Plastic glove material

A glove and plastic technology, applied in the field of plastic materials, can solve the problems of unsatisfactory sealing, tensile force, softness, and durability, and achieve the effect of improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now in conjunction with embodiment, the present invention is described in further detail:

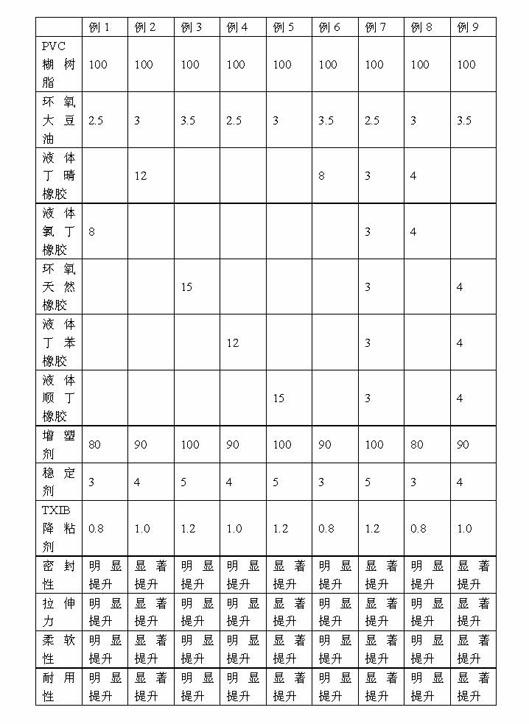

[0015] The present invention includes PVC paste resin; one or more of liquid nitrile rubber, liquid chloroprene rubber, epoxy natural rubber, liquid styrene-butadiene rubber and liquid cis-butadiene rubber; epoxy soybean oil; plasticizer; stabilizer; TXIB Viscosity reducer, PVC paste resin is the degree of polymerization: 1200-1450; K value is 70-75 PVC paste resin, stabilizer is calcium zinc stabilizer, organic tin stabilizer, barium cadmium zinc stabilizer, barium zinc stabilizer, More than one rare earth stabilizer, the dosage of each component and the performance comparison results of the finished plastic gloves and rubber or PU gloves are shown in the following table (the dosage unit is kg):

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com