Patents

Literature

289 results about "Bromoethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bromoethane, also known as ethyl bromide, is a chemical compound of the haloalkanes group. It is abbreviated by chemists as EtBr (which is also used as an abbreviation for ethidium bromide). This volatile compound has an ether-like odour.

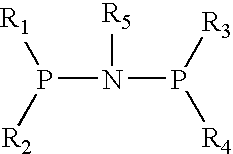

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS7786336B2High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneAluminoxane

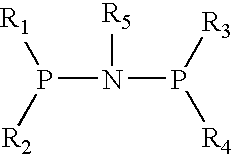

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as:in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; the accelerator is selected from the group consisting of 1,1,2,2,-tetrachloroethane, 1,1,2,2-tetrabromoethane, 1,1,2,2-tetrafluoroethane, and compounds having a formula of X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkylene or arylene group; the molar ratio of chromium compound, ligand containing P and N, activator and accelerator is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·ma−1 Cr·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

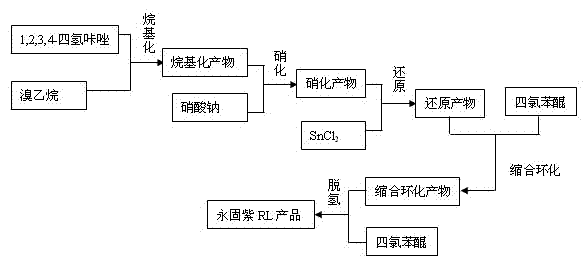

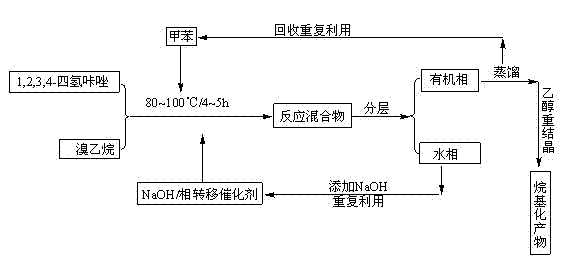

Method for synthesizing permanent violet

The invention discloses a method for synthesizing permanent violet. The method comprises the following steps of: 1) alkylating, namely, in a closed reaction kettle, putting carbazole into solution consisting of an inert halogenated aryl hydrocarbon solvent and an alkali metal hydroxide; and performing a reaction with bromoethane in the presence of a quaternary ammonium salt catalyst; 2) nitrifying, namely, treating an obtained N-ethyl carbazole-contianing organic phase by using dilute nitric acid; and after cooling, crystallizing and separating, obtaining a midbody 3-nitryl-N-ethyl carbazole by washing paste; 3) reducing, namely, after dissolving a 3-nitryl-N-ethyl carbazole material in inert halogenated aryl hydrocarbon, performing hydrogenated reduction by using fermium-containing Raney's nickel as a catalyst; and 4) performing a condensation reaction and a ring closing reaction. The method has the advantages that: 1) in the alkylation of the invention, the inert halogenated aryl hydrocarbon is taken as a solvent, so that pollution and cost are reduced and production devices are simplified at the same time; 2) in the method, the temperature for the nitration is improved, so that raw material consumption and the discharge of waste water are reduced; and 3) the process of industrial hydrogenated reduction is perfected, so that the problem of waste water reduction treatment is solved basically, and energy consumption is reduced obviously.

Owner:江西紫荆颜料化工有限公司

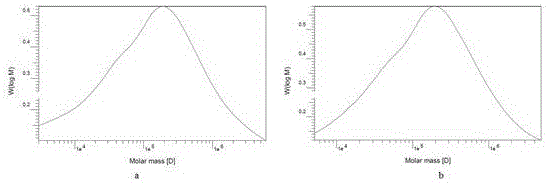

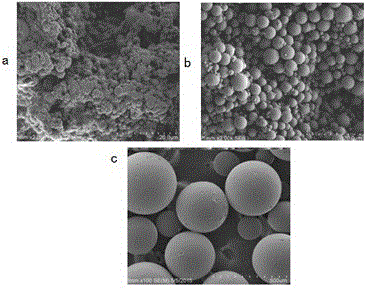

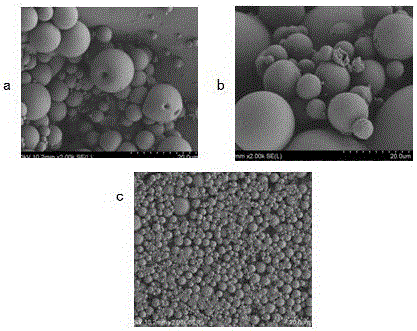

Hyperbranched polyamide modified chitosan quaternary ammonium salt microsphere for wastewater treatment and preparation method and application thereof

ActiveCN105669986ALarge specific surface areaImprove adsorption capacityOther chemical processesWater contaminantsEthylenediamineQuaternary ammonium cation

The invention provides hyperbranched polyamide modified chitosan quaternary ammonium salt which is obtained through the reaction of hyperbranched polyamide, chitosan and alkyl halide.The hyperbranched polyamide is prepared from trimesoyl chloride and ethylenediamine through a solution polymerization method.The alkyl halide comprises methyl iodide, ethyl iodide, methyl bromide or ethyl bromide.The microsphere prepared from the quaternary ammonium salt is applied to treatment of methyl orange wastewater, the final dye removal rate can reach 99.67%, the microsphere is renewable, and the preparation process is simple and free of pollution.

Owner:ZHANJIANG JIALI GLOVE PRODS

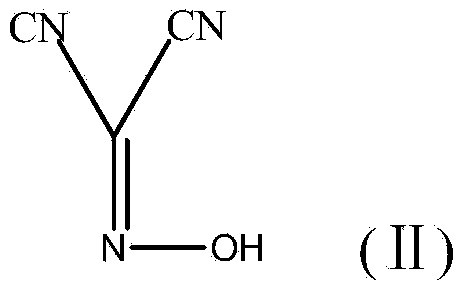

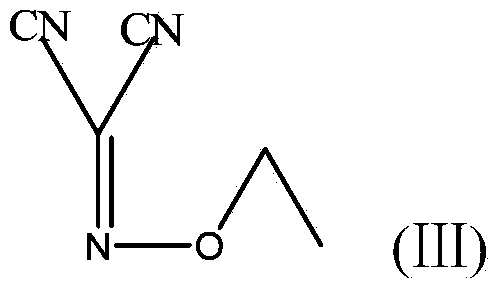

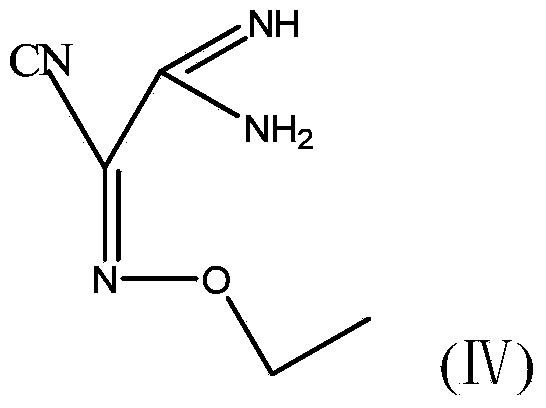

Method for preparing (Z)-5-amino-alpha-(ethoxy imino group)-1, 2, 4-thiadiazole-3-acetic acid

ActiveCN103804321AShort synthetic routeFew synthetic stepsOrganic chemistryAcetic acidPotassium thiocyanate

The invention discloses a method for preparing (Z)-5-amino-alpha-(ethoxy imino group)-1, 2, 4-thiadiazole-3-acetic acid. The method comprises steps of firstly, carrying out oximation reaction on malononitrile and sodium nitrite under the action of acetic acid so as to obtain a compound A, then carrying out Williamson synthesis on the compound A and bromoethane or diethyl sulfate under alkaline condition, so as to obtain a compound B, then carrying out amidine reaction on the compound B and ammonia water, so as to obtain a compound C, carrying out cyclization reaction on the compound C and potassium rhodanide for ring closing so as to obtain a compound D, and finally, hydrolyzing the compound D under the action of a strong base, so as to obtain (Z)-5-amino-alpha-(ethoxy imino group)-1, 2, 4-thiadiazole-3-acetic acid. The method has few synthesis steps, has low cost, uses the materials which are cheap and easy to obtain, is beneficial to industrial production, and has light contamination; the purity of the product can reach 99%, so that synthesis of high-purity ceftaroline fosamil in the subsequent step is guaranteed.

Owner:山西海泰电子材料有限公司

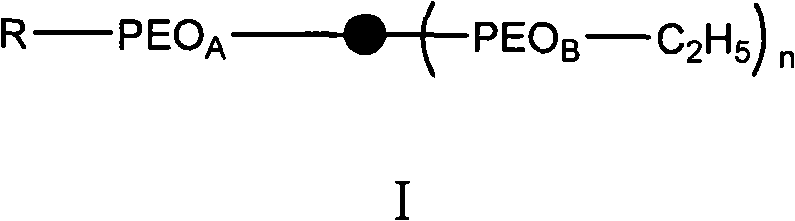

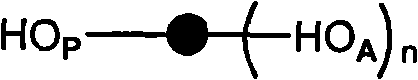

Multi-arm star-shaped polyethylene glycol containing single-activity functional groups and preparation method thereof

The invention belongs to the synthetic chemistry field of macromolecules and relates to multi-arm star-shaped polyethylene glycol containing single-activity functional groups and a preparation method thereof. The preparation method comprises the following steps of: firstly, preparing a molecular compound containing n active hydroxyls and one protected hydroxyl; initiating ethylene oxides to carry out ring-opening polymerization by using the n active hydroxyls on the compound and diphenylmethyl potassium as common initiation systems, and then sealing ends by using bromoethane to obtain n-arm star-shaped polyethylene glycol; eliminating protection groups of the protected hydroxyl in a joint from an acid environment to obtain n-arm star-shaped polyethylene glycol containing one active hydroxyl; initiating ring-opening polymerization for the second time by using the active hydroxyl and the diphenylmethyl potassium as common initiation systems to obtain the multi-arm star-shaped polyethylene glycol (ABn); and finally, selectively modifying the functional groups of the hydroxyl at the tail ends of the n+1 arm to prepare the multi-arm star-shaped polyethylene glycol containing single-activity functional groups.

