Patents

Literature

51results about How to "Excellent printing characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

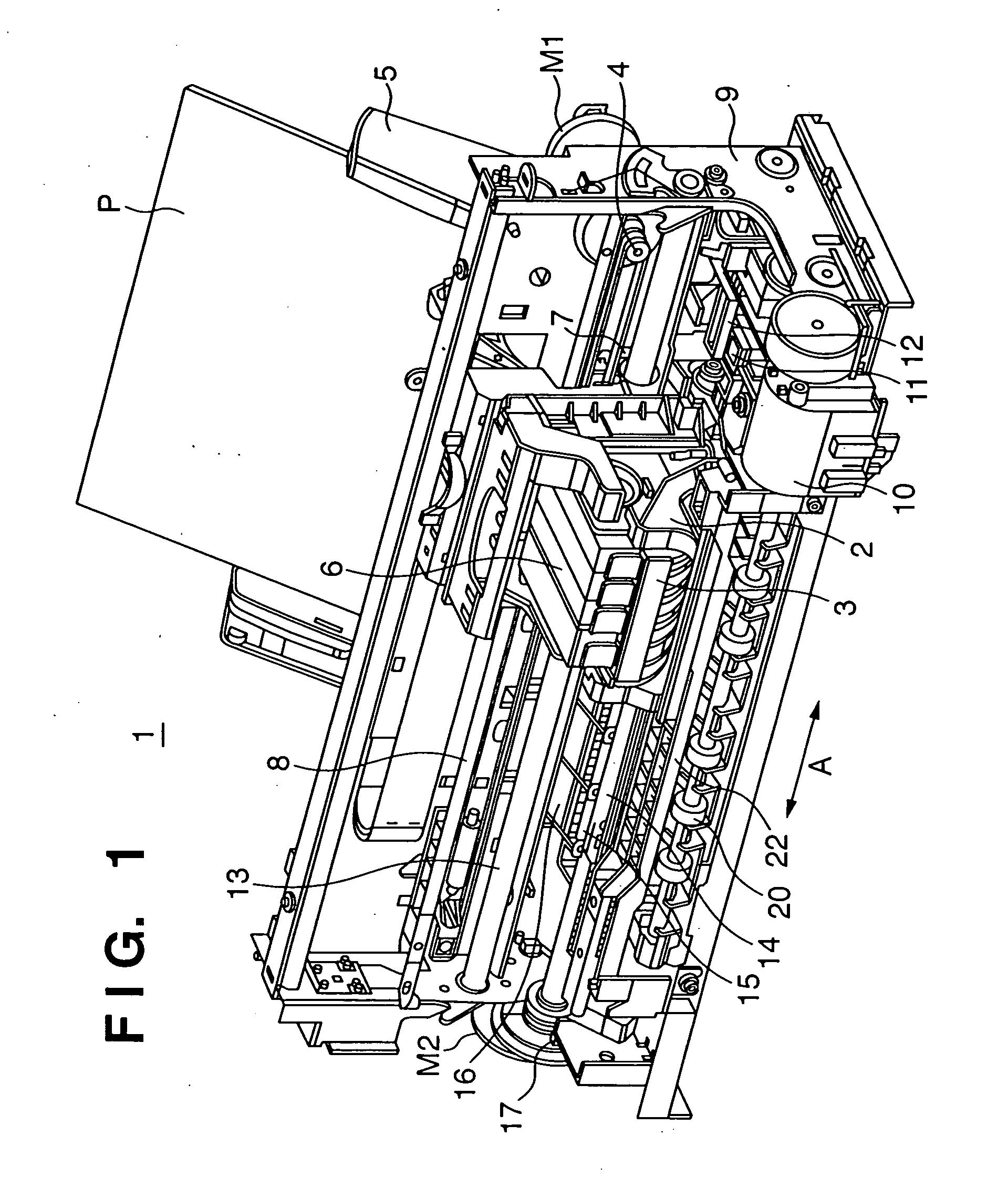

Method of driving a printhead using a constant current and operating MOS transistor in saturation region

InactiveUS7216960B2Increase line widthIncrease the number ofPrintingElectrical resistance and conductanceWire width

