Advanced treatment and recycling process for wastewater containing heavy metal ions

A heavy metal ion and advanced treatment technology, applied in metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high investment and operation costs, cumbersome pH value control, cumbersome operation and management, etc., to achieve Moderate engineering investment and operating costs, high removal rate of heavy metal ions, and convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The raw data of wastewater from a lead smelting enterprise are as follows: the advanced treatment capacity is 80m3 / h

[0055] Monitor water quality at the total discharge outlet of the workshop (unit: mg / L)

[0056] project

pH

CODcr

total copper

total zinc

total lead

Total arsenic

Total Cadmium

the first time

3.8-4.2

120

178

2.5

126

6.0

1.92

6.64

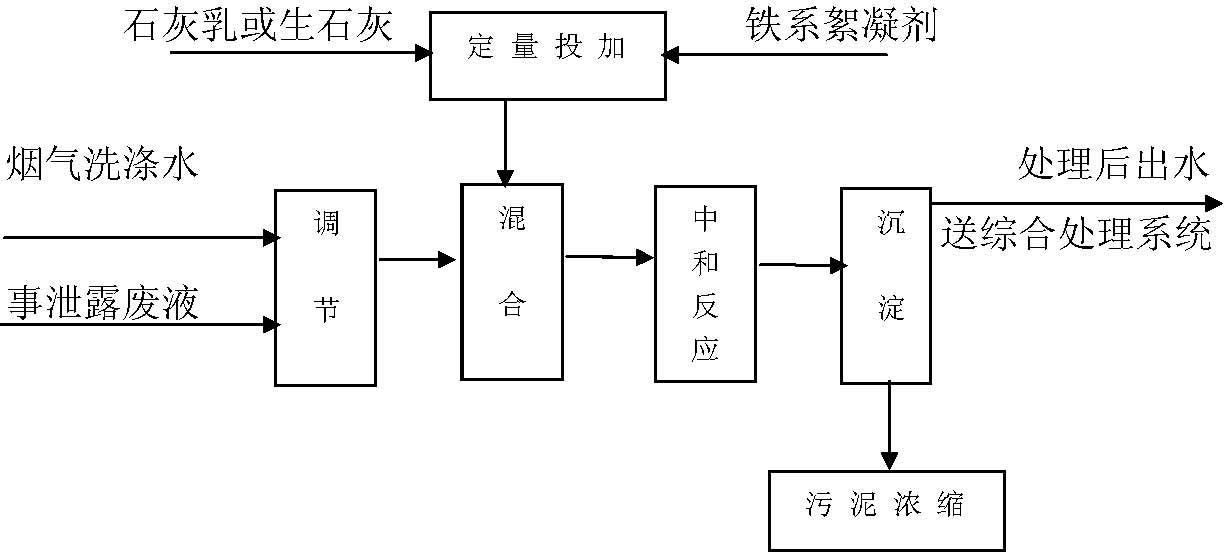

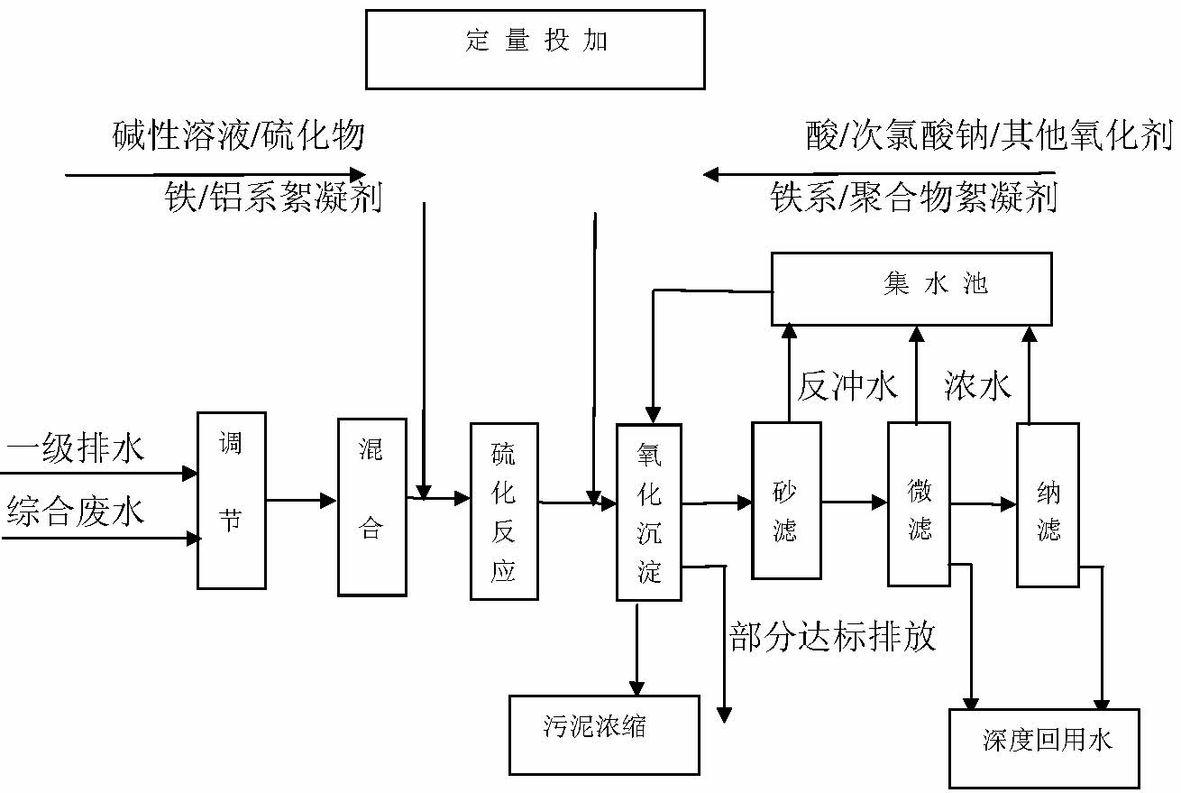

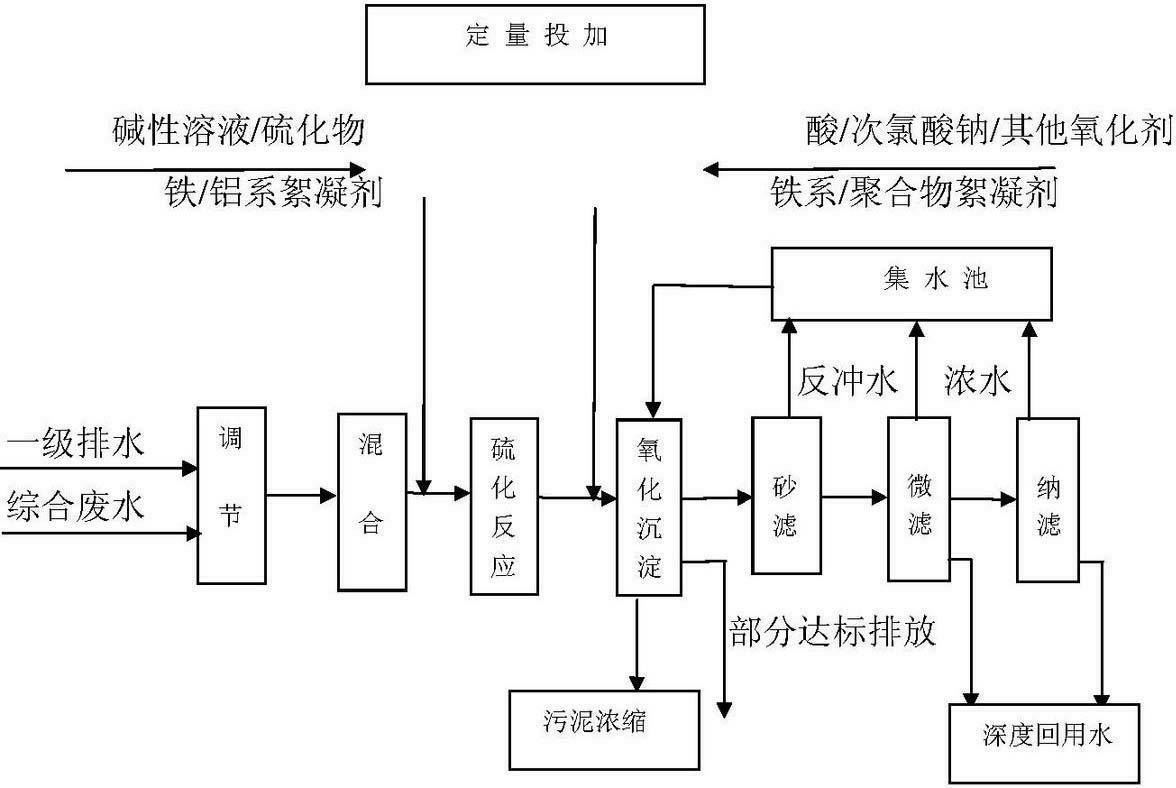

[0057] 1. Automatically adjust the water quality and quantity of acidic wastewater such as flue gas washing water and leaked waste liquid in the production system through the electromagnetic flowmeter. According to the content of heavy metals in the water quality, add lime milk solution to adjust the pH value to 9.0 through the pH meter, and then wait for each cubic meter to be treated The water is controlled by an electromagnetic flowmeter and 200 ml of iron-based polymer flocculant polyferric sulfate (P...

Embodiment 2

[0063] The raw data of wastewater from a lead smelting enterprise are as follows:

[0064] The deep treatment capacity is 80m3 / h

