Patents

Literature

2819 results about "Trimethylolpropane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

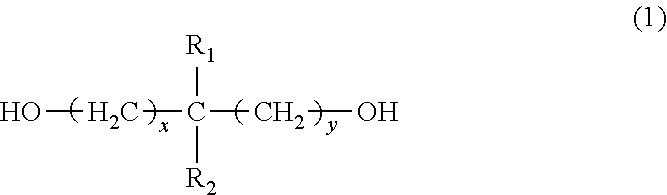

Trimethylolpropane (TMP) is the organic compound with the formula CH₃CH₂C(CH₂OH)₃. This colourless solid is a triol. Containing three hydroxy functional groups, TMP is a widely used building block in the polymer industry.

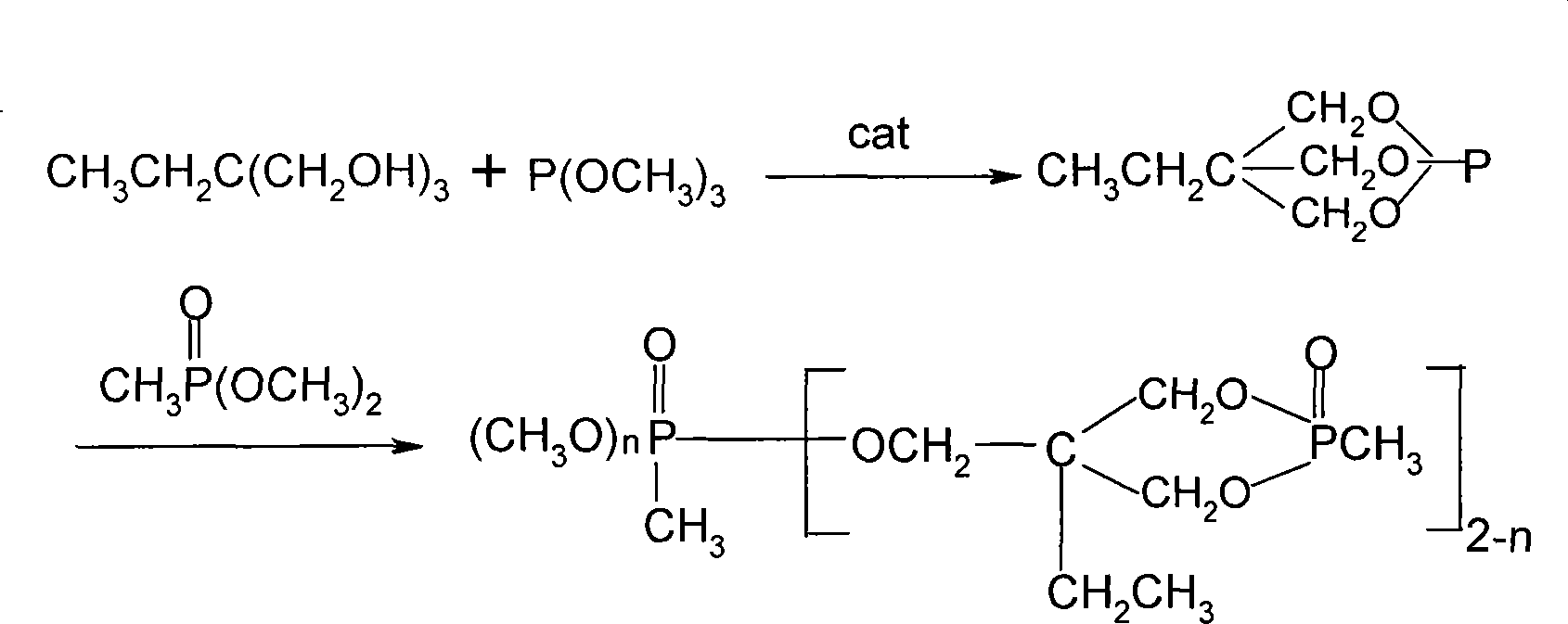

Method for preparing annular phosphonate or annular phosphate flame retardant

InactiveCN101230274AThe preparation method is simple and environmentally friendlyEasy to operateFlame-proof filament manufactureGroup 5/15 element organic compoundsDimethyl methylphosphonateTriethylphosphite

The invention provides a preparation method of annular phosphonate or annular organic phosphate flame retardant. The steps are that (1) trimethylolpropane and trimethyl phosphate or triethyl phosphate are taken as the material, and react to synthesize into midbody under the condition of catalyzer; (2) phosphonate or organic phosphate is added into the midbody and is heated, and then the product of annular phosphonate or annular organic phosphate flame retardant can be obtained. The phosphite ester is selected from trimethyl phosphate and triethyl phosphate. The phosphonate is selected from dimethyl-phosphine and diethyl ethyl phosphine. The organic phosphate is selected from trimethyl phosphate, triethyl phosphate, phosphate propyl, tributyl phosphate and tricresyl aromatic ester. The invention overcomes the shortcomings of the prior art, the new preparation method of annular phosphonate or annular organic phosphate flame retardant is environment-friendly, solution is not needed, and the operation is simple. The termination product has excellent color and luster, low acid value and excellent viscosity; and does not need additional decoloration.

Owner:NANJING NORMAL UNIVERSITY +1

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

Ultraviolet curing organic silicon modified polyurethane aqueous dispersoid and preparation method thereof

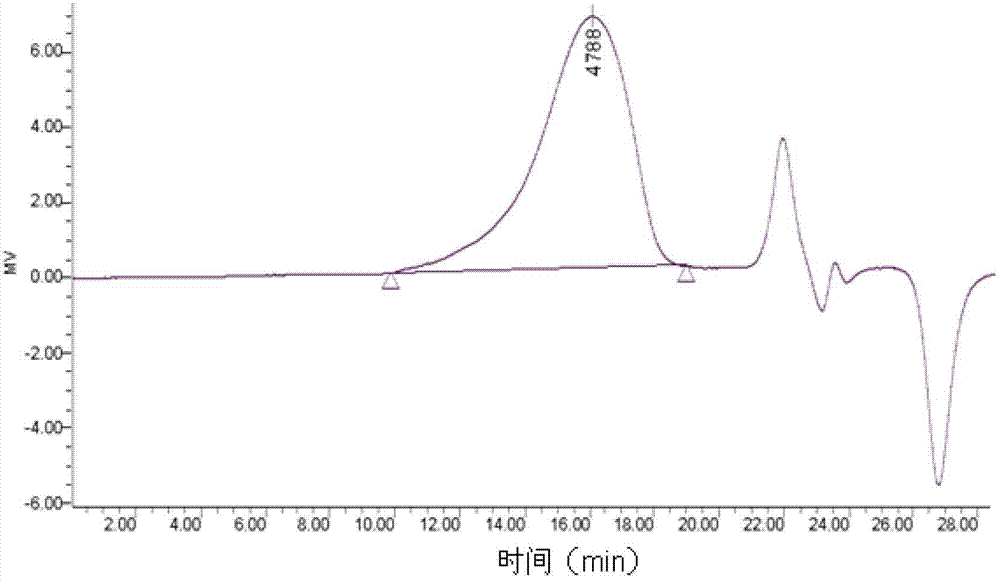

InactiveCN101735599AGood mechanical propertiesImprove water resistanceInksPolyurea/polyurethane coatingsPolyesterPropanoic acid

The invention discloses ultraviolet curing organic silicon modified polyurethane aqueous dispersoid and a preparation method thereof. The method comprises the following steps: firstly, dripping polyester or polyether diol, end hydroxyalkyl silicon oil, trimethylolpropane and the like into aromatic or aliphatic diisocyanate, and reacting the mixture to obtain organic silicon modified polyurethane prepolymer; then, adding polyhydromethyl propionic acid into the organic silicon modified polyurethane prepolymer, and reacting the mixture to obtain chain-extended organic silicon modified polyurethane prepolymer; and performing end capping reaction on the chain-extended organic silicon modified polyurethane prepolymer by using hydroxyethyl methacrylate or hydroxy-propyl acrylate to obtain organic silicon modified polyurethane acrylate oligomer, finally adding a neutralizer such as triethylamine and the like into the oligomer to perform neutralization reaction on the system, adding water into the mixture for diluting, and stirring and emulsifying the mixture to obtain the ultraviolet curing organic silicon modified polyurethane aqueous dispersoid. The ultraviolet cured coating film has better water tolerance and adhesive force, and can be widely applied in the fields of environmental protection, building, household appliances, ink, coating and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Water-blown, flame retardant rigid polyurethane foam

The present invention provides a flame-retardant polyurethane foam made with non chlorofluorocarbon / hydrogenated chlorofluorocarbon-containing blowing agents and without trimethylolpropane-based polyols that achieves a Class I rating as determined by a modification of the ASTM E-84 tunnel test and may find application in electronic cabinetry, architectural decorative moldings, and interior transportation vehicle walls.

Owner:COVESTRO LLC

Method of preparing low temperature solidifying environment protection type cathode electrophoresis coating

InactiveCN101054487AImprove stabilityLow curing temperaturePaints for electrolytic applicationsPolyamide coatingsEpoxyLow temperature curing

The invention discloses an environment-friendly cathode electrophoretic coating with a low heating loss and low solvent content which can be cold cured. The method includes following steps and craft conditions: (1) preparation of curing agent and modification of mainbody resin. The curing agent is prepared by reaction of isocyanate, ketoximes solvent and trimethylolpropane so as to produce multifunctional group for closing the isocyanate curing agent. The whole reaction of mainbody resin modification includes chain extension reaction of epoxide resin, ring-opening reaction of amine and polyamide to the epoxide resin, the preparation of semi enclosed isocyanate and grafting reaction steps; (2) preparation of the catalytic curing agent slurry; (3) preparation of cathode electrophoretic coating latex and color paste. The invention improves the epoxide resin stability, reduces the resin curing temperature, and declines the heating loss of the dope and the discharge of the solvent. It applies extracting method in the latex producing process to reduce the solvent content so as to produce a environment-friendly cathode electrophoretic coating which can be cold cured.

Owner:佛山科富科技有限公司

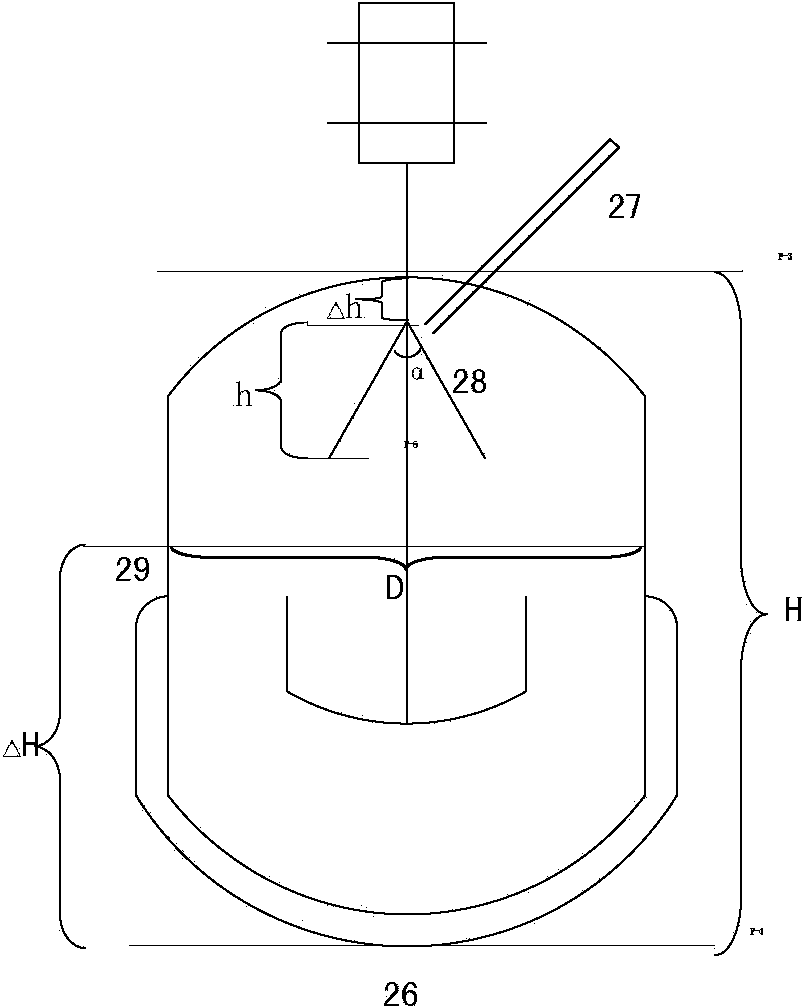

Preparation method of light-colored polyisocyanate curing agent

ActiveCN103881050AIncreased contact areaUniform on a microscopic scalePolyurea/polyurethane coatingsAlcoholLiquid state

The invention relates to a preparation method of a light-colored polyisocyanate curing agent. The preparation method comprises the following steps: (a) purifying a raw material-trimethylolpropane to obtain trimethylolpropane with the carbonyl compound content lower than 0.1wt%; (b) reacting trimethylolpropane with the carbonyl compound content lower than 0.1wt% or a mixture of trimethylolpropane with the carbonyl compound content lower than 0.1wt% and micromolecular dihydric alcohol with excess diisocyanate in a reactor with a conical liquid distribution plate to obtain a liquid-state prepolymer reaction solution containing excess diisocyanate; and (c) removing monomers from the prepolymer reaction solution obtained in the step (b) by adopting a two-stage film evaporator, and diluting by a solvent to obtain the curing agent with the diisocyanate monomer content lower than 0.5wt%. The color number of the diisocyanate curing agent prepared based on the method can be lower than 20Hazen.

