Patents

Literature

4171 results about "Yield rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

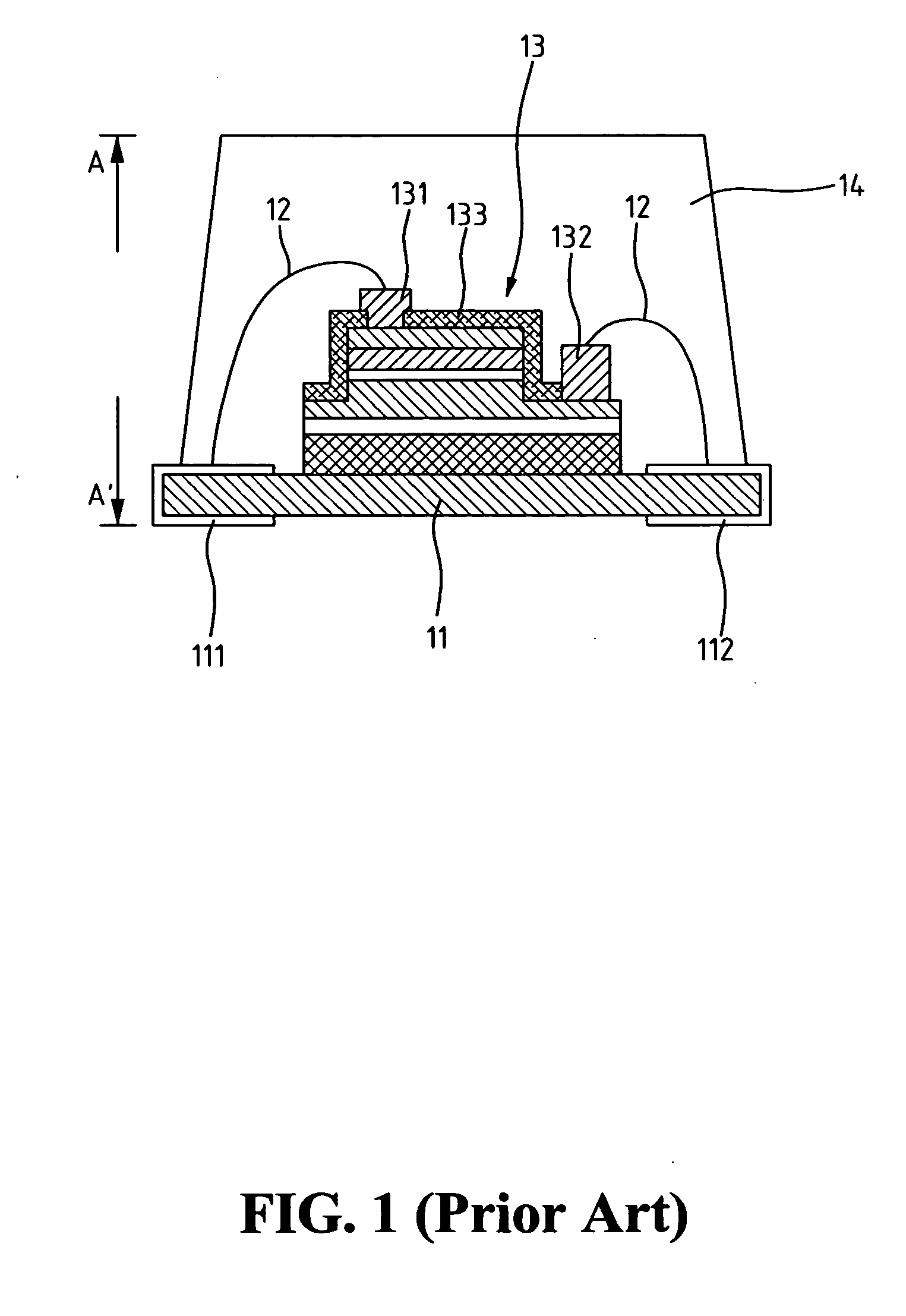

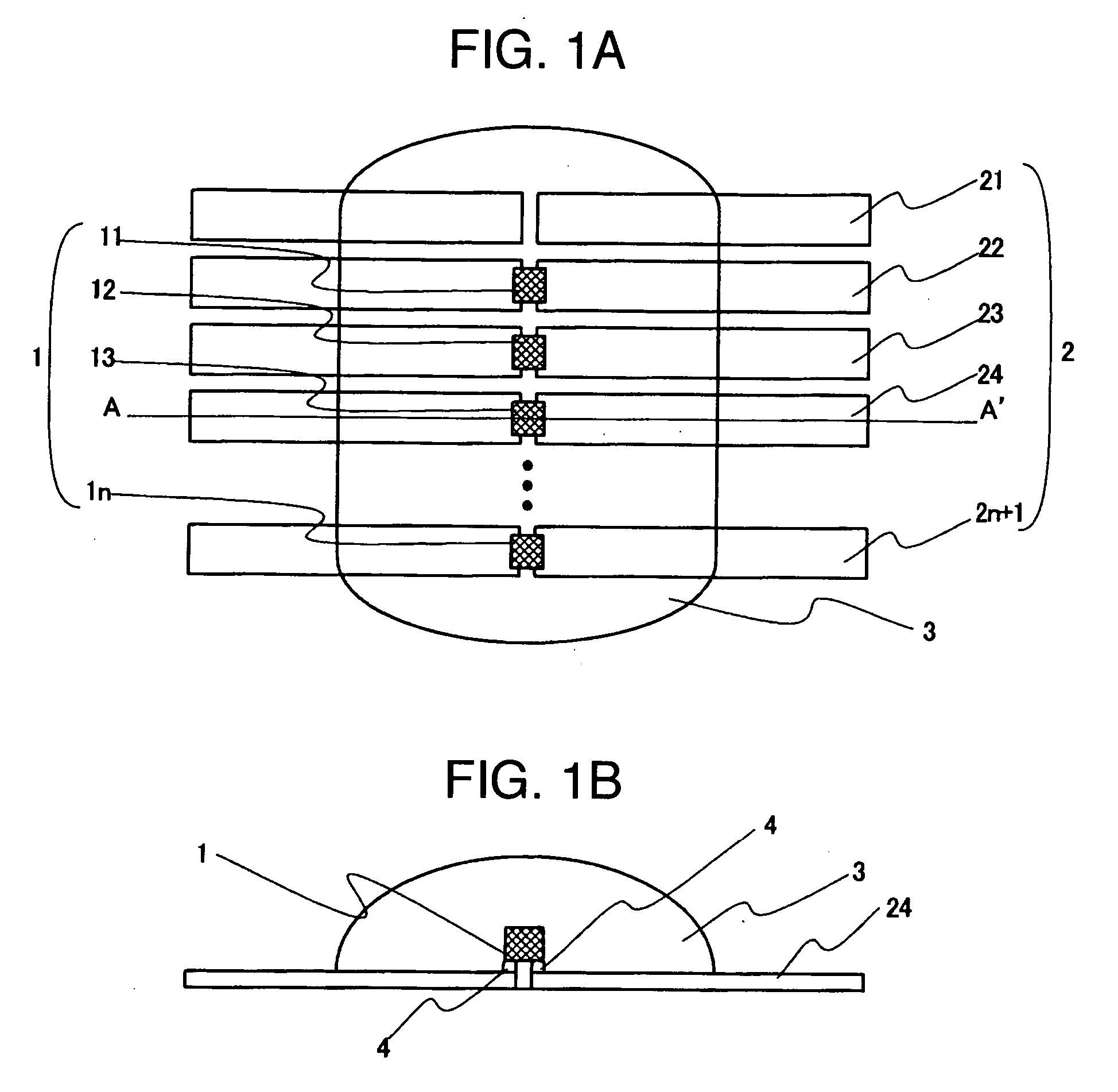

Phase-change memory device and manufacturing method thereof

InactiveUS20050018526A1Easy to manufactureHigh yield rateSolid-state devicesDigital storagePhase-change memoryDielectric layer

