Patents

Literature

489results about "Dewatering/demulsification with mechanical means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

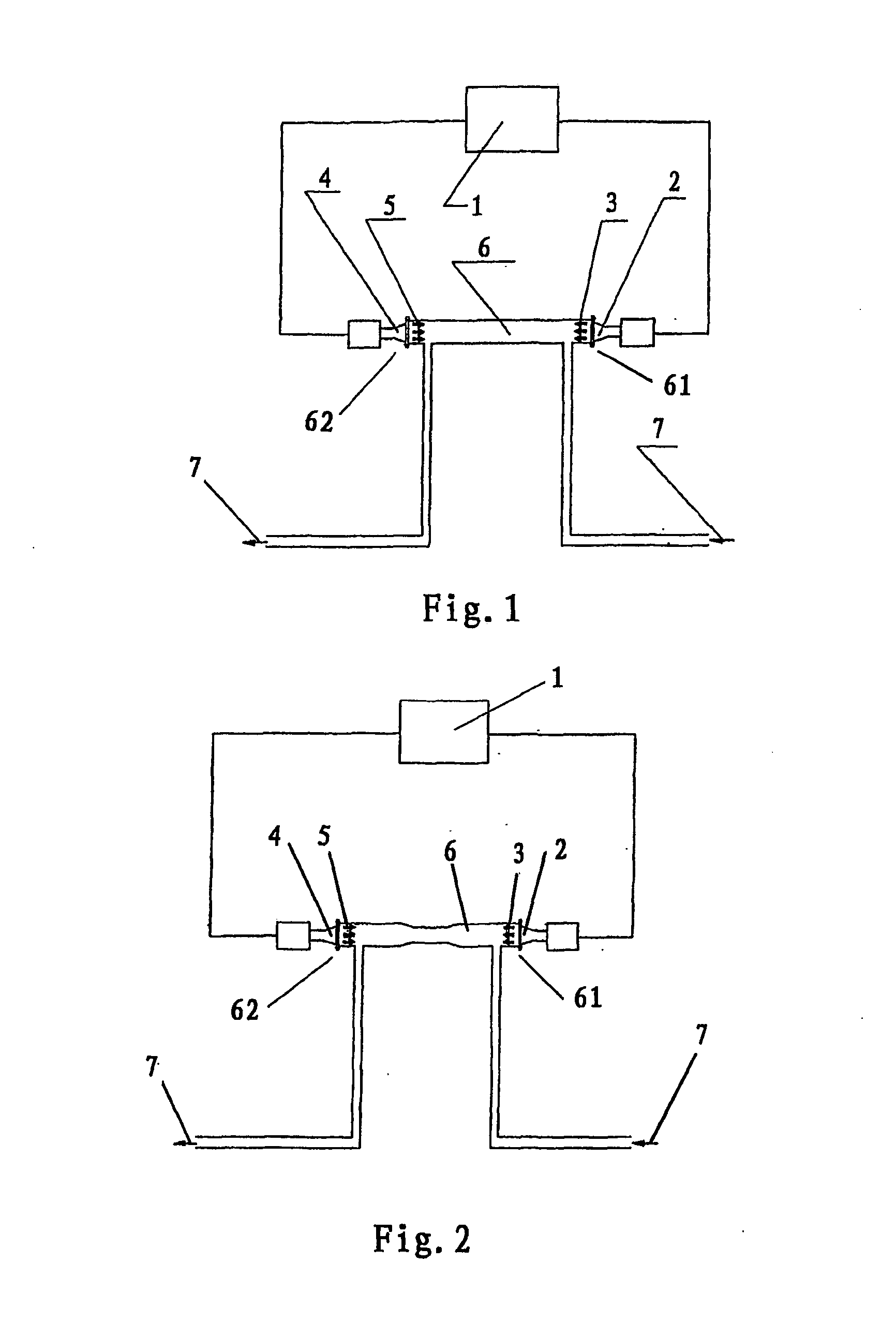

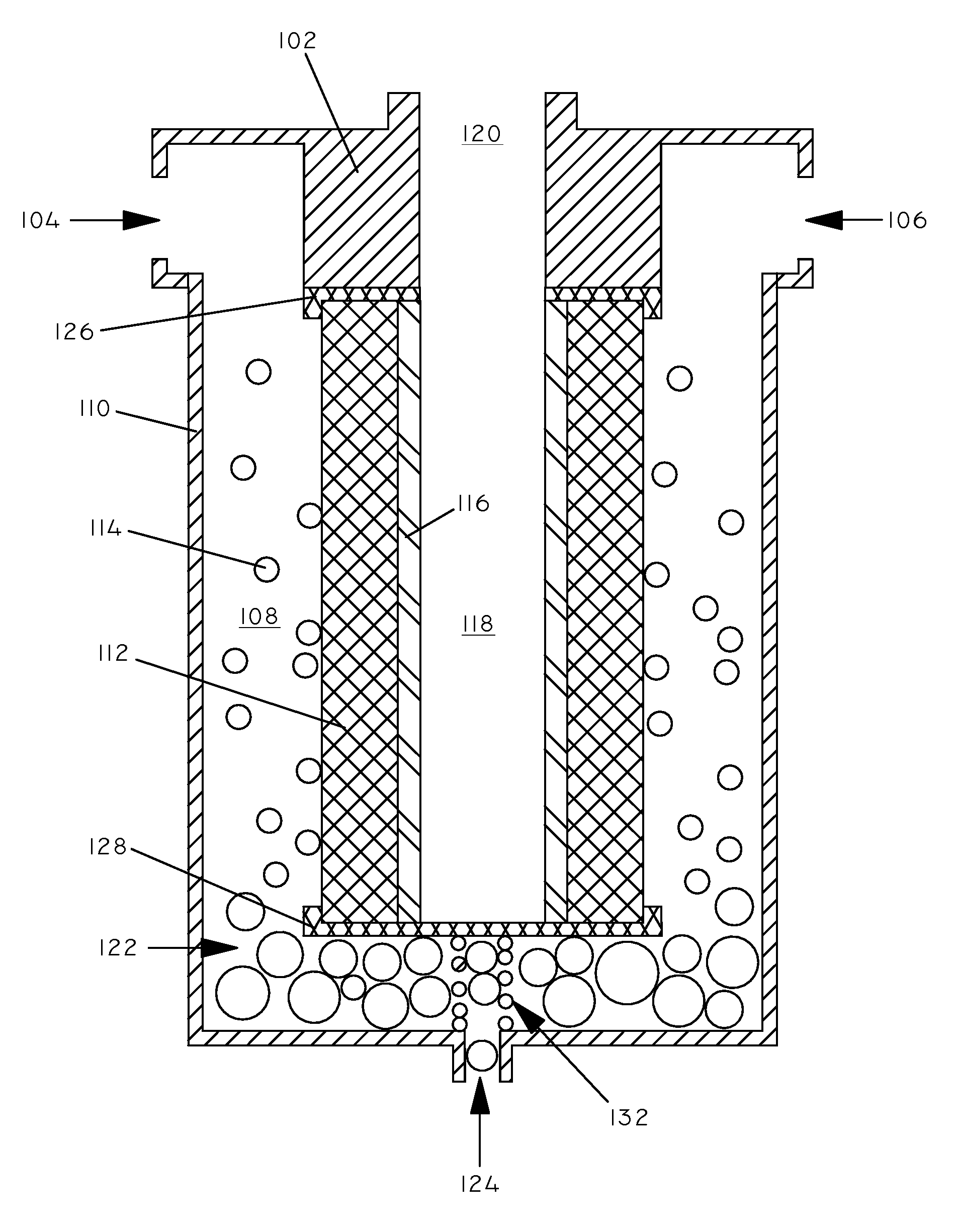

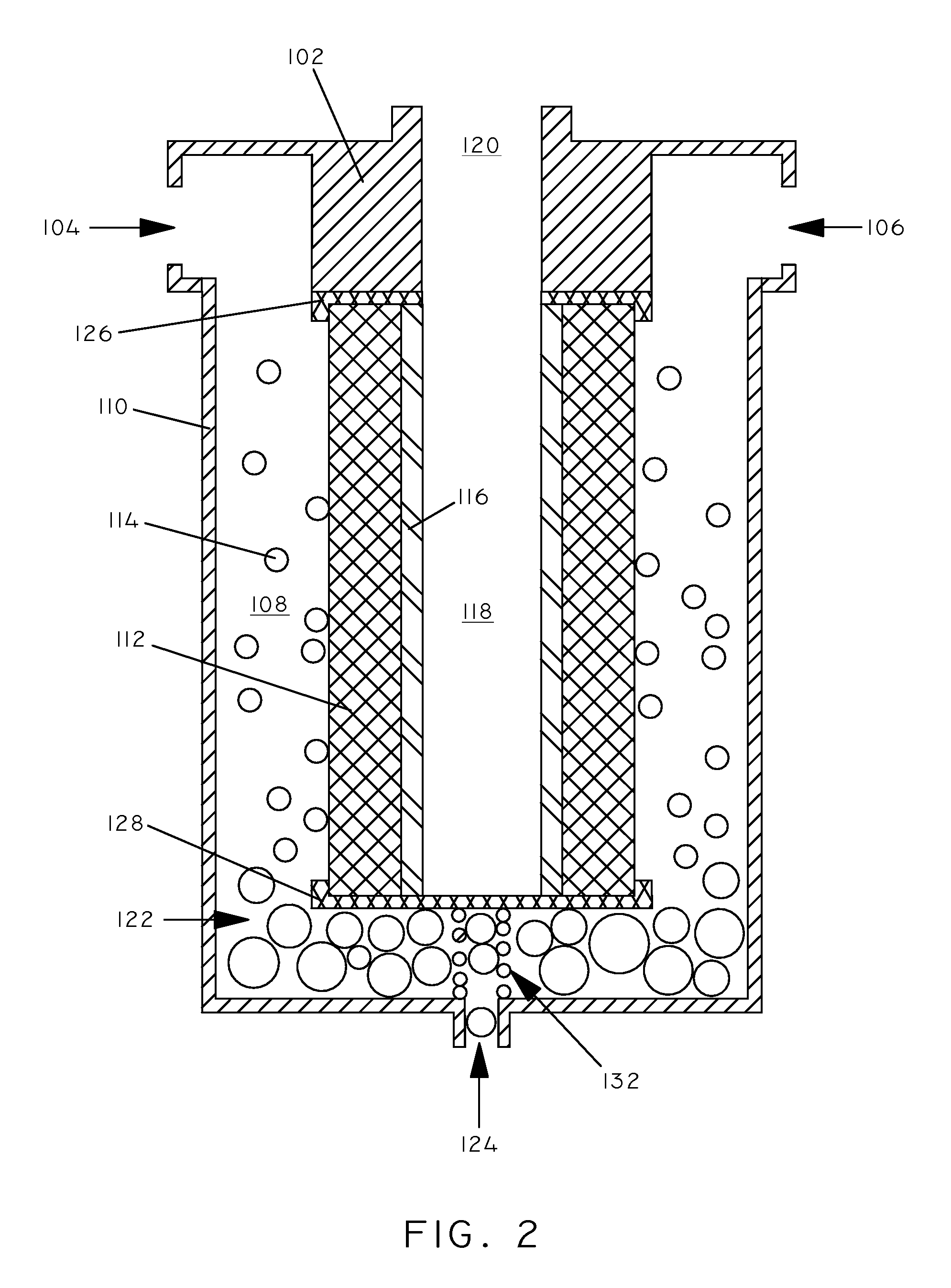

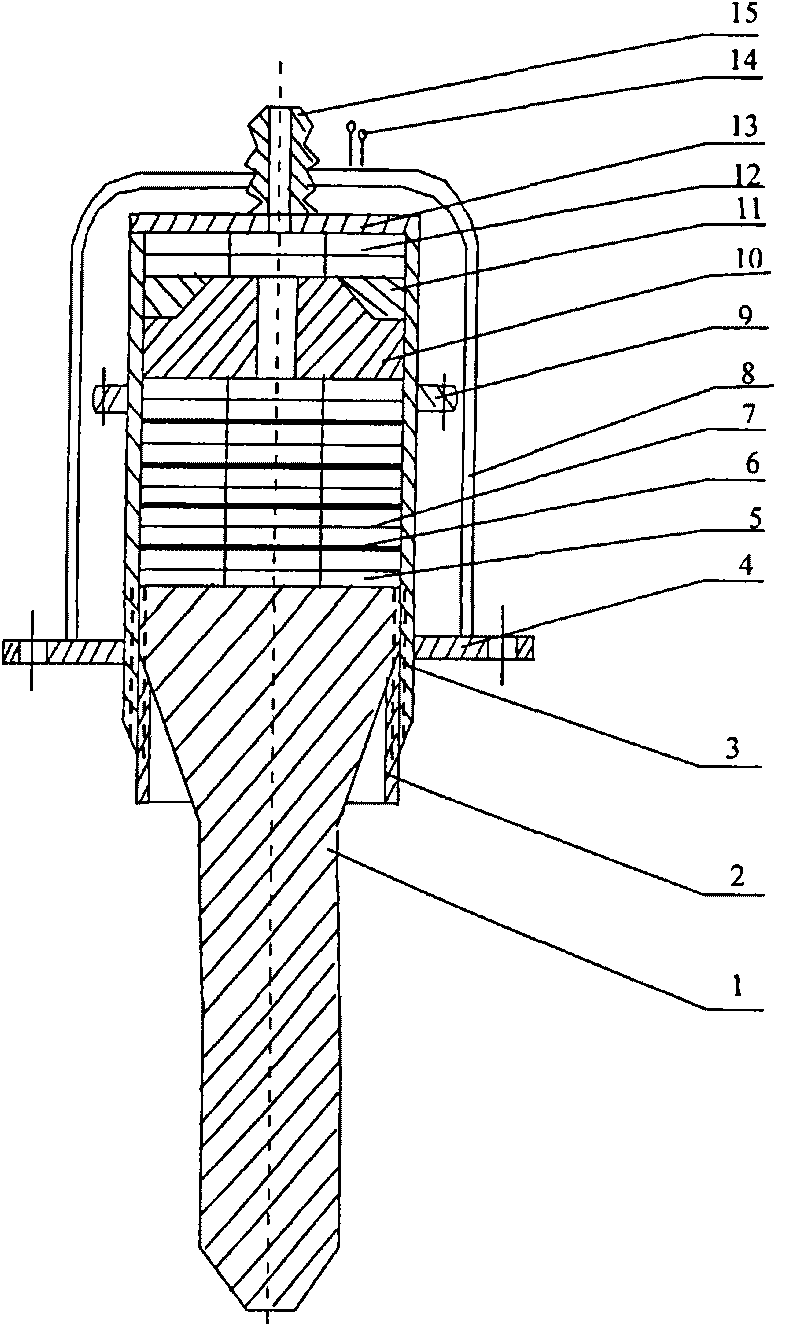

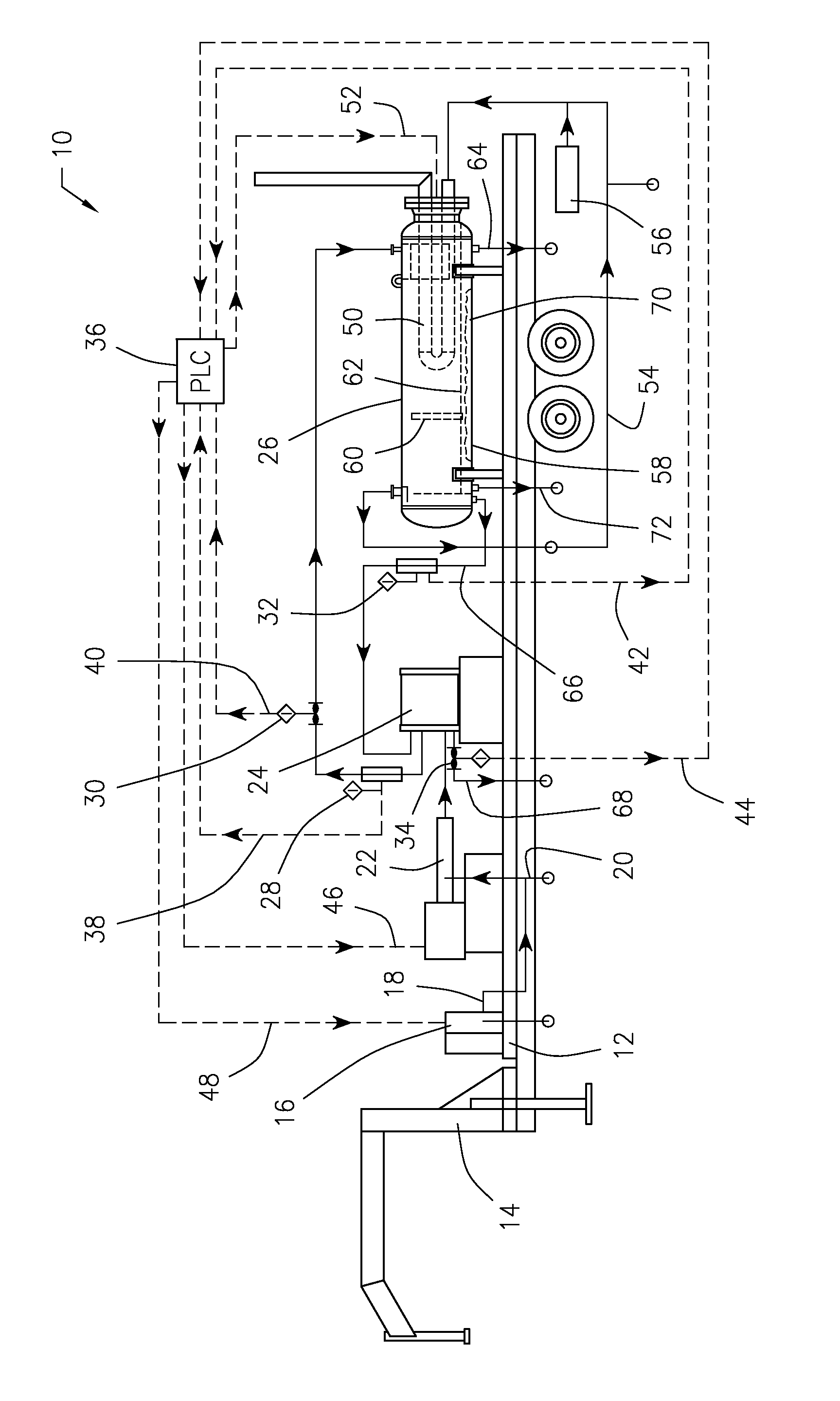

Method and Apparatus for Demulsifying an Oil-Water Emulsion Via Ultrasonic

ActiveUS20070272618A1Good effectExtension of timeDewatering/demulsification with mechanical meansLiquid separation by electricityUltrasound - actionOil water emulsion

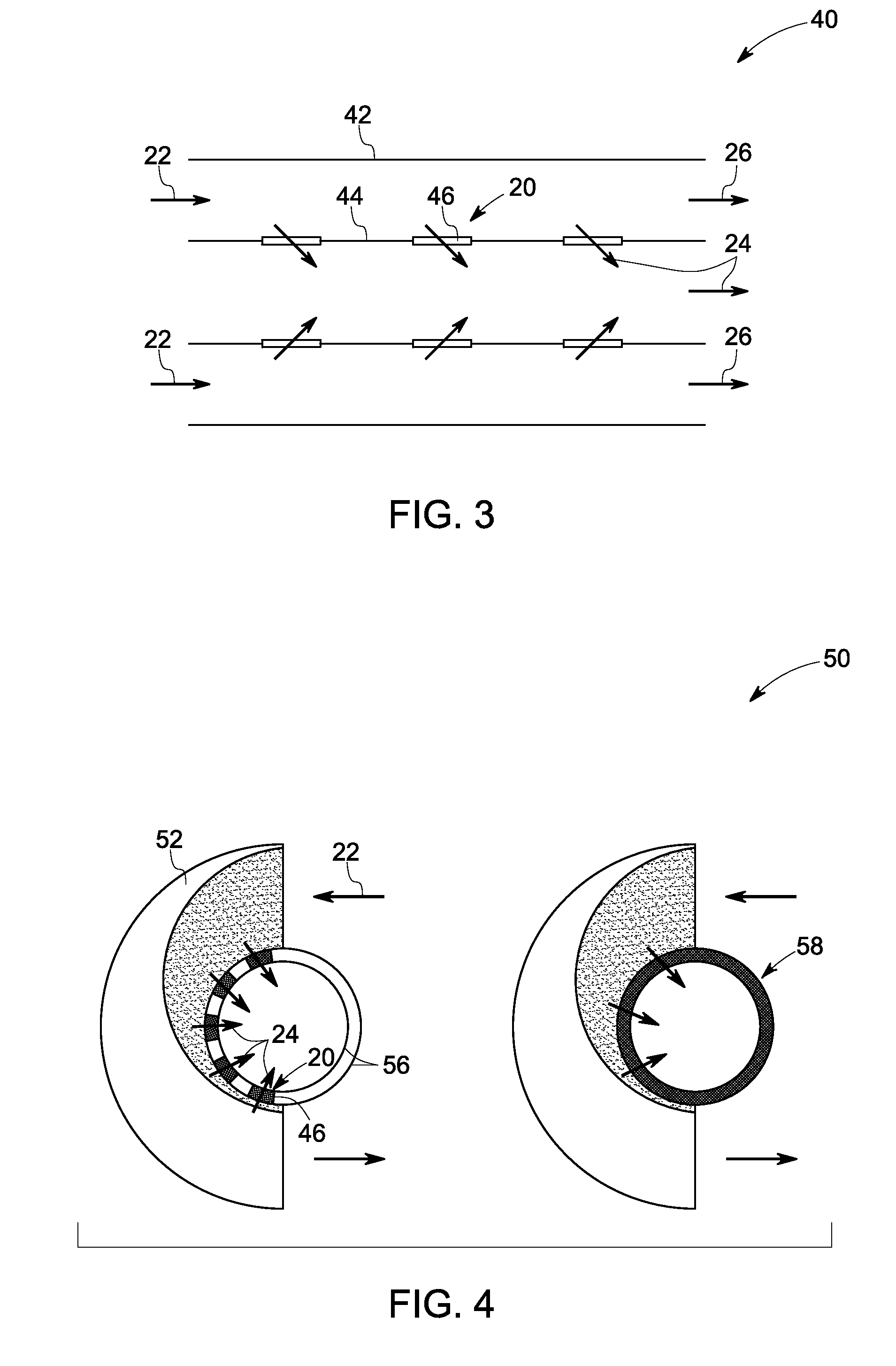

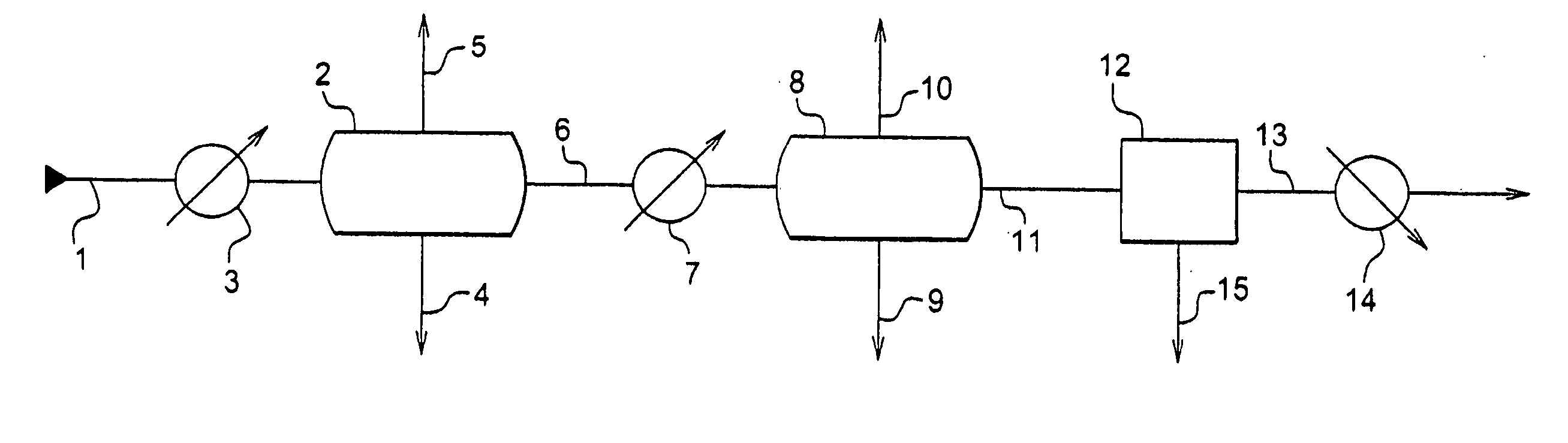

A method for demulsifying water-oil emulsions through ultrasonic action, comprises a step of making the water-oil emulsions flow through at least one ultrasonic acting region in a flow direction, wherein: within the ultrasonic acting region, a concurrent ultrasonic wave whose traveling direction is the same as the flow direction of the water-oil emulsions is generated by at least a one first ultrasonic transducer provided at the upstream end of the ultrasonic acting region, and at same time, a countercurrent ultrasonic wave whose traveling direction is opposite to the flow direction of the water-oil emulsions is generated by at least a one second ultrasonic transducer provided at the downstream end of the ultrasonic acting region; and the concurrent ultrasonic wave and the countercurrent ultrasonic wave act simultaneously on the water-oil emulsions which flow through the ultrasonic acting region, so as to demulsify the water-oil emulsions. After being demulsified, the water-oil emulsions gravity settle and separate, or settle and separate under an electric field, so as to be dewatered. The present invention can apply to various water-oil separating technologies in the procedures from mining to processing of crude oil.

Owner:CHINA PETROCHEMICAL CORP

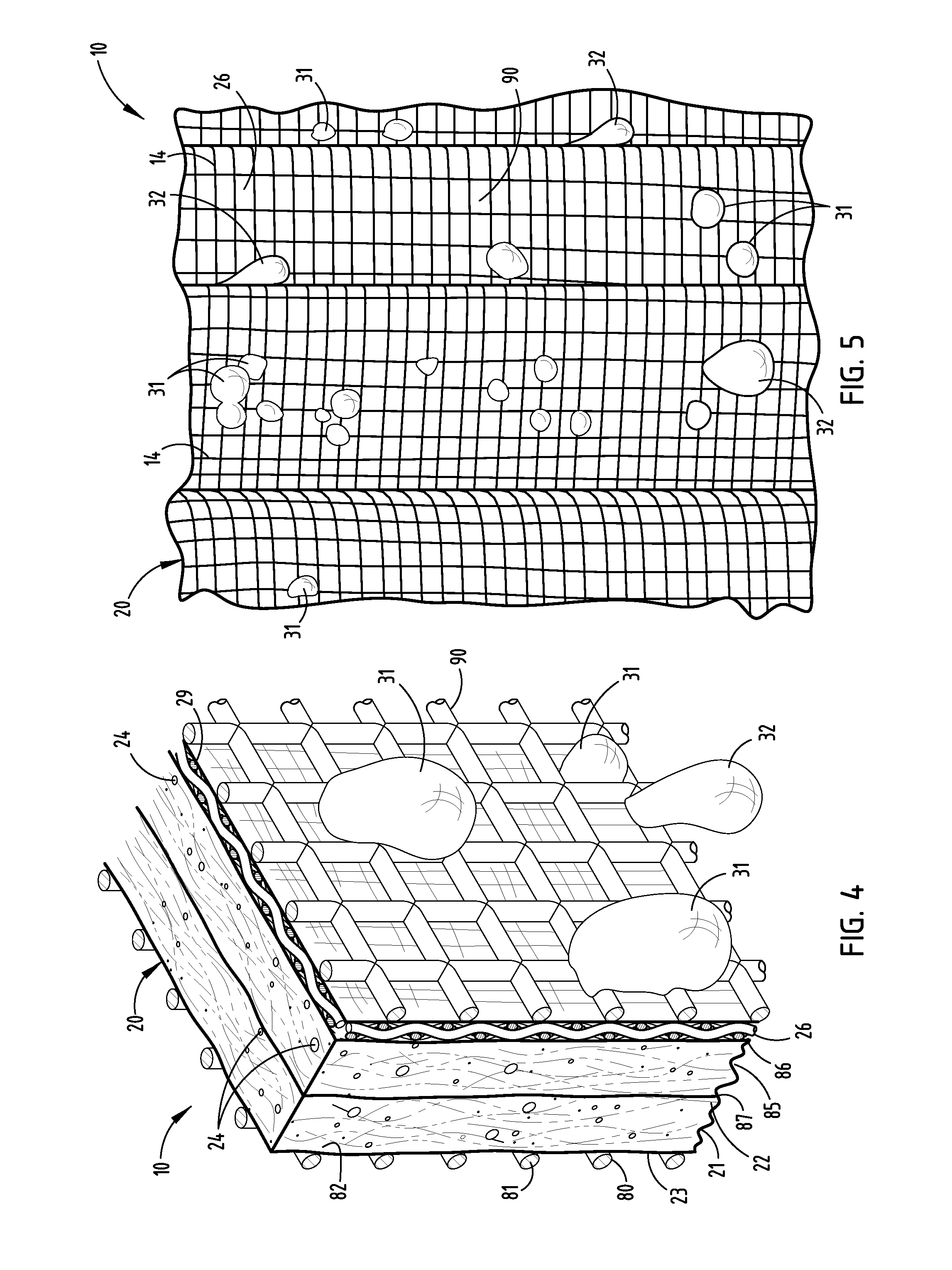

Separation media and methods especially useful for separating water-hydrocarbon emulsions having low interfacial tensions

InactiveUS20110084028A1Dewatering/demulsification with mechanical meansSedimentation separationFiberEmulsion

Separation media, separation modules and methods are provided for separating water from a water and hydrocarbon emulsion and include a fibrous nonwoven coalescence layer for receiving the water and hydrocarbon emulsion and coalescing the water present therein as a discontinuous phase to achieve coalesced water droplets having a size of 1 mm or greater, and a fibrous nonwoven drop retention layer downstream of the coalescence layer having a high BET surface area of at least 90 m2 / g or greater sufficient to retain the size of the coalesced water droplets to allow separation thereof from the hydrocarbon.

