Patents

Literature

1610 results about "Microfiltration membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

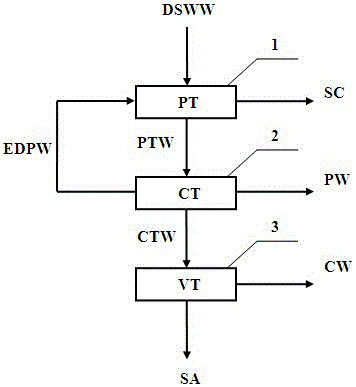

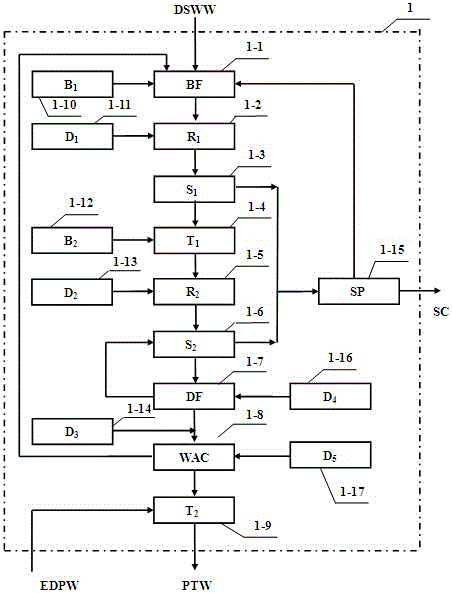

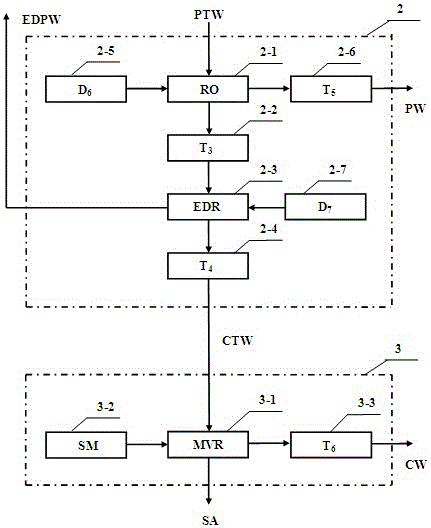

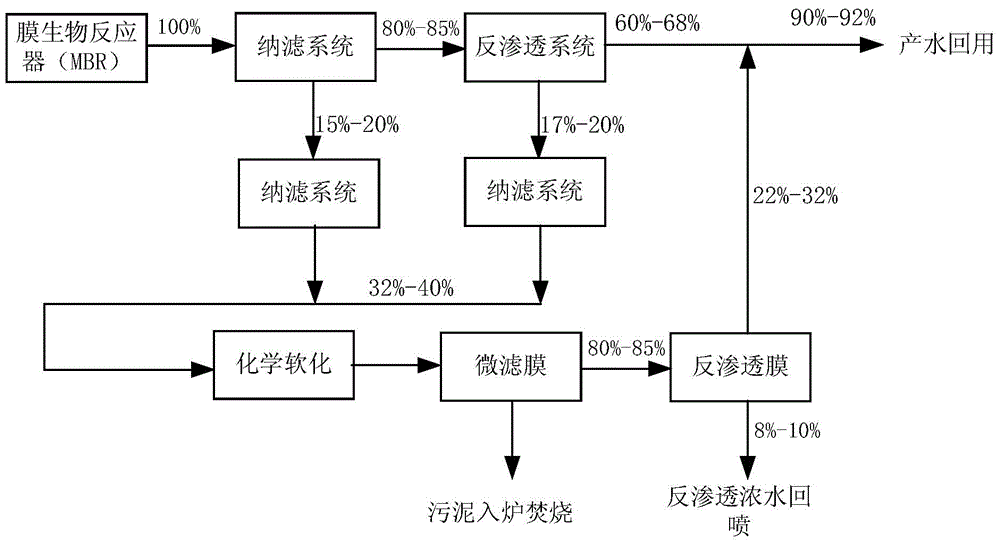

Desulfurization waste water zero discharging process and system

ActiveCN104843927ASolve pollutionWaste water treatment from gaseous effluentsMultistage water/sewage treatmentWater useHydration reaction

The invention discloses a desulfurization waste water zero discharging process. The process comprises a chemical dosing softening process and a microfiltration membrane treatment process; after incoming water is subjected to two-stage softening, nanofiltration and reverse osmosis separation are performed; sodium sulfate decahydrate with the purity of more than 99% is separated out by utilizing freezing crystallization; a reverse osmosis concentrated water regeneration sodium ion exchange device is utilized; sodium chloride with the purity of more than 98% is separated out by utilizing evaporative crystallization; solids are comprehensively utilized, and no liquid is discharged outside. The invention further provides a desulfurization waste water zero discharging system. According to the desulfurization waste water zero discharging process and the system, water in desulfurization waste water can be separated to be reutilized as domestic and industrial usable water, and other impurities in the desulfurization waste water are separated in solid form, so that pollutants harmful to the natural environment do not generate, and the problem that the desulfurization waste water pollutes the environment can be completely solved.

Owner:华电水务工程有限公司

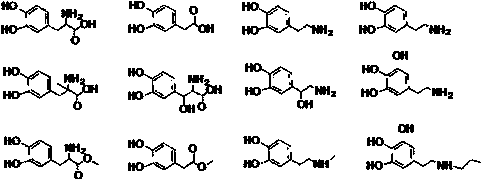

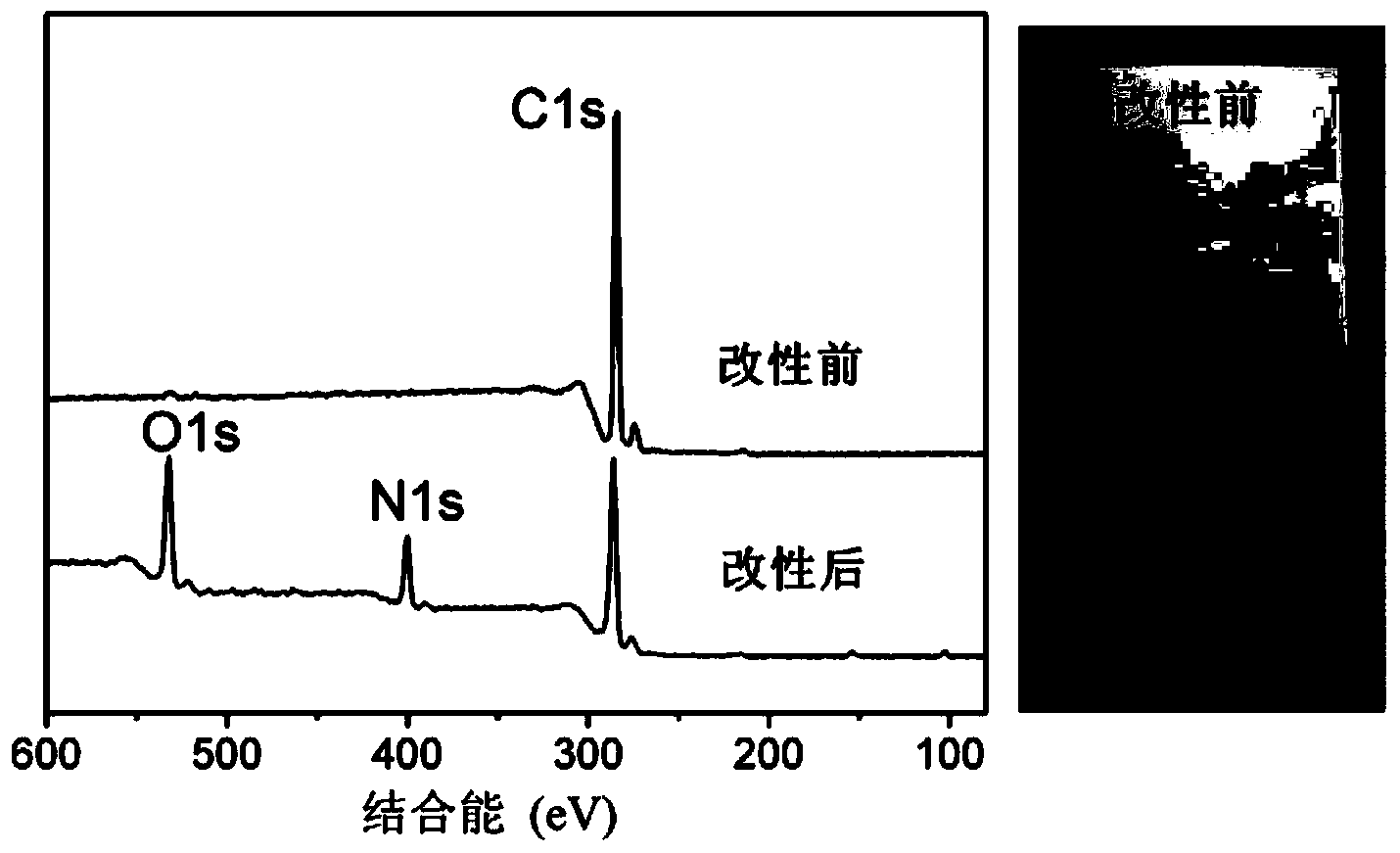

Preparation method and application of anti-pollution hydrophilic separating membrane

ActiveCN103480278AReduce dosageMeet the needs of hydrophilic immobilizationSemi-permeable membranesMembrane permeabilizationMicrofiltration membrane

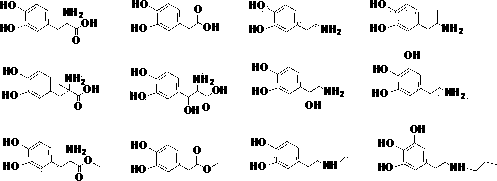

The invention discloses a preparation method and an application of an anti-pollution hydrophilic separating membrane. The preparation method is characterized in that a pyrocatechol derivative is used as an accelerant and a curing agent between a separating membrane material and a hydrophilic material, when blending casting film liquid of the separating membrane is prepared, the pyrocatechol derivative is added to blending liquid of the separating membrane material and the hydrophilic material, and the pyrocatechol derivative is subjected to polymerization cross-linking in a phase conversion process of the membrane preparation, so that the effect of fixing the hydrophilic material is achieved. The preparation method of the anti-pollution hydrophilic separating membrane has strong universality and is suitable for the blending of multiple hydrophilic materials and multiple membrane materials. The preparation method is simple, easy to operate, mild in conditions, economic, high-efficiency, environmentally-friendly, easy for industrialization and suitable for the preparation of multi-functional hydrophilic micro-filtration membranes, ultra-filtration membranes, nano-filtration membranes, reverse-osmosis membranes, positive-osmosis membranes, pressure-delay osmosis membranes, pervaporation membranes and the like which are used for liquid and gas separation and membrane reactors.

Owner:YANTAI LVSHUIFU MEMBRANE MATERIAL

Purification of beta casein from milk

ActiveUS20070104847A1Without negatively impactingFunctionalMilk preparationFood membrane processMilk SerumMicrofiltration membrane

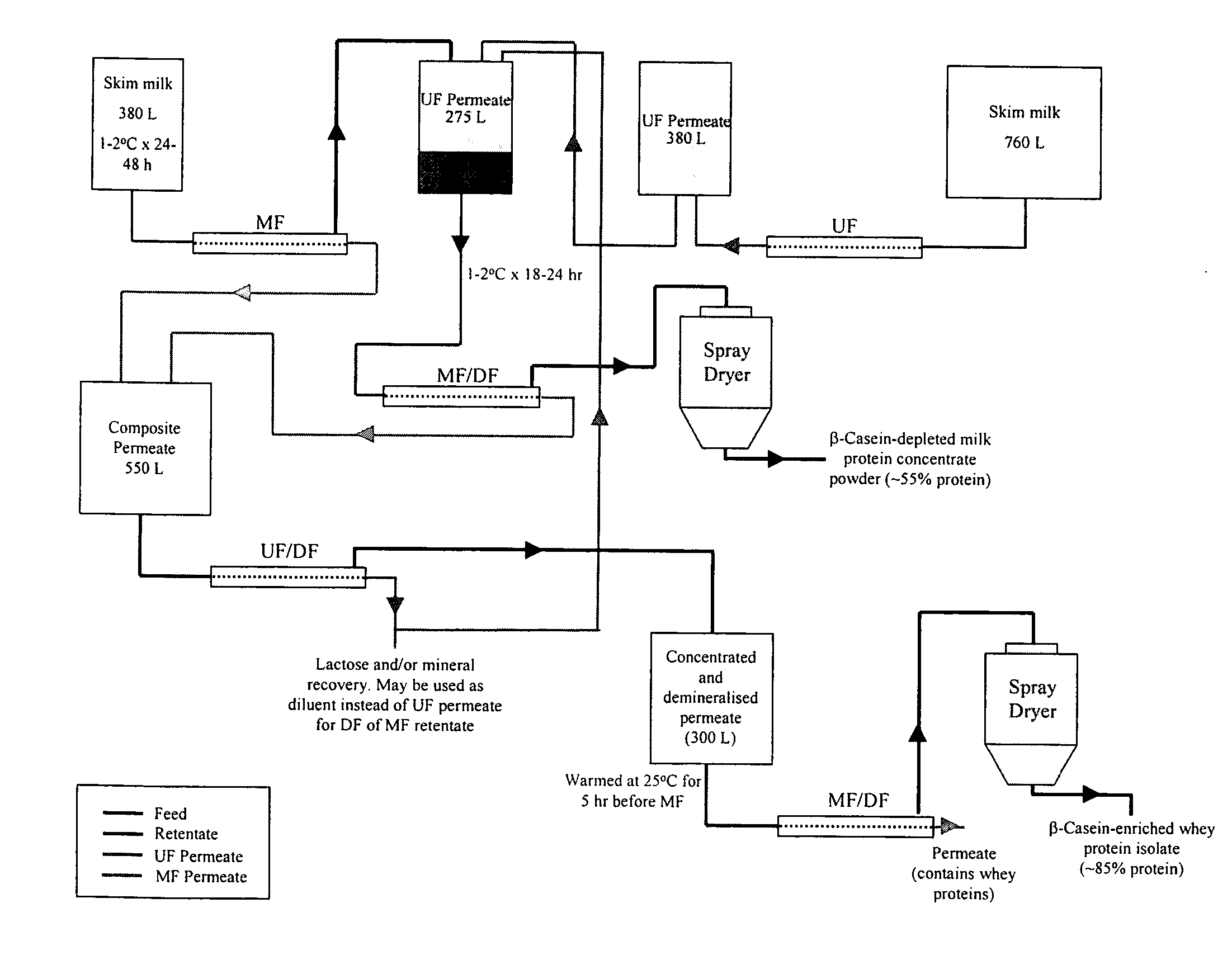

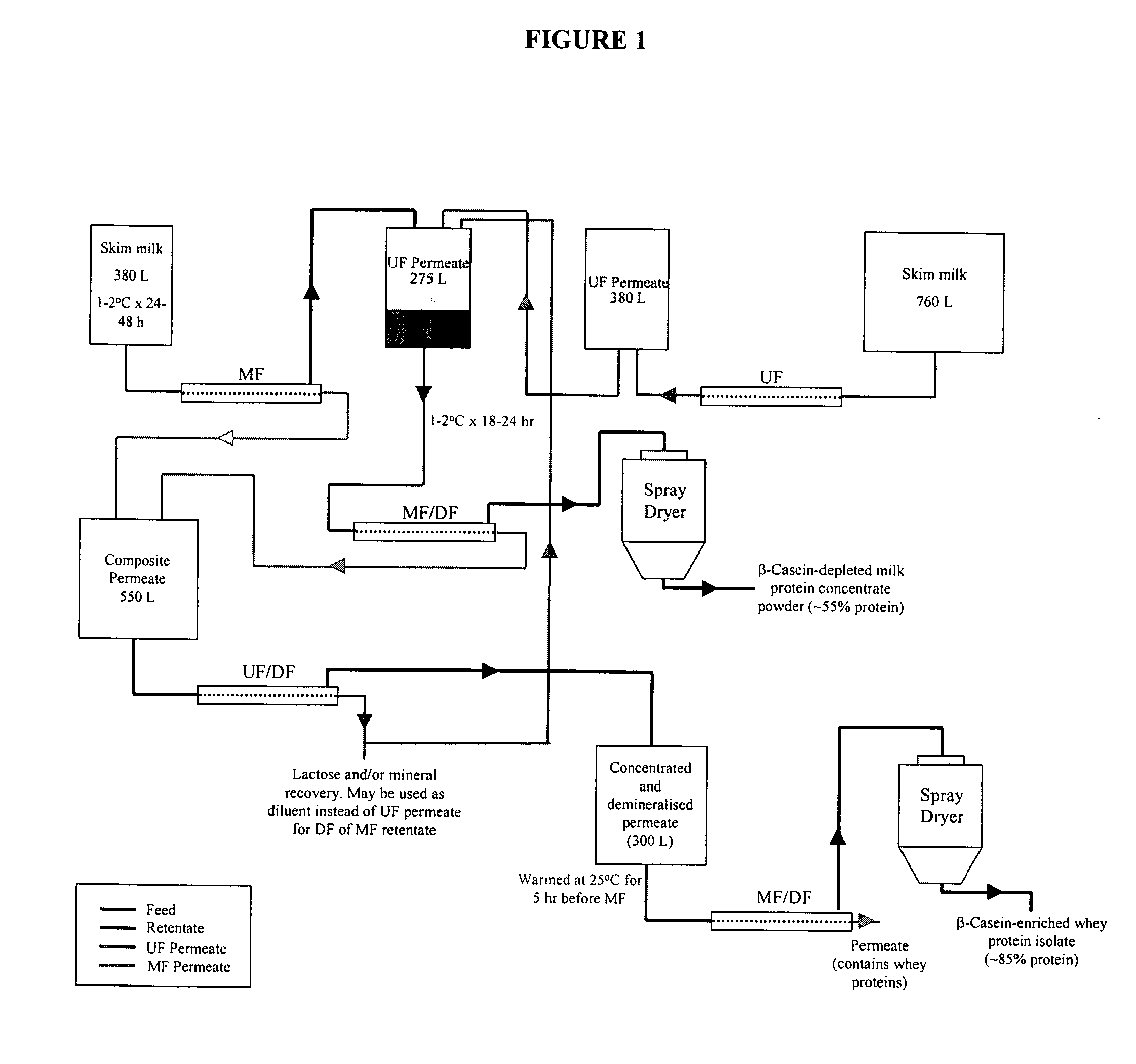

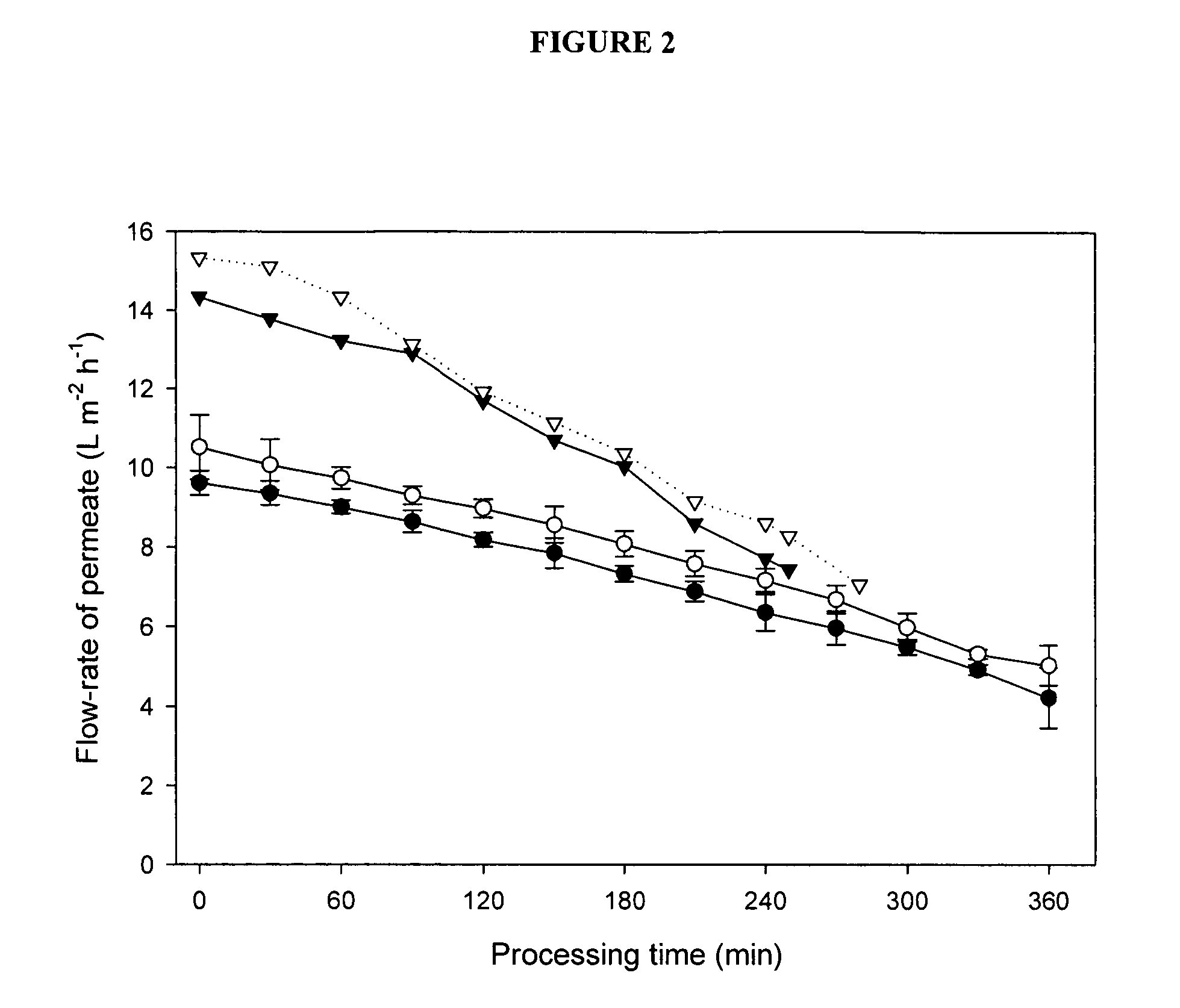

A method is provided for obtaining β-casein from skim milk. Purification of β-casein from milk is achieved through a process of microfiltration using cross-flow polymeric microfiltration membranes. Cooling of the milk prior to microfiltration results in improved separation of β-casein from the other milk serum proteins. Further filtration and demineralization of the microfiltered permeate results in enrichment of the fraction containing soluble β-casein. An integrated scheme that allows a dairy plant to continuously separate and purify β-casein is provided. Also provided is a method for obtaining cheese with improved meltability and reduced bitterness.