Owner:FUDAN UNIV

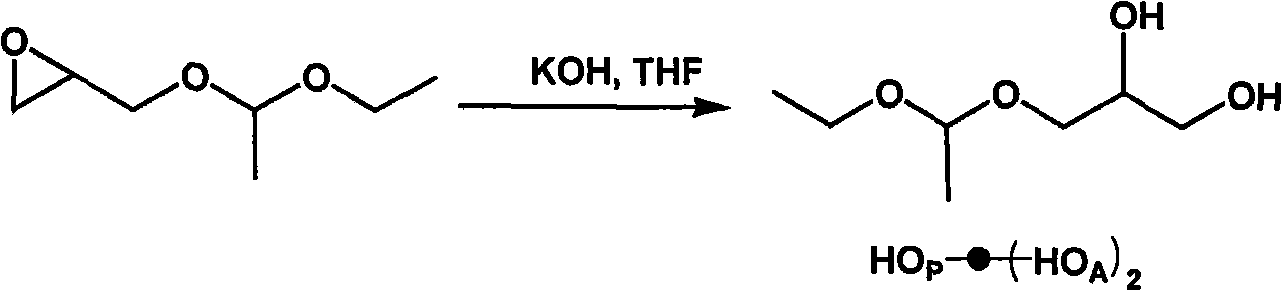

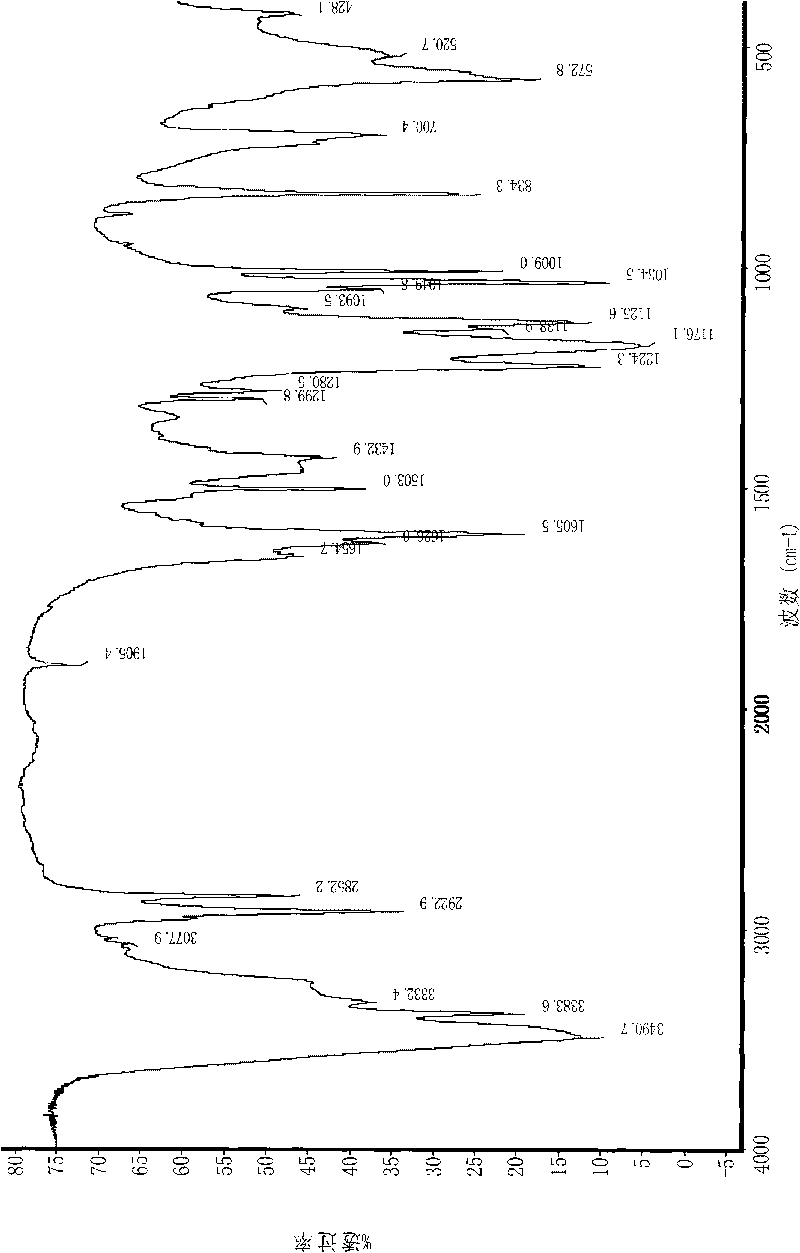

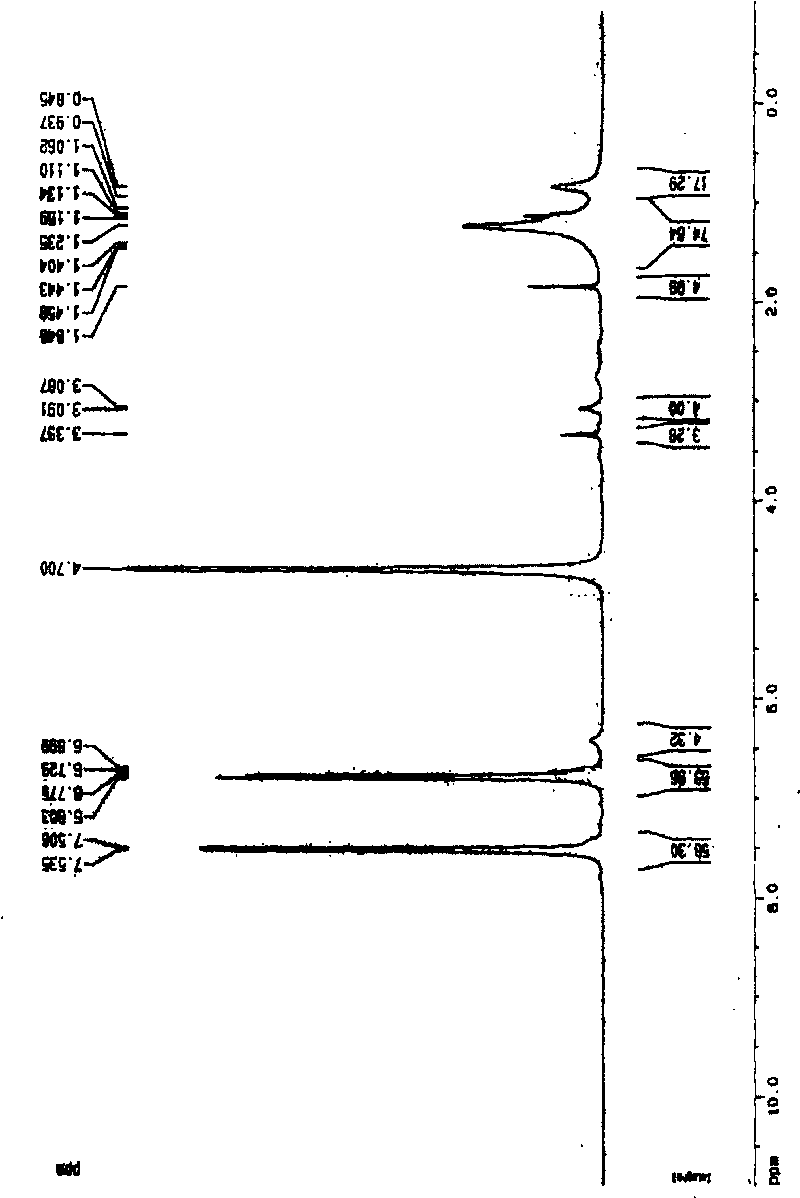

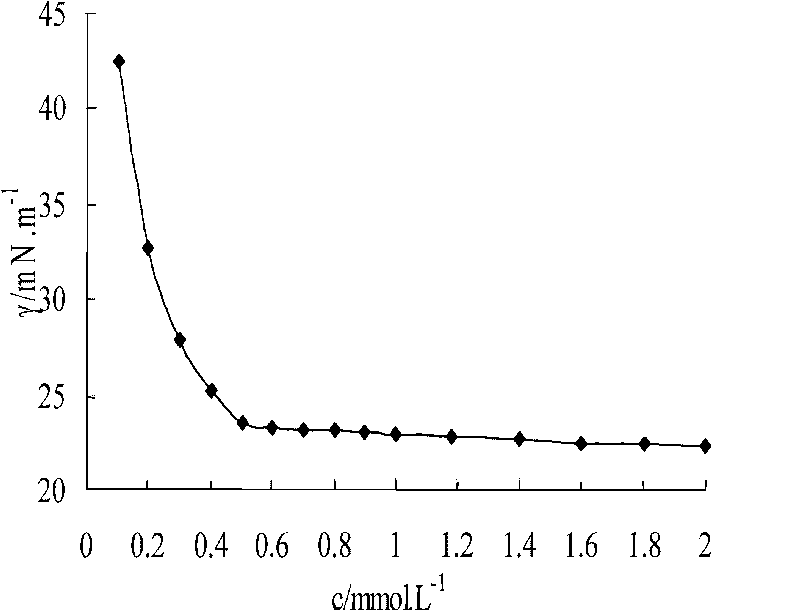

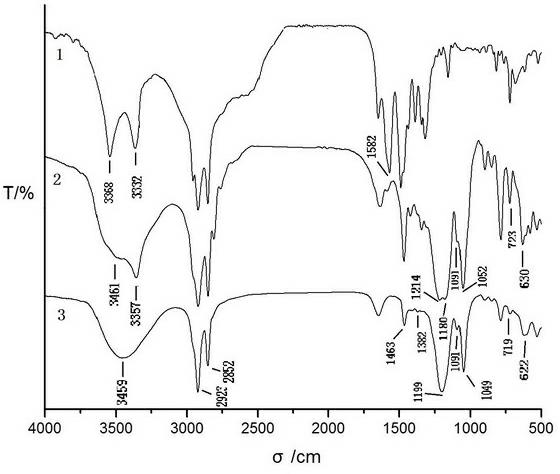

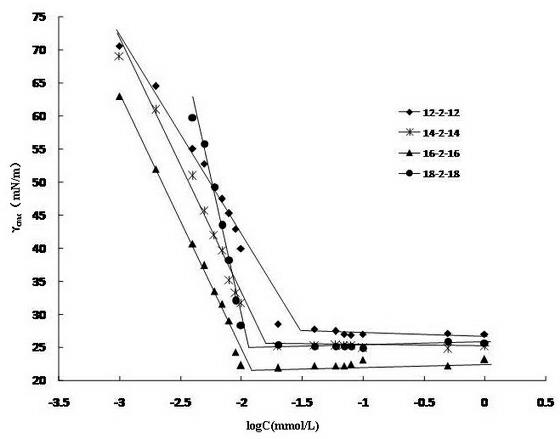

Biquaternary ammonium salt and bisulfonate surfactant and synthesis method thereof

InactiveCN101703905AThe synthesis method is simpleEasy to operateTransportation and packagingSulfonic acids salts preparationSynthesis methodsHigh surface

The invention relates to a biquaternary ammonium salt and bisulfonate surfactant, which is N,N'-ethylene bis[ethyl alkyl (sodium) p-benzene-sulfonate ammonium bromide]. The synthesis method of the biquaternary ammonium salt and bisulfonate surfactant comprises the following steps of: (1) dissolving a sodium hydroxide in a mixed solvent of ethanol and water to prepare solution, adding the solution into a three-necked flask with a stirrer and a return condenser, then adding a sulfanilic acid into the flask and slowly dripping 1,2-dibromoethane under a condition of a pH value of 8 to 10; (2) adding the product generated by step (1) in a reactor, adding a long-chain bromoalkane with stirring, adjusting the pH to around 8 and iltering out and drying a precipitate precipitated after the reaction is completed; and (3) adding the product generated by step (2) into a reactor, adding a mixed solution of distilled water and ethanol, stirring the solution to dissolve the product, adding an bromoethane, adjusting the pH to around 8, cooling the solution, filtering out under vacuum, washing and drying precipitate precipitated when the reaction is completed and thus obtaining the surfactant. The surfactant has the advantages of very high surface activity, simple synthesis method, mild reaction condition, simple and convenient operation, easy purification and separation and very good formulation performance.

