Self-heat-preservation building block and self-heat-preservation wall body consisting of self-heat-preservation building blocks

A self-insulating block and block technology, applied in the direction of walls, building components, building structures, etc., can solve the problems that building wall materials cannot have both load-bearing, thermal insulation, fire prevention, etc., and achieve significant social and economic benefits. Guarantee the effect of integrity and block strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

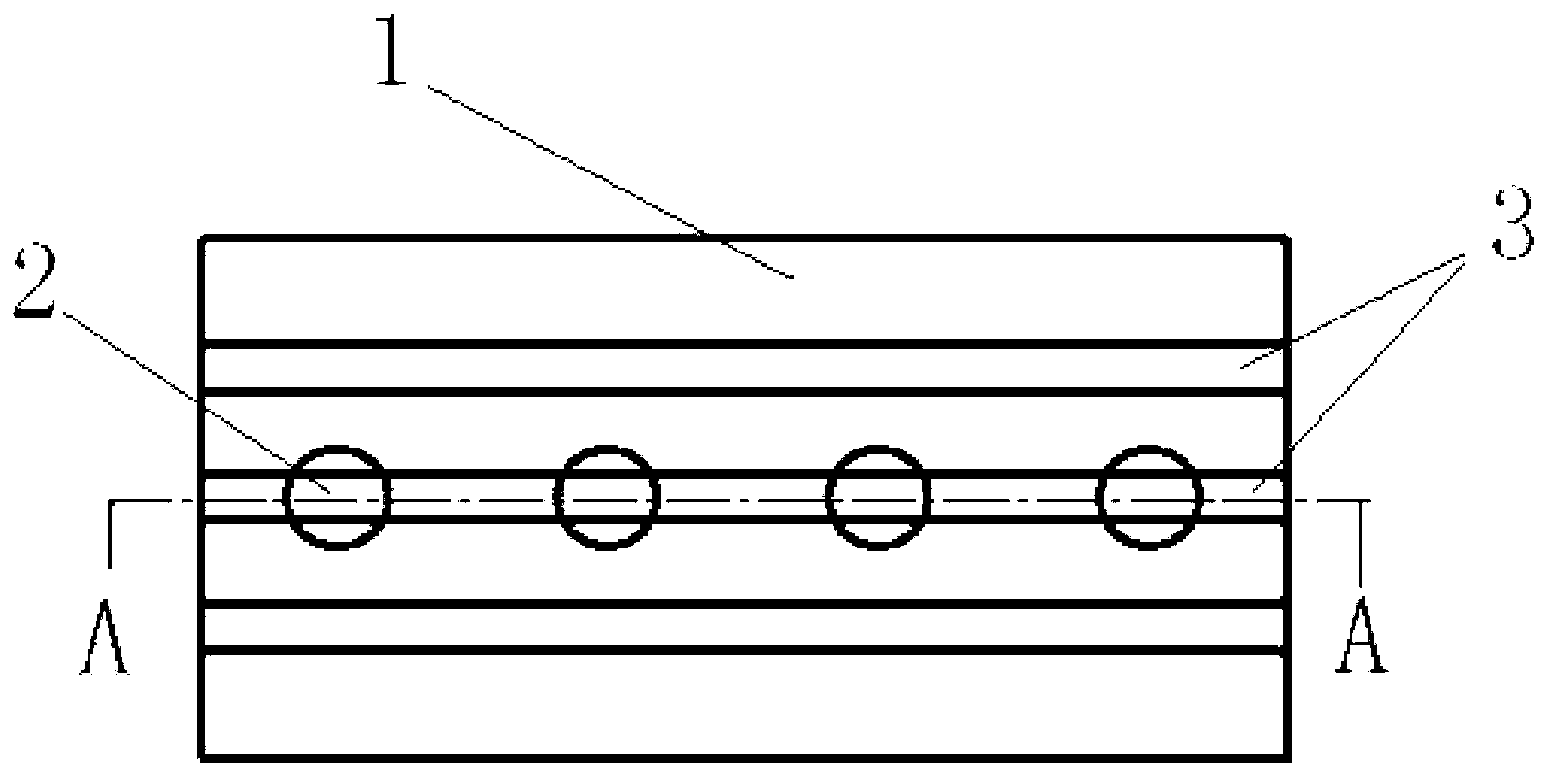

[0054] Such as figure 1 , 2 As shown, a self-insulating block, the block body 1 is made of foamed cement, three horizontal through grooves 3 are arranged on the block; three vertical through holes 2 are arranged in the block, the horizontal through grooves 3 and the vertical Fill the through hole 2 with concrete slurry to form a concrete column integrated with the block body 1 to obtain a block.

