Patents

Literature

1561 results about "Artificial stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial stone is a name for various synthetic stone products produced from the 18th century onward. Uses include statuary, architectural details, fencing and rails, building construction, civil engineering work, and industrial applications such as grindstones.

Inorganic binders employing waste glass

InactiveUS6296699B1Improve processingHighly moldableCovering/liningsAlkali metal silicate coatingsSodium silicateArtificial stone

The present invention relates to a binder composition comprising a glass powder with a particle size of at least less than 0.15 mm and an alkali activator containing at least one alkali metal and at least one silicate. Preferably, a sodium silicate with a SiO2:Na2O weight ratio between about 1.6:1 to about 2.0:1. Mixed with water, the binder composition can be cured at ambient temperature, but rapidly yields a very high strength at an elevated temperature between about 40° C. to about 120° C. Preferably, between about 70° C. to about 90° C. The invention further provides a method of making artificial stone using glass as a sole binder and aggregate.

Owner:JIN WEIHUA

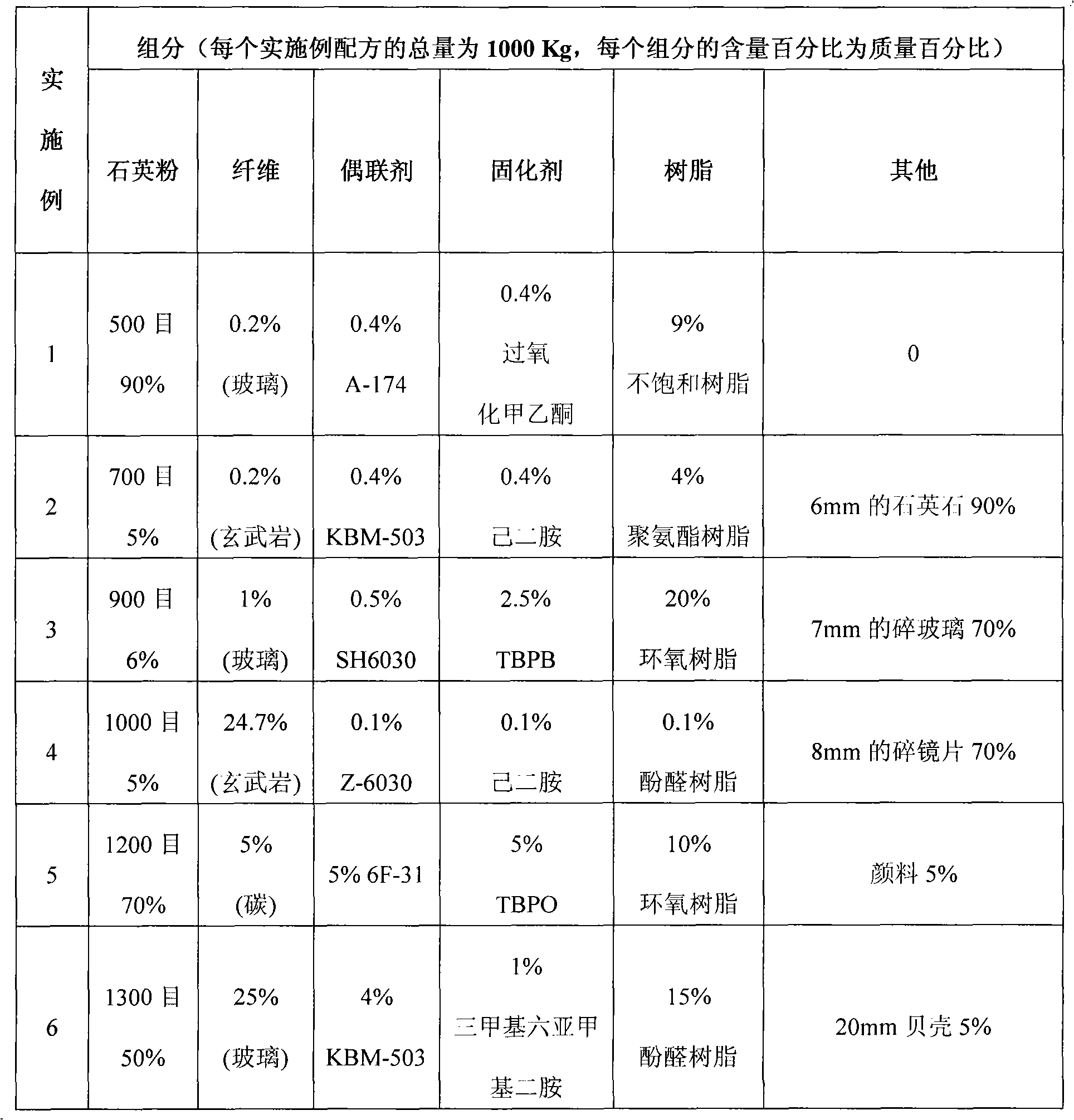

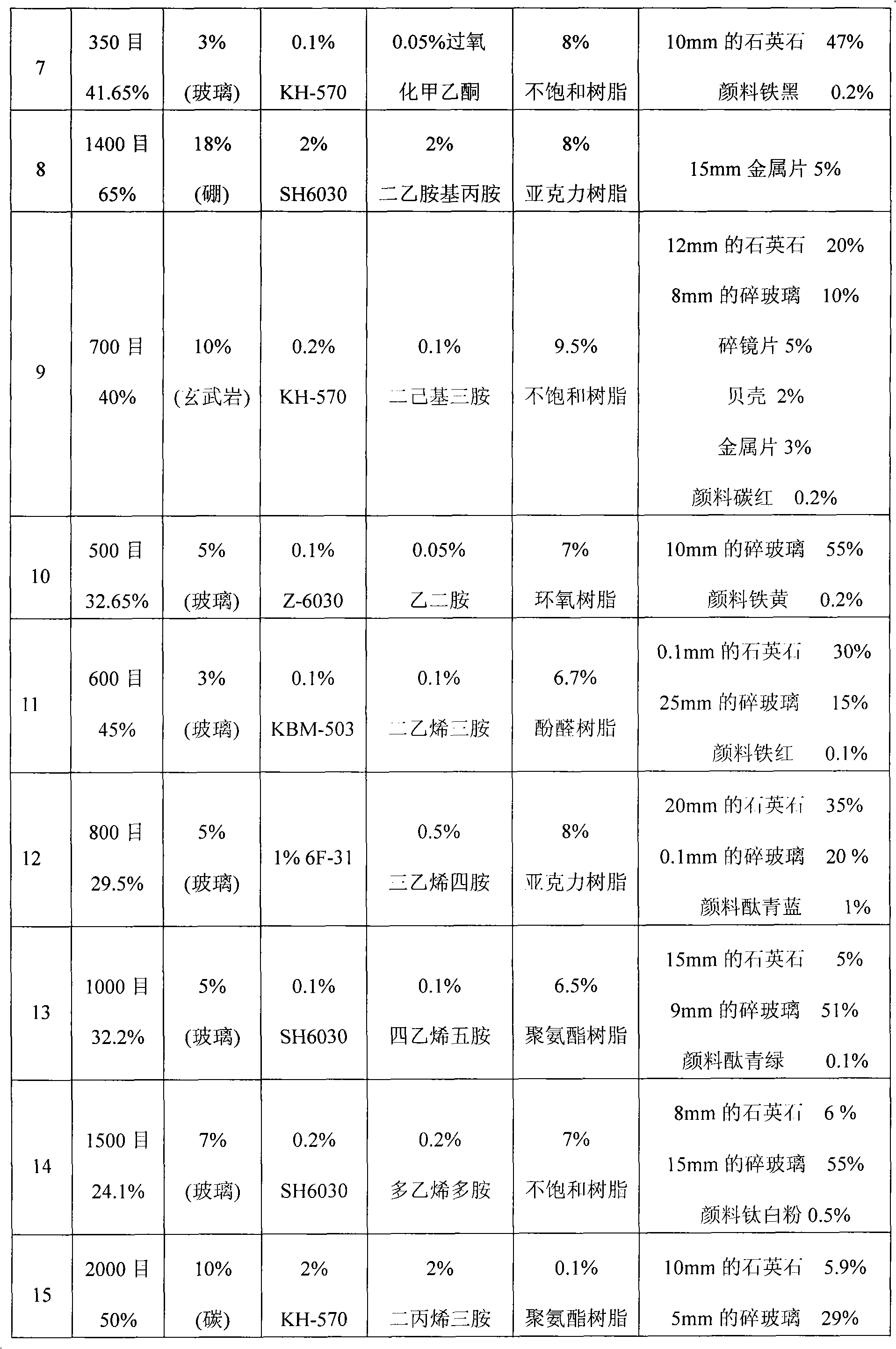

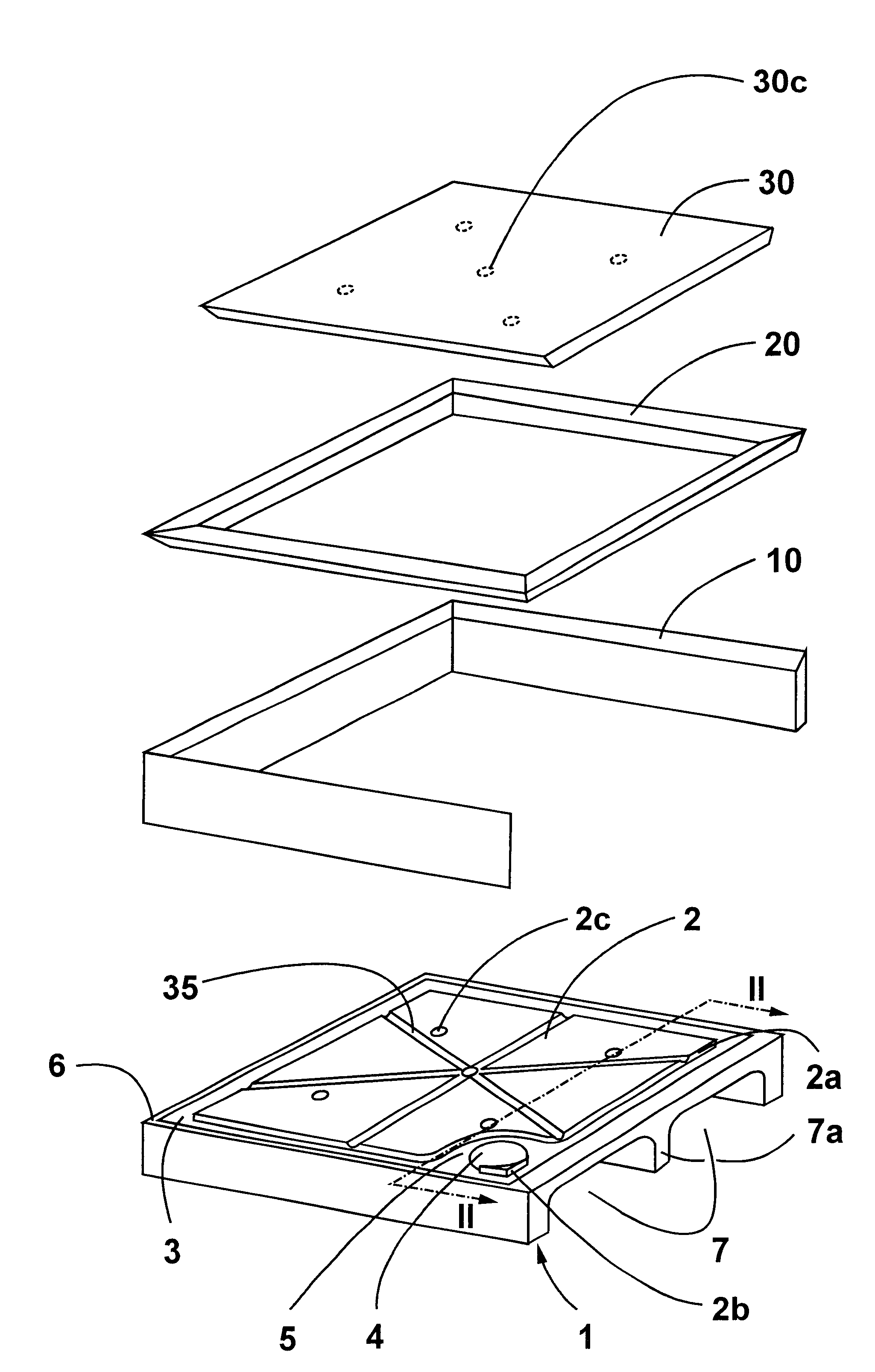

Artificial quartz in lump and fabrication technology thereof

The invention discloses a man-made quartz stone, which comprises 0 to 90 percent of quartz stone, 5 to 90 percent of silica flour, 1 to 25 percent of fiber, 0.1 to 20 percent of resin, 0.1 to 5 percent of a coupling agent, 0.1 to 5 percent of a curing agent, 0 to 70 percent of cullet, 0 to 70 percent of broken glass block, 0 to 5 percent of paint, 0 to 5 percent of shell, 0 to 5 percent of metal sheet by mass. The tear resistance, the compressive strength and the buckling strength of the man-made quartz stone are significantly improved compared with the prior man-made quartz stone. The invention further relates to a manufacturing process for a man-made quartz stone plate or block and vessel.