Owner:SOUTHWEST PETROLEUM UNIV

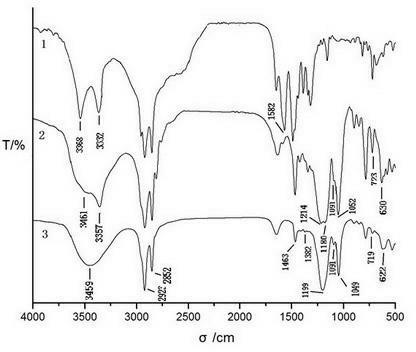

Bishydroxyl sulfoacid betaine surface active agent and synthesis method thereof

InactiveCN102491922AEasy to separateEasy to purifySulfonic acids salts preparationDrilling compositionBetaineActive agent

The invention relates to an ethylene-bishydroxyl sulfoacid betaine surface active agent (DBA for short). The synthesis method comprises the following steps: (1) adding alkyl primary amine (n=11,13,15,17) and 3-chlorine-2-hydroxysulfpropylcellulose Na into a reactor, using ethanol water as a solvent and using (Na2CO3 as a acid bonding agent, keeping a potential of hydrogen (pH) value to be equal to 7-10, performing mixing and backflow for 13-16 hours, performing leaching, cooling filtrate to the room temperature to precipitate white crystals, and performing the leaching, washing, recrystallization and drying; (2) adding a product in the step (1), the ethanol water and the Na2CO3 into the reactor to be heated and mixed, adding 1,2- dibromoethane into mixture and performing backflow for 2-3 hours after dissolution; and (3) adding superfluous bromoethane in a reaction system, performing mixing and backflow for 48-72 hours, performing leaching, standing filtrate at zero DEG C for 10-12 hours to precipitate white crystal, and performing the leaching, the washing and the recrystallization to produce a target product DBA. The synthesis method is temperate in reaction condition and simple and convenient to operate, and the product is easy to separate and refine and has high surface activity.

Owner:SOUTHWEST PETROLEUM UNIV

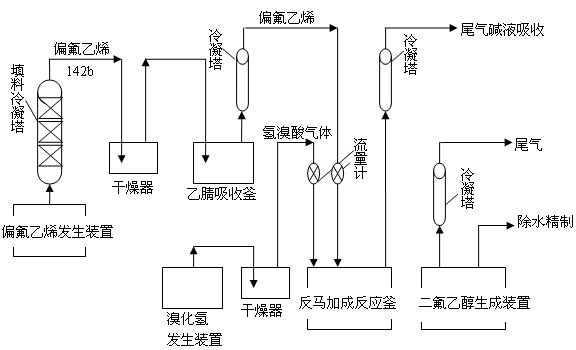

Method for synthesizing difluoroethanol

ActiveCN102304024ASimple processReduce pollutionOrganic compound preparationHydroxy compound preparationTolueneSolvent

The invention discloses a method for synthesizing difluoroethanol. The method comprises the following steps of: (1), in a reaction kettle, adding polar or weak polar solvent and initiator in a mass ratio of (300: 1) to (30: 1); heating to 50-150 DEG C and continuously feeding vinylidene fluoride gas and hydrobromic acid gas in a mol ratio of (1: 1.05) to (1: 2.05); distilling to obtain 1,1-difluoro-2-bromoethane and absorbing tail gas by alkali solution; and (2), in the reaction kettle, adding 1,1-difluoro-2-bromoethane and sodium carbonate water solution with the mass concentration of 10-30% in a mol ratio of (2.5: 1) to (1.2: 1) and agitating under a backflow condition and reacting for 2-5 hours; cooling, adding methylbenzene, and distilling most water by co-boiling methylbenzene and water; then rectifying to obtain the difluoroethanol with the purity of more than 98%. The method provided by the invention has the advantages of high synthesis yield, less pollution, simple process, convenience in continuous operation of self-made vinylidene fluoride and hydrobromic acid gases, safety and reliability.

Owner:许茂乾

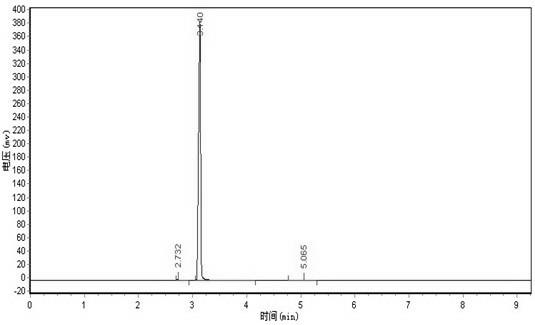

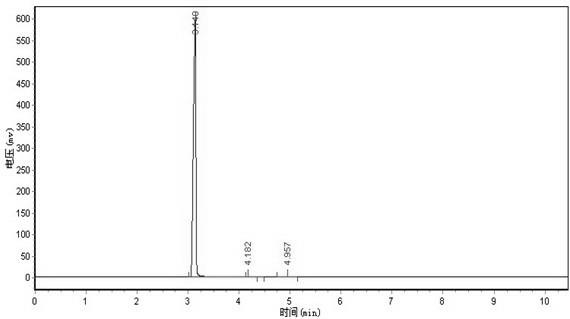

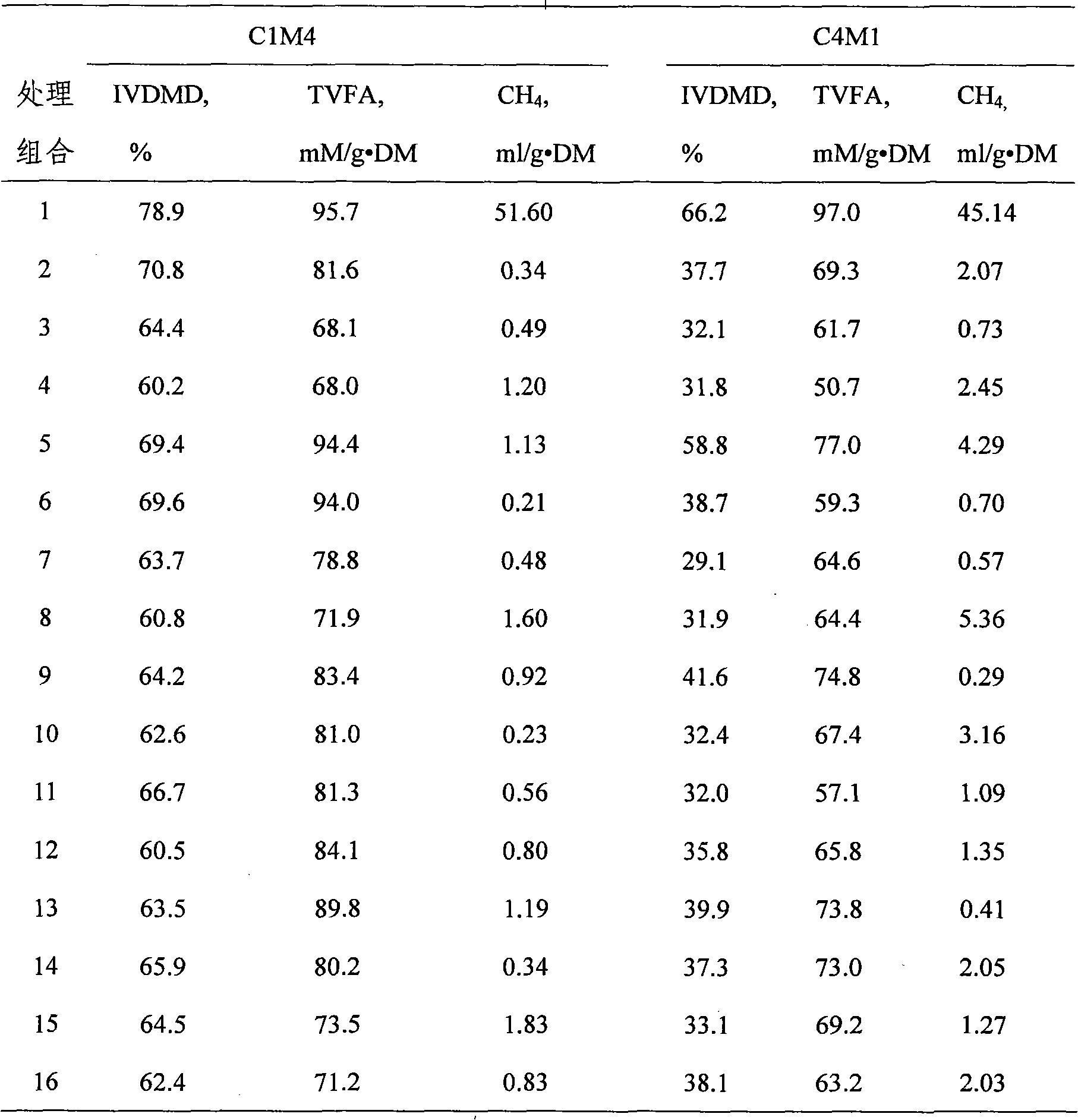

Compound quick-action inhibitor against generation of methane and preparation method and application thereof

InactiveCN101611762AImprove protectionImprove energy efficiencySolid waste disposalAnimal feeding stuffHuman wastePoultry manure

The invention discloses a compound quick-action inhibitor against generation of methane in the technical field of greenhouse gas emission reduction. The preparation method comprises: 1) mixing nitroethane, 2-nitroethylalcohol and 2-nitryl-1-propyl alcohol by weight percent of 0-5:0-6:0-7 (the weight percents can not be 0 simultaneously) to formulate solution A; and 2) mixing pyromellitic formic diimide and 2-bromoethane sodium sulfonate by weight percent of 0-3:0-2 (the weight percents can not be 0 simultaneously) to formulate powder B. The compound quick-action inhibitor has very obvious effect in inhibiting methane, is especially applicable to inhibiting the action of generating methane in rumen, and is beneficial to protecting the environment and improving the utilization rate of feed energy of ruminants. The preparation method is simple, the operability is strong, and the inhibitor is applicable to livestock and poultry breeding feed processing, livestock and poultry manure excrement biogas treatment and municipal domestic waste biogas treatment, and has the efficiency up to over 90 percent in inhibiting the action of generating methane by microorganism, as well as high practical value.

Owner:CHINA AGRI UNIV

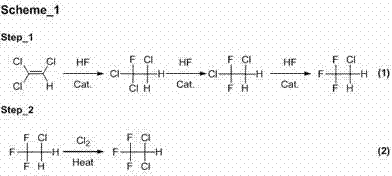

Preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and recycling method of waste difluoro trichloroethane

InactiveCN104761446AEnable recyclingIncrease added valuePreparation by hydrogen halide split-offPreparation from carboxylic acid halidesBromoethanePhenol

The invention relates to a preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and a recycling method of waste difluoro trichloroethane. The preparation method comprises the following steps: with waste difluoro trichloroethane produced in the production process of dichlorotrifluoroethane as a raw material, carrying out dehydrochlorination to obtain difluoro dichloroethylene, carrying out addition reaction on difluoro dichloroethylene and bromine to obtain difluoro dichlone dibromoethane; reacting difluoro dichlone dibromoethane with sulfur trioxide to obtain 2-bromo-2,2-difluoroacetyl chloride; and reacting 2-bromo-2,2-difluoroacetyl chloride with alcohol or phenol to obtain 2-bromo-2,2-difluoro acetate series products. According to the preparation method and the recycling method, recycling of waste difluoro trichloroethane is realized; 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate are prepared by a temperature oscillation method, so that the production cost is reduced; and meanwhile, the preparation method is an environment-friendly technique for producing products.

