Patents

Literature

3830results about "Water-repelling agents addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

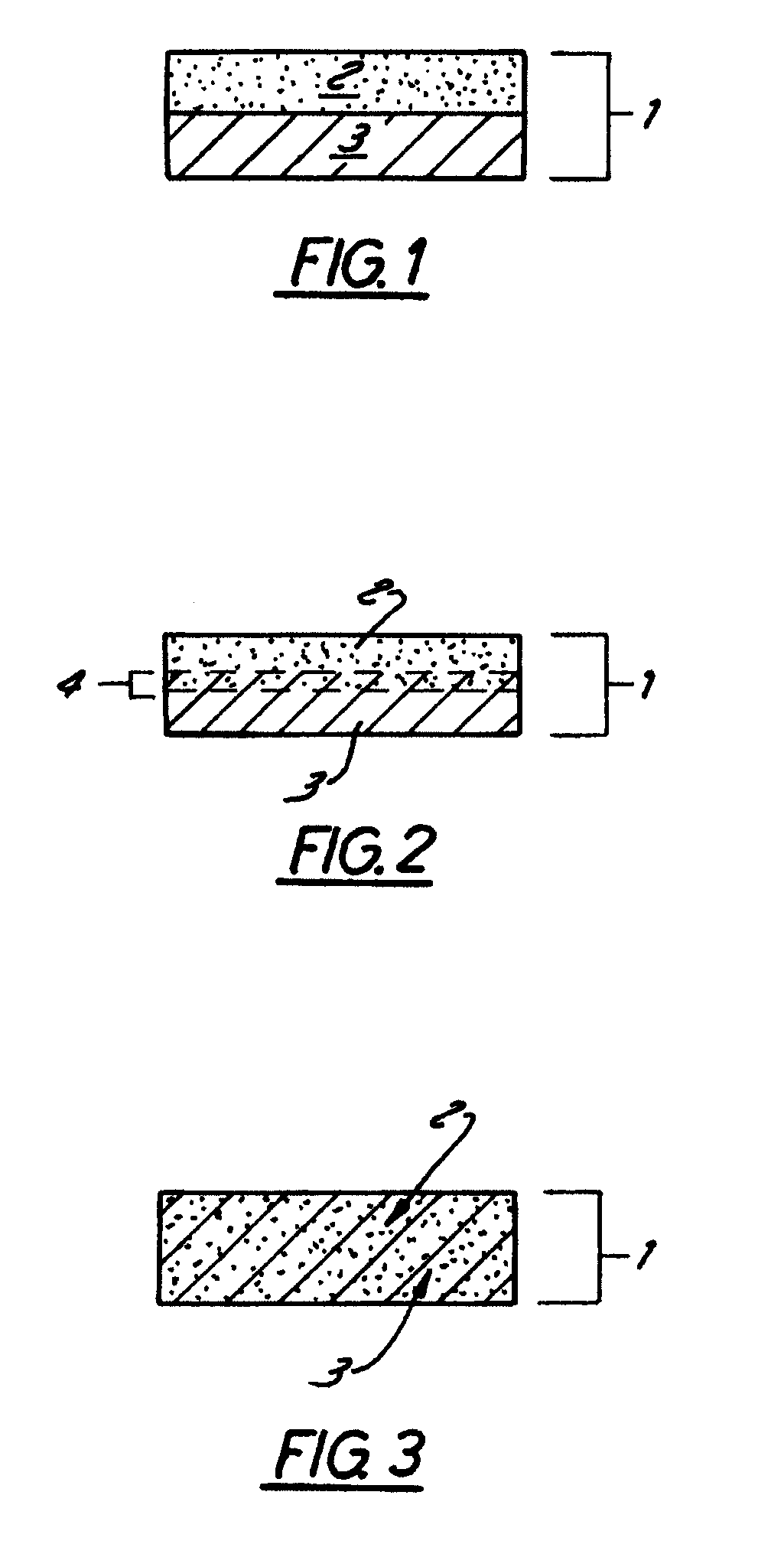

Dual-zoned absorbent webs

InactiveUS6911573B2Fast shippingImprove adaptabilityNatural cellulose pulp/paperMechanical working/deformationCelluloseEngineering

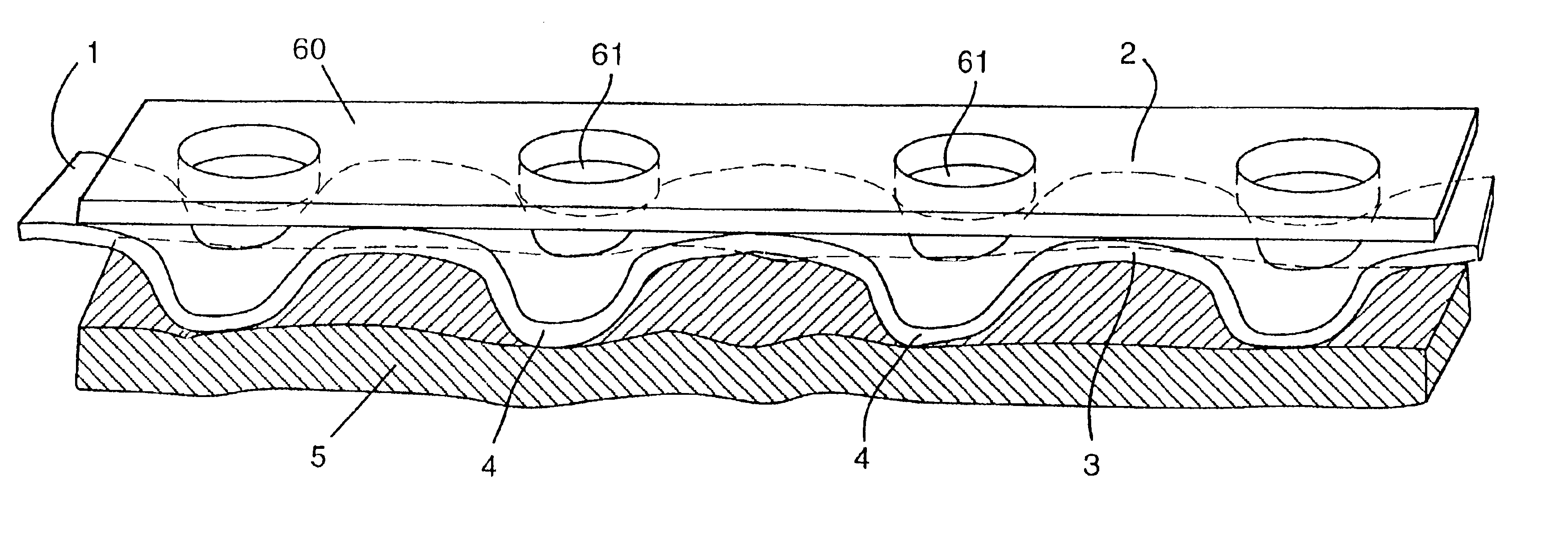

The present invention is a method for producing an absorbent article. A wet resillient, cellulosic basesheet having elevated and depressed regions with an Overall Surface Depth of at least 0.2 mm is prepared. The cellulosic basesheet has an upper surface and a lower surface. A contiguous, fibrous nonwoven web having a plurality of openings is integrally attached onto the upper surface of the cellulosic basesheet such that a portion of the openings are superposed over the depressed regions of the cellulosic basesheet. An absorbent core and an impervious web are attached to the lower surface of the cellulosic basesheet such that the absorbent core is sandwiched between the impervious web and the cellulosic basesheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

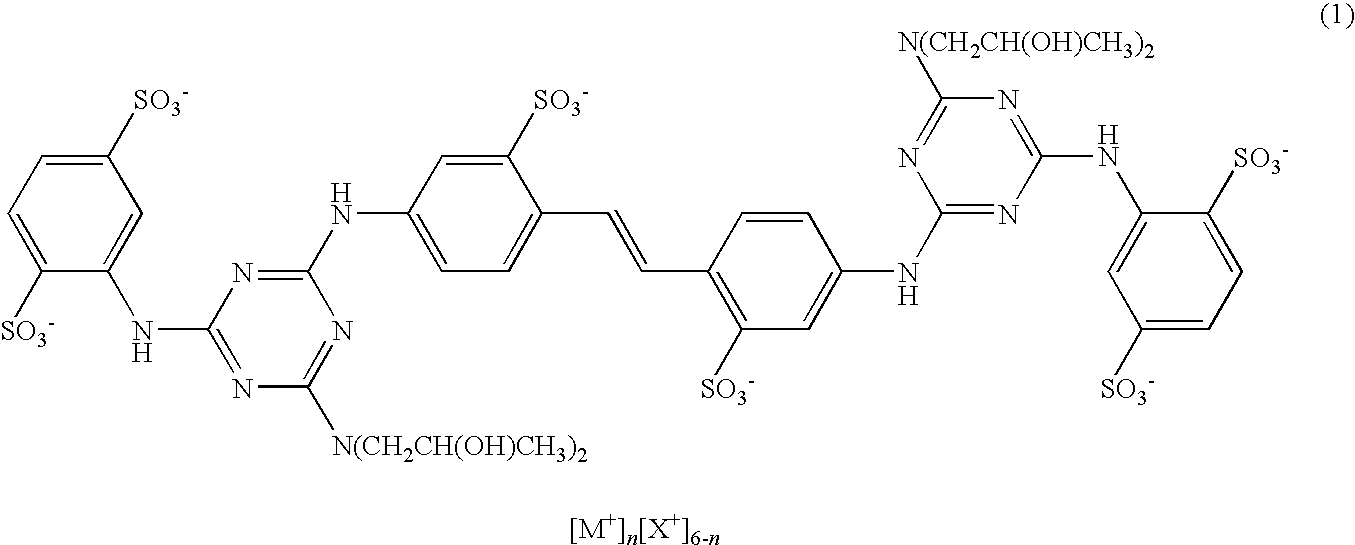

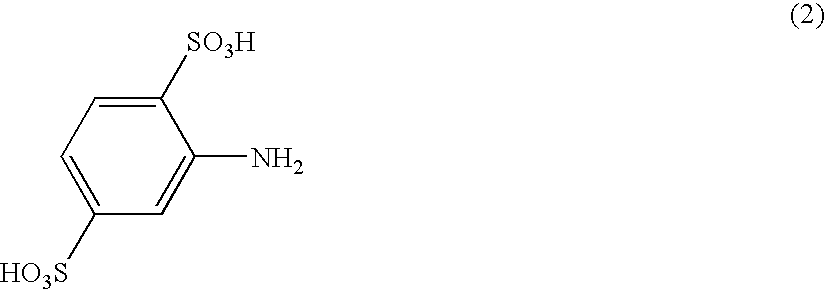

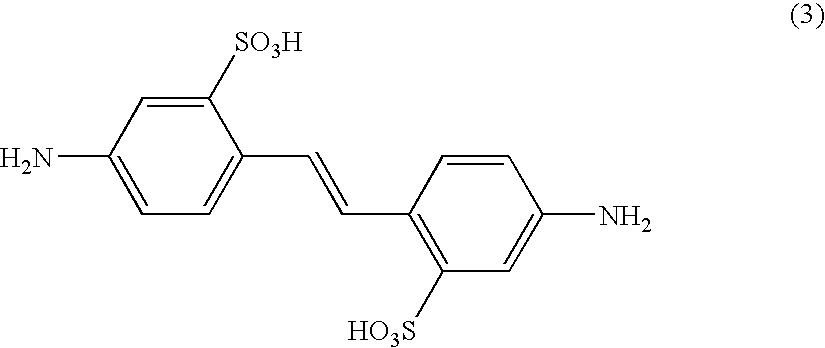

Method and composition for the sizing of paper with a mixture of a polyacid and a polybase

InactiveUS6171444B1Easy to produceHigh color fastnessNatural cellulose pulp/paperSpecial paperHueWater resistant

Compositions and methods are provided for the sizing of paper, to enhance the quality of images printed thereon. The novel sizing compositions contain as a sizing agent a mixture of a polyacid and a polybase. When applied to a paper substrate, such as in an internal or external sizing process, the sizing compositions result in a sized paper substrate that provides high quality printed images when printed with an ink containing a reactive dye having ionizable and / or nucleophilic groups capable of reacting with the sizing agent. Images printed on a paper substrate coated with the sizing compositions of the invention are bleed-resistant, water-resistant (e.g., water-fast), and / or are characterized by an enhanced chroma and hue.

Owner:SRI INTERNATIONAL

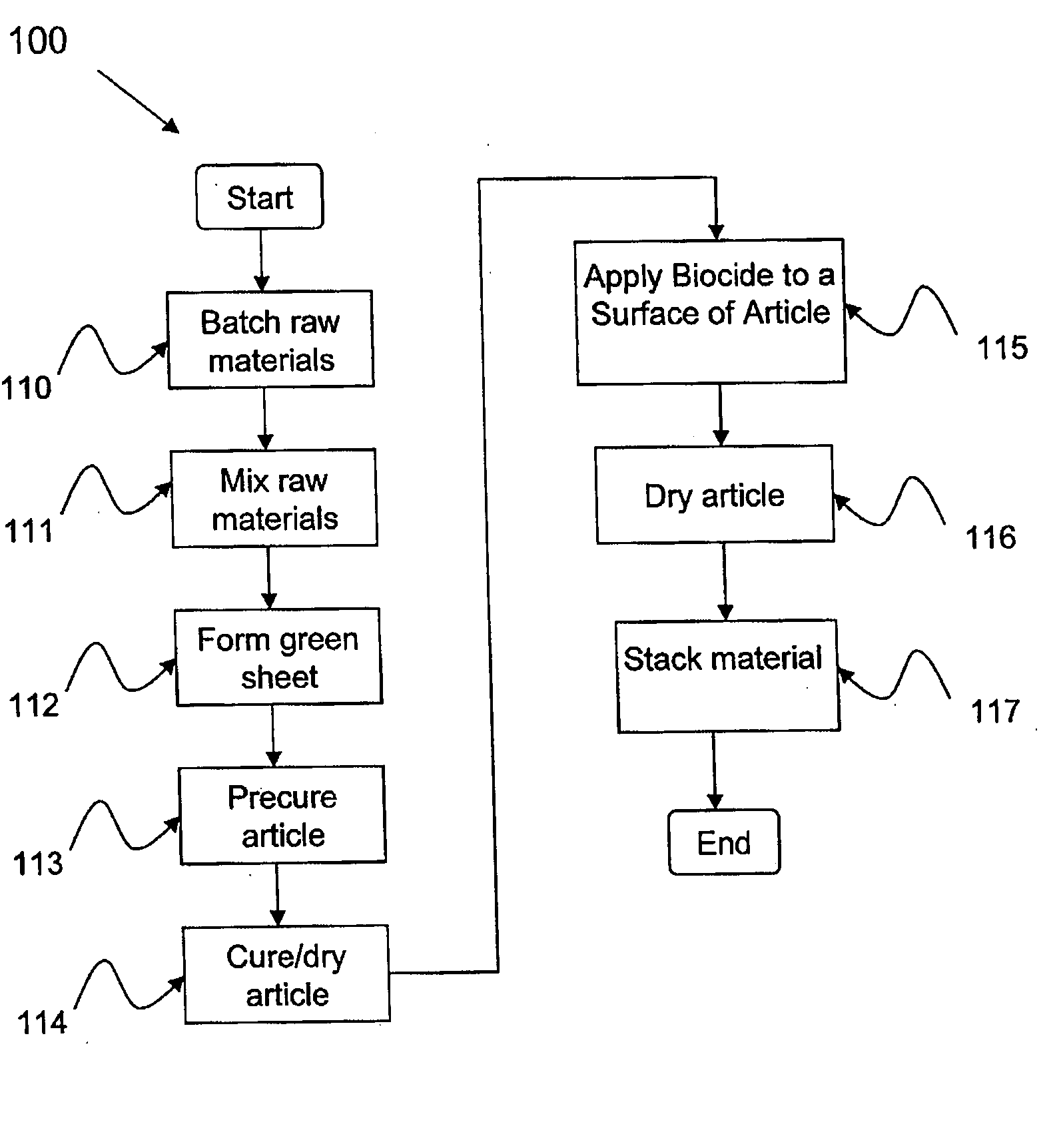

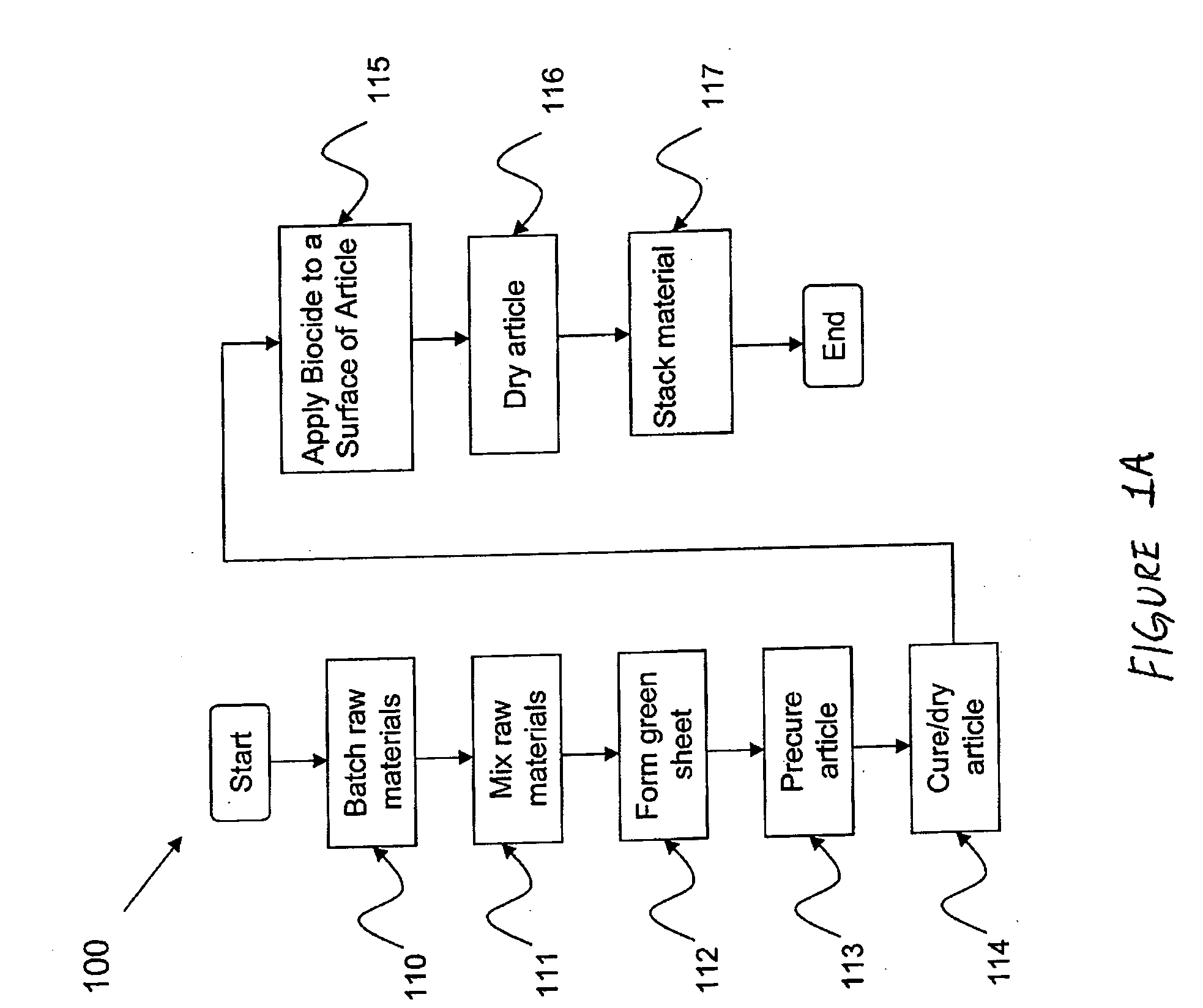

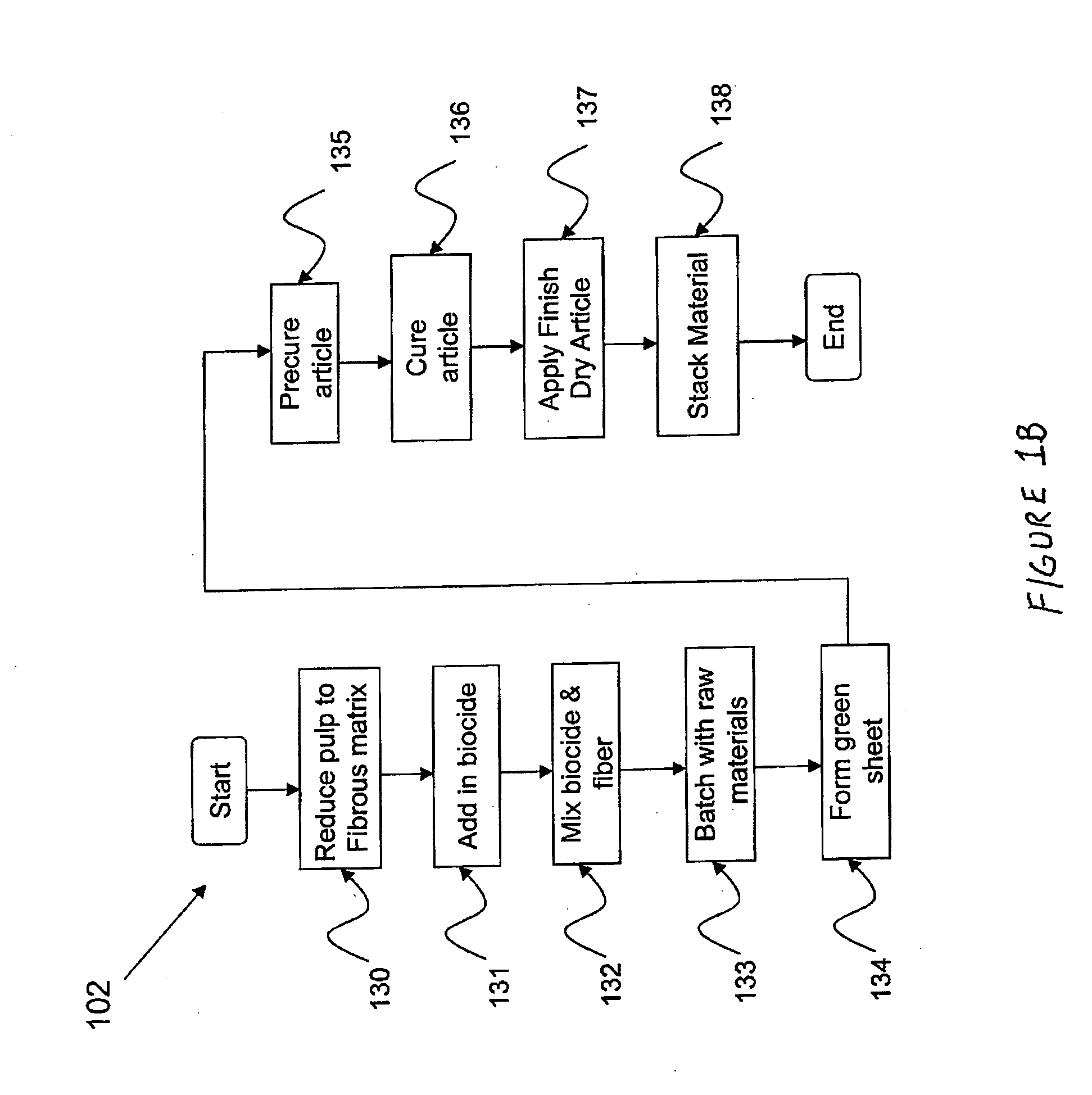

Building materials with bioresistant properties

InactiveUS20050126430A1Effective biocide treatmentAffecting performanceFireproof paintsAntifouling/underwater paintsFiberBiological resistance

A building article incorporating a biocidal agent, such as copper oxine, that inhibits the growth of mold, fungi, algae, mildew, bacteria, lichen, and other undesirable biological growth is provided. The biocidal agent can be a biocide, fungicide, germicide, insecticide, mildewcide, or the like. The biocidal agent can be interspersed throughout the matrix of the article; applied as a surface treatment to the article; or applied as a treatment to the fibers reinforcing the article. The building article can include tile backer boards, decks, soffits, trims, decking, fencing, roofing, cladding, sheathing, and other products. The building article can also include a variety of different composite materials such as cement, gypsum, wood, and wood / polymer composites.

