Patents

Literature

172results about How to "Good flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus-containing crosslinked gel polymer electrolyte and on-site thermal-polymerization preparation method and application thereof

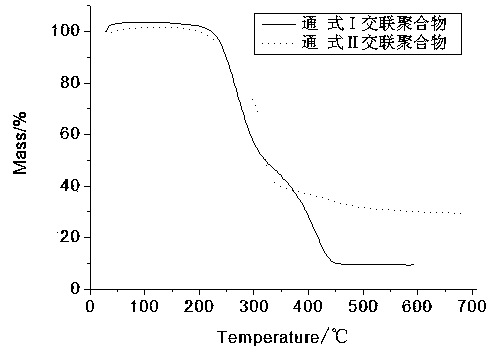

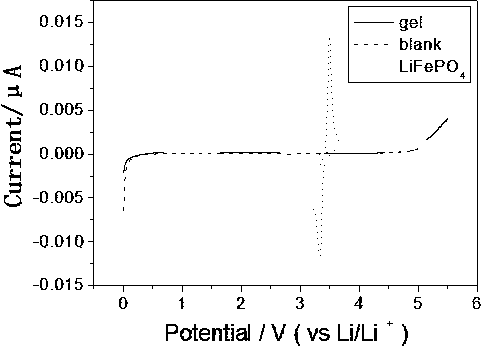