Owner:WANHUA CHEM GUANGDONG

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

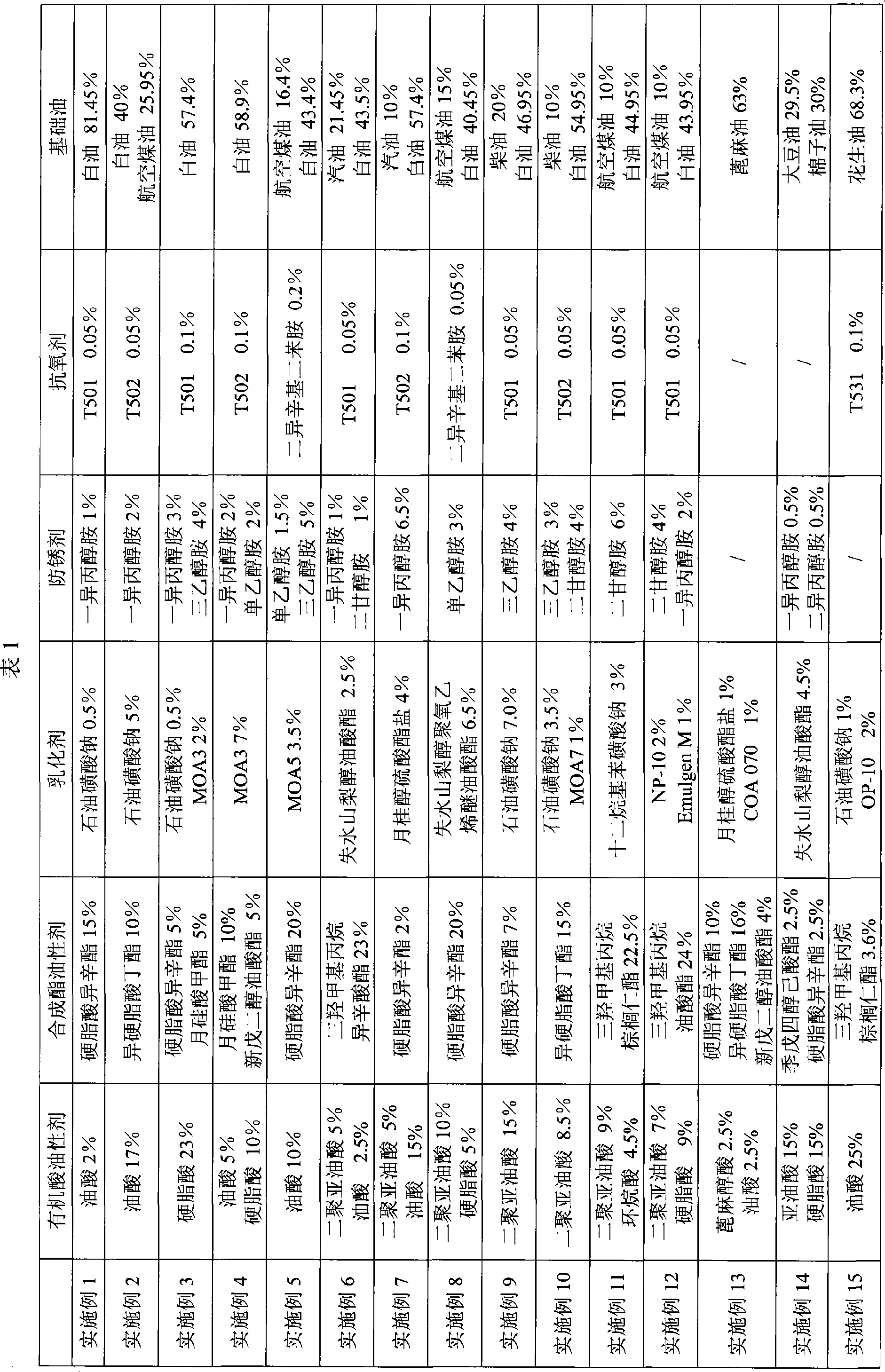

Drilling fluid lubricating agent

ActiveCN101486896AMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionStearateTrimethylolpropane

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil composition for refrigerators and compressors with the composition

ActiveUS20100147016A1Improve compatibilityImprove sealingPositive displacement pump componentsHeat-exchange elementsPolyolesterCarboxylic acid

A lubricating oil composition for refrigerators comprising a base oil which comprises as a main component a polyol ester compound obtained from a polyhydric alcohol selected from among pentaerythritol, dipentaerythritol, trimethylolpropane, and neopentyl glycol and a C4 to C20 aliphatic monocarboxylic acid and which has an acid value of 0.02 mgKOH / g or less and a hydroxyl value of 5 mgKOH / g or less. A compressor using the lubricating composition. The lubricating oil composition is applicable to such refrigerators that use a refrigerant having a specific structure, such as an unsaturated fluorinated hydrocarbon compound, and being usable in current car air conditioner systems, and has excellent compatibility with the refrigerant, good sealing properties, capability of imparting a low coefficient of friction to sliding members and, yet, excellent stability. The compressor uses the lubricating composition.

Owner:IDEMITSU KOSAN CO LTD

Polyurethane aqueous dispersion and preparation method thereof

InactiveCN104311778AReduce manufacturing costLow priceOrganic compound preparationCarboxylic acid esters preparationCross-linkHydrophilic monomer

The invention discloses a polyurethane aqueous dispersion and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing trimethylolpropane or glycerol and acid anhydride and preparing a carboxylic acid type hydrophilic monomer; on the basis of molar parts, adding 20-60 parts of polymer dibasic alcohol, 4-10 parts of carboxylic acid type hydrophilic monomer and 30-60 parts of a diisocyanate monomer into a reactor, heating to 60 DEG C-100 DEG C and carrying out heat preservation; adding1-10 parts of small-molecular dibasic alcohol, 2-10 parts of a non-ionic hydrophilic chain extender and 1-6 parts of a cross-linking agent and reacting until the content of NCO is less than 5%; and adjusting the viscosity of the reactant, cooling, adding a neutralizing agent for neutralizing, adding water for emulsifying, adding an amine chain extender and removing the solvent by distillation to obtain the polyurethane aqueous dispersion. The carboxylic acid type hydrophilic monomer has stable performance and low cost, the polyurethane aqueous dispersion prepared from the carboxylic acid type hydrophilic monomer has high content of solids and the coating has relatively high hardness and excellent chemical product resistance.

