Patents

Literature

2539 results about "Epoxidized soybean oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

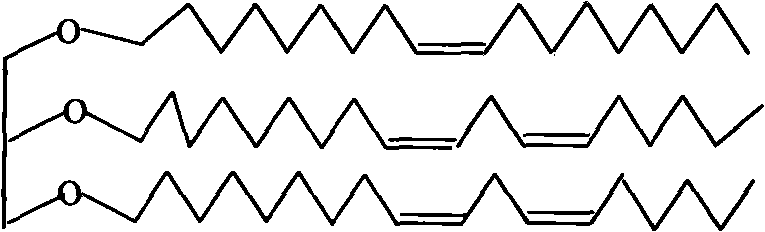

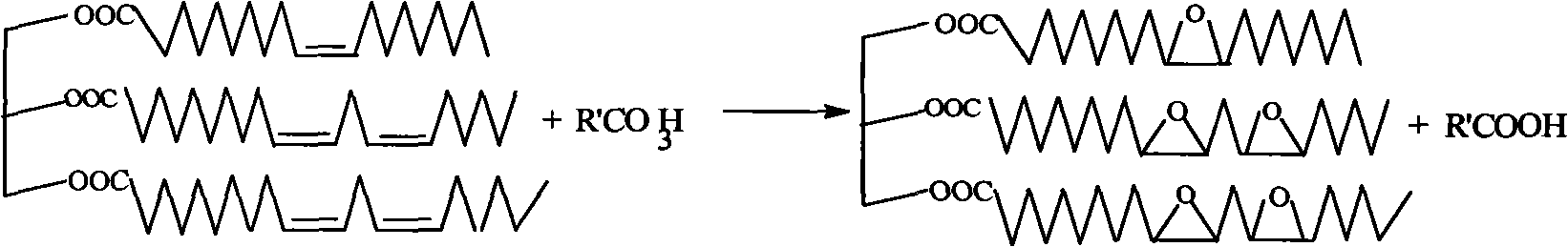

Epoxidized soybean oil (ESBO) is a collection of organic compounds obtained from the epoxidation of soybean oil. It is used as a plasticizer and stabilizer in polyvinyl chloride (PVC) plastics. ESBO is a yellowish viscous liquid.

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

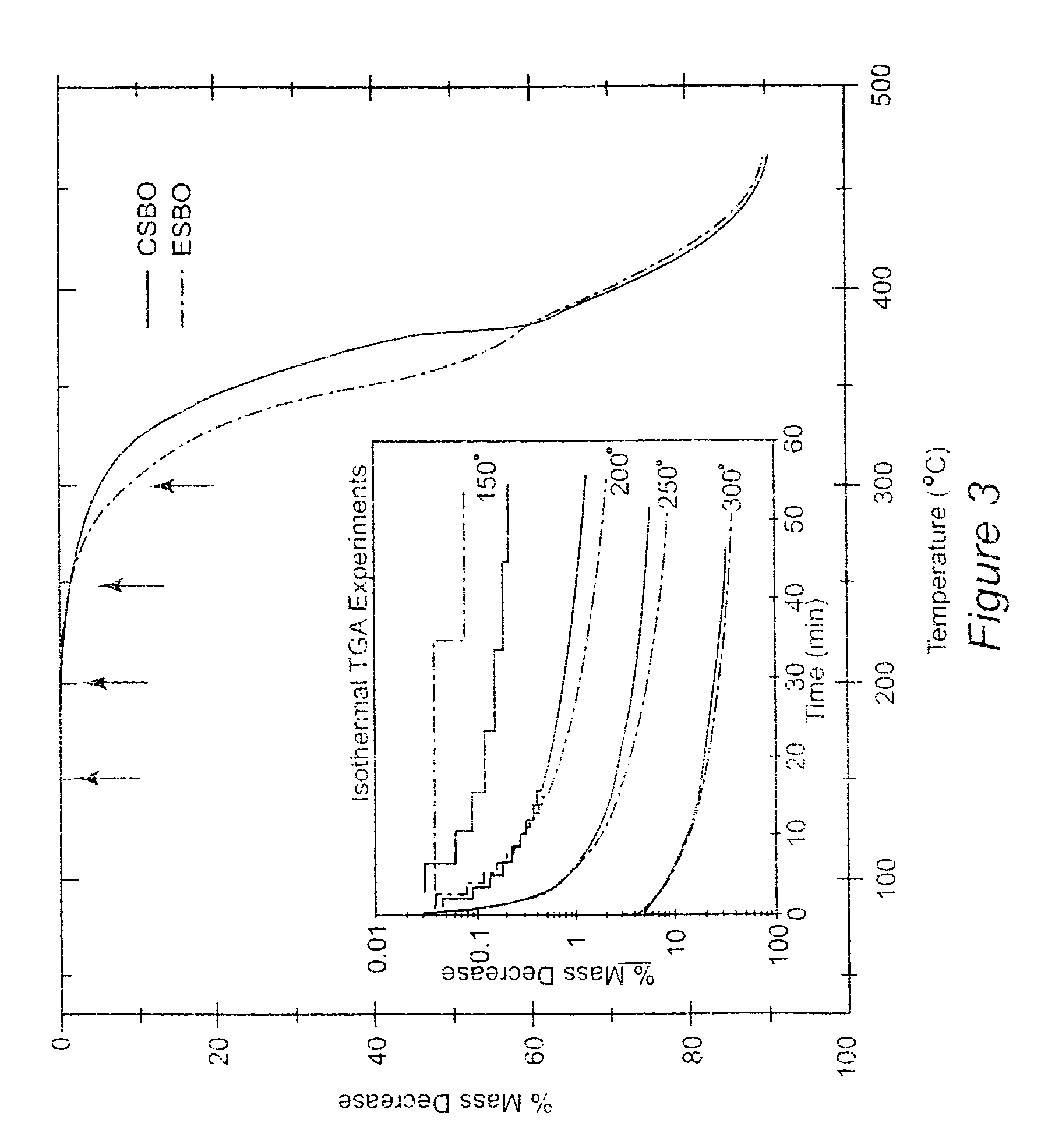

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly “all-natural” elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

Modified polylactic acid material and preparation method and application thereof

The invention provides a modified polylactic acid material and a preparation method and application thereof. The modified polylactic acid material comprises the following raw materials in part by weight: 40 to 70 parts of polylactic acid, 10 to 20 parts of thermoplastic polyester elastomer, 10 to 20 parts of plasticizer and 10 to 20 parts of organic or inorganic filler, wherein the thermoplastic polyester elastomer is polyester thermoplastic polyurethane; the plasticizer is one or two of tributyl acetocitrate, epoxidized soybean oil, propylene glycol polyester adipate or dioctyl maleate; and the organic or inorganic filler is one or more of starch, talcum powder, calcium carbonate, mica, montmorillonite, clay or titanium dioxide. The modified polylactic acid material has the advantages of improving the flexibility of a polylactic acid material and reducing the cost of a biodegradable material. A mechanical performance test shows that in the modified polylactic acid material, the tensile strength is 15 to 70 MPa and the fracture tensile rate is 20 to 38 percent.

Owner:江苏天仁生物材料有限公司

Method for preparing hard polyurethane foam plastics with soybean oil

ActiveCN101314632AImprove water resistanceImprove heat resistancePolyesterFatty acid glycerol esters

The invention provides a method for preparing hard polyurethane foam plastics from soybean oil. The method comprises the steps as follows: (1) carrying out epoxidation including the sub-steps of subjecting soybean oil and epoxidizing agent to reaction to obtain epoxidized soybean oil; (2) carrying out ring-opening reaction including the sub-steps of subjecting epoxidized soybean oil and nucleophilic reagent of reactive hydrogen to the ring-opening reaction of epoxy chemical bond in the presence of a catalyst to obtain mixed hydroxyl fatty acid glyceride; (3) carrying out alcoholysis and esterification including the sub-steps of adding alcohol, heating for alcoholysis to obtain mixed hydroxyl fatty acid monoester, i.e. soybean oil based polyol, and esterifying with organic acid and acid anhydride to generate polyester polyol; and (4) sequentially adding 80-150 weight parts of isocyanate, 0.3-4 weight parts of triethanolamine and 0.5-4 weight parts of foam stabilizer to 100 weight parts of soybean oil based polyol, intensively stirring, adding 0.5-3 weight parts of distilled water, and uniformly foaming while stirring at the high speed.

Owner:NANTONG HAIERMA TECH CO LTD

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly "all-natural" elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

Polyimide porous membrane and lithium ion battery comprising same

ActiveCN101665580AUniform hole diameter distributionImprove breathabilitySecondary cellsCell component detailsBenzoic acidChlorinated paraffins

The invention discloses a polyimide porous membrane and a lithium ion battery comprising the same. The polyimide porous membrane is prepared by the following method, and the method comprises the following steps: forming a polyamic acid membrane by using the mixture of a mixture containing polyamic acid, pore-forming substance and solvent, and subjecting the polyamic acid membrane to amidation at the temperature higher than the decomposing temperature of the pore-forming substance, wherein the solvent is a solvent which dissolves the polyamic acid but slightly dissolves or does not dissolve thepore-forming substance; and the pore-forming substance may be one or combination of benzoic acid polyol ester, phthalic acid dialkyl ester, polyprotic acid alkyl ester, phenyl alkysulfonate, chlorinated paraffin and epoxidized soybean oil. The service life and the processing yield of the lithium ion battery made of the polyimide porous membrane serving as a battery membrane are improved. Moreover, the polyimide porous membrane also has higher thermal stability, and greatly improves the safety performance of the battery.

Owner:BYD CO LTD

Nonisocyanate polyurethane materials, and their preparation from epoxidized soybean oils and related epoxidized vegetable oils, incorporation of carbon dioxide into soybean oil, and carbonation of vegetable oils

Novel carbonated vegetable oils (such as carbonated soybean oil) are made by reacting carbon dioxide with an epoxidized vegetable oil. The carbonated vegetable oils advantageously may be used for producing nonisocyanate polyurethane materials.

