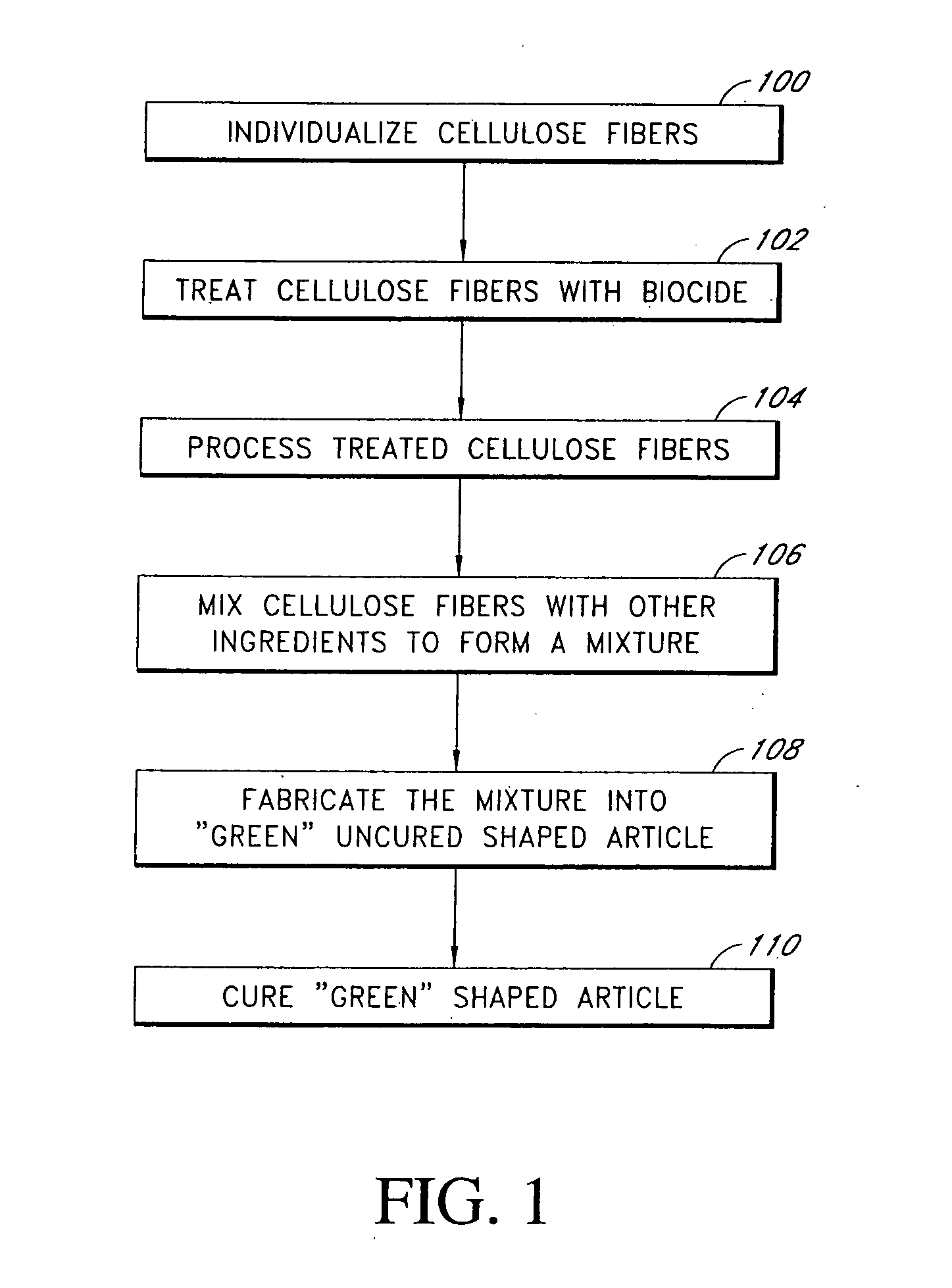

Fiber cement composite material using biocide treated durable cellulose fibers

InactiveUS20050016423A1Increased durabilityImproves rot resistanceFireproof paintsAntifouling/underwater paintsBiotechnologyHydration reaction

A fiber cement composite material providing improved rot resistance and durability, the composite material incorporating biocide treated fibrous pulps to resist microorganism attacks. The biocide treated fibers have biocides attached to inner and outer surfaces of individualized fibers to protect the fibers from fungi, bacteria, mold and algae attacks. The biocides selected have strong affinity to cellulose and do not interfere with cement hydration reactions. This invention also discloses the formulation, the method of manufacturing and the final fiber cement products using the biocide treated fibers.

