Patents

Literature

38045 results about "Toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing. One definition of material toughness is the amount of energy per unit volume that a material can absorb before rupturing. It is also defined as a material's resistance to fracture when stressed.

Hemostatic compositions for arresting blood flow from an open wound or surgical site

A hemostatic composition for stopping or decreasing blood flow from an open wound or medical or surgical procedure. Compositions of the invention comprise a mixture of a cationic polymer and a cation exchange material. In one embodiment, the composition comprises a mixture: (1) a high molecular weight copolymer of diallyl dimethyl ammonium chloride (DADMAC) and acrylamide [DADMAC copolymer], and (2) the hydrogen form of a crosslinked, sulfonated polystyrene (hydrogen resin). In an exemplified embodiment, a composition of the invention comprises the mixture of DADMAC copolymer and hydrogen resin provided in a dry powdered form. The compositions of the invention may be applied directly to a wound or treatment site, or they may be incorporated into a wound dressing, such as a bandage. The seal formed at a wound or treatment site treated with the present invention is adhesive and exhibits considerable toughness.

Owner:BIOLIFE

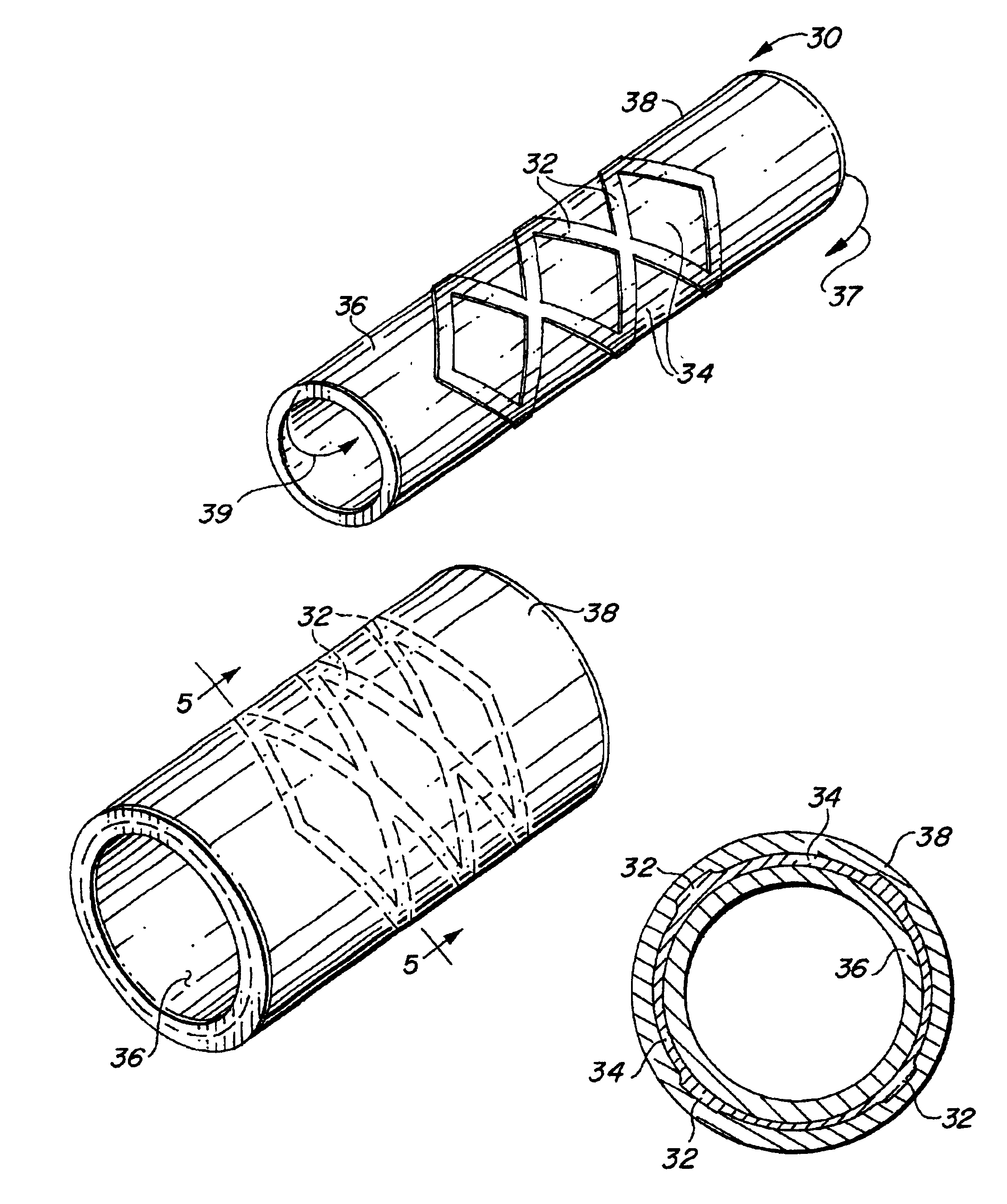

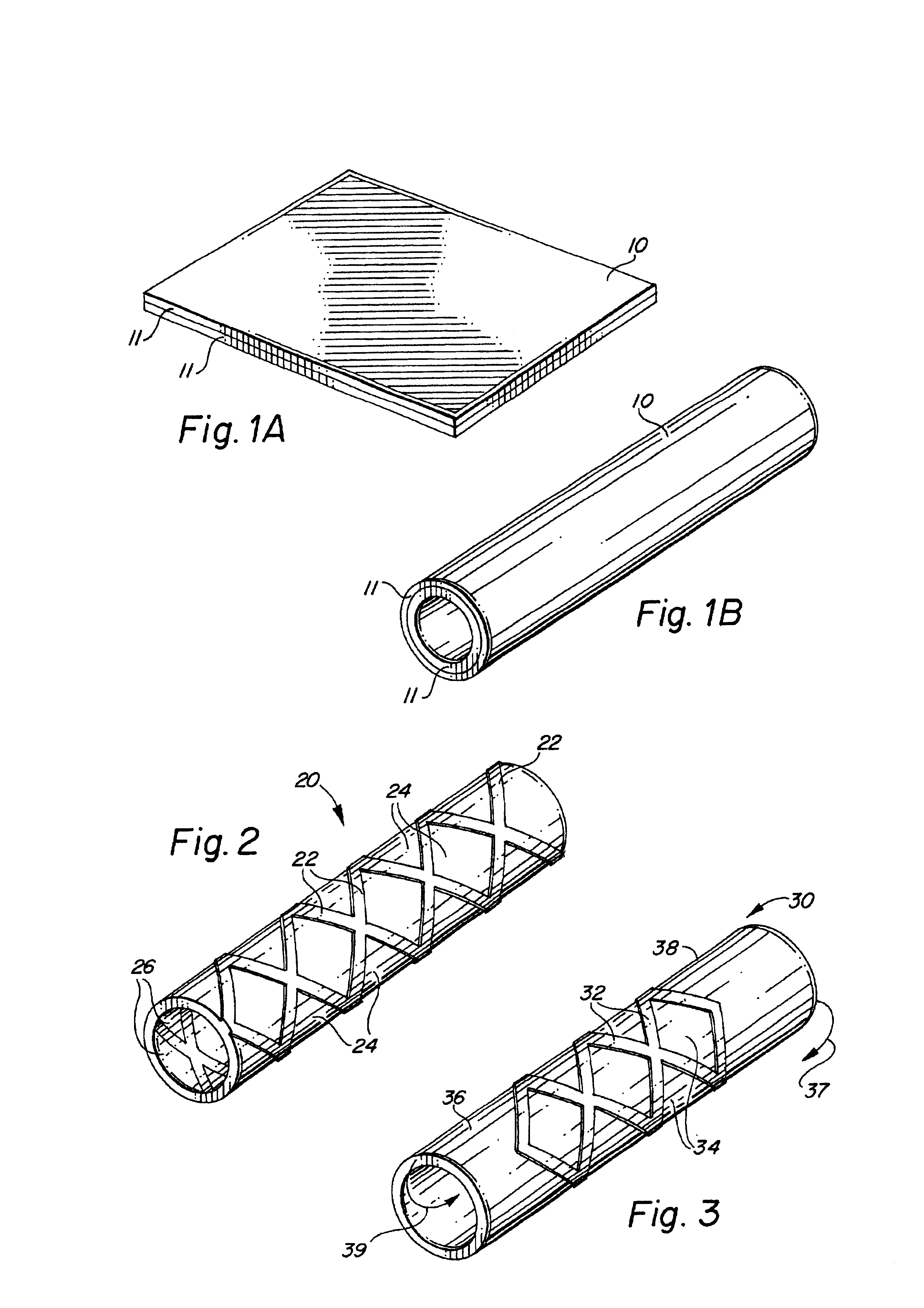

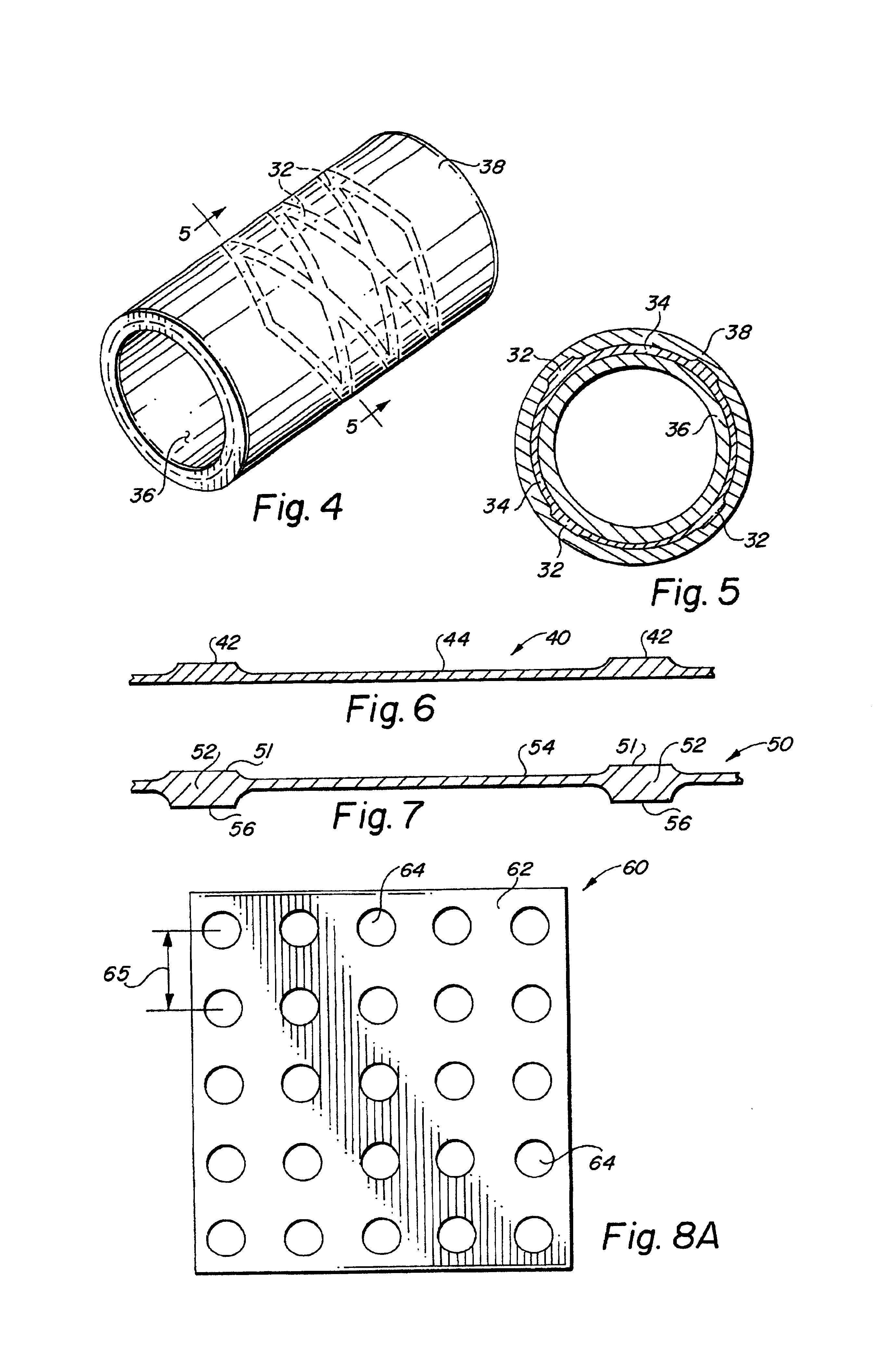

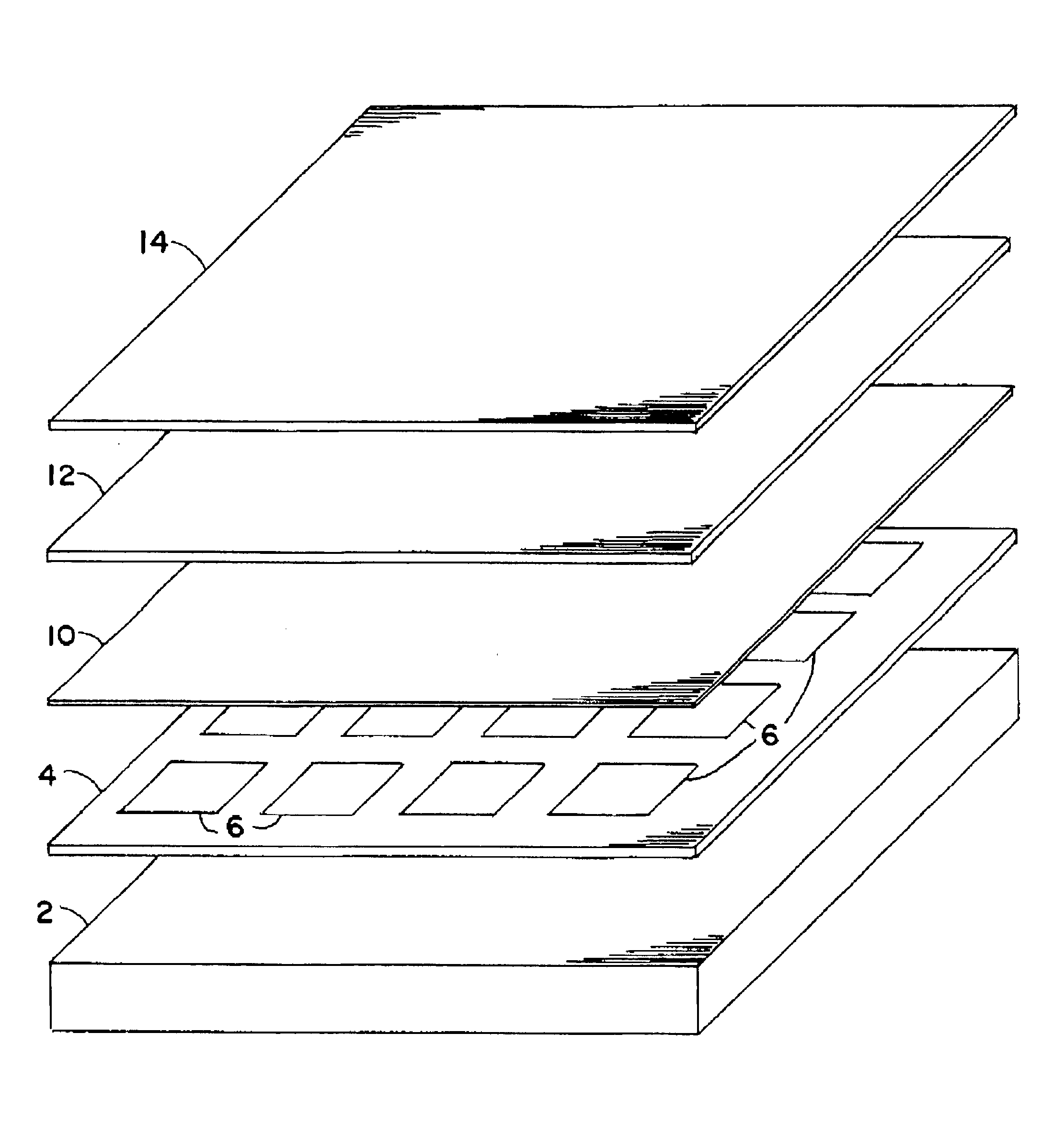

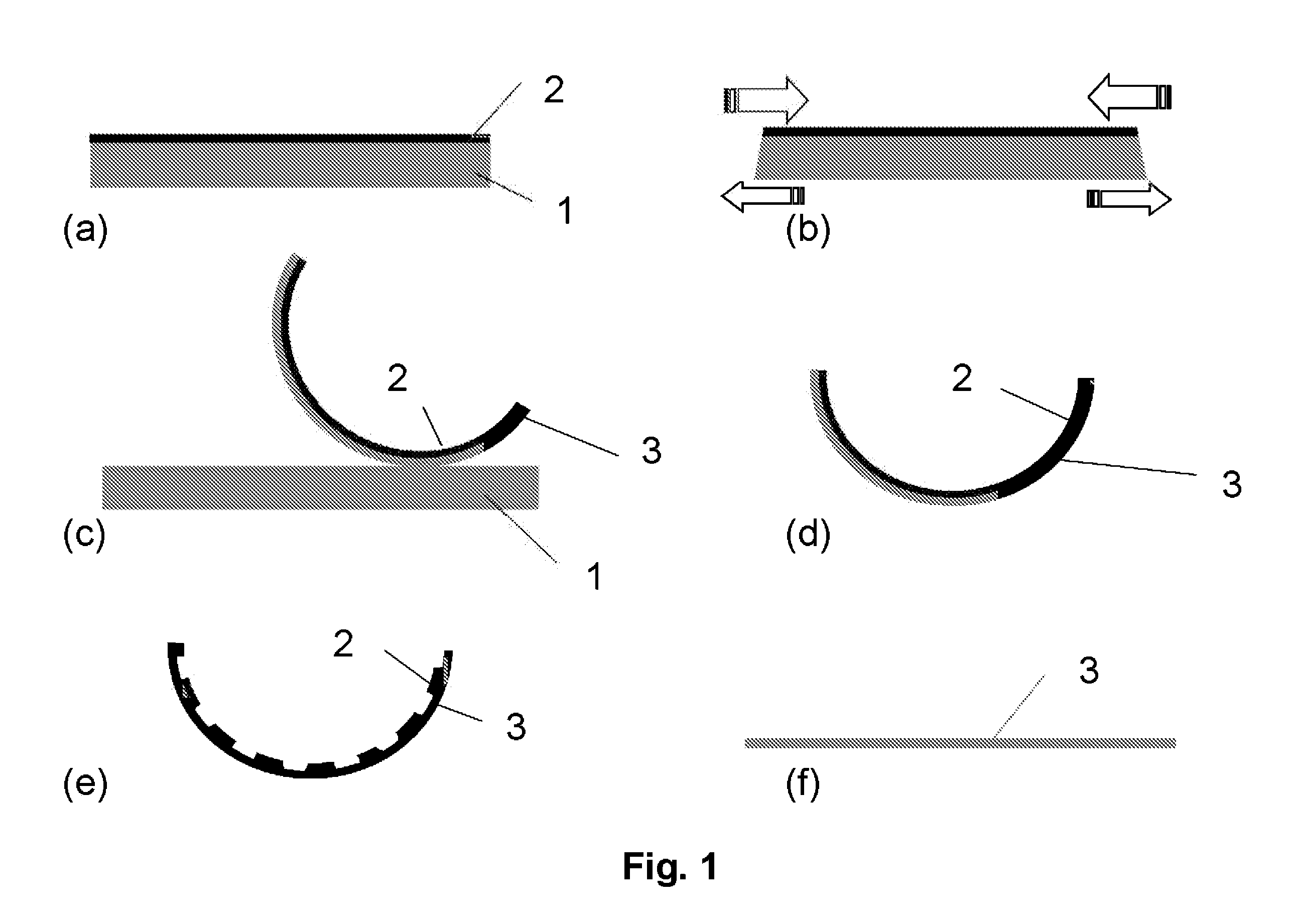

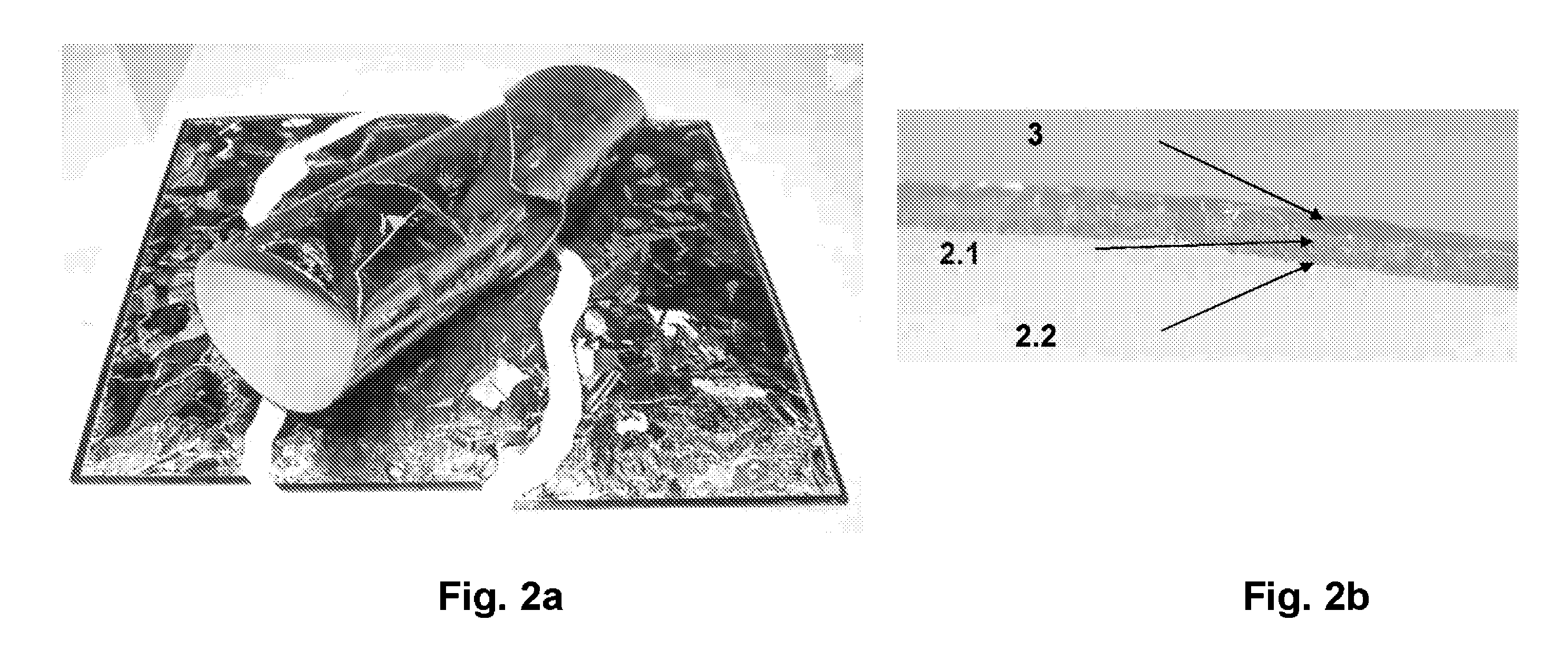