Owner:VIRGINIA TECH INTPROP INC

Delustring medical soft PVC modified material with low temperature resistance and low DOP precipitation

ActiveCN102020815AExcellent resistance to precipitationGood matting effectPolymer sciencePlasticizer

The invention discloses a delustring medical soft PVC modified material with low temperature resistance and low DOP precipitation, which is prepared from the following ingredients in parts by weight: 100 parts of PVC resin powder, wherein the PVC resin powder consists of the following ingredients in parts by weight: 20% to 80% of delustring resin powder ( with the degree of polymerization ranging from 1000 to 1500 and 19.0% to 25.0% of the content of tetrahydrofuran insoluble substances, i.e. gel), 20 to 80% of common resin powder (with the degree of polymerization ranging from 1000 to 1800); 0 to 5 parts of acrylate copolymer modifier ACR, 20 to 80 parts of plasticizer DOP, 0.8 to 3 parts of stabilizer, 0.2 to 1.5 parts of antioxidant, 1 to 6 parts of assistant stabilizer, i.e. epoxidized soybean oil, and 0.2 to 0.8 parts of lubricant. The delustring medical soft PVC modified material includes excellent low temperature resistance and low plasticizer precipitation property, has the characteristics of delustring and is suitable for the manufacturing of disposable medical liquid (blood) infusion thin-film bag and soft catheter.

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

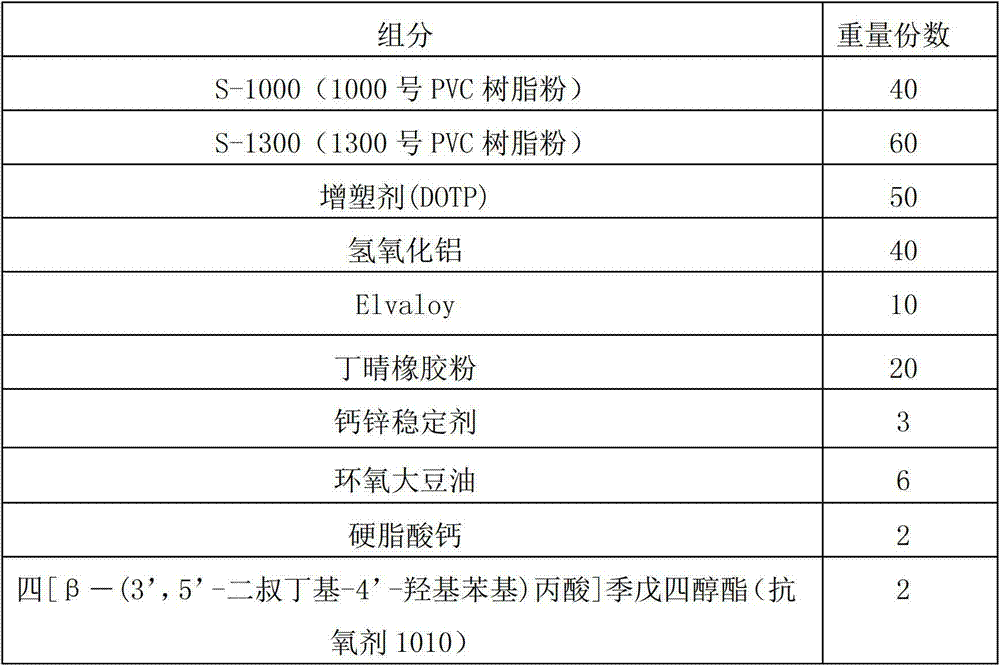

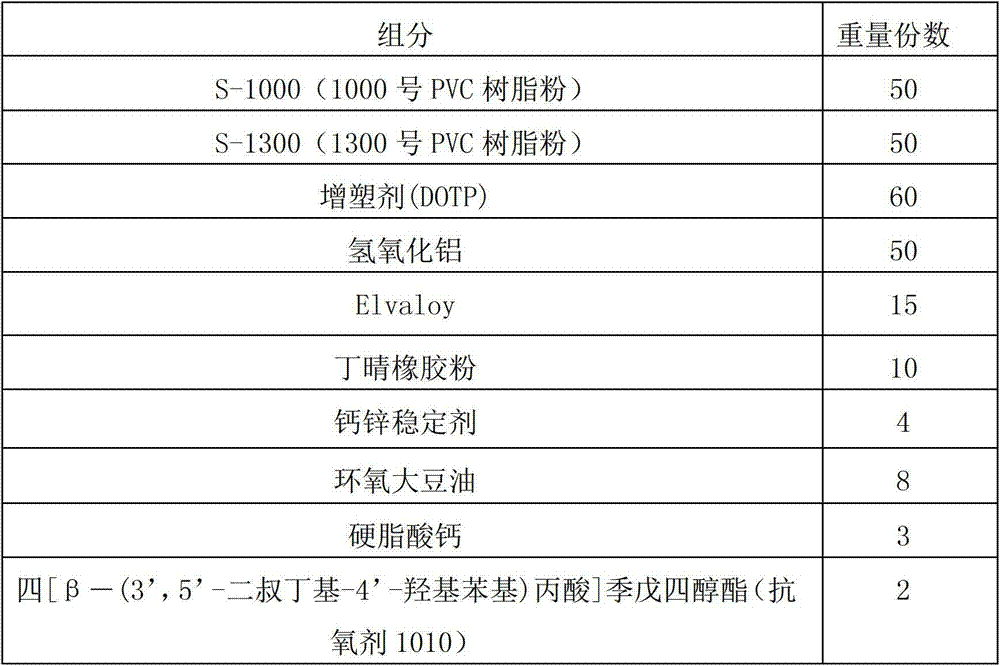

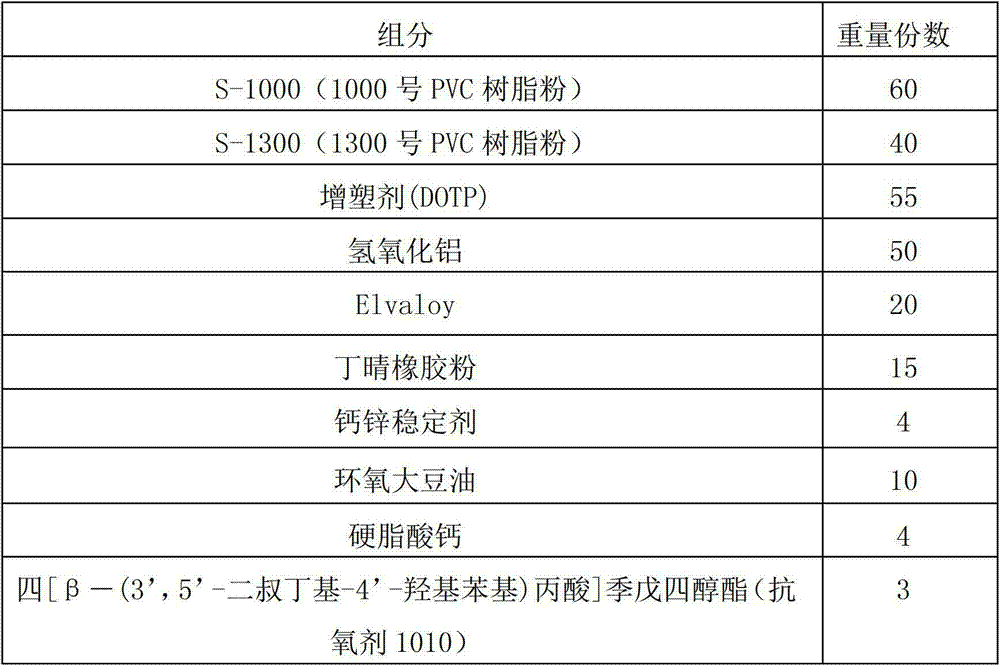

Cold-resistant oilproof flame-retardant PVC (Polyvinyl Chloride) cable material and preparation method thereof

InactiveCN103205070AGood oil resistanceImprove cold resistanceInsulated cablesInsulated conductorsPolyolefinPolymer science

The invention relates to a cable material, and in particular relates to a cold-resistant oilproof flame-retardant PVC (Polyvinyl Chloride) cable material and a preparation method thereof. The polyvinyl chloride cable material comprises the following components: PVC resin powder, a plasticizer, nitrile butadiene rubber powder, a stabilizer, epoxidized soybean oil, a fire retardant, Elvaloy, an antioxidant and a lubricant. The preparation method comprises the following steps of: evenly stirring the PVC resin powder, the plasticizer, the nitrile butadiene rubber powder, the stabilizer, the epoxidized soybean oil, the fire retardant, the Elvaloy, the antioxidant and the lubricant in a high-speed mixer; performing banburying in a banbury mixer at the temperature between 120 and 140 DEG C; extruding by using double screw rods; granulating by grinding and hot-cutting; conveying materials by using a cyclone separator; and screening by using a vibrating screen and packaging, thereby obtaining the finished cold-resistant oilproof flame-retardant PVC cable material product. Compared with the common flame-retardant PVC cable material, the polyolefin cable material provided by the invention has the effects that the cold-resistant performance is improved; the oilproof performance of the product is improved greatly; and the problem that the cold-resistant PVC cable material plasticizer is easy to separate out is solved.

