Dispersant effect on aluminum pigments

A pigment and dispersion technology, applied in the direction of pigment slurry, application, household appliances, etc., can solve the problems of alcohol system incompatibility, difficult to handle by the preparation personnel, difficult to use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

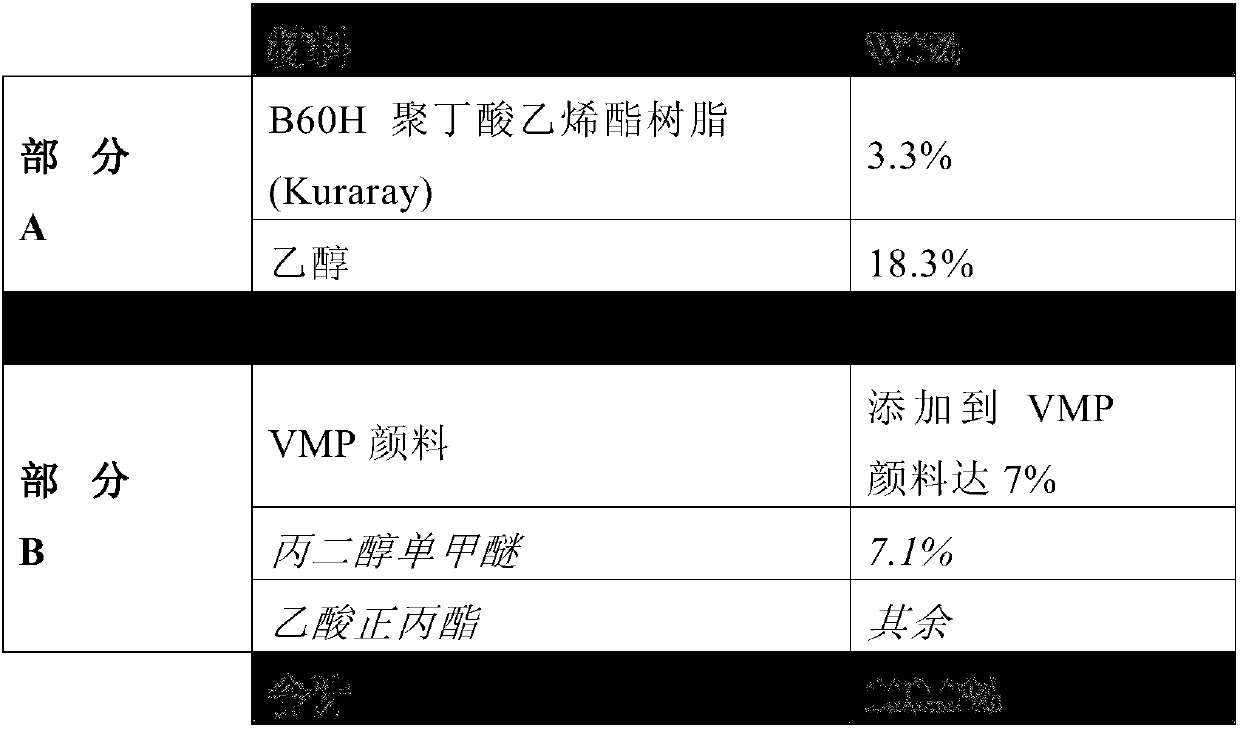

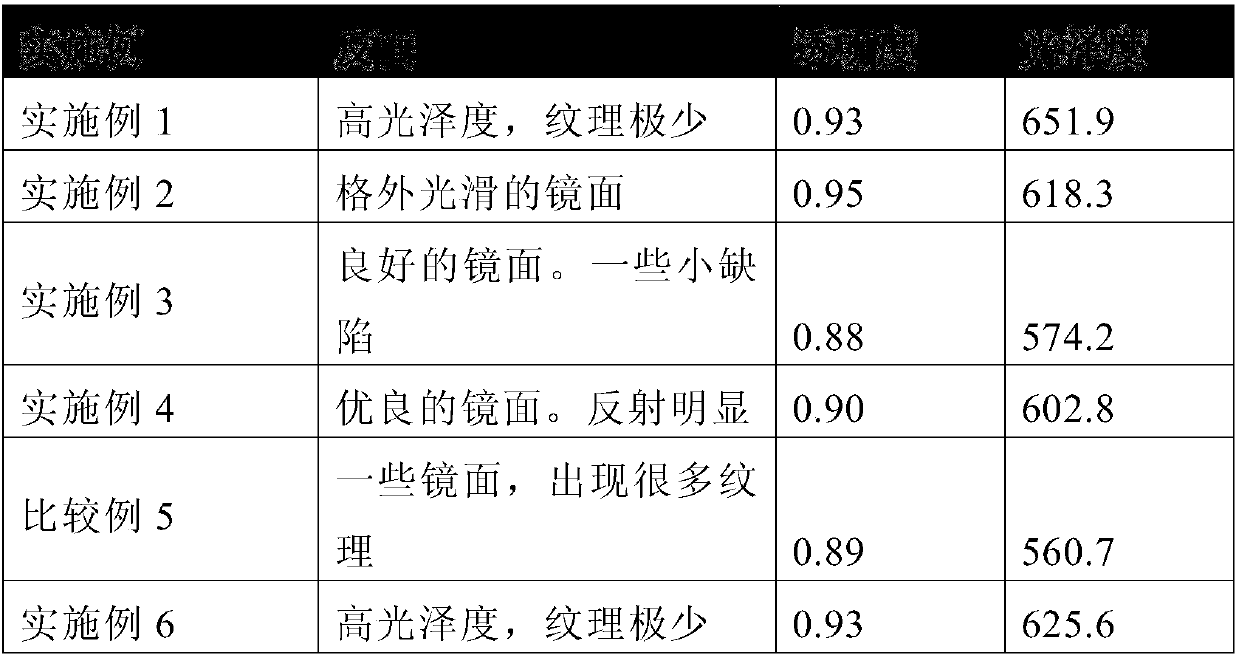

[0067] Example 1 (3864-169-6)

[0068] 64.2 g of Benda-Lutz Splendal 6002 (10.9% VMP aluminum in ethyl acetate) (Sun Chemical) was charged into a 250 mL plastic bottle with a screw top. The VMP pigment slurry was diluted with 57.2 g of ethanol and mixed. The mixture was centrifuged at 2500 RPM for 30 minutes. 57.2 g of supernatant was removed. An additional 57.2 g of ethanol was added to the bottle and mixed well with the precipitate and remaining supernatant. The mixture was centrifuged at 2500 RPM and 57.2 g of supernatant was removed. At this point 0.35g of Disperbyk 111 (BYK) was added to the remaining slurry. The mixture was blended thoroughly to produce a slurry of treated 10% VMP pigment in 90% 3:1 ethanol:ethyl acetate. The type of pigment, the pigment loading in the slurry, the final solvent composition and the additive dispersants used are reported in Table 1.

Embodiment 2

[0069] Example 2 (3864-77C)