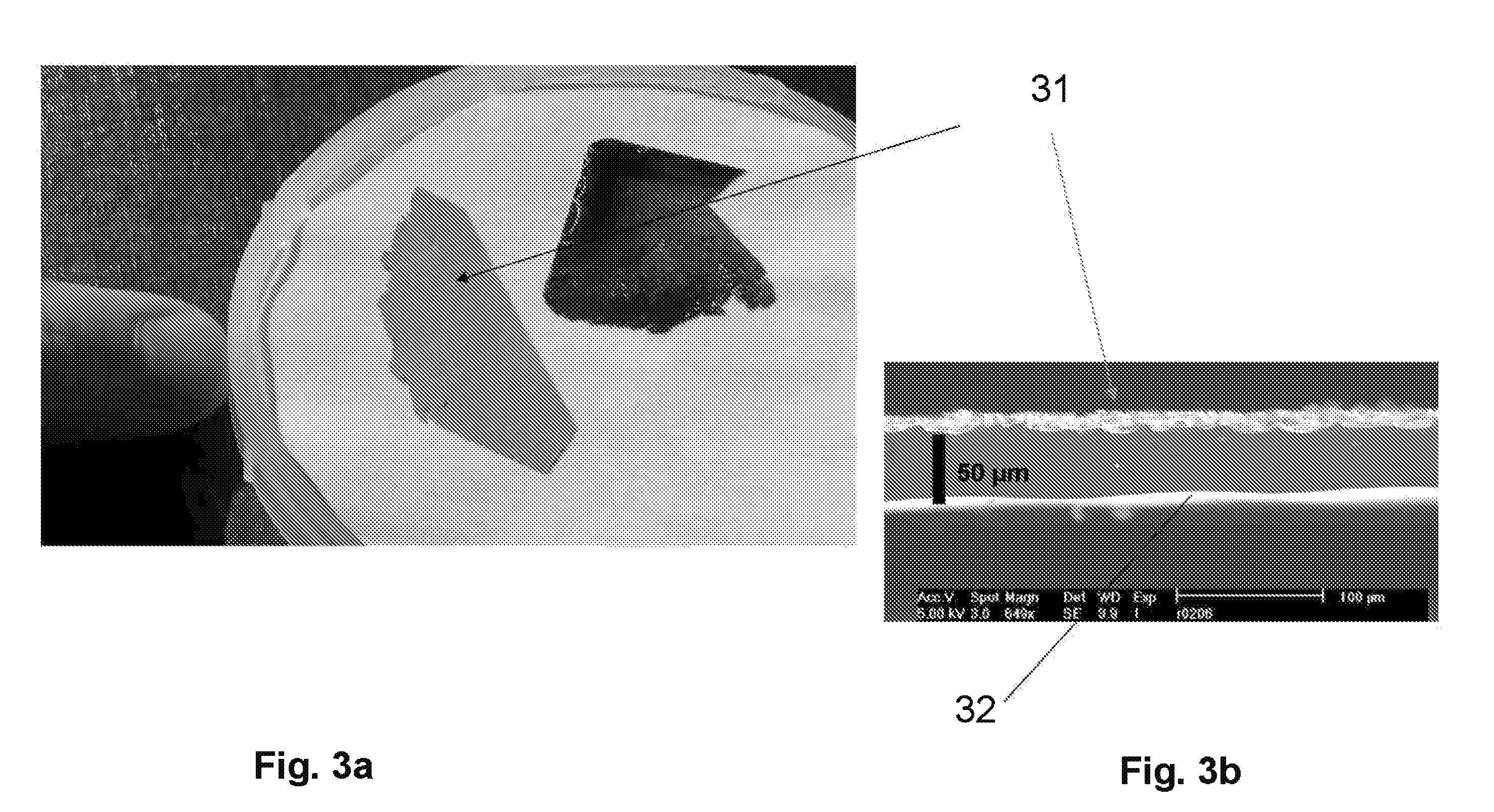

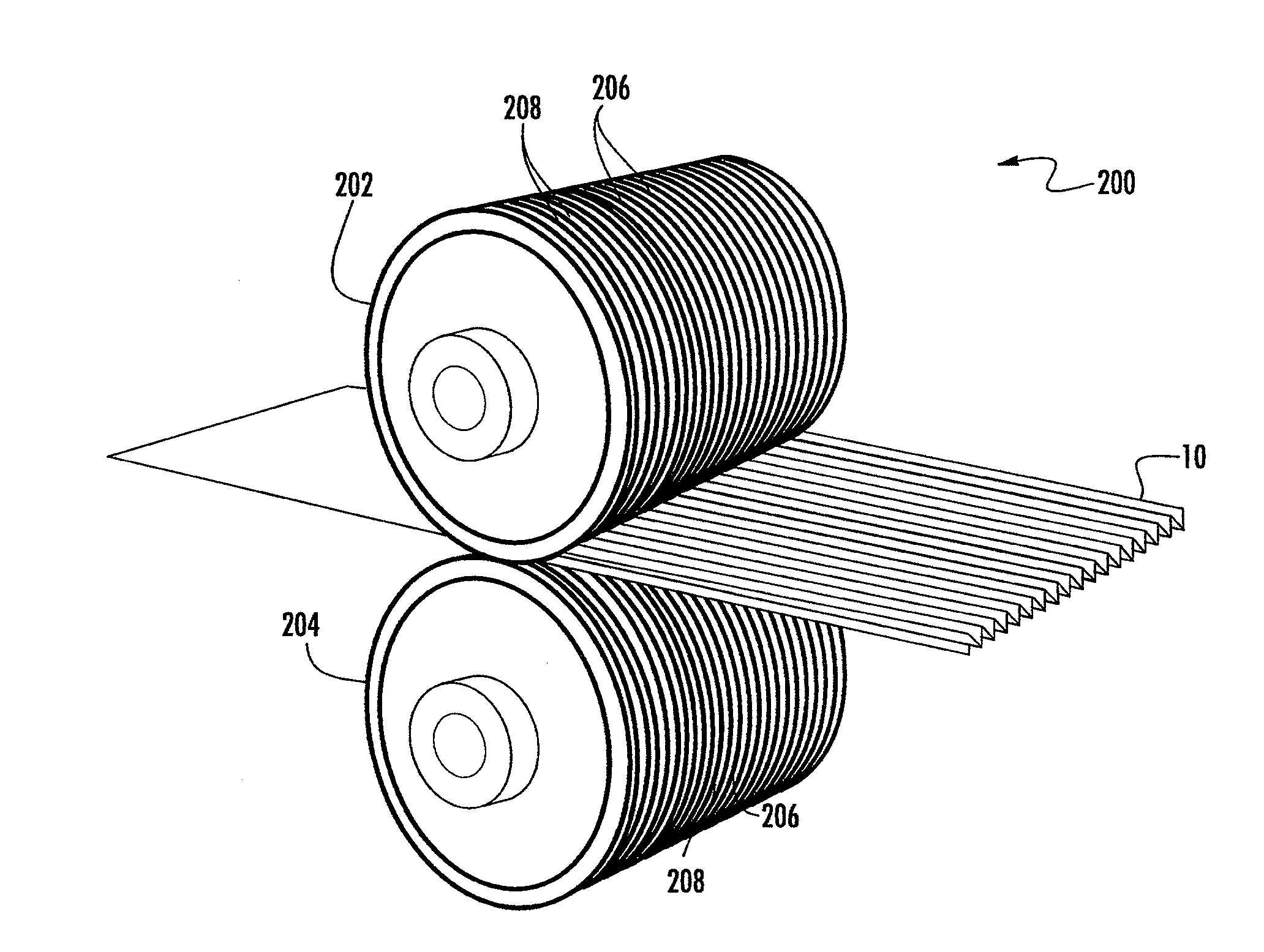

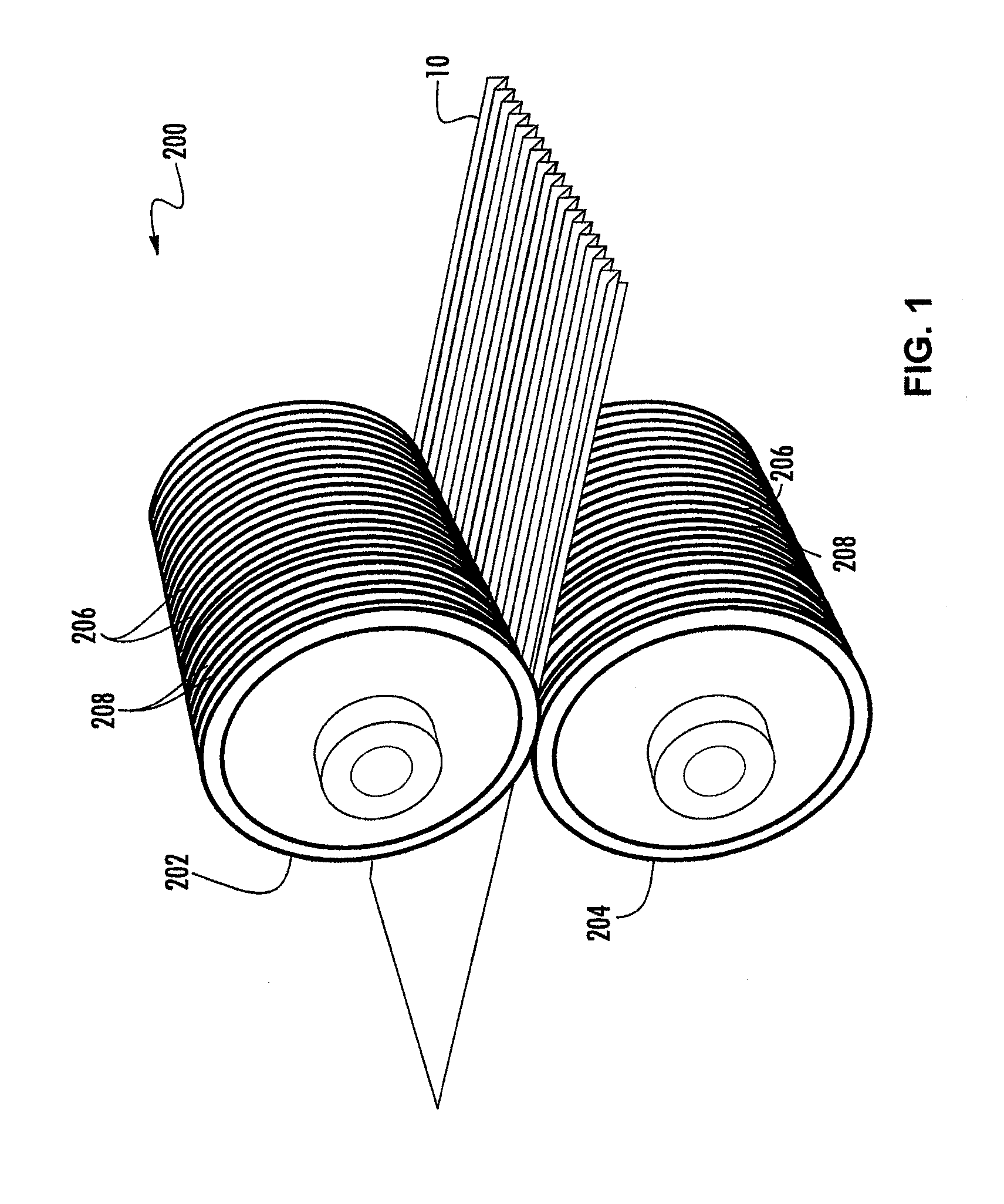

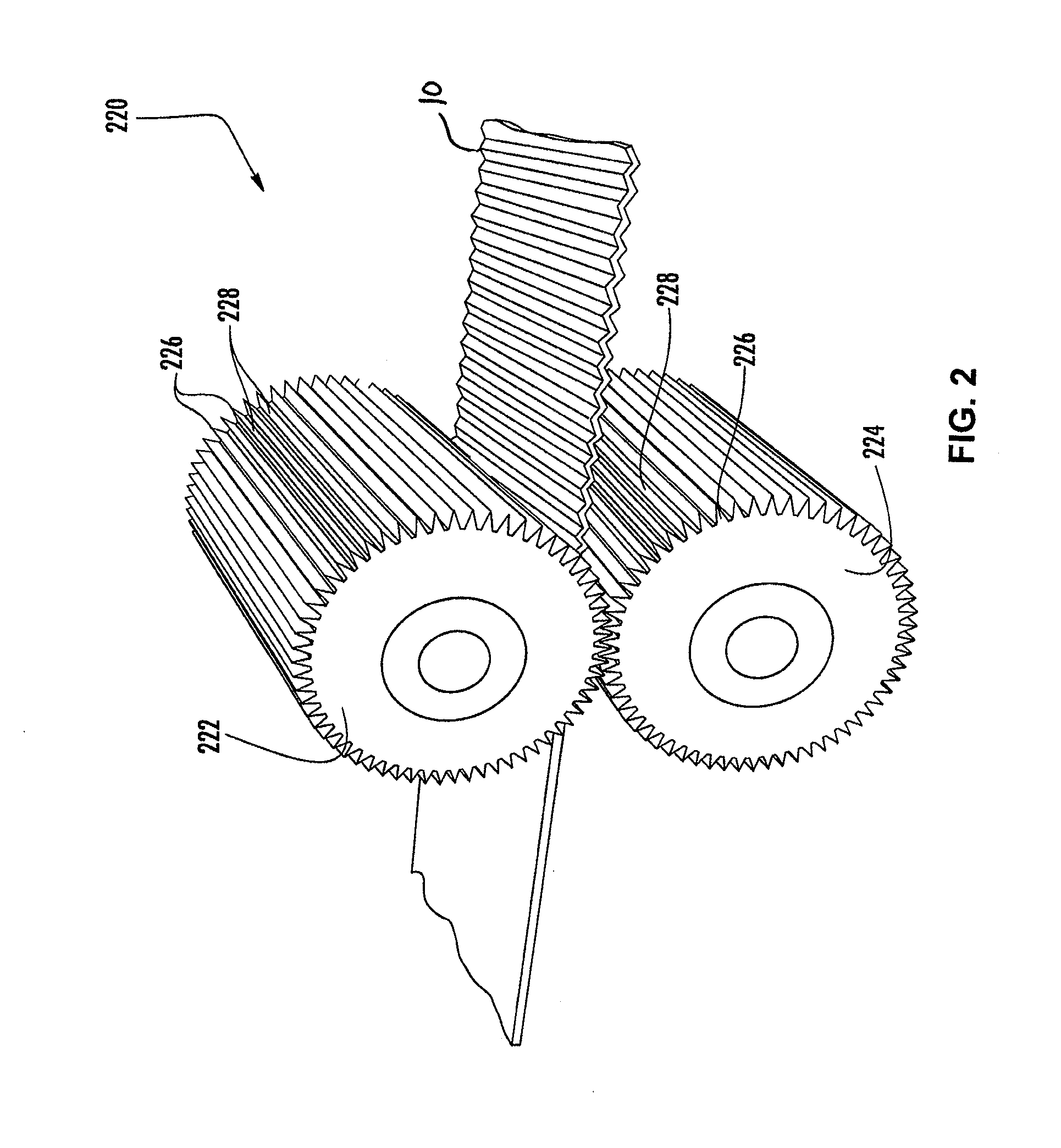

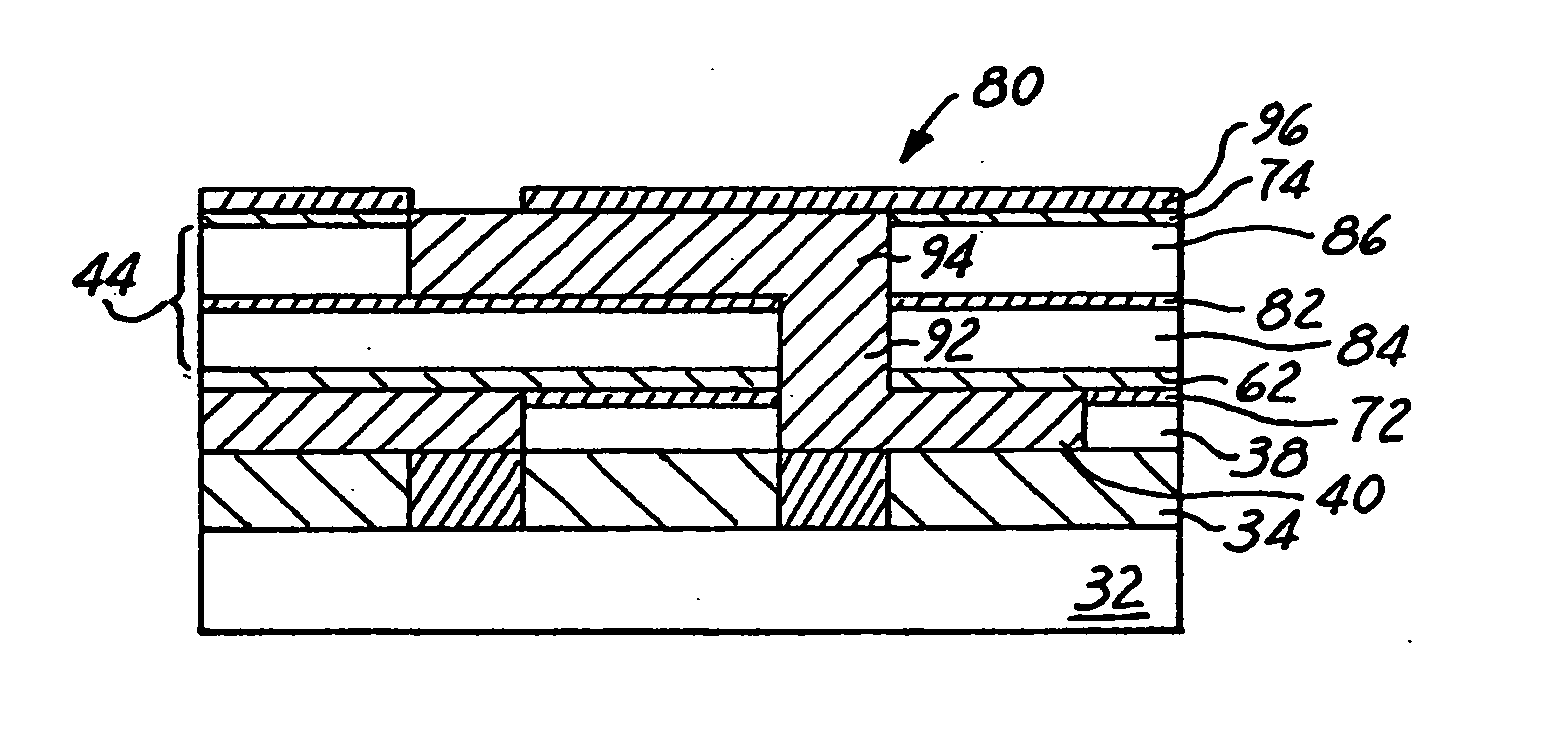

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

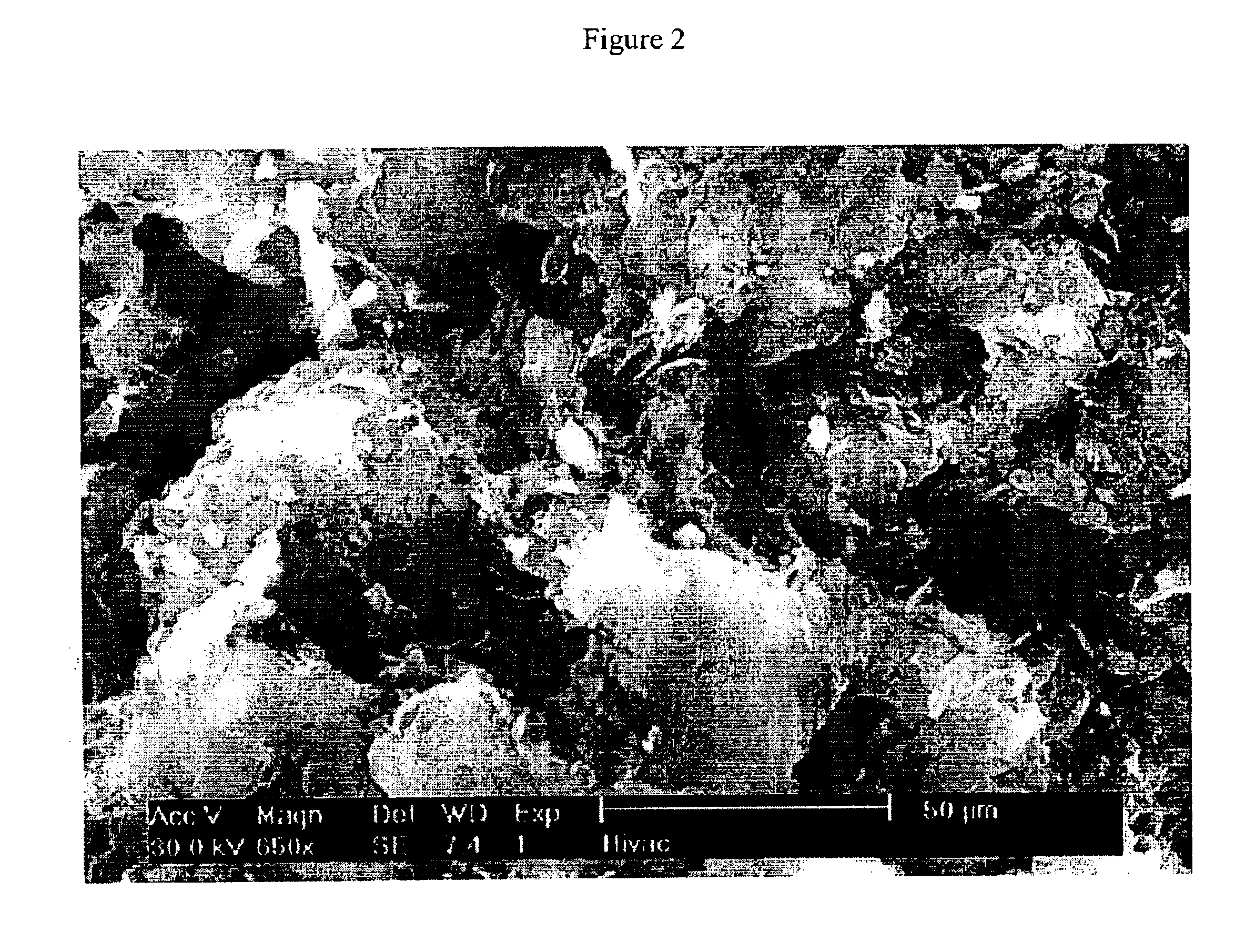

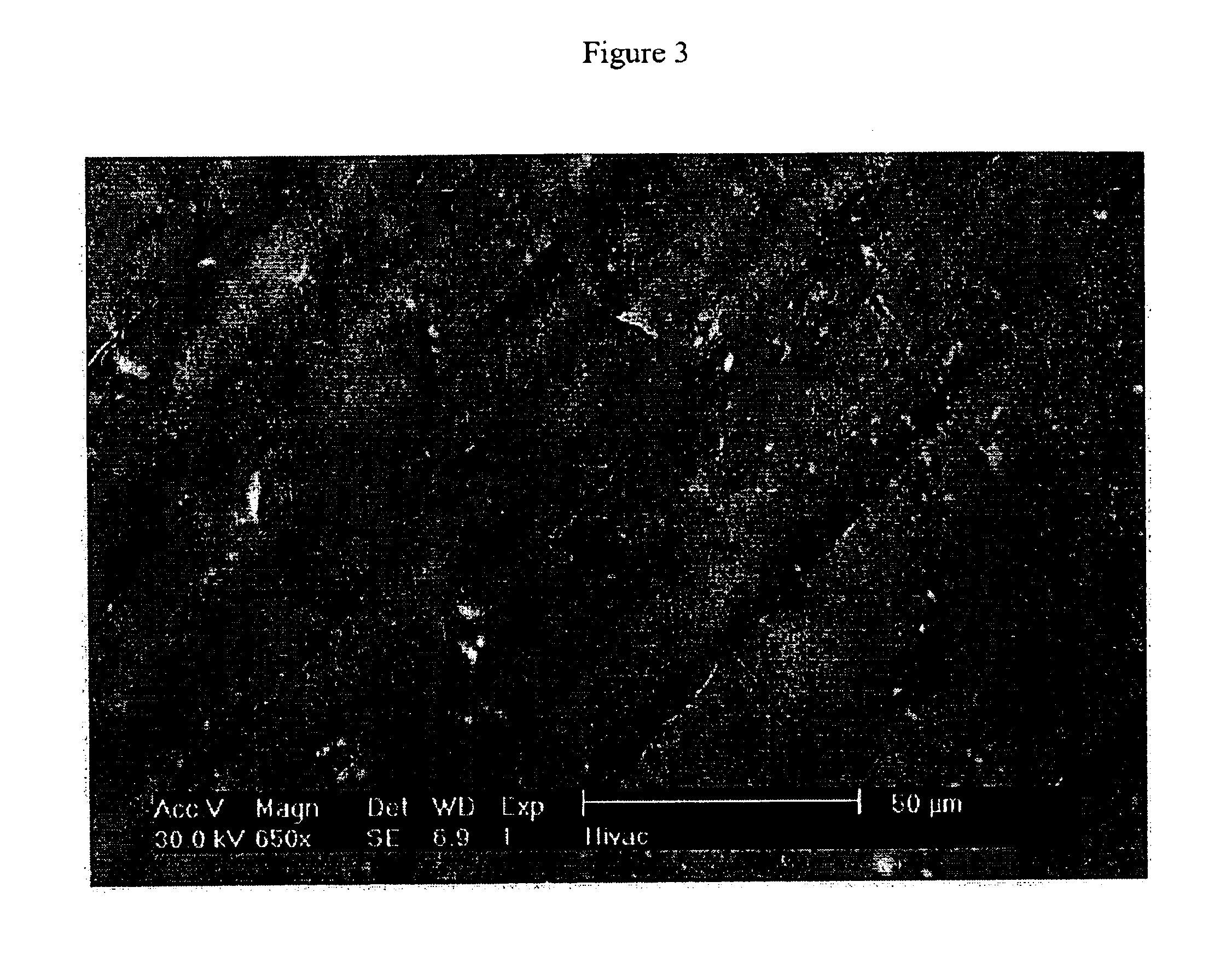

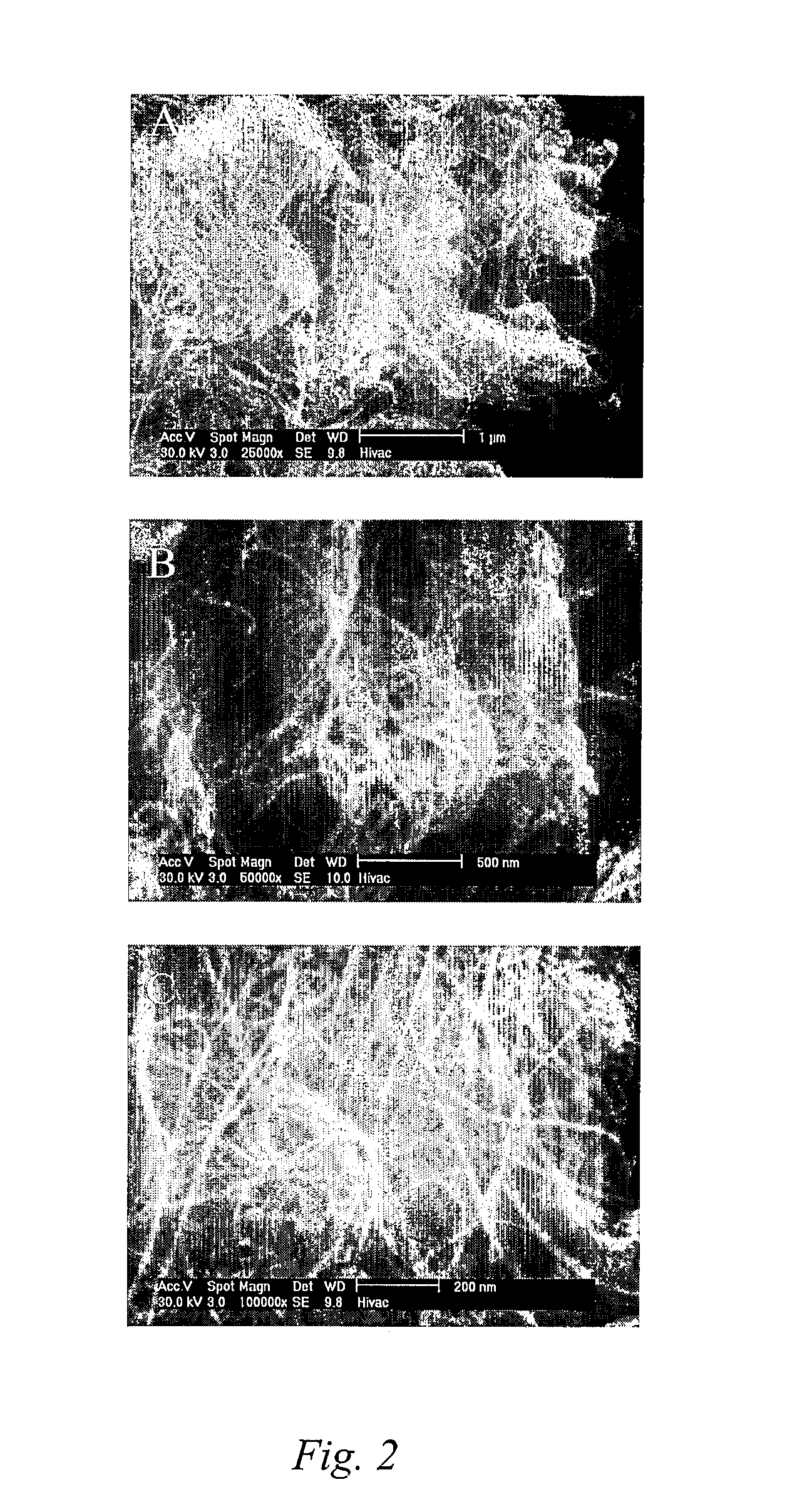

Entangled single-wall carbon nanotube solid material and methods for making same

InactiveUS6899945B2Material nanotechnologySynthetic resin layered productsCross-linkSolvent evaporation

Buckyrock is a three-dimensional, solid block material comprising an entangled network of single-wall carbon nanotubes (SWNT), wherein the block comprises greater than 75 wt % SWNT. SWNT buckyrock is mechanically strong, tough and impact resistant. The single-wall carbon nanotubes in buckyrock form are present in a random network of individual single-wall carbon nanotubes, SWNT “ropes” and combinations thereof. The random network of the SWNT or SWNT ropes can be held in place by non-covalent “cross-links” between the nanotubes at nanotube contact points. In one embodiment, SWNT buckyrock is made by forming a SWNT-water slurry, slowly removing water from the slurry which results in a SWNT-water paste, and allowing the paste to dry very slowly, such that the SWNT network of the SWNT-water paste is preserved during solvent evaporation. Buckyrock can be used in applications, such as ballistic protection systems, involving light-weight material with mechanical strength, toughness and impact resistance.