Owner:JAMES HARDIE TECH LTD +1

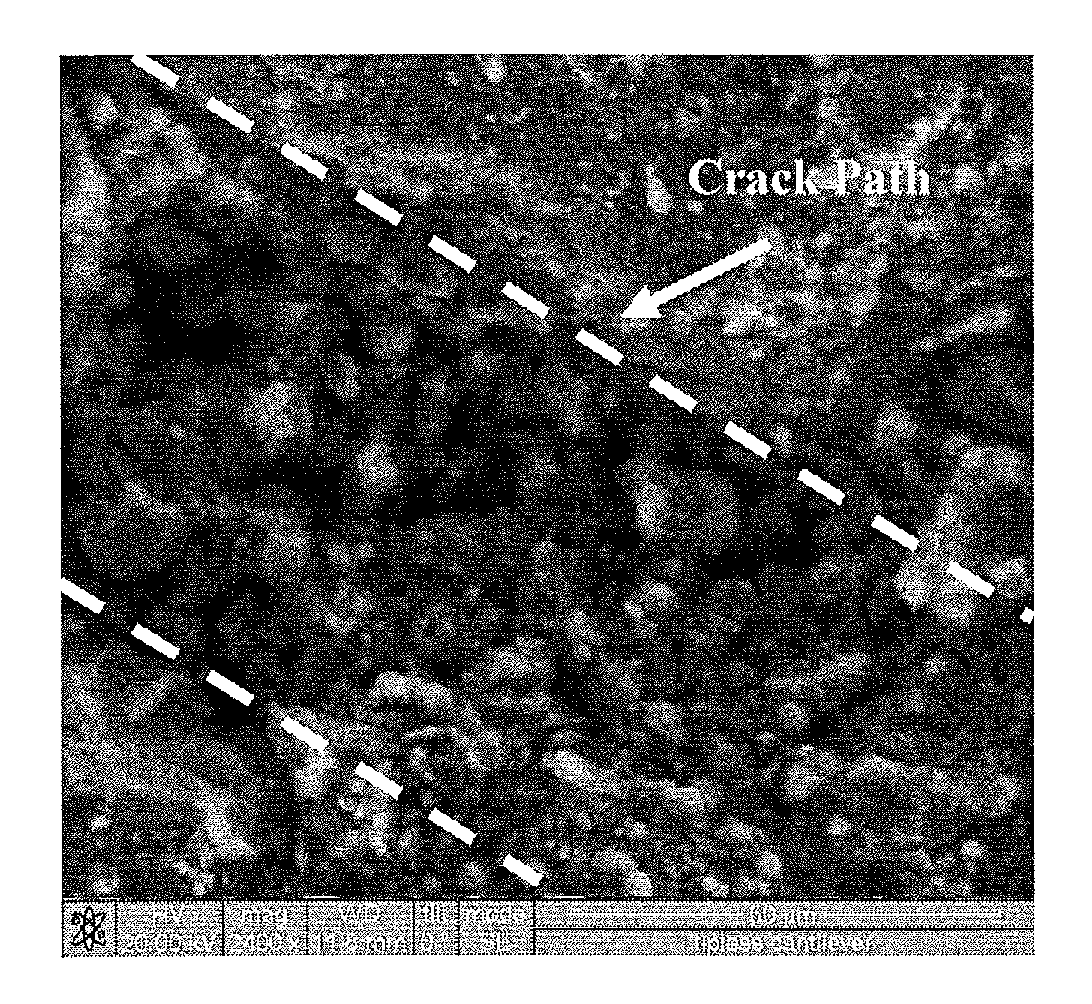

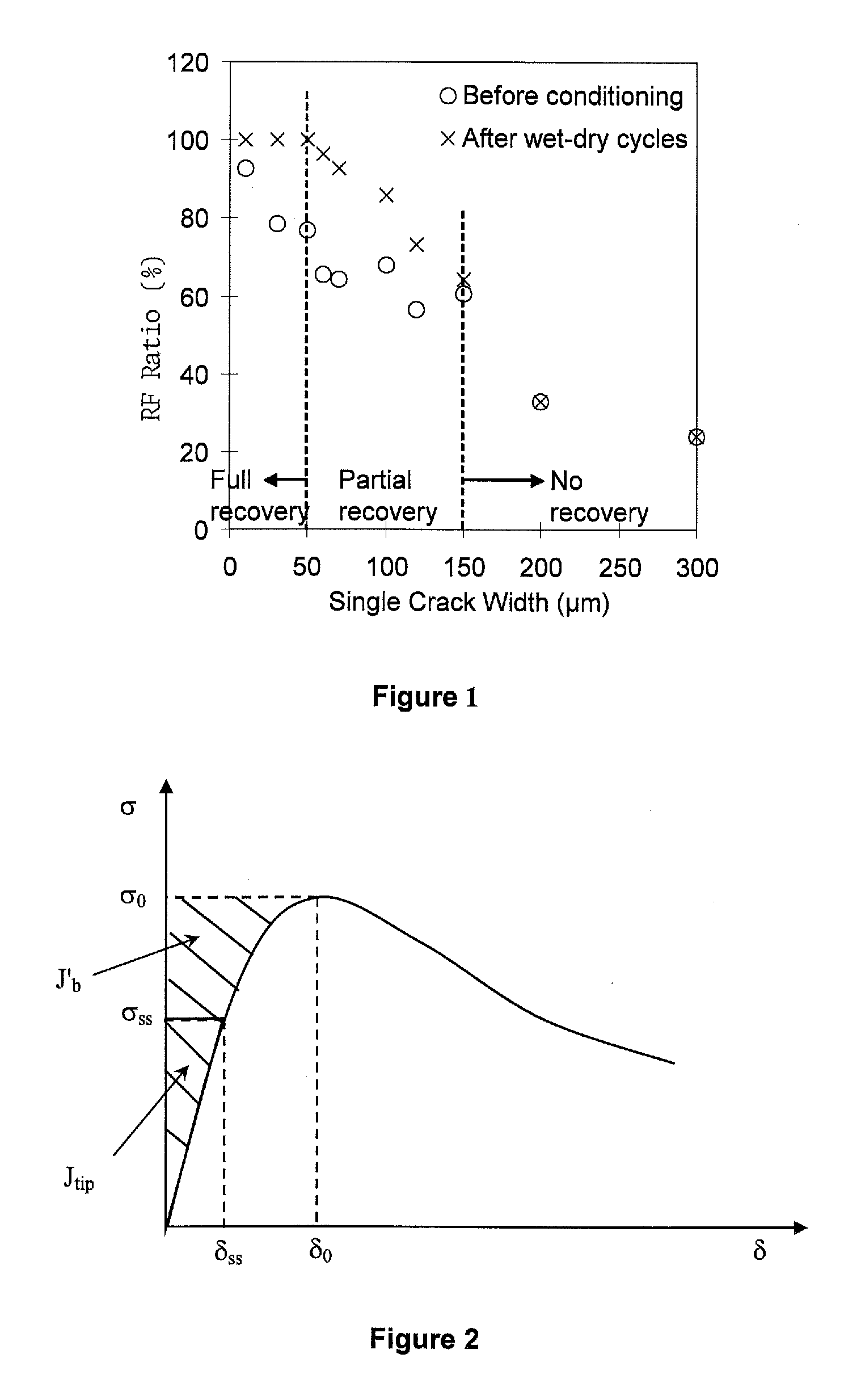

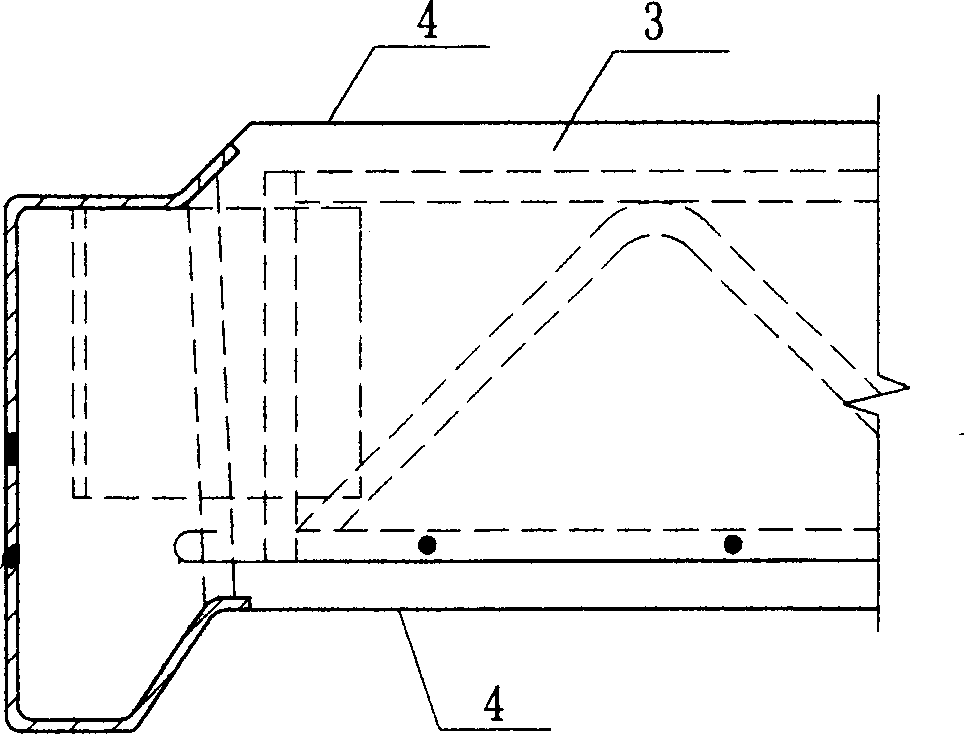

Engineered self healing cementitious composites

ActiveUS20080261027A1Highly controlled crack widthPreferable flowabilitySolid waste managementSynthetic resin layered productsSelf-healingCement composites

Cementitious composites engineered for self-healing, combining self-controlled tight crack width and extreme tensile ductility. Self-healing takes place automatically at cracked locations without external intervention. In the exemplary embodiment, fiber-reinforced cementitious composites with self-controlled tight crack width less than 50 μm and tensile ductility more than 2% are prepared. Self-healing in terms of mechanical and transport properties recovery of pre-damaged (by pre-cracking) composite is revealed in a variety of environmental exposures, include wetting and drying cycles, water permeation, and chloride submersion.

Owner:RGT UNIV OF MICHIGAN

Foamed cement composite slab and its production method

InactiveCN1429698AEfficient thermal insulationGood weather resistanceCeramic shaping apparatusHeat proofingHigh resistancePolymer science

A composite foamed cement slab is composed of a main frame made of steel or concrete, a foamed cement core, a steel truss in the foamed cement core and connected to the main frame, and the surface layer reinforced by anticracking material. Its advantages are high heat-insulation and sound-proofness, high resistance to cracking, impact, water, acid and alkali, high durability and weatherability, light weight and low cost.