Embodiment 2

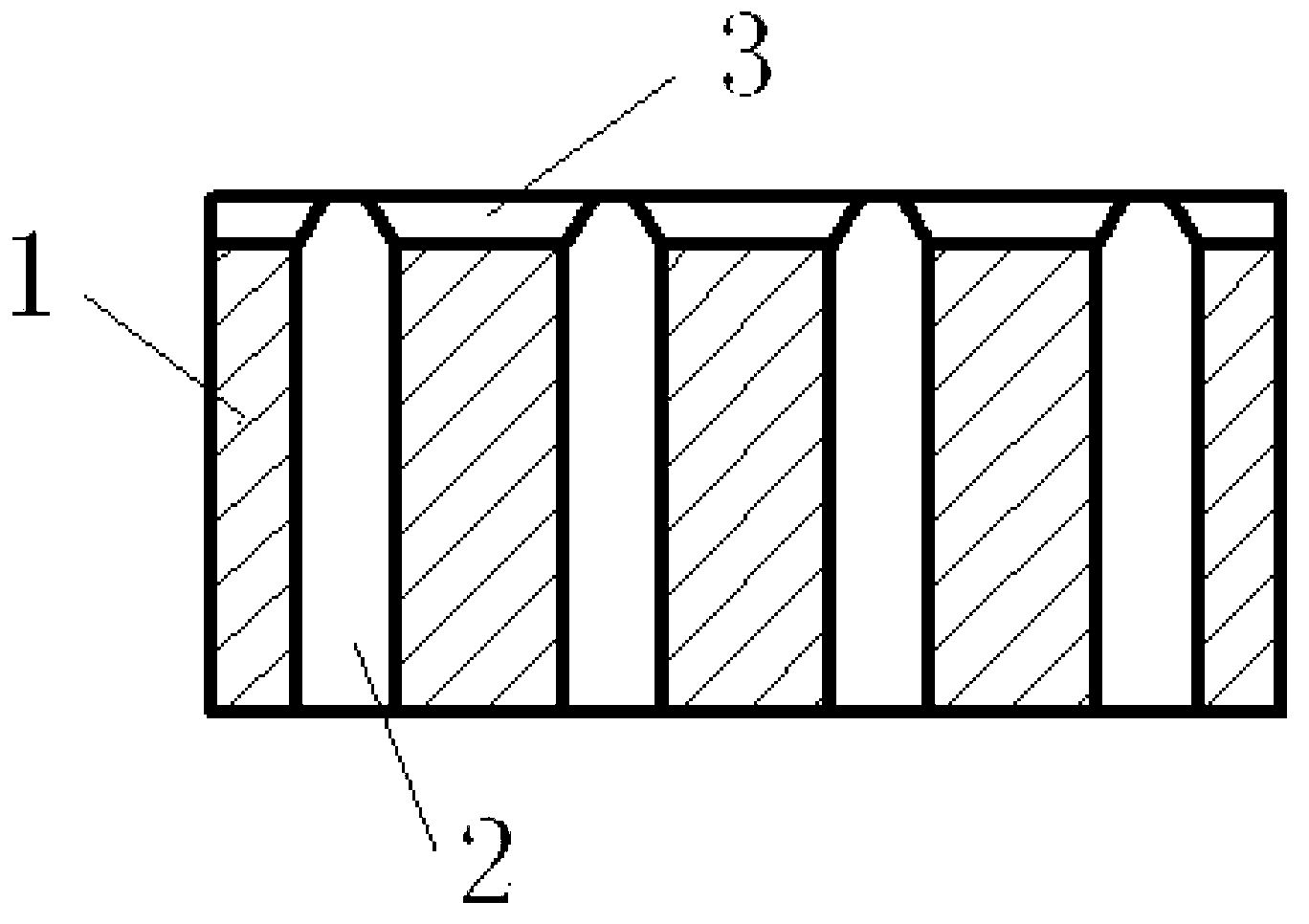

[0056] Such as image 3 , 4 As shown, a self-insulating block, the block body 1 is made of the firewall body honeycomb foam insulation material in the Chinese patent CN201010582361.3, named "a kind of fire wall honeycomb foam insulation material", Four vertical through holes 2 are arranged in the block, which are evenly distributed into two rows; two horizontal through grooves 3 are arranged on the block; the vertical through holes 2 and the horizontal through grooves 3 are connected, and the vertical through holes 2 and the horizontal through grooves Φ6 steel bars are arranged in 3, and concrete slurry is filled in the vertical through hole 2 and the horizontal through groove 3, so that the concrete column and the block body 1 are integrated to form a block.

