Patents

Literature

113results about How to "Increased ring compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

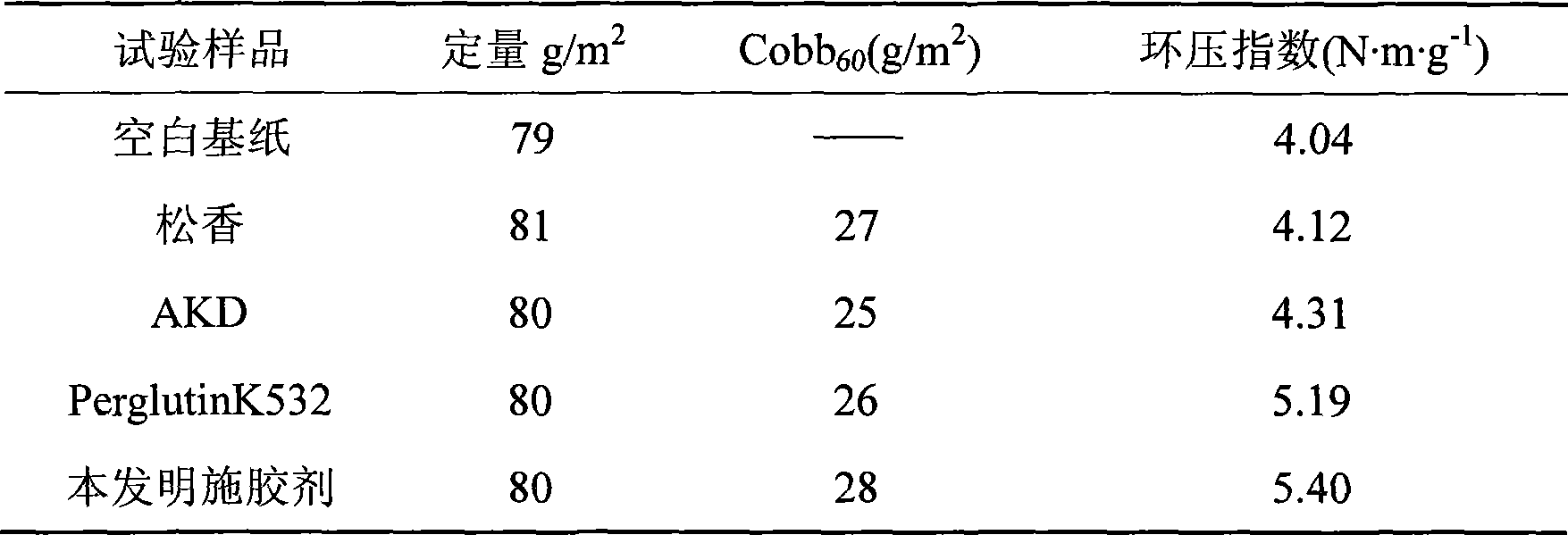

Paper surface sizing agent and preparation method thereof

ActiveCN101148842AIncreased ring compressive strengthLose weightWater-repelling agents additionPaper/cardboardCross-linkEmulsion

The present invention relates to paper surface treating agent, and is especially one kind of paper surface sizing agent and its preparation process. The paper surface sizing agent is prepared with cationic monomer, cross-linking monomer, (methyl) acrylate monomer and (methyl) styrene, and through free radical emulsion polymerization in mixture emulsion comprising dispersant, emulsifier and initiator. It has high performance and environment friendship. It is applied in sizing paper surface together with starch to raise the compression strength of paper, raise Cobb value and improve other performance of paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

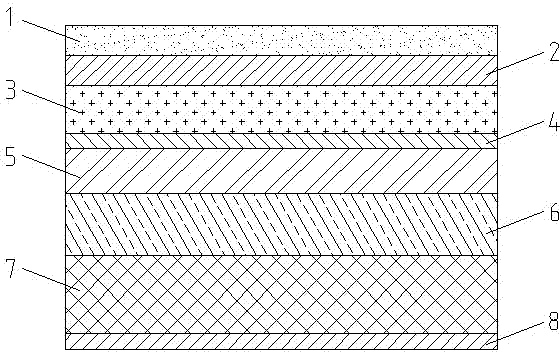

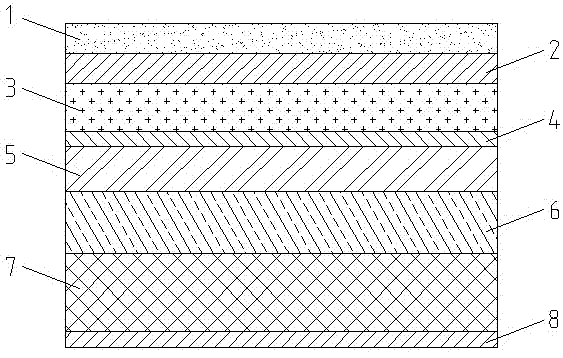

Coated natural kraft and manufacturing method thereof

ActiveCN102199898AHigh strengthIncreased ring compressive strengthDefoamers additionWater-repelling agents additionSurface layerPulp and paper industry

The invention relates to coated natural kraft and a manufacturing method thereof. The traditional coated kraft does not have the advantages of attractive appearance, environment friendliness, high strength and good printing performance. The coated natural kraft disclosed by the invention comprises natural kraft, a surface sizing layer and a surface coating layer and is characterized in that a bottom layer comprises OCC (Old Corrugated Case) waste paper pulp and a core layer comprises waste paper; a surface layer comprises natural wood pulp and waste paper pulp, wherein the weight percentage of the natural wood pulp is 30% to 90% and the balance is the waste paper pulp; the surface sizing layer comprises a front sizing layer and a back sizing layer; and the surface coating layer comprises a bottom coating layer, a middle coating layer and a surface coating layer. The manufacturing method for the coated natural kraft sequentially comprises a natural kraft preparing working procedure, a sizing working procedure, a coating working procedure and a molding working procedure. The coated natural kraft has the advantages of reasonable structure design, attractive appearance, environment friendliness, high strength, good printing performance, simple preparation technology, low production cost and good quality.

Owner:JIAN GRP

Method for manufacturing high ring-pressure strength corrugated base paper

InactiveCN101255663AHigh glass transition temperatureIncreased ring compressive strengthNon-fibrous pulp additionPaper/cardboardFiberCross-link

The invention discloses the preparation method of a high ring crush strength corrugated base paper, firstly, a starch is added into the corrugated paper slurry then stirred to be even; secondly, a non-ionic epoxy resin is added; finally, a polyacrylamide is added and stirred to be even, then making the high ring crush strength corrugated base paper is carried out. Because the invention uses a component whose structure and characteristic are different from a ring crush strength intensifier present widely used, the component comprises a plurality of benzene rings and epoxy groups. The benzene rings can endow the ring crush strength intensifier with very high glass transition temperature, and then enhances the ring crush strength of the corrugated base paper; at the same time, the cross linking function of the epoxy groups can make a powerful covalent bond combination exist between the paper fiber, which makes the corrugated base paper have certain wet strength.

Owner:SHAANXI UNIV OF SCI & TECH

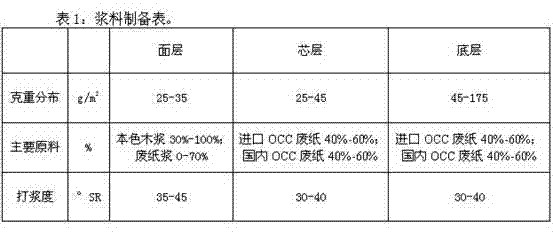

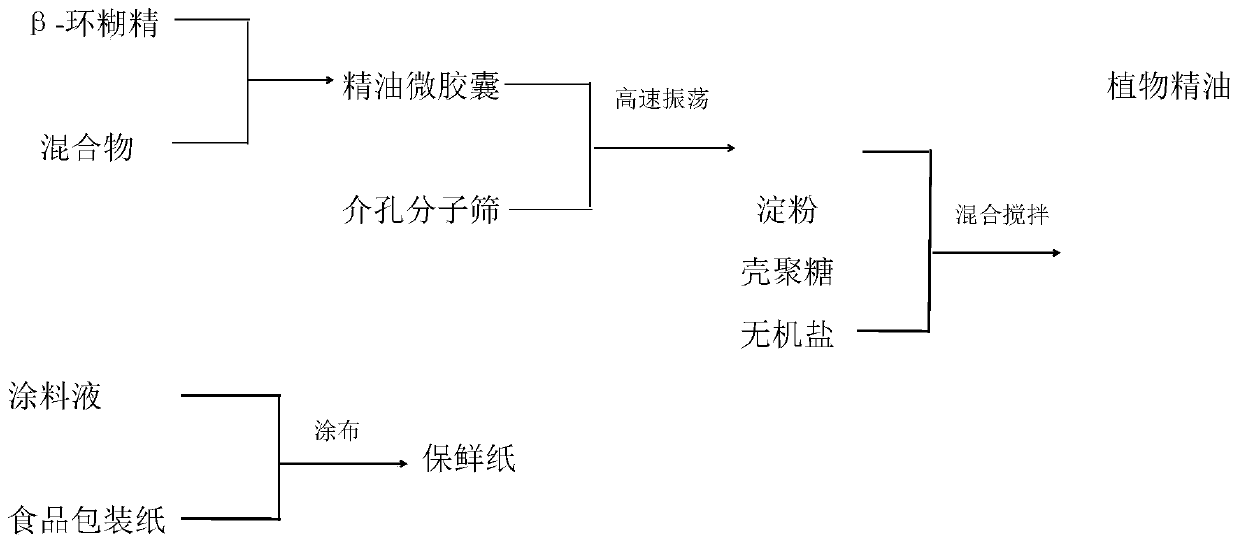

Preparation method of composite functional fresh-keeping paper based material with enhanced slow release function

ActiveCN110055820AExtended release timeGood sustained release effectFlexible coversWrappersInorganic saltsMolecular sieve

The invention discloses a preparation method of a composite functional fresh-keeping paper based material with enhanced slow release function. The preparation method comprises following steps: 1, beta-cyclodextrin and essential oil are weighed to prepare essential oil microcapsules; 2, the essential oil microcapsules and a mesoporous molecular sieve are mixed, water is added, and high speed oscillation treatment is carried out so as to obtain a molecular sieve loaded with the essential oil microcapsules; 4, the molecular sieve loaded with the essential oil microcapsules, a starch solution, a chitosan solution, and an inorganic salt solution are mixed and stirred at a ratio, deionized water is added to adjust the solid content to be 5 to 10% so as to obtain a coating solution; 5, the surface of food package body paper is uniformly coated with the coating solution; and 6, the coated paper is dried fully at room temperature so as to obtain the functional fresh-keeping paper based material. The fresh-keeping paper prepared using the above preparation method is capable of prolonging the storage period of packaged products, and the service life of the fresh-keeping paper can be prolongedat the same time.