Owner:CUBIC DIGITAL TECH CO LTD

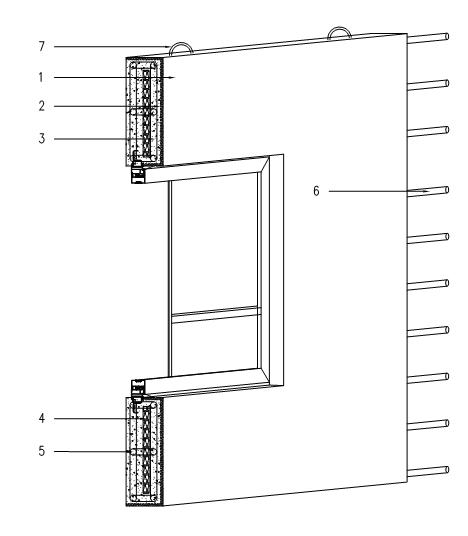

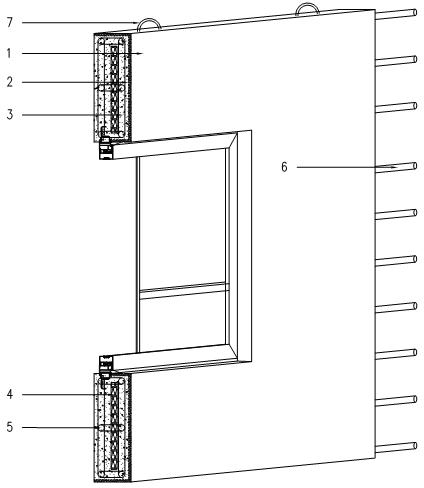

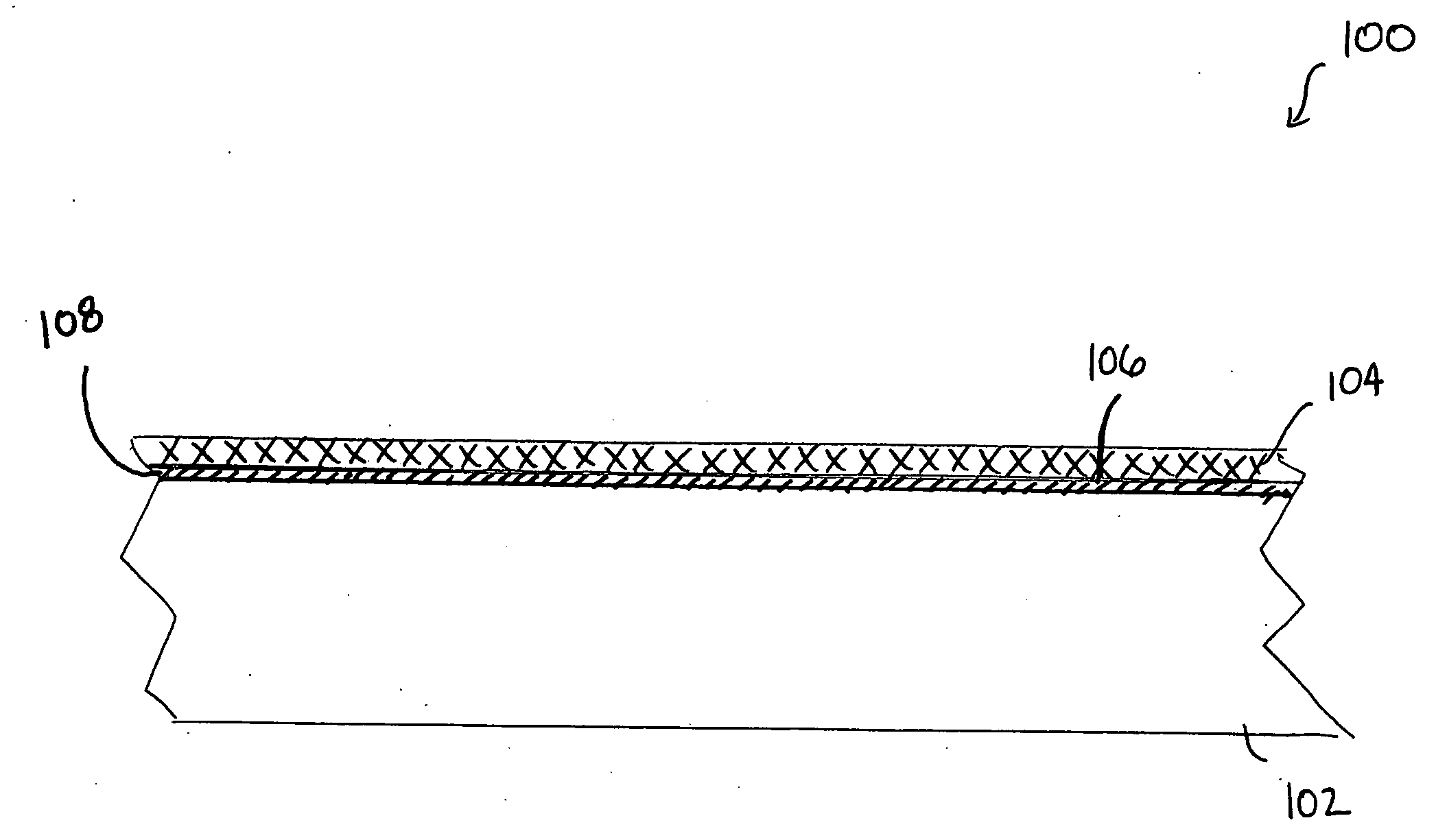

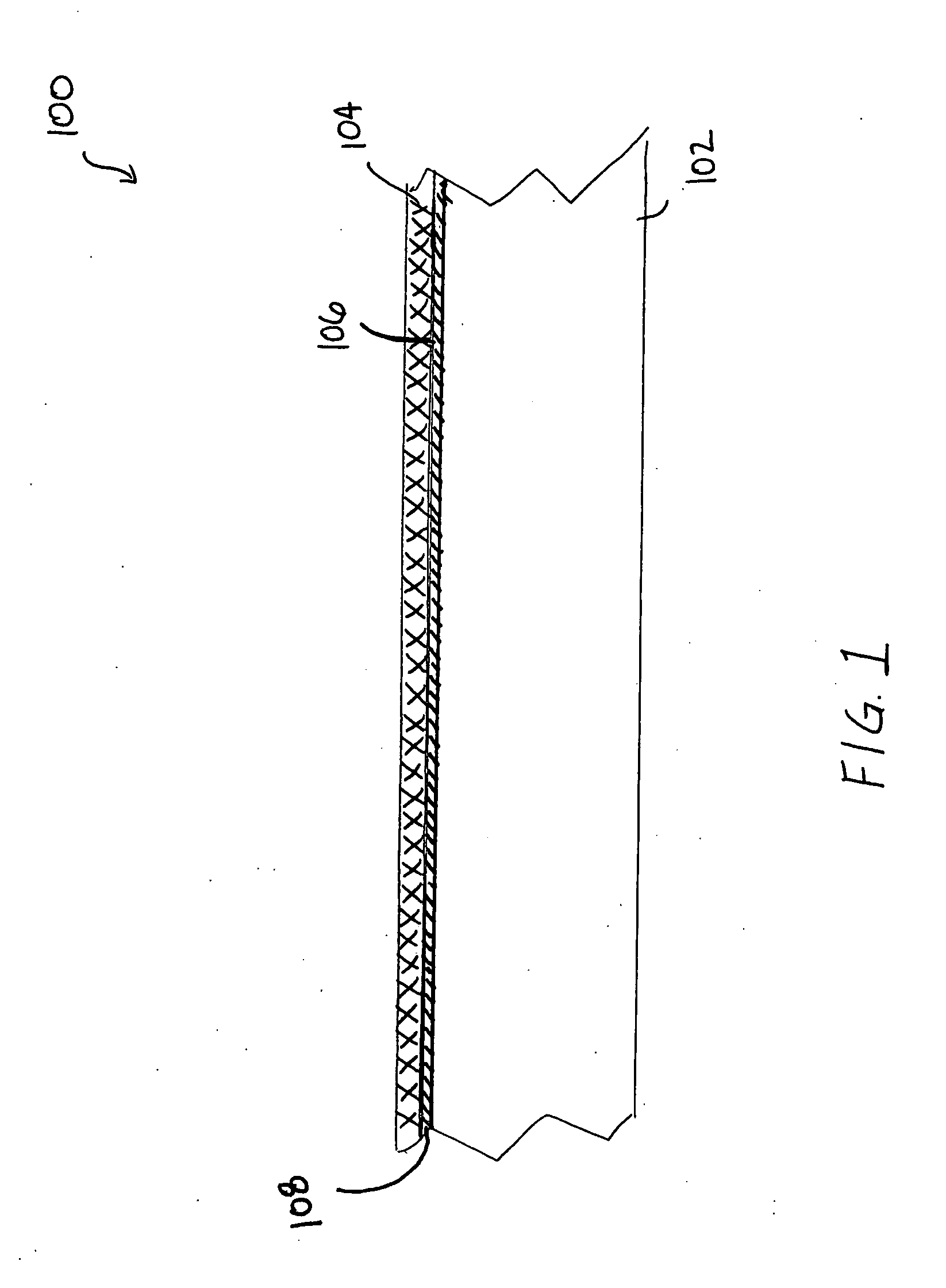

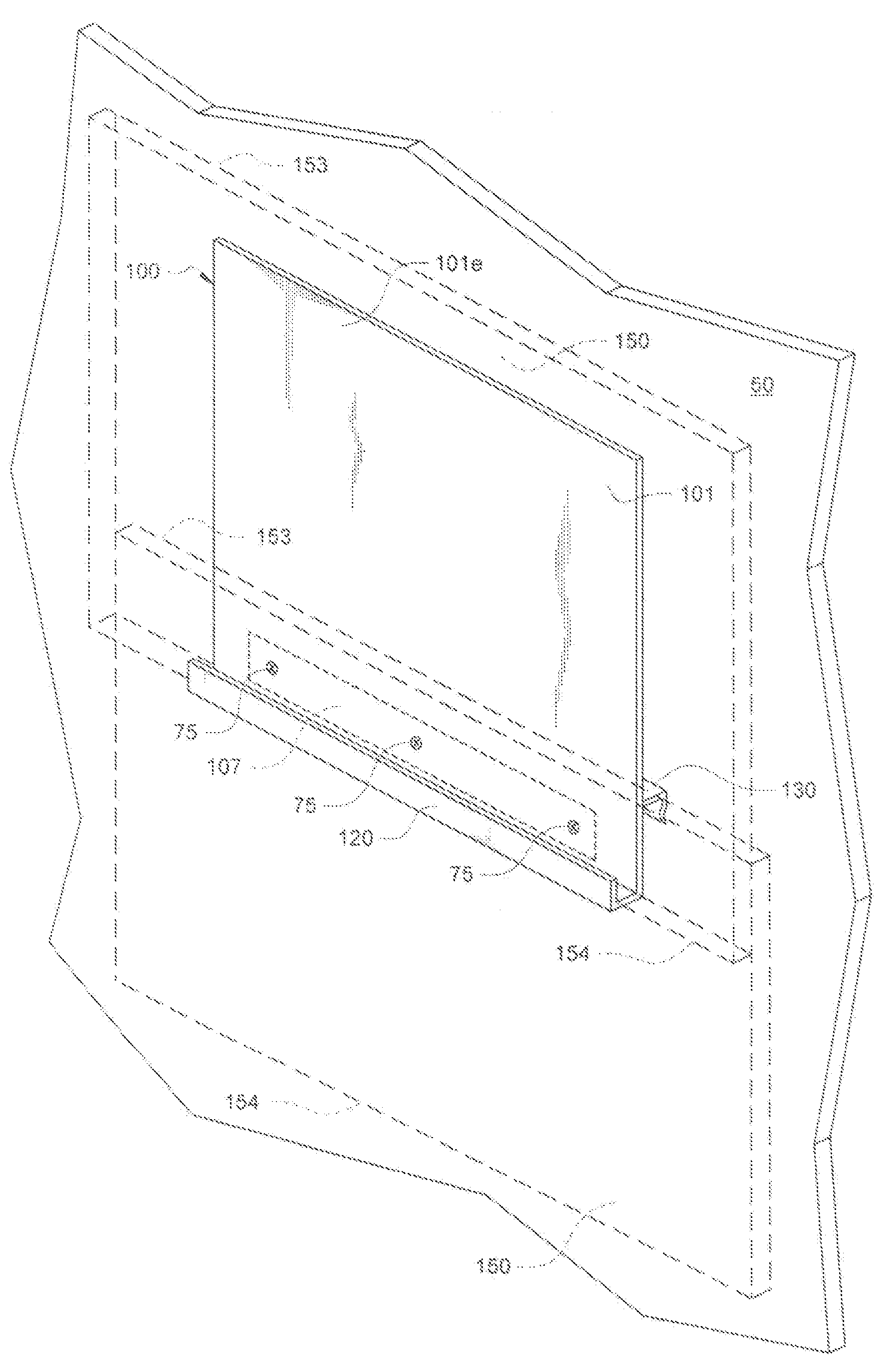

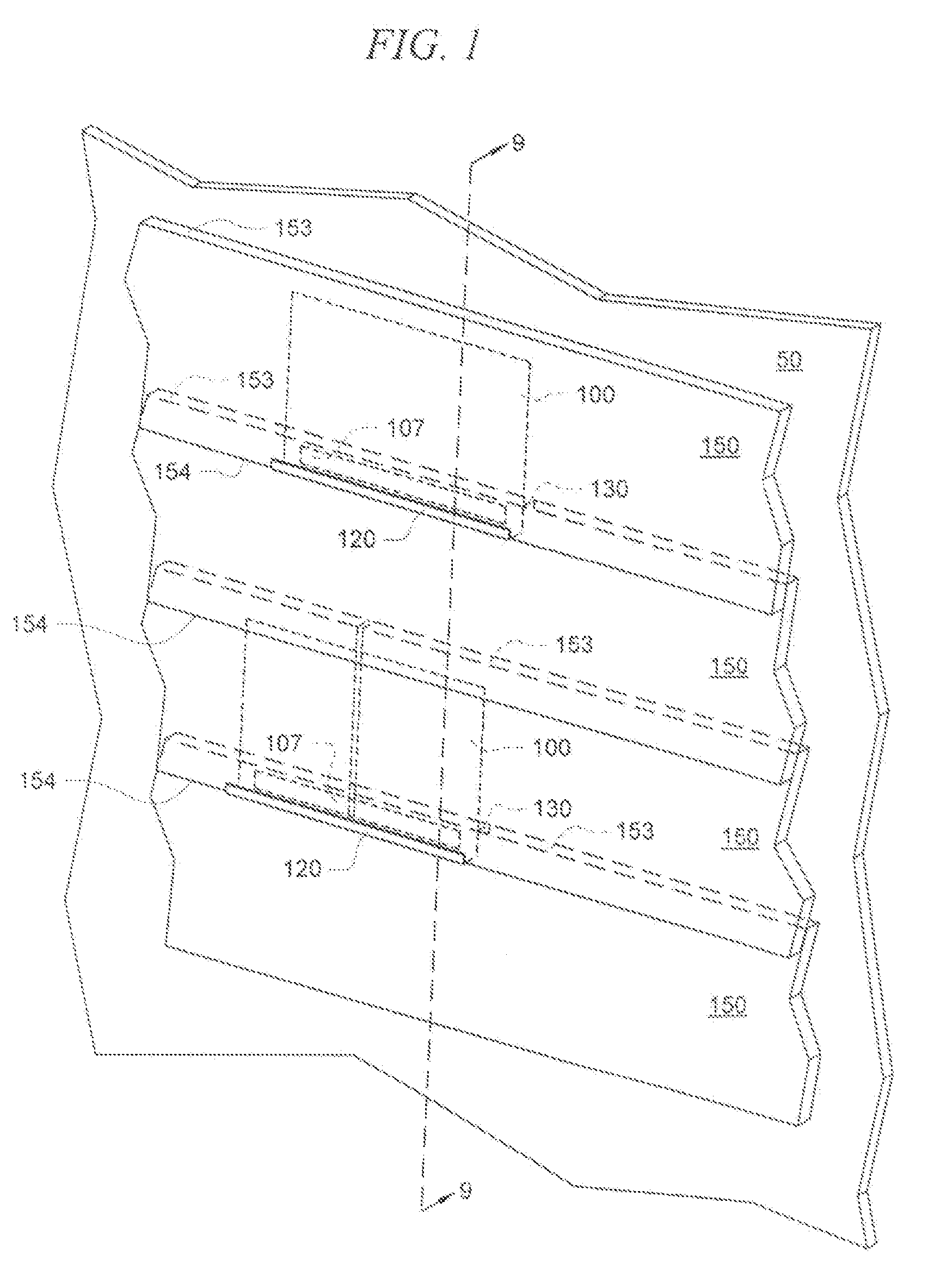

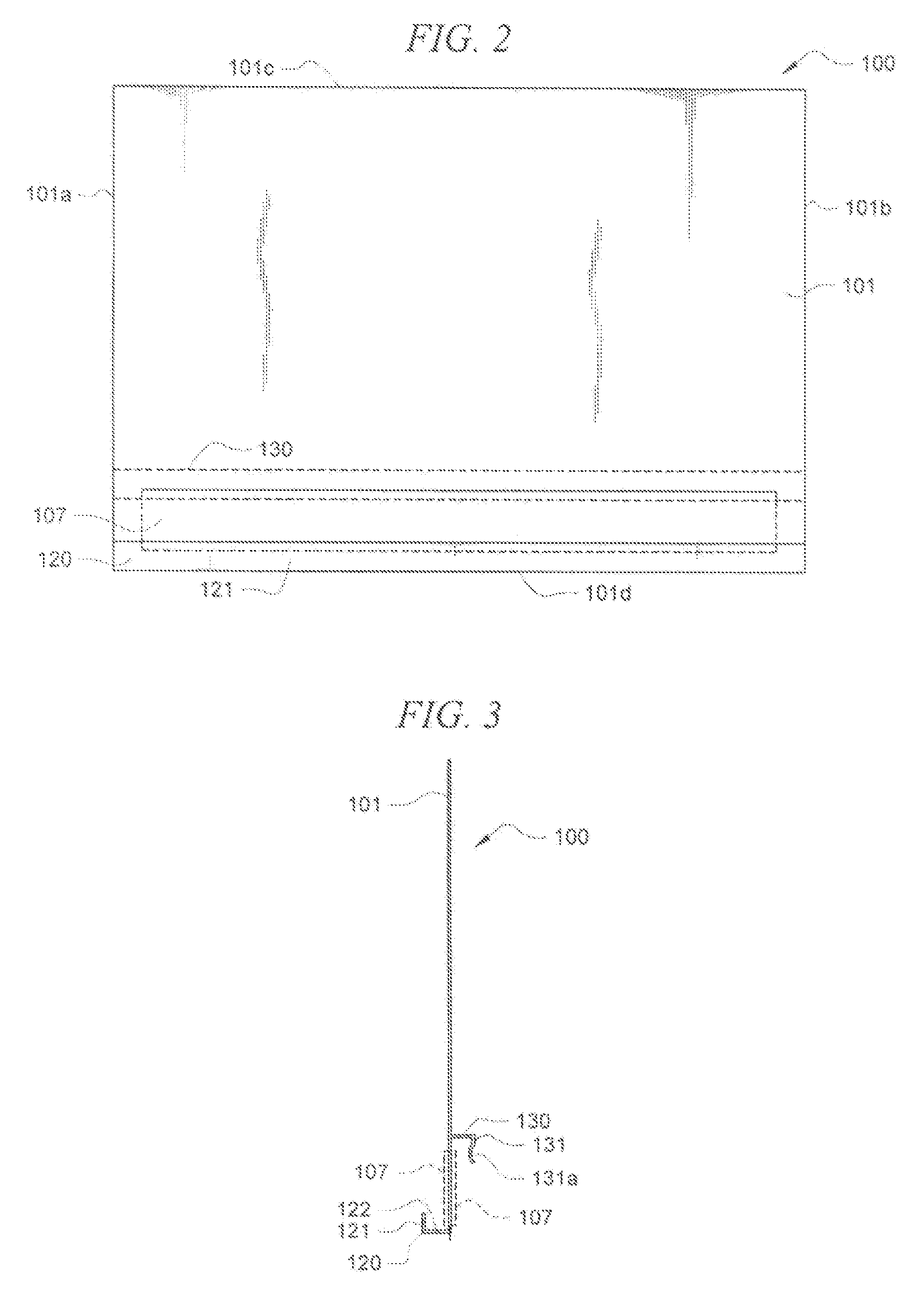

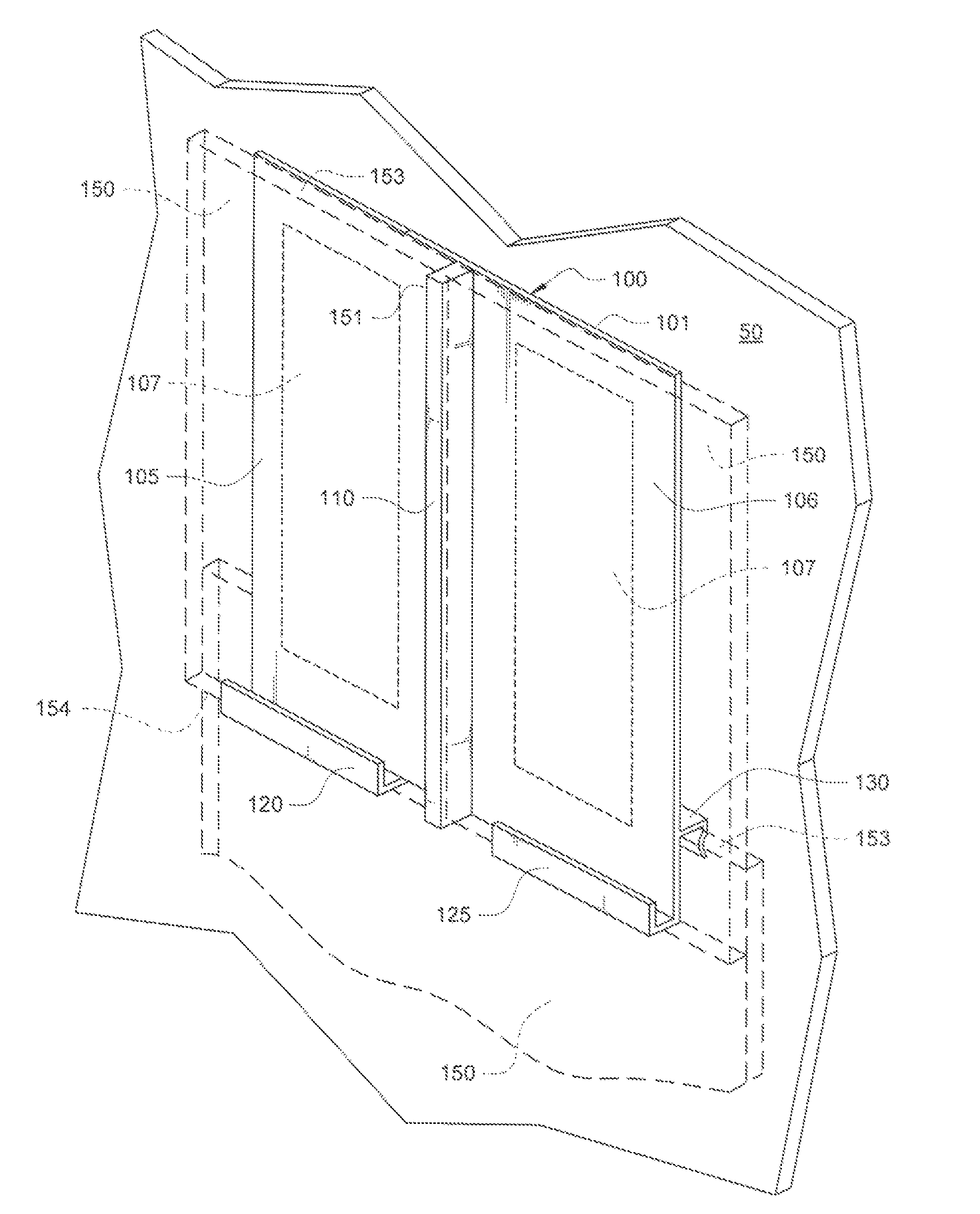

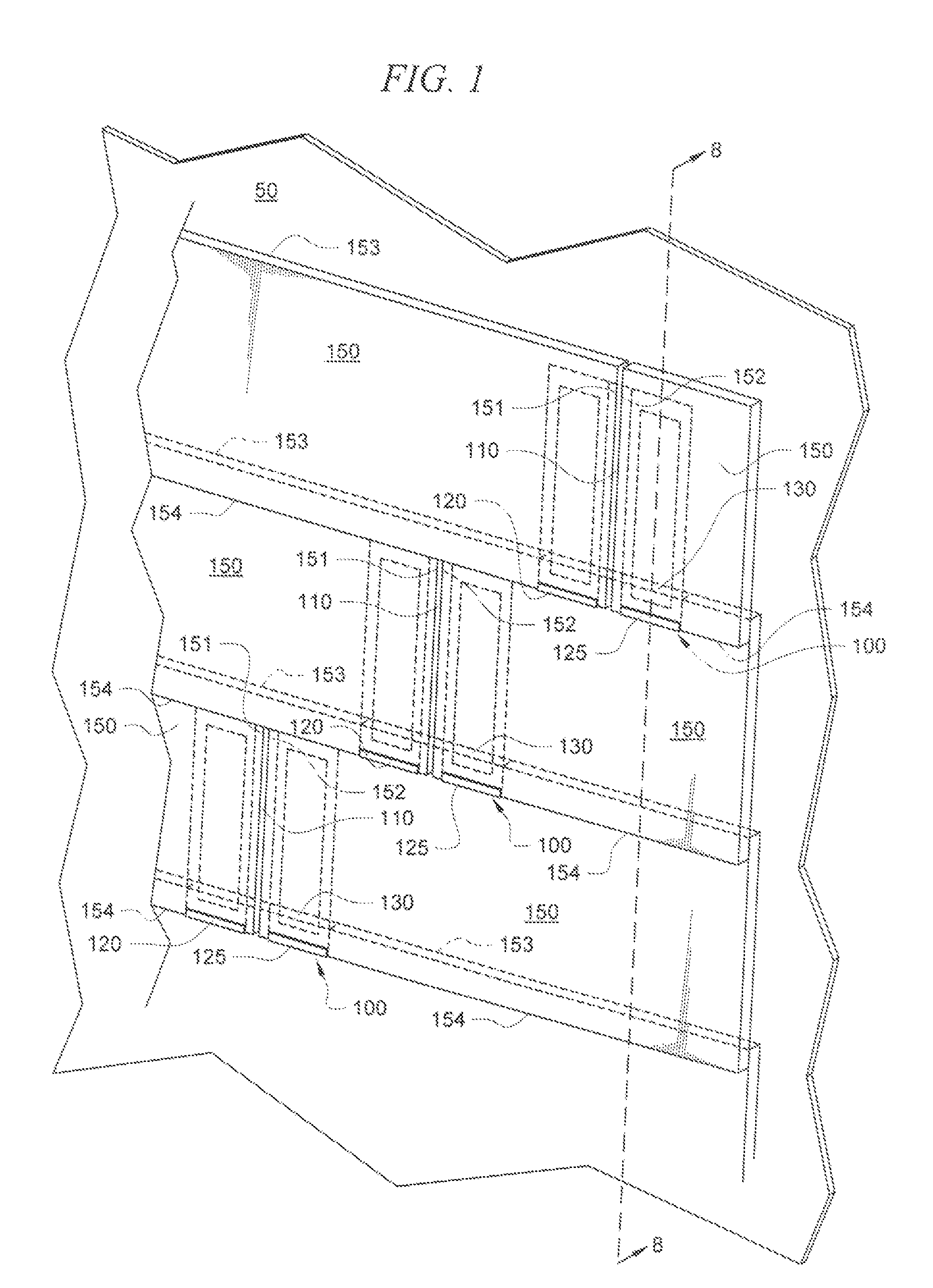

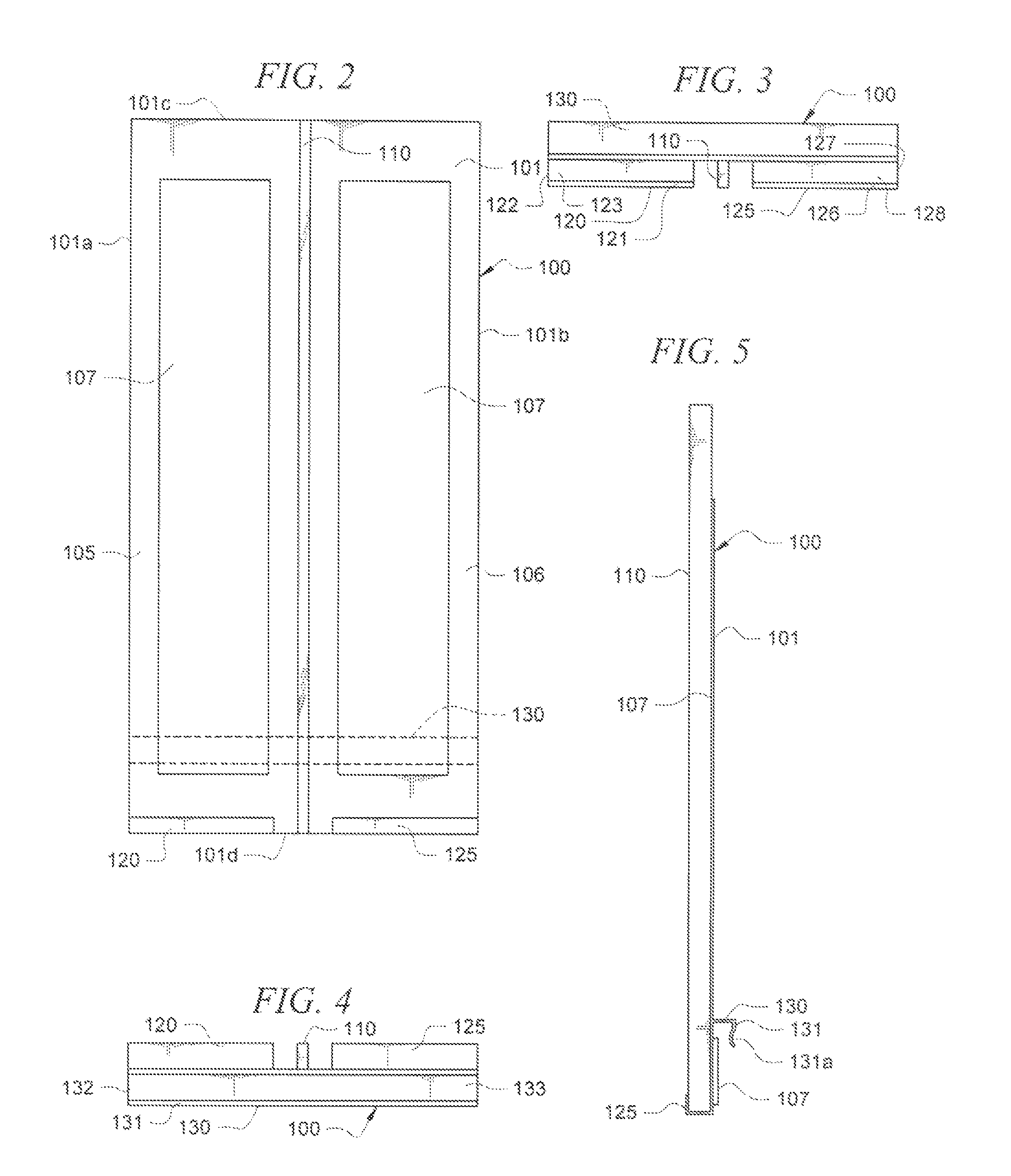

Apparatus for Aiding in the Installation and Sealing of Siding

InactiveUS20080209834A1Eliminate unsightly appearanceRoof covering using tiles/slatesCovering/liningsCement compositesEngineering

An apparatus (100) for aiding in the installation of successive horizontal layers of siding members (150) to a sidewall construction (50). The apparatus (100) also aids in the sealing of the seams between successive horizontal siding layers. In the exemplary embodiment of the invention, the apparatus (100) is used to aid in the installation and sealing of siding members (150) comprised of a fiber cement composite material. The fiber cement composite siding members (150) are heavier than traditional siding pieces and require more than one person to lift for installation. With the use of the apparatus (100), successive horizontal layers of composite siding members (150) can be installed on the sidewall construction (50) by a single person. One or more sealing members 207 secure and seal the siding members (150) to the apparatus (100) and provide a moisture impervious seal between the seams of successive layers of the horizontal siding members (150).

