Patents

Literature

465 results about "Mortar joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In masonry, mortar joints are the spaces between bricks, concrete blocks, or glass blocks, that are filled with mortar or grout. If the surface of the masonry remains unplastered, the joints contribute significantly to the appearance of the masonry. Mortar joints can be made in a series of different fashions, but the most common ones are raked, grapevine, extruded, concave, V, struck, flush, weathered and beaded.

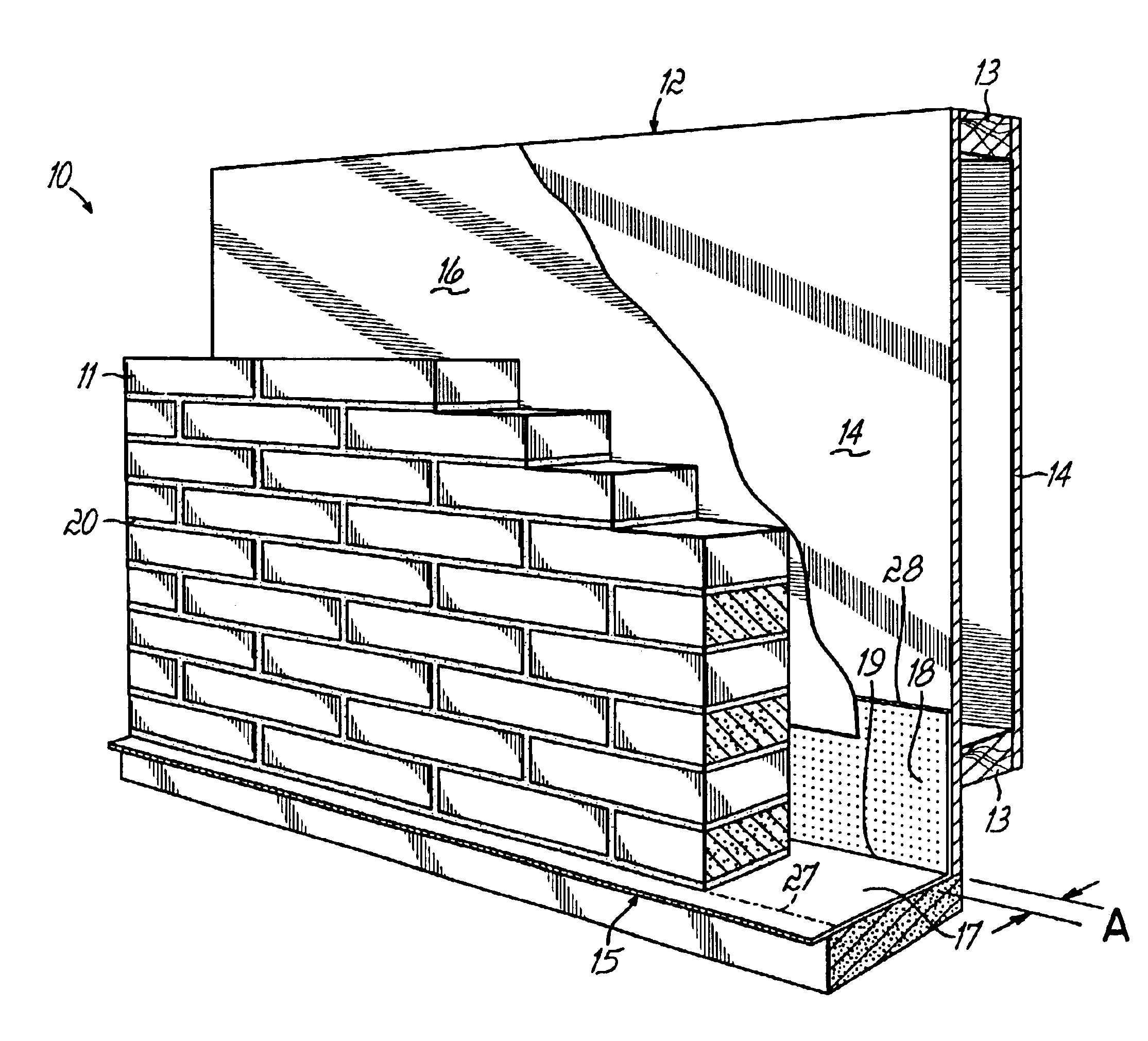

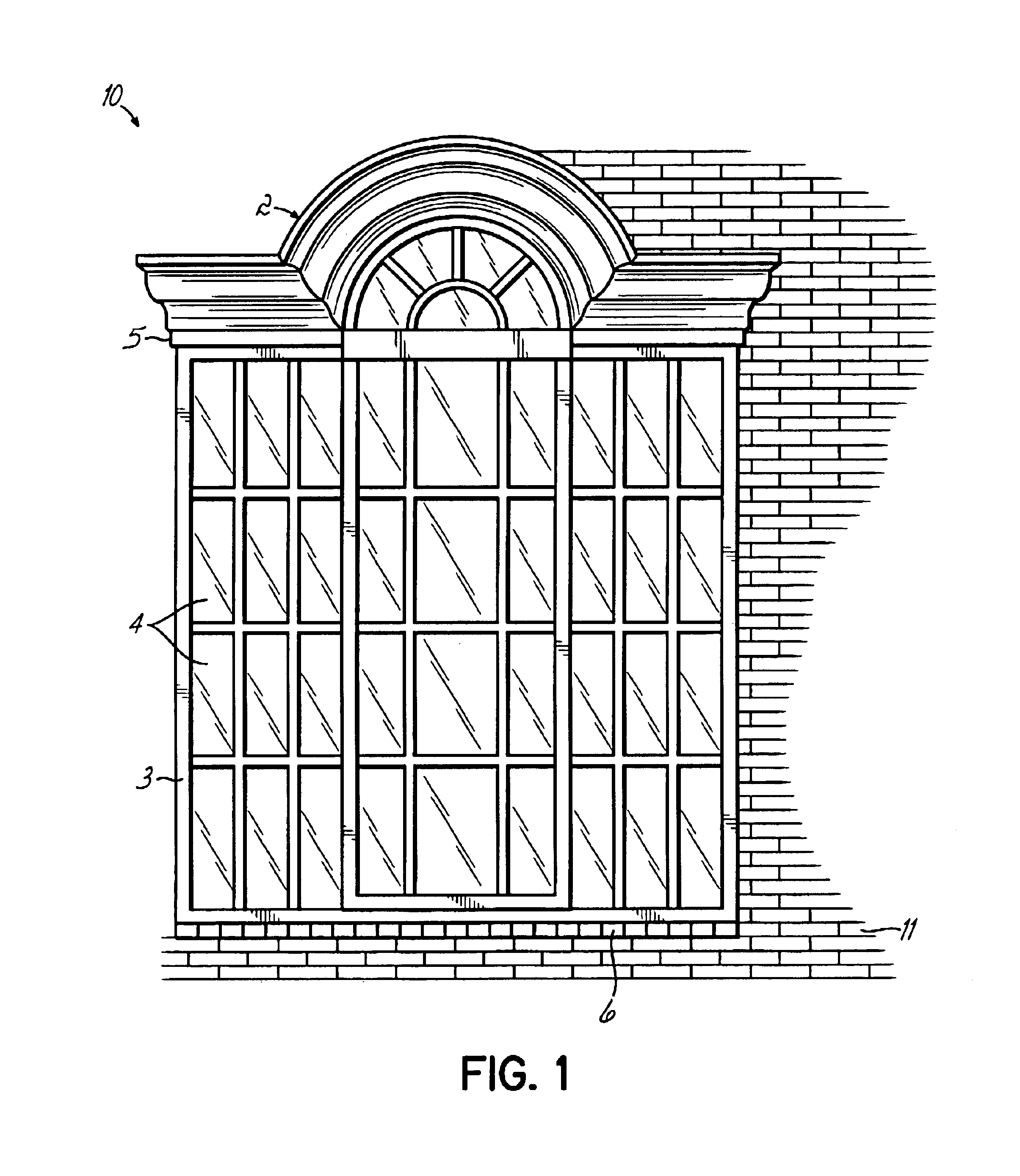

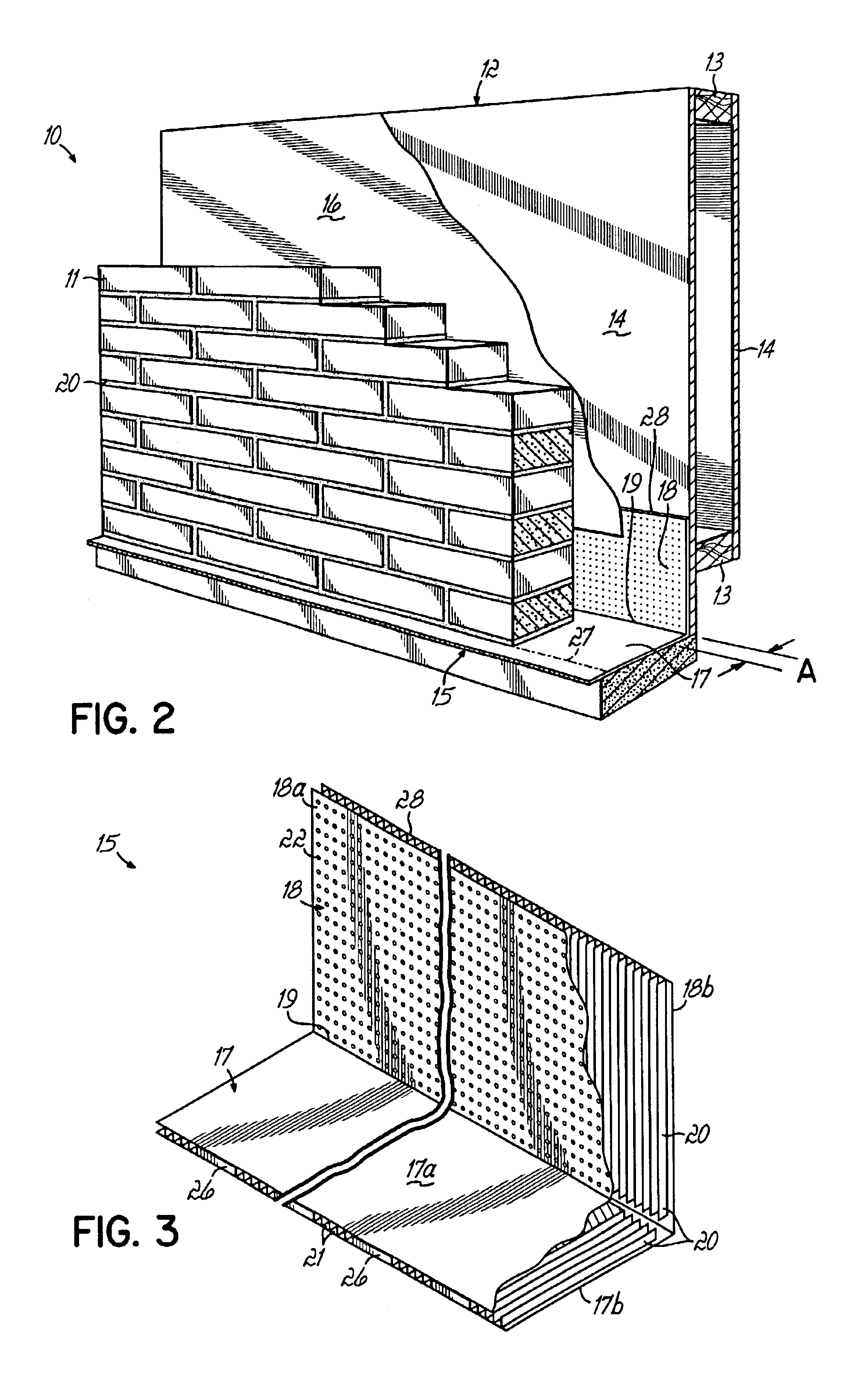

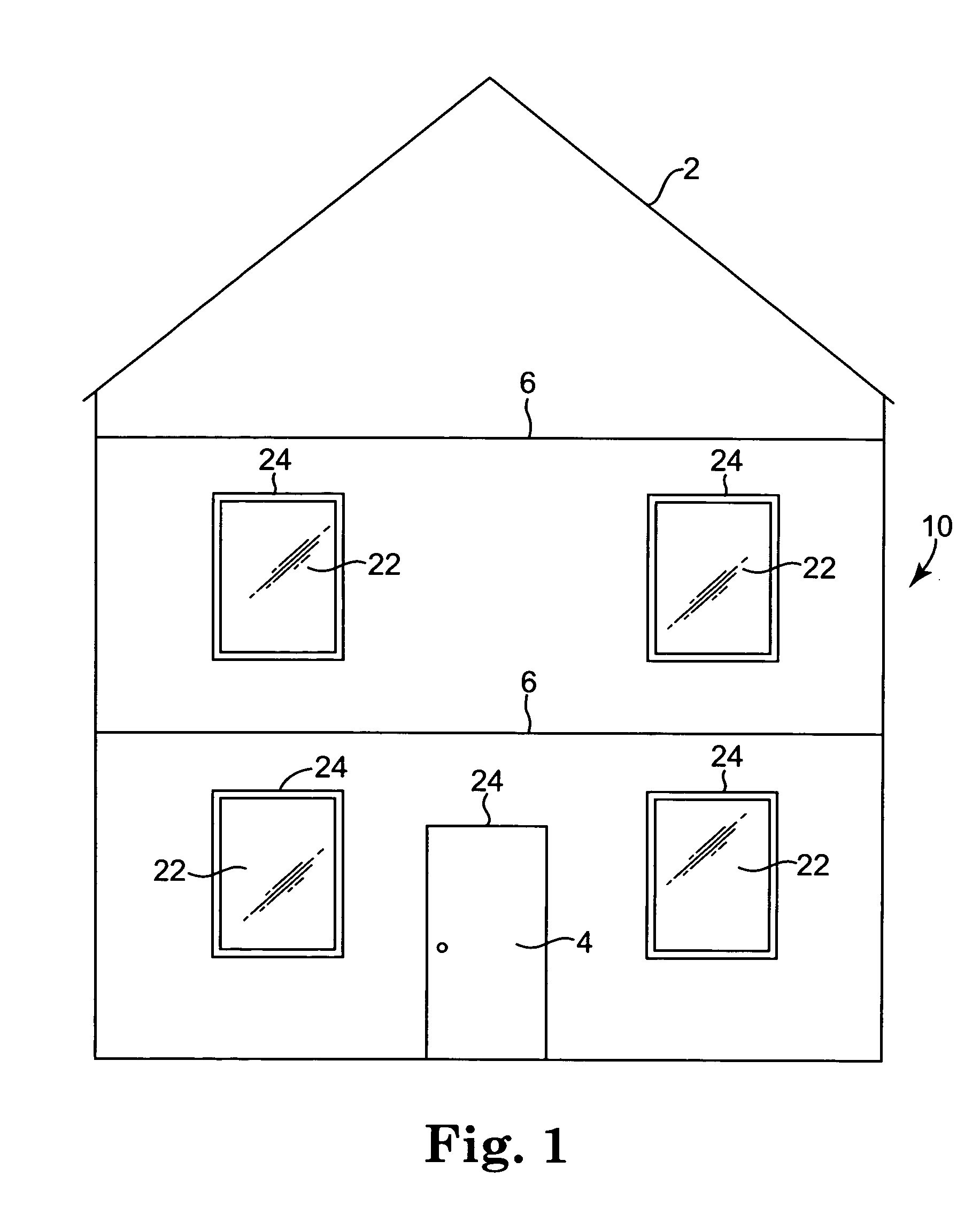

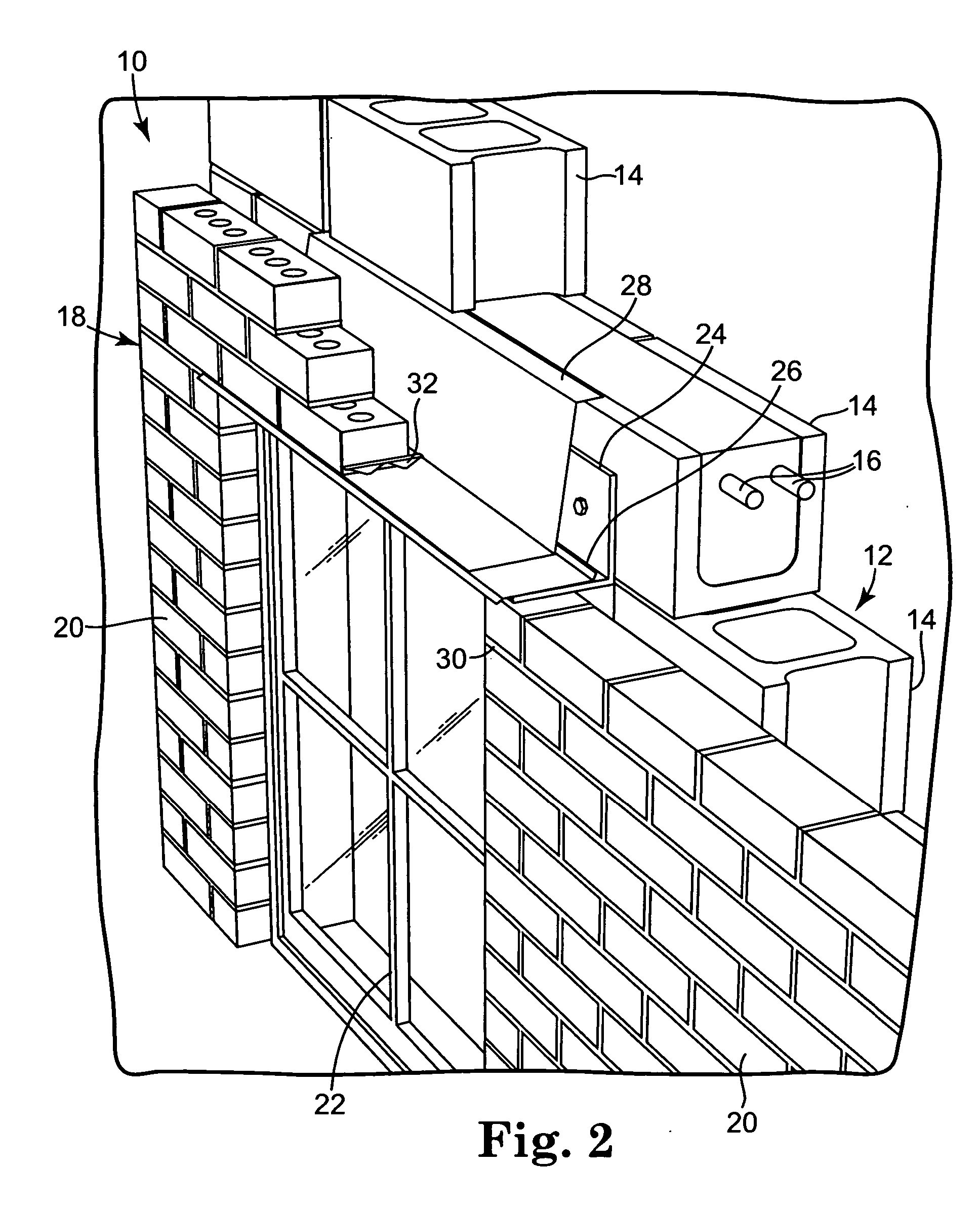

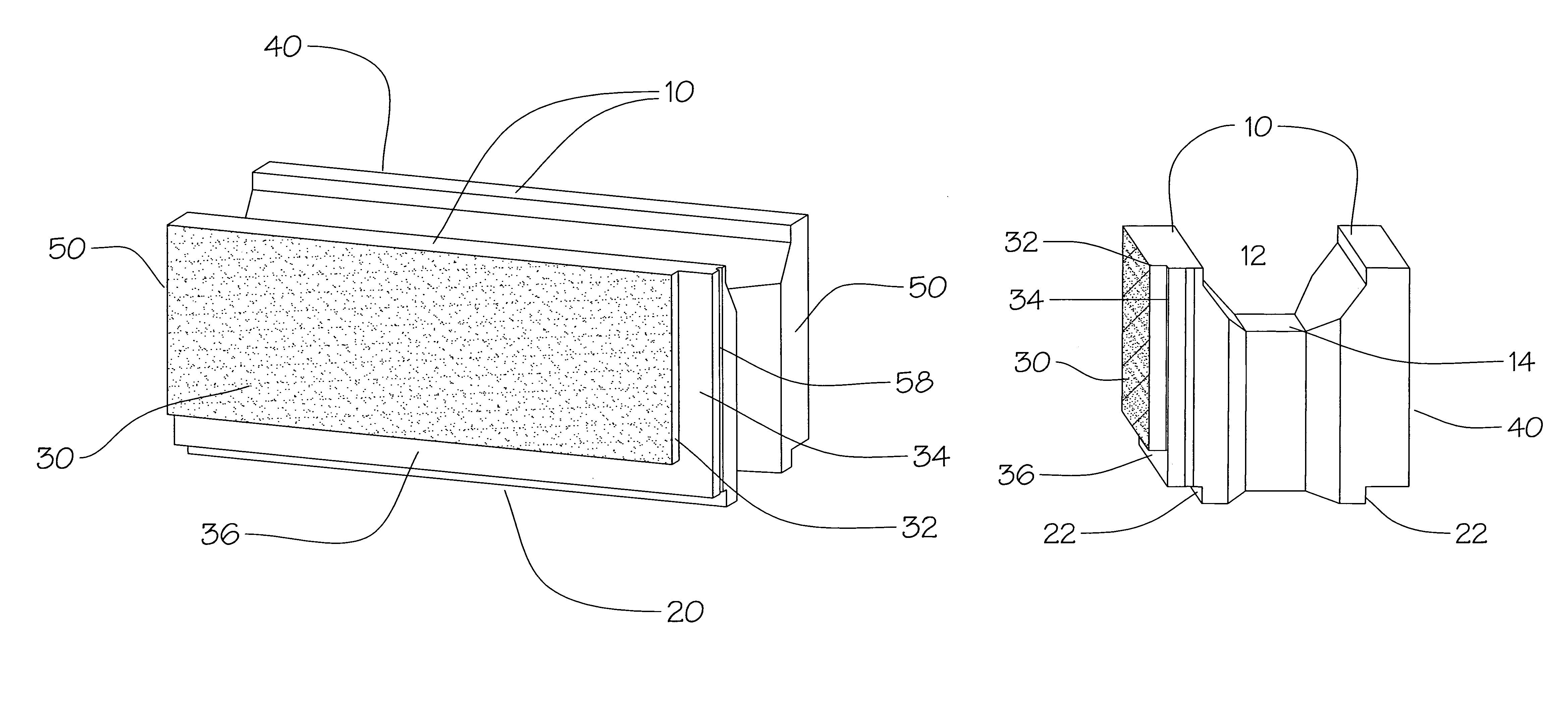

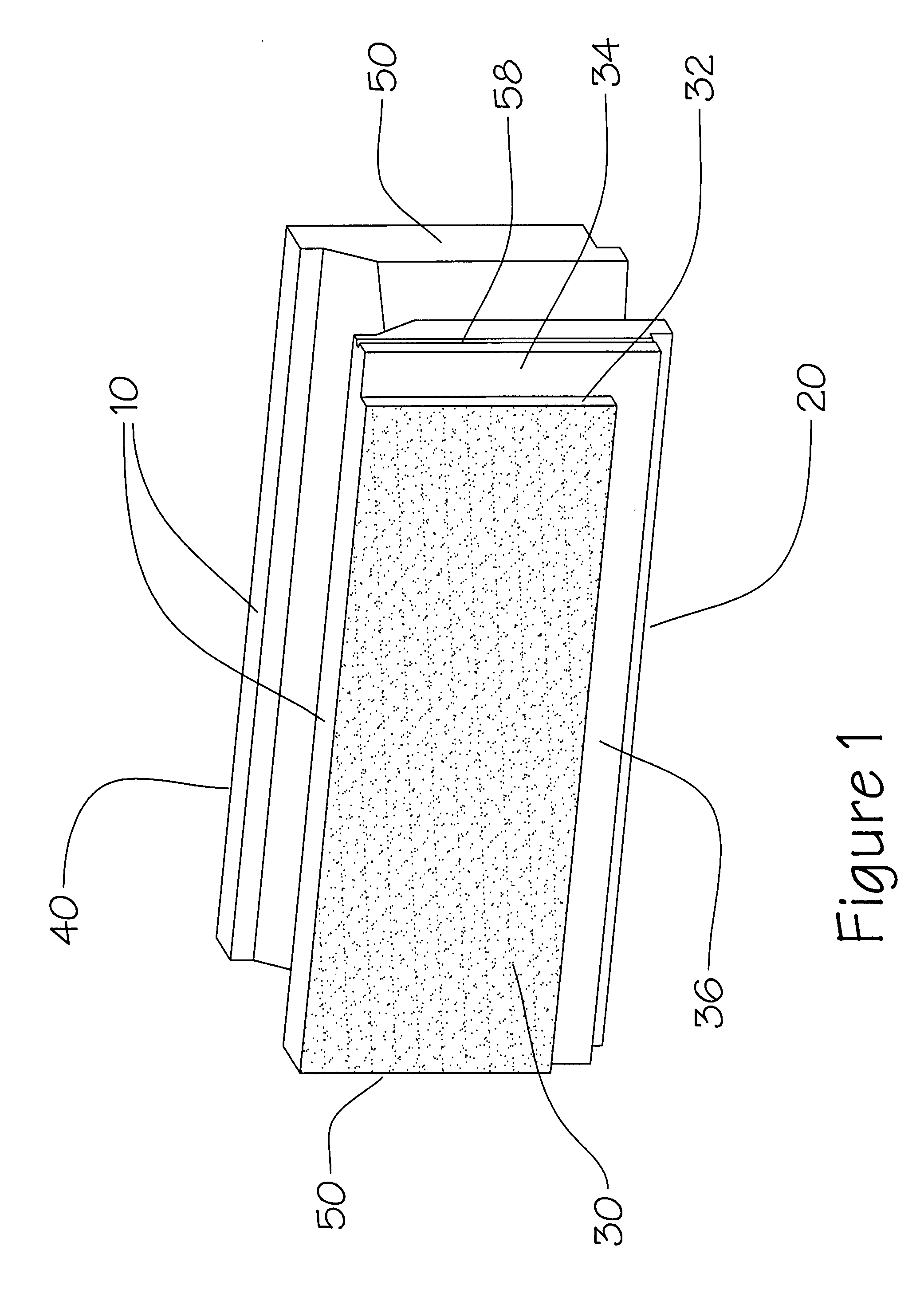

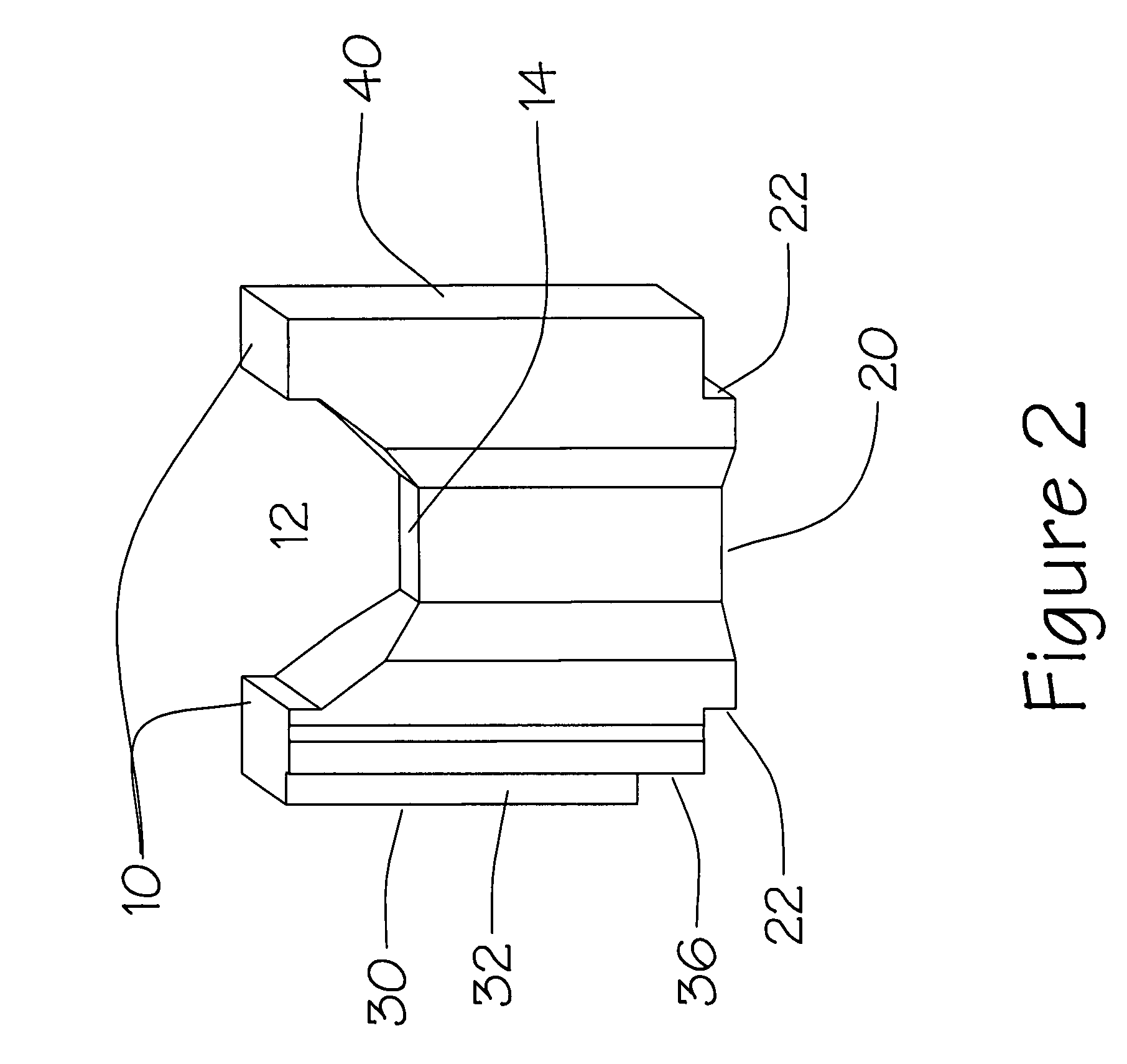

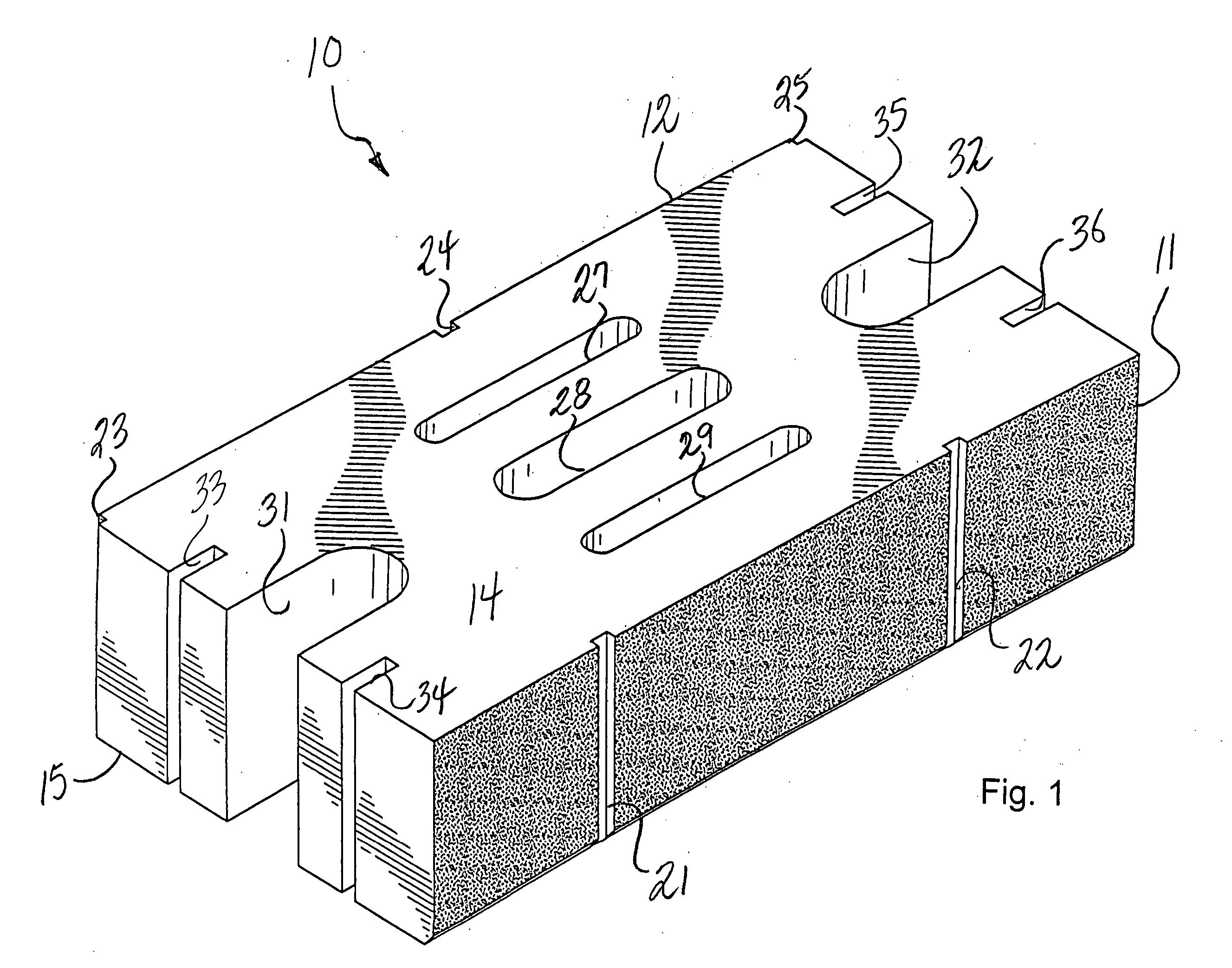

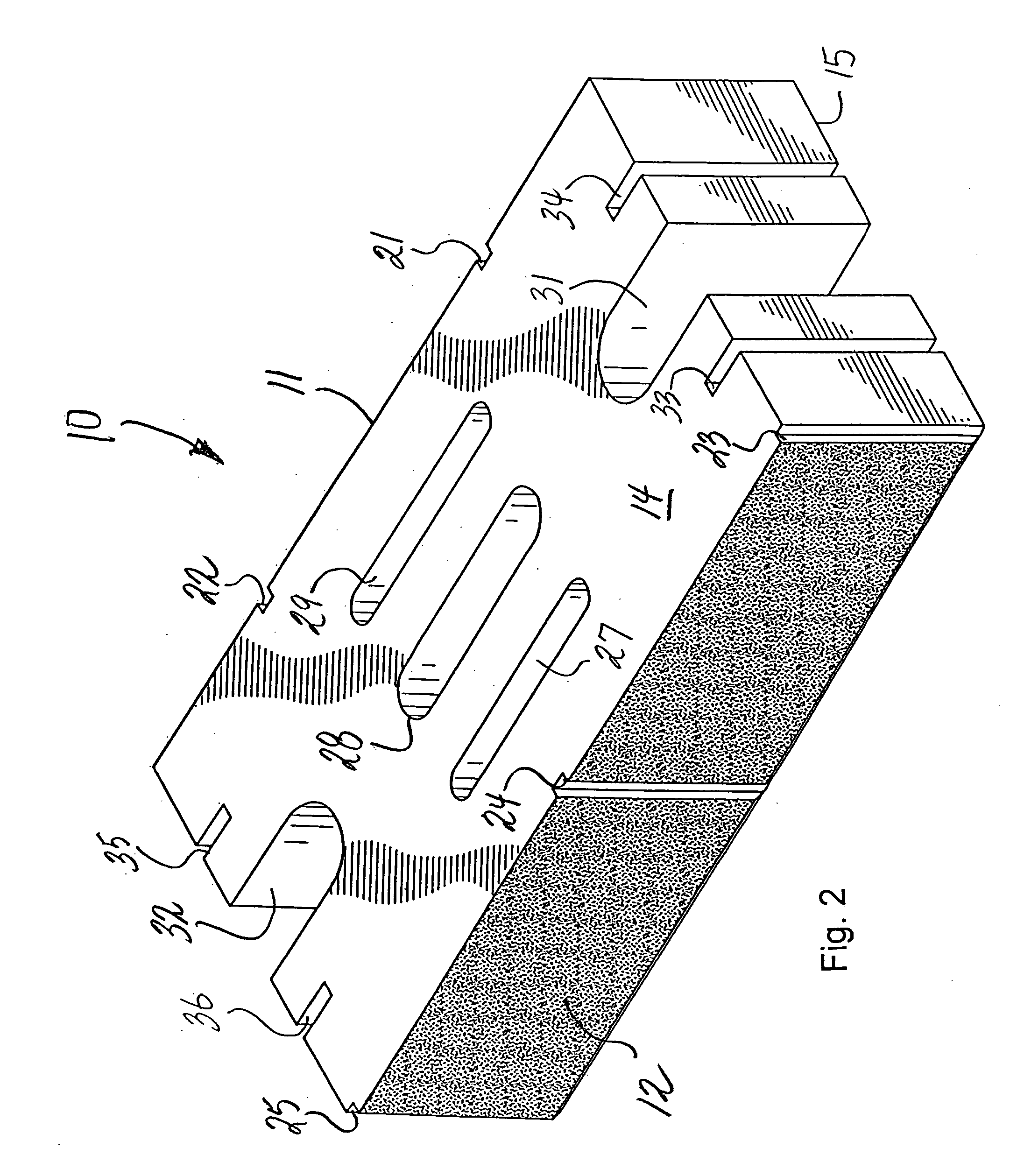

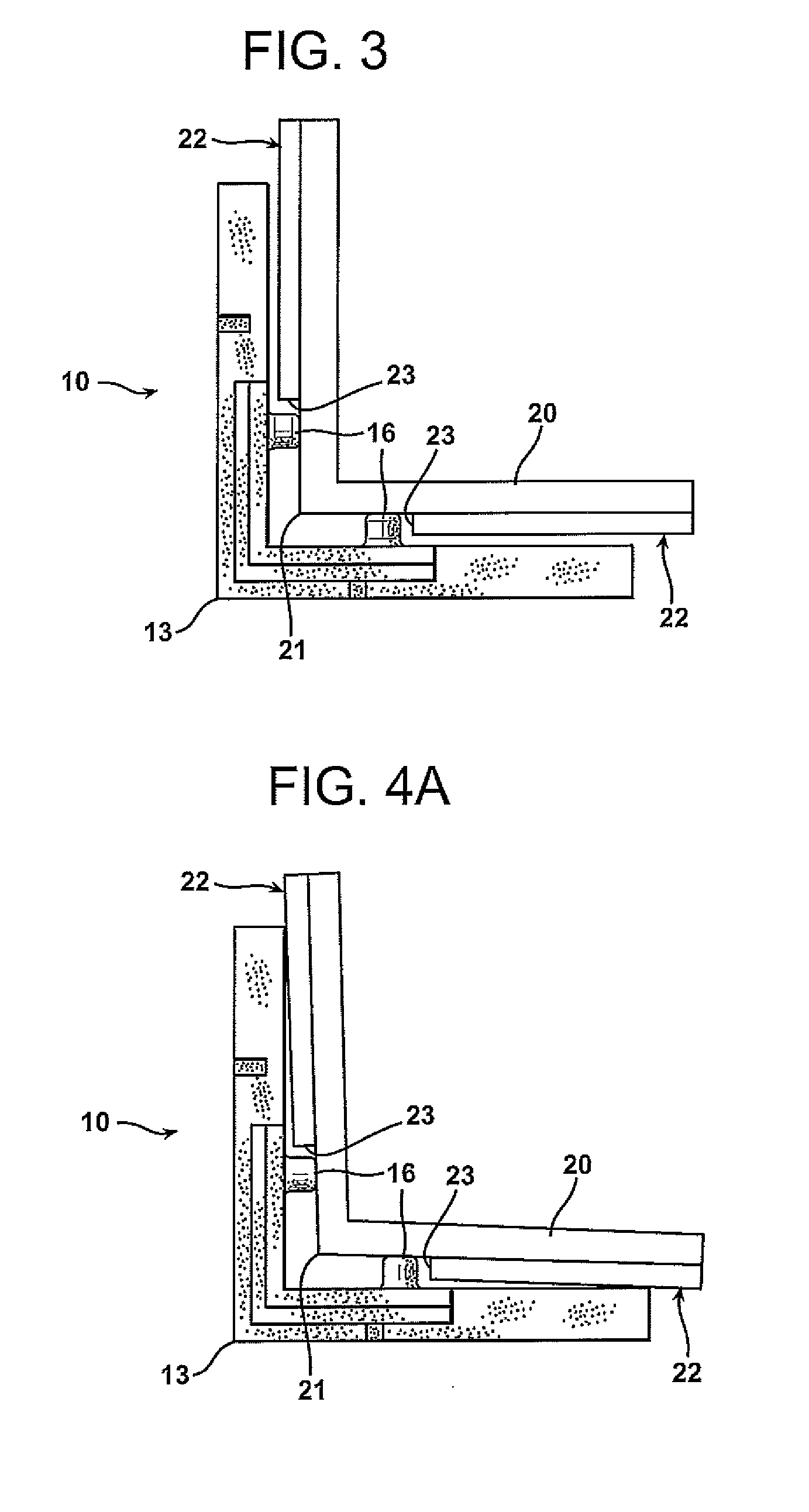

Flashing and weep apparatus for masonry wall window and door installations

ActiveUS6964136B2Easy to installEasy to implementRoof covering using slabs/sheetsRoof covering using tiles/slatesCavity wallMoisture