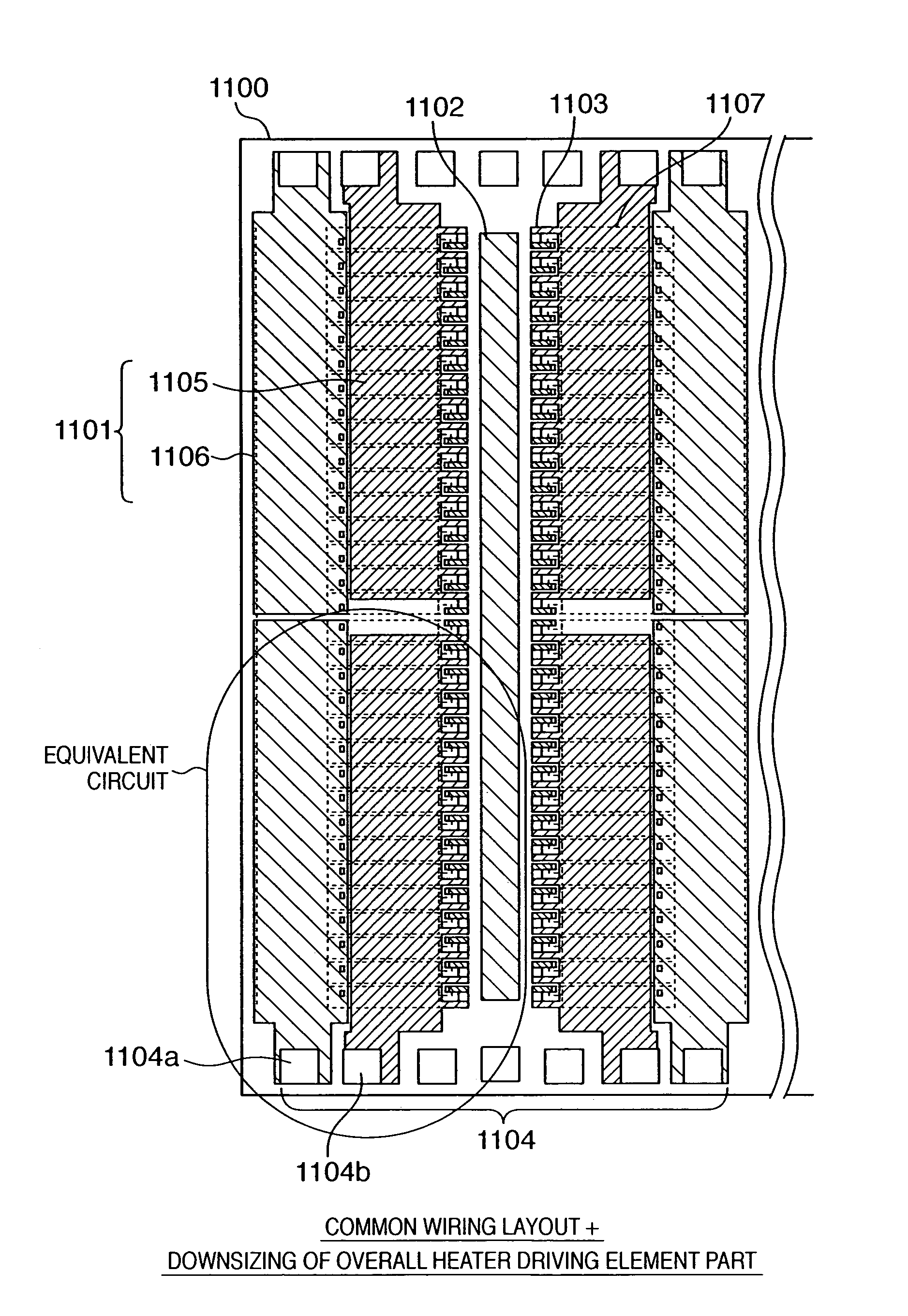

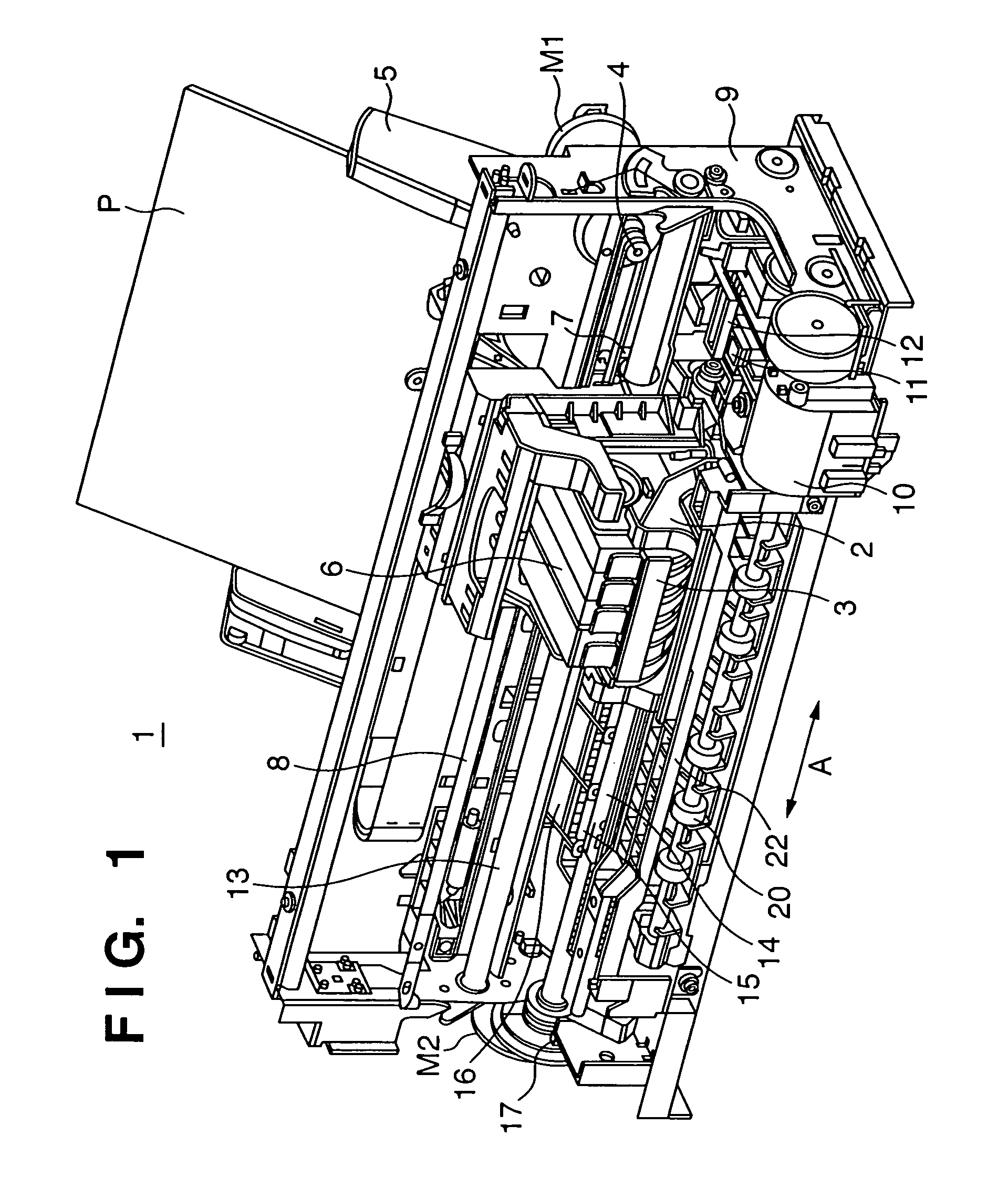

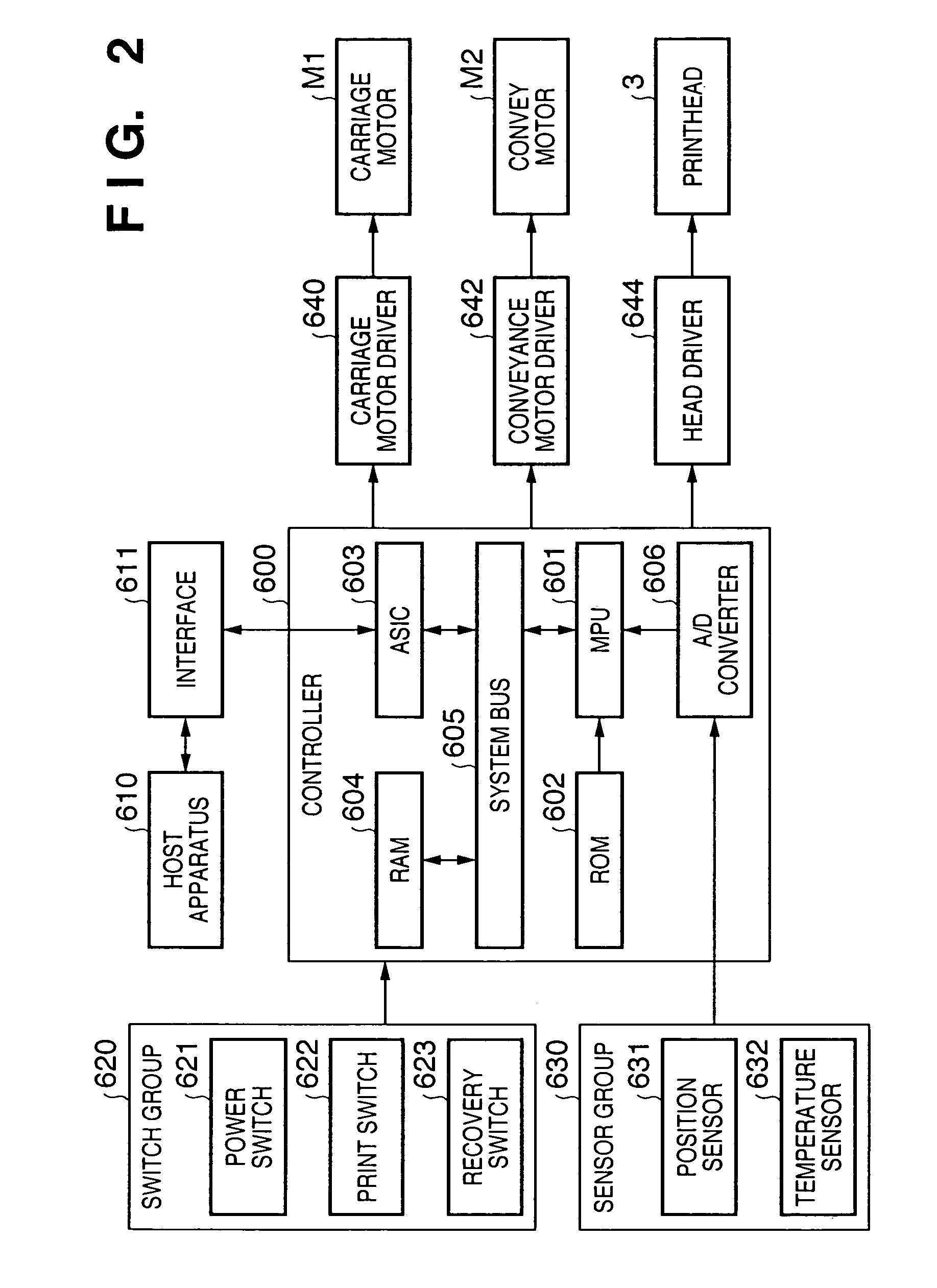

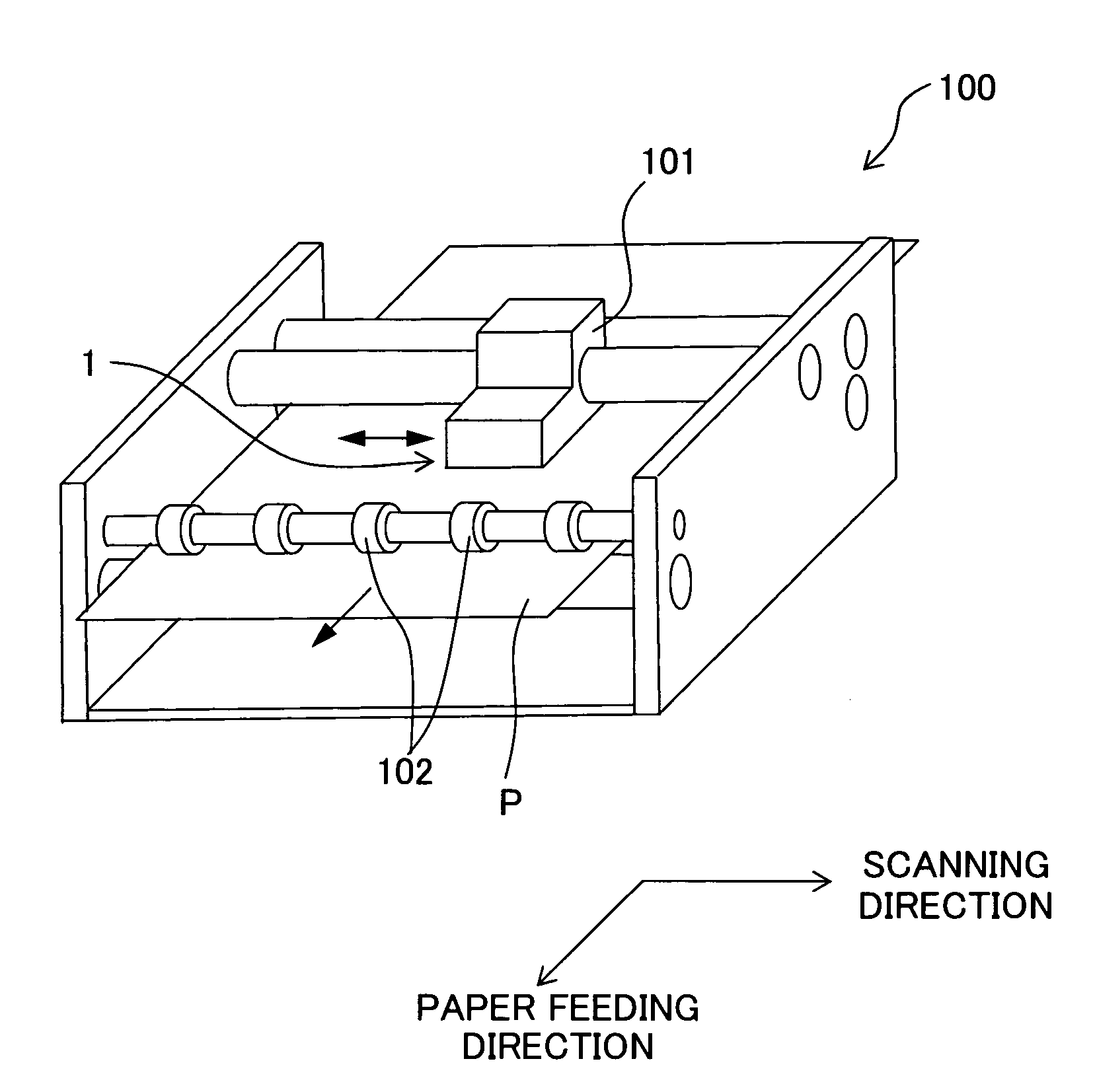

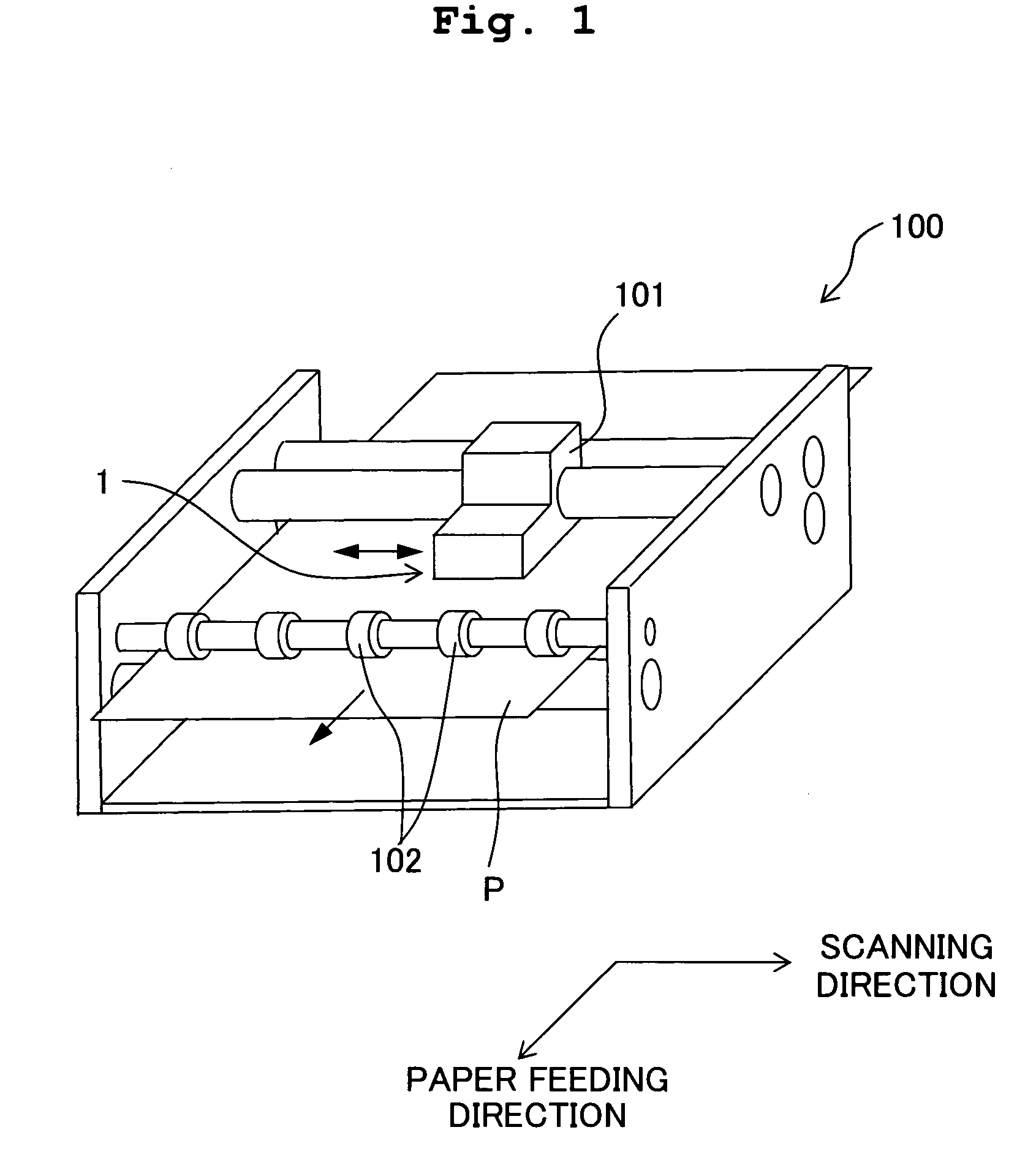

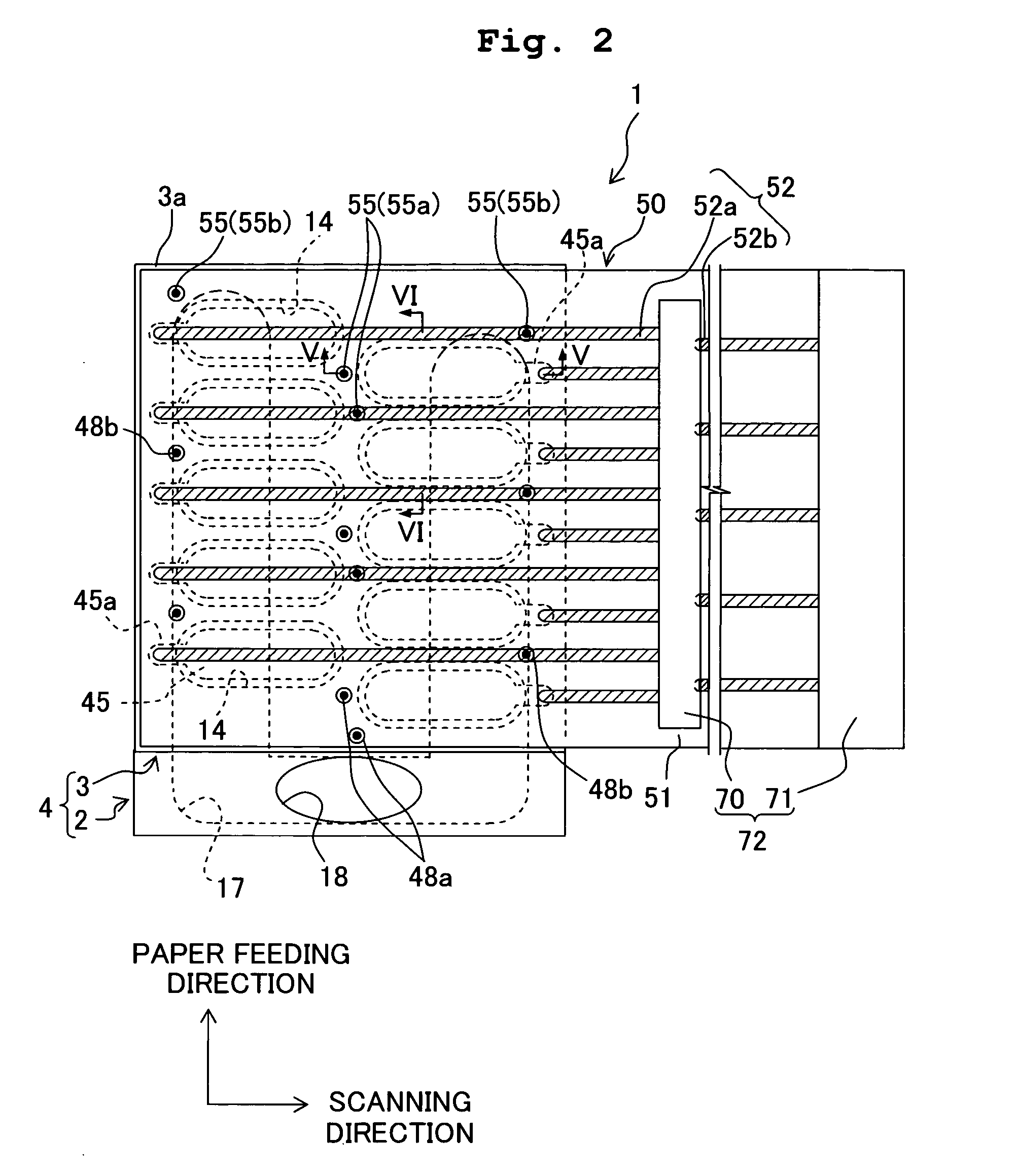

This invention relates to a printhead substrate capable of suppressing an increase in wiring width and an increase in the size of a substrate formed by a film forming process while increasing the number of simultaneously driven printing elements in order to improve the printing performance, a printhead using the substrate, and a printing apparatus using the printhead. The wiring lines of the substrate are formed into a common wiring line, and energy applied to a heating resistance element is prevented from deviating from a stable ink discharge range owing to the difference in the number of simultaneously driven heating resistance elements. For this purpose, a driving element is greatly downsized in comparison with a conventional one, and the operation region of a MOS transistor is shifted from the non-saturation region to the saturation region.

Owner:CANON KK

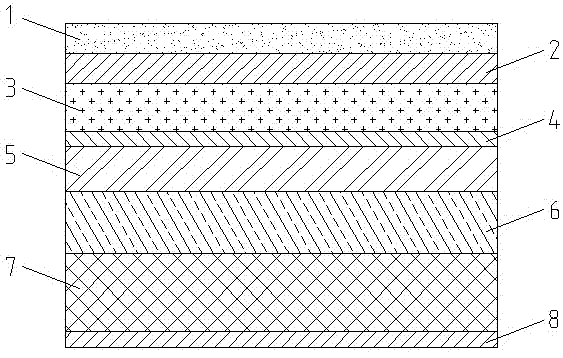

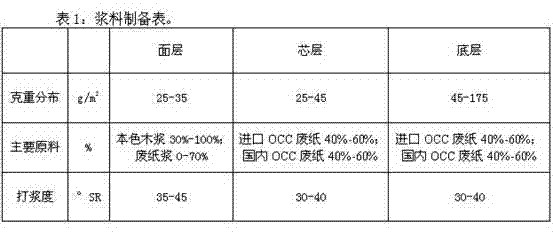

Coated natural kraft and manufacturing method thereof

ActiveCN102199898AHigh strengthIncreased ring compressive strengthDefoamers additionWater-repelling agents additionSurface layerPulp and paper industry

The invention relates to coated natural kraft and a manufacturing method thereof. The traditional coated kraft does not have the advantages of attractive appearance, environment friendliness, high strength and good printing performance. The coated natural kraft disclosed by the invention comprises natural kraft, a surface sizing layer and a surface coating layer and is characterized in that a bottom layer comprises OCC (Old Corrugated Case) waste paper pulp and a core layer comprises waste paper; a surface layer comprises natural wood pulp and waste paper pulp, wherein the weight percentage of the natural wood pulp is 30% to 90% and the balance is the waste paper pulp; the surface sizing layer comprises a front sizing layer and a back sizing layer; and the surface coating layer comprises a bottom coating layer, a middle coating layer and a surface coating layer. The manufacturing method for the coated natural kraft sequentially comprises a natural kraft preparing working procedure, a sizing working procedure, a coating working procedure and a molding working procedure. The coated natural kraft has the advantages of reasonable structure design, attractive appearance, environment friendliness, high strength, good printing performance, simple preparation technology, low production cost and good quality.