Owner:SOUTH CHINA UNIV OF TECH

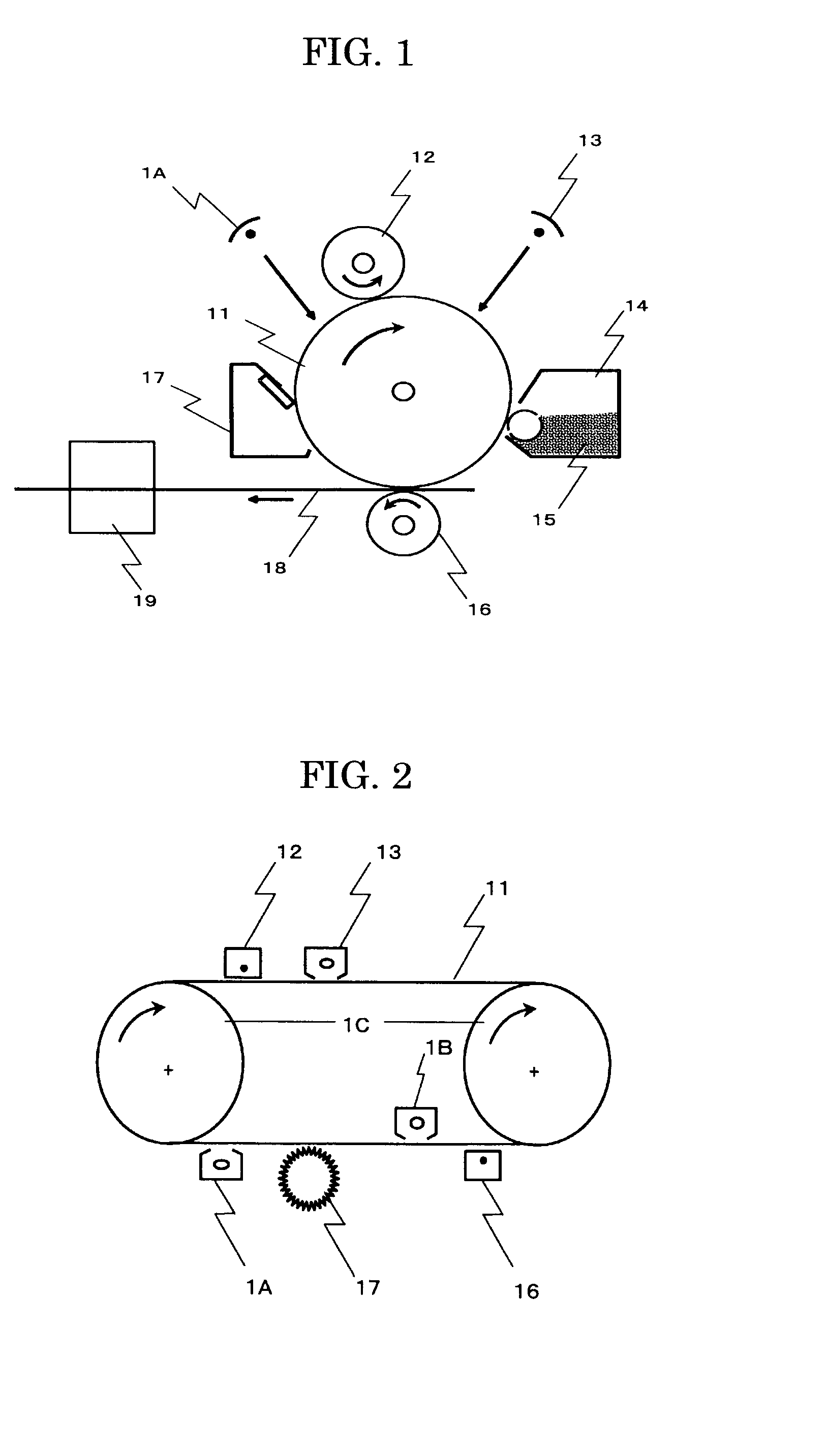

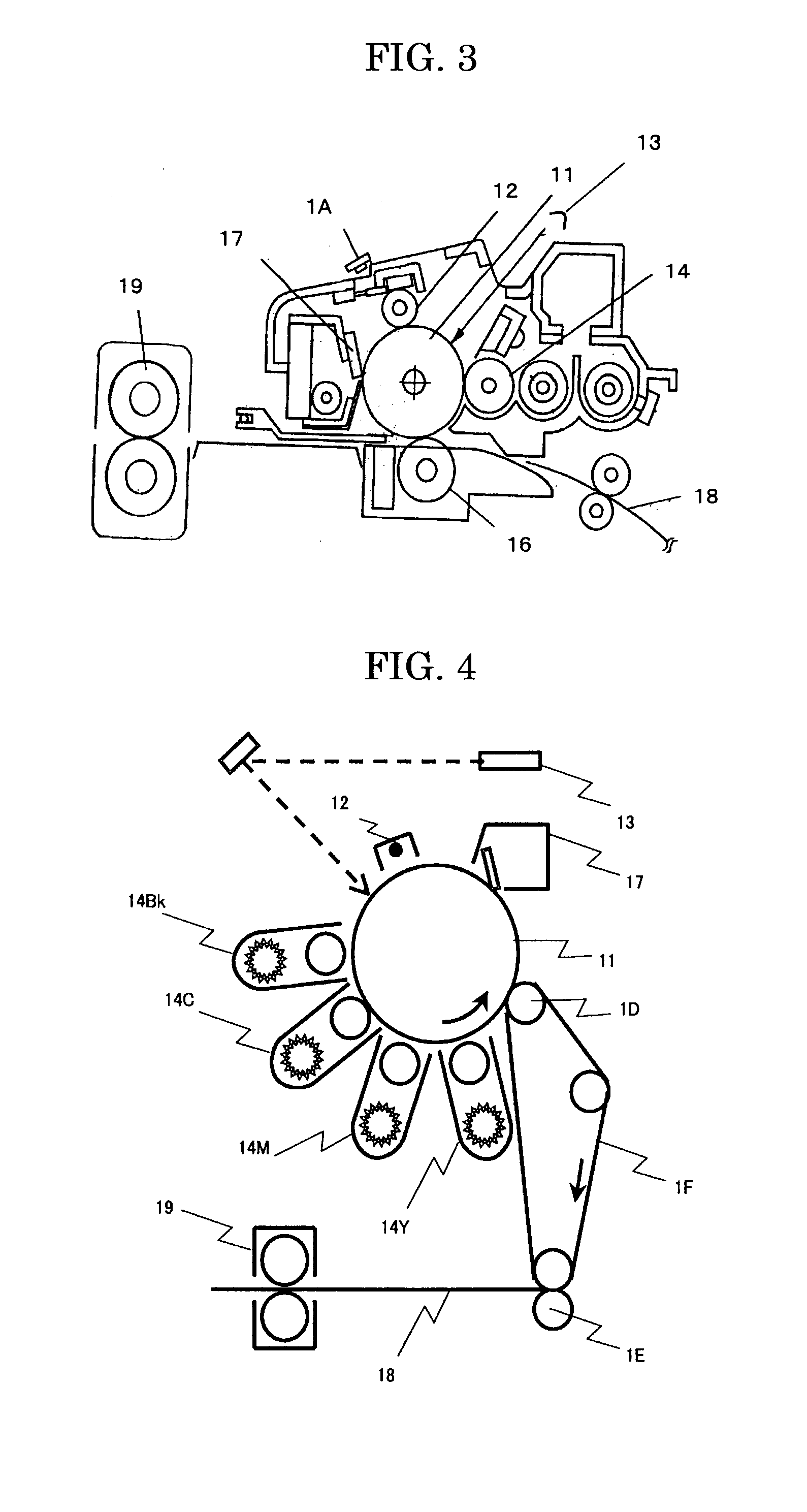

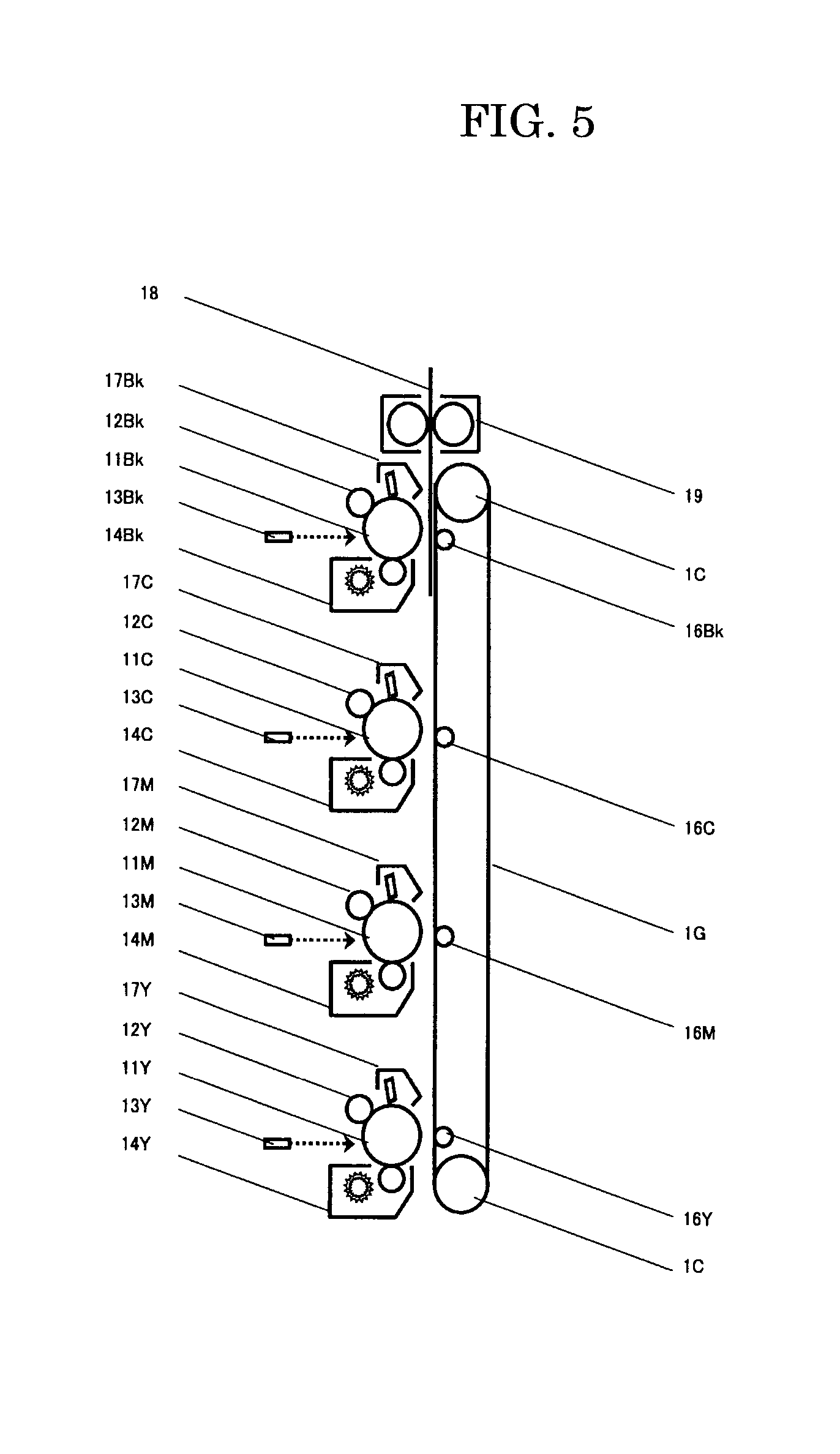

Electrophotographic photoconductor, and electrophotographic apparatus

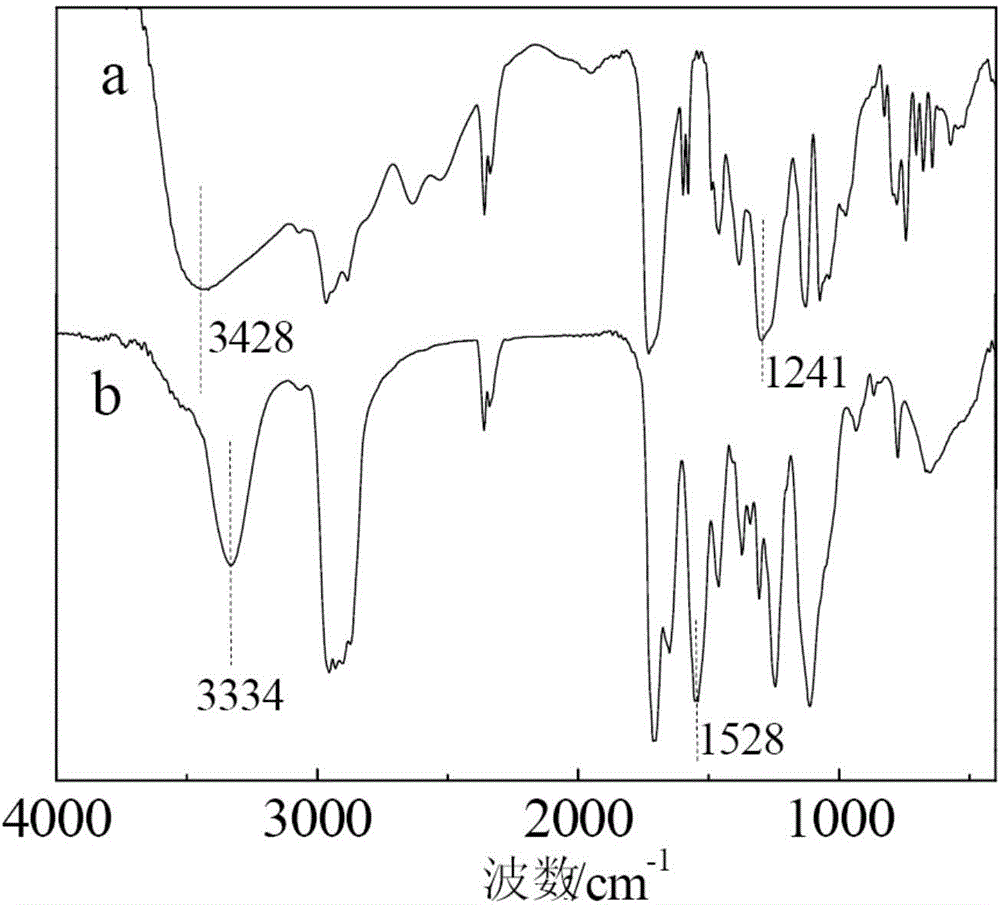

InactiveUS20080085459A1Improve surface smoothnessImprove wear resistanceElectrographic process apparatusCross-linkElectrical conductor

There is provided an electrophotographic photoconductor which contains at least a conductive substrate, a photoconductive layer comprising a charge generating material and charge transport material, and a surface layer disposed on the photoconductive layer, disposed in this order, wherein the surface layer is a cross-linked resin which contains at least trimethylolpropane triacrylate, a charge transport material having a heat-curable or radical-polymerizable functional group, a silicone compound having a radical-polymerizable functional group, a fluorinated surfactant having a radical-polymerizable functional group, and a silicone compound removing material having a radical-polymerizable functional group having a wettability of 55 mN / m or more to less than 65 mN / m with the silicone compound.