Owner:ZHEJIANG UNIV OF TECH

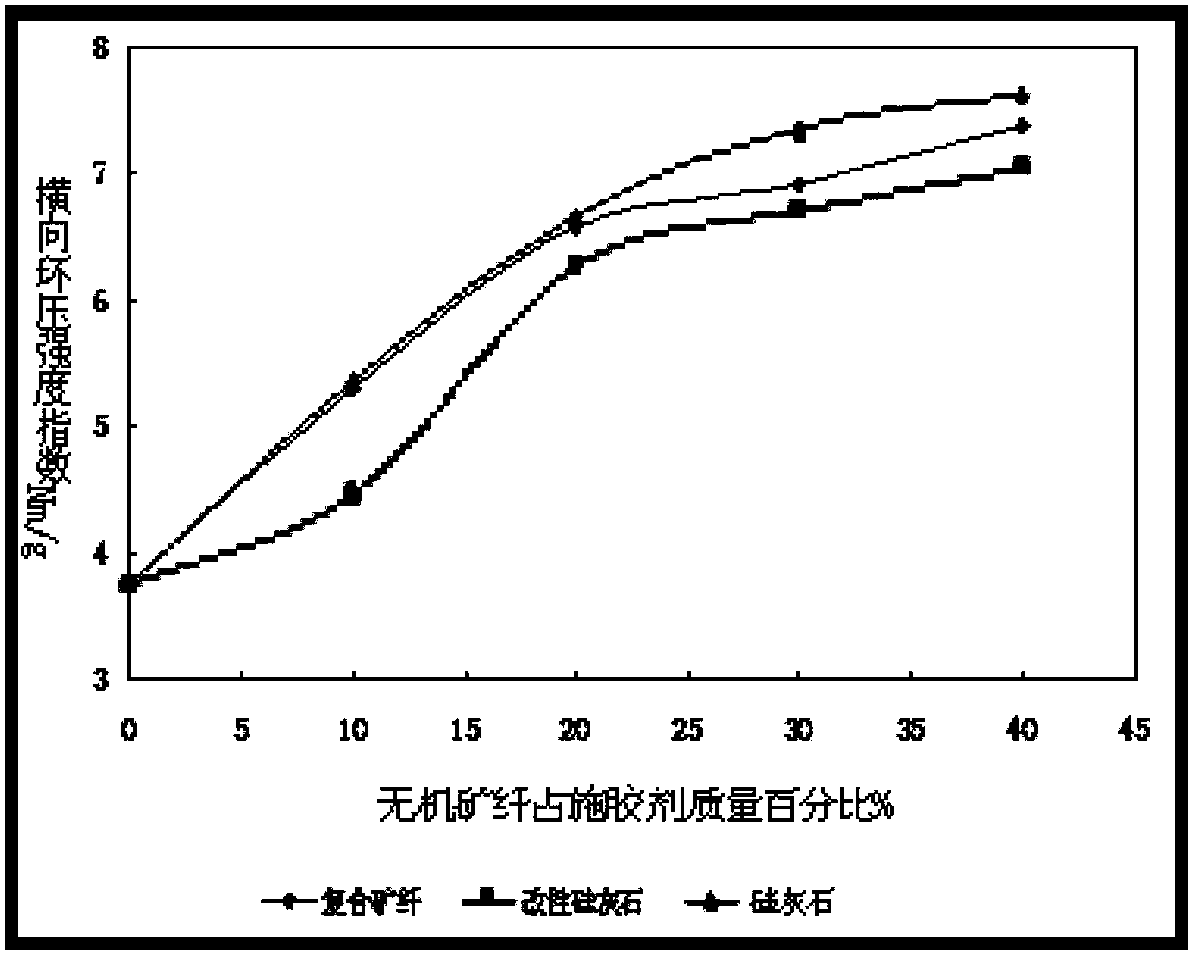

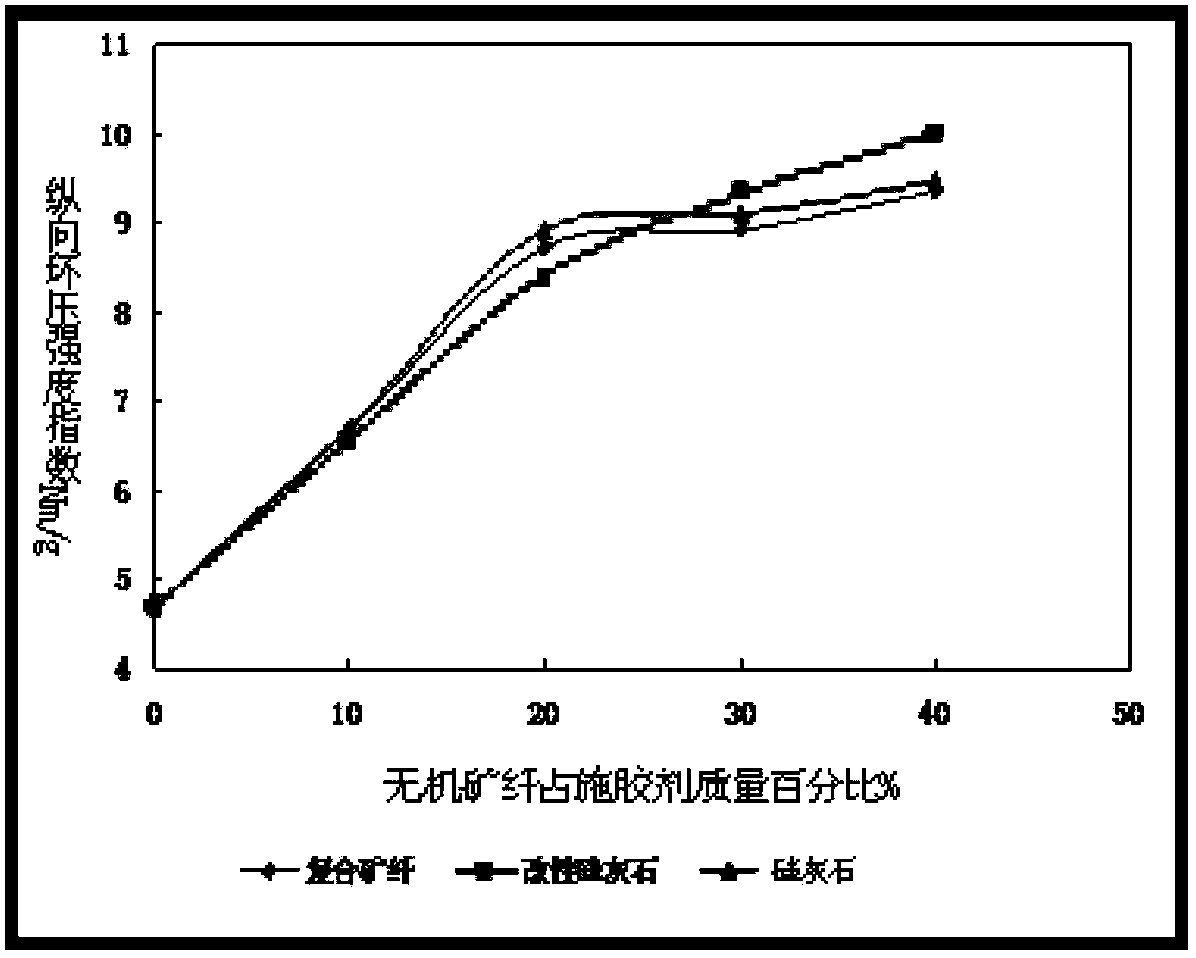

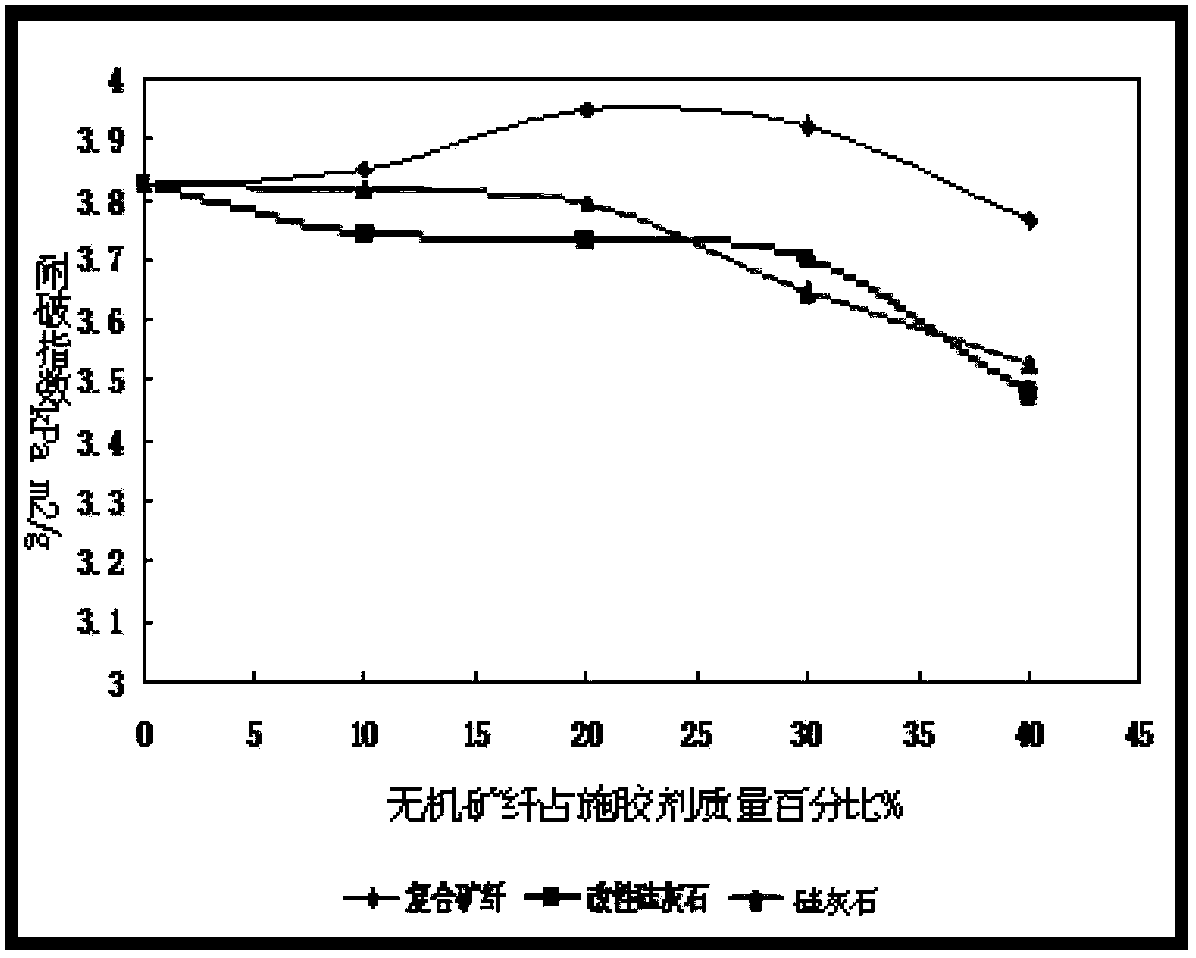

Inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and preparation method thereof

ActiveCN103388286AIncreased ring compressive strengthReduce paper production costsWater-repelling agents additionPapermakingSizing

The invention relates to an inorganic mineral fiber ring crush strength-improvement surface sizing agent for papermaking and a preparation method thereof. The inorganic mineral fiber ring crush strength-improvement surface sizing agent comprises surface sizing starch and inorganic mineral fibers. The mineral fibers comprise composite mineral fibers, modified wollastonite or wollastonite. The inorganic mineral fiber ring crush strength-improvement surface sizing agent comprises 5-40wt% of the inorganic mineral fibers. The norganic mineral fiber ring crush strength-improvement surface sizing agent can greatly improve corrugated paper ring crush strength and improve a tensile index and folding strength of a coated paper.

Owner:大连环球矿产股份有限公司

Surface sizing agent and its production method

InactiveCN101457499ASubstantiveGood water solubilityWater-repelling agents additionFunctional monomerMechanical stability

The invention relates to a method for preparing a surface sizing agent for papers. The raw materials used for preparing the surface sizing agent for papers consist of main agents and assistant agents. The main agents are rigid monomers, soft monomers and functional monomers; and the assistant agents are compound emulsifying agents, protective colloids and evocating agents. The proportions of the main agents by weight are as follows: 100 portions of rigid monomers, 40 to 100 portions of soft monomers and 5-40 portions of functional monomers; and the proportions of the assistant agents by weight are as follows: 1 to 10 portions of compound emulsifying agents, 1 to 10 portions of protective colloids and 1 to 8 portions of evocating agents. Compared with the styrene-maleic anhydride surface sizing agent prepared by common emulsifying agents, the surface sizing agent for papers prepared by the method has good mechanical stability, the latex contains no residual emulsifying agents, the particle surface is clean, and no side influence resulted from the emulsifying agents is existed during the sizing and drying process; the surface sizing agent has good membrane forming performance on the paper surface so as to provide excellent water-proof performance and surface flatness for the paper; and the surface sizing agent can increase the stiffness and the smoothness of the paper surface greatly.