Owner:JIAN GRP

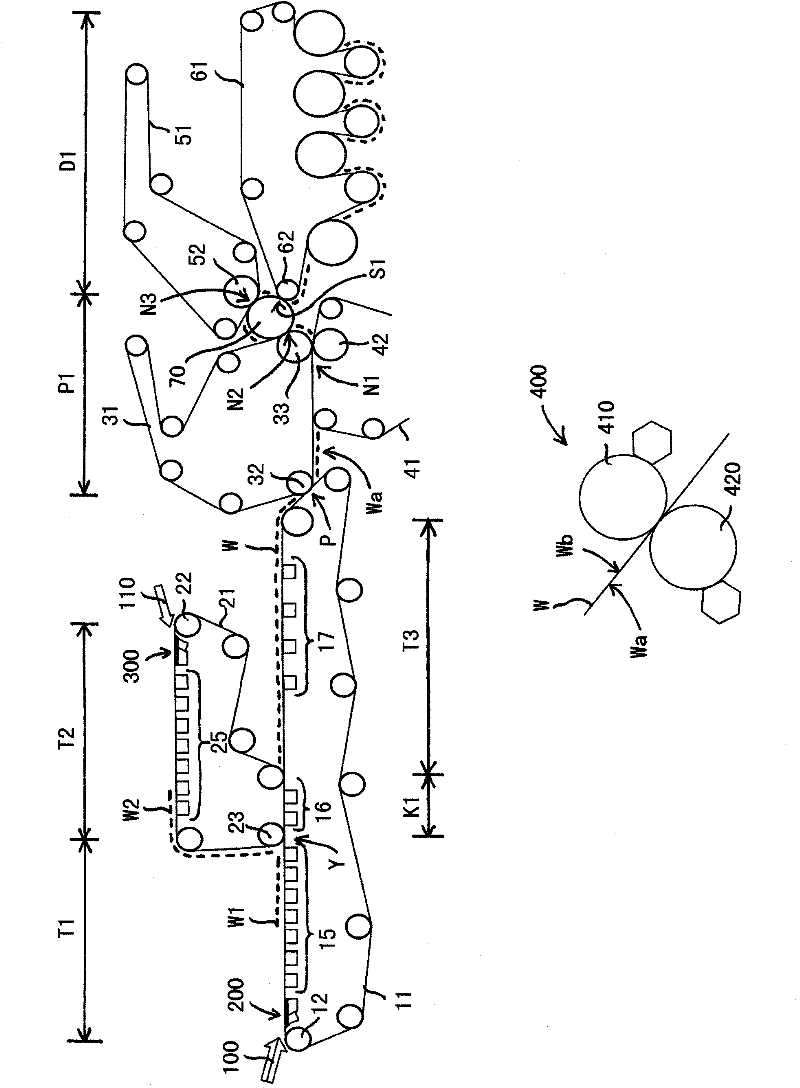

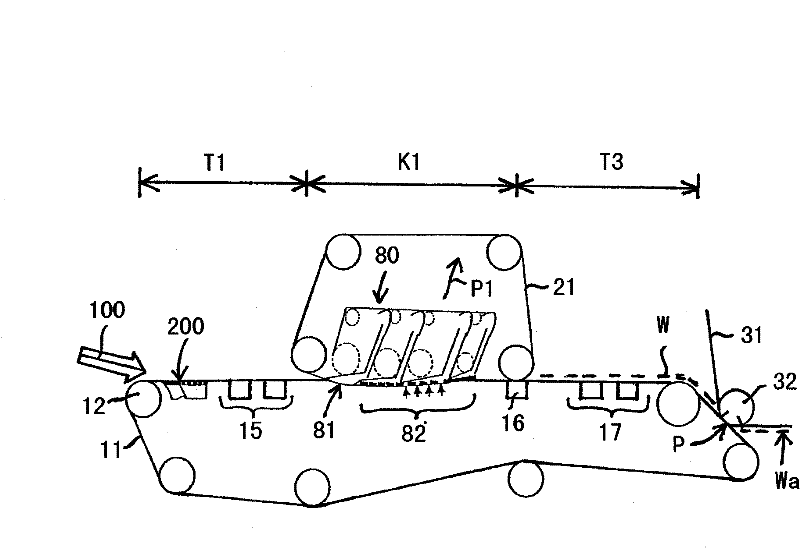

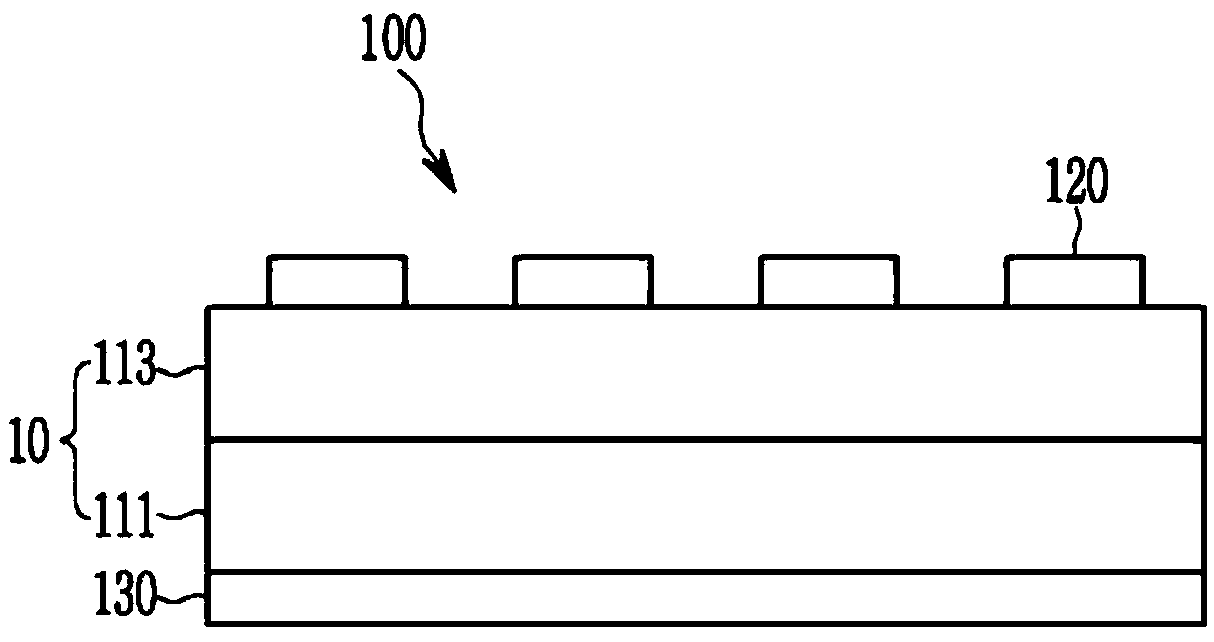

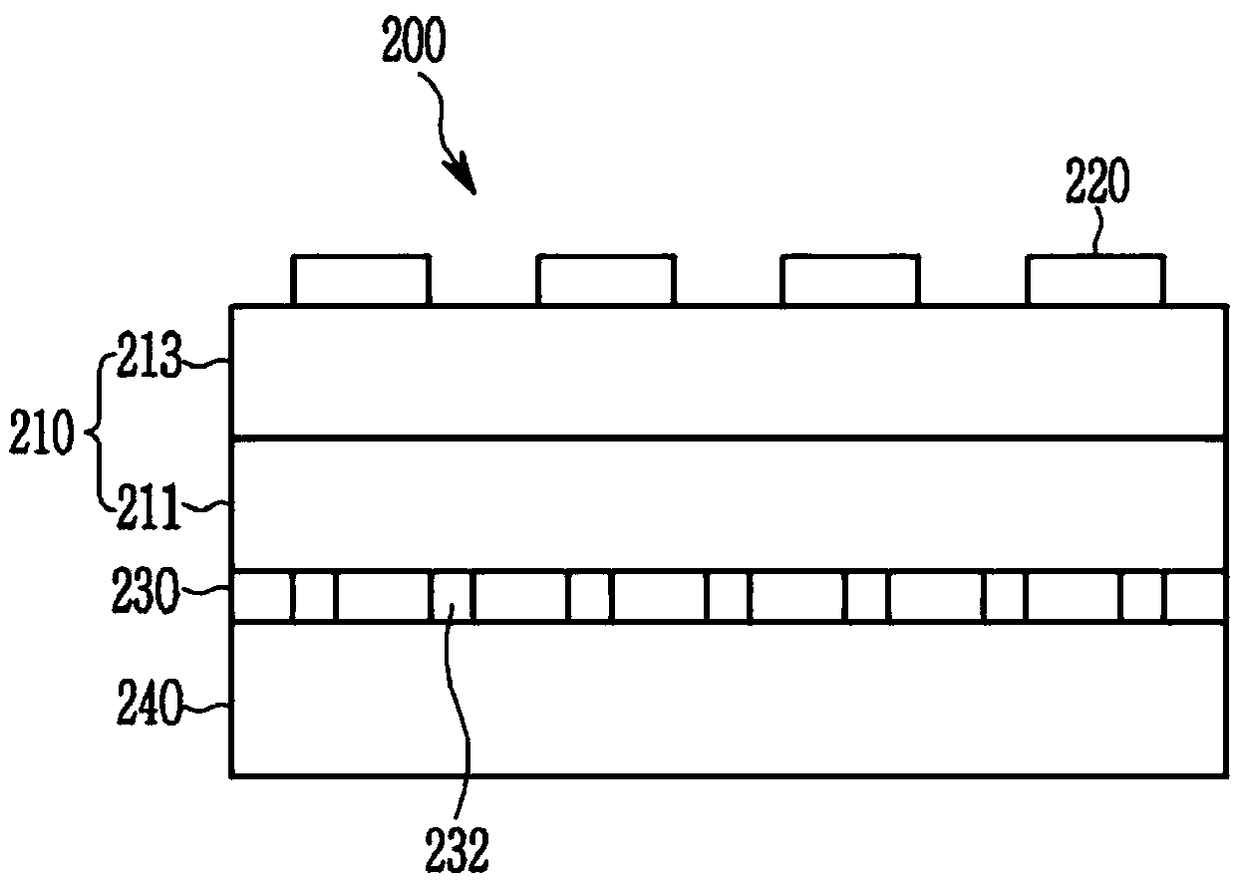

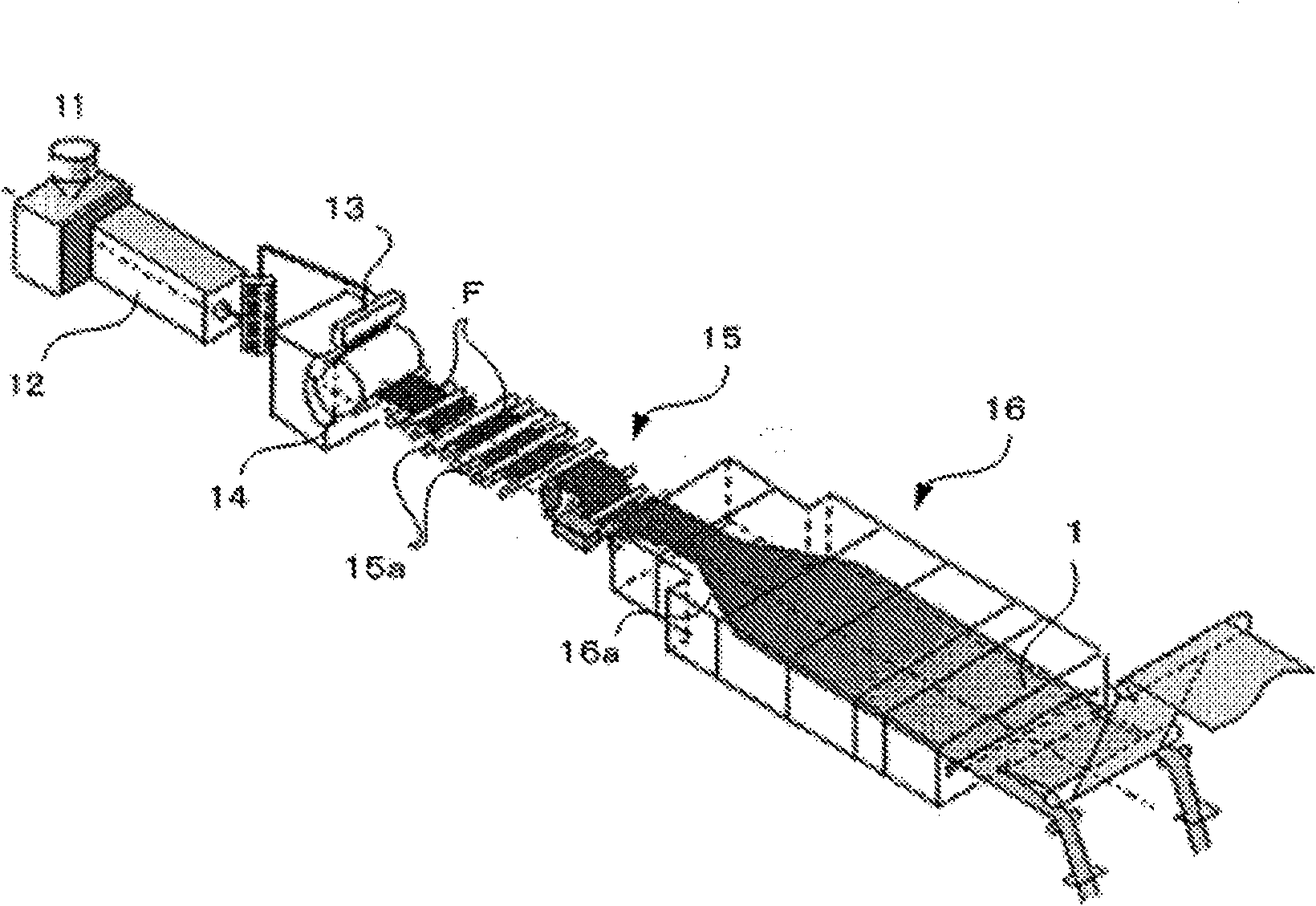

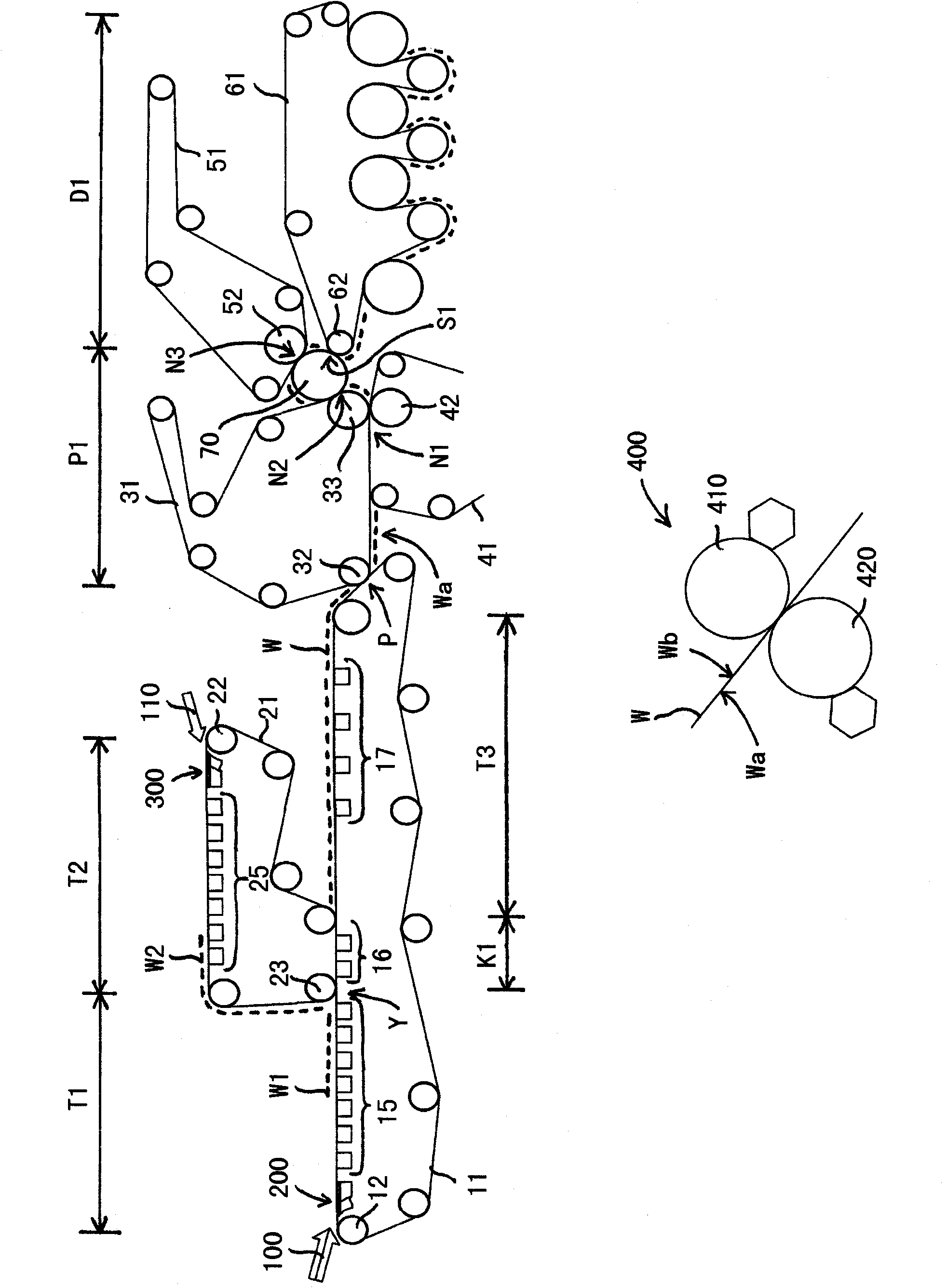

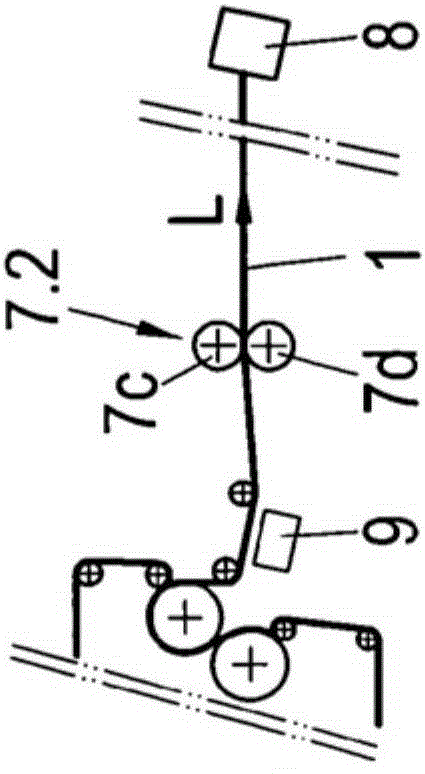

Board machine

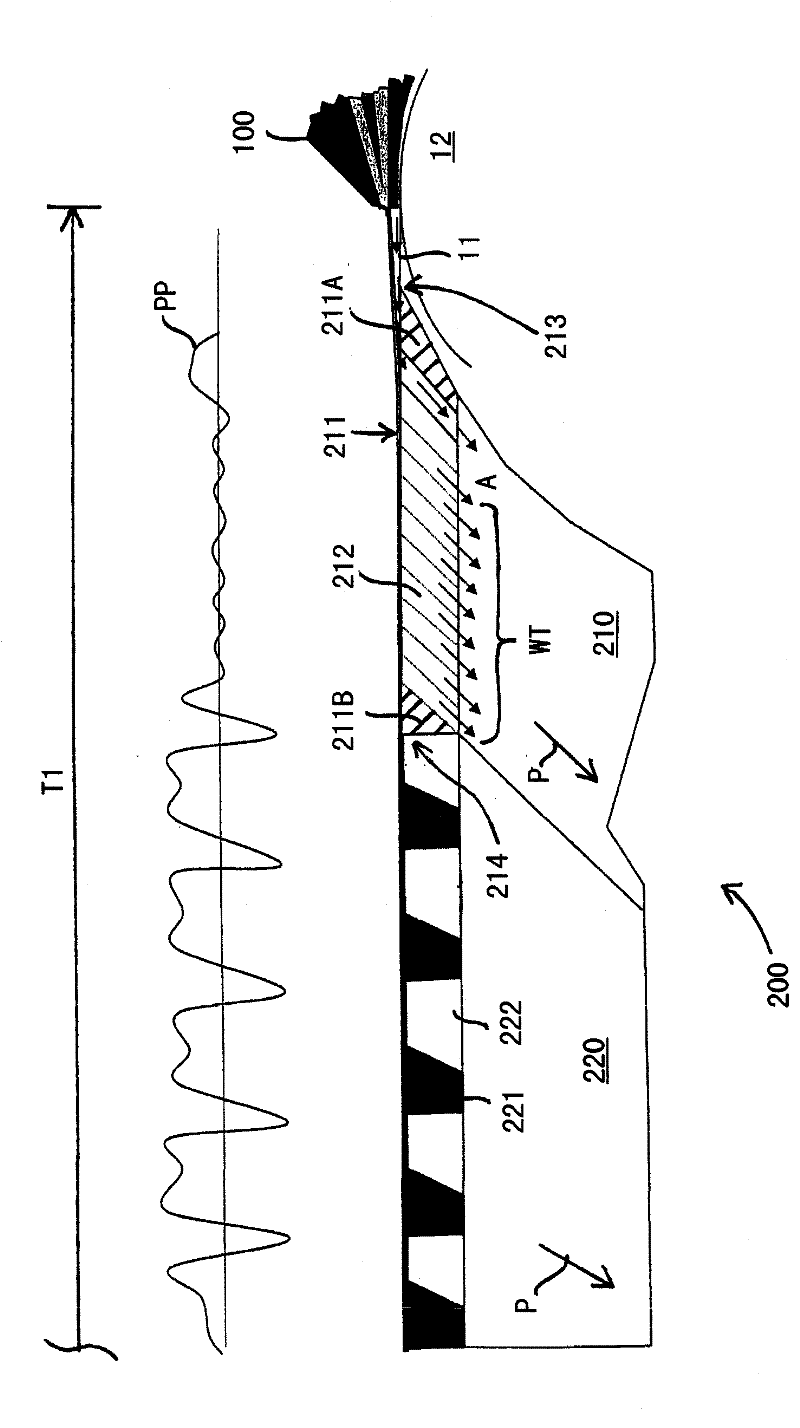

InactiveCN102131981ADoes not affect layered purityAvoid deformationMachine wet endEngineeringCoating

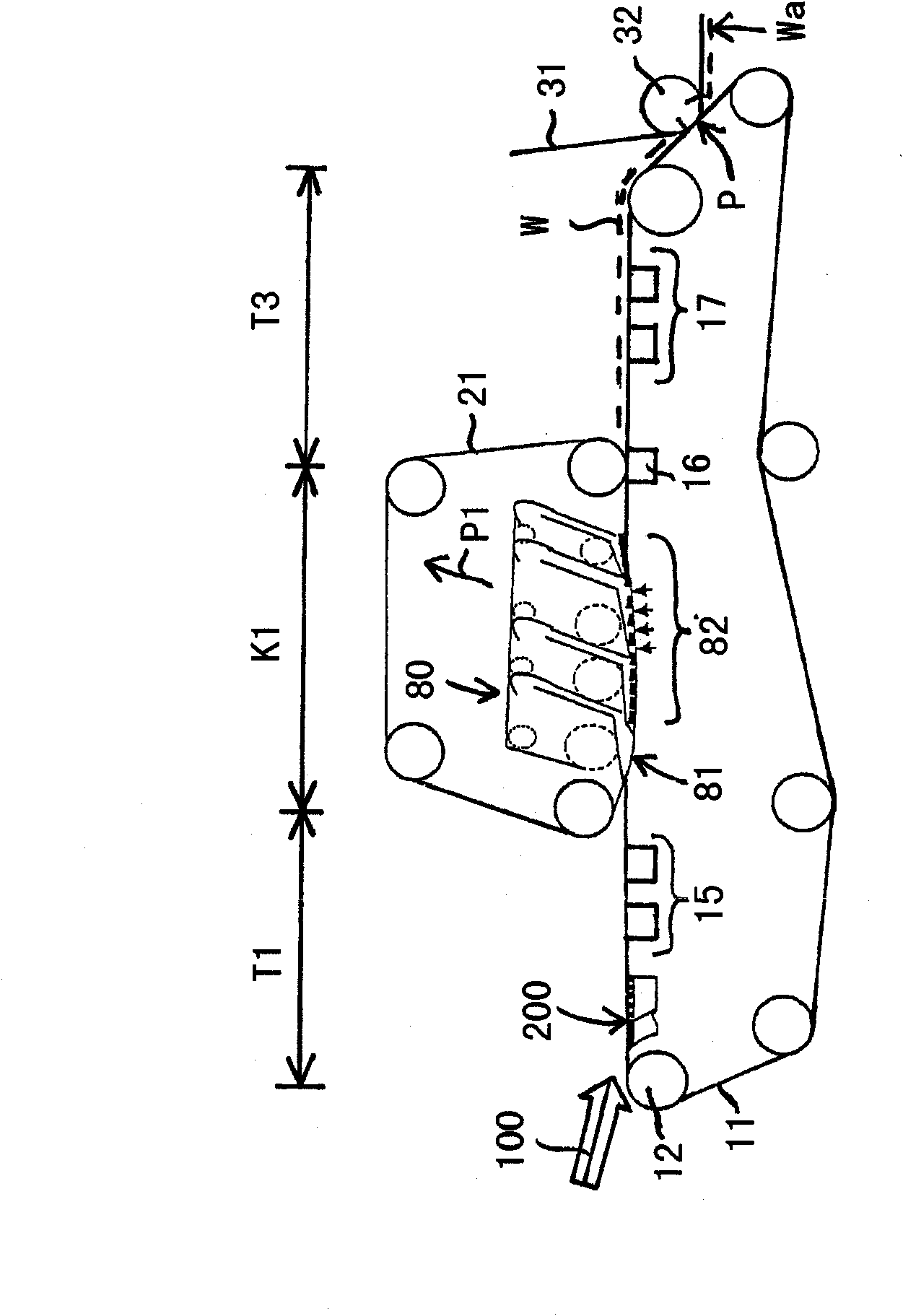

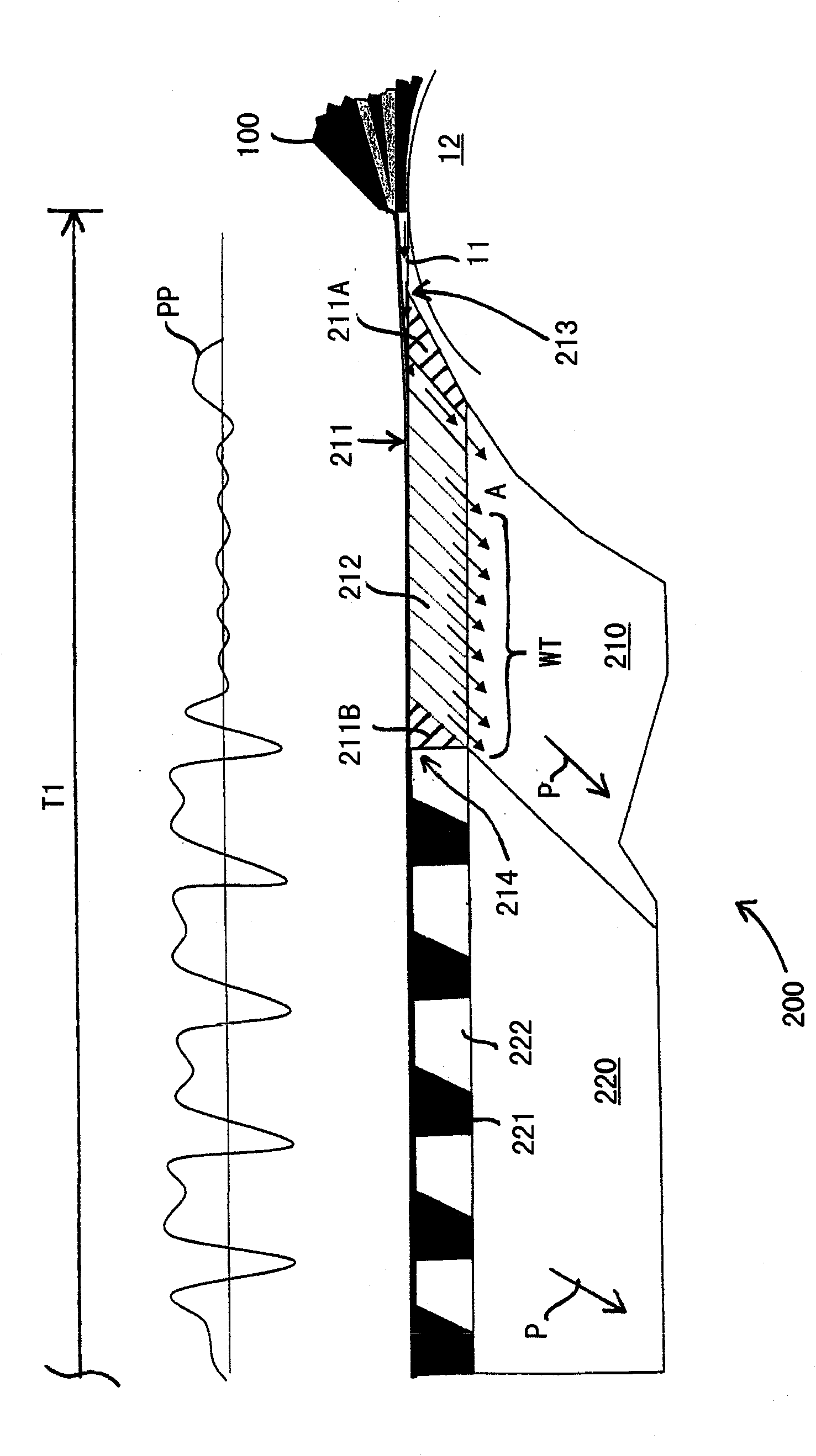

A board machine comprises a forming section where a lower wire loop (11) forms a fourdrinier-wire section (Tl) at the beginning of which is located a forming board (200) which consists of at least one stationary, non-pulsating forming shoe (210). In the forming shoe (210), there is a cover (211) provided with thorough holes (212), setting against the inner surface of the lower wire loop (11). A first headbox (100), which is a multi-layer headbox, feeds a pulp suspension jet onto the forming shoe (210). The board machine further comprises a press section (Pl) where a surface (Wa) of the web (W) having been against the lower wire loop (11) is pressed against a smooth surface, a dryer section (Dl) where the web (W) is dried with at least one cylinder-dryer group and a coating section (400) where at least the surface (Wa) of the web (W) having been against the lower wire (11) is coated.

