Patents

Literature

1490results about How to "High surface energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS20060286775A1Enhance cleaning processIncreased surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingSurface energyOxide

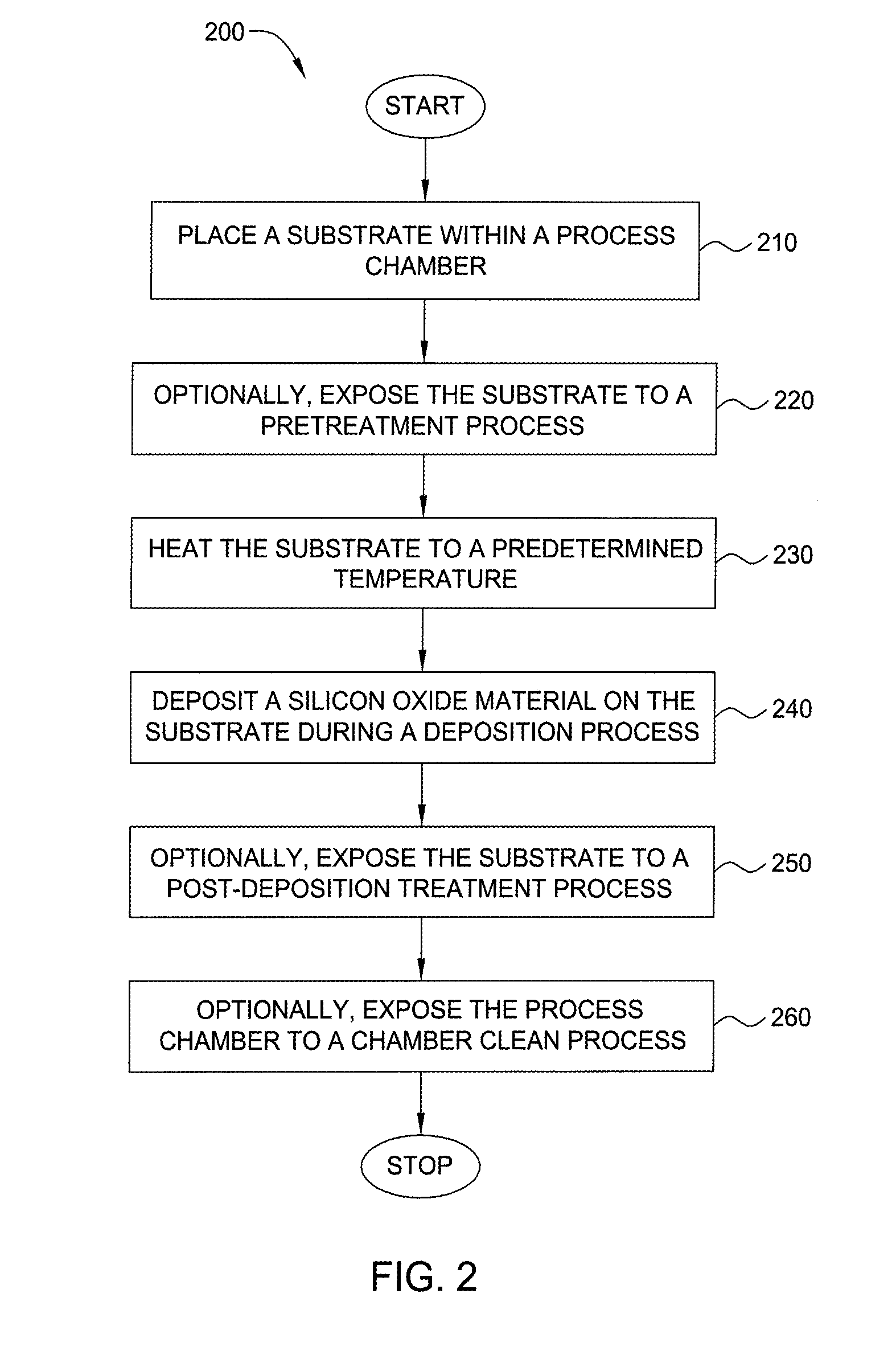

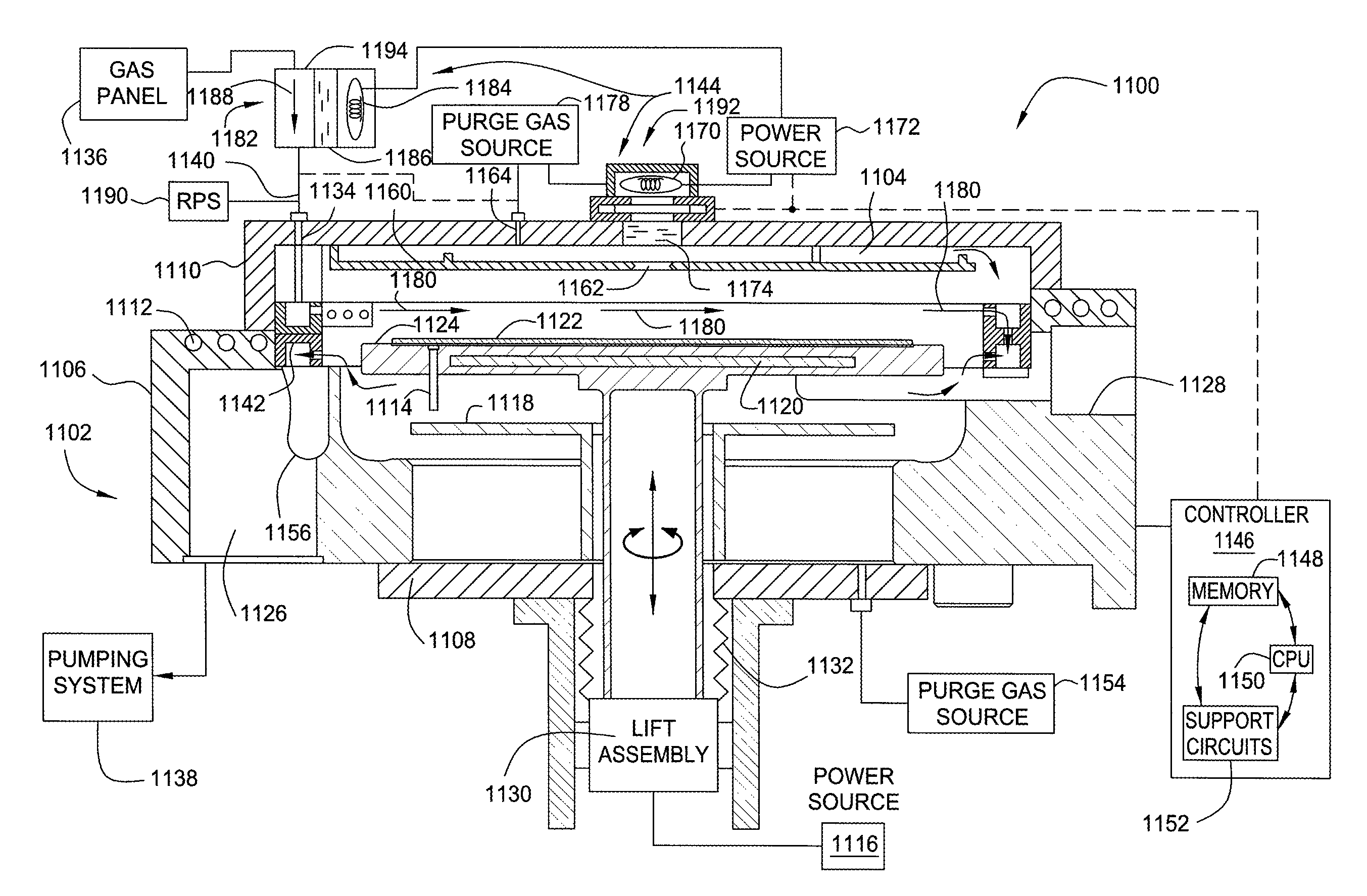

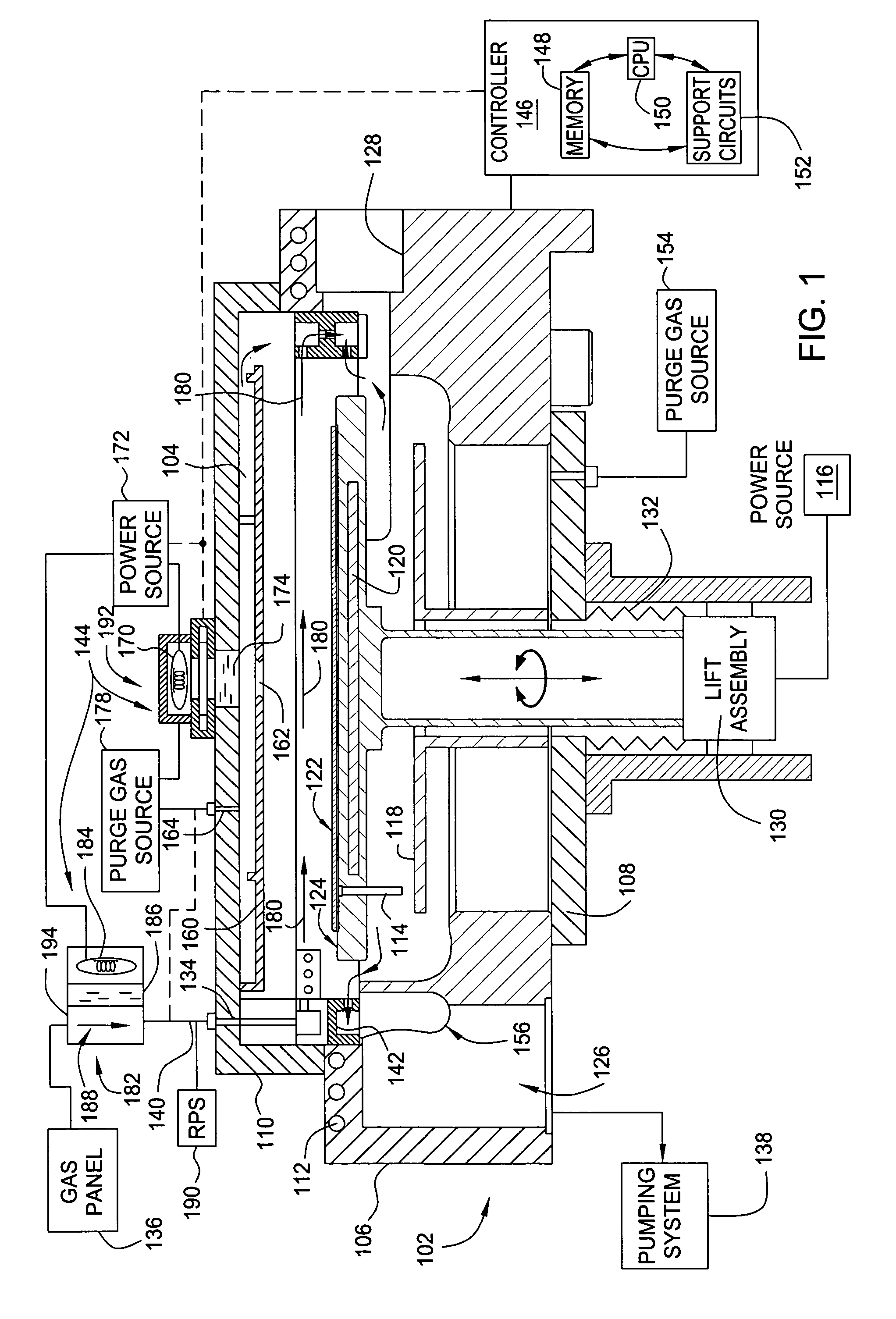

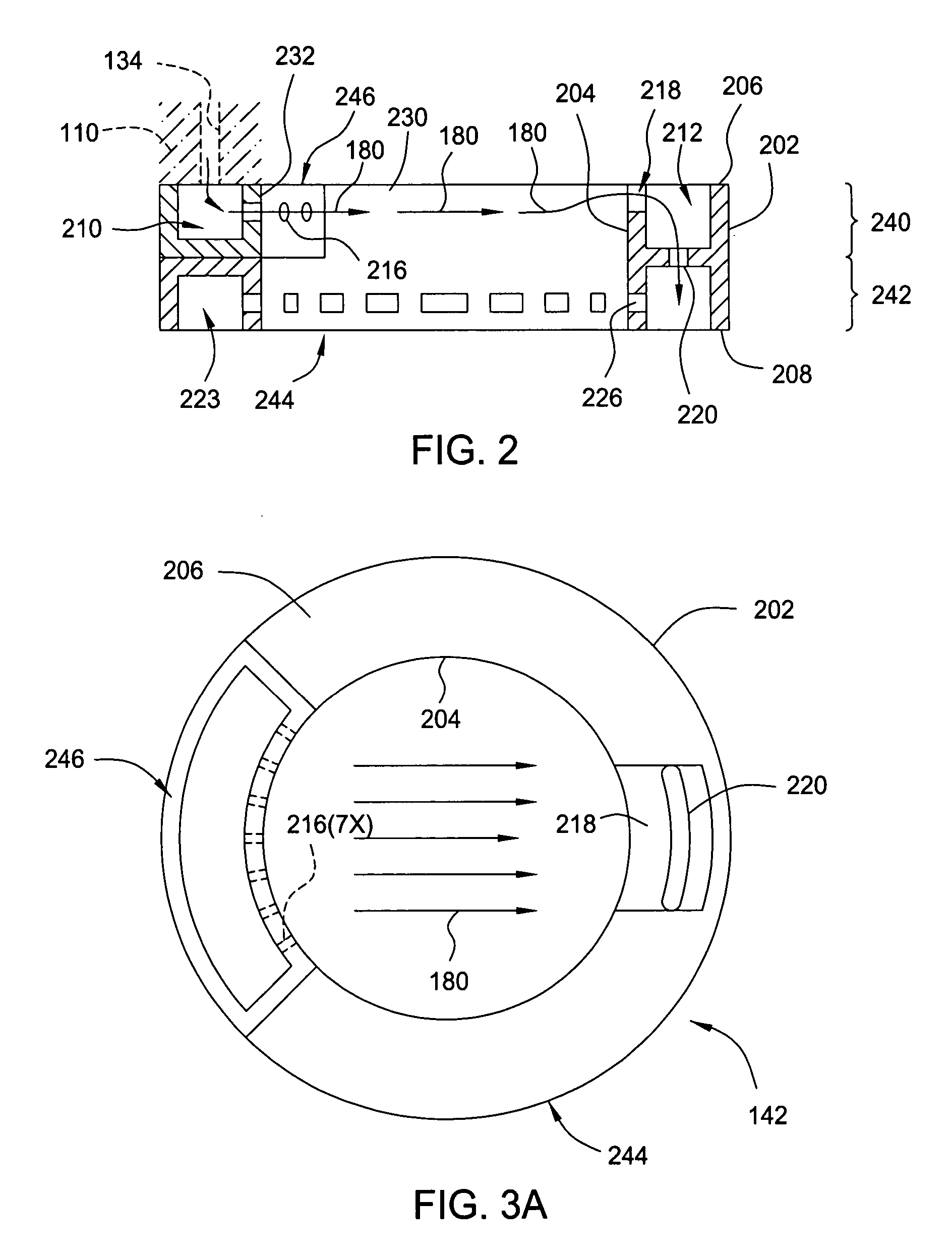

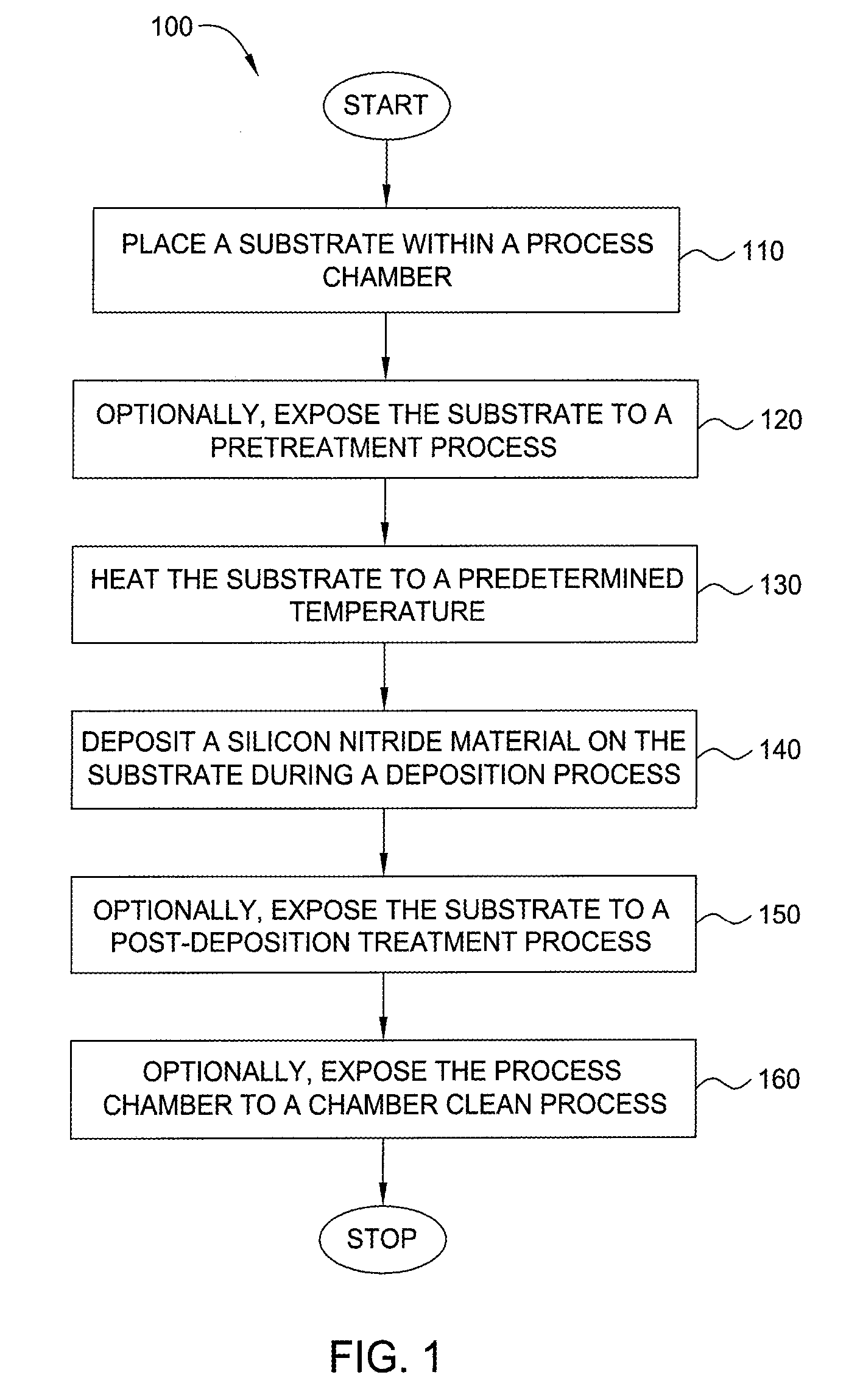

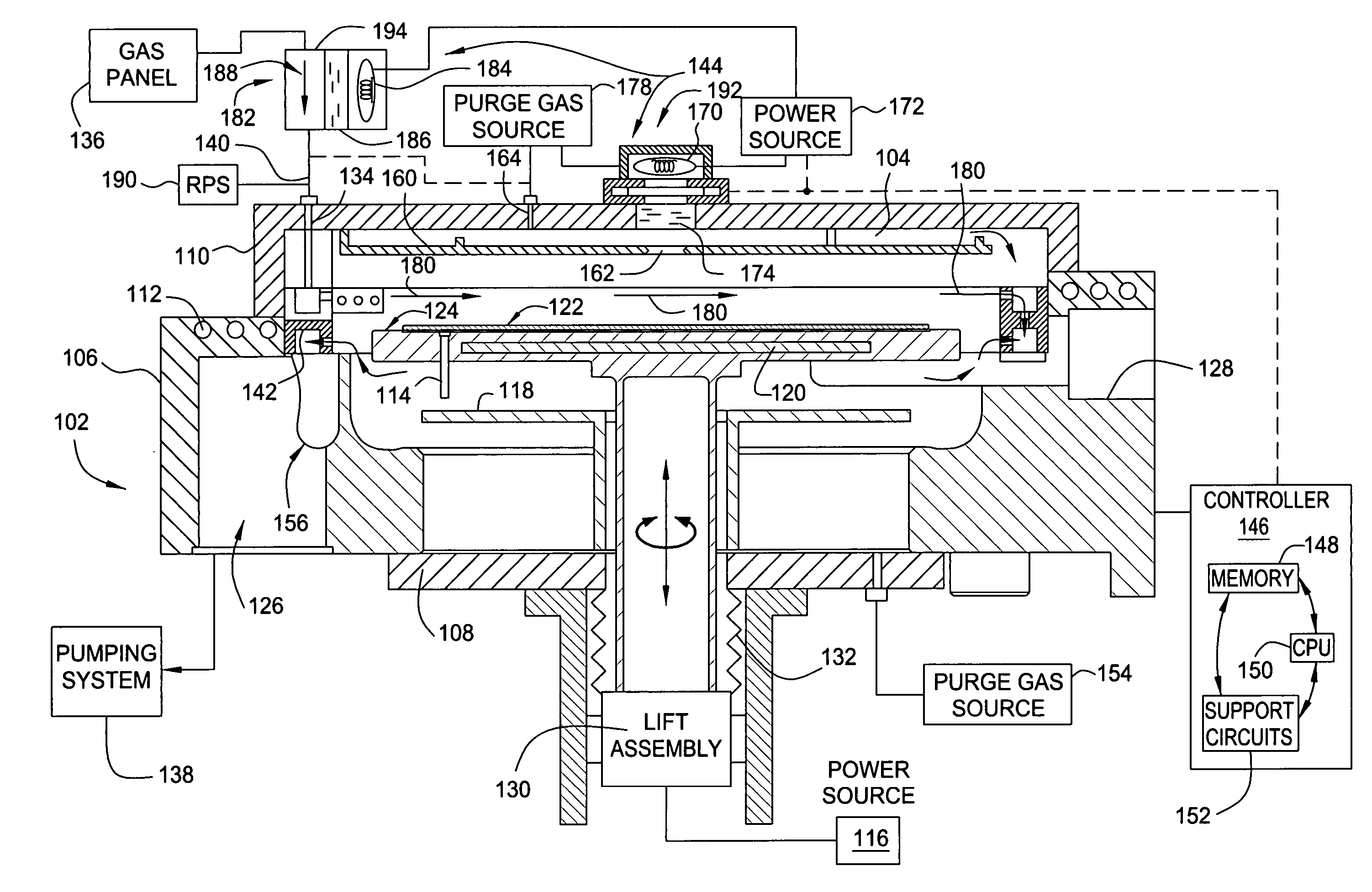

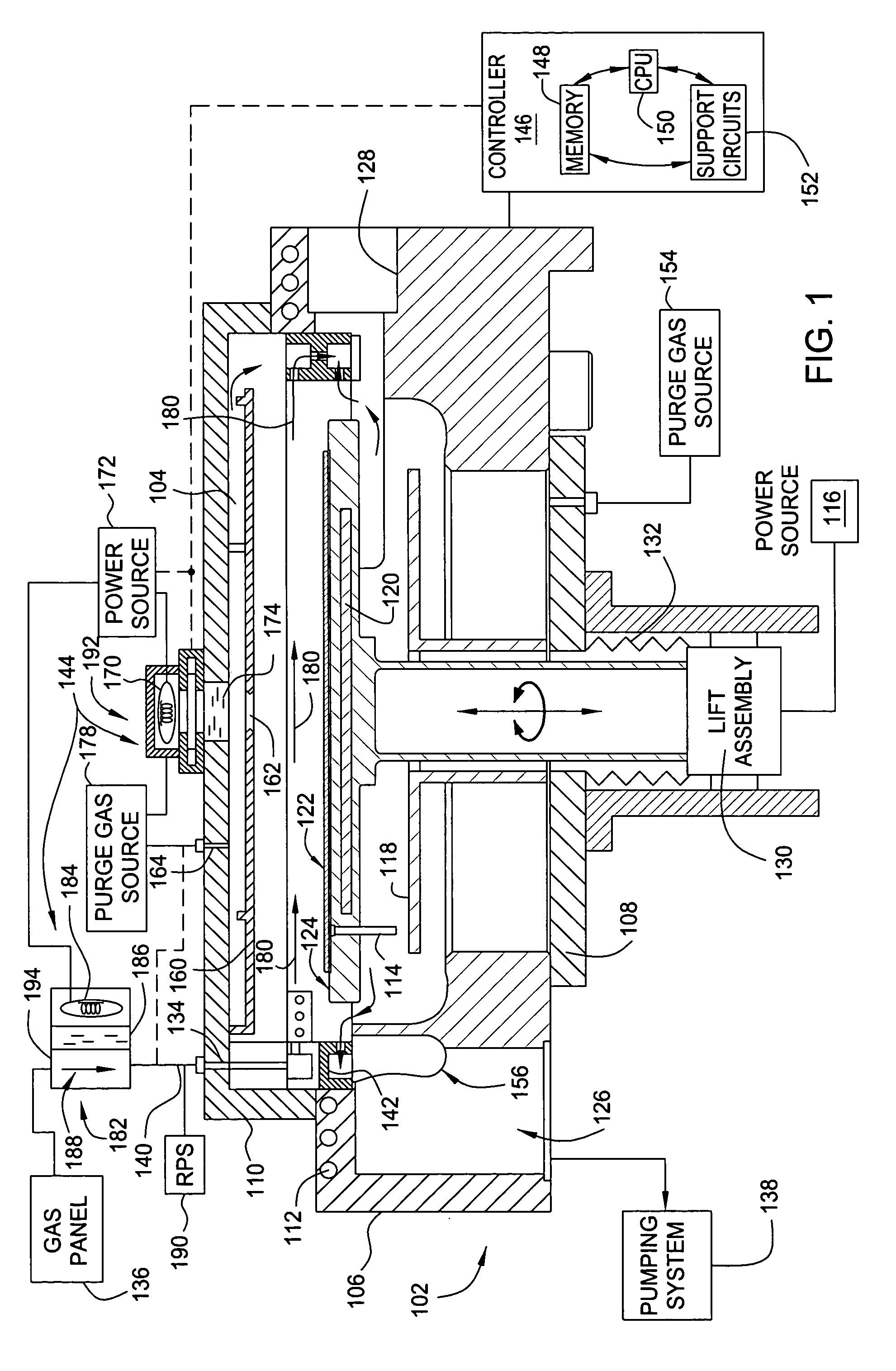

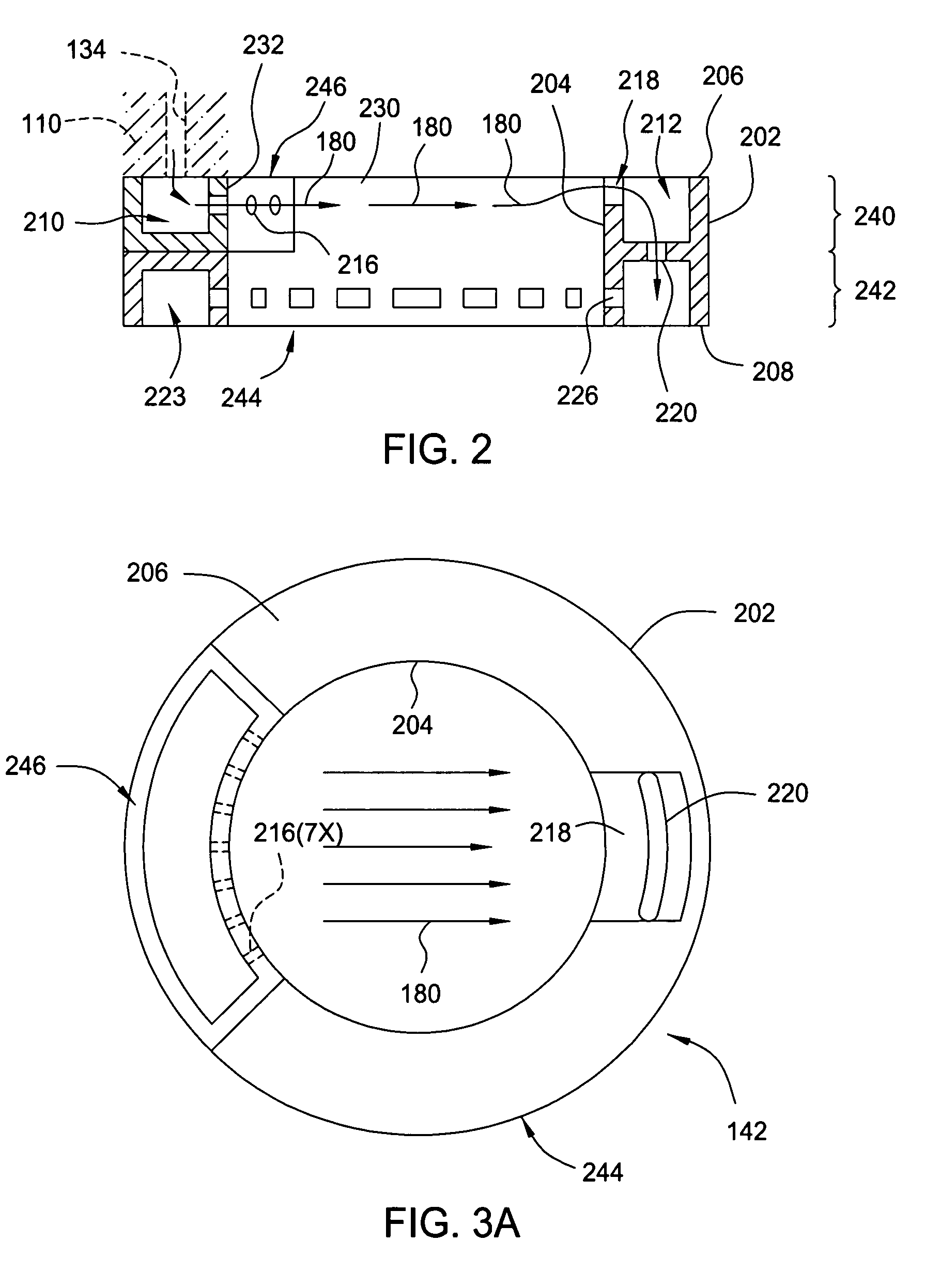

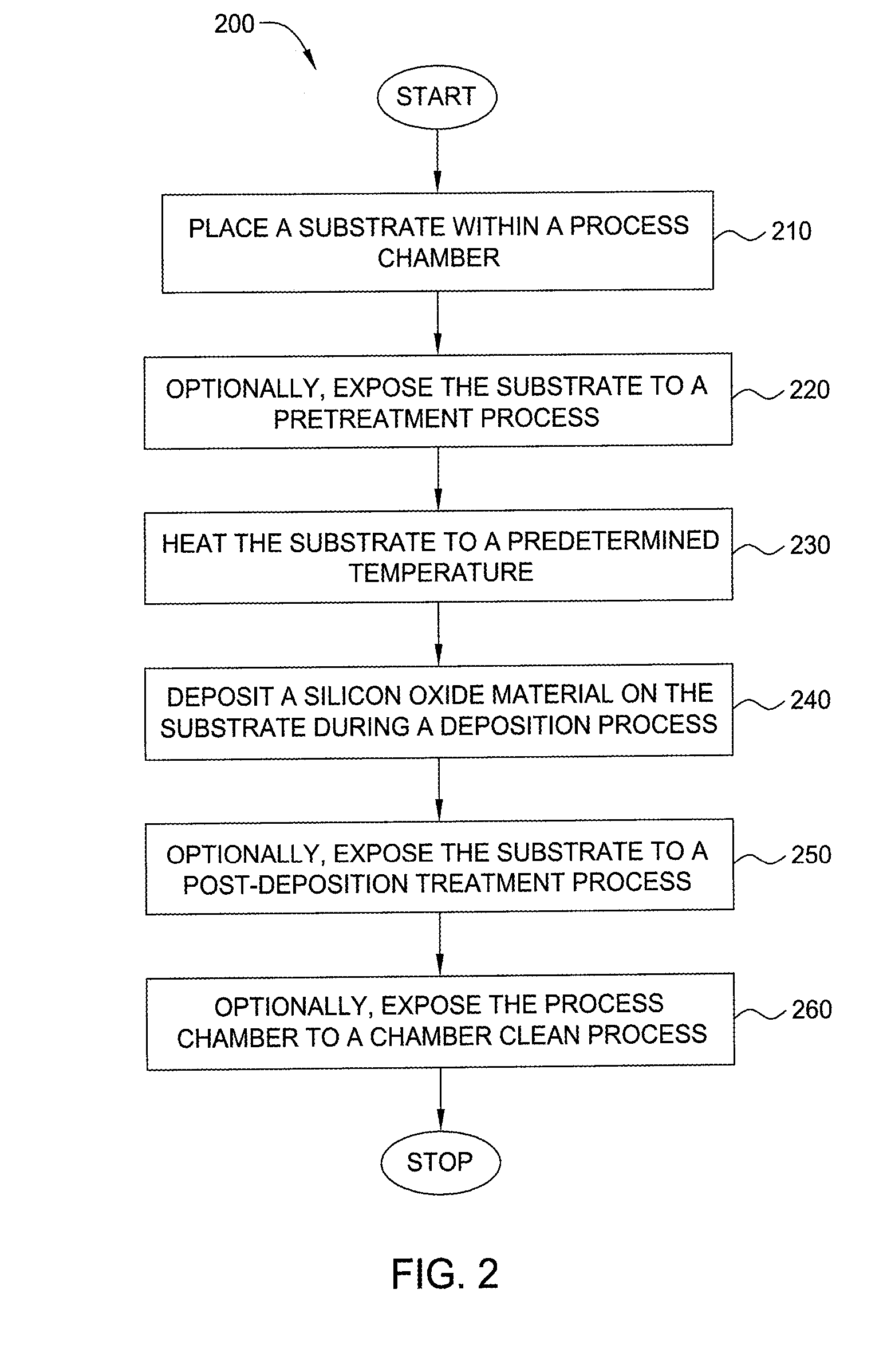

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS7651955B2Easy to cleanHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingAutoxidationDeposition temperature