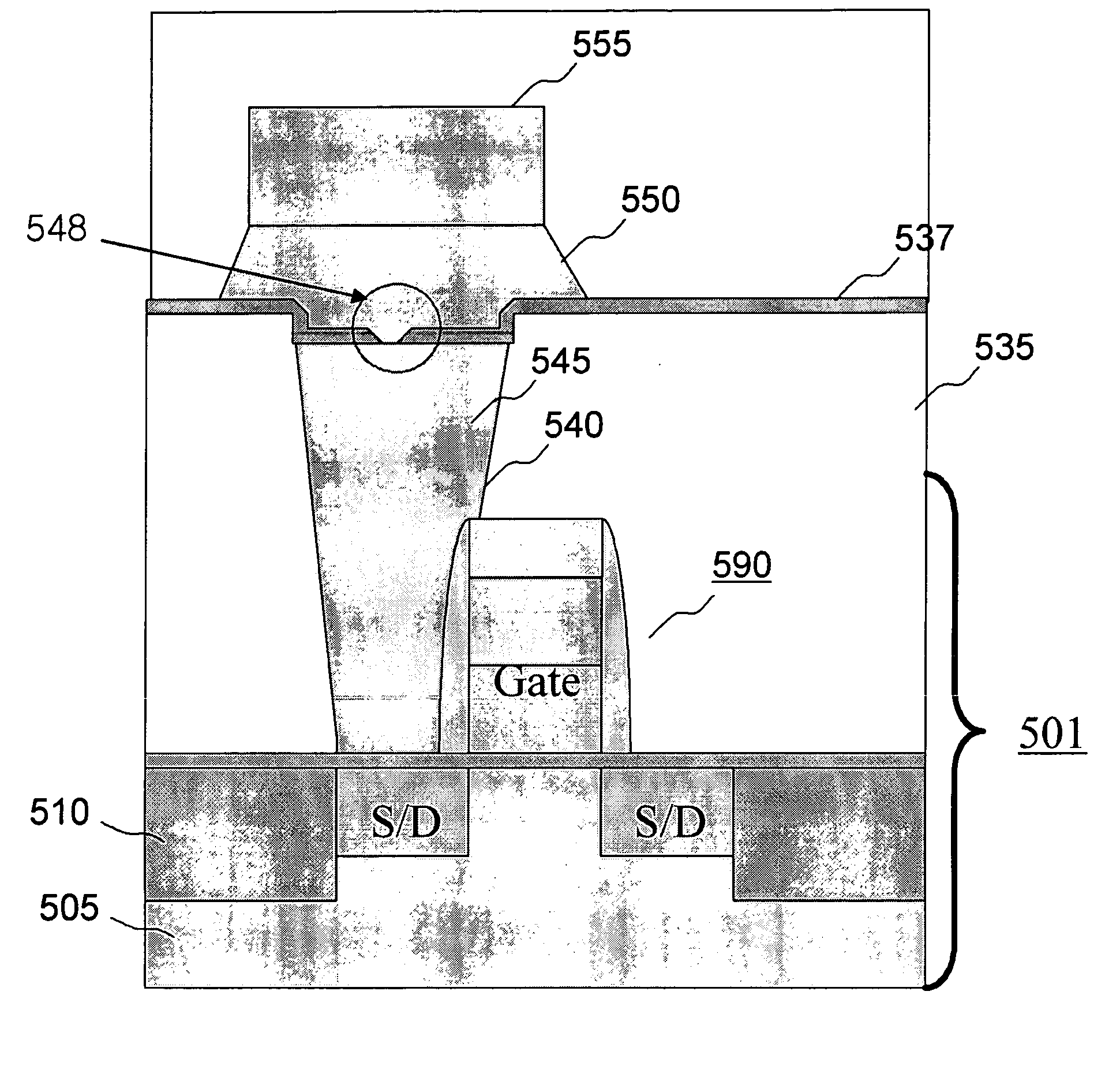

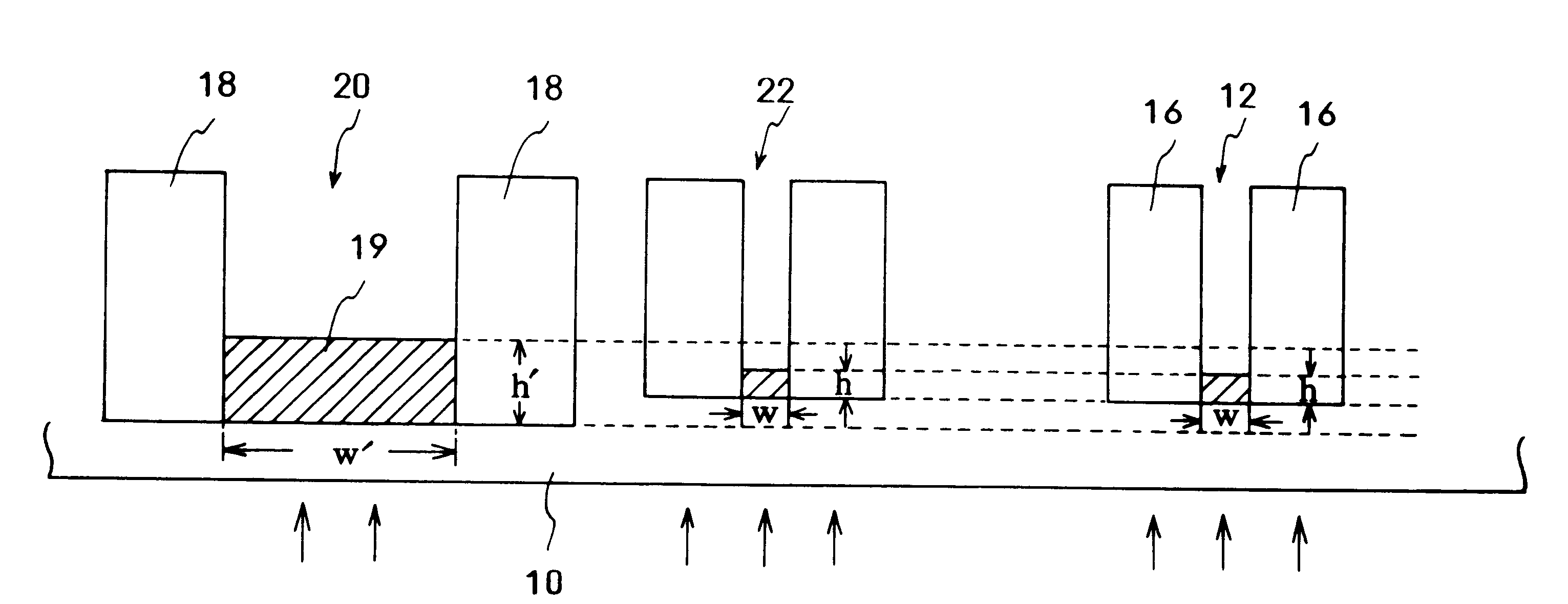

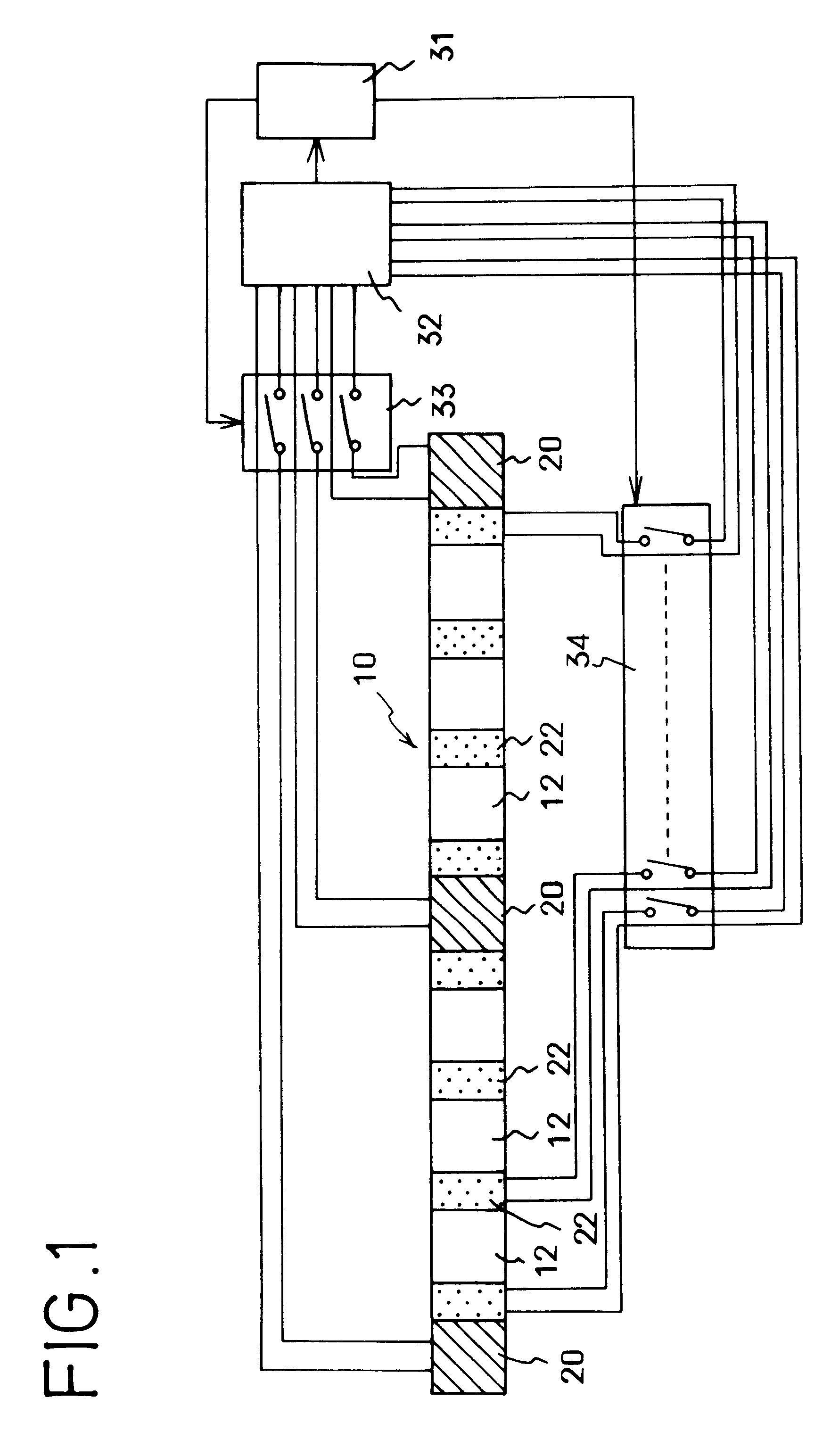

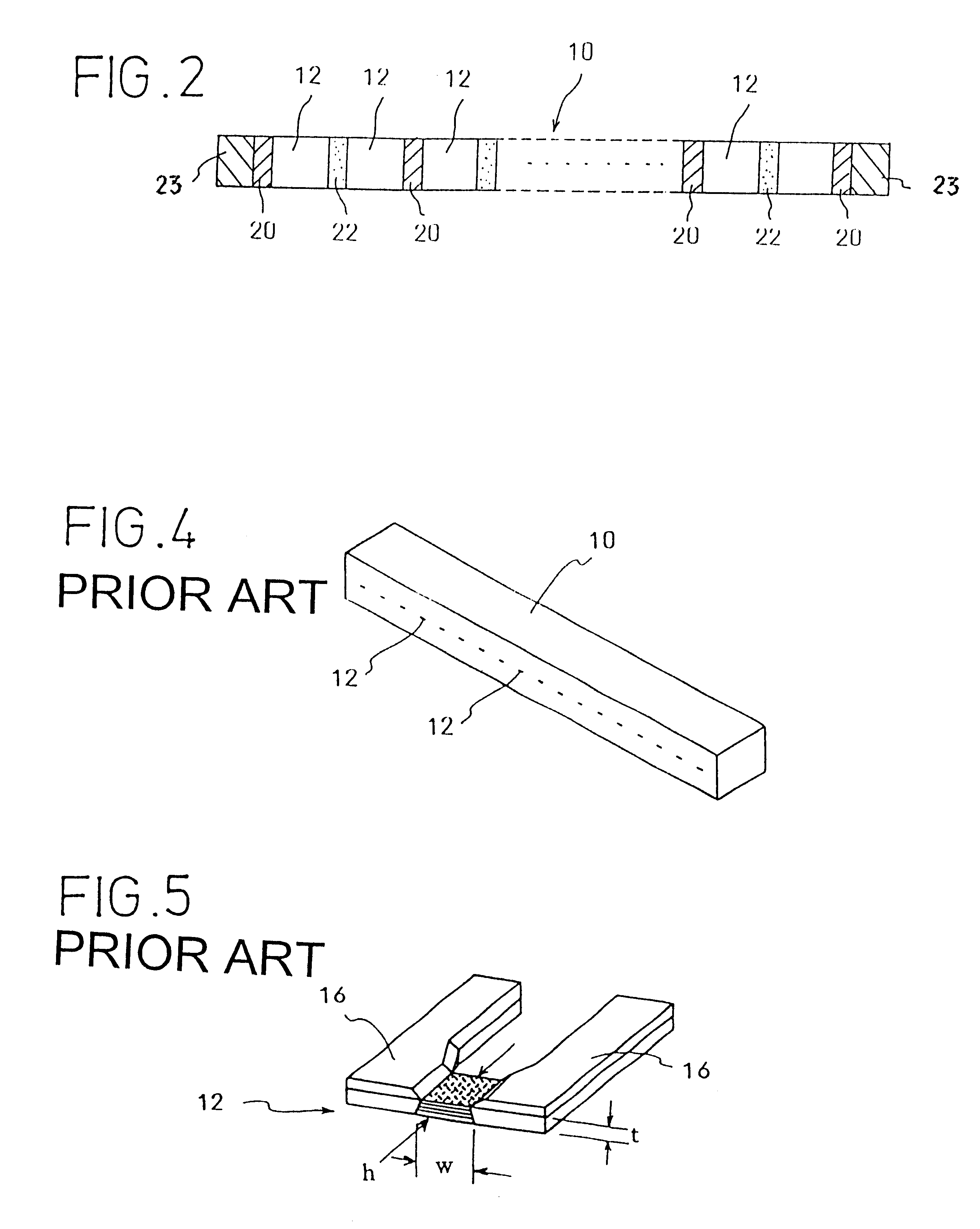

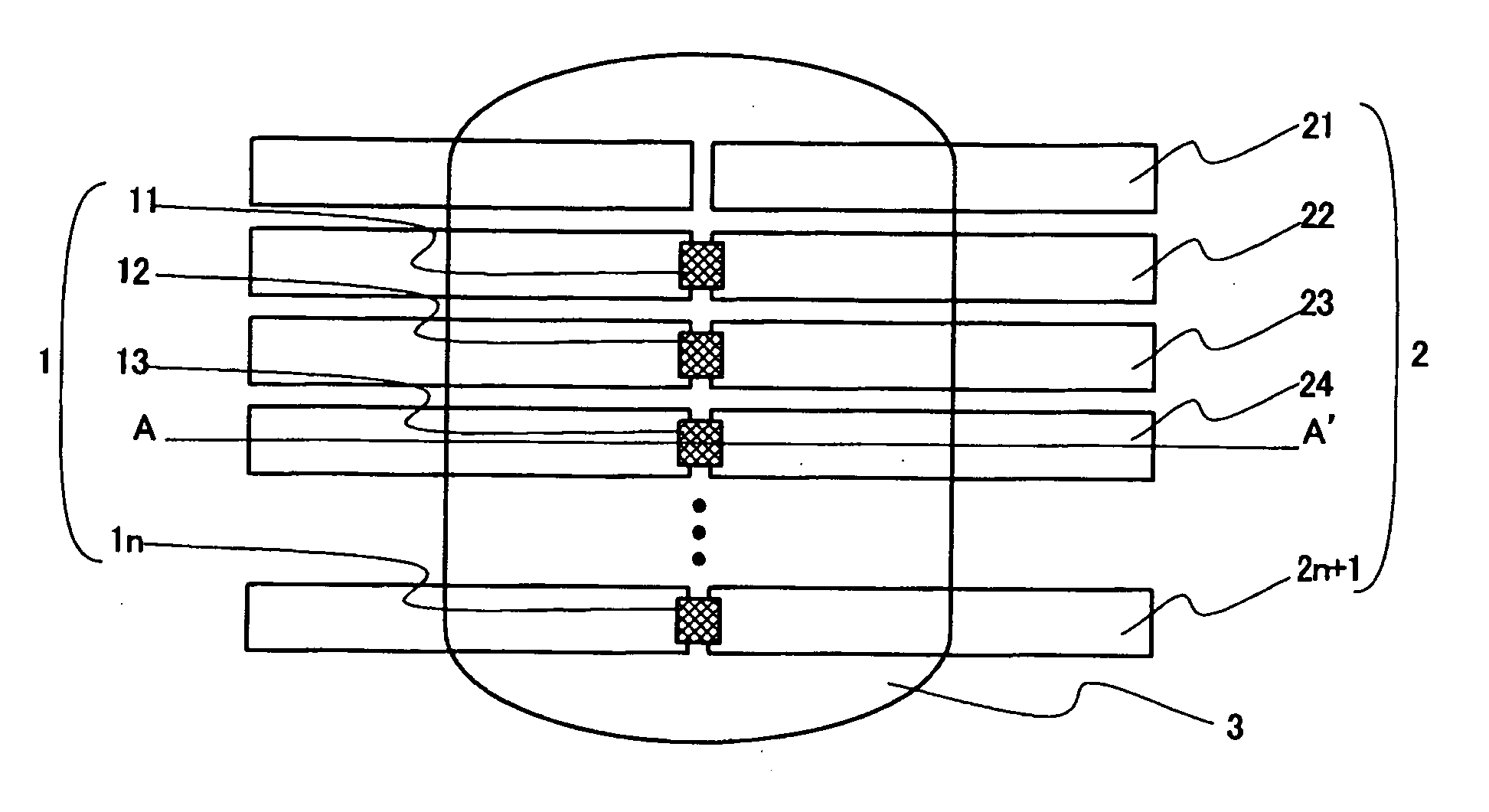

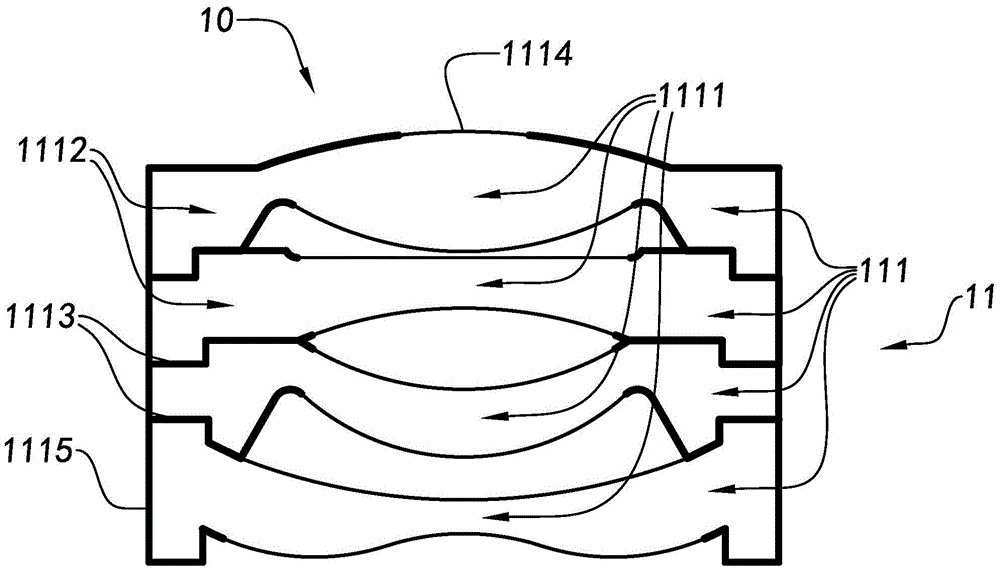

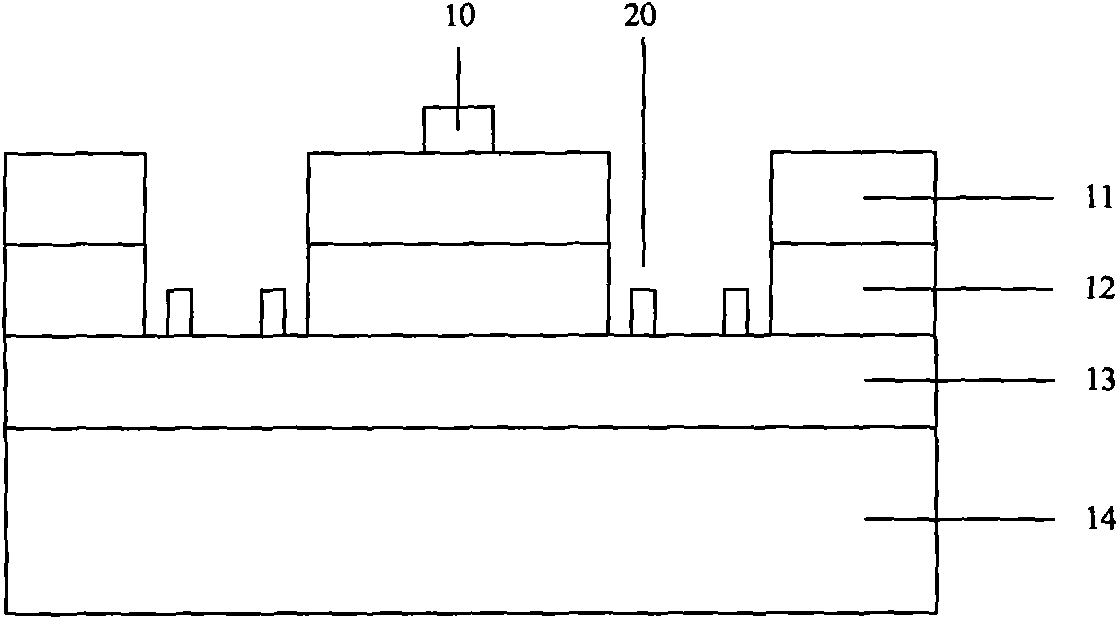

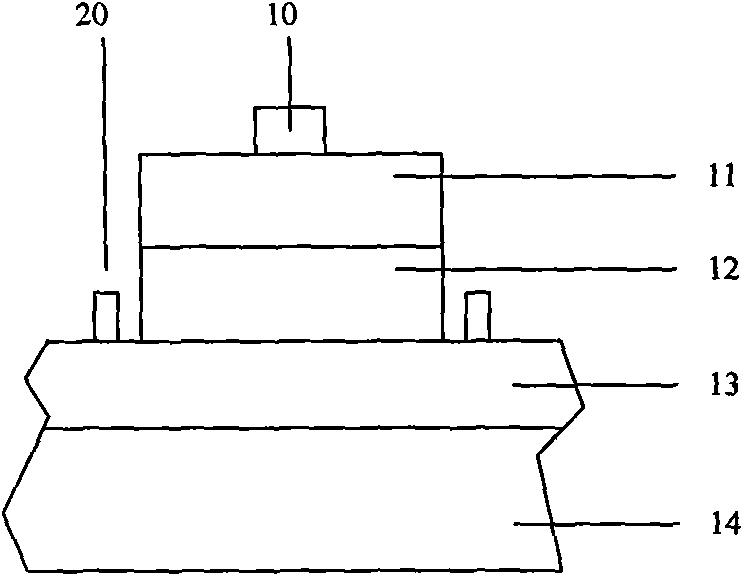

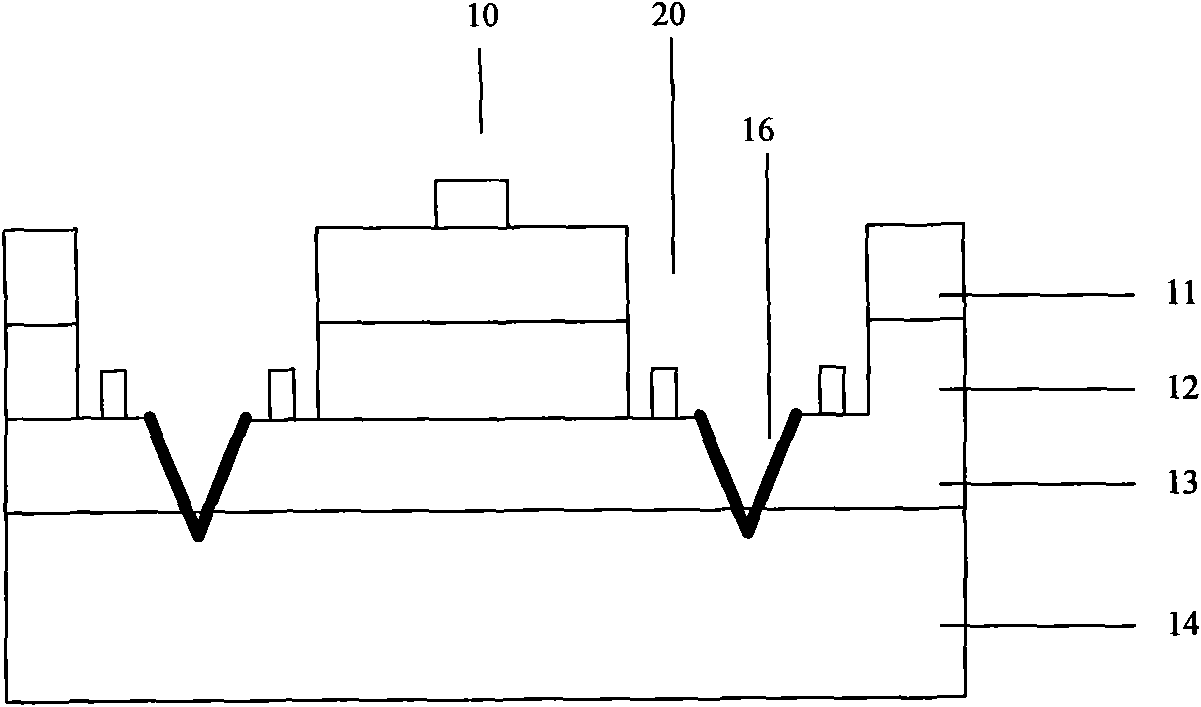

The present invention is to provide a phase change memory device having a new structure which can be easily manufactured by mass-production with a high yield rate, therefore, reducing the cost of process and providing reliable device characteristics, and a manufacturing method thereof. The present invention provides a phase-change memory device comprising: a lower dielectric layer; a lower electrode, at least a part of the lateral surface of the lower electrode being surrounded by the lower dielectric layer; a thin dielectric layer including a pore having smaller area than the top surface of the lower electrode, aligned to the top surface of the lower electrode and extending to the top surface of the lower electrode; and a phase-change resistor filling the pore and formed on the thin dielectric layer. In the proposed structure of the present invention, the pores or local damaged spots can provide a micro path of current and localize the phase-changing volume in the phase-change resistor. Thus, the phase-change memory device can be operated with very low power.

Owner:LEE HEON

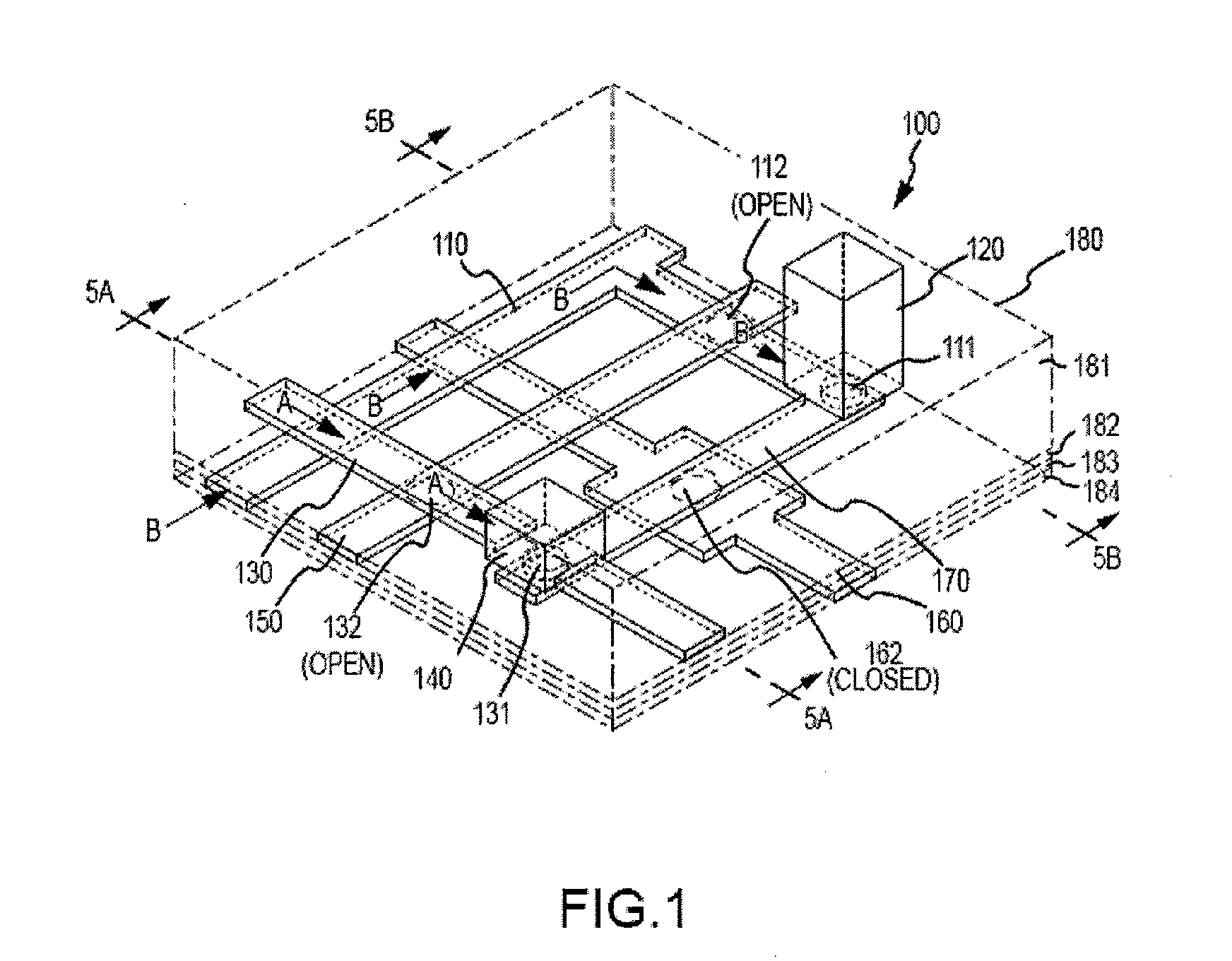

Microfluidic devices and methods

ActiveUS20100230613A1Shorten mixing timeManufacturing yield rate is increasedOptical radiation measurementHeating or cooling apparatusTemperature controlFluorescent imaging

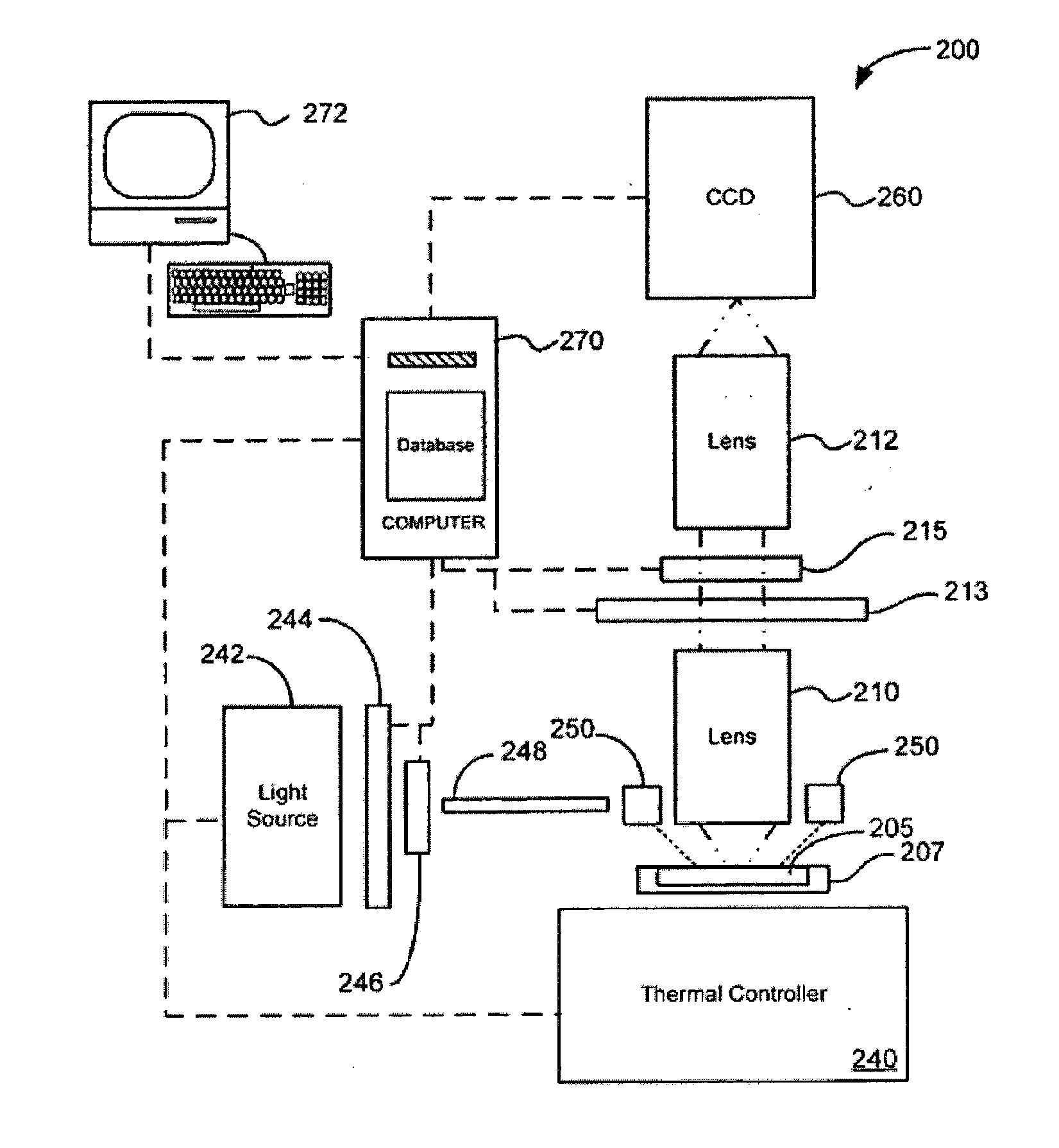

Embodiments of the present invention provide improved microfluidic devices and related apparatus, systems, and methods. Methods are provided for reducing mixing times during use of microfluidic devices. Microfluidic devices and related methods of manufacturing are provided with increased manufacturing yield rates. Improved apparatus and related systems are provided for supplying controlled pressure to microfluidic devices. Methods and related microfluidic devices are provided for reducing dehydration of microfluidic devices during use. Microfluidic devices and related methods are provided with improved sample to reagent mixture ratio control. Microfluidic devices and systems are provided with improved resistance to compression fixture pressure induced failures. Methods and systems for conducting temperature controlled reactions using microfluidic devices are provided that reduce condensation levels within the microfluidic device. Methods and systems are provided for improved fluorescent imaging of microfluidic devices.

Owner:STANDARD BIOTOOLS INC

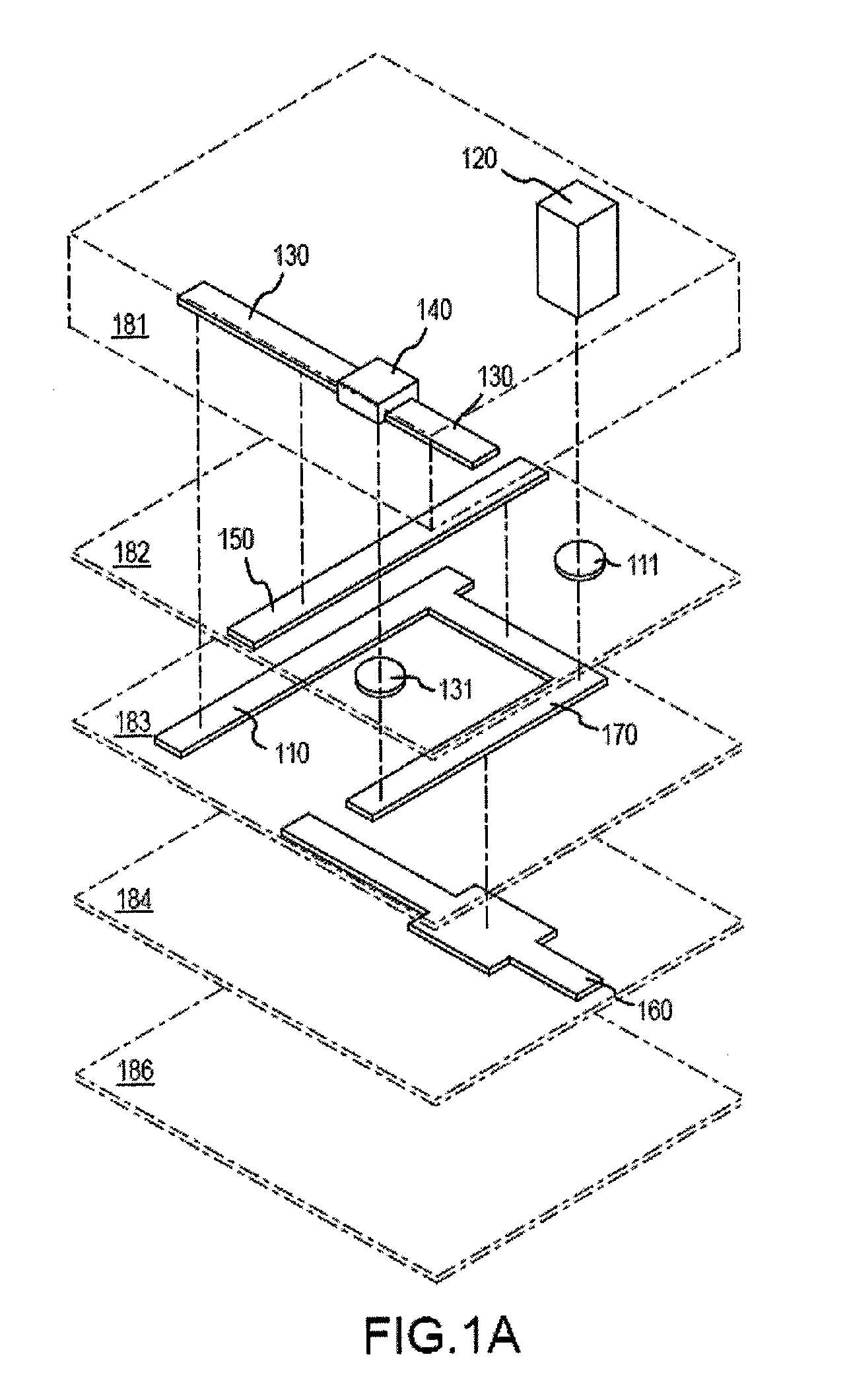

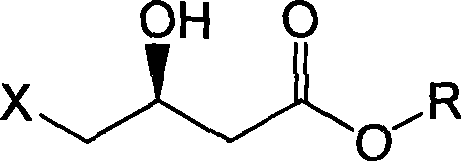

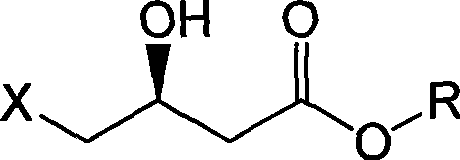

Preparation method for (S)-4-hydroxyl-2-oxo-1-pyrrolidine ethanamide

The present invention provides a preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide. The preparation method comprises: (S)-4-halogen-3-hydroxyl butyric ester as a raw material reacts under the conditions with polar solvent and alkalinity to prepare the crude product of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide; and the crude product is purified. The preparation method is characterized in that inorganic alkali is added for a plurality of times in the reaction process under the condition with alkalinity so as to control the pH value in the reaction to be less than or equal to 8.5. A large quantity of repeated tests are completed to determine that the optimum pH value of the reaction under the condition with alkalinity is less than or equal to 8.5, and the alkali is added in batches to strictly control the pH value of the whole reaction process, so that the alkali conditions required in the reaction can be satisfied and the reaction can be performed completely, and the target product (S)-oxiracetam is prevented from being damaged in the alkaline solution, thereby improving the yield rate of the target product (S)-oxiracetam and reducing the cost.

Owner:CHONGQING RUNZE PHARM CO LTD

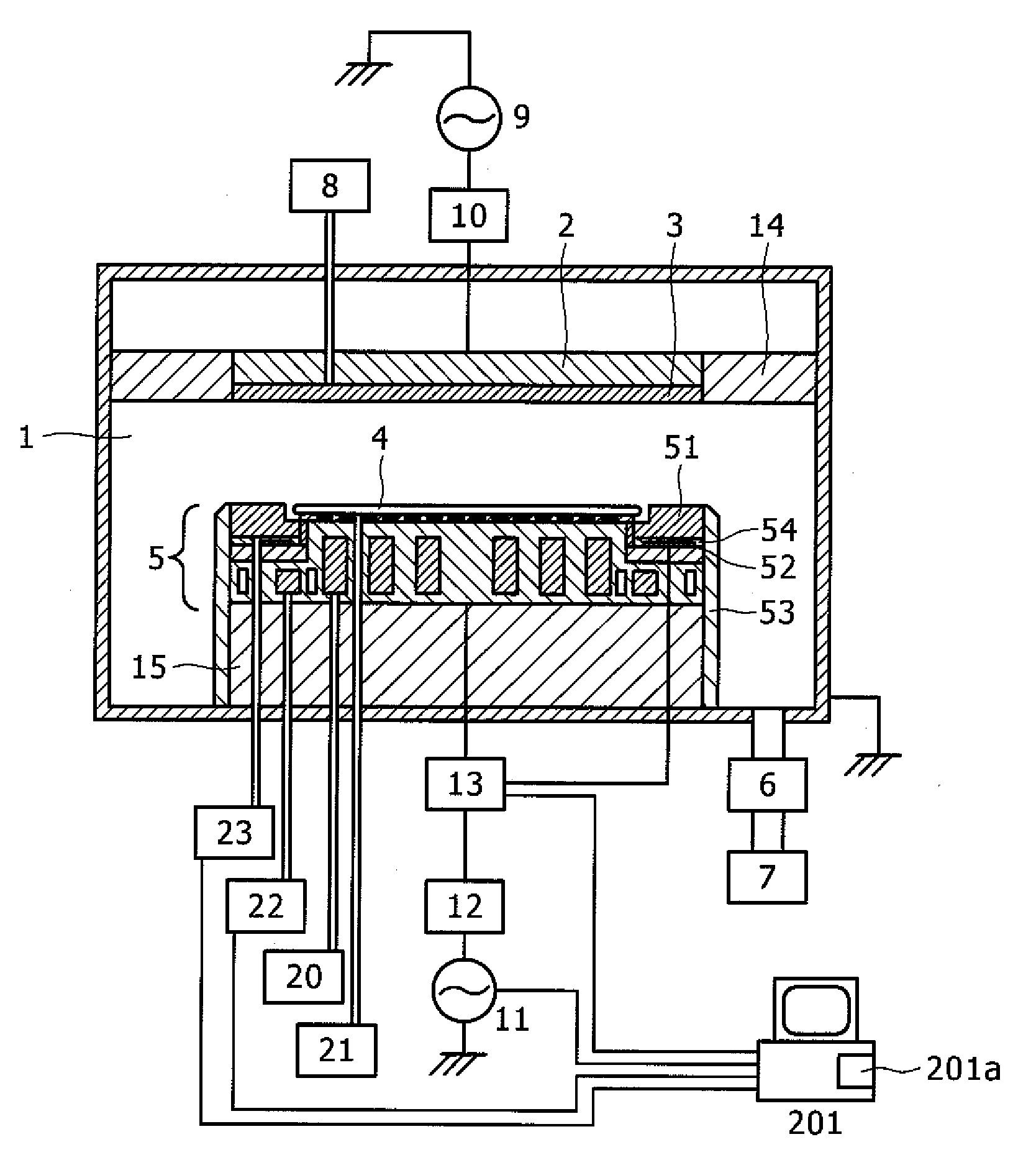

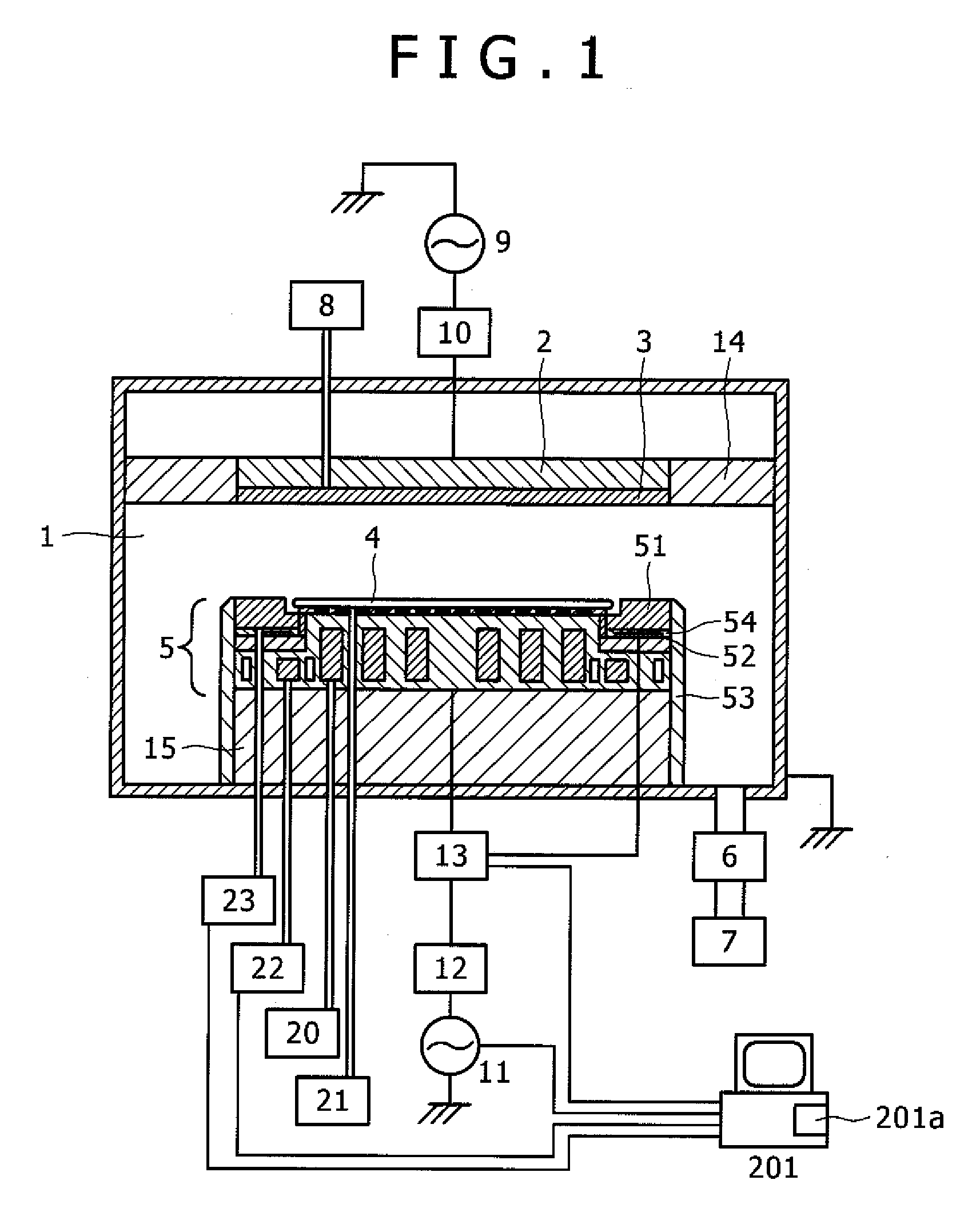

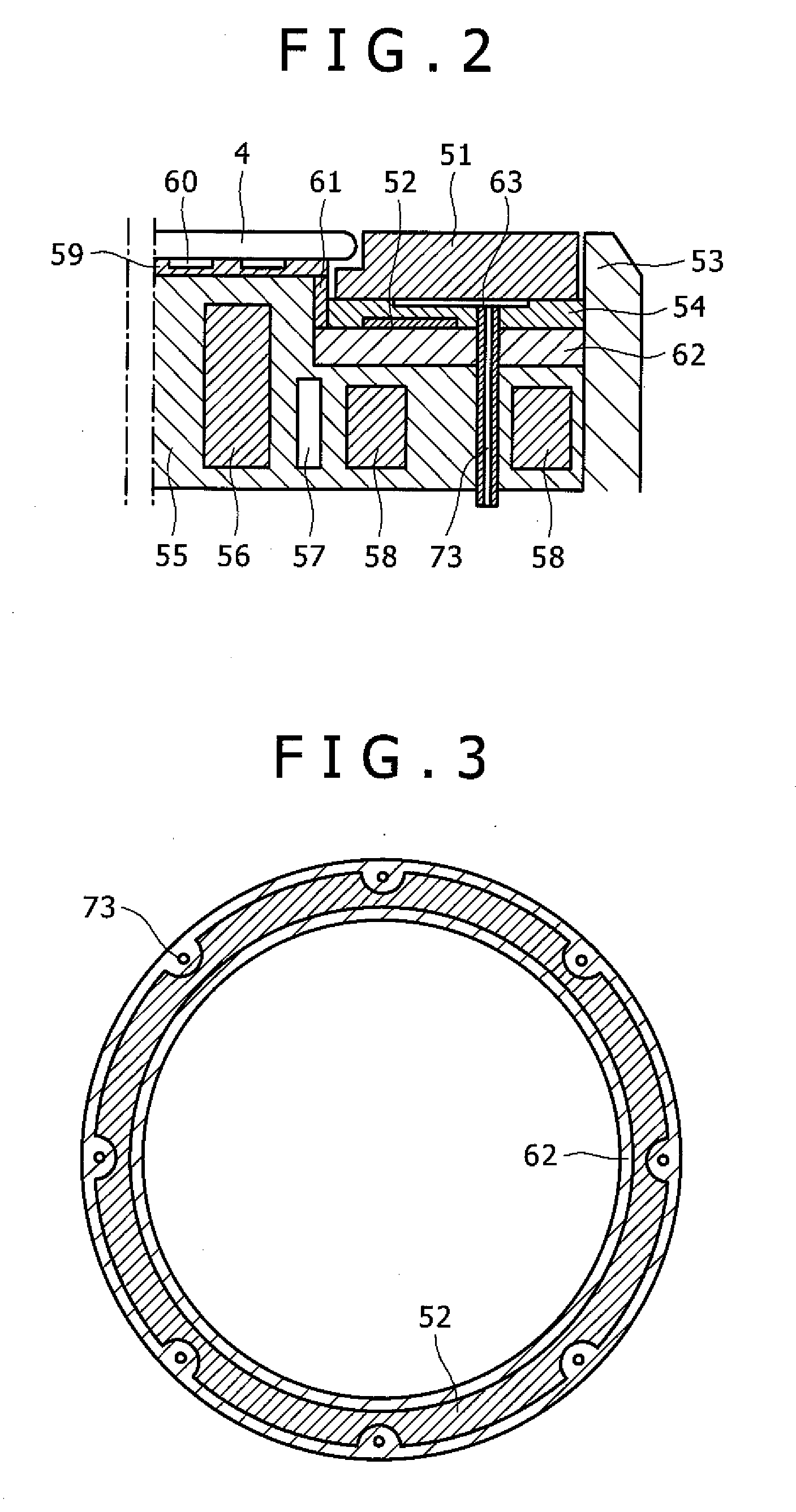

Plasma processing apparatus and plasma processing method

InactiveUS20100326957A1Degradation of etching characteristic can be preventedAvoid degradationElectric discharge tubesDecorative surface effectsTemperature controlElectric power

An electrostatic adsorption layer, an electrode layer, and an insulating layer are provided in a lower portion of a focus ring disposed in an outer periphery of a substrate stage. A high frequency bias is applied to the focus ring by applying a high frequency electric power to the electrode layer. Further, the focus ring is electrostatically chucked to the electrostatic chucking layer and a heat transfer gas is provided between the focus ring and the electrostatic adsorption layer. Thus, the focus ring can be cooled and the temperature of the focus ring is controlled to a predetermined value. With this structure, an etching characteristic at a wafer edge portion can be maintained favorably for a long time. Also, a yield rate at the edge portion can be favorably maintained for a long time, a wet period can be prolonged, and the device operation rate can be improved.