Owner:A AHLSTROM CORP

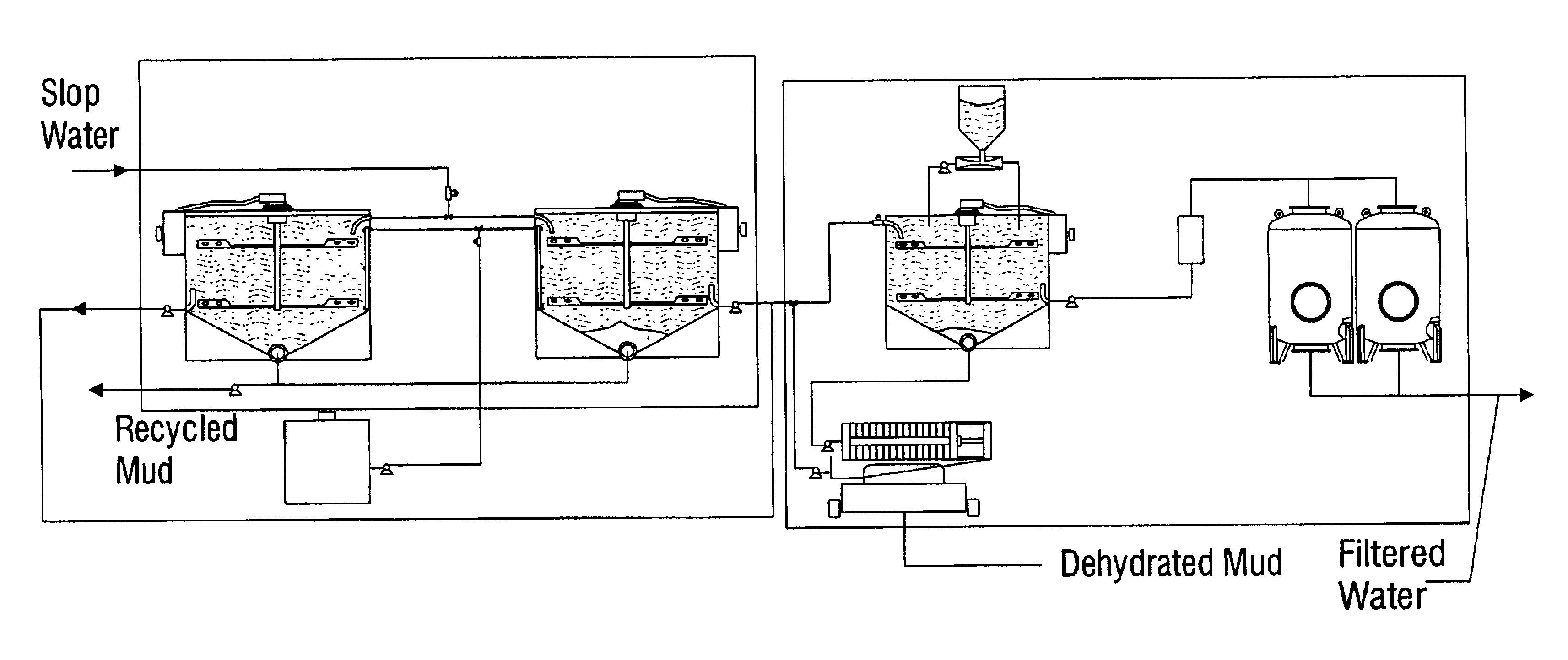

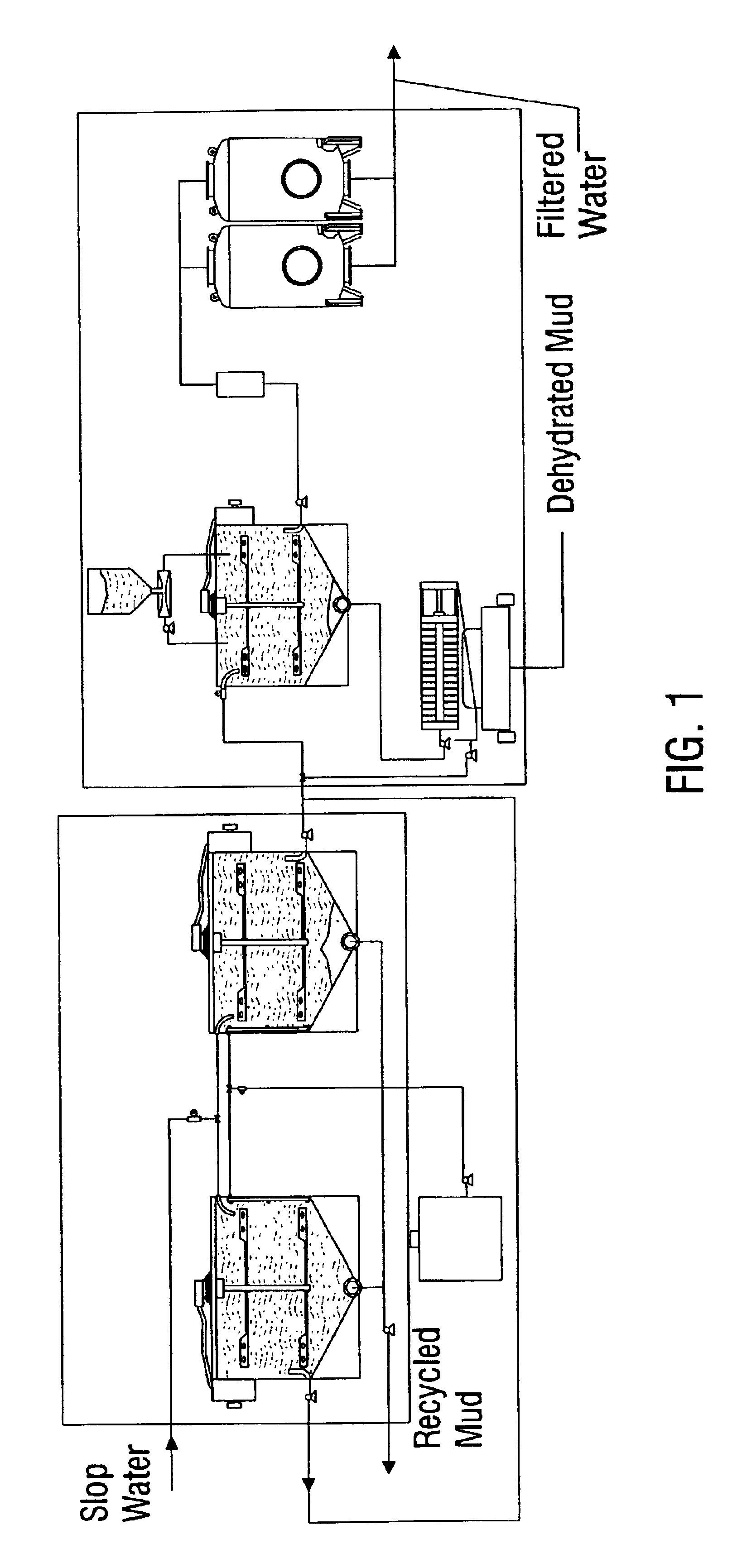

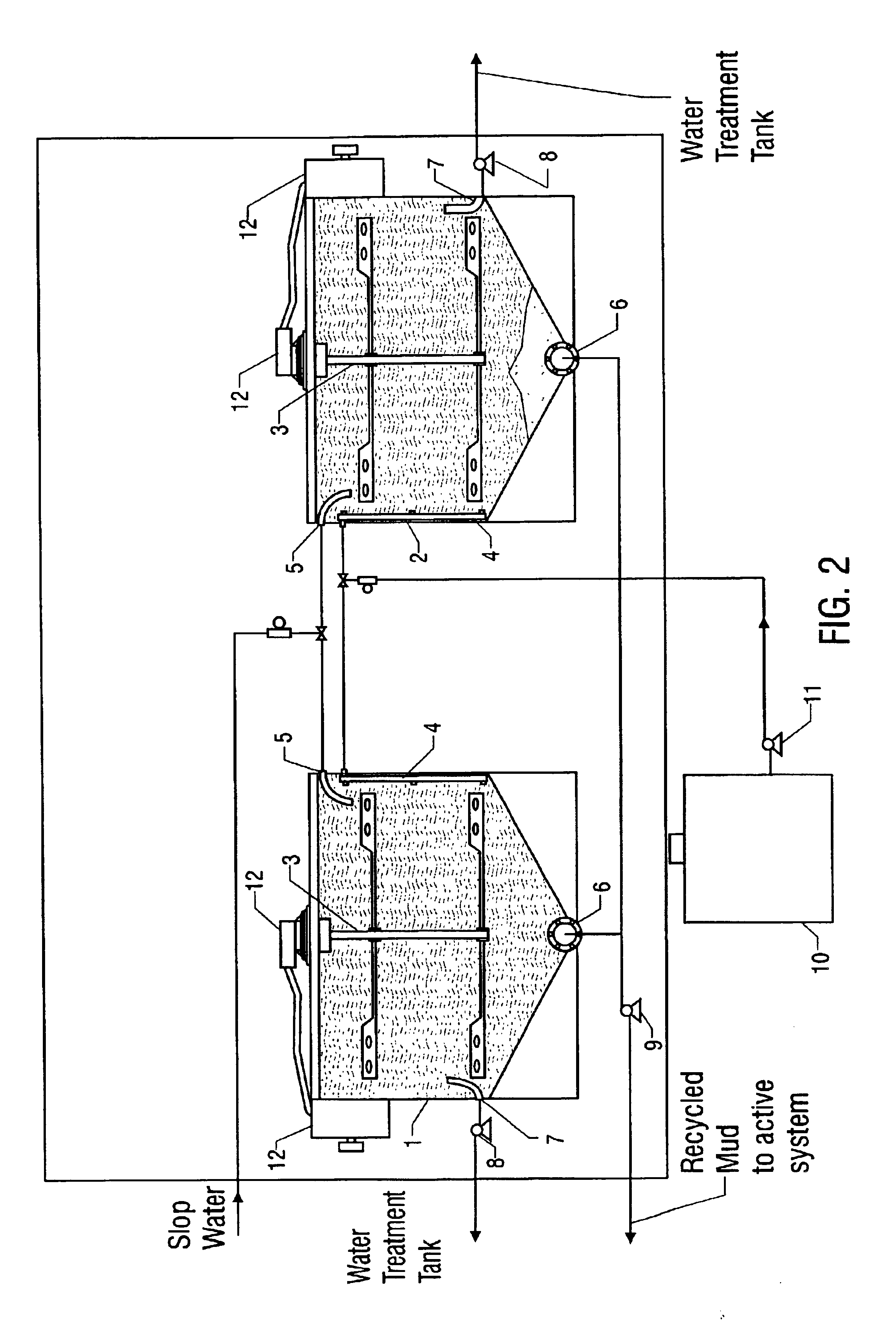

Method for recycling of oil based drilling fluid contaminated with water and water contaminated with oil based drilling fluid

InactiveUS6881349B2Waste water treatment from quariesDewatering/demulsification with chemical meansDemulsifierAlkyl polyglycoside

A mobile apparatus and method for recycling an invert emulsion based drilling fluid, in which the invert emulsion based drilling fluid includes an oleaginous component and an aqueous component. The apparatus includes an emulsion breaking tank, a water treatment tank, a filter press, and hydrocarbon filters. The method includes: mixing said invert emulsion drilling fluid with a emulsion breaker, wherein the emulsion breaker is a mixture of an alkyl glucoside and an alkane sulfonate; and separating the oleaginous component of the invert emulsion drilling fluid from the aqueous component of the invert emulsion drilling fluid. The method preferably utilizes an emulsion breaker that is a combination of an anionic surfactant, a nonionic surfactant and an alkyl polyglycoside surfactant.

Owner:MI

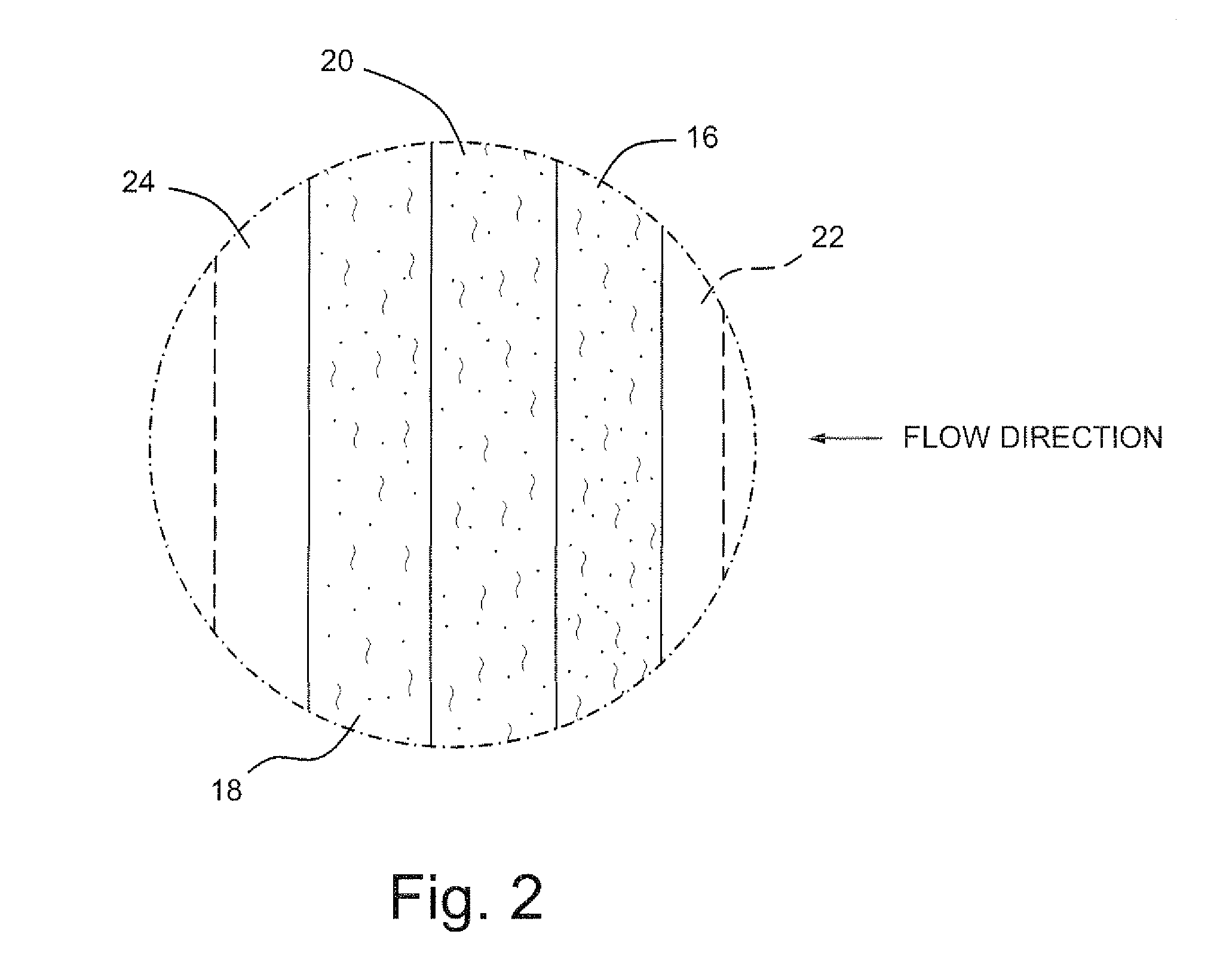

Systems, articles, and methods for removing water from hydrocarbon fluids

The present invention relates to systems, articles, and methods for removing water from hydrocarbon fluids. In an embodiment, the invention includes a water / fuel separation system including a filter housing and a filter element disposed within the filter housing. The filter element can include a separation article including a porous polymer layer having and a porous substrate comprising a hydrophobic surface. In an embodiment, the invention includes a filter element for separating emulsified water from a hydrocarbon fluid. In an embodiment, the invention includes a method for filtering water out of a hydrocarbon fluid including passing a hydrocarbon fluid through a separation article including a polymer layer comprising polytetrafluoroethylene; and a porous substrate comprising a hydrophobic surface, the polymer layer disposed on the porous substrate.

Owner:DONALDSON CO INC

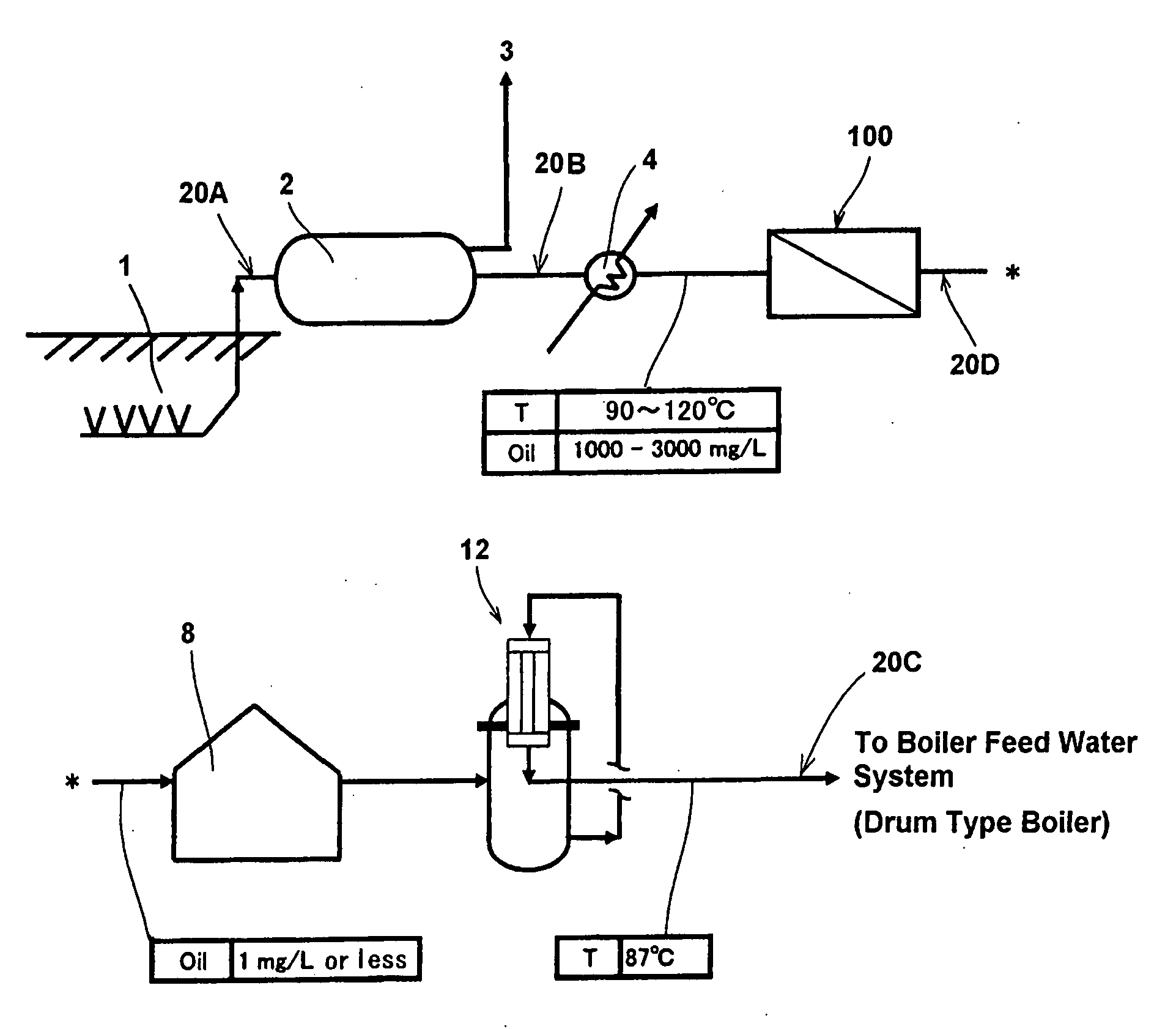

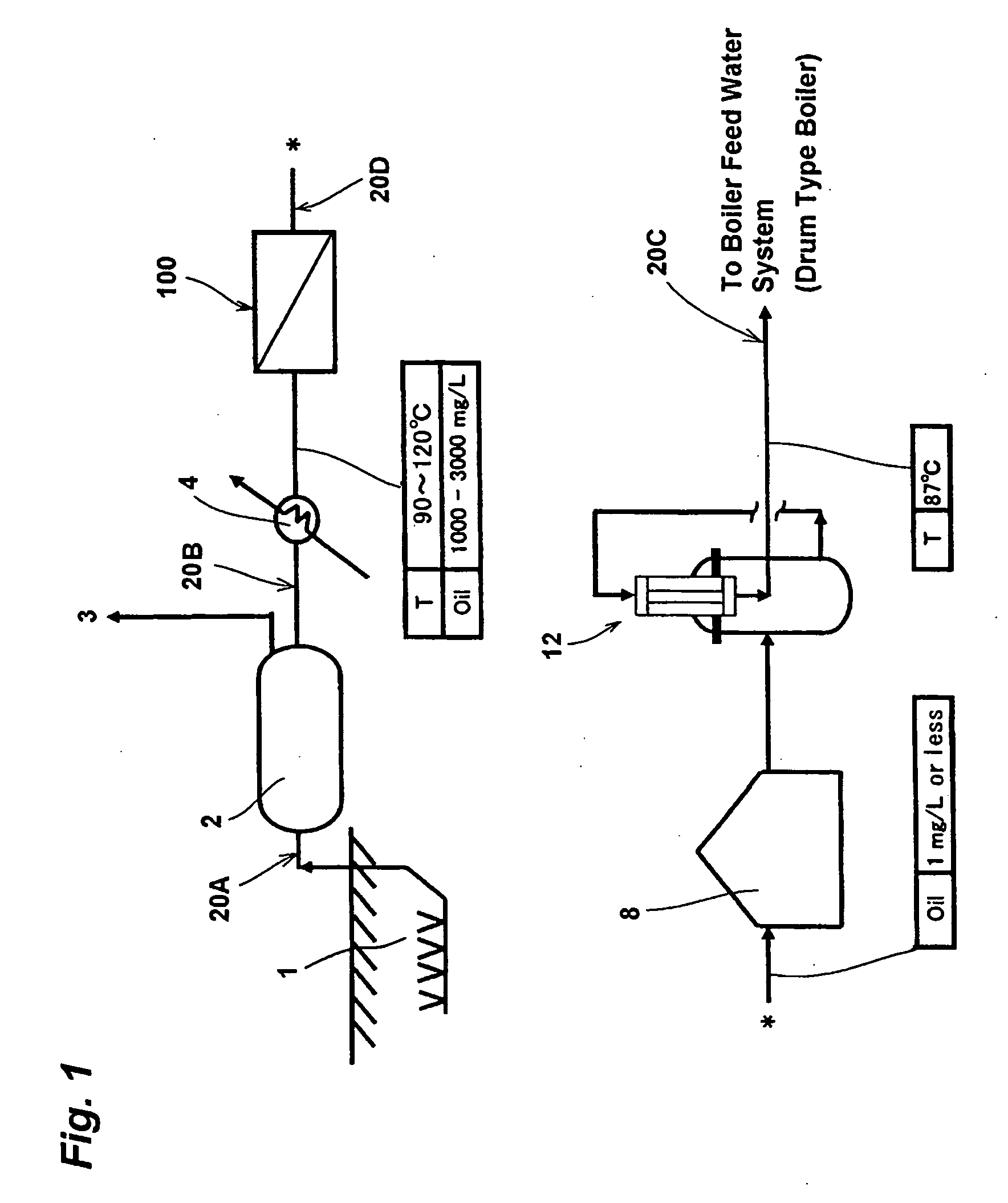

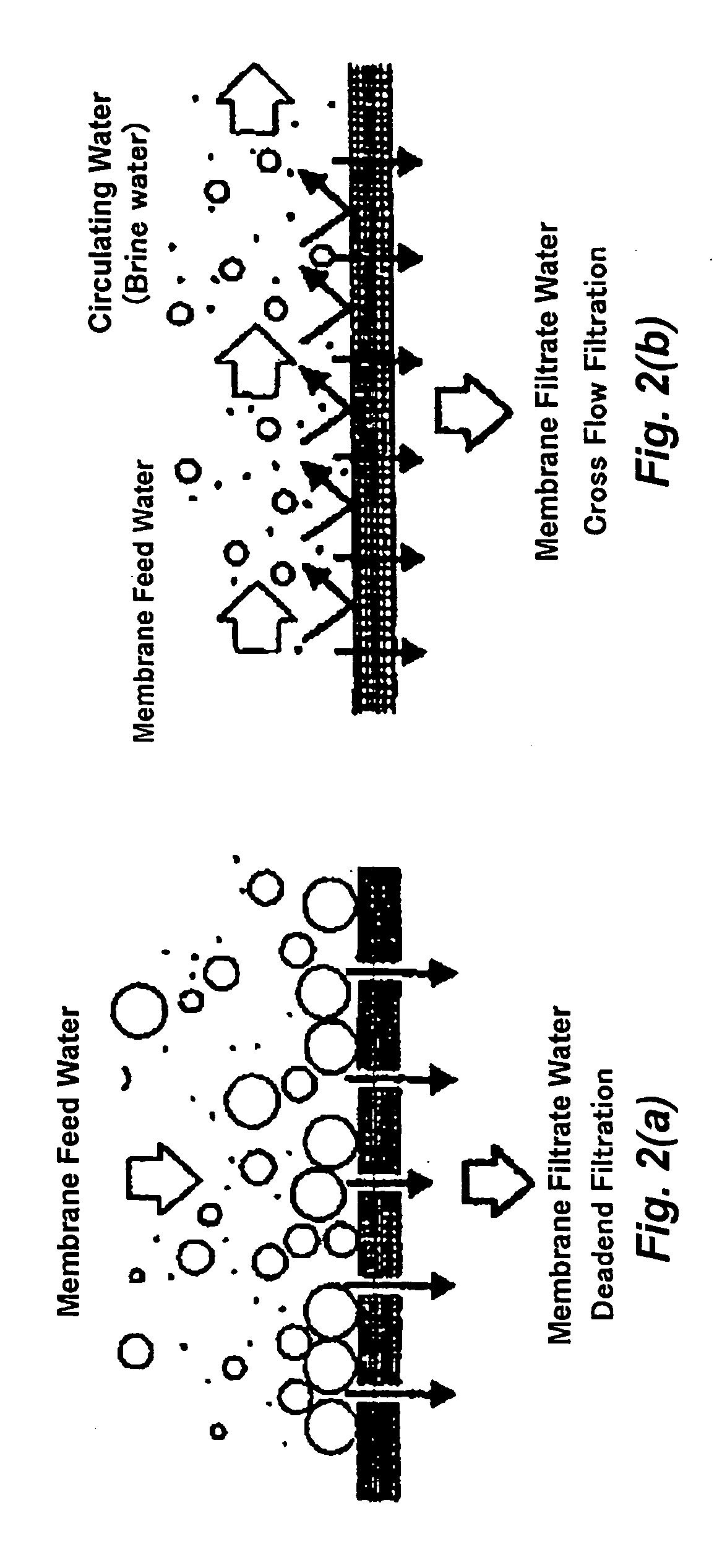

Method of produced water treatment, method of water reuse, and systems for these methods

ActiveUS20100264068A1Fatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansRecovery methodMicrofiltration membrane

A method of produced water treatment in an in-situ recovery method of producing bitumen from oil sand, the method has the steps of: separating bitumen from bitumen-mixed fluid so as to leave produced water, the bitumen-mixed fluid having been recovered from the oil sand wells; and filtering the produced water via a microfiltration membrane made of polytetrafluoroethylene.

Owner:SUMITOMO ELECTRIC IND LTD +1

Refinery desalter improvement

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

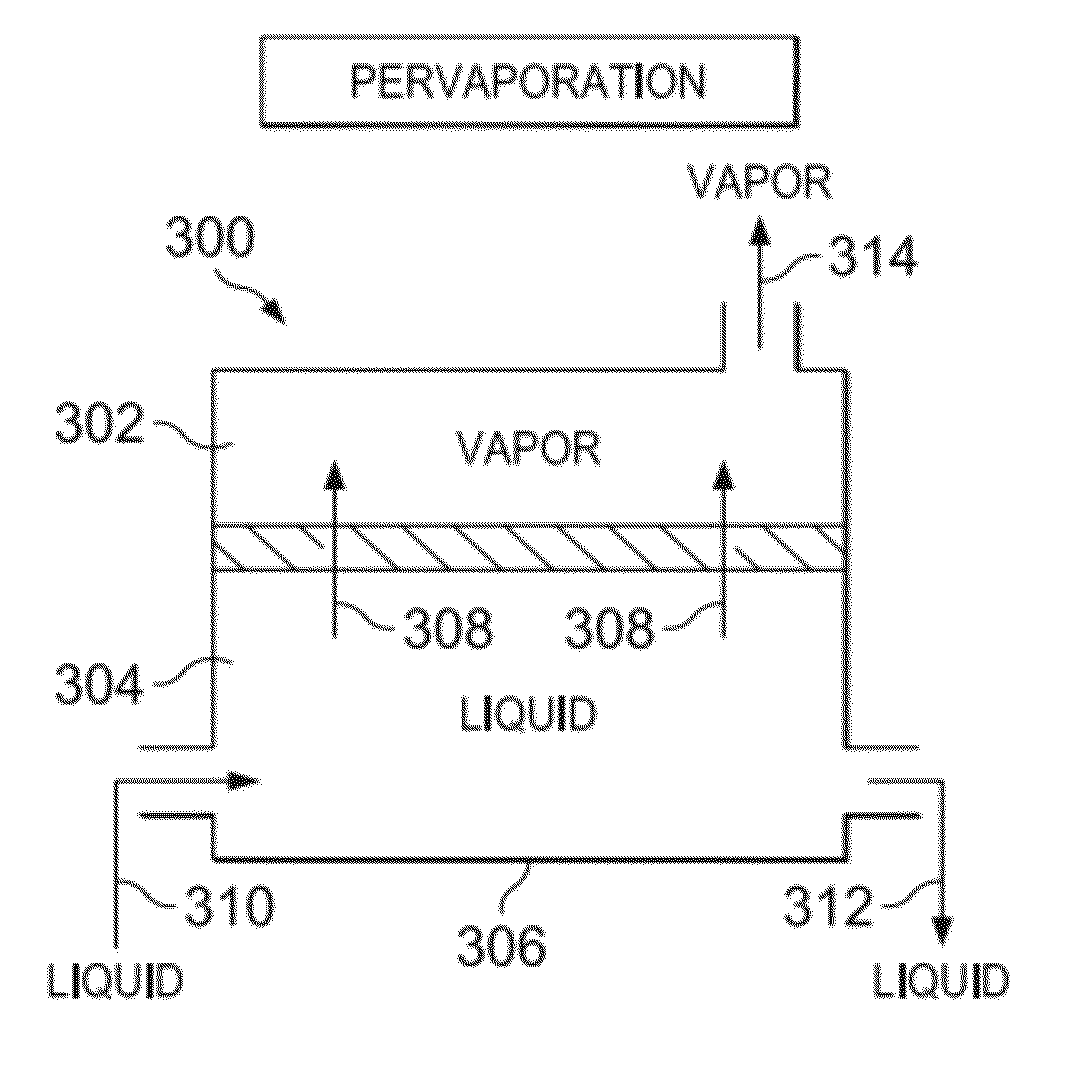

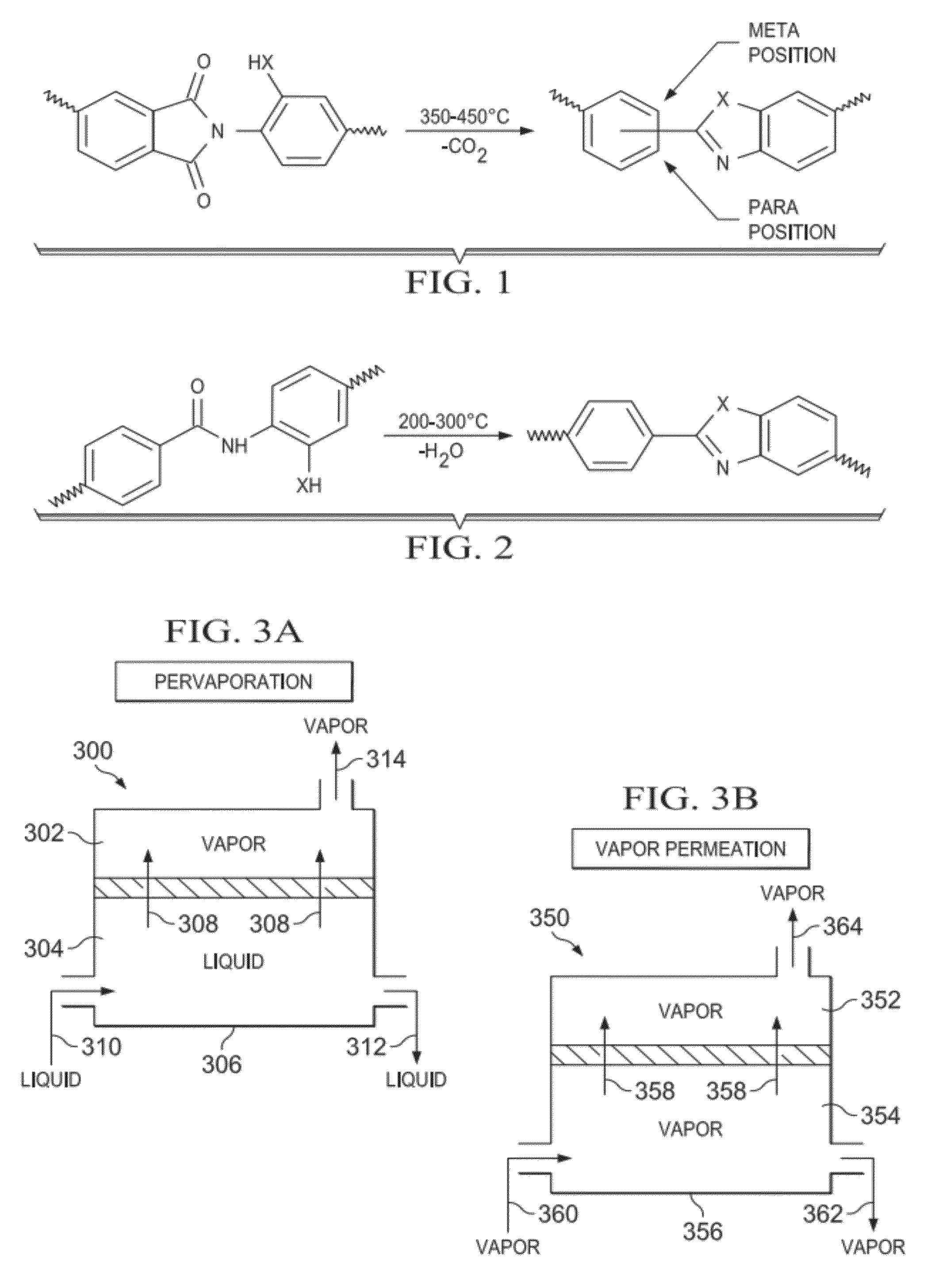

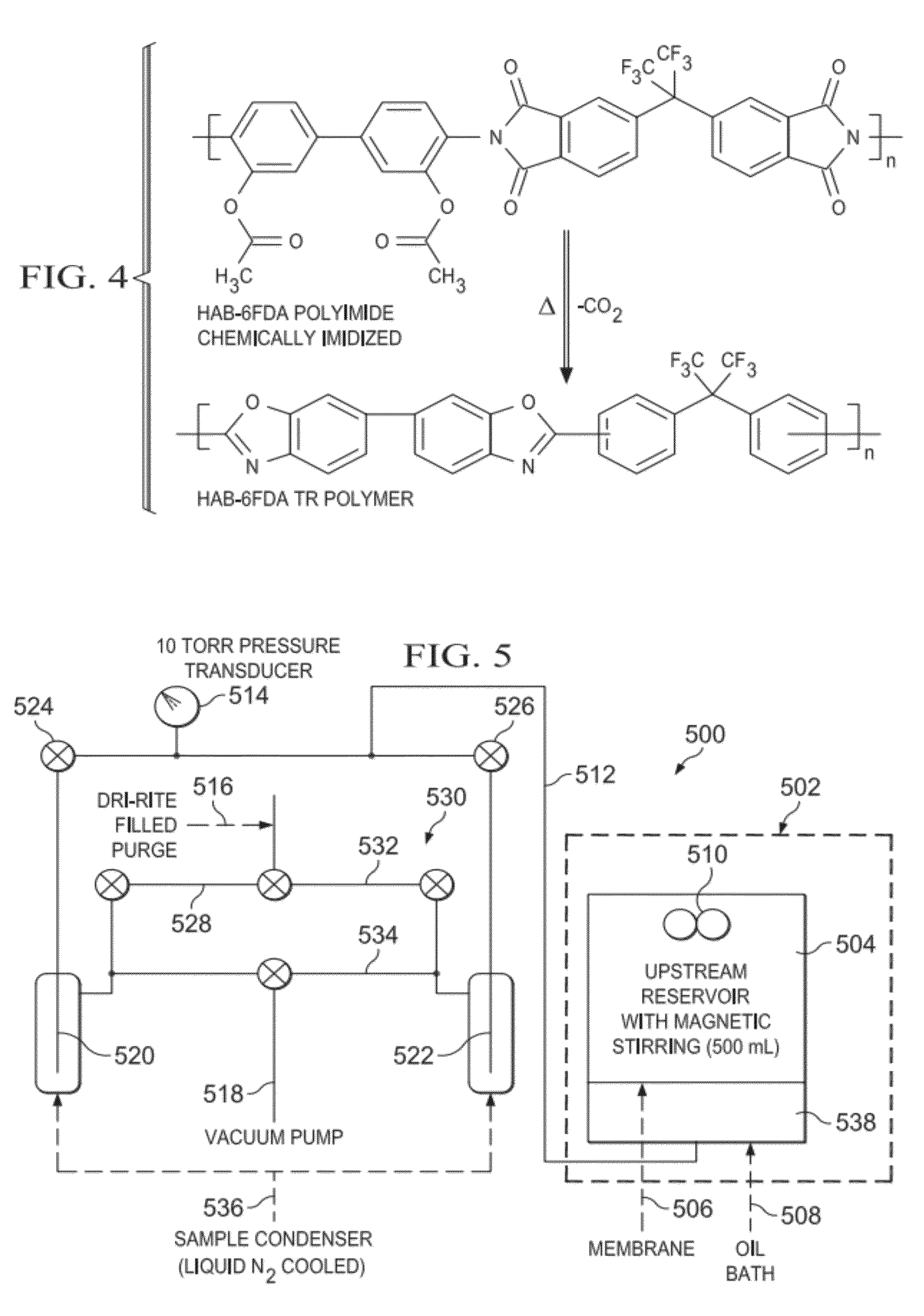

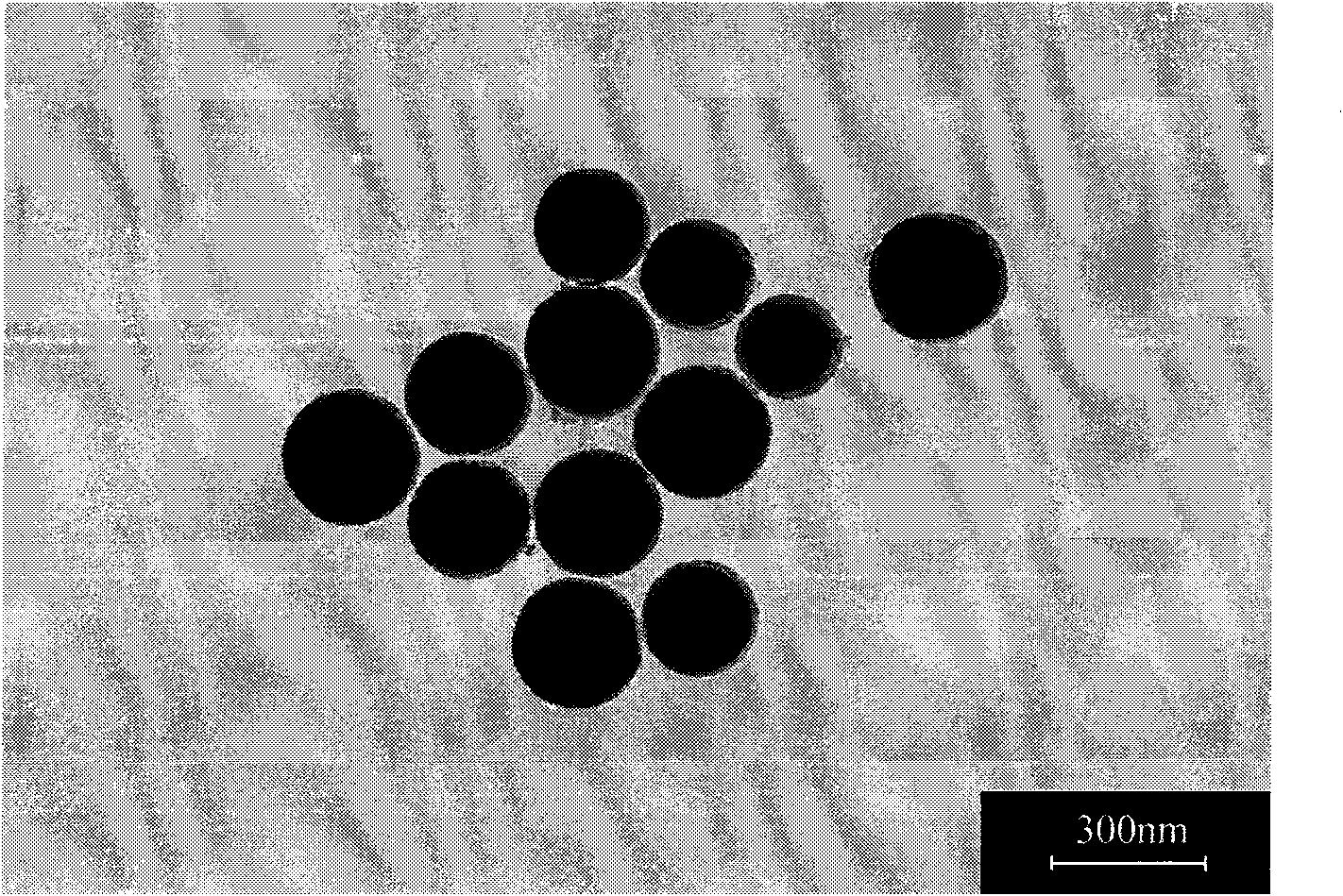

Thermally Rearranged (TR) Polymers as Membranes for Ethanol Dehydration

InactiveUS20120305484A1Improved separation propertiesGood chemical stabilityDewatering/demulsification with mechanical meansSolid sorbent liquid separationBiodieselOrganic solvent