Owner:张璐 +1

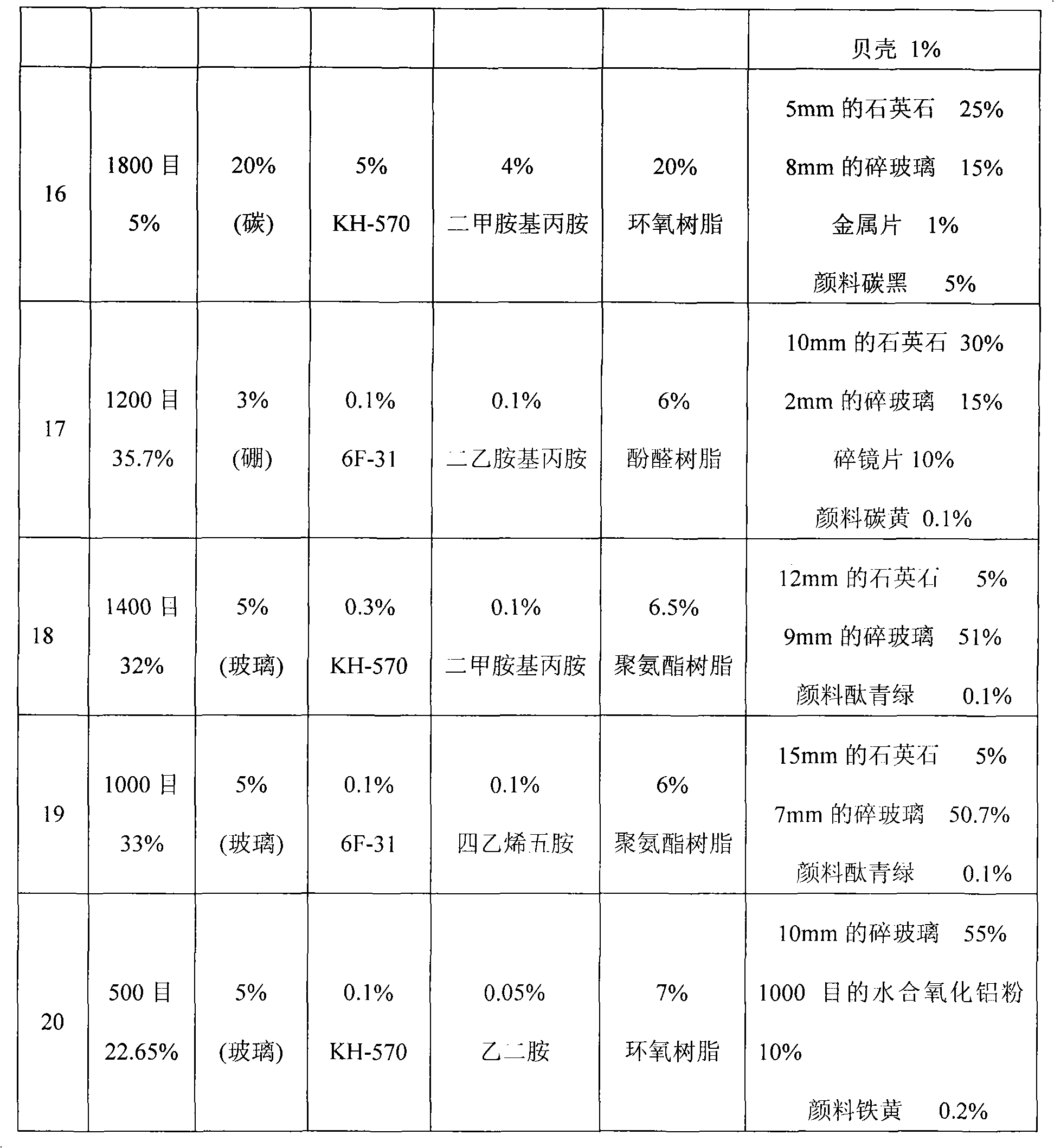

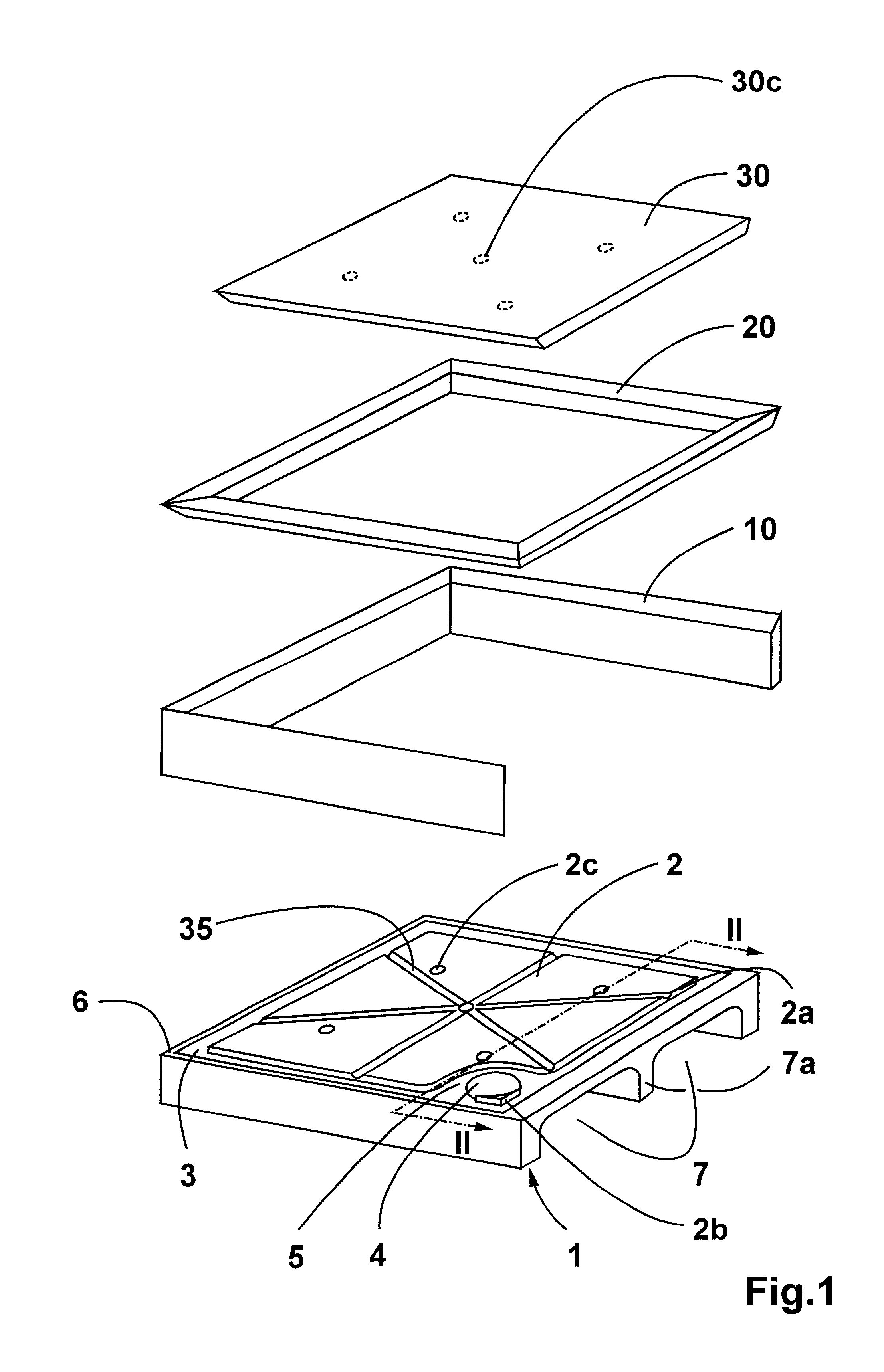

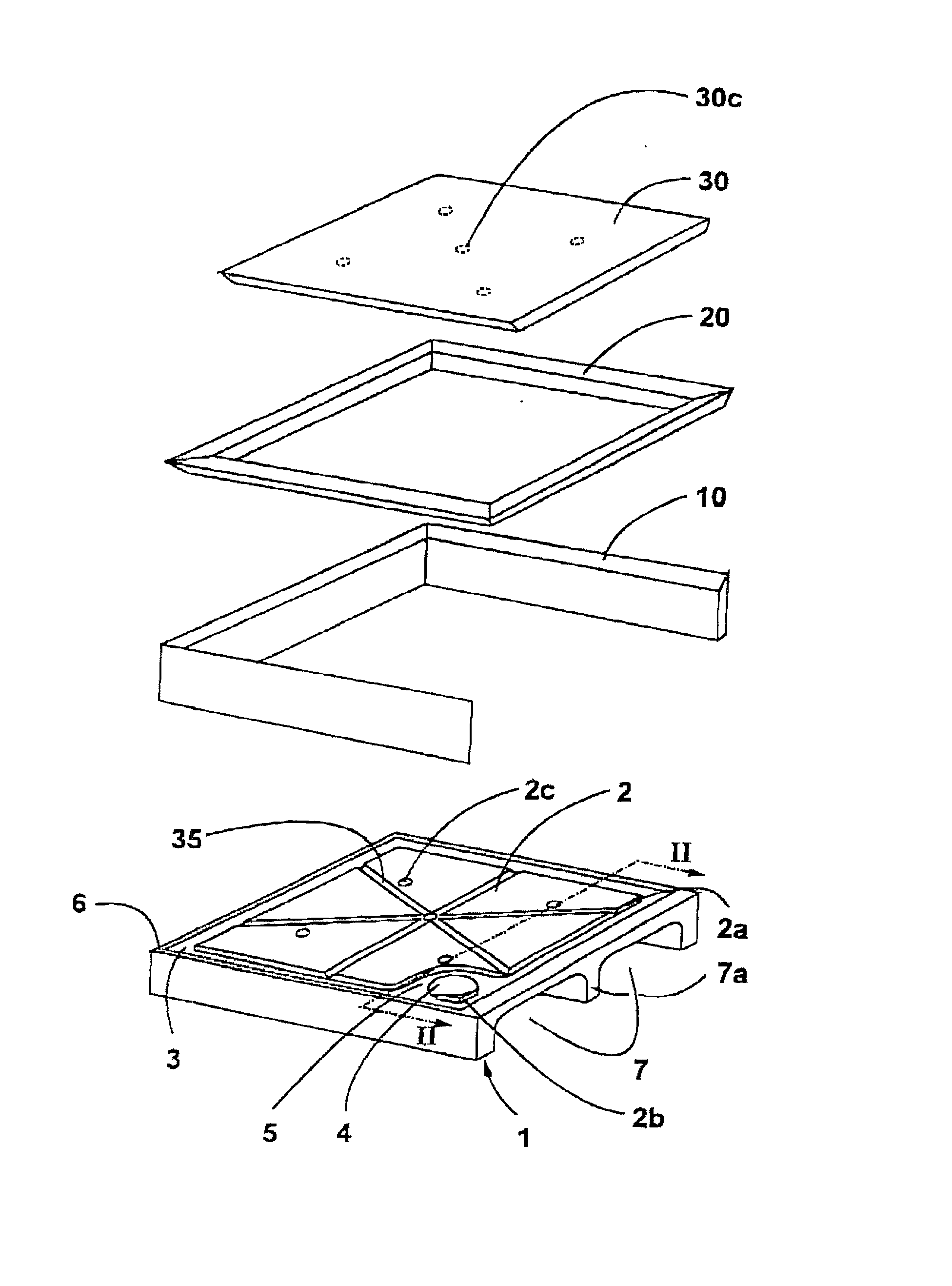

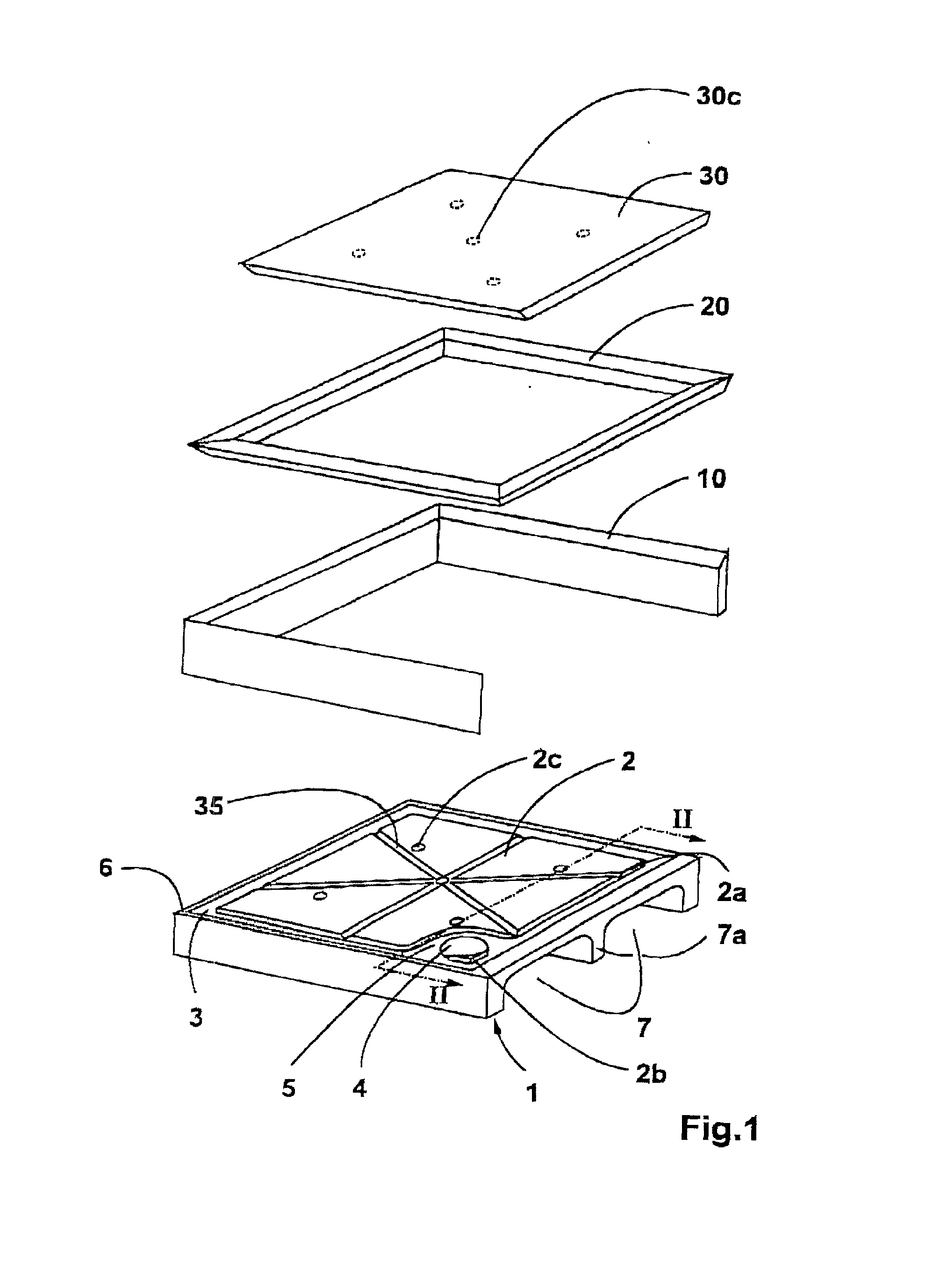

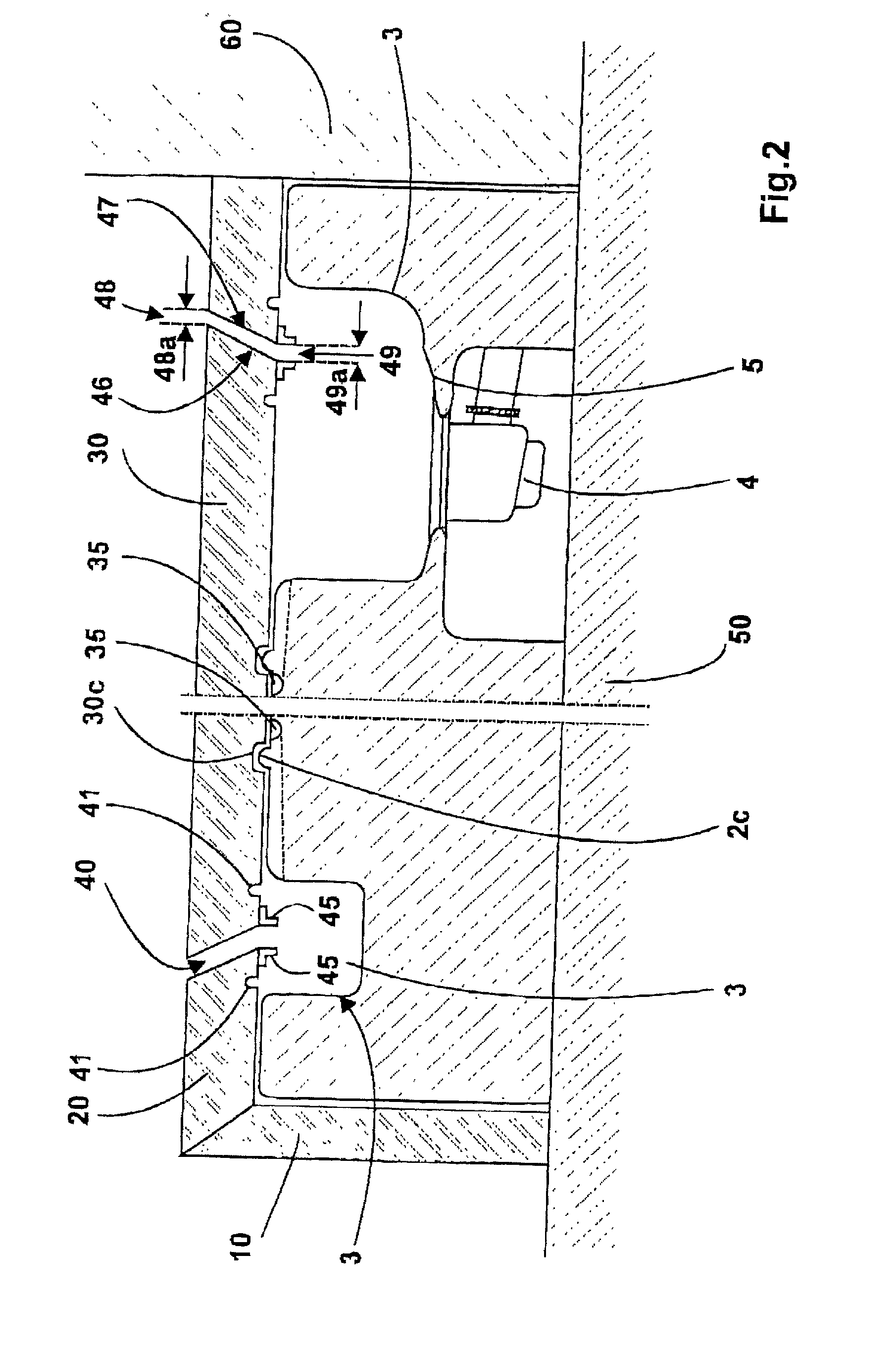

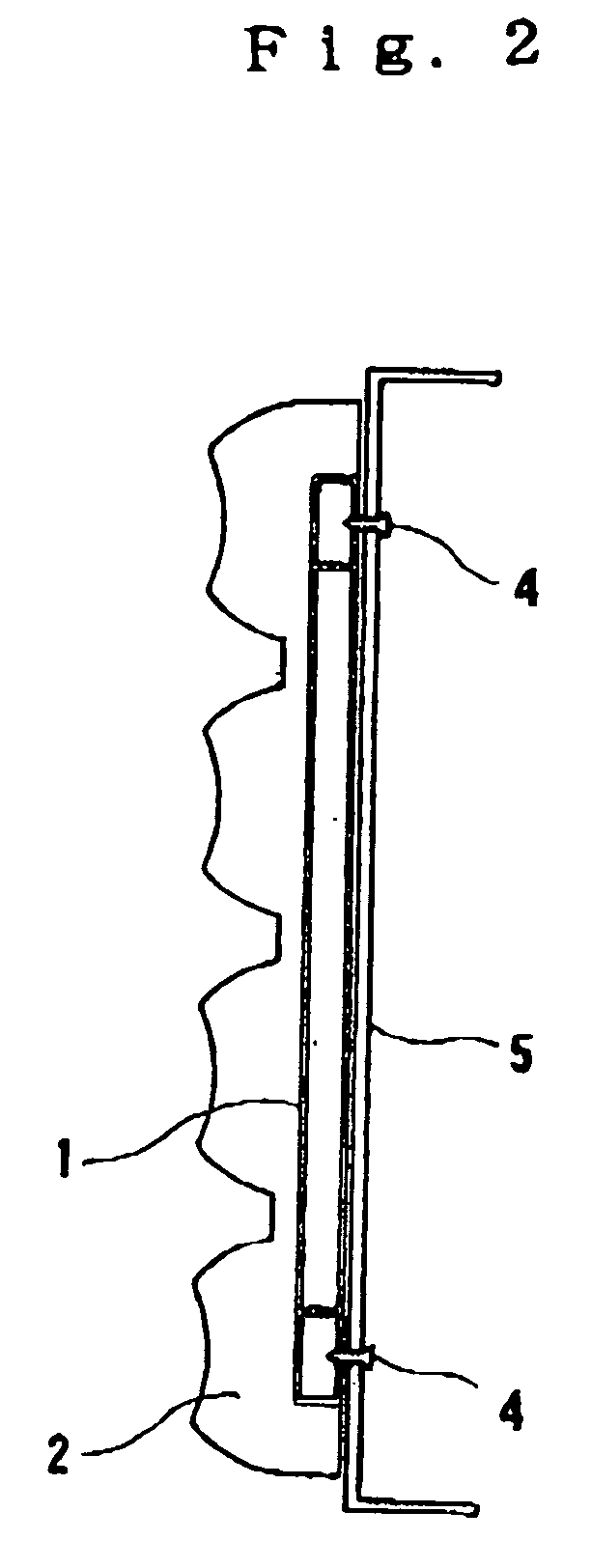

Supporting body for a shower tub

Supporting body (1) being part of a shower tub made of stone, tiles or artificial stone and comprising at least one landing (2) that is surrounded by a margin (6), a channel (3) discharging into a drain (4).

Owner:GERLOFF MICHAEL

Noctilucent or fluorescent artificial stone composition

InactiveUS6136226AImprove liquidityNo lossLuminescent compositionsArtificial stoneInorganic materials

PCT No. PCT / JP97 / 00681 Sec. 371 Date Dec. 31, 1998 Sec. 102(e) Date Dec. 31, 1998 PCT Filed Mar. 5, 1997 PCT Pub. No. WO98 / 39268 PCT Pub. Date Sep. 11, 1998Provided is a luminous or fluorescent artificial stone composition in which the resin content is 11% by weight or less, from 0.3 to 1.0 W1 of a weight (W1) of a fine powder component of an inorganic material having a size of from 10 to 70 mesh is a fine powder component of a transparent inorganic material, and a weight (W2) of a finely divided component of an inorganic material having a size of 100 mesh-under and a weight (W3) of a luminous or fluorescent component of 100 mesh-under have the following relationshipW1:(W2+W3)=1:2 to 5:1W2:W3=1:2 to 5:1.

