Patents

Literature

33261results about "Walls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

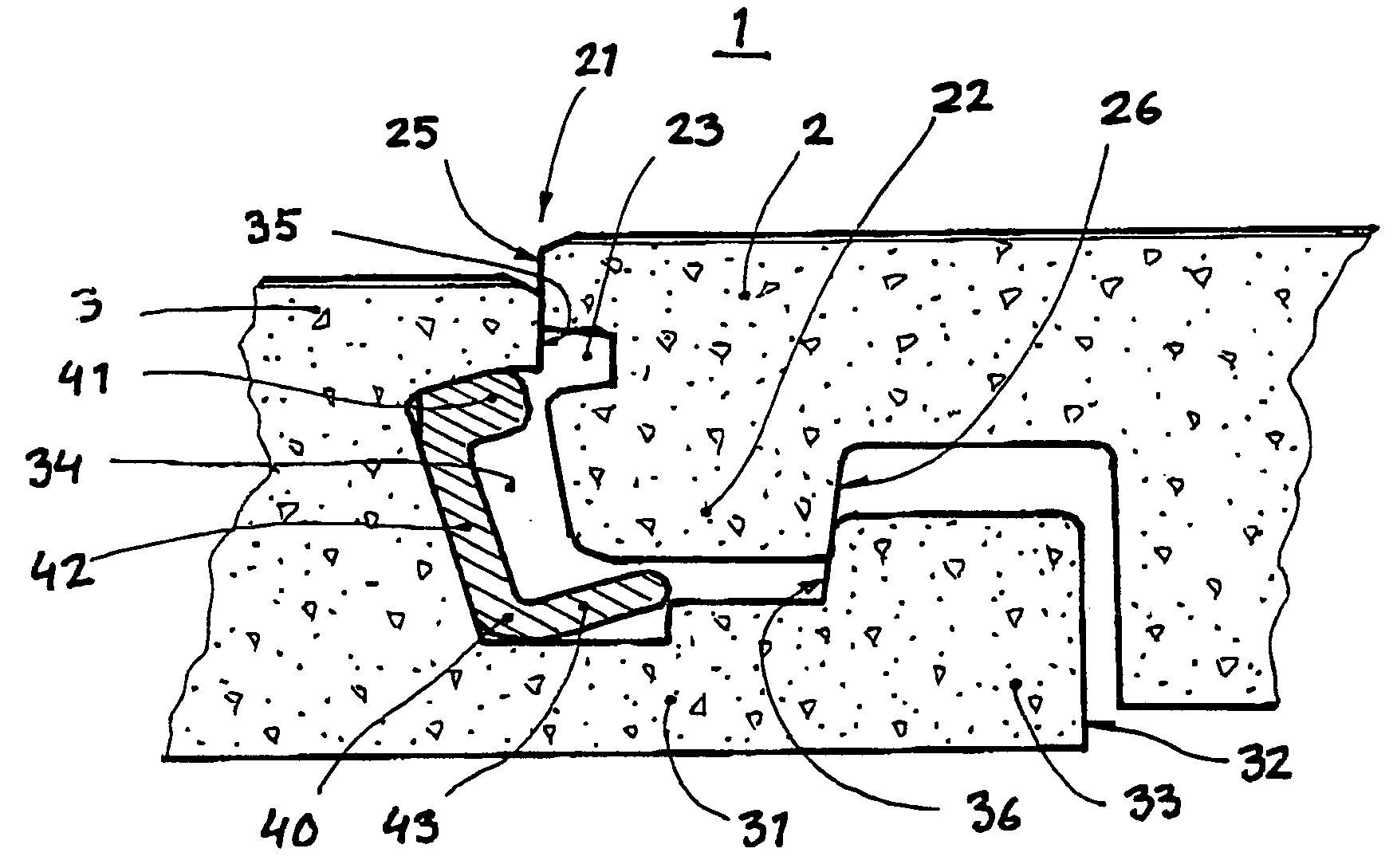

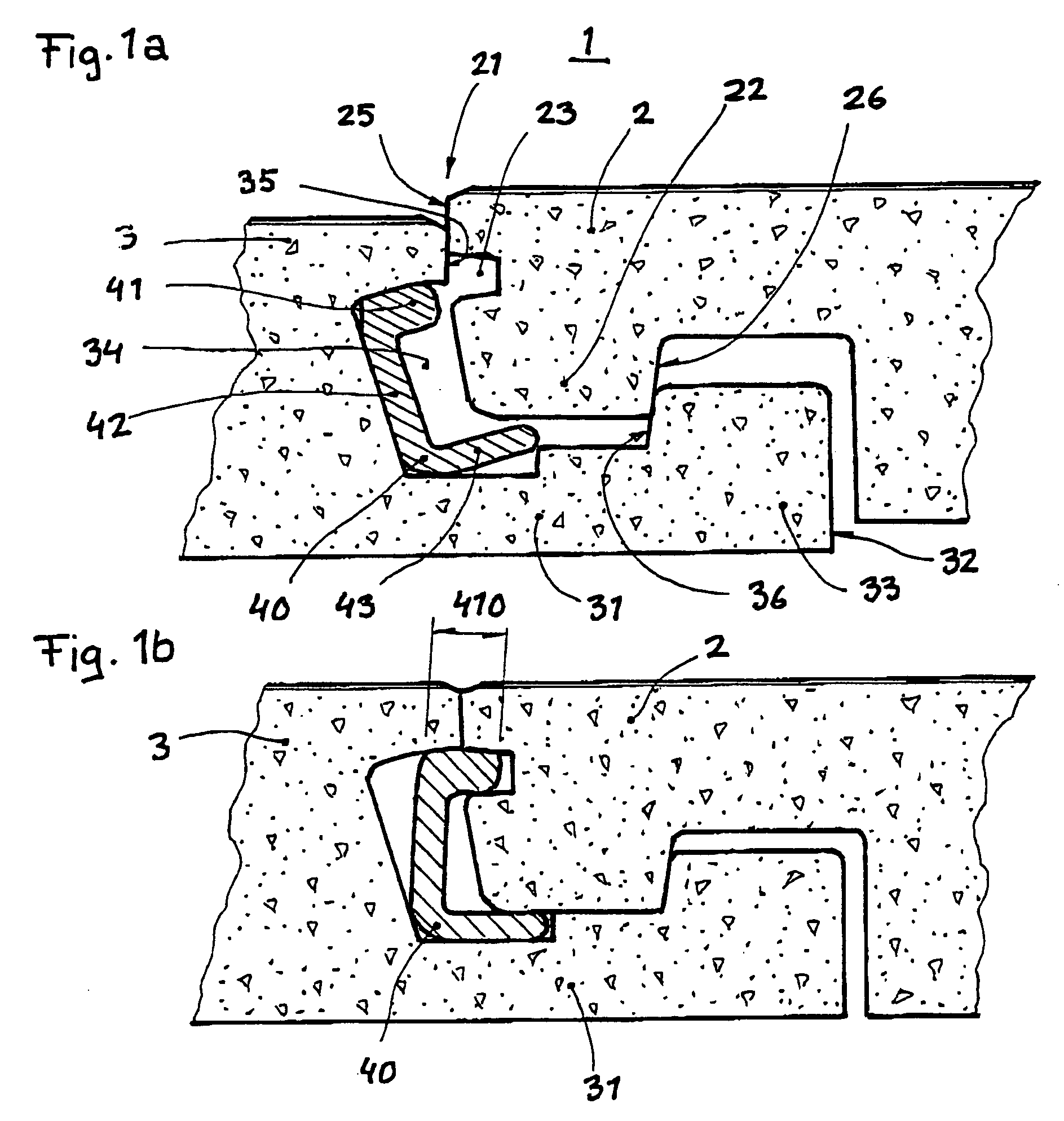

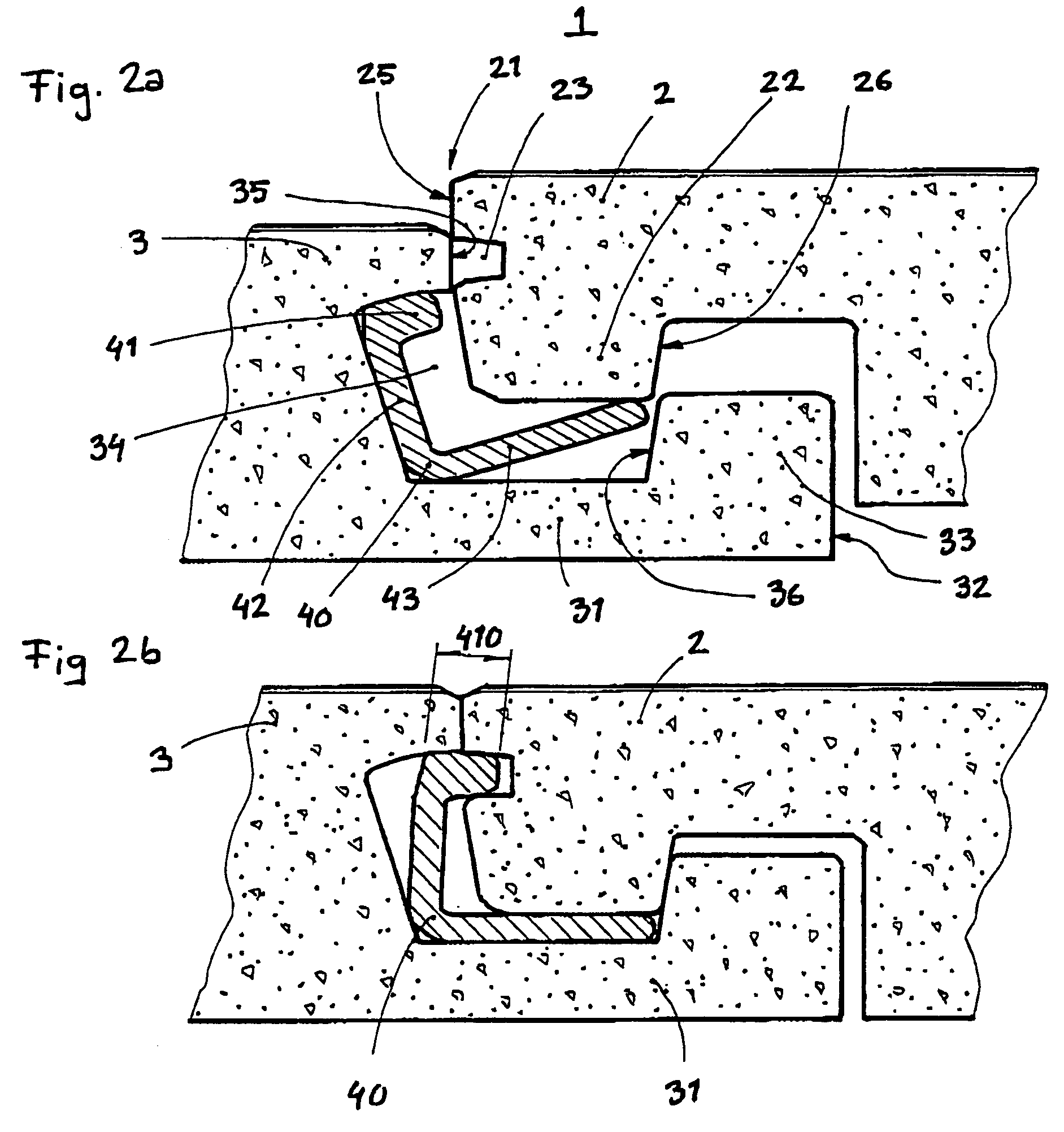

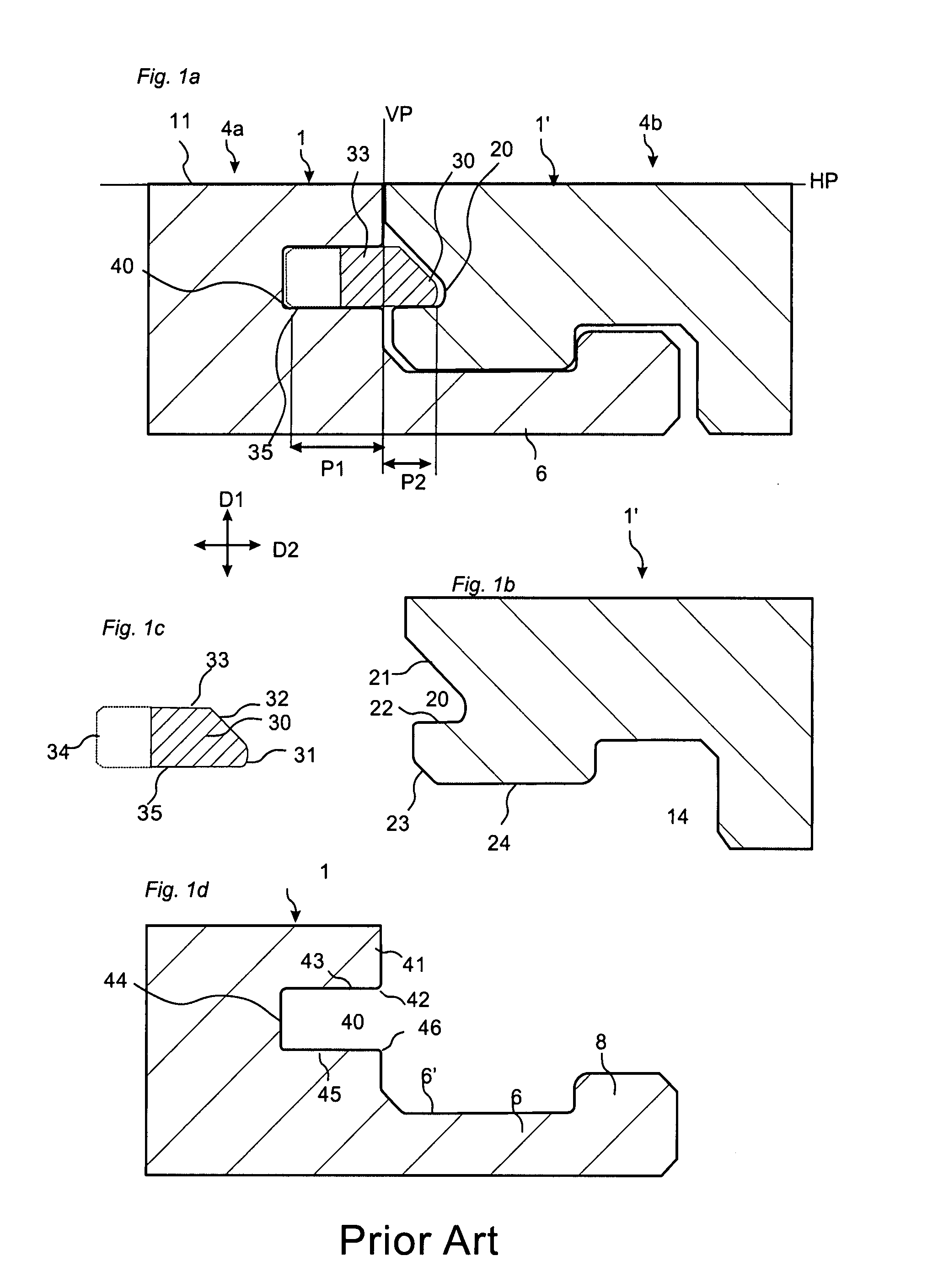

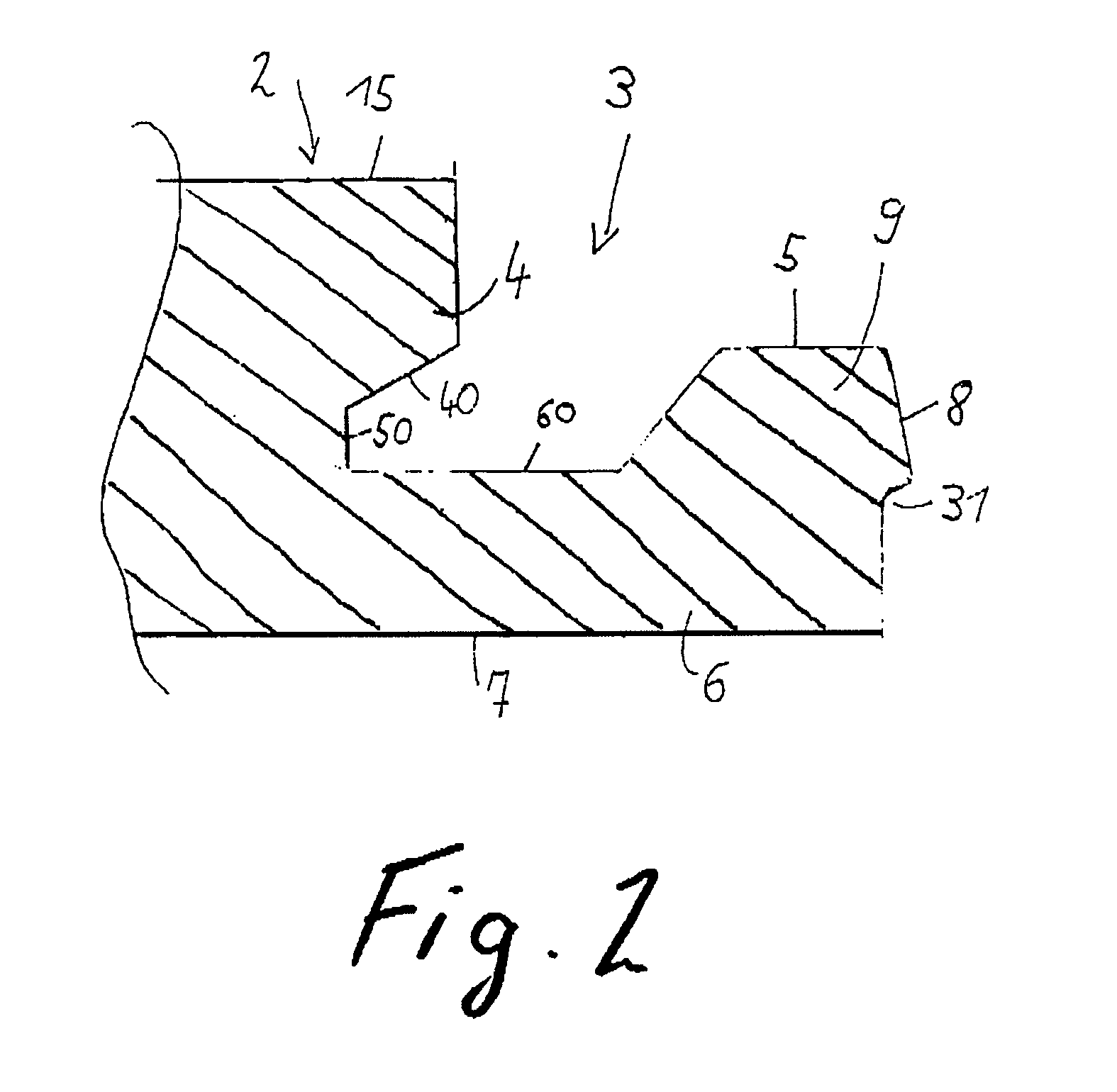

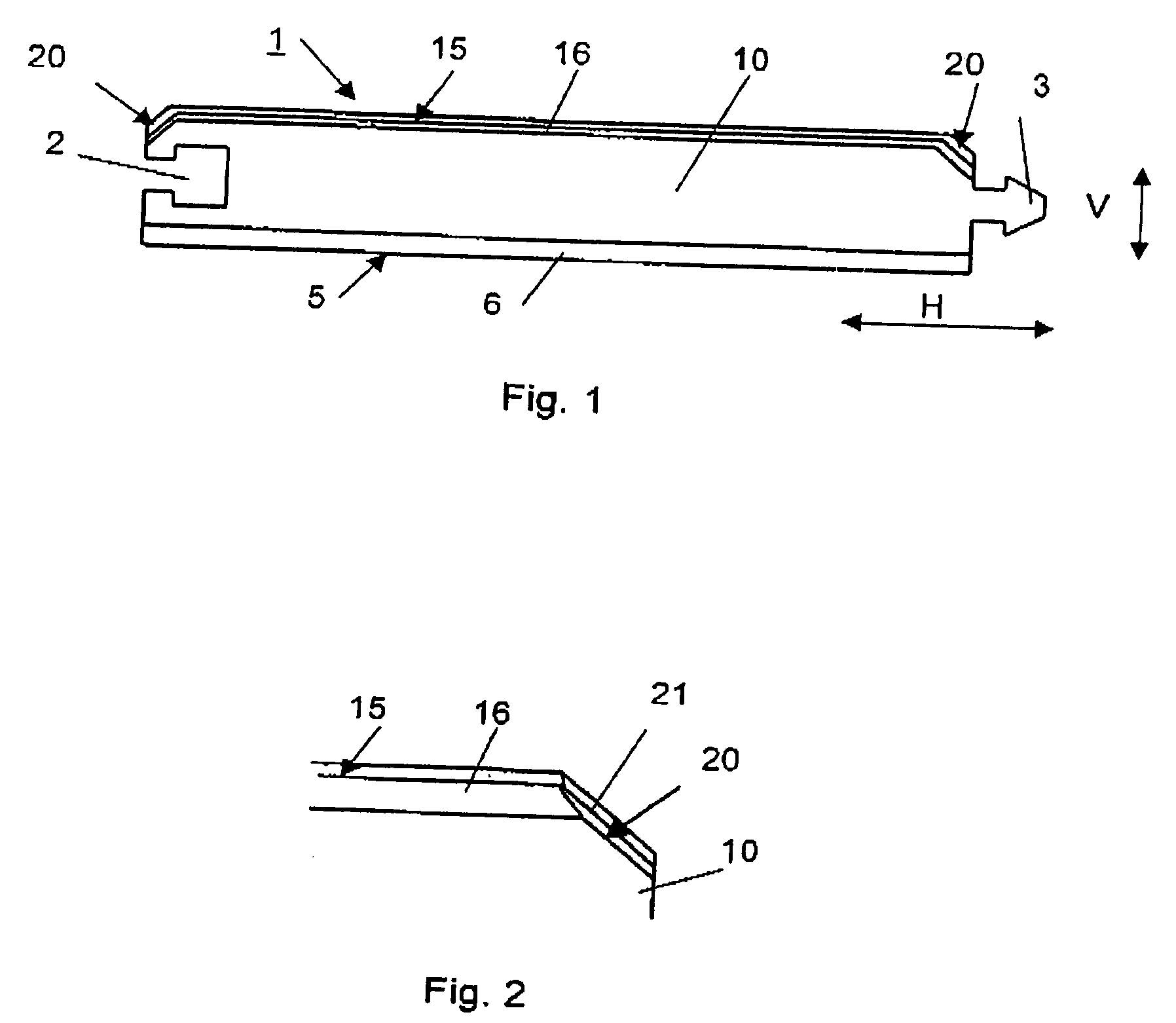

Joint for panels

A joint (1) having a first edge (2) and a second edge (3), the first edge (2) being provided with a distal edge (21) and a downwards protruding heel (22) The distal edge (21) is further provided with an upper joint edge (25) beneath which a groove (23) is arranged. The second edge (3) is provided with lower cheek (31) having a distal end (32) at which an upwards protruding lower cheek heel (33) is arranged. The second edge (3) is further provided with an upper joining edge (35) beneath which an undercut (34) is arranged. A moveable locking element (40) is arranged in the space created by the undercut (34). The moveable locking element (40) have a locking tongue (41), a locking tongue leg (42) and a manoeuvring leg (43).

Owner:PERGO

Panel element

InactiveUS6880307B2Simple glueless layingKeep in touchStrutsCovering/liningsEngineeringFloor covering

The invention relates to a panel element for forming a floor covering, consisting of several identical interconnectable panel elements and having the following features: two first sides of each panel element, called the “longitudinal sides”, these sides having a groove and a tongue; the tongue of a panel element which is positioned at an angle with an installation level of a first, identical panel element can be introduced into the groove of the first panel element; the tongue interacts with the groove of the adjacent, identical panel element in such a way that two interconnected panel elements are protected against separating forces which are exerted along both of the axes extending perpendicularly to the longitudinal side of the panel elements; two second sides of the panel element, called the end sides, are provided with fixing means and a groove and tongue, these forming an end-side connection between two adjacent panel elements; the end-side grooves and tongue can be interconnected by means of the panel element being lowered onto an identical panel element that has already been installed, essentially crosswise to the installation level, so that the panel element is protected from lifting forces, i.e. forces which are exerted considerably perpendicularly to the installation level.