[0070]71.4 g of Benda-Lutz Splendal 6002 (9.8% VMP aluminum in ethyl acetate) (Sun Chemical) was charged into a 250 mL plastic bottle with a screw top. The VMP pigment slurry was diluted with 64.4 g of ethanol and mixed. The mixture was centrifuged at 2500 RPM for 30 minutes. 64.4 g of supernatant was removed. An additional 64.4 g of ethanol was added to the bottle and mixed well with the precipitate and remaining supernatant. The mixture was centrifuged at 2500 RPM and 64.4 g of supernatant was removed. At this point 0.7g of SFD-R255 (SunChemical) was added to the remaining slurry. The mixture was blended thoroughly to produce a slurry of treated 10% VMP pigment in 90% 3:1 ethanol:ethyl acetate. The type of pigment, the pigment loading in the slurry, the final solvent composition and the additive dispersants used are reported in Table 1.

Embodiment 3

[0071] Example 3 (3864-95A)

[0072] 71.4 g of Benda-Lutz Splendal 6002 (9.8% VMP aluminum in ethyl acetate) (Sun Chemical) was charged into a 250 mL plastic bottle with a screw top. The VMP pigment slurry was diluted with 64.4 g of ethanol and mixed. The mixture was centrifuged at 2500 RPM for 30 minutes. 64.4 g of supernatant was removed. An additional 64.4 g of ethanol was added to the bottle and mixed well with the precipitate and remaining supernatant. The mixture was centrifuged at 2500 RPM and 64.4 g of supernatant was removed. At this point 0.18 g Solplus D540 (Lubrizol) was added to the remaining slurry. The mixture was blended thoroughly to produce a slurry of treated 10% VMP pigment in 90% 3:1 ethanol:ethyl acetate. The type of pigment, the pigment loading in the slurry, the final solvent composition and the additive dispersants used are reported in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com