Owner:DOPPEL

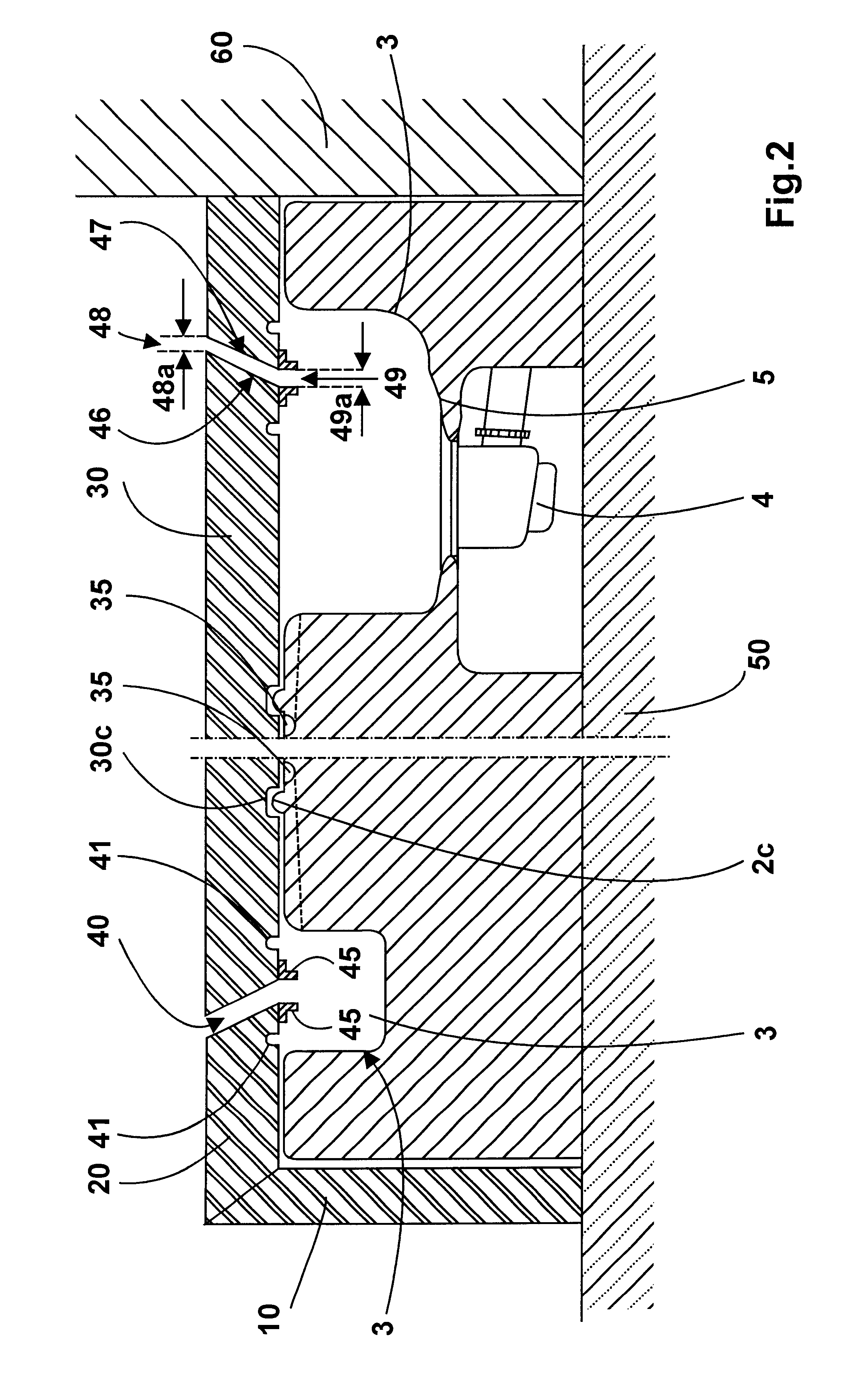

Artificial stone

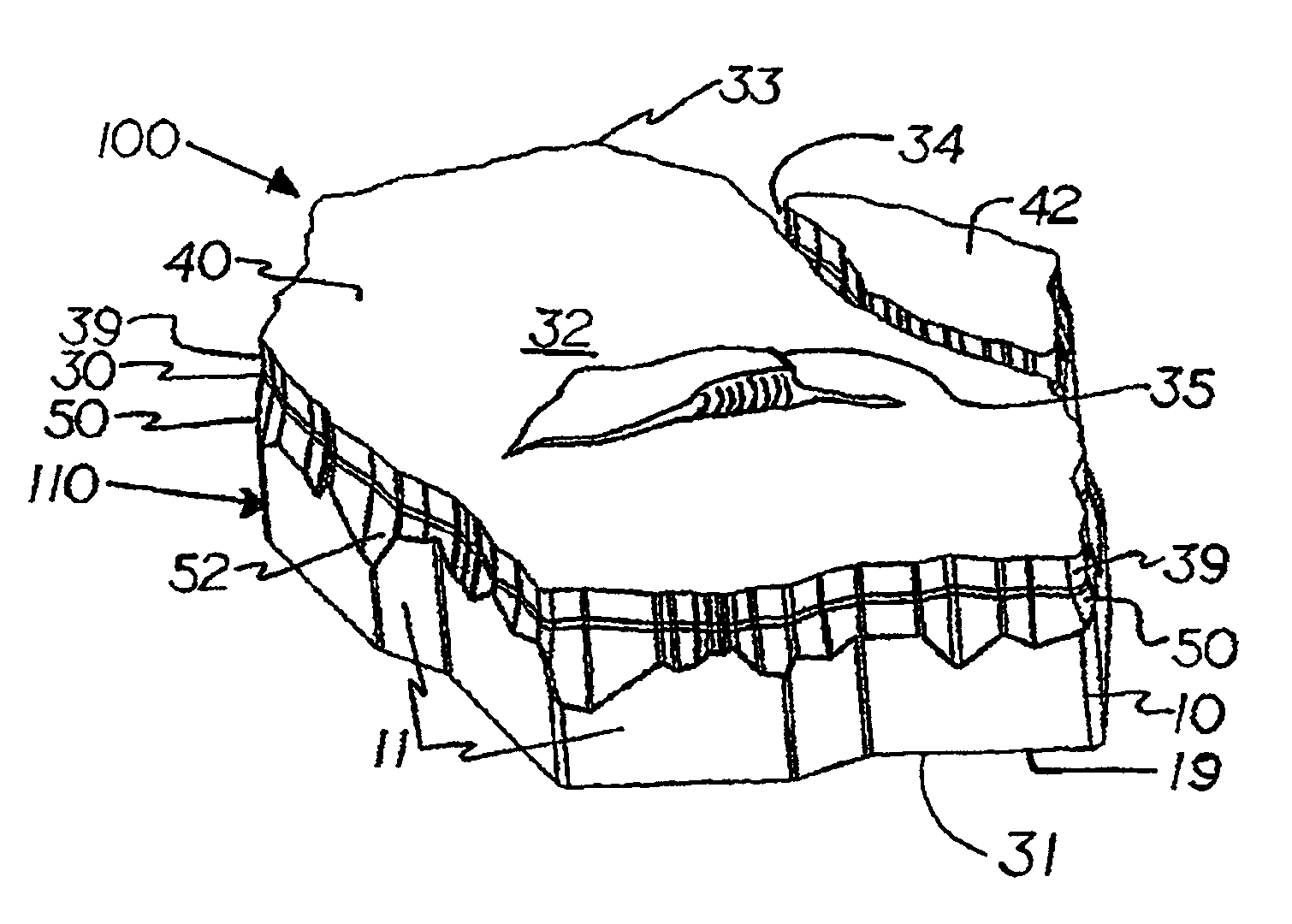

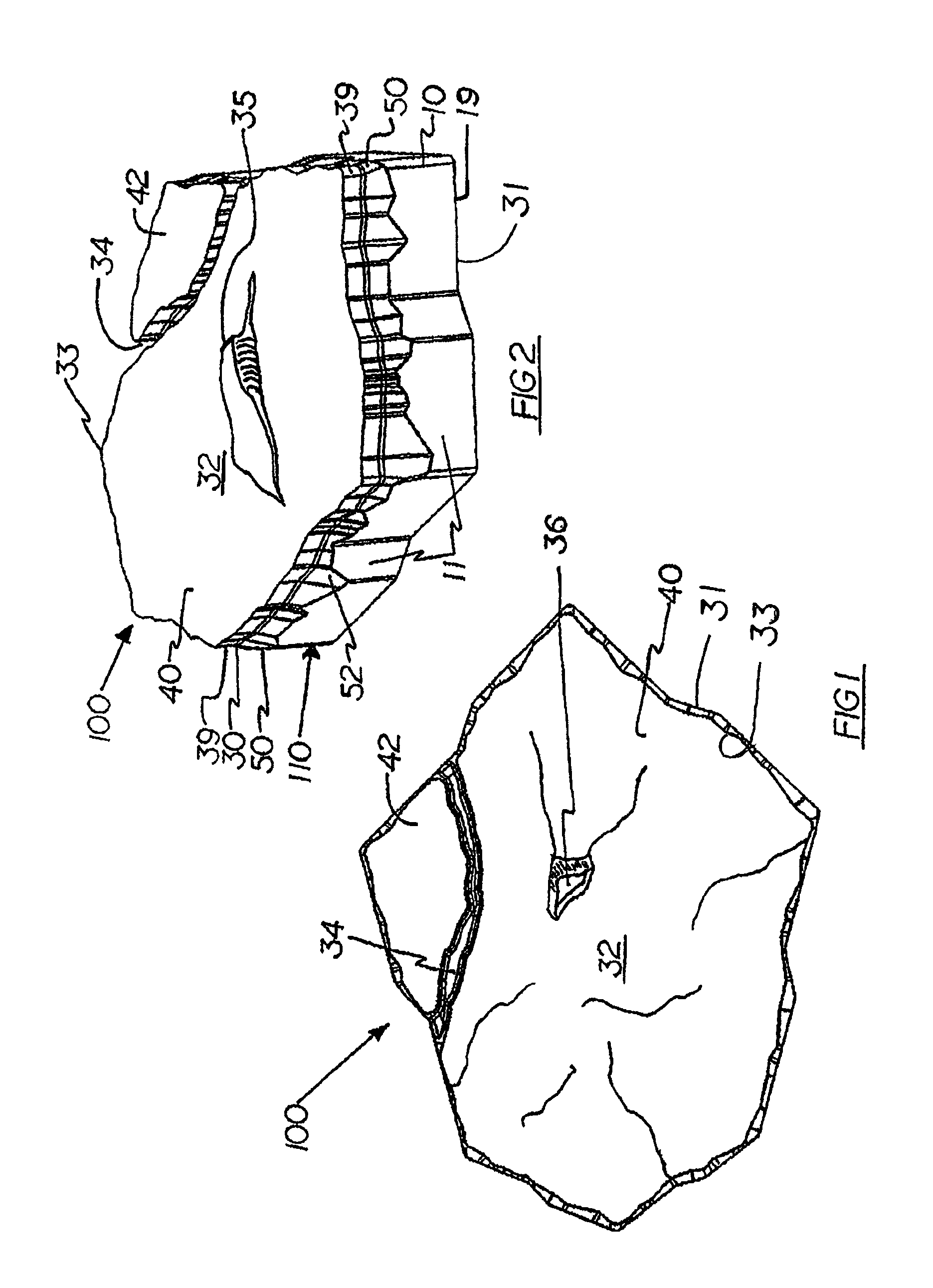

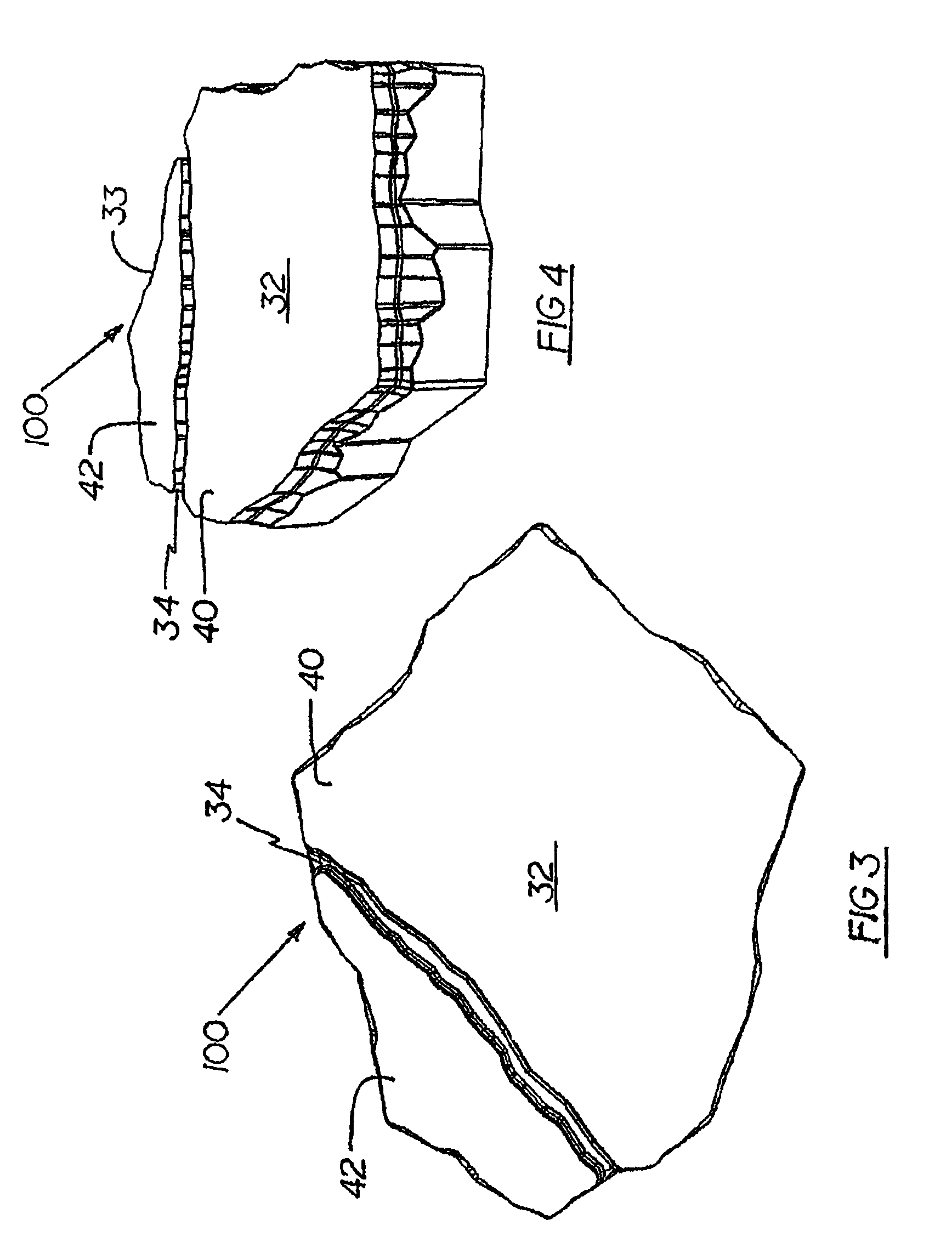

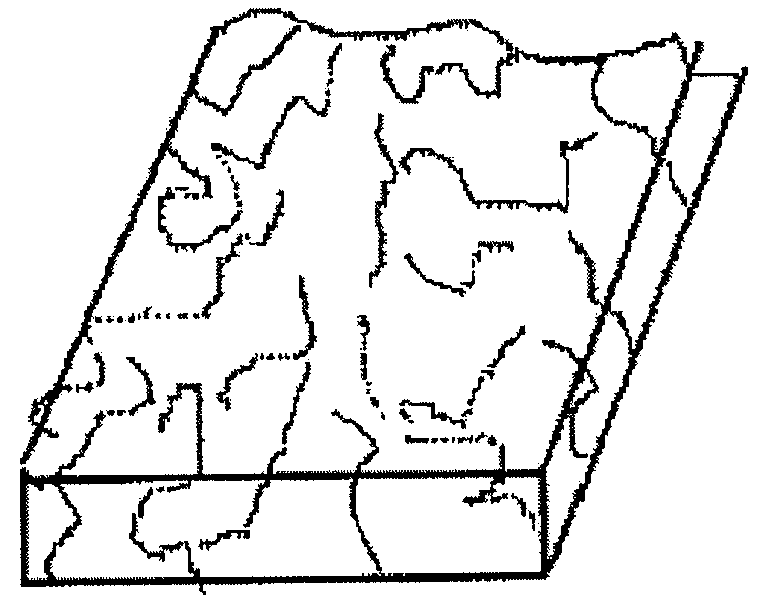

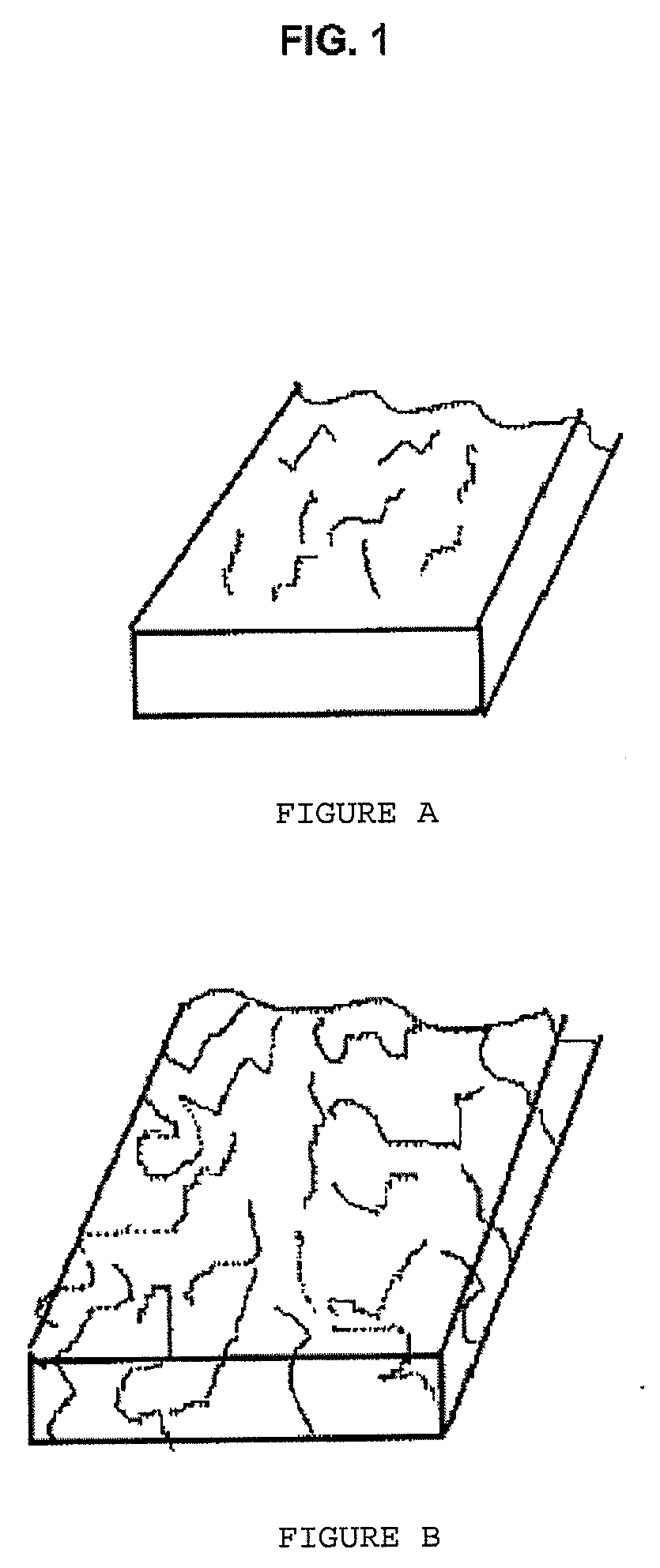

ActiveUS20110067333A1Enhance natural appearanceLarge widthCovering/liningsNatural patternsRepeat patternEngineering

An artificial stone is disclosed for use in creating a covering for a supporting surface. The artificial stone includes a body for placement on the supporting surface, which is shaped for mating engagement with like stones with intermediate perimeter joints to produce a continuous surface covering. The stone has a facing surface on the body, which facing surface has a contour defining a surface area and is subdivided by at least one simulated joint into a major surface portion and at least one minor surface portion. The major surface portion is free of simulated joints and extends over at least about 60% of the total surface of the facing surface. The stone further includes at least one perimeter recess in the body for generating a gap between the stone and another like stone in mating engagement therewith, which gap is wider than adjacent the adjoining perimeter joint. Stones of this construction can easily be arranged in a regular, repeated pattern to generate a continuous covering for the supporting surface with the surface of the resulting covering having an irregular, natural appearance. The irregular top contours of the stones, the uneven division of the facing surface and the perimeter recesses and the resulting gaps between mating stones simulate the appearance of a natural stone surface covering for walkways, roadways, pavements or walls.

Owner:OLDCASTLE BUILDING PROD CANADA INC

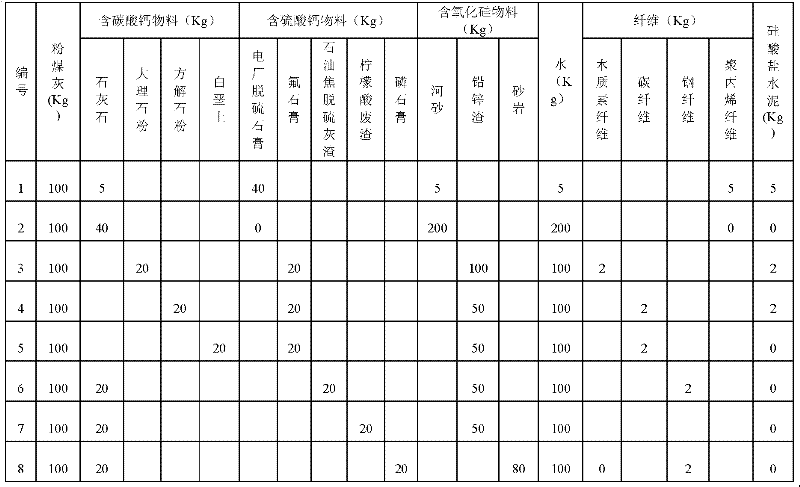

Inorganic artificial combining stone and preparation method thereof

InactiveCN102557571AExpand raw material resourcesLow costCeramic shaping apparatusCement productionFiberKaolin clay

The invention discloses inorganic artificial combining stone and a preparation method thereof. The artificial combining stone uses silicon acid-base solution to arouse metakaolin to react and generate geopolymer to serve as an inorganic cementing agent, and the artificial combining stone mainly contains the metakaolin, the silicon acid-base solution, natural stone aggregate, decoration aggregate, a thickening time control agent, inorganic pigment and fibers. The preparation method is firstly enabling the thickening time control agent and the inorganic pigment to be dissolved in the silicon acid-base solution to obtain mixed serous fluid, evenly blending the metakaolin, the natural stone aggregate, the decoration aggregate, the fibers and the mixed serous fluid, preparing the artificial combining stone through model entering or material distribution, vibration under the vacuum condition, molding in a pressing mode, maintaining, cutting, polishing, burnishing and surface protection. The artificial combining stone not only has decoration features which can be equal to that of resin artificial stone, but also is non-toxic, environment-friendly, low in cost, resisting in corrosion of most majority of acid-base salts, durable in high temperature and excellent in durable performance, obviously avoids whiting and saltpetering phenomena after a long time use, and is strong in pollution resisting capability.

Owner:SOUTH CHINA UNIV OF TECH

Supporting body for a shower tub

InactiveUS20020066140A1Precise positioningEffectively preventBathsDouchesEngineeringArtificial stone

Supporting body (1) being part of a shower tub made of stone, tiles or artificial stone and comprising at least one landing (2) that is surrounded by a margin (6), a channel (3) discharging into a drain (4).