Owner:JAMES HARDIE TECH LTD

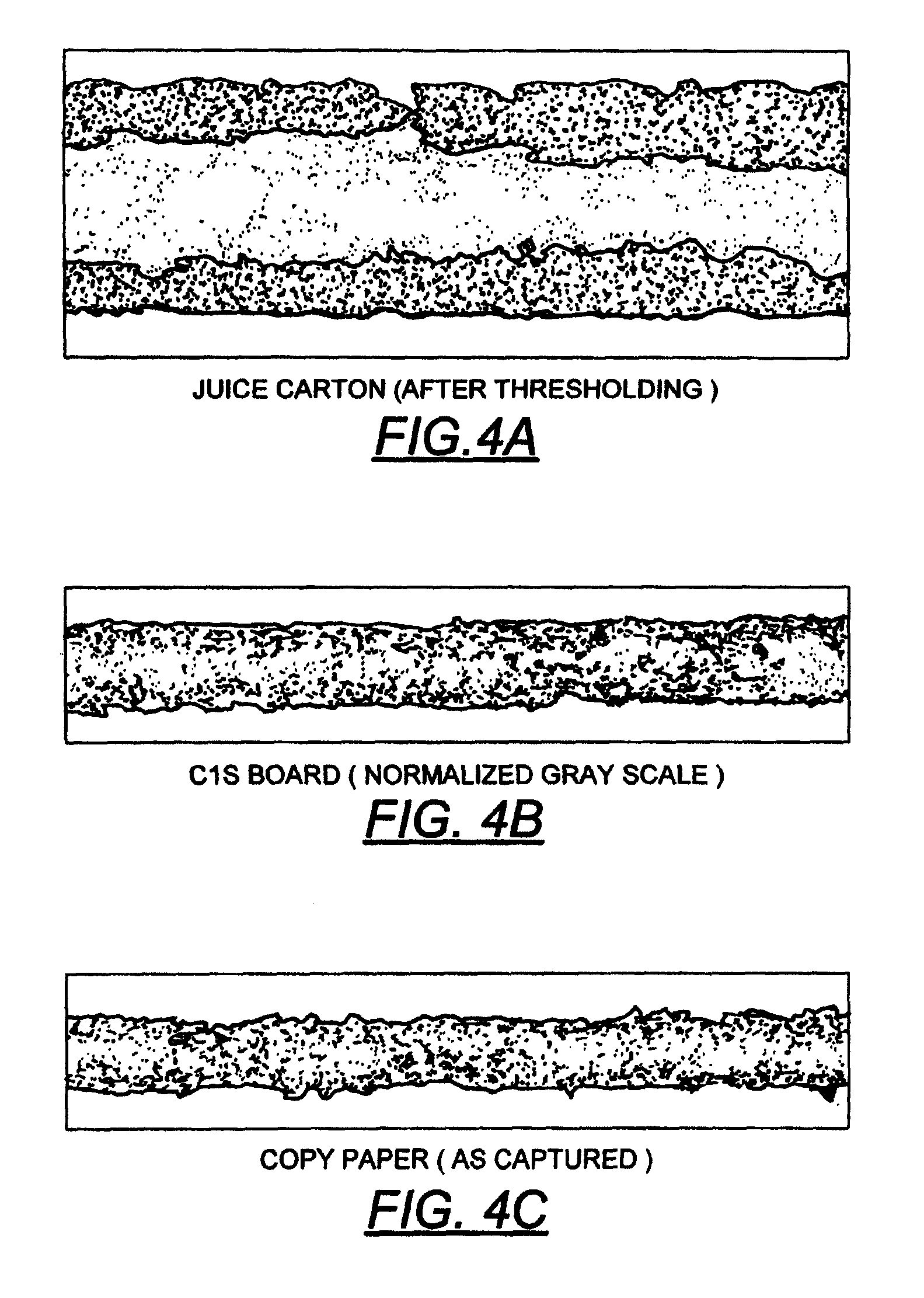

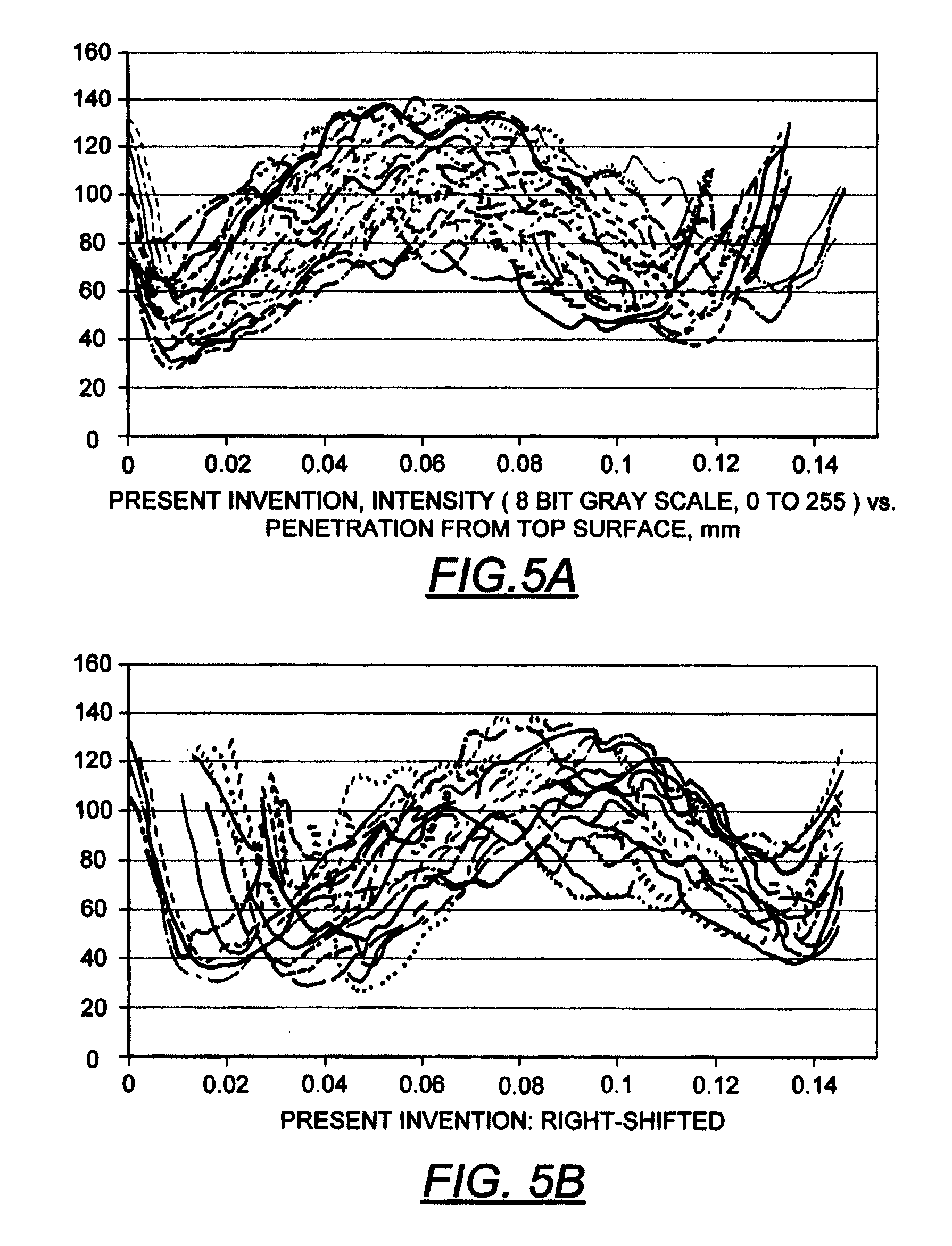

Absorbent sheet exhibiting resistance to moisture penetration

ActiveUS20040250969A1Reduce feelingsReduce wetted areaNatural cellulose pulp/paperMechanical working/deformationWaxFiber

An absorbent paper sheet is treated with an aqueous wax dispersion such that the sheet includes a fused wax and emulsifier residue in an amount of from about 1 to about 20 weight percent of the sheet based on the combined weight of the fiber, wax residue and an emulsifier residue in the sheet. The fused wax emulsion operates to make at least one surface of the sheet laterally hydrophobic, exhibiting a moisture penetration delay of at least about 2 seconds and less than about 40 seconds as well as a typical contact angle with water at one minute of at least about 50 degrees. There is thus provided absorbent products which exhibit both absorbency and resistance to moisture penetration. The treated sheet further exhibits microbial barrier properties, impeding transfer of bacteria, for example, through the sheet. There are produced tissue products which resist moisture penetration from propelled liquids as well as sequester sorbed liquids in the interior of the tissue.

Owner:GPCP IP HLDG LLC

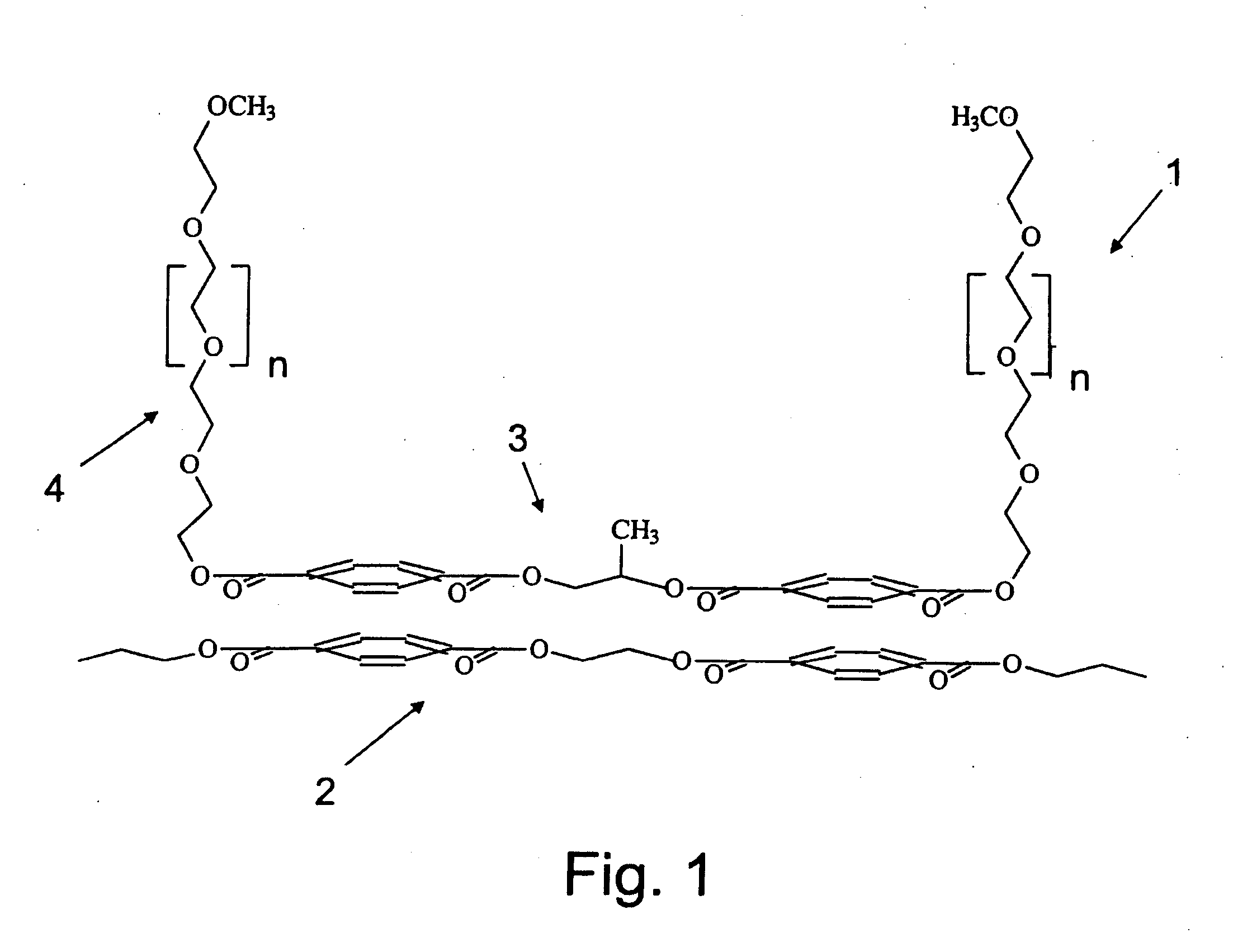

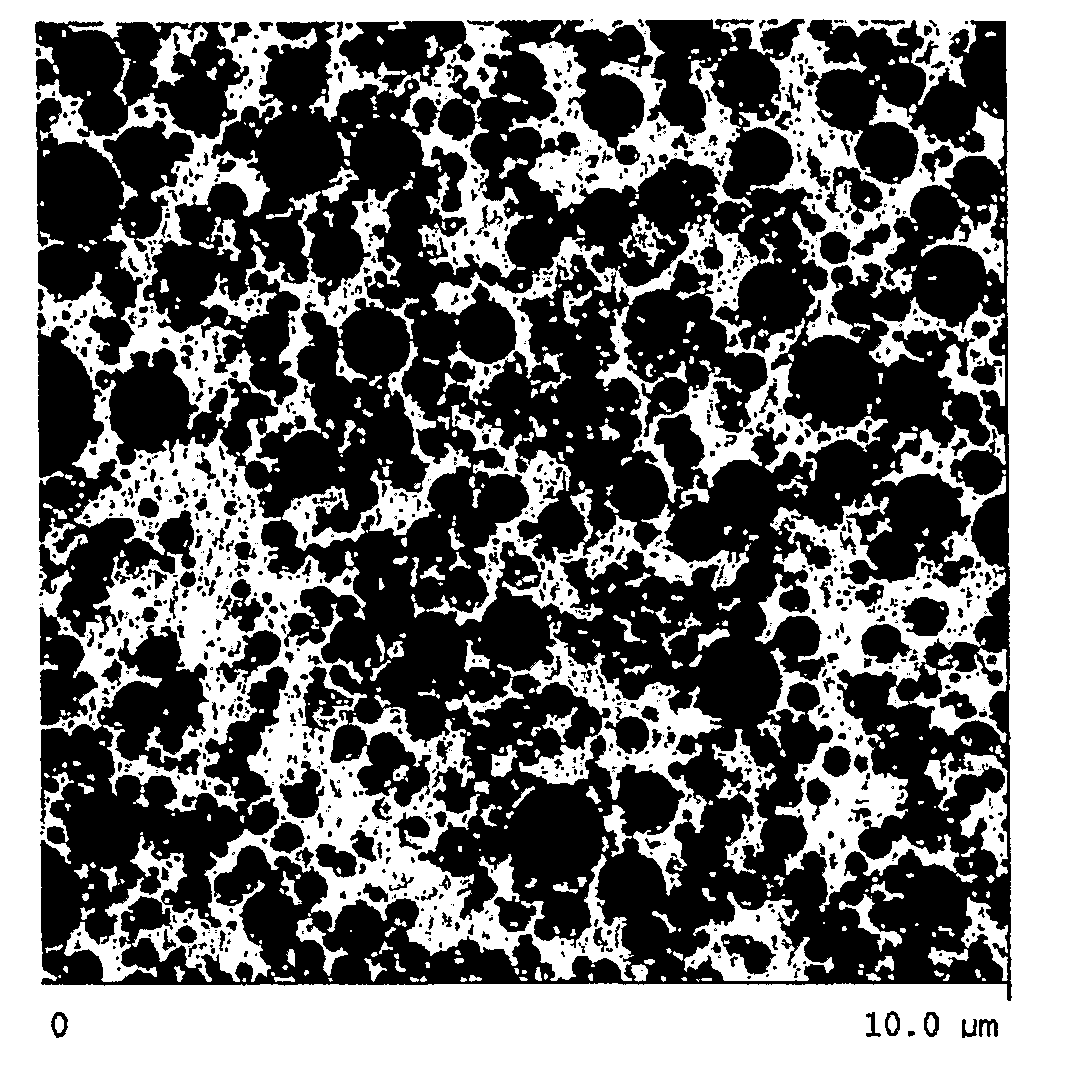

Super-amphiphobic polymer and super-amphiphobic surface prepared from super-amphiphobic polymer

InactiveCN102432742AGood scrub resistanceAccelerated corrosionWater-repelling agents additionPaper/cardboardPolymer scienceMicrosphere

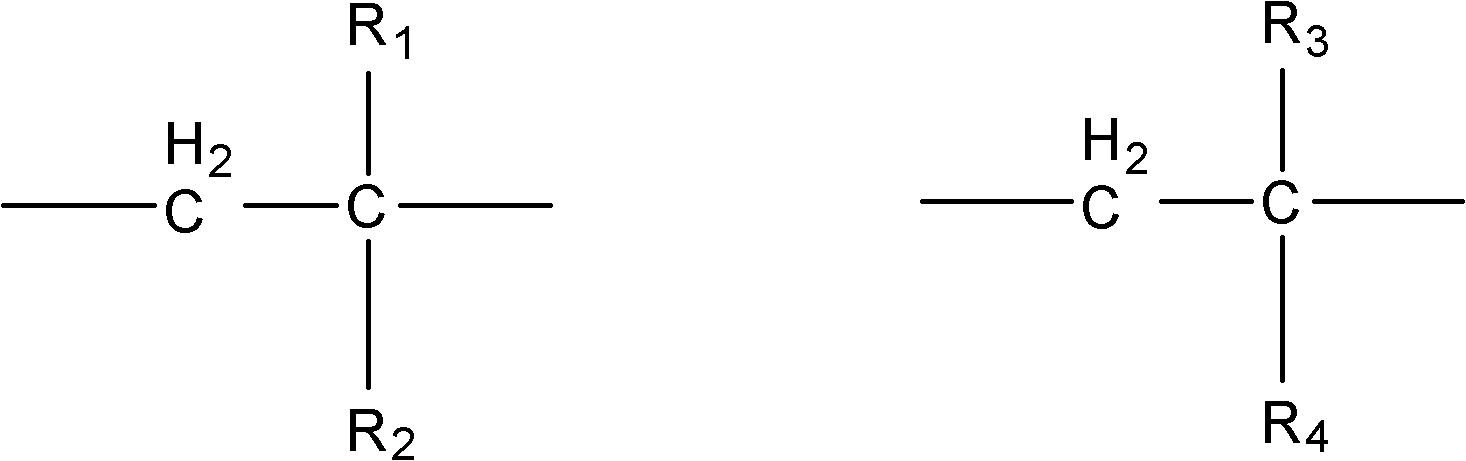

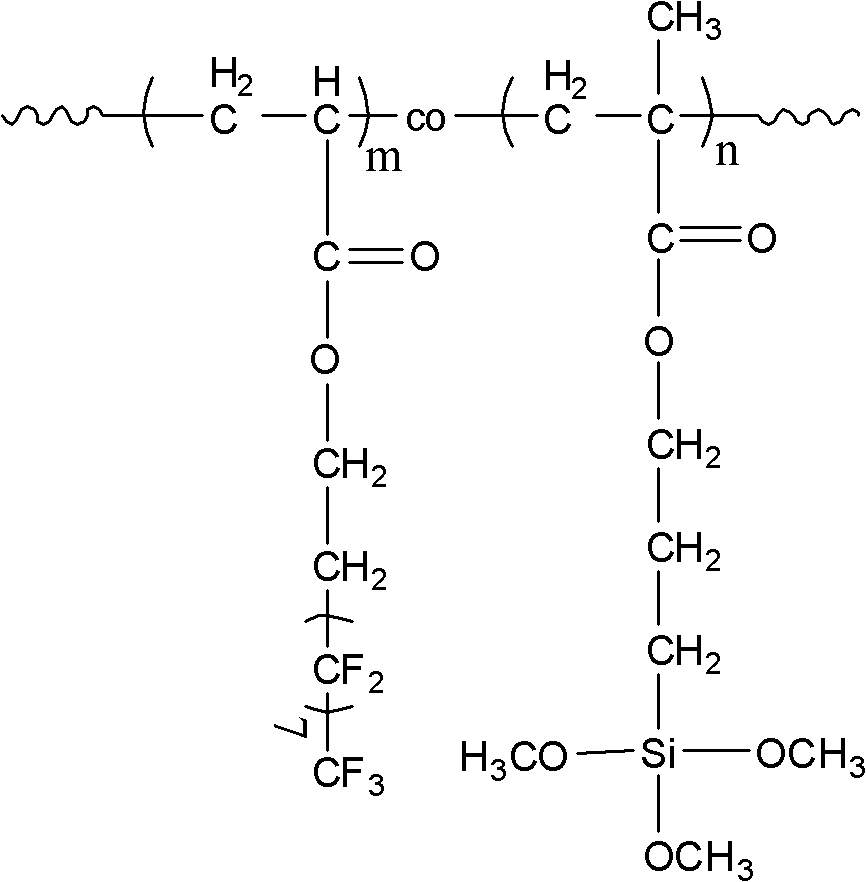

The invention belongs to the field of macromolecule super-amphiphobic materials and discloses a super-amphiphobic polymer and a super-amphiphobic surface. The super-amphiphobic polymer is a random copolymer composed of structural units shown as a formula I and a formula II. The super-amphiphobic surface is obtained by comprising the following steps of: pre-processing a substrate material; placinga micro-balloon in a fluorine-containing solvent, and ultrasonically dissolving to obtain a micro-balloon supernatant solution; adding the super-amphiphobic polymer, a hydrochloric acid tetrahydrofuran solution and water into the micro-balloon solution while stirring, placing the substrate material, and reacting for 5-24 h; and taking out the substrate material, washing by using the fluorine-containing solvent, methanol and water in turn, drying in vacuum, and obtaining the super-amphiphobic surface. The super-amphiphobic polymer disclosed by the invention can give good surface hydrophobic ability and oleophobic ability to the substrate. Because the polymer has the characteristics of the fluorine-containing polymer so that the polymer can be chemically bonded with the surface of the substrate, the obtained super-amphiphobic surface has good scrubbing resistant property and corrosion resistant property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Method for forming a fibrous structure comprising synthetic fibers and hydrophilizing agents

InactiveUS20070232178A1Natural cellulose pulp/paperWater-repelling agents additionEngineeringFiber structure

