Patents

Literature

484 results about "Lead smelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plants for the production of lead are generally referred to as lead smelters. Primary lead production begins with sintering. Concentrated lead ore is fed into a sintering machine with iron, silica, limestone fluxes, coke, soda ash, pyrite, zinc, caustics or pollution control particulates. Smelting uses suitable reducing substances that will combine with those oxidizing elements to free the metal. Reduction is the final, high-temperature step in smelting. It is here that the oxide becomes the elemental metal. A reducing environment (often provided by carbon monoxide in an air-starved furnace) pulls the final oxygen atoms from the raw metal.

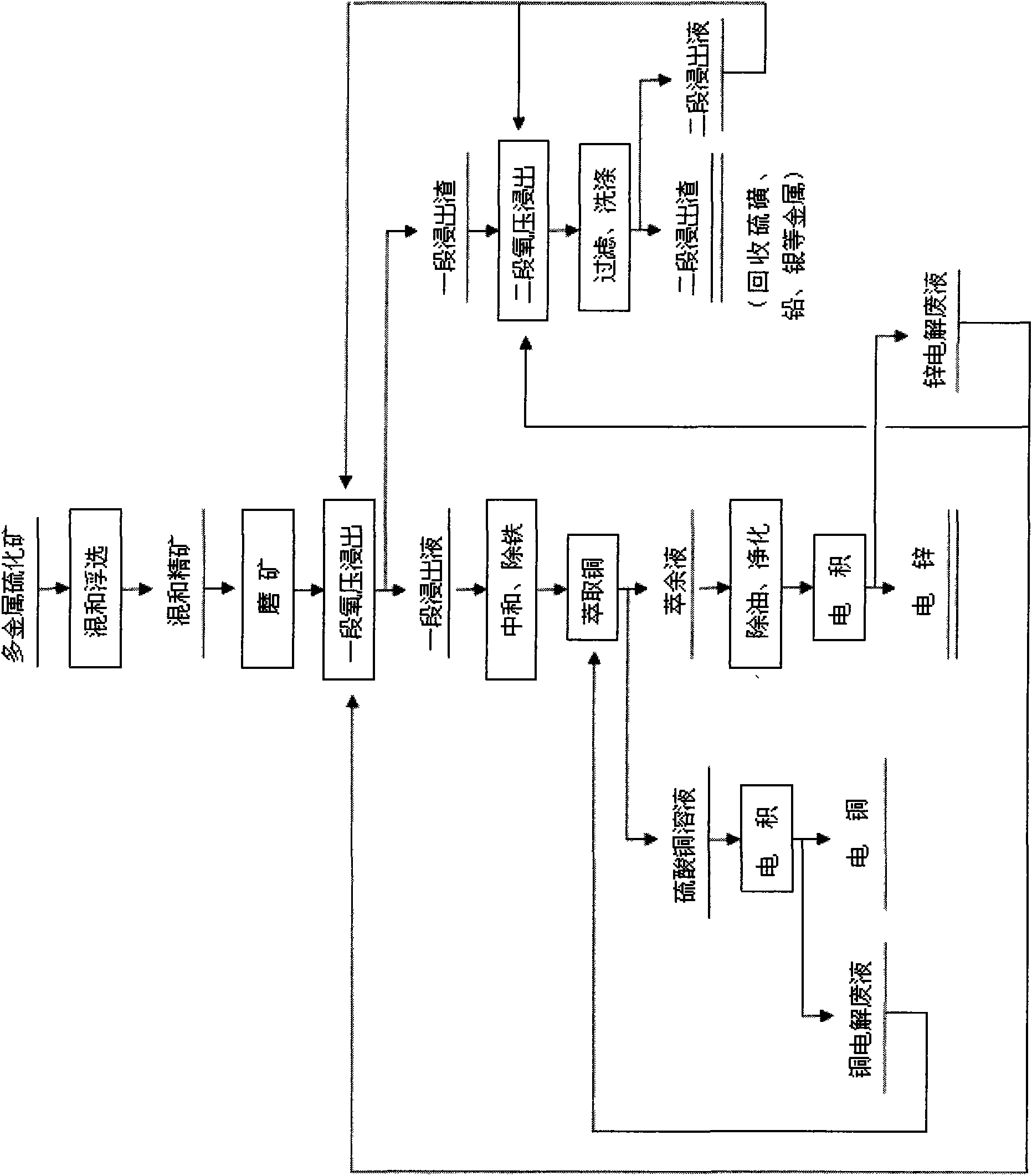

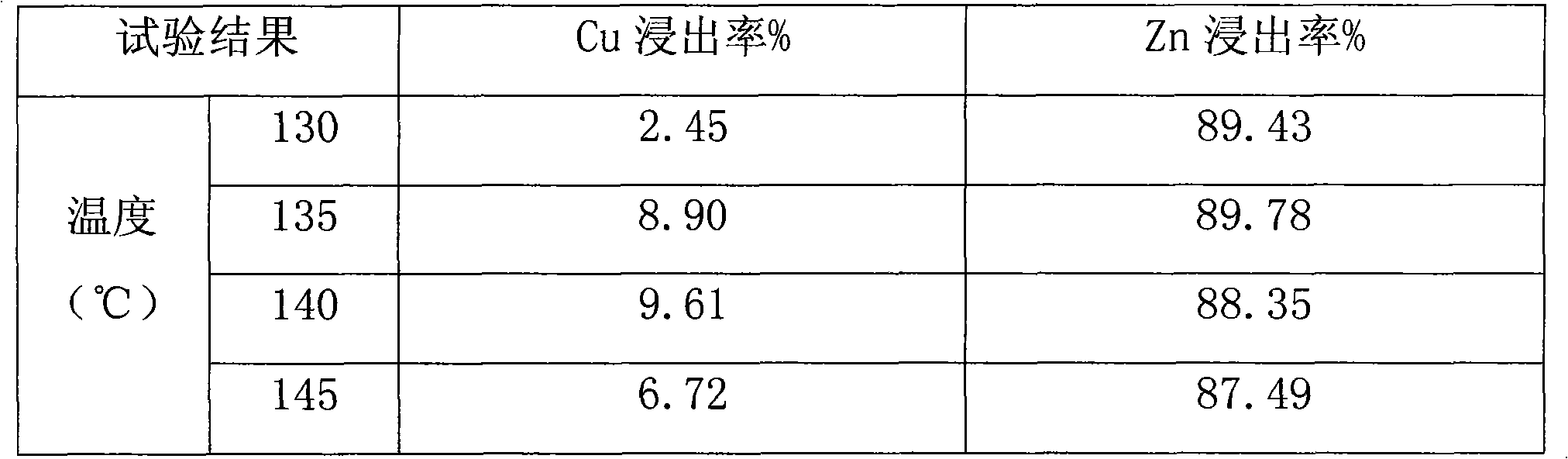

Comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc

InactiveCN101643857AHigh recovery rateSimple processSulfur preparation/purificationFlotationRecovery methodLead smelting

The invention discloses a comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc and adopts dressing-metallurgy combination method and hydrometallurgy-pyrometallurgy combination method to recover metals. The recovery method comprises the following steps: first performing bulk flotation to the complex polymetal sulphide ore, fine grinding the obtained concentrate, leaching by using two-step counter flow oxygen pressure leaching process, extracting and separating copper and zinc from the obtained leachate, electrodepositing the strip liquor of copper-loaded organic phase to obtain cathode copper, cleaning the obtained raffinate and electrodepositing to obtain cathode zinc; pressurizing leaching residue to perform flotation separation and obtain sulfur concentrate and lead silver residue, distilling sulfur concentrate to obtain sulfur; performing lead smelting process to lead silver residue to obtain electrolytic lead product and lead anodic slime; and comprehensively recovering noble metals such as gold, silver and the like from lead anodic slime. The method can greatly improve the metal recovery rate, resource utilization and the economic efficiency of mines and generate a lot of sulfur so as to obviously reduce the sulfur dioxide pollution to the atmosphere.

Owner:WESTERN MINING CO LTD

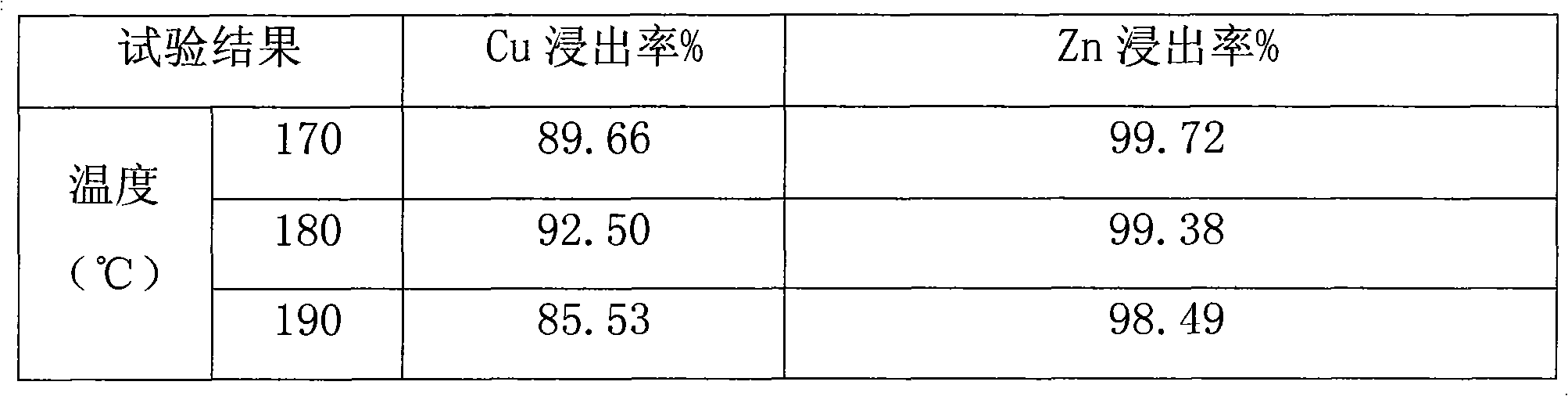

Method for recycling tin from lead bullion

InactiveCN104141152AImprove efficiencyImprove production costsPhotography auxillary processesElectrolysisLead smelting

The invention discloses a method for recycling tin from lead bullion, and belongs to the technical field of pyrogenic process and wet process combined metallurgy. The method comprises the steps that after liguation decoppering processing is carried out on the lead bullion, caustic soda, caustic soda and salt are added into the lead bullion according to the content of the tin in the lead bullion to gather and remove the tin in the lead bullion, and tin-rich slag is obtained; sodium carbonate and reduction coal are added into the tin-rich slag and all tin-containing slag produced by a lead smelting system, and the tin-rich slag and the tin-containing slag generate terne metal through reduction smelting; the terne metal is processed through vacuum distillation to obtain crude tin; highly purified precipitated tin is obtained from the crude tin through electrolytic refining of mixed acid with silicofluoric acid-sulfuric acid as an electrolytic medium, and the precipitated tin is processed through simple smelting to obtain a tin ingot product meeting the national standard. The method sets the precedent for producing tin ingot products through comprehensive utilization of tin resources obtained from lead through smelting, has the advantages of being concise in technology, high in tin product yield, low in processing cost and the like, particularly separates tin alloys through introduction of vacuum distillation, and has the significant advantages in the aspects such as energy conservation and environment protection.

Owner:蒙自矿冶有限责任公司

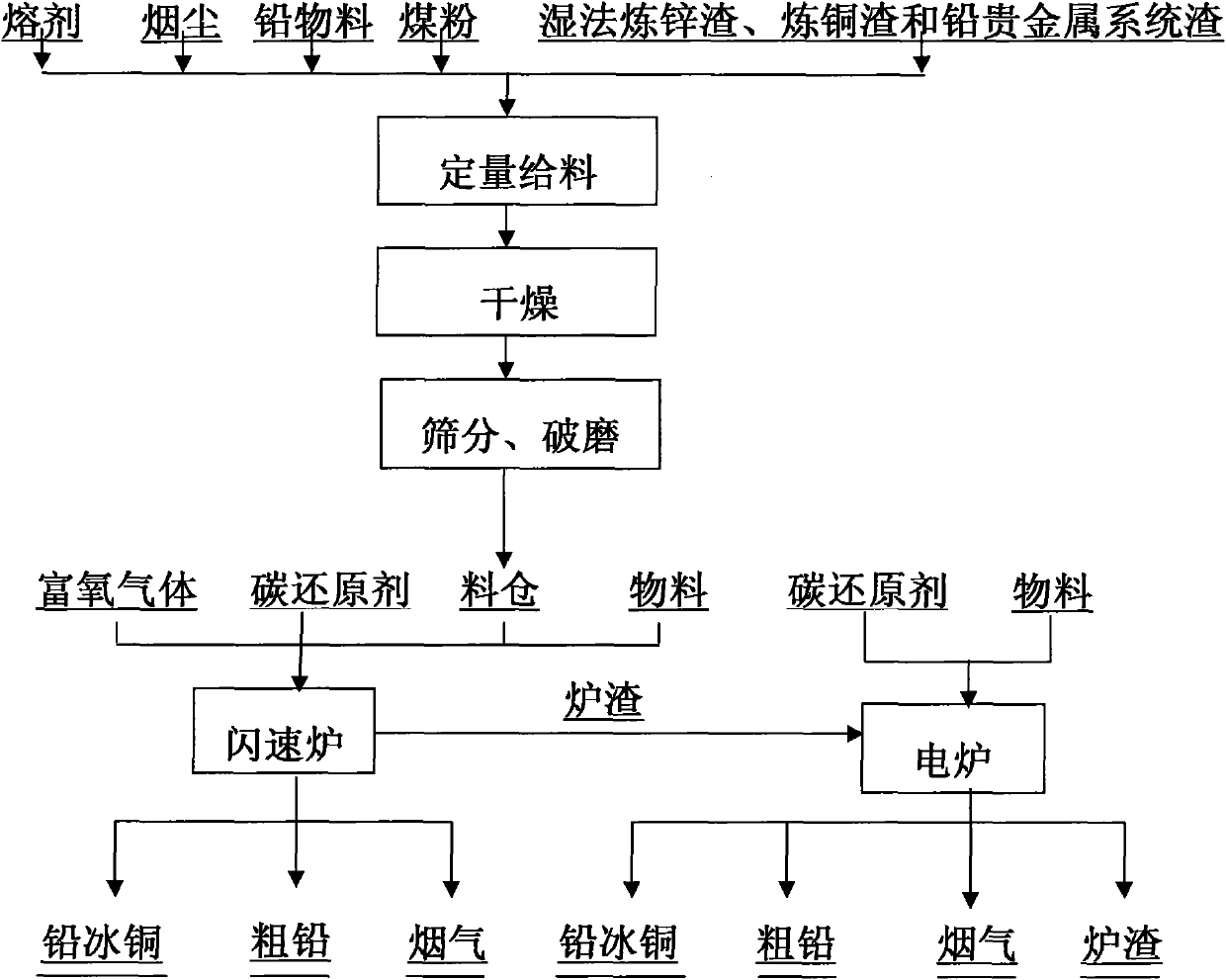

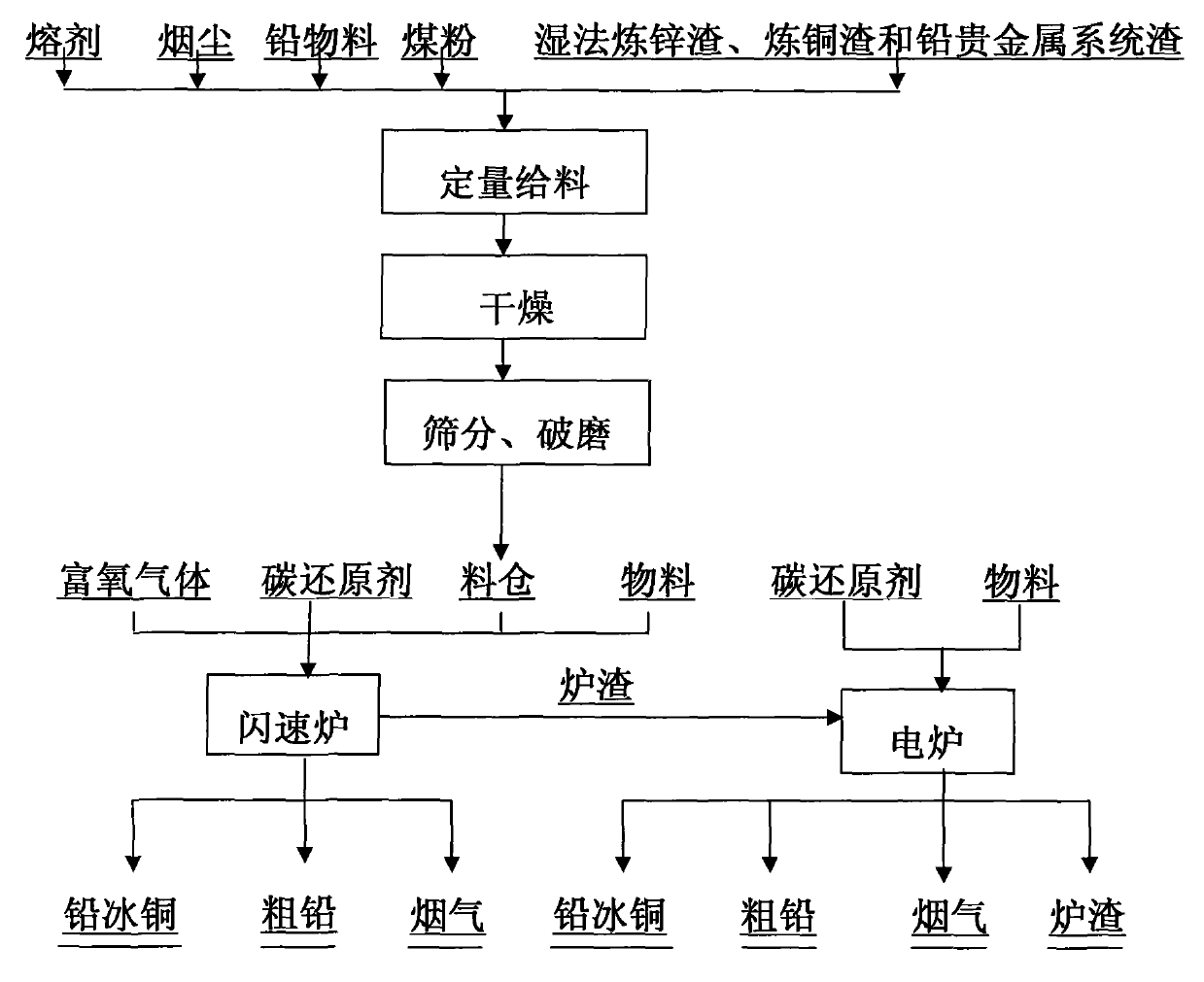

Method for smelting lead-containing material

InactiveCN101768670ANo explosion hazardAdaptableProcess efficiency improvementLead smeltingSmelting process

