Patents

Literature

83542results about How to "Improve sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

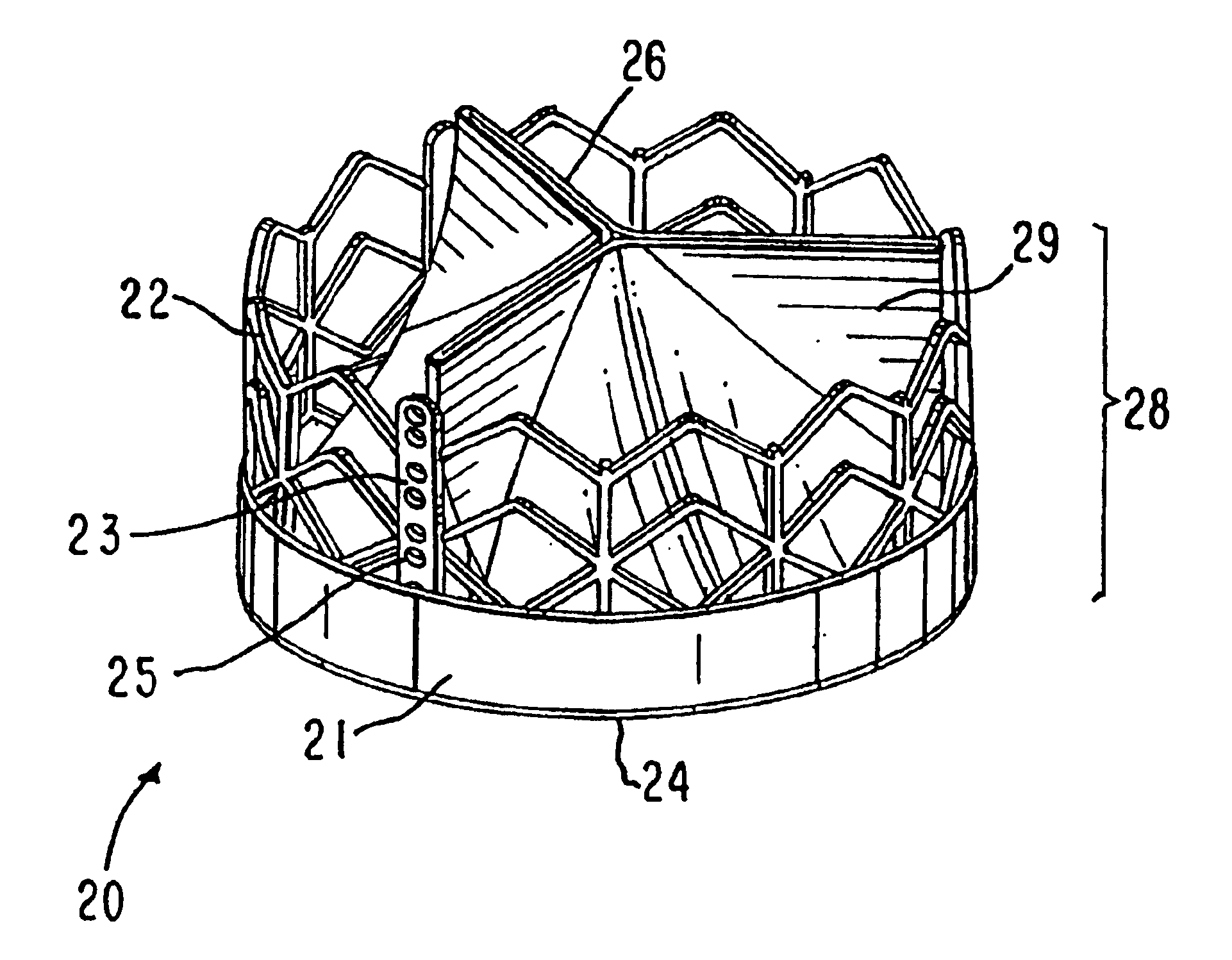

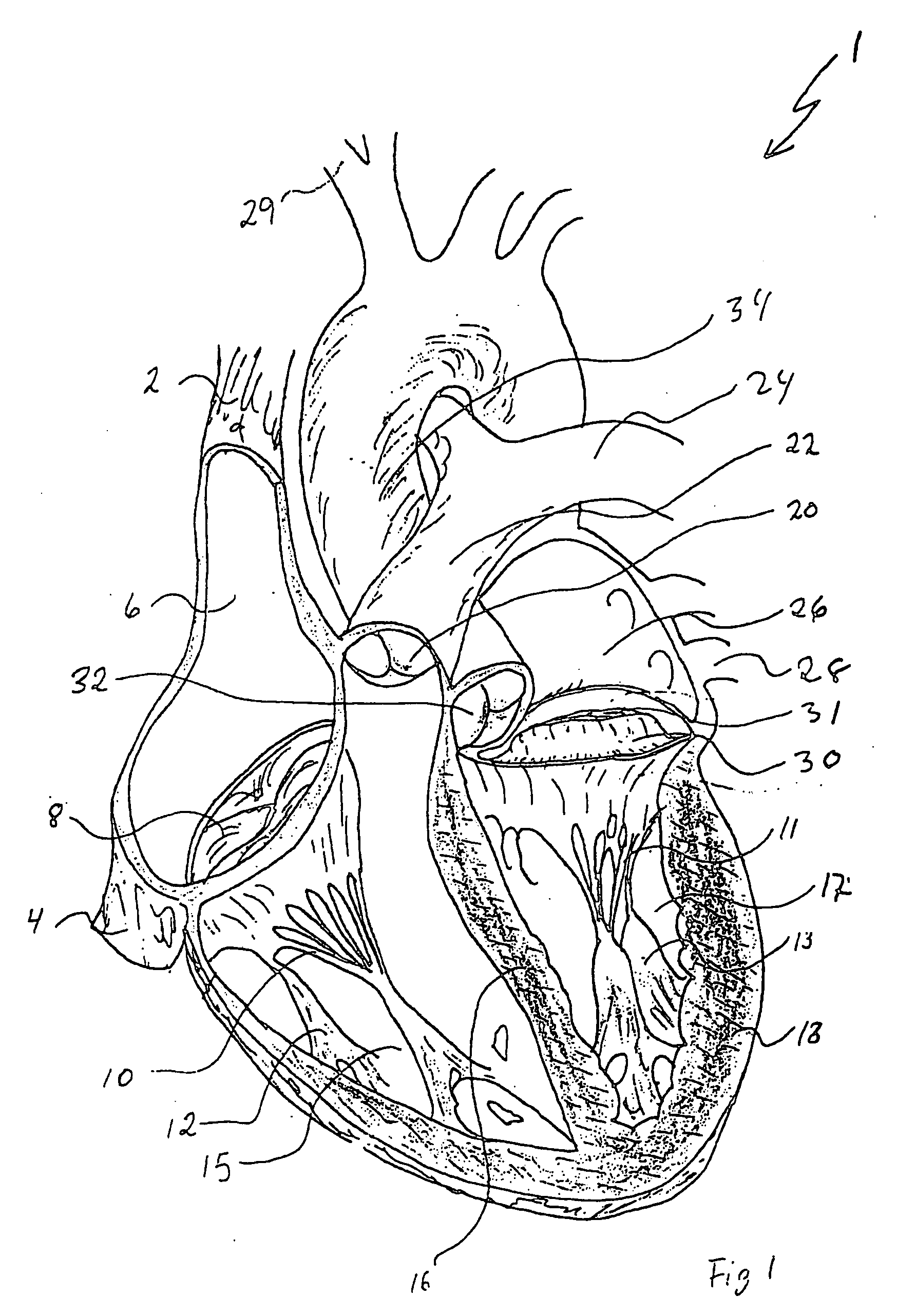

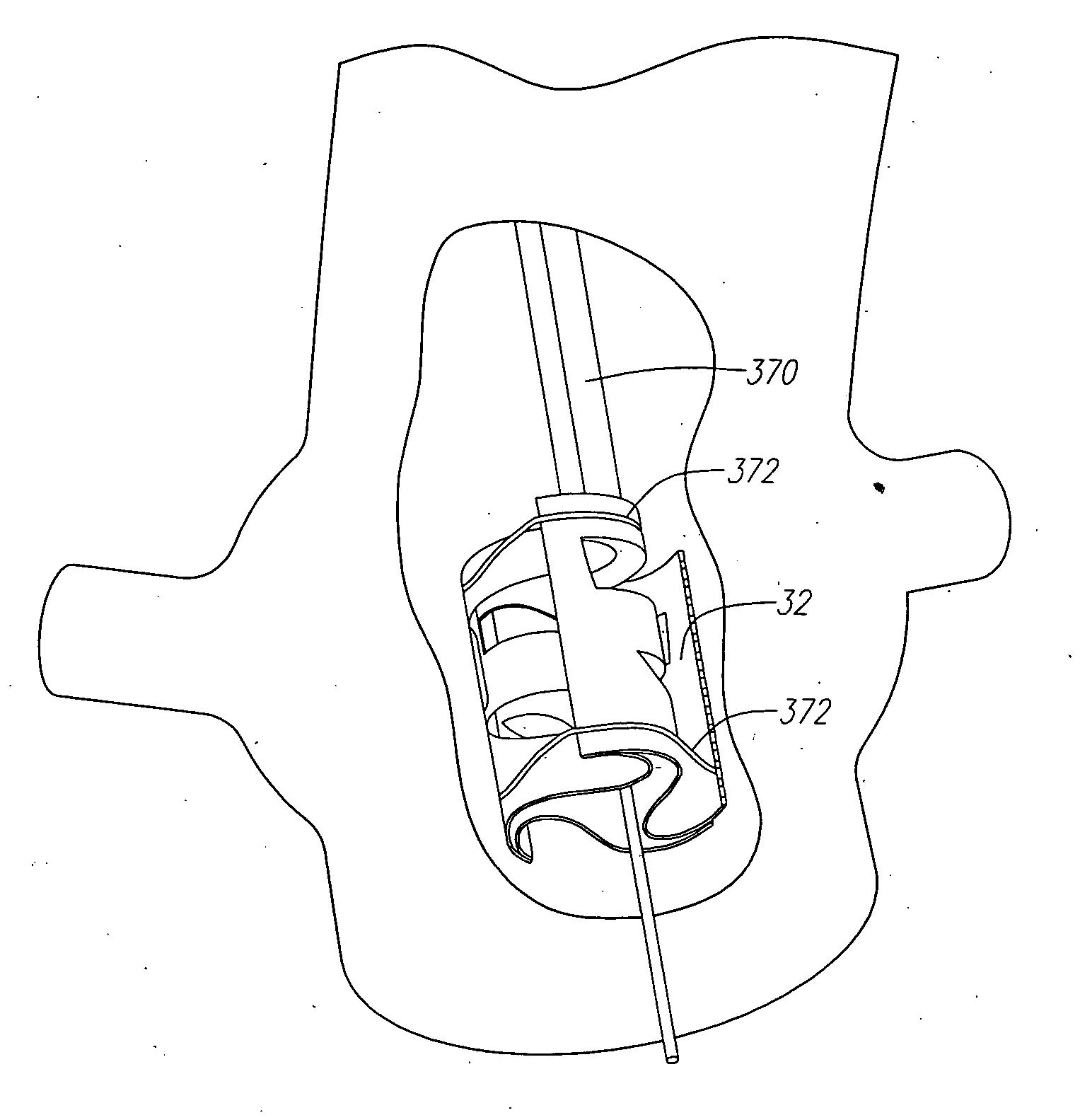

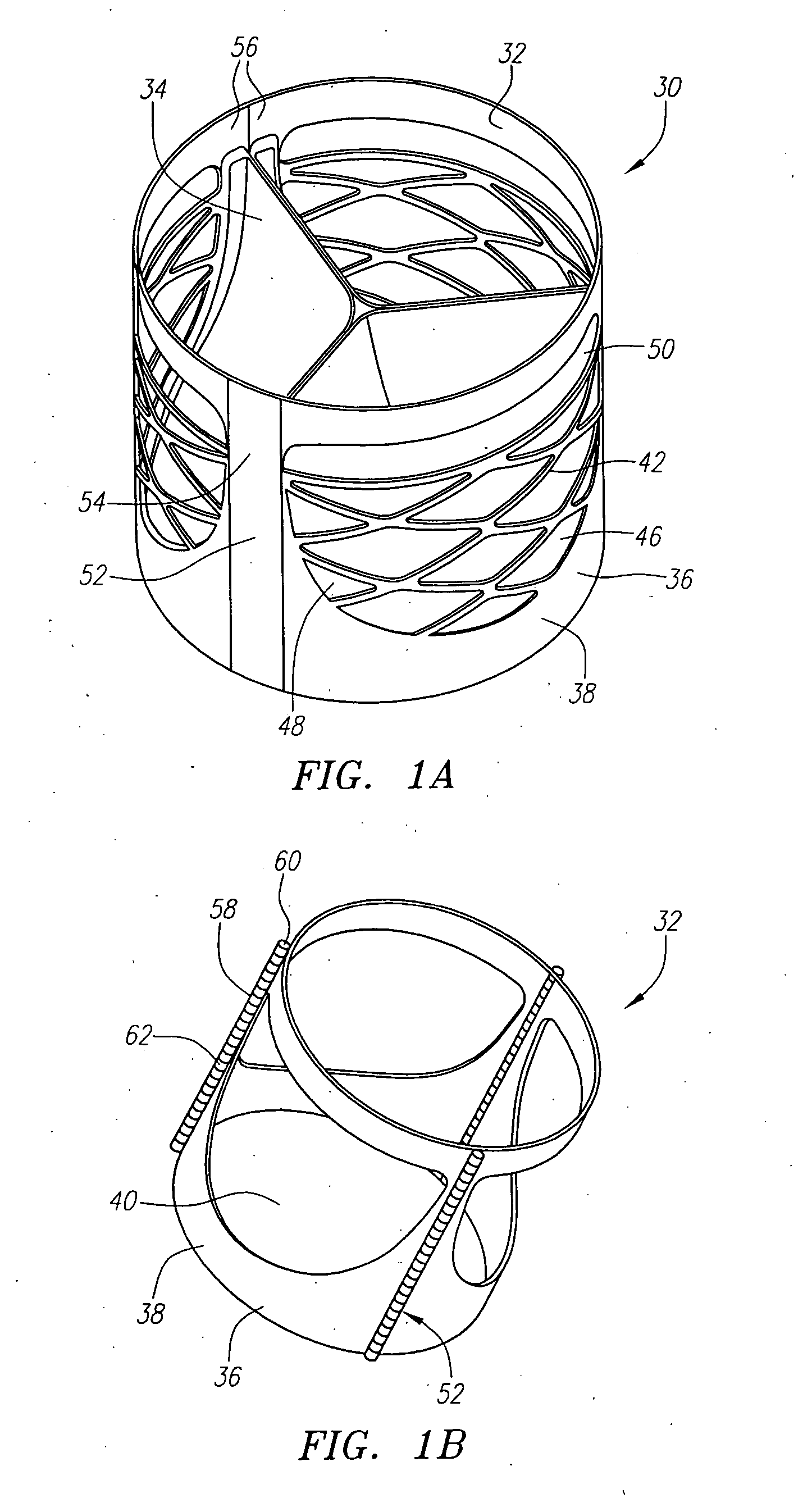

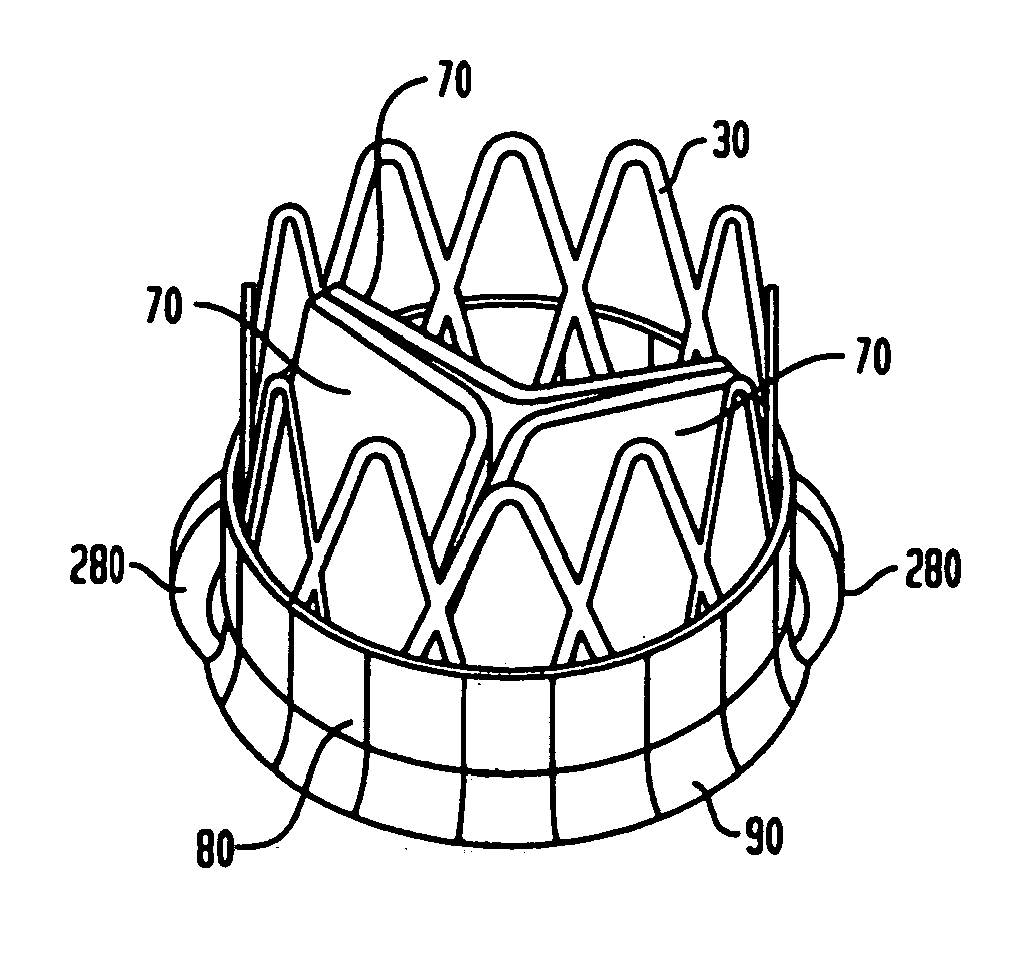

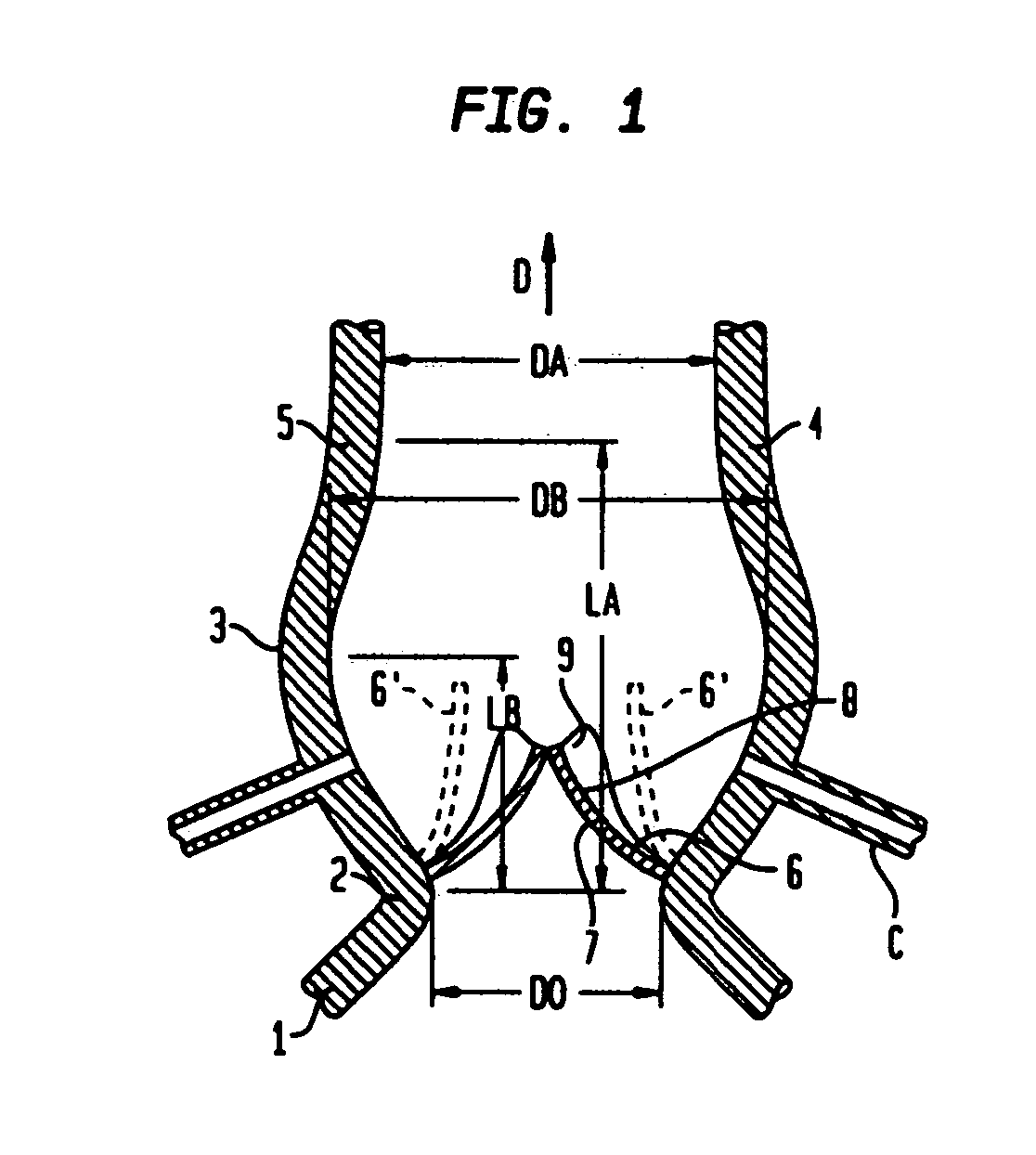

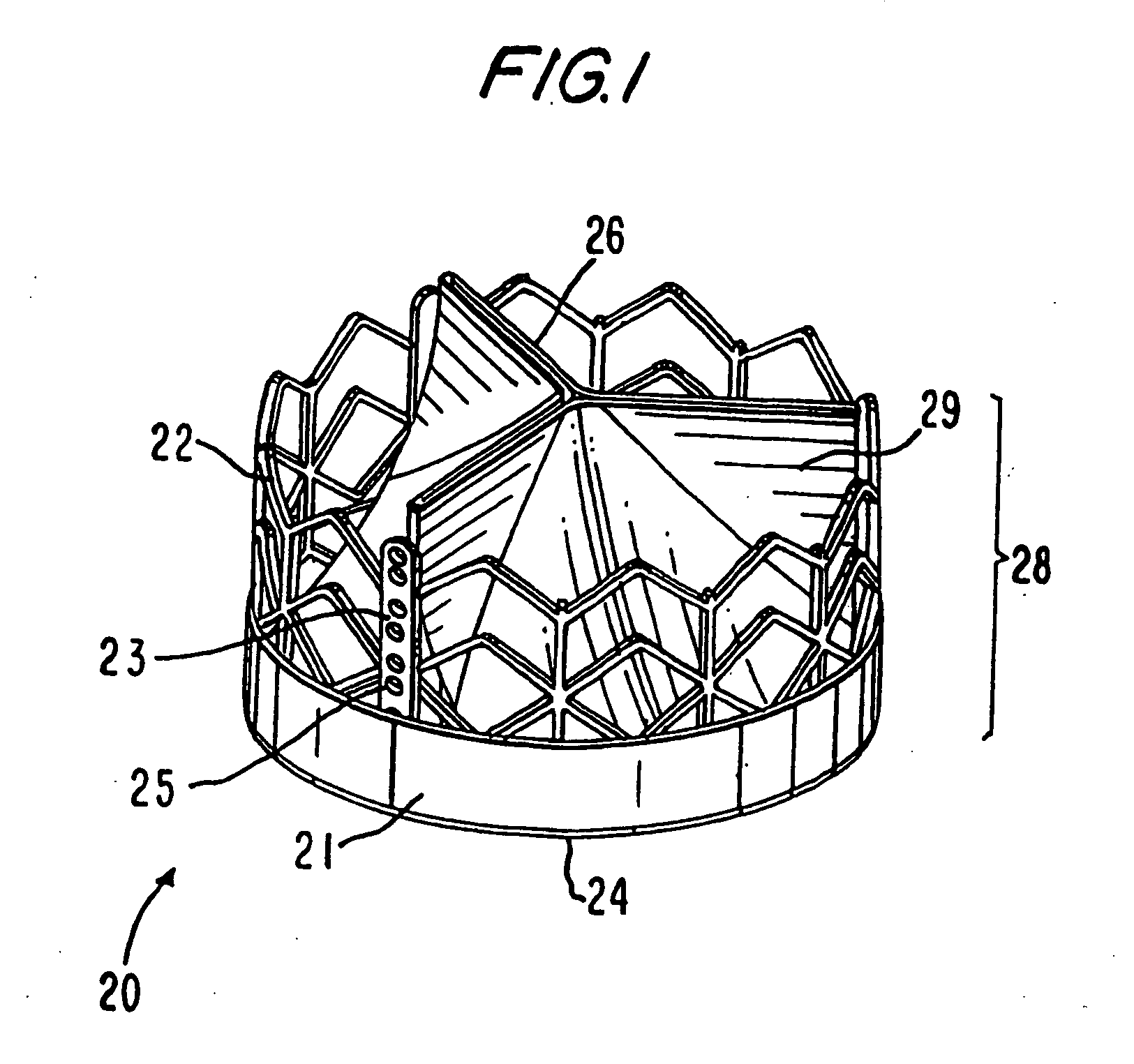

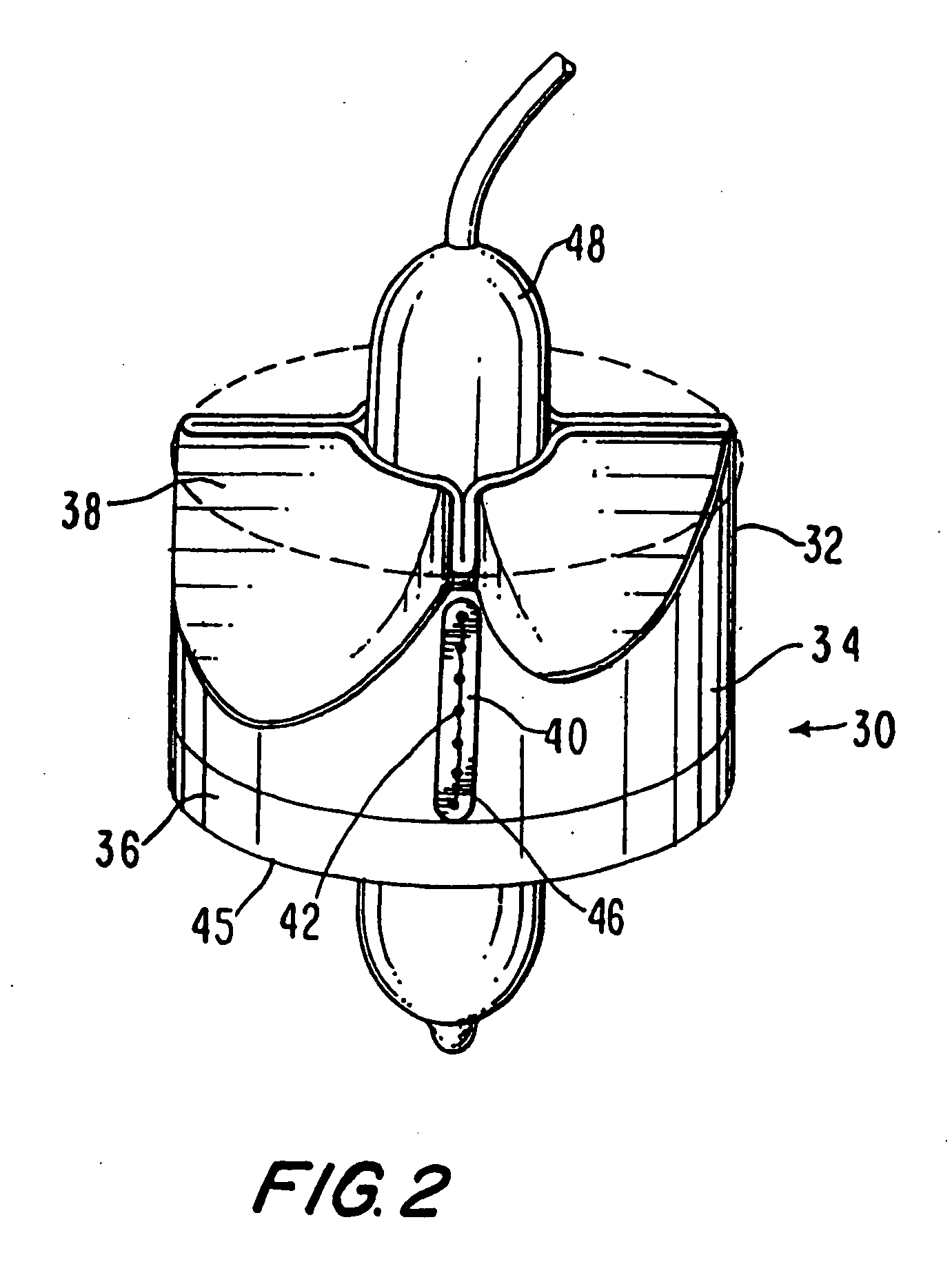

Implantable prosthetic valve

InactiveUS6893460B2Prevent blood flowImprove sealingStentsBalloon catheterGuide tubeBiomedical engineering