Owner:WISCONSIN ALUMNI RES FOUND

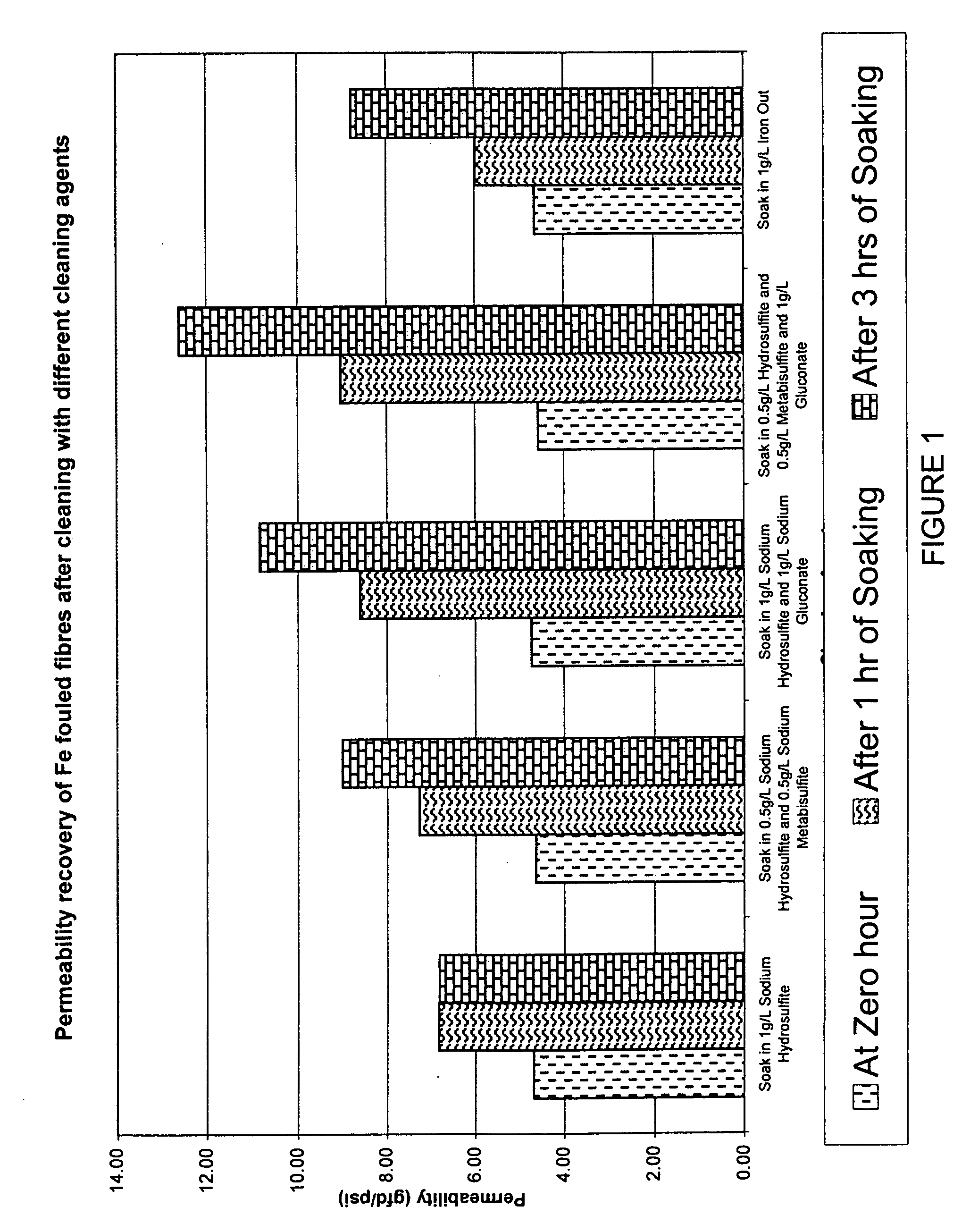

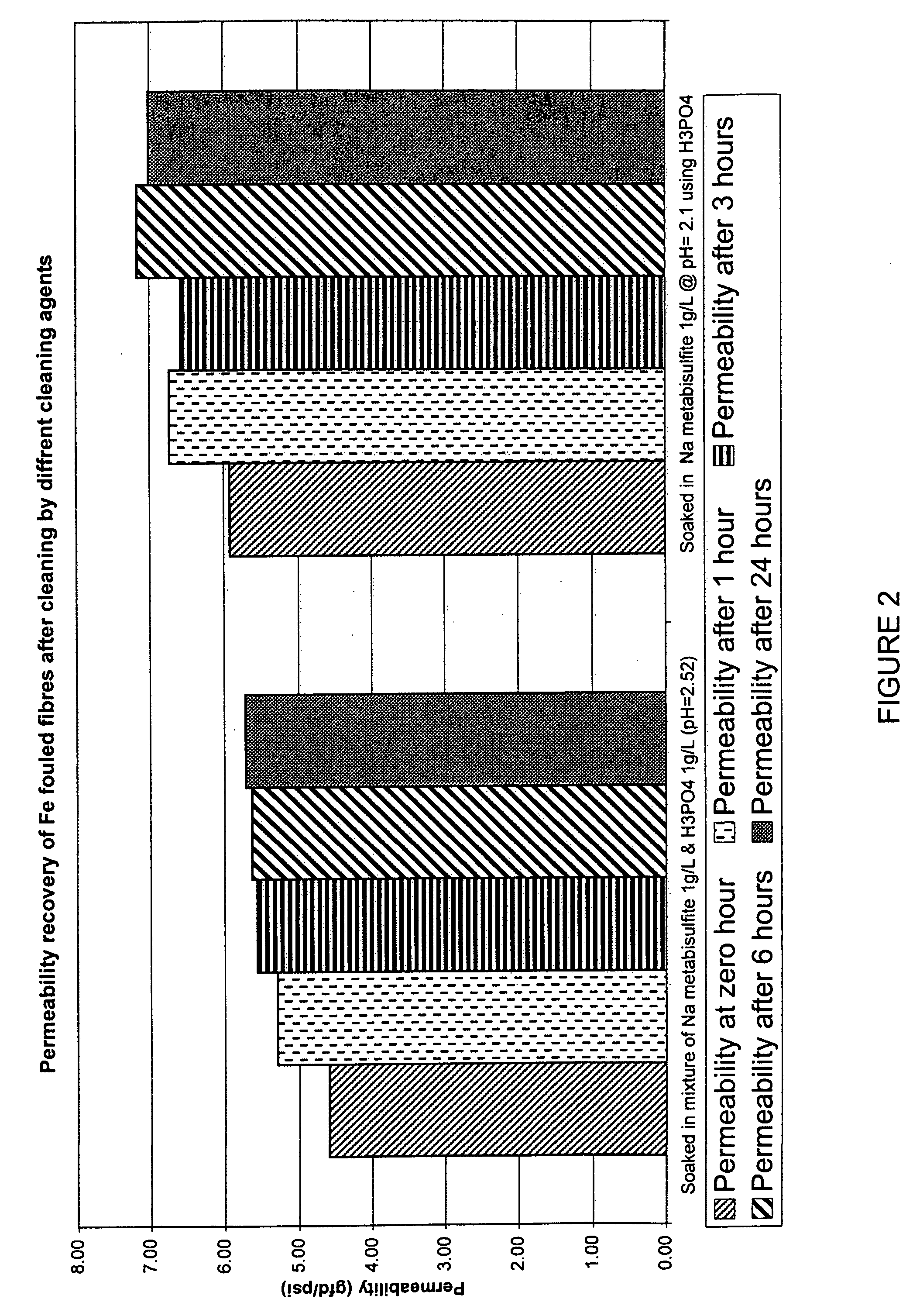

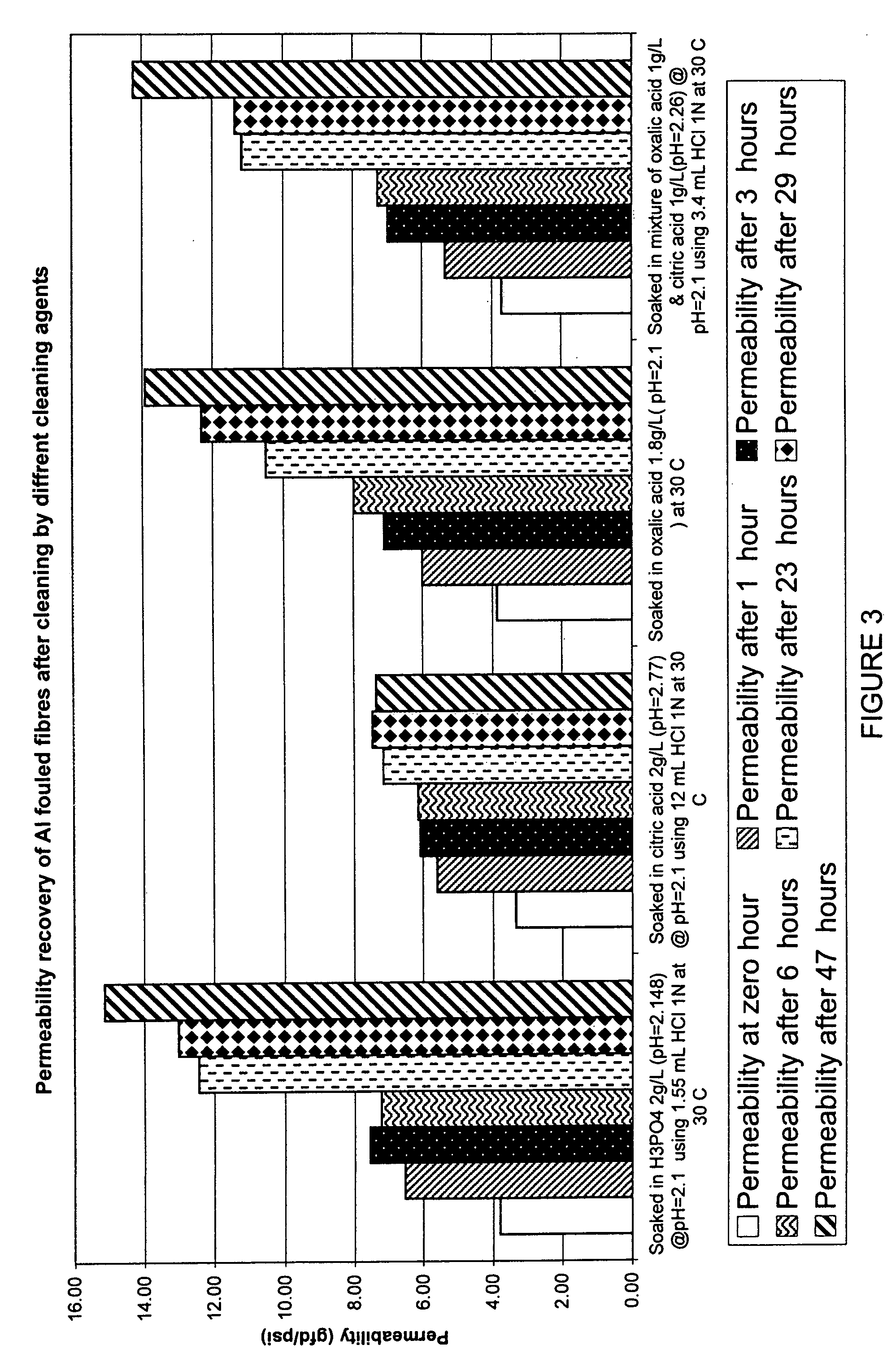

Chemical cleaning for membranes

Membranes, for example immersed polymeric ultrafiltration or microfiltration membranes, are cleaned by contacting them with a chemical cleaner comprising one or more of a gluconate, a hydrosulfite, a metabisulfite or an acid, for example phosphoric acid. The membranes may have been exposed to organic or inorganic foulants, some of which may have resulted from pretreatment involving adding coagulants, for example coagulants containing iron or aluminum, to water to be treated. Methods for treating a waste cleaning solution were described.

Owner:SYED MURTUZA ALI +3

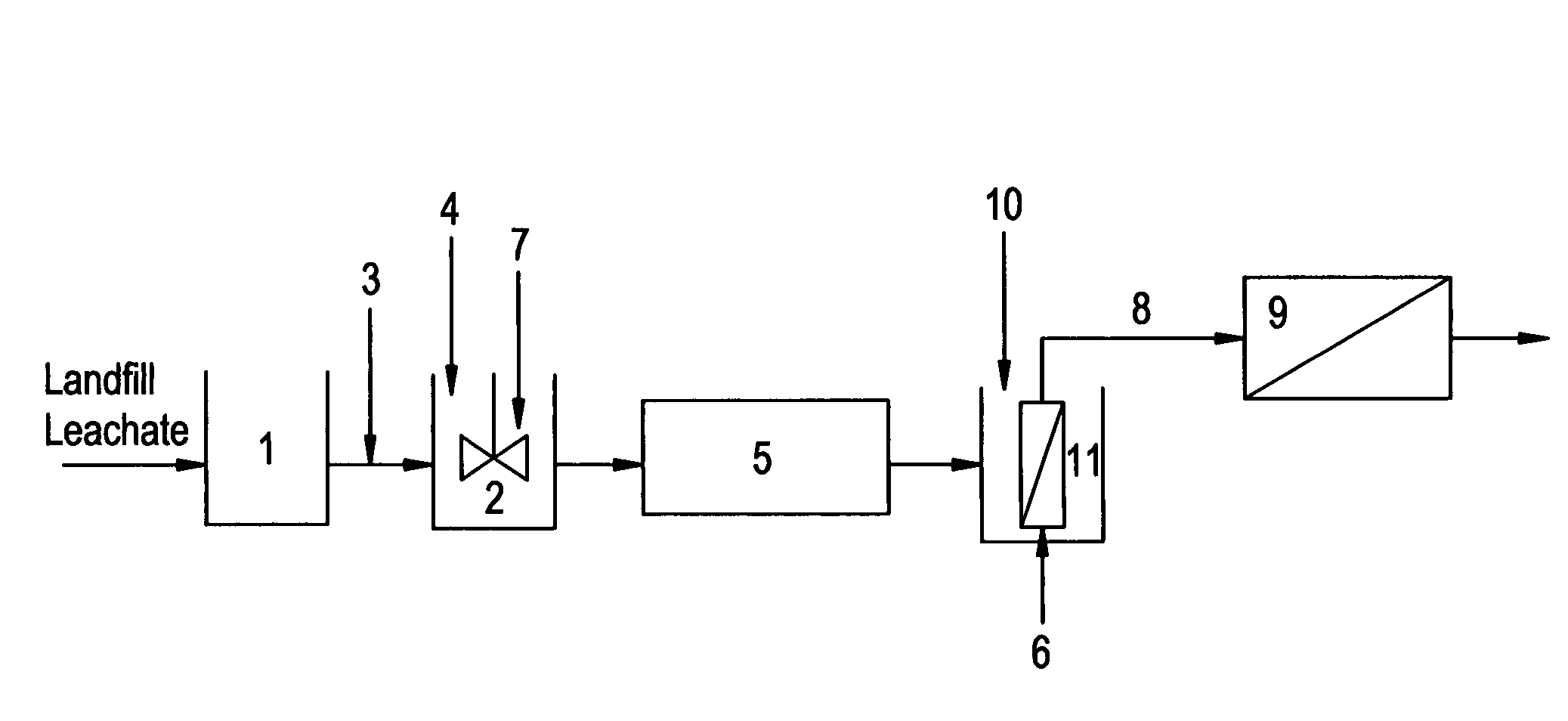

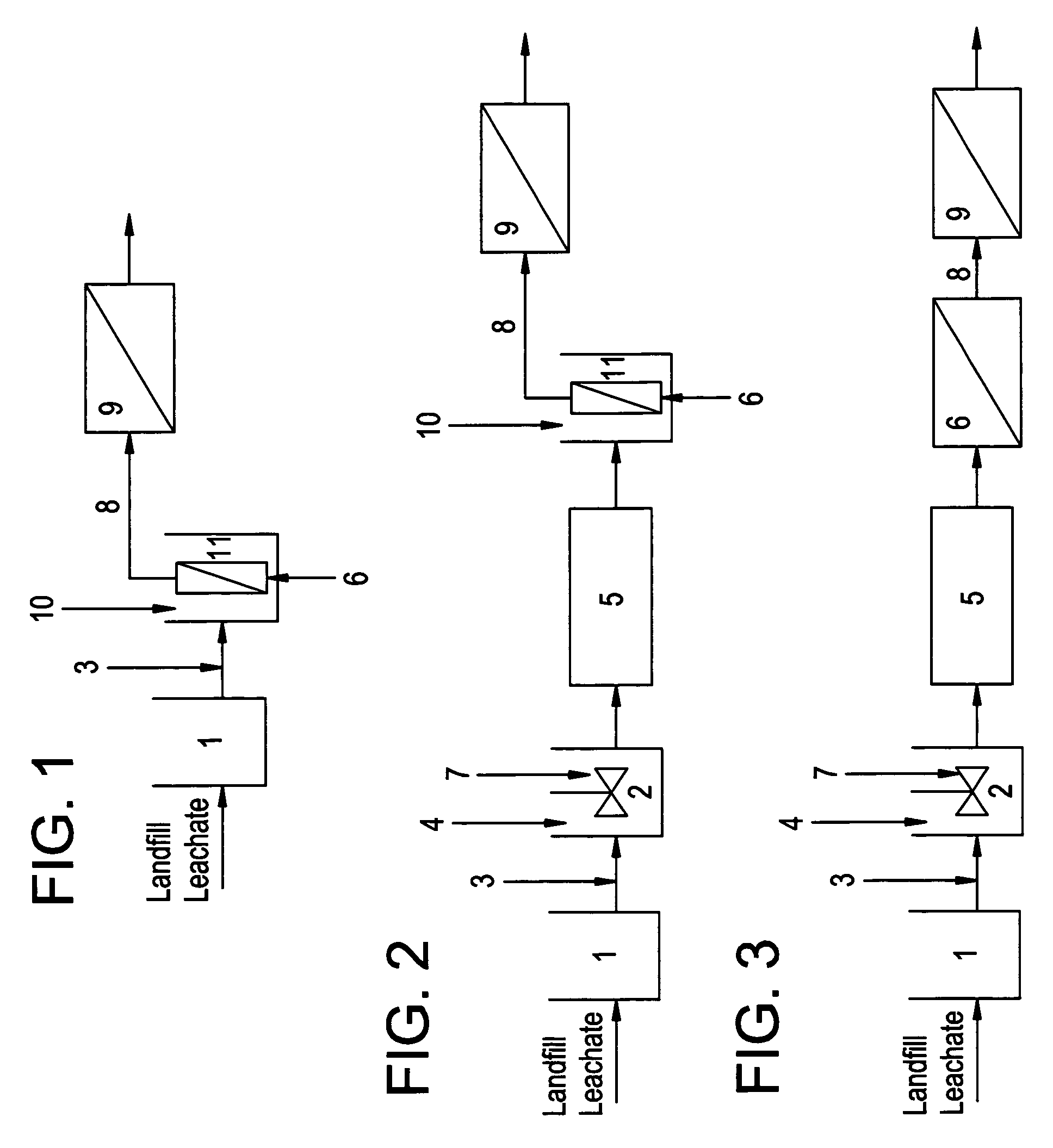

Method of improving performance of ultrafiltration or microfiltration membrane process in landfill leachate treatment

A method of processing landfill leachate by use of a membrane separation process is disclosed. Specifically, the following steps are taken to process landfill leachate: collecting landfill leachate in a receptacle suitable to hold said landfill leachate; treating said landfill leachate with one or more water soluble polymers, wherein said water soluble polymers are selected from the group consisting of: amphoteric polymers; cationic polymers; zwitterionic polymers; and a combination thereof; optionally mixing said water soluble polymers with said landfill leachate; passing said treated landfill leachate through a membrane, wherein said membrane is an ultrafiltration membrane or a microfiltration membrane; and optionally back-flushing said membrane to remove solids from the membrane surface.

Owner:ECOLAB USA INC

Membrane post treatment

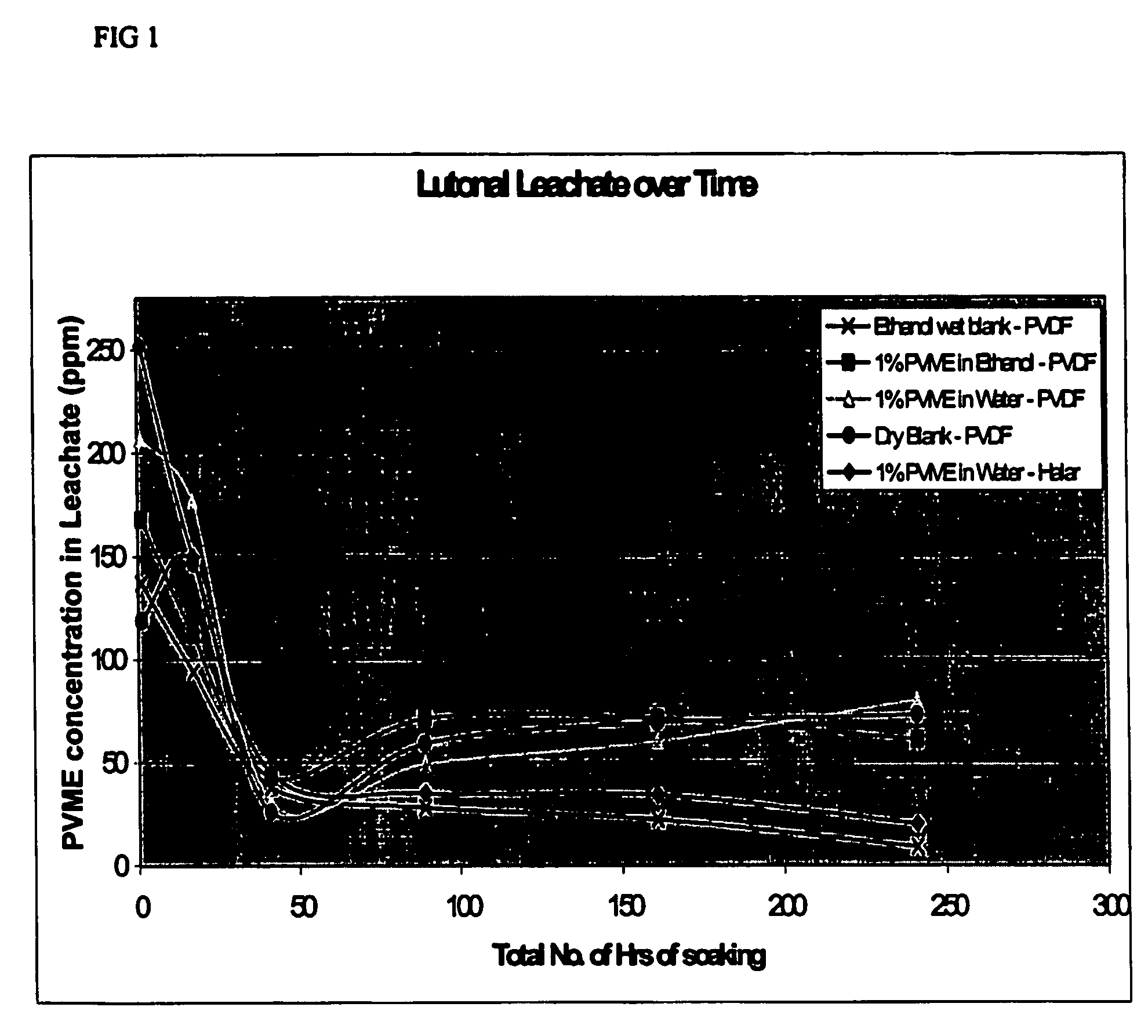

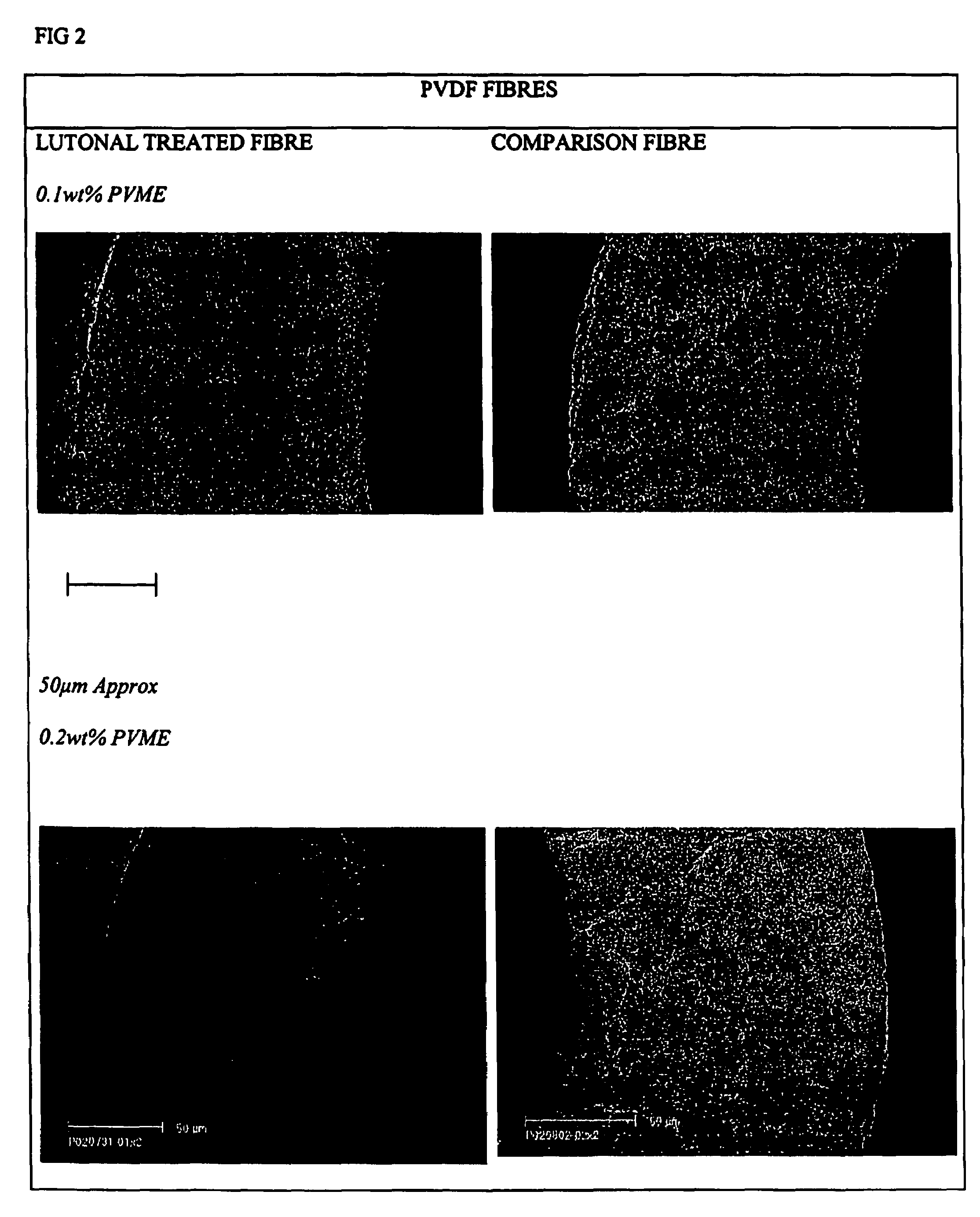

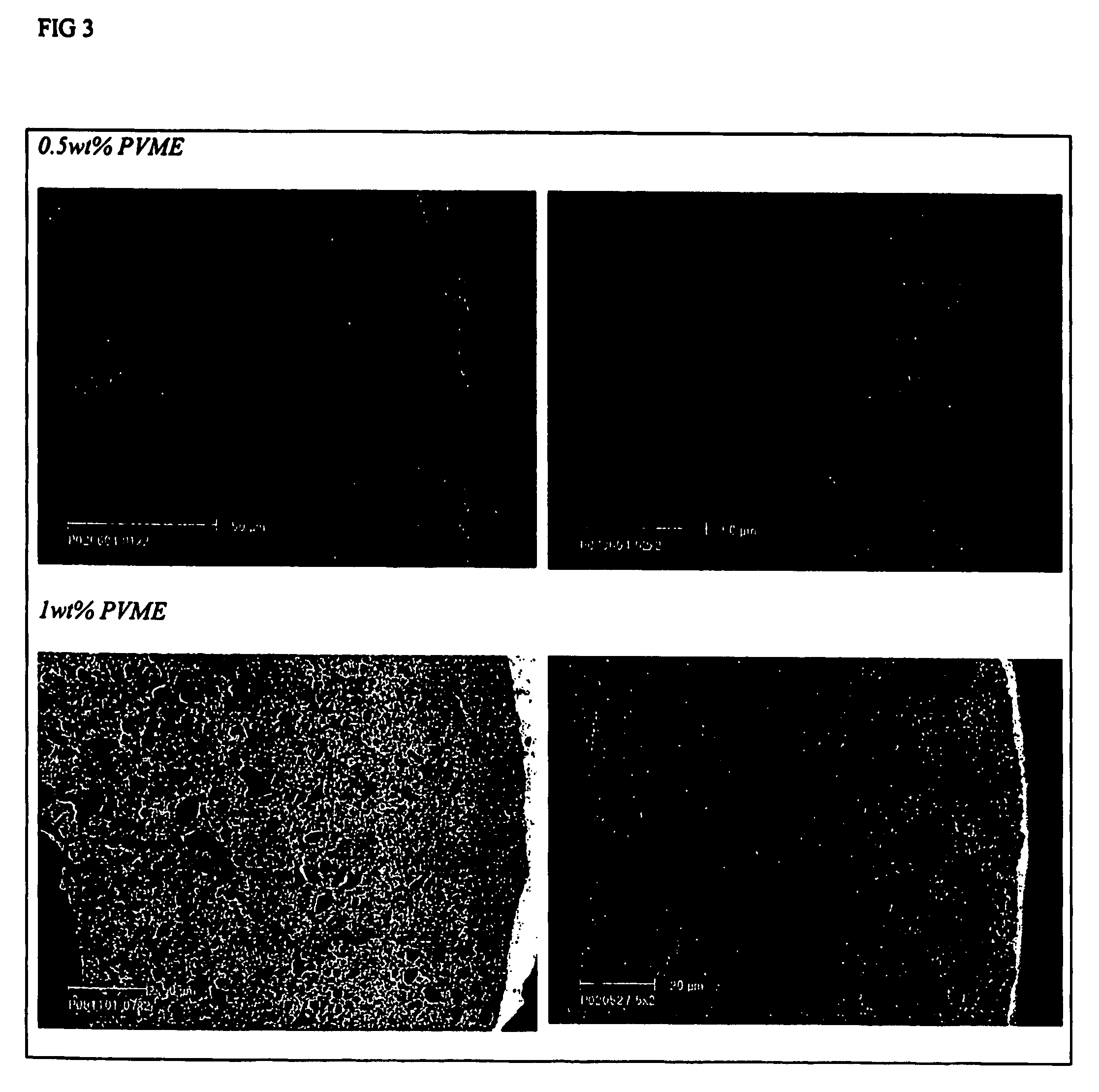

InactiveUS7662212B2Low toxicityReduce riskSolid sorbent liquid separationPretreated surfacesHydrophilizationMicrofiltration membrane

The invention relates to polymeric ultrafiltration or microfiltration membranes of, for instance, Halar, PVDF or PP, incorporating PVME or vinyl methyl ether monomers. The PVME may be present as a coating on the membrane or dispersed throughout the membrane or both. The membranes are preferably hydrophilic with a highly asymmetric structure with a reduced pore size and / or absence of macrovoids as a result of the addition of PVME. The PVME maybe cross-linked. The invention also relates to methods of hydrophilising membranes and / or preparing hydrophilic membranes via thermal or diffusion induced phase separation processed.