Owner:THE PROCTER & GAMBLE COMPANY

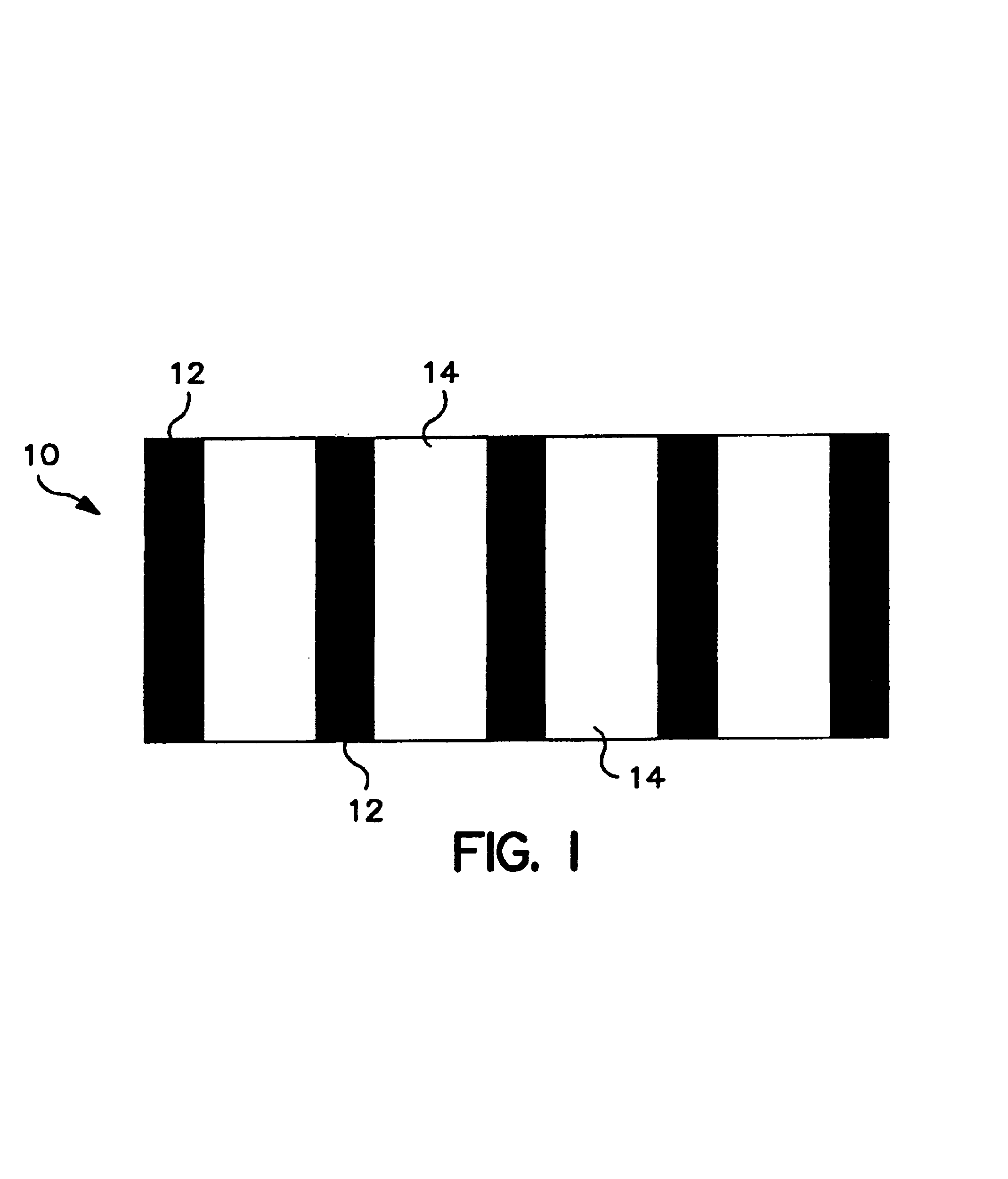

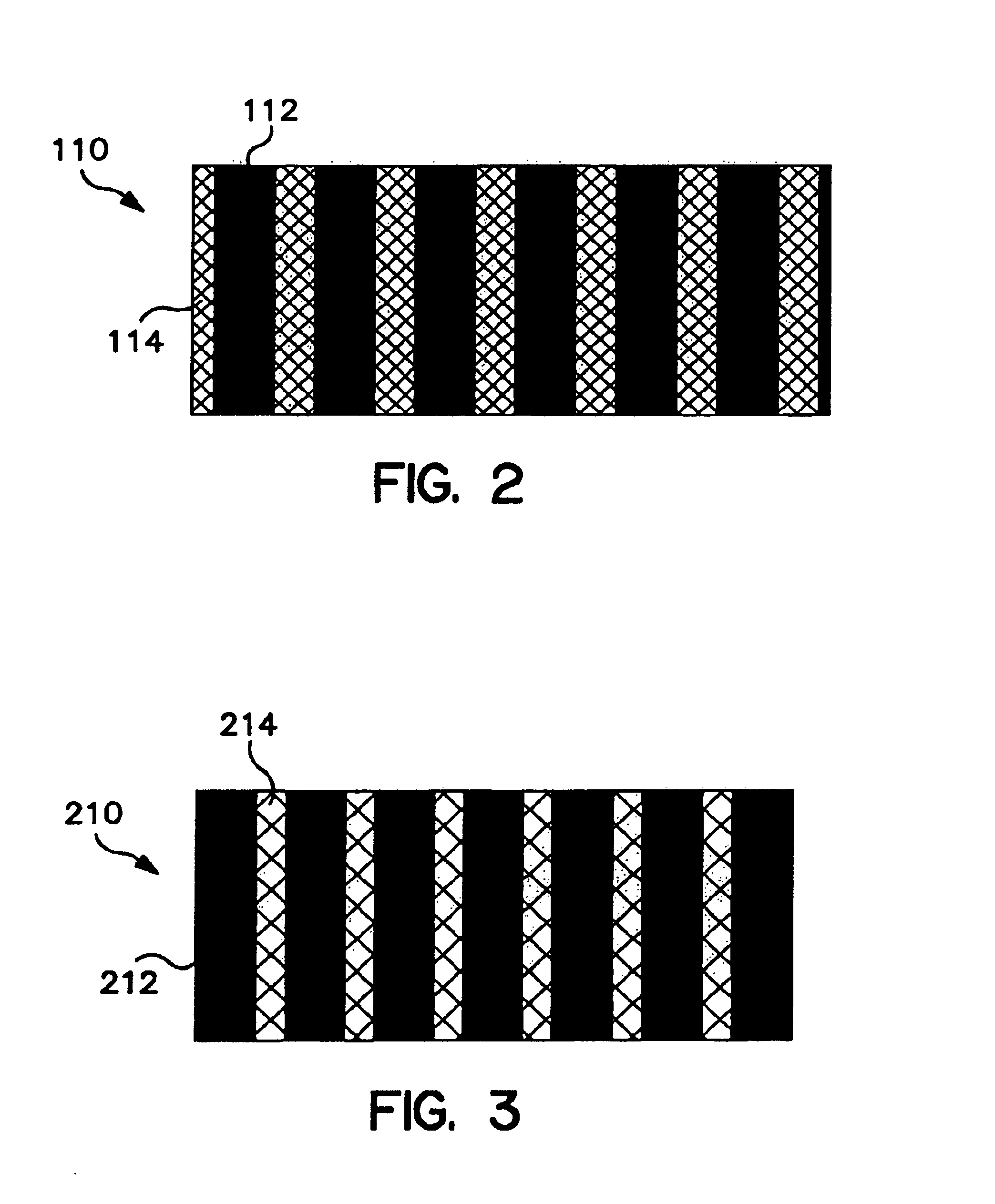

Paper wiping products treated with a hydrophobic additive

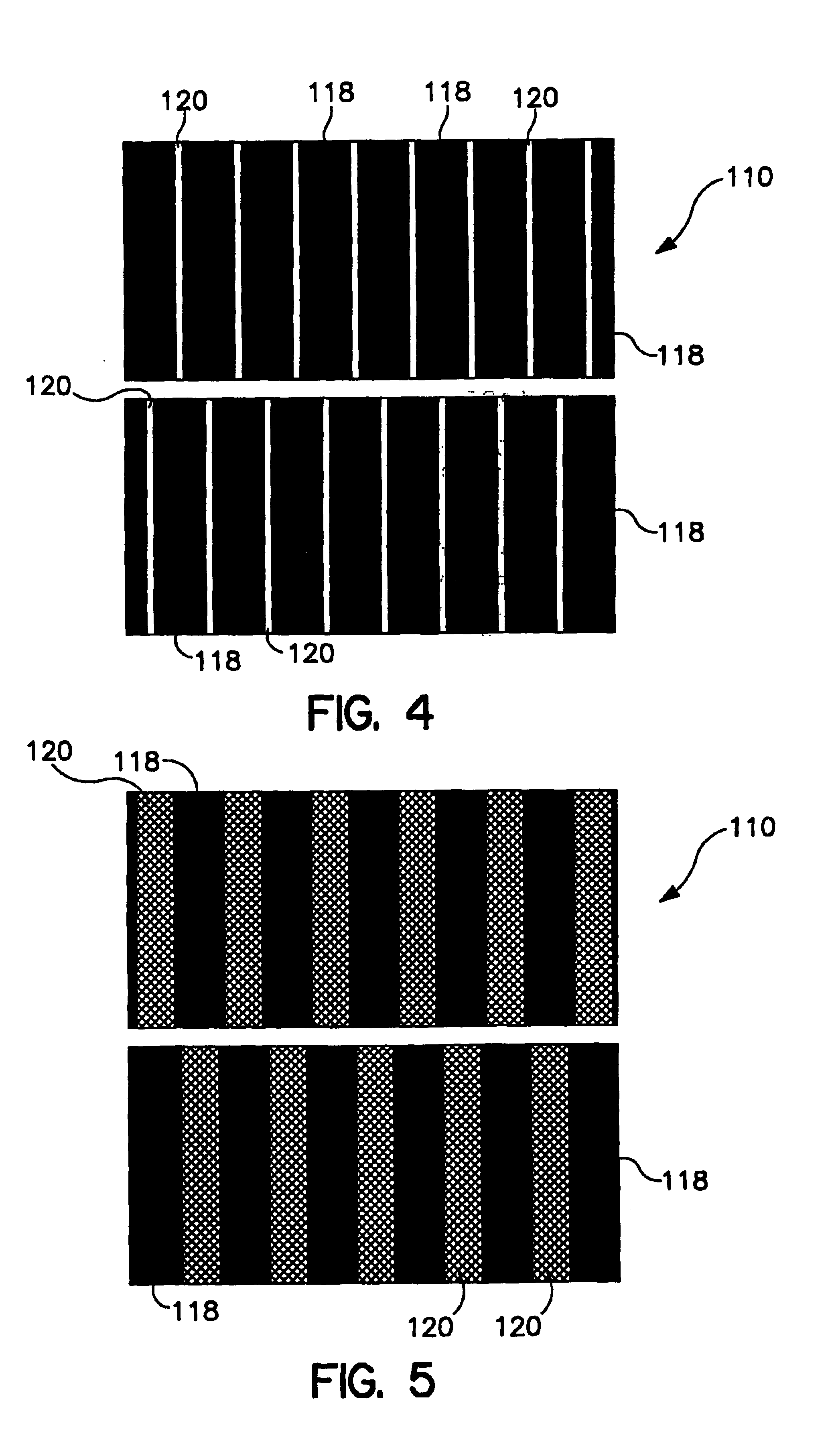

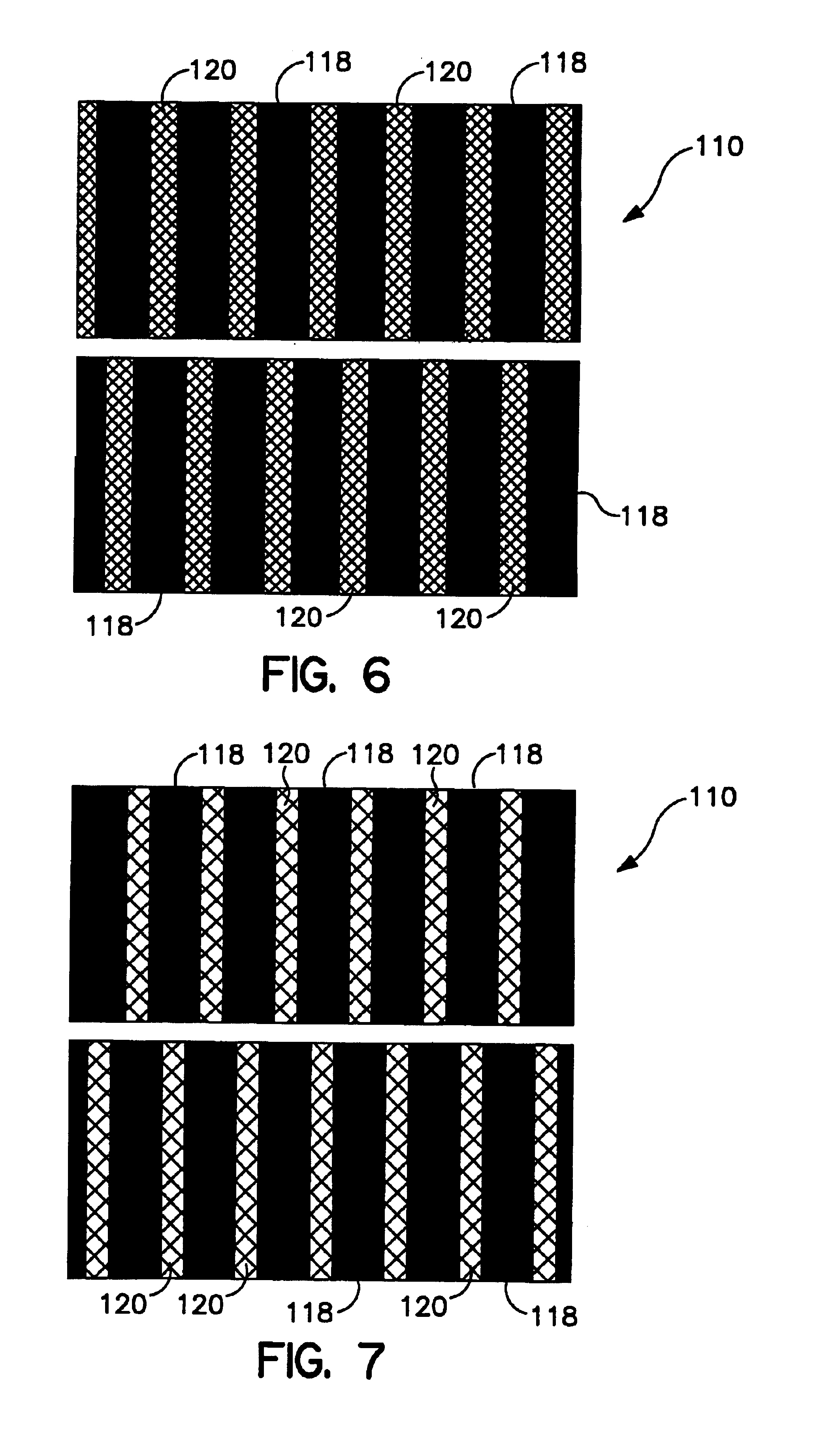

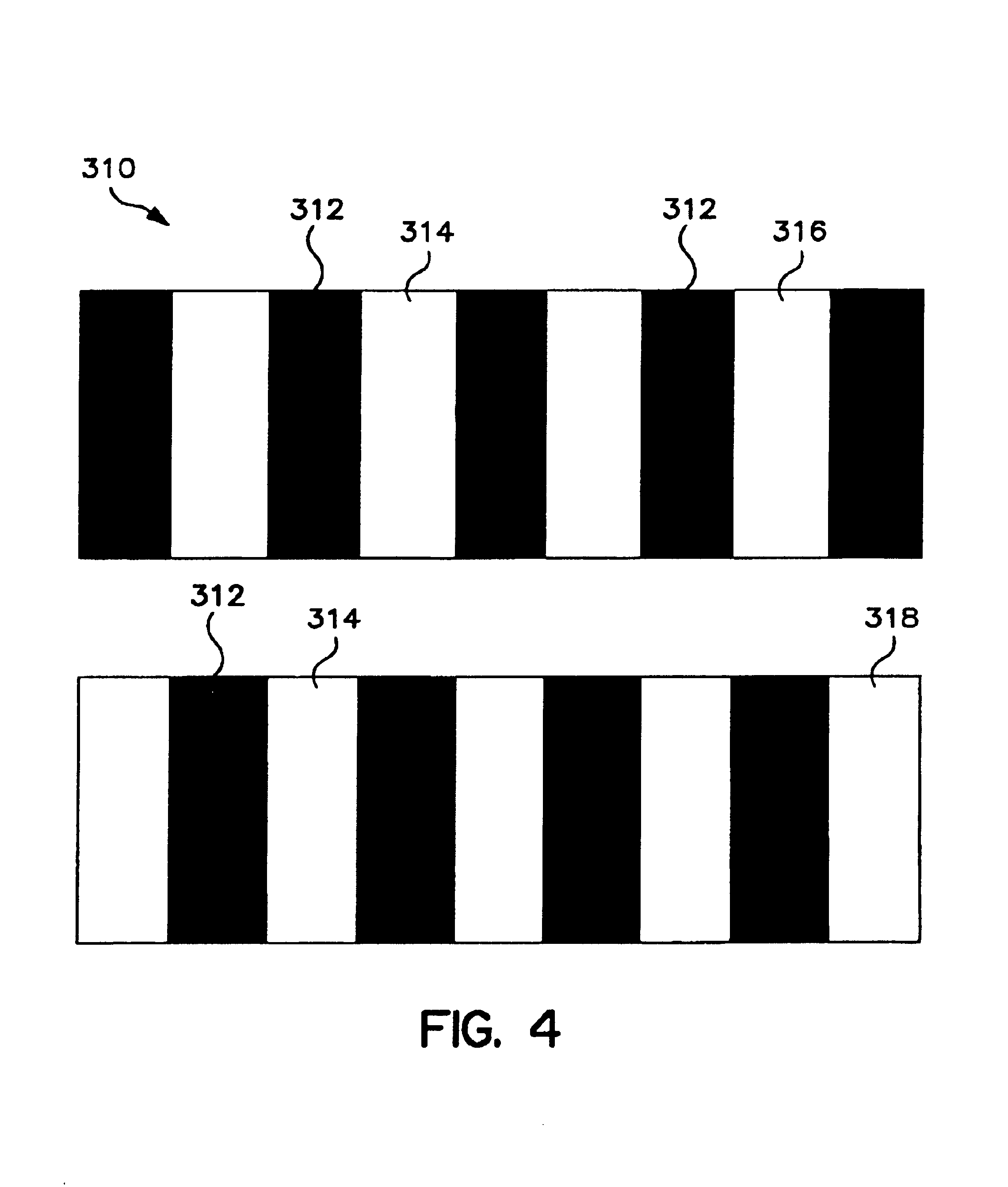

InactiveUS6896766B2Improve propertiesMaintaining acceptable wetability propertyCosmetic preparationsBiocideProcess regionPaper towel

Paper products treated on two surfaces with a liquid resistant composition are disclosed. The paper products can be, for instance, bath tissues, facial tissues, paper towels, and industrial wipers. The liquid resistant compositions can include any additive that provides benefits to the product. For instance, the liquid resistant composition can be a softener containing a hydrophobic additive. In one embodiment, the hydrophobic additive is a polysiloxane. In accordance with the present invention, the water resistant composition is applied to each surface according to a pattern. Each of the patterns includes treated and untreated areas. The patterns are positioned on the paper product such that untreated areas on one surface are in correspondence with the treated areas on the other surface of the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Treatment Liquid for Plastic Film, Primer Liquid for Printing, Ink Composition, and Method for Ink Jet Recording Using Them

InactiveUS20080152825A1Improve rub resistanceImprove scratch resistanceLiquid surface applicatorsWater-repelling agents additionPlastic filmPolymer chemistry

This invention provides a treatment liquid for an ink jet recording medium having a recording face of a plastic film, wherein the treatment liquid including at least a specific cyclic ester compound or a specific cyclic amide compound, a primer liquid for printing, and an ink composition. According to the present invention, a plastic recorded matter possessing excellent adhesion and waterfastness can be formed on a recording medium having a recording face of a plastic film.

Owner:SEIKO EPSON CORP

Water based hydrophobic self-cleaning coating compositions

InactiveUS20090064894A1Efficient use ofWater-repelling agents additionSemiconductor/solid-state device manufacturingWater basedHydrophobic silica

A coating composition comprising hydrophobic particles having an average size of between 7 nm and 4,000 nm and a wetting agent for promoting dispersion of the hydrophobic particles in water. The hydrophobic particles may be oxides, such as silica, titania, or zinc oxide. In one embodiment, the hydrophobic particles comprise fumed silica. The coating composition may be brushed, spin coated, or dipped onto a surface. In one embodiment, once the coating composition dries, the coating formed thereby is characterized by a contact angle formed with a water droplet in excess of 165 degrees. A method of making a coating composition comprising providing hydrophobic particles having an average size of between 7 nm and 4,000 nm, mixing a wetting agent with the hydrophobic particles to form a paste, and dispersing the paste in water by mixing to form a mixture.

Owner:VALVOLINE LICENSING & INTPROP LLC

Enhanced surface sizing of paper

Size press compositions and methods for producing sized paper products, including liner board, are disclosed. The size press compositions contain at least one non-reactive cationic surface sizing agent, at least one reactive sizing agent, at least one promoter resin, at least one binder, and water. The at least one non-reactive cationic surface sizing agent may be a polymer in the form of a dispersion, an emulsion or a latex with a positive zeta potential below about pH 6. The at least one reactive sizing agent may be a dispersion, an emulsion or a latex including an alkyl ketene dimer or an alkyl succinic anhydride. The at least one promoter resin may be a polyaminoamide-epichlorohydrin resin or poly (dimethyldiallylammonium chloride).