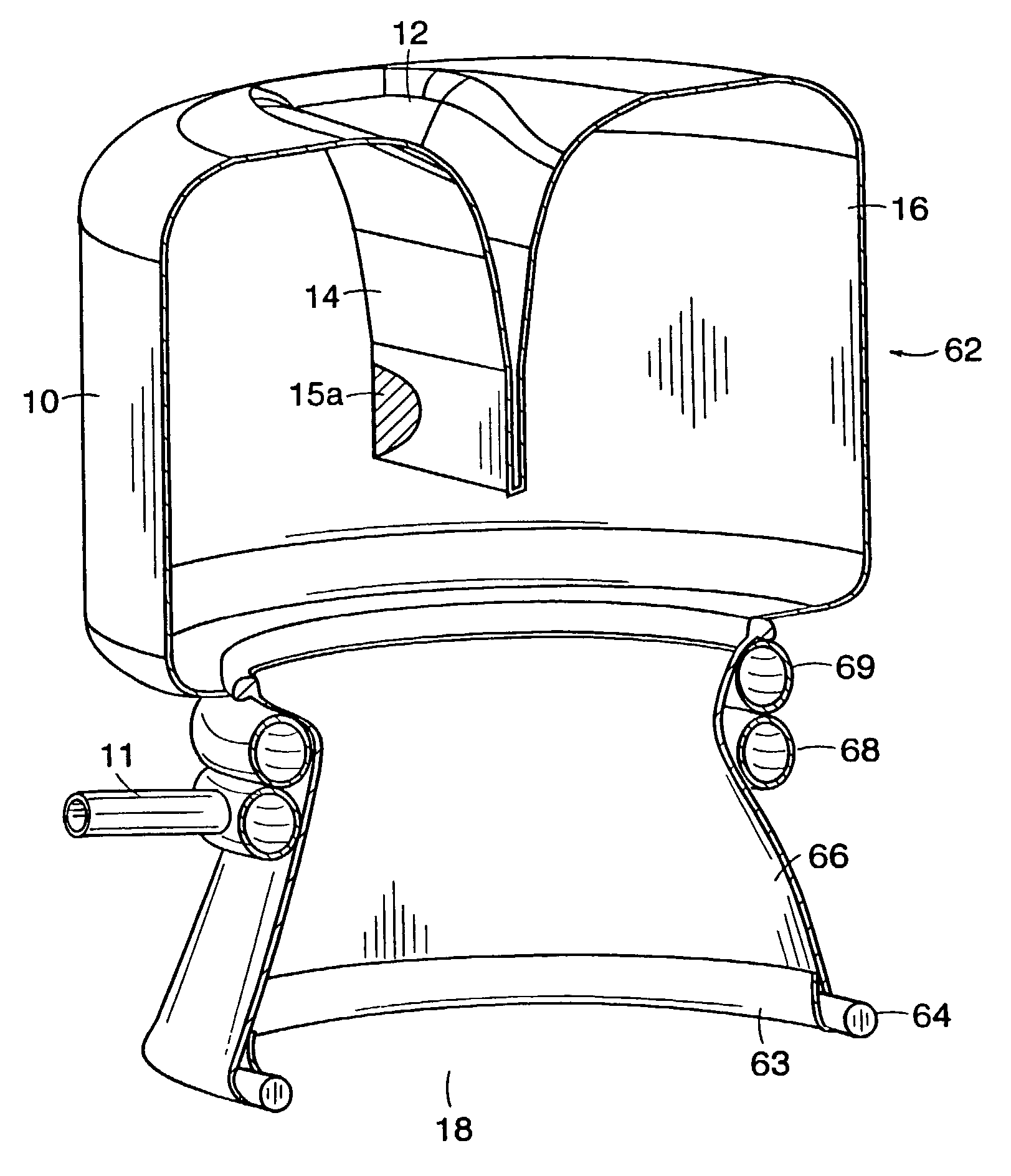

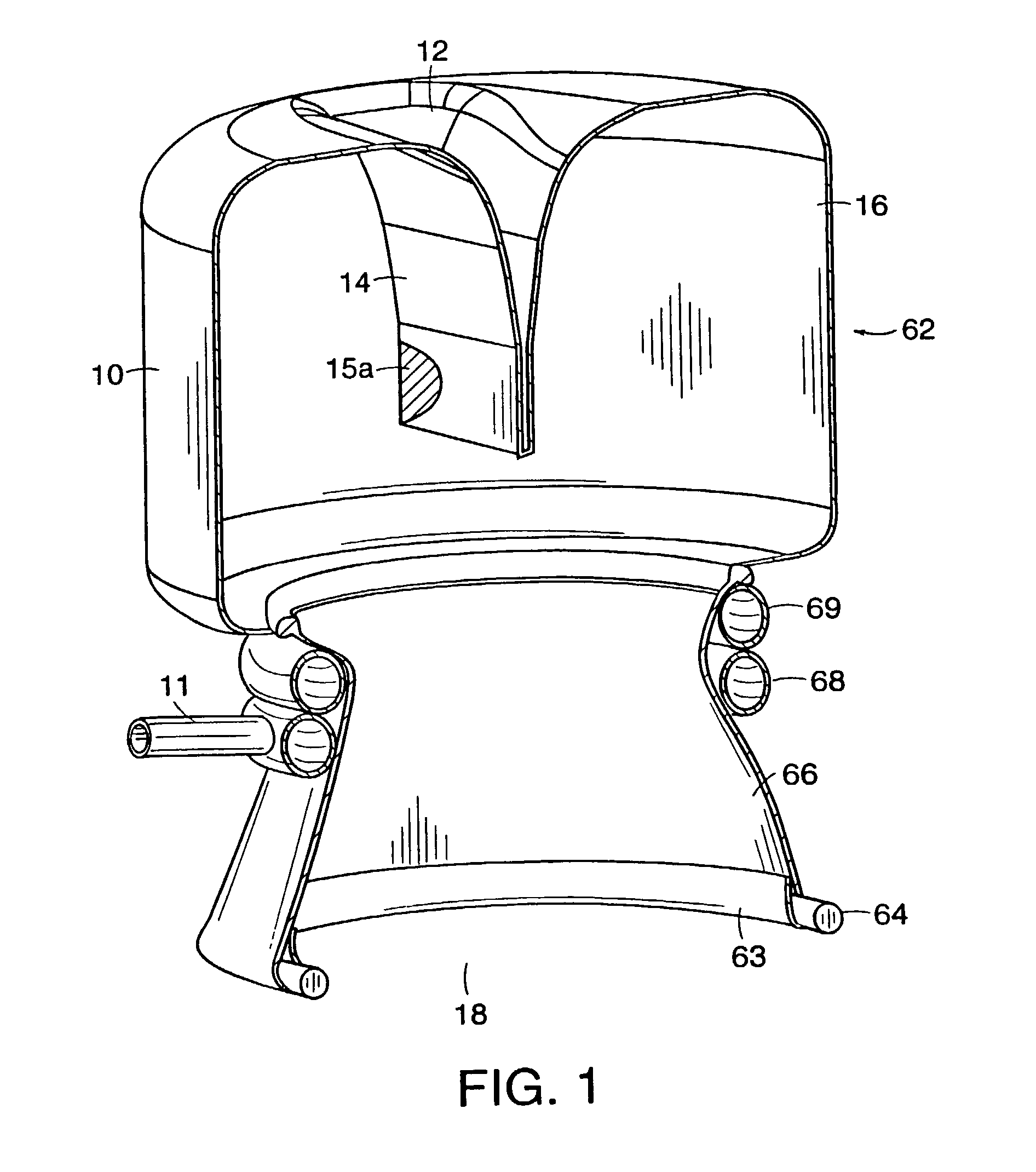

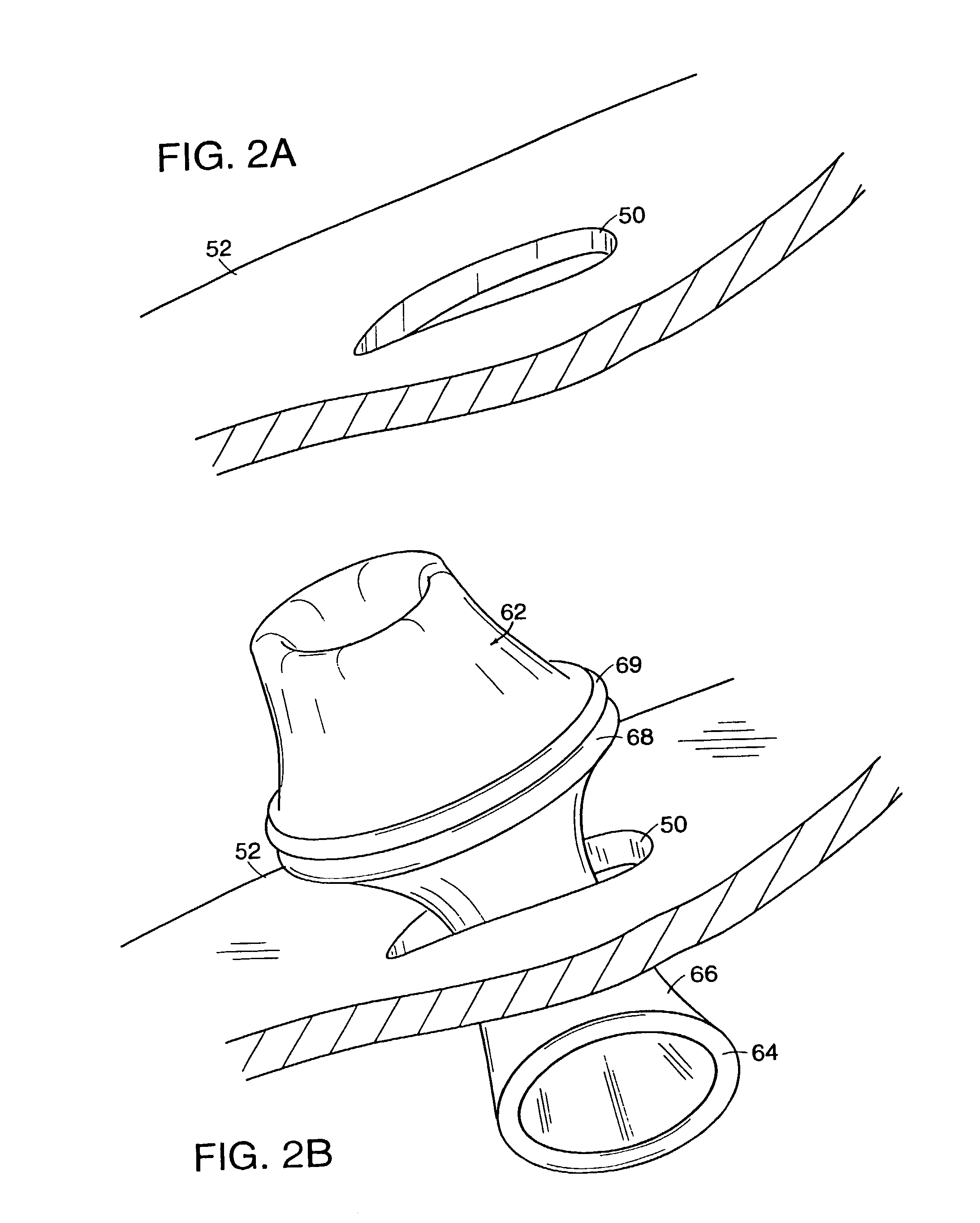

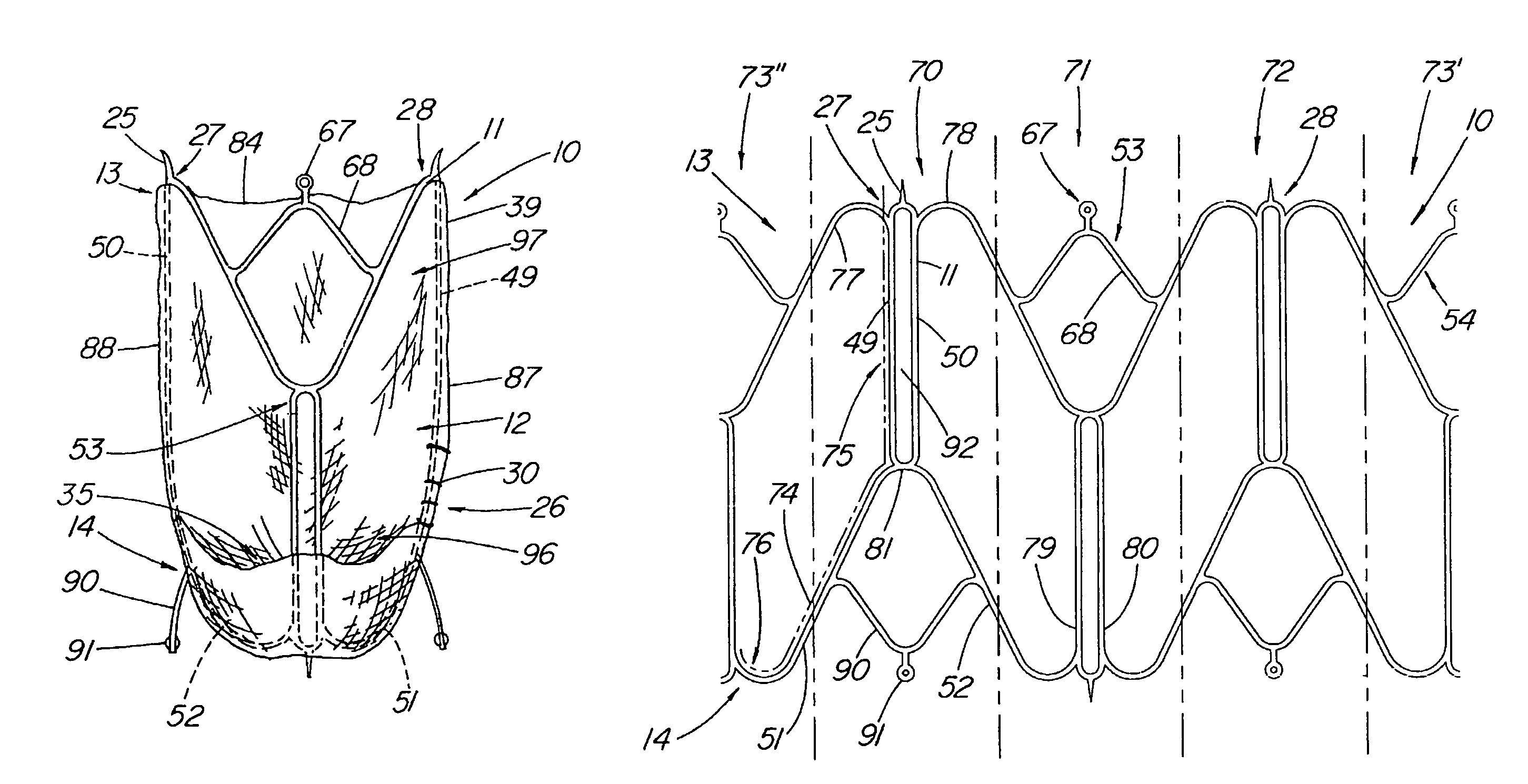

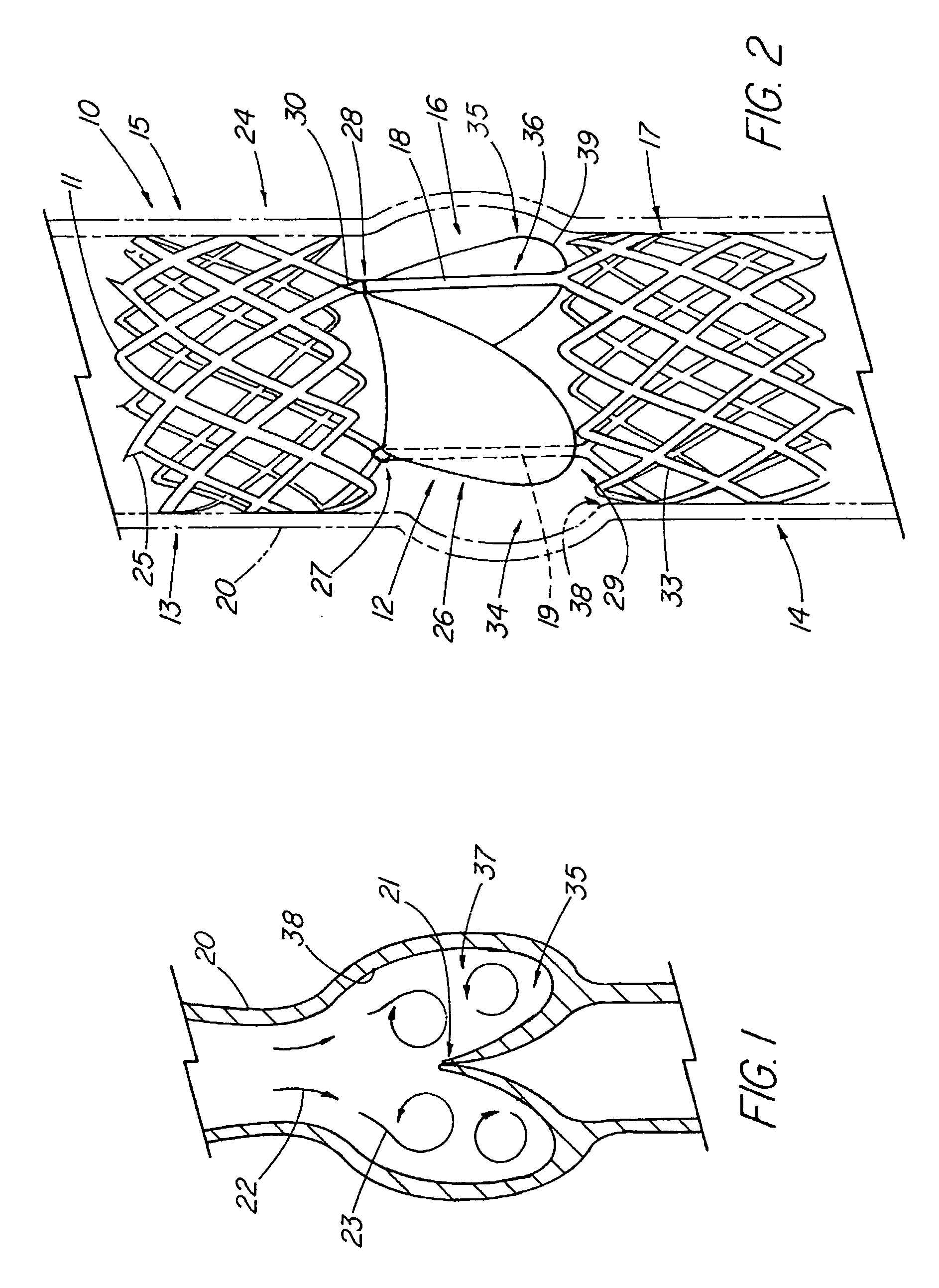

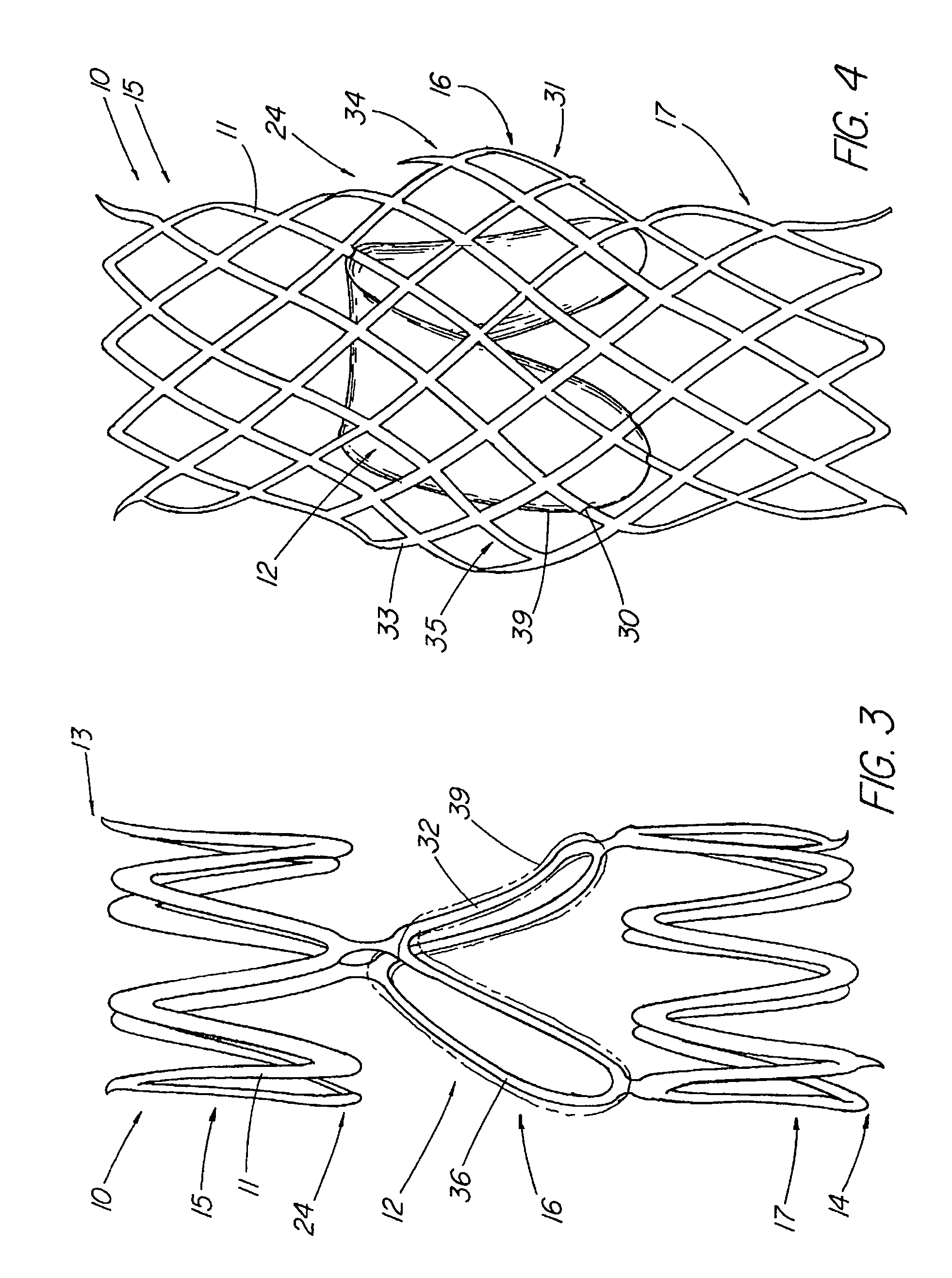

A valve prosthesis device is disclosed suitable for implantation in body ducts. The device comprises support stent, comprised of a deployable construction adapted to be initially crimped in a narrow configuration suitable for catheterization through the body duct to a target location and adapted to be deployed by exerting substantially radial forces from within by means of a deployment device to a deployed state in the target location, the support stent provided with a plurality of longitudinally rigid support beams of fixed length; valve assembly comprising a flexible conduit having an inlet end and an outlet, made of pliant material attached to the support beams providing collapsible slack portions of the conduit at the outlet. When flow is allowed to pass through the valve prosthesis device from the inlet to the outlet the valve assembly is kept in an open position, whereas a reverse flow is prevented as the collapsible slack portions of the valve assembly collapse inwardly providing blockage to the reverse flow.

Owner:EDWARDS LIFESCI PVT

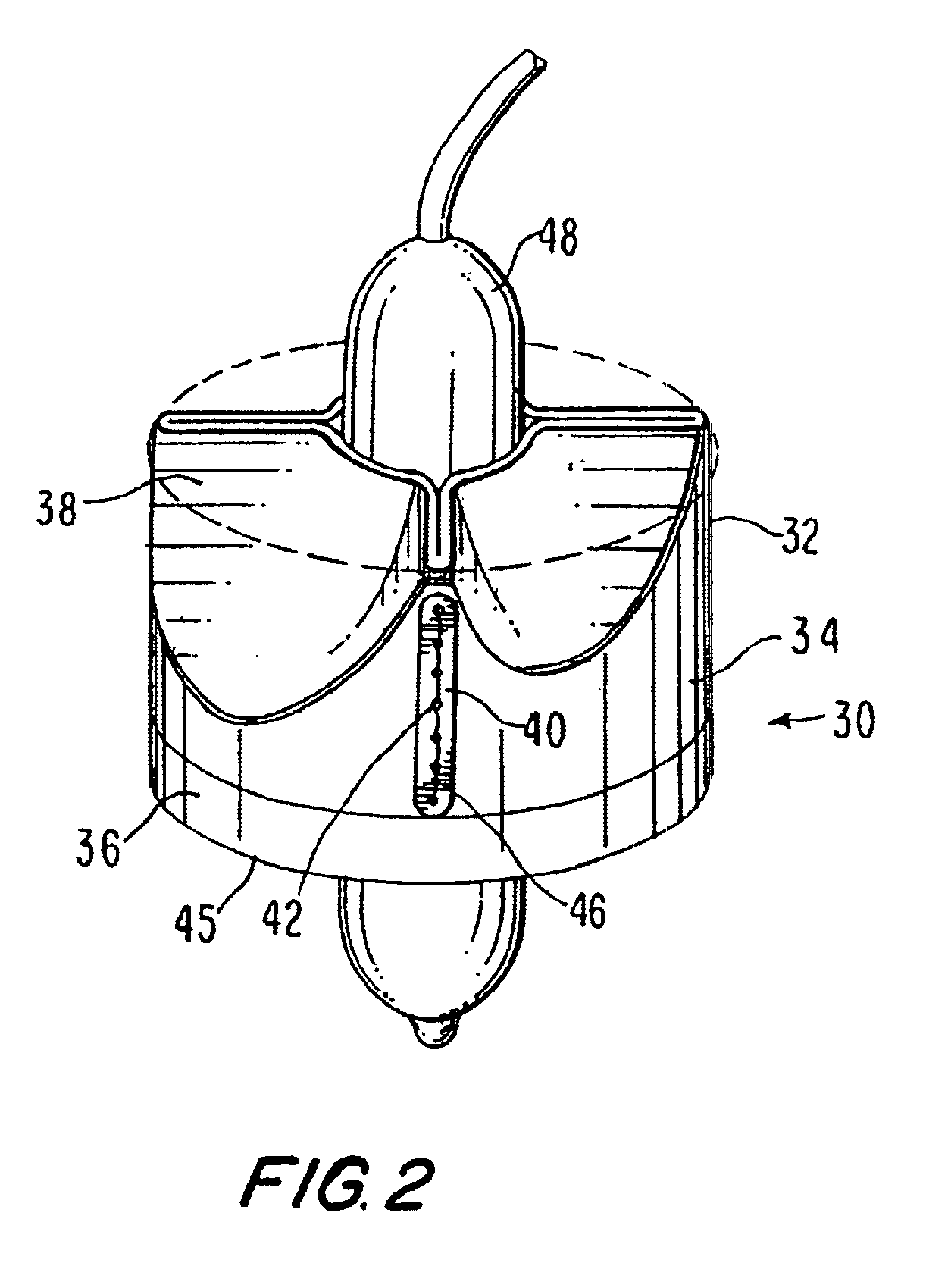

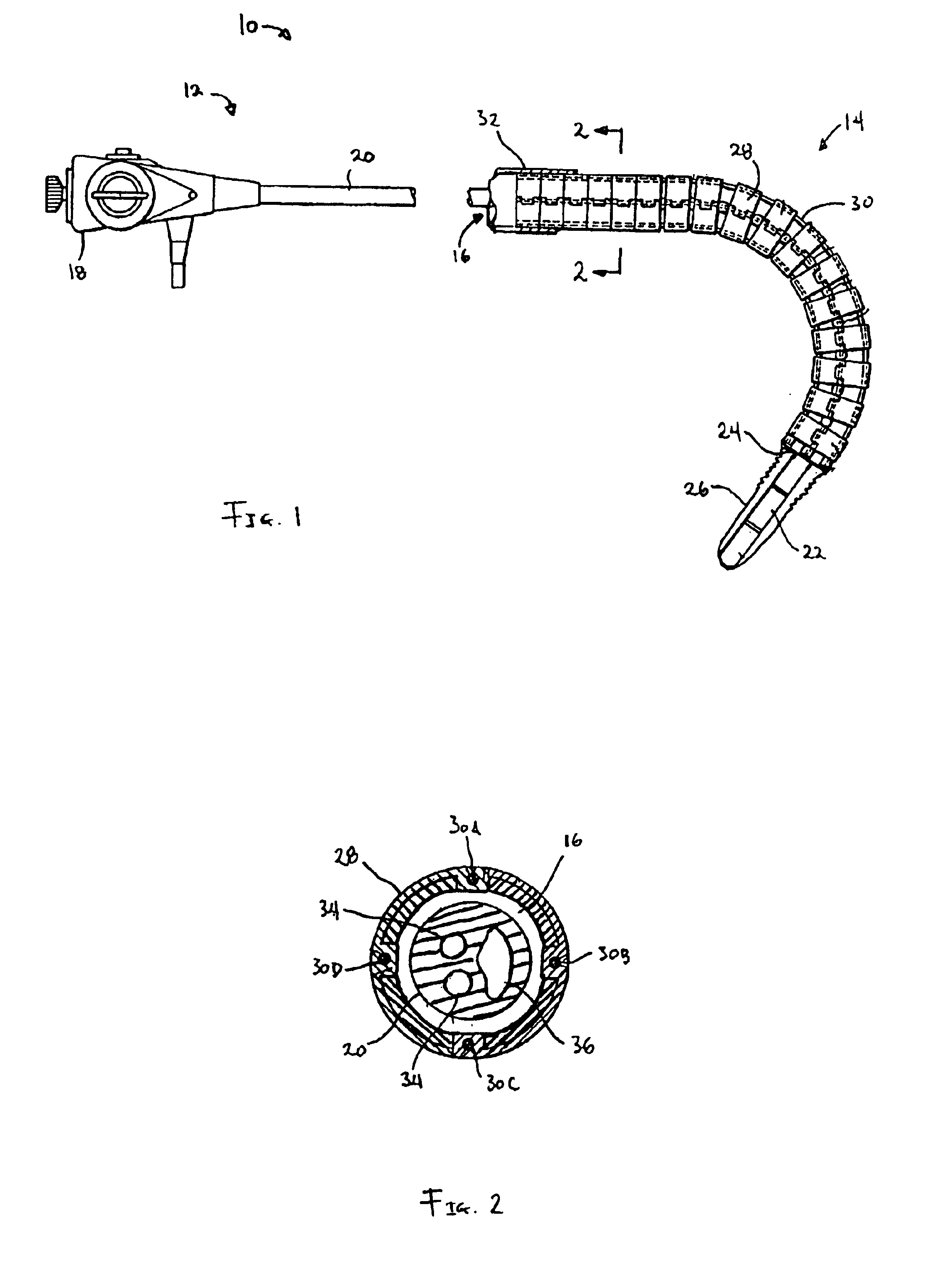

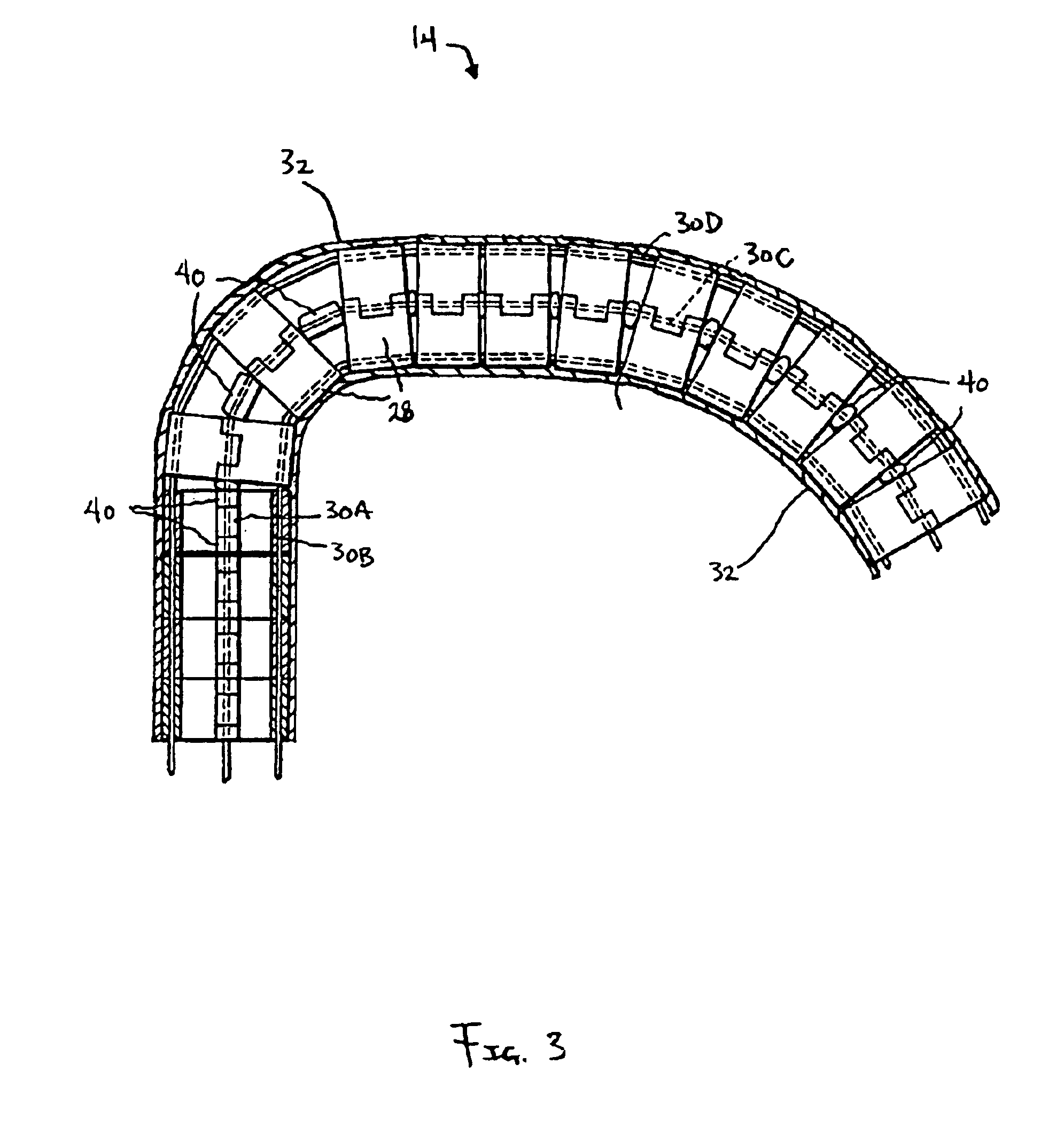

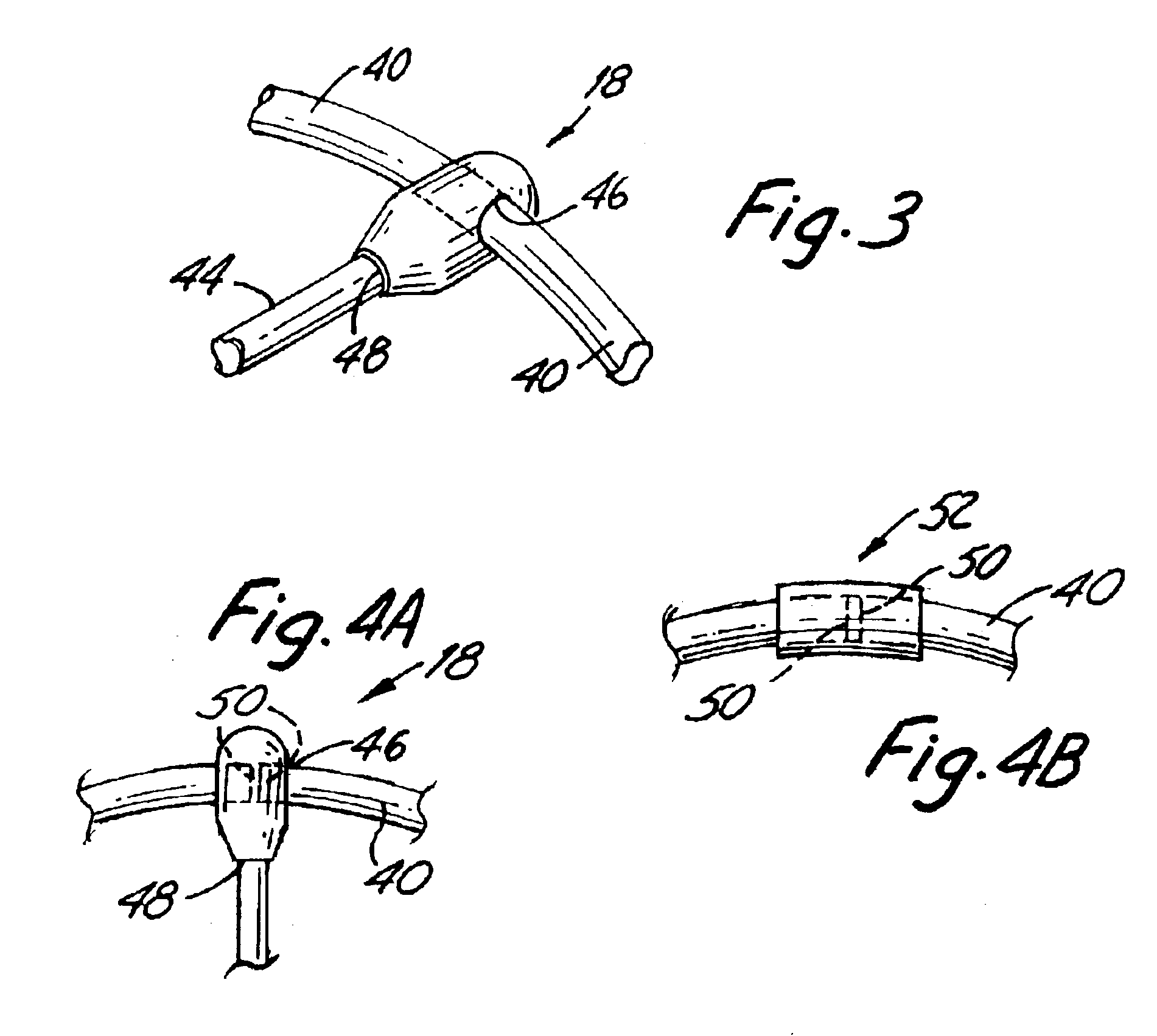

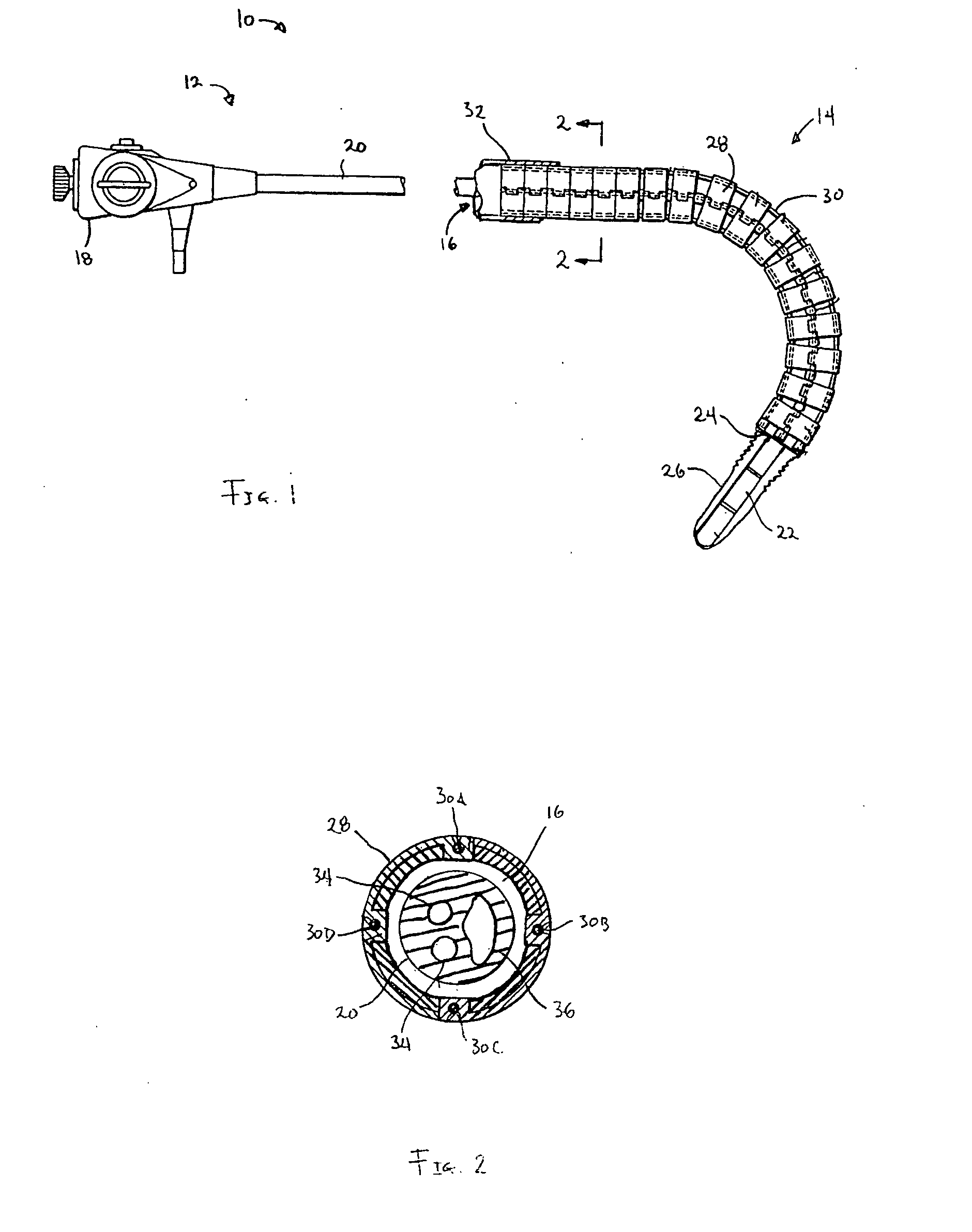

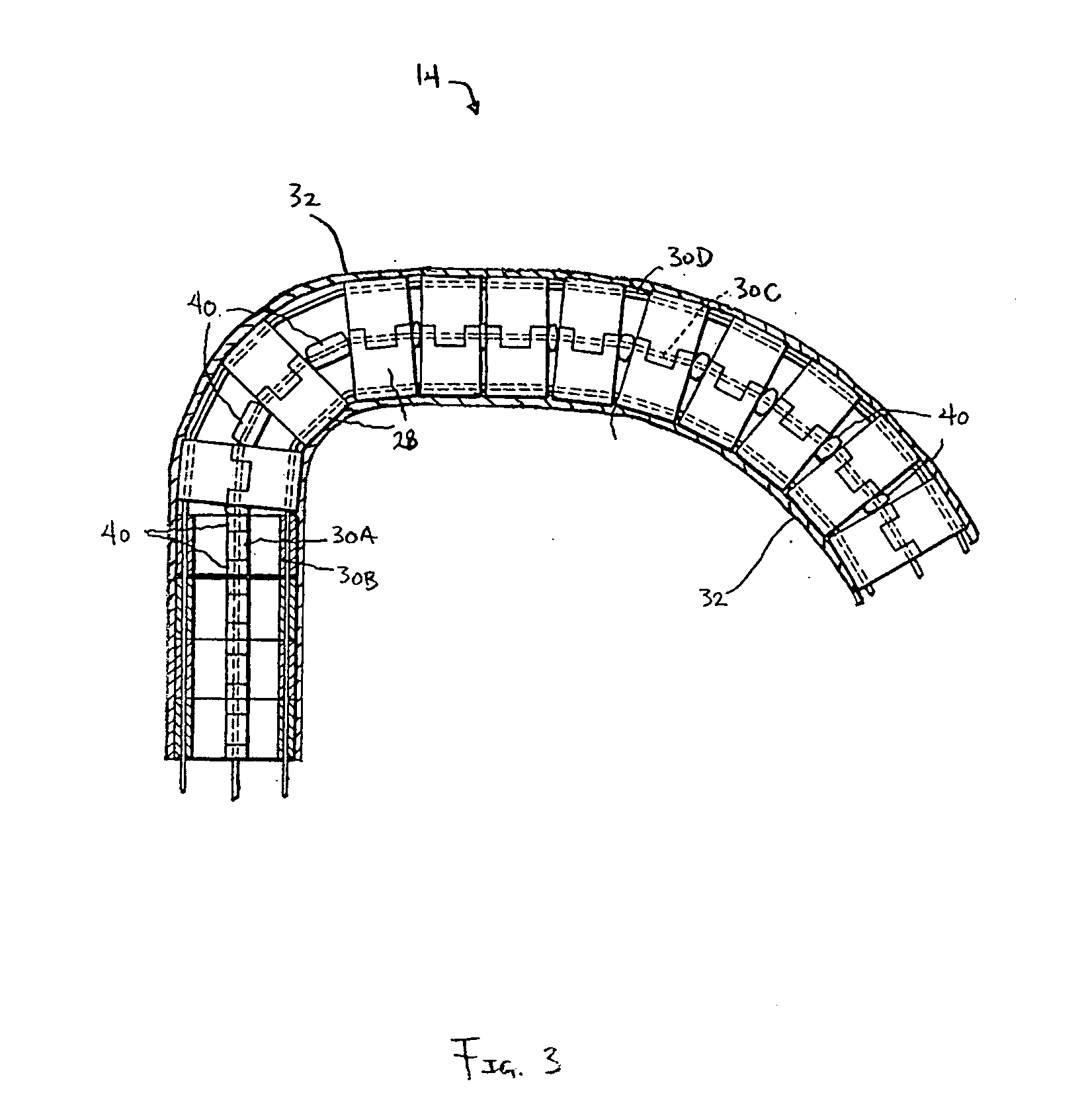

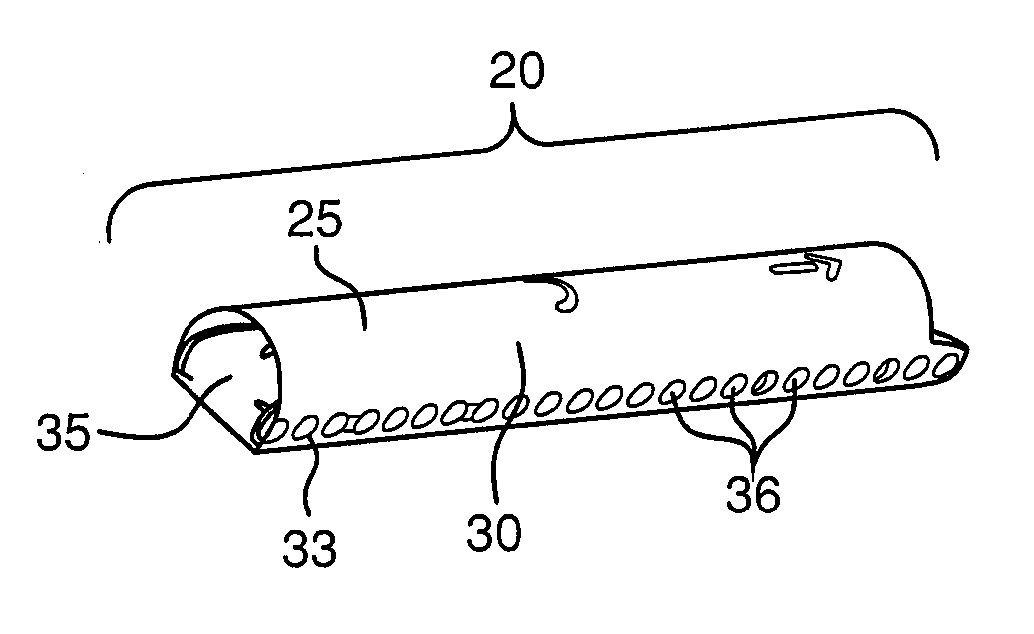

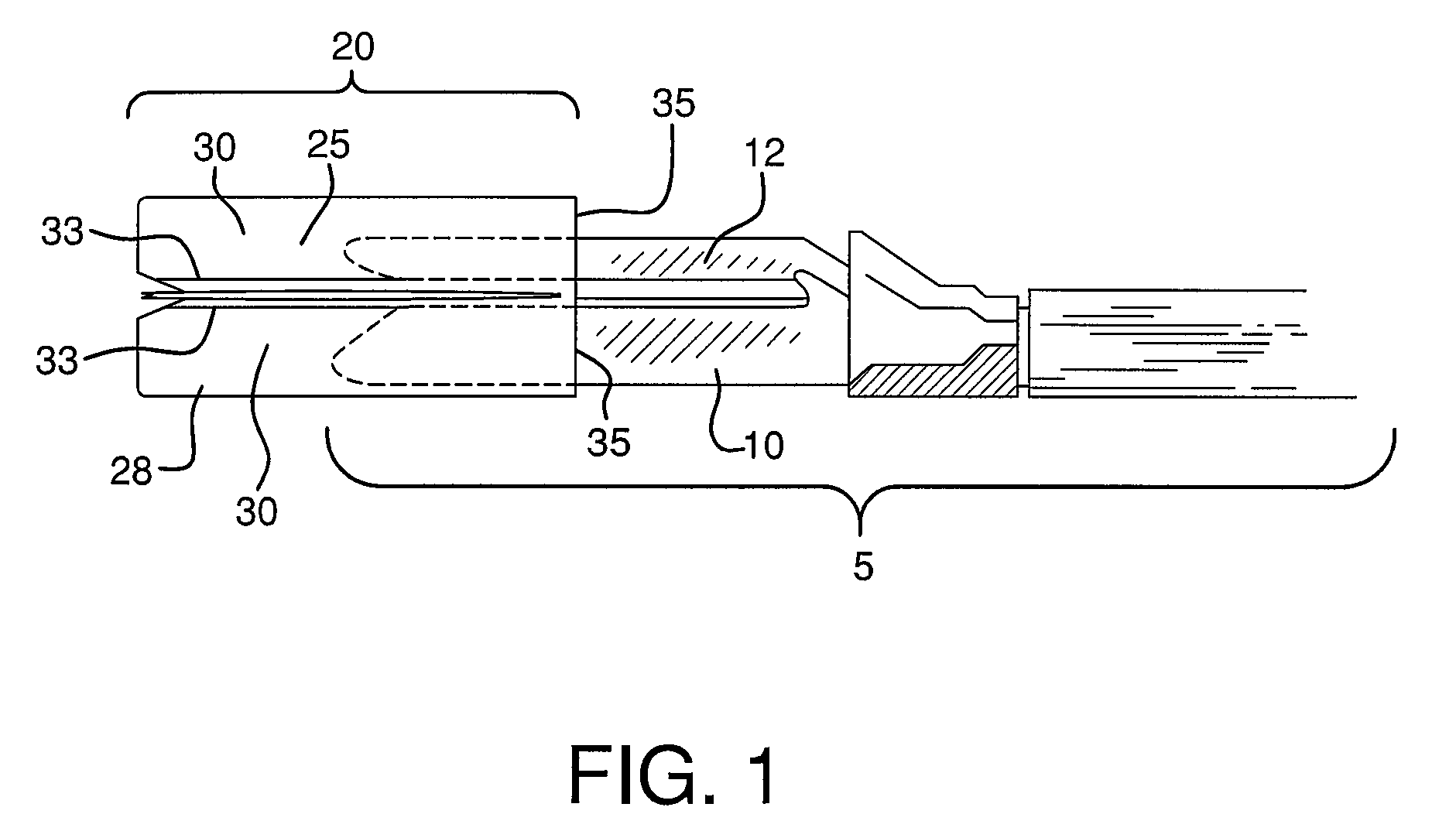

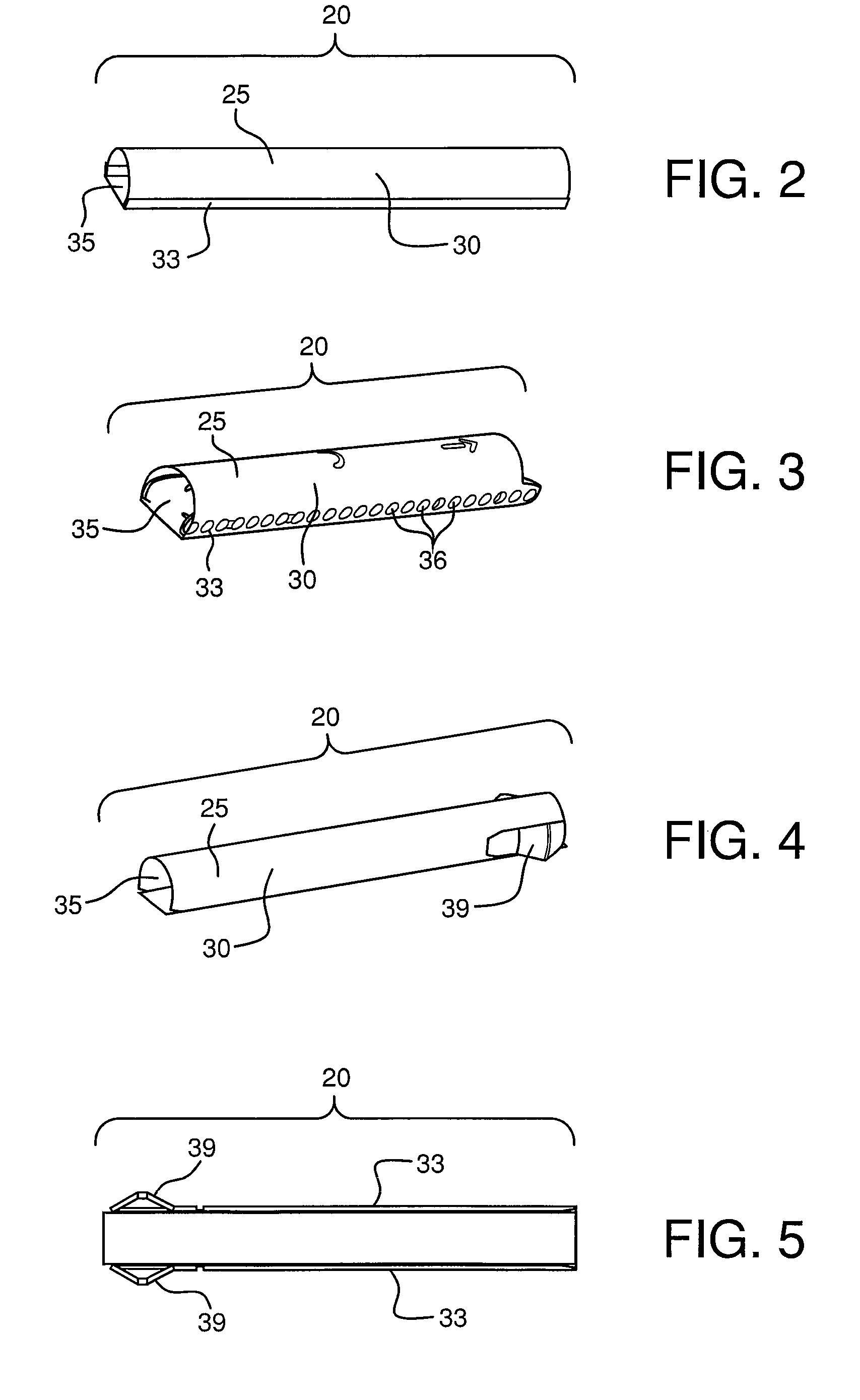

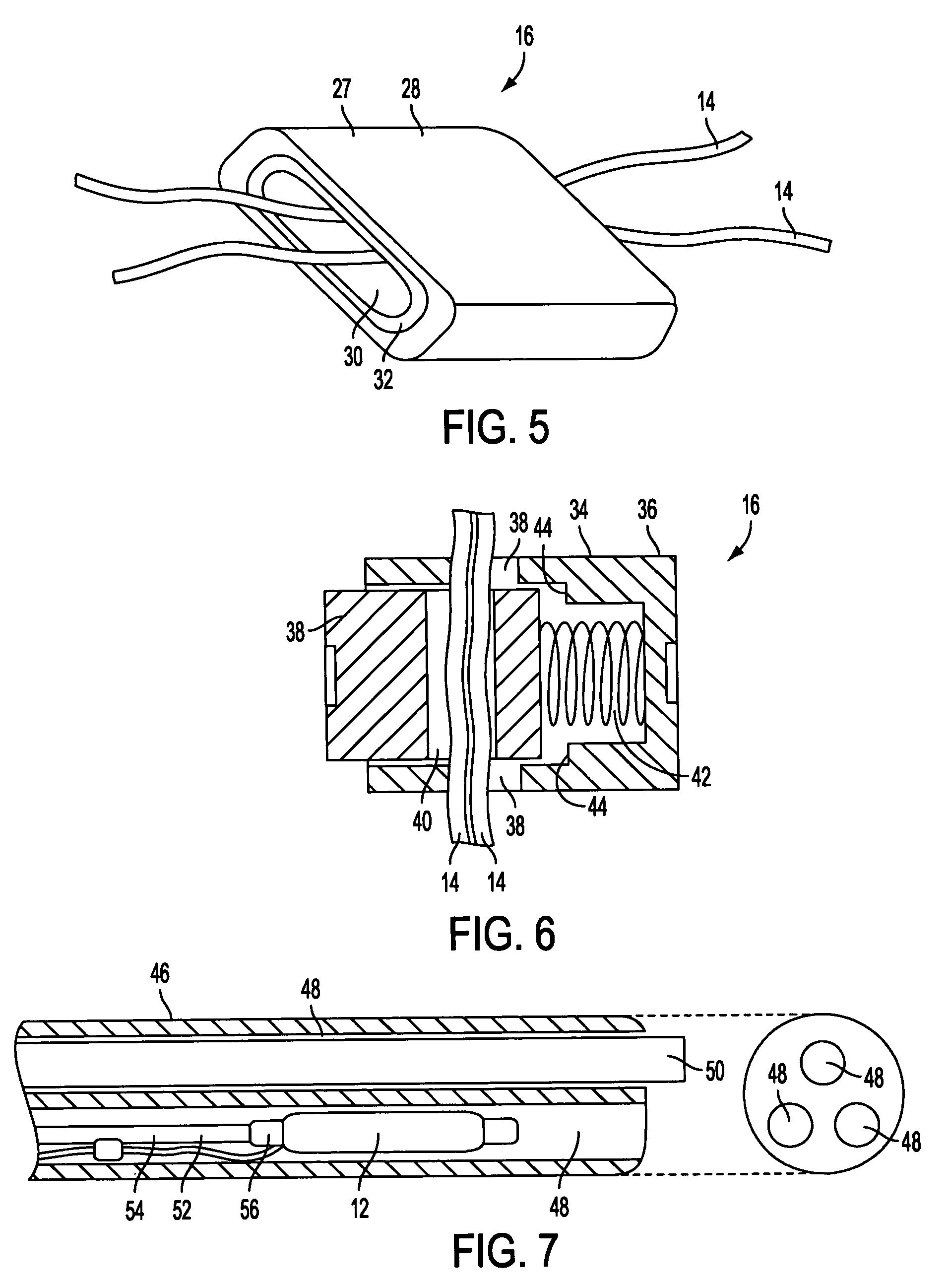

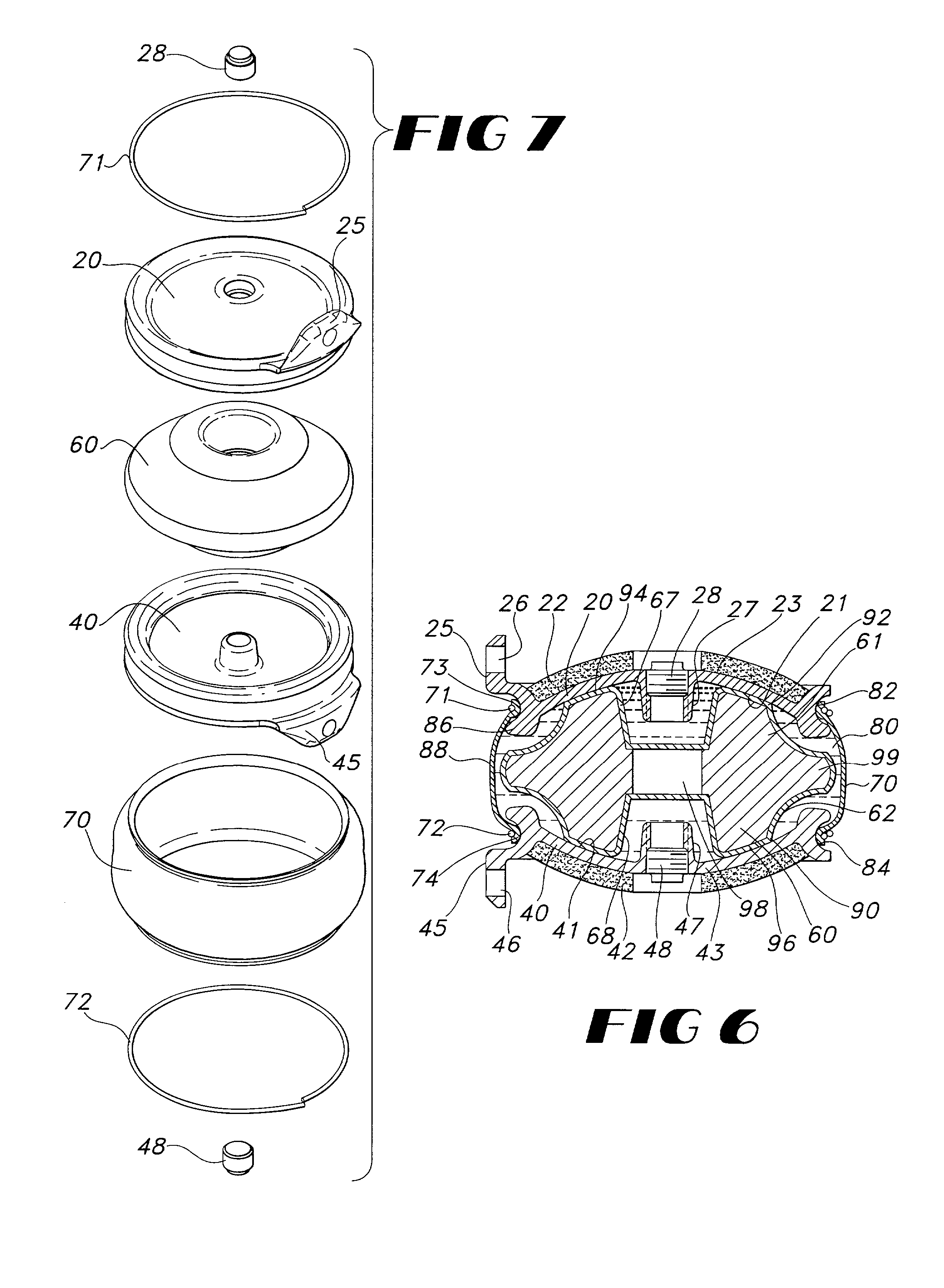

Endoscope having a guide tube

InactiveUS6837846B2Facilitates advancement and withdrawalPreventing tissue from being pinchedGuide needlesCannulasDistal portionBiomedical engineering