The invention discloses a method for smelting a lead-containing material, relating to the technological process for processing complex lead materials by utilizing a smelting method. The method is characterized in that a flash furnace and a depletion furnace are combined for smelting during the smelting process. The method of the invention has the advantages of short and continuous flow, energy saving, large capacity, efficient source utilization, environment protection, good safety and good industrial hygiene, no danger of foam slag exploration and safe production. The lead smelting process with high smelting strength and various advantages realizes single-step lead smelting, and has stronger adaptability on materials. The process is not only suitable for treating lead ore with complex components, but also suitable for treating wet smelting zinc slag, wet smelting copper slag and lead noble metal system slag, can do complementation of lead, zinc and copper and has more advantages over lead, zinc and copper jointed enterprises. The recovery rates of lead and concomitant valuable metals of copper, zinc and noble metals are higher.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

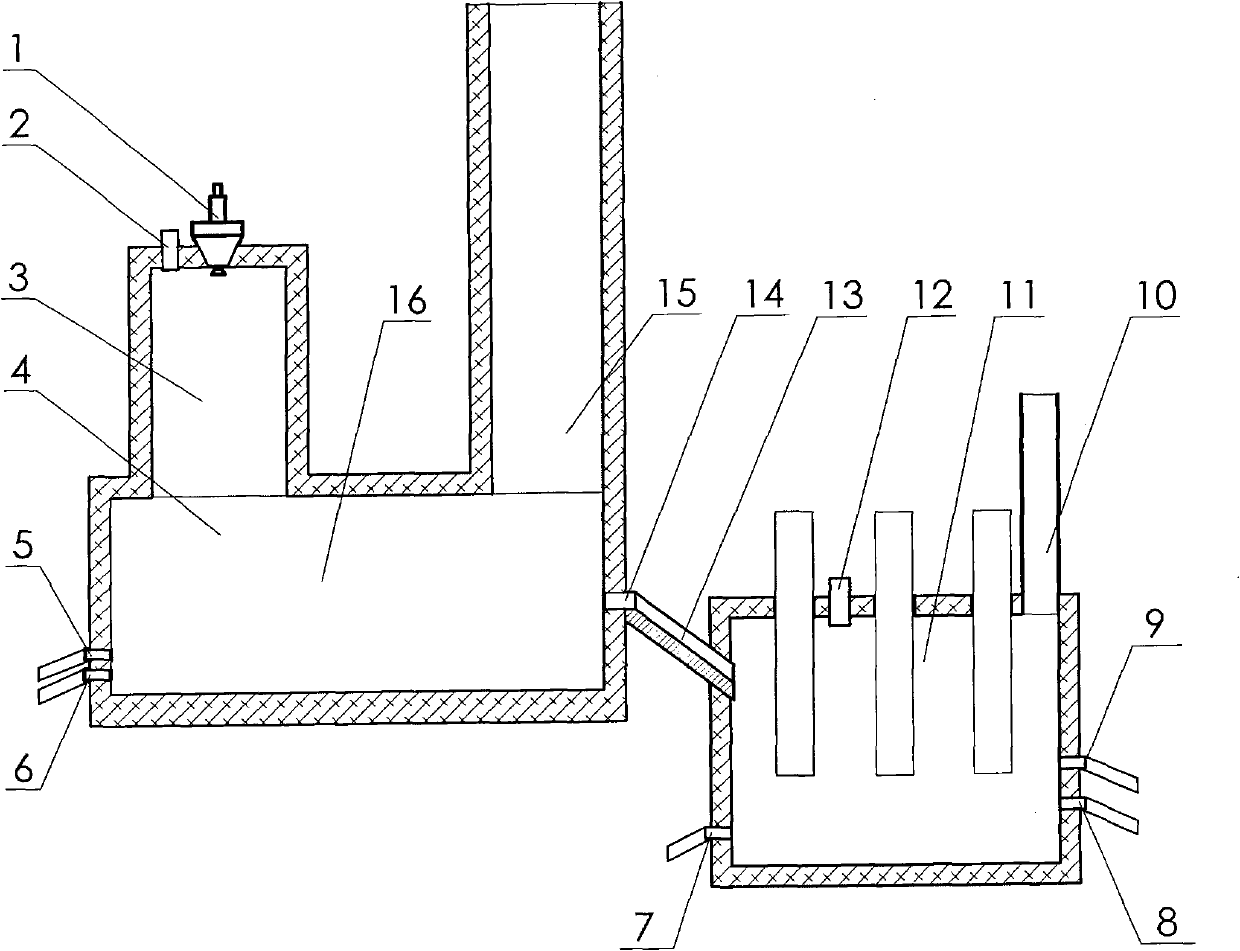

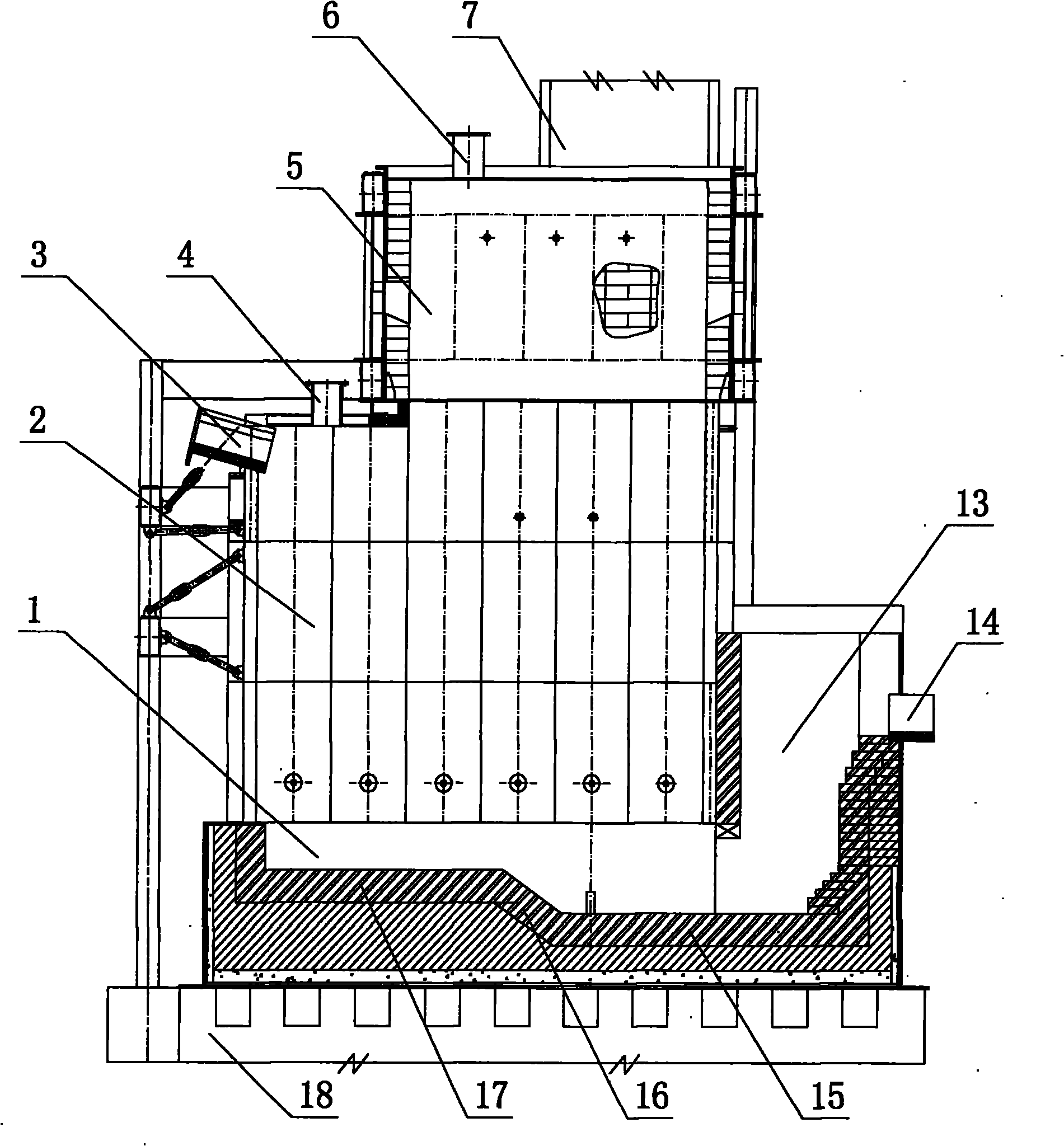

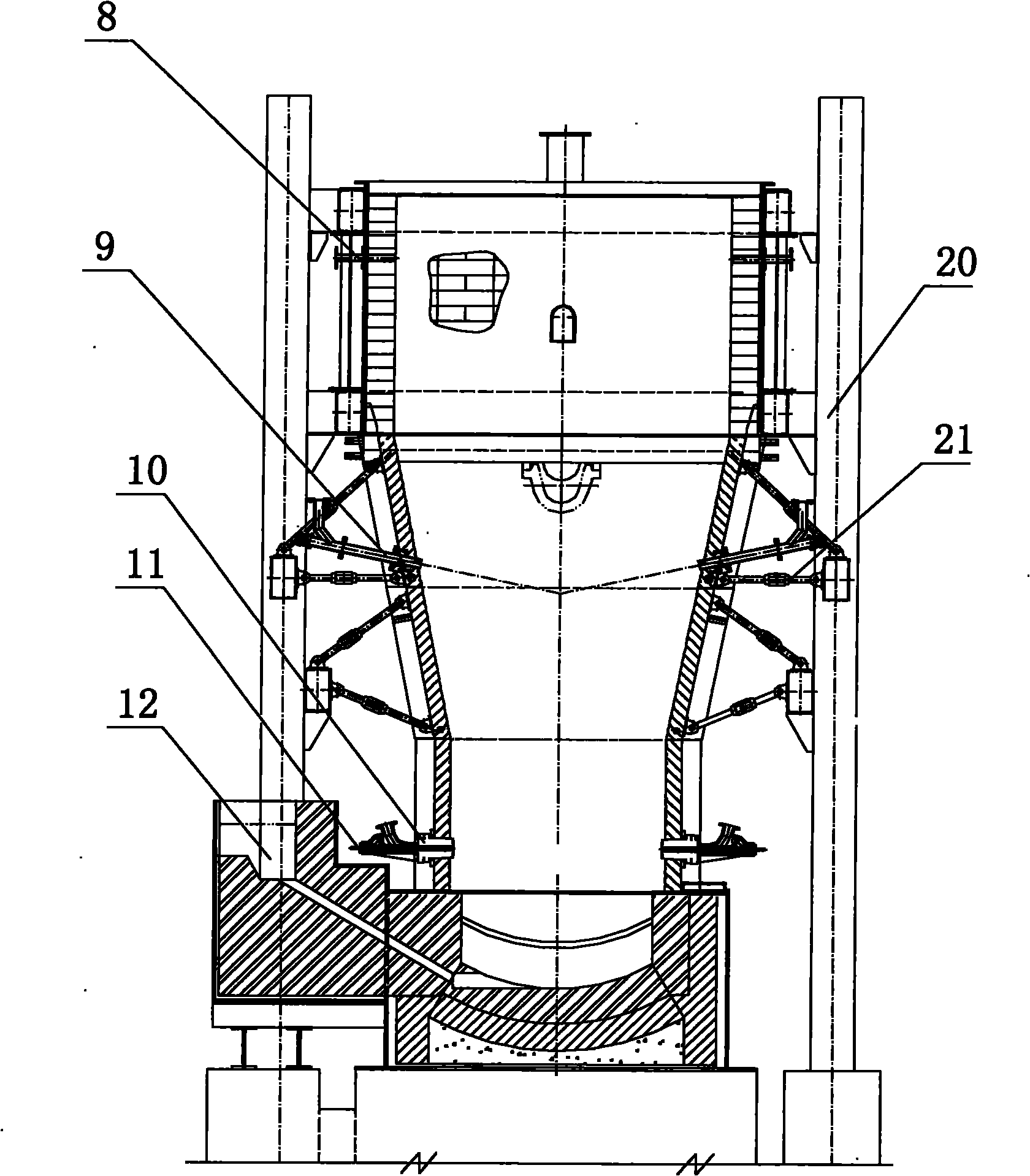

Direct lead smelting method in molten pool and its device

This invention relates to method for smelting lead by using molten pool directly and the device. It comprises the following steps: feeding the high-lead residue melt into bottom-blown molten pool by downspouting to deoxidize; providing melt with oxygen and natural gas or oxygen and gas from bottom or downside of the bottom-blown molten reduction furnace by using gas spray gun; adding carbon particles to reduction furnace from feed opening; the high-lead residue melt is transformed to crude lead, flue gas and final slag through reduction. The device comprises melting bath calcar, and the taphole of melting bath calcar is connected to the feed opening of bottom-blown molten reduction furnace through downspouting, the gas spray gun is installed on the bottom or downside of bottom-blown molten reduction furnace. The invention is characterized by low energy consumption, good work environment and saved investment.

Owner:HENAN YUGUANG GOLD & LEAD

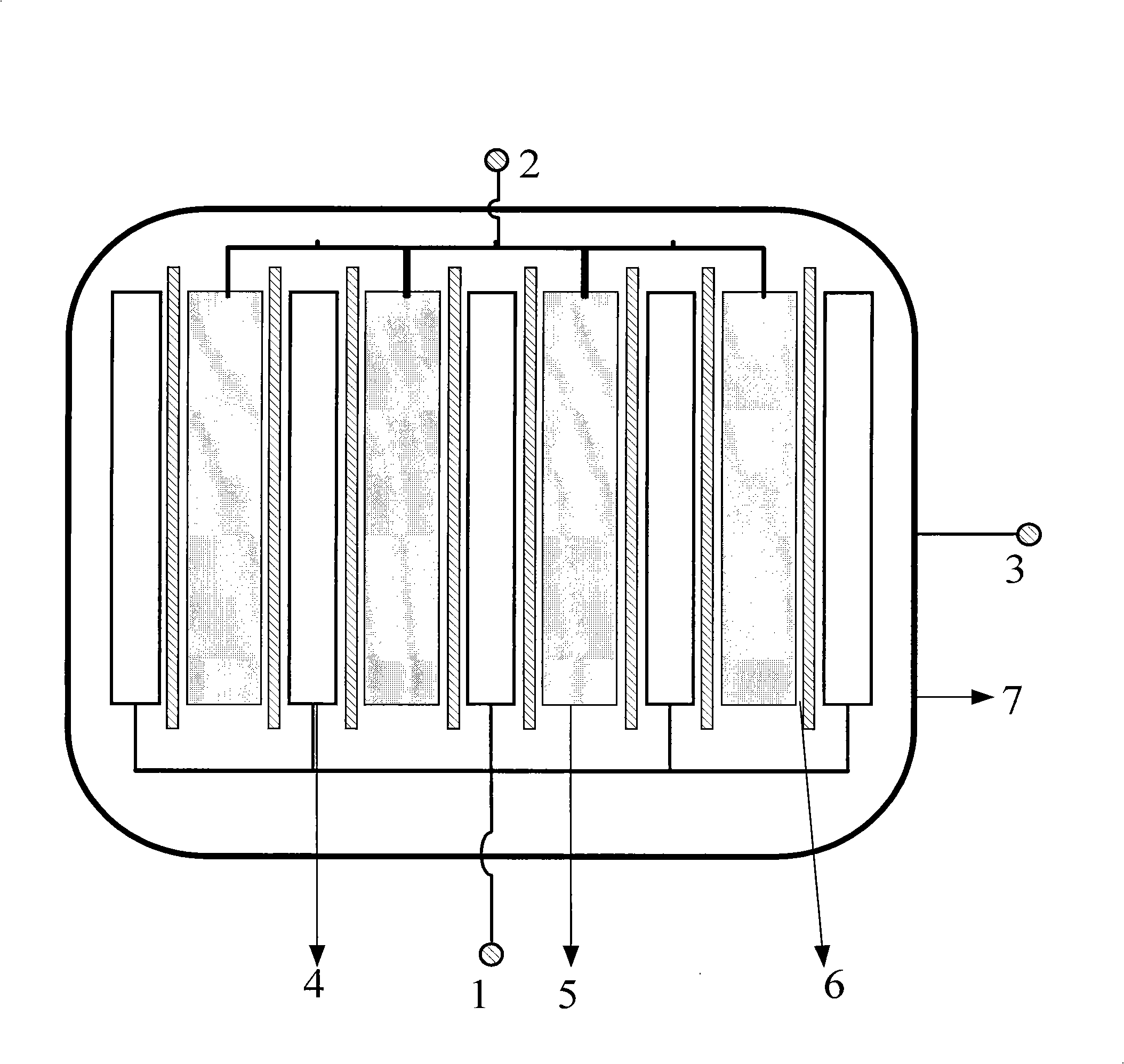

Method of recycling waste lead acid battery lead by electrolyzing with acid-wet method

InactiveCN101291008AEasy to fixLow costWaste accumulators reclaimingProcess efficiency improvementRecovery methodLead smelting

The invention relates to a method for recovering lead, in particular to a method for electrolyzing and recovering lead in a waste lead-acid accumulator by using an acid-mode wet method. The method comprises the following steps that: firstly, the waste lead-acid accumulator is treated with a pouring acid, a shell of the waste lead-acid accumulator is peeled off and separated to obtain a dilute sulphuric acid, waste plastic and a battery unit or a battery pack; secondly, the battery unit or the battery pack separated from the waste battery is positioned in an electrolytic cell; the lead is reduced by adopting a duplicate power-supply and multi-module electrolysis process; and a lead plate is formed on a slab lattice for recovering the lead. The lead recovery method eliminates the pollution of exhaust gas and waste slag containing the lead and SO2 in the prior pyrogenic lead-smelting process and overcomes the disadvantages of complex flow and low lead recovery coefficient in the prior wet lead smelting process.

