Patents

Literature

1066results about How to "Reliable workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

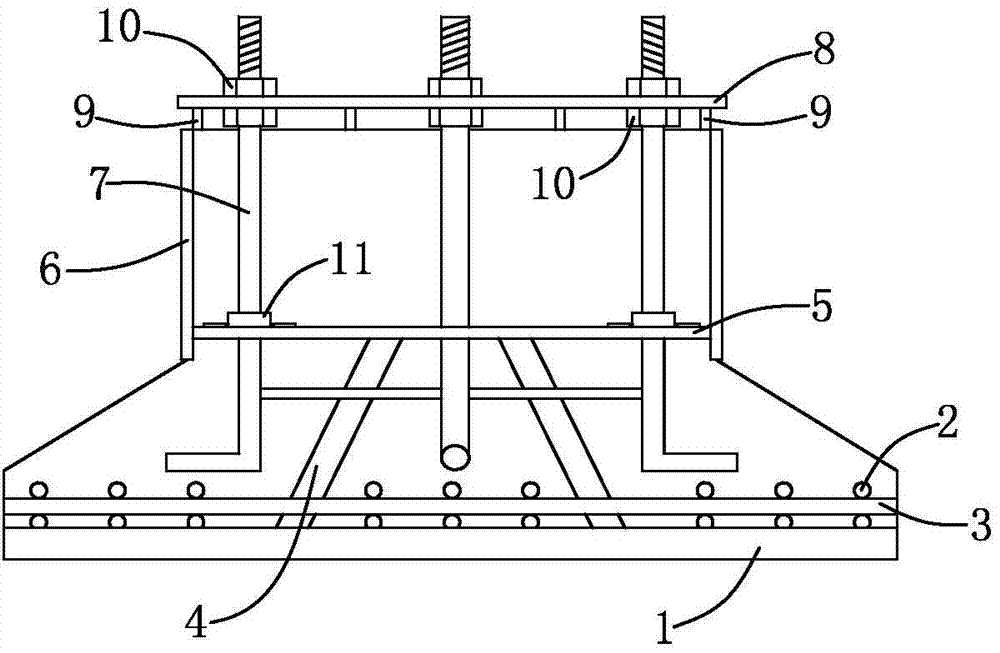

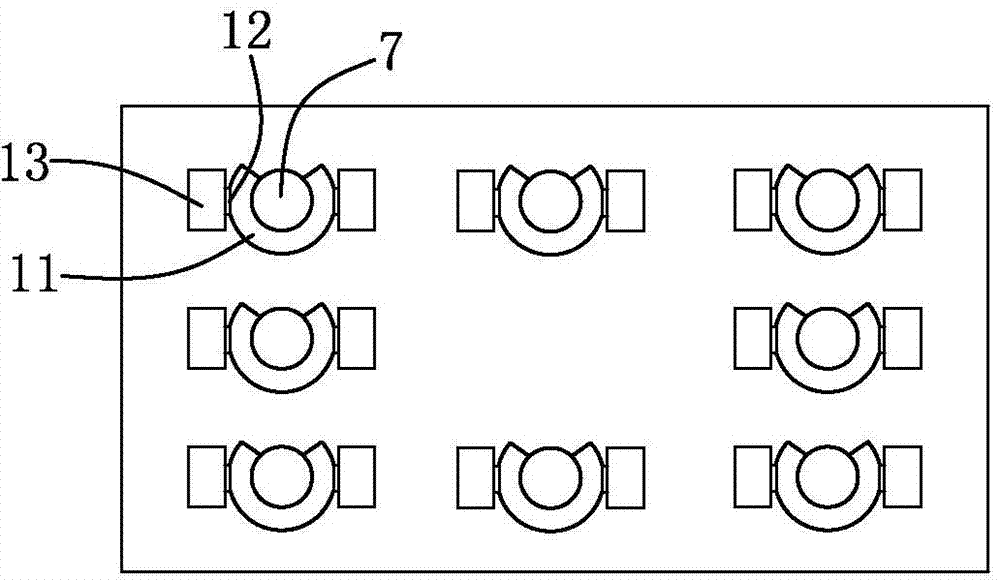

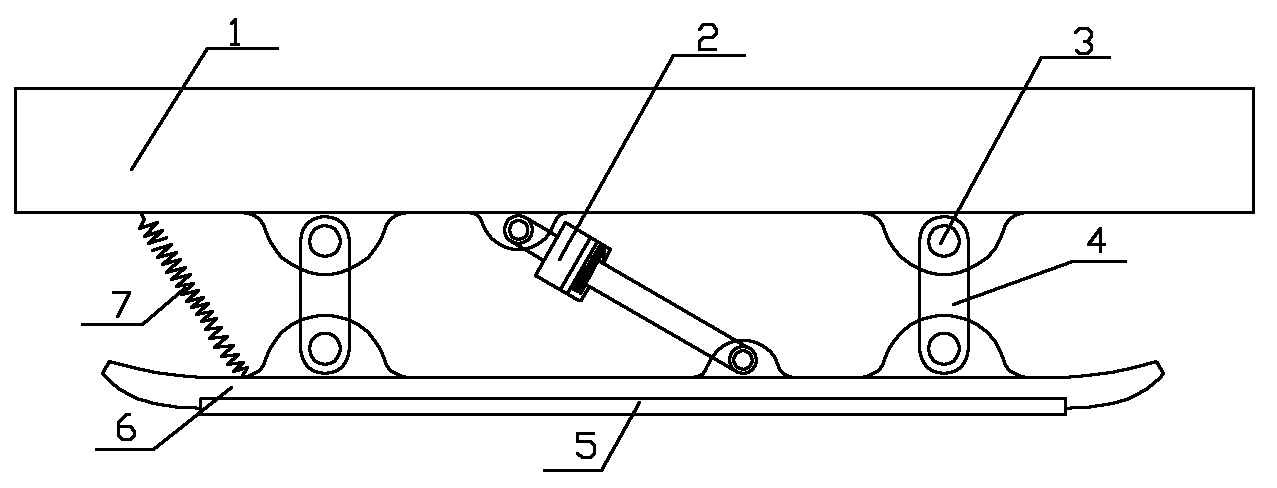

Pre-buried construction method for high-precision foundation bolts

The invention discloses a pre-buried construction method for high-precision foundation bolts. The method includes the following steps that (a), construction preparation is performed; (b), a control net is established; (c), a positioning clamp and a positioning control plate are manufactured; (d), foundation steel bars are buried in advance; (e), the positioning clamp is installed; (f), the foundation bolts are installed; (g), the foundation bolts are reinforced and protected; (h), concrete pouring is performed; (i), the clamp is dismantled; (j) acceptance inspection and handover are performed to finish the pre-buried construction. The manufactured high-precision positioning clamp is adopted for performing clustering control over the pre-buried foundation bolts of each set of equipment foundations, elastic clamping tools are arranged on the outer sides of the foundation bolts, supporting legs of the elastic clamping tools are embedded into clamping holes in the positioning clamp, and the elastic clamping tools are clamped on the positioning clamp of the foundation bolts, so that the foundation bolts are further reinforced and prevented from loosening. The pre-buried construction method has the effects of being reliable in technology, high in construction precision, easy to understand and master and convenient to operate, and meanwhile is short in construction period and low in cost.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

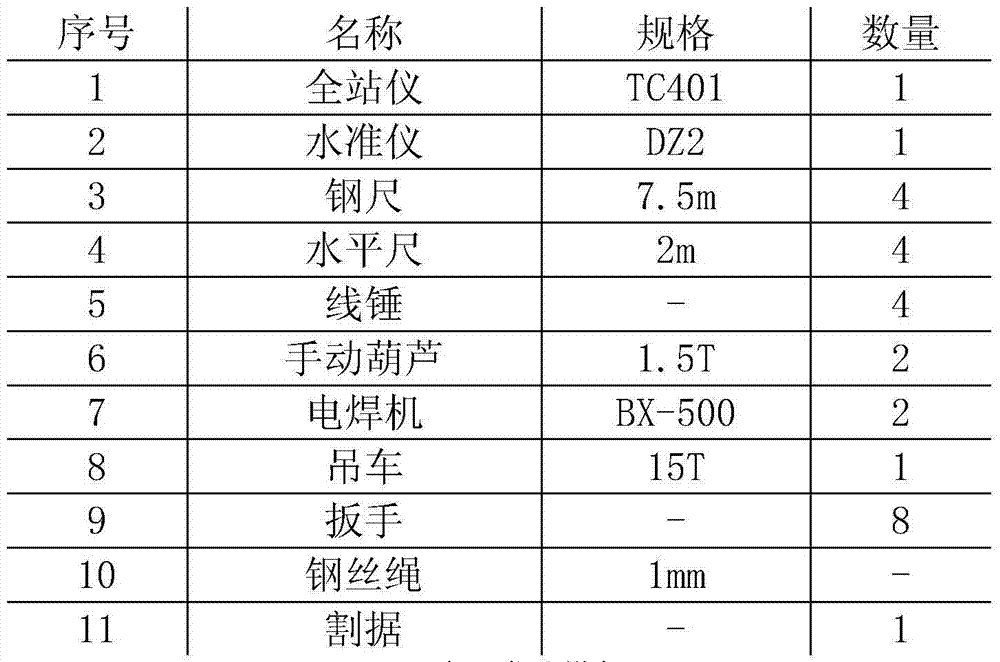

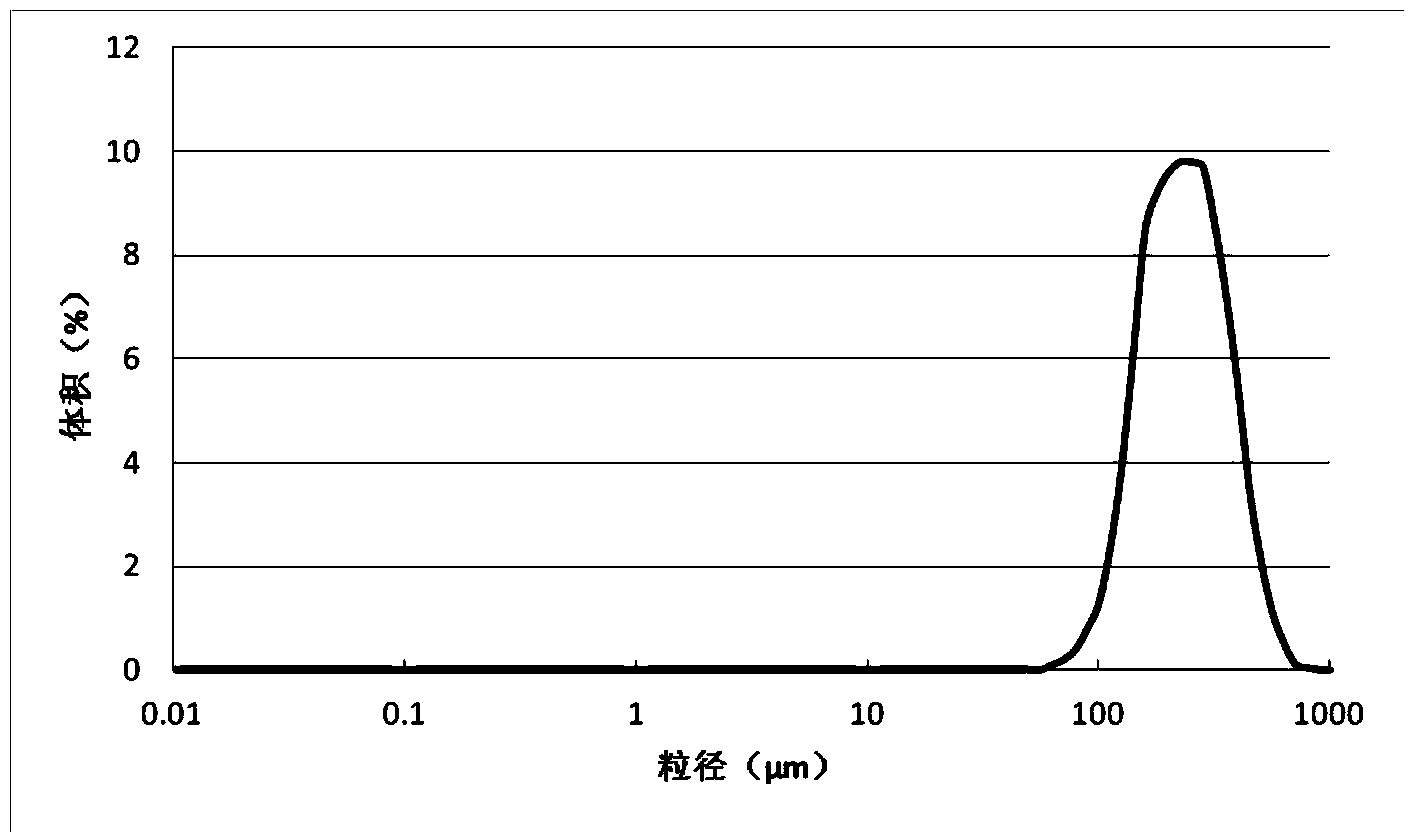

Injectable crosslinked hyaluronic acid gel and preparation method thereof

The invention relates to an injectable crosslinked hyaluronic acid gel and a preparation method thereof. The injectable crosslinked hyaluronic acid gel is prepared by blending hyaluronic acid gel granules and chlorinated sodium phosphate physiological buffer solution; the hyaluronic acid gel granules are prepared by comprising the steps of crosslinking treatment, emulsion crosslinking granulation, purification and drying and swelling, filling and sterilization technologies. The hyaluronic acid gel granules are uniform in granule size, the residual of the crosslinking agent is less than 0.2ppm, the injection pushing is proper, and the in-vivo degradation time can last more than 8-12 months. The implant has an excellent esthetical restoration effect, is applicable to being injected to and subcutaneous dermis deep layer to subcutaneous superficial layer, restoration of moderate to severe wrinkles or folds, and can satisfy the restoration demand of wrinkles or folds caused due to skin aging.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