Synthesis and use of a new class of polymeric materials with favorable separation characteristics for the dehydration of ethanol and other organic solvents is described herein. The thermally rearranged (TR) polybenzoxazole (PBO), polybenzimidazole (PBI) and polybenzothiazole (PBT) membranes of the present invention can be used for the dehydration of ethanol during processing to fuel grade biodiesel by either pervaporation or vapor permeation. The unique microstructure of the membranes provides excellent separation characteristics, and this, coupled with their inherent thermal and chemical stability, enables their usage in other separations, such as the dehydration of other organic solvents.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

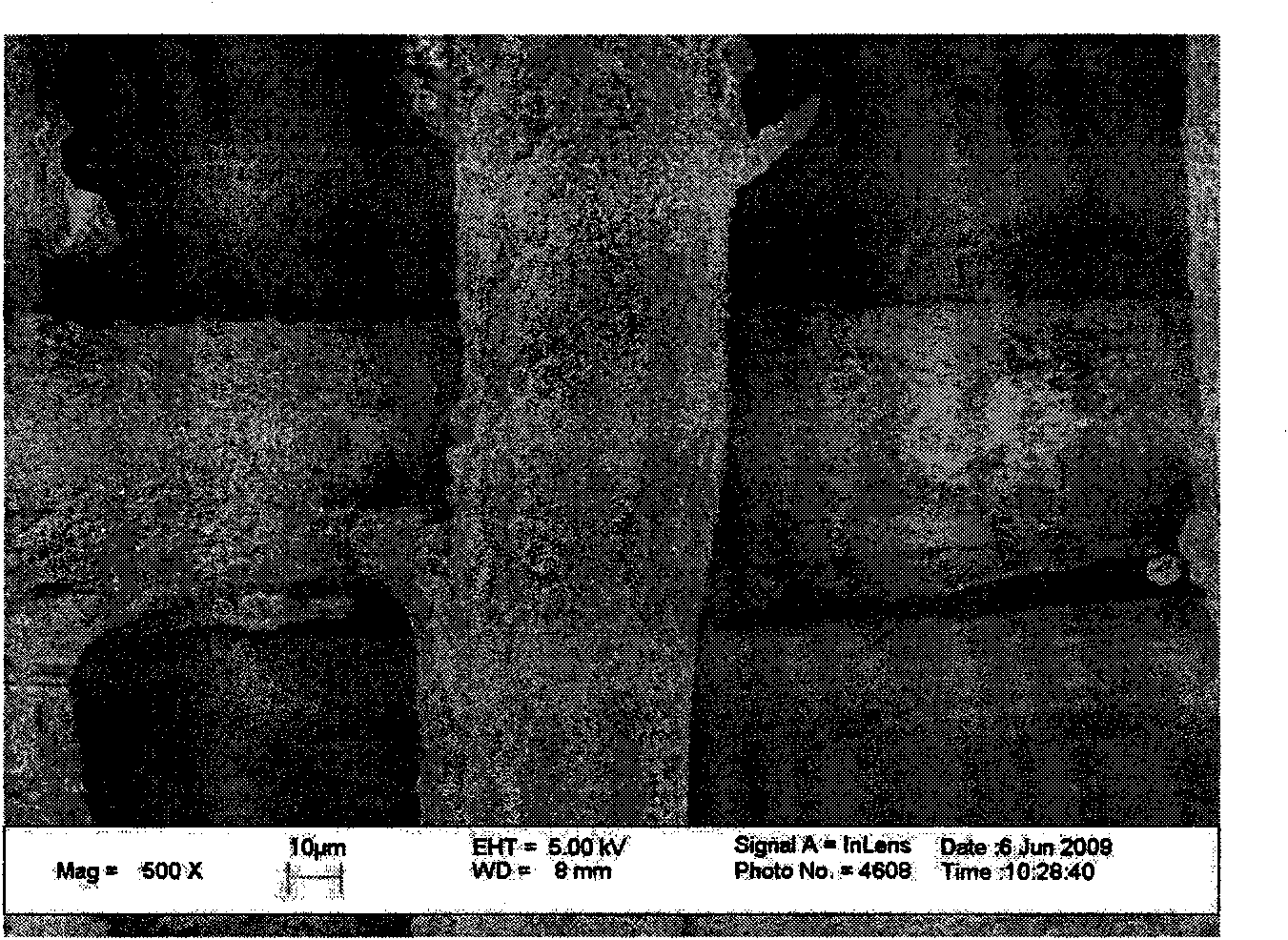

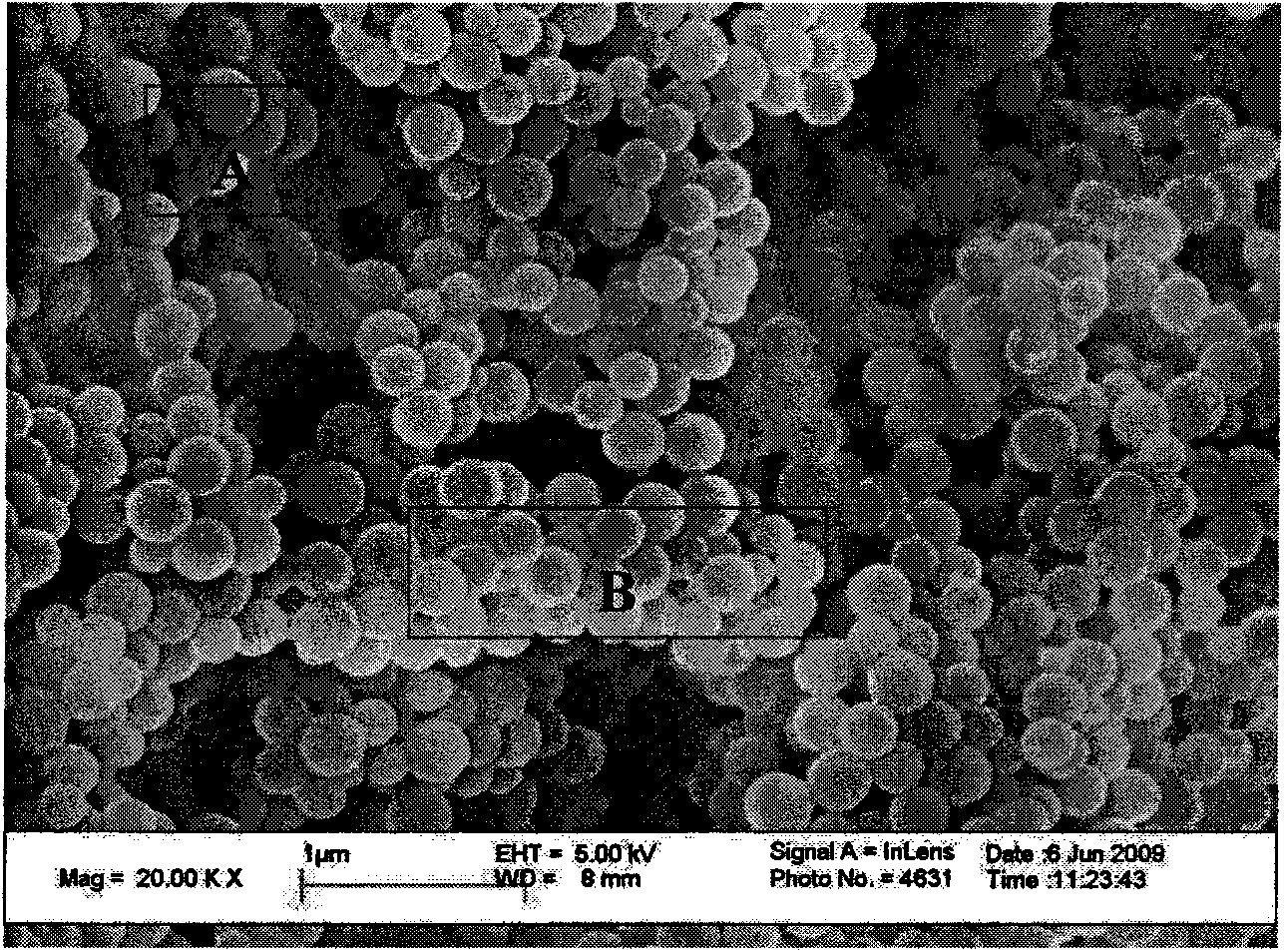

Lyophobic and oleophylic micro nano-coatings applied to of oil filtering dehydration and preparation method thereof

InactiveCN101601940AImprove hydrophobicityAvoid oleophobic effectDewatering/demulsification with mechanical meansFiltration separationMicro nanoFiltration

The invention discloses Lyophobic and oleophylic micro nano-coatings applied to oil filtering dehydration and a preparation method thereof. Base material of the coatings is metal mesh grid with 50-1800 meshes, the surface of the metal mesh grid is coated with a layer of dense micro nano-coating which is dense thin film composed of nano silica global particles with partical size ranging from 90nm to 500nm.In the method of the invention, the sol-gel method is adopted, tetraethyl ester serves as the precursor, ammonia water serves as the catalyst, ethanol serves as the solvent, alkyl oxosilane serves as lyophobic modifier, the method of hydrolytie polycondensation is adopted to obtain lyophobic nano silica sol, the process of impregnation or spraying is adopted to coat the gel on the metal mesh grid with 50-1800 meshes, after thermal treatment, oil-water separation net with lyophobic and oleophylic properties is obtained. The method of the invention features simple process, no harm to the environment, no need of fluorine material, wide application to coalescing separator as a separation filter element and the function of filtration and dehydration of oil.

Owner:SOUTH CHINA UNIV OF TECH

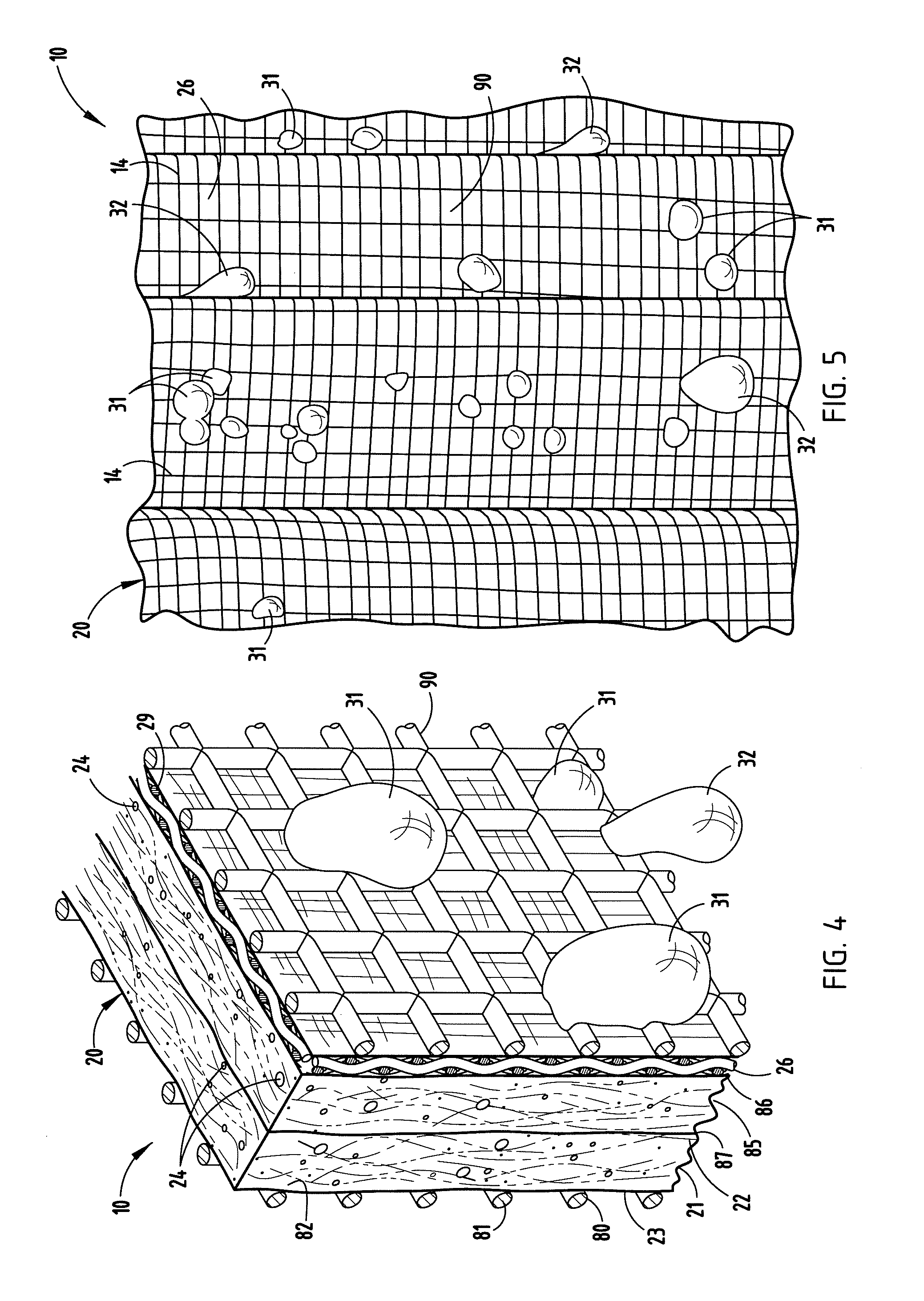

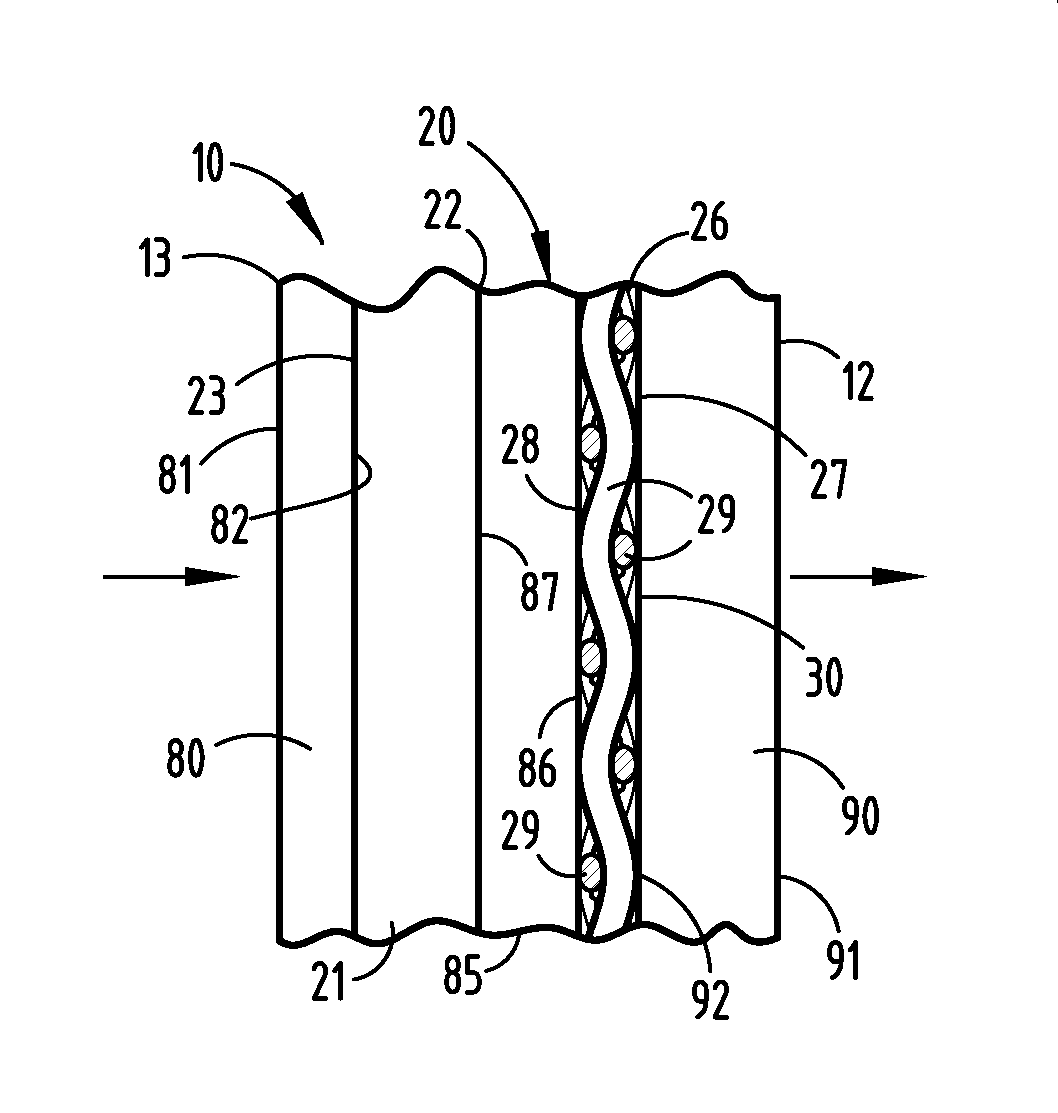

Apparatus and method for removing contaminants from industrial fluids

InactiveUS20110259796A1Efficiently and effectively removedReduce manufacturing costSemi-permeable membranesDewatering/demulsification with mechanical meansFilter systemEngineering

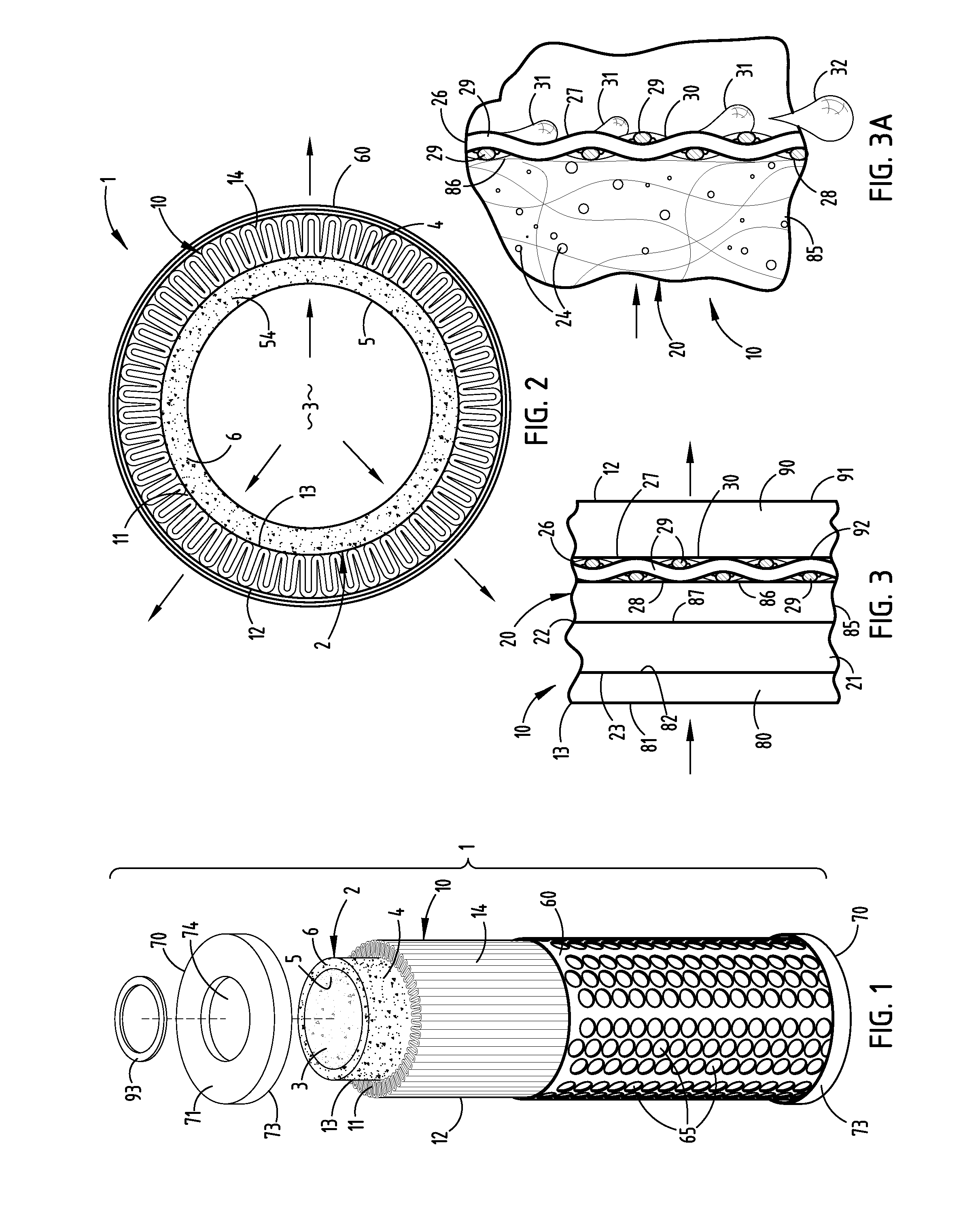

A filter system for removing contaminants from oil based industrial liquids and the like includes a support tube with a permeable sidewall through which the industrial liquid flows in an inside out direction. A multilayer coalescence media surrounds the support tube, and includes at least one layer of a non-woven fibrous material that is partially wettable by the dispersed water in the industrial liquid, and commences coalescence of the same to form small primary water droplets, and at least one sheet of a precisely woven monofilament fabric stacked on the downstream side of the non-woven material. The woven fabric is substantially wettable by the dispersed water, and has a fixed open mesh with uniformly sized and spaced apart pore openings which continue to coalesce the primary water droplets into large water drops which fall from the filter for collection along the bottom of the apparatus.

Owner:KAYDON CUSTOM FILTRATION CORP

Apparatus and method for removing contaminants from industrial fluid

InactiveUS20140034580A1Efficiently and effectively removedReduce manufacturing costDewatering/demulsification with mechanical meansWater/sewage treatmentFilter systemEnvironmental engineering

A filter system for removing contaminants from oil based industrial liquids and the like includes a support tube with a permeable sidewall through which the industrial liquid flows in an inside out direction. A multilayer coalescence media surrounds the support tube, and includes at least one layer of a non-woven fibrous material that is partially wettable by the dispersed water in the industrial liquid, and commences coalescence of the same to form small primary water droplets, and at least one sheet of a precisely woven monofilament fabric stacked on the downstream side of the non-woven material. The woven fabric is substantially wettable by the dispersed water, and has a fixed open mesh with uniformly sized and spaced apart pore openings which continue to coalesce the primary water droplets into large water drops which fall from the filter for collection along the bottom of the apparatus.

Owner:KAYDON CUSTOM FILTRATION CORP

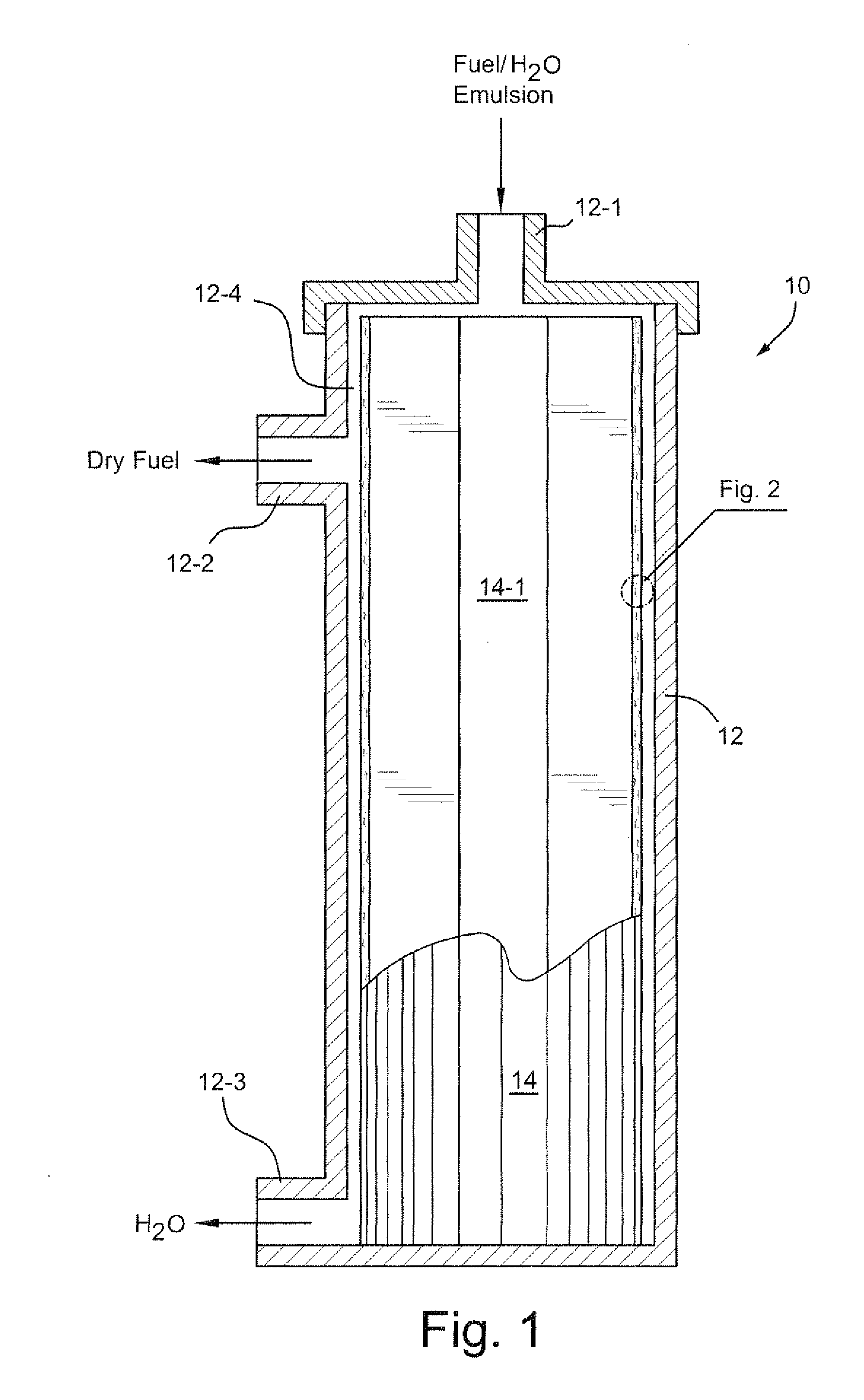

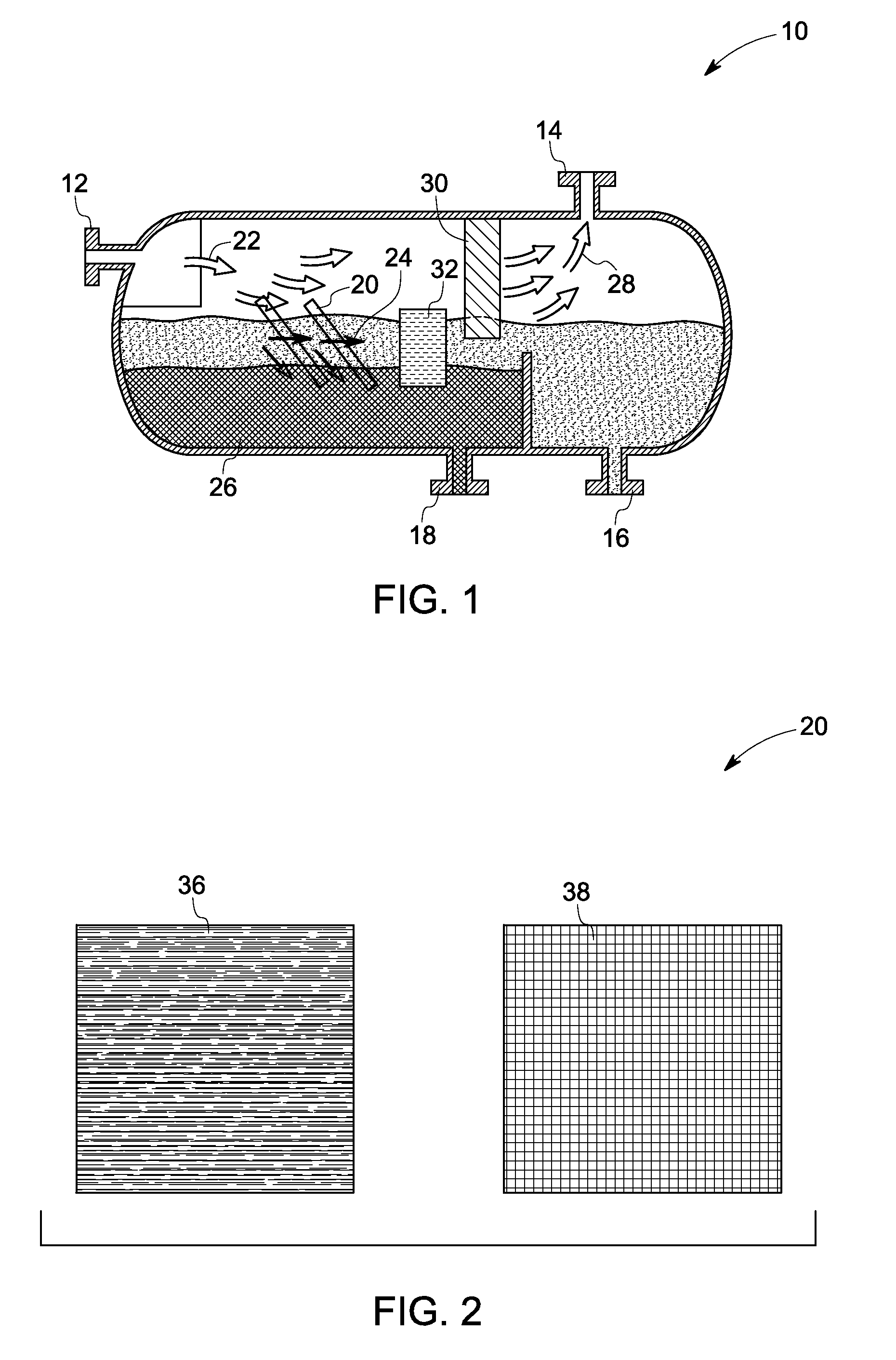

Oil water separation apparatus

InactiveUS20100326922A1Dewatering/demulsification with chemical meansLiquid degasificationOcean bottomOil water

In one aspect, the present invention provides a subsea separation vessel for the separation of a mixture comprising oil and water comprising (a) at least one inlet for introducing a oil-water mixture; (b) a flow path for conducting the oil-water mixture; (c) at least one oil-water separation structure; and (d) at least one fluid outlet. The oil-water separation structure includes a multifunctional surface. The oil-water separation structure is located within the flow path and wherein the multifunctional surface is superhydrophobic with respect to water, and either oleophilic or superoleophilic with respect to oil. A method for separating oil from an oil-water mixture is also provided.