Owner:JIANGSU LINRY NEW MSTAR TECH

Preparation of silica reinforced polyisoprene-rich rubber composition and tire with component thereof

This invention relates to the preparation of a cis 1,4-polyisoprene rubber-rich rubber composition containing precipitated silica which has been pre-treated with a fatty alcohol and / or epoxidized soybean oil together with an organosilane containing polysulfide coupling agent and to tires having at least one component comprised of such rubber composition. The invention particularly relates to a process of (a) preparing a natural rubber-rich rubber composition comprised of pre-treating precipitated silica aggregates prior to blending with, or in the presence of, dry natural rubber with a fatty alcohol and / or epoxidized soybean oil to the exclusion of sulfur curative for the natural rubber, mixing an organalkoxysiloxane based polysulfide coupling agent with said dry natural rubber coincidentally with or subsequent to said precipitated silica aggregate fatty alcohol and / or epoxidized soybean oil pre-treatment to form a composite thereof, to the exclusion of sulfur curative, followed by (b) mixing the resulting rubber mixture with sulfur curative and (c) curing the resulting rubber composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

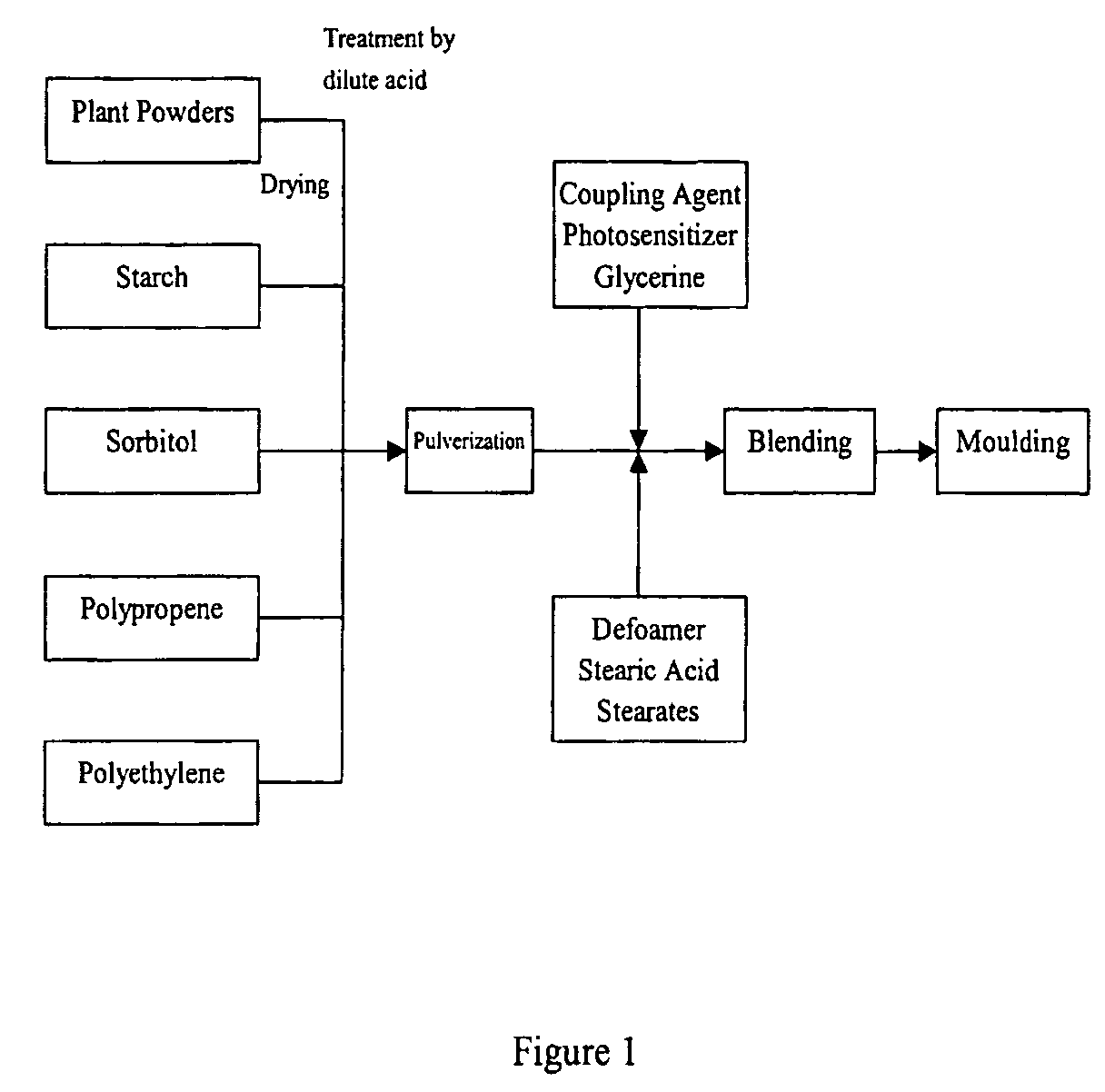

Biodegradable composition for the preparation of tableware, drink container, mulching film and package and method for preparing the same

The present invention relates to a biodegradable composition for the preparation of table-ware, mulching film and package, which comprises: 2-6% by weight of starch; 35-45% by weight of plant powders; 20-30% by weight of calcium carbonate; 2-7% by weight of sorbitol; 7-13% by weight of polypropylene; 2-5% by weight of polyethylene; 2-6% by weight of coupling agent; 1-2% by weight of defoamer; 2-5% by weight of stearic acid; 2-6% by weight of stearate; 3-6% by weight of glycerine or epoxidized soybean oil; and 60-100 ppm photosensitizer. The present invention also relates to a method for preparing the composition, which comprises: treating a plant waste with a diluent acid, drying and pulverizing, then mixing it with starch, polypropylene, and polyethylene, sorbitol, defoamer, coupling agent, stearic acid, stearate, glycerine and photosensitizer homogeneously; and blending the mixture obtained in a double-screw extruder at a temperature of 160-180° C. to obtain the composition of the present invention.

Owner:XU HAO

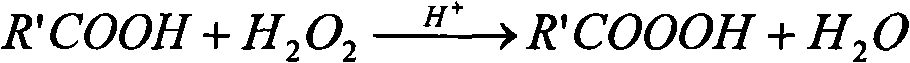

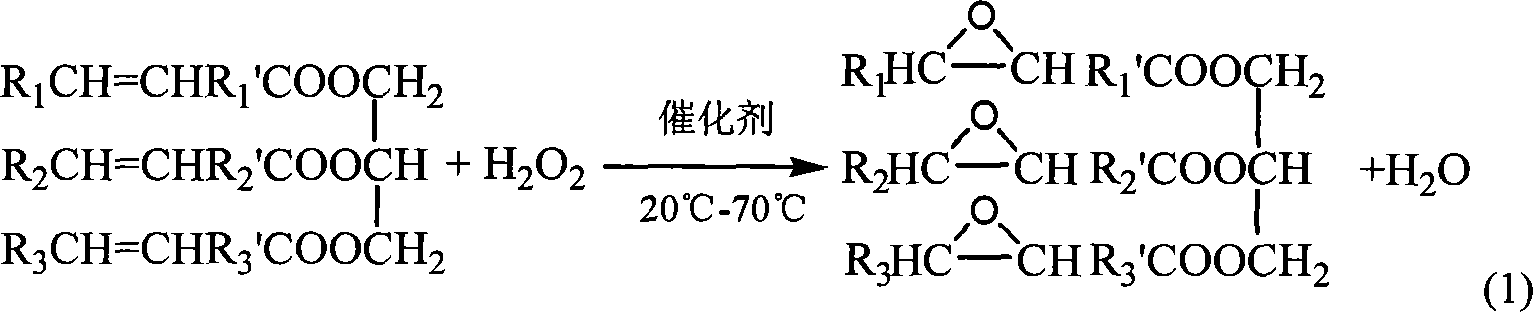

Method for preparing epoxidized soybean oil or epoxy fatty acid methyl(ethyl) ester by heteropolyacid liquid phase catalysis

InactiveCN101235021AReduce usageDisadvantages of Avoiding Recycling DifficultiesOrganic chemistryEpoxyHeteropoly acid

A heteropoly acid liquid-phase catalysis preparation method of epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) belongs to liquid-phase catalysis oxidization technical field, which utilizes biomass soybean oil and unsaturated fatty acid methyl ester (ethyl ester) and uses solid heteropoly acid salt compound as catalyst, without carboxyl acid, protonic acid and solvent, to synthesize epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) via hydrogen dioxide solution reaction, without acid waste water generation in epoxidation to protect environment. The epoxy soybean oil or epoxy fatty acid methyl ester (ethyl ester) can be used as plasticizer to be widely used in non-toxic polyvinyl chloride (PVC) product and transparent PVC product, as transparent bottle, transparent box, food and drug package, PVC medical blood bag and environment-friend uv-curing coating or the like.