Owner:上海埃格环保科技有限公司

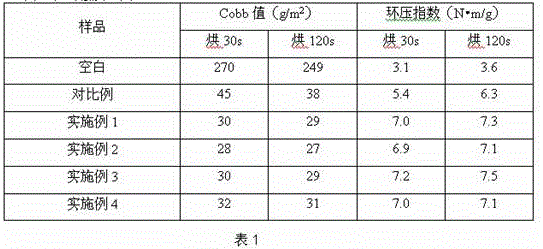

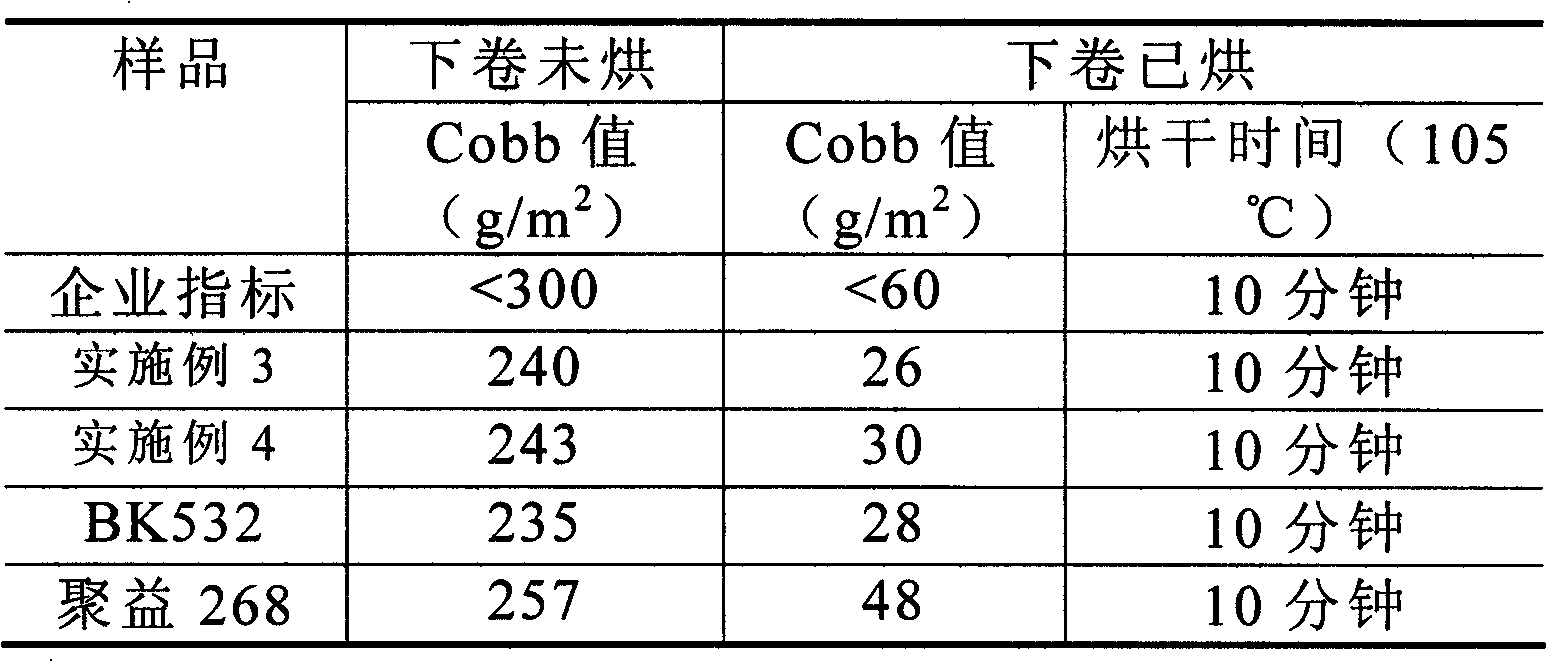

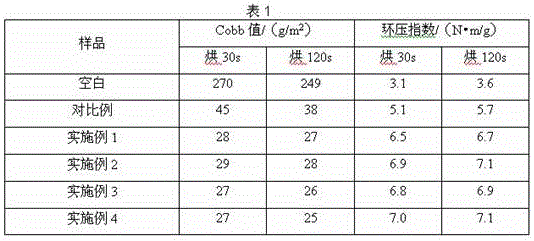

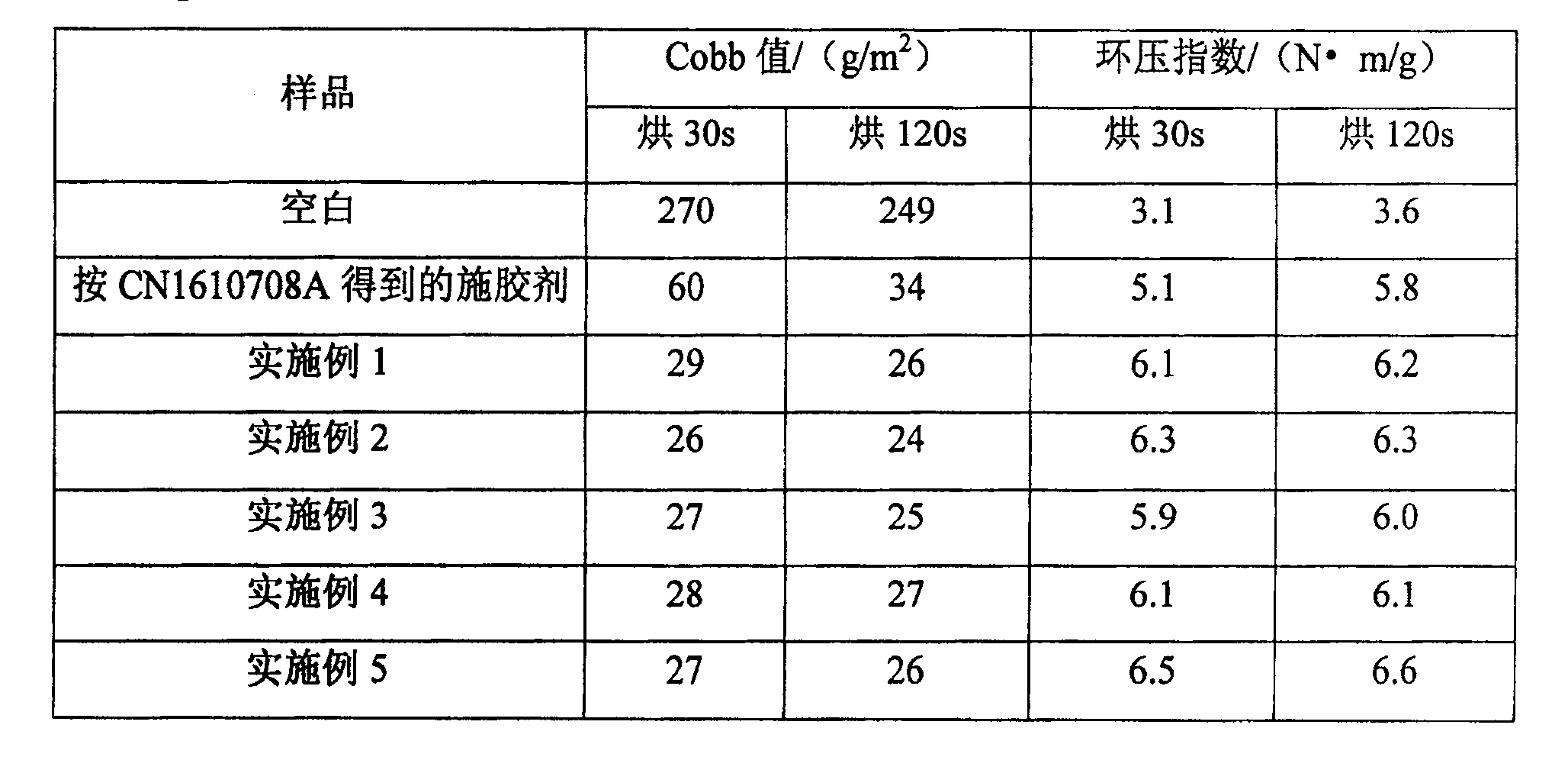

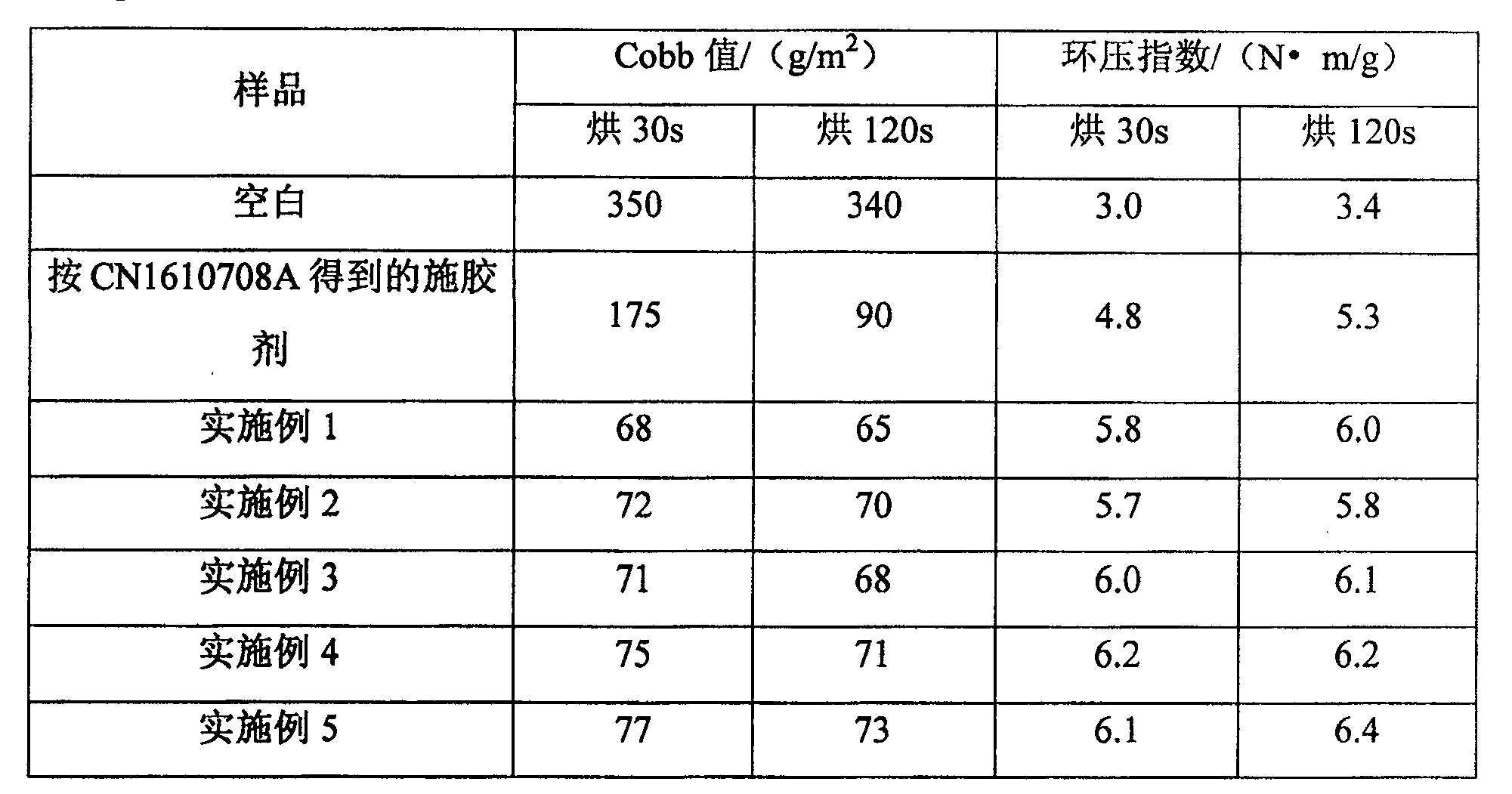

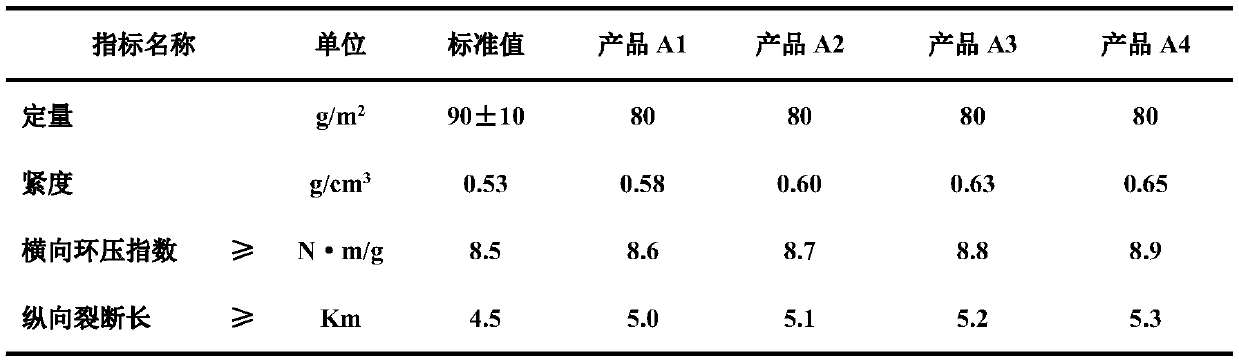

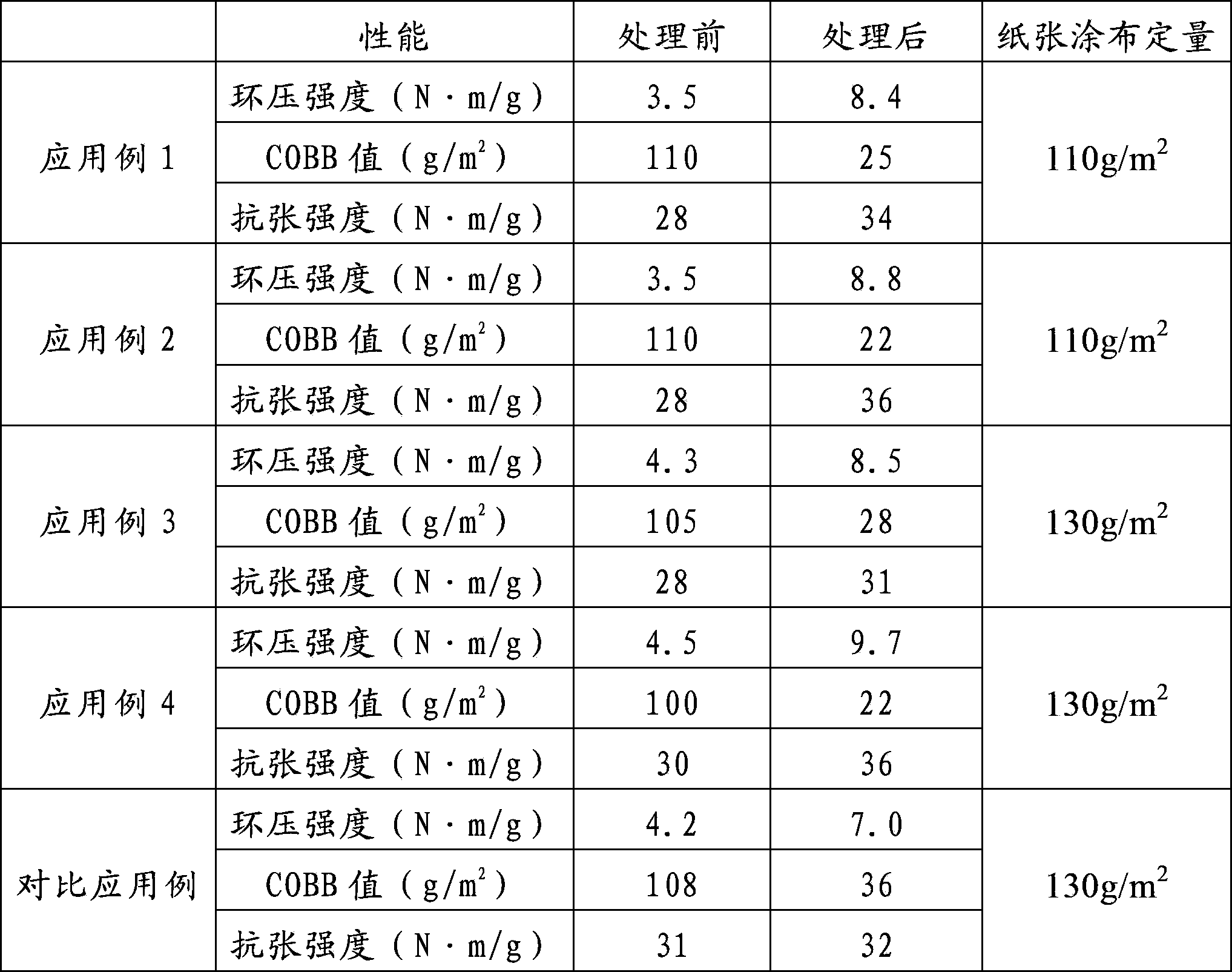

Preparing method of surface sizing agent for corrugated paper, product and application of surface sizing agent