Owner:FLOORING IND LTD

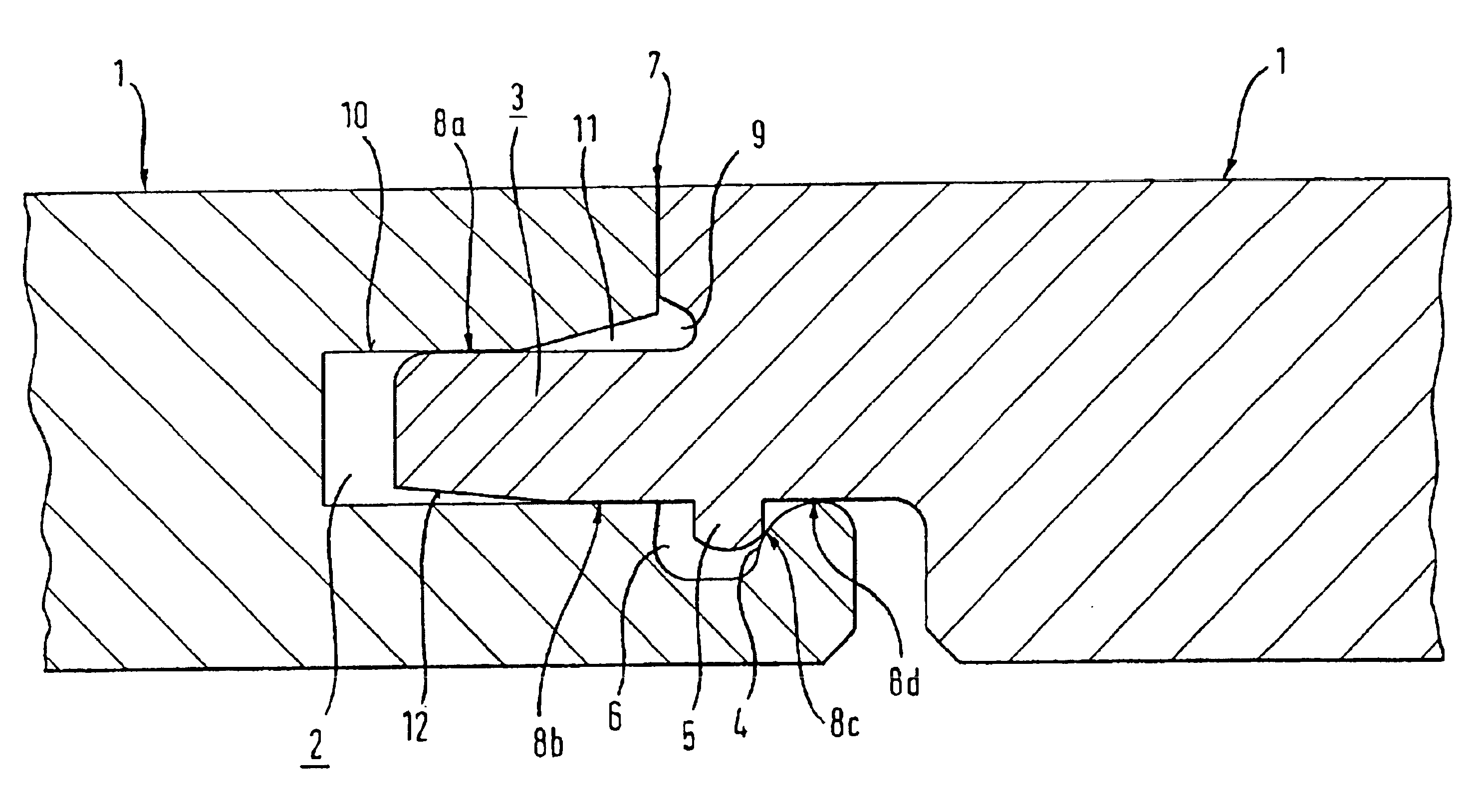

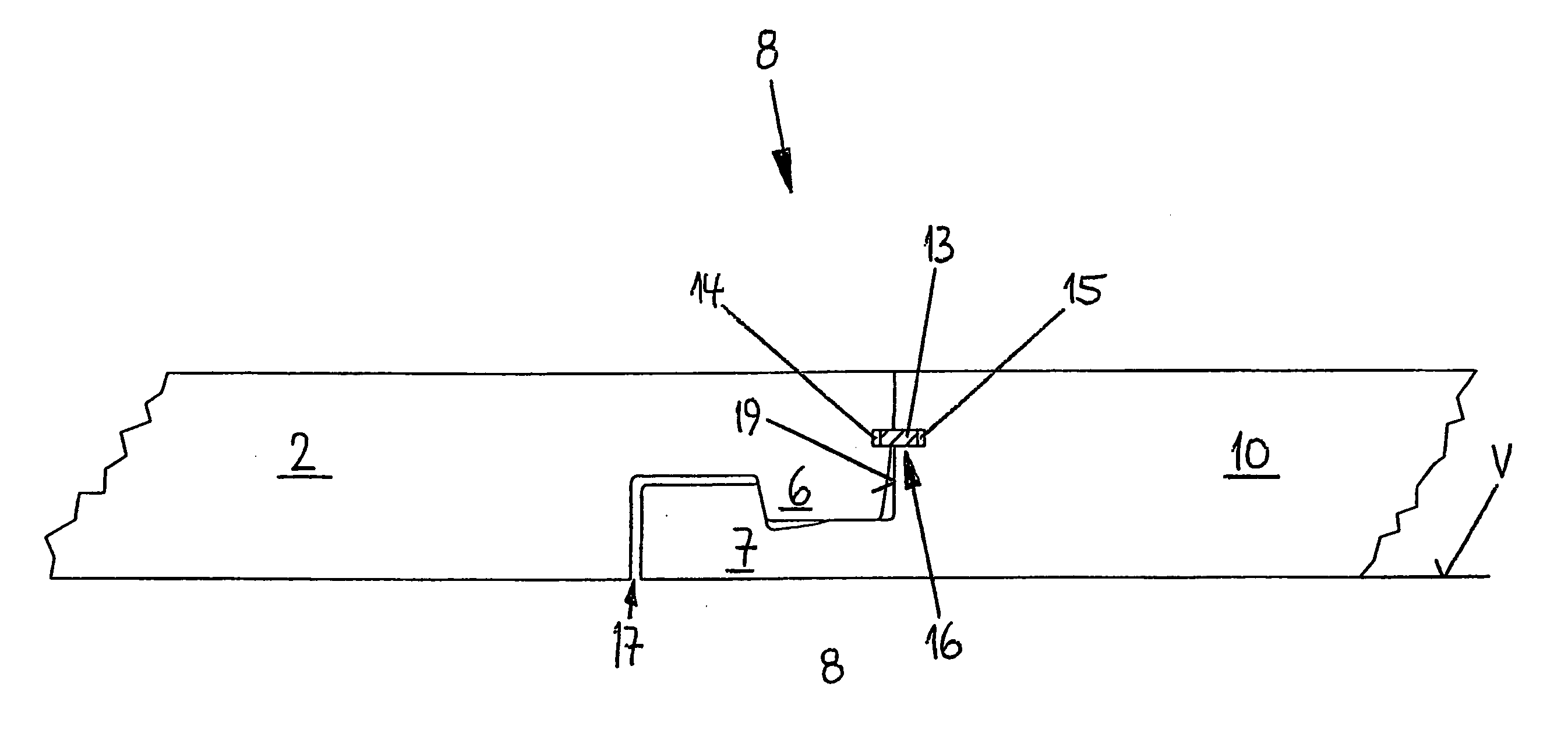

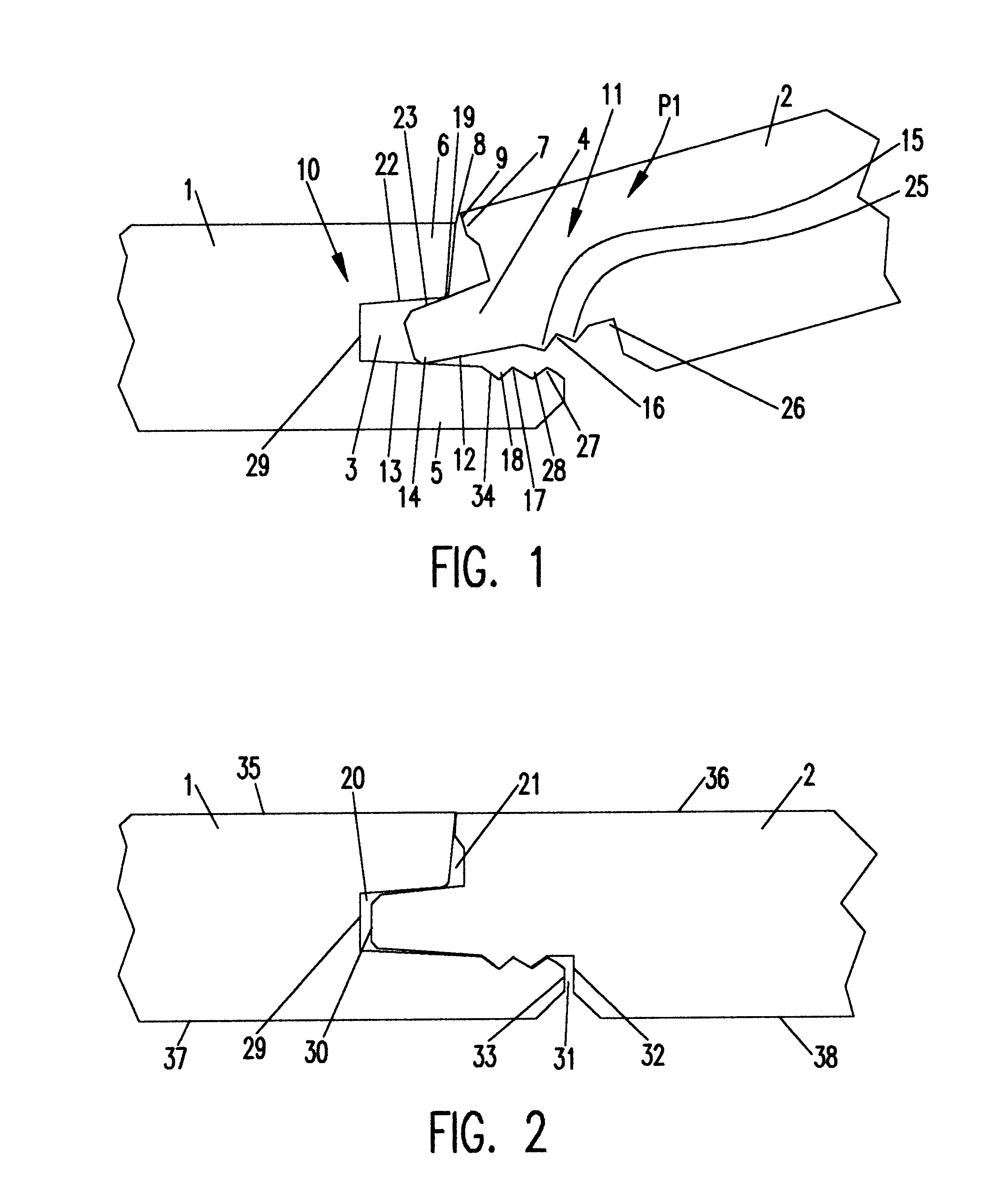

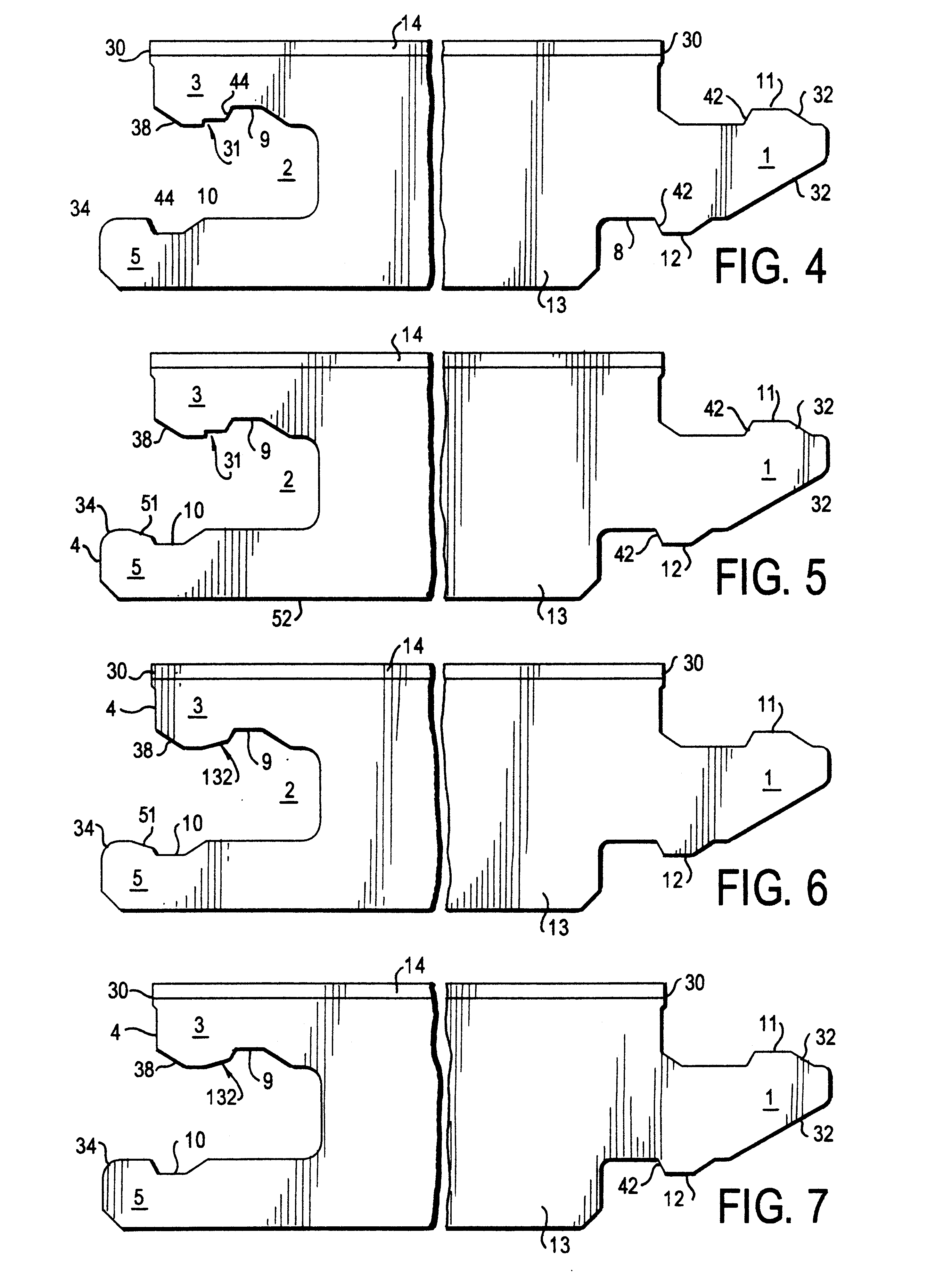

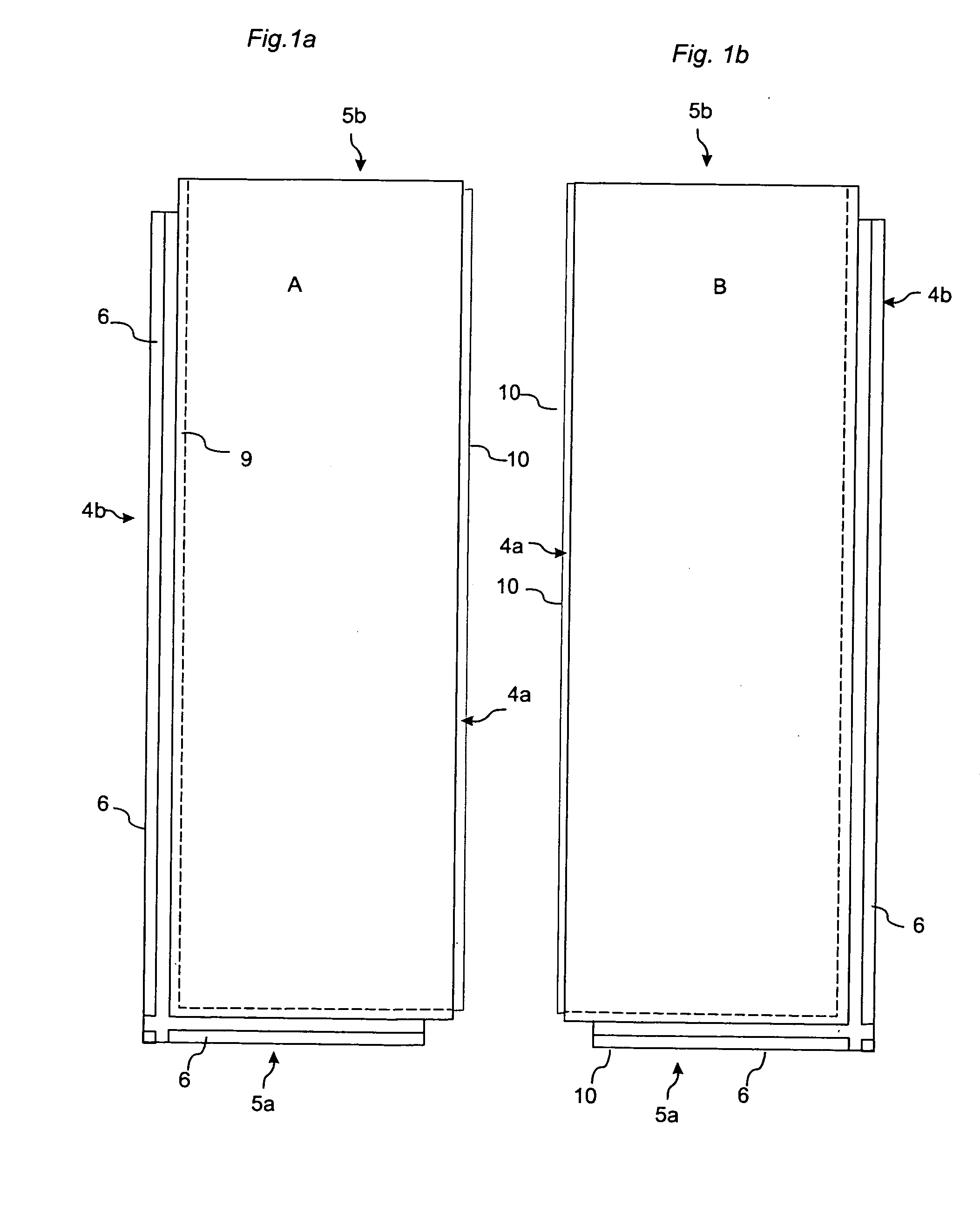

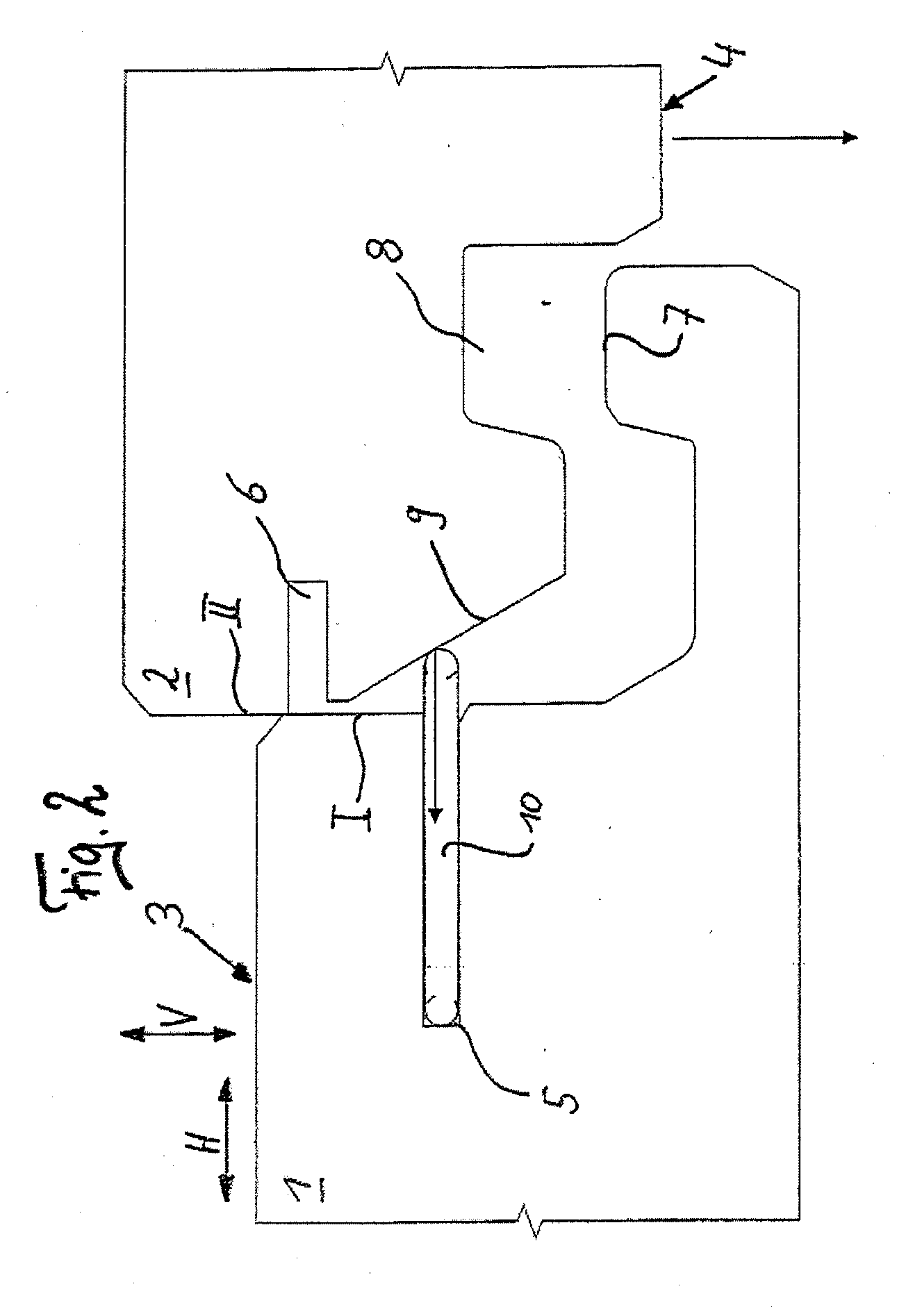

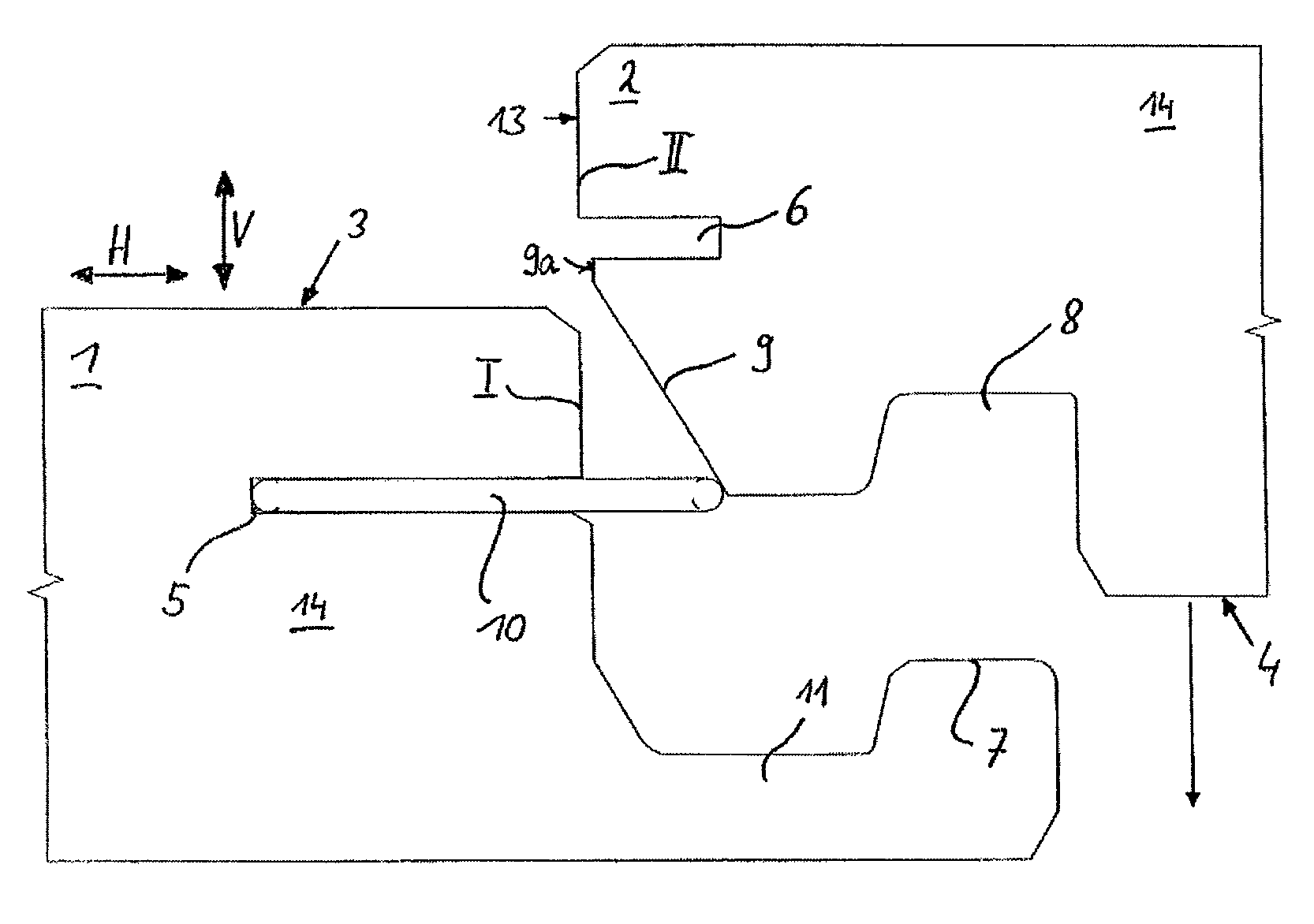

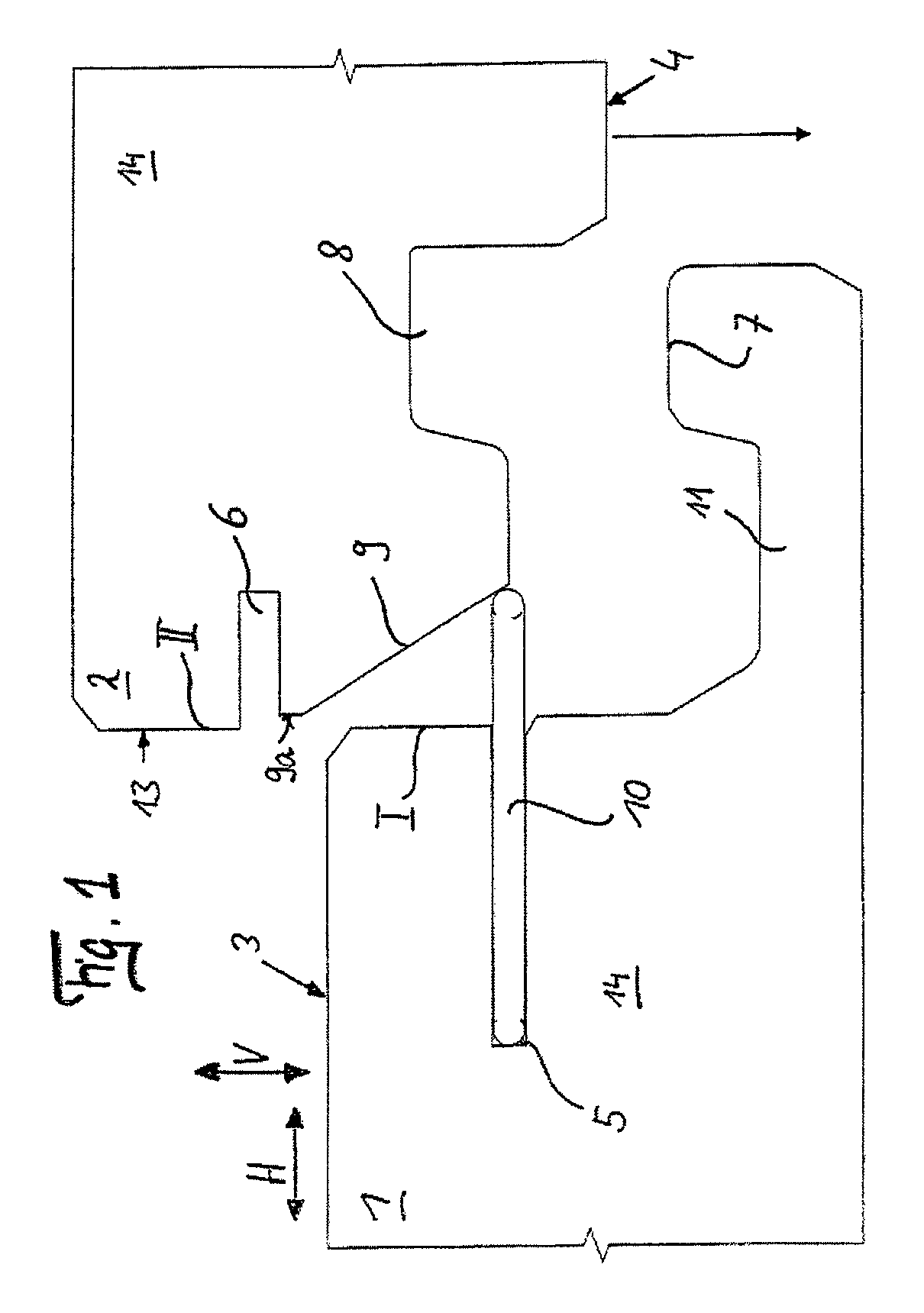

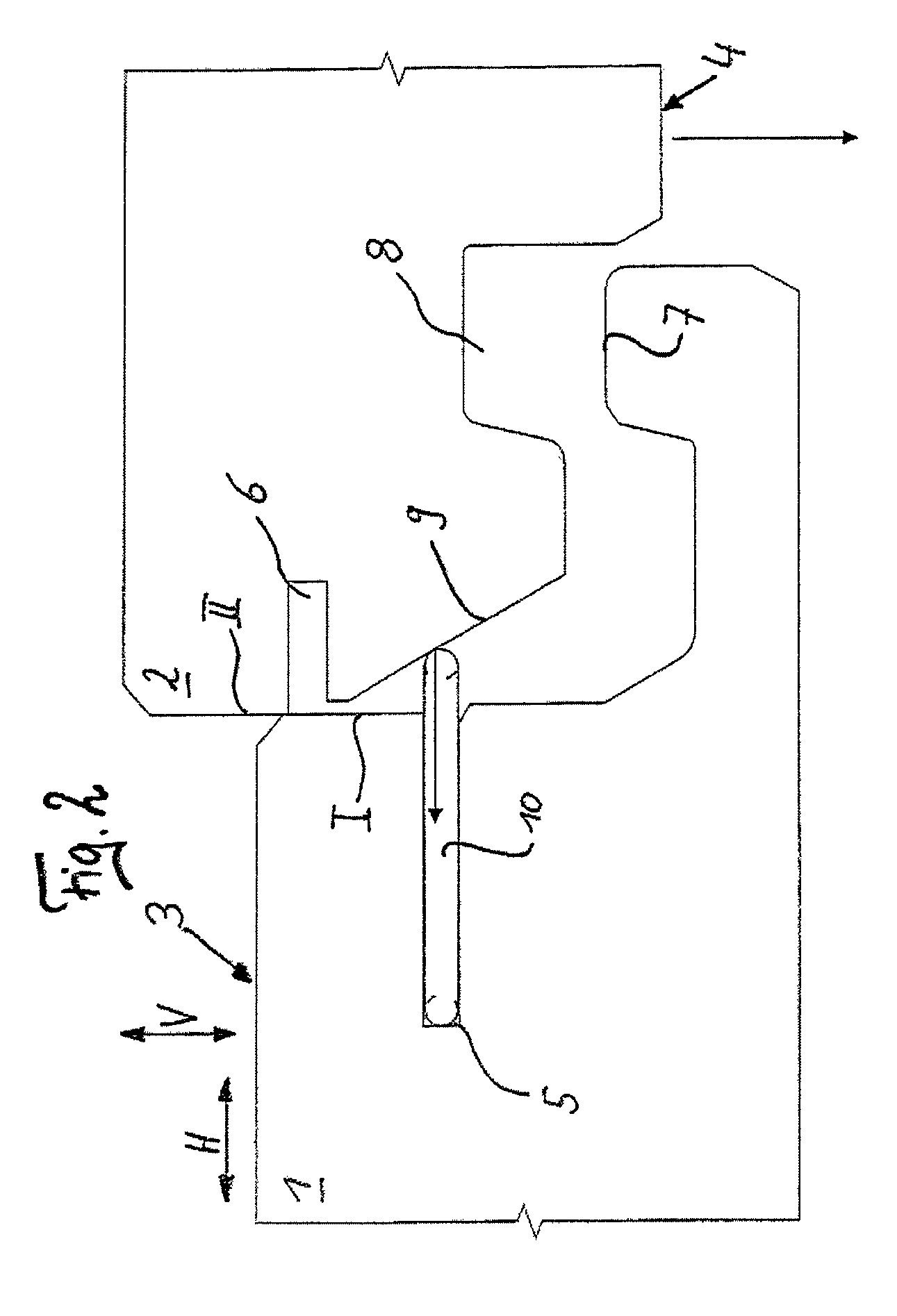

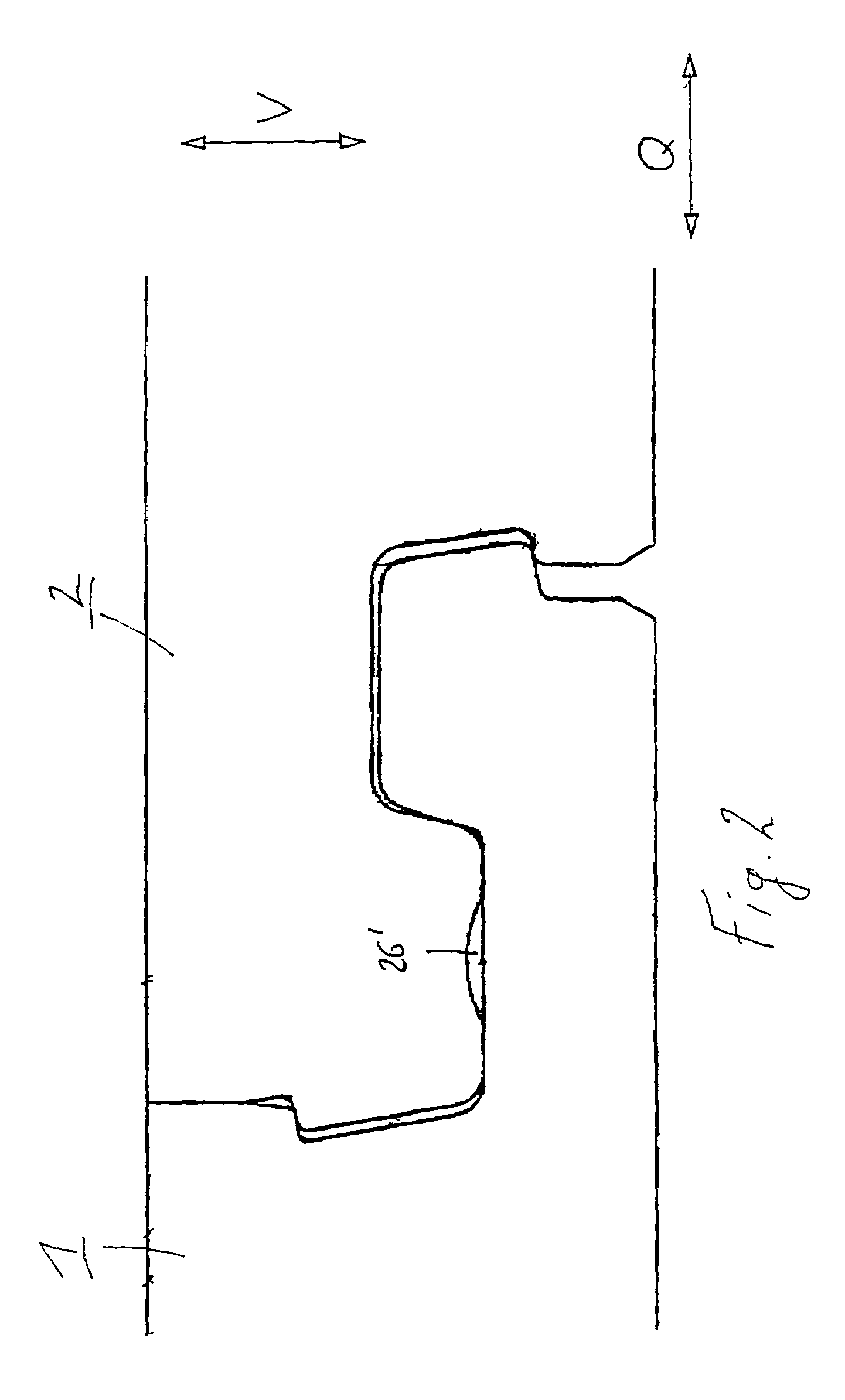

Panel and fastening system for such a panel

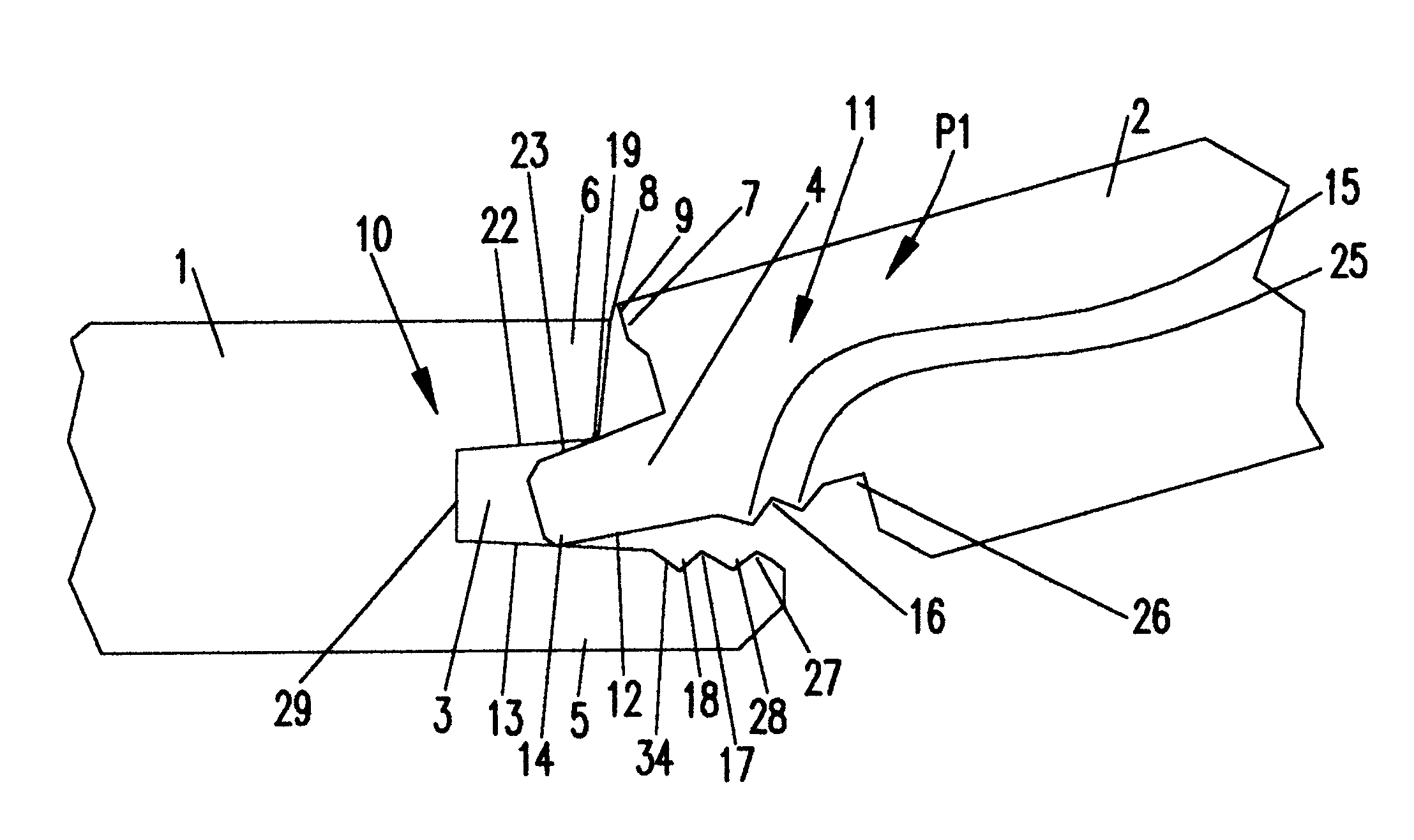

The invention relates to a fastening system (1) for rectangular, tabular panels (2, 3, 10), especially floor panels. Comprising retaining profiles disposed on the small faces of said panels (2, 3, 10). Opposite retaining profiles match said retaining profiles in such a manner that similar panels (2, 3, 10) can be interlinked. The panels are provided with opposite first retaining profiles that are configured in such a manner that on a panel (2, 3, 10) being in first line a new panel (2) can be locked in second line by attaching the new panel (2) to the installed panel (3) at a temporary angle relative to the installed panel (3) and then swiveling it down into the plane of the installed panel (3). The panel further comprises opposite second retaining elements that comprise corresponding hook elements (6, 7). A hook connection (8) can be established by means of one of the hook elements (6, 7) of the new panel (2) and a hook element (6, 7) of a panel (3) that is already installed in second line by swiveling down the new panel (2). Every hook connection (8) is associated with an additional locking element (13, 22, 26, 27, 34, 35, 36, 40, 46) that prevents, in the hooked state of two panels (2, 3, 10), the hook connection (8) from being released in a direction perpendicular to the plane of the installed panels (2, 3 10).