Owner:JIANGNAN UNIV

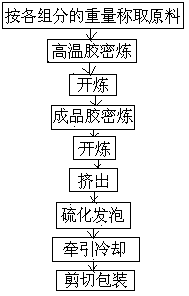

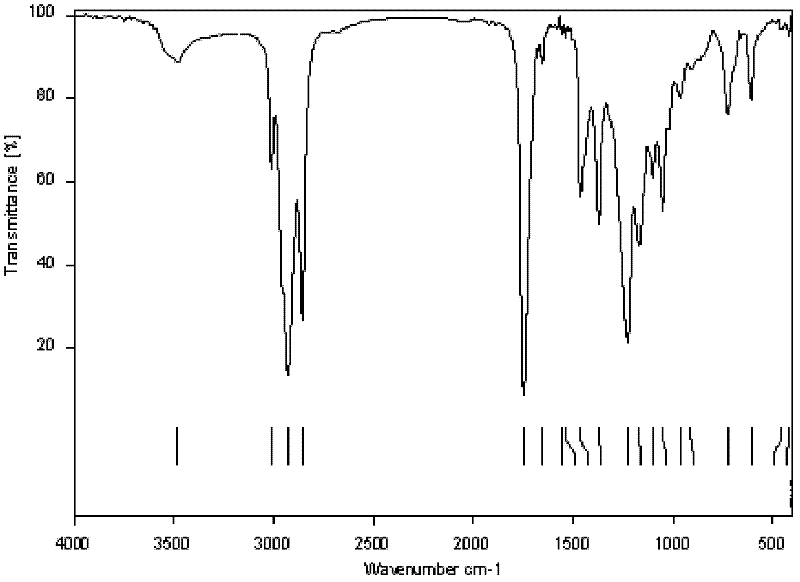

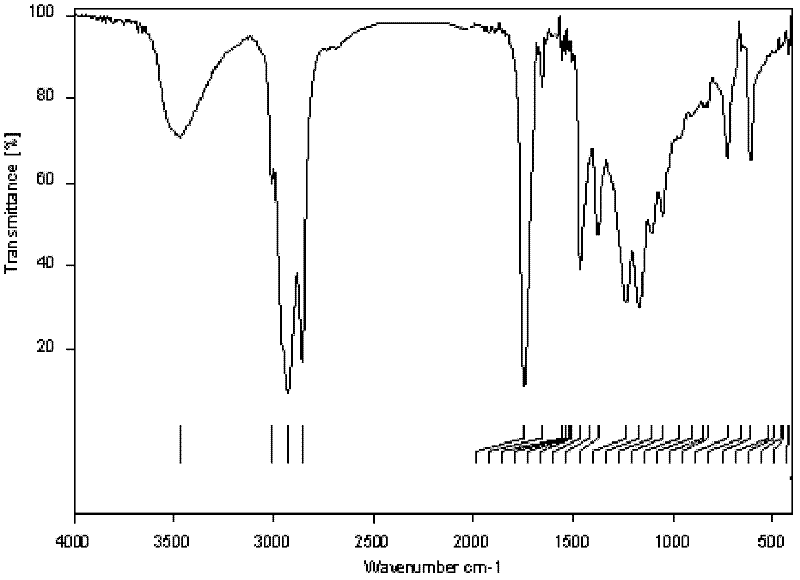

Environment-friendly rubber plastic heat-insulating material and its preparation method

The invention relates to an environment-friendly rubber plastic heat-insulating material and its preparation method, and the rubber plastic heat-insulating material is prepared from butyronitrile rubber (NBR), antimonous oxide (Sb2O3), zinc oxide, sulfur, dioctyl-phthalate (DOP), epoxidized soybean oil (ADDA), mercaptobenzothiazole (M), anti-aging agent (4020), antioxidant (AST-500), protective wax (HGB-3), ethylene-vinyl acetate copolymer (EVA), dicumyl peroxide (DCP crosslinking agent), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, foaming agent-dinitrosopentamethylene tetraamine (H), diphenylguanidine (D), pigment, anti-aging agent (RD), anti scorching agent (PVI), and the like. By limited use of raw materials containing chlorine ion components and cooperation of a new vulcanization foaming technology, environment-friendly and heat-insulating performances of the product can be stabilized, the prepared environment-friendly rubber plastic heat-insulating material has no corrosion performance in use, the material life is prolonged, metal pipes in refrigeration equipment can be effectively protected, and maximized performance of the product can be performed.

Owner:周良文

Slow-release organic fertilizer for tea leaves and preparation method thereof

InactiveCN103351219AWith fertilizer effect controlled releaseApplicable growthFertilizer mixturesPotassiumCopper oxide

Owner:ANHUI INNOVATIVE AGRI TECH

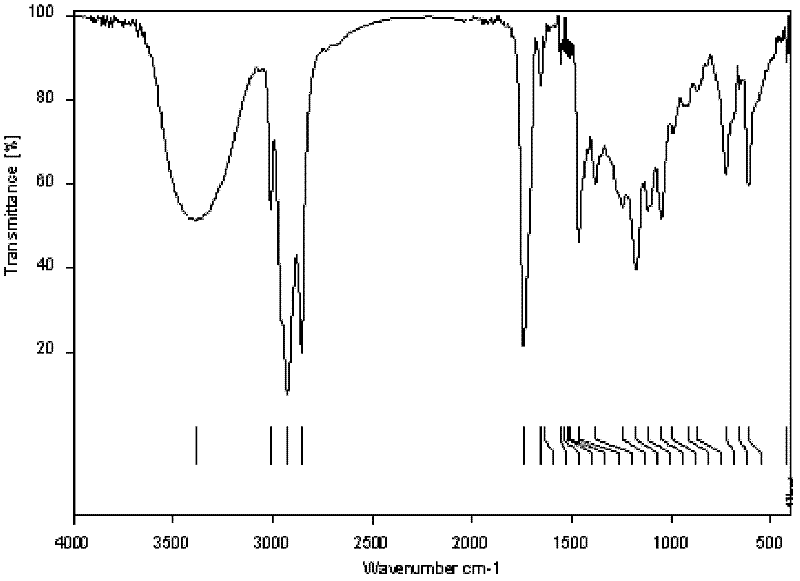

Diacetyl epoxy glyceryl oleates and synthesis method thereof

The invention discloses diacetyl epoxy glyceryl oleates. The general formula of the diacetyl epoxy glyceryl oleates may be (I) or (II). The diacetyl epoxy glyceryl oleates are more stable and flowable than epoxidized soybean oil, the molecular weight of the diacetyl epoxy glyceryl oleates is low, and the diacetyl epoxy glyceryl oleates have high compatibility with polyvinyl chloride (PVC) and arehigh-performance nontoxic plastic plasticizer. The invention also discloses a method for synthesizing diacetyl epoxy glyceryl oleates by starting from oleic acid, which comprises: performing ester exchange of oleic acid and glycerol in the presence of a catalyst to obtain monooleins; compounding monooleins with acetyl to obtain diacetyl monooleins; and performing an epoxidation reaction in an environment with formic acid and hydrogen peroxide, and thus synthesizing diacetyl epoxy glyceryl oleates.

Owner:NANTONG HAIERMA TECH CO LTD

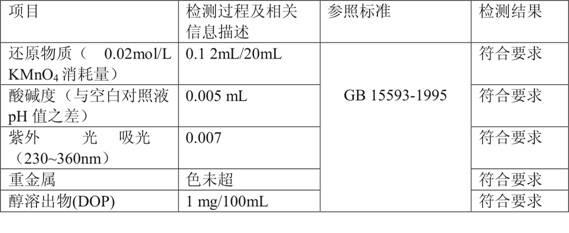

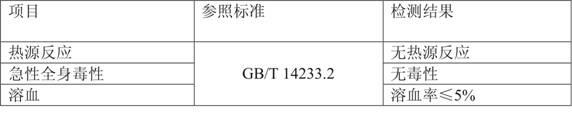

Medical multifunctional polyvinyl chloride composite material

The invention relates to a medical multifunctional polyvinyl chloride composite material which consists of polyvinyl chloride (PVC) resin powder, a nano modified material, a plasticizer, a stabilizer and a lubricant. In the formula, every 100 portions of PVC resin powder is added with 0.5 portion to 3 portions of nano modified material, 20 portions to 40 portions of phthalic acid ester, 10 portions to 30 portions of trimellitate, 10 portions to 30 portions of citrate, 5 portions to 10 portions of epoxidized soybean oil (ESO), 0.5 portion to 1 portion of calcium stearate (CaSt), 0.5 portion to 1 portion of zinc stearate (ZnSt) and 0.1 portion to 0.5 portion of silicon oil according to portions by weight. The nano modified material is nano silver-supported zinc oxide or nano silver-supported titanium dioxide and has the main effects of having anti-bacterial function and being capable of improving the physical properties of resins. The composite material has reasonable formula, stable performance, simple technology, nano antibacterial function and low dissolution performance of the plasticizer, and can be used for producing various medical apparatuses.

Owner:WEIHAI JIERUI MEDICAL PRODUCTS CO LTD

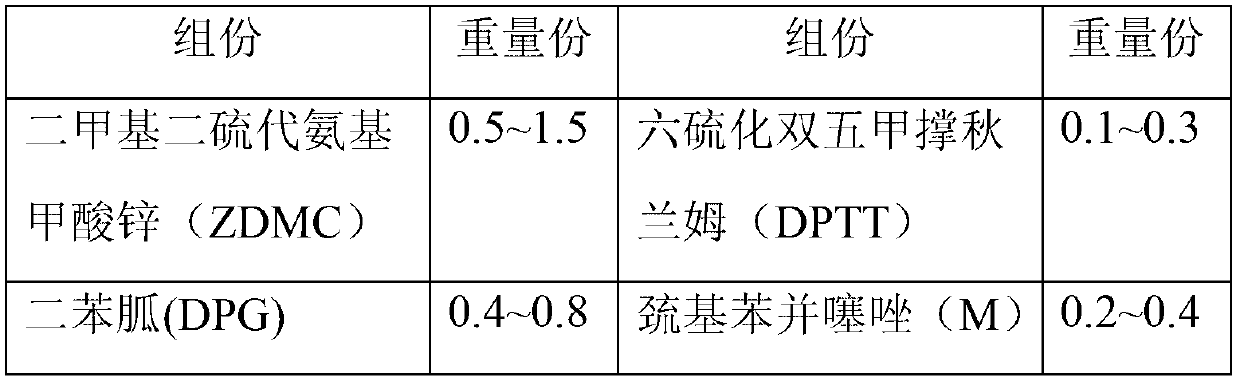

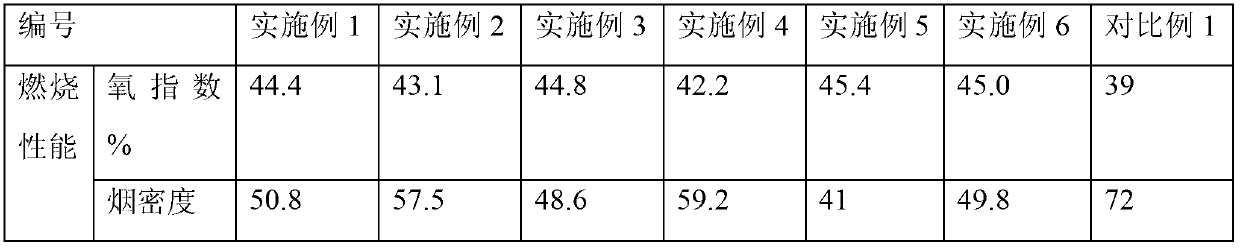

High flame retardancy type soft foam plastic insulation product and preparation method thereof

ActiveCN103102533AHigh oxygen indexImprove flame retardant performancePolyvinyl chloridePolyethylene glycol

The invention provides a high flame retardancy type soft foam plastic insulation product and a preparation method thereof. The product comprises the following components in parts by weight: 12 to 15 parts of nitrile rubber, 8 to 10 parts of talcum powder, 0.5 to 0.8 parts of polyethylene glycol, 0.2 to 0.4 parts of antiager 4020, 15 to 20 parts of chlorinated paraffin, 0.6 to 0.9 parts of paraffin, 1 to 2 parts of epoxidized soybean oil, 0.1 to 0.3 parts of antiager RD, 0.4 to 0.7 parts of carbon black, 7 to 10 parts of polrvinyl chloride, 26 to 36 parts of fire retardant based on the total amount, 2 to 5 parts of dioctyl ester, 8 to 12 parts of azodicarbonamide, 0.2 to 0.5 parts of stearic acid, 0.4 to 0.7 parts of zinc oxide, 0.4 to 0.7 parts of sulphur, and 1.3 to 1.8 parts of accelerant based on the total amount. By adopting the high flame retardancy type soft foam plastic insulation product, the technical problem that the oxygen index and the smoke density are mutually conflicted in the technological manufacture is solved, and the bottleneck due to mutual limitation is broken through.