Owner:BEIJING UNIV OF CHEM TECH

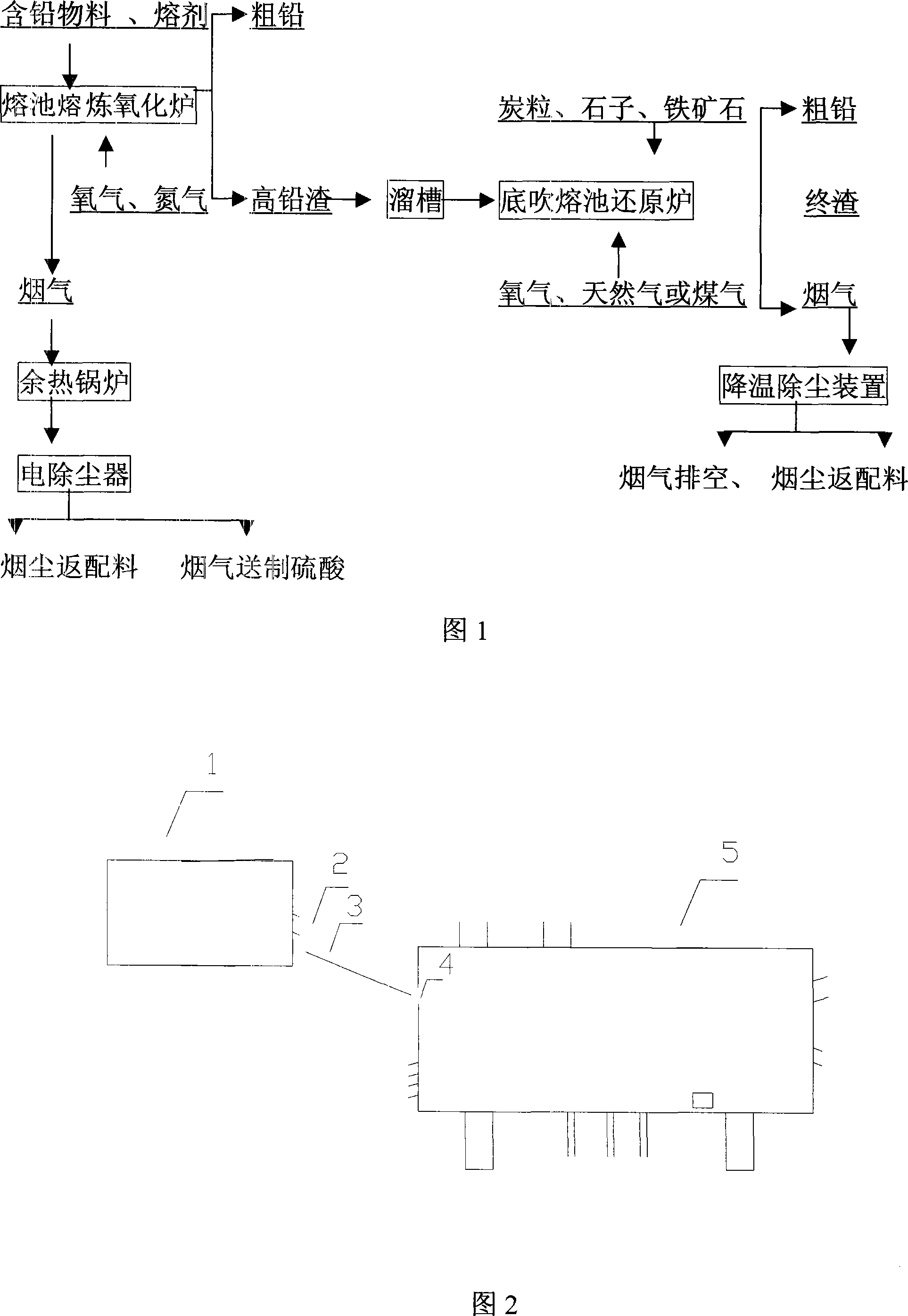

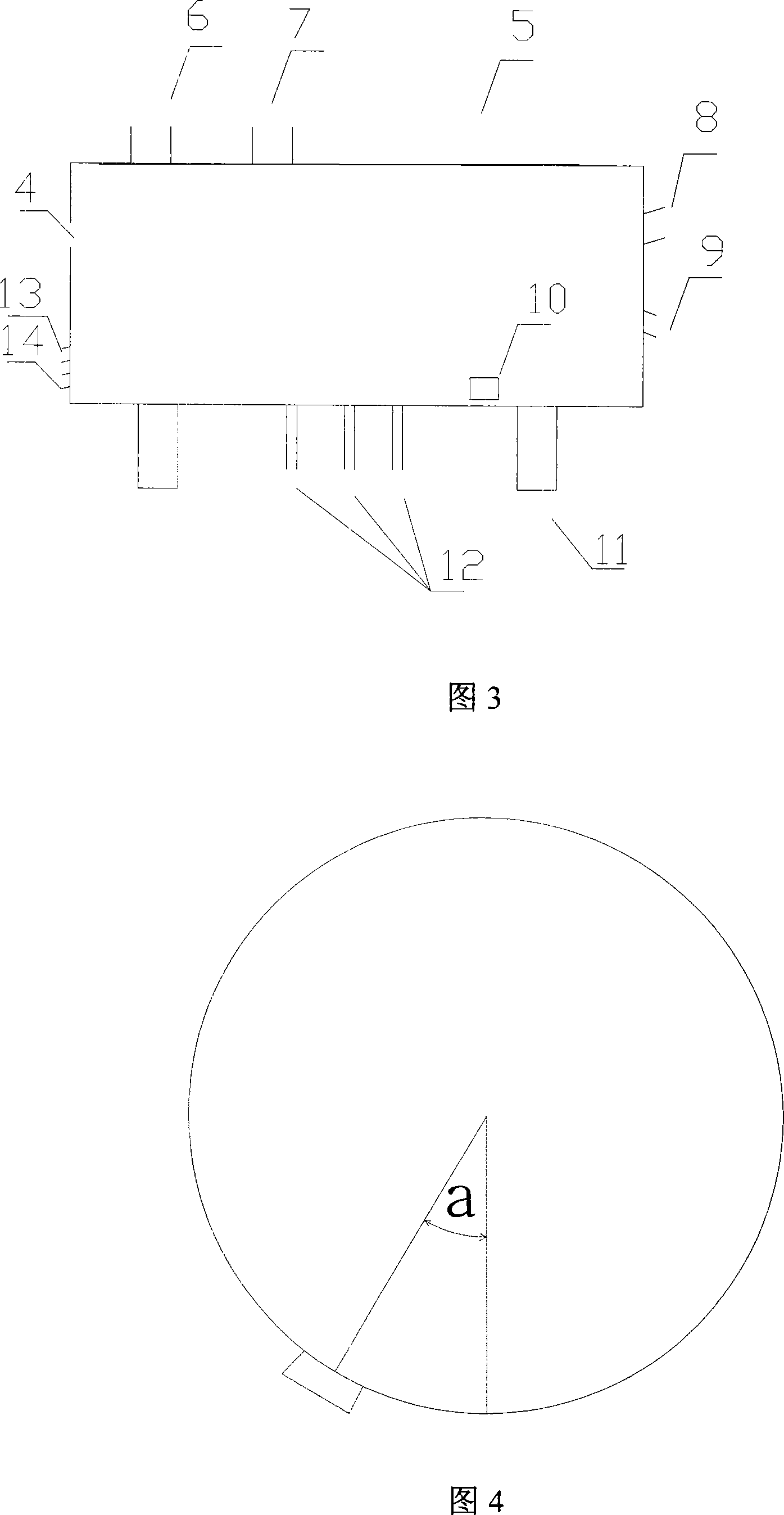

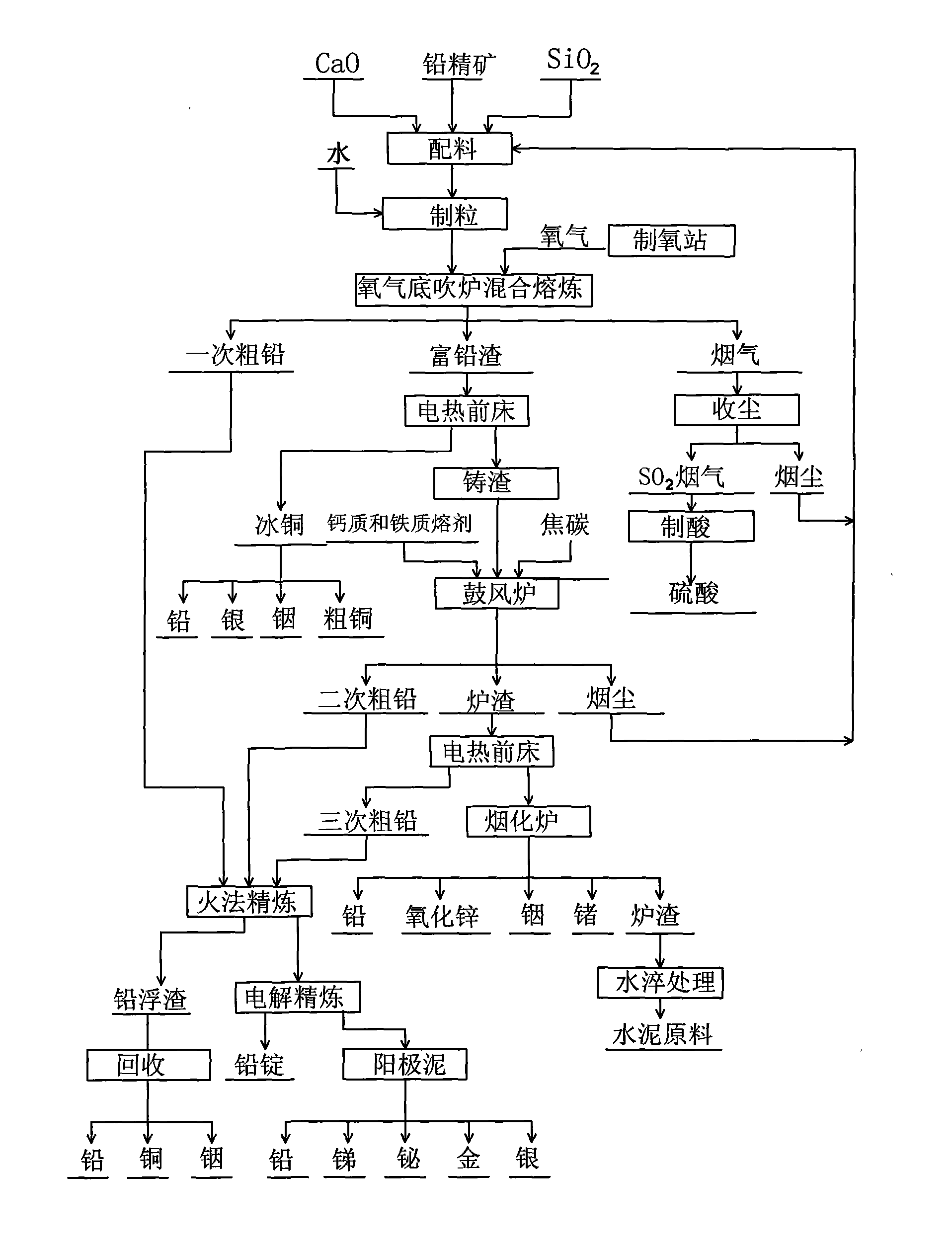

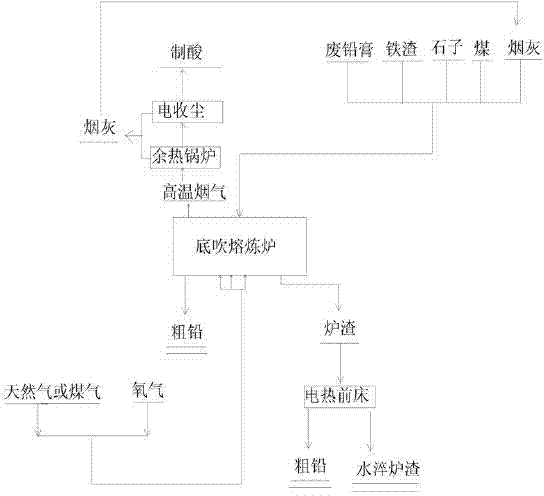

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399AHigh melting temperaturePromote oxidation reactionPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2 to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

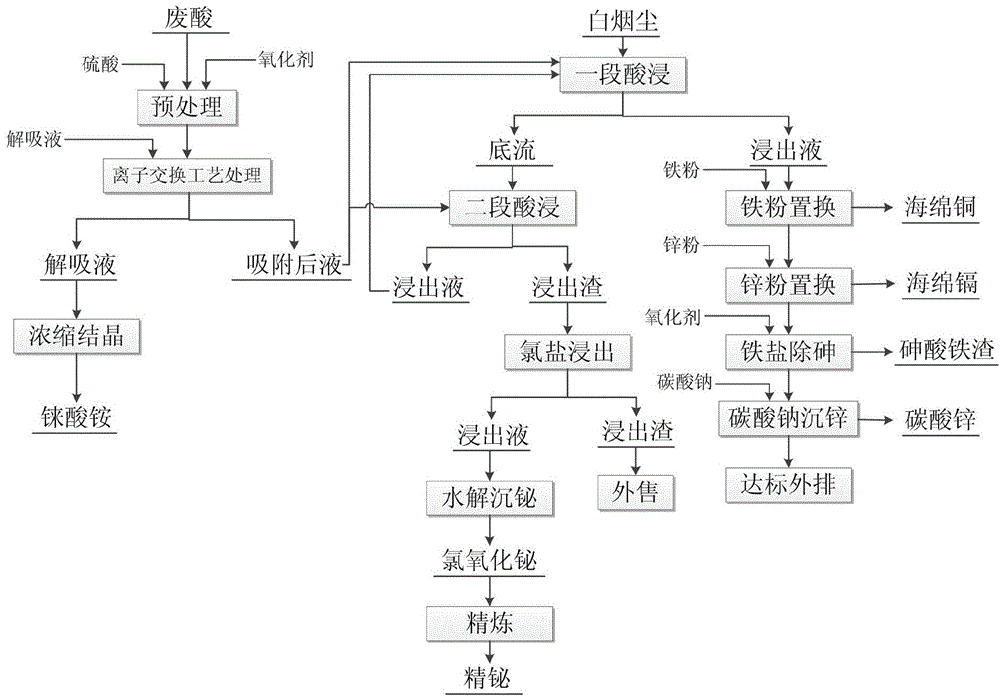

Process of recovering copper smelting waste acid and white smoke dusts

InactiveCN104593604AEfficient selective adsorptionEasy to handleProcess efficiency improvementParticulatesWater treatment

The invention provides a process of recovering copper smelting waste acid and white smoke dusts. The process comprises the following steps: removing suspended particulate matters in the waste acid, regulating the acidity and the redox potential of the liquid, and enabling ions including molybdenum ions in the liquid to exist in a high positive ion mode; then selectively adsorbing rhenium by utilizing ion exchange resin, after adsorption is saturated, carrying out desorption to obtain a rhenate liquid, and carrying out concentration and crystallization to obtain rhenate; using the waste acid after adsorbing the rhenium for leaching the white smoke dusts; treating the white smoke dusts by adopting two segments of countercurrent acid leaching-chloride leaching process, recovering valuable metals including copper, zinc and cadmium of an acid leaching liquid, carrying out harmless treatment on harmful elements including arsenic by virtue of a molysite method, recovering valuable metals including bismuth of a chloride leaching liquid, and selling lead sulfate, serving as a main component of chloride leaching residues, to a lead smelting plant. According to the process provided by the invention, the rhenium in the waste acid can be efficiently separated and recovered, the leaching white smoke dusts of the waste acid can be fully utilized, and the waste acid and white smoke dust leaching liquids can be comprehensively treated by utilizing a set of copper recovering and arsenic harmless treatment system, so that the process matching ability is good, the comprehensive recovery rate of the valuable metals is high, the waste water treatment effect is good, the investment is little, the production cost is low, and the economical benefit is good.

Owner:ZIJIN MINING GROUP

Zinc leaching slag treatment method

ActiveCN103421955AShort processShorten the smelting processProcess efficiency improvementLead smeltingMolten bath

A zinc leaching slag treatment method comprises the following steps: 1) The dried zinc leaching slag is evenly mixed with coke powder, and then the mixture is added to a volatilization kiln through a feeding scraper-trough conveyer at the tail of the kiln; 2) under the high-temperature condition of the volatilization kiln, the mixture generates kiln slag and smoke, valuable metals in the zinc leaching slag are deoxidize, as a result, lead and zinc steam is generated and gathered in the smoke, and gold, silver and copper enters to the kiln slag; 3) the kiln slag is delivered to a smelting furnace, furnace burden is added from the top of the smelting furnace, oxygen-enriched air is blown through an oxygen lance, the furnace hearth is stirred, the smelting temperature of the smelting furnace and the ratio of oxygen quantity to kiln slag dry measure are controlled, and slagging smelting is completed; 4) after the slagging smelting carried out in step 3), the valuable metals gold, silver and copper in the kiln slag are gathered in matte, the generated lead steam is gathered in smoke, and the kiln slag is cooled gradually. According to the zinc leaching slag treatment method, the technological process is short, the energy consumption is low, the cost is low, and the valuable metal recovery rate is high.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