Owner:AKZENTA PANEELE PROFILE GMBH

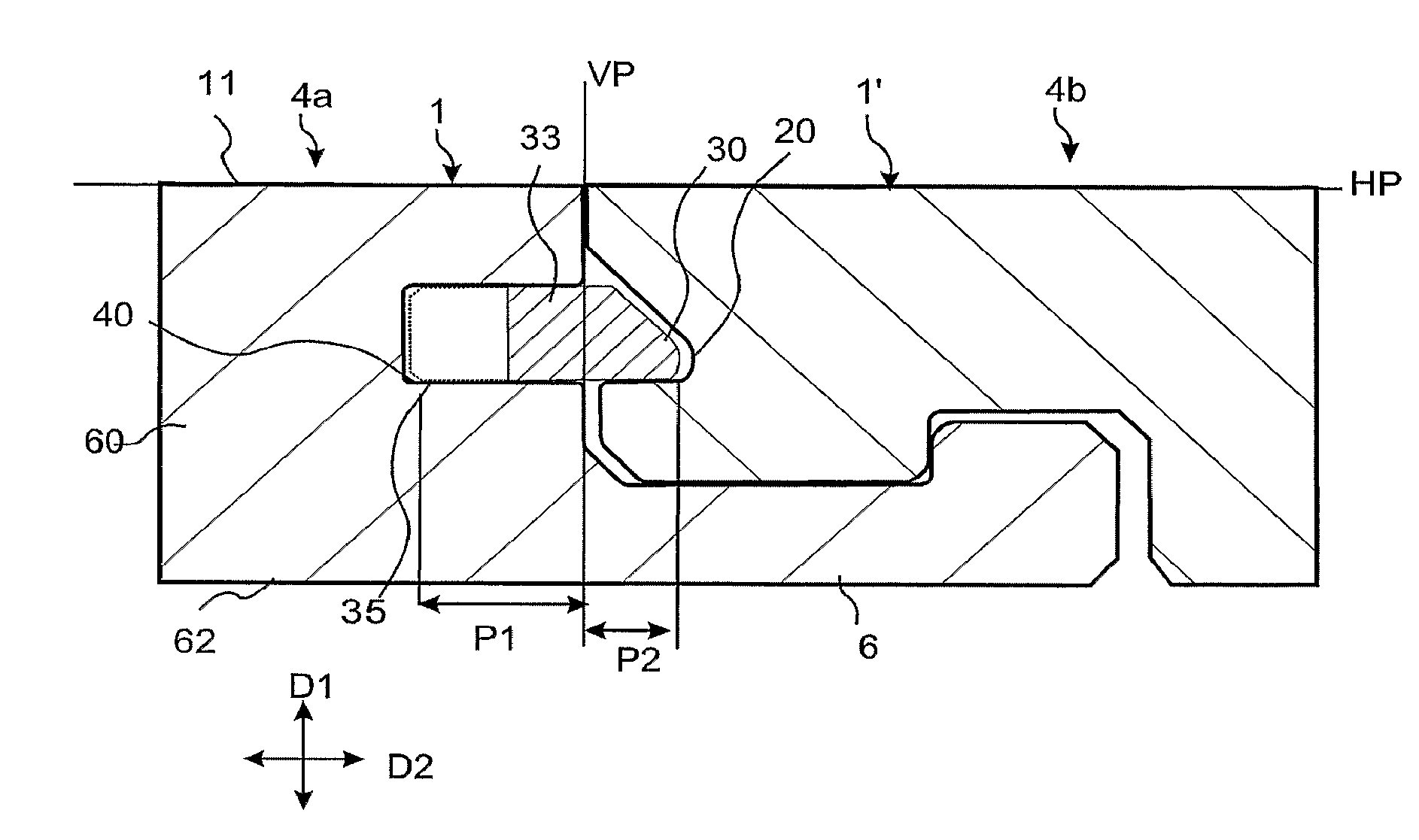

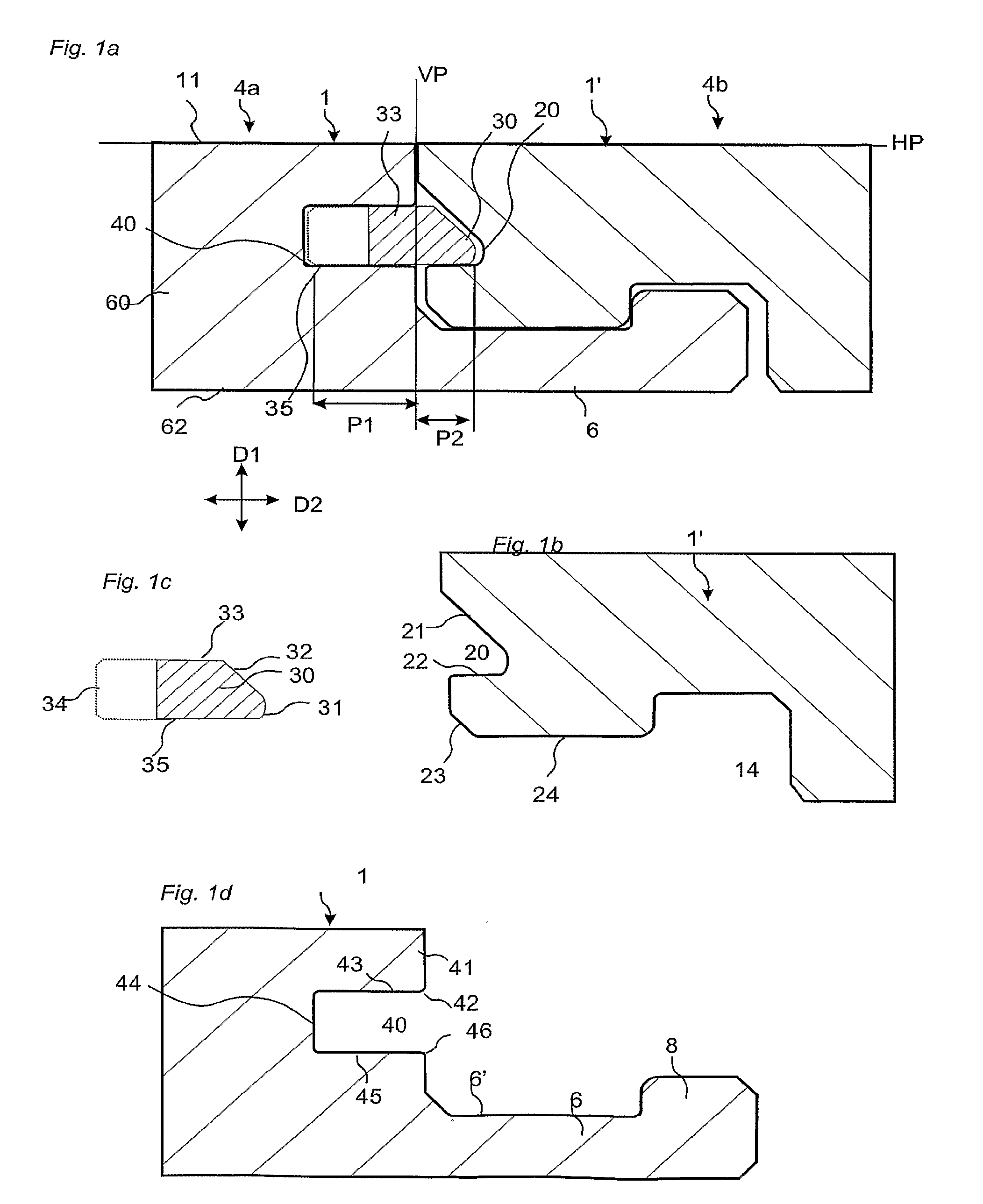

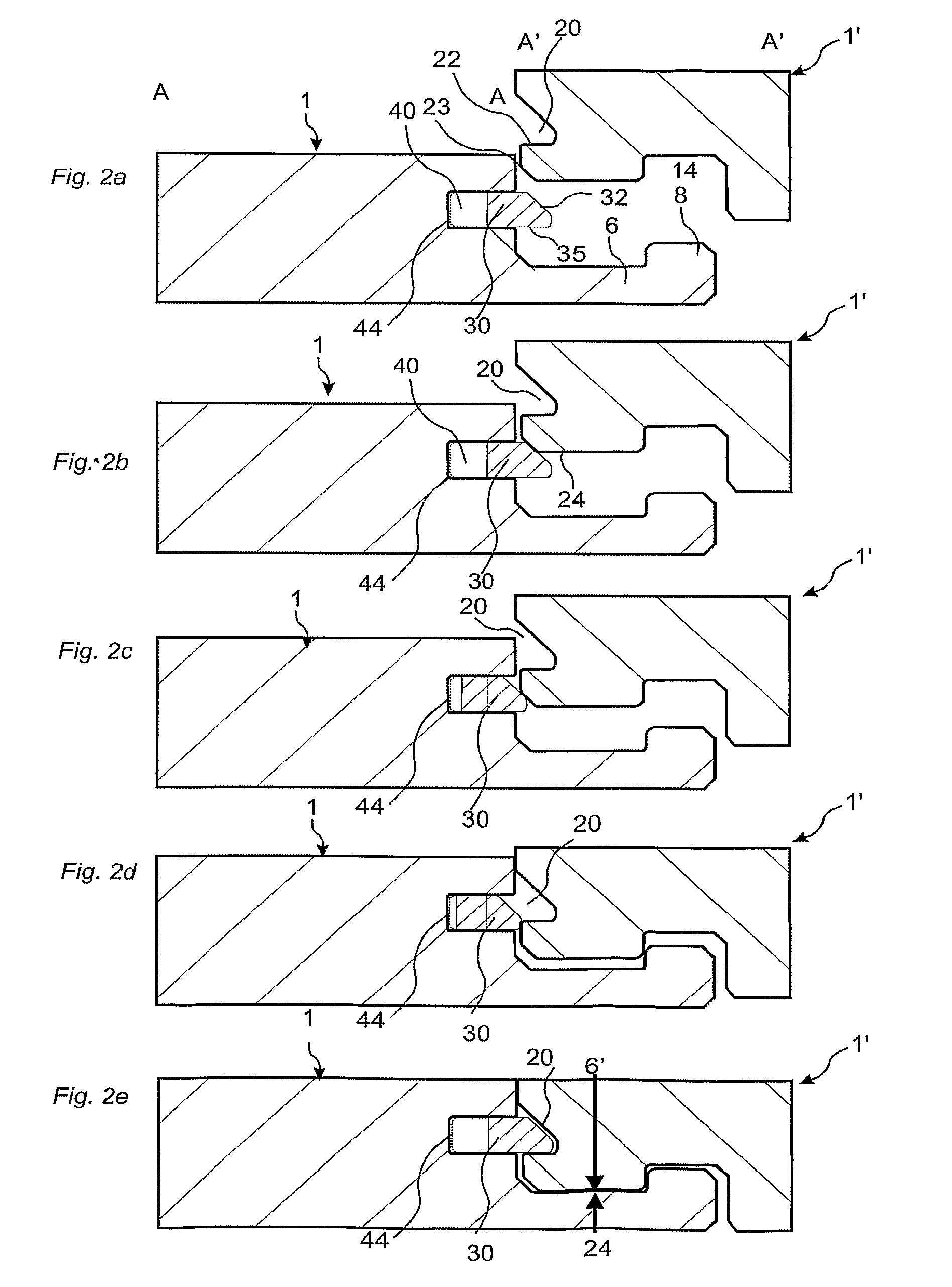

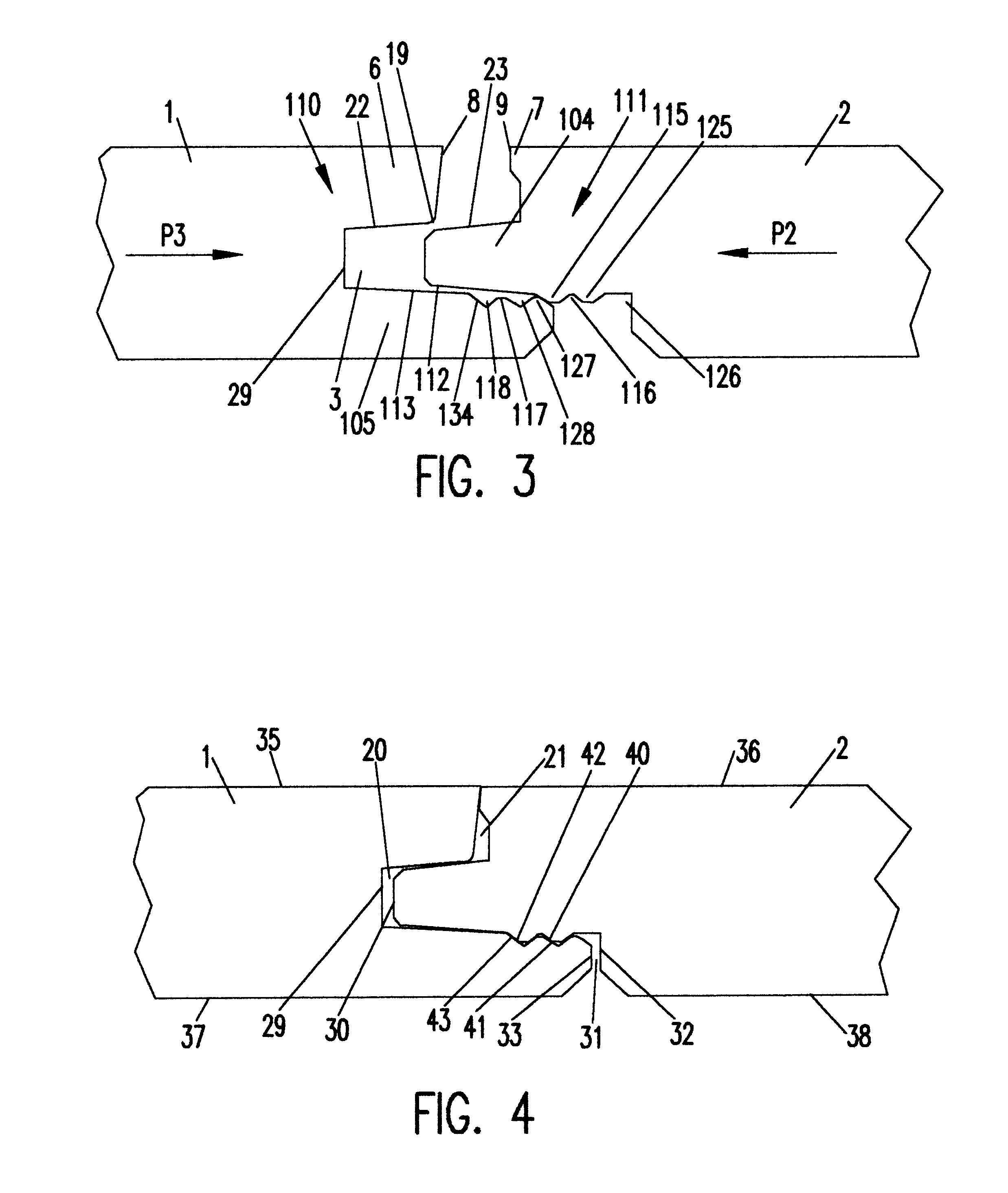

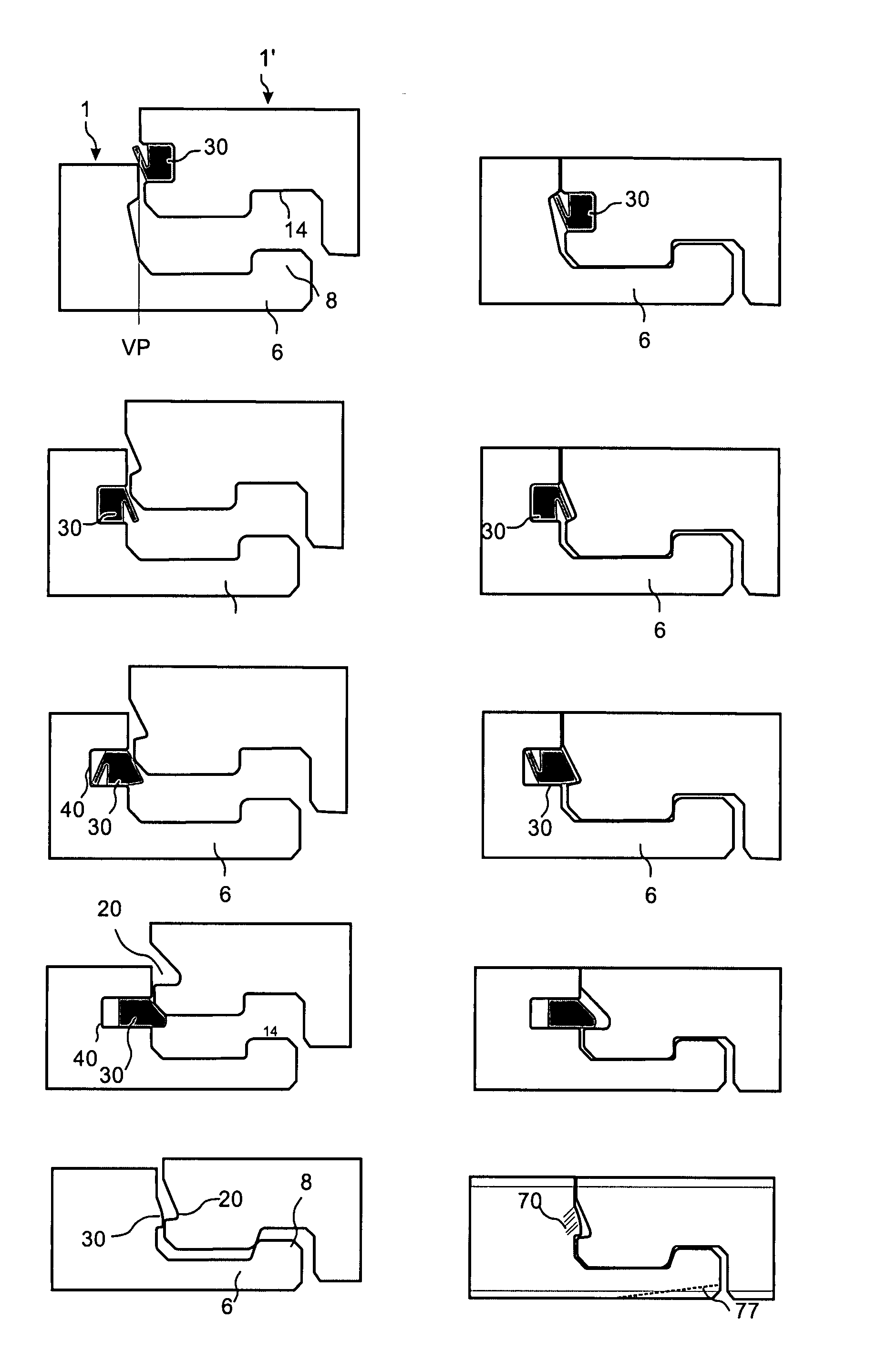

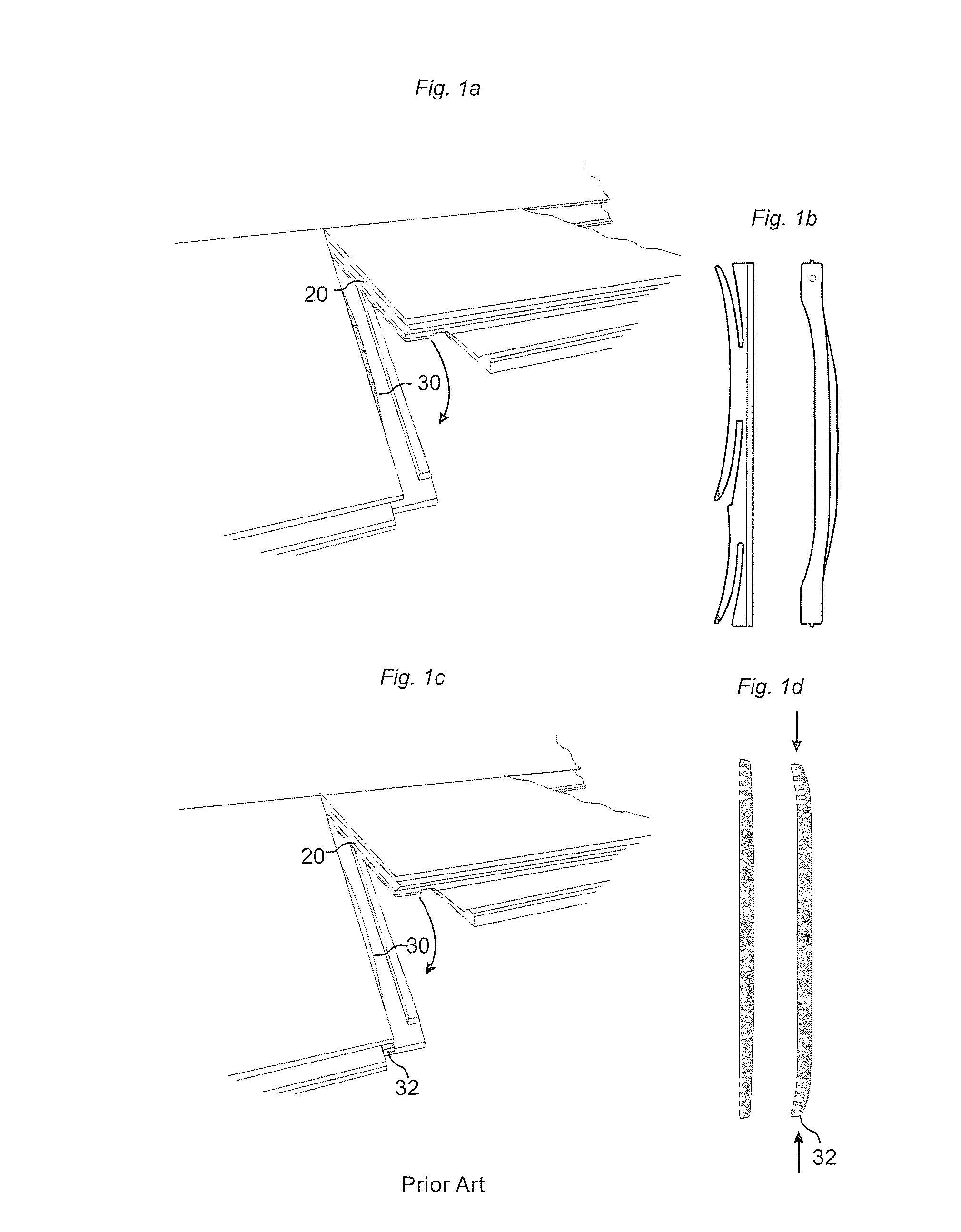

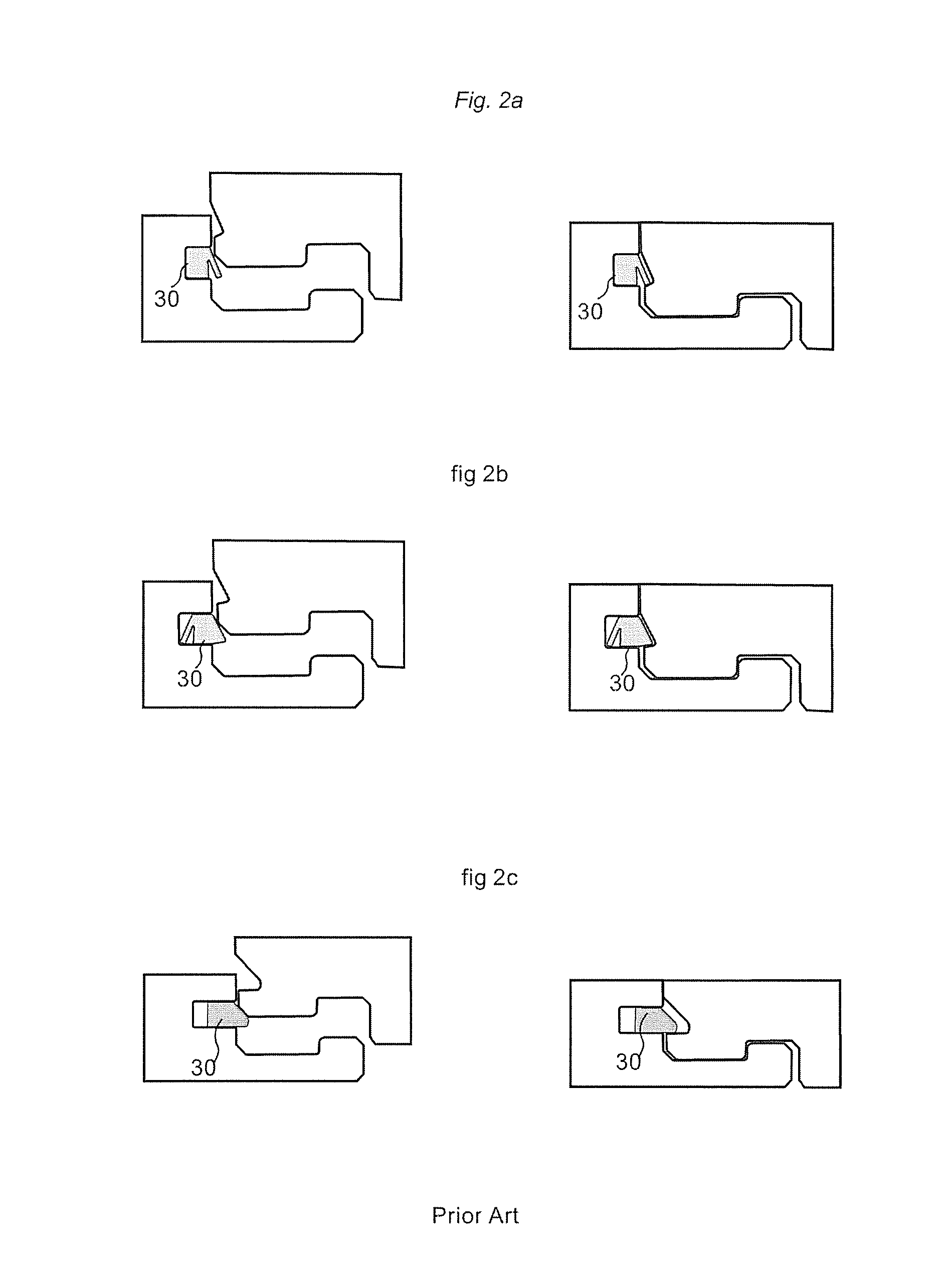

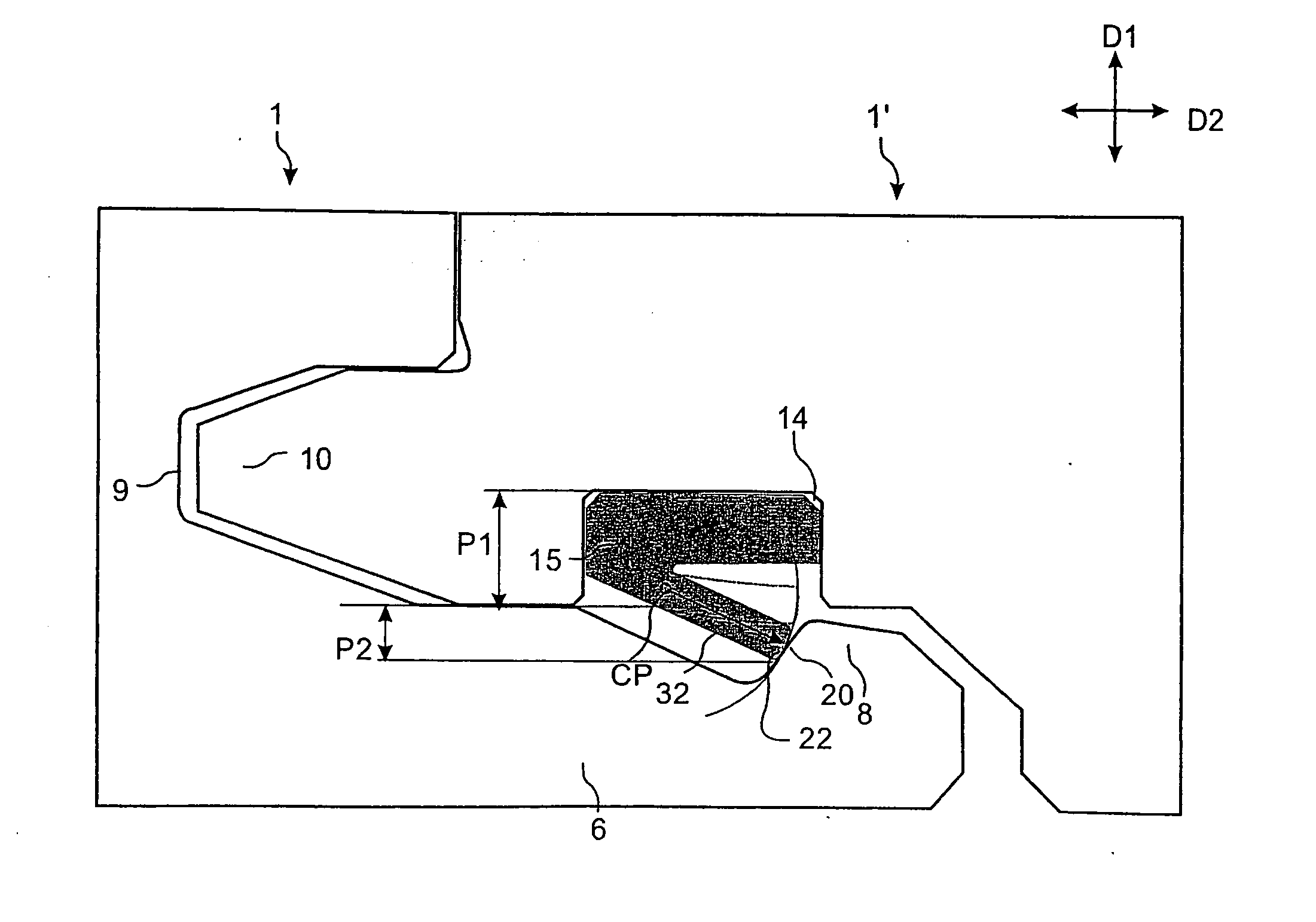

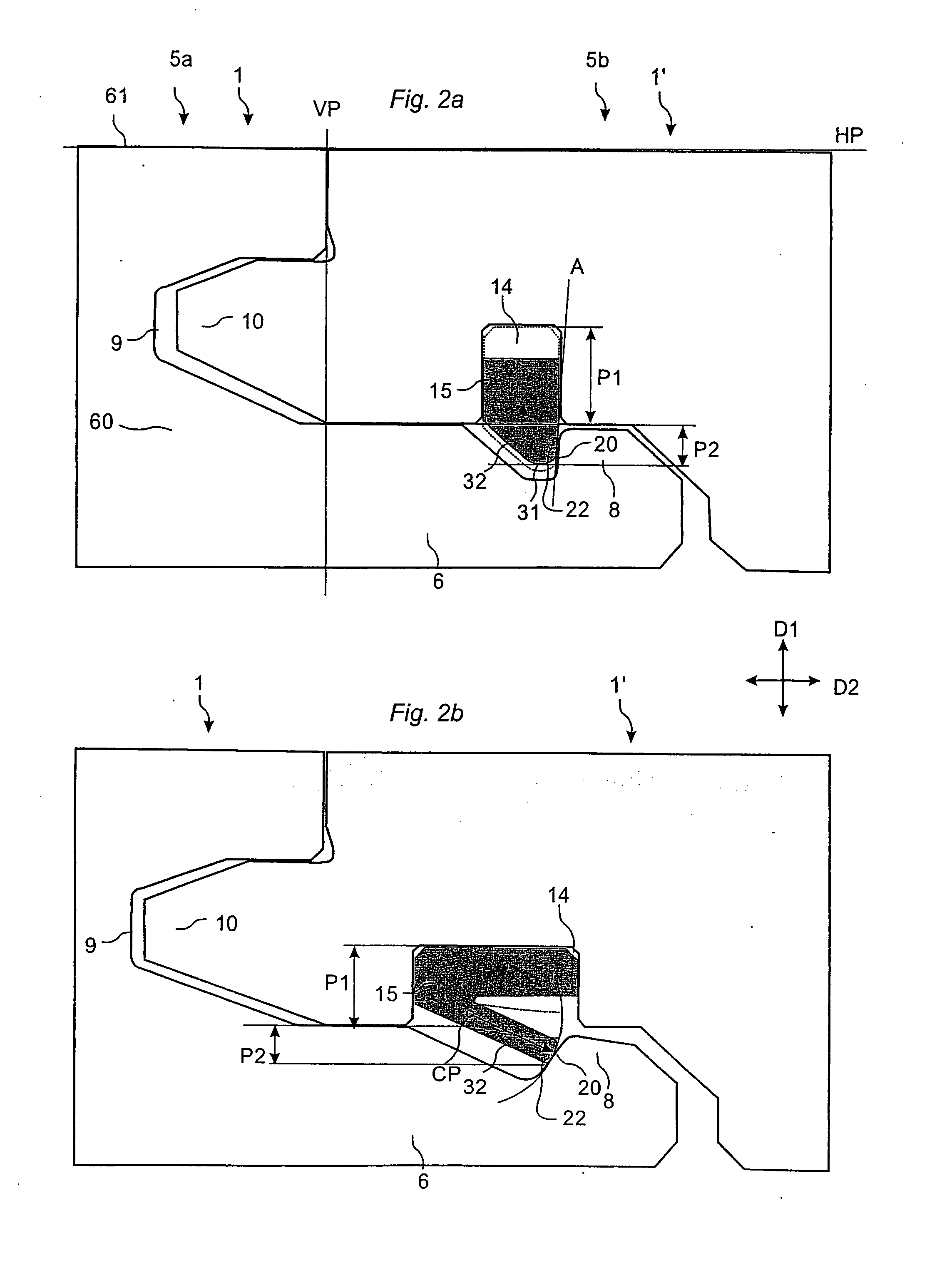

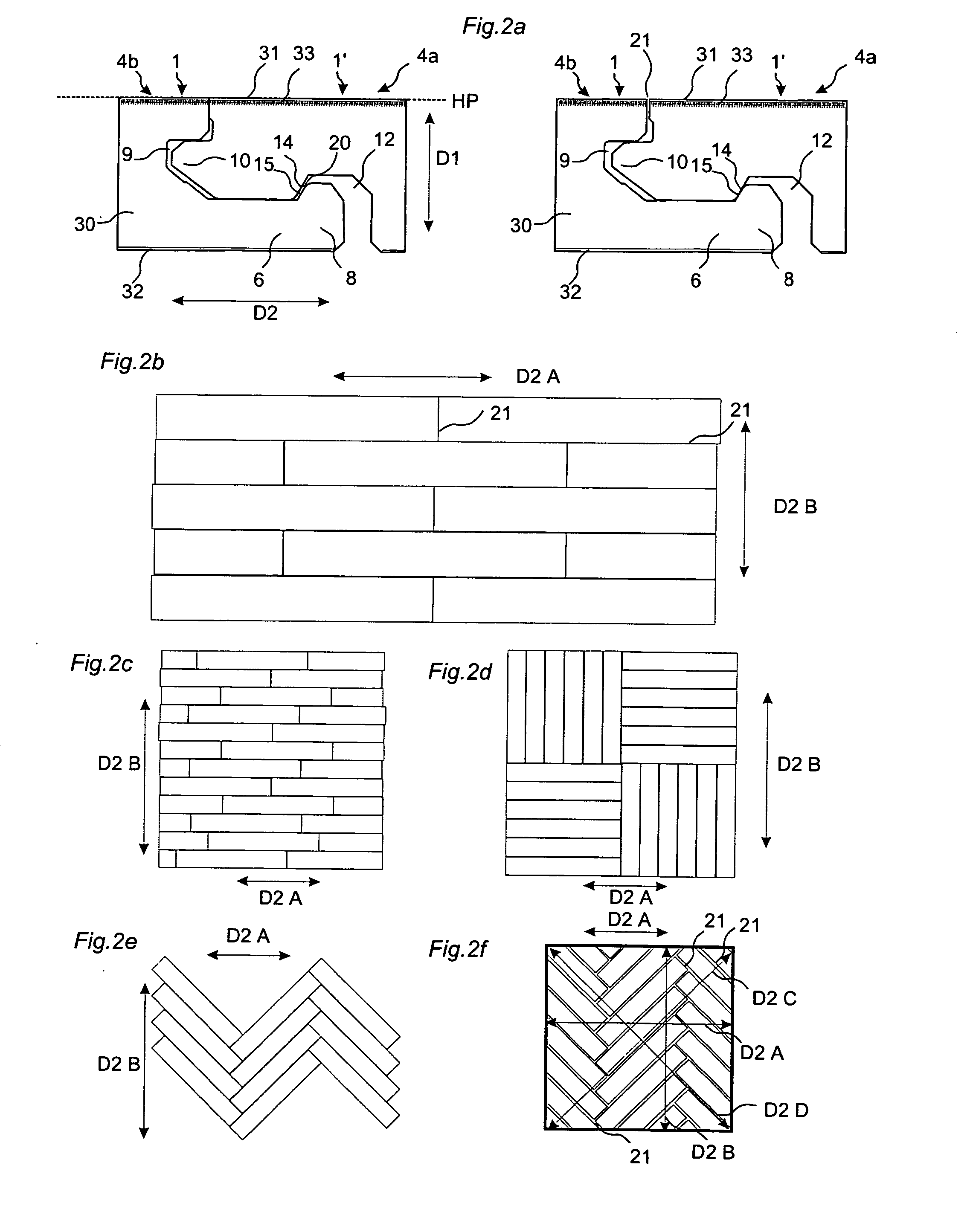

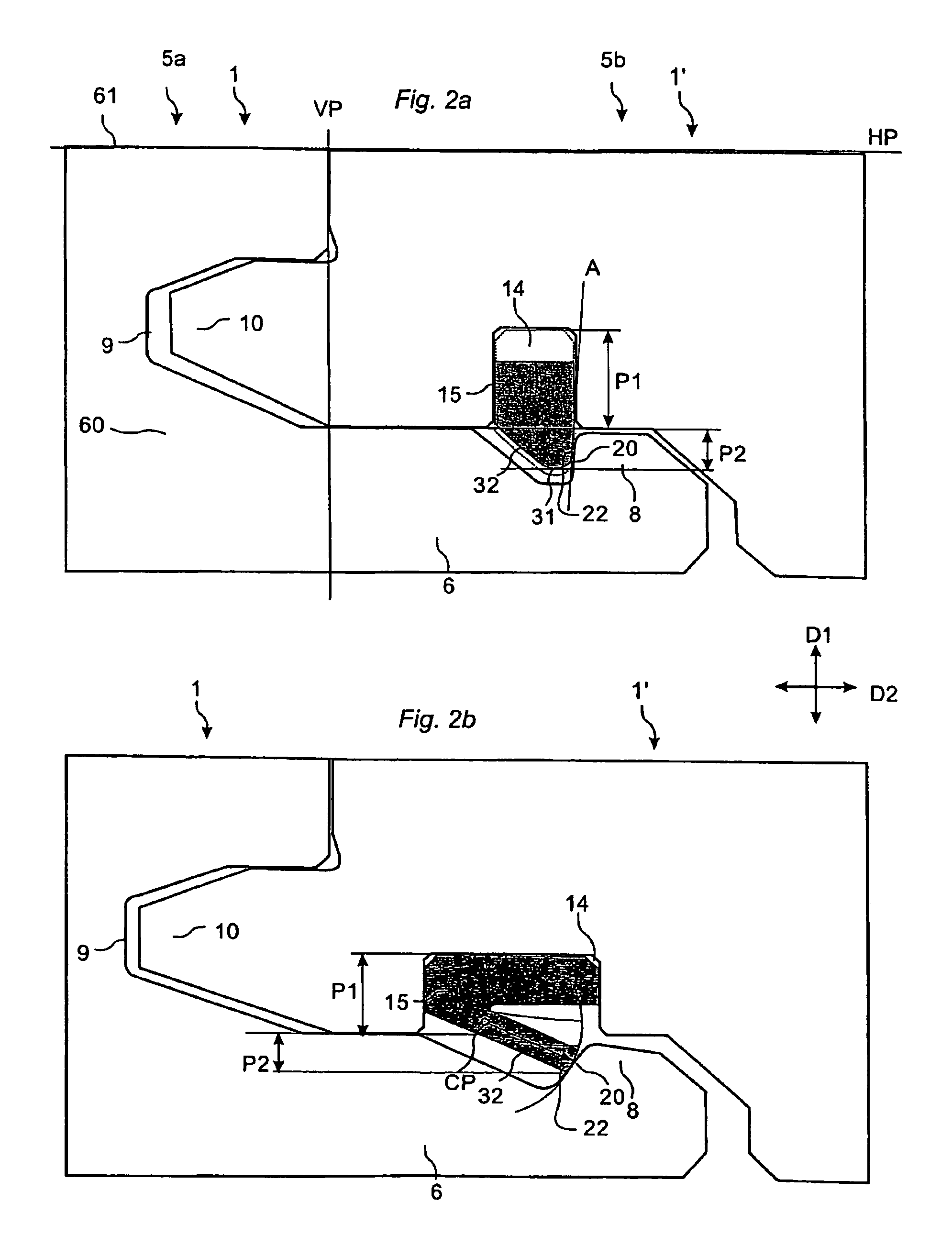

Mechanical Locking of Floor Panels With a Flexible Tongue

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system having a flexible tongue (30) in a displacement groove (40), which during a vertical folding motion is displaced. Moreover, a tongue blank (50), a production method and an installation method are shown.

Owner:VÄLINGE INNOVATION AB

Locking System And Flooring Board

InactiveUS20080028707A1Good orientationCost of waste differsCeilingsStrutsEngineeringMechanical engineering

