High-resilience chemical crosslinked polyethylene foam material and preparation method thereof

A polyethylene foaming and chemical cross-linking technology, which is applied in the field of high-resilience chemical cross-linked polyethylene foaming materials and its preparation, can solve problems such as poor rebound effect, short service life, and easy collapse of cells, and achieve The effect of improving the service life, improving the strength and improving the rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

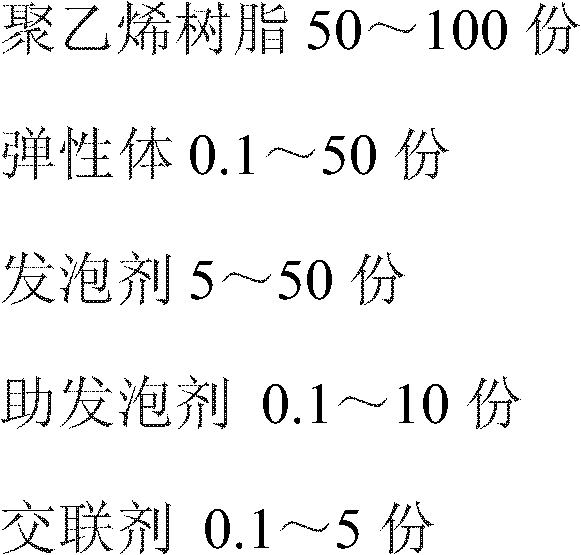

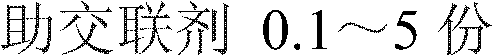

Method used

Image

Examples

Embodiment 1

[0043] Step 1: First, 80 parts of low-density polyethylene (MI0.8) and 20 parts of polyethylene-vinyl acetate (EVA, VA content 20%) are selected as the thermoplastic elastomer, and put into an internal mixer for banburying, and the resin is melted and mixed Finally, add 20 parts of azodicarbonamide and 2 parts of zinc oxide as a foaming aid to the internal mixer for 3 minutes; finally add 0.5 parts of crosslinking agent dicumyl peroxide and trimethylol Add 0.3 parts of propane trimethacrylate into the internal mixer and banbury for 2 minutes, then take it out and carry out open milling. The temperature of banburying and opening refining is controlled at 100-130°C.

[0044] Step 2: Crushing the blend obtained by kneading and adding it to a twin-screw extruder for granulation at a temperature of 100-125° C. and a screw speed of 30 r / min.

[0045] Step 3 Add the pellets to a single-screw extruder to extrude the mother sheet at a temperature of 100-125° C. and a screw speed of 30...

Embodiment 2

[0050]Step 1: Put 80 parts of low-density polyethylene (MI0.8) and 20 parts of EPDM into an internal mixer for internal mixing. After the resins are melted and mixed, mix 10 parts of azodicarbonamide 2 parts, 2 parts of zinc oxide, an auxiliary foaming agent, were added to the banbury mixer for 3 minutes; finally, 0.5 parts of cross-linking agent diisolidene peroxide, 0.3 parts of auxiliary cross-linking agent trimethylolpropane trimethacrylate Add in the internal mixer and banbury for 2 minutes, take it out and start refining. The temperature of banburying and opening refining is controlled at 100-130°C.

[0051] Step 2: Pulverize the blend obtained by kneading and add it to a twin-screw extruder for granulation. The temperature is 100-125° C., and the screw speed is 30 r / min.

[0052] Step 3 Add the pellets to the single-screw extruder to extrude the mother sheet at a temperature of 100-125°C and a screw speed of 30r / min to obtain a sheet with a thickness of 2mm and a width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com