Owner:SOLENIS TECH CAYMAN

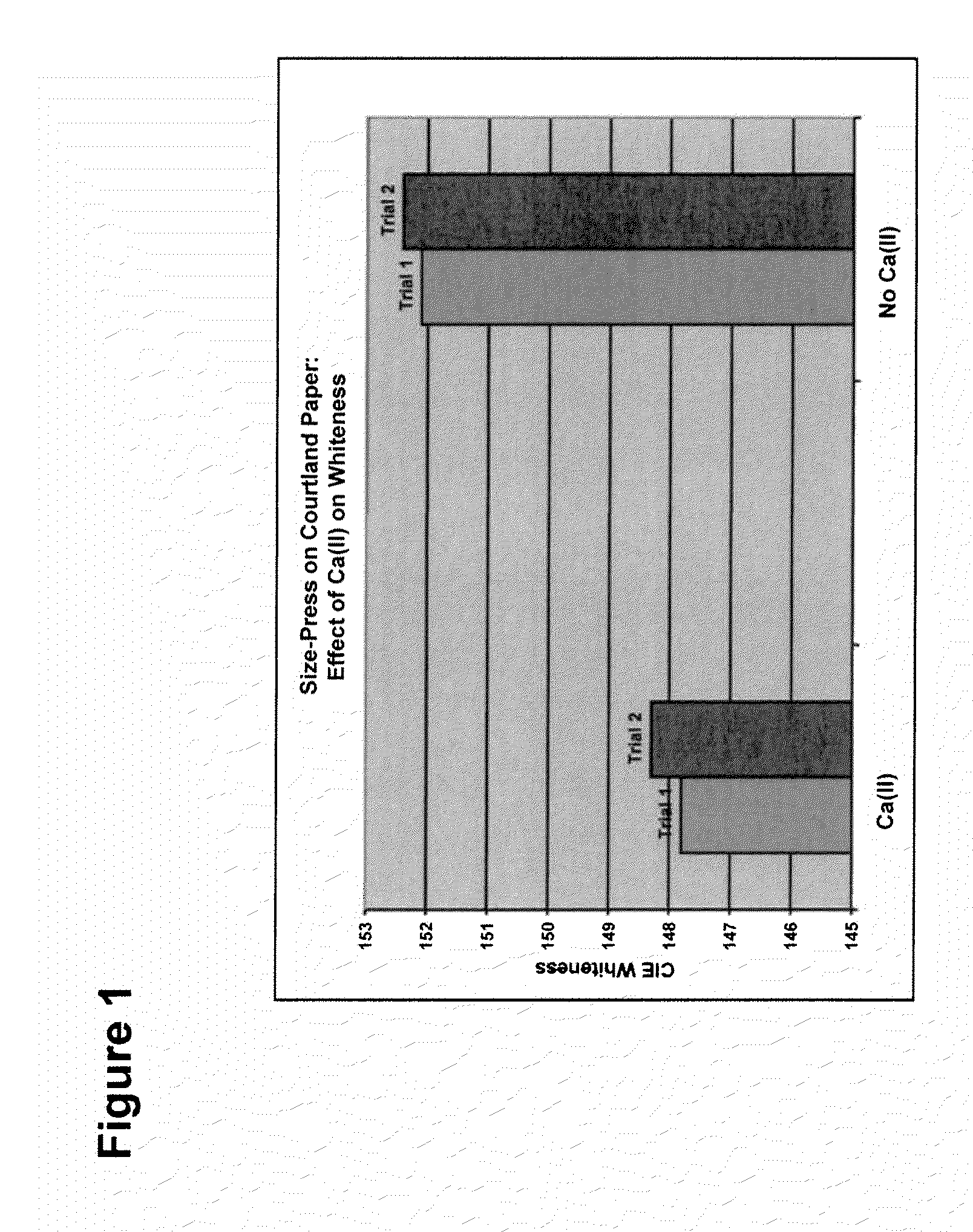

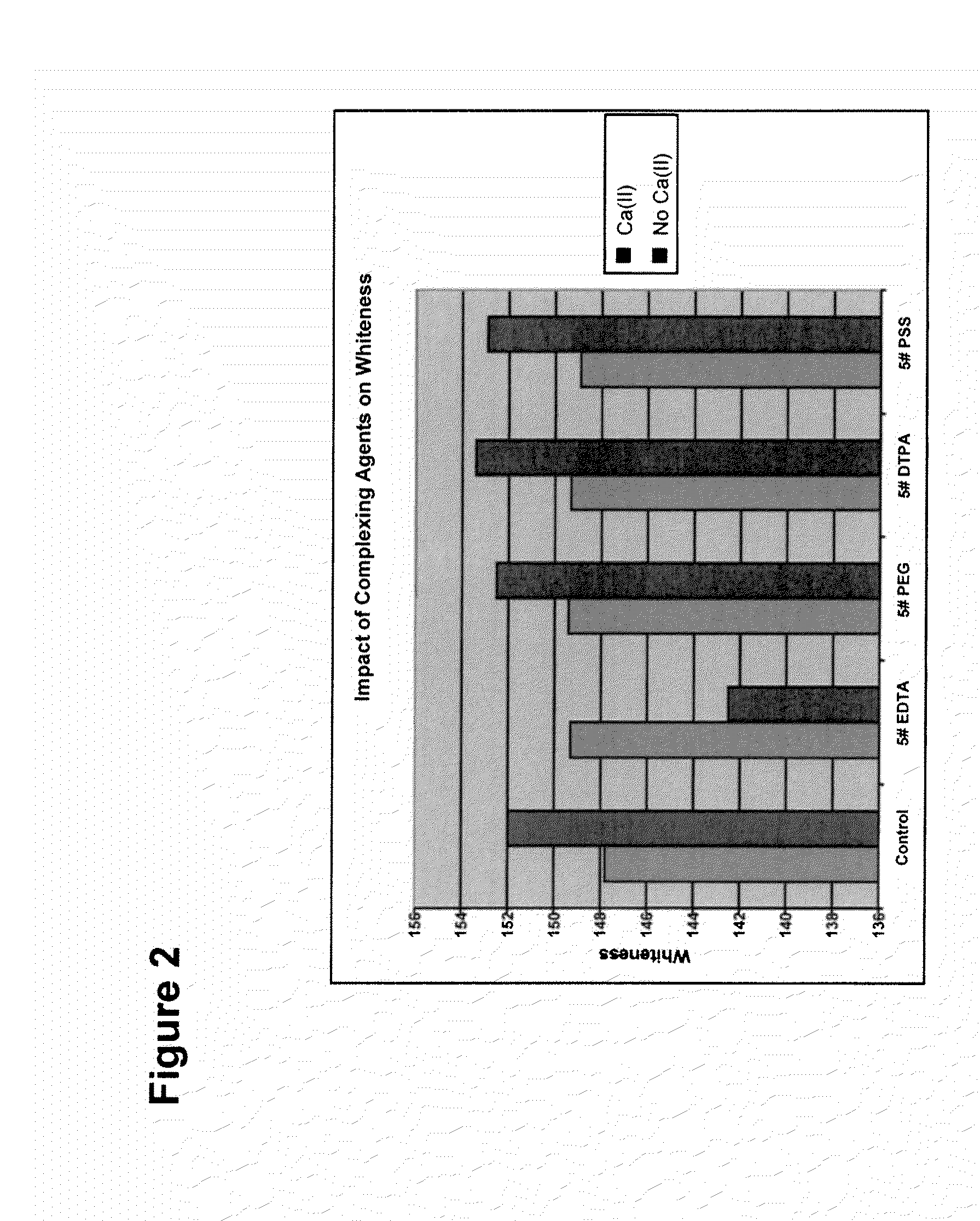

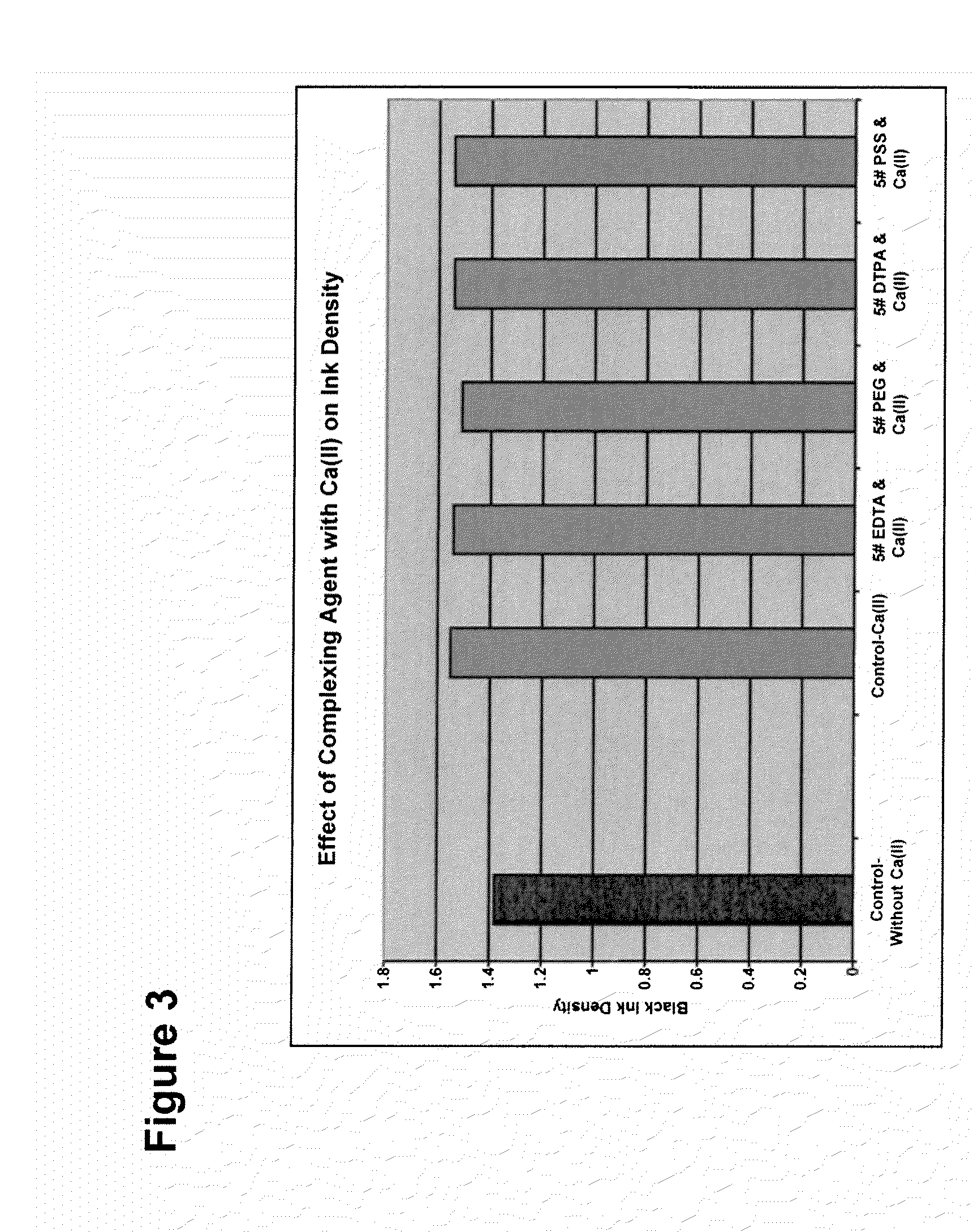

Composition and recording sheet with improved optical properties

ActiveUS20090317549A1Good optical performanceImprove printing effectNatural cellulose pulp/paperSpecial paperOptical propertyDivalent metal