Owner:VÄLINGE INNOVATION AB

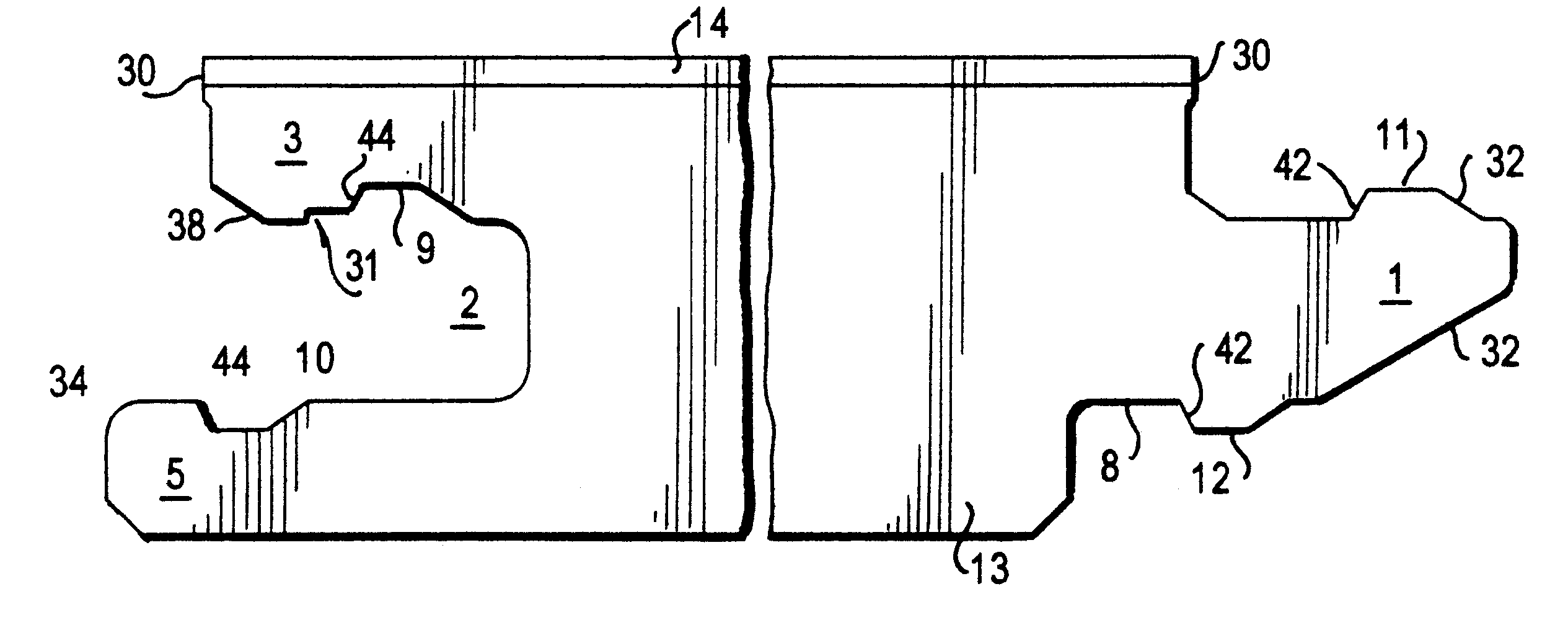

Flooring panel

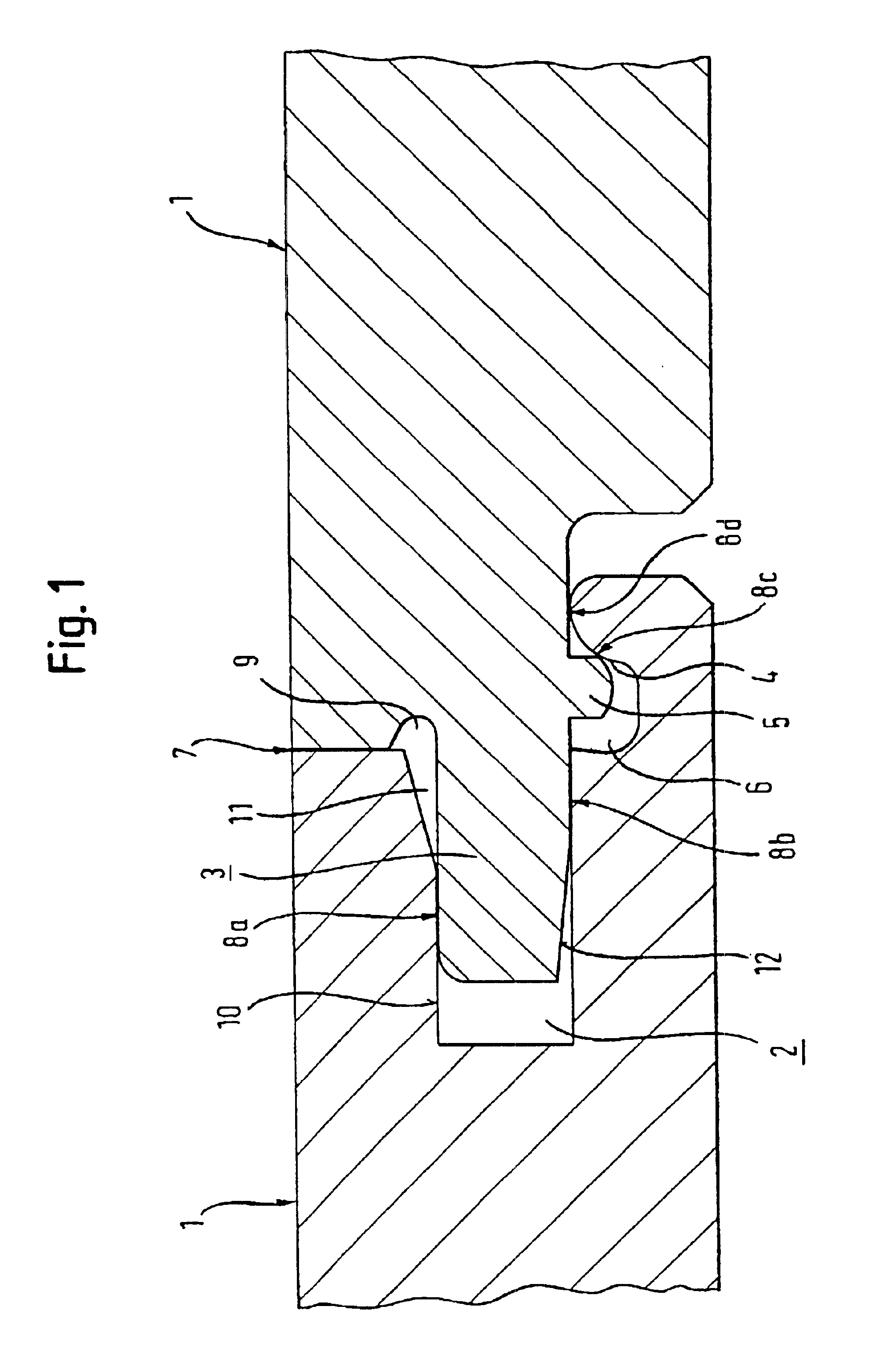

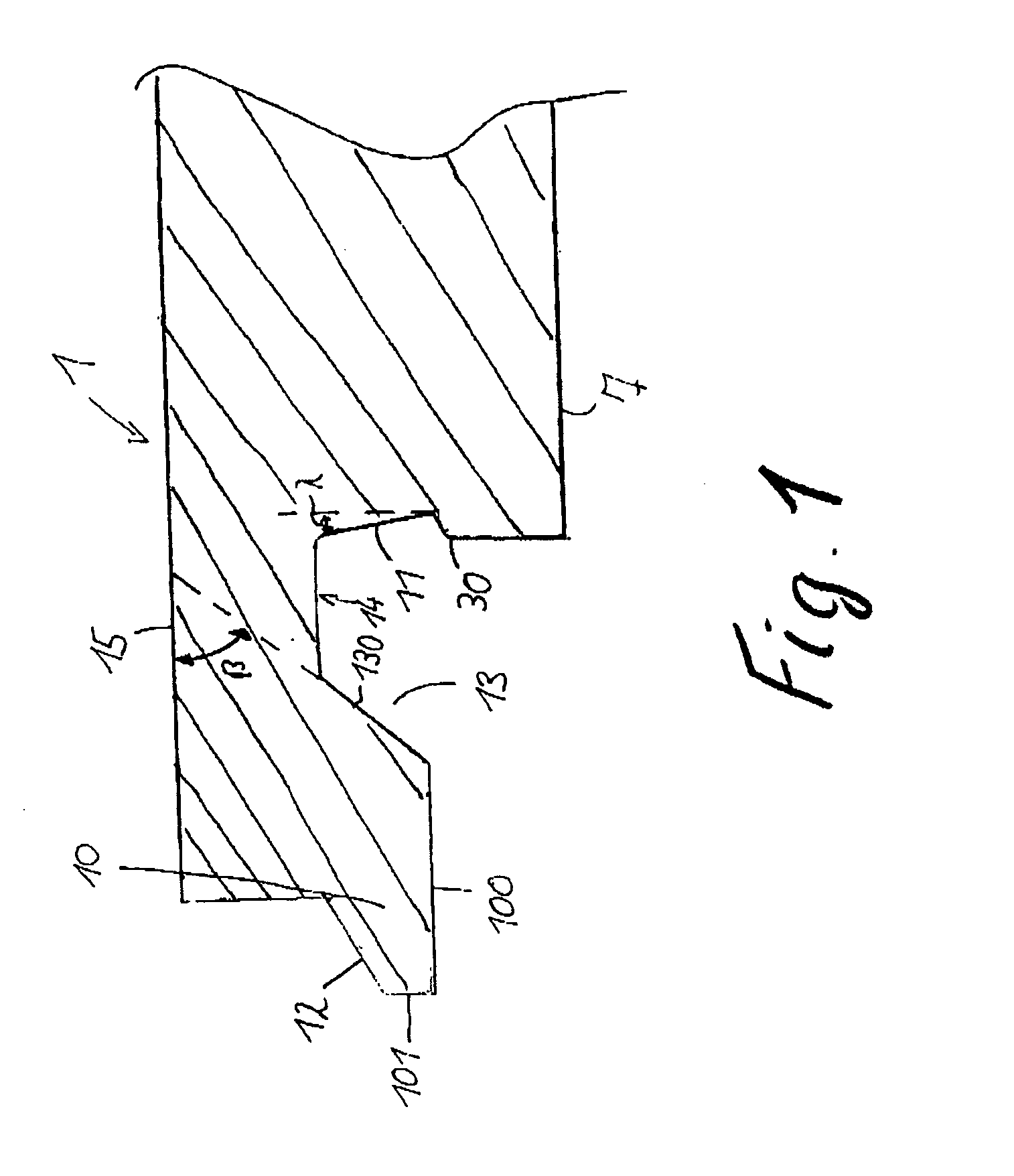

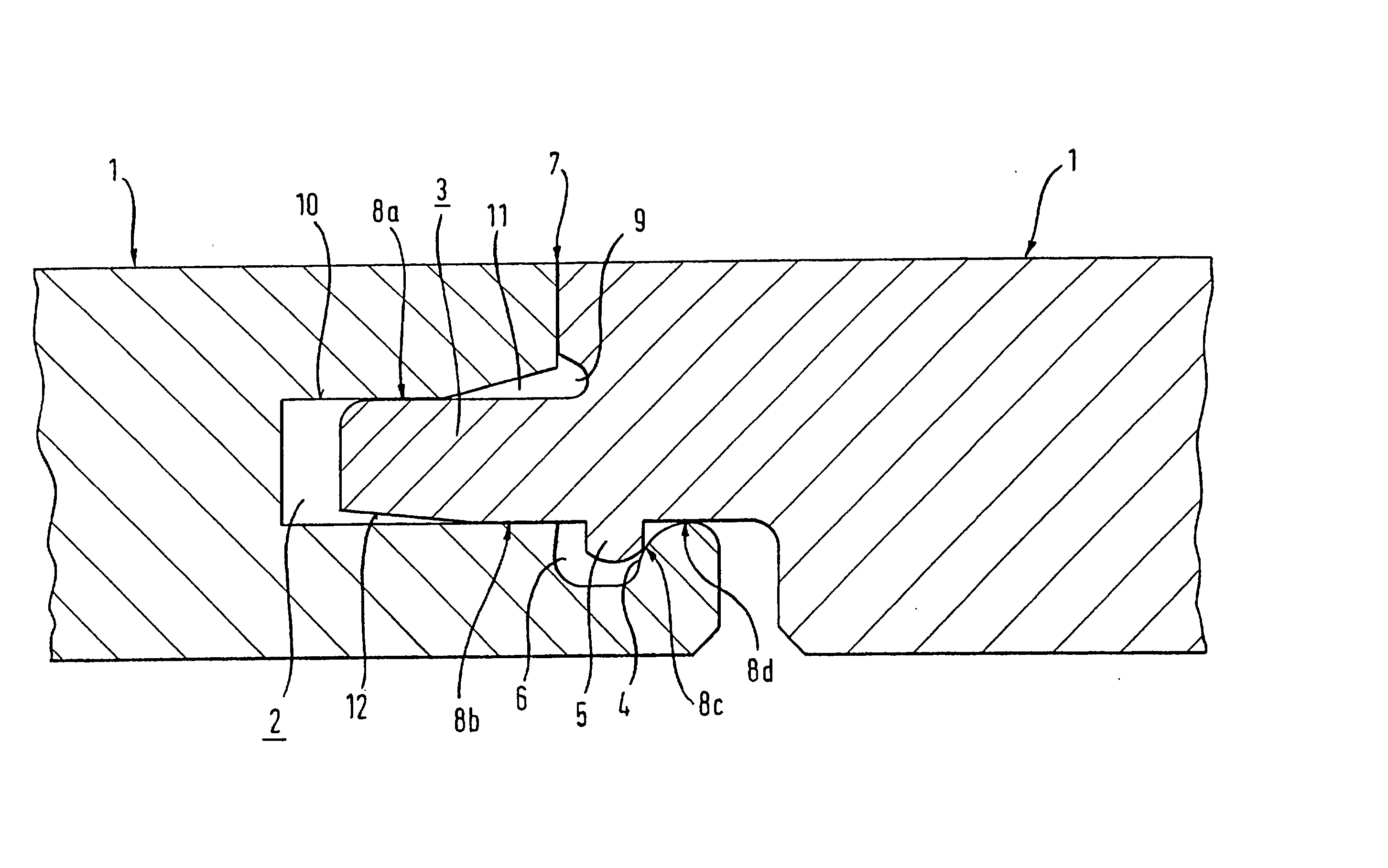

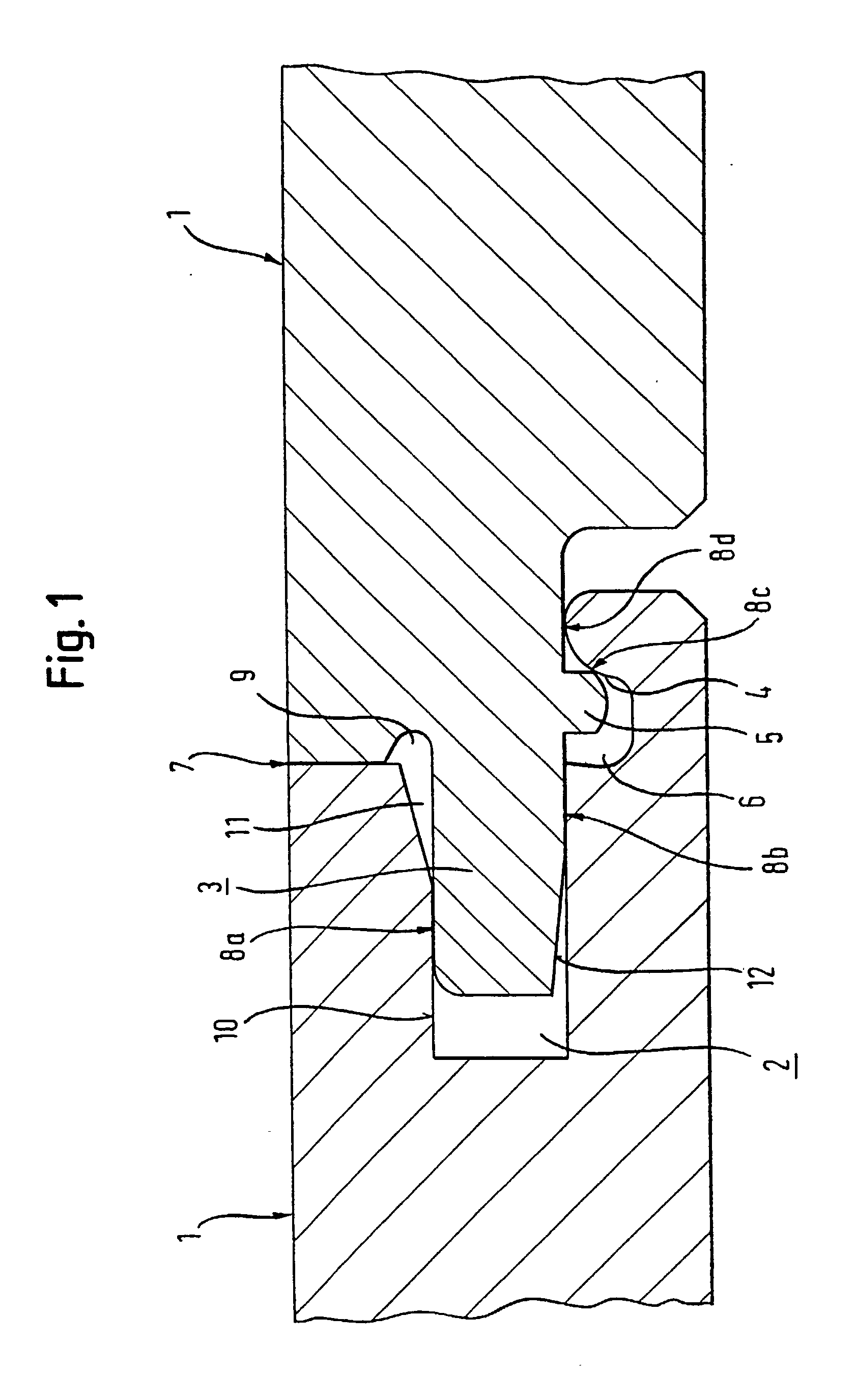

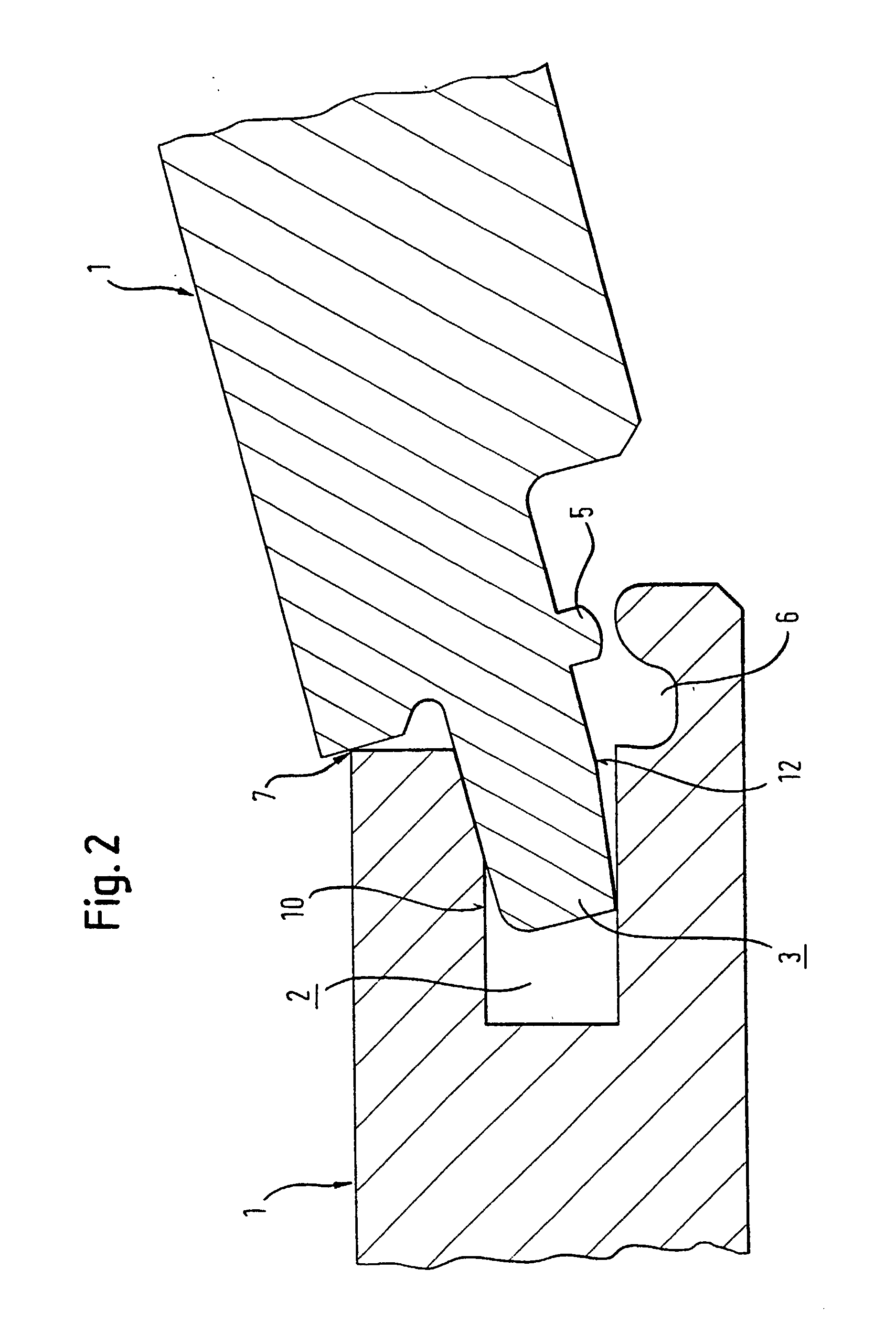

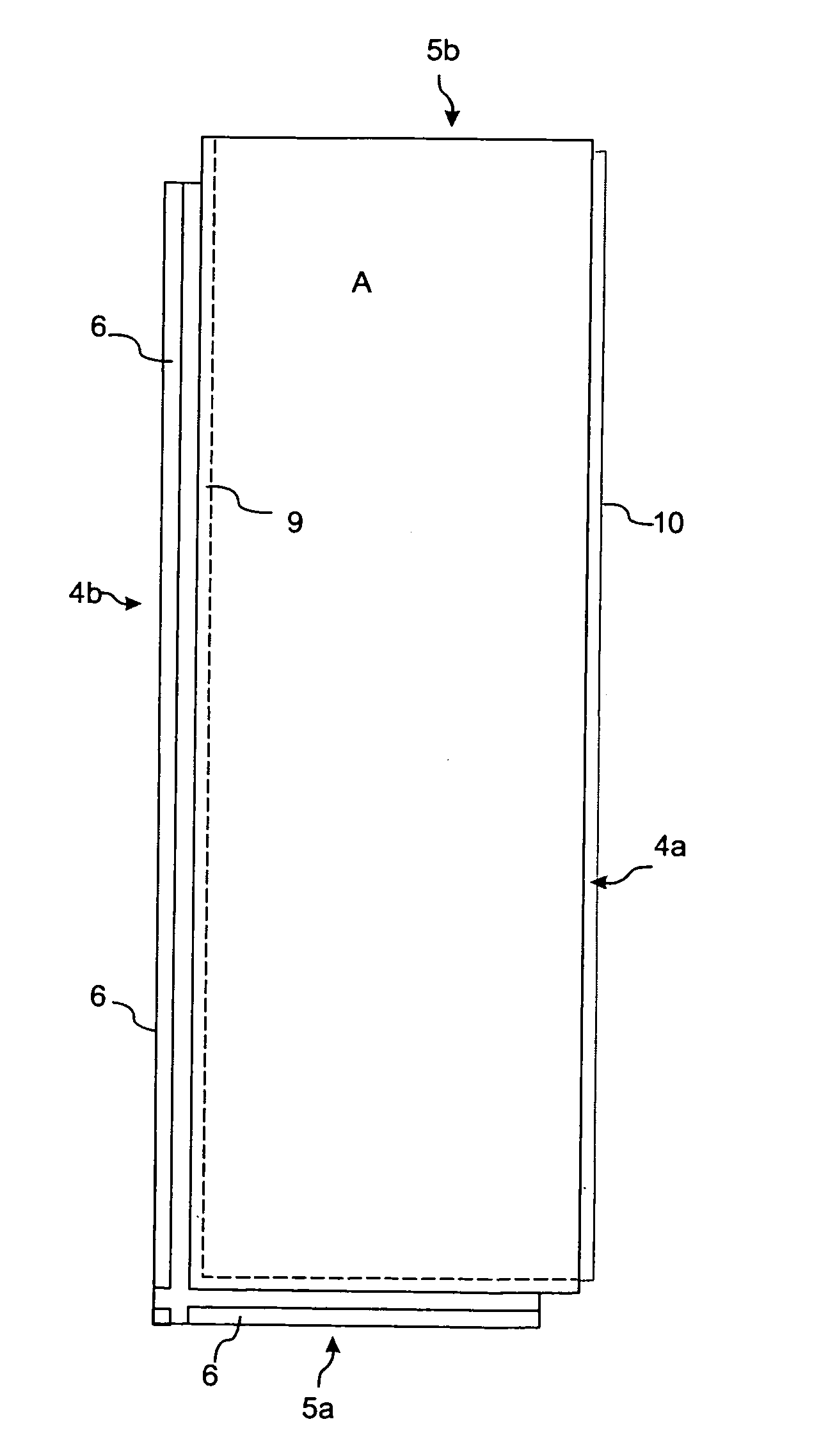

Flooring panel with two connection members whose sides face each other for attachment to other flooring panels of the same type. A first connection member has an upper projection, a lower projection, and groove between them. A second connecting member features a tongue for insertion in the groove of an adjacent connection member. In order to achieve good assembly as well as economical production of the panels, provision is made for a lower protuberance, lower indentation, lower auxiliary protuberance, and lower auxiliary indentation on the lower projection of the first connection member. The profile thus created is fitted to a corresponding profile on the lower side of the tongue which has an upper indentation, an upper protuberance, an upper auxiliary indentation, and an upper auxiliary protuberance.

Owner:KRONOTEX

Flooring panel or wall panel

Owner:PERSTORP AB +1

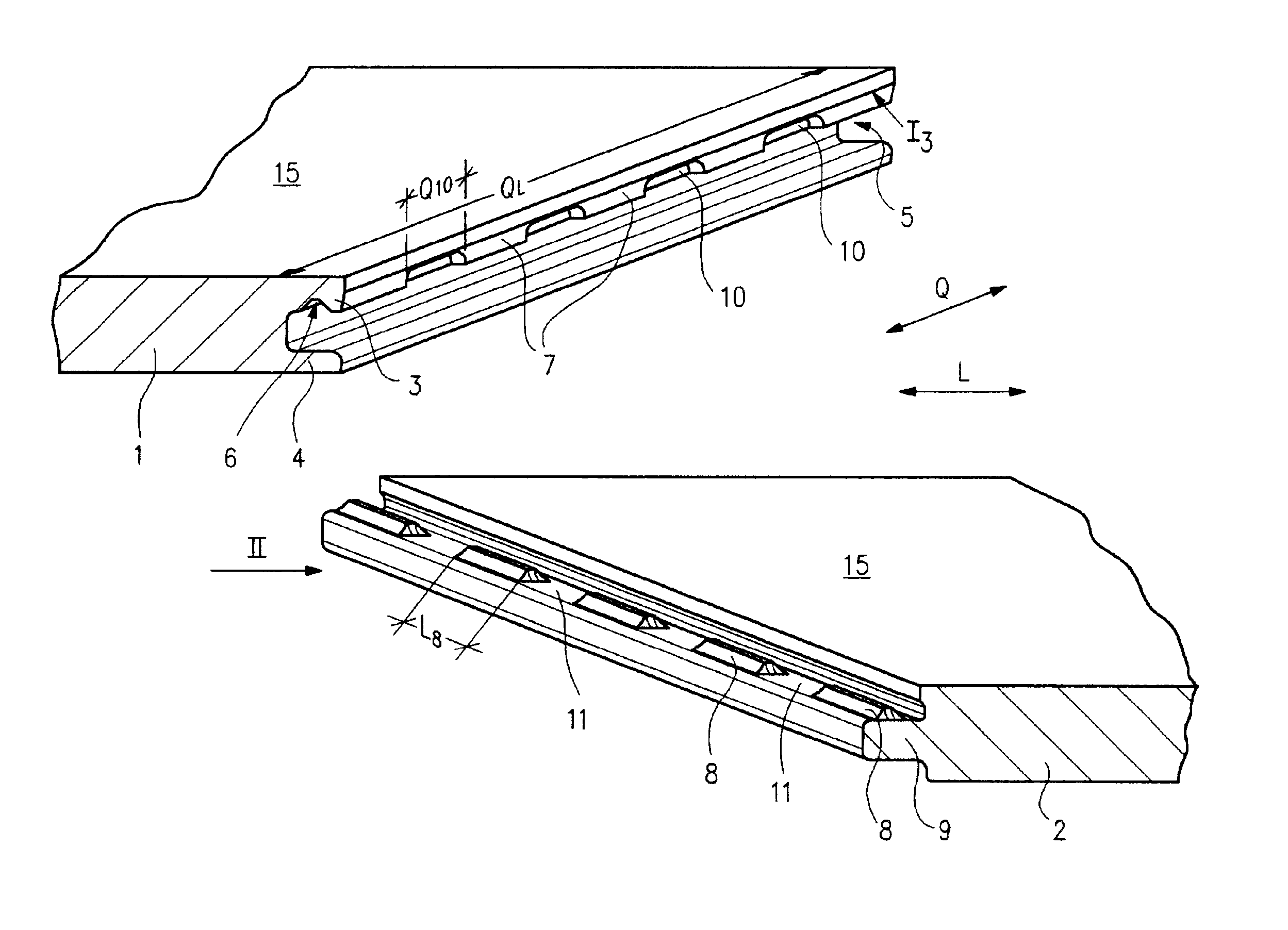

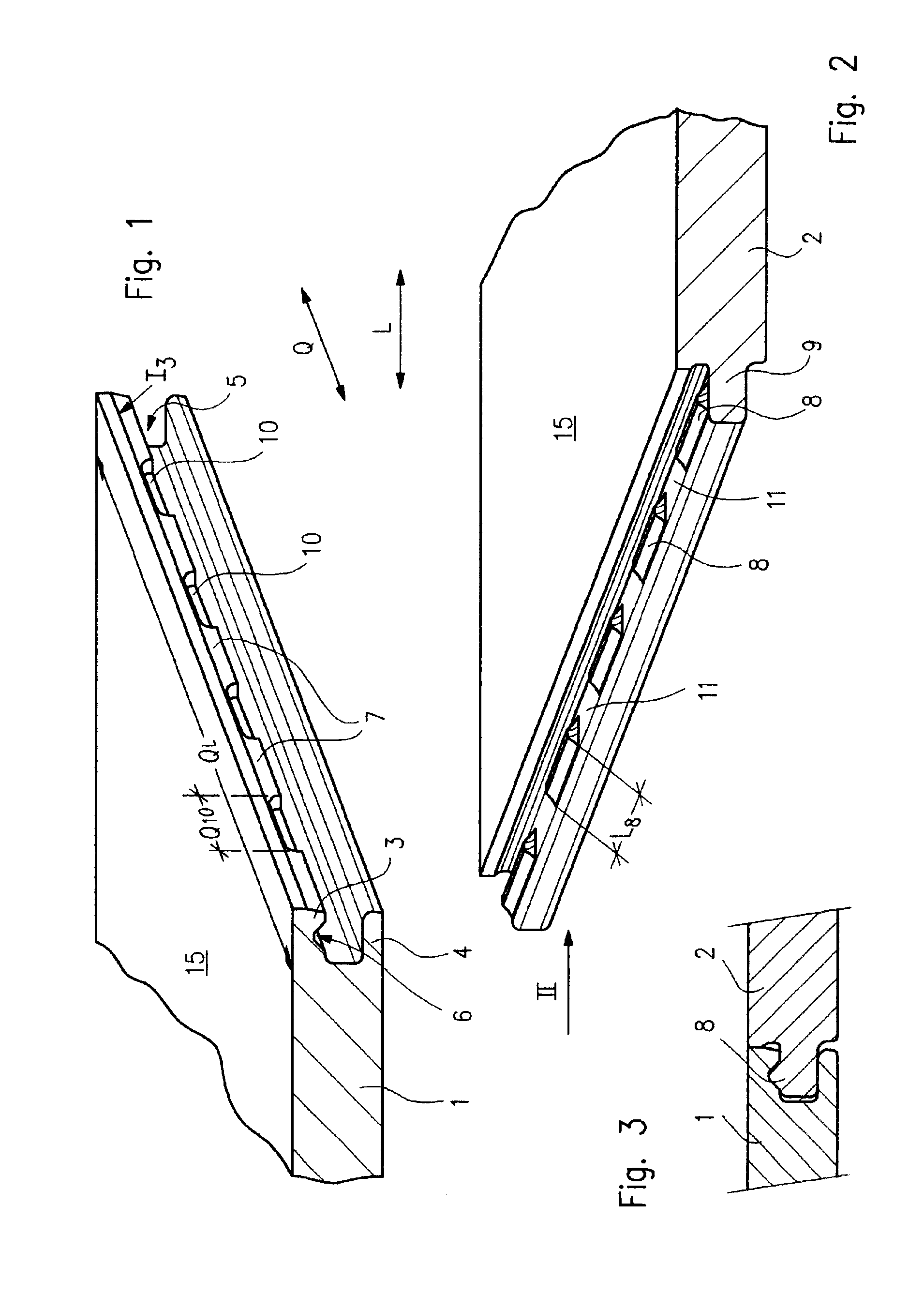

Structural panels and method of connecting same

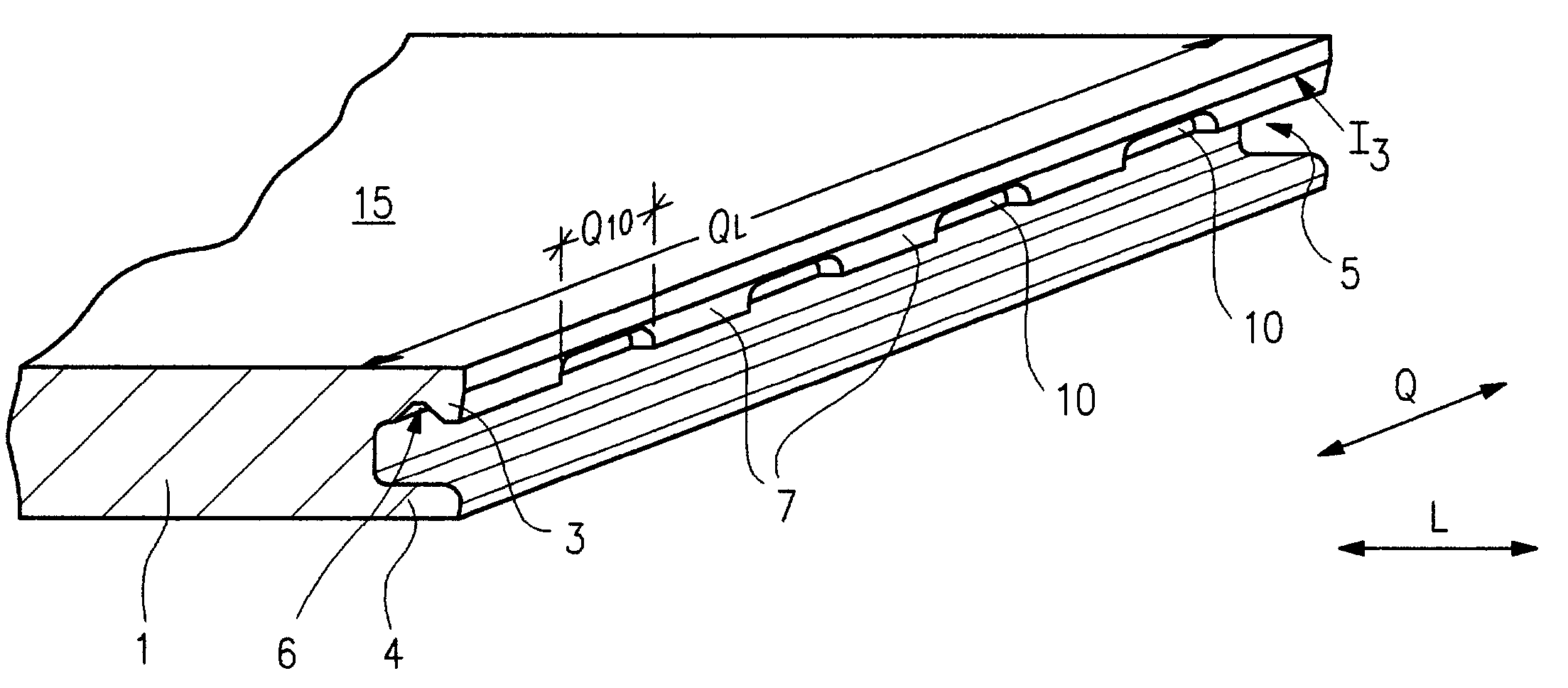

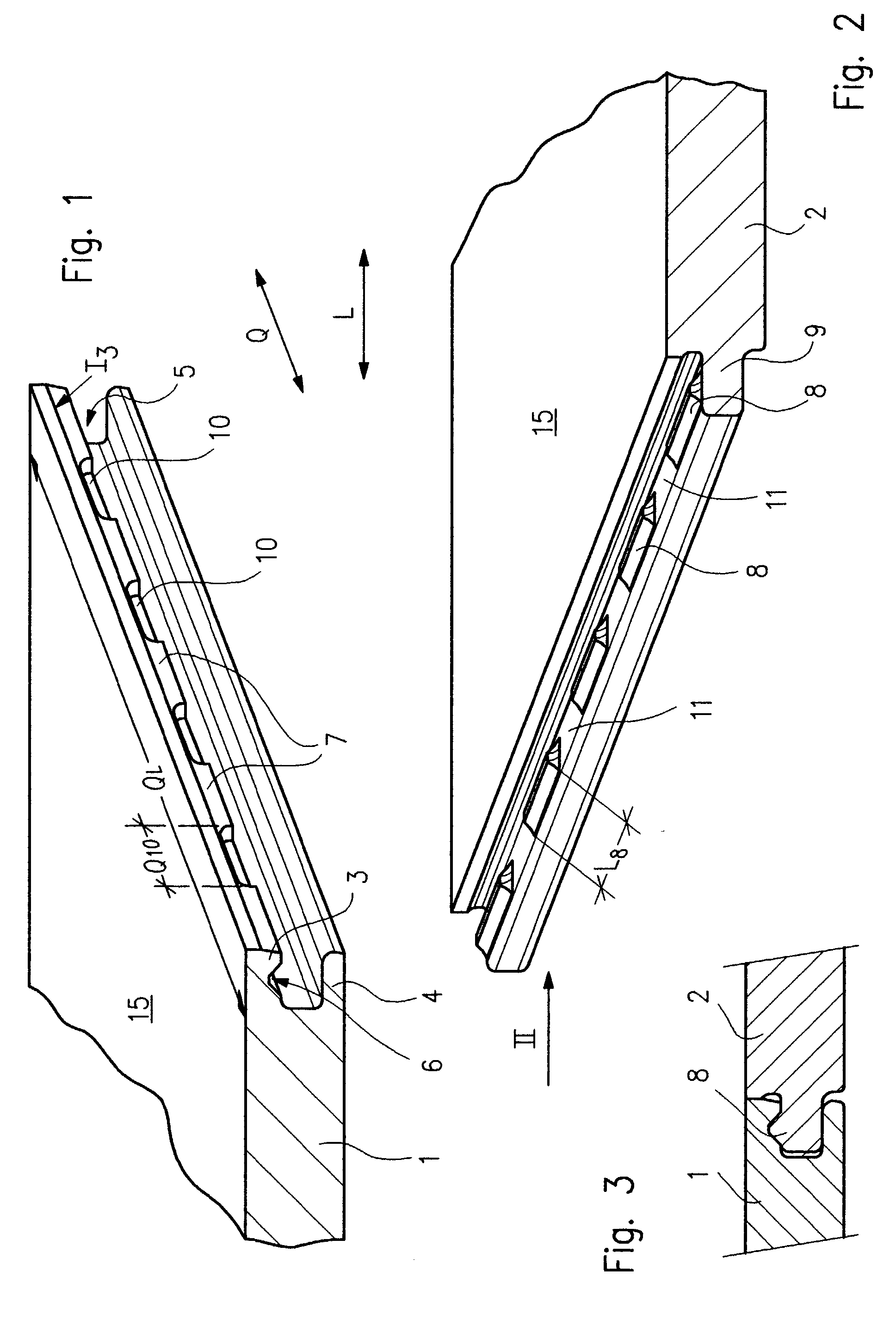

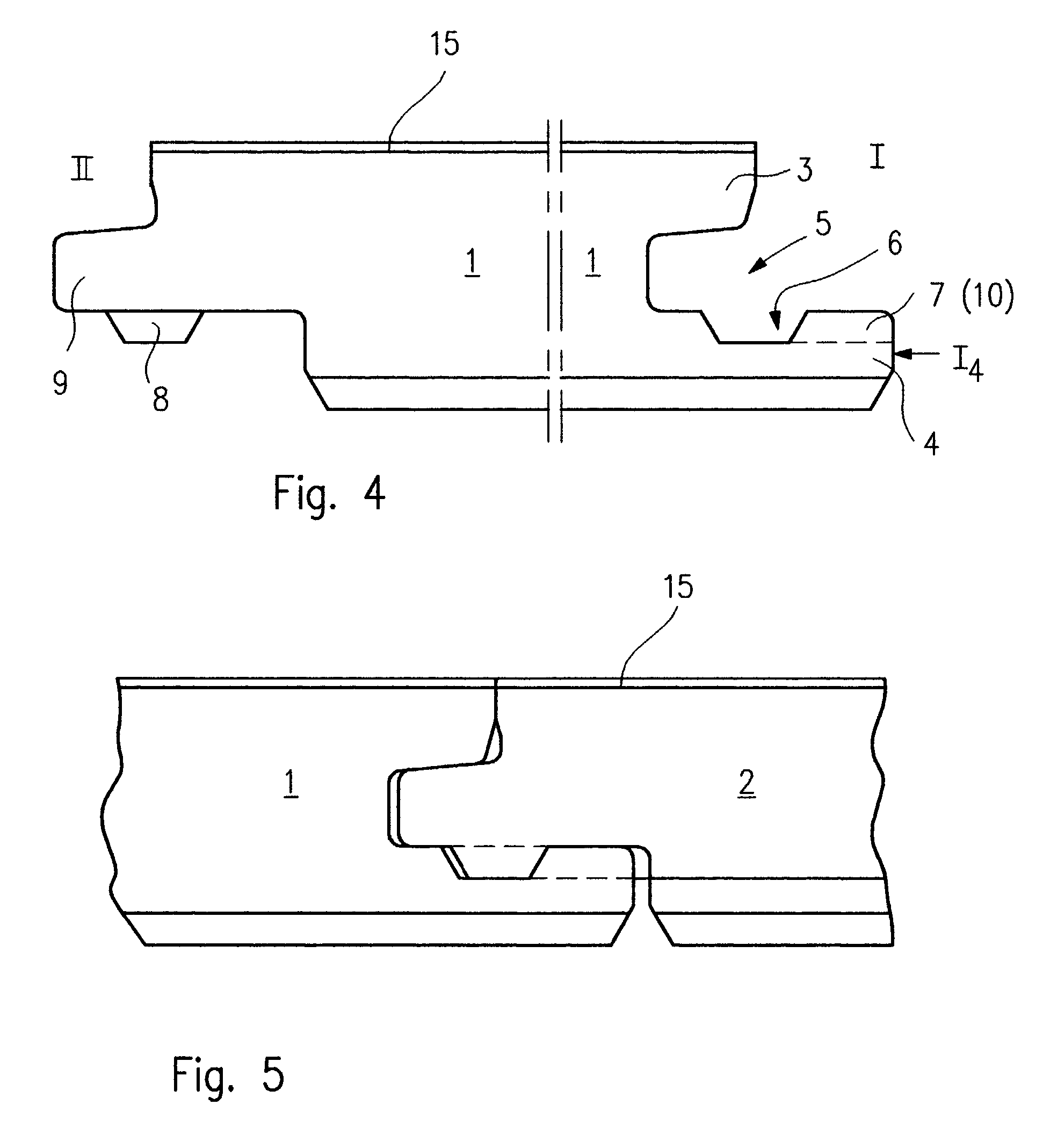

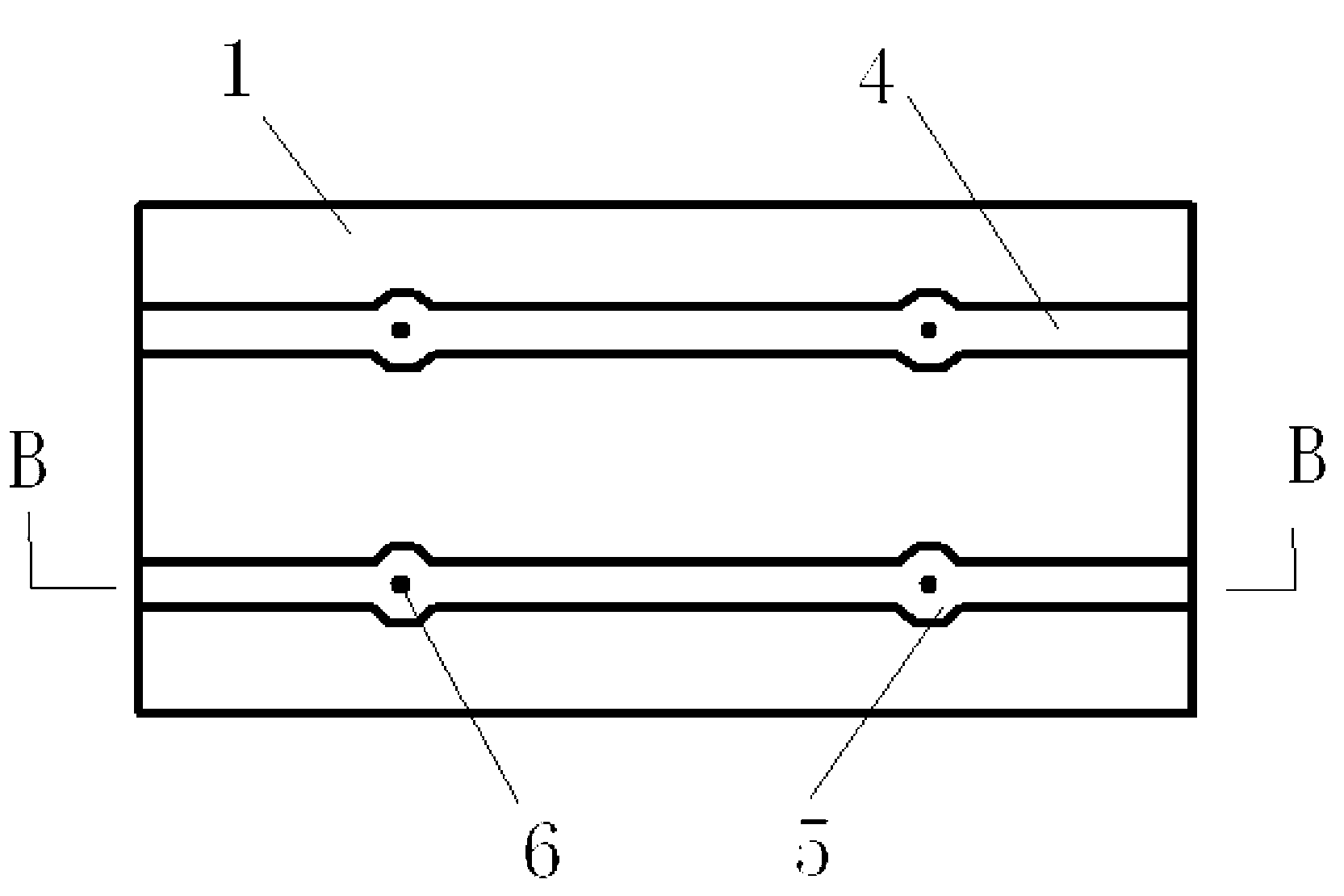

A device for connecting and locking structural panels, particularly floor panels, having a groove forming an upper lip and a lower lip over the entire length of at least one lateral border and with a tongue formed on the opposite lateral border corresponding to the groove. To lock panels that have been connected, the tongue is provided with at least one projection and the groove exhibits at least one indentation on the lip that faces the projection, which device is characterized by the indentation being longer than the projection, and on its lateral border (I3, I4) the lip provided with at least one indentation exhibits at least one recess reaching back to the indentation. The length of the recess is at least as great as the length of the projection, and seen in the longitudinal direction, the recess and the projection occupy positions that are staggered, one relative to the other.