Owner:METSO PAPER INC

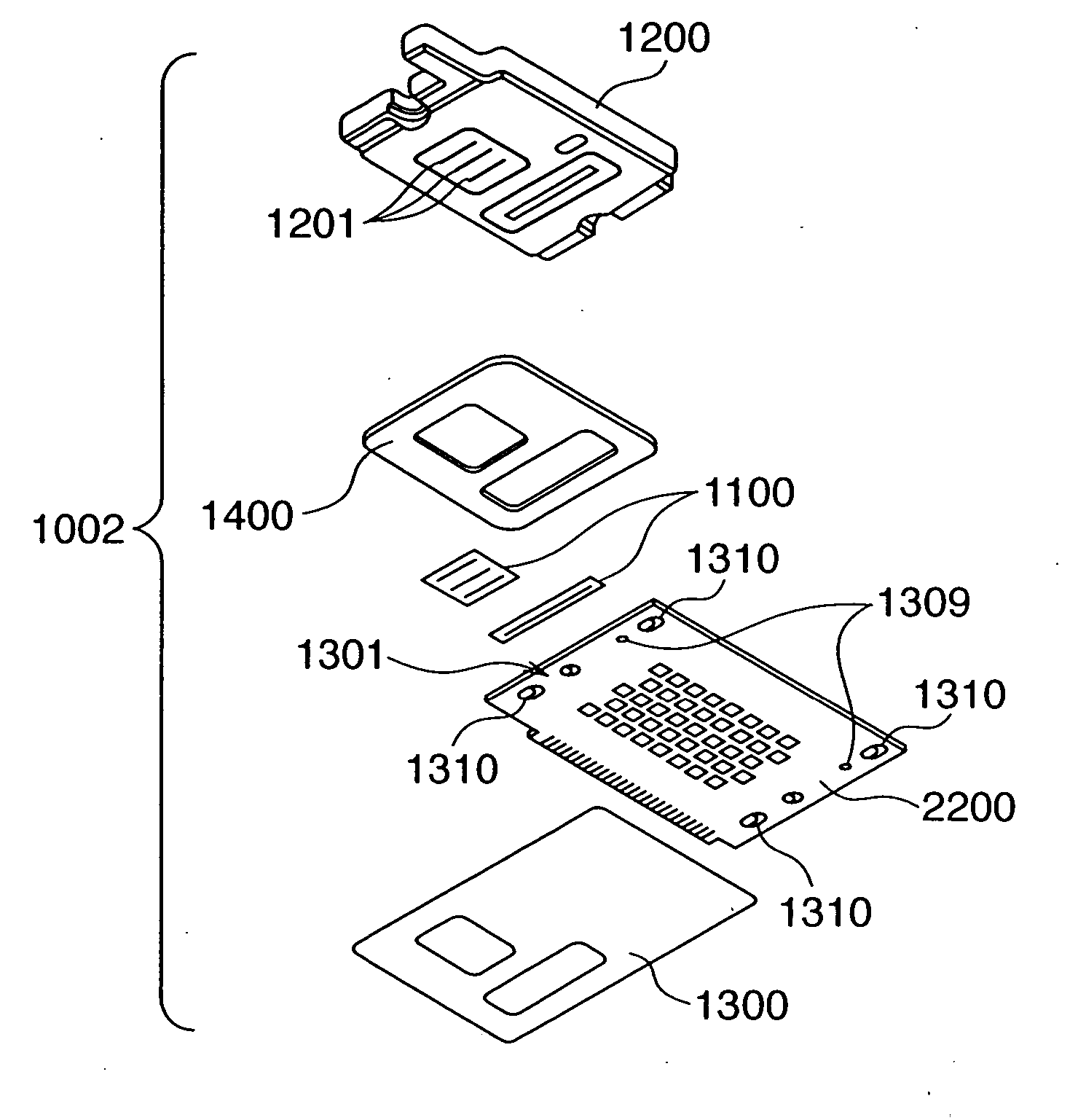

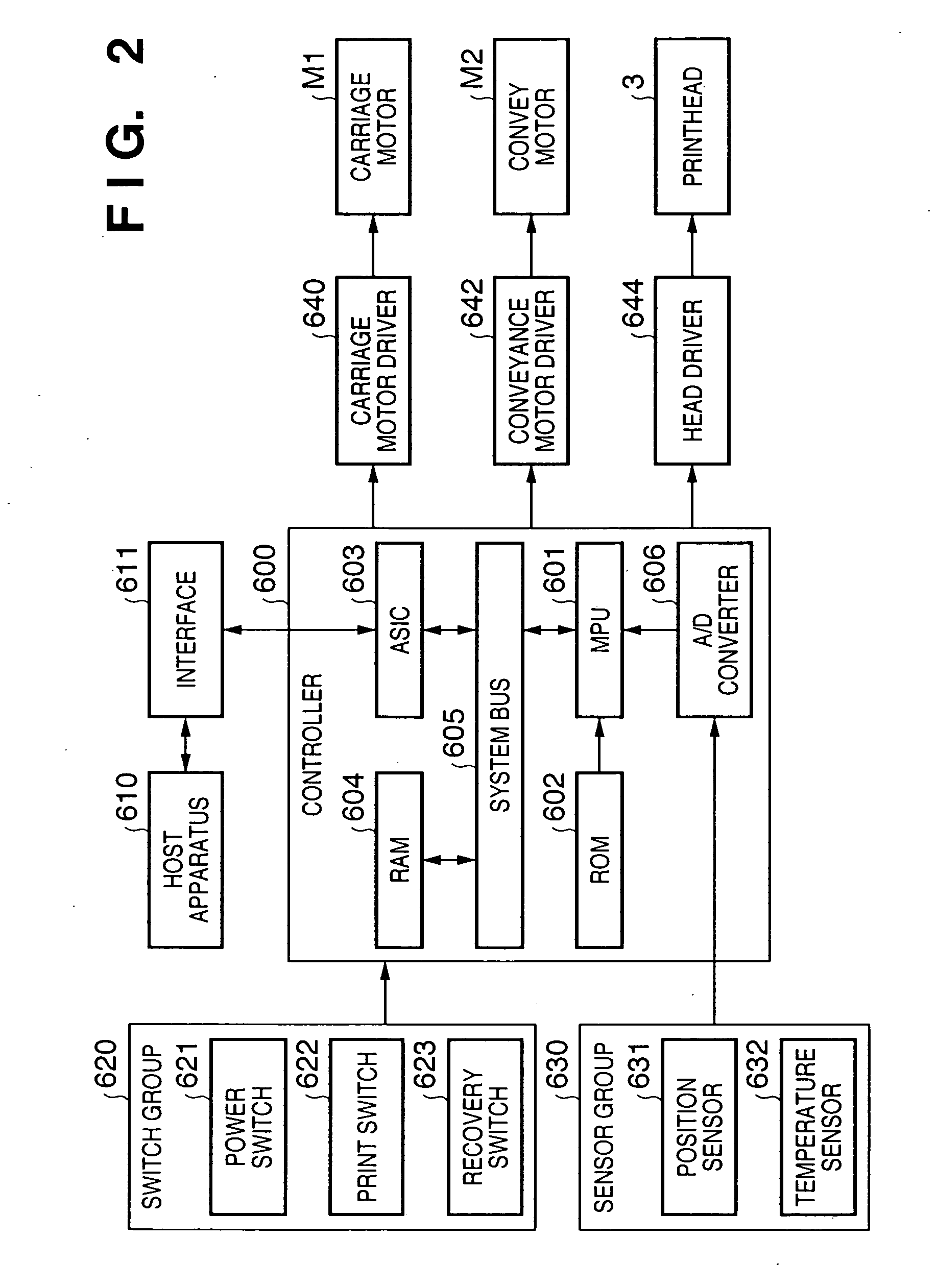

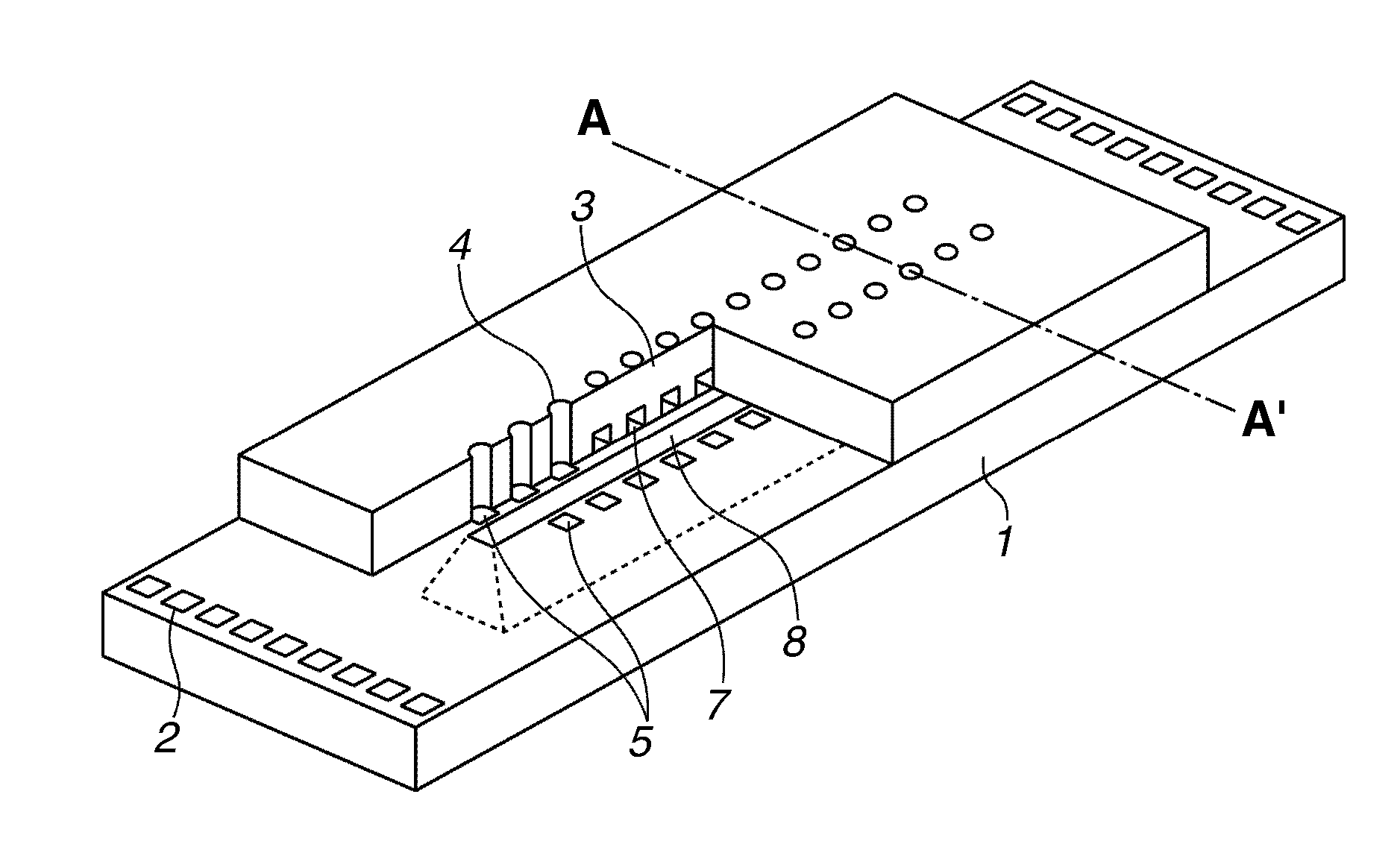

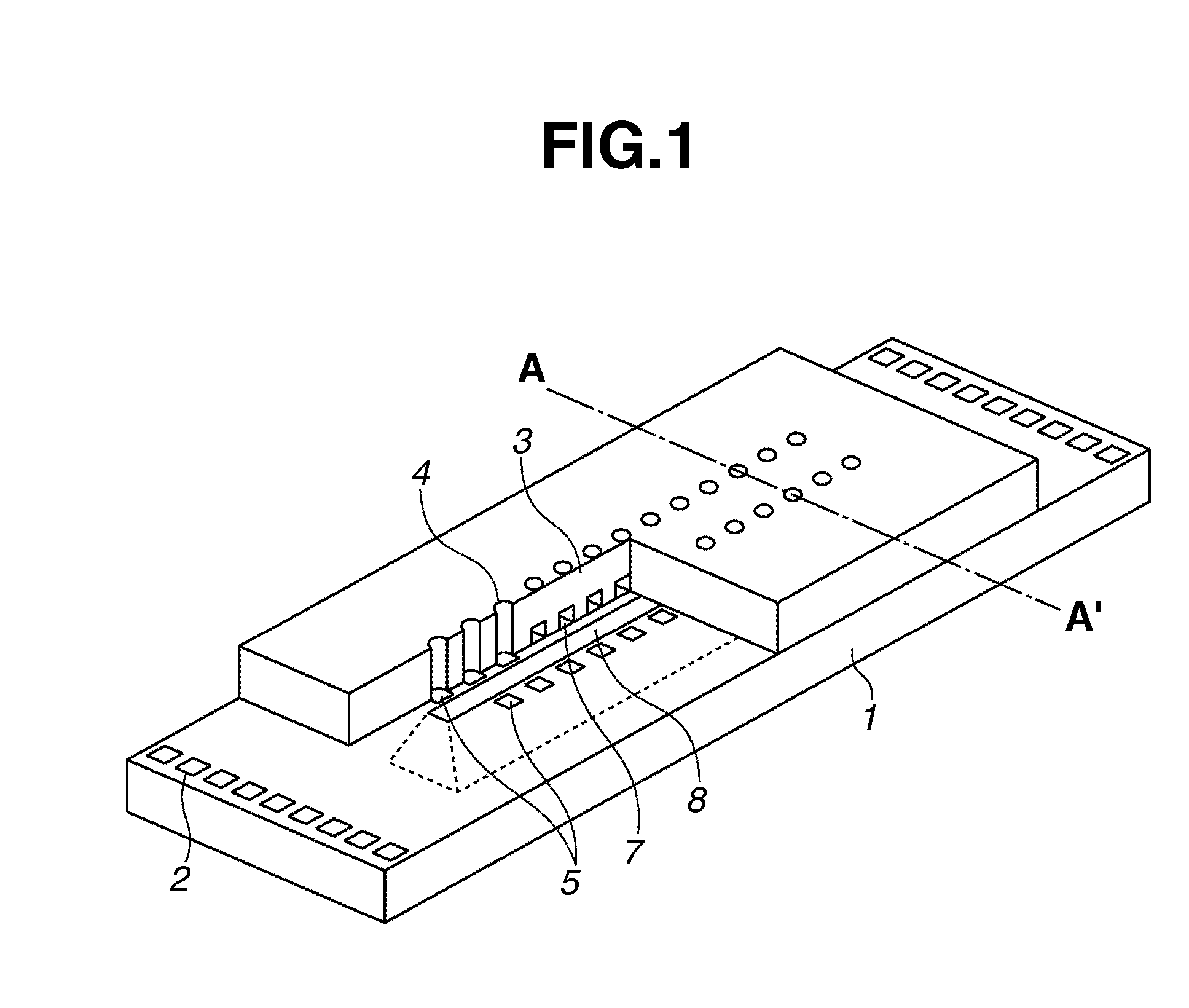

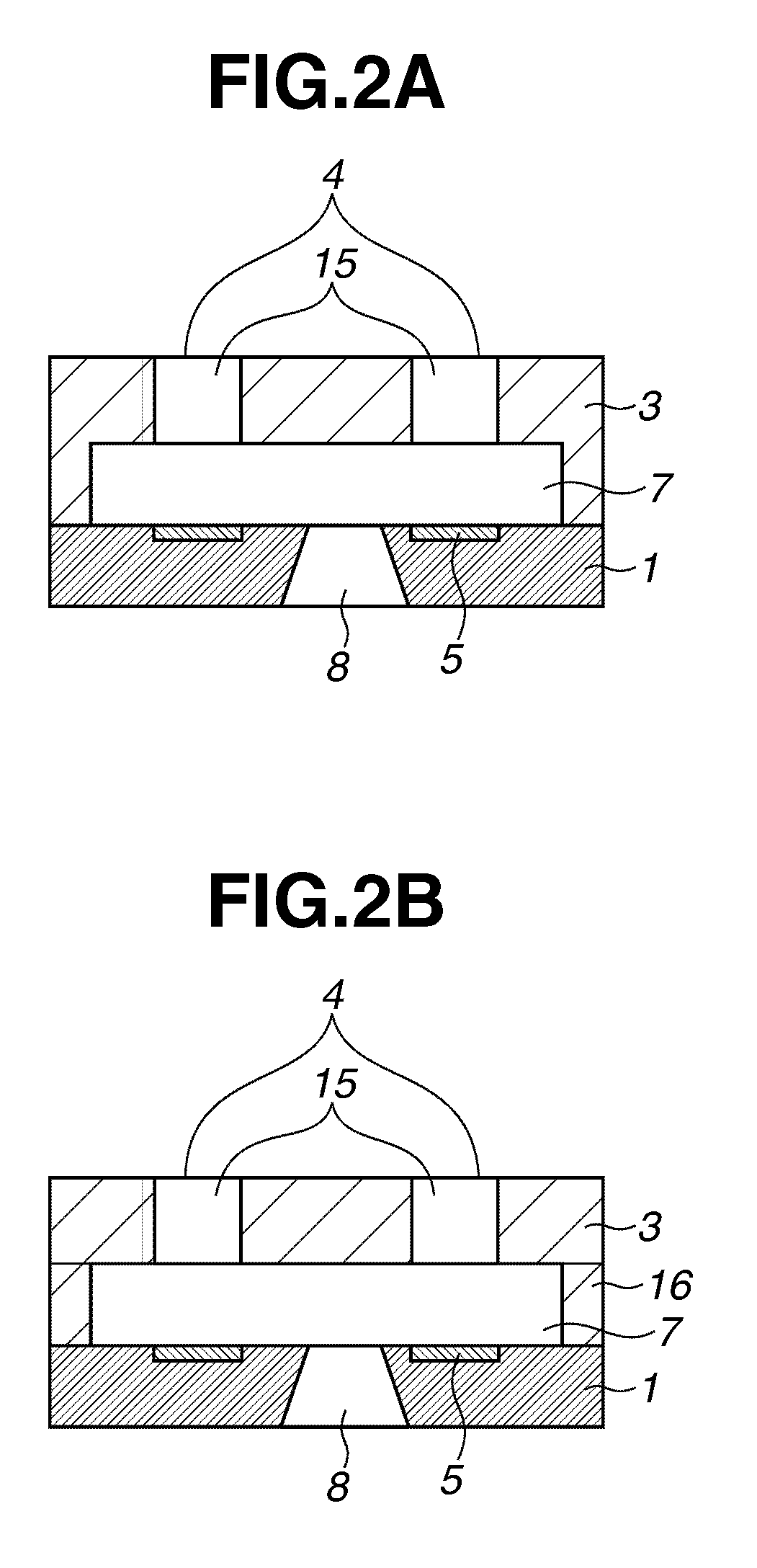

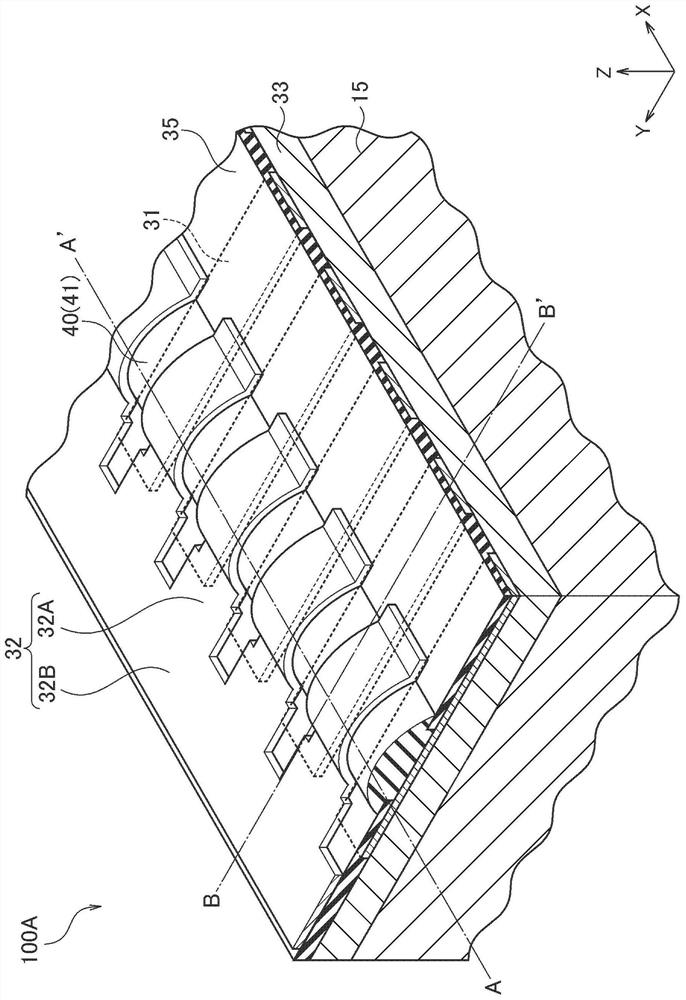

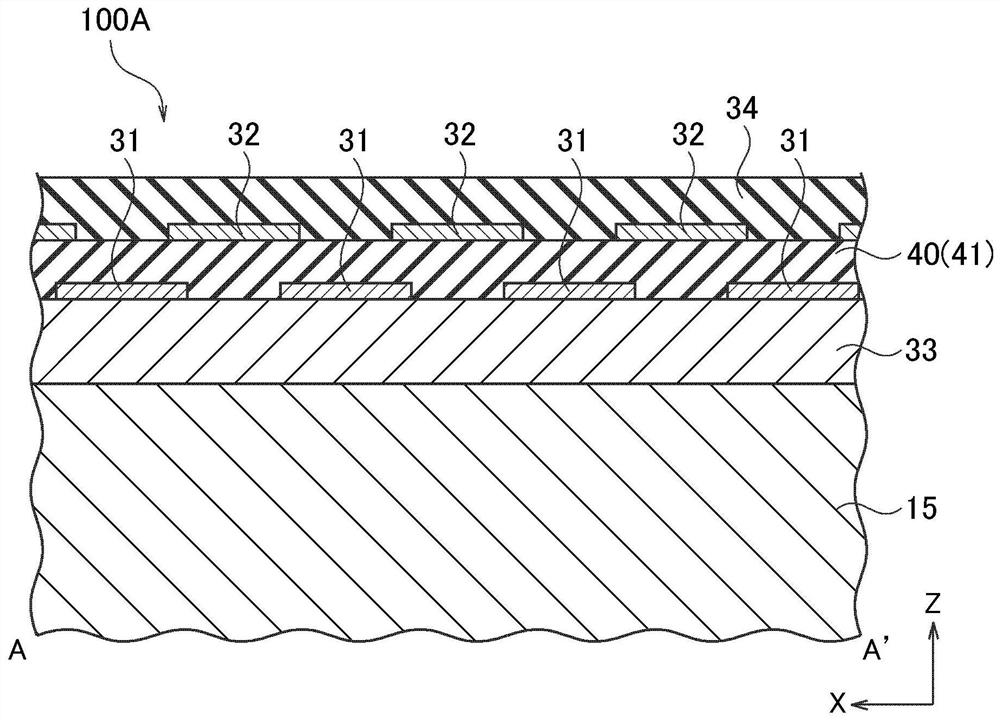

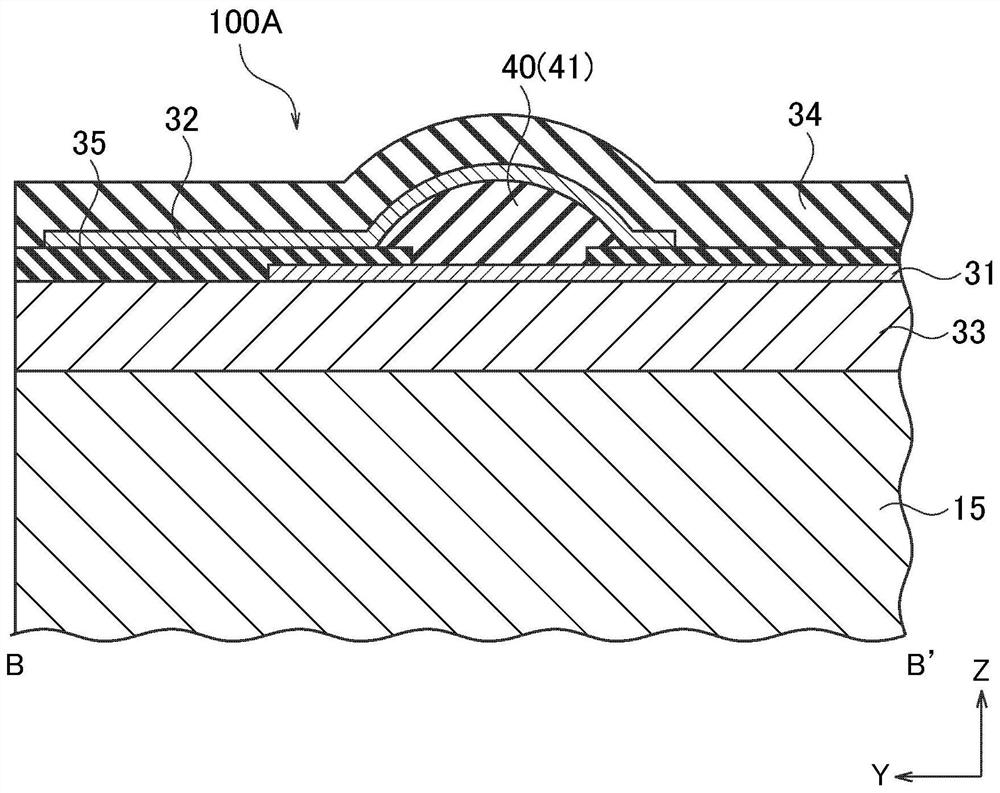

Printhead substrate, printhead using the substrate, head cartridge including the printhead, method of driving the printhead, and printing apparatus using the printhead

InactiveUS20050140736A1High quality printingLittle power lossPrintingElectrical resistance and conductanceWire width

This invention relates to a printhead substrate capable of suppressing an increase in wiring width and an increase in the size of a substrate formed by a film forming process while increasing the number of simultaneously driven printing elements in order to improve the printing performance, a printhead using the substrate, and a printing apparatus using the printhead. The wiring lines of the substrate are formed into a common wiring line, and energy applied to a heating resistance element is prevented from deviating from a stable ink discharge range owing to the difference in the number of simultaneously driven heating resistance elements. For this purpose, a driving element is greatly downsized in comparison with a conventional one, and the operation region of a MOS transistor is shifted from the non-saturation region to the saturation region.

Owner:CANON KK

Aqueous textile printing composition and continuous textile printing method of aqueous textile printing composition

InactiveUS20080044582A1Excellent printing characteristicsEfficient productionLiquid surface applicatorsFibre treatmentScreen printingTextile printer

An aqueous textile printing composition is provided having superior printing characteristics that can be used with multicolor rotating screen printing machines without causing environmental problems.