Owner:GLOBAL HLDG II INC

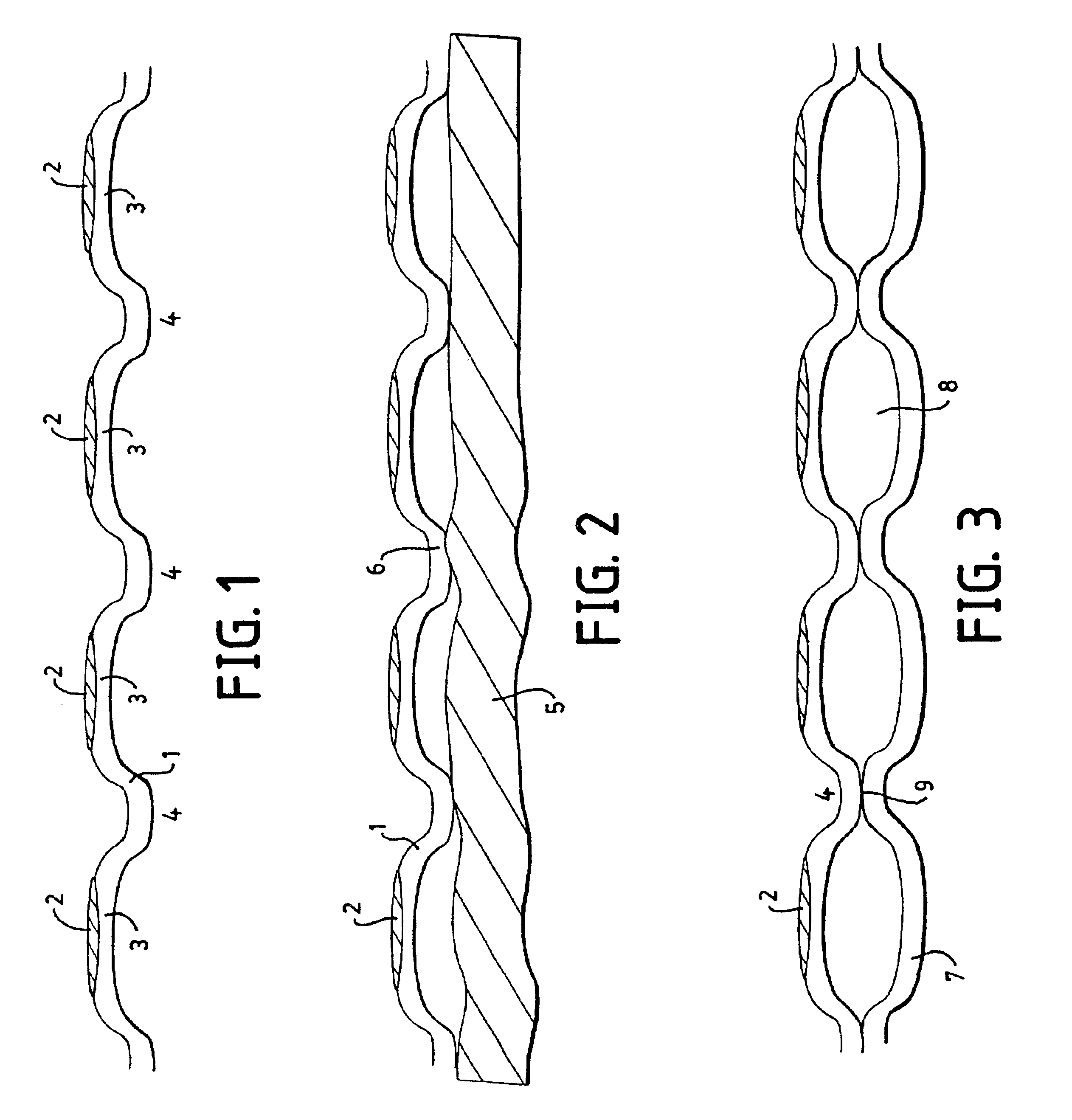

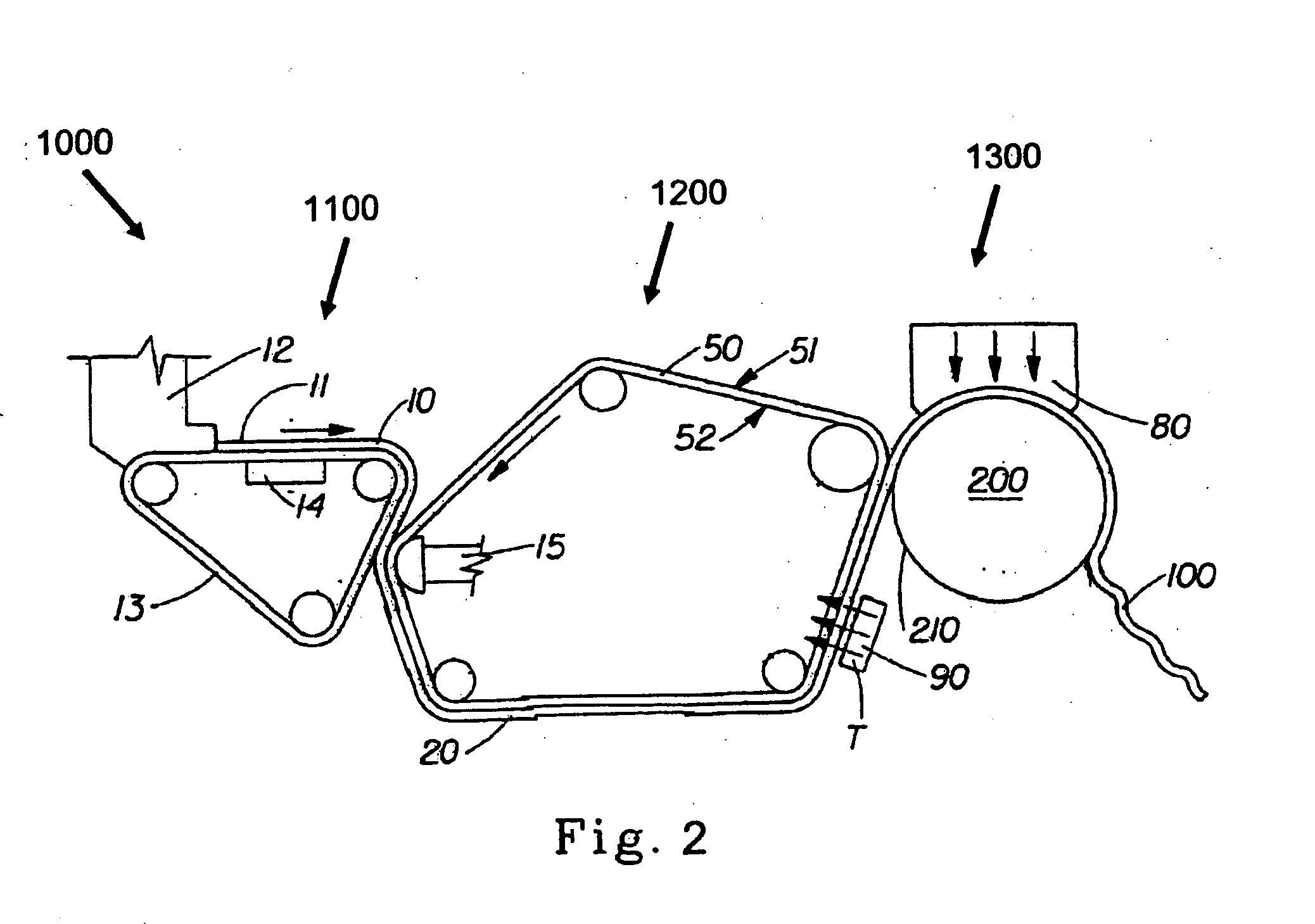

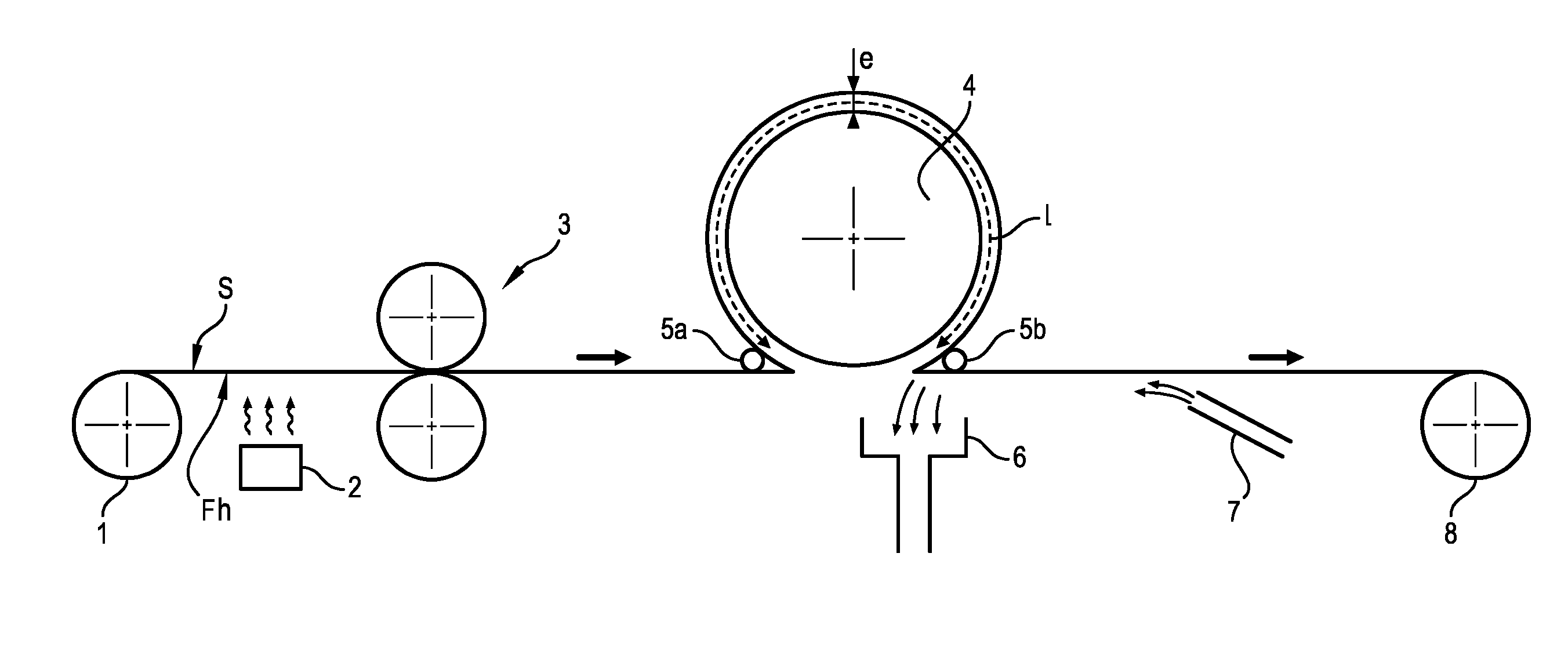

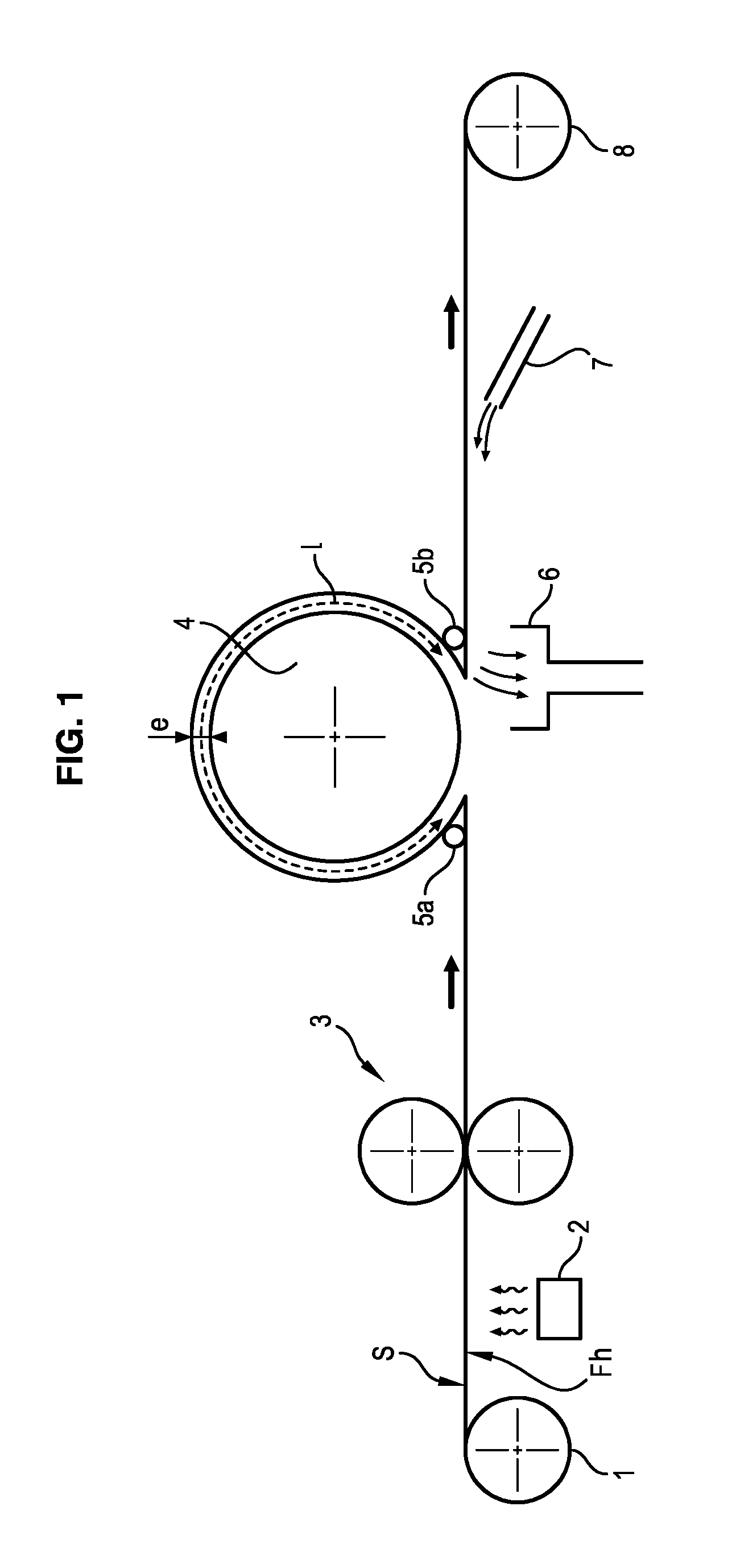

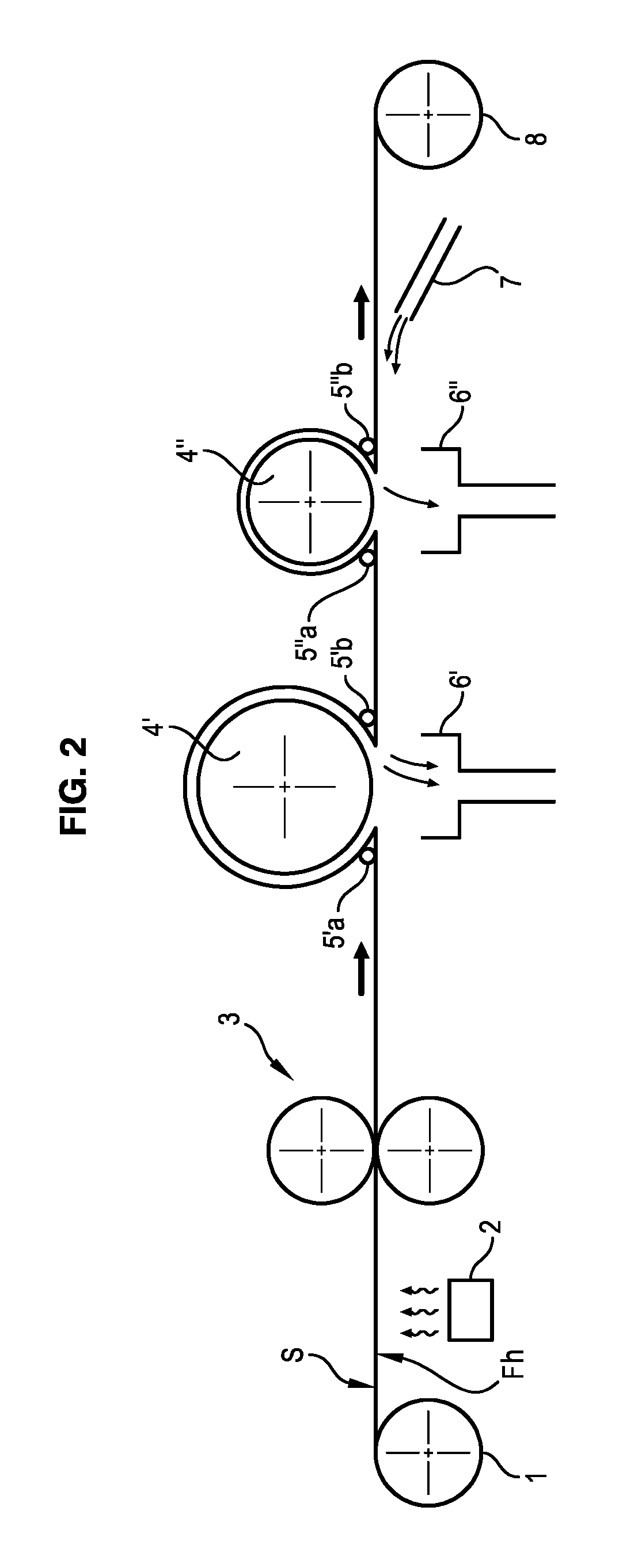

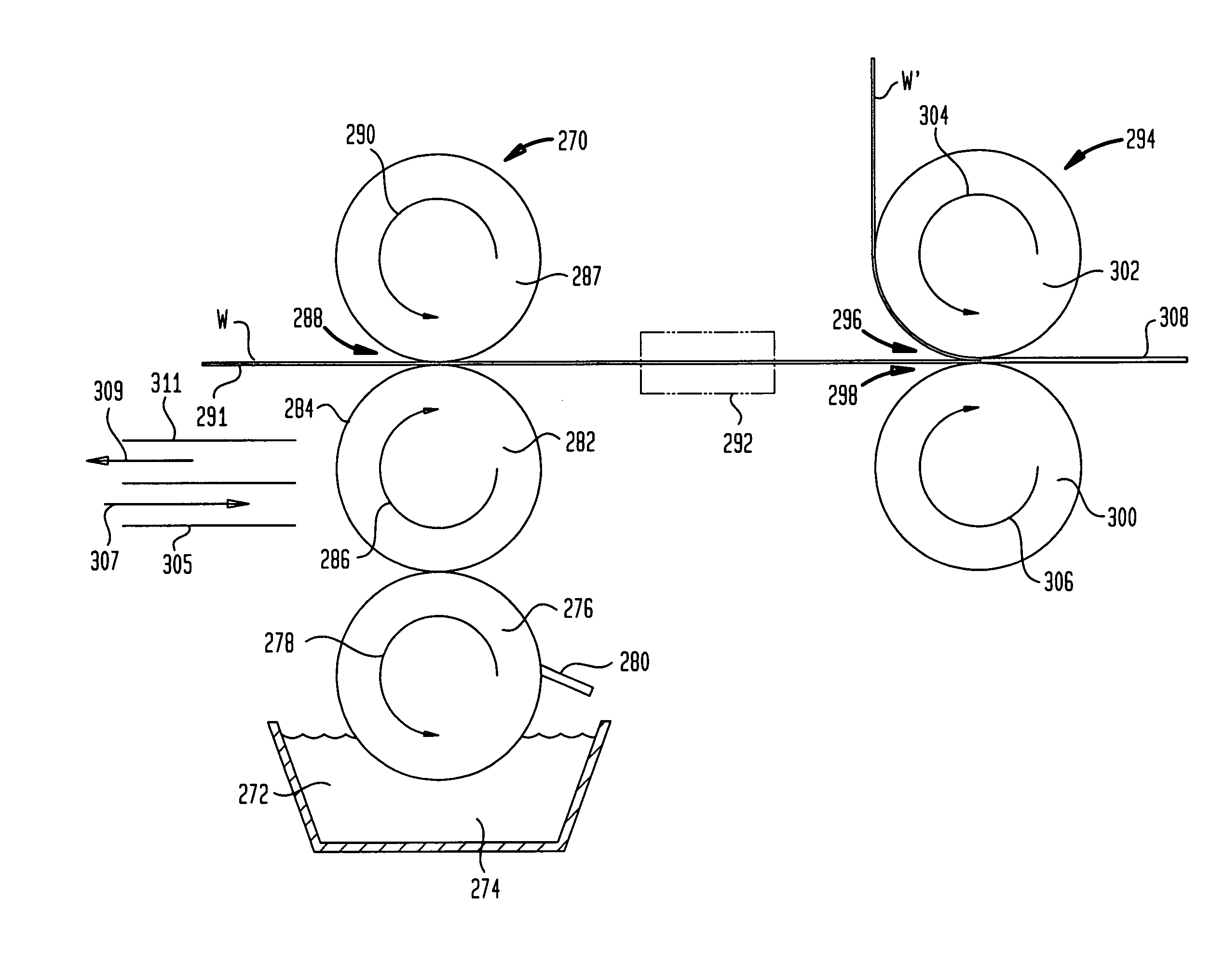

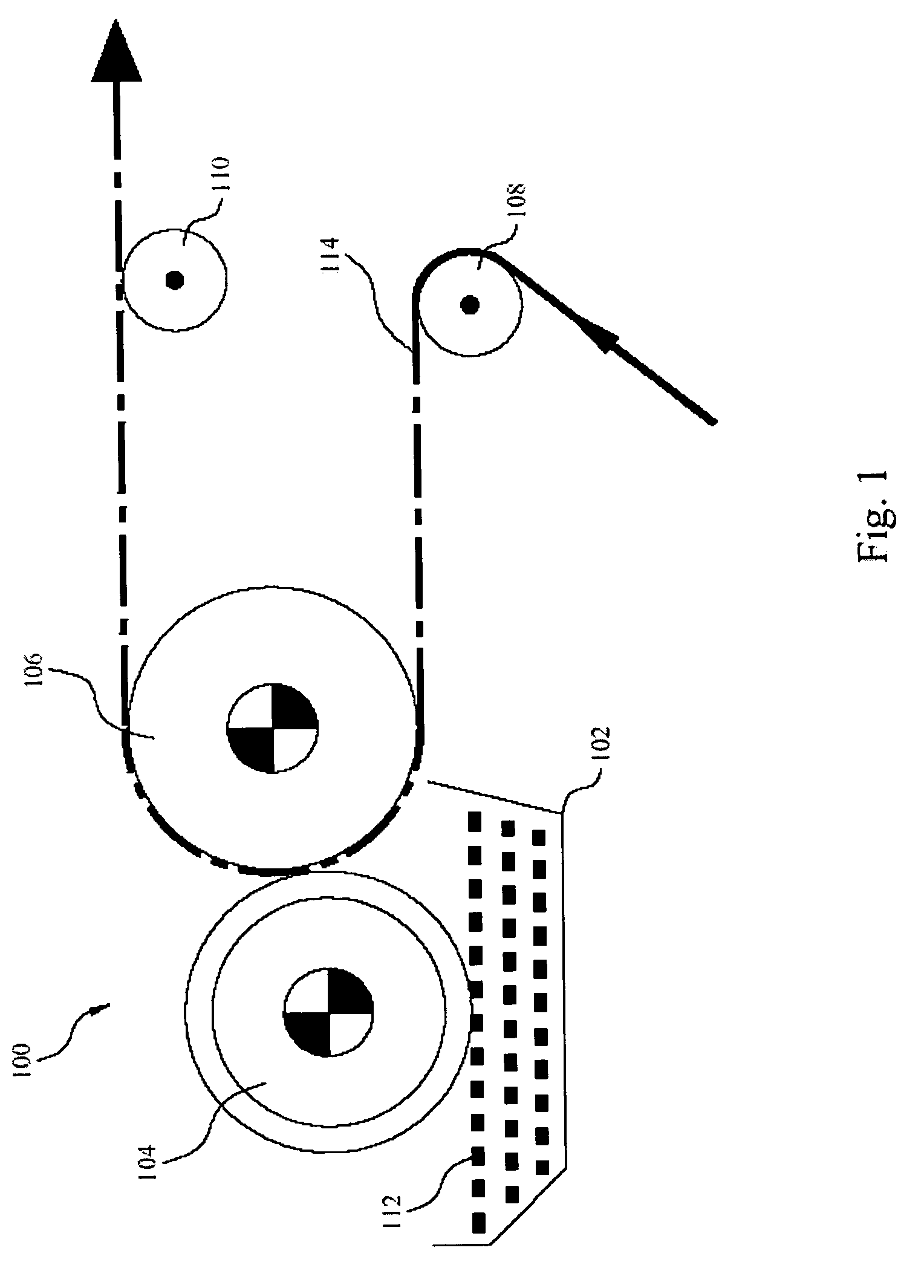

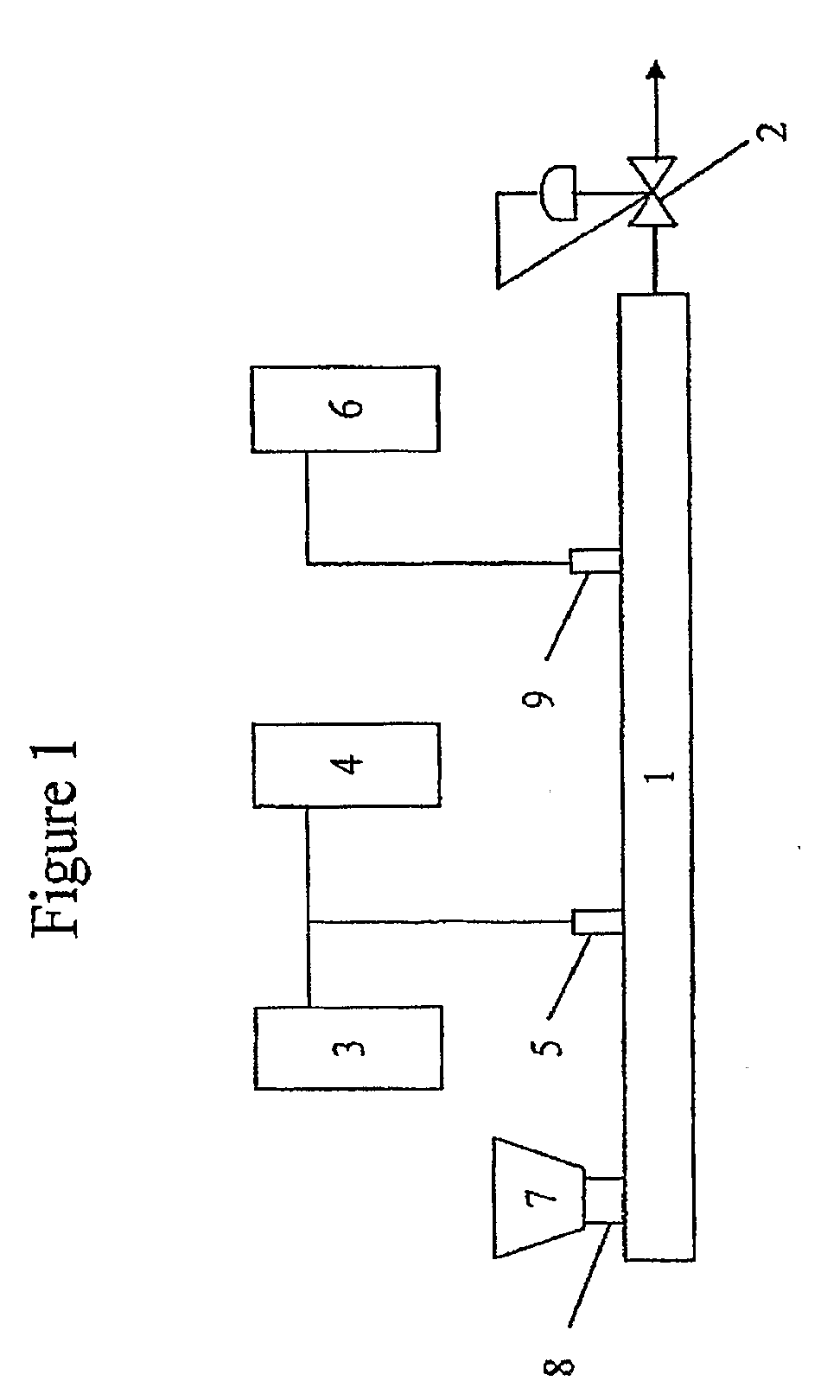

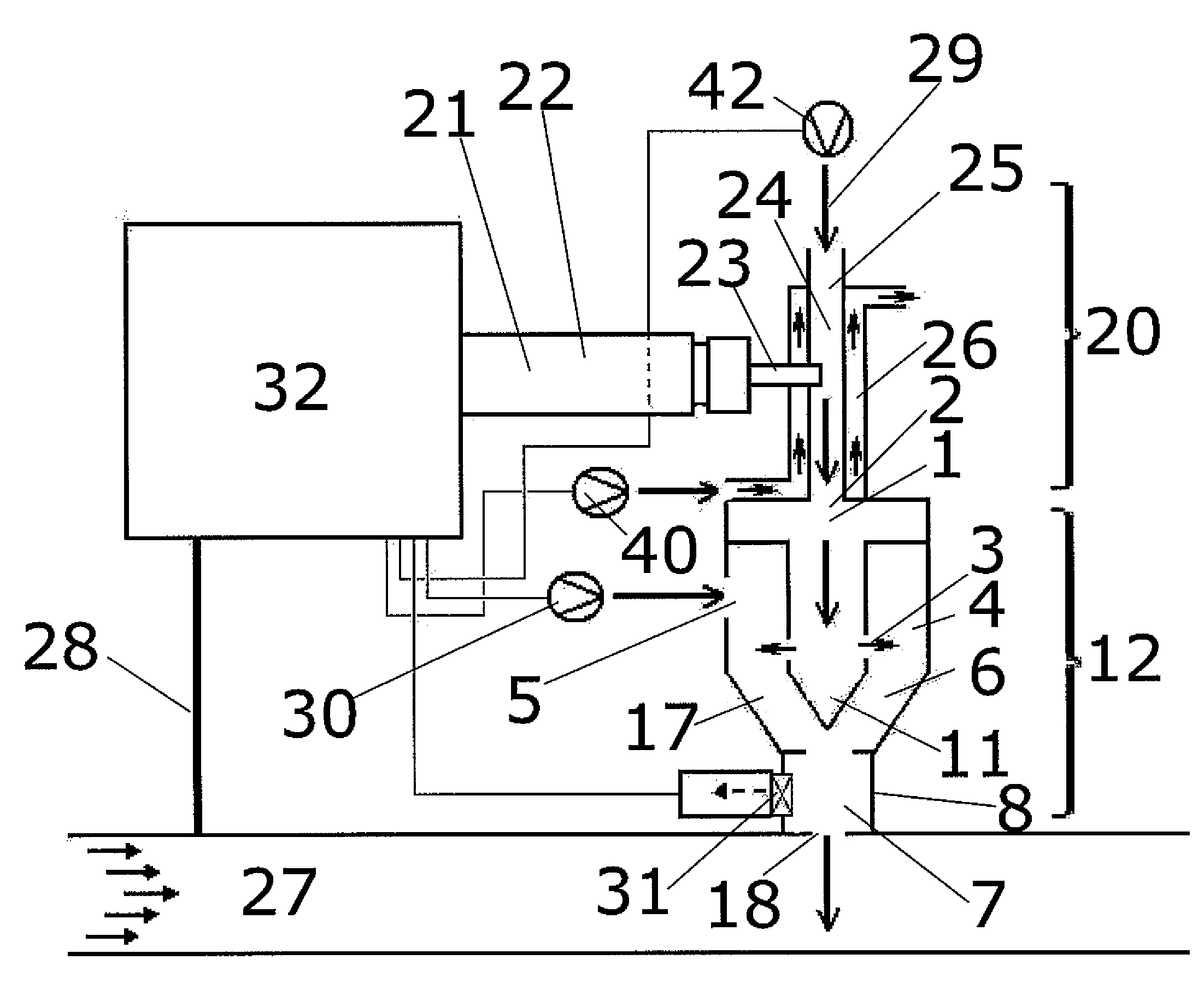

Machine and treatment process via chromatogenous grafting of a hydroxylated substrate

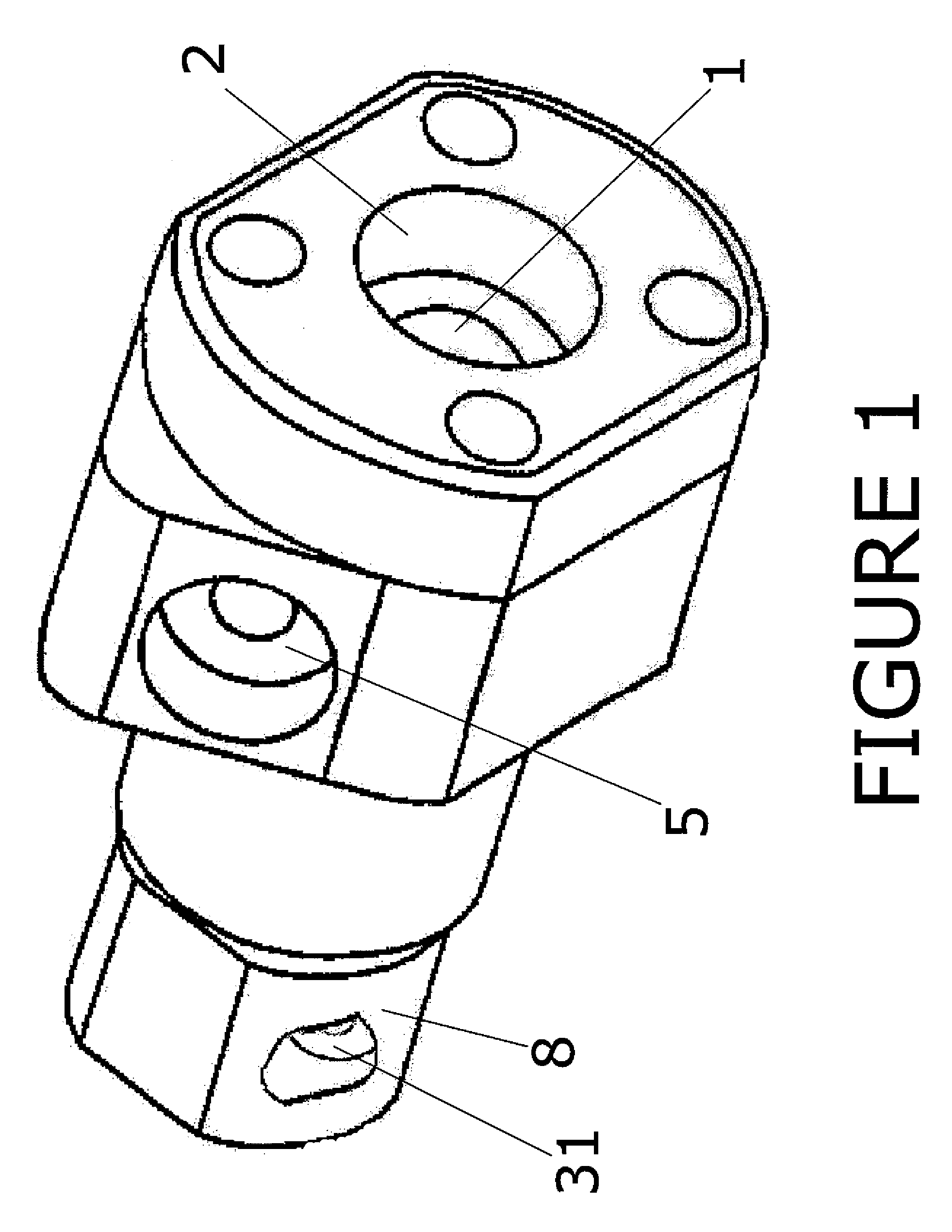

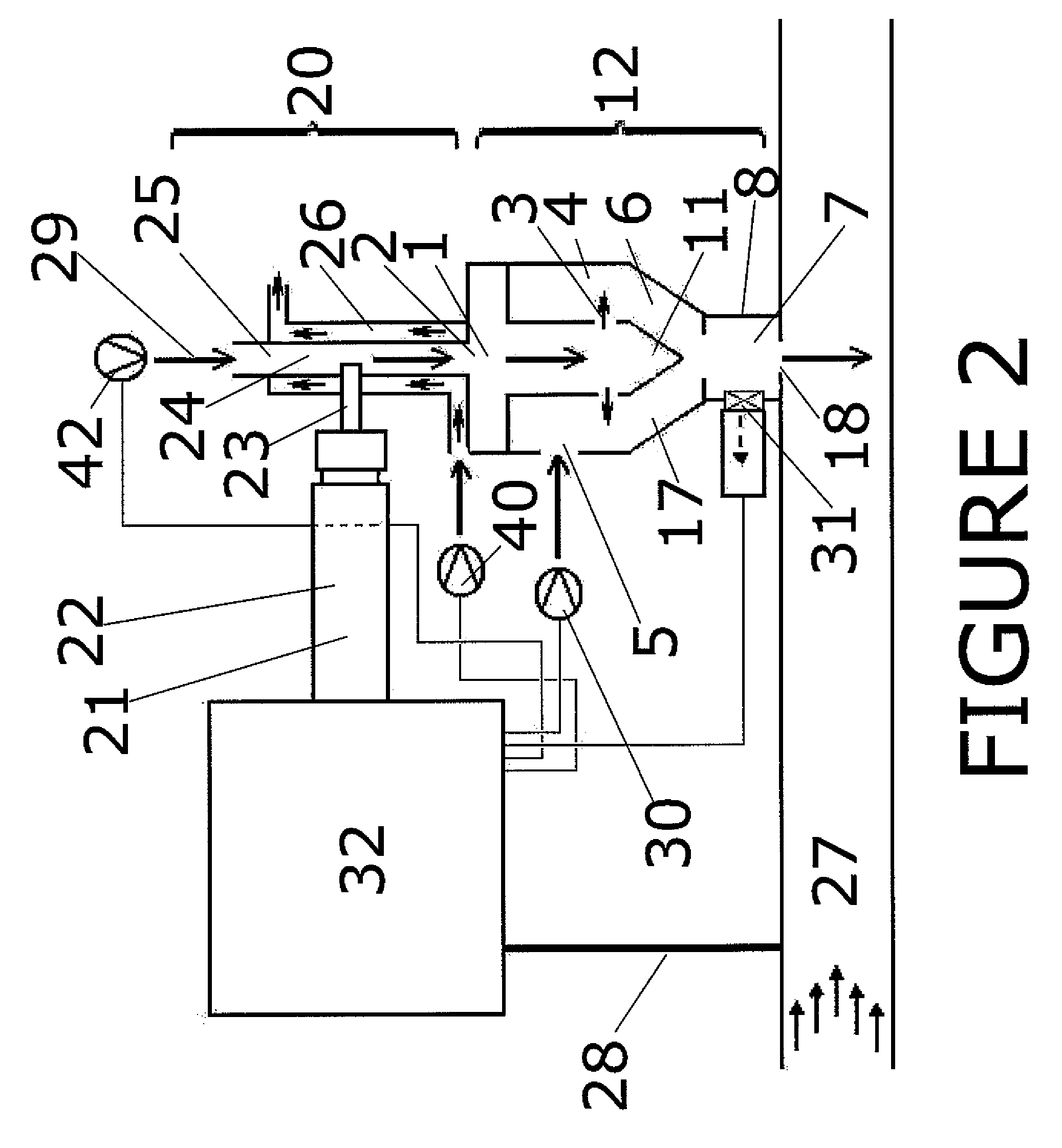

ActiveUS20130236647A1DissipationWater-repelling agents additionNon-macromolecular organic additionGraft reactionPulp and paper industry

The invention relates to a machine for chromatogenous grafting treatment of a scrolling substrate (S) having a hydroxylated face (Fh), comprising:an application device (3) of a grafting reagent on the hydroxylated face (Fh) of the substrate,a heating roller (4) for the development of the grafting reaction on the hydroxylated face (Fh) of the substrate, said roller (4) being provided with a bar-end system (5a, 5b) for applying a face of the substrate (S) against said heating roller (4),an extraction device (6) of the hydrochloric acid produced during the grafting reaction,an application device (7) of an air knife on the treated face of the substrate for eliminating the residual grafting reagent.The invention also relates to a chromatogenous grafting process used in said machine.