Owner:HITACHI HIGH-TECH CORP

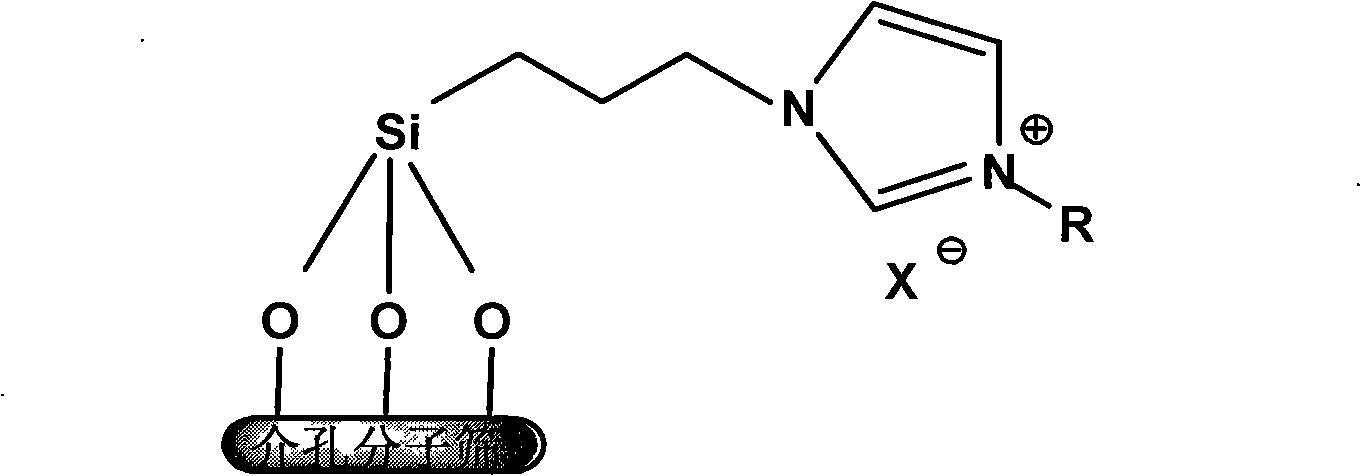

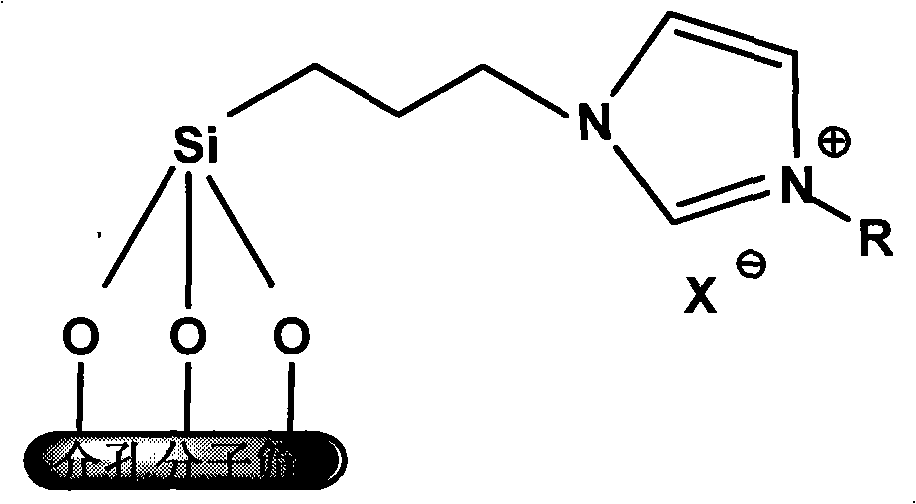

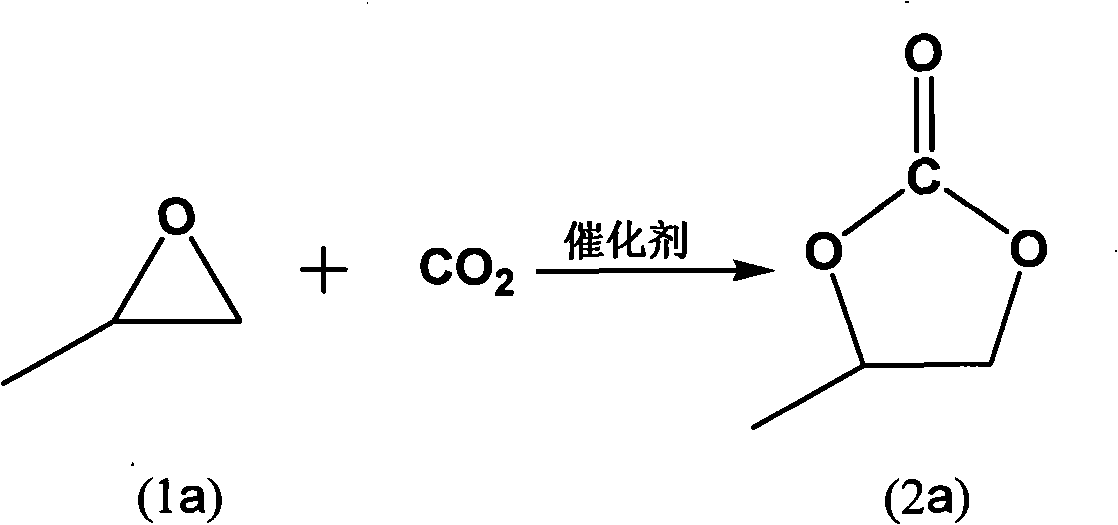

Process for synthesizing cyclic carbonate with catalysis of solid carried ion liquid catalyst

ActiveCN101318949AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveCarbonate ester

The invention relates to a method for synthesizing a cyclic carbonate ester by the catalysis of immobilized ionic liquid. The invention is characterized by utilizing a chemical method to prepare an immobilized ionic liquid catalyst. In the method, a mesoporous molecular sieve is used as a carrier; and the immobilized ionic liquid catalyst is prepared through different steps and catalyzes an epoxy compound to produce the cyclic carbonate ester. Compared with the prior immobilized catalyst, the immobilized catalyst is utilized to greatly improve a yield rate and selectivity in a short reaction time under a lower reaction temperature and a lower reaction pressure.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

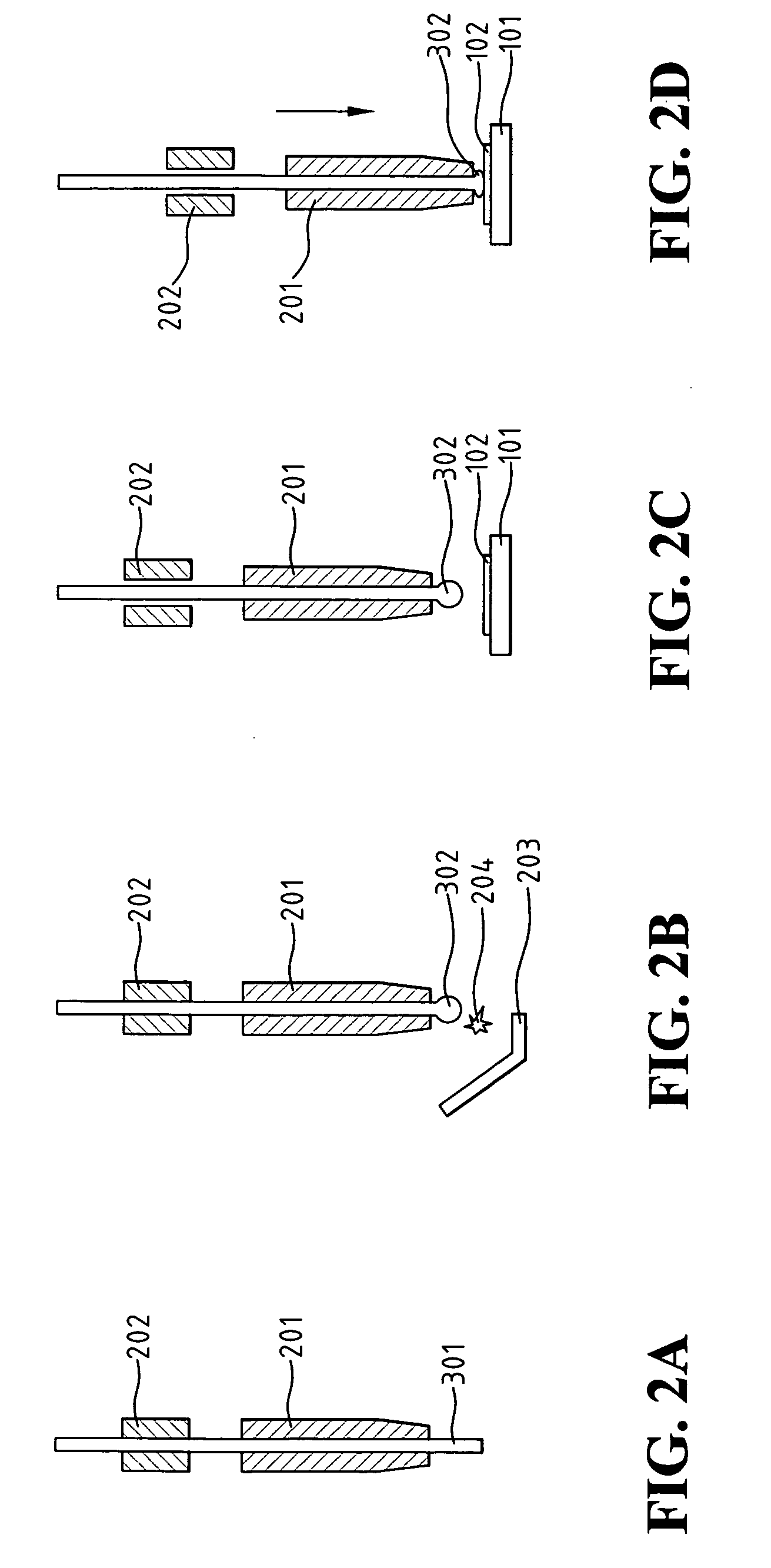

Wire-bonding method for chips with copper interconnects by introducing a thin layer

InactiveUS20050266672A1Prevent oxidationGood adhesionSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectLead bonding

A wire-bonding method for chips with copper interconnects by introducing a thin layer is provided for solving the problem of oxidizing a copper bonding-pad during bonding processing in order not to deteriorate the bonding strength and yield rate thereof. The wire-bonding method of the present invention comprises: a step for providing a chip with a copper bonding-pad; another step for providing an aqueous solution to form a Cuprous oxide thin layer on the copper bonding-pad; and yet another step for setting a plurality of copper interconnects on the copper bonding-pad and providing an ultrasonic power for removing the Cuprous oxide layer to have the interconnects bonded on the copper bonding-pad.