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

Method for silicon based dielectric deposition and clean with photoexcitation

InactiveUS20060286819A1Enhancing chamber cleaningSpeed up the processSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricCompound (substance)

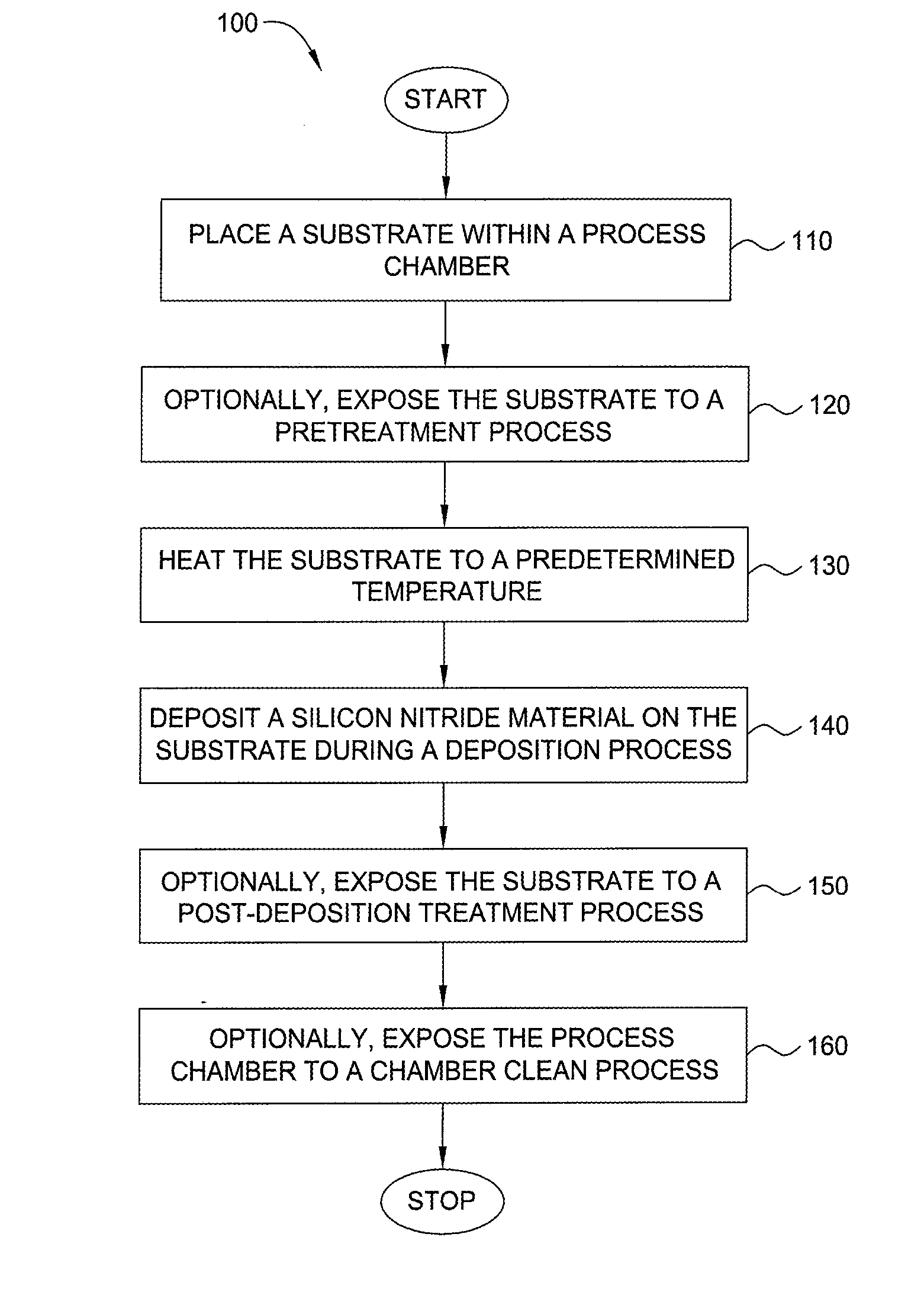

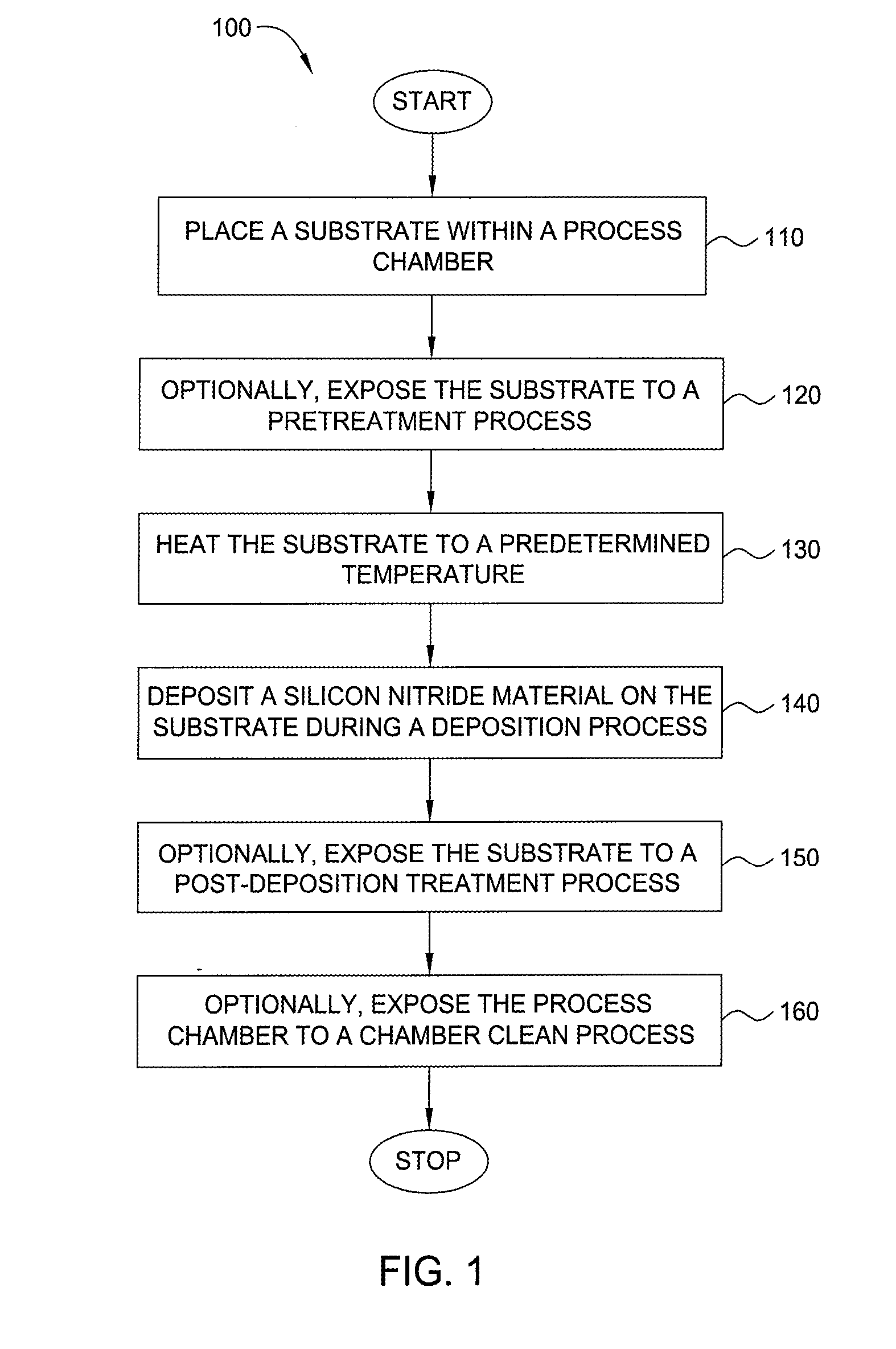

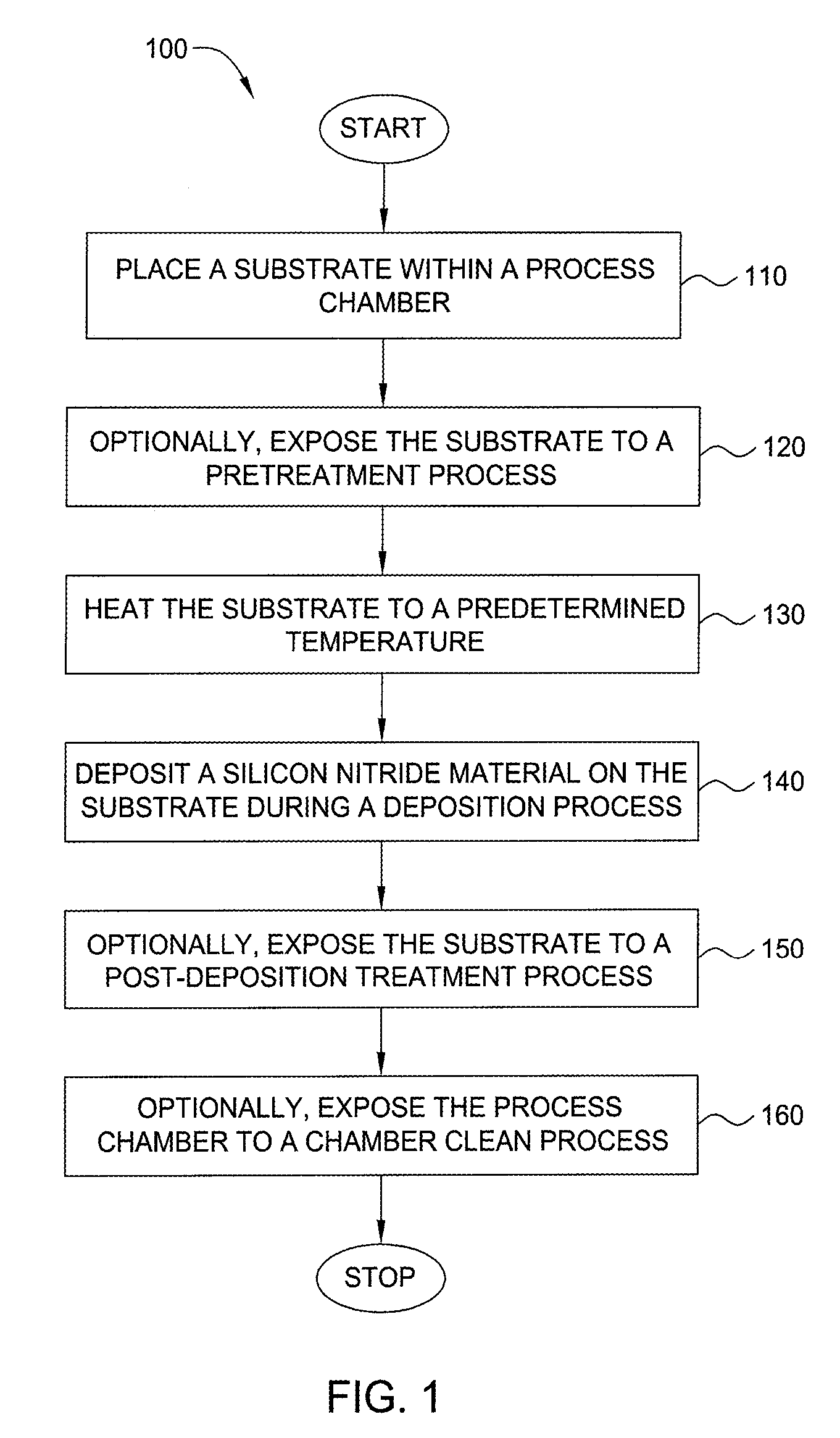

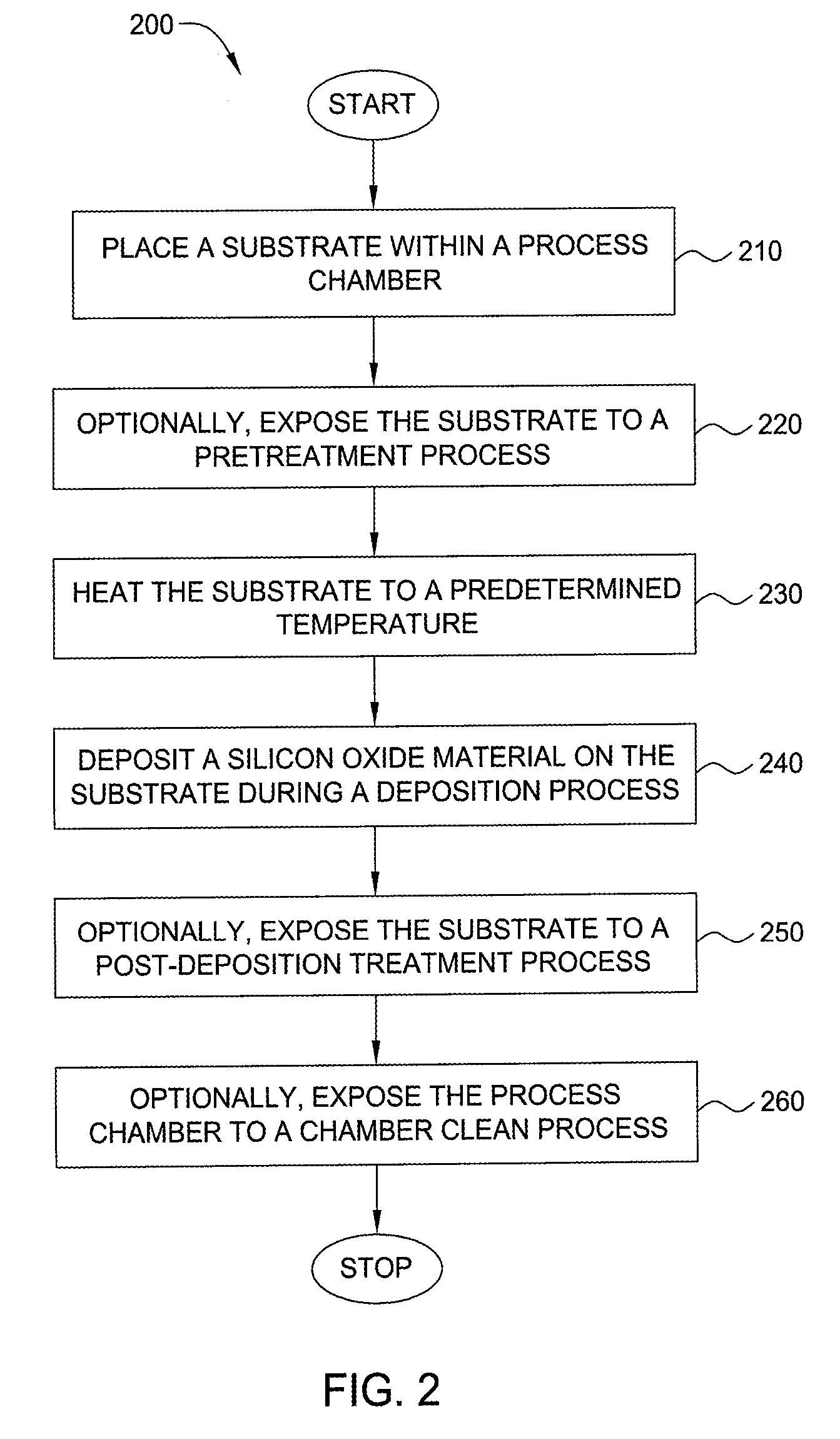

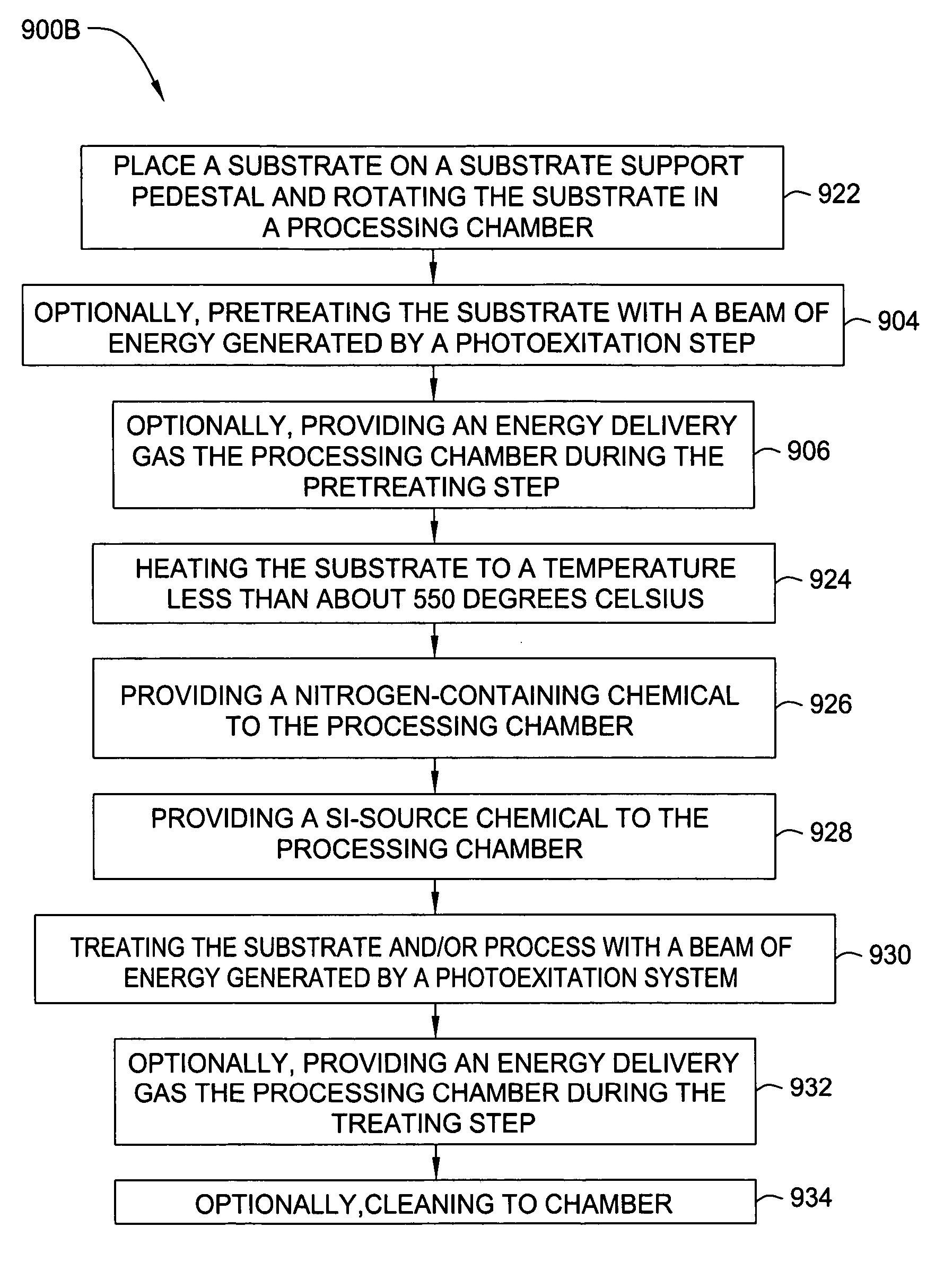

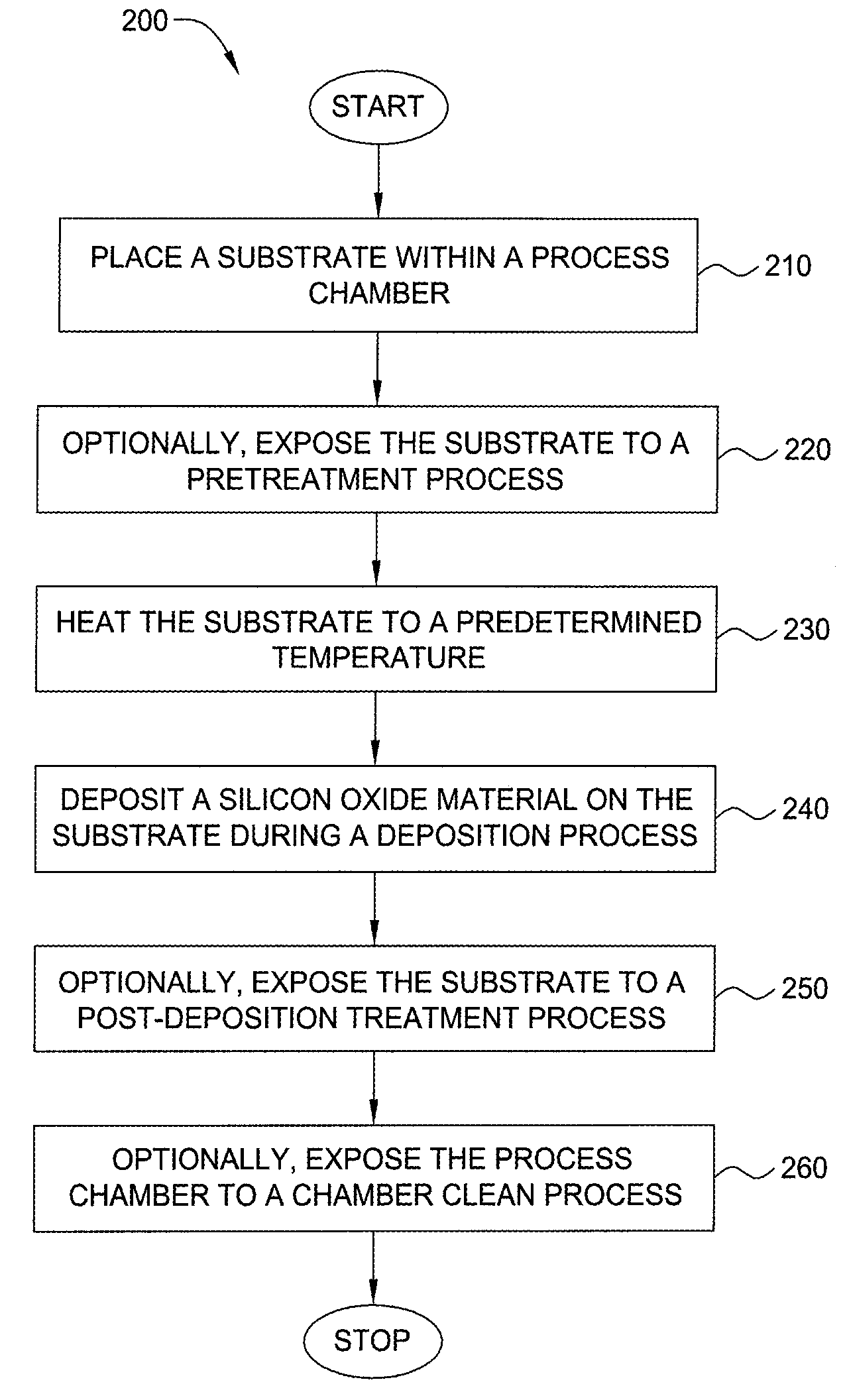

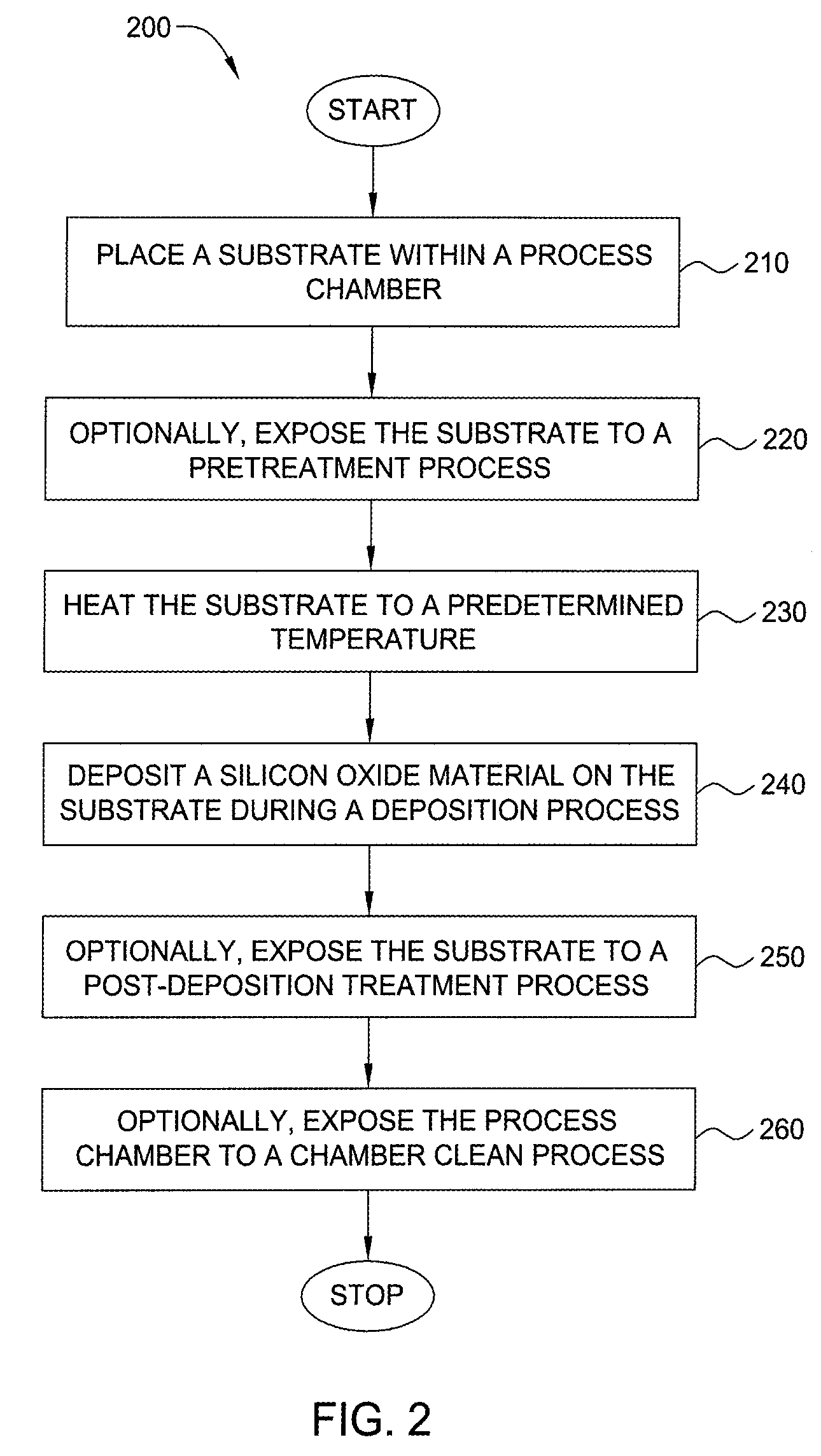

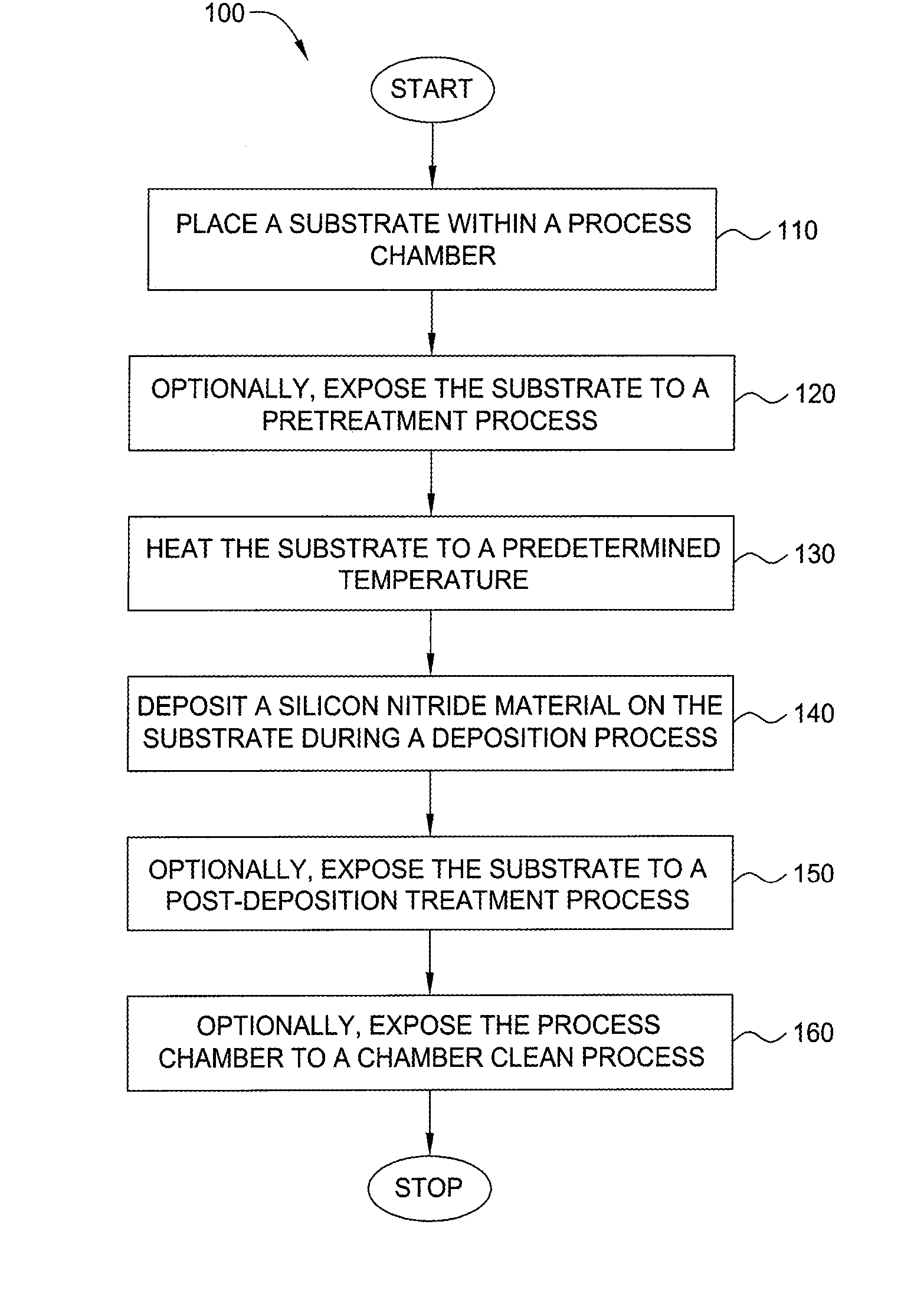

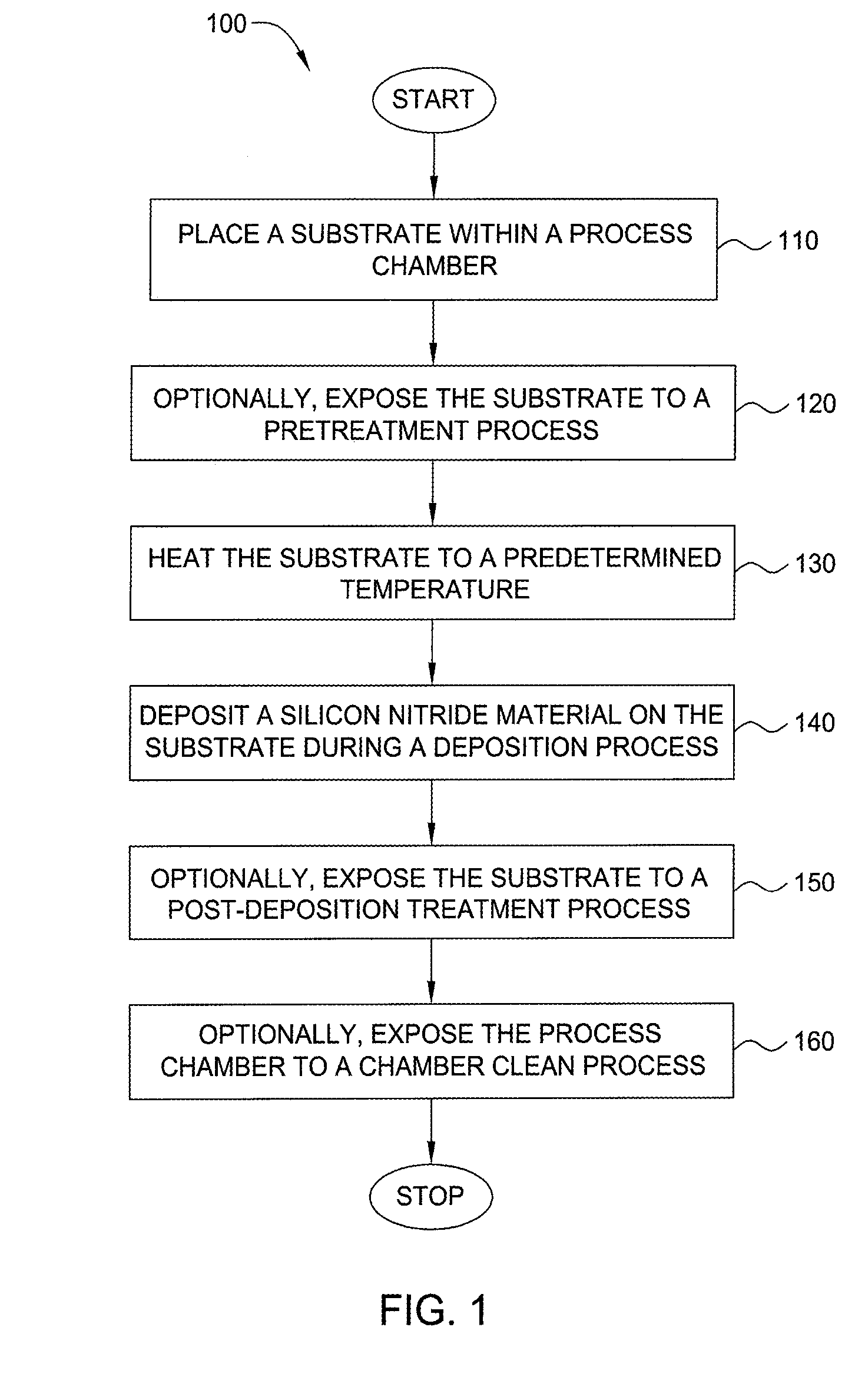

Embodiments of the invention generally provide a method for depositing films using photoexcitation. The photoexcitation may be utilized for at least one of treating the substrate prior to deposition, treating substrate and / or gases during deposition, treating a deposited film, or for enhancing chamber cleaning. In one embodiment, a method for depositing silicon and nitrogen-containing film on a substrate includes heating a substrate disposed in a processing chamber, generating a beam of energy of between about 1 to about 10 eV, transferring the energy to a surface of the substrate; flowing a nitrogen-containing chemical into the processing chamber, flowing a silicon-containing chemical with silicon-nitrogen bonds into the processing chamber, and depositing a silicon and nitrogen-containing film on the substrate.