ActiveCN106368059AReduce the Cobb valueIncreased ring compressive strengthWater-repelling agents additionCoated paper substrateAcetic acidPulp and paper industry

The invention provides a preparing method of a surface sizing agent for a corrugated paper, a product and an application of the surface sizing agent. The surface sizing agent for the corrugated paper is prepared by uniformly mixing a base stock of the surface sizing agent for the corrugated paper with a cationic additive. The preparing method for the base stock of the surface sizing agent for the corrugated paper comprises the steps of adding cationic monomer, siloxane, (metyl)acrylic monomer, (metyl)styrene, an initiator, acetic acid, and water into a reaction vessel, carrying out free radical polymerization reaction to obtain the base stock of the surface sizing agent for the corrugated paper. The preparing method for the cationic additive comprises the steps of adding alkylketene dimmer into an aqueous solution of cationic emulsifier, fully stirring the solution and carrying out emulsification and dispersion to obtain the cationic additive. The surface sizing agent for the corrugated paper obtained through the method can not only cure quickly, sharply improve ring crush compression resistance of the corrugated paper and sharply reduce a COBB value, but also has a very strong anti-dampness performance.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

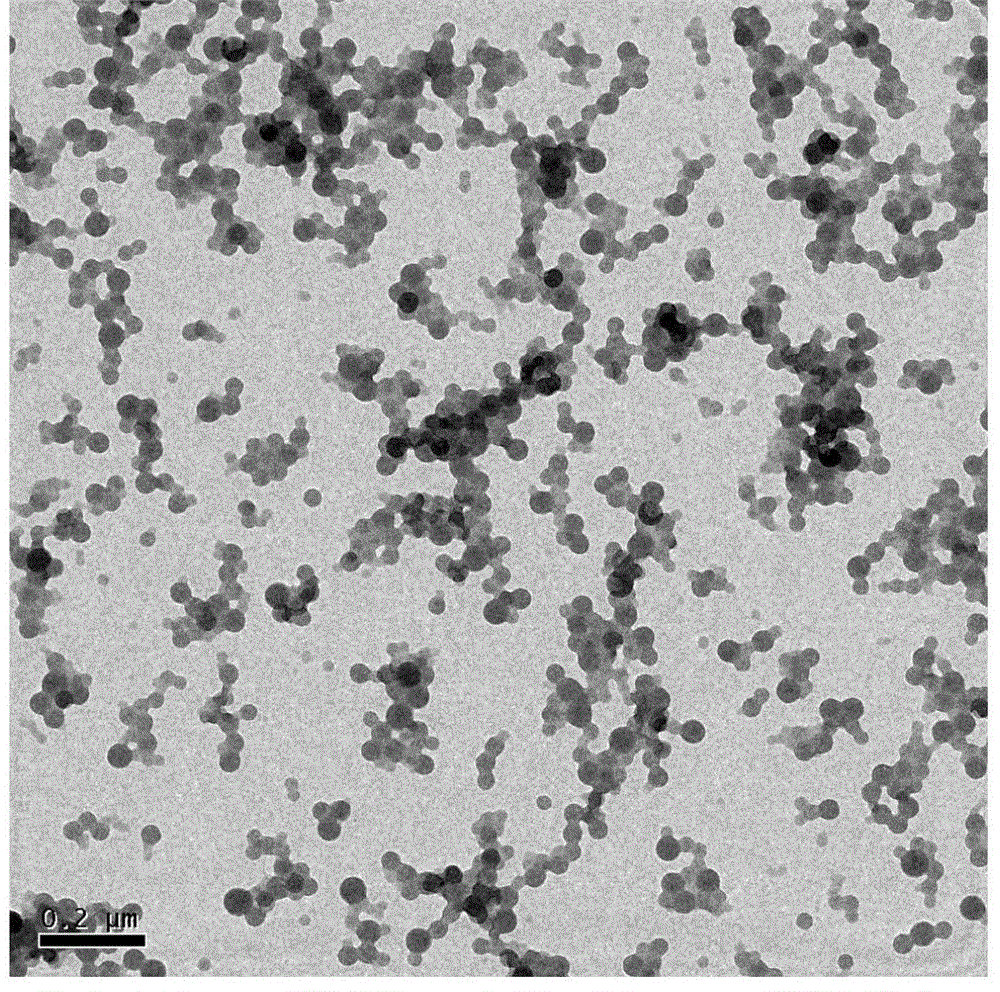

Preparation method for paper nanometer level surface sizing agents capable of realizing fast curing

ActiveCN102351973AOvercome the disadvantage of strong water absorptionIncrease the effective contact areaWater-repelling agents additionFiberPolyamide

The invention relates to a paper surface sizing agent, in particular to a preparation method for paper nanometer level surface sizing agents capable of improving the paper water resistance, surface intensity and annular pressure intensity and realizing the fast curing, which belongs to the technical field of chemical engineering and solves the technical problems of poor product quality and the like in the prior art. The surface sizing agent is prepared by the method of firstly preparing cation type polymer emulsifying agents and then preparing nanometer styrene-acrylates microemulsion. The method has the advantages that the defect of strong self water absorption performance of small molecular emulsifying agents is overcome, and in addition, the effective contact area between the surface sizing agent and the paper surface fiber is greatly improved, so the curing speed after the paper surface sizing and the sizing effect can be respectively and obviously accelerated and improved. The characteristic that paper making wet reinforcing agents of polyamide propylene oxide chloride resin can be fast combined with the fiber, and the cation type polymer emulsifying agents are adopted for taking reaction with epoxy chloropropane to obtain cation charges, so the fast combination of products with the paper surface fiber in the sizing process is promoted, and the curing speed is accelerated.

Owner:ZHEJIANG KESIKE CHEM NEW MATERIAL CO LTD

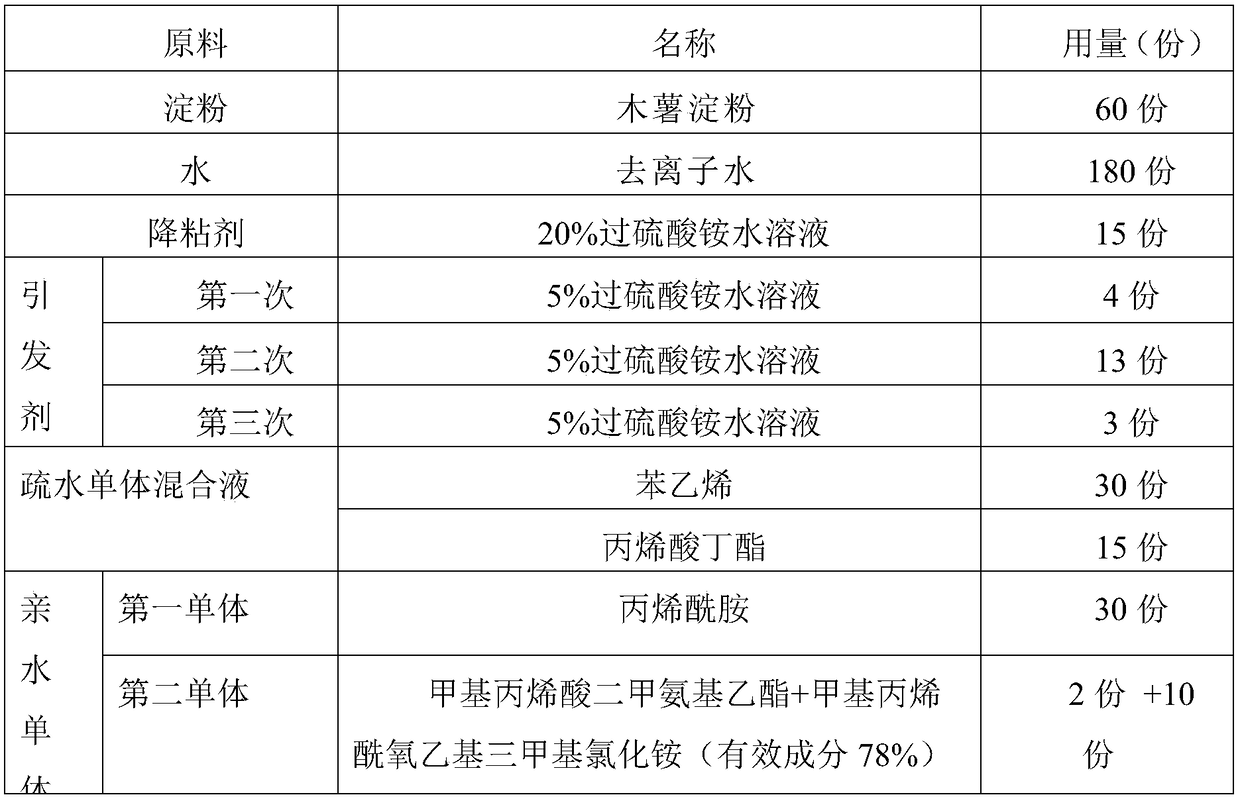

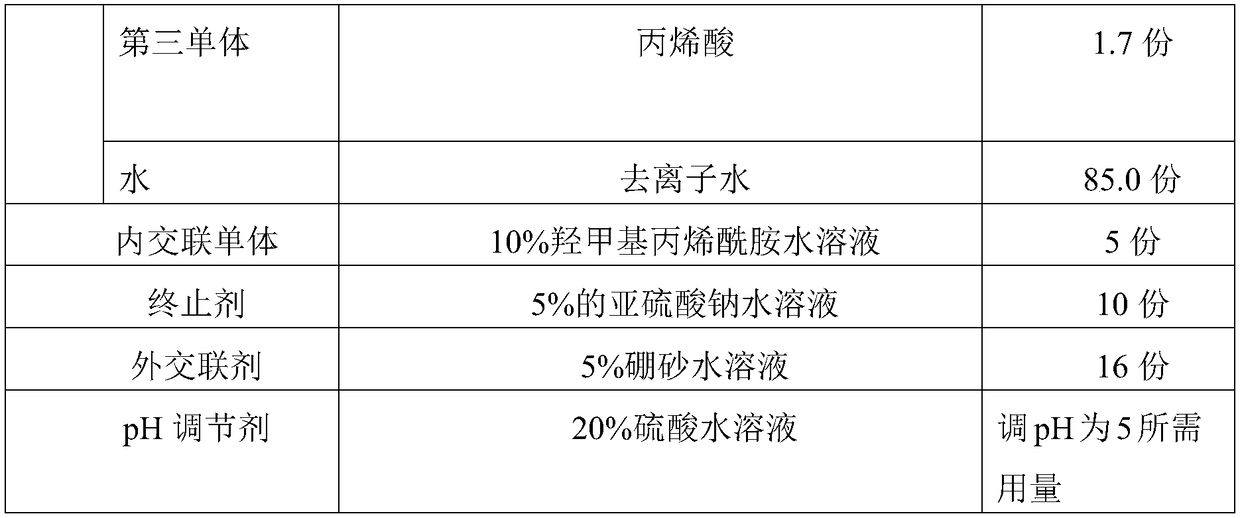

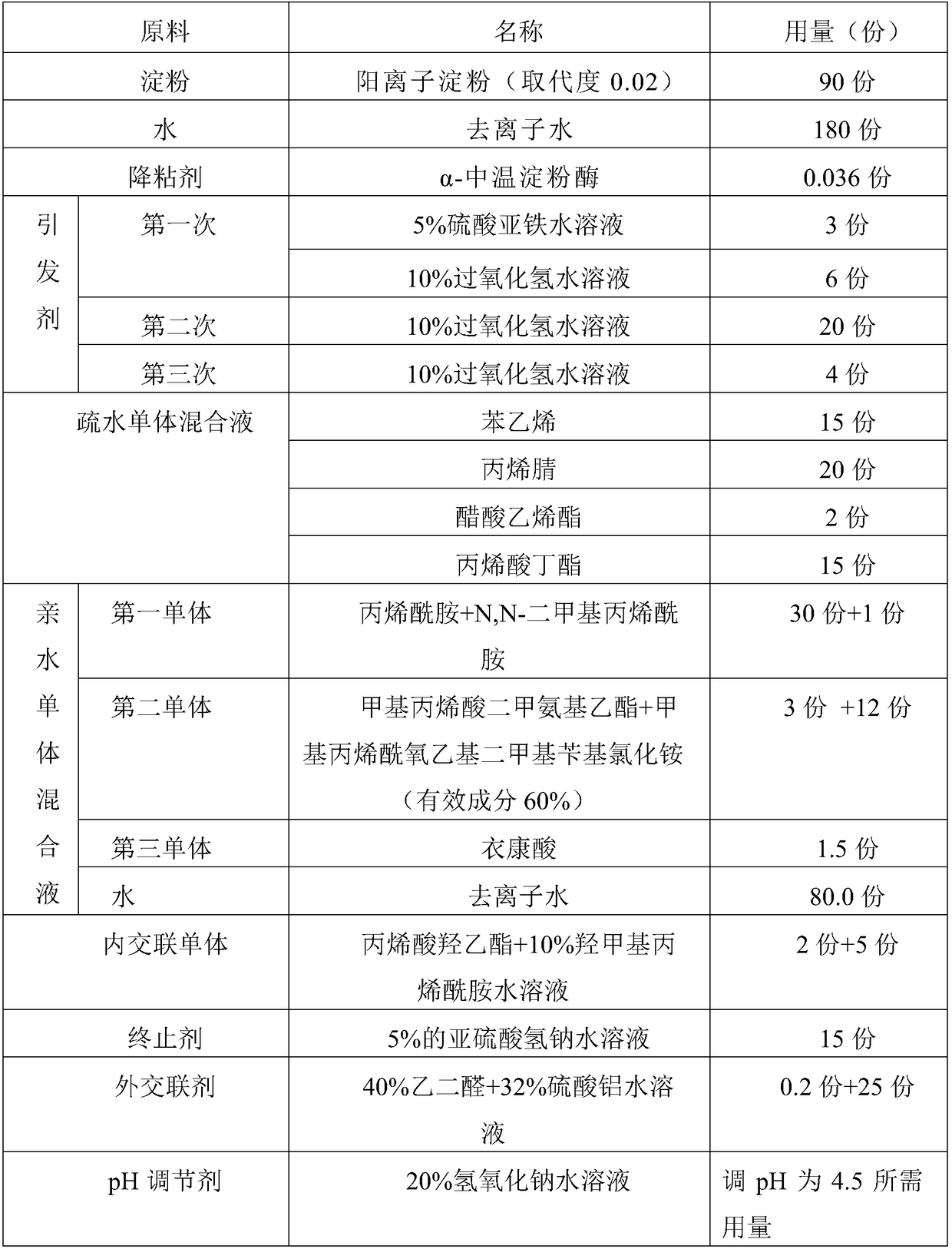

Preparation method of sizing enhancer

ActiveCN108341912APromote degradationSimple production processWater-repelling agents additionReinforcing agents additionHydrophilic monomerReflux