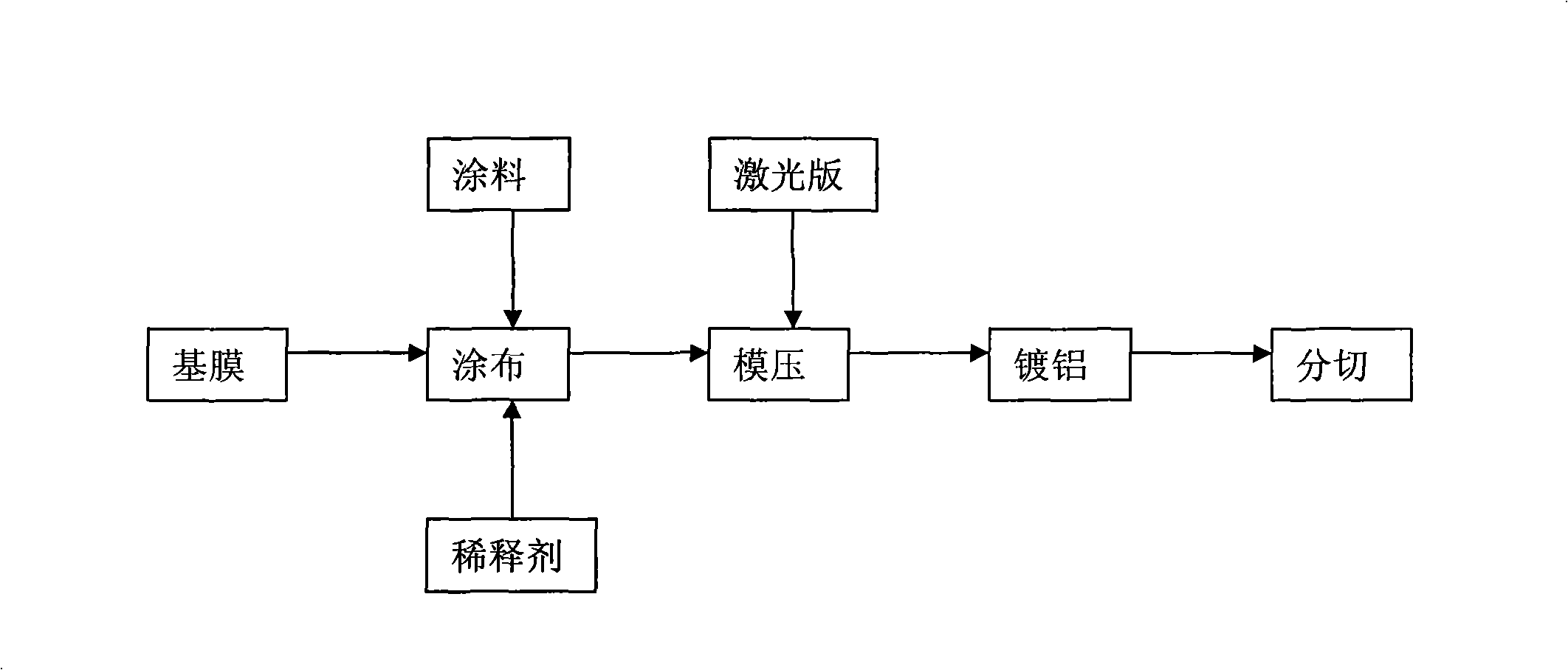

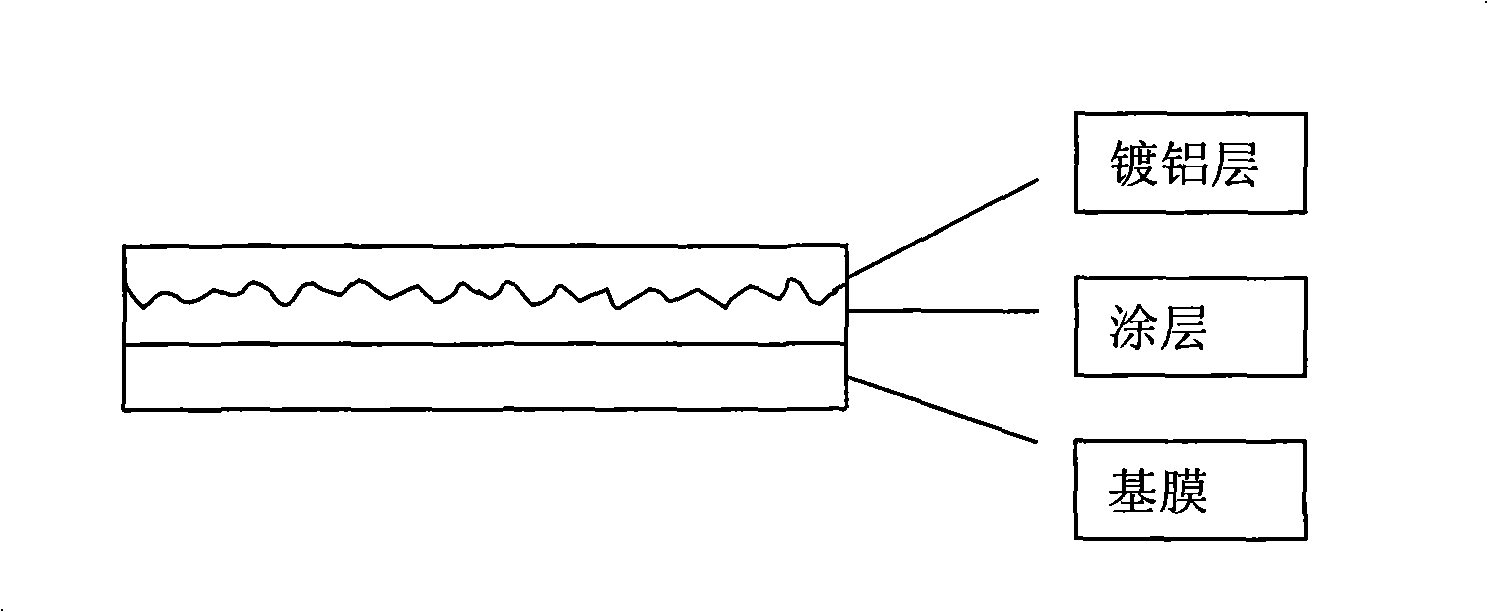

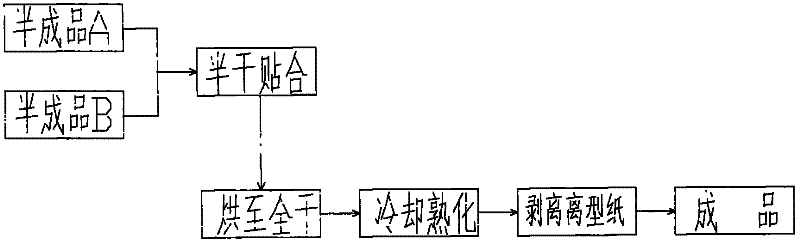

Process for producing PET laser transfer membrane

InactiveCN101537745ASimple processNovel processDecorative surface effectsPretreated surfacesBasementCoated membrane

The invention relates to a process for producing a PET laser transfer membrane. A PET membrane is used as a basement transfer membrane, and laser transfer pigment is coated and spread on the PET membrane. The method includes the following steps: a laser transfer pigment is coated and spread on the PET basement transfer membrane by an anilox roll at one step to form a coating layer, and a precoating membrane can be formed after the operation of drying is carried out; the precoating membrane is processed by the operation of laser mould pressing, and interference figures on a laser slab are printed on the coating layer of the precoating membrane by heat pressing so as to form a mould pressing membrane; and aluminum is coated on the mould pressing membrane, an aluminum layer is formed on an information layer, and the PET laser transfer membrane can be prepared, wherein the pigment includes thermoplastic acroid resin and cellulose acetate. The process has the advantages that the special singly coated laser transfer pigment and the unique manufacture process control are selected, and the entire process is simple, novel, stable and reliable. As the laser mould pressing transfer coating layer has the properties of easy mould pressing, favorable stripping, and the like, the operation of coating just needs to be carried out for one time, and therefore the production efficiency can be greatly improved. After being transferred and stripped, the aluminum coated membrane can be recycled to be repeatedly used for many times, and therefore cost can be greatly reduced; and the PET laser transfer membrane is the environmentally friendly anti-counterfeit laser material for packaging and printing.