Owner:RICE UNIV

Solar cell modules with improved backskin

InactiveUS6660930B1High dielectric strengthExtended service lifePV power plantsSemiconductor/solid-state device detailsIonomerEngineering

A laminated solar cell module comprises a front light transmitting support, a plurality of interconnected solar cells encapsulated by a light-transmitting encapsulant material, and an improved backskin formed of an ionomer / nylon alloy. The improved backskin has a toughness and melting point temperature sufficiently great to avoid any likelihood of it being pierced by any of the components that interconnect the solar cells.

Owner:SCHOTT SOLAR AG (DE)

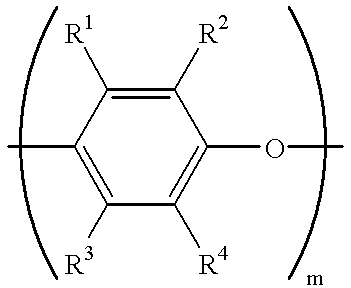

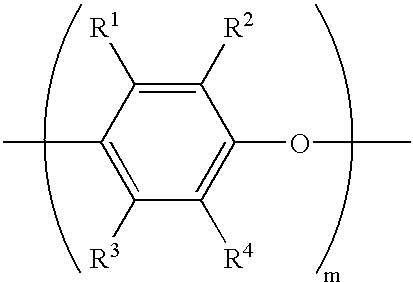

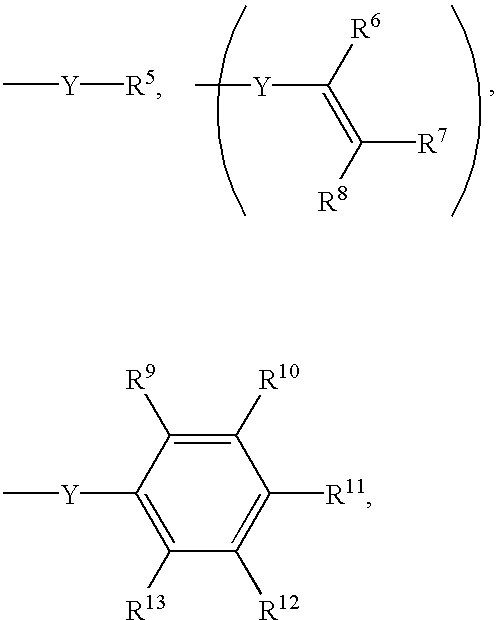

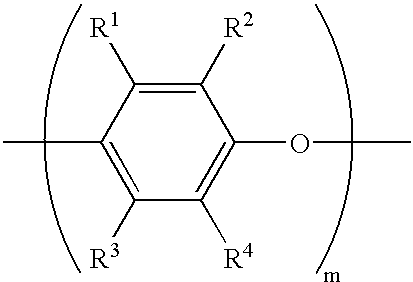

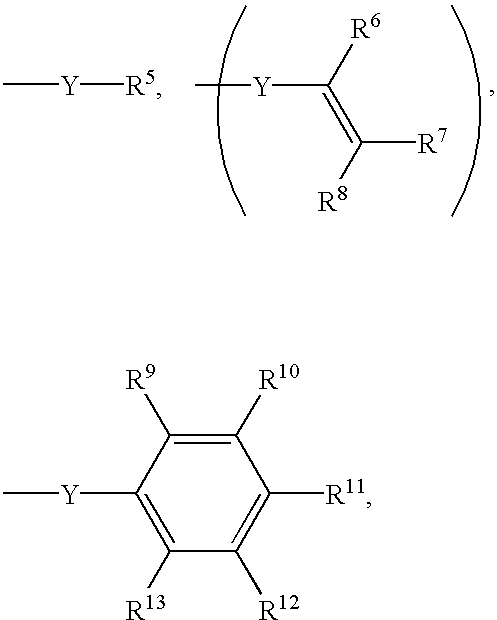

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS6627704B2Fast curingReduce sensitivitySynthetic resin layered productsPolyether coatingsHeat resistanceEther

Owner:SABIC INNOVATIVE PLASTICS IP BV

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS20010053820A1Fast curingReduce sensitivitySynthetic resin layered productsThin material handlingHeat resistanceEther

A thermosetting composition comprises a capped poly(arylene ether), an alkenyl aromatic monomer, and an acryloyl monomer. The composition provides good flow properties and fast curing rates. After curing, the composition exhibits good stiffness, toughness, heat resistance, and dielectric properties.

Owner:SABIC INNOVATIVE PLASTICS IP BV

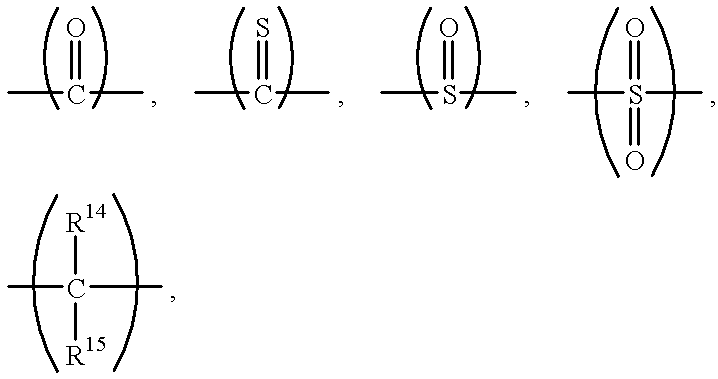

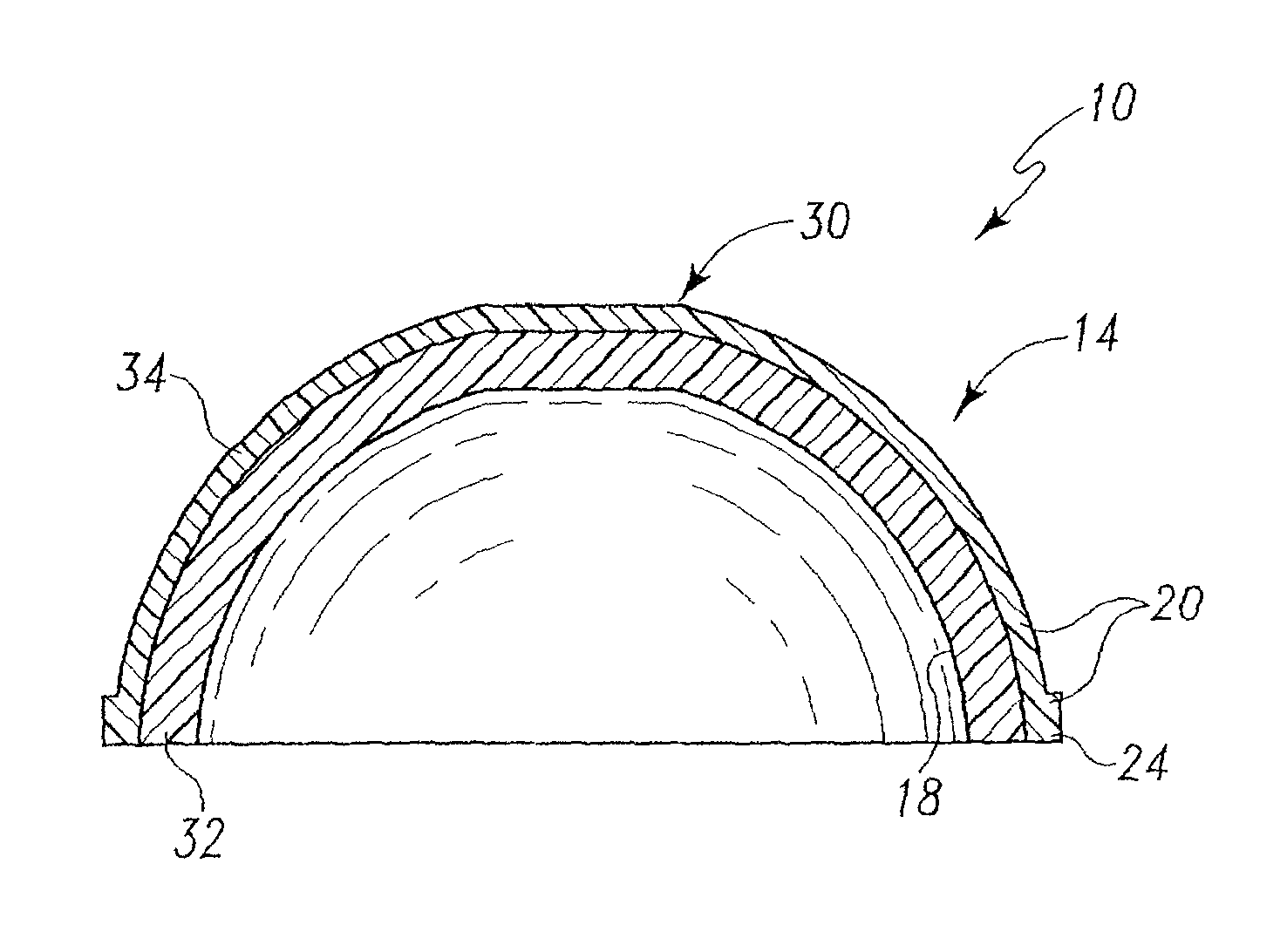

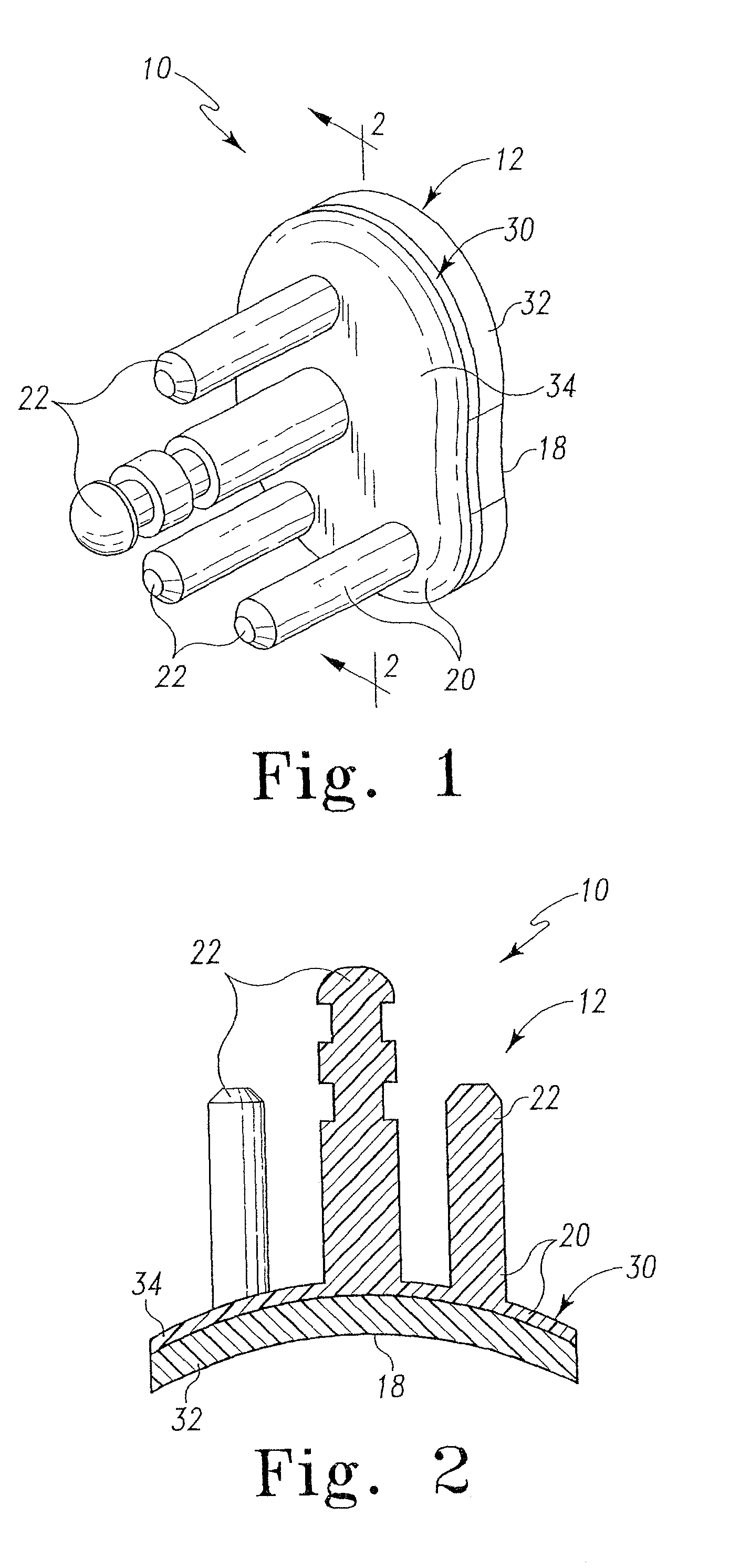

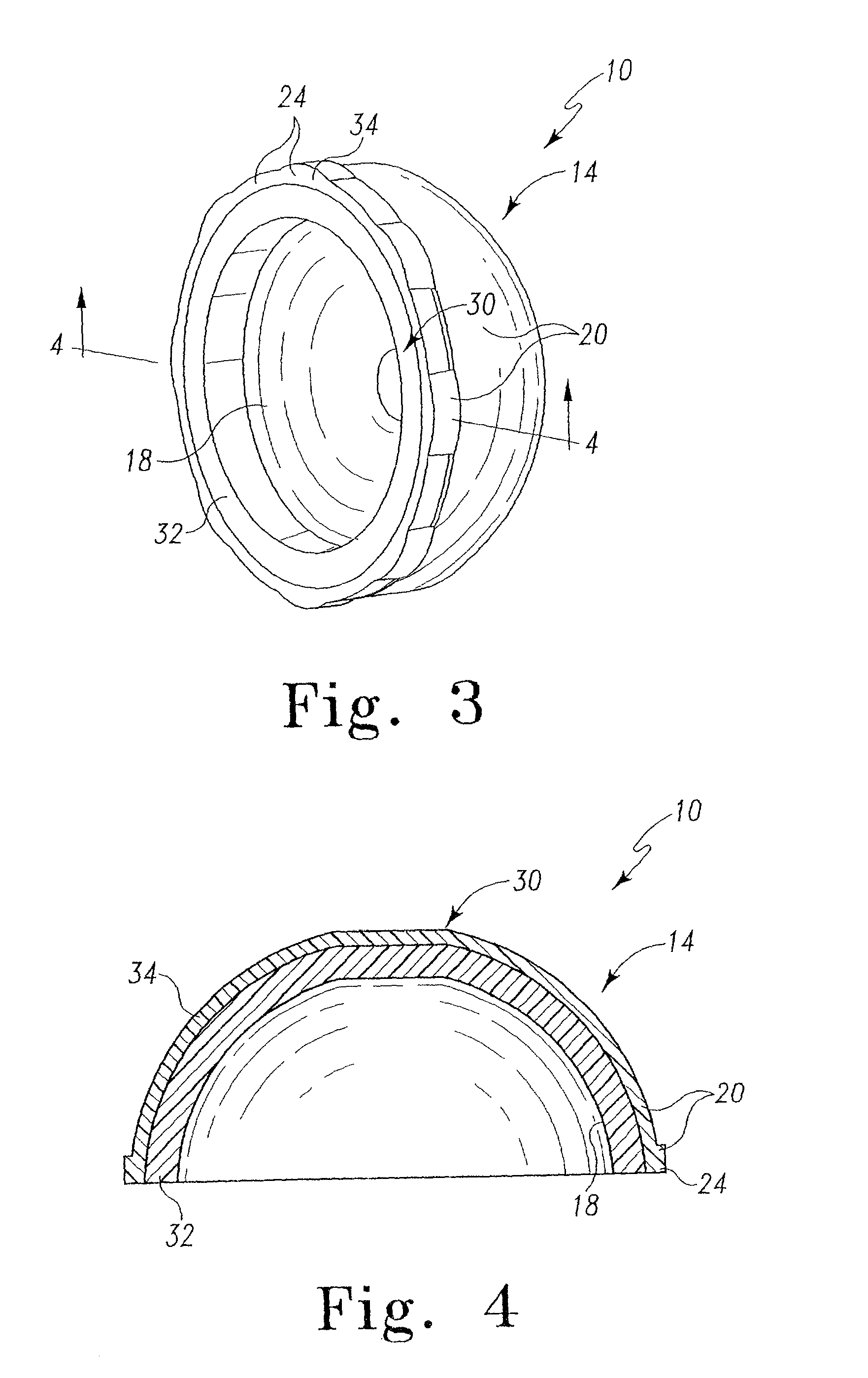

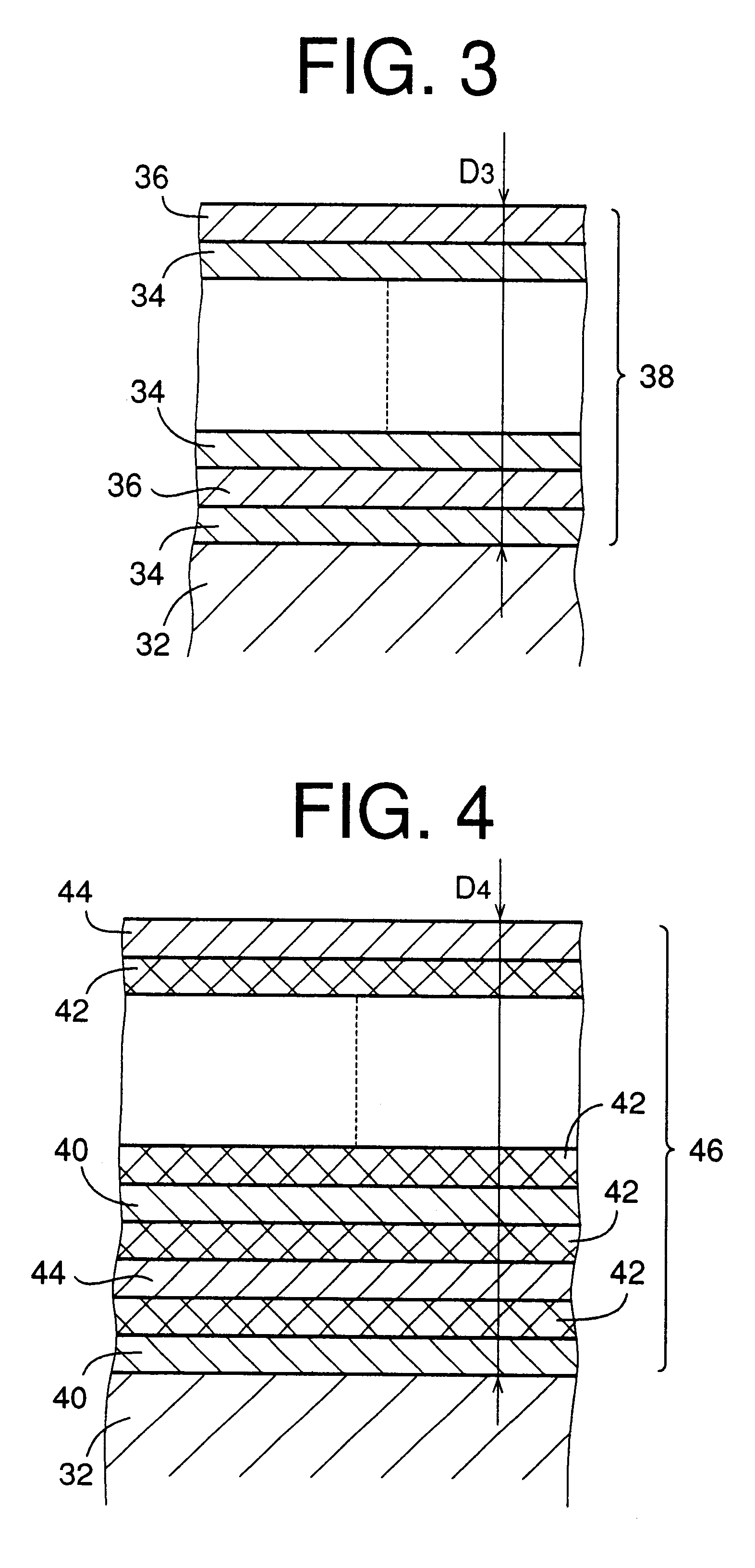

Composite prosthetic bearing having a crosslinked articulating surface and method for making the same

InactiveUS7819925B2Promote oxidationEasy to wearBone implantSynthetic resin layered productsProsthesisCrosslinked polymers

An implantable prosthetic bearing is constructed of a composite material having a first layer and second layer. The first layer has an articulating surface defined therein, whereas the second layer has a engaging surface defined therein for engaging either another prosthetic component or the bone itself The first layer of the implantable prosthetic bearing is constructed of crosslinked polymer such as Ultra-High Molecular Weight Polyethylene, whereas the second layer of the implantable prosthetic bearing is constructed of polymer such as Ultra-High Molecular Weight Polyethylene that is either non-crosslinked or crosslinked to a lesser degree than the first layer. In such a manner, the first layer possesses mechanical properties which are advantageous in regard to the articulating surface (e.g., enhanced wear and oxidation resistance), whereas the second layer possesses mechanical properties which are advantageous in regard to the engaging surface (e.g., high ductility, toughness, and creep resistance). A method of making a prosthetic bearing is also disclosed.