Owner:EVOQUA WATER TECH LLC

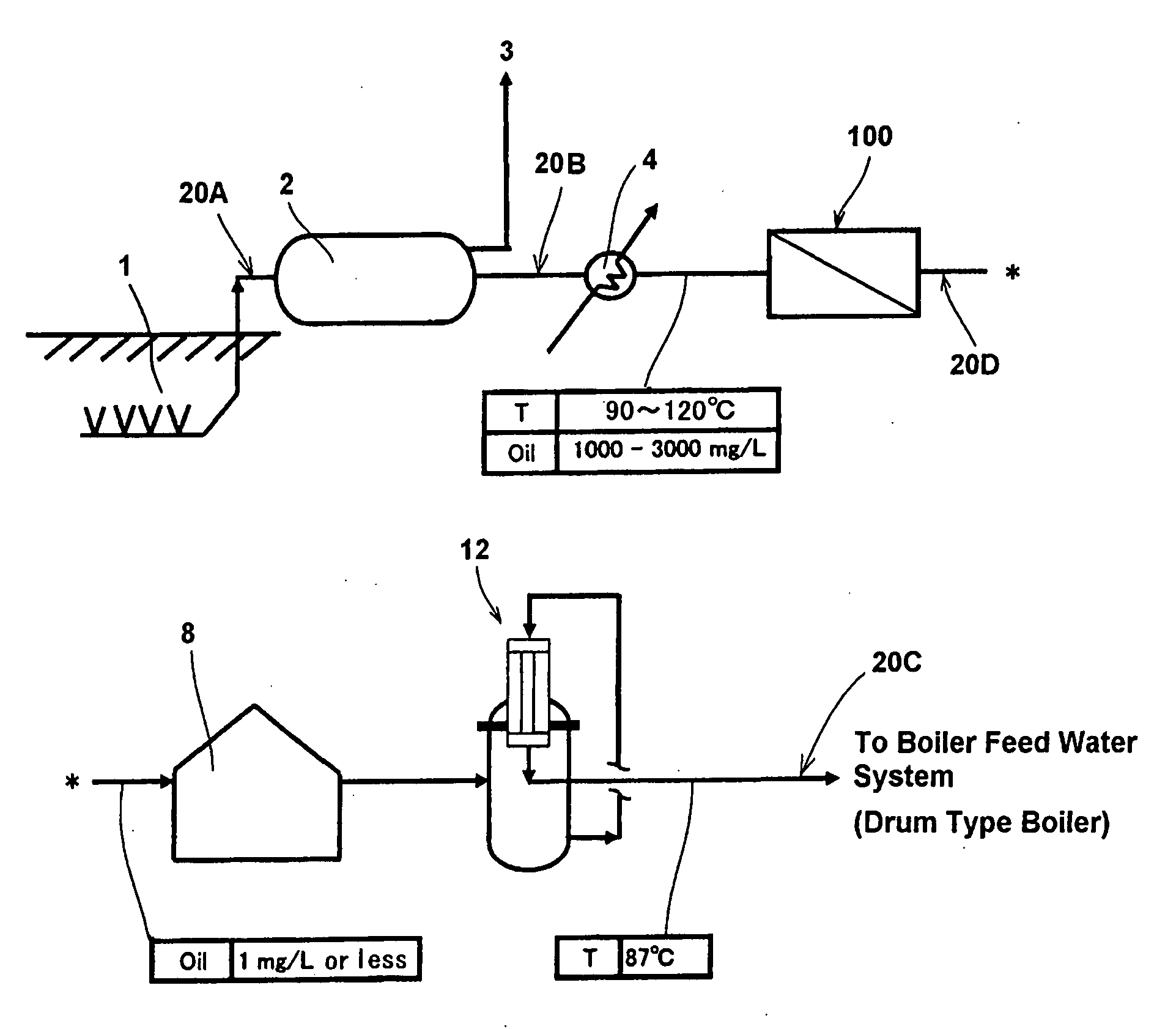

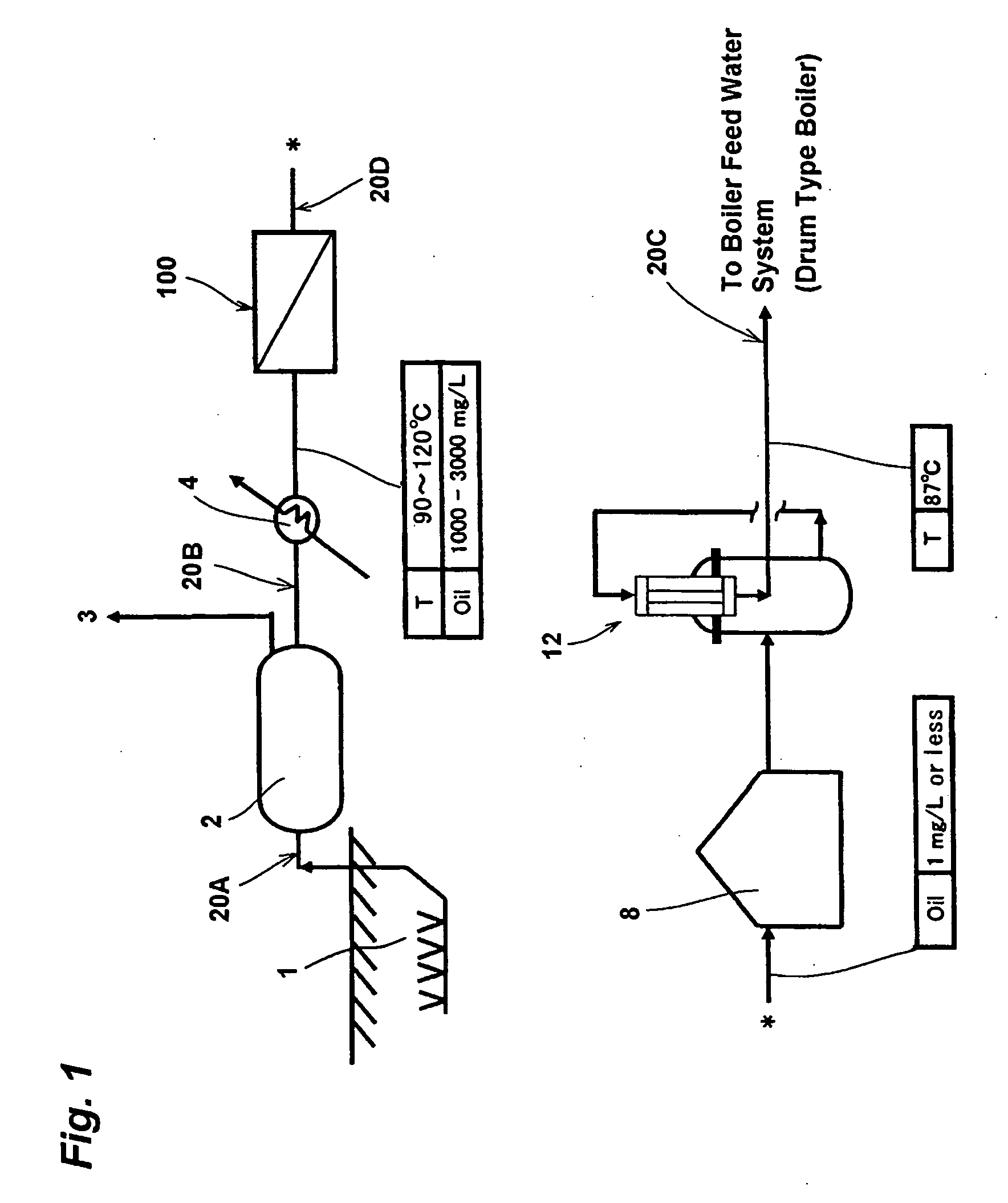

Method of produced water treatment, method of water reuse, and systems for these methods

ActiveUS20100264068A1Fatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansRecovery methodMicrofiltration membrane

A method of produced water treatment in an in-situ recovery method of producing bitumen from oil sand, the method has the steps of: separating bitumen from bitumen-mixed fluid so as to leave produced water, the bitumen-mixed fluid having been recovered from the oil sand wells; and filtering the produced water via a microfiltration membrane made of polytetrafluoroethylene.

Owner:SUMITOMO ELECTRIC IND LTD +1

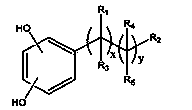

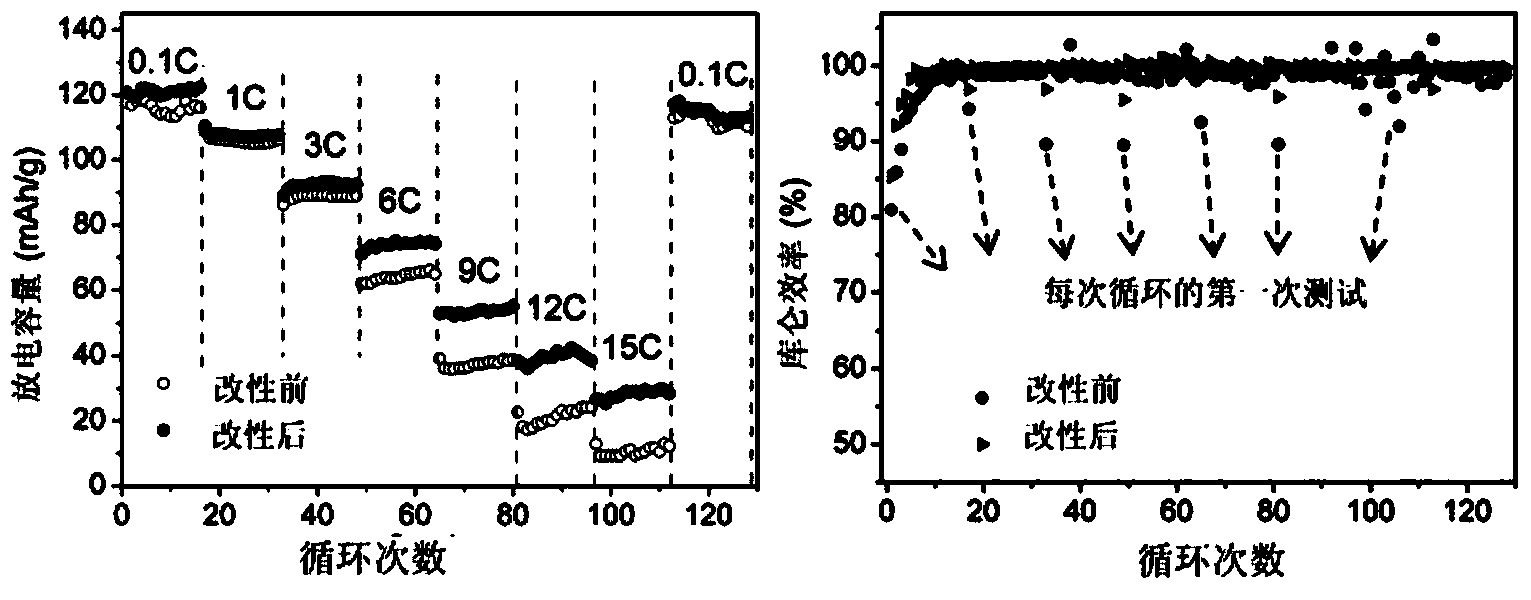

Method for surface modification of hydrophobic polymer microporous membrane

The invention discloses a method for surface modification of a hydrophobic polymer microporous membrane. The method comprises the steps of dissolving a pyrocatechol compound and a polyamine molecule in a solvent, and adjusting the mixture to be alkaline so as to obtain a modification solution; soaking the hydrophobic polymer microporous membrane in the modification solution to realize the surface modification of the hydrophobic polymer microporous membrane through reaction, wherein the structural formula of the pyrocatechol compound is shown by a formula I, and in the formula I, R is H, -CH3, -(CH2)nCOOH, -CHO or OH and n is an integer between 0 and 2. The microporous membrane modified by the method disclosed by the invention can be applied in the fields of diaphragms of positive and negative materials of lithium secondary batteries, nickel-hydrogen batteries, nickel-cadmium batteries, polymer batteries and the like, as well as separation membranes including reverse osmose membranes, micro-filtration membranes, nano-filtration membranes, ultrafiltration membranes, electrodialysis membranes, gas separation membranes and the like to improve the performances of materials and devices.

Owner:INST OF CHEM CHINESE ACAD OF SCI

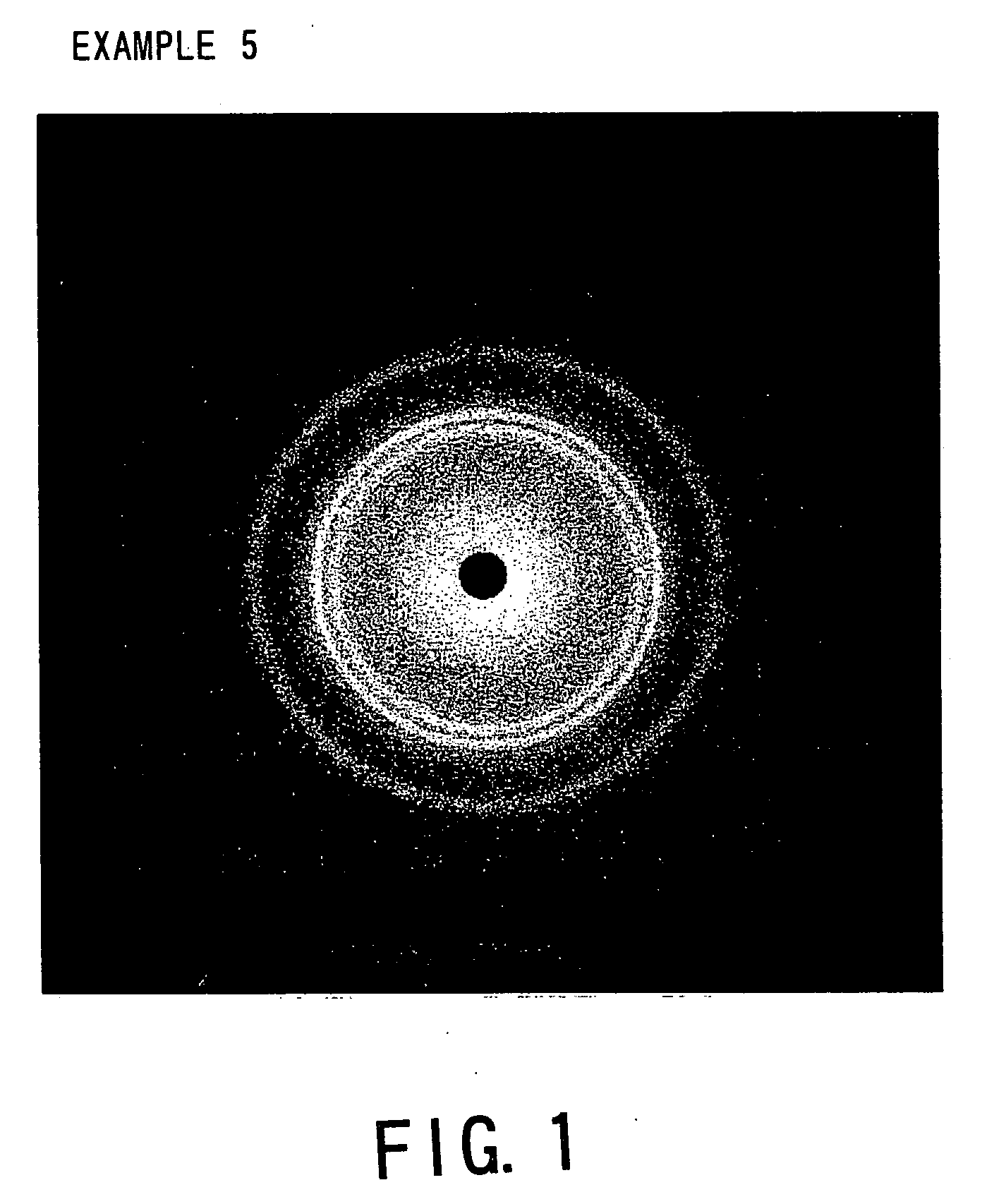

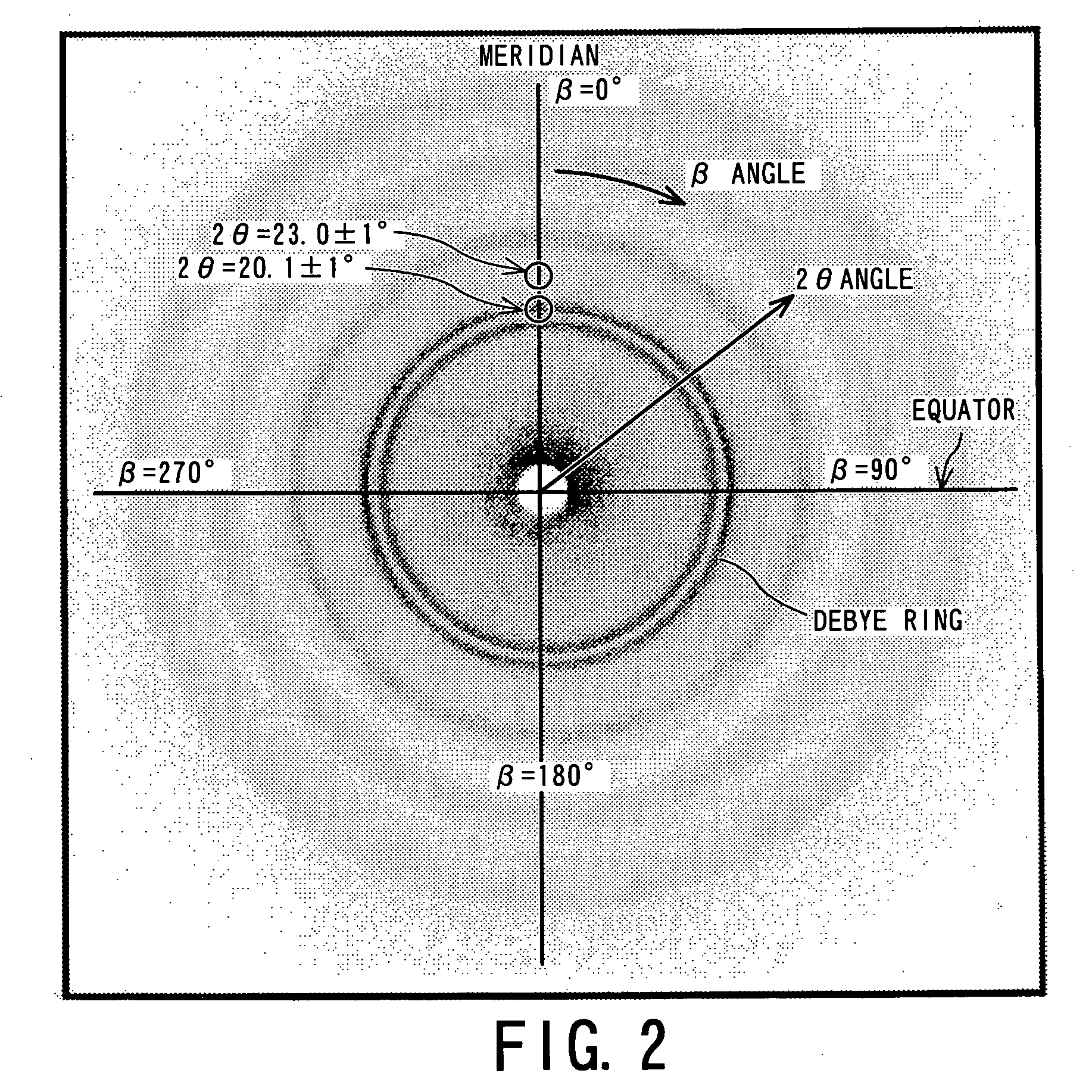

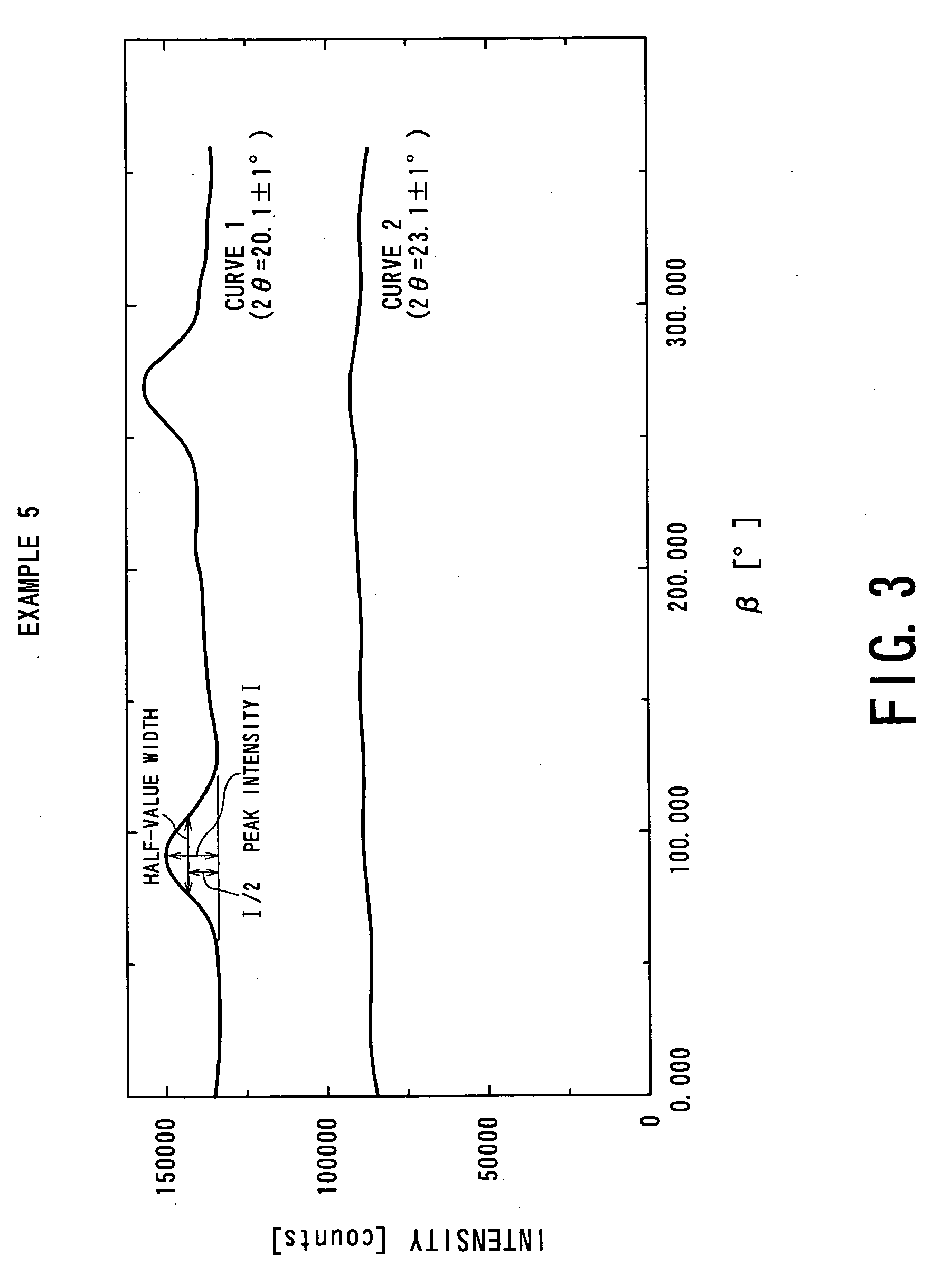

Porous membrane of vinylidene fluoride resin and process for producing the same

ActiveUS20060178480A1Improve heat distortion resistanceFacilitate stretchingSemi-permeable membranesMembranesSolventPorous membrane

There is provided a porous membrane of vinylidene fluoride resin which has pores of appropriate size and distribution and also excellent mechanical strength represented by tensile strength and elongation at break and is useful as a microfiltration membrane or a separator for batteries. The porous membrane of vinylidene fluoride resin is characterized by the presence in mixture of a crystalline oriented portion and a crystalline non-oriented portion as confirmed by X-ray diffraction, and is produced by subjecting a melt-extruded composition obtained by mixing a vinylidene fluoride resin having a molecular weight distribution which is appropriately broad and high as a whole with a plasticizer and a good solvent for vinylidene fluoride resin, to cooling for solidification from one surface, extraction of the plasticizer and stretching.