Owner:HEBEI HUAMEI CHEM & BUILDING MATERIALS GRP

Novel environment-friendly polyvinyl chloride cable material

The invention provides a novel environment-friendly polyvinyl chloride cable material. The material consists of polyvinyl chloride WS-1300, plasticizer UN399, stabilizer CZ-756E (105), epoxidized soybean oil, bisphenol A antioxygen, antimonous oxide (SB203), polyethylene (PE), activated light calcium carbonate and carbon black. The chemical substance content of the material is reduced by improving the formula of the cable material, so that the product has the advantages of effectively solving the problem of toxic gases releasing in polyvinyl chloride material heating and plastifying process, reducing the harm to the human bodies in the production process, resisting the temperature of between 40 and 105 DEG C, along with cleanness and environmental protection, light specific gravity, high plasticization degree, no deformation, fracture or aging, superior product performance, and wider application range and field.

Owner:ZHENJIANG HUAYIN INSTR & ELECTRICAL EQUIP

Mixing type nonisocyanate polyurethane and preparation method thereof

The invention relates to hybrid non-isocyanate polyurethane which is prepared through adopting the following method: epoxidized soybean oil and weak base catalyst are added in a reaction kettle, and then carbon dioxide gas is pumped in; at the action of reaction temperature, reaction pressure and stirring, reaction is started, and cyclic carbonate is generated after the reaction; the cyclic carbonate is mixed with epoxy resin and organic base catalyst is added; then, the mixture is mixed with primary amine compound so as to be formed into sheets; finally, sulfuration is carried out under the condition of sulfuration with the product placed for 7 to 9 days at room temperature. The hybrid non-isocyanate polyurethane has the advantages that: the hybrid non-isocyanate polyurethane is synthesized through the mixing and the reaction of natural regenerable vegetable resource and epoxy resin, thereby reducing the dependence on petrochemical resource, making full use of the regenerable vegetable resource and carbon resource and reducing environmental pollution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

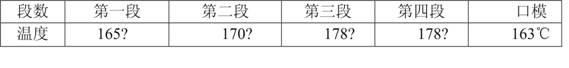

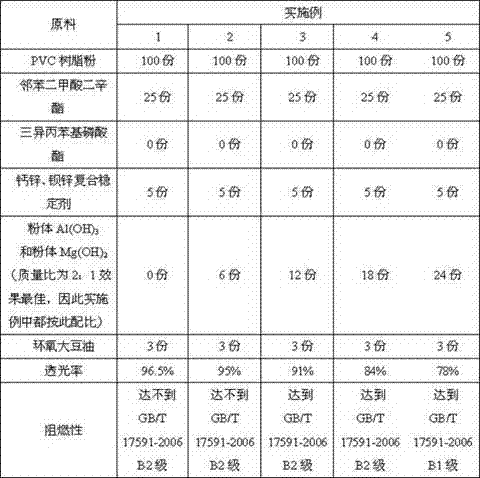

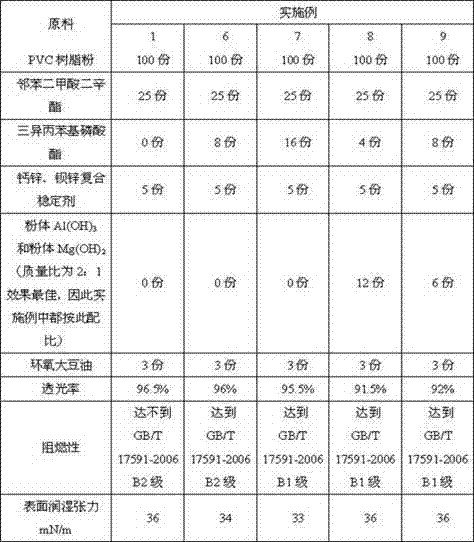

Flame-retardant transparent floor film and production technology thereof

The invention relates to a flame-retardant transparent floor film and a production technology thereof. The flame-retardant transparent floor film is prepared by treating the following main raw materials in parts by weight: 100 parts of PVC (Poly Vinyl Chloride) resin powder, 15 to 30 parts of a main plasticizer, 4 to 8 parts of a fire-retardant plasticizer, 4 to 6 parts of a stabilizer, 6 to 12 parts of an inorganic filler, and 2 to 4 parts of epoxidized soybean oil by a PVC die rolling technology. By adopting the flame-retardant transparent floor film and the production technology thereof, the conflict between the flame retardant performance, the transparence and the jet-printing performance is solved; the inorganic fillers are adopted, thus micromolecules separated by the liquid fire-retardant plasticizers are easily absorbed, and ideal transparence and the jet-printing performance can be provided for the product under efficient flame retardant performance; in addition, the generation of phenomena of wheel adhering, albinism and hard coiling can be effectively avoided by utilizing the flame-retardant transparent floor film; and simultaneously, the flame-retardant transparent floor film is excellent in wear resistance.

Owner:ZHEJIANG BOTAI PLASTIC

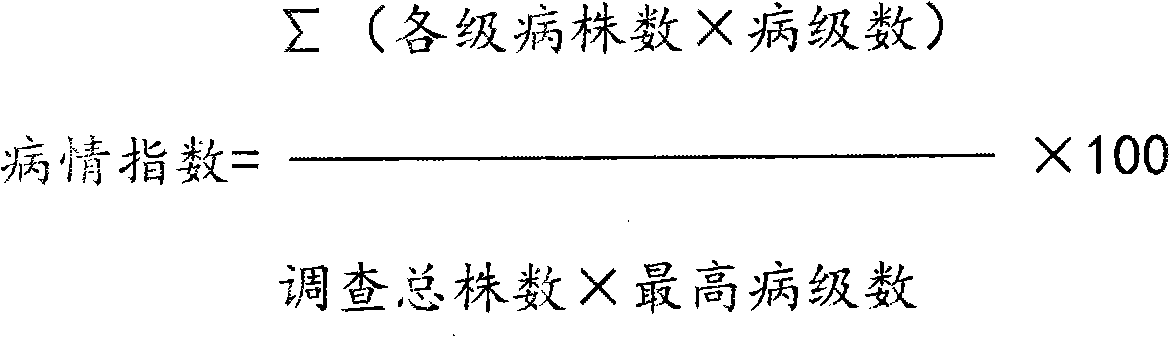

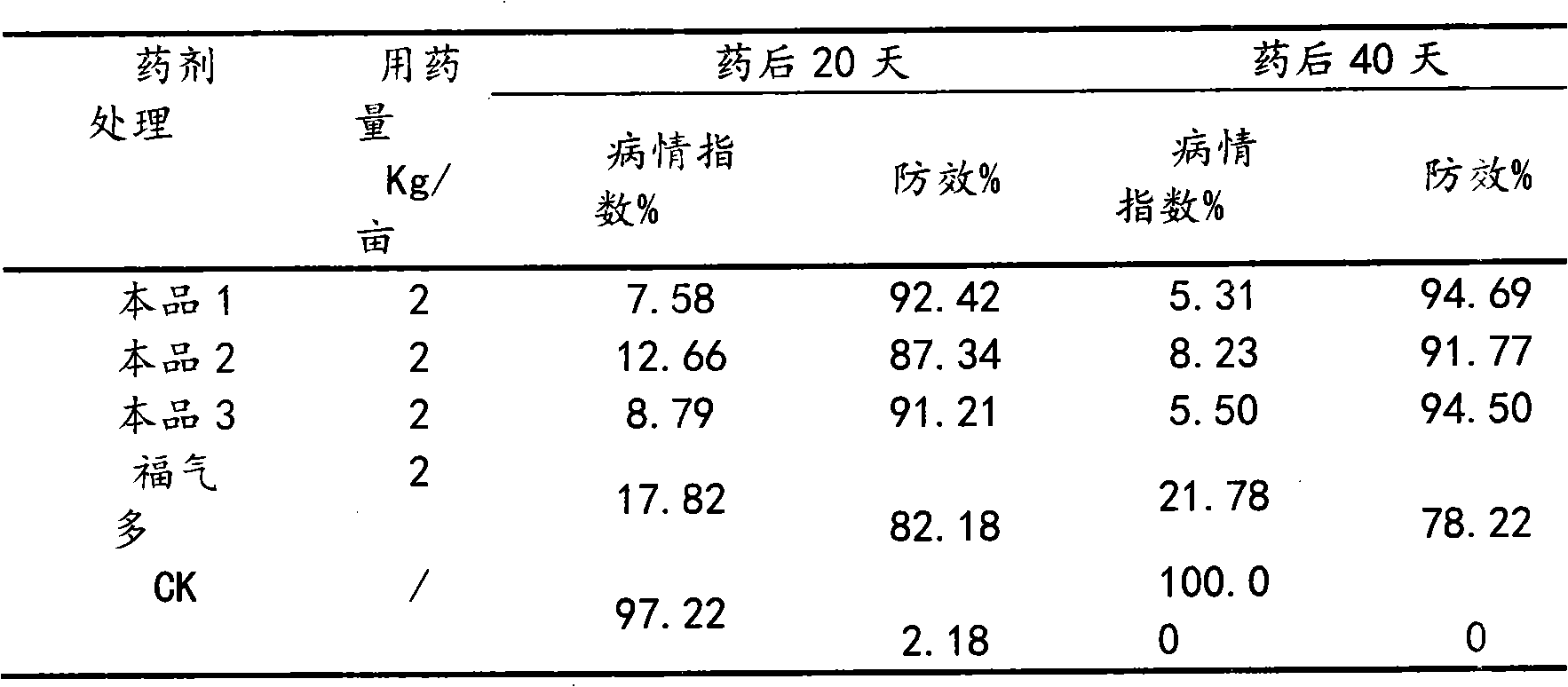

Nematoid-killing composition containing abamectin and paecilomyces lilacinus

InactiveCN102077846AAvoid infectionIncrease parasitic rateBiocideNematocidesPaecilomyces lilacinusAbamectin