Owner:NATIONAL CHUNG CHENG UNIV

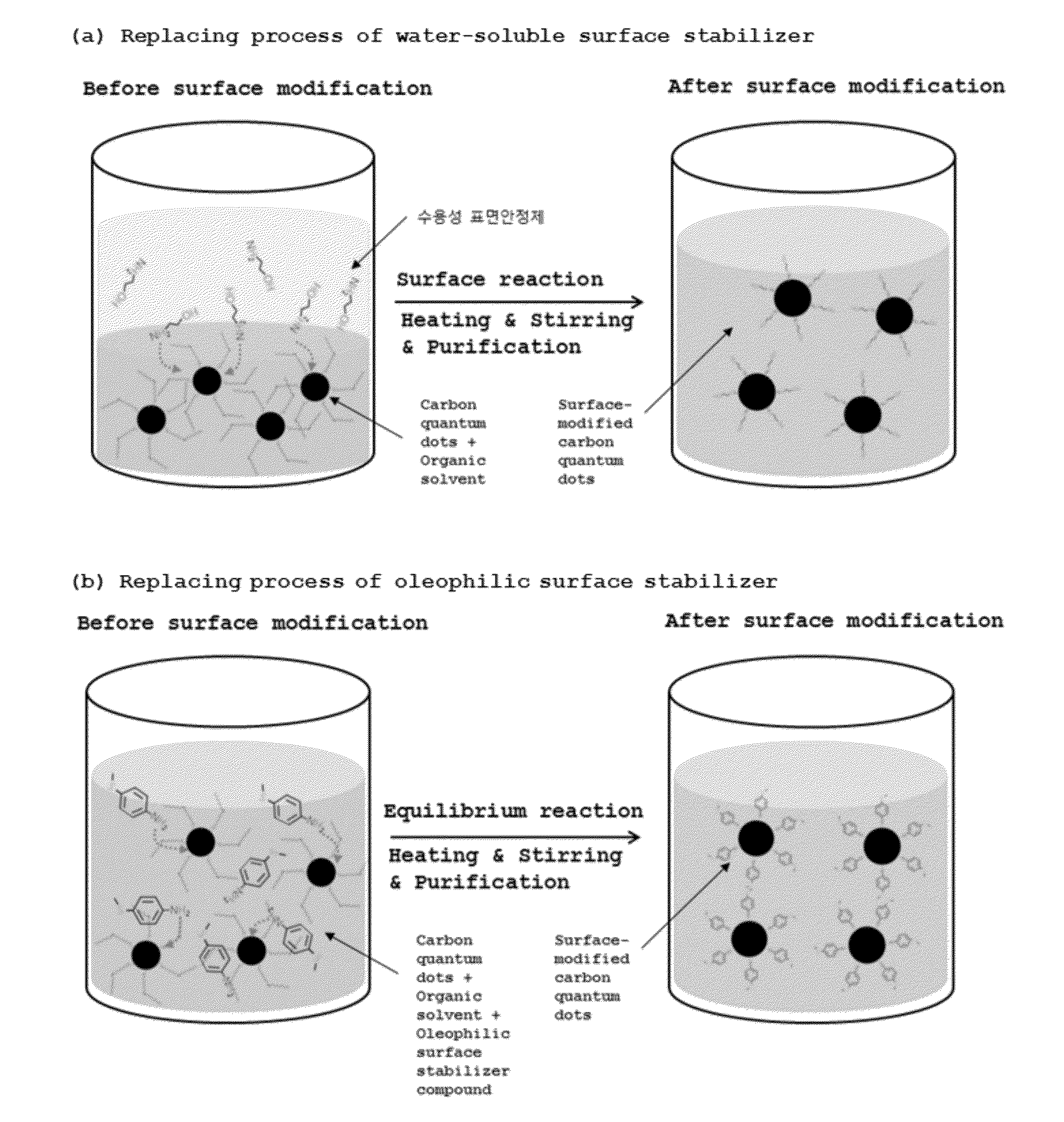

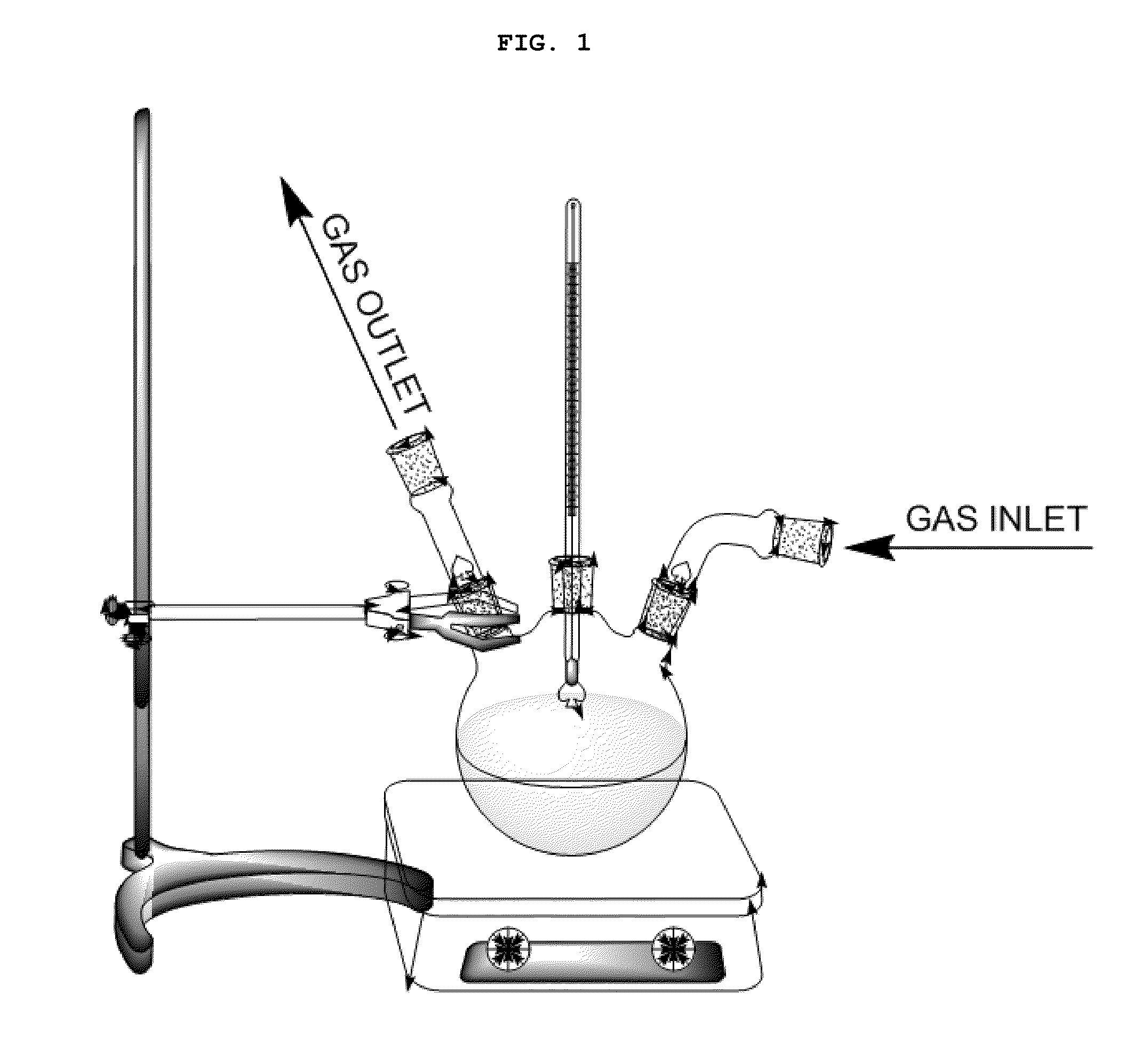

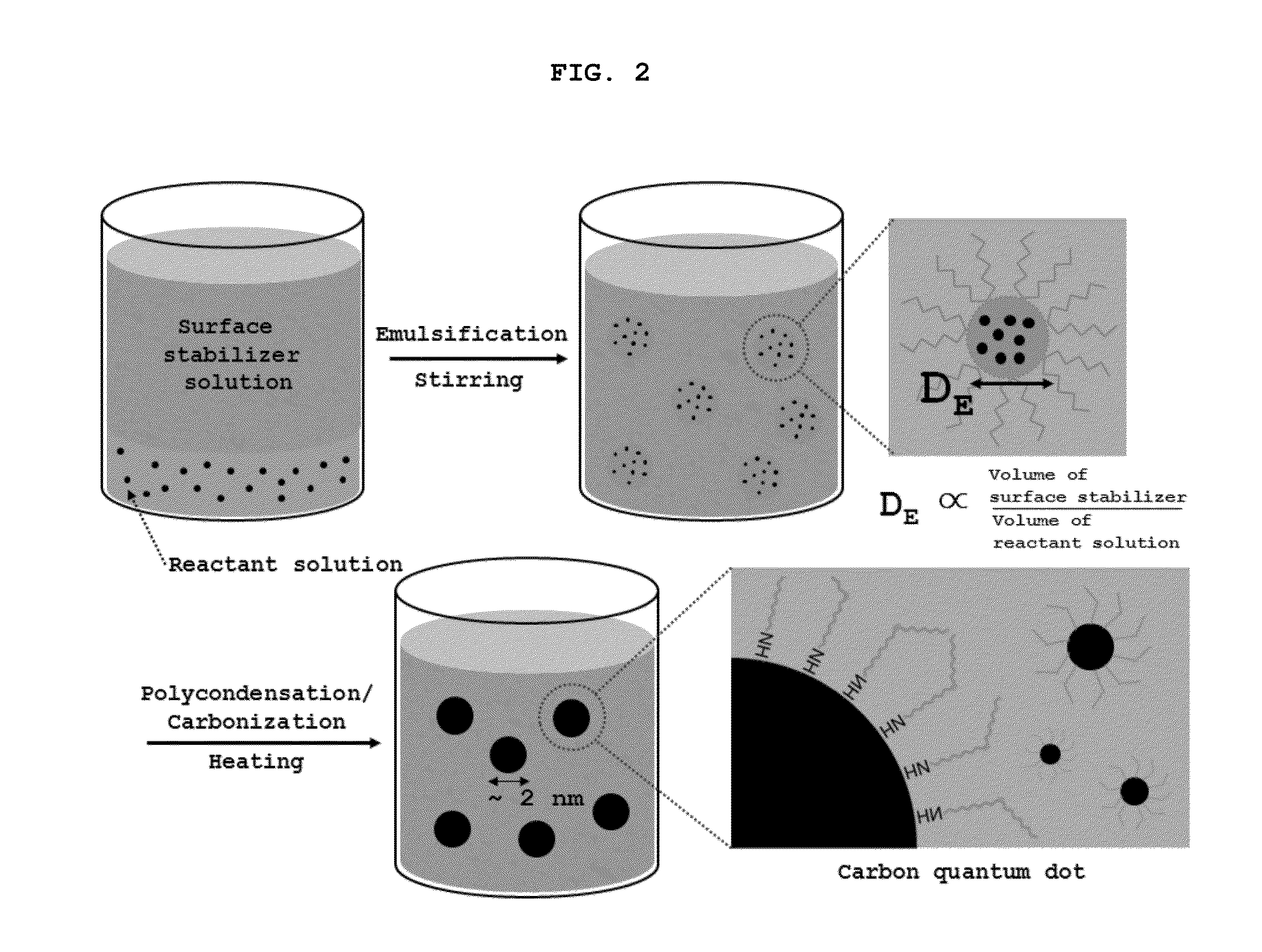

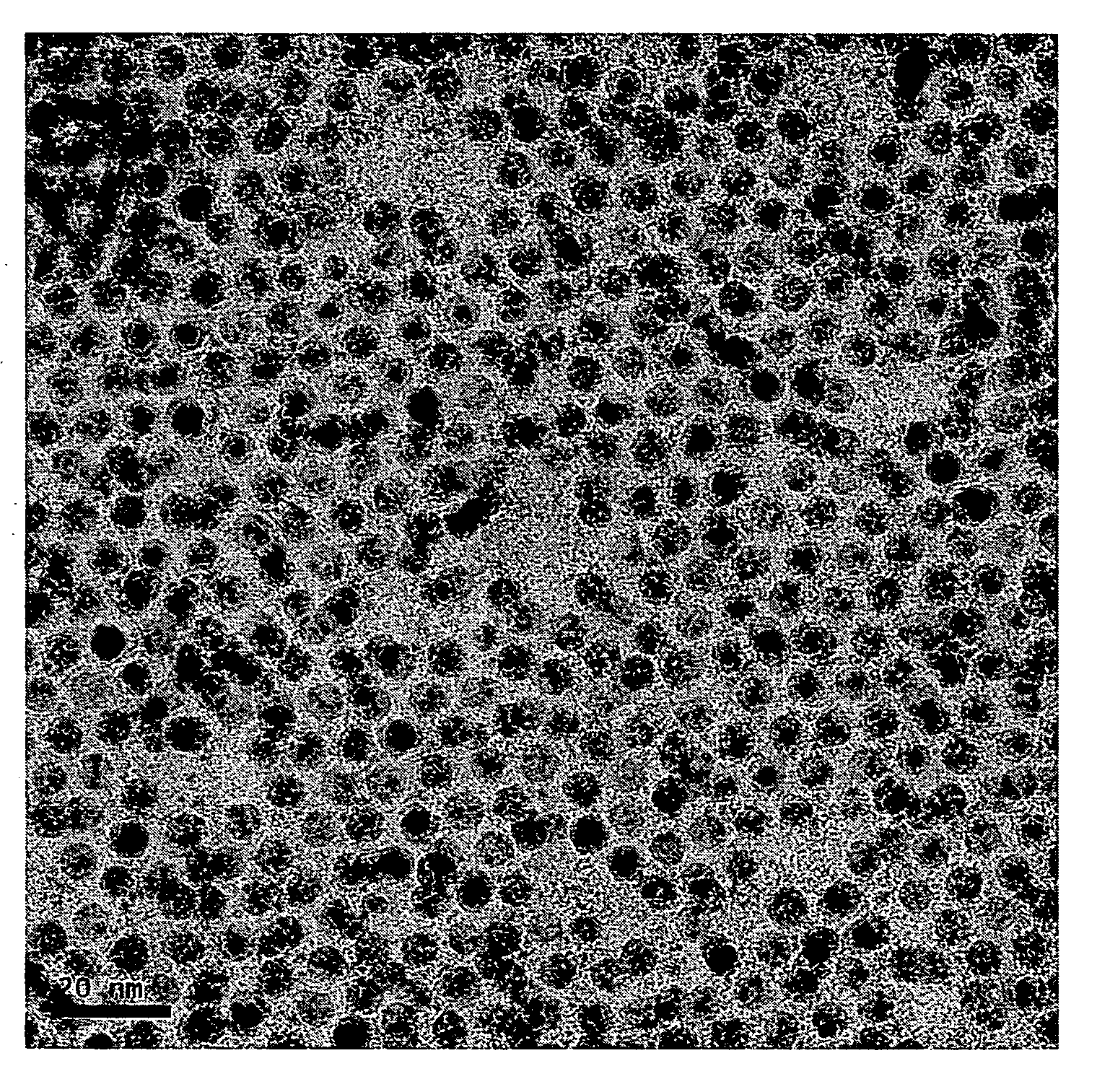

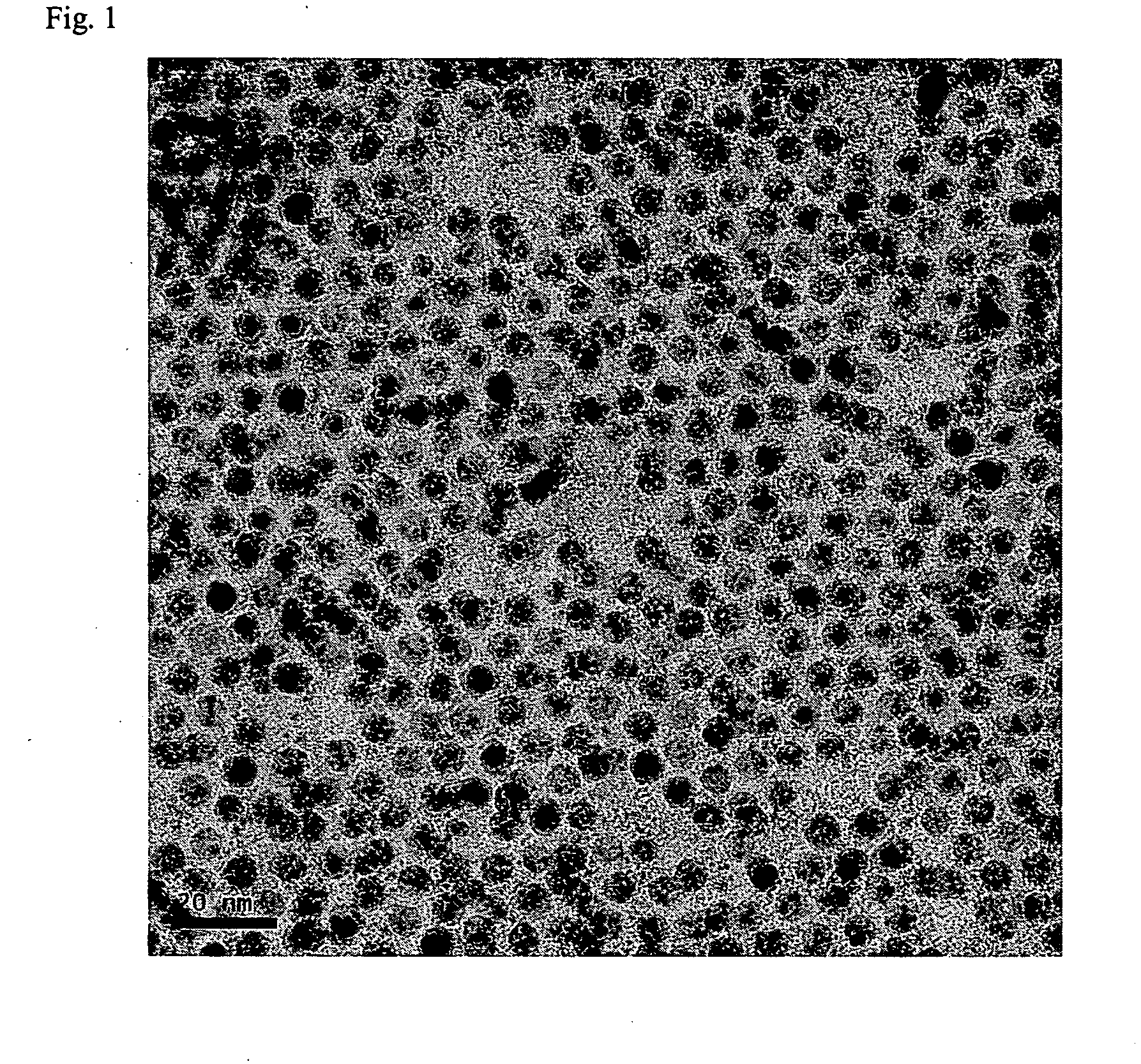

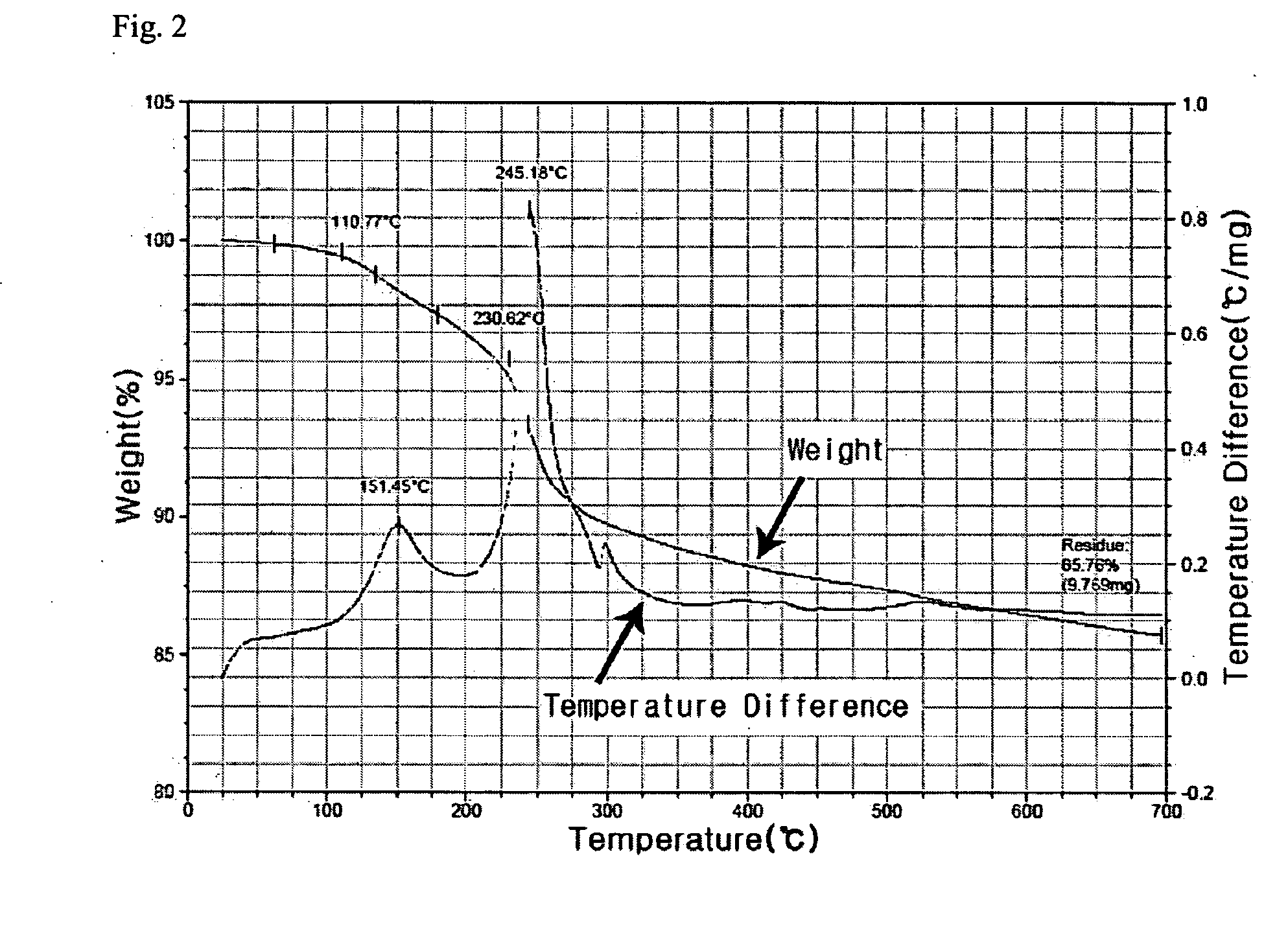

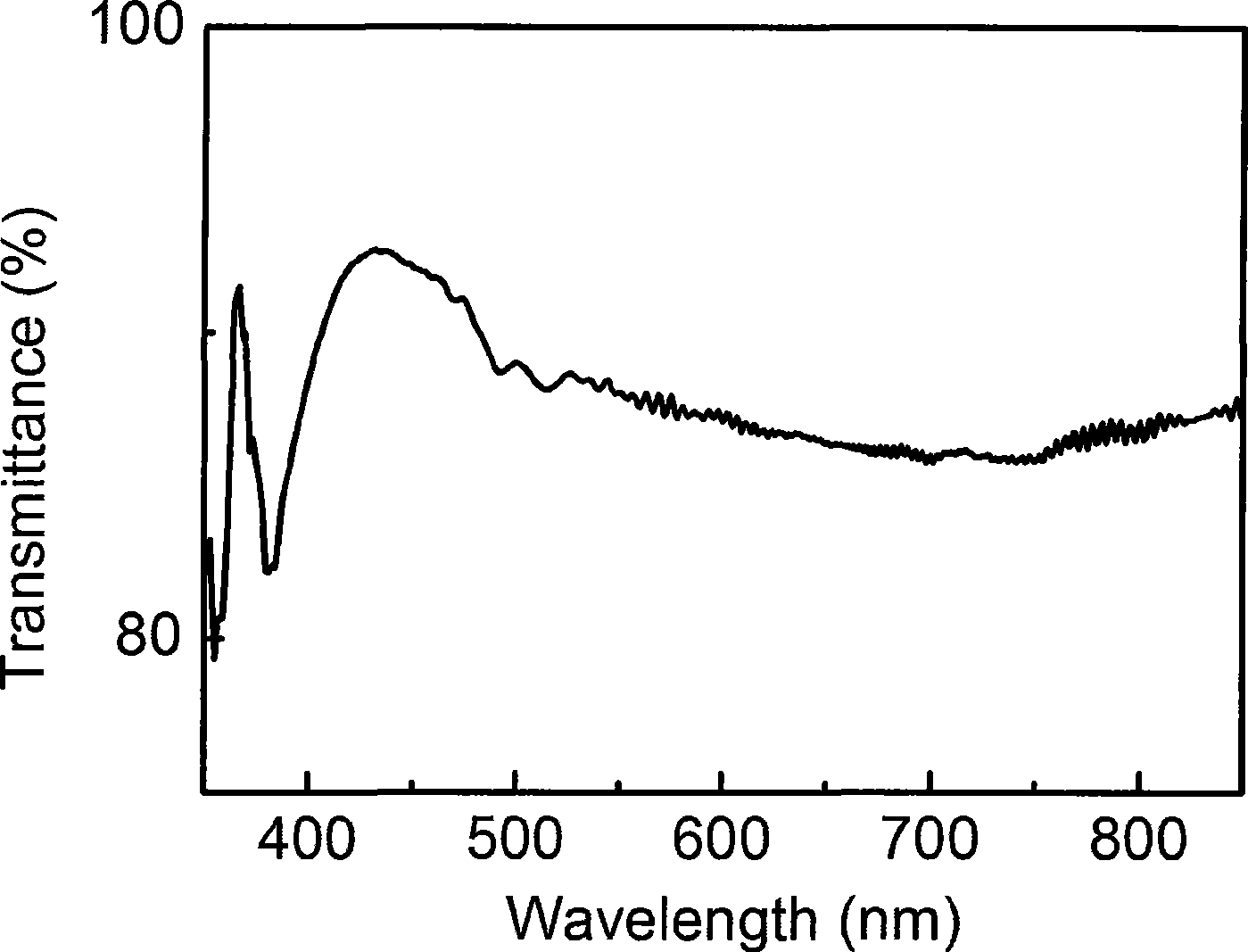

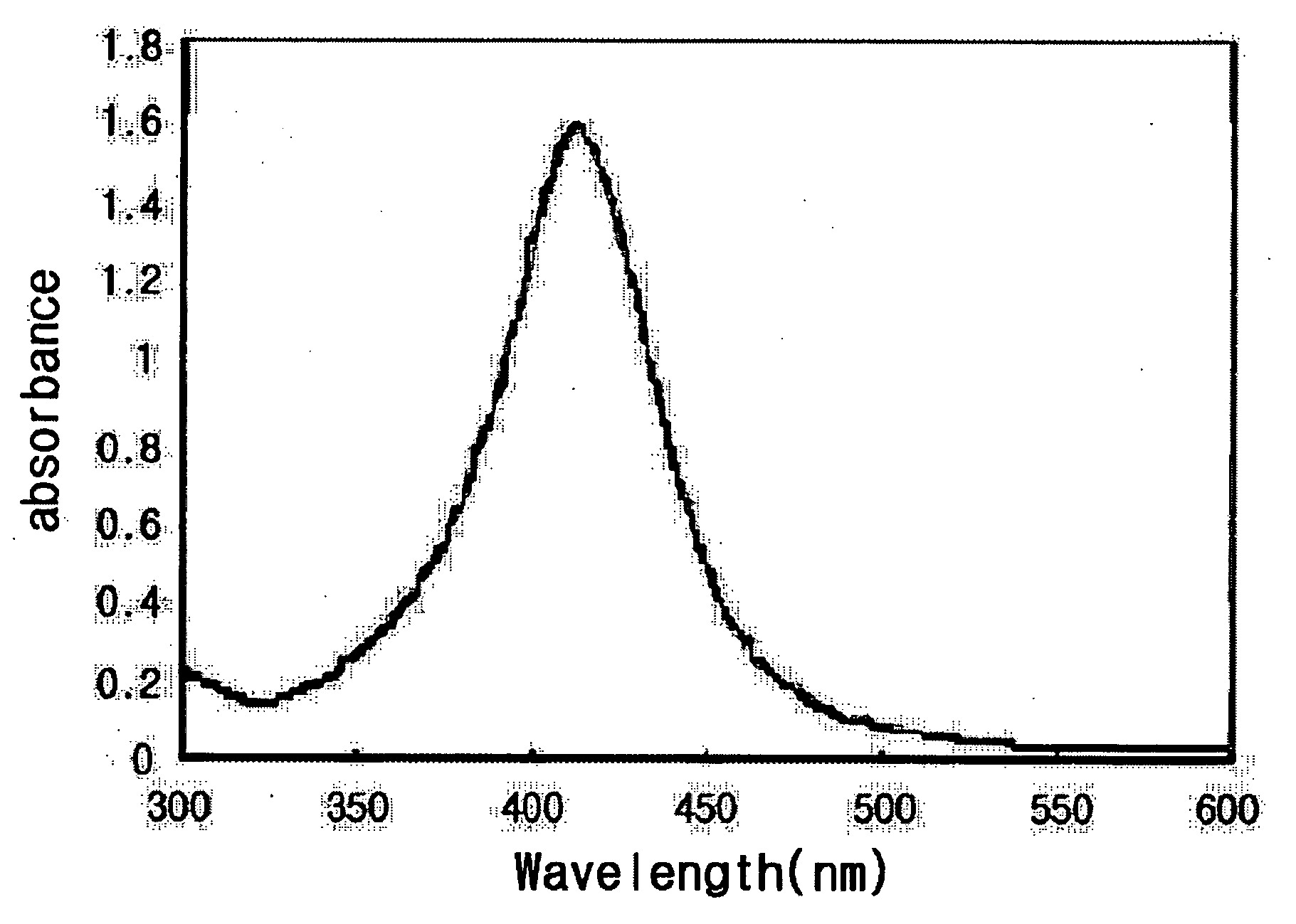

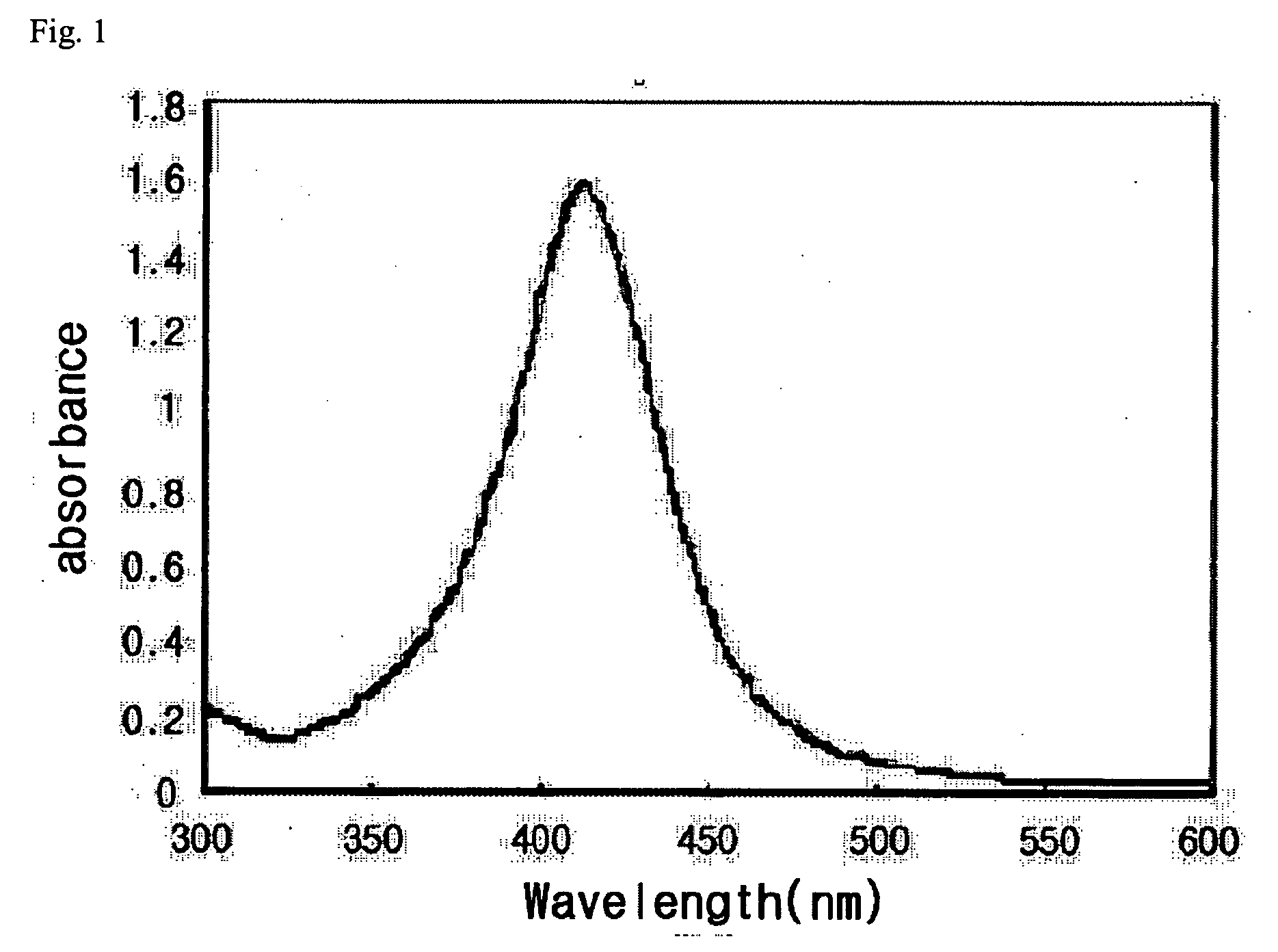

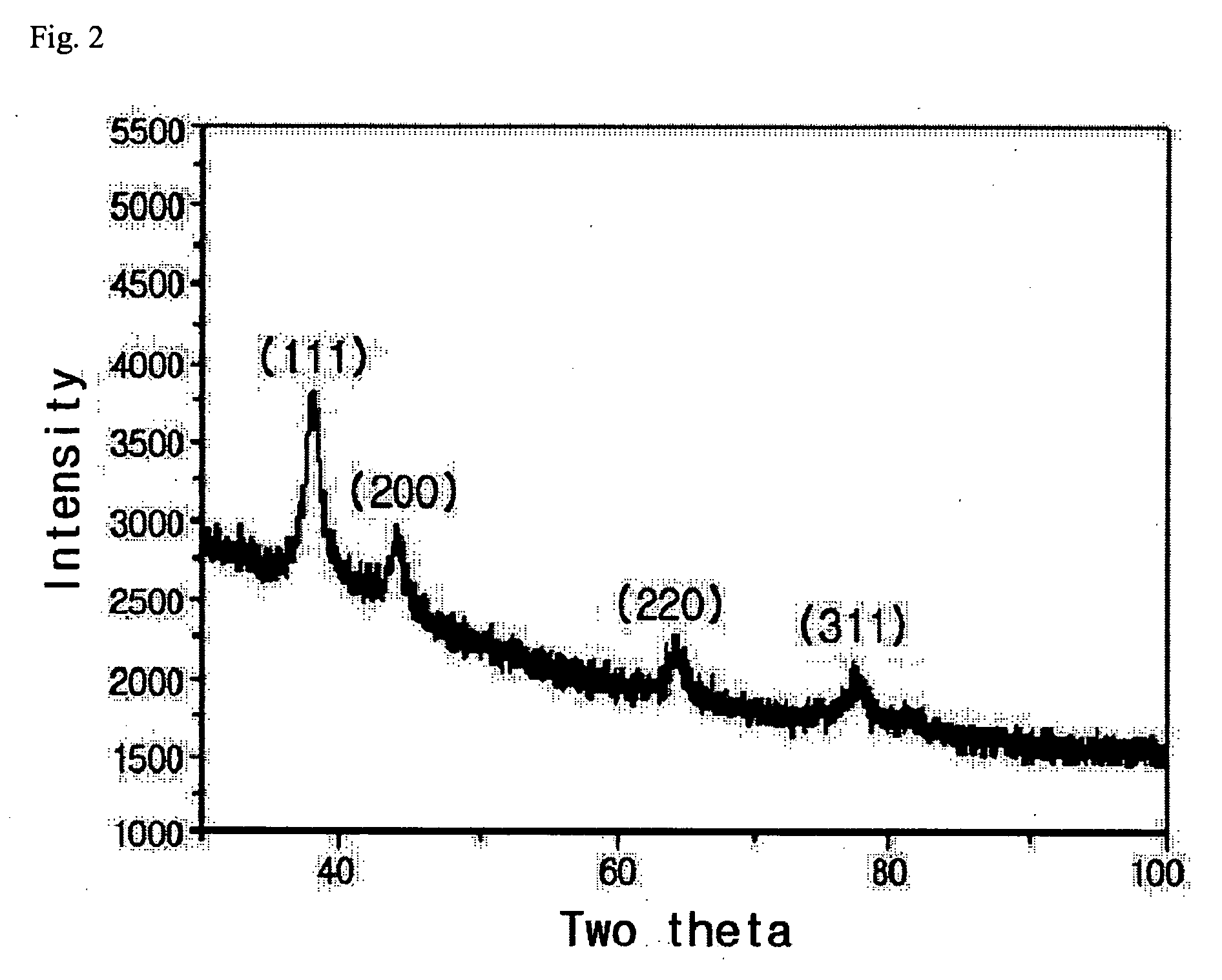

Process for preparing carbon quantum dots using emulsion

InactiveUS20150361334A1High reaction yieldEffective controlOrganic chemistryNano-carbonQuantum yieldEmulsion

The present invention provides a process for preparing carbon quantum dots having uniform size by using emulsion, and a process for doping the inside of the carbon structure with other element or replacing the surface with a surface stabilizer having a specific chemical functional group different from existing stabilizers in order to control the properties of the carbon quantum dots. The process for preparing the carbon quantum dots according to the present invention makes a mass production possible and the process thereof is simple. Furthermore, the process is easy to control the size of the quantum dots and the reaction yield rate of the method is excellent. In addition, according to the present invention, it is possible to synthesize carbon quantum dots having uniform size and superior quantum yield rate and it makes it possible to embody the color as equivalent to existing molecular chromophores or heavy metal quantum dots by changing the structure of the chromophore.

Owner:POSTECH ACAD IND FOUND

Method for producing silver nanoparticles and conductive ink

InactiveUS20090223410A1Uniform sizeHigh yield rateMaterial nanotechnologyMetal-working apparatusDispersion stabilityOxygen

A method of producing metal nanoparticles in a high yield rate and uniform shape and size, which is thus suitable for mass production. In addition, metal nanoparticles are provided that have superior dispersion stability when re-dispersed in various organic solvents, which thus suitable for use as a conductive ink having high conductivity. The method of producing nanoparticles includes mixing a metal precursor with a copper compound to a hydrocarbon based solvent, mixing an amine-based compound to the mixed solution of the metal precursor with copper compound and hydrocarbon based solvent, and mixing a compound including one or more atoms having at least one lone pair, selected from a group consisting of nitrogen, oxygen, sulfur and phosphorous to the mixed solution of the amine-based compound, metal precursor with a copper compound and hydrocarbon based solvent.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

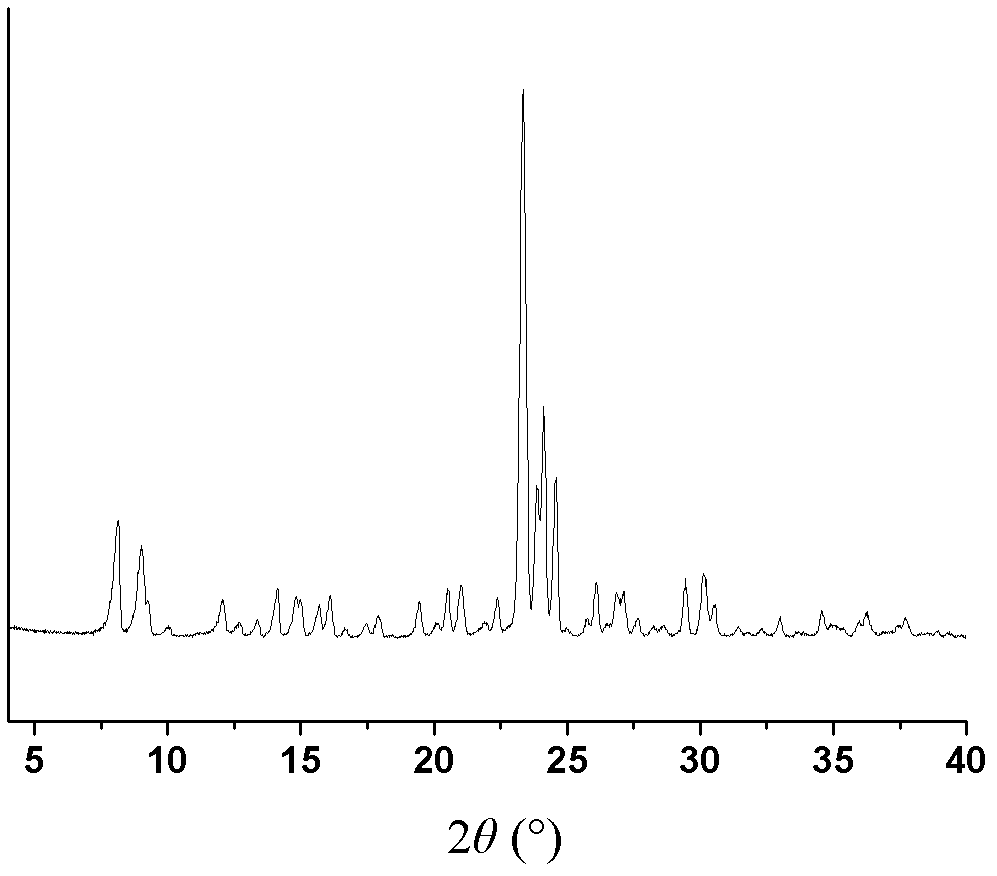

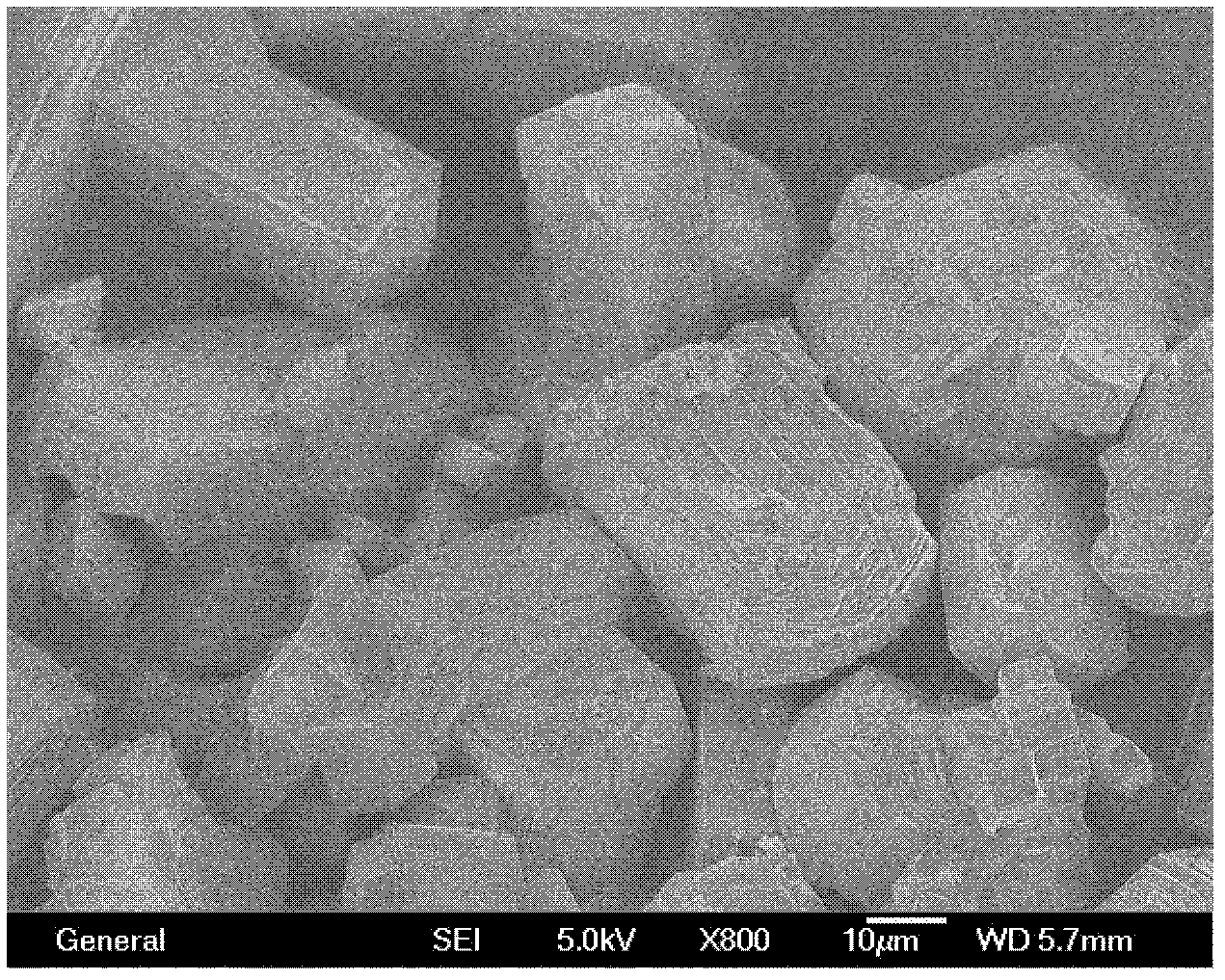

Method for synthesizing molecular sieve under solvent-free condition through grinding solid phase raw materials

ActiveCN102627287AHigh crystallinityThe synthesis steps are simplePentasil aluminosilicate zeoliteSolvent freeSolvent

The invention relates to a method for preparing a molecular sieve, aiming to provide a method for synthesizing a molecular sieve under a solvent-free condition through grinding solid phase raw materials. The method comprises the following steps of: grinding and mixing the pre-weighed solid raw materials which include silicon sources, metal atom sources, an organic template agent, and an alkalinity regulator, putting the grinded material into a reactor, and performing a crystallization reaction for 1-8 days at a temperature ranged from 80 DEG C to 180 DEG C; and drying for over 12 hours at a temperature of 80 DEG C after washing the reaction product thoroughly by using deionized water to obtain a final product. A ZSM-5 molecular sieve, a Beta molecular sieve, a ZSM-39 molecular sieve, and a SOD molecular sieve, which have a good crystallinity and a controllable silicon-aluminum ratio, can be prepared through the method provided by the invention. The synthetic route only involves a mixture of the raw materials without a use of any solvents, which simplifies the synthetic process compared to the traditional method, improves the yield rate and the single reactor utilization rate greatly, reduces the production cost greatly, saves energy and reduces emission, and has a wide industrial application prospect.