Owner:TROPICAL STAR

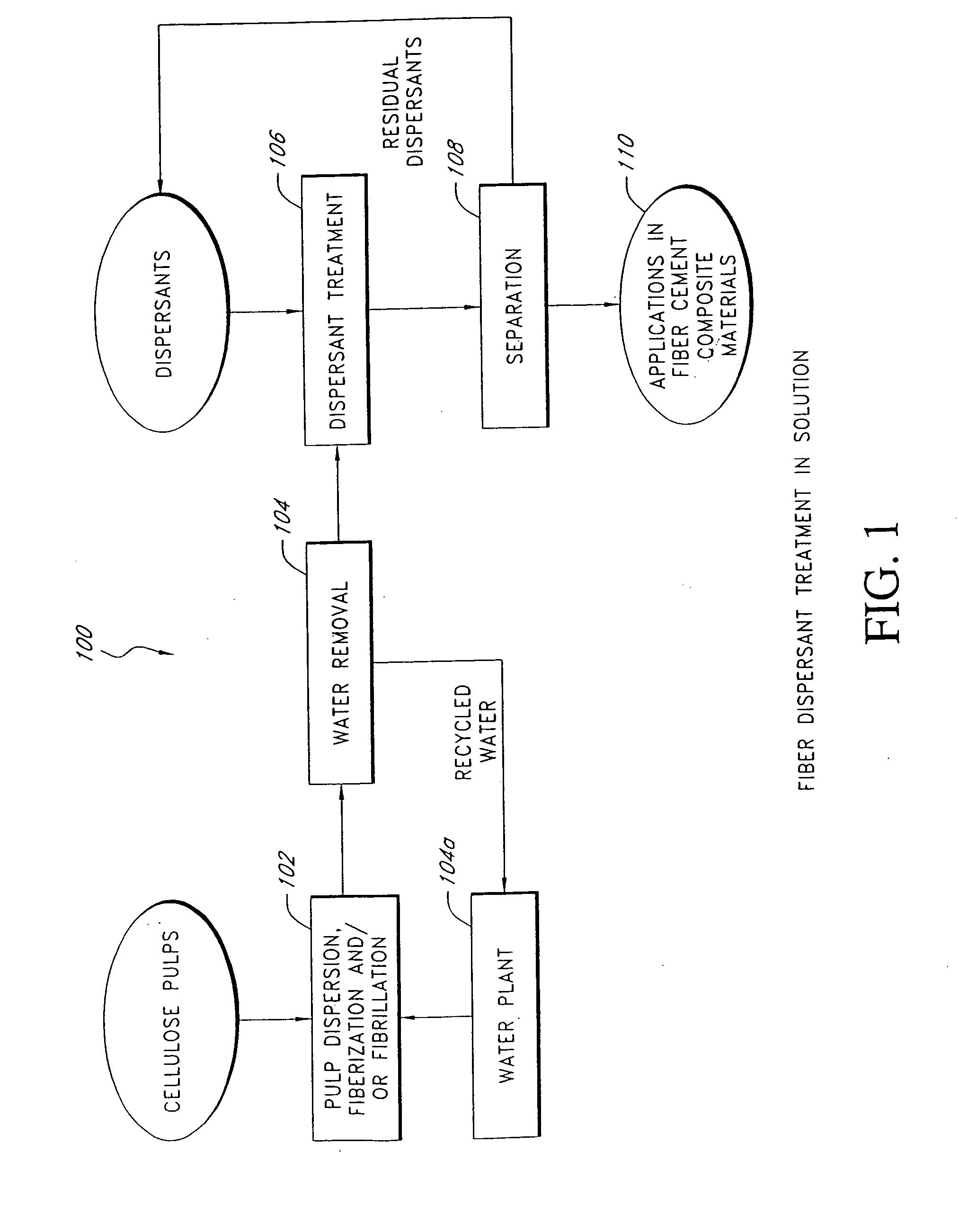

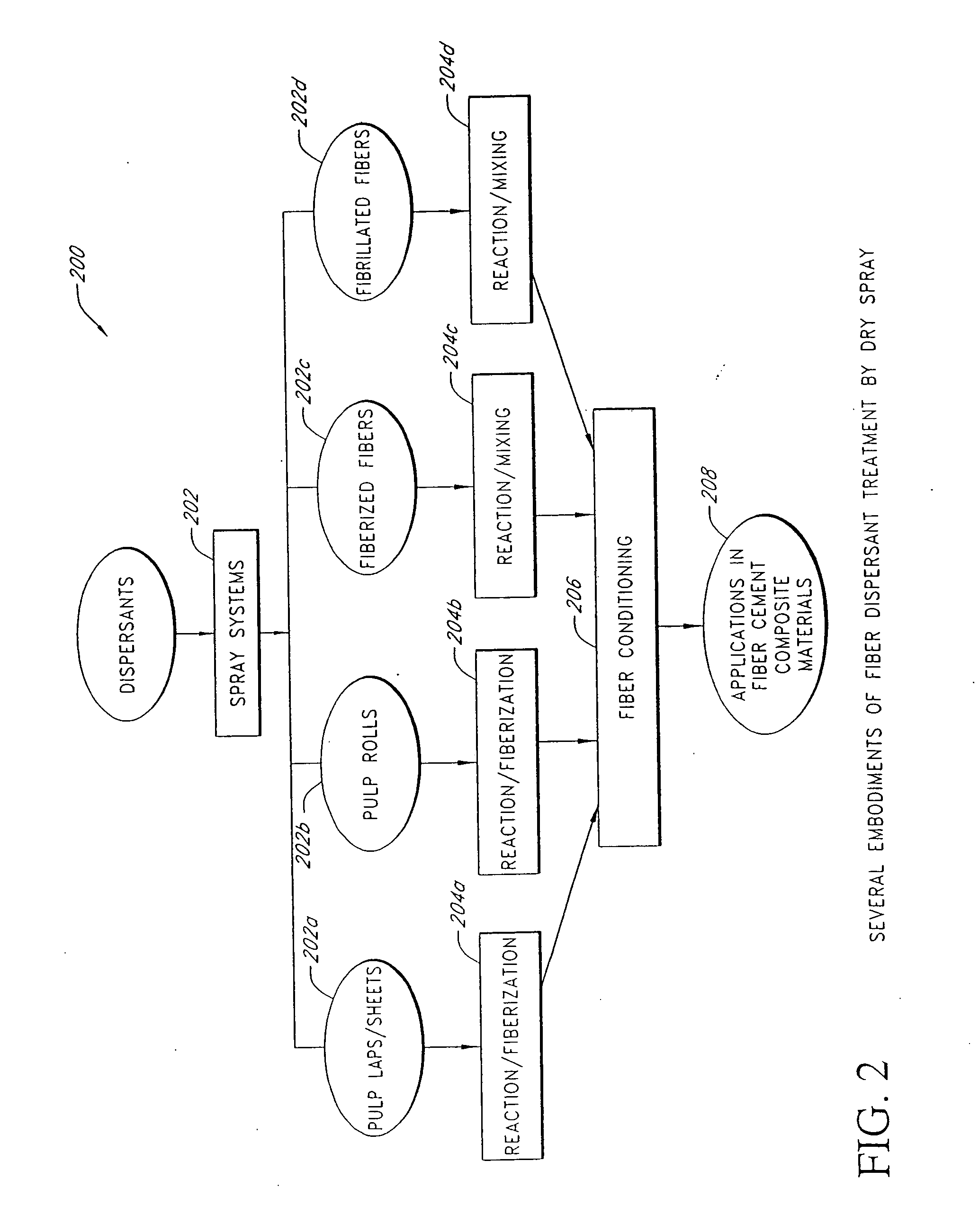

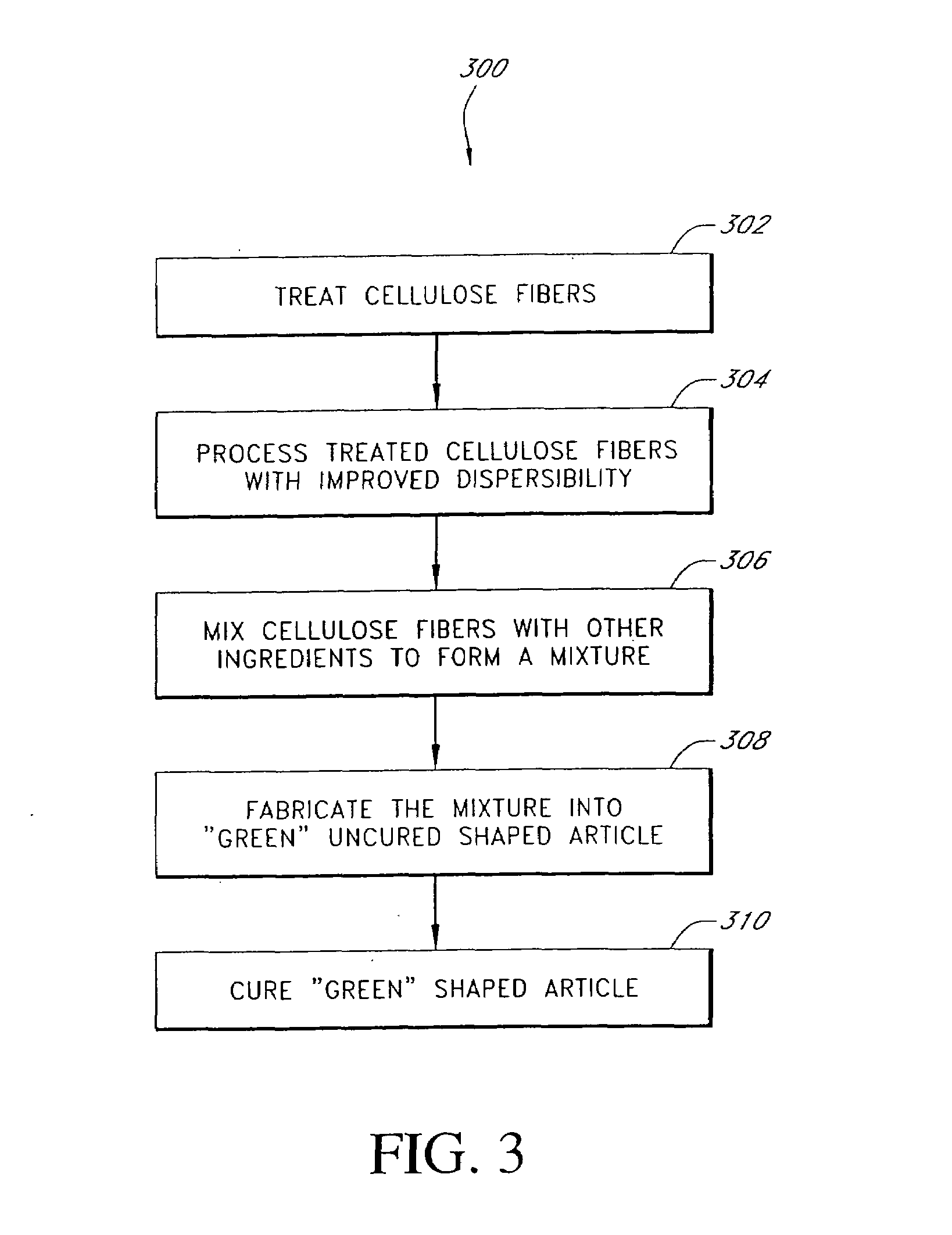

Fiber reinforced cement composite materials using chemically treated fibers with improved dispersibility

InactiveUS20080148999A1Good dispersionAvoid bondingPulp properties modificationSolid waste managementChemical treatmentSurface finish

A fiber-reinforced building material in one embodiment incorporates cellulose fibers that are chemically treated with a dispersant to impart improved dispersibility to the fibers. The fibers are treated with a dispersant which deactivates the hydroxyl sites of the fiber surfaces and in some cases, making the fiber surface more hydrophobic. The dispersant inhibits the hydroxyl groups on the cellulose fiber surface from bonding with hydroxyl groups of other fibers and from bonding with hydroxyl groups of the same fiber, thereby significantly reducing inter-fiber and intra-fiber hydrogen bonding. The treated fibers can be readily dispersed and uniformly distributed throughout a mixture without re-clustering or reclumping once the mechanical mixing action stops. The chemically treated fibers with improved dispersibility improve the fiber distribution and reinforcing efficiency, which in turn improves key physical and mechanical properties of the material such as the modulus of rupture, z-direction tensile strength, and toughness, and surface finishes. With improved fiber reinforcing efficiency, less dosage of fiber is needed to achieve the required physical and mechanical properties.