An endoscope having a guide tube is described herein. The assembly has an endoscope which is slidably insertable within the lumen of a guide tube. The guide tube is configured to be rigidizable along its entire length from a relaxed configuration. The endoscope has a steerable distal portion to facilitate the steering of the device through tortuous paths. In the relaxed configuration, a portion of the guide tube is able to assume the shape or curve defined by the controllable distal portion of the endoscope. Having assumed the shape or curve of the endoscope, the guide tube may be rigidized by the physician or surgeon to maintain that shape or curve while the endoscope is advanced distally through the tortuous path without having to place any undue pressure against the tissue walls.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Endoscope having a guide tube

InactiveUS20050124855A1Facilitates advancement and withdrawalPreventing tissue from being pinchedGuide needlesCannulasDistal portionCatheter

An endoscope having a guide tube is described herein. The assembly has an endoscope which is slidably insertable within the lumen of a guide tube. The guide tube is configured to be rigidizable along its entire length from a relaxed configuration. The endoscope has a steerable distal portion to facilitate the steering of the device through tortuous paths. In the relaxed configuration, a portion of the guide tube is able to assume the shape or curve defined by the controllable distal portion of the endoscope. Having assumed the shape or curve of the endoscope, the guide tube may be rigidized by the physician or surgeon to maintain that shape or curve while the endoscope is advanced distally through the tortuous path without having to place any undue pressure against the tissue walls.

Owner:INTUITIVE SURGICAL

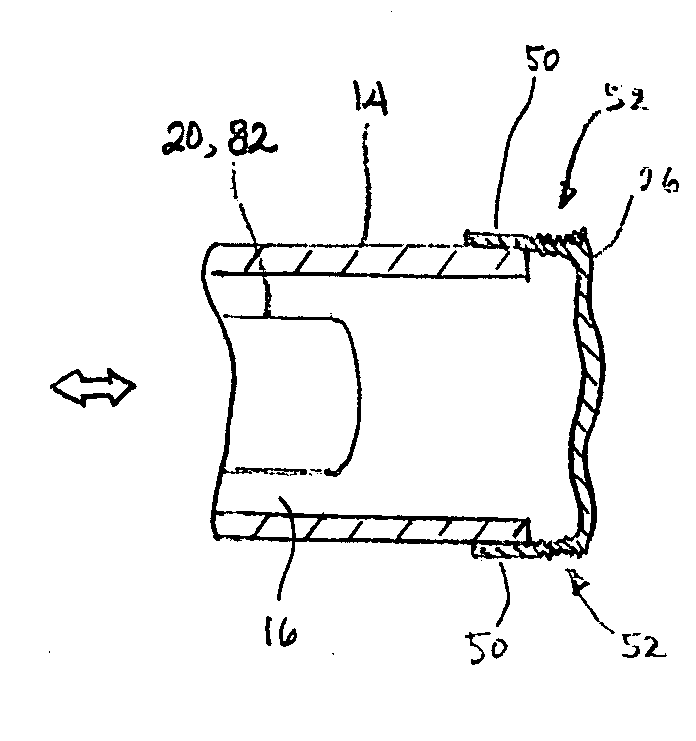

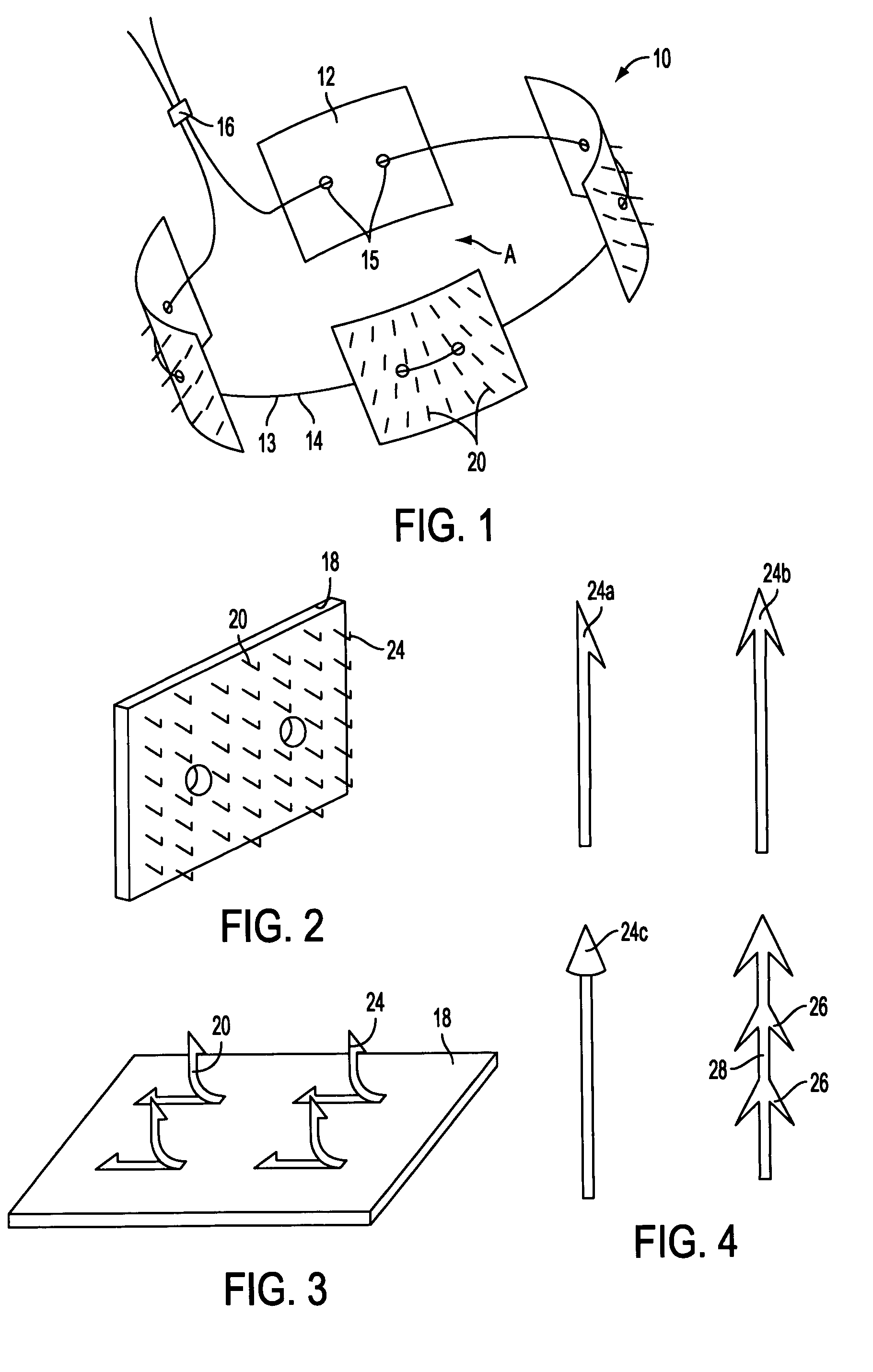

Surgical staple line reinforcements

ActiveUS8317790B2Reduce the possibilityReinforcing surgical staplesJoint implantsStaplesSurgical stapleEngineering

A surgical staple line reinforcement is provided for use with a variety of surgical staplers to protect against tissue damage from surgical staples. The surgical staple line reinforcement is made up of a tubular structure of bio-implantable material with one or more stiffening members attached to or integrated within the tubular structure to resist, prevent or inhibit movement, rotation, or longitudinal compression of the tubular structure.

Owner:WL GORE & ASSOC INC

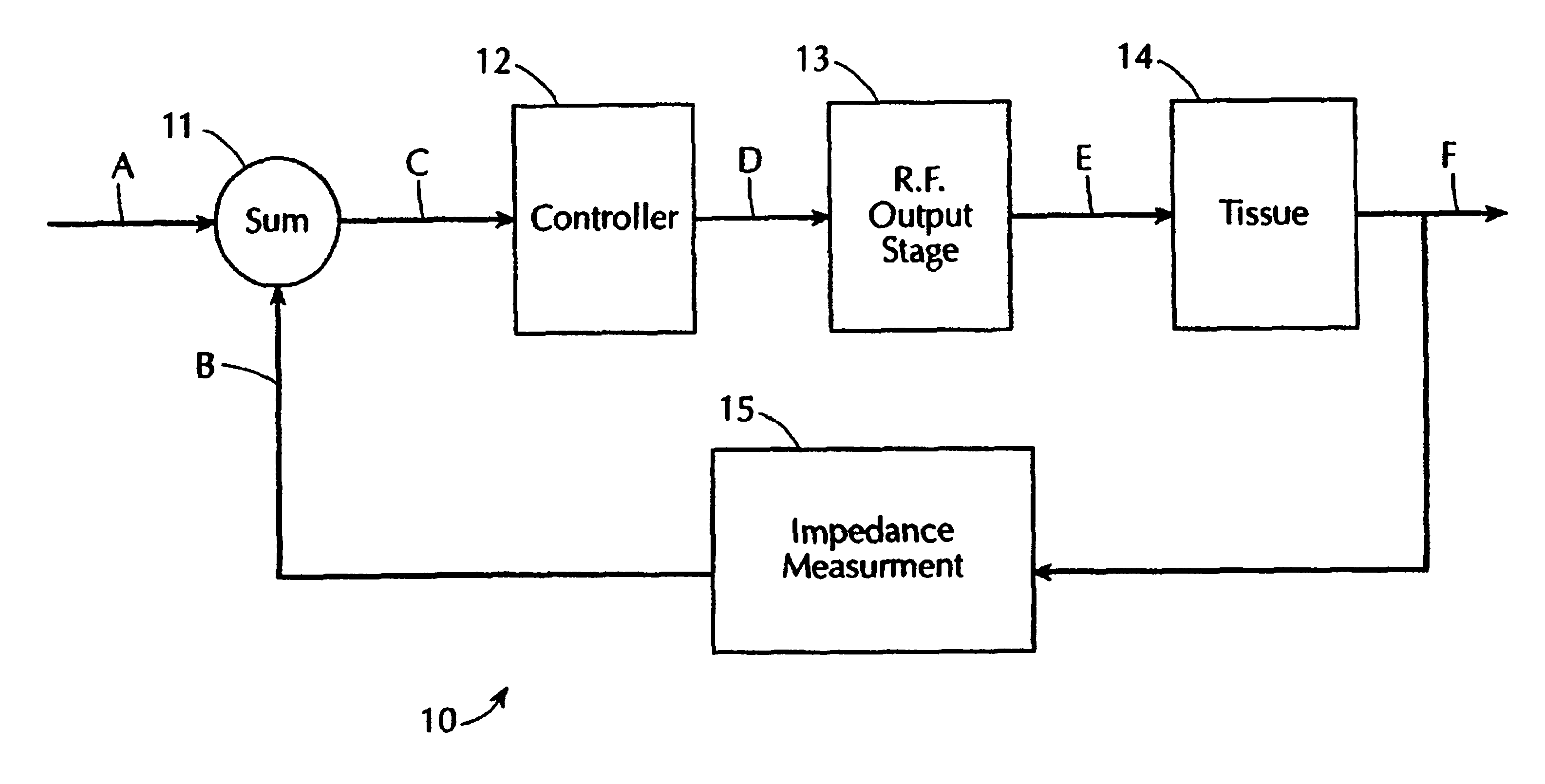

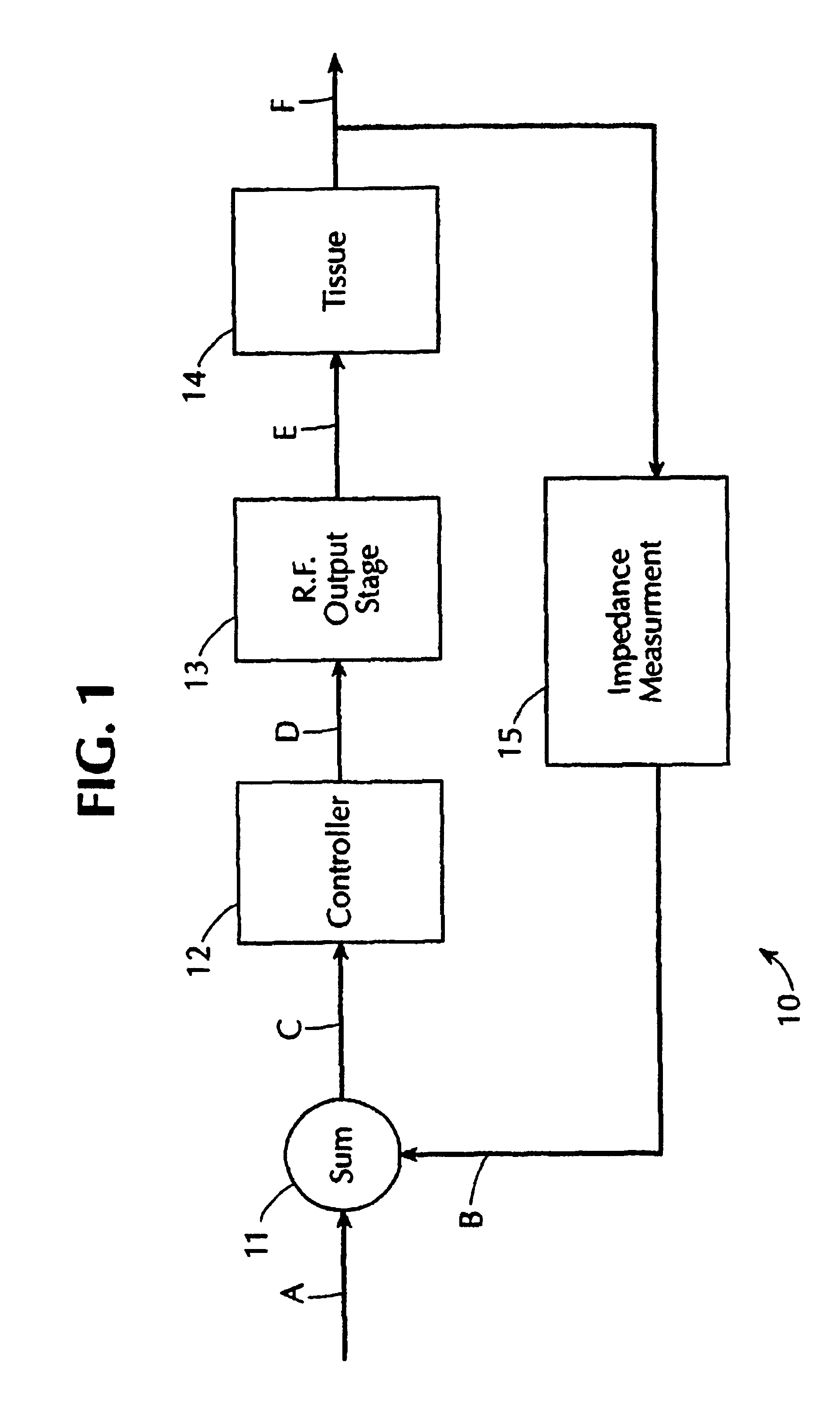

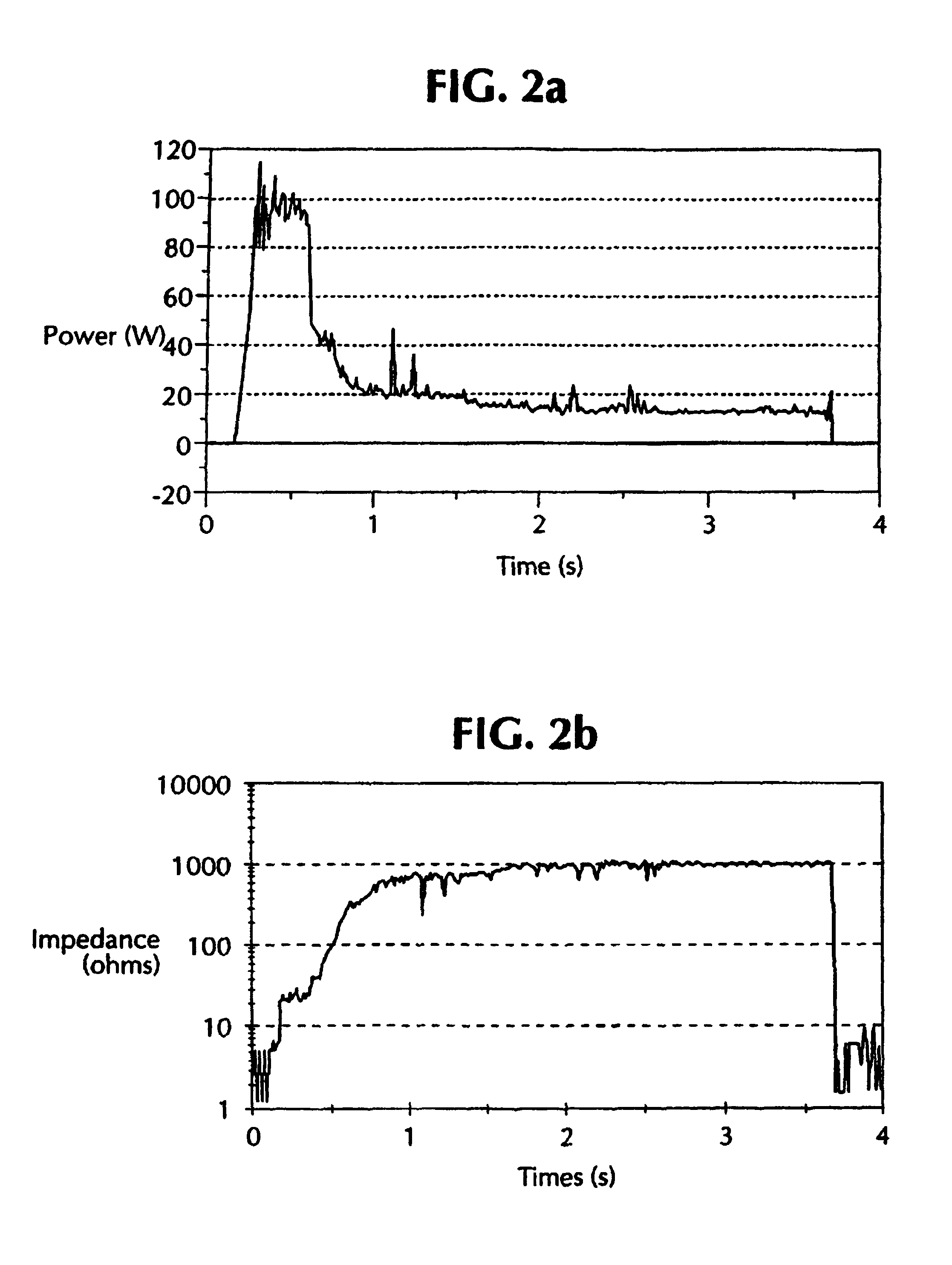

Electrosurgical generator with adaptive power control

InactiveUSRE40388E1Lower Level RequirementsImproved tissue sealing characteristicPulse automatic controlSurgical instruments for heatingThermal energyVessel sealing

An electrosurgical generator has an output power control system that causes the impedance of tissue to rise and fall in a cyclic pattern until the tissue is desiccated. The advantage of the power control system is that thermal spread and charring are reduced. In addition, the power control system offers improved performance for electrosurgical vessel sealing and tissue welding. The output power is applied cyclically by a control system with tissue impedance feedback. The impedance of the tissue follows the cyclic pattern of the output power several times, depending on the state of the tissue, until the tissue becomes fully desiccated. High power is applied to cause the tissue to reach a high impedance, and then the power is reduced to allow the impedance to fall. Thermal energy is allowed to dissipate during the low power cycle. The control system is adaptive to tissue in the sense that output power is modulated in response to the impedance of the tissue.

Owner:COVIDIEN AG

Blood flow controlling apparatus

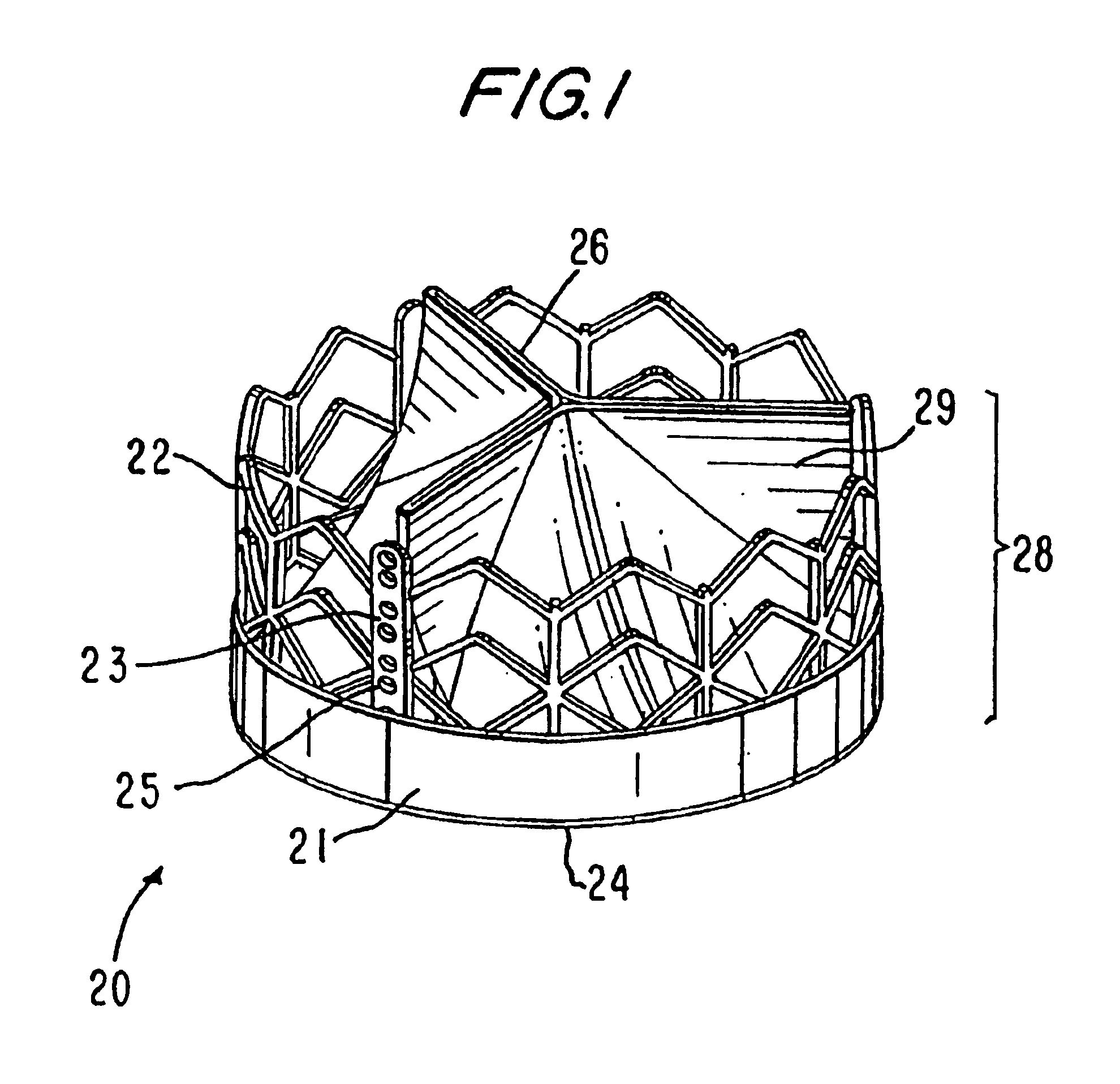

InactiveUS20060241745A1Avoid improper sealingPrevent leakageSuture equipmentsAnnuloplasty ringsNative tissuePlasma viscosity

A blood flow controlling apparatus, which is configured to be implanted into a blood circulatory system of a patient, comprises an anchoring means, which is arranged to fix the position of the apparatus in the blood circulatory system, and a valve means being connected to the anchoring means. The valve means is configured to be arranged within the blood circulatory system and is configured to be extendable in a direction transverse to blood flow in order to make contact with native tissue when inserted in the blood circulatory system. The valve means is further configured to release said contact as a result of being exposed to blood flow in a permitted direction.

Owner:EDWARDS LIFESCIENCES AG

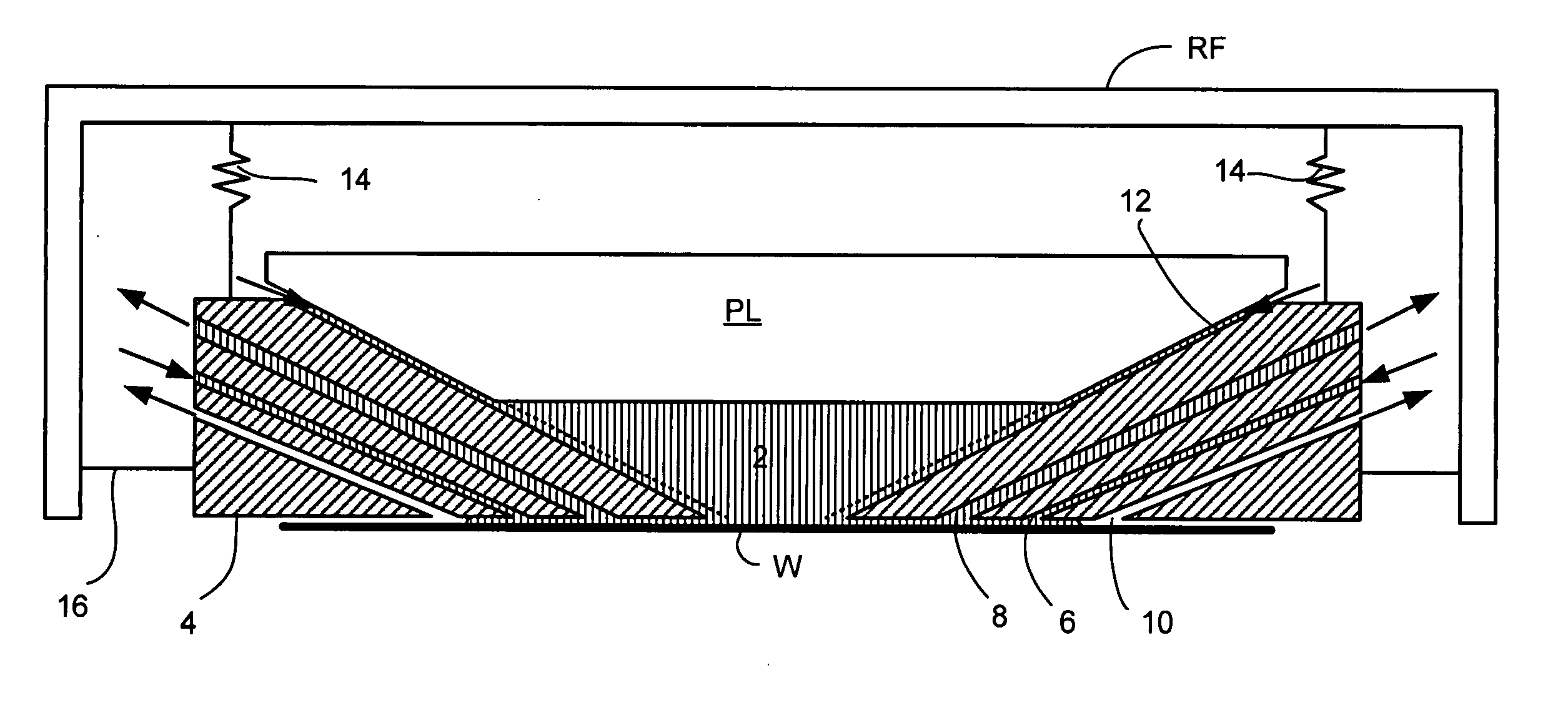

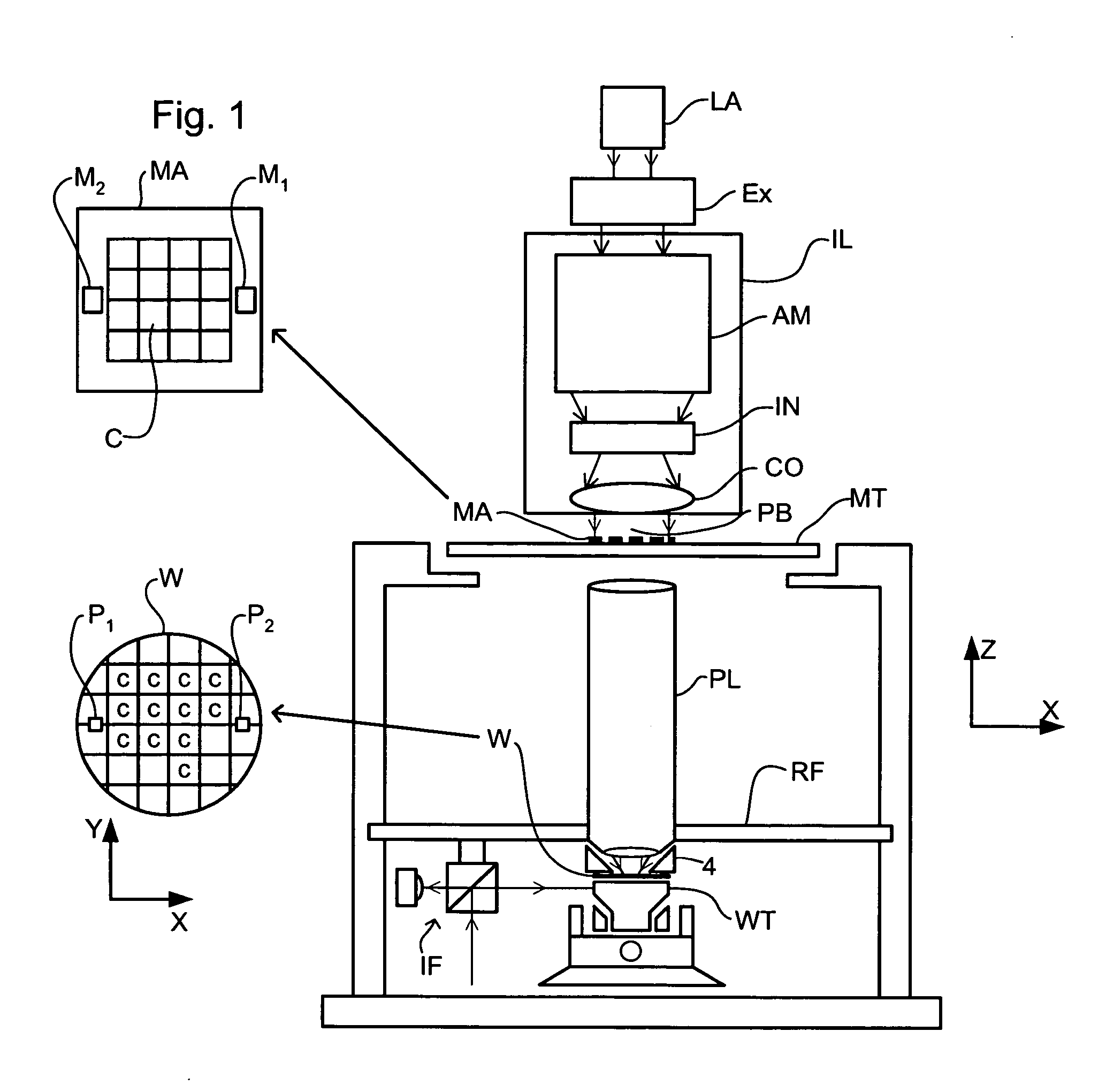

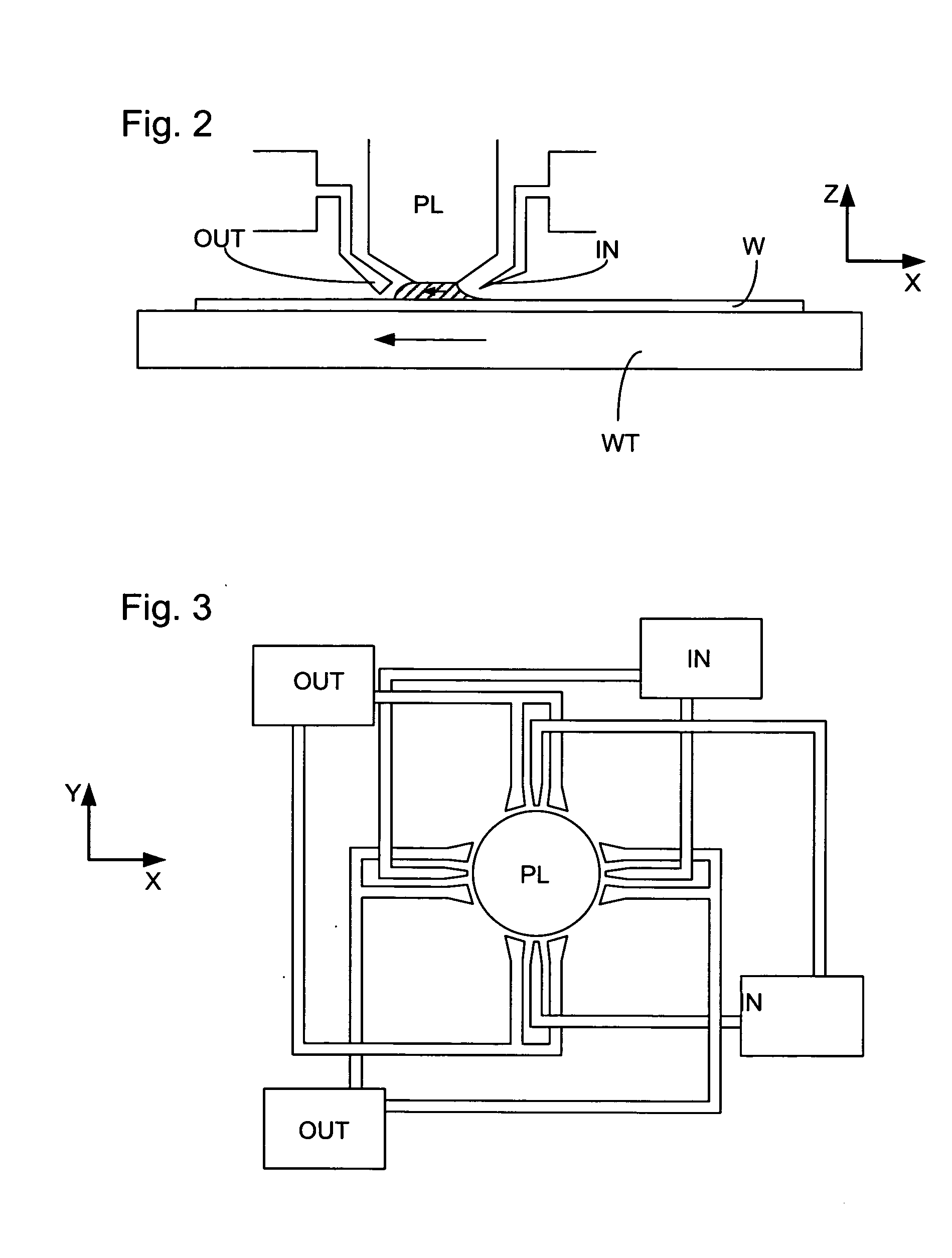

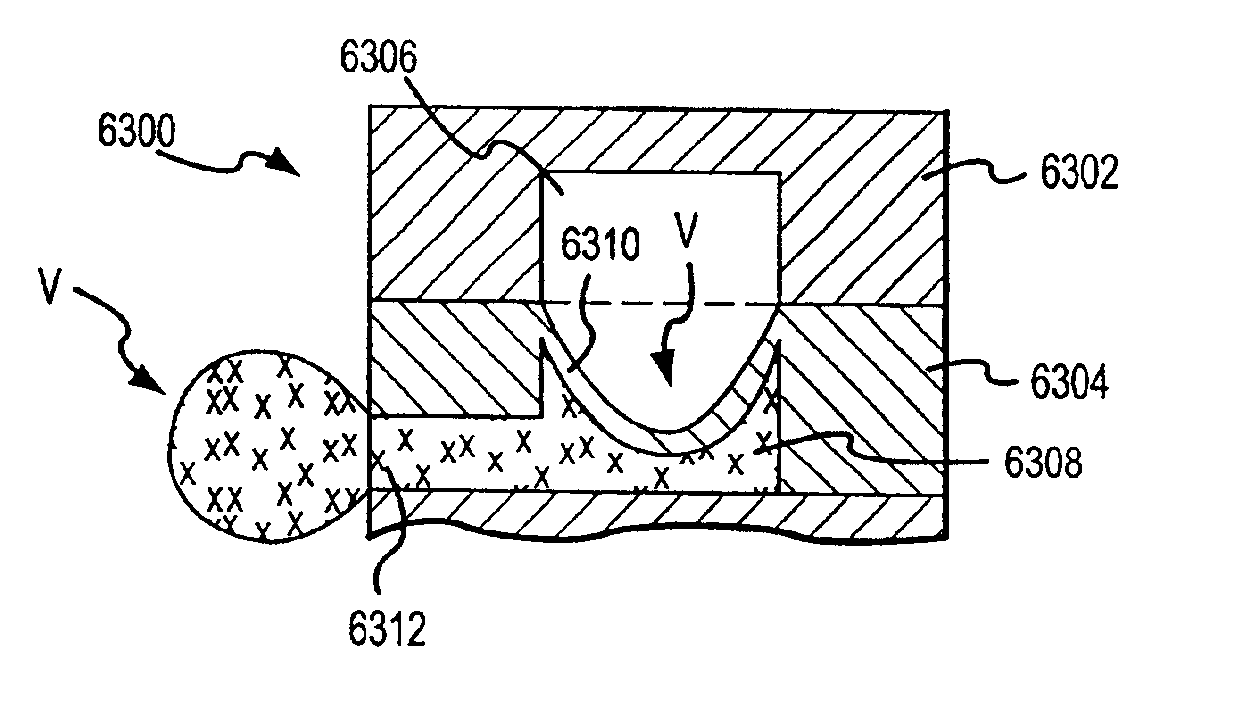

Lithographic apparatus and device manufacturing method

ActiveUS20050018155A1Less sensitiveKeep distanceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusProjection systemEngineering

A lithographic projection apparatus wherein a liquid supply system provides a space between a projection system and a substrate with liquid. The liquid supply system comprises a member. A liquid seal is formed between the member and the substrate by a flow of liquid. In an embodiment, the liquid seal is formed by a flow of liquid from an inlet to an outlet of the member.