Owner:KUREHA KAGAKU KOGYO KK

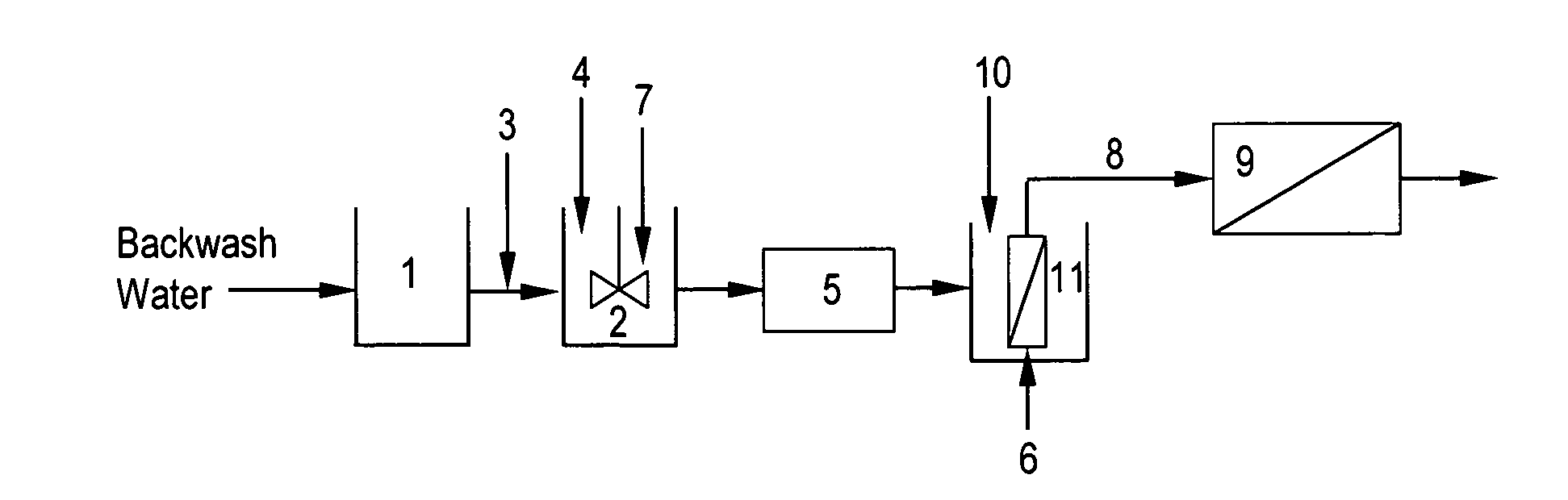

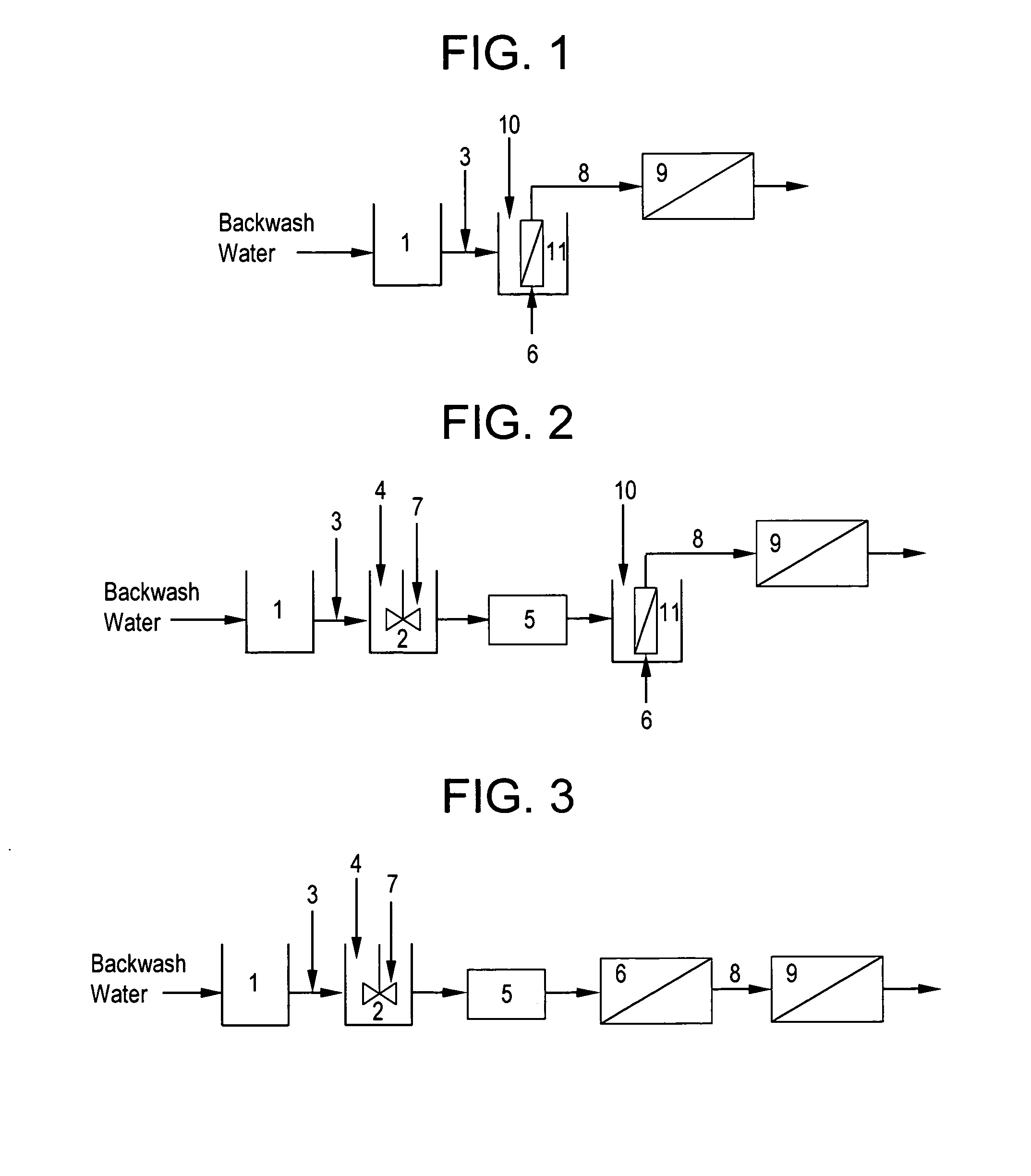

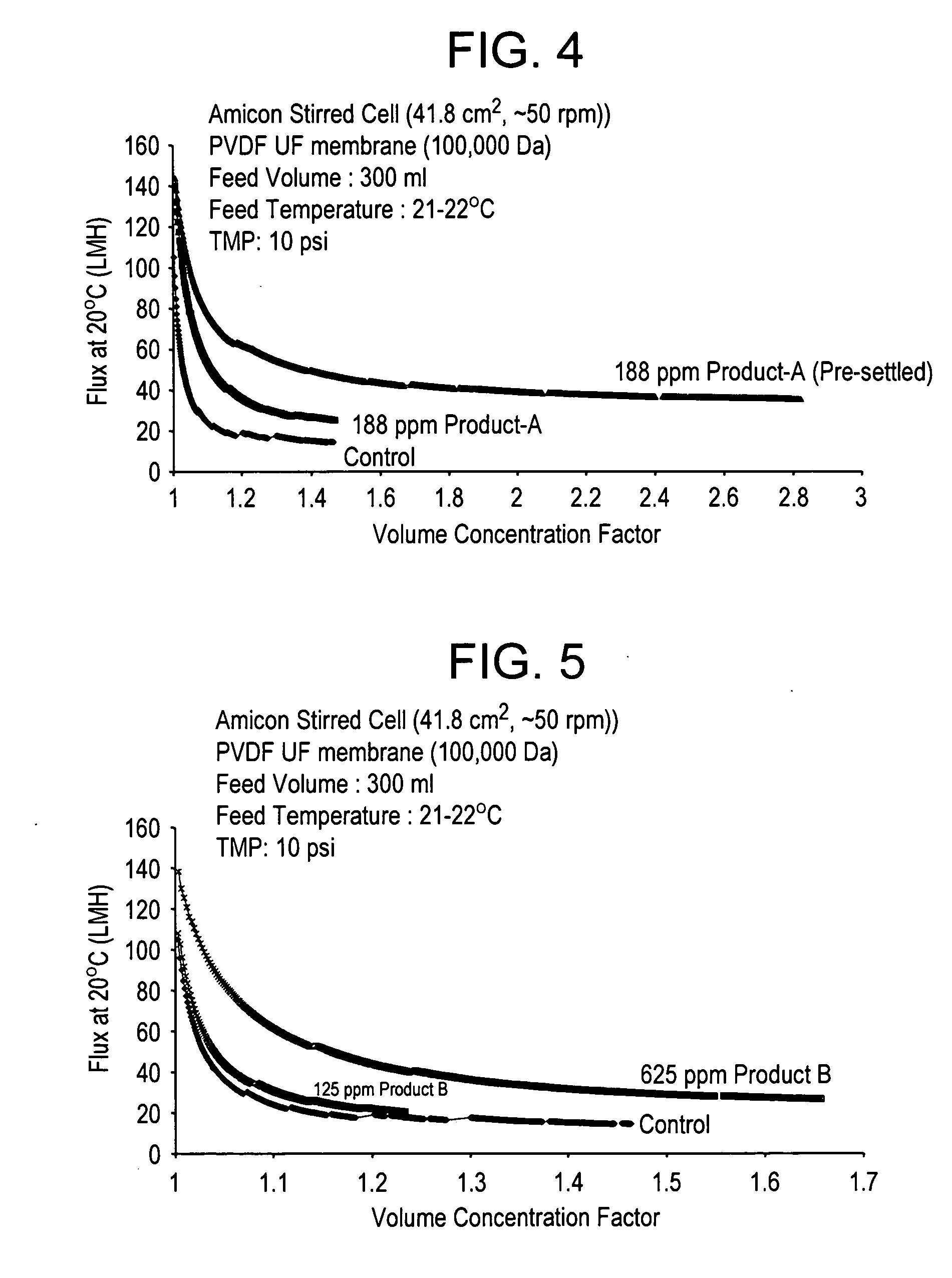

Method of improving performance of ultrafiltration or microfiltration membrane processes in backwash water treatment

A method of processing backwash water by use of a membrane separation process is disclosed. Specifically, the following steps are taken to process backwash water: collecting backwash water in a receptacle suitable to hold said backwash water; treating said backwash water with one or more water soluble polymers, wherein said water soluble polymers are selected from the group consisting of: amphoteric polymers; cationic polymers, wherein, said charge density is from about 5 mole percent to about 100 mole percent; zwitterionic polymers; and a combination thereof; optionally mixing said water soluble polymers with said backwash water; passing said treated backwash water through a membrane, wherein said membrane is an ultrafiltration membrane or a microfiltration membrane; and optionally back-flushing said membrane to remove solids from the membrane surface.

Owner:ECOLAB USA INC

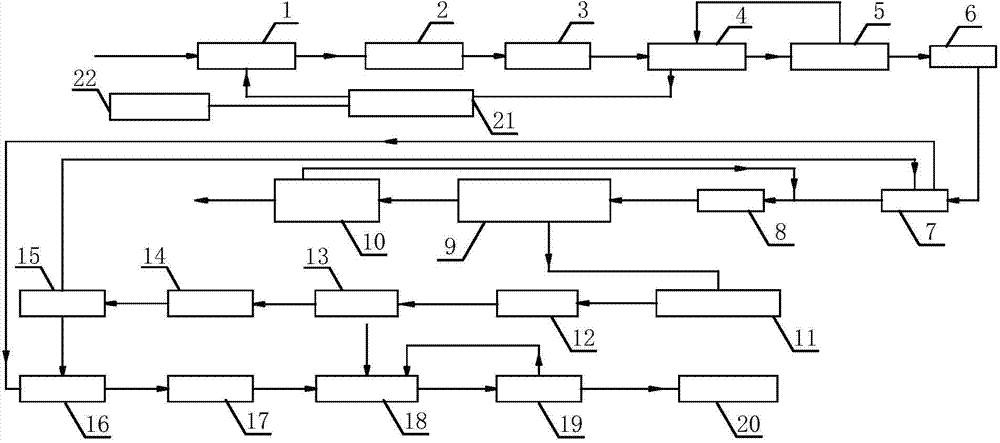

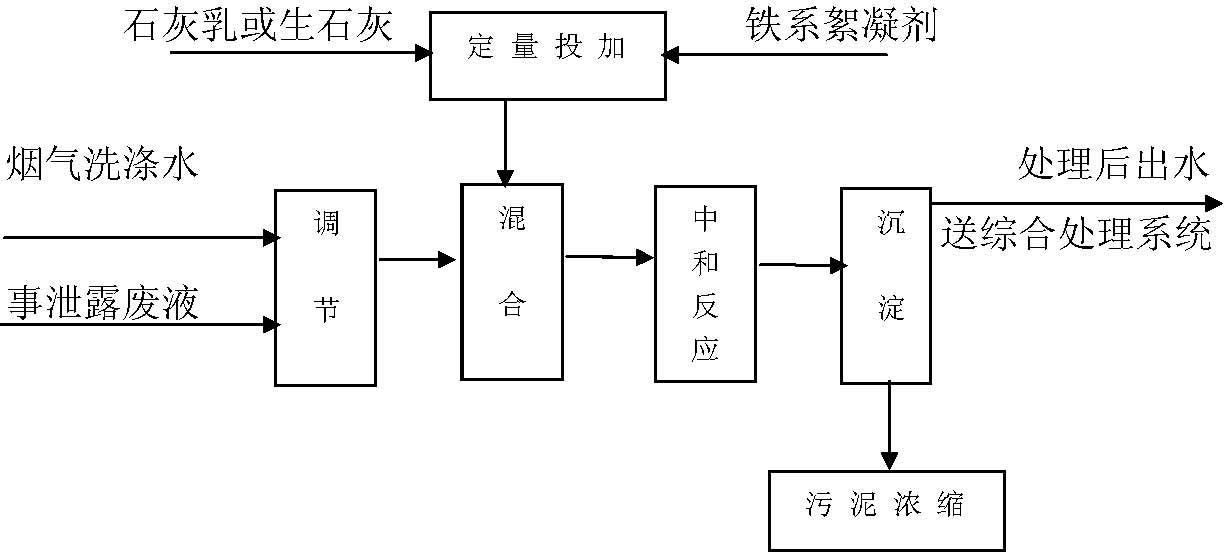

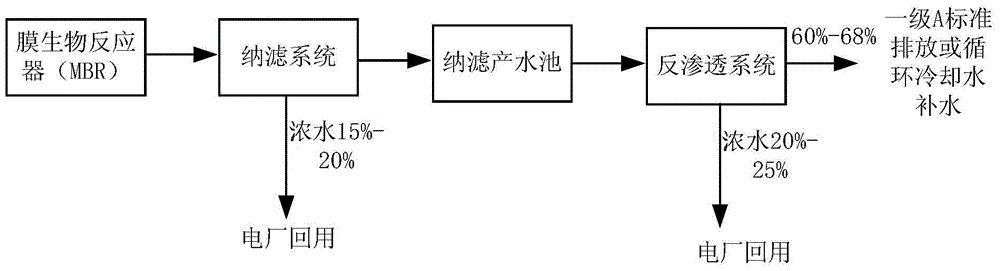

Recycling treatment device for desulfurized waste water and method thereof

ActiveCN105130084ATo achieve the purpose of resource managementRealize resource processingMultistage water/sewage treatmentReverse osmosisEvaporation

The invention discloses a recycling treatment device for desulfurized waste water and a method thereof. The recycling treatment device is characterized according to the characteristics of the desulfurized waste water, i.e., high-hydrochloric-acid inorganic waste water, a membrane treatment technology and an evaporation and crystallization treatment technology are adopted for carrying out the high-efficiency combined design, and the recycling treatment device comprises a pretreatment system, a membrane concentration treatment system and an evaporation and crystallization treatment system. The method comprises the following steps: firstly utilizing lime, sodium carbonate and a weak-acid bed for softening, and filtering by a cross-flow tube type microfiltration membrane, and removing calcium-magnesium ions and heavy-metal pollutants, then utilizing reverse osmosis and electrodialysis to carry out concentrated reduction on pretreated water, and reusing water produced from the reverse osmosis; finally evaporating and crystalizing concentrated liquid of the membrane concentration treatment system, respectively producing sodium sulfate and sodium chloride for recovering, reusing condensed water, thus achieving the purpose of recycling treatment of the desulfurized waste water. The recycling treatment device and the method disclosed by the invention have the advantages that (1) the softening of the lime, the sodium carbonate and the weak-acid bed is thorough; (2) the reverse osmosis and electrodialysis concentration are high-efficiency and the water produced by the reverse osmosis can be reused; (3) the sodium sulfate and the sodium chloride are respectively recovered from evaporation and crystallization; (4) the recycling treatment of the desulfurized waste water is realized.

Owner:江苏卓博环保科技有限公司

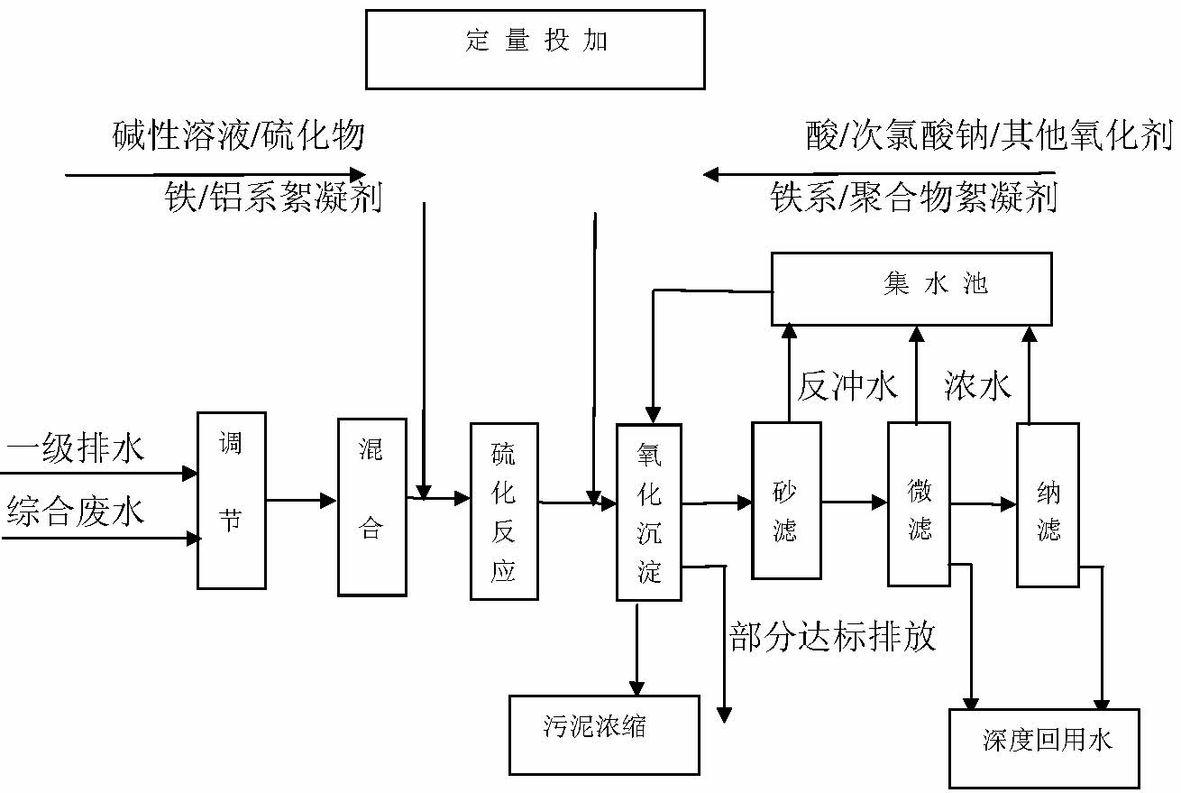

Advanced treatment and recycling process for wastewater containing heavy metal ions

InactiveCN102603097AHigh removal rateEasy to handle and manageMembranesWater contaminantsWater qualityCobalt

The invention discloses an advanced treatment and recycling process for wastewater containing heavy metal ions, which comprises the following steps of: primarily sedimenting wastewater of lead, zinc and other smelting enterprises respectively to remove most lead, zinc and arsenic in the wastewater; secondarily sedimenting to basically remove lead, cadmium, mercury, arsenic, zinc, copper, nickel, cobalt and other heavy metals in the wastewater; carrying out ceramic microfiltration membrane microfiltration treatment to remove SS in the wastewater to below 1mg / L so as to meet the requirement on quality of supplement water for circulating and cooling water, and the water is used as low-quality reuse water. The process disclosed by the invention is convenient to operate and manage, the operation is automatized, monitoring is easy to realize, the engineering investment and the operation cost are moderate, the heavy metal ion removal rate is high, and the process is easy to apply and popularize in the whole industry.

Owner:郑州鸿跃环保科技有限公司 +2

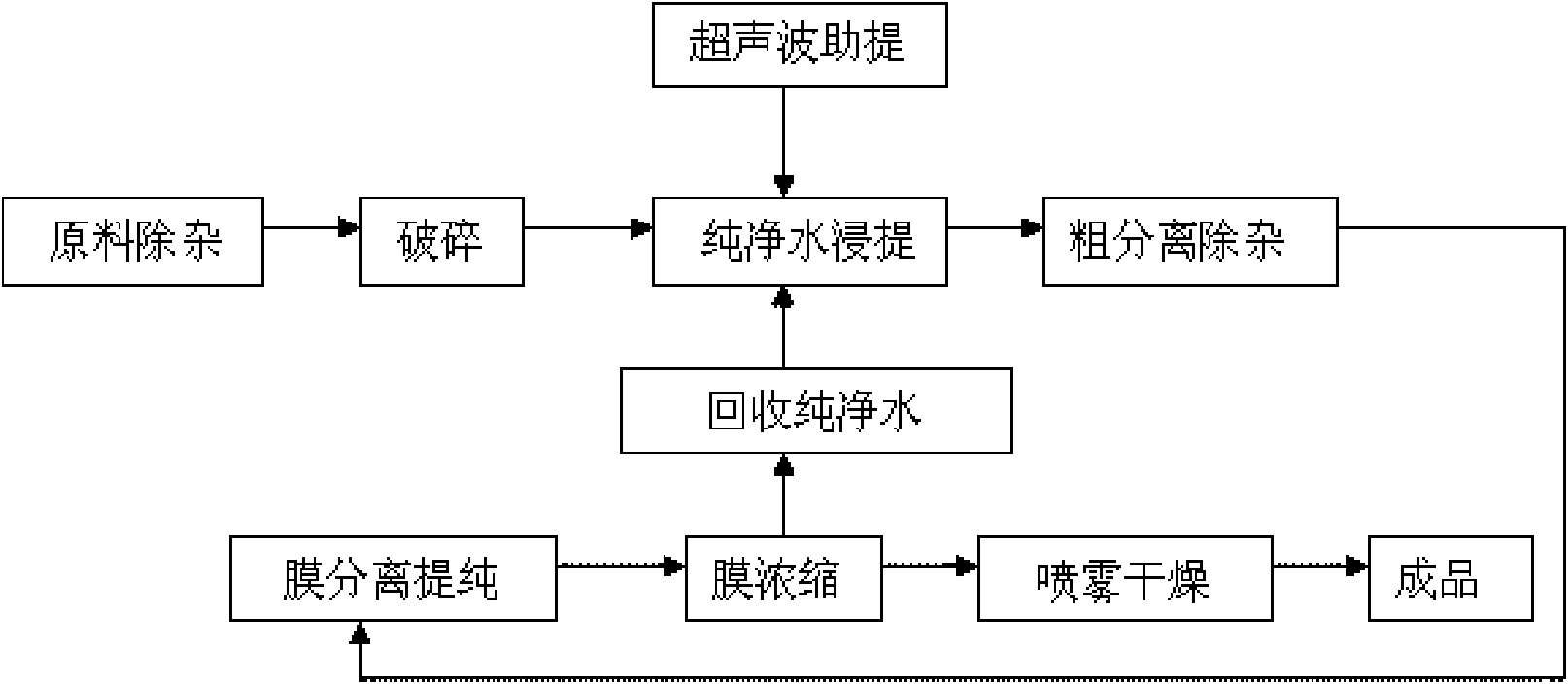

Method and process for extracting animal micro-molecule polypeptides and amino acids by utilizing complex enzyme

InactiveCN103255190AImprove enzymatic hydrolysis efficiencyReduce manufacturing costFermentationWater bathsNeutral protease

The invention discloses a method and process for extracting animal micro-molecule polypeptides and amino acids by utilizing a complex enzyme. The method comprises the following steps: (1) crushing animal tissues so that the animal tissues can pass through a sieve of 80-200 meshes, and adding water to prepare a suspension with the concentration of 8-30 percent; (2) raising the temperature to be 35-40 DEG C, regulating the pH value to be 8.0-9.0 by using sodium carbonate, adding a complex enzyme I accounting for 0.5-2.0 percent of the animal tissues, performing ultrasonic enzymolysis at 14-16 kHz for 1-2 hours so that the proteins between cells are subjected to full enzymolysis, regulating the pH value to be 6.5-7.5, adding a complex enzyme II accounting for 0.5-3.0 percent of the animal tissues, fully and uniformly stirring, controlling the temperature of the water bath to be 37-45 DEG C, and performing ultrasonic enzymolysis at 15-17 kHz for 1-6 hours; (3) raising the temperature of the enzymolysis solution to be 90-100 DEG C to inactivate the enzyme for 20-30 minutes after the enzymolysis is finished; (4) filtering the solution subjected to enzymolysis through a 0.22mu m microfiltration membrane; and (5) concentrating the filtrate to the relative density of 1:1.0-1:1.2 to prepare the concentrated solution, wherein the complex enzyme II consists of Alcalase, Flavourzyme, Protamex, neutral protease and papain. According to the method, the enzymolysis efficiency can be improved, and the production cost can be reduced.