Owner:MATSUI SHIKISO KAGAKU INDSHO

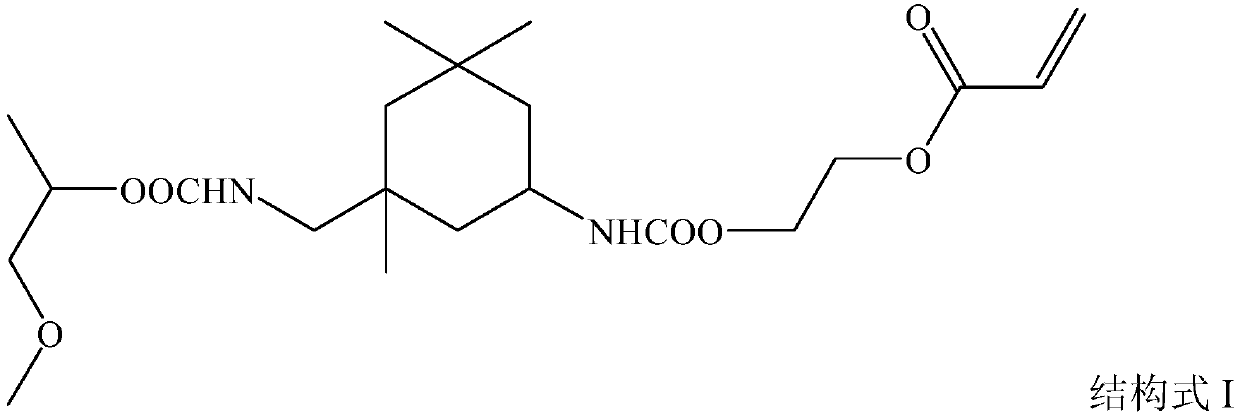

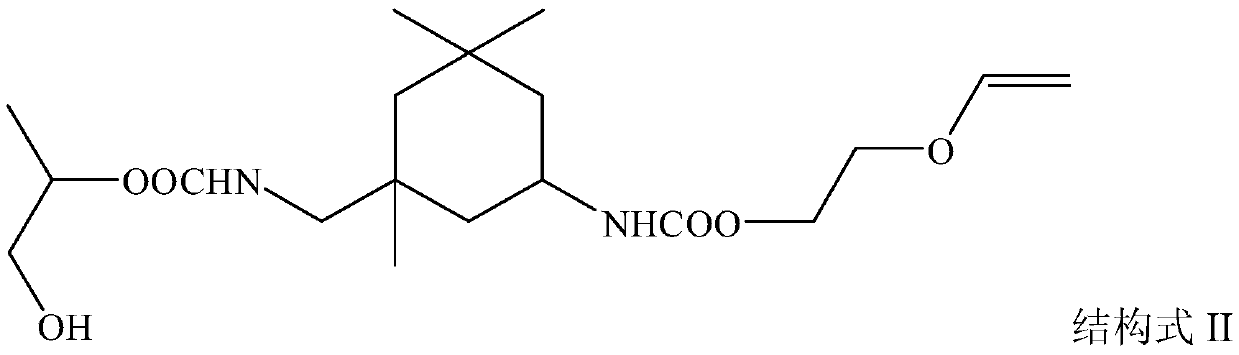

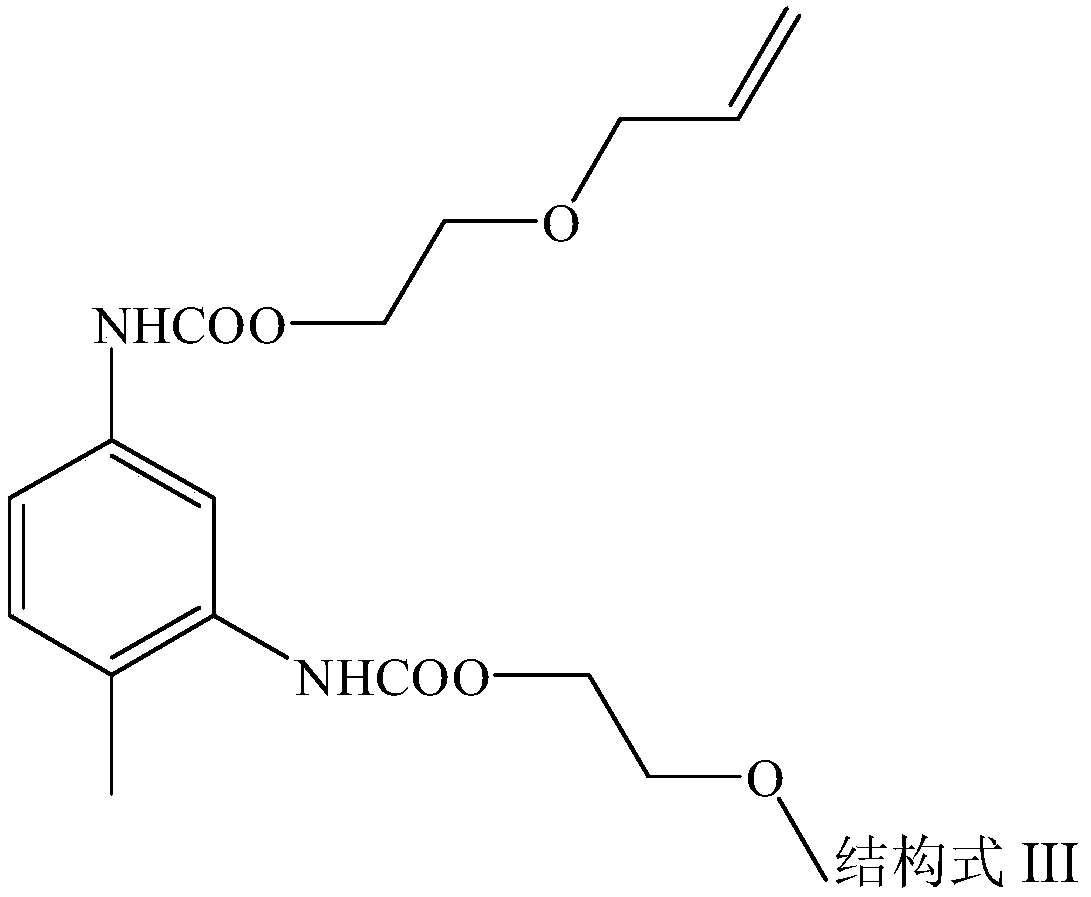

Three-dimensional forming material and preparation method and application thereof

InactiveCN111393567AExcellent printing characteristicsImprove thermal stabilityAdditive manufacturing apparatusCarbamic acid derivatives preparationPolymer scienceOligomer

The invention provides a three-dimensional forming material and a preparation method and application thereof. The three-dimensional forming material is prepared from the following components in percentage by mass: 5 to 50 percent of monofunctional polyurethane oligomer, 35 to 85 percent of monofunctional monomer, 0 to 30 percent of polyfunctional compound, 0.5 to 8 percent of photoinitiator and 0.2 to 5 percent of additive, wherein the monofunctional polyurethane oligomer contains a cyclic group, and the density of urethane bonds in the monofunctional polyurethane oligomer is 3.3 mol / Kg or more. The three-dimensional forming material is good in printing smoothness and has the advantages of being low in shrinkage rate, low in warping and not prone to arching, and the purposes of greatly improving the printing forming efficiency and reducing the printing cost can be achieved.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Method for manufacturing liquid discharge head

InactiveUS20100233630A1Forming accuratelyAccurate shapePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringWavelength range

A method for manufacturing a liquid discharge head that includes a flow path wall member which forms a wall of a flow path communicating with a discharge port for discharging a liquid and a substrate which forms the flow path in contact with the flow path wall member includes providing a first layer, which is made of a photosensitive resin on the substrate, for forming a pattern having a shape of the flow path, providing a second layer which is capable of absorbing light within a photosensitive wavelength range of the photosensitive resin and has a shape corresponding to the shape of the flow path, on the first layer so as to come into contact with the first layer, performing patterning of the first layer which includes exposure of the first layer with the light using the second layer as a mask, and forming the pattern from the first layer, providing a cover layer which is made of a photosensitive resin and serves as the flow path wall member so as to cover the second layer and the pattern, forming the discharge port on the cover layer by performing patterning of the cover layer which includes exposure of the cover layer with the light, and forming the flow path by removing the second layer and the pattern.

Owner:CANON KK

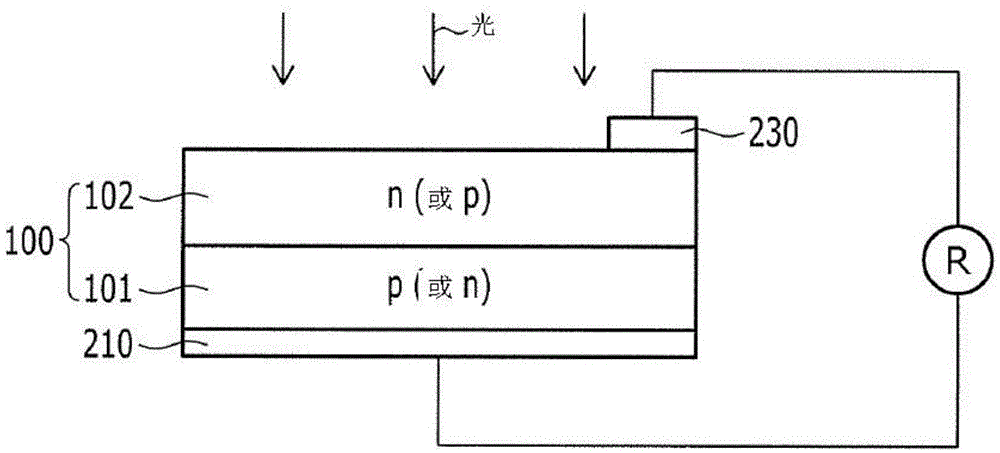

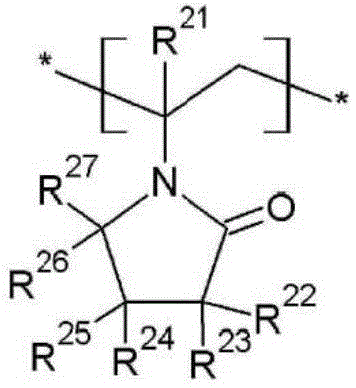

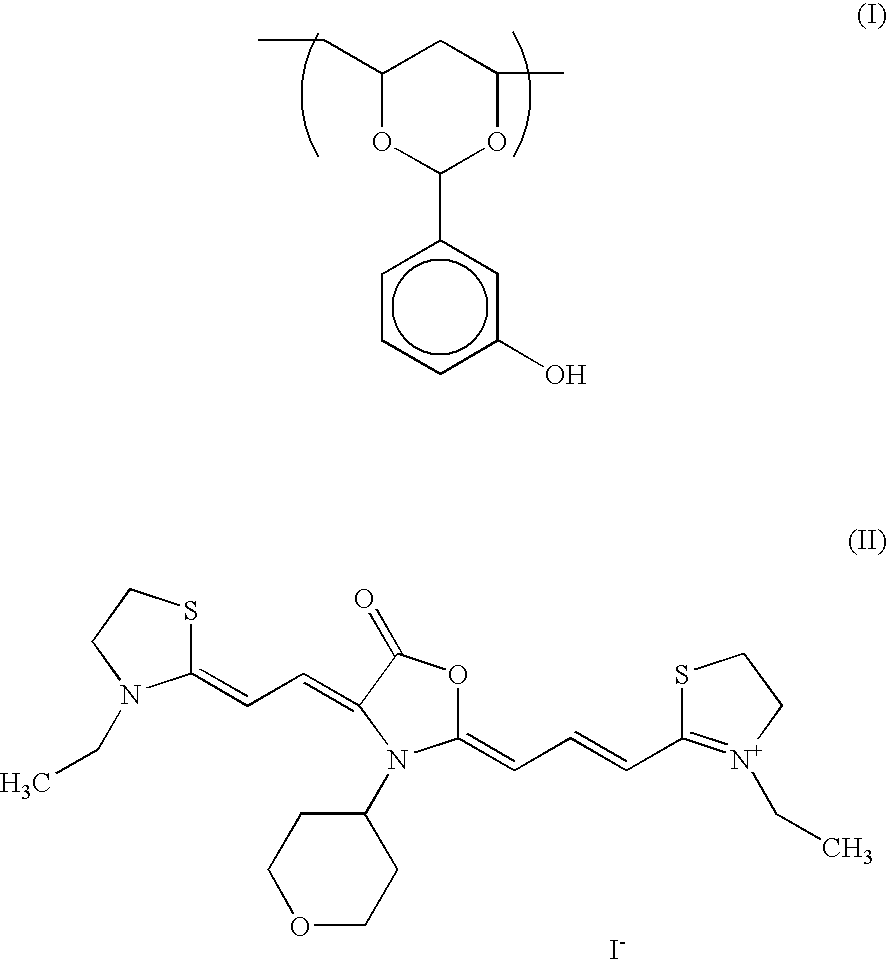

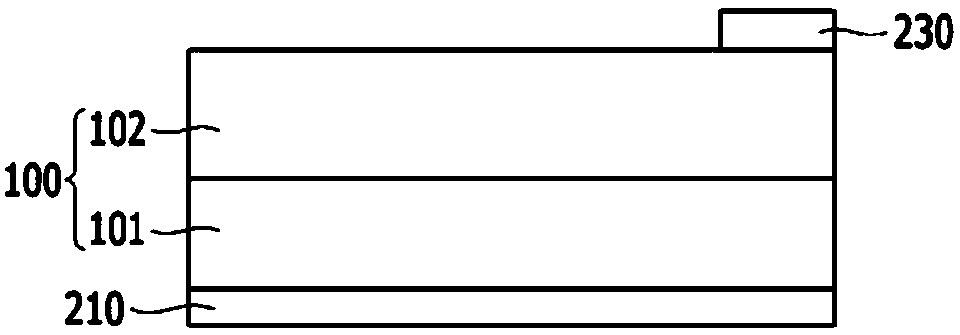

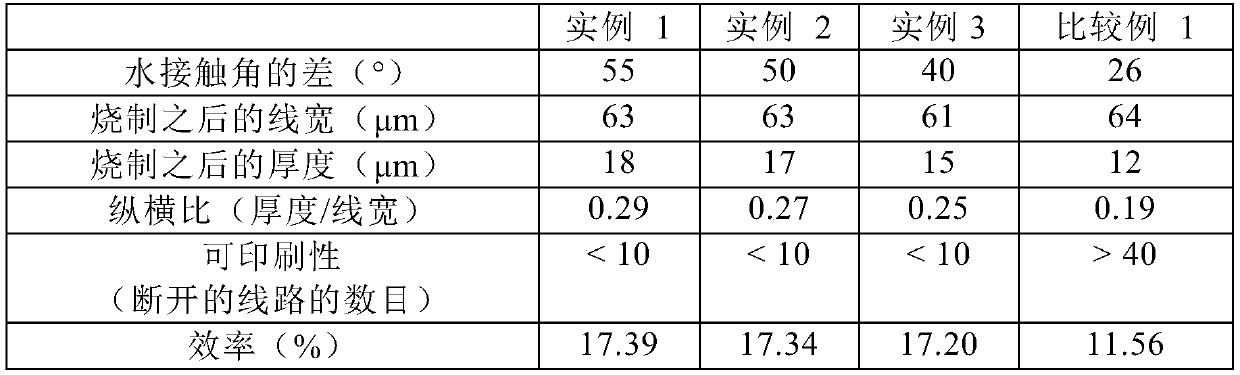

Composition for forming electrode, electrode manufactured using same and solar cell

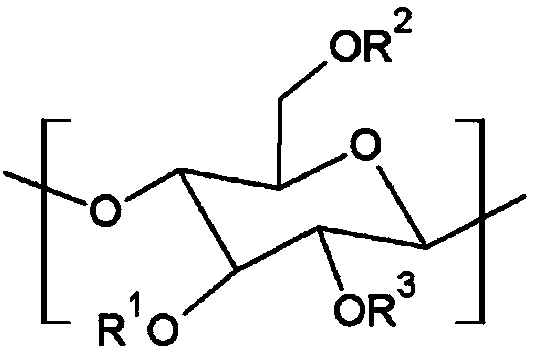

ActiveCN108630337AImprove adhesionExcellent printing characteristicsNon-conductive material with dispersed conductive materialPhotovoltaic energy generationCellulose compoundsSolvent

The invention relates to a composition for forming an electrode for a solar cell, the composition including a conductive powder, a glass fit, an organic binder, and a solvent, the organic binder including a cellulose compound that includes a structural unit represented by Chemical Formula 1, manufacture of the electrode of the solar cell using the composition for forming an electrode for a solar cell, and a solar cell including the electrode. The definition of each substituent of Chemical Formula 1 is the same as in the specific embodiment. The compositions for forming the electrode of the present invention has improved print characteristics, dispersibility, and storage stability.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

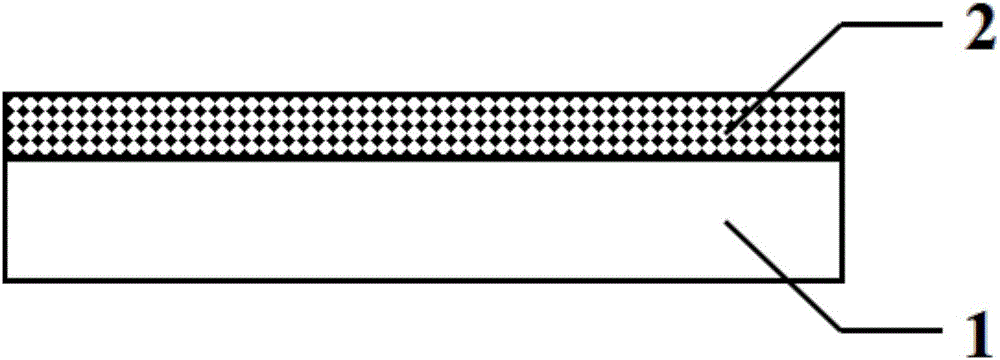

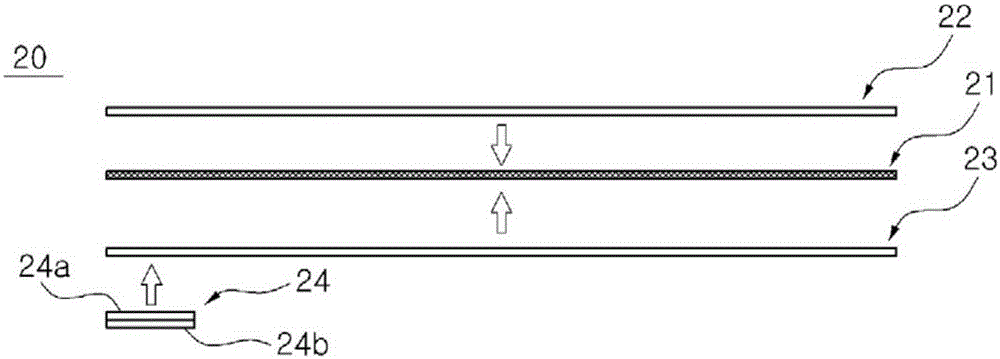

Image recording media

InactiveCN1368917AAvoid diversionExcellent Image Recording MediaDuplicating/marking methodsCoatingsChemistryImage recording

Provided is an ink image recording medium with excellent color rendering properties, which can effectively prevent the coloring components in the ink from transferring into the micropores of the medium. The image recording medium comprises (i) a substrate layer containing permeable micropores and (ii) an ink image-receiving layer containing a water-soluble salt as a coagulant, which layer is placed on the surface of the substrate layer, and the substrate layer is activated by a surfactant. The bottom layer and the inner surface of micropores are hydrophilic, and the ink image receiving layer contains polar organic polymers.

Owner:3M INNOVATIVE PROPERTIES CO

High-elasticity heat transfer membrane and preparation method thereof

InactiveCN105751722AHigh tensile strengthImprove toughnessPolyurea/polyurethane coatingsThermographyHot stampingUltimate tensile strength

The invention discloses a high-elasticity heat transfer membrane and a preparation method thereof. The high-elasticity heat transfer membrane comprises a BOPP (biaxially-oriented polypropylene) base membrane, wherein the BOPP base membrane is coated with an elastic color layer; the BOPP base membrane has high tensile strength, high toughness, excellent transparency, excellent printing characteristics and high strippability; the elastic color layer has a tensile property, and the color of the heat transfer membrane can be changed by adjusting ingredients of dye. The color layer can stretch with stretching of cloth after hot stamping, and the attractiveness of the elastic cloth is improved.

Owner:SUZHOU WONDERFUL NEW MATERIAL CO LTD

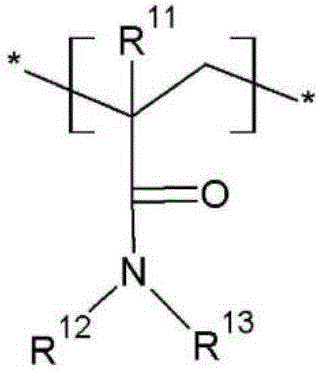

Composition for forming electrode, electrode manufactured using the same and solar cell

ActiveCN106469580AHigh resolutionExcellent printing characteristicsNon-conductive material with dispersed conductive materialPhotovoltaic energy generationFritSolvent

The invention relates to a composition which can form fine patterns with high resolutions and which has excellent printing characteristics, dispersibility and storage stability for forming an electrode, the electrode manufacturing using the same and a solar cell. The composition for forming the electrode comprises a conductive powder, glass frit, an organic binder and a solvent, wherein the organic binder comprises a polymer comprising a first structural unit and a second structural unit represented by the Chemical Formula 2.The first structural unit is selected from the group consisting of structural units represented by Chemical Formula 1A, the structural unit represented by Chemical Formula 1B and combinations thereof.

Owner:上海匠聚新材料有限公司

Resin with excellent processability for lightguide plate

InactiveCN1694910AEasy to processHigh transparencyMechanical apparatusPlanar/plate-like light guidesMeth-Light guide

This invention provides a resin for light guiding plates which retains physical properties as acrylic resins such as transparency and exhibits good processability with minimum scorching of an edge during polishing or cutting. This resin for light guiding plates is made of a polymer prepared by polymerizing a mixture comprising 100 parts by weight of a polymerizable material consisting of 91 to 100% by weight of methyl methacrylate and 0 to 9% by weight of a monofunctional acrylate, and 0.01 to 2 parts by weight of a polyfunctional (meth)acrylate. The resin preferably comprises 0.01 to 1000 ppm of a diffusing agent.