Owner:上海宝绿包装材料科技有限公司

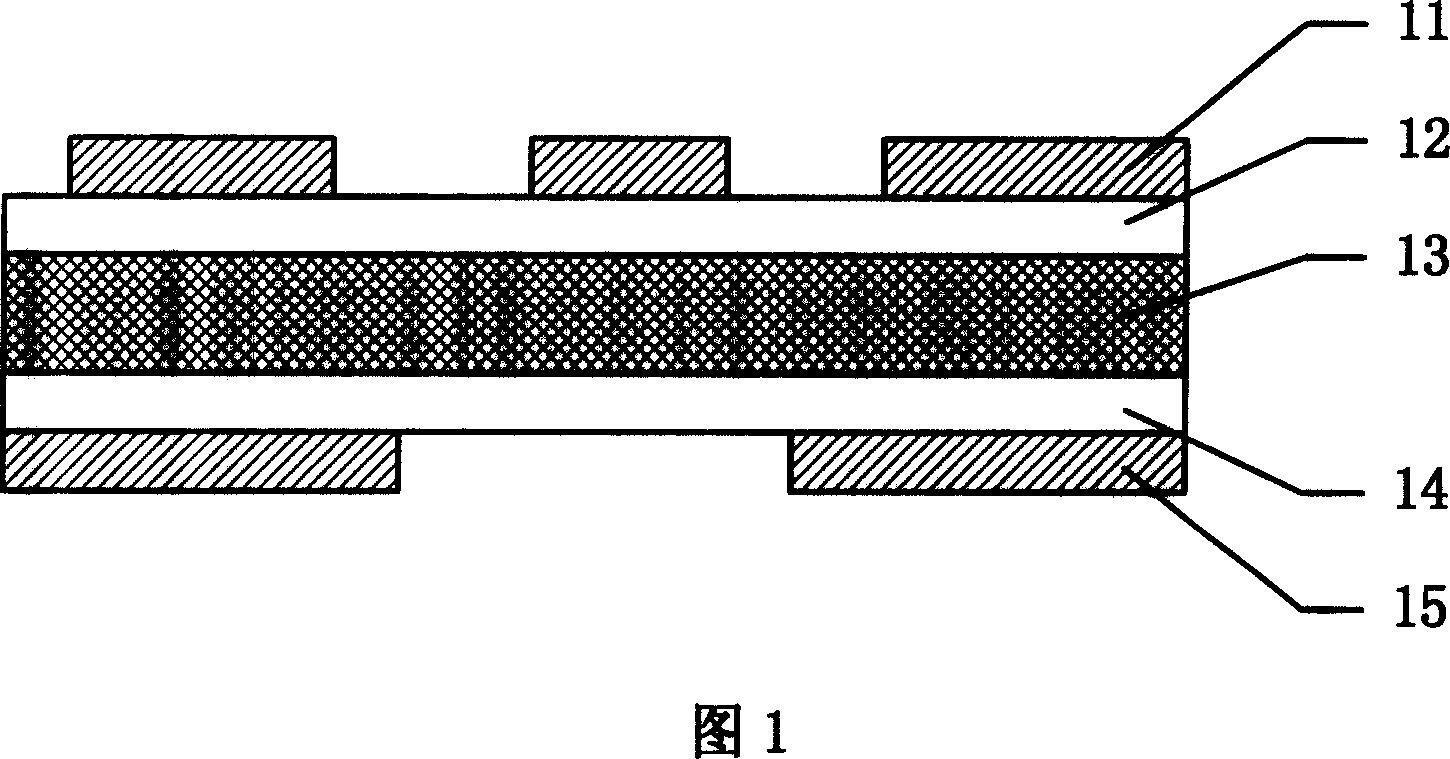

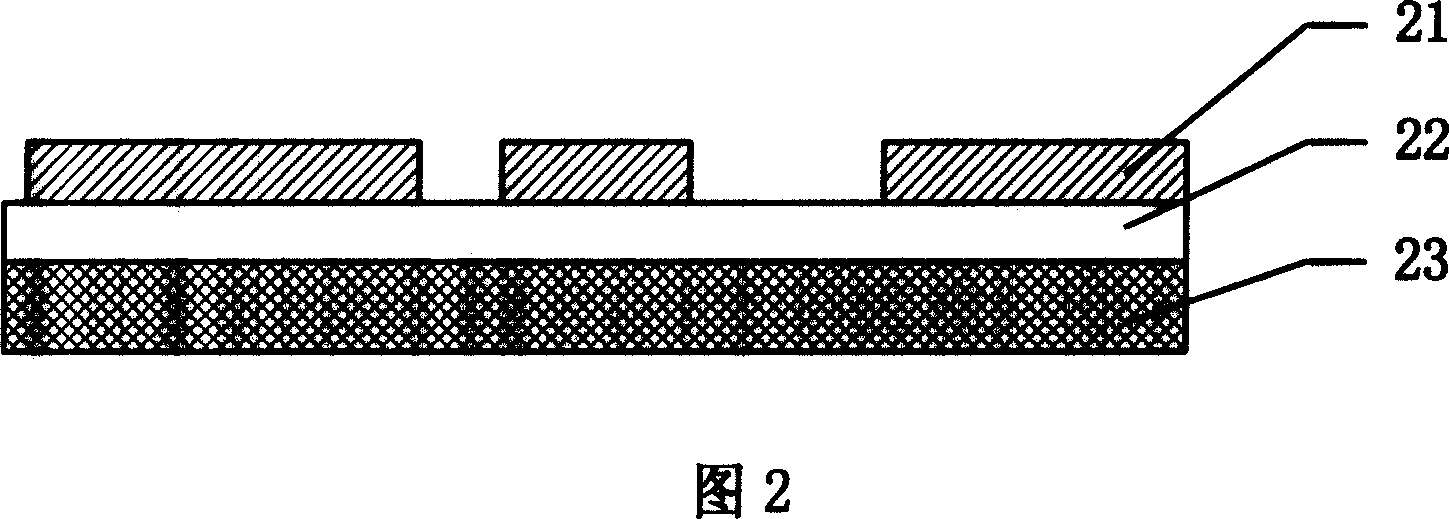

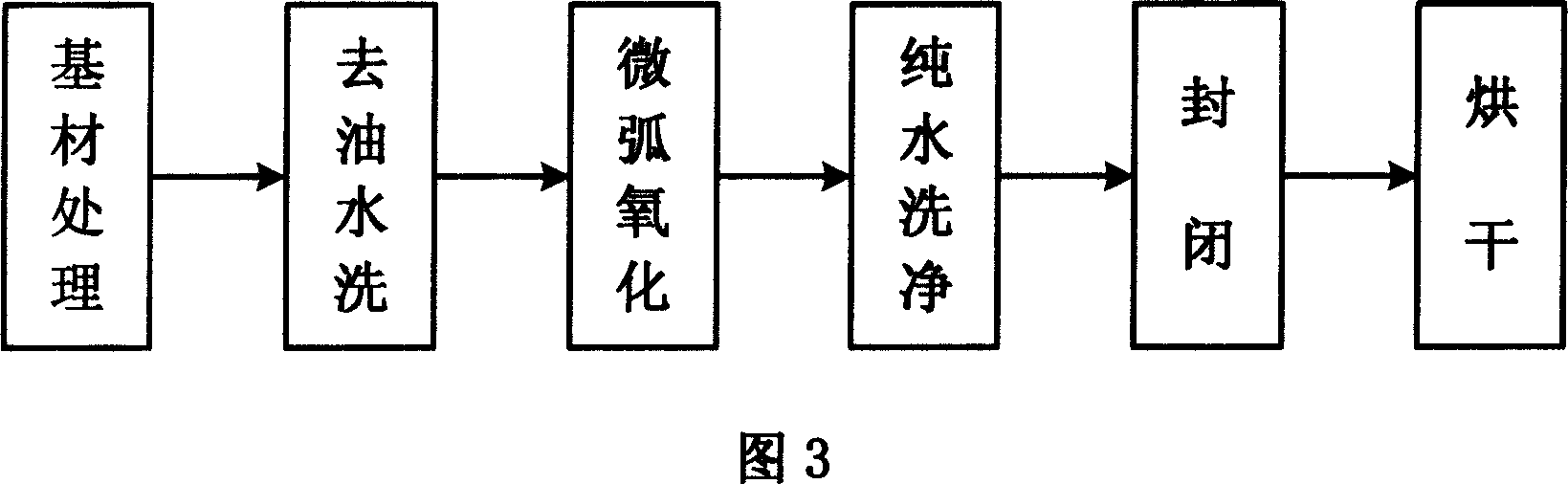

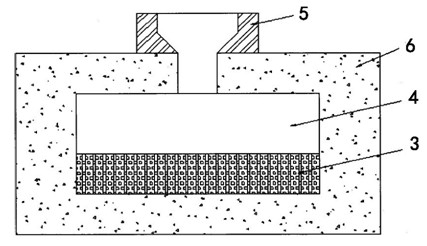

Aluminum-base printing circuit board and its production

InactiveCN101076224AReliable workmanshipSimple processing equipmentPrinted circuit manufactureCircuit susbtrate materialsInsulation resistanceMicro arc oxidation

The bottom layer of invention uses aluminium baseboard; the intermediate layer is a heat conduction insulation layer; the surface layer is an electric conduction layer. It features the following: the heat insulation layer is a ceramic-like thin film layer with 10-400 micron thick and >=100Momega insulation resistance, which chemical composition is aluminium oxide. The preparation method comprises: making pretreatment, de-oiling and washing for the surface of the aluminium baseboard using mechanical method or chemical method to form a clean workpiece plane; using the microarc oxide treatment and the microplasma surface ceramic method to make a heat conduction insulation layer on the workpiece surface; finally, overlapping an electric conduction layer on the heat conduction insulation layer; etching circuit pattern.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

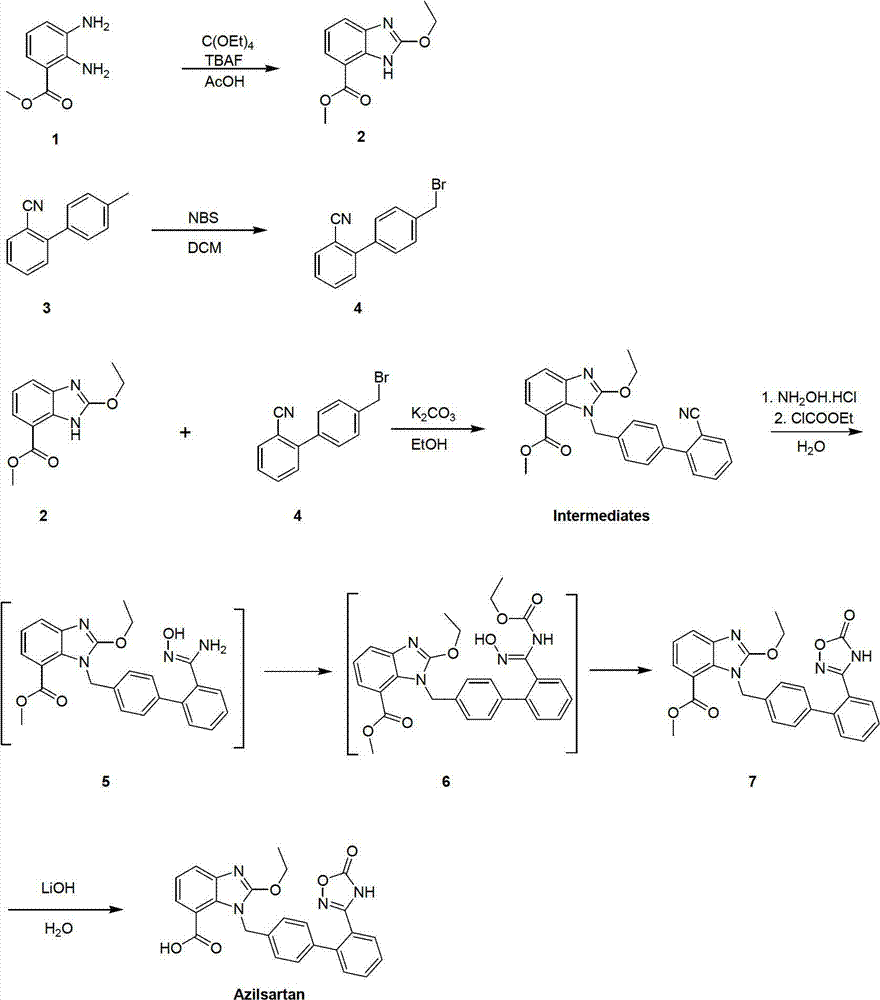

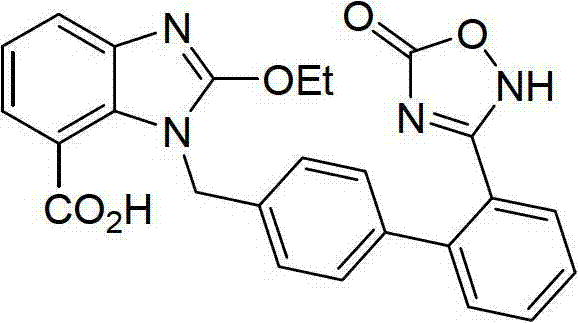

Preparation method of azilsartan

InactiveCN102766138AReduce usageEmission reductionOrganic chemistryEthyl chloroformateCarboxylic salt

The invention relates to a preparation method of azilsartan, comprising the following steps of: (1) preparing ethoxybenzimidazole-7-methyl carboxylate; (2) preparing 2-cyan-4'-bromomethyl biphenyl; (3) dissolving the ethoxybenzimidazole-7-methyl carboxylate and the 2-cyan-4'-bromomethyl biphenyl into ethanol; adding potassium carbonate to react to obtain 1-[(2'-cyan diphenyl-4-yl)methyl]-2-ethoxybenzimidazole-7-methyl carboxylate; (4) suspending the 1-[(2'-cyan diphenyl-4-yl)methyl]-2-ethoxybenzimidazole-7-methyl carboxylate in water; adding hydroxylamine hydrochloride, sodium hydroxide and tetrabutylammonium fluoride; heating and reflowing, and then cooling; adding the sodium hydroxide and ethyl chloroformate, heating and reflowing to obtain azilsartan methyl ester; and (5) hydrolyzing the azilsartan methyl ester to obtain a product. The preparation method of the azilsartan, disclosed by the invention, has the advantages of being short in process route, high in yield, and safe and reliable; and the purity of the azilsartan obtained by using the method is high.

Owner:WENZHOU PEOPLES HOSPITAL

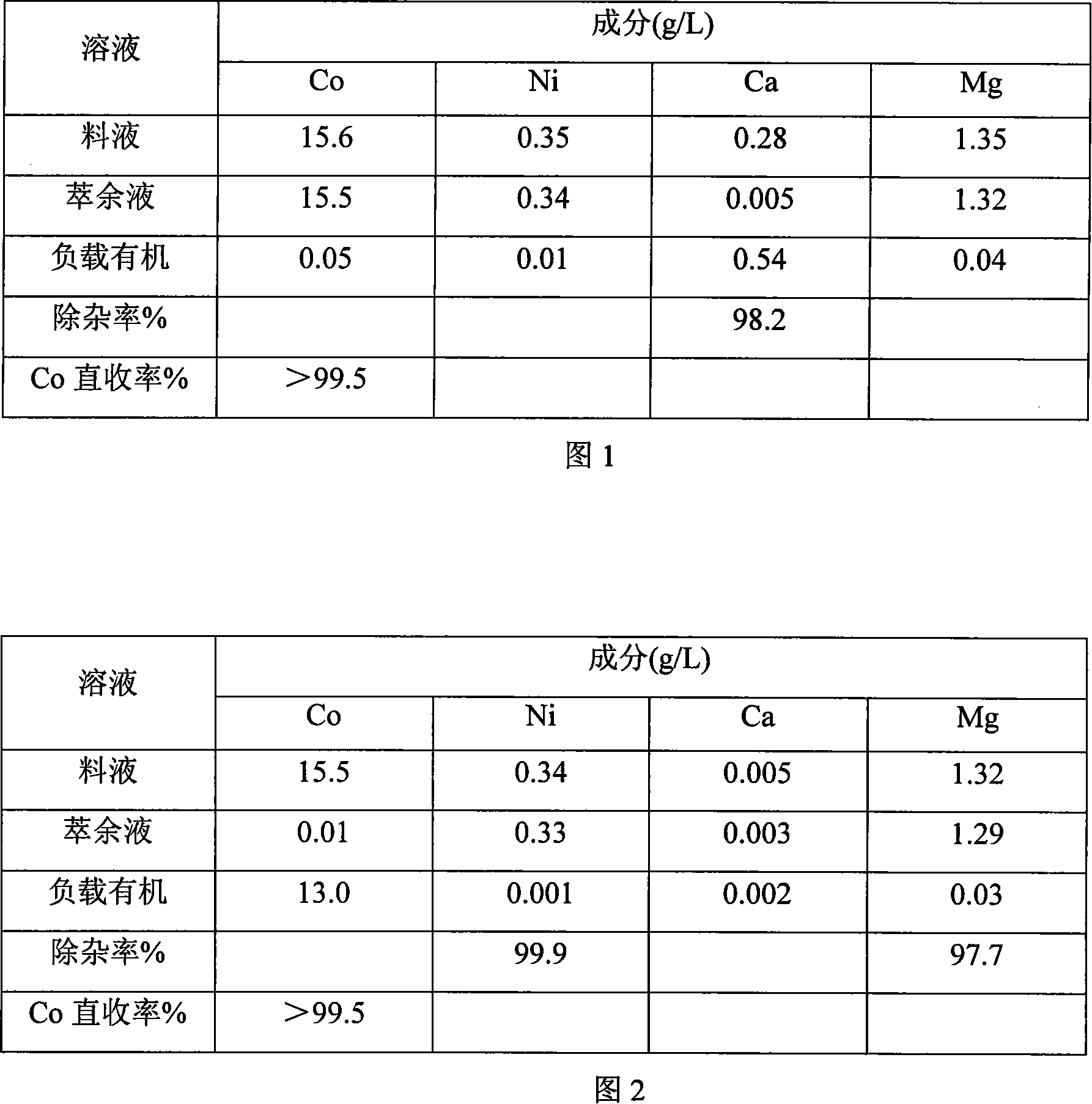

Extraction method for removing calcium and magnesium from copper-cobalt ore leachate

The process of extracting Co and eliminating Ca from copper-cobalt ore includes obtaining mixture leachate with soluble sulfate of Co, Ni, Ca and Mg; and extracting the mixture leachate with organic solvent, which comprises organic matter bis(2-ethyl hexyl) phosphoric acid or ”�2- ethyl hexyl phosphonate ester in 15-25 vol% and kerosene in 75-85 vol%. The organic solvent extracting procedure includes two steps, the first step of transferring Ca into the organic phase while leaving Co, Ni and Mg in the water phase, and the second step of transferring Co to the organic phase while leaving Ni and Mg in the water phase. The process can obtain cobalt sulfate solution with Co content up to 90-100 g / l, Ca ion content lowered to 0.01 g / l, Ni ion content lowered to 0.005 g / l, and Mg ion content lowered to 0.1 g / l and suitable for producing T-cobalt oxide and cobalt salt.