Owner:淮安六元环新材料有限公司

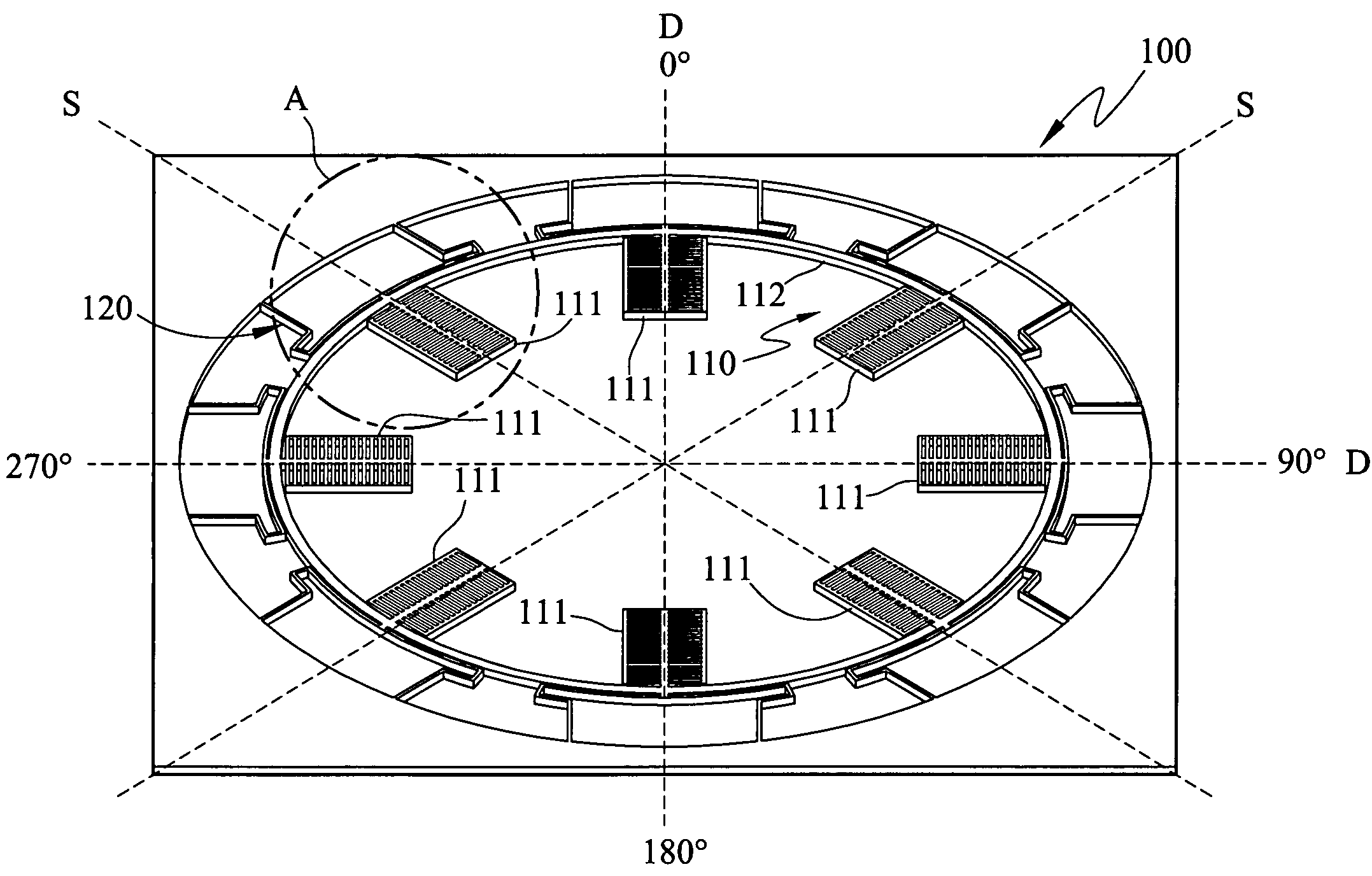

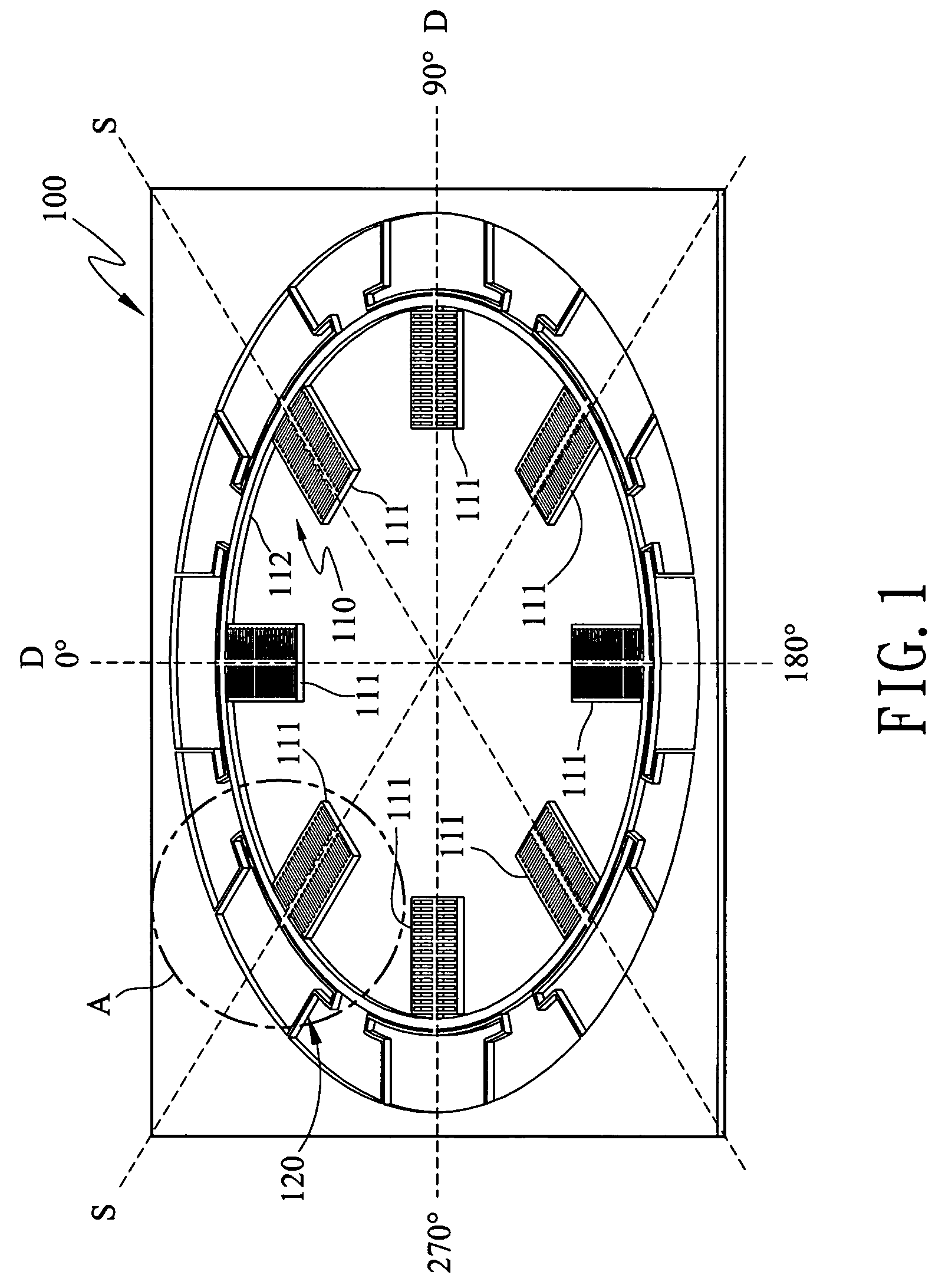

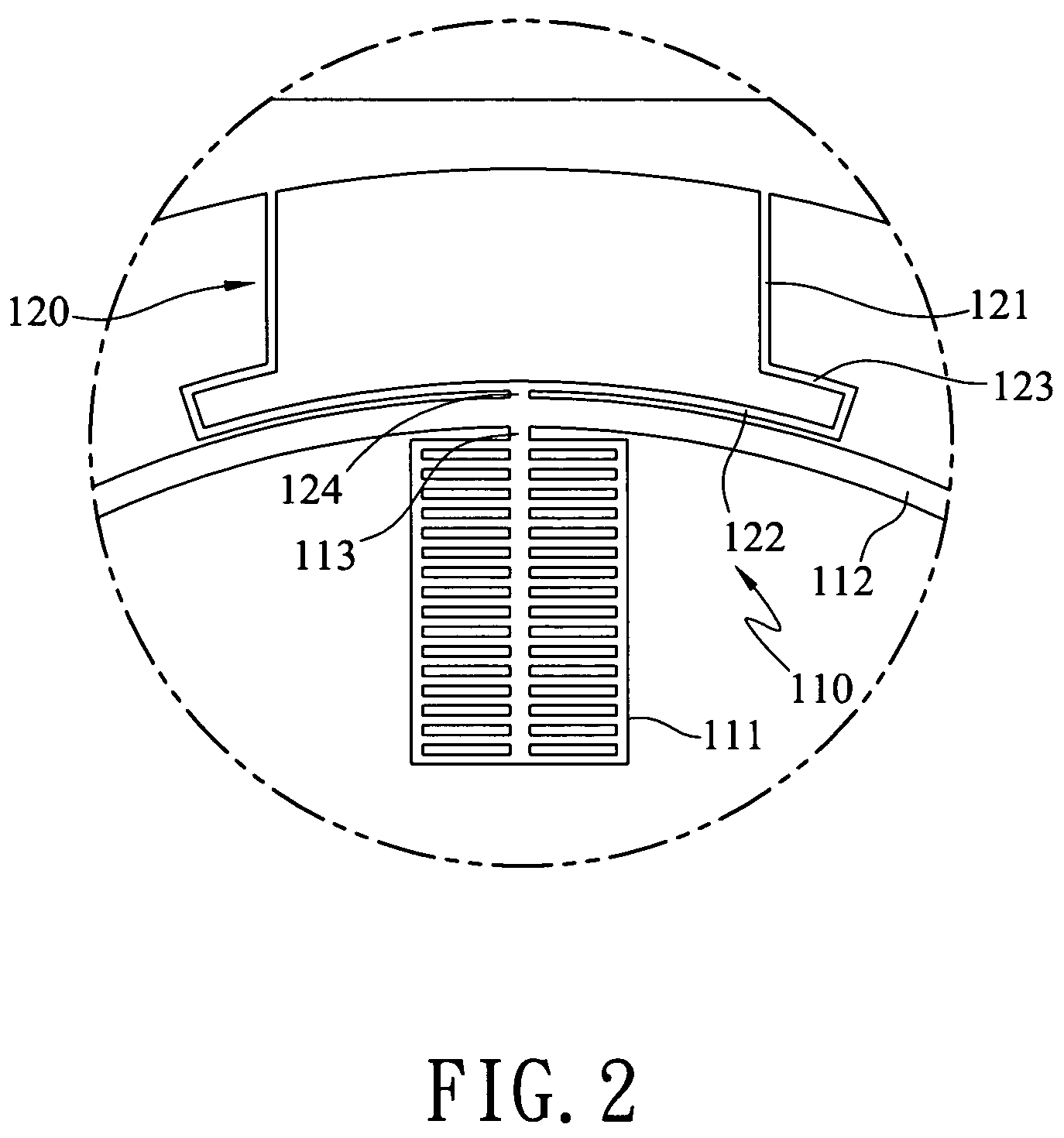

Micro angular rate sensor

InactiveUS7155978B2Great massIncrease the areaAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitancePlanar electrode

A micro angular rate-sensing device is provided. A vibrator, having a plurality of proof masses connected to a ring, is arranged in a first base. Flexible supporting members connect to the vibrator to suspend the vibrator in the first base. Electrodes drive the vibrator to oscillate and control the oscillation mode of the vibrator in driving mode. Planar electrodes are arranged relative to the proof masses on a second base. The motion of the proof masses relative to the planar electrodes is sensed through the capacitance between the proof masses and the planar electrodes. The resonant structure with greater mass of the device generates greater Coriolis force and increases the sensing area. Thus, the intensity of sensed signals and noise-signal ratio are greatly increased. Furthermore, the device does not rely much on high aspect ratio manufacturing technology. Thus the manufacturing cost is reduced and the yield rate is increased.

Owner:NAT CHUNG SHAN INST SCI & TECH +1

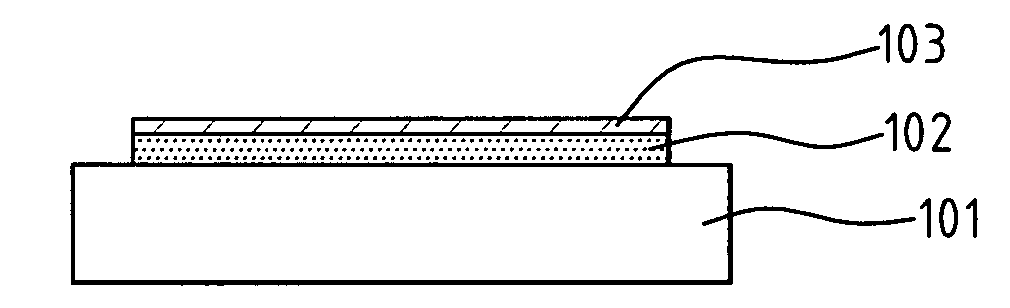

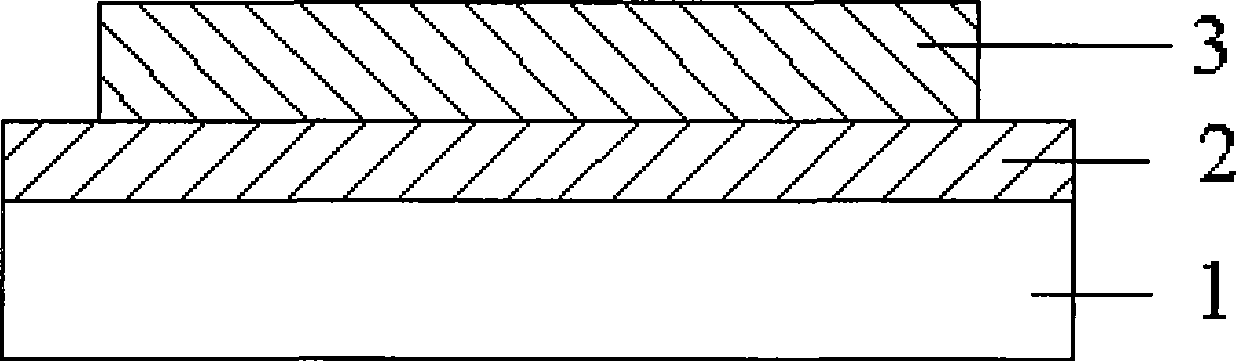

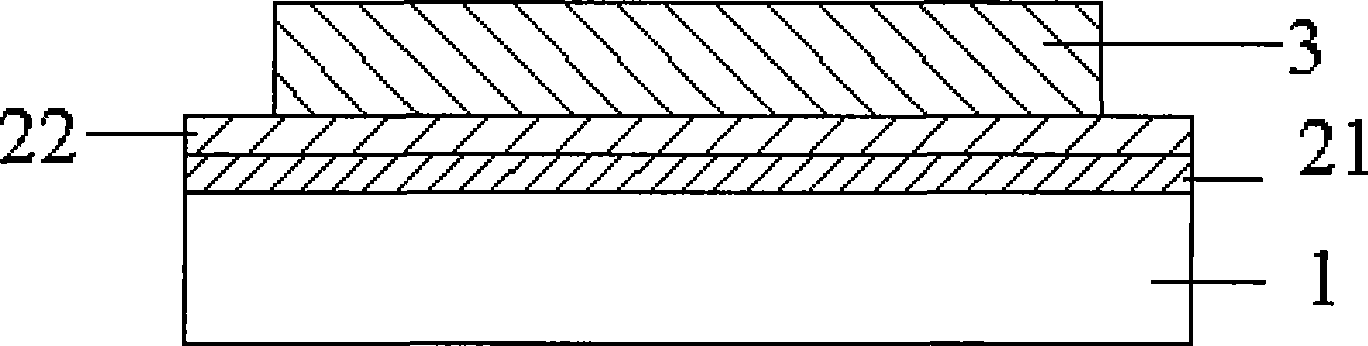

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

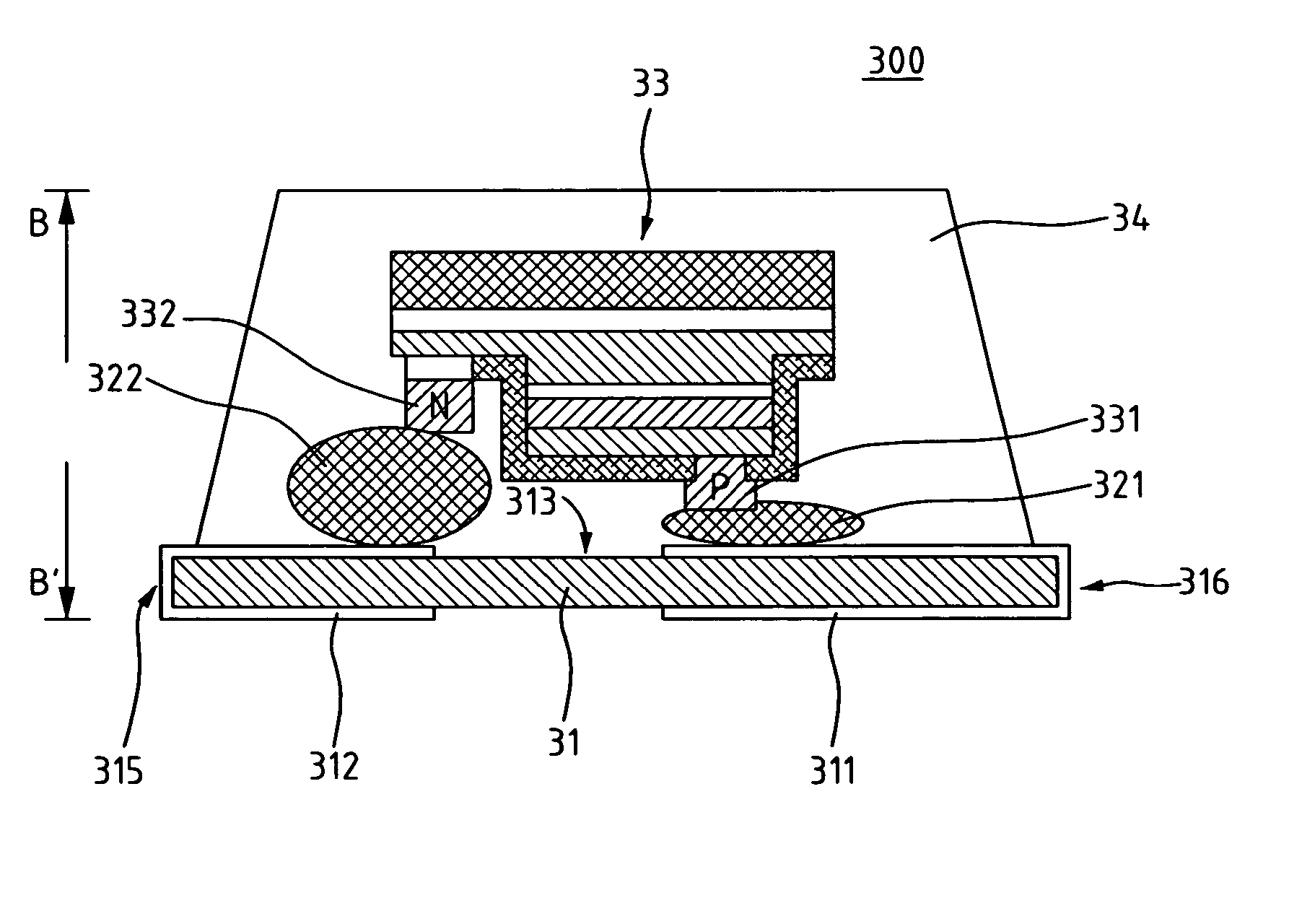

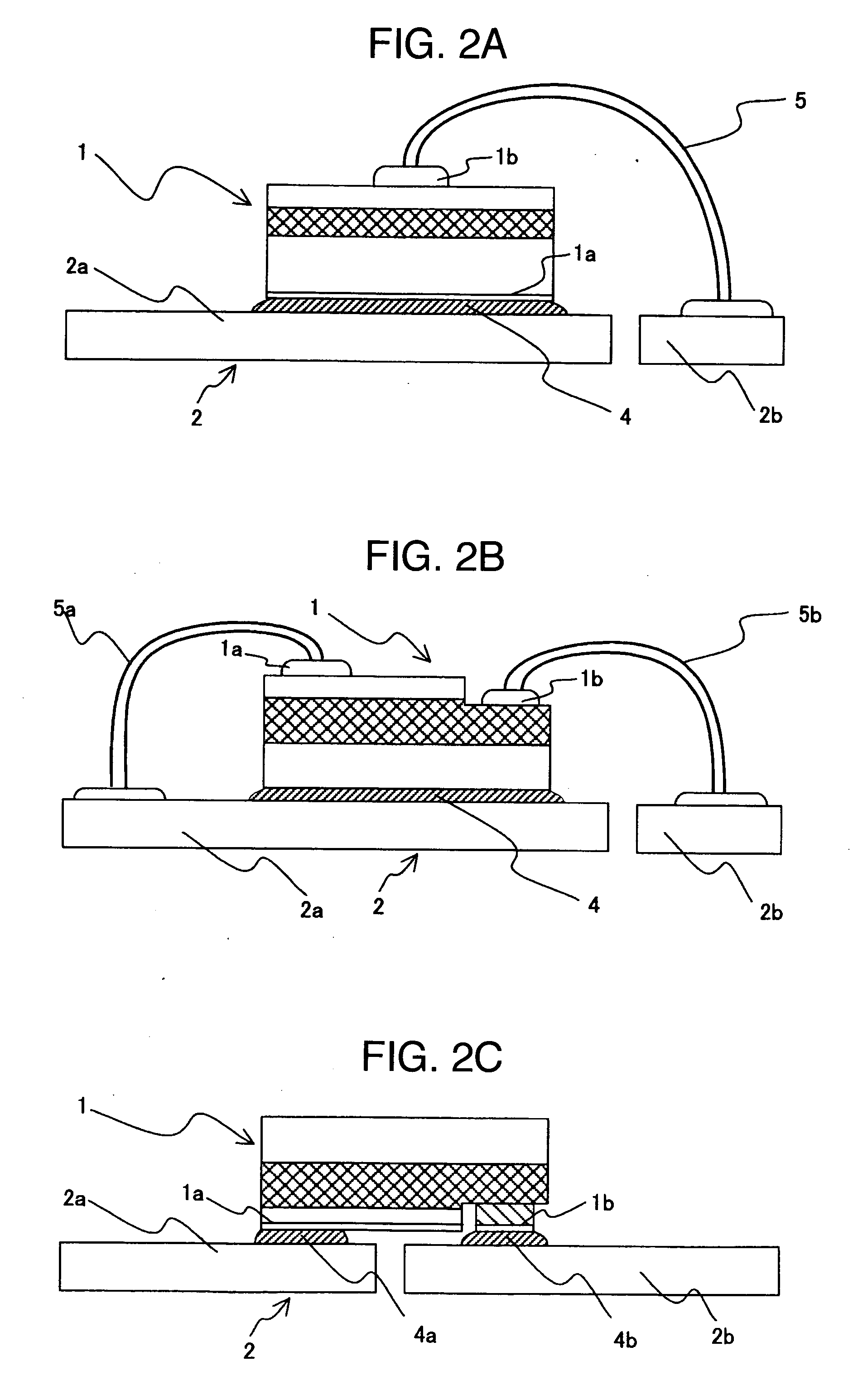

LED device with flip chip structure

InactiveUS20060208364A1Increase brightnessLow costSemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

The present invention provides an LED device with a flip chip structure. The LED device comprises an insulating substrate, an LED flip chip, a molding compound, a first conductive element, and a second conductive element. The LED flip chip is electrically connected to the connection pads on the insulating substrate via the two conductive elements. The P-type and N-type electrodes are connected to the P-type and N-type electrodes layers, respectively. The invention need not require a conventional wire bonding process. It not only increases the yield rate of the product but also makes the product more compact.