A flashing and weep apparatus allows for simple installation and accurate placement windows and doors in cavity wall construction. In a first embodiment, the flashing and weep apparatus is a two-panel extrusion that has a flashing panel that acts as a non-porous support for the masonry veneer. This embodiment also includes a second panel which is joined at a generally right angle to the first panel to be juxtaposed against the outer face of the inner wall in the cavity wall construction. Weep channels are formed between the two panels and allow for the drainage and dissipation of water and other moisture in the cavity wall system. In a second embodiment, membrane is initially attached to and draped along the lower portion of the inner wall immediately above the sill or lintel. The membrane extends across the cavity spacing between the walls to underlie the masonry components forming the outer veneer. Weep channels on the membrane communicate and transmit water and moisture from the cavity between the walls to the exterior of the veneer. The weep channels are positioned at the joint between adjacent bricks. The membrane extending beyond the mortar joint at the masonry veneer is trimmed during the installation process so as not to extend beyond the outer veneer wall while still providing an easily installed and implemented flash and weep system.

Owner:TY DAS BUILDING PROD LLC

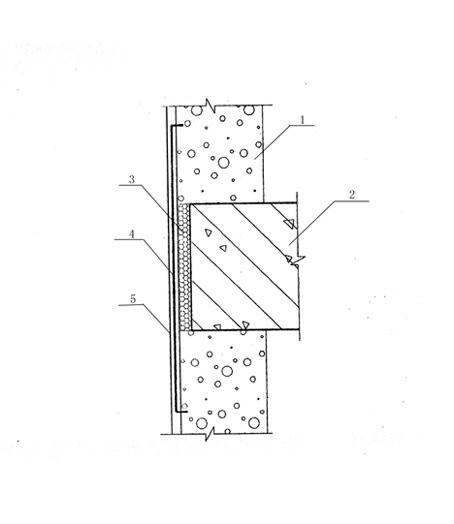

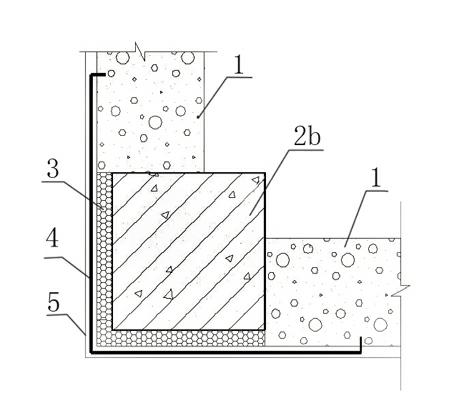

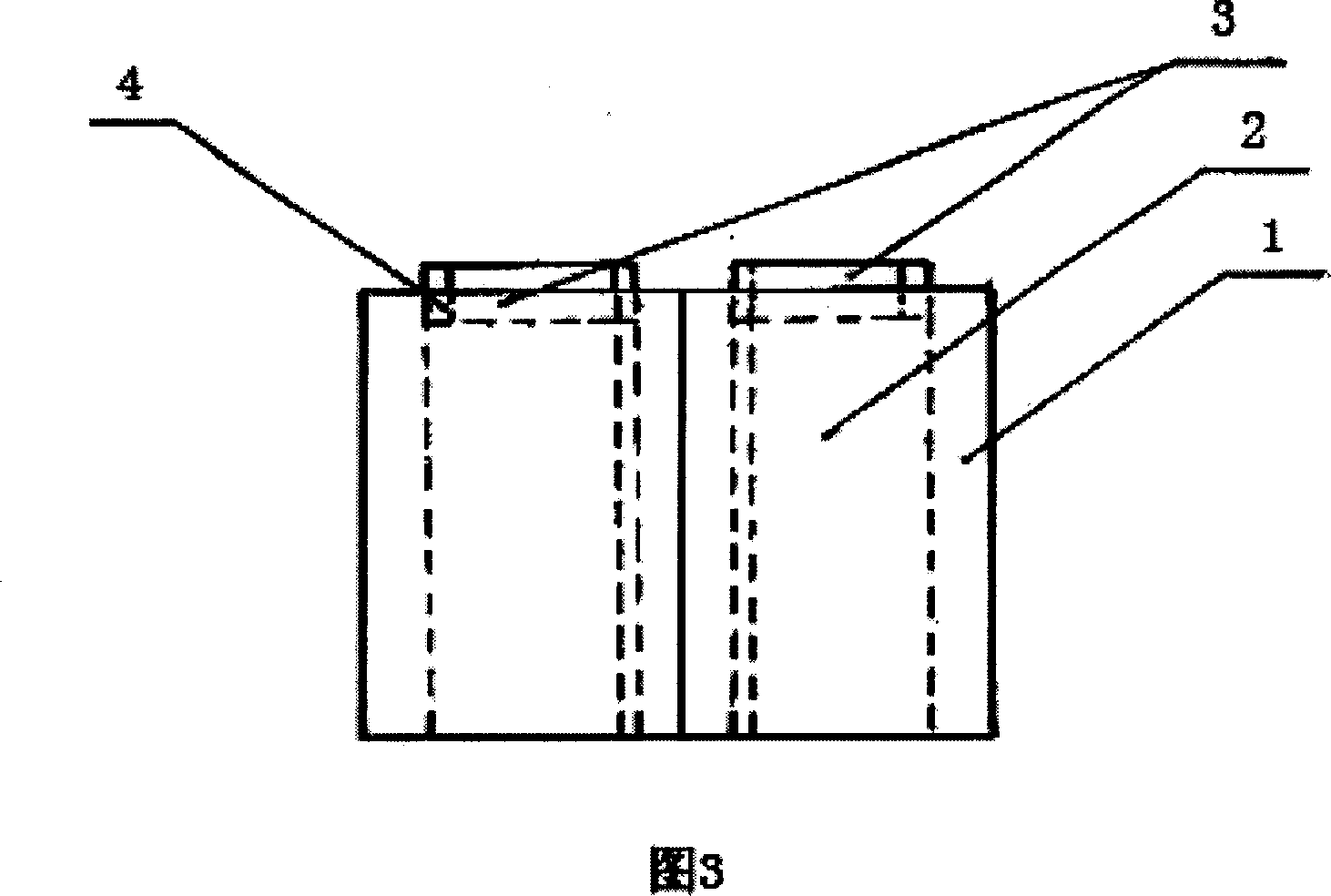

Automatic heat preservation, energy saving and air-entrapping concrete brick wall and manufacturing method thereof

InactiveCN102162282AImprove performanceMeet the requirements of the outer protective structureConstruction materialSolid waste managementInsulation layerThermal bridge

The invention relates to an automatic heat preservation, energy saving and air-entrapping concrete brick wall and a manufacturing method thereof. The invention is characterized that: a heat preservation wall plate is protruded, relative to the outer surfaces of a beam and a stand column or a concrete plate, 20 to 50 millimeters or flatly bricked; beam and column part heat preservation layers are bonded on the outer surfaces of the beam and the stand column or the concrete plate; and alkali-proof grids or steel mesh sheets are paved on the surfaces of the heat preservation layers. During bricking of the wall, the comprehensive performance of the heat preservation wall can be enhanced under the condition of no addition of the heat preservation layers on the whole wall by using energy saving and air-entrapping concrete bricks and heat preservation bricking mortar as well as heat preservation processing measures taken on hot bridge parts such as the beam, the column and the like, so the requirement of a periphery protective structure of a building wall can be met, and heat energy loss due to the hot bridges formed in mortar joints of the wall can be avoided effectively; therefore, the design standard requirement of China on heat preservation and energy saving of a building is met, and the manufacturing cost of the wall and the comprehensive cost of the building are reduced greatly.

Owner:徐振飞

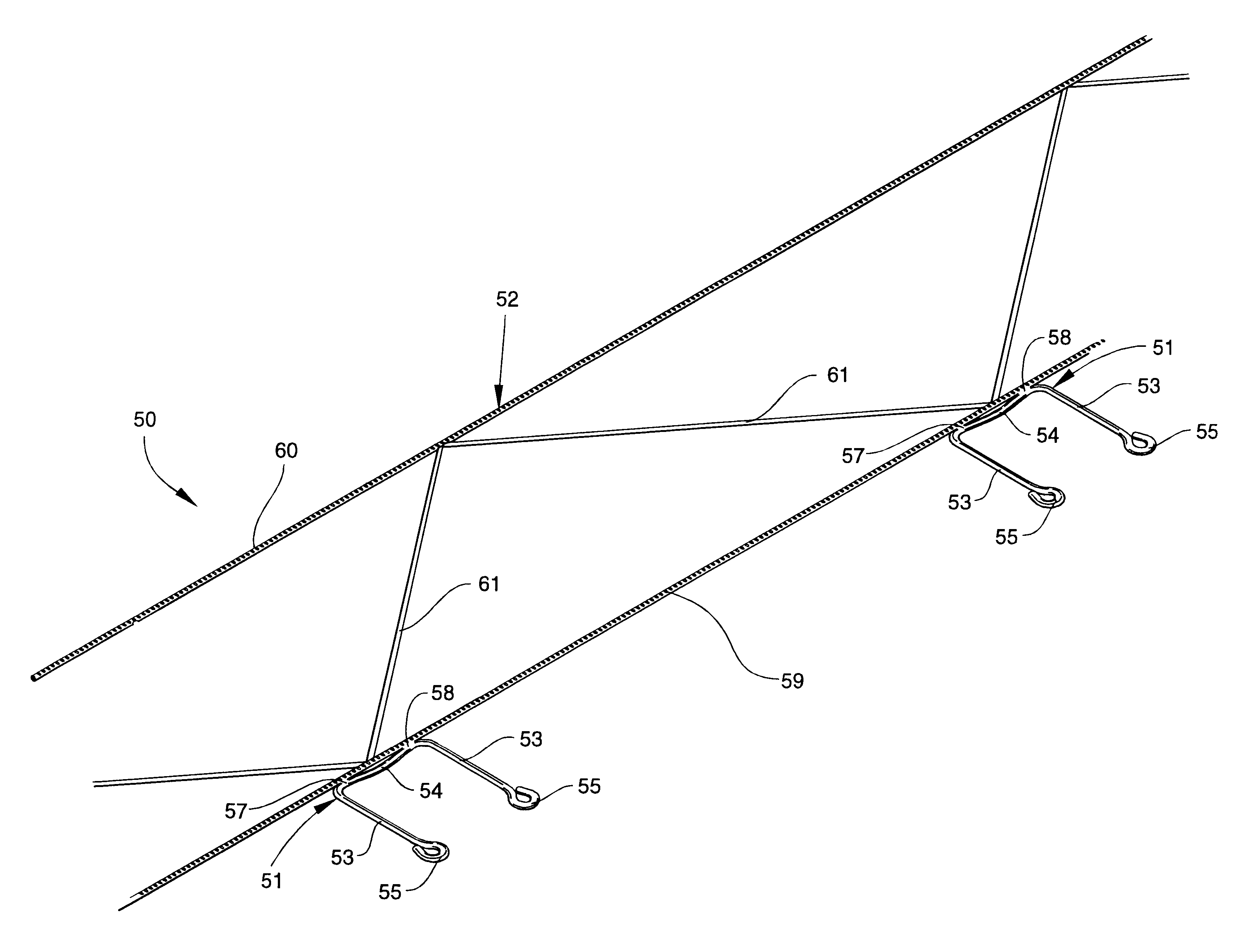

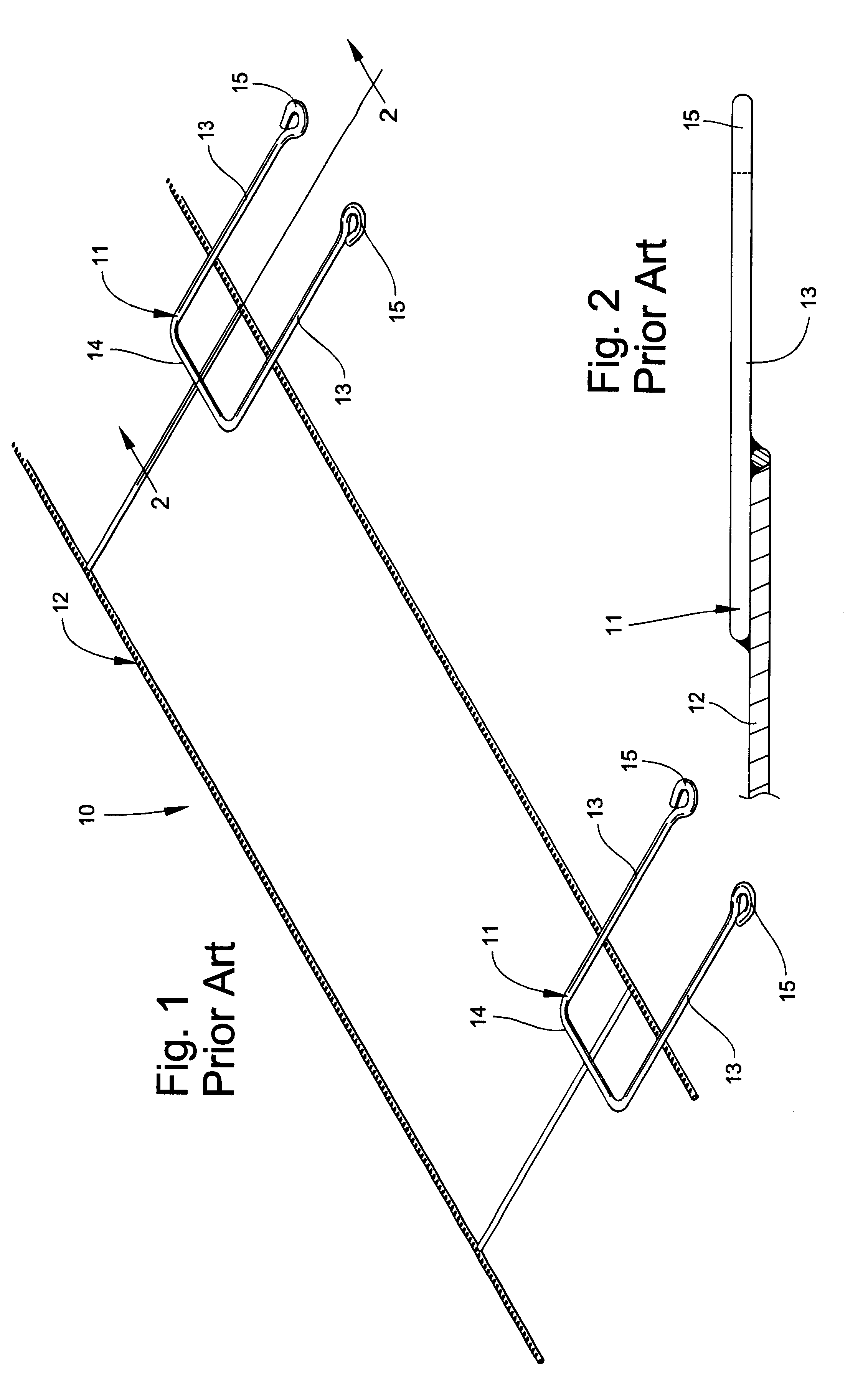

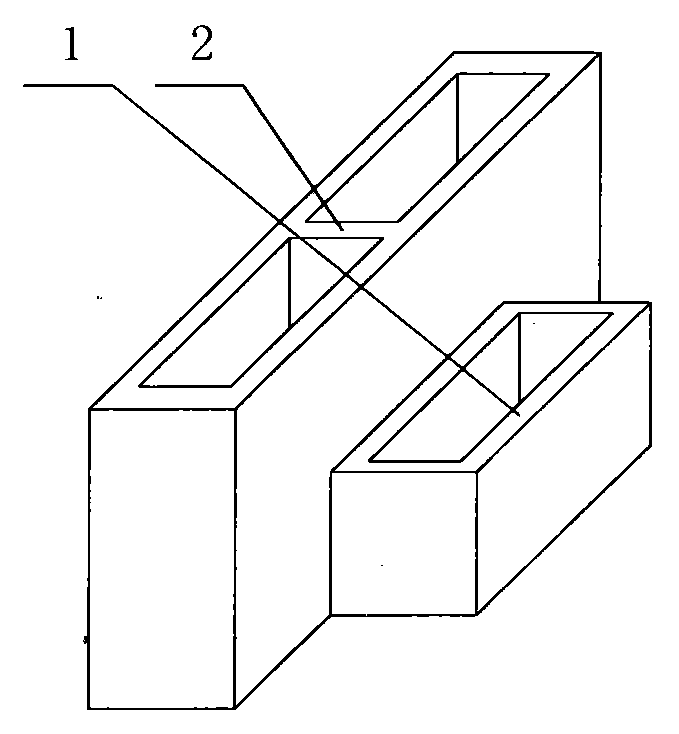

Masonry anchoring system

InactiveUS6735915B1Improve structural stabilityAvailable spaceConstruction materialStrutsBraced framePortal frame