The invention discloses a preparation method of a sizing enhancer. The method is as follows: after cooking and viscosity reduction of starch, introducing nitrogen, cooling to 60-80 DEG C, adding an initiator, and reacting for 10 to 30 minutes; dropwise adding a hydrophobic monomer mixture, a hydrophilic monomer mixture solution, an internal crosslinking monomer solution and an initiator aqueous solution respectively, wherein the dropwise-adding time is controlled to 20 to 90 minutes, and the reaction temperature is controlled at 65 DEG C to 95 DEG C during the time; after the dropwise additionis completed, controlling the temperature at 80 DEG C-95 DEG C for reacting for 10 to 60 minutes, replenishing an initiator, continuing to react at 80 DEG C to 95 DEG C for 30 to 90 minutes, after areactor is free of reflux and the viscosity at 25 DEG C reaches 50 to 500 mPa.s, adding a terminator, cooling, adding an external crosslinking agent, and adjusting the pH to 4 to 6 to obtain the sizing enhancer. The sizing enhancer can be used for in-slurry sizing and surface sizing, and has the advantages such as good reinforcing effect, fast sizing and aging speed, and good resistance to moisture respiration.

Owner:九洲生物技术(苏州)有限公司

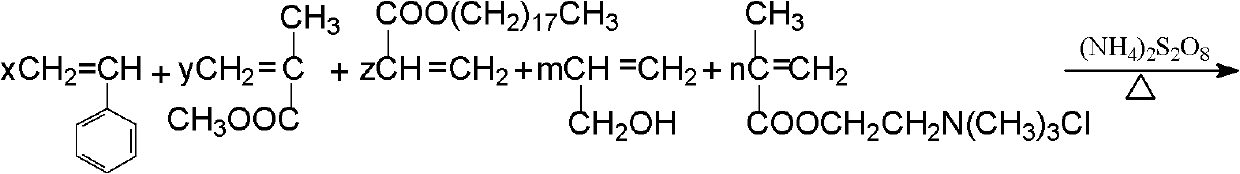

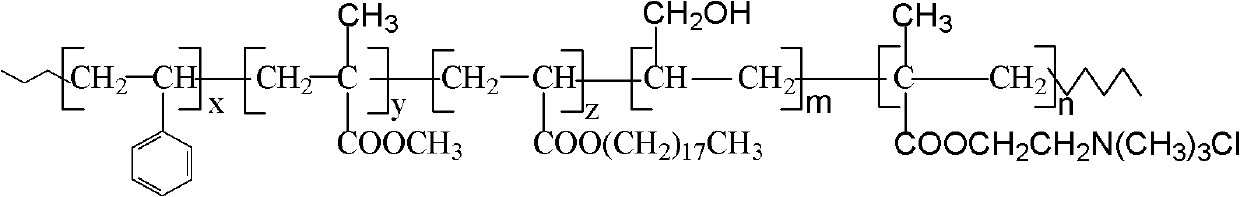

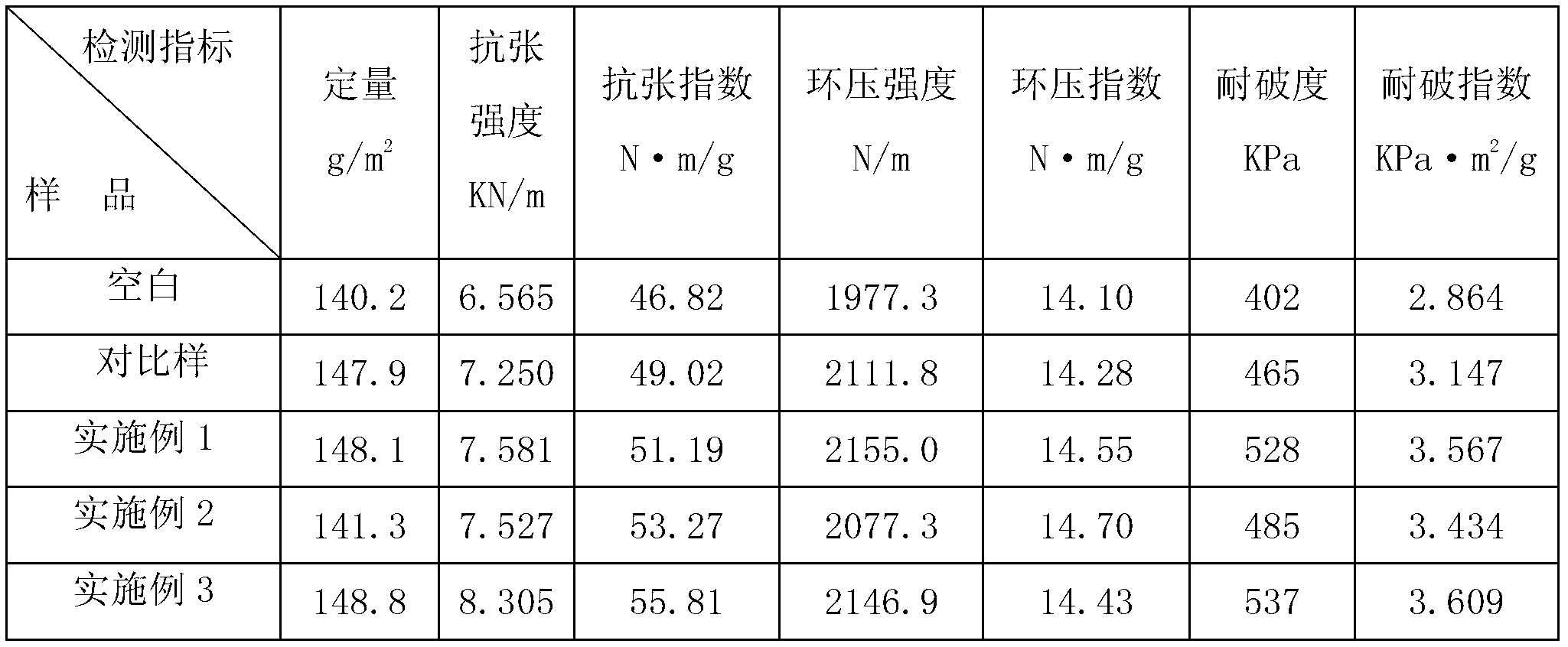

Cationic styrene-acrylate surface sizing agent and preparation method thereof

InactiveCN101871184AImprove bindingIncreased ring compressive strengthWater-repelling agents additionFiberSizing

The invention discloses a cationic styrene-acrylate surface sizing agent and a preparation method thereof. The cationic styrene-acrylate surface sizing agent has a molecular structure shown in the specifications. The cationic styrene-acrylate surface sizing agent is prepared by performing soap-free emulsion polymerization reaction on polyvinyl alcohol 1788 serving as a dispersing agent, ammonium persulfate serving as an initiator, and styrene, methyl methacrylate, octadecyl acrylate, allyl alcohol and methacrylatoethyl trimethyl ammonium chloride serving as a mixed monomer. The prepared cationic styrene-acrylate surface sizing agent can form a strong ionic bond with electronegative paper fiber so as to improve the adhesion of the cationic styrene-acrylate surface sizing agent and corrugated base paper fiber and improve the ring crush strength of corrugated base paper; and simultaneously, the sizing agent forms a film layer on the surface of the corrugated base paper so as to improve the water resistance of the corrugated base paper.

Owner:SHAANXI UNIV OF SCI & TECH

Impermeable four-layer composite corrugated board

ActiveCN104369513AIncreased ring compressive strengthHigh strengthNon-macromolecular adhesive additivesStarch adhesivesCardboardAdhesive

The invention discloses an impermeable four-layer composite corrugated board which is formed by surface paper, inner paper and two layers of core paper, wherein the two layers of core paper, as well as the core paper and the inner paper are adhered through an adhesive A; the two layers of core paper and the surface paper are adhered through an adhesive B; the adhesive A comprises the following components in parts by weight: 950-1050 parts of water, 280-290 parts of corn starch, 8-12 parts of sodium hydroxide, 2-3 parts of sodium borate and 55-58 parts of tannin; the adhesive B comprises the following components in parts by weight: 750-850 parts of water, 280-290 parts of corn starch, 8-12 parts of sodium hydroxide, 2.5-3.5 parts of sodium borate and 48-52 parts of tannin. According to the composite corrugated board, a glue layer is additionally arranged in the middle, so that the ring crush compression resistance of the composite corrugated board is obviously enhanced, and the strength is 5%-10% higher than that of a five-layer corrugated board quantified comprehensively. The corrugated board is impermeable within 90 minutes (preferably 15 hours), and can play a good role in protecting packaged goods.

Owner:NANTONG CHUANREN PRINTING PACKAGING

Preparation method of surface sizing agent

ActiveCN103410049AIncreased ring compressive strengthHigh burst resistanceWater-repelling agents additionPulp and paper industrySizing

The invention relates to a preparation method of a surface sizing agent. The surface sizing agent is prepared by the processes of treating, oxidizing, dissolving and gelatinizing starch, storing, adding auxiliaries and sizing. According to the preparation method disclosed by the invention, the sizing effect on corrugated paper is improved by oxidizing the starch and adding the auxiliaries, and the overall performances of the corrugated paper are greatly improved; and simultaneously, the operation process flow is simple and convenient, and the cost is low.

Owner:安徽浙源再生纸业科技有限公司

Wear-resistant flame retardation wallpaper raw paper and making method thereof

InactiveCN105908561AImprove brushing effectTightly boundVegetable material additionWax additionWear resistantGas phase

The invention discloses a wear-resistant flame retardation wallpaper raw paper. Present technologies and present formulas are improved, meerschaum powder-antimony oxide-chlorinated paraffin is adopted as a flame retardant and is modified, H. and OH. free radicals in the chain reaction and for keeping combustion in a paper combustion reaction gas phase are captured to change the reaction mode in the gas phase, the heat release amount of the reaction is reduced to quench flame, and nanometer calcium carbonate is added to raw materials after being organically modified to improve the brush ability of raw paper and make the raw paper be closely combined with a decoration layer and not shed. The flame retardation property of the flame retardation wallpaper raw paper meets GB / T14656-93 requirements, the tearability, the folding strength, the ring crush strength and the tensile strength are improved, and wallpaper produced by using the raw paper has the advantages of environmental protection, no pollution, wear resistance, difficult shedding, full utilization of the moisture absorption, ventilation, bacteriostasis, anti-bacterium, warmness in winter, coolness in summer and humidity adjustment characteristics of bamboo charcoal fibers to purify and adjust air, and avoiding of damages of harmful materials to the health of human bodies.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Mineral fiber softening agent

InactiveCN105155267AStrong Penetrating AdhesionImprove bindingInorganic fibres/flakesFibre treatmentAdhesivePlant fibre

The invention discloses a mineral fiber softening agent. The mineral fiber softening agent is prepared from the following raw materials in part by weight: 40-55 parts of vinyl acetate-ethylene copolymer emulsion, 15-25 parts of vital gluten, 5-15 parts of inorganic adhesives, 3-5 parts of chlorinated polyethylene emulsion, 0.5-2 parts of organic adhesives and 0.2-0.5 part of silane unsaturated monomer. The vital gluten, the inorganic adhesives and the organic adhesives are subjected to compound modification in an acylation manner, by a strong polarity polar group of the chlorinated polyethylene emulsion, the obtained softening agent has high-permeation adhesion on mineral fibers, permeates in the fibers and firmly wraps surfaces of the mineral fibers, and owing to viscoelasticity of the vital gluten, the mineral fibers have good flexibility. Because the softening agent contains the water-soluble inorganic adhesives, metal cation electrolytes are formed on surfaces of the mineral fibers when the mineral fibers are softened by the softening agent, potential difference is generated between the surfaces of the mineral fibers and surrounding liquid, particularly, a binding force of the mineral fibers and plant fibers is increased, when the plant fibers are replaced, the mineral fibers can be connected with the plant fibers, ionic bonds are formed by combination of ions, and bonding strength of the fibers is improved.