Owner:JIANGXI SUNWAY CHEM CO LTD

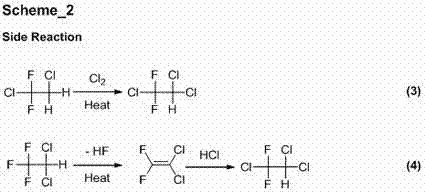

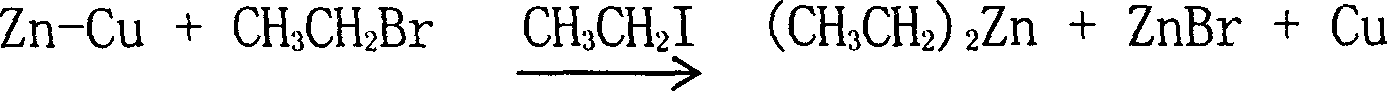

Process for preparing diethyl zinc

InactiveCN1827623ASimple production processReduce manufacturing costZinc organic compoundsZinc alloysCopper

The invention relates to a method for preparation of compounds and especially to a method for preparation of zinc diethyl. The preparation technology of the said method includes the following steps: a. adding powdered copper-zinc alloy into a reactor with an agitator, of which the powdered copper-zinc alloy occupies 8-12 % of the reactor, replacing the air in the reactor with inert gas, afterwards, beginning to stir; b. heating the temperature of the reactor to 40-150 DEG C while stirring, simultaneously, dripping iodoethane and bromoethane, after the reaction is initiated, gradually dripping bromoethane continuously, and controlling the temperature at 40-100 DEG C to stably reflux the reactants; c.after the reflux, controlling the temperature of the reactor at 100-120 DEG C, continuously stirring the reactants for 0.5-2 hours, and then beginning to distill in reduced pressure state to obtain high-purity zinc diethyl. The technical project of this invention is characterized in that it is of simple process, low cost, and high yield rate and purity of the obtained product.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

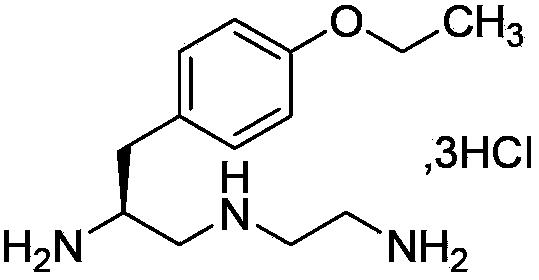

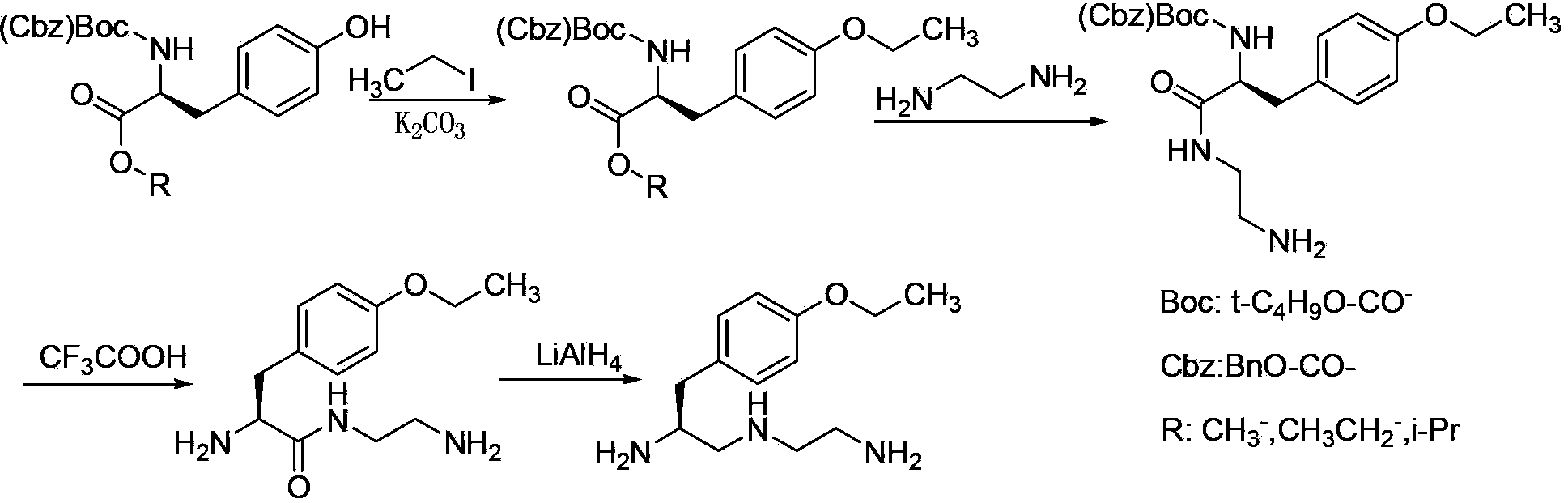

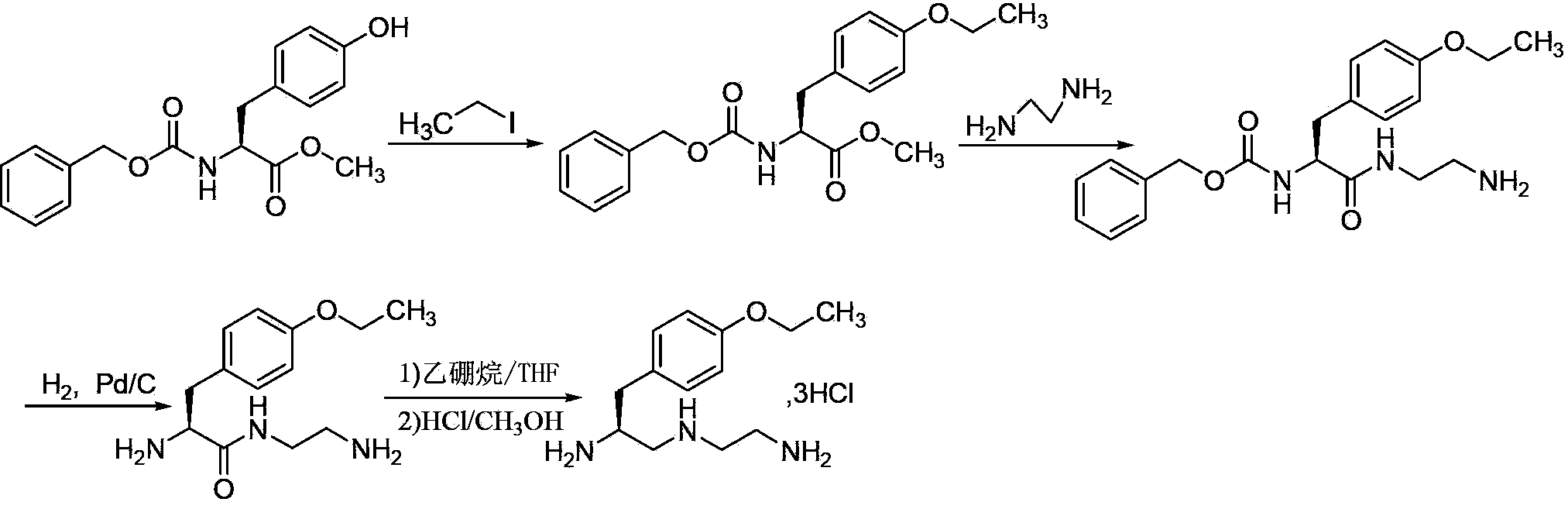

Preparation method of S-1-(4-ethyoxylbenzyl)-3-azapentane-1,5-diaminetrihydrochloride

ActiveCN103896788AOrganic compound preparationBulk chemical productionSulfonyl chlorideEthylenediamine

The invention relates to a preparation method of S-1-(4-ethyoxylbenzyl)-3-azapentane-1,5-diaminetrihydrochloride. The preparation method comprises the following steps: adopting L-tyrosine alkyl ester as a starting raw material, carrying out alkylation reaction with bromoethane, carrying out reduction on an obtained product by use of sodium borohydride, carrying out esterification on alkyl sulfonyl chloride, reacting an obtained reaction product with ethylenediamine, removing an amino protective group by hydrogen chloride to obtain the S-1-(4-ethyoxylbenzyl)-3-azapentane-1,5-diaminetrihydrochloride. The preparation method has the advantages of simplicity in operation, mild reaction condition, safety, controllability, high reaction yield and good product purity, and is more suitable for industrial production.

Owner:QILU PHARMA HAINAN +1

Permanent violet product synthesis and production process

The invention discloses a permanent violet product synthesis and production process. 1,2,3,4-tetrahydrocarbazole is used as an initial raw material, and undergoes alkylation, nitration, reduction, condensation cyclization and dehydrogenation technologies. Bromoethane is added in an alkylation step to carry out alkylation, sodium nitrate is added in a nitration step to carry out a nitration reaction, SnCl2 is added in a reduction step to carry out a reduction reaction, tetrachlorobenzoquinone is added in a condensation cyclization step to carry out a reaction in order to obtain a condensation product, and tetrachlorobenzoquinone is selected in a dehydrogenation step as a dehydrogenation agent. 1,2,3,4-tetrahydrocarbazole is adopted as a raw material, and the benzene ring of 1,2,3,4-tetrahydrocarbazole mainly undergoes the nitration technology, so generated byproducts are less, and the yield and the purity of the product are improved; and the permanent violet product synthesis and production process has the advantages of improvement of the problems comprising many byproducts, difficult separation and purification, low final product yield and the like of previous processes, less byproducts of all the steps, easy separation even direct access to a next step reaction without separation, and substantial increase of the yield and the purity of the final product.

Owner:MAANSHAN JINPU NEW MATERIAL TECH

Long-acting flame retarding coating fabric with safety protection performance, and preparation process thereof

ActiveCN102615901AHigh strengthImprove uniformityFibre treatmentSynthetic resin layered productsSlurryMoisture permeation

The present invention discloses a long-acting flame retarding coating fabric with safety protection performance, and a preparation process thereof. According to the fabric, a first prime coat and a second prime coat are provided; a surface coating comprises a polyurethane resin, bromoethane, antimony oxide, and zinc borate; and a lining woven from a flame retarding polyacrylonitrile fiber silk is adhered to the other side of a coating layer, wherein the flame retarding polyacrylonitrile fiber silk comprises polyacrylonitrile fiber, cotton and aramid fiber, and a ratio of the polyacrylonitrile fiber to the cotton to the aramid fiber is 4:3.5-4.5:0.9-1.1. The preparation method comprises: respectively soaking and dissolving bromoethane, antimony oxide and zinc borate powder in toluene for at least 24 hours; uniformly mixing the bromoethane, the antimony oxide, the zinc borate powder and a hydrophilic polyurethane moisture permeation primer according to a mass ratio of 40:22-18:4-6:95-105 to form a prime coat slurry; mixing polyacrylonitrile fiber, cotton and aramid fiber according to a mass ratio of 4:3.5-4.5:0.9-1.1, silking to form the flame retarding polyacrylonitrile fiber silk, and adopting a flame retarding lining woven from the flame retarding polyacrylonitrile fiber silk, and adhering on the other side of the surface coating; and uniformly mixing a white slurry and a surface coating slurry to form a blended surface coating slurry. With the fabric of the present invention, the flame retarding time is long, the amount of the smoke generation is small, the droplet is not easily generated, the flame retarding effect is resistant to washing, and the hydrolysis of the flame retarding substances is avoided.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Recovering process for Gram-waste water

The present invention discloses Grignard process of recovering waste water as one radically improved technological process. The Grignard process includes hydrolysis with ammonium bromide aqua to recover bromine ion via preparing bromoethane and recovering magnesium ion via preparing magnesium sulfate, so as to recover ions from Grignard waste water. The said process is simple, high in yield and low in cost.