Owner:GENERAL ELECTRIC CO

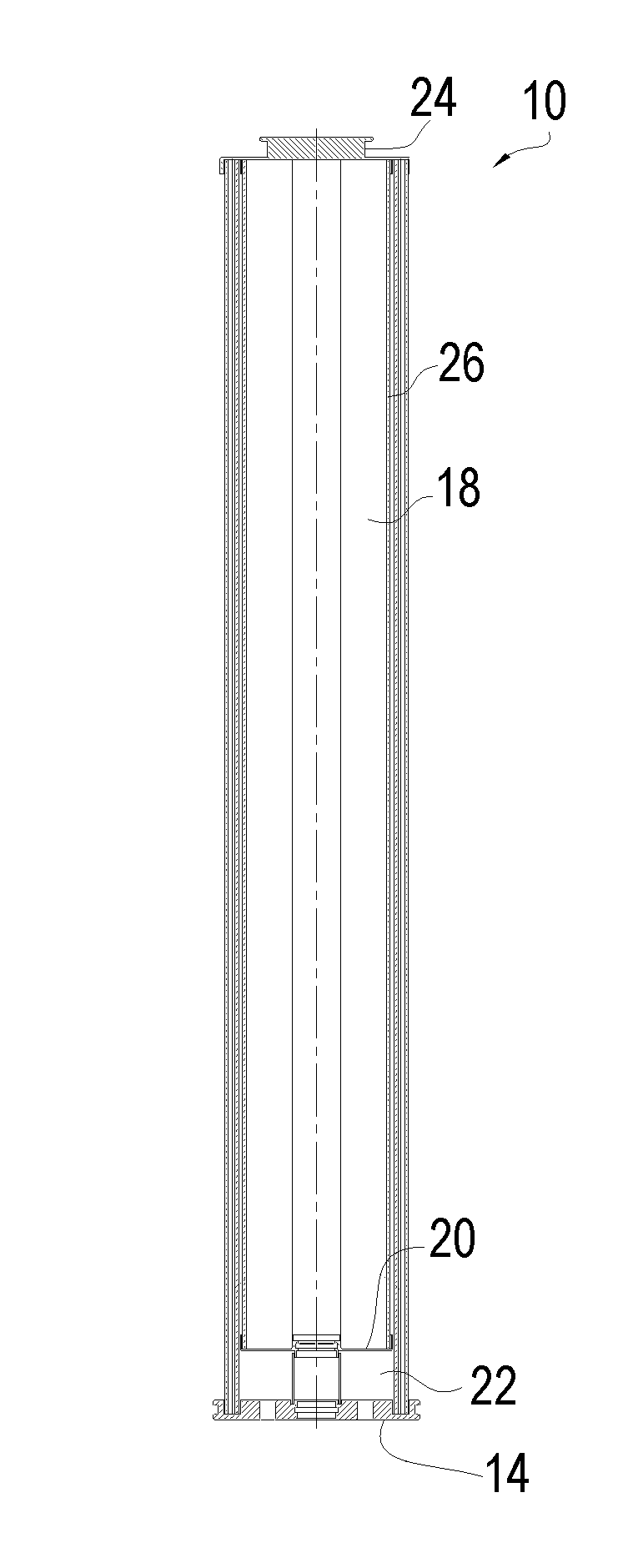

Deep dehydrating method and device for oil product

ActiveCN103980934APlay a role in demulsificationPlay a role in coalescenceFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiberMicrowave

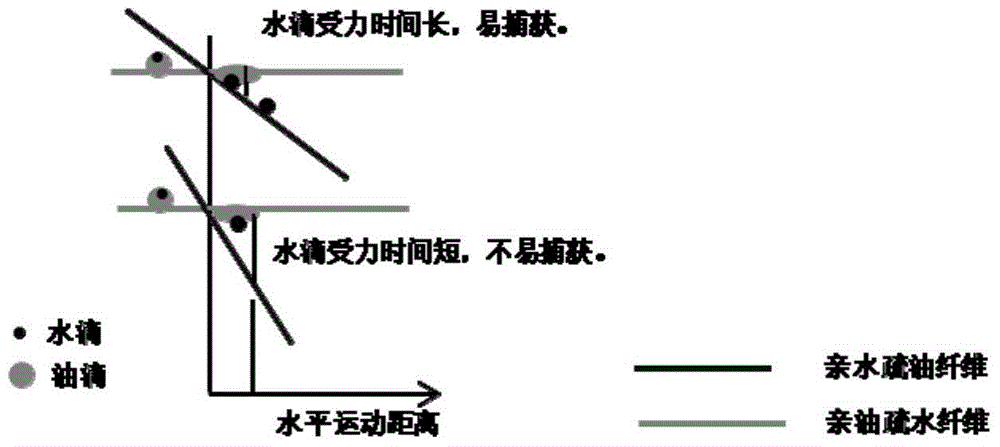

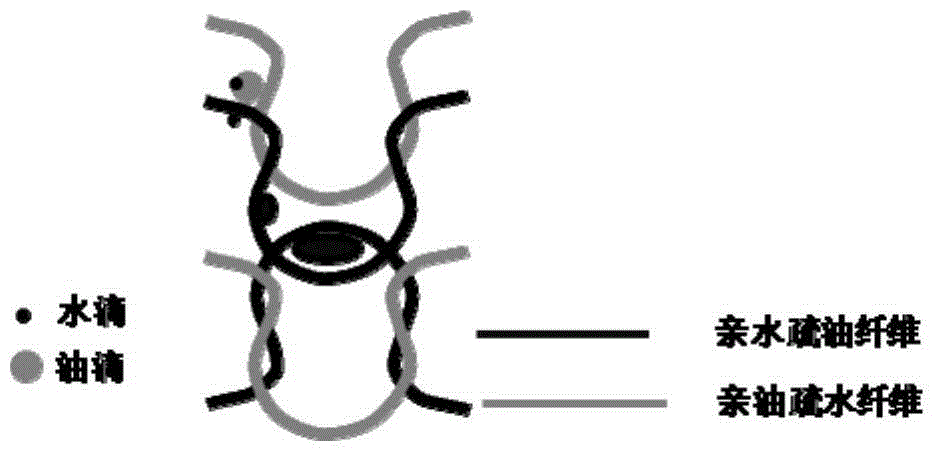

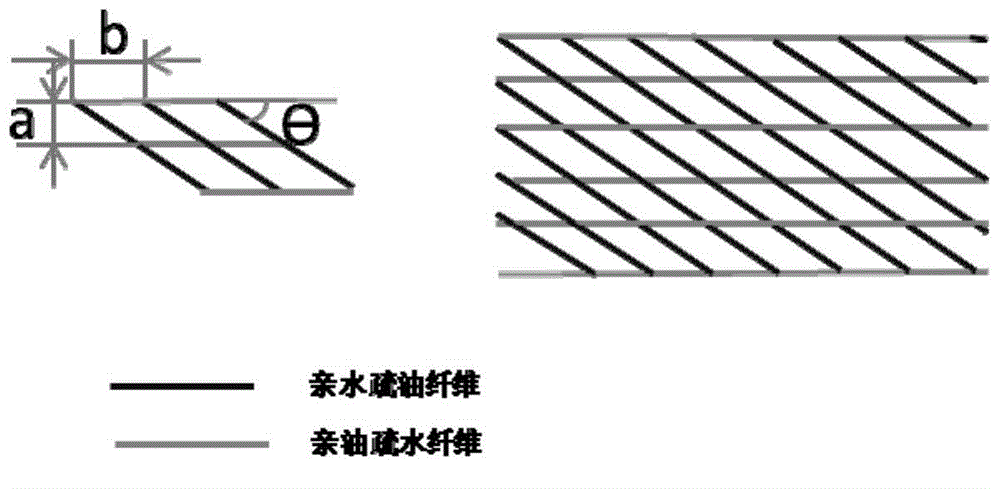

The invention relates to a deep dehydrating method and device for an oil product. The deep dehydrating method for the oil product comprises the steps of firstly, enabling the oil product with trace water to pass through a rectifier to ensure that a fluid is uniform; secondly, realizing the capture, agglomeration and growth of trace water drops and demulsification and separation of a trace water-in-oil emulsion through one or more segments of X-shaped oleophylic / lyophobic and hydrophilic / oleophobic fiber braid layers; next, realizing the rapid agglomeration, growth and separation of the water drops through microwave-forced settlement separation; finally, realizing the capture and separation of the extremely trace water drops in the oil product through one segment of omega-shaped oleophylic / lyophobic and hydrophilic / oleophobic fiber braid layer, thereby realizing the deep dehydration of the oil product. The invention also provides a set of device for realizing the method. The device comprises a shell, a feeding pipe, a rectifier, a fiber agglomeration layer, a microwave forced separation layer, a liquid level meter and other parts. The method is high in separation efficiency, low in energy consumption and long in continuous operation period, and can be widely applied to the deep dehydrating processes of all oil products with trace water.

Owner:EAST CHINA UNIV OF SCI & TECH

Method and apparatus using super absorbent polymers for dehydration of oil

InactiveUS7033493B2Dewatering/demulsification with mechanical meansLiquid suspension thickening by filtrationEmulsionSuper absorbent

Water is separated from an emulsion of water and oil by passing the emulsion through a bed of superabsorbent polymer granules which break the emulsion and absorb water from the mixture of water and oil. An apparatus for separating water from an emulsion of water and oil has at least one separation cell containing a bed of super absorbent polymer granules.

Owner:STOCKHAUSEN GMBH & CO KG DEGUSSA-HUELS AKTIENGESE

Asphalt mastic utilizing petroleum refinery waste solids

InactiveUS7025822B2Easy to useImprove utilizationDewatering/demulsification with mechanical meansHydrocarbon oils refiningEmulsionAsphalt mastic

An asphalt mastic is prepared by combining comminuted waste solids from a petroleum refinery with liquid asphalt that is either a hot asphalt or an asphalt emulsion. The resulting composition is similar in performance to Trinidad Lake Asphalt and is useful either on its own or as a binder for asphalt-aggregate compositions, in both cases optionally in combination with polymeric additives that are common in the asphalt industry.

Owner:SIERRA PROCESS SYST A CORP OF THE STATE OF CALIFORNIA

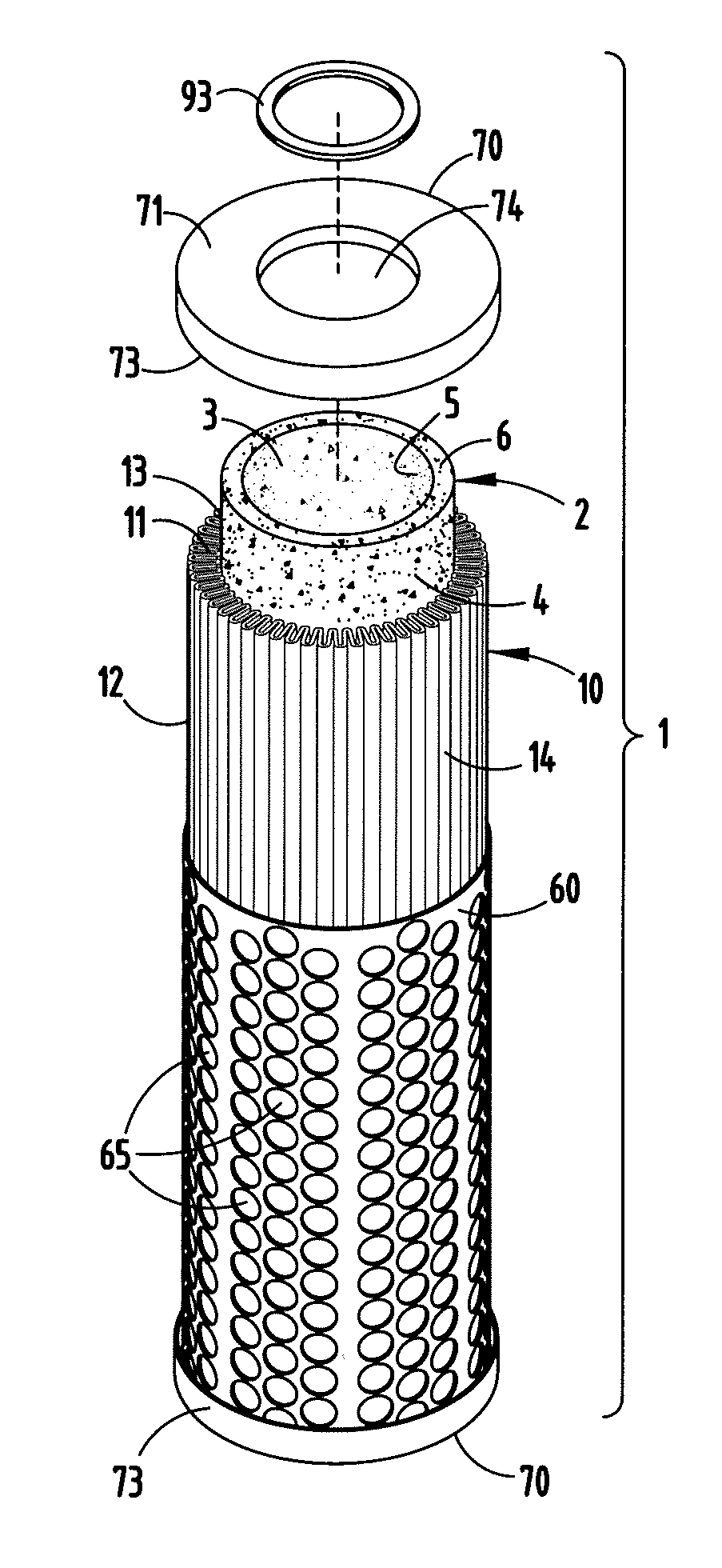

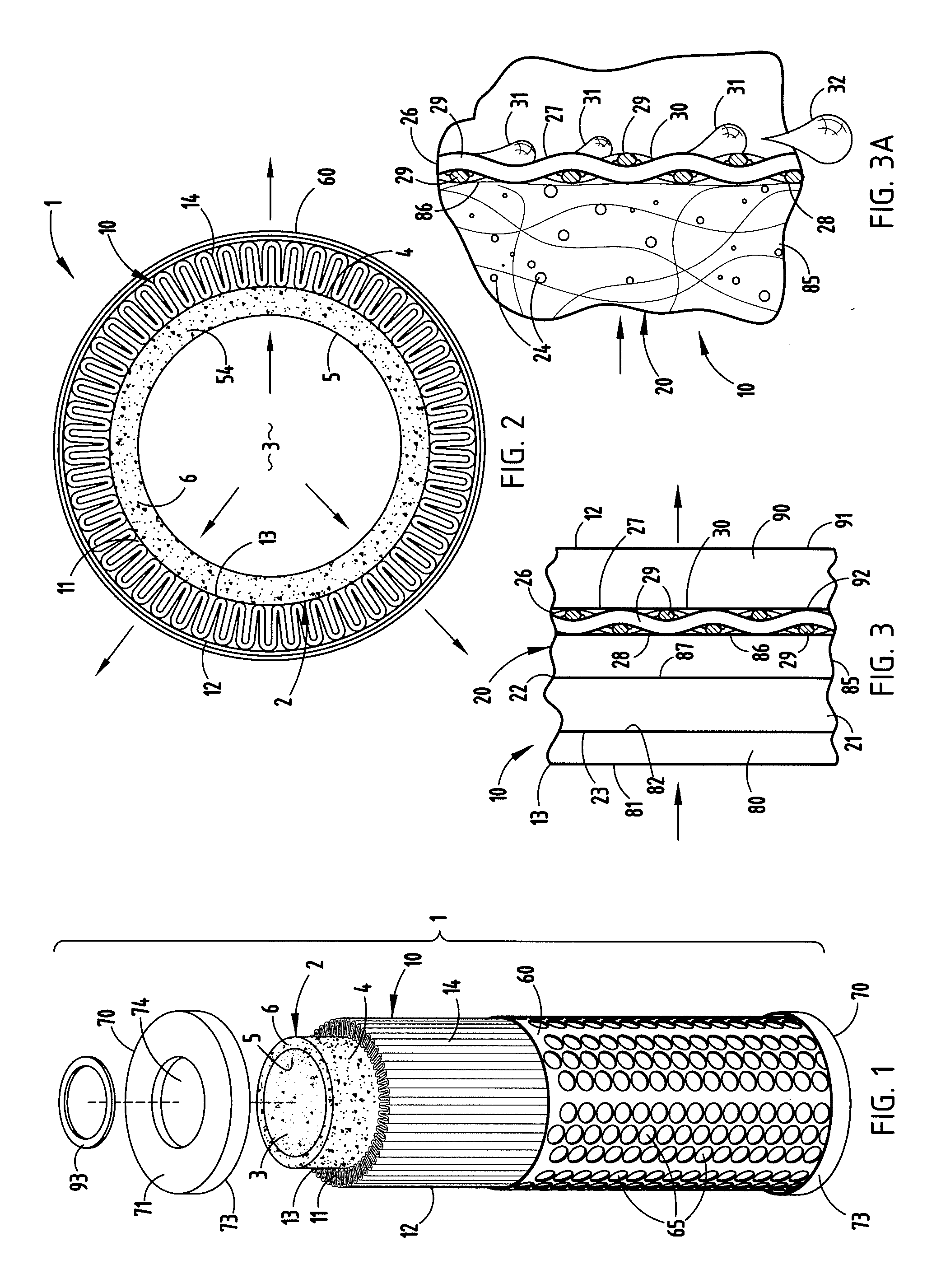

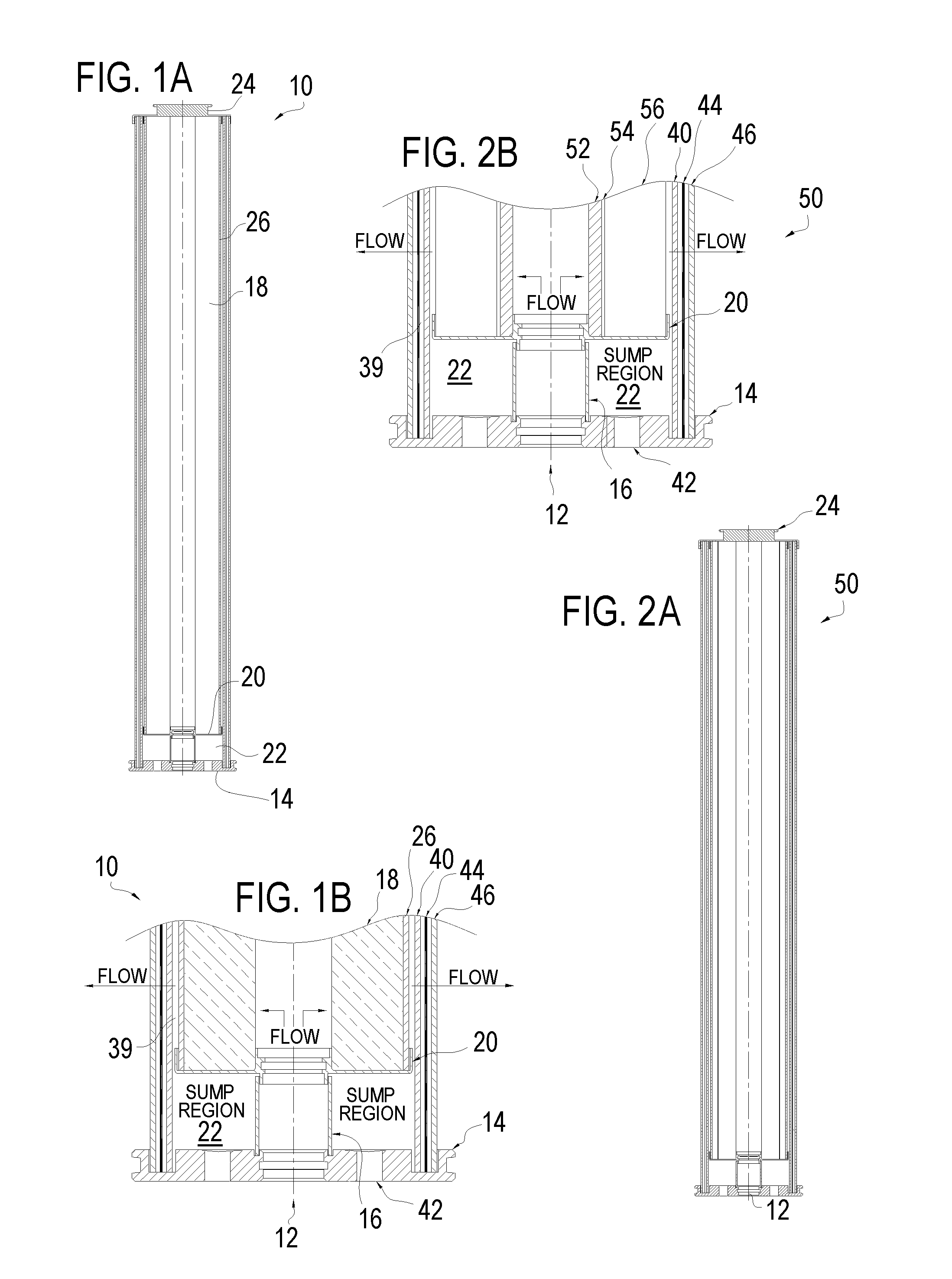

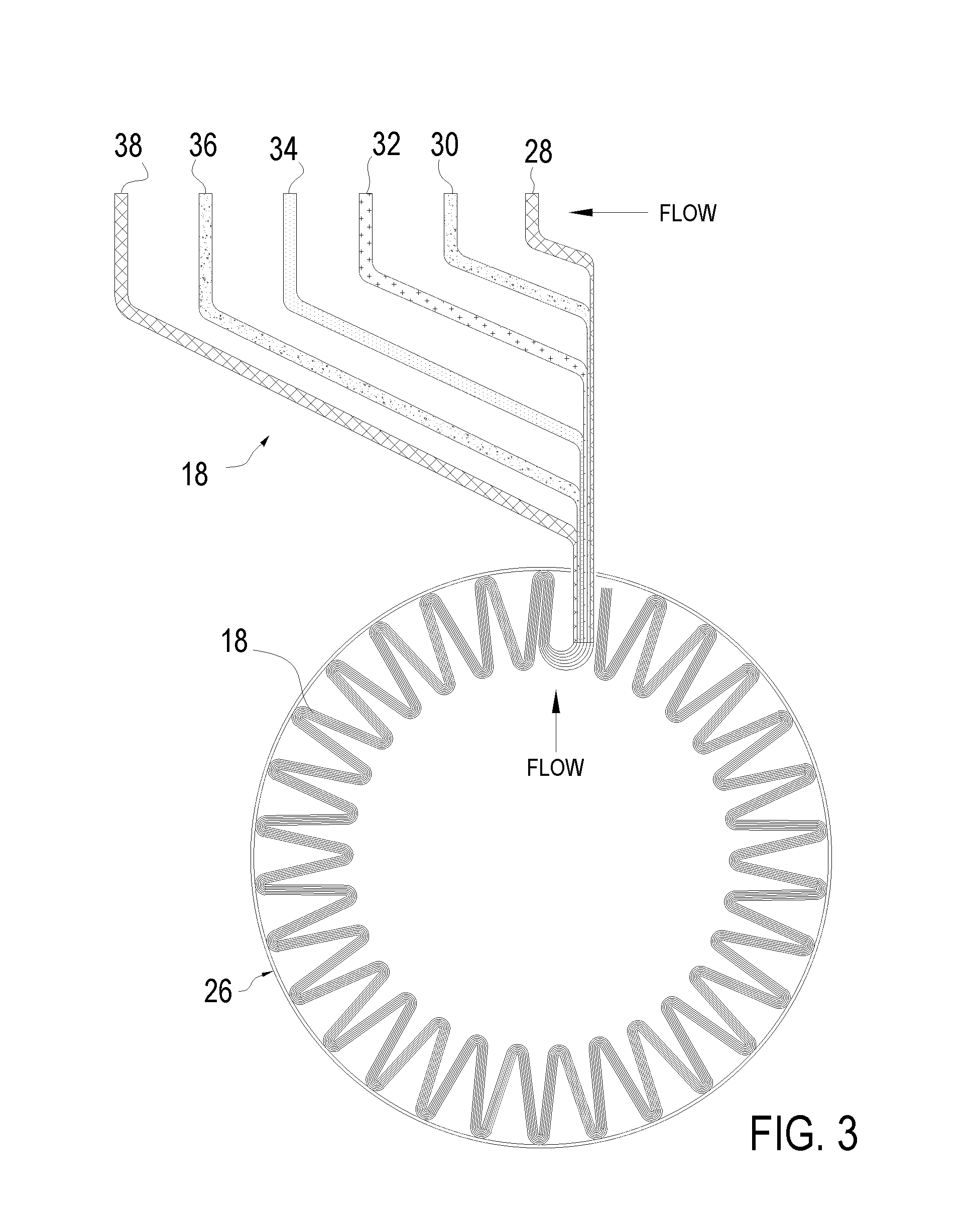

Coalescing filter element and filter assembly therefore

ActiveUS20140311963A1Efficient and cost-effectiveDewatering/demulsification with mechanical meansSeparation devicesParticulatesFiltration

A coalescing filter element provides an integrated filter element with a three stage design with a hydrophobic or hydrophilic coalescing layer. A coalescing filter element comprises: a) At least one particulate filtration layer; b) A coalescing layer promoting coalescing of water particles, wherein the coalescing layer is downstream of the at least one particulate filtration layer relative to the flow of fluid through the element; c) An annular coalescing space downstream of the coalescing layer; d) A sump in a lower portion of the filter element in fluid communication with the annular coalescing space; and e) A hydrophobic layer downstream of the annular coalescing space, wherein fluid being cleaned by the element flows through the hydrophobic layer. The coalescing layer may be a hydrophobic or a hydrophilic coalescing layer. A filter assembly will include the coalescing filter element of the present invention.

Owner:SCHROEDER INDS L L C

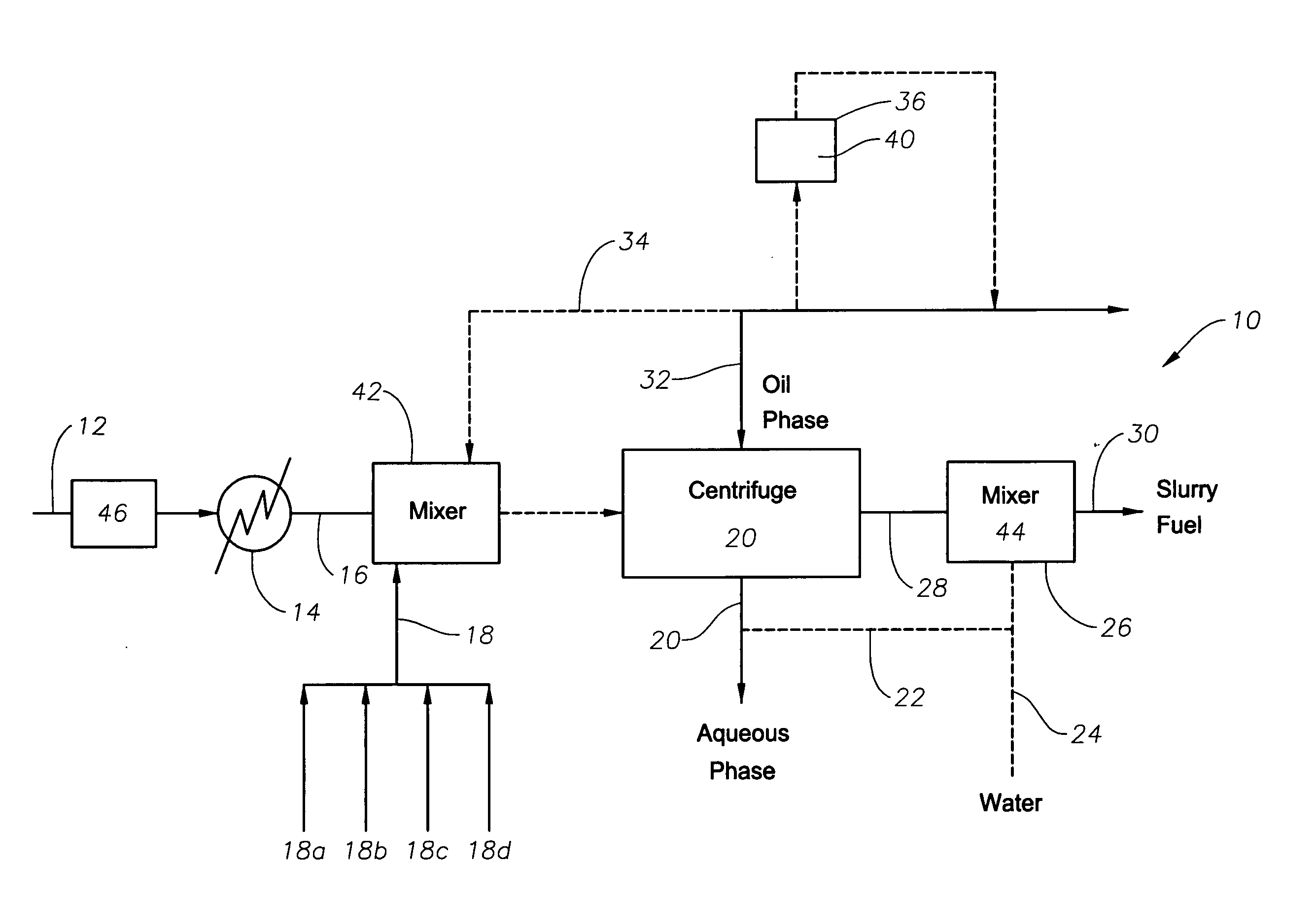

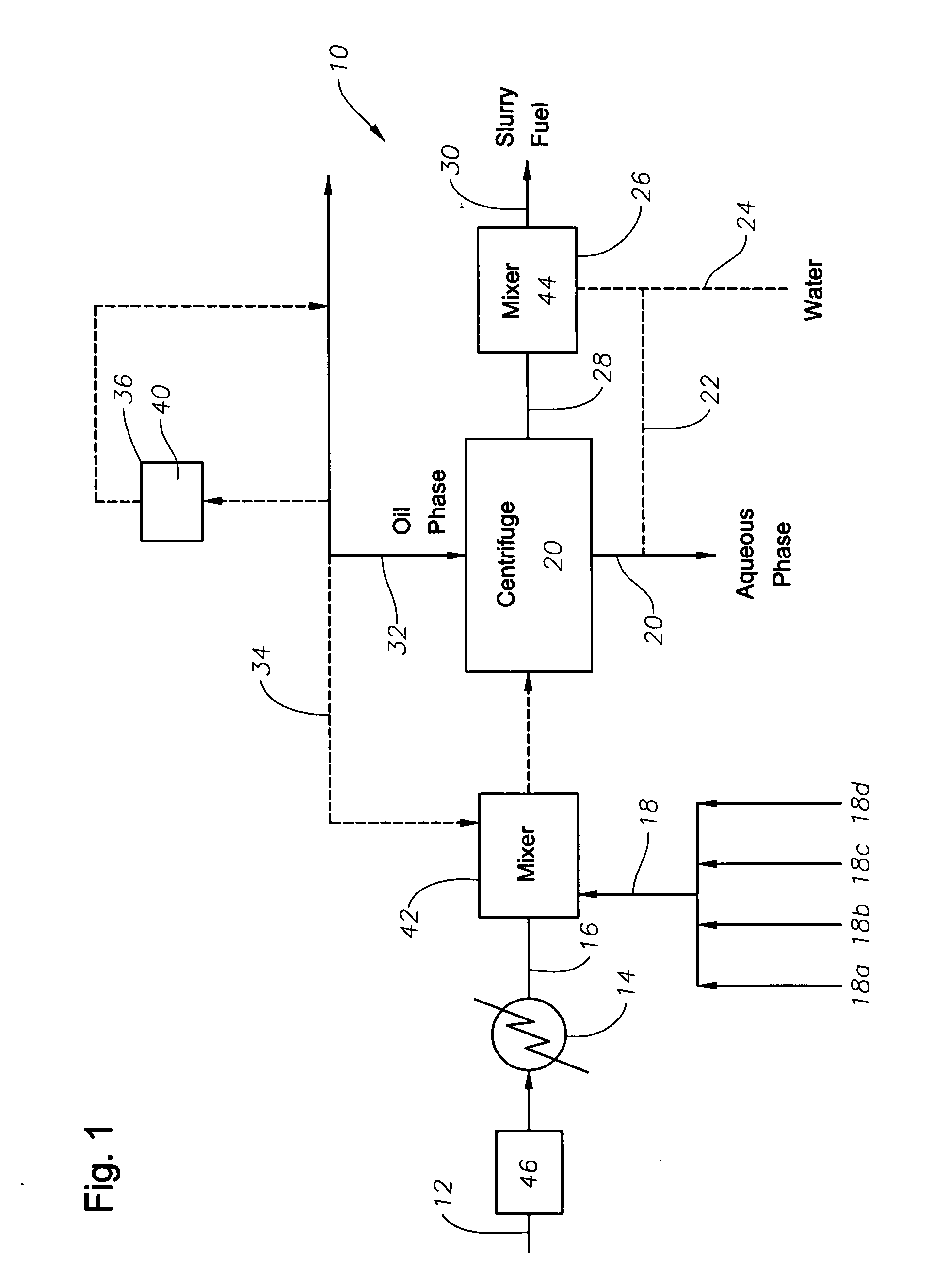

Method for utilizing hydrocarbon waste materials as fuel and feedstock

ActiveUS20060070912A1Low costDewatering/demulsification with mechanical meansRefining by heating/coolingFiberCarbon fibers

The fuel properties of petroleum hydrocarbon waste having an API gravity varying from about 5 to 30 are improved by heating the hydrocarbon to a temperature of about 35° C. to 90° C. and mixing the heated hydrocarbon stream with a suitable solvent to reduce the viscosity of the hydrocarbon, which is then separated by a centrifuge to obtain an aqueous phase stream, an oil phase stream, and a separated solids stream. The oil phase stream has a viscosity range of about 250 centipoise (cP) to about 1000 cP. The oil phase stream is utilized in a refinery, while a slurry fuel is prepared with the separated solids stream and aqueous phase stream as a feedstock for road asphalt, a fuel for a combustor, or a fuel for a gasification process. The oil phase stream is used for fuels and feedstock for making carbon fiber.