Owner:DEPUY SYNTHES PROD INC

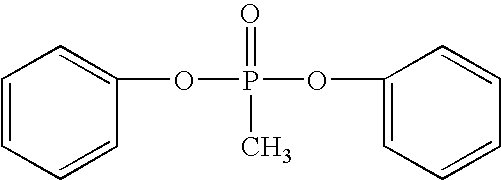

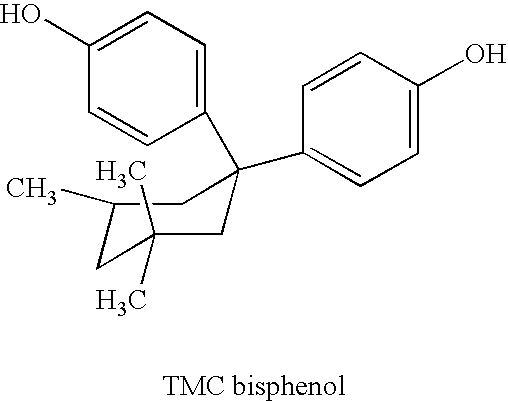

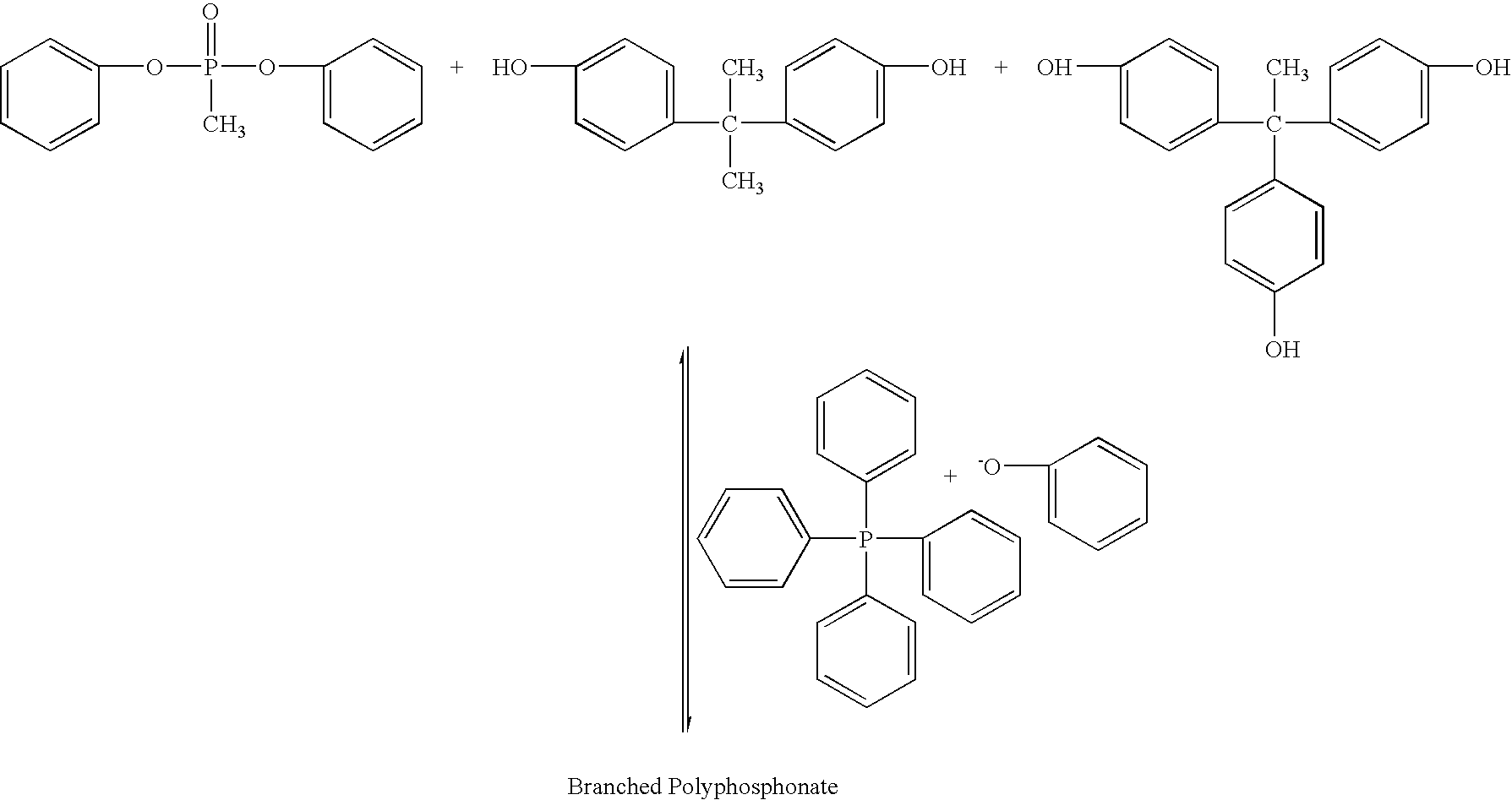

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

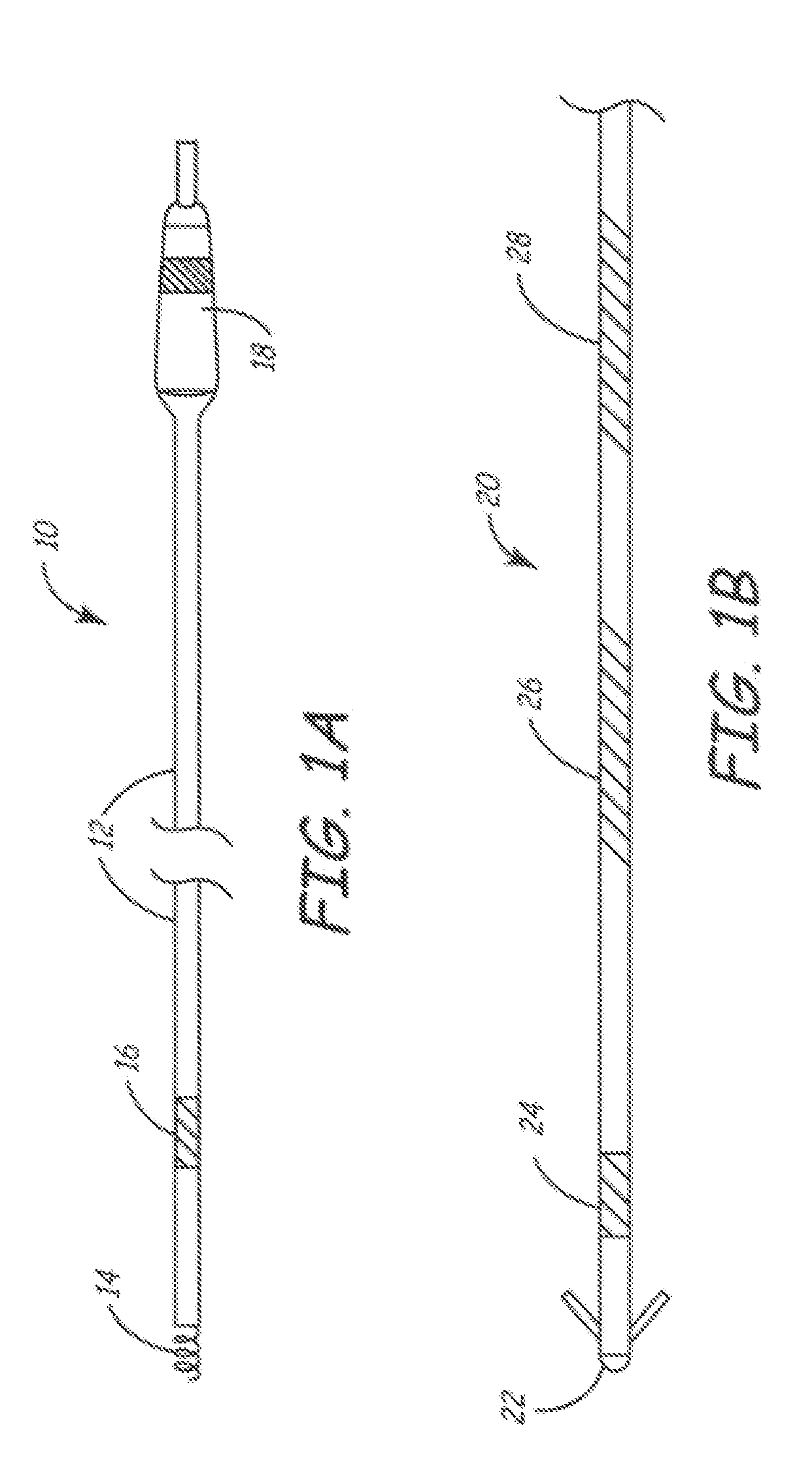

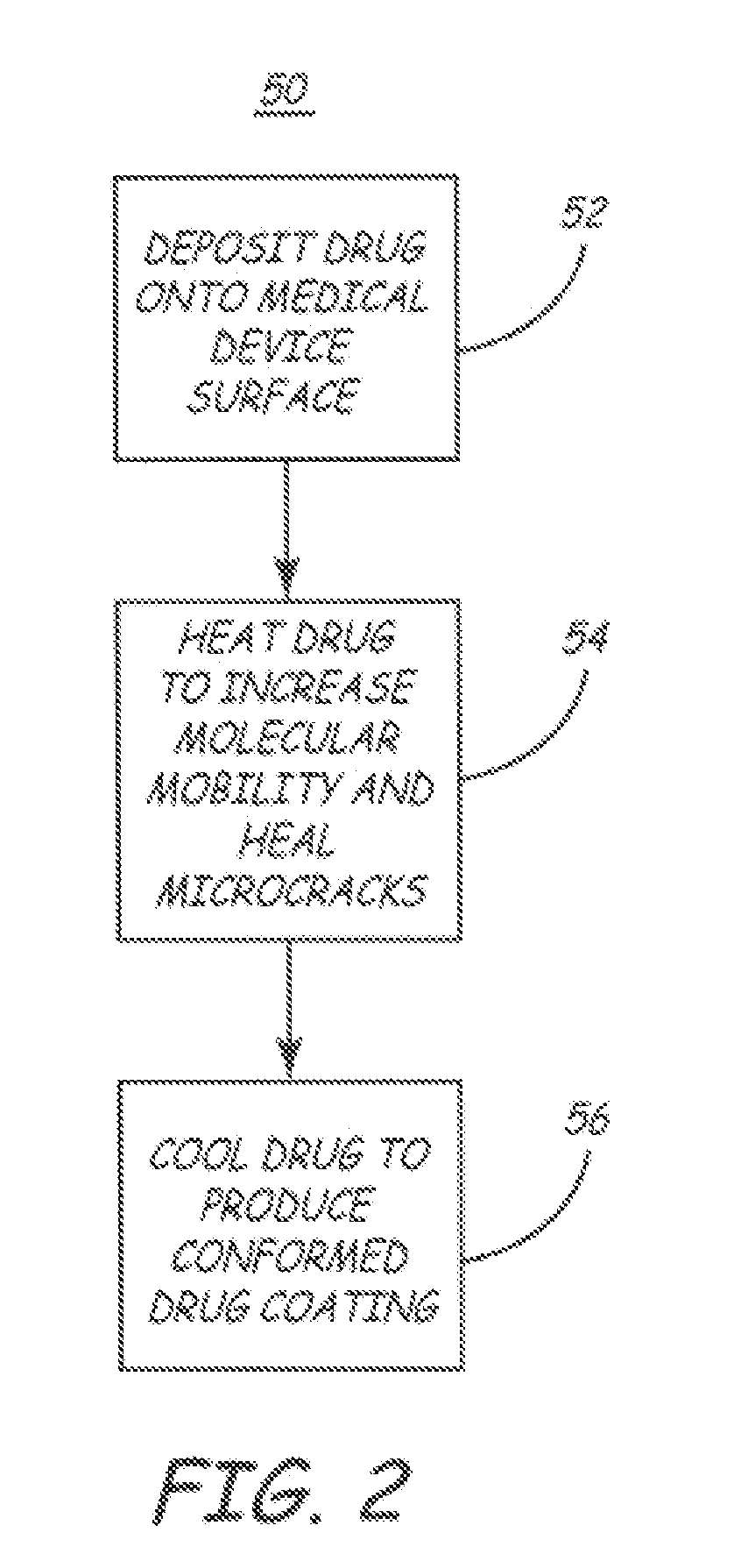

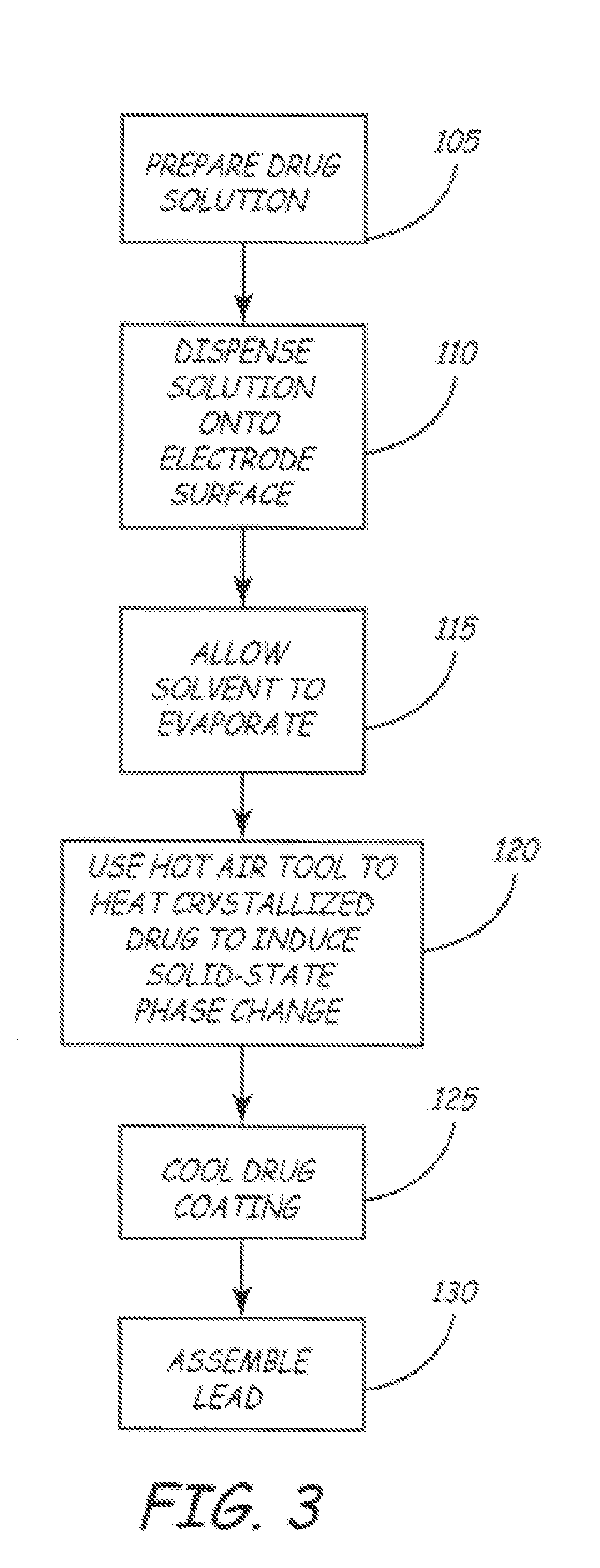

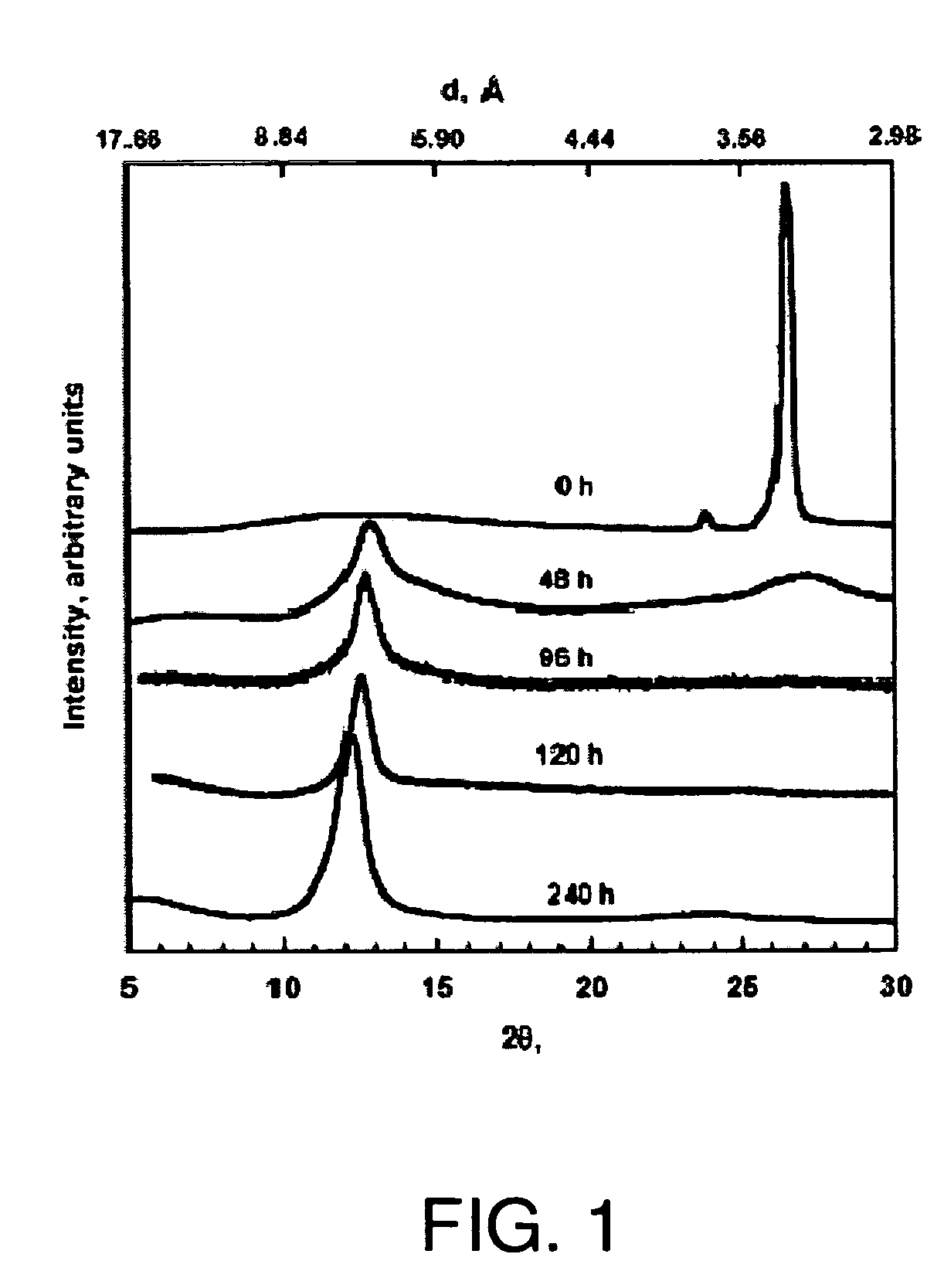

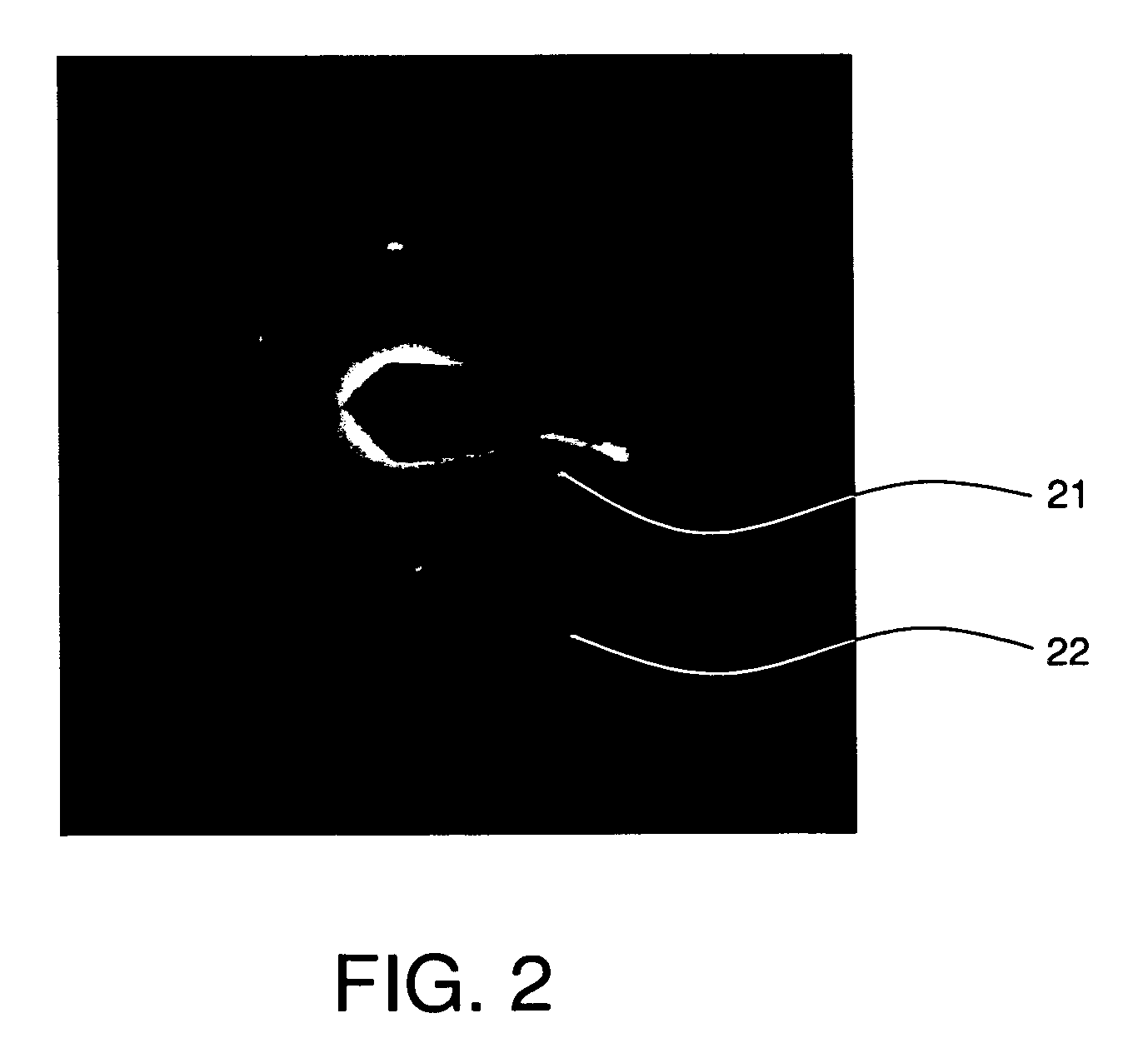

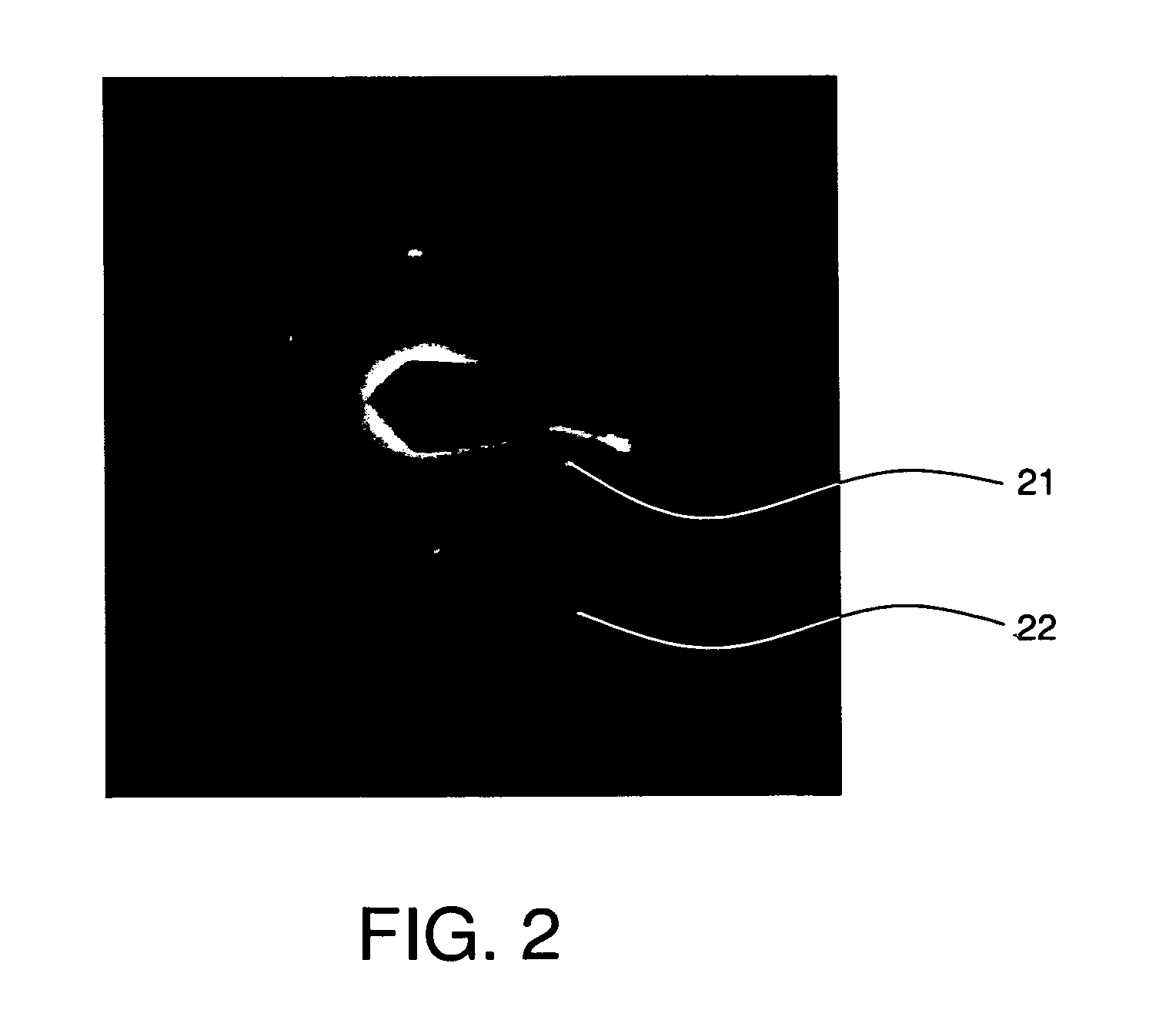

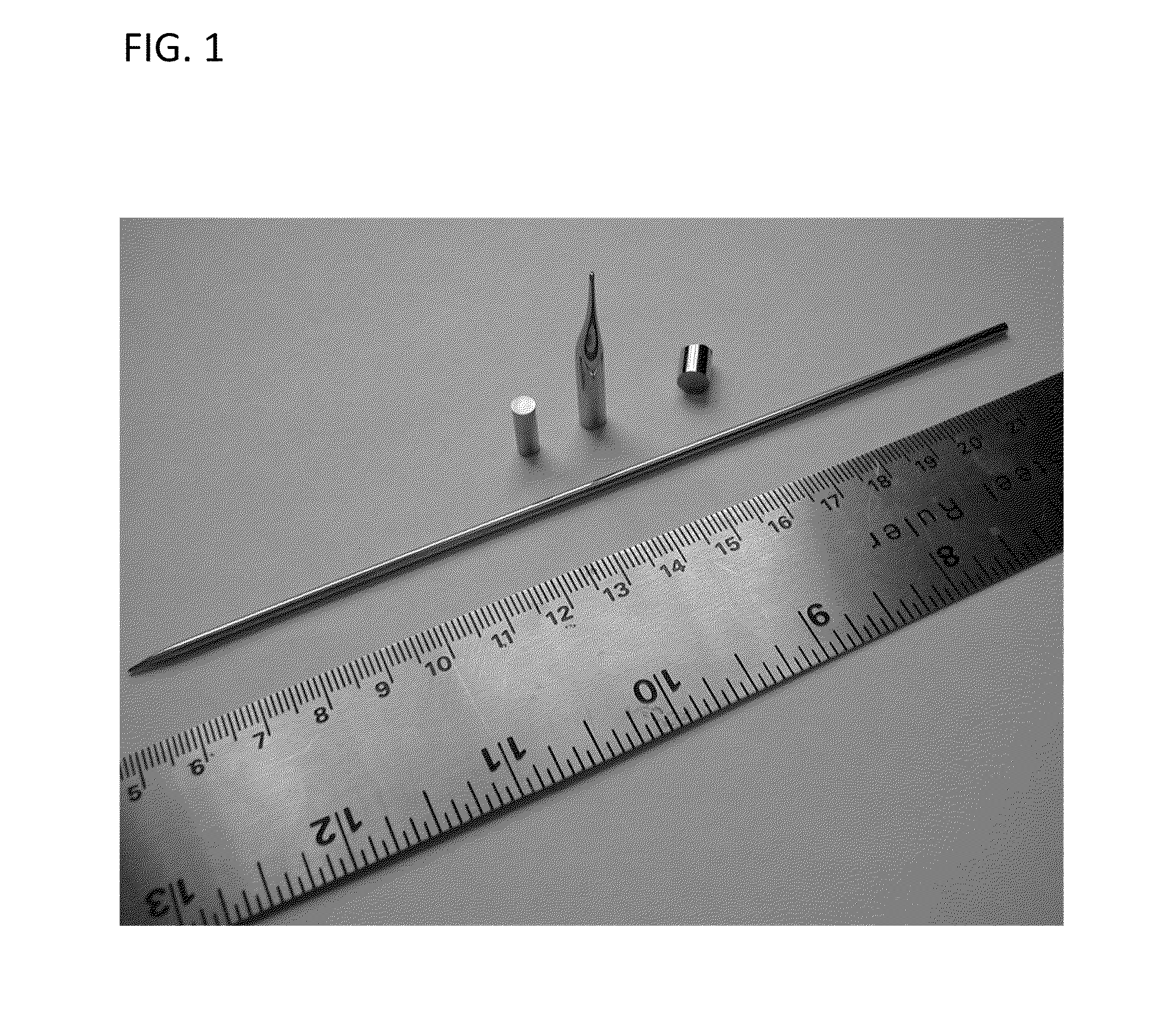

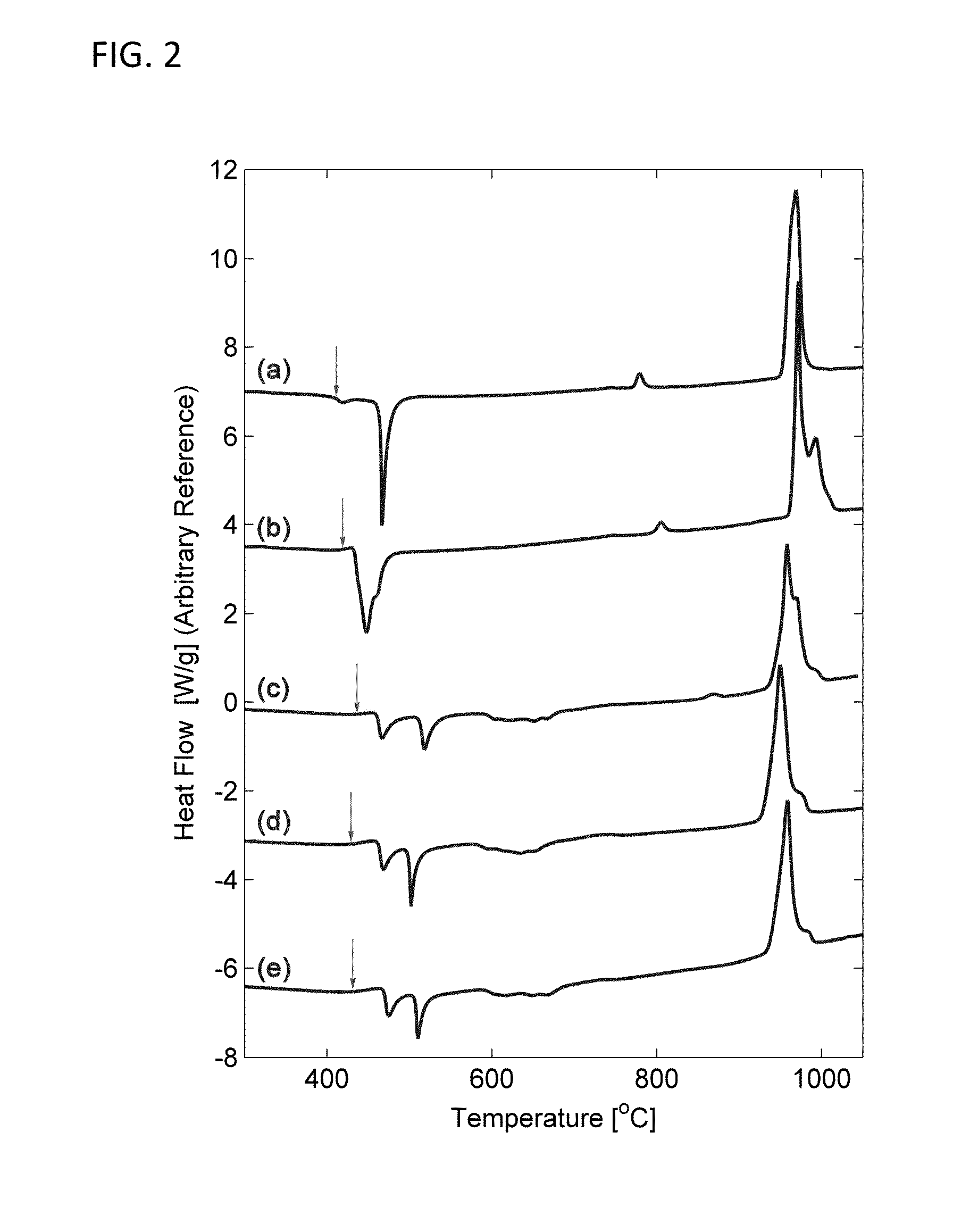

Method for applying a drug coating to a medical device

A method for coating a medical device with a drug is provided. Energy, preferably thermal energy, is applied to a crystalline deposit of a drug on the surface of a medical device to increase the molecular mobility and form a conformable drug coating with a low density of micro-cracks and other mechanical defects that can degrade the coating toughness and effective adhesion to the device surface. In a preferred embodiment, solution evaporation methods are used to deposit a crystalline coating of an anti-inflammatory steroid on a medical electrode. Heat applied at a controlled temperature, for a predetermined amount of time, induces a solid-state phase change of the drug coating providing a smooth, uniform, well-attached, conformable coating to form a layer that will elute from the electrode over time when implanted in a patient's body.

Owner:MEDTRONIC INC

Shaped articles from cycloaliphatic polyester compositions

ActiveUS20050124779A1Improve melt processing characteristicIncrease stiffnessEnvelopes/bags making machinerySynthetic resin layered productsFiberPolyester

Disclosed are oriented, shaped articles such as, for example, film, fibers, bottles, and tubes, with excellent strength, toughness, clarity, chemical resistance, and UV resistance. The articles can be prepared from cycloaliphatic polyesters and from compositions comprising cycloaliphatic polyesters and cycloaliphatic polyester elastomers. The articles may be oriented by stretching in at least one direction and have a modulus which results in a soft feel. Also disclosed are polyester compositions comprising cycloaliphatic polyesters and polyester elastomers.

Owner:EASTMAN CHEM CO

Method for the production of thin substrates

InactiveUS20070249140A1Improve efficiencyLarge thicknessFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellInduced stress