Owner:JAMES HARDIE TECH LTD

Fibre-reinforced cement compound external wall panel and method of producing the same

The present invention relates to a fiber-reinforced cement composite exterior wallboard and the preparation method. In the present invention, 60 to 100 portion of cement are used as the cementing material; 10 to 20 portion of calcium powder and 10 to 30 portion of silica powder are used as the aggregate material; 2 to 10 portion of closed microporous expanded perlite after pretreatment are used as the light aggregate material; 5 to 20 portion of wood fiber, 2.5 to 15 portion of wood powder and 0 to 1.5 portion of polypropylene fiber are used as the reinforcing material; besides, 0.2 to 20 portion of methyl cellulose, 20 to 40 portion of secondary powder coal ash, 0 to 8 portion of pulp and 0 to 6 portion of initial setting agent are added; after mixed in a material mixing machine and kneaded in a kneading machine, the materials are arranged in a mold and then compressed by a flat sulfuration machine to form the exterior wallboard. The exterior wallboard of the present invention uses low-cost materials and material without harmful substances to human bodies such as asbestos and so on; with a simple and fine production process, the prepared products has good performances of heat preservation, heat insulation and sound insulation, and is an energy-saving exterior wallboard. The present invention also solves the problems of wet operation and strong labor intensity in operation of preparing exterior wallboards.

Owner:BEIJING NEW BUILDING MATERIALS PLC

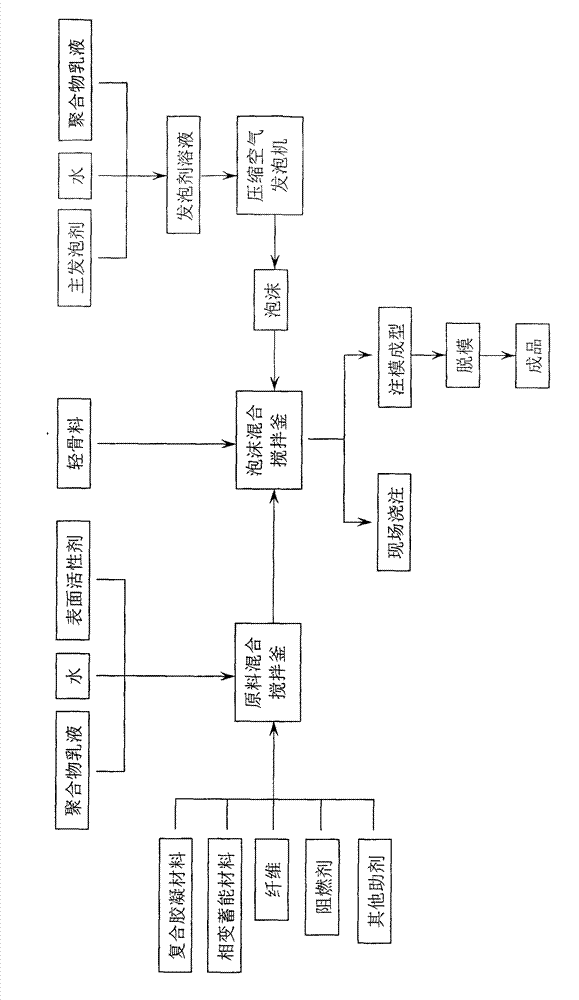

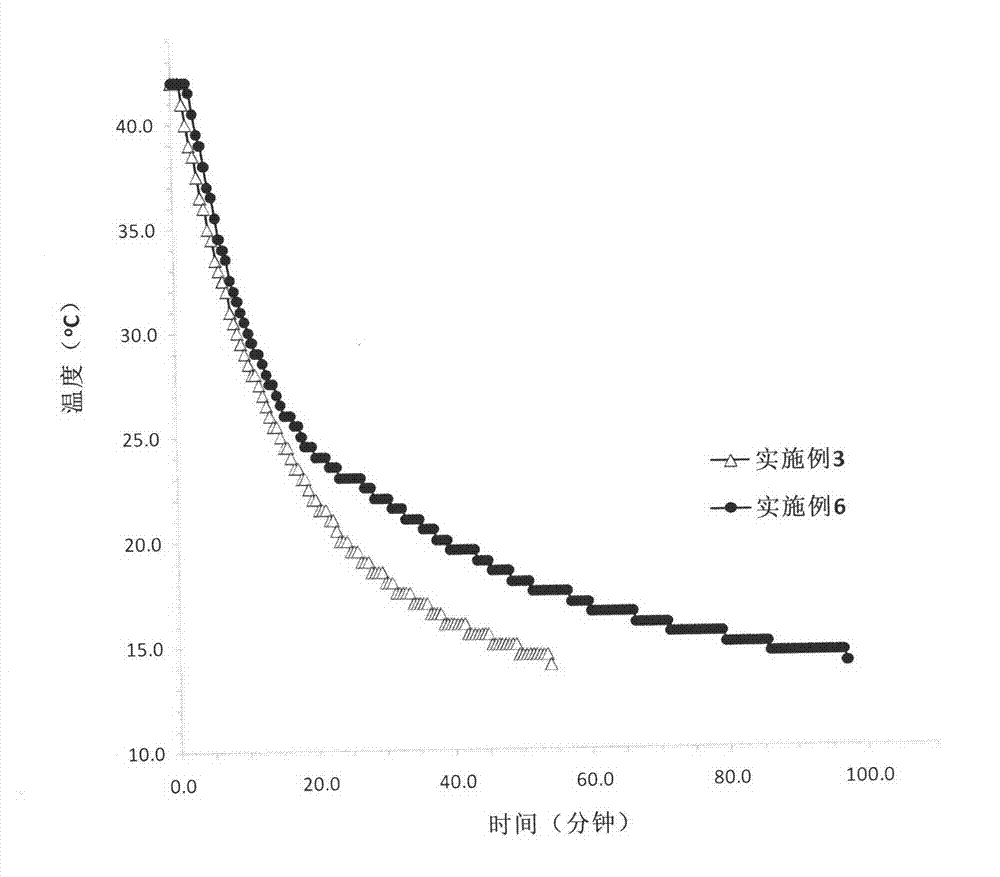

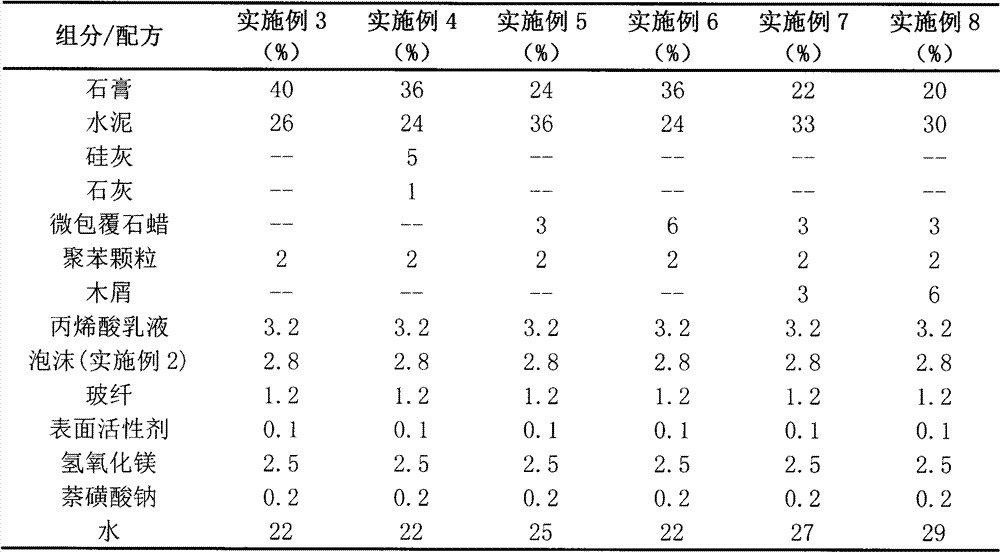

Energy storage energy-efficient foam gypsum cement composite material and preparation method thereof

ActiveCN102765959AImprove fire performancePrevent high temperature penetrationCeramicwareInsulation layerThermal insulation

The invention relates to an energy storage energy-efficient foam gypsum cement composite material and a preparation method thereof. The formula thereof is composed of a composite cementing material, lightweight aggregate, a phase change energy storage material, polymer latex, foam and a foaming agent. The composite cementing material is mainly composed of semi-hydrated gypsum and cement. The preparation method thereof comprises the steps of: preparing a foaming agent solution to prepare stable foam; thoroughly mixing water, polymer emulsion and other liquid state components with the composite cementing material, the phase change energy storage material and other additives such as solid-state components; and sending the solid-liquid mixed slurry to a foam-mixing kettle filled with the lightweight aggregate, while introducing the foam, to prepare the foam gypsum cement composite slurry. The inorganic composite foam material of the present invention has an energy storage function absorbing heat during the day and radiating heat at night, so as to effectively maintain a comfortable indoor temperature, is fire-proof, heat preservative, humidity-adjustable, good in water-resistance, and high in strength, and can be used for manufacturing fireproof insulation layers or fireproof insulation zones for interior and exterior walls of buildings, heat insulation, fire proof and heat preservation wallboards, door panels and core materials, steel structure fireproof cladding materials and the like.

Owner:南京依科国特新材料科技有限公司

Apparatus for aiding in the installation and sealing of siding

InactiveUS7584587B2Prevent penetrationRoof covering using tiles/slatesCovering/liningsCement compositesEngineering

An apparatus (100) for aiding in the installation of successive horizontal layers of siding members (150) to a sidewall construction (50) of a building. The apparatus also seals the vertical and horizontal seams between adjoining and successive horizontal layers of the siding members (150). In the exemplary embodiment of the invention, the apparatus (100) is used to aid in the installation and sealing of siding members (150) comprised of a fiber cement composite material. The fiber cement composite siding members (150) are heavier than traditional siding pieces and require more than one person to lift for installation. With the use of the apparatus (100), successive horizontal layers of composite siding members (150) can be installed on the sidewall construction (50) by a single person. One or more sealing members (107) secure and seal the siding members (150) to the apparatus (100) and provide a moisture impervious seal between adjoining and successive horizontal layers of the siding members (150).