Owner:ZHEJIANG UNIV +1

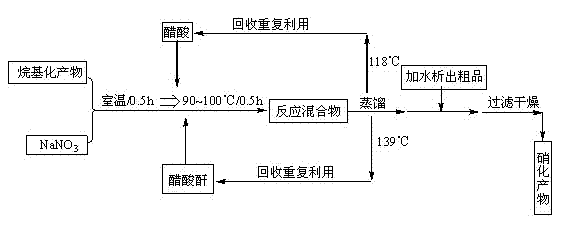

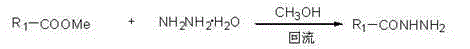

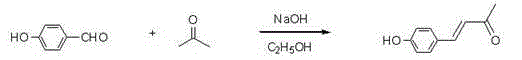

Preparation method and use of pentadiene ketone compound containing 1,3,4-oxadiazole sulfo-ethyoxyl

The invention discloses a preparation method and biological activity of a pentadiene ketone compound, containing 1,3,4-oxadiazole sulfo-ethyoxyl, with a function of preventing and treating a plant virus disease, namely a compound expressed in a general formula (I) and a preparation method of the compound. According to the method, by using substituted carboxylic acid, hydrazine hydrate, carbon disulfide, acetone, 4-substituted hydroxy benzaldehyde, substituted aromatic aldehyde, 1,2-dibromoethane and the like as raw materials, methanol, ethanol and N,N-dimethylformamide as solvents and potassium carbonate, sodium hydroxide and potassium hydroxide as catalysts, pentadiene ketone compound containing 1,3,4-oxadiazole sulfo-ethyoxyl is prepared through seven-step synthesis. The compounds I3, I4, I6, I11, I13, I14, I16 and I17 have good functions in cucumber mosaic virus, tobacco mosaic virus, southern rice black-streaked dwarf virus and the like. The formula is shown in the specification.

Owner:GUIZHOU UNIV

Method for preparing alpha-ethyl furan methanol

The invention belongs to the technical field of chemical engineering, and particularly relates to a method for preparing alpha-ethyl furan methanol.The method comprises the first step of a Grignard-addition reaction, wherein a methylbenzene-tetrahydrofuran mixed solvent, furfural and chloroethane are added into a head tank, magnesium chips, the methylbenzene-tetrahydrofuran mixed solvent and bromoethane are added into a reaction still, heating is carried out, then the head tank is opened, materials are dropwise added into the reaction still for reacting, the temperature is kept at 45 DEG C to 55 DEG C, and after the materials are dropwise added, a furfuryl Grignard reagent is generated; the second step of a hydrolysis reaction, wherein a hydrolysis agent is dropwise added to the furfuryl Grignard reagent and stirred, the hydrolysis agent is dropwise added till the system is clear, the temperature is controlled to range from 15 DEG C to 30 DEG C, an alpha-ethyl furan methanol solution is obtained through filtering and is distilled at vacuum negative pressure, and alpha-ethyl furan methanol is obtained.According to the method, the solvent, the material proportion and other parameters are optimized, production cost is reduced, and the purity and yield of alpha-ethyl furan methanol are improved.

Owner:广东省肇庆香料厂有限公司

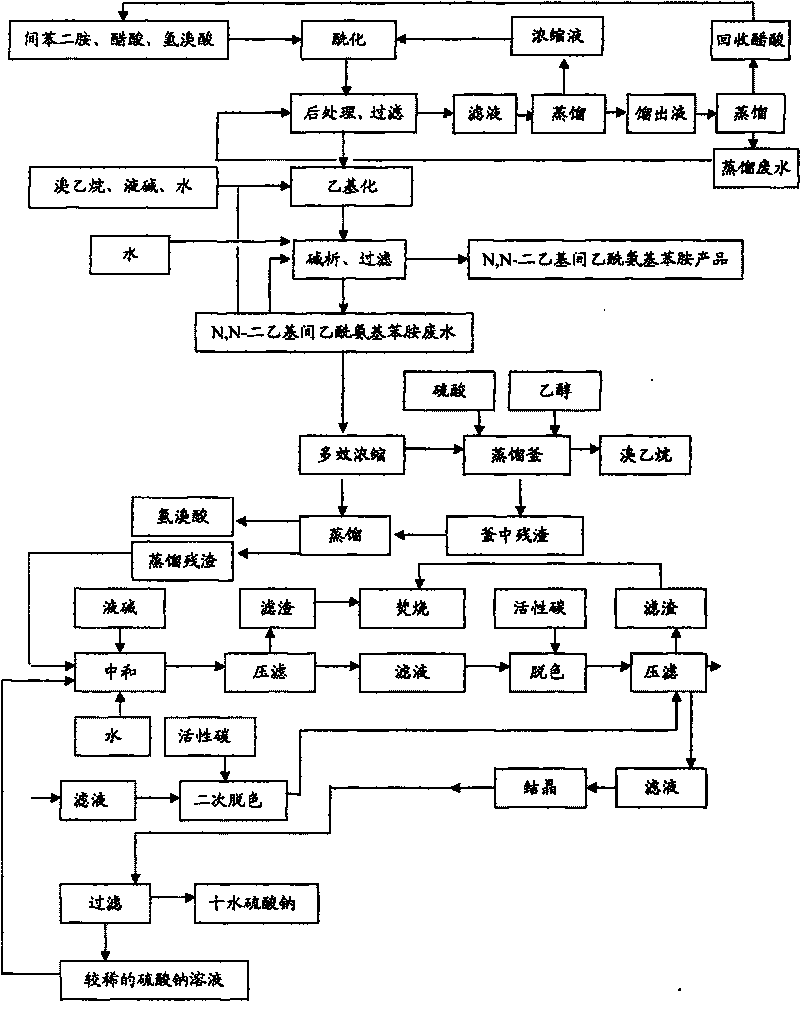

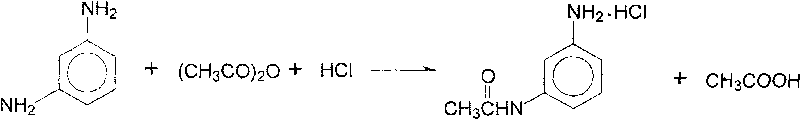

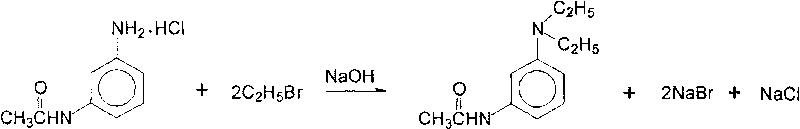

Method for producing m-acetamino-N,N-diethyl aniline

ActiveCN101723845ASolve the reuse problemLow costOrganic compound preparationCarboxylic acid amides preparationFiltrationAniline

The invention discloses a method for producing m-acetamino-N,N-diethyl aniline, which comprises the following steps: (1) mixing m-phenylenediamine, glacial acetic acid and hydrobromic acid to perform an acylation reaction to obtain an acetylated compound; (2) performing ethylation of the acetylated compound and bromoethane, and after the reaction is finished, diluting and filtering the reaction system, and eluting the product filtered out to obtain m-acetamino-N,N-diethyl aniline; (3) concentrating mother solution produced by filtration and elution in the step (2); and (4) dripping sulfuric acid and ethanol into the mother solution to perform an reaction to obtain bromoethane and collecting the bromoethane for use in the ethylation in the step (2). The production method of the invention has the advantages that: the active ingredients in waste water produced in production are fully used; the recycling of the waste water reduces cost; and clean production is realized.

Owner:ZHEJIANG RUNTU

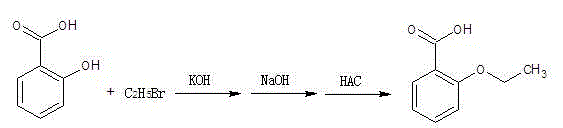

Preparation method of o-ethoxybenzoic acid

ActiveCN103553908ALow costSimple processPreparation from carboxylic acid saltsOrganic compound preparationAcetic acidFiltration

The invention relates to a preparation method of o-ethoxybenzoic acid, which comprises the following steps: adding salicylic acid, acetone and potassium hydroxide into a reaction bulb, dropwisely adding bromoethane while stirring at room temperature, heating under reflux for 9-15 hours, recovering the acetone under reduced pressure, adding water and liquid alkali, heating under reflux for 2-4 hours, cooling to room temperature, regulating the pH value to 3-4 with glacial acetic acid, cooling to 1-15 DEG C, separating by vacuum filtration, washing with water, and carrying out vacuum drying to obtain the o-ethoxybenzoic acid, wherein the salicylic acid:potassium hydroxide:bromoethane:liquid alkali mol ratio is 1:(2.0-2.5):(2.1-2.5):1.4. The method has the advantages of simple technique, low raw material cost, high yield and good quality, and is convenient to operate and convenient for industrial production.

Owner:苏州诚和医药化学有限公司

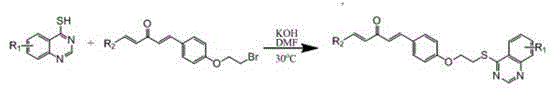

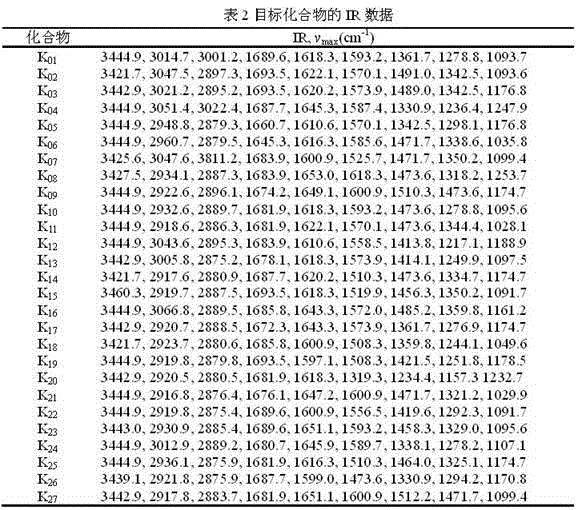

Quinazoline-containing thioether substituted pentadiene ketone derivatives, and preparation method and application thereof

ActiveCN104610169AEnhanced inhibitory effectOrganic chemistryDisinfectantsOrthanilic acidBenzoic acid

The invention discloses a preparation method and bioactivity of new compounds for preventing and treating plant virus diseases (quinazoline-containing thioether substituted pentadiene ketone compounds), particularly compounds disclosed as the following general formula (I) and a preparation method thereof. The quinazoline-containing thioether substituted pentadiene ketone compounds are prepared from ortho-aminobenzoic acid, formamide, thionyl chloride, thiocarbamide, 4-hydroxybenzaldehyde, acetone, substituted aromatic aldehyde, substituted heterocyclic aldehyde and 1,2-ethylene dibromide by seven reaction steps by using 1,2-dichloroethane, ethanol and N,N-dimethylformamide as solvents and NaOH, K2CO3 and KOH as catalysts. The compounds K01, K02, K03, K04, K05, K06, K07, K09, K10, K12, K13, K15, K16, K17, K18, K19, K20, K21, K23 and K27 have favorable anti-plant virus activity (I).