A method is provided for producing a thin substrate with a thickness below 750 microns, comprising providing a mother substrate, the mother substrate having a first main surface and a toughness; inducing a stress with predetermined stress profile in at least a portion of the mother substrate, said portion comprising the thin substrate, the induced stress being locally larger than the toughness of the mother substrate at a first depth under the main surface; such that the thin substrate is released from the mother substrate, wherein the toughness of the mother substrate at the first depth is not lowered prior to inducing the stress. The method can be used in the production of, for example, solar cells.

Owner:KATHOLIEKE UNIV LEUVEN

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS6812276B2Fast curingReduce sensitivitySynthetic resin layered productsSpecial tyresEndcappingHeat resistance

Owner:SABIC GLOBAL TECH BV

Reverse thermal gels and the use thereof for rapid prototyping

InactiveUS6863859B2Reduce surface tensionHigh strengthAdditive manufacturing apparatusPhotosensitive materialsLower critical solution temperatureWater soluble

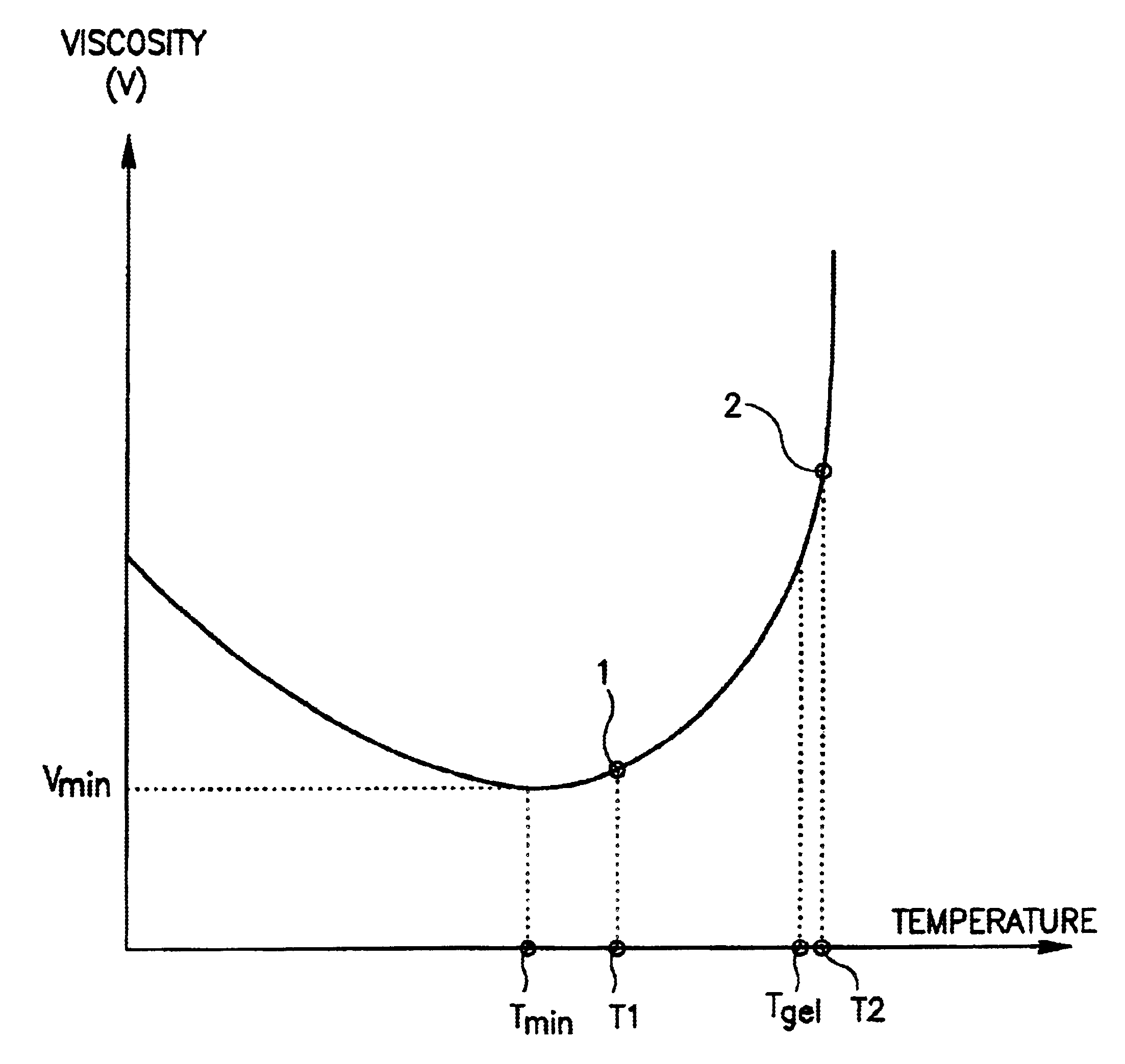

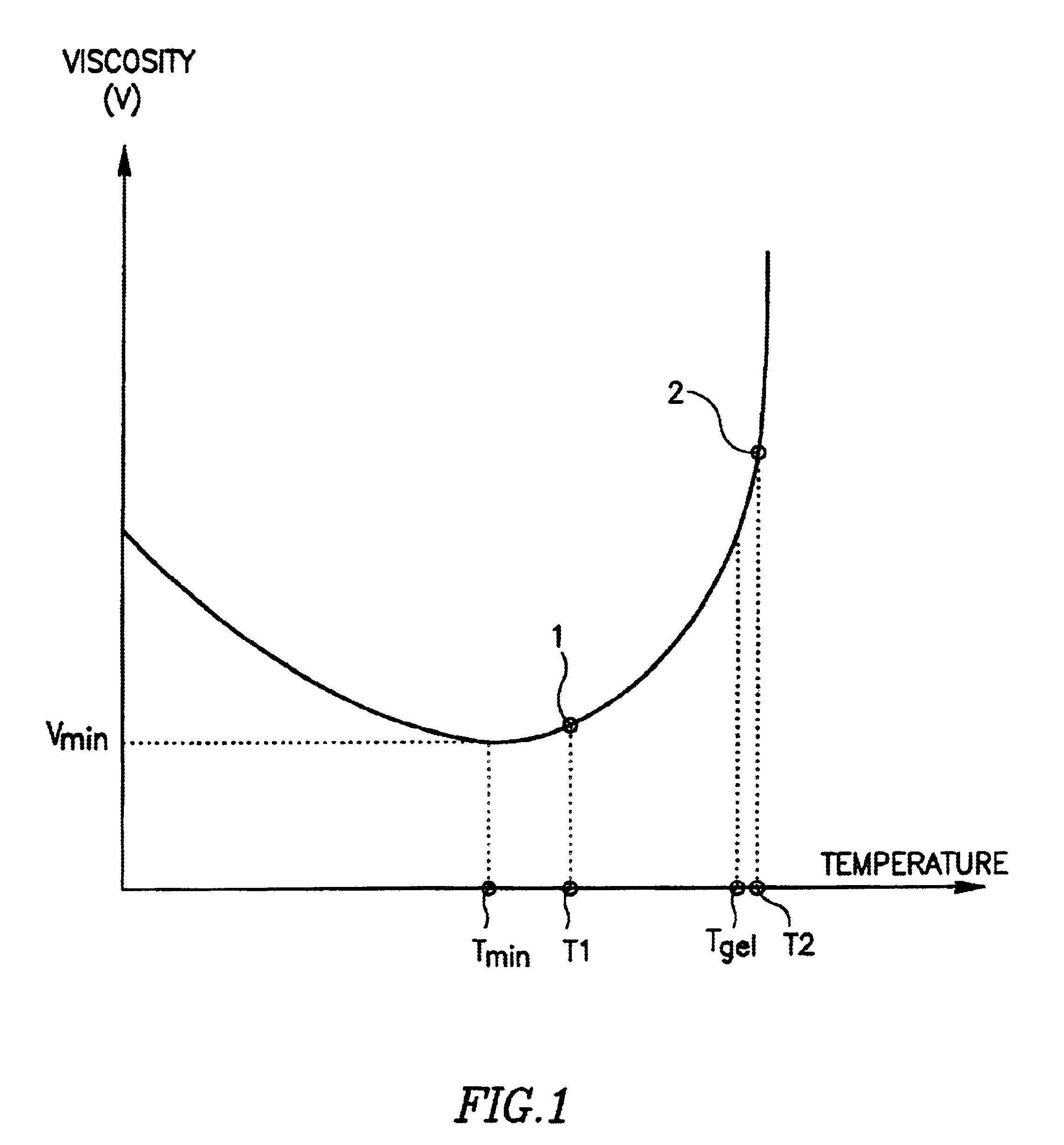

The present invention relates to novel polymeric compositions that exhibit Reverse Thermal Gelation (RTG) properties for use as Support Materials (SM) in the manufacture of three-dimensional objects. These polymers are Temperature Sensitive Polymers that respond with a significant change of properties to a small change in temperature. Temperature Sensitive Polymers exhibit cloud point (CP) or lower critical solution temperature (LCST) in aqueous solutions. Water-soluble Temperature Sensitive Polymers are chosen to give low viscosity liquid at low temperature when dissolved in water and by that to permit easy dispensing at low temperature. Raising the temperature above their gelation temperature (Tgel) will result in solidification of the composition. At its gel position the material has favorable characteristics as a support and building material. The gel layers have the appropriate toughness and dimensional stability to support the model layers during the building process. After the building process is completed the gel can be cooled down to a temperature below its Tgel so the gel can liquefy and be removed easily by rinsing with water.

Owner:STRATASYS LTD

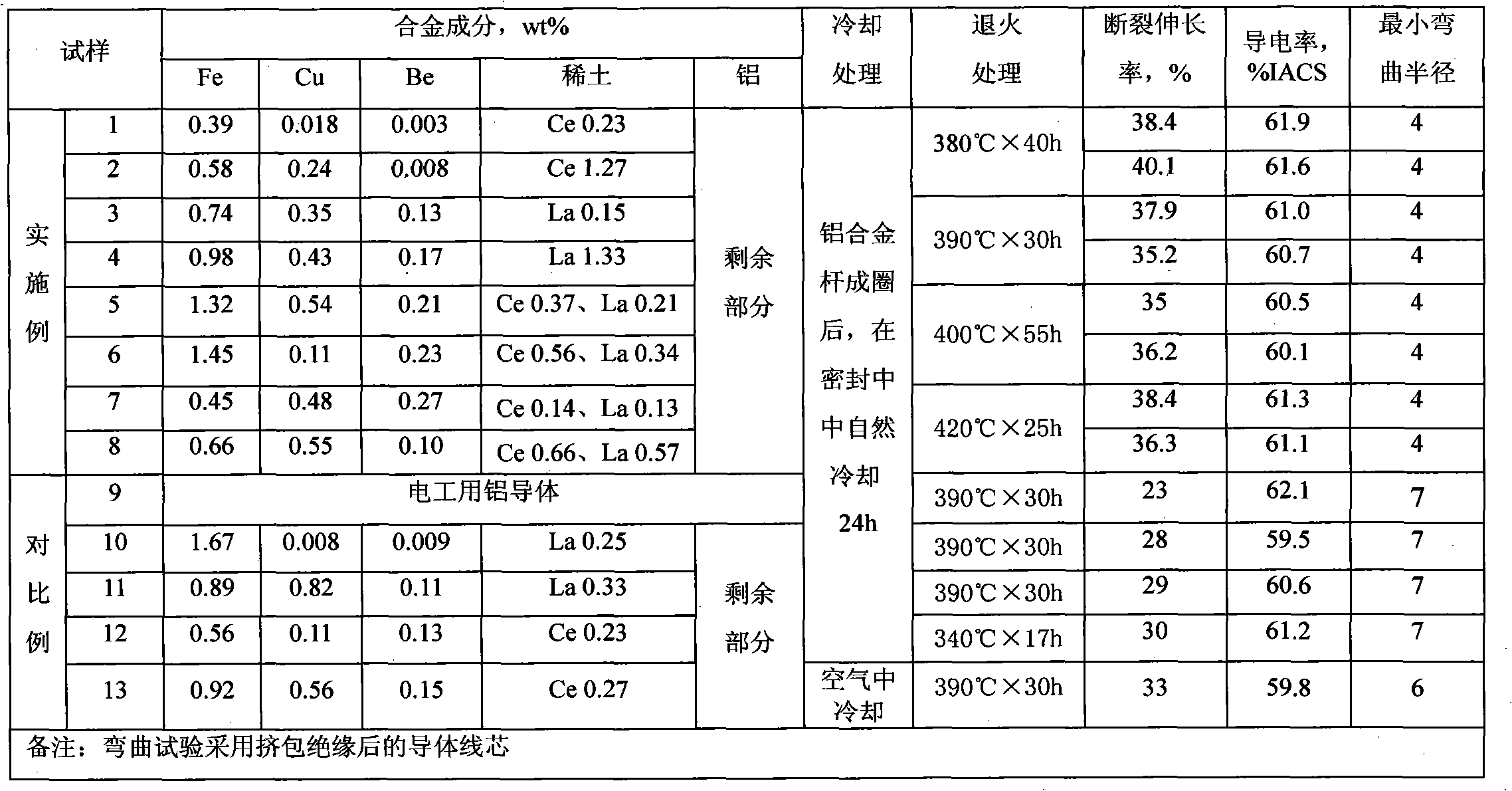

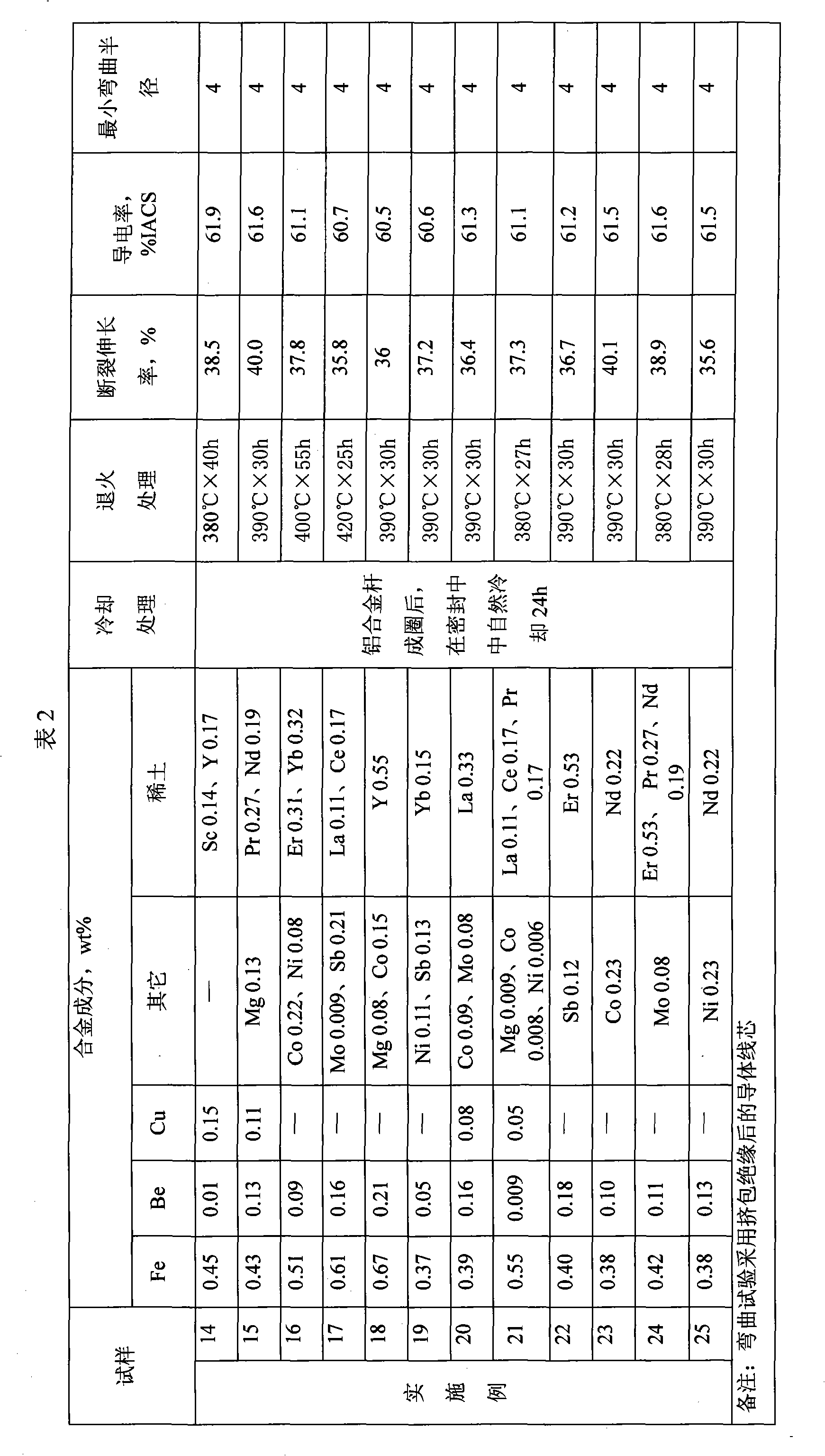

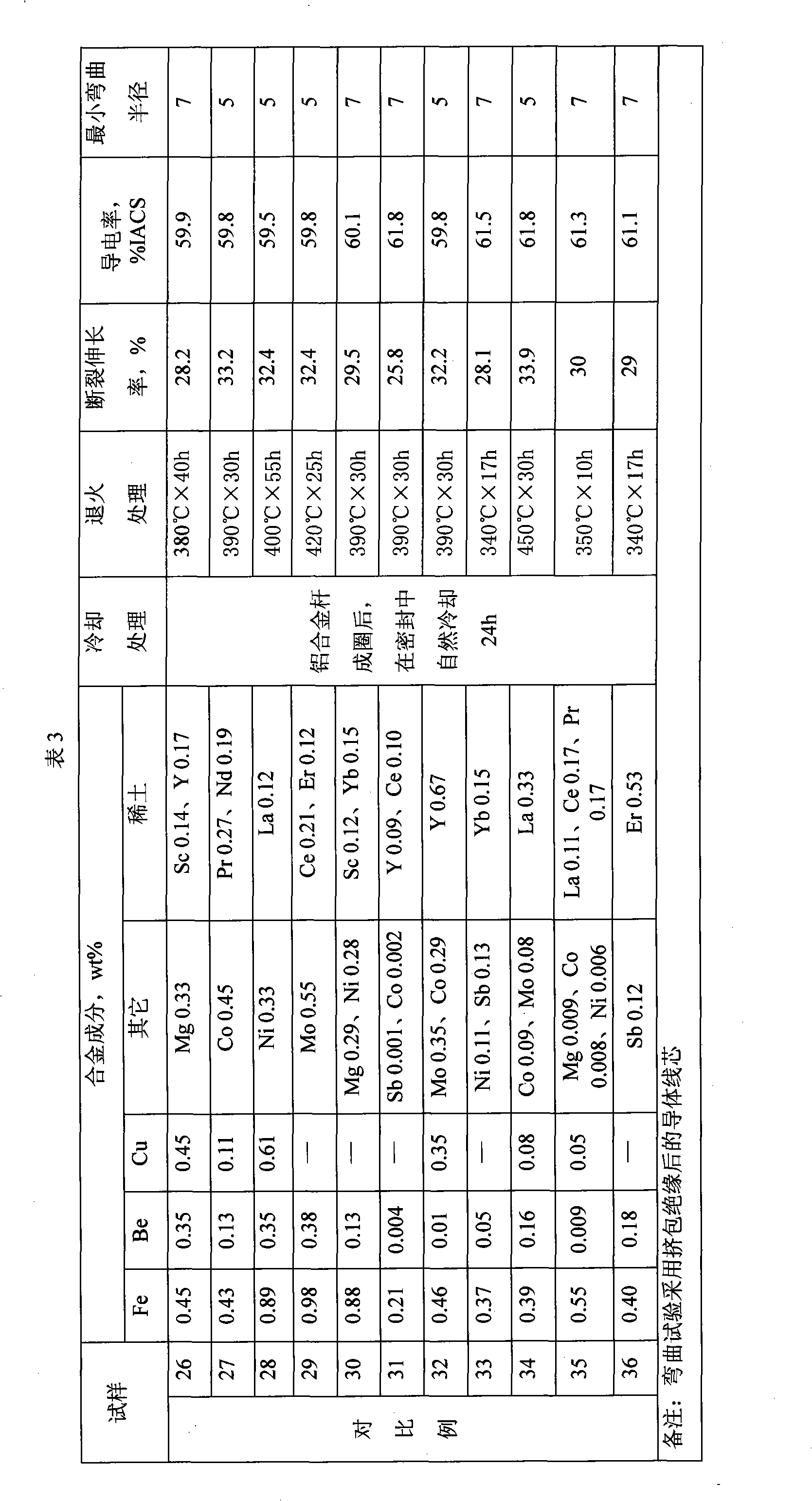

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

Poly (arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS20030096123A1Fast curingReduced curing rate oxygen sensitivitySynthetic resin layered productsSpecial tyresHeat resistanceEther