Owner:WEIHAI KANGBOER BIOLOGICAL PHARMA +1

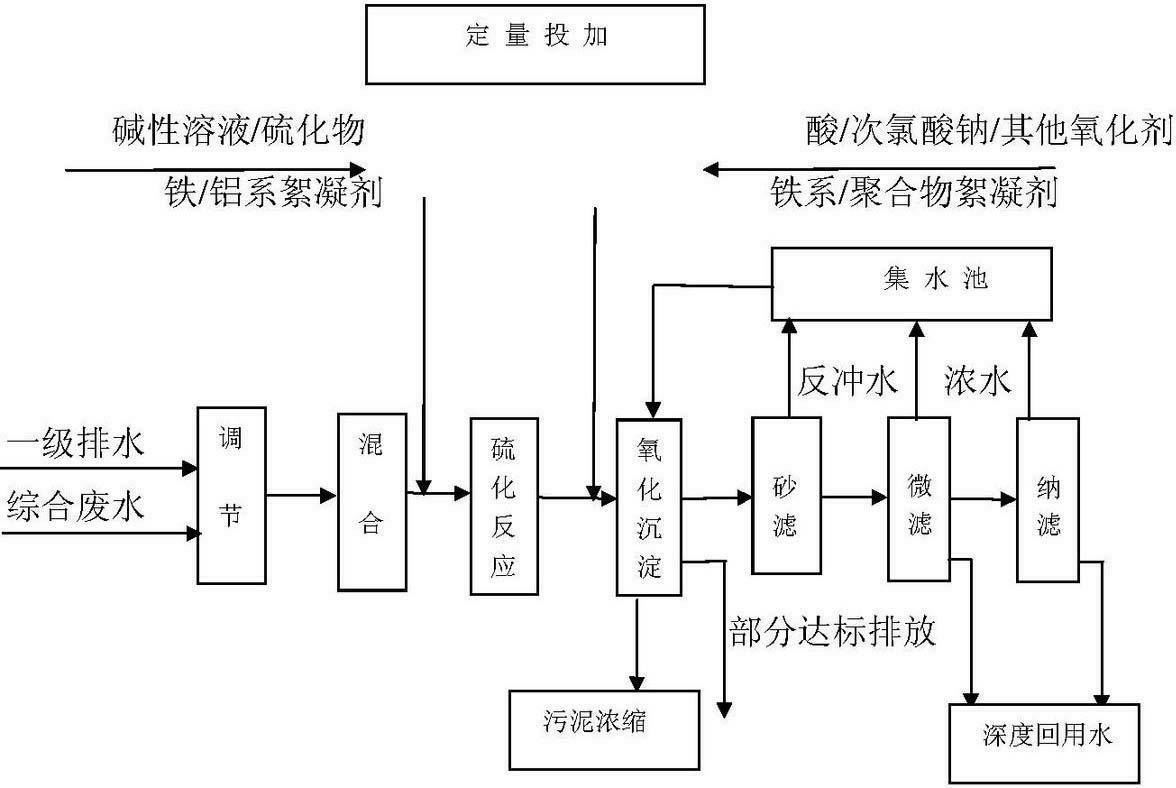

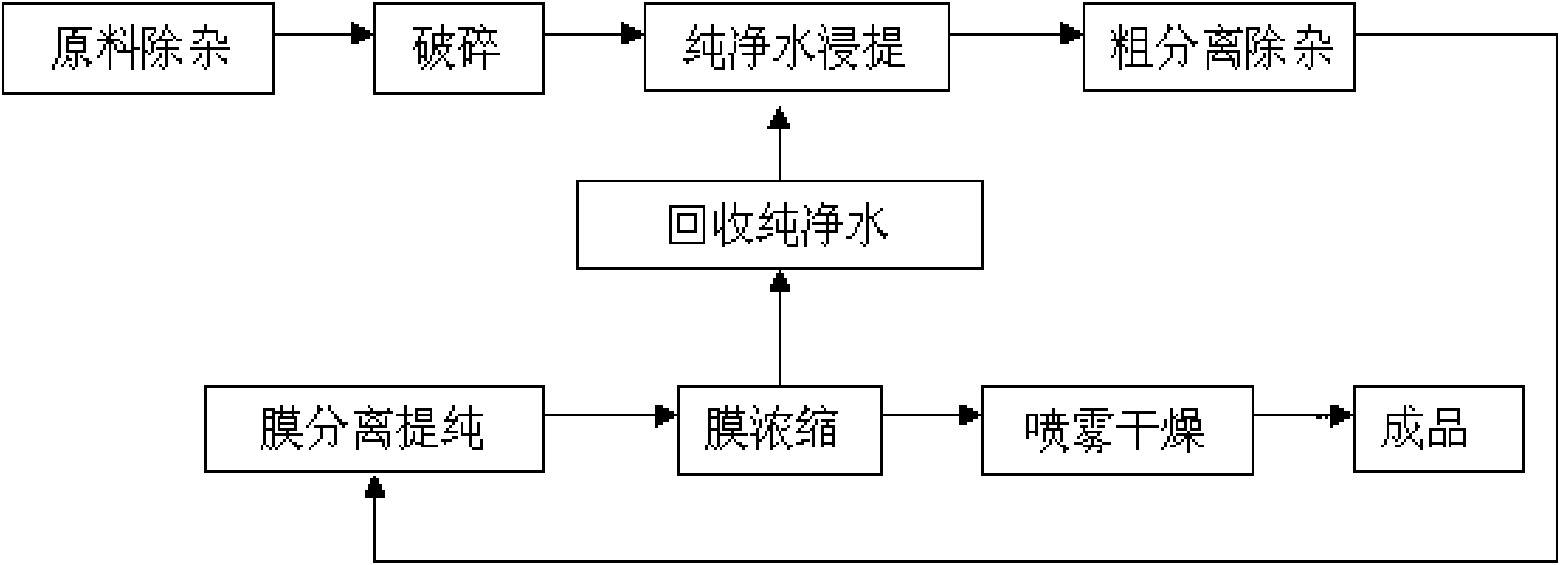

New process for extracting high-purity gardenia yellow pigment by membrane separation and purification technology

InactiveCN101659794AImprove environmental performanceImprove extraction efficiencySemi-permeable membranesNatural dyesFiltration membraneUltrafiltration

The invention relates to a new process for extracting high-purity gardenia yellow pigment by a membrane separation and purification technology. The new process comprises processes of purified water leaching, crude separation and impurity removal, membrane separation and purification, and membrane concentration. After purified water extraction and ultrasonic assisted extraction, raw gardenia is separated by three centrifuges with different specifications and then obtained leaching liquor enters a membrane separation, purification and concentration system which consists of a microfiltration membrane (MF), an ultrafiltration membrane (UF), a nano-filtration membrane (NF) and a reverse osmosis membrane (RO), thus an OD value of the obtained gardenia yellow pigment can be controlled below 0.4 and color number can be increased to be more than 400. The finished product obtained by the process has no residual organic solvent and completely meets technical requirements for exporting to developed countries, including Europe and America, etc. as well as developed areas. The process is safe and clean in the whole production process, capable of realizing zero pollution and zero emission, has high environmental protection performance, and has advantages of greatly reducing energy consumption and lowering production cost due to the membrane concentration technology. The process further has advantages of simple process, stable product quality, high purity, etc.

Owner:广西山云生化科技股份有限公司

Preparation method and application of graphene oxide/MXene composite film

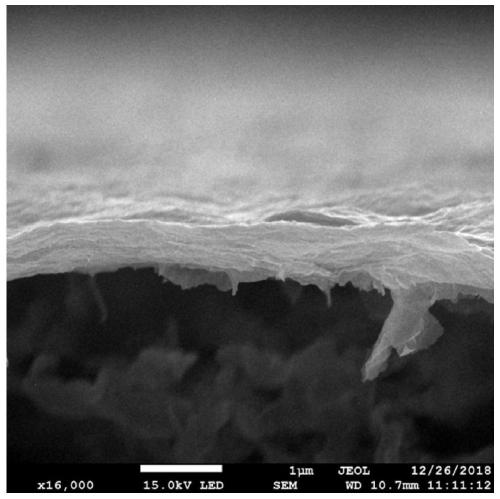

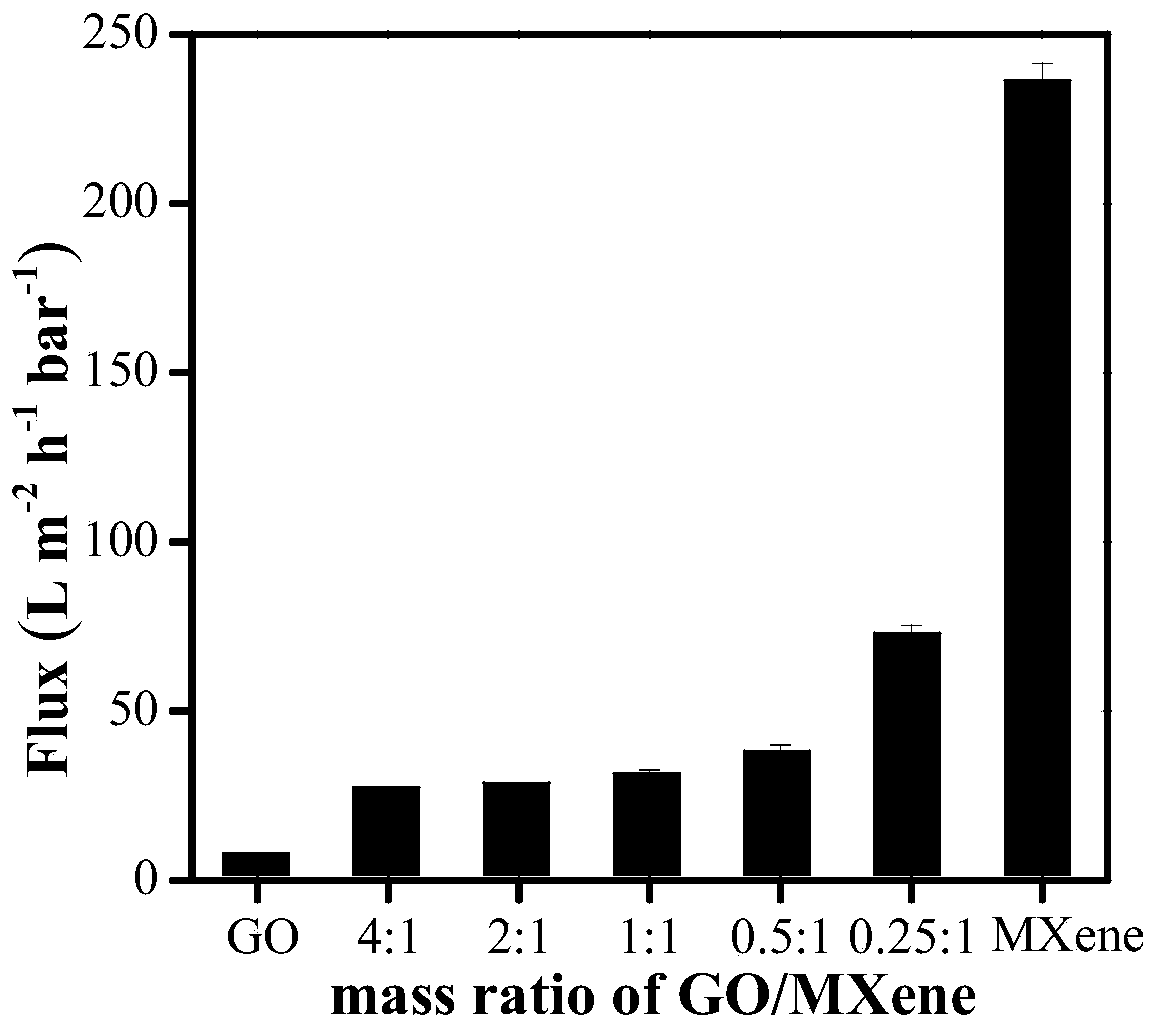

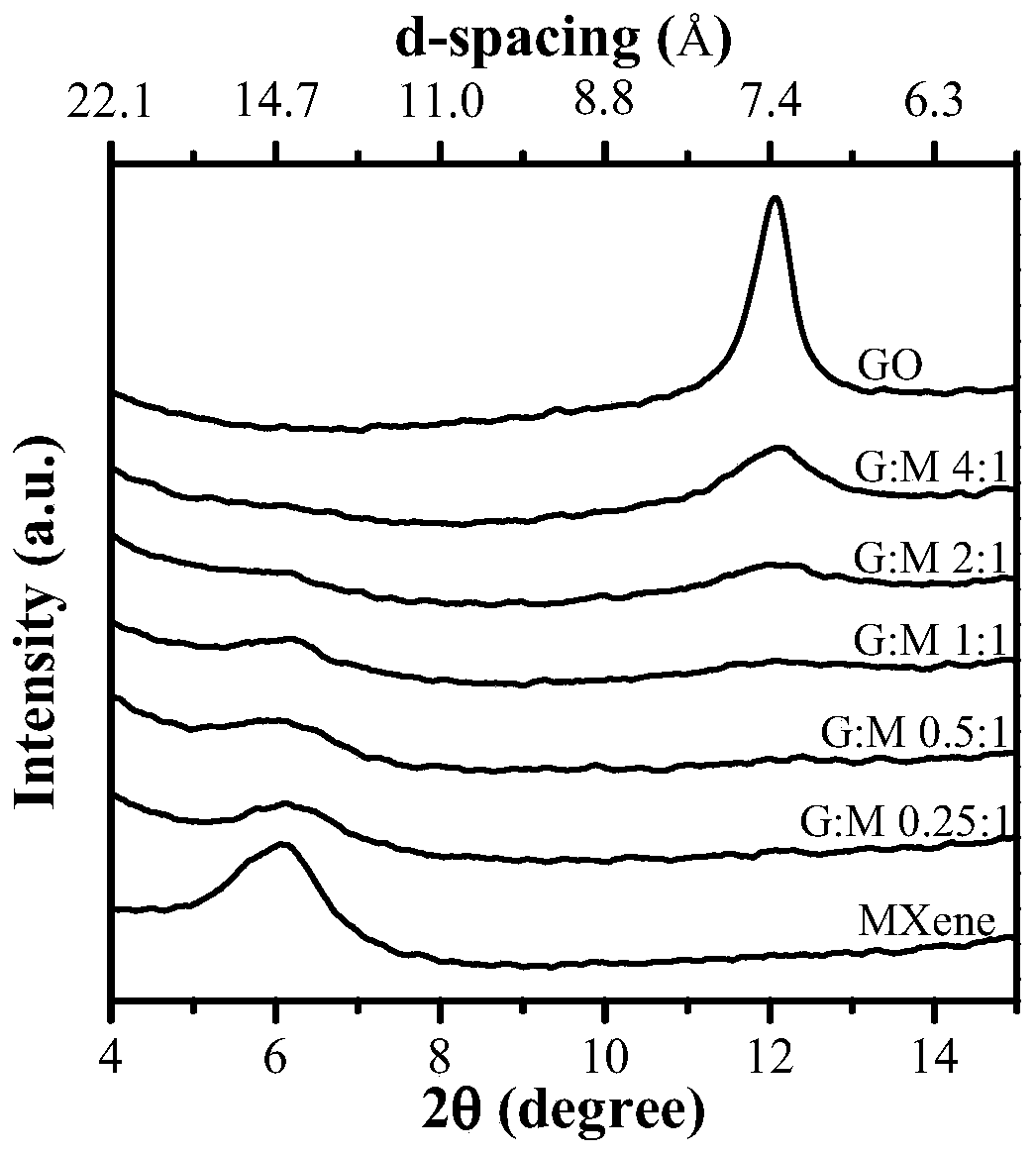

InactiveCN110124529AIncreased pure water fluxHigh removal rateSemi-permeable membranesOther chemical processesComposite filmMicrofiltration membrane

The invention provides a preparation method and application of a graphene oxide / MXene composite film. The method comprises the following steps: mixing a graphene oxide solution and an MXene solution in proportion to obtain a mixed solution, carrying out ultrasonic treatment on the mixed solution, pouring the solution into a suction filtration bottle with a microfiltration membrane, and carrying out vacuum filtration treatment for compounding and supporting the two two-dimensional materials on the surface of the microfiltration membrane to obtain the composite membrane. The pure water flux of the graphene oxide (GO) / MXene composite membrane is far greater than that of a pure graphene oxide membrane; with the increase of the MXene doping proportion, the flux is in an increasing trend; the removal rate of the composite membrane to small molecular dyes in water is up to 99.5% or above; the method is simple, easy to operate, easy to use on a large scale and beneficial to popularization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method and application of graphene oxide composite membrane

InactiveCN105727758AAdjustable spacingImprove performanceSemi-permeable membranesDispersed particle separationGas separationHummers' method

The invention discloses a preparation method and application of a graphene oxide composite membrane, and belongs to the technical field of gas separation membranes.The preparation method of the graphene oxide composite membrane comprises the steps that an aqueous dispersion liquid of graphene oxide is prepared through a Hummer method, and ultrasonic dispersion is conducted; metal salt or oxysalt is added, and heating and mixing are conducted; the surface of a micro-filtration membrane is covered with the prepared dispersion liquid through a vacuum filtration method; the membrane is put into a drying oven to be dried.The preparation method of the graphene oxide composite membrane has the advantages that the preparation method is simple, the thickness of the obtained membrane is smaller than 10 nm, the space between graphene sheet layers is adjustable, the obtained composite membrane is used for gas separation and has excellent comprehensive performance.Particularly, the graphene oxide composite membrane prepared from sodium tetraborate has high CO2 permeation flux and CO2 / CH4 and CO2 / N2 selectivity, and it is obtained through mixed gas tests under the humidifying condition that the CO2 permeation flux can reach 650 GPU, CO2 / CH4 selectivity is 75, and CO2 / N2 selectivity is 58.

Owner:TIANJIN UNIV

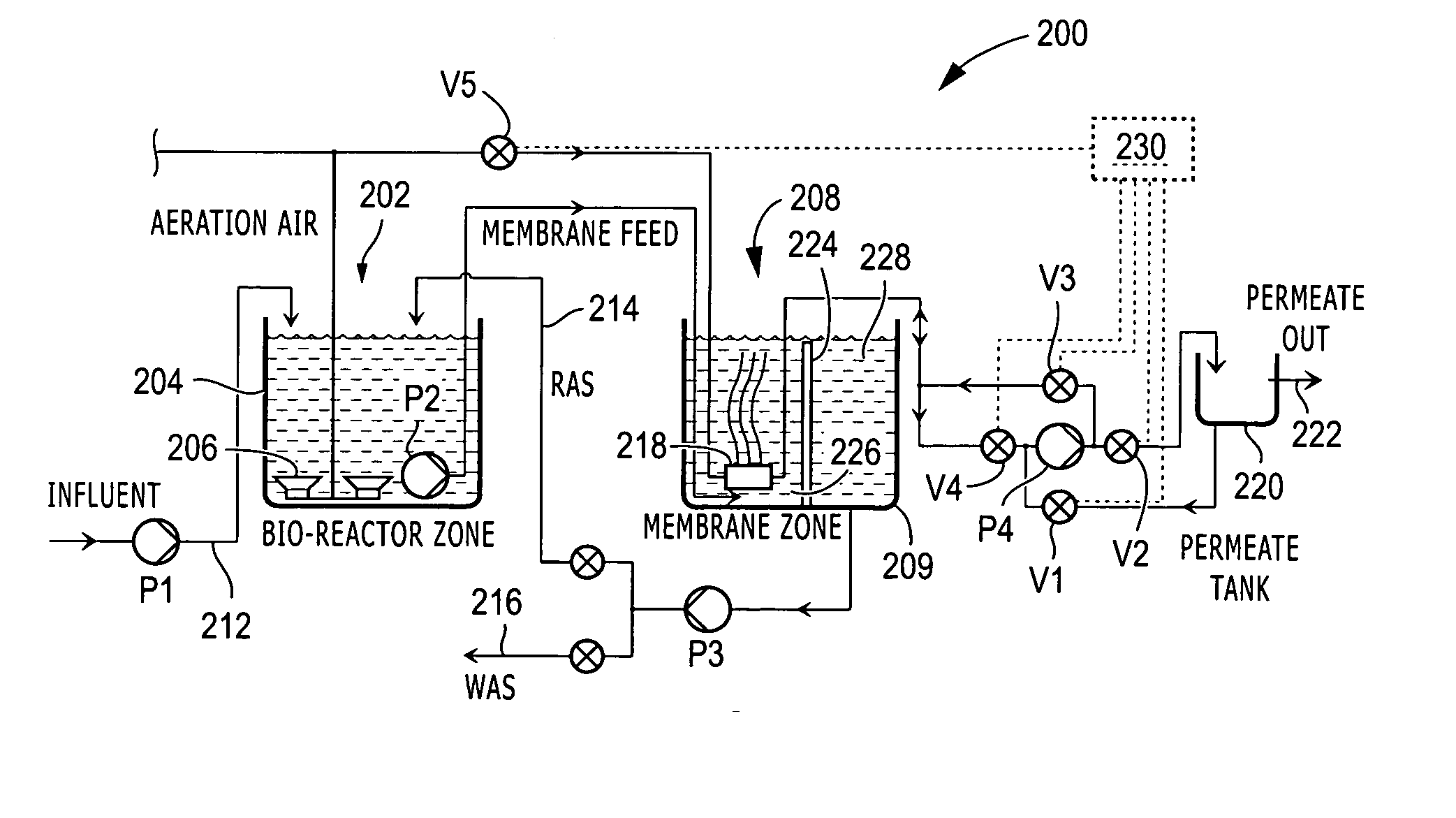

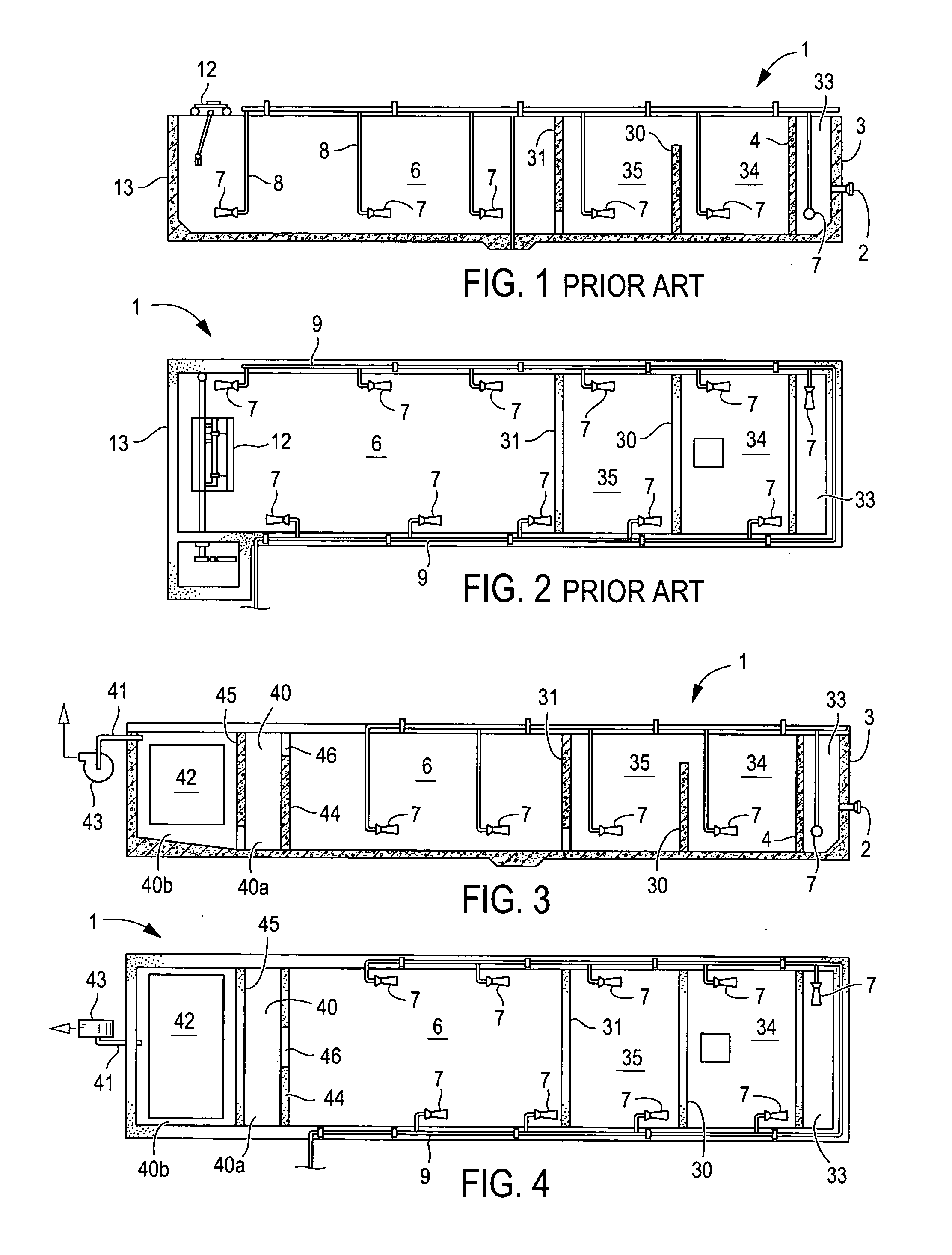

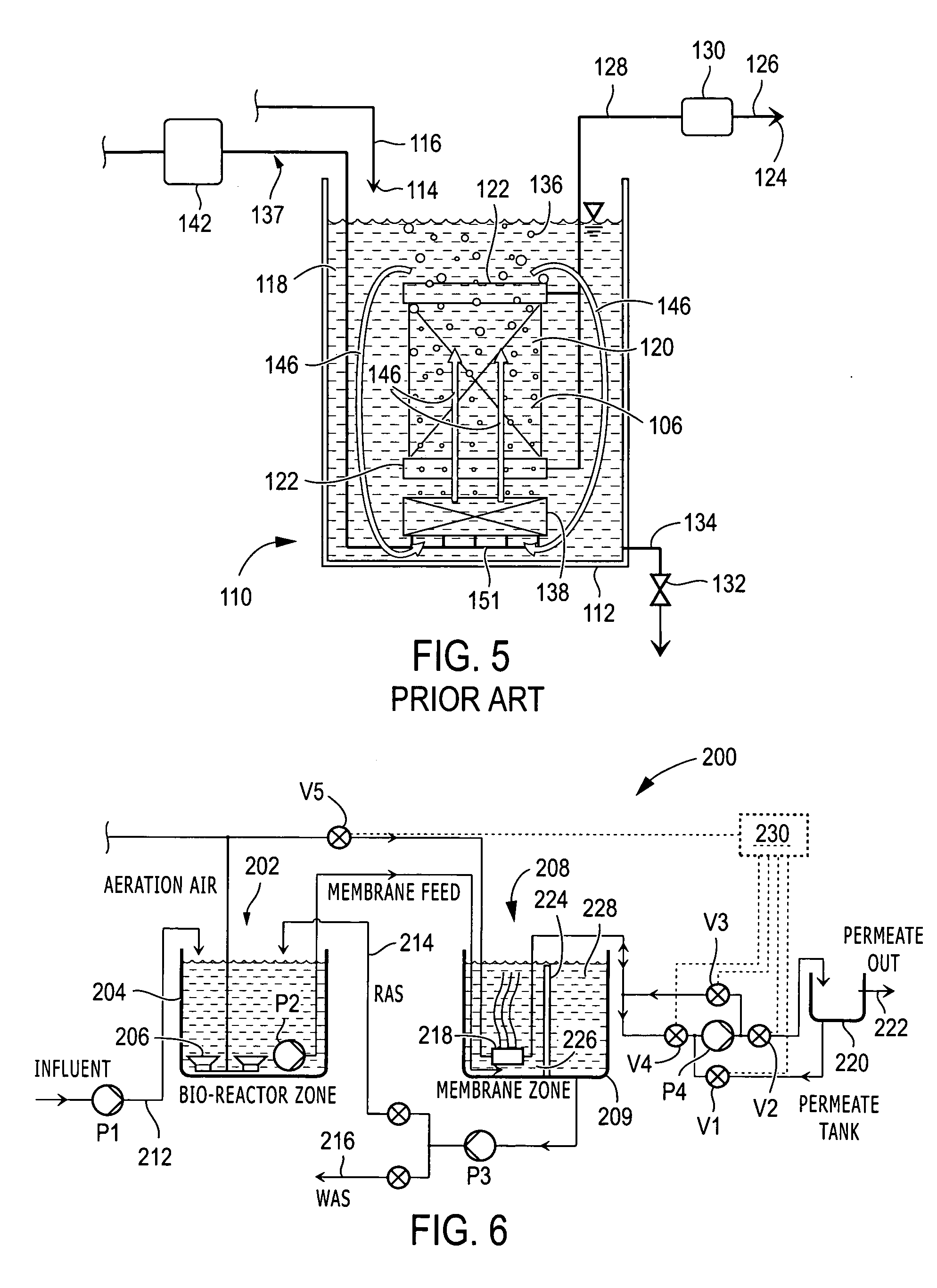

Energy-efficient biological treatment with membrane filtration

ActiveUS20060081534A1Easy to operateLiquid separation auxillary apparatusTreatment using aerobic processesSequencing batch reactorUltrafiltration

A membrane filtration system comprising one or more submerged ultrafiltration or microfiltration membrane assemblies at ambient pressure, each membrane assembly positioned 100-240 mm from a nearest wall, baffle, or adjacent membrane assembly and no more than 1 meter above a floor and at least 150 mm below the liquid level. Mixed liquor is discharged underneath each membrane assembly to create a vertical flow velocity in a range of 1-8 mm / second along an entire length of the membrane assembly. In a sequenced batch reactor system, a coarse bubble air diffuser for scouring each membrane assembly is supplied with air only during the backwash cycle of the filtration system and not during the filtration cycle. In a membrane bioreactor system, the biological treatment section is physically separated from the filtration section and fine bubble air diffusion is used in the biological treatment section.