Owner:GUIZHOU UNIV

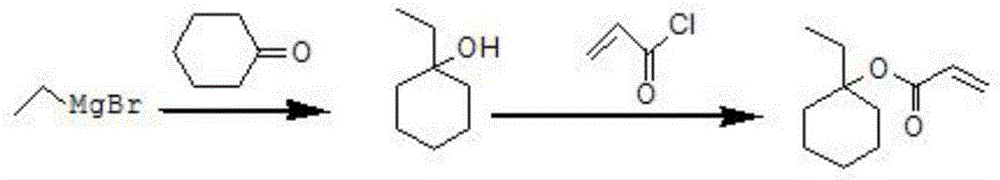

Method for preparing 1-ethylcyclohexyl acrylate

ActiveCN104910012AHigh purityEasy to operatePreparation from carboxylic acid halidesOrganic compound preparationCyclohexanoneGrignard reagent

The invention relates to a method for preparing 1-ethylcyclohexyl acrylate. The method comprises the following steps: magnesium turnings are fetched, and a mixed liquid of bromoethane and a reaction solvent is dropped into the magnesium turnings; bromoethane is subjected to a reaction with the magnesium turnings, such that a Grignard reagent is prepared; cyclohexanone is dissolved in toluene, and the solution is dropped into the Grignard reagent; when dropping is finished, a reaction is continued under a maintained temperature; when the Grignard reaction is finished, the temperature of the reaction system is reduced to 0-40 DEG C, and an acid-binding agent is added; a dichloromethane solution of propionyl chloride is dropped in, and an esterification reaction is carried out; when dropping is finished, the reaction is continued for 1-5h under a temperature maintained at 10-70 DEG C, such that a reaction liquid is obtained; the reaction liquid is poured into water for quenching; liquid separation is carried out; a water phase is extracted with dichloromethane; organic phases are combined; washing and drying are carried out, and the solvent is removed, such that a crude product is obtained; a polymerization inhibitor is added into a distillation flask, and the crude product is subjected to reduced-pressure distillation; and a distillate at a temperature of 98-100 DEG C under a pressure of 60Pa is collected, such that 1-ethylcyclohexyl acrylate is obtained. The method provided by the invention has the advantages of high yield, low cost, simple preparation, and suitability for expanded production. With the method, a GC purity can reach 99.5%. The method has a good application prospect.

Owner:VALIANT CO LTD

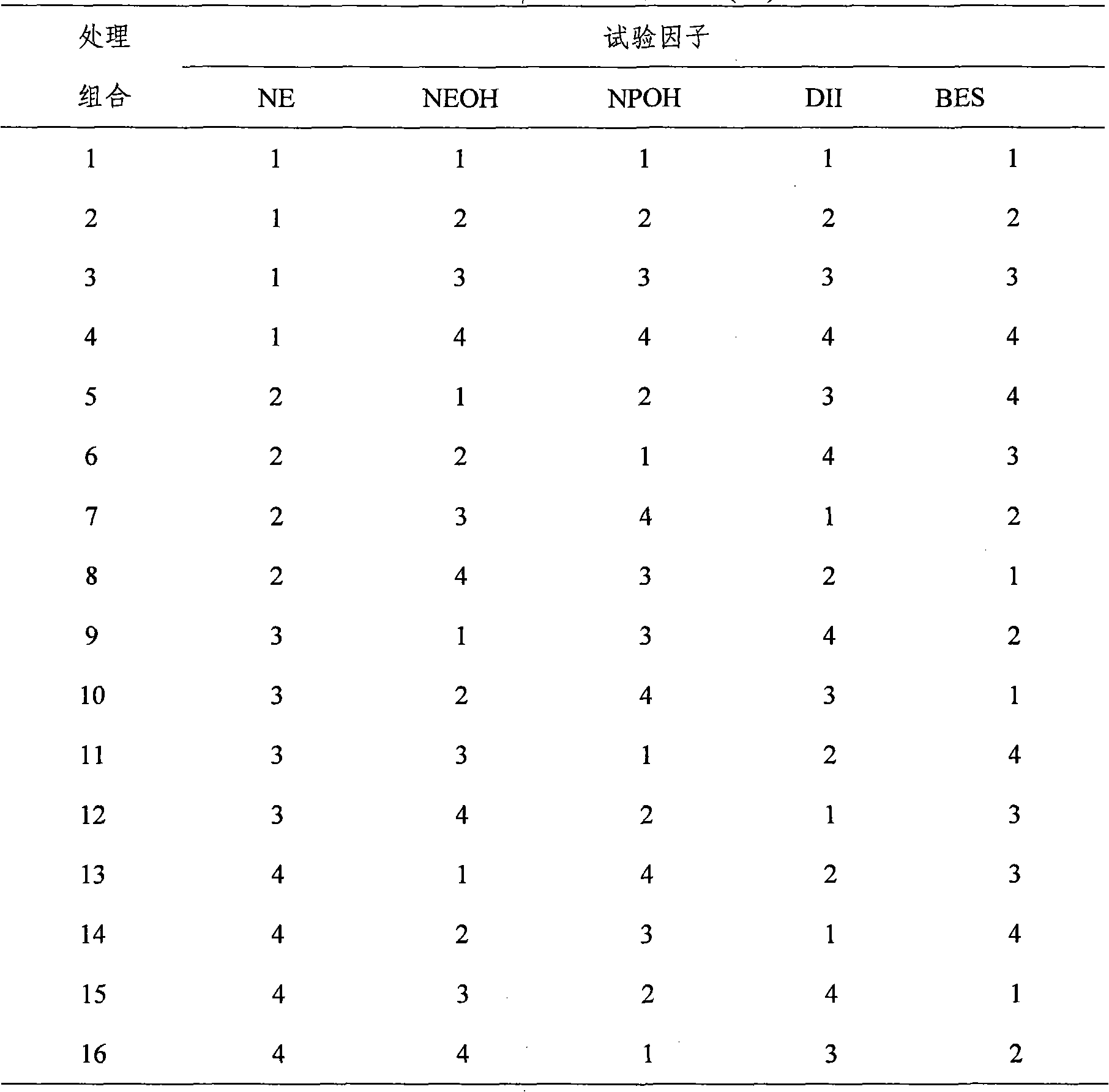

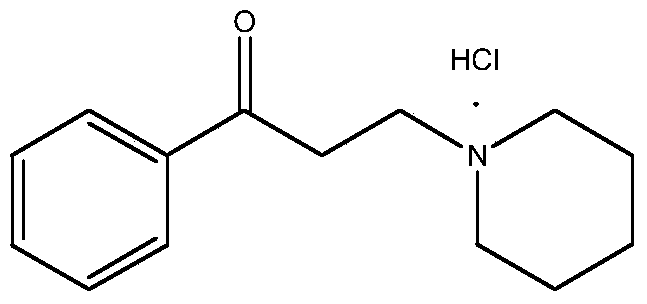

Prepn process of 2-[2-(2,2,2-trifluoro ethoxy)] phenoxy ethamine

InactiveCN101066930ASufficient sourceLow priceOrganic compound preparationAmino-hyroxy compound preparationAlkyl transferAminolysis

The present invention relates to preparation process of 2-[2-(2, 2, 2-trifluoro ehtoxy)] phenoxy ethamine. The preparation process includes the etherification of 2-(2, 2, 2-trifluoro ehtoxy) phenol as material with 1, 2-dibromoethane to obtain 2-[2-(2, 2, 2-trifluoro ehtoxy)] phenoxy bromethane, the alkylation of 2-[2-(2, 2, 2-trifluoro ehtoxy)] phenoxy bromethane with phthalamide, and final aminolysis with hydrazine hydrate to obtain 2-[2-(2, 2, 2-trifluoro ehtoxy)] phenoxy ethamine.

Owner:CHINA PHARM UNIV

Preparation method for obeticholic acid

InactiveCN104926909AEasy to operateHigh yieldSteroidsBulk chemical productionEtherSodium borohydride

The invention provides a preparation method for obeticholic acid. The preparation method comprises the following steps of: adding 3alpha-hydroxyl-7-keto-5beta-cholanic acid and methanol into a reaction container and carrying out esterification reaction in an acidic environment to obtain 3alpha-hydroxyl-7-keto-5beta-methyl cholanate; adding 3,4-dihydro-2H-pyran and dioxane and protecting hydroxyl by tetrahydropyrane ether; adding bromoethane, lithium diisopropylamide and site alpha of diastereomeric methylated keto-carbonyl; then adding methanol, removing the protecting group which protects tetrahydropyrane ether and reducing hydroxyl in the acidic environment; adding sodium borohydride and reducing the mixture to 3alpha-hydroxyl-6beta-methyl-7-hydroxyl-5beta-methyl cholanate; and adding methanol and carrying out alkali hydrolysis to obtain 3alpha-hydroxyl-6beta-methyl-7-hydroxyl-5beta-cholanic acid, namely the target product obeticholic acid. According to the preparation method provided by the invention, the process line is mild in reaction, simple to operate and high in yield.

Owner:ZHEJIANG TIANSHUN BIOTECH

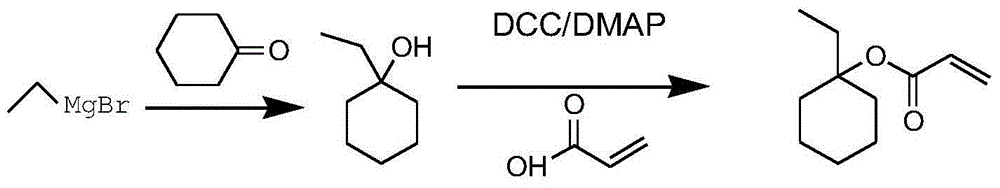

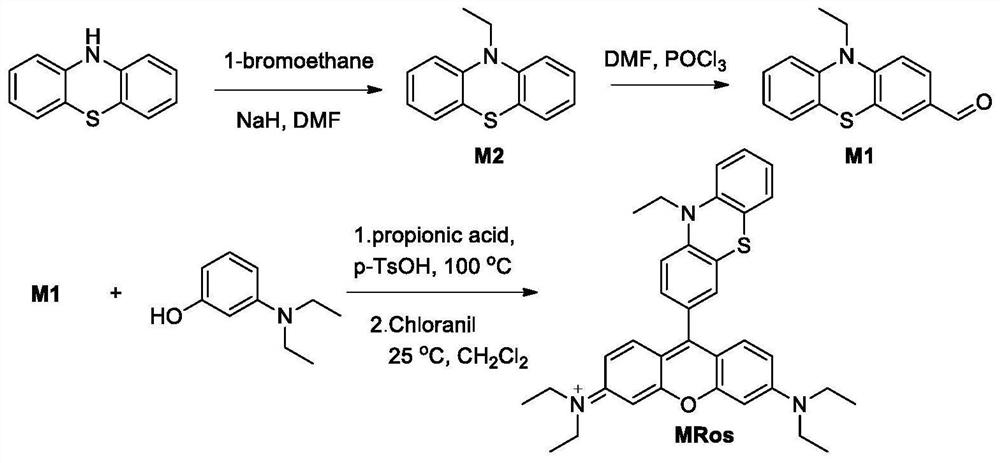

Fluorescent probe for detecting hypochlorous acid/sodium hypochlorite as well as preparation method and application thereof

ActiveCN111732581AThe synthesis process is simpleIncreased sensitivityOrganic chemistryFluorescence/phosphorescenceFluoProbesPhosphoric acid

The invention belongs to the technical field, and particularly relates to a fluorescent probe for detecting hypochlorous acid / sodium hypochlorite as well as a preparation method and application thereof. The preparation method comprises the following steps: reacting 10H-phenothiazine with bromoethane to obtain 10-ethyl-10H-phenothiazine; carrying out a Vilsmeier reaction on the 10-ethyl-10H-phenothiazine to obtain 3-formyl-10-ethyl-10H-phenothiazine; reacting 3-diethylamino phenol with the 3-formyl-10-ethyl-10H-phenothiazine to obtain 9-(10-ethyl-10H-phenothiazine)-3,6-bis(diethylamino) xanthylium chloride, namely the fluorescent probe for detecting hypochlorous acid / sodium hypochlorite disclosed by the invention. The fluorescent probe is used for detecting hypochlorous acid / sodium hypochlorite in living cells, the hypochlorous acid / sodium hypochlorite fluorescent probe is mixed with a phosphate buffer solution and a DMF buffer solution and then added into a to-be-detected solution to obtain a mixed solution, and whether hypochlorous acid / sodium hypochlorite exists or not is detected through the change of 596 nm fluorescence intensity.