Owner:SABIC GLOBAL TECH BV

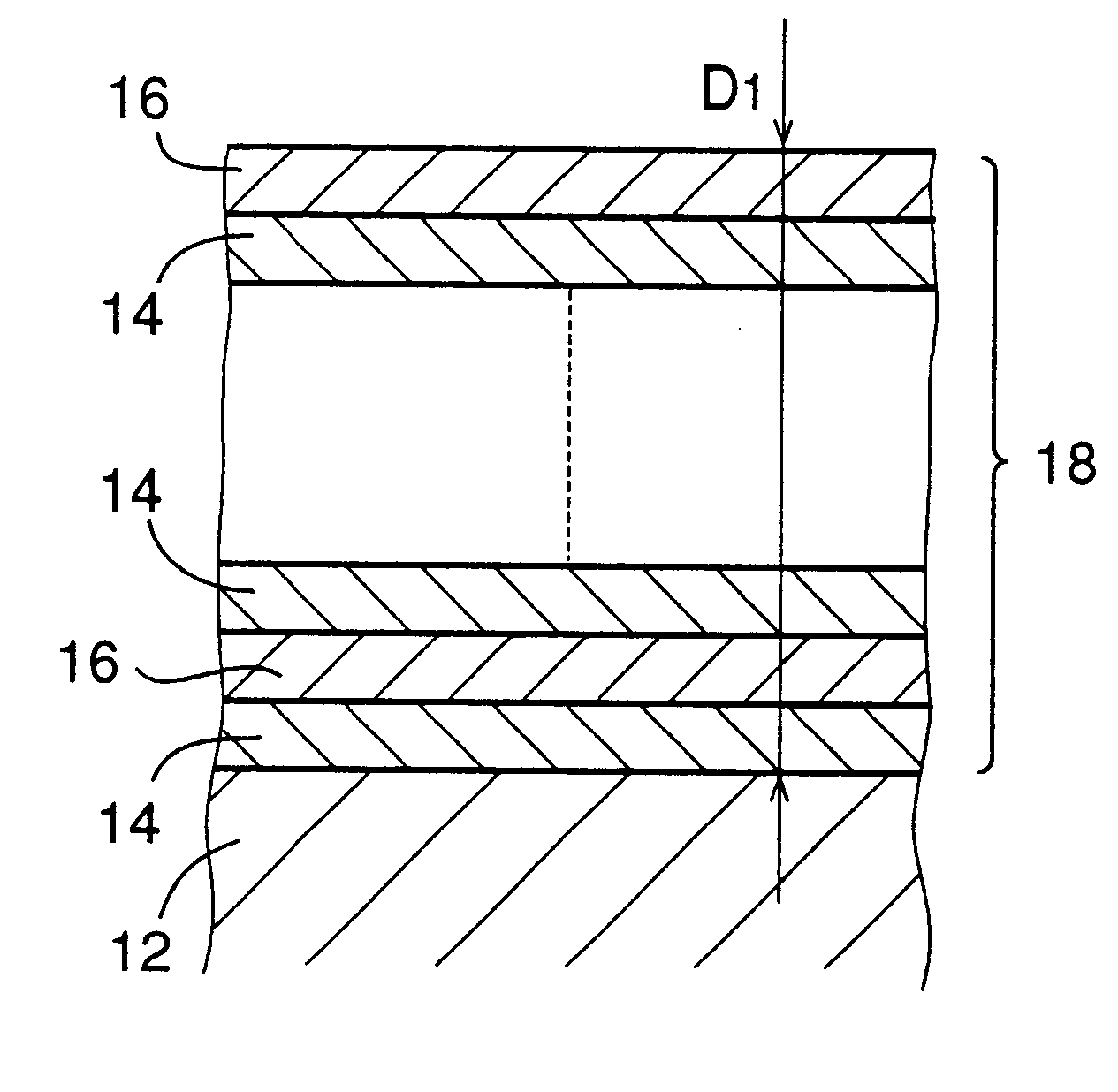

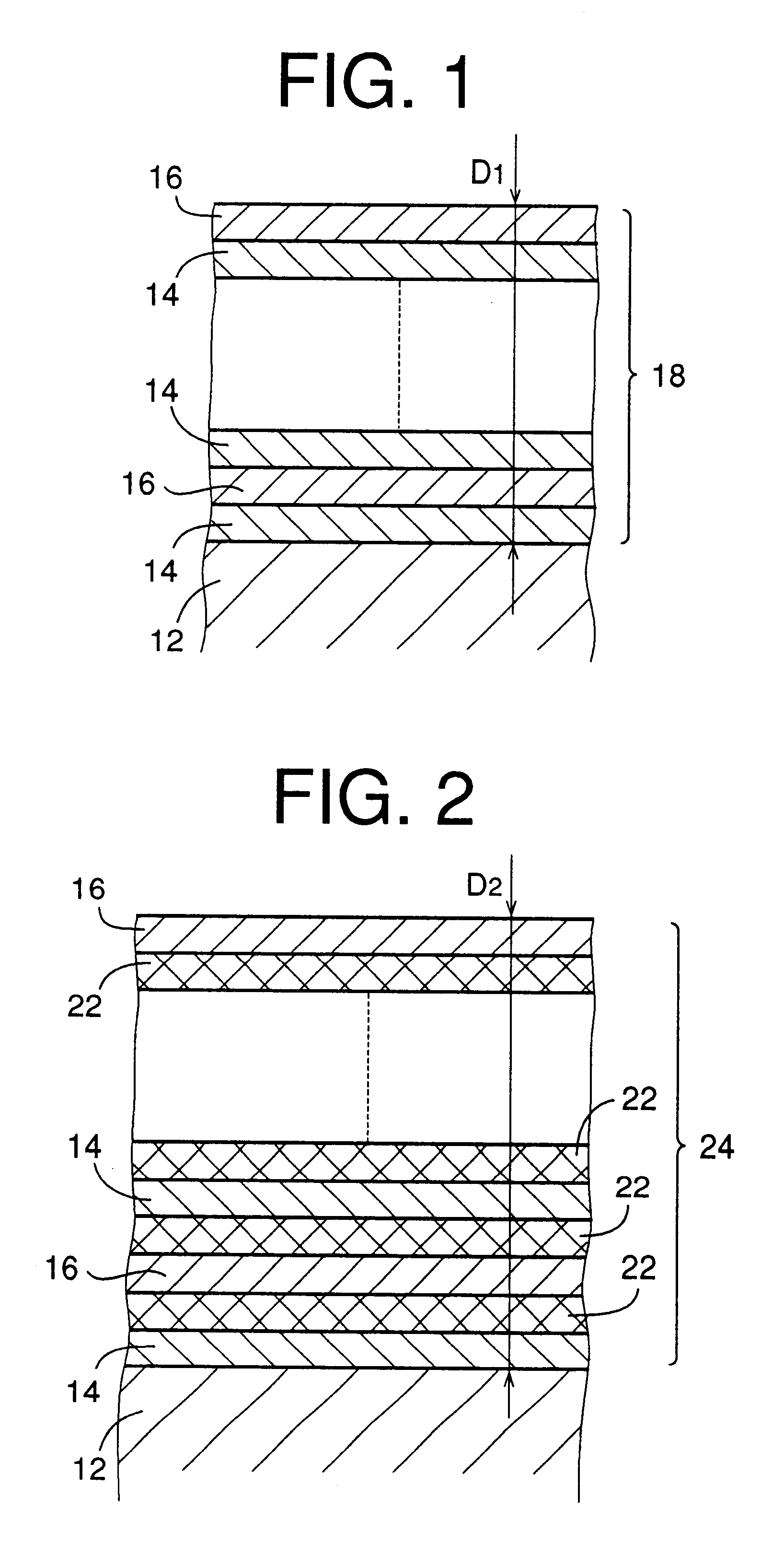

Hard multilayer coated tool having increased toughness

InactiveUS6309738B1Improve toughnessLower resistancePigmenting treatmentVacuum evaporation coatingTitaniumToughness

A hard multilayer coated tool including: (a) a substrate; and (b) a multilayer coating covering the substrate, the multilayer coating comprising first and second coating layers which are alternately laminated on the substrate, each of the first coating layers having and average thickness of 0.10-0.50 mum and containing titanium therein, each of the second coating layers having and average thickness of 0.10-0.50 mum and containing aluminum therein, the multilayer coating having and average thickness of 0.50-10.0 mum.

Owner:OSG

Extensible Nonwoven Fabric

ActiveUS20140276517A1High elongationImprovement in one or moreBaby linensWoven fabricsExtensibilityNonwoven fabric

Extensible nonwoven fabrics having improved elongation, extensibility, abrasion resistance and toughness. In particular, embodiments of the invention are directed to extensible spunbond fabrics comprising a polymeric blend of a metallocene catalyzed polypropylene, polyethylene, and a third polymer component.

Owner:FITESA GERMANY +1

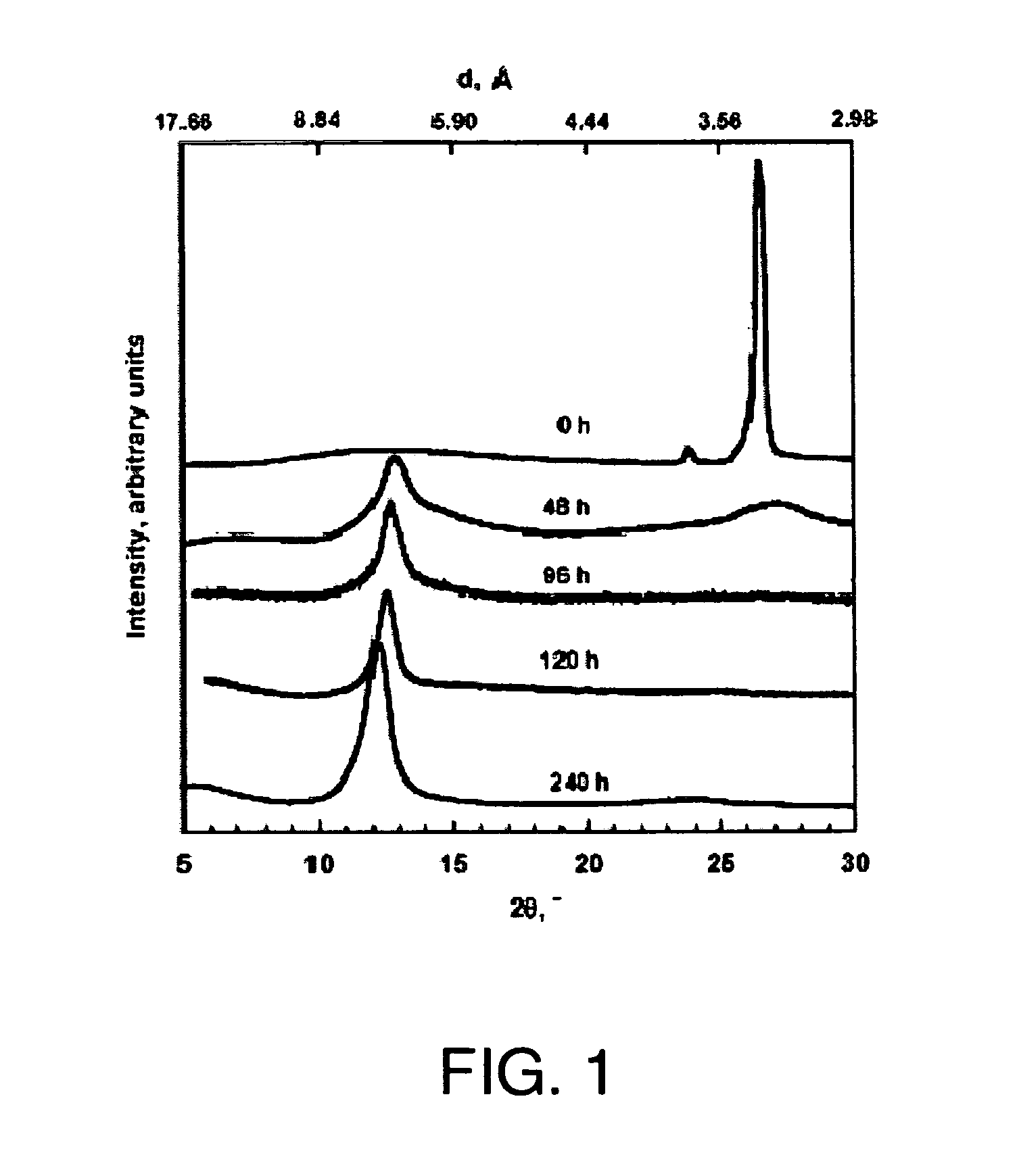

Preparation method for sodium alginate-acrylamide-based hydrogel

InactiveCN103396562AOvercome the shortcomings of generating air bubbles and forming uneven hydrogelsEasy to operateCross-linkPolyacrylamide Hydrogel

The invention discloses a preparation method for sodium alginate-acrylamide-based hydrogel. The preparation method comprises the following steps of: dissolving sodium alginate powder in deionized water; then sequentially adding an acrylamide monomer, a methylene diacrylamide cross-linking agent, ammonium persulfate and an N,N,N',N'-tetramethylethylenediamine catalyst; uniformly stirring the materials, pouring the mixture into a glass die, and heating the mixture to obtain a hydrogel; completely soaking the hydrogel in a 0.01-1 mol / L non-monovalent cation aqueous solution for 1-10 hours, wherein cations diffuse and enter in a hydrogel network structure, and induce sodium alginate to cross-link, so as to generate the high-strength and high-toughness sodium alginate-acrylamide-based hydrogel during the process. The hydrogel disclosed by the invention has the following performances: the highest tensile strength can achieve 1 MPa, and the highest tensile elasticity modulus can achieve 250 KPa; a loading-unloading test is performed on the hydrogel, and when the great tensile multiple before unloading is 8, the highest dissipated energy can achieve 2180 KJ / m<3>.

Owner:XI AN JIAOTONG UNIV

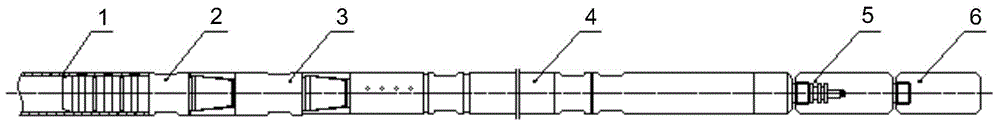

Coiled tubing tool set with cable perforations and technology

InactiveCN104533392AHigh strengthImprove toughnessSurveyFluid removalHorizontal wellsEconomic benefits

The invention discloses a coiled tubing tool set with cable perforations. The coiled tubing tool set comprises coiled tubing, a coiled tubing joint and a logging tool string or a perforation tool set. A cable is arranged in the coiled tubing. According to the coiled tubing tool set with the cable perforations, the structure of combining the coiled tubing and the logging tool string or the perforation tool set is adopted, and on the one hand, due to the characteristic that the coiled tubing is high in strength, toughness and loading capacity to work under pressure, the perforation requirements for highly-deviated wells and horizontal wells can be met, and the application range is wider; on the other hand, the coiled tubing can continuously work, work time is short, and efficiency is high. Meanwhile, due to production under pressure, a press does not need to be introduced, and the overall equipment occupied area is small. Therefore, through the coiled tubing, the cost of a work well is lowered, and economic benefits are improved. The invention further discloses a coiled tubing technology with cable perforations adopting the coiled tubing tool set with the cable perforations.

Owner:JEREH ENERGY SERVICES

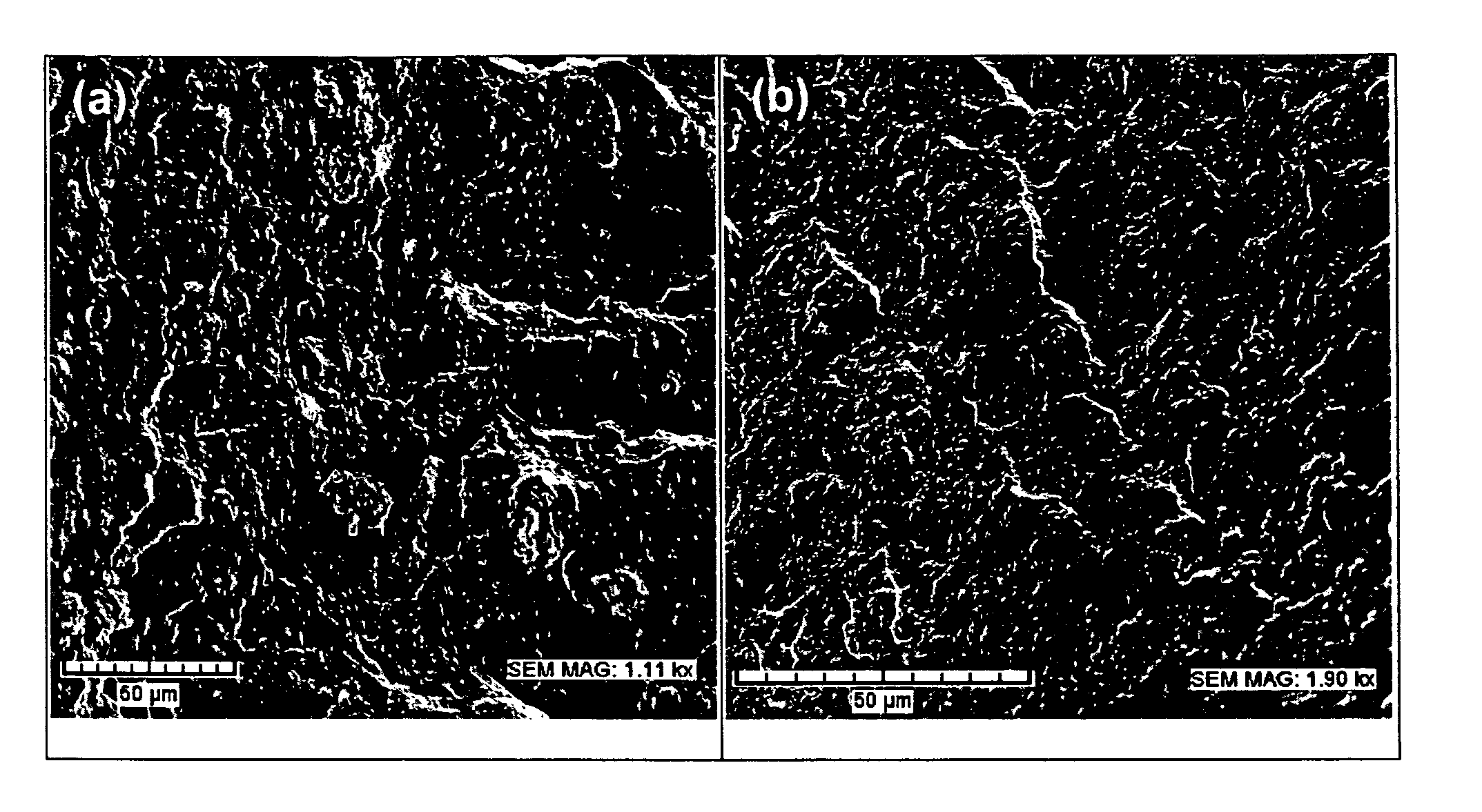

Functional graphene-rubber nanocomposites

ActiveUS7745528B2Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerX-ray

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Functional graphene-rubber nanocomposites

ActiveUS20100096597A1Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerPolymer science