The invention relates to a nematoid-killing composition containing abamectin and paecilomyces lilacinus, which is characterized by comprising abamectin and paecilomyces lilacinus; 100g of nematoid-killing composition is prepared by the following components of 0.1-5g of abamectin, 0.1-1 billion live spores / g of paecilomyces lilacinus, 1-10g of stabilizing agent, 1-90g of solvent and 10-90g of assistant, wherein the assistant is any one or the combination of any two of attapulgite, kaoline, sepiolite, light calcium and kieselguhr and is prepared into a granular formulation or suspending agent or wettable powder; the stabilizing agent is any one or the combination of any two of castor oil, soybean oil, epoxidized soybean oil, propylene glycol, methyl oleate, ethylene glycol, butylated hydroxytoluene (BHT) and butylated hydroxyanisole (BHA); and the solvent is any one of dimethylbenzene, trimethylbenzene and dimethylformamide. The nematoid-killing composition is used for controlling the knot nematode and has better control effect on the knot nematode.

Owner:佛山市盈辉作物科学有限公司

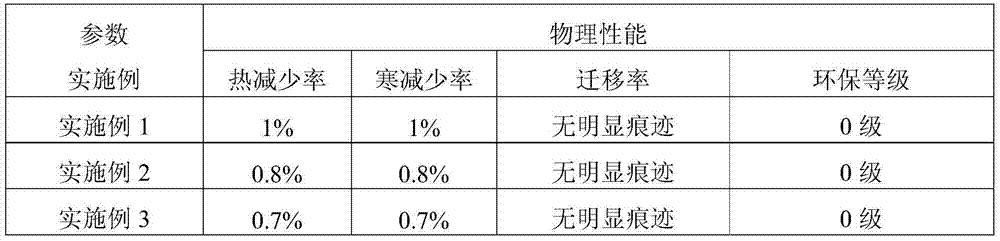

PVC (Polyvinyl Chloride) sealing strip and application thereof

ActiveCN103923412AImprove migration resistanceImprove heat resistanceDomestic cooling apparatusLighting and heating apparatusPolyesterElastomer

The invention discloses a PVC (Polyvinyl Chloride) sealing strip and an application thereof. The PVC sealing strip comprises 40-50 parts of PVC resin, 25-50 parts of plasticizer, 2-10 parts of elastomer, 2-5 parts of stabilizer, 15-25 parts of filler and 1-3 parts of lubricant, wherein the plasticizer is at least one of a diisononyl adipate plasticizer, a trioctyl trimellitate plasticizer, an epoxidized soybean oil plasticizer and a polyester plasticizer. The PVC sealing strip provided by the inveniton has high migration resistance, heat resistance, cold resistance and environmental friendliness performance.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