Owner:ZHEJIANG HUAYOU COBALT

Treatment method for zero discharge of ionic liquid water solution

ActiveCN101224933AAchieve recyclingReduce salt contentChemical industryWater/sewage treatment bu osmosis/dialysisSalt contentEvaporation

The invention discloses a processing method of zero drainage of ion liquid aqueous solution, which comprises the following steps in sequence: 1) a membrane concentrating set is used for concentrating the ion liquid aqueous solution to 5-15 percent; a membrane element is the combination of a reverse osmosis membrane or a nanofiltration membrane and a reverse osmosis membrane element; 2) one or any combination of flash evaporation, falling film evaporation or climbing film evaporation is used for concentrating the solution to 60-90 percent; 3) a movable scraper type wiped film evaporator is used for concentrating the solution to more than 95 percent. The method combines the advantages of membrane concentration, reduction vaporization and wiped film evaporation technology, thus completely recycling ion liquid and water of 0.005-10 percent of ion liquid aqueous solution; the pureness of the ion liquid obtained is more than 95 percent and the salt content of the water is lower than 0.001 percent. The method is characterized by saving energy and water, reliable technique, high product quality, easy realization and wide adaption scope, thus having important practical value in the green chemical field that uses the ion liquid as a solvent.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

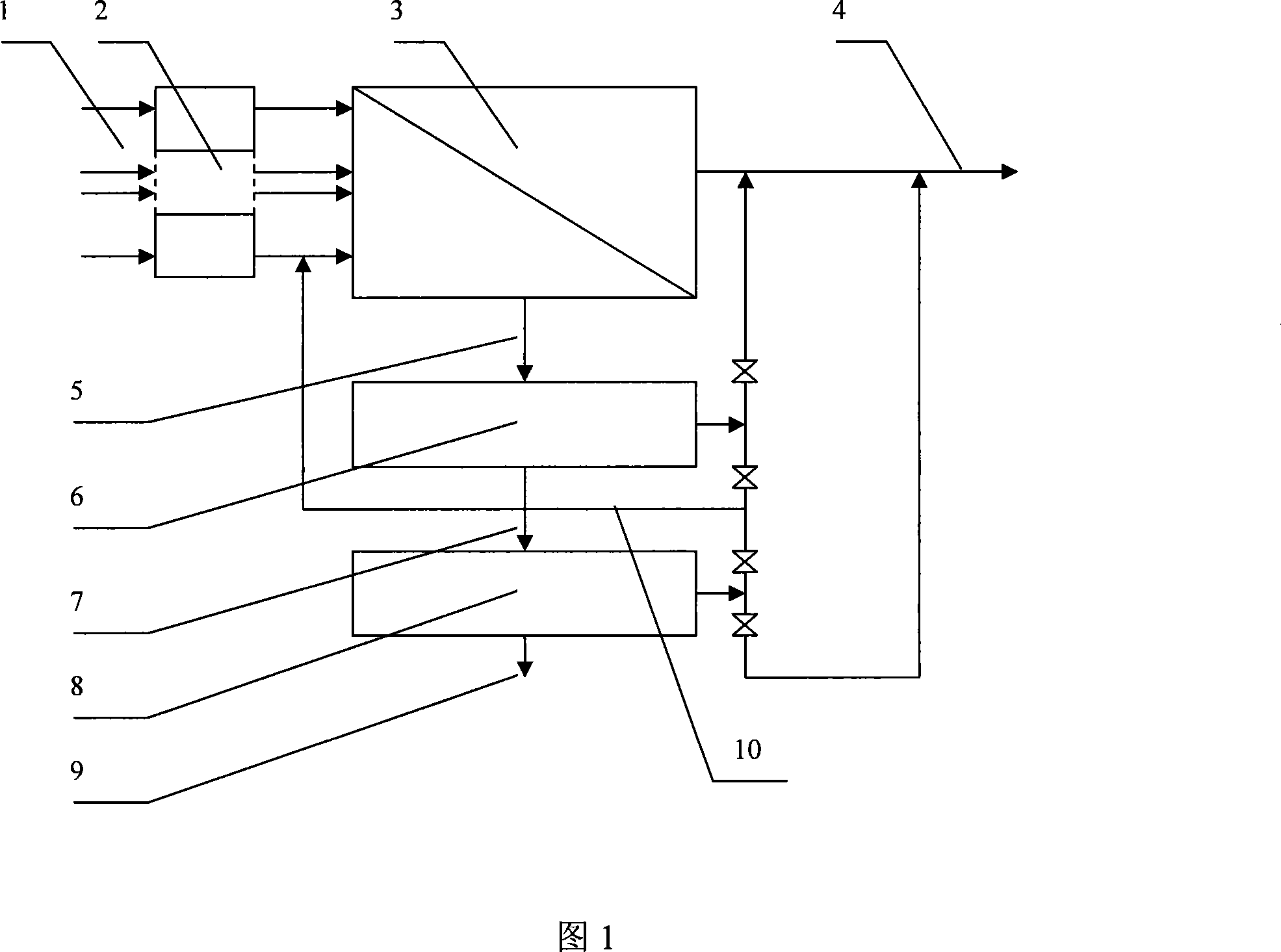

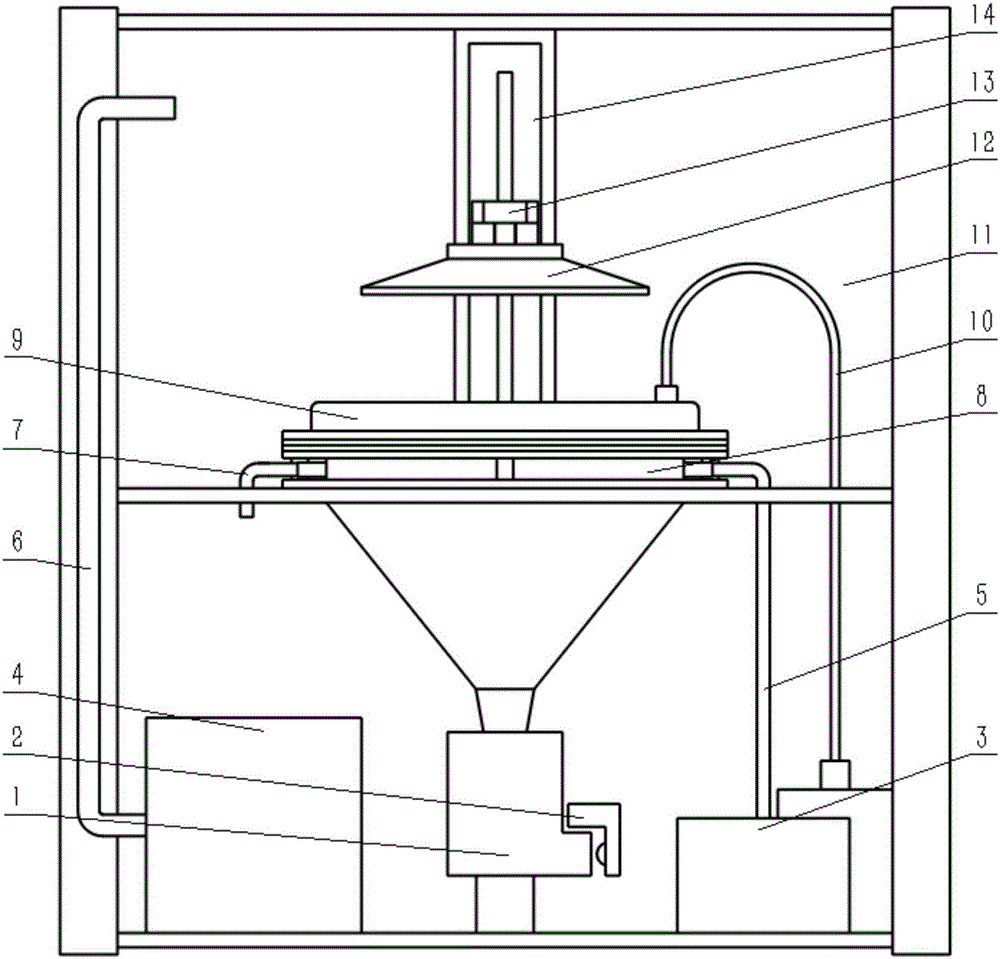

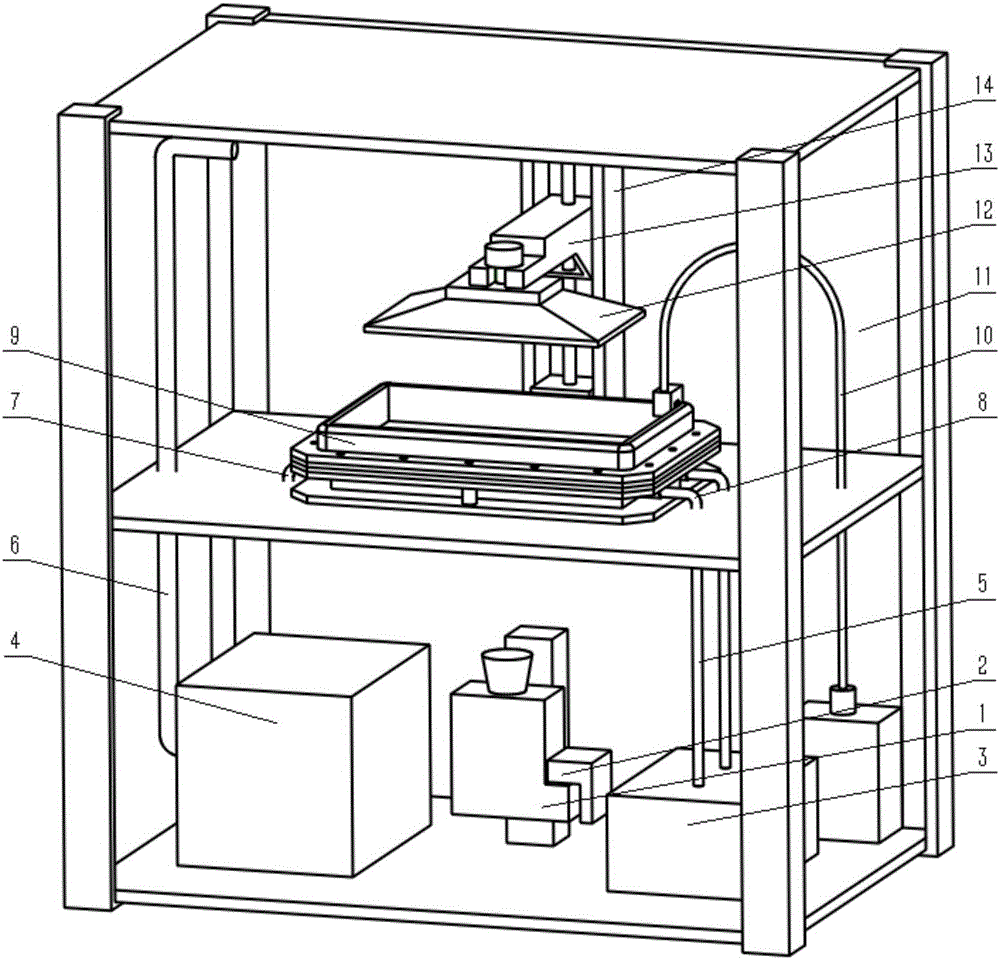

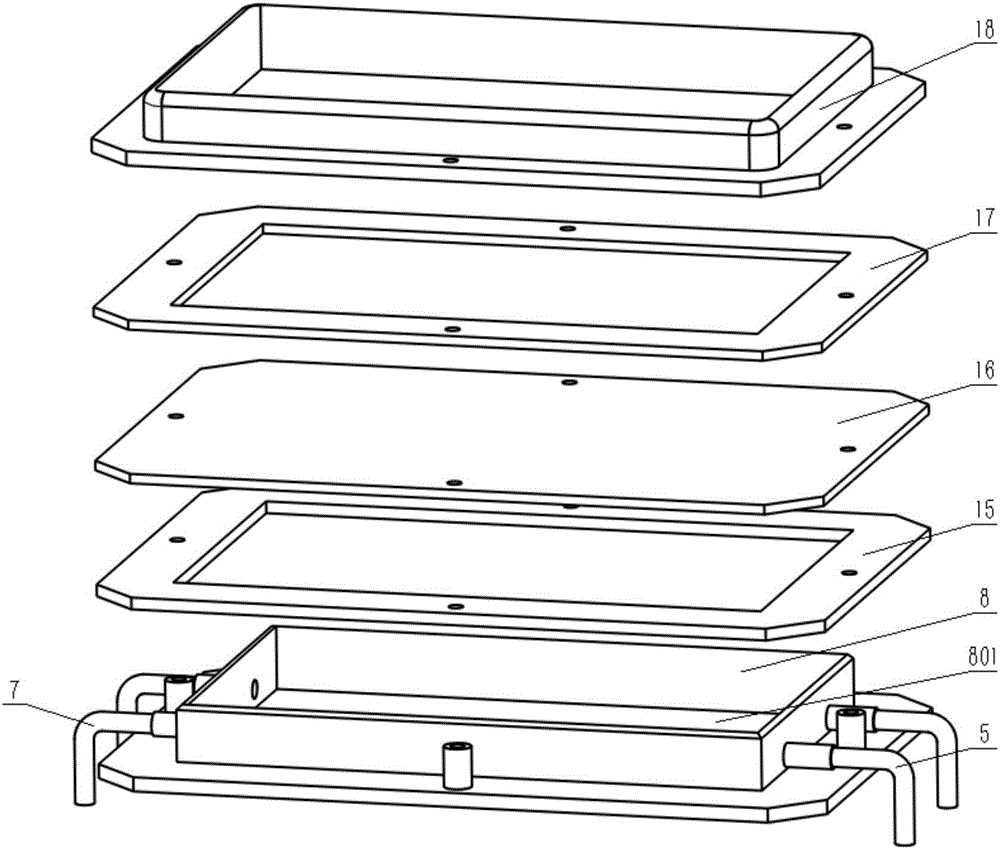

High-speed continuous photocuring type 3D printing device and working method thereof

ActiveCN106426915ALow costEfficient continuous printingManufacturing irradiation arrangementsManufacturing material handlingLiquid surfacesOxygen rich

The invention discloses a high-speed continuous photocuring type 3D printing device and a working method thereof. The 3D printing device comprises a machine case body which is divided into an upper cavity and a lower cavity by a middle partition board, wherein an image forming module is arranged in the lower cavity, a window box and an oxygen supply cooling module are arranged in the upper cavity and are combined to be fixedly mounted on the middle partition board, the oxygen supply cooling module is arranged right below the window box, and the image forming module I is arranged right below the window box; a printing platform is arranged right above the window box and is mounted on a Z-direction worktable; and the window box is connected with a raw material feeding unit. The 3D printing device is integrated with the advantages of a compound oxygen-rich film, oxygen supply cooling and liquid surface auxiliary pressurization of the window box, so that the low-cost and efficient continuous printing of large-sized products with arbitrary shapes is realized, the range of applicable materials is wide, the printed products are high in precision and quality and good in uniformity, and the process is stable and reliable. An industrial-grade solution is provided for the high-speed continuous photocuring type 3D printing.

Owner:SHENZHEN ELEGOO TECH CO LTD

Preparation method of layered ternary ceramic reinforced copper composite material

The invention belongs to the technical field of powder metallurgy, and in particular relates to a preparation method of a layered ternary ceramic reinforced copper composite material. According to the preparation method, the reinforced effect of a strengthening phase can be fully exerted and the synergistic effect of a substrate and the strengthening phase are also fully exerted, so that the conductivity of the material is well matched with the strength of the substrate. The preparation method comprises the following steps: (1) carrying out ball-milling and mixing on 2wt%-45wt% of layered ternary metal ceramic powder and remained copper powder in a ball mill; (2) carrying out mould pressing on the mixed powder obtained in the step (1) so as to form a blocky green body; and (3) at the hydrogen or noble gas atmosphere, warming up the blocky green body to 800 DEG C-1250 DEG C at the warming speed rate of 20-40 DEG C / min, insulating for 0.5-3 hours, and cooling so as to obtain the layered ternary ceramic reinforced copper composite material.