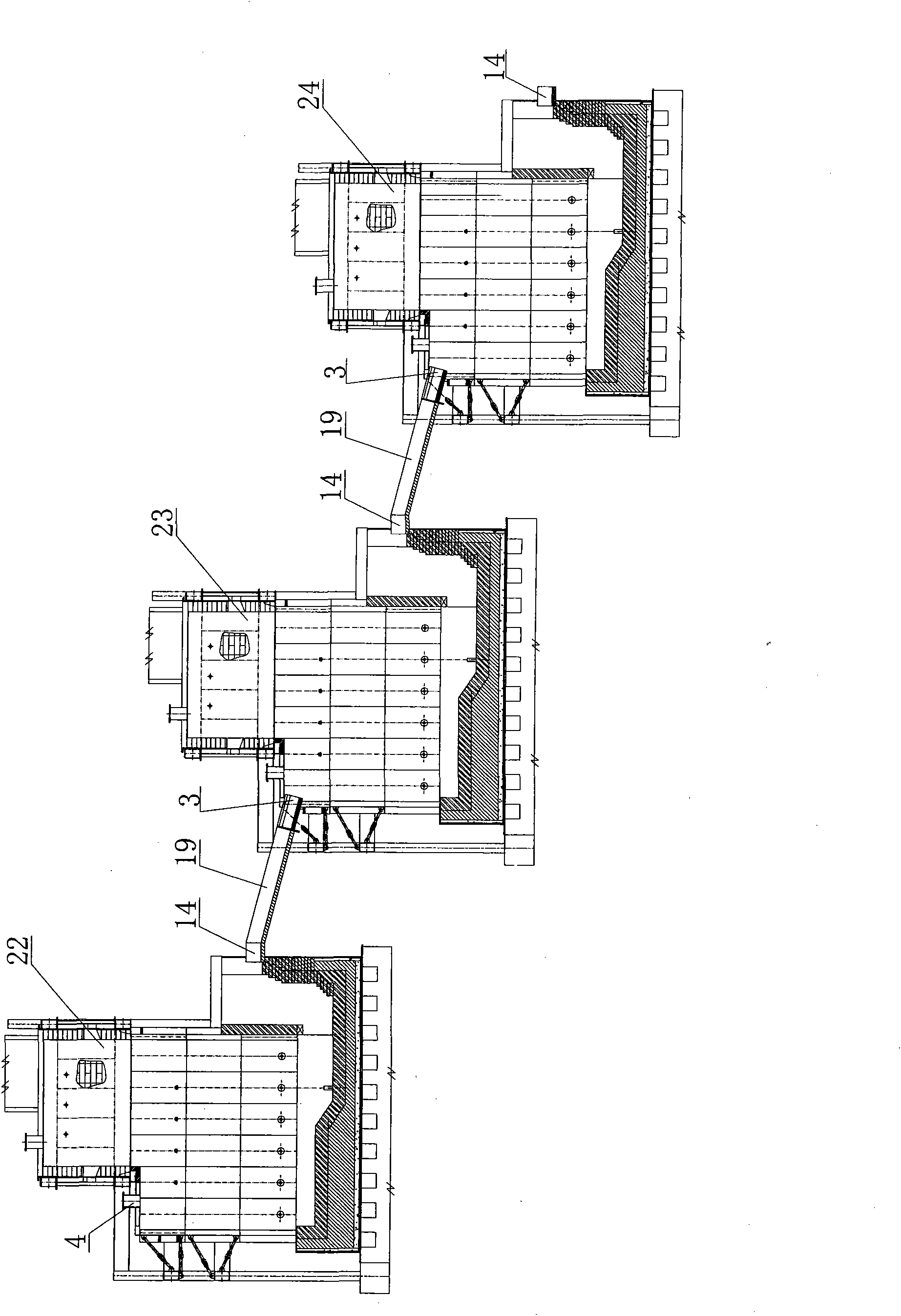

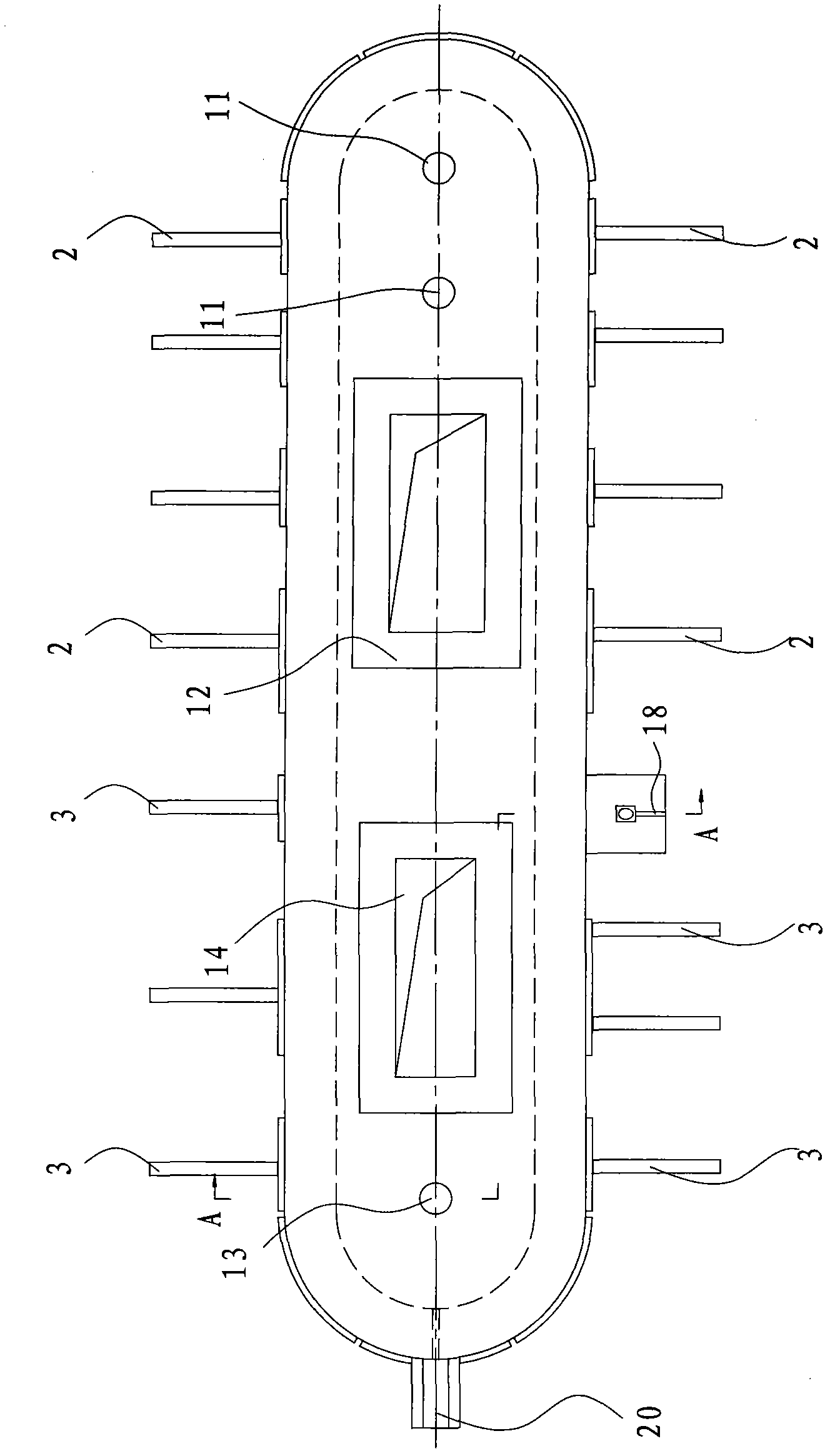

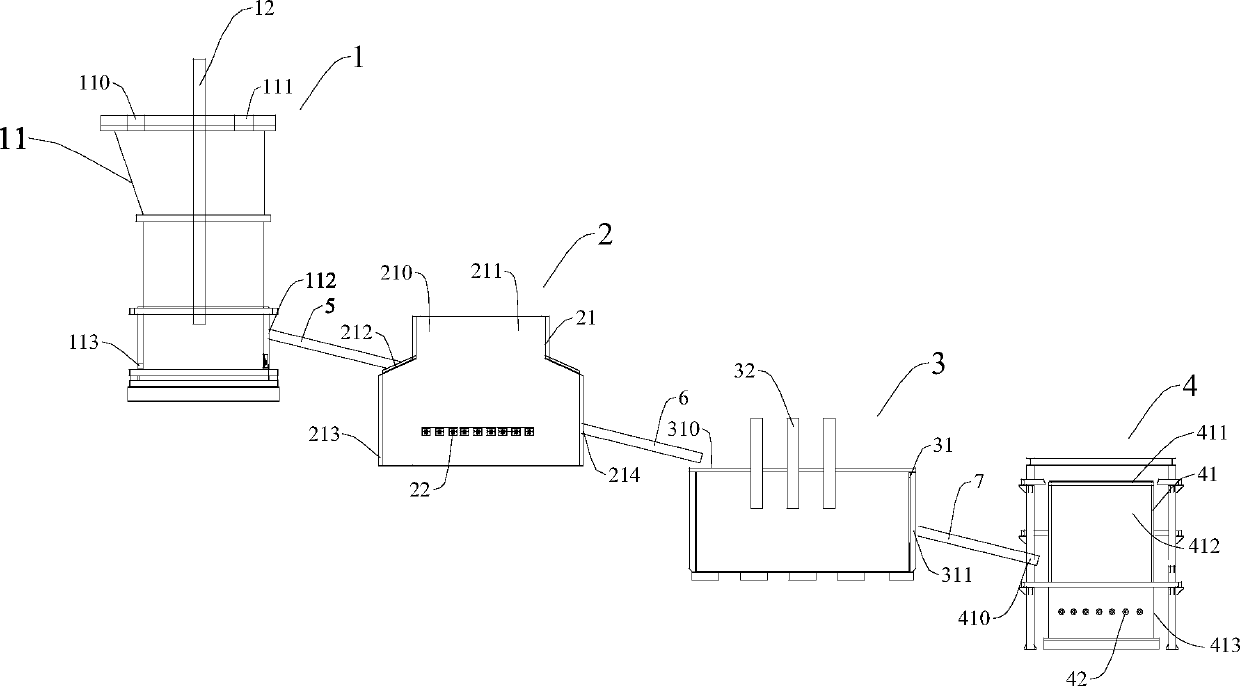

Direct lead-smelting comprehensive metallurgical device and smelting process

The invention relates to an energy-saving high-efficient direct lead-smelting comprehensive metallurgical device, which is formed by serially joining three melting bath smelting furnaces: a first furnace, a second furnace and a third furnace; and the second furnace consists of a furnace cylinder and a furnace body which is arranged on the furnace cylinder. The top part of the upper furnace body is provided with a smoke exhaust port and a standby feeding port; a charge feeding port and a slag feeding port are arranged above the lower furnace body; and the bottom part of the lower furnace body is provided with a slag siphonic water-collecting well. The furnace body is provided with three rows of supply-air outlets. The bottom part of the furnace cylinder is provided with a metal siphonic outlet. Due to the adoption of the direct lead-smelting comprehensive metallurgical device, the heat loss is small, the heat utilization rate is high, sulfuric dioxide smoke with high concentration can be produced, and the requirement for producing the acid can be more favorably satisfied; and molten high-lead thermal slag which is produced through oxidation and smelting directly flows into a reducing furnace, so the heat of the thermal molten slag can be adequately utilized. The land occupied area is small, the investment can be saved, the heat loss is less, the heat utilization rate is high, the heat energy can be adequately utilized, a great amount of energy consumption can be saved, output of smoke is small, the content of harmful ingredients in smoke is low, and the environmental pollution problem can be more effectively solved.

Owner:JIYUAN WANYANG SMELTING GROUP +2

Method for processing zinc leaching residues at high proportion by using oxygen bottom blown furnace

ActiveCN101985695AReduce pollutionRealize industrial productionProcess efficiency improvementLead smeltingChemical reaction

The invention belongs to a pyrometallurgical technology of leaded materials and the like, in particular to an economic and harmless method for processing zinc leaching residues produced in a zinc hydrometallurgy process. In the technology, the intensified smelting characteristic of an oxygen bottom blown furnace is used, and sulfide is added to maintain heat balance of the smelting and accurately control oxidizing atmosphere, thus the added zinc leaching residues at high proportion can be subject to decomposition, desulfuration, scorification and the other chemical reactions in the oxygen bottom blown furnace, wherein the recovery rates of Pb, Zn, Cu, Ag, S and the other valuable metals in the zinc plant leaching residues are more than 99%.The method provided by the invention has the advantages of simple operation and high metal recovery rate; and in addition, in the method, resources are saved, i.e. wastes are comprehensively recovered, environmental contamination is avoided, the technological flow of a mature SKS lead smelting process can be used fully, and the comprehensive utilization level is improved.

Owner:YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

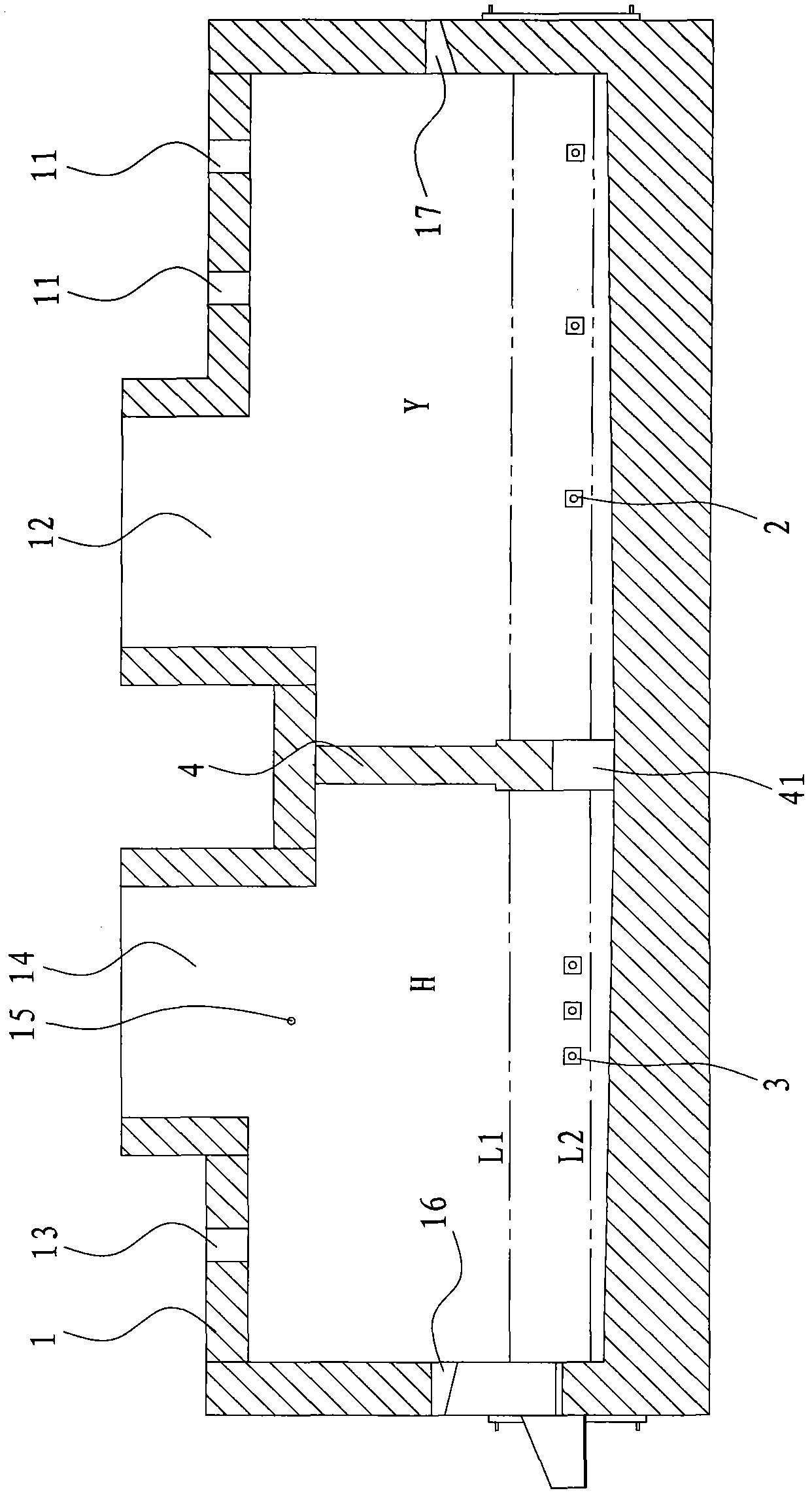

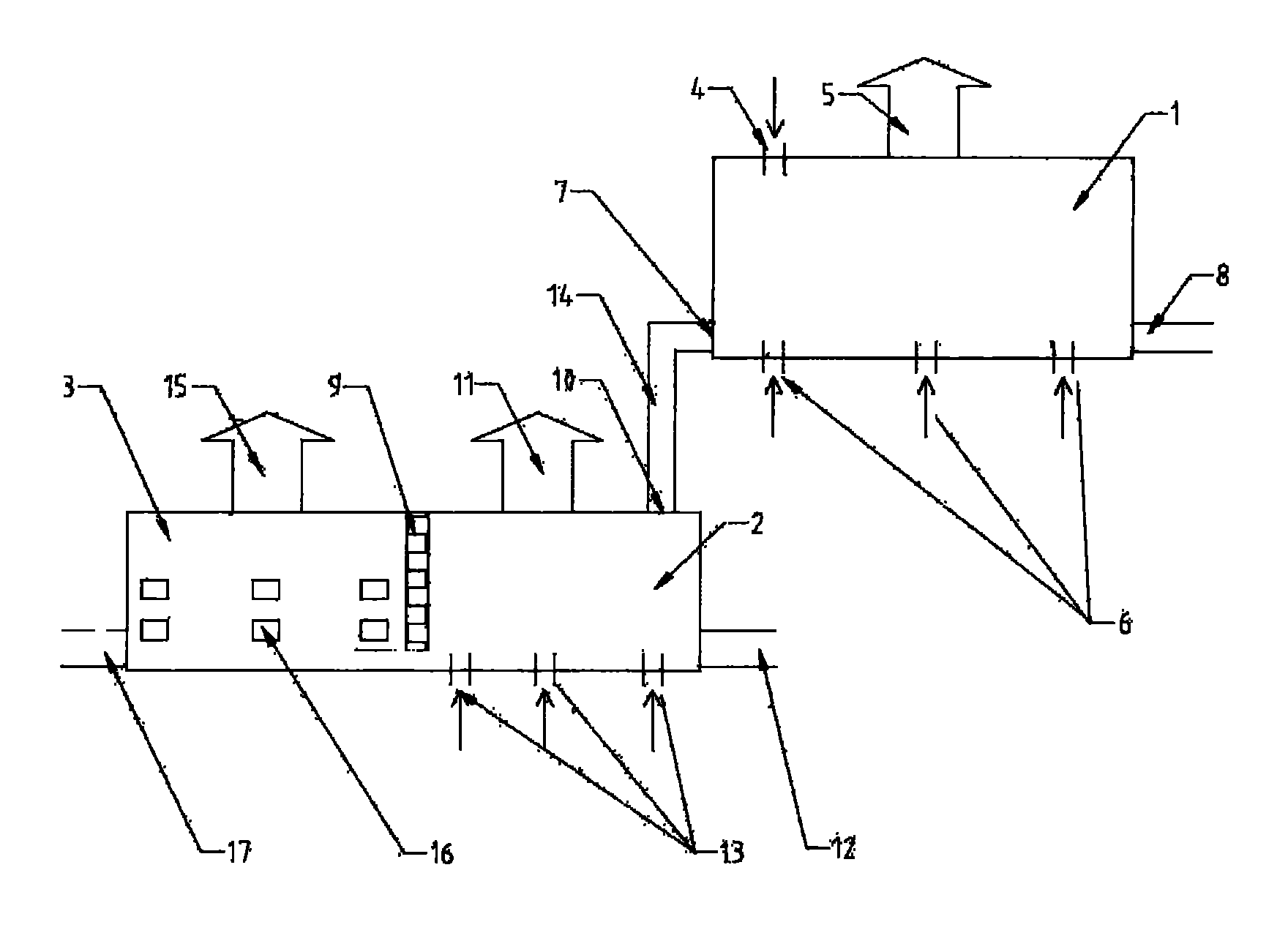

Continuous lead-smelting device and continuous lead-smelting process

ActiveCN102011014AStable lead contentTake advantage ofLighting and heating apparatusLead smeltingFlue gas

The invention discloses a continuous lead-smelting device which comprises a reaction furnace, a side-blown spraying gun for an oxidation zone and a side-blown spraying gun for a reduction zone, wherein, the reaction furnace is internally equipped with a partition wall for dividing a furnace chamber of the reaction furnace into the oxidation zone and the reduction zone, the lower part of the furnace chamber forms a molten pool, the bottom of the partition wall is equipped with a communicating channel for communicating the oxidation zone with the reduction zone, the roof of the oxidation zone is respectively equipped with a feed inlet for the oxidation zone and a flue gas outlet for the oxidation zone respectively, the roof of the reduction zone is equipped with a reductant feed inlet and a flue gas outlet for the reduction zone, and the furnace wall of the furnace chamber is equipped with a siphon lead discharge port and a slag discharge port; the side-blown spraying gun for the oxidation zone is connected with the side wall of the oxidation zone of the reaction furnace so as to laterally blow oxygen into the molten pool of the oxidation zone; and the side-blown spraying gun for the reduction zone is connected with the side wall of the reduction zone of the reaction furnace so as to laterally blow fuel and oxygen into the reduction zone. The continuous lead-smelting device disclosed by the invention has the advantages that oxidation and reduction are realized in single reaction furnace, lead content in slag is low, stability and tightness are good, environmental protection property is high, heat content of the slag is fully utilized and energy consumption is lowered. The invention further provides a continuous lead-smelting process.