Owner:KRONOTEC

Mechanical locking of floor panels

ActiveUS20090193748A1Avoid vertical displacementReduce vertical frictionTongue/grooves making apparatusWallsEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system having tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

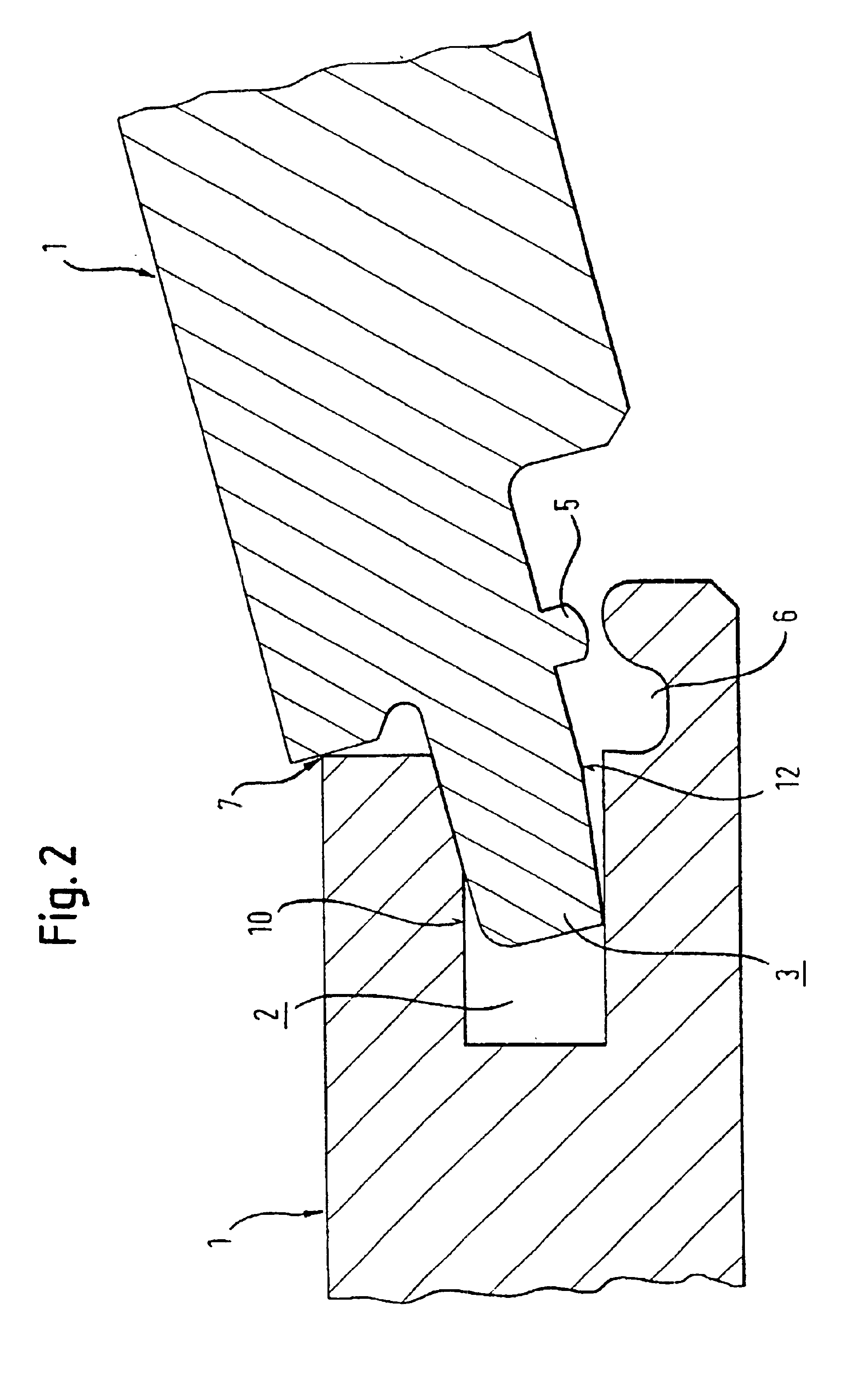

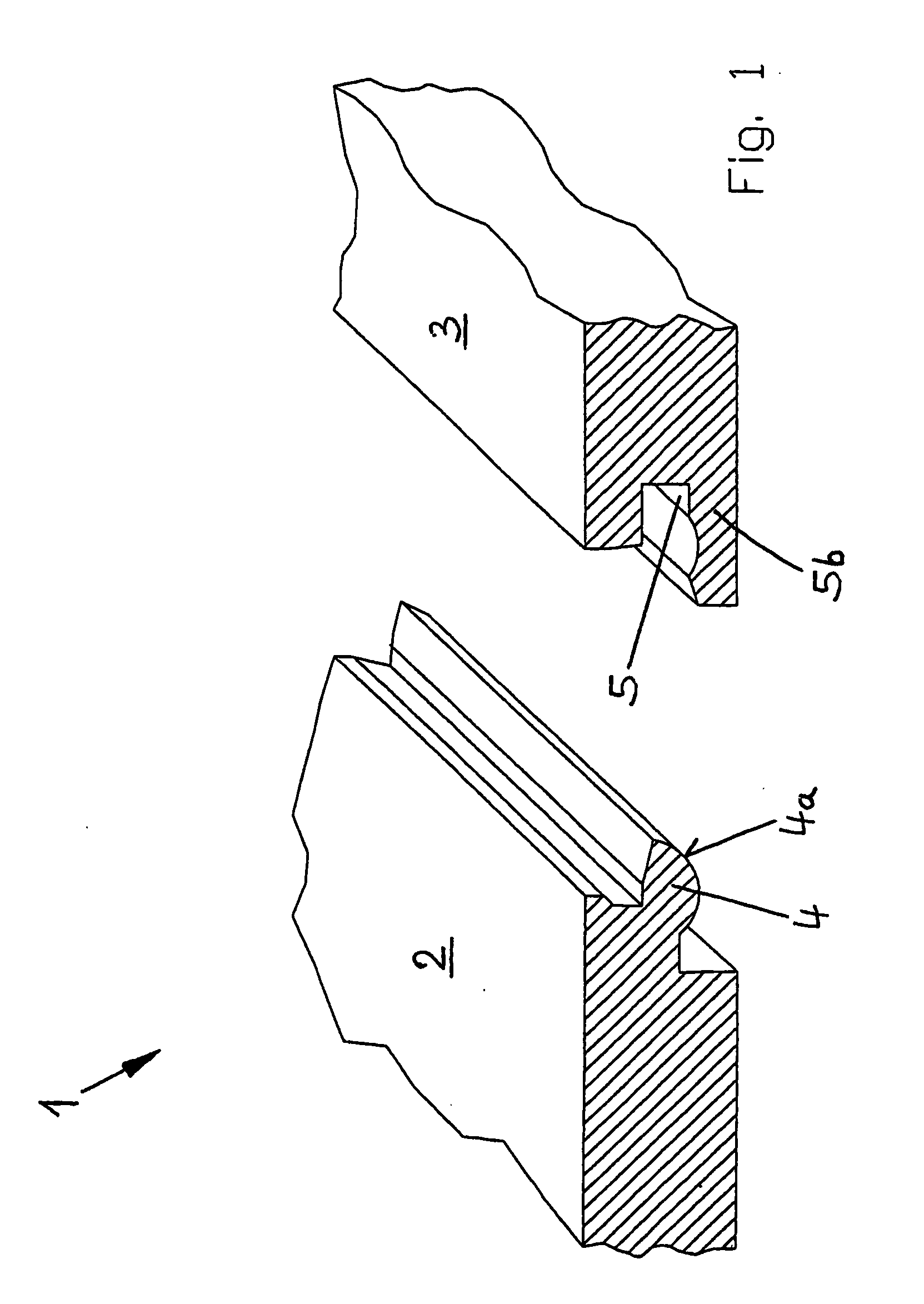

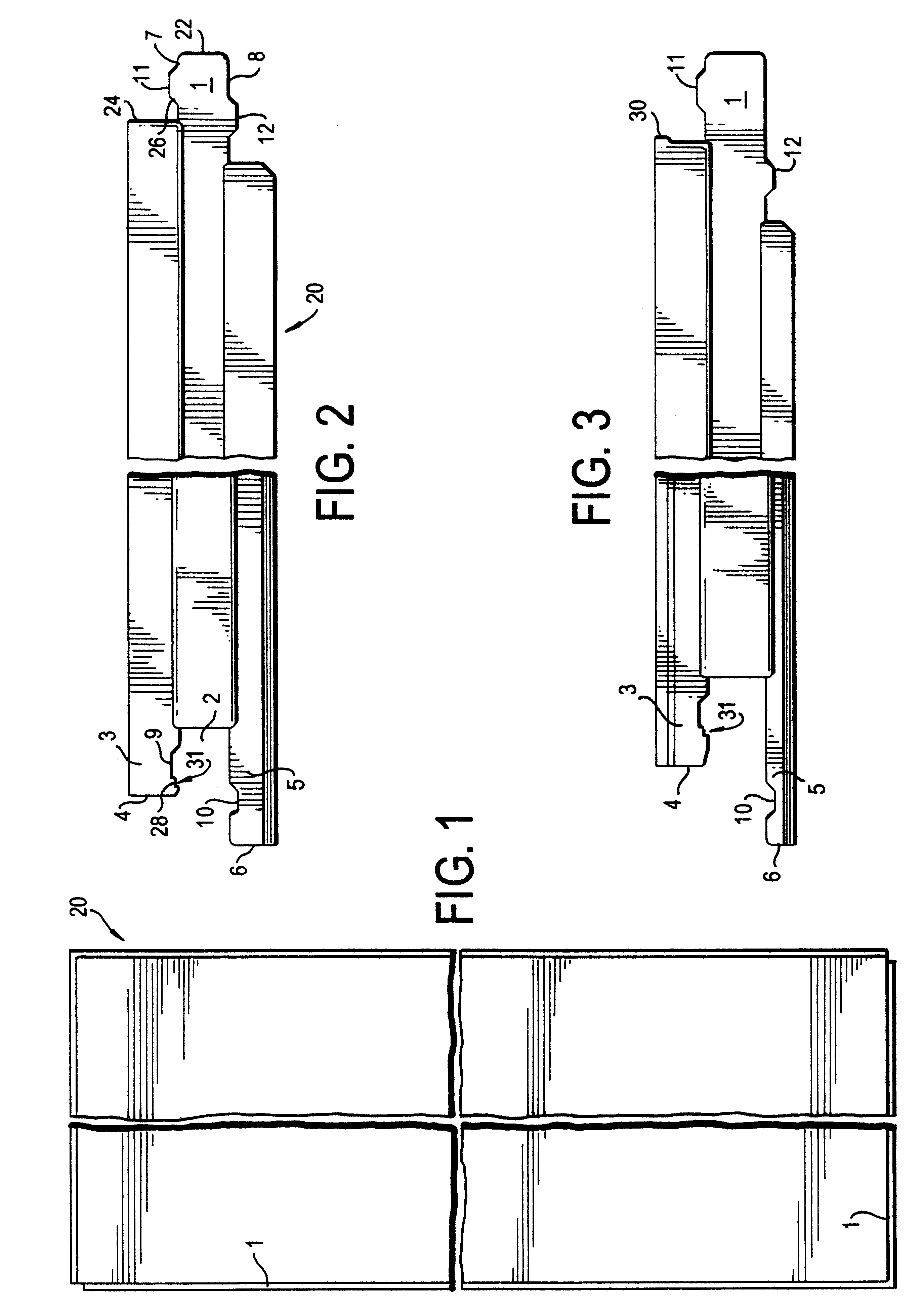

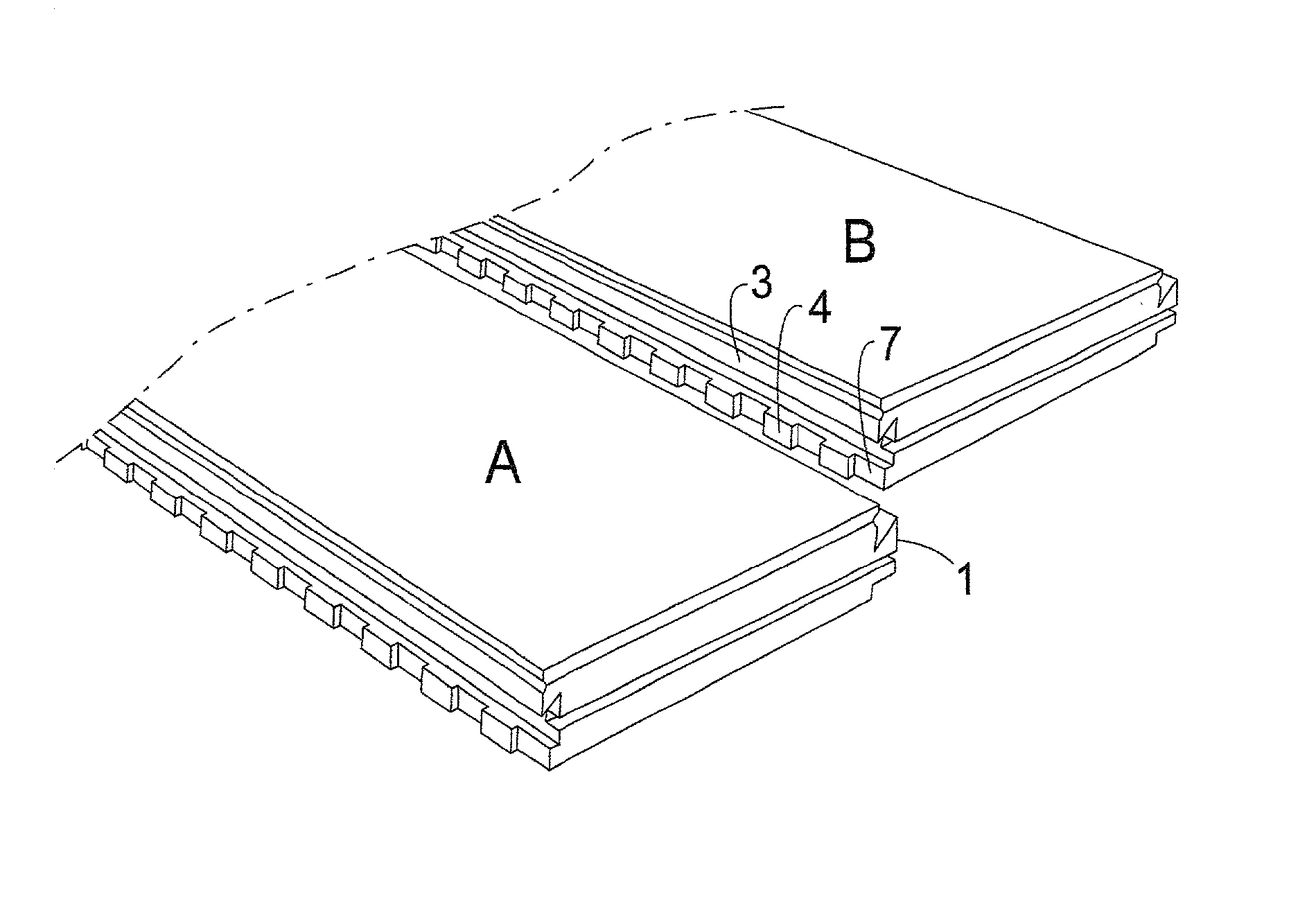

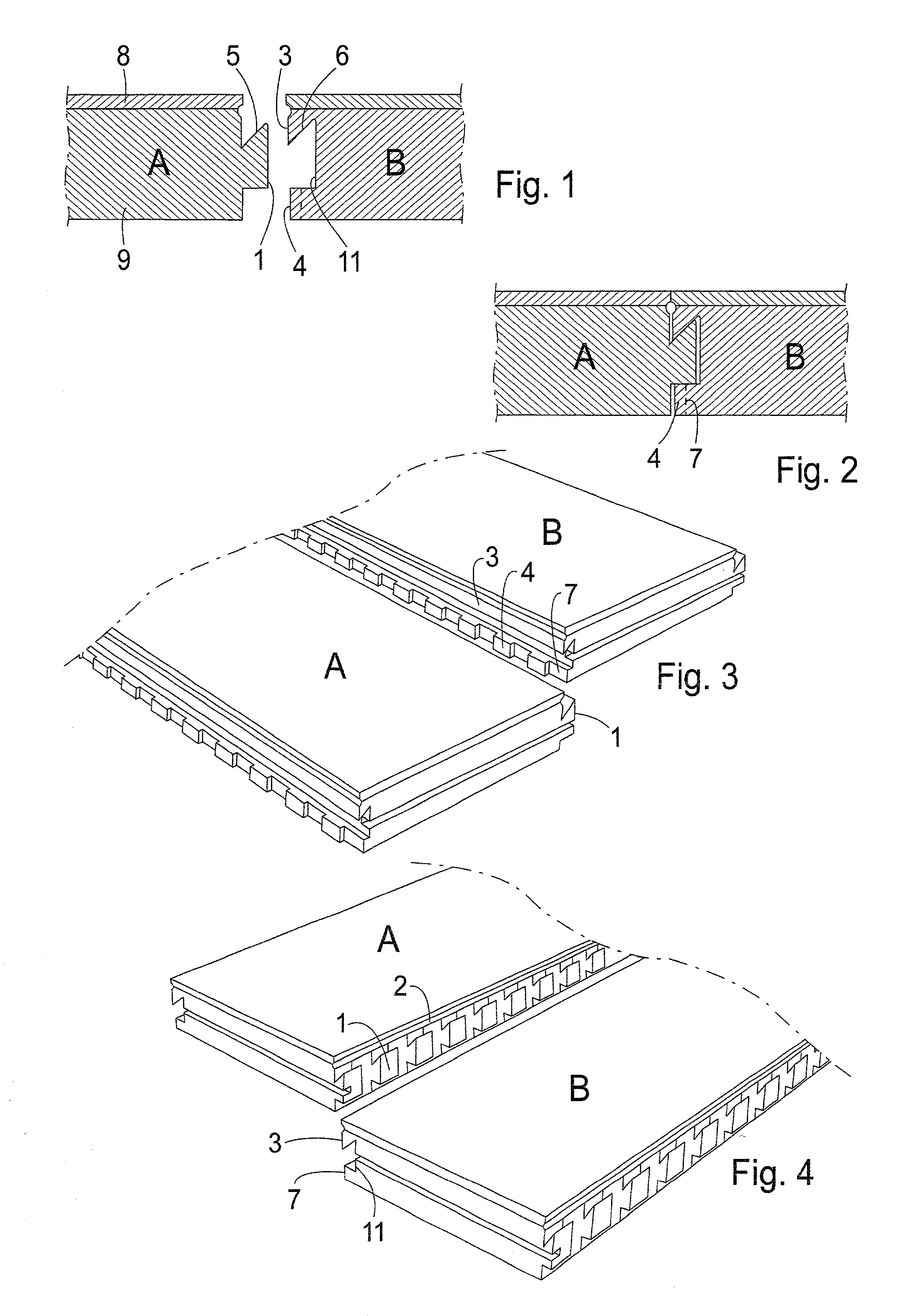

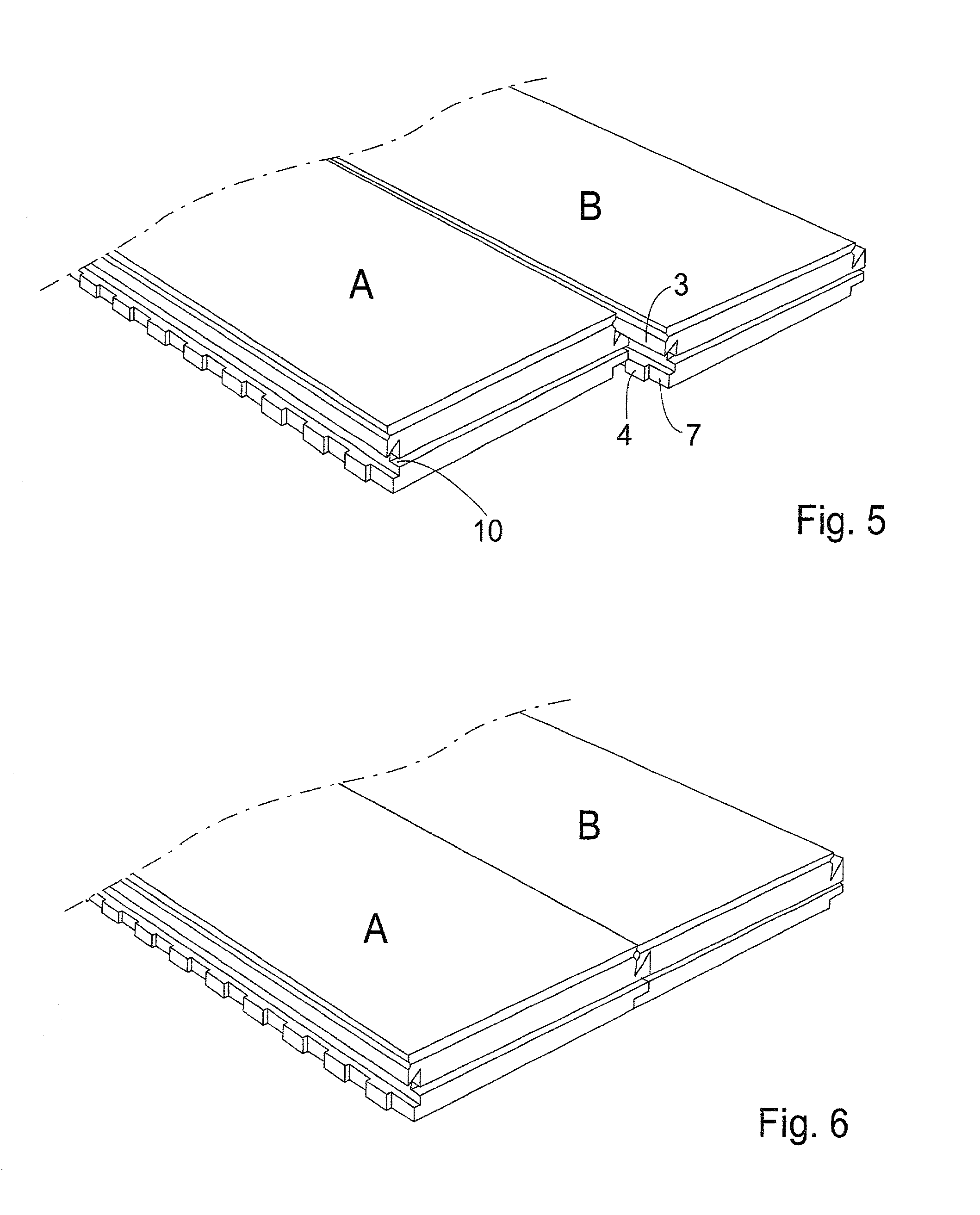

Joining system and method for floor boards and boards therefor

The invention relates to a joining system and method for floorboards, e.g. for parquetry. The joining system comprises floor boards intended to be joined with each other, wherein a first board (A) has a protrusion fitting into a recess in a second board (B). The protrusion on the first board comprises hooks (1) with intermediate slots (2) or chamfers. The recess (11) in the second board (B) is delimited on the top side by a solid edge (3), and on the bottom side by an edge having heads (4) dimensioned to be inserted through the slots (2) of the first board (A). The invention will replace the traditional groove and tenon technique. By providing slots or chamfers in the protrusion corresponding to the tenon, and corresponding cuts in the lower limiting edge of the groove, the boards can be joined in a substantially vertical or transversal movement and then be locked by a horizontal movement in the longitudinal direction of the boards. At the same time, the protrusion is shaped like hooks engaging the groove. Hereby, the joining will be very simple to perform, whilst at the same time providing a strong joint.

Owner:SODERBERG JAN

Structural panels and method of connecting same

A device for connecting and locking structural panels, particularly floor panels, having a groove forming an upper lip and a lower lip over the entire length of at least one lateral border and with a tongue formed on the opposite lateral border corresponding to the groove. To lock panels that have been connected, the tongue is provided with at least one projection and the groove exhibits at least one indentation on the lip that faces the projection, which device is characterized by the indentation being longer than the projection, and on its lateral border (I3, I4) the lip provided with at least one indentation exhibits at least one recess reaching back to the indentation. The length of the recess is at least as great as the length of the projection, and seen in the longitudinal direction, the recess and the projection occupy positions that are staggered, one relative to the other.

Owner:KRONOTEC

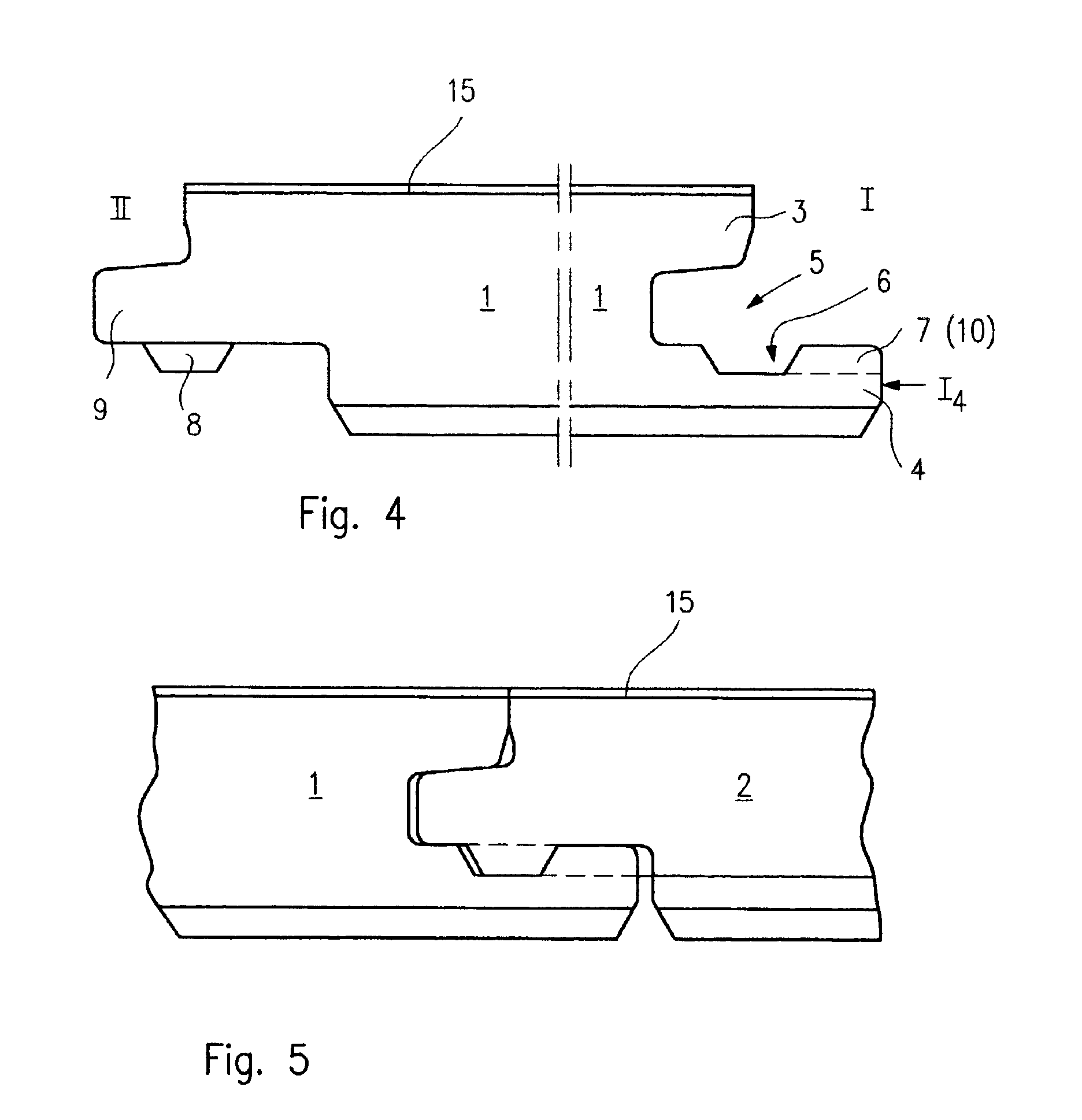

Floor panel and method of laying a floor panel

ActiveUS20040128934A1Quick and straightforward layingReliably latchStrutsCovering/liningsEngineeringMechanical engineering

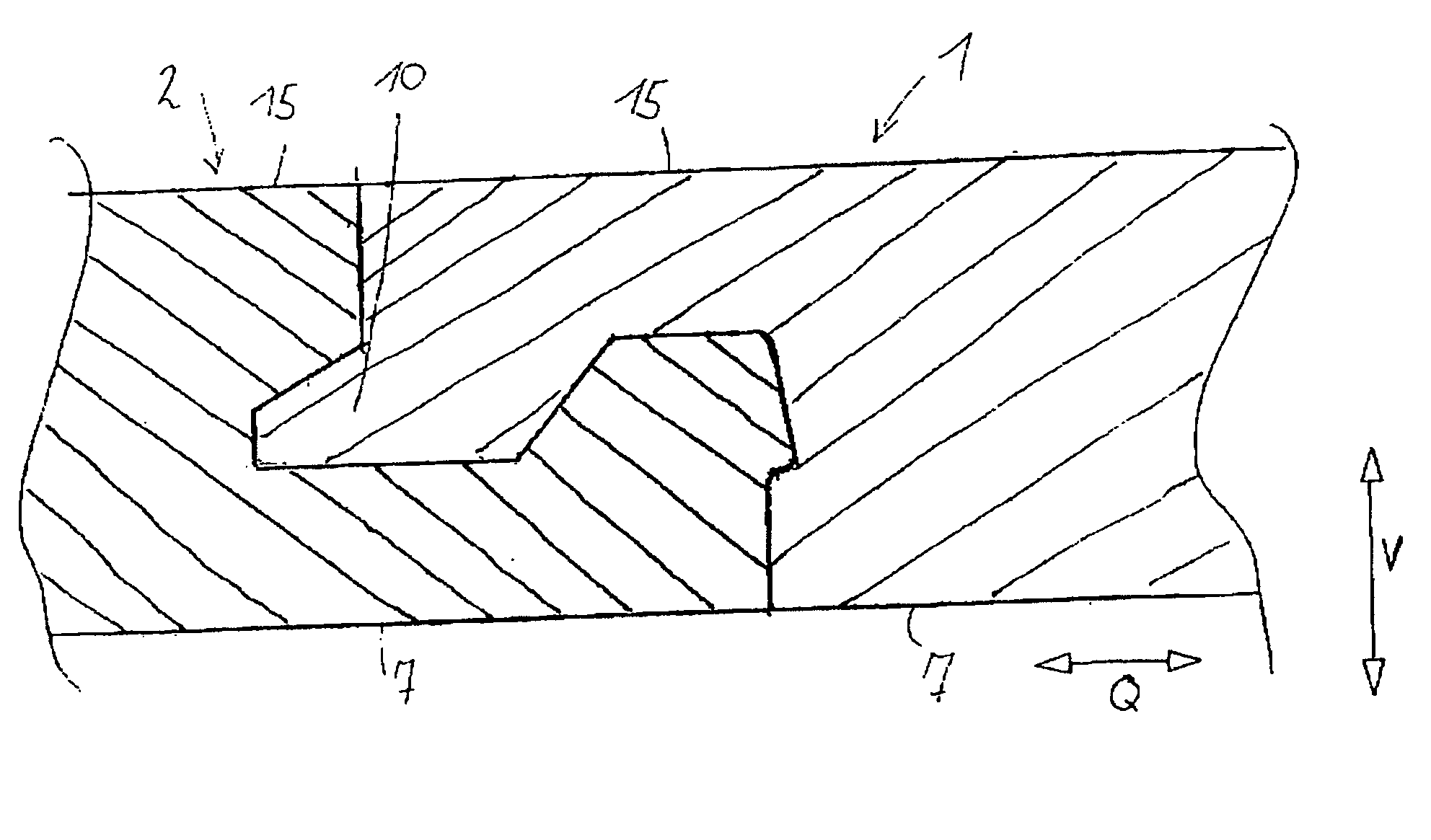

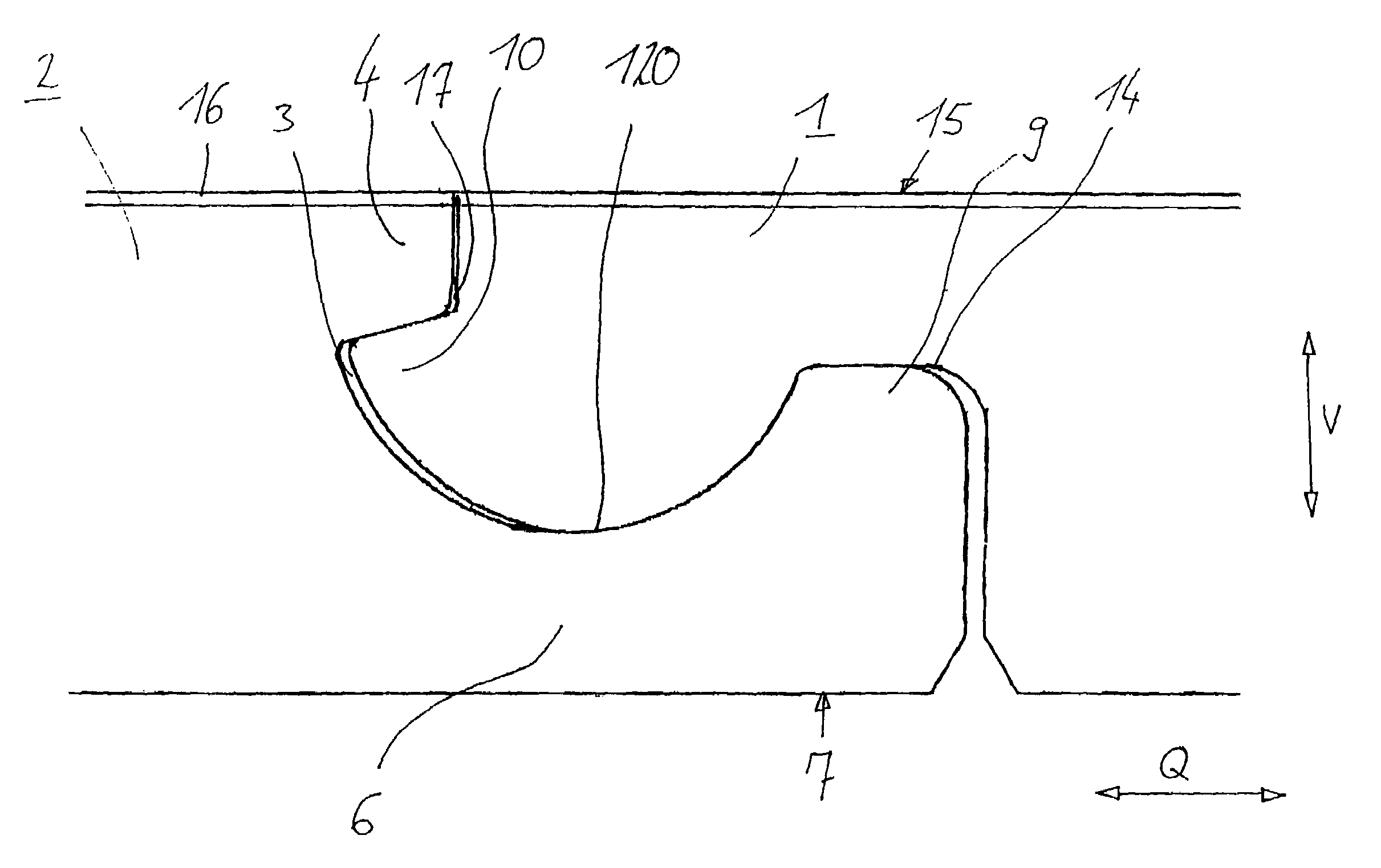

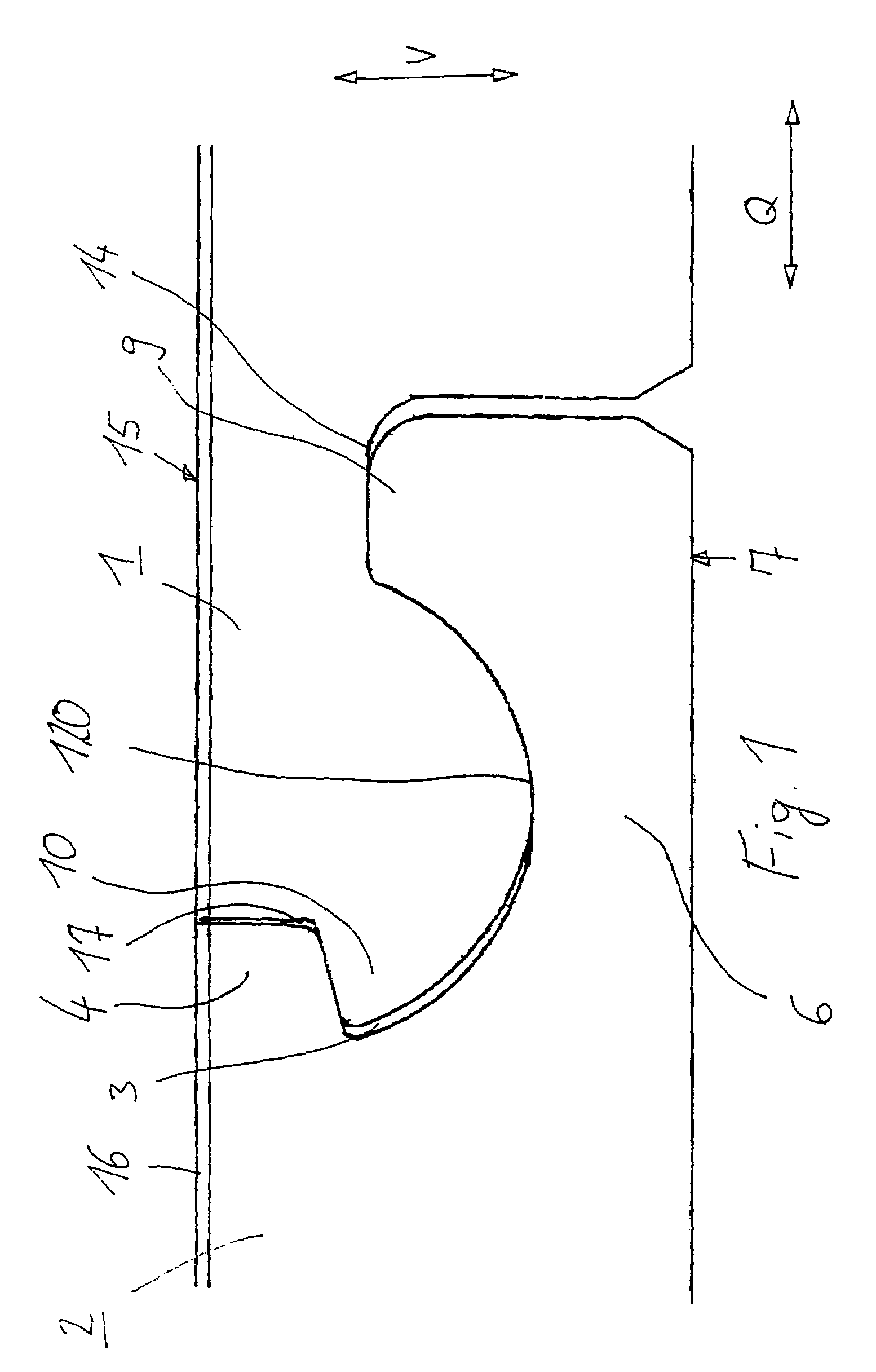

Floor panel which is provided with means for releasably connecting at least two panels, it being the case that a tongue is formed to extend in the longitudinal direction of the side edge and corresponding recess is formed opposite it, that the recess comprises a top lip and a bottom lip, and the bottom lip forms a shoulder with a front shoulder side, said shoulder blocking the panels in the transverse direction (Q), that an undercut is adjoined by a recess, with a bearing region which corresponds to the shoulder, and a wall, which, with the front shoulder side in the installed state, is located opposite the latter, and that corresponding form-fitting elements are formed on the wall and the front shoulder side, said form-fitting elements, in the installed state, engaging one inside the other and bringing about locking in the vertical direction (V), and an underside of the tongue and a top side of the bottom lip runs parallel to the top side.