Owner:MASONRY REINFORCING OF AMERICA

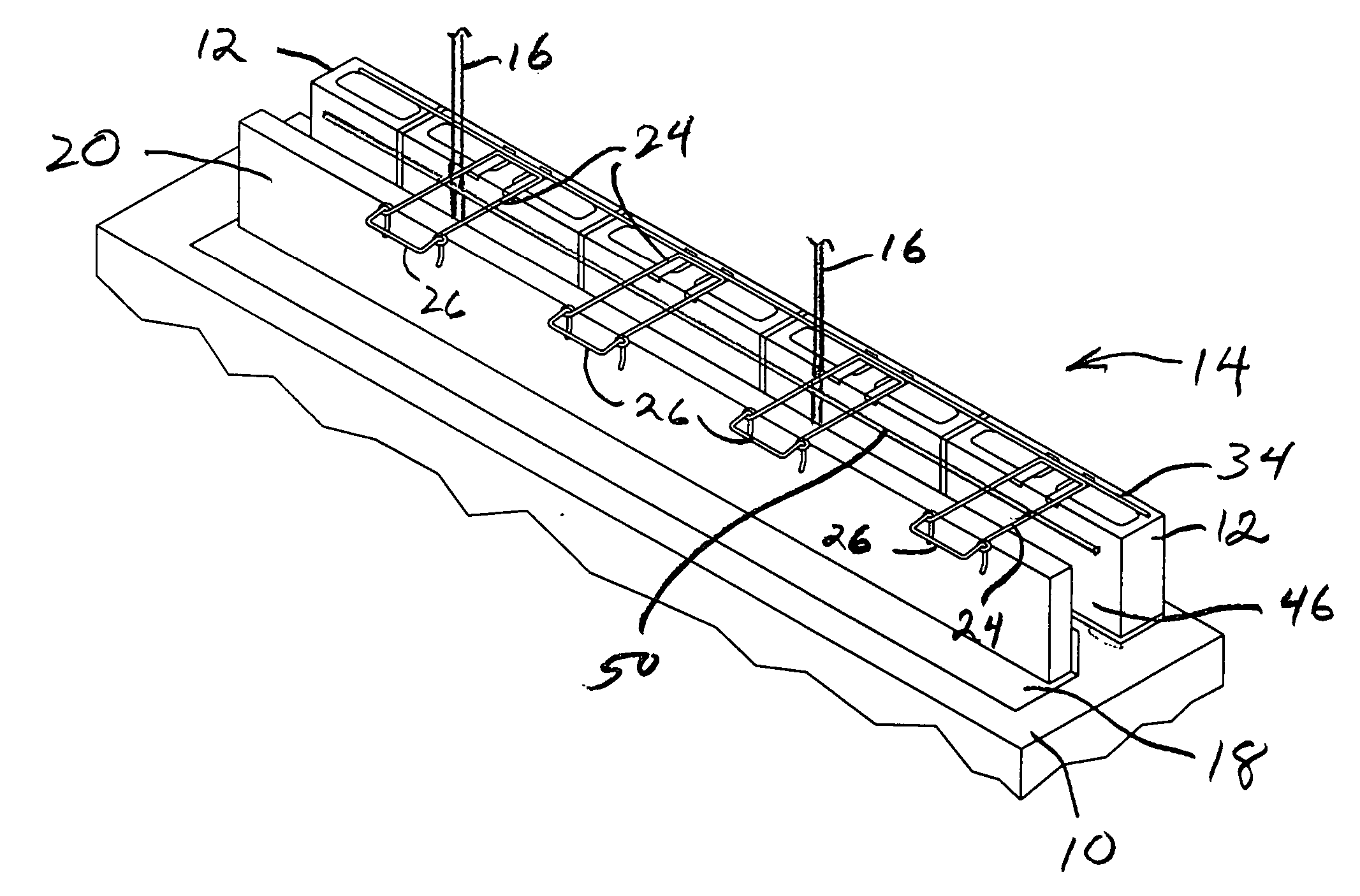

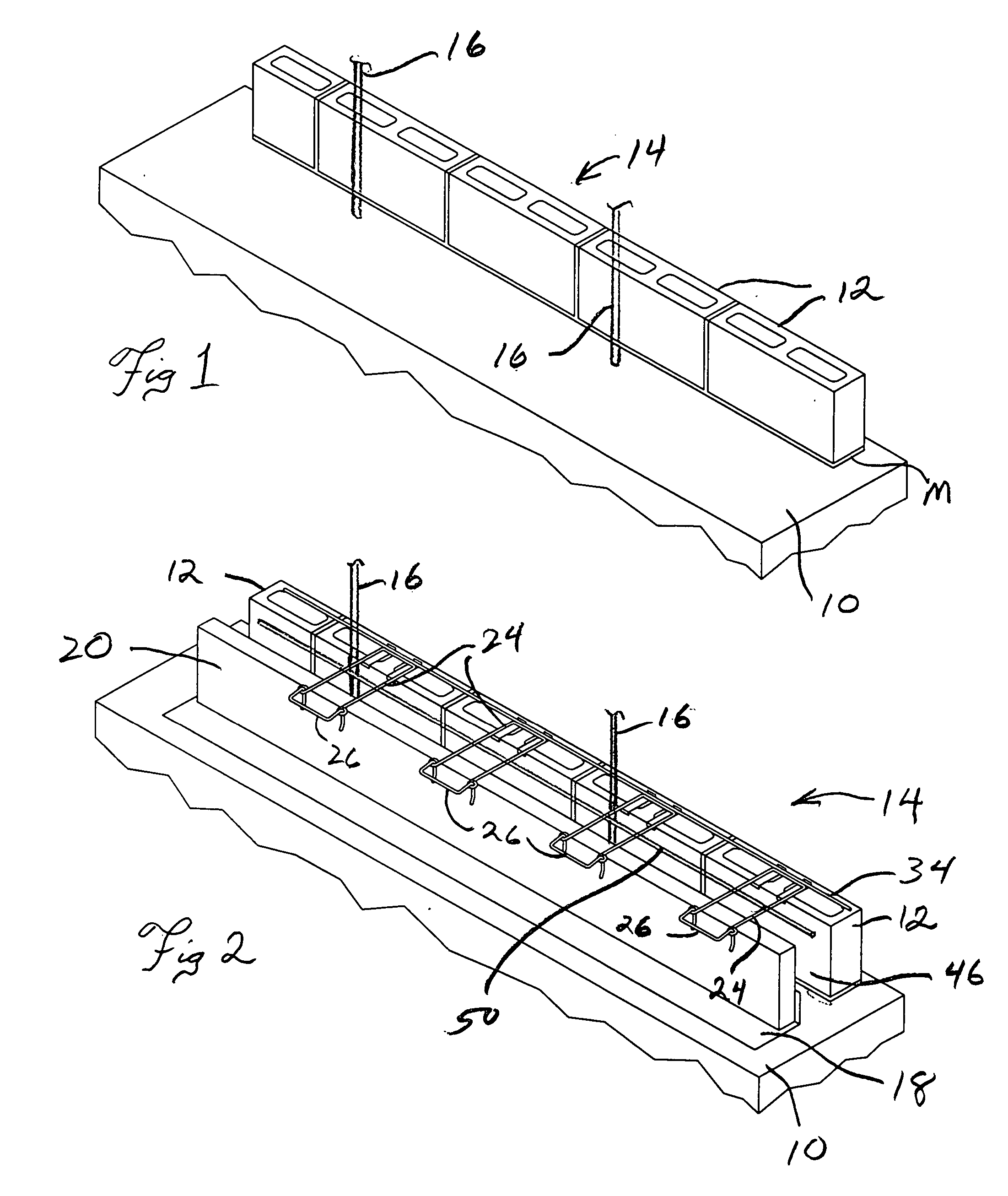

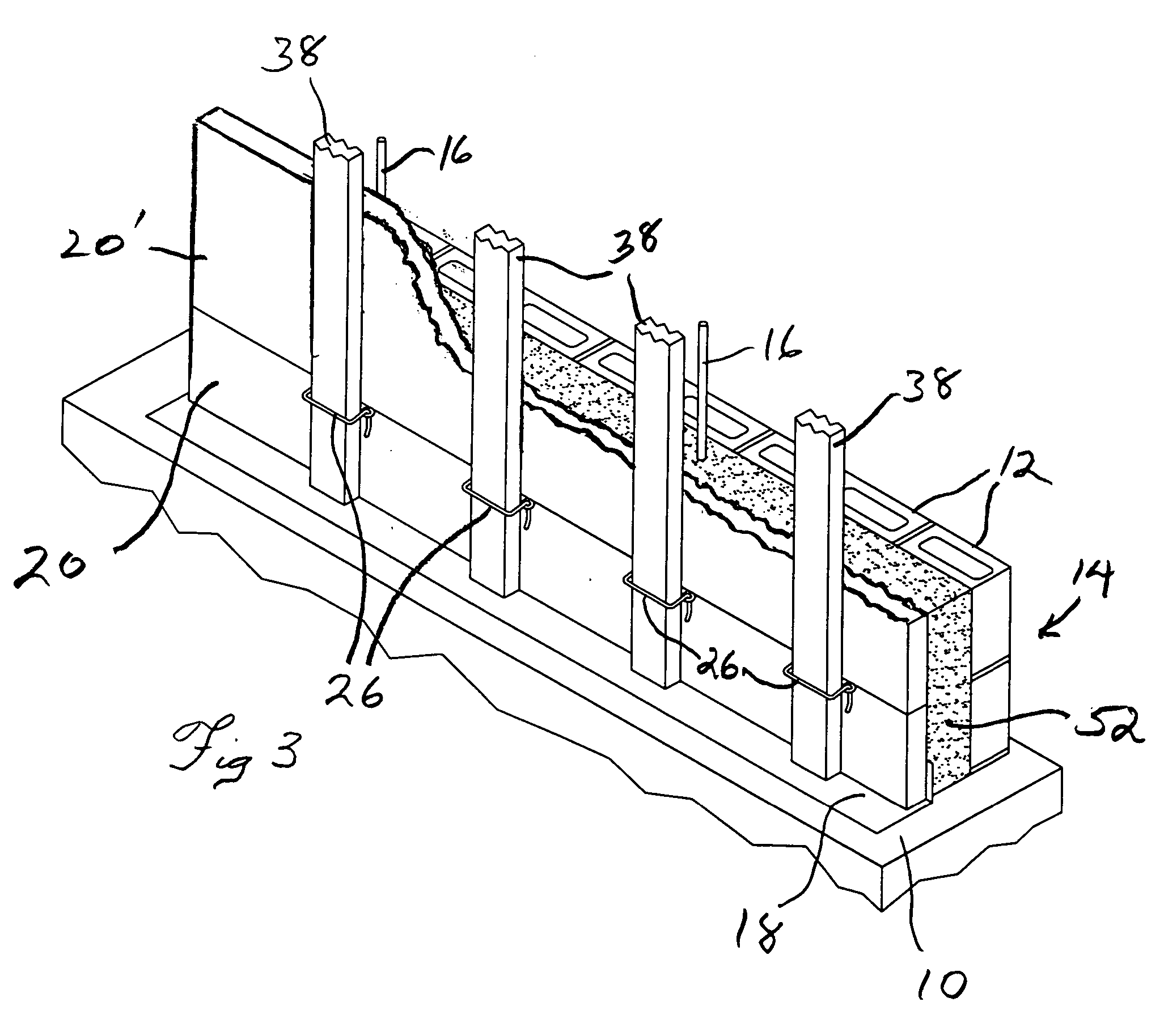

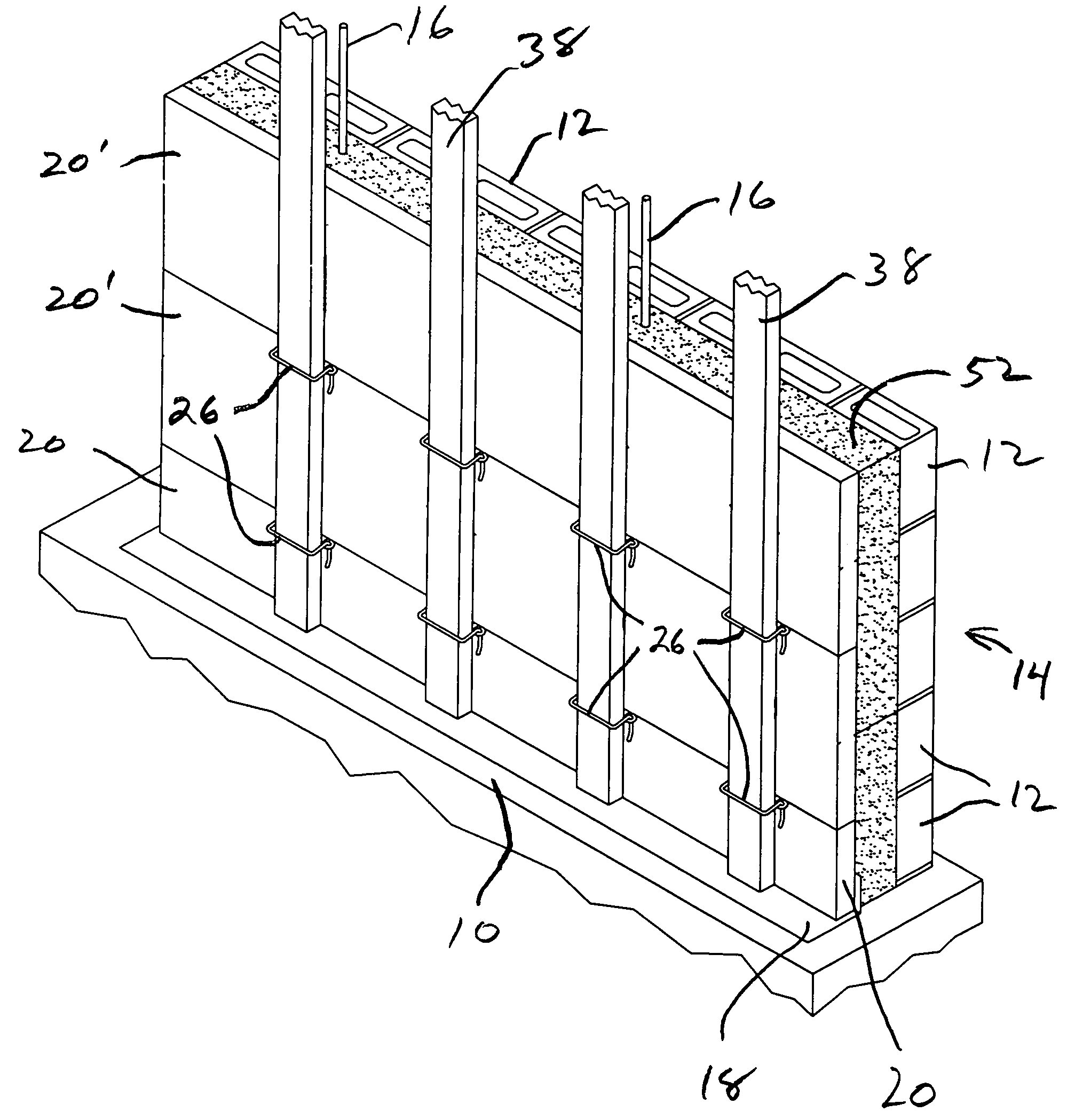

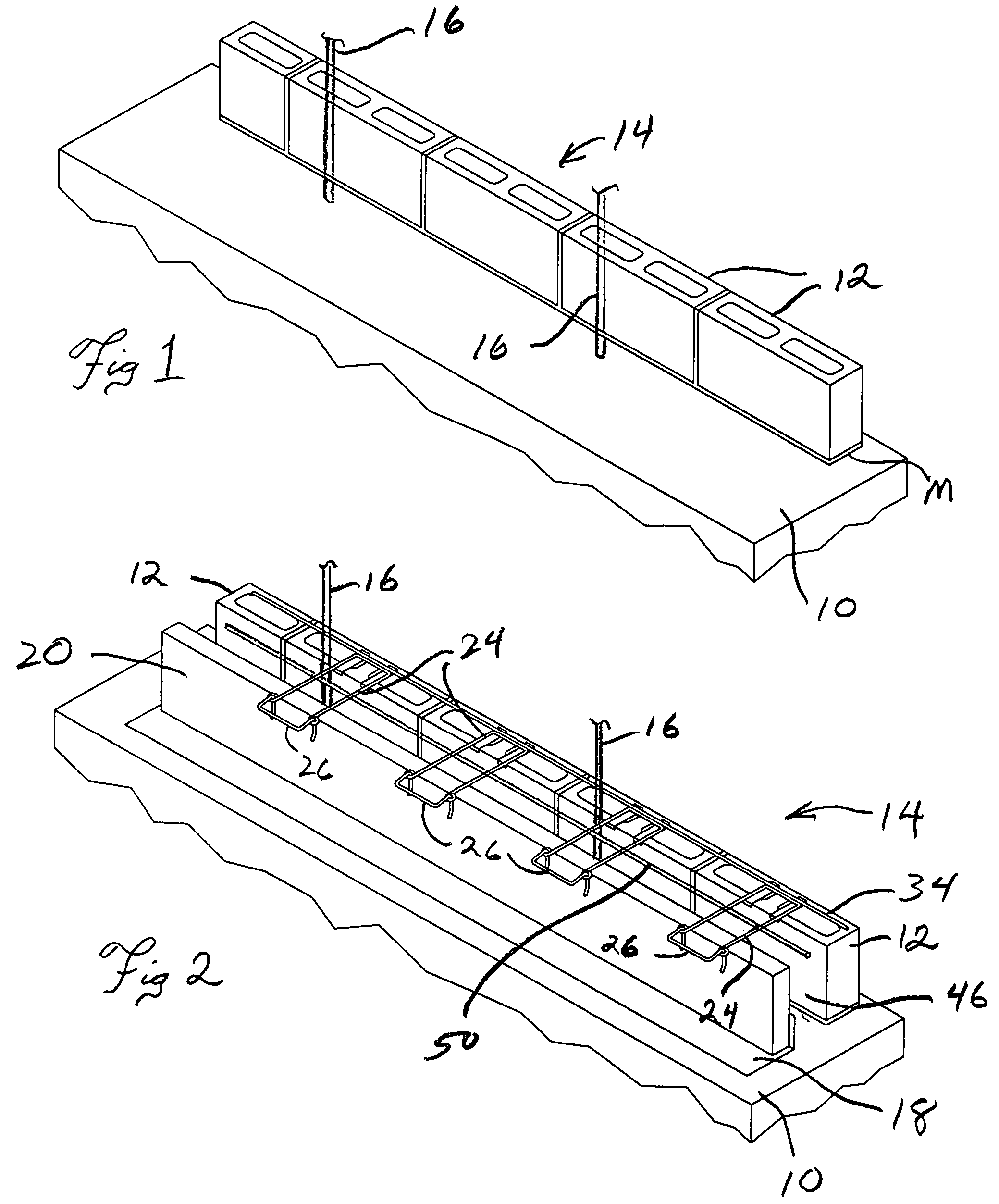

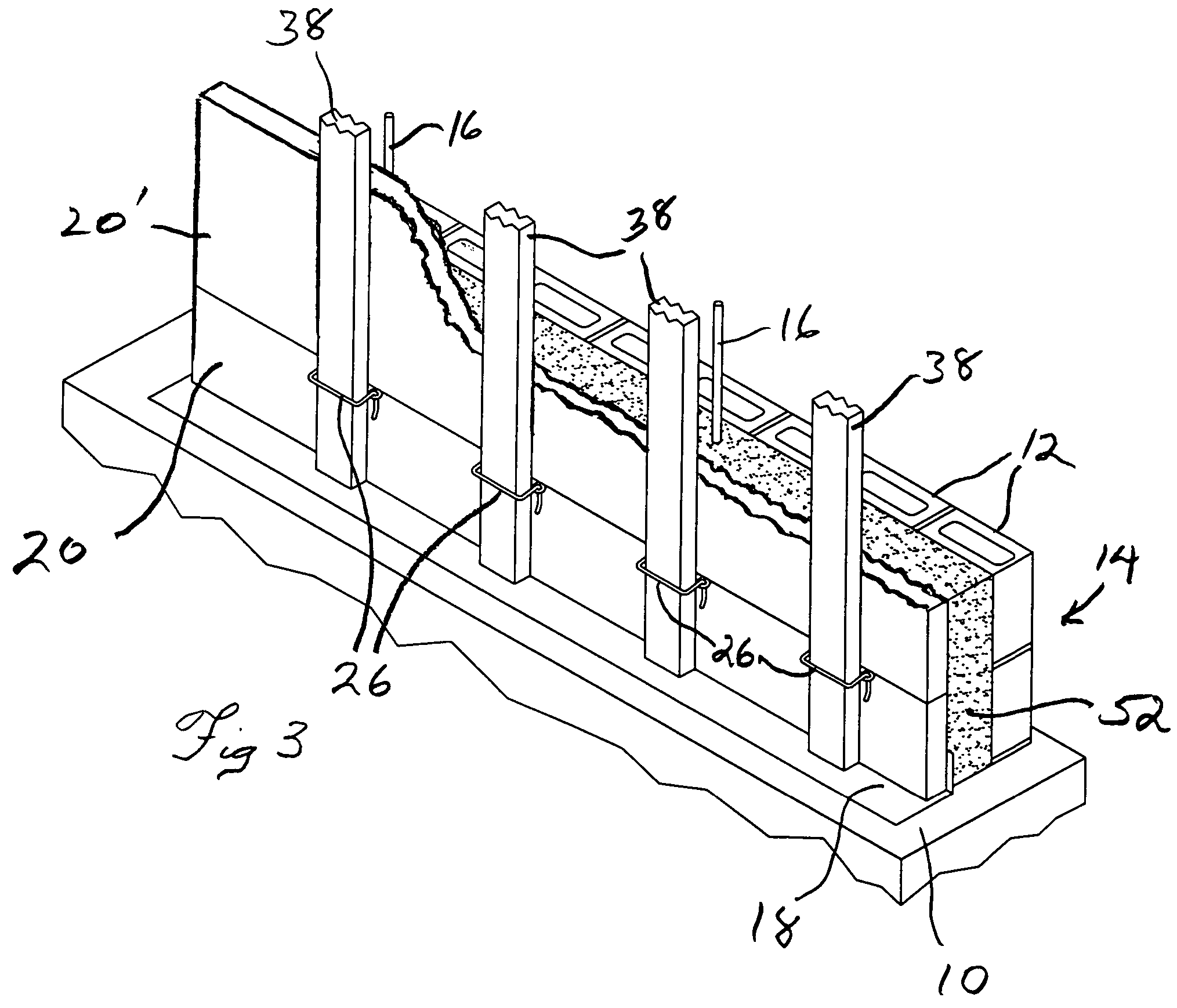

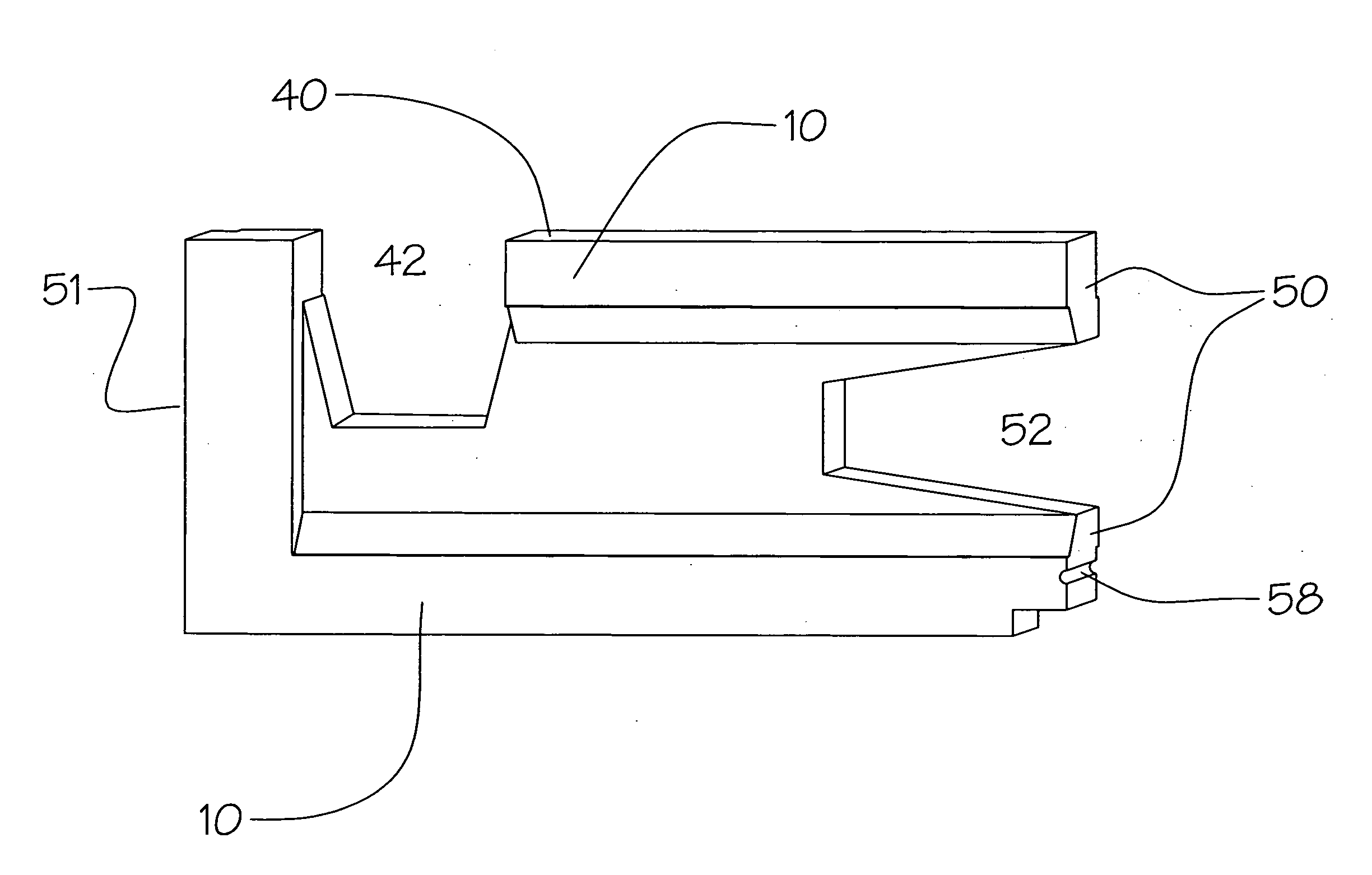

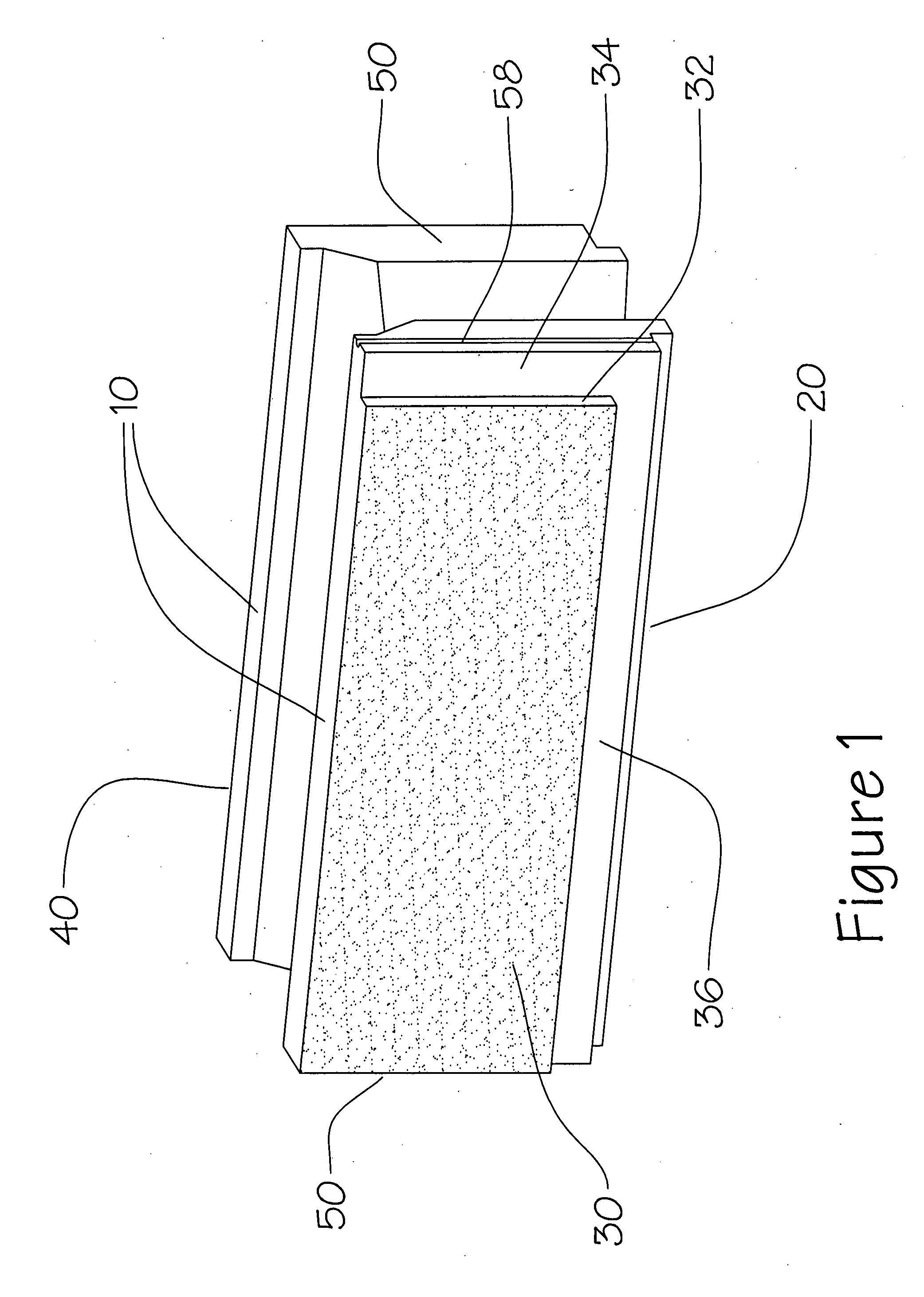

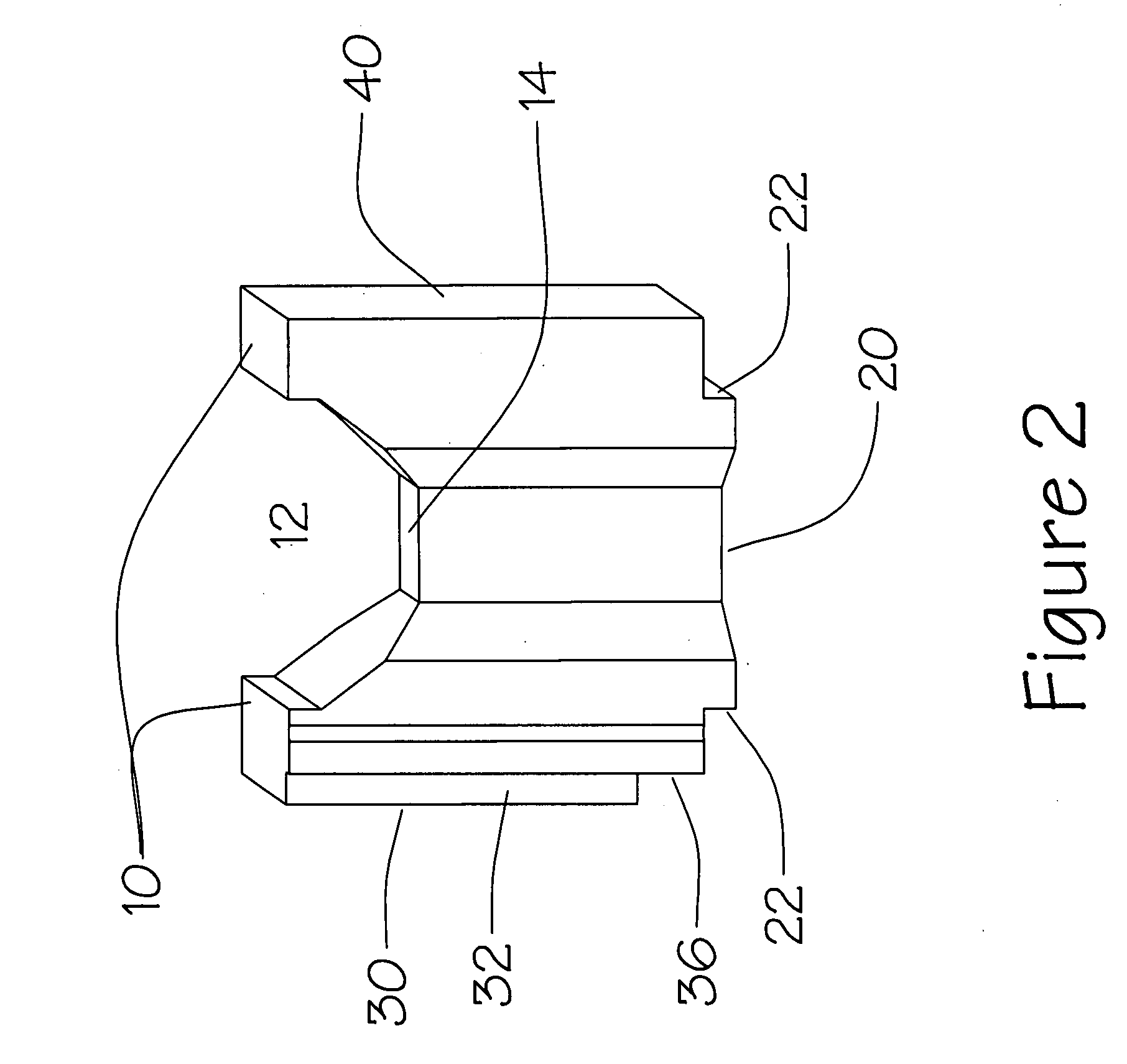

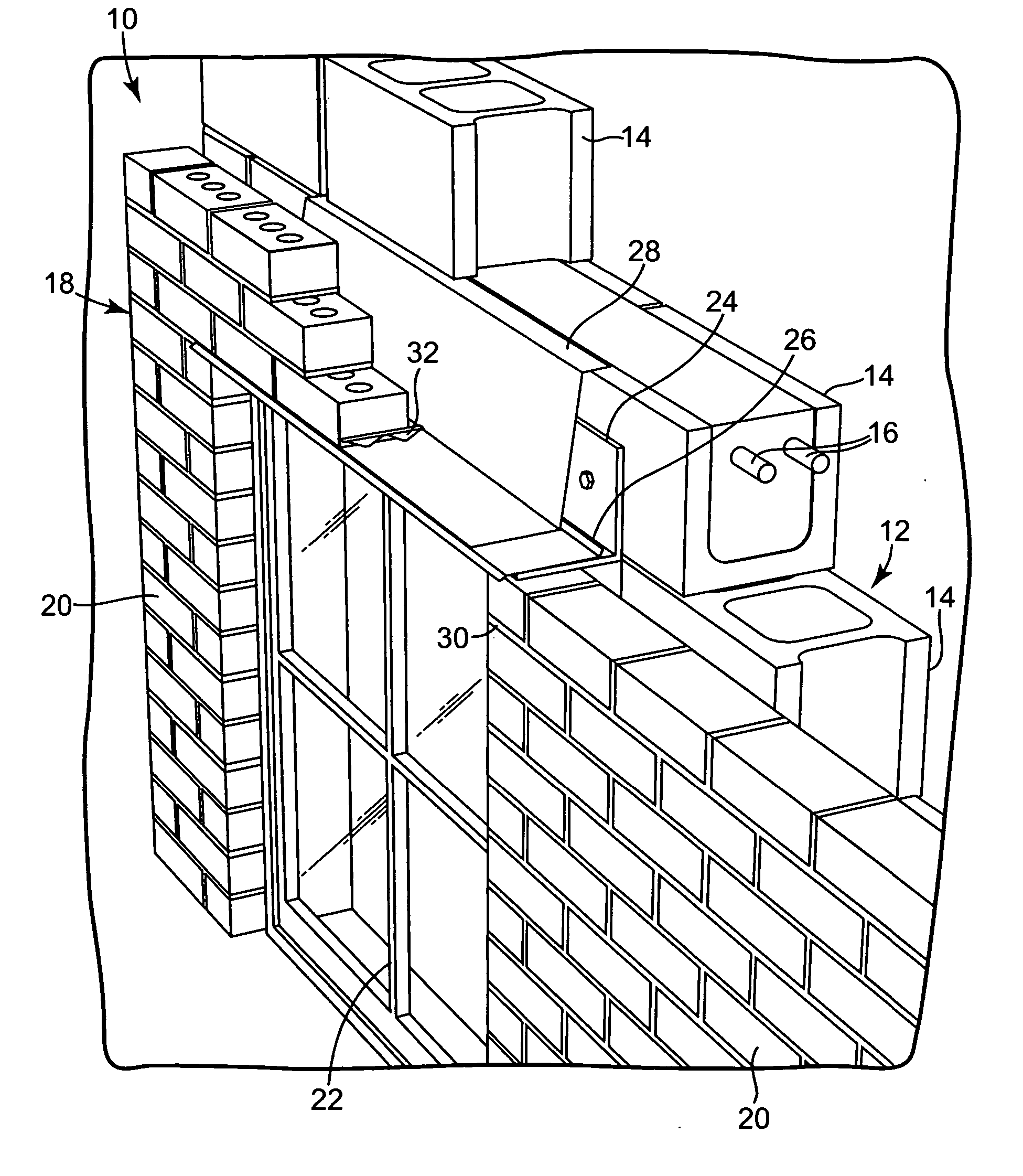

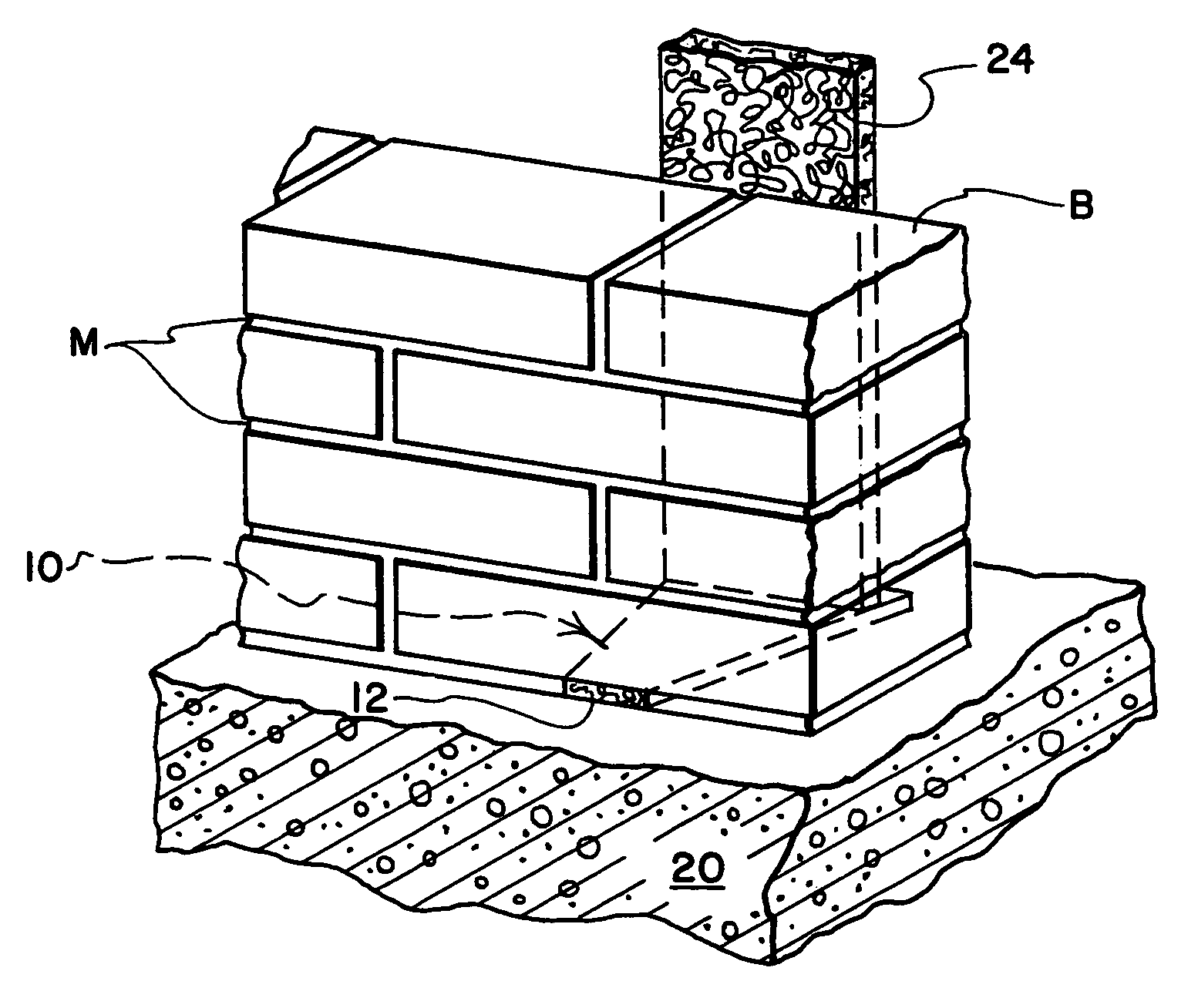

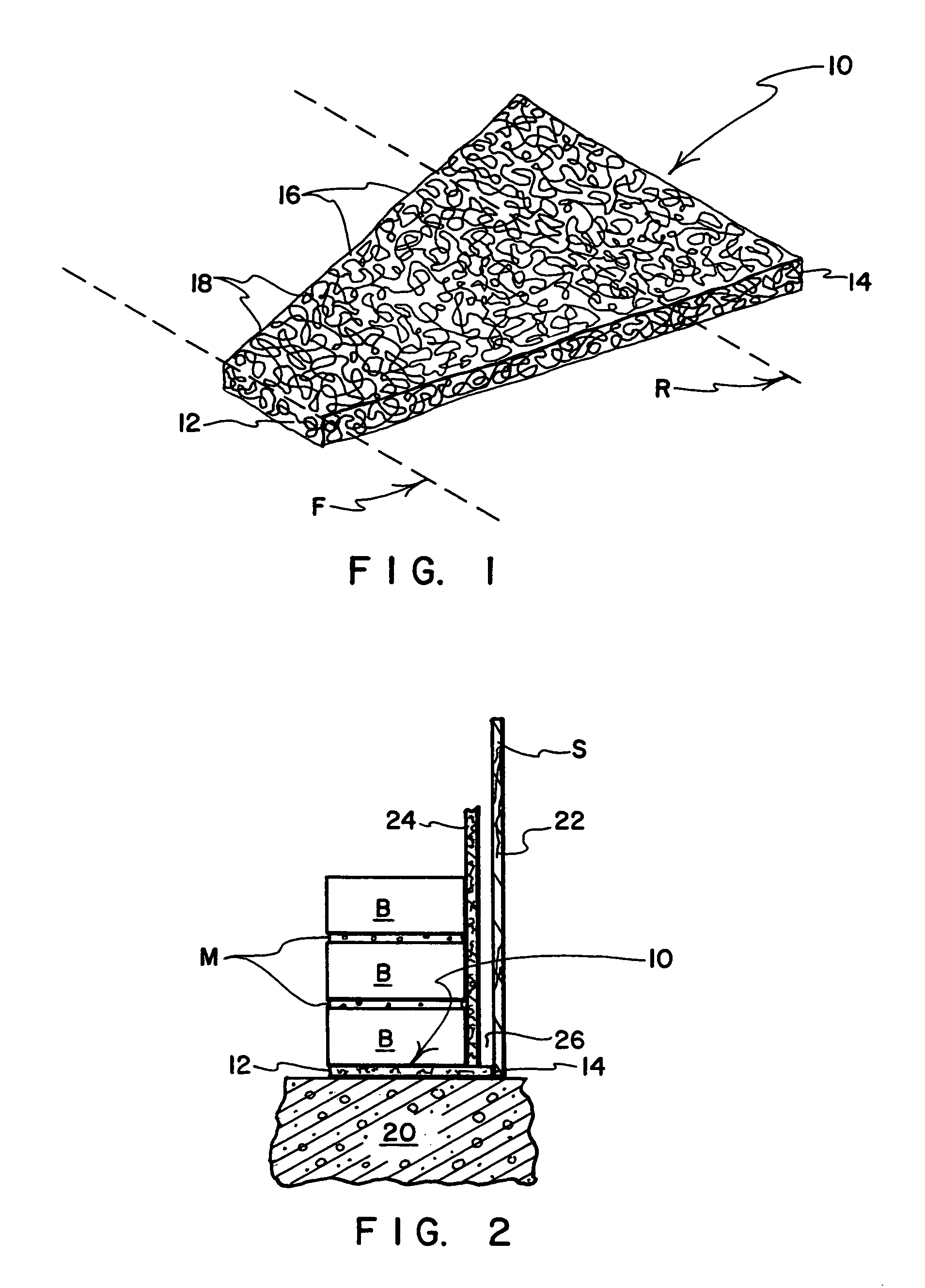

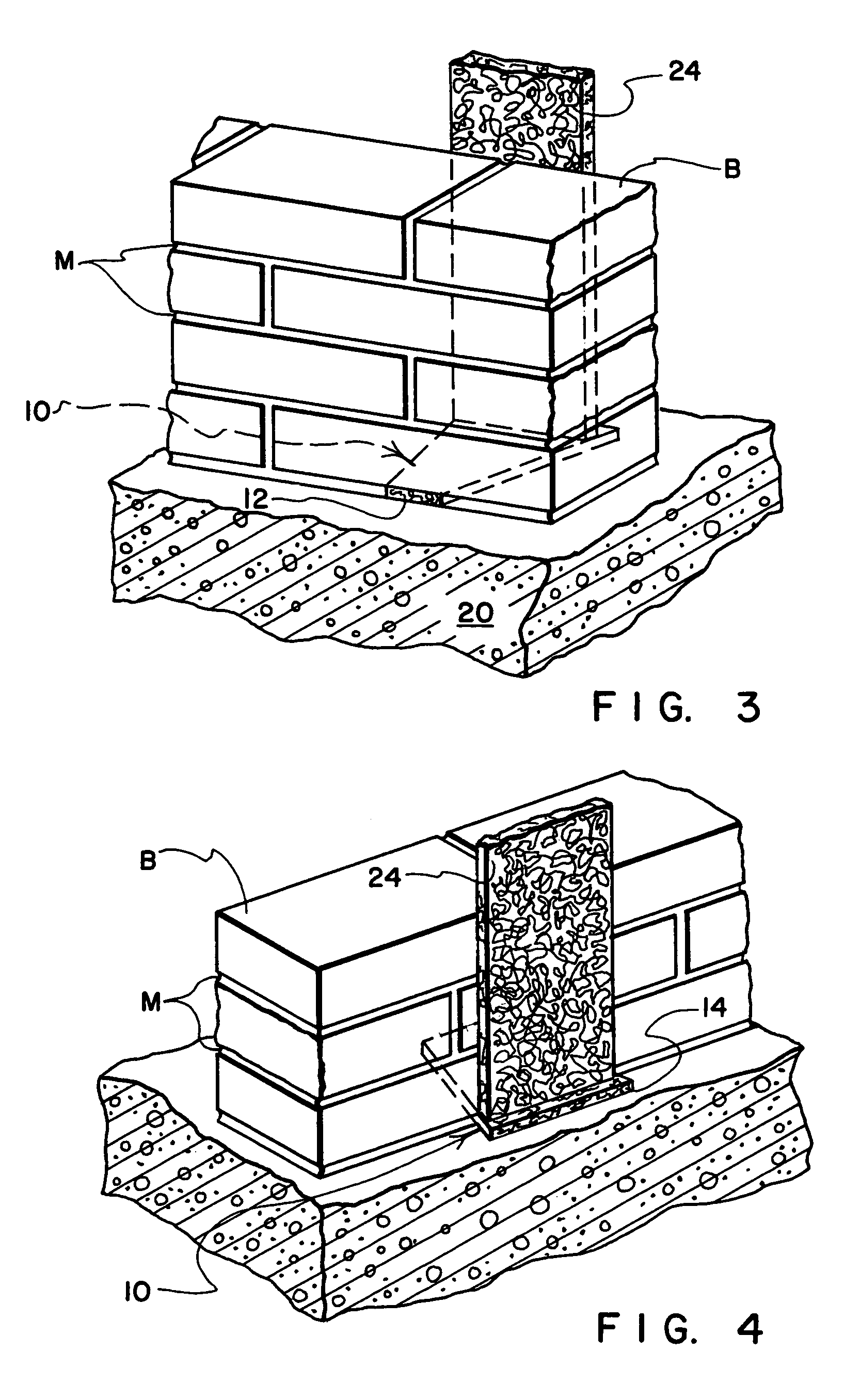

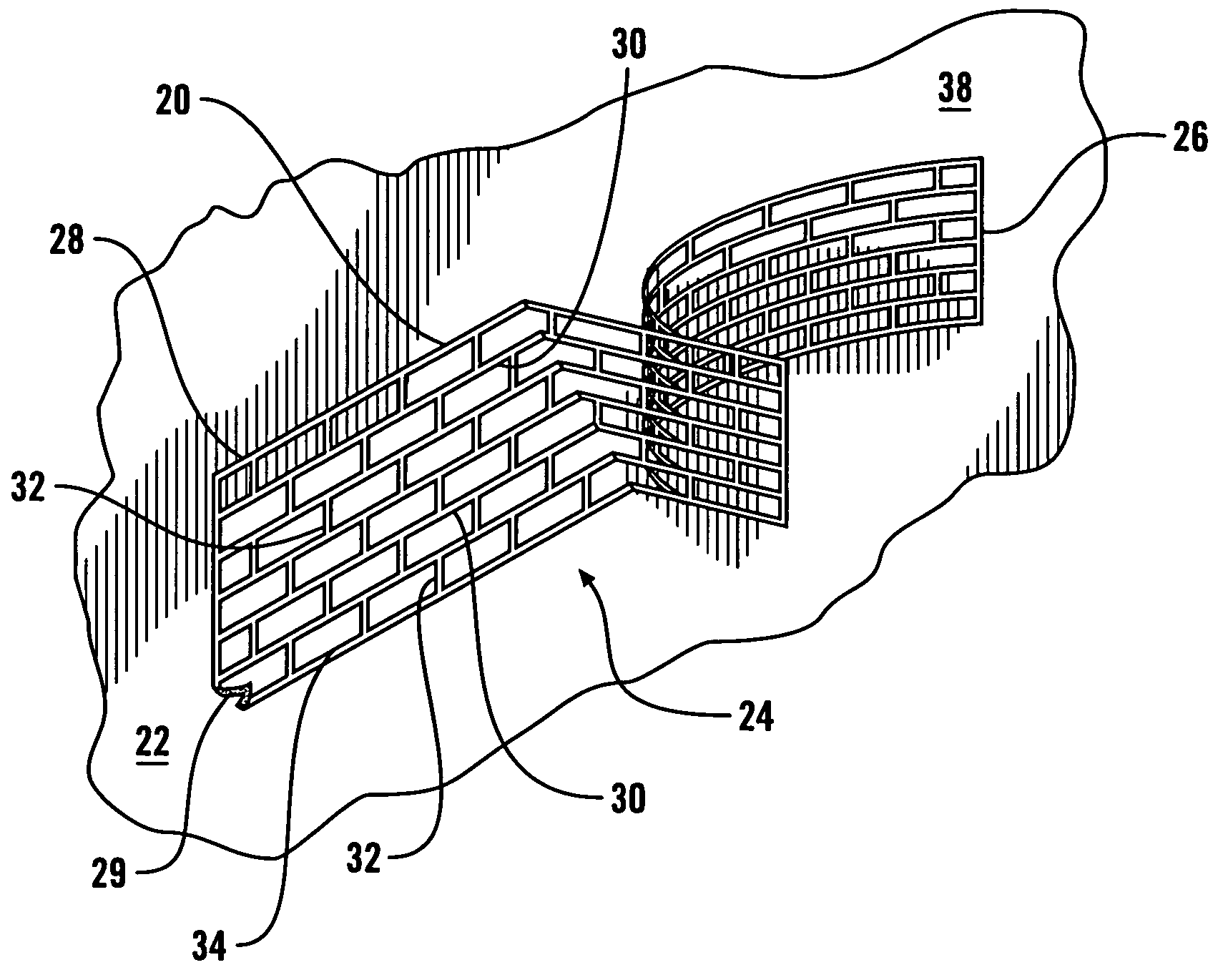

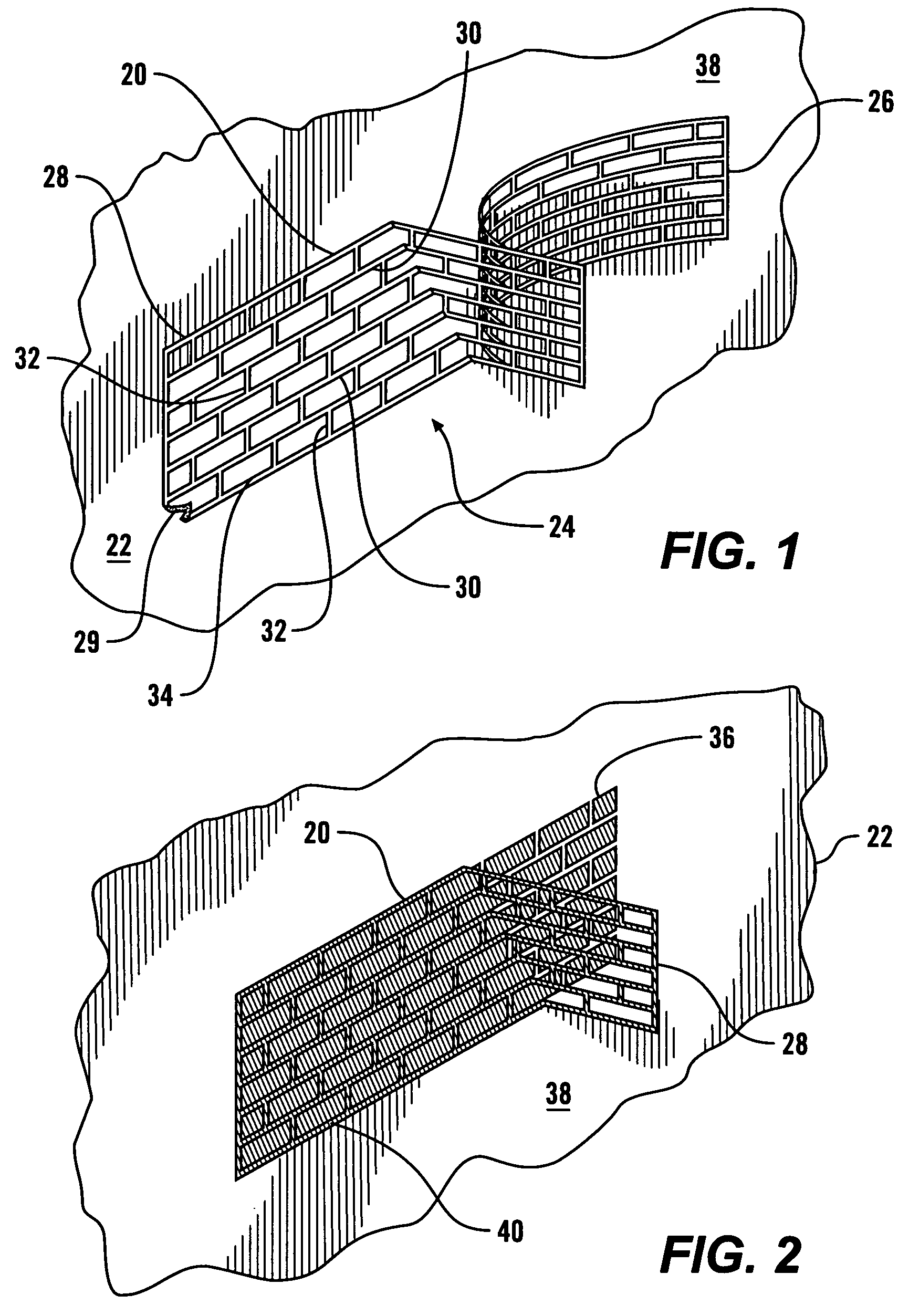

Masonry cavity wall construction and method of making same

InactiveUS20060242921A1Easy to installSimplifies building wall constructionBuilding roofsWallsMortar jointRebar

A masonry cavity wall structure includes a cast-in-place reinforced concrete structural wall member erected between and in confronting engagement with the outer side of a first, inner masonry wythe and the inner side of an outwardly spaced-away, upstanding wall of rigid insulation panels supported by wire tie members in embedded engagement in the mortar joints of the inner wythe, the inner wythe and tie-supported insulation panels also being used during construction of the cavity wall to provide the supporting concrete formwork for the poured structural wall member. A second, outer veneer wythe is erected a predetermined spaced distance outwardly from the insulation panels and forms an airspace cavity therebetween, the wire tie members also engaged in the mortar joints of the second, outer wythe whereby to structurally tie the masonry cavity wall together. The placement of the cast-in-place reinforced structural wall immediately adjacent the inner wythe and inwardly of the insulation provides maximum thermal mass qualities of the cavity wall construction.

Owner:MASSIE MICHAEL C

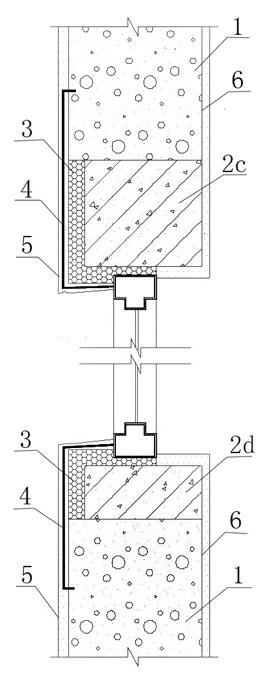

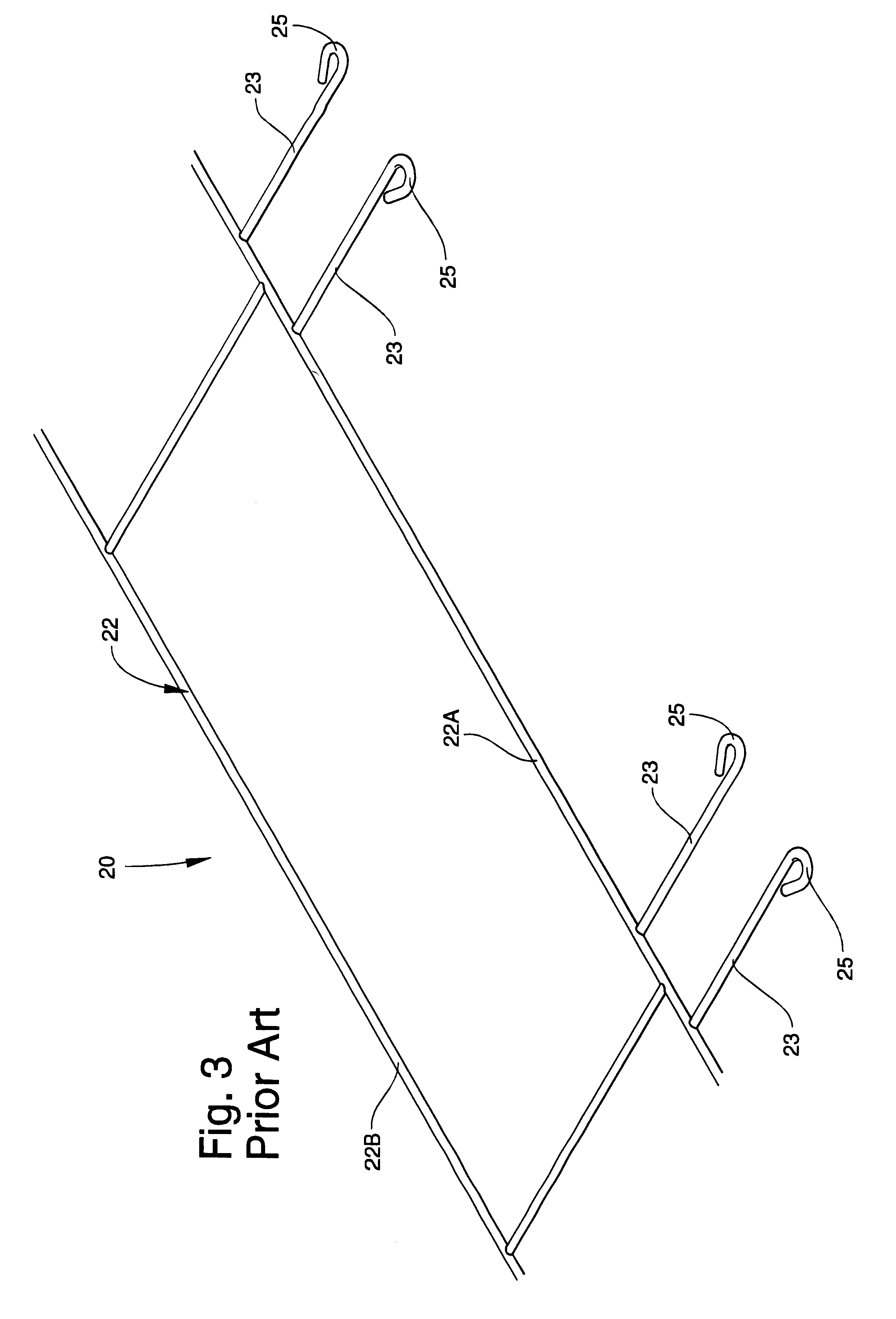

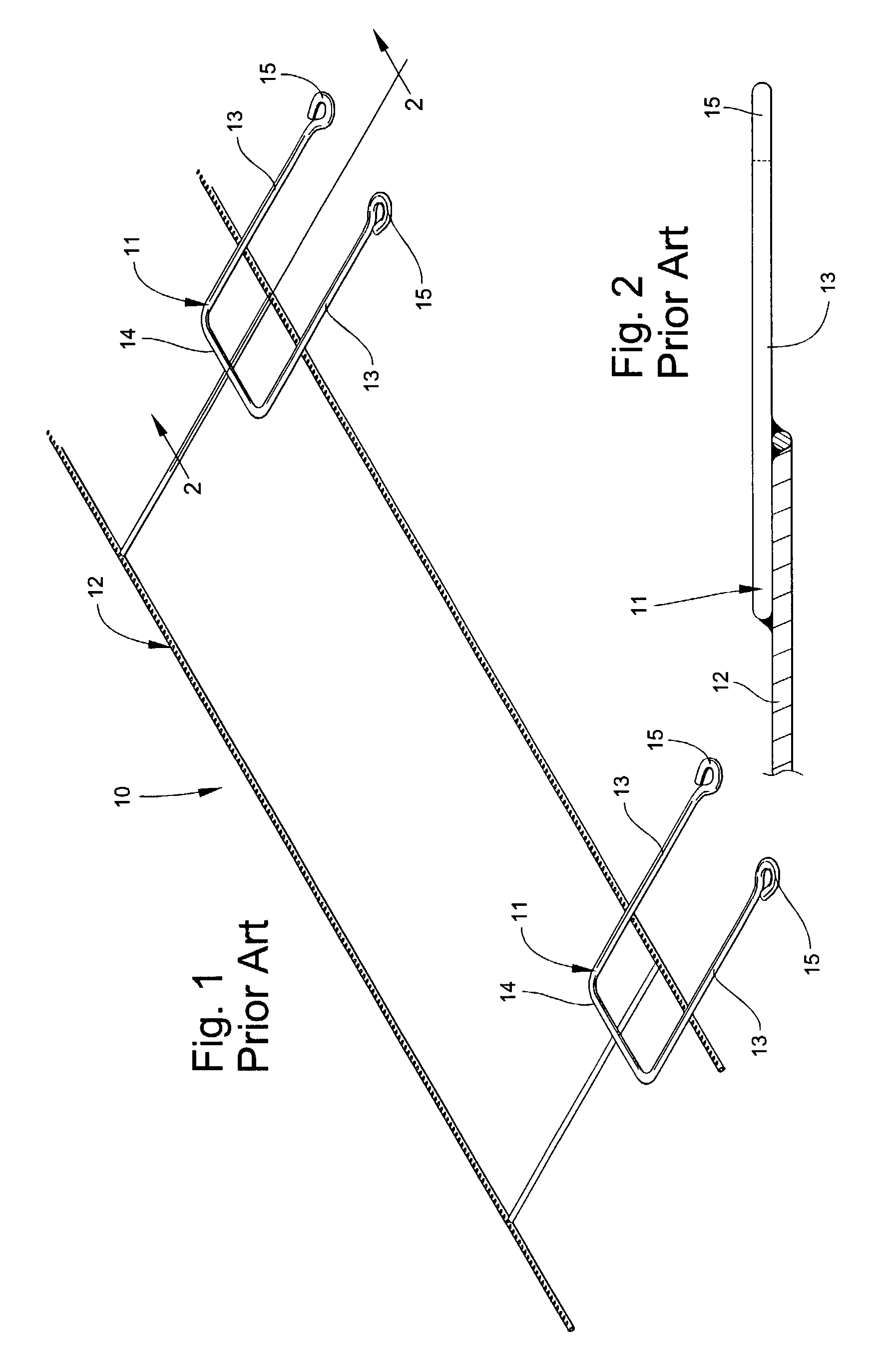

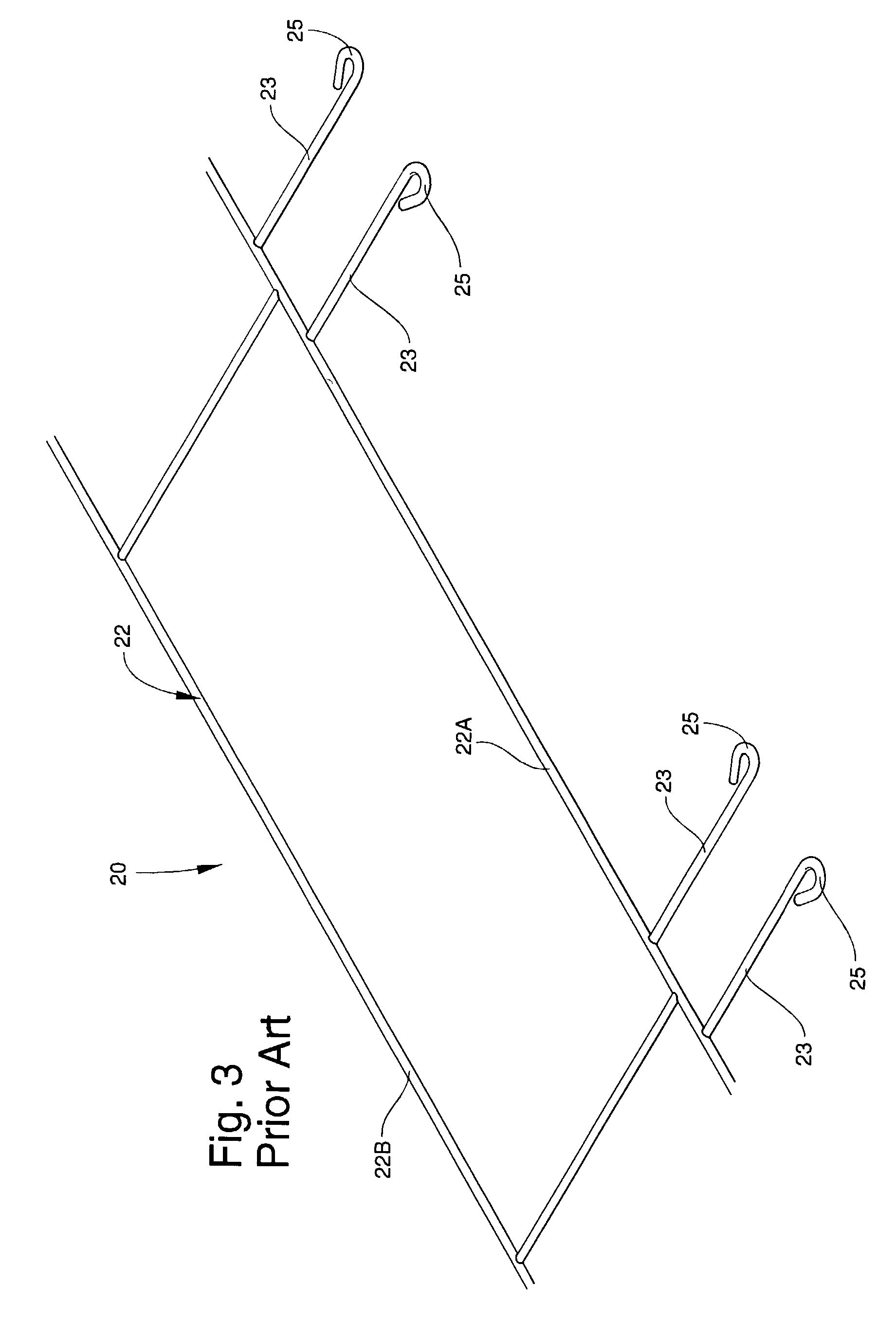

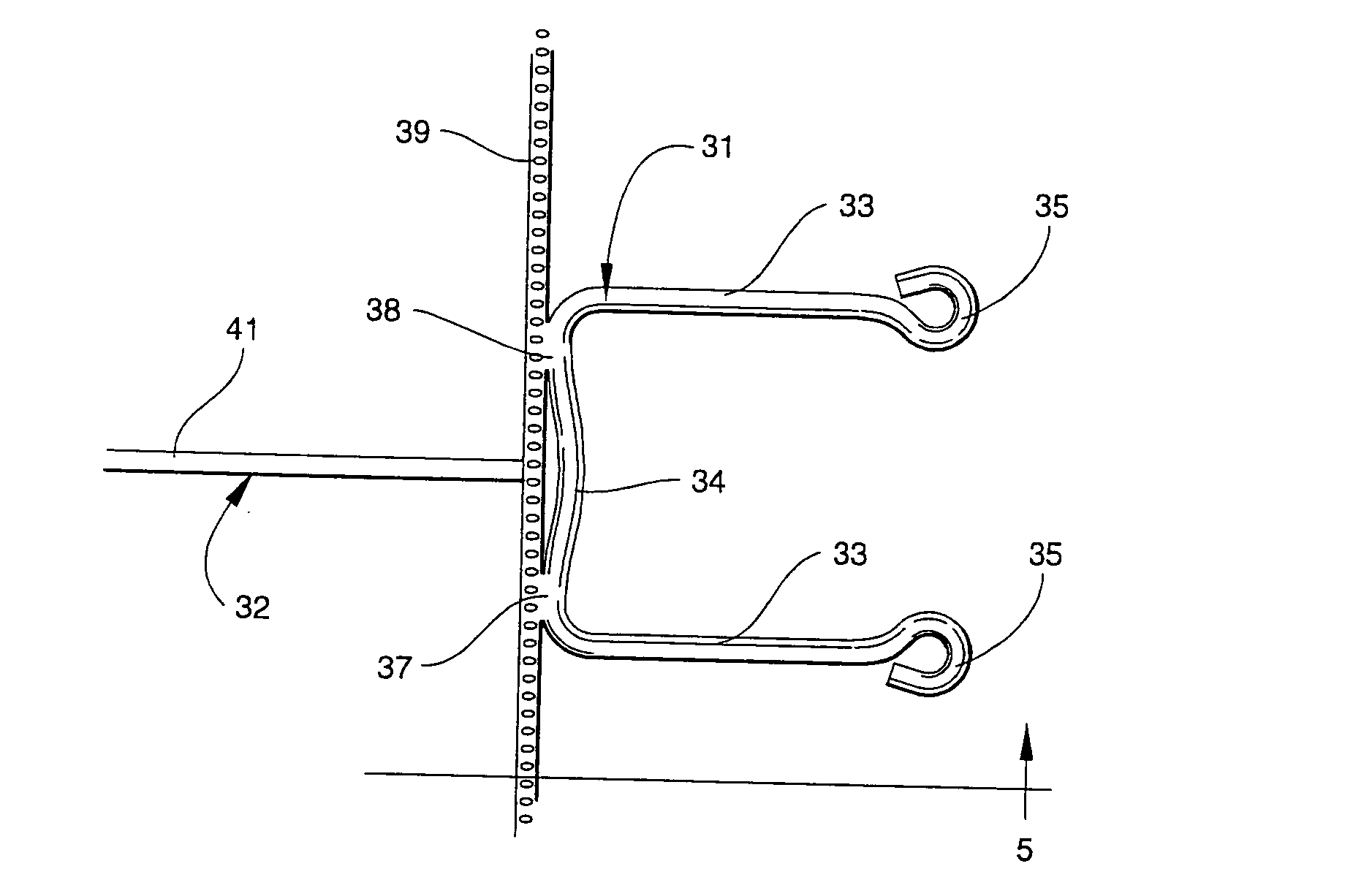

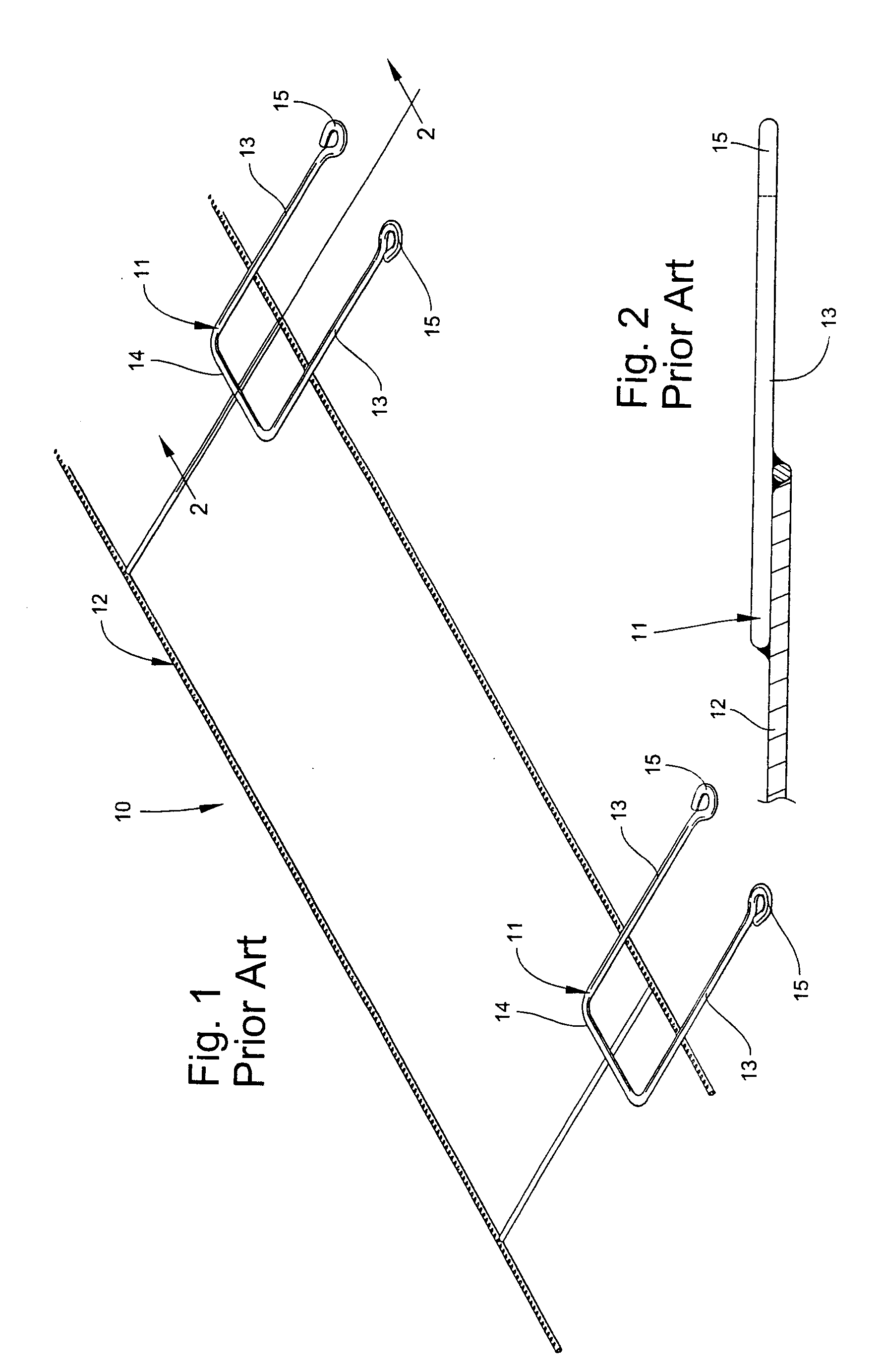

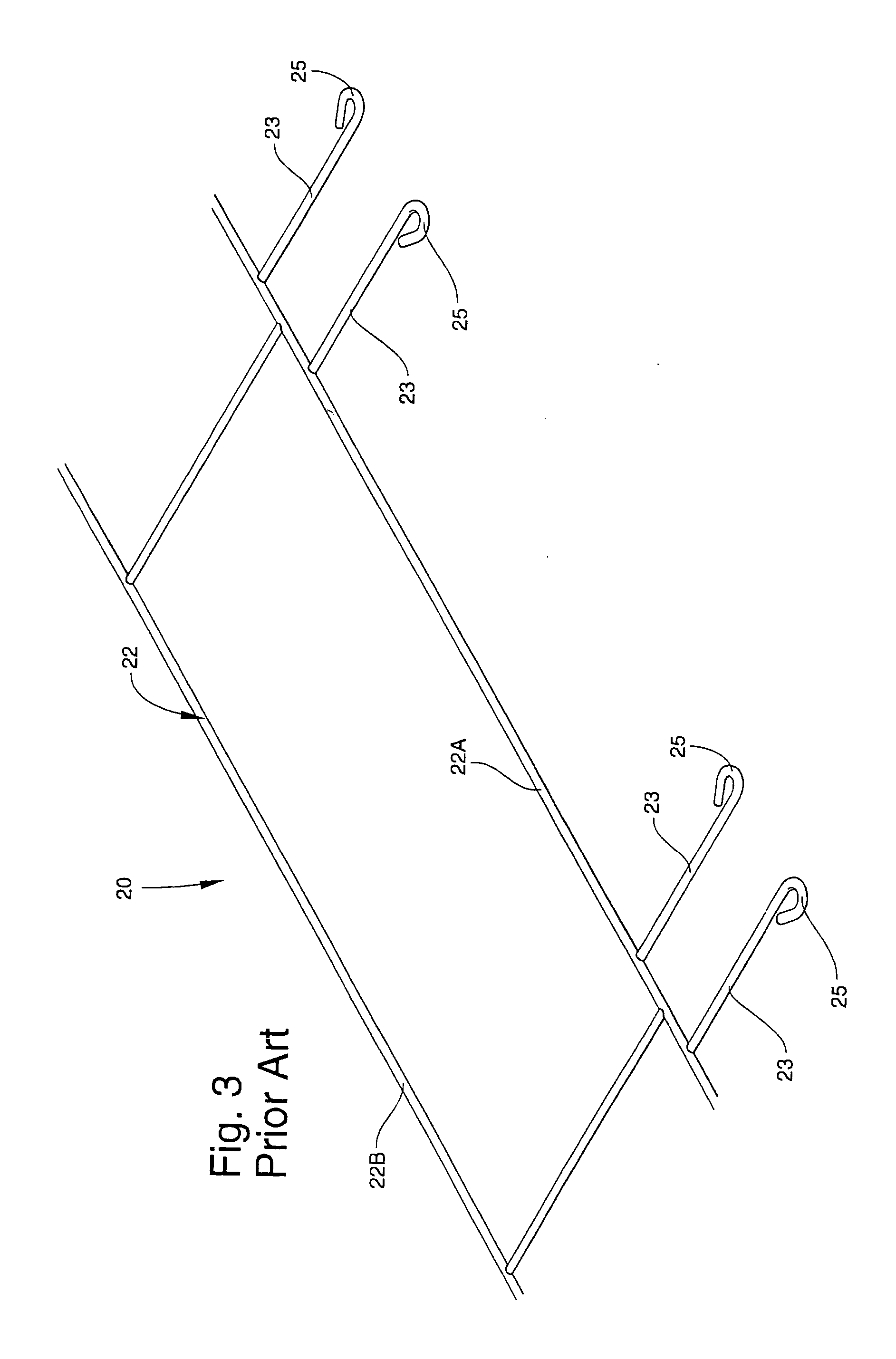

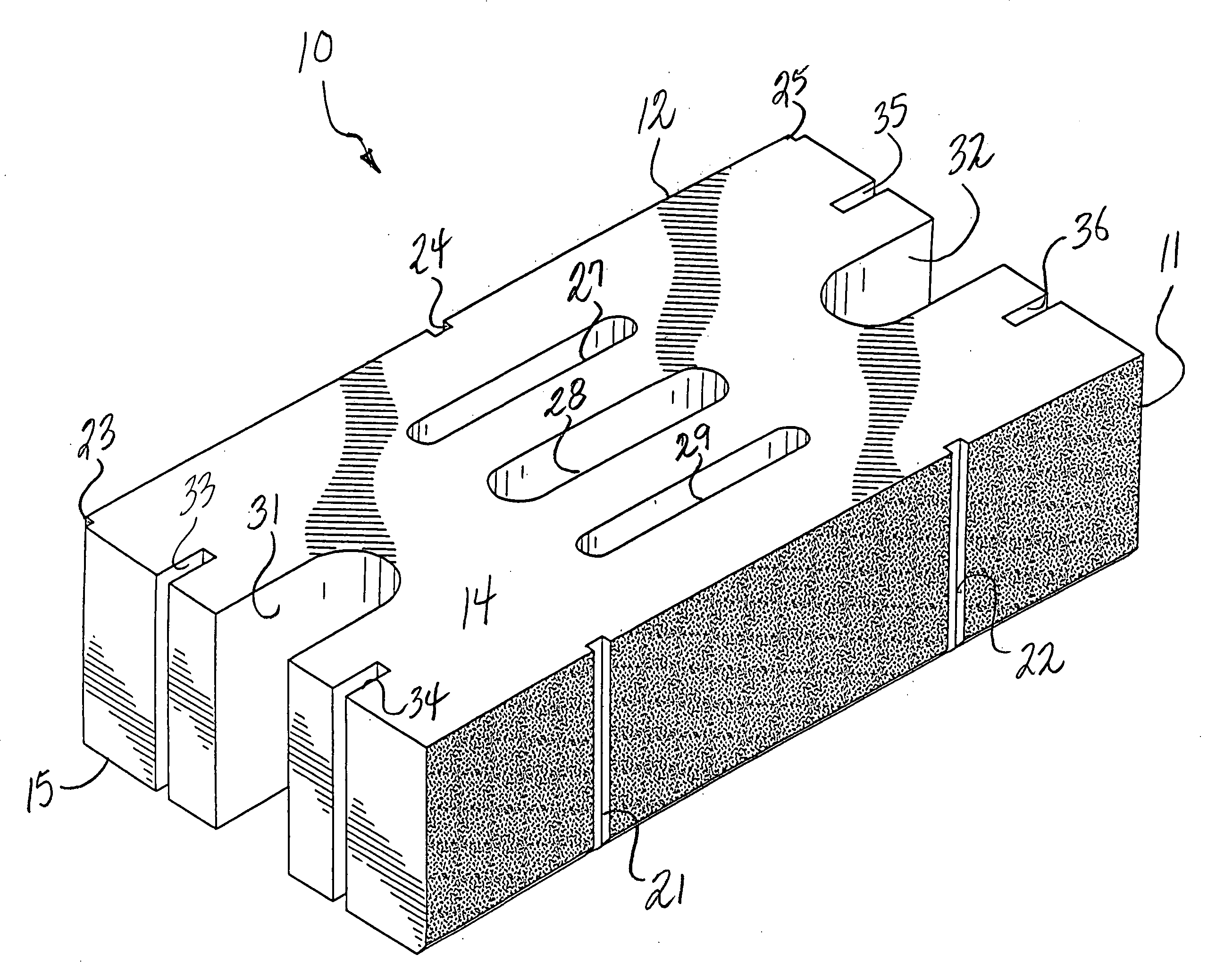