Owner:ASML NETHERLANDS BV

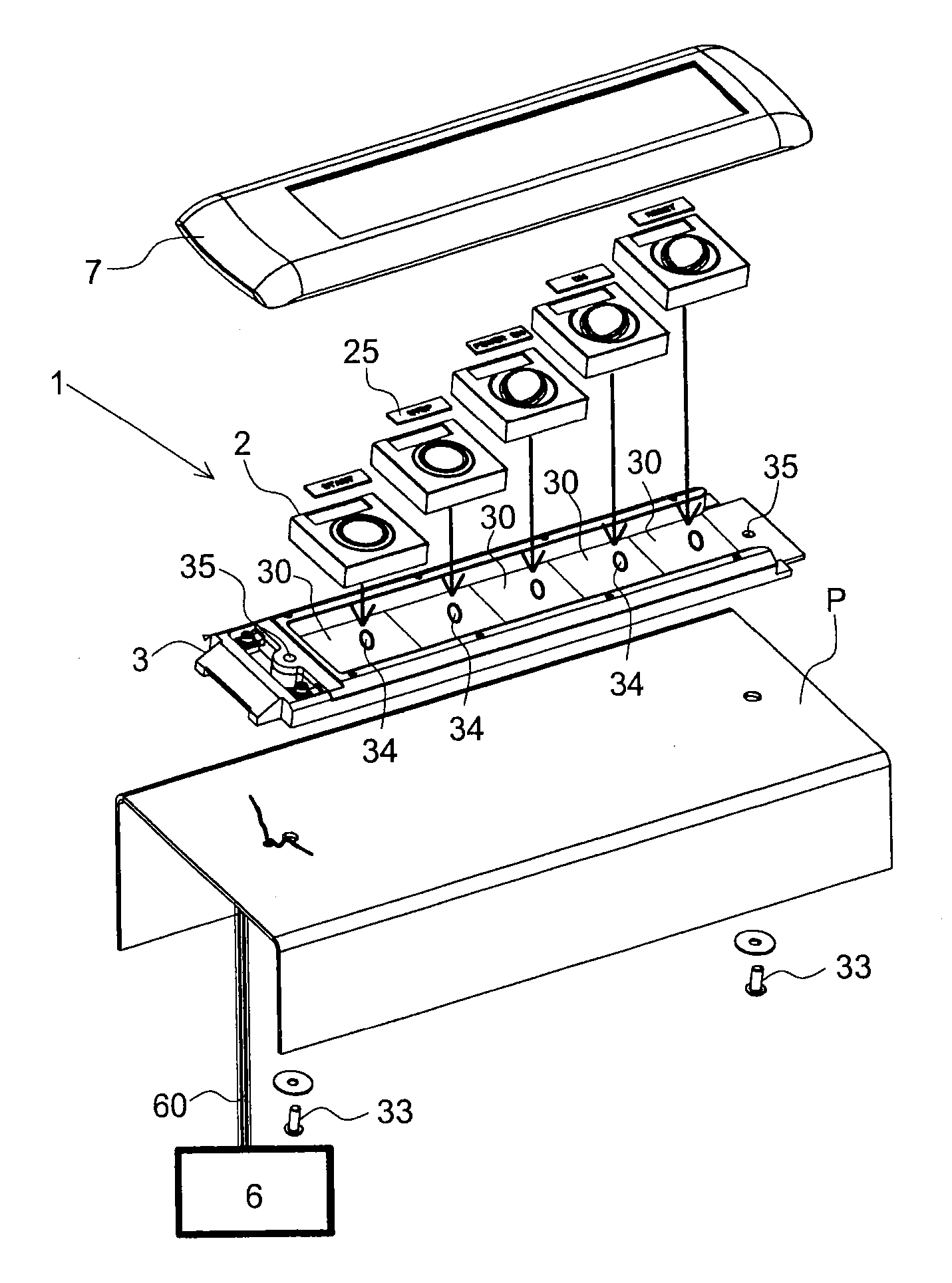

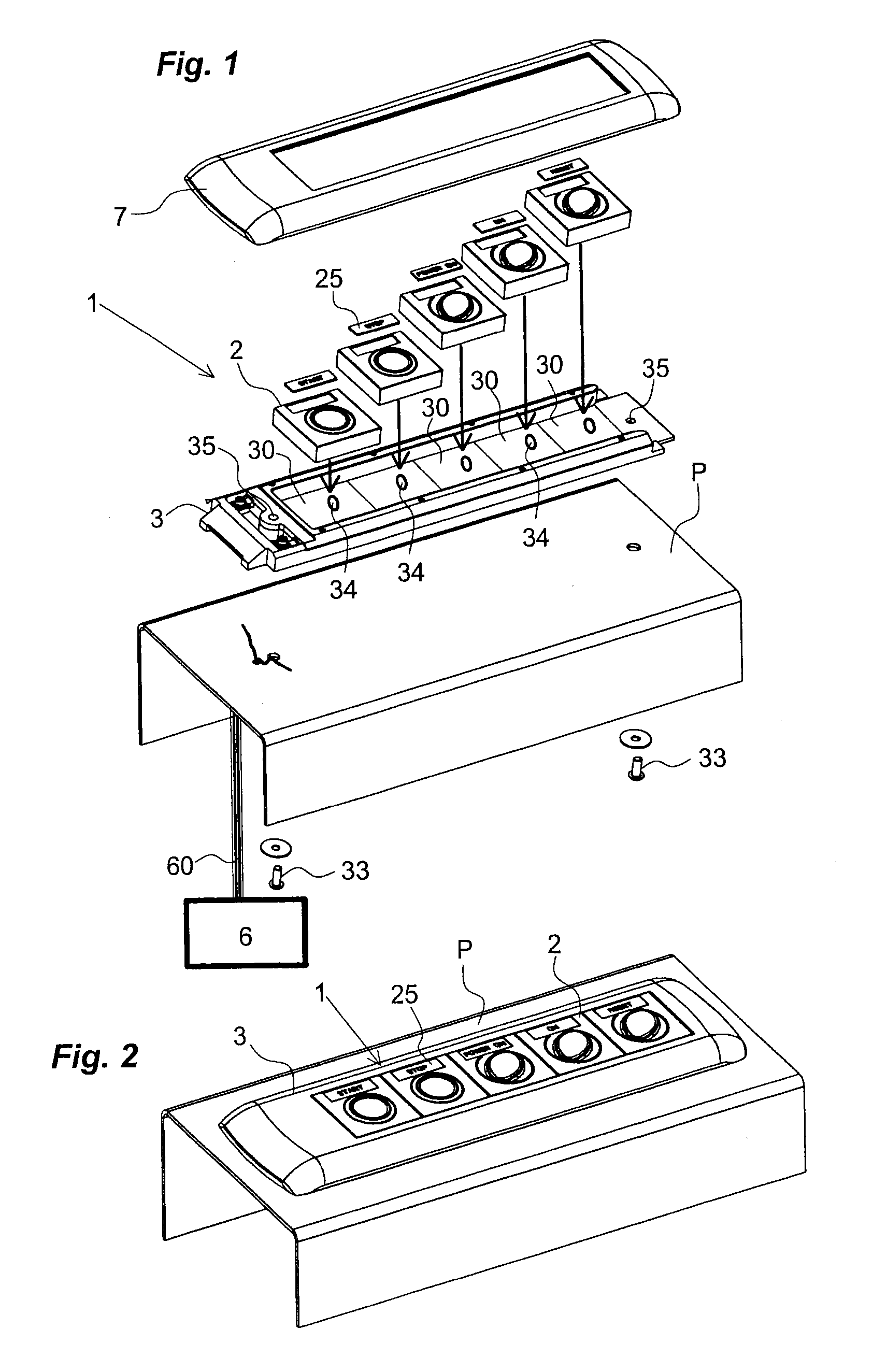

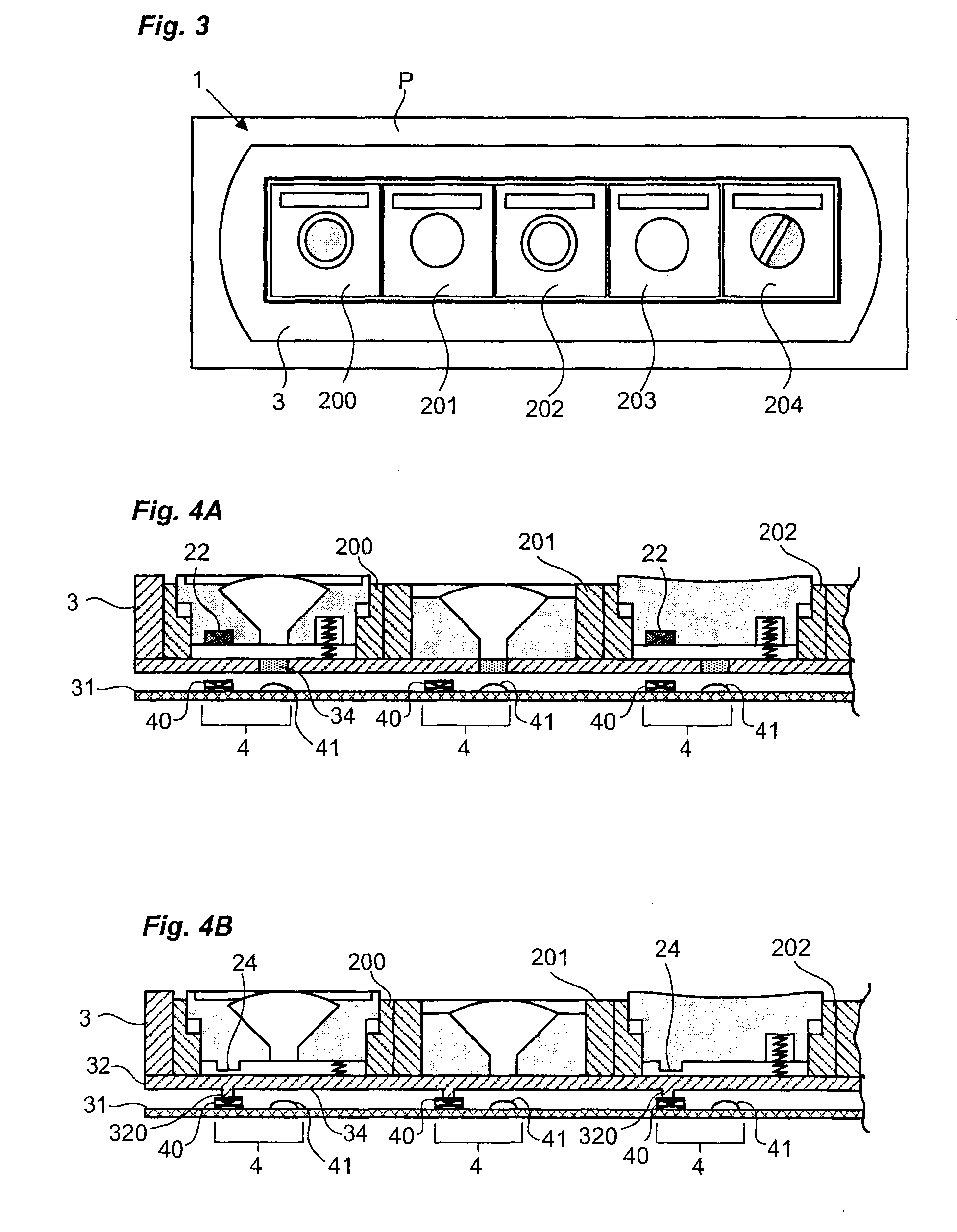

Human-machine dialog system

ActiveUS9411370B2Low costImprove sealingInput/output for user-computer interactionDigital data processing detailsDocking stationDialog system

The invention concerns a human-machine dialog system (1) comprising:a support (3) having a plurality of identical docking stations (30), each docking station (30) being associated with a universal human-machine dialog device (4), each universal human-machine dialog device (4) comprising at least a display member (41) and a sensor member (40),a plurality of modular members (2), each modular member (2) being arranged to be positioned in a docking station (30) in a removable and interchangeable manner and comprising a human-machine dialog interface (20) arranged to cooperate with said display member (41) and / or said sensor member (40).

Owner:SCHNEIDER ELECTRIC IND SAS

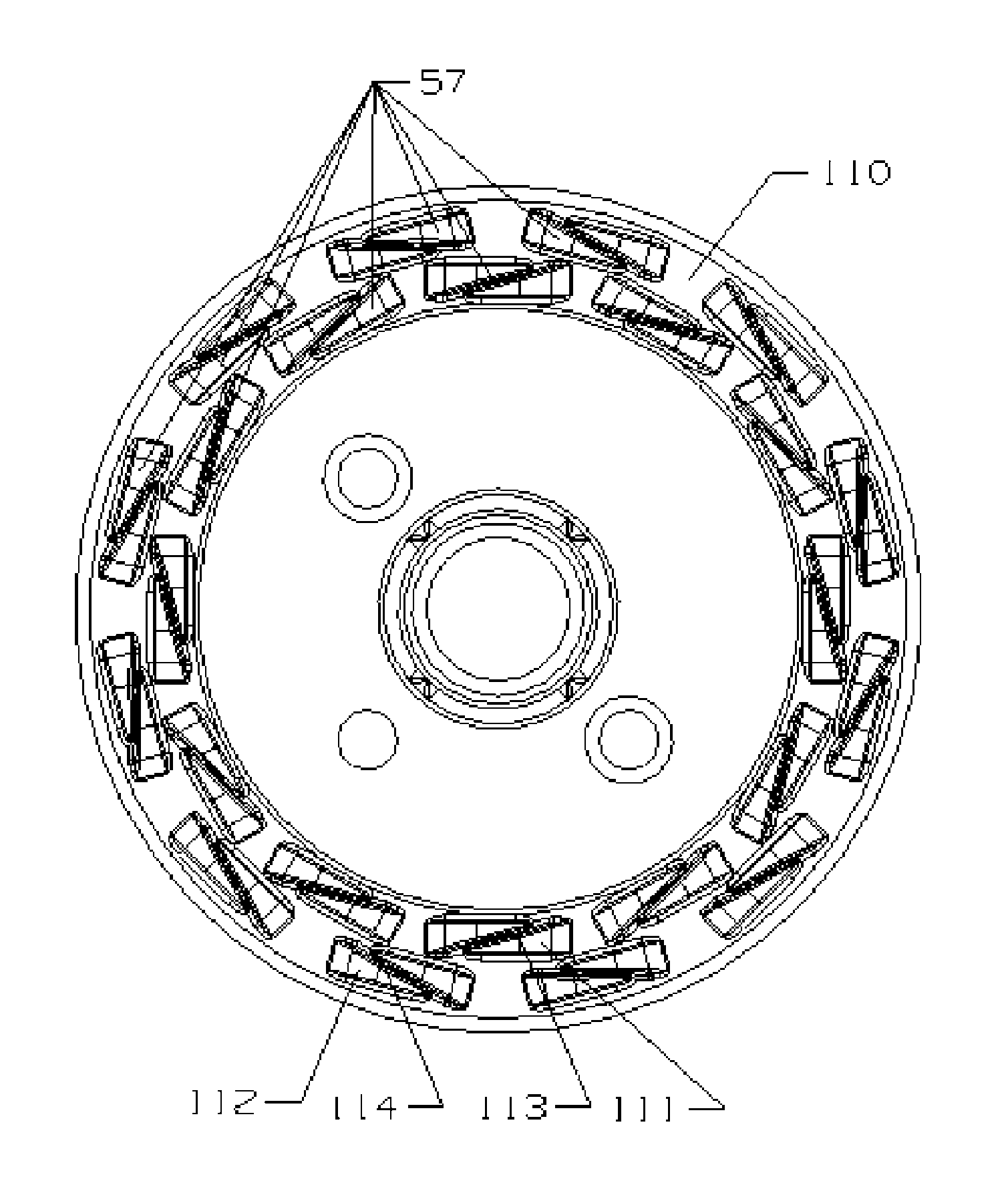

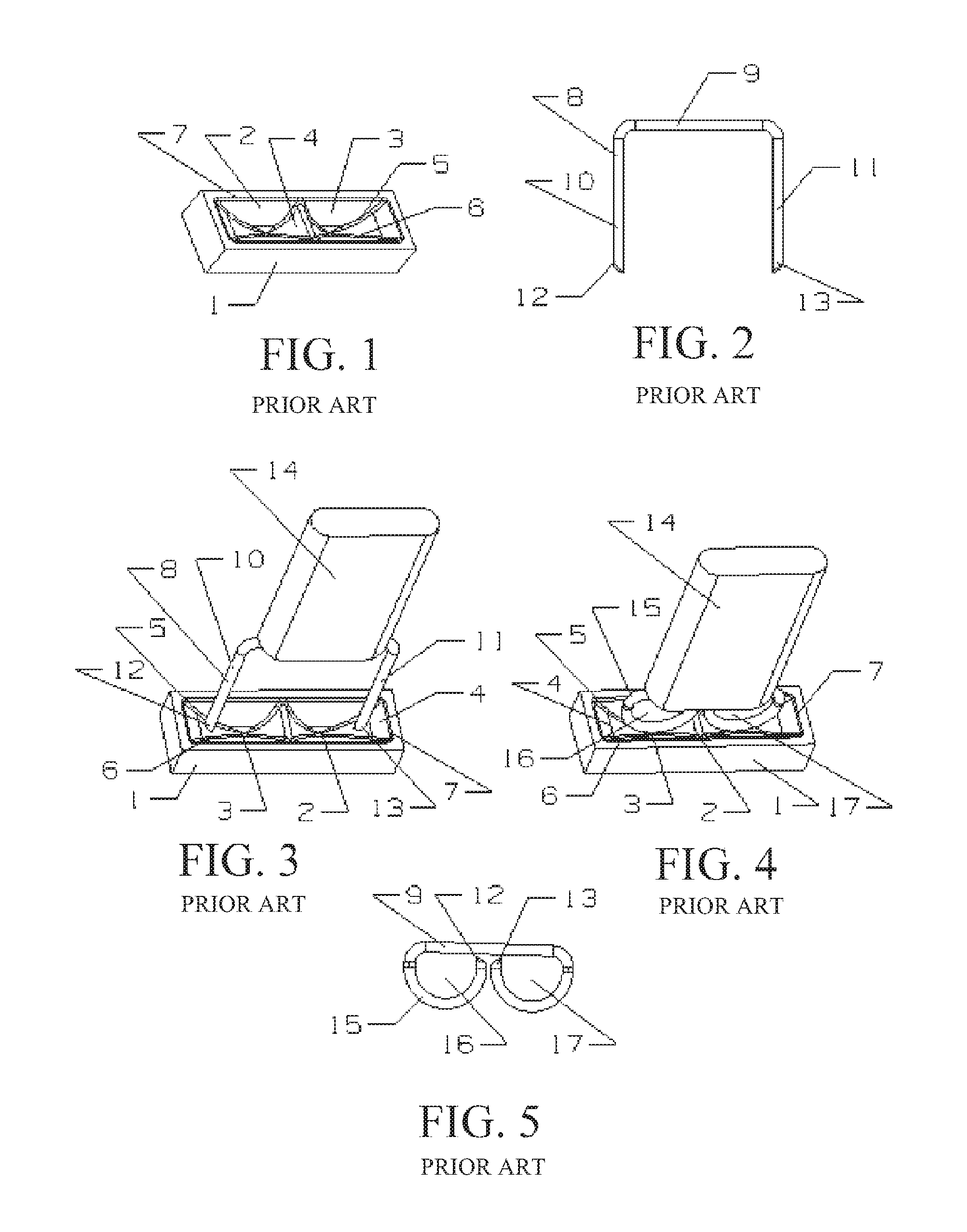

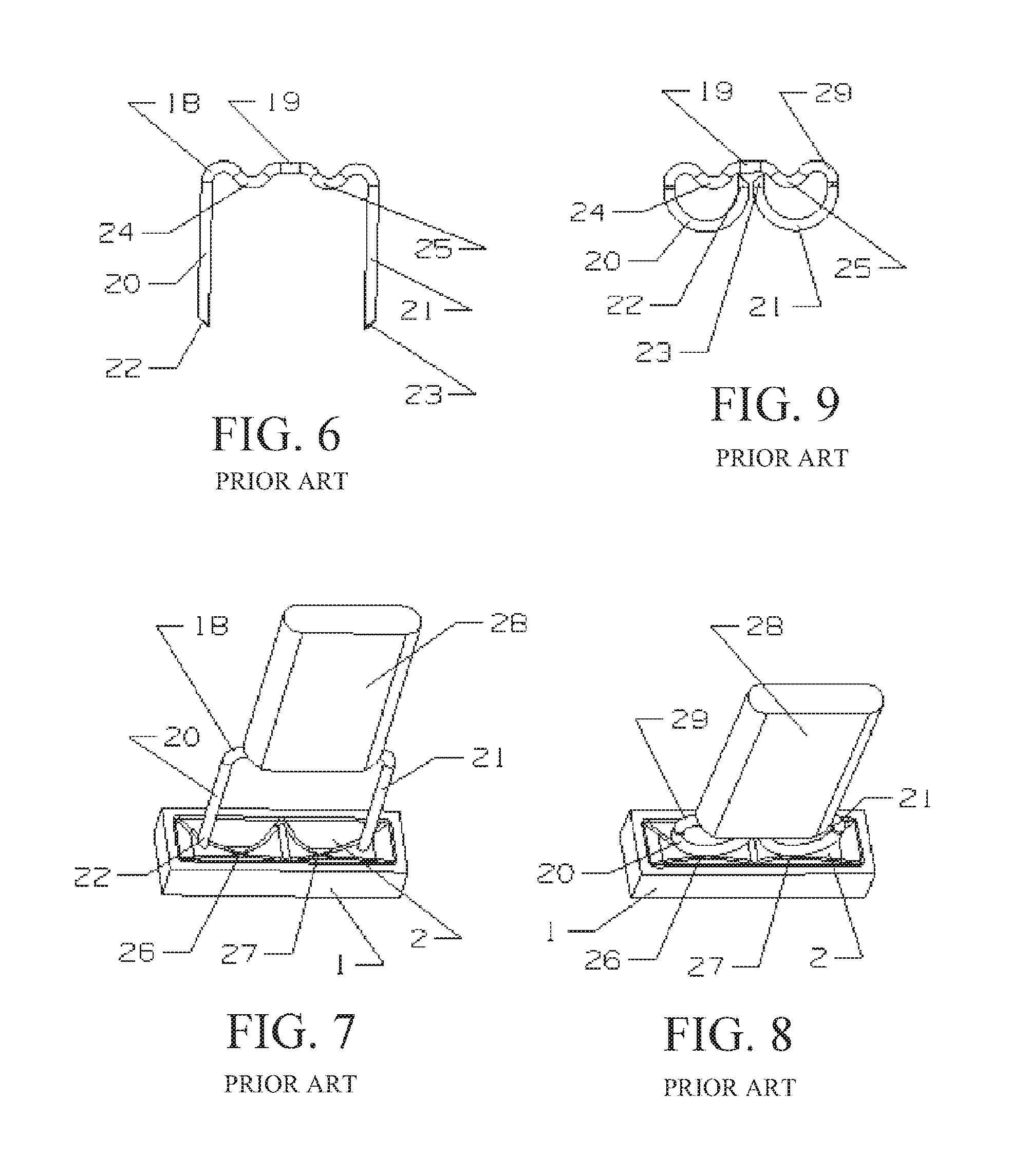

Surgical staple and staple pocket for forming kidney-shaped staple

ActiveUS9561030B2Improve sealingFacilitating the healing of the surrounding tissueStaplesNailsSurgical stapleEngineering

The present invention disclosed a surgical staple (50) and staple pocket (57) for forming kidney-shaped staple therefor, with the staple pocket (57) being recessed inward on the tissue contacting surface of the staple anvil (58), and with M-shaped staple (50) being used, wherein the degree of projection of the middle portion of the back span (51) of the M-shaped staple (50) arranged at the inner circle or arranged at a proximal side of a cutter slot (121) is larger than that of the back span (51) of the M-shaped staple (50) arranged at the outer circle or arranged at a distal side of the cutter slot (121), so that when the staple (50) of the same height are adapted to staple tissues to be stapled of different thickness, staple driver (68) bends the M-shaped staple (50) on the staple pocket (57) to form kidney-shaped staple (50) so as to achieve the operational effect of being able to seal the stapled tissue, to stop bleeding and to heal the tissue therearound.

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

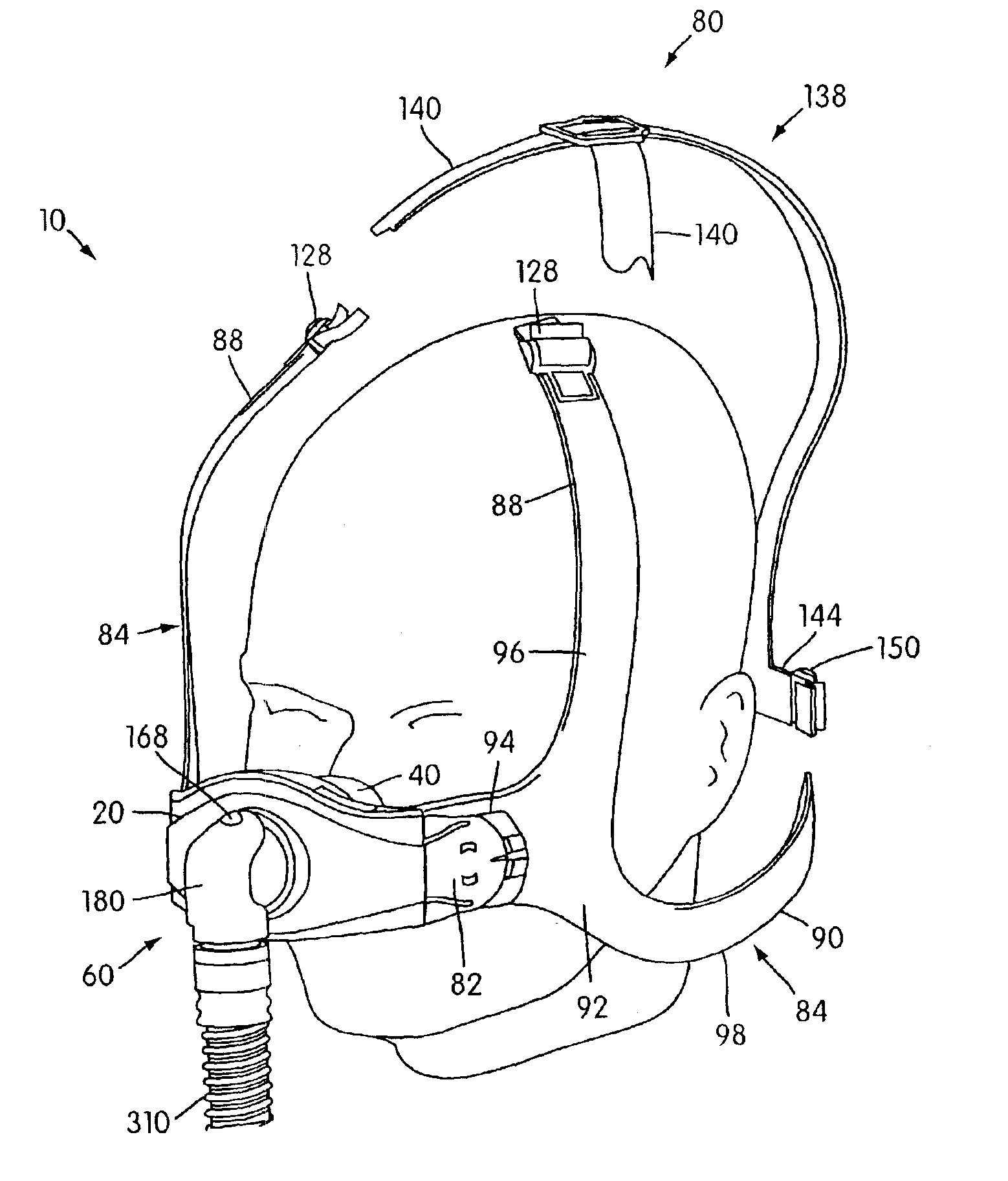

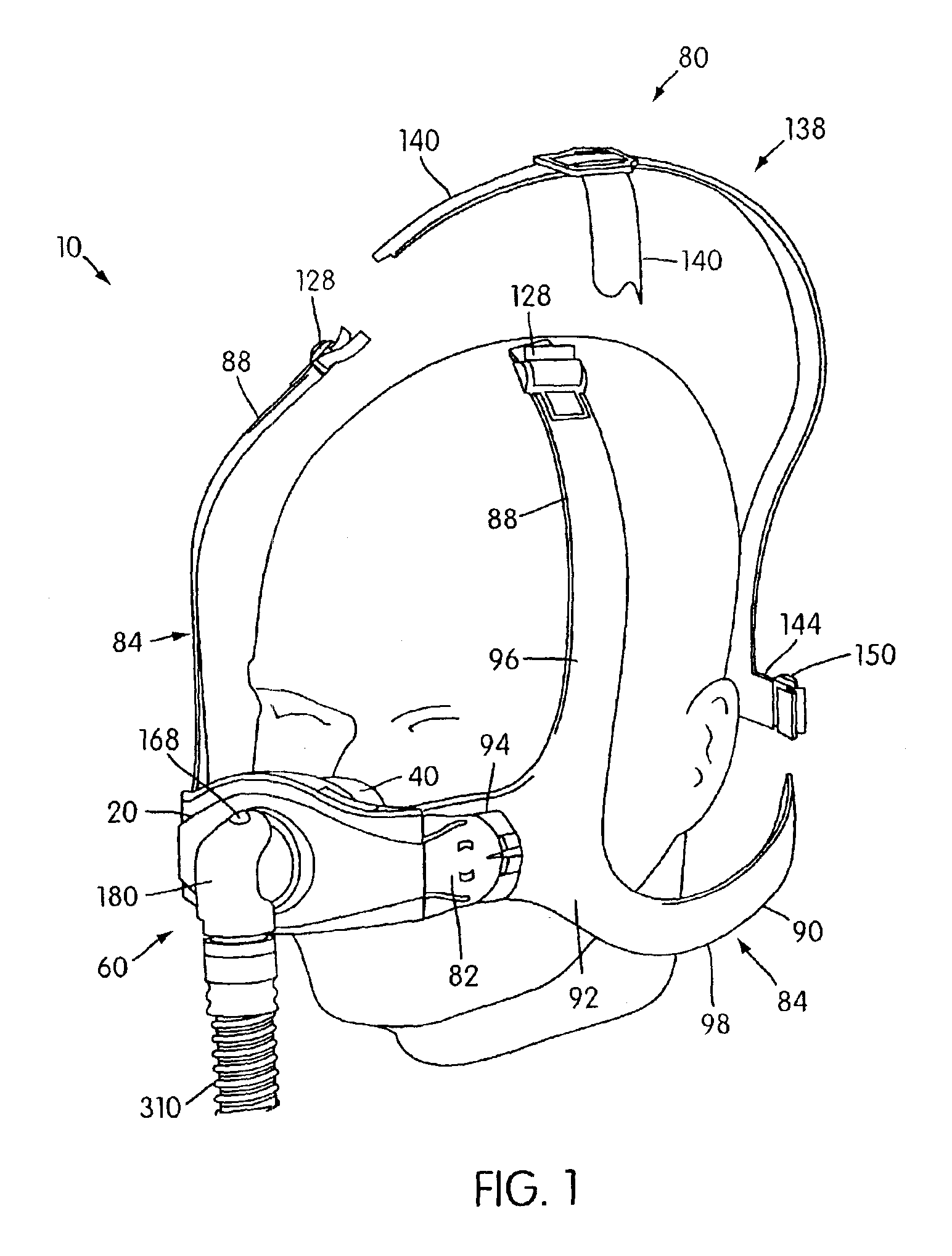

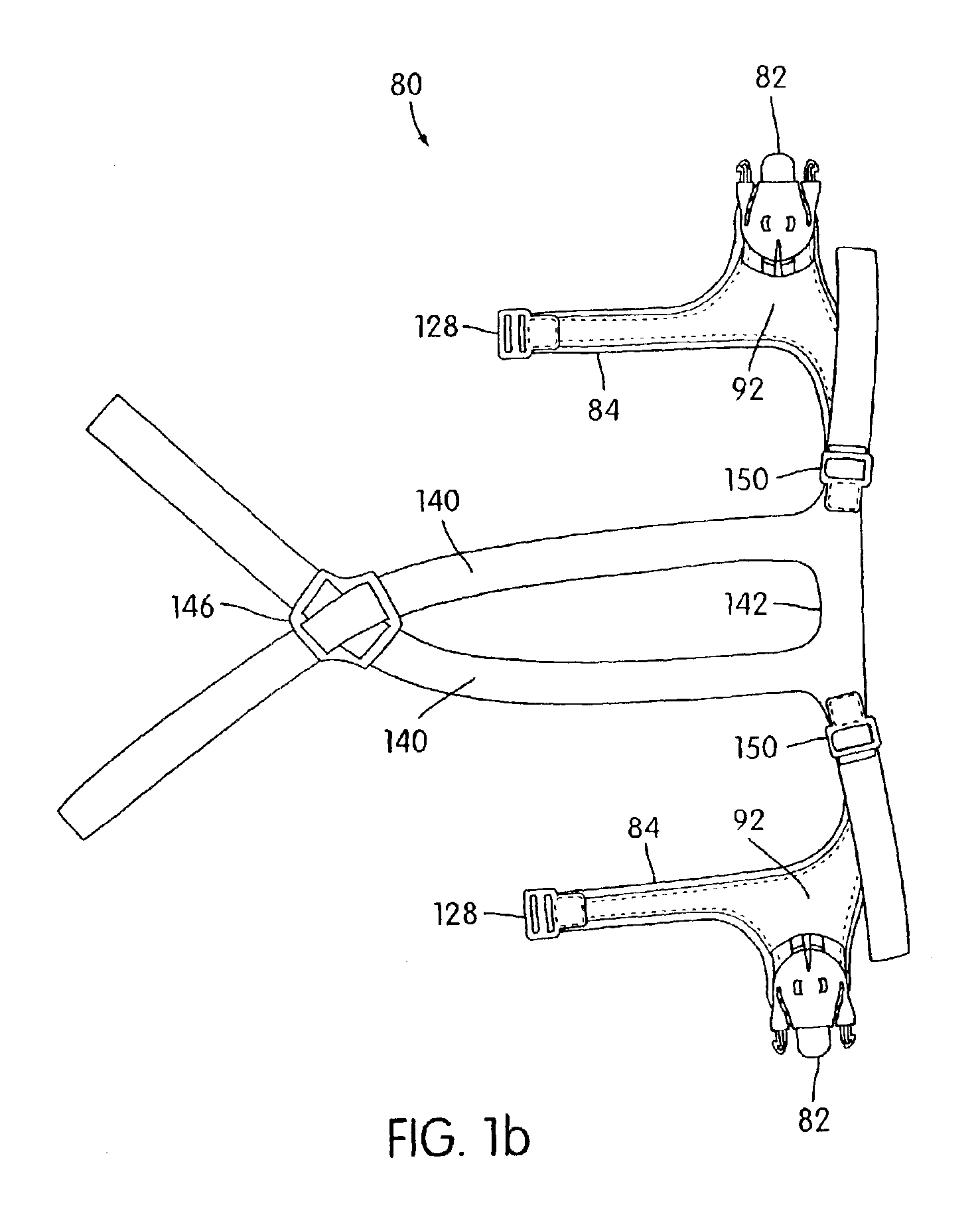

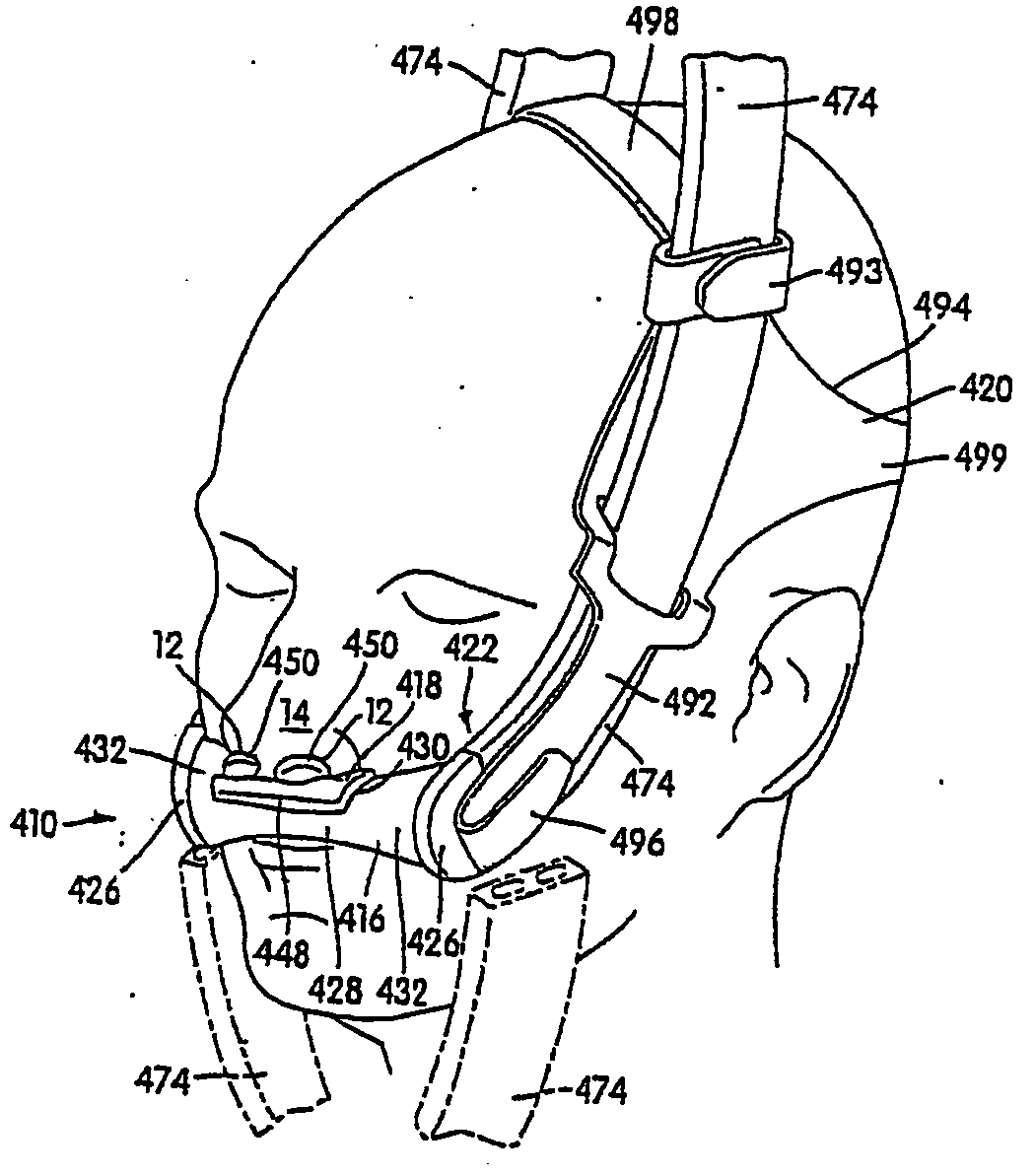

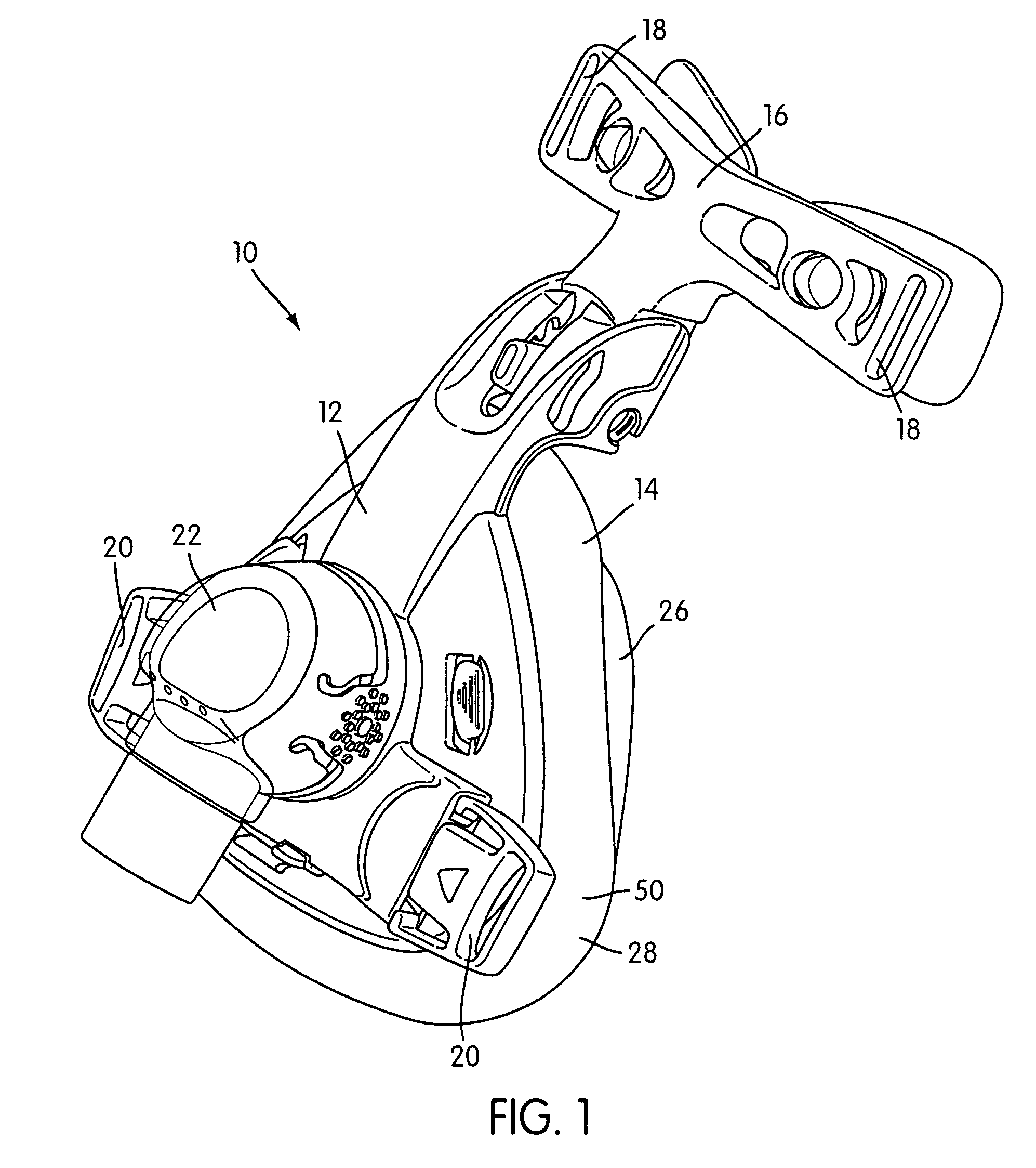

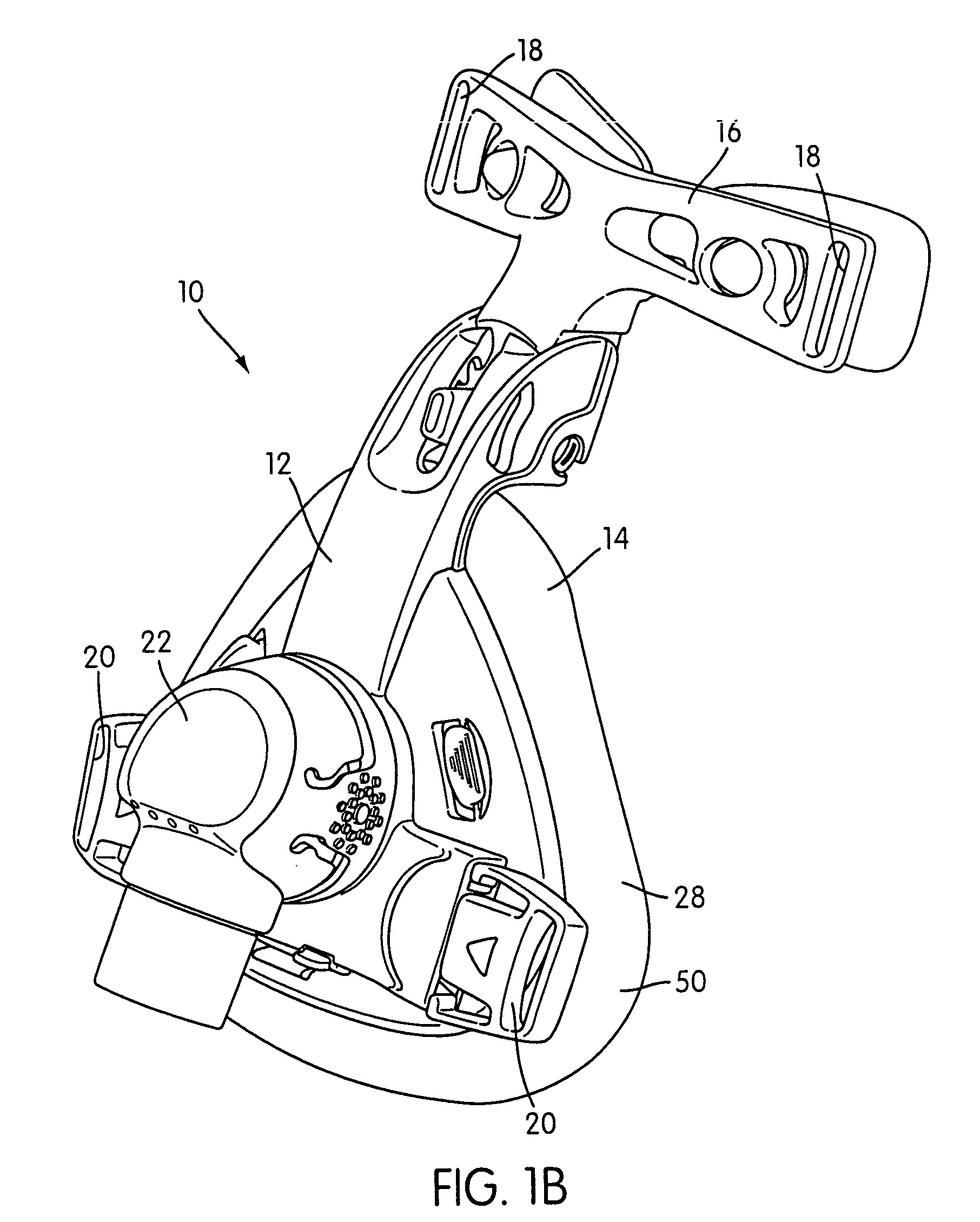

Ergonomic and adjustable respiratory mask assembly with headgear assembly

ActiveUS6907882B2Comfortable patient interfacePatient compliance is goodChemical protectionHeat protectionRespiratory maskEngineering

A respiratory mask assembly for delivering breathable gas to a patient includes a frame having a main body and a side frame member provided on each lateral side of the main body. Each side frame member includes an integrally formed first connector portion. A headgear assembly is removably attachable to the frame. The headgear assembly has a second connector portion adapted to be removably coupled with the first connector portion provided on the frame. The second connector portion is manually movable to a releasing position to detach the headgear assembly from the frame. The headgear assembly is rotationally adjustable with respect to the frame.