Owner:VÄLINGE INNOVATION AB

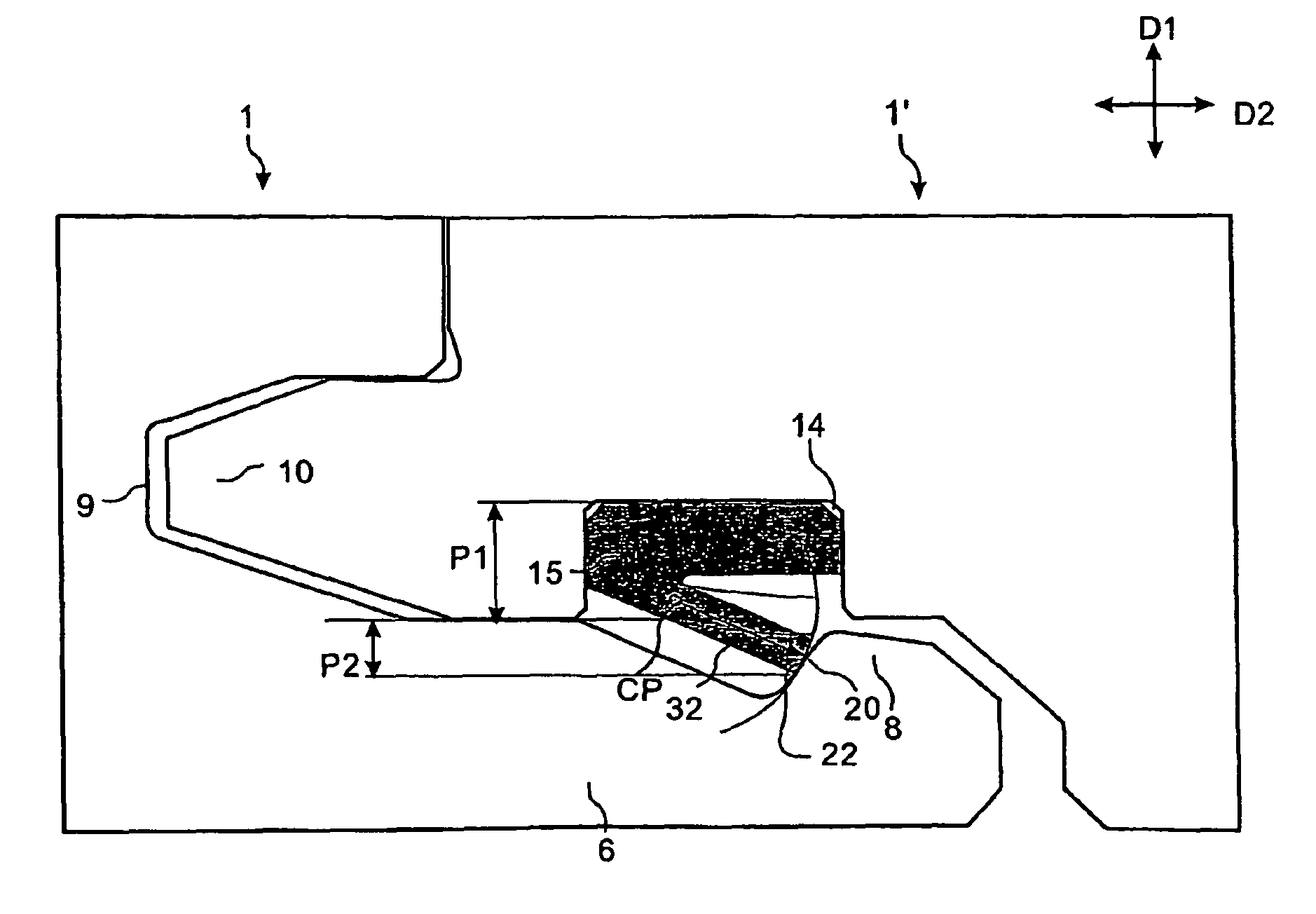

Mechanical locking system for panels and method of installing same

ActiveUS20080034708A1Simple horizontal displacementReduces snapping resistanceCovering/liningsWallsMechanical engineeringEngineering

Floor panels ( 1, 1 ') are provided with a mechanical locking system including a flexible locking element 15 in a locking groove 14 which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

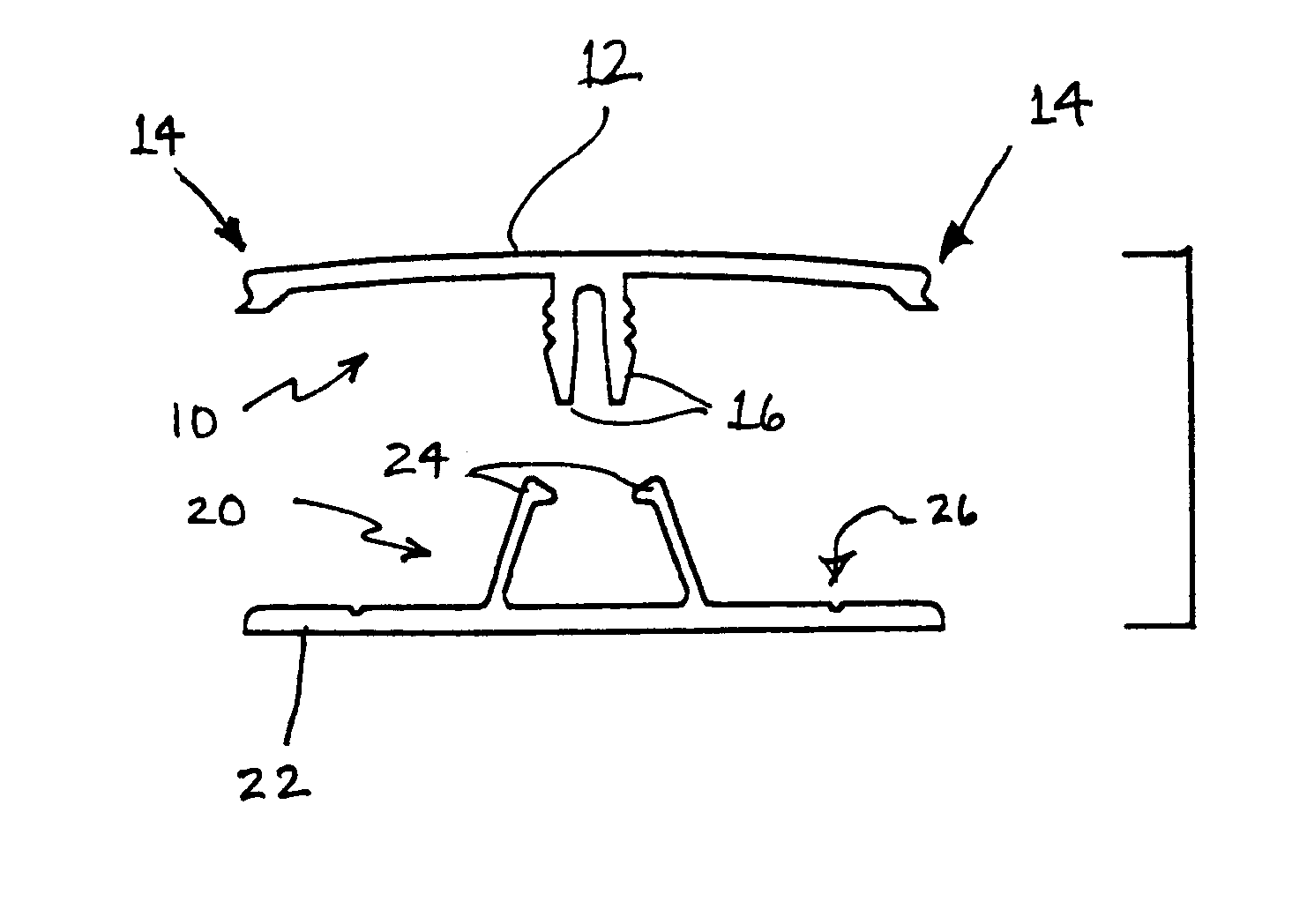

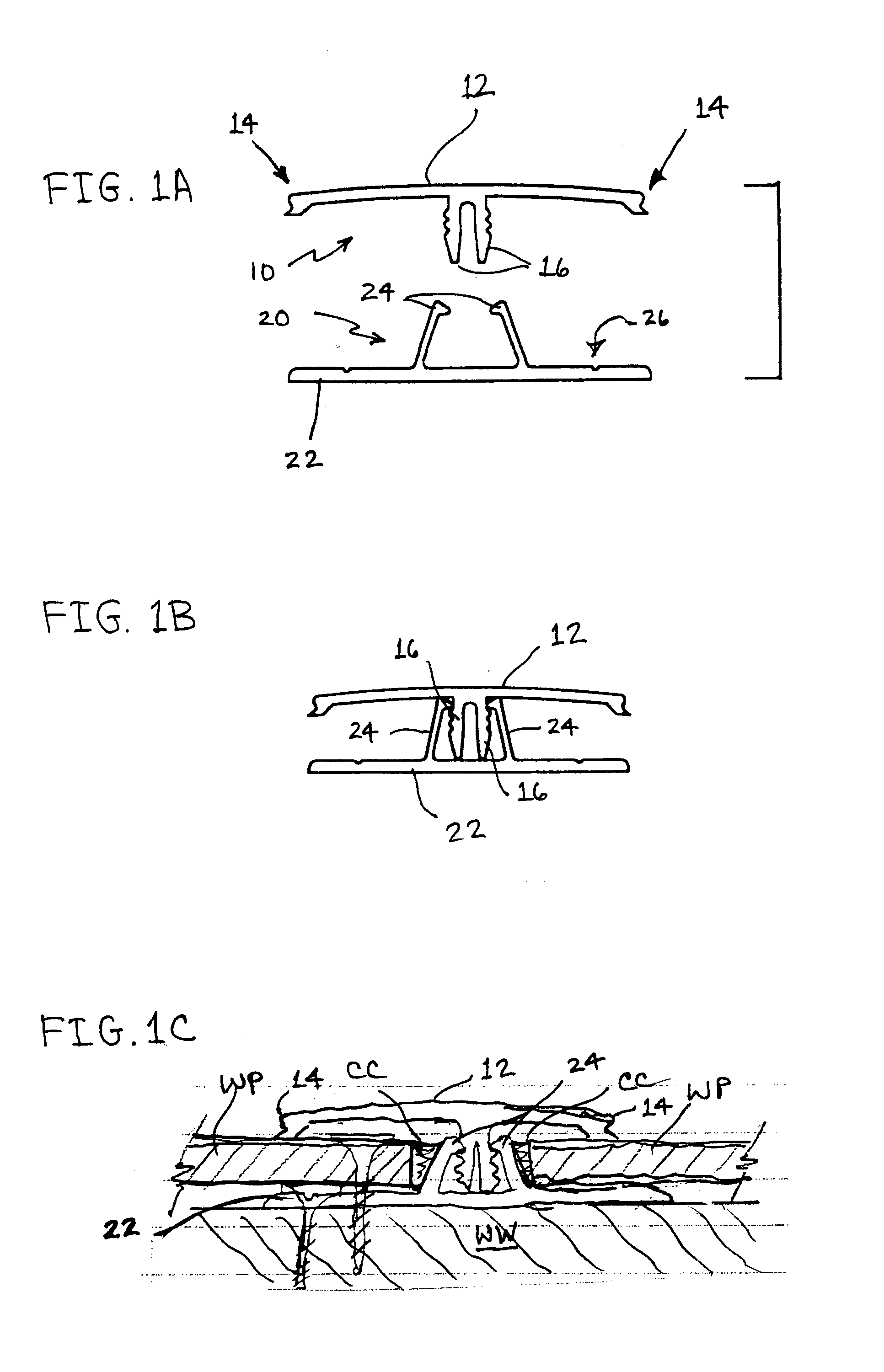

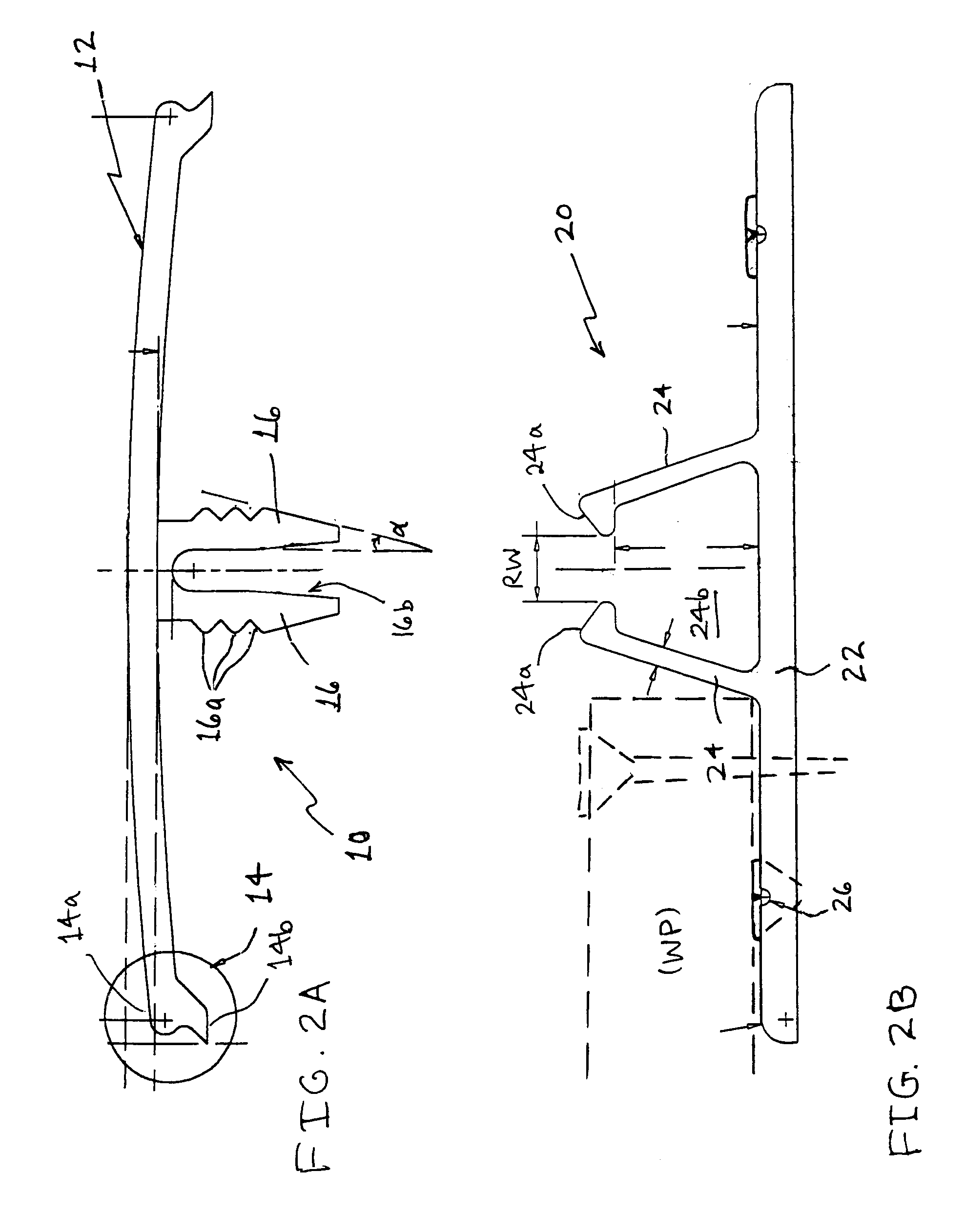

Extrusion devices for mounting wall panels

InactiveUS6588165B1Easy to insertImprove grip strengthCeilingsRoof covering using tiles/slatesEngineeringEdge space

An extrusion device for mounting a wall panel has an outer cap extending to an edge on at least one side which is positioned against an outer surface of a wall panel, having a pair of spaced-apart insertion fingers, and a receiver base having a planar mounting portion and a pair of angled receiver flanges projecting upwardly to receive the insertion fingers therein. The two-piece extrusion permits wall panels to be mounted or removed from the underlying wall structure in on-sequential order. The receiver base and cap can be provided on both sides to form an "H" type extrusion, or on only one side in a "J" type extrusion. Preferably, the outer cap is made of metal, and the tips of the insertion fingers are beveled at a slight angle of about 7° to 14° to allow easy insertion into the receiver flanges. The cap has compound water-shedding edges formed with a rounded rain-drip edge spaced in close proximity to a sharply inclined knife edge. In another variation, a one-piece extrusion device has a rear base portion and a front cover portion forming a pocket therewith, and a ramp formed on the base portion within the width of the front cover portion for gradually forcing the edge of a wall panel inserted in the pocket toward the front cover portion clear of the heads of screws used to mount the base portion to the underlying wall structure. The base portion is formed with a hook indentation on a back side of the ramp on a rear surface of the base portion, and interconnects with a "Z" type extrusion having a hook end to form a right angle connection. The one-piece extrusion may be formed as a "J" (one-sided), "H" (two sided), "C" (corner), or other suitable types.

Owner:WRIGHT JOHN T

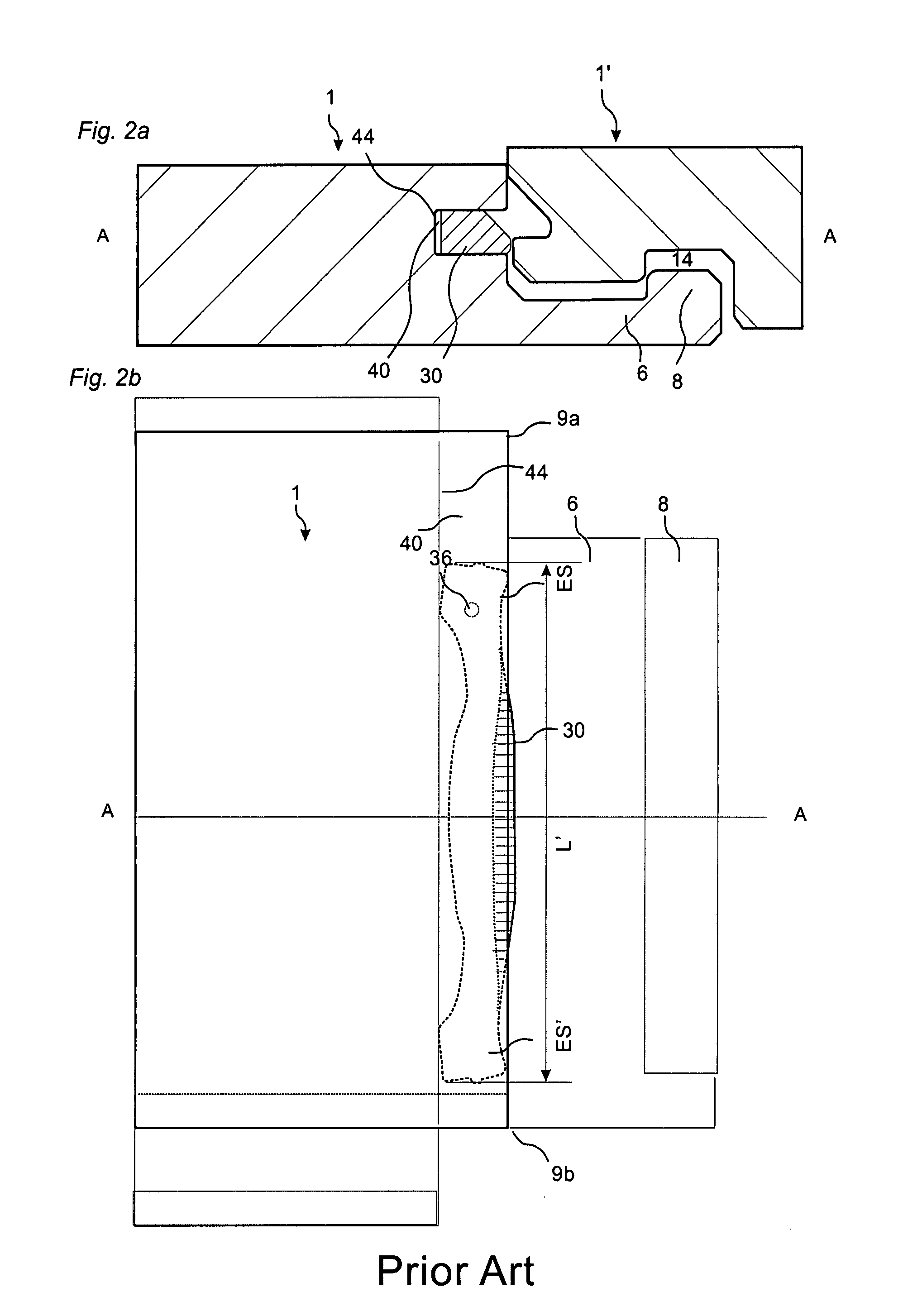

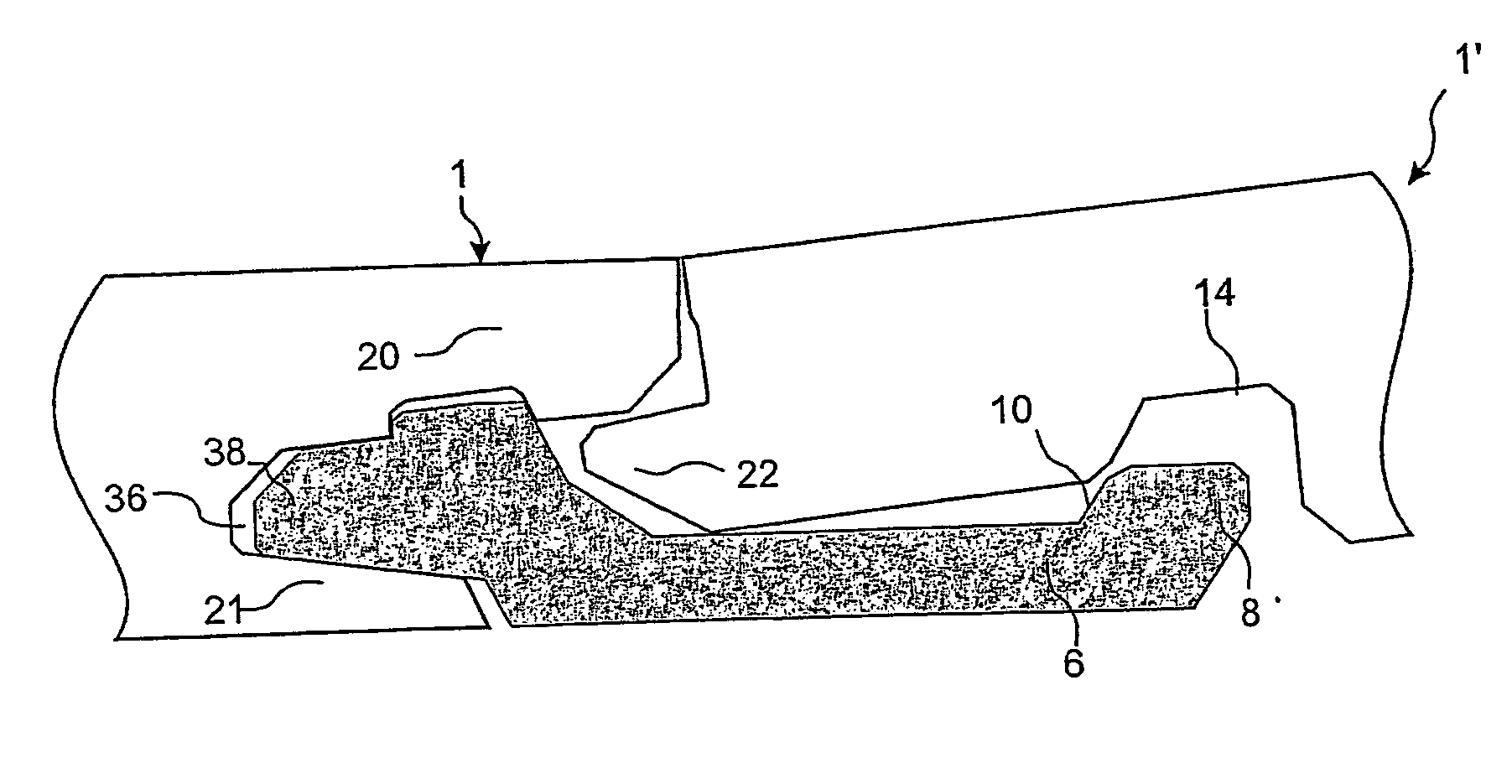

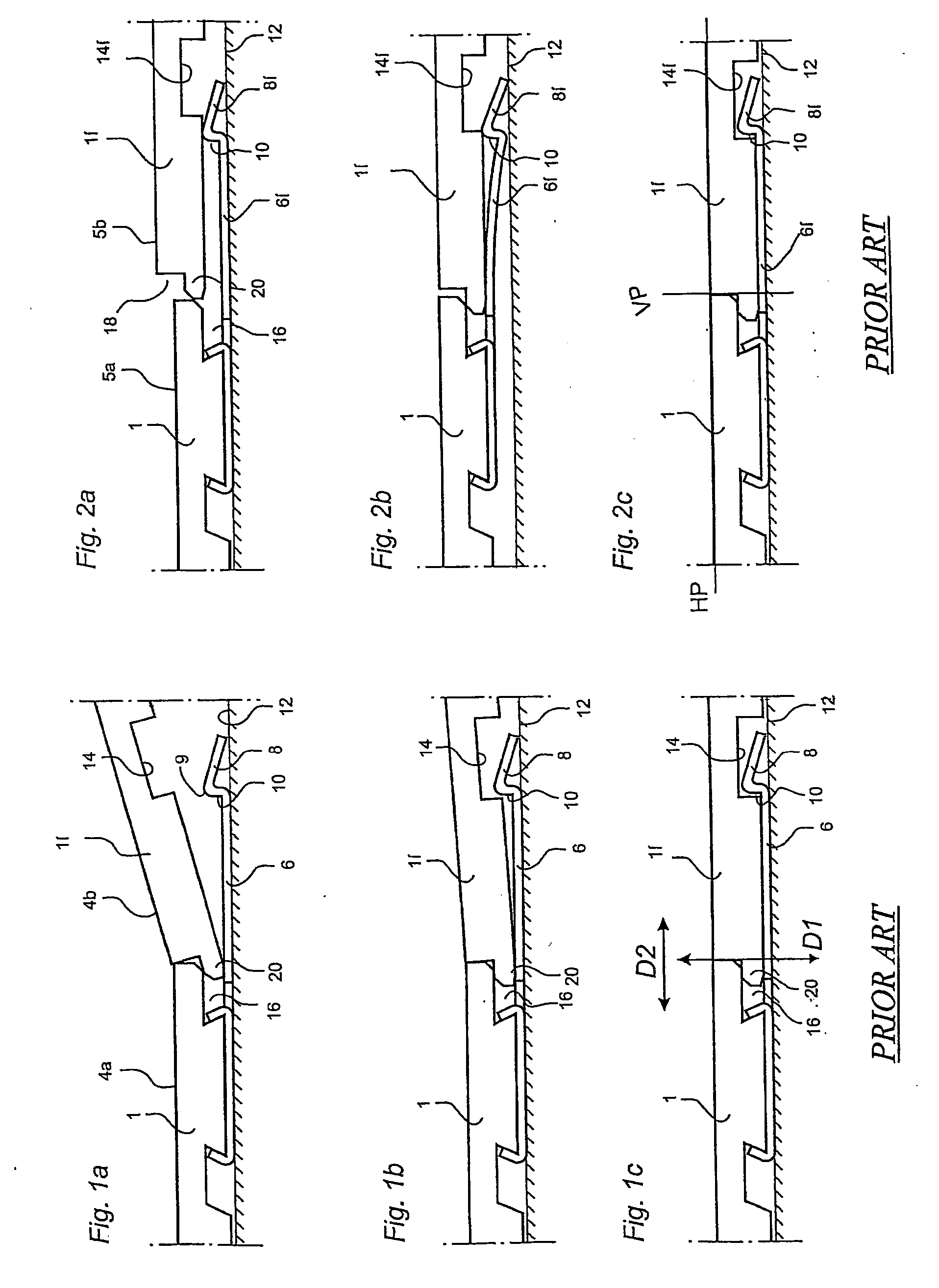

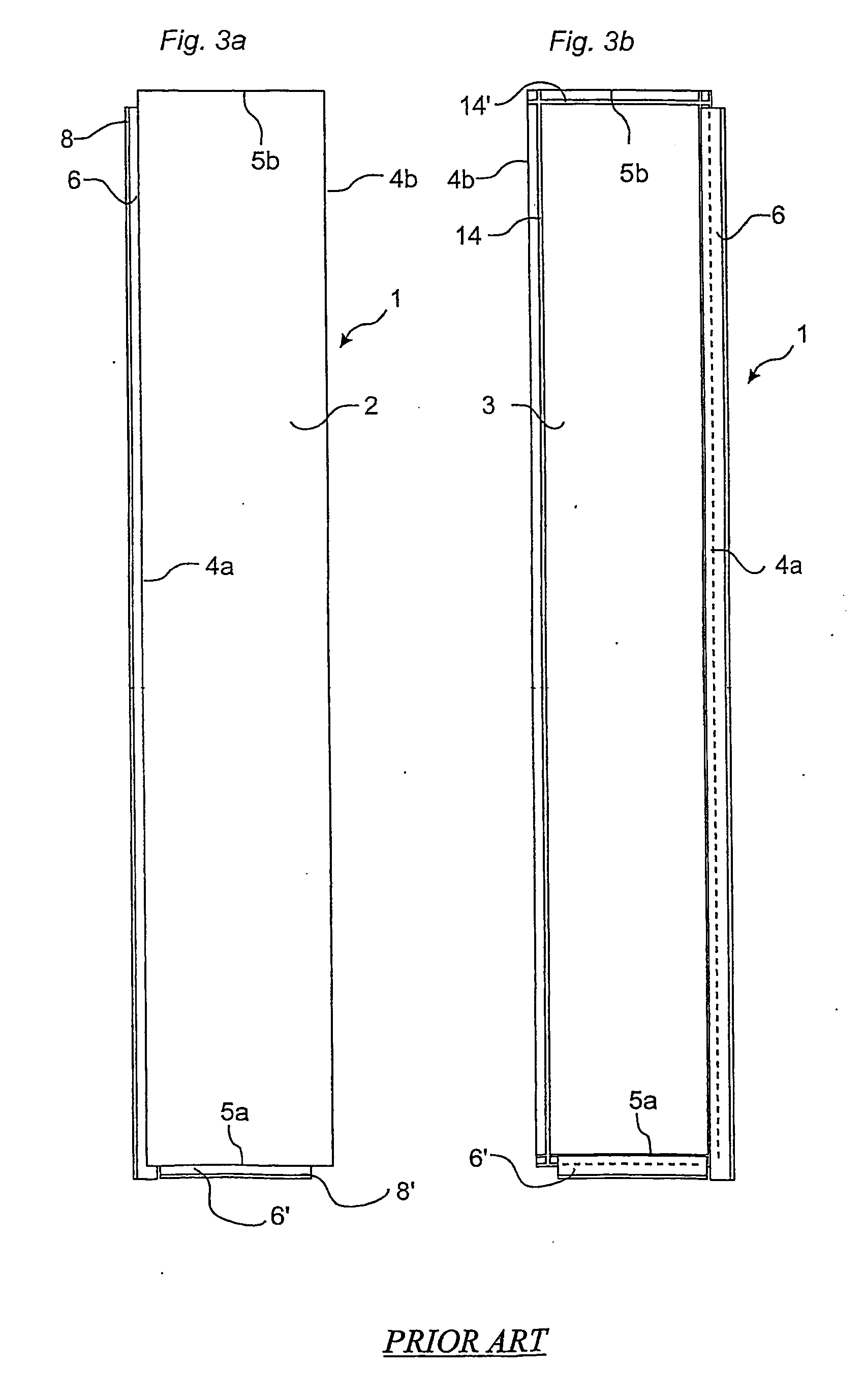

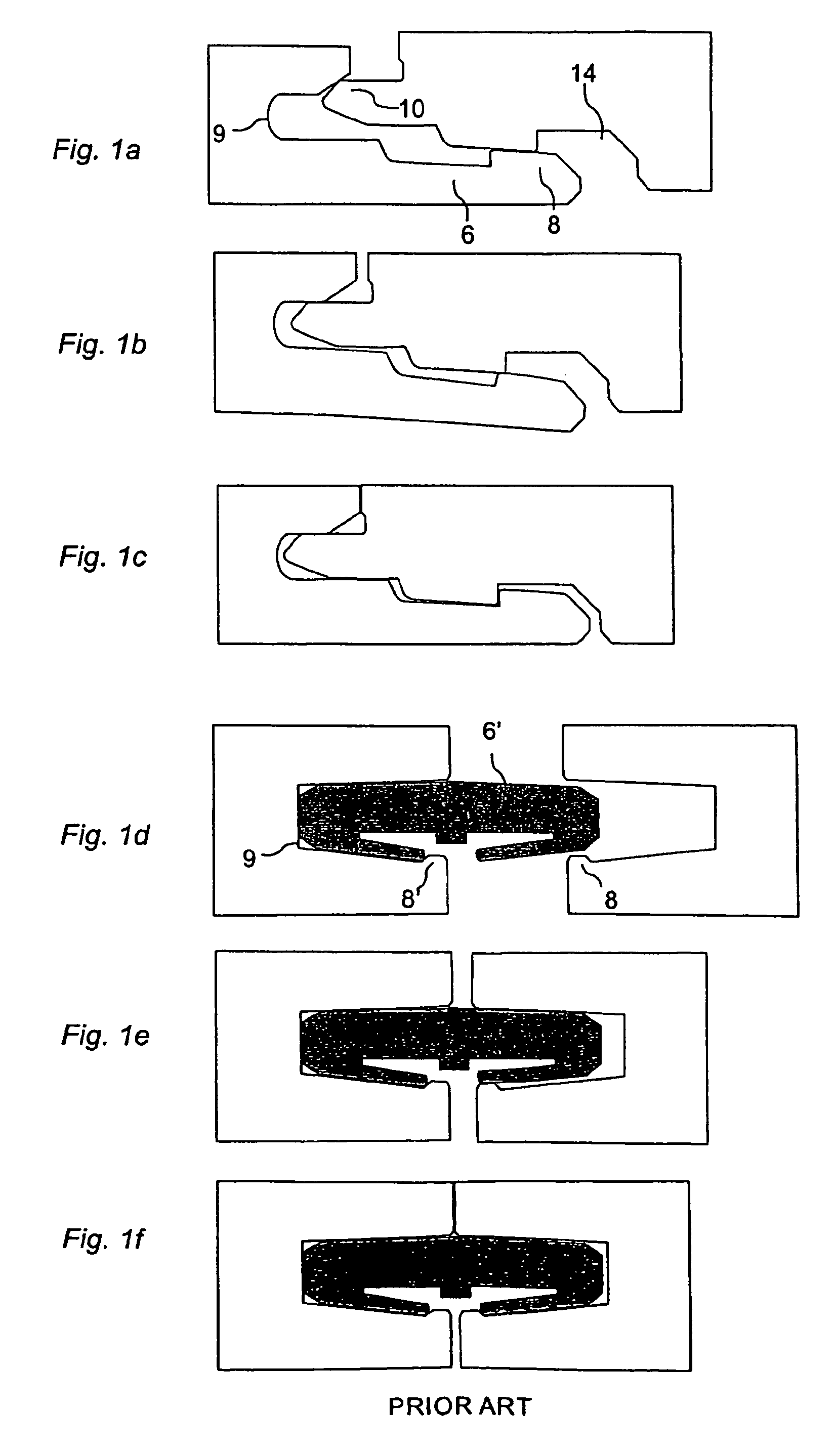

Mechanical locking system for floorboards

InactiveUS20060070333A1High strength requirementsCost advantageTongue/grooves making apparatusWallsEngineeringMechanical engineering