Owner:APPLIED MATERIALS INC

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS7648927B2Easy to cleanHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingAutoxidationDeposition temperature

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

Method for treating substrates and films with photoexcitation

InactiveUS7601652B2Easy to cleanSpeed up the processSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenCompound (substance)

Embodiments of the invention generally provide a method for depositing films using photoexcitation. The photoexcitation may be utilized for at least one of treating the substrate prior to deposition, treating substrate and / or gases during deposition, treating a deposited film, or for enhancing chamber cleaning. In one embodiment, a method for depositing silicon and nitrogen-containing film on a substrate includes heating a substrate disposed in a processing chamber, generating a beam of energy of between about 1 to about 10 eV, transferring the energy to a surface of the substrate; flowing a nitrogen-containing chemical into the processing chamber, flowing a silicon-containing chemical with silicon-nitrogen bonds into the processing chamber, and depositing a silicon and nitrogen-containing film on the substrate.

Owner:APPLIED MATERIALS INC

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS20060286776A1Enhance chamber cleaning processHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingVolatilesSilicon oxide

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

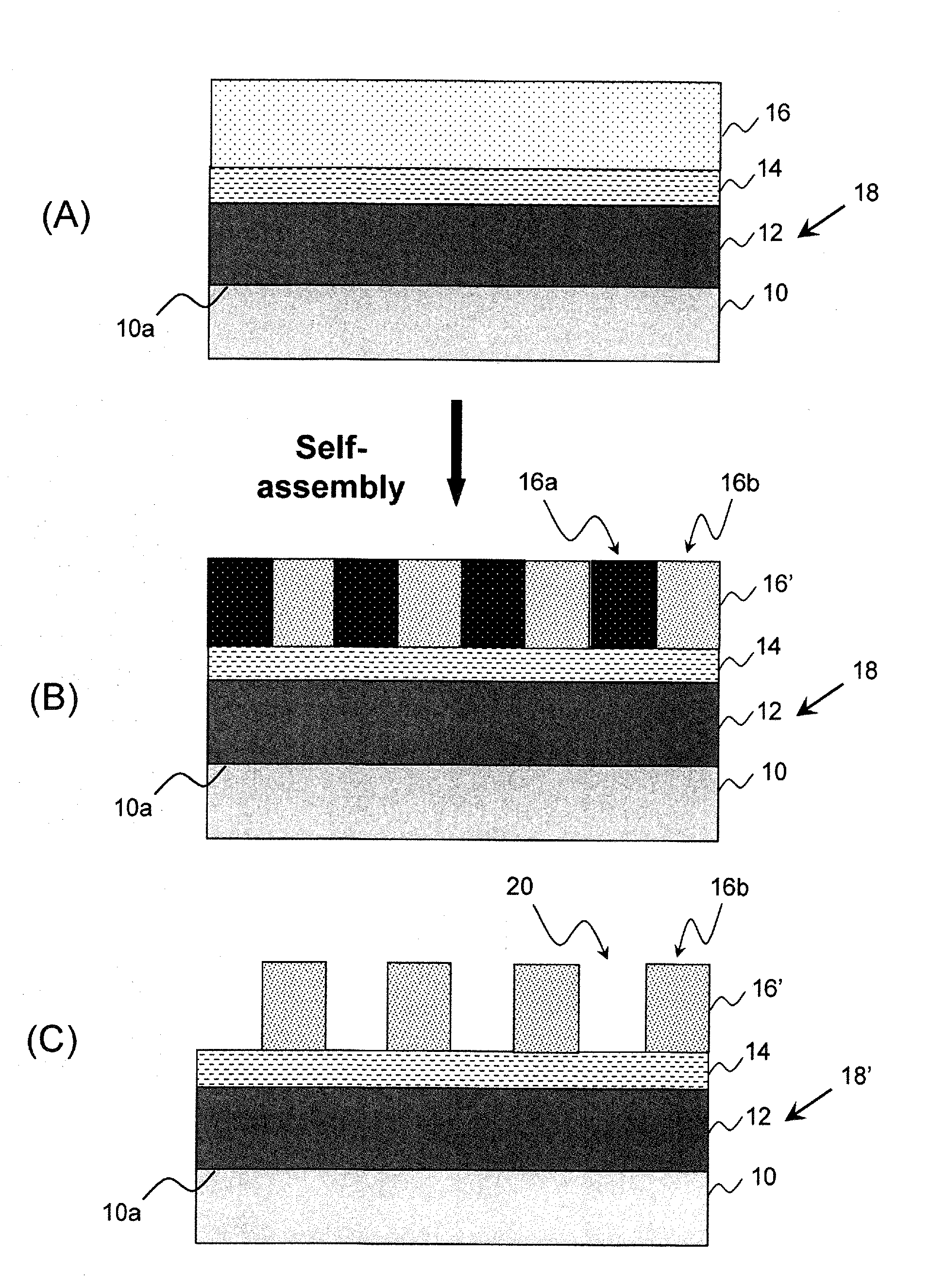

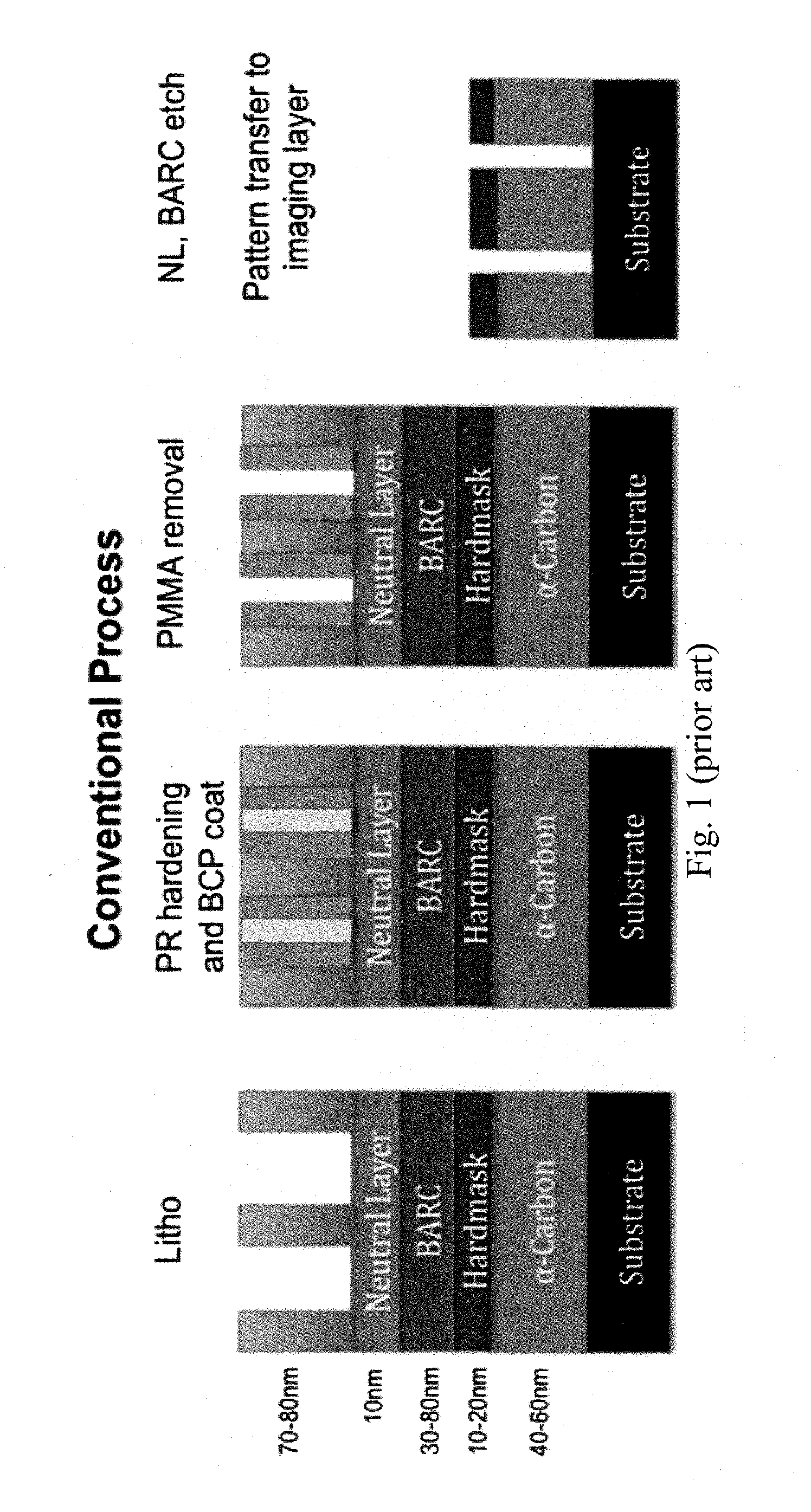

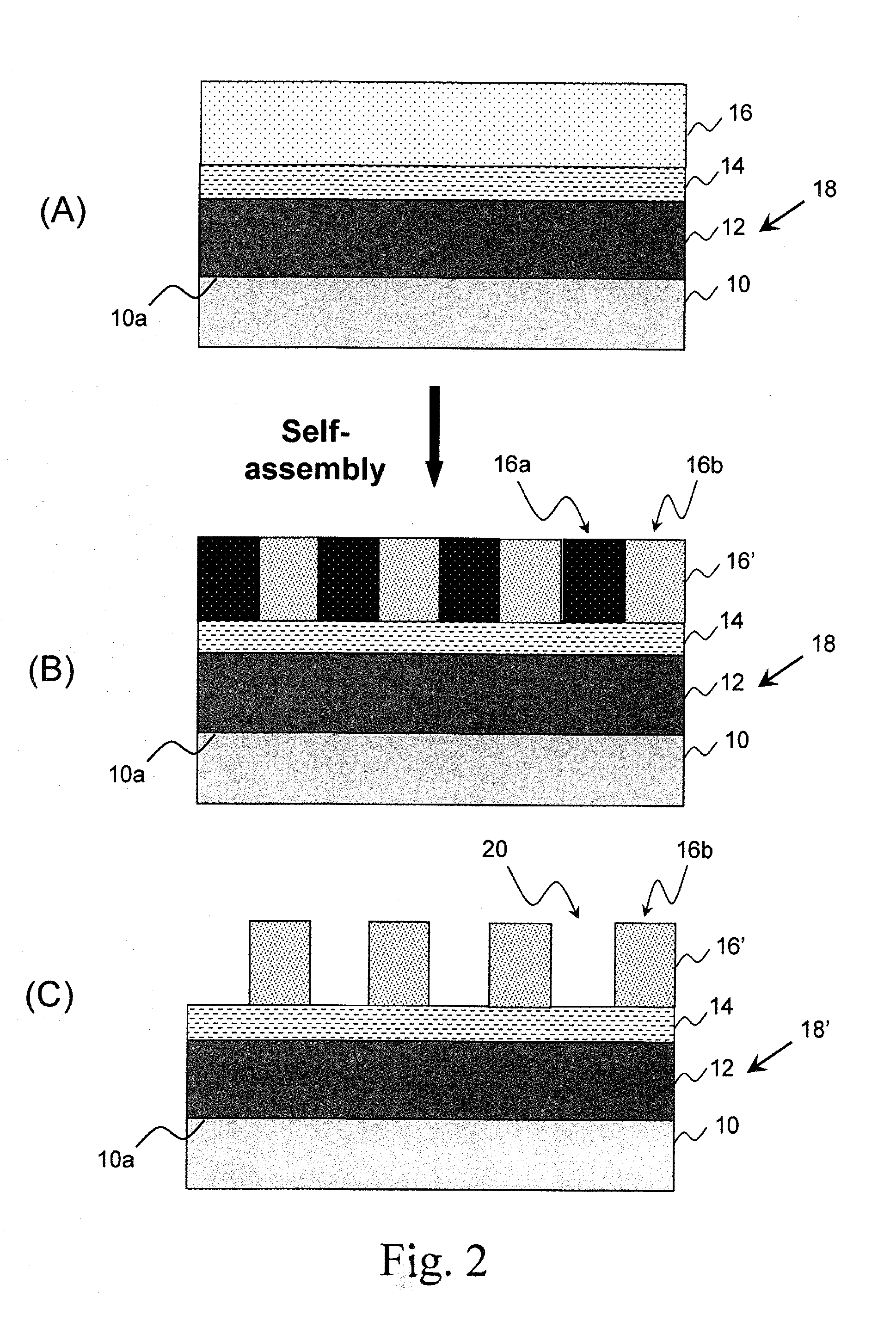

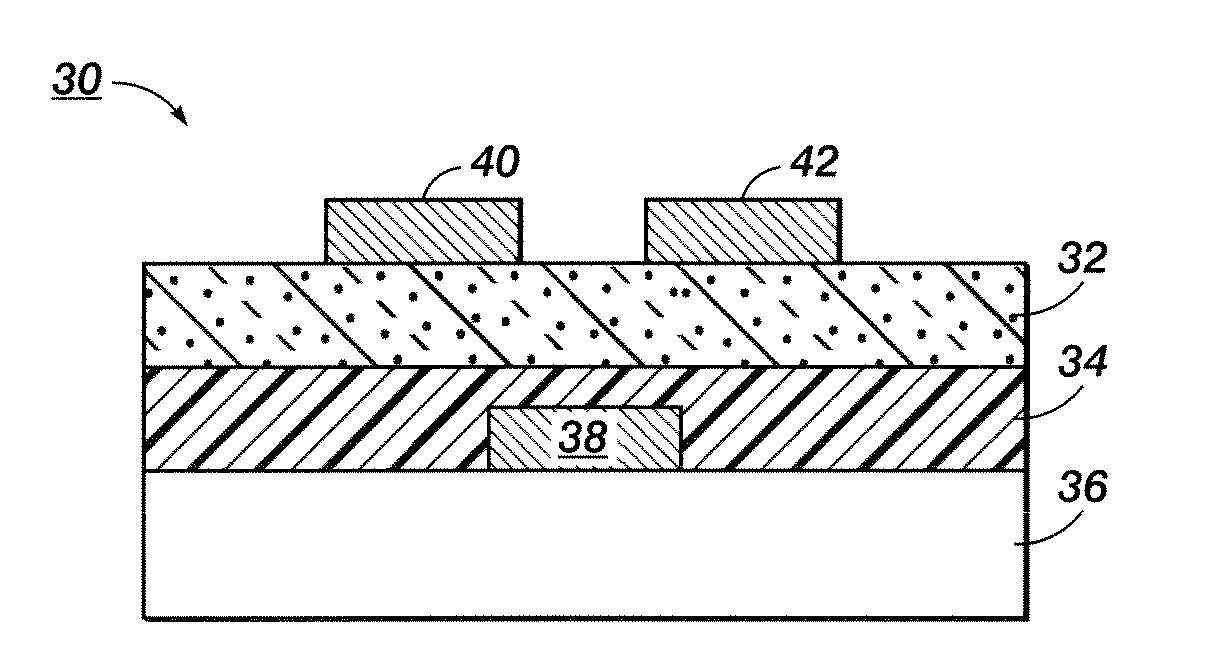

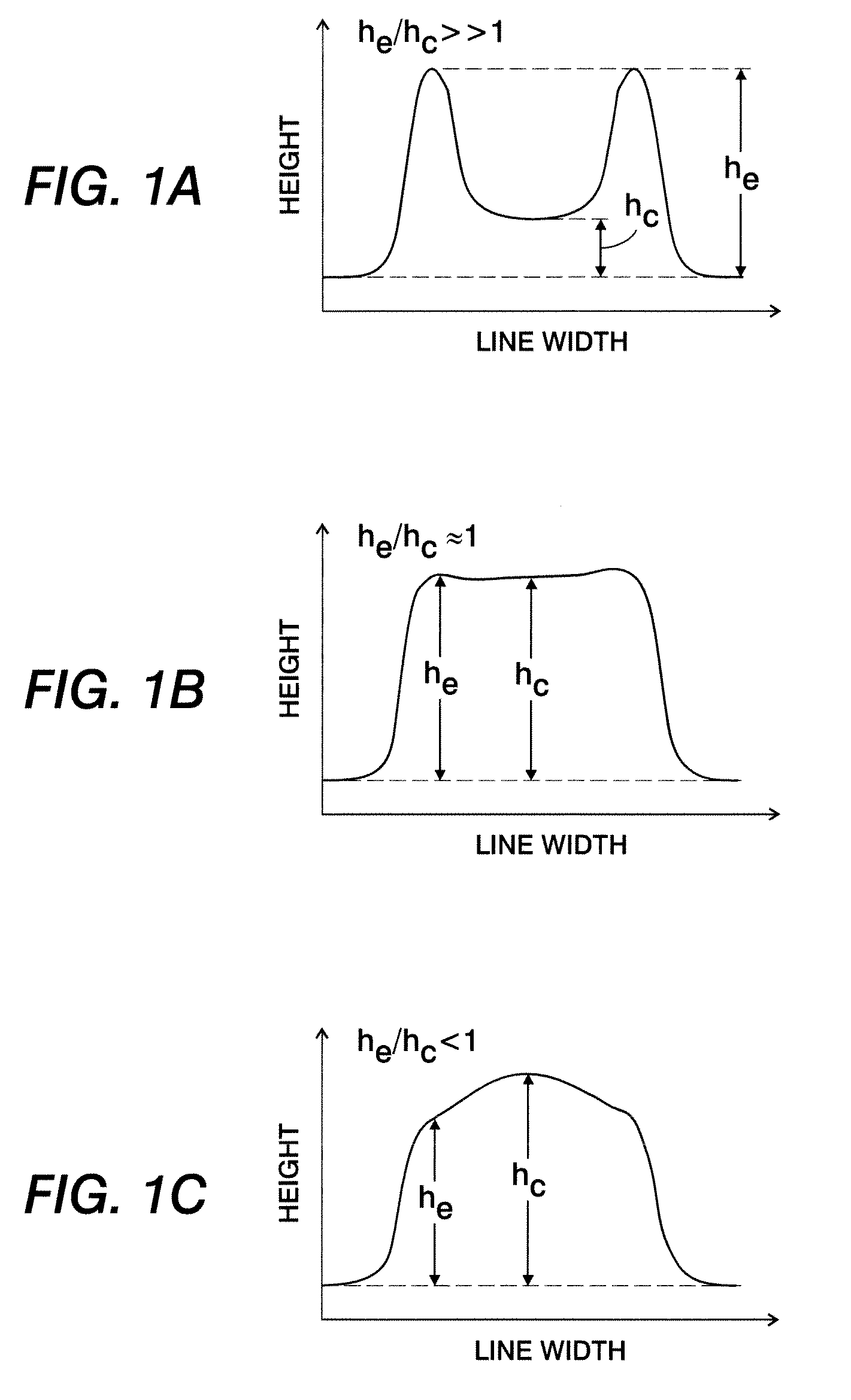

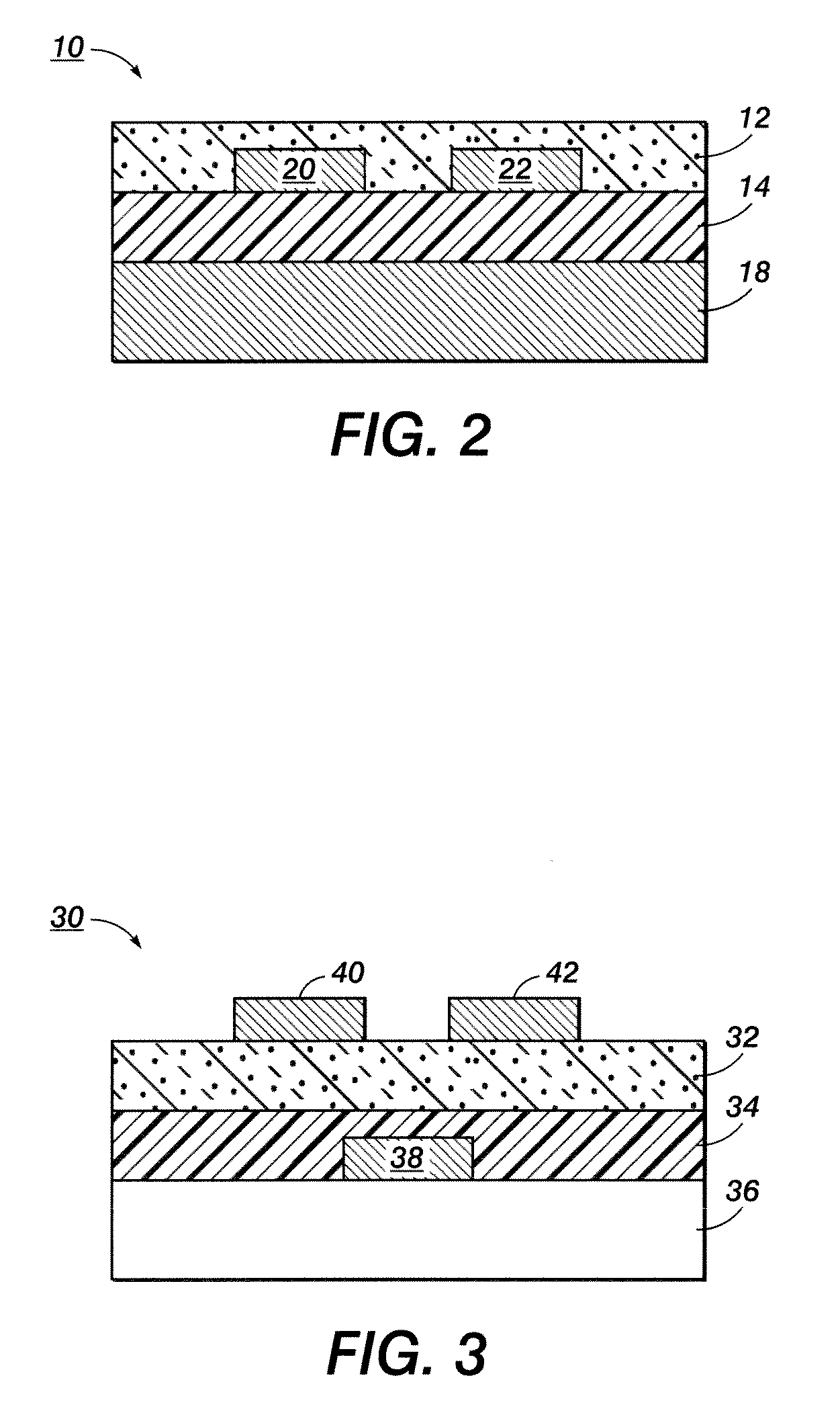

Silicon hardmask layer for directed self-assembly

ActiveUS20130273330A1Easy alignmentHigh surface energyFixed microstructural devicesDecorative surface effectsChemistryDirected self assembly

Compositions for directed self-assembly patterning techniques are provided which avoid the need for separate anti-reflective coatings and brush neutral layers in the process. Methods for directed self-assembly are also provided in which a self-assembling material, such as a directed self-assembly block copolymer, can be applied directly to the silicon hardmask neutral layer and then self-assembled to form the desired pattern. Directed self-assembly patterned structures are also disclosed herein.

Owner:BREWER SCI

Silver nanoparticle ink composition

An ink composition comprises silver nanoparticles, hydrocarbon solvent, and an alcohol co-solvent. The ink composition is suitable for printing conductive lines that are uniform, smooth, and narrow on various substrate surfaces.

Owner:XEROX CORP

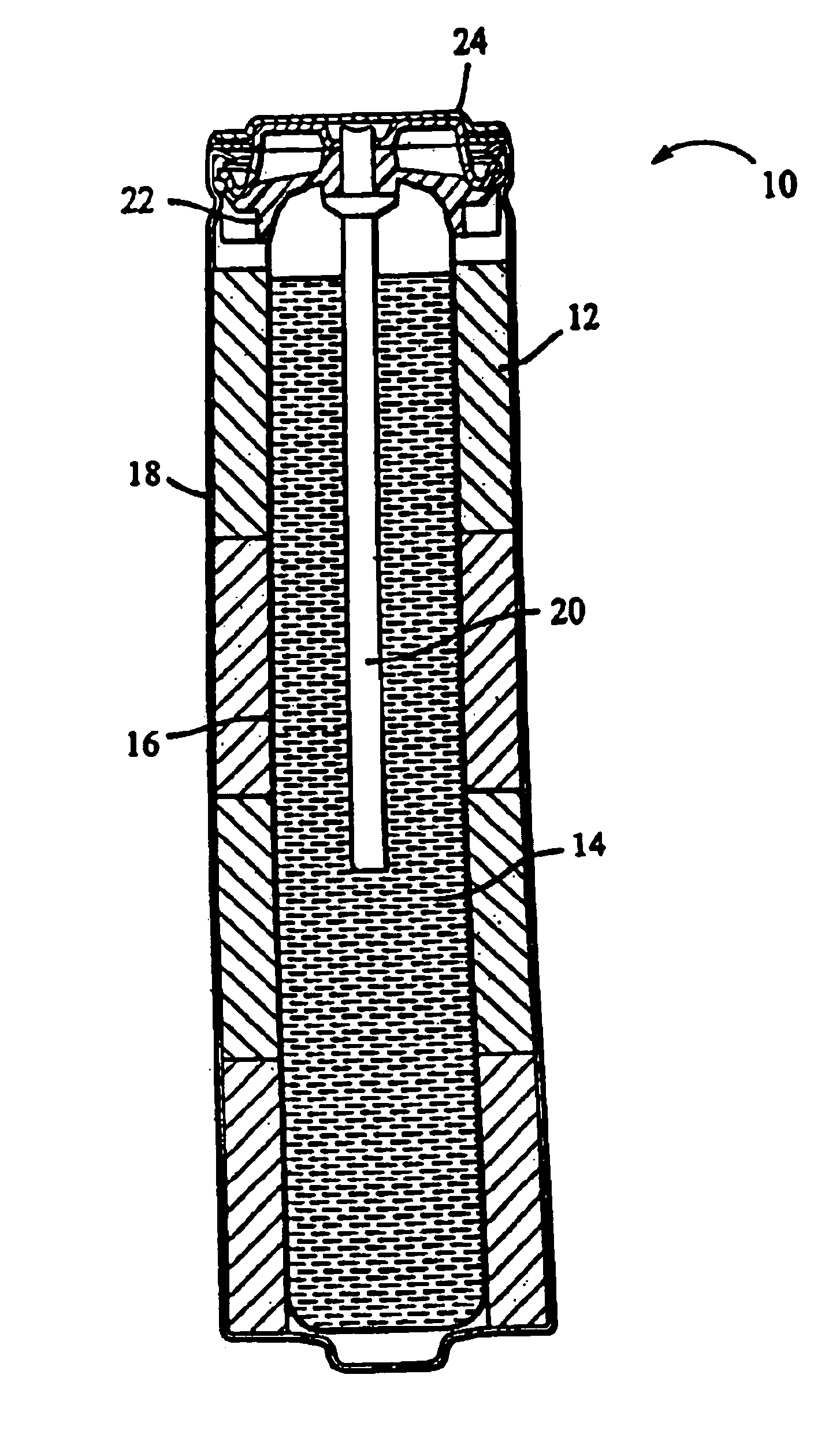

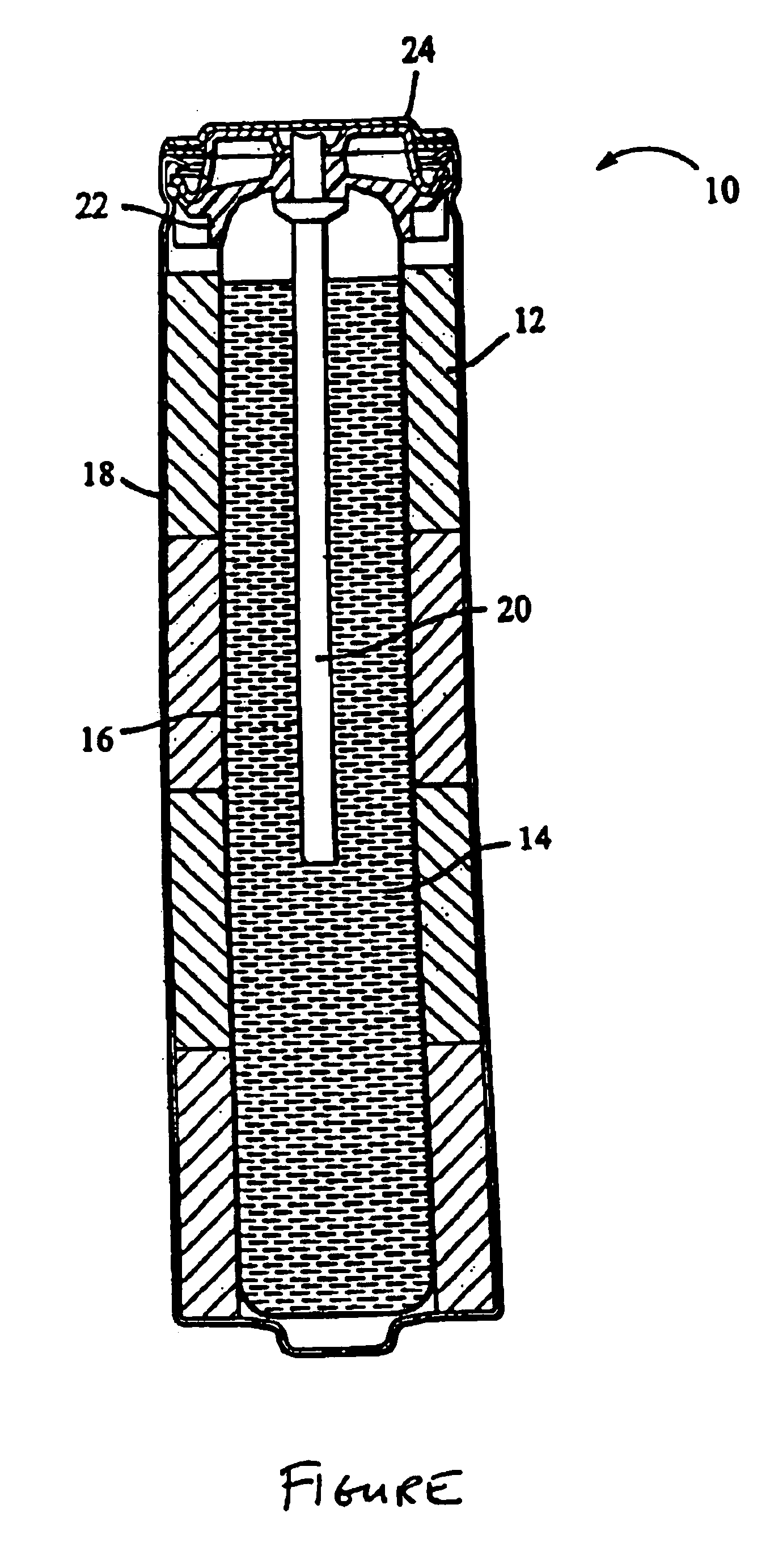

Battery cathode

InactiveUS6858349B1Improve conductivityOvercome lack of conductivityPositive electrodesPrimary cell electrodesFiberCarbon fibers

A primary alkaline battery includes a cathode having a cathode active material and carbon fibers, an anode, a separator and an alkaline electrolyte. The carbon fibers have diameters less than about 250 nanometers.