Owner:CENT NAT DE LA RECHERCHE SCI +1

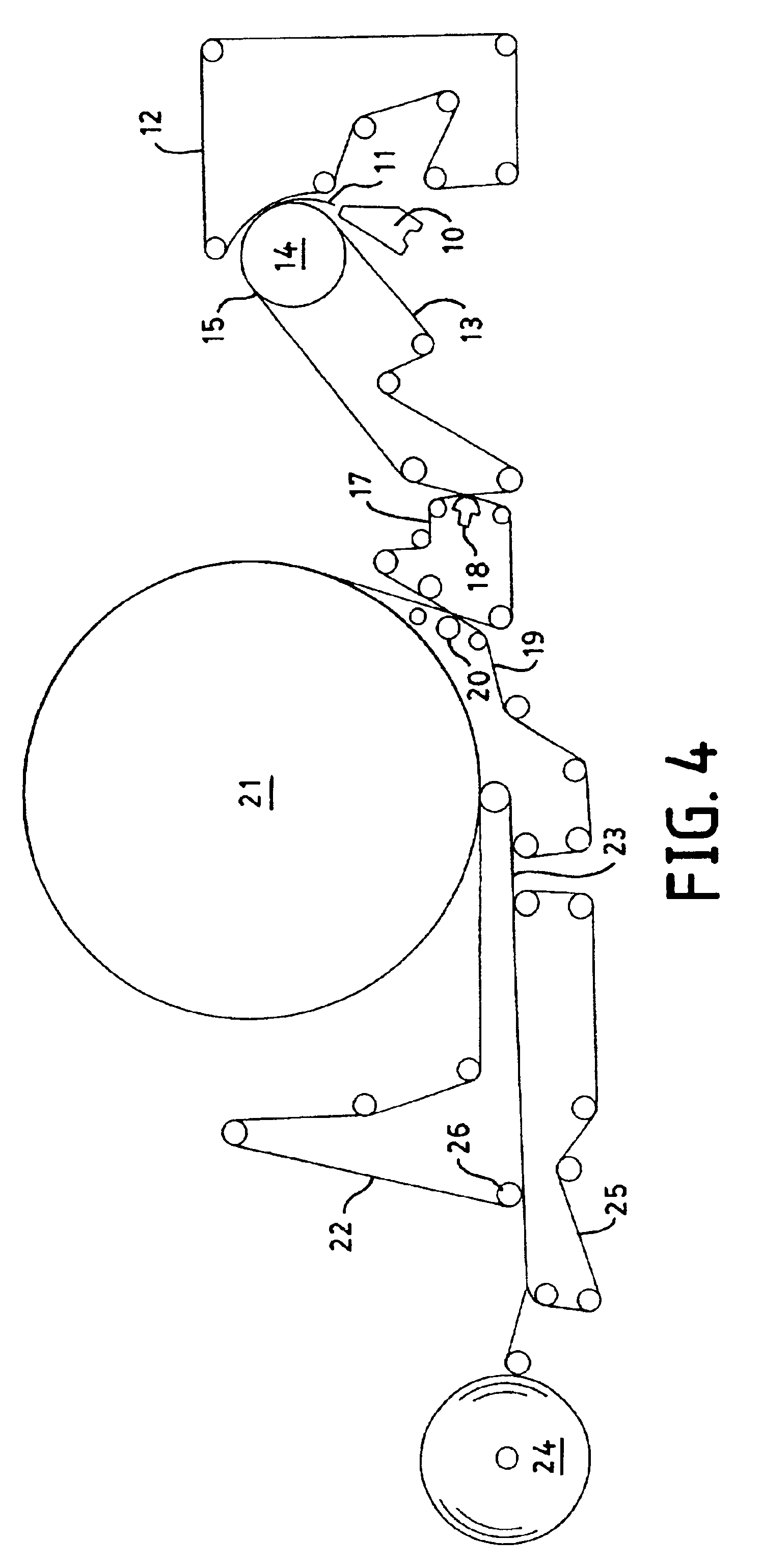

Molded fiber manufacturing

InactiveUS20050150624A1Reduce energy consumptionPrevent air infiltrationFibreboardWater-repelling agents additionFiberMolded pulp

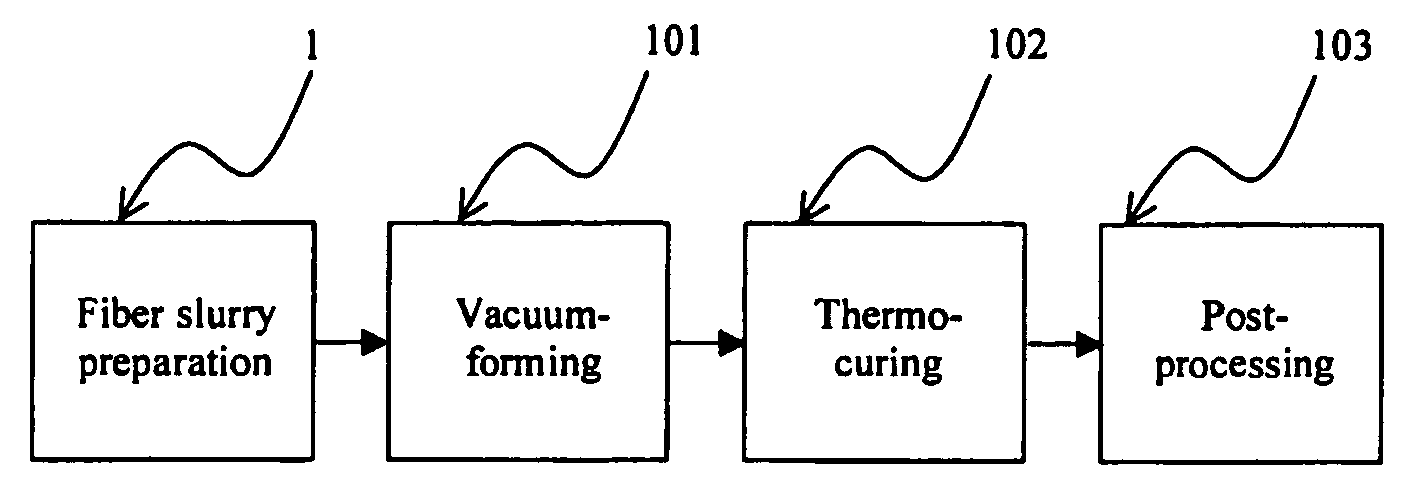

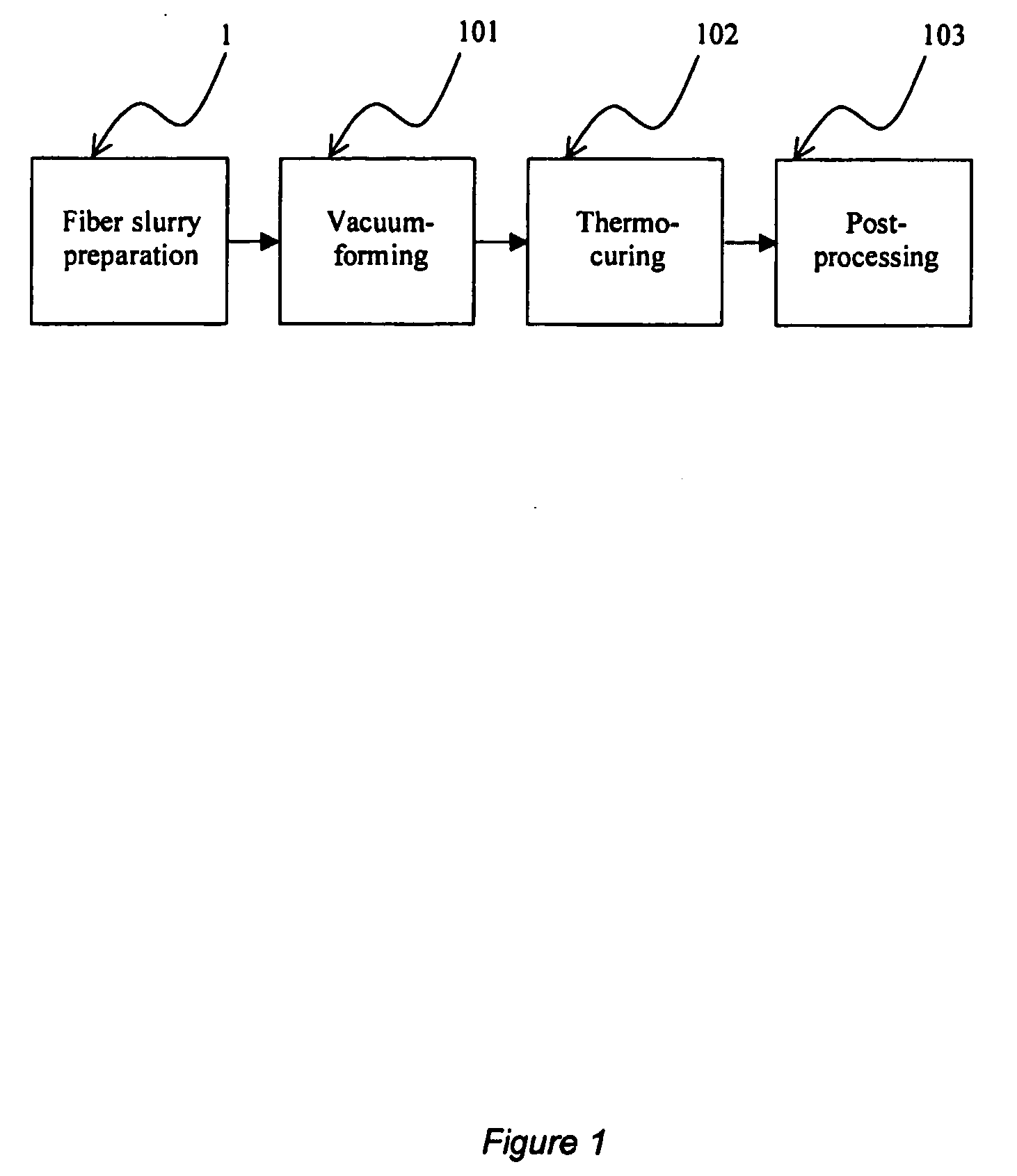

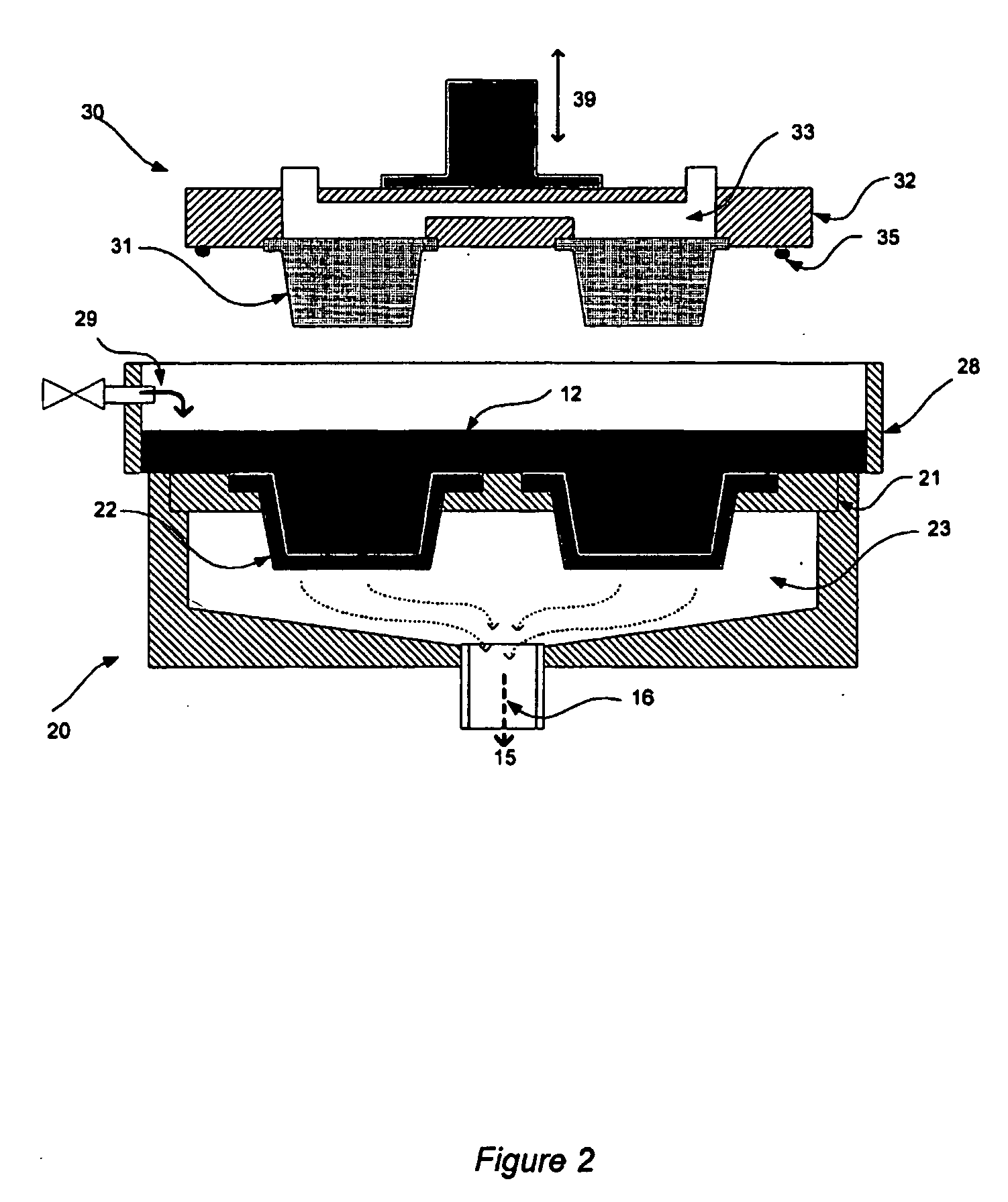

Molded fiber products using agriculture residues are economical and environmentally beneficial. Molded fiber manufacturing is different from molded pulp. The present invention discloses a method of and an apparatus for the manufacturing of molded fiber shaped body (10) using low consistency fiber slurry (12) subject to vacuum-forming and thermo-curing. The use of porous material as mold inserts for both vacuum-forming (101) and thermo-curing (102) stations provides improved productivity and enables ease of mold release. The incorporation of self-cleaning techniques further ensures consistent performance of the manufacturing system.

Owner:GRENIDEA TECH PTE

Paper surface sizing agent and preparation method thereof

ActiveCN101148842AIncreased ring compressive strengthLose weightWater-repelling agents additionPaper/cardboardCross-linkEmulsion

The present invention relates to paper surface treating agent, and is especially one kind of paper surface sizing agent and its preparation process. The paper surface sizing agent is prepared with cationic monomer, cross-linking monomer, (methyl) acrylate monomer and (methyl) styrene, and through free radical emulsion polymerization in mixture emulsion comprising dispersant, emulsifier and initiator. It has high performance and environment friendship. It is applied in sizing paper surface together with starch to raise the compression strength of paper, raise Cobb value and improve other performance of paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

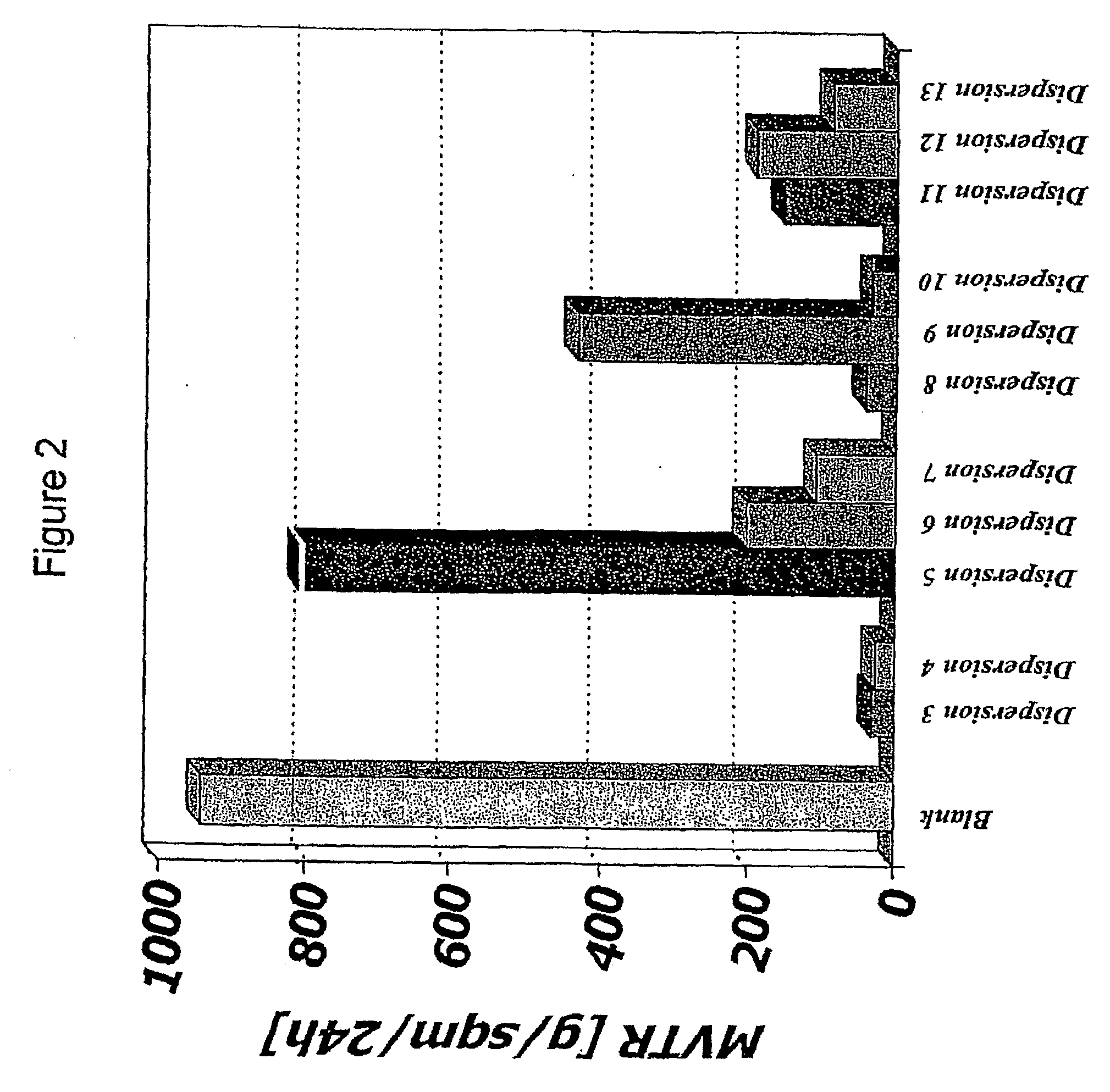

Aqueous dispersions of hydrophobic material

InactiveUS6165259AImprove stabilityLow viscosityNatural cellulose pulp/paperSpecial paperHydrophobeOrganic compound

The invention relates to an aqueous dispersion containing a dispersant and a disperse phase containing a hydrophobic material, the dispersant comprising an anionic compound having a molecular weight less than 50,000 and being selected from the group consisting of carbon-containing compounds and silicon-containing compounds, and a cationic organic compound having a molecular weight less than 50,000. The invention further relates to the preparation and use of the dispersion in the production of paper. The invention also relates to a substantially water-free composition containing a hydrophobic material, an anionic compound having a molecular weight less than 50,000 and being selected from carbon-containing compounds and silicon-containing compounds, and a cationic organic compound having a molecular weight less than 50,000, as well as it use in the preparation of an aqueous dispersion.