Owner:CHINA ENFI ENGINEERING CORPORATION

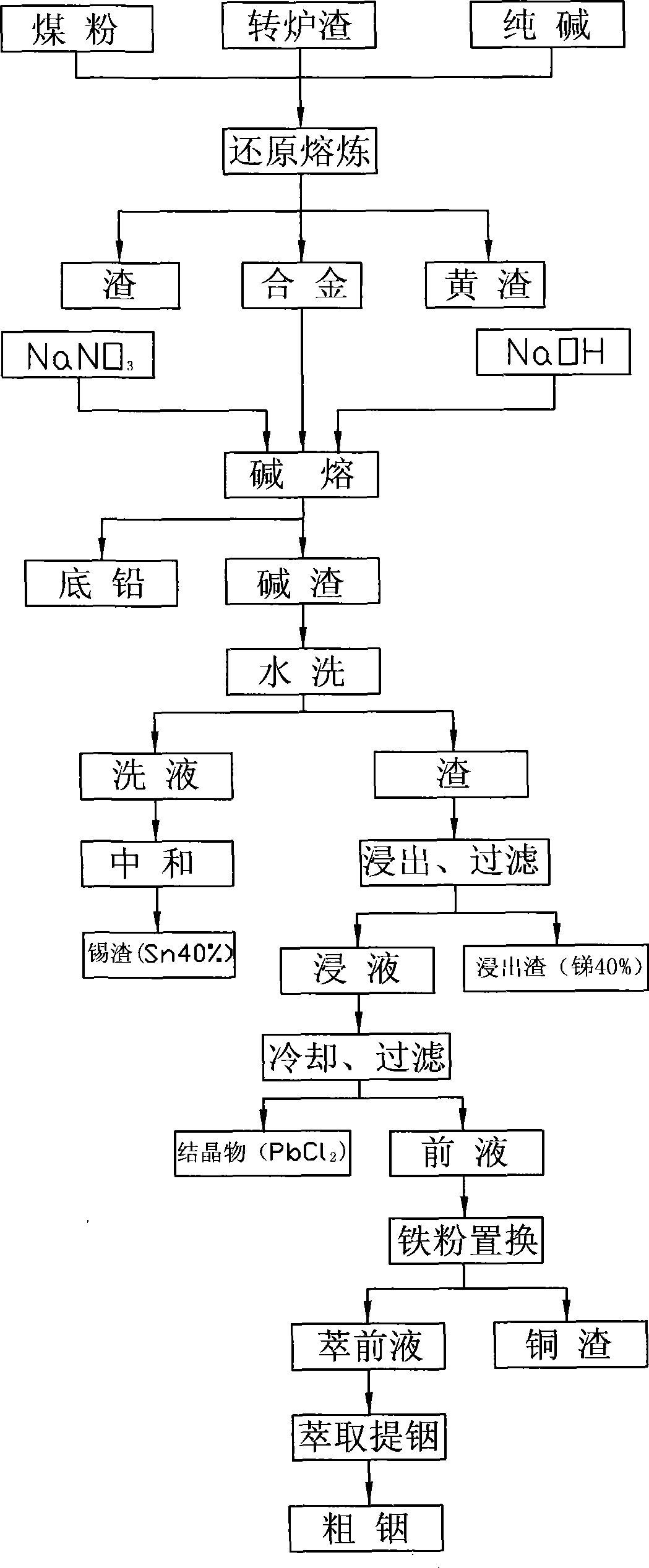

Technology of extracting and separating valuable metals such as Pb, In, Sb, Cu and Sn from lead smelting converter slags

The invention relates to a technology of extracting and separating valuable metals such as Pb, In, Sb, Cu and Sn from lead smelting converter slags, comprising the following steps: adding carbonaceous reducing agent in raw materials which are produced in the process of crude lead smelting and contain Pb, In, Sb, Cu and Sn; smelting the raw materials and the carbonaceous reducing agent in an electric furnace or a reverberatory at the temperature over 1000 DEG C, reducing the Pb, Cu, Sb, Sn, In and the like into metals and forming alloy, sorting out silicon and other components as slags; mixing sodium hudroxide with weight accounting for 40-60% of the alloy weight into the alloy, adding oxidizer and copper removal agent with weight accounting for 5-20% of the alloy weight, oxidizing the In, Sn, Sb and Cu for slagging and extracting the metallic lead; washing oxidizing slags to extract Sn, neutralizing the Sn by adding acid through washing water, regulating pH value to 3-4 and obtaining tin slags; obtaining stibium slags after acid leaching and separating of washing slags; obtaining copper sponge by replacement with ferrous powder by pickle liquor; extracting indium from replaced liquid and extracting organic phase by adopting TBP+octanol+karaffin oil, with extraction phase ratio of O / A equal to 1:1. The direct yield and recovery rate of metallic In, Pb, Sn and Sb are respectively over 90% and 95%.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY

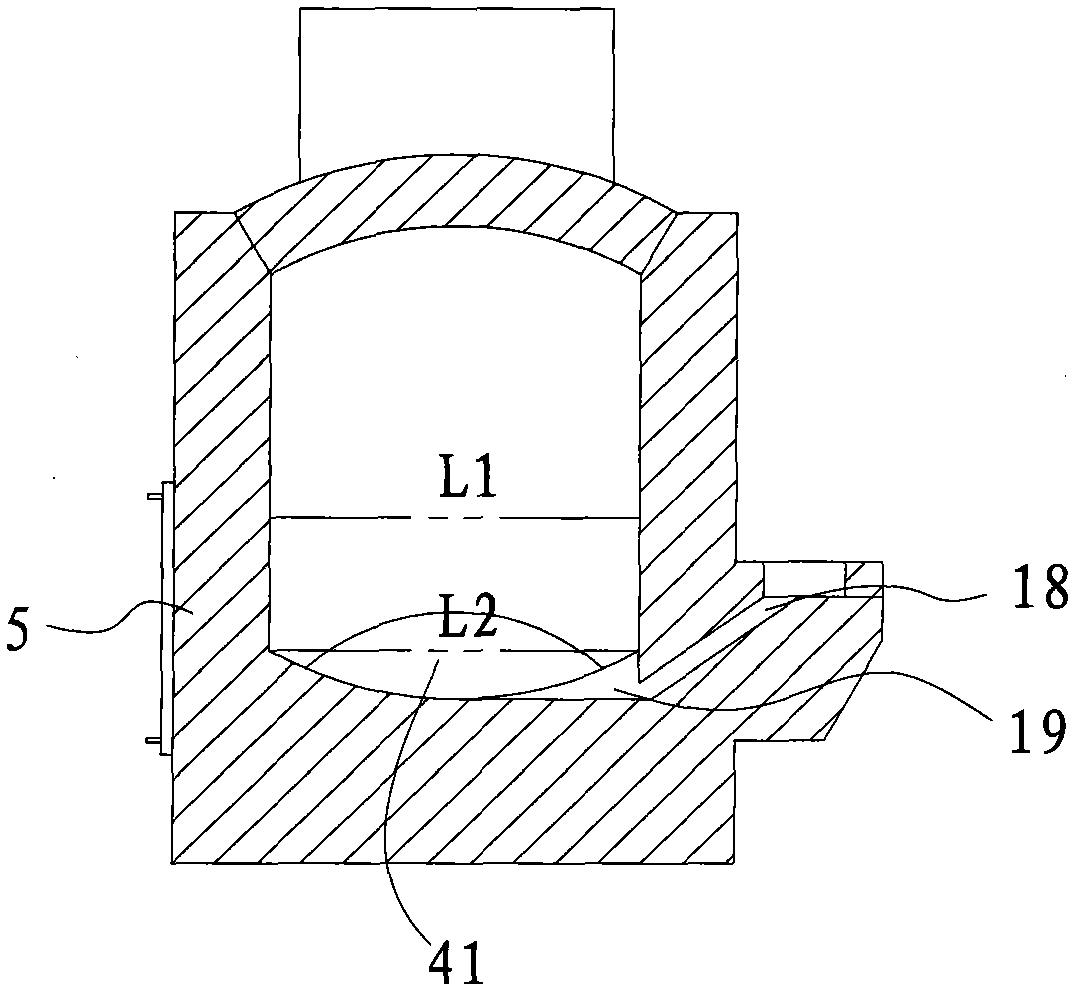

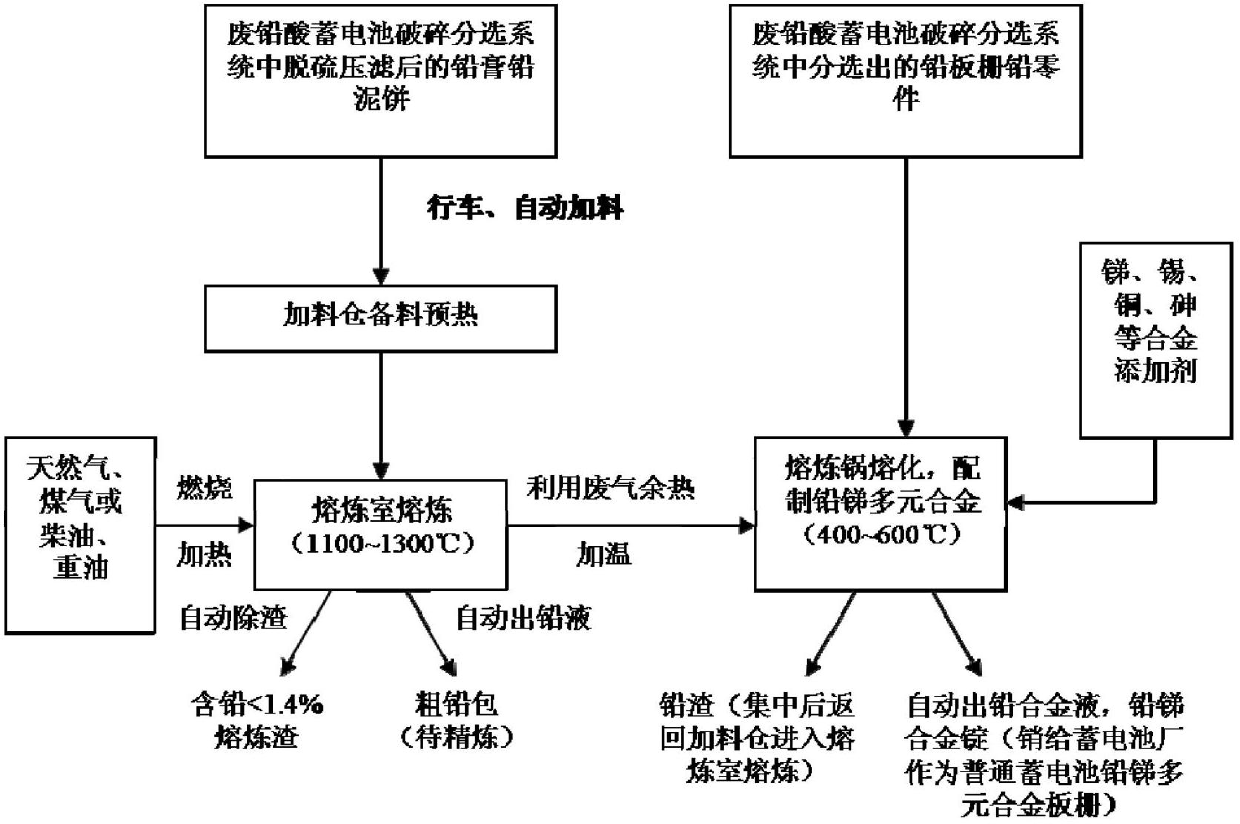

One-step lead smelting process and device for waste lead-acid storage battery lead plaster bottom-blowing smelting

InactiveCN103667725AAvoid pollutionImprove sealingProcess efficiency improvementLead smeltingFlue gas

The invention belongs to the field of metallurgy and specifically relates to a one-step lead smelting process and a one-step lead smelting device for waste lead-acid storage battery lead plaster bottom-blowing smelting. A bottom-blowing smelting furnace device is used for performing bath smelting, high-temperature desulphurization and reduction to lead plaster of waste storage batteries, so as to produce water-quenched slag with low lead content, crude lead and flue gas which is suitable for making acid. By using a bottom-blowing furnace and an electric heating fore well to treat the lead plaster of the waste storage batteries to produce crude lead and waste slag, compared with the prior art, the one-step lead smelting process and a one-step lead smelting device for waste lead-acid storage battery lead plaster bottom-blowing smelting has the advantages that the process flow is short, the smelting strength is high, the recovery rate is high, the air-tightness is good, the environmental friendliness is good, the effect of continuous production can be realized, the automation level is high, the production cost is lower, the investment is saved and the like.

Owner:HENAN YUGUANG GOLD & LEAD

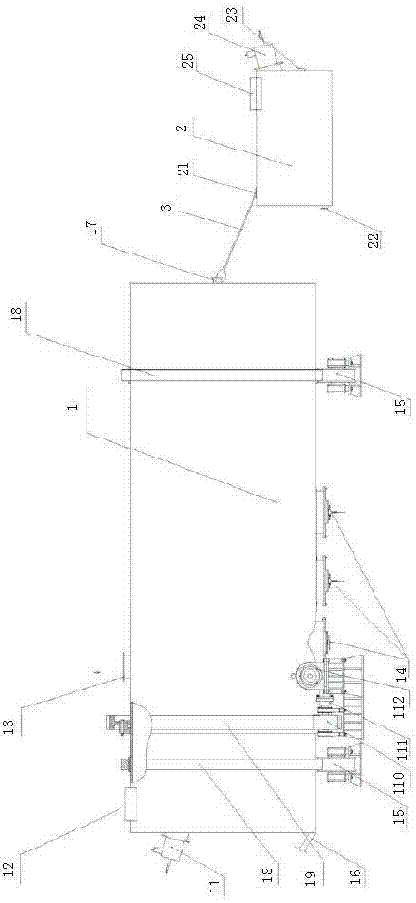

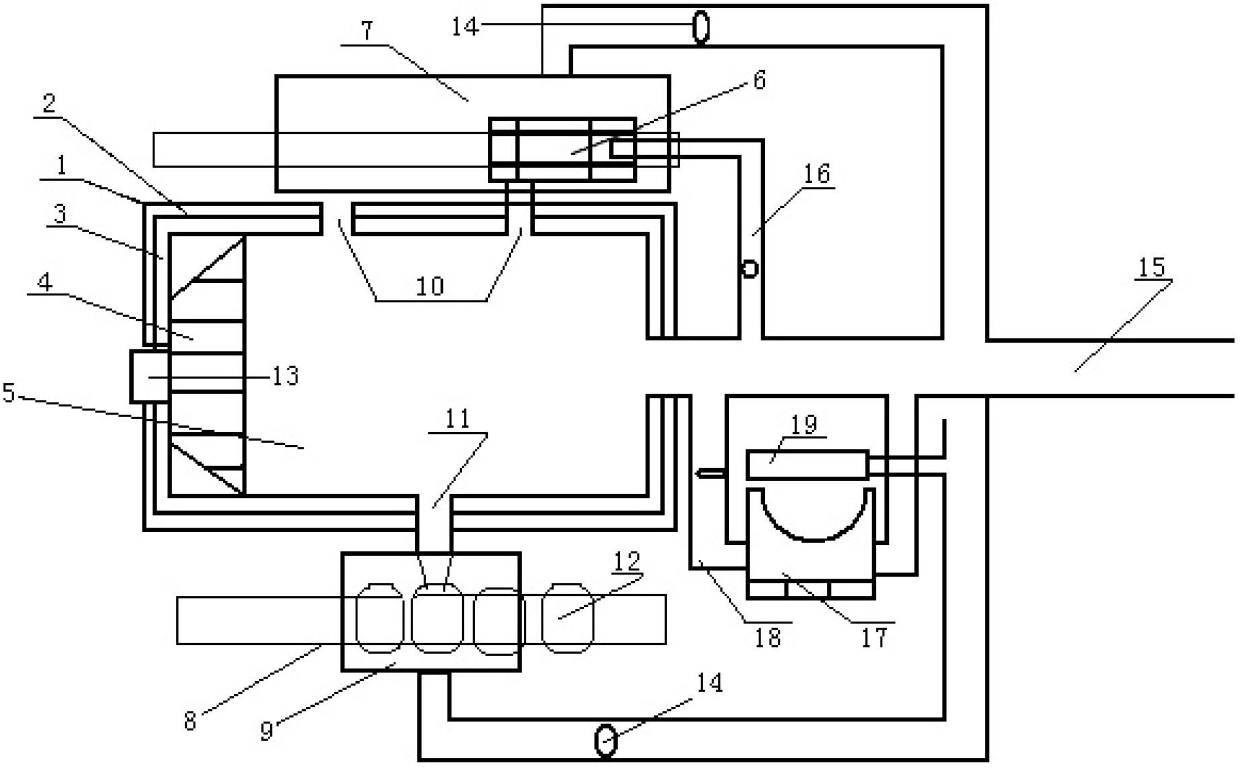

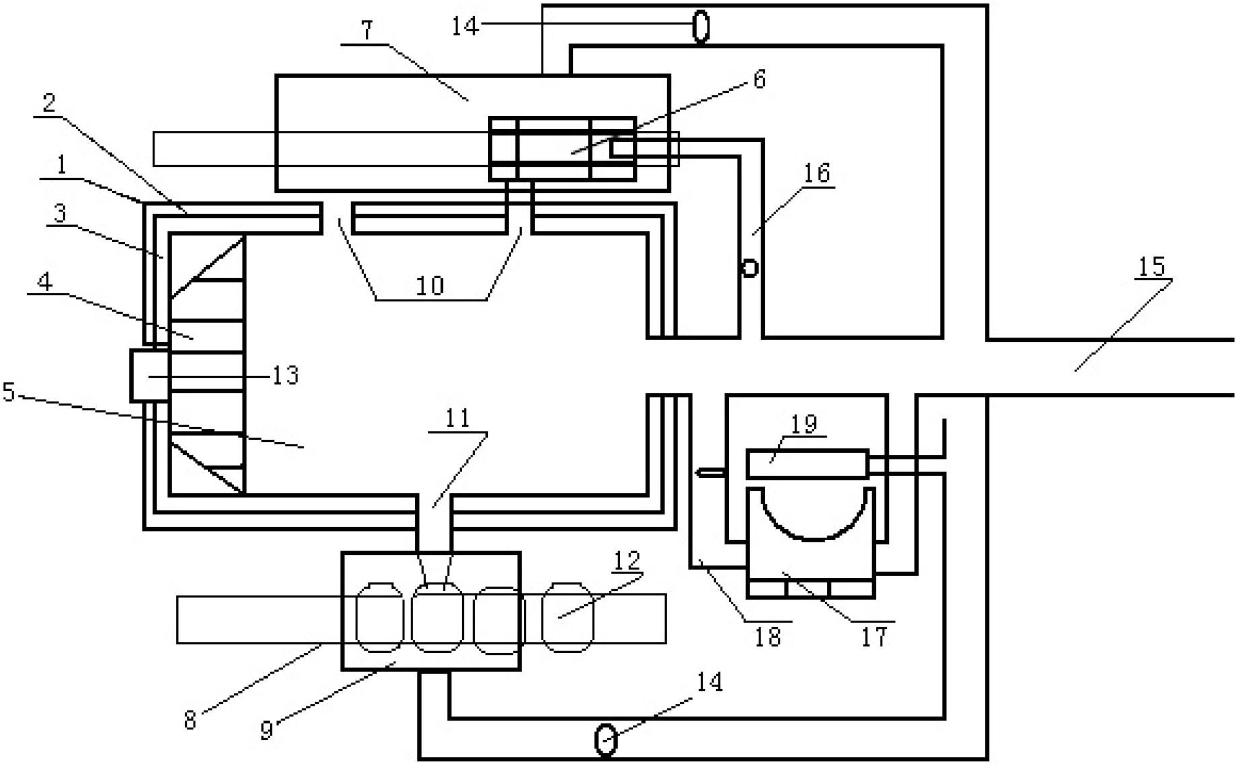

Energy-saving environment-friendly type smelting furnace

ActiveCN102679728ASolve the problem of manual feedingAvoid explosionCrucible furnacesLead smeltingEngineering