Owner:GERLOFF MICHAEL

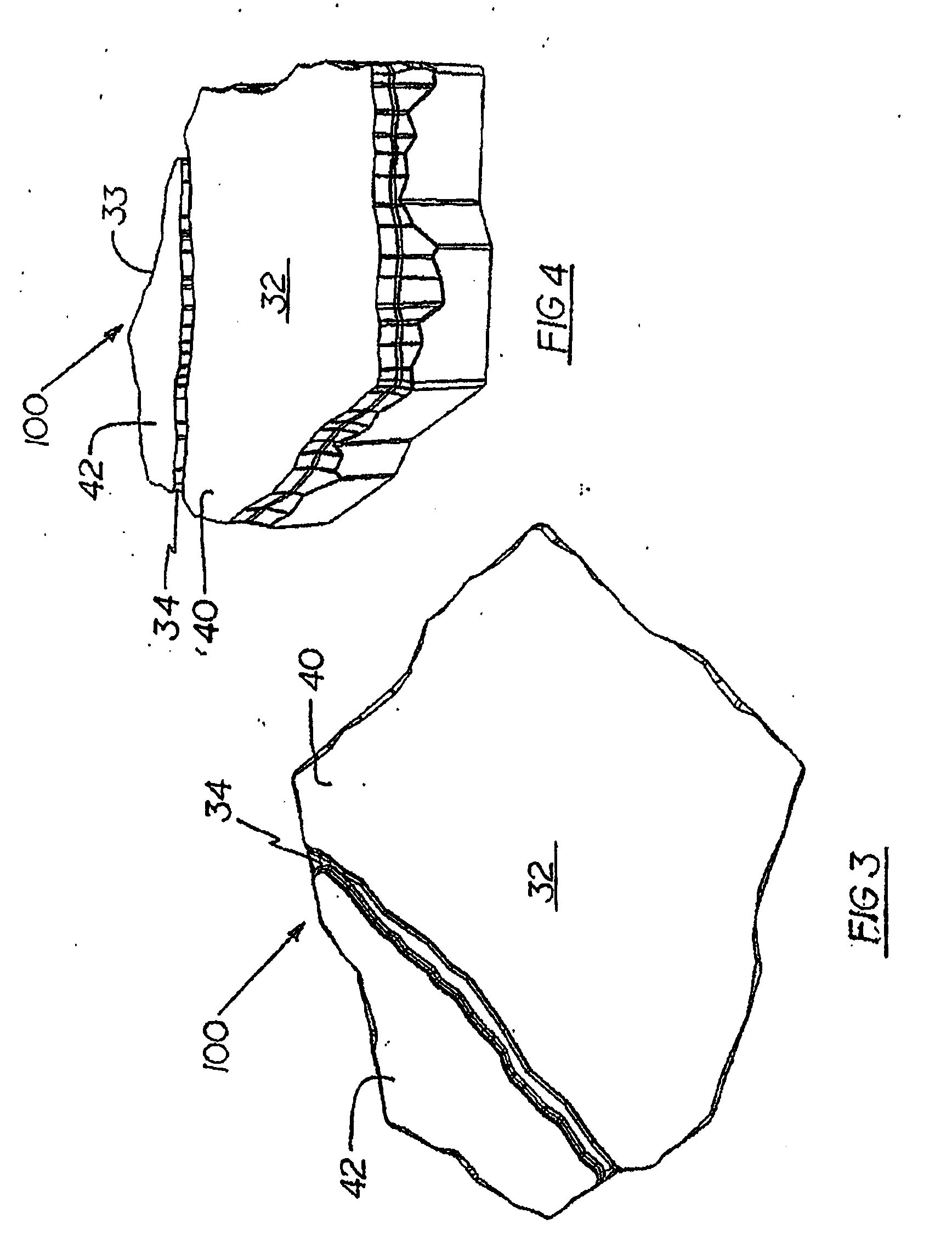

Artificial stone

Owner:OLDCASTLE BUILDING PROD CANADA INC

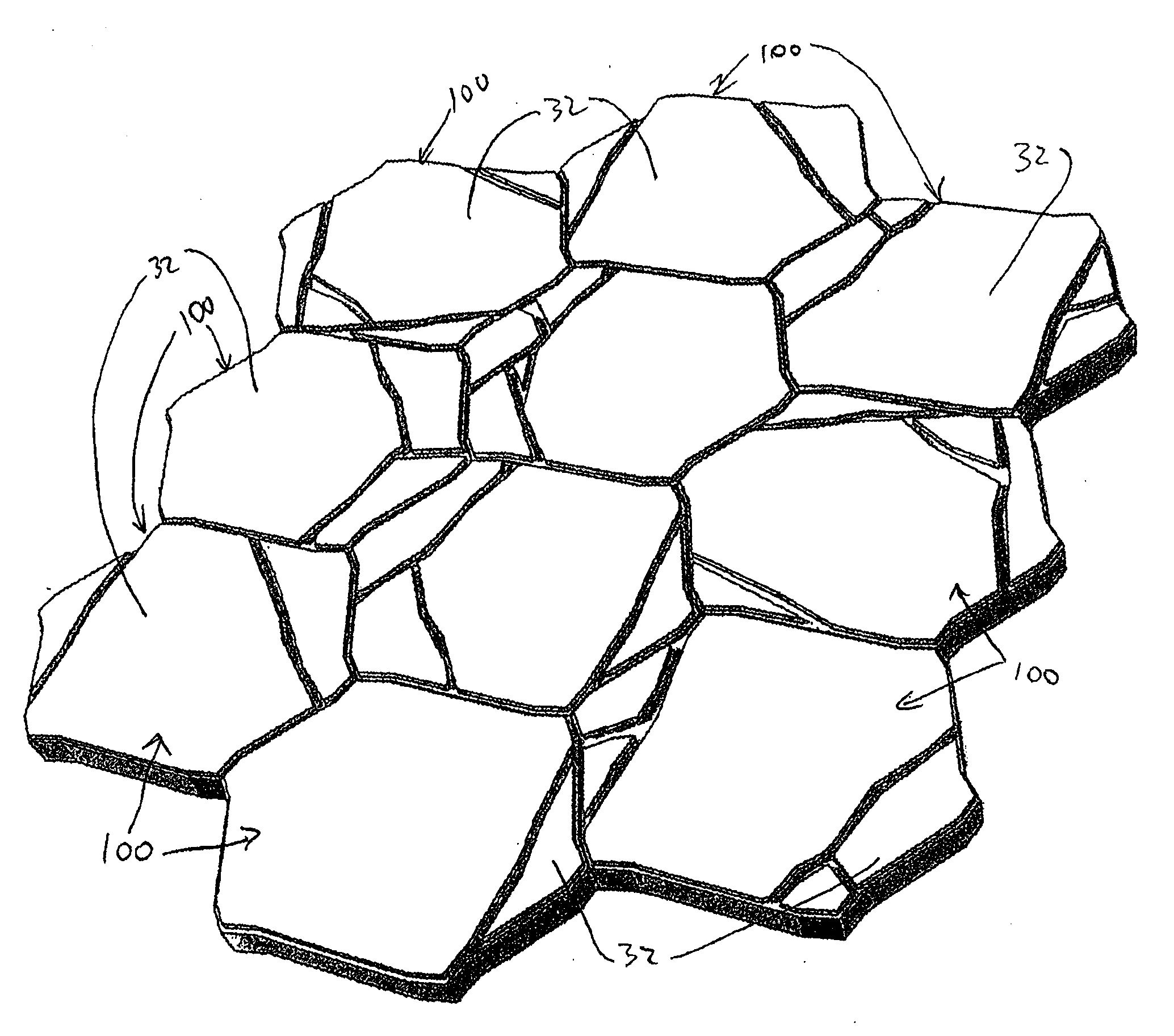

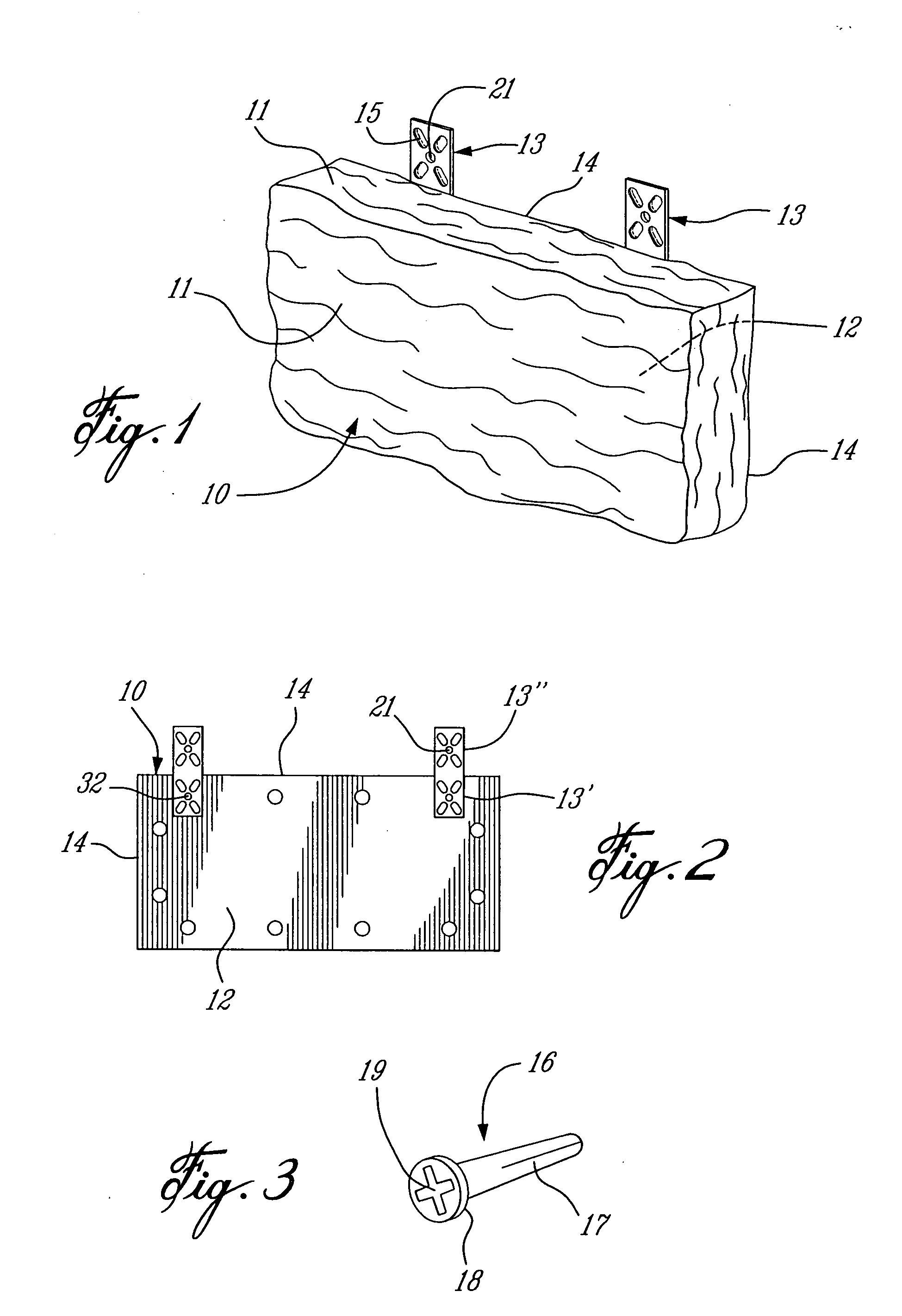

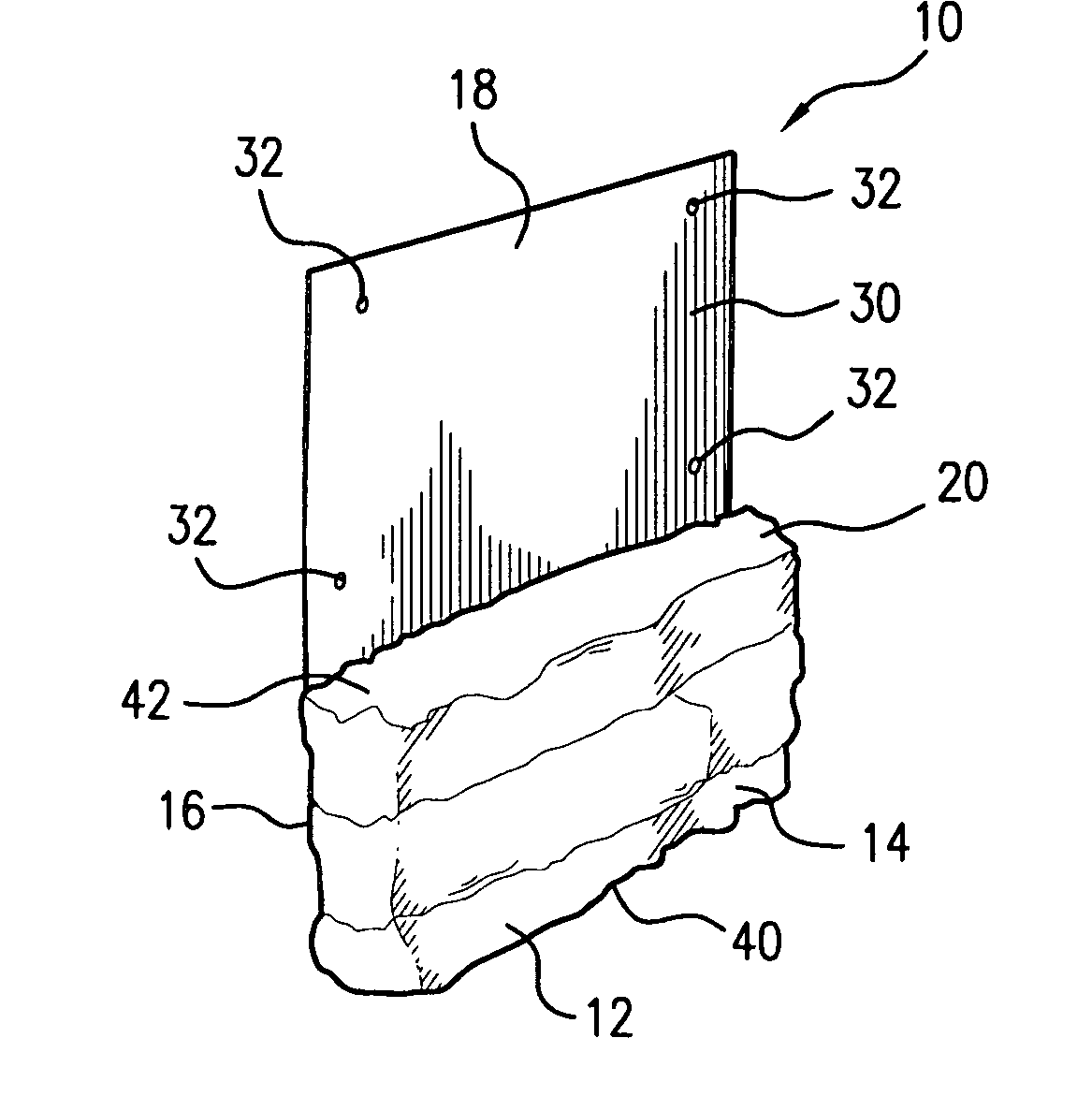

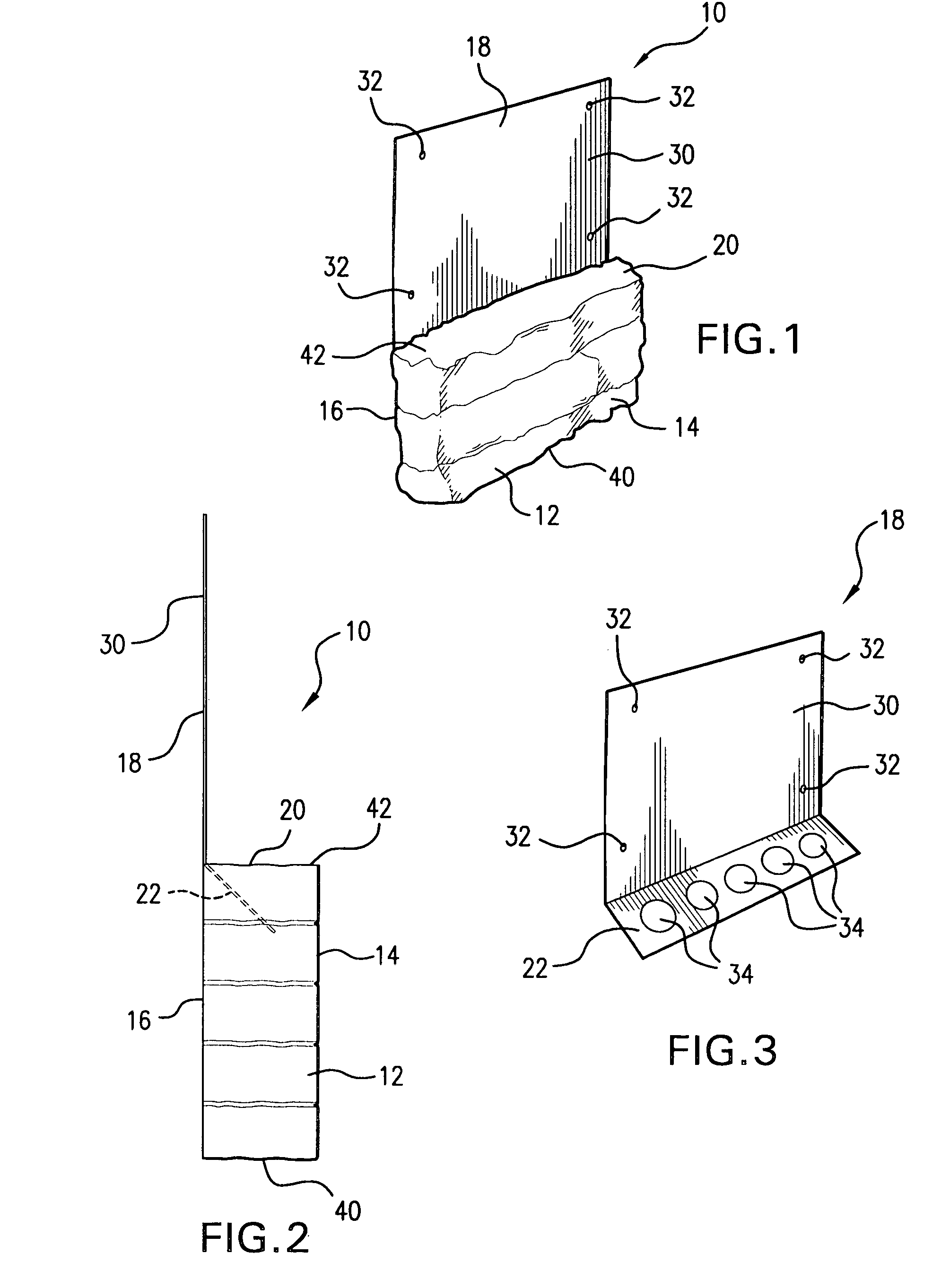

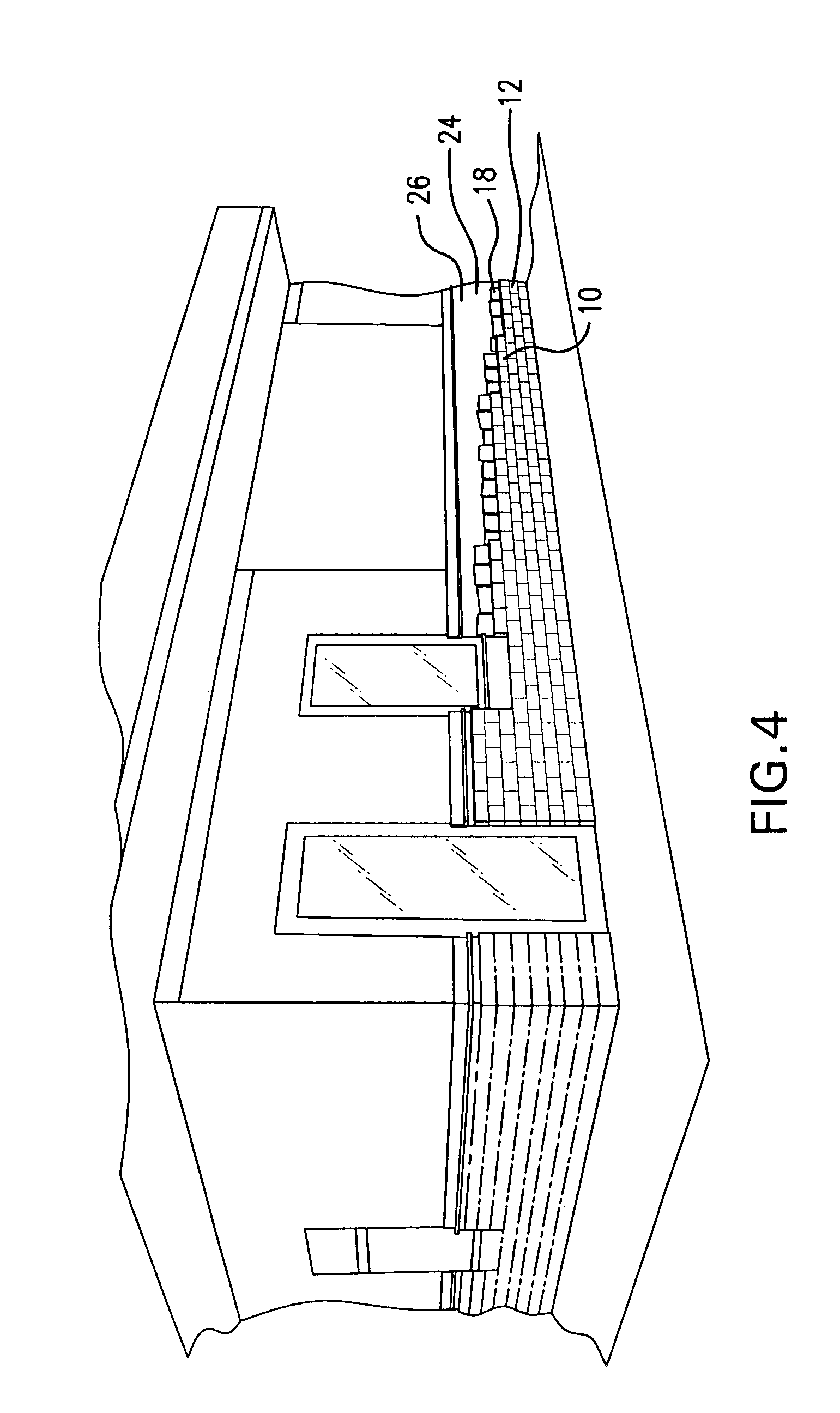

Artificial stone anchoring system and method

An artificial stone and a method of fabricating a stone surface area therewith are described. The artificial stone comprises a stone body cast of a cement aggregate and has an outer visible surface area shaped to resemble a real stone. The stone body has a substantially flat rear surface. Fastener means are provided to secure one or more attachment brackets to the rear surface and adjacent at least one edge portion of the stone body to suspend the artificial stone on a support surface. The stone body is preferably cast with a light aggregate including polymeric particles.