Masonry anchoring system

InactiveUS20040083667A1Stable structureExtension of timeConstruction materialStrutsBraced framePortal frame

An masonry anchor is disclosed for anchoring two spaced apart masonry walls together to form a single wall structure. The masonry anchor includes a ladder or truss type support frame for positioning on top of a mortar joint in one wall, and a bracket having a pair of elongate arms connected by a cross-member affixed to the support frame. The cross-member is angled for providing two spaced apart points on the cross-member for contacting the support frame and affixing the cross-member thereto. The elongate arms extend transversely from the support frame and are sized to extend into the space between the two walls. Each of the arms have an eye portion formed at the end opposite the cross-member to receive a connecting member connected to the second wall. The support frame and the bracket reside in the same horizontal plane.

Owner:MASONRY REINFORCING OF AMERICA

Masonry cavity wall construction and method of making same

InactiveUS7735292B2High thermal mass qualities of the wall structureEasy to installBuilding roofsWallsReinforced concreteRebar

A masonry cavity wall structure includes a cast-in-place reinforced concrete structural wall member erected between and in confronting engagement with the outer side of a first, inner masonry wythe and the inner side of an outwardly spaced-away, upstanding wall of rigid insulation panels supported by wire tie members in embedded engagement in the mortar joints of the inner wythe, the inner wythe and tie-supported insulation panels also being used during construction of the cavity wall to provide the supporting concrete formwork for the poured structural wall member. A second, outer veneer wythe is erected a predetermined spaced distance outwardly from the insulation panels and forms an airspace cavity therebetween, the wire tie members also engaged in the mortar joints of the second, outer wythe whereby to structurally tie the masonry cavity wall together. The placement of the cast-in-place reinforced structural wall immediately adjacent the inner wythe and inwardly of the insulation provides maximum thermal mass qualities of the cavity wall construction.

