Acrylic acid ester modified epoxy soybean oil, its preparation method and application thereof

A technology of epoxy soybean oil and acrylate, which is applied in the field of polymer materials, can solve the problem of less acrylate modified epoxy soybean oil, and achieve the effect of widening application and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

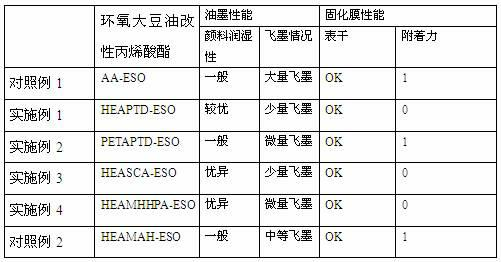

Examples

Embodiment 1

[0038] Example 1 Preparation of HEAPTD-ESO

[0039] (1) Mix HEA and PTD at a ratio of 1.05:1, then add 0.15% p-methoxyphenol (MEHQ) as a polymerization inhibitor relative to the total mass of the mixture, and 1.4% triphenylene relative to the total mass of the mixture Phosphine (TPP) (or other catalysts), slowly heated to 100 ° C, the mixture slowly becomes a clear liquid;

[0040] (2) When the acid value of the reaction system in step (1) decreases and no longer changes, add epoxidized soybean oil. The amount of epoxidized soybean oil added is based on the number of carboxyl moles converted from the epoxy value to the actual acid value at 1.1:1 Then add triphenylphosphine and MEHQ respectively to ensure that the mass fractions are 1.4% and 0.15%, and the temperature rises to 120 °C. During the reaction, the acid value is continuously sampled and tested until the acid value drops to 5 mg / g, stop the reaction. The final product is light khaki viscous liquid, namely HEAPTD-E...

Embodiment 2

[0041] Example 2 Preparation of PETAPTD-ESO

[0042] (1) Mix PETA and PTD at a ratio of 1.08:1, then add 0.15% p-methoxyphenol (MEHQ) as a polymerization inhibitor relative to the total mass of the mixture, and 1.4% triphenylene relative to the total mass of the mixture Phosphine (TPP) (or other catalysts), slowly heated to 110 ° C, the mixture slowly becomes a clear liquid;

[0043] (2) When the acid value of the reaction system in step (1) decreases and no longer changes, add epoxidized soybean oil. The amount of epoxidized soybean oil added is based on the number of carboxyl moles converted from the epoxy value to the actual acid value at 1.1:1 Calculation of the ratio, and then add triphenylphosphine and MEHQ respectively, to ensure that the mass fractions are 1.4% and 0.15%, the temperature is controlled at 100 ℃, and the acid value is continuously sampled and tested during the reaction until the acid value drops to 5 mg / g, stop the reaction. The final product is lig...

Embodiment 3

[0044] Example 3 Preparation of HEASCA-ESO

[0045] (1) Mix HEA and succinic anhydride (SCA) at a ratio of 1.08:1, then add 0.15% p-methoxyphenol (MEHQ) as a polymerization inhibitor relative to the total mass of the mixture, and 1.4% relative to the total mass of the mixture % of triphenylphosphine (TPP) (or other catalysts), slowly heated to 110 ° C, the mixture slowly becomes a clear liquid;

[0046] (2) When the acid value of the reaction system in step (1) decreases and no longer changes, add epoxidized soybean oil. The amount of epoxidized soybean oil added is based on the number of carboxyl moles converted from the epoxy value to the actual acid value at 1.1:1 Calculation of the ratio, and then add triphenylphosphine and MEHQ respectively, to ensure that the mass fractions are 1.4% and 0.15%, the temperature is controlled at 105 ℃, and the acid value is continuously sampled during the reaction until the acid value drops to 5 mgKOH / g, stop the reaction. The final pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com