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

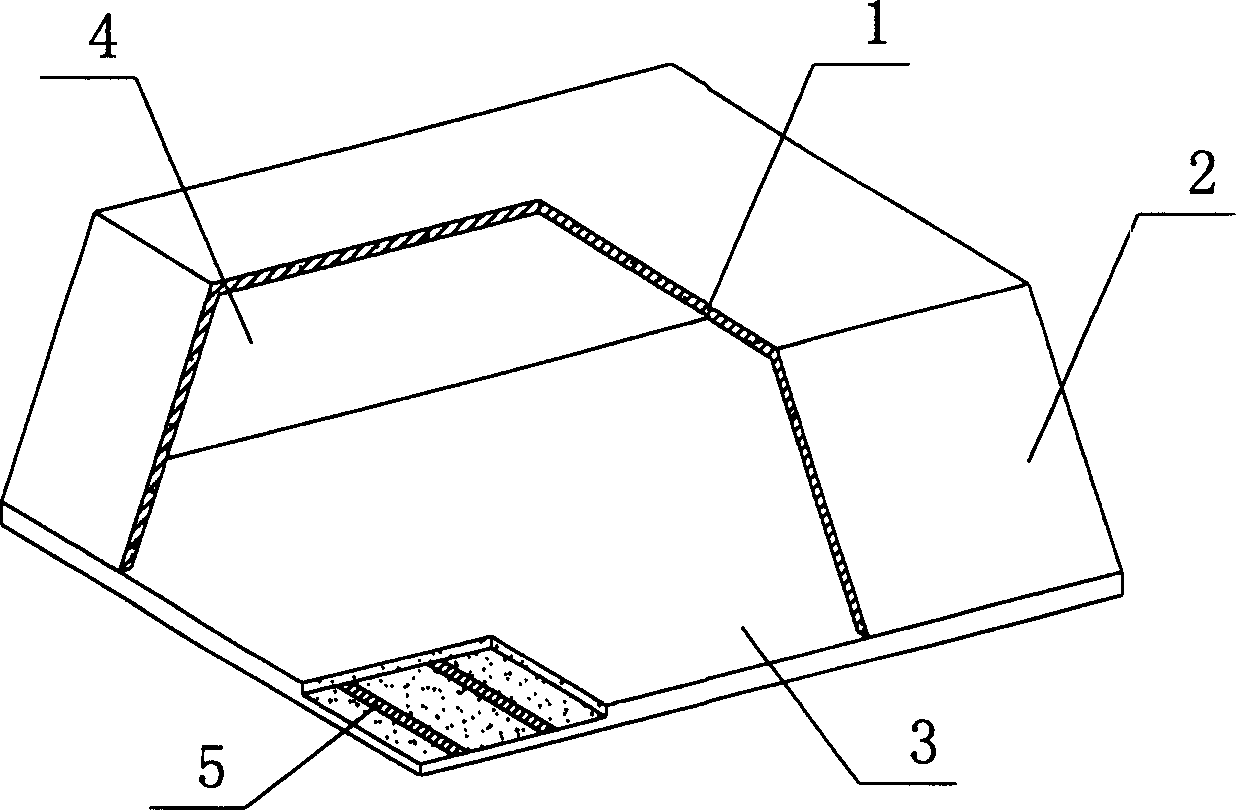

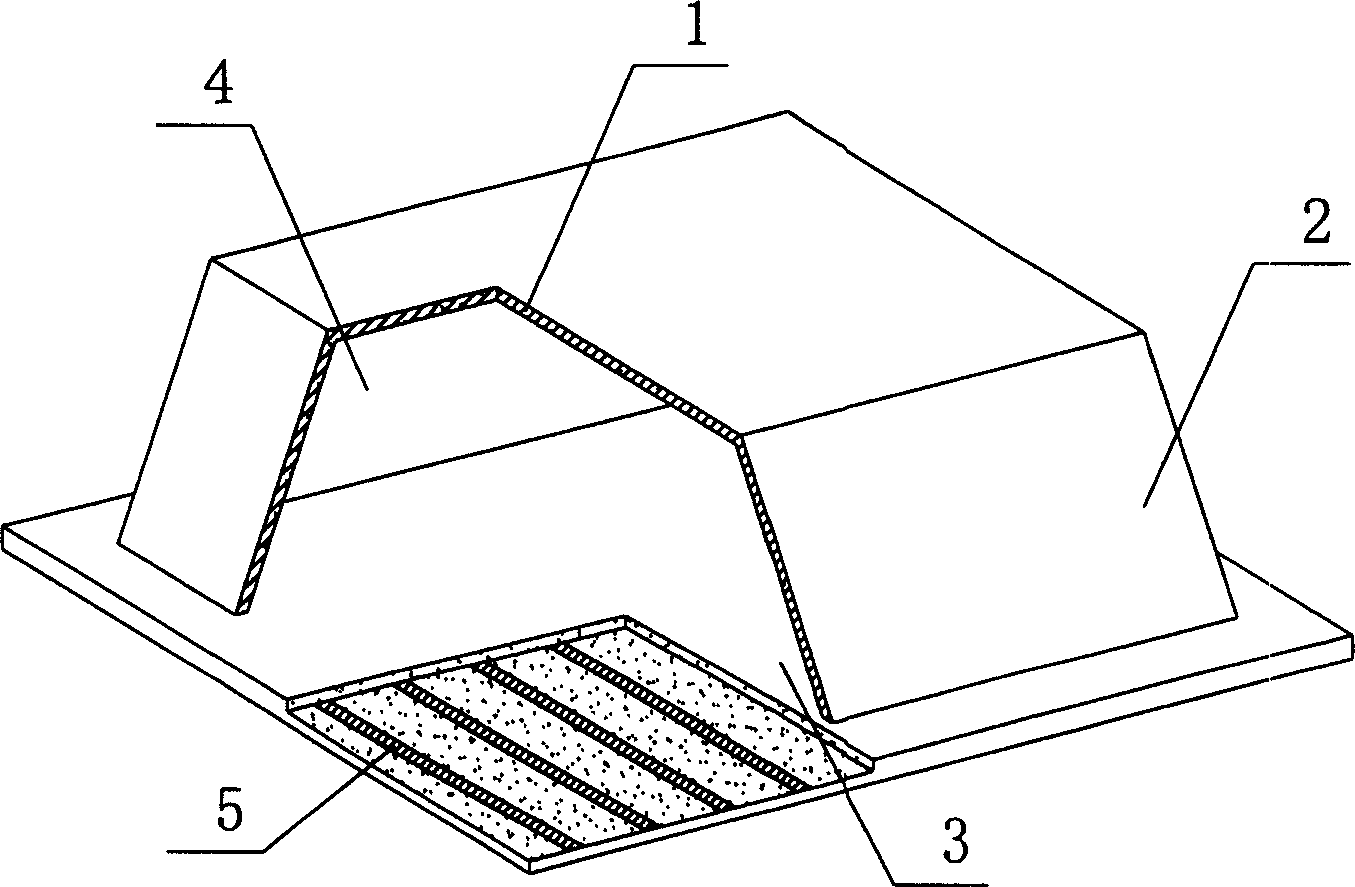

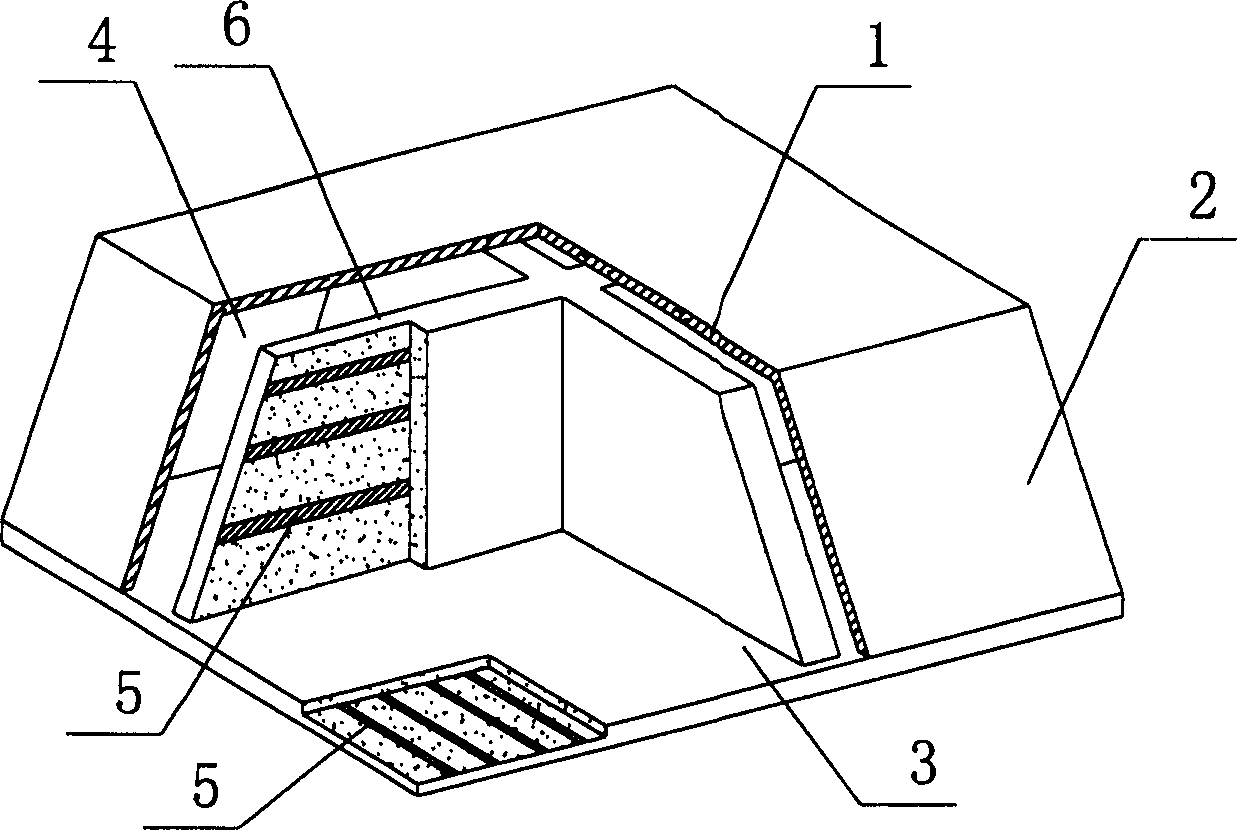

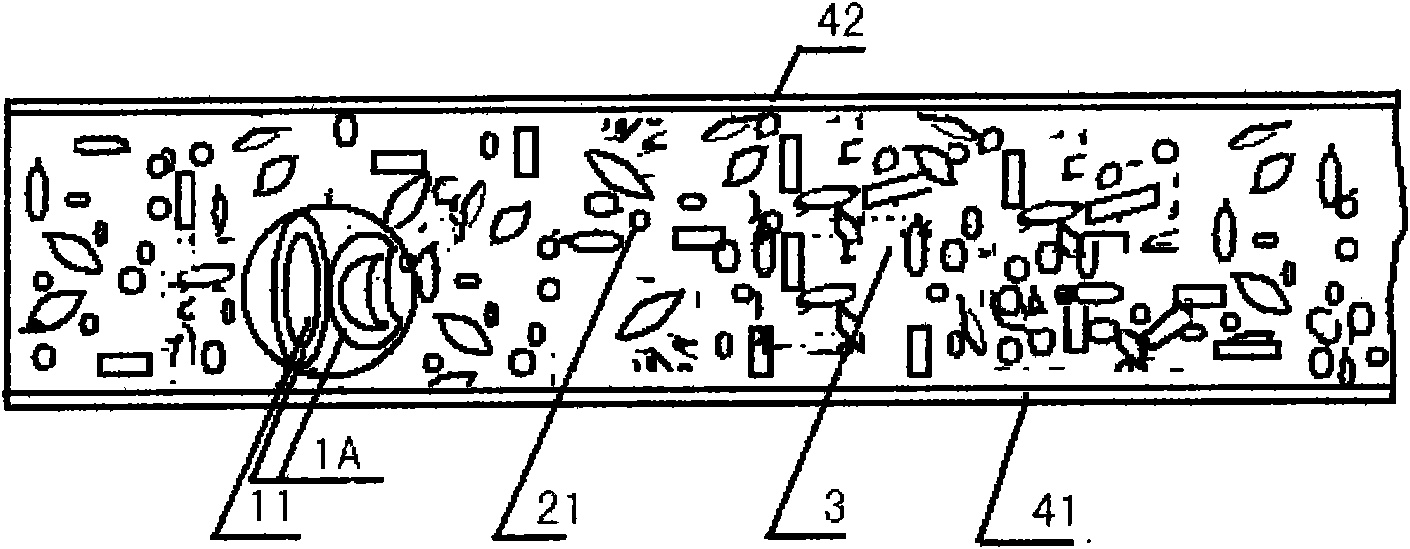

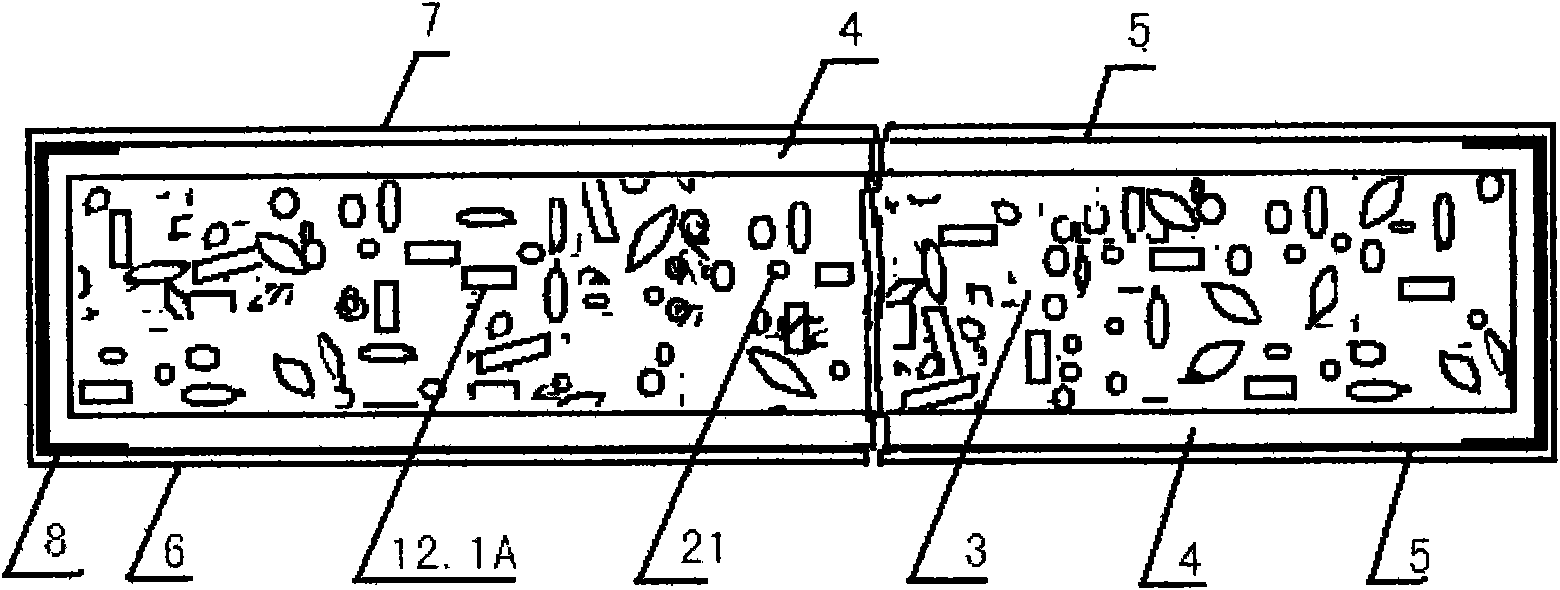

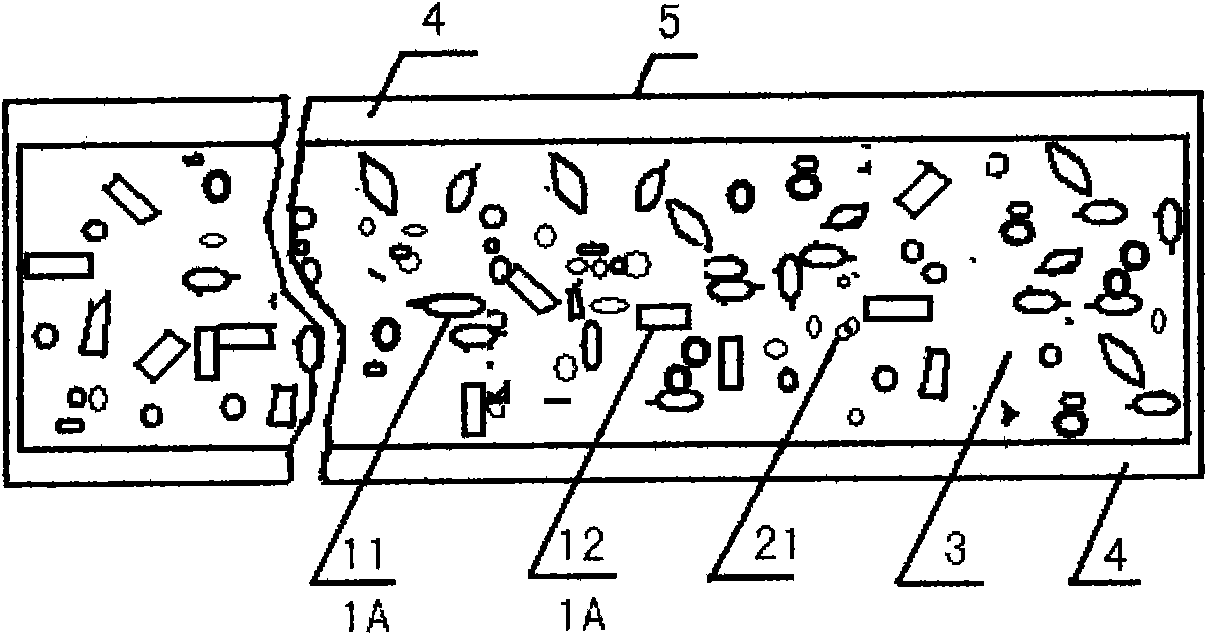

Thin-wall form member for hollowing out concrete

A thin-wall hollow form for concrete to in-situ pour hollow non-beam floor is composed of top plate, peripheral wall and bottom plate, and is characterized by that its bottom plate contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure, high strength, toughness and resistance to deformation and vibration, light weight and low cost.

Owner:湖南邱则有专利战略策划有限公司

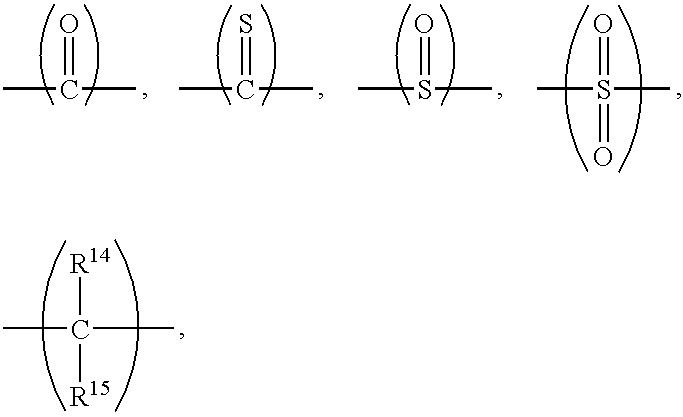

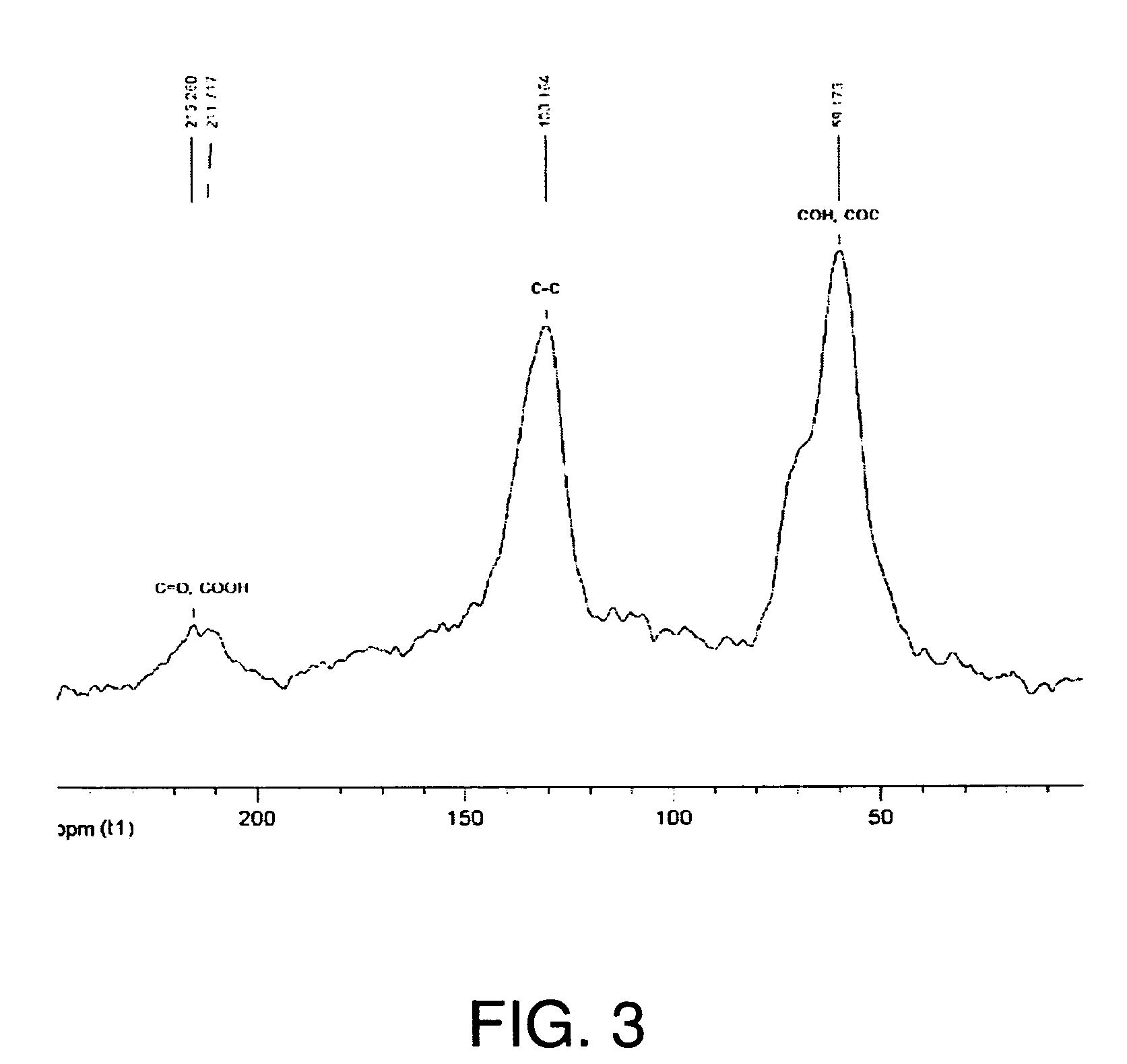

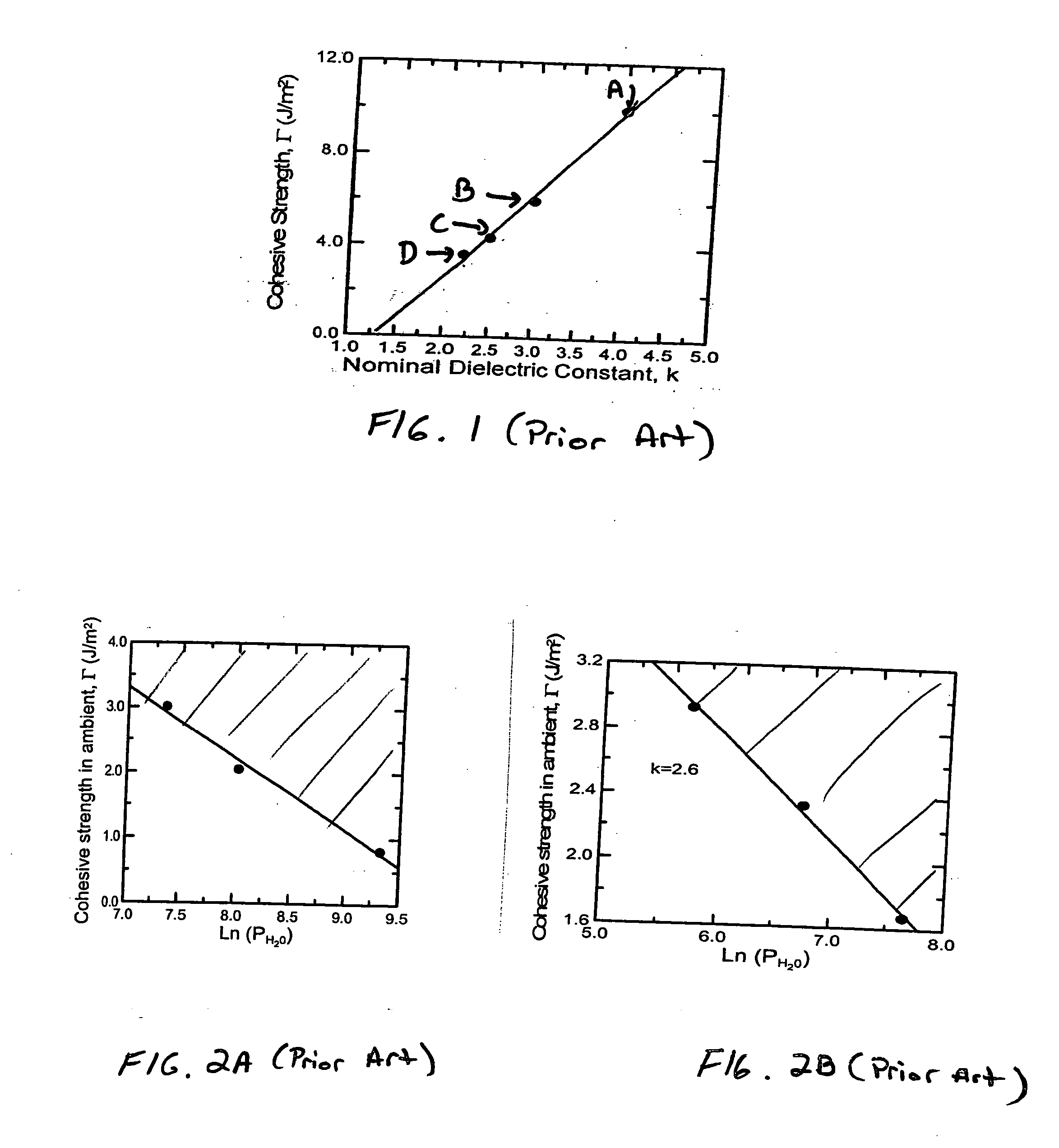

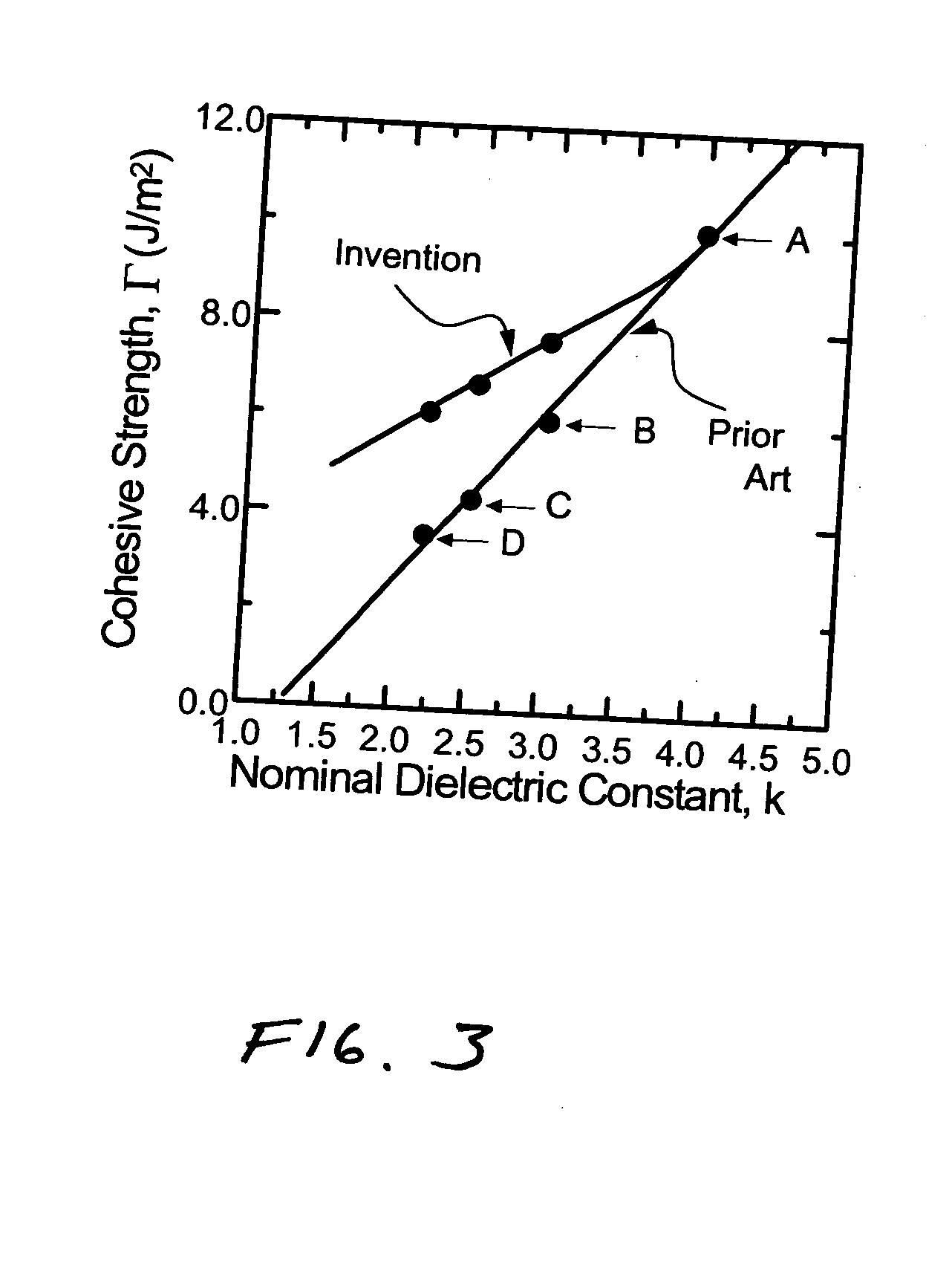

SiCOH dielectric material with improved toughness and improved Si-C bonding, semiconductor device containing the same, and method to make the same

InactiveUS20050194619A1Small slopeDelayed slopeSolid-state devicesSemiconductor/solid-state device manufacturingElectronic structureDevice material

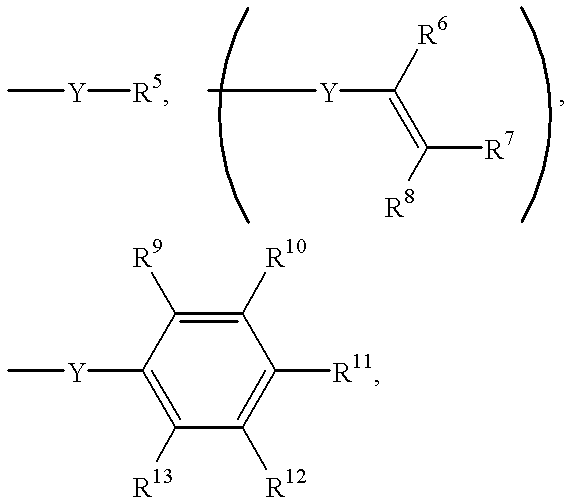

A low-k dielectric material with increased cohesive strength for use in electronic structures including interconnect and sensing structures is provided that includes atoms of Si, C, O, and H in which a fraction of the C atoms are bonded as Si—CH3 functional groups, and another fraction of the C atoms are bonded as Si—R—Si, wherein R is phenyl, —[CH2]n— where n is greater than or equal to 1, HC═CH, C═CH2, C═C or a [S]n linkage, where n is a defined above.