Owner:LES PIERRES STONEDGE

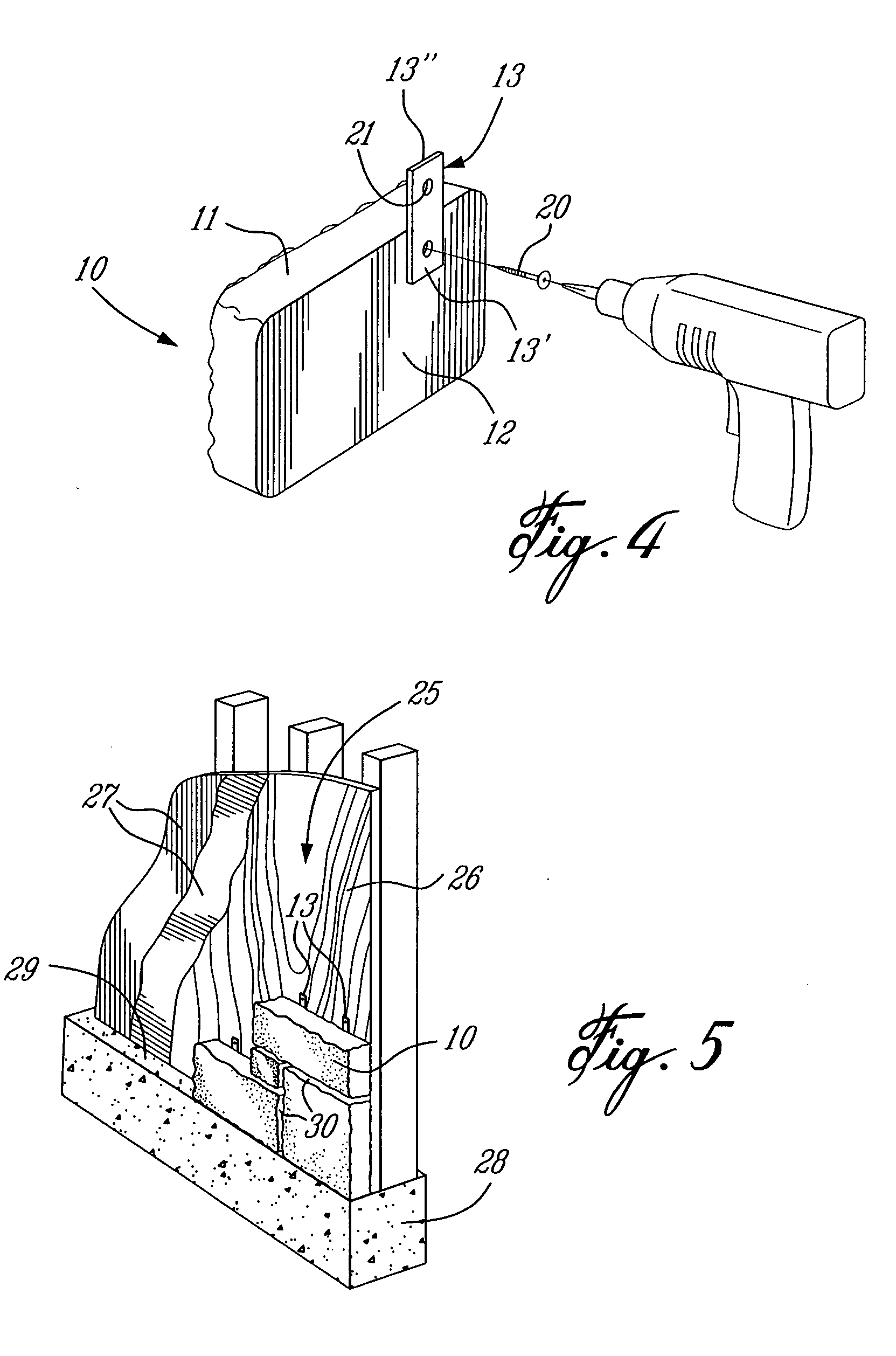

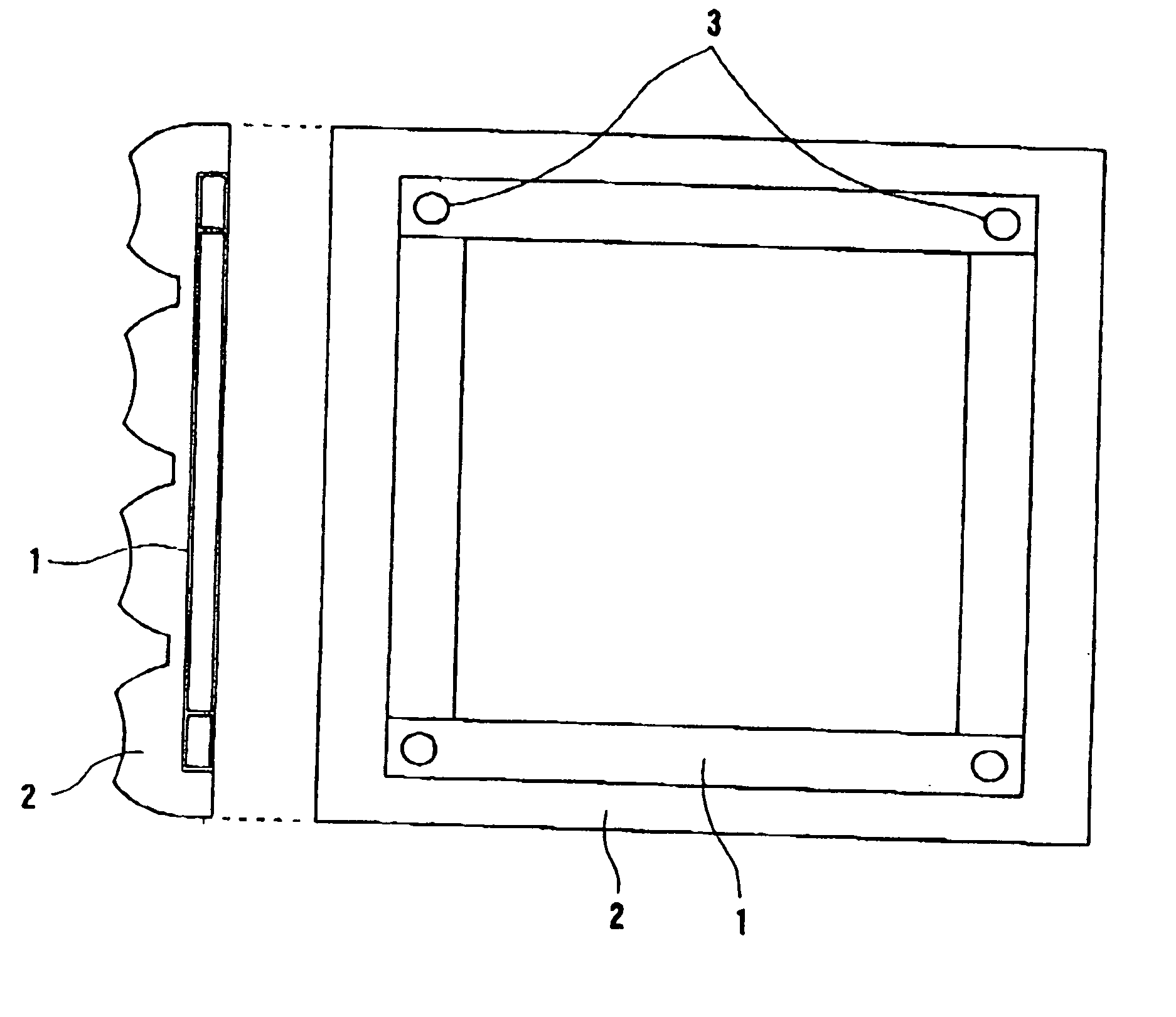

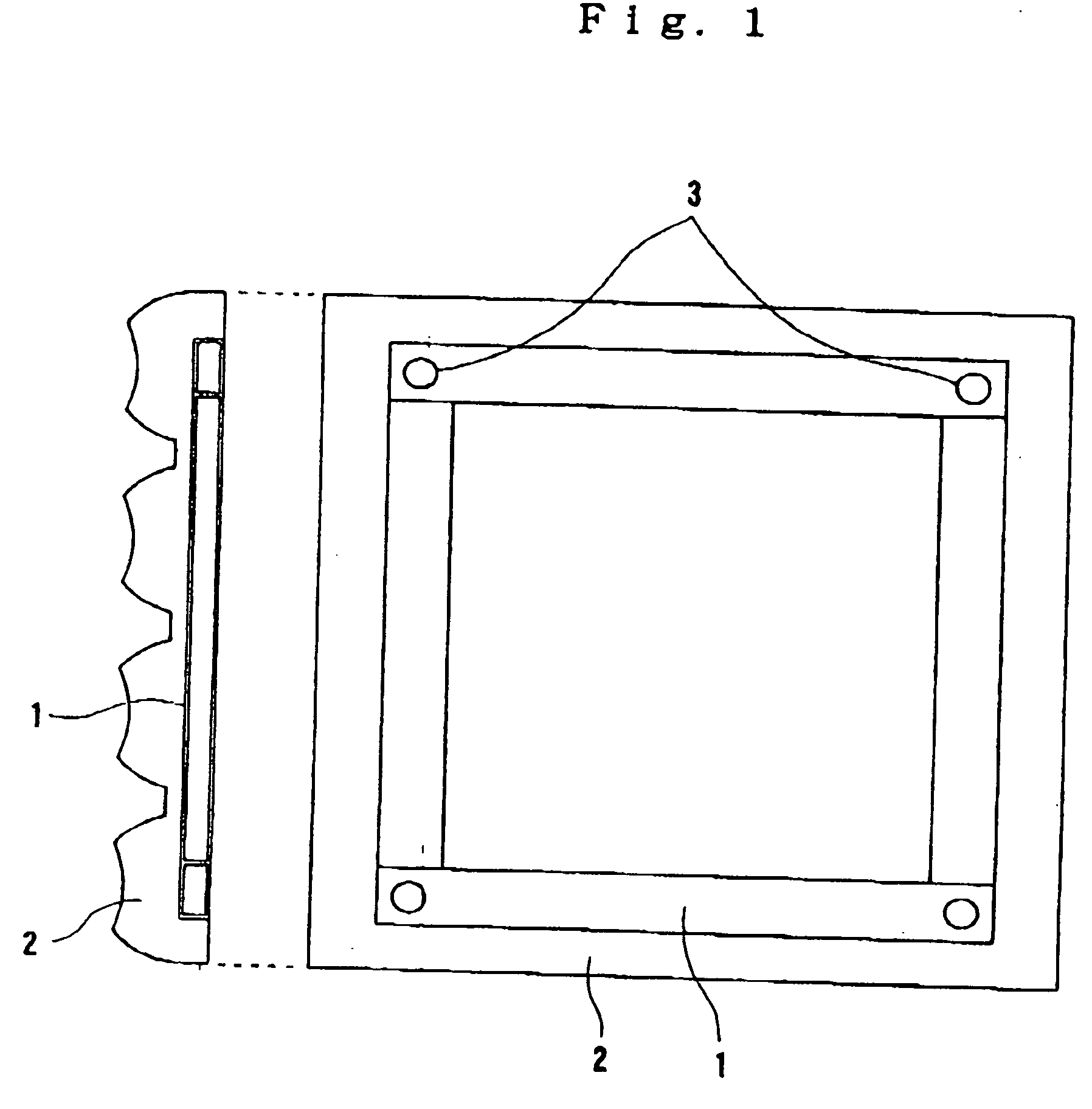

Artificial stone wall panel

InactiveUS20060101752A1Simplify preparationSimplify workHair accessoriesToupeesProduction rateEdge surface

A novel artificial stone wall panel comprising: an artificial stone, the composition of which comprises an inorganic fine powder component with a size of from 9.5 mm to 180 μm, an inorganic finely divided component with a size of less than 180 μm and a resin component in an amount of from 7 to 30% by weight based on the total artificial stone composition, the weight ratio of the inorganic fine powder component to the inorganic finely divided component (inorganic fine powder component:inorganic finely divided component) being in a range of from 1:1 to 5:1; and a support for installing the artificial stone on a wall surface, embedded to the artificial stone, wherein part of the support is exposed at the back surface or edge surface of the artificial stone, and a process for producing the same is provided. This artificial stone wall panel is realized by mold-integrating an artificial stone and a means for installing such artificial stone to an external wall surface, and may be used as an external wall material with excellent design having clear contrast and natural texture, which is easy to prepare and install, and which is advantageous in view of productivity, workability and cost.

Owner:DOPPEL

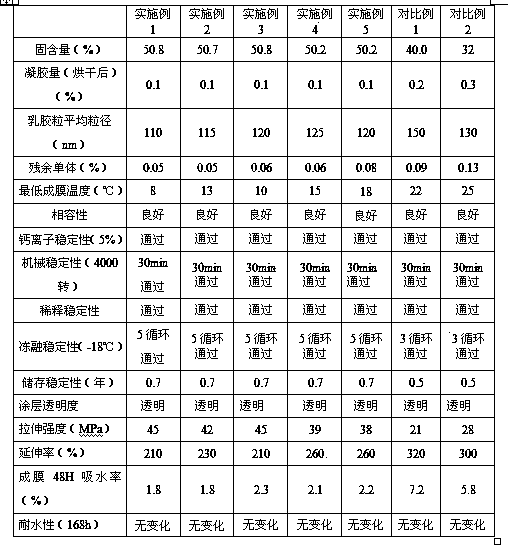

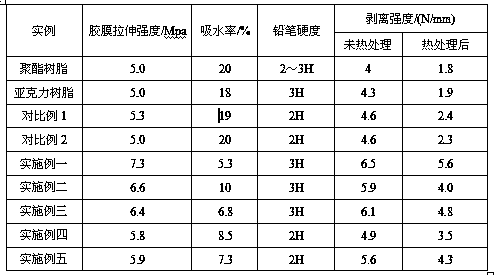

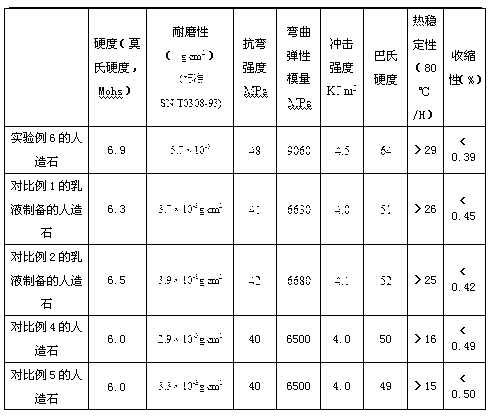

Polyurethane modified acrylic emulsion, preparation method of acrylic emulsion and prepared artificial stone

The invention provides polyurethane modified acrylic emulsion, a preparation method of the acrylic emulsion and a prepared artificial stone. According to the technical scheme, the method comprises the following steps of: synthesizing hydroxyl acrylate emulsion, and dispersing the synthesized polyurethane prepolymer in the hydroxyl acrylate emulsion, so that the polyurethane is grafted to the hydroxyl acrylate emulsion; forming a core-shell structure. The polyurethane modified acrylic emulsion synthesized by the route has a core-shell crosslinking structure, the polyurethane is the shell, and the acrylic acid is the shell. The compatibility between two incompatible polymers can be improved, so that the tensile strength, modulus, hardness, durability and stability of the obtained material are further improved. Compared with an interpenetrating network, the polyurethane modified acrylic emulsion has high micro-phase separation degree and high transparency. Compared with the acrylic component prepared by synthesizing polyurethane and polymerizing in polyurethane particles, the acrylic component has high crosslinking degree, high molecular compatibility and high transparency and hardness. The polyurethane modified acrylic emulsion has high hardness and high water resistance brought by crosslinking density of the interpenetrating network; moreover, the polyurethane modified acrylic emulsion has the advantages of high wear resistance and the like of the core-shell structure, the carboxyl group content is low, and high water resistance is brought.

Owner:广东海顺新材料科技有限公司

Artificial stone with photocatalysis

InactiveCN101642926AReduce manufacturing costHigh bonding strengthMixing operation control apparatusCeramic shaping apparatusNitric oxideNitrogen oxide

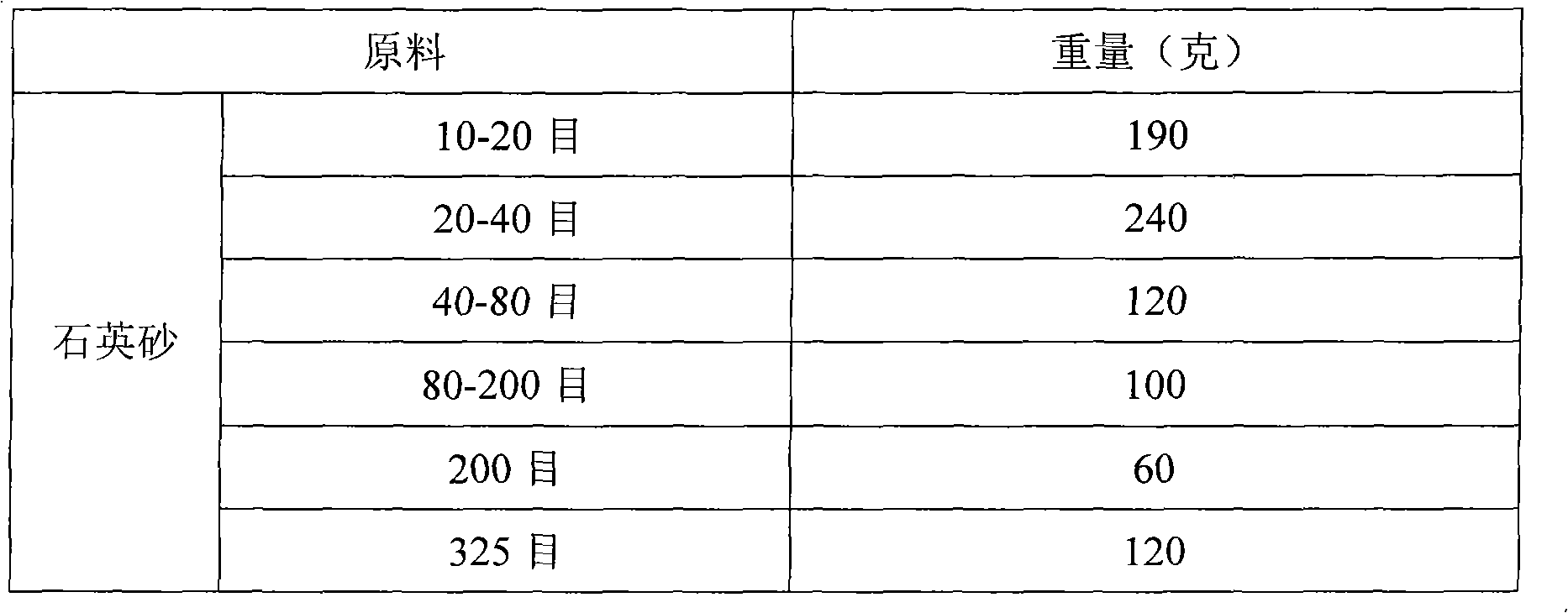

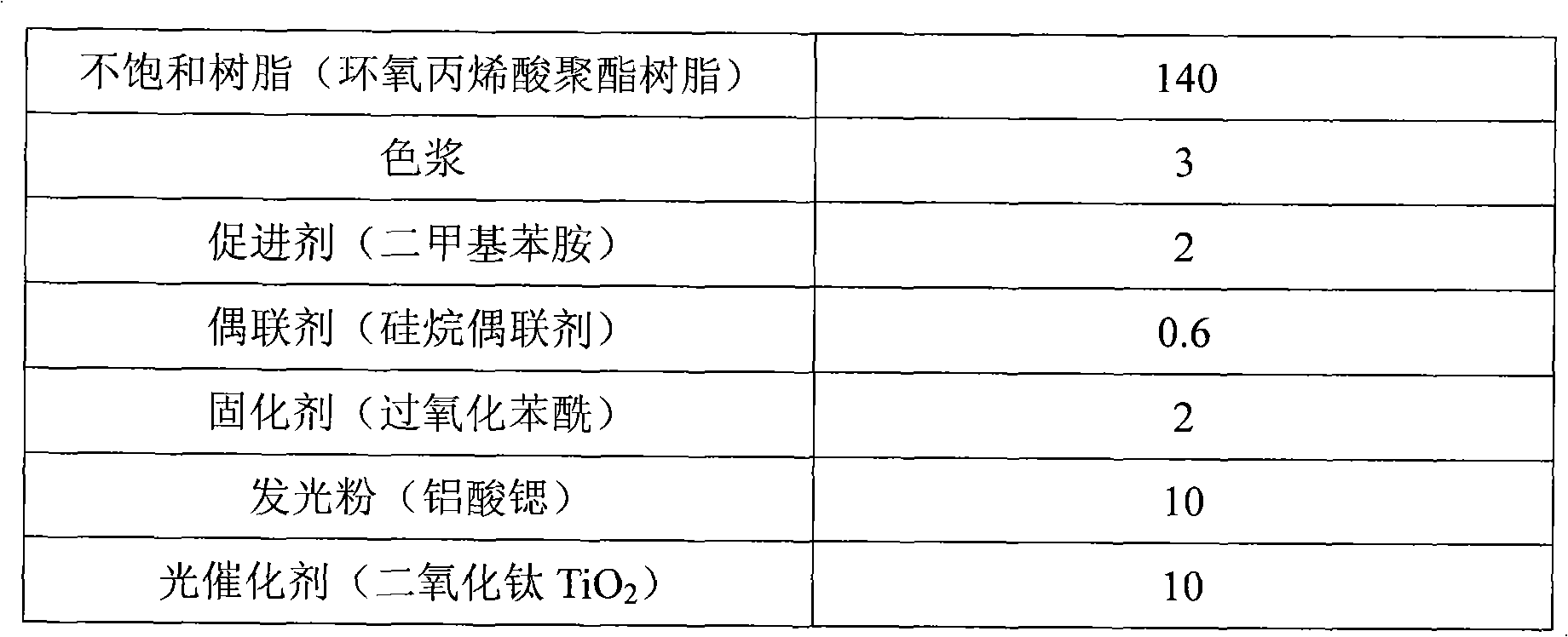

The invention relates to a preparation method of an artificial stone, in particular to a preparation method of an artificial quartz stone with noctilucent function. The artificial quartz stone comprises raw materials containing natural quartz sand, unsaturated resin, accelerator, coupling agent and curing agent, a defined amount of color paste, fluorescent powder and photocatalyst. The artificialstone of the invention has the functions of decoration and indication, has broad-spectrum antibacterial property, can degrade organic pollutants in ambient environment, can remove the waste gas such as nitric oxide and the like, etc.