Owner:MASSIE MICHAEL C

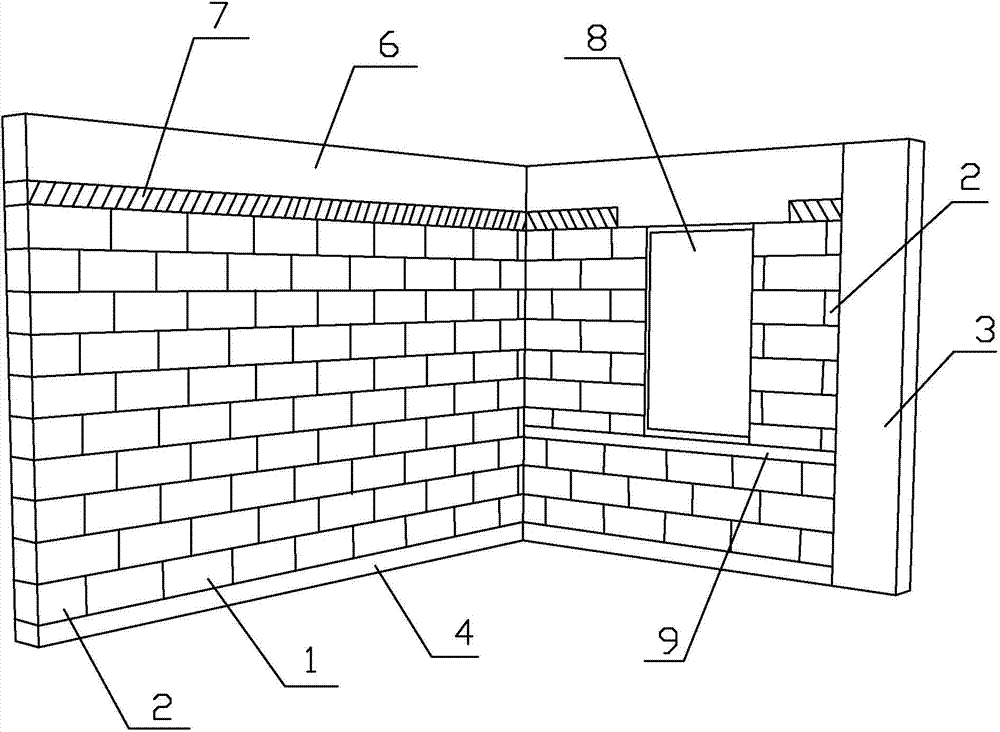

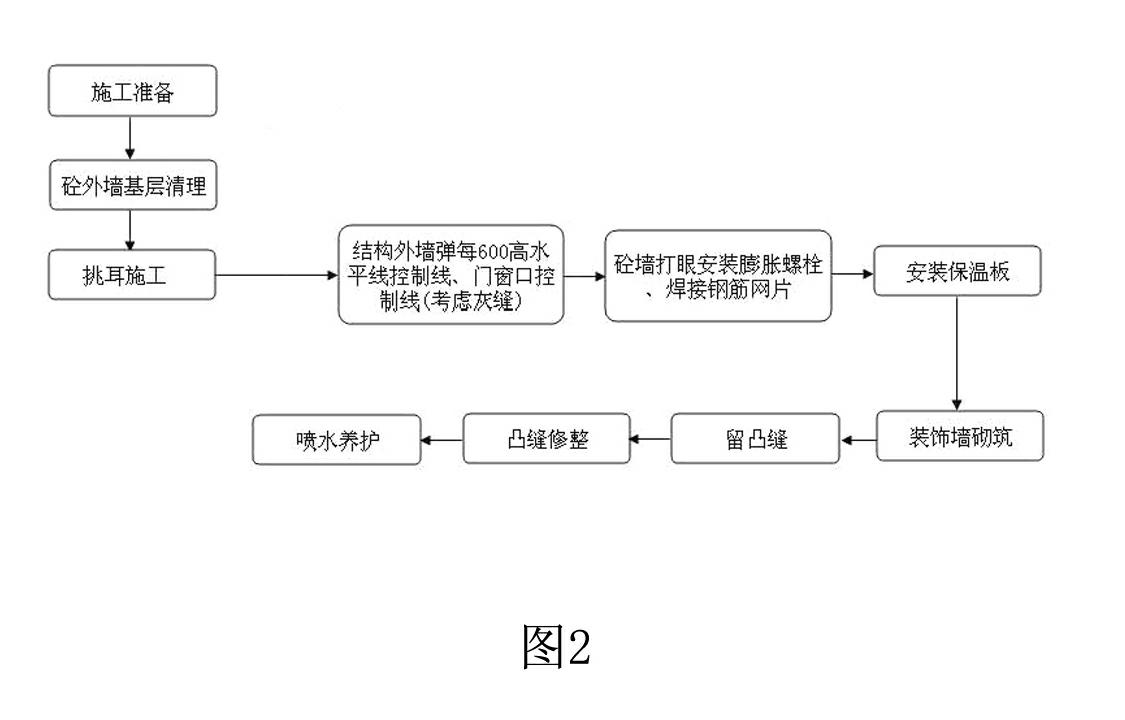

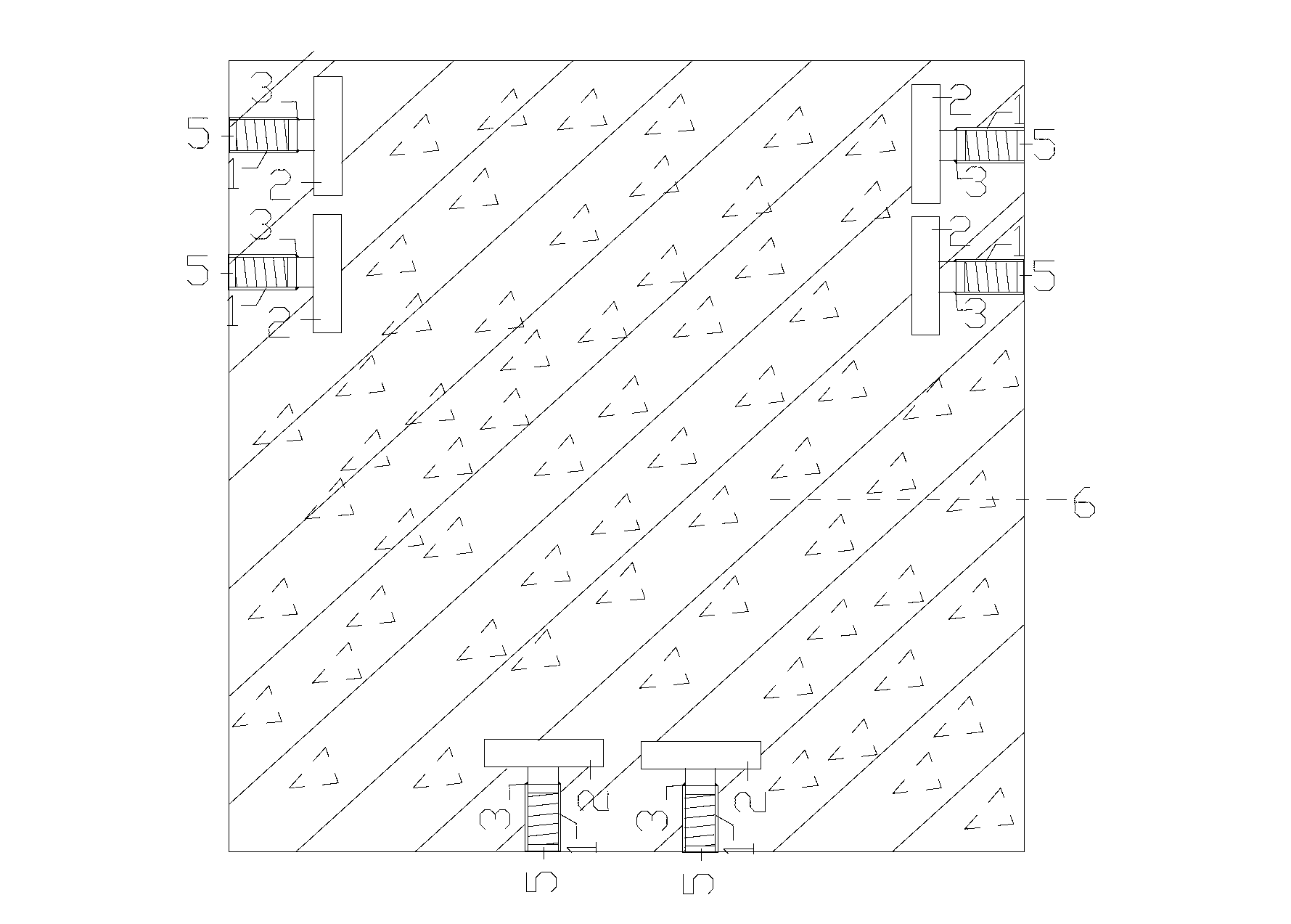

Autoclaved sand aerated concrete block wall construction method based on BIM technique

ActiveCN104712076AReduce lossImprove masonry efficiencyWallsBuilding material handlingData informationWindow opening

The invention relates to an autoclaved sand aerated concrete block wall construction method based on the BIM technique. The method comprises the steps of acquiring data information required by wall construction according to a two-dimensional wall CAD building structural working drawing; conducting three-dimensional modeling on a wall by means of BIM molding software, inputting the data information into the three-dimensional model of the wall, and making autoclaved sand aerated concrete blocks serve as building blocks in the three-dimensional model of the wall; arranging the building blocks in the three-dimensional model of the wall, and conducting coding on the building blocks in different specifications; acquiring data information including the specifications and number of the building blocks, mortar joint thickness and door and window openings required by wall construction from the three-dimensional model of the wall; extracting and making a plan for various materials and a machining material list; purchasing the building blocks and having the building blocks in place; conducting building block processing; conducting wall construction. According to the method, wall building block arrangement is conducted by means of the BIM technique, building block arrangement precision and speed are high, building block consumption is reduced, and wall construction efficiency is improved.

Owner:崔新明

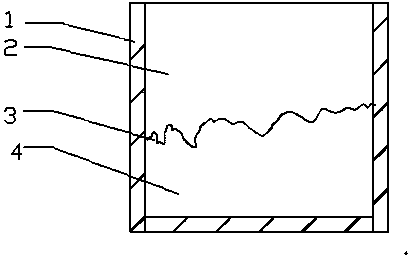

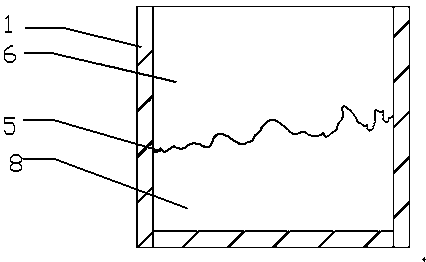

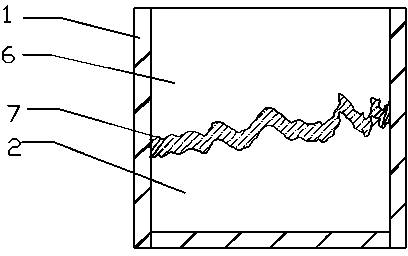

Method for copying joint waviness by artificial rock material and experimental method

InactiveCN103926129AAvoid the dangers of climbing dangerous rocksHigh measurement accuracyPreparing sample for investigationUsing optical meansLaser scanningPerformed Imaging

The invention discloses a method for copying joint waviness by an artificial rock material and an experimental method. The method includes the following steps: firstly, measuring the joint surface contour line waviness by a three-dimensional laser scanning method; refining a graph and removing noise points from the graph by contour tracking, performing image scaling transformation and coordinate transformation on a joint contour line, and obtaining coordinate values of points on the contour line by an interpolation method; reading joint surface contour line data, digitalizing the joint surface contour line waviness, introducing the digitalized joint surface contour line waviness into a spark cutting control machine, processing a steel block by 2Cr13 alloy steel and making mortar joints; and laying joint mud or mineral clay with different thicknesses and water contents between the mortar joints, and carrying out a mechanical experiment of the joints. The method disclosed by the invention can be used for truly reflecting the physical states of filler rock masses containing joints, the influence of the joints to the strength and deformation properties of the rock masses can be researched by subsequent experiments, and the method is suitable for a variety of rock masses ranging from high-quality ones to broken ones.

Owner:CENT SOUTH UNIV

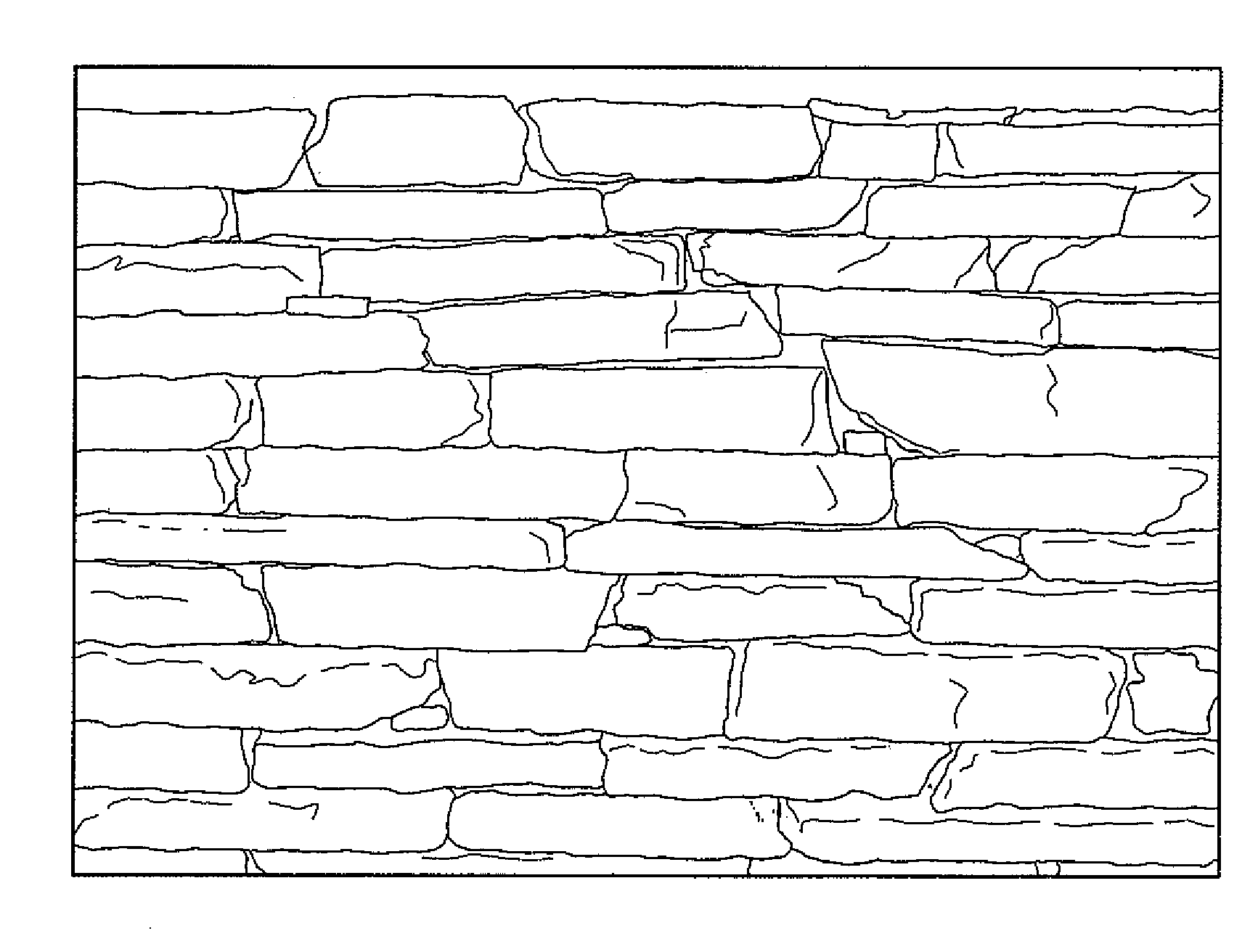

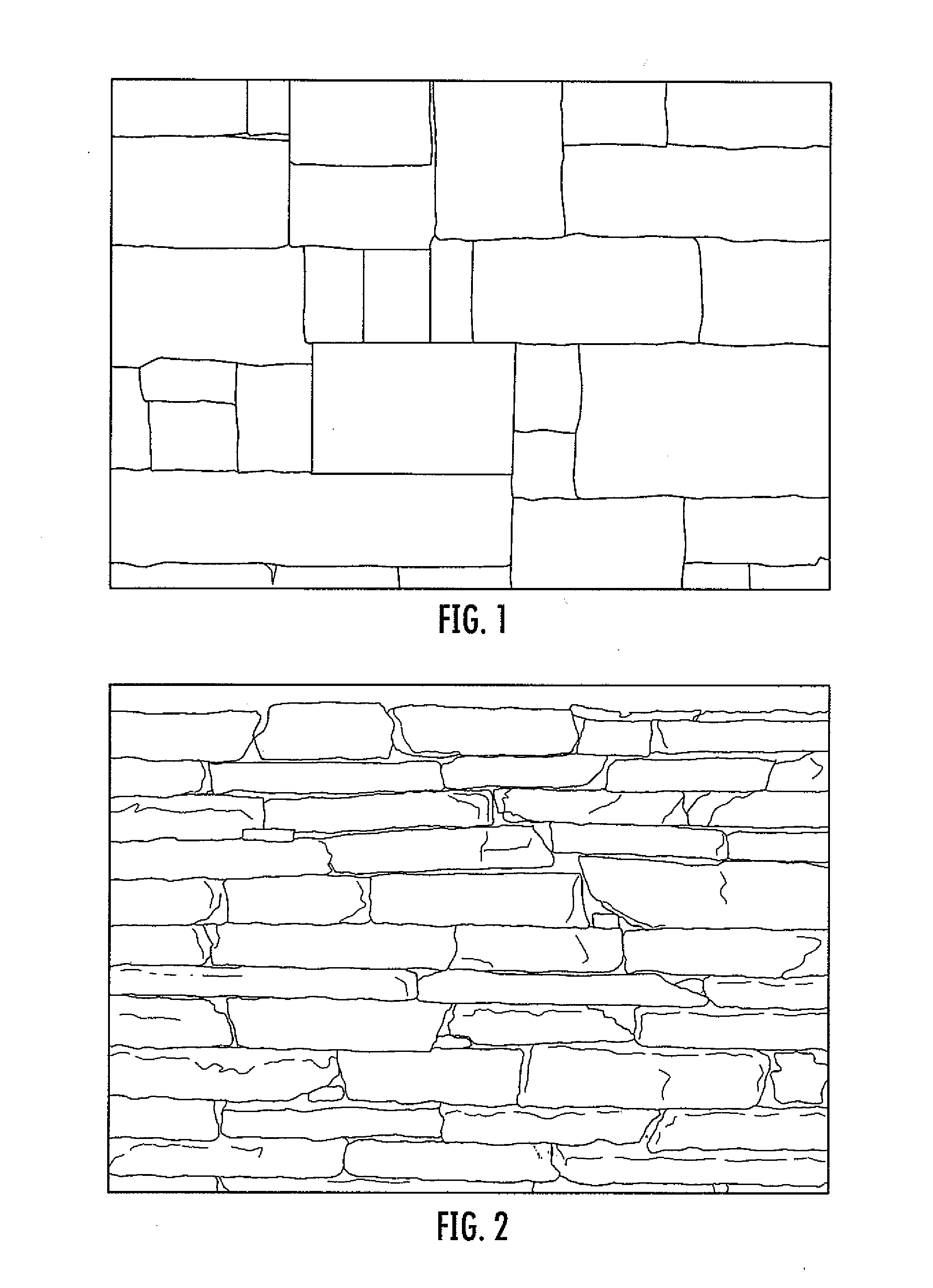

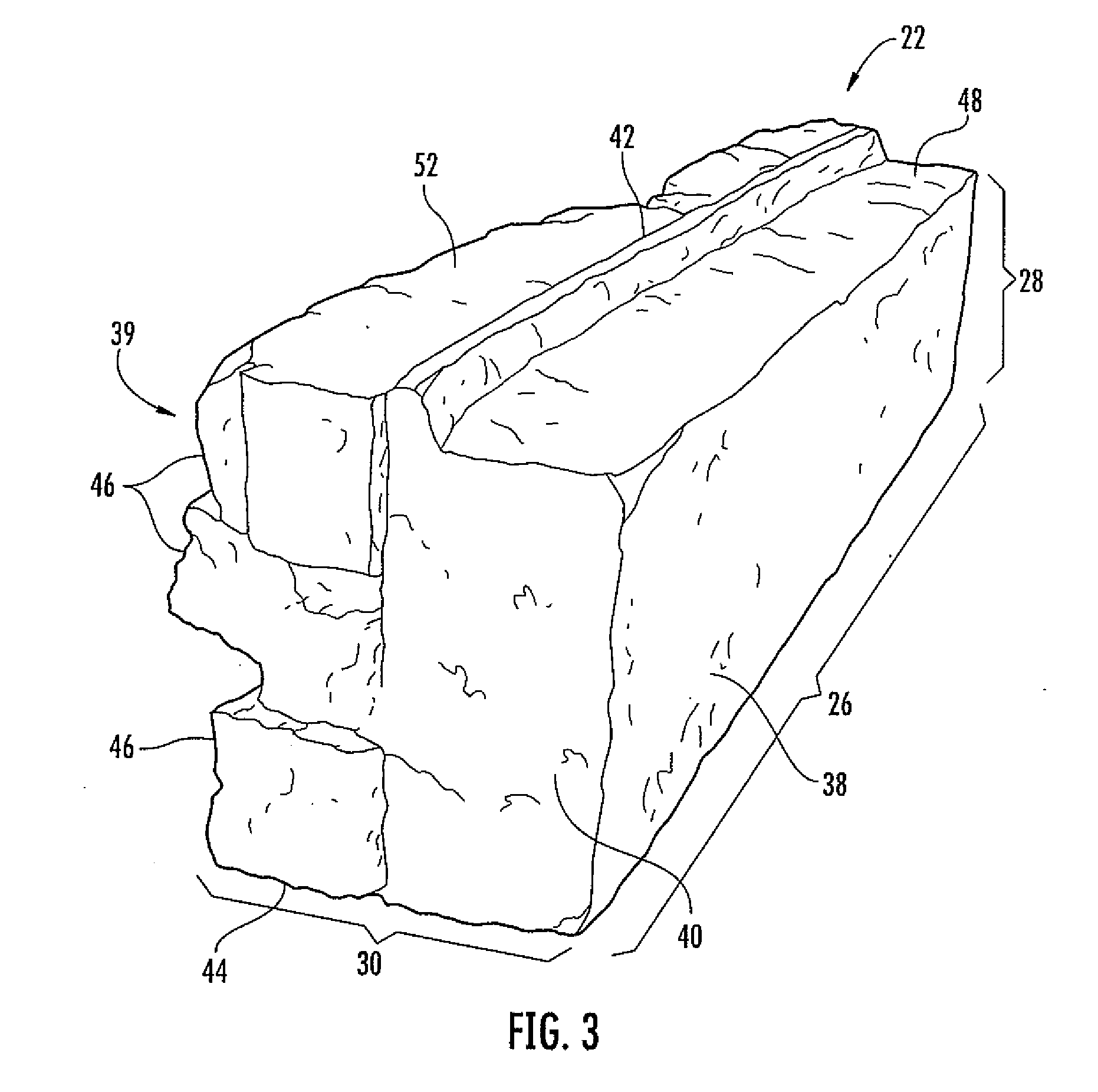

Stone fabrication system with hidden mortar joint

ActiveUS20090126301A1Good weather resistanceEasily interspersed into brick wallNatural patternsWallsNatural stoneMaterials science

A manufactured stone block for use in building a structure having a front surface with a simulated natural stone appearance. A portion of an upper surface of the block includes a recessed mortar joint for a user to place mortar therein to secure the manufactured stone block to an adjacent surface.

Owner:BROWN DUSTIN A +1

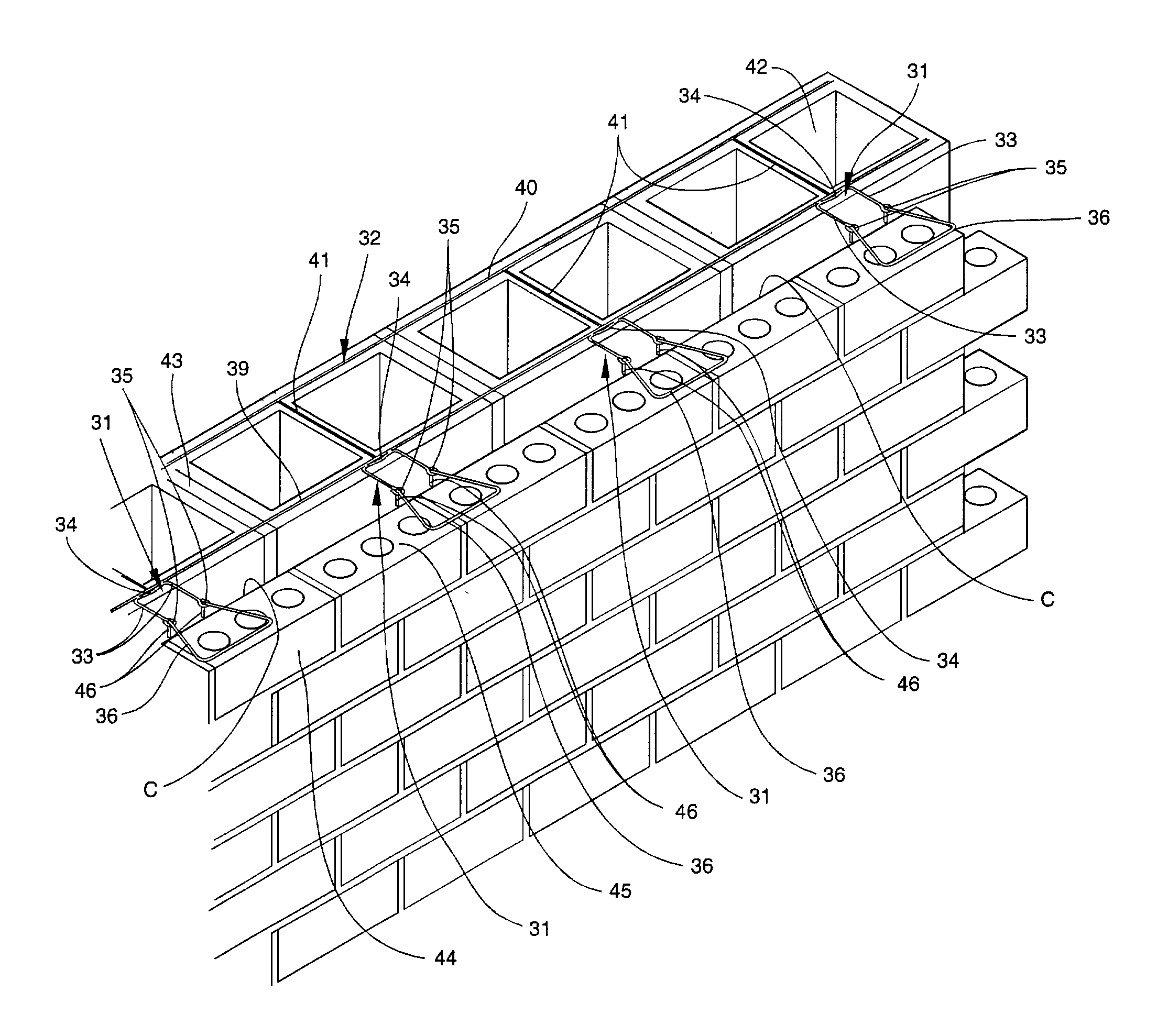

Masonry anchoring system

A masonry anchor system is disclosed for anchoring two spaced apart masonry walls together to form a single wall structure. The masonry anchor system includes a ladder or truss type support frame for positioning on top of a mortar joint in one wall, and a connecting bracket having a pair of elongate arms connected by a cross-member affixed to the support frame. The cross-member is curved to provide two spaced apart points on the cross-member for contacting the support frame and affixing the cross-member thereto. The elongate arms extend transversely from the support frame and are sized to extend into the space between the two walls. Each of the arms have an eye portion formed at the end opposite the cross-member to receive a connecting member connected to the second wall. The support frame and the bracket reside in the same horizontal plane.

Owner:MASONRY REINFORCING OF AMERICA

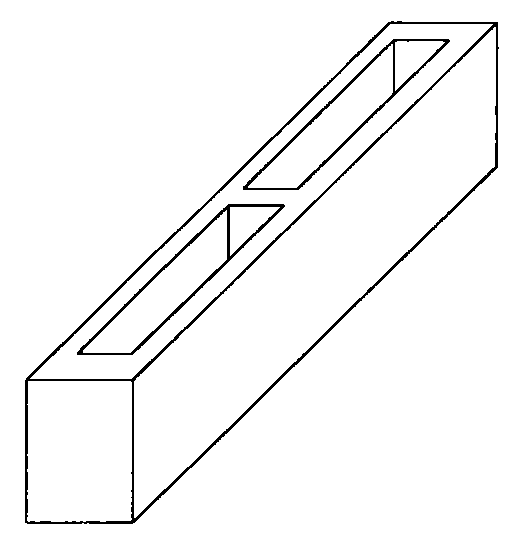

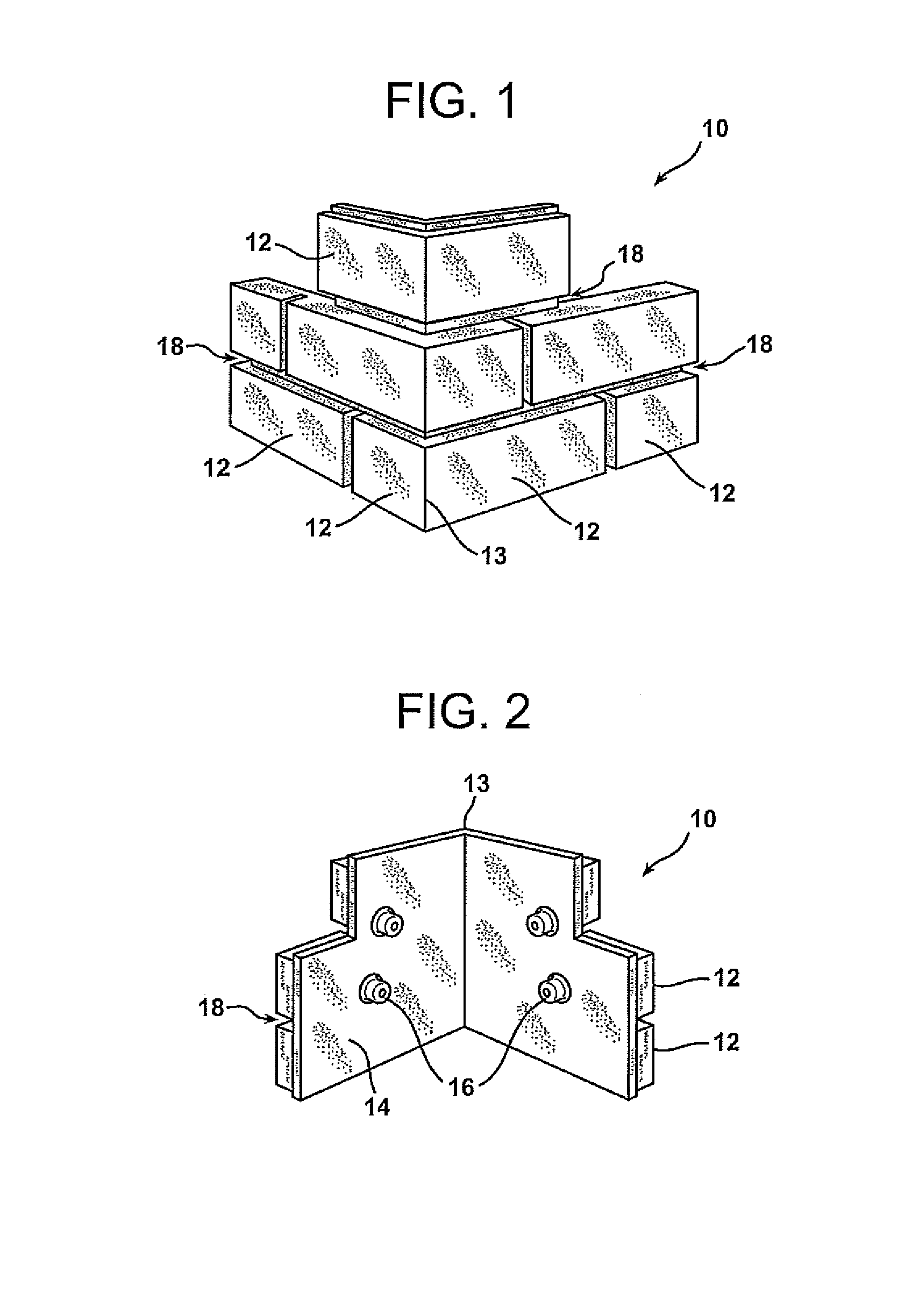

Interlocking Masonry Blocks

ActiveUS20090113835A1Improve worker efficiencyShorten the timeConstruction materialWallsVertical channelRebar

The present invention provides a block useful in the construction of walls and structures that is shaped in the general form of a rectangular solid. A horizontal channel extends along the entire length dimension of the block, open coincident with the top of the block. An open vertical channel associated with each end faces outwards toward an adjacent masonry block end. A protruding portion extends from the flat bottom with the same width of the open channel on the top, so that an interlocking connection is formed. A protruding rectangular portion is optionally incorporated into the front face portion, and also optionally into the rear face portion, leaving a recess along one end, and along the top, so that when assembled into a wall, the recessed parts of the face portion give the appearance of mortar joints. Vertical and horizontal rebar may be set within the aligned channels of the blocks when assembled into a wall. The blocks do not require excessive lifting when assembled to a wall or structure to clear vertically aligned set rebar.