Owner:LEDARTS OPTO

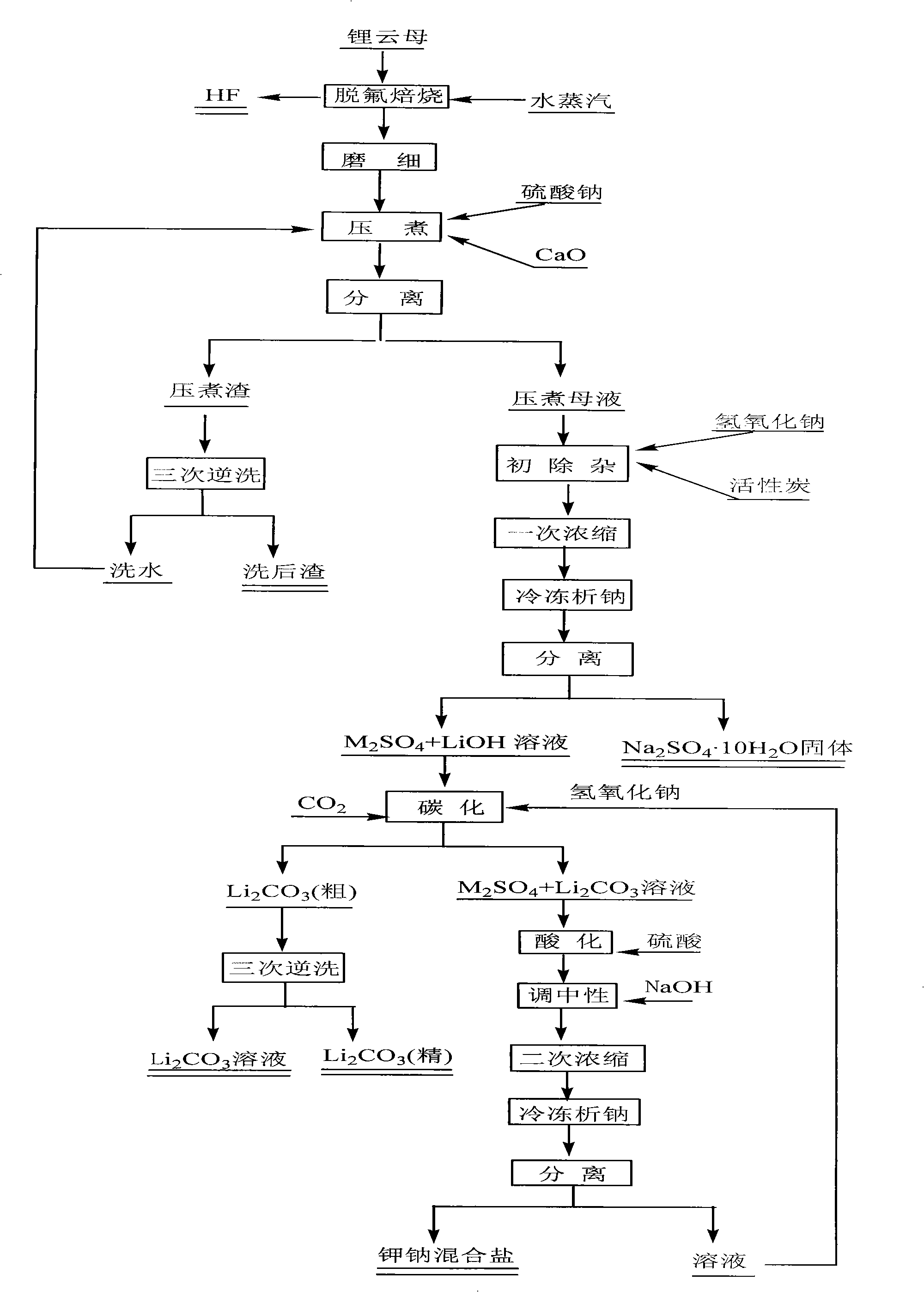

Method for preparing lithium carbonate by extracting lithium from lepidolite

ActiveCN101302018AImprove leaching rateIncrease concentrationLithium carbonates/bicarbonatesCarbonizationIon exchange

Owner:GANFENG LITHIUM CO LTD

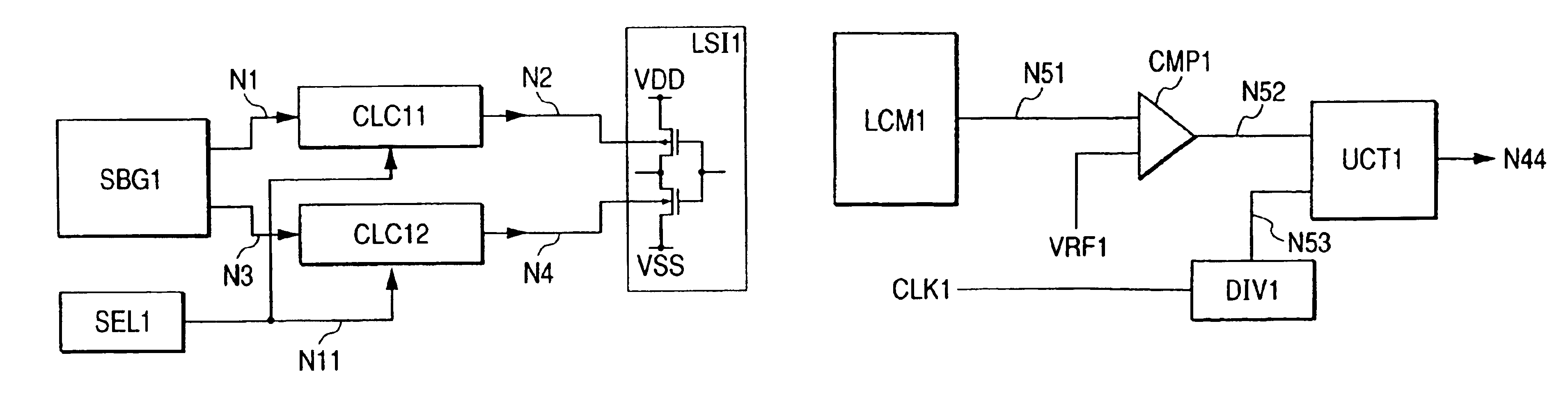

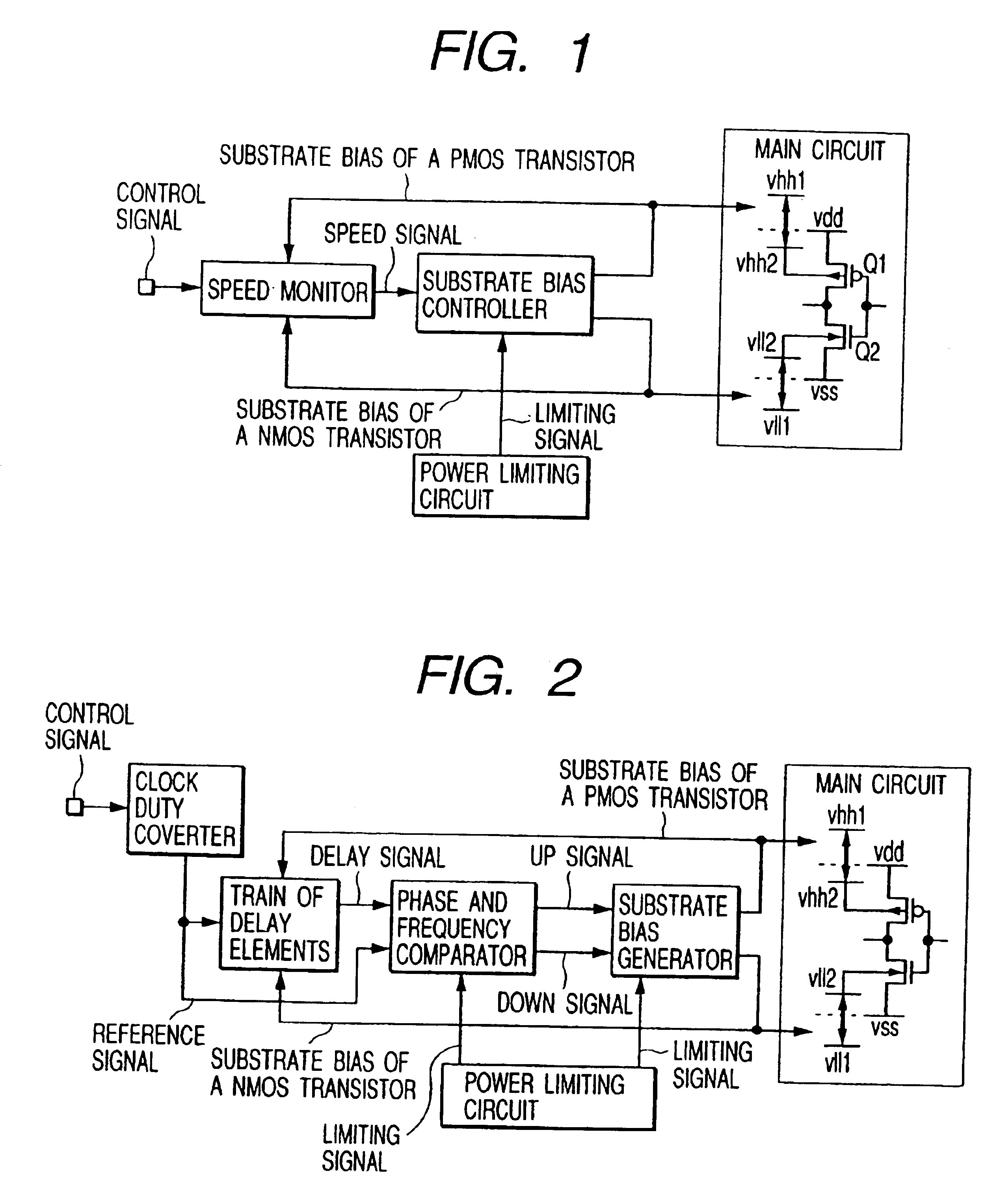

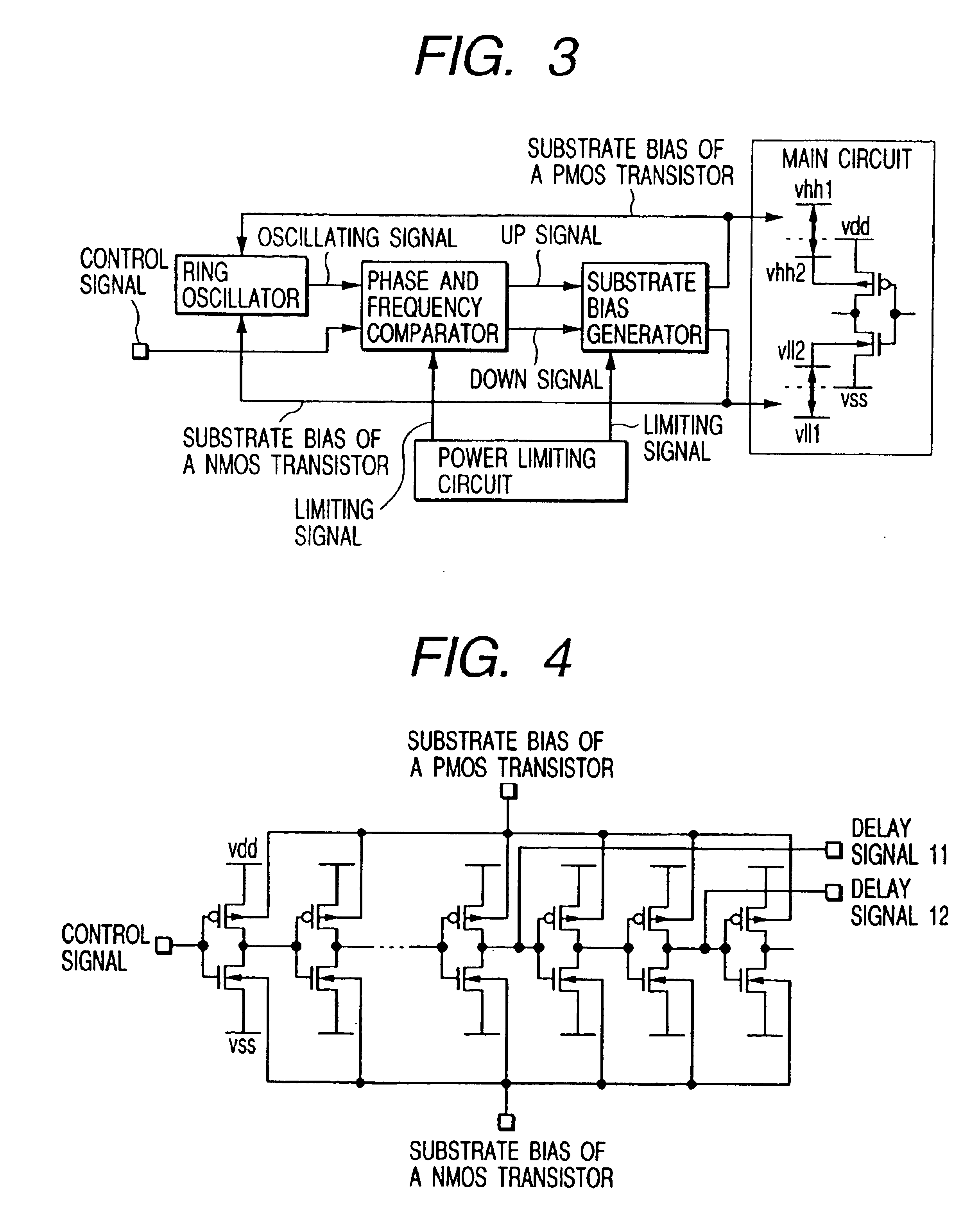

Semiconductor integrated circuit device including a substrate bias controller and a current limiting circuit

In a semiconductor integrated circuit device, for realizing high speed, as well as superior product yield rate and usability, while reducing circuit scale and improving on product yield rate and reliability thereof, a main circuit, constructed with CMOS elements, is coupled to a speed monitor circuit for forming a speed signal corresponding to an operating speed thereof and to a substrate bias controller for supplying corresponding substrate bias voltages to the main circuit in response to the speed monitor circuit. A current limiting circuit is also provided in conjunction with the substrate bias controller to prevent an overflow of current due to bias voltage.

Owner:RENESAS ELECTRONICS CORP

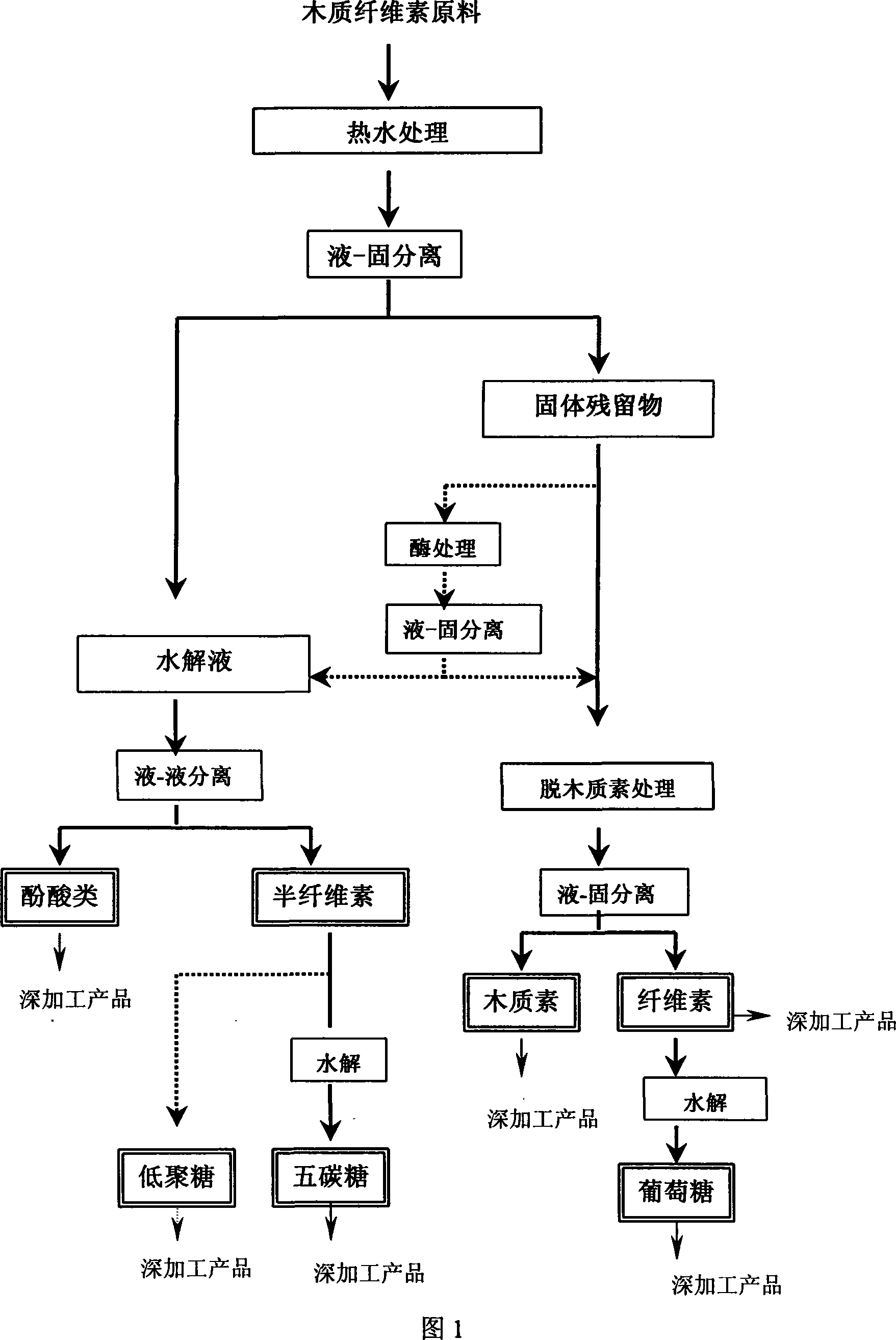

Method for synchronously extracting hemicellulose, cellulose and lignin and reclaiming phenolic acid compounds

InactiveCN101143881AProtect chemical structureReduce generationLignin derivativesPaper material treatmentOrganic solventChemical composition

The present invention provides a technique method which separates lignose, hemicellulose, cellulose and phenolic acid from lignocellulosic biomass. Under the selected pH value and temperature, the lignocellulosic biomass is processed by hot water, so that the hemicellulose and the phenolic acid are preferentially resolved in aqueous solution, delignification processing is carried out, organic solvent or alkaline solution is applied to carry out high-temperature cooking, the generated liquid-solid phase product can be easily and effectively separated, and thus the hemicellulose, the cellulose and the phenolic acid can be respectively obtained. Moreover, enzymatic treatment can be selectively added, and a solid phase product is obtained at the first stage of a group of enzymatic treatment with a cooperative effect. Because the ferulic acid linkage between the hemicellulose and the lignose can be selectively broken, the separation of the chemical components has a high yield rate and high purity.

Owner:孔延华

Green biological active feed

InactiveCN101978850AImprove balancePromote growthFood processingClimate change adaptationBiotechnologyDisease

The invention discloses a green biological active feed, which relates to the technical field of feeds. The green biological active feed is prepared from the following materials in part by weight: 40 to 80 parts of straw, 5 to 30 parts of corn four, 5 to 25 parts of cake dregs, 5 to 25 parts of wheat bran, 0.1 to 0.2 part of complex bacteria and 0.1 to 0.2 part of complex enzyme. During preparation, the straw is crushed and then is uniformly mixed with the corn flour, the cake dregs and the wheat bran; the complex bacteria and the complex enzyme are mixed into the mixture; water is added into the mixture to ensure that the water content reaches 45 to 50 percent, and the mixture is filled in a big tank, sealed and stored for later use; or the mixture is baked or dried by natural wind for storage and later use. The green biological active feed has the following advantages of: (1) improving the balance of intestinal flora, and improving the feed utilization rate; (2) promoting the growth of meat livestock and poultry, and shortening the breeding cycle; (3) strengthening the body conditions of laying hens, ducks and geese, and having a significant strengthening action on prolonging theegg-laying peak period; (4) strengthening the body condition of female domestic animals, and improving the yielding rate; (5) strengthening the body conditions of the livestock and poultry, enhancingthe disease prevention and disease resisting capacities, and reducing the sickness rate; and (6) purifying the culture environment, and improving the meat quality due to no public nuisances and no residues.

Owner:徐贵阁

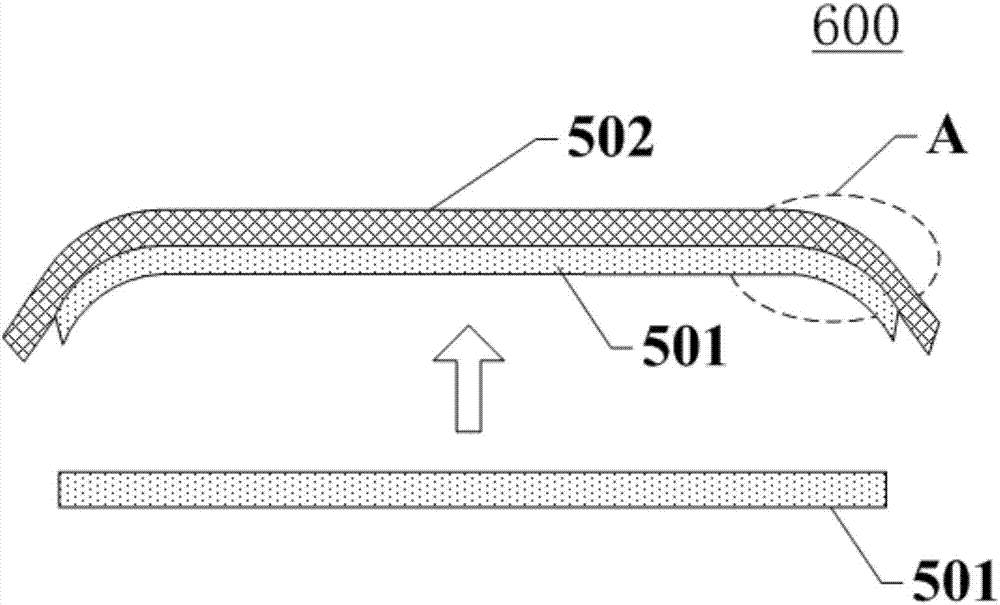

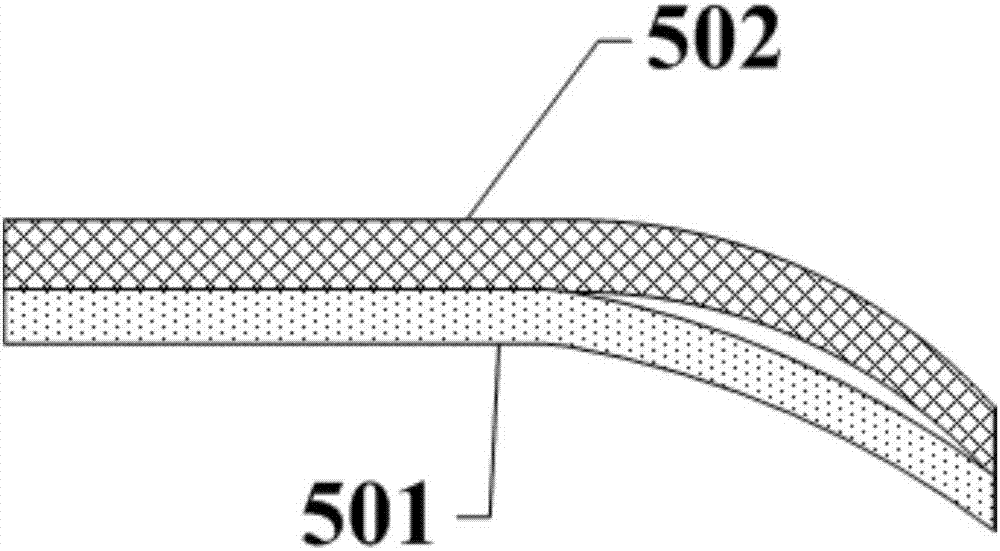

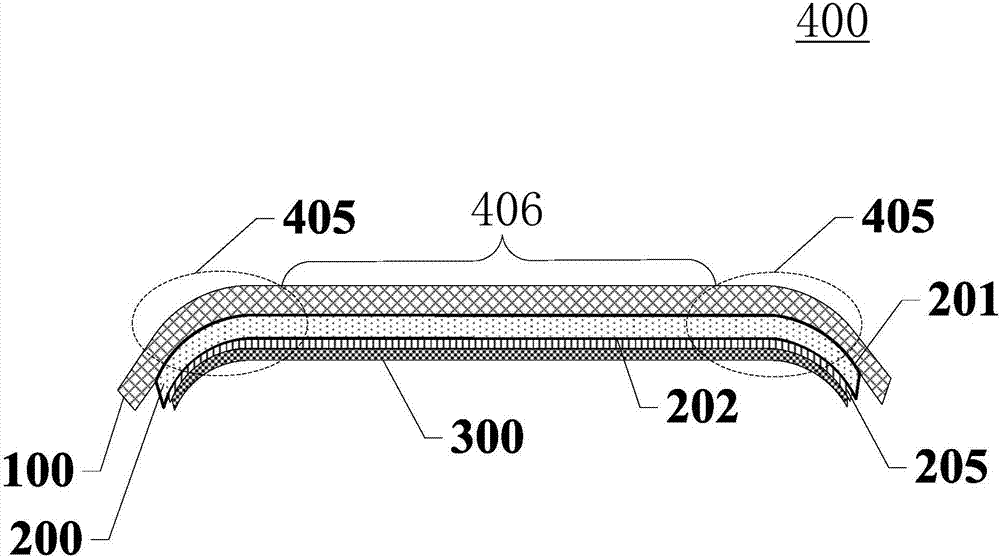

Display device

ActiveCN107978623AImprove production yieldExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display device and relates to the technical field of display. The display device comprises a cover plate, a flexible display panel and a support film arranged successively, the cover plate, the flexible display panel and the support film are all of curved-surface shapes, a first surface of the flexible display panel is attached to a first side of the cover plate, the support film is arranged in the side close to a second surface of the flexible display panel, the first surface is arranged opposite to the second surface, and the cover plate is positioned in a light output side of the flexible display panel; and within certain temperature range, the cover plate and the support film are of rigid structures. Thus, the flexible display panel positioned between the support film and the cover plate is fixed by the rigid support film and cover plate, deformation does not occur, the flexible display panel in a bending area of the display device is prevented from beingdisengaged from the cover plate and causing damage of the display device, the production yield rate of the display device is improved, and the service life of the display device is prolonged.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