Owner:广州市朗尔化工助剂有限公司

VOC-free water-based epoxy polyurethane surface sizing enhancer and preparation method thereof

InactiveCN104328711AImproves paper strength propertiesGood adhesionPaper coatingReinforcing agents additionFunctional monomerChemistry

The invention discloses a VOC-free water-based epoxy polyurethane surface sizing enhancer which is composed of the following materials, by weight, 12-75 parts of vinyl monomer, 8-35 parts of polymer polyol, 2.5-20 parts of a polyisocyanate compound, 0.12-0.75 part of trimethylol propane, 3-18 parts of a hydrophilic chain extender, 0-0.18 parts of a catalyst, 0.8-5 parts of vinyl monomer containing activated hydrogen, 0.12-2.5 parts of an initiator and 5-57 parts of a monomer mixture, wherein the monomer mixture contains 4-35 parts of vinyl monomer and 1-22 parts of functional monomer containing epoxy groups. The invention also discloses a preparation method of the VOC-free water-based epoxy polyurethane surface sizing enhancer. By the use of the enhancer, a surface sizing agent with good adhesion property and film-forming property can be obtained. During the preparation process of the enhancer, there is no organic solvent. The preparation process is simple, safe, environmentally friendly and pollution-free.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation and application of emulsion type reinforcing agent for case board paper

ActiveCN103254347AHigh tensile strengthIncreased ring compressive strengthReinforcing agents additionEmulsionFunctional monomer

The invention discloses a preparation method of an emulsion type reinforcing agent. The method includes: (1) seed emulsion preparation: dissolving a nonionic emulsifier in water, adding a monomer to perform emulsification so as to obtain a seed monomer pre-emulsion; dissolving an initiator in water to obtain a seed initiator solution; mixing a cationic plant gum with water, adding a nonionic emulsifier, raising the temperature to 70-75DEG C, adding a seed initiator aqueous solution, and then slowly adding the seed monomer pre-emulsion, thus obtaining the seed emulsion; and (2) emulsion preparation: dissolving the nonionic emulsifier in water, adding the monomer and a functional monomer, thus obtaining a monomer pre-emulsion; dissolving the initiator in water to obtain an initiator solution; and adding the monomer pre-emulsion and the initiator solution into the seed emulsion obtained in step (1) simultaneously to react, thus obtaining the emulsion type reinforcing agent. The emulsion type reinforcing agent prepared by the invention has the effects of improving the tensile strength and the ring crush strength of paper at the same time.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

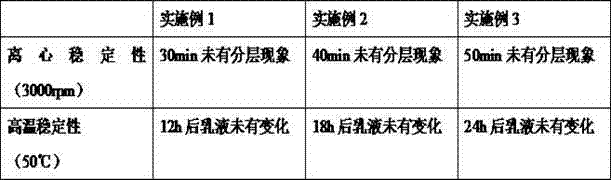

Cationic rosin size sizing agent and preparation method thereof

ActiveCN103866619AImprove stabilityIncreased ring compressive strengthWater-repelling agents additionRosinChemistry

The invention relates to a cationic rosin size sizing agent and a preparation method thereof. The cationic rosin size sizing agent is prepared from the following components in parts by weight: 6-8 parts of cationic rosin size, 9-12 parts of acetic acid vinyl ester, 2-3 parts of polyacrylonitrile, 5-6 parts of tetradecyl methacrylate, 12-15 parts of polyoxyethylene sorbitan tristearate, 3-4 parts of white alum and 240-260 parts of deionized water. The preparation method of the cationic rosin size sizing agent comprises the following steps: heating, complexing, reacting, and cooling. The prepared cationic rosin size sizing agent has good centrifugal stability and high-temperature stability, and the ring crush compression resistance of paper can be obviously improved.

Owner:SUZHOU HENGKANG NEW MATERIALS

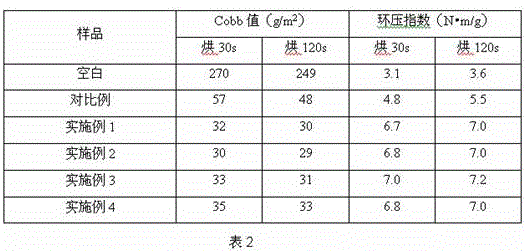

Novel surface sizing agent and preparation method thereof

ActiveCN106368062AIncreased ring compressive strengthReduce the Cobb valueWater-repelling agents additionPaper coatingAcetic acidGram

The invention discloses a novel surface sizing agent and a preparation method thereof. The preparation method comprises the following steps: 1, uniformly mixing methyl styrene, an acrylate monomer, a cationic monomer and an initiator to form a mixed monomer; 2, adding 10-20% of the mixed monomer obtained in the step 1 into a four-necked flask, heating to the temperature of 80-140 DEG C, reacting for 5-20 minutes, and dripping the residual mixed monomer; 3, adding acetic acid, and reacting at the temperature of 80-140 DEG C for 20-60 minutes; 4, adding preheated deionized water at the temperature of 80-140 DEG C, continuously reacting for 0.5-2 hours, adding siloxane for reacting 0.5-3 hours, cooling, and filtering, thereby obtaining the novel surface sizing agent. The novel surface sizing agent disclosed by the invention is capable of greatly reducing a Cobb value, promoting rapid curing, and greatly improving the ring crush compression resistance of corrugated paper and reducing gram weight of paper on the premise of maintaining invariable sizing agent amount.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

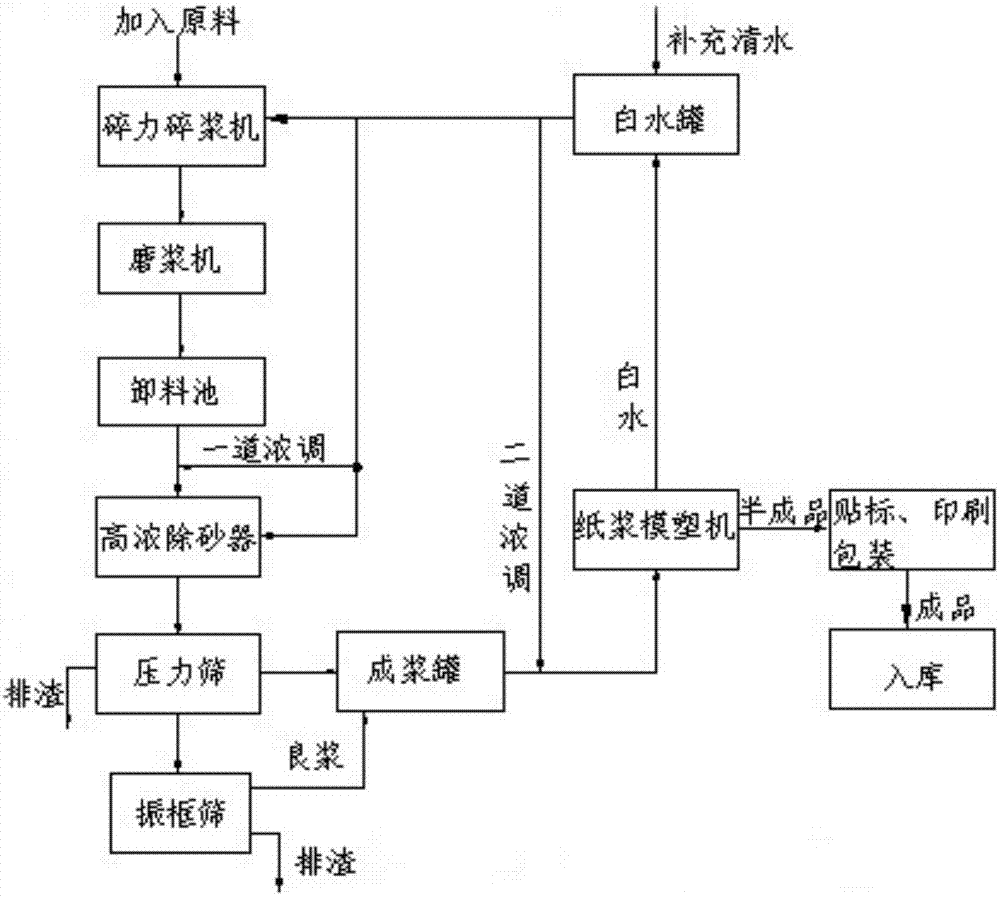

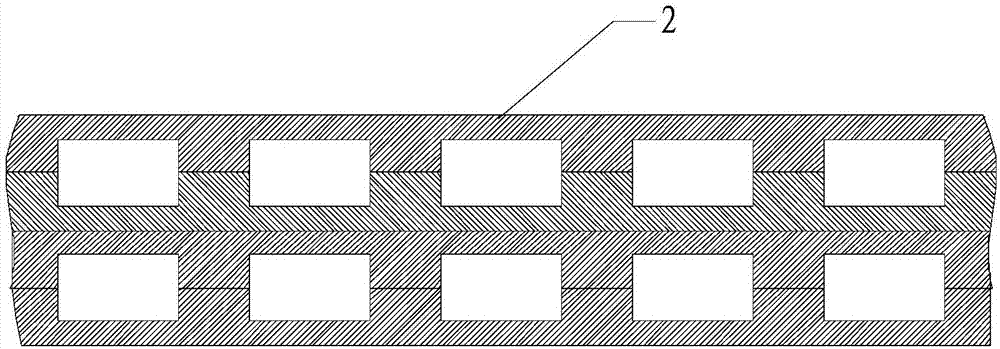

Novel paper pulp molding processing technology and molding die thereof

InactiveCN107354825AImprove water resistanceIncreased ring compressive strengthTextiles and paperHigh concentrationFiber

The invention relates to a novel paper pulp molding processing technology and a molding die thereof. The technology comprises the steps of conducting beating on plant fiber slurry by a beater; diluting paper pulp; adding the paper pulp into a pulp grinder to be ground; diluting the paper pulp to have the concentration of 3% by concentration adjustment equipment; screening heavy impurities out by a high-concentration slag remover; conducting screening by a pressure sieve, and making the paper pulp enter a slurry forming tank after screening; conducting screening by a vibrating frame sieve, and making the paper pulp enter the slurry forming tank after screening; conducting secondary dilution on the slurry by the concentration adjustment equipment, controlling the concentration of the slurry within 1-1.5%, and completing slurry preparation; utilizing a vacuum die suction machine to adsorb the slurry, and conducting dehydration to form wet ground paper; adsorbing the wet ground paper onto a molding die arranged in a multi-layer and stage-division mode to be molded through different stages, and obtaining the multi-layer wet paper die; bonding and extruding the multi-layer wet paper die; heating, drying and shaping the wet paper die to form paper pulp molded products. The products produced through the adoption of the technology are higher in thickness, better in waterproof performance, and suitable for large toys, real-person models and the like.

Owner:张宝华

Papermaking auxiliary agent and production method thereof

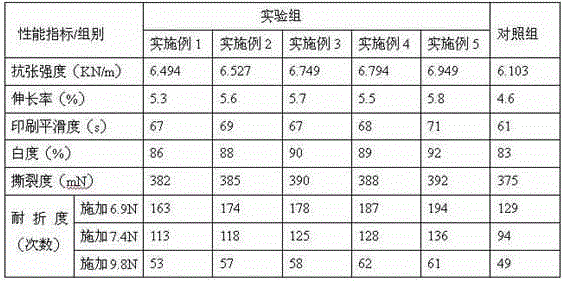

InactiveCN105862504ASimple processGood dispersionNon-macromolecular organic additionWax additionFolding endurancePolyethylene glycol

The invention discloses a papermaking auxiliary agent. The papermaking auxiliary agent is prepared from the following main raw materials in parts by weight: 10-16 parts of carboxymethyl chitosan, 6-10 parts of polyacrylamide, 12-16 parts of talcum powder, 8-18 parts of quartz powder, 3-5 parts of polyethylene glycol, 1-4 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), 2-5 parts of alkylphenol ethoxylates, 1-4 parts of polyoxypropylene glycerol ether, 1-2 parts of sodium benzoate, 2-4 parts of vegetable wax oil, 1-2 parts of ammonium sulfate, 2-3 parts of disodium hydrogen phosphate and 3-6 parts of lactitol. The papermaking auxiliary agent disclosed by the invention adopts a simple process flow; and bad foams in a preparation process of paper pulp can be eliminated and the pulp is dispersed very well, so that paper sheets have very good tensile strength, elongation percentage, printing smoothness, whiteness, tearing strength and folding endurance.