Owner:INTEL CORP

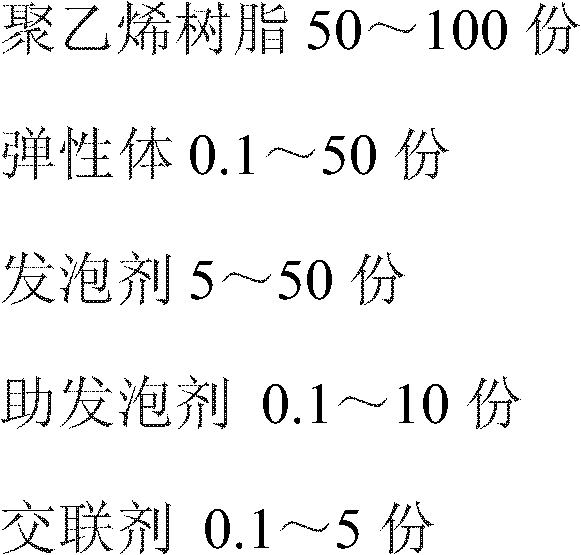

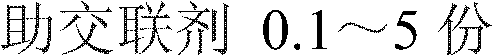

High-resilience chemical crosslinked polyethylene foam material and preparation method thereof

The invention discloses a high-resilience chemical crosslinked polyethylene foam material and a preparation method thereof. The material mainly comprises the following components by weight: 50-100 parts of polyethylene resin, 0.1-50 parts of elastomer, 5-50 parts of foaming agent, 0.1-5 parts of cross-linking agent, 0.1-10 parts of foaming assistant, and 0.1-5 parts of cross-linking assistant; the components are internally mixed, pelletized, mixed, extruded, and formed into non-cross-linking extruded master slices, and then the master slices are cross-linked and foamed by heating. According to the invention, the elastomer is mixed into PE (poly ethylene) resin to form the foam material, so the resilience of the product is high; meanwhile, the product further has high elongation at break and tensile strength, excellent toughness, and stable chemical and physical properties, so that the product can be widely used in the fields of packaging, sports and protection, transportation and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

High strength and high toughness modified poly-propylene material

The present invention belongs to the field of polymer material technology, and is especially one kind of modified polypropylene material comprising at least polymer base, strengthening agent and toughening agent. The polymer base may be polypropylene or polypropylene composition; the strengthening agent is inorganic or organic matter with great aspect ratio, such as inorganic or organic crystal whisker, fiber, mica, etc; and the toughening agent may be polypropylene beta-nucleater, rubber elastomer, etc. The modified polypropylene material has high strength, high toughness, etc and may be applied widely in automobile, pipeline, electric appliance and other fields.

Owner:FUDAN UNIV

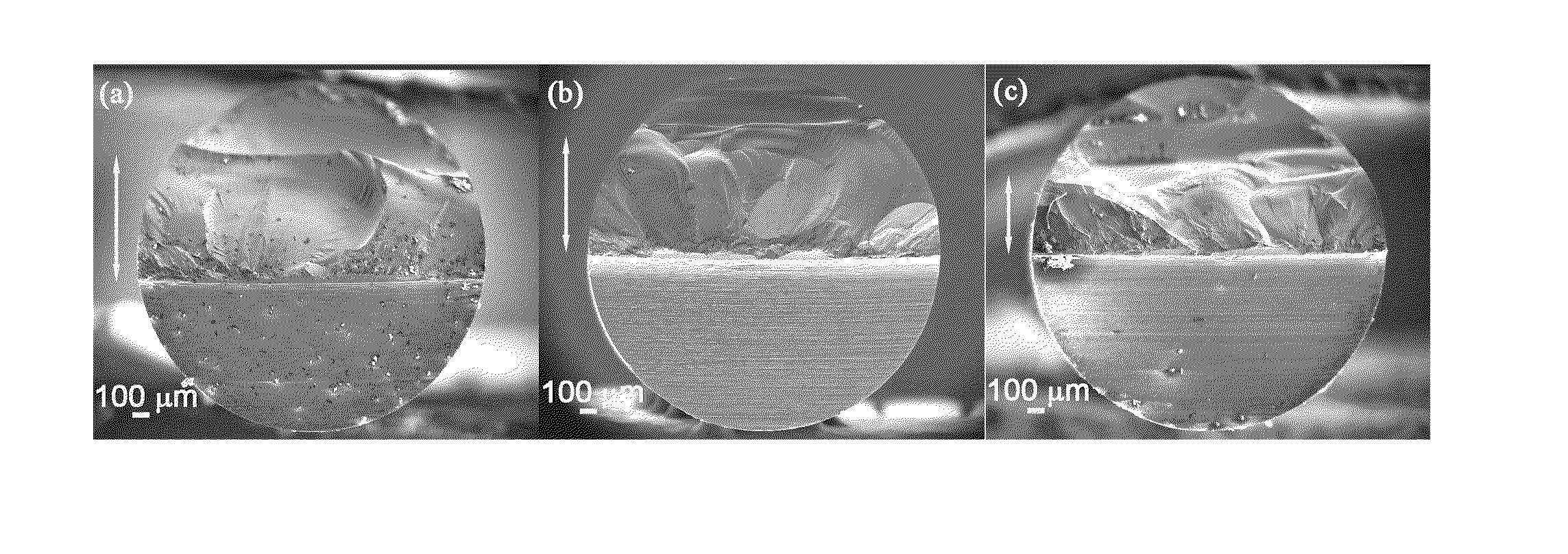

Tough iron-based bulk metallic glass alloys

A family of iron-based, phosphor-containing bulk metallic glasses having excellent processibility and toughness, methods for forming such alloys, and processes for manufacturing articles therefrom are provided. The inventive iron-based alloy is based on the observation that by very tightly controlling the composition of the metalloid moiety of the Fe-based, P-containing bulk metallic glass alloys it is possible to obtain highly processable alloys with surprisingly low shear modulus and high toughness.

Owner:CALIFORNIA INST OF TECH

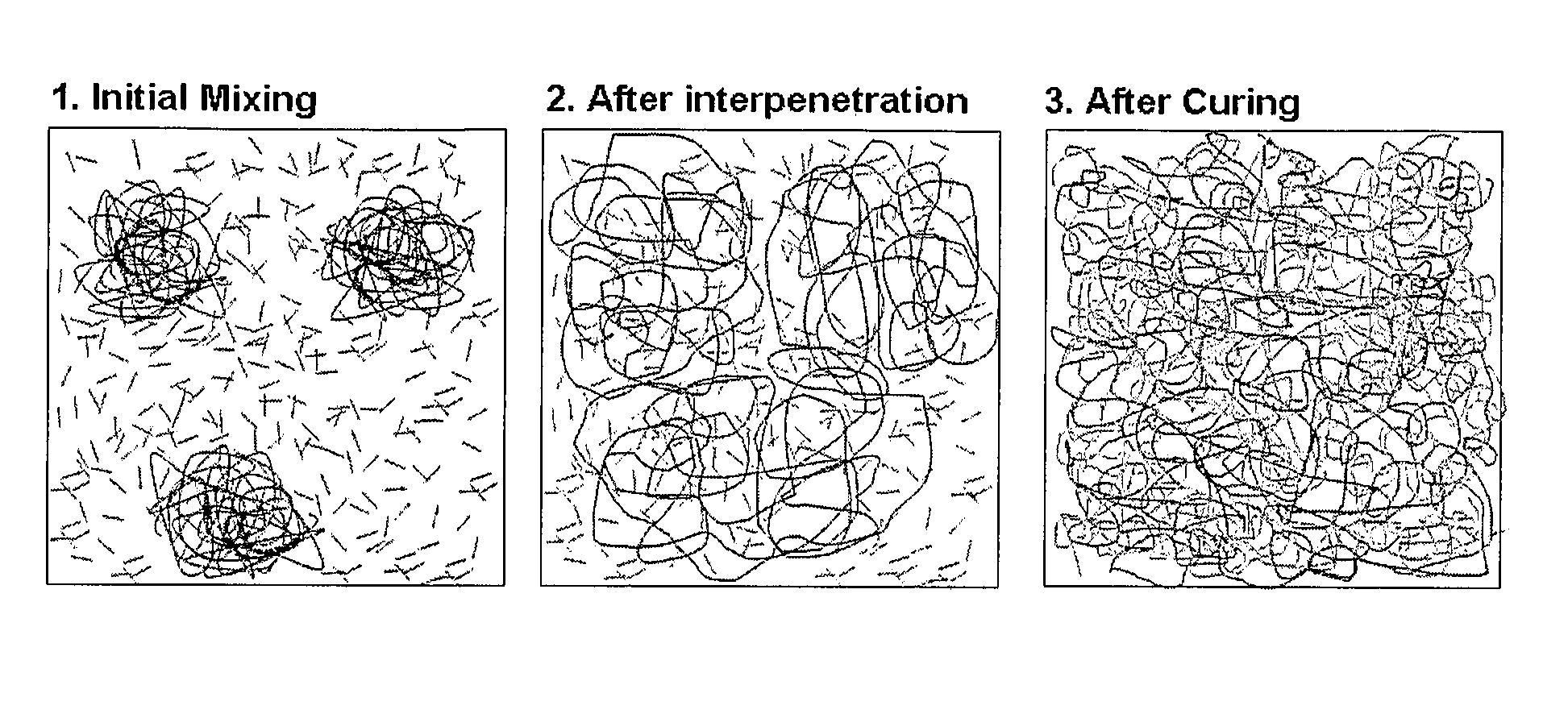

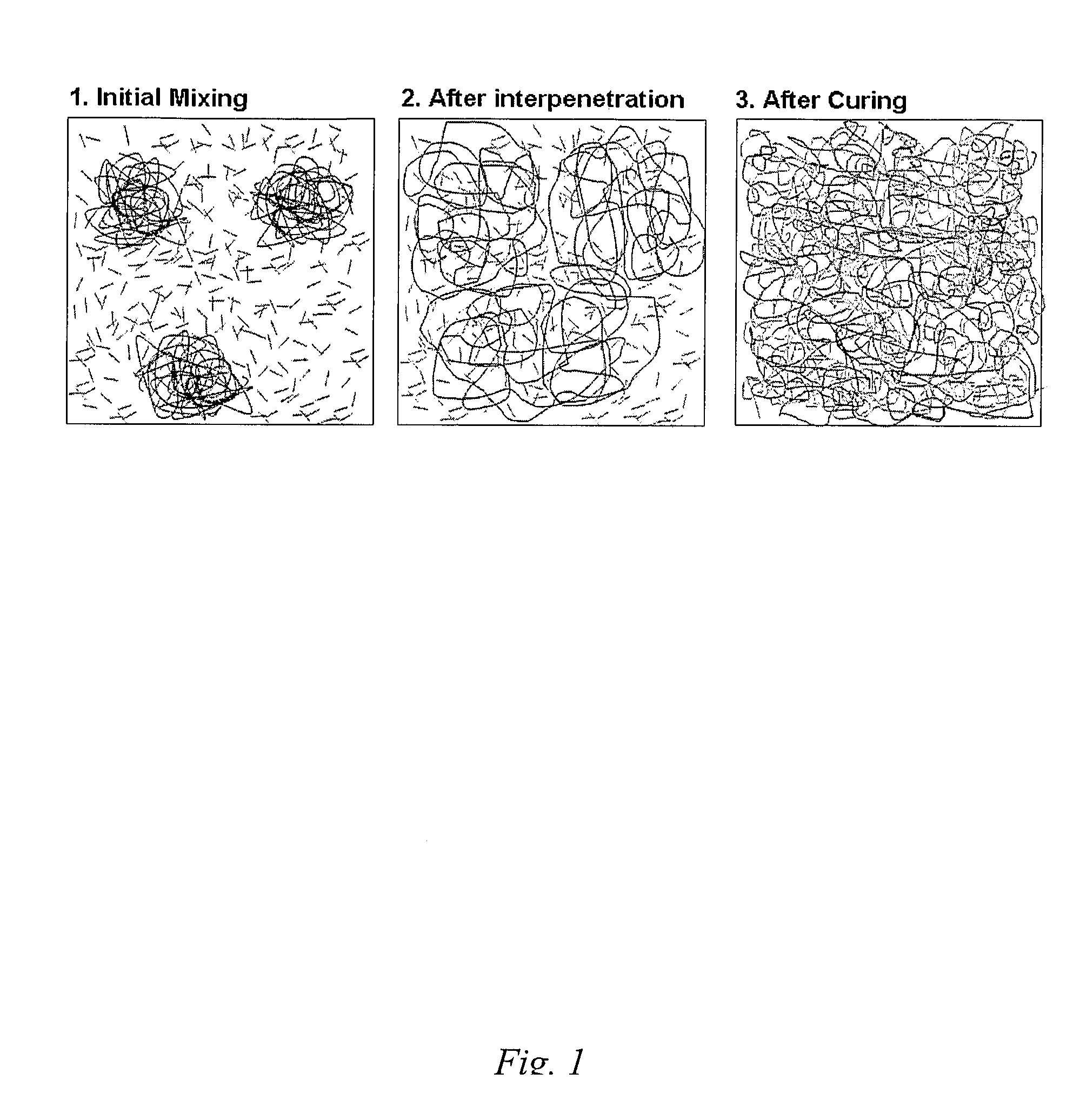

Polymer / Carbon-Nanotube Interpenetrating Networks and Process for Making Same

ActiveUS20080048364A1Improve propertiesHigh strengthPigmenting treatmentMaterial nanotechnologyCross-linkConductive polymer composite

The present invention is directed to new methods for combining, processing, and modifying existing materials, resulting in novel products with enhanced mechanical, electrical and electronic properties. The present invention provides for polymer / carbon nanotube composites with increased strength and toughness; beneficial for lighter and / or stronger structural components for terrestrial and aerospace applications, electrically and thermally conductive polymer composites, and electrostatic dissipative materials. Such composites rely on a molecular interpenetration between entangled single-wall carbon nanotubes (SWNTs) and cross-linked polymers to a degree not possible with previous processes.

Owner:RICE UNIV

Closures for bottles

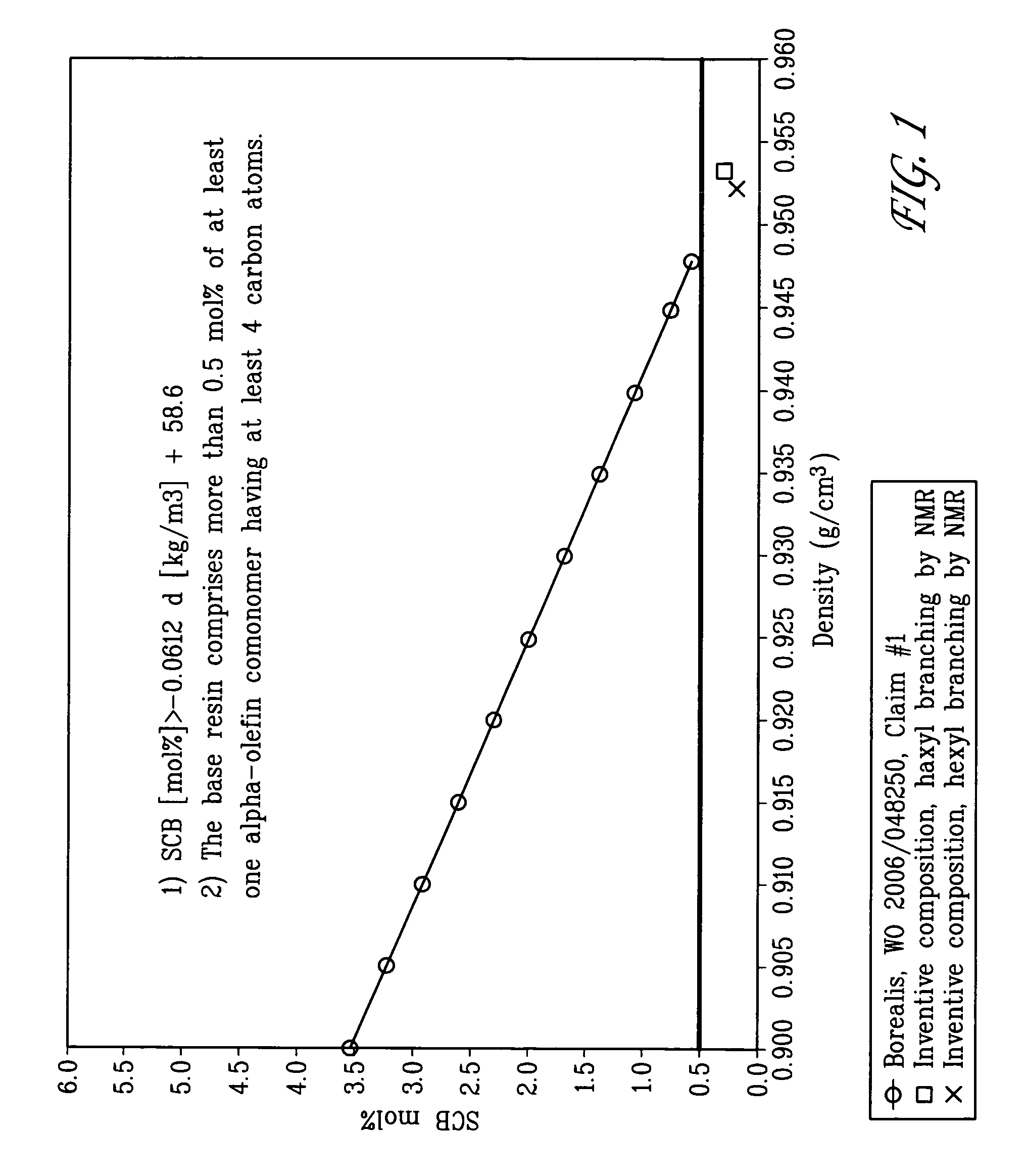

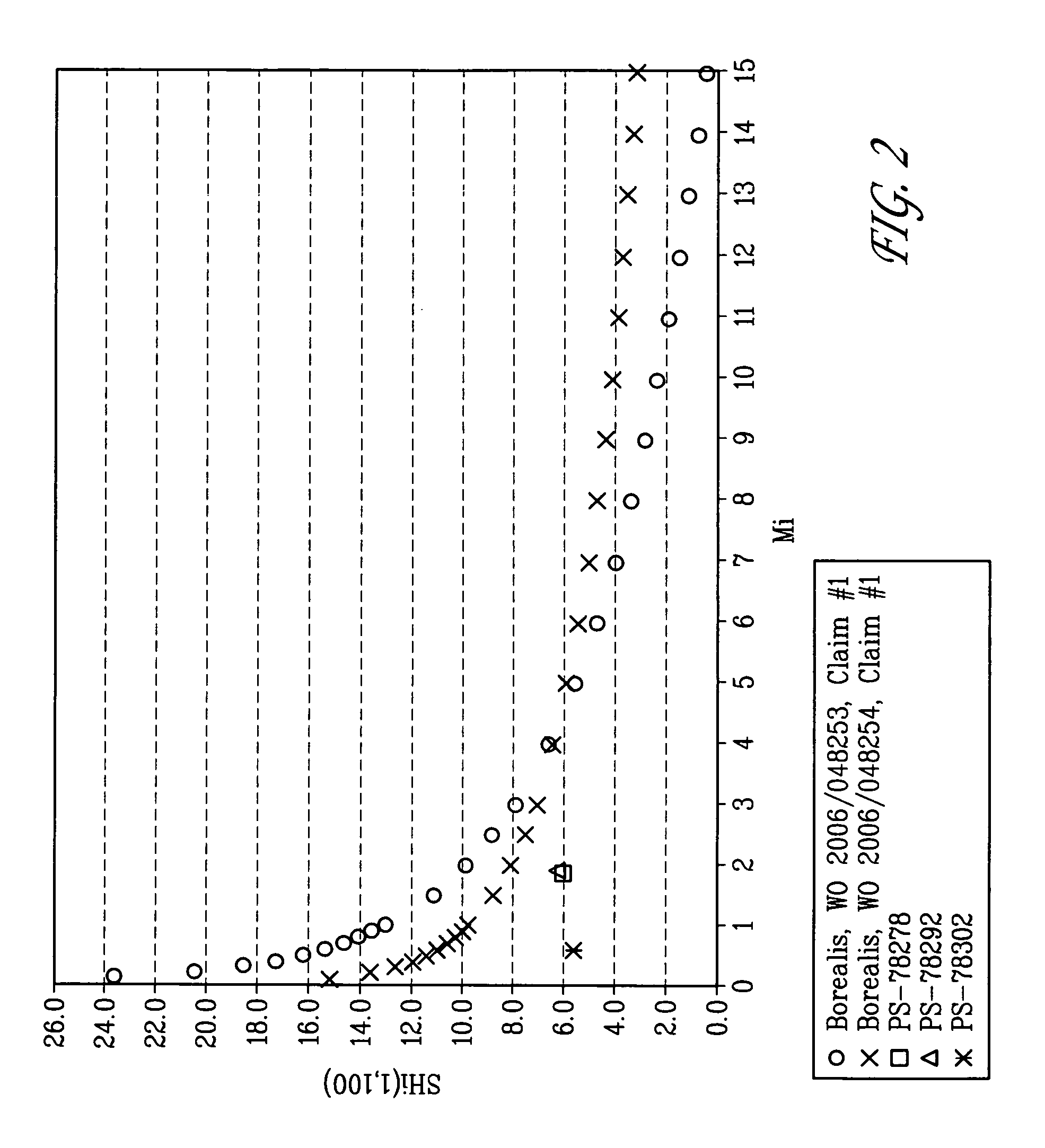

ActiveUS8022143B2Improved balance of Theological and processing and organoleptic propertyCompression moldingPolymer science

A dual reactor solution process gives high density polyethylene compositions containing a first ethylene polymer and a second ethylene polymer which have a good balance of processability, toughness, and environmental stress crack resistance combined with good organoleptic properties. The polyethylene compositions are suitable for compression molding or injection molding applications and are particularly useful in the manufacture of caps and closures for bottles.

Owner:NOVA CHEM (INT) SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com