Owner:RICOH KK

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

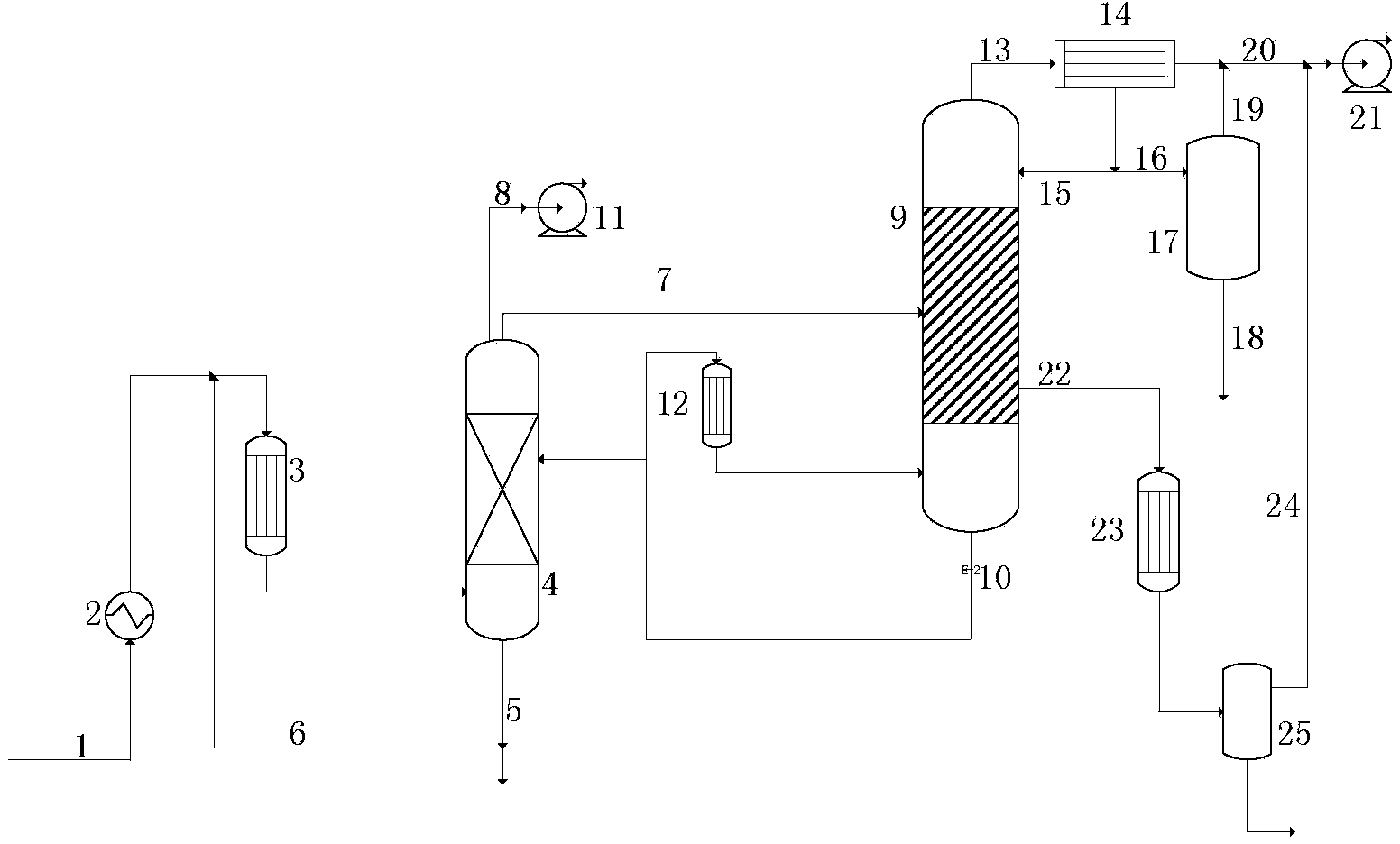

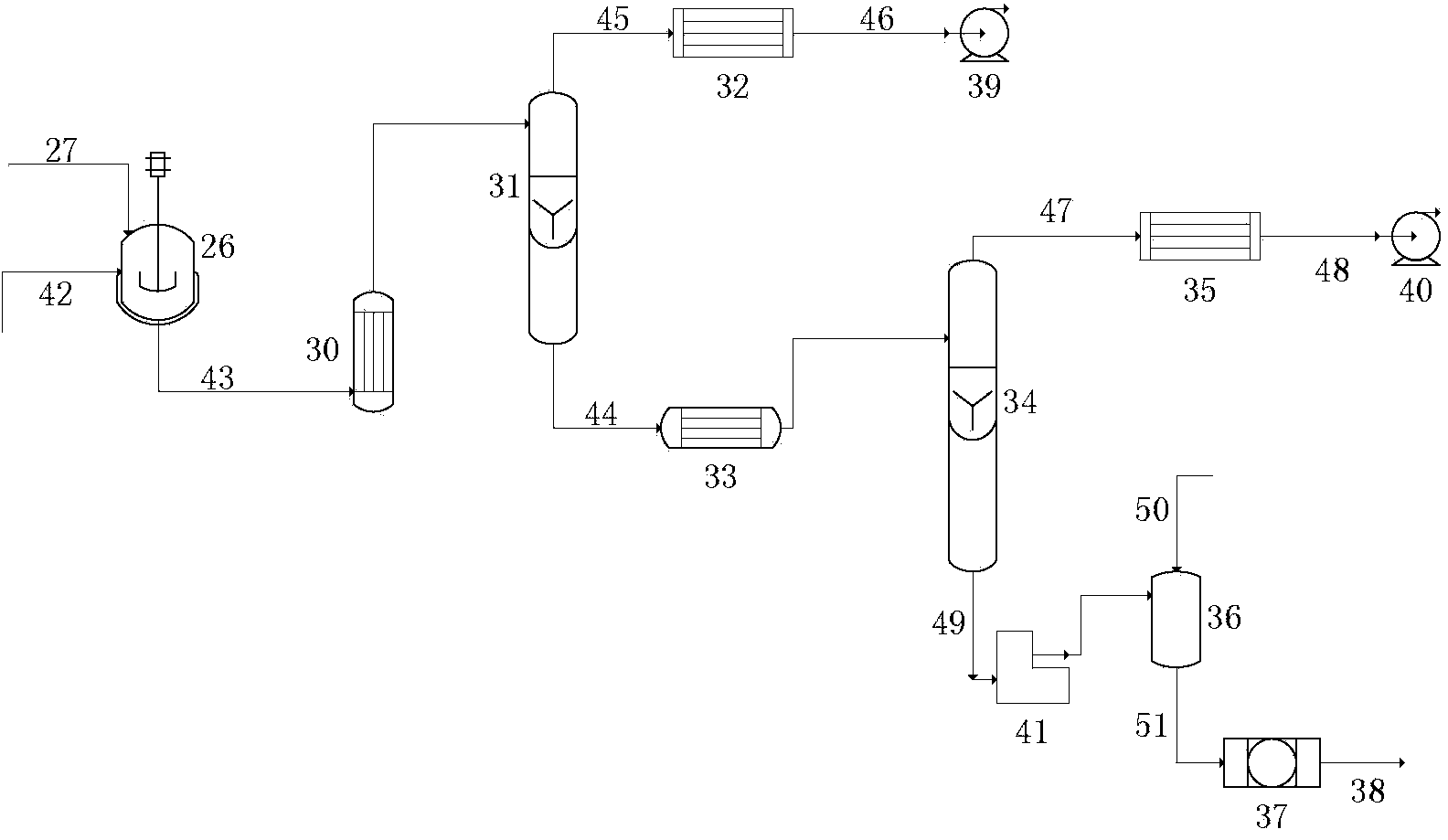

Method for preparing trimethylolproane

ActiveUS7253326B1Effective and economicalOrganic compound preparationOxygen compounds purification/separationAlcoholCannizzaro reaction

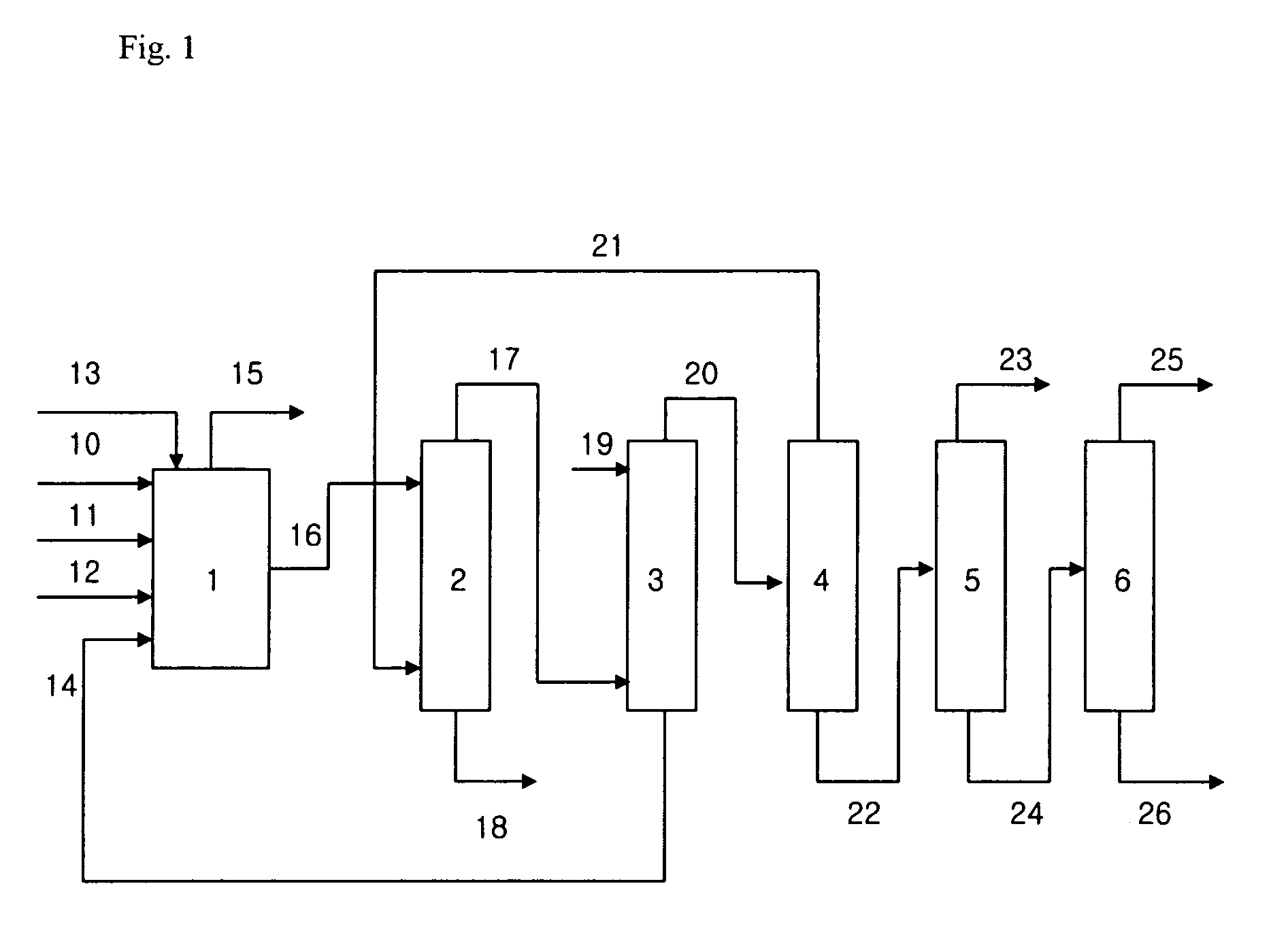

The present invention relates to a method for preparing trimethylolpropane (TMP) comprising the steps of: 1) synthesizing trimethylolpropane by using n-butyl aldehyde, an aqueous solution of formaldehyde and an aqueous solution of alkali metal hydroxide through aldol condensation reaction and Cannizzaro reaction; 2) extracting trimethylolpropane from a resultant mixture of the step 1) by contacting the resultant mixture with an alcohol having 6 to 10 carbons; 3) removing alkali metal ion from a resultant extract of the step 2) by contacting the resultant extract with water; and 4) distilling the alkali metal ion-removed extract obtained from the step 3). According to the present invention, a separate formaldehyde recovery process can be omitted, the extraction efficiency of TMP can be maximized with using a relatively small amount of extraction solvent, the separation and recovery processes for extraction solvent can be simplified since a mixture of solvents is not used for TMP extraction, and the yield of TMP can be maximized while the amount of generated waste water can be minimized, thereby producing TMP economically with good efficiency.

Owner:LG CHEM LTD

Aqueous polyurethane and preparation thereof

The invention belongs to the technical field of fine chemicals and preparation thereof, and in particular relates to waterborne polyurethane and a preparation method thereof. In order to solve the problems of environmental pollution and non-ideal overall performance of the prior art, the invention adopts a technical proposal that the waterborne polyurethane is prepared by the method sequentially comprising the following: (1) a step of preparing polyurethane prepolymer, which is to take polyglycol and diisocyanate as raw materials for polymerization reaction and form the polyurethane prepolymer; (2) a step of performing chain extension reaction, which is to add hydrophilic chain extender and trimethylolpropane as a crosslinking agent to the polyurethane prepolymer so as to perform chain extension reaction; (3) a step of performing end capping reaction, which is to add organic functional silane to a reactor so as to perform end capping reaction; and (4) a step of emulsifying, which is to add organic base, regulate the pH value between 7.0 and 7.5, add deionized water in a state of stirring and obtain a white emulsion. Compared with the prior art, the preparation method has the advantages of eliminating pollution, and improving the overall performance of the product.

Owner:SHAANXI UNIV OF SCI & TECH

Triazine weedicide, and metabolite molecular engram polymer microspheres, preparation method and application thereof

ActiveCN102532390AWith "memory" functionMeet the requirements of multi-residueOther chemical processesMicroballoon preparationWater bathsMetabolite

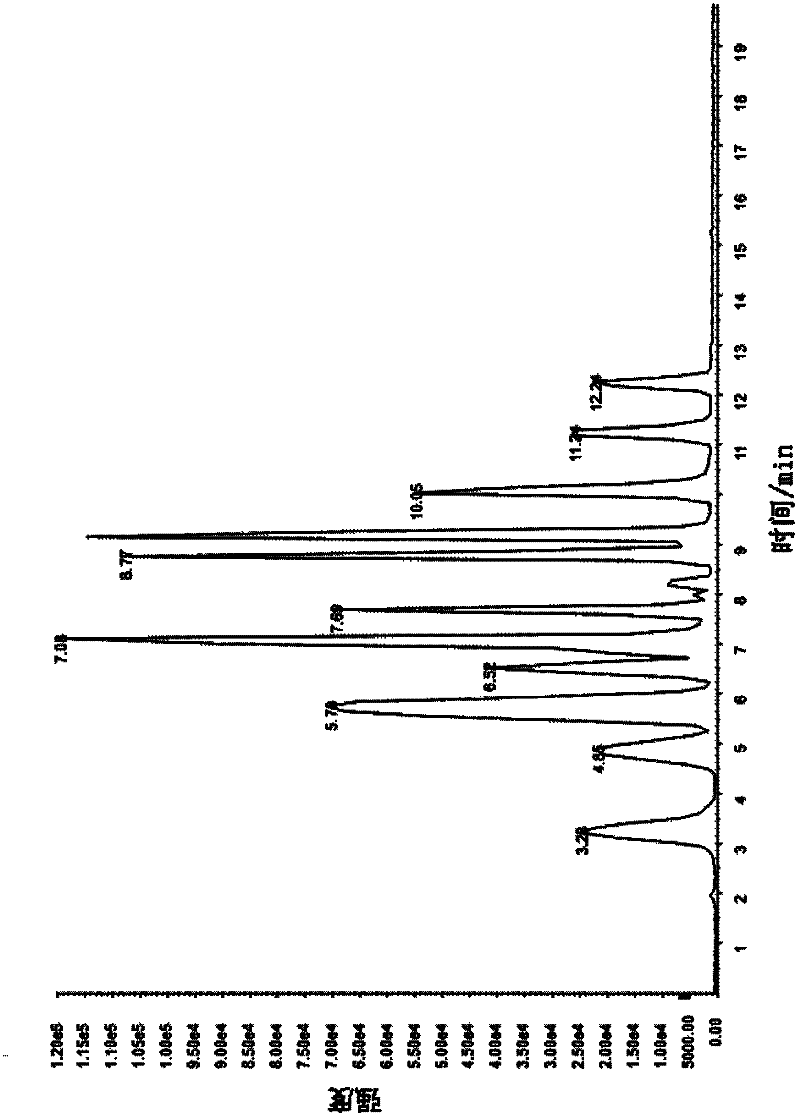

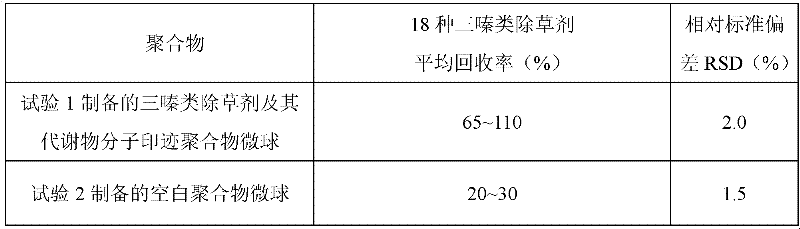

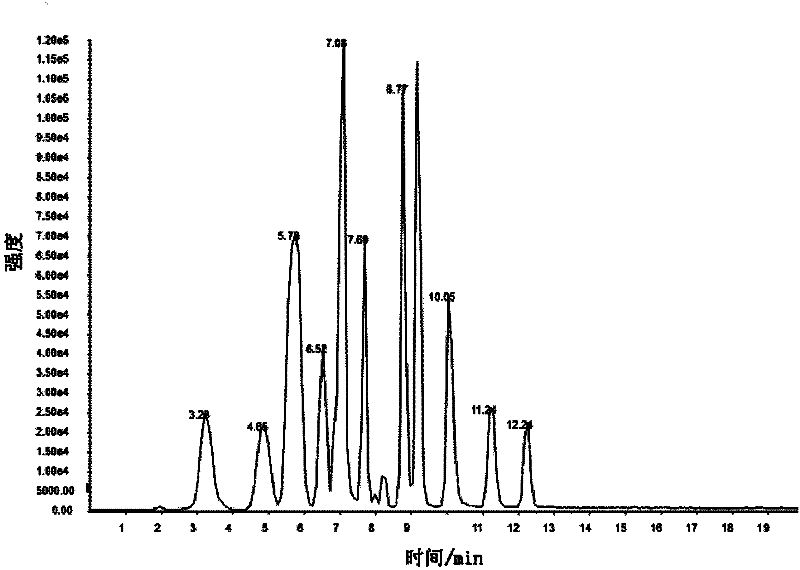

The invention discloses a triazine weedicide, and metabolite molecular engram polymer microspheres, a preparation method and an application thereof, which relate to molecular engram polymer microspheres and a preparation method and an application thereof and are used for solving the problem that the conventional molecular engram polymer can only specially absorb one kind of substance and realizing the effect of separating and enriching a plurality of triazine pesticide residues in a sample respectively. The molecular engram polymer microspheres are prepared by the following steps of: dissolving double template molecules and methacrylic acid into acetonitrile; oscillating; adding trimethylolpropane trimethylacrylate and azobisisobutyronitrile; performing ultrasonic treatment, charging nitrogen, removing oxygen and sealing; and heating in a constant-temperature water bath, cooling, grinding, sieving, eluting and drying. The molecular engram polymer microspheres are applied to a filling material of a solid phase extraction column. A product obtained in the invention has the advantages of high specificity, large absorption amount, wide application range, simple method and low cost. High specific separating and enriching characteristics on the triazine weedicide are achieved, the recovery rate is 65-110 percent, and the requirement of multiple residues can be met.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Lubricating oil composition for refrigerators

