Automatic continuous cast welding method for lead-acid batteries and cast welding machine thereof

A lead-acid battery, casting and welding machine technology, applied in the field of lead-acid battery casting and welding, can solve the problems of many workers, scattered layout, waste of workshop space, etc., and achieve the effects of simple machine arrangement, reduced machine cost, and favorable treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments.

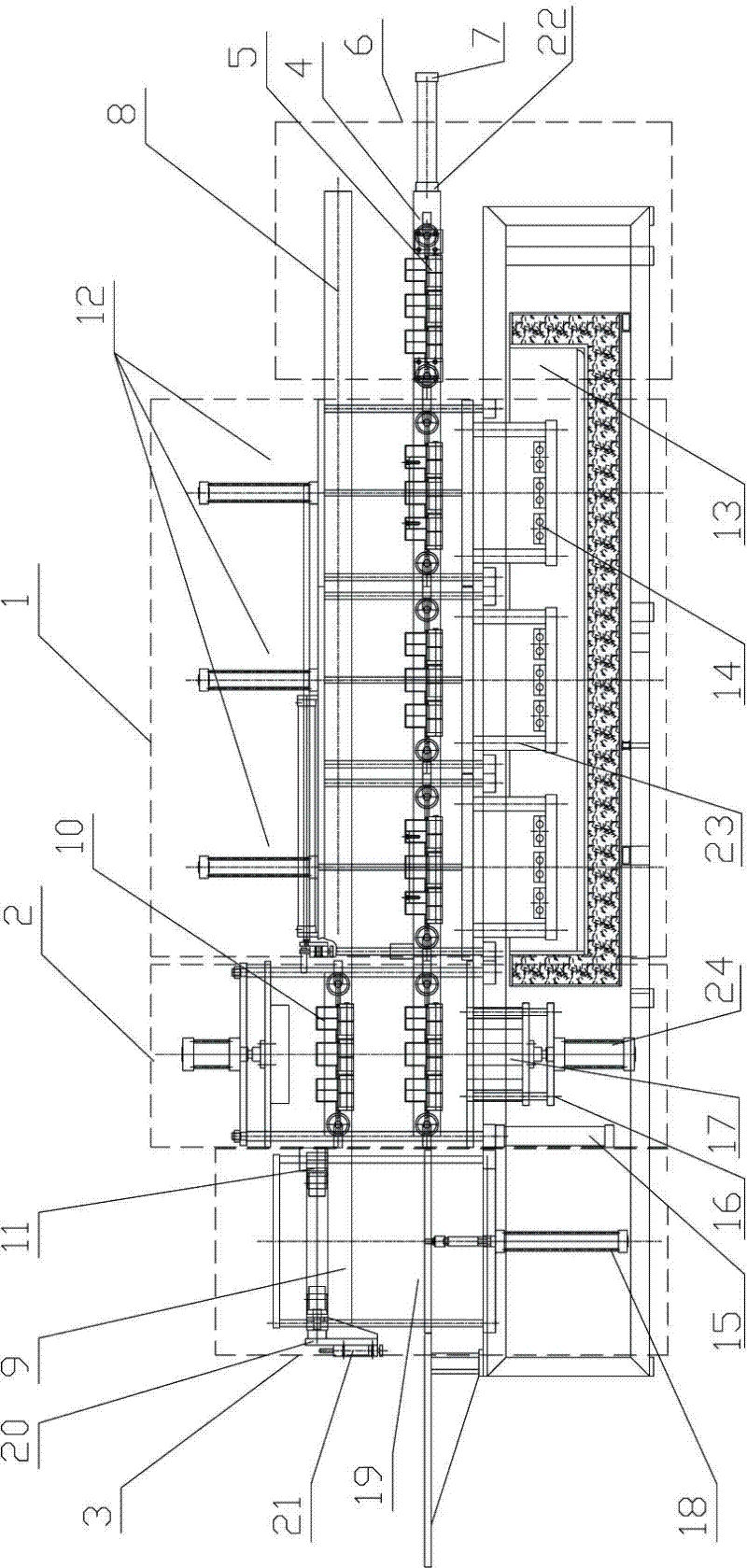

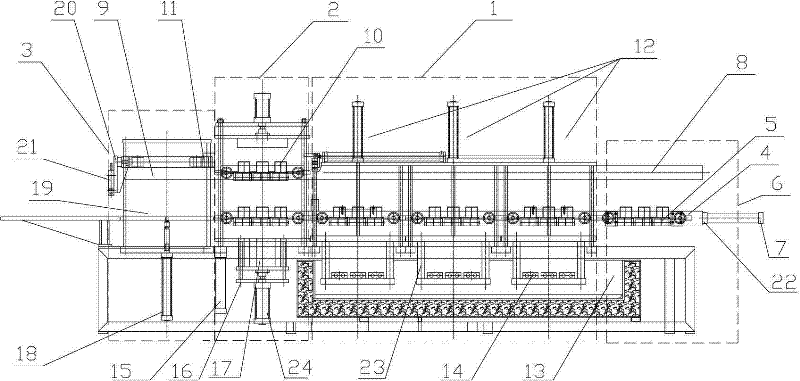

[0028] According to attached figure 1 As shown, the automatic continuous casting and welding machine for lead-acid batteries described in this embodiment includes casting and welding station 1, slotting station 2, unloading station 3, feeding station 6, conveying line 4, placed in the conveying station A plurality of battery clamps 5 on the line 4, a battery clamp circulation track 8 placed above the conveying line 4, and a gripper hand sliding track above the battery clamp circulation track 8 corresponding to the part of the slotting station 2 and the unloading station 3 9. Wherein, the gripper hand sliding track 9 is provided with a gripper hand 11 capable of clamping the battery 10 on the battery fixture circulation track 8, and the casting and welding station 1, the slotting station 2, and the unloading station 3 Work across the conveying line 4 in sequence in sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com