Owner:MAGUINNESS ELIZABETH

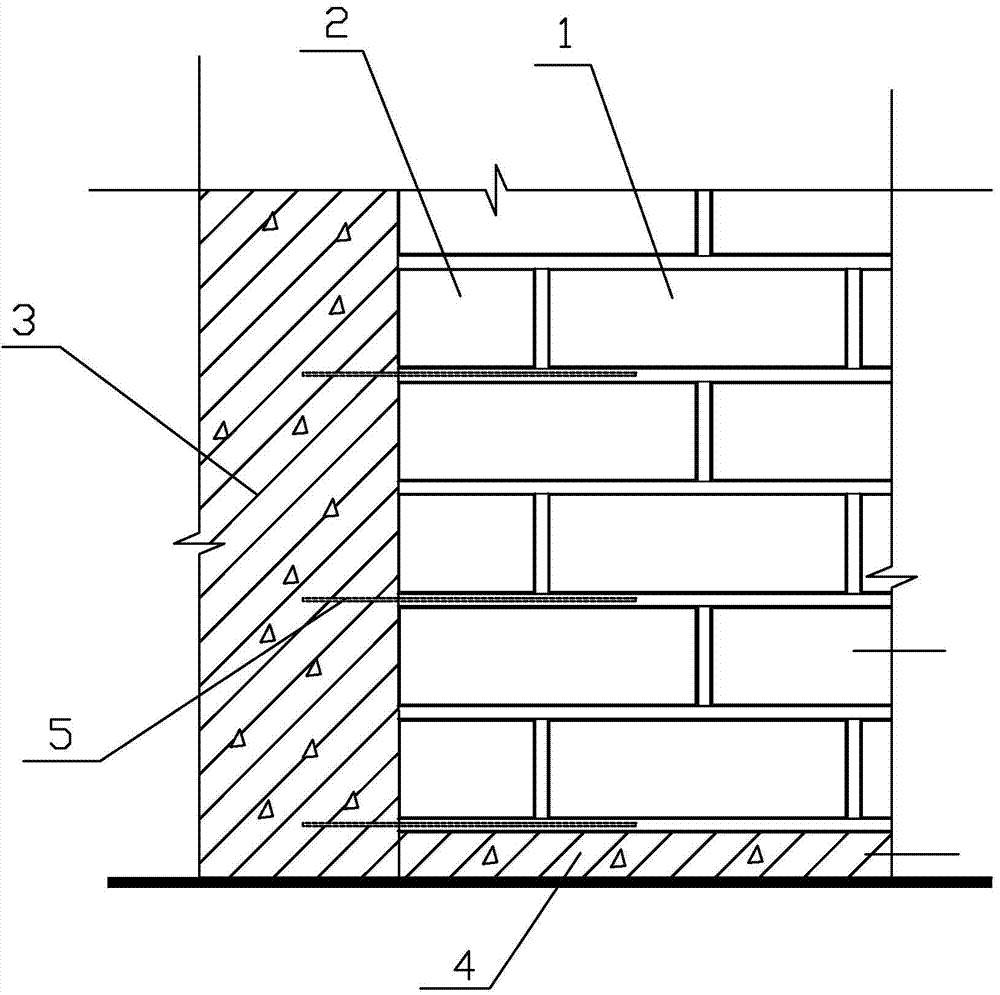

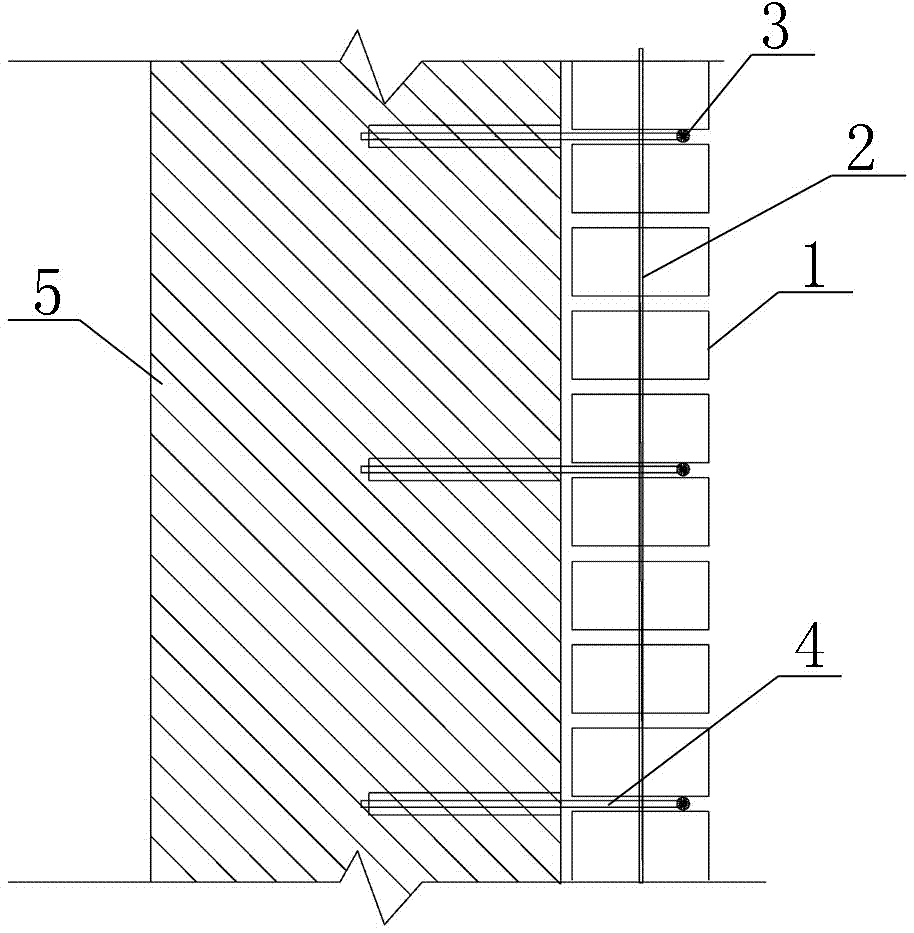

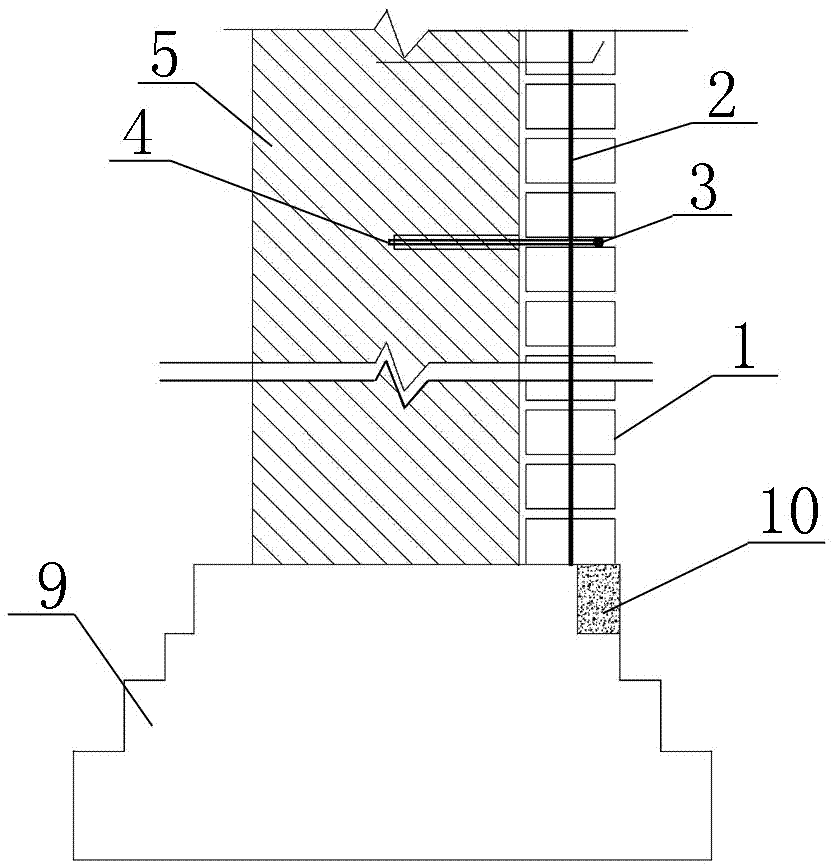

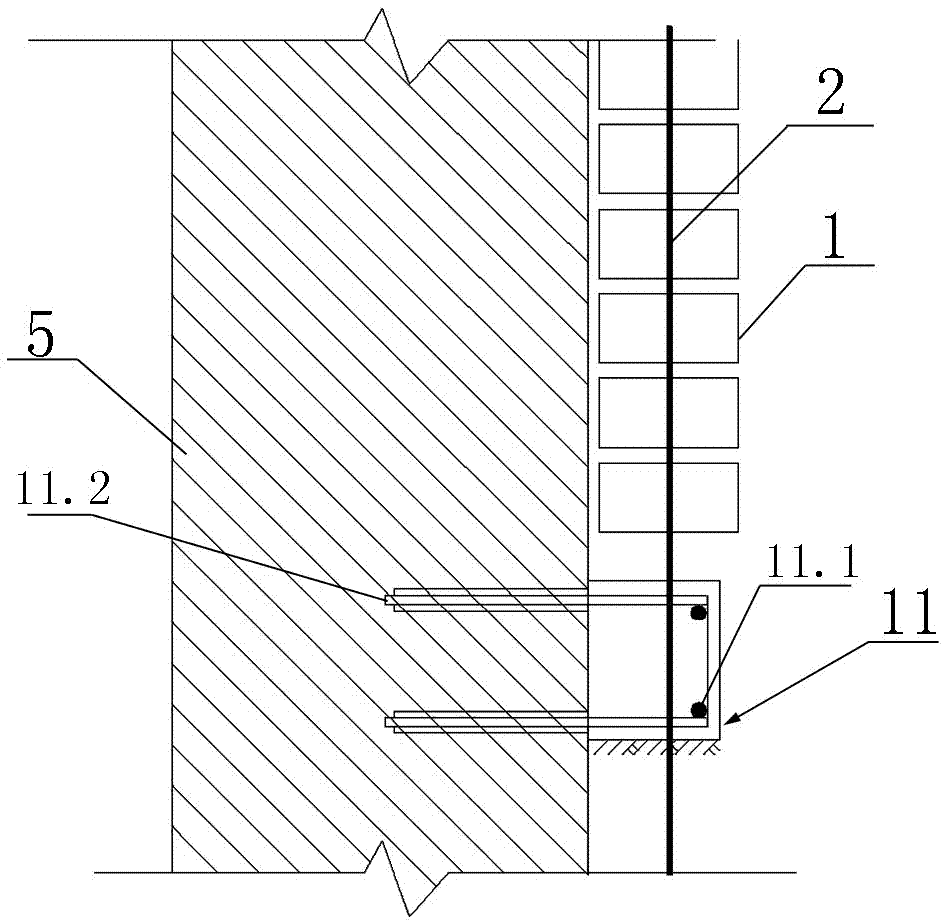

Existing building exterior wall reconstruction structure and construction method

The invention discloses an existing building exterior wall reconstruction structure and a construction method. The existing building exterior wall reconstruction structure comprises a newly-built wallbody, vertical reinforcing steel bars, horizontal reinforcing steel bars and tie bars, wherein the newly-built wall body is tightly attached to the outer side face of an existing building wall body,and is built with porous bricks; pores of upper-layer porous bricks and lower-layer porous bricks of the newly-built wall body are vertically formed correspondingly; one group of horizontal reinforcing steel bars is arranged at intervals along the outer side face of the existing building wall body; the vertical reinforcing steel bars are inserted into the pores of the porous bricks in the full length; one group of horizontal reinforcing steel bars is arranged at intervals along a vertical direction; the horizontal reinforcing steel bars are arranged in mortar joints of two adjacent layers of porous bricks; the two ends of the horizontal reinforcing steel bars are fixedly connected with the vertical reinforcing steel bars on a corresponding side; the tie bars are horizontally arranged between the existing building wall body and the newly-built wall body. The existing building exterior wall reconstruction structure and the construction method provided by the invention have the advantagesthat the technical problems of difficulty in reconstructing and upgrading the existing wall body and recovering the original appearance, incapability of making the building reach designed service life and resource waste are solved.

Owner:BUCG THE EIGHTH CONSTR DEV

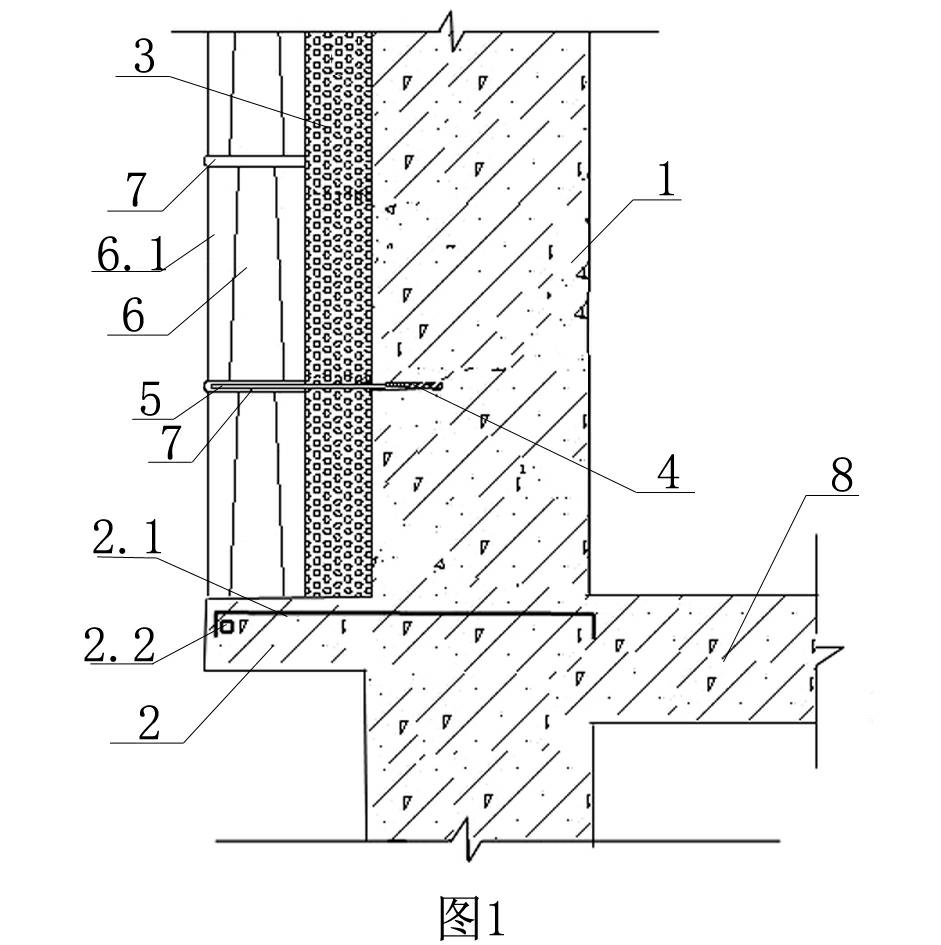

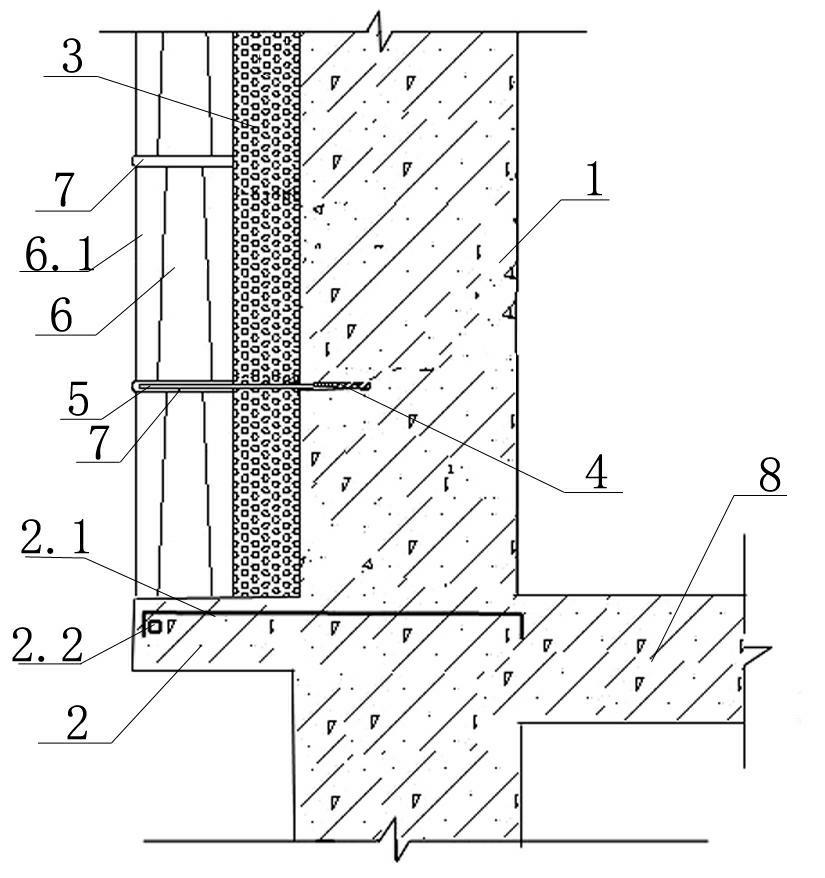

Composite exterior wall decorated with energy-saving blocks and construction method thereof

InactiveCN102094470AHas insulation effectThermal insulationConstruction materialWallsInsulation layerReinforced concrete

The invention relates to a composite exterior wall decorated with energy-saving blocks and a construction method thereof, and belongs to the technical fields of a building engineering component and a construction process. Concrete hollow blocks are taken as the external decorative layer; reinforced concrete raising ears are raised outside the intersection between a reinforced concrete structural wall and floors; the concrete hollow blocks are built on the top of the reinforced concrete raising ears; horizontal mortar joints between the neighboring concrete hollow blocks protrude outside the outer surfaces of the blocks; full steel tie bar meshes are alternately pre-embedded in the horizontal mortar joints and are welded on expansion bolts which are horizontally and alternately embedded into the reinforced concrete structural wall; and insulation boards are filled in gaps formed by the neighboring steel tie bar meshes, the reinforced concrete structural wall and the concrete hollow blocks. By utilizing the composite exterior wall and the construction method thereof, the problem of combination between concrete and an insulation layer as well as the blocks is solved; and the composite exterior wall and the construction method have the advantages of decoration and heat insulation double efficacies, high safety, beautiful appearance and the like, and can be widely applied to decoration and construction of the exterior wall.

Owner:BEIJING CENTGATE DEV & CONSTR

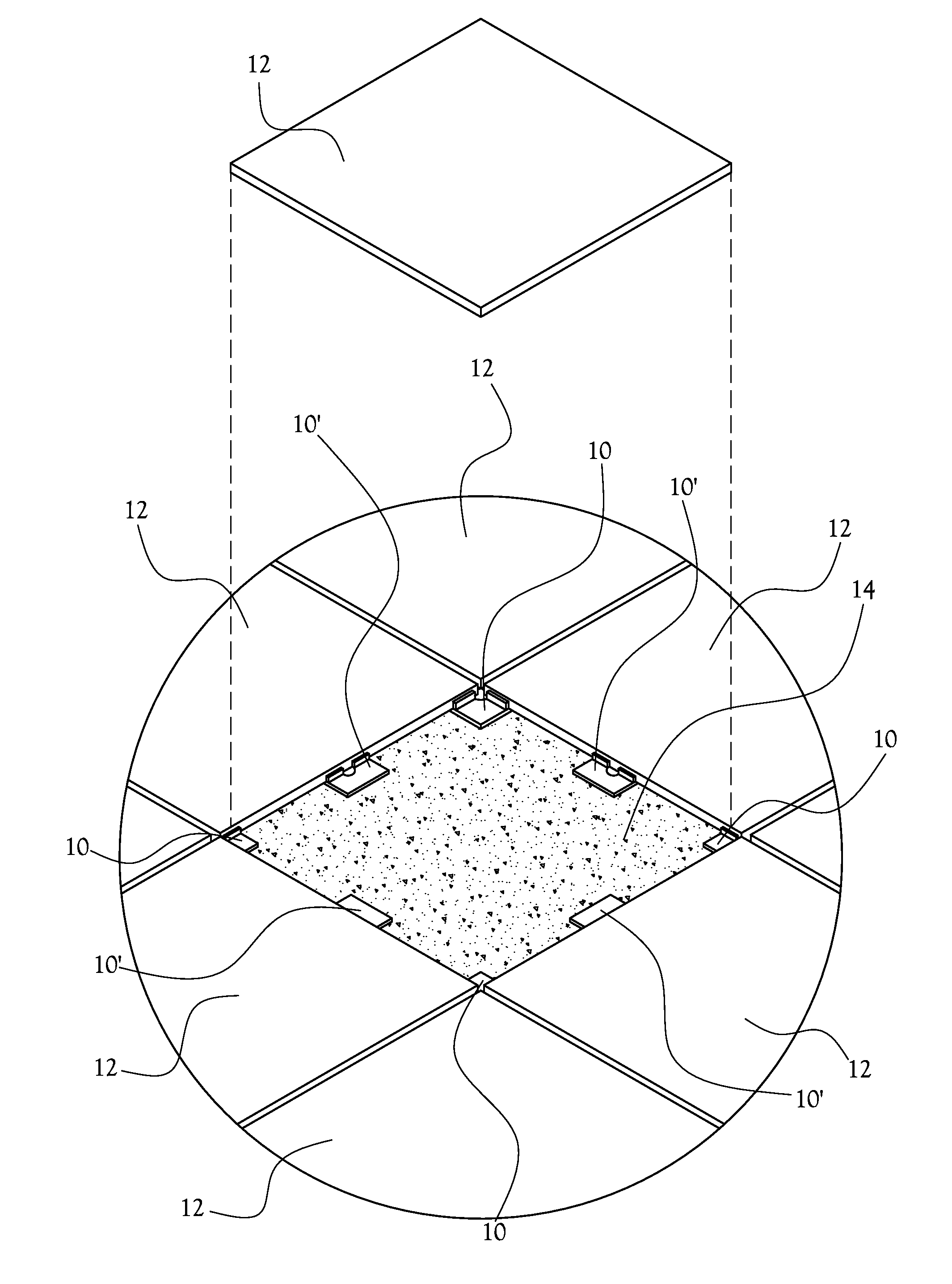

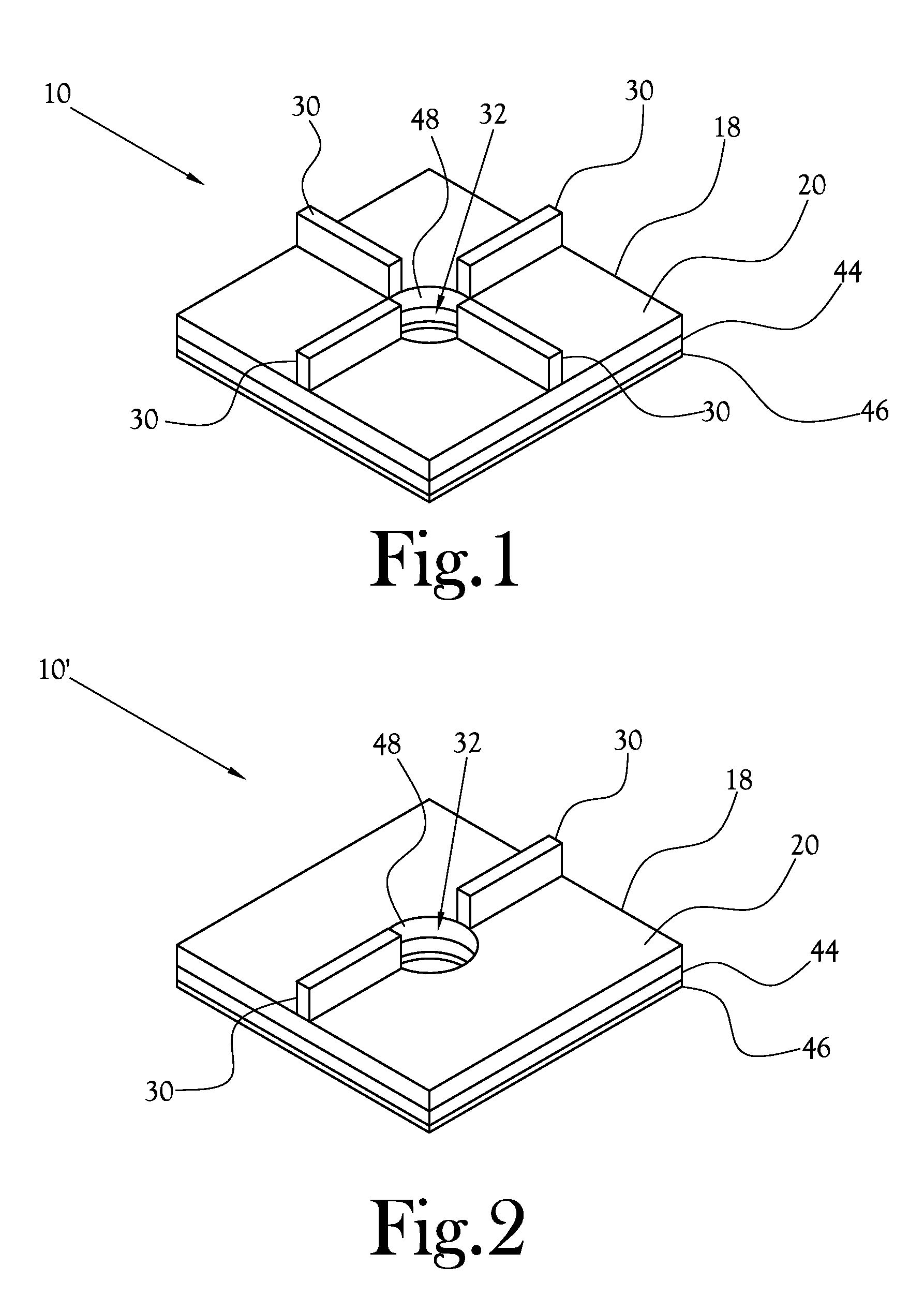

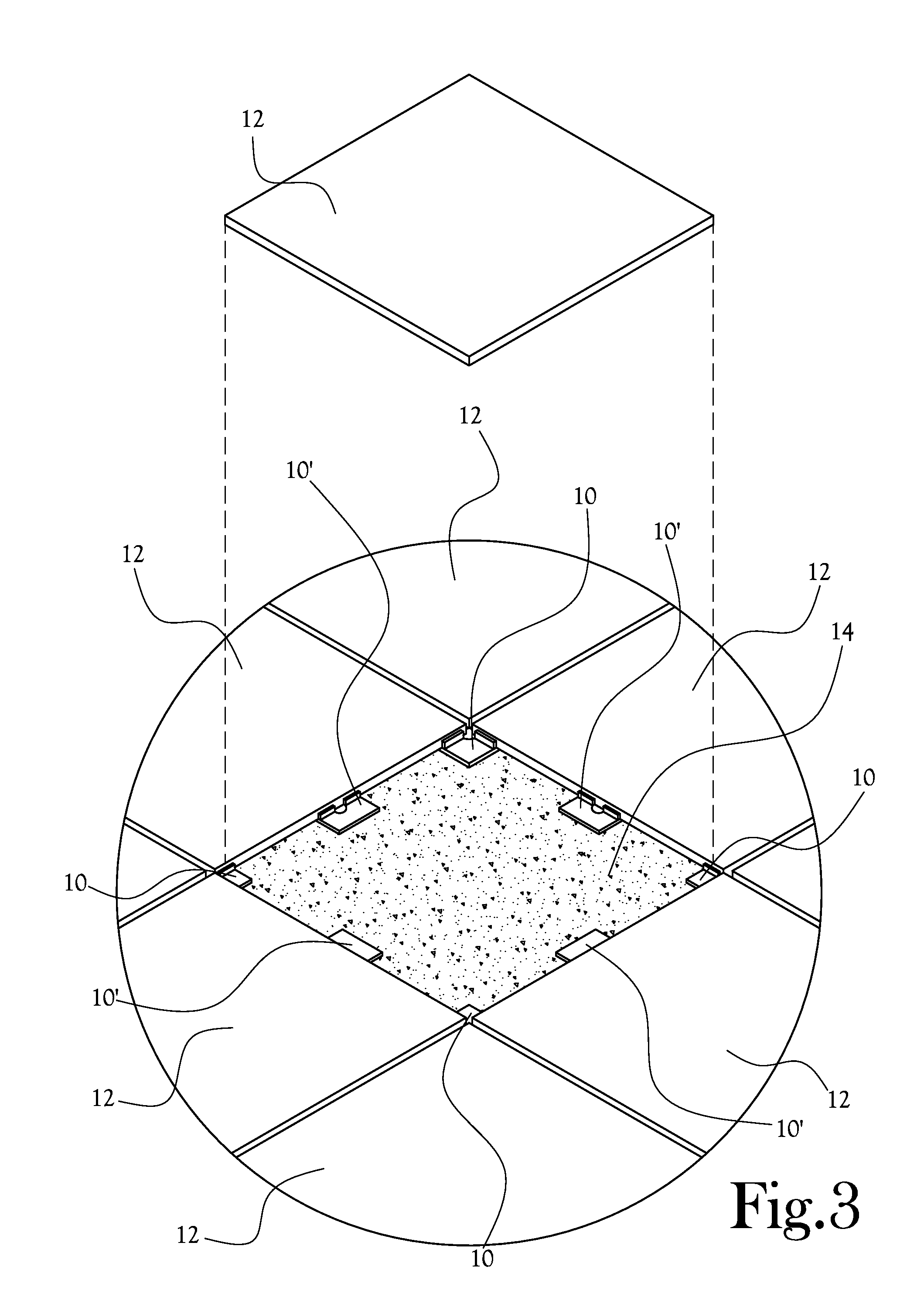

Spacer and Associated Method for Laying Tile

InactiveUS20130074425A1Facilitate additional alignmentImprove the level ofCovering/liningsFlooringEngineeringMechanical engineering

A spacer for laying tile, which is useful for example in establishing a desired spacing and alignment between at least two adjacent tiles and between the tiles and a working surface, is disclosed. A substantially planar base plate is provided which is sized to extend between the working surface and an interface of adjacent sides of at least two adjacent tiles to establish a space between the tiles and the working surface for receipt of a substrate layer therein. A plurality of fins extend from a first surface of the base plate. Each fin is sized and configured along the base plate to extend between and abut adjacent sides of at least two adjacent tiles to establish a space between the tiles for receipt of a mortar joint therebetween.

Owner:MIYAMOTO SCOTT

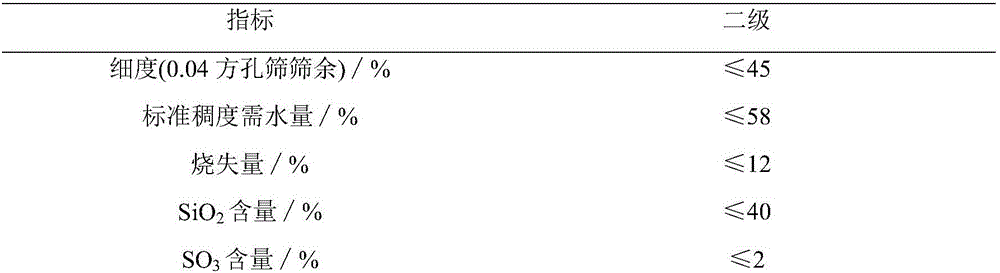

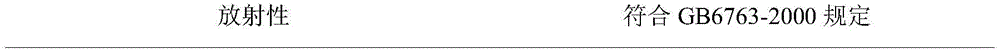

Self-heat insulation aerated concrete building block and mortar for construction of building blocks

InactiveCN105924113AHigh mechanical strengthLow thermal conductivitySolid waste managementCalcium in biologyFiber

The invention provides a self-heat insulation aerated concrete building block and mortar for construction of building blocks, and relates to the field of building walls. The building block is prepared by the following components in parts by weight: 60-110 parts of a siliceous material and 25-65 parts of a calcareous material which are used as main materials, 2-6 parts of vitreous beads, 5-30 parts of an additive, 0.07-0.2 parts of a foaming agent, 1-10 parts of a foaming conditioning agent, 0.08-0.2 parts of a foam stabilizer, and water. The building block has the advantages of fire prevention, flame retardation, good mechanical strength, low heat conduction coefficient, and good thermal insulation performance. The mortar is mixed from the following components in percentages by weight: 15-45% of Portland cement, 10-30% of coarse sand, 30-50% of fine sand, 0.05-0.15% of PP fiber, 0.02-0.07% of methyl 2-hydroxyethyl cellulose, 3-5% of heavy calcium powder, 3-8% of coal ash, 0.5-1.5% of rubber powder, and water. The mortar has a high hardening volume density, so that generation of wall cracks and mortar joints is prevented, and thermal insulation performance of the wall is guaranteed.

Owner:YANCHENG INST OF TECH

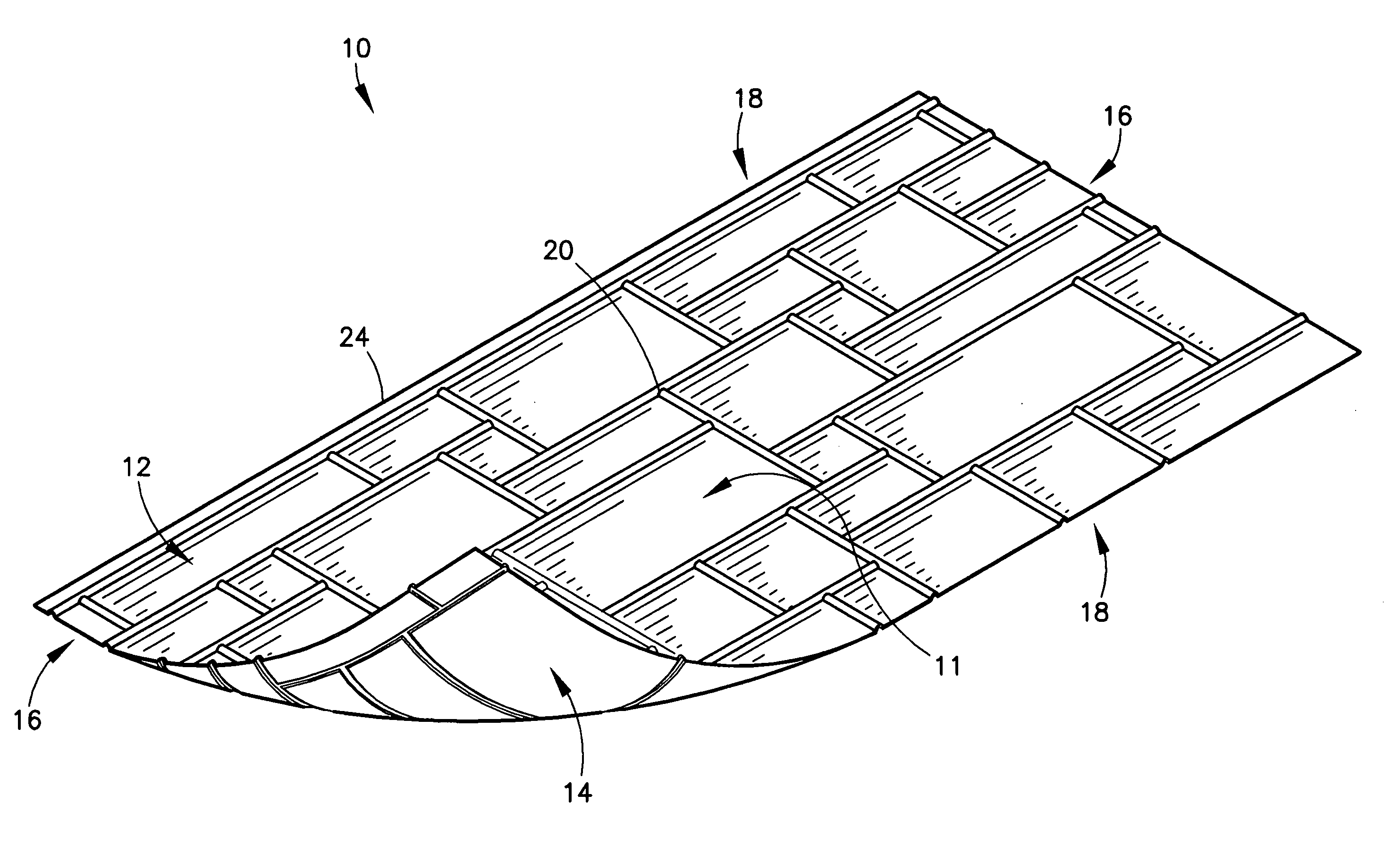

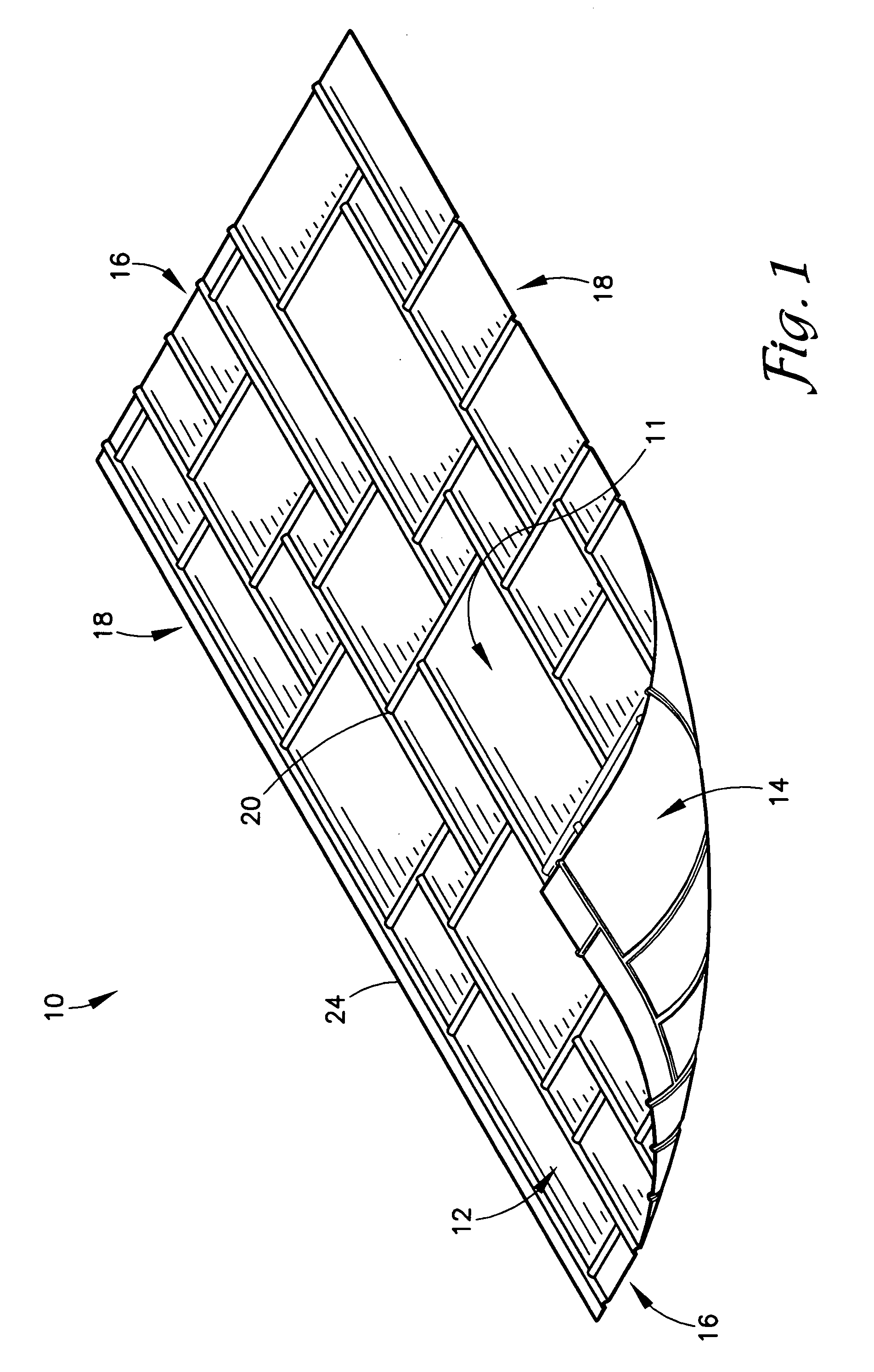

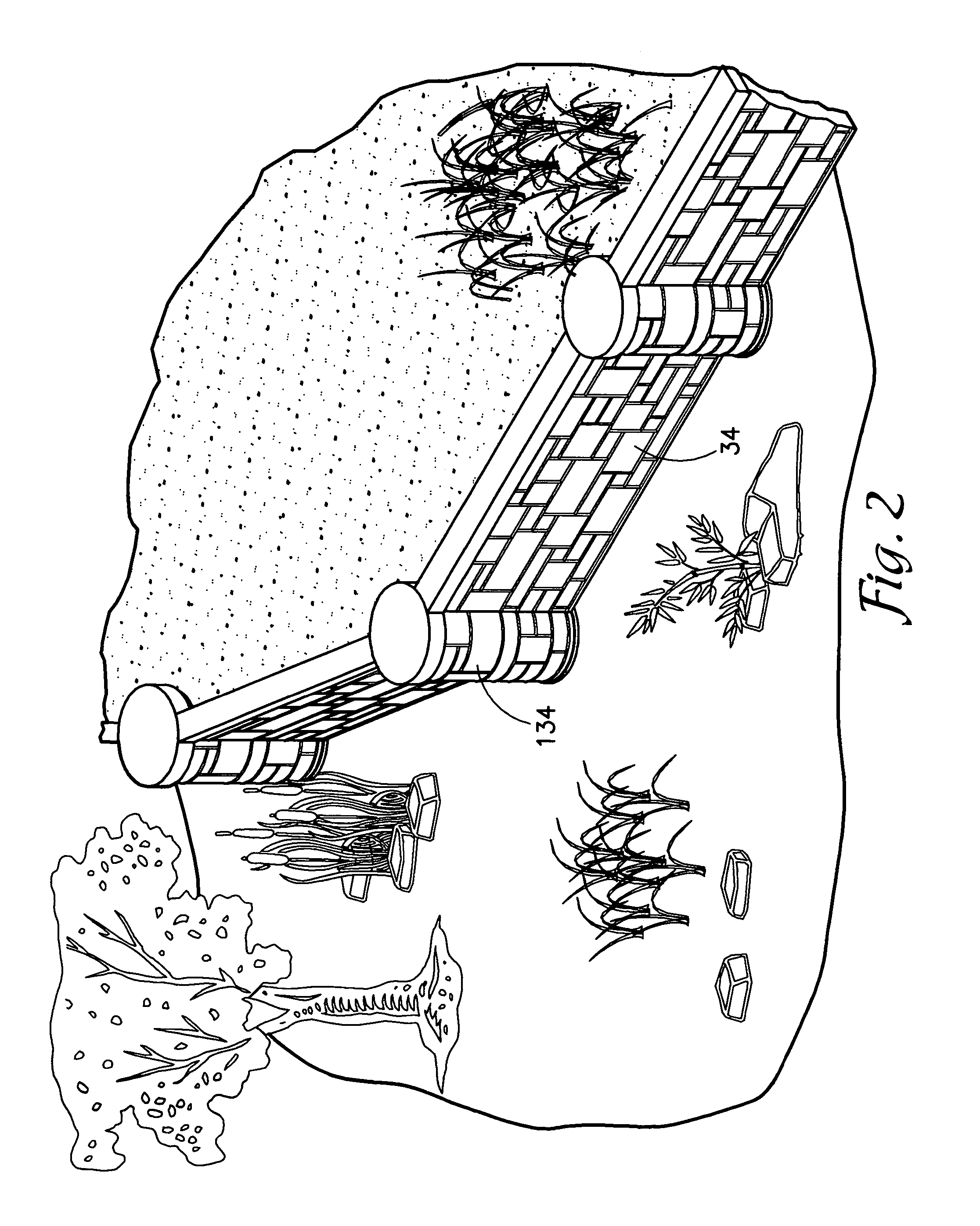

Reversible and flexible liner for imprinting a decorative pattern on a malleable surface and a method of using same