ActiveUS20100133463A1Improve compatibilityLow global warming potentialHeat-exchange elementsAdditivesPhosphorous acidScavenger

A lubricating oil composition for refrigerators including (A) a base oil containing as a main component a polyol ester compound obtained from a polyhydric alcohol selected from among pentaerythritol, dipentaerythritol, trimethylolpropane and neopentyl glycol and a C4 to C20 aliphatic monocarboxylic acid, (B) a phosphorus-based additive comprised of a phosphoric acid triester and / or a phosphorous acid triester, and (C) at least one acid scavenger selected from among glycidyl esters, glycidyl ethers and α-olefin oxides.The lubricating oil composition is applicable to such refrigerators that use a refrigerant having a specific structure, such as an unsaturated fluorinated hydrocarbon compound, and being usable in current car air conditioner systems, and has excellent compatibility with the refrigerant, good sealing properties, capability of imparting a low coefficient of friction to sliding members and, yet, excellent stability.

Owner:IDEMITSU KOSAN CO LTD

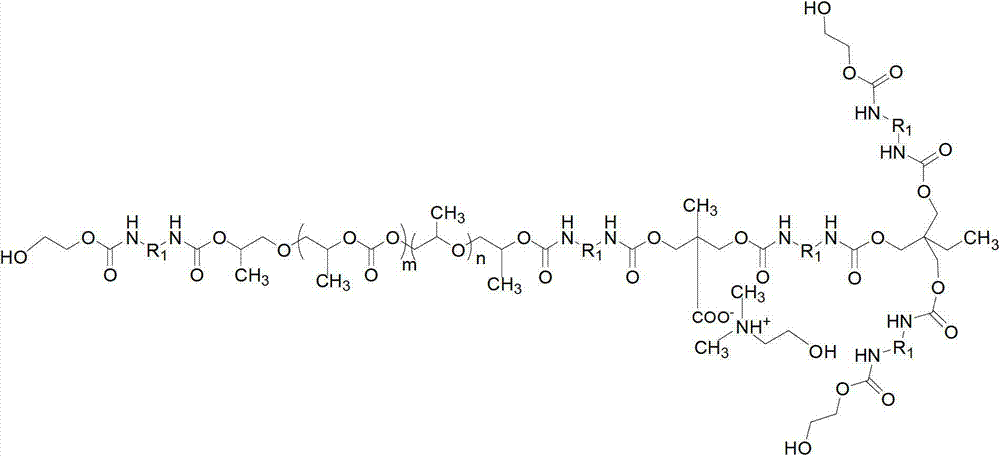

Waterborne polyurethane adhesive and preparation method thereof

ActiveCN103045150AOvercome water resistanceOvercome mechanical propertiesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention provides a waterborne polyurethane adhesive which comprises polyurethane with a structure of a formula (I). The invention also provides a method for preparing the waterborne polyurethane adhesive. The polyurethane provided by the invention is prepared by reacting poly (carbonate ester-ether) with a structure of a formula (II) with trimethylolpropane, diisocyanate, dyhydroxy methyl acrylic acid, ethylene glycol and dimethyl ethanolamine. The poly (carbonate ester-ether) dihydric alcohol has a polyester structure and a polyether structure, the defects that the polyester is poor in water resistance and the polyether is poor in mechanical performance are overcome, a prepared polyurethane main chain is provided with a polyester unit and a polyether unit through a copolymerization reaction, and the adhesion performance is improved.

Owner:吉林天泽二氧化碳科技有限公司

Coloring agent for textile fabric

The invention discloses a coloring agent for a textile fabric. The coloring agent consists of the following ingredients in parts by weight: 1 to 2 parts of polypropylene glycol, 2 to 3 parts of tetracarboxydiphthalic ether dianhydride (ODPA), 1 to 2 parts of zinc stearate, 4 to 5 parts of trimethylolpropane, 4 to 5 parts of mica powder, 5 to 6 parts of butyl methacrylate, 4 to 5 parts of dibutyltin dilaurate, 3 to 4 parts of polyurethane, 6 to 7 parts of iron oxide red, 1 to 2 parts of dibutyl phthalate, 3 to 4 parts of ethyl acetate, 3 to 4 parts of an initiator, 5 to 6 parts of closed blocked isocyanate, 5 to 6 parts of water and 2 to 3 parts of polyvinylpyrrolidone. The coloring agent for the textile fabric is easy for coloring and unlikely to fade.