Owner:ITT MFG ENTERPRISES LLC

PDMS/PVDF pervaporation composite membrane, preparation method and application thereof

InactiveCN101703898AHigh permeation fluxEasy to prepareSemi-permeable membranesCarboxylic compound separation/purificationAcetic acidMicrofiltration membrane

The invention discloses a PDMS / PVDF (polydimethylsiloxane / polyvinylidence fluoride) pervaporation composite membrane which comprises a polyvinylidence fluoride supporting layer and a polydimethylsiloxane separating layer with different bore diameters. The composite membrane has high separating capability and separating efficiency when applied to separating acetic acid in an acetic acid water solution. The PDMS / PVDF pervaporation composite membrane comprises a separating layer and a supporting layer, wherein the separating layer is uniformly attached on the supporting layer, the total thickness of the composite membrane is 120-150 micrometers, the thickness of the skin separating layer is 30-40 micrometers, the supporting layer is made of polyvinylidence fluoride microfiltration membranes with bore diameters being respectively 0.1-2.0 micrometers, and the separating layer is made of the polydimethylsiloxane.

Owner:NANJING UNIV OF TECH

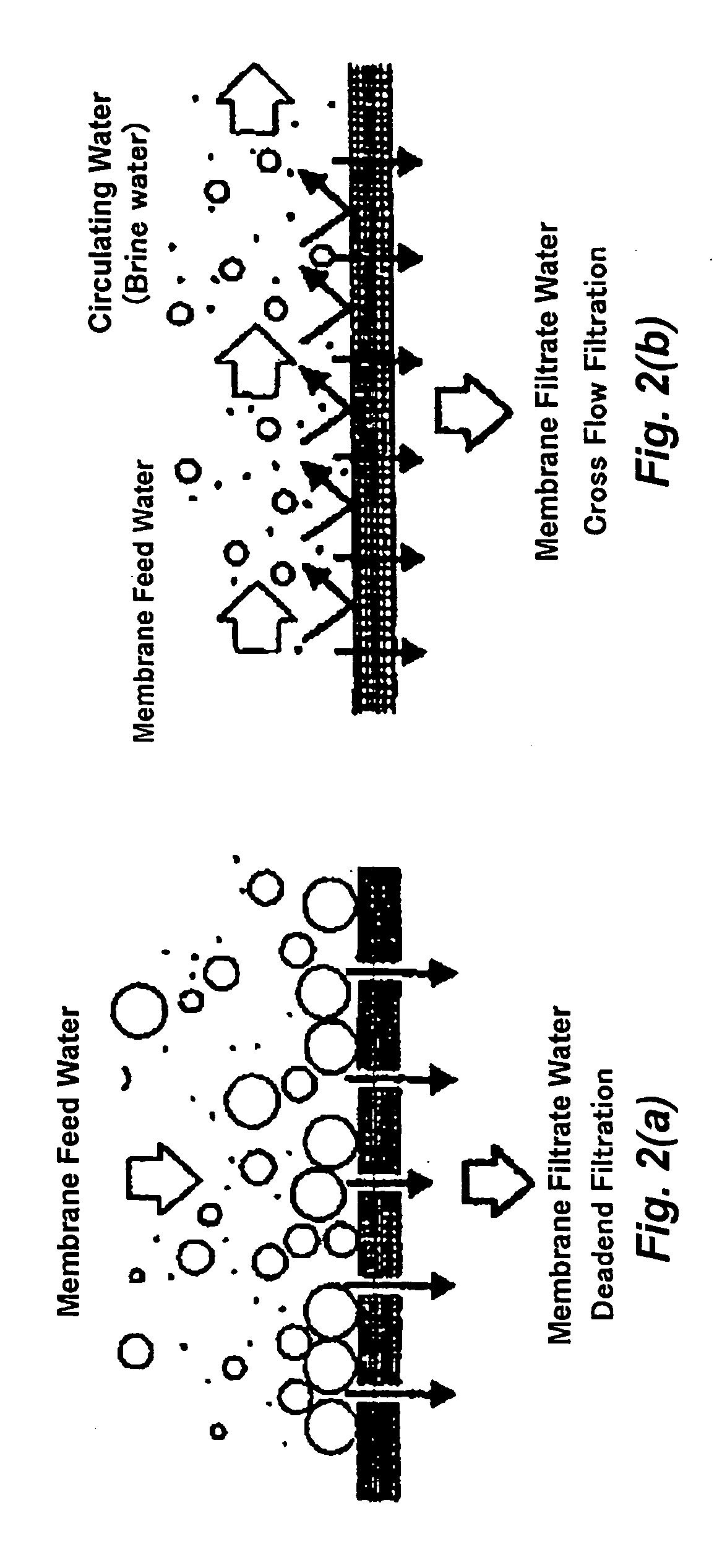

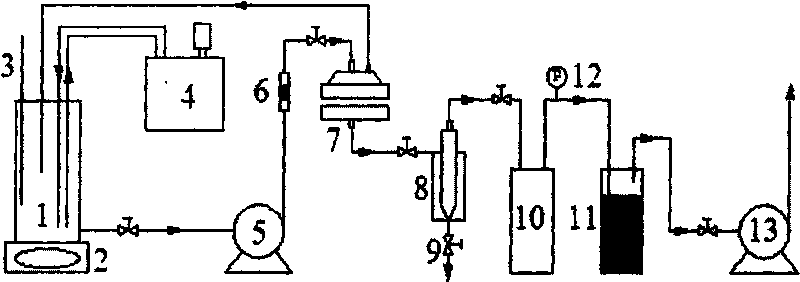

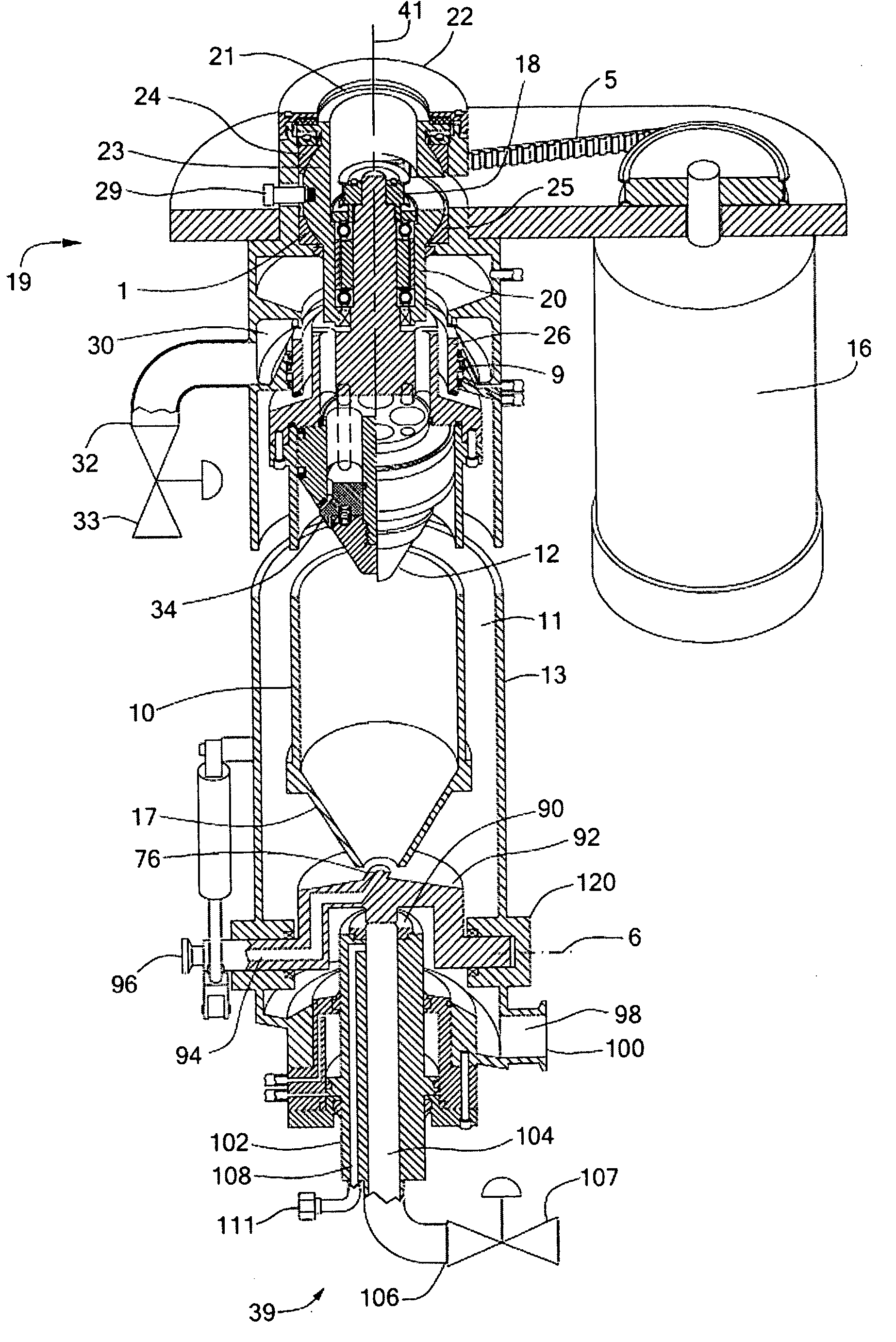

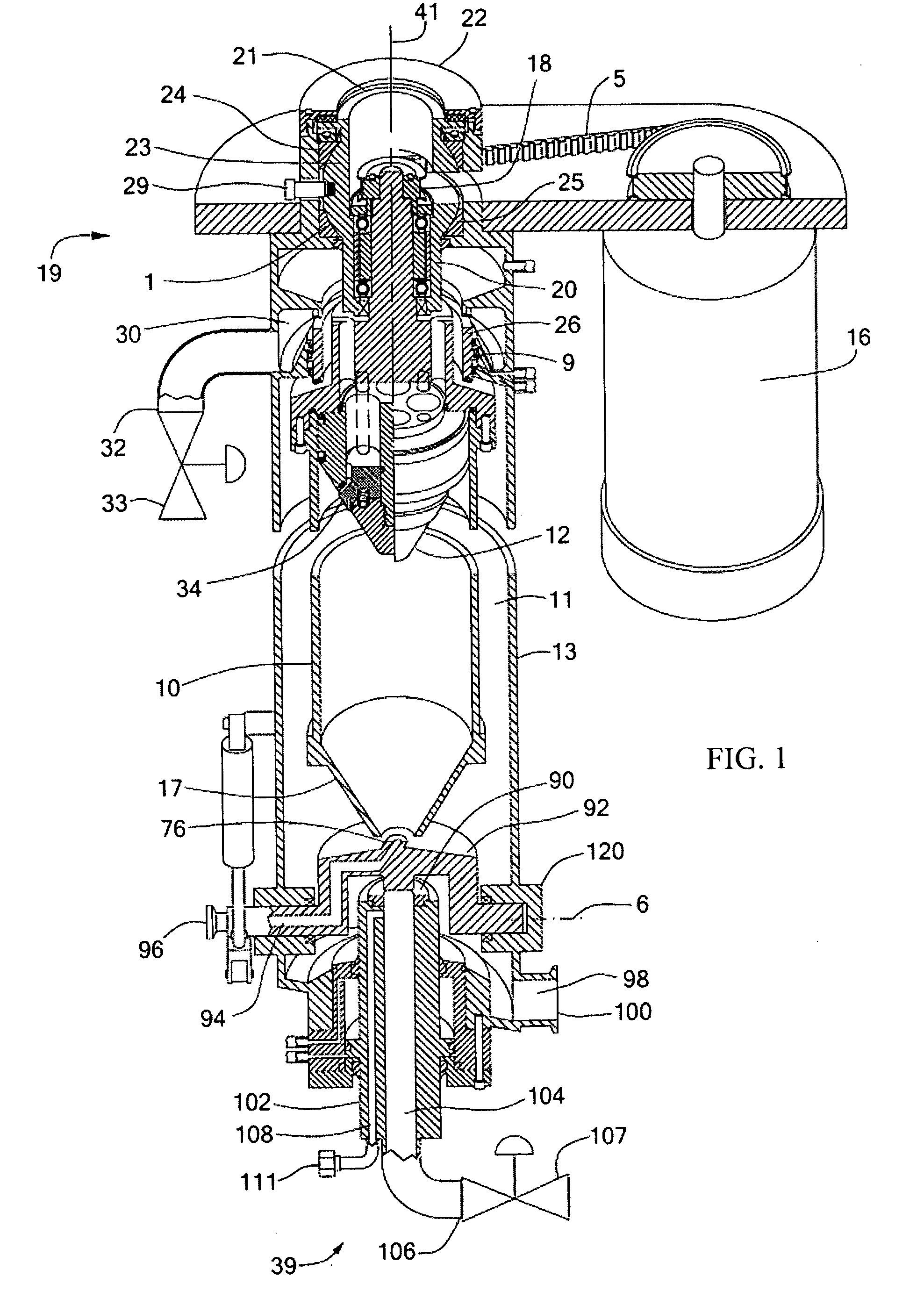

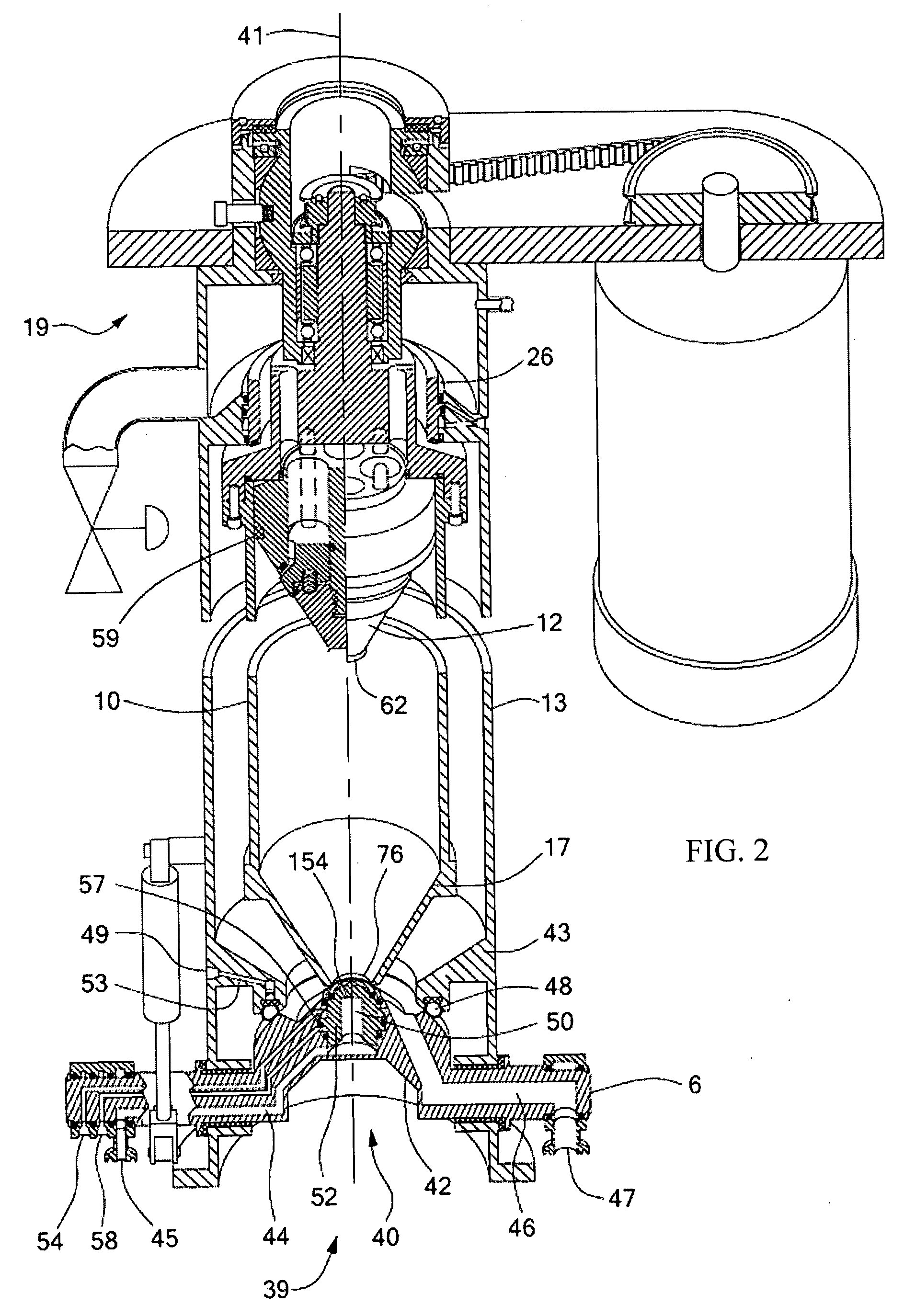

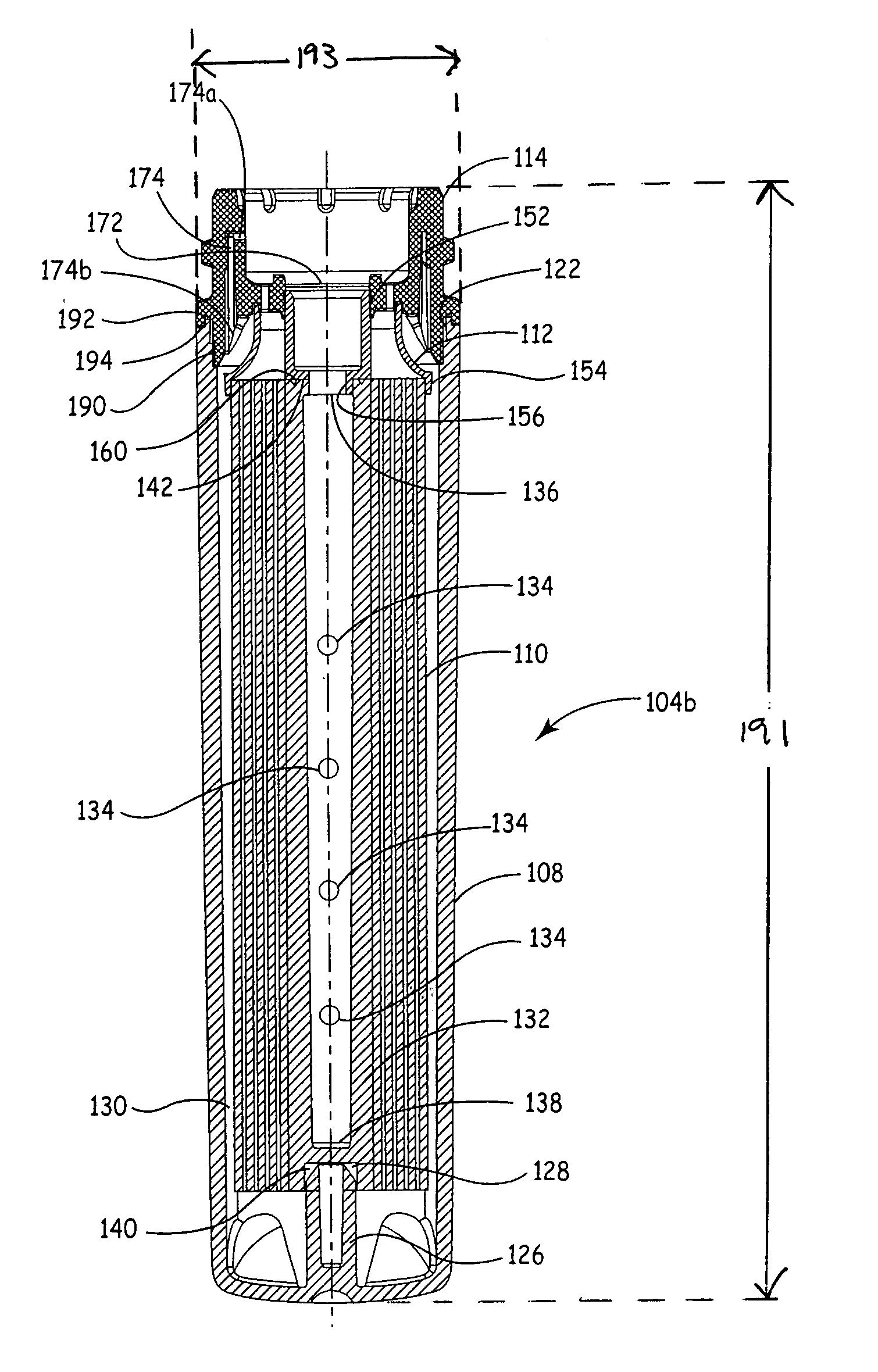

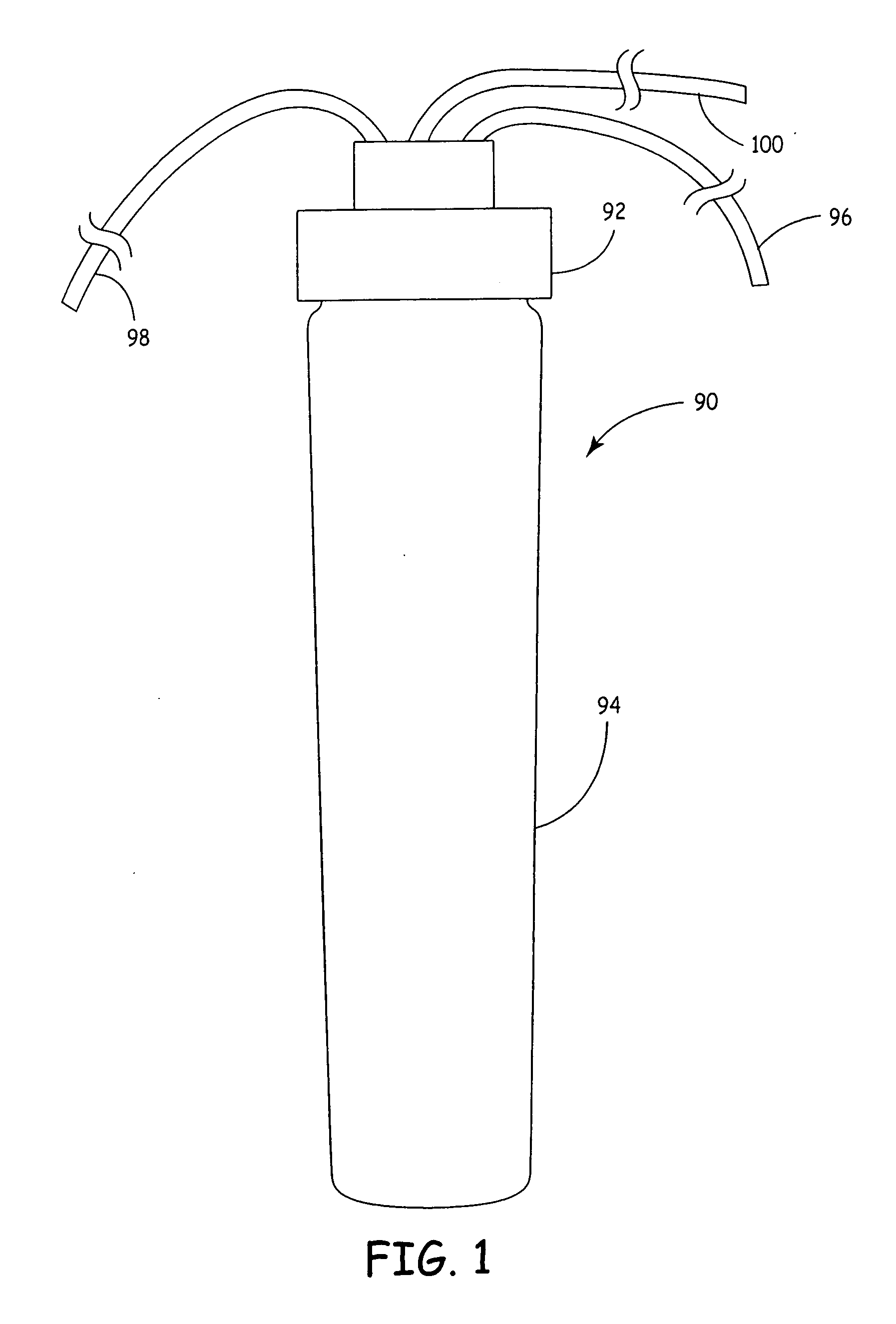

Solids recovery using cross-flow microfilter and automatic piston discharge centrifuge

InactiveUS20070114161A1Increase fluid pressureImprove throughputWater/sewage treatment by centrifugal separationMembranesCentrifugationMicrofiltration membrane

In a system for combined centrifugation and microfiltration, retentate from a cross-flow microfilter is fed to an automatic piston discharge centrifuge for solids removal, thereby enhancing the efficiency of both processes. The centrifuge includes a cylindrical bowl having a conical lower end with an opening through which feed liquid is injected. Solids separate from the feed liquid and accumulate along the inner surface of the bowl as the bowl rotates at high speed. A microfiltration membrane can be added to improve solids retention in the bowl and provide a filtered centrate. During solids discharge, a piston is urged downward along a vertical axis. The downward movement of the piston forces accumulated solids from the bowl via the opening in the conical lower end thereof.