Owner:AKZO NOBEL NV

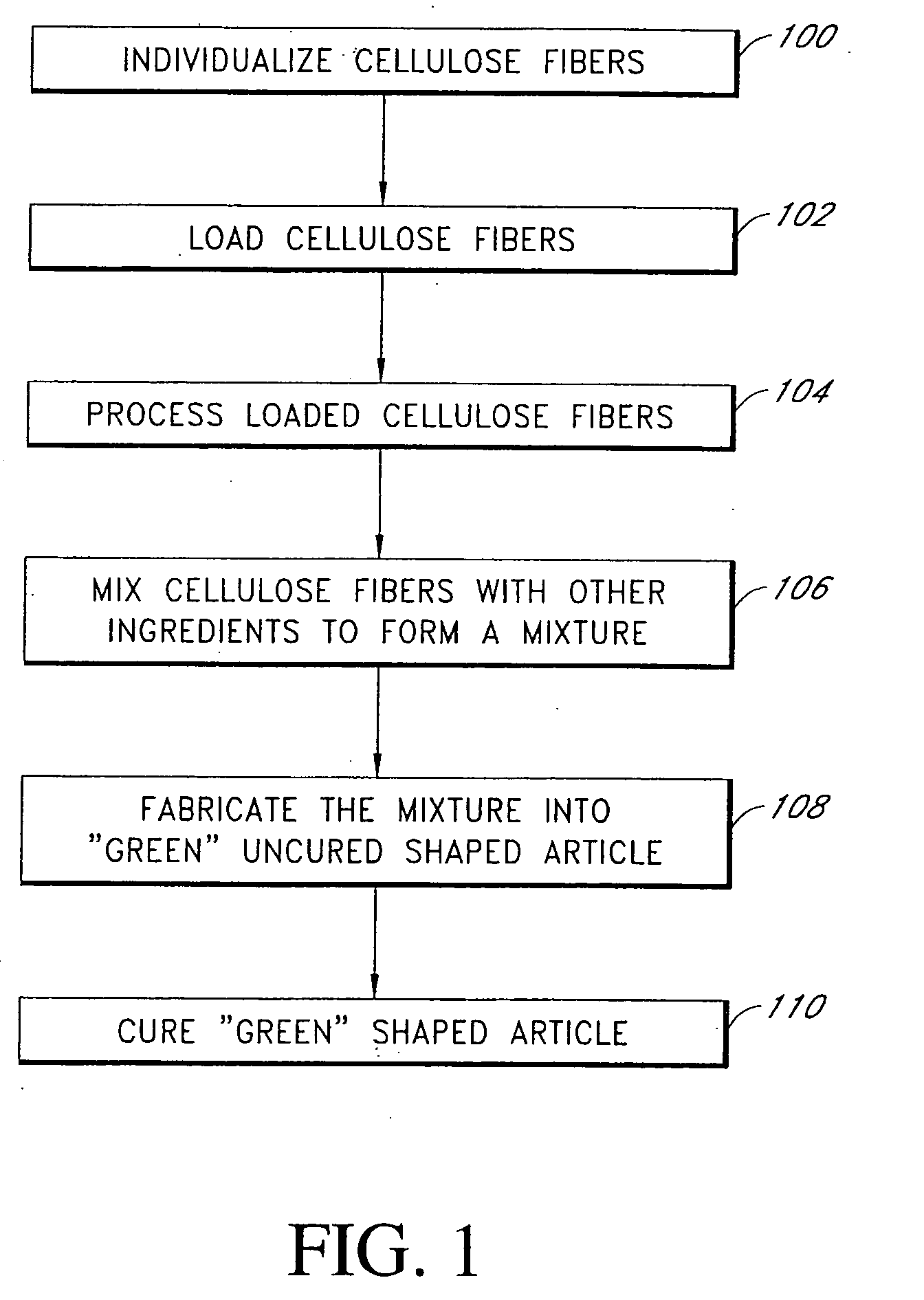

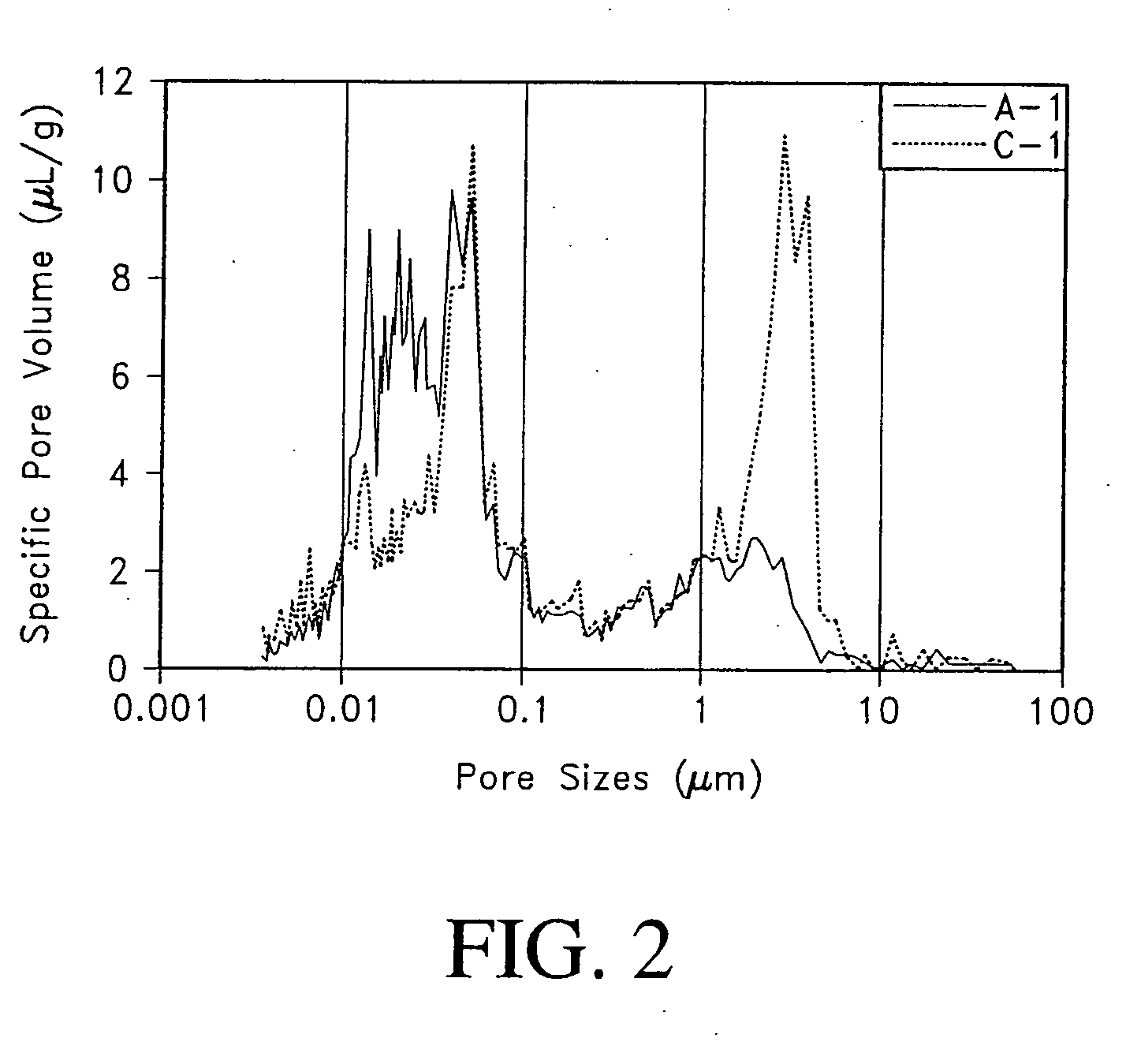

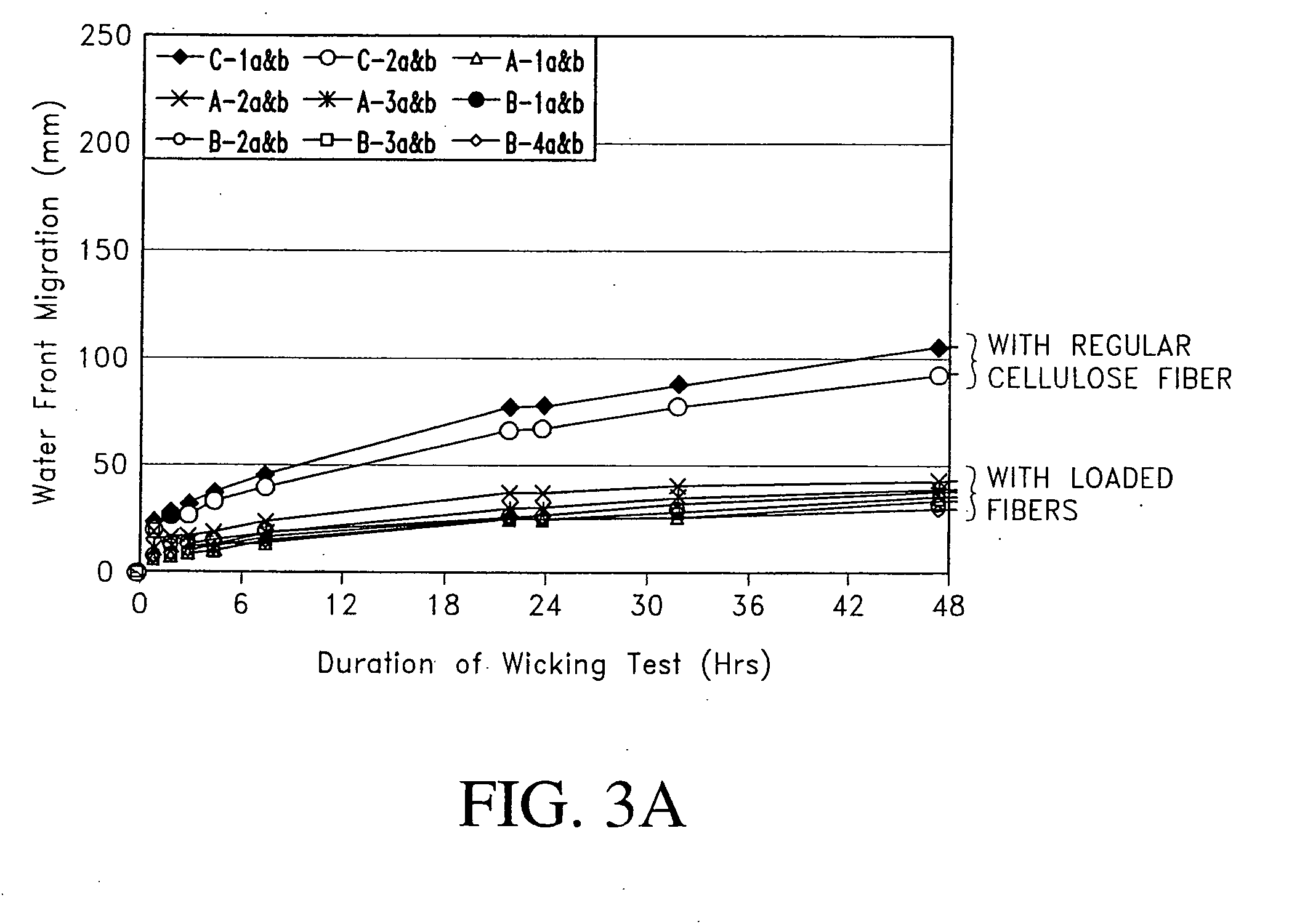

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS20050235883A1Low water absorptionLow water migrationConstruction materialWater-repelling agents additionCement compositesCellulose fiber

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:MERKLEY DONALD J +1

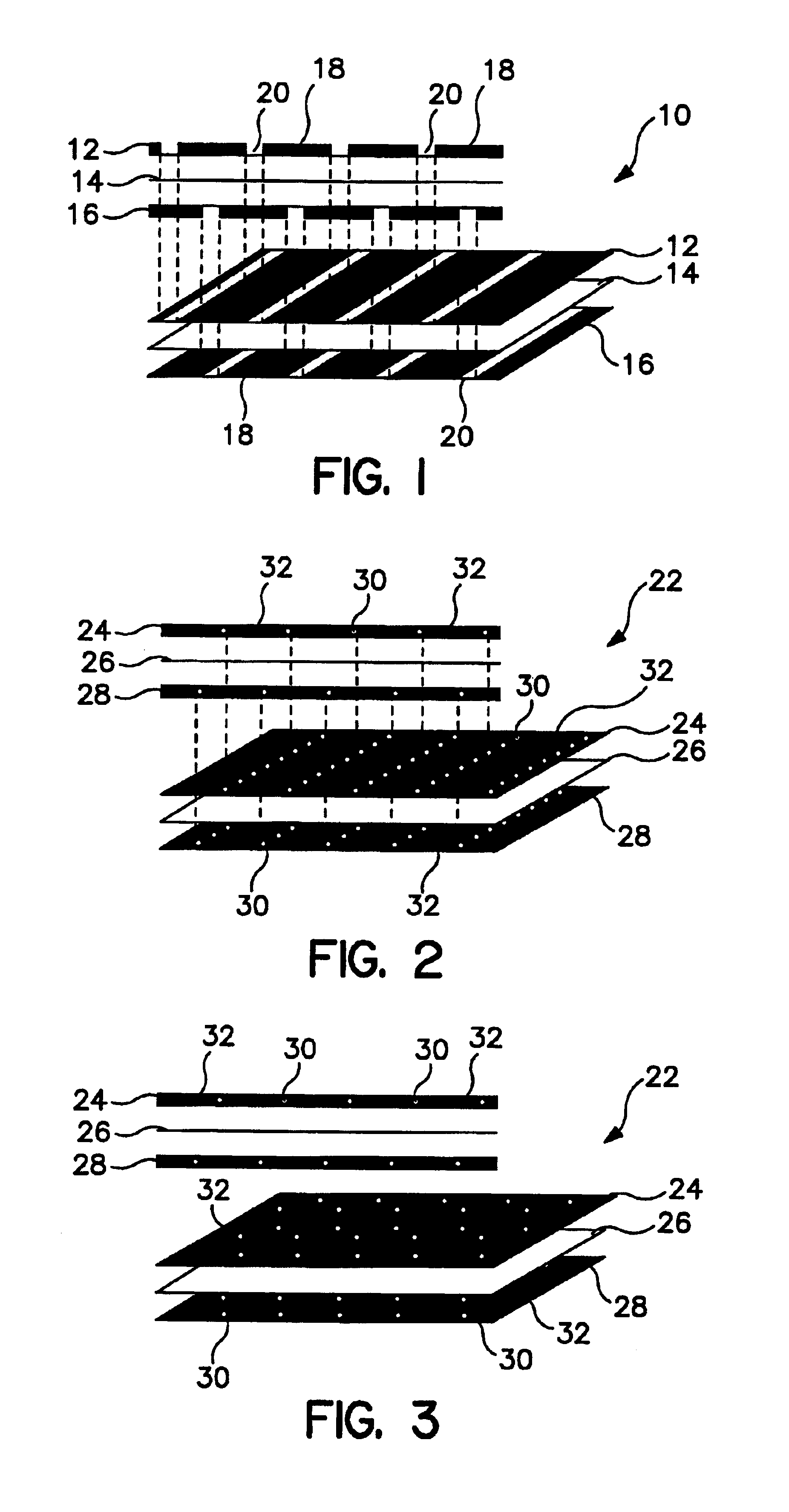

Tissue products having uniformly deposited hydrophobic additives and controlled wettability

InactiveUS6949167B2Improve propertiesAcceptable wettability characteristicBiocideNatural cellulose pulp/paperChemistryWetting

Tissue products are disclosed that contain a hydrophobic additive, such as a polysiloxane. In accordance with the present invention, the tissue products are further treated with a wetting agent. The wetting agent may be applied after application of the hydrophobic additive to one or more surfaces of the base sheet. The wetting agent improves the wettability properties of the base sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Nonwoven wallpaper base paper and manufacture method thereof as well as nonwoven wallpaper produced from the same

ActiveCN101255665ANo damp feelingGood flexibilitySpecial paperWater-repelling agents additionFiberAdhesive

The invention relates to a non-woven wallpaper, particularly relates to a non-woven wallpaper base paper and the non-woven wallpaper prepare by the base paper. The non-woven wallpaper base paper comprises a fiber pulp and an adhesive, wherein, the fiber pulp includes a wood-pulp fiber and a function fiber, the weight ratio of the wood-pulp fiber and the function fiber is 0-95%: 5-100%, and the adhesive accounts for 1-10% of the gross weight of the base paper. The wallpaper of the invention does not contract when processed, does not have moist feeling, is complete when uncovered, and has good flexibility. The wallpaper made by a flame-resistant fiber is able to burn under the fire, but extinguishes after leaving the fire, and has good flame-resistant performance.

Owner:浙江凯恩新材料有限公司 +1

Wax emulsion preservative compositions and method of manufacture

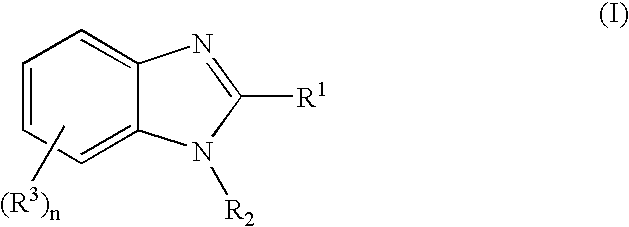

An emulsion comprising water as the continuous phase, a wax as the discontinuous phase, an emulsifier and a preservative having the general structure:wherein R1 can be a heterocycle containing nitrogen and sulfur, such as thiazolyl, isothiazolyl, or thiadiazolyl, which can optionally be substituted with C1–C6 alkyl; R2 can be hydrogen or C1–C6 alkyl, specifically hydrogen; n is 0, 1, 2, or 3; each instance of R3 can independently be hydrogen, C1–C6 alkyl, phenoxy, C1–C6 alkoxy, halo, amino, C1–C6 alkylamino, di C1–C6 alkyl amino, imidazolyl, thiazolyl, isothiazolyl, thiadiazolyl, thienyl, furyl, pyrryl, naphthyl, phenyl, halophenyl, C1–C6 alkyl phenyl, or C1–C6 alkoxyphenyl. The preservative may be added to the emulsion after the emulsion is formed. The emulsion can be incorporated into a gypsum product such as gypsum board or gypsum wood fiber board. The gypsum product may be made by forming a slurry containing gypsum, water, and the emulsion into a solid product. A method for improving the water resistance of a lignocellulosic composite product prepared by mixing lignocellulosic material with a binder to form a mixture and solidifying the mixture in a selected configuration to form the composite product may include adding to the mixture an emulsion as described above.

Owner:MOMENTIVE SPECIALTY CHEMICALS

Filled paper and method of manufacturing the same

ActiveUS8414739B2Improve paper strengthEasy maintenanceNatural cellulose pulp/paperSpecial paperSlurryPolysaccharide

There is provided a filled paper containing a coated filler obtained by coating a filler with a acrylamide copolymer (composite PAM) comprising (A) an anionic polysaccharide and (B) a cationic and / or an amphoteric acrylamide copolymer. The composite PAM is obtained, for example, by mixing the component (A) and the component (B). Since the filler is treated with a combination of the components (A) and (B) different from each other in charge properties and structure, suitable coagulation effect can be attained and the coated filler has excellent affinity for pulp slurry. Therefore, even in the case of a highly filled paper, a large paper strengthening effect can be attained by using a small amount of the chemical agent.

Owner:HARIMA CHEM INC +1

Absorbent sheet exhibiting resistance to moisture penetration

ActiveUS7300547B2Reduce feelingsReduce wetted areaNatural cellulose pulp/paperMechanical working/deformationWaxFiber

An absorbent paper sheet is treated with an aqueous wax dispersion such that the sheet includes a fused wax and emulsifier residue in an amount of from about 1 to about 20 weight percent of the sheet based on the combined weight of the fiber, wax residue and an emulsifier residue in the sheet. The fused wax emulsion operates to make at least one surface of the sheet laterally hydrophobic, exhibiting a moisture penetration delay of at least about 2 seconds and less than about 40 seconds as well as a typical contact angle with water at one minute of at least about 50 degrees. There is thus provided absorbent products which exhibit both absorbency and resistance to moisture penetration. The treated sheet further exhibits microbial barrier properties, impeding transfer of bacteria, for example, through the sheet. There are produced tissue products which resist moisture penetration from propelled liquids as well as sequester sorbed liquids in the interior of the tissue.

Owner:GPCP IP HLDG LLC

Method for treating surfaces of textile

InactiveUS20050271821A1Drying processUniform coatingWater-repelling agents additionPretreated surfacesAnti bacterialViscosity

A method for treating surfaces of textile is disclosed. A coating solution, in which a polymer with reactive groups is utilized to give various functions, such as hydrophobicity, anti-bacteria or hydrophilicity (hygroscopicity) is formed. The coating solution with different viscosities, specially low viscosity, 100 cps or less, can be continuously coated onto a surface of the textile by employing a surface treating technique of gravure coating and appropriately adjusting the gravure meshes. After drying, a highly durable, washable and firm textile with single or multi-functions, such as outer hydrophobic surface and inner anti-bacterial and (or) hydrophilic (hygroscopic) surface.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Methods and agents for improving paper printability and strength

InactiveUS20010051687A1Improving printability strengthLess viscousNatural cellulose pulp/paperSpecial paperCardboardSizing

Compositions containing hydrophilic polyacrylamide and hydrophobic surface size agents and the use of such compositions in paper and board to improve printability, sizing and strength are provided in the instant invention.

Owner:KEMIRA OY

Cellulose Articles Containing an Additve Composition

ActiveUS20080295985A1Improve propertiesImproved grease resistanceNatural cellulose pulp/paperSpecial paperSpecific volumeCellulose fiber

In one embodiment, the present invention provides a method of forming a cellulose article having a specific volume of less than 3 cc / gm. The method includes the step of incorporating cellulose fibers with a compound, wherein the compound includes an aqueous dispersion. The aqueous dispersion may have at least one polymer selected from the group consisting of an ethylene-based thermoplastic polymer, a propylene-based thermoplastic polymer, and mixtures thereof; at least one polymeric stabilizing agent; and water. In certain embodiments, a combined amount of the at least one polymer and the at least one stabilizing agent comprises about 25 to about 74 volume percent of the aqueous dispersion.

Owner:DOW GLOBAL TECH LLC

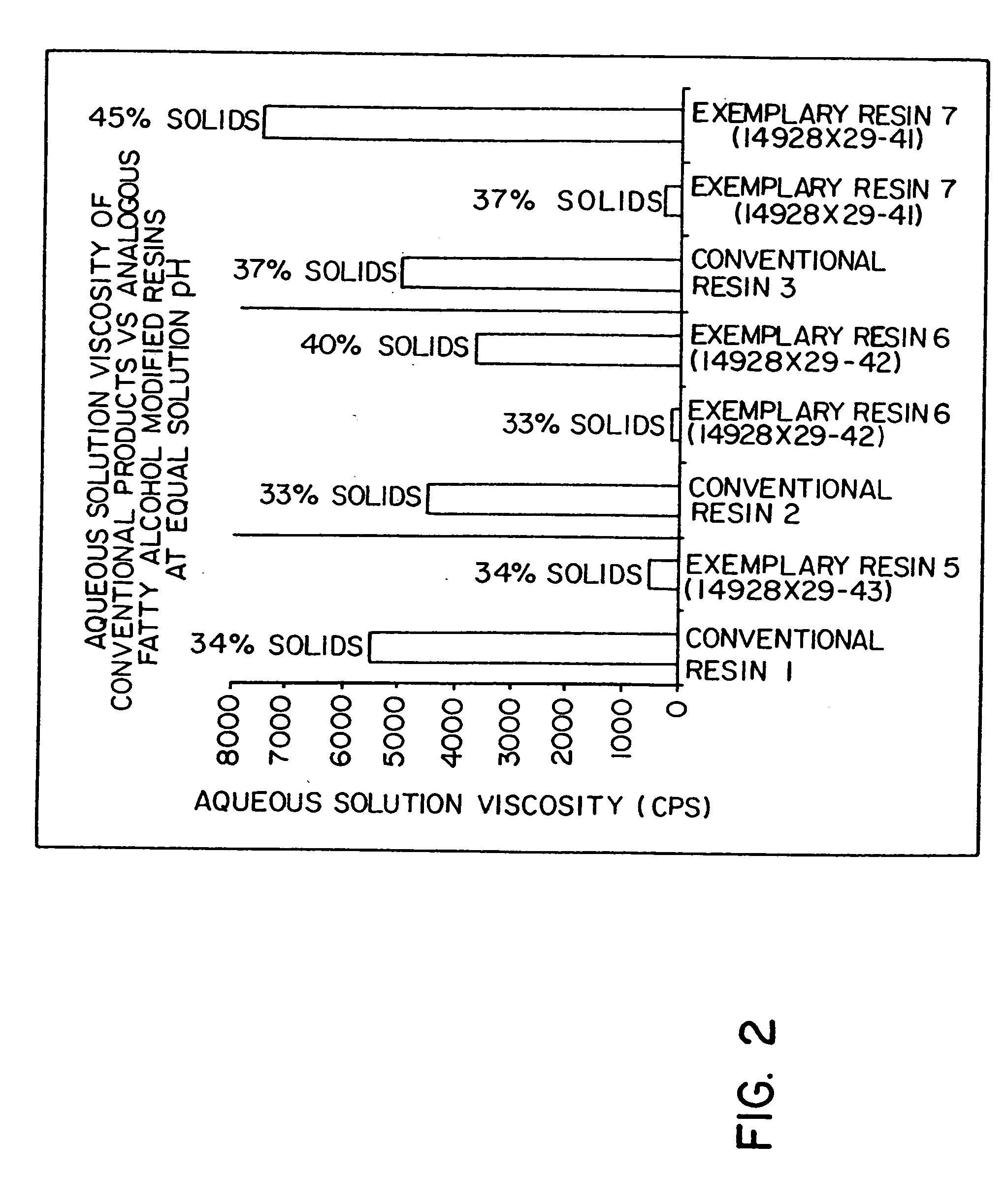

Continuous bulk polymerization and esterification process and compositions

InactiveUS20050059782A1High viscosityWater-repelling agents additionTransportation and packagingPolymeric surfacePolymer science

A continuous bulk polymerization and esterification process includes continuously charging into a reaction zone at least one ethylenically unsaturated acid-functional monomer and at least one linear or branched chain alkanol having greater than 11 carbon atoms. The process includes maintaining a flow rate through the reaction zone sufficient to provide an average residence time of less than 60 minutes and maintaining a temperature in the reaction zone sufficient to produce a polymeric product incorporating at least some of the alkanol as an ester of the polymerized ethylenically unsaturated acid-functional monomer. The polymeric product is used in various processes to produce water-based compositions including emulsions and dispersions such as oil emulsions, wax dispersions, pigment dispersions, surfactants and coatings which contain the polymeric product. A polymeric surfactant includes at least one ethylenically unsaturated acid-functional monomer which has been radically incorporated into the polymeric surfactant and at least one ester of the incorporated ethylenically unsaturated acid-functional monomer which has a linear or branched chain alkyl group with greater than 11 carbon atoms. The molar critical micelle concentration of the polymeric surfactant is less than 1.0×10−2 moles / liter. Aqueous 2 percent solutions of certain polymeric surfactants have a surface tension of less than 45 mN / m at 30° C. and exhibit a decrease in surface tension of at least 5 mN / m as the temperature warms from 30° C. to 50° C.