Owner:RESMED LTD

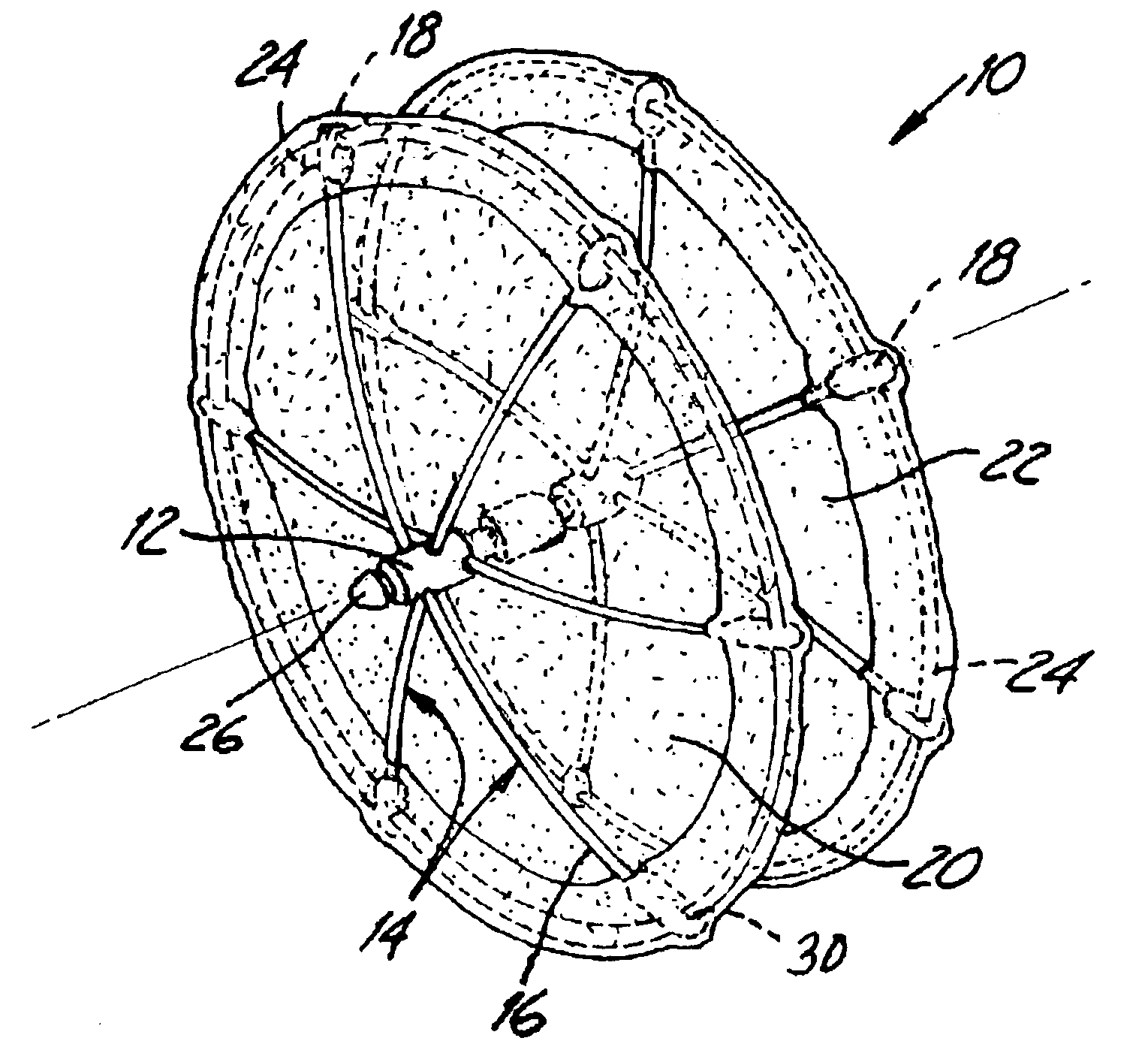

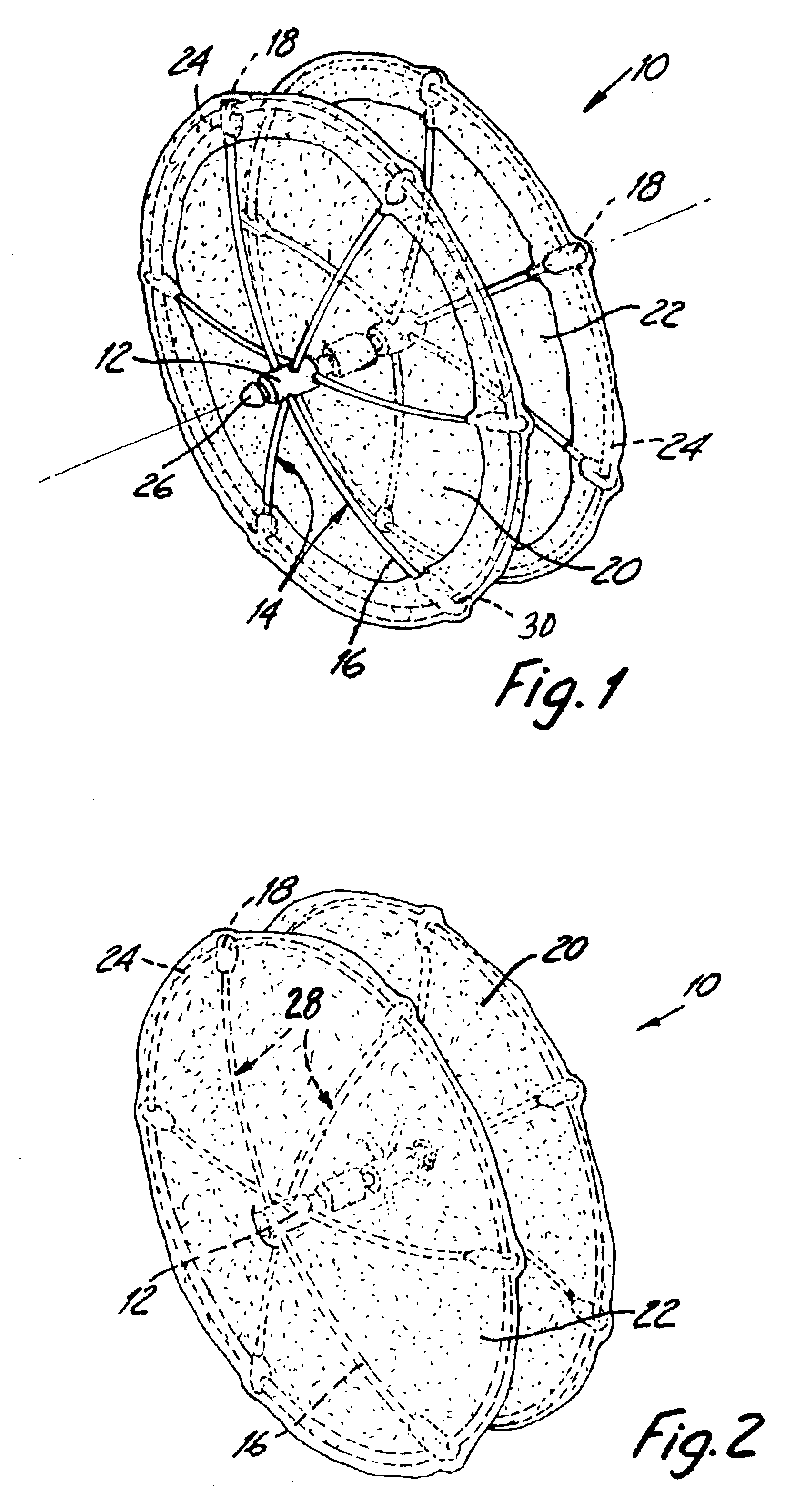

Implantable artificial partition and methods of use

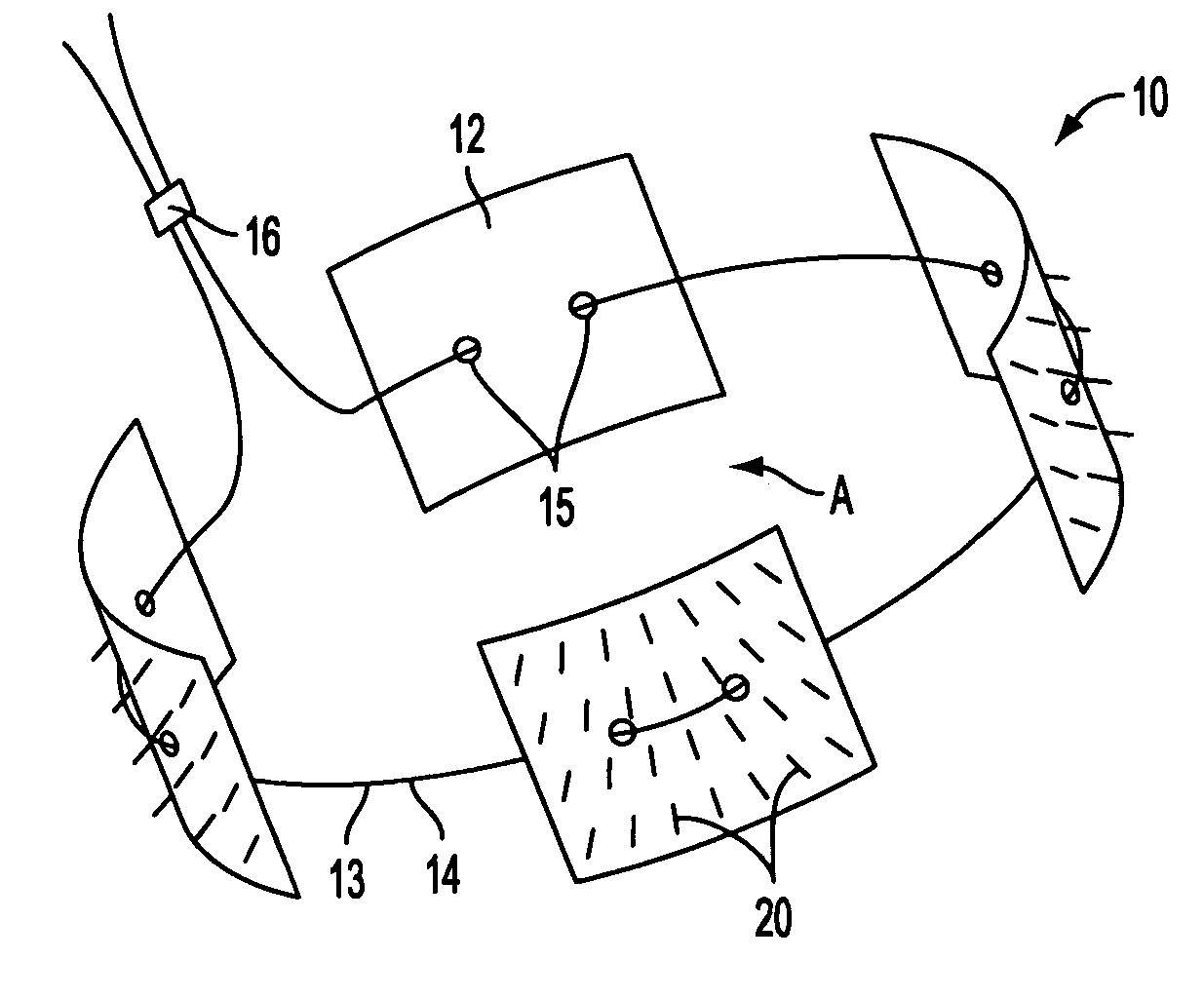

InactiveUS7160312B2Reduce the cross-sectional areaReduce probabilitySuture equipmentsHeart valvesMedicineGastro intestinal

Apparatus and methods are provided for partitioning a gastro-intestinal lumen by intraluminally reducing a local cross-sectional area thereof. The apparatus comprises a plurality of anchors adapted for intraluminal penetration into a wall of the gastro-intestinal lumen to prevent migration or dislodgement of the apparatus, and a partition, which may include a drawstring or a toroidal balloon, coupled to the plurality of anchors to provide a local reduction in the cross-sectional area of the gastro-intestinal lumen.

Owner:USGI MEDICAL

Implantable joint prosthesis

ActiveUS20020128715A1Increased durabilityImprove stabilityDiagnosticsJoint implantsIntervertebral discSurgical implant

The invention relates to a surgical implant that provides an artificial diarthroidal-like joint, suitable for use in replacing any joint, but particularly suitable for use as an intervertebral disc endoprosthesis. The invention contains two rigid opposing shells, each having an outer surface adapted to engage the surfaces of the bones of a joint in such a way that the shells are immobilized by friction between their outer surfaces and the surfaces of the bone. These outer surfaces are sufficiently rough that large frictional forces strongly resist any slippage between the outer surface and the bone surfaces in the joint. They may be convex, and when inserted into a milled concavity, are immediately mechanically stable. Desirably, the outer surfaces of the shells are adapted to allow for bony ingrowth, which further stabilizes the shells in place. The inner surfaces of the shells are relatively smooth, and adapted to slide easily across a portion of the outer surface of a central body disposed between the shells. The central body has a shape that cooperates with the shape of the inner surface of the shell so as to provide a range of motion similar to that provided by a healthy joint. A flexible sheath extends between edges of the opposing shells. The inner surface of this sheath, together with the inner surfaces of the rigid shells, defines a cavity encasing the central body. At least a portion of this cavity is filled with a fluid lubricant, further decreasing the frictional force between inner surfaces of the shell and the surface of the central body.

Owner:COMPANION SPINE LLC

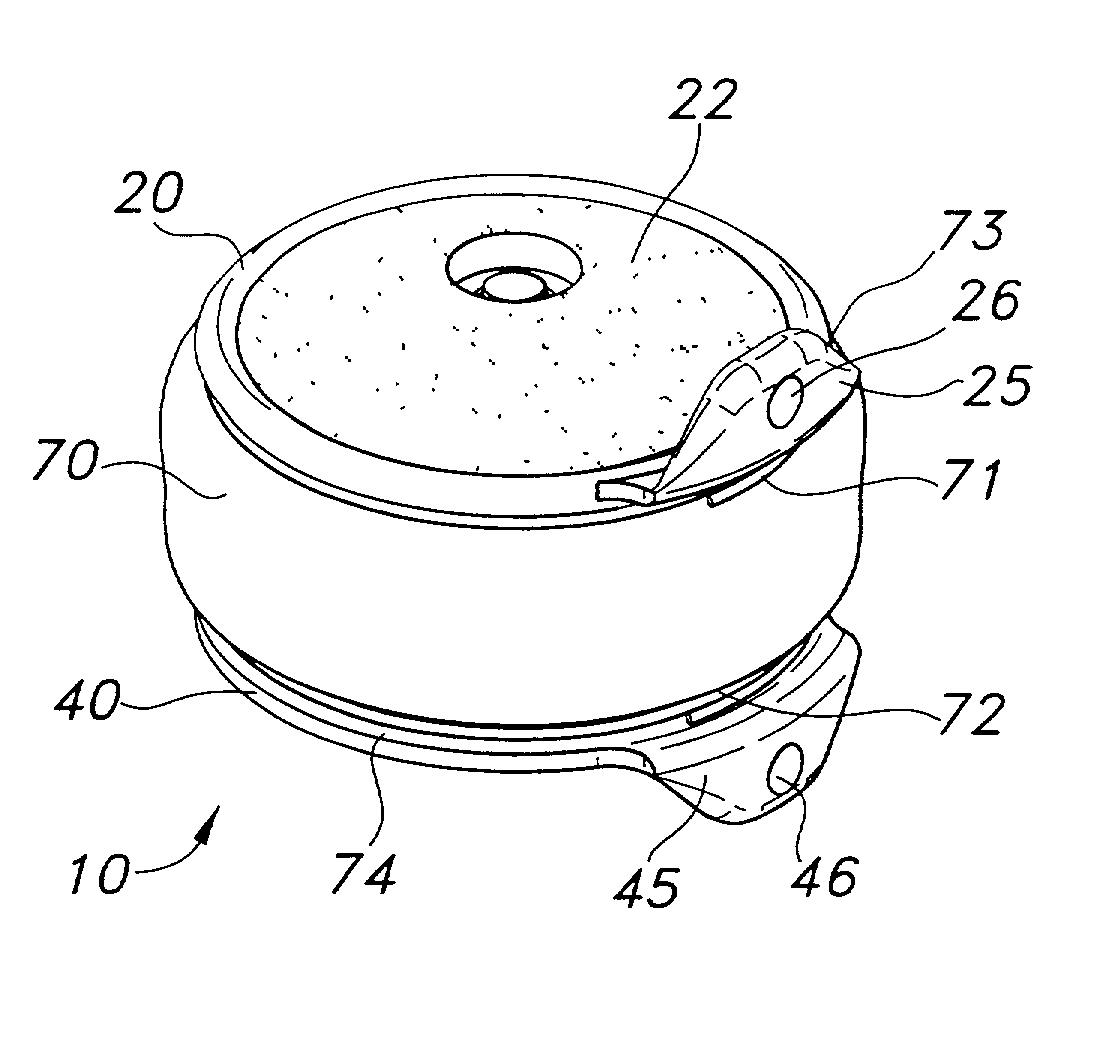

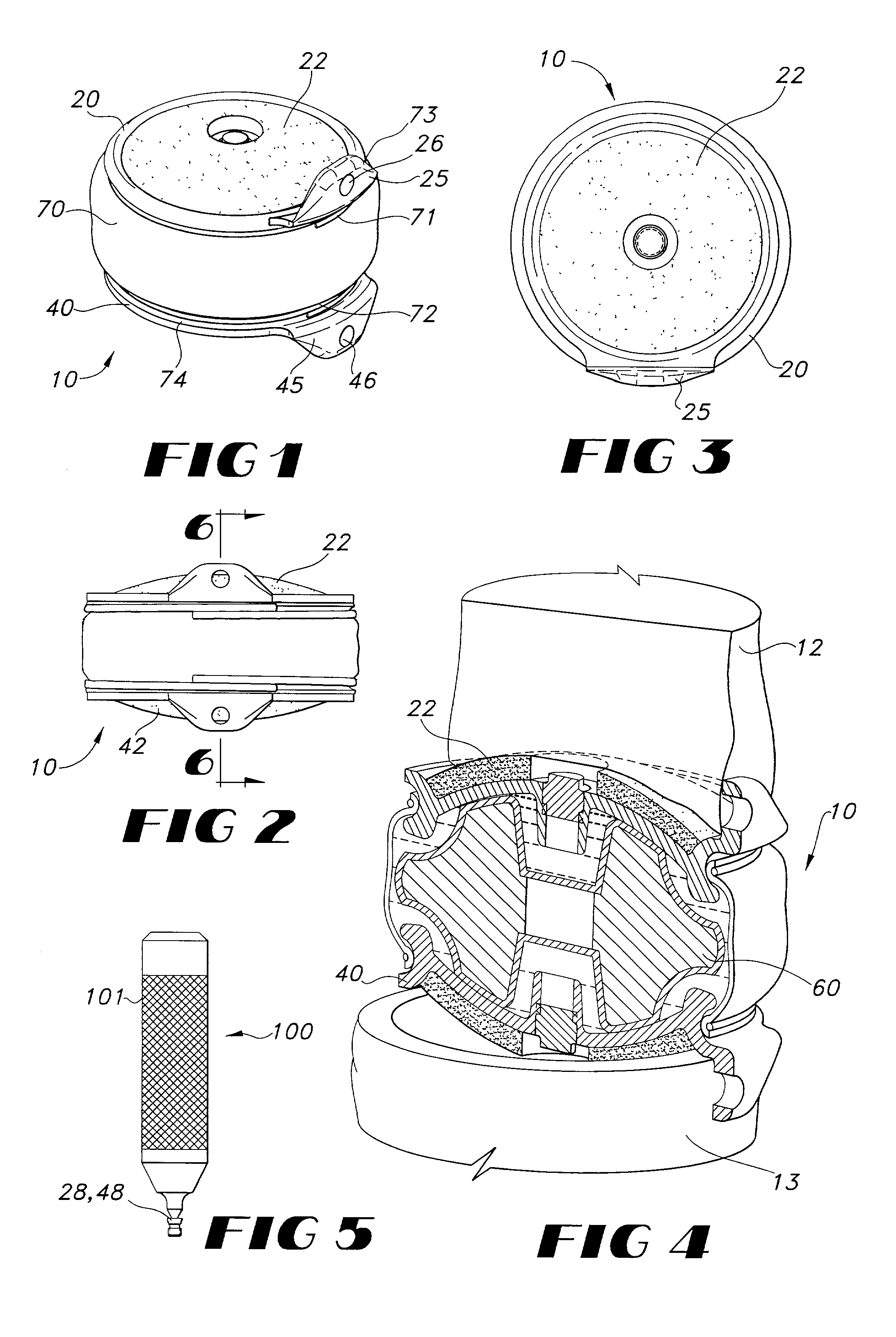

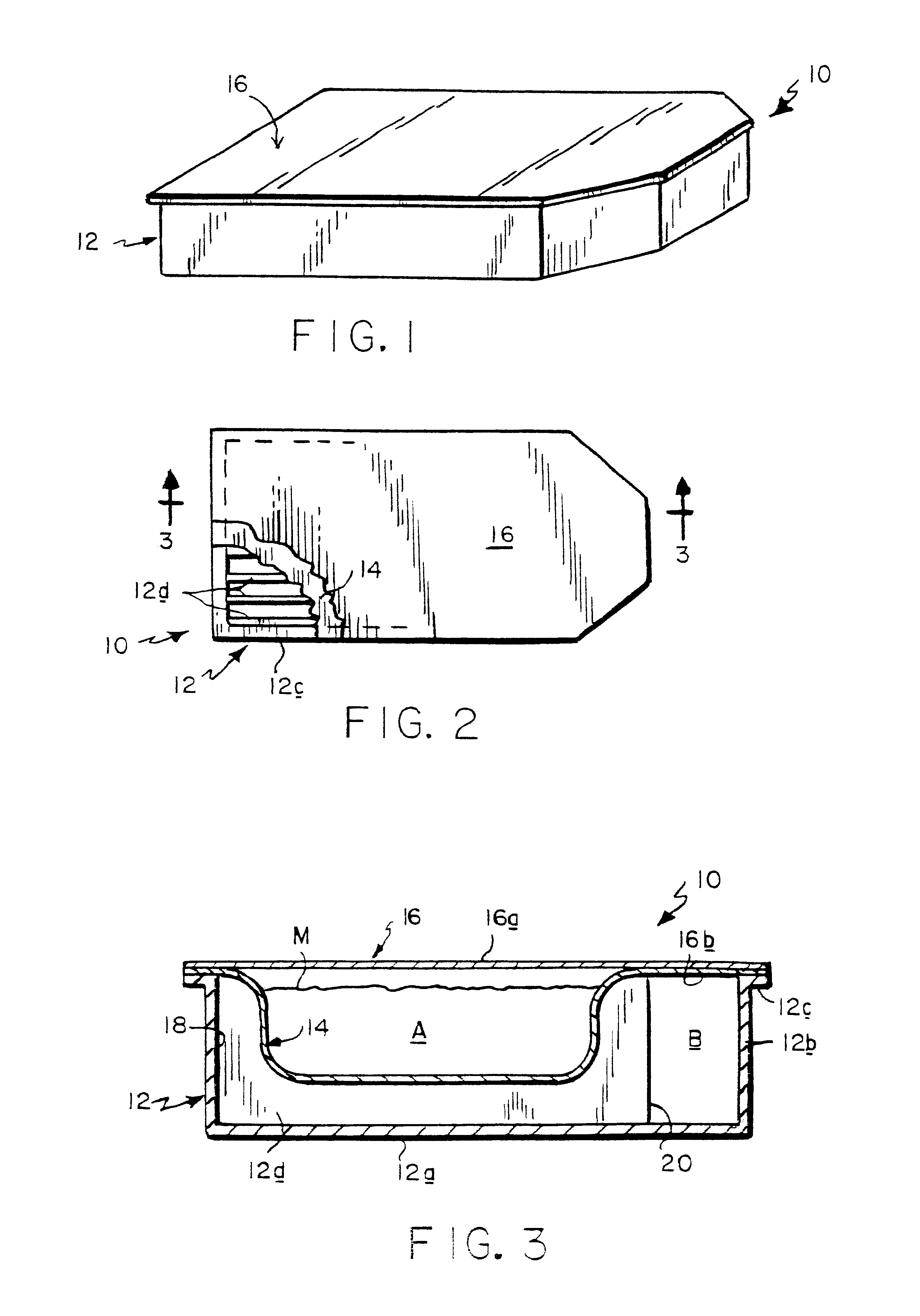

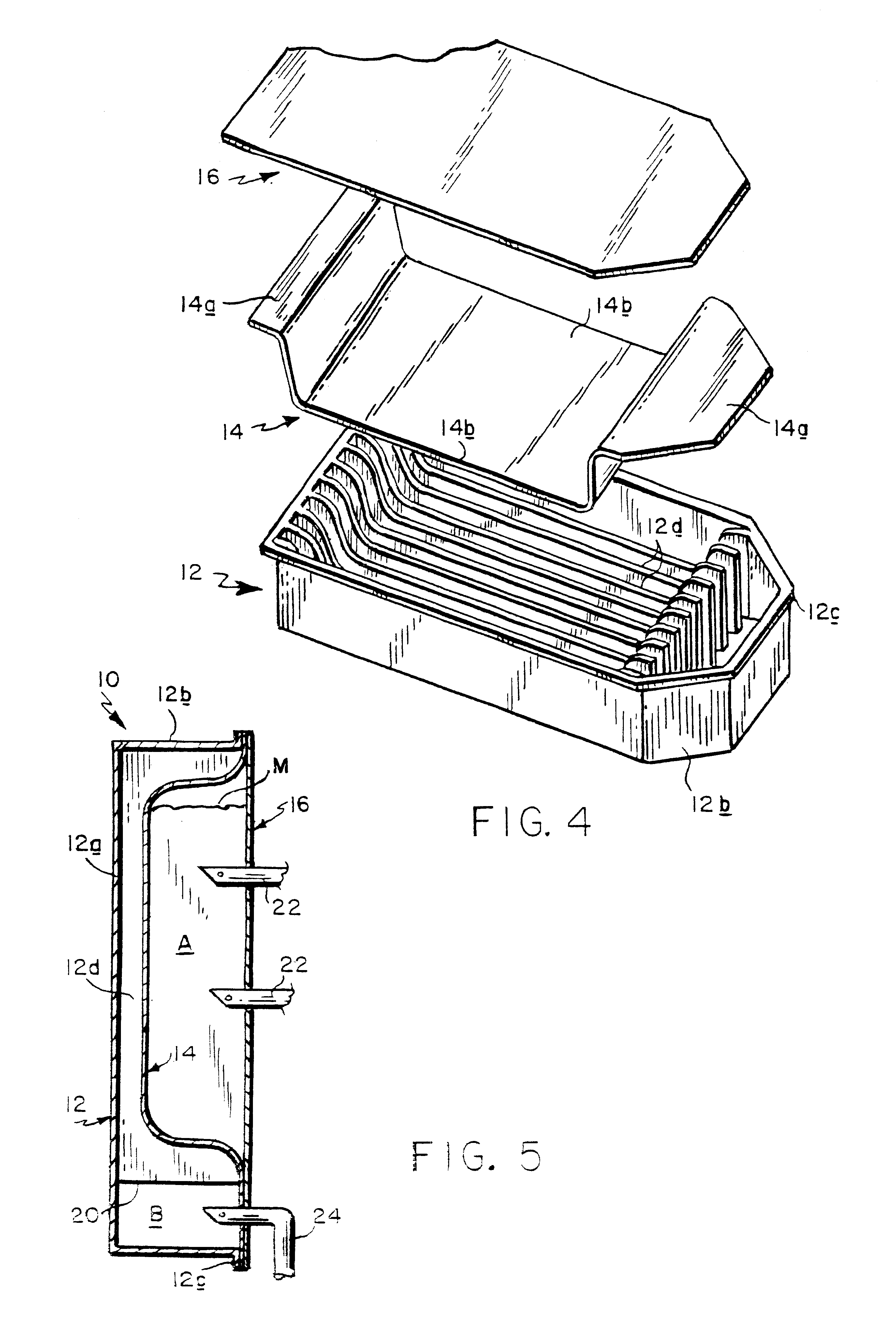

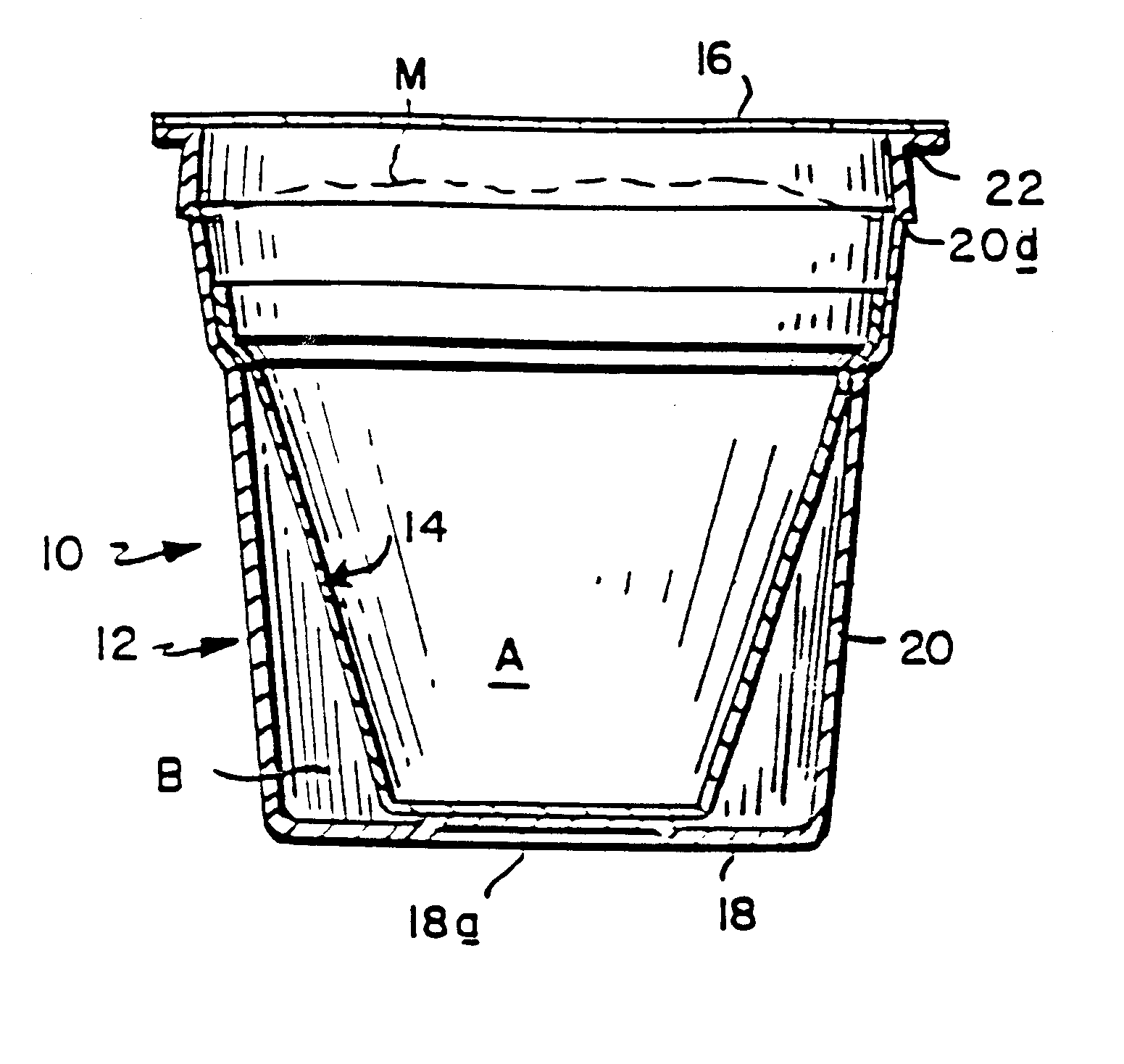

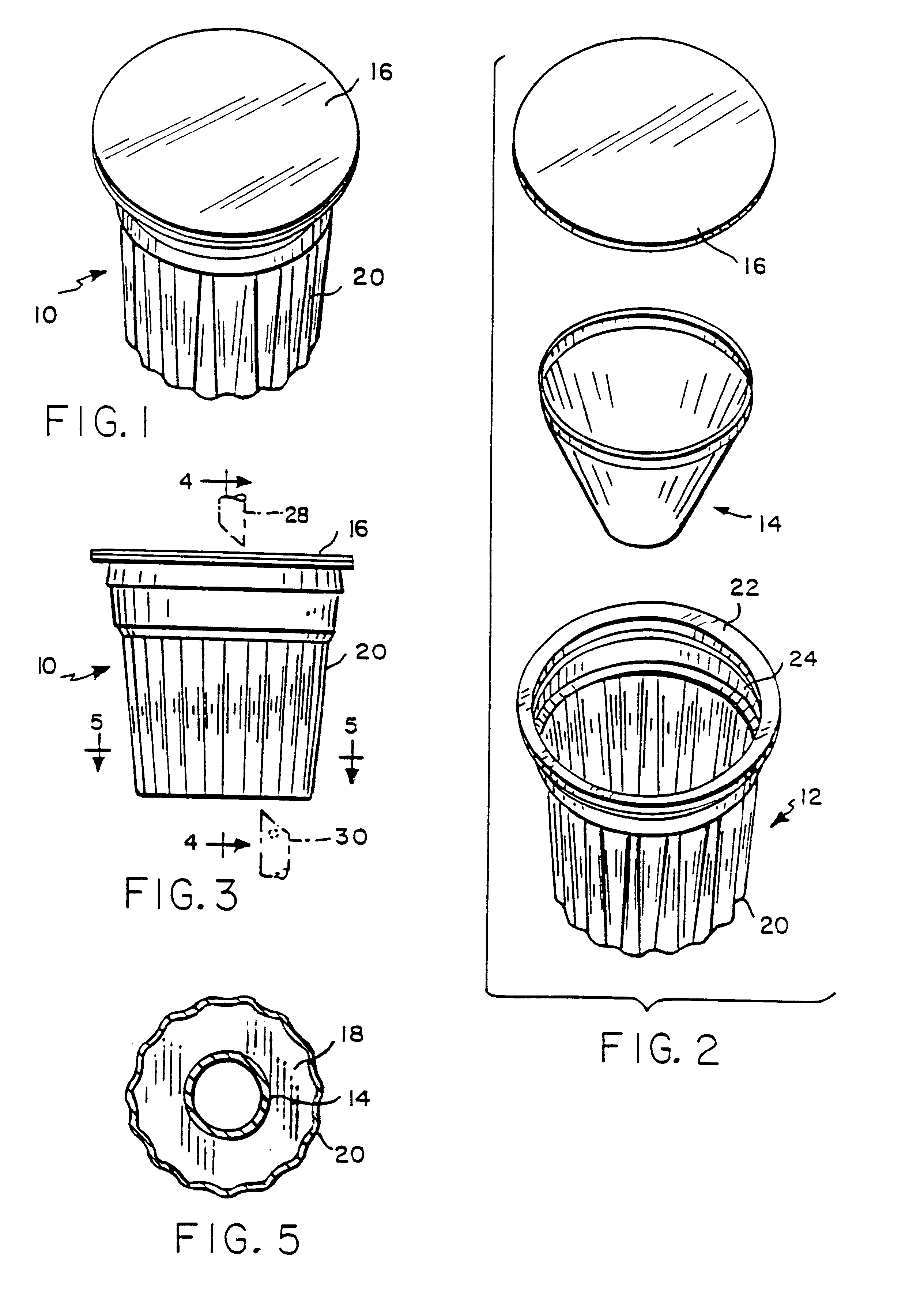

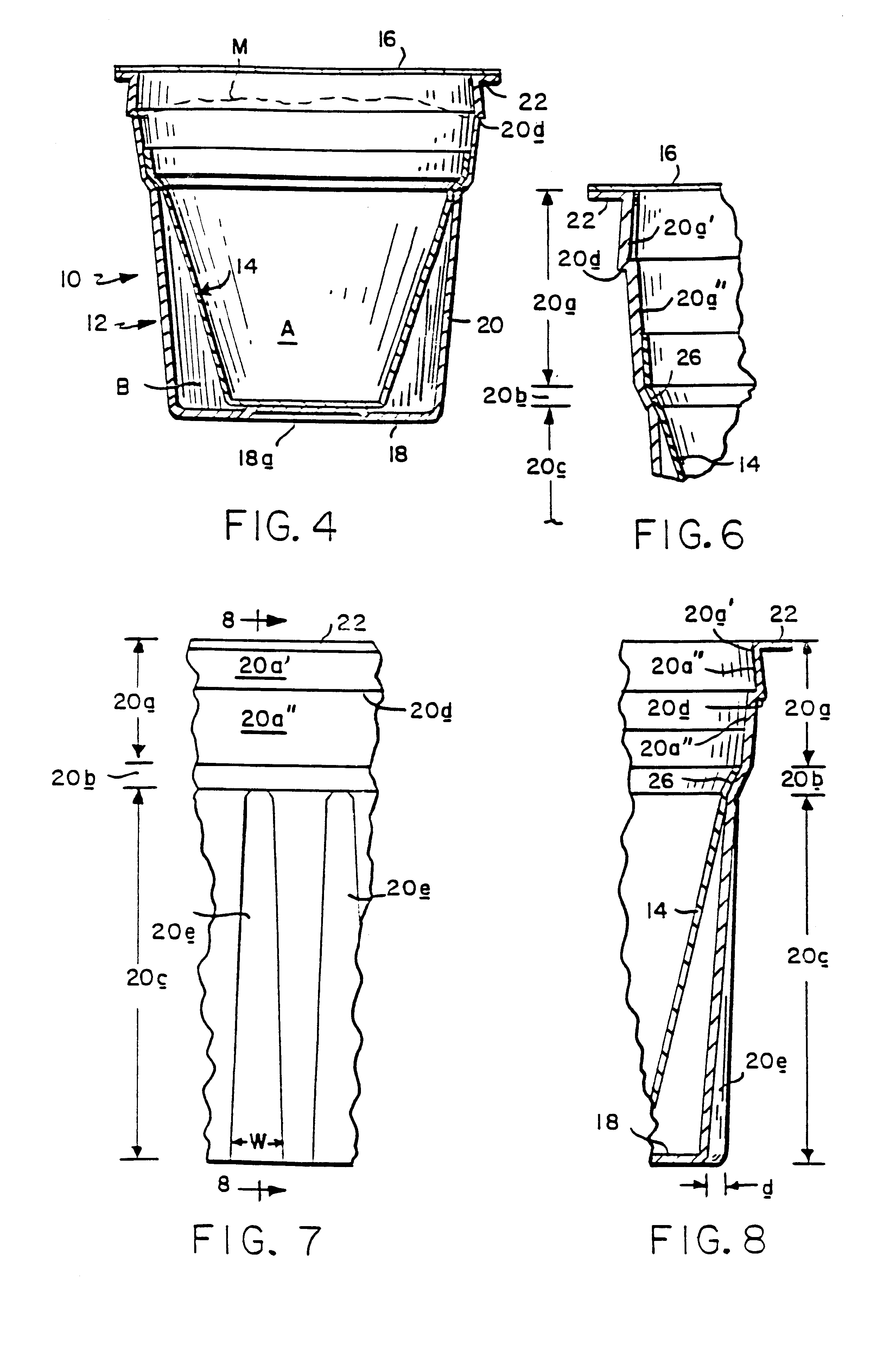

Disposable single serve beverage filter cartridge

InactiveUS6607762B2Lower resistanceImprove sealingReady-for-oven doughsBeverage vesselsBiomedical engineeringFilter element