Owner:SAUDI ARABIAN OIL CO

Asphalt mastic utilizing petroleum refinery waste solids

InactiveUS20050241529A1Wide rangeEasy to useDewatering/demulsification with mechanical meansCoatingsBitumen emulsionAsphalt mastic

An asphalt mastic is prepared by combining comminuted waste solids from a petroleum refinery with liquid asphalt that is either a hot asphalt or an asphalt emulsion. The resulting composition is similar in performance to Trinidad Lake Asphalt and is useful either on its own or as a binder for asphalt-aggregate compositions, in both cases optionally in combination with polymeric additives that are common in the asphalt industry.

Owner:SIERRA PROCESS SYST A CORP OF THE STATE OF CALIFORNIA

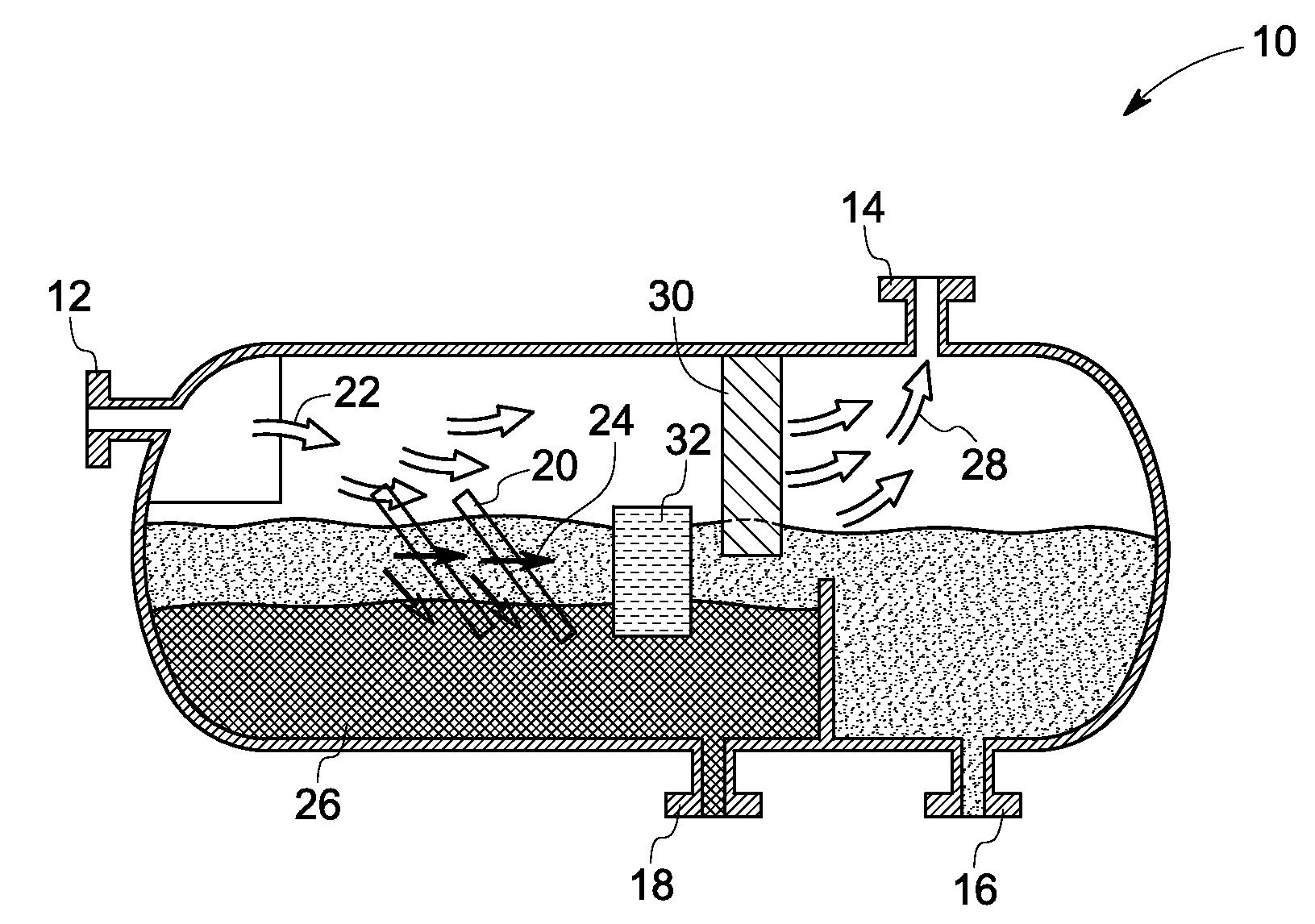

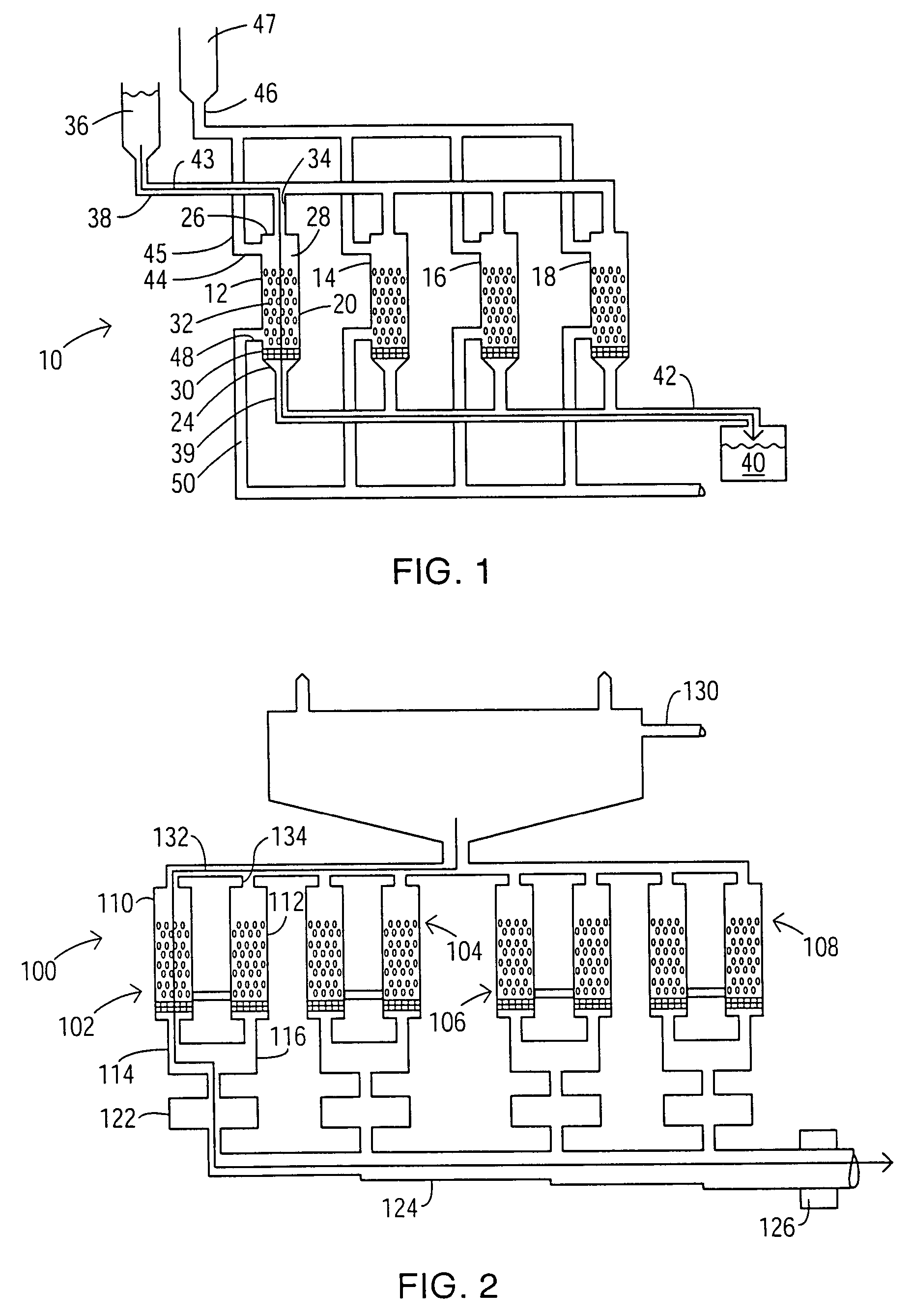

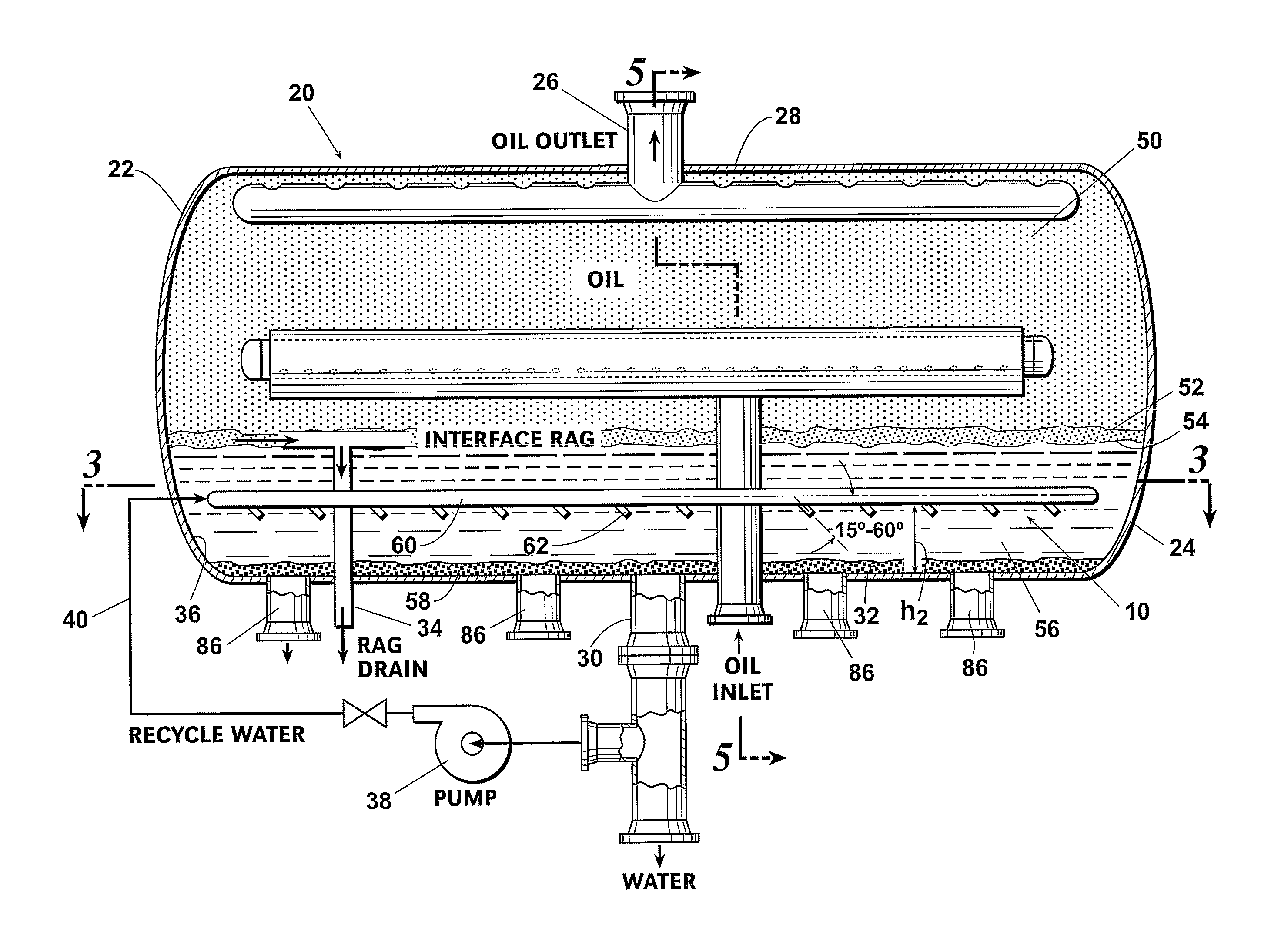

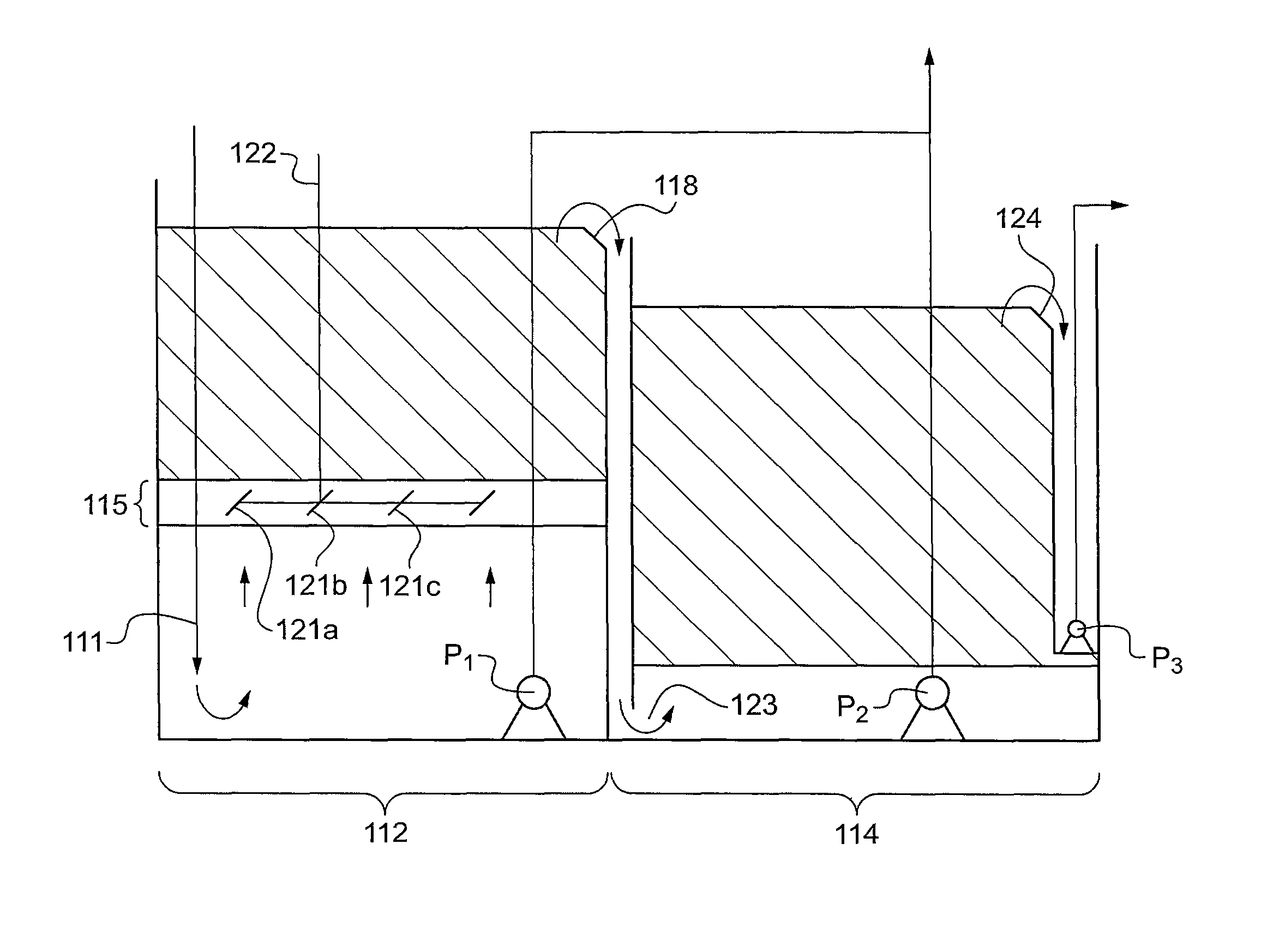

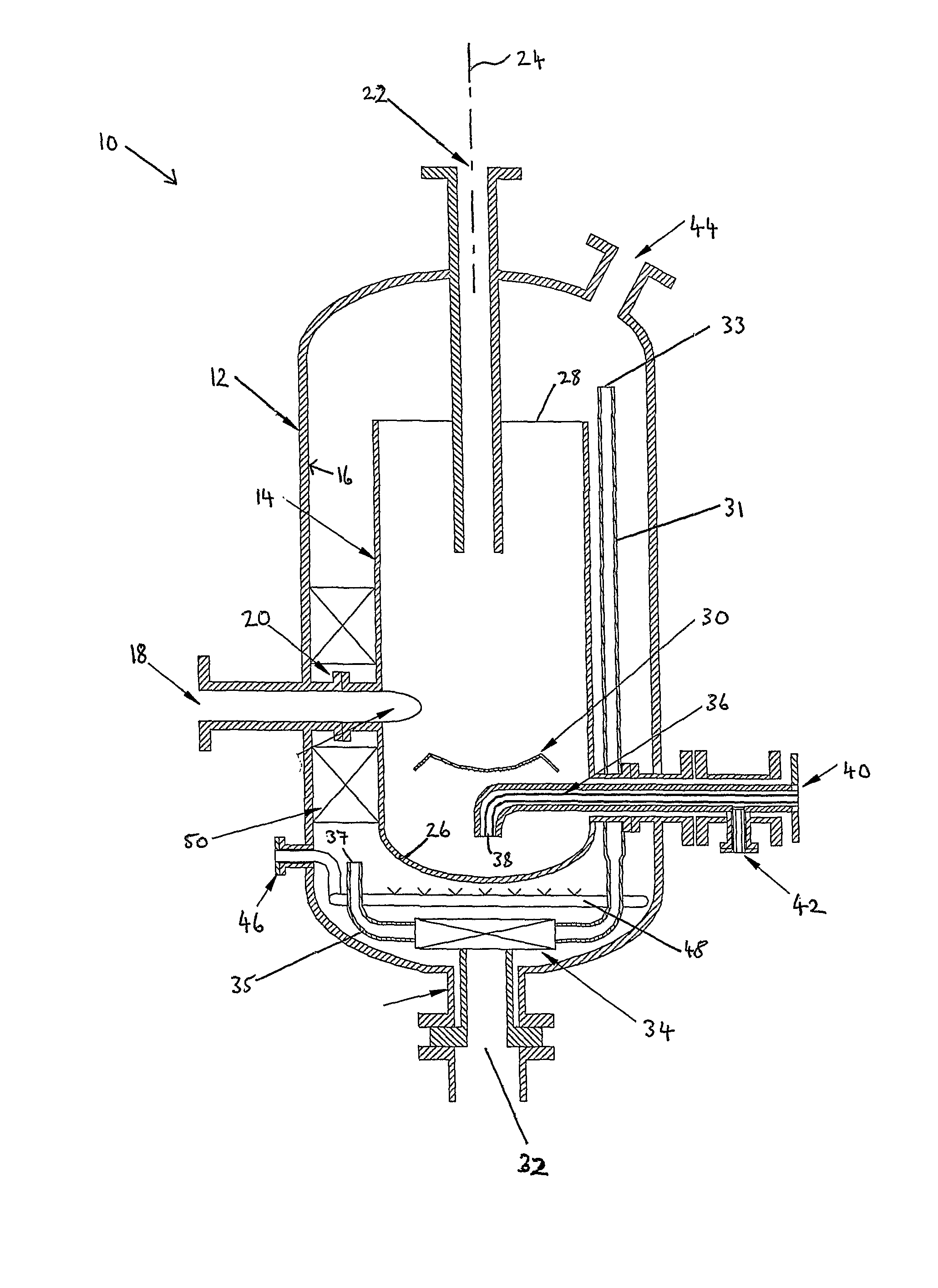

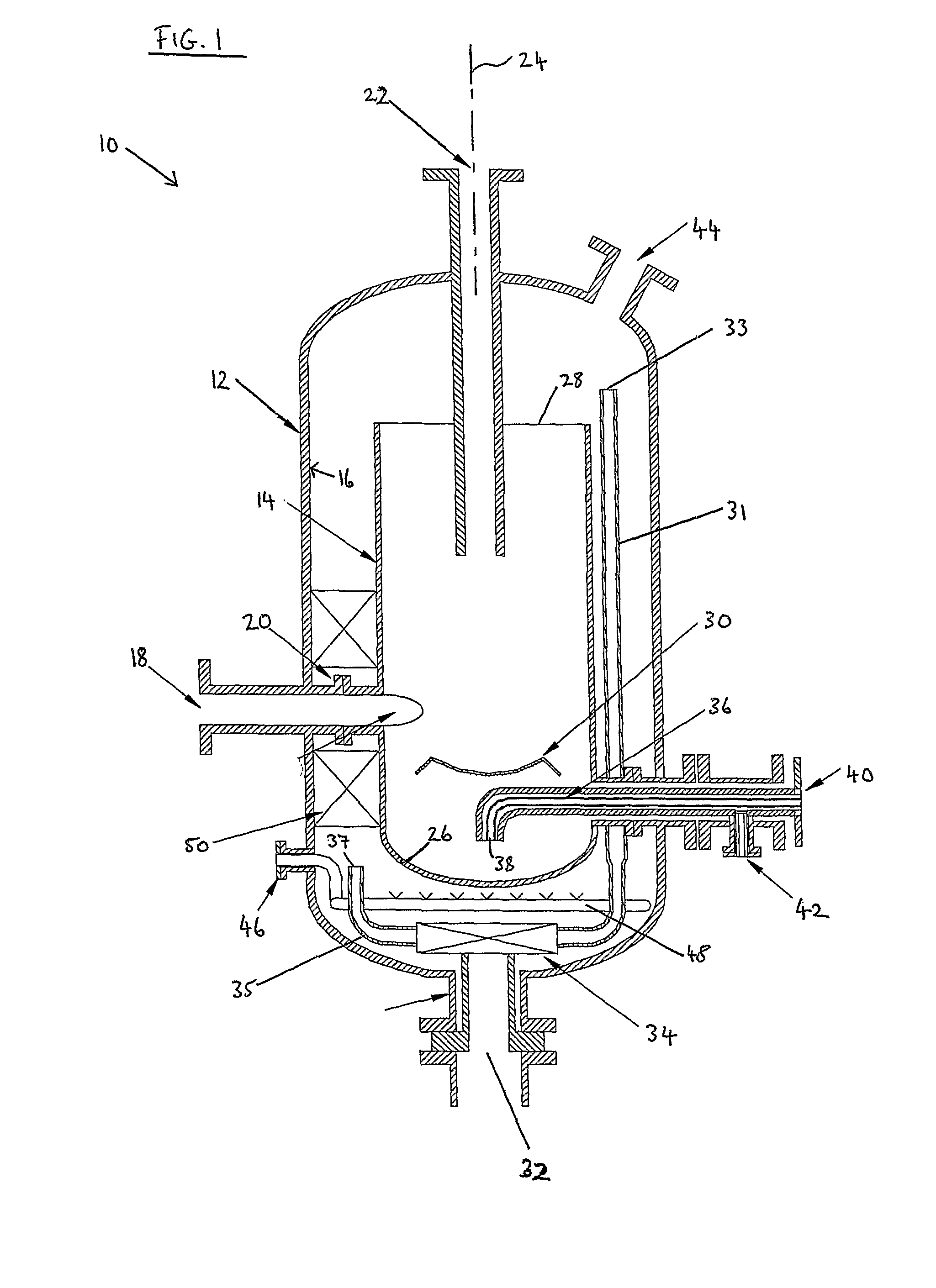

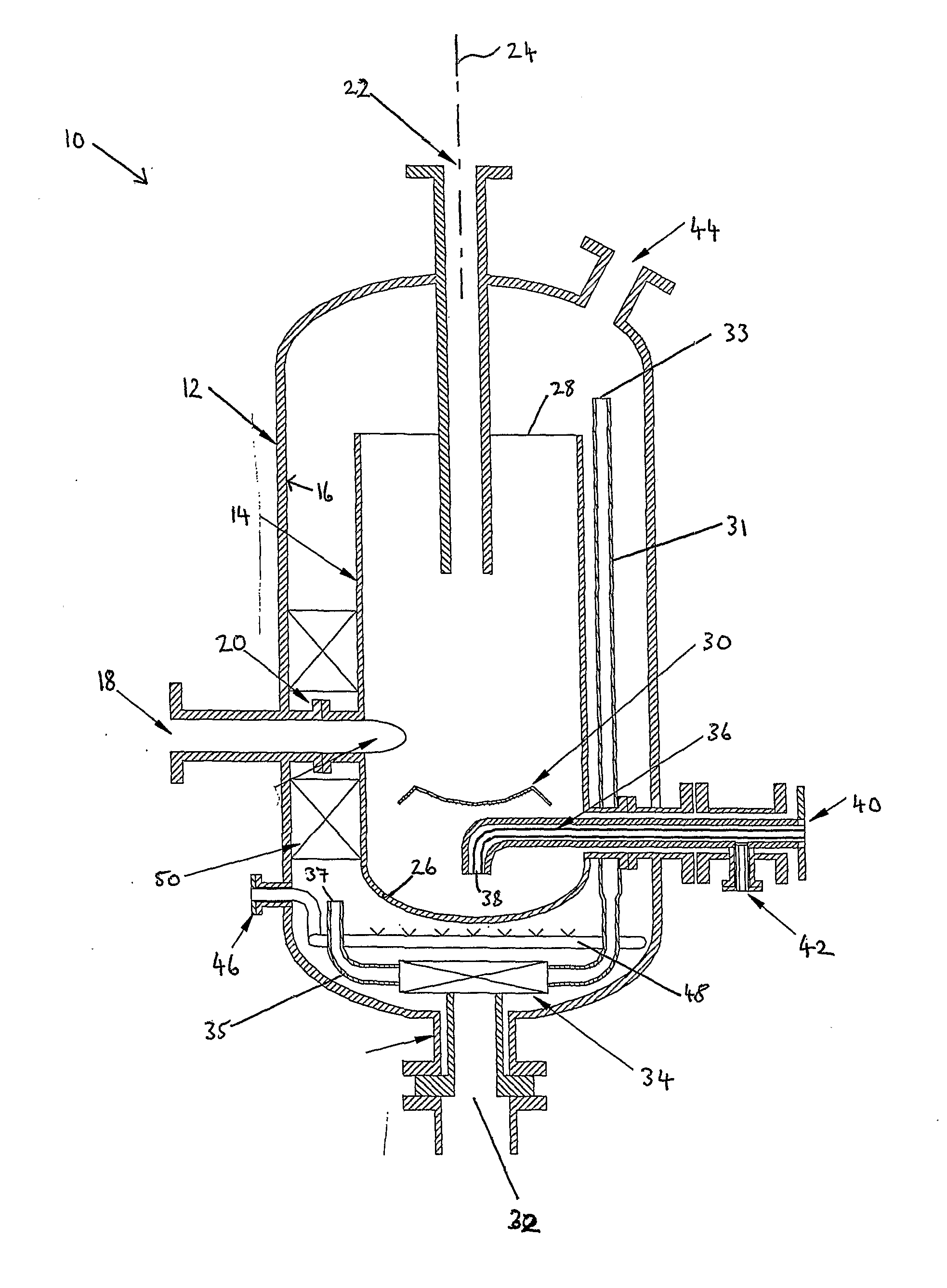

Interface and Mud Control System and Method for Refinery Desalters

ActiveUS20130083620A1Slow and continuous agitationLiquid separation auxillary apparatusDewatering/demulsification with mechanical meansVertical planeEngineering

A method and system for controlling an interface emulsion layer and mud layer within a desalter vessel includes injecting a water flow through a plurality of nozzles arranged about a piping circuit located in the brine water layer. Each nozzle is oriented toward an interior space of the desalter vessel and is arranged oblique to the piping circuit. The water flow through the plurality of nozzles causes a horizontal and vertical rotation of a volume of water that is effective for suspending solids in the water and promoting a collapse of the interface emulsion layer. The water flow through each nozzle, which may be a recycled water flow, is preferably in a range of 1 to 3 fpm and each nozzle is preferably oriented at an angle of about 15° and 60° in a horizontal plane and a downward angle of about 15° and 60° in a vertical plane.

Owner:CAMERSON INT CORP

Aged effluent oil treatment technology used for oil fields and oil refineries

InactiveCN103013557ASolving an intractable status quoImprove qualityDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansEngineeringOil water

The invention discloses an aged effluent oil treatment technology used for oil fields and oil refineries, which comprises the following steps of: tempering the effluent oil: adding hot water, an emulsion breaker and a cleaning agent in a modulating pot, stirring and heating, standing in the pot, and lifting and pumping from the bottom part to a solid-liquid separation sledge material filter; performing solid-liquid separation: heating the filtered oil water mixture and small particle solid impurities by using a material heater, entering the inlet of a horizontal spiral centrifuge, meanwhile, successively adding a flocculent according to flow, discharging aged oil solid impurity wastes from the solid outlet of the horizontal spiral centrifuge, collecting the separated out solid oil water mixture by a buffer pot, and lifting and pumping to an oil-water separation sledge material inlet by an oil water lifting pump; and performing oil-water separation: finally heating the oil water mixture in an oil water separating pot, standing, settling, entering the separated out crude oil in an oil chamber, and automatically pumping to a crude oil external transportation process by a purified oil lifting pump. By adoption of the treatment technology, the technical problem of difficulty in treating various aged effluent oils which are generated in production process of oil fields and are difficult to treat is likely to be solved.