Owner:DURACELL U S OPERATIONS

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS20030066672A1Eliminate needHeat dissipationMolten spray coatingScreening gaskets/sealsMolten stateThermal spraying

Heat dissipation and electromagnetic interference (EMI) shielding for an electronic device having an enclosure. An interior surface of the enclosure is covered with a conformal metallic layer which, as disposed in thermal adjacency with one or more heat-generating electronic components or other sources contained within the enclosure, may provide both thermal dissipation and EMI shielding for the device. The layer may be sprayed onto the interior surface in a molten state and solidified to form a self-adherent coating.

Owner:PARKER INTANGIBLES LLC

Melt-stable semi-crystalline lactide polymer film and process for manufacture thereof

InactiveUS6121410AHigh surface energyEasy to printCoatings with pigmentsSurgeryLactidePolymer chemistry

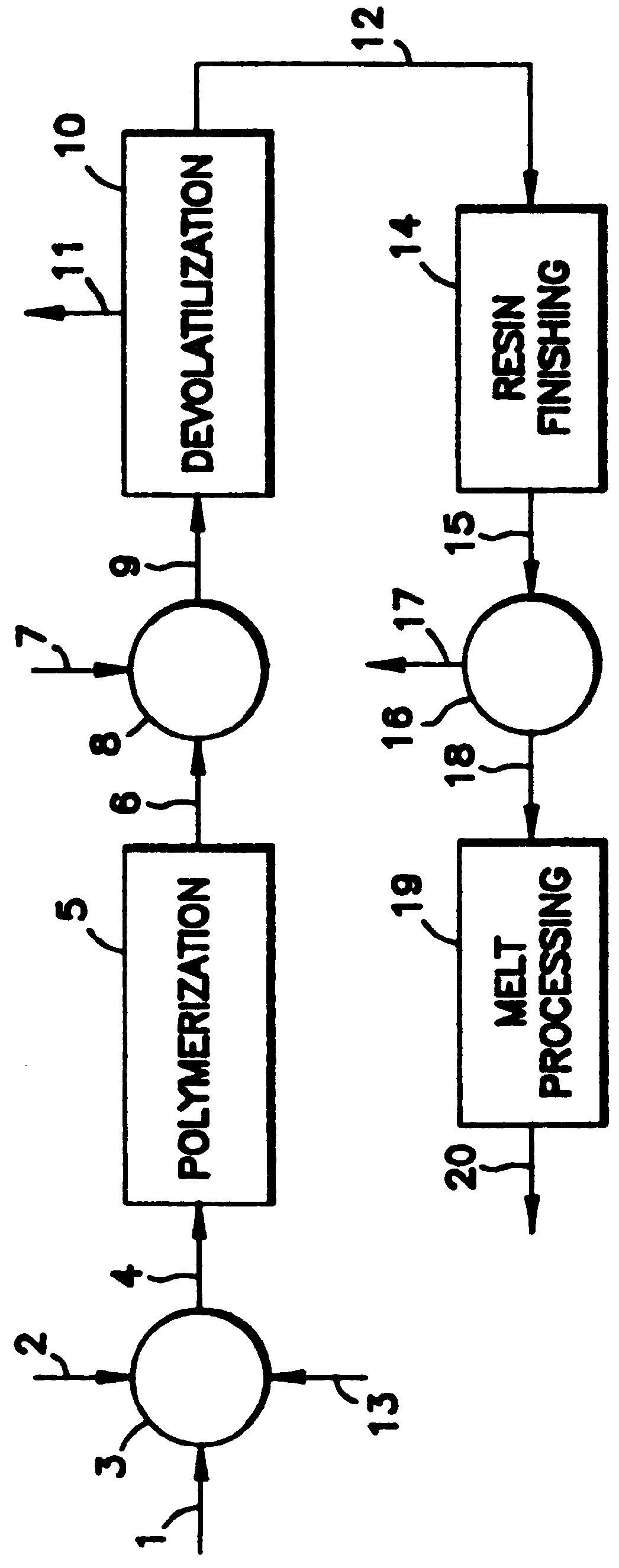

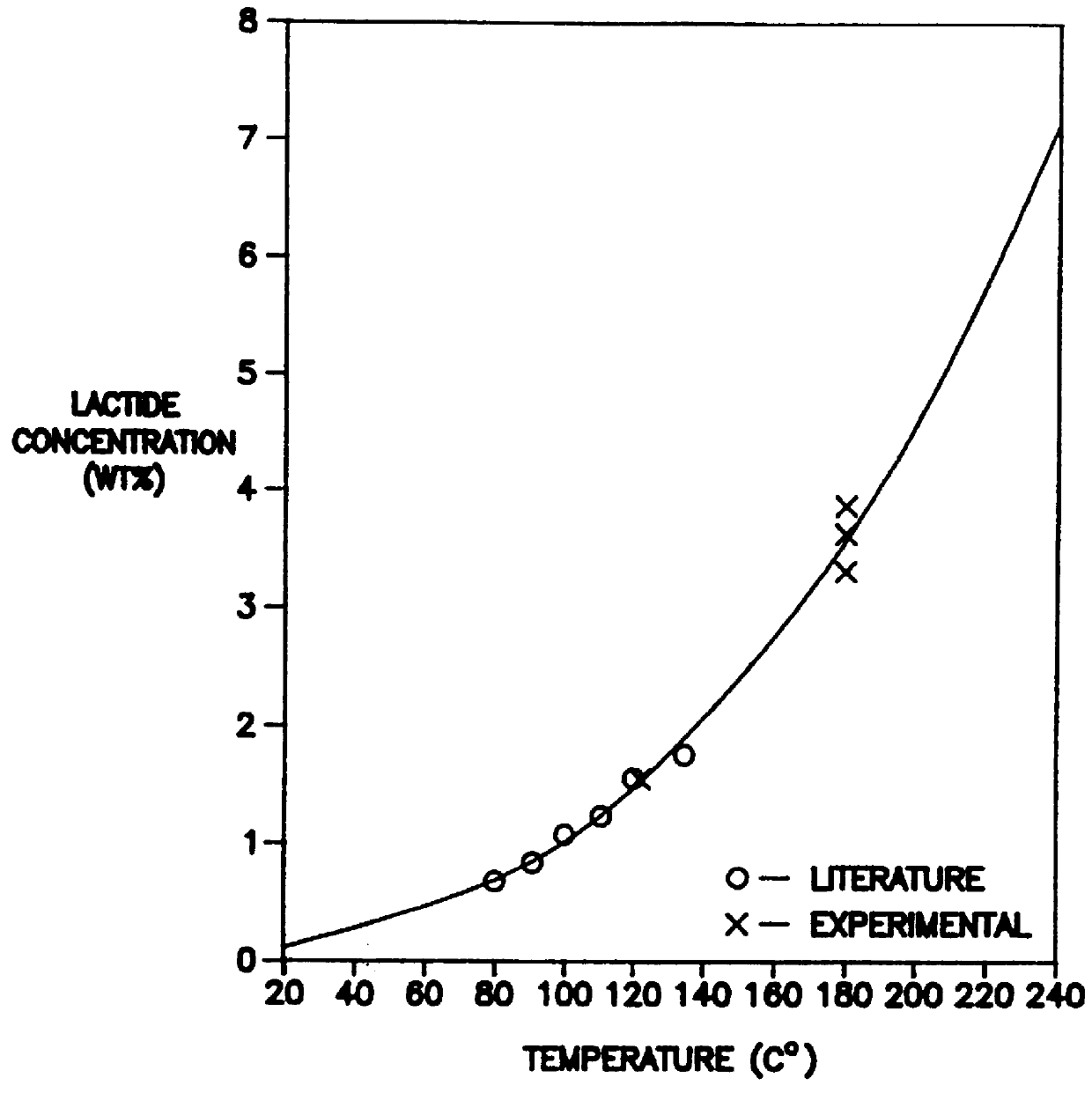

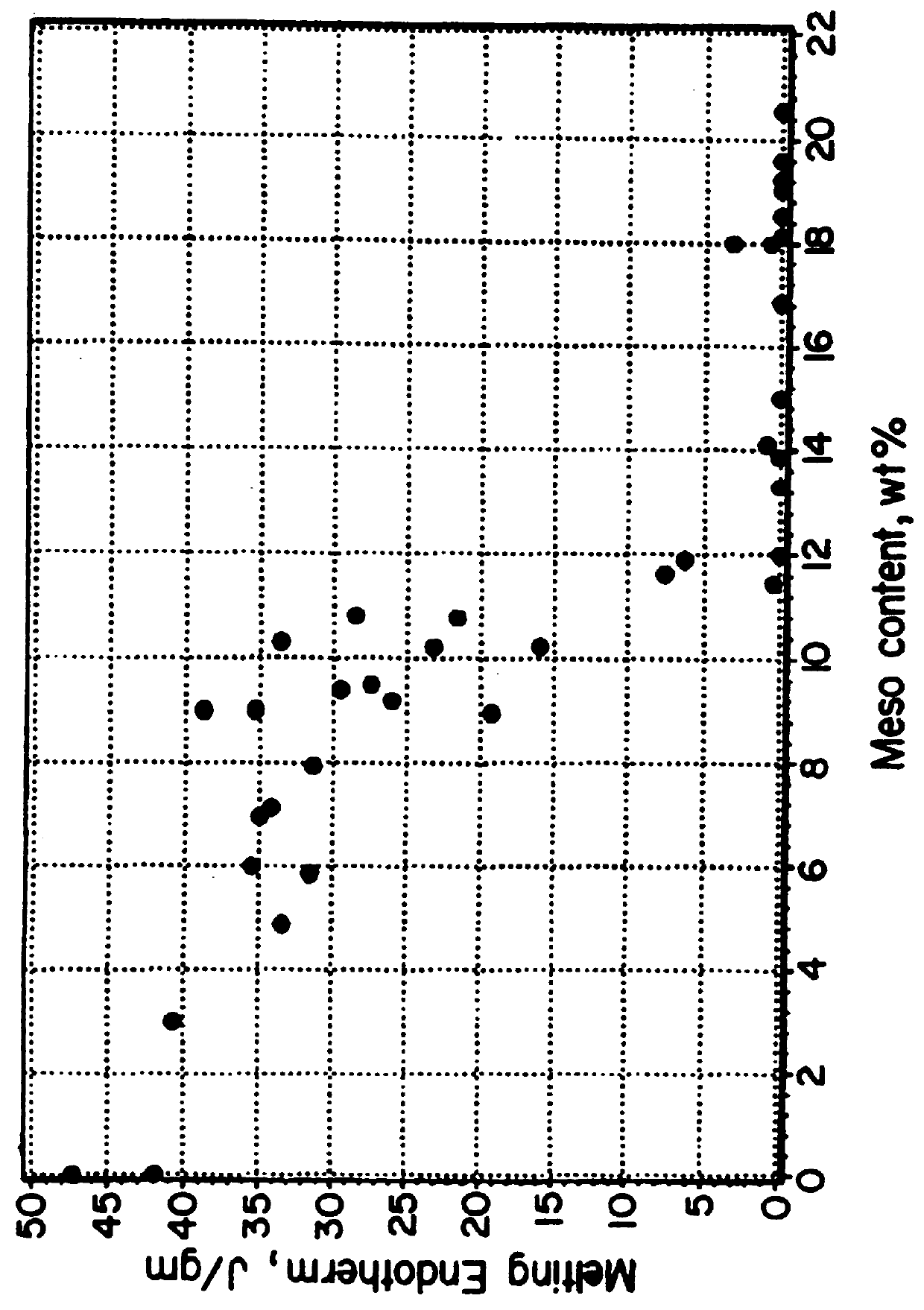

A semi-crystalline film comprised of a lactide polymer. The lactide polymer comprises a plurality of poly(lactide) polymer chains, residual lactide in concentration of less than about 5 percent and water in concentration of less than about 2000 parts-per-million. A process for manufacturing a semi-crystalline film with the lactide polymer composition is also disclosed.

Owner:CARGILL INC

Doped modified lithium nickel cobalt manganese material, preparation method thereof and lithium ion battery

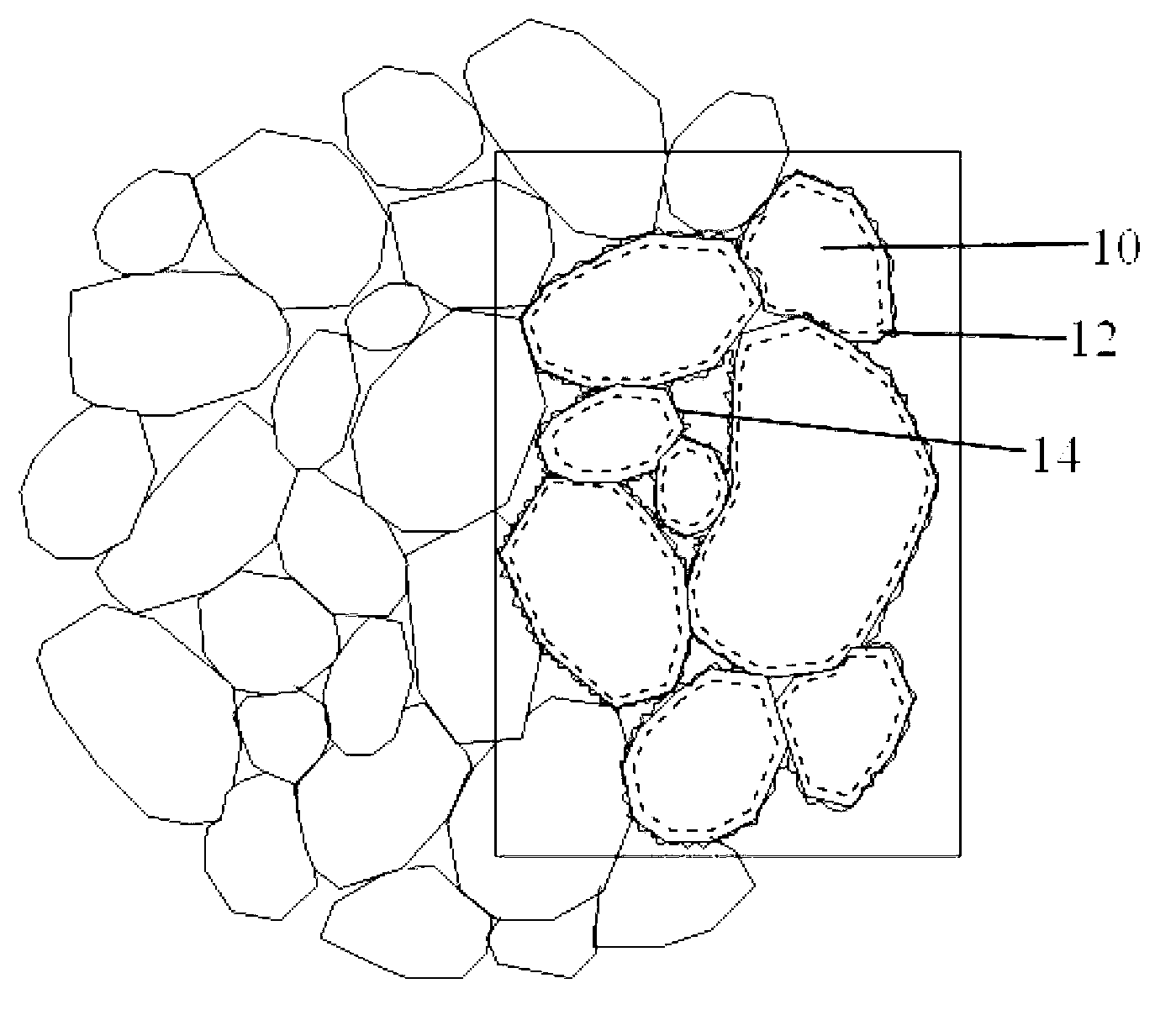

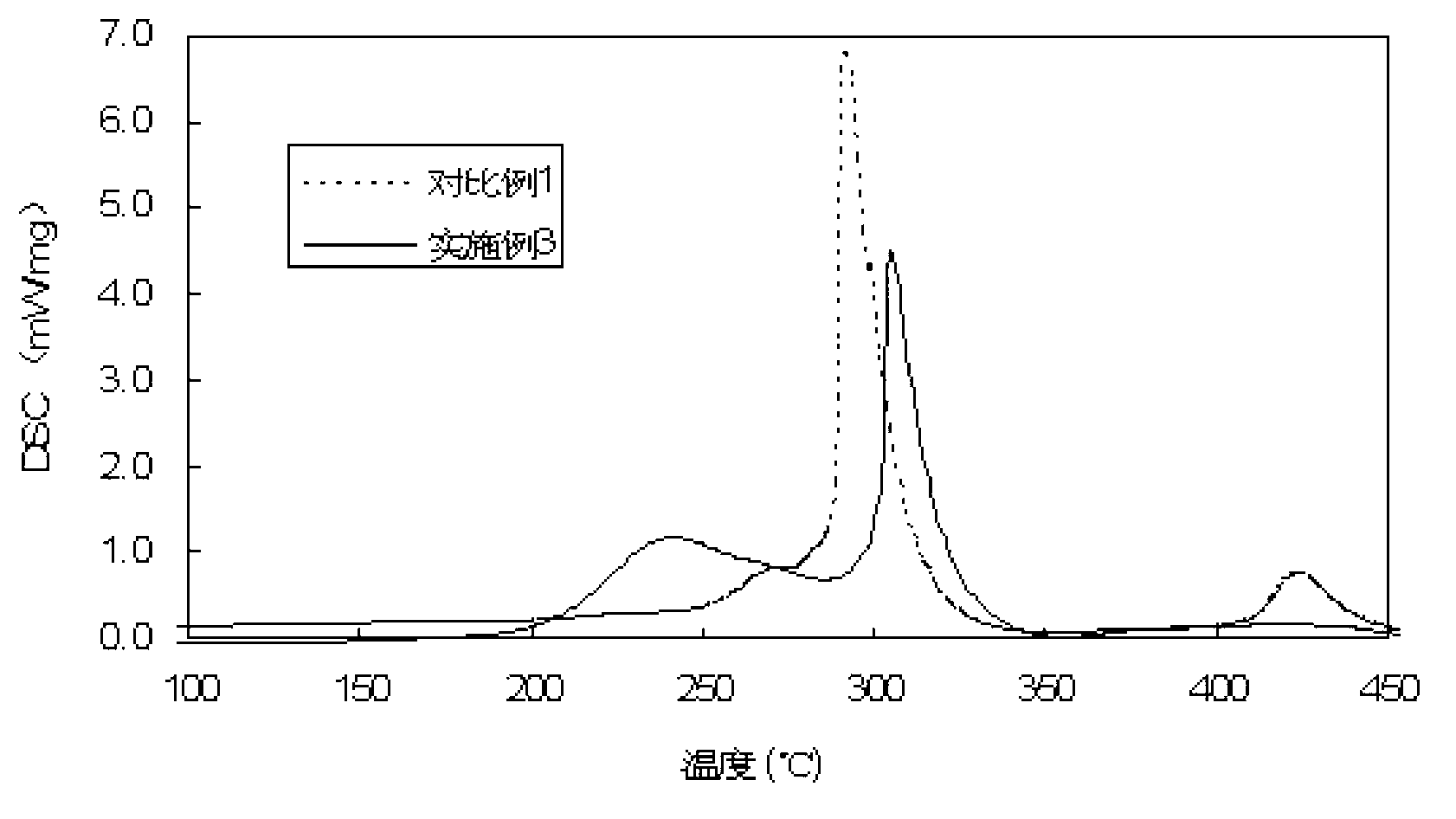

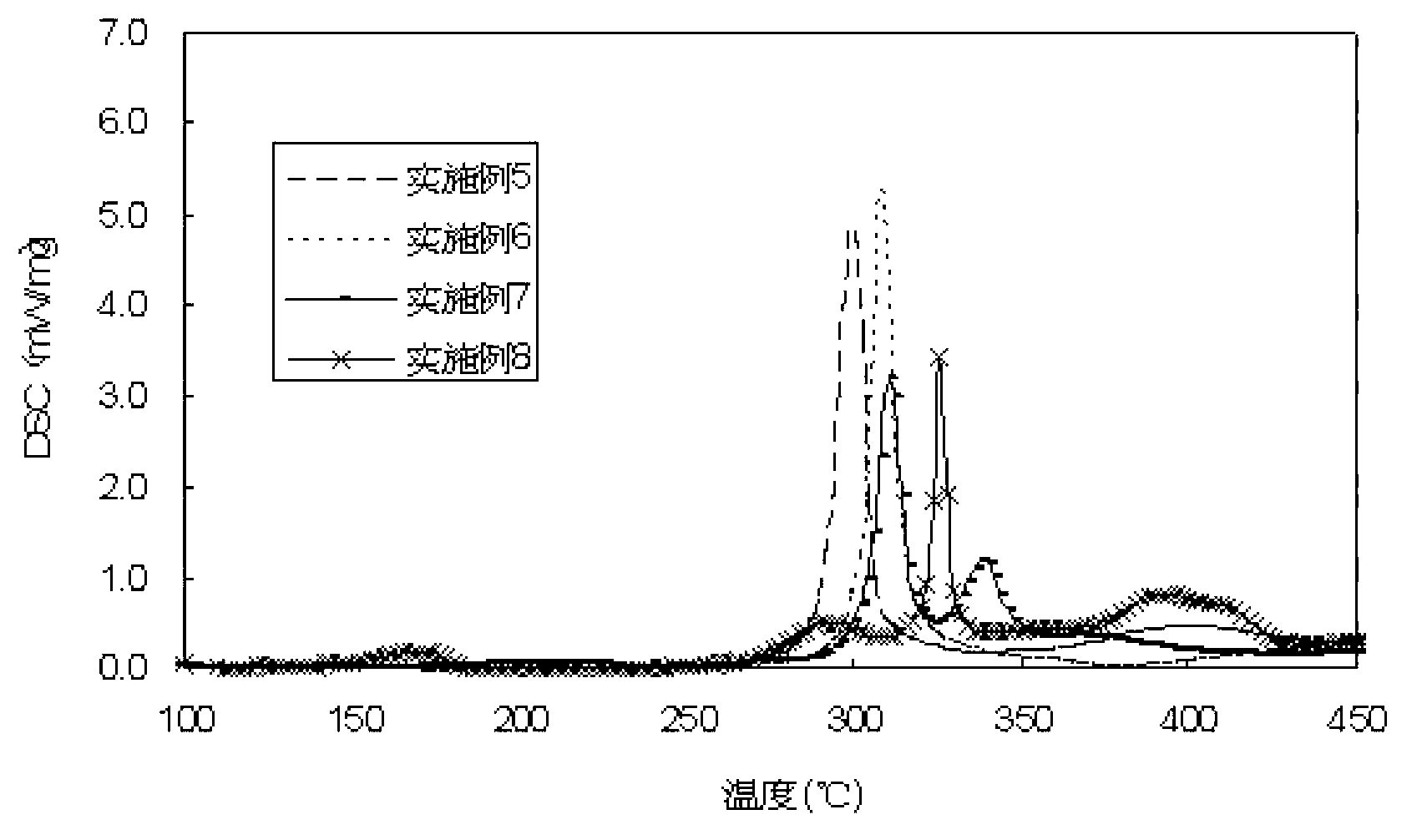

ActiveCN103296249AHigh surface energyImprove adsorption capacityElectrode carriers/collectorsSecondary cellsLithium electrodeOxide

The invention discloses a doped modified lithium nickel cobalt manganese material, a preparation method thereof and a lithium ion battery. A secondary particle of the doped modified lithium nickel cobalt manganese material is composed of a primary particle and is spherical or spherical-like in shape, and the surface of the primary particle is non-uniformly doped with a nano metal oxide layer. In the preparation method, a precursor of the lithium nickel cobalt manganese material is doped with nano metal oxides during a synthesis stage and undergoes doping modification. Compared with the prior art, the doped modified lithium nickel cobalt manganese material is used as an anode activity material of the lithium ion battery, under a charge / discharge condition of 4.45 V, has good circulation and good thermal stability, and can meet requirements of high energy density, high power density, long service life and high safety of the lithium ion battery.