Owner:CENT IRON & STEEL RES INST

Once process for extracting and separating Ni, Mg and Co from nickel sulfate solution recovered from waste nickel-hydrogen and nickel-cadmium cells

ActiveCN1752232AEliminates steps to remove magnesiumLow costProcess efficiency improvementHydrogenKerosene

A process for extracting Ni, Mg and Co from the used NiH or NiCd battery includes such steps as immersing the positive electrodes of used NiH or NiCd batteries in sulfuric acid to obtain liquid extract, regulating pH=4.5-5.0, fractionating to transfer Mg and Co in the organic phase prepared from bis-(2-ethylhexyl) phosphonate mono-(2-ethylhexyl) ester and kerosene and to retain Ni in water phase, respectively washing Ni and Mg, and draining the Mg washing liquid from another outlet.

Owner:广东芳源新材料集团股份有限公司

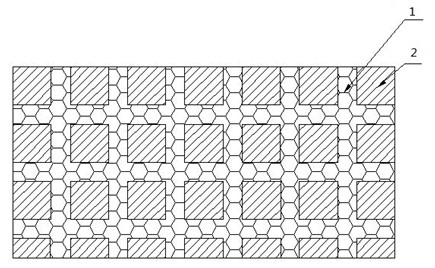

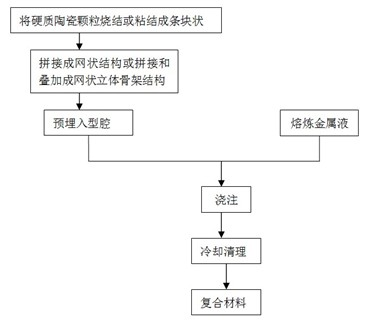

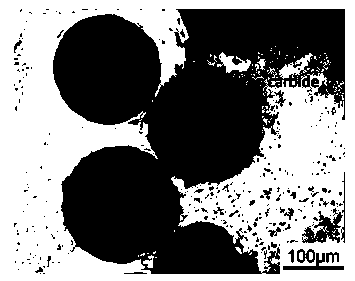

Method for preparing ceramic particle reinforced steel-based mesh material

The invention provides a method for preparing a ceramic particle reinforced steel-based mesh material, which comprises: forming a mixture of hard ceramic particles and alloy powder into strip blocks by powder sintering or by using and adhesive; joining the strip blocks into a corresponding mesh structure or joining and overlapping the strip blocks into mesh three-dimensional framework structure; and performing normal sand casting or lost foam casting, namely melting a substrate metal material, pouring the molten substrate metal material in a molding cavity, allowing the molten substrate metal material to cool and condense at room temperature, removing sand and obtaining the ceramic particle reinforced steel-based mesh material. The obtained ceramic particle reinforced steel-based mesh material gives full play to the high wear resistance of the ceramic particle hard phase and the toughness of the steel base; and the method with convenience for regulation and reliable process solves the problem of incomplete reaction of the composite material, nonuniform reinforcing phase particle distribution, pollution weakening on a reinforcing phase interface and the like and is used in wear resistance fields of mines, power, metallurgy, coal, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

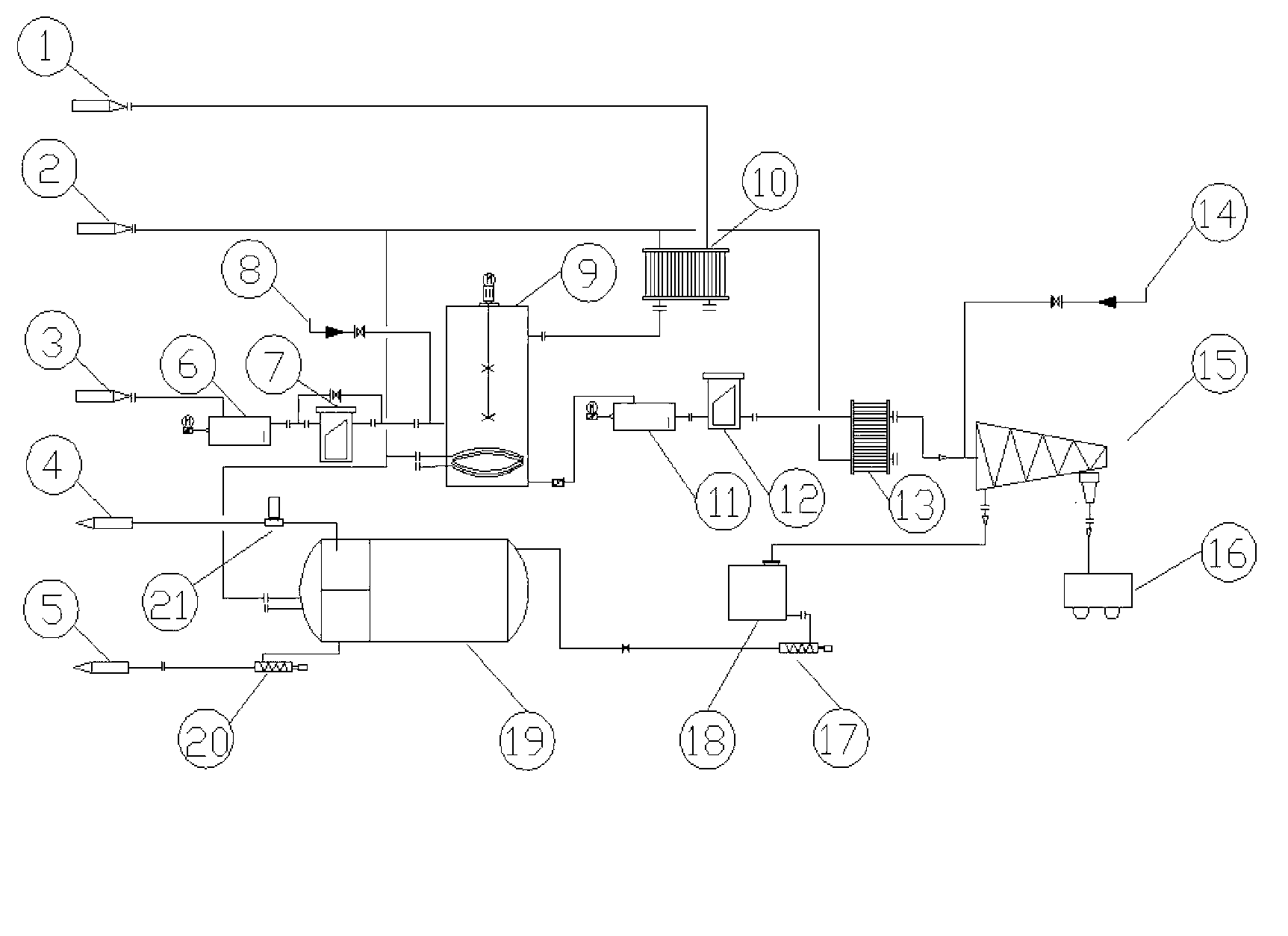

Aged effluent oil treatment technology used for oil fields and oil refineries

InactiveCN103013557ASolving an intractable status quoImprove qualityDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansEngineeringOil water

The invention discloses an aged effluent oil treatment technology used for oil fields and oil refineries, which comprises the following steps of: tempering the effluent oil: adding hot water, an emulsion breaker and a cleaning agent in a modulating pot, stirring and heating, standing in the pot, and lifting and pumping from the bottom part to a solid-liquid separation sledge material filter; performing solid-liquid separation: heating the filtered oil water mixture and small particle solid impurities by using a material heater, entering the inlet of a horizontal spiral centrifuge, meanwhile, successively adding a flocculent according to flow, discharging aged oil solid impurity wastes from the solid outlet of the horizontal spiral centrifuge, collecting the separated out solid oil water mixture by a buffer pot, and lifting and pumping to an oil-water separation sledge material inlet by an oil water lifting pump; and performing oil-water separation: finally heating the oil water mixture in an oil water separating pot, standing, settling, entering the separated out crude oil in an oil chamber, and automatically pumping to a crude oil external transportation process by a purified oil lifting pump. By adoption of the treatment technology, the technical problem of difficulty in treating various aged effluent oils which are generated in production process of oil fields and are difficult to treat is likely to be solved.

Owner:北京惠博普能源技术有限责任公司

Aqueous polyurethane emulsion for synthetic leather and preparation thereof

The invention relates to the technical field of synthetic leather materials, in particular to an aqueous polyurethane emulsion for synthetic leather and a preparation method thereof. Environment-friendly aqueous polyurethane resins with different adaptabilities are manufactured by selecting materials with different functions, such as isocyanate, polyester polyol, a modified nano-silicon dioxide and the like by a high-molecular alloy technology. The aqueous polyurethane resin has the advantages of adequate raw material sources, reliable process and high solid content up to 30-40%, no organic solvent in a product, environmental protection and wide application range. The synthetic leather prepared by the aqueous polyurethane emulsion has the advantages of excellent abrasive resistance, high tear strength, high extensibility up to 400-700% and high tensile strength up to 20-45MPa and can replace PVC artificial leather, PU leather and natural leather; the synthetic material has the advantages of good hand feeling, comfort and good recoverability, as well as good water resistance, good abrasive resistance, good acid resistance, good alkali resistance, high temperature resistance and the like; and compared with the traditional synthetic leather, various technical performances of the synthetic material are obviously improved.

Owner:ENDIAN (GUANGDONG) LEATHER GOODS & FASHION TECH CORP

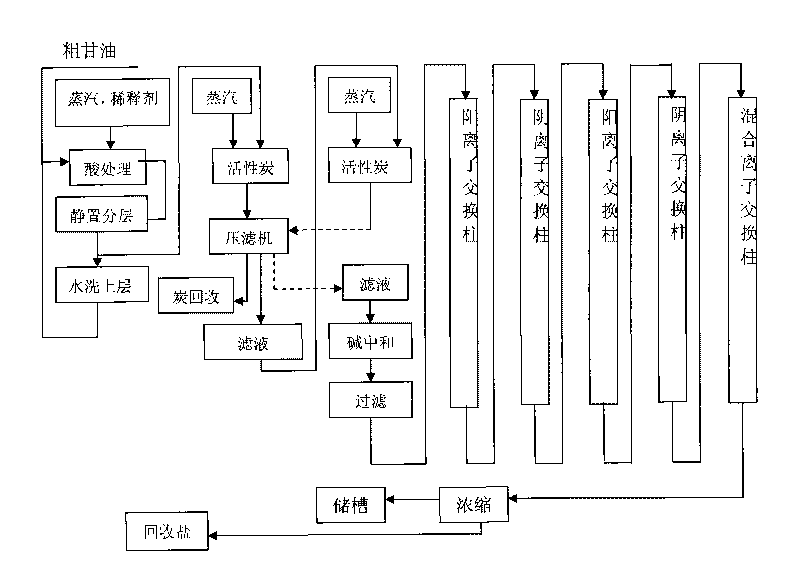

Refining production method of glycerin

InactiveCN101759526ALess investmentSave energyIon-exchange column/bed processesHydroxy compound separation/purificationTrans esterificationBiodiesel

The invention provides a refining production method of crude glycerin. Byproducts of grease ester exchange or hydrolyzation are used as ingredients, and byproducts of biodiesel can also be used as ingredients. The method comprises the following steps: acidizing treatment, decolourization, alkali return for neutralization, concentration for salt removal, ion exchange and concentration treatment, wherein the ion exchange step comprises the substep of sequentially using cations, anions, cations, anions and zwitterions to exchange resin posts in a mixed way, the operation temperature of the resin posts is controlled between 40 and 60 DEG C, the flow rate is 15 mL / min, and finally, the pure glycerin solution is collected. The process of the invention has the advantages of simple operation condition, low temperature, little pollution and high yield, and can avoid the deterioration of the glycerin at the high temperature, the yield is higher than 97 percent, and the product purity is higher than 99.2 percent. The invention also provides a multiplex mixed type anion-cation exchange resin post combination device applicable to the method.

Owner:HUNAN ACAD OF FORESTRY

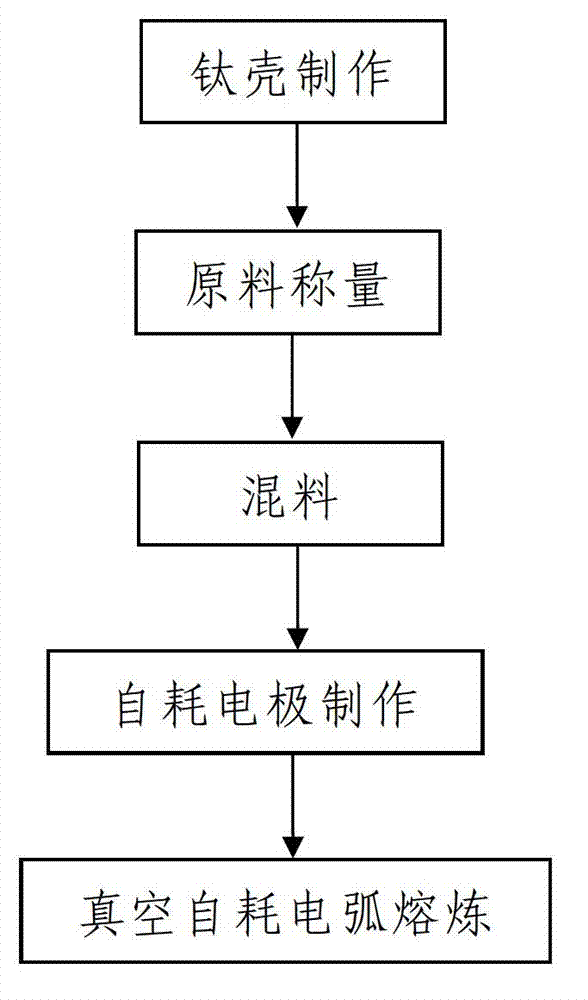

Preparation method of titanium alloy cast ingot containing high-melting-point elements

The invention discloses a preparation method of a titanium alloy cast ingot containing high-melting-point elements, which comprises the following steps: 1, weighing raw materials: proportionally weighing the raw materials according to nominal chemical components of a titanium alloy to be prepared, wherein the raw materials include fine-grained sponge titanium, a titanium shell coated on the outer side of an electrode block to be prepared and high-melting-point metal powder; 2, mixing: evenly mixing the weighed fine-grained sponge titanium and high-melting-point metal powder to obtain a uniform mixture; 3, preparing a consumable electrode: pressing the evenly mixed uniform mixture into the electrode block, coating a titanium shell layer on the outer side of the electrode block, and welding the electrode block to form the consumable electrode; and 4, smelting: smelting the prepared consumable electrode in a vacuum consumable electric arc furnace to obtain the titanium alloy cast ingot containing high-melting-point elements. According to the invention, the method is simple in steps, reasonable in design, low in input cost, simple to use and operate and good in use effect; and the prepared titanium alloy cast ingot is uniform in components and has no high-density inclusions.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Steel for straight welding petroleum casing pipe with steel grades of N80, P110 and L80 and manufacture of casing pipe

InactiveCN101643883ATalentedReliable workmanshipDrilling rodsFurnace typesChemical compositionExtraction of petroleum

The invention relates to steel for a straight welding petroleum casing pipe with steel grades of N80, P110 and L80 and the manufacture of the casing pipe. The steel for the straight welding petroleumcasing pipes with the steel grades of N80, P110 and L80 contains the following chemical components in percentage by weight: 0.10-0.24 C, 0.18-0.22 Si, 1.4-1.6 Mn, 0.06-0.08 P, 0.002-0.008 S, 0.3-0.6 Cr, 0.12-0.14 Nb, 0.08-0.12 V, 0.18-0.22 Ti, and the balance of Fe and inevitable impurities. The steel for the petroleum casing pipe with the high steel grades, which is used for well drilling production and technique, is excellent, has reliable technology, stable property, low cost and convenient use and can be widely used for the petroleum casing pipe used for the well drilling production and technique and save production cost for the extraction of petroleum and gas contained in oil fields, thereby having wide market application prospect.