Owner:上海贵雅橱柜有限公司 +1

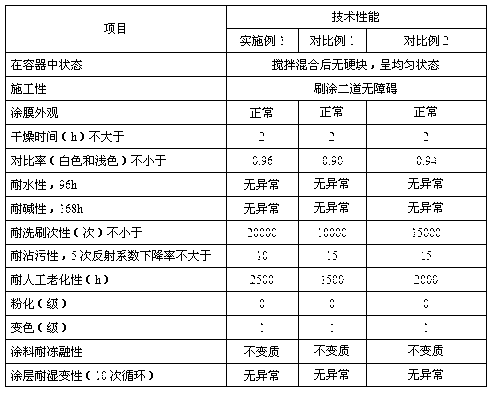

Organosilicone modified acrylate emulsion, preparation method thereof and water-based artificial stone prepared from organosilicone modified acrylate emulsion

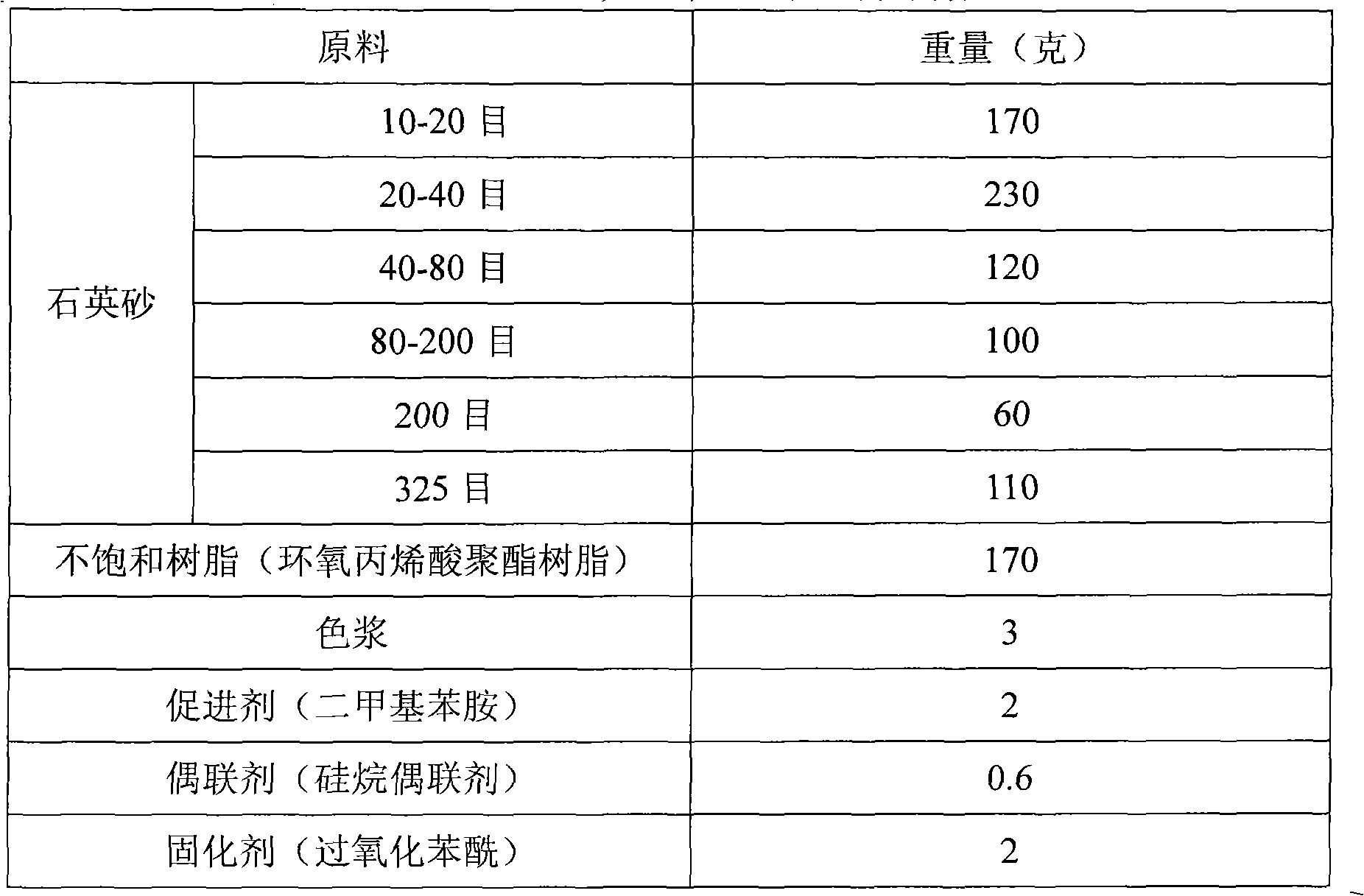

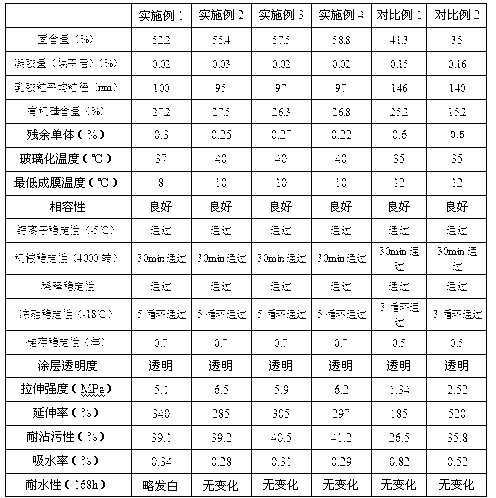

The invention provides an organosilicon modified acrylate emulsion with a weight-average molecular weight of 201205 and also provides a preparation method of the organosilicon modified acrylate emulsion and an artificial stone prepared from the organosilicon modified acrylate emulsion. According to the specific technical scheme, the preparation method comprises the following steps of: (1) preparing a siloxane intermediate emulsion; (2) preparing a silicon-acrylic copolymer core emulsion; and (3) preparing a silicon-acrylic copolymer shell emulsion. The molecular structure of the organosilicon modified acrylate emulsion has a special core-shell structure design, wherein an innermost core of a particle is made of an organosilicon component, an intermediate layer of the particle is made of a polyacrylate component and the shell of the particle is made of a multi-crosslinked organosilicon and polyacrylate component. The organosilicon modified acrylate emulsion not only has high organosilicon content, but also has high hardness and adhesive force. Compared with a common product, the organosilicon modified acrylate emulsion has higher emulsion hardness and resistance to soiling and water. The artificial stone prepared from the organosilicon modified acrylate emulsion has the advantages of good compatibility, high abrasion resistance, low water absorption, good heat resistance, high fire resistance and low shrinkage rate in an artificial stone formula.

Owner:广东海顺新材料科技有限公司

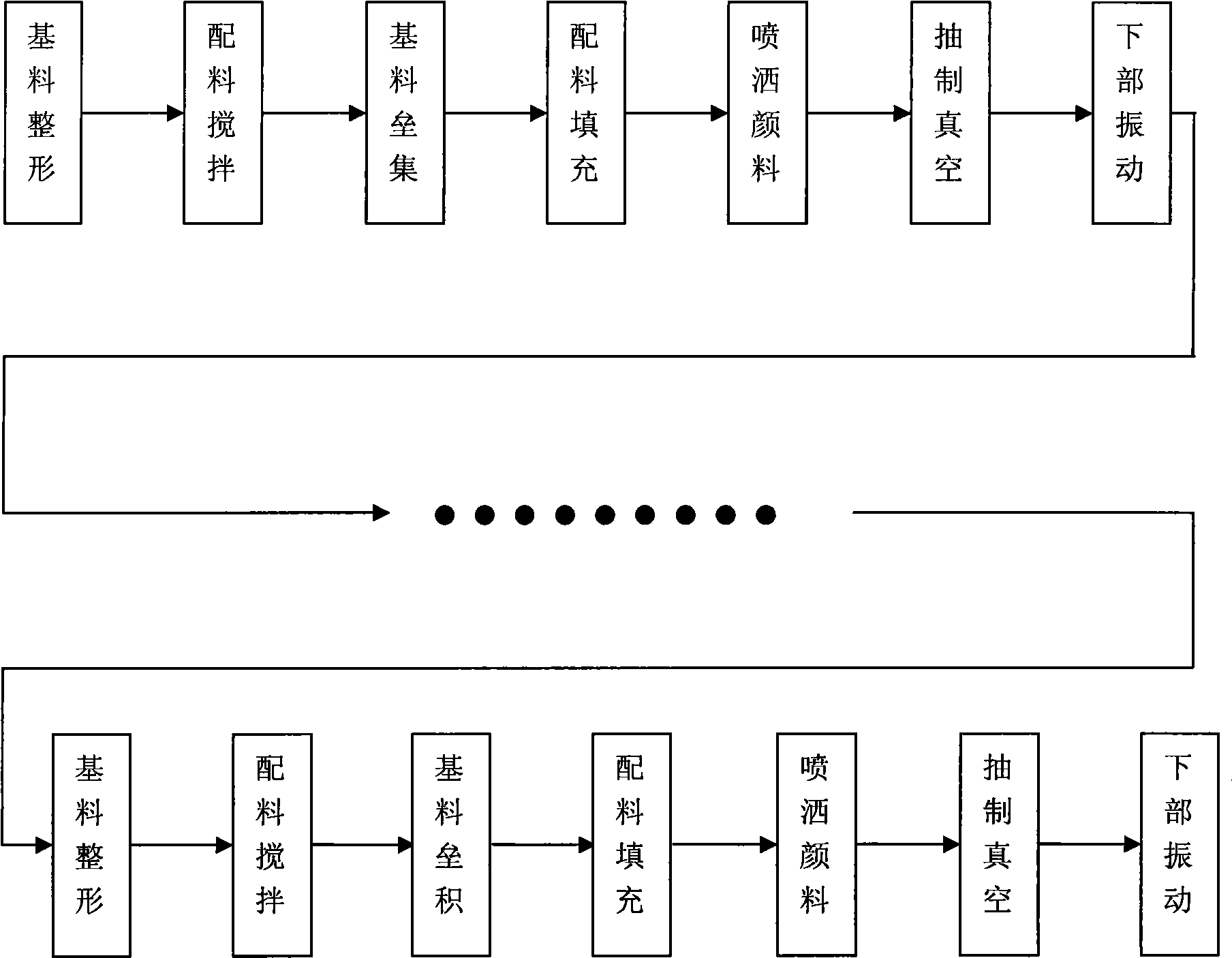

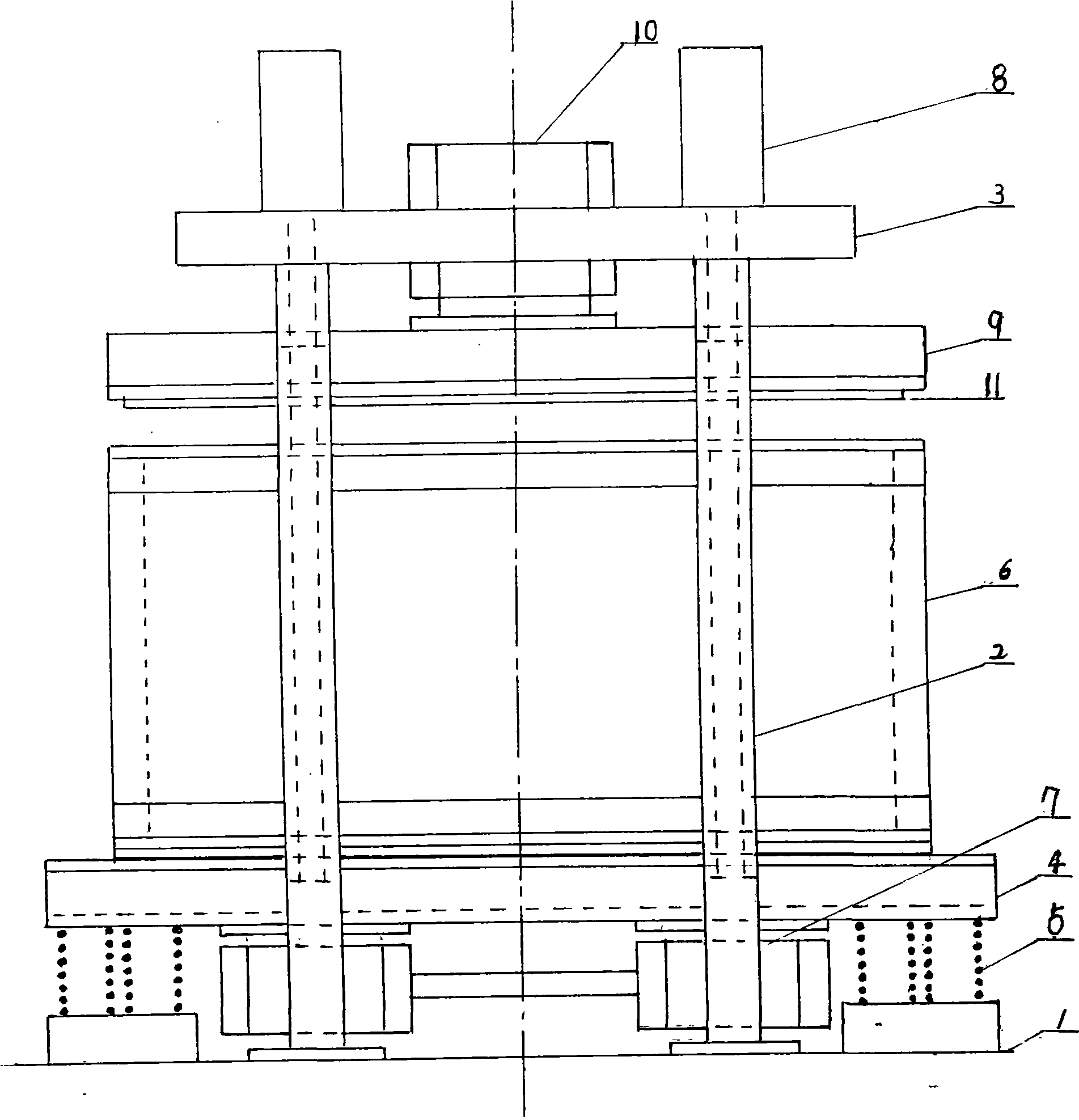

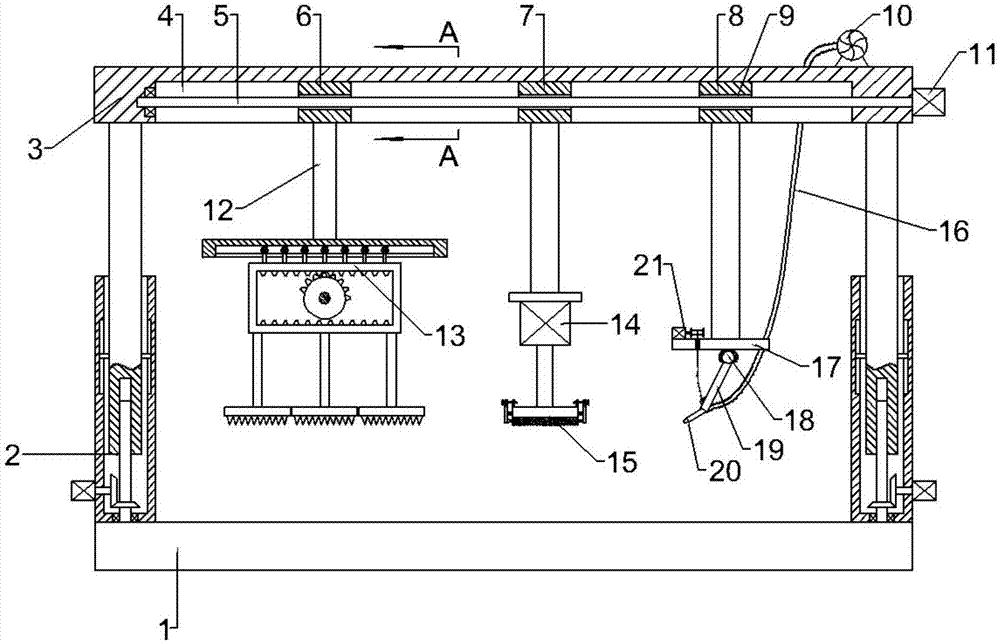

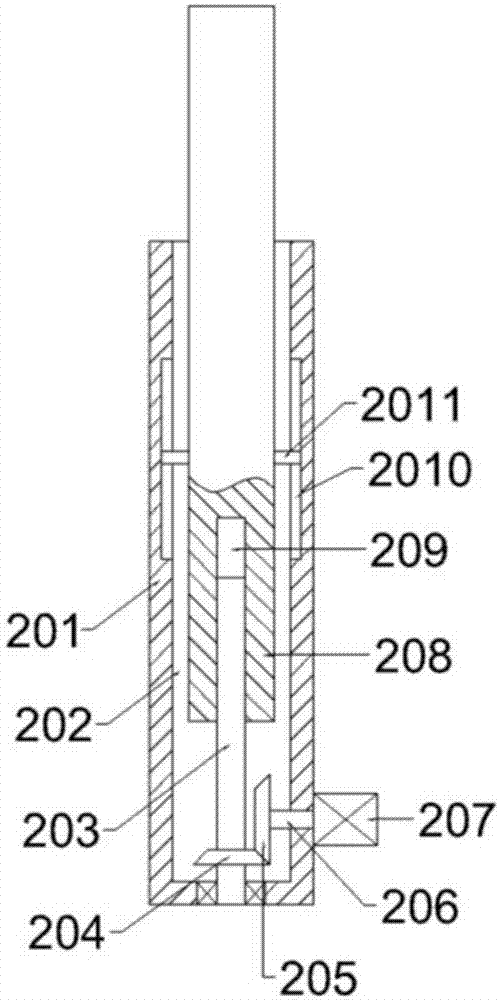

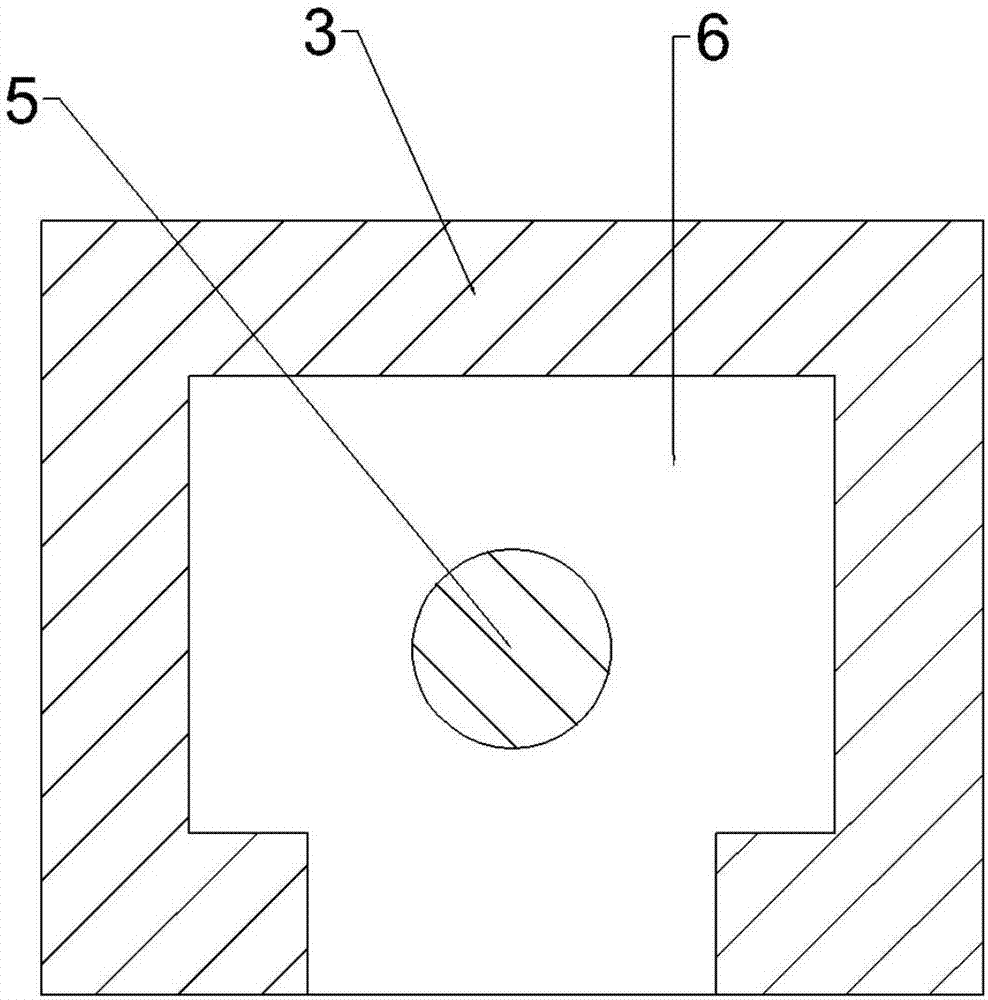

Method for synthesizing stone by layered vibration and moulding vibration device

ActiveCN101486217AImprove compactnessReduce manufacturing costMixing operation control apparatusCeramic shaping apparatusVacuum pumpingMachining process

The invention belongs to the field of artificial synthetic stone for building materials, and in particular relates to a method for producing synthetic stone by layered vibration and a molding vibration device for solving the problems of the prior artificial synthetic stone production process and equipment. The method comprises the following synthetic steps: firstly, a base material and an ingredient are alternately distributed in a mold box layer by layer, the ingredient is paved on the base material, and the base material and the ingredient vibrate under vacuum pumping to complete a first layer; secondly, a second layer is machined according to the first step, and the first step is repeated continuously to complete the molding of quarry stone; and finally, the machining process is completed by sawing, grinding and cutting. The device comprises a base plate, an upright post and a supporting frame; the upper part of the supporting frame is provided with a vibrating table; a buffering spring is arranged between the vibrating table and the soleplate; the upper part of the vibrating table is provided with a mold box; the lower part of the vibrating table is provided with a vibrator; the periphery of the supporting frame is provided with an oil cylinder; the bottom end of a piston of the oil cylinder is hung with a vacuum cover; and a vacuum pump is arranged on the vacuum cover. The process is advanced; the particle diameter of the raw material is not limited; a product has high-grade texture and artistic quality; and the device has a simple structure and low construction cost.