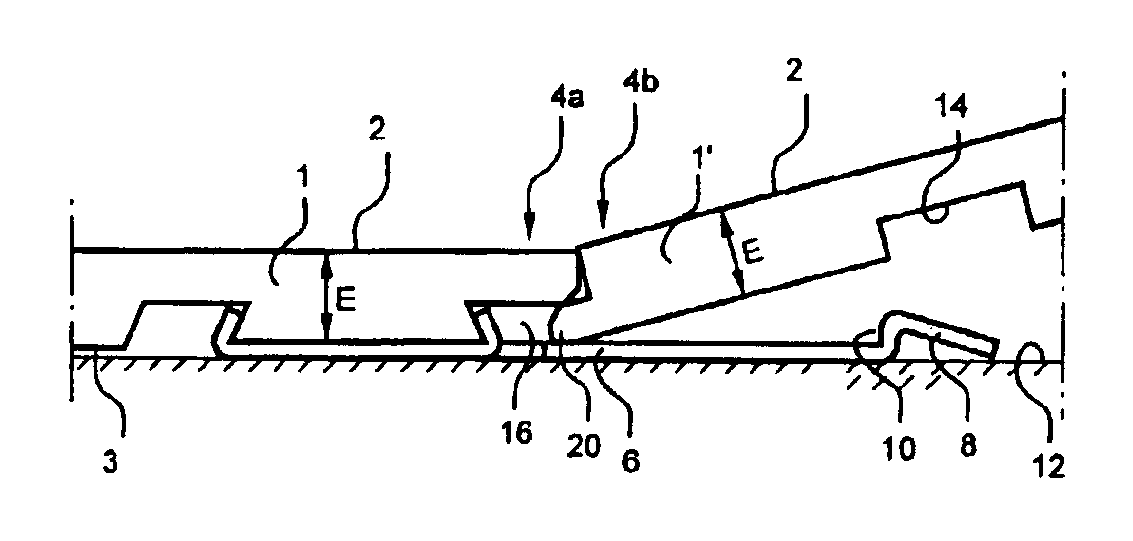

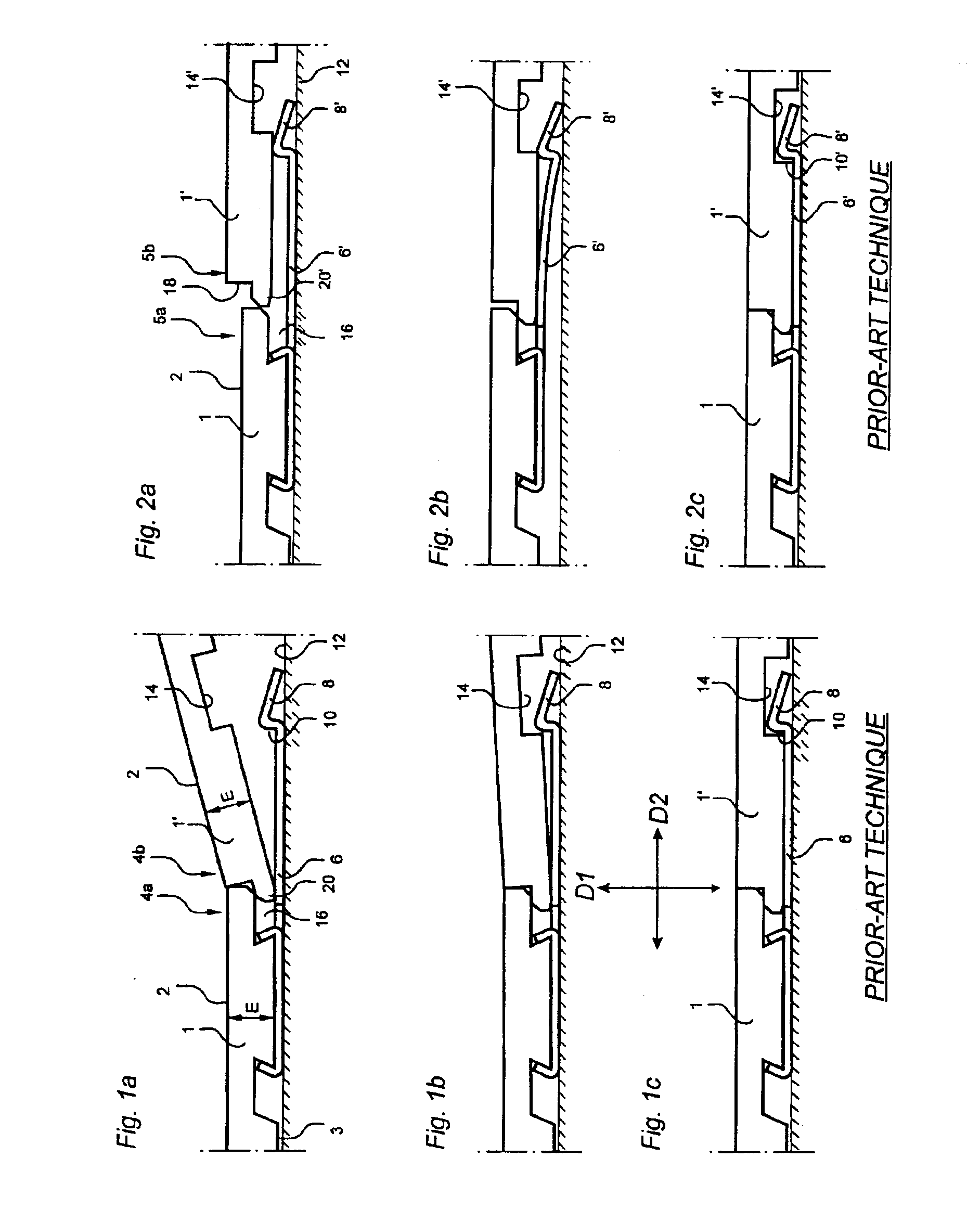

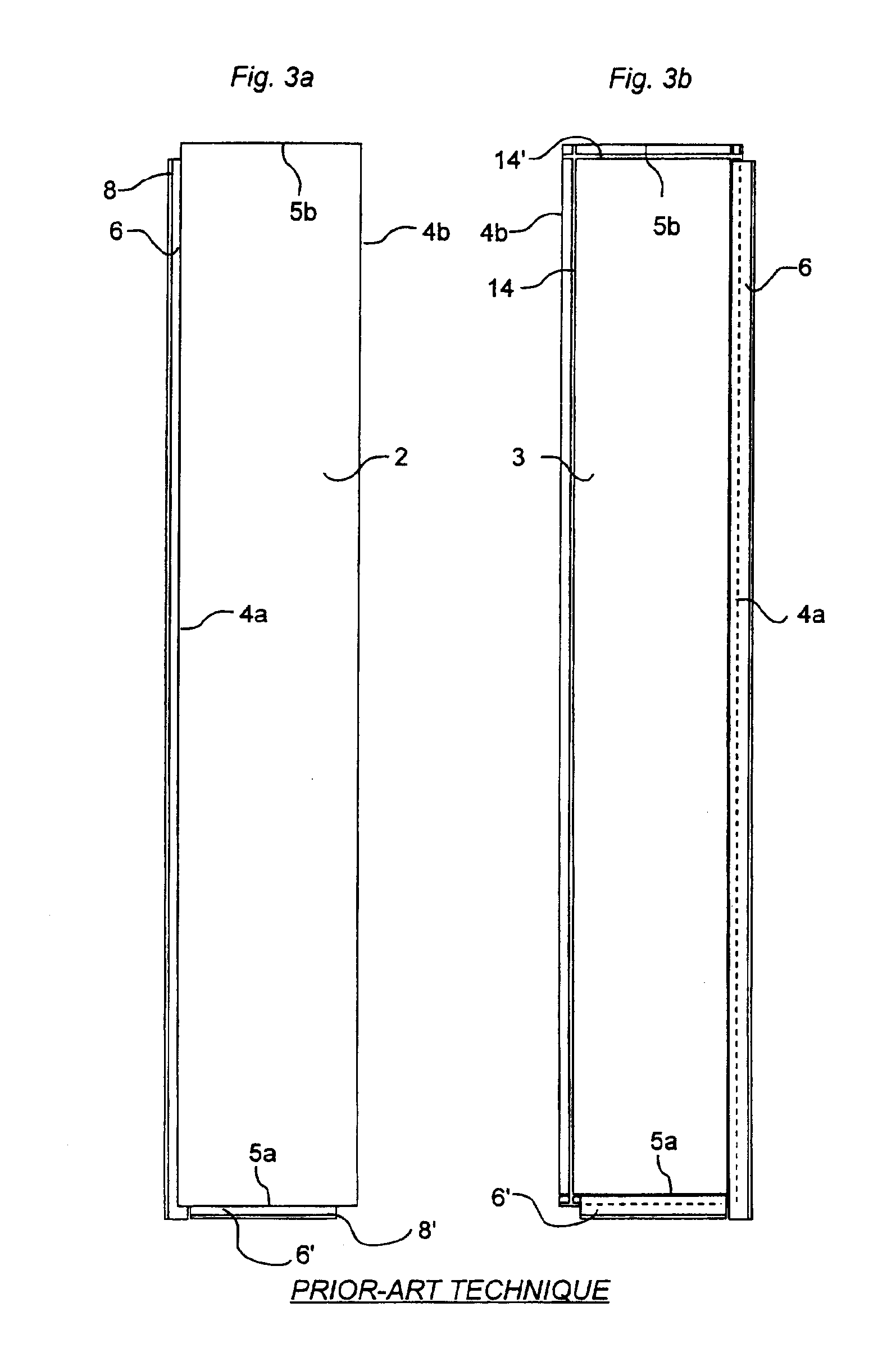

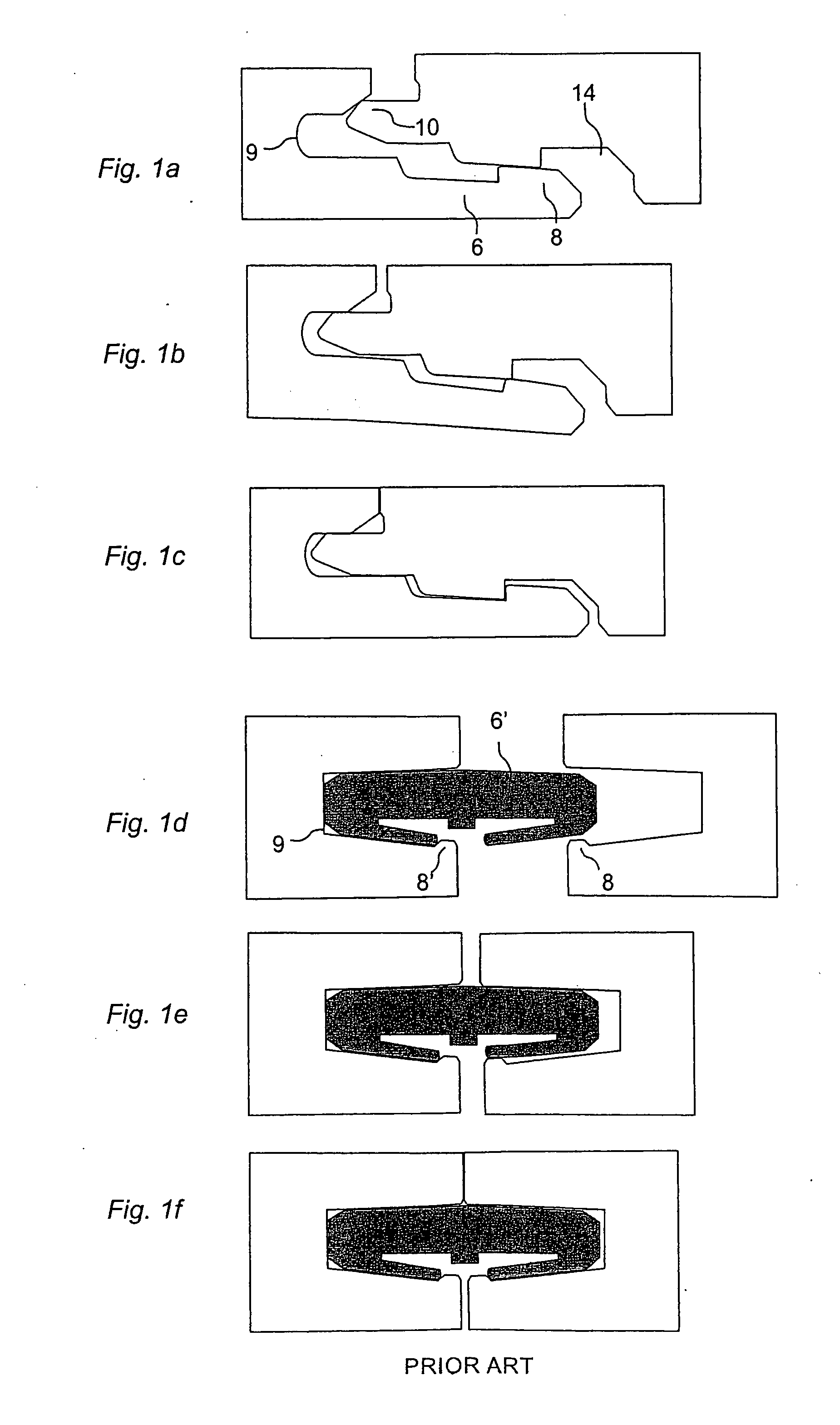

Floorboards (1, 1′) are shown, which are provided with a mechanical locking system consisting of a separately machined locking strip (6) which is mechanically joined with the floorboard (1), the locking strip (6) being designed for mechanical fixing to the floorboard (1) by means of a joint, which is operable by snapping-in and / or inward angling, and the locking strip (6) being designed to connect the floorboard (1) with the essentially identical floorboard (1′) by at least inward angling. Moreover, a locking strip, a strip blank, a set of parts for making a floorboard and methods for manufacturing a floorboard and a locking strip, respectively, are shown.

Owner:VÄLINGE INNOVATION AB

Panel element

InactiveUS20030037504A1Simple yet reliable layingPrecise arrangementCovering/liningsWallsEngineeringFloor covering

The invention relates to a panel element for forming a floor covering, consisting of several identical interconnectable panel elements and having the following features: two first sides of each panel element, called the "longitudinal sides", these sides having a groove and a tongue; the tongue of a panel element which is positioned at an angle with an installation level of a first, identical panel element can be introduced into the groove of the first panel element; the tongue interacts with the groove of the adjacent, identical panel element in such a way that two interconnected panel elements are protected against separating forces which are exerted along both of the axes extending perpendicularly to the longitudinal side of the panel elements; two second sides of the panel element, called the end sides, are provided with fixing means and a groove and tongue, these forming an end-side connection between two adjacent panel elements; the end-side grooves and tongue can be interconnected by means of the panel element being lowered onto an identical panel element that has already been installed, essentially crosswise to the installation level, so that the panel element is protected from lifting forces, i.e. forces which are exerted considerably perpendicularly to the installation level.

Owner:FLOORING IND LTD

Floor covering and locking systems

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Glider bar for flooring system

A flooring system for use with floating floors is described which includes a glider bar having base portions including extending rails in the form of dovetail protrusions. The bases and rails are longitudinally moveable relative to anchoring plates, which anchoring plates are affixed to a subflooring. Flush finished floor moldings are slid longitudinally along the rails and are glued or mechanically fixed, at one side only, to the adjacent floating laminate flooring. By this assembly, smooth transitions between adjacent floating floors, or where floating floors meet another hard floor covering, or carpet, can be achieved. The system can also be used with flush stair nosing elements.

Owner:PERGO

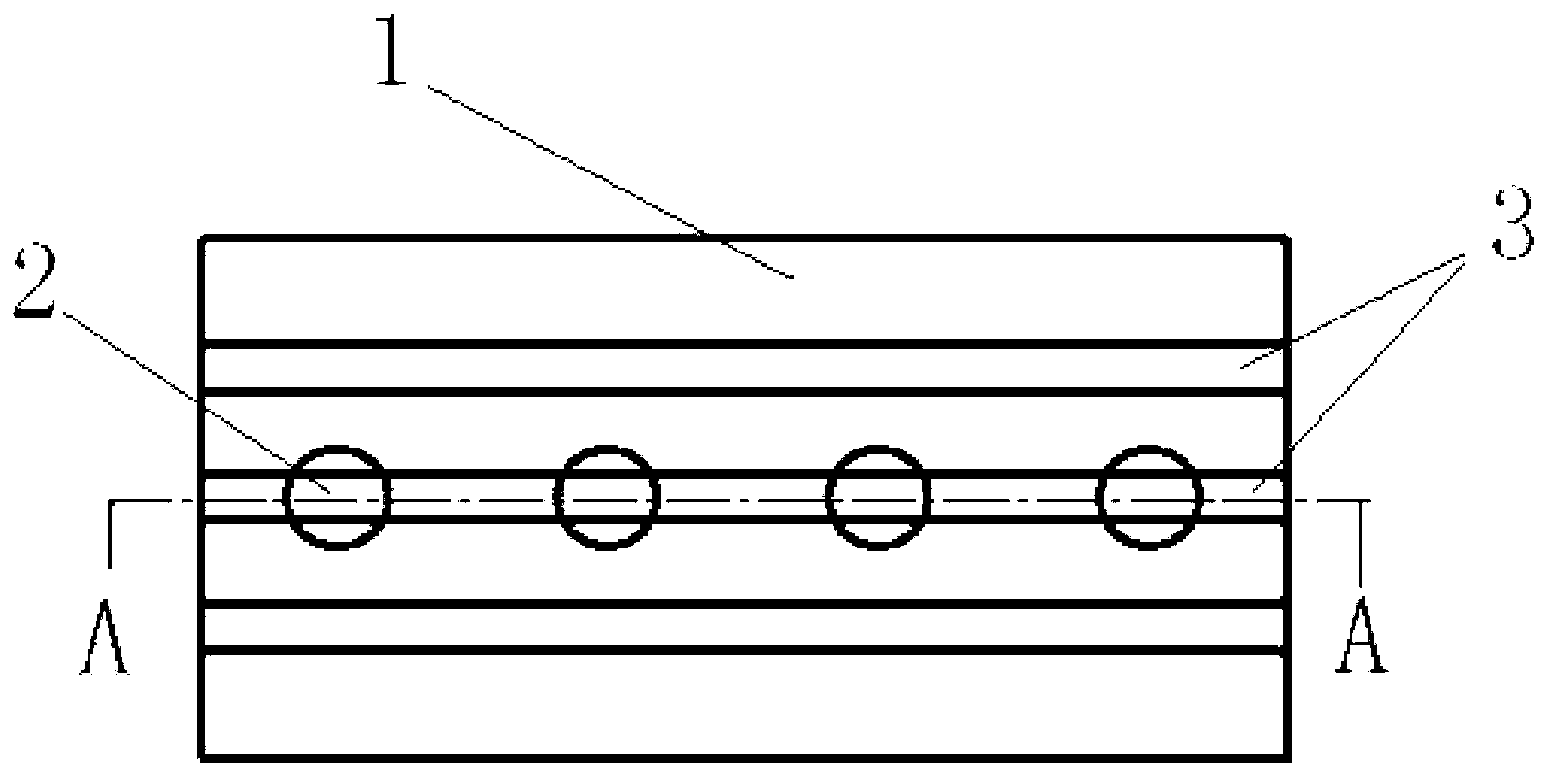

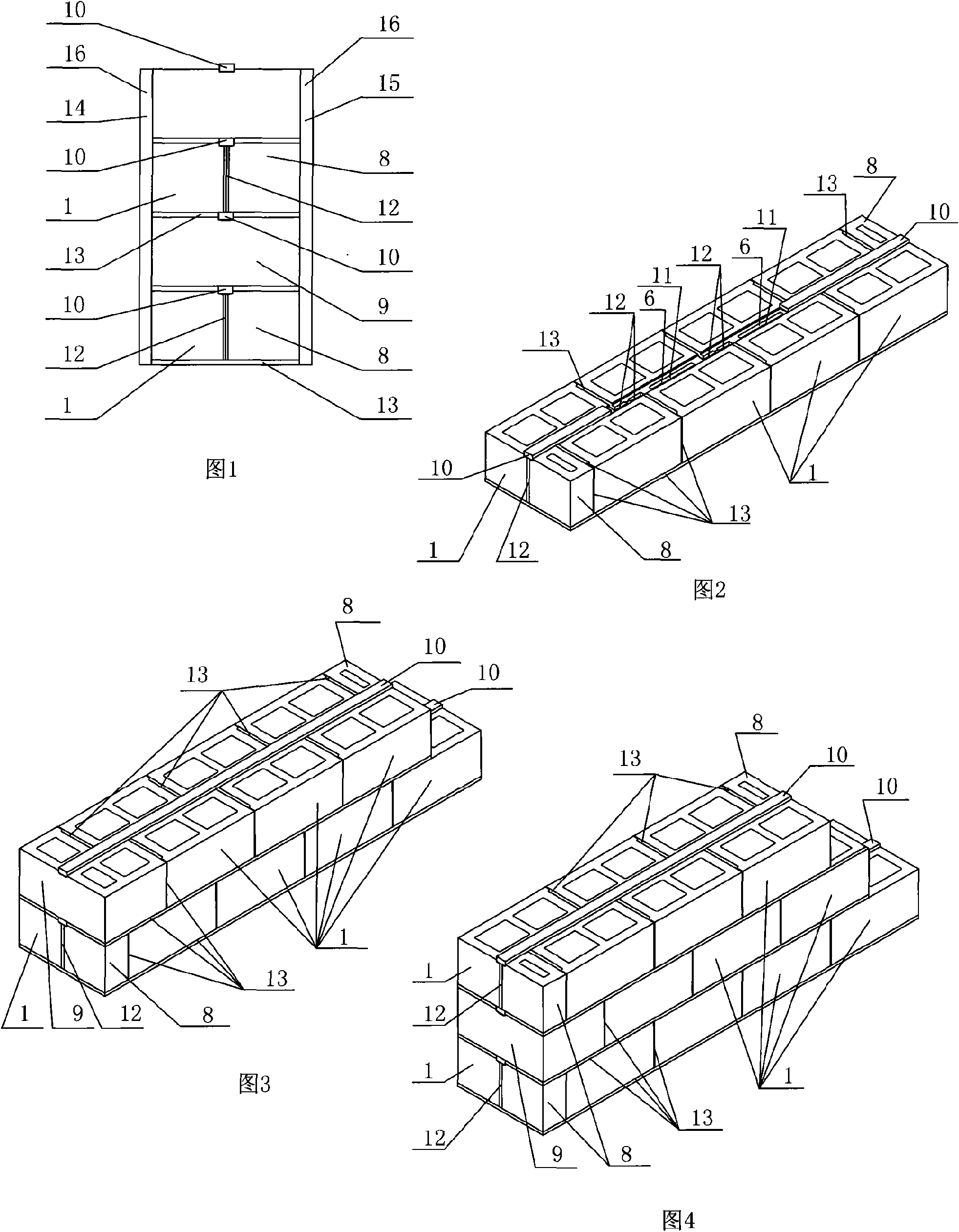

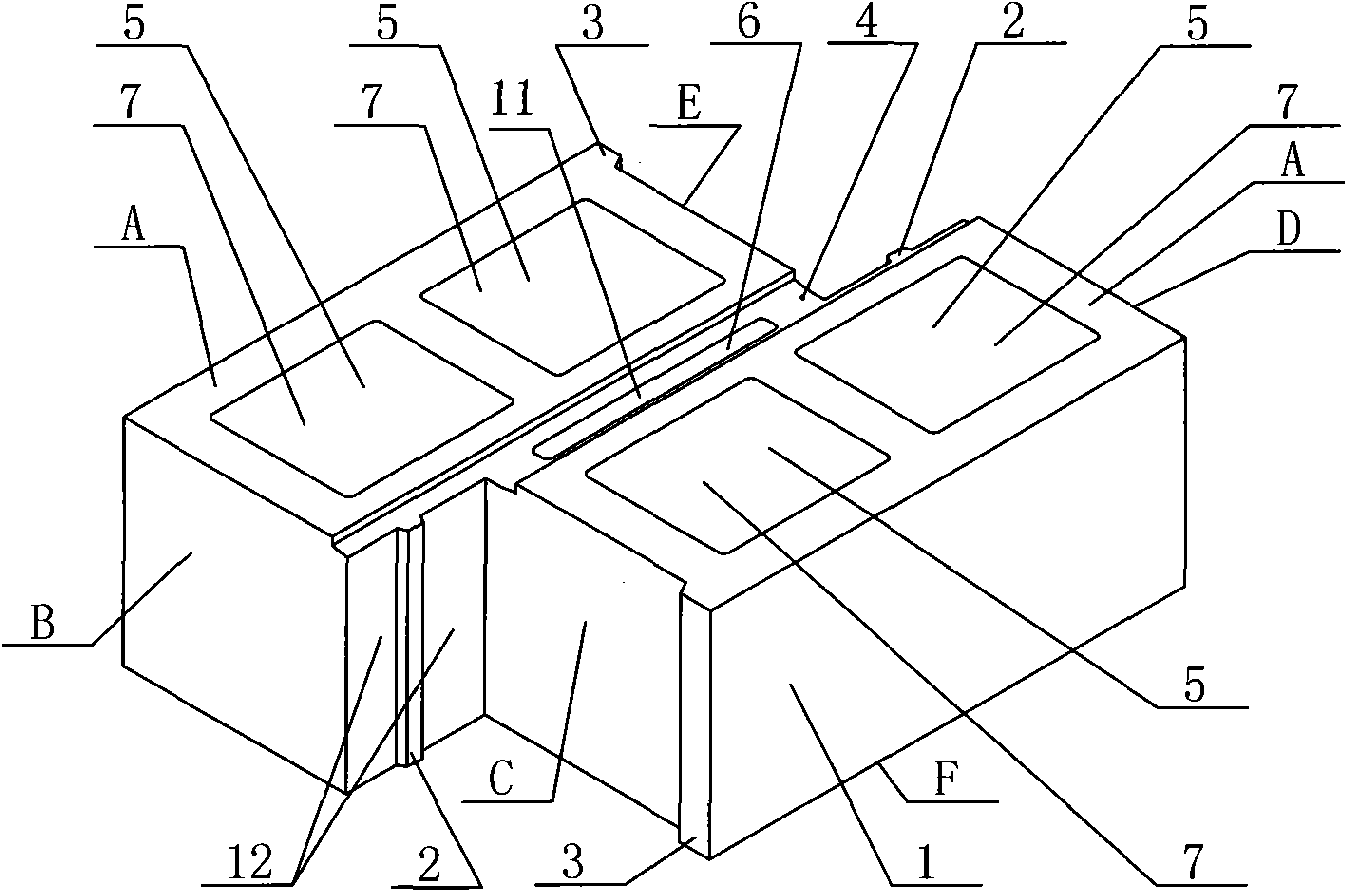

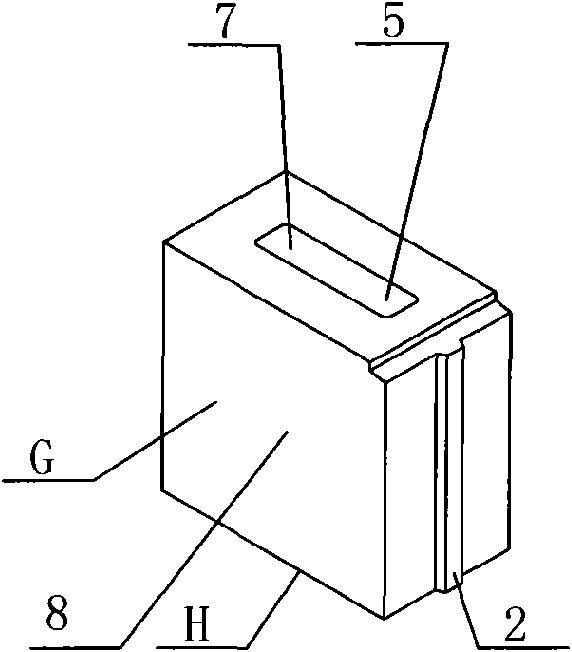

Self-heat-preservation building block and self-heat-preservation wall body consisting of self-heat-preservation building blocks

ActiveCN103243857AMeet heat preservation and energy saving requirementsPlay a role in heat preservationConstruction materialWallsWhole bodySlurry

The invention relates to the field of building materials, and in particular relates to a self-heat-preservation building block and a self-heat-preservation wall body consisting of self-heat-preservation building blocks, which aim to solve the technical problem that conventional building wall body materials cannot have the functions of bearing, heat preservation and fire prevention simultaneously. According to the technical scheme, the self-heat-preservation building block comprises a building block body which is made of foamed cement; transverse through slots are formed in the upper surface of the building block; vertical through holes are formed in the building block; one or several of concrete slurry, cement mortar, plaster and heat preservation plaster is / are filled into the transverse through slots to form core columns; concrete slurry or cement mortar is filled into the vertical through holes to form core columns; and the core columns and the building block body are combined to form a whole body. The self-heat-preservation wall body consists of the self-heat-preservation building blocks. The self-heat-preservation building block and the self-heat-preservation wall body have functions of heat preservation and fire prevention as well as bearing.

Owner:丹东市兄弟建材有限公司

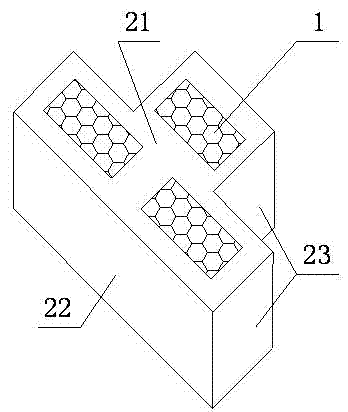

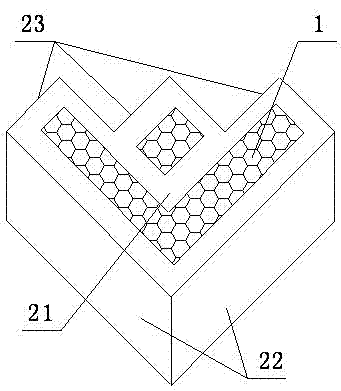

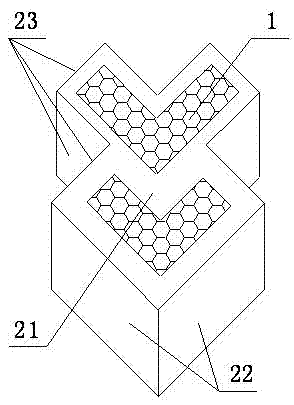

Self-insulation wall with high energy conservation property

The invention discloses a self-insulation wall with a high energy conservation property, and belongs to the field of building wall materials. The self-insulation wall with the high energy conservation property is mainly characterized in that building blocks of a self-insulation wall body are shaped like a T, building blocks of a self-insulation right-angle wall corner are in a flower shape and a scissor shape, building blocks of a self-insulation T-shaped wall corner are provided with either a T-shaped top with a handle or a T-shaped bottom with a handle, when the wall body is built, one of every two horizontally adjacent self-insulation wall bricks is placed in a T shape, the other one is placed in a reverse T shape, when the right-angle wall corner is built, the flower-shaped and scissor-shaped building blocks of the self-insulation right-angle wall corner are alternatively placed, and when the T-shaped wall corner is built, the building blocks, provided with either the T-shaped top with the handle or the T-shaped bottom with the handle, of the self-insulation T-shaped wall corner are alternatively placed. The self-insulation wall with the high energy conservation property has the advantage of improving the energy conservation property.

Owner:SHANDONG UNIV OF SCI & TECH

Mechanical locking system for panels and method of installing same

ActiveUS7841145B2Function increaseLower resistanceCovering/liningsWallsEngineeringMechanical engineering

Floor panels are provided with a mechanical locking system including a flexible locking element in a locking groove, which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

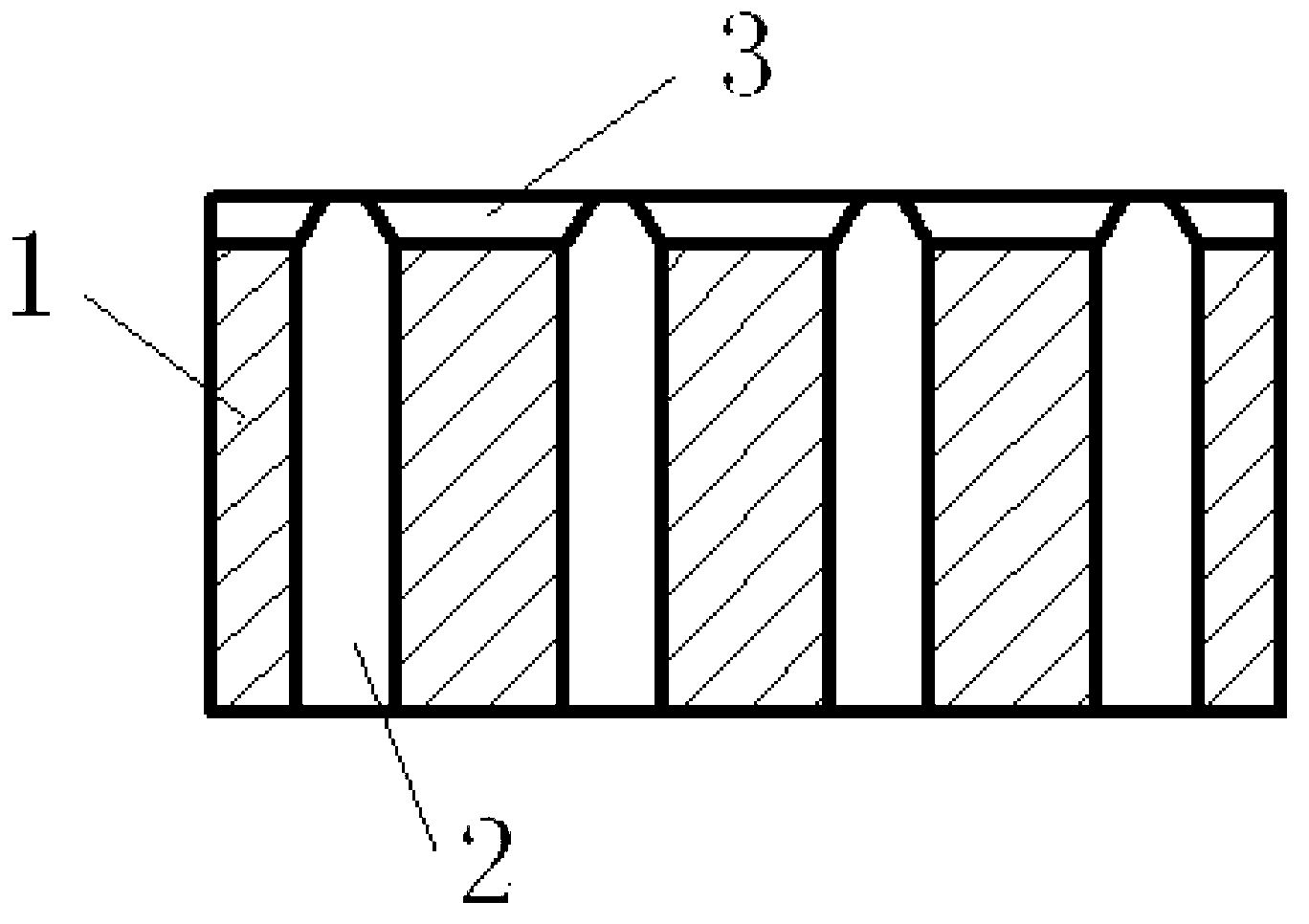

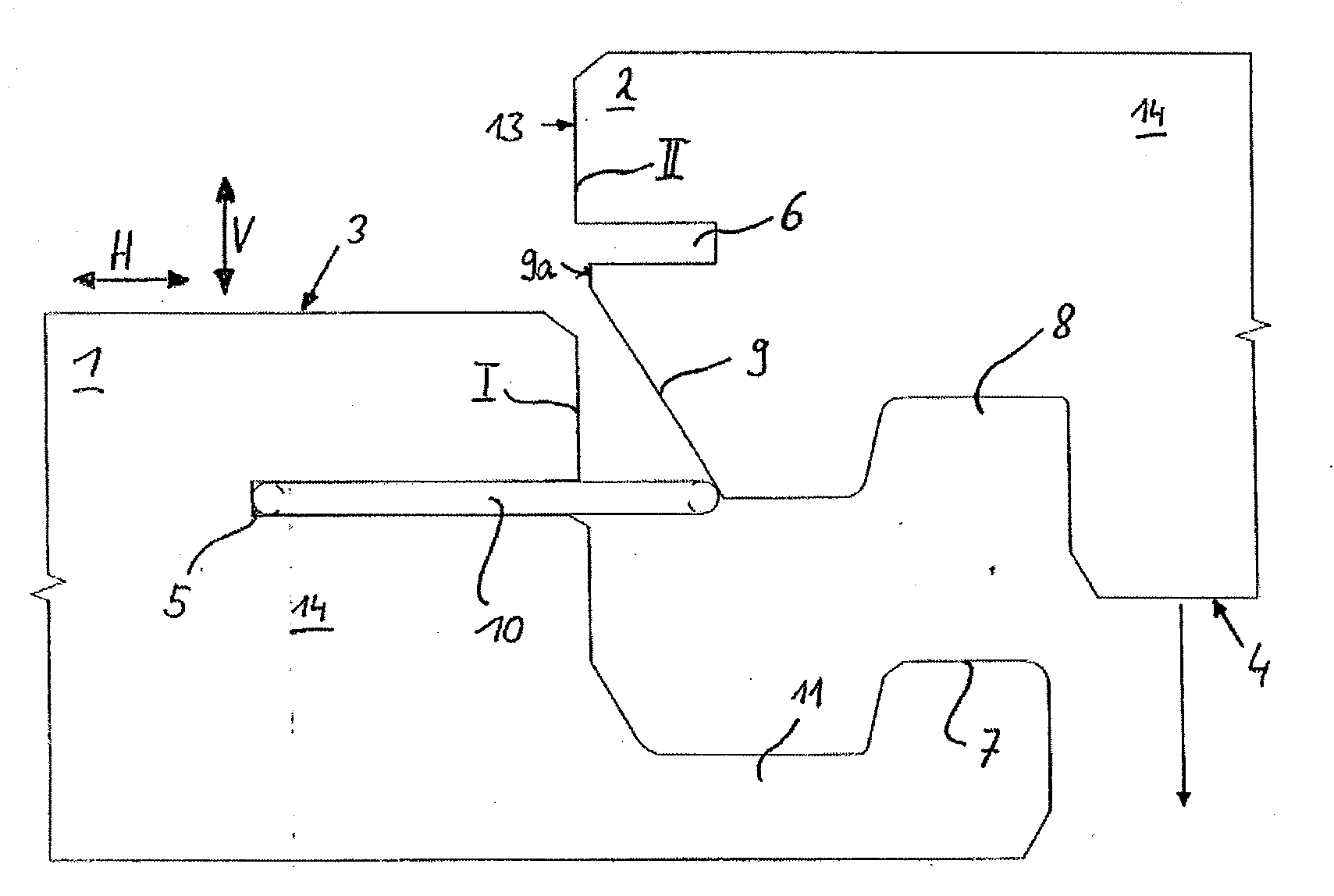

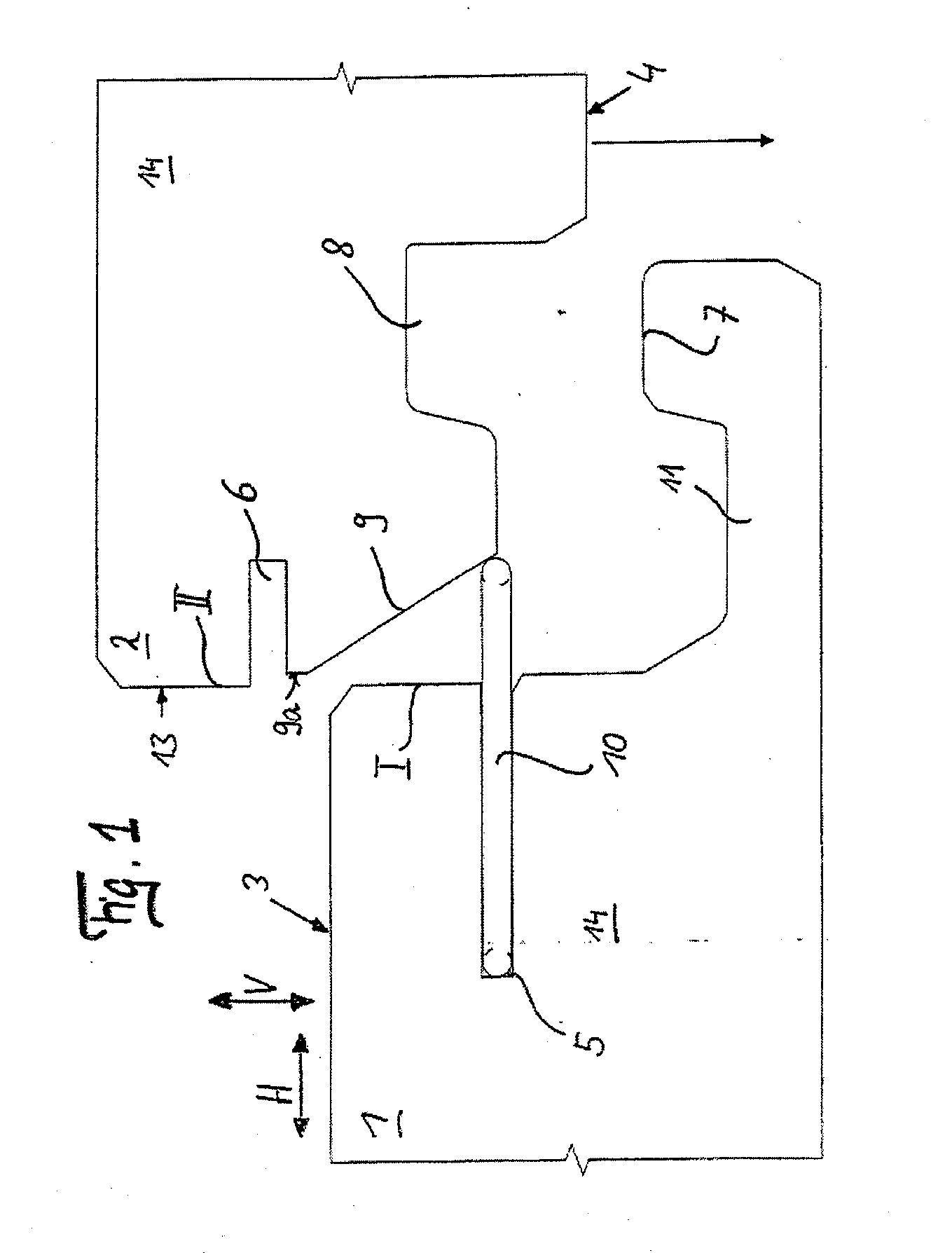

Technical method for building self-insulating and energy-saving wall with Z-shaped energy-saving building blocks

In the invention, the same clad bricks are laid in the forward direction, and a positioning convex platform 2 and a longitudinal positioning convex platform 3 are used for realizing transverse and longitudinal self-locking positioning, thereby naturally ensuring the designed thickness and surface smoothness of the wall, forming a combined still air layer 12 which is 9mm to 10mm wide and vertical to the ground, and further blocking heat bridges in vertical bricklaying seams. The cavity of a 28-30mm-wide groove 4 in the horizontal bricklaying seam between two clad bricks is filled with a broken bridge insulation board 10 which is as wide as the groove and has a thickness of 15mm; the broken bridge insulation board 10 is used for sealing a long-strip groove still air layer 11 and the combined still air layer 12 and cutting off the heat bridges in the horizontal bricklaying seams; the exposed part of broken bridge insulation board with a height of 10mm, is used for controlling the coating thickness of anti-crack masonry mortar 13 to be even and uniform. When the self-insulating and energy-saving wall is built, Z-shaped energy-saving building blocks 1 of the upper clad bricks and the lower bricks are laid in a staggered manner so as to cut off heat bridges in vertical bricklaying seams. The structure of the invention, with a reasonable thickness, can satisfy the requirement of saving 50 percent of energy in various regions, or even higher requiremets without an internal or external insulating layer of walls. Simultaneously, the structure is easy to build and the formation of the block shape effectively ensures the thickness of walls and the smoothness of wall surfaces. The thermal insulation function of the still air layer with a thickness of 10mm to 12mm strengthens the heat insulation effect. The insulation boards (28-30mm wide and 15mm thick) between the two clad bricks is capable of cutting off the heat bridge effects.

