Water-based UV black ink with super-high solid content and preparation method thereof

A technology of ultra-high solid content, black ink, applied in the field of preparation of the black ink, can solve the problems of unsatisfactory crosslinking density, adhesion and mechanical properties, unsatisfactory carbon black pigment dispersibility, low unsaturated functionality, etc. , to achieve the effect of improving the photo-initiated efficiency, the probability of the reaction, and the content of unsaturated bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

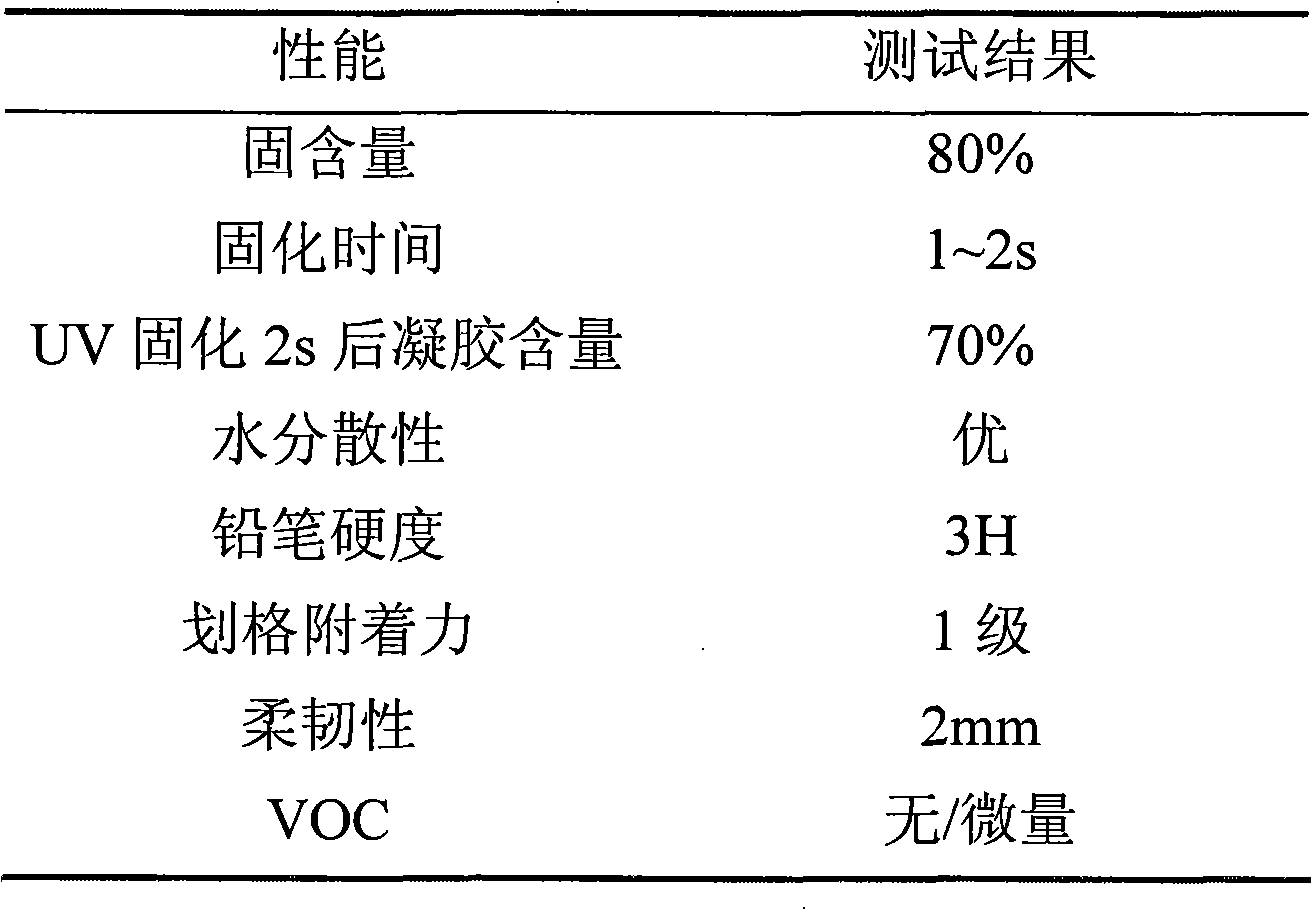

[0035] Embodiment 1: Prepare ultra-high solid content water-based UV black ink according to the following steps.