Owner:TAIYUAN NORMAL UNIV

Synthesizing method for whitening agent raw materials

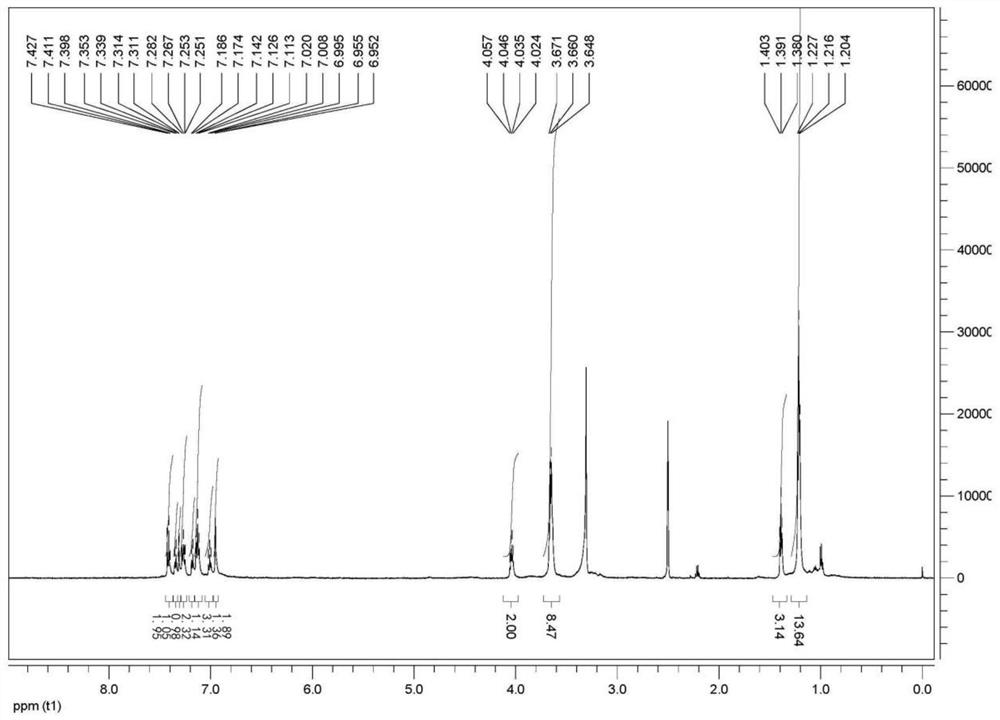

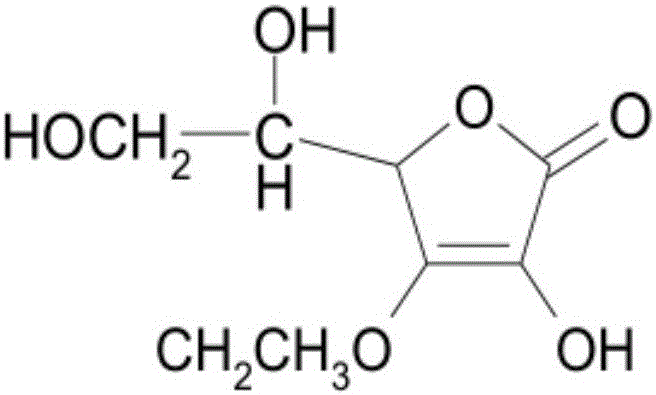

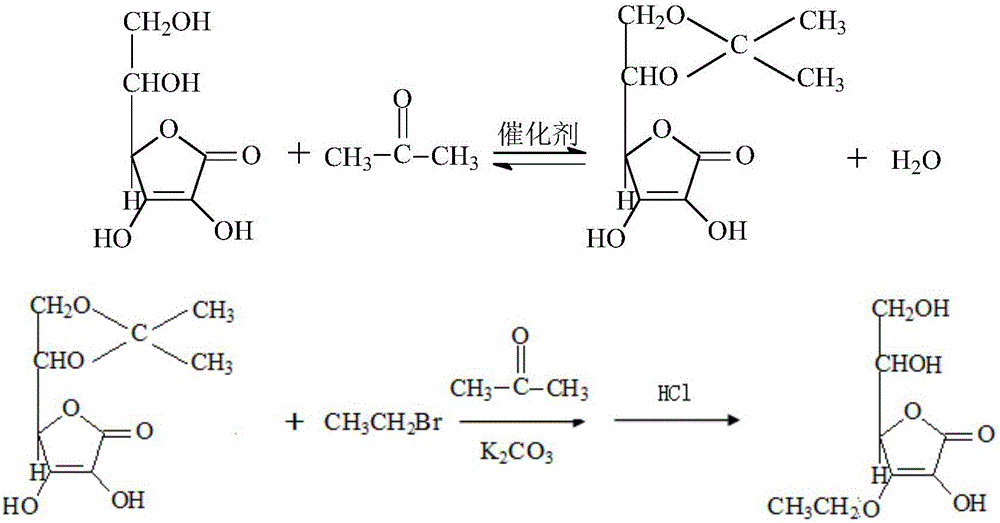

Vitamin C ethyl ether is an oleophylic and hydrophilic amphiprotic vitamin C ramification. The vitamin C and acetone are raw materials, anhydrous cupric sulfate serves as a catalyst for the reaction to synthesize 5,6-O-isopropylidene-L-ascorbic acid (IAA for short); IAA and bromoethane (CH3CH2Br) serve as raw materials, and under the existence of acetone and potassium carbonate, 3-O-ethane-5,6-O-isopropylidene-L-ascorbic acid is synthesized; hydrochloric acid is added to remove a protecting group; and superior product vitamin C ethyl ether is obtained through recrystallization. Compared with a traditional synthetic method, the technology is simple and convenient to conduct, raw materials are easy to obtain, the raw materials are bulk chemical raw materials, the cost is low, the yield is high, and industrial popularization is easy.

Owner:BEIJING HUAXIN LONGYUE TECH CO LTD

Flame-retardant coating fabric high in moisture-penetrability

The invention discloses a flame-retardant coating fabric high in moisture-penetrability. The flame-retardant coating fabric high in moisture-penetrability comprises a first base coating and a second base coating, wherein the first base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of a bridging agent, 1.6-2 parts of an accelerant, 1.4-1.6 parts of a washable agent and 9-11 parts of phosphate ester flame-retardant oil. The second base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of the bridging agent, 1.6-2 parts of the accelerant, 1.4-1.6 parts of the washable agent and 9-11 parts of phosphate ester flame-retardant oil. The flame-retardant coating fabric high in moisture-penetrability is small in smoke generation quantity, free of molten drop, high in flame-retardant effect and highly washable; the flame-retardant substance has a small possibility of hydrolyzing.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Preparation method of densifier for diverting acid

Disclosed is a preparation method of a densifier for diverting acid. According to the preparation method, butanol, bromoethane, N-alkyl-N, N-bis(2-hydroxyethyl)octodecane and purified water are mixed according to a certain proportion and undergo a heating reaction at a certain temperature for 6 hours so as to obtain the densifier for diverting acid. The process is simple and easy to control. The product obtained is stable. In addition, the product has good acidification and visco-elastic properties.

Owner:扬州润达油田化学剂有限公司

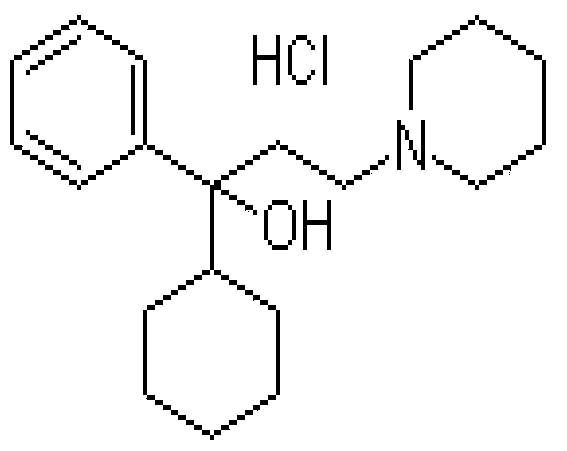

Preparation method of benzhexol hydrochloride

The invention relates to the technical field of medicines, and concretely relates to a preparation method of a Parkinson disease treatment medicine benzhexol hydrochloride. The preparation method comprises the following steps: 1, adding tetrahydrofuran to a reaction bottle, adding magnesium chips, sequentially adding 5-10% of a bromoethane tetrahydrofuran solution, a solution A and a solution B into the reaction bottle in a dropwise manner while stirring, carrying out a heat insulation reaction after the dropwise addition is finished, and cooling; 2, adding piperidylpropiophenone hydrochloride, heating, carrying out a heat insulation reaction, distilling, and cooling after the distillation is finished; 3, adding a hydrochloric acid solution, heating and carrying out heat insulation after the addition, and cooling; and 4, filtering the above obtained mixture, washing the obtained filter cake by using water, and drying to obtain benzhexol hydrochloride.