Owner:CARR ROBERT BRET

Pigment ink for inkjet printing of high fastness textile and preparation method thereof

The invention discloses a pigment ink for inkjet printing of high fastness textile and a preparation method thereof. The ink comprises the following components by mass percent: 30-50% of pigment / branched polymer nano composite particle dispersoid, 10-50% of water soluble cosolvent, 1-5% of non-ionic surfactant, and the balance of deionized water. The preparation method comprises the following steps: sequentially adding the pigment / branched polymer nano composite particle dispersoid, a water-soluble cosolvent and a non-ionic surfactant into the deionized water in proportion, mixing uniformly, stirring by a stirrer at a speed of 500-1000rpm (revolutions per minute) for 20-40 minutes, regulating pH value of the ink to be 7-9, and filtering by virtue of a 500nm microfiltration membrane so as to obtain the coating ink. The ink needs no adhesive, the grain size of the pigment particle in the ink is less than 200nm, and the ink has good storage stability; after jet printing, the textile is baked so as to obtain good color fastness, thus improving the brightness.

Owner:JIANGSU GEMEIGAO DEV CO LTD

Hollow-fiber porous water filtration membrane of vinylidene fluoride resin and process for producing the same

ActiveUS7455772B2Increase resistanceHigh strengthSemi-permeable membranesMembranesFiberFiltration membrane

A vinylidene fluoride resin having a weight-average molecular weight as relatively high as 300,000 or higher is mixed with a plasticizer and good solvent for the vinylidene fluoride resin to obtain a composition. A molten extrudate of the composition in a hollow-fiber membrane state is contacted, on its outer side, with a cooling liquid inert to the vinylidene fluoride resin to thereby cool the extrudate. During the solidification, the vinylidene fluoride resin is moderately and mildly crystallized. Thus, a hollow-fiber porous vinylidene fluoride resin membrane is produced which has a high crystallinity represented by an enthalpy of crystal melting 58 J / g or higher. The hollow-fiber porous membrane obtained is excellent in mechanical strength represented by tensile strength and elongation at break and in chemical resistance. It is effectively used as a water microfiltration membrane.

Owner:KUREHA KAGAKU KOGYO KK

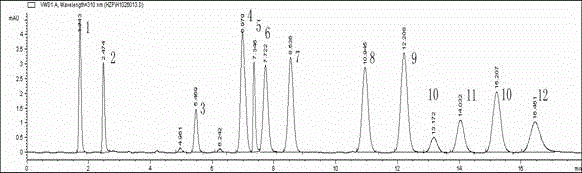

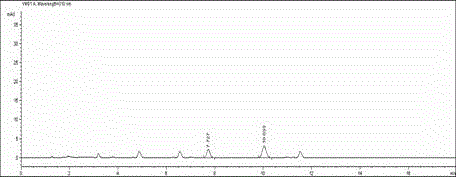

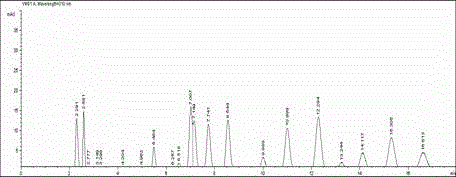

High performance liquid chromatography detection method for residual quantity of multiple ultraviolet absorbents in cosmetics

InactiveCN103063763AAchieving Simultaneous DetectionReduce dissolutionComponent separationHplc mass spectrometryQuantitative assay

The invention relates to the field of analytical chemistry and food safety, and provides a high performance liquid chromatography detection method for residual quantity of multiple ultraviolet absorbents in cosmetics. A cosmetic sample of 0.4g is weighed and placed in a plastic centrifuge tube of 50 ml, sample extraction liquid of 20ml is added, after the cosmetic sample of 0.4g and the sample extraction liquid of 20ml are mixed for 2 minutes in a vortex mode, sonic oscillation extraction is carried out for 20 minutes, 8000 revolutions per minute centrifugation is carried out for 10 minutes and, and supernate is to be purified; and after test solutions sequentially pass through microfiltration membranes of 0.45 micrometer and 0.20 micrometer, a high performance liquid chromatograph is adopted to carry out qualitative determination and quantitative assay. The detection method has the advantages of being simple, fast, accurate, efficient, and the like, and can detect 12 ultraviolet absorbents at the same time. Technical indexes of detection minimum, the recovery rate, the degree of precision, and the like all meet relevant demands for ultraviolet absorbent detection in sun block cosmetics at home and abroad. The method is suitable for detection and monitoring of the ultraviolet absorbents in the sun block cosmetics, and has great significance on promoting of import and export trade of cosmetics of our country, ensuring of safety of the cosmetics, and guarantee of human body health.

Owner:林维宣

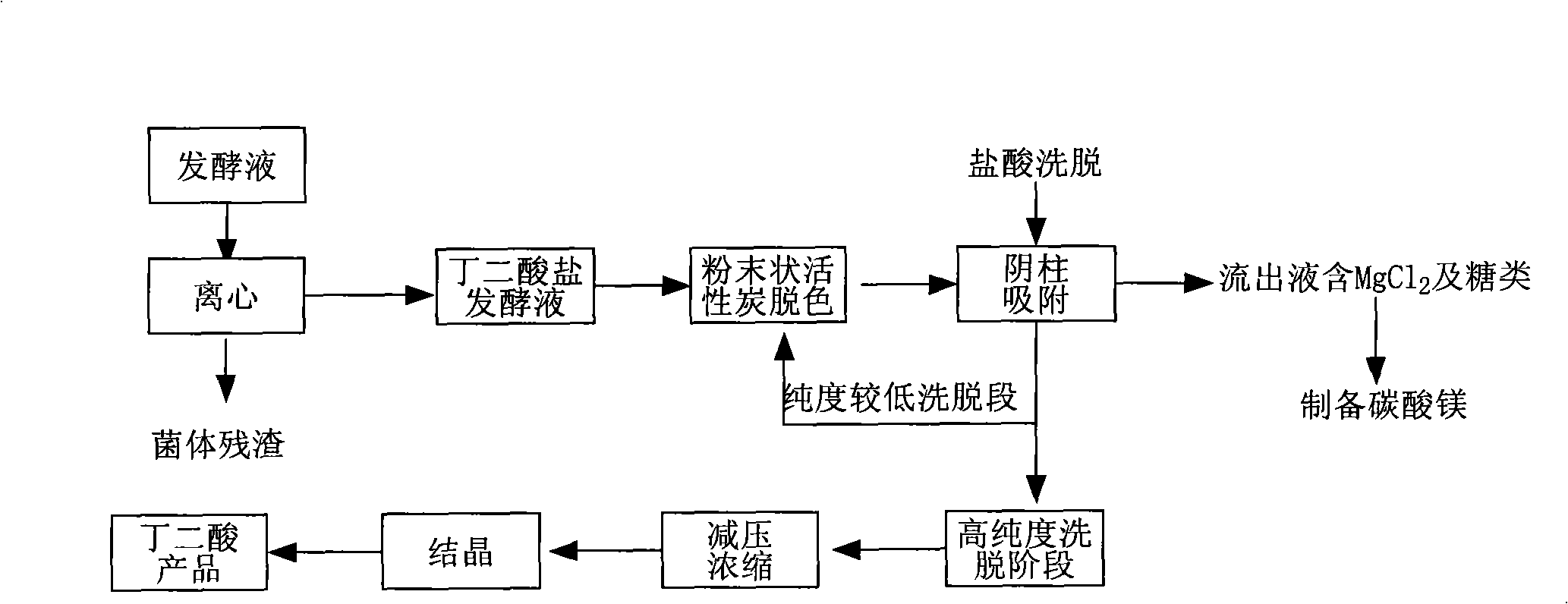

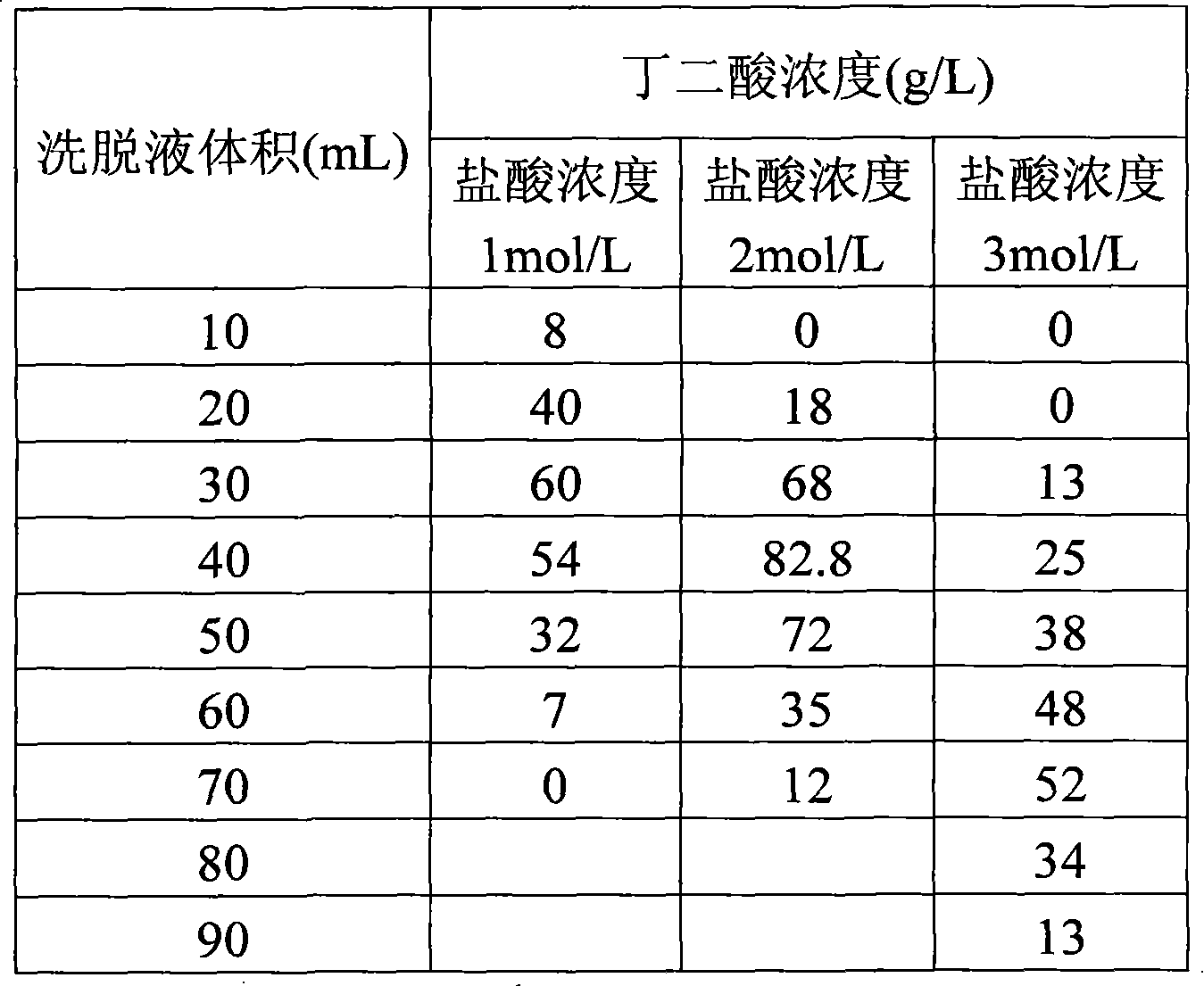

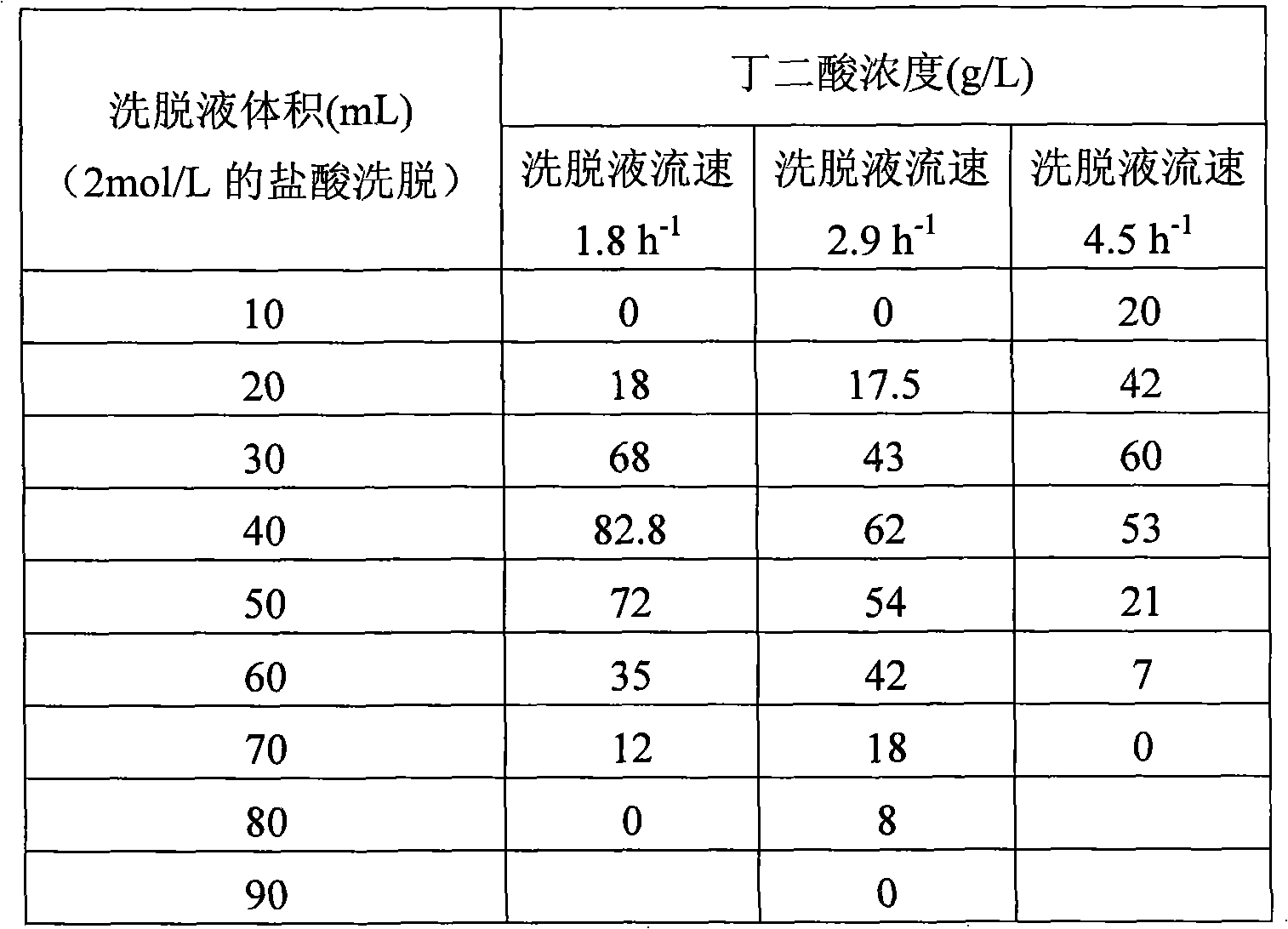

Method for extracting amber acid in fermentation liquor by anion resin adsorption

InactiveCN101348428AEnable recyclingReduce consumptionAmmonium sulfatesFermentationSuccinic acidImpurity

A method for sorption extraction of succinic acid in fermentation broth by an anion resin belongs to the biochemical technical field. The method comprises the following steps that succinic acid fermentation broth undergoes decoloring treatment by heated active carbon; fungus residue is eliminated through centrifugal filtration or microfiltration membrane filtration; the obtained fermentation clear solution is adsorbed by an alkaline anion resin column, and impurity is flushed away by water after adsorption saturation and then is eluted by hydrochloric acid solution or sulfuric acid solution, thereby obtaining succinic acid solution; the succinic acid solution undergoes depressurized concentration and crystallization so as to obtain a succinic acid product; moreover, MgCl2 and residual sugar in effluent after anion resin column adsorption of the fermentation broth is reclaimed; the MgCl2 in the effluent generated during anion resin adsorption is passed through CO2 or (Na)2CO3 so as to prepare magnesium carbonate which is reclaimed and used in buffering and adjusting pH during fermentation; and sugar in filtrate is reclaimed and used in fermentation ingredients for further fermentation. The method can realize recovery and reuse of materials during operation, and substantially reduces material consumption during extraction; moreover, the method reduces the treatment cost of waste water for environmental protection, and increases the economic benefit of products.

Owner:JIANGNAN UNIV

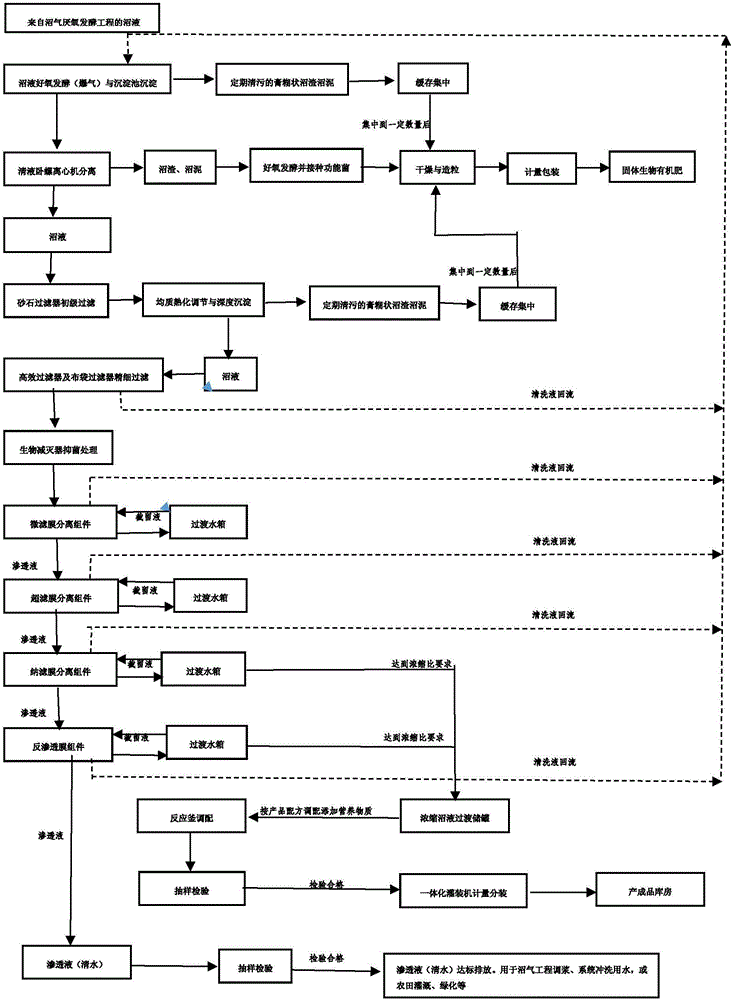

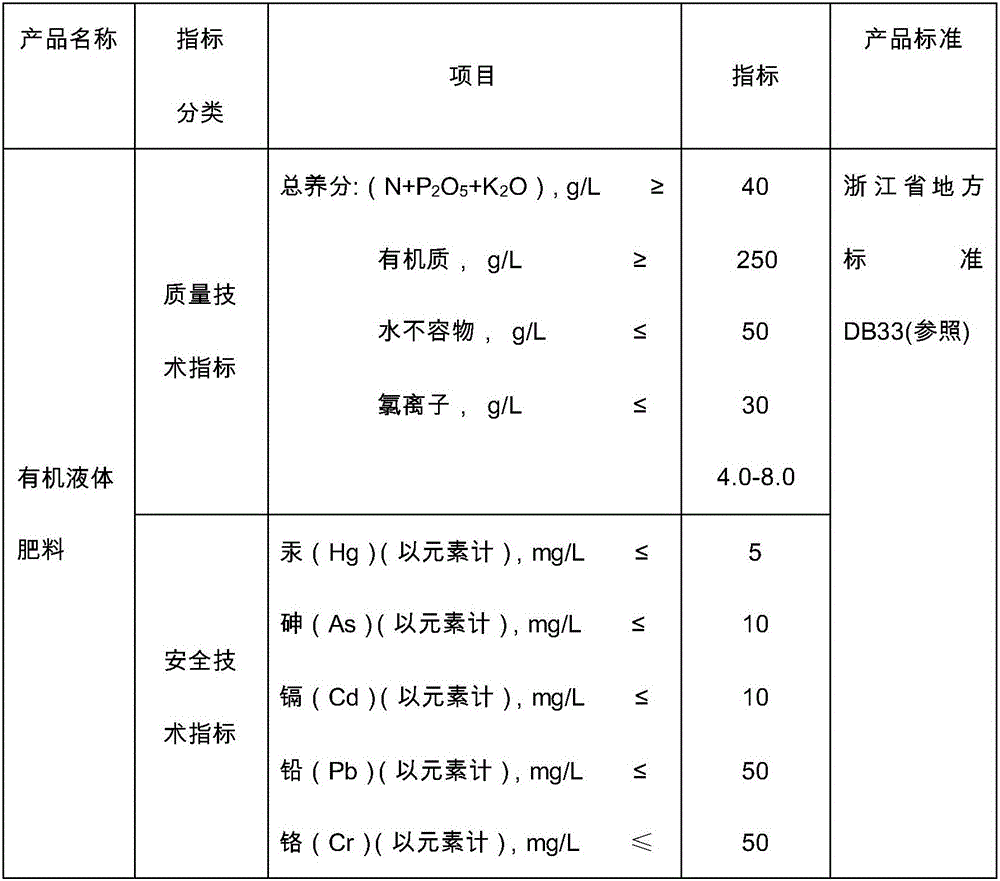

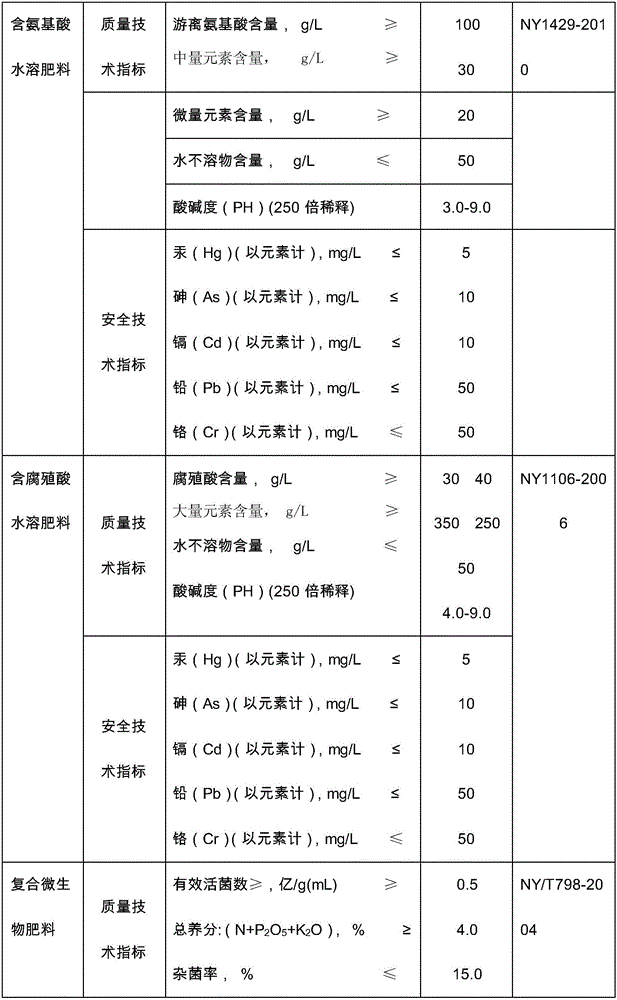

Production process for producing organic fertilizer through concentrating biogas slurry by using multistage membrane separation technology

InactiveCN106336253AFully removedReduce pollutionBio-organic fraction processingClimate change adaptationUltrafiltrationSeparation technology

The invention discloses a production process for producing an organic fertilizer through concentrating biogas slurry by using a multistage membrane separation technology; the production process comprises the following steps: a, pretreatment: carrying out pretreatment of biogas slurry after anaerobic fermentation through precipitation, aerobic fermentation, solid-liquid separation, primary filtration, homogeneous curing adjustment, deep precipitation, fine filtration and biological bacteria inhibition; b, multistage membrane separation before concentration: carrying out microfiltration membrane separation and ultrafiltration membrane separation of the biogas slurry after fine filtration and biological bacteria inhibition; c, multistage membrane concentration: carrying out multistage membrane concentration of the biogas slurry penetrated fluid obtained by ultrafiltration membrane separation through nanofiltration membrane concentration, reverse osmosis membrane concentration and concentration membrane protection; d, blending: adding large, medium and trace elements and other nutritional ingredients and functional components into the intercepted concentrate obtained by nanofiltration and reverse osmosis membrane separation, blending to obtain a liquid organic fertilizer, and sub-packaging; and e, product packaging. The production process has the advantages of flexible structure, advanced equipment and scientific process layout, can meet resource comprehensive utilization development of biogas slurry of all large and medium sized biogas projects.