The invention discloses an energy-saving environment-friendly type smelting furnace, belonging to the field of lead recycling equipment. The smelting furnace comprises a heat supply smelting system, a feeding system, a discharging system, and a waste gas and smoke dust collecting system, wherein the heat supply smelting system comprises a bracket, a smelting chamber, a heating device and a lead smelting pot; the feeding system is formed by a feeding cabin rail and a feeding cabin which is slidingly arranged on the feeding cabin rail; the discharging system is arranged below a discharging opening of the smelting chamber of the heat supply smelting system and corresponds to the discharging opening; the waste gas and smoke dust collecting system comprises an upper dust removing chamber and a lower dust removing chamber; the upper dust removing chamber is arranged above the smelting chamber of the heat supply smelting system and is communicated with the feeding system; the upper dust removing chamber is communicated with a waste gas collecting pipeline through a pipeline; the lower dust removing chamber is arranged below the smelting chamber of the heat supply smelting system and is communicated with the discharging system; and the lower dust removing chamber is communicated with the waste gas collecting pipeline through a pipeline. The smelting furnace has the advantages of simple structure, energy saving and good environment-friendly performance.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

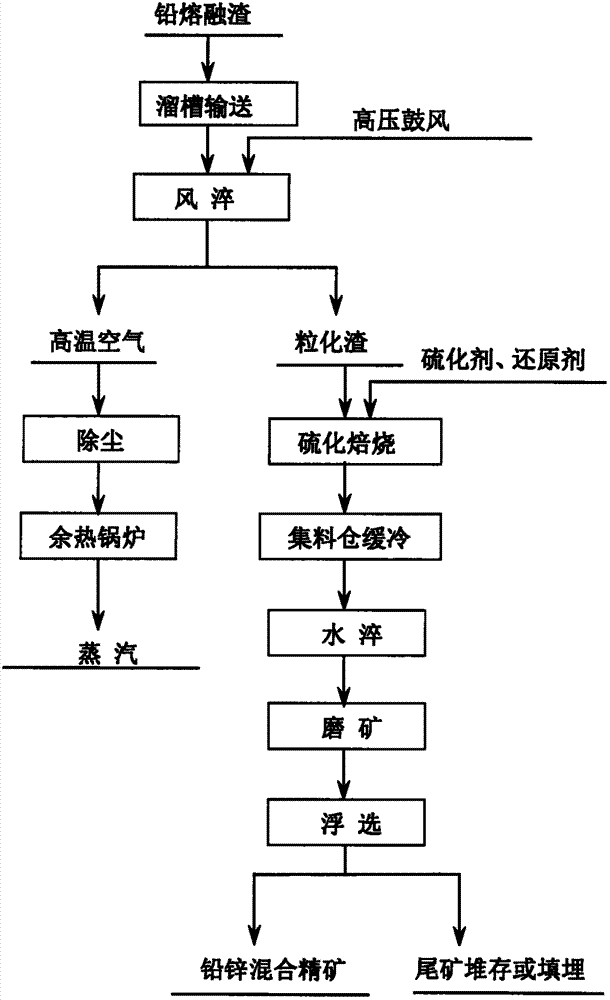

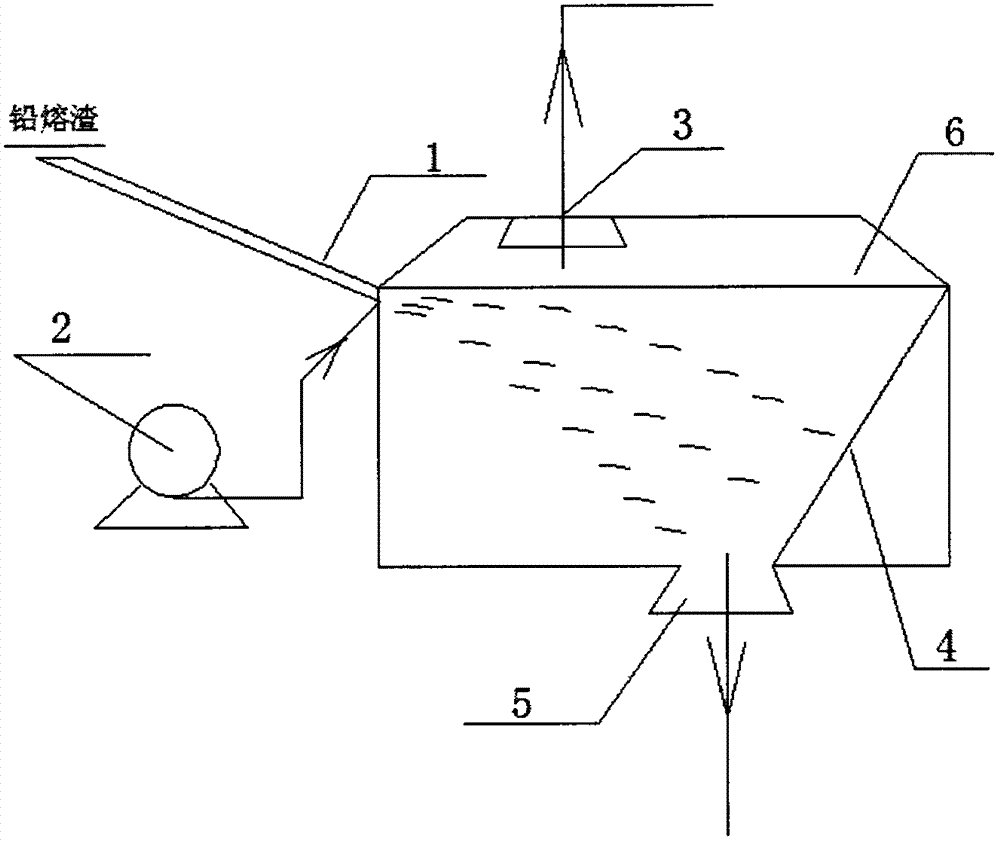

Floating and smelting combined method for air-granulating lead smelting slag and utilizing waste heat

InactiveCN103088209AHigh recovery rateThe combined process of dressing and smelting is simpleIncreasing energy efficiencyWaste heat treatmentVulcanizationLead smelting

The invention discloses a floating and smelting combined method for air-granulating lead smelting slag and utilizing waste heat and belongs to the field of floating and smelting. Aims at solving the problems that a fuming furnace is high in energy consumption, a dust collection system is complex and pollution is high, the method disclosed by the invention comprises the following steps of: a) conveying, namely conveying lead smelting slag to an air-granulating device; b) carrying out air-granulating on the lead smelting slag to obtain granulated slag; c) vulcanizing and roasting, including the steps of transferring the granulated slag into a vulcanizing reactor and adding a vulcanizing agent and a reducing agent to carry out vulcanization reaction; d) cooling, including the steps of cooling a material after vulcanizing and carrying out water quenching after temperature of the material is reduced to 200 DEG C or below to obtain water-quenched slag; and e) floating and grinding, including the steps of grinding and grading the water-quenched slag to obtain the material with the size of 45mum or below and then floating the water-quenched slag in a floating system to obtain a lead and zinc bulk concentrate. By adopting the floating and smelting combined method disclosed by the invention, roasting raw material does not need to be smashed, conversion rate of lead vulcanization and zinc vulcanization are respectively more than 80% without independent heating, and the floating and smelting combined method disclosed by the invention has the characteristics of good vulcanized product floatation performance, low processing cost, less pollution and high metal recycling rate.

Owner:CENT SOUTH UNIV

Method for recycling and harmless treating of waste electronic glass

InactiveCN102199707ALess investmentLarge amount of processingProcess efficiency improvementLead smeltingSmelting process

The invention relates to a method for recycling and harmless treating of waste electronic glass, and relates to a smelting process utilizing an existing pyrometallurgical lead smelting method to treat various lead-containing glass substances generated after discarding of televisions and computers of which cathode ray tubes are displays. The method provided by the invention is characterized by crushing discarded electronic glass, mixing and proportioning with mineral raw materials, an auxiliary agent and carbon used as a reducing agent from lead smelting process to obtain a mixed material, and spraying the mixed material with air to a flash smelting reaction furnace for flash smelting to obtain crude lead and smelting slag; and remixing the smelting slag with carbon used as a reducing agent in a depletion electric furnace for further reducing to obtain slag with lead content lower than 2%. The method provided by the invention can effectively treat lead-containing dangerous solid wastes, and has the advantages of low treatment cost, high treatment capacity and no generation of secondary pollutants; the raw materials have high adaptability; and the generated smelting slag can be effectively utilized.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

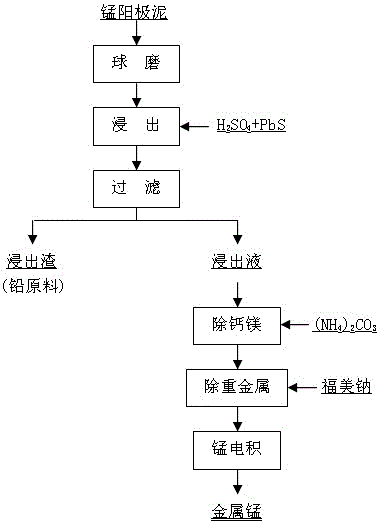

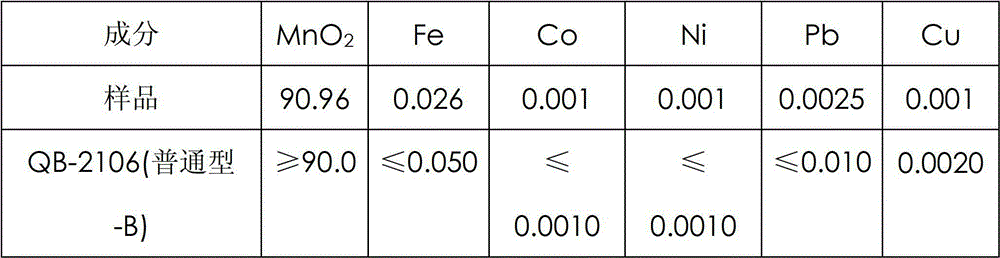

Method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime

ActiveCN106544511AWide variety of sourcesLow costPhotography auxillary processesProcess efficiency improvementLead smeltingElectrolysis

The invention provides a method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime. The method comprises the steps that firstly, the manganese anode slime, lead sulfide concentrate and ball milling liquid are mixed and subjected to wet-type ball milling; secondly, leaching of valuable metals such as manganese and selenium is conducted, leachate is reserved, and leached residues serve as lead smelting raw materials for recycling lead and silver; thirdly, a calcium-magnesium removing agent is added for impurity removing; and fourthly, a neutralizer, namely, ammonium hydroxide, and ammonium sulfate are added, a cleaning agent, namely, sodium dimethyl dithiocarbamate is dropwise added, and after stewing is conducted, activated carbon is added for adsorption, filter pressing is conducted, an electrolyzing additive is dropwise added into filtrate, and electrolytic manganese metal is prepared through electrolyzation. The method is small in investment, simple in technology, low in cost and capable of effectively increasing the comprehensive recovery rate.

Owner:ZHUZHOU SMELTER GRP

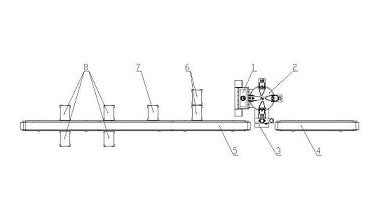

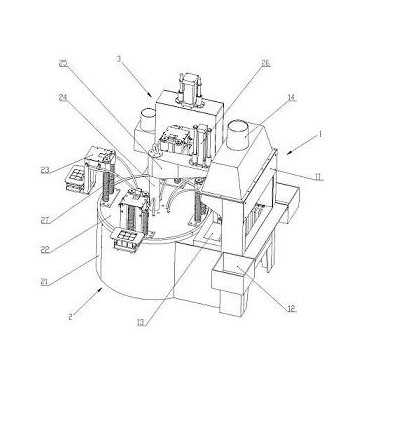

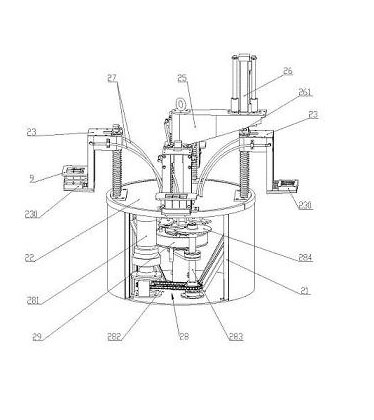

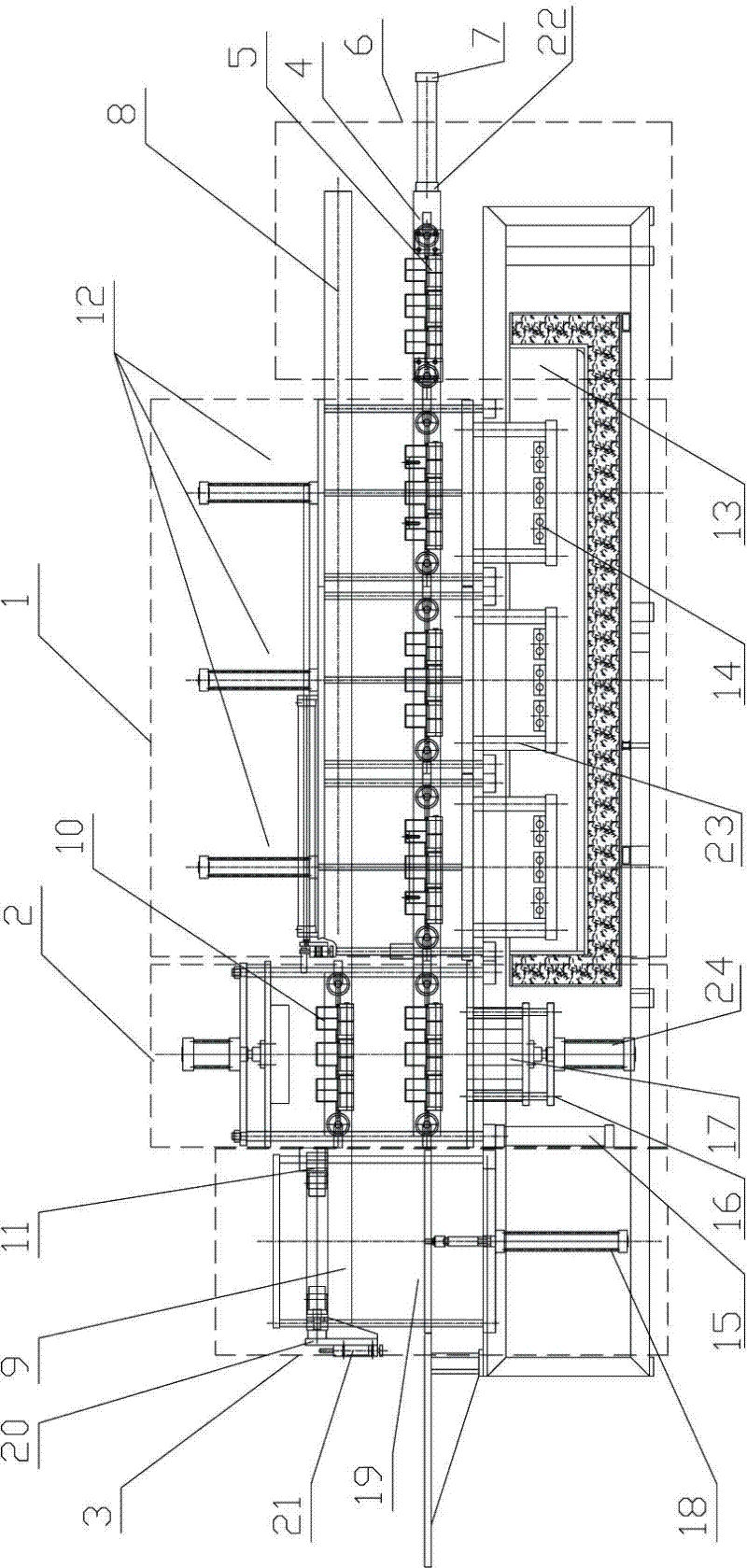

Busbar cast welding device for lead-acid storage battery

The invention discloses a busbar cast welding device for a lead-acid storage battery, comprising a lead smelting furnace, a demouldng and box-feeding machine and a workpiece conveyor, wherein the workpiece conveyor is a rotary conveyor, a turntable of the workpiece conveyor is uniformly provided with four lifting frames respectively provided with a busbar cast welding mold with a cooling jacket, four working stations are arranged around the turntable, the lead smelting furnace is positioned on the first working station, and the demoulding and box-feeding machine is positioned on the fourth working station. The cast welding device disclosed by the invention has a compact and reasonable integral structure, and workpieces are conveyed by adopting a 3600 rotary conveyor for four-working station operation, wherein the second and the third working stations are vacant and serve as cooling intervals after busbars are subjected to cast welding; and meanwhile, a cooling water feeding device of a mold jacket on each lifting frame of the rotary conveyor is skillfully designed, thereby efficiently cooling the busbar subjected to cast welding in the mold with cooling water, changing the traditional air cooling mode with high energy consumption and numerous and complex equipment, greatly shortening cooling time, decreasing turnover molds, improving production efficiency and reducing production cost.