Owner:STATE GRID CORP OF CHINA +1

Method of producing slabs of artificial stone and polymerisable resin having a veined effect by means of vibro-compression under vacuum

The invention relates to a process for manufacturing artificial stone boards with polymerizable resins with a “veined effect” by means of the vibro-compaction under vacuum system comprising a first grinding phase of the different materials forming the filler, a second phase containing a resin with the catalyst and optionally a third phase consisting of the mixing of the two previous phases until the homogenization of the materials with the resin, a fourth phase of moulding and compaction of the obtained paste by vibro-compression under vacuum, a fifth hardening phase by polymerization of the resin by means of heating and a last cooling, cutting and polishing phase.

Owner:COSENTINO RES & DEV

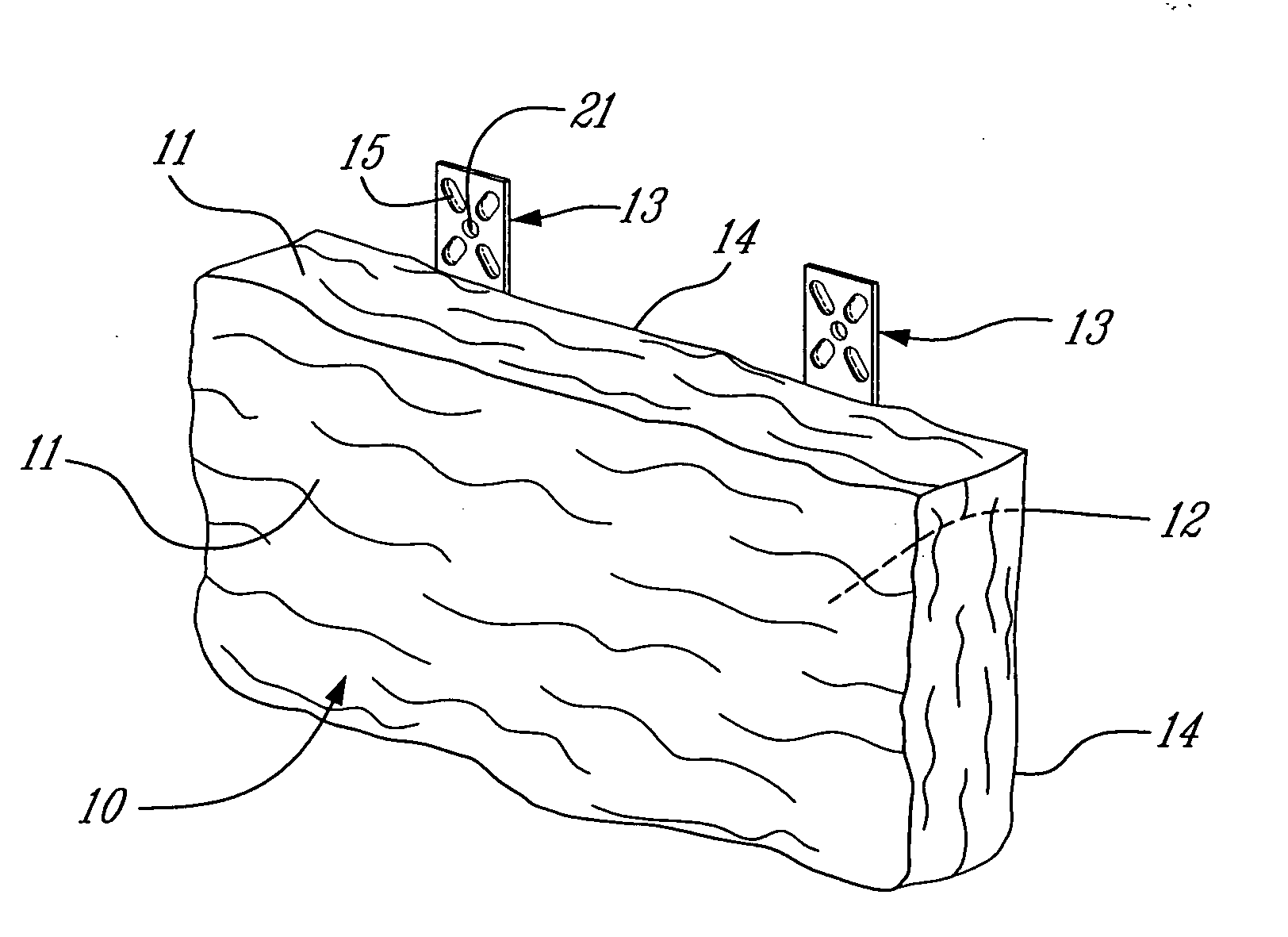

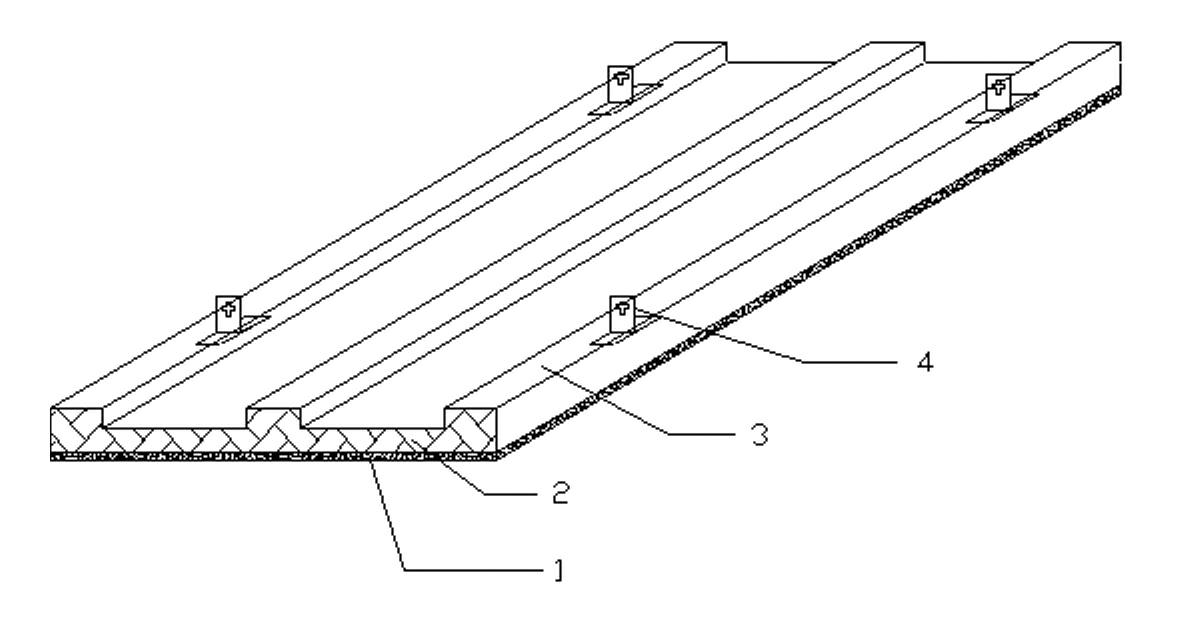

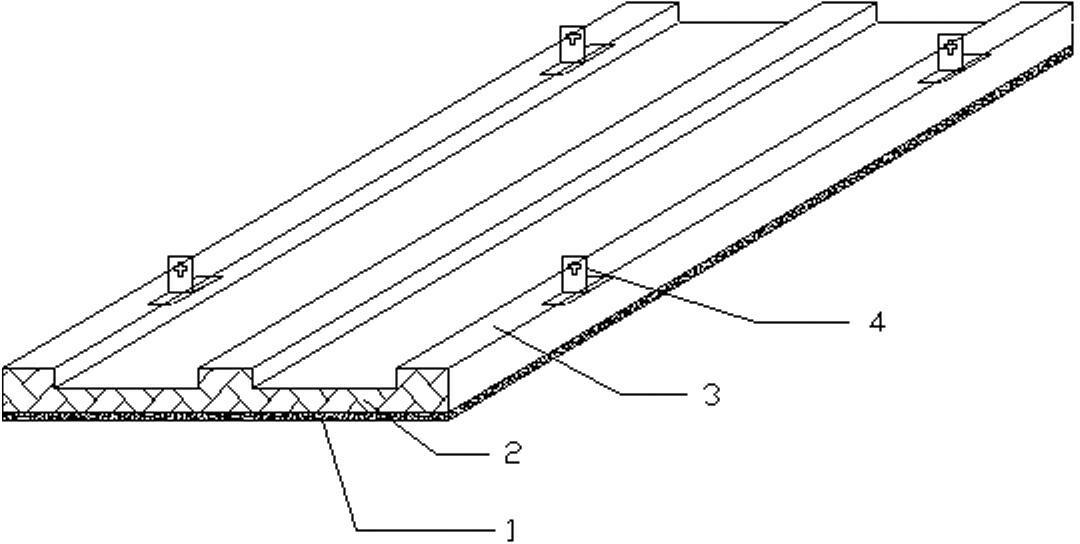

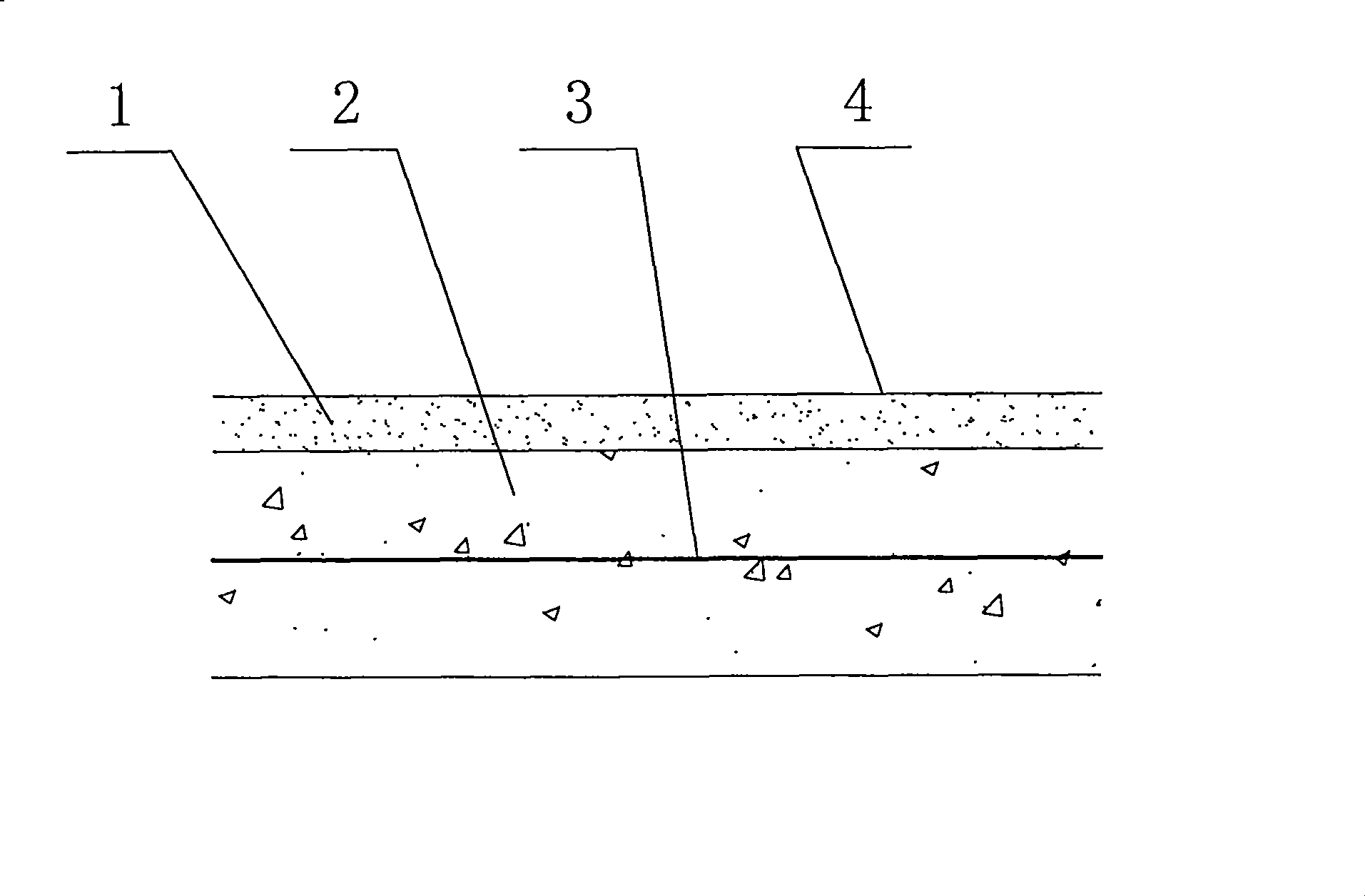

Fiber reinforcing times force stone decoration product and production method thereof

InactiveCN102433979ASolve the defects that the stone texture is not strong and the decorative effect is distortedSolve the defects of weak texture and distorted decorative effectCovering/liningsCeramic shaping apparatusArtificial stoneMaterials science

The invention relates to a fiber reinforcing times force stone decoration product and a production method thereof. In particular, the artificial stone technology and the fiber reinforcing technology are combined to produce a decoration product which is excellent in stone texture, outstanding in physical performance and suitable for surface decoration of a building structure. The fiber reinforcing times force stone decoration product comprises a times force stone decoration layer, a fiber reinforcing cement structure layer, a fiber reinforcing cement reinforcing rib and an installation connecting device. The times force stone decoration layer is provided with the fiber reinforcing cement structure layer, and the fiber reinforcing cement reinforcing rib is arranged on the fiber reinforcing cement structure layer. The times force stone decoration layer, the fiber reinforcing cement structure layer and the fiber reinforcing cement reinforcing rib are formed by composite molding in a die, and then the installation connecting device is arranged on the reinforcing rib. The improved times force stone decoration technology and the fiber reinforcing cement technology are adopted, the building decoration product which is excellent in stone texture, high in anti-bending impact-resistant strength, good in durability and high in flame resistance is achieved, and requirements for different models and plates of different sizes are met.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

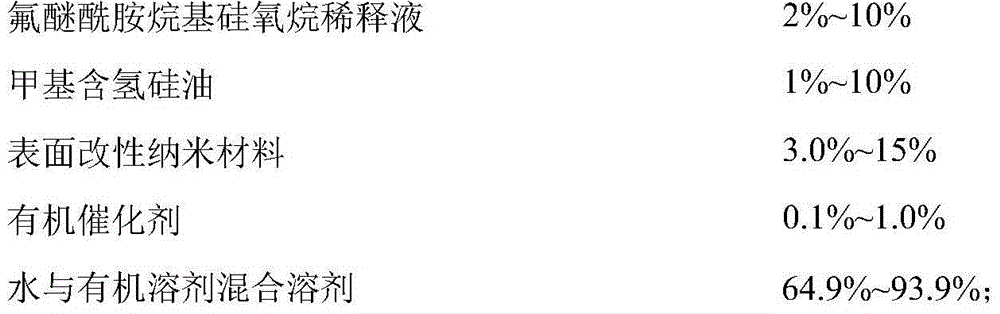

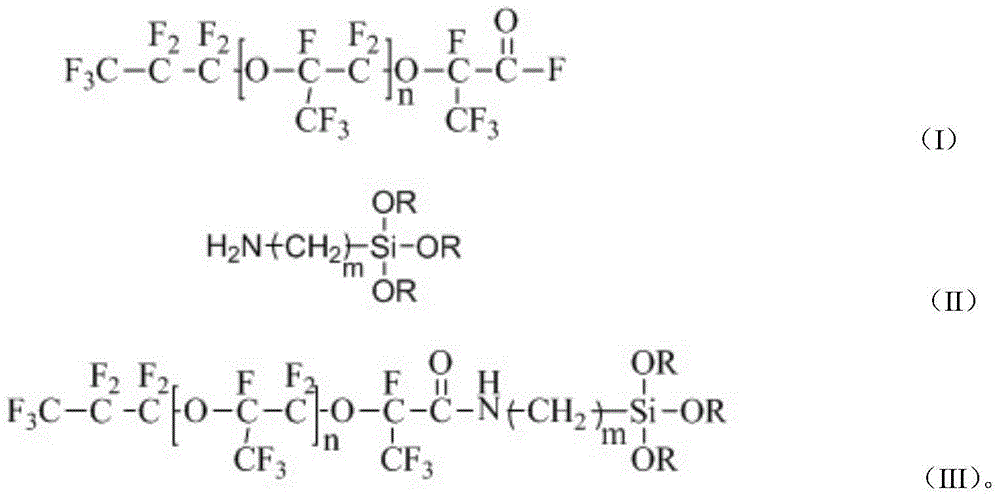

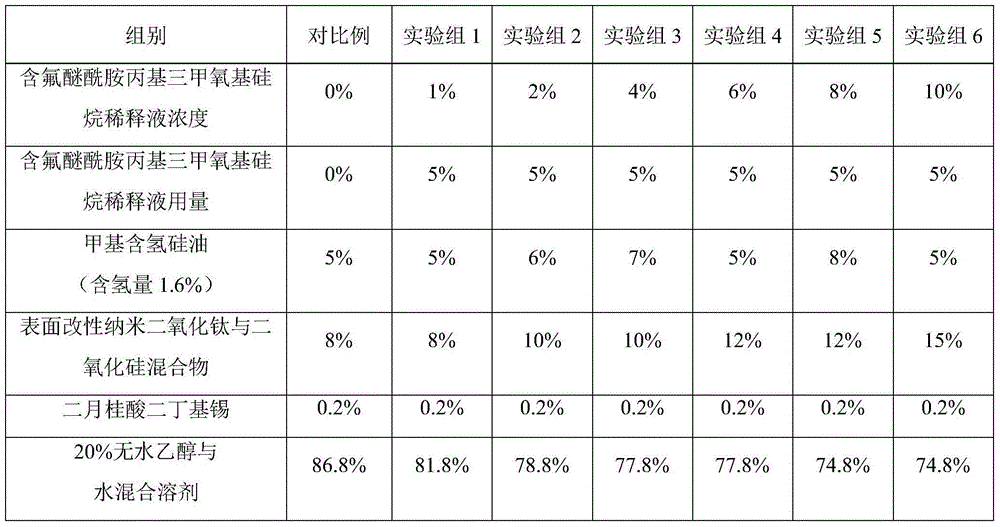

Penetration type nano stone protecting agent and preparation method thereof

ActiveCN104312396AHigh strengthImprove wear resistanceAntifouling/underwater paintsPaints with biocidesSolventRaw material

The invention relates to preparation of a stone protecting treatment agent, and particularly provides a penetration type nano stone protecting agent and a preparation method thereof. The stone protecting treatment agent consists of fluorine ether amide propyl triethoxy siloxane diluent which is prepared from components by self, a surface nano modified nano material, methyl hydrogen silicone oil, an organic catalyst and a solvent, wherein the components are mixed and stirred at room temperature uniformly, thereby obtaining the stone protecting treatment agent. The stone protecting treatment agent is sprayed or brushed on the surface of marble, granite and an artificial stone material, after being maintained for 24 hours in a dry and ventilation environment, an ordinary stone material can have the effects of surface hydrophobility, oil resistance, dust prevention, antibiosis and self-cleaning. The preparation method provided by the invention is simple and reliable, the operation is convenient, the raw materials are easy to obtain and low in cost, the environment is not polluted, and the industrial production is facilitated.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Building artificial stone block integrated machining equipment with reciprocating grinding function

InactiveCN107414625AImprove sanding effectImprove grinding efficiencyGrinding wheel securing apparatusGrinding carriagesProcess efficiencyEngineering

The present invention provides an integrated building artificial stone processing equipment with a reciprocating grinding function, which includes a base, a height adjustment device is fixedly connected to both ends of the base, and a support plate is fixedly connected to the top ends of the two height adjustment devices. The support plate is provided with a moving groove with the opening facing downwards, and the first moving block, the second moving block and the third moving block are arranged in the moving groove from left to right, and the first moving block, the second moving block and the The third moving block is provided with threaded through holes, and the three threaded through holes are jointly threaded with horizontal threaded rods, and the two ends of the horizontal threaded rods are erected at the two ends of the support plate. The invention has the following beneficial effects: it realizes the integrated treatment of grinding, polishing and cleaning, effectively improves the processing efficiency of stone materials, has a high degree of integration, effectively reduces labor input, keeps the operator away from the processing site, and reduces The incidence of occupational diseases among workers has been reduced.