Owner:TROPICAL STAR

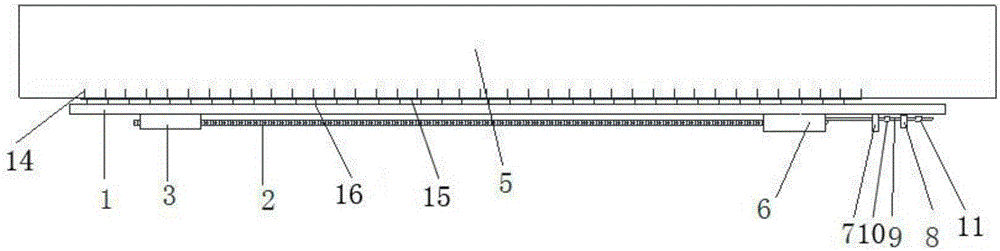

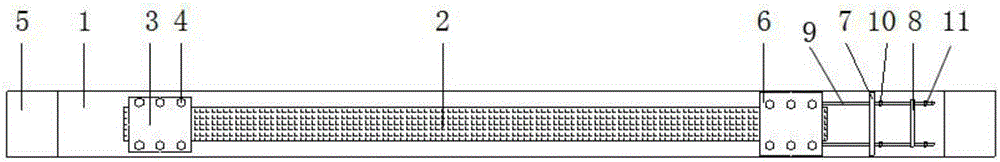

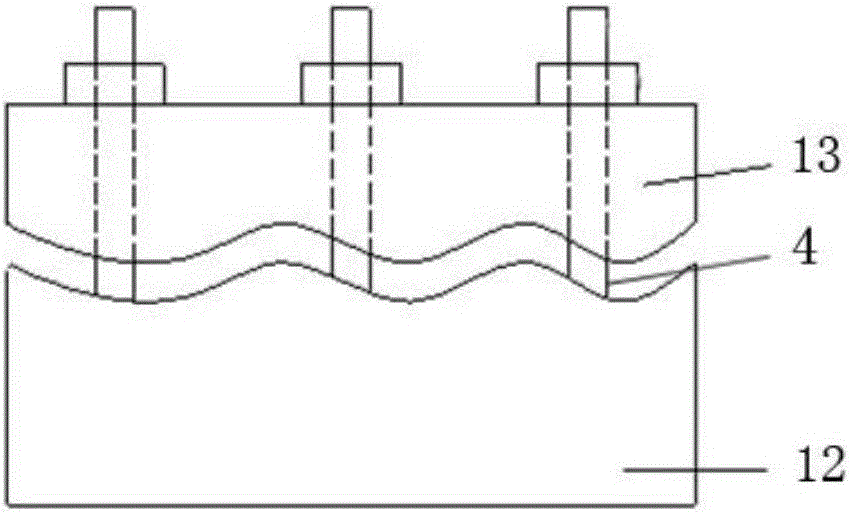

Method for reinforcing concrete beam by prestressed carbon fiber plate and steel-concrete

ActiveCN105887702AImprove bearing capacitySolve the problem of difficult anchoringBridge erection/assemblyBridge strengtheningSheet steelCement composites

The invention provides a method for reinforcing concrete beam by a prestressed carbon fiber plate and steel-concrete. The method comprises the following main steps of firstly, chiseling off a concrete protecting layer on the bottom surface of the concrete beam, drilling and embedding steel bars, and arranging a layer of a steel bar mesh; secondly, blanking a steel plate, and respectively welding waved toothed plates at an anchoring end and a tensioning end of the steel plate for constraining the carbon fiber plate; thirdly, fixing the steel plate on the steel bar mesh, and taking the reinforcing steel plate as a bottom die to prepare and cast self-compacting concrete; fourthly, applying prestress by adopting a jack, tensioning the carbon fiber plate and anchoring; finally, varnishing cement composite mortar on the surface of the prestressed carbon fiber plate and the waved toothed plates as protecting layers to finish the bending resistance and reinforcing of concrete. According to the reinforcing method provided by the invention, the convenience in construction is realized, and the required equipment is simple; the bending capacity, rigidity and the durability of the existing concrete beam can be remarkably improved, and the service life is prolonged; the reinforcing method is particularly suitable for conditions of concrete spalling, carbonization and other damages at the bottom of the concrete beam.

Owner:WUHAN UNIV OF TECH

Enhanced cement composite grinding aid

InactiveCN101665339AAvoid dependenceMeet Raising Cement EarlyCement productionCement compositesTriisopropanolamine

The invention patent relates to an enhanced cement composite grinding aid, pertaining to a cement additive. The enhanced cement composite grinding aid has the following main ingredients in percentagesby weight: 45 percent to 90 percent of diethanol isopropanolamine, 10 percent to 30 percent of molasses, 5 percent to 20 percent of lignosulphonate, 0 percent to 15 percent of inorganic dispersant and 0 percent to 30 percent of water. The main ingredient of the grinding aid, diethanol isopropanolamine, is a substitute for trolamine and triisopropanolamine in respect of property and the property thereof is superior to single trolamine or triisopropanolamine grinding aid. The application of the enhanced cement composite grinding aid to cement production can effectively increase output per machine hour of a grinder, improve cement strength in early period and later period, and reduce cement production cost.

Owner:惠州市富力新技术有限公司

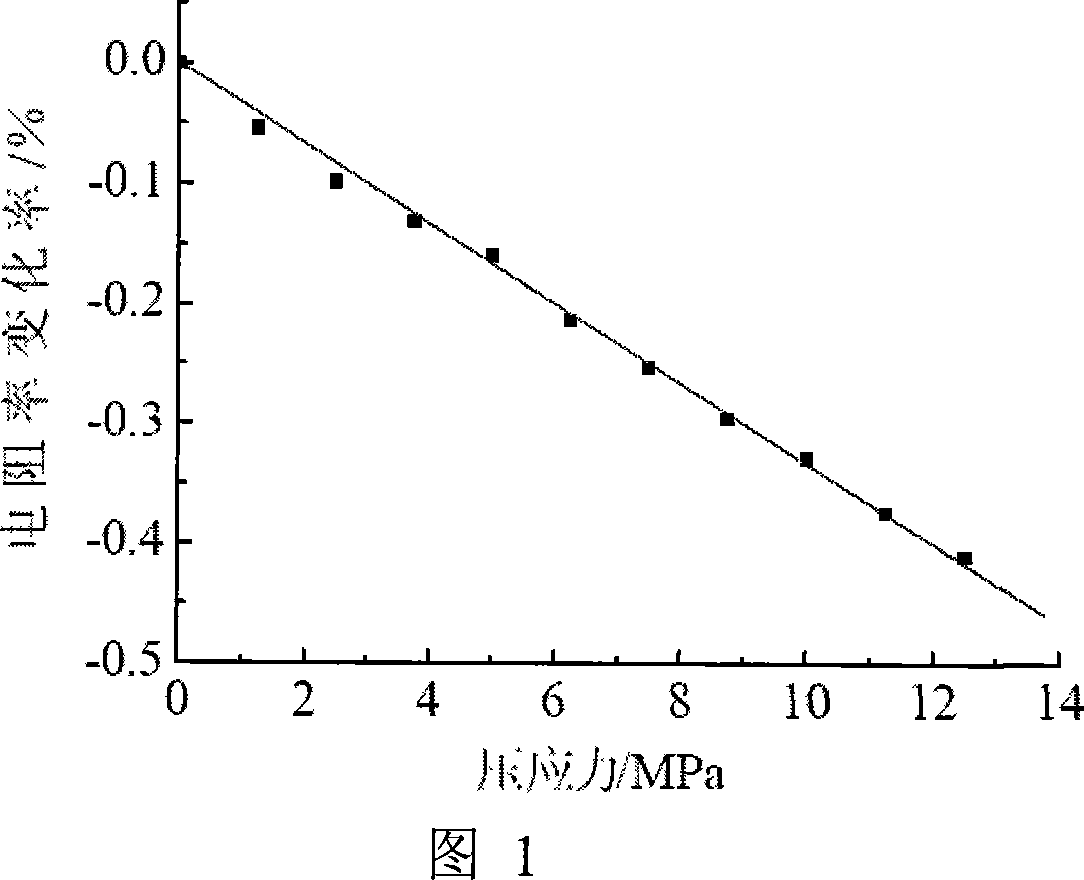

Pressure-sensitive cement-base composite material

InactiveCN101121582AHigh sensitivity to force-electric coupling effectHigh sensitivitySolid waste managementCelluloseElectricity

The present invention discloses a pressed cement composite material, which relates to a cement composite material; the present invention is to solve the shortcoming in the existing pressed cement material that: the sense ability for the force-electricity coupling effect is much lower, the existing method is influenced by the humidity greatly, and the base polarization is easy to influence the test of the electricity signal. The present invention consists of a function component and cement material; the function component is a nickel powder or a mixture between the nickel powder and one or more than one material including carbon cellulose, carbon, graphite and steel residual; the cement material is a glue material or a composite material between the glue material and the bone material; thereinto, the function component occupies between 1 percent and 80 percent in the total weight; and the rested is the cement material. The sense ability of the pressed cement composite material in the present invention is much higher; the sensitivity can reach to more than hundred or thousand, which is higher than the sensitivity of the existing pressed cement composite material with the function component including carbon cellulose, carbon and steel residual and so on. Besides, the force-electricity coupling effect for the material is much smaller by the humidity; the test of the electricity signal is not easy to be influenced by the base polarization.

Owner:HARBIN INST OF TECH

Three-dimensional fiber inorganic composite product and production method thereof

ActiveCN102296776AMeet a wide range of needsImprove plasticityCovering/liningsCement compositesReinforced concrete

The invention relates to a three-dimensional fiber inorganic composite (FCC: Fiber Cement Composite) product and a production method thereof, and the three-dimensional fiber inorganic composite product comprises a decorative layer and a three-dimensional fiber-reinforced cement structure layer. The decorative layer is prepared from decorative mortar and can be subjected to fiber reinforcement; and the structure layer is prepared from the fiber with high elastic modulus, the fiber with low elastic modulus and reinforced concrete mortar in three-dimensional distribution, and 0-3 layers of reticular reinforcing material is further laid. The decorative layer and the structure layer are compounded in a mold with the decorative effect and can be prepared by adopting an integral formula and process. The product is prepared through the fiber mixing technology and the premixing and forming technology, a high-performance novel material applied to the fields of building decoration engineering, anti-cracking engineering construction, building exterior wall repair and the like is realized, the product has the advantages of light weight, high strength, high durability, anti-cracking property and the like, and fiber-reinforced exterior wall plates, decoration members and other products in complex shapes and fineness can be further manufactured. Simultaneously, as the production process is simple, the degree of mechanized production is high, the production cost is low and the range of market applications is broad.

Owner:江苏倍立达新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com