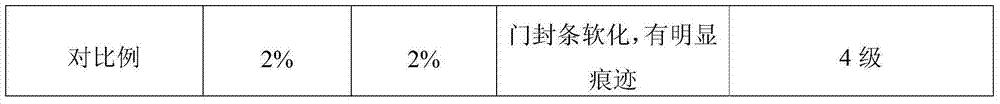

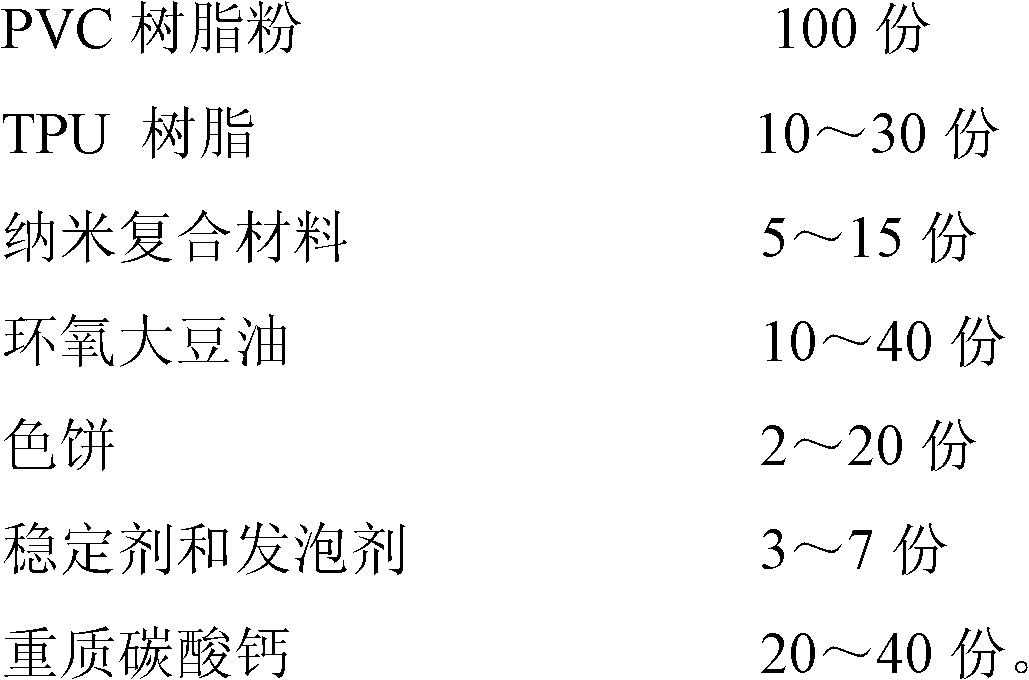

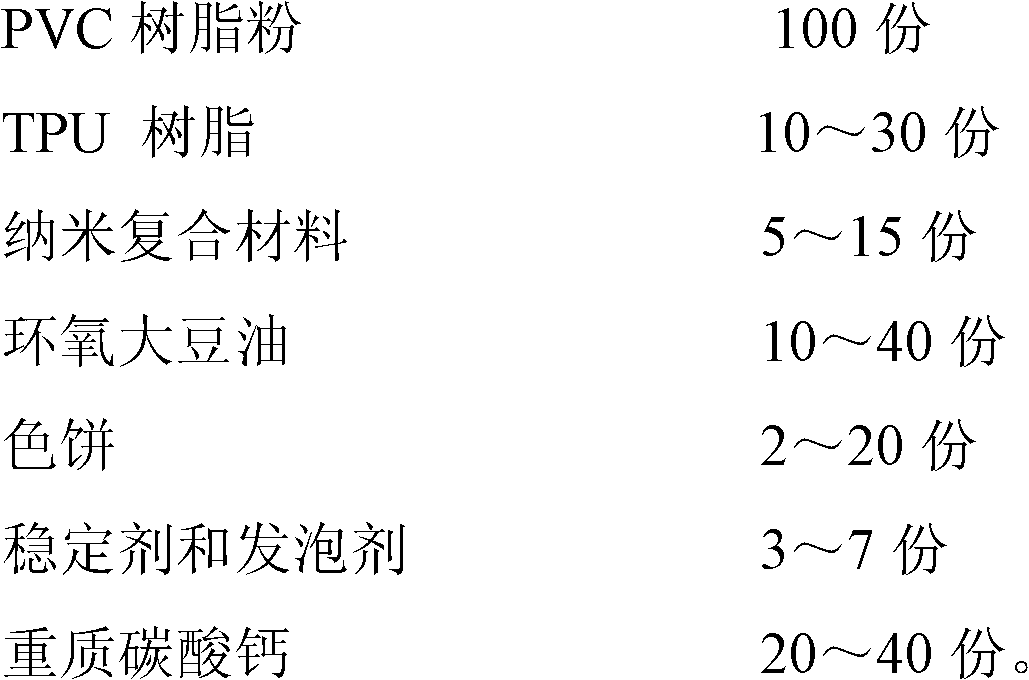

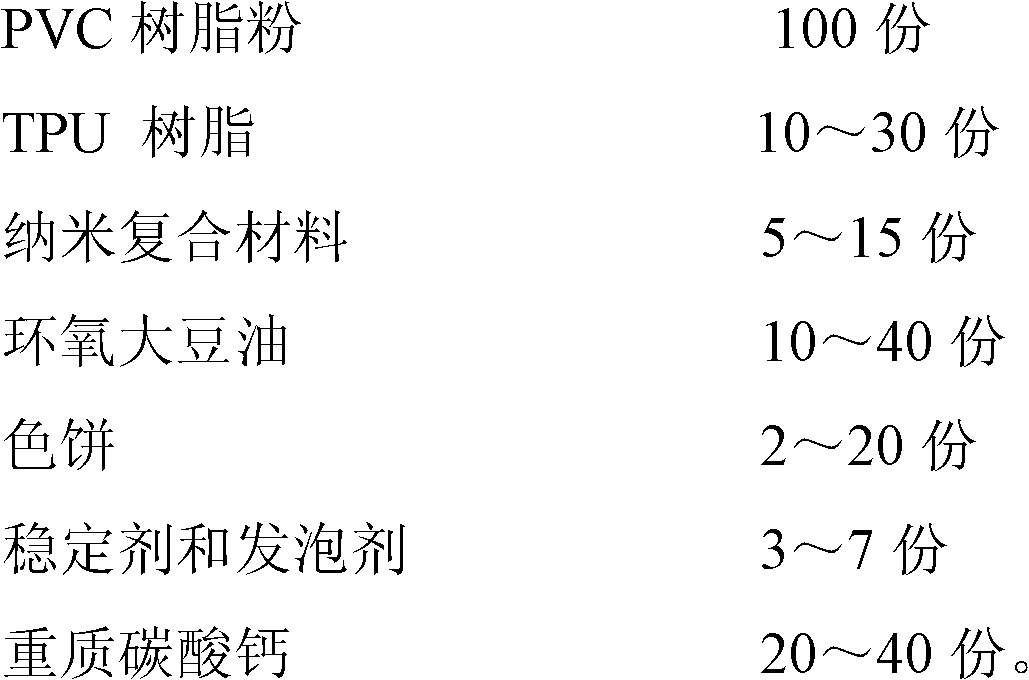

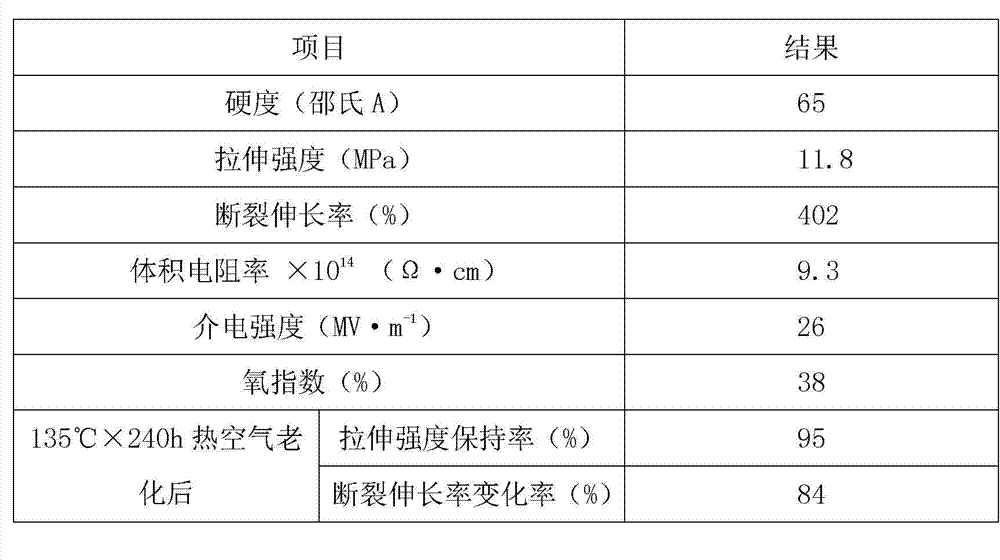

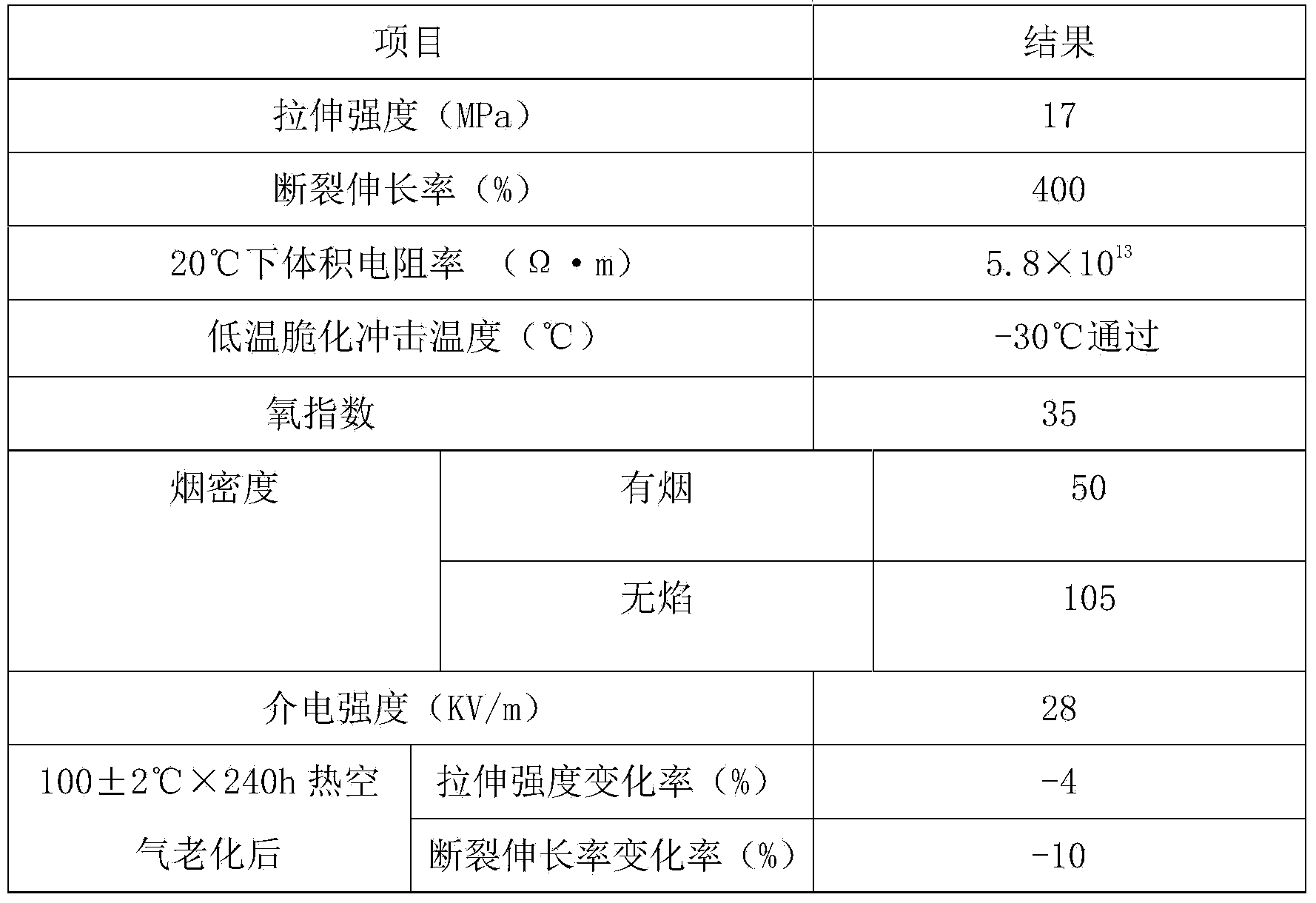

High-wear-resistant artificial leather and preparation method thereof

InactiveCN102154844AHigh hardnessImprove rigidity and toughnessTextiles and paperFoaming agentWear resistant

The invention discloses high-wear-resistant artificial leather, which is prepared by performing calendaring on a high-wear-resistant agent sizing agent. The high-wear-resistant agent sizing agent consists of the following components in parts by weight: 100 parts of PVC (Polyvinyl Chloride) resin powder, 10-30 parts of TPU (Thermoplastic Polyurethane) resin, 5-15 parts of nano composite material, 10-40 parts of epoxidized soybean oil, 2-20 parts of color cake, 3-7 parts of stabilizing agent and foaming agent and 20-40 parts of ground limestone. The artificial leather has higher mechanical property and ultrahigh wear resistance; and the surface wear resistance revolution number the high-wear-resistant artificial leather is more than or equal to 6,000 times.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

Preparation method of full biodegradation film

The invention discloses a preparation method of a full biodegradation film, which takes poly adipic acid / polybutylene terephthalate (PBAT) and starch as base materials, poly-epsilon carpolaction (PCL), epoxidized soybean oil (ESO), and phosphorous acid dialkyl ester as plasticizers, and montmorillonoid or calcium carbonate, talcum powder and the like as inorganic fillers. The method comprises the steps that modification and pelleting are performed in a twin screw; modified resin is added to a film blowing machine for film blowing; and the full biodegradation film can be obtained finally. The full biodegradation film produced by the method is better in physical characteristic, can be directly prepared into a film bag, and can serve as a daily-used packaging film, a waistcoat bag, a food packaging bag and the like; the preparation method of the full biodegradation film is simple in technology, and easy to control, and is suitable for industrial mass production; the film bag produced by the method is high in strength, can be biodegraded fully after use, and is easy to dispose; and environmental pollution is reduced.

Owner:DONGGUAN XINHAI ENVIRONMENT PROTECTION MATERIAL

One-step preparation method of polyol with soybean oil

InactiveCN101747184AOrganic compound preparationCarboxylic acid esters preparationPolyesterSynthesis methods

The invention discloses a one-step synthesis preparation method of soybean oil polyol. In the last patent 200710151008.8, the two-step synthesis method of soybean oil polyol is provided. According to the same principle, the two-step method is evolved into the one-step method, and the soybean oil is directly synthesized into polyol by the one-step method. The invention has the advantages that: the middle separation process of epoxidized soybean oil and water is eliminated, and simultaneously the process that the PH value is adjusted to be neutral is eliminated, so that the reaction cycle is greatly shortened, thereby, the reaction time is shortened to 5 to 8 hours; and simultaneously, the loss of epoxidized soybean oil during middle treatment is also eliminated, and the obtained polyol hydroxyl value after the reaction is between 200 to 500mgKOH / g; and the viscosity can be controlled by changing distillation temperature. The polyol is mainly used to partly or fully replace polyether or polyester polyols to synthesize polyurethane foam.