Owner:NINGDE AMPEREX TECH

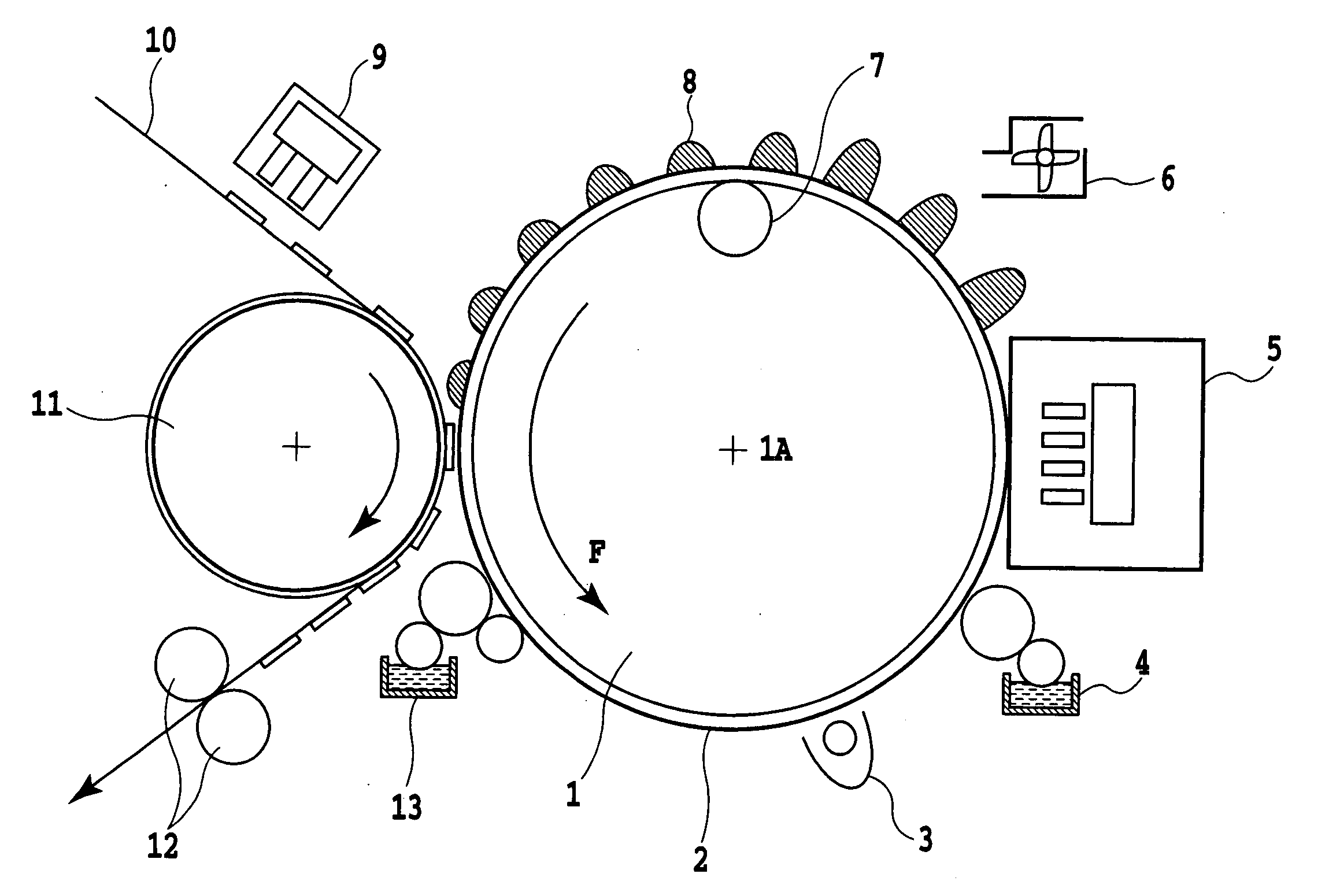

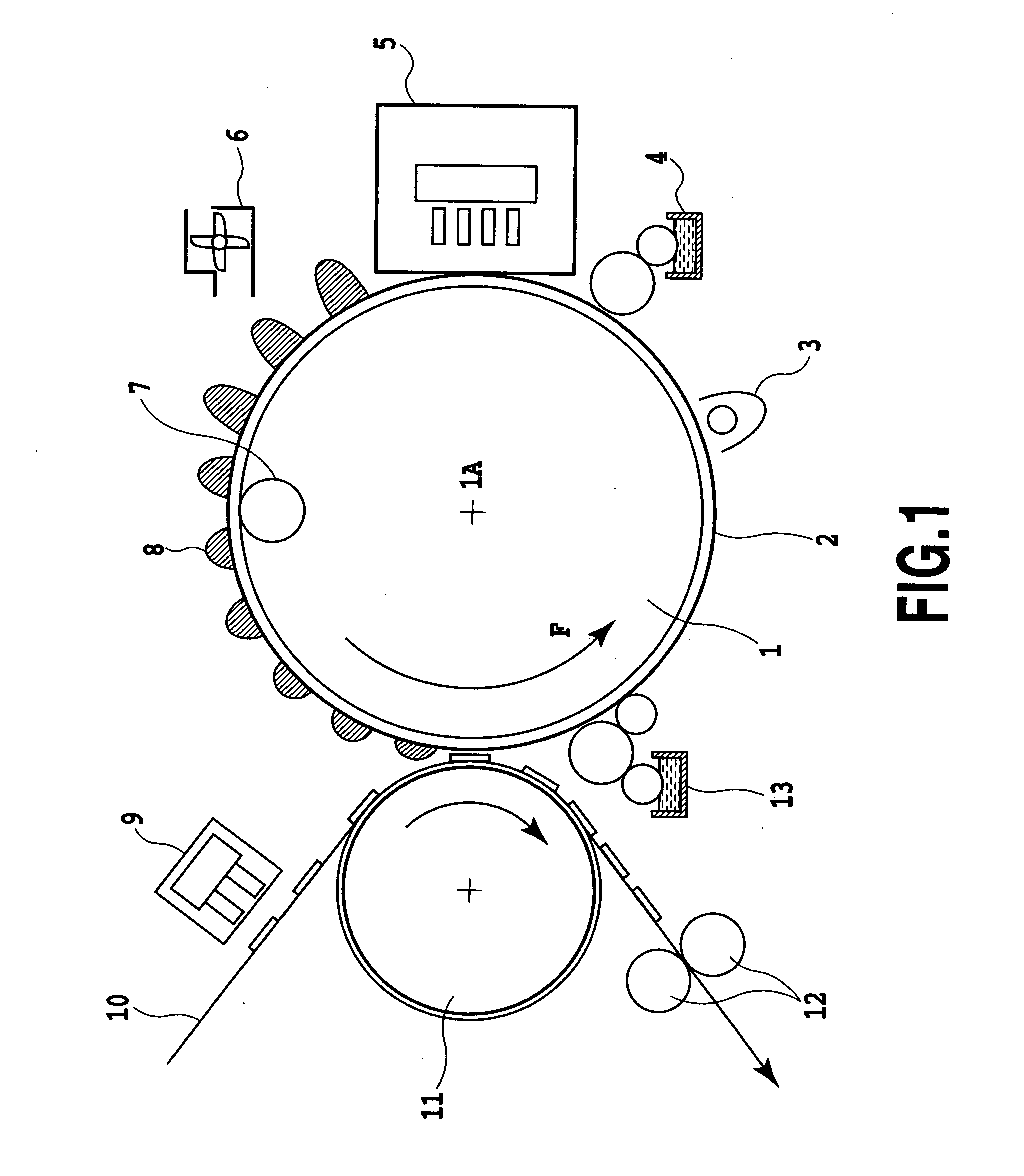

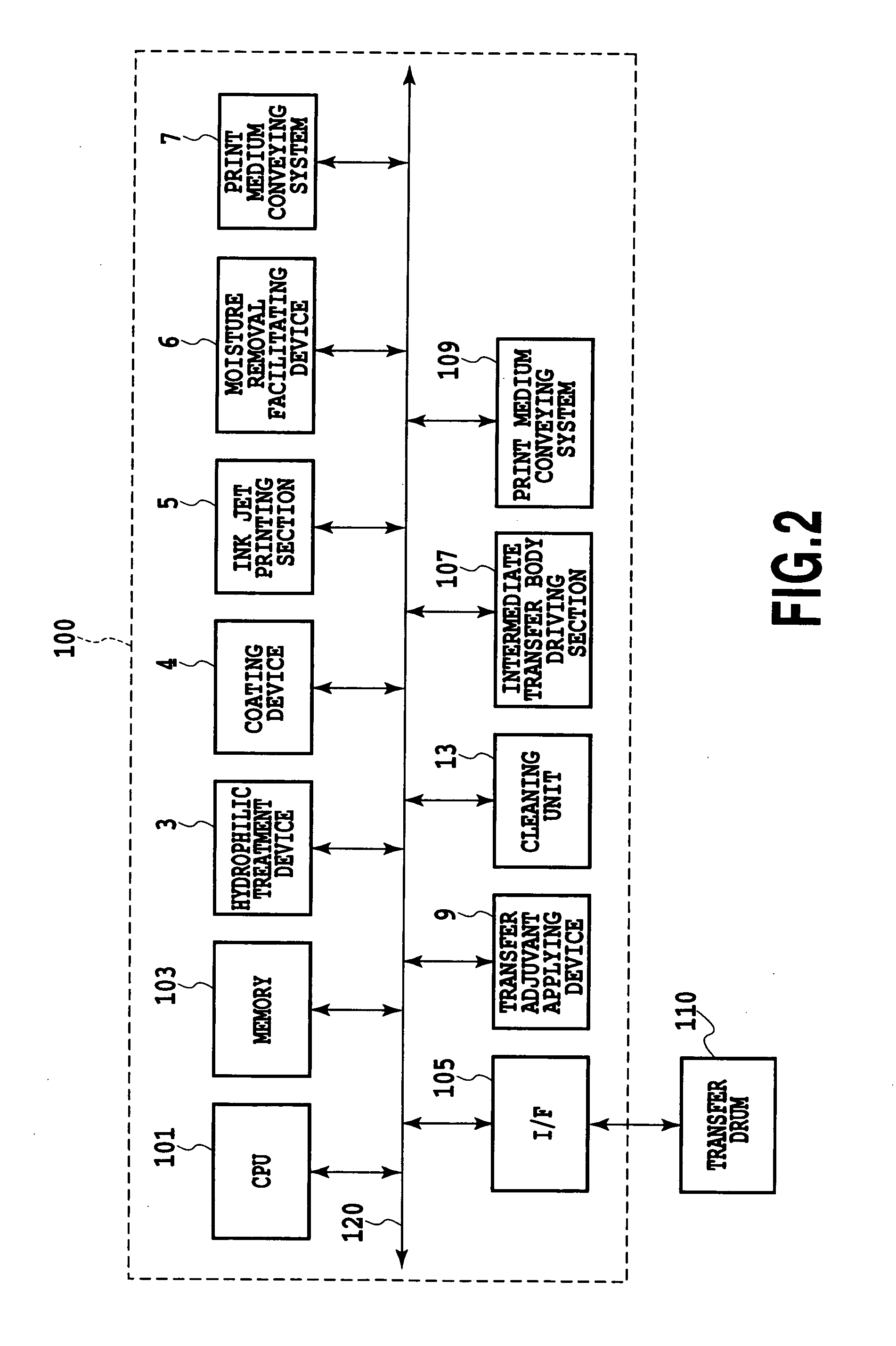

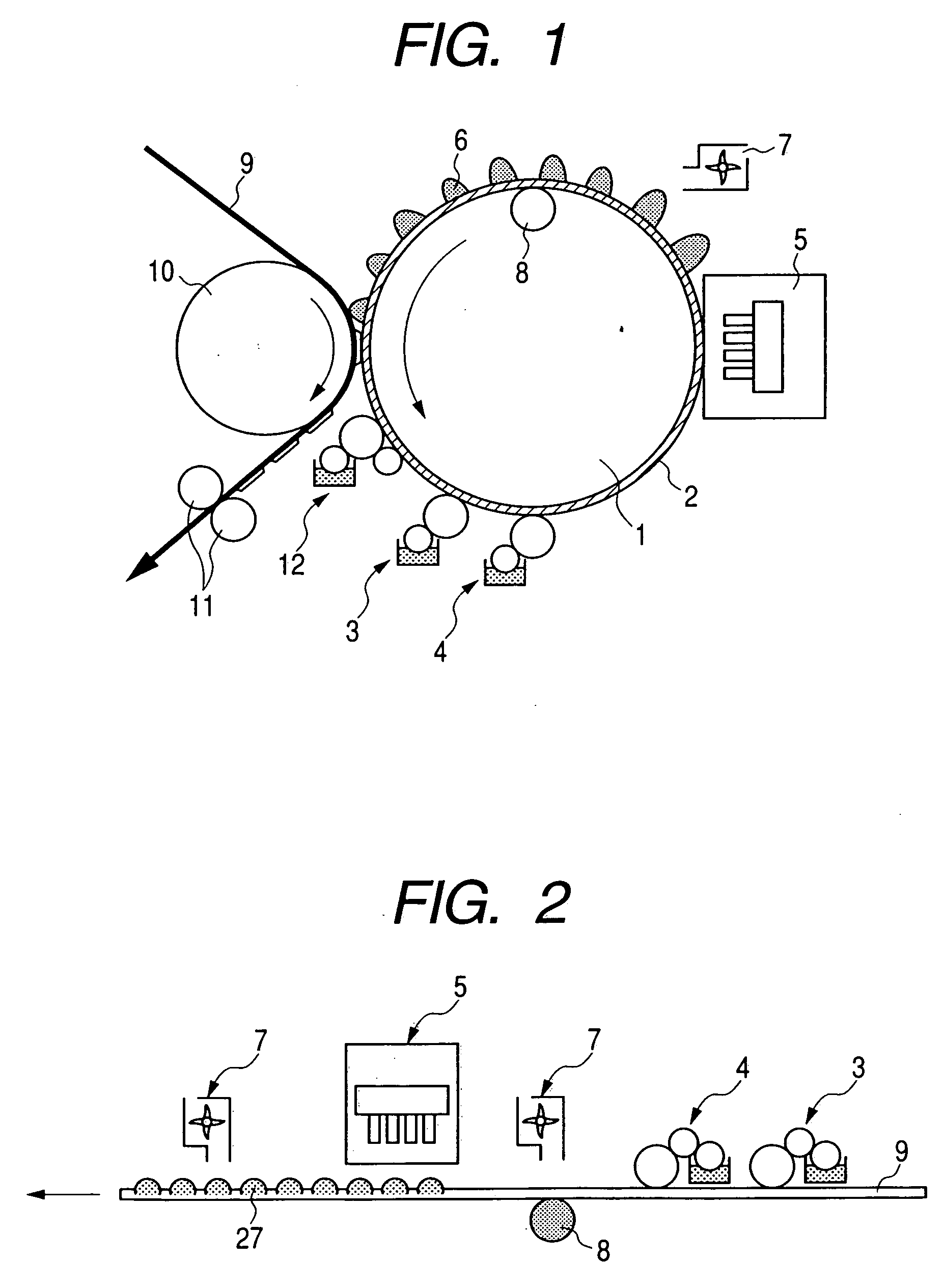

Method and apparatus for forming image

A method and apparatus for forming an image which can form a high-quality image on a great variety of print media regardless of the surface roughness or ink absorptivity of the print medium, without sacrificing the high degree of freedom of the ink jet printing system are provided. An ink jet printing section ejects ink to an intermediate transfer body to form an ink image on the intermediate transfer body. Before the ink image thus obtained is transferred to a print medium, an ink transfer adjuvant is applied to the print medium. Then, the ink image formed on the intermediate transfer body is transferred to the print medium to which the ink transfer adjuvant has been applied.

Owner:CANON KK

Formula and preparation process of alcohol group nanometer composite and surface modified dry powder mold paint

The invention relates to an auxiliary material for casting and moulding, in particular to a formula of alcohol group dry powder mold paint for sand mold casting. The dry powder mold paint comprises surface modifier, suspending agent, binder and refractory powder, wherein the surface modifier is 0.6-4.2wt% of refractory powder, the suspending agent is 4.0-8.0wt% of refractory powder and the binderis 4.0-6.2wt% of refractory powder. The alcohol group nanometer composite and surface modified dry powder mold paint of the invention adopts nanometer layered clay and nano-SiO2 to form composite suspending agent so that the controllability of operation technological parameters of the alcohol group dry powder mold paint is good and the process performance and operating performance of the obtainedpulp-type paint can both meet the demand of the casting factory.

Owner:深圳市景鼎现代科技有限公司

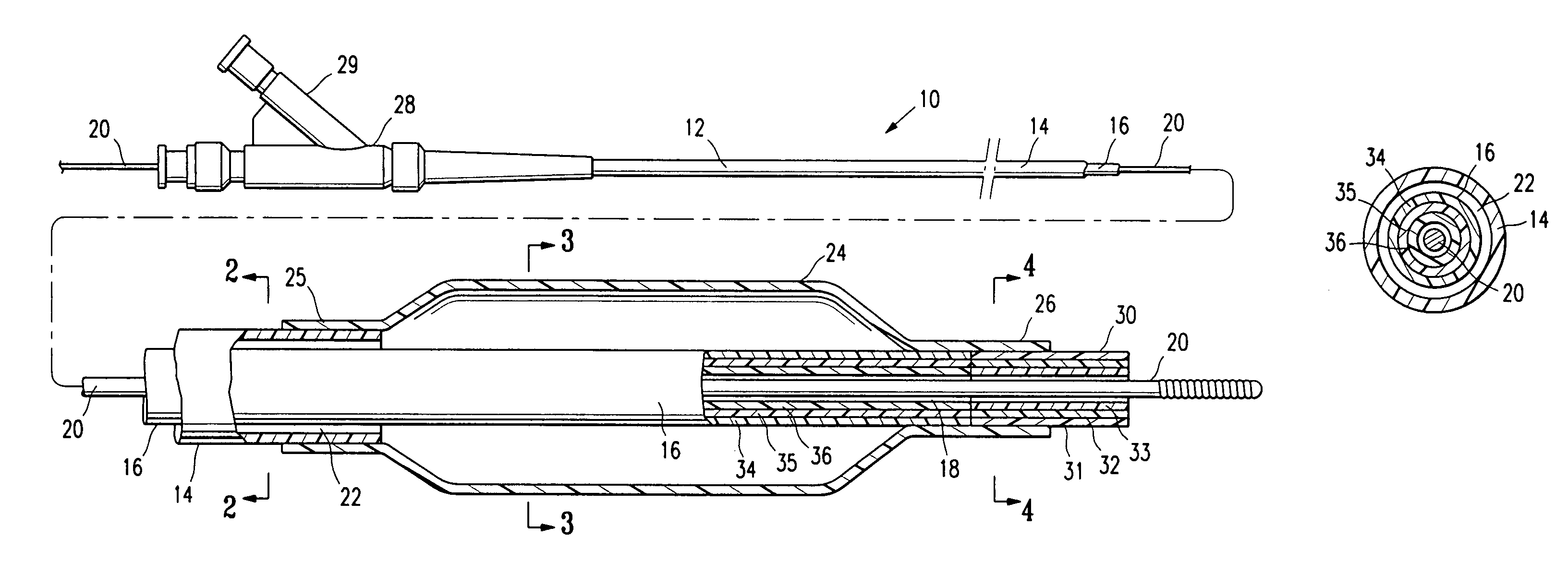

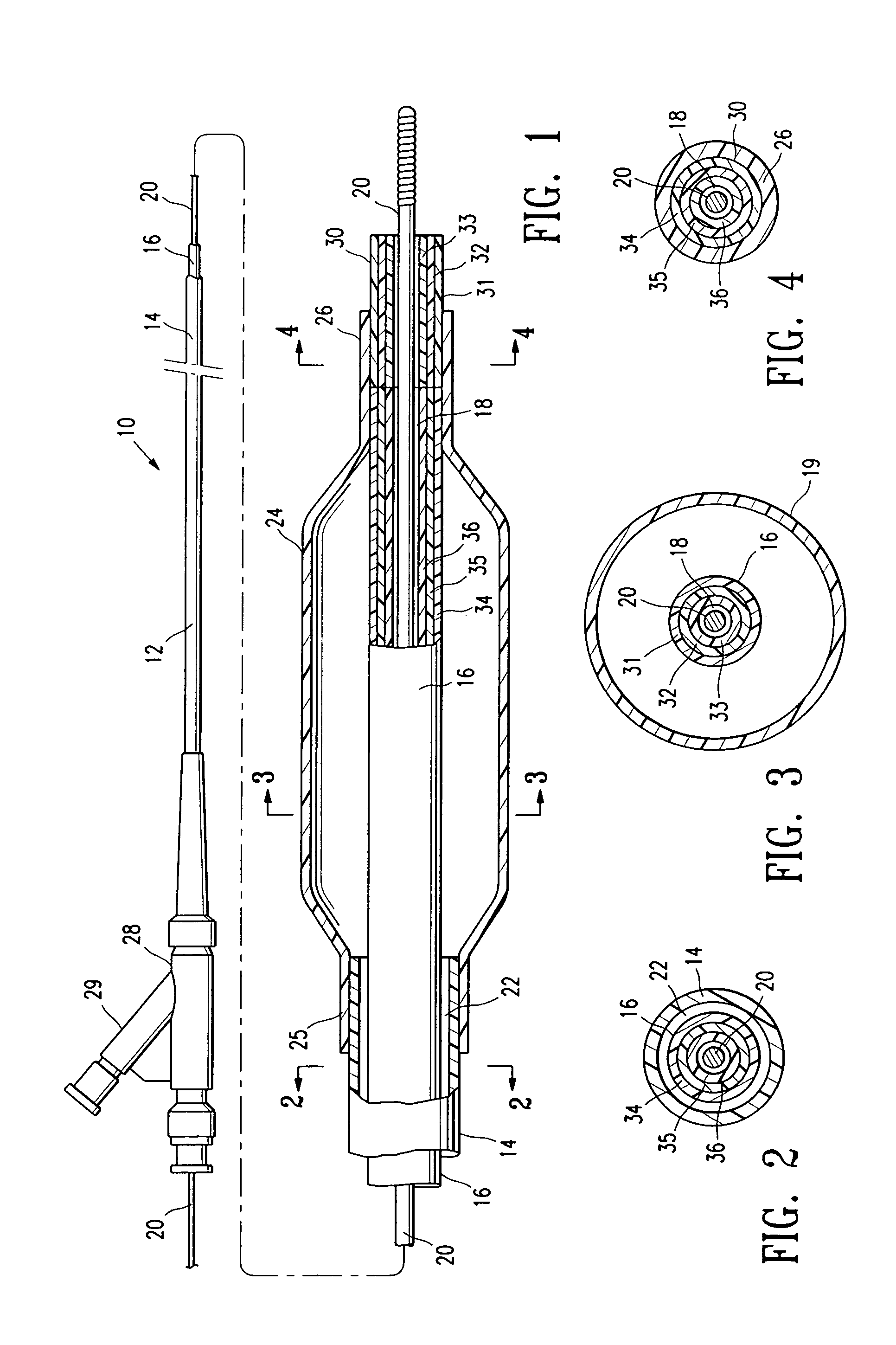

Balloon catheter having a multilayered distal tip

ActiveUS7341571B1Reduce coefficient of frictionDrag minimizationBalloon catheterSurgeryBalloon catheterBlood coagulations

A catheter having a distal tip with an inner layer formed of a polymeric material having a coefficient of friction and surface energy which are relatively low, such that the inner layer has a lubricious, non-polar inner surface repulsive to polar liquids. As a result, blood coagulation in the distal tip, and adherence of the distal tip on the guidewire are prevented or minimized.

Owner:ABBOTT CARDIOVASCULAR

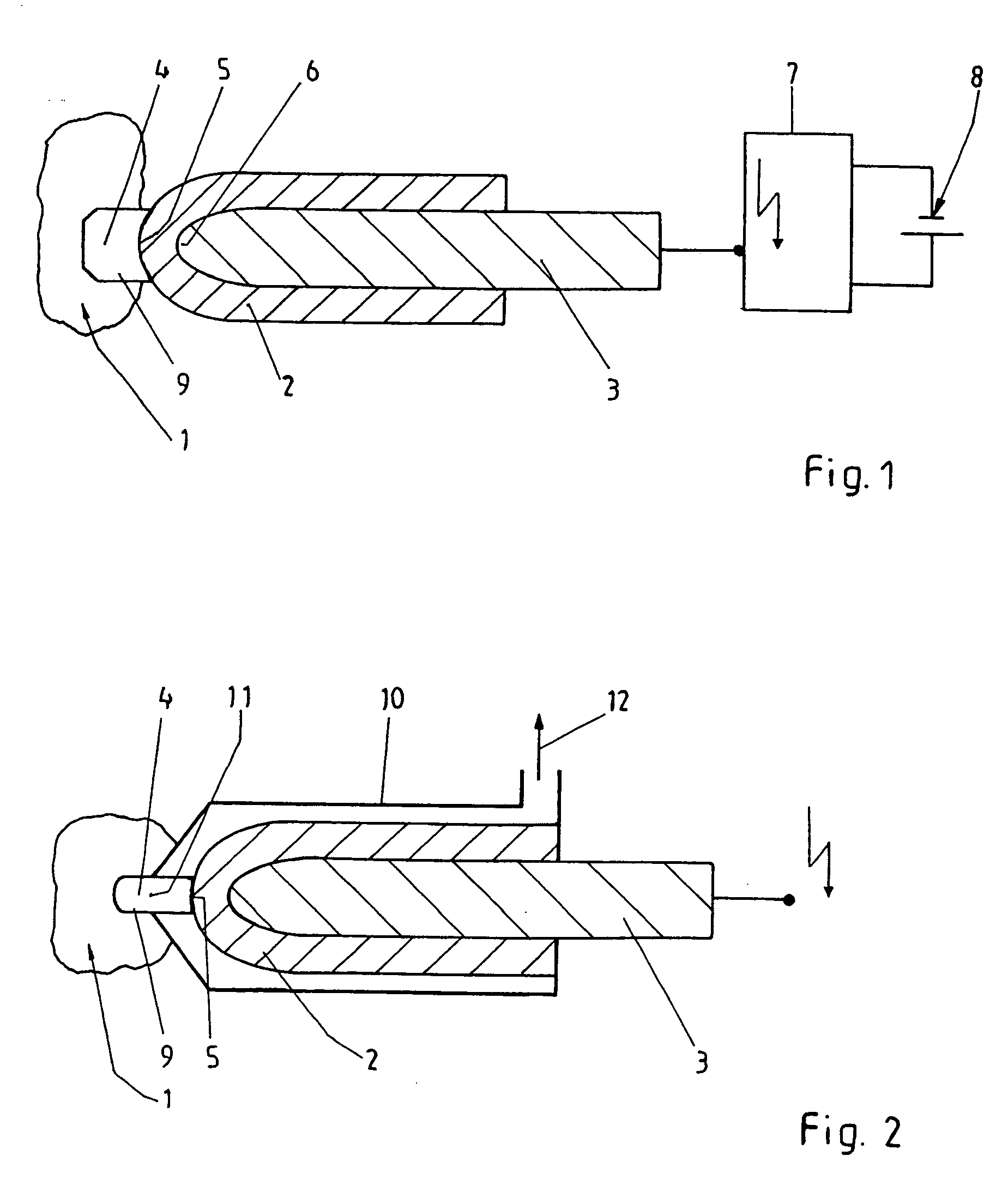

Treatment of biological material containing living cells using a plasma generated by a gas discharge

ActiveUS20060084158A1Sure easyHigh surface energyMicroorganismsMedical devicesDielectricElectrical polarity

In order to treat a biological material (1) containing living cells with a plasma (4) generated by a gas discharge at atmospheric pressure (9) an electrode (3) is arranged at a distance to the biological material (1). Further, a solid body dielectric (2) is arranged between the electrode (3) and the biological material (1), directly in front of the electrode (3) and at a distance to the biological material (1). Then a high alternating voltage consisting of separated high voltage pulses of alternating polarity is applied to the electrode (3) for igniting and maintaining a dielectric barrier gas discharge within a region between the dielectric (2) and the biological material (1).