Owner:北京惠博普能源技术有限责任公司

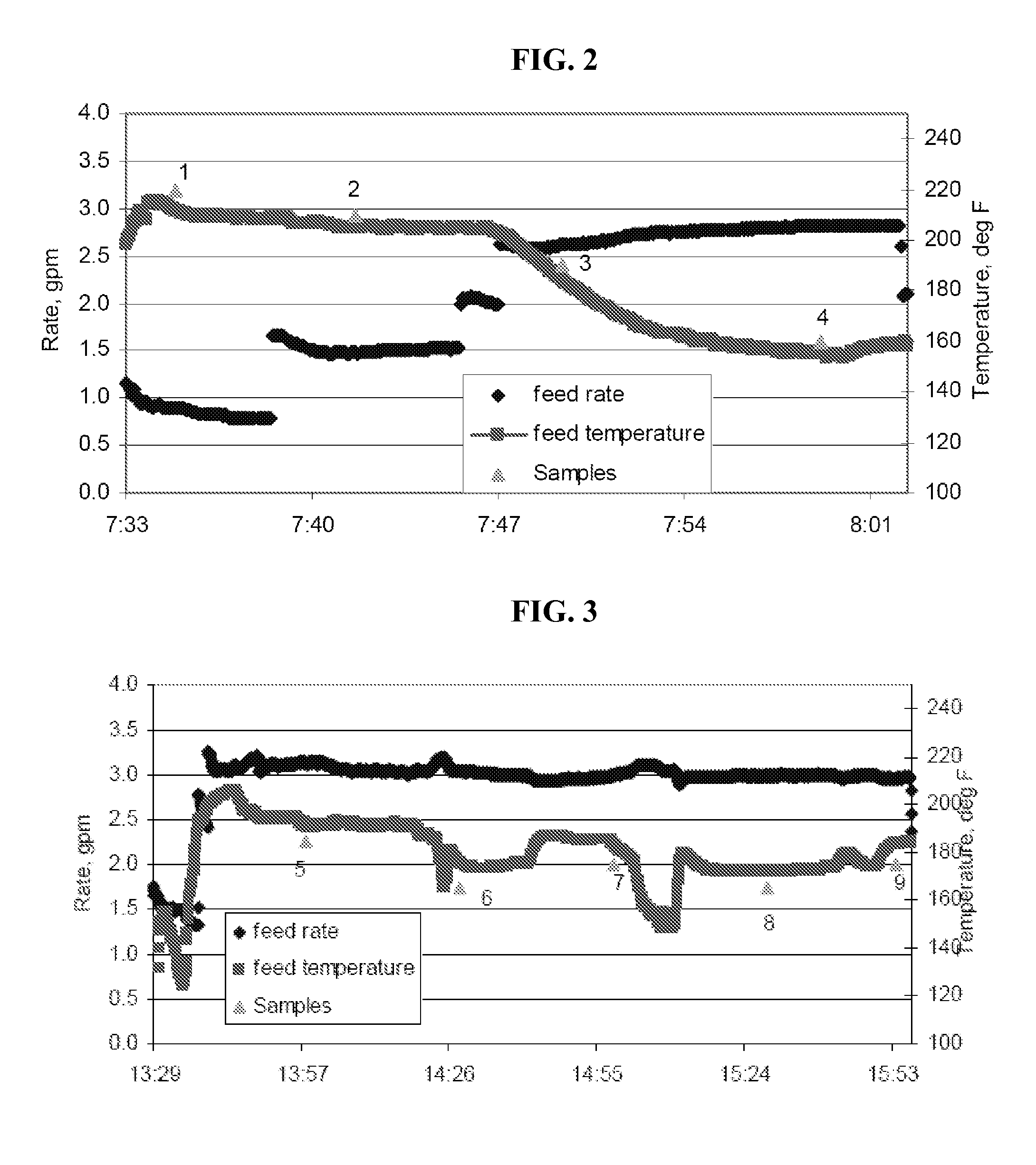

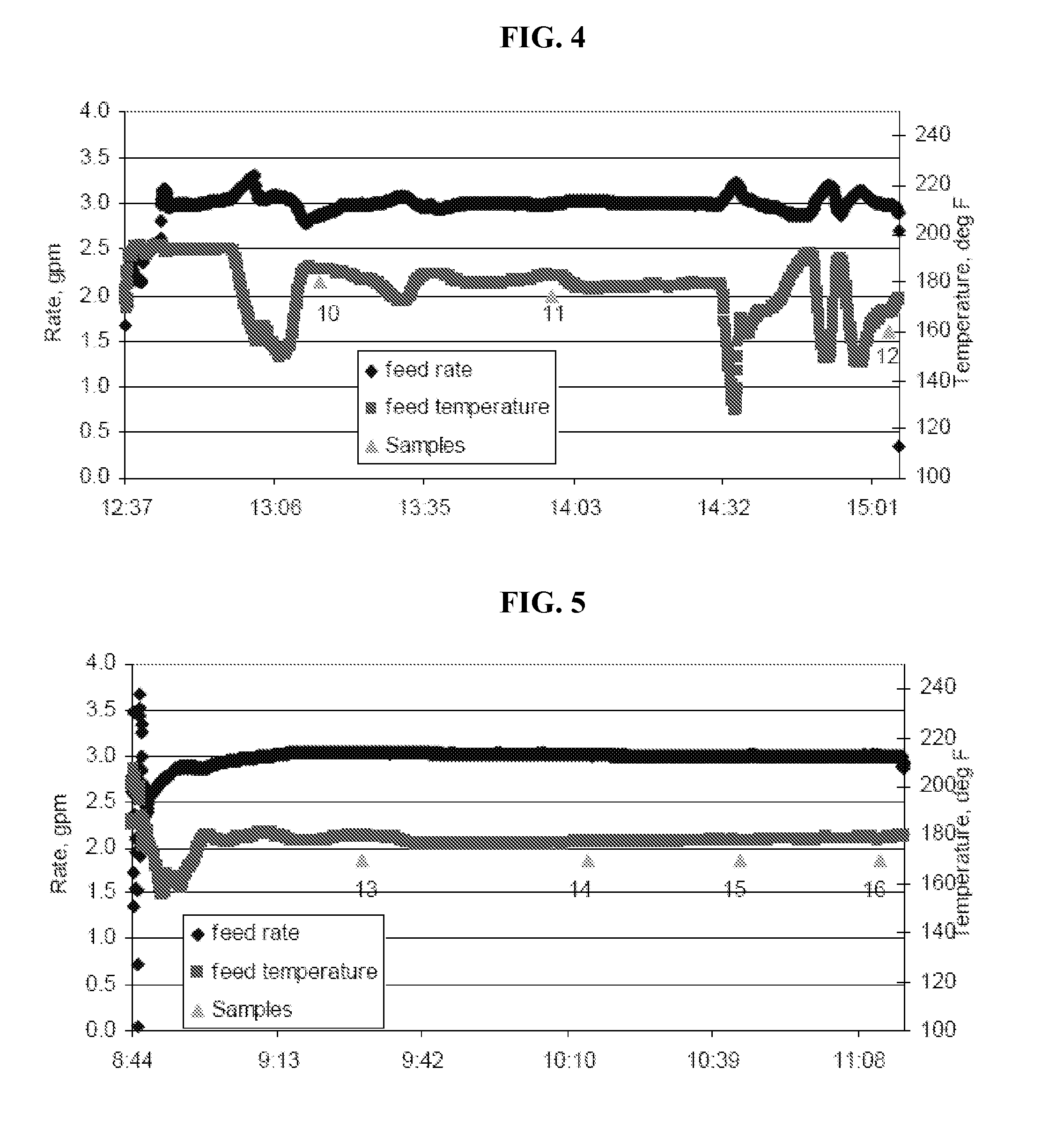

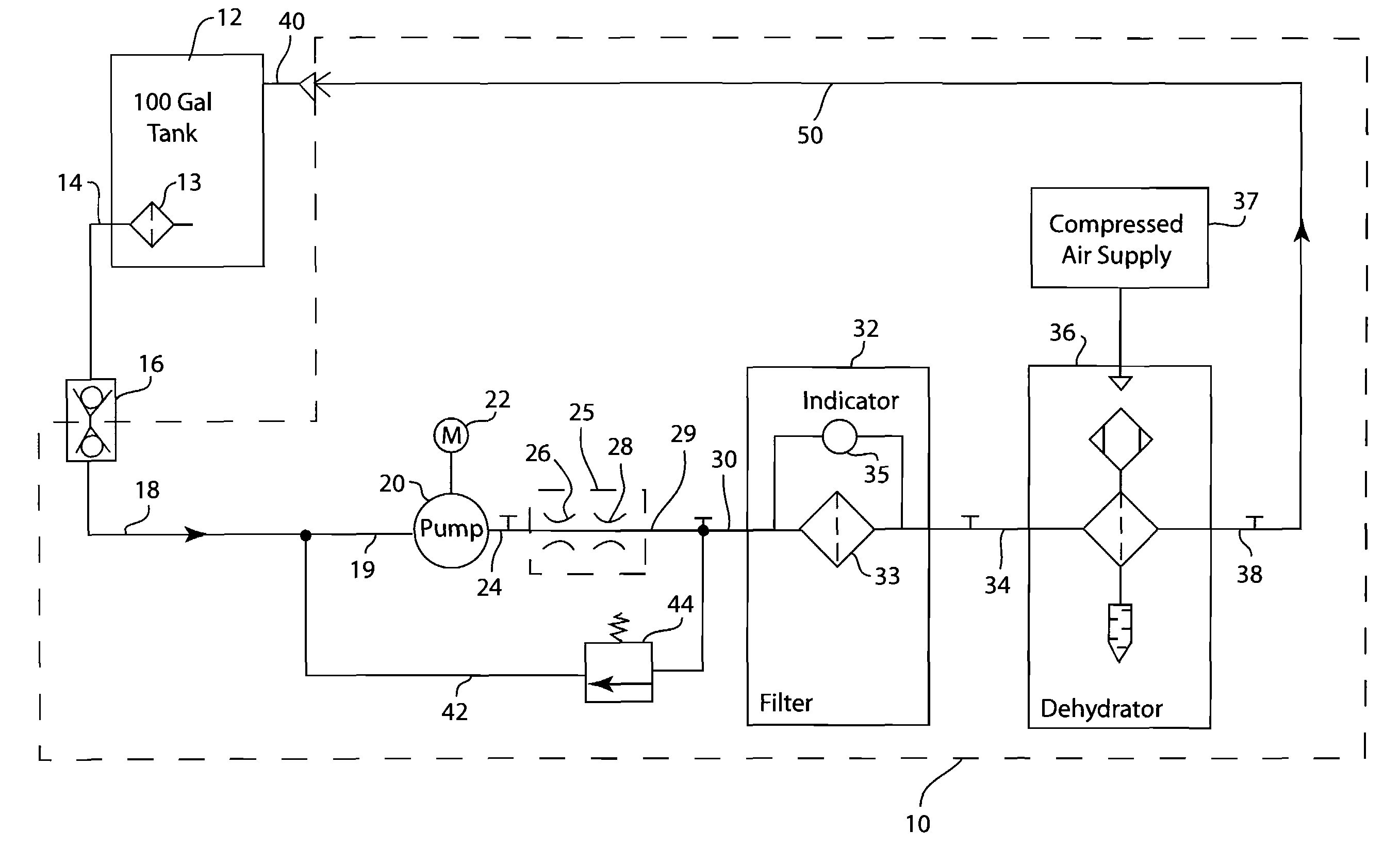

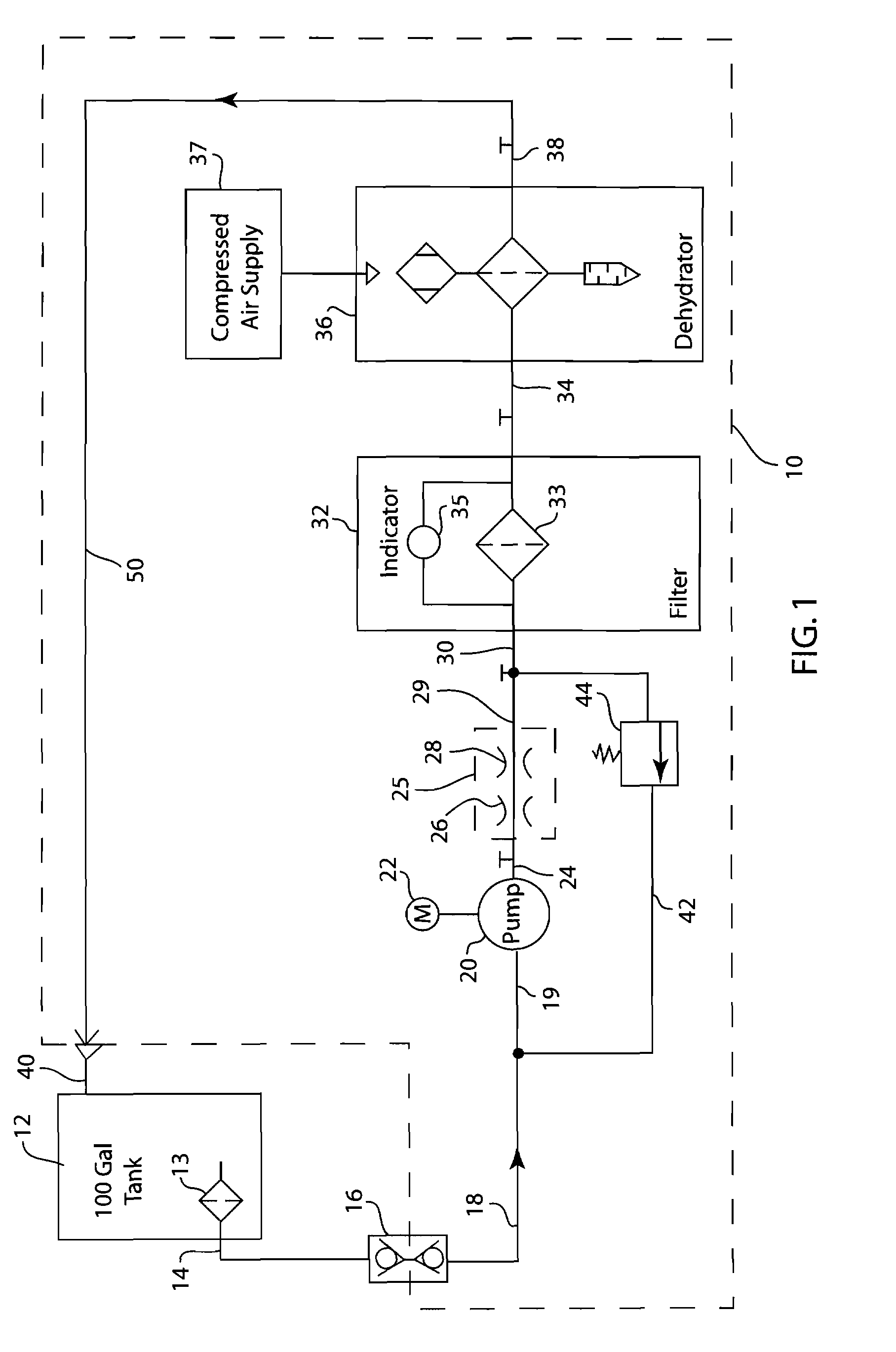

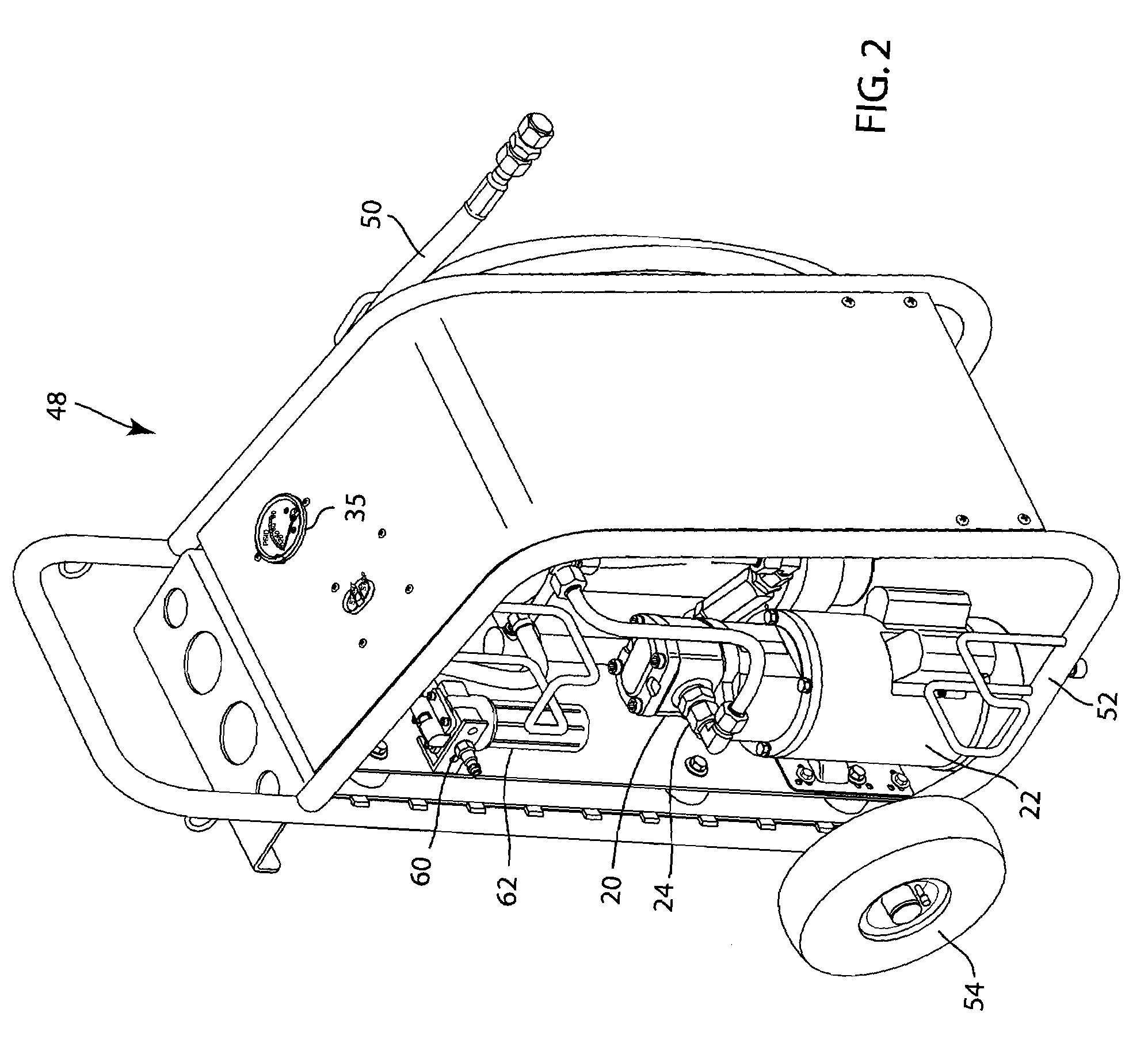

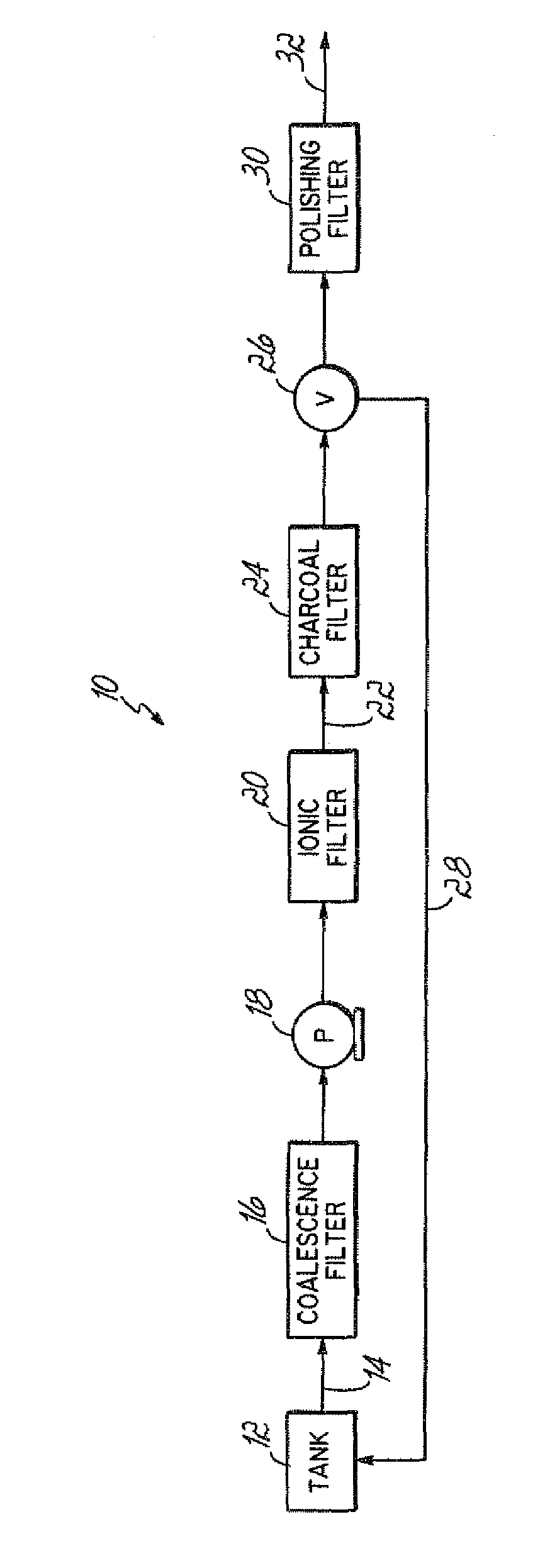

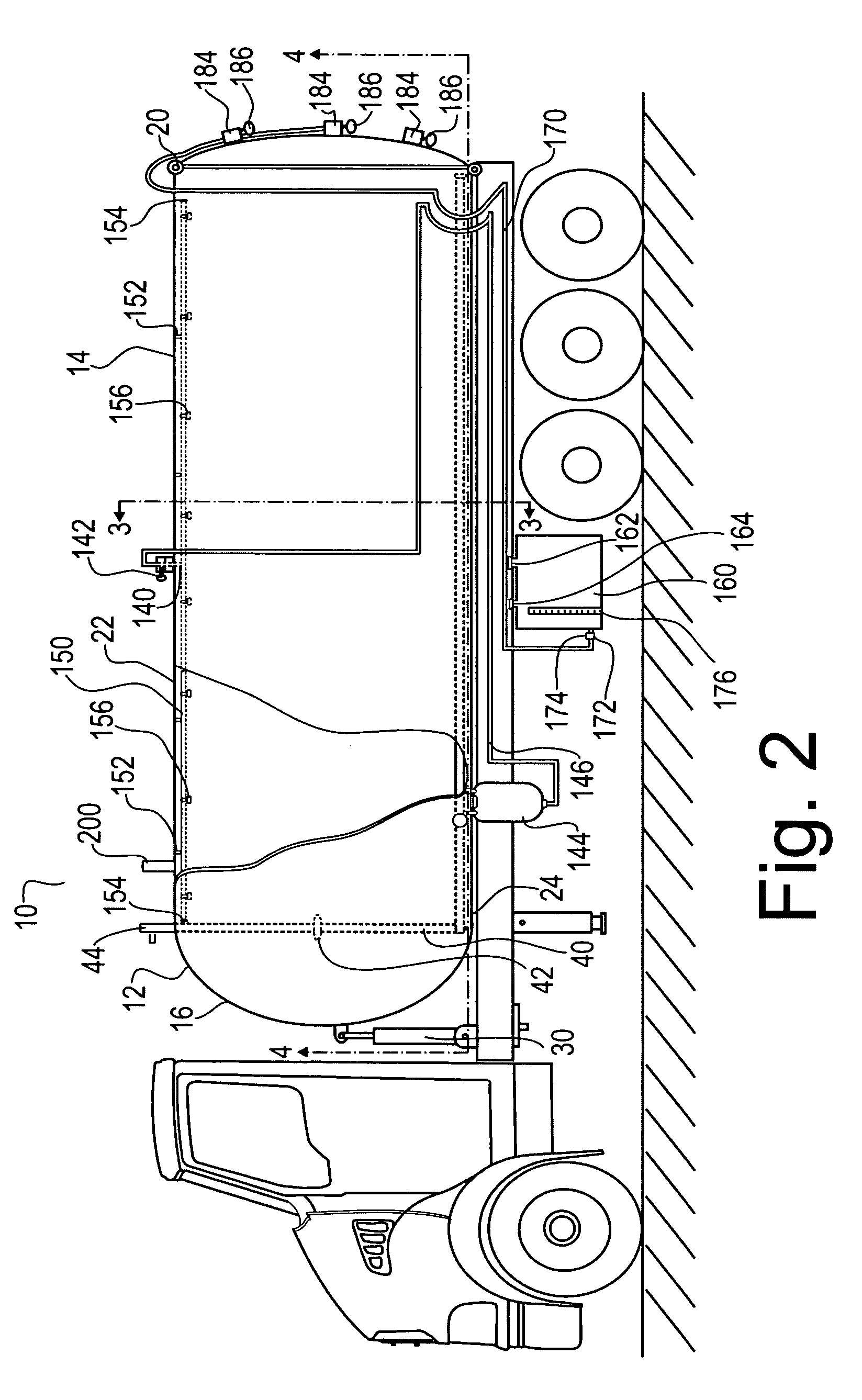

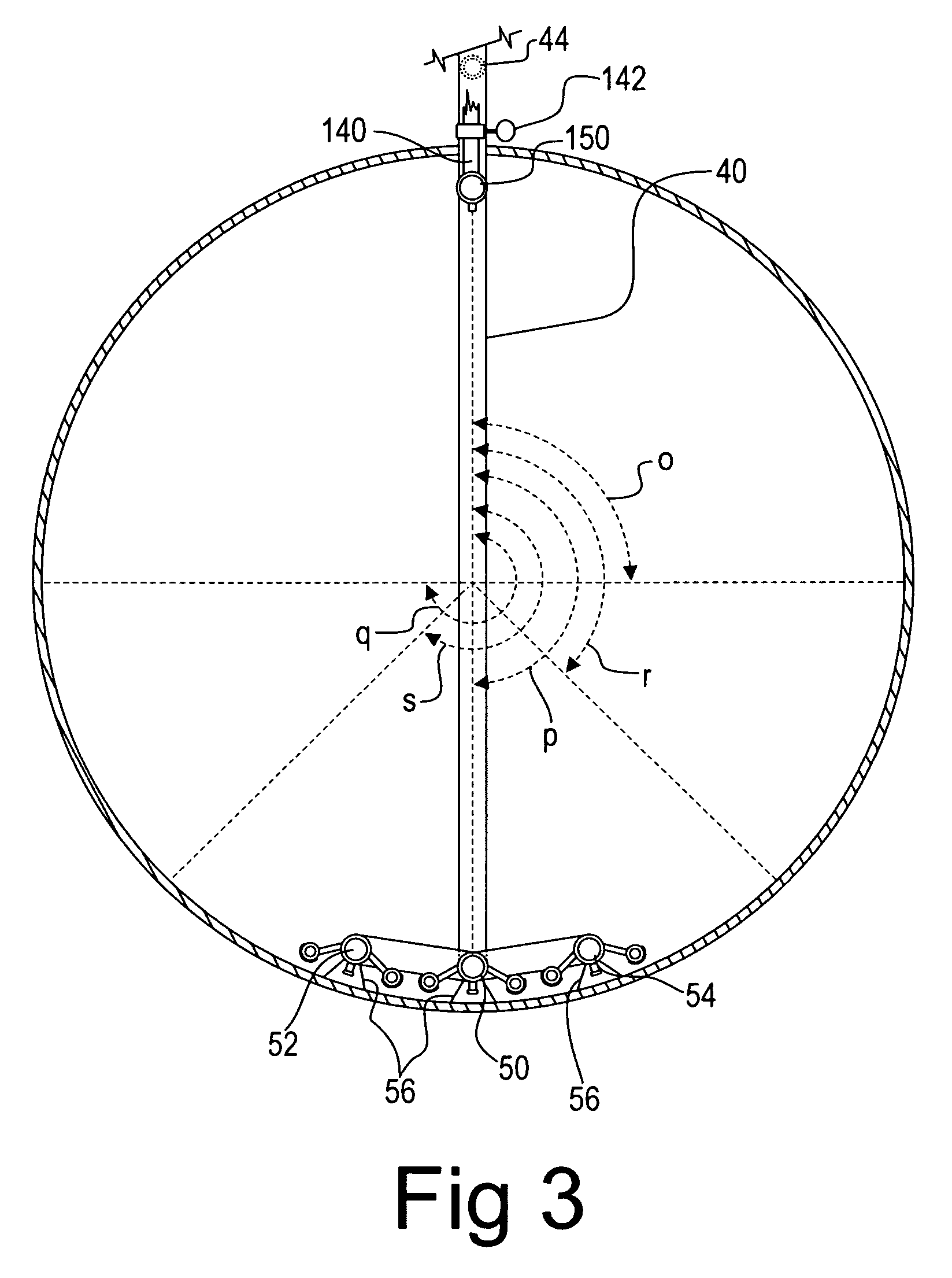

Hydraulic fluid dehydration system and method including pre-heating

ActiveUS20080173356A1Reduce amountIncrease flow rateDewatering/demulsification with mechanical meansPipe heating/coolingEngineeringHydraulic fluid

A mobile dehydration system that is operable to remove water from a supply of fluid, such as hydraulic fluid. The mobile dehydration system includes a fluid pump that draws the supply of hydraulic fluid from a storage tank. The flow of hydraulic fluid passes through a fluid heater that elevates the temperature of the hydraulic fluid. The fluid heater includes at least one flow restricting orifice that reduces the pressure of the flow of hydraulic fluid, thereby elevating the temperature of the hydraulic fluid. The outlet of the fluid heater is connected to a dehydrator that removes water from the flow of hydraulic fluid. A fluid feedback line is connected between the outlet of the fluid heater and the inlet of the fluid pump to return a portion of the hydraulic fluid flow when the flow rate through the dehydrator is less than the flow rate from the fluid pump.