Owner:华锐石油钢管有限公司 +1

Soybean polypeptide without hydrolysis and bitter tastes as well as preparation method and application thereof

The invention discloses soybean polypeptide without hydrolysis and bitter tastes as well as a preparation method and application thereof. The preparation method provided by the invention comprises the following steps of: firstly producing a great deal of proteases by utilizing a solid microbial fermentation method, and removing the bitter taste and the hydrolysis taste in the polypeptide by utilizing the proteases produced by the microbial fermentation so that the favorable flavor of the soybean polypeptide is ensured, and decomposing a part of soybean protein into small-molecular polypeptide; and then preparing the soybean protein into a solution, converting a solid fermentation system into a liquid enzymolysis system, inhibiting the growth of microbes by improving the temperature of the enzymolysis system, adding high-efficiency protease, and hydrolyzing the polypeptide into the soybean polypeptide with less molecular weight by utilizing high efficiency, stability and specificity of an enzymolysis method. According to the invention, the hydrolysis degree of the soybean protein is 20-40 percent, and the prepared soybean polypeptide has the average length of 2.5-4.0 amino acid, the average molecular weight below 1,000Da and not bitter and hydrolysis tastes. The soybean polypeptide can be directly added into foods and also applied to cosmetics.

Owner:广州合诚实业有限公司

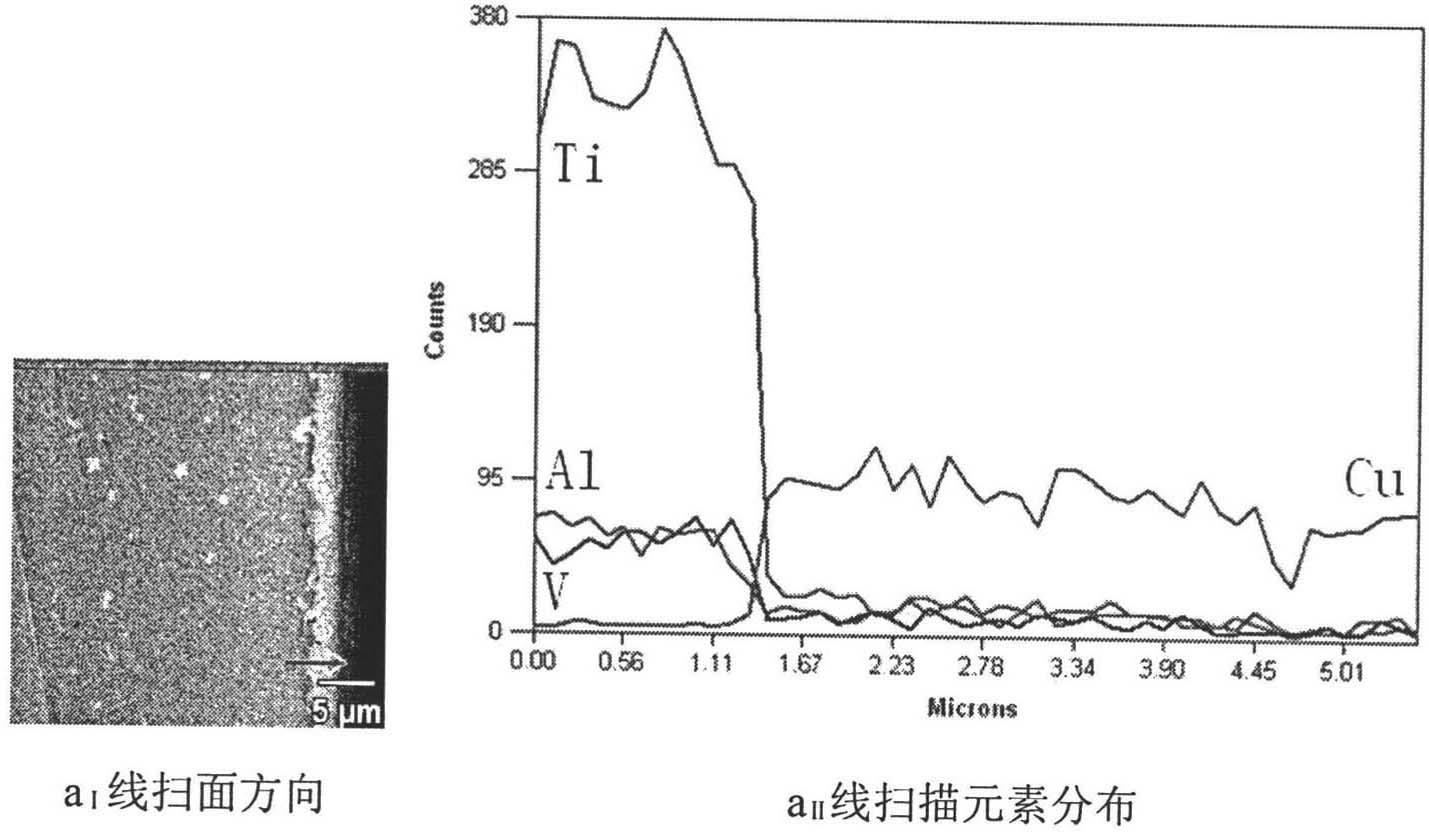

A kind of tc4 titanium alloy surface electroplating copper process method

The invention discloses a copper electroplating process on the surface of a TC4 titanium alloy. The sample or workpiece is sequentially subjected to alkali washing, degreasing and degreasing, water washing, pickling corrosion, water washing, activation treatment, water washing, electroplating, cleaning, surface passivation, Wash and tumble dry. The invention solves the technical problem that copper plating on the surface of TC4 titanium alloy is difficult to achieve, without pre-plating treatment, the surface of TC4 titanium alloy is directly electroplated with copper at room temperature, the process is stable and reliable, and can obtain good bonding force, uniformity, compactness and smooth surface Copper plating, and has the advantages of simple process, convenient operation, high efficiency, low cost, and easy realization. The bonding force was detected by methods such as file edge method, scratch method, friction method and polishing method, and the coating and the substrate showed very good bonding force.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

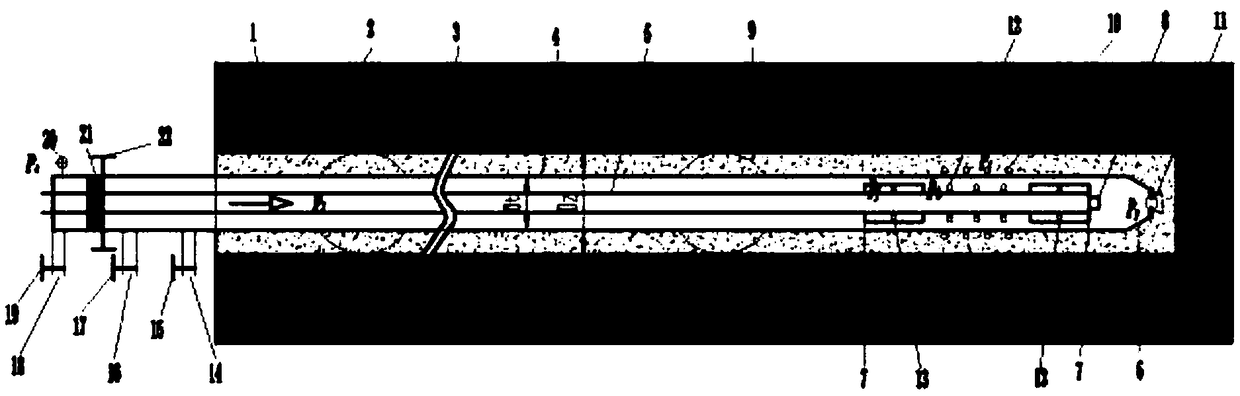

Coal mine underground coal seam long drill hole staged fracturing permeability increase and gas extraction method

ActiveCN108643877AIncrease the scope of fracturing anti-reflectionEfficient extractionFluid removalGas removalUnderground tunnelCement paste

The invention discloses a coal mine underground coal seam long drill hole staged fracturing permeability increase and gas extraction method. The coal mine underground coal seam long drill hole stagedfracturing permeability increase and gas extraction method comprises the steps that a long drill hole with the length more than 100m are drilled into a coal seam using a underground tunnel drilling machine for a coal mine or a kilometer drilling machine; a rigid casing with an one-way valve is lowered into to protect the hole directly using the underground tunnel drilling machine or the kilometerdrilling machine, and casing centralizers are installed at regular intervals; after the casing is lowered, preset volumetric cement paste is injected into an annular space between the outer wall of the casing and a drill hole wall to carry out blocking and sealing; a rigid fracturing pipe with two or multiple packers is lowered into the casing to carry out coal seam staged fracturing step by stepor multistage staged fracturing; and the fracturing pipe and the packers are removed after staged fracturing permeability increase, the casing of coal seam long drill hole opening is accessed with a gas extraction pipeline after drainage finishes to carry out efficient extraction of gas. The engineering amount of a tunnel and hole-drilling can be greatly reduced, the coal seam gas extraction efficiency is improved, and the coal mine underground gas treatment cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

Method for extracting silver from silver slag

The invention discloses a method for extracting silver from silver separated residue, which relates to a method for recycling silver from the solid residue of copper anode sludge after the metal such as Se, Cu, Te, Au, and Ag is separated and extracted. The invention is characterized in that the invention comprises the steps that firstly, the silver separated residue is pulped, industrial H2SO4 is adopted to adjust the acidity of the solution, the oxidizing agent NaClO3 is added to control oxidation reduction potential of the solution to perform oxidizing pretreatment, Ag2O, Ag2SO4, Ag2S, and simple substance Ag in the silver separated residue which can be hardly leached are changed into AgCl which can be easily leached by Na2SO3, and the AgCl is reduced into coarse Ag powder through CH2O under the alkalinity condition. The method of the invention has the advantages that the equipment is simple, the process flow is simple, the silver recovery ratio is high, the loss of the noble metal such as Pt and Pd, etc. in the silver separated residue can not be caused, and the invention is suitable for large-scale industrial production.

Owner:JINCHUAN GROUP LIMITED

Preparation method of particle-reinforced metal matrix composite material

The invention discloses a preparation method of a particle-reinforced metal matrix composite material, and belongs to the technical field of a novel material. The method comprises the following steps: firstly, putting reinforced particles and matrix powder into a ball grinder, so as to evenly mix; then putting the mixed powder into a graphite jig, putting into spark plasma sintering (SPS) equipment; setting a proper sintering parameter, and putting the sintered sample into a vacuum tube furnace to set heating temperature, so as to change a bonding interface between the reinforced particles and the matrix in the composite material, or prompt interface reaction. The reinforced particles in the composite material prepared by the method can be well evenly distributed inside a composite layer, so that the comprehensive properties of the materials are greatly improved, the composite material is even and single in texture, the mechanical property can be changed to a certain extent, and reference is provided for high-temperature wear-resisting fields, such as steel, metallurgy, coal and the like, parts under chilled and heated conditions or other researchers for researching the composite material performances.