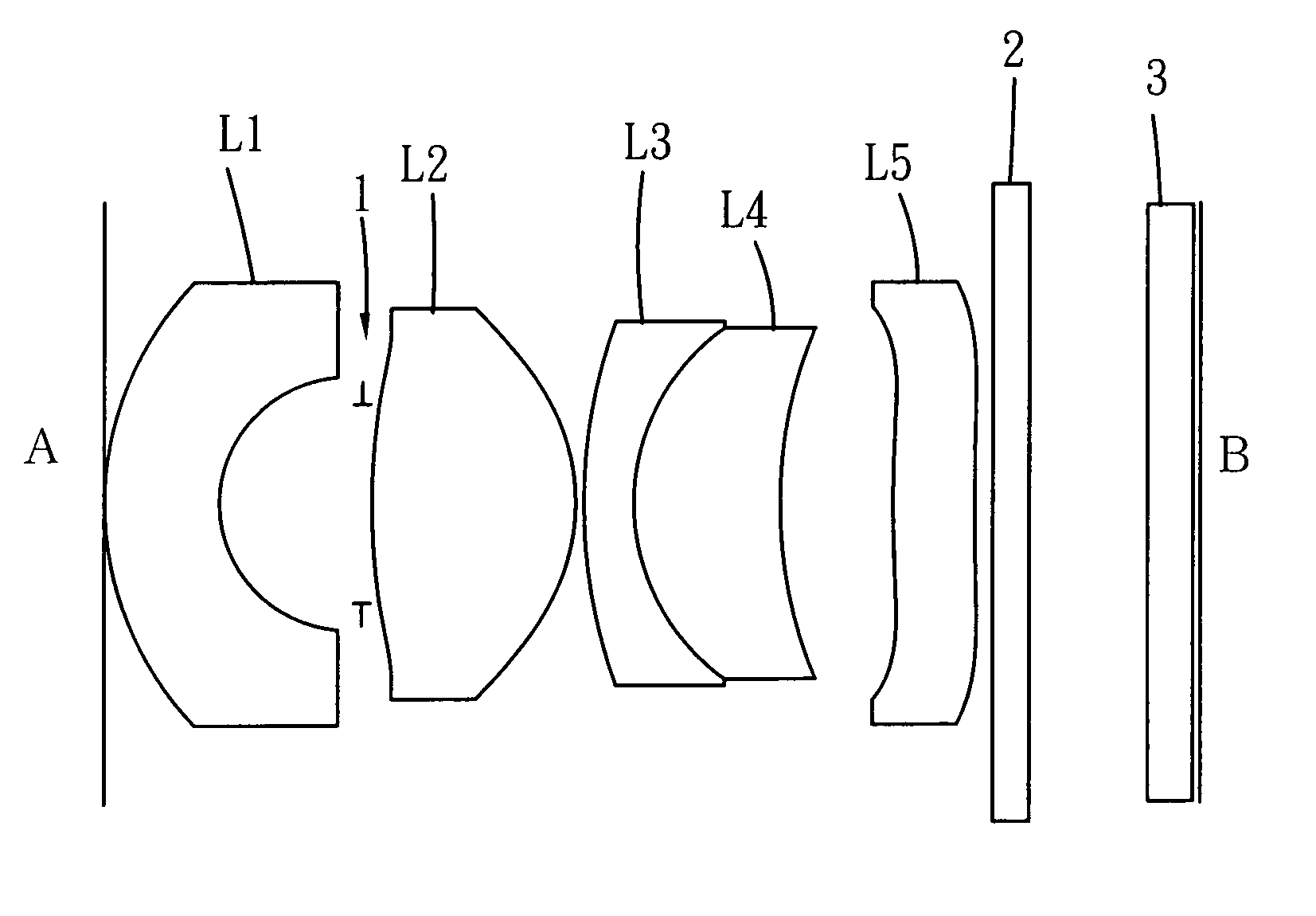

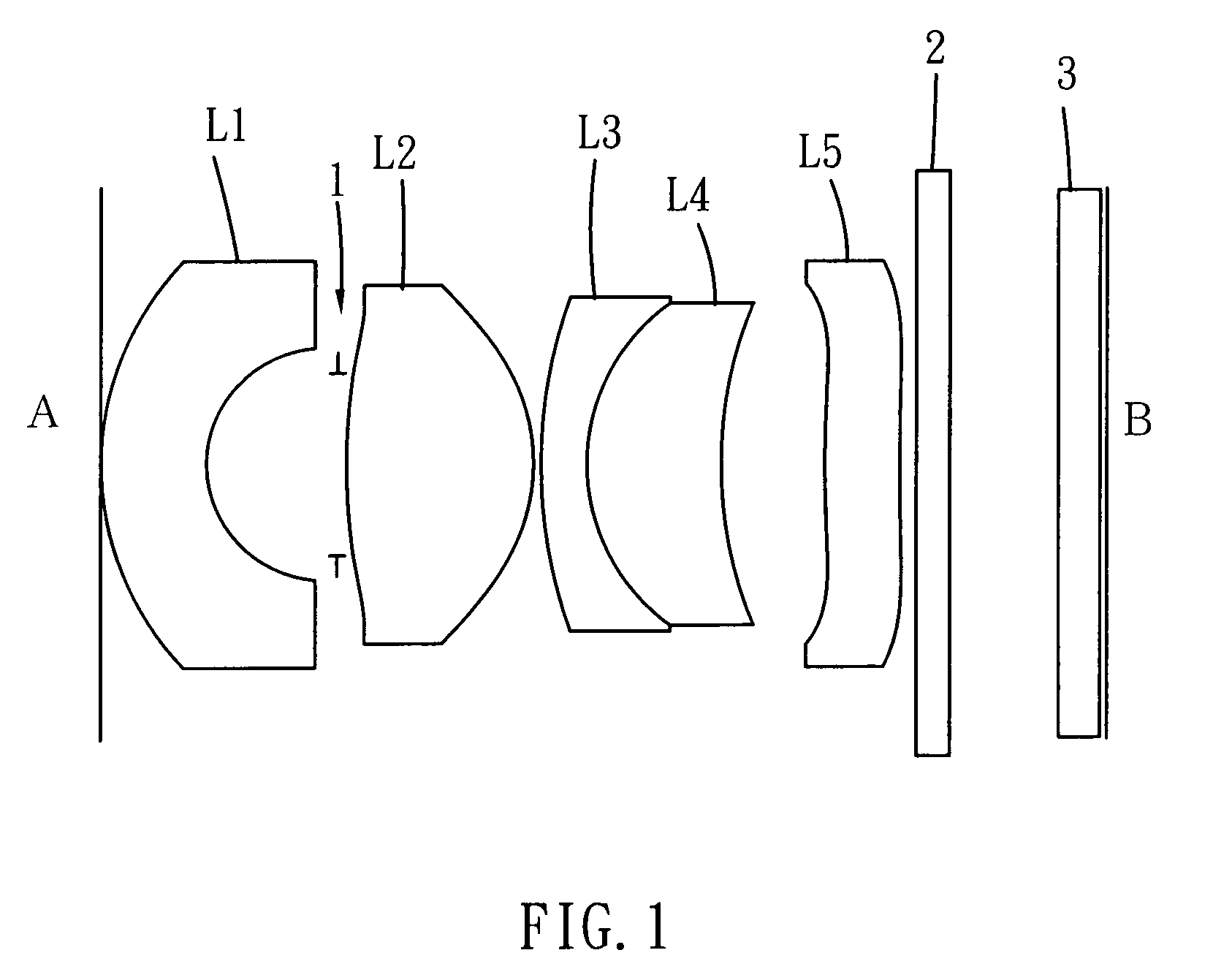

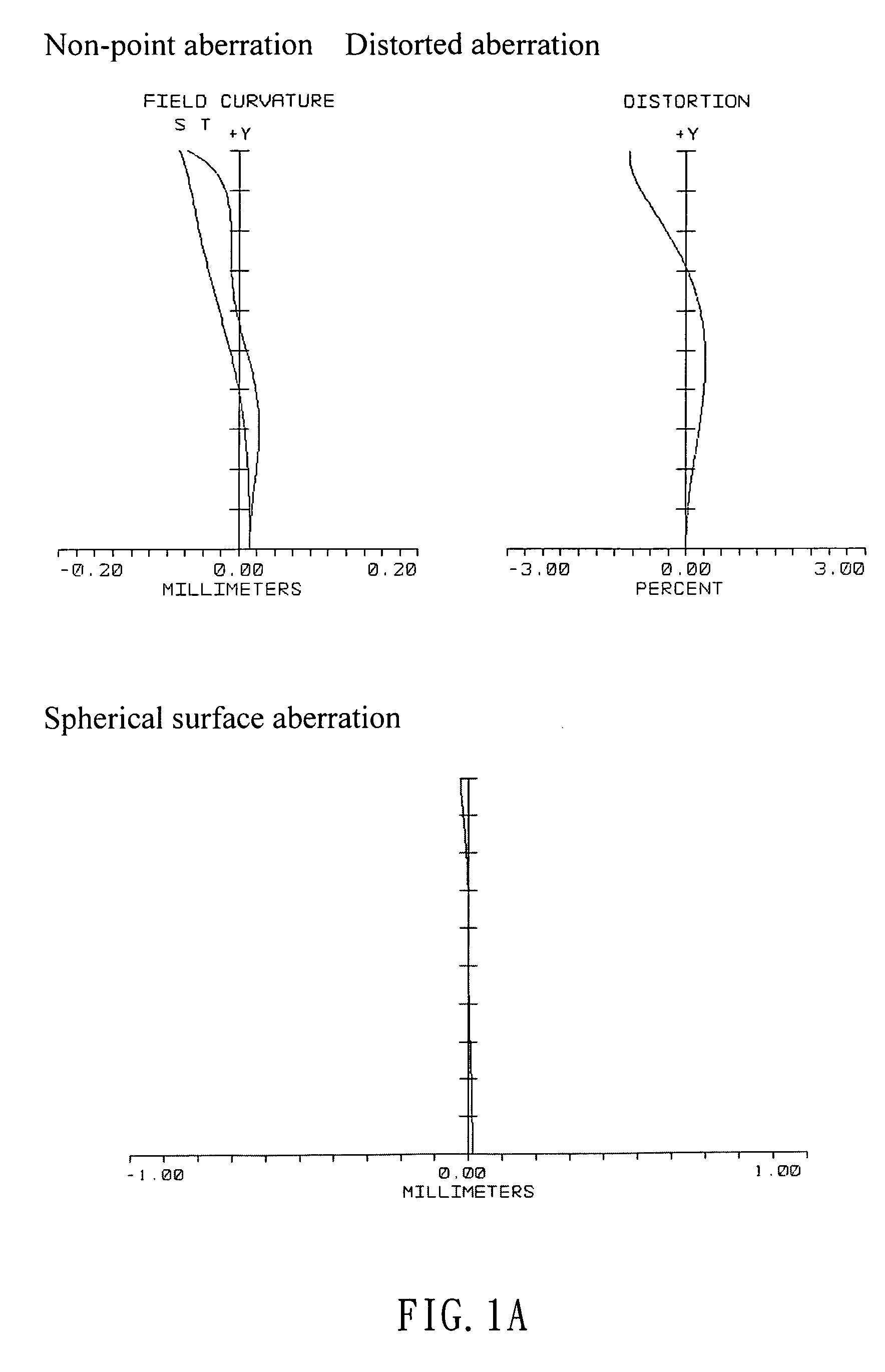

Imaging lens module

An imaging lens module includes a fixed diaphragm and an optical module. The optical module includes first, second, third, fourth and fifth lenses arranged from an object side to an image side in a sequence of: the first lens, having a negative refractive power, a convex surface disposed towards the object side, and a concave surface disposed towards the image side; the diaphragm; the second lens having a positive refractive power and a convex lens disposed towards the image side; and the third lens; being a meniscus negative lens; the fourth lens, being a positive lens, and adhered with the third lens to form a composite lens; the fifth lens, having a positive refractive power, such that the imaging lens module is a lens module with the features of high imaging quality and high yield rate.

Owner:NEWMAX TECH

Metal nanoparticles and method for producing the same

InactiveUS20070018140A1High yield rateCheap methodMaterial nanotechnologyNanostructure manufactureAlkaline earth metalSolvent

A method of producing metal nanoparticles, having a high yield rate achieved by a simple heat-treatment of a metal alkanoate. The method of the invention is not only environment-friendly as it does not require additional solvents or supplements, but also economical as highly expensive equipment is not demanded. In addition, the invention provides metal nanoparticles having uniform shape and distribution, and provides conductive ink including the metal nanoparticles thus obtained. One aspect may provide a method of (a) producing a metal alkanoate by reacting a metal precursor with an alkanoate of alkali metals, alkaline earth metals or ammonium in an aqueous solution (b) filtrating and drying the metal alkanoate, and (c) heat-treating the metal alkanoate of (b).

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

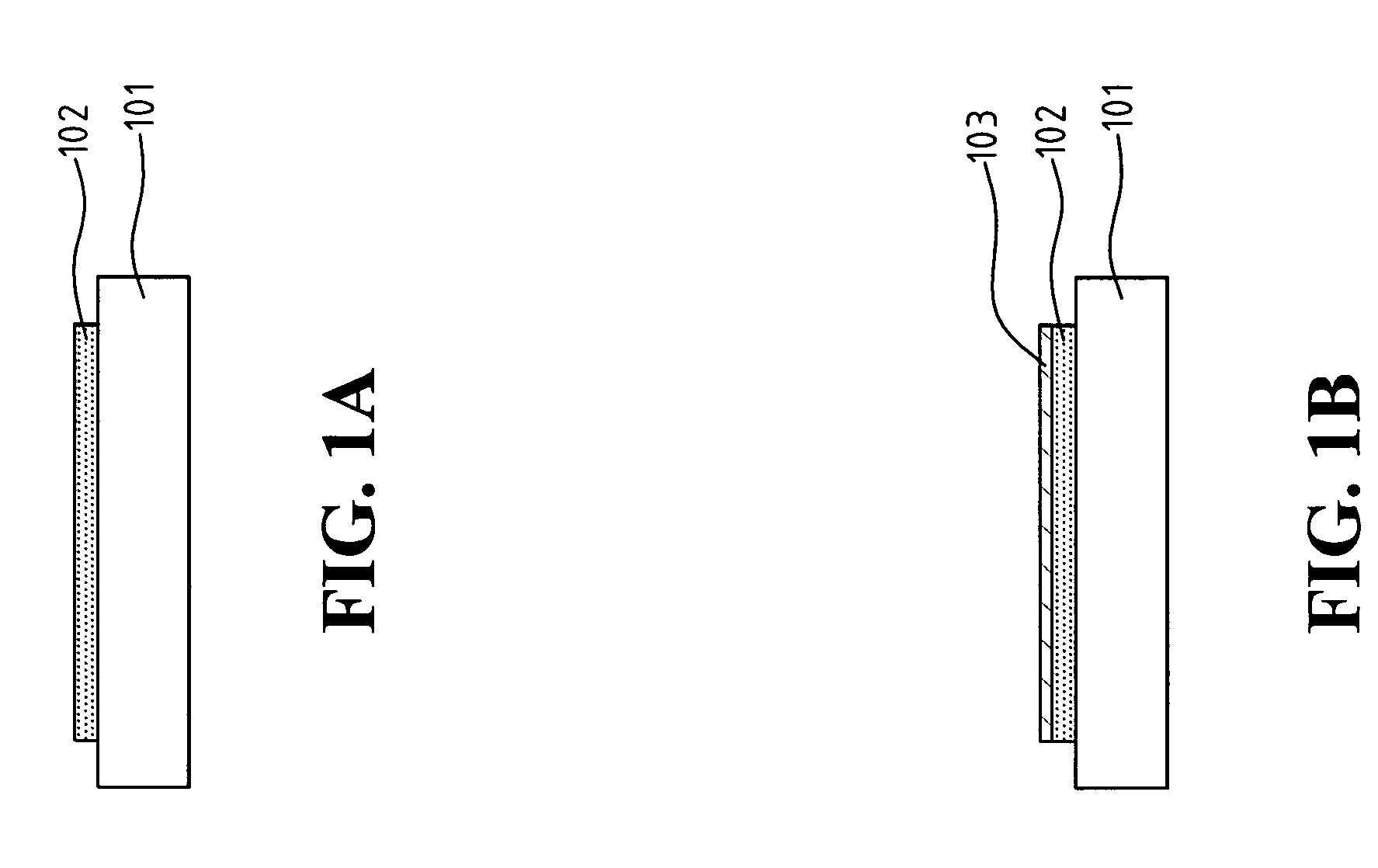

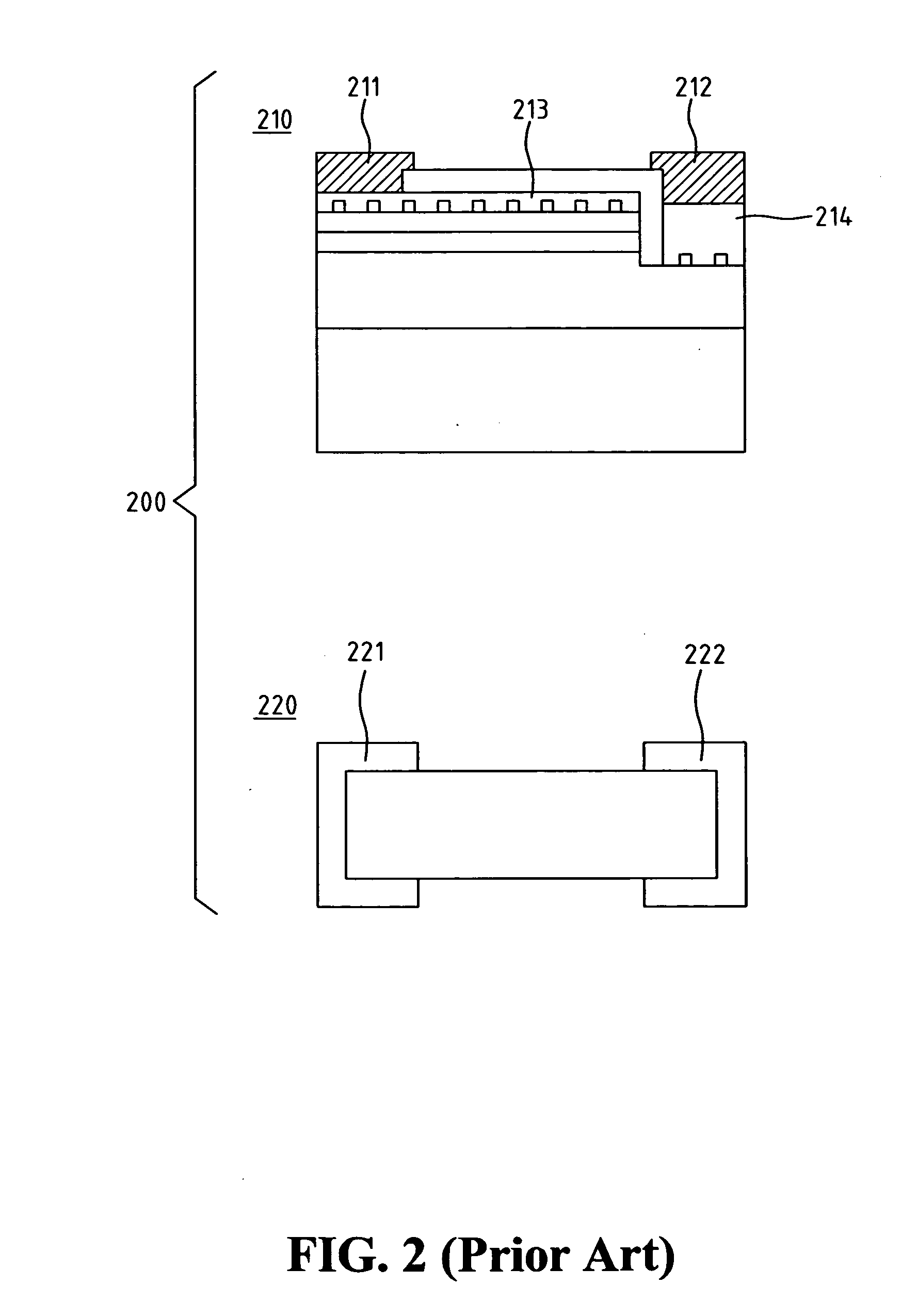

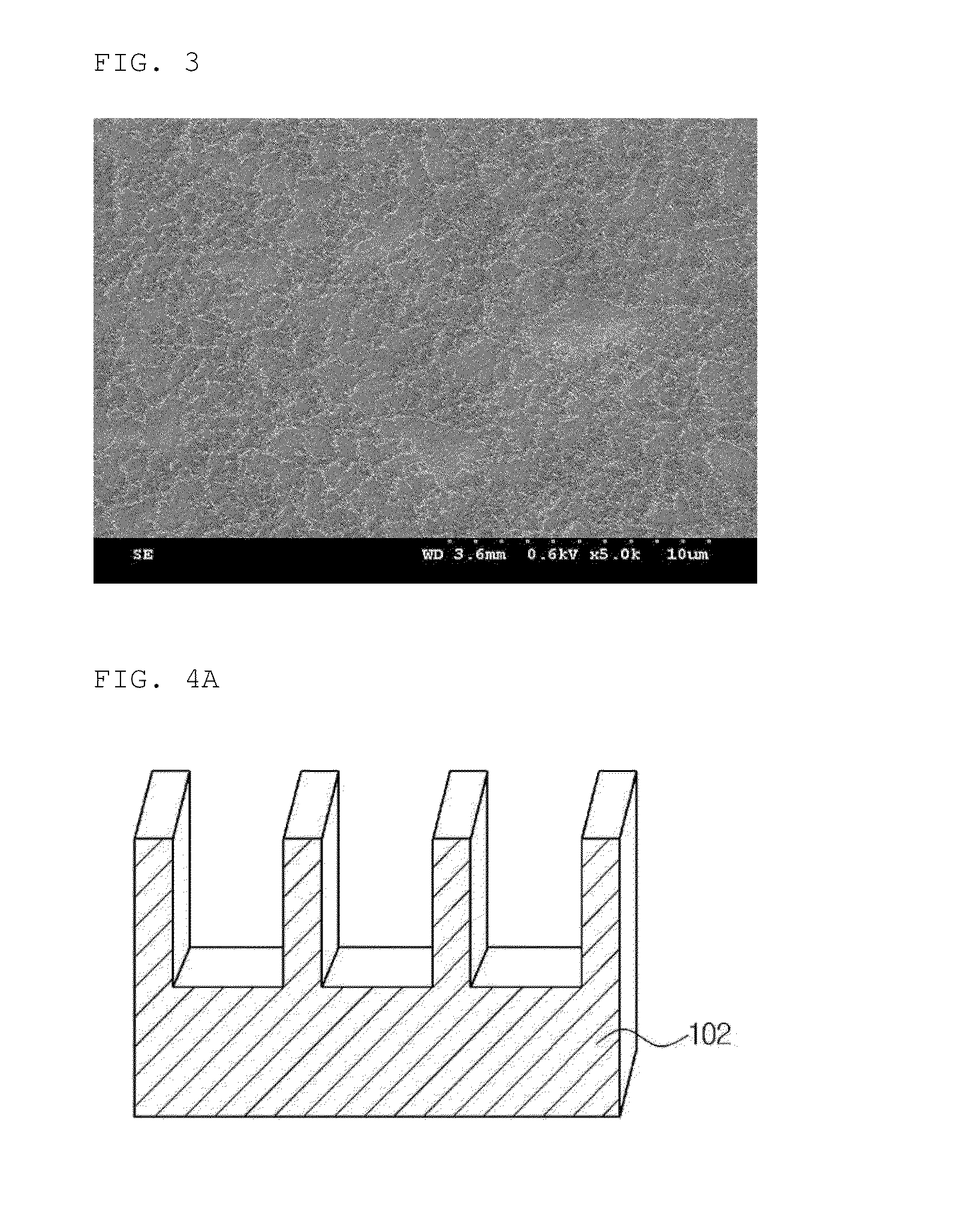

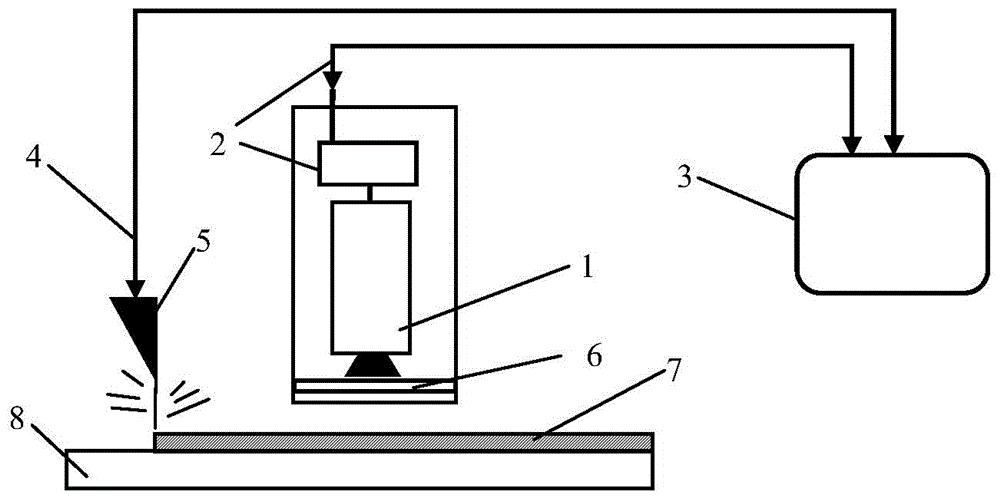

Supporting substrate for manufacturing flexible information display device, manufacturing method thereof, and flexible information display device

InactiveUS20150060870A1Low investment costIncrease equipment costLamination ancillary operationsLayered product treatmentDisplay deviceEngineering

Disclosed are a supporting substrate for manufacturing a flexible information display device capable of easily separating the flexible information display device from the supporting substrate without deforming or damaging the flexible information display device, a manufacturing method thereof, and a flexible information display device manufactured thereby. The supporting substrate for manufacturing a flexible information display device includes: a coating layer formed therein with a plurality micro-protrusions formed on the supporting substrate; and a temporary bonding / debonding layer formed on the coating layer and including an adhesive material mechanically interlocked with and bonded to the supporting substrate through Van der Waals bonding force. The method provides a method capable of economically manufacturing the display device having a high resolution while reviewing a cost competitive force by reducing a device investment cost and improving the yield rate in the flexible flat panel information display device.

Owner:LEE KEUN SOO +2

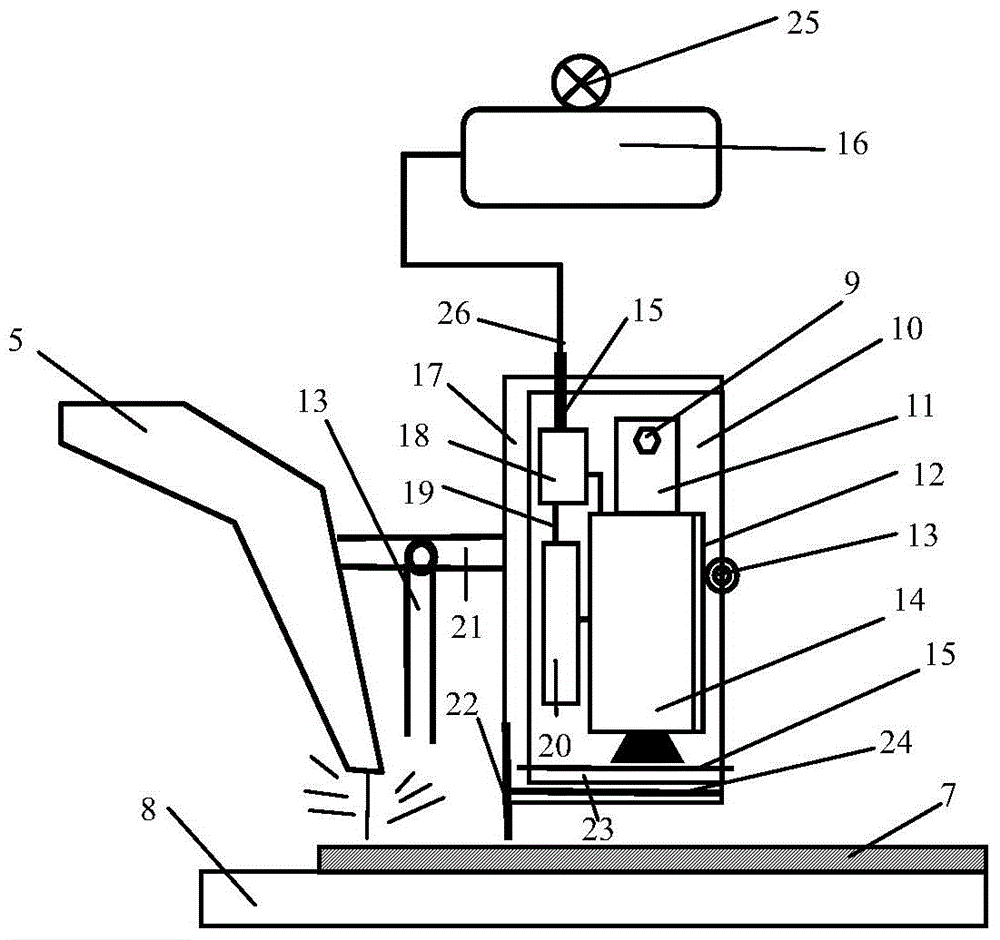

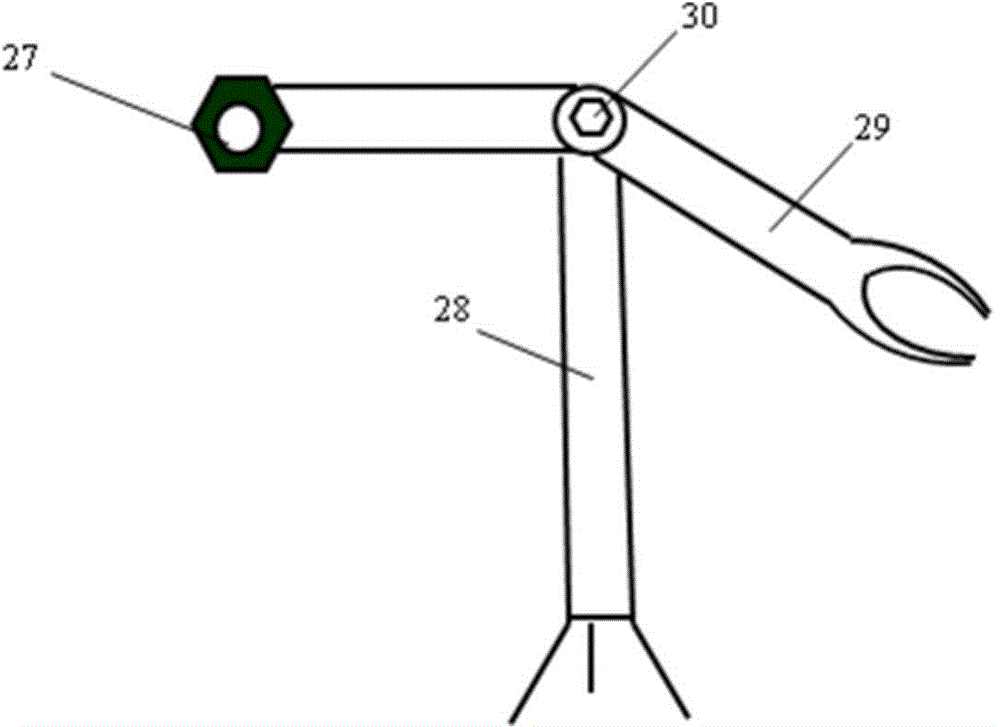

Welding quality analysis device based on infrared vision and analysis method thereof

InactiveCN104977305ALower regenerationIncrease the level of automationWelding/cutting auxillary devicesOptically investigating flaws/contaminationMelting tankVision processing

The invention discloses a welding quality analysis device based on infrared vision and an analysis method thereof. The analysis device comprises an infrared vision collecting system that is adjustably and fixedly connected to a welding facility, a vision processing system, in which welding defect intelligent recognition algorithm is embedded, and a feed control system, which can evaluate the welding quality, give an alarm, and adjust the parameters of the welding facility. The analysis method comprises the following steps: (1) collecting the infrared vision information of a molten pool or an area near a molten pool in real time through infrared sensing; (2) processing the infrared vision information by the welding defect intelligent recognition algorithm so as to obtain the weld seam positions and welding defect characteristics; (3) evaluating the welding quality in real time, and controlling the welding facility and giving an alarm aiming at different welding defects. According to the provided intelligent analysis device and intelligent analysis method, the welding process can be monitored in real time, the welding defects can be recognized, the welding seam position can be traced, the welding quality can be evaluated, the welding loss can be reduced, and the finished product yield rate can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of manufacturing magnetic head

InactiveUS6532646B2Easy to controlUneven suppression characteristicsElectrical transducersHeads using thin filmsEngineeringYield rate