Owner:MEDIA CART HLDG +1

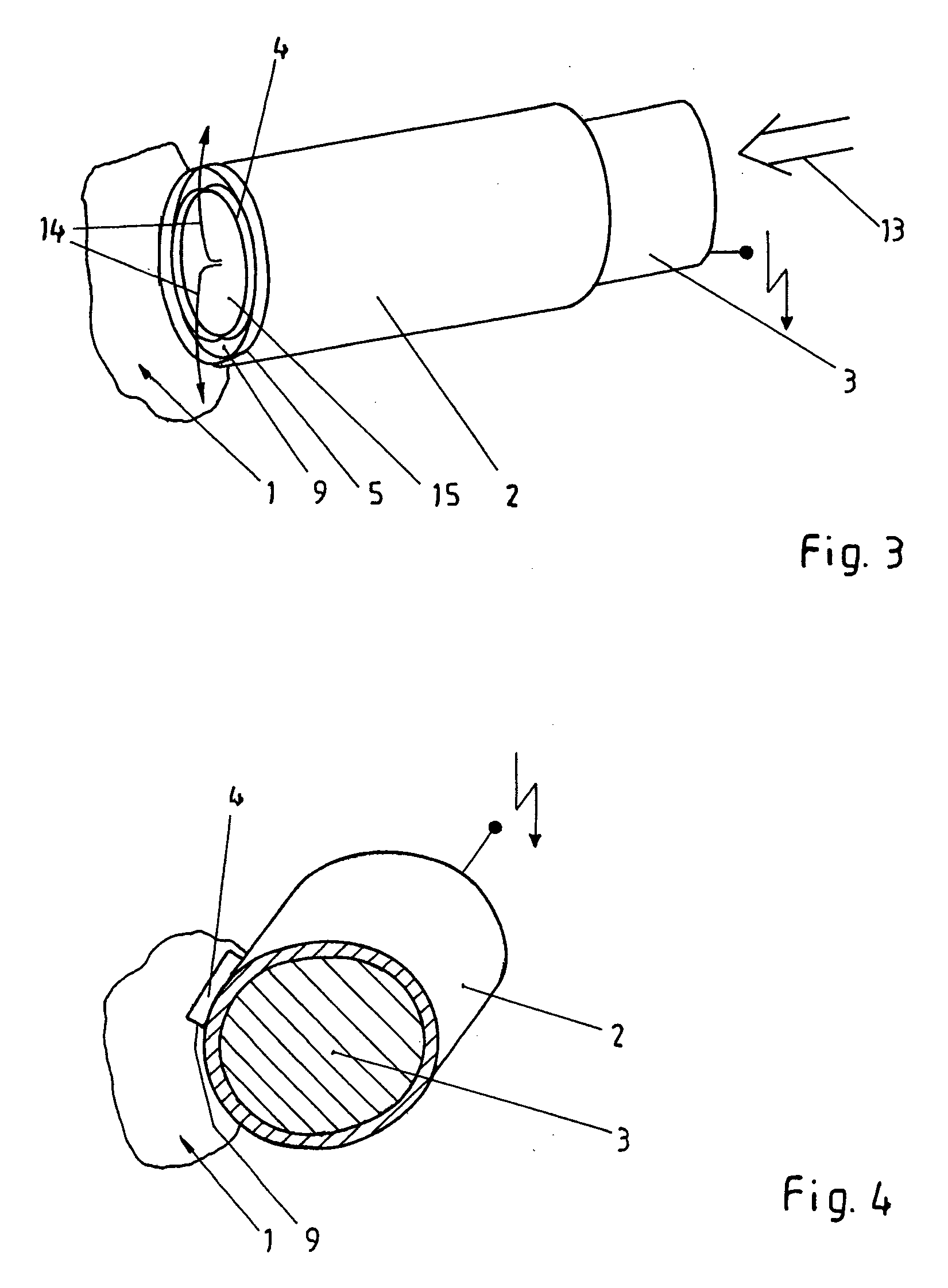

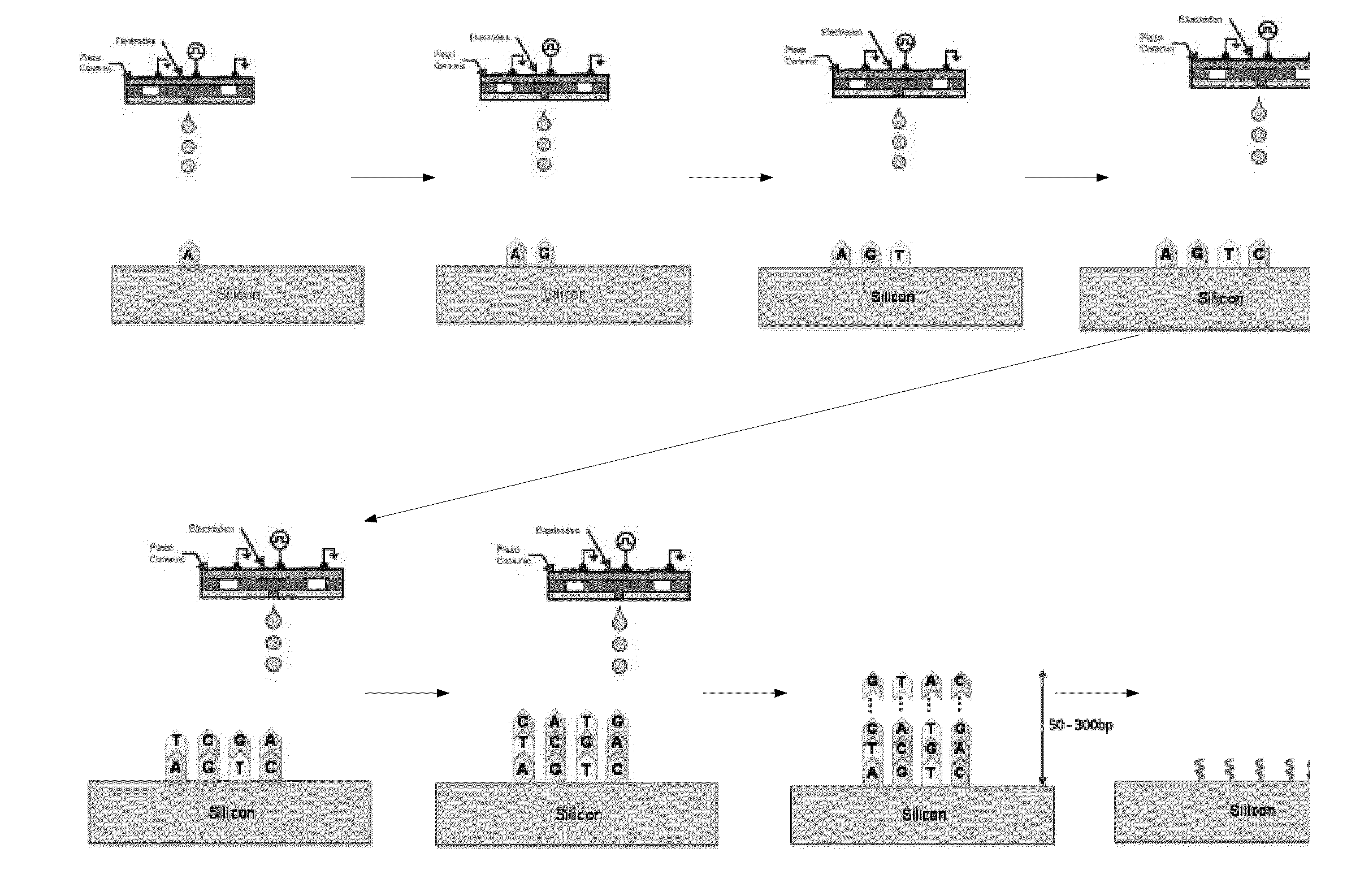

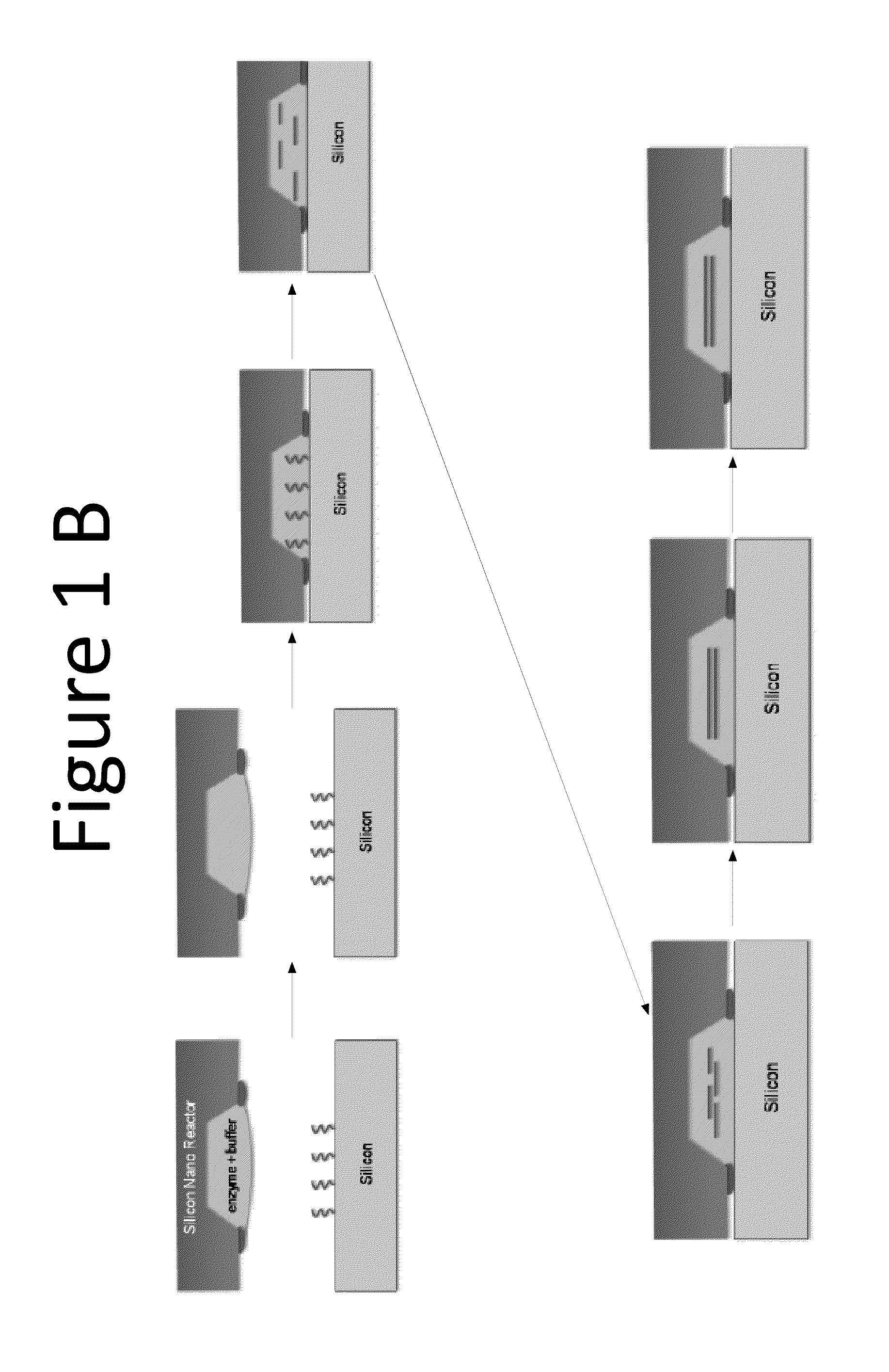

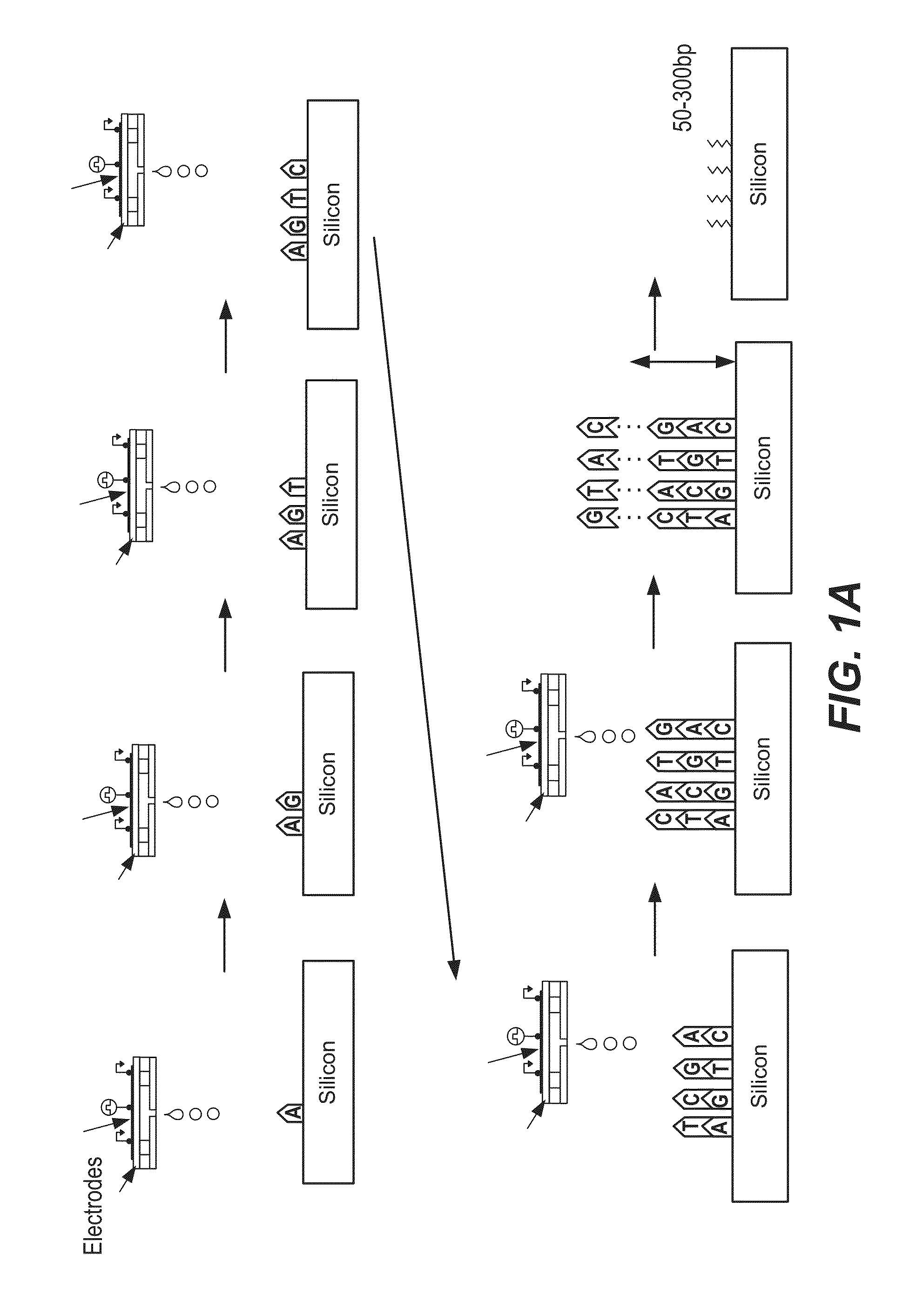

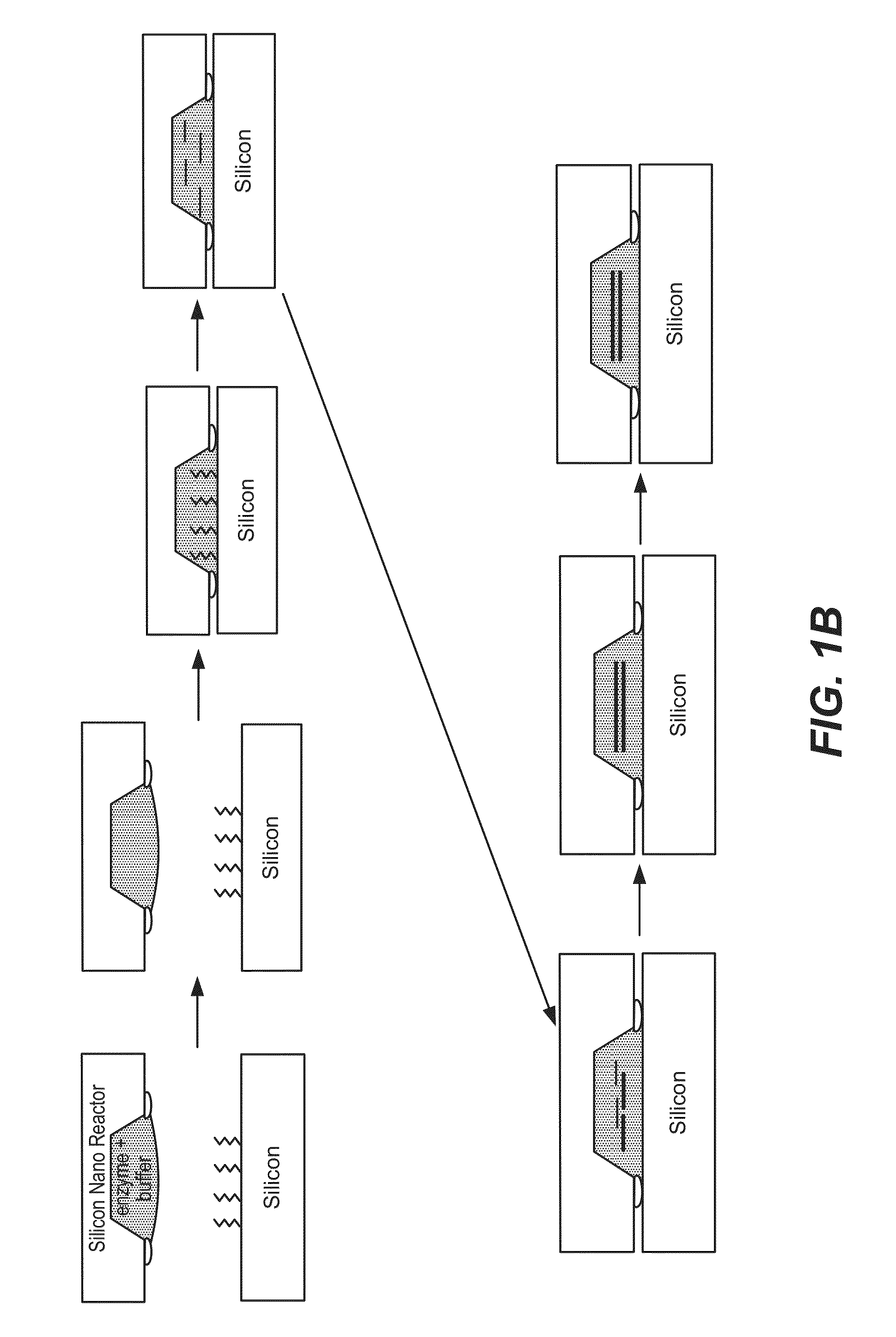

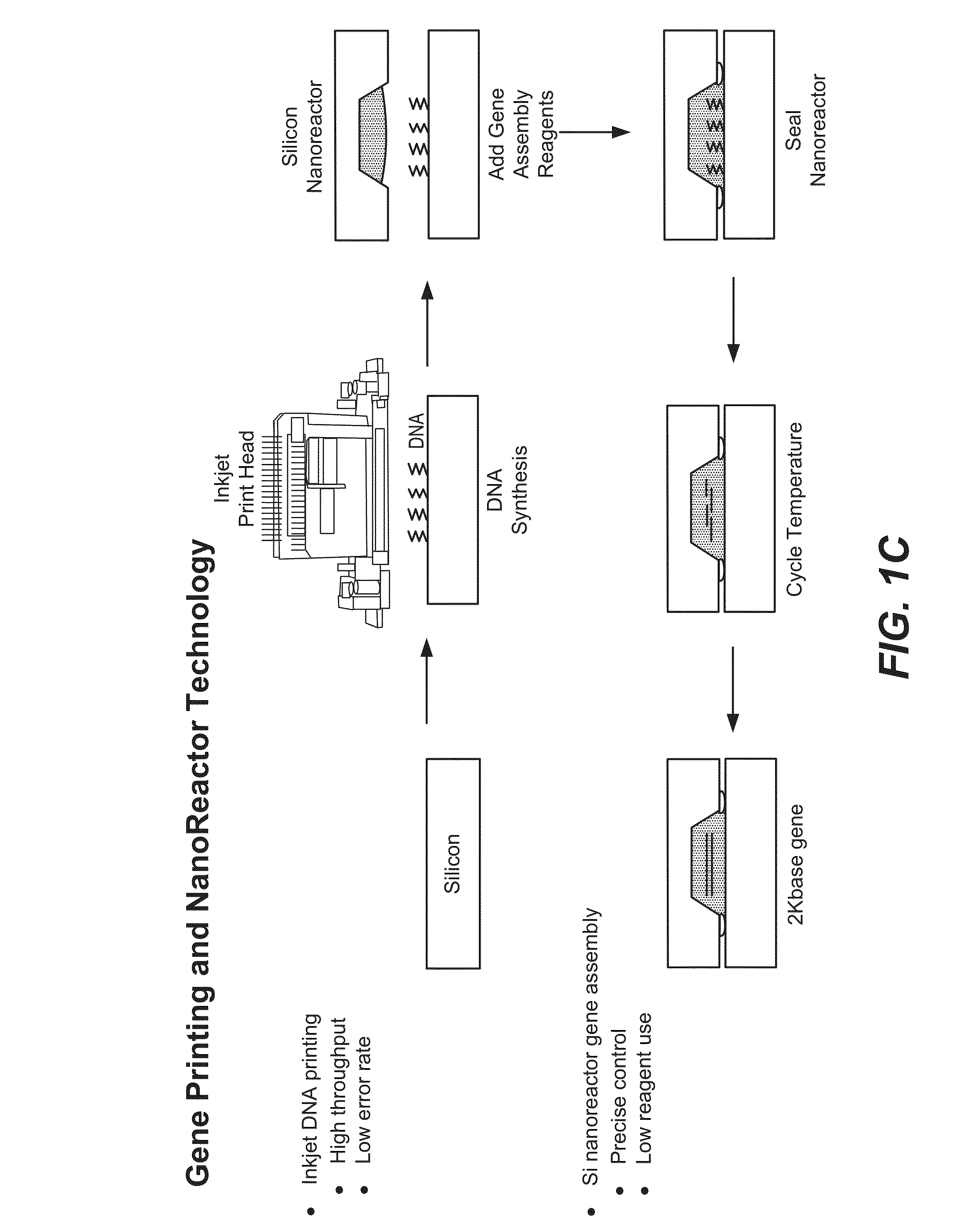

De novo synthesized gene libraries

ActiveUS20150038373A1Less errorHigh surface energySequential/parallel process reactionsMicrobiological testing/measurementOligonucleotideDe novo synthesis

Owner:TWIST BIOSCI

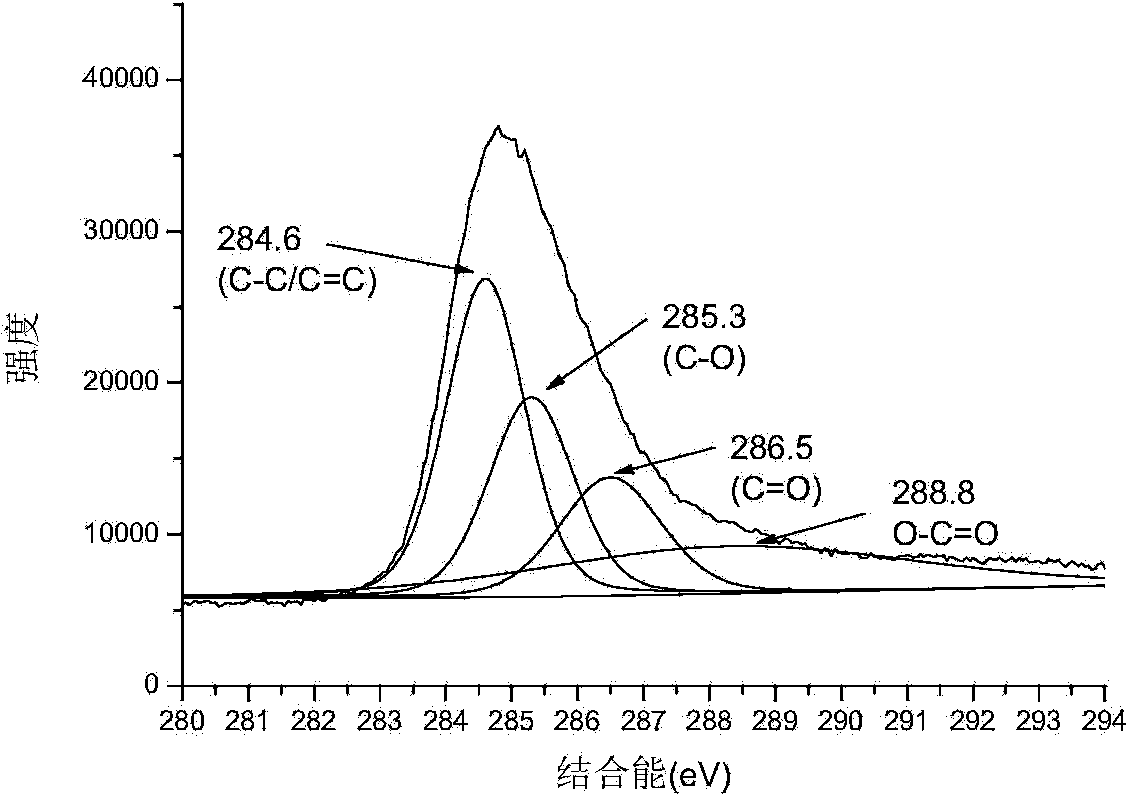

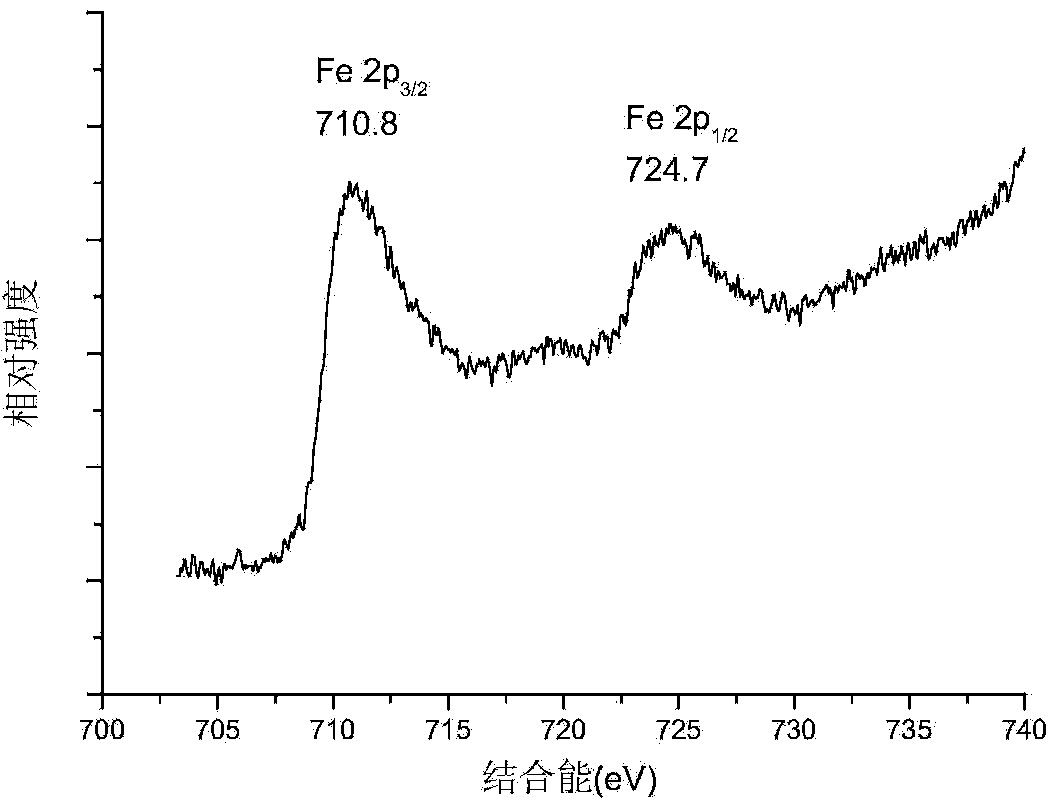

Polyaniline/oxidized graphene/ferriferrous oxide absorbing material and preparation method

InactiveCN104163919AStrong dielectric loss performanceHigh surface energyMaterials preparationTernary complex

The invention belongs to the field of electromagnetic wave absorbing material preparation and relates to a polyaniline / oxidized graphene / ferriferrous oxide composite material and its preparation method. The preparation method comprises the following steps: (1) preparing graphite oxide; (2) preparing ferriferrous oxide nanoparticles; (3) preparing a polyaniline / oxidized graphene / ferriferrous oxide ternary complex; and (4) weighing the polyaniline / oxidized graphene / ferriferrous oxide ternary complex and paraffin, and uniformly mixing to obtain the polyaniline / oxidized graphene / ferriferrous oxide absorbing material. The material provided by the invention has characteristics of low cost, simple preparation technology, strong electromagnetic wave absorbing capability, wide absorption band, low density and the like, has good electromagnetic property, and has important application value in the field of microwave absorption and electromagnetic shielding.