Owner:KUNMING UNIV OF SCI & TECH

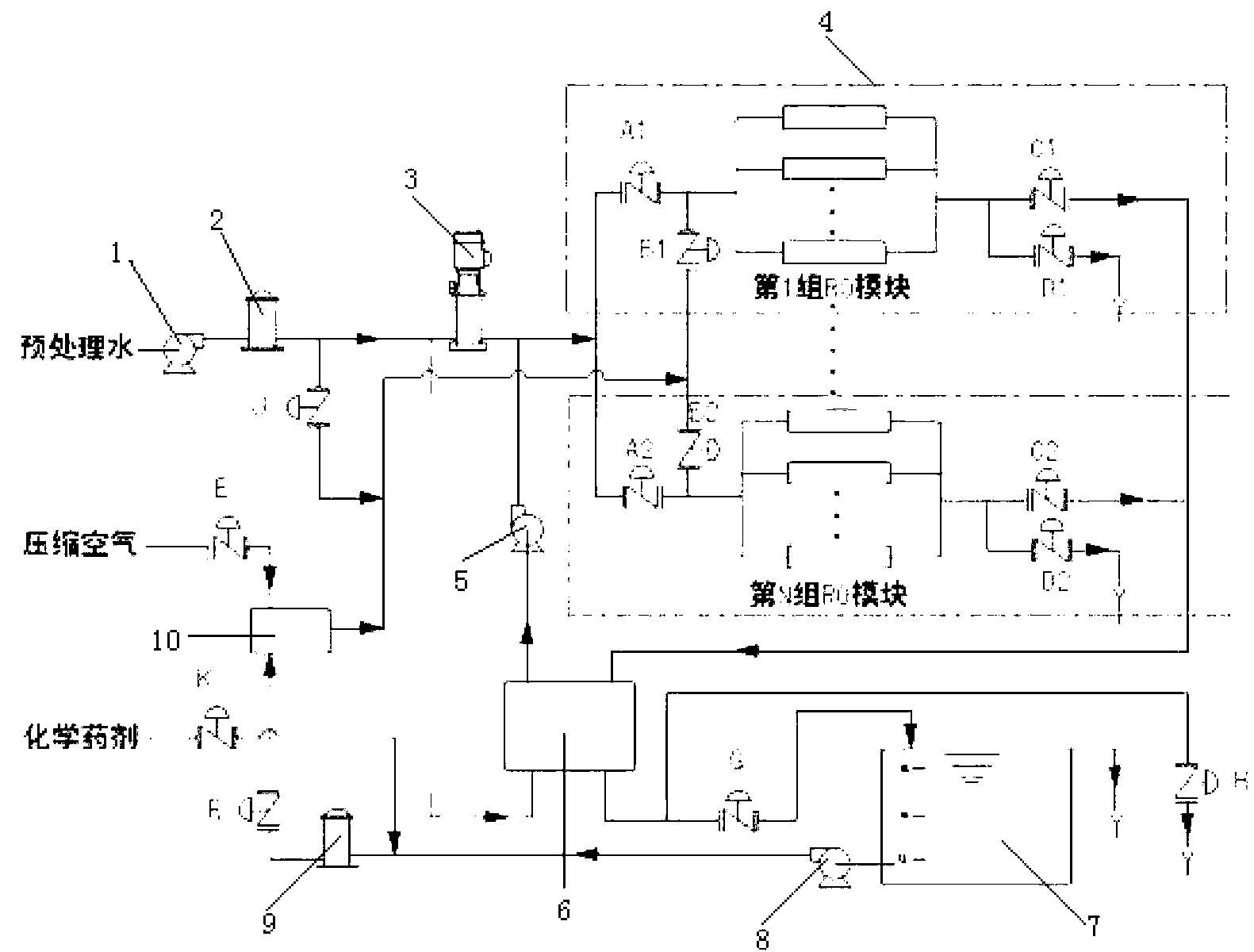

Washing method for preventing reverse osmosis membrane or nano-filtration membrane from being polluted

ActiveCN103301753ALarge water supplyReduce operating pressureSemi-permeable membranesGeneral water supply conservationSocial benefitsWater desalination

The invention belongs to the technical field of seawater desalting and water treatment and relates to a washing method for preventing a reverse osmosis membrane or a nano-filtration membrane from being polluted. The washing method comprises the following steps of: firstly carrying out gas-water two-phase flow washing or simultaneous chemical washing; then extracting reverse osmosis concentrated water to wash the surface of the reverse osmosis membrane; discharging the reverse osmosis concentrated water through a concentrated water discharging valve; then, conveying pretreated water to a reverse osmosis module and displacing and discharging washing concentrated water on a reverse osmosis concentrated water side until the conductivity is recovered to 98% of the conductivity of the pretreated water; finally, closing a washing water discharging valve and opening the concentrated water discharging valve to recover normal operation of the reverse osmosis module; and sequentially washing other sets of reverse osmosis modules. The washing method disclosed by the invention is reliable in process, simple and convenient to operate, lower in energy consumption, good in economic benefits and social benefits, and environment-friendly.

Owner:OCEAN UNIV OF CHINA

Rare-earth doped leadless and low-melting point sealing glass and its preparation method

InactiveCN101456674AMaintain the ability to formExpand the scope of glass formingRare earthCopper oxide

The invention relates to a method for preparing rare earth doped lead-free sealing glass with low melting point, which comprises the following steps: based on raw materials adopted by a Bi2O3-ZnO-B2O3 glass system, adding proper amount of rare earth oxide into the raw materials, and mixing, melting, annealing, grinding and sieving the mixture to obtain the rare earth doped lead-free sealing glass with the low melting point. The sealing glass comprises the following main components by weight portion: 65.22 to 85.22 portions of bismuth oxide, 4.63 to 11.78 portions of boric acid, 5.76 to 10.76 portions of zinc oxide, 0.80 to 2.80 portions of copper oxide, 0.42 to 2.42 portions of cobalt oxide, 3.32 to 8.47 portions of barium carbonate, 0.4 to 1.8 portions of aluminum oxide, and 0.1 to 6.0 portions of rare earth oxide. The method solves the problems that the sealing glass with the low melting point has low sealing temperature, high sealing strength, stable glass structure and the like under lead-free conditions, and has the advantages of simple process, practicability and reliability; and the prepared rare earth doped lead-free sealing glass with the low melting point is particularly suitable for sealing and closing of stainless steel materials, electrons and electric appliances.

Owner:WUHAN UNIV OF TECH

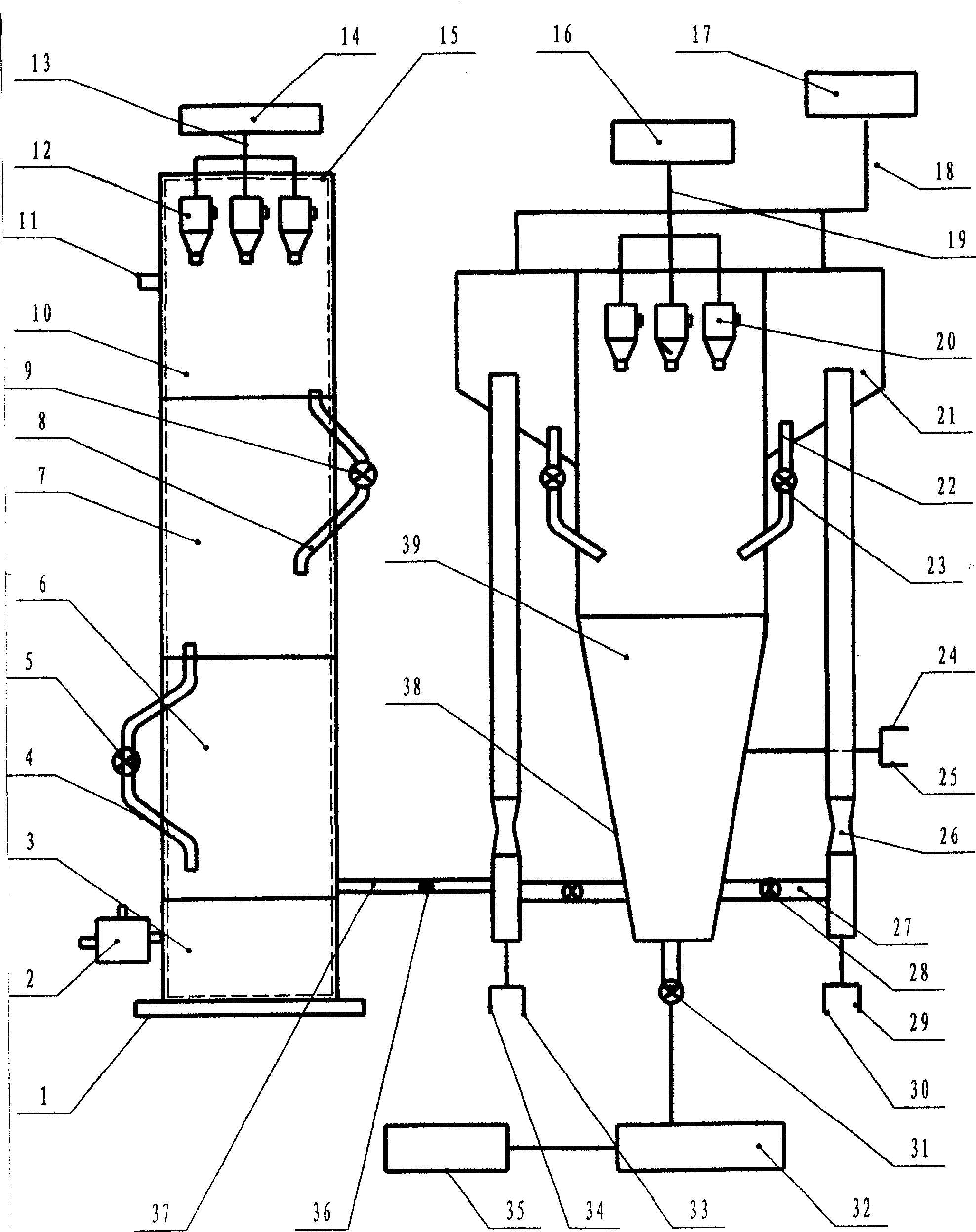

Powder coal grading clean multigang utilization technology using themal dissociation as the first stage

InactiveCN101063039AReliable workmanshipSave on operating costsLiquid hydrocarbon mixture productionSpecial form destructive distillationChemical industrySolid phases

The invention discloses a dust coal grading clean multigang utilizing technique with decomposition as the first grade, which comprises the following steps: processing and sorting raw coal through raw coal processing machine; getting the raw coal with a finite grain size; entering into fluidized-bed drying pyrogenic installation; proceeding dry pyrogenic reaction; getting high carbon half pulverized coke; entering into multiple circulating fluidized bed gasifying installation; proceeding multiple circulating gasifying reaction; getting synthesis gas; leading into chemical industry production; entering solid phase ash coke with low carbon content into circulating fluidized bed boiler; flaming completely. This invention possesses stable craft and low cost, which can utilize all of heat energy in craft course.

Owner:董久明

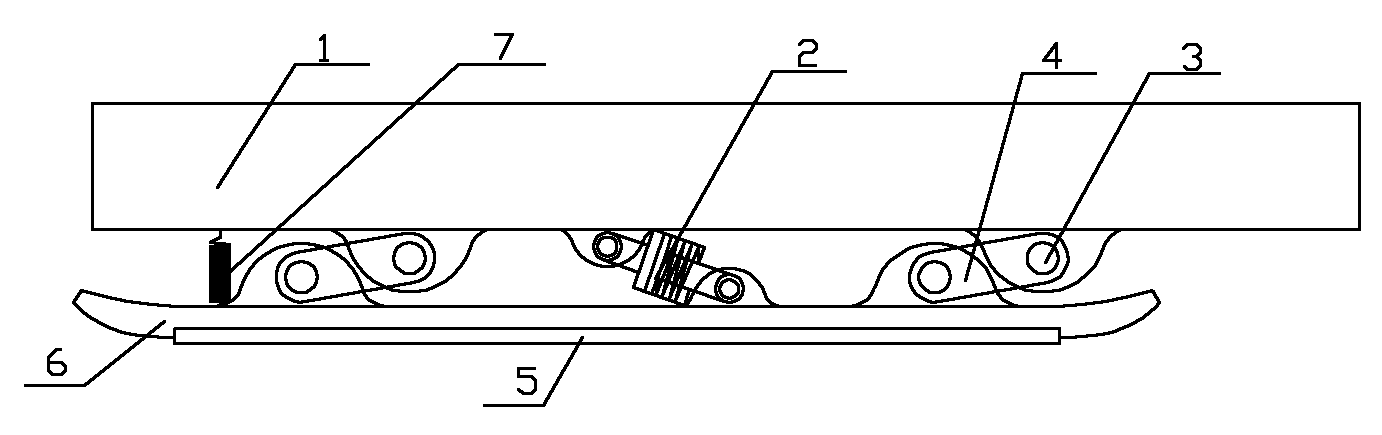

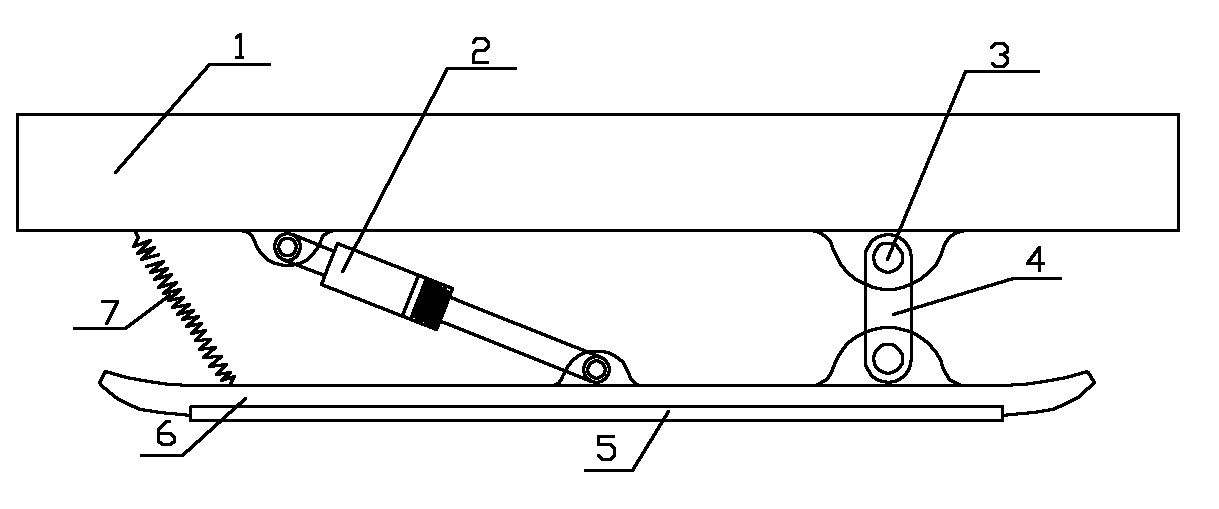

Automobile auxiliary brake-powered speed-reduction friction device and braking method thereof

InactiveCN102009644AReduce the temperatureLarge braking forceBraking element arrangementsFluid braking transmissionRuns down a slopeControl circuit

The invention relates to an automobile brake device and a braking method thereof, in particular to an automobile auxiliary brake-powered speed-reduction friction device and a braking method thereof. The automobile auxiliary brake-powered friction device comprises an automobile chassis longitudinal beam, wherein the lower part of the automobile chassis longitudinal beam is provided with a friction brake pedal; a friction plate is arranged below the friction brake pedal; and a transmission mechanism which is connected with a control circuit is also arranged between the automobile chassis longitudinal beam and the friction brake pedal. The device and the method can increase a braking force effectively by using the friction force generated by friction between the friction brake pedal and the ground when an automobile is braked in emergency or runs down a slope continuously, so that the braking distance in emergent brake is reduced or traffic safe accidents caused by the braking failure of a drum brake at an overhigh temperature when the automobile runs down the slope continuously.