Owner:江苏金牛华尔车服饰有限公司

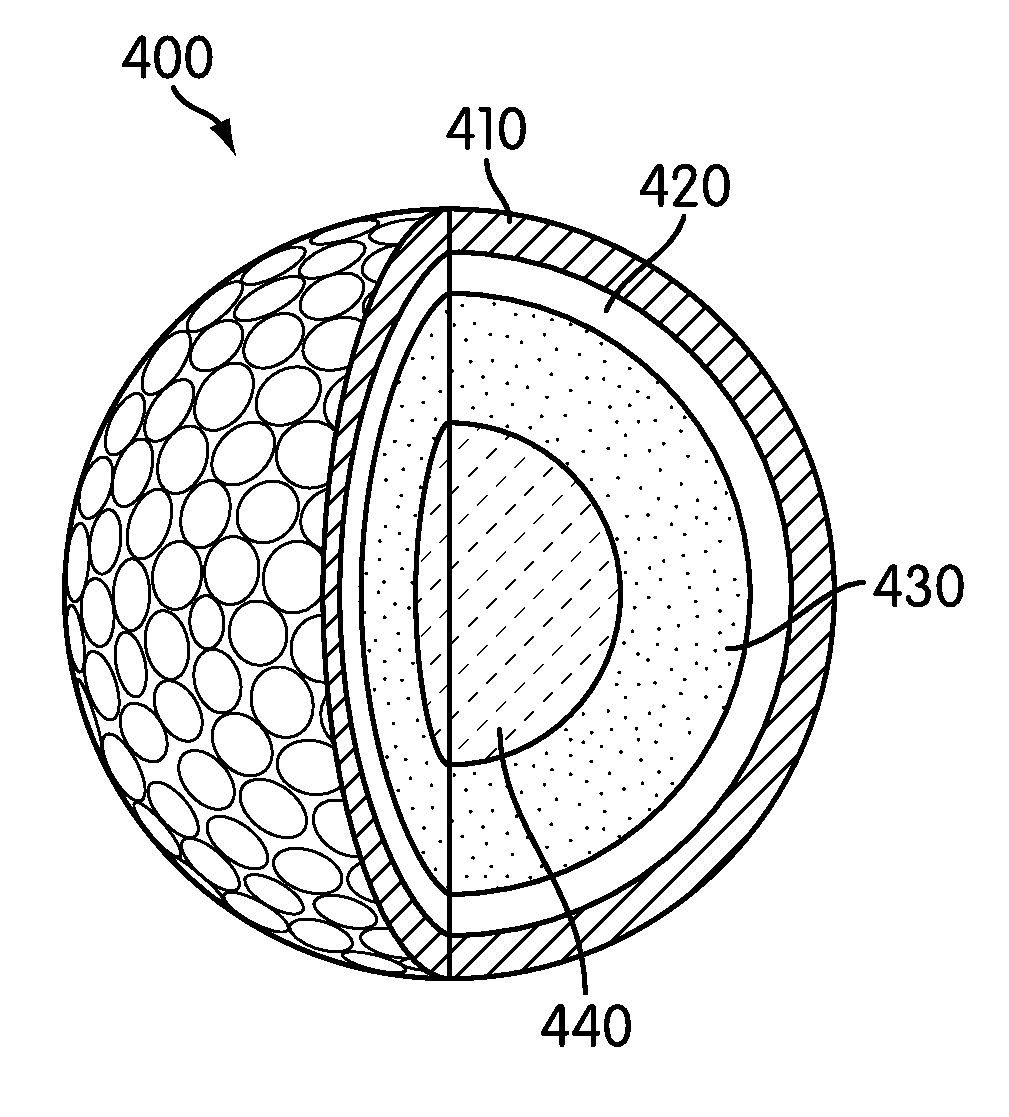

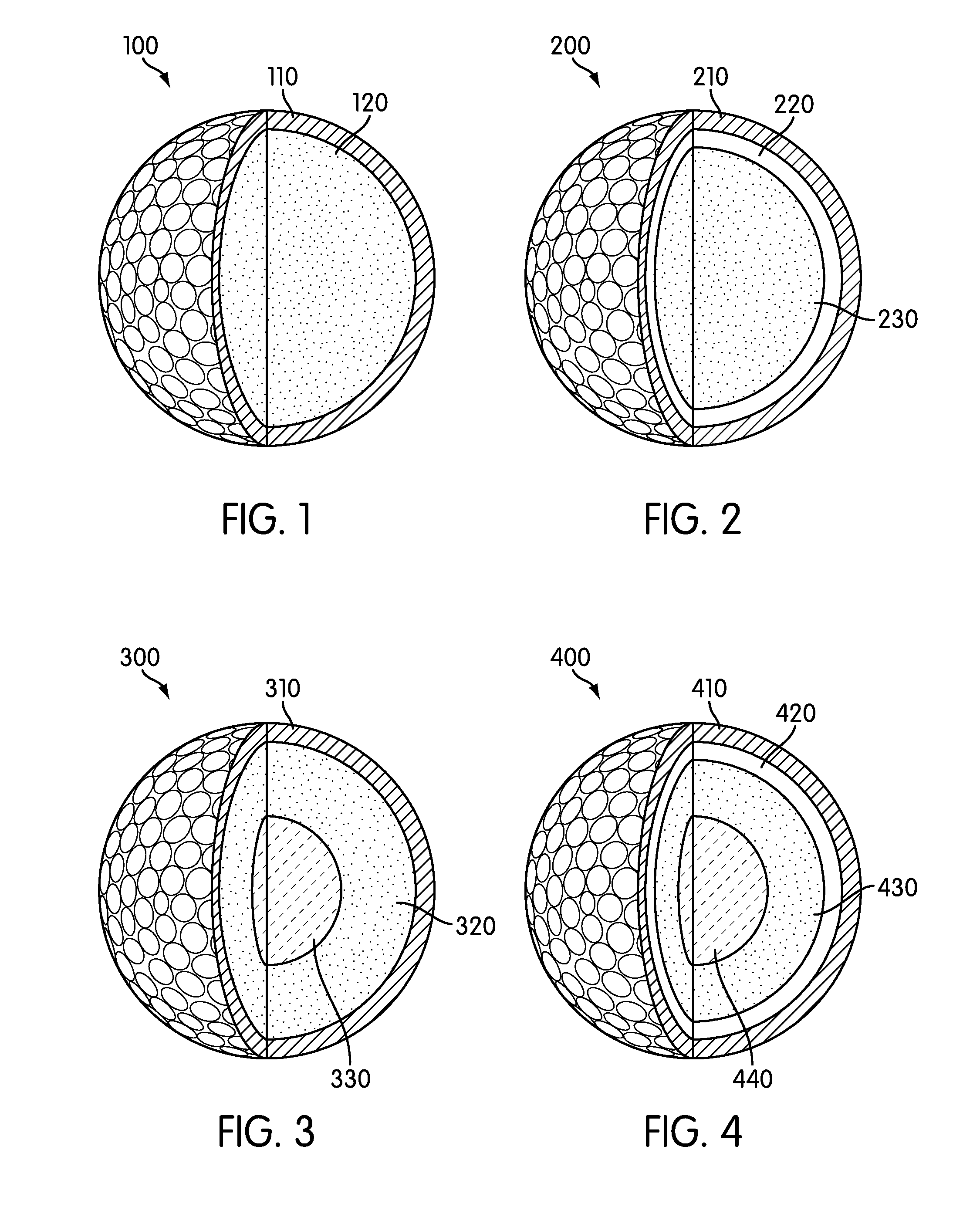

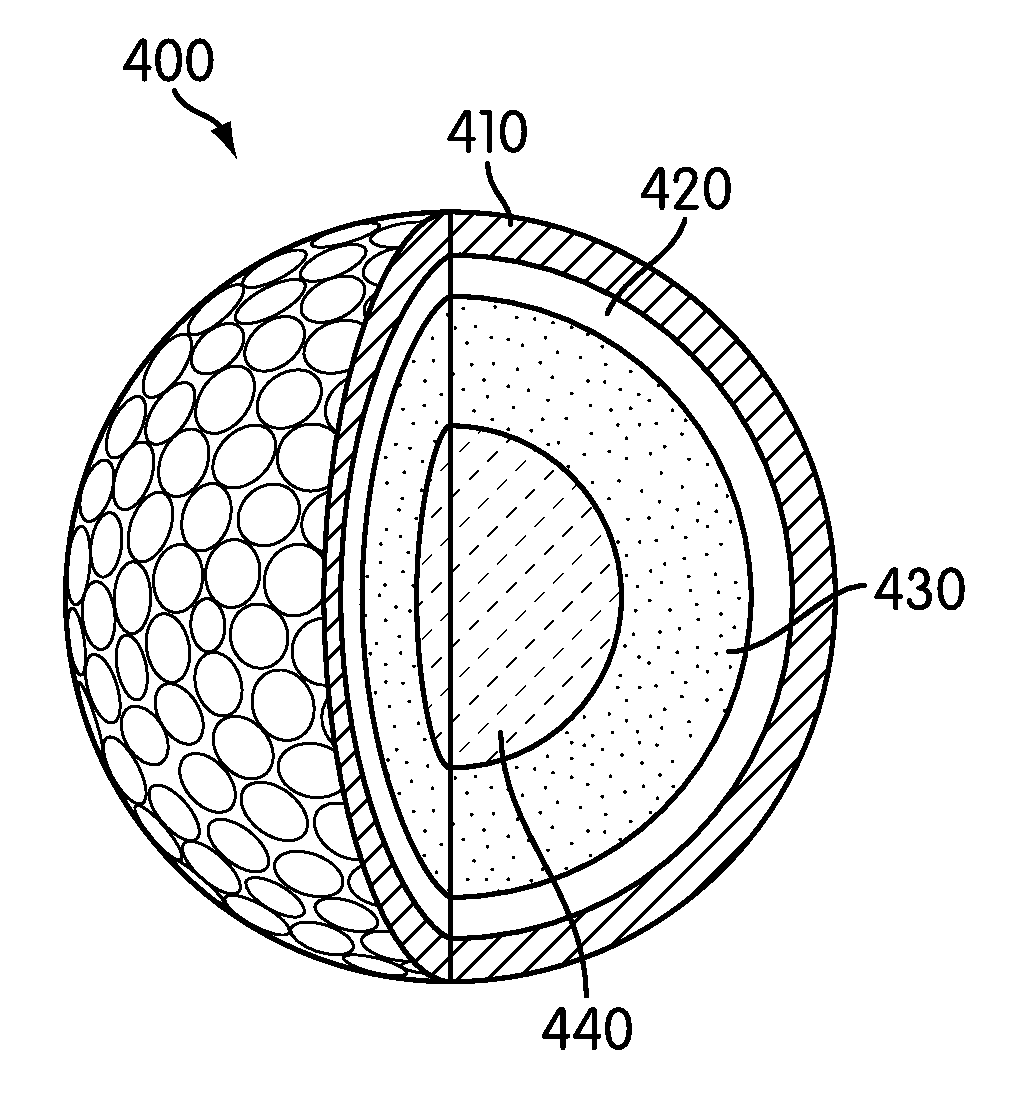

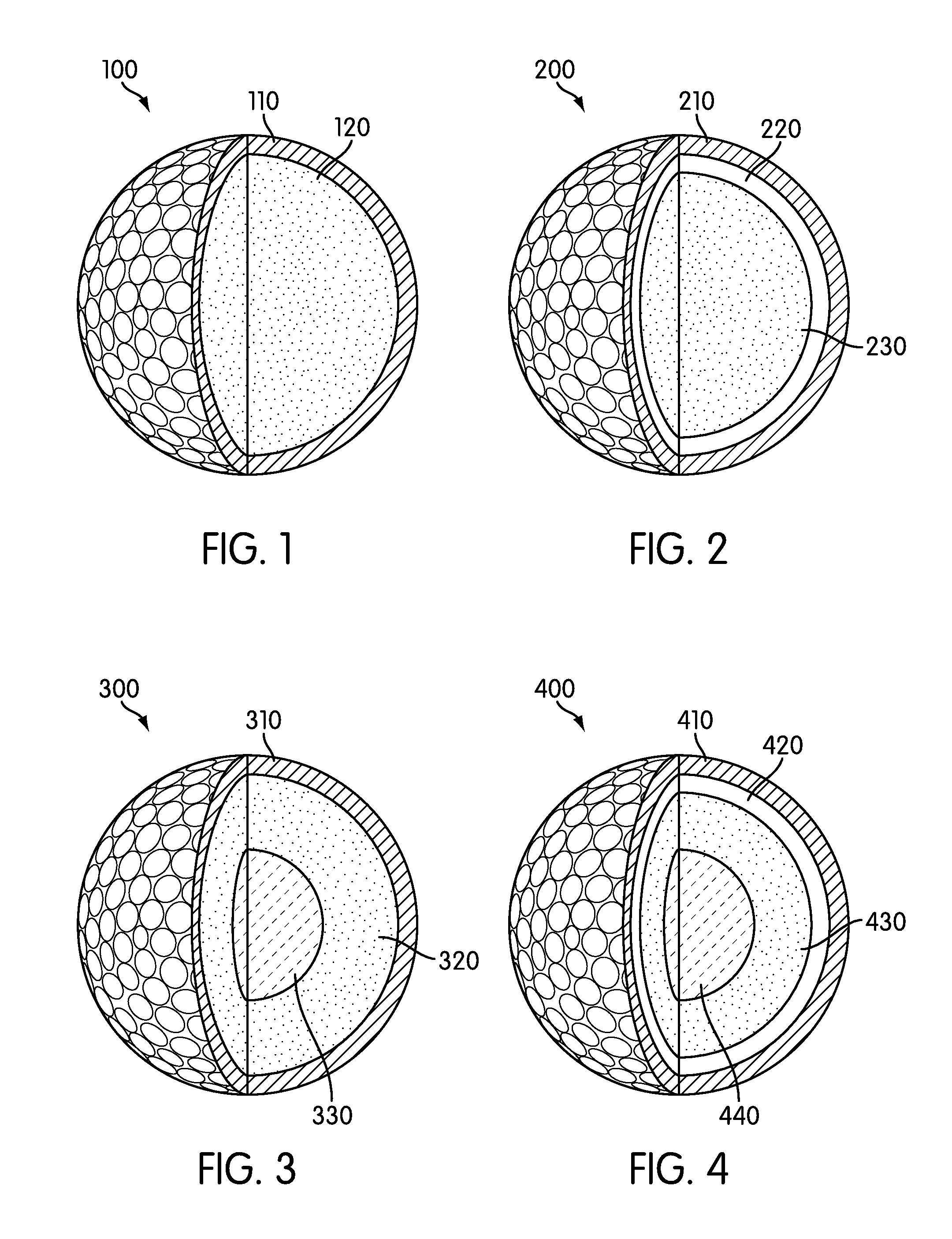

Golf Balls Including A Crosslinked Thermoplastic Polyurethane Cover Layer Having Improved Scuff Resistance

This disclosure relates to golf balls having a cover layer made from a crosslinked thermoplastic polyurethane elastomer. The crosslinked thermoplastic polyurethane elastomer includes crosslinks located in the hard segments, where the crosslinks being the reaction product of unsaturated bonds located in the hard segments catalyzed by a free radical initiator. The crosslinks may be formed from an unsaturated diol as a chain extender. The unsaturated diol may be trimethylolpropane monoallylether (TMPME). The cover layer may have certain properties, such as a desirable flexural modulus value and a desirable Shore D hardness value, that further contribute to the golf ball having a high degree of scuff resistance.

Owner:NIKE INC +1

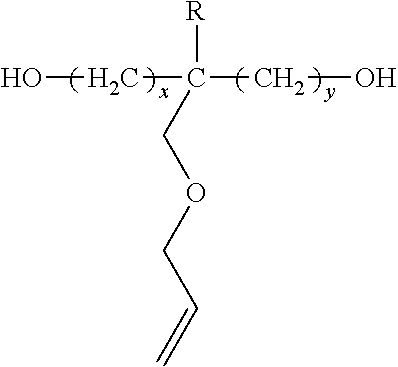

Crosslinkable Thermoplastic Polyurethane

ActiveUS20110186329A1Improve the heating effectMaintain good propertiesElectric discharge tubesInsulated cablesThermoplasticPolymer science

The TPU of this invention contains unsaturation in its polymeric backbone. The unsaturation can be present in the soft segment or in the hard segment or in both the soft and hard segments of the TPU. The TPU can be molded like a thermoplastic, and can be subsequently crosslinked by exposure to electron beam irradiation into thermoset articles having excellent chemical resistance, dimensional stability, set properties, heat resistance, oxidative resistance, and creep resistance. In one embodiment, the TPUs of this invention are the reaction product (1) a hydroxyl terminated intermediate, (2) a polyisocyanate, (3) a saturated glycol chain extender, and (4) a glycol chain extender containing carbon-carbon double bonds, such as the allyl moieties present in trimethylolpropane monoallyl ether. In another embodiment of this invention, the thermoplastic polyurethane which is crosslinkable by e-beam irradiation is comprised of the reaction product of (1) a saturated hydroxyl terminated intermediate, (2) an unsaturated hydroxyl terminated intermediate, wherein the unsaturated hydroxyl terminated intermediate contains carbon-carbon double bonds, (3) a polyisocyanate, and (4) a saturated glycol chain extender.

Owner:LUBRIZOL ADVANCED MATERIALS INC

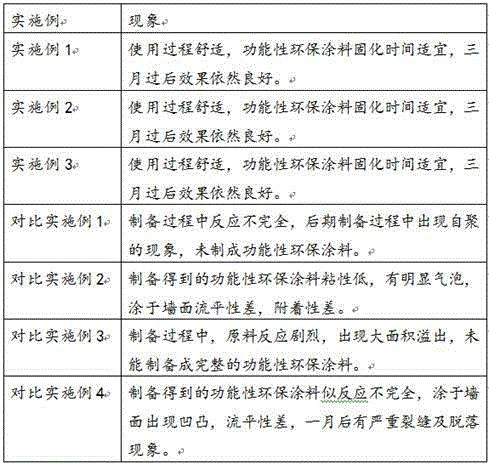

Method for preparing functional environmentally-friendly paint

The invention relates to a method for preparing a functional environmentally-friendly paint. The preparation method comprises: adding 10-100 parts of glycerol, 10-100 parts of pentaerythritol, 5-80 parts of trimethylolpropane, 20-200 parts of phthalate, 3-60 parts of adipic acid, 10-80 parts of trimellitic anhydride, and 15-150 parts of maleic acid into a reactor; heating the reactor to make the substances therein react; after a complete reaction, adding in 0.03-3 parts of a defoamer; cooling the reactants, and gradually adding in 0.05-2 parts of hydrogenated castor oil and 0.05-2 parts of a polymerization inhibitor during the cooling process; adding in 8-95 parts of styrene to modify a product; and adding in 4-60 parts of triethylamine, 3-70 parts of a solvent, 15-230 parts of a pigment and a filler, 0.01-2 parts of a leveling agent, 0.5-6 parts of a catalyst, 3-7 parts of a first solid additive, 1.5-6 parts of a second solid additive, 6-9 parts of a first composite modifier, 7-11 parts of a second composite modifier, and 8-14 parts of a third composite modifier to obtain the functional environmentally-friendly paint. The functional environmentally-friendly paint prepared by the method is stable in performance, little in environmental effect, and suitable for large-scale popularization.

Owner:ANJI QILONG NEW BUILDING MATERIAL

Polyurethane matt varnish for benzene-free odor-less furniture

ActiveCN101684388AImprove mechanical propertiesGood gloss and color retentionPolyurea/polyurethane coatingsCyclohexanoneFoaming agent

The invention provides a polyurethane matt varnish for benzene-free odor-less furniture, which is composed of a main agent, a curing agent and a diluent. The main agent comprises 66.5-75.5% of hydroxyacrylic resin, 16.0-25.0% of solvent, 0.1-0.3% of defoarming agent, 0.05-0.1% of flatting agent, 0.1-0.5% of anti-settling agent, 0.1-0.5% of dispersing agent, and 4-8% of delustering agent; the curing agent comprises40.0-50.0% of toluene diisocyanate tripolymer, 20.0-30.0% of toluene diisocyanate-trimethylolpropane affixture, and 20.0-30.0% of butyl acetate; the diluent comprises 60.0-70.0% of butyl acetate, 15.0-20.0% of cyclohexanone, and 15.0-25.0% of propylene glycol methyl ether acetate. The product of the invention is favorable for construction, and no odor exists after the construction of the previous night.