Owner:UNIV OF SCI & TECH BEIJING

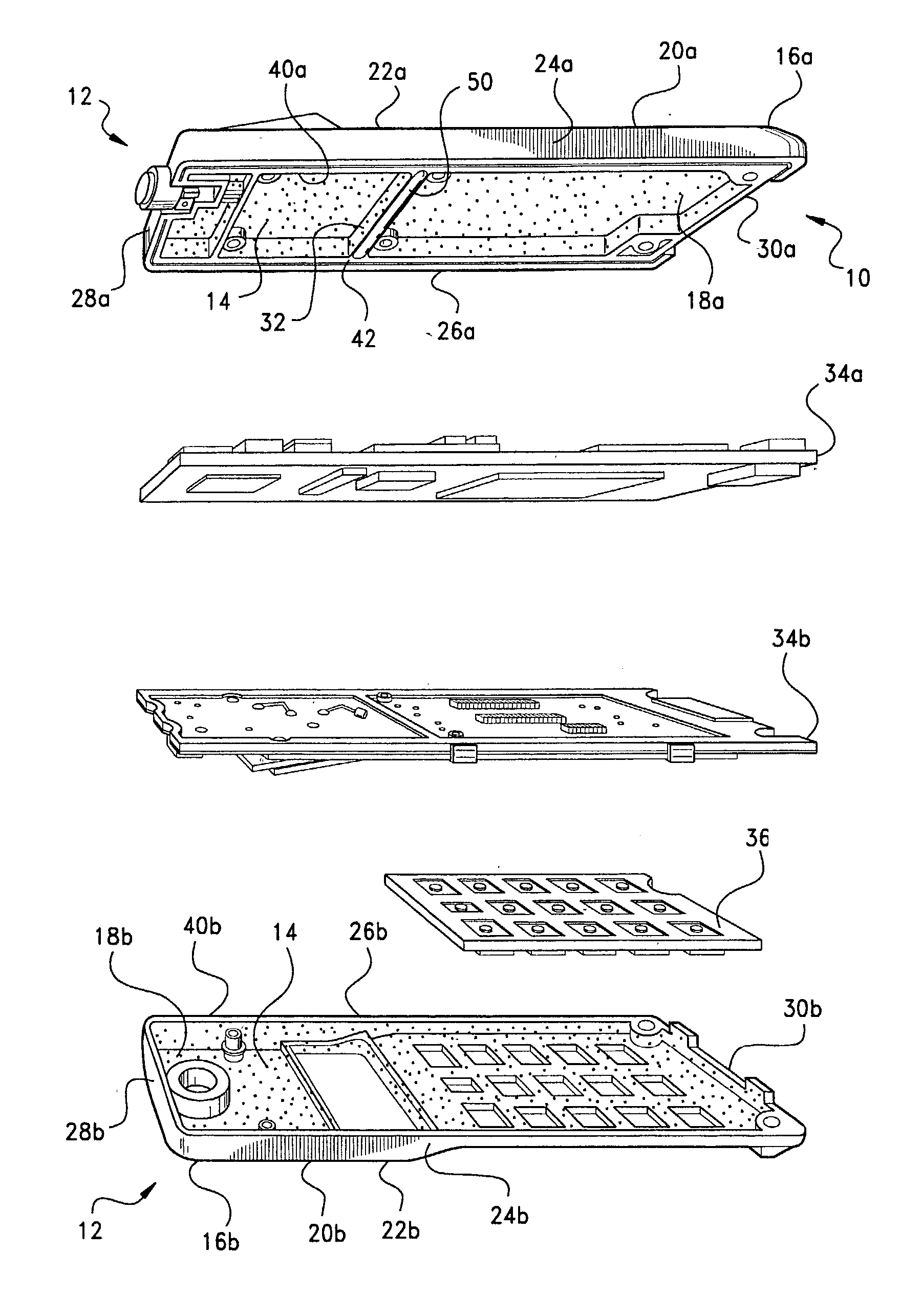

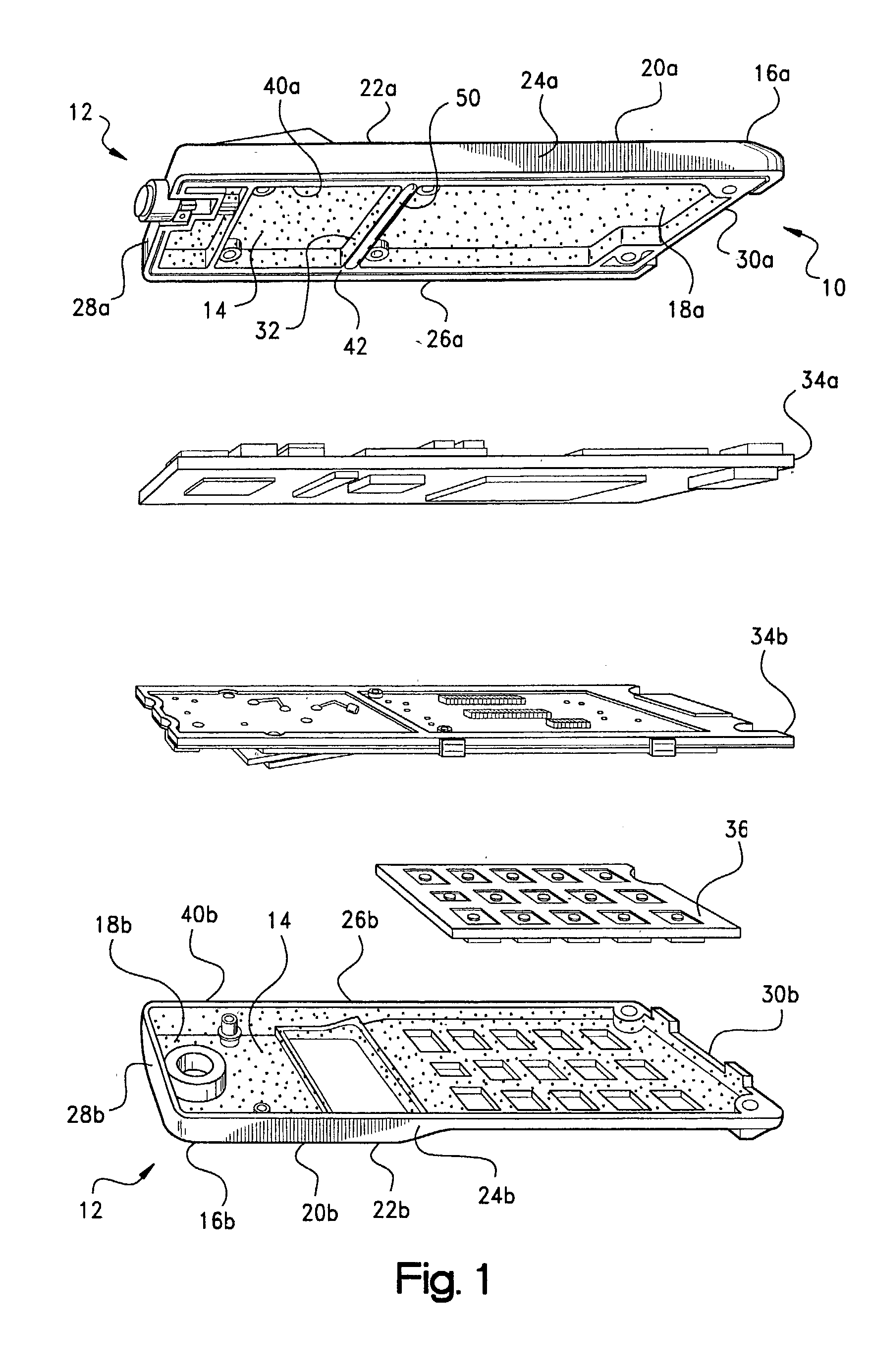

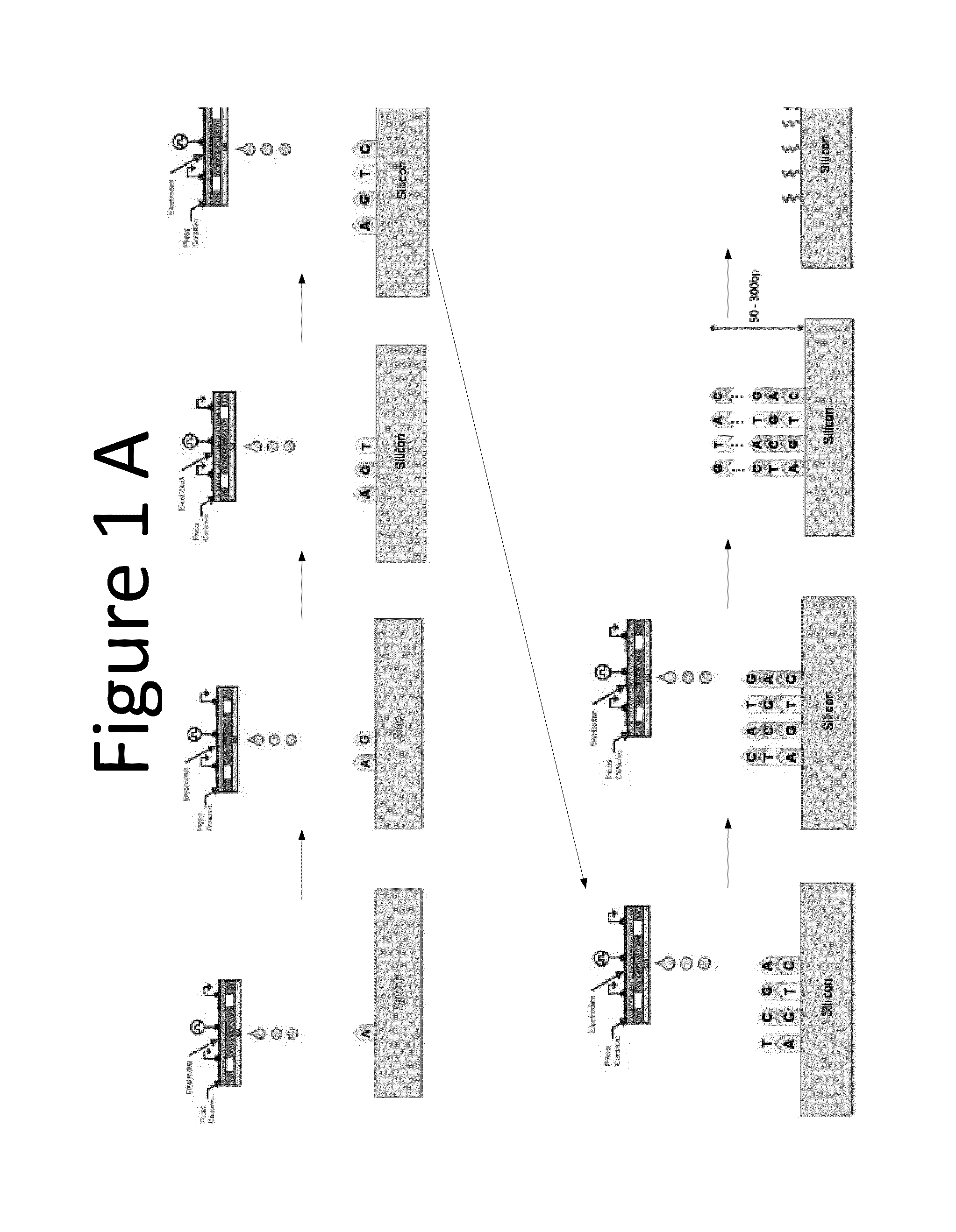

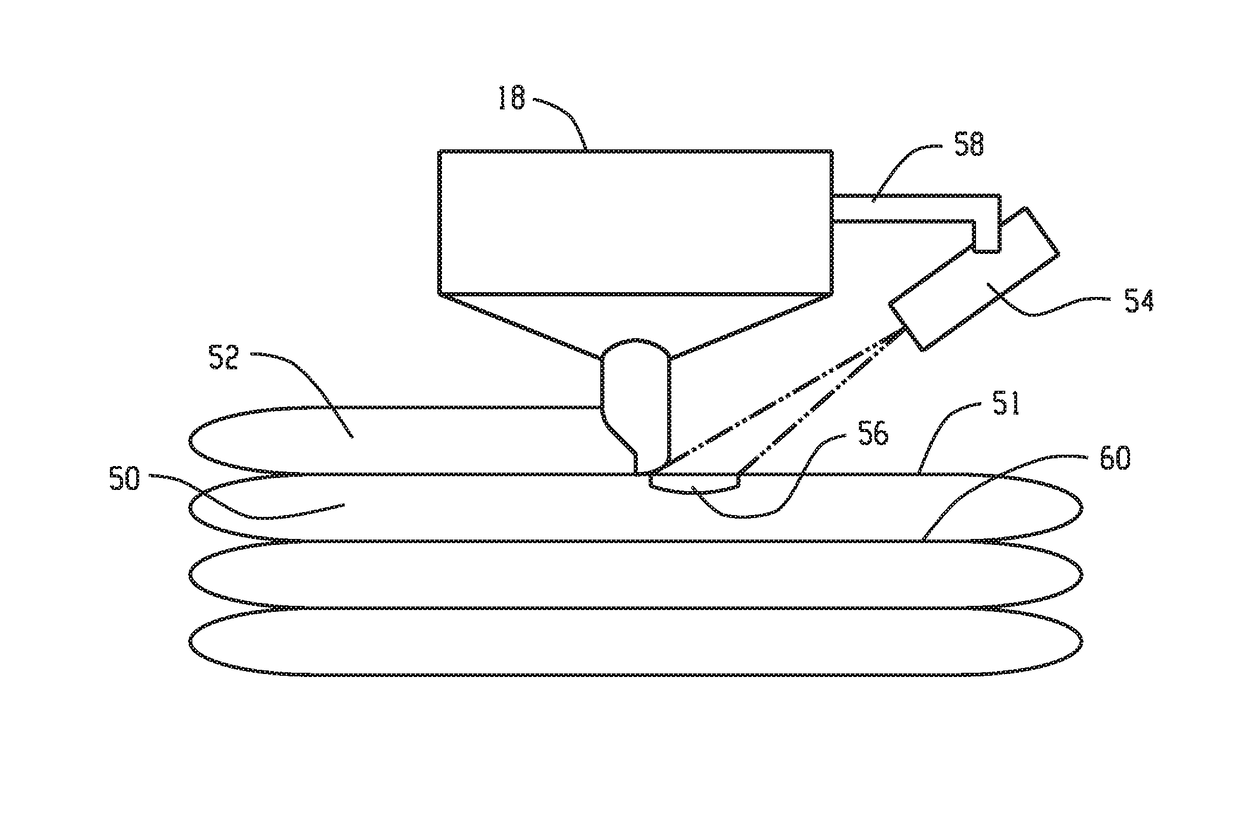

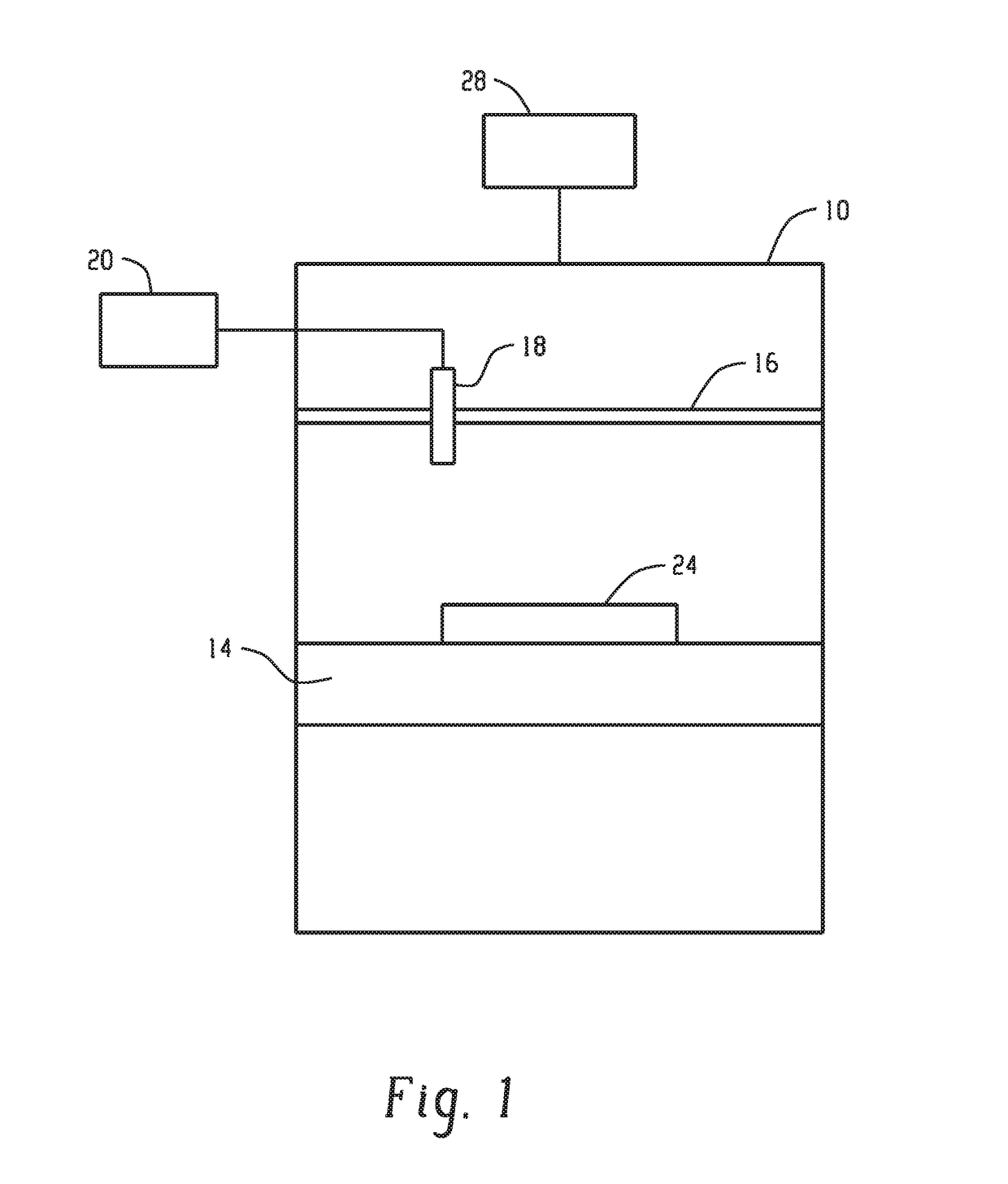

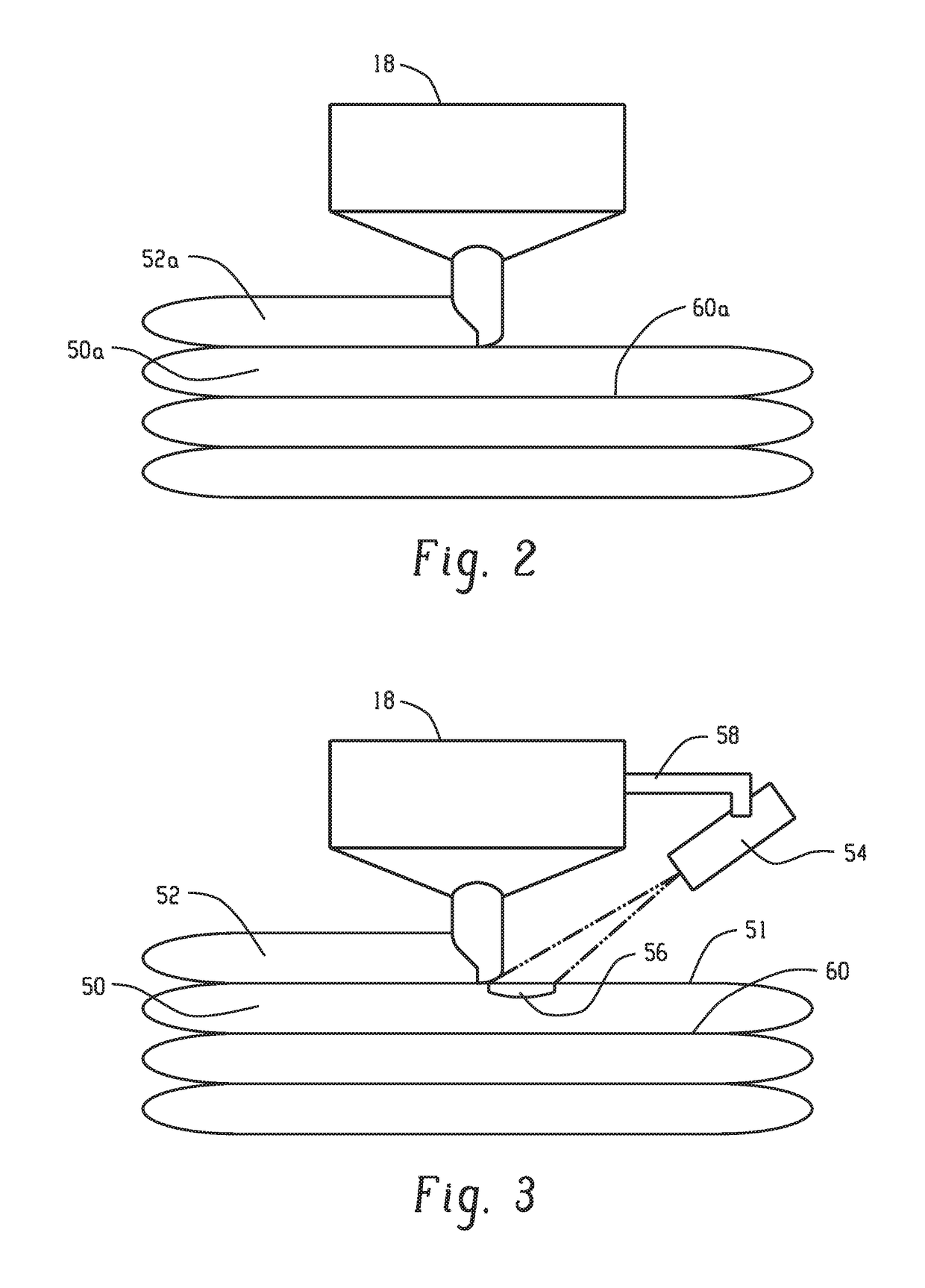

Method and apparatus for increasing bonding in material extrusion additive manufacturing

InactiveUS20170157845A1High surface energyAdditive manufacturing with liquids3D object support structuresEngineeringEnergy source

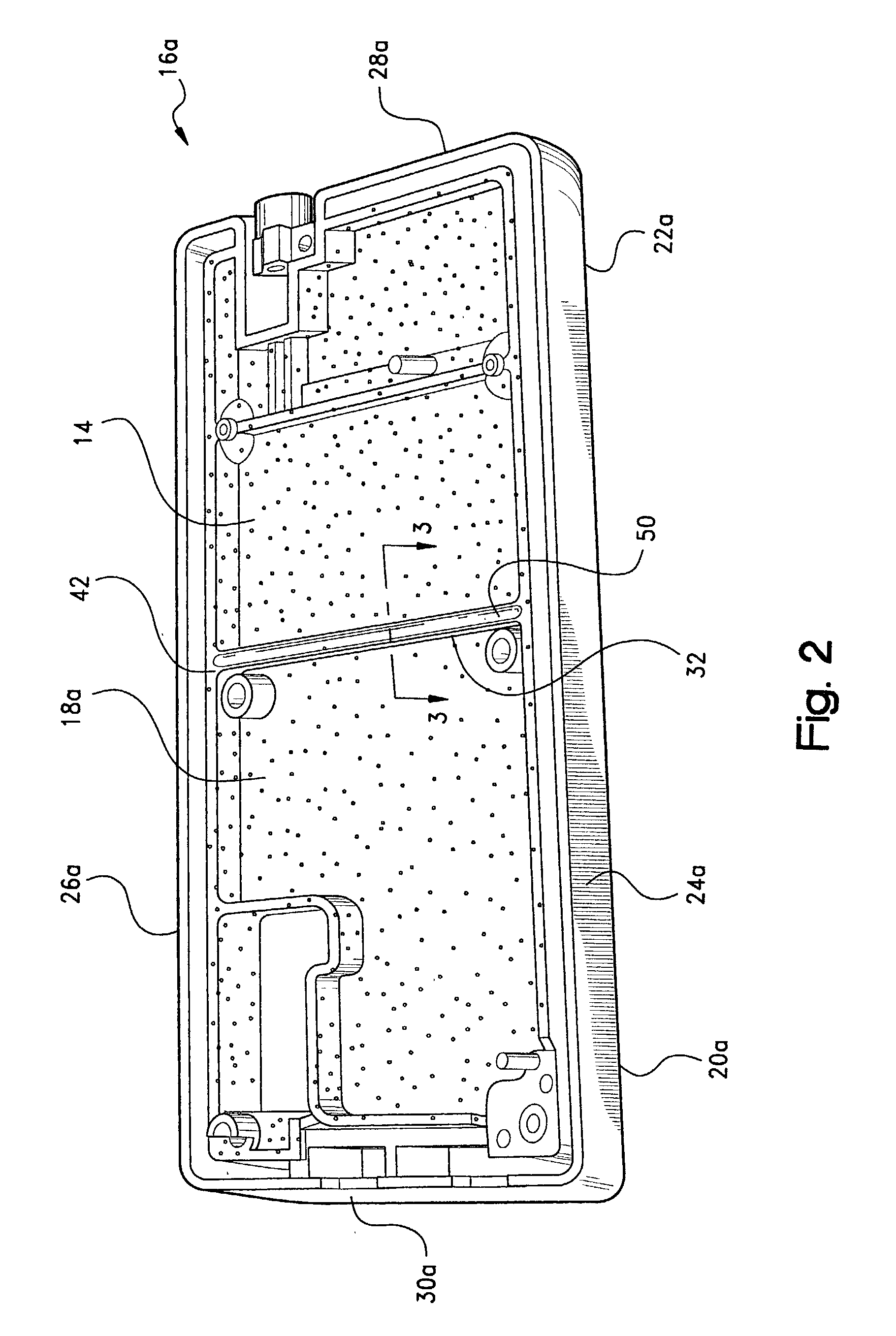

A method of forming a three dimensional object comprising: depositing a layer of thermoplastic polymeric material in a preset pattern on a platform (14) to form a deposited layer (50); directing an energy source (54), via an energy beam at an energy source target area (56) on the deposited layer (50) to increase the surface energy of the deposited layer at the energy source target area; contacting the energy source target area (56) with a subsequent layer (52) wherein the subsequent layer (52) is deposited along a path of the preset pattern; wherein directing an energy source (54) at the energy source target area (56) comprises applying energy to the layer at an area preceding the depositing of the subsequent layer to that area; and repeating the preceding steps to form the three dimensional object.

Owner:SABIC GLOBAL TECH BV

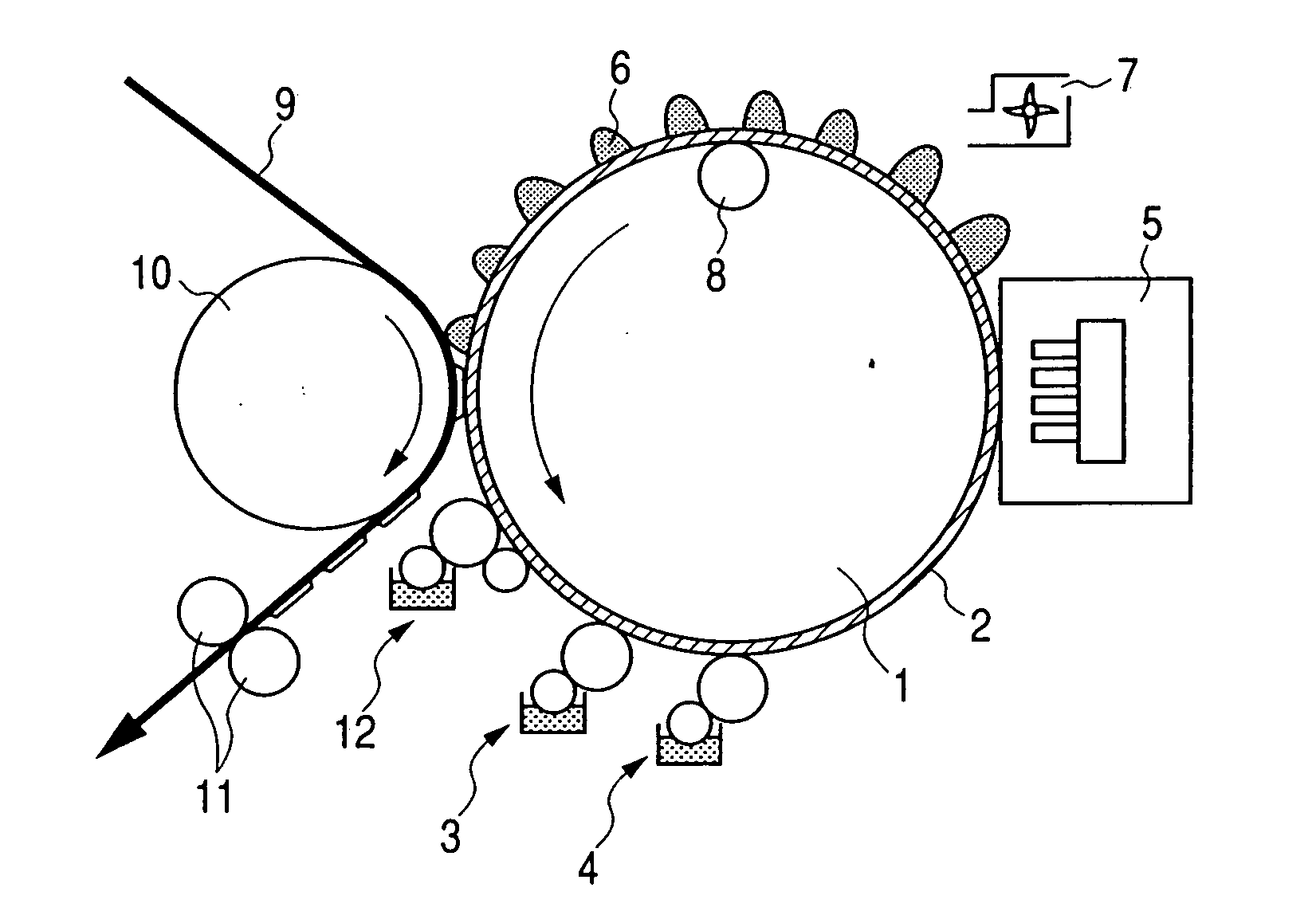

Image forming process and image forming apparatus

InactiveUS20060164488A1High recording flexibility of recordingImprove surface wettabilityMeasurement apparatus componentsDecorative surface effectsImage formationComputer science

Disclosed herein is an image forming process comprising the steps of applying a first material for improving the wettability of the surface of an intermediate transfer medium to the intermediate transfer medium, applying a second material for lowering the flowability of an ink to the intermediate transfer medium to which the first material has been applied, applying the ink to the intermediate transfer medium, to which the first material and second material have been applied, from an ink-jet recording head to form an image of the ink on the intermediate transfer medium, and transferring the ink image formed to a recording medium.

Owner:CANON KK

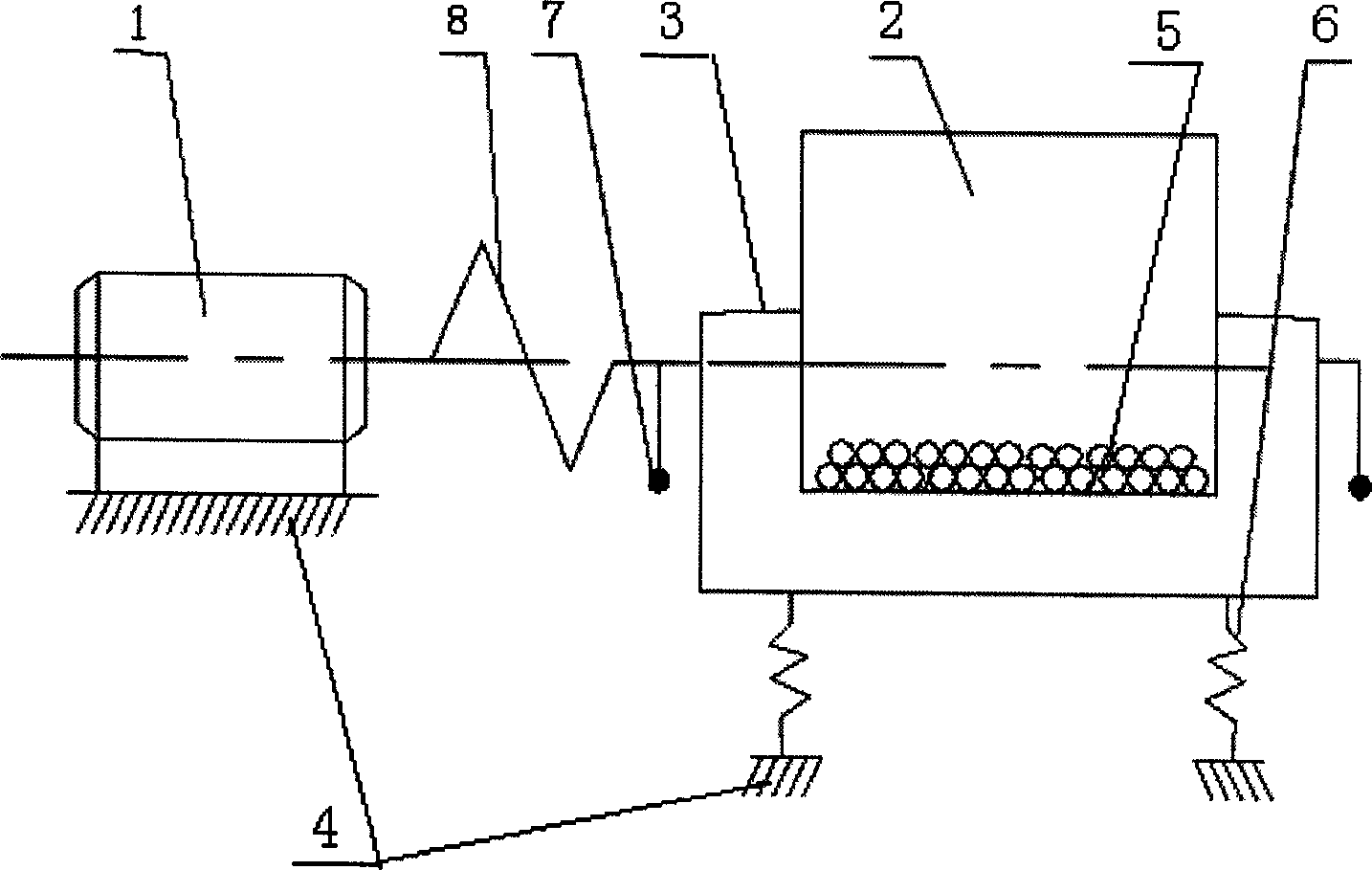

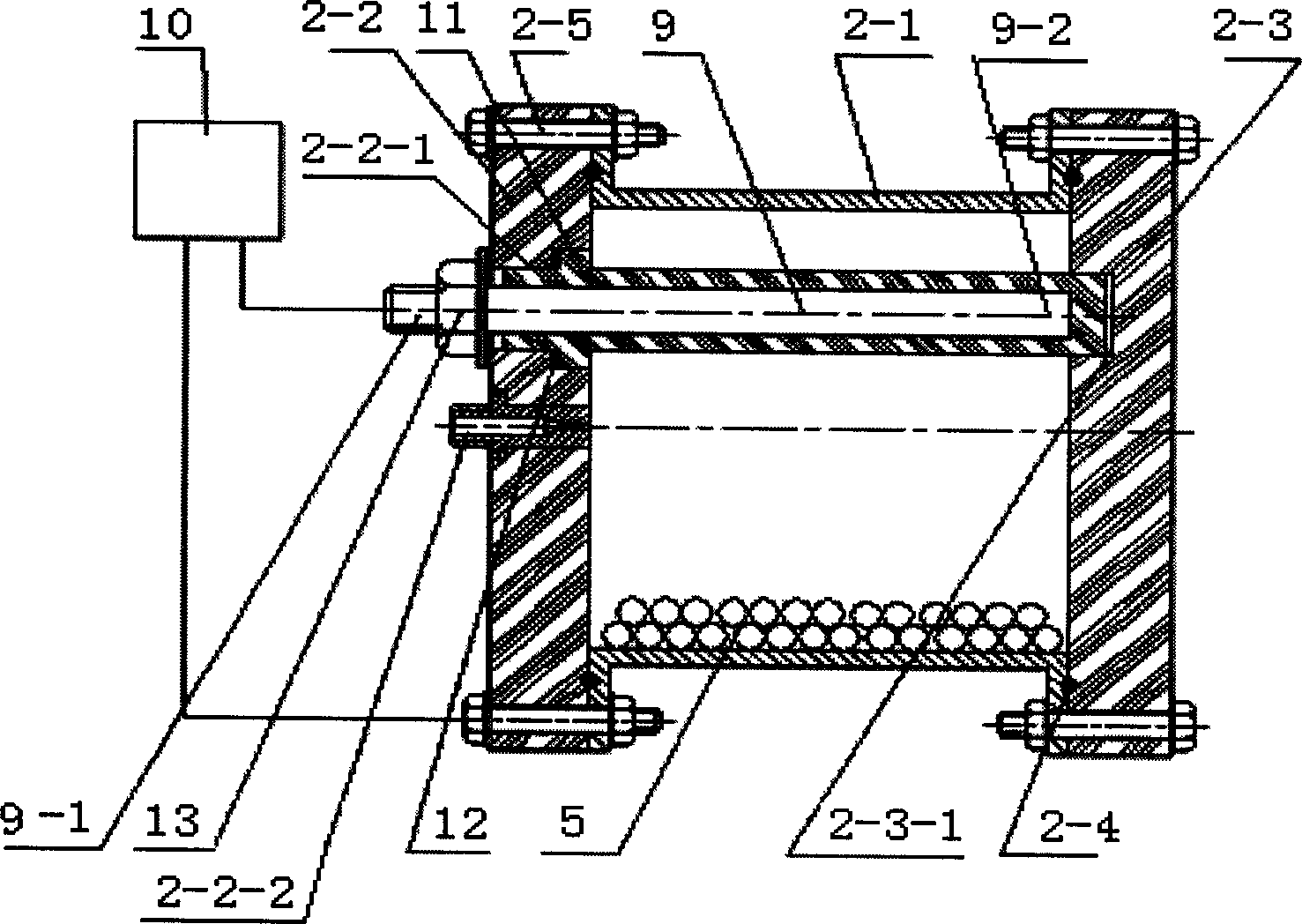

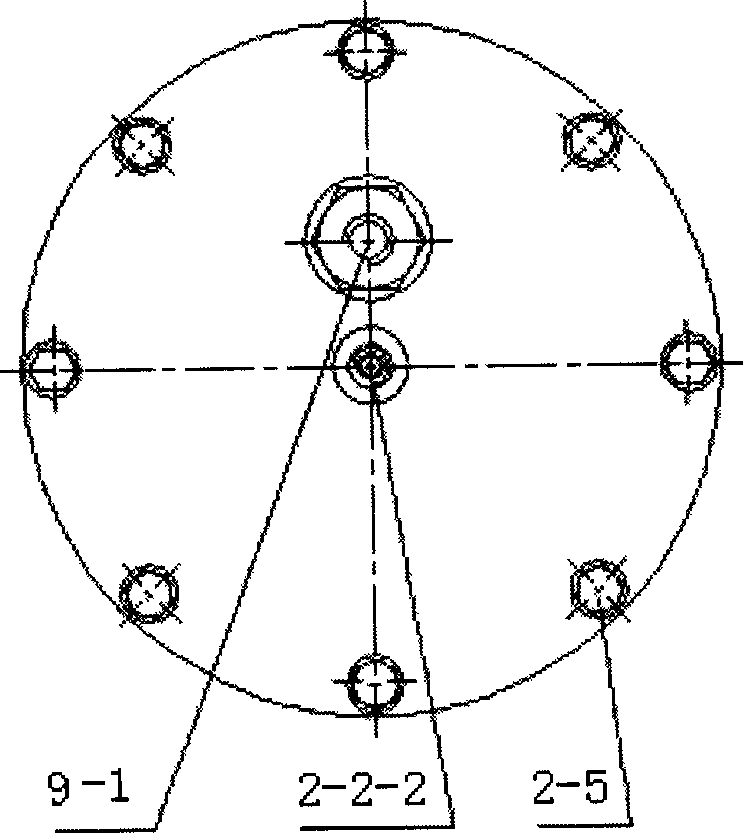

High energy ball mill method with plasma aid

A plasma aided high-energy ball grinding method includes such steps as installing the front cover plate and rod electrode of ball grinder, respectively connecting the ball grinder and rod electrode to the poles of plasma power supply, loading the powder to be ground in the ball grinder, pumping negative pressure, filling discharging gas medium, turning on the plasma power supply, regulating discharge parameters for corona discharge or glow discharge, and turning on the motor to drive the vibration exciting block for ball grinding.