InactiveUS20050097827A1Easy to disassembleNot to cut the linerArtificial islandsUnderwater structuresMechanical engineeringMortar joint

A liner for imprinting a decorative pattern on a malleable surface, such as concrete, and a method of doing same, wherein the liner is flexible so as to imprint on curved surfaces and reversible so as to imprint opposing indentations of the decorative pattern. The liner comprises bottom and top faces, opposing side edges, and opposing end edges. Due to the flexibility, the opposing end edges and opposing side edges may contact each other, which allows for the liner to be used in any curved mold for imprinting any curved surface. Due to the reversibility, either protruding or recessed mortar joints may be imprinted on the surface. The method provides for removably securing the liner to the mold; pouring a wetted flowable material into the mold that will harden; and separating the mold and liner combination from the hardened surface.

Owner:QUICK IMPRINT SYST

Building construction and construction method for autoclaved aerated concrete blocks

The invention provides a steam curing aerated concrete block building structure and a construction method thereof. Watering is not required before the laying, the average mortar joint thickness is less than or equal to 8 mm, and bonding mortar is utilized to bond blocks; anti-crack mortar which is a novel building structure used for filling wall is adopted as a bonding layer, thereby reaching the effects that the laying of the steam curing aerated concrete blocks is firm, the surface layer plastering is good, the anti-crack effect of the wall surface is good, and the defects that the mortar hydration during laying and surface finishing in the traditional construction method is inadequate, the cracking and leakage of the wall body caused by the dry-wet circulation of the wall body are difficult to be controlled, and the plastering layer is hollow and will shed are overcome. Meanwhile, the invention also provides a technical process for the steam curing aerated concrete block wall body and the wall surface construction.

Owner:黄照明

Self-thermal-insulation earthquake-proof building block and application method

InactiveCN103174252AReduce in quantityImprove carrying capacityConstruction materialWallsVertical planeThermal insulation

The invention belongs to the technical field of building materials, and relates to a building block. The building block comprises a longitudinal outer wall and a transverse outer wall which are enclosed to form a hollow thermal insulation cavity, and is characterized in that: the middle part of the longitudinal outer wall is provided with a reinforcing rib which protrudes towards the direction of the hollow thermal insulation cavity; the reinforcing rib and the longitudinal outer wall are enclosed together to form a middle grouting passage which is vertically run-through; the middle grouting passage is symmetrically arranged along a middle vertical plane of the longitudinal outer wall of the building block; and the outer end face of the transverse outer wall is provided with a vertical end face grouting groove. The building block has the characteristics of high self-thermal-insulation capacity, light deadweight, high strength and the like, and has a flat appearance, high integrity and high earthquake-proof capacity after being built; in addition, by matching with a method for building a vertical thermal insulation wall or a thermal insulation wall without mortar joints by applying the self-thermal-insulation earthquake-proof building block, the construction efficiency can be greatly increased, and easiness for standardization, high cost performance and high easiness for guaranteeing the construction quality are guaranteed. The building block can be widely applied to overall maintenance outside a building structure and a bearing structure of a low-rise building, and has extremely broad market prospect.

Owner:JIANGXI WEIYI TECH DEV

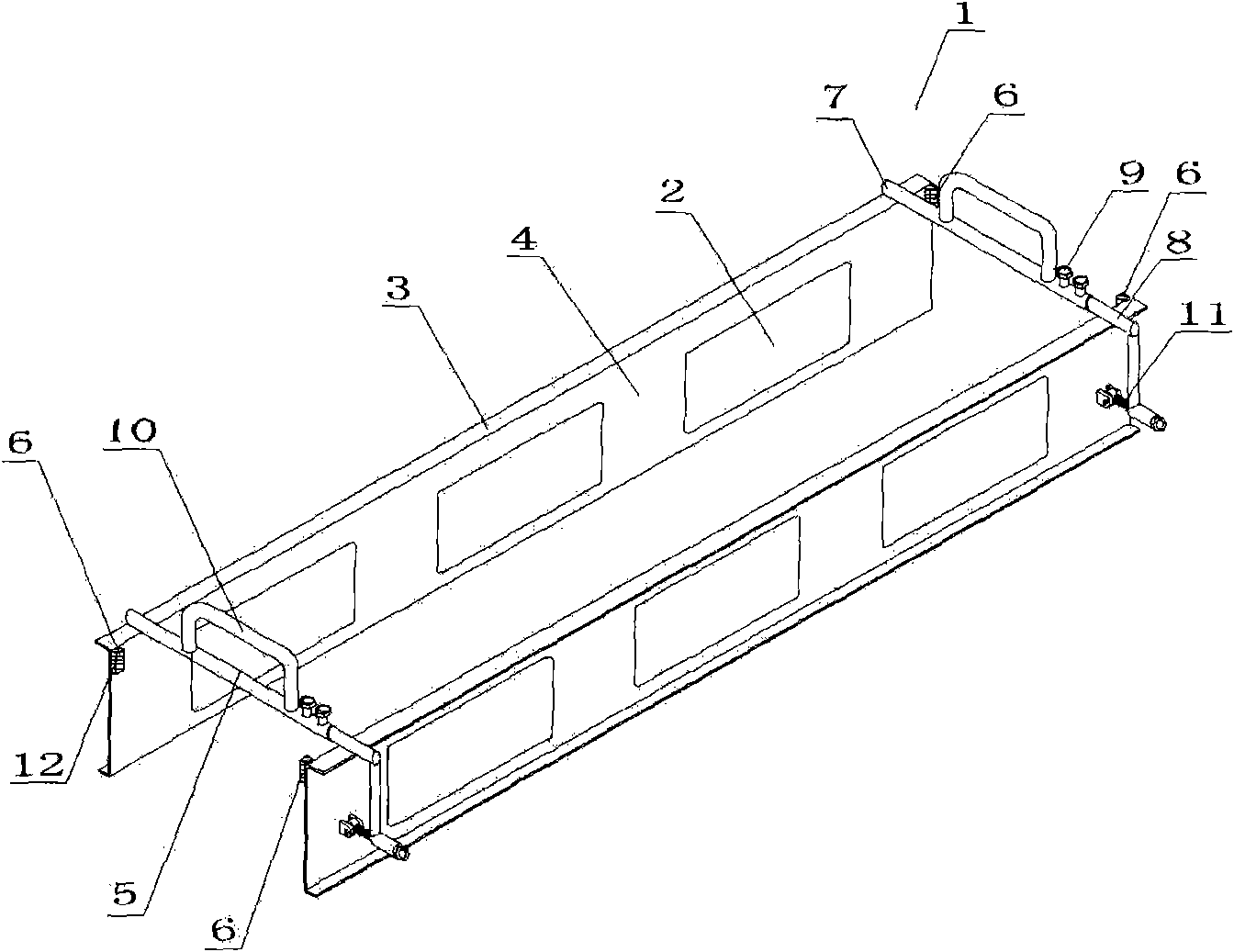

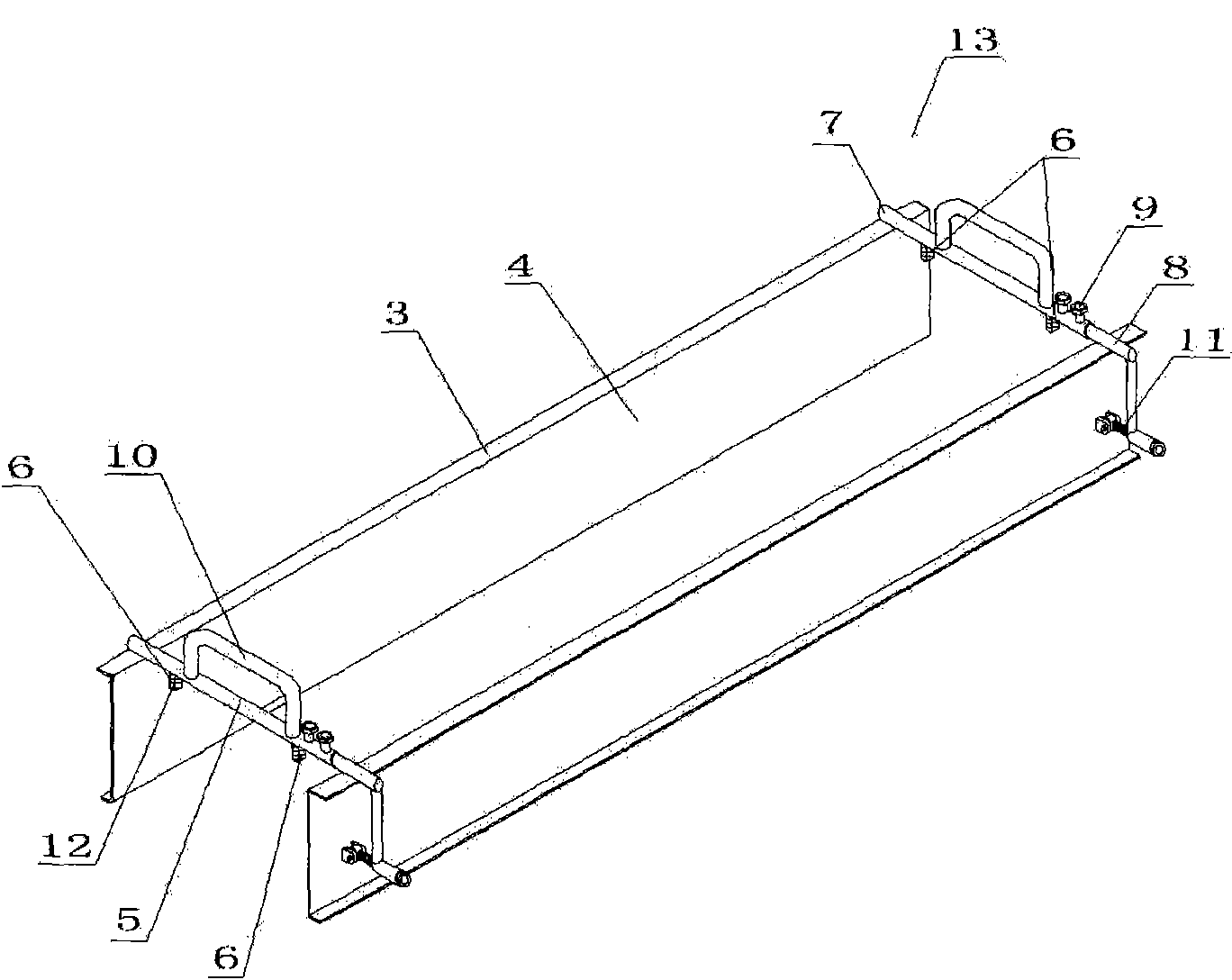

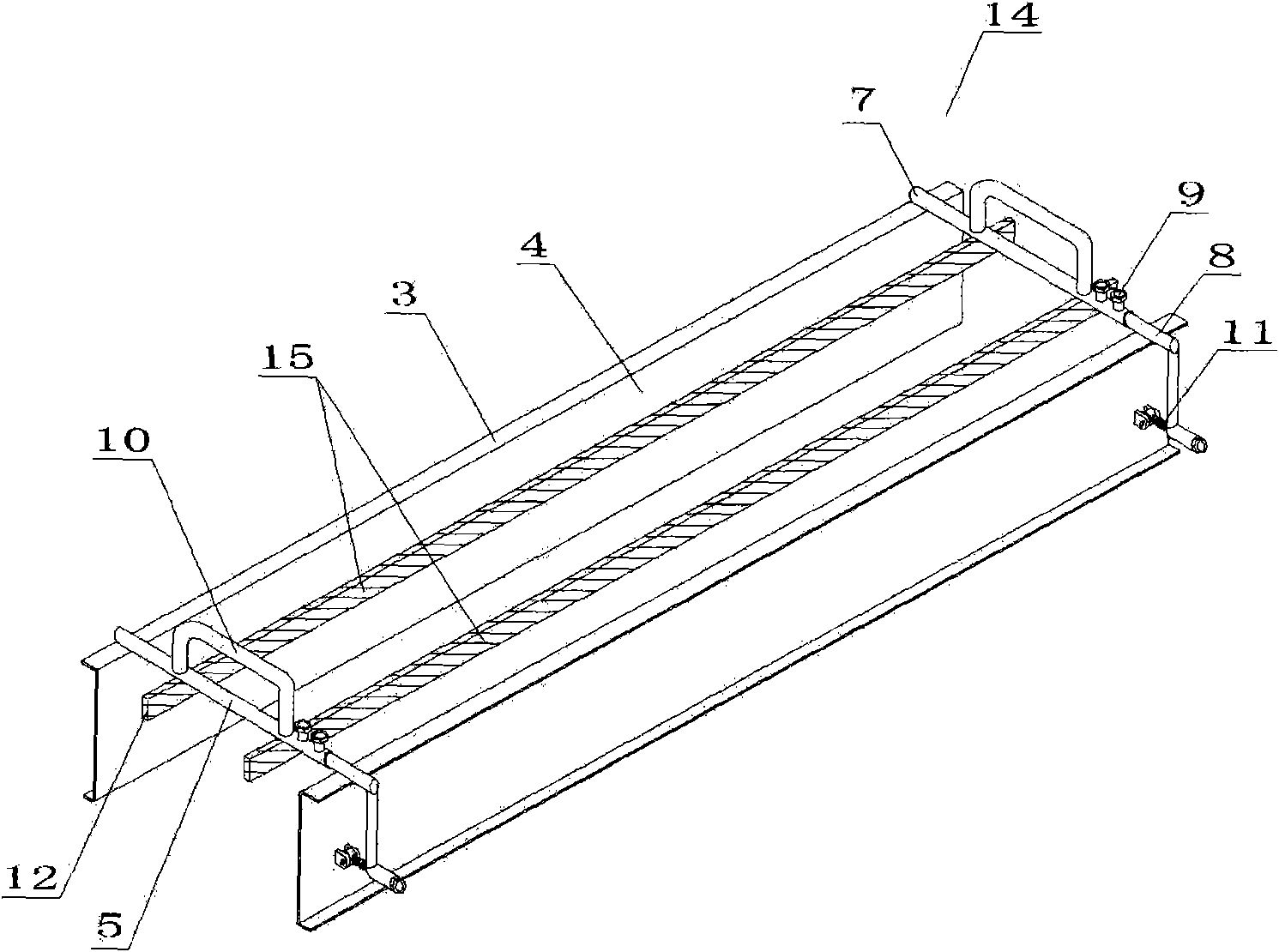

Mortar spreader for building wall and using method thereof

InactiveCN101892747AReduce wasteConstruction site clean and tidyBuilding material handlingMaterials scienceShovel

The invention discloses a mortar spreader for building various walls and a using method thereof. The mortar spreader is characterized by consisting of a side plate, a thickness gage, a connecting piece and a mortar shovel, wherein the mortar with a specified thickness is spread within a mortar spreading range specified by the mortar spreader when the wall is built; and the vertical mortar is tamped by the mortar shovel. The mortar spreader is favorable for standardizing the thickness of a horizontal mortar joint and the width of a vertical mortar joint during the building of the mortar, so the wall crack caused by non-uniform building of the mortar is reduced, the building efficiency of the wall can be improved and the mortar for building can be saved.

Owner:上海奥伯应用技术工程有限公司

Head joint drainage device, wall system and method for draining moisture from a head joint

A wall system, head joint drainage device and method adapted to allow drainage of moisture from a head joint of a structure meeting a horizontal interruption when the wall system is formed with a plurality of building products set with mortar forming a mortar joint between adjacent ones of the plurality of modular building products. A spacer has a top portion, having a length approximately equal to a depth of the plurality of building products and a width approximately equal to a width of the mortar joint, adapted to block the mortar from reaching the horizontal interruption and has a side portion adapted to keep the portion a distance away from the horizontal interruption, the distance allowing moisture drainage from the head joint.

Owner:MASONRY TECH

Weep venting system for masonry walls

A system for venting moisture from wall and building structures, especially masonry walls constructed from masonry elements such as of brick, block, stone, faux stone or the like, without weakening the wall or building structure, utilizes open matrix weep vent members that are fabricated, for example from a mass of intertwined and intertangled polymeric filaments that are bonded at a plurality of intersections thereby to form one-piece or unit-handled weep vent members that preferably are inserted in place of mortar at spaced locations along horizontally extending mortar joints between rows of bricks, blocks or other masonry wall elements. Weep vent members that embody the present invention have wider portions at their rearward or intake end regions, and narrower portions at their forward or discharge end regions, with a preferred form characterized by a generally trapezoidal shape that helps to retain the weep vent members in their associated mortar joints, and that provide a funnel-like ducting of moisture from their relatively wider rear end regions toward their relatively narrower forward end regions.