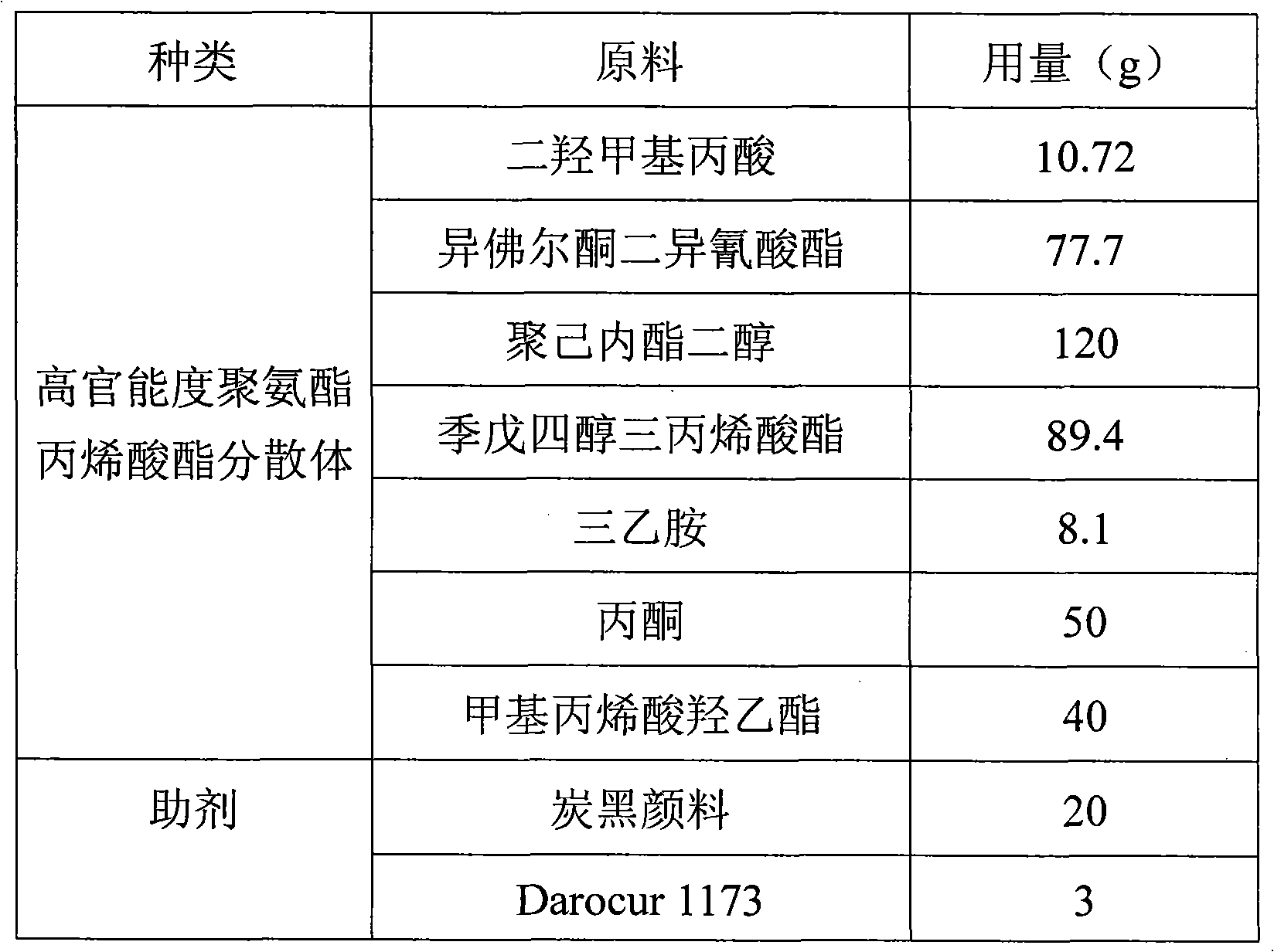

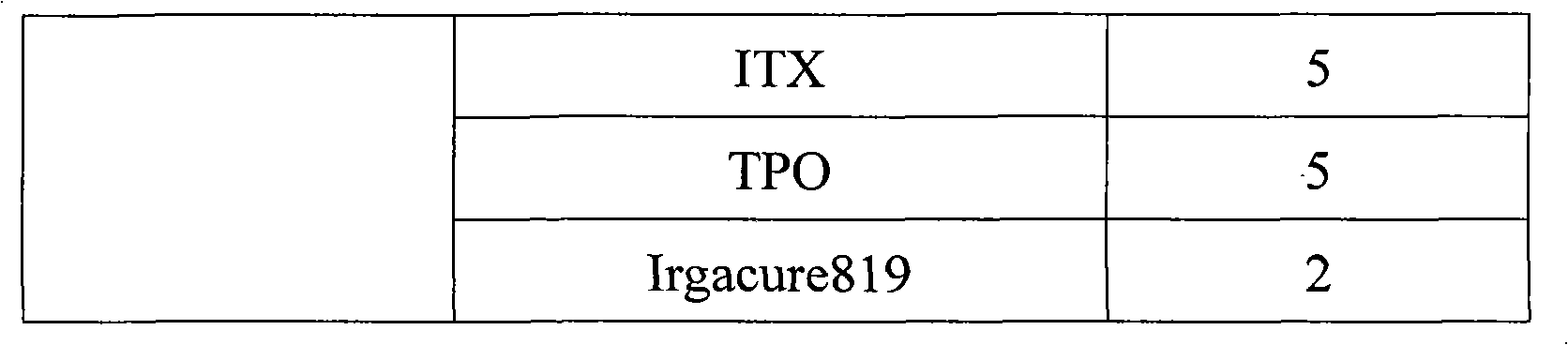

[0036] Prepare raw materials: Prepare materials according to the formula in Table 1.

[0037] Table 1

[0038]

[0039]

[0040] Add dimethylolpropionic acid, isophorone diisocyanate, polycaprolactone diol, a small amount of dibutyltin dilaurate, and acetone to a three-necked flask equipped with a stirrer, a condenser, and a nitrogen passage. Under protection, keep stirring and heat up to 60°C, and keep it warm for 1-2 hours; add pentaerythritol triacrylate to the system, and add an appropriate amount of acetone to adjust the viscosity, and continue to react at 70°C for 3-6 hours to obtain a high-functionality water-based UV resin prepolymer. Cool down to 30°C, add triethylamine to the prepolymer to neutralize the acetone solution of the prepolymer, and add hydroxyethyl methacrylate and carbon black pigment to disperse at high speed for 1-2 hours. Finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com