Owner:MITSUBISHI CHEM CORP

Printer, liquid discharging head, and flexible flat cable of liquid discharging head

ActiveUS20070024679A1Excellent printing characteristicsAvoid deformationInking apparatusPiezoelectric actuatorsEngineering

An ink-jet head includes a head main body including a channel unit in which a pressure chamber is formed, and a piezoelectric actuator having a piezoelectric deformation portion facing the pressure chamber, and an FPC which has a substrate and a plurality of wires, and which is arrange on an upper side of the piezoelectric actuator. A plurality of projections bent to form a projection toward the head main body is formed in the FPC. A front end of the projections is in contact with an area not facing the pressure chamber, on a surface of the piezoelectric actuator. Accordingly, it is possible to suppress hindering of a deformation of the piezoelectric deformation portion accompanied by a liquid discharge, due to a contact with a flexible flat cable.

Owner:BROTHER KOGYO KK

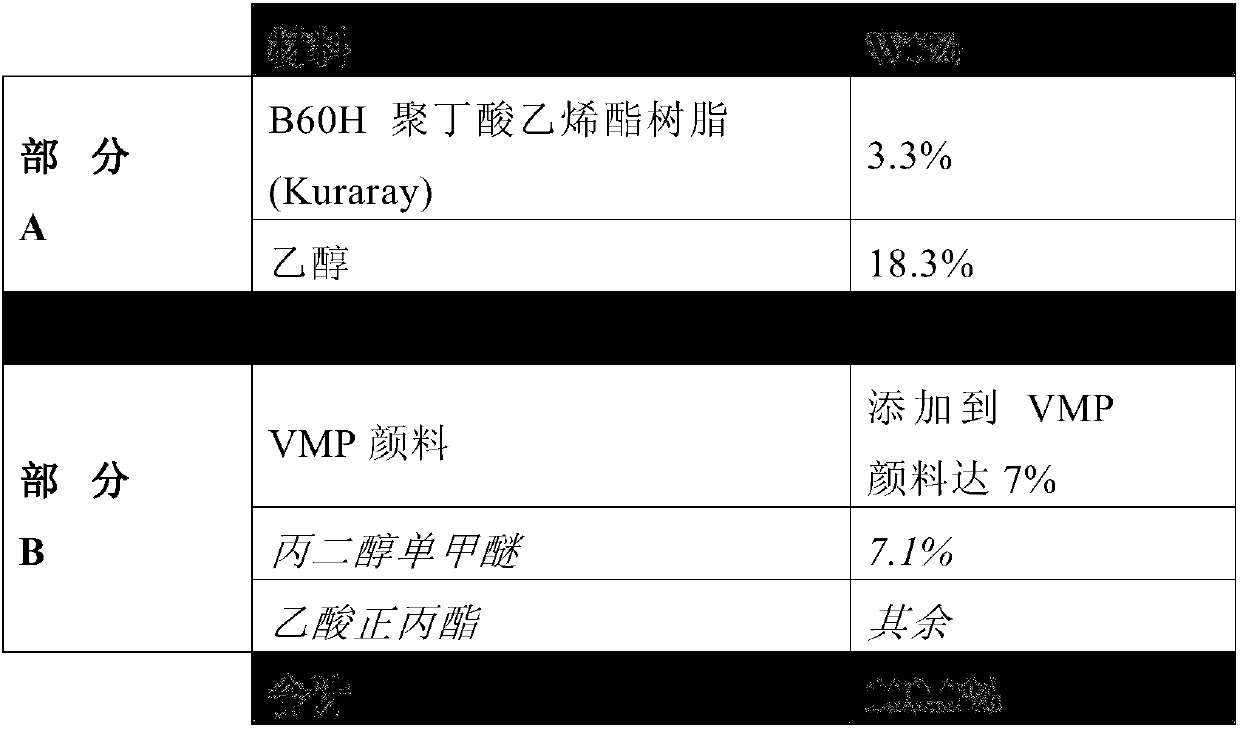

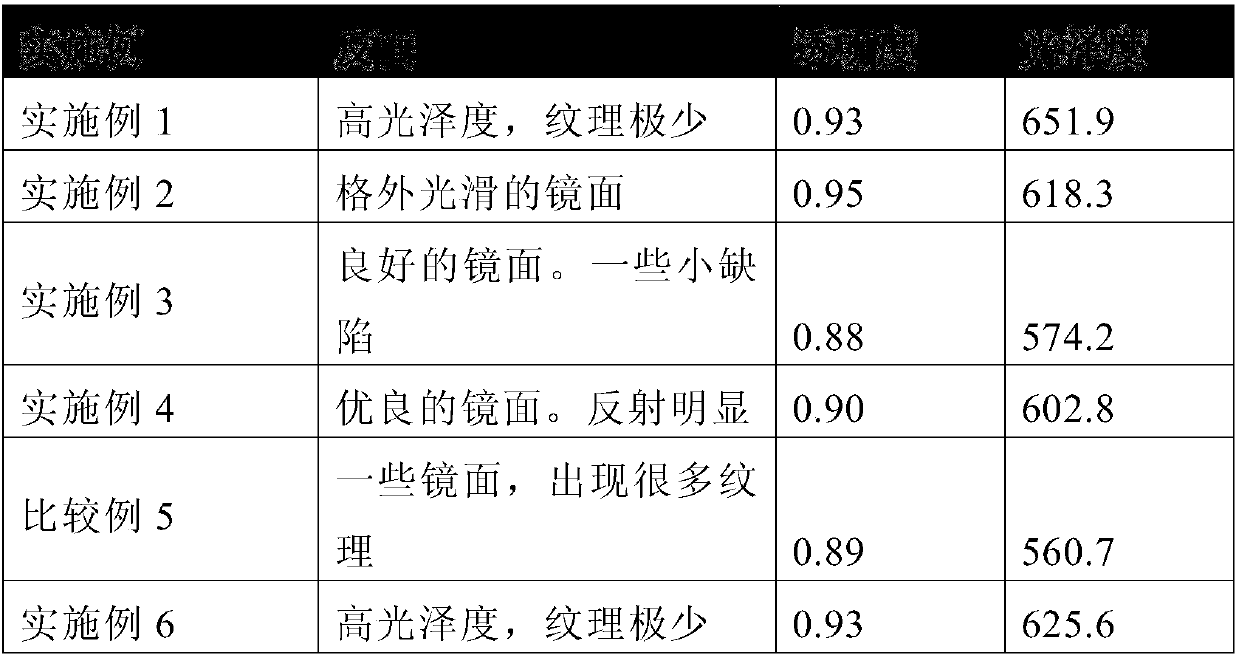

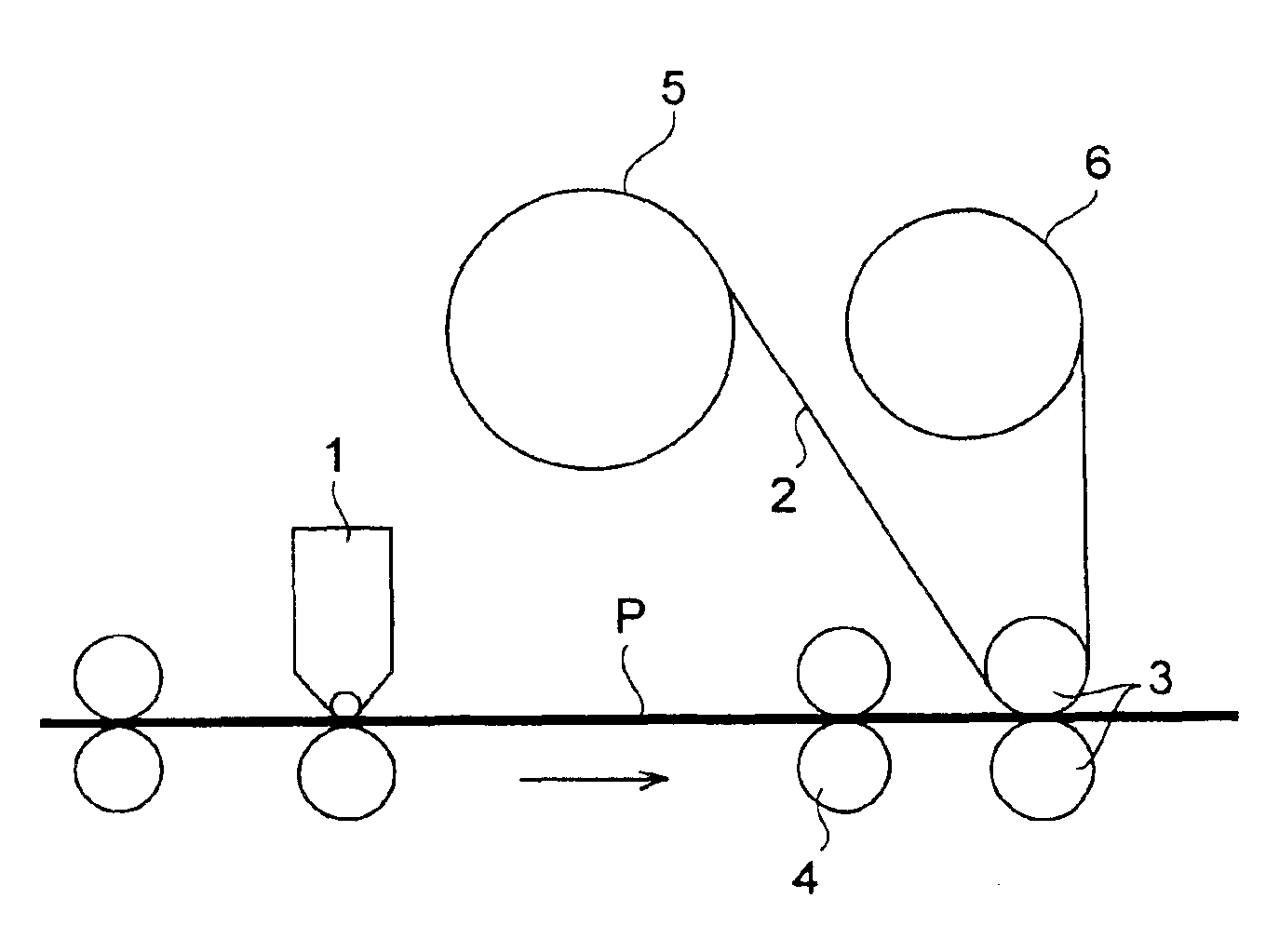

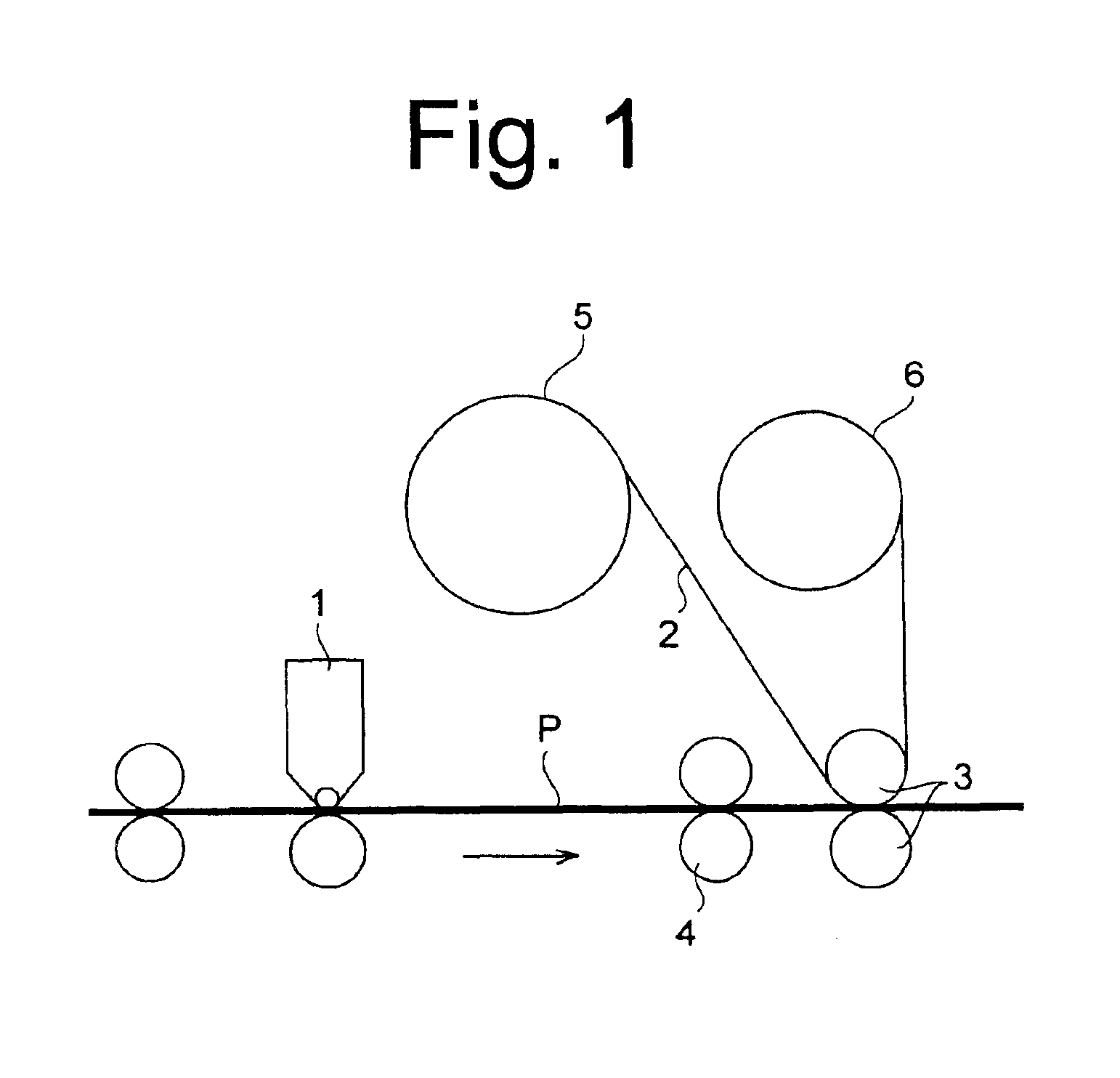

Dispersant effect on aluminum pigments

InactiveCN108026383AHigh solid contentMaintain or improve physical handlingPigmenting treatmentInksPhotopigmentMaterials science

In the present application, we report a pigment preparation comprised of an aluminum pigment, a dispersing additive and a solvent, that can either 1) reach high, >10% solids with favorable rheology; 2) be formulated into high alcohol systems; or 3) both. The pigment preparation of the present application has better formulation flexibility than other VMP aluminum pigment slurries currently available on the market.

Owner:SUN CHEM CORP

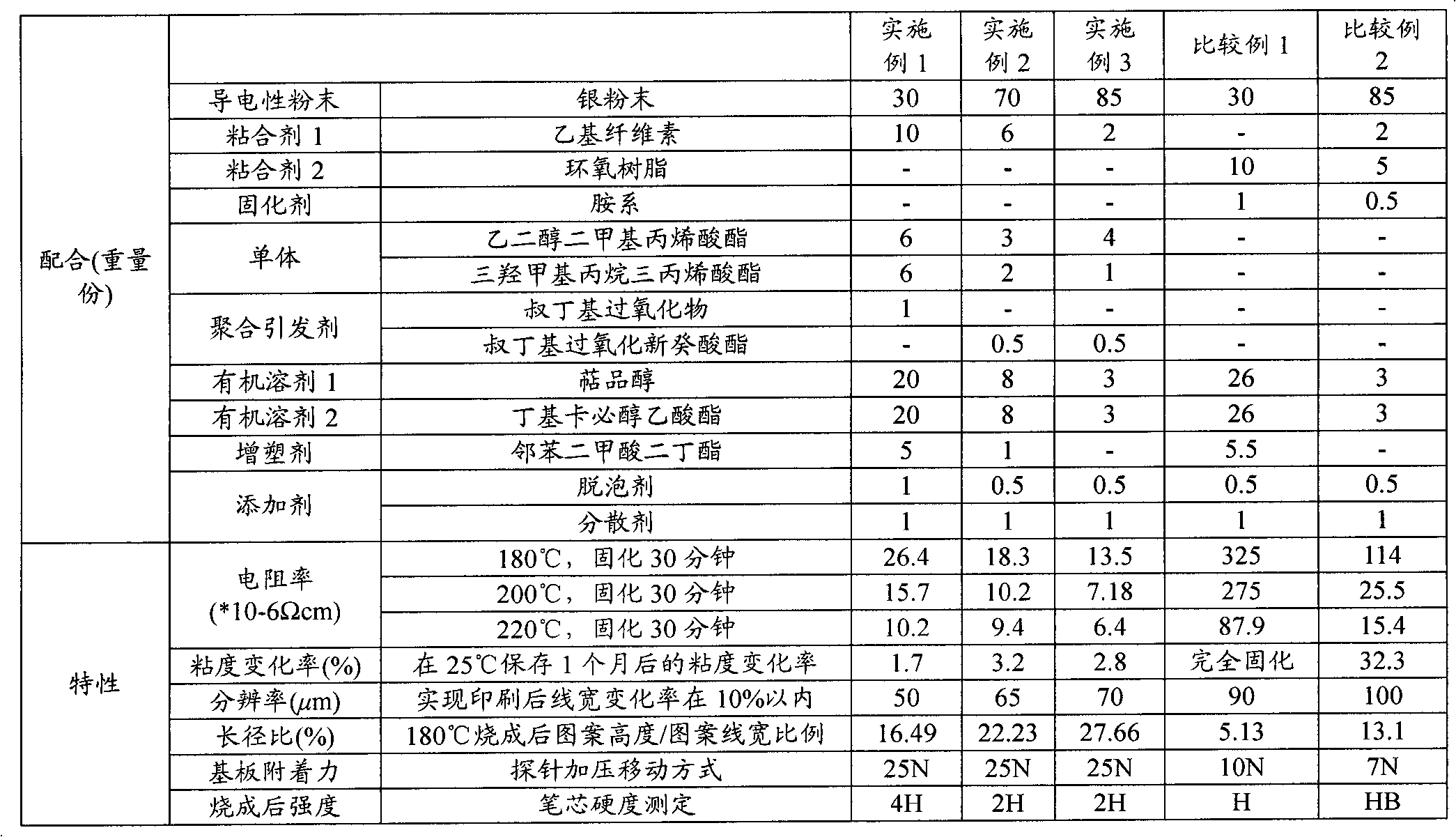

Low temperature fireable paste composition for forming an electrode or wiring

InactiveCN102388421AHigh resolutionExcellent printing characteristicsNon-conductive material with dispersed conductive materialPhotovoltaic energy generationCelluloseHardness

The present invention relates to a paste composition for forming an electrode or wiring. The paste composition for forming an electrode or wiring according to the present invention comprises: a) conductive powder, b) a cellulose-based binder, c) an acrylate-based monomer, d) a radical polymerization initiator, and e) a solvent. As compared to conventional paste compositions, the paste compositionof the present invention is fireable at a low temperature and has superior hardness, electrical resistivity, and stability properties, and therefore has a valuable use in forming an electrode or wiring for a solar cell, RFID (radio frequency identification), or a PCB (printed circuit board).

Owner:DONGJIN SEMICHEM CO LTD

Method of processing light-sensitive material

InactiveUS6869743B1Excellent printing characteristicsLow costDiffusion transfer processesPhotography auxillary processesCoating systemClose contact

There is disclosed a method of processing a light-sensitive material which comprises exposing a light-sensitive material having at least one light-sensitive layer on a support, and subjecting to development by a dipping system or a coating system, and then, peeling at least the light-sensitive layer off by bringing a peeling material into close contact with the light-sensitive material, wherein the peeling material is a material having a liquid-absorbing rate in which a liquid-absorption amount within 0.1 second after getting in contact with a liquid is 60% or more based on a liquid-absorption amount within 0.2 second after the same.

Owner:MITSUBISHI PAPER MILLS LTD

Recording material

InactiveUS20050171329A1Promote degradationImprove adhesionThermographyPolyester coatingsSolubilityRecording layer

Provided is a recording material which is improved in an adhesive property between a recording layer and a base material and is excellent in a printing aptitude in a heat transfer recording system or an ink jet recording system, a writing property and a stamp property and which can contribute to waste problems continuing to grow large and is excellent in a biodegradability. The above recording material has a recording layer formed by coating a coating solution containing a biodegradable resin comprising a non-crystalline polylactic acid resin and a filler on at least one face of a base material comprising a crystalline biodegradable polylactic acid resin, wherein a solvent used for the coating solution is a solvent having a solubility parameter of 7.5 to 12.5 (cal / cm3)1 / 2, and a content of the above solvent in the coating solution is 40 to 90 mass %; and the above solvent contains 20 mass % or more of a solvent having a relative dielectric constant of 15 or more.

Owner:NISSHINBO IND INC

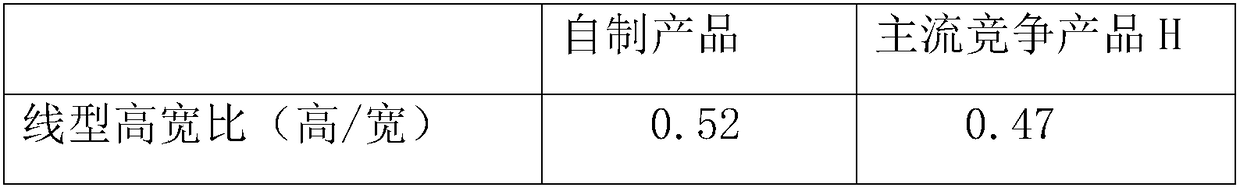

Organic carrier used for front silver paste and preparation method thereof

ActiveCN109390074AGuaranteed Aspect RatioImprove efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesAcrylic resinTG - Triglyceride

The invention discloses an organic carrier used for a front silver paste. The organic carrier is characterized by being composed of the following raw materials by weight: 25% to 35% of diethylene glycol octyl ether, 15% to 27%vof tripropylene glycol methyl ether, 10% to 18% of butyl group carbitol acetate, 20% to 25% of triglyceride-modified silicone resin, 0.3% to 2% of rosin-modified acrylic resin, 1%~ 4% of dispersant (BYK-110), and 1% to 4% of dispersant (BYK-111). According to the invention, the triglyceride-modified silicone resin is introduced in the organic carrier prepared by the invention, so the depth-width ratio of the line type is ensured; the efficiency of a cell sheet is improved, and the organic carrier has excellent printing characteristics; by introducing a small amount of rosin-modified acrylic resin, the adhesion of the silver film layer and the silicon substrate after the silver paste is dried is ensured; falling-off phenomena will not occur; the solderability of the silver film layer after sintering with the soldering ribbon is promoted; and improvement of the adhesion is ensured.