[0065] Monitor water quality at the total discharge outlet of the workshop (unit: mg / L)

[0066] project

pH

CODcr

total copper

total zinc

total lead

Total arsenic

Total Cadmium

the second time

4.1

135

165

2.9

129

7.2

2.23

7.21

[0067] Automatically adjust the water quality and quantity of acidic wastewater such as flue gas washing water and leaked waste liquid in the production system through an electromagnetic flowmeter. According to the content of heavy metals in the water quality, add lime milk solution to adjust the pH value to 9.5 through a pH meter, and then pass through each cubic meter of water to be treated. The electromagnetic flowmeter controls the addition of 200 ml of iron-based polymer flocculant polyferric sulf...

Embodiment 3

[0073] The raw data of wastewater from a lead smelting enterprise are as follows 5.3.1:

[0074] The deep treatment capacity is 80m3 / h

[0075] 5.3.1-Water quality monitoring at the total discharge outlet of the workshop (unit: mg / L)

[0076] project

pH

CODcr

total copper

total zinc

total lead

Total arsenic

Total Cadmium

the third time

3.8

132

186

3.1

119

5.8

2.07

6.30

[0077] Automatically adjust the water quality and quantity of acidic wastewater such as flue gas washing water and leaked waste liquid in the production system through electromagnetic flowmeters. According to the content of heavy metals in the water quality, add lime milk solution to adjust the pH value to 10.0 through the pH meter, and then pass through each cubic meter of water to be treated. The electromagnetic flowmeter controls the addition of 200ml of iron-based polymer flocculant p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com