Owner:商孝霞

Sizing agent for treating paper surface and its preparing method and use

InactiveCN100500995CIncreased ring compressive strengthImprove Cobb valueWater-repelling agents additionEmulsion polymerizationStyrene Monomer

The present invention discloses one kind of paper surface sizing agent and its preparation process and application. The preparation process includes the free radical emulsion polymerization of dispersant, emulsifier, initiator, cationic monomer, (methyl) acrylate monomer and (methyl) styrene monomer at 30-95 deg.c for 2-6 hr. The dispersant is gelatin, and the initiator is persulfate. The paper surface sizing agent has high performance and environment friendship, and when it is used together with starch in sizing paper surface, it can raise the ring pressure strength greatly, improve Cobb value obviously and speed the curing obviously.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

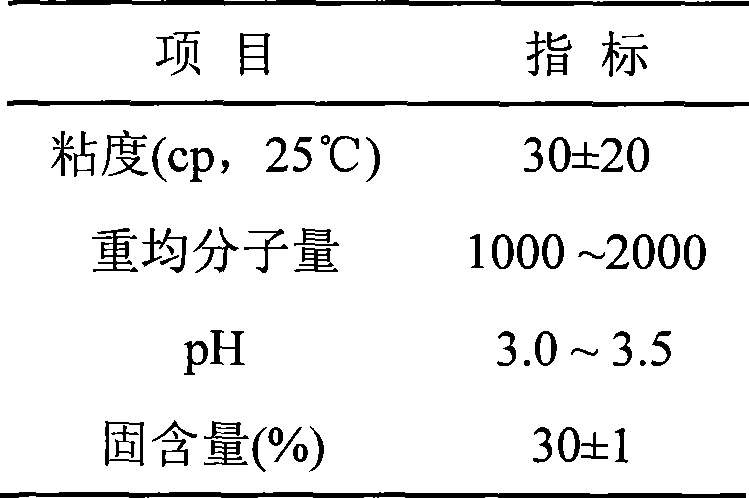

Synthetic method for cationic surface sizing agent

ActiveCN101519859AImprove conversion rateMild responseWater-repelling agents additionOrganic solventEmulsion polymerization

The invention provides a synthetic method for a cationic surface sizing agent, which comprises the following steps: taking an organic solvent as a homogeneous reaction medium, taking styrene, acrylic ester and cationic monomer as comonomers, and adding a chain transfer agent and an initiator for polyreaction to prepare the cationic surface sizing agent with weight average molar mass between 1,000 and 2,000; and the weight percentage of the components is as follows: 60 to 75 percent of the organic solvent, 10 to 15 percent of the styrene, 10 to 15 percent of the acrylic ester, 2 to 10 percent of the cationic monomer, 0.1 to 1 percent of the chain transfer agent and 0.1 to 1 percent of the initiator. The synthetic method adopts a homogeneous non-emulsion polymerization process and a high-efficiency catalytic system, and has high conversion rate; and the prepared surface sizing agent can improve the ring crush strength of paper, improve a Cobb value, quicken mature speed without getting damp, reduce linting and dusting of the paper, obviously improve water resistance and strength of the paper, and improve application performances such as wear resistance, hydrophilicity of printing ink, ventilation property, stiffness and the like.

Owner:广州星业科技股份有限公司

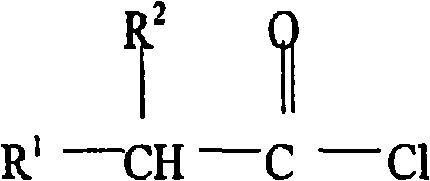

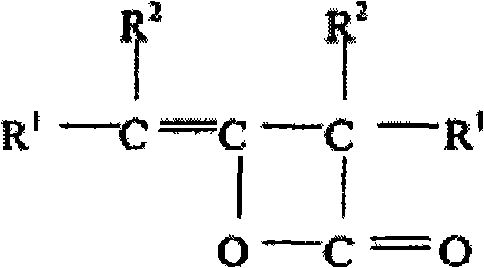

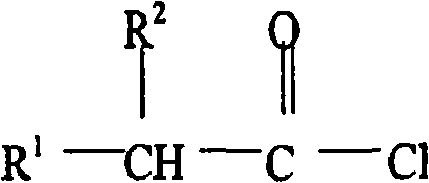

Alkyl ketene, preparation method and application thereof

ActiveCN101575322AHigh dimer contentSimple processOrganic chemistryWater-repelling agents additionSolventSalt solution

The invention discloses alkyl ketene, a preparation method and application thereof. The preparation method comprises the following steps: heating up 30 to 70 portions of amine by weight to a temperature of between 55 and 85 DEG C, adding 100 portions of acyl chloride by weight within 0.5 to 2 hours, and reacting continuously after adding the acyl chloride for 0.5 to 3 hours; adding 100 to 200 portions of water of which the temperature is between 70 and 80 DEG C by weight, mixing and then standing the mixture, and removing a salt solution at the bottom layer; adding 100 to 200 portions of water of which the temperature is between 70 and 80 DEG C by weight again, mixing and standing the mixture, and removing the water at the bottom layer; and dehydrating the mixture, filtering the mixture while the mixture is hot, and cooling the filtered mixture to obtain an alkyl ketene dimer. The method uses no solvent, is more environment-friendly and has simple process; and the product has high content of the alkyl ketene dimer, and has good water resisting effect when the product is used as a sizing agent. The obtained alkyl ketene dimer can be used for sizing paper sheets and can greatly improve the Cobb value of the paper sheets and enhance the ring crushing strength of the paper sheets.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

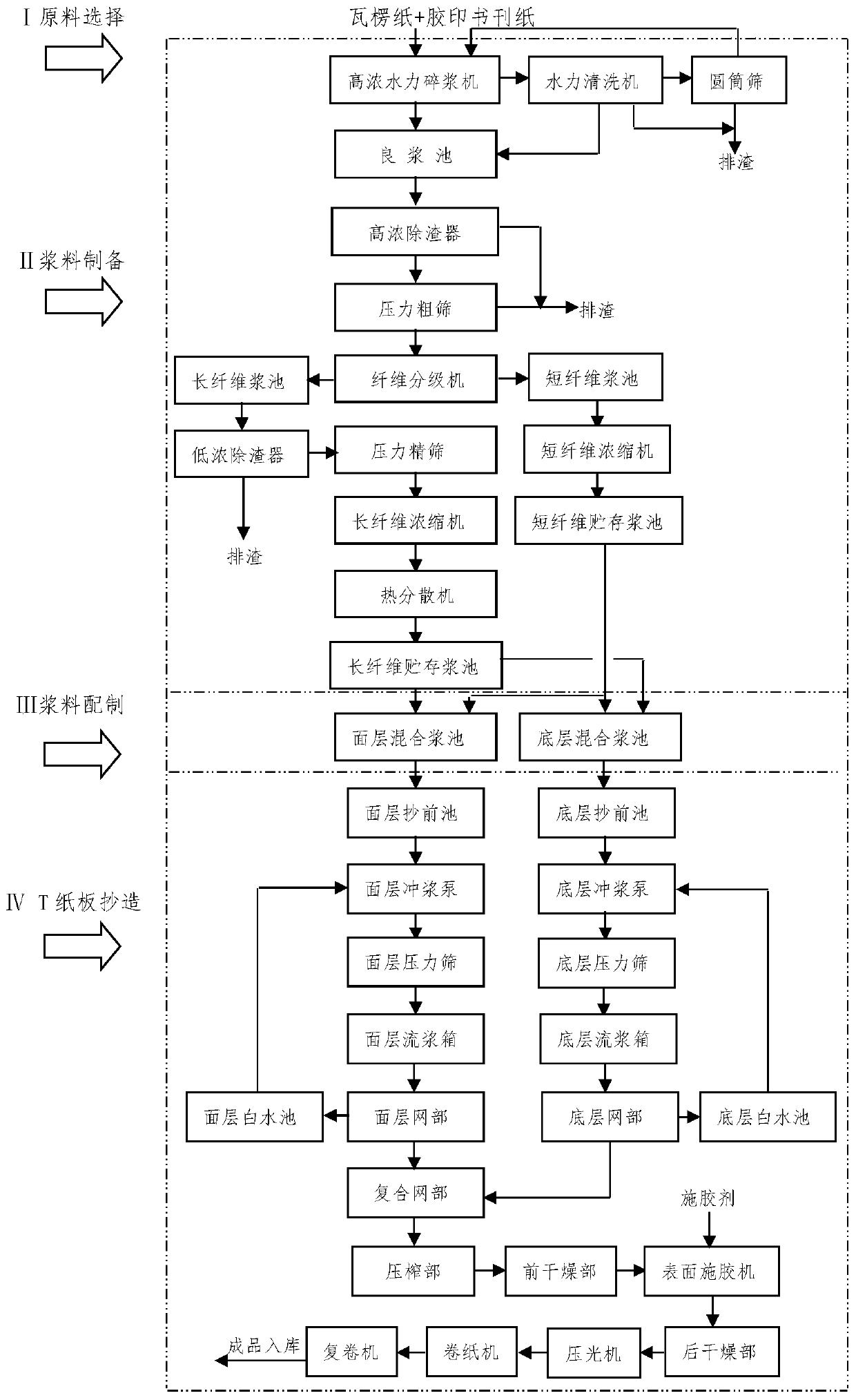

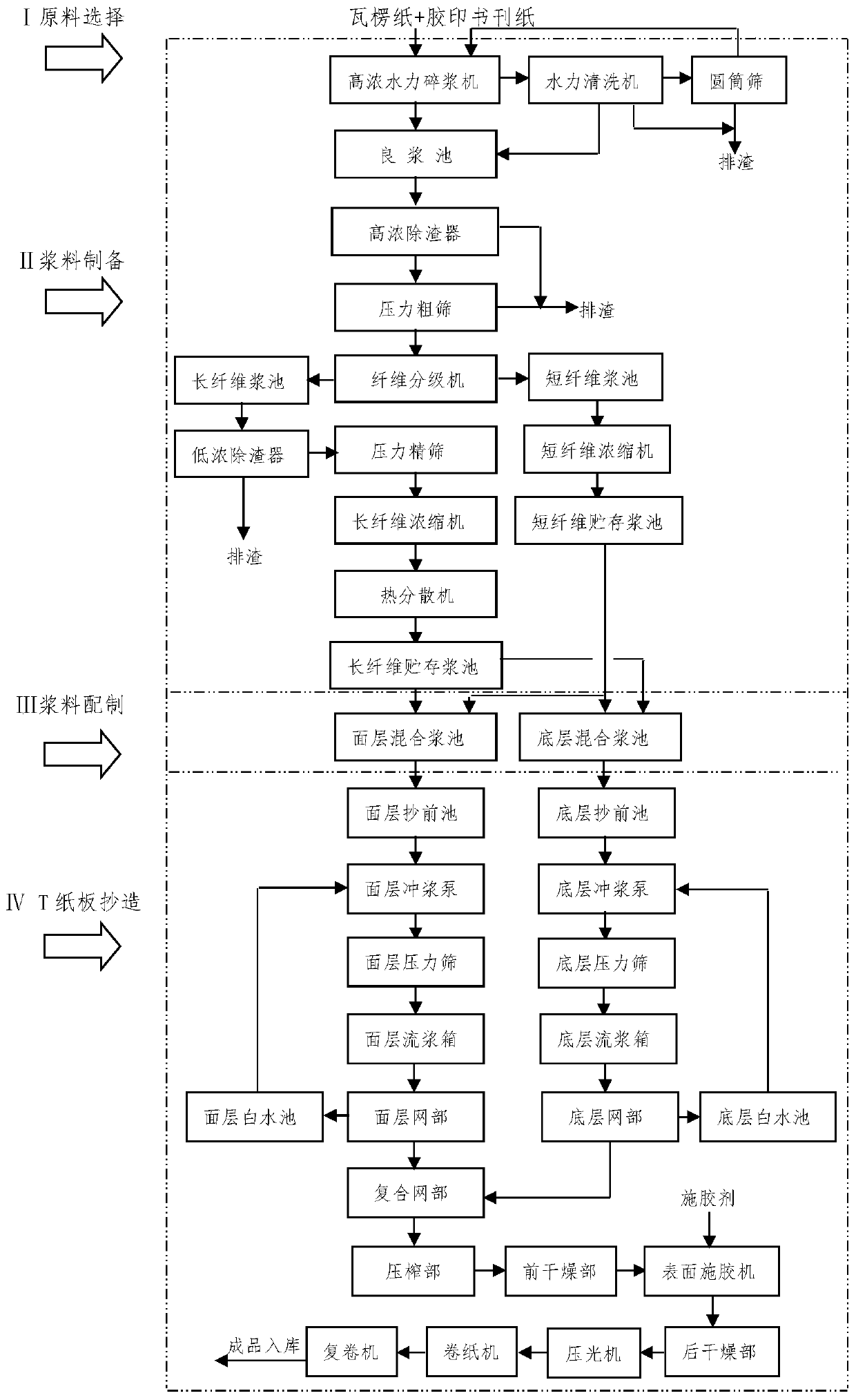

Preparation method for improving ring pressure strength of low-gram-weight T paper board

InactiveCN109837799AFair useHigh tensile strengthWater-repelling agents additionPaper/cardboardCardboardFiber

The invention discloses a preparation method for improving the ring pressure strength of a low-gram-weight T paper board, and the preparation method comprises the following four steps: (1) selecting raw materials, namely taking corrugated paper and offset printing periodical paper as raw materials; (2) preparing slurry, to be more specific, mixing the two raw materials obtained in the step (1) according to a ratio, carrying out crushing, impurity removal, fiber grading, heat dispersion and concentration treatment, and respectively storing long fiber slurry and short fiber slurry in respectiveslurry pools for later use; (3) preparing pulp, to be more specific, preparing surface layer pulp and bottom-layer pulp according to the proportions from the long fiber slurry and the short fiber slurry obtained in the step (2); and (4) making the T paper board, to be more specific, respectively allowing the surface layer pulp and the bottom-layer pulp obtained in the step (3) to pass through a fan pump and a pressure screen, then be conveyed to a surface layer and bottom layer pulp box pulp feeding total pipe for being loaded onto a net for forming, then enter a pressing part, a front and a rear drying part, surface sizing, a calender and the like for treatment after vacuum dewatering by a net part, and enter a winding machine, a rewinding machine and a packaging machine to obtain the low-gram-weight T paper board.