Owner:KEURIG GREEN MOUNTAIN INC

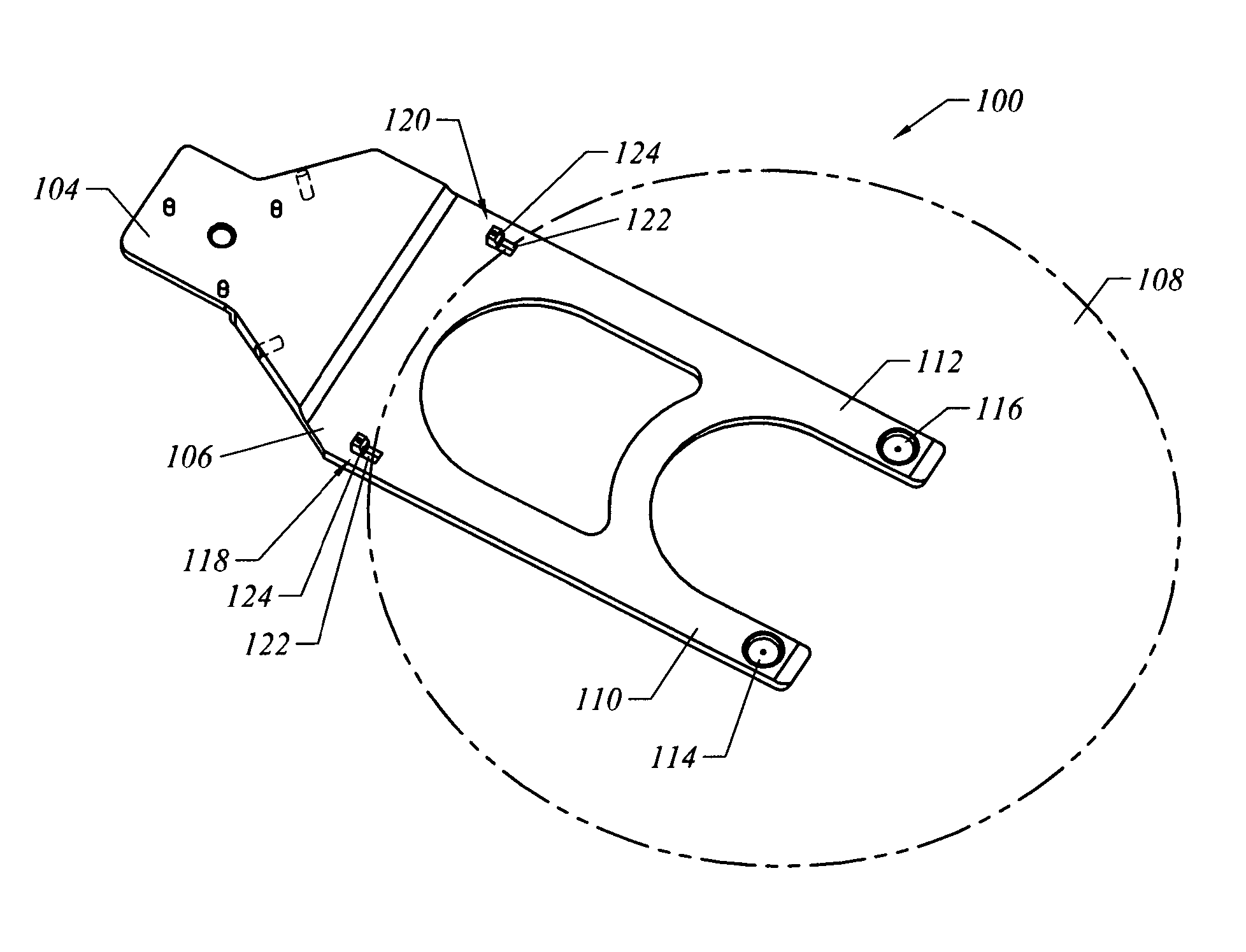

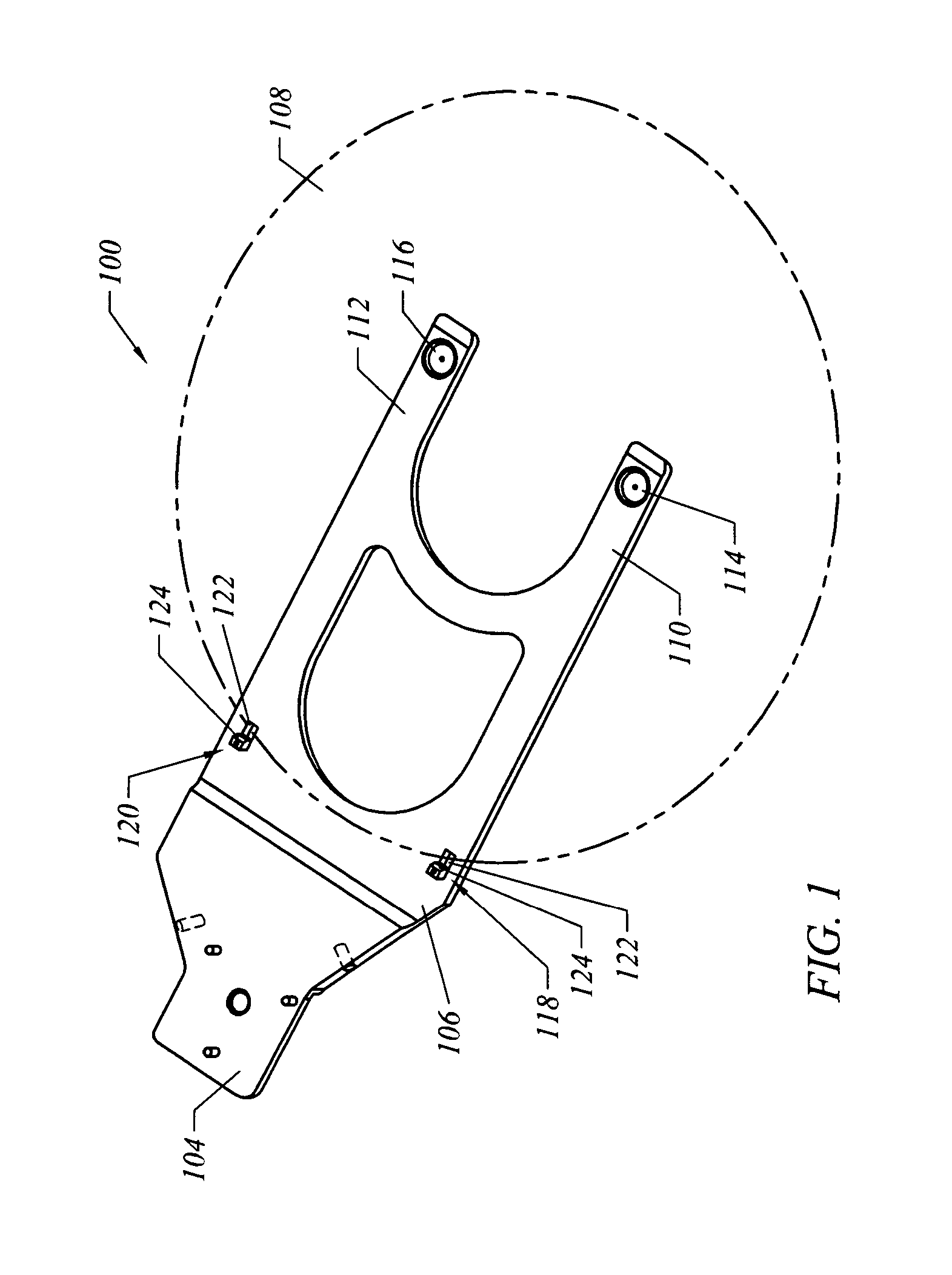

Ultra low contact area end effector

ActiveUS7055875B2Eliminates and greatly minimizes particulate transferImprove sealingGripping headsSemiconductor/solid-state device manufacturingEngineeringActuator

The present invention comprises a vacuum end effector having workpiece supports that work in conjunction with distorted workpiece surfaces. In one embodiment, each workpiece support has the ability to gimbal and conform the workpiece surface in contact with an outer edge of the support. Each workpiece support preferably provides a knife-like contact edge to minimize the contact area between the support and the workpiece while still providing an effective vacuum area to hold the wafer securely on the support. In another embodiment, each workpiece support is replaceable without having to remove the end effector from the robot assembly

Owner:BOOKS AUTOMATION US LLC

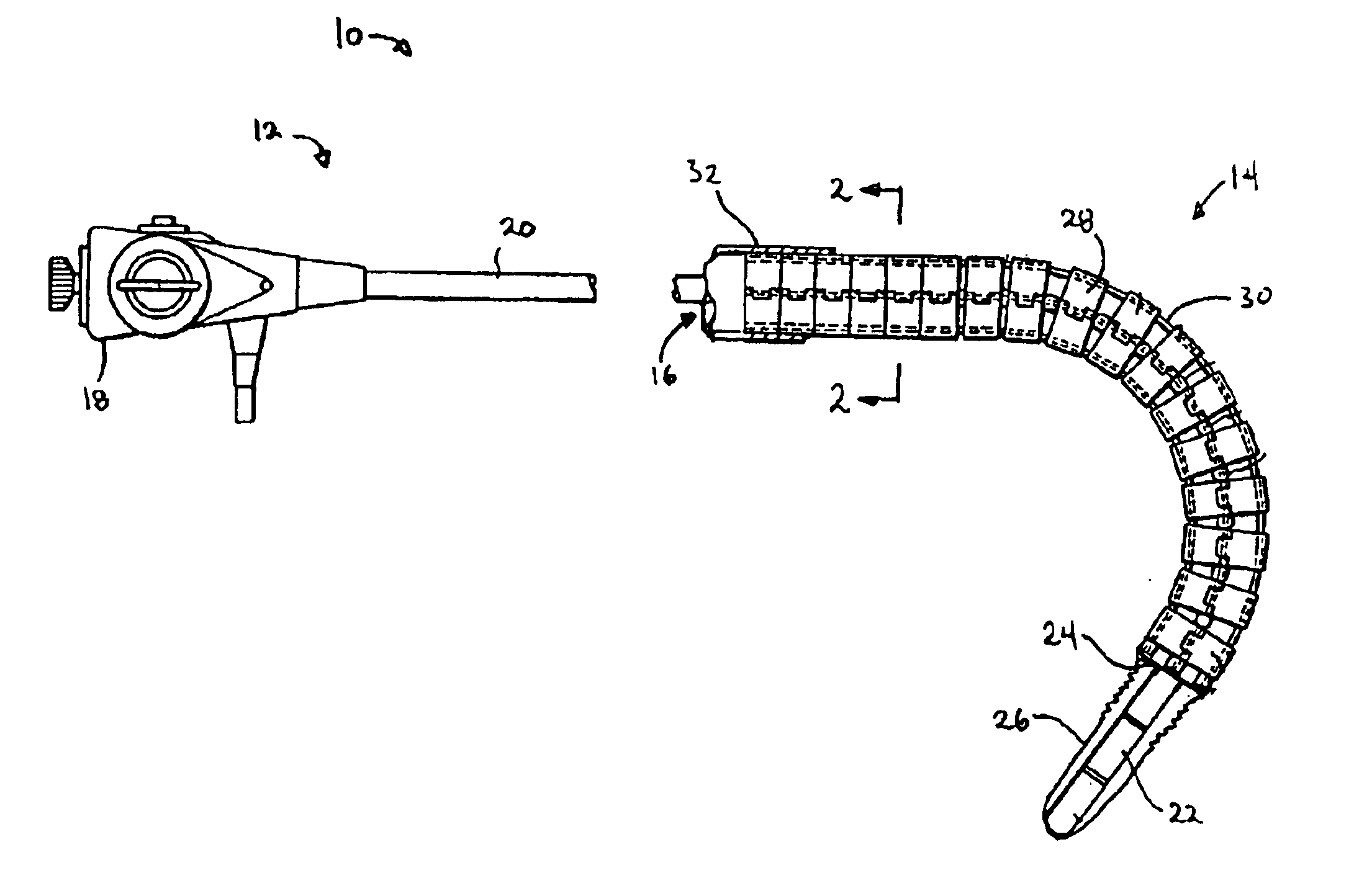

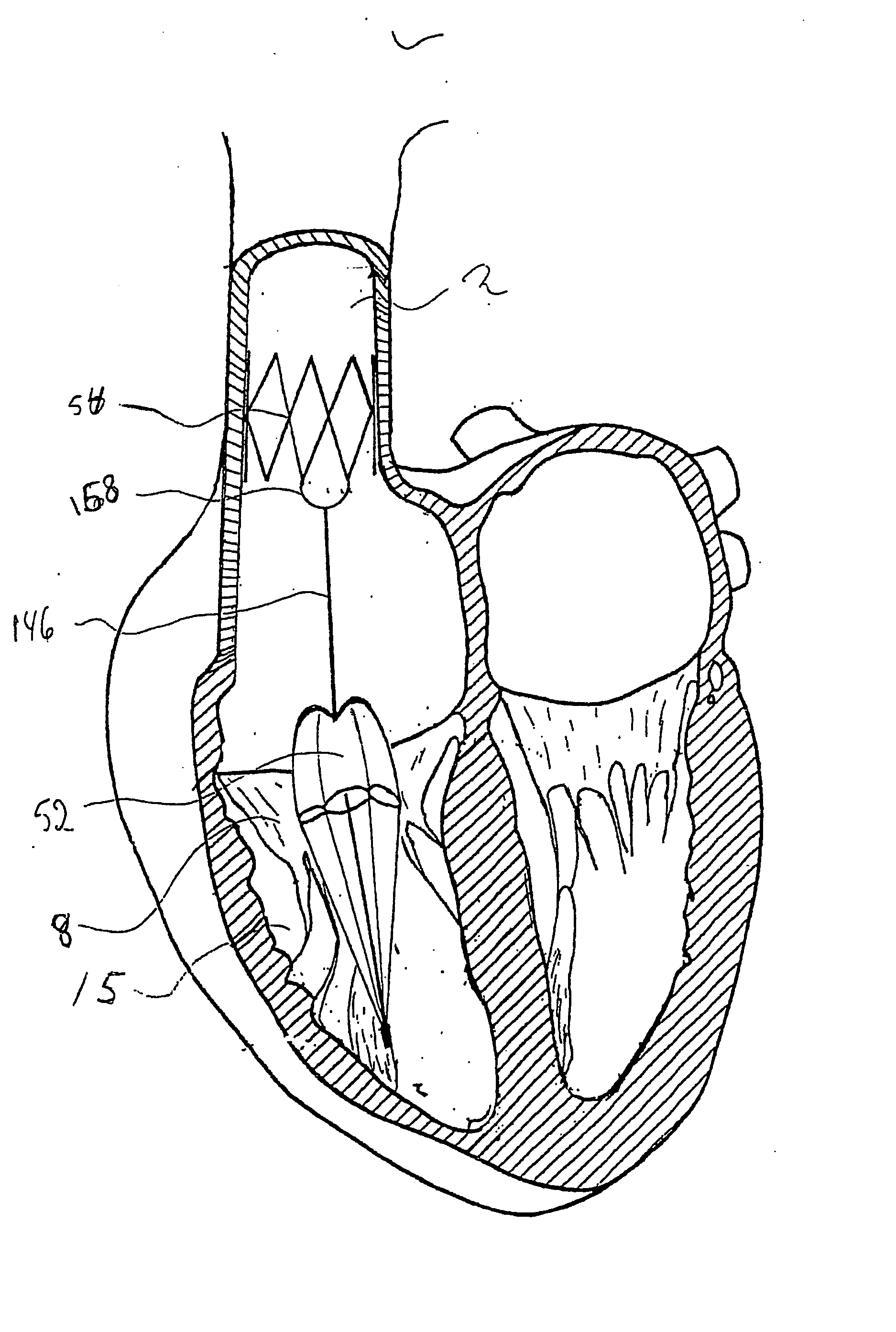

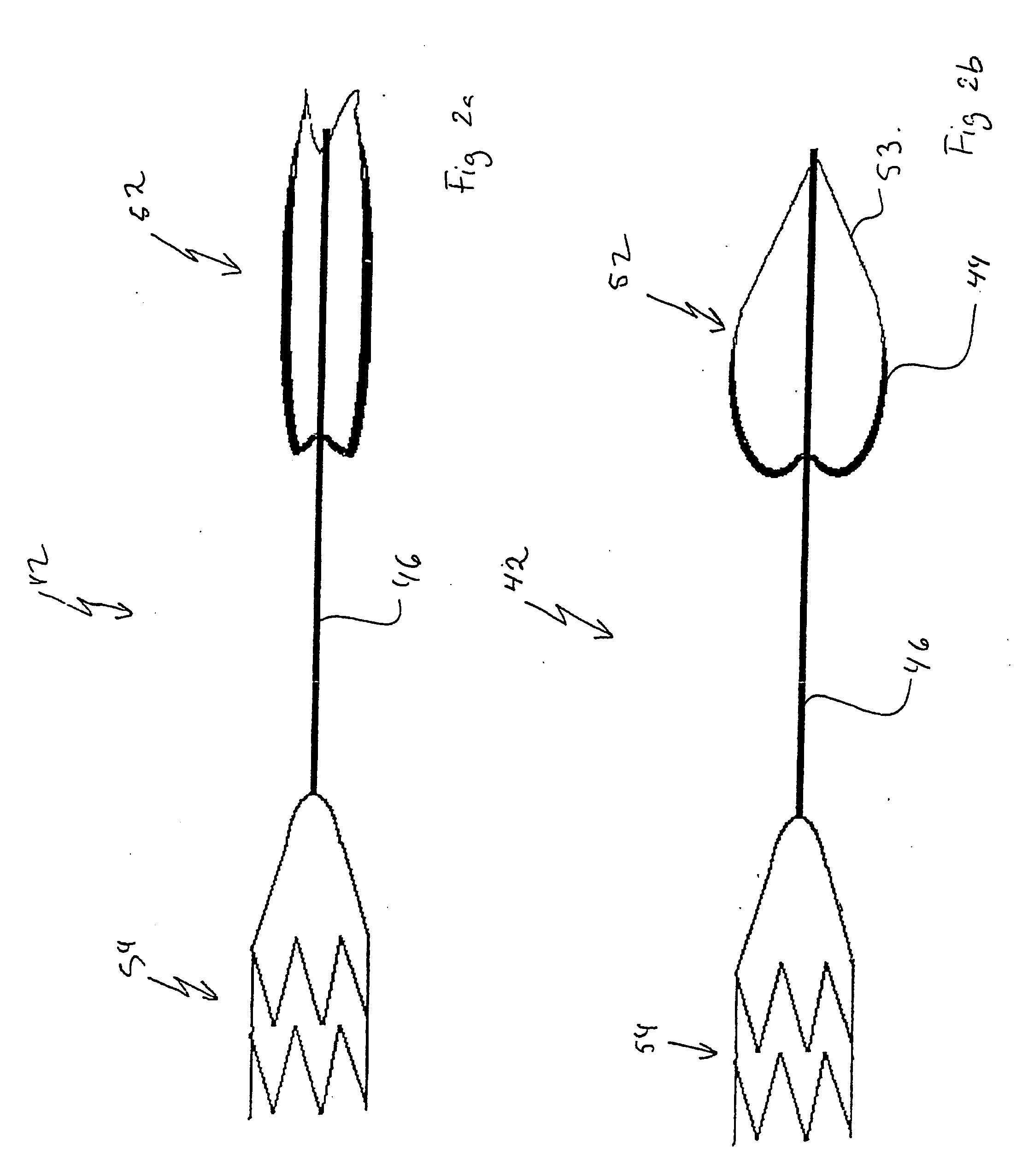

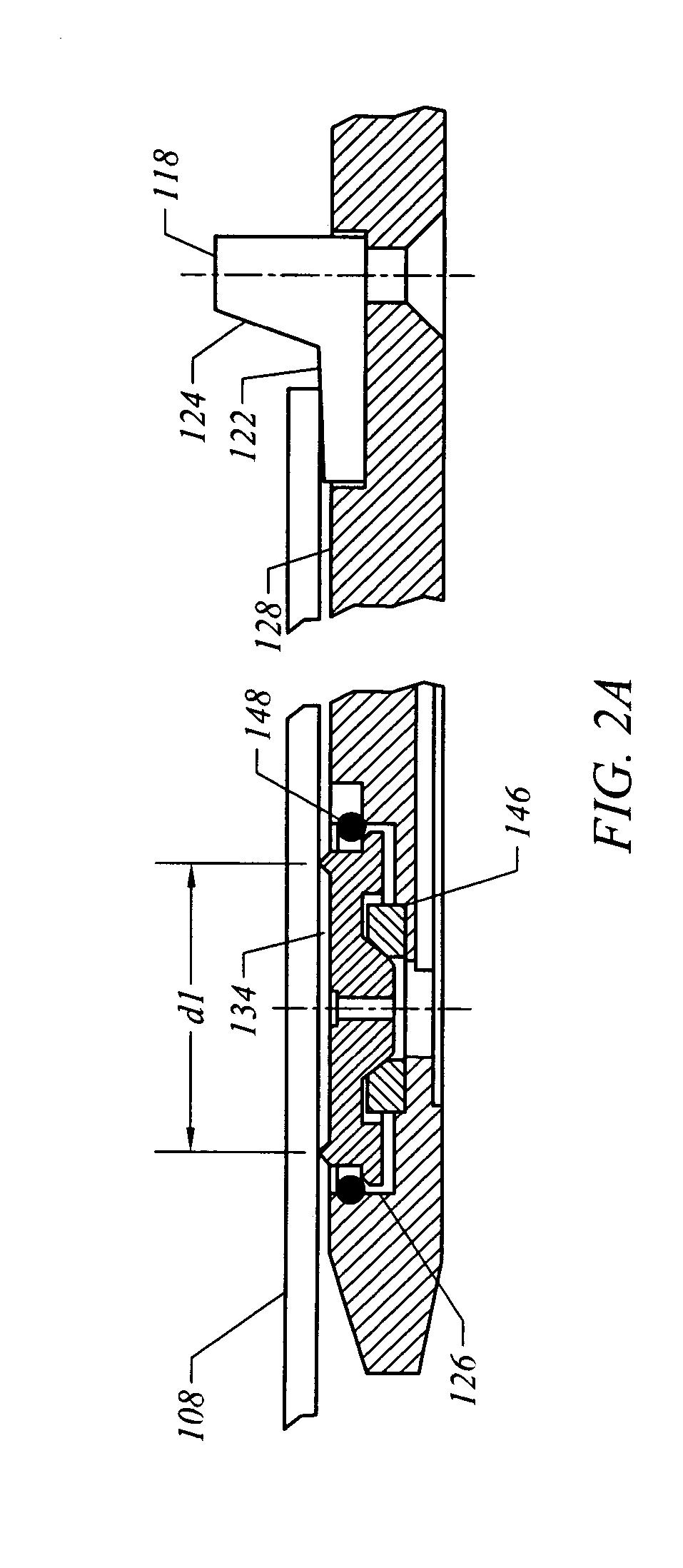

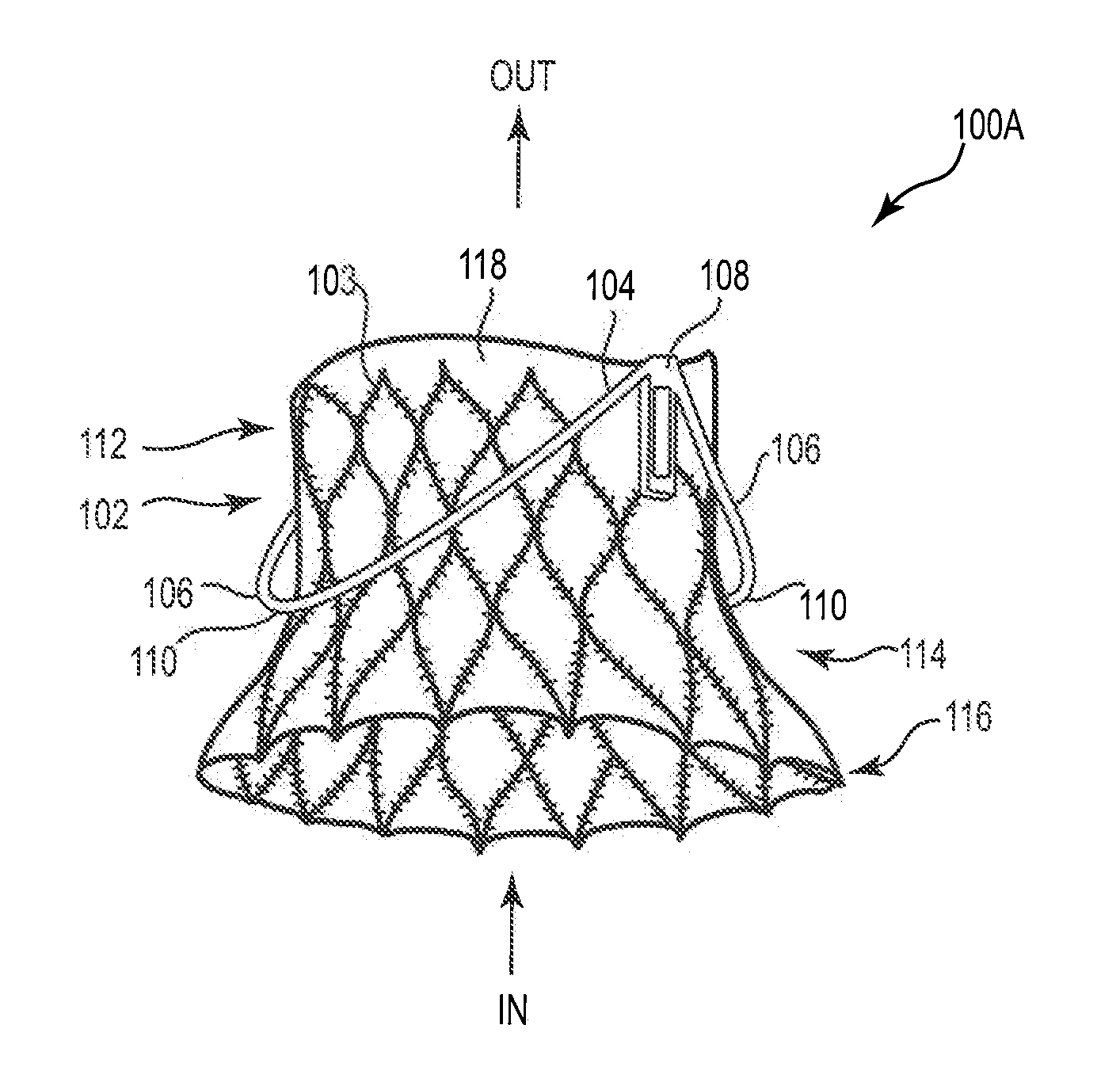

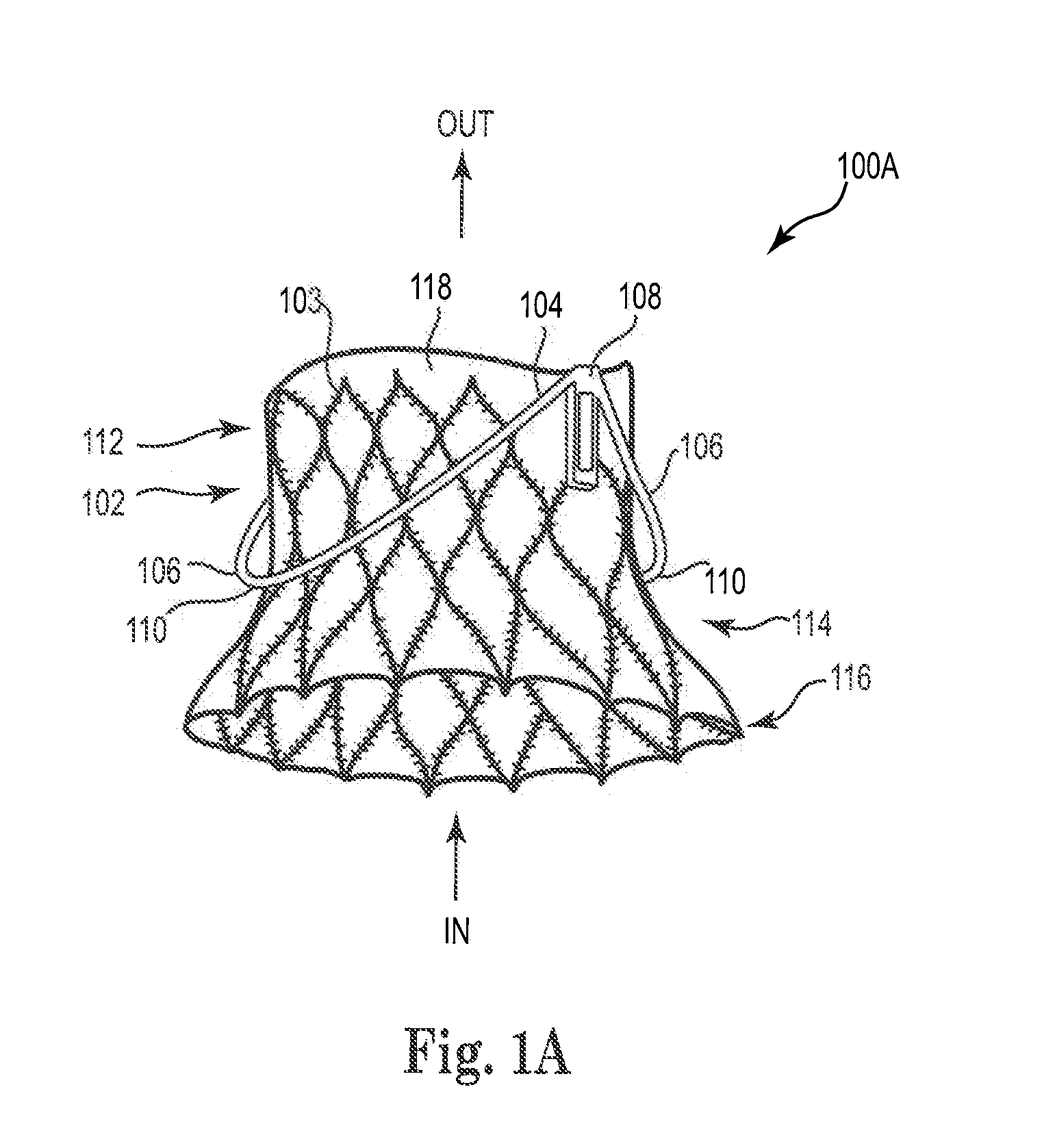

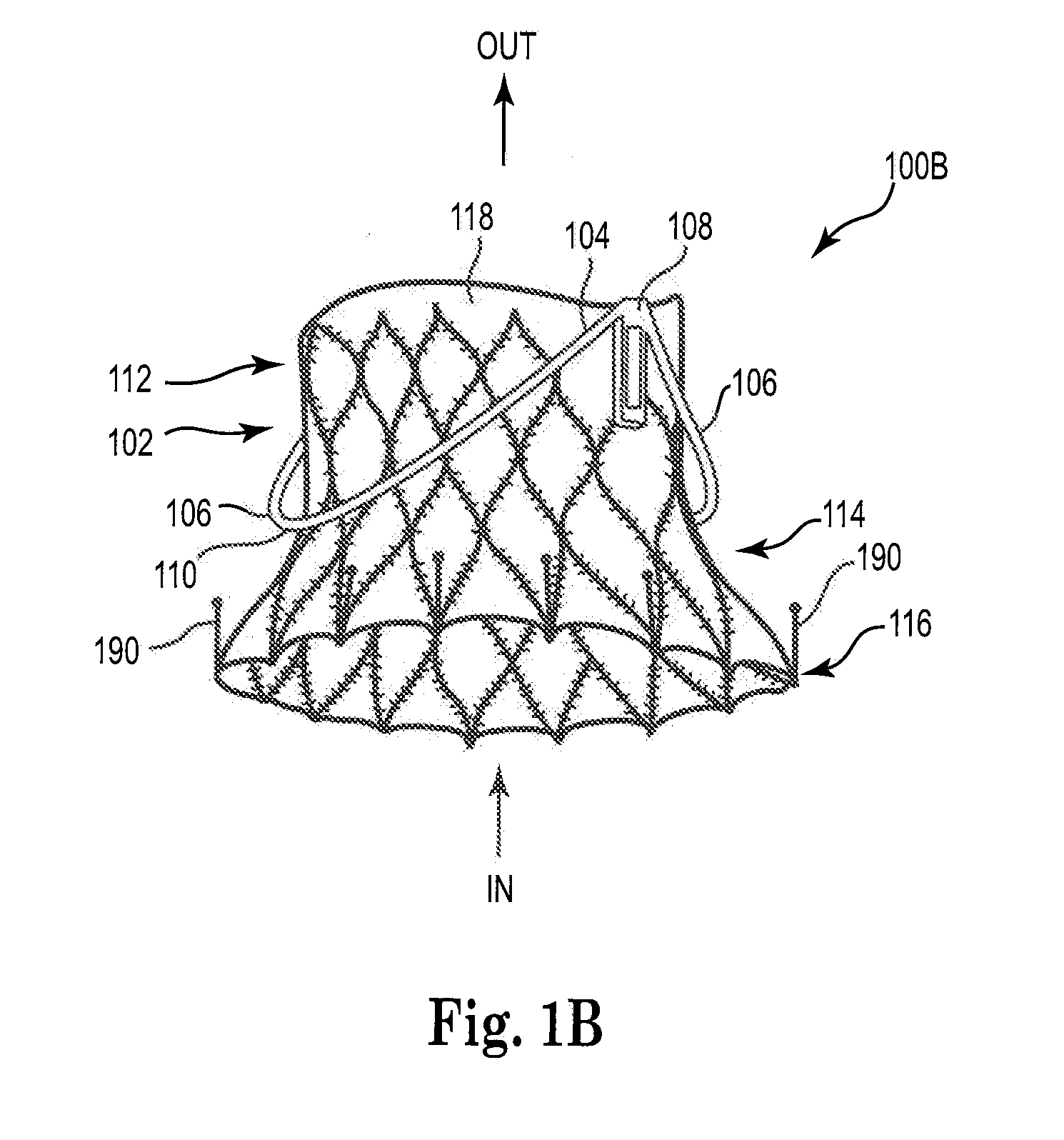

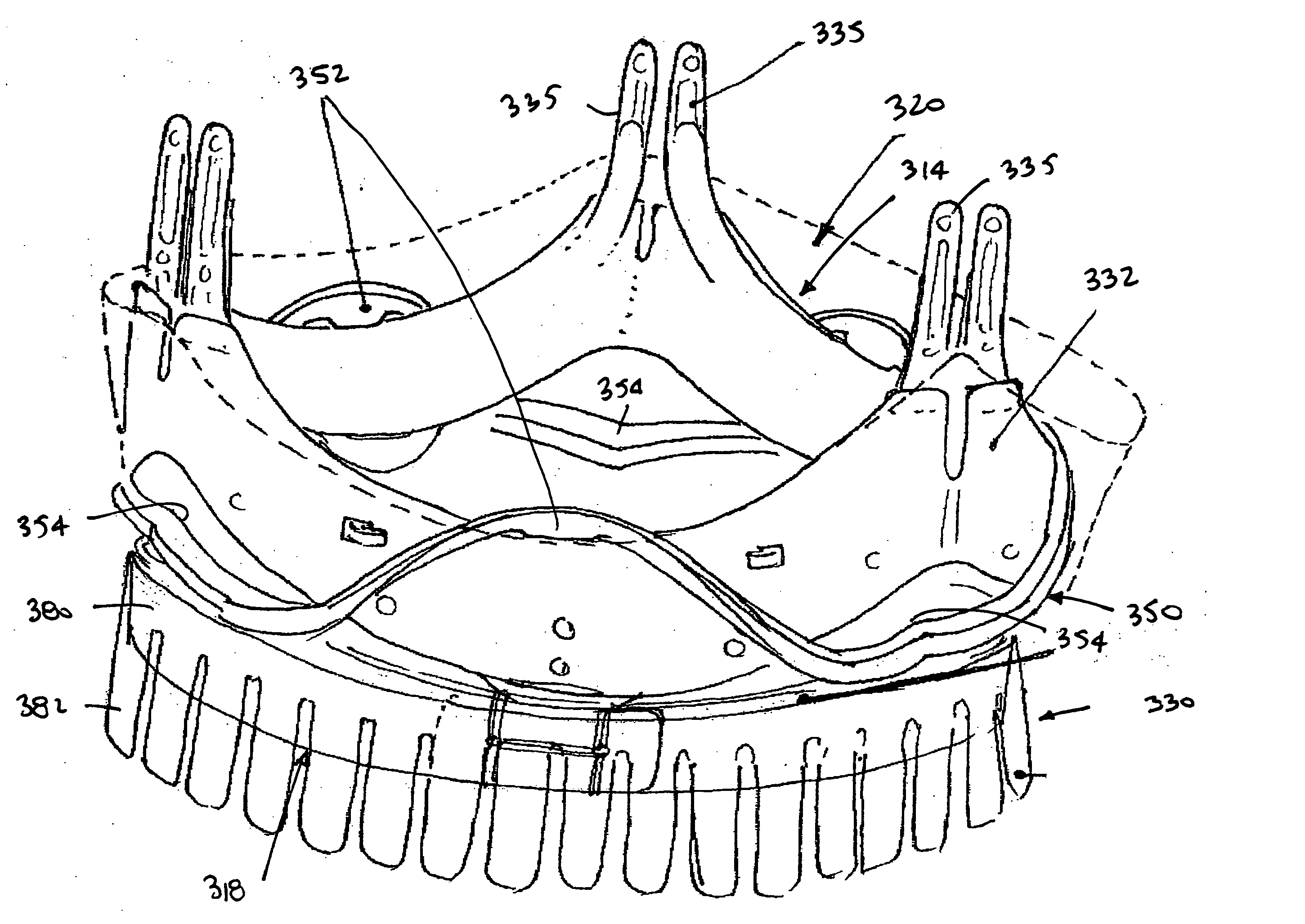

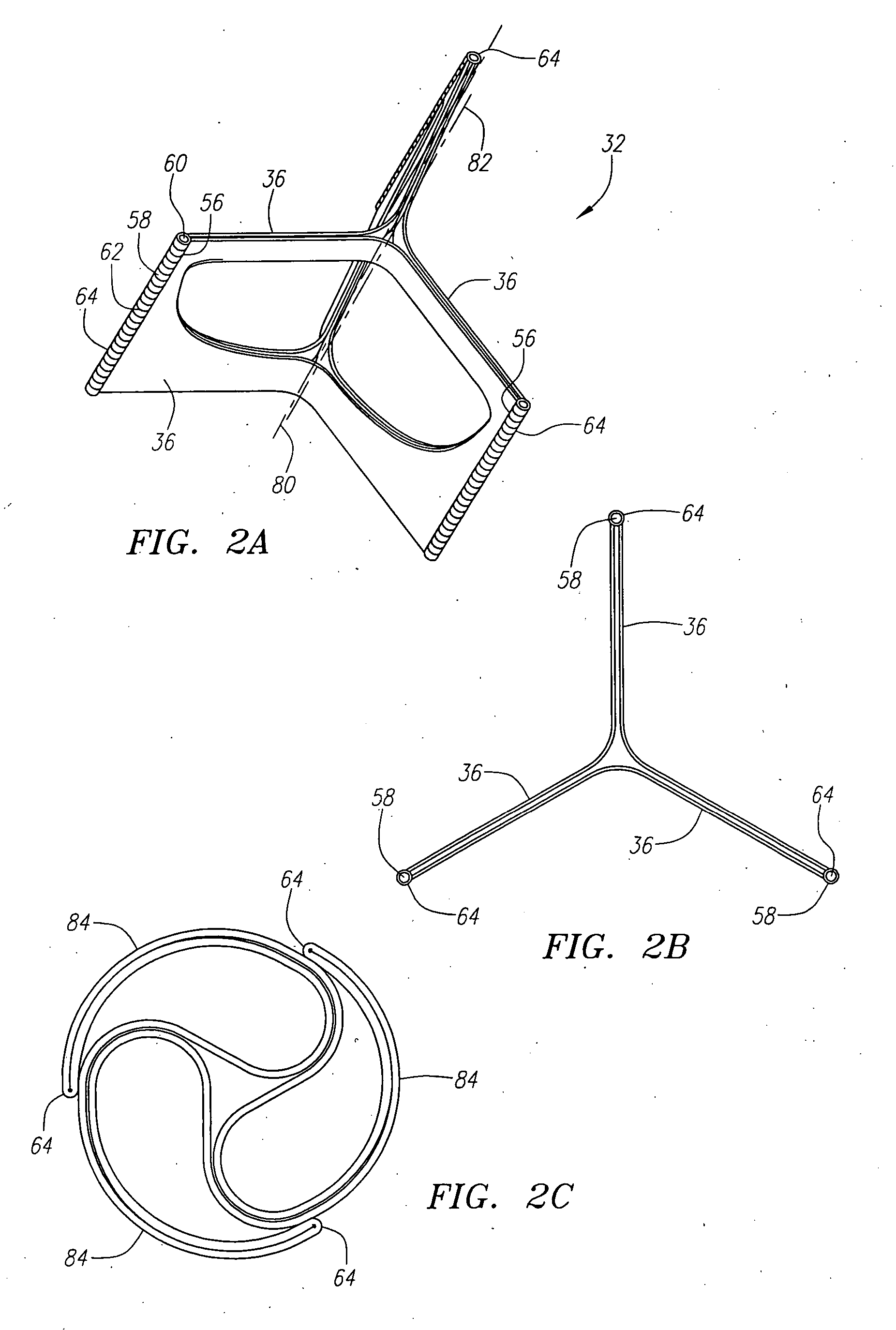

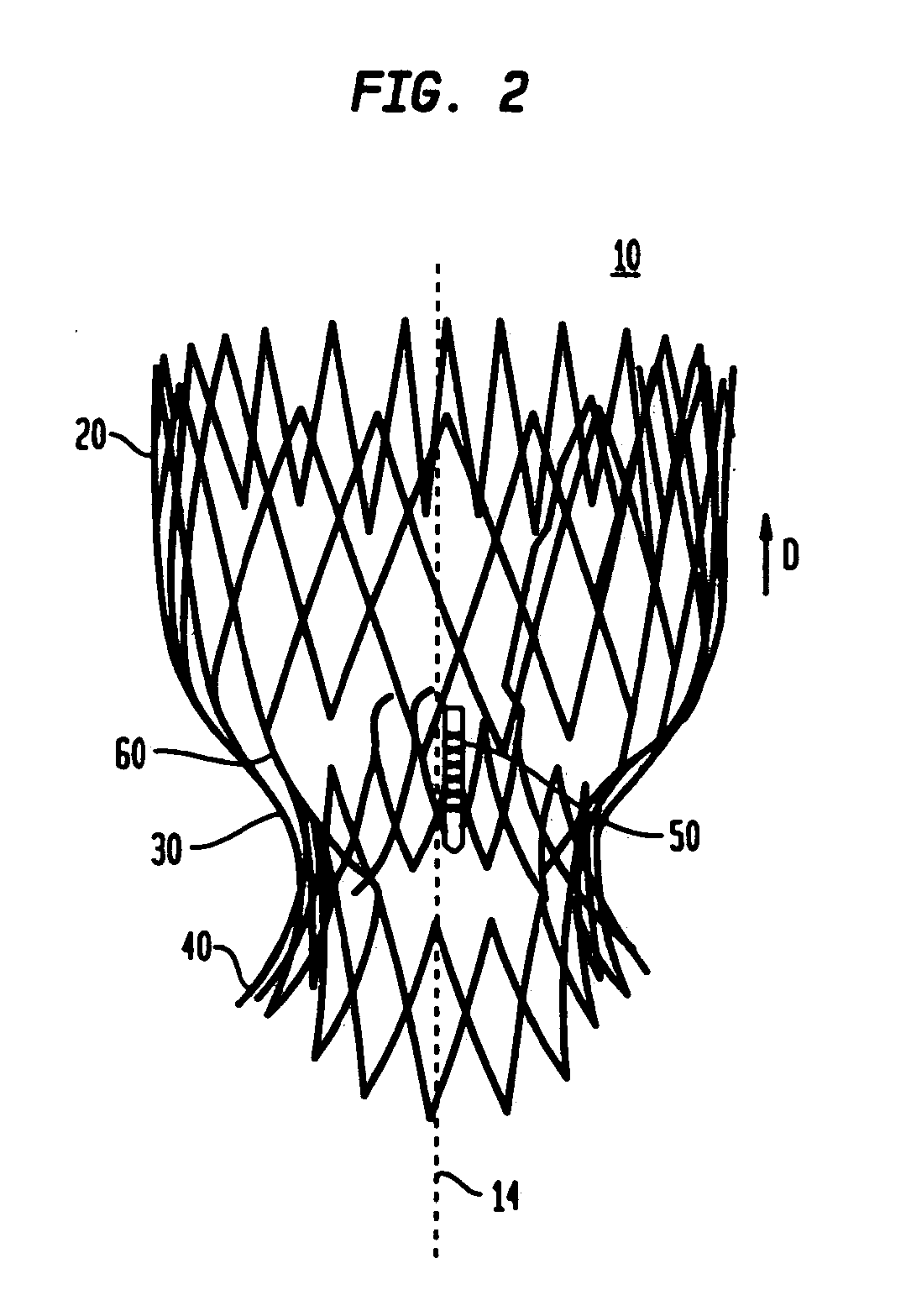

Mitral Prosthesis and Methods for Implantation

ActiveUS20120035722A1Minimizing peri-valvular leaksMaintain stabilityStentsHeart valvesMitral valve leafletLeft atrium

A mitral valve prosthesis and methods for implanting the prosthesis transapically (i.e., through the apex of the heart), transatrially (i.e., through the left atrium of the heart), and transseptally (i.e., through the septum of the heart). The prosthesis generally includes a self-expanding frame and two or more support arms. A valve prosthesis is sutured to the self-expanding frame. Each support arm corresponds to a native mitral valve leaflet. At least one support arm immobilizes the native leaflets, and holds the native leaflets close to the main frame.