Owner:NINGXIA SHUNBAO MODERN AGRI CO LTD

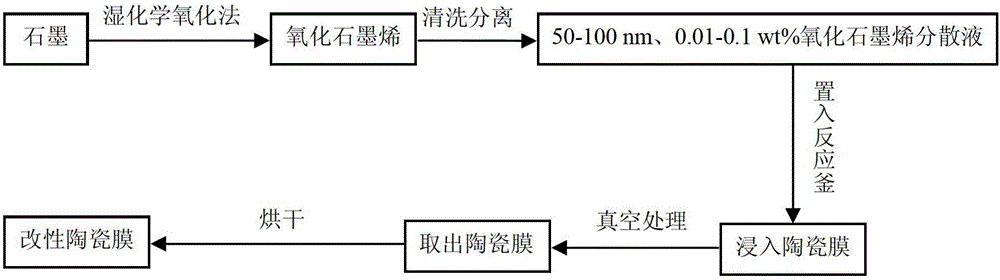

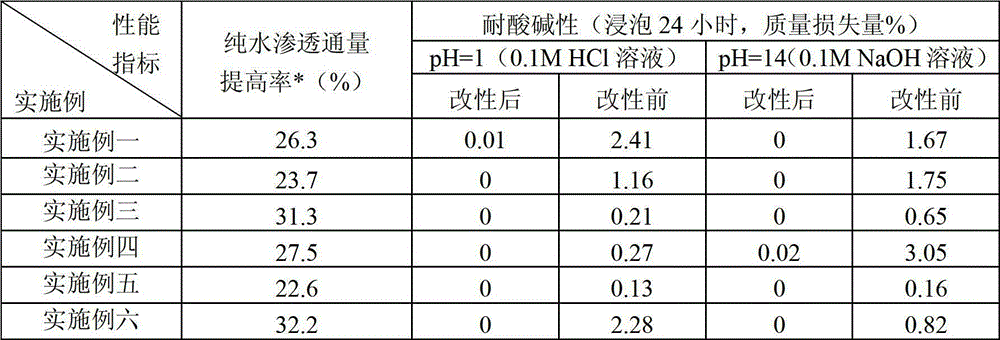

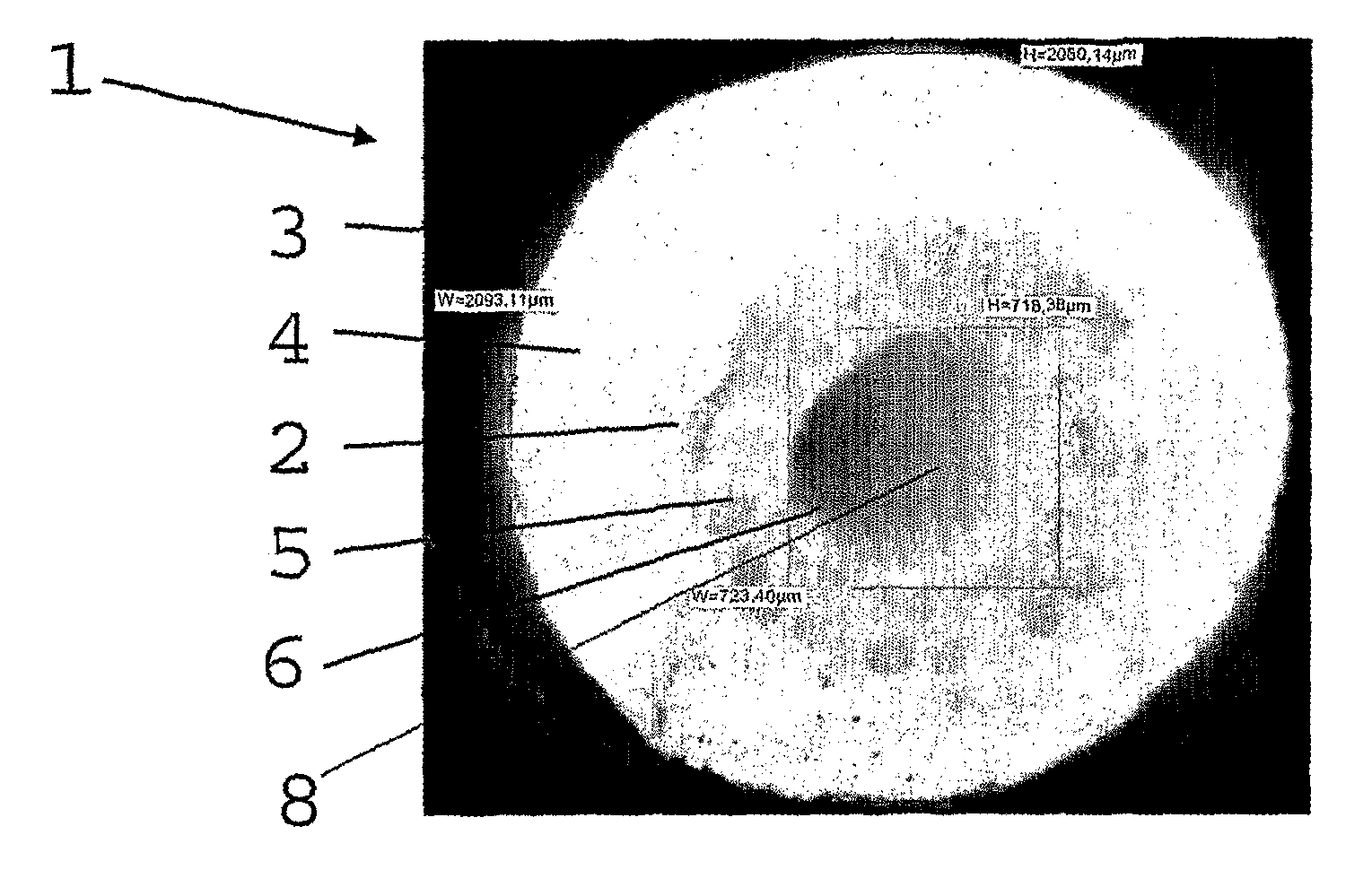

Method for modifying modified ceramic microfiltration membrane by adopting graphite oxide

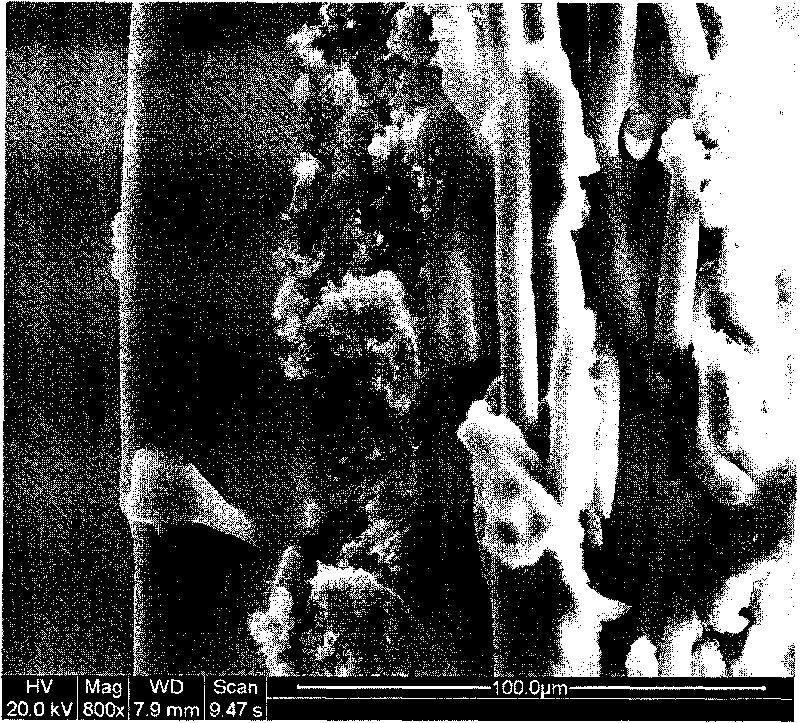

InactiveCN102908908AGood hydrophilicImprove hydrophobicitySemi-permeable membranesMicrofiltration membraneMaterials science

The invention discloses a method for modifying a modified ceramic microfiltration membrane by adopting graphite oxide, comprising the steps of preparing a modified solution, namely a graphite oxide dispersed water solution, immersing and coating a ceramic microfiltration membrane in vacuum and carrying out drying treatment to prepare the graphite oxide modified ceramic microfiltration membrane. According to the method, the separation efficiency of the ceramic microfiltration membrane is obviously improved and the acid and alkali resisting performance is effectively improved, so that good separation effect is obtained, and the service life of the ceramic microfiltration membrane is prolonged. Furthermore, the method has the advantages of simple process, low cost, green environmental friendliness and easily-controlled operation condition, and is good for being further popularized and applied.

Owner:JINGDEZHEN CERAMIC INSTITUTE

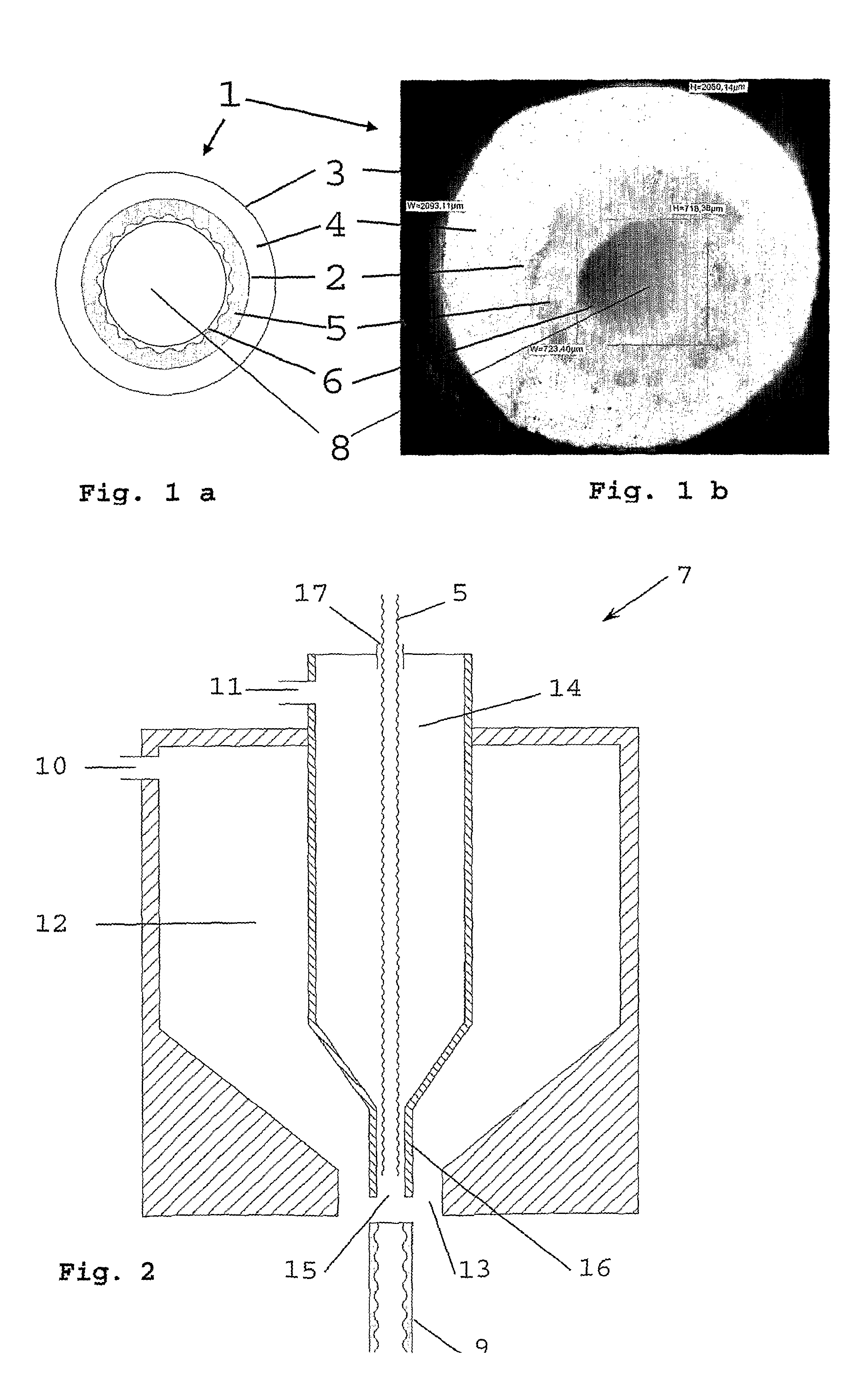

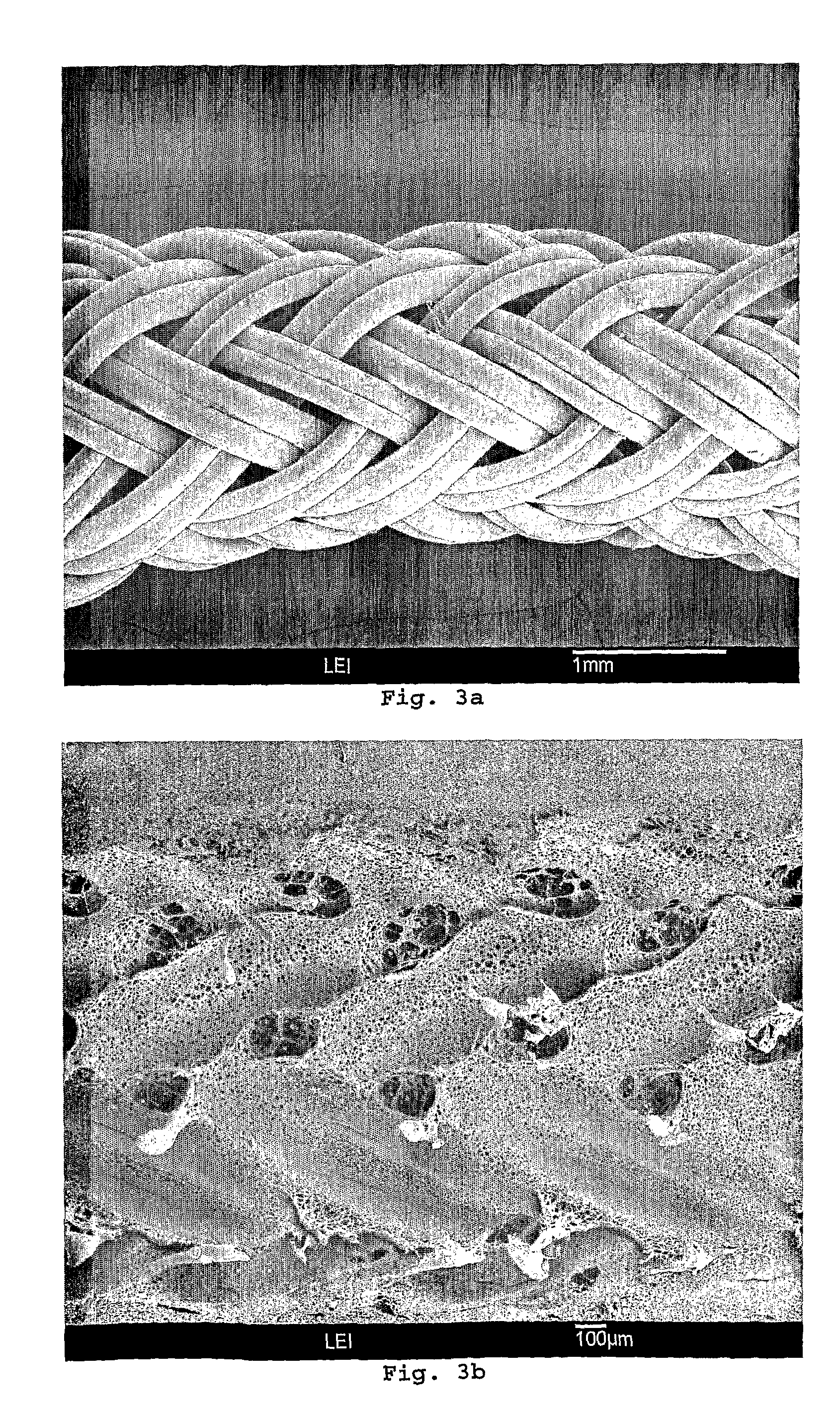

Reinforced capillary membranes and process for manufacturing thereof

InactiveUS7861869B2Prevent excessive penetrationMembranesSemi-permeable membranesPolymer scienceMicrofiltration membrane

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

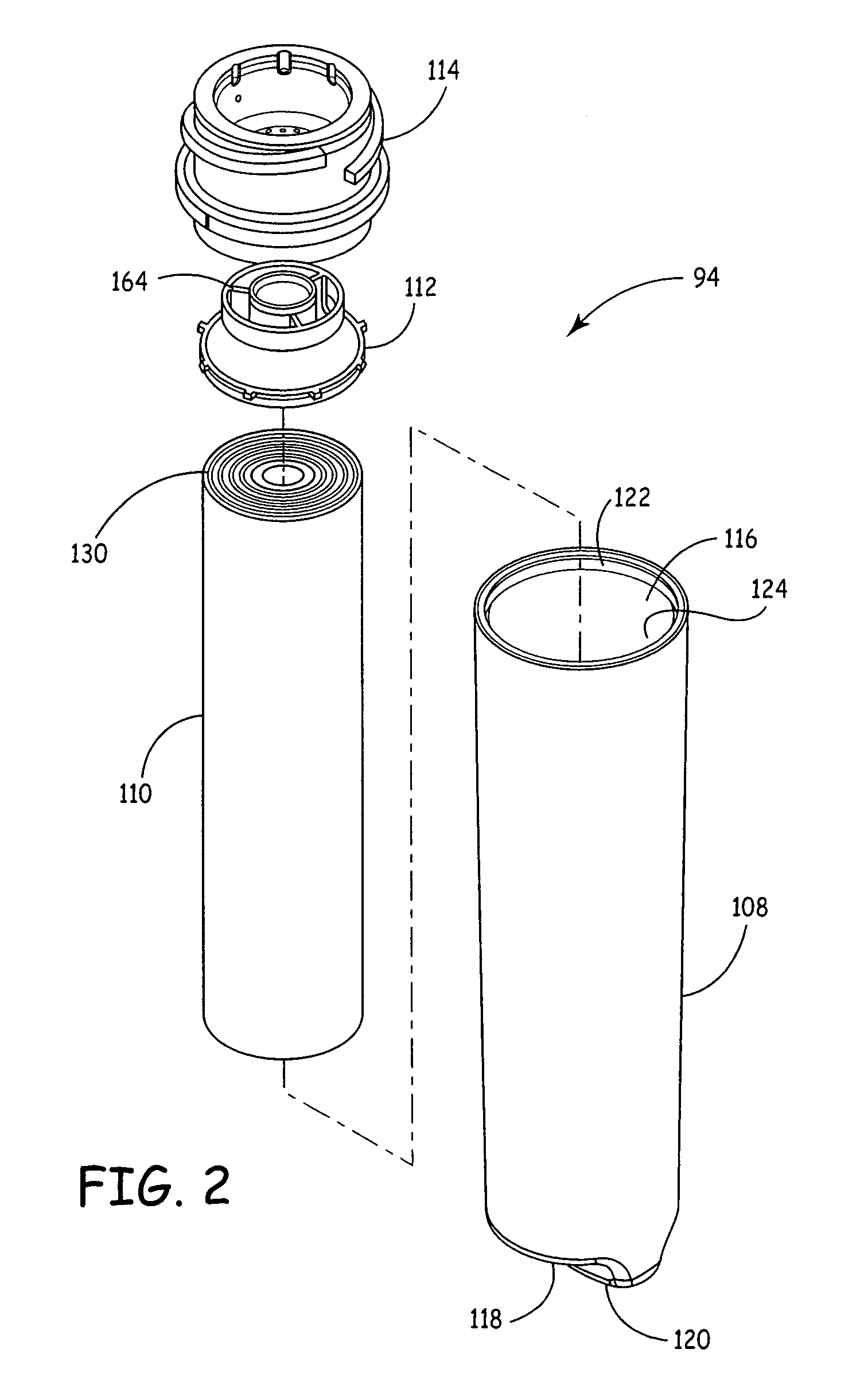

Crossflow filtration system with quick dry change elements

InactiveUS20050173319A1For quick replacementFiltering characteristics of the crossflow filtration system can be adjustablyUltrafiltrationSedimentation separationMicrofiltration membraneUltrafiltration

A crossflow filtration system including at least one quick dry change crossflow filtration cartridge designed to rotatably interface with a manifold assembly. The quick dry change crossflow filtration cartridge can comprise a membrane element, for example an ultrafiltration membrane, microfiltration membrane, nanofiltration membrane or high-flux reverse osmosis membrane element enclosed within a housing. The quick dry change cartridge includes an inlet stream, a permeate stream and a concentrate stream. The manifold assembly includes three similar flow paths; an inlet stream, a permeate stream and a concentrate stream. When engaged, the cartridge and manifold assembly define continuous inlet flow paths, permeate flow paths and concentrate flow paths that connect across the interface. Thus, all of the connections to the water filtration system can be made onto the manifold, and the resulting connected system is compact and easy to connect.

Owner:3M INNOVATIVE PROPERTIES CO

Porous film of vinylidene fluoride resin and method for producing same

InactiveUS20060148912A1Improve hydrophilicityIncreased in initial water permeation rateSemi-permeable membranesMembranesHydrophilic monomerMicrofiltration membrane

A porous membrane of vinylidene fluoride resin excellent in hydrophilicity and having a good balance among strength, elongation and water permeation rate, which is thus useful as a microfiltration membrane or a separator of battery. The porous membrane is formed from a copolymer of 100 mols of a vinylidene fluoride monomer and 0.01-10.0 mols of a hydrophilic monomer having at least one species of hydrophilic group selected from epoxy group, hydroxy group, carboxy group, ester group, amide group and acid anhydride group.

Owner:KUREHA KAGAKU KOGYO KK

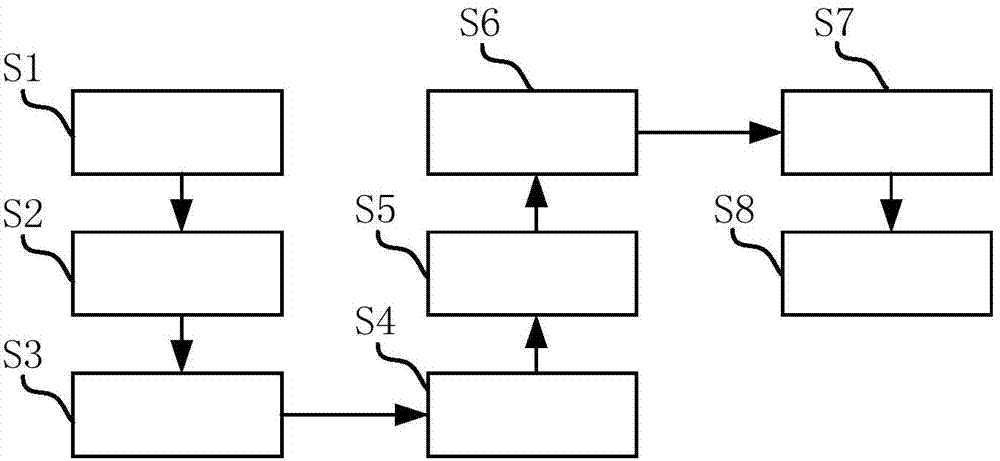

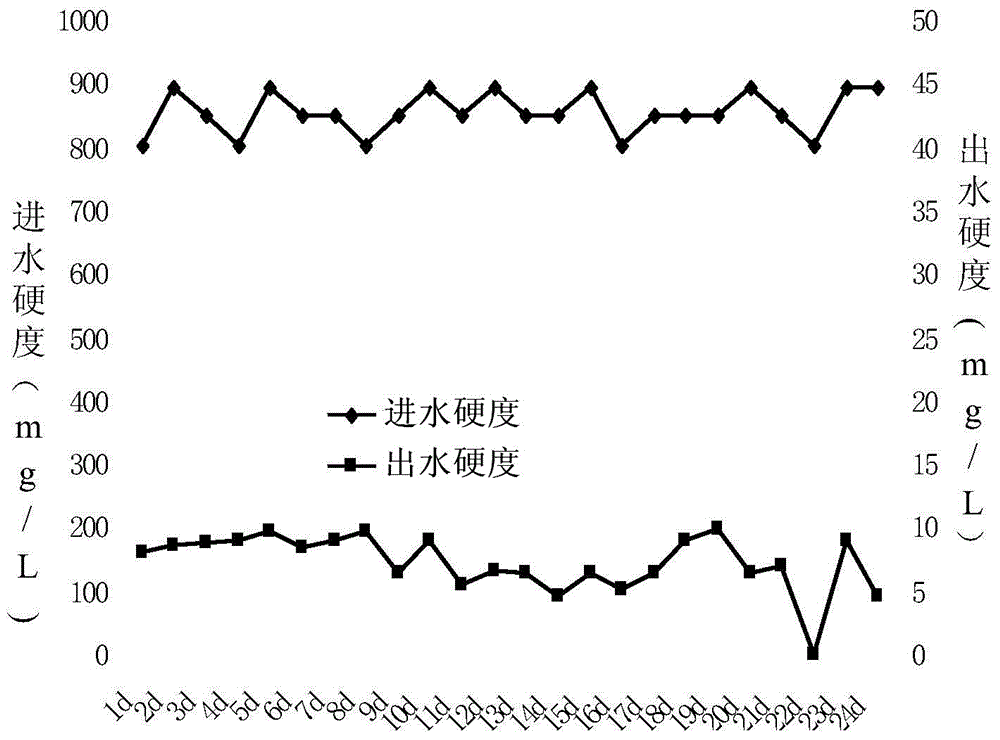

Treatment method and device of landfill leachate concentrate

InactiveCN104787929AIncrease productionAchieve recyclingUltrafiltrationMultistage water/sewage treatmentReverse osmosisWater resources

The invention relates to a treatment method and a device of landfill leachate concentrate. The method comprises the following steps: Step S1: carrying out chemical softening treatment on the concentrate to reduce hardness of the concentrate, Step S2: filtering effluent of Step S1 with a microfiltration membrane to remove suspended solids from the concentrate, and Step S3: carrying out reverse osmosis treatment on effluent of Step S2 with a disc tubular reverse osmosis membrane to form recycled effluent. The method and the device have the following advantages: 1, a 'chemical softening, microfiltration membrane and DTRO (Disk Tubular Reverse Osmosis)' technology is employed for treating the nanofiltration and reverse osmosis concentrate, the fresh water yield of a whole system is increased, the recycling of water resources is achieved, and operating cost of a power plant is saved; and 2, the 'chemical softening, microfiltration membrane and DTRO' technology is employed for treating the nanofiltration and reverse osmosis concentrate, so that the concentrate is reduced, and the predicament that the yield of the concentrate is high, and the power plant cannot eliminate the concentrate is solved.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD

Adsorption oxidation method for treating high-concentration acrylonitrile wastewater

InactiveCN102190387AReduce COD valueLarge specific surface areaMultistage water/sewage treatmentWater/sewage treatment by sorptionHigh concentrationSuspended particles

The invention relates to an adsorption oxidation method for treating high-concentration acrylonitrile wastewater, which comprises the following steps of: adding aqueous solution of a flocculating agent into the acrylonitrile wastewater, stirring, and standing until flocs are settled at the bottom of a container for later use; making the wastewater pass through a microfiltration membrane or an ultrafiltration membrane to remove suspended particles, the flocs and acrylonitrile oligomer from the wastewater, regulating the pH value of the wastewater, adding activated carbon and a Fenton reagent, and stirring for adsorption oxidation; filtering the wastewater by using activated carbon filter cloth, adding the activated carbon and hydrogen peroxide into the wastewater, and stirring for secondary adsorption oxidation; and filtering the wastewater by using the activated carbon filter cloth, and neutralizing filtrate by using sodium hydroxide until the filtrate is neutral. The method improves treatment efficiency, is not limited by the chemical oxygen demand (COD) of the wastewater, avoids secondary pollution, is low in energy consumption, easy and convenient to operate and small in occupied area, and has the characteristics that the method is high-efficiency, economic and environment-friendly.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com