Owner:上海银浆科技有限公司

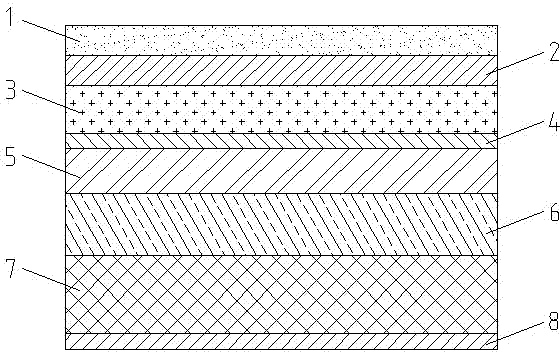

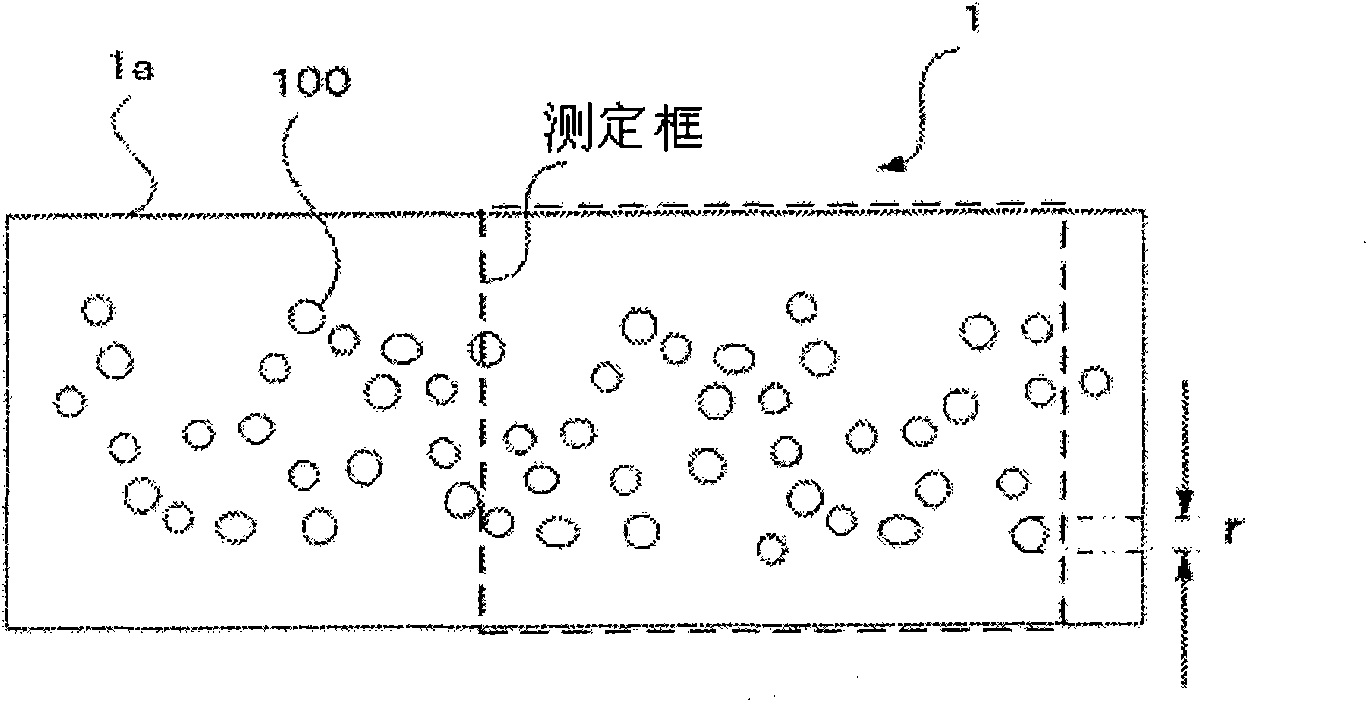

Void-containing resin molded product, process for producing the void-containing resin molded product, and image receiving film or sheet for sublimation transfer recording material or thermal transfer

InactiveCN101663350AExcellent printing characteristicsDuplicating/marking methodsCoatingsPolymer sciencePolymer

This invention provides a void-containing resin molded product having a high level of heat insulating properties, and a process for producing the void-containing resin molded product, and a image receiving film or sheet for a sublimation transfer recording material or a thermal transfer recording material, comprising a void-containing resin molded product and having excellent printing properties.The void-containing resin molded product is composed of a crystalline polymer only and has voids in its interior. The void-containing resin molded product is characterized by satisfying a requirementof X / Y ratio = not more than 0.27 wherein X represents the coefficient of thermal conductivity of the void-containing resin molded product, W / mK; and Y represents the coefficient of thermal conductivity of a polymer molded product which has the same thickness as the void-containing resin molded product, is formed of the same crystalline polymer as the crystalline polymer constituting the void-containing resin molded product but free from any void, W / mK.

Owner:FUJIFILM CORP

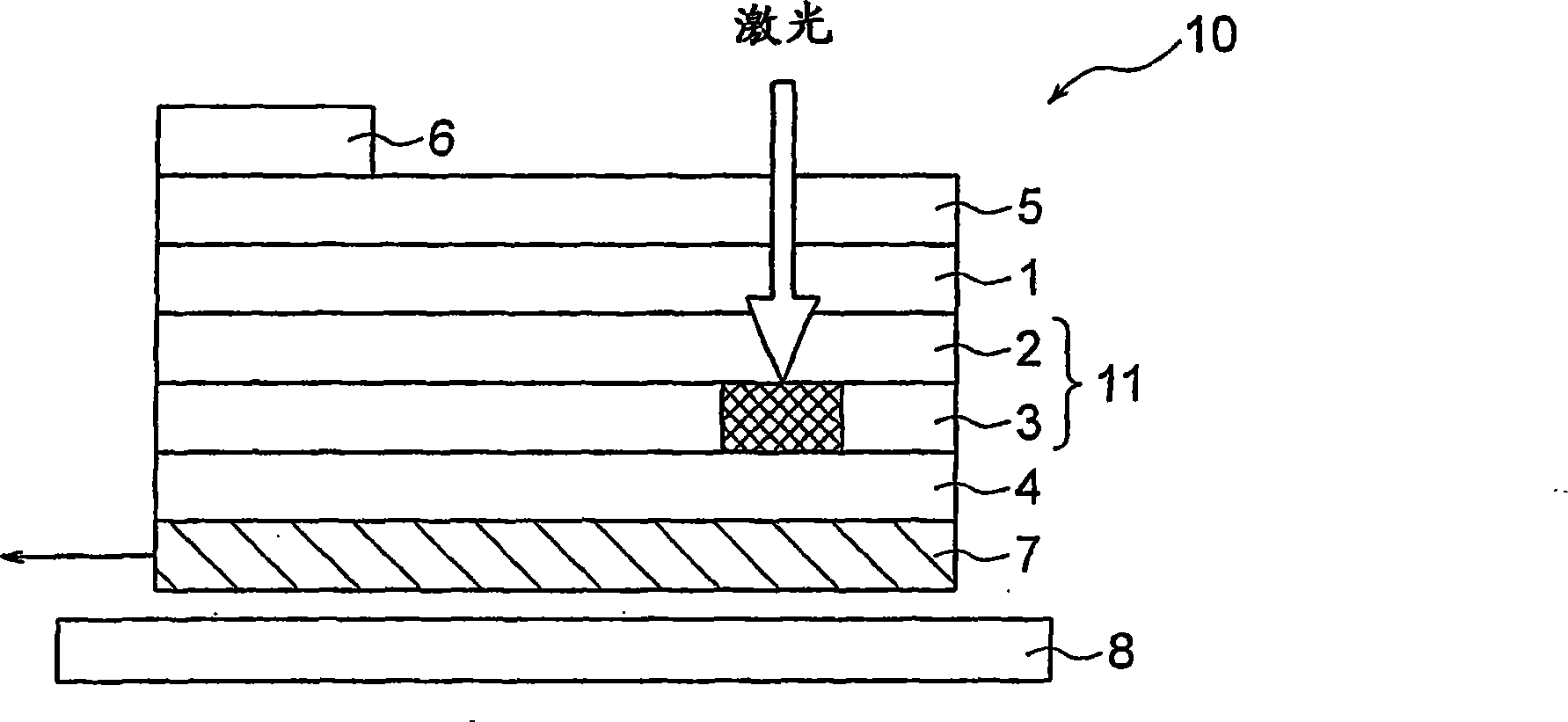

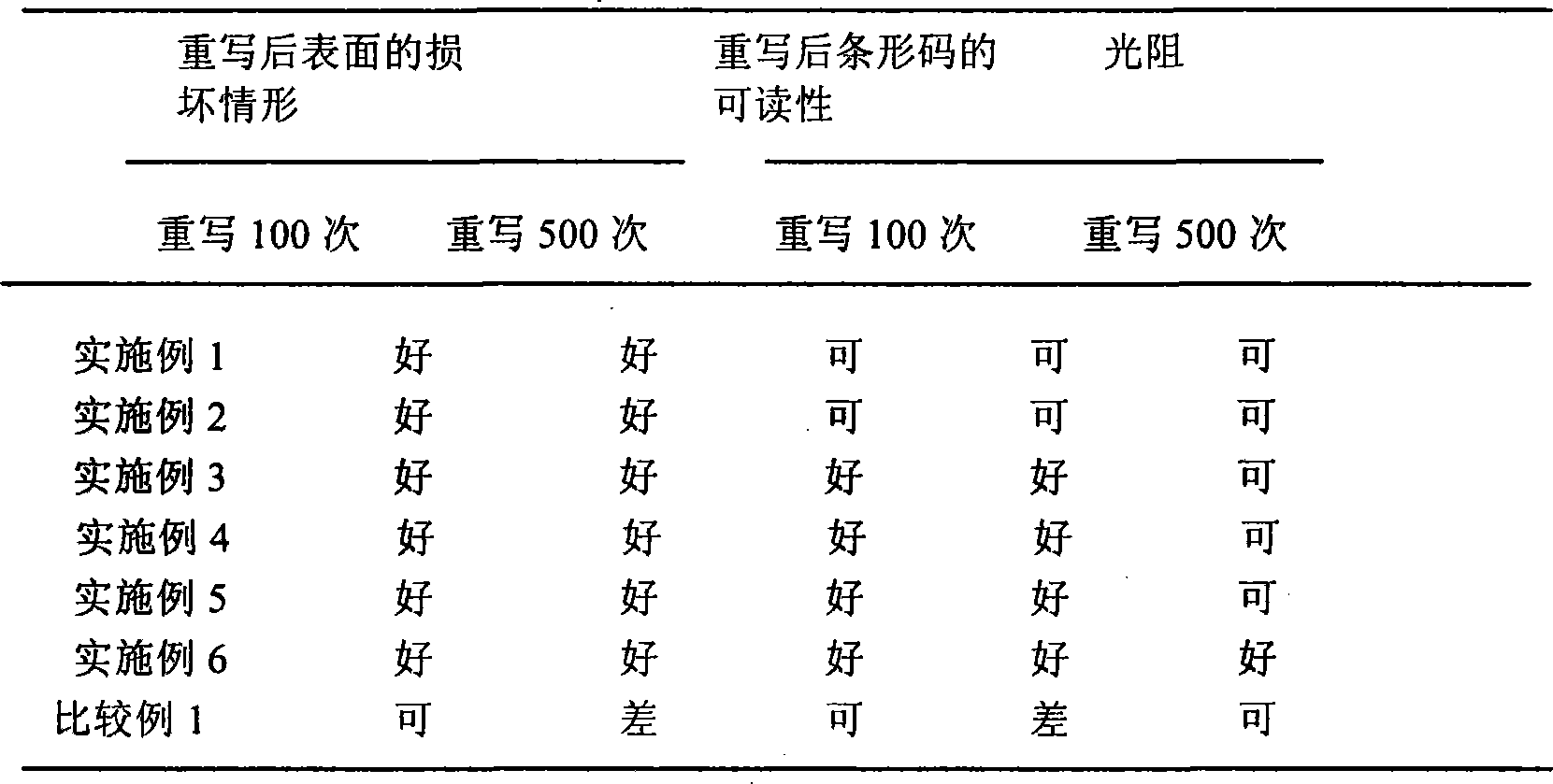

Rewritable thermal label of non-contact type

InactiveCN101239545AGood rewrite persistenceExcellent printing characteristicsStampsThermographyHeat sensitiveOptoelectronics

Owner:LINTEC CORP

Method for producing toner for developing electrostatic images

ActiveUS20170248857A1Efficient productionFew coarse particleSievingGas current separationEngineeringCoarse particle

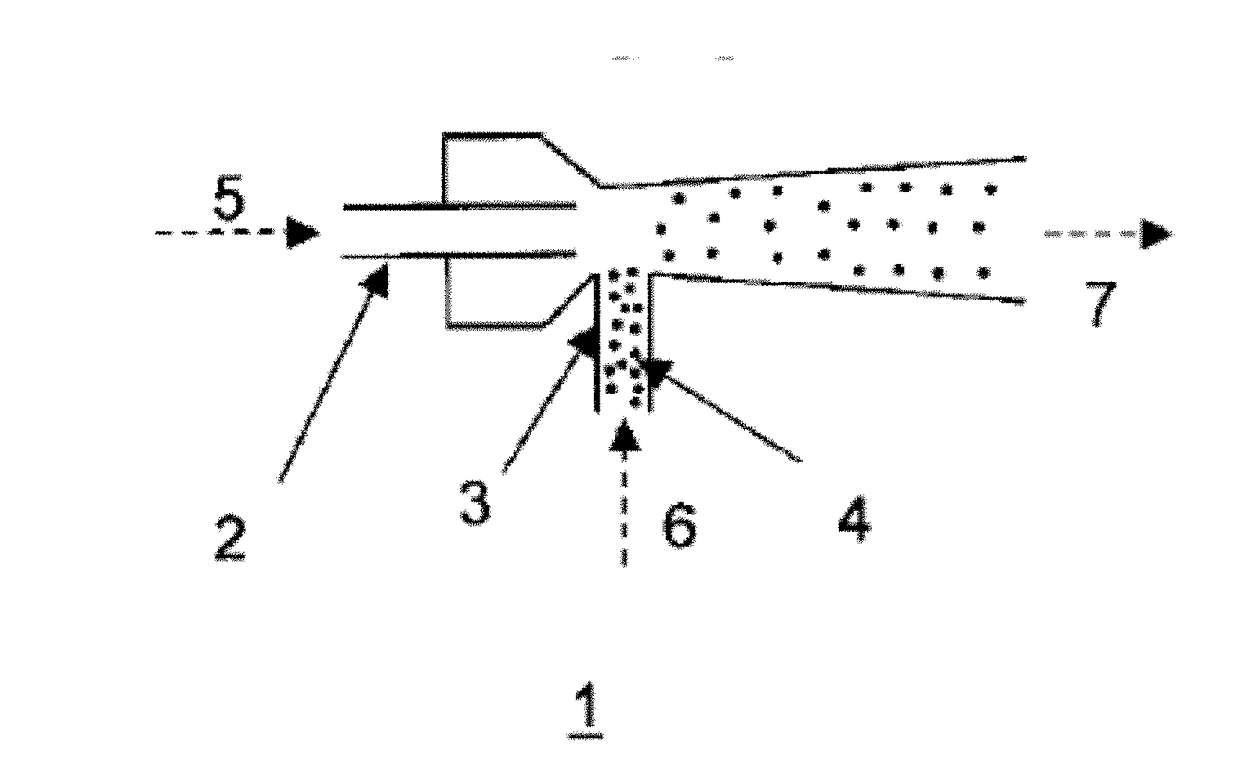

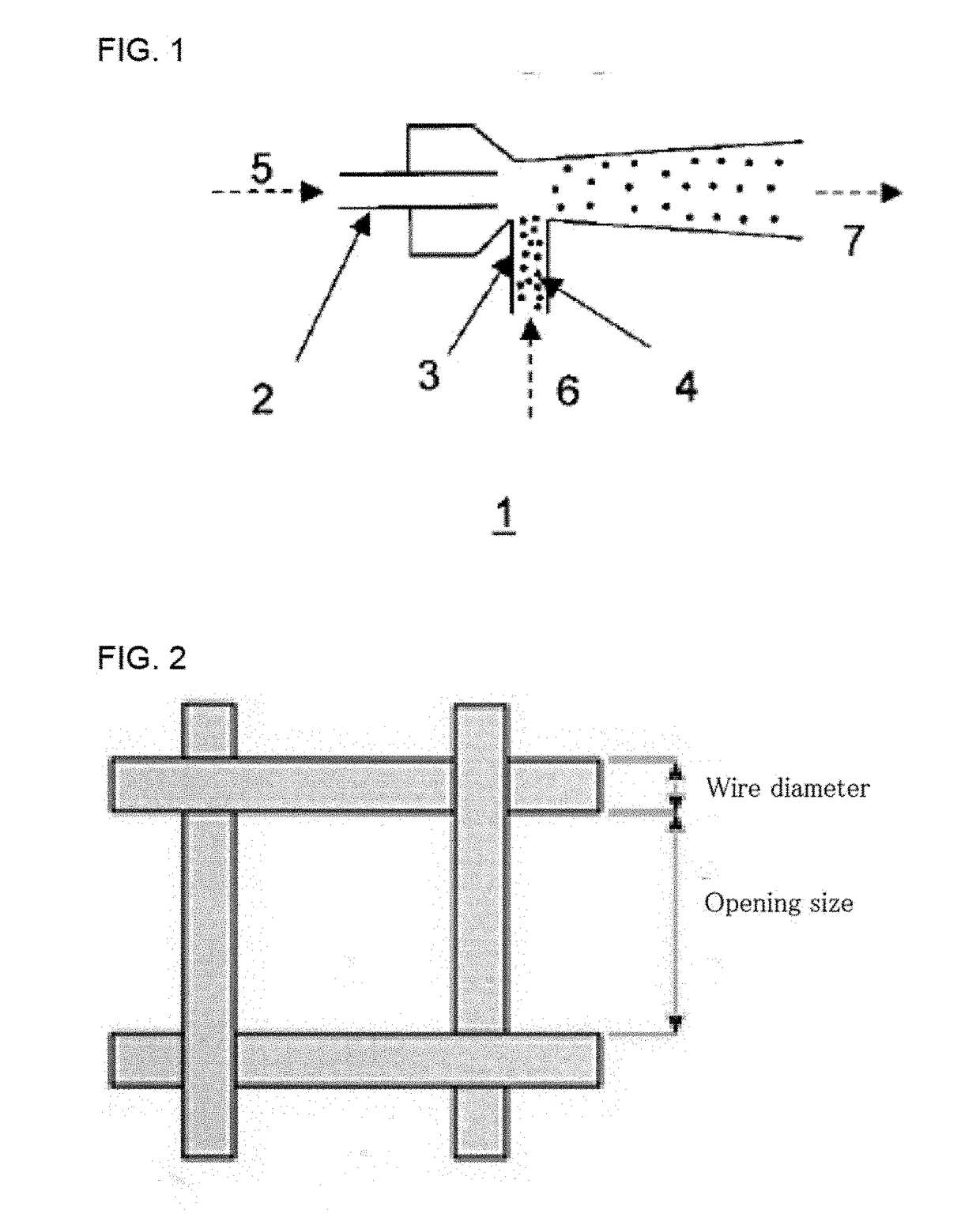

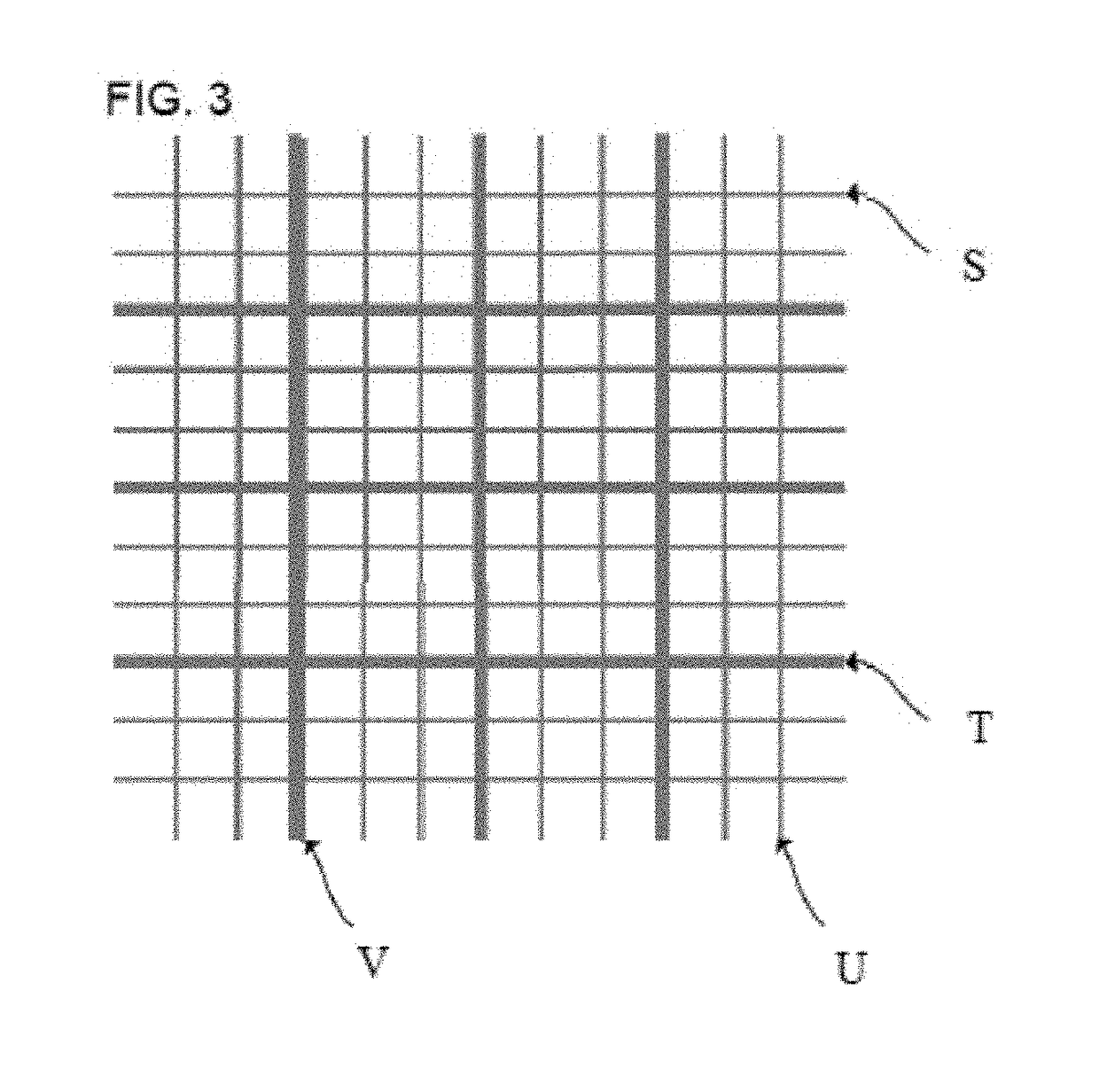

A method for efficiently producing a toner for developing electrostatic images, which contains very few coarse particles and having excellent printing characteristics. The method can comprise a sieving step of removing coarse particles from colored resin particles by, using an air flow, suppling the colored resin particles to a sieve, wherein a metal mesh laminate comprising at least two metal meshes attached to each other by sintering, the metal meshes being different in opening size, is used as the sieve; wherein the metal meshes of the metal mesh laminate are laminated in order of opening size and, of the metal meshes constituting the metal mesh laminate, one having a smallest opening size is disposed on a side of supplying the colored resin particles; and wherein the opening size of the metal mesh having the smallest opening size is in a range of from 32 to 110 μm.