Owner:康玉范

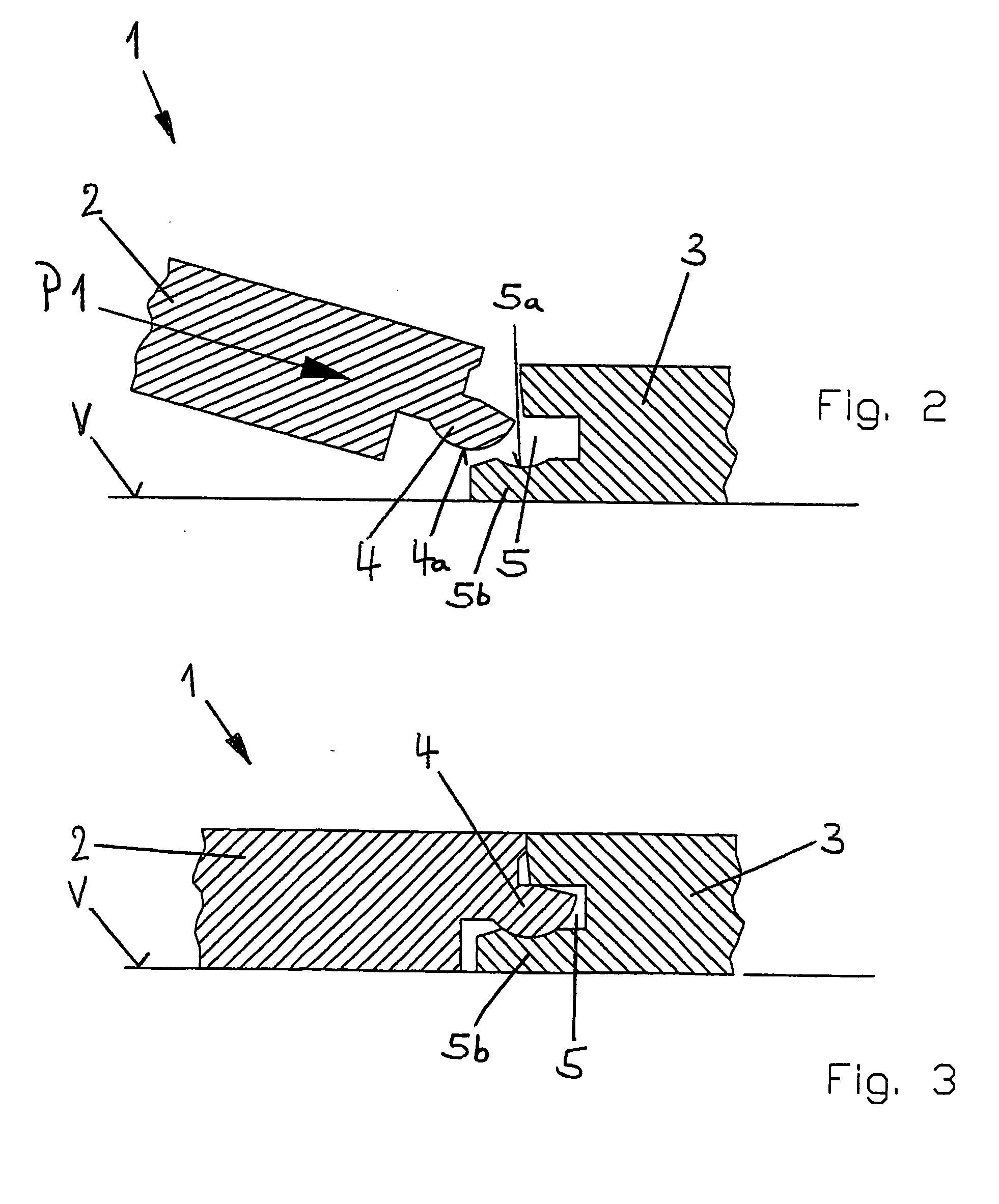

Device and method for locking two building boards

Owner:FLOORING TECH

Device and method for locking two building boards

InactiveUS7621092B2Easy to manufactureMore cost-effectiveWallsSheet joiningArchitectural engineeringEngineering

Owner:FLOORING TECH

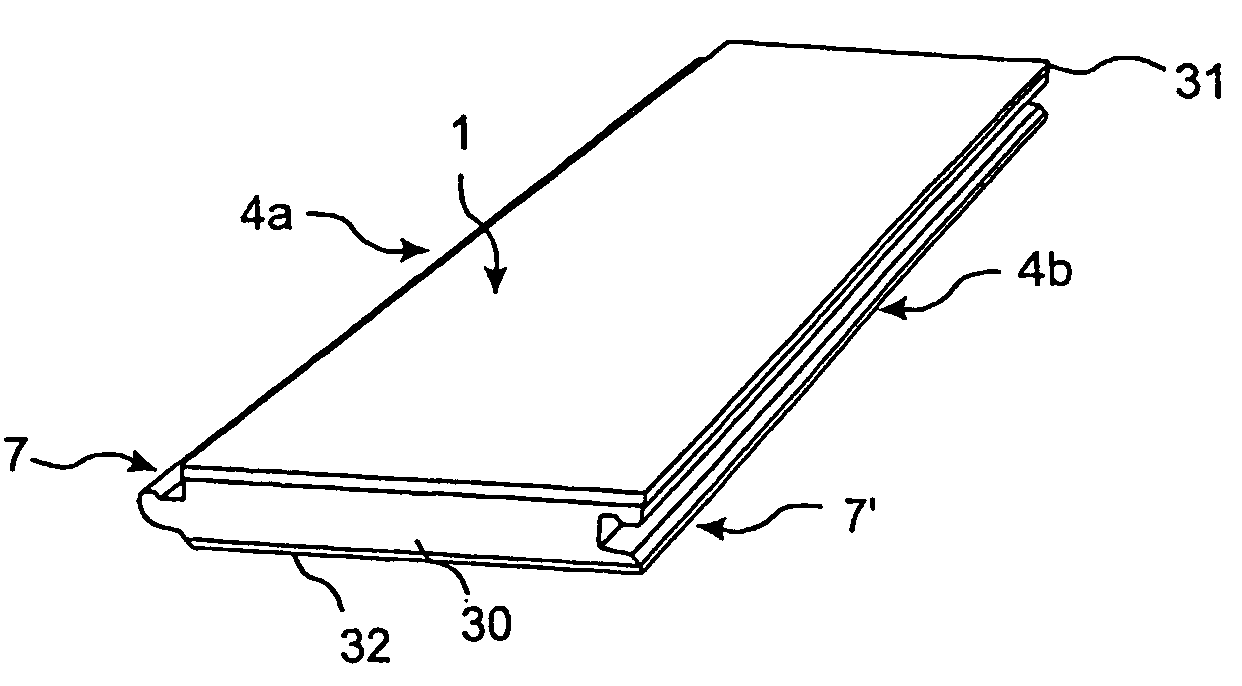

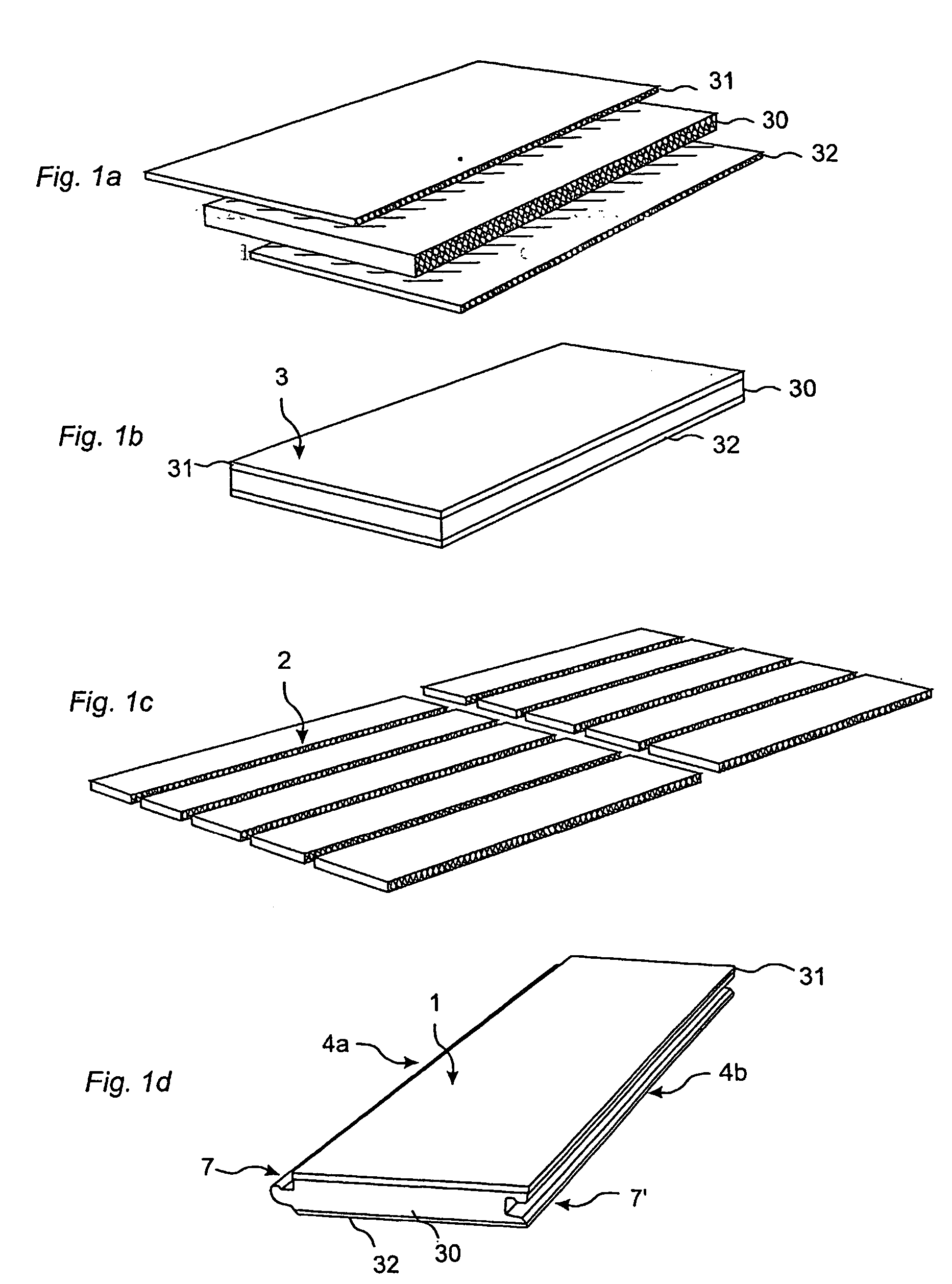

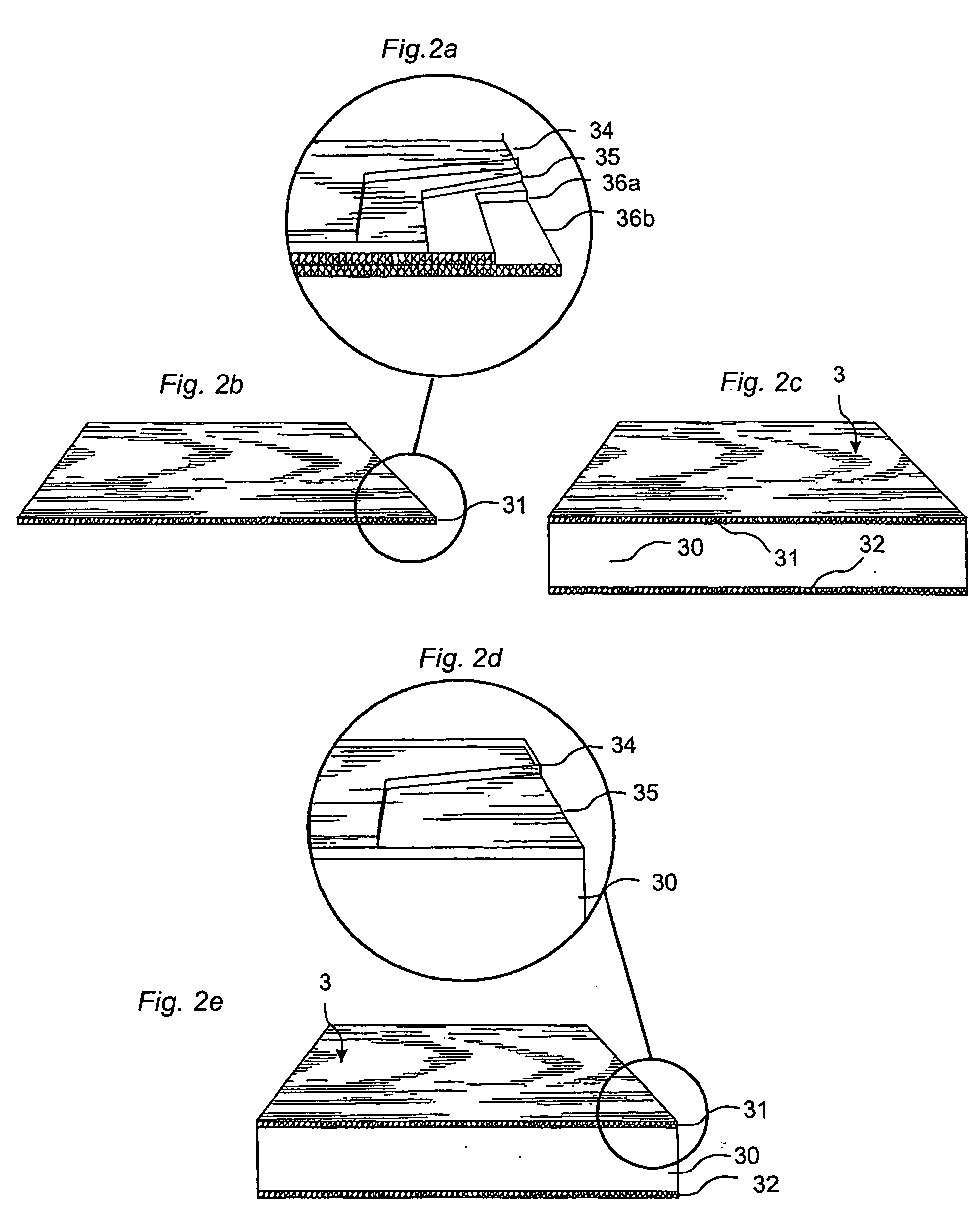

Floorboards for floorings

Floorboards for making a floating floor have a core ( 30 ) which comprises at least two layers of material (L 1, L 2 ), which are arranged at different distances from the surface layer ( 31 ), and which differ in respect of material properties or material composition. Semi manufactures for making such floorboards are also disclosed.

Owner:VÄLINGE INNOVATION AB

Flooring panel

A panel, in particular a flooring panel, of a wood material which is provided with a mechanism for the detachable connection of a least two panels, whereby form-fitting elements for locking in the vertical direction and in the horizontal direction with another panel are embodied on at least one lateral edge of a first panel, whereby a chamfer is embodied on at least one lateral edge starting from an upper side. The chamfer or the form-fitting elements are coated or impregnated with at least one melamine layer.

Owner:KRONOTEC

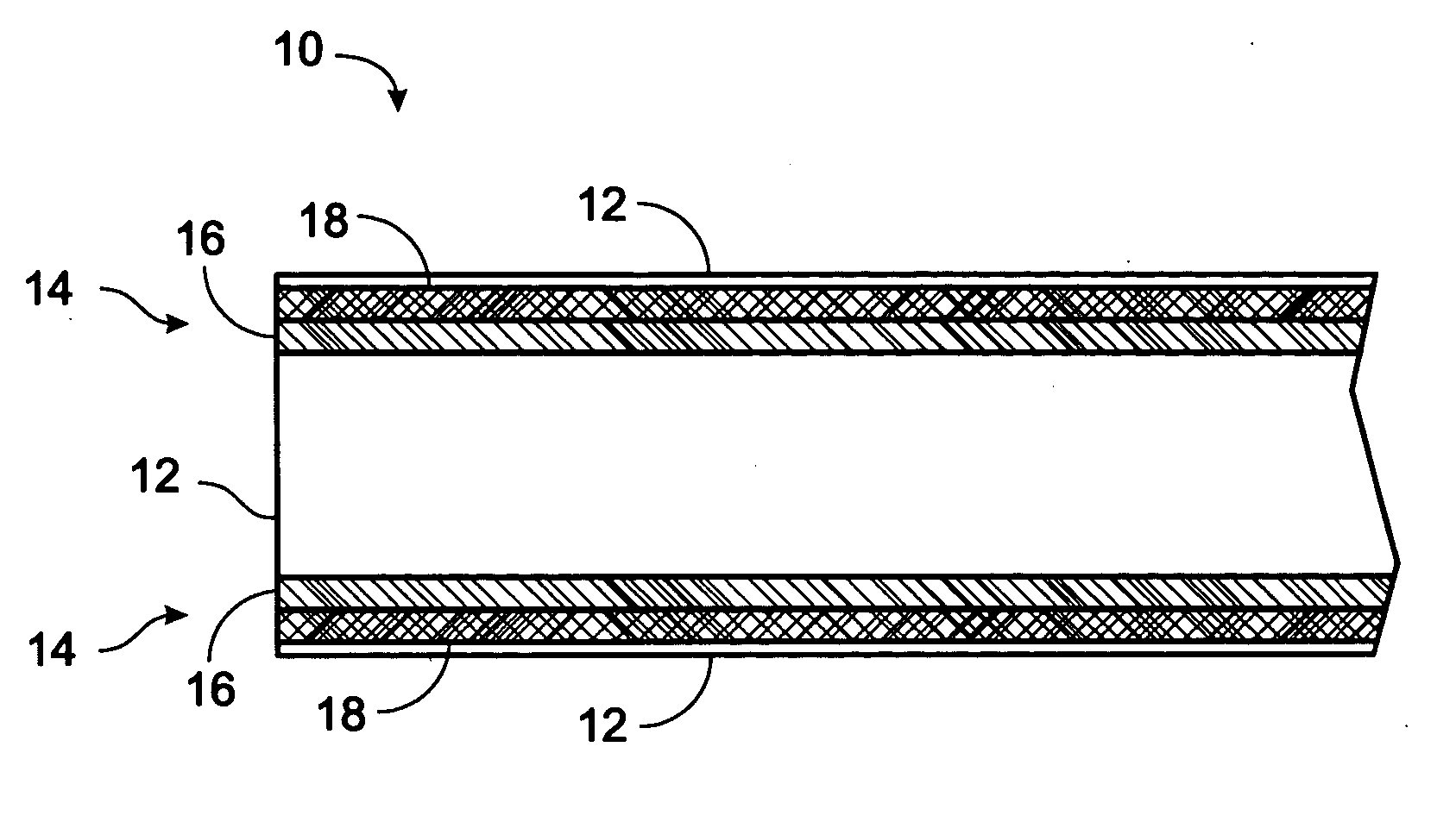

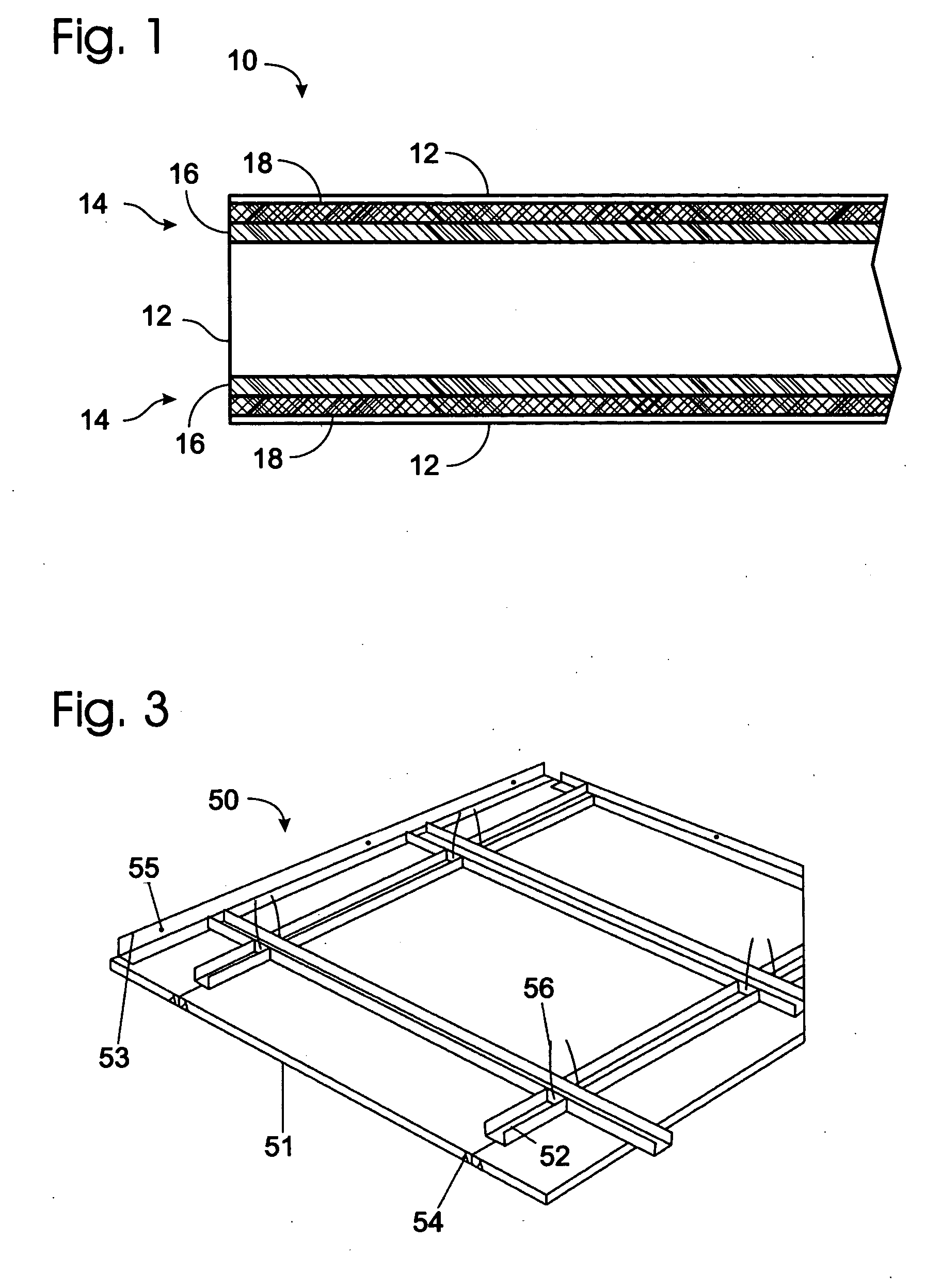

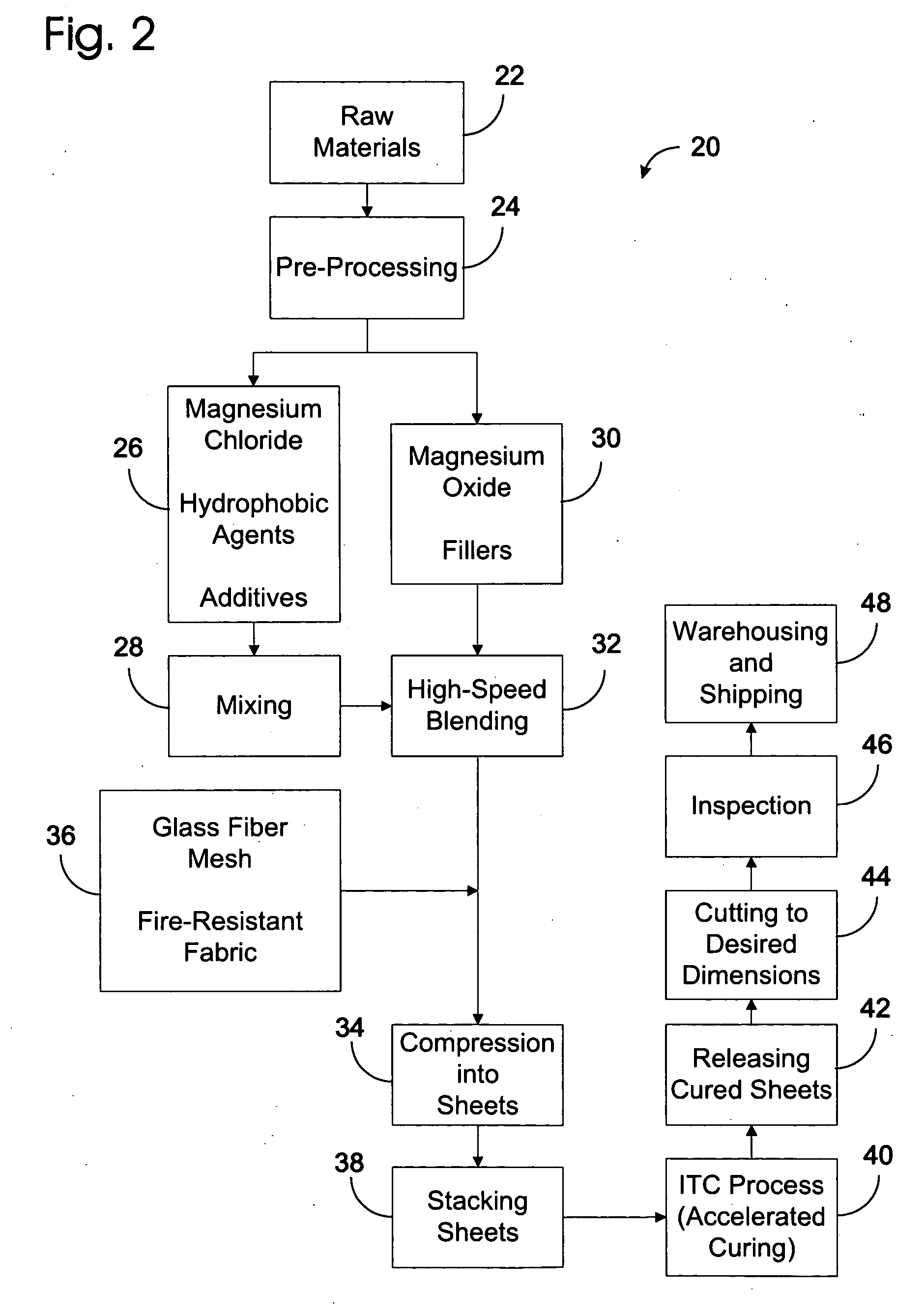

Fire-resistant panel and method of manufacture

A highly fire-resistant and environmentally-friendly panel of 2 mm to 28 mm may be manufactured by a blending of magnesium compounds, sodium silicate, kaolin, fillers, and additives to form the core materials, reinforced by 4 layers of fire-resistant glass fiber meshes and fabrics. Using a proprietary ITC process that accelerates the chemical reactions of the ingredients to generate sufficient heat without external supply of energy, the panels may be completely cured within 24 hours instead of 10 days. The use of waste materials, energy-saving curing system and no gas emission manufacturing process combined to make this panel an eco-friendly product which offers the world's highest-rated fire resistance of 5 hours, high flexural strength, low density, durability and effective water-resistance.

Owner:REP TECH

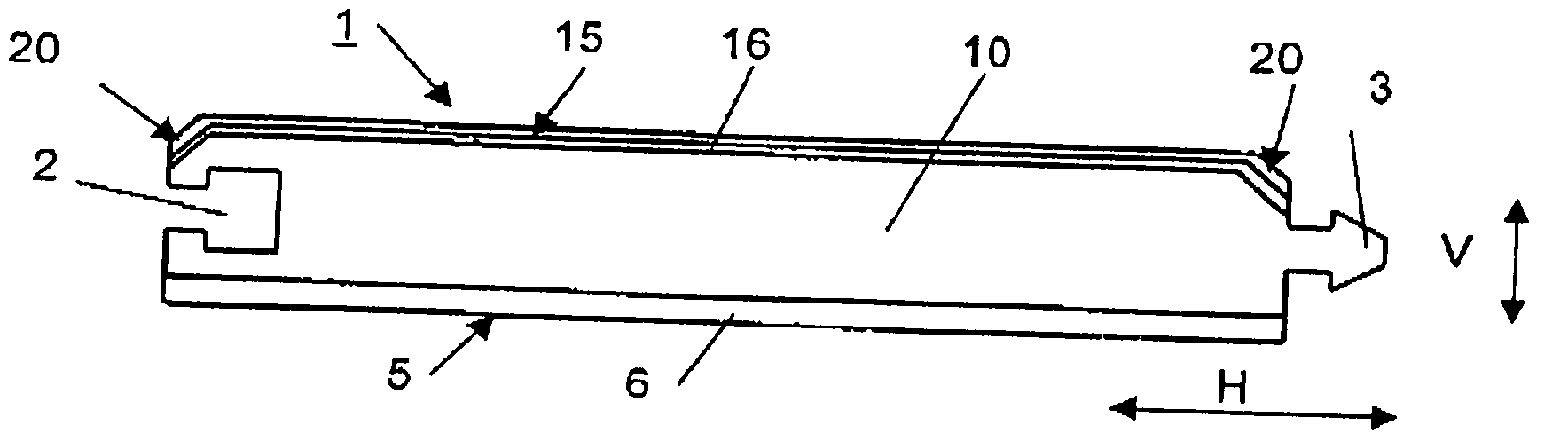

Floor panel

ActiveUS7617651B2Ensure uniform motionLittle effectStrutsWallsTip of the tongueElectrical and Electronics engineering

Floor panel which is bounded in a horizontal plane by a top side, which is provided with a decorative layer or the like, and an underside, which is provided for bearing on an underlying surface, the floor panel being provided with means for the releasable connection of at least two panels, it being the case that the connecting means are formed on at least one first side edge such that locking takes place in the transverse direction (Q) and vertical direction (V), that form-fitting elements for locking in the vertical direction (V) with a further panel are formed on a second side edge, which runs at an angle to the first side edge, that the form-fitting elements are spaced apart from one another in the transverse direction (Q) and in the vertical direction (V) on two spaced-apart, essentially vertically oriented walls, in which case a tongue is formed on the first side edge, the tongue extending in the longitudinal direction of the side edge, and a recess, corresponding to the tongue, is formed on an opposite side edge, the underside of the tongue, starting from the tip of the tongue, having a continuously curved contour.

Owner:VÄLINGE INNOVATION AB

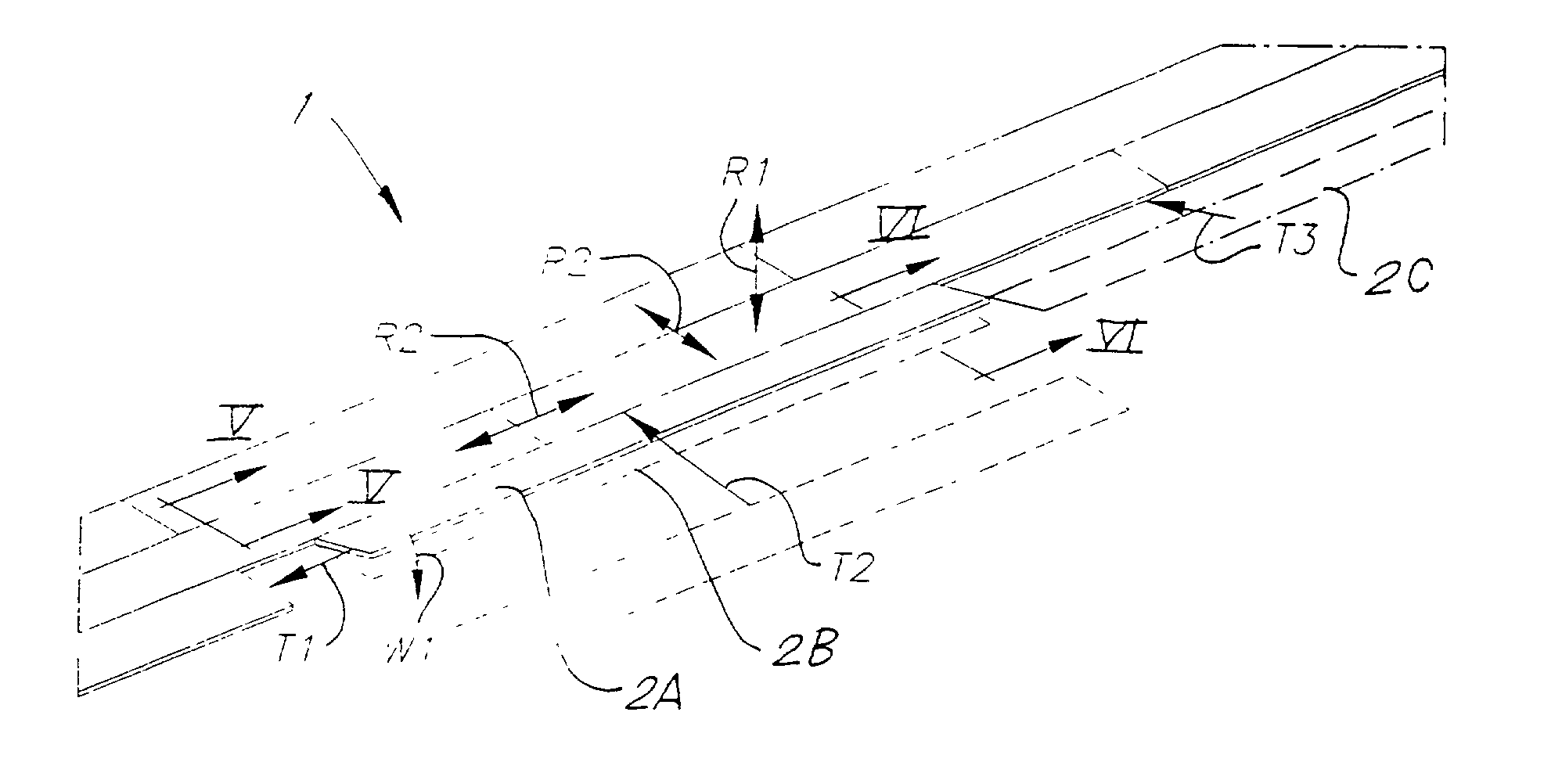

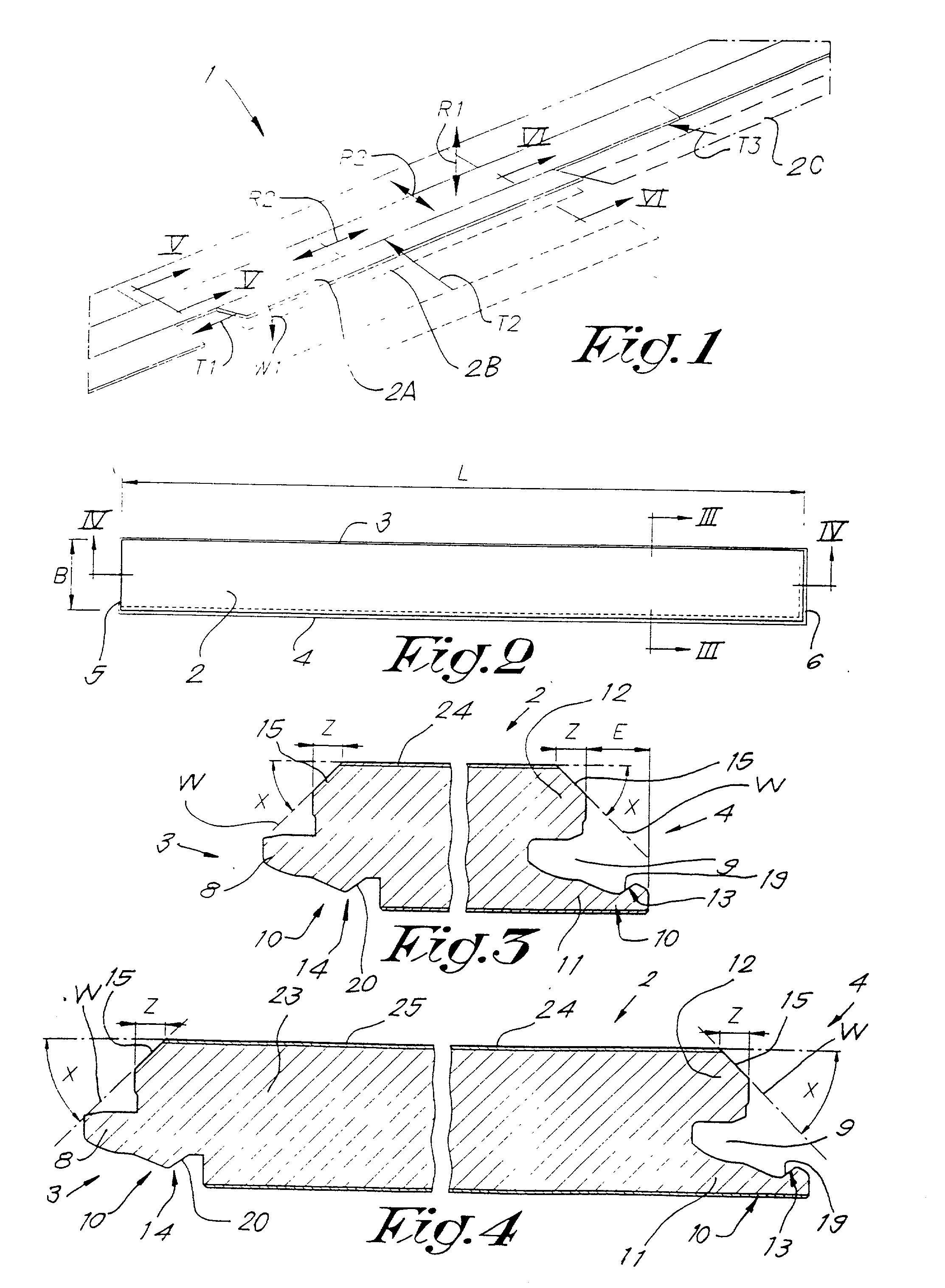

Floor covering

InactiveUS20020056245A1Easy to movePrevent mutual rotationCovering/liningsNatural patternsEngineeringMechanical engineering

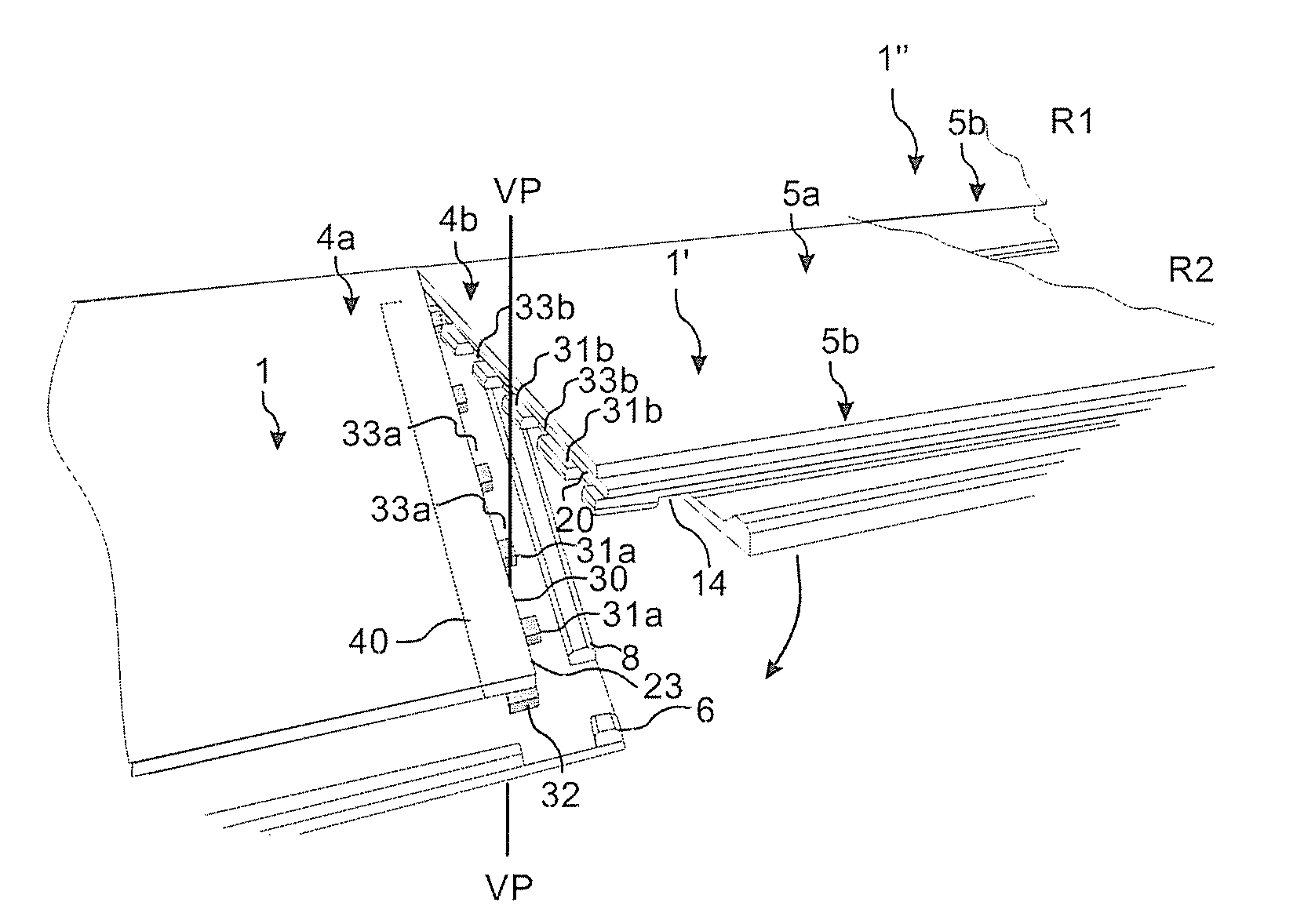

A floor covering of hard panels (2) having at least on two opposite edges (3-4; 5-6), coupling elements (7) made in one piece with the panels (2), so that several of such panels (2) can be mutually coupled, whereby these coupling elements (7) provide for an interlocking in a direction (R1) perpendicular to the plane of the floor covering (1), as well as in a direction (R2) perpendicular to the edges (3-4; 5-6) and parallel to the plane of the floor covering (1), and whereby these coupling elements (7) are made such that the panels (2) can be rotated into and / or out of one another at least along the above-mentioned edges (3-4; 5-6). The panels (2) are provided, at least on the above-mentioned edges (3-4; 5-6), near the top side, with a part from which has been removed an amount of material such as by a level.

Owner:FLOORING IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com