Owner:于宥源

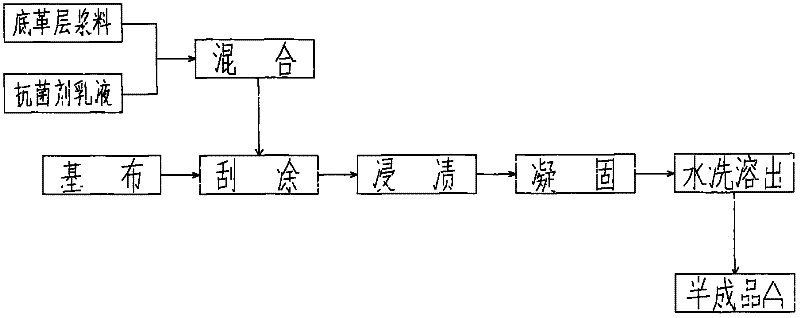

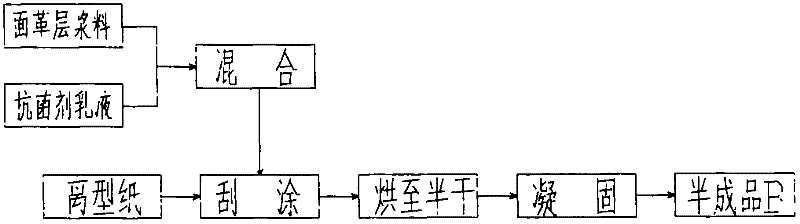

Polyurethane synthetic leather capable of inhibiting bacteria and resisting mildew and preparation method thereof

ActiveCN102454107AEvenly dispersedHigh utility valueFibre treatmentK pneumoniaeStaphylococcus aureus

The invention discloses polyurethane synthetic leather capable of inhibiting bacteria and resisting mildew and a preparation method thereof. The polyurethane synthetic leather capable of inhibiting bacteria and resisting mildew comprises a polyurethane resin and a composite antiseptic uniformly dispersed in polyurethane, wherein, the composite antiseptic comprises 0.01 to 20 parts of an inorganic antiseptic, 0.01 to 35 parts of an organic antiseptic, 0.0001 to 0.4 part of a compatilizer and 0.0001 to 0.4 part of an anti-blushing agent. The polyurethane synthetic leather provided in the invention has instant, high efficiency and lasting functions of inhibiting bacteria and resisting mildew; according to results of antibacterial property detection, the antibacterial polyurethane synthetic leather has good inhibition and killing effects on staphylococcus aureus, Klebsiella pneumoniae, escherichia coli, mixed mycete, etc., an antibacterial rate is greater than 99%, and a mildew-resistant grade is up to 1-0 grade. The preparation method comprises the following steps: dispersing the composite antiseptic with dimethyl formamide (a DMF solvent), adjusting viscosity of an obtained mixture until the viscosity of the mixture is close to the viscosity of molding slurry of the polyurethane synthetic leather, uniformly mixing the mixture with the molding slurry of the polyurethane synthetic leather and carrying out molding so as to prepare the polyurethane synthetic leather capable of inhibiting bacteria and resisting mildew. The method is simple and reliable, does not change an original process route and enables production cost for a product to be controlled.

Owner:BEIJING CHAMGO NANO TECH

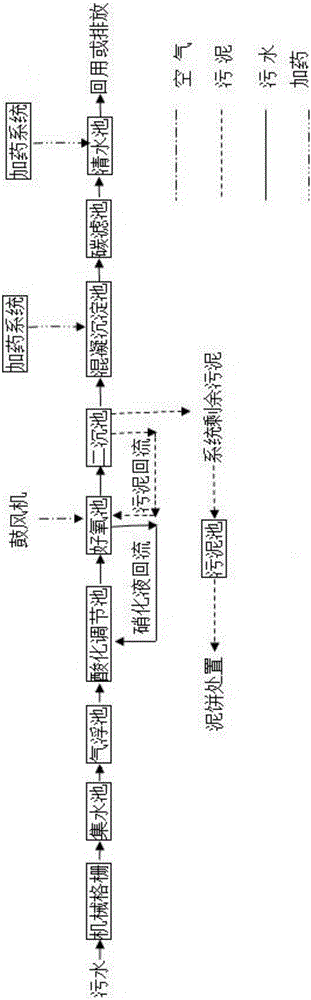

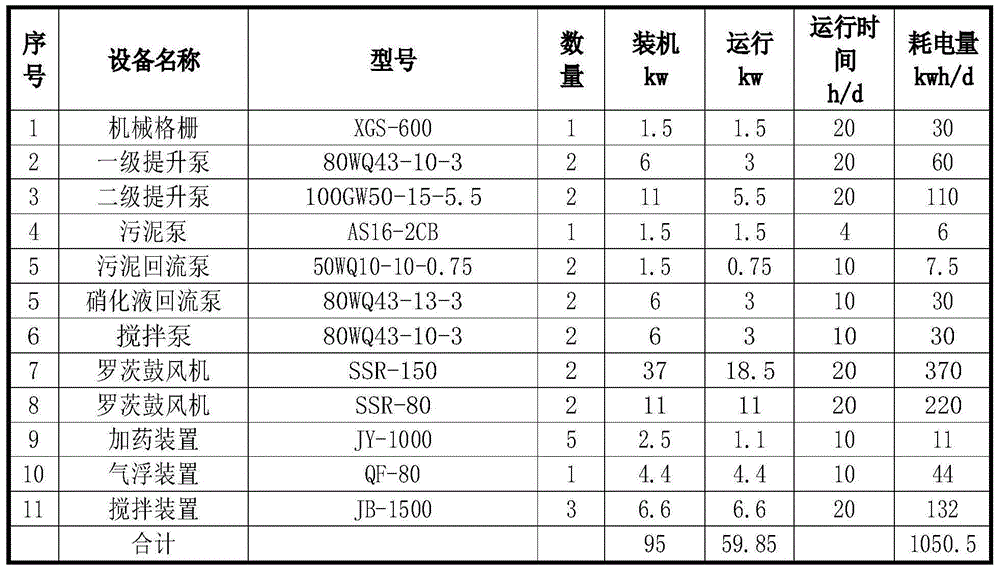

Treatment method for slaughter wastewater

InactiveCN105110565AImprove biodegradabilityFunctionalWaste water treatment from animal husbandryMultistage water/sewage treatmentAutomatic controlSludge

The invention discloses a treatment method for slaughter wastewater. The treatment method includes the steps of pretreatment, biochemical treatment, precipitation separation, oxidative decolorization, activated carbon adsorption, disinfection treatment and sludge concentration. Through adopting the advanced, practical, mature and reliable treatment technology, the inflow requirements for water large in water quality fluctuation and amount are met, and it is ensured that the treated wastewater can not be discharged until reaching standards. By the adoption of the reasonable technology and reasonable arrangement, the construction cost is lowered as far as possible, and on the premise of guaranteeing safe, economical and stable operation of a system, the good treatment effect is achieved with the minimum investment. Based on the rule of the advanced and mature technology and reliable quality, the relation between manual operation and automatic control is reasonably handled, an automation technology is adopted for the step where manual operation is inconvenient, and the labor cost is high, and therefore the operation management level of the system is increased.

Owner:济南兄弟环保科技有限公司

High-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and coating and preparing method of coating

ActiveCN105463359AImprove solid solution strengtheningPlay a reinforcing roleMolten spray coatingChromium carbideTurbine blade

The invention discloses high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and a high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide coating prepared through the composite powder. The composite powder comprises, by weight percentage, 65-85% of Cr3C2, 10-25% of NiCr, 1-5% of Nb and 1-5% of Ta. The coating is prepared in the manner that the composite powder is subjected to hypersonic flame spraying or high-enthalpy plasma spraying or is subjected to hypersonic flame spraying or high-enthalpy plasma spraying, and then the high-enthalpy plasma remelting technology is combined. The coating is greatly improved in the aspects of microhardness, combing strength, corrosion resistance and cavitation resistance. Meanwhile, the production cost is low, the preparing method is reliable in technology, performance is stable, and the coating is suitable for being applied to the fields such as hydraulic machine flow passage components, compressor screws and turbine blades on a large scale.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

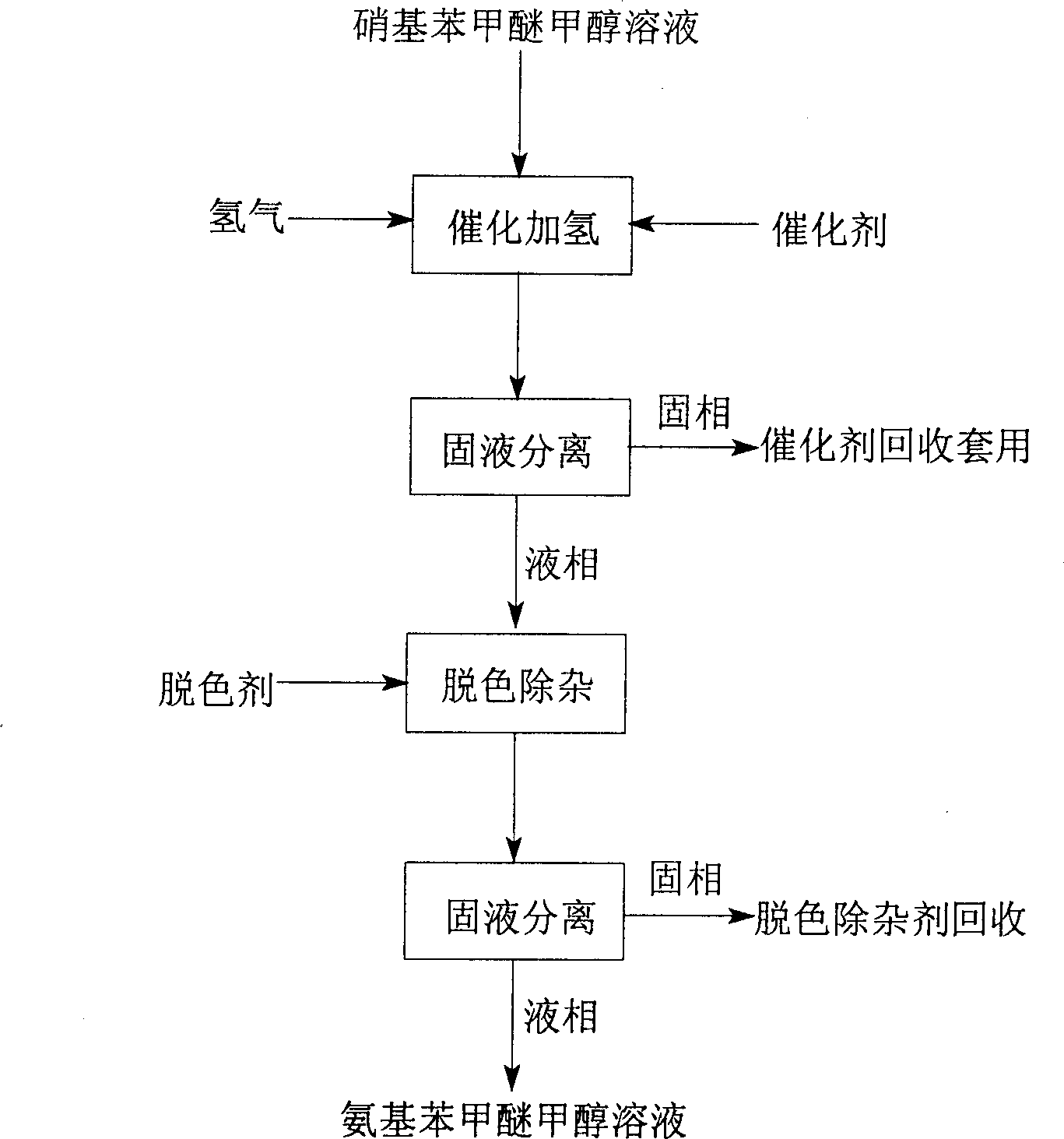

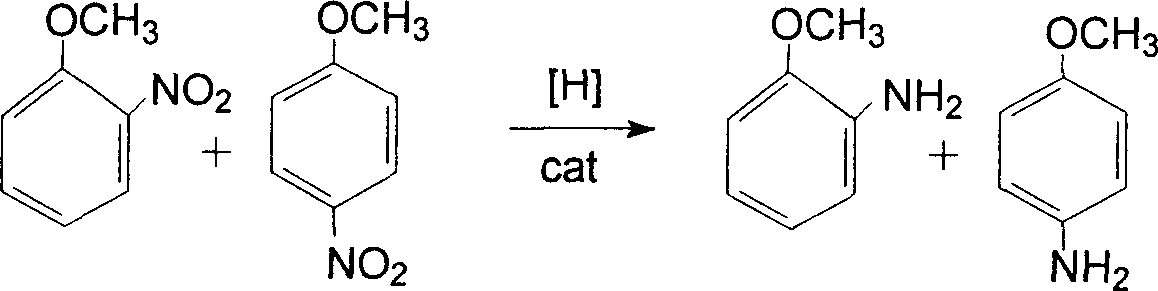

Tech. of preparing amino benz methyl-phenoxide by nitro methyl-phenoxide mixture catalyzing hydrogenation

InactiveCN1861570AImprove dispersionImprove recycling efficiencyOrganic compound preparationAmino-hyroxy compound preparationSolventImpurity

A process for preparing amino phenylmether from nitro phenylmether mixture by catalytic hydrogenating includes such steps as catalytic hydroreducing reaction between methanol, nitro phenylmether mixture and catalyst, recovering catalyst, decoloring, removing impurities, filtering to obtain liquid phase (the solution of amino phenylmether, methanol and water), separation and refining.

Owner:CHANGZHOU JIASEN CHEM +1

High-strength high-plasticity magnesium alloy and preparation method thereof

The invention relates to the field of metal materials, in particular to a high-strength high-plasticity magnesium alloy and a preparation method thereof. The magnesium alloy comprises the chemical components by mass percent: 6.1-9.5% of aluminum, 1.0-5.0% of tin, and the balance of magnesium and additional element / elements. The additional element / elements is / are one or more types of silicon, yttrium, strontium and stibium. The magnesium alloy comprises the following additional elements by mass percent: 0-3.0% of silicon, 0-3.0% of yttrium, 0-0.2% of strontium and 0-2.0% of stibium. The preparation method comprises the following steps: under the protection of gas, melting the preheated pure magnesium at a preset temperature, adding the preheated aluminum and the tin in a certain proportioninto the melt, keeping static at a constant temperature, heating to a higher preset temperature, adding the additional element / elements, keeping static at a constant temperature, evenly stirring, refining, removing the slag, and finally casting into ingots. The magnesium alloy has the advantages of high strength and high plasticity; and the preparation method has the advantages of simple technique, high reliability, easy popularization and application, and the like.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com