Owner:ZEON CORP

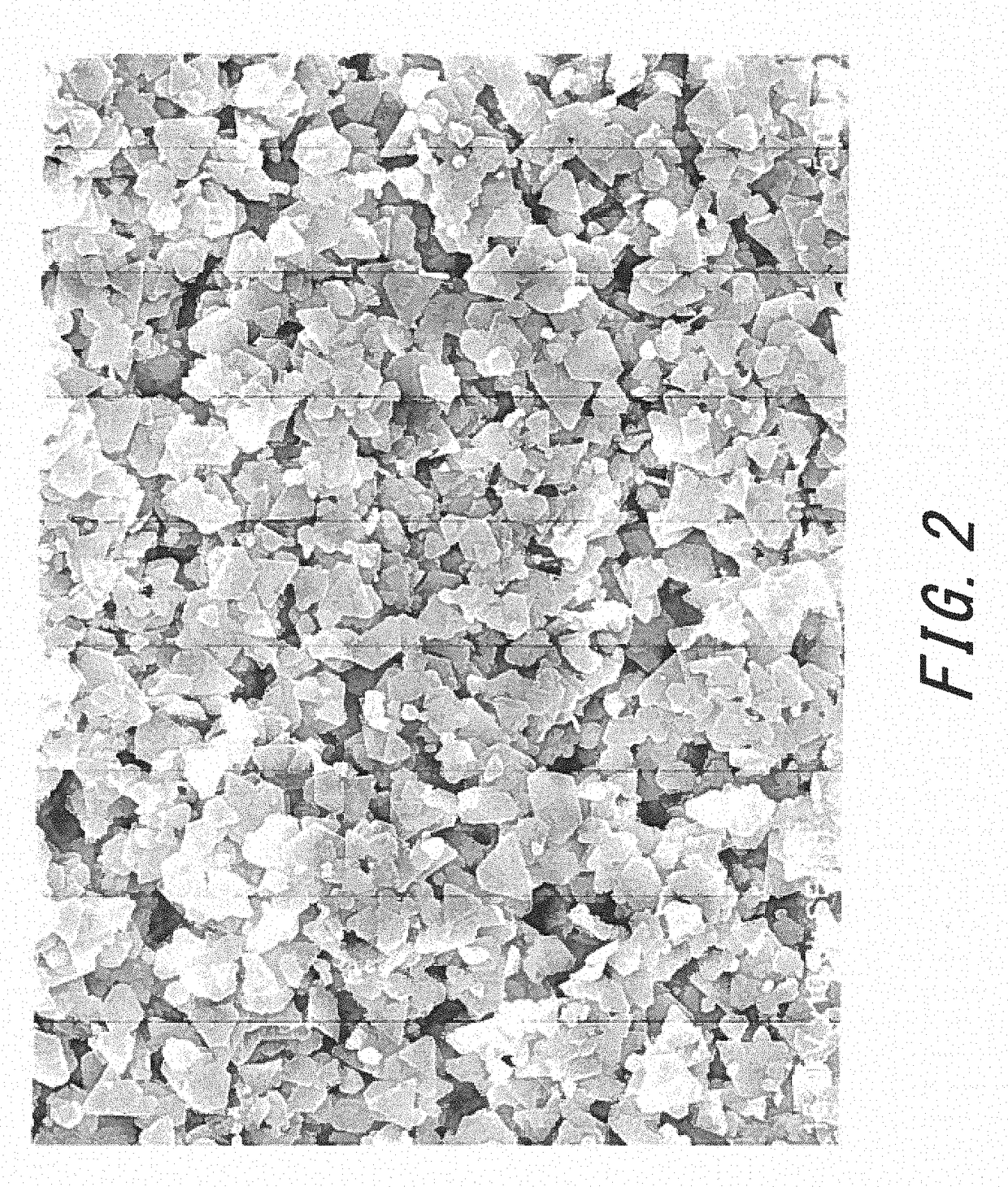

Electrically conductive fine particles

InactiveUS20170326639A1Excellent printing characteristicsImprove thermal conductivityPrinted circuit assemblingNon-insulated conductorsMetalThermal conductivity

[Object] To provide fine particles 2 having good printing characteristics, good thermal conductivity, and good electrical conductivity.[Solution] The fine particles 2 are flake-like. A main component of the fine particles 2 is an electrically conductive metal. A typical metal is silver. A particle diameter D50 of particles including a large number of the fine particles 2 is equal to or greater than 0.10 μm but equal to or less than 0.50 μm, a particle diameter D95 of the particles is equal to or less than 1.00 μm, and a maximum particle diameter Dmax of the particles is equal to or less than 3.00 μm. A particle diameter D10 of the particles is equal to or greater than 0.05 μm. A BET specific surface area of the particles is equal to or greater than 2.0 m2 / g. A tap density TD of the particles is equal to or greater than 2.0 g / cm3. An average Tave of thicknesses of the fine particles 2 is equal to or less than 0.05 μm.

Owner:TOKUSEN IND CO LTD

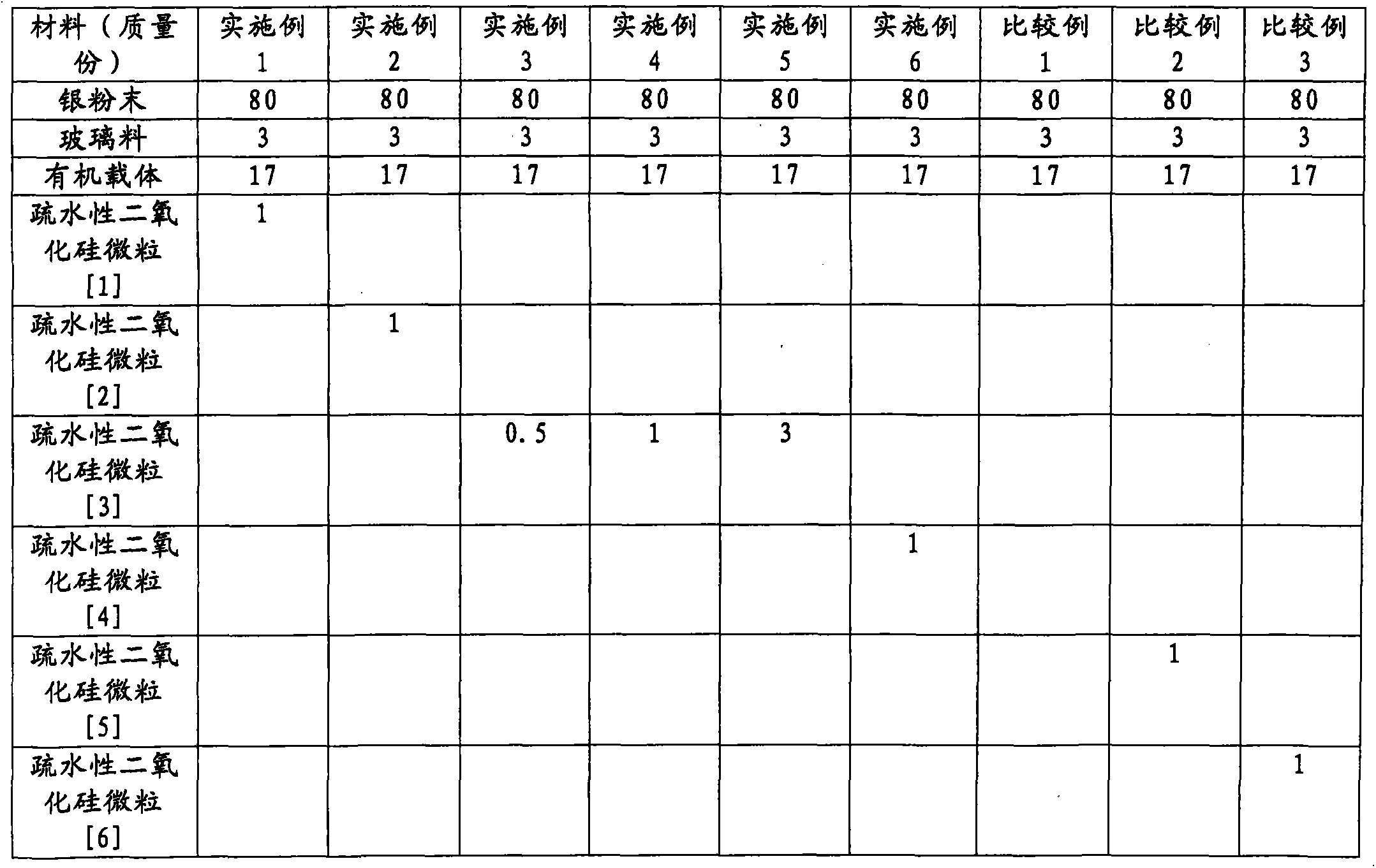

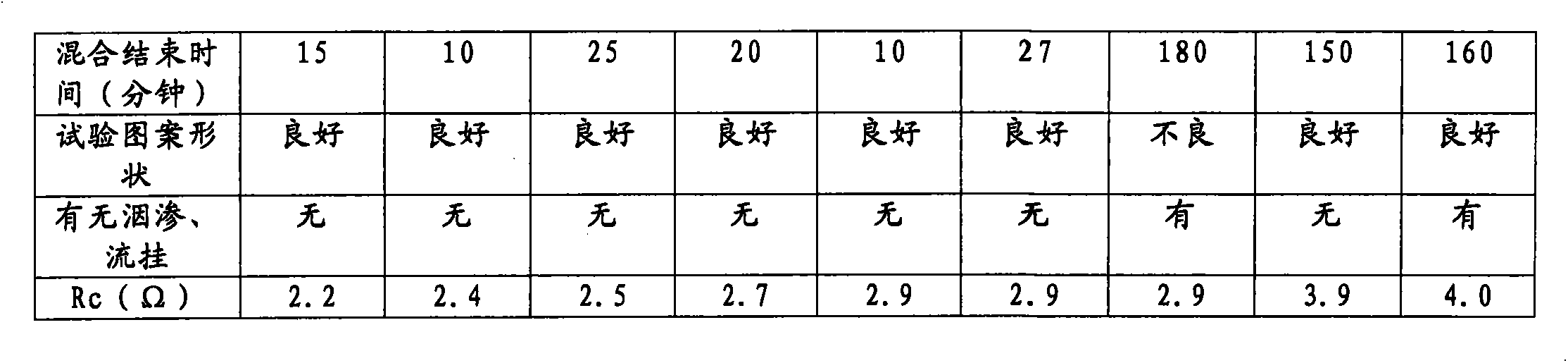

Paste composition for solar cell electrode

ActiveCN103578601AImprove workabilityExcellent printing characteristicsOxide conductorsSilicon oxidesSilane compoundsConductive paste

Provided is a paste composition for a solar cell electrode, which is characterized by including a conductive powder body, glass material, an organic carrier, silicon dioxide made by hydrophobization of hydrophilic silicon dioxide which is obtained by the hydrolysis and condensation of tetrafunctional silicohydride compounds or part of hydrolysis products or their mixture, and the bulk specific weight of the silicon dioxide is more than 300g / L. According to the invention, by adding the special silicon dioxide to a conductive paste, the paste composition for the solar cell electrode is improved in flowability during the mixing, excellent in working, and excellent in printing property.

Owner:SHIN ETSU CHEM IND CO LTD

Method of forming electrode pattern for solar cell, electrode manufactured using the same and solar cell

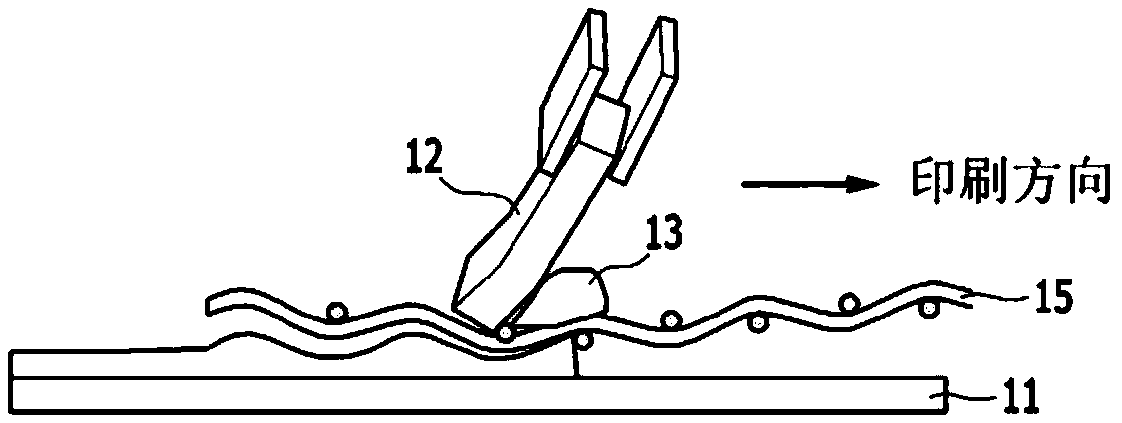

ActiveCN109673169AImprove efficiencyImprove resolutionPhotovoltaic energy generationSemiconductor devicesFritOrganic layer

Provided are a method of forming an electrode pattern for a solar cell, an electrode manufactured using the same, and a solar cell. The method of forming an electrode pattern for a solar cell includespreparing a composition for forming a solar cell electrode including a conductive powder, a glass frit, an organic binder, and a solvent, and coating the composition for forming a solar cell electrode on a screen mask with an organic layer followed by drying and firing the same, wherein a difference of water contact angles of the composition for forming a solar cell electrode and the screen maskwith the organic layer ranges from 40 degrees to 60 degrees.

Owner:上海匠聚新材料有限公司

Board machine

InactiveCN102131981BDoes not affect layered purityAvoid deformationMachine wet endMechanical engineeringCoating

A board machine comprises a forming section where a lower wire loop (11) forms a fourdrinier-wire section (Tl) at the beginning of which is located a forming board (200) which consists of at least one stationary, non-pulsating forming shoe (210). In the forming shoe (210), there is a cover (211) provided with thorough holes (212), setting against the inner surface of the lower wire loop (11). A first headbox (100), which is a multi-layer headbox, feeds a pulp suspension jet onto the forming shoe (210). The board machine further comprises a press section (Pl) where a surface (Wa) of the web (W) having been against the lower wire loop (11) is pressed against a smooth surface, a dryer section (Dl) where the web (W) is dried with at least one cylinder-dryer group and a coating section (400) where at least the surface (Wa) of the web (W) having been against the lower wire (11) is coated.

Owner:METSO PAPER INC

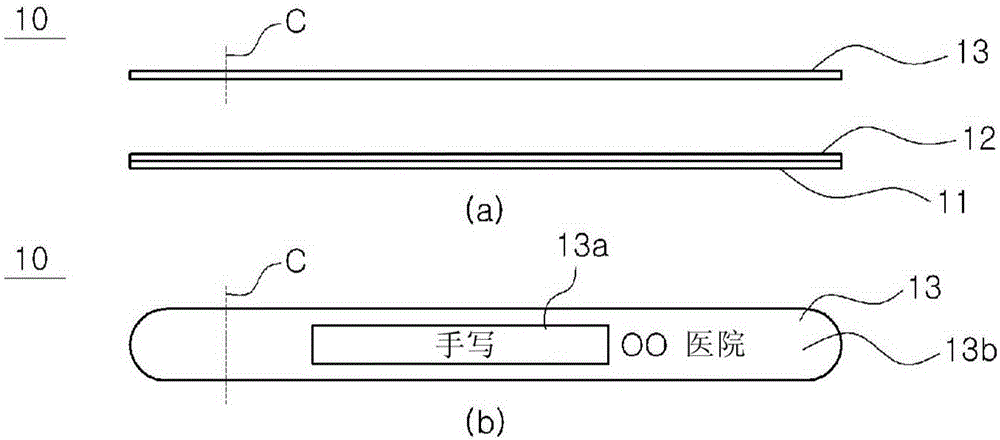

Disposable wristband

InactiveCN105190729AExcellent printing characteristicsWon't scratchStampsIdentification meansFiberAllergy

The present invention relates to a disposable wristband. In particular, by manufacturing the wristband using a nylon cross-ply, being a type of fibre material, it is possible to print on the wristband, to prevent cutting skin, to provide good wearability, and to prevent causing skin troubles such as allergies.

Owner:OHSUNG SYST CO LTD

Black paper-making coating and method for producing black paperboard by utilizing same

ActiveCN102182109BQuality improvementImprove surface smoothnessNon-fibrous pulp additionCoatings with pigmentsPaperboardMethylated cellulose

The invention belongs to the technical field of paper making and relates to a black paper-making coating and a method for producing a black paperboard by utilizing the black paper-making coating. The black paper-making coating is formed by mixing the following components in parts by weight: 10-15 parts of black pigment, 4-5 parts of CMC (Carboxy Methylated Cellulose), 300-450 parts of calcium carbonate, 70-100 parts of kaolin, 15-18 parts of urea, 3-9 parts of hydrophobic agent, 3-10 parts of sodium hydroxide, 3-8 parts of dispersing agent, 3-10 parts of lubricating agent, 1 part of antifoaming agent, 50-240 parts of latex and a proper amount of water. The invention also provides a method for producing the black paperboard by utilizing the black paper-making coating. The black paperboard prepared by the method has the advantages of smooth surface, no stretching or shrinkage and no deformation, favorable printing characteristic, and the like.

Owner:FUYANG RONGSHENG PAPER

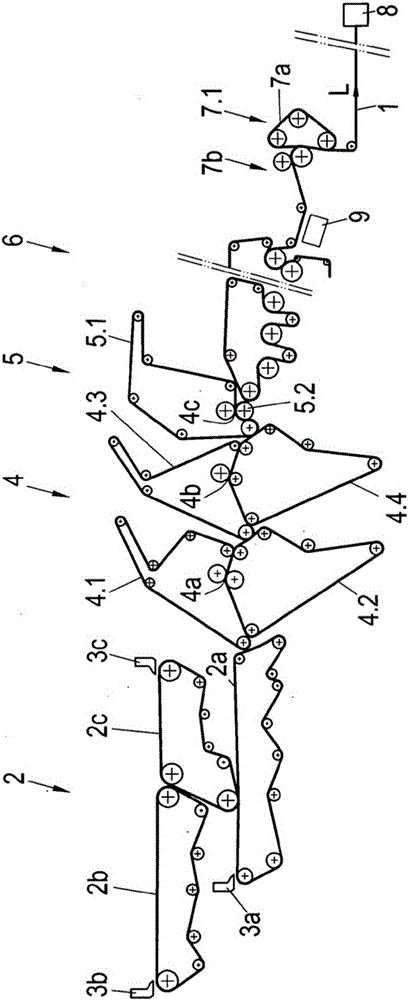

Machine and method for producing one or more layers of fibrous webs consisting of cardboard or wrapping paper

Owner:VOITH PATENT GMBH

Low temperature fireable paste composition for forming an electrode or wiring

InactiveCN102388421BHigh resolutionExcellent printing characteristicsNon-conductive material with dispersed conductive materialPhotovoltaic energy generationCelluloseHardness

The invention is directed to a paste composition used for forming an electrode or wiring, wherein it comprises a) a conductive powder; b) a cellulose binder; c) an acrylate monomer; d) a radical polymerization initiator; and e) a solvent, and it is curable at a low temperature when compared to the prior paste compositions and it has excellent hardness, electrical resistivity and stability so that it can be usefully used for forming an electrode or wiring for a solar cell, RFID (Radio Frequency Identification) or PCB (Printed Circuit Board).

Owner:DONGJIN SEMICHEM CO LTD

Thermal printing head, manufacturing method thereof and thermal printer

The present invention provides a thermal print head that improves print characteristics with respect to a print medium. In addition, the invention provides a manufacturing method of the thermal printing head. Further, a thermal printer including the thermal print head is provided. The thermal print head of the present invention comprises: a heat storage layer; a first electrode part on the heat storage layer; a heating resistor on the first electrode portion; a second electrode portion on the heating resistor; and a protective film covering the second electrode portion and the heating resistor.

Owner:ROHM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com