Weep venting system for masonry walls

a technology for venting systems and masonry walls, applied in the direction of walls, construction, building components, etc., can solve the problems of not being able to easily pull out masonry walls, and moving forward, and achieve the effect of efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

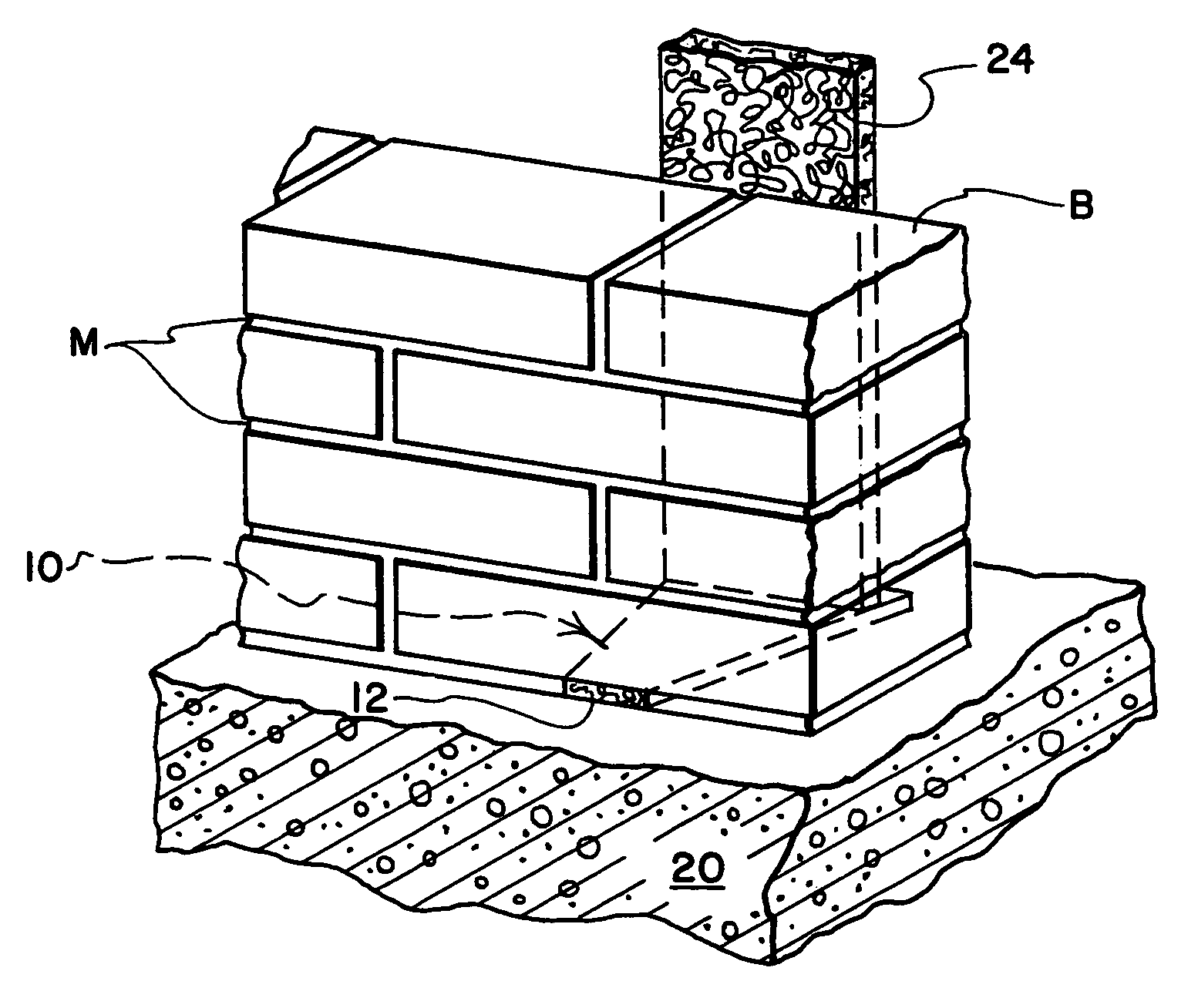

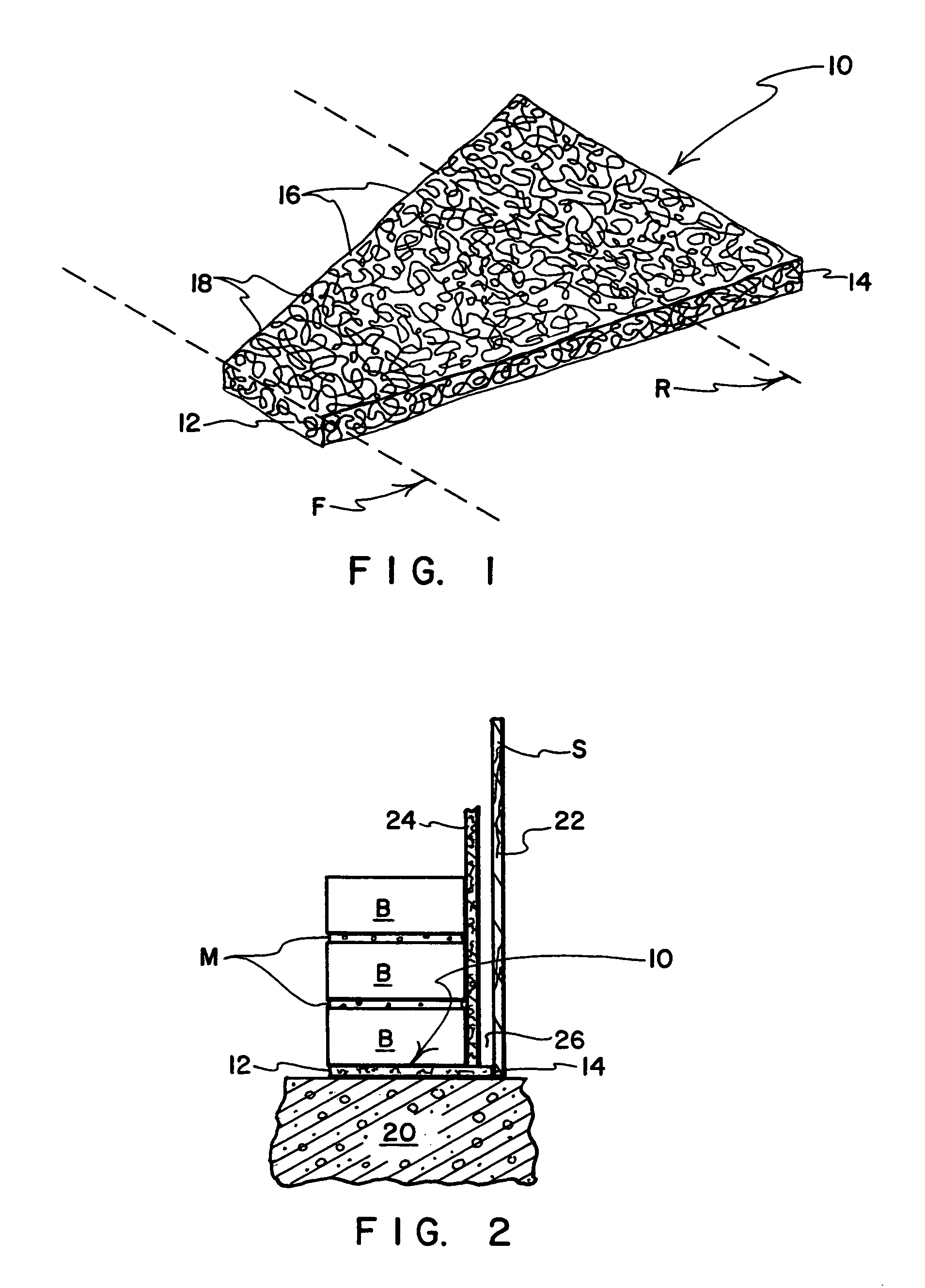

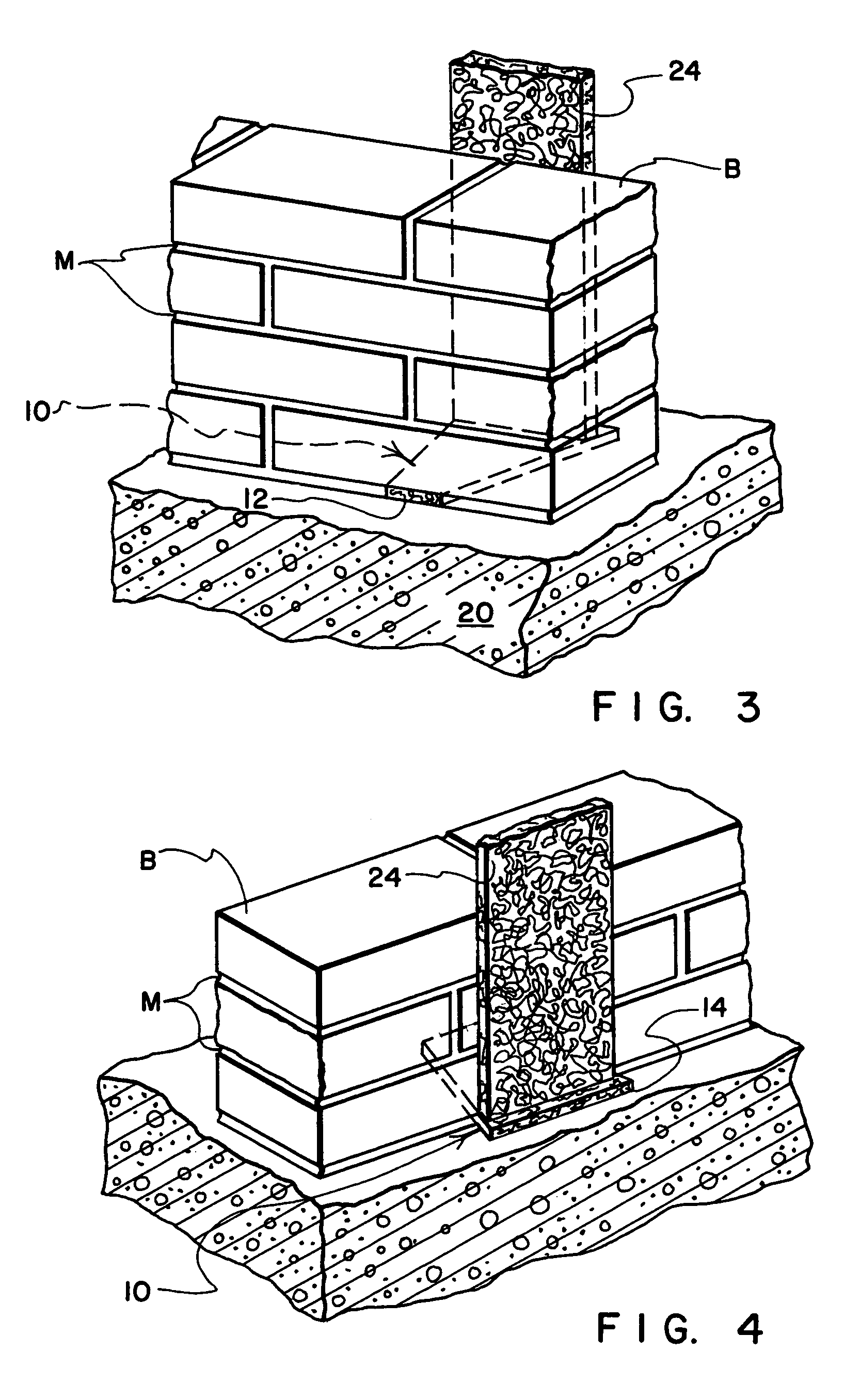

[0011]Referring to the drawings, there is shown in FIG. 1 at 10 the subject weep vent in a preferred form for utilization. In the form shown, the weep vent 10 is generally trapezoidal or as a truncated triangle as shown in phantom lines. The weep vent 10 has a narrower forward end region 12, and a wider rearward end region 14. While a trapezoidal shape is preferred due to the efficiency with which weep vent members of this type can be cut from a sheet of bonded filament material, a feature that resides at the heart of the invention is the provision of a weep vent member that has a wider inner, rear or interior end region and a relatively narrower outer, front or exterior end region, and that therefore narrows in cross-section as the member extends from its inner, rear or interior end region toward its outer, front or exterior end region.

[0012]The weep vent 10 is formed from an intertangled mass of filaments, strands or strips 16. The many filaments, strands or strips that form the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com