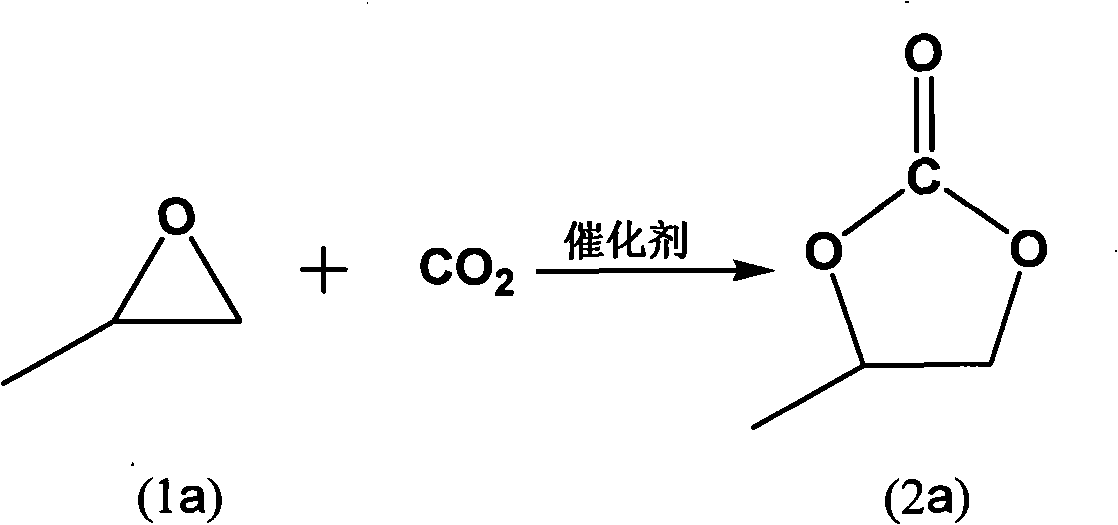

Process for synthesizing cyclic carbonate with catalysis of solid carried ion liquid catalyst

A cyclic carbonate, ionic liquid technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

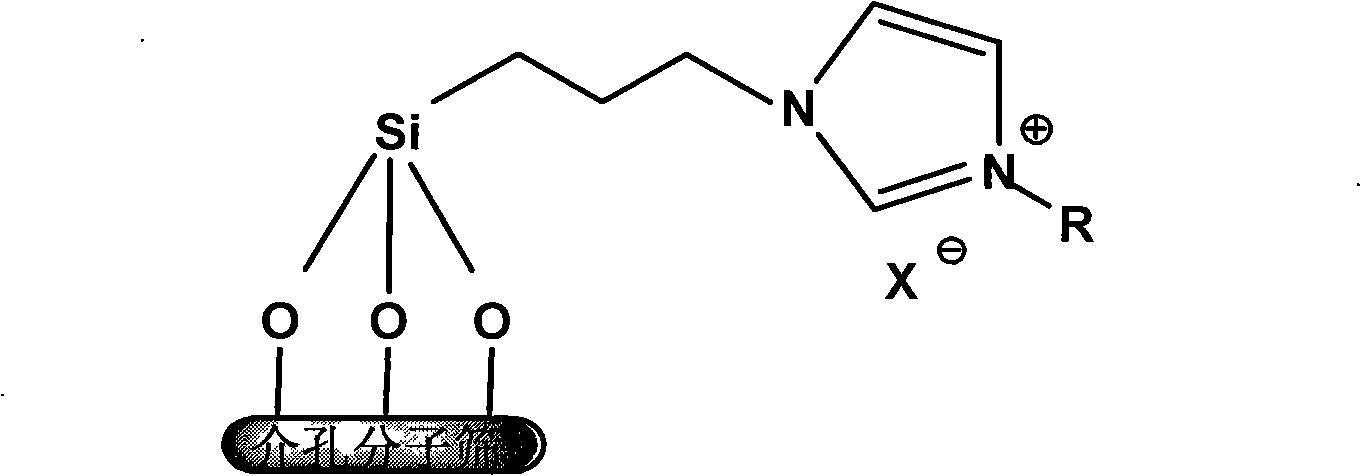

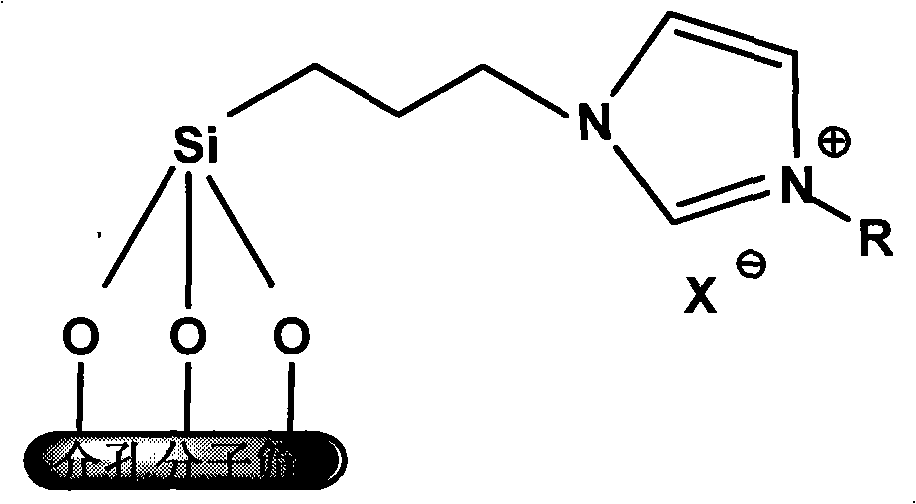

[0012] The modified MCM-41 reference [Nie Chunfa, Suo Jiquan. Molecular Catalysis, 2004, 18(1):61] was prepared. 4g of modified MCM-41 and 2g of imidazole were refluxed in xylene for 4h, filtered, and the solid was washed with absolute ethanol and dried under vacuum at 60°C, then 5g of imidazole-modified MCM-41 was taken and 3g of bromoethane was added. Reflux in xylene at 120°C for 24h, filter, and dry to obtain ethylimidazolium bromide ionic liquid supported by MCM-41.

Embodiment 2

[0014] The modified MCM-41 was prepared in the same manner as in Example 1. 4g of the modified MCM-41 and 3g of imidazole were refluxed in xylene for 4h, filtered, the solid was washed with absolute ethanol, and dried in vacuum at 60°C, and 5g of imidazole was taken. Add 3.5g of bromobutane, reflux in xylene at 120°C for 24h, filter and dry to obtain MCM-41-supported butylimidazolium bromide ionic liquid.

Embodiment 3

[0016] The modified MCM-41 was prepared in the same manner as in Example 1. 4g of the modified MCM-41 and 2g of imidazole were refluxed in xylene for 4h, filtered, the solid was washed with absolute ethanol, and dried under vacuum at 60°C, and then 5g of imidazole was taken. Add 4g of bromohexane, reflux in xylene at 120°C for 24h, filter and dry to obtain the hexylimidazolium bromide ionic liquid supported by MCM-41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com