Owner:上海展辰涂料有限公司 +1

Golf Balls Including Crosslinked Thermoplastic Polyurethane

This disclosure relates to golf balls made from a crosslinked thermoplastic polyurethane elastomer. The crosslinked thermoplastic polyurethane elastomer includes crosslinks located in the hard segments, where the crosslinks being the reaction product of unsaturated bonds located in the hard segments as catalyzed by a free radical initiator. The crosslinks may be formed from an unsaturated diol as a chain extender. The unsaturated diol may be trimethylolpropane monoallylether (TMPME). The golf ball may include the crosslinked thermoplastic polyurethane elastomer in the cover layer, in which case the cover layer may exhibit a high degree of scuff resistance.

Owner:NIKE INTERNATIONAL LTD

Organosilicone modification polyurethane color fixing agent and preparation method thereof

The invention relates to a textile color fixing agent, and in particular to an organosilicone modification polyurethane color fixing agent and a preparation method thereof. The organosilicone modification polyurethane color fixing agent is synthesized from end hydroxyl polysiloxane, polypropylene glycol (PPG), isophorone diisocyanate (IPDI), N-methyl diethanol amine, trimethylolpropane (TMP), acetone, glacial acetic acid and methyl ethyl ketoxime as raw materials. As trimethylolpropane is adopted as a chain extender, a synthesized polyurethane prepolymer has multiple branch chains, and the cross-linking property and the filming property in curing can be improved; as methyl ethyl ketoxime is adopted to seal the end, sufficient active groups can be maintained for the prepolymer to react with active groups on a fabric and dye in high temperature baking, the color fastness and the washing fastness of the fabric can be improved, and meanwhile due to introduction of a polysiloxane chain segment, the softness of the settled fabric can be improved.

Owner:HANGZHOU MEIGAO HUAYI CHEM

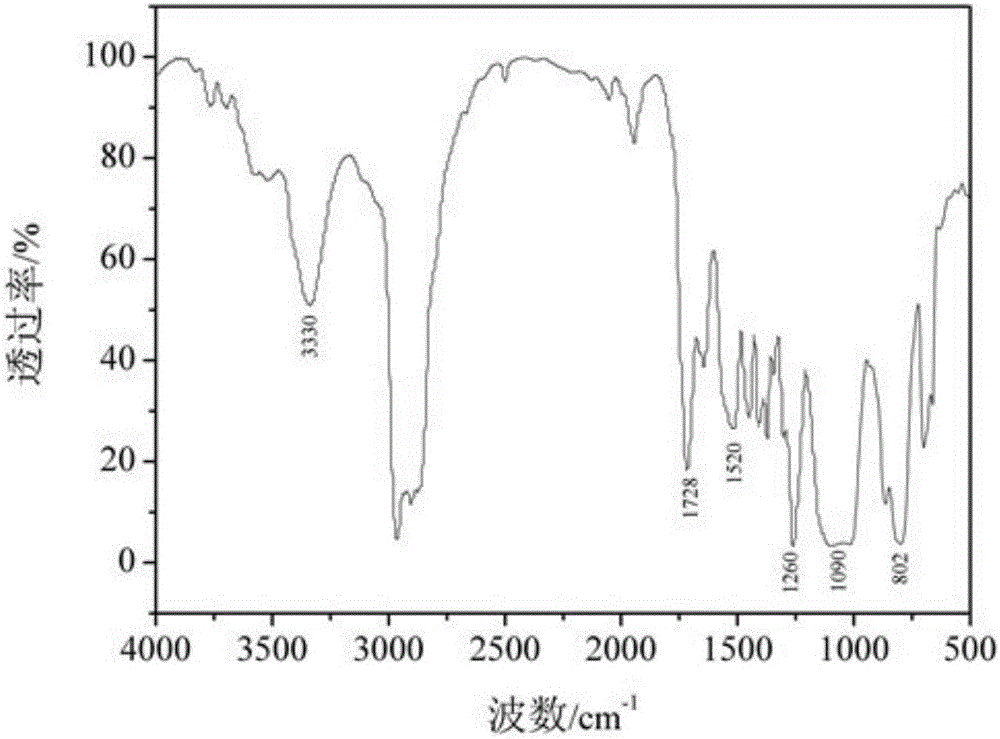

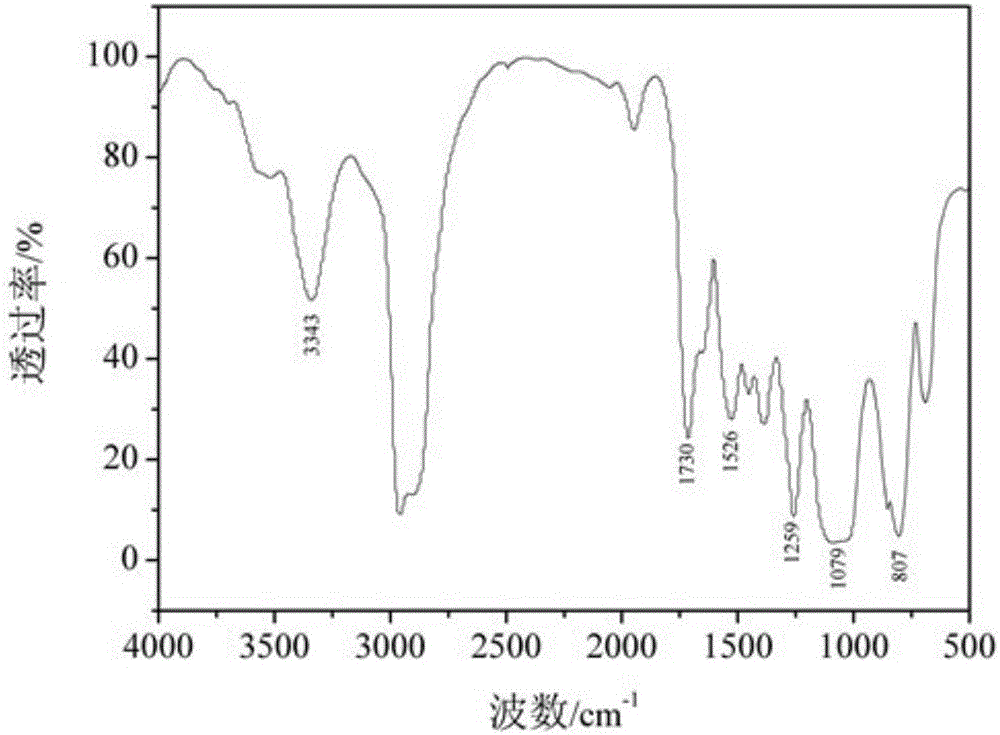

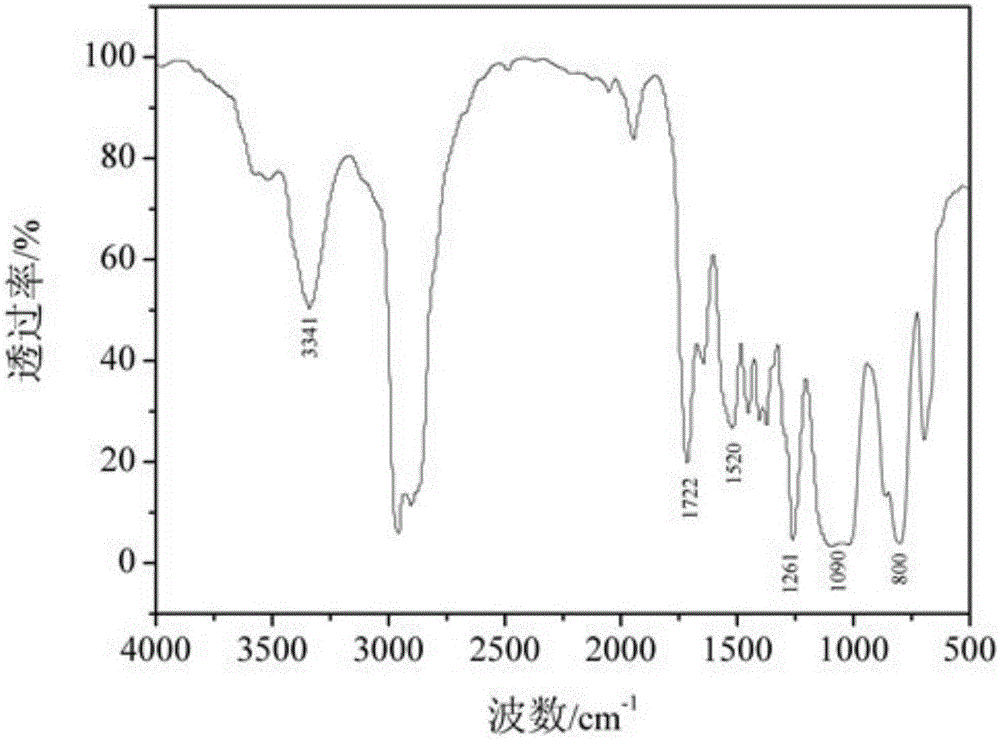

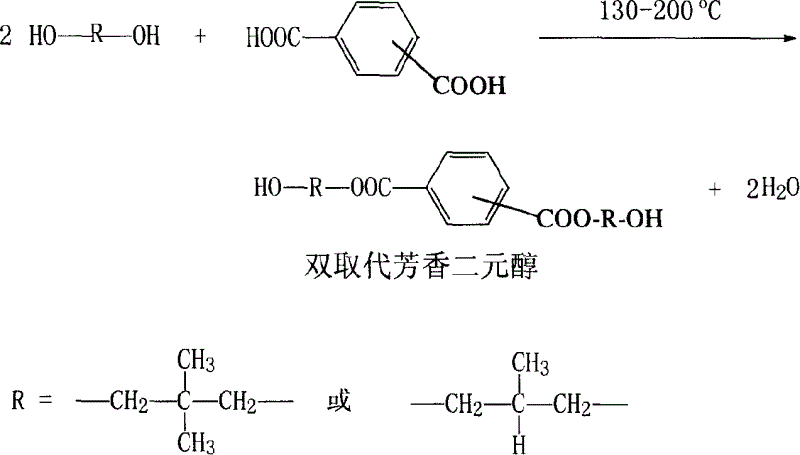

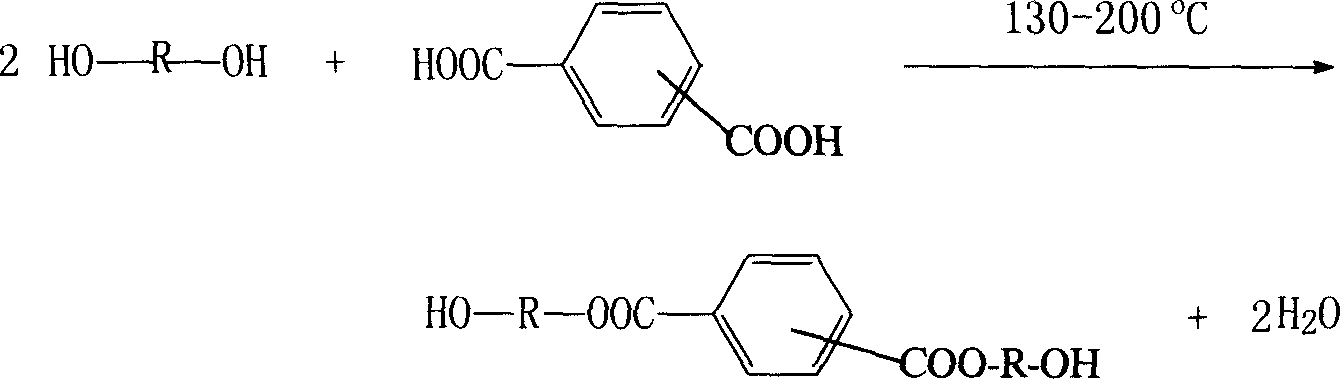

Method for preparing novel F level high speed polyurethane enamelled wire paint

InactiveCN1635038AImprove heat resistanceImprove mechanical propertiesPolyurea/polyurethane coatingsCable/conductor manufactureSolventTrimethylolpropane

The invention discloses a method for preparing novel F level high speed polyurethane enamelled wire paint, wherein the hydroxyl preparation consists of, using organic titanium-antimony complex as catalyst, substituted aromatic dibasic alcohol as adjuvant, tri (alpha-ethoxyl) isocyanate as modifier for polycondensation 6 hours at 130-200 deg. C under atmosphere pressure, and closed constituent preparation consists of using substituted aromatic tertiary amine as catalyst, thus reacting 4,4'-methyl diphenylene diisocyanate with trimethylolpropane, and obtaining a proportion of isocyanate urea rings with thermotolerant structure.