Owner:JIANGSU TASLY DIYI PHARMA CO LTD

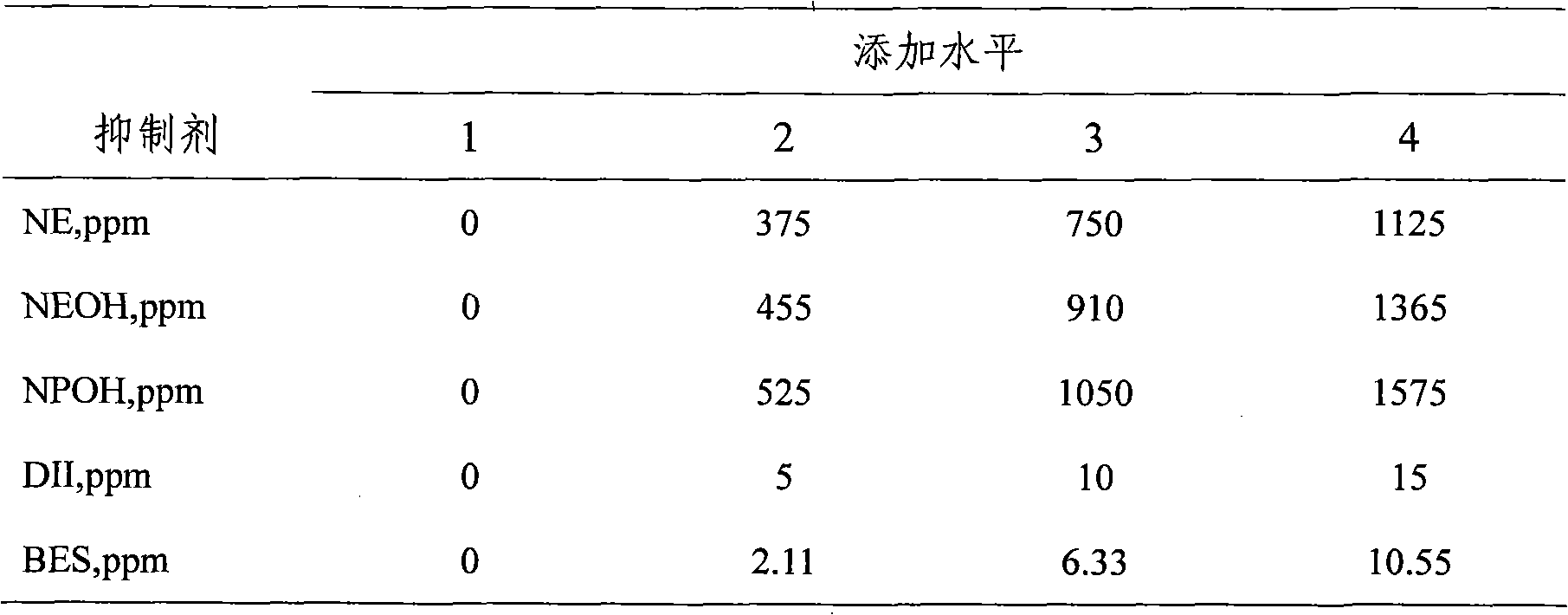

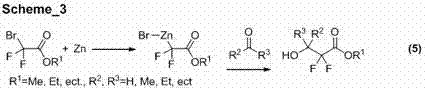

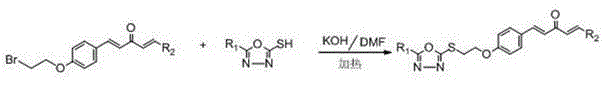

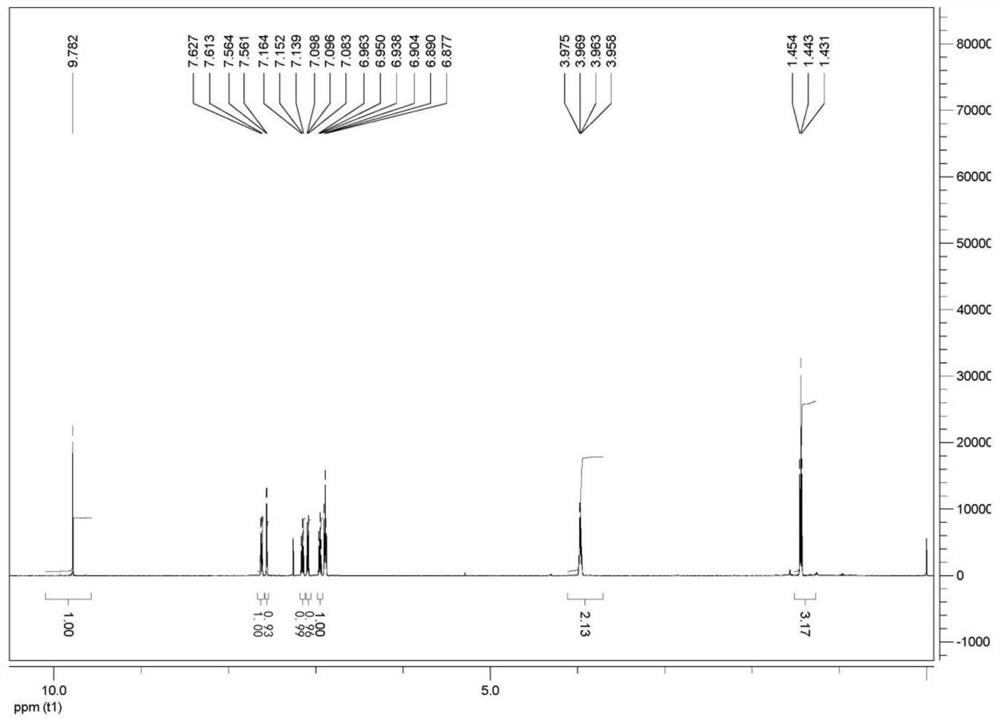

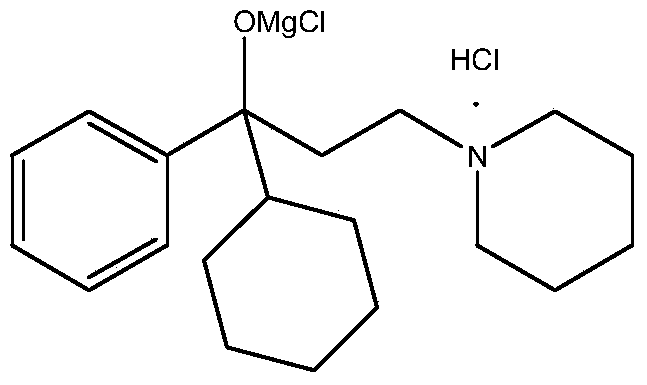

Prepn and application of N-[2-(aryloxy)ethyl]-2-(arylthio) benzyl amine derivative

The present invention relates to the structure, preparation process and application of N-[2-(acryloxy)ethyl]-2-(arylthio) benzyl amine derivative with depression resisting activity, and belongs to the field of medicine chemical technology. The structure is shown. The preparation process includes the reaction between aryl phenol and 1, 2-dibromo ethane to produce 2-aryloxy bromoethane, the reaction of 2-aryloxy bromoethane with methanol solution of ammonia to produce 2-aryloxy ethylamine; the Ullmann sulfidation reaction between one-methoxyphenyl thiophenol and one-chlorobenzoic acid to produce sulfide; the reduction and chlorination of sulfide to produce 2-(2-arylphenylthio) benzyl chloride; and final N-alkylation with 2-aryloxy ethylamine to produce the destination product. The compound in the form of free alkali or salt is used in preparing medicine for depression.

Owner:TIANJIN UNIV

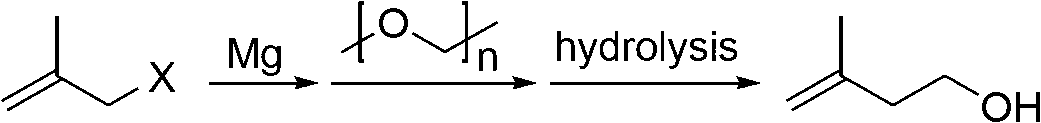

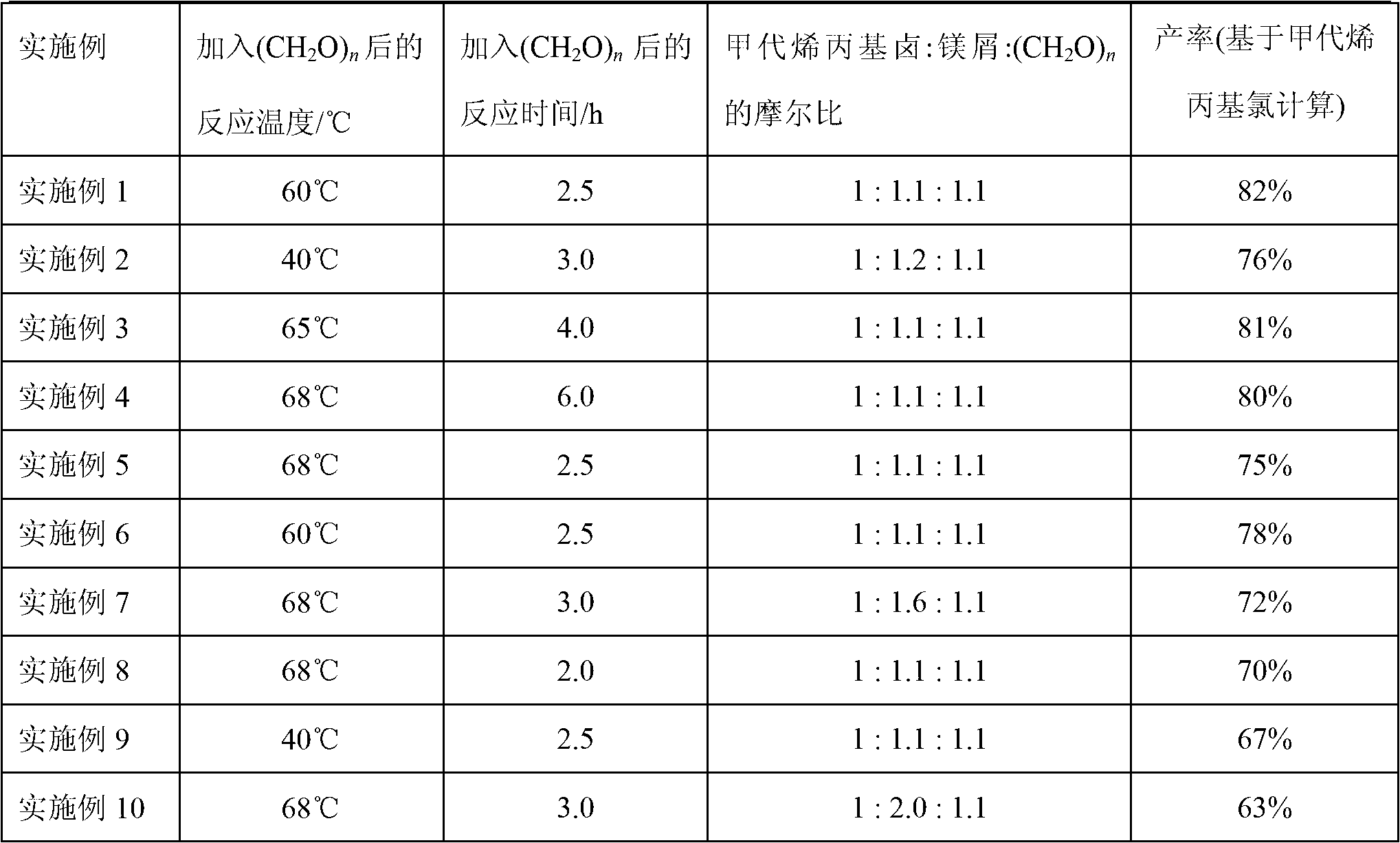

Method for preparing 3-methyl-3-buten-1-ol

The invention relates to a method for preparing 3-methyl-3-buten-1-ol, which comprises the following steps: adding magnesium chips into an anhydrous solvent under the protection of inert gas, then adding bromoethane to initiate the reaction; after the color of the mixed solution is light, adding methallyl halide to carry out Grignard reaction so as to prepare a Grignard reagent; adding formaldehyde or paraformaldehyde into the Grignard reagent to perform addition reaction; then performing after-treatment to obtain 3-methyl-3-buten-1-ol. According to the method provided by the invention, rigorous requirements on the process condition and difficult storage and transportation problems of the adopted raw material in the prior art are overcome, the raw materials suitable for storage and transportation are adopted, and the process is simple.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Prepn process of 2-[2-(2,2,2-trifluoro ethoxy)] phenoxy ethamine Prepn process of 2-[2-(2,2,2-trifluoro ethoxy)] phenoxy ethamine](https://images-eureka.patsnap.com/patent_img/d4ba267e-0e5a-493b-87c7-d3a10903ba4a/A20071002363800031.PNG)

![Prepn process of 2-[2-(2,2,2-trifluoro ethoxy)] phenoxy ethamine Prepn process of 2-[2-(2,2,2-trifluoro ethoxy)] phenoxy ethamine](https://images-eureka.patsnap.com/patent_img/d4ba267e-0e5a-493b-87c7-d3a10903ba4a/A20071002363800041.PNG)

![Prepn and application of N-[2-(aryloxy)ethyl]-2-(arylthio) benzyl amine derivative Prepn and application of N-[2-(aryloxy)ethyl]-2-(arylthio) benzyl amine derivative](https://images-eureka.patsnap.com/patent_img/1c1a0d5a-301b-4ea6-b72c-a61f05a5cf10/A2005100135550002C1.PNG)

![Prepn and application of N-[2-(aryloxy)ethyl]-2-(arylthio) benzyl amine derivative Prepn and application of N-[2-(aryloxy)ethyl]-2-(arylthio) benzyl amine derivative](https://images-eureka.patsnap.com/patent_img/1c1a0d5a-301b-4ea6-b72c-a61f05a5cf10/A2005100135550003C1.PNG)

![Prepn and application of N-[2-(aryloxy)ethyl]-2-(arylthio) benzyl amine derivative Prepn and application of N-[2-(aryloxy)ethyl]-2-(arylthio) benzyl amine derivative](https://images-eureka.patsnap.com/patent_img/1c1a0d5a-301b-4ea6-b72c-a61f05a5cf10/A20051001355500051.PNG)