Owner:SOUTH CHINA UNIV OF TECH

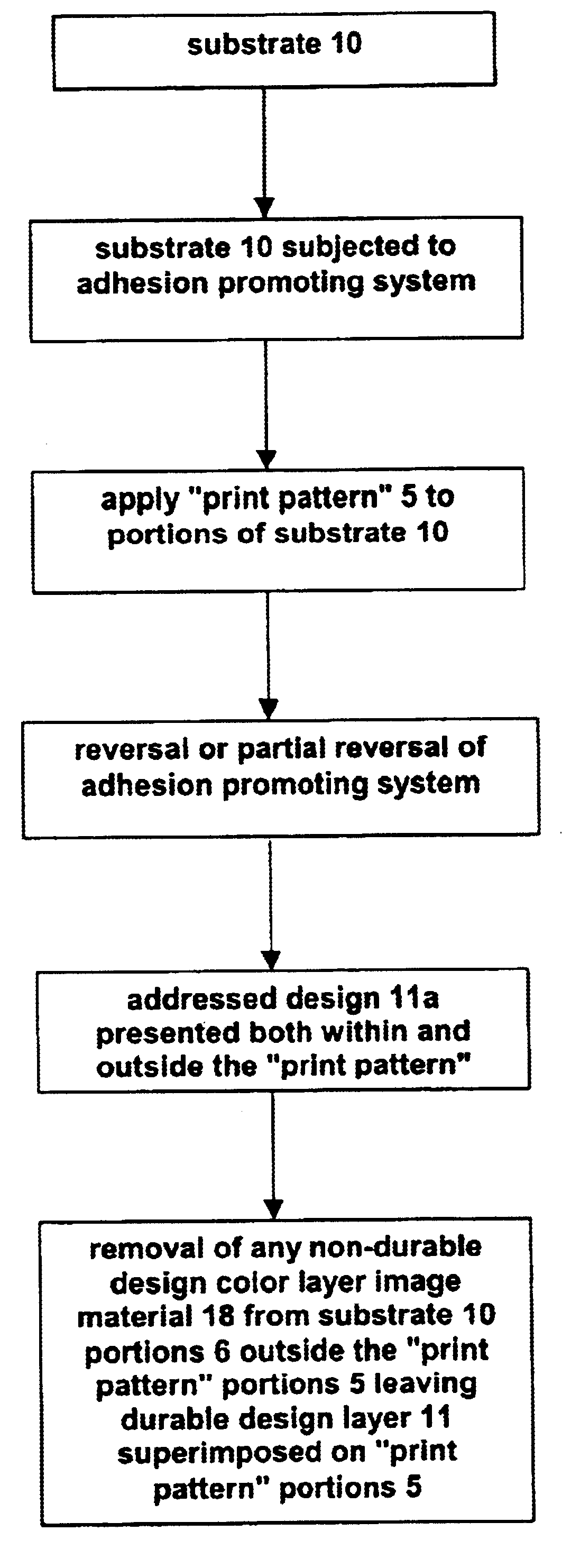

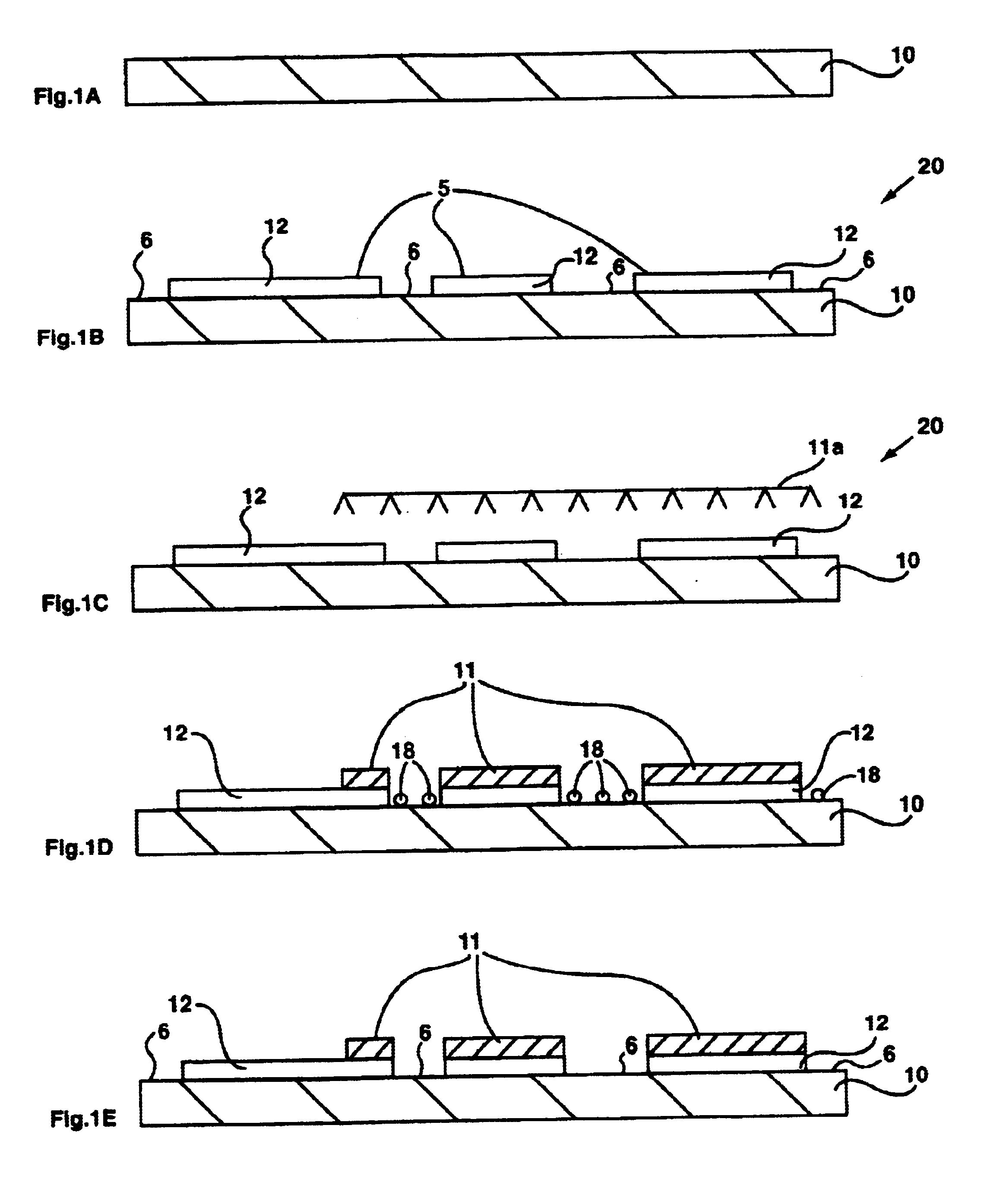

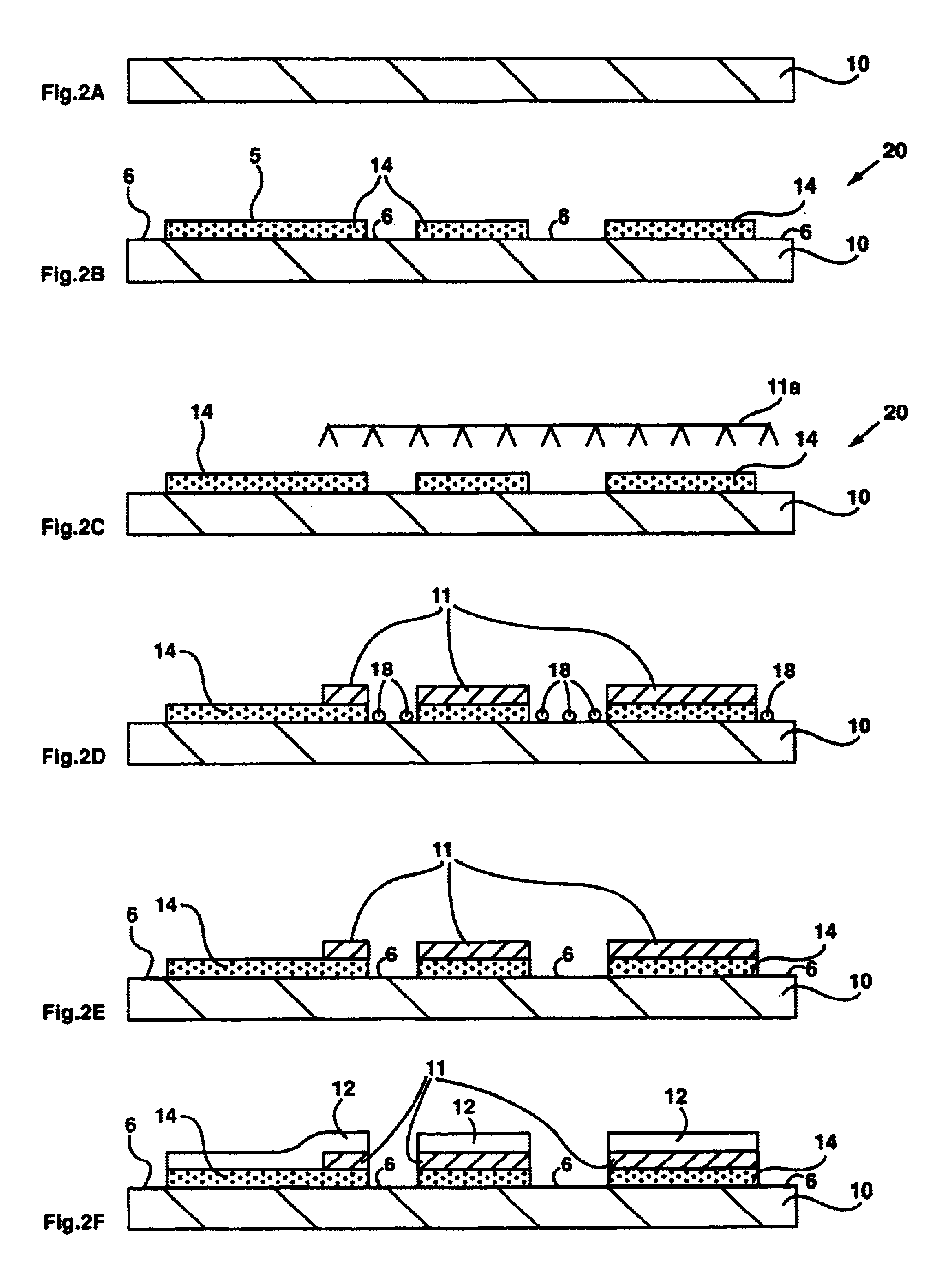

Printing with differential adhesion

InactiveUS6899775B2Facilitates subsequent removalLower surface energyElectric discharge heatingRadiation applicationsEngineeringHigh surface

This invention relates to the printing of a substrate having a pre-printed “print pattern” with a “design layer” of ink where there is differential adhesion within and without the print pattern. The print pattern is receptive to an ink, and the design layer ink forms a durable image material with good bond to the print pattern, but the ink does not form a durable image material on the portions of the substrate outside the print pattern. The design layer ink is a UV-curable ink, and the print pattern may have a higher surface energy than the portions of the substrate outside the print pattern.

Owner:CONTRA VISION

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

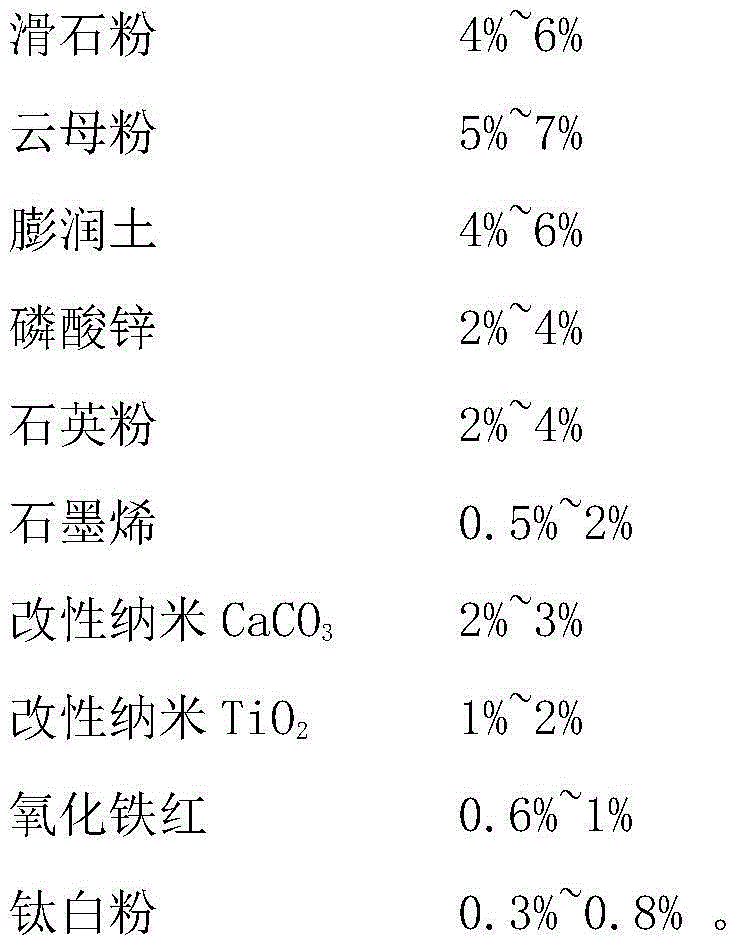

Marine anticorrosive coating

InactiveCN104087126AImprove anti-corrosion performanceGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsHigh resistanceEpoxy

The invention discloses a marine anticorrosive coating. The marine anticorrosive coating consists of the following components in percentage by mass: 30-40 percent of film forming matter, 21.5-33.8 percent of pigment filler, 6.2-15.4 percent of aids and 30-42.3 percent of solvent, wherein the film forming matter consists of 16-23 mass percent of water-based phenolic epoxy resin and 14-16 mass percent of waterborne polyurethane; the pigment filler comprises graphene; the solvent is deionized water. The marine anticorrosive coating has high corrosion resistance, high flexibility, high wear resistance, high oil and aging resistance and good antirust performance. The film forming matter integrates high adhesion force, high strength, low shrinkage rate and high corrosion resistance of the water-based phenolic epoxy resin as well as high flexibility, wear resistance, oil and aging resistance and good film-forming performance of the waterborne polyurethane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

De novo synthesized gene libraries

ActiveUS20160089651A1Less errorHigh surface energySequential/parallel process reactionsMicrobiological testing/measurementGenomic libraryDe novo synthesis

Owner:TWIST BIOSCI

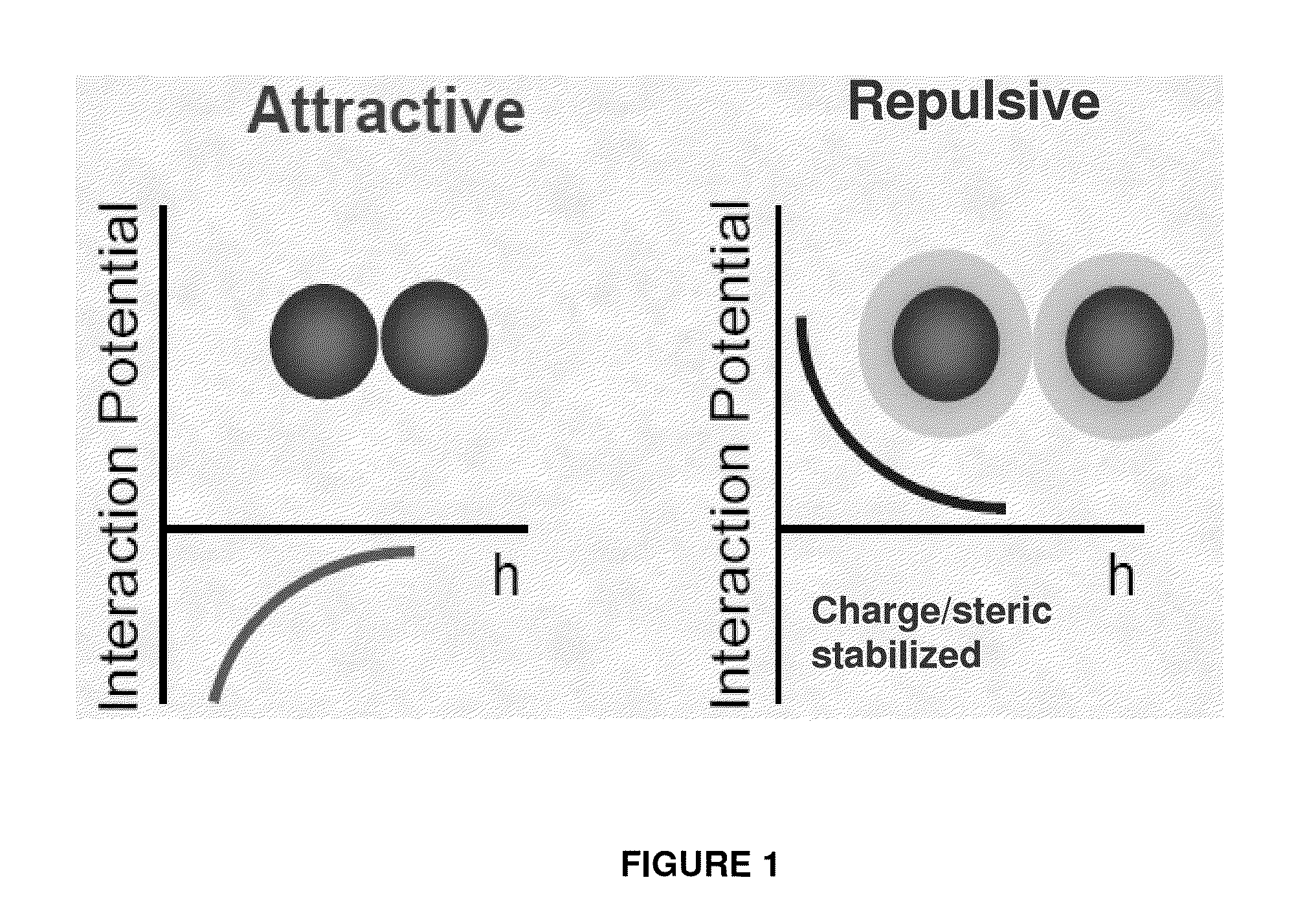

Aqueous processing of composite lithium ion electrode material

ActiveUS20130108776A1High surface energyMaterial nanotechnologyRadiation applicationsSurface energyCurrent collector

A method of making a battery electrode includes the steps of dispersing an active electrode material and a conductive additive in water with at least one dispersant to create a mixed dispersion; treating a surface of a current collector to raise the surface energy of the surface to at least the surface tension of the mixed dispersion; depositing the dispersed active electrode material and conductive additive on a current collector; and heating the coated surface to remove water from the coating.

Owner:UT BATTELLE LLC

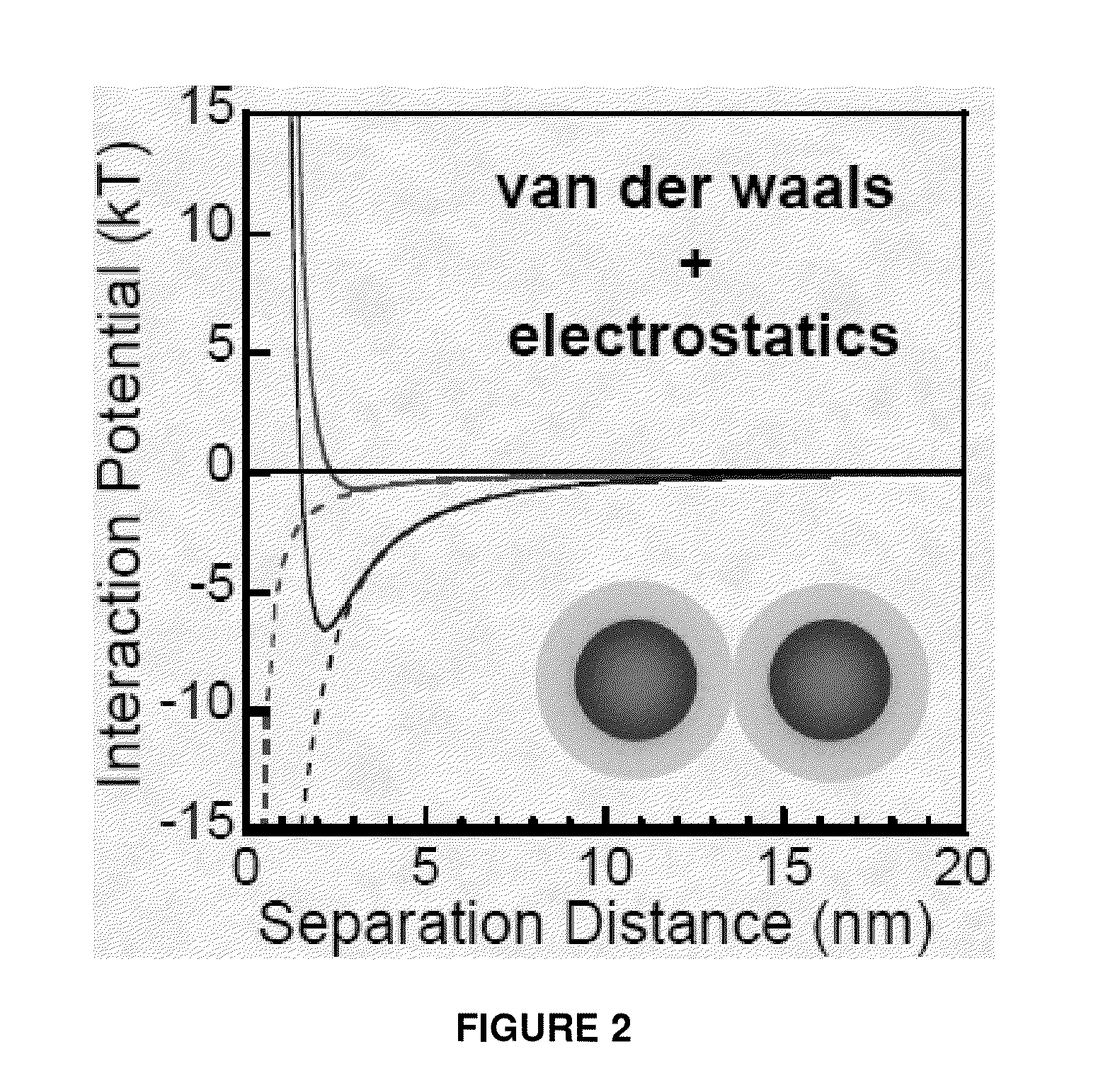

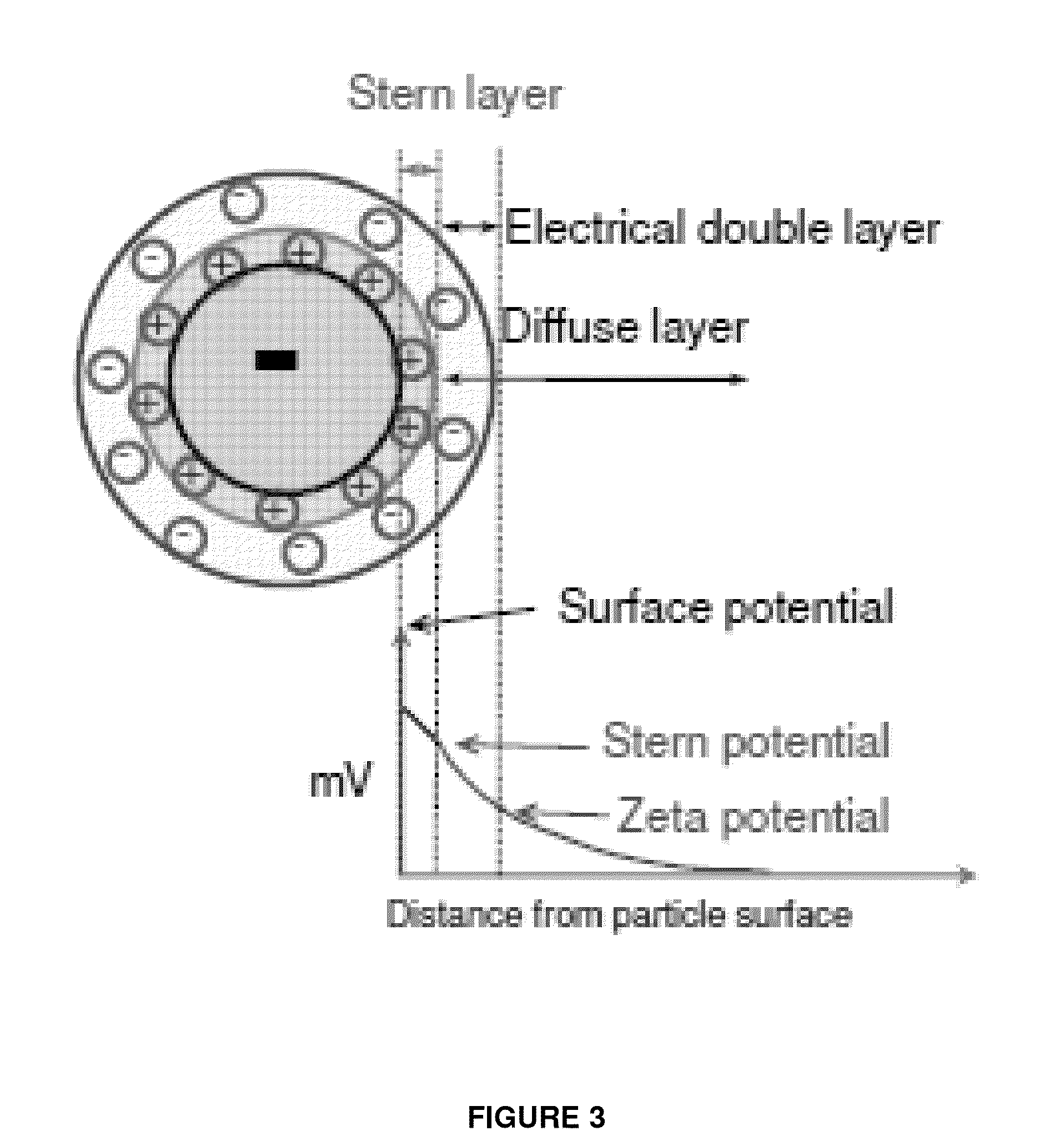

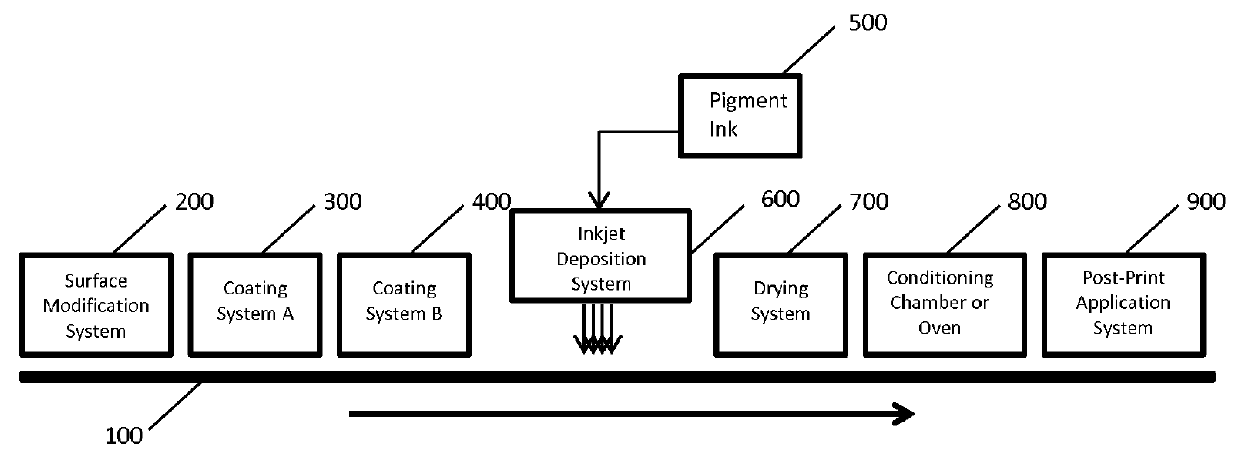

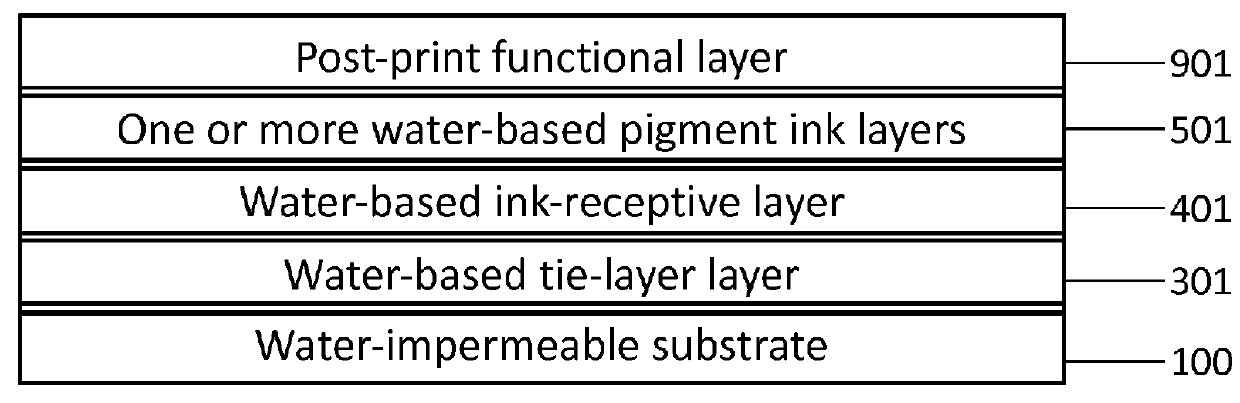

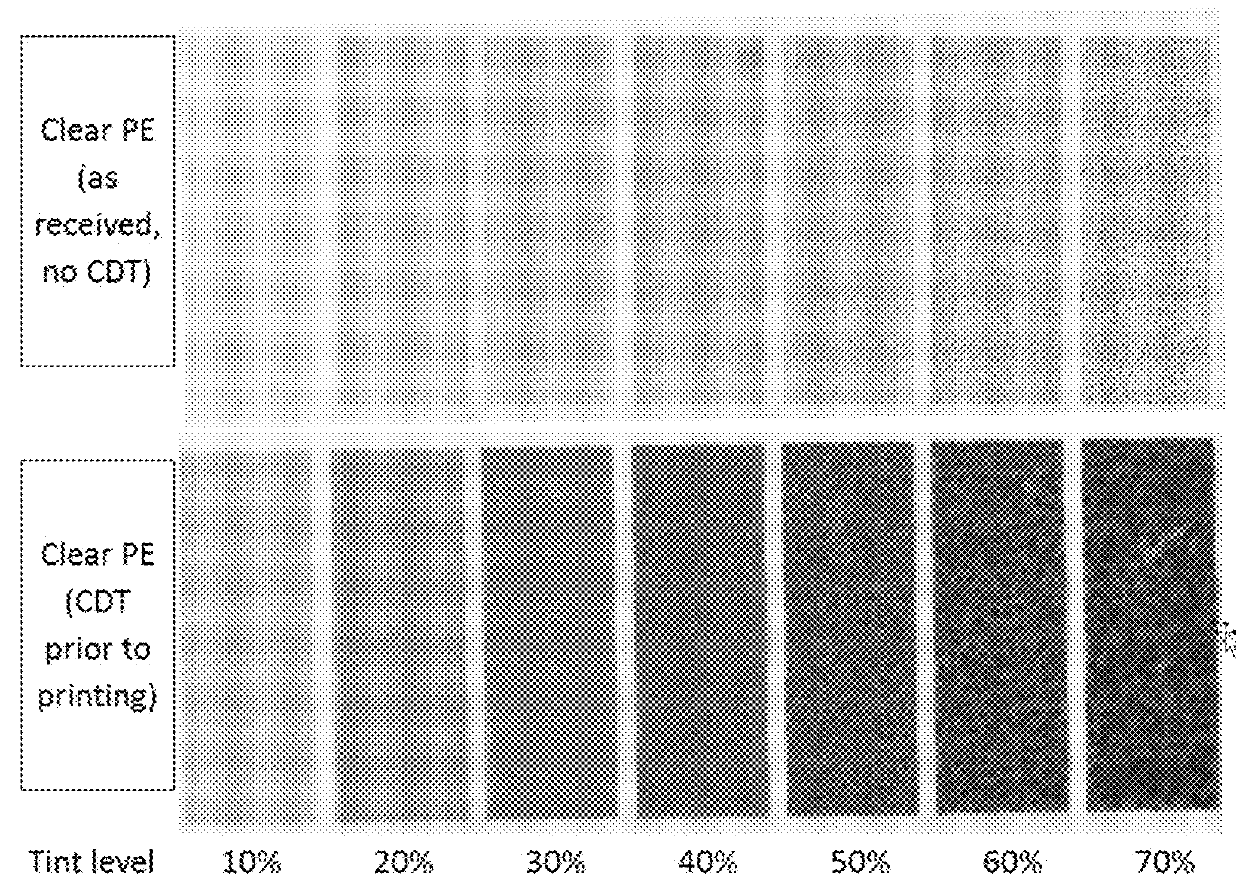

Printing on water-impermeable substrates with water-based inks

ActiveUS9376582B1Improve printing qualityIncreased durabilityDuplicating/marking methodsInksWater basedWater soluble

A method of printing with water-based inkjet inks on a water-impermeable, low-surface-energy substrate, includes:a) modifying surface properties of the substrate to increase the surface energy;b) coating the modified surface of the substrate with a first layer comprising a colorless water-based tie-layer composition;c) coating over the first layer with a second layer including a colorless and transparent water-based ink-receptive composition including:i) a water-soluble multivalent metal salt; andii) a hydrophilic binder polymer;d) depositing directly on the surface of the second layer one or more water-based ink compositions containing an anionically stabilized pigment colorant, wherein the one or more water-based ink compositions are deposited in a predetermined pattern with an inkjet deposition system in response to electrical signals; ande) drying the first and second coated layers and the deposited inks to substantially remove the water.

Owner:EASTMAN KODAK CO

Highly-flame-retardant modified acrylate coating

InactiveCN104263182AGood flame retardancyStrong heat resistanceFireproof paintsPolyurea/polyurethane coatingsAmmonium polyphosphateEmulsion

The invention discloses a highly-flame-retardant modified acrylate coating. The raw materials for preparing the coating comprise the following ingredients: 65-80 parts of phosphate ester modified acrylic emulsion, 5-10 parts of polysiloxane, 3-10 parts of waterborne polyurethane emulsion, 2-6 parts of resorcinol bis(diphenyl) phosphate, 0.5-1.8 parts of tri-isopropylphenyl phosphate, 10-30 parts of nanometer aluminum hydroxide, 15-32 parts of titanium dioxide, 5-20 parts of nano-silica, 19-35 parts of ammonium polyphosphate, 5-10 parts of dipentaerythritol, 3-10 parts of beta-cyclodextrin, 3-8 parts of an organic solvent, 3-5 parts of a film-forming additive, 2-5 parts of an auxiliary, and 30-60 parts of water. The highly-flame-retardant modified acrylate coating disclosed by the invention is good in flame retardancy, high in heat resistance, high in strength, and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Polymer Films for Medical Device Coating

ActiveUS20100228348A1Efficient use ofCost-effectivePharmaceutical containersPretreated surfacesPolymer chemistryPolymer thin films

A method for depositing a coating comprising a polymer and impermeable dispersed solid on a substrate, comprising the following steps: discharging at least one impermeable dispersed solid in dry powder form through a first orifice; discharging at least one polymer in dry powder form through a second orifice; depositing the polymer and / or impermeable dispersed solid particles onto said substrate, wherein an electrical potential is maintained between the substrate and the impermeable dispersed solid and / or polymer particles, thereby forming said coating; and sintering said coating under conditions that do not disrupt the activity and / or function of the substrate. A similar method is provided for depositing a coating comprising a hydrophobic polymer and a water-vapor-trapping material on a substrate.

Owner:MT ACQUISITION HLDG LLC

Preparation method of carbon fiber reinforcement grafted by graphene oxide

A preparation method of a carbon fiber reinforcement grafted by graphene oxide relates to a preparation method of a carbon fiber reinforcement grafted by graphene oxide. The invention solves the problems of harsh process conditions, long process period, toxic process, and difficult industrial production for current carbon fiber surface modification methods. The invention adopts a 'grafting' method, and grafts graphene oxide on acidified carbon fiber surfaces through an acylation reaction by using polyamide-amine with a lot of amido active groups; the invention has low cost, is simple, practical, environment-friendly, and nontoxic, and can be completed within a short period. The method particularly comprises the following steps: mixing acidified carbon fibers and a polyamide-amine methanolsolution, reacting to prepare carbon fibers modified by polyamide-amine, adding the prepared carbon fibers in a graphene oxide acetone suspension, mixing, reacting, filtering, drying the precipitatestill the weight is constant. The obtained carbon fiber reinforcement has interfacial shear strength with epoxy resin of up to 79.77-105.50 MPa which is improved.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com