Embodiment 3

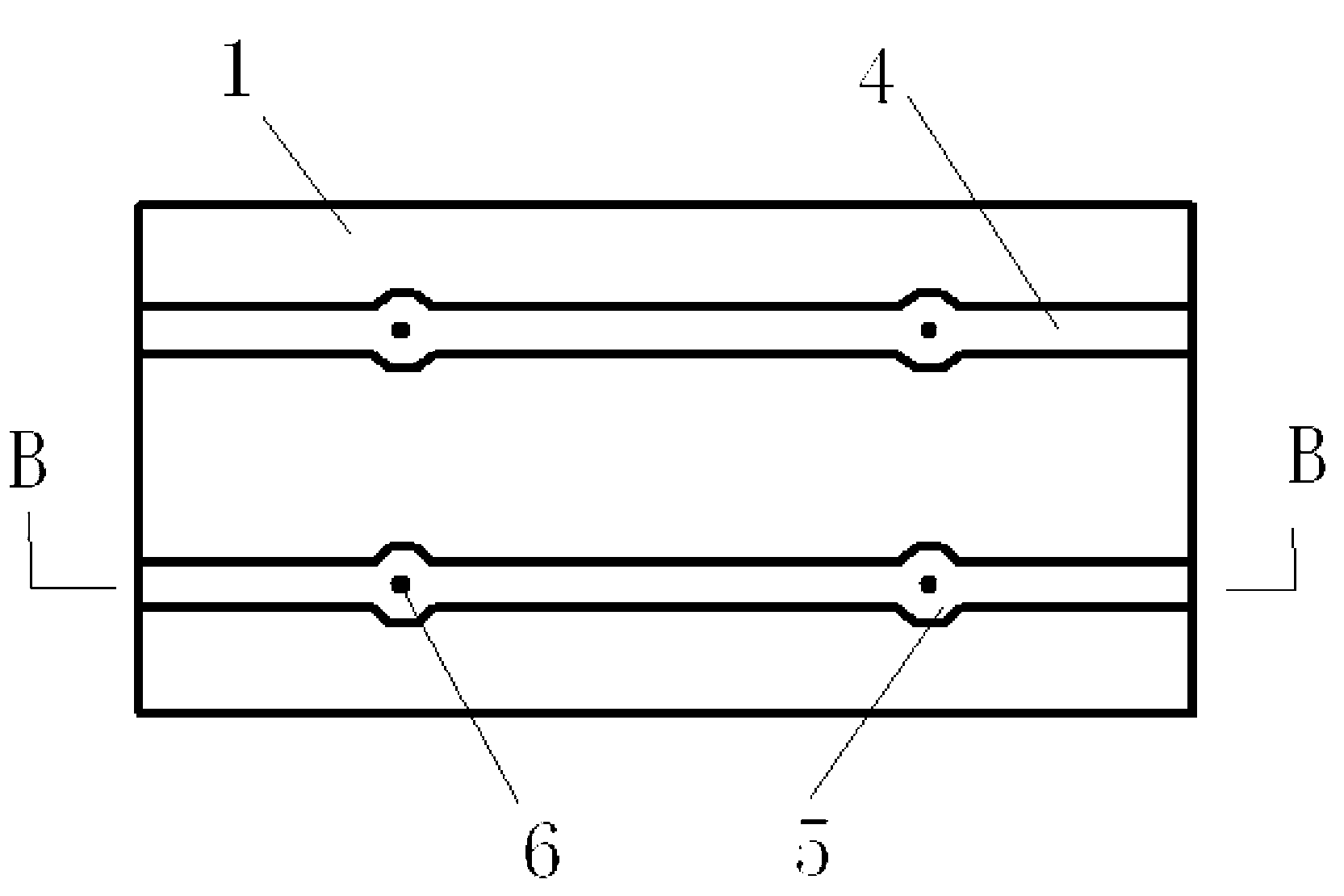

[0058] Such as Figure 5 , 6 As shown in , 7, a high-strength thermal insulation wall, the block body 1 is made of the firewall body honeycomb foam insulation material in the Chinese patent number CN201010582361.3 titled "A Firewall Honeycomb Foam Thermal Insulation Material" The block body 1 is built into the wall shape required by the design, and the blocks 7 are connected with thermal insulation cement to form a horizontal mortar joint 10 and a vertical mortar joint 8, and the vertical through holes 2 of the blocks 7 correspond one-to-one. An overall vertical channel is formed, and the horizontal channels 3 of the block 7 form an overall horizontal channel in one-to-one correspondence, and Φ12 steel bars are arranged in the overall vertical channel and the overall horizontal channel; Connected to each other, pouring concrete slurry into the integral channel and the integral channel to form the core column 4, 5 and the block body 1 to solidify as one to form a wall, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com