Owner:NANJING FORESTRY UNIV

Preparation method for corrugated paper ring crush reinforcing agent

ActiveCN103806335AHigh strengthIncreased ring compressive strengthReinforcing agents additionCross-linkChange color

The invention relates to a preparation method for a corrugated paper ring crush reinforcing agent. The method comprises the steps of: (1) preparation of melamine glyoxal resin; (2) incomplete oxidation of starch: mixing water, an oxidizing agent and starch evenly, conducting heating to 85-95DEG C, and carrying out heat preservation reaction for 20-30min to obtain a starch incompletely oxidized product; (3) synthesis of the corrugated paper ring crush reinforcing agent: lowering the temperature of the reaction in step (2) to 60-85DEG C, and adding the melamine glyoxal resin obtained in step (1) into the starch incompletely oxidized product obtained in step (2) to undergo cross-linking reaction for 20-50min, then adding water to conduct dilution, and then adding a cationic salt, and stirring the mixture evenly. After treating the surface of corrugated paper by the corrugated paper ring crush reinforcing agent prepared by the method provided by the invention, the ring crush compression resistance, water resistance and tensile resistance of the corrugated paper are all significant improved. The product cures quickly on machine, and does not change color after drying.

Owner:山东奥赛新材料有限公司

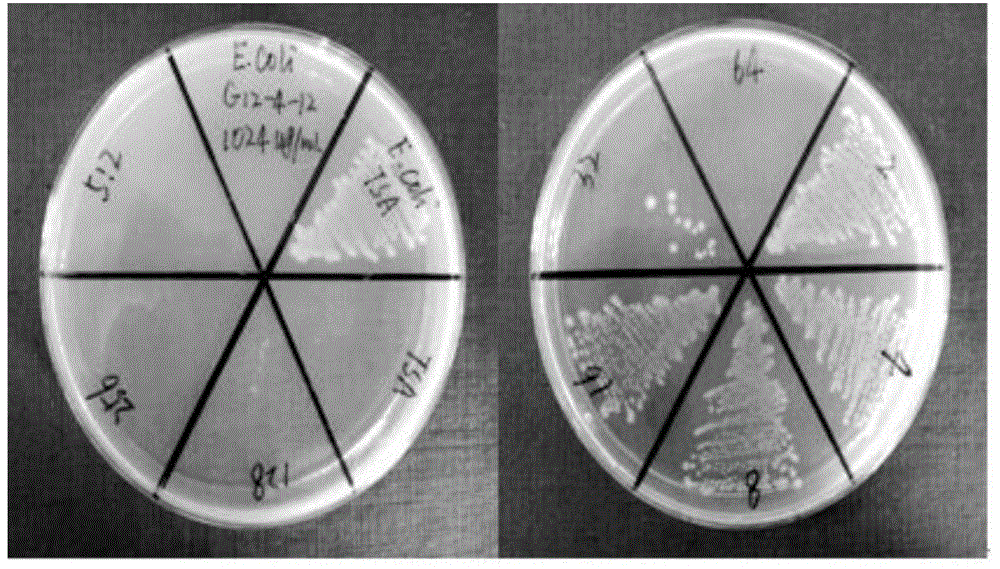

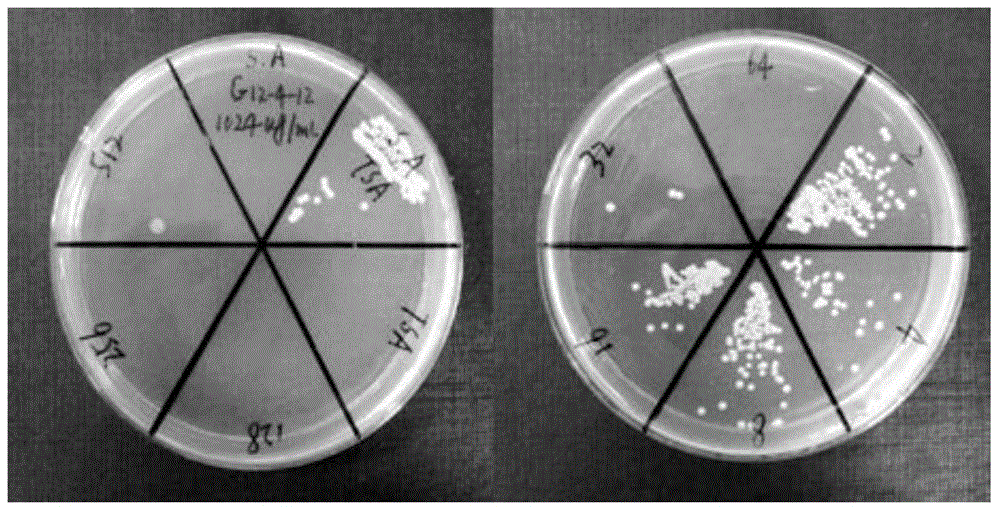

High-efficiency benzene acrylic antibacterial multipolymer emulsion type surface sizing agent and preparation method thereof

InactiveCN104452449AGood colorImprove mechanical stabilityWater-repelling agents additionBenzeneCross-link

The invention discloses a high-efficiency benzene acrylic antibacterial multipolymer emulsion type surface sizing agent and a preparation method thereof, belonging to the technical field of antibacterial paper surface treatment agent. The surface sizing agent is prepared by performing free radical emulsion polymerization on the following components in parts by weight by using a pre-emulsification-half-continuous combined feeding process: 0.4-8 parts of a dispersing agent, 0.1-5 parts of an emulsion agent, 0.1-2 parts of an initiator, 0.4-5 parts of a cross-linking monomer, 0.4-12 parts of a (methyl) acrylic ester monomer and 4-28 parts of (methyl) styrene. As the surface sizing agent is applied to the surface of paper, the ring crush compression resistance of paper is greatly improved, the Cobb value is remarkably increased, the remoistening phenomenon is avoided, the sized paper is excellent in antibacterial and anti-mold property, and the surface sizing agent is an environment-friendly product.

Owner:HUBEI UNIV

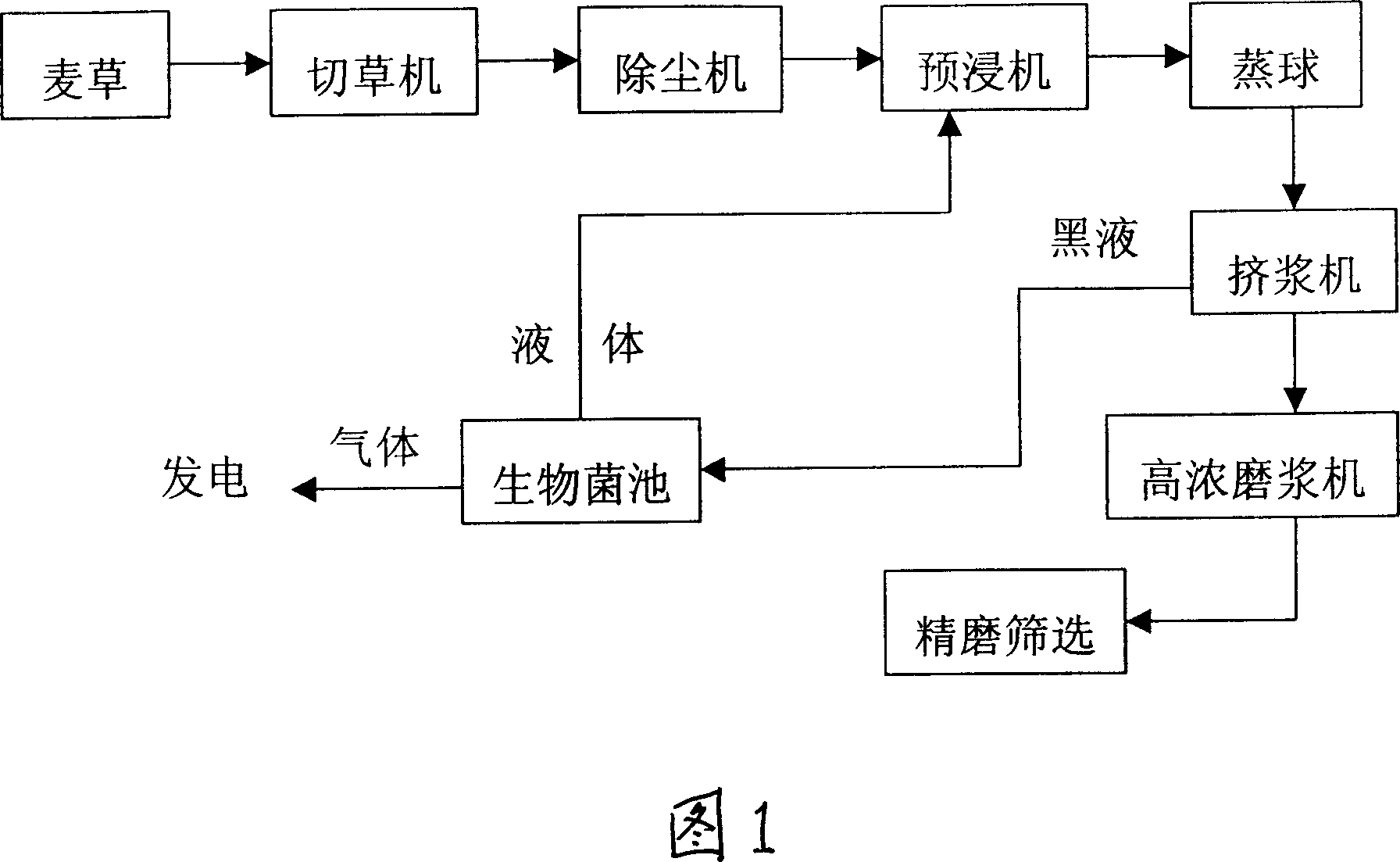

Wheat-straw biological clean pulping technology by black liquor bacterizing treatment

InactiveCN1932145AImprove pulping qualityGuaranteed closed recyclingCellulose material pulpingBlack liquorSlurry

The present invention relates to a wheat straw cleaner biopulping process. Its main technique is characterized by that firstly, the wheat straw raw material is cooked by using original bacterial liquor as cooking liquor, then the cooked stock can be passed through a pulp-extruding machine to make pulp liquor separation and the obtained black liquor can be fed into a biological bacterial pool and mixed with the described original bacterial liquor so as to form a biological liquor which can be used as cooking liquor of wheat straw raw material and form closed circulation. Said invention also provides the concrete preparation method of original biological bacterial liquor by using methanogen, saccharomycetes and white rottera as original biological bacterial seed.

Owner:山东贵和显星纸业有限公司

Corrugating base paper enhancer and preparation method thereof

InactiveCN108611919AHigh positive chargeReduce distractionsNon-fibrous pulp additionFiberPotassium hydroxide

The invention discloses a corrugating base paper enhancer and a preparation method thereof, wherein the enhancer includes: cationic polyacrylamide, hydroxypropyl chitosan, polyamide polyamine epichlorohydrin resin, a crosslinker, potassium hydroxide, layered silicate, microcrystalline cellulose, a surfactant, NaHCO3 and a coupling agent. The basic material of the enhancer is made from the cationicpolyacrylamide, hydroxypropyl chitosan and polyamide polyamine epichlorohydrin resin and has high positive charge property and can form strong electrostatic effect with fibers and reduce interferencedue to anionic trash in wastepaper; being compounded with the layered silicate and microcrystalline cellulose, the basic material also can improve retention of fine fibers in pulp and increase evenness of paper, thus increasing ring crush compression resistance of the corrugating base paper.

Owner:JURONG MAOYUAN WEAVING FACTORY

Surface sizing agent, raw material composition and preparation method and application thereof

ActiveCN111576086AIncreased ring compressive strengthLow viscosityWater-repelling agents additionPaper coatingPolymer scienceFunctional monomer

The invention discloses a surface sizing agent, a raw material composition and a preparation method and application thereof. The raw material composition of the surface sizing agent comprises the following components in parts by weight: 1 part of biomass-based material, 0.003 to 0.2 part of alkaline substance, 0.15 to 1.5 parts of hard monomer and soft monomer, 0.015 to 0.2 part of initiator, 0.03to 0.5 part of complexing agent, 0.03 to 0.6 part of functional monomer, 0.06 to 0.5 part of emulsifying agent and 1.5 to 5 parts of water. The functional monomer is one or more of methacryloyloxyethyl trimethyl ammonium chloride, methacryloyloxyethyl dimethyl benzyl ammonium chloride, acryloyloxyethyl trimethyl ammonium chloride and acryloyloxyethyl dimethyl benzyl ammonium chloride; the structural formula of the emulsifier is shown in the specification, wherein R is C10-C14 alkyl. The surface sizing agent is good in water resistance, low in viscosity and good in compatibility with a starchsizing agent, and the ring crush compression strength of corrugated base paper is improved.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

Preparation method of surface sizing agent for starch-based papermaking

ActiveCN108708215AHigh strengthEnhanced swelling balanceWater-repelling agents additionPaper coatingChemistryUrea

The invention discloses a preparation method of a surface sizing agent for starch-based papermaking. The method comprises the steps that firstly, corn starch, amylase and water are mixed, a heating reaction is conducted, formaldehyde, urea and a basic catalyst are added, a temperature increase reaction is conducted, and a starch-based copolymer is obtained; then, corn starch, an accelerant, lignin, titanium dioxide particles, carboxymethyl chitosan and water are mixed, a temperature increase reaction is conducted, and an oxidized corn starch paste solution is obtained; finally, the starch-based copolymer and the oxidized corn starch paste solution are mixed, and the surface sizing agent is obtained. According to the surface sizing agent, the ring crush compression resistance of paper sheets can be improved, and the water resistance of the paper sheets can also be improved.

Owner:JURONG MAOYUAN WEAVING FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com