Owner:左晓兵 +1

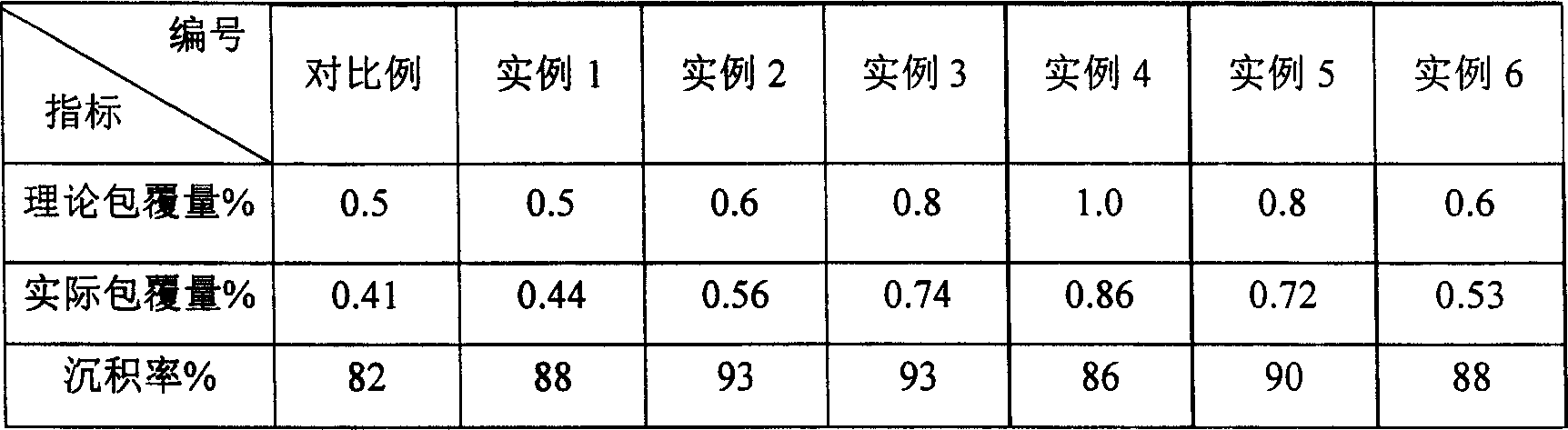

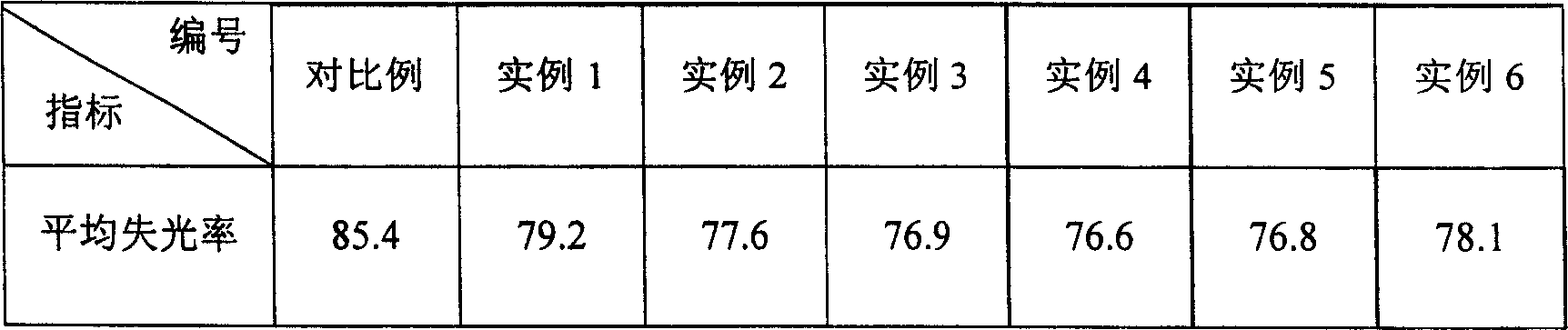

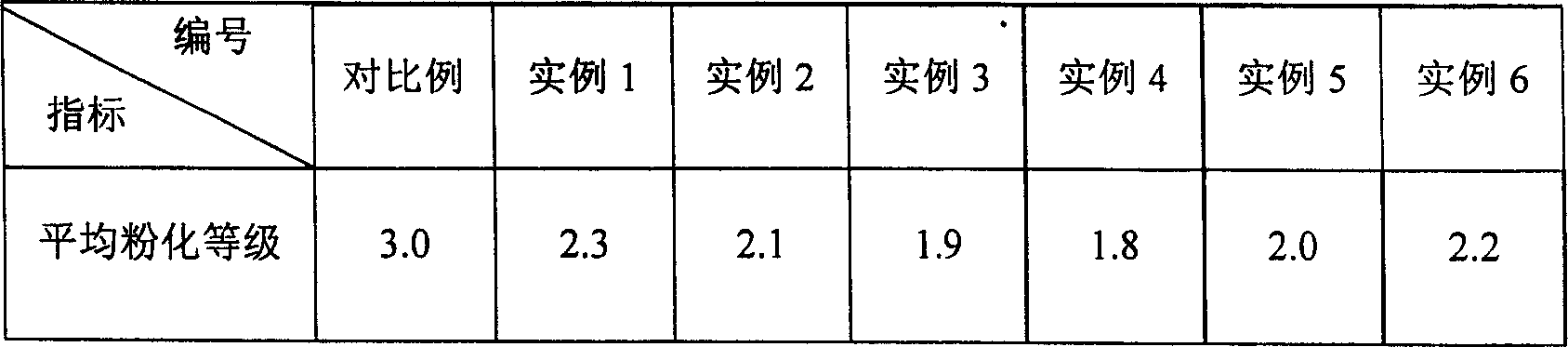

Process for preparing titanium dioxide with high weatherability

InactiveCN1837296AIncrease deposition rateGloss loss improvementInorganic pigment treatmentSulfateTrimethylolpropane

The invention discloses a preparing method of high weatherability titanium oxide, which is characterized by the following: adapting non-disposing surface disposal auric sulfate bloodstone titanium oxide and 0.1-0.3 percent hexametaphosphate, 0.1-0.2 percent isopropanolamine as dispense; dispersing titanium oxide paste; heating until 50-60 deg.c; adjusting pH value at 4.0-5.0 through dilute sulphuric acid solution; coating ZrO2 and Al2O3 separately; adding 0.5-1.0 percent zirconium sulfate and NaOH solution first; adding 2.0-4.5 percent Al2O3 and NaOH solution; washing; drying; adding 0.1-0.3 percent trimethylolpropane disposer; proceeding steam grinding to produce good weatherability titanium oxide.

Owner:江苏镇钛化工有限公司

Subluminous weather-resistant coating powder and preparation thereof

InactiveCN1613935AHigh glass transition temperatureGood weather resistancePowdery paintsPolyester coatingsAdipic acidTrimethylolpropane

A low lustre weather resisting powdery paint is composed of polyester resin A and B. The weight percent of the composition of A is : the new pentadiol 80-100, 2-methyl-1,3-propylene glycol 0-20, 1,4-cyclohexane dimethyl alcohol 0-10,1,6-hexylene glycol 0-5,trimethylolpropane 0-3, terephthalic acid 100-130, m-phthalic acid 10-50, adipic acid 0-5,dibutyl tin oxidate 0.1-0.3; and the B is :the new pentadiol80-100, 2-methyl-1,3-propylene glycol 0-10, 1,4-cyclohexane dimethyl alcohol 0-5, 1,6-hexylene glycol 0-5, trimethylolpropane 0-10, terephthalic acid 120-150, m-phthalic acid 10-50, adipic acid 0-8, dibutyl tin oxidate 0.1-0.3. The A and B are of high transformation temperature, good stability and so on, The paint has the lustre domain of 15-40%.

Owner:GUANGZHOU QINGTIAN INDAL

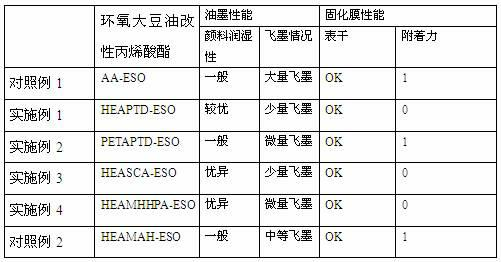

Acrylic acid ester modified epoxy soybean oil, its preparation method and application thereof

ActiveCN102660387ANovel structureImprove adhesionOrganic chemistryFatty acid chemical modificationPolymer scienceMeth-

The invention discloses an acrylic acid ester modified epoxy soybean oil, its preparation method and an application thereof. According to the preparation method of the acrylic acid ester modified epoxy soybean oil, acrylate monomer bearing a hydroxyl group reacts with acid anhydride to obtain a half-ester intermediate, and the half-ester intermediate reacts with epoxy soybean oil to obtain the acrylic acid ester modified epoxy soybean oil. The acrylate monomer bearing a hydroxyl group is hydroxyethyl acrylate, hydroxyethyl methacrylate, pentaerythritol triarylate, hydroxypropyl acrylate, hydroxypropyl methacrylate, trimethylol propane diacrylate or trimethylol propane dimethacrylate. Acid anhydride is o phthalic anhydride, succinic anhydride, methyl hexahydrophthalicanhydride, hexahydrophthalic anhydride or tetrahydrophthalic anhydride. The acrylic acid ester modified epoxy soybean oil has a novel structure. When applied in paper printing ink, the acrylic acid ester modified epoxy soybean oil can improve adhesive force of a cured film and also can improve wetability of pigments and remarkably minimize occurrence of misting. The preparation method helps widen the application range of the modified epoxy soybean oil.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

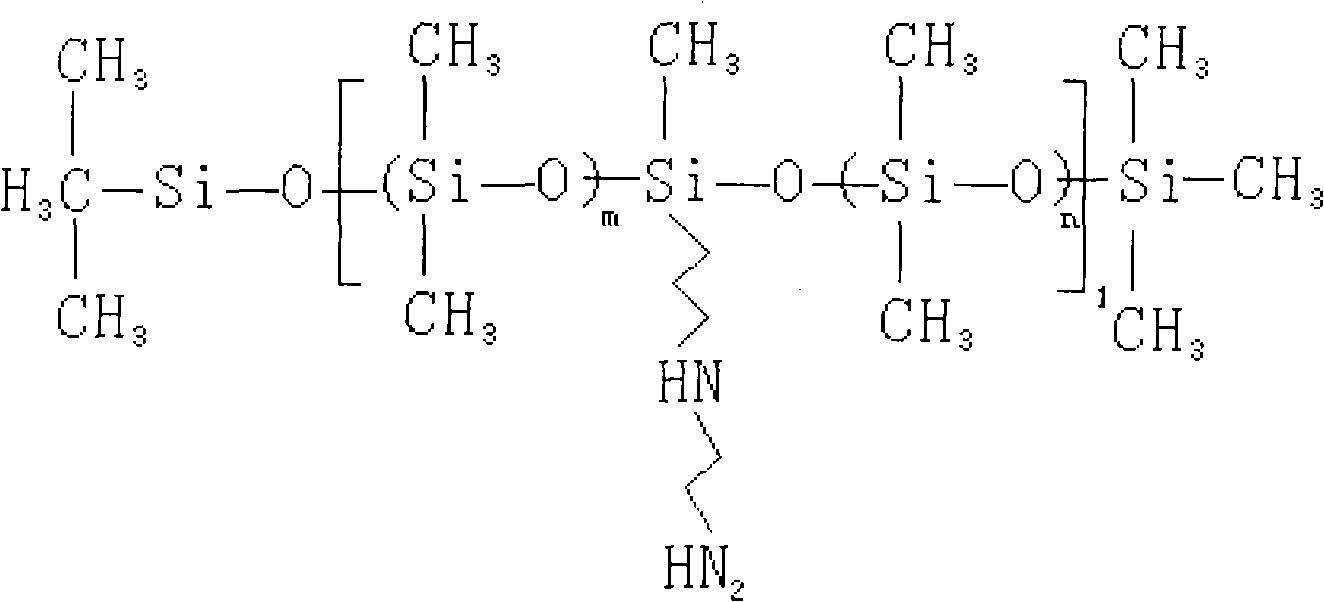

Amino silicone modified waterborne polyurethane and preparation method thereof

InactiveCN102167795AReduce joinLower surface energyPolyurea/polyurethane coatingsPropanoic acidSide chain

The invention discloses amino silicone modified waterborne polyurethane. The waterborne polyurethane is prepared from the following raw materials in parts by weight: 150-220 parts of polyether, 100-150 parts of isophorone diisocyanate, 15-20 parts of dimethylol propionic acid, 0.5-0.8 part of catalyst, 0-5 parts of trimethylolpropane, 15-30 parts of 1,4-butanediol, 4-5 parts of acetone, 10-15 parts of triethylamine, 5-10 parts of side chain amino silicone oil and 620-630 parts of deionized water. The preparation method of the amino silicone modified waterborne polyurethane is that side chain amino silicone oil is introduced in the aqueous phase chain extending process for modification; and the waterborne polyurethane has low preparation cost and good water resistance and adhesive force, is environmentally friendly and has no security threat.

Owner:王奇

Method for preparing self-cross linking type water-based acrylic resin and polyurethane hybrid

ActiveCN101519480AAvoid the disadvantage of high costImprove low temperature impact resistancePolyesterHydrophilic monomer

The invention relates to a method for preparing self-cross linking type water-based acrylic resin and polyurethane hybrid, comprising the following process: (1) unsaturated hydroxyl-terminated polyester is synthesized after the polycondensation of trimethylolpropane monoallyl ether, polyhydric alcohol and polybasic acid; (2) the unsaturated hydroxyl-terminated polyester is used as the soft segment of polyurethane, dihydric alcohol, hydrophilic monomer and isocyanate are added to the polyurethane to react with the polyurethane to prepare unsaturated double-linked water-based polyurethane; and (3) the water-based acrylic resin and polyurethane hybrid in nucleocapsid structure is polymerized from the unsaturated double-linked water-based polyurethane used as surface active agent and the acrylic resin used as monomer by emulsifier-free emulsion. The unsaturated double-linked water-based polyurethane and fluorine-contained acrylic resin are grafted innovatively, and the synthesized environmentally-friendly resin has the excellent performance of both the acrylic resin and polyurethane resin and can be widely used as the base material of water-based woodenware coating, building coating and metal coating.

Owner:广东天银实业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com