Owner:FUJITSU LTD

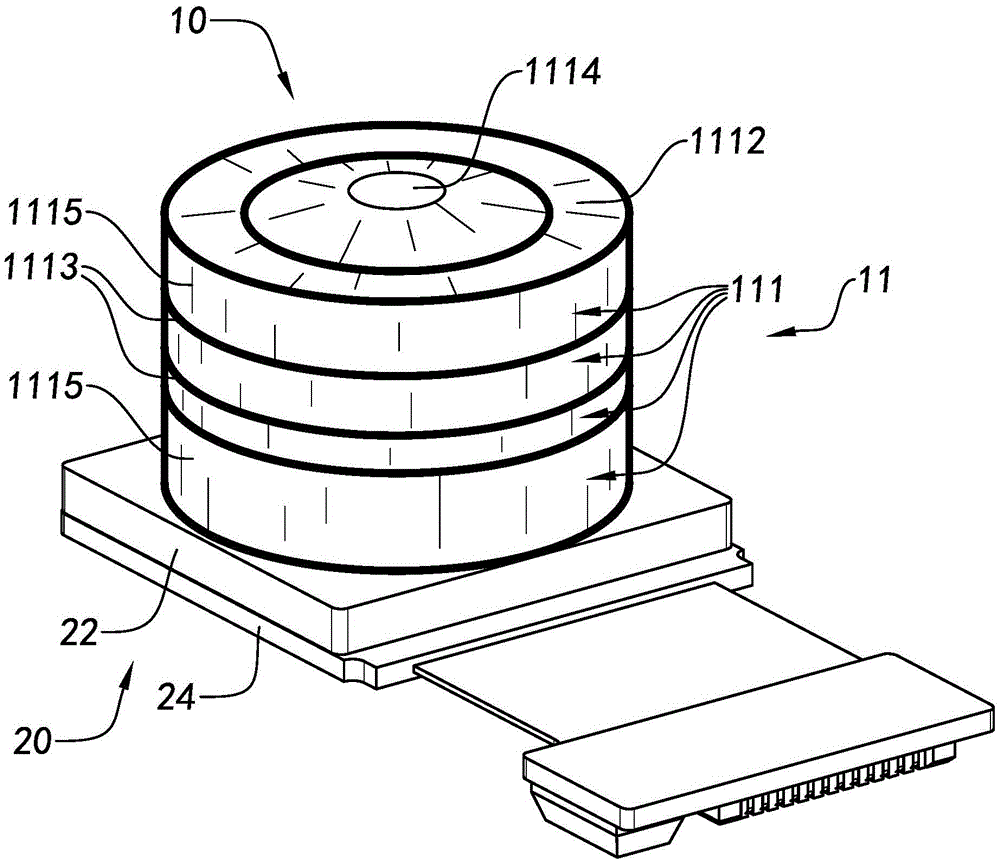

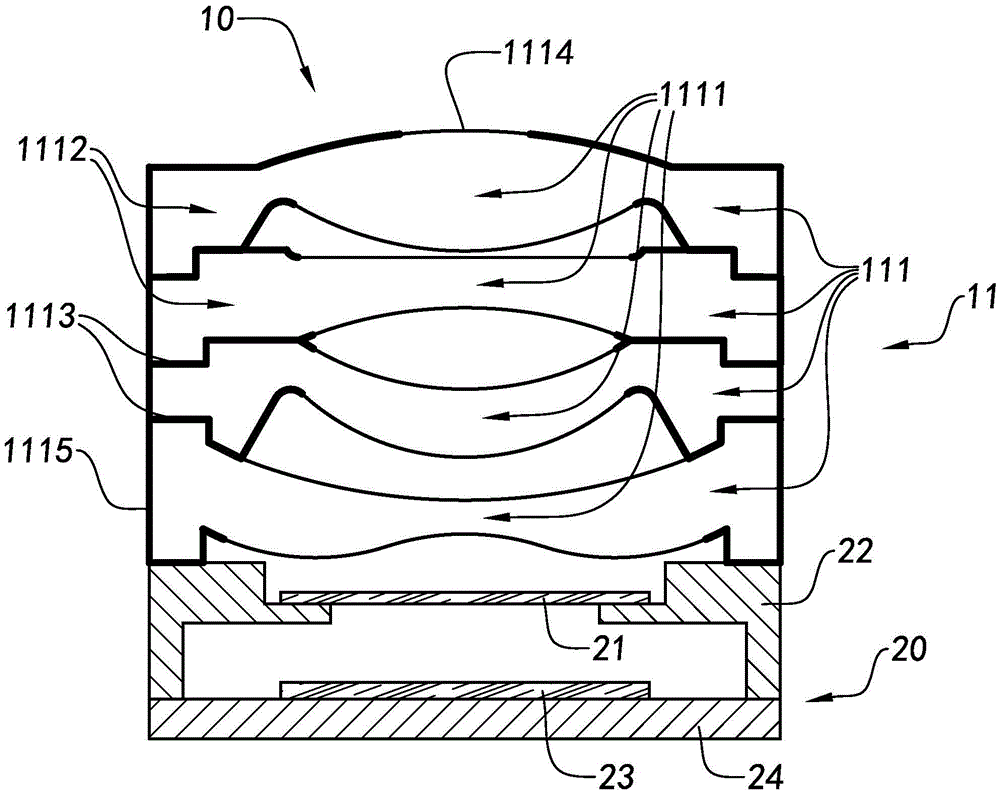

Illuminating apparatus, method for fabricating the same and display apparatus using the same

ActiveUS20060091406A1Reduce the number of installationsImprove yieldPoint-like light sourceSolid-state devicesEngineeringSoldering

An illuminating apparatus has a reduced number of mounting spots by soldering or the like to permit an increased yield rate and a reduced cost. The illuminating apparatus has light emitting diodes, lead frames, and a transparent sealer. N light emitting diodes, N sets of lead frames mounted with the N light emmitting diodes, and one set or more of lead frames each not mounted with a light emitting diode are sealed by the transparent sealer for integration into a modular illuminating apparatus. Also provided are a method for fabricating the illuminating apparatus, and a display apparatus using the illuminating apparatus.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Optical lens, camera module group and assembly method thereof

The present invention discloses an optical lens, a camera module group and an assembly method thereof. The camera module group comprises a sensitization chip and an optical lens; the optical lens includes a plurality of optical glasses, wherein the assembly position one optical glass is adjustable, and the blacking extinction processing of each optical glass is performed; and a connection part, a light beam incidence aperture and a shielding part are formed on corresponding optical glasses so as to embed and assemble each optical glass together in order, therefore parts such as a spacing ring, a diaphragm, a lens barrel structure piece and the like used in a traditional camera module group are omitted, and the manufacture precision, the yield rate and the imaging quality of the camera module group are improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

Method for fabricating light-emitting diode (LED) chip

InactiveCN101552312AImprove yieldOptimize photoelectric parametersSemiconductor devicesThinningIrradiation

The invention provides a method for fabricating light-emitting diode (LED) chip. The method comprises the following steps: (1) forming a N type nitride layer and a P type nitride layer on a sapphire substrate and a multiquantum trap layer between the N type nitride layer and the P type nitride layer to obtain a LED wafer; (2) performing right side scribing to the LED wafer by laser irradiation technology until scribing in to the substrate; (3) etching the LED wafer in the step (2) by etching technology and fabricating a N electrode and a P electrode; (4) performing back side grinding, thinning and splitting to the LED wafer in the step (3) to obtain the LED chip. In the invention, the right side scribing is performed before fabrication of the N and P electrode; the melted level generated in the laser irradiation cutting formation and the residues deposited on the LED wafer side and the surface electrode are removed by the etching process in the fabrication of N and P electrode; thereby, the photoelectric parameter of the chip and the yield rate of the LED chip are optimized.

Owner:EPILIGHT TECH +1

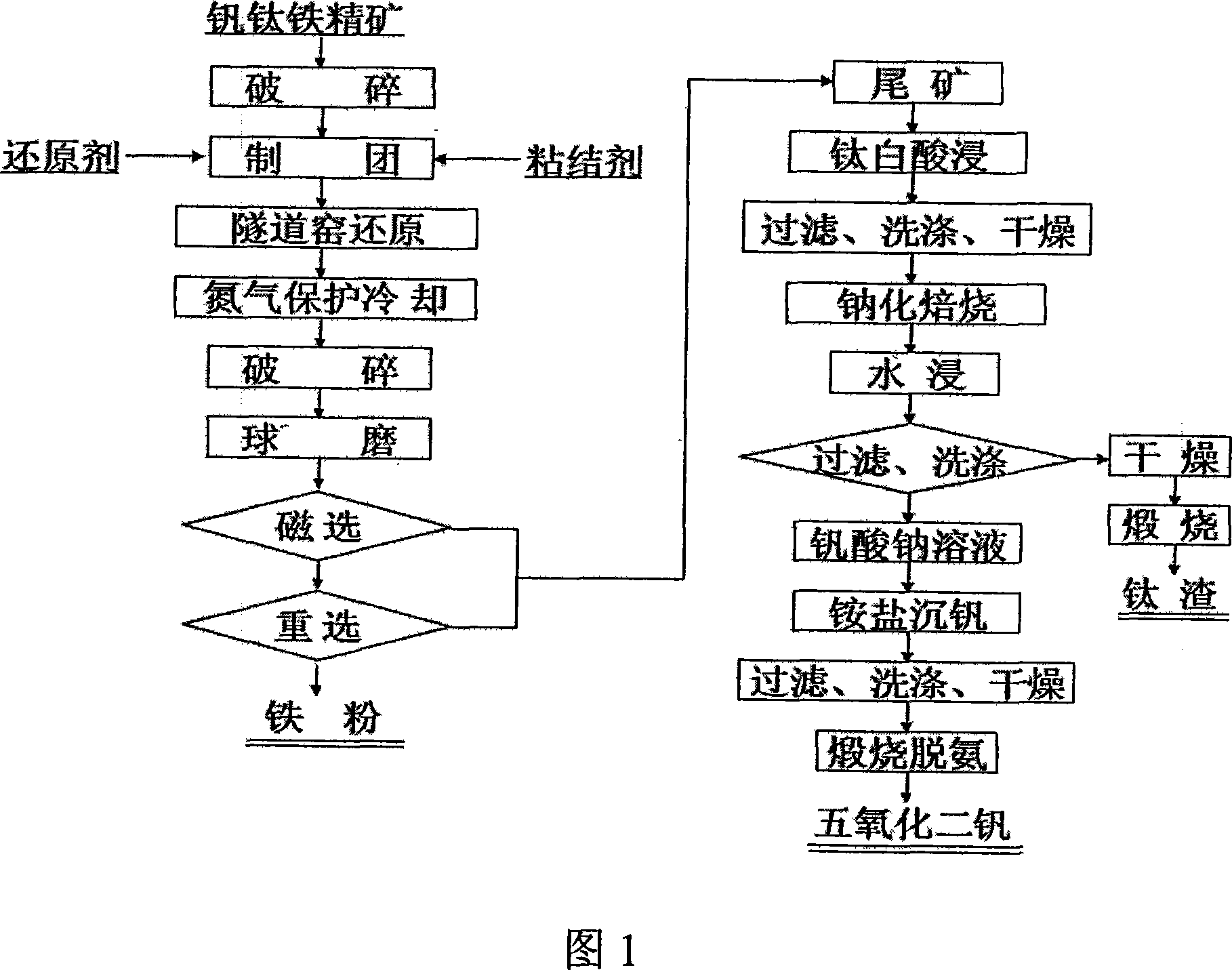

Method for comprehensive utilization of V-Ti-bearing iron ore concentrate by using tunnel kiln reduction-grinding - separation

InactiveCN101113488AAvoid defects such as loopsHigh yieldProcess efficiency improvementTunnel kilnResource utilization

The invention relates to an iron powder production method by using a tunnel kiln to reduce concentrate pellets containing carbon vanadium ferrotitanium with titanium slag and vanadium pentoxide as combined products. Concentrate pellets are made from vanadium-titanium iron concentrate through crashing and damp milling. The iron powder and tailings are obtained by putting the concentrate pellets into the tunnel kiln to be reduced, crashing, wet-grinding, magnetic separation and gravity separation. The tailings are soaked with titania waste acid to eliminate remnants magnesium and iron. Then the tailings are filtrated and dried to obtain a new material. And then the new material is added with sodium salt to do salt roast and then to be soaked by water, then titanium slag and sodium vanadate are obtained respectively after the water soaking. At last, the vanadium pentoxide is obtained by ammonium vanadate precipitating and calcination deaminase to the sodium vanadate liquid. The invention eliminates the disadvantage of high energy consumption by electric furnace smelting and bad separating effect of vanadium and titanium, difficult control of vanadium and titanium trend and low yield rate of extracting vanadium and titanium through converter blowing iron molten, etc. The invention has the advantages of high yield rate of vanadium, titanium and iron and high resources utilization rate and explores a novel practical way for comprehensive utilization of vanadium, titanium and iron concentrate ore.

Owner:攀枝花锐龙冶化材料开发有限公司

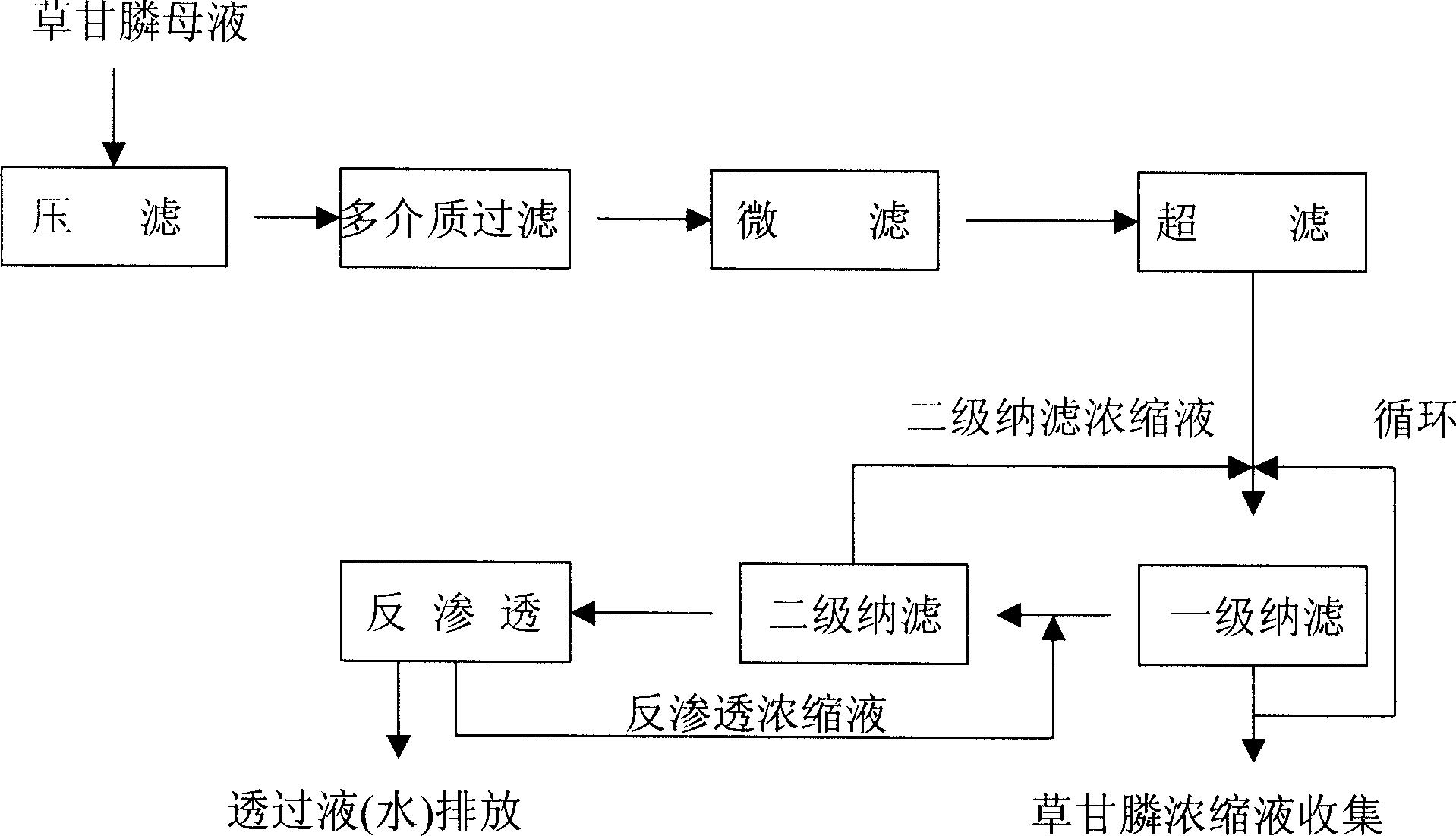

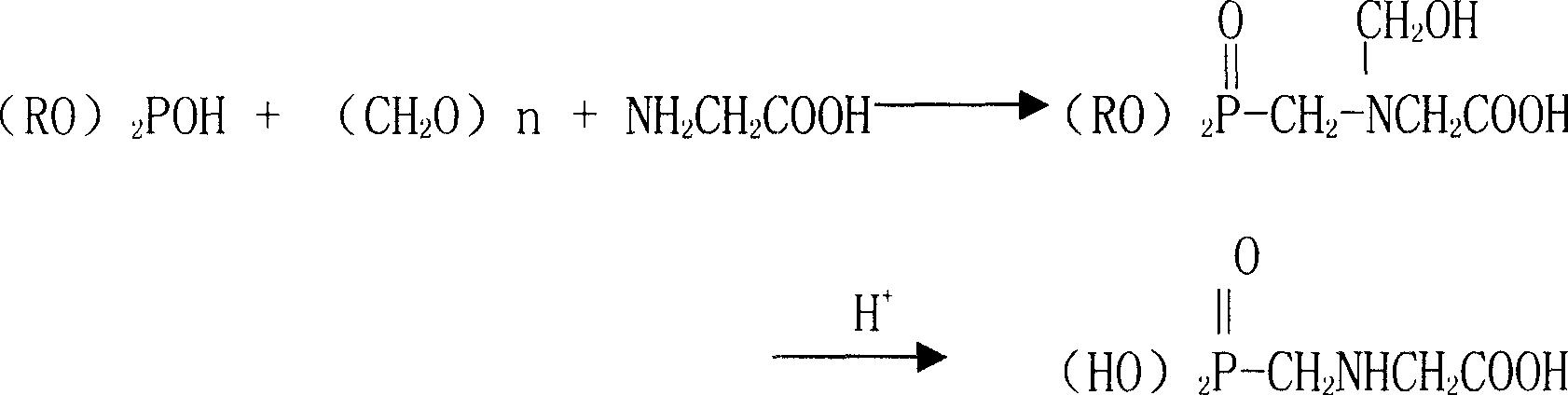

Process for separation and purification of glyphosate from glyphosate solution by membrane technology

InactiveCN1827626AAvoid decompositionQuality improvementBiocideGroup 5/15 element organic compoundsSolid componentDecomposition

The invention discloses a method for extracting glyphosate from heavy glyphosate stock solution by membrane separation technique. It consists of filtering the mother liquid, removing the solid component of the system, then according to the molecular structure, molecular mass, particle size and electric charge, from the big one to the small one, separating step by step by selecting appropriate hyperfiltration membrane, nanofiltration membrane and reverse osmosis membrane to obtain the effective composition of glyphosate. The invention unitizes the separation, concentration and the purification, and is performed at normal temperature. The barrier separation process is excellent in that it is of no change of phase, avoids the decomposition of glyphosate caused by high enrichment and concentration, effectively improves the product quality and yield rate, greatly reduces the energy consumption, is of consecutive operation, low operation cost, and it is energy-saving, highly effective, environment-friendly, furthermore, it can be operated by combining with routine thickening operating unit or be operated individually and is suitable for industrial continuous production.

Owner:捷马化工股份有限公司

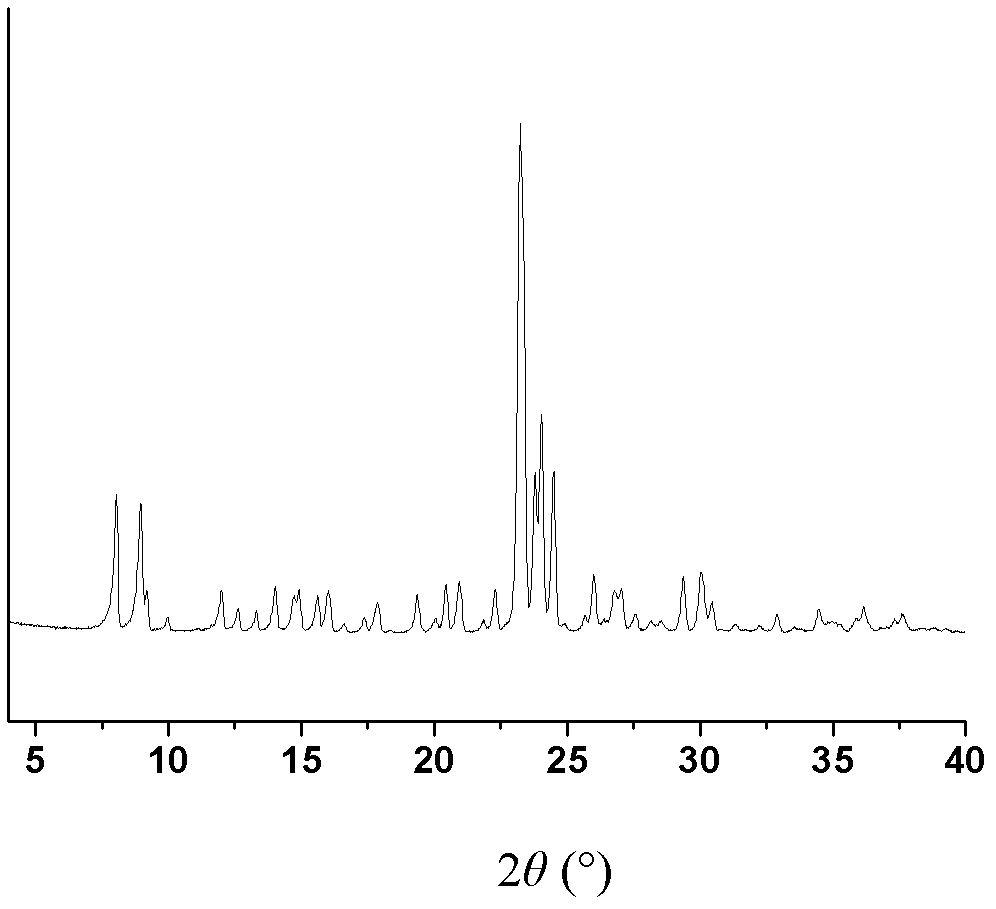

Catalyst for preparing propylene from methanol and preparation and using method thereof

InactiveCN101234353AHigh activitySolution to short lifeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCeriumReaction temperature

The invention discloses a catalyst used for making propylene by methanol, a preparation method and an application method thereof, which belongs to the field of catalyst preparation and application and is characterized in that: the catalyst is H-ZSM-5 molecular sieve modified by cerium; wherein, the weight ratio of Ce and ZSM-5 is 0.005 to 0.15 : 1, Ceo2 is added into dilute nitric acid, then the solution is poured into the vessel with H-ZSM-5 and is impregnated for 5 to 12hr after being heated and dissolved under 50 to 70 DEG C, and is dried under 100 to 120 DEG C after being filtered, then is roasted 3 to 5hr under 400 to 600 DEG C; the catalyst is then obtained, and then the catalyst is put into a reactor with methanol being added, with reaction temperature being controlled in 300 to 500 DEG C, and reaction pressure being 0 to 1MPa, and liquid air speed being 0.1 to 10hr<-1>; propylene is mainly generated after the reaction. The catalyst used for making propylene by methanol with the preparation method and the application method have the advantages of simple technology, high catalyst reactivity, long service life, good propylene selectivity, high yield rate and low cost.

Owner:HANERGY TECH

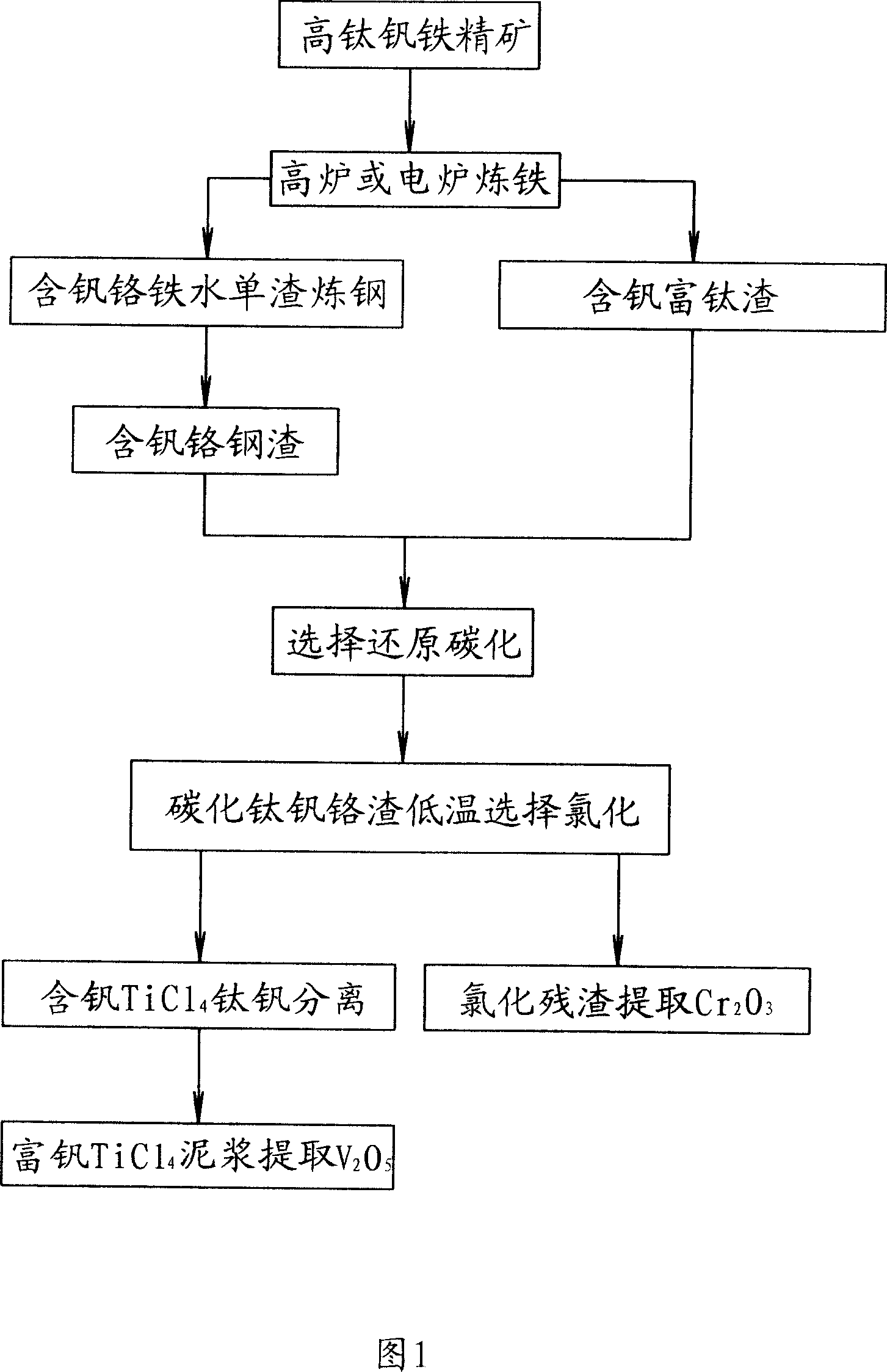

Method for extracting iron titanium vanadium from high-titanium iron concentrate

InactiveCN101113495AHigh yieldFew kindsBlast furnace detailsManufacturing convertersSteelmakingCarbonization

The invention discloses an iron-titanium-vanadium extracting method from high-titanium ferrovanadium concentrate ore. By adopting the method to make steel, fine TiCI4 and V2O5 have the advantages that: technological processes are simple and reasonable; energy consumption is low; yield rate of iron-titanium-vanadium is high and three wastes (waste gas, waste water and waste slag) are fewer. The method comprises the steps: iron smelting: a high furnace or an electric furnace is adopted to smelt iron to make melten iron containing vanadium and chromium and make titanium-enriched slag as byproduct and the rate of vanadium reduced and added into iron is 60-78 percent; single-slag steel-making: melten iron containing vanadium and chromium is put into a converter furnace directly to make steel by the function of oxygen blowing, and steel slag containing vanadium and chromium is obtained as byproduct; carbonized titanium-vanadium-chromium slag with 80-95 percent of carbonization rate is made by smelting reduction carbonization by the electric furnace smelting selection; TiCl4 containing vanadium is made by selective chlorination of carbonized titanium-vanadium-chromium slag in a fluidized bed at low temperature, and residual slag of chlorination containing CrCl3 is byproduct; vanadium titanium separation: VOCI3 is directly reduced by cycloolefine or naphthenic acid to make VOCl2 which can not dissolve in TiCI4, while the VOCI3 can be dissolved in TiCI4. Then the fine TiCI4 is made and the slurry TiCI4 containing rich vanadium is also made as byproduct; V2O5 is extracted from the rich vanadium containing slurry TiCI4.

Owner:张荣禄

High-strength and heat-resistant magnesium alloy containing two rare earths and preparation method thereof

ActiveCN103820689AImprove mechanical properties at room temperatureStable high temperature mechanical propertiesRare-earth elementSmelting process

The invention discloses a high-strength and heat-resistant magnesium alloy containing two rare earths. The high-strength and heat-resistant magnesium alloy containing the two rare earths comprises the components as follows: 14.0-17.0wt% of Y rare earth, namely Gd, Y and Er, 0.5-2.5wt% of Ce rare earth, namely one or several of La, Ce, Pr, Nd and Sm, 0.3-1.0wt% of Zr, impurities and the balance of Mg, wherein Gd is 11.0-15.0wt%, Y is 0.5-4.0wt% and Er is 0.5-2.0wt%; the content of Nd and Sm elements is 0.2wt% or less of the total amount of the magnesium alloy, or 0; the impurities including Fe, Si, Mn and a small amount of chloride; Fe is less than or equal to 0.002wt %, Si is less than or equal to 0.04wt%, Mn is less than or equal to 0.02wt%, and chloride is less than or equal to 0.002wt%; the impurity content is more than 0; Er in the Y rare earth can be replaced by one or several of Tb, Dy, Ho, Yb and Tm. The magnesium alloy has relatively high mechanical properties at room temperature and relatively stable high temperature creep resistance, and has relatively high yield rate of rare earth elements in the smelting process.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com