Owner:MEDTRONIC VENTOR TECH

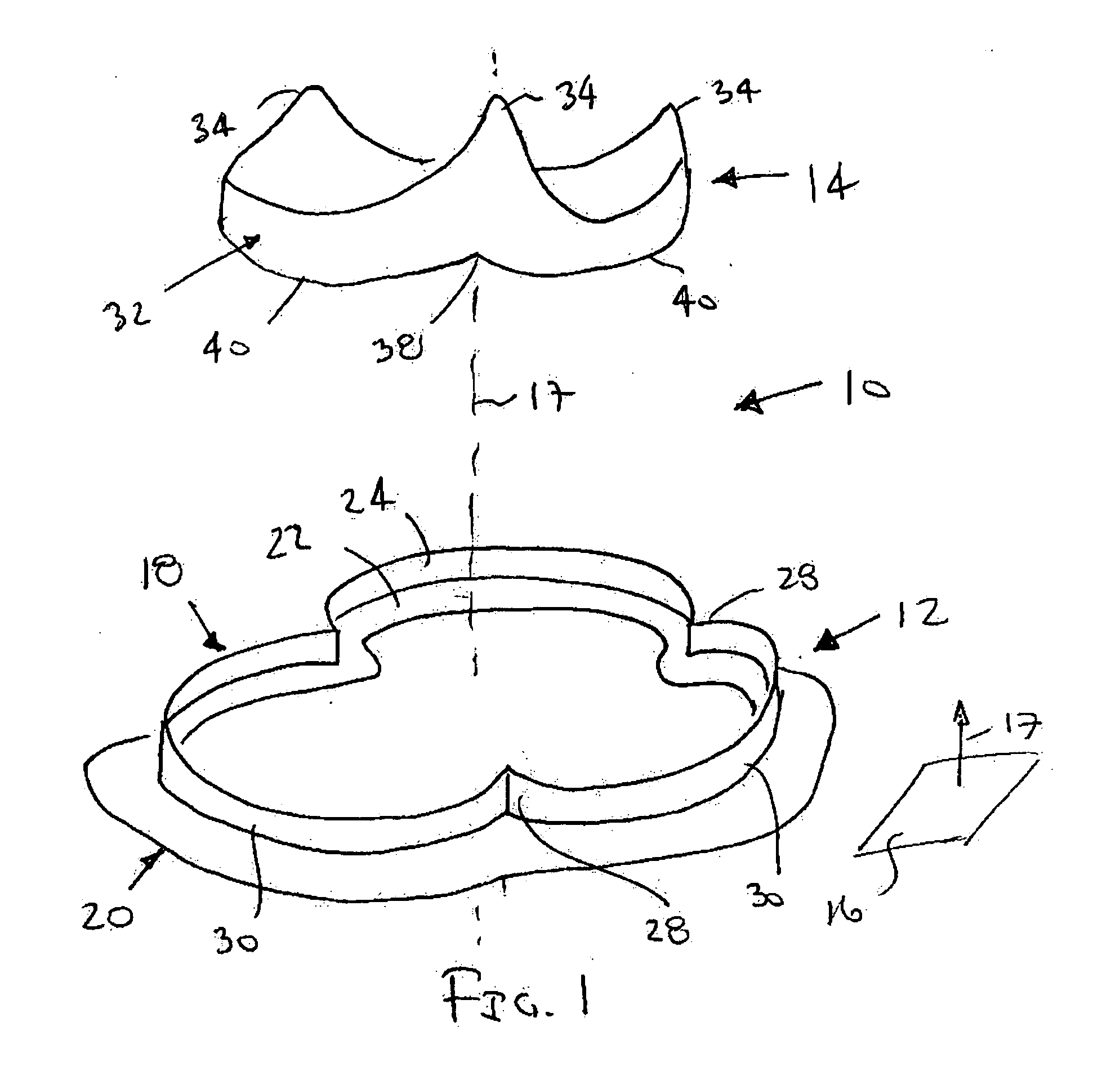

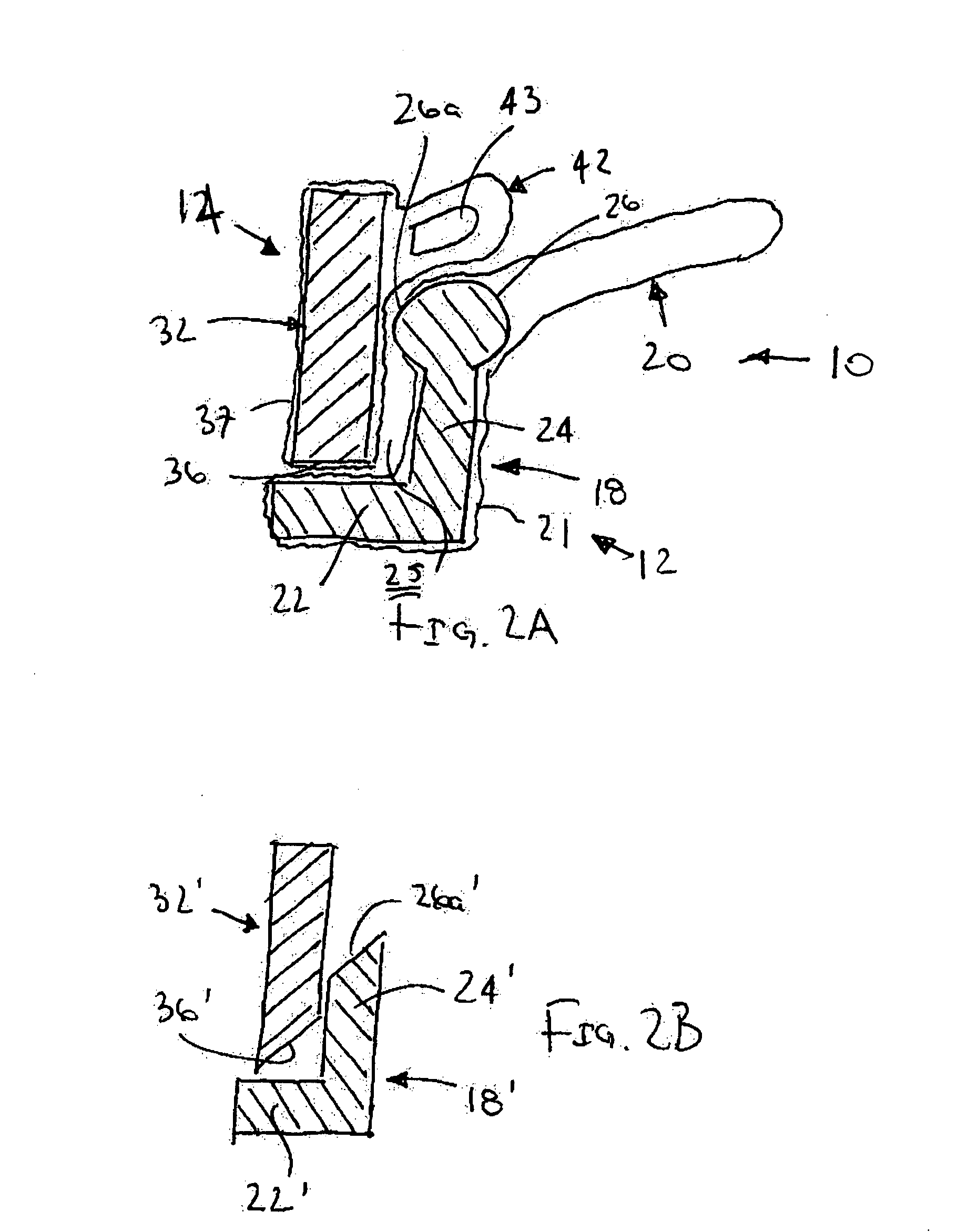

Conformable prosthesis for implanting two-piece heart valves and methods for using them

A heart valve assembly includes an annular prosthesis and a valve prosthesis. The annular prosthesis includes an annular ring for dilating tissue within a biological annulus and a conformable sewing cuff extending radially from the annular member. The valve prosthesis includes a frame and a valve component. The annular ring is introduced into the biological annulus to dilate tissue surrounding the biological annulus and the sewing cuff conforms to tissue above the biological annulus. Fasteners are directed through the sewing cuff to secure the annular prosthesis to the biological annulus. The annular prosthesis may include a baleen element for biasing fabric on the annular ring outwardly to enhance sealing against the biological annulus. A valve prosthesis is then advanced into the sinus cavity, and secured relative to the annular prosthesis. The sewing cuff may enhance a seal between the valve prosthesis and annular prosthesis.

Owner:MEDTRONIC INC

Beverage filter cartridge

InactiveUS6645537B2Increase storage capacityImprove the immunityReady-for-oven doughsBeverage vesselsMechanical engineeringEngineering

Owner:KEURIG GREEN MOUNTAIN INC

Prosthetic heart valves, scaffolding structures, and systems and methods for implantation of same

InactiveUS20050203615A1Inhibit migrationGood tissue adhesionBalloon catheterHeart valvesPercutaneous aortic valve replacementProsthetic valve

Prosthetic valves and their component parts are described, as are prosthetic valve delivery devices and methods for their use. The prosthetic valves are particularly adapted for use in percutaneous aortic valve replacement procedures. The delivery devices are particularly adapted for use in minimally invasive surgical procedures.

Owner:AORTX

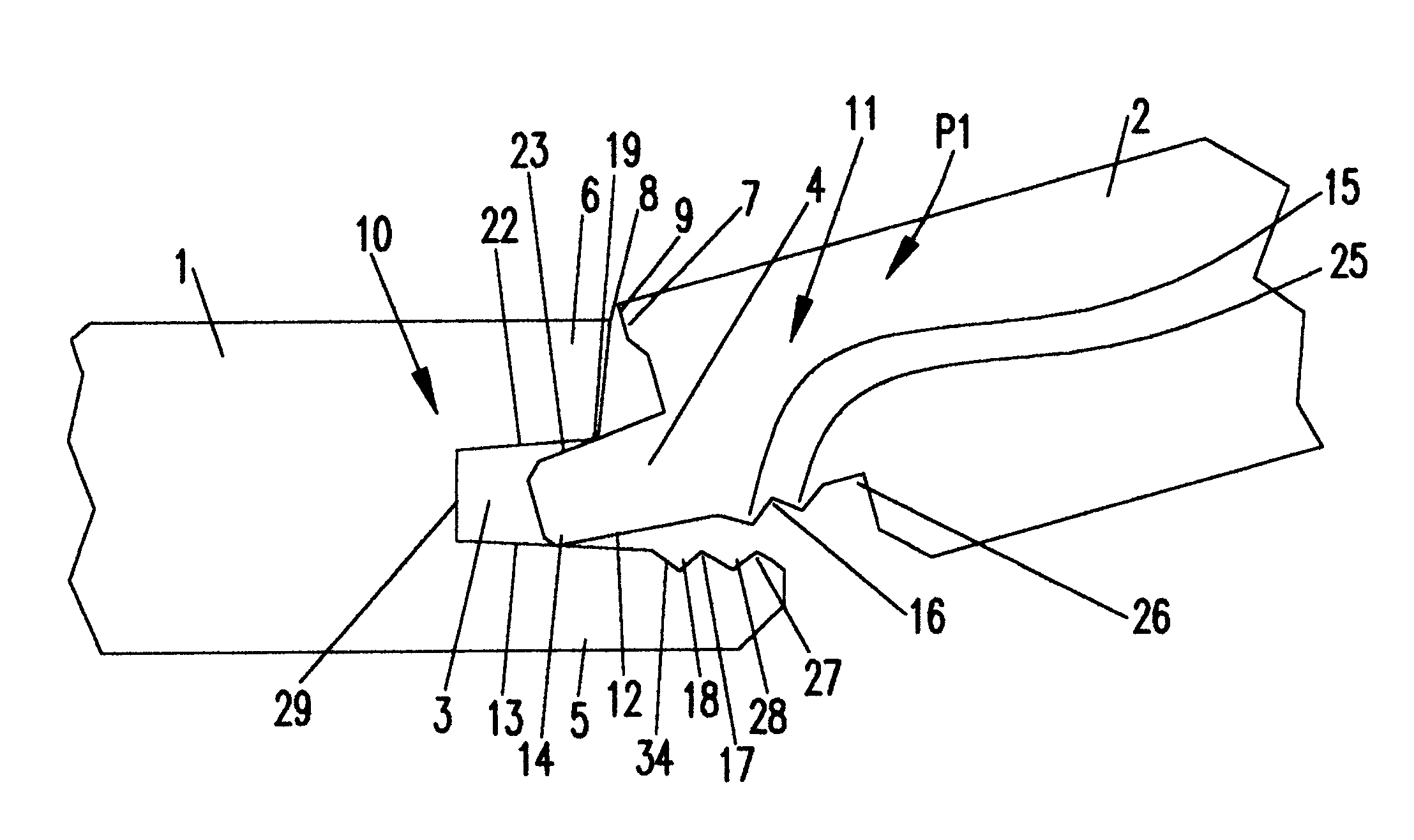

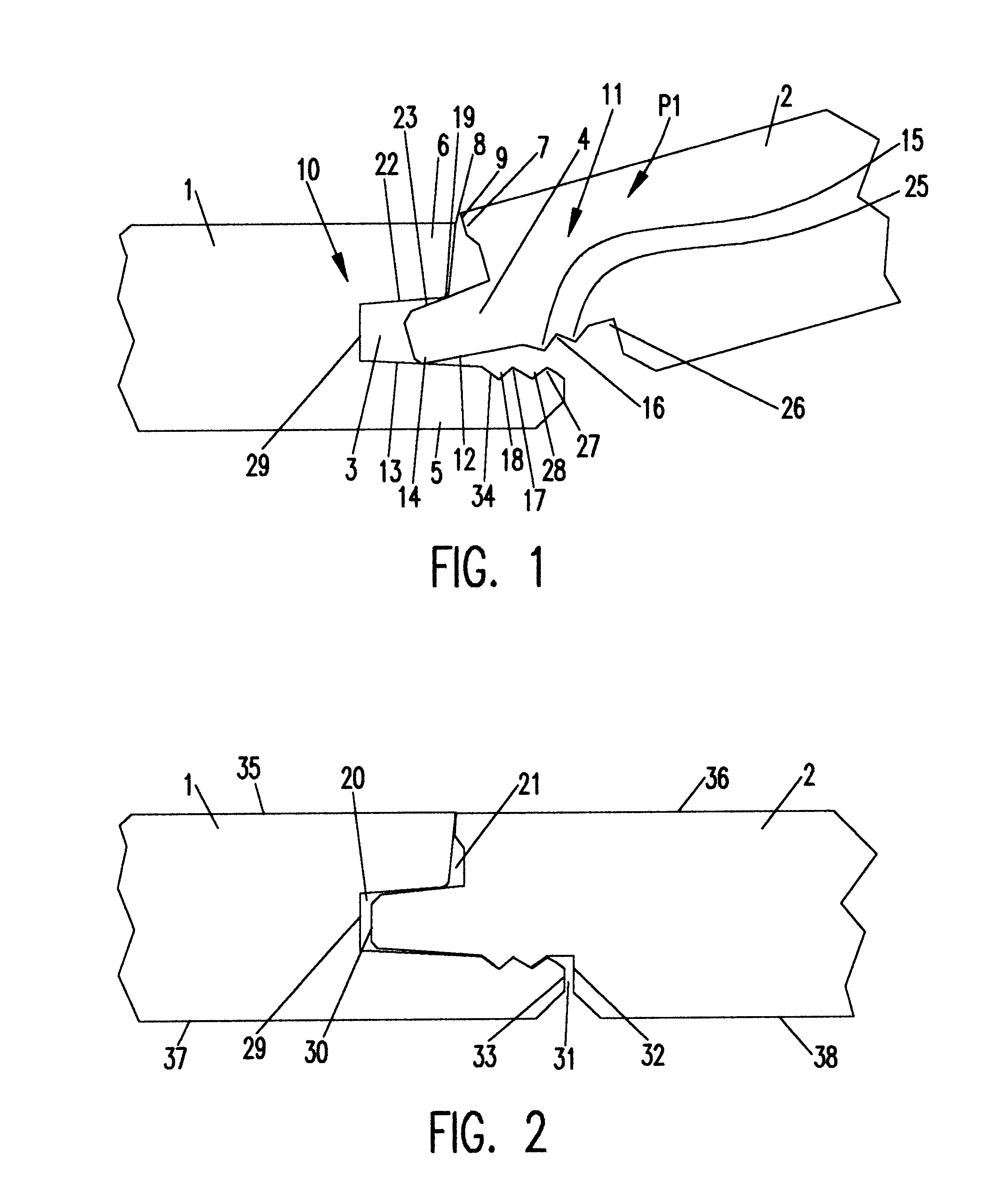

Flooring panel

Flooring panel with two connection members whose sides face each other for attachment to other flooring panels of the same type. A first connection member has an upper projection, a lower projection, and groove between them. A second connecting member features a tongue for insertion in the groove of an adjacent connection member. In order to achieve good assembly as well as economical production of the panels, provision is made for a lower protuberance, lower indentation, lower auxiliary protuberance, and lower auxiliary indentation on the lower projection of the first connection member. The profile thus created is fitted to a corresponding profile on the lower side of the tongue which has an upper indentation, an upper protuberance, an upper auxiliary indentation, and an upper auxiliary protuberance.

Owner:KRONOTEX

Surgical access port

A device for retracting edges of an incision in a surface to form an opening including: a flexible, tubular skirt having an upper end, a lower end, and a channel therebetween; a ring connected to the lower end of the skirt for maintaining the lower end in an open configuration and defining an exit opening to the channel; and an inflatable collar connected to the skirt and surrounding the upper end. The ring is designed to fit through the incision and remain under the surface when it is oriented parallel to surface. The collar, when inflated, maintains the upper end in an open configuration and defines an entry opening to the channel. During use, the ring is inserted through the incision and the collar is inflated while remaining outside of the incision, thereby drawing the skirt against the edges of the incision and retracting the edges of the incision to form the opening. The retracting device can be included in a surgical access port, which further includes a flexible sleeve connected to at least one of the inflatable collar and the skirt, extending the channel from the exit opening of the skirt to an open end of the flexible sleeve distal to the skirt. The device can include a light source in the vicinity of the exit opening.

Owner:ETHICON ENDO SURGERY INC

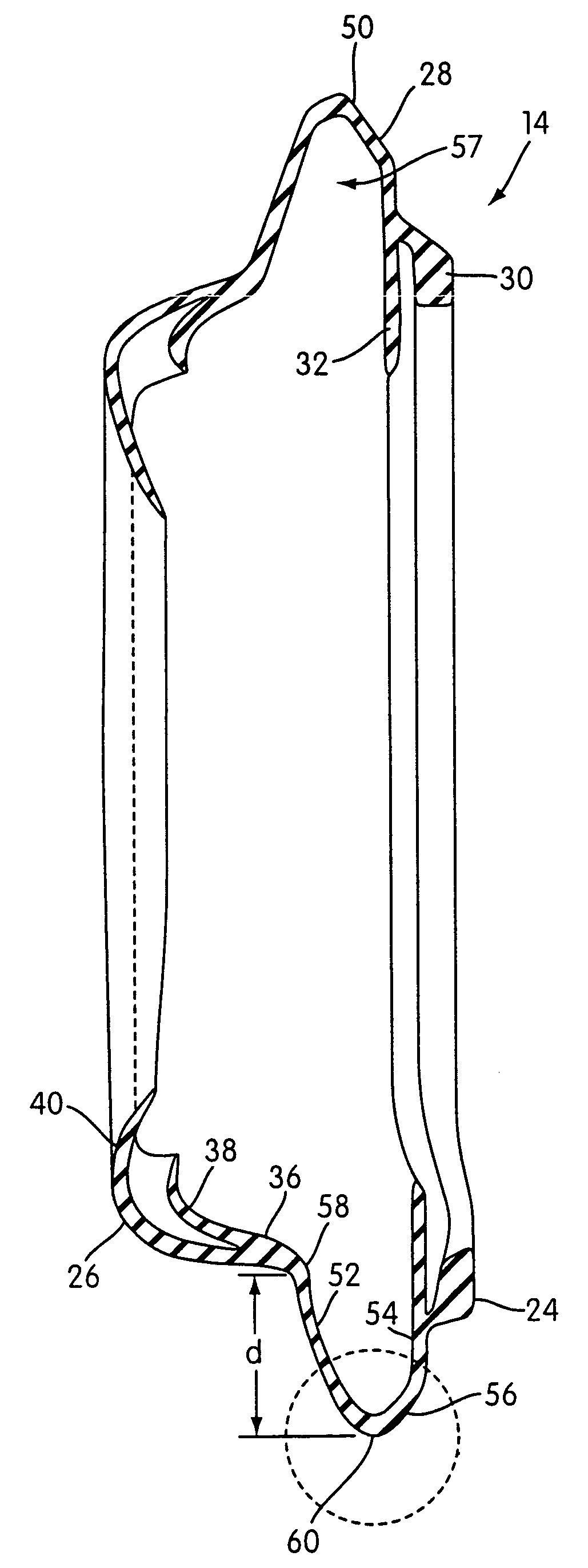

Artificial valve prosthesis with improved flow dynamics

ActiveUS7618447B2Easy to removeMore turbulent flowVenous valvesBlood vesselsVenous ValvesProsthetic valve

An expandable venous valve having a support structure that configured to enlarge the area adjacent to the valve structure such that the flow patterns of retrograde flow are modified in a way that facilitates the flushing of the pockets at the base of the valve area to prevent stagnation of bodily fluid, which in the venous system, can lead to thrombus formation. The enlarged pocket areas can be created by forming an artificial sinus adjacent the valve structure in an unsupported section of vessel wall between two support frame section or the support frame can comprise an expanded-diameter intermediate or proximal section that forms an artificial sinus adjacent the valve structure. In another group of embodiments, the attachment pathway between opposing leaflets and the support frame and / or vessel wall comprises a proximal portion that places the leaflets in extended contact with one another and a distal portion forms a large angle with respect to the adjacent walls such that a large pocket is created at the base of the leaflets. In one embodiment, the attachment pathway extends distally along a pair of substantially parallel longitudinal attachment struts to create an extended leaflet contact area, then angles circumferentially and distally from the former along distal attachment struts to define the bottom edge of the leaflets.

Owner:COOK MEDICAL TECH LLC

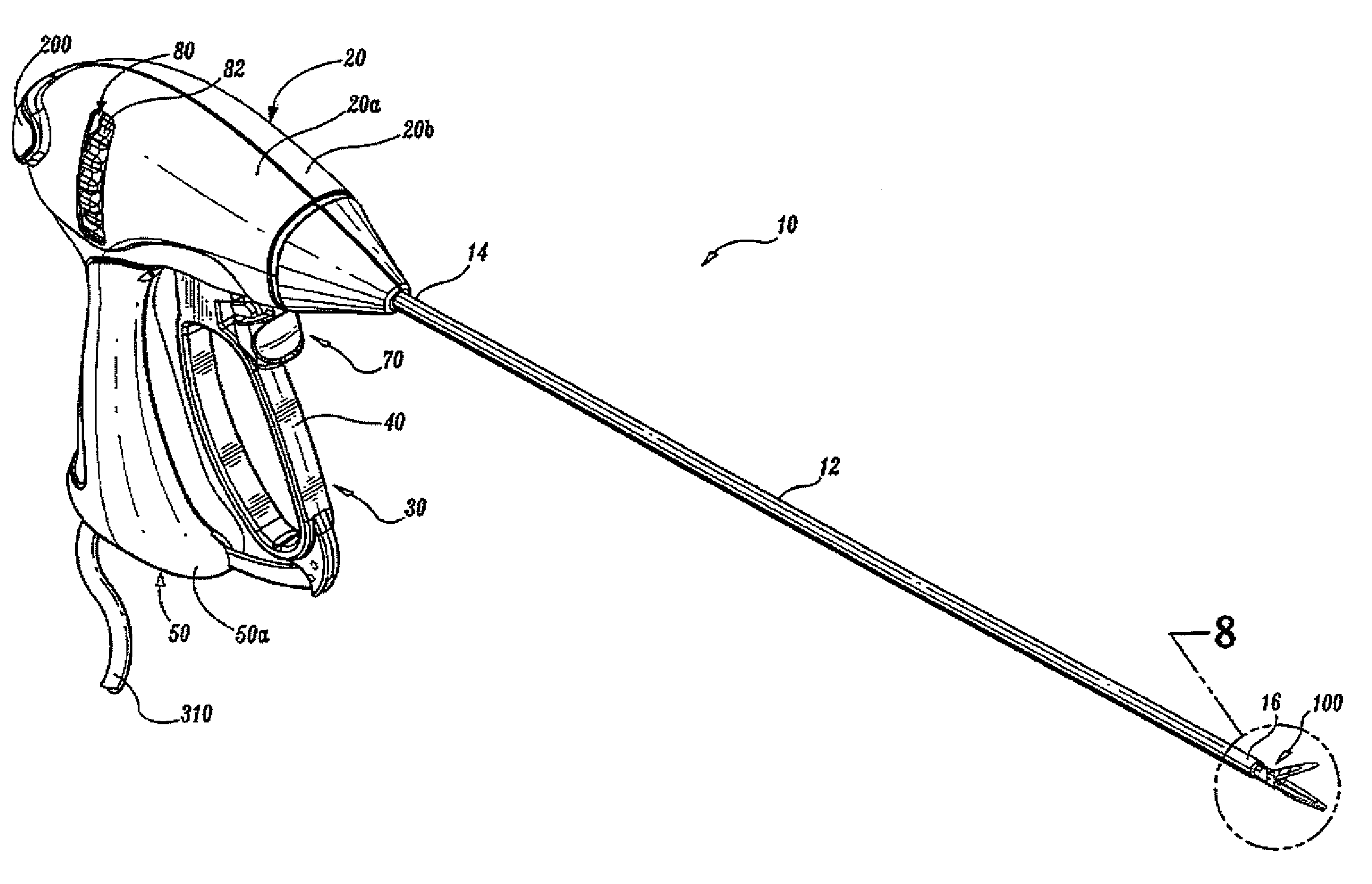

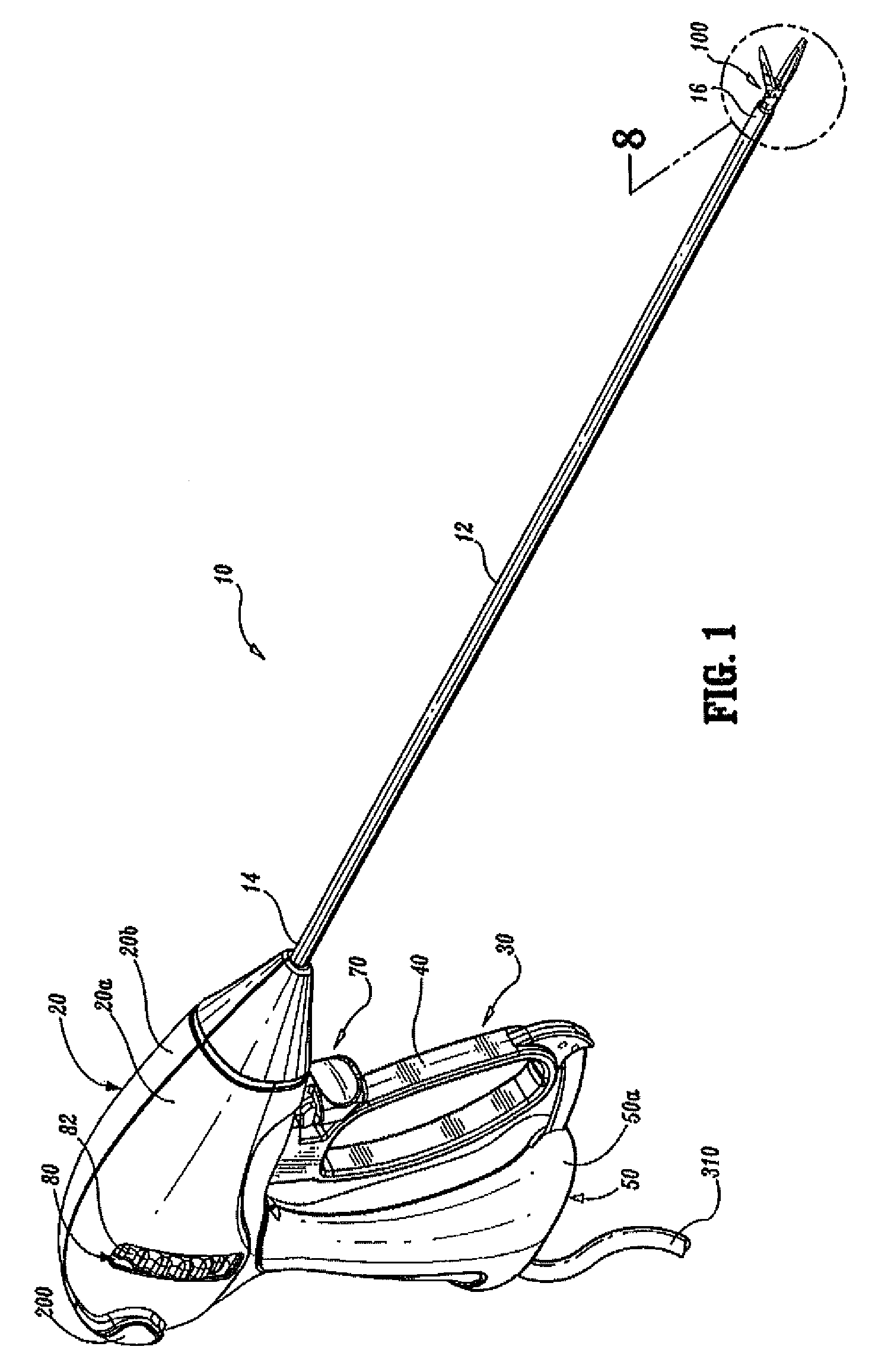

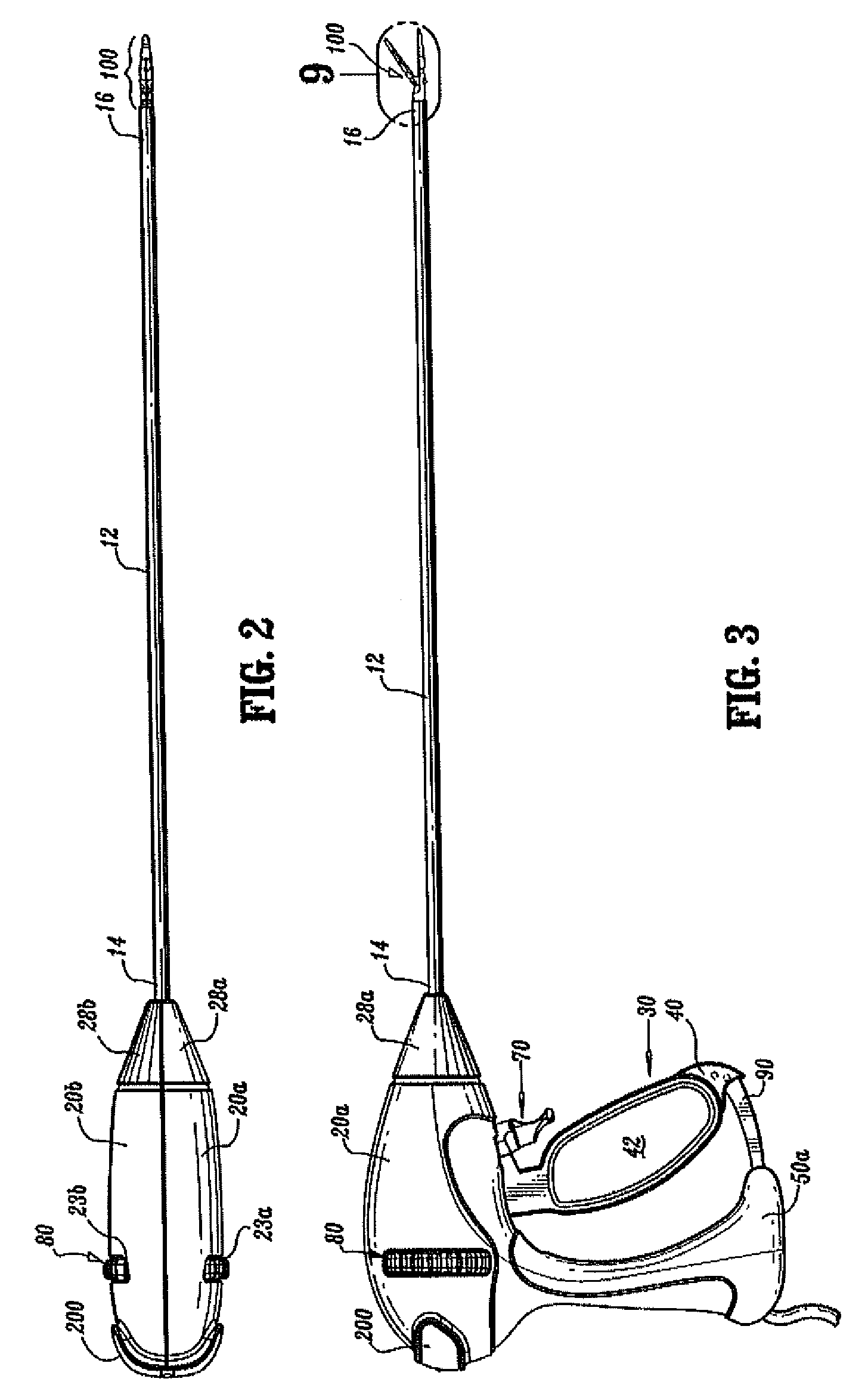

Vessel sealer and divider

ActiveUS8197479B2Facilitating grasping and retainingReduced flexibilitySurgical instrument detailsSurgical forcepsReciprocating motionEngineering

An endoscopic bipolar forceps includes a housing and a shaft, the shaft having an end effector assembly at a distal end thereof, which includes two jaw members for grasping tissue therebetween. Each jaw member is adapted to connect to an electrosurgical energy source, enabling them to affect a tissue seal to tissue held therebetween. A drive assembly is included within the housing for moving the jaw members. A movable handle is also included, such that movement of the handle actuates the drive assembly to move the jaw members relative to each other. A knife channel is included within the end effector configured to allow reciprocation of a knife blade within the knife channel. The knife blade includes a proximal edge adapted to engage a proximal edge of the end effector to impede translation of the knife blade when the jaw members are in an open configuration and the knife blade is retracted within the end effector assembly.