Owner:PUTZMEISTER AMERICA

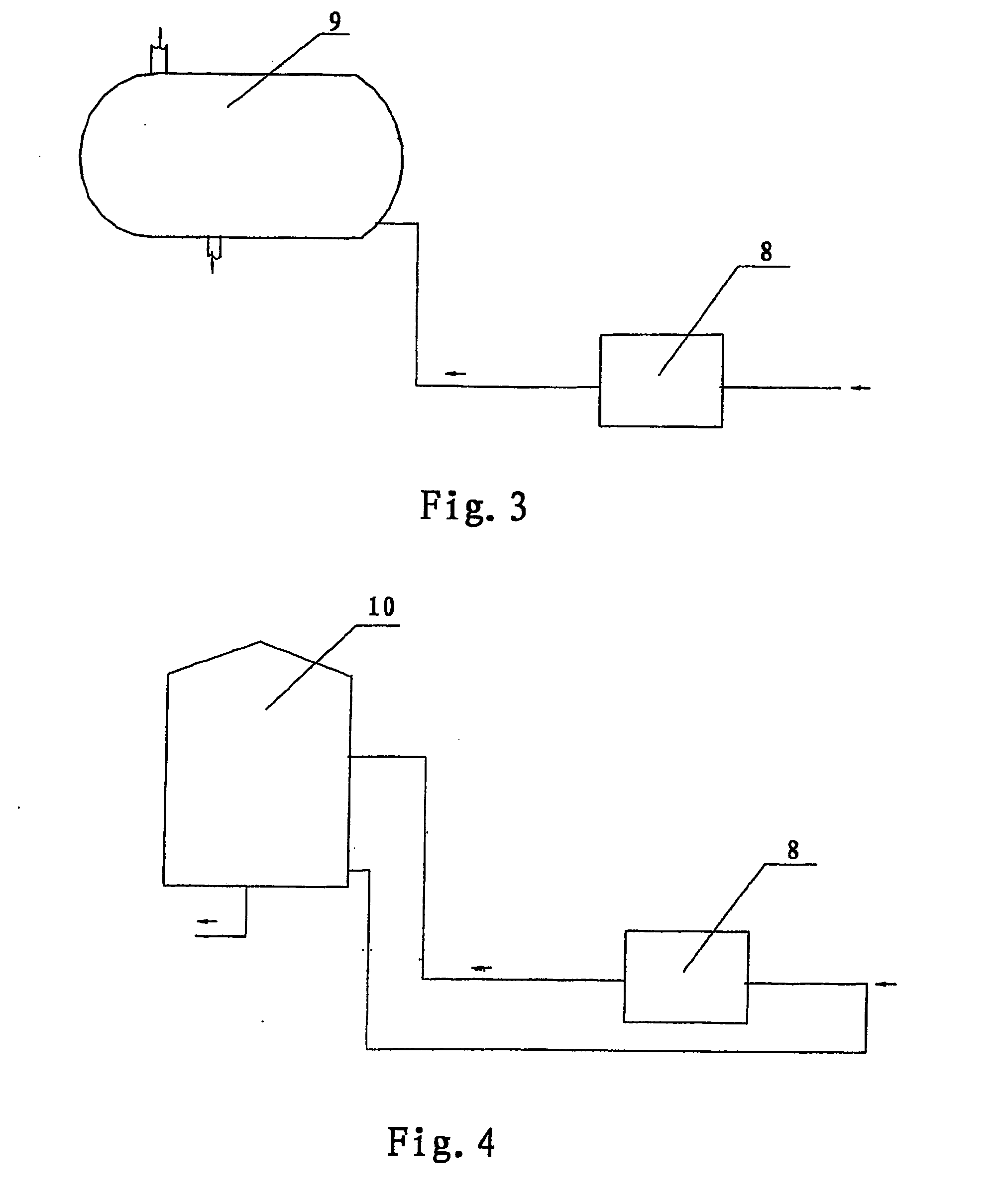

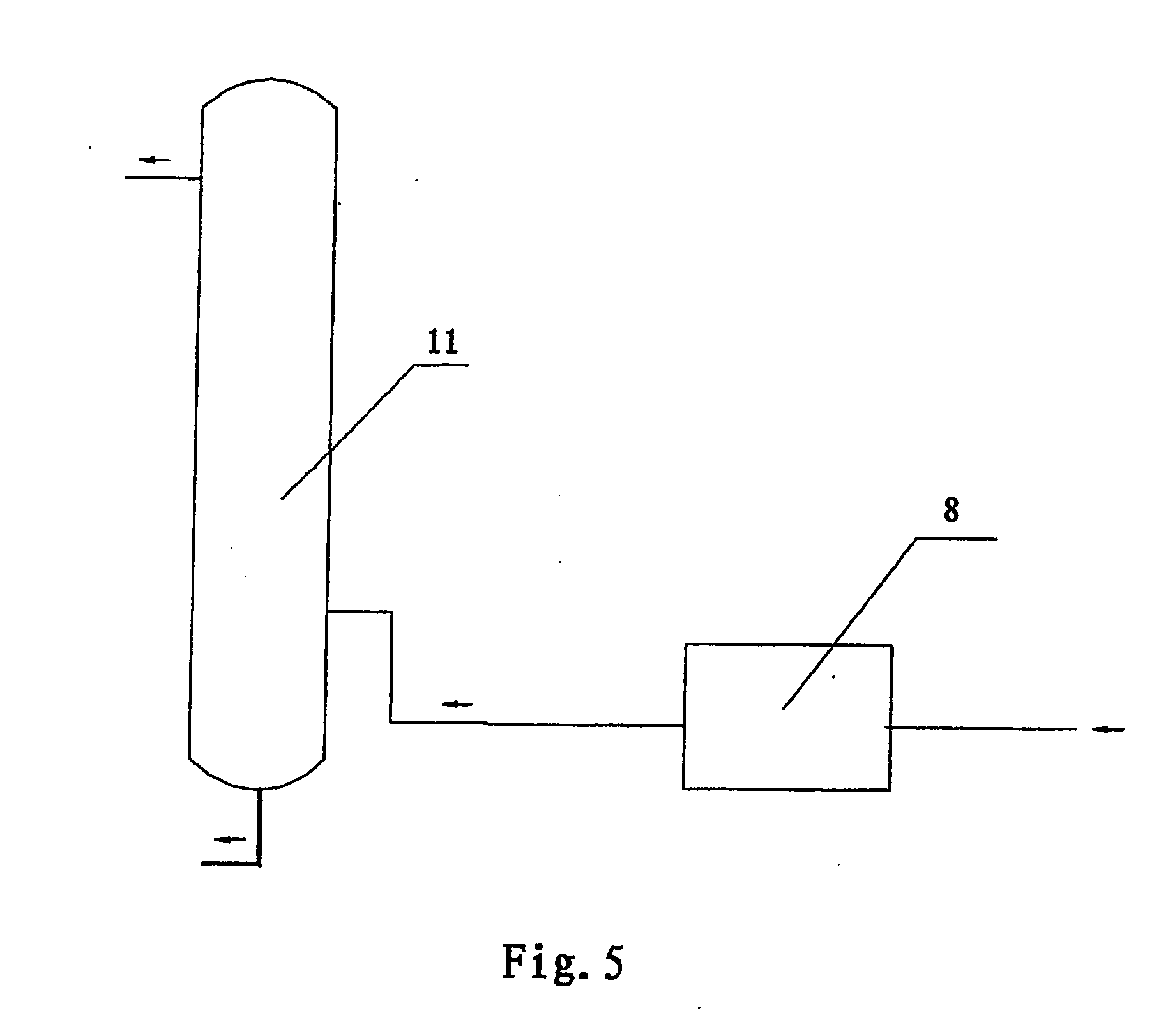

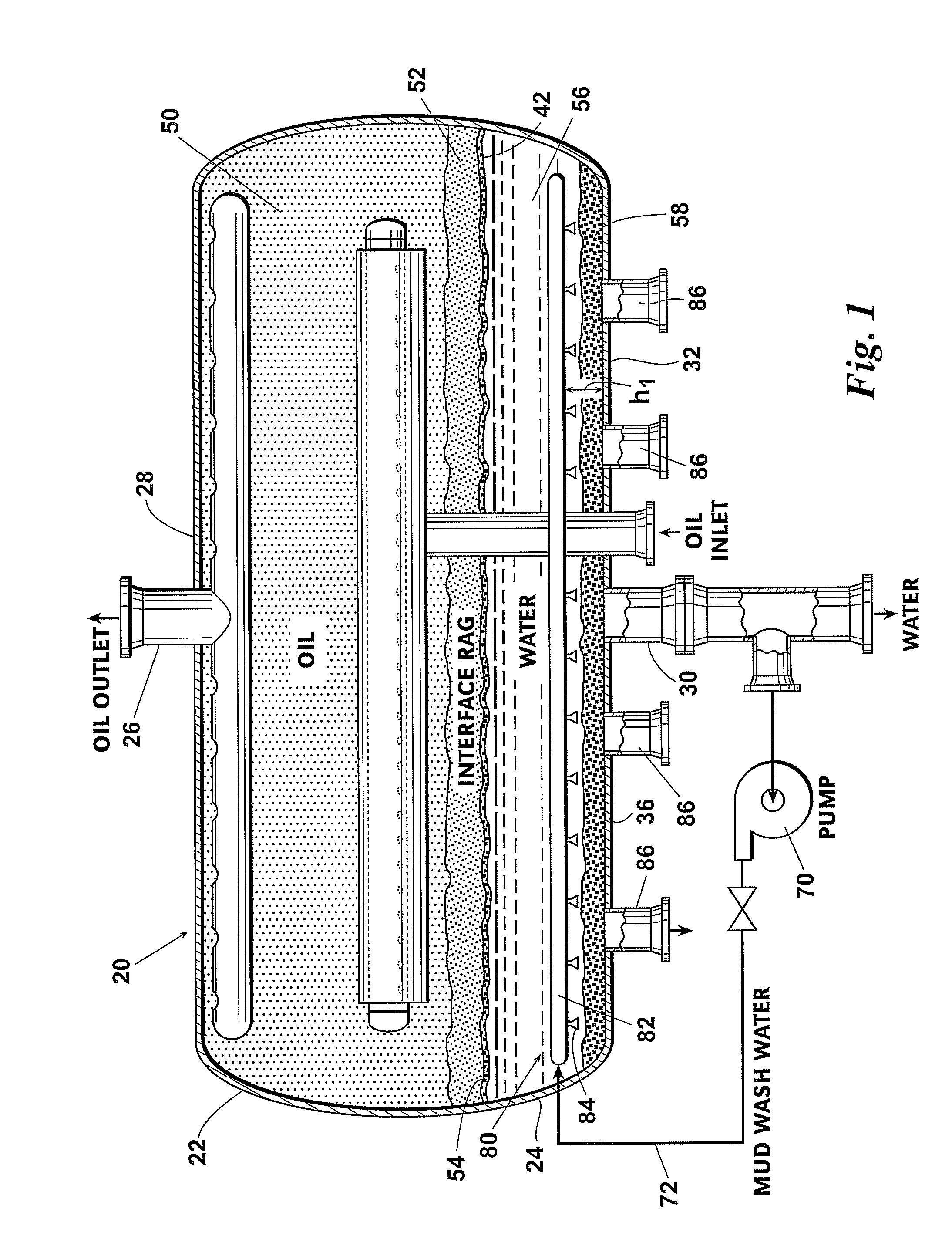

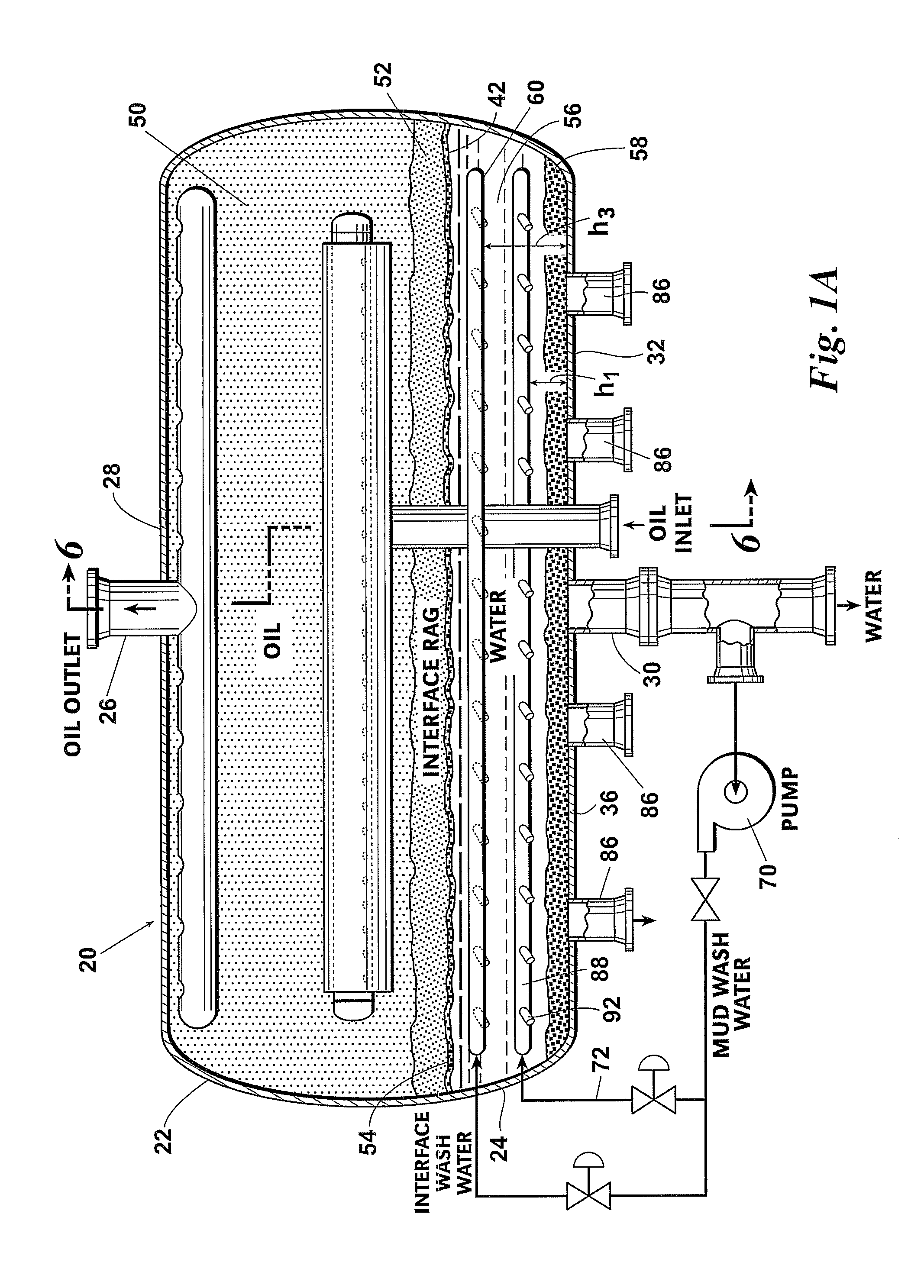

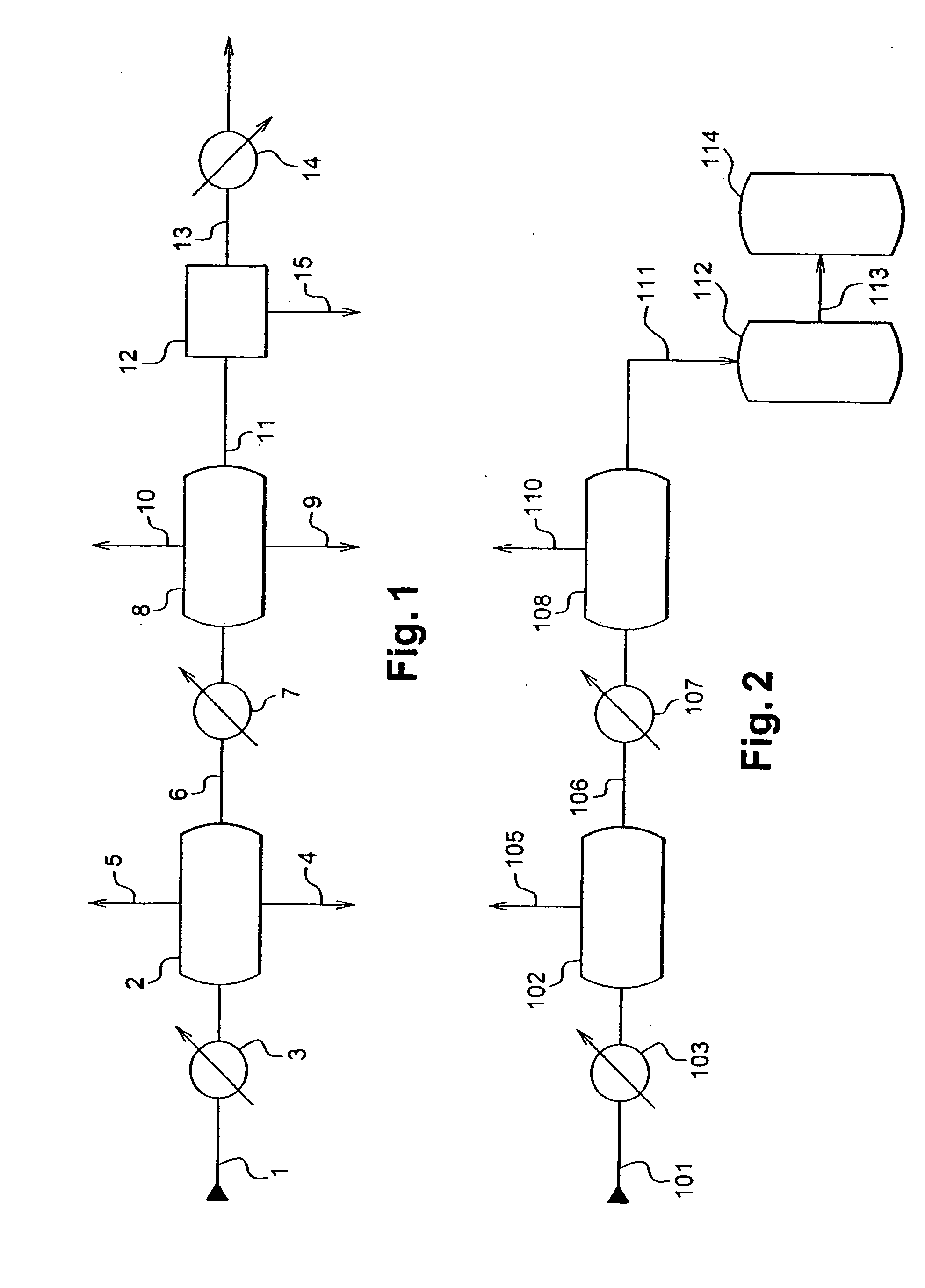

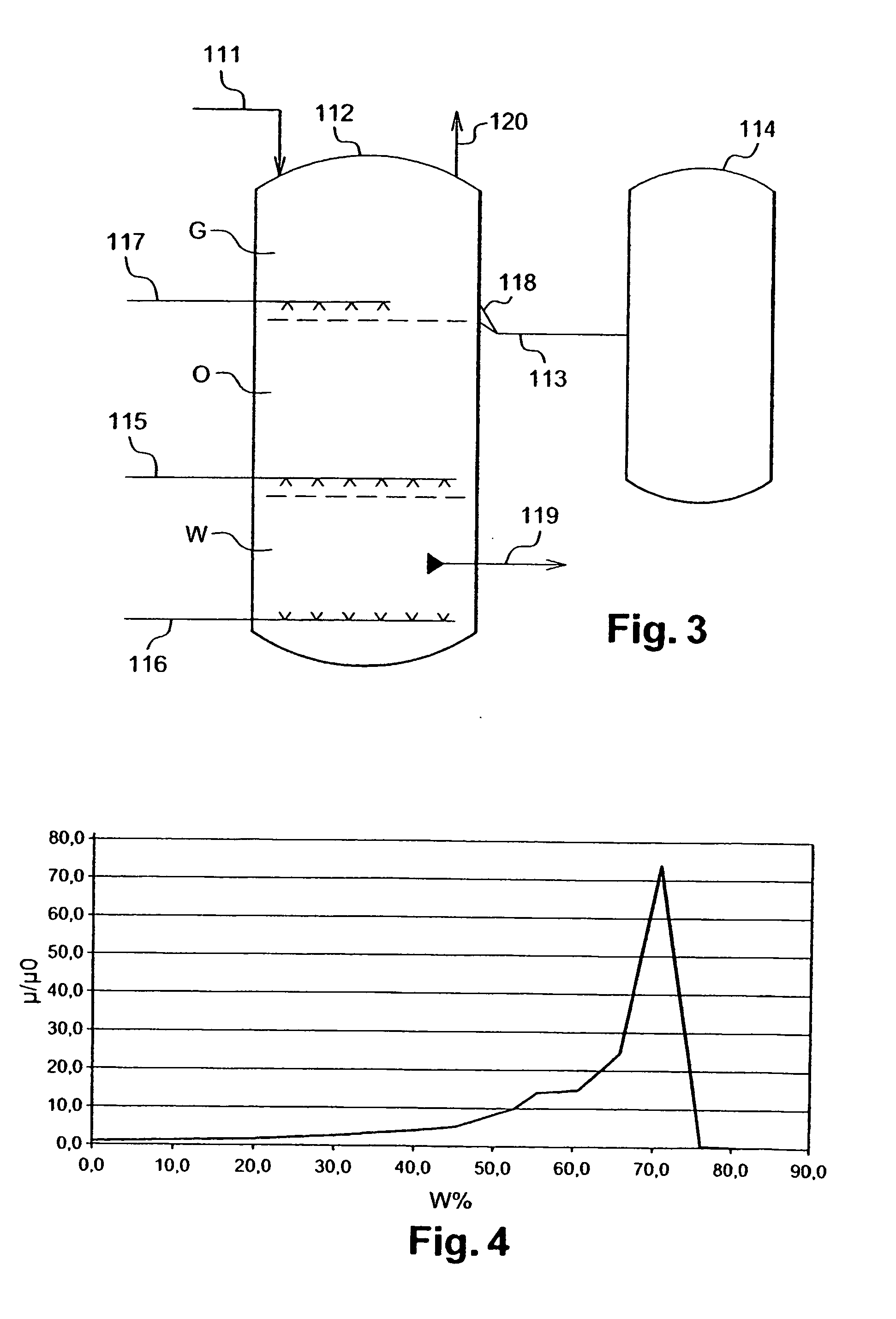

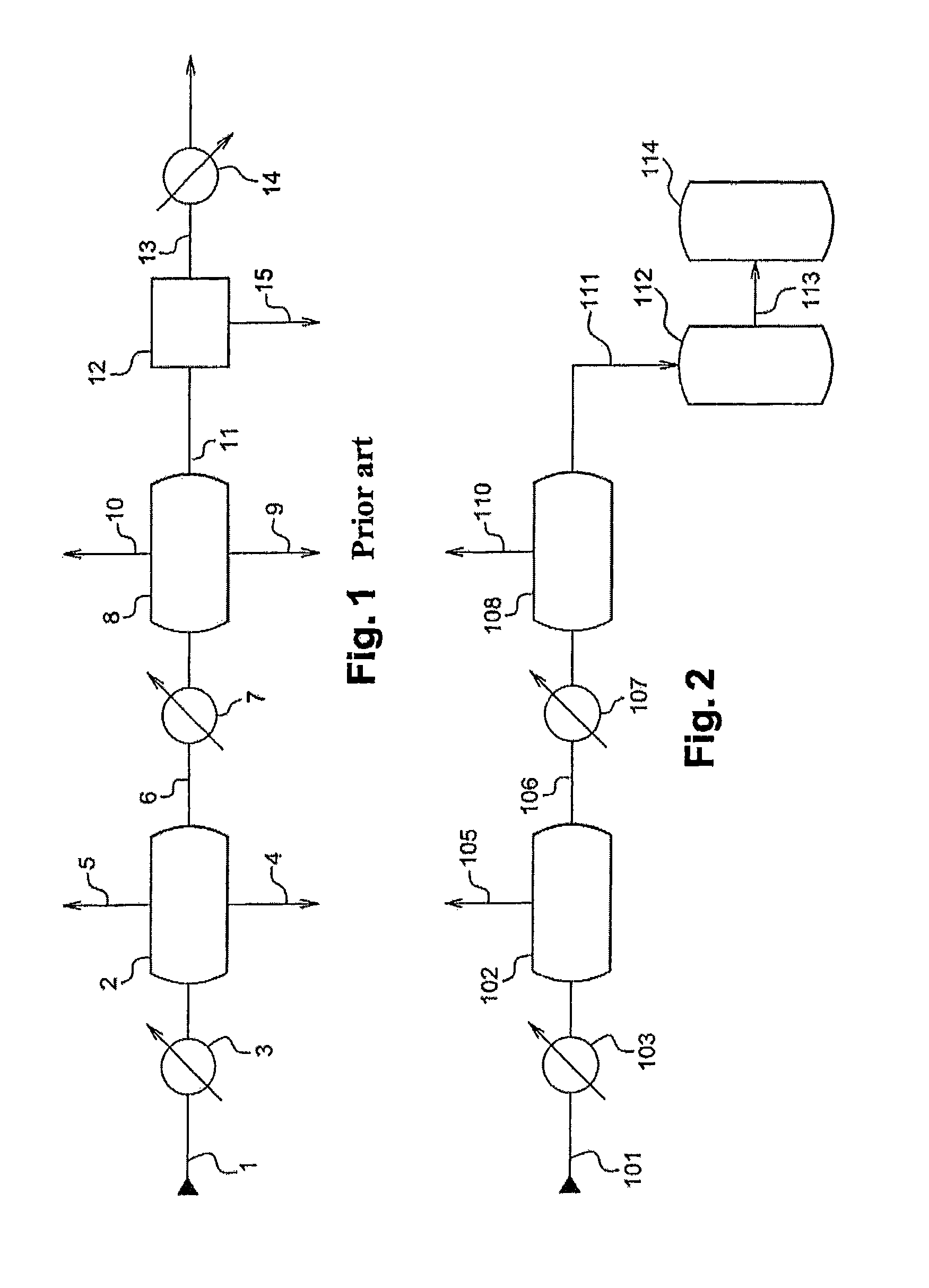

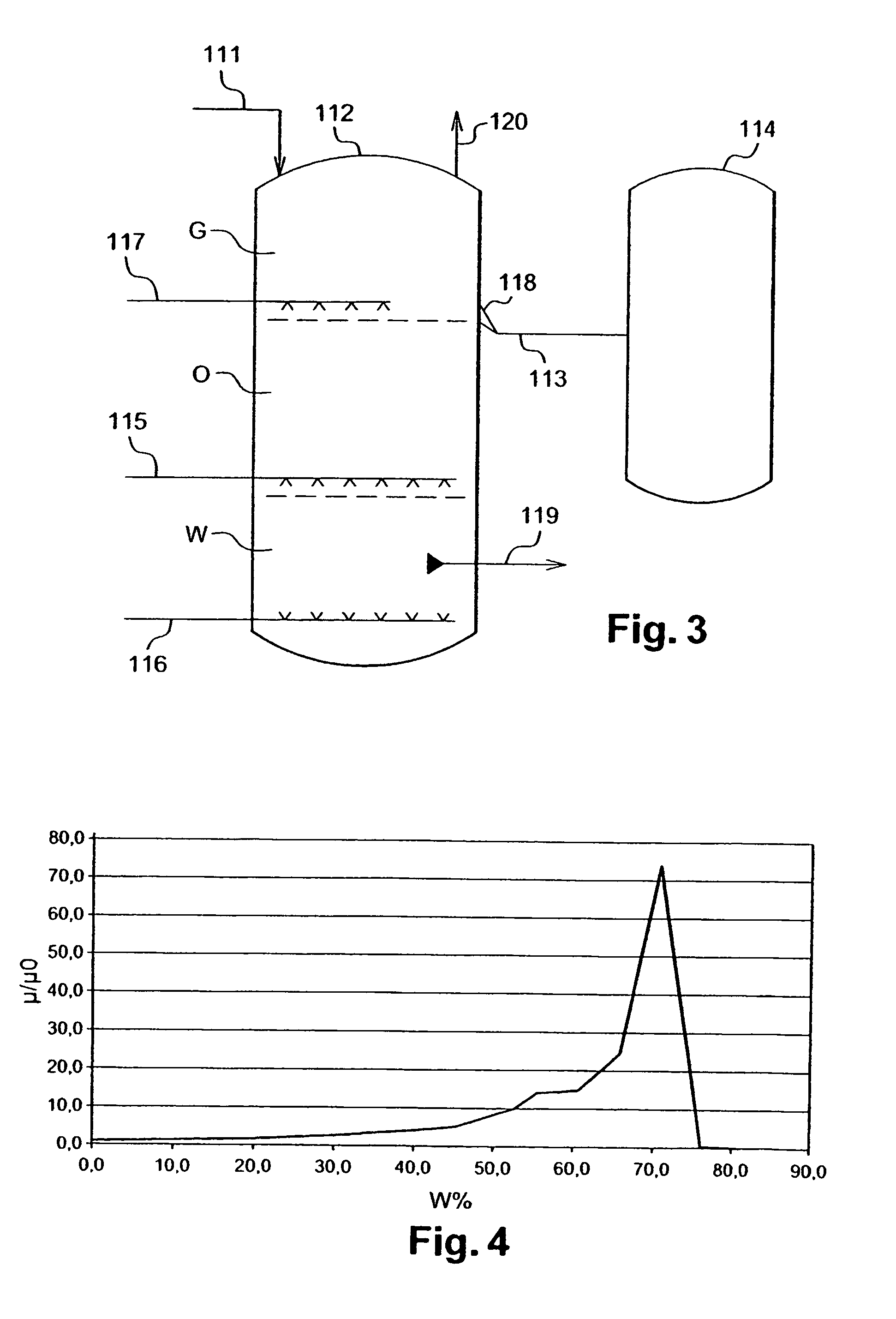

Process for the Treatment of Crude Oil, Process for the Separation of a Water-in-Oil Hydrocarbon Emulsion and Apparatus for Implementing the Same

ActiveUS20070267325A1Increased ballastIncrease consumptionWorking-up pitch/asphalt/bitumen by selective extractionLiquid degasificationOil waterHydrocarbon

The invention relates to a process for the purification of crude and apparatus for its implementation. This process comprises a separation into gas and degassed emulsion and separation of the degassed emulsion into water and oil. The invention also relates to a process of separating a hydrocarbon emulsion and apparatus for implementing this. This process comprises washing of the emulsion at an oil / water interface.