Owner:魏明乐 +1

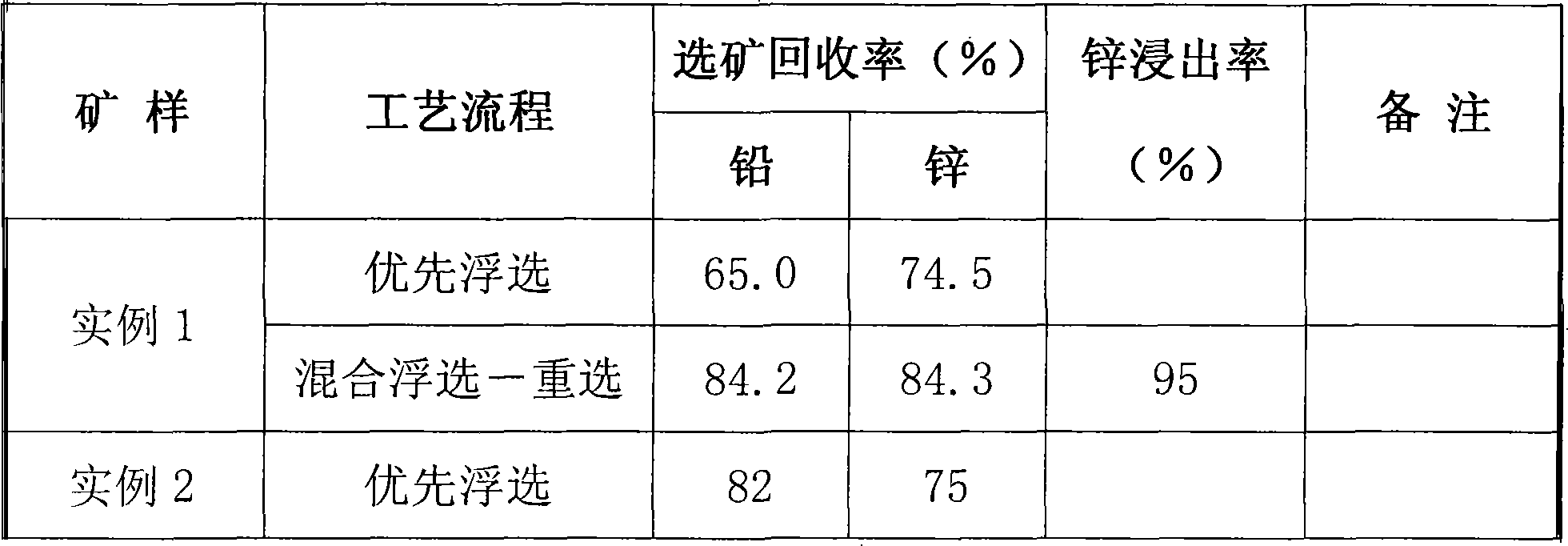

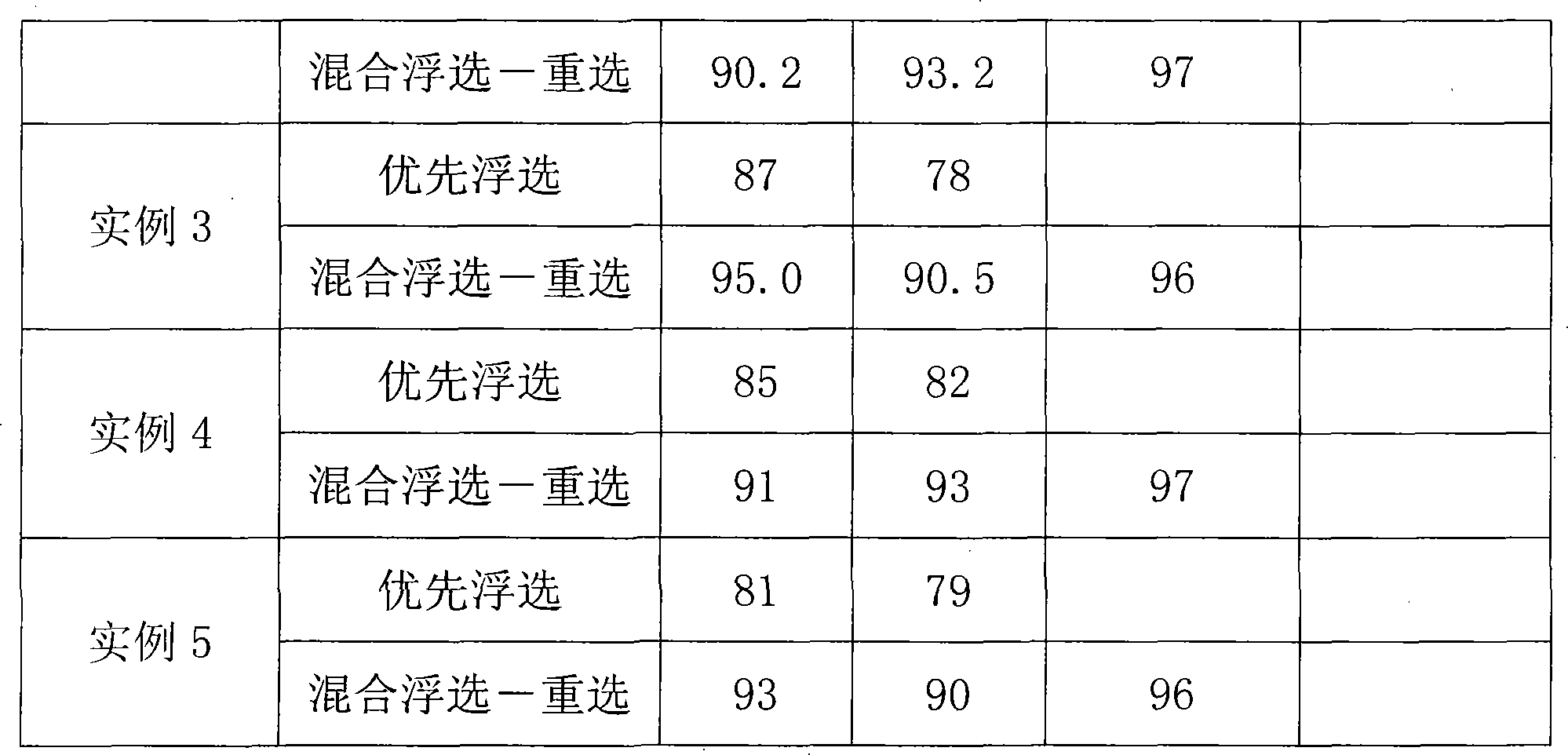

Selecting-smelting method for processing complex hard-washing low ore grade pulmbous sulfide zincium mine

InactiveCN101245407AHigh recovery rateReduce total usageFlotationProcess efficiency improvementLead smeltingZinc metal

The invention relates to a method for treatment of dressing and smelting low-grade lead-zinc sulphur ore with complex dressing and pertains to the filed of metallurgy. The specific steps of the method comprise that the low-grade lead-zinc sulphur ore with complex dressing is selected, the lead-zinc crude mixed concentrate is obtained by adopting a flotation technique and is then selected by adopting a gravity dressing technique so as to obtain part of lead concentrate and lead-zinc sulphur mixed concentrate; the lead-zinc sulphur mixed concentrate is added with acid to mix slurry after being treated with fine grinding and then done with acid pickling in a high-pressure kettle with high temperature and high pressure and oxygen and then the solid-liquid separation is carried out; leaching solution is used for producing zinc metal by the conventional technique of zinc hydrometallurgy, while leaching slag is used for recycling lead and silver metal with the conventional pyrometallurgical technique of lead smelting. The method of the invention adopts less species of additive medicine and dosage thereof and has higher recovery rate of lead and zinc products and lower production cost; meanwhile, tail water can be directly recycled with benefit for environmental protection. In addition, the smelting process of the method is characterized by shorter process, lower production cost and no smoke emission benefiting environmental protection.

Owner:YUNNAN METALLURGICAL GROUP

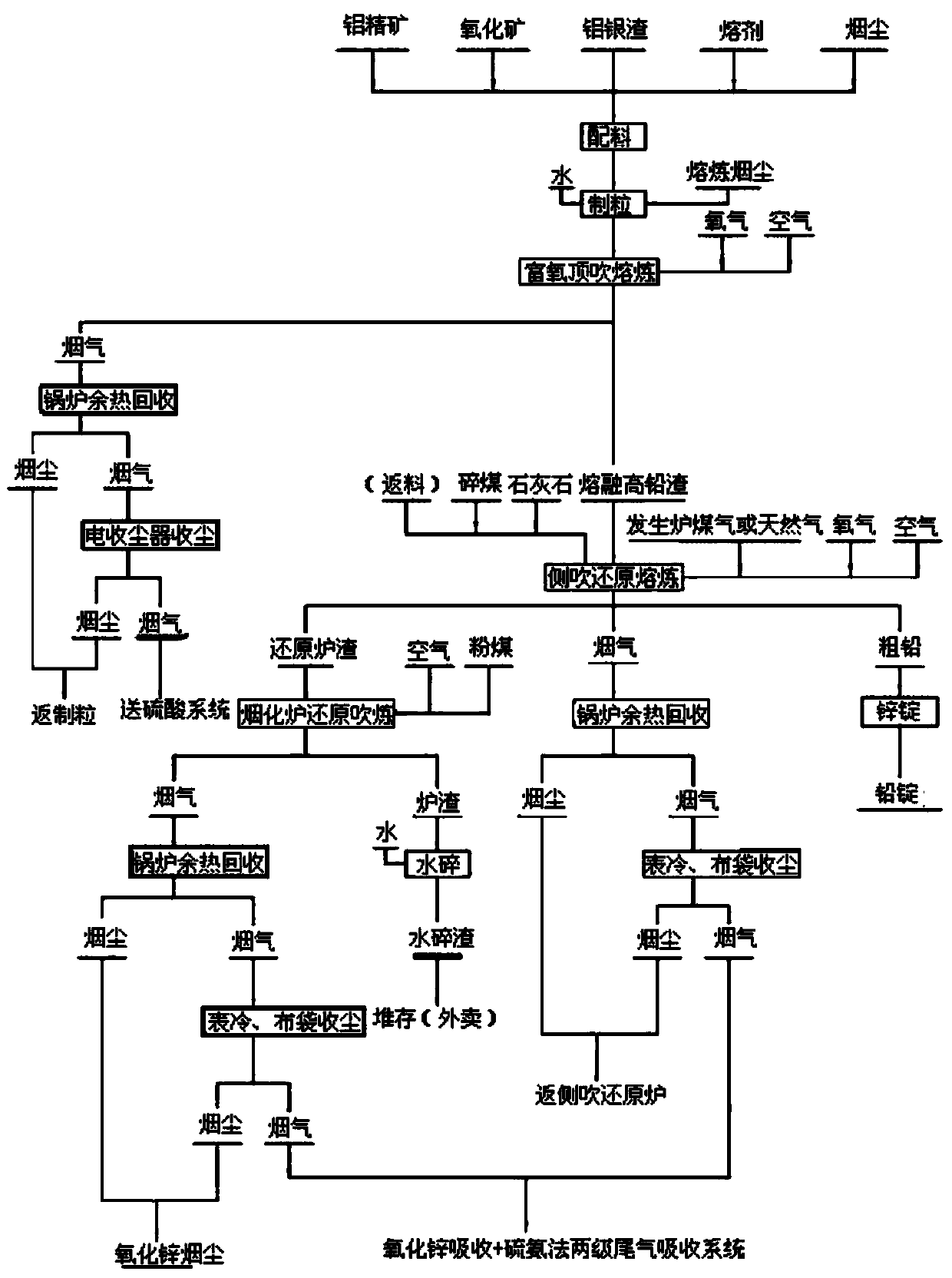

Rich-oxygen top-blown smelting/liquid high-lead slag side-blown direct-reduction lead smelting process

The invention discloses a rich-oxygen top-blown smelting / liquid high-lead slag side-blown direct-reduction lead smelting process. The lead smelting process includes: adding a lead-containing material into a rich-oxygen top-blown smelting furnace and performing top-blown oxidizing smelting to obtain primary crude lead, melt high-lead slag and sulfur dioxide flue gas; feeding the melt high-lead slag discharged from the rich-oxygen top-blown smelting furnace into a liquid high-lead slag side-blown reduction furnace and performing side-blown reduction smelting to obtain secondary crude lead, reduction furnace slag and reduction furnace flue gas; and discharging the primary crude lead from the rich-oxygen top-blown smelting furnace and discharging the secondary crude lead from the liquid high-lead slag side-blown reduction furnace. The lead smelting process according to embodiments is environmental friendly, reduced in energy consumption and high in metal recovery rate.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

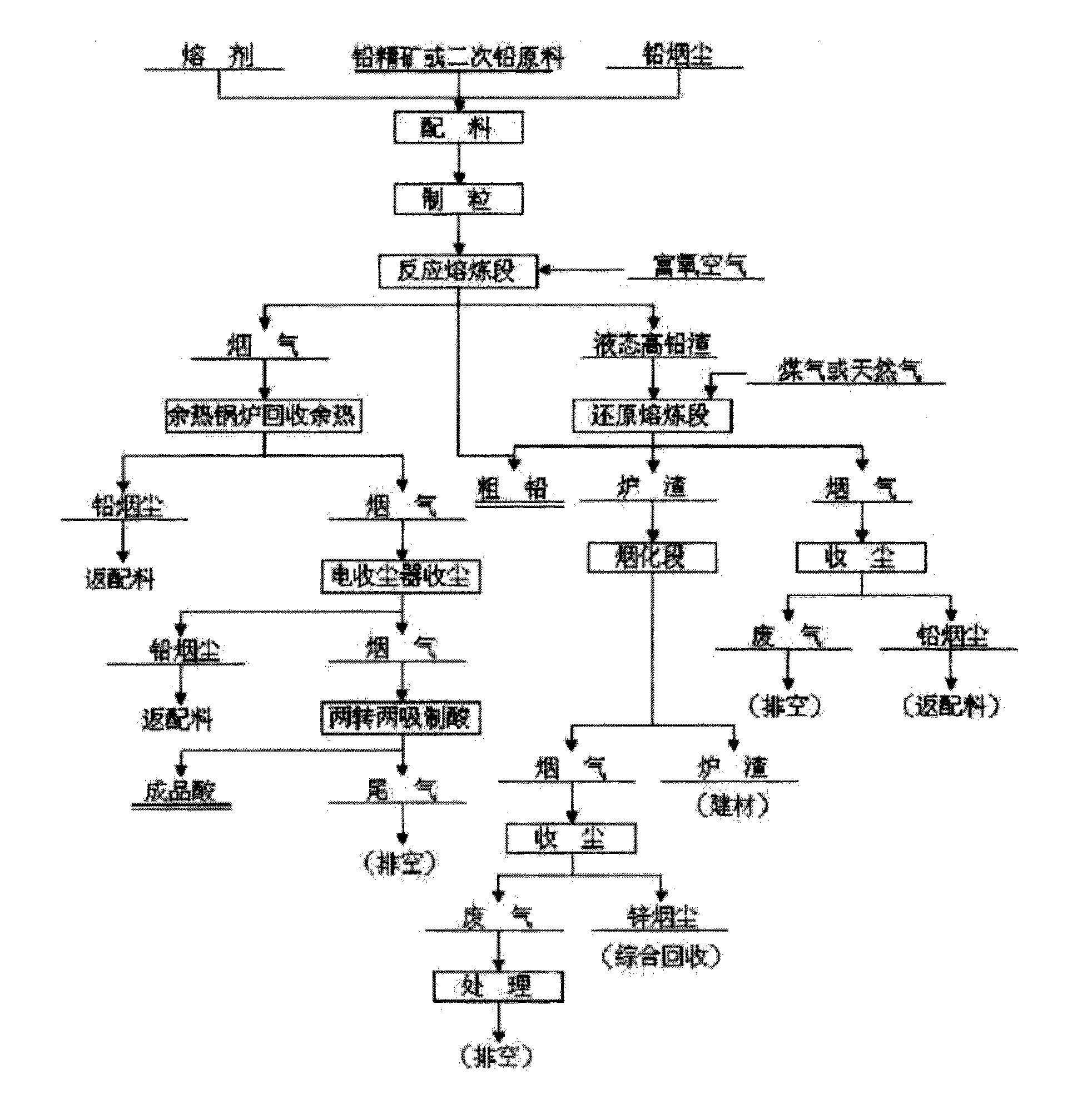

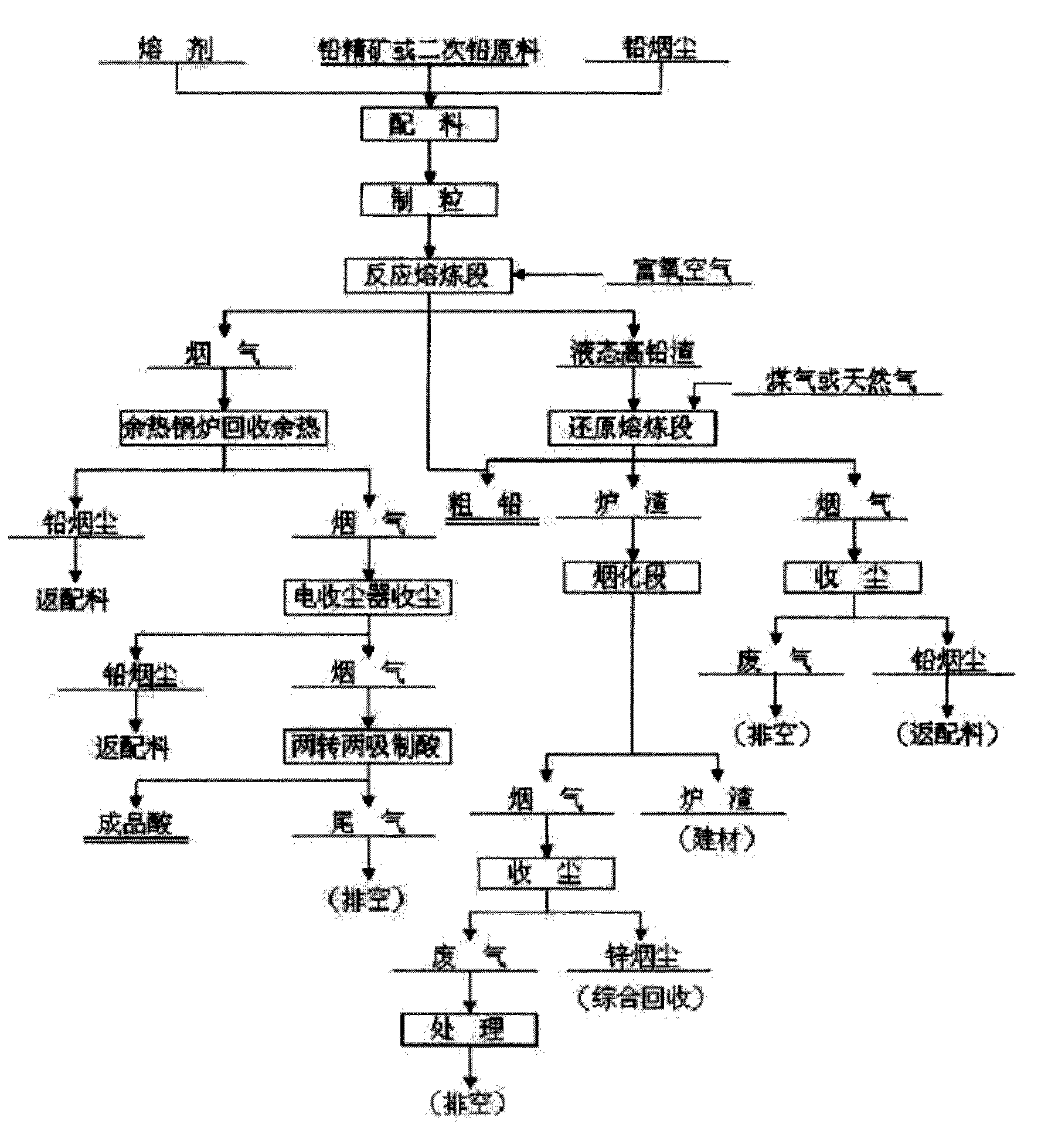

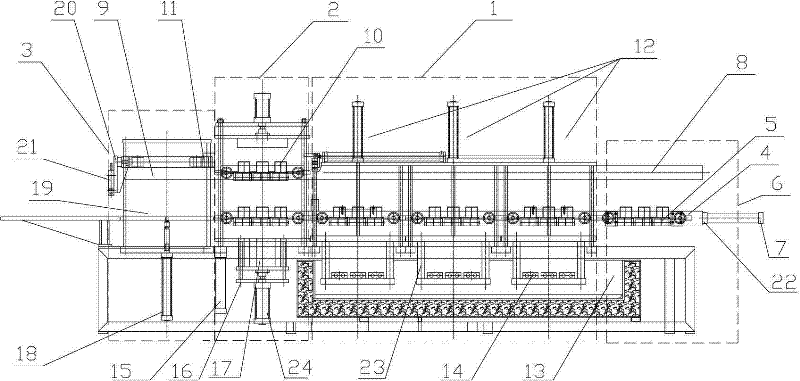

Continuous lead smelting clean production process

InactiveCN102031393APrevent escapeImprove recycling ratesProcess efficiency improvementLead smeltingLiquid state

The invention discloses a continuous lead smelting clean production process. The process comprises the following steps of: proportioning materials such as lead sulfide concentrate or a secondary lead raw material, a flux, lead dust and the like as required; performing a mixed granulation process; feeding a reaction smelting section of the entire equipment; smelting by an oxygen enriched bottom blowing method; directly feeding liquid-state high-lead slag into a reduction smelting section to perform reduction smelting so as to produce coarse lead; and directly feeding the reduced liquid-stage slag into a fuming section to perform fuming treatment so as to comprehensively recover valuable metals from the liquid-stage slag. Therefore, continuous clean production is realized in the true sense.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for producing copper and iron containing mixed slag

InactiveCN107723470ASolve pollutionAchieve recyclingRecycling and recovery technologiesProcess efficiency improvementMolten stateLead smelting

The invention relates to a method for producing copper and iron containing mixed slag. The method comprises the following steps: S1, mixing the slag, namely, adding copper slag to a smelting reactiondevice; adding one or a plurality of lead smelting slag, blast furnace slag, steel slag and iron alloy slag to form the mixed slag; synchronously adding one or a plurality of copper oxide mineral, copper sulphide mineral and copper-containing materials; uniformly mixing; heating the mixed slag until a molten state is achieved so as to obtain the reaction slag; monitoring the reaction slag in realtime; and regulating and controlling to obtain the reacted slag; and S2, separating and recovering. According to the method, the hot slag can be handled, and molten copper slag, the molten metallurgical slag, a physical heat source and a hot metallurgical flux are fully utilized, and moreover, cold slag can be handled; the metallurgical modification of the slag can be achieved by slag mixing or cold mixing. Therefore, the efficient recycling of metallurgic resource and heat energy is effectively realized; and the environmental pollution is effectively solved.