Owner:KEENE BUILDING PRODS

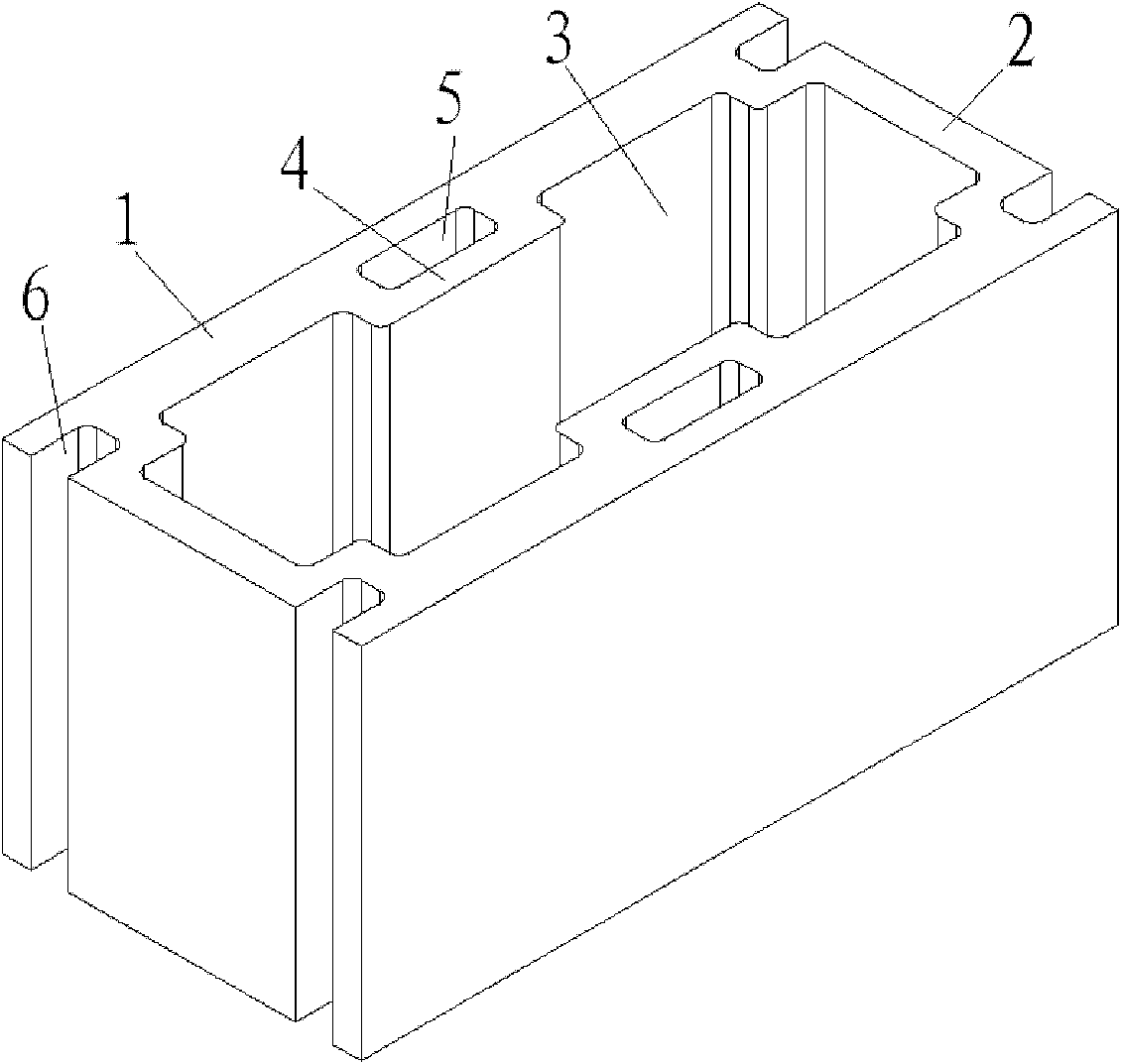

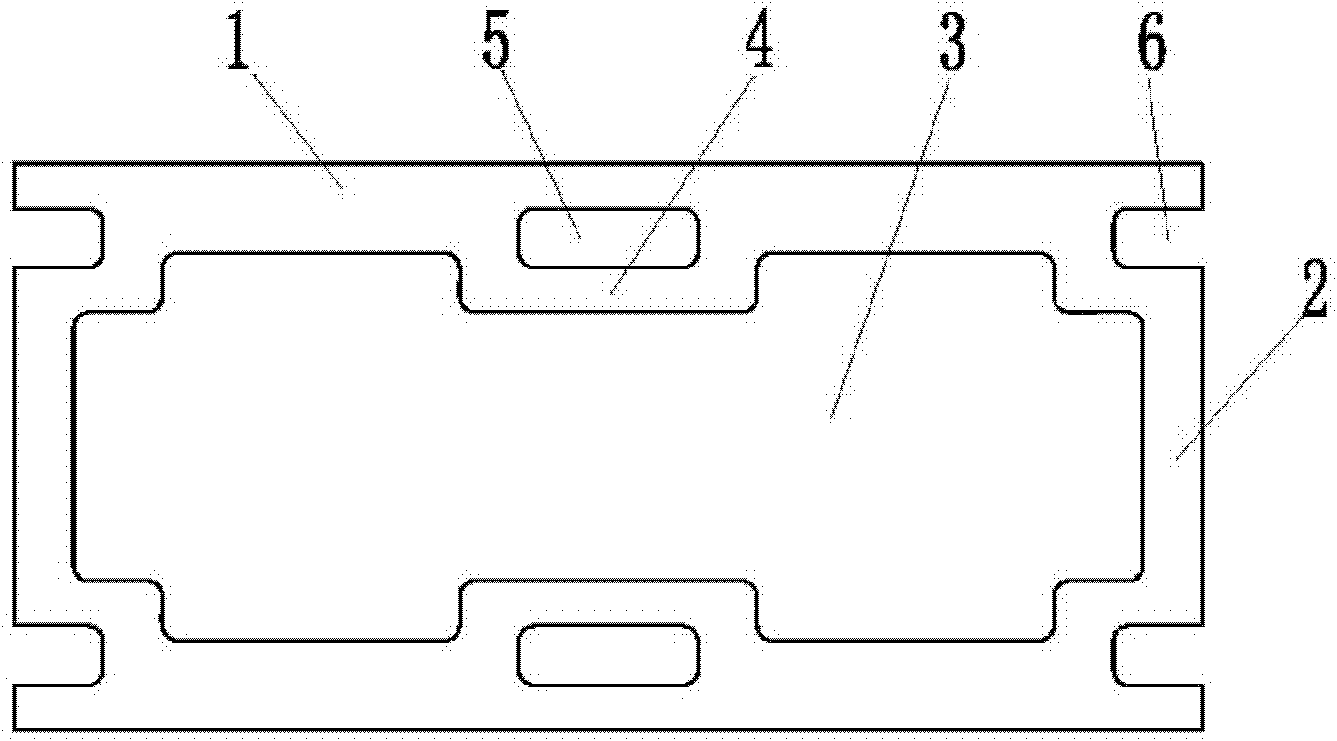

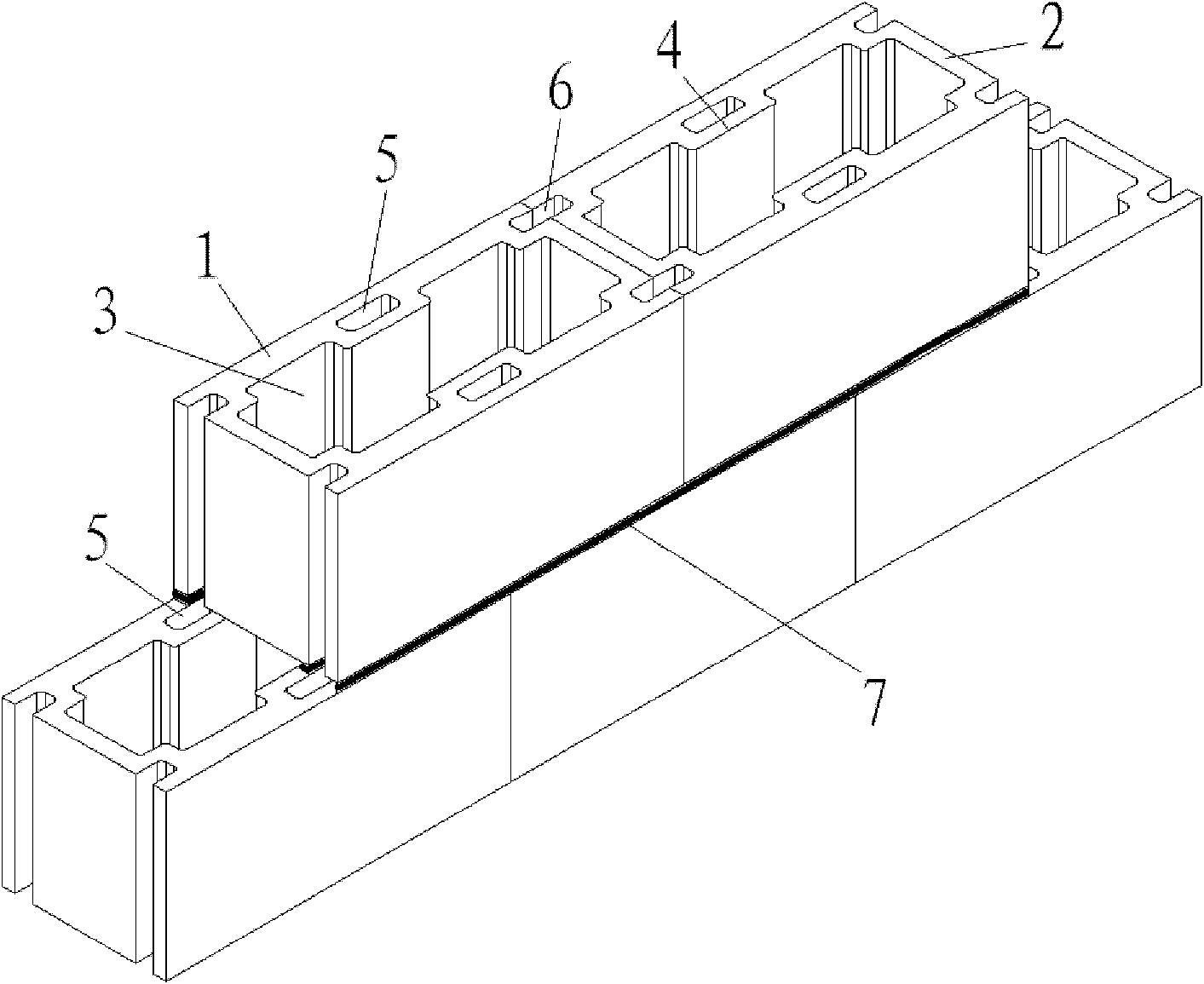

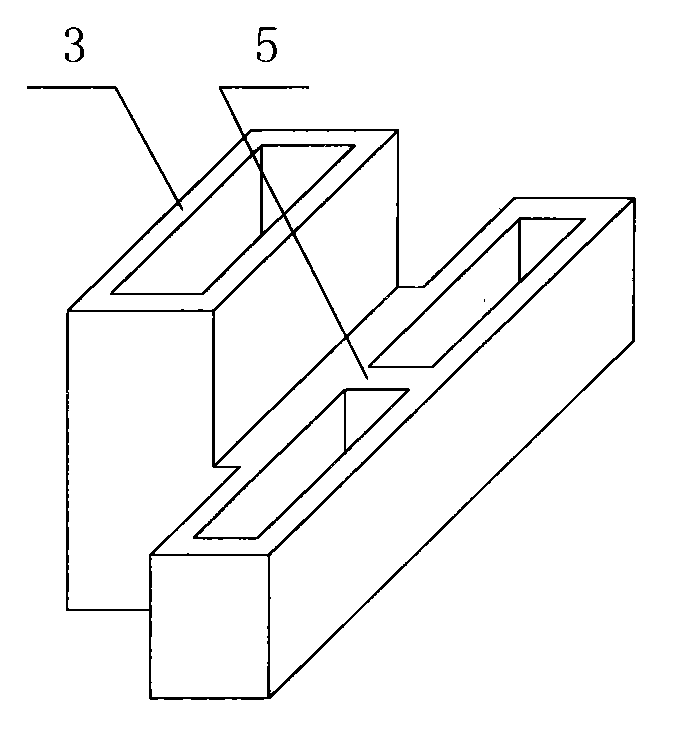

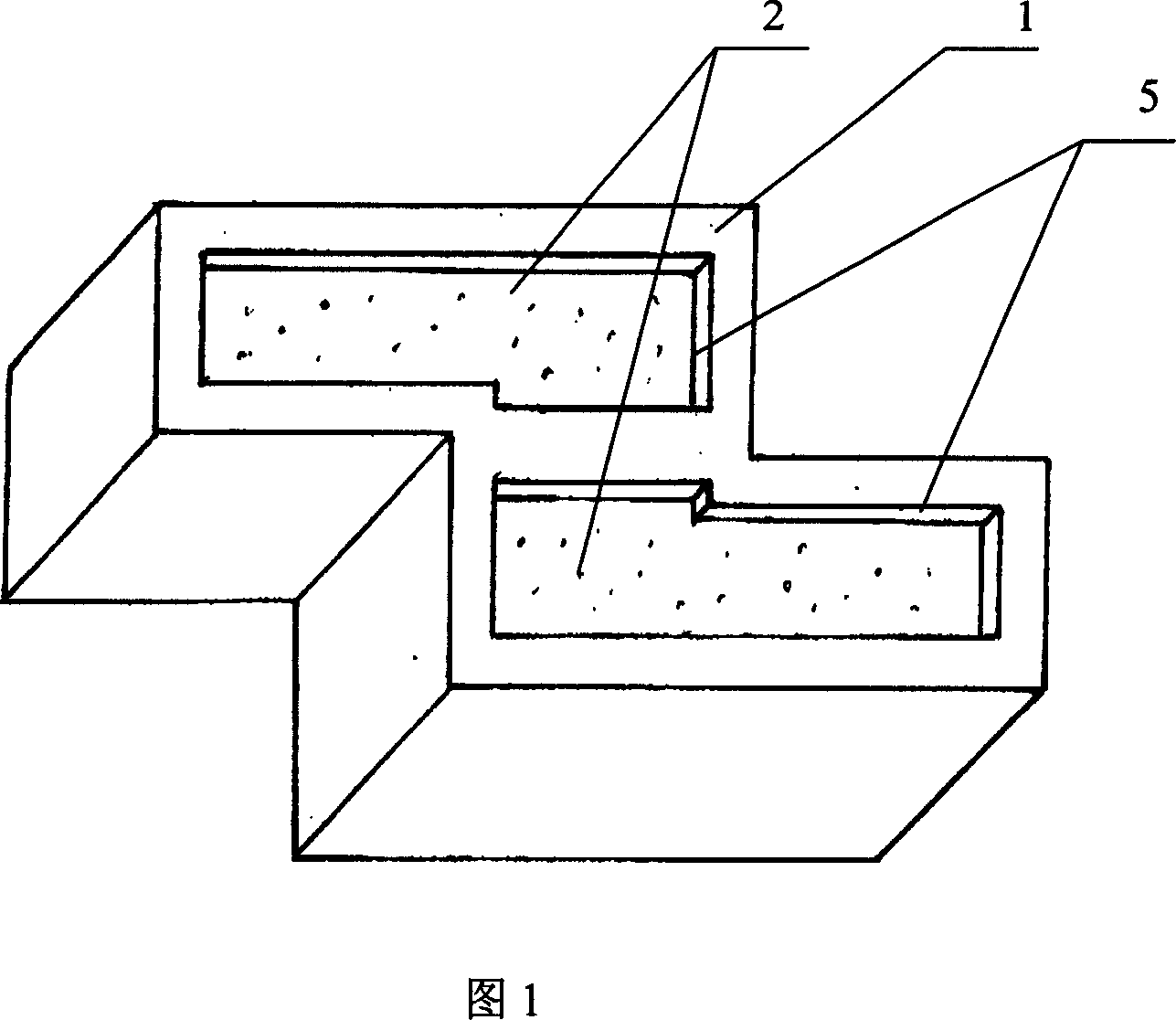

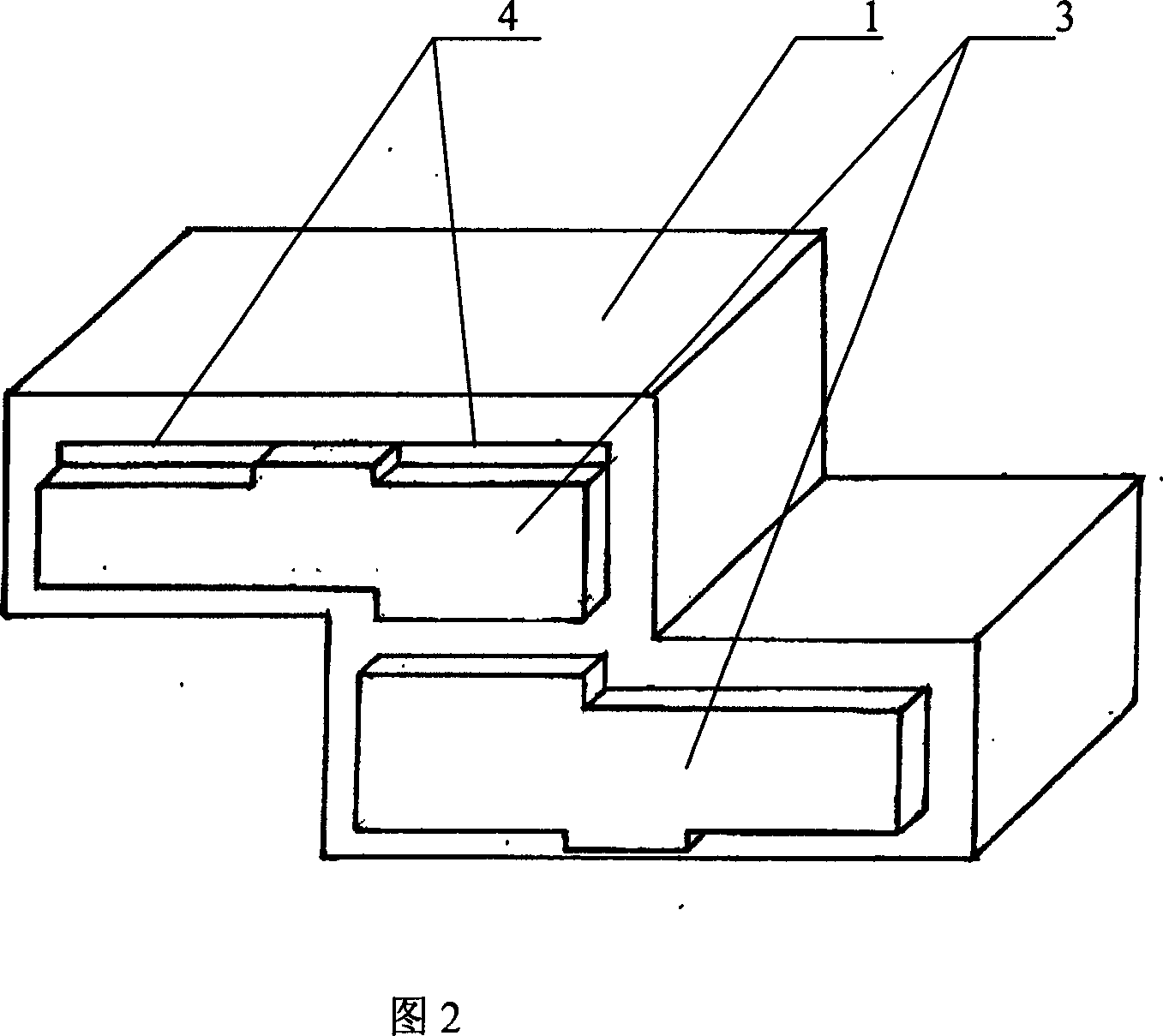

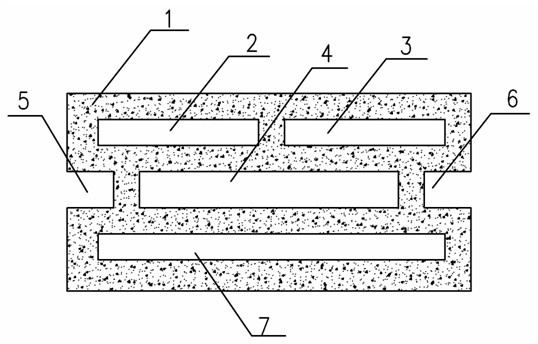

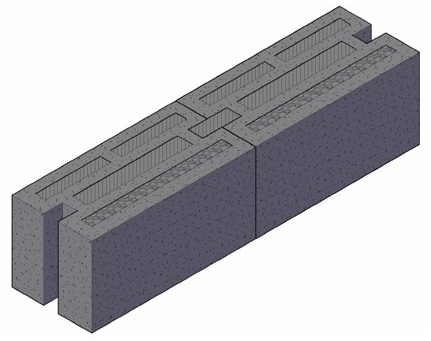

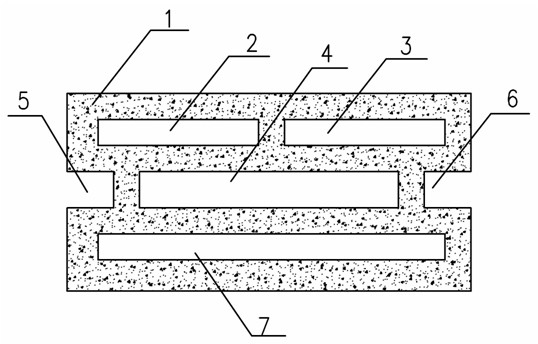

Self-insulation building block capable of completely eliminating mortar joint cold bridges and building method of self-insulation building block

InactiveCN102912920AImprove insulation effectConstruction materialWallsMaterials scienceMortar joint

The invention discloses a self-insulation building block capable of completely eliminating mortar joint cold bridges and a building method of the self-insulation building block and belongs to the field of building materials. The self-insulation building block is used for building energy-saving walls. Unequal-thickness T-shaped self-insulation building blocks, unequal-thickness L-shaped self-insulation building blocks and cuboid self-insulation building blocks are combined to build a self-insulation wall, so that vertical mortar joints of the wall are changed from traditional plummet plate joints to plummet bent joints, horizontal mortar joints of the wall are changed from traditional horizontal plate joints to step bent joints, and the vertical mortar joint cold bridges and the horizontal mortar joint cold bridges are eliminated. The self-insulation building block has the advantage that insulation effect of the self-insulation wall is improved remarkably.

Owner:SHANDONG UNIV OF SCI & TECH

Interlocking masonry blocks

The present invention provides a block useful in the construction of walls and structures that is shaped in the general form of a rectangular solid. A horizontal channel extends along the entire length dimension of the block, open coincident with the top of the block. An open vertical channel associated with each end faces outwards toward an adjacent masonry block end. A protruding portion extends from the flat bottom with the same width of the open channel on the top, so that an interlocking connection is formed. A protruding rectangular portion is optionally incorporated into the front face portion, and also optionally into the rear face portion, leaving a recess along one end, and along the top, so that when assembled into a wall, the recessed parts of the face portion give the appearance of mortar joints. Vertical and horizontal rebar may be set within the aligned channels of the blocks when assembled into a wall. The blocks do not require excessive lifting when assembled to a wall or structure to clear vertically aligned set rebar.

Owner:MAGUINNESS ELIZABETH

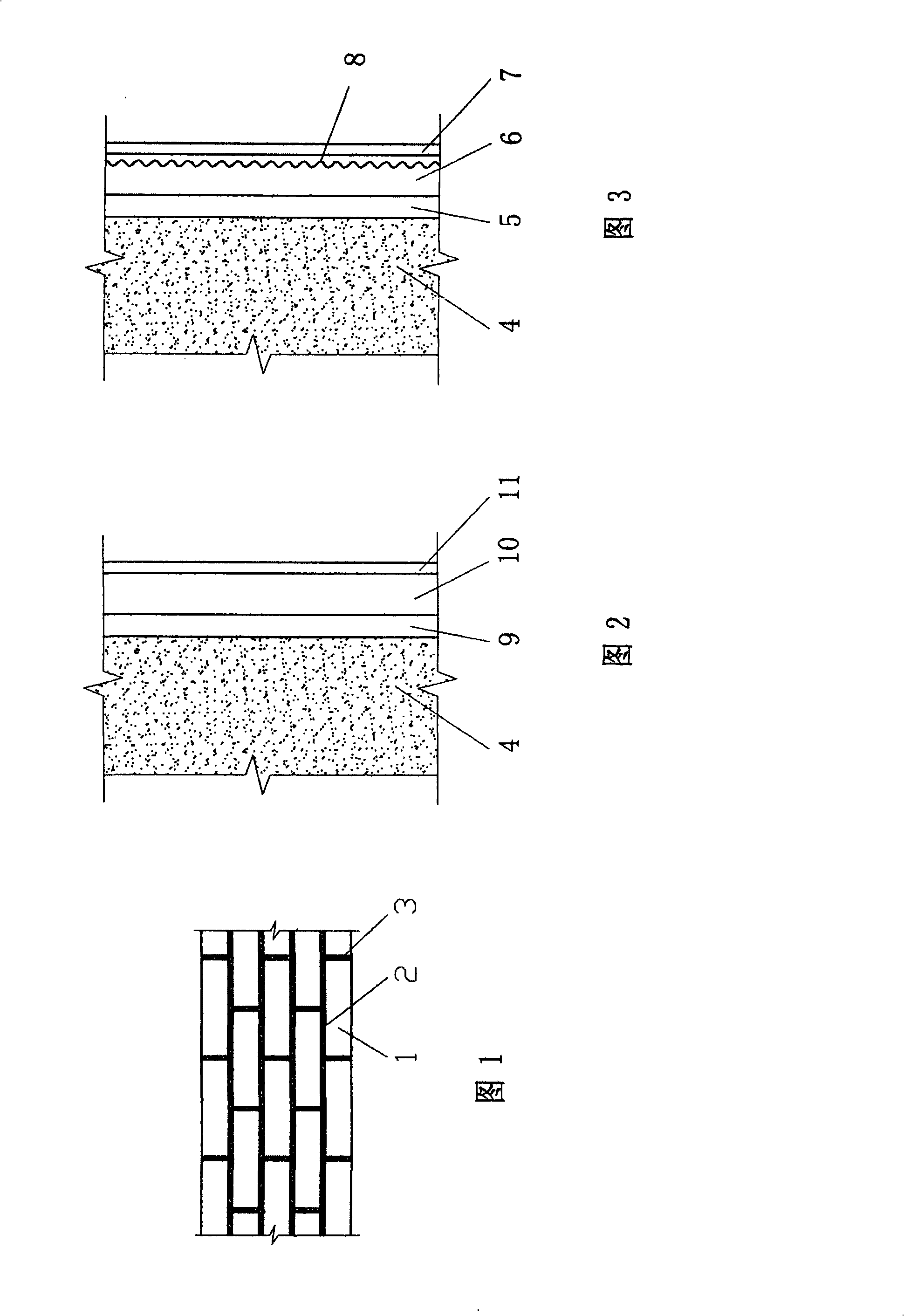

Heat insulating building blocks and producing method

InactiveCN101078281ASolve heat conductionAvoid cold bridge effectConstruction materialCeramic shaping apparatusEngineeringCold effects

The invention relates to a heat-insulation block for building wall, especially the heat-insulation block with energy saving and heat insulation performances applied for manufacturing outer wall, belonging to the building material. The production in invention is Z-shape. Heat-insulation core block is filled in the shell. The upper surface of said heat-insulation core block is lower than the heat-insulation block by 1-2cm. In using, it also comprises a sheet heat-insulation block embedded on the upper part of block partially. The shape of sheet heat-insulation block must obligate space to satisfy that it can insert into the upper part of heat-insulation block partially while the upper surface of sheet heat-insulation block is contacted with the bottom face of block in last layer in building wall directly. The merit of invention is that after the block in invention is adopted to build wall, the heat-insulation material crosses in wall so that not only heat exchange of portrait masonry joint in wall is solved but also heat exchange of transversal masonry joint in wall is solved; cold-effect effect generated by masonry joint is solved; when the product in invention is used there is no need to do heat-insulation treatment for outer wall furthermore and cost is saved.

Owner:石正

Wall surfacing template

A template assembly for use in the production of a variable depth building wall surface, which may be simulative of multiple units separated by mortar joints, such as a simulated brick, stone, tile, or mosaic surface. The template assembly is formed of a backing sheet which is releasably attached to a substrate formed of nonwoven spunbond polyester material, which may be fiberglass reinforced. The substrate is a unitary sheet having a plurality of upwardly extending strips connected by a plurality of sidewardly extending strips. The strips define a plurality of openings within which simulated building units may be formed. A first layer is applied to a wall surface, the template backing is removed and the template adhered to the first layer, and then a second layer is applied over the template. When the template is removed, those areas corresponding to the template strips will be recessed from the second layer.

Owner:DASA ENTERPRISES

Construction block

A modular construction block is adapted for being assembled together with a number of other blocks in stacked courses to form a wall. The construction block includes first and second opposing block faces, a top and bottom, and opposing ends. The first block face has a first plurality of vertical score lines. The second block face has a second plurality of vertical score lines. The first and second plurality of vertical score lines resemble respective mortar joints, whereby the assembled wall resembles a brick structure.

Owner:SHILLINGBURG CURTIS W

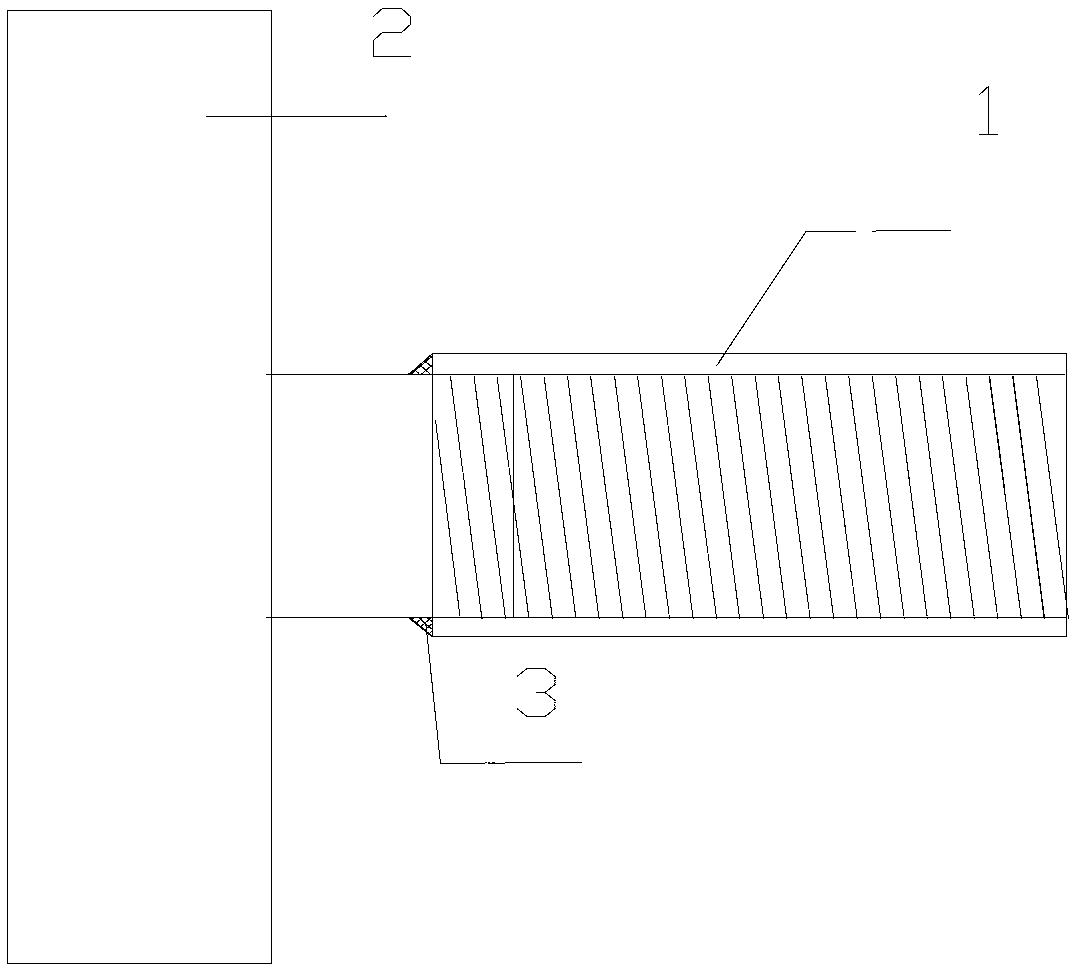

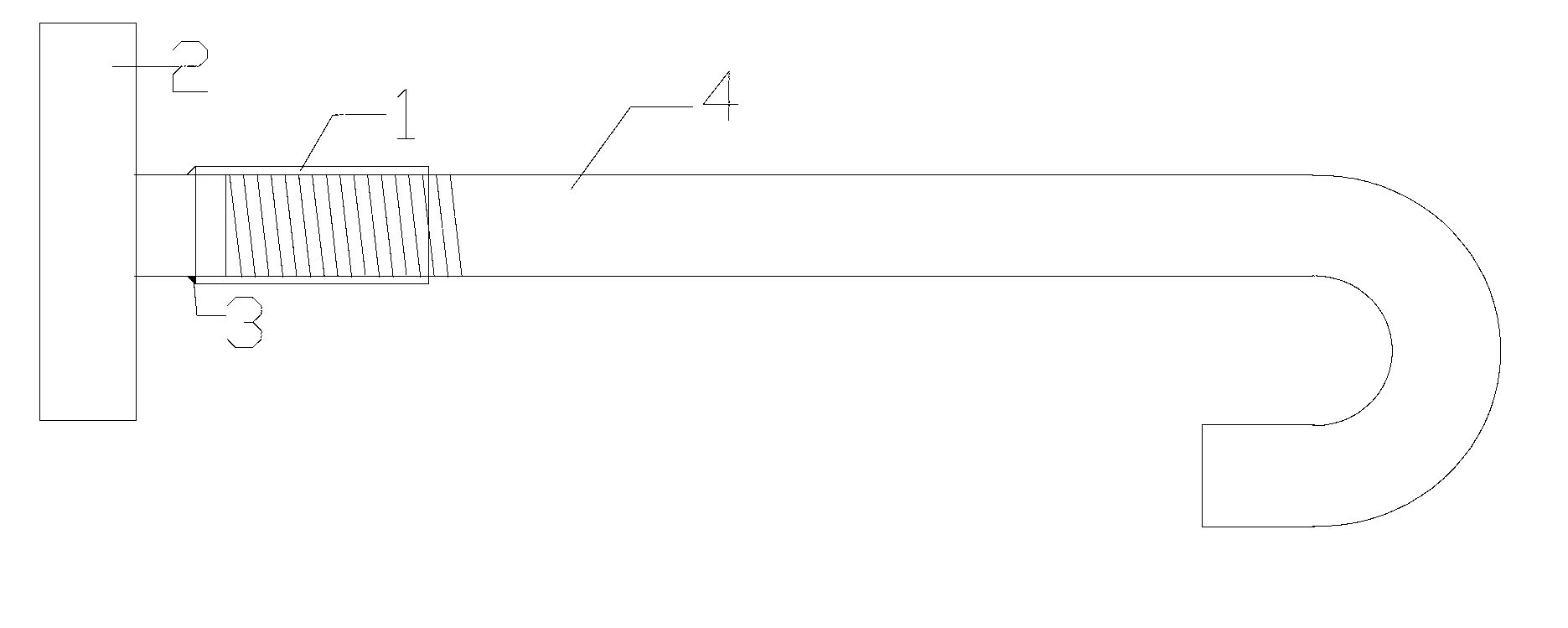

Construction method for planting wall lacing bars after pre-burying of sleeve assemblies

InactiveCN103015735AReliable mechanical propertiesEasy to operateBuilding material handlingScrew threadTorque wrench

The invention discloses a construction method for planting wall lacing bars after pre-burying of sleeve assemblies. The method comprises the following steps of: (1) welding sleeves on straight bars of T-shaped mechanical anchorage ribs by using an electric welding machine to form sleeve assemblies, wherein screw threads are formed in the sleeves; (2) before pouring concrete onto a concrete structure, pre-burying the sleeve assemblies into wall lacing bar positions on the concrete structure according to design requirements, and screwing a plugging plastic bolt on the end part of each sleeve; (3) after concrete pouring on the concrete structure is completed, unscrewing the plugging plastic bolts on the end parts of the sleeves, screwing the wall lacing bars into the sleeves, tightening the wall lacing bars with the sleeves by using a spanner, checking qualification by using a torque spanner, and connecting the wall lacing bars and the sleeves into a whole through screw threads; and (4) during building of a later-built wall body, placing the wall lacing bars into mortar joints of the later-built wall body, and bonding the wall lacing bars together with the concrete structure reliably. The method is easy to operate; and the wall lacing bars can be placed into the mortar joints of the later-built wall body to be reliably bonded with the concrete structure.

Owner:CHINA CONSTR SIXTH ENG BUREAU CIVILENG +1

Building block compositely filled with phase change material and thermal insulation material

InactiveCN102535730AComfortable indoor environmentImprove insulation effectConstruction materialWallsThermal bridgeEngineering

The invention discloses a building block compositely filled with a phase change material and a thermal insulation material, and belongs to the technical field of preparation of building materials. Two grooves with the same size are formed on the two sides of the building block; four rectangular through holes are formed in the building block, are formed in an upper row, a middle row and a lower row and are staggered from one another; two through holes with the same size are formed in the upper row; one through hole and the two grooves are formed in the middle row; one long through hole is formed in the lower row; an inorganic thermal insulation material is filled in the two through holes in the upper row and the through hole in the middle row; and a phase change material capsule bonding plate is filled in the through hole in the lower row. The building block compositely filled with the phase change material and the inorganic thermal insulation material has high temperature regulation and energy storage performance, thermal insulation performance and fireproof performance, and a heat bridge of a mortar joint between every two adjacent building blocks can be reduced due to the design of the grooves.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

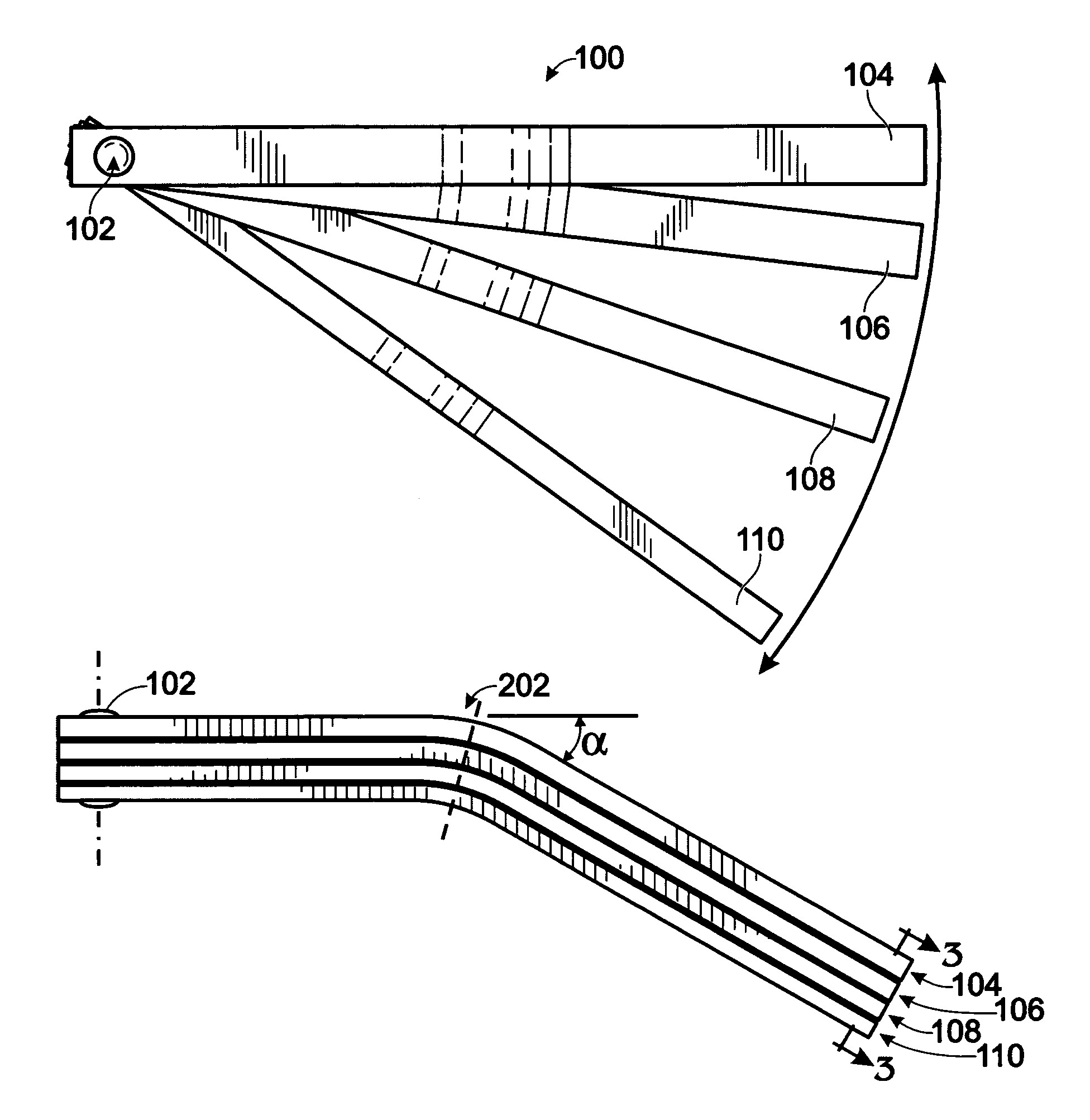

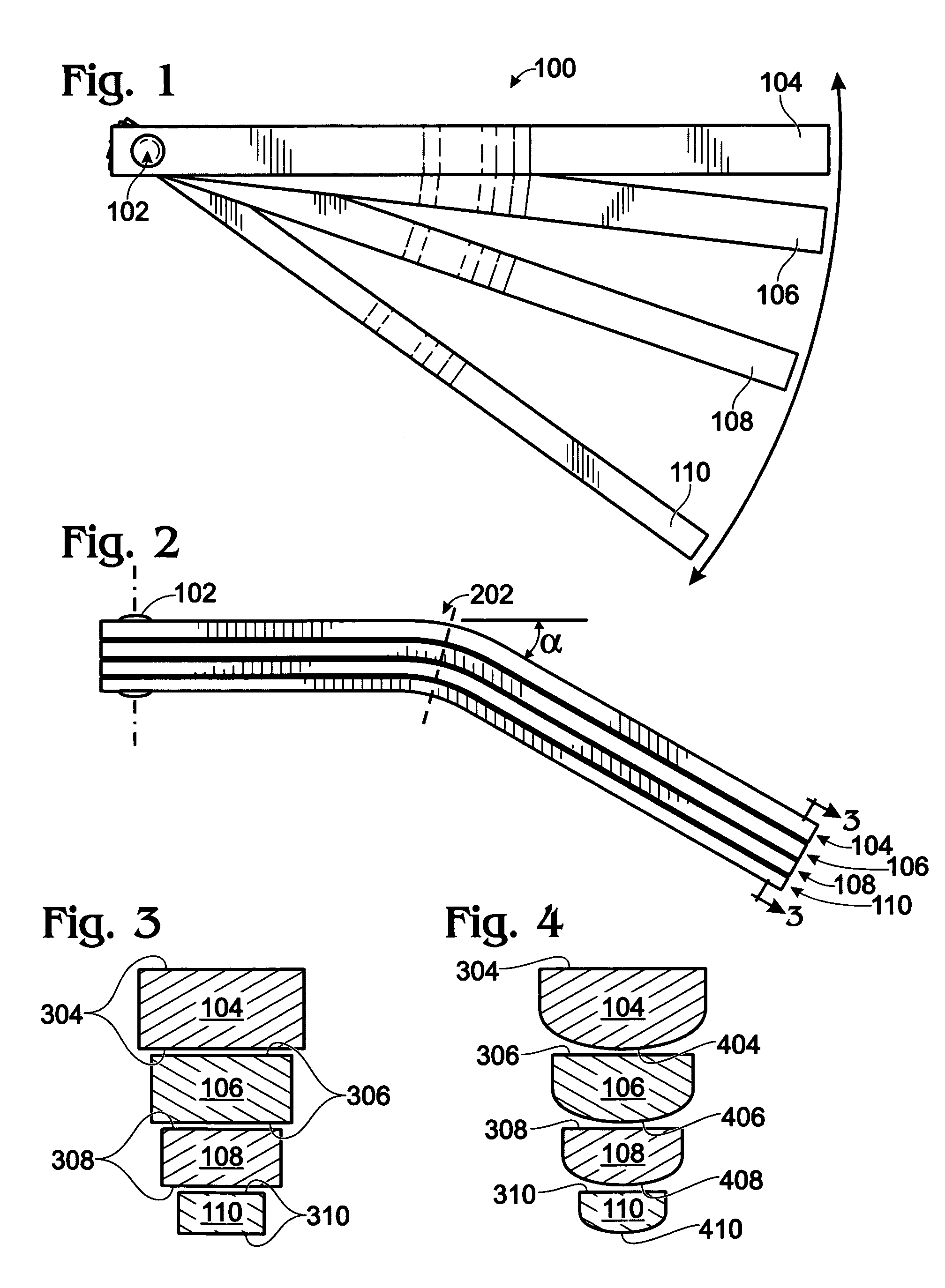

Tuck point tool

InactiveUS7047588B2Reduce manufacturing costConveniently small enough to storeMeasurement devicesBuilding material handlingGroutMortar joint

A masonry tuck point tool has a plurality of tuck blades pivotally attached at one end. Among the tuck blades is a selected tuck blade that has the desired width of the grout or mortar joint to be formed. There are also at lease one remaining tuck blade. All tuck blades have a distinct blade width and similar blade lengths. The selected tuck blade is pivoted approximately 180 degrees away from the remaining tuck blades thereby allowing the remaining tuck blades to be used as a handle at the one end while the opposite end of the selected tuck blade is used to strike a grout or mortar joint between two adjacent masonry elements.

Owner:BENNETT HARRY

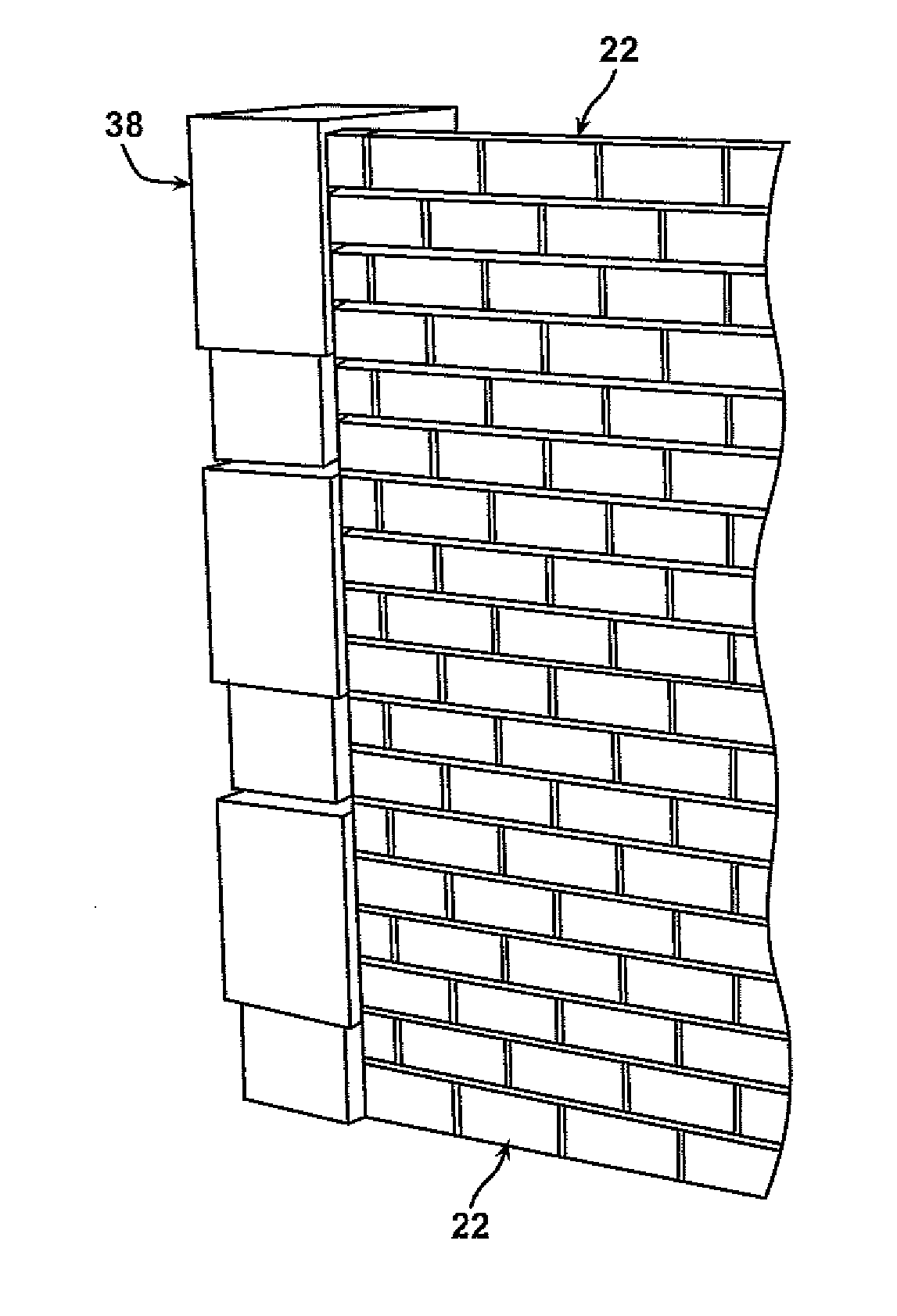

Over-Mount Corner

ActiveUS20090235596A1The process is convenient and fastCovering/liningsNatural patternsBraced frameEngineering

A quoin formed of individual over-mount corner units constructed as simulated brick to match the adjoining wall panels forming the exterior cover of an exterior wall of a building is provided. The corner units are formed with a front portion configured as courses of brick separated by mortar joints joined to a rear plate that provides a support frame for the corner unit. Multiple standoffs are positioned on the rear plate opposite mortar joints formed on the front portion to provide a location for driving fasteners to mount the corner unit onto the building substructure. The overlapping nature of the corner units with respect to the wall panels allows the wall panels to be cut imprecisely at the exterior corner. The standoffs maintain a predetermined spacing between the building substructure and the rear plate to establish a channel for the drainage of moisture due to condensation or rain infiltration.

Owner:BORAL STONE PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com