Owner:刘丽

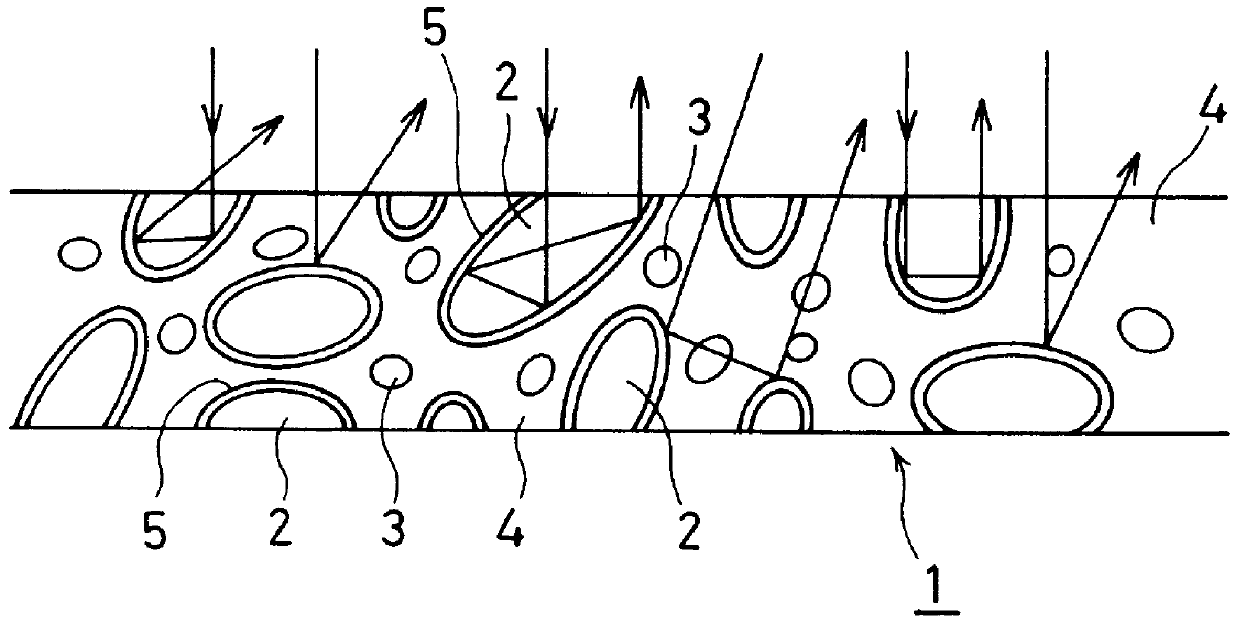

Artificial stone with irregular pore and preparation method thereof

The invention provides an artificial stone with irregular pores and a preparation method thereof. The artificial stone composed of a cementitious material, a pore forming agent and a thickener is prepared by the following method: preparing a slurry; casting the prepared slurry in a mould; and vibrating for molding in a vibration table. Compared with the natural stone, the artificial stone with irregular pores provided by the invention has the advantages of low cost, multiple effect changes, environment-friendliness, no radiation, low density, excellent thermal insulation, sound insulation and refractory properties, and good mechanical property; and the artificial stone with irregular pores has strong durability and color stability in all kinds of weather conditions, and is an ideal decorative material.

Owner:SHANGHAI APE STONE

Acrylic artificial stone and method for preparing same

The invention relates to an acrylic artificial stone with natural marble surface patterns and excellent hot water resistance and a method for preparing the same. The acrylic artificial stone comprises the following components by weight portion: 40 to 70 portions of acrylic-based resin monomer, 10 to 25 portions of thickening agent, 200 to 350 portions of inorganic filler, 0.01 to 2 portions of curing agent, and 0 to 30 portions of unsaturated resin, wherein the thickening agent is a hot melt mixture of acrylic polymers and the acrylic-based resin monomer, and the molecular weight of the acrylic polymers is between 100,000 and 400,000. The method for preparing the acrylic artificial stone comprises the following steps of: putting the unsaturated resin, the acrylic-based resin monomer, the thickening agent, the inorganic filler and the curing agent in a kneader according to a formula to obtain an acrylic molding compound; and filling the molding compound in a mold and curing the molding compound at a temperature of between 100 and 145 DEG C and under a pressure of between 10 and 20MPa to prepare the acrylic artificial stone. The prepared acrylic artificial stone has excellent appearance and performance.

Owner:上海新天和树脂有限公司 +1

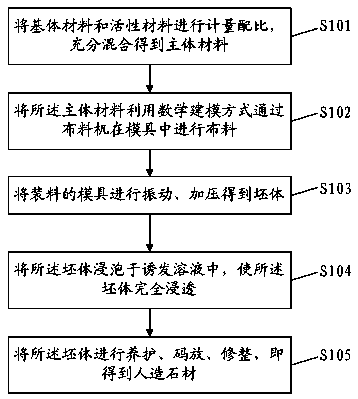

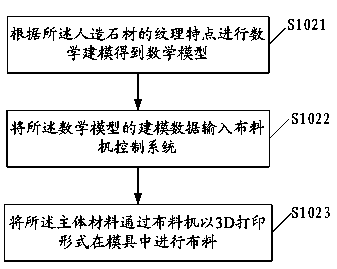

Artificial stone and preparation method thereof

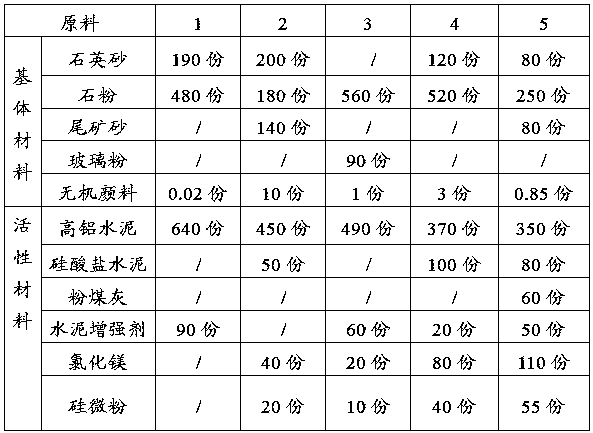

InactiveCN103864376AHigh degree of simulationLow water absorptionFeeding arrangmentsPortland cementArtificial stone

Embodiments in the invention disclose an artificial stone. The artificial stone comprises a base material and an active material, wherein the base material comprises, by mass, 150 to 800 parts of aggregate, the active material comprises, by mass, 200 to 800 parts of a cross-linking agent, the aggregate is one selected from or a mixture of quartz sand, stone powder, tailing sand and glass powder, and the cross-linking agent is one selected from or a mixture of high-alumina cement, Portland cement and fly ash. The embodiments of the invention also disclose a preparation method for the artificial stone. The method comprises the following steps: weighing the base material and the active material in proportion and carrying out uniform mixing so as to obtain a main material; subjecting the main material to spreading in a mold with a spreading machine in the manner of mathematical modeling; vibrating and pressurizing the mold filled with the material so as to obtain a green body; soaking the green body in an induction solution; and subjecting the green body to maintenance, stacking and finishing so as to obtain the artificial stone. The prepared artificial stone has same appearance, structural configuration, physicochemical properties and the like compared with natural stone.

Owner:广州渥图生物科技有限责任公司

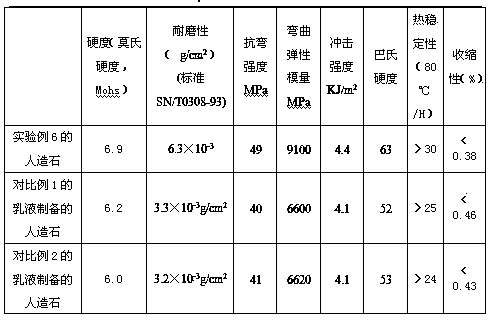

High-strength composite inorganic artificial stone and preparing method thereof

The invention discloses a high-strength composite inorganic artificial stone and a preparing method thereof; the inorganic artificial stone comprises the following components by the weight percentage: 30-65% of aggregates, 25-60% of cement, 1-10% of a composite modifying agent, 1-5% of a water reducing agent, 0-1.5% of a retarder, and 8-20% of water, wherein the particle sizes of the aggregates are graded according to the weight of the aggregates. The preparing method of the inorganic artificial stone comprises the steps: successively adding the aggregates with predetermined weight particle size graduation, the cement, the composite modifying agent and the water reducing agent into a stirrer successively, uniformly stirring, adding an appropriate weight of water, then uniformly stirring, distributing the material and pressing under a vacuum state, carrying out wet culture and curing, cutting, and polishing to obtain the product. The inorganic artificial stone has the advantages of high bending strength, environmental-protection production process, lower cost, high yield rate of the product, outstanding performance and the like.

Owner:WANFENG COMPOUND STONE TECH

Noctilucent or fluorescent artificial stone

InactiveUS6146548AImprove liquidityImprove vibrationLuminescent compositionsArtificial stoneMaterials science

PCT No. PCT / JP97 / 00417 Sec. 371 Date Dec. 15, 1998 Sec. 102(e) Date Dec. 15, 1998 PCT Filed Feb. 17, 1997 PCT Pub. No. WO98 / 35919 PCT Pub. Date Aug. 20, 1998A noctilucent or fluorescent artificial stone comprising a mixture of a resin and 5-65 wt % with respect to the total weight of the artificial stone of a transparent inorganic aggregate, on which a luminous or fluorescent substance emitting light accompanied by absorption of ultraviolet rays, is baked, or coated.

Owner:DOPPEL

Method of Producing Slabs of Artificial Stone and Polymerisable Resin Having a Veined Effect By Means of Vibro-Compression Under Vacuum

The invention relates to a process for manufacturing artificial stone boards with polymerizable resins with a “veined effect” by means of the vibro-compaction under vacuum system comprising a first grinding phase of the different materials forming the filler, a second phase containing a resin with the catalyst and optionally a third phase consisting of the mixing of the two previous phases until the homogenization of the materials with the resin, a fourth phase of moulding and compaction of the obtained paste by vibro-compression under vacuum, a fifth hardening phase by polymerization of the resin by means of heating and a last cooling, cutting and polishing phase.

Owner:COSENTINO RES & DEV

Cast-in-situ granolithic flooring and production method thereof

The invention provides a cast-in-situ granolithic flooring. The granolithic flooring is made from a gelling material, an aggregate, an additive and a pigment, the gelling material is selected from various types of cement and / or gypsum, the aggregate is anyone or all selected from marble and / or granite and / or quartz stone broken particles, glass sands, bead pieces, shells, colorful synthetic glass particles and acrylic particles, and the additive is one or all selected from a water reducer, a reinforcing agent, a plasticizer, a leveling agent, a tackifier and an organic high molecular polymer. The raw materials of the granolithic flooring have low prices, are easy to obtain, and are recyclable, so the granolithic flooring belongs to an environmentally-friendly and renewable high-tech product, and can widely replace natural stones and resin type artificial stones to reduce the natural stone resource consumption for the society, reduce the use of organic solvents and reduce environmental hazards.

Owner:刘锦文

Artificial stone siding product

Owner:SILVERMINE STONE SIDING LLC

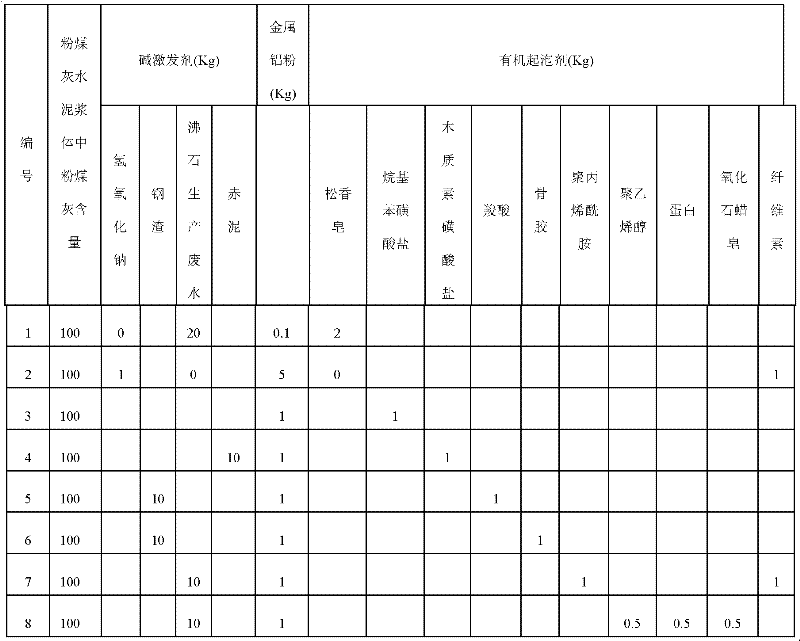

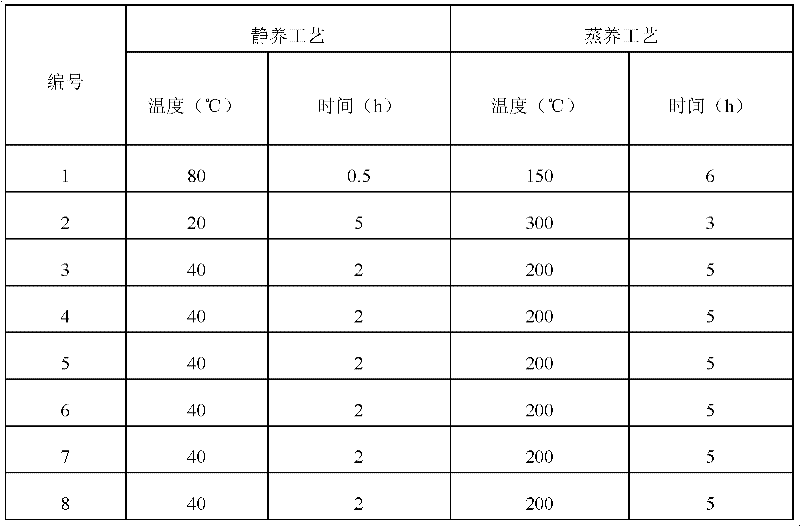

Preparation method for pulverized coal-ash-based porous artificial stone

InactiveCN102584322AImprove productivityShorten steaming timeSolid waste managementCeramicwareFiberWater vapor

The invention discloses a preparation method for a pulverized-coal-ash-based porous artificial stone. The preparation method is characterized in that the method comprises the steps of: adding materials containing calcium carbonate, calcium sulfate and silicon oxide, water, fibers and Portland cement into pulverized coal ash, evenly agitating, adding alkali-activator, metal aluminum powder and organic foaming agent, and evenly mixing; and statically curing, cutting into cement blocks or cement blank plates, and curing the cement blocks or cement blank plates in a vapor environment to obtain the pulverized-coal-ash-based porous artificial stone. The artificial stone mainly contains tobermorite and xonotlite, can replace the existing autoclaved aerated concrete and can be used as a load-bearing building block, a filler wall, a partition wall, a roof board or a wall board.

Owner:SHAANXI UNIV OF TECH

Simulation stone facing concrete element and method for producing the same

InactiveCN101418538ANice appearanceStrong three-dimensional senseArtificial islandsCovering/liningsFiberSurface layer

The invention relates to a concrete member for an artificial stone surface layer and a production method thereof. The member consists of the artificial stone surface layer and a fibrous concrete layer. The artificial stone surface layer is prepared from cement, carpolite, quartz sand and water and is manufactured through adopting a thrashing process. The appearance of the member has attractiveness and strong third dimension; the whole pattern is harmonious; color is abundant, natural and bright and does not fade; and the member has consistent texture effect with a marble or granite veneer, reduces cost by 30 percent and reduces weight by 25 to 35 percent. The method has a simple production process and does not need a special machine. The artificial stone surface layer and the fibrous concrete layer are tightly combined into a whole, are skidproof and wearable, have high strength (compressive strength is more than or equal to 60 MPa, and bending strength is more than or equal to 11 MPa) and are uneasy to rupture. The method has convenient construction, low expense and wide application range, can be used for manufacturing a tree protective plate, a road plate brick, an inspection well cover and other planar members and can be also used for manufacturing an upright post, a decorative metope and other three-dimensional members.

Owner:句容市科达技术开发有限公司

Geopolymer-based inorganic artificial stone

The invention relates to geopolymer-based inorganic artificial stone. The traditional artificial stone has the shortcomings of easy yellowing, deformation and aging, high cost, highly-possible fire or melting after receiving heat radiation and the like. The geopolymer-based inorganic artificial stone provided by the invention is prepared from the following raw materials in percentage by mass: 5-15% of water glass, 5-20% of superfine slag powder, 60-80% of stone particles, 0.1-0.3% of pigment, 0.1-0.5% of redispersible latex powder, 1-3% of fiber and 3-5% of water. The geopolymer-based inorganic artificial stone provided by the invention has the characteristics of stable structure, high strength, good wear resistance, environment-friendly raw materials, simple production process, low cost and high smooth finish, and is non-toxic and environment-friendly. Apart from low cost, high product hardness and good surface smoothness, the geopolymer-based inorganic artificial stone also has the advantages that the production process is simple and convenient, the raw materials are widely available, the production process is environment-friendly, and the raw materials are environment-friendly.

Owner:广西启利新材料科技股份有限公司

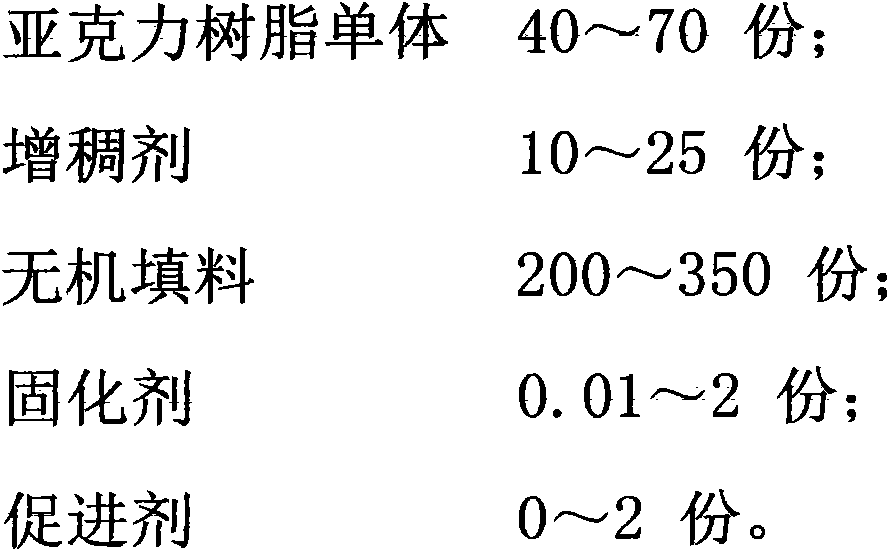

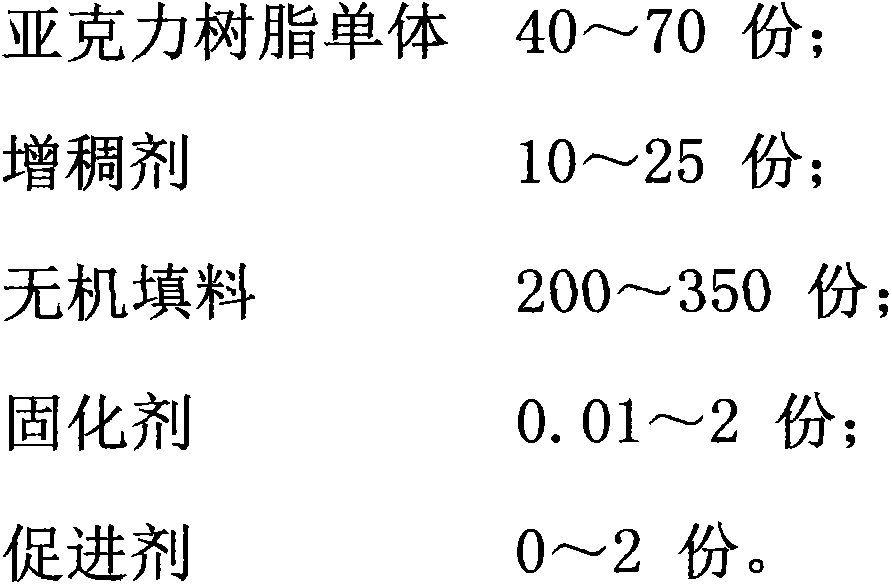

Pure acrylic artificial stone as well as manufacturing method thereof

The invention discloses an acrylic artificial stone. The acrylic artificial stone comprises the following components in parts by weight: 40-70 parts of acrylic resin monomers, 10-25 parts of a thickening agent, 200-350 parts of inorganic fillers, 0.01-2 parts of a curing agent and 0-2 parts of an accelerant. The manufacturing method of the pure acrylic artificial stone comprises the following steps: A, preparing the thickening agent; B, kneading; and C, forming. Compared with the prior art, the pure acrylic artificial stone disclosed by the invention has the advantage that thickening performance and storage stability are excellent by mixing the special thickening agent and monomers in the invention; the acrylic artificial stone made of acrylic molding plastics has excellent appearance and performance, and can be used for an industrial purpose.

Owner:江门市德山复合材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com