Owner:TYCO HEALTHCARE GRP LP

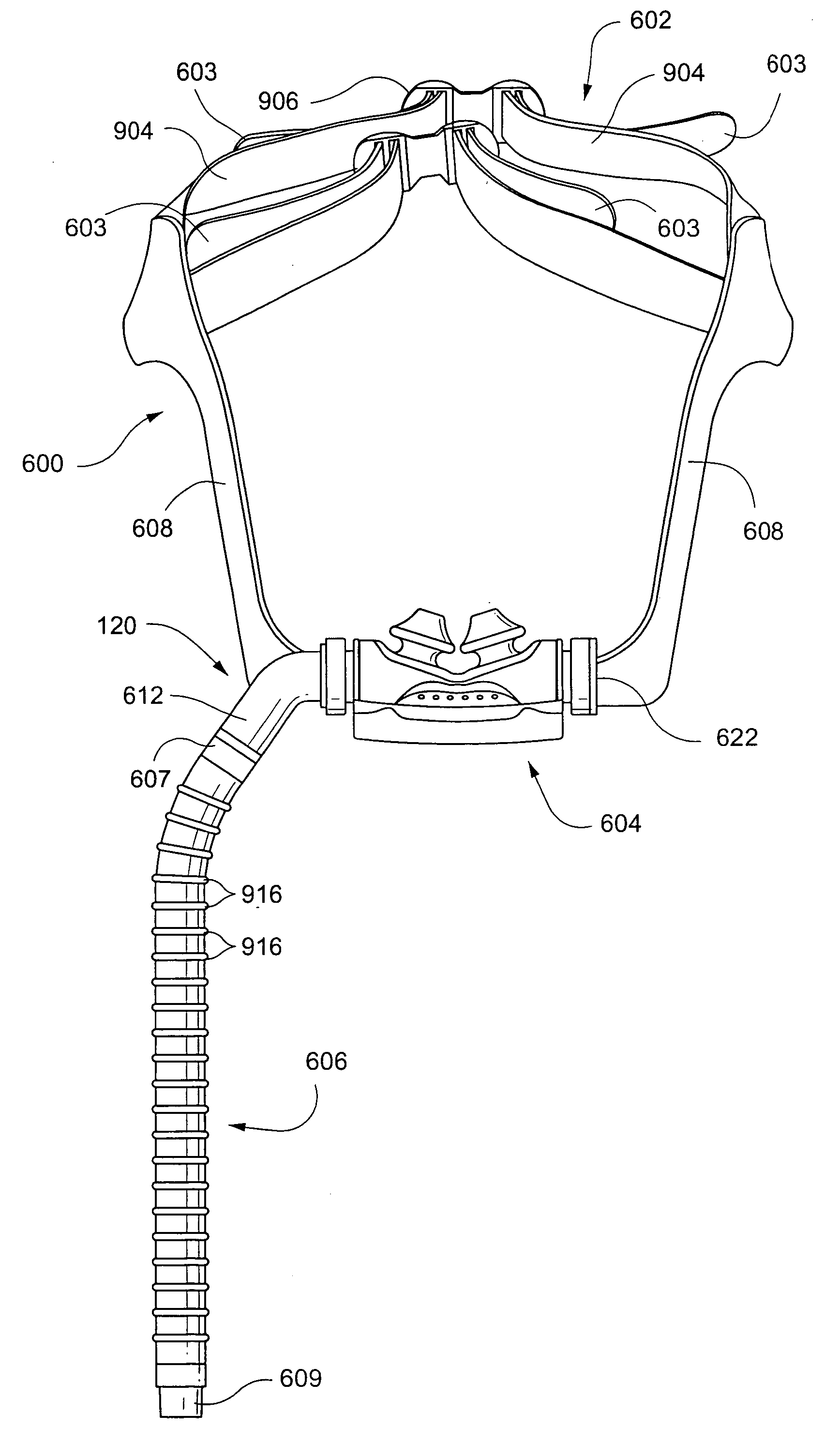

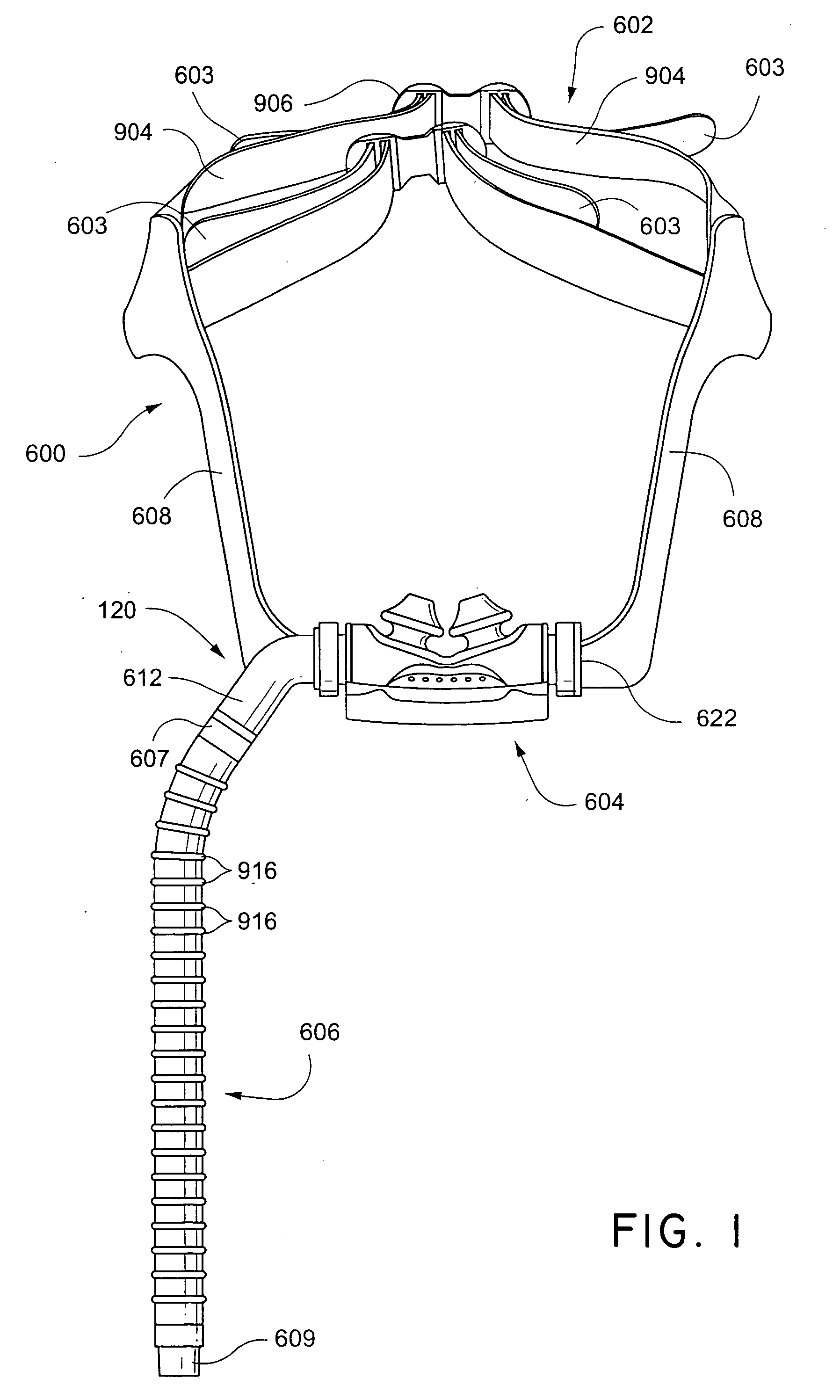

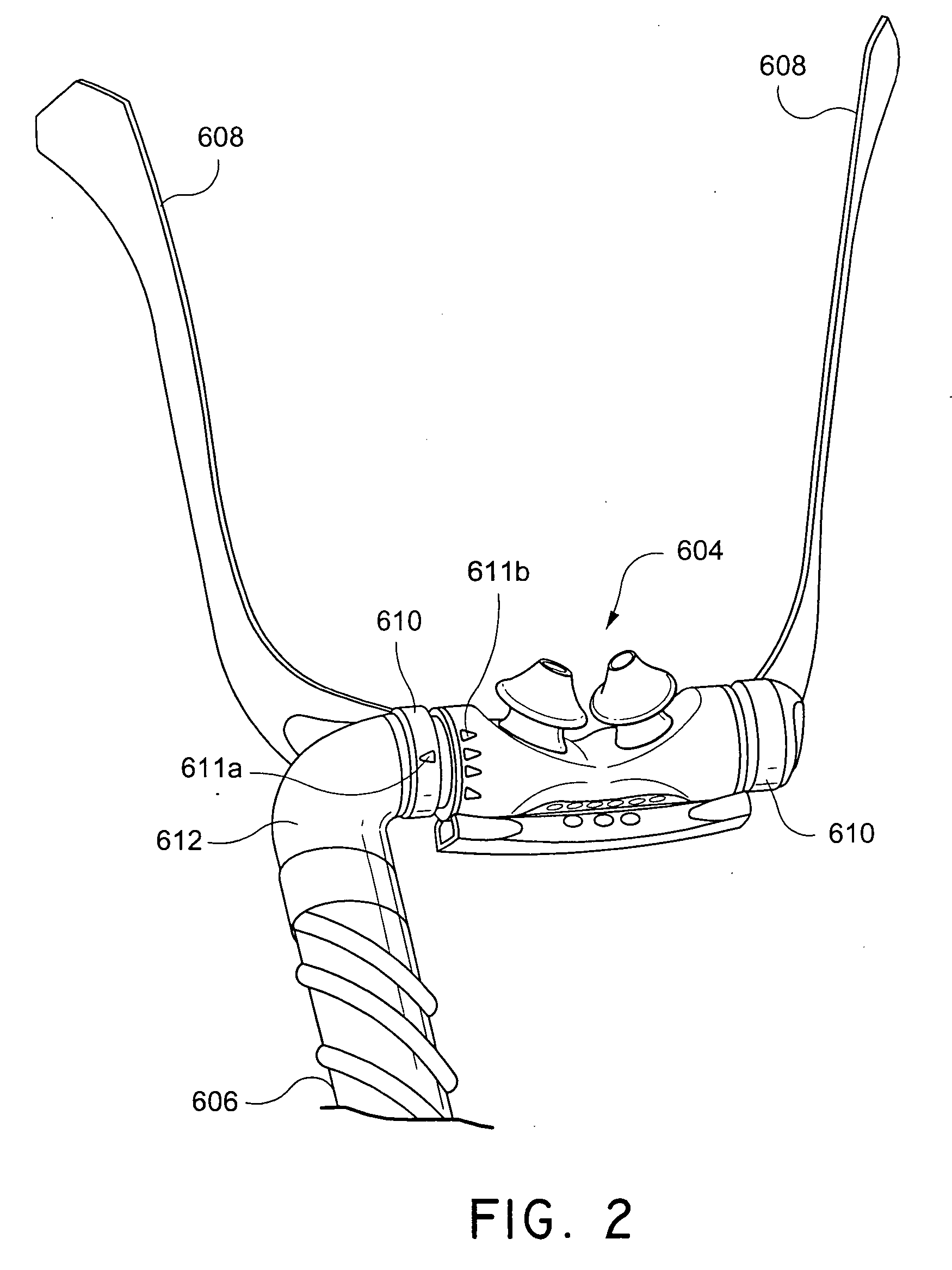

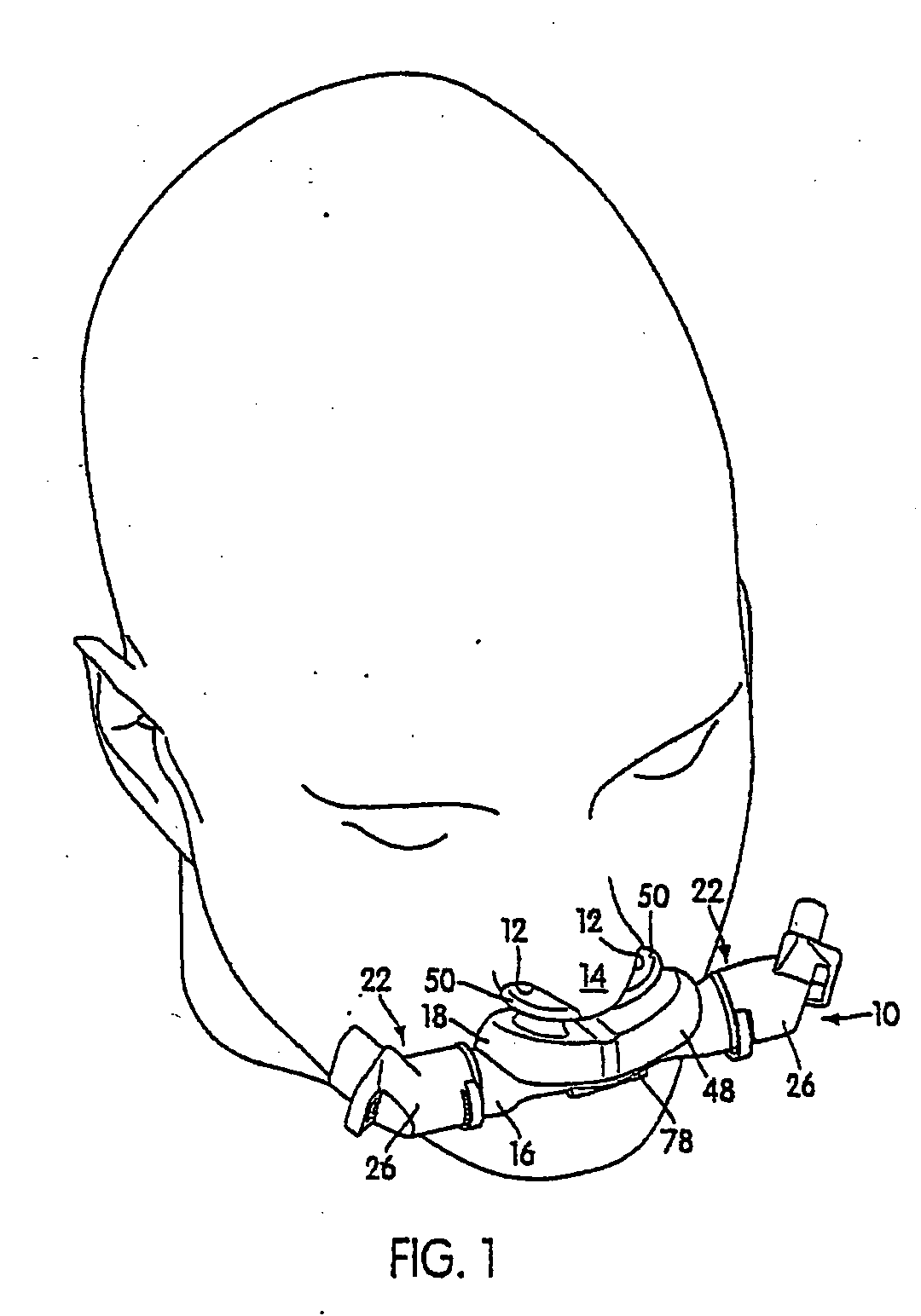

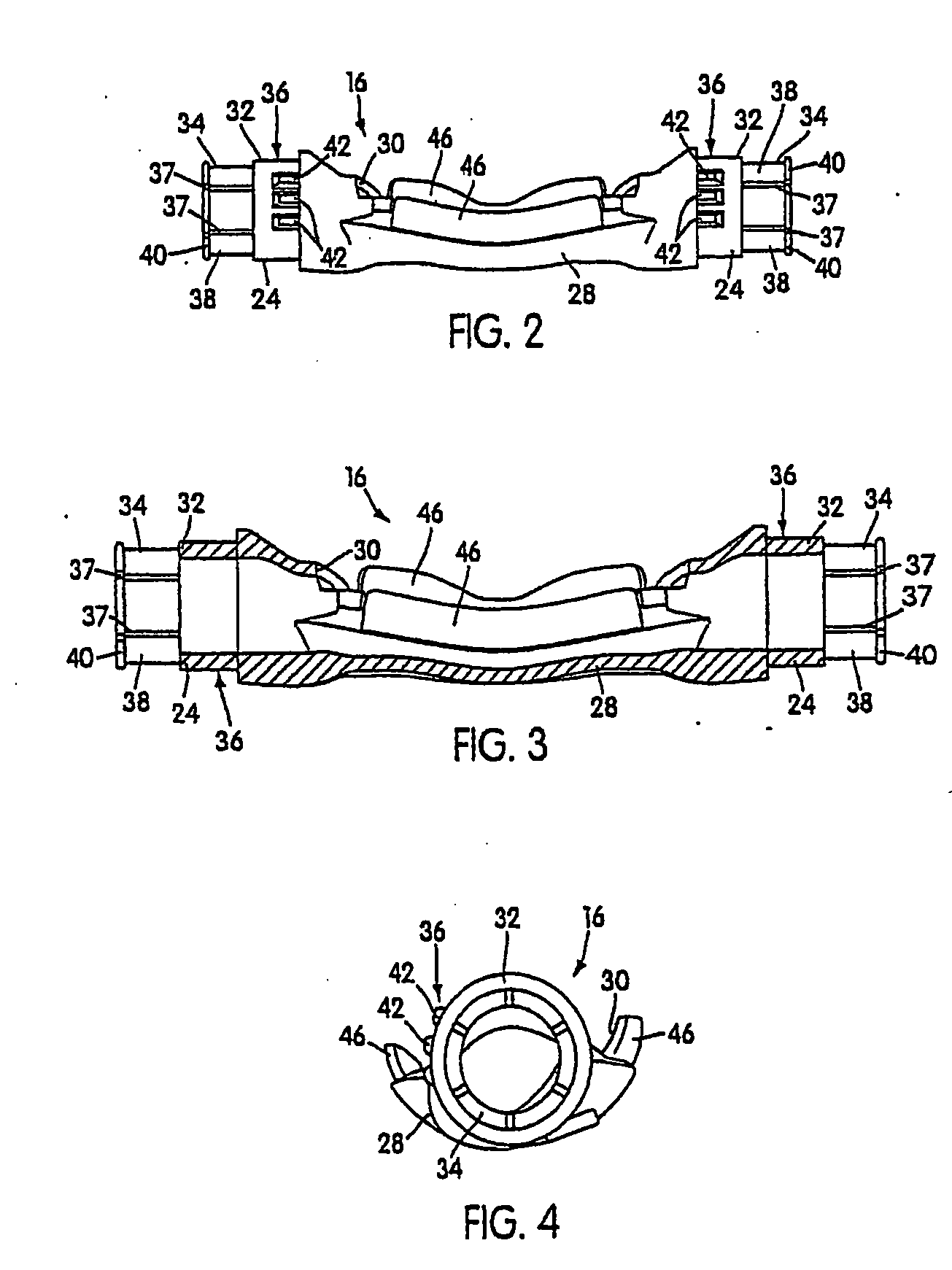

Nasal assembly

ActiveUS20050241644A1More comfortableEasy to useBreathing masksRespiratory masksNasal cavityEngineering

A nasal assembly for delivering breathable gas to a patient includes a frame having an integrally formed first connector portion. A nozzle assembly includes a gusset or base portion and a pair of nozzles. At least one inlet conduit is structured to deliver breathable gas into the frame and nozzle assembly for breathing by the patient. A pair of second connector portions are removably and rotatably connected to respective first connector portions of the frame and are in communication with respective inlet conduits, e.g., directly or via angle connectors. A headgear assembly is removably connected to the pair of second connector portions and / or the angle connectors so as to maintain the frame and the nozzle assembly in a desired adjusted position on the patient's face.

Owner:RESMED LTD

Nasal assembly

ActiveUS20060137690A1Sealing stability forceLarge range of motionBreathing filtersRespiratory masksNasal cavityEngineering

A nasal assembly for delivering breathable gas to a patient includes a frame having an integrally formed first connector portion. A nozzle assembly includes a gusset or base portion and a pair of nozzles. At least one inlet conduit is structured to deliver breathable gas into the frame and nozzle assembly for breathing by the patient. A pair of second connector portions are removably and rotatably connected to respective first connector portions of the frame and are in communication with respective inlet conduits, e.g., directly or via angle connectors. A headgear assembly is removably connected to the pair of second connector portions and / or the angle connectors so as to maintain the frame and the nozzle assembly in a desired adjusted position on the patient's face.

Owner:RESMED LTD

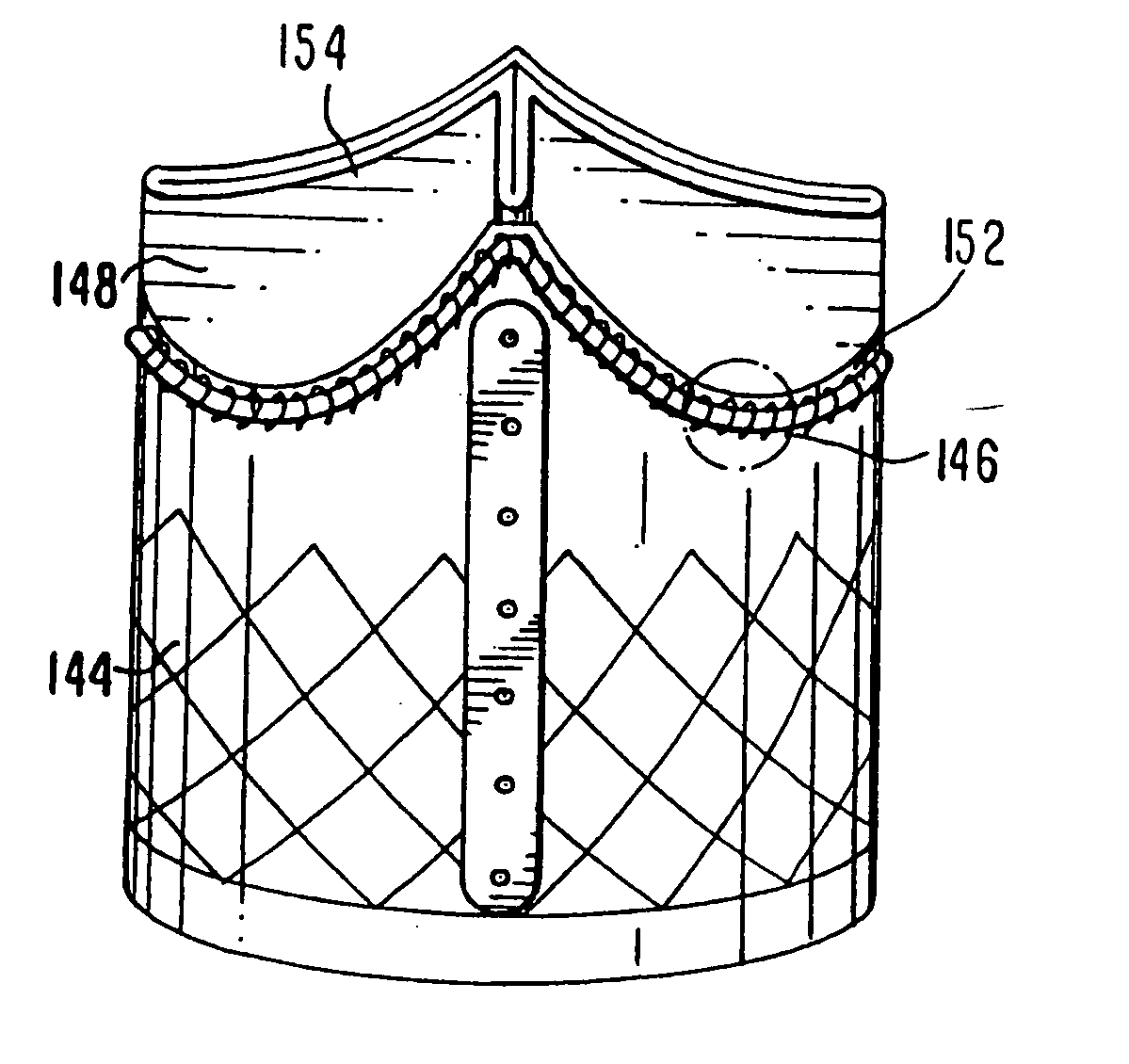

Collapsible and re-expandable prosthetic heart valve cuff designs and complementary technological applications

ActiveUS20110098802A1Improve sealingPromote intimate engagementStentsBalloon catheterInsertion stentPattern matching

A prosthetic heart valve is provided with a cuff (85, 285, 400) having features which promote sealing with the native tissues even where the native tissues are irregular. The cuff may include a portion (90) adapted to bear native aortic valve. The valve may include elements (210, 211, 230, 252, 253) for biasing the cuff outwardly with respect to the stent body when the stent body is in an expanded condition. The cuff may have portions of different thickness (280) distributed around the circumference of the valve in a pattern matching the shape of the opening defined by the native tissue. All or part (402) of the cuff may be movable relative to the stent during implantation.

Owner:ST JUDE MEDICAL LLC

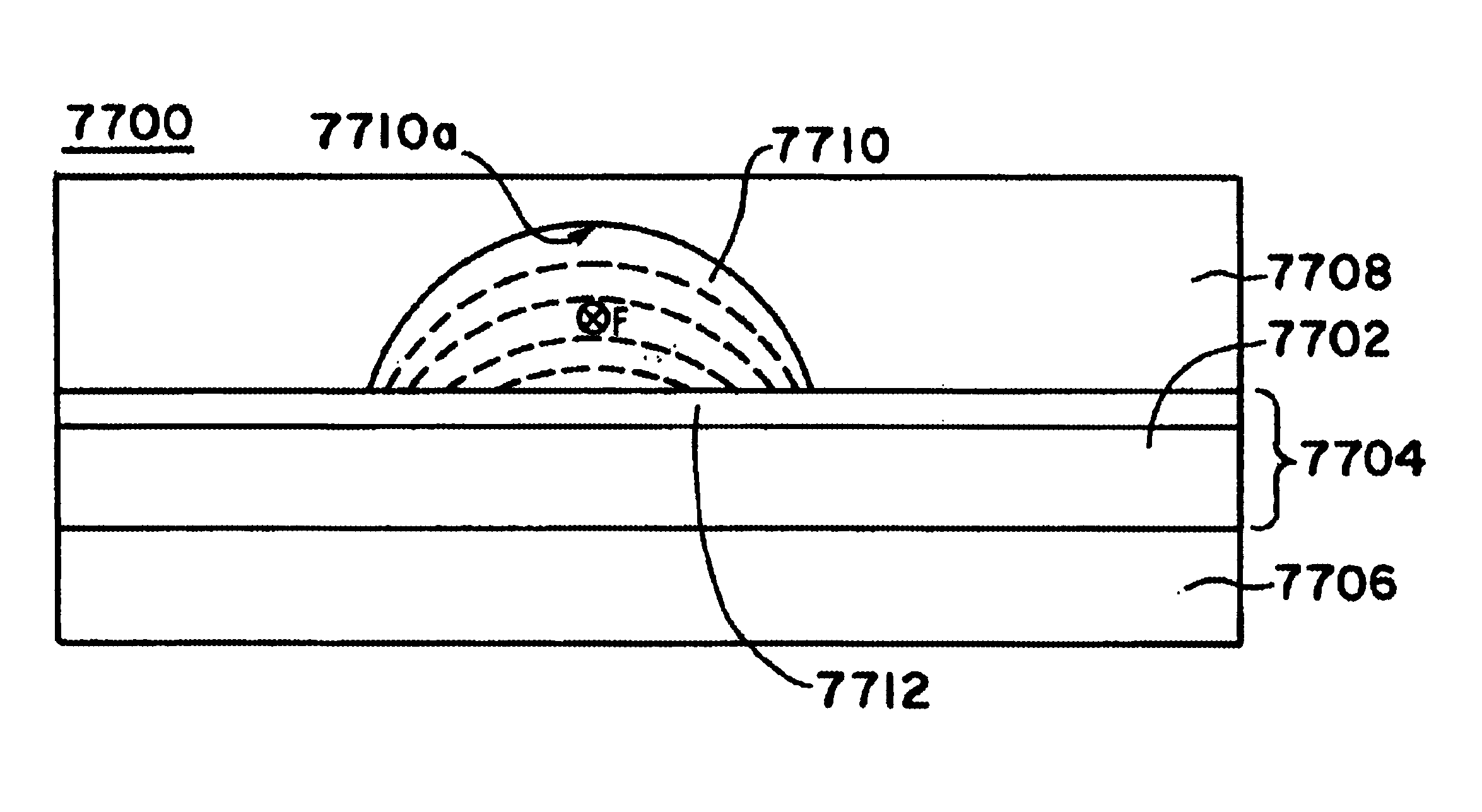

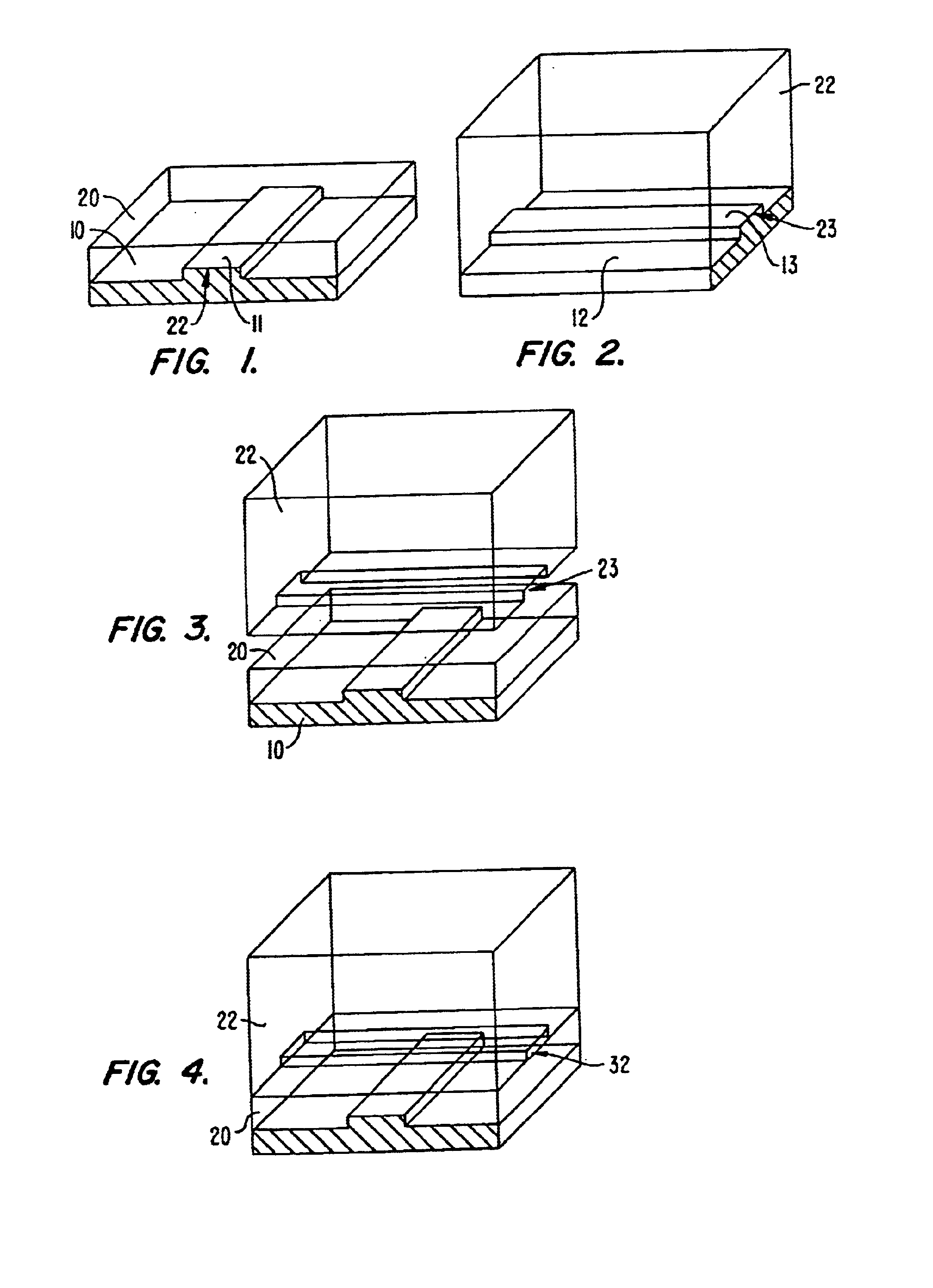

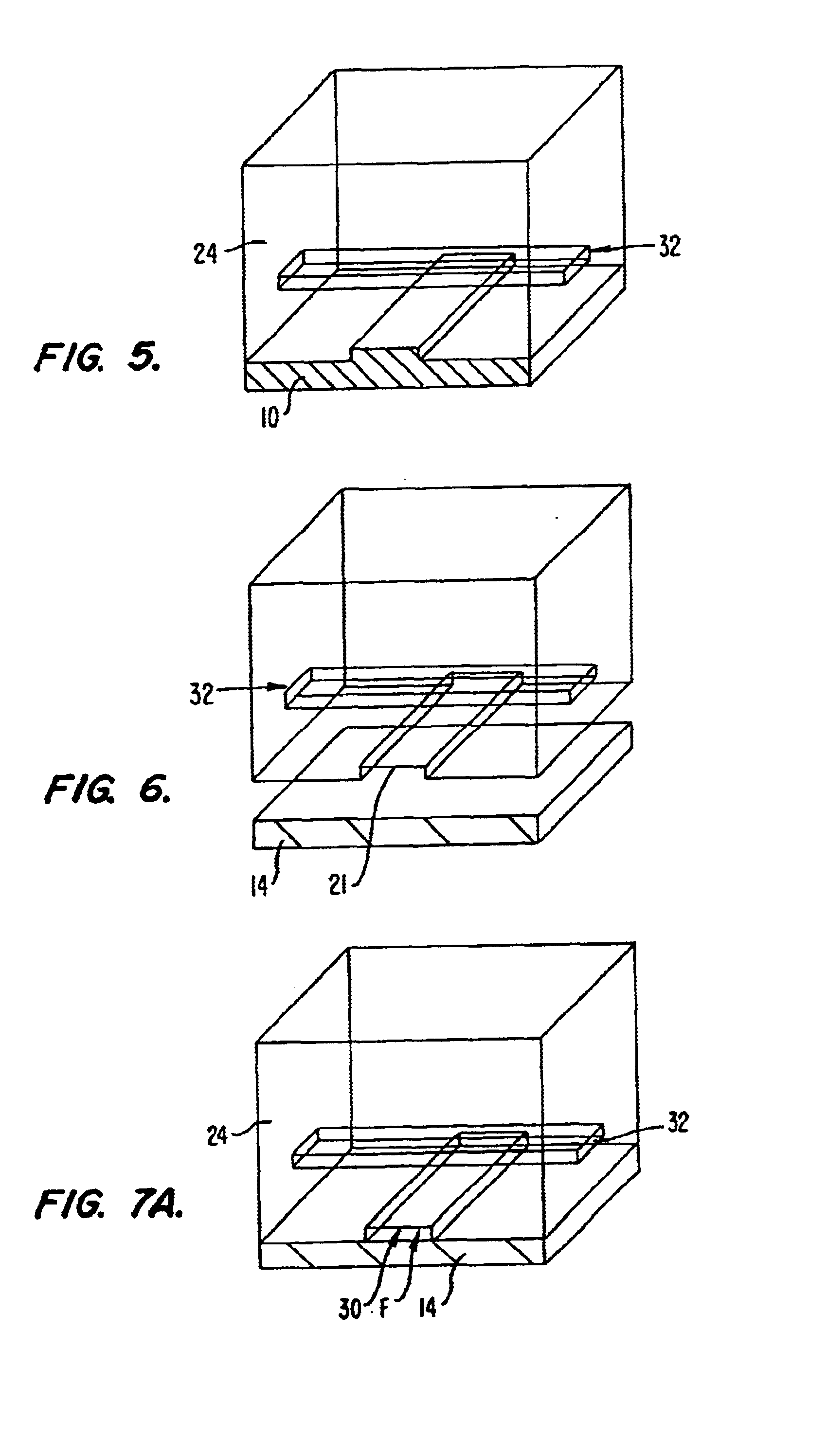

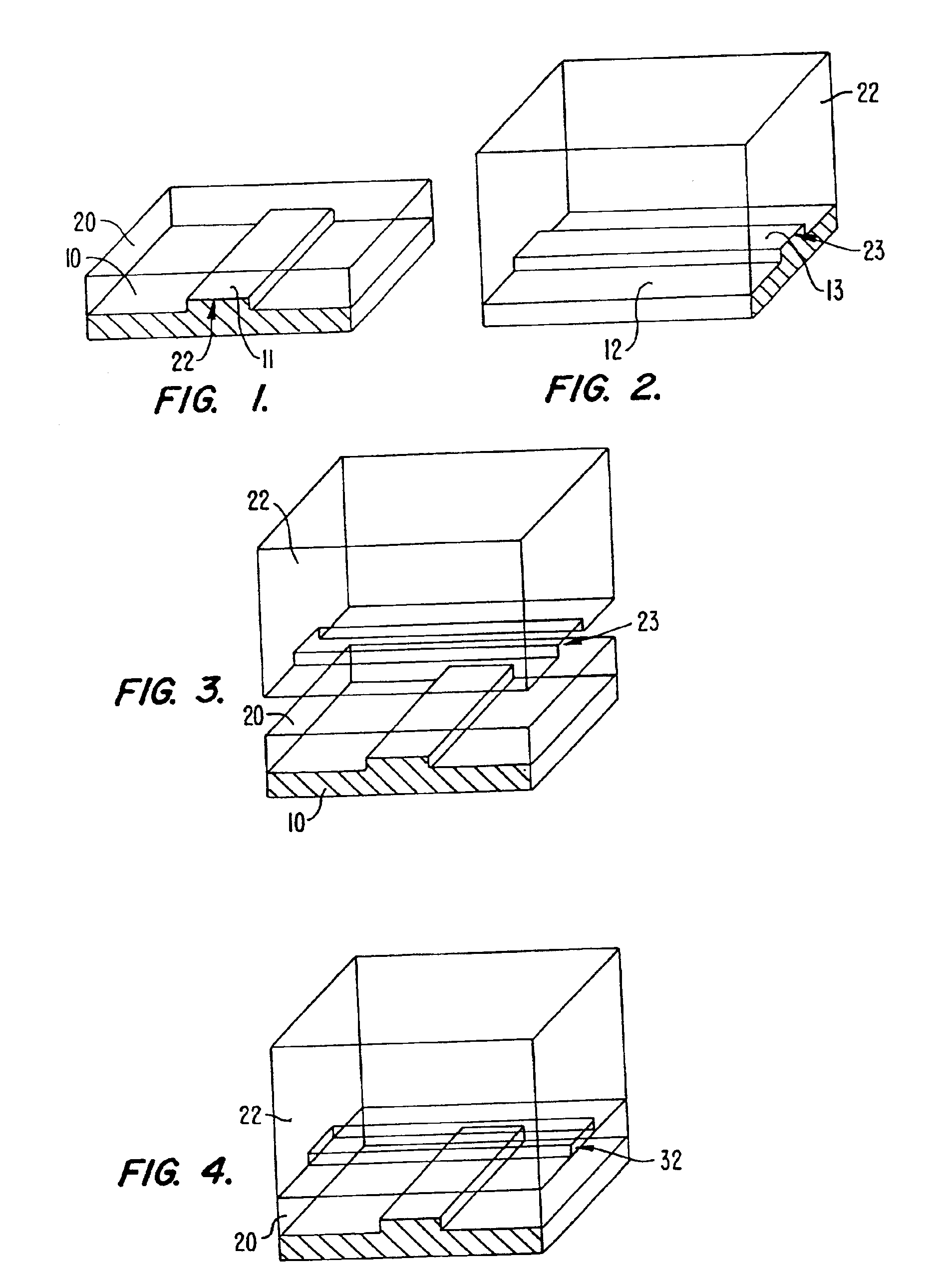

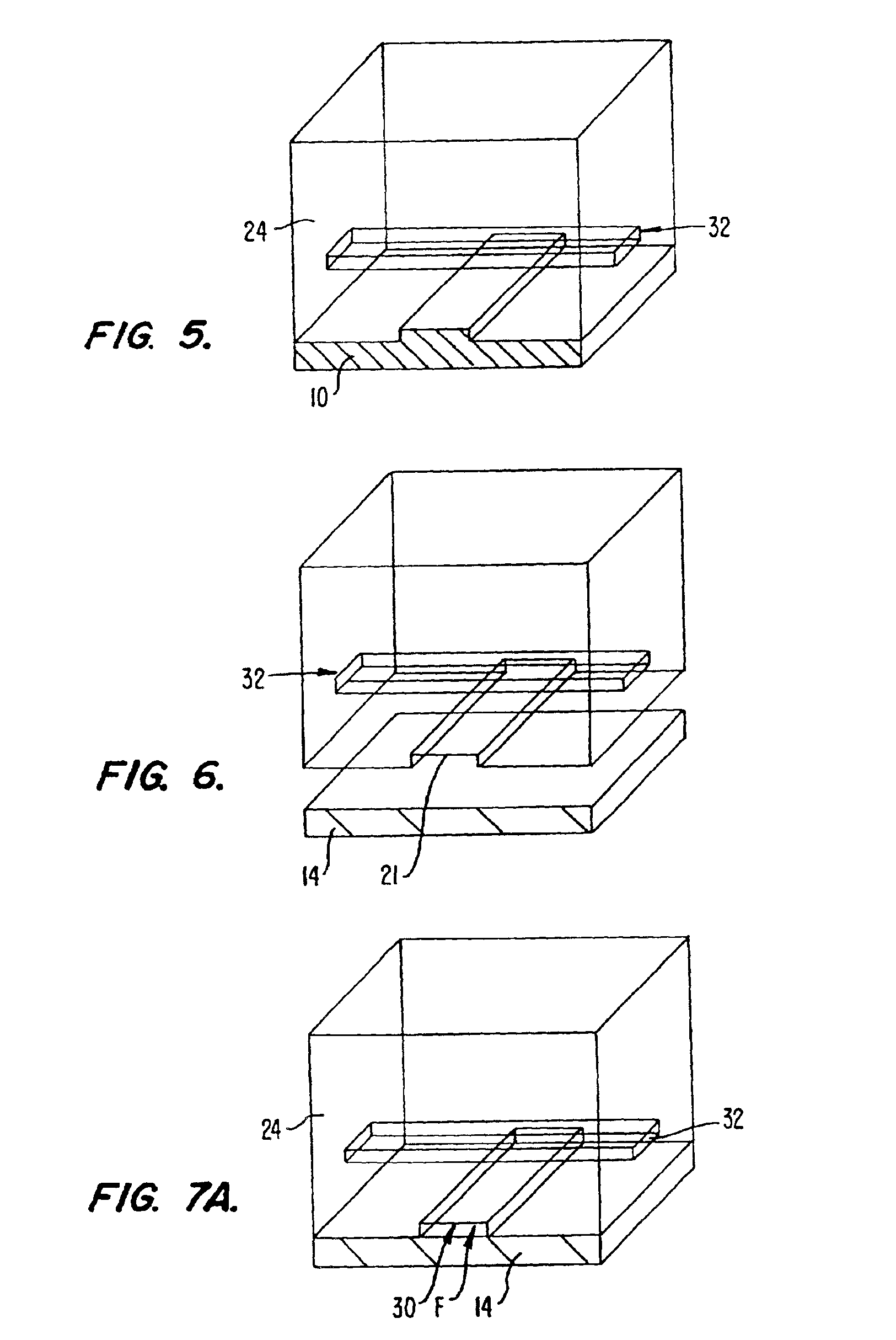

Microfabricated elastomeric valve and pump systems

InactiveUS6929030B2High speedSmall sizeFixed microstructural devicesVolume/mass flow measurementEngineeringPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

Microfabricated elastomeric valve and pump systems

InactiveUS6899137B2Increase speedSmall sizeFixed microstructural devicesVolume/mass flow measurementElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

Implantable prosthetic valve

A valve prosthesis device is disclosed suitable for implantation in body ducts. The device comprises support stent, comprised of a deployable construction adapted to be initially crimped in a narrow configuration suitable for catheterization through the body duct to a target location and adapted to be deployed by exerting substantially radial forces from within by means of a deployment device to a deployed state in the target location, the support stent provided with a plurality of longitudinally rigid support beams of fixed length; valve assembly comprising a flexible conduit having an inlet end and an outlet, made of pliant material attached to the support beams providing collapsible slack portions of the conduit at the outlet. When flow is allowed to pass through the valve prosthesis device from the inlet to the outlet the valve assembly is kept in an open position, whereas a reverse flow is prevented as the collapsible slack portions of the valve assembly collapse inwardly providing blockage to the reverse flow.

Owner:EDWARDS LIFESCI PVT

Cushion for a respiratory mask assembly

ActiveUS7523754B2More comfortableAvoid Sealing ProblemsChemical protectionHeat protectionChinRespirator

A respiratory mark assembly for delivering breathable gas to a patient includes a frame and a cushion. The cushion has a non-face contacting portion structured to be connected to the frame, a face-contacting portion structured to engage the patient's face, and an intermediate portion that interconnects the non-face contacting portion and the face-contacting portion. The intermediate portion includes a gusset portion that applies a first component of force to the patient's face through the face-contacting portion. A spring structure is coupled with the face-contacting portion of the cushion. The spring structure applies a second component of force to the patient's face through the face-contacting portion. The first and second components of force applied by the gusset portion and spring structure, respectively, determine a contact force of the cushion applied to the patient's face through the face-contacting portion. The intermediate portion may also include an elastic cuff portion. Further, in the case of an oral mask, the sealing section may include a portion that is designed to promote a better seal in the chin region of the mask.

Owner:RESMED LTD

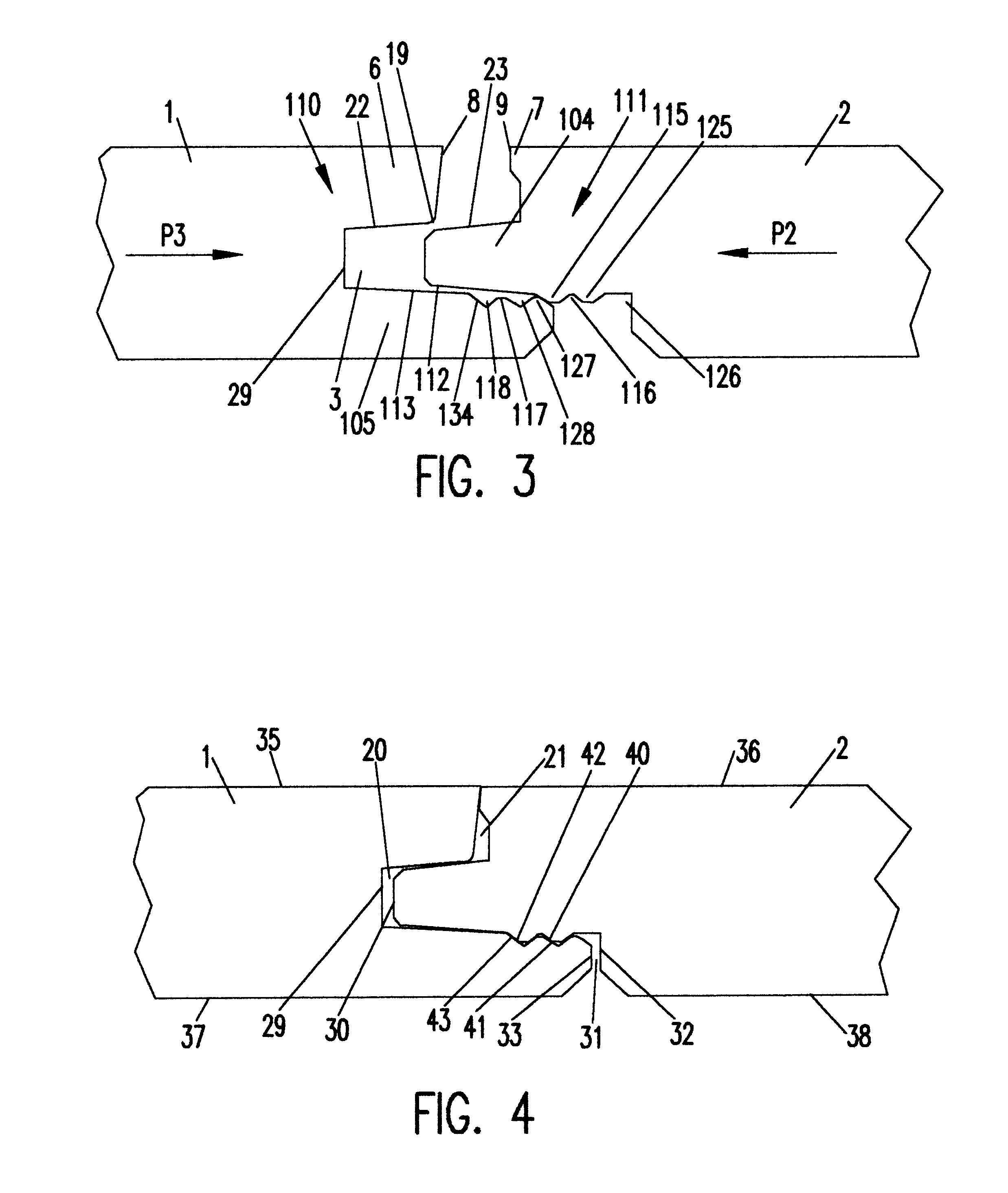

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com