Owner:TOTAL PUTEAUX FR

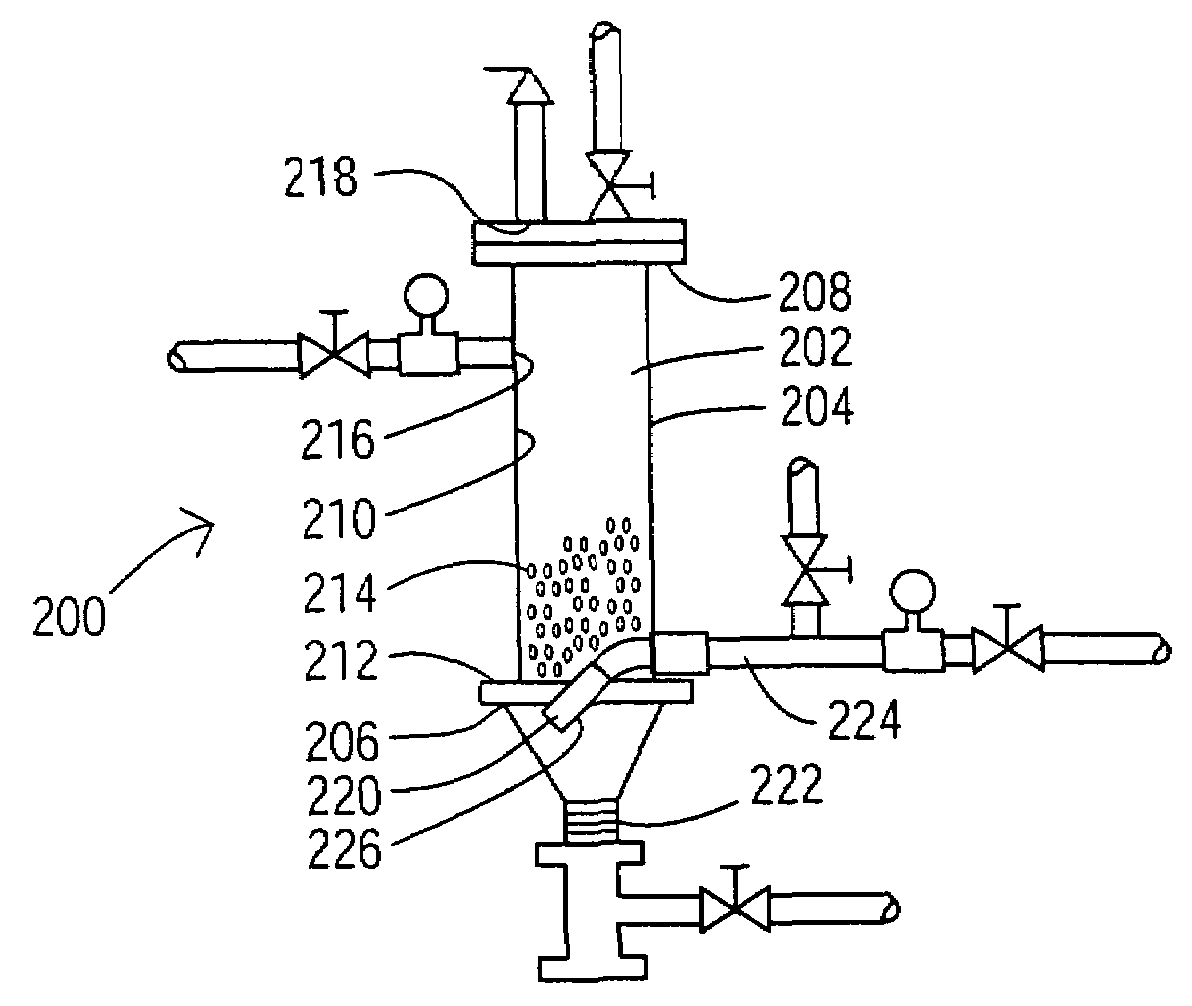

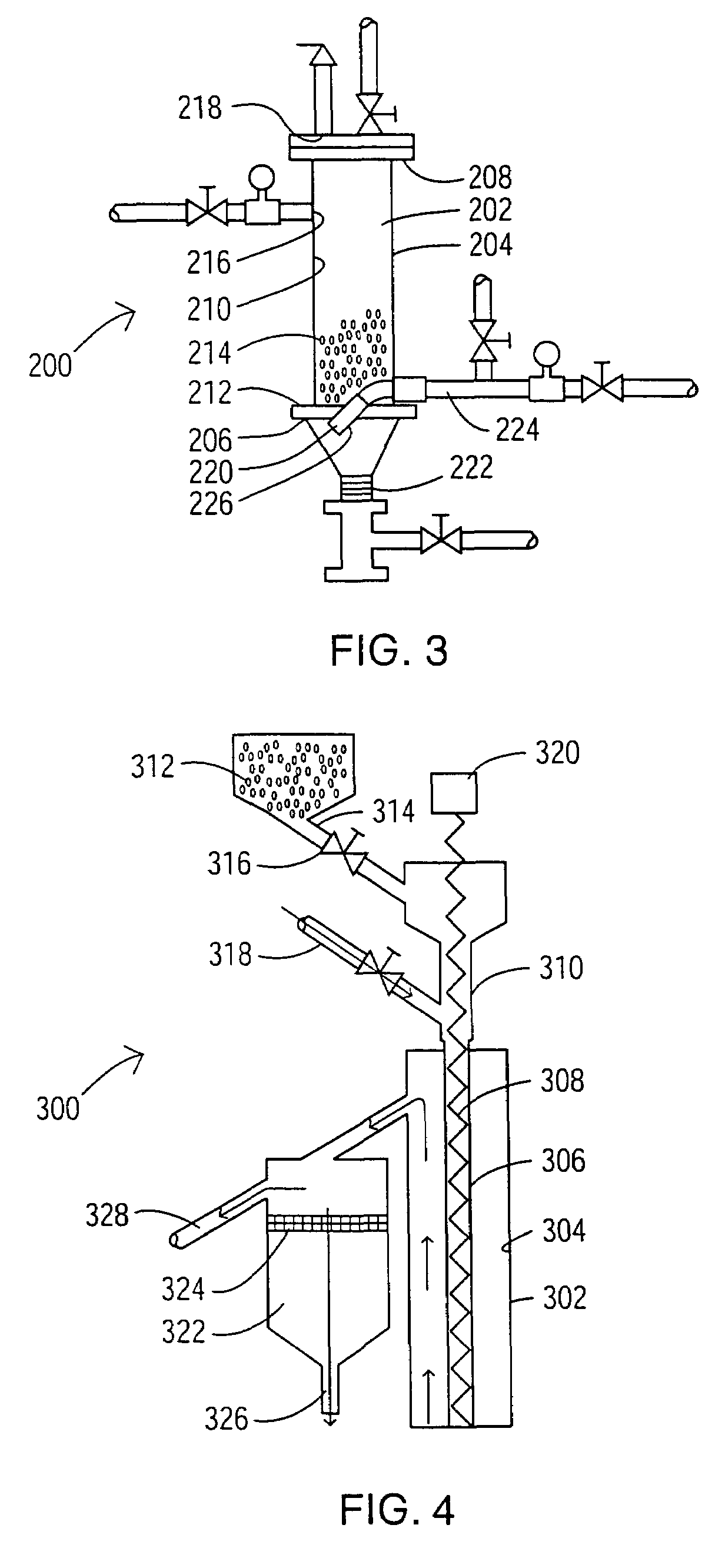

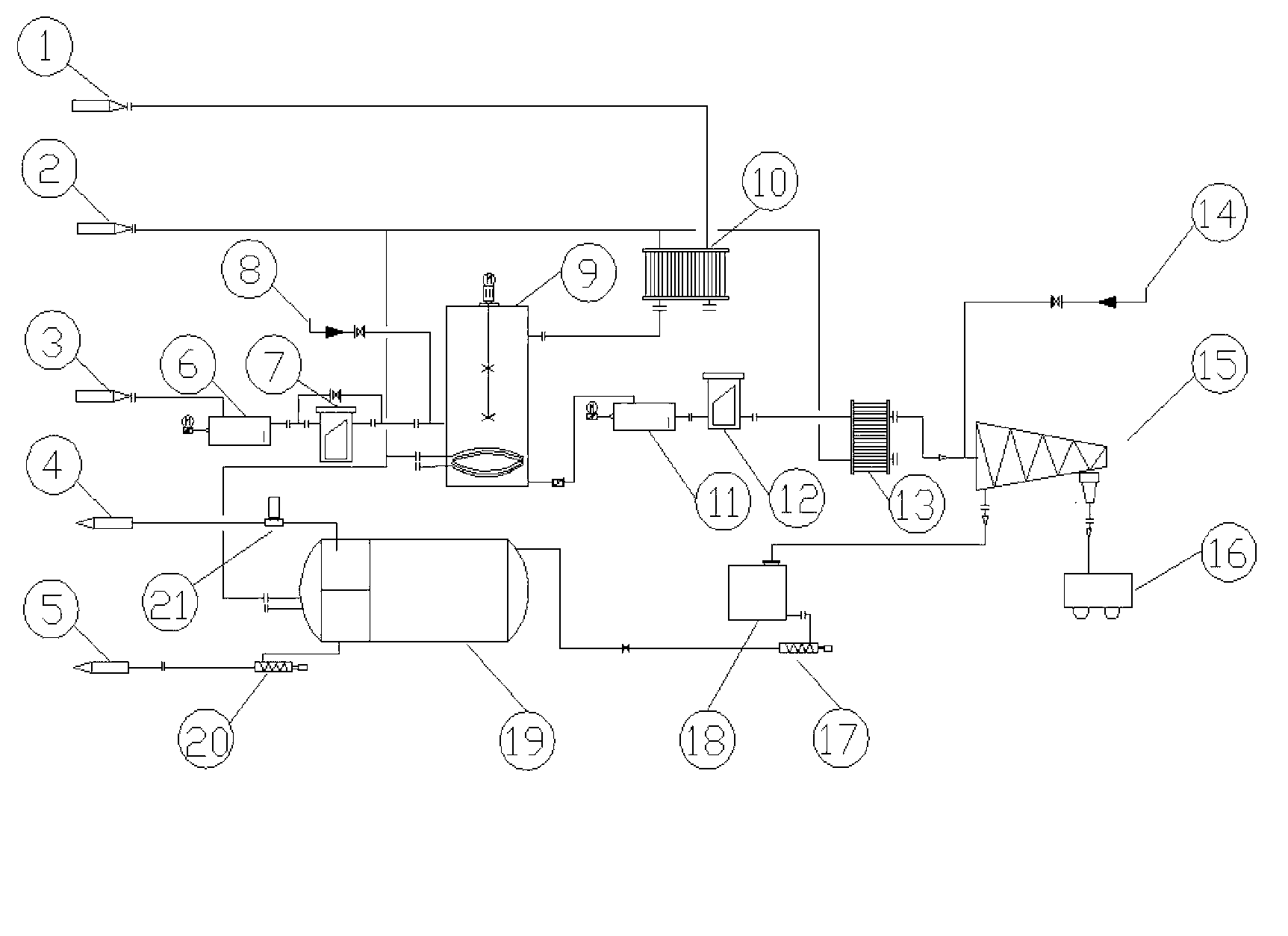

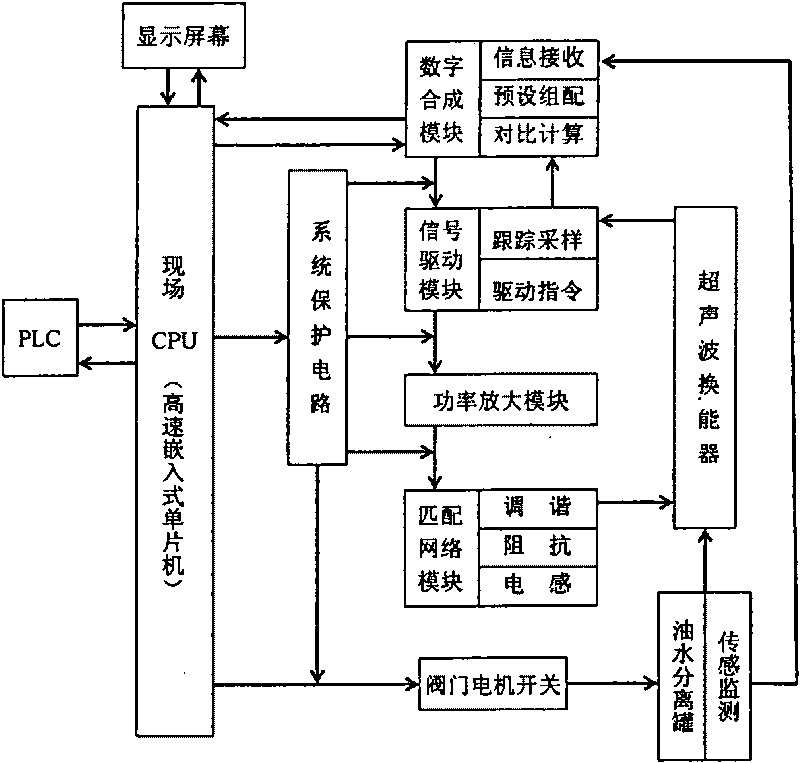

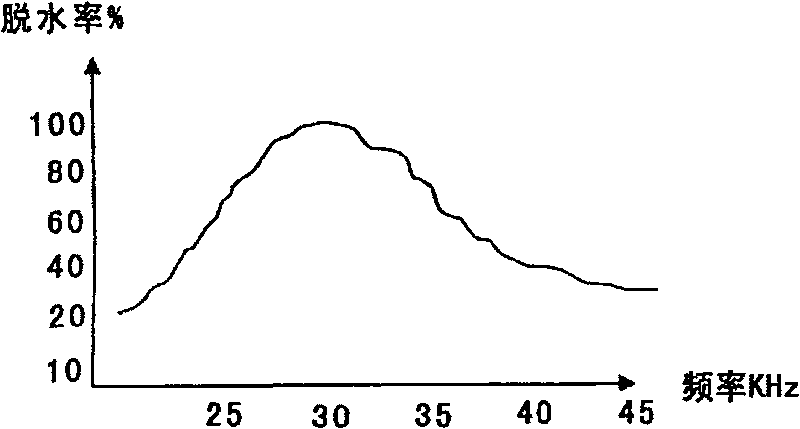

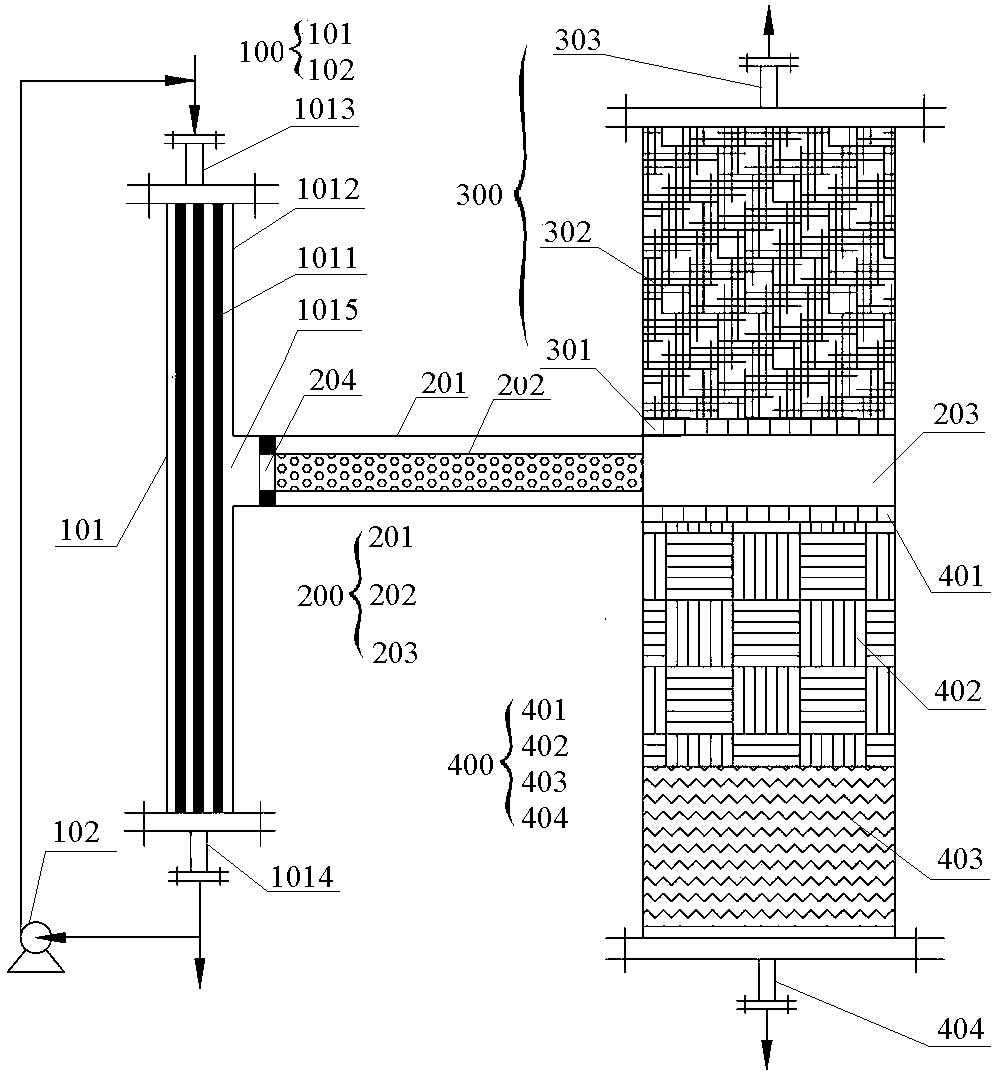

Crude oil ultrasonic emulsion breaking dehydrating device and emulsion breaking dehydrating method thereof

InactiveCN101724439AReal-time automatic tracking displayControl and adjust the function of running job parametersDewatering/demulsification with mechanical meansDewatering/demulsification regulation/controlChemical activityChemistry

The invention relates to an oil-water separating technology in petroleum crude oil extracting and refining industry, in particular to a crude oil ultrasonic emulsion breaking dehydrating device and emulsion breaking dehydrating method thereof. The invention, combining with the characteristic of ultrasonic wave and chemical activity effect of chemical demulsifier, breaks the stable structure of crude oil emulsion, causes the crude oil emulsion to be rapidly changed in structure and realizes less consumed electric quantity, low demulsifier usage amount, through oil water separation and separation on crude oil with extremely low content in water and sedimented muddy sand. The invention is mainly applicable to china oil stations and oil extracting centralized field in oil field; and the invention can be applied if the oil field can normally extract oil and requires crude oil emulsion breaking dehydrating treatment.

Owner:SIPING ZHONGKE TECH

Process for the treatment of crude oil, process for the separation of a water-in-oil hydrocarbon emulsion and apparatus for implementing the same

ActiveUS8790509B2Increased ballastIncrease consumptionLiquid degasificationDewatering/demulsification with mechanical meansPurification methodsHydrocarbon

The invention relates to a process for the purification of crude and apparatus for its implementation. This process comprises a separation into gas and degassed emulsion and separation of the degassed emulsion into water and oil. The invention also relates to a process of separating a hydrocarbon emulsion and apparatus for implementing this. This process comprises washing of the emulsion at an oil / water interface.

Owner:TOTAL PUTEAUX FR

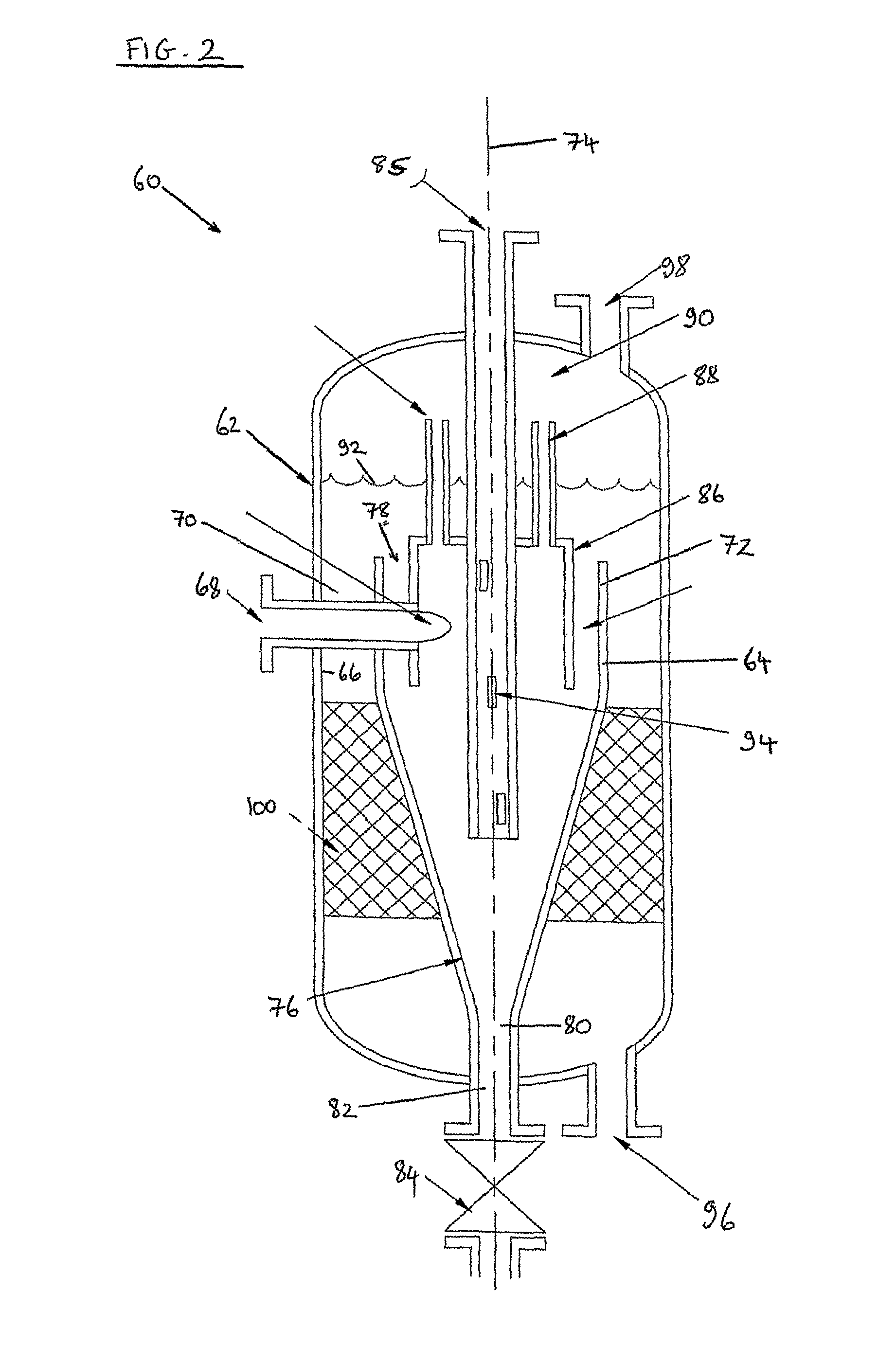

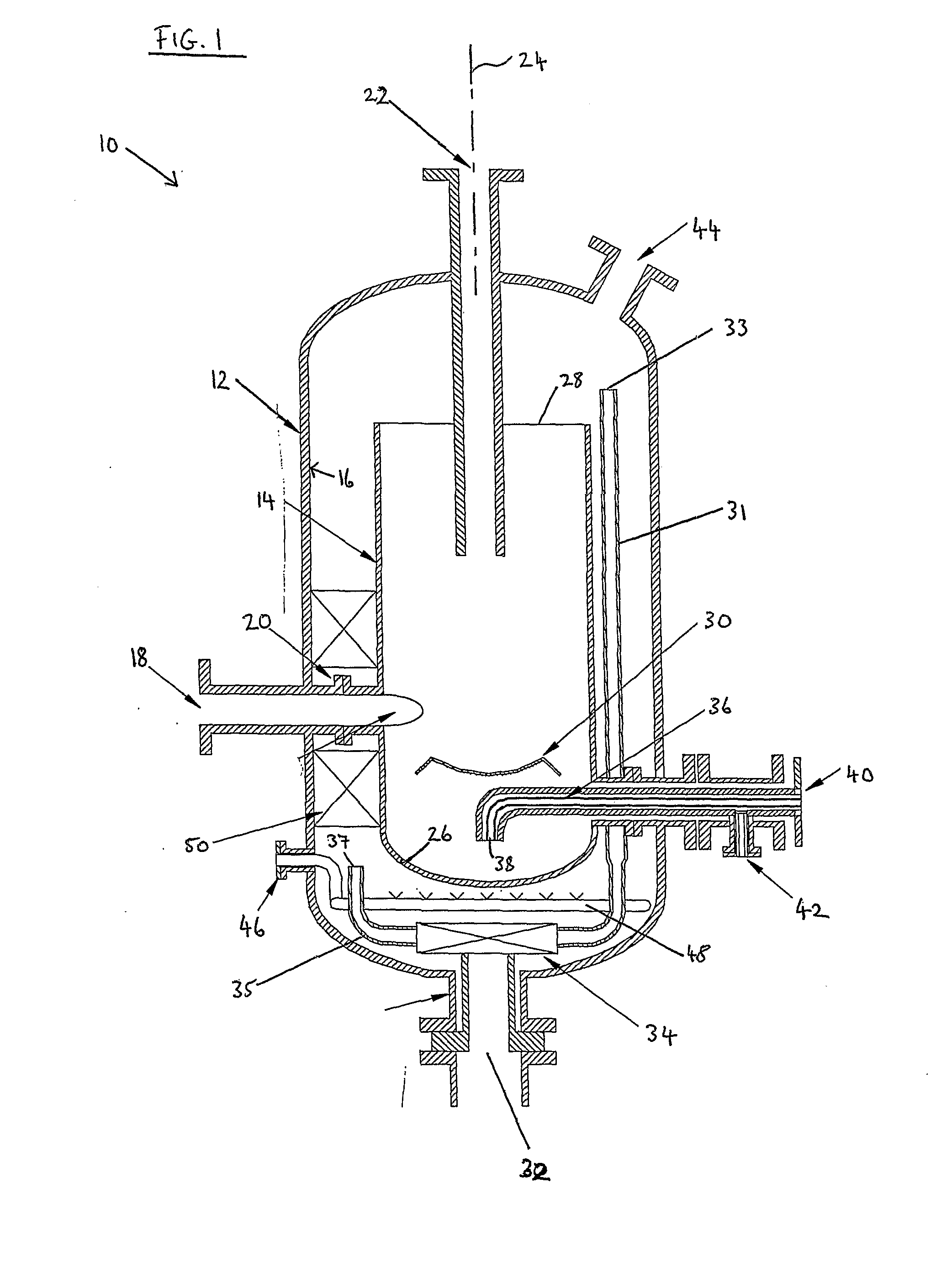

Separator to separate a liquid/liquid/gas/solid mixture

ActiveUS8114283B2Reliable methodIncrease productionLiquid degasificationReversed direction vortexCycloneProduct gas

A separator for separating or partially separating oil, water, gas and solids from hydrocarbon production well fluids comprises a vessel and a cyclone contained within the vessel. An inlet passage passes through a wall of the vessel and into the cyclone, the inlet passage having means for causing the flow to rotate within the cyclone. A first outlet passage for an oil rich phase extends from a position within the cyclone and substantially on a central axis of the cyclone; a second outlet passage for a water phase extends from a base of the vessel; and a third outlet passage for the solids extends from a lower end of the cyclone.

Owner:DPS BRISTOL HOLDINGS LTD

Separator to Separate a Liquid/Liquid/Gas/Solid Mixture

ActiveUS20090020467A1Reliable methodIncrease productionLiquid degasificationDewatering/demulsification with mechanical meansCycloneProduct gas

A separator for separating or partially separating oil, water, gas and solids from hydrocarbon production well fluids comprises a vessel and a cyclone contained within the vessel. An inlet passage passes through a wall of the vessel and into the cyclone, the inlet passage having means for causing the flow to rotate within the cyclone. A first outlet passage for an oil rich phase extends from a position within the cyclone and substantially on a central axis of the cyclone; a second outlet passage for a water phase extends from a base of the vessel; and a third outlet passage for the solids extends from a lower end of the cyclone.

Owner:DPS BRISTOL HOLDINGS LTD

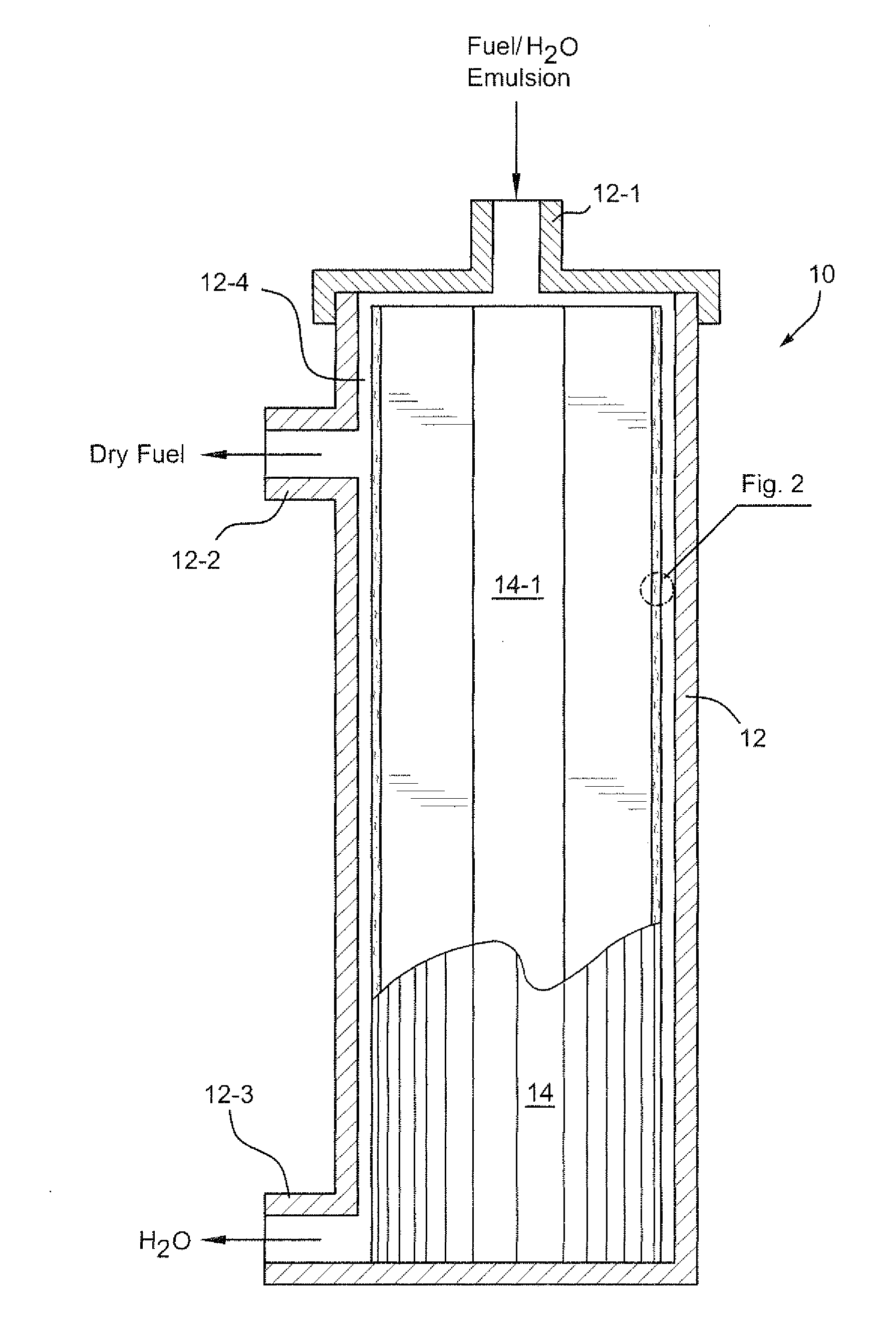

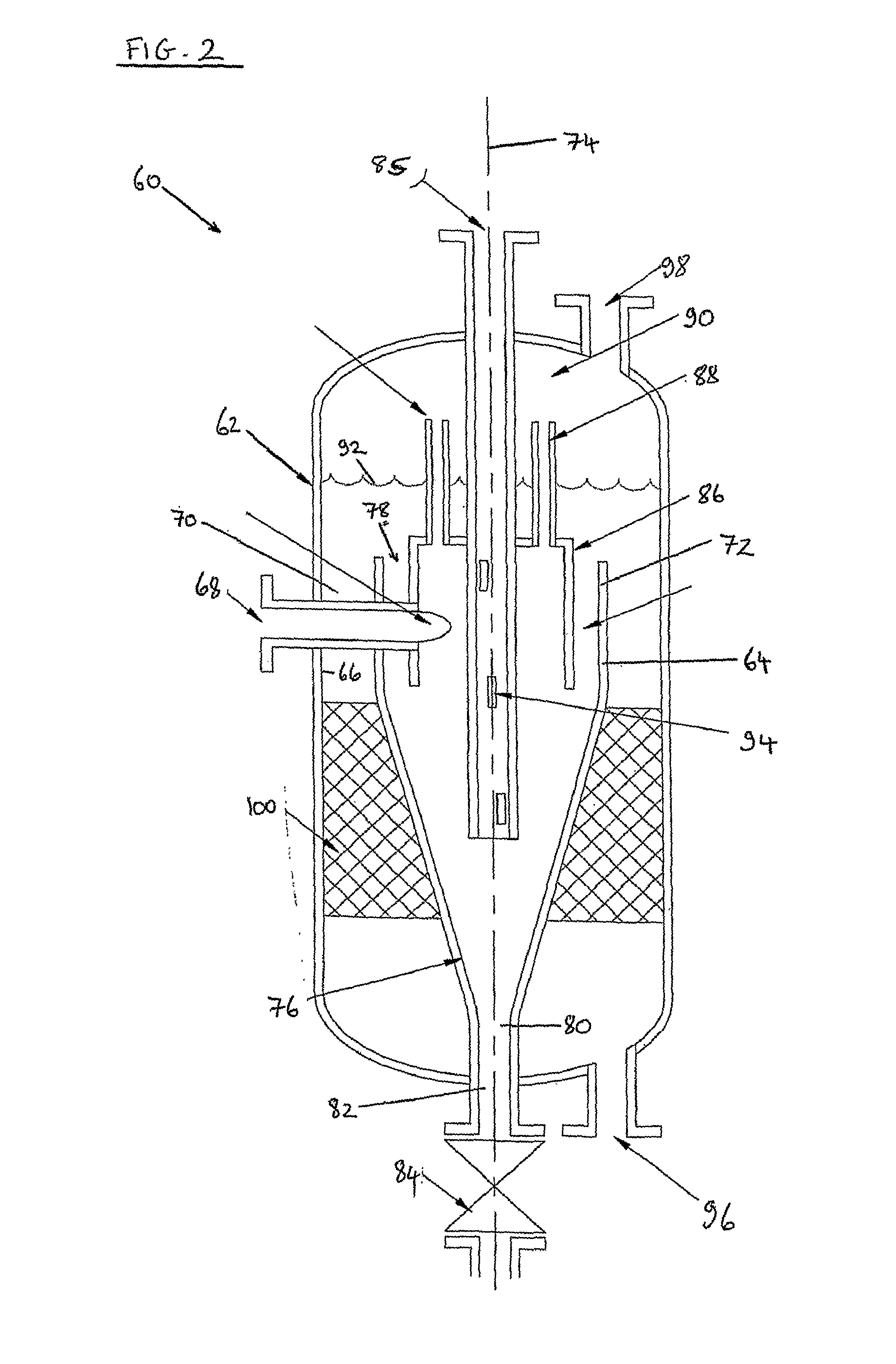

Biodiesel fuel processing

InactiveUS20070175088A1Low viscosityShorten the timeDewatering/demulsification with mechanical meansBiofuelsBiodieselNaphtha

Biodiesel is formed by blending an with a hydrocarbon fuel, preferably #2 diesel, gasoline, or kerosene. Water in the mixture, and other impurities, are removed by adding a coalescing aid such as naphtha, xylene or naphthalene and passing the mixture through a series of filters including a coalescing filter. Optional components that can be added to the fuel include cetane additives, lubricants such as trimethylbenzene and ethylene, as well as performance enhancers such as acetone.

Owner:J F BERNS

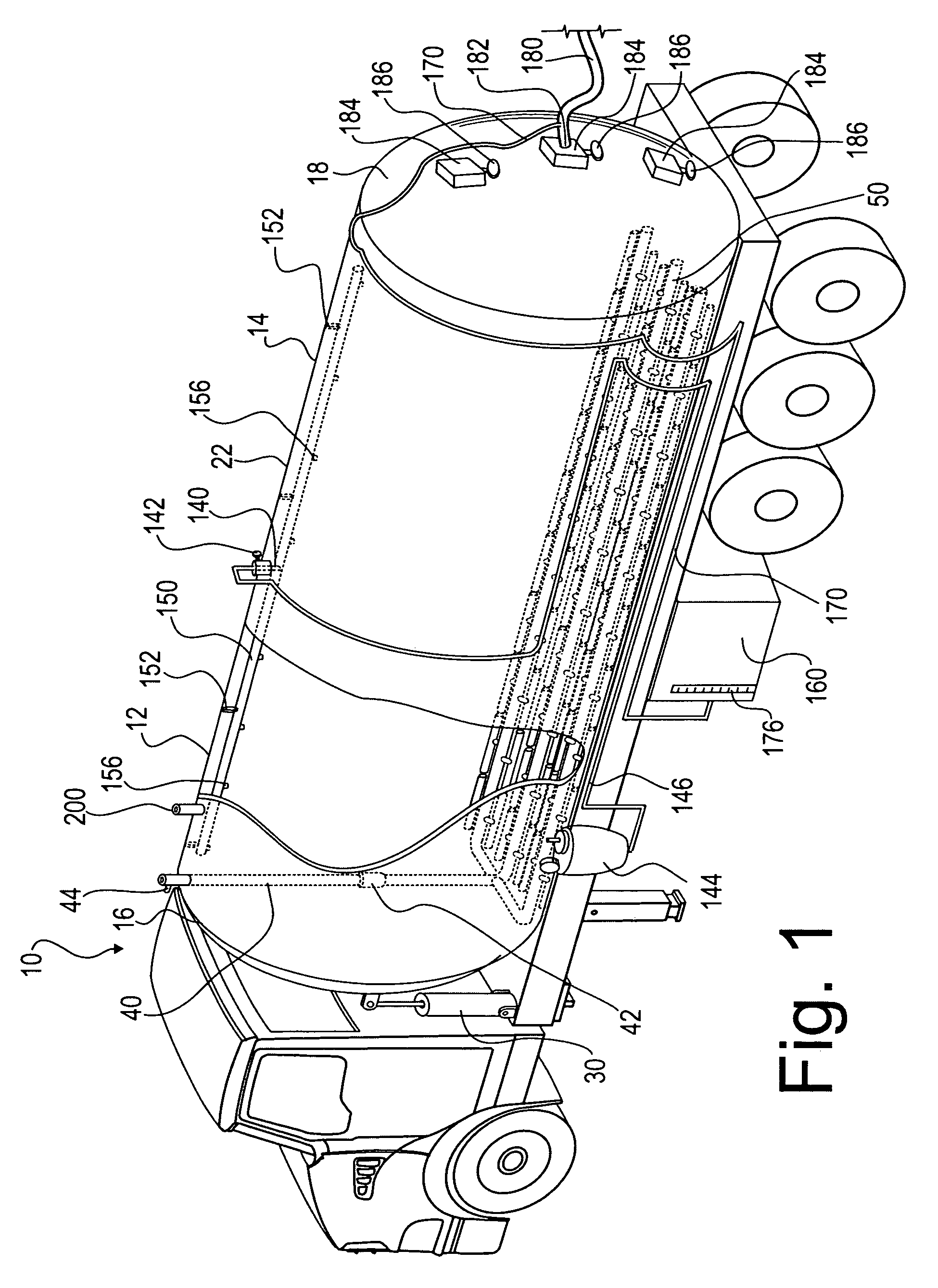

Process and apparatus for enhanced recovery of oil from oily particulate material

InactiveUS7588682B2Low costEconomical to useDewatering/demulsification with mechanical meansLiquid hydrocarbon mixture productionEnhanced recoveryParticulate material

Owner:NORMAN KEVIN

Local produced oil dehydrator

ActiveUS9157035B1Avoid necessityEasy to relocateDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDemulsifierSediment

A portable, semi-portable, or permanent system for removing BS&W from crude oil at the local production or bulk storage site. A demulsifier is added to the crude as it enters a low shear pump which pumps the mixture through a plate and frame type heat exchanger where the incoming crude is preheated using outgoing heated and dehydrated crude. Then the incoming crude enters an oil-water separator where it is further heated by a secondary heater within the separator and passes through a special coalescing section. Water and basic sediment separate from the crude are discharged from the bottom of the separator. The heated dehydrated crude exits the separator, flows back through the heat exchanger where it is cooled as it preheats incoming crude, and then is pumped to clean oil storage. BS&W and flow monitors on the incoming crude and outgoing crude are used to control operation of the system.

Owner:BREAKTHROUGH ENGENUITY LLC +1

Oil-water separation system and separation method

ActiveCN109652117AReduce cloggingPrevent adhesionFatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansFiltrationDistributor

The invention discloses an oil-water separation system and a separation method. The oil-water separation system comprises a membrane filtration / demulsification system, a pre-separation system, a lightphase separation system and a heavy phase separation system; the membrane filtration / demulsification system comprises a membrane module and a circulating pump, and the pre-separation system comprisesa feeding tube, a hollow filter element and a steady flow zone; the light phase separation system sequentially comprises a material uniform distributor I, an upper coalescence separation zone and a light phase discharge port from bottom to top; and the heavy phase separation system sequentially comprises a material uniform distributor II, a lower coalescence separation zone, a light phase and heavy phase separation zone and a heavy phase discharge port from top to bottom. The separation system can be used to achieve continuous removal and preliminary of granular suspended matters in a material to be separated, rapid removal of free water drops or oil drops and demulsification and coalescence of a small amount of a heavy phase entrained in a light phase and a small amount of the light phase entrained in the heavy phase, has the advantages of short material residence time, high dewatering / deoiling efficiency and small device size, can realize deep removal of water, especially emulsifiedwater, in an oil product and deep removal of emulsified oil drops in sewage, has obvious advantages in oil-water separation of complex-composition and high-viscosity particle-containing severely emulsified oil products, and enables the moisture or oil removal rate to reach 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

Devices And Processes For Deasphalting And/Or Reducing Metals In A Crude Oil With A Desalter Unit

ActiveUS20100089797A1Easy to processReduce dirtDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDesalterWater soluble

This invention relates to devices and processes for removing asphaltenes and / or metals from crude oil to increase refinery processing of heavy materials. The desalters of this invention reduce and / or remove at least a portion of asphaltenes and / or metals form the crude oil. The separation occurs by mixing water with the crude oil to result in an aqueous phase having water and water soluble salts, an interface phase having asphaltenes and / or metals along with water, and a hydrocarbon phase having desalted, deasphalted and / or reduced metal crude oil.

Owner:BP CORP NORTH AMERICA INC

Popular searches

Cleaning using liquids Non-miscible liquid separation Water/sewage treatment by oxidation Water/sewage treatment by irradiation Other chemical processes Water contaminants Water/sewage treatment with mechanical oscillations Water/sewage treatment by magnetic/electric fields Energy based chemical/physical/physico-chemical processes Machines/engines

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com