Owner:TIANJIN POLYTECHNIC UNIV

Nano-wollastonite powder modified ethylene propylene diene copolymer cable material

ActiveCN102964697AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsPolyesterPolymer science

The invention discloses a nano-wollastonite powder modified ethylene propylene diene copolymer cable material, which is prepared FROM the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland ethylene propylene diene copolymer 3950, 20-30 parts of butyl rubber BBK232, 10-15 parts of SG-3 PVC (polyvinyl chloride) resin, 10-15 parts of trioctyl trimellitate, 2-5 parts of propanediol sebacate polyester, 2-5 parts of epoxidized soybean oil, 5-10 parts of polyethylene wax, 0.2-0.5 part of bisphenol A, 1-2 parts of zinc stearate, 0.5-1 part of lead sulfate tribasic, 1-2 parts of sulphur, 3-5 parts of zinc oxide, 30-40 parts of wollastonite powder, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Ethylene-propylene-diene monomer rubber used for manufacturing wind energy cable and preparation method thereof

ActiveCN102617942AImprove mechanical propertiesEasy to stretchPolymer scienceDecabromobiphenyl ether

The invention discloses an ethylene-propylene-diene monomer rubber used for manufacturing a wind energy cable and a preparation method thereof. The ethylene-propylene-diene monomer rubber comprises the following components: 90-110 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 0.2-0.5 part of stearic acid, 2-9 parts of paraffin oil, 2-5 parts of lead sulfate tribasic, 1-4 parts of zinc oxide, 80-120 parts of activated kaolin, 0.3-1.5 parts of coupling agent, 0.5-2.6 parts of cross-linking agent, 0.5-2.0 parts of assistant crosslinker, 1-3 parts of semi-reinforcing carbon black, 1-4 parts of plasticizer, 0.5-2 parts of antimonous oxide, 0.5-2 parts of zinc borate, 1-5 parts of basic magnesium carbonate, 1-4 parts of antioxygen, 0.1-0.5 part of sulphur, 2-5parts of epoxidized soybean oil, 5-15 parts of decabromodiphenyl ether, 12-30 parts of antimony oxide and 2-5 parts of organic modified bentonite. The material has the advantages of wide applicable temperature range, god performance and long service life.

Owner:无锡市远登电缆有限公司

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

Nano-wollastonite modified adhesive for packaging

InactiveCN102965036AHigh bonding strengthImprove water resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyvinyl chlorideEthyl acetate

The invention discloses a nano-wollastonite modified adhesive for packaging. The adhesive is prepared from the following raw materials in parts by weight: The adhesive is prepared from the following raw materials in parts by weight: 100-120 parts of styrene, 100-150 parts of ethyl acetate, 20-25 parts of duprene rubber CR121, 15-20 parts of xylene, 1-2 parts of 4,4'-diphenyl methane diisocyanate, 8-12 parts of polyisobutylene, 2-3 parts of (3-aminopropyl)trimethoxysilane, 2-3 parts of polytetramethylene ether glycol, 3-5 parts of SG-2 PVC (polyvinyl chloride) resin, 1-2 parts of ferrocene, 10-15 parts of 704 silicon rubber, 8-12 parts of butyl rubber CBK139, 3-5 parts of epoxidized soybean oil, and the like. The adhesive is excellent in heat resistance heat resistance and cold resistance, high in cohesive strength, water-resistant, moisture-proof, good in storage stability, good in environment friendliness, good in using effect and convenient.

Owner:TONGLING XIANGYUN FIRE FIGHTING TECH

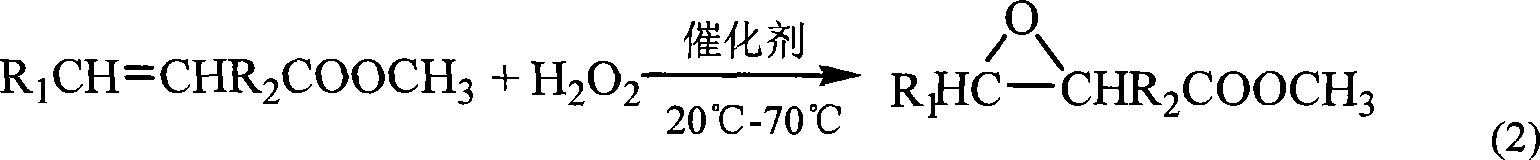

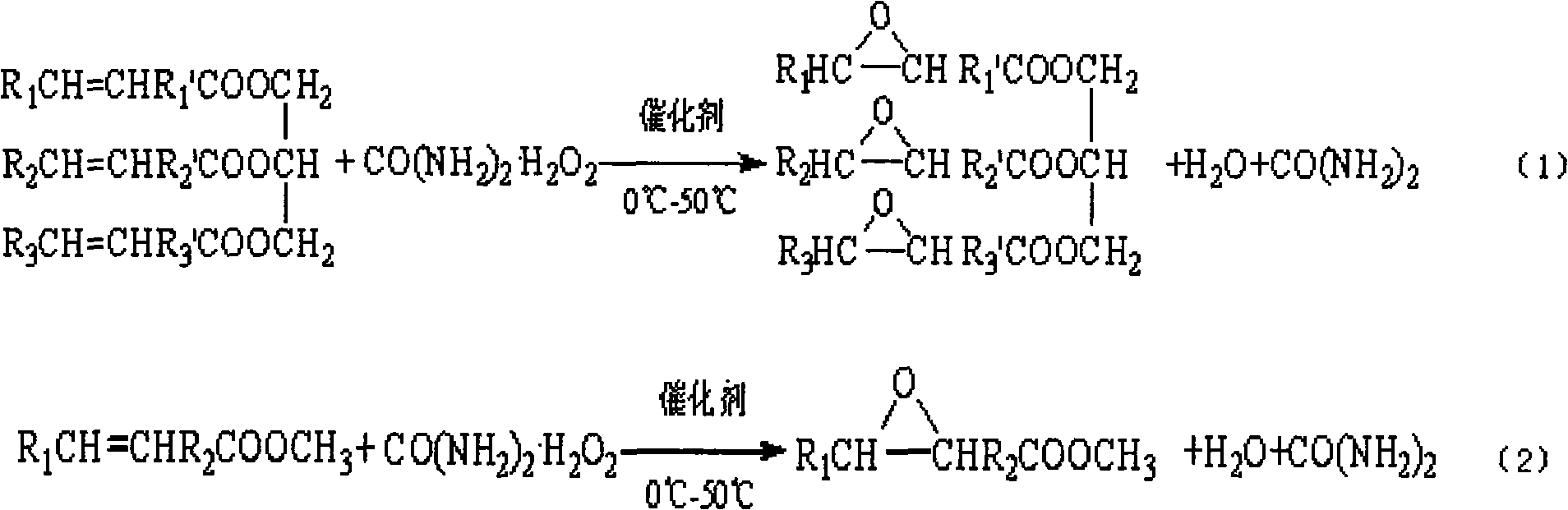

Method for preparing epoxidized soybean oil or epoxy fatty acid methyl (ethyl) ester through catalysis of organic rhenium oxide-urea peroxide

InactiveCN101591588AReduce usageLess corrosiveOrganic chemistryFatty acid chemical modificationEpoxyPolyvinyl chloride

The invention discloses a method for preparing epoxidized soybean oil or epoxy fatty acid methyl (ethyl) ester through the catalysis of organic rhenium oxide-urea peroxide, which belongs to the technical field of liquid-phase catalytic epoxidation. The method utilizes a biomass material, namely soybean oil or unsaturated fatty acid methyl (ethyl) ester, adopts organic rhenium oxide as a catalyst, utilizes urea peroxide to react to synthesize the epoxidized soybean oil or the epoxy fatty acid methyl (ethyl) ester under the conditions without carboxylic acid and protonic acid, and avoids the use of strong acid catalysts during the epoxidation, so the method has small corrosion on equipment; the method avoids the use of the carboxylic acid, makes the post-treatment simple, and has no wastewater; and the method ensures that the process has simple operation, meets the requirement of epoxidized clean production, and is environment-friendly. The product can be taken as a plasticizer to be widely applied to nontoxic polyvinyl chloride (PVC) products and transparent PVC products, namely industrialized products such as transparent bottles, transparent boxes, food and drug packing materials, medical PVC 'blood transfusion bags', environment-friendly photocurable coatings and the like.

Owner:JIANGNAN UNIV

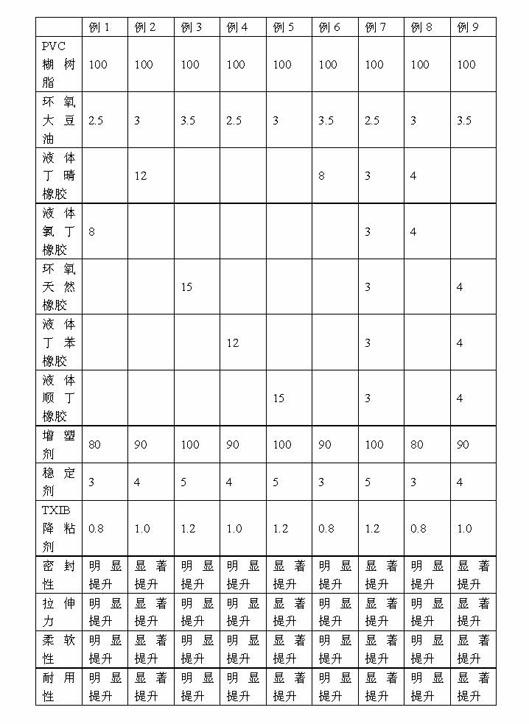

Plastic glove material

The invention discloses a plastic glove material, which is characterized by comprising the following components by weight: 100 kg of PVC (Polyvinyl Chloride) paste resin, 8-15 kg of more than one of liquid butadiene-acrylonitrile rubber, liquid chloroprene rubber, epoxy natural rubber, liquid styrene-butadiene rubber and liquid cis-butadiene rubber, 2.5-3.5 kg of epoxidized soybean oil, 80-100 kg of plasticizer and 3-5 kg of stabilizing agent, wherein the polymerization degree of the PVC paste resin is 1,200-1,450, and the K value of the PVC paste resin is 70-75. Compared with the prior art, the plastic glove material has the advantages of no need of using an acidic chemical for post-treatment and improved sealing property, tensile strength, flexibility and durability.

Owner:广东天耀进出口集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com