Owner:NORTHEASTERN UNIV

Automatic continuous cast welding method for lead-acid batteries and cast welding machine thereof

The invention provides an automatic continuous cast welding method for lead-acid batteries and a cast welding machine thereof. According to the method, firstly battery clamps from the previous procedure on the conveying line are pushed in order in a feeding position, the battery clamps reach a cast welding position where the battery clamps undergo die-closing operation, cast welding operation anddemoulding operation in sequence at the same time, then the battery clamps are delivered to a loading position for loading to separate pole plates from batteries and put into boxes, the batteries arepushed to the next procedure after separation, and the empty battery clamps return to the previous procedure for continuous recycling. The feeding position, the cast welding position and the loading position are arranged linearly in sequence. During cast welding, a plurality of cast welding mechanisms of the cast welding position alternately perform cast welding operation on a plurality of groupsof batteries at the same time, and the feeding operation, the cast welding operation and the loading operation are completed independently and continuously. With the scheme, the time is saved, the machine is simple and compact in arrangement, the size of the cast welding machine is reduced by more than 3 / 4 compared with the prior art, the cost is reduced, and the output of one production line canbe achieved by using one lead smelting furnace.

Owner:崔锋

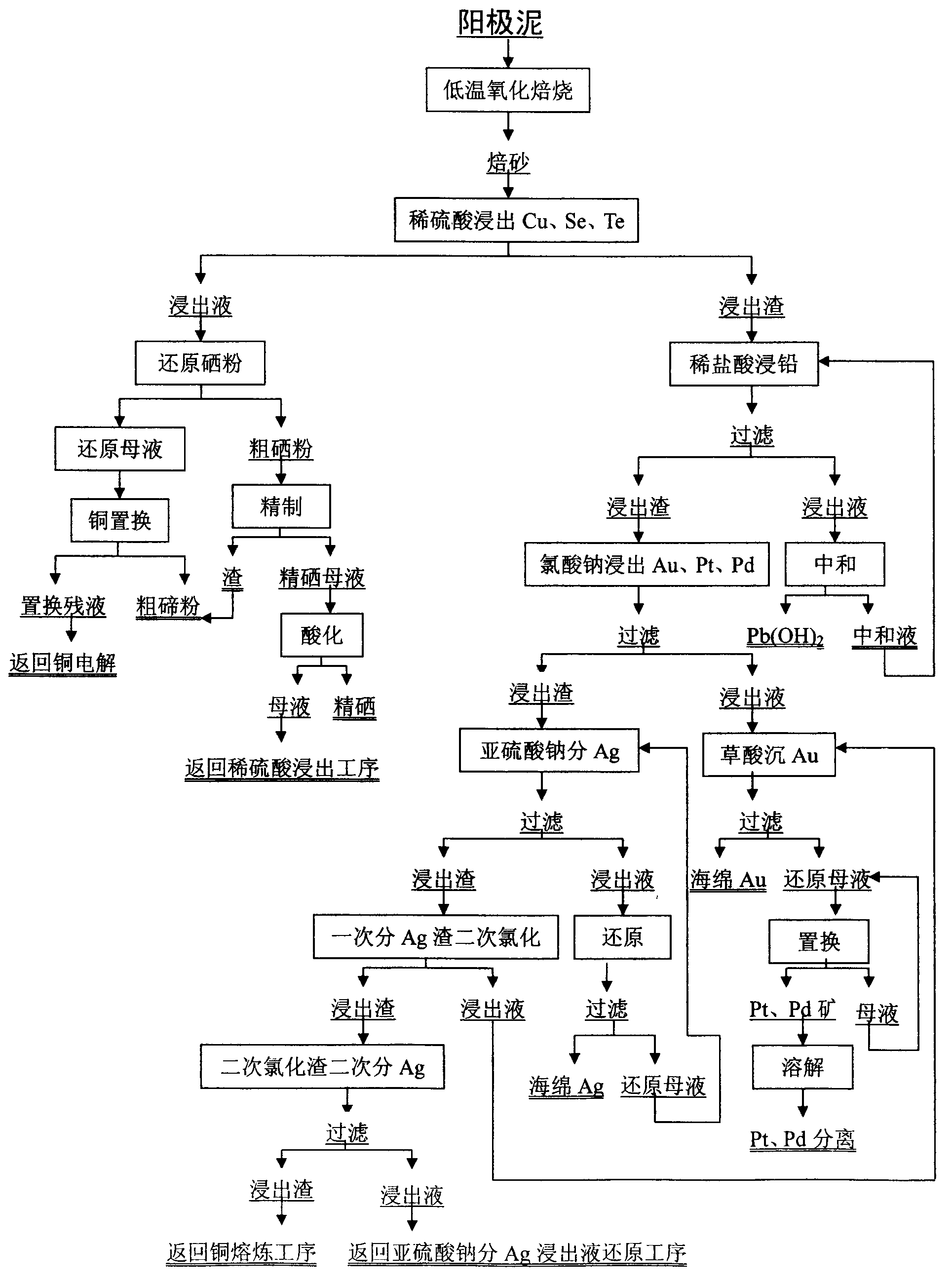

Closed-circuit process technique for recovering multiple metals from copper and lead electrolysis anode mud

InactiveCN102936659AHigh recovery rateRaise the gradeProcess efficiency improvementElemental selenium/telluriumElectrolysisLead smelting

The invention discloses a closed-circuit process technique for recovering multiple metals from copper and lead electrolysis anode mud. The closed-circuit process technique is characterized in that a closed-circuit process is formed by connecting various chemical engineering including anode mud low-temperature oxidation roasting, copper, selenium and tellurium leaching through diluted sulphuric acid, lead soaking through diluted hydrochloric acid, neutralization, gold, platinum and palladium leaching through sodium chlorate, gold immersion through oxalic acid, replacing, dissolving, silver separating through sodium sulfite, restoring, secondary chlorination on primarily separated silver slug, secondary silver separation through secondary chlorination slug, selenium powder restoring, refining, acidizing and copper replacing. By means of the closed-circuit process technique, eight elements of gold, silver, platinum, palladium, selenium, tellurium, copper and lead can be recovered comprehensively, the recovering rate is high, the recovering rate of gold is larger than 99%, the recovering rate of silver is larger than 99%, the recovering rate of platinum is larger than 98%, the recovering rate of palladium is larger than 99%, the recovering rate of copper is larger than 99%, the recovering rate of selenium is larger than 98%, the recovering rate of tellurium is larger than 94%, the recovering rate of lead is larger than 96%, the level of refined selenium reaches 99.5%, the level of crude tellurium reaches 95.6%, the level of sponge silver reaches 99.97%, the level of sponge gold reaches 99.9%, and platinum, palladium, copper and lead exist in the type of intermediate products and can reach high level through further refining. The process technique is a closed-circuit circulating process flow, generates no waste liquid and waste residue, and is a perfect copper and lead electrolysis anode mud processing process and suitable for being popularized and used in copper and lead smelting enterprises.

Owner:崖巨钊

Method for processing complex nickel raw material by utilizing flash smelting system

InactiveCN102888519AImprove dehydration efficiencyHigh recovery rateRotary drum furnacesCrucible furnacesLead smeltingSmelting process

The invention provides a method for processing a complex nickel raw material by utilizing a flash smelting system. The method comprises steps as follows: (1) drying wet concentrates: dewatering and drying wet copper-nickel mixed concentrate containing 8-12% of water until the water content is less than 0.3%; (2) mixing materials: mixing dried concentrate with quartz powder and pulverized coal; (3) feeding into a furnace for reacting: uniformly mixing the mixed material with oxygen-enriched air, and feeding into a reaction column of a flash smelting furnace by virtue of a concentrate nozzle for smelting and reacting, and then transferring the produced low-nickel flow to the next process; (4) blowing in a converter; and (5) slowly cooling, and separating. The method provided by the invention has the adaptability to raw materials higher than that of conventional nickel smelting technology and is simple in smelting process; and furthermore, little valuable metal is contained in the waste smelting slag, high recovery rate of the metal in smelting is achieved, and low energy consumption is ensured.

Owner:JINCHUAN GROUP LIMITED

Method for extracting platinum group metals from waste automotive three-way catalyst

InactiveCN102134647AReduce pollutionCraft briefProcess efficiency improvementLead smeltingTernary catalyst

The invention relates to a method for extracting platinum group metals from a waste automotive three-way catalyst. The method is characterized in that the platinum group metals in the waste automotive three-way catalyst are captured through lead smelting to obtain a material with Pt, Pd and Rh, and the material is heated to a certain temperature under the vacuum condition to volatilize the lead of the material and achieve the aim of highly enriching the platinum group metals of the material. By adopting the method, the extraction process of the platinum group metals in the waste automotive three-way catalyst is short, the efficiency is high and the environmental pollution of the process is lower.

Owner:YUNNAN UNIV

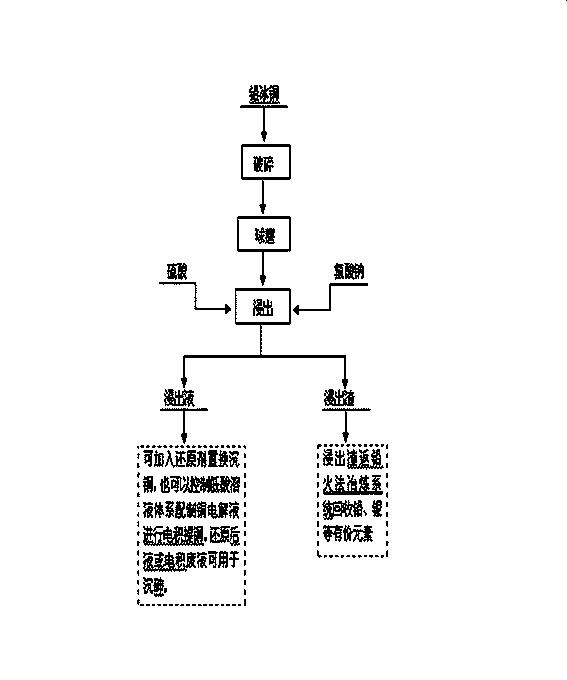

Method of recycling zinc, manganese, lead and silver from zinc electrowinning anode mud

ActiveCN102912138AWide variety of sourcesLess investmentProcess efficiency improvementPregnant leach solutionElectrolysis

The invention discloses a method of recycling zinc, manganese, lead and silver from zinc electrowinning anode mud. The method comprises the following steps of: after carrying out wet ball grinding on the zinc electrowinning anode mud, filtering, wherein filtrate is taken as a raw material for a zinc smelting system; mixing filter residues and acidic solution, adding a reducing agent to carry out reduction reaction, leaching manganese, filtering to obtain leaching liquid and leaching slag, purifying the leaching liquid, and preparing manganese dioxide through an electrolysis method; and recycling lead and silver with the leaching slag as high-lead slag and a raw material of a lead smelting system. The method, provided by the invention, has the characteristics of less investment, simple process, low cost, easiness in operation and the like; the whole process is a green metallurgical process flow, and is environmental-friendly, the comprehensive recovery and utilization efficiency of resources can be effectively improved, the battery-level manganese dioxide obtained by electrolysis is taken as a new energy material so as to be beneficial for environmental protection and high value-added utilization of resources. The method is easy to realize large-scale industrial application.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

Process for efficiently and selectively separating copper in lead copper matte

InactiveCN104017991AAdaptableHigh recovery ratePhotography auxillary processesProcess efficiency improvementPregnant leach solutionLead smelting

The invention discloses a process for efficiently and selectively separating copper in lead copper matte. The process comprises the following steps: smashing and grinding the lead copper matte taken as a raw material and screening to reach below 80 meshes; sending the lead copper matte which is ground and screened into a leaching tank and leaching by using a sulfuric acid; reacting for 3 to 5 hours at a normal pressure under the conditions that the oxidation potential of the solution is controlled within 450mV to 800mV, the concentration of sodium chlorate is controlled within 200g / L to 500g / L, the liquid-solid ratio is controlled within (5-15):1, the temperature is controlled within 70 DEG C to 100 DEG C and the concentration of the sulfuric acid is controlled within 1.0mol / L to 1.5mol / L; and leaching the copper under an acid condition by taking the sodium chlorate as an oxidizing agent. During the oxidizing and leaching process, sulfur in the lead copper matte is oxidized into elemental sulfur which is transferred into slags, wherein copper which is oxidized enters the solution in a form of copper ions while lead remains in the slags in a form of lead sulfate together with gold and silver. After the leaching process is finished, the solid-liquid separation is carried out, so that the primary separation of the copper and other valuable elements is realized; a certain amount of scrap iron is added into the leaching solution rich in the copper so as to replace the deposited copper, so that the spongy copper, which is a primary product, can be obtained; the leaching slags are sent into a pyrogenic lead smelting system, so that the valuable elements such as Pb and Ag are comprehensively recycled.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for separating copper and silver from dross produced by producing copper from smelting lead

The invention provides a method for separating copper and silver from dross produced by producing the copper from smelting lead. The method comprises the following steps of: putting solid dross materials produced by producing the copper from smelting the lead under a vacuum condition, collecting volatile materials after heating and insulating the solid dross materials for many times, and condensing the volatile materials to obtain a lead-silver alloy, wherein remaining solid is a lead- and silver-removed copper alloy; taking the lead-silver alloy as a raw material to enter a conventional lead smelting process or an electrolytic refining process, wherein the silver is enriched in anode mud, so that recovered silver is obtained; and directly taking the lead- and silver-removed copper alloy as raw materials to obtain recovered metal copper by using a conventional method. The method has the advantages of high adaptability of raw materials, simplicity, environmental protection, high metal separating and recovering efficiency, short process flow, convenience for operation and obvious economic benefit, and can be used for treating various lead-, silver- and copper-containing copper-based or lead-based alloys; a vacuum distilling method is adopted; and silver content and lead content in the remaining solid are 200g / t and 0.01% respectively.

Owner:KUNMING UNIV OF SCI & TECH

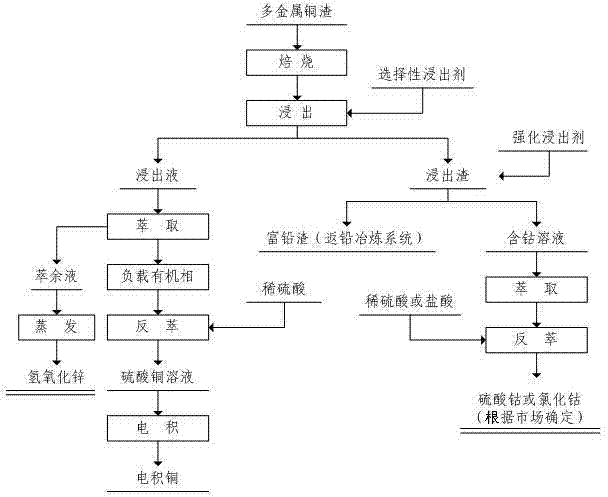

Method for producing electrodeposited copper from polymetallic copper slag

ActiveCN104846202AImprove leaching efficiencyHigh recovery ratePhotography auxillary processesProcess efficiency improvementZinc hydroxideLead smelting

The invention discloses a method for producing electrodeposited copper from polymetallic copper slag, which includes the following steps: the polymetallic copper slag is roasted to oxidize, so that the complex states of valuable metals in the polymetallic copper slag are transformed into oxides, changed into a state which can be selectively leached; leaching first adopts selective leaching agent to leach copper and zinc, the leachate is extracted, reextracted and electrodeposited, so that electrodeposited copper is obtained, and raffinate is vaporized and crystallized, so that zinc hydroxide is obtained; mechanical intensified leaching agent is then used for intensely leaching leaching residue, so that cobalt, nickel and the like in the leaching residue are leached, lead, iron and the like are enriched into the slag, the lead-rich slag is adopted as material for lead smelting, the leachate is extracted and reextracted, so that cobaltous sulfate or cobalt chloride is obtained, and if the nickel content in the leachate is overhigh, multi-stage extraction can be carried out to separate cobalt and nickel, so that nickel sulfate or nickel chloride is produced. The method can comprehensively recover a variety of metals, the leaching efficiency is high, the recovery rate is high, the method is environment-friendly, and is easy to implement, the method ensures that all the valuable metals in the polymetallic copper slag can be effectively separated and recycled, and the solid waste utilization rate can reach more than 99 percent.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com