Owner:BASF CORP

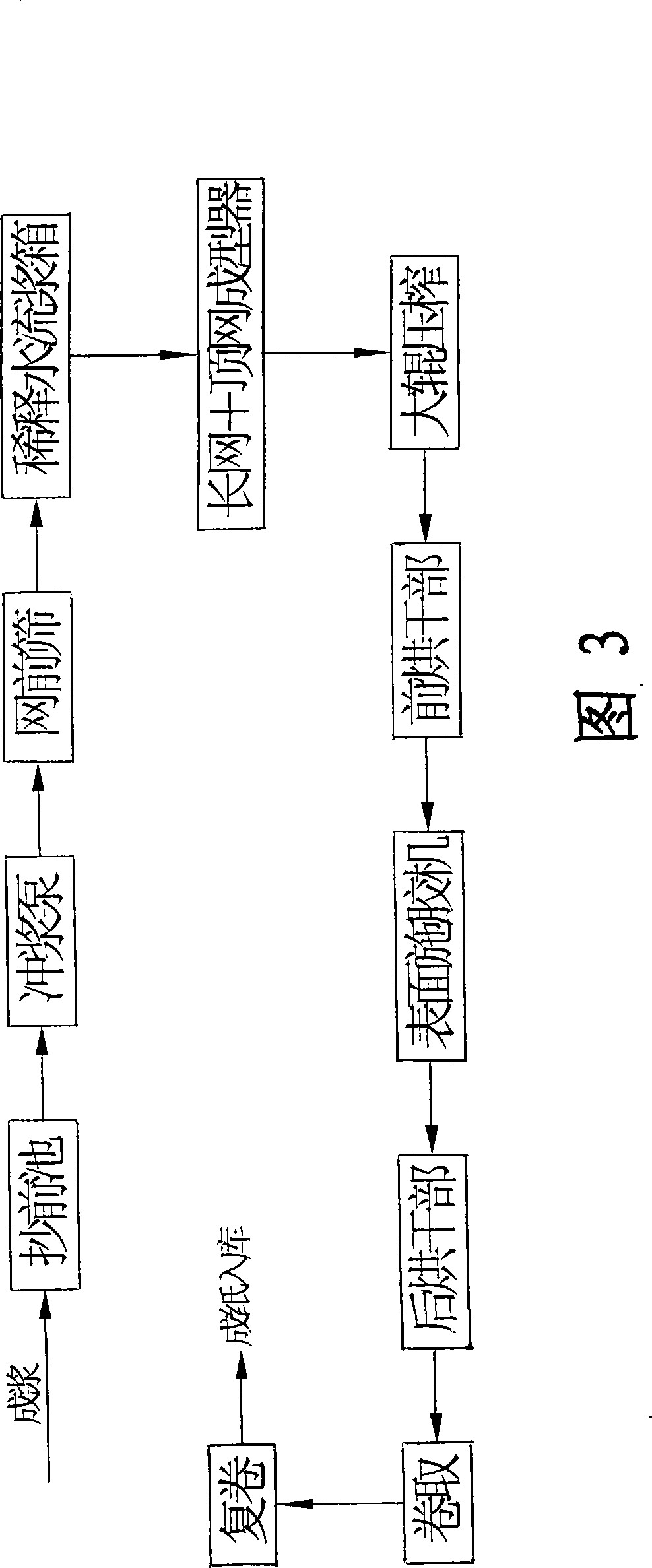

Long fibre nonwoven wallpaper base stock and preparation method thereof, and nonwoven wallpaper prepared by the same

ActiveCN101343846AGood flexibilityNice appearanceWater-repelling agents additionPaper/cardboardPulp and paper industryMachining process

The invention relates to a non-woven wall paper, in particular to a long fiber non-woven wall paper raw paper and the preparation method and the non-woven wall paper prepared in the method. The long fiber non-woven wall paper raw paper comprises fiber pulp material and adhesive agent, wherein the fiber pulp material comprise wood pulp fiber and functional fiber, the weight proportion between the wood pulp fiber and the functional fiber adopts 0 to 95 percent to 5 to 100 percent, and the adhesive agent occupies 1 to 10 percent of the total weight of the raw paper; the functional fiber at least contains a functional fiber which fineness is 0.8 to 25 D, and which length is 15 to 60 mm. The surface of the wall paper in the invention presents natural stripes, the outer appearance is artistic, and further treatment is not required. Simultaneously, during the wall paper product processing, no shrinkage and moist feeling occur, the paper uncover is complete, and the paper flexibility is good. The wall paper product adopting flame-resistant fiber can be burnt on the fire source, the fire is extinguished after leaving the fire source, and the non-woven wall paper has a good flame-resistant performance.

Owner:浙江凯恩新材料有限公司 +1

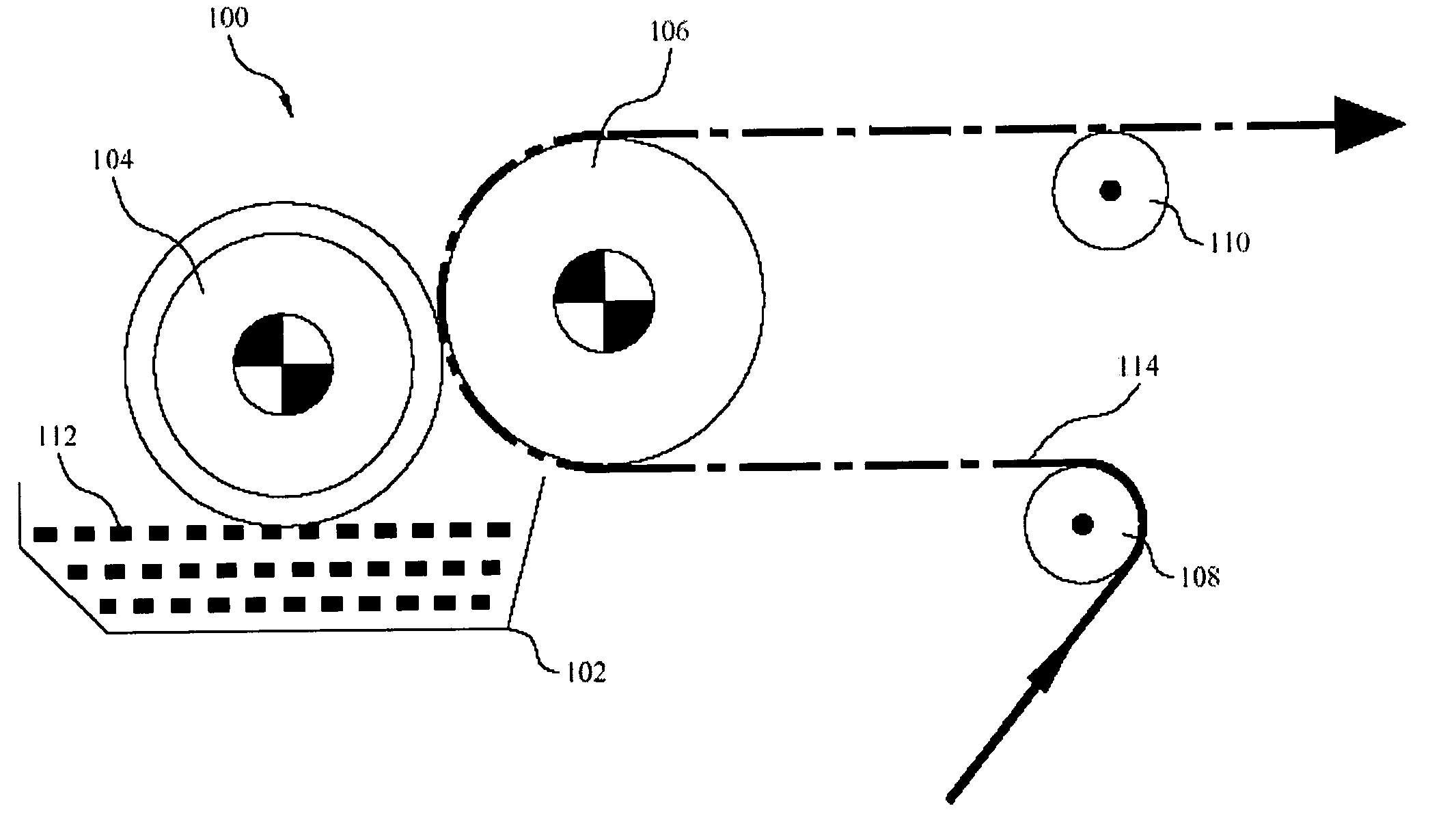

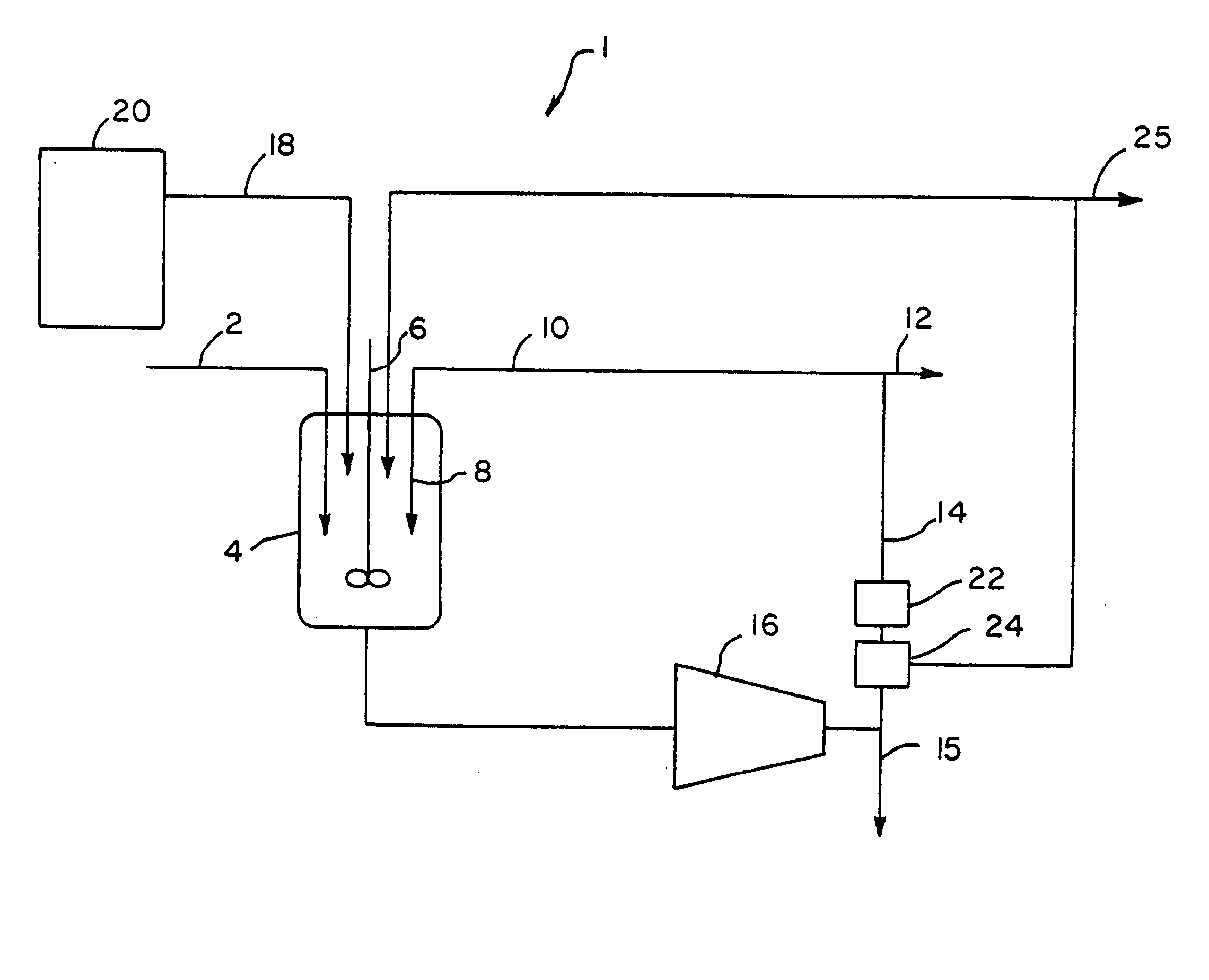

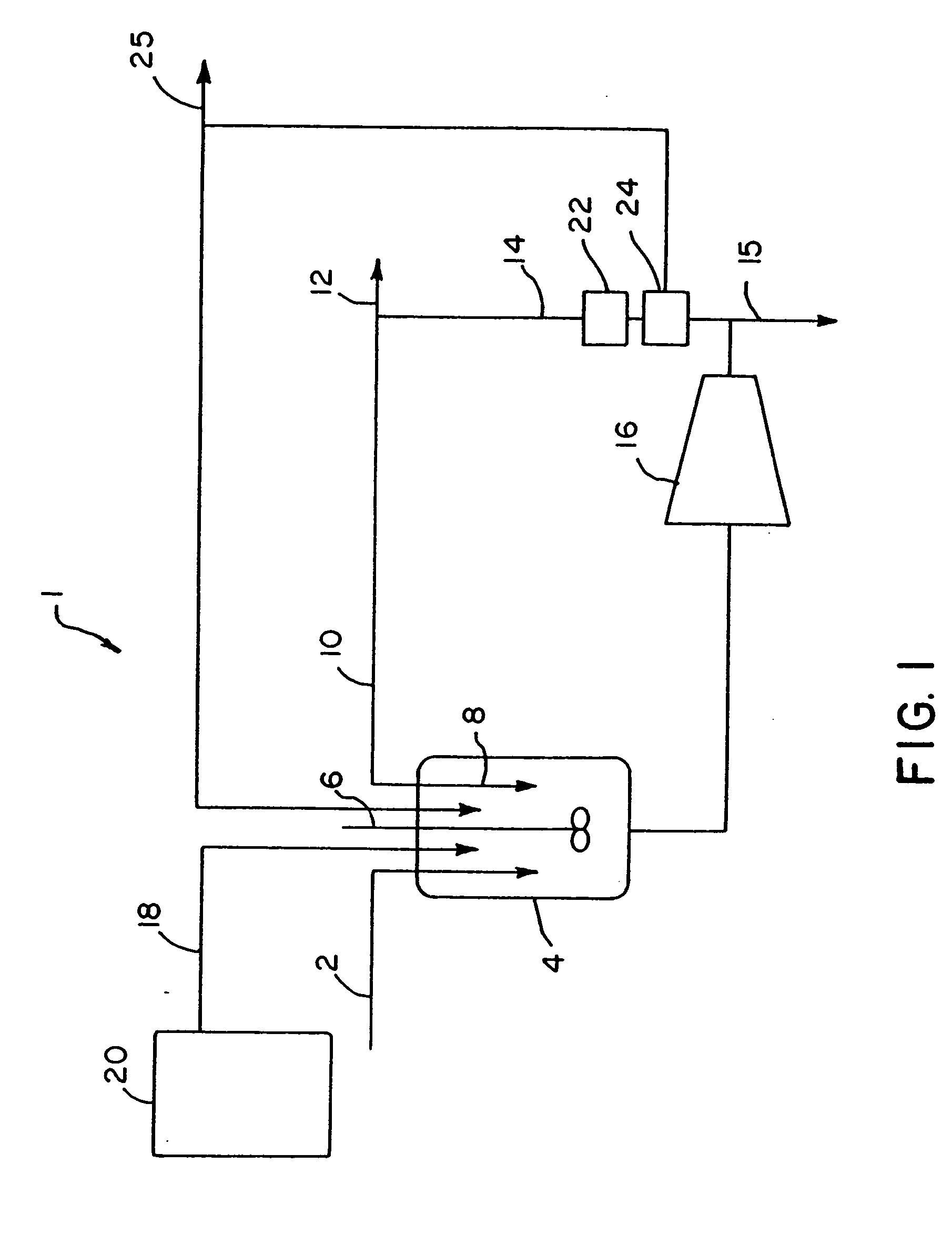

ASA emulsification with ultrasound

The invention provides a method and apparatus for optimally feeding an ASA emulsion into a papermaking process. An intense transmission of ultrasonic energy rapidly and efficiently forms an ASA emulsion. Nearly simultaneous to forming the emulsion, the emulsion is fed into a high-speed dual conduit feeding apparatus, which quickly mixes the ASA emulsion with other chemicals and feeds the mixture directly into a papermaking process. The invention operates so fast that virtually no hydrolysis of the ASA occurs. This both prevents damage to the papermaking machinery and improves the quality of the produced paper. The invention operates 10-20 times faster than mechanical based emulsion methods and requires 1 / 7 as much energy to operate. The invention also self-monitors the process and can automatically correct any detected problems with the fed ASA emulsion.

Owner:ECOLAB USA INC

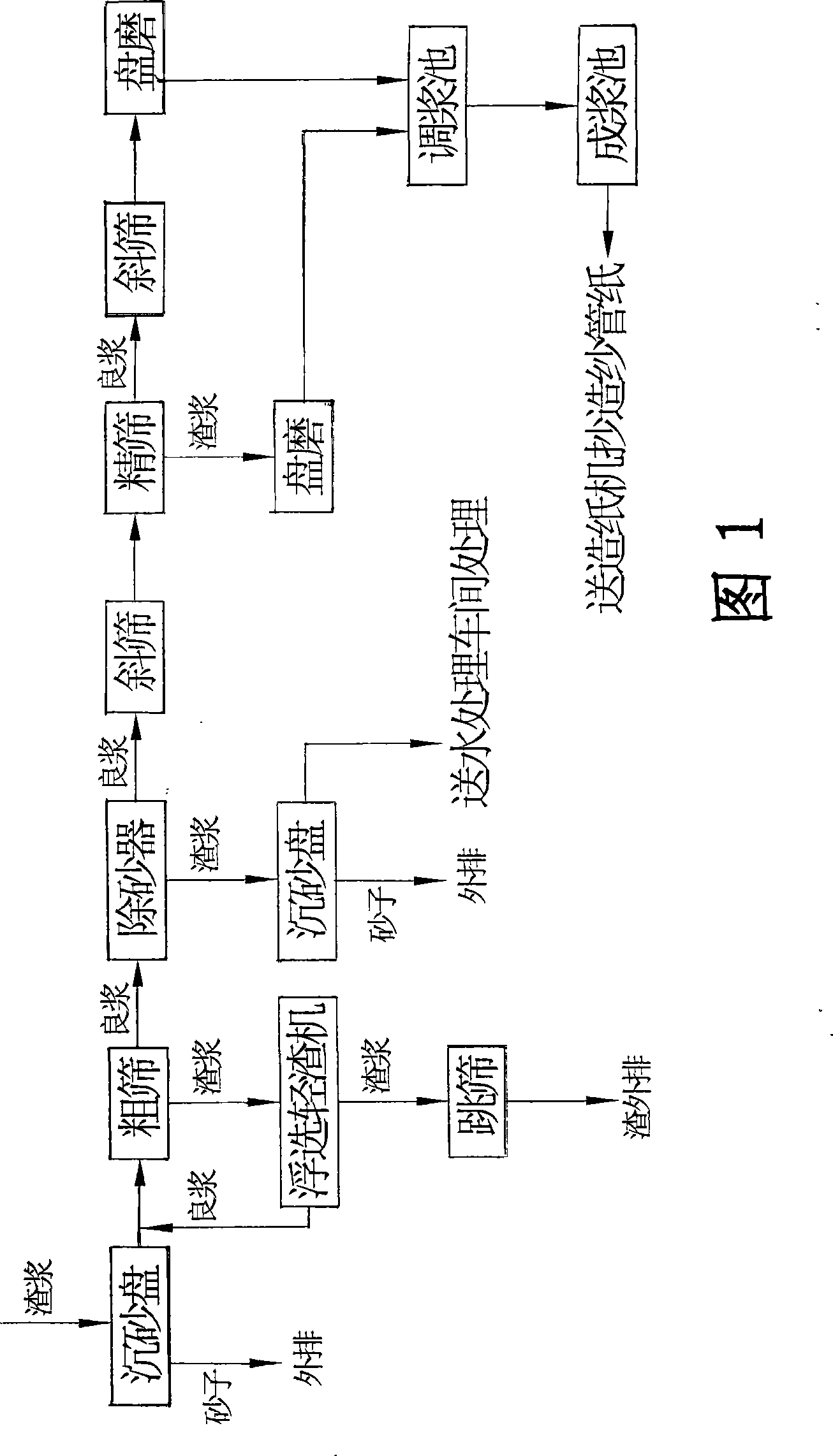

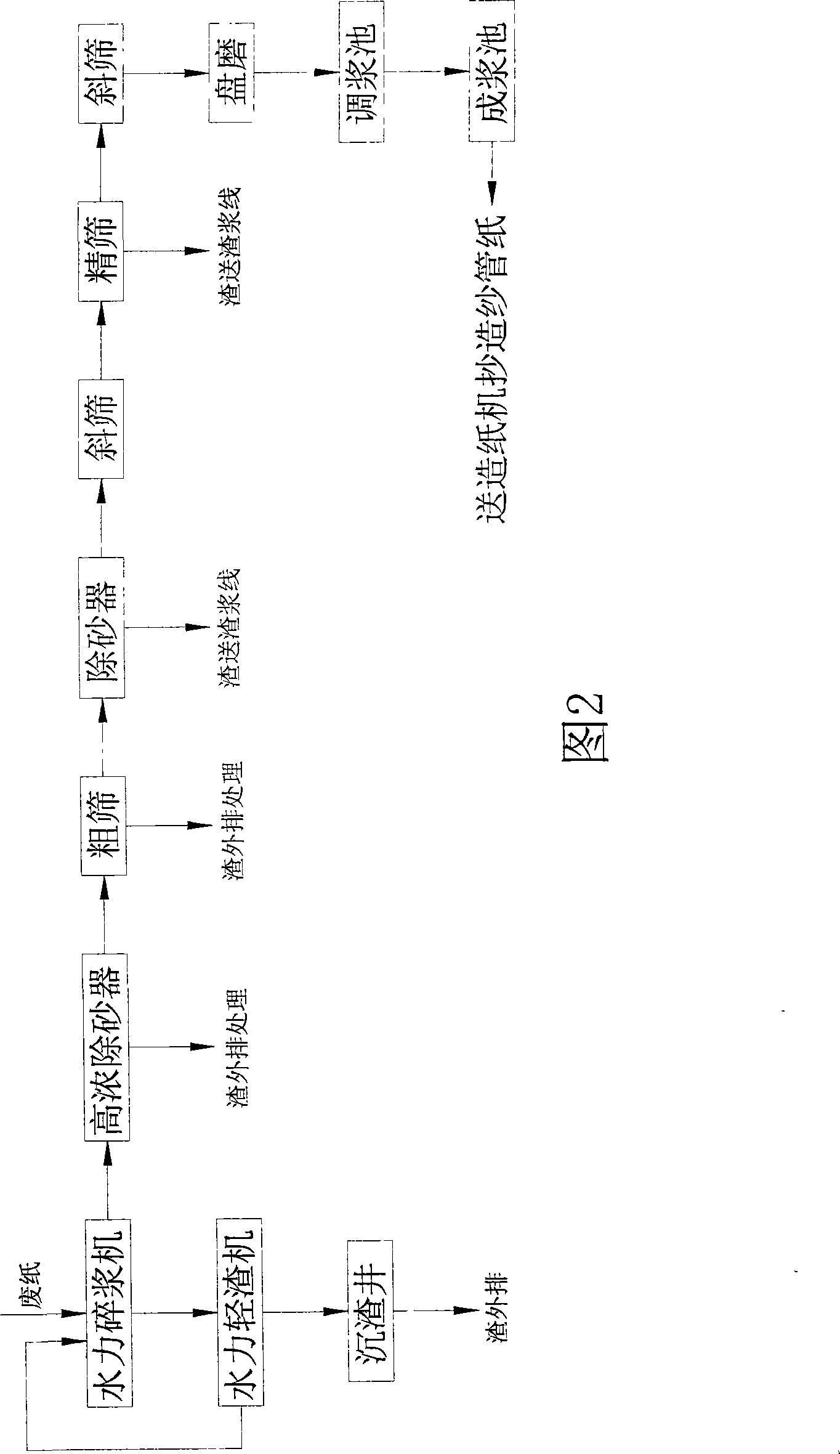

Method for producing recuperated yarn tube base paper by using waste slag and product thereof

ActiveCN101435171ASave resourcesAvoid churnWater-repelling agents additionPaper recyclingYarnProcess engineering

The invention relates to a manufacturing method which utilizes waste residue to produce regenerated yarn cop base paper and an obtained product thereof. The method comprises the following steps: the full stuff of processed waste slurry residue and the full stuff of processed waste paper are mixed according to proportion to carry out sand paper tube forming and then the regenerated yarn cop base paper is obtained. By adopting the method, waste paper resources can be saved, waste water treatment can be reduced, and the obtained regenerated yarn cop base paper has the advantages of low ration, good quality and the like.

Owner:JIAN GRP

Paper substrates containing high surface sizing and low internal sizing and having high dimensional stability

InactiveUS7736466B2Improve surface strengthNatural cellulose pulp/paperSpecial paperEngineeringHigh surface

This invention relates to a paper substrate containing high surface sizing and low internal sizing and having high dimensional stability, as well as methods of making and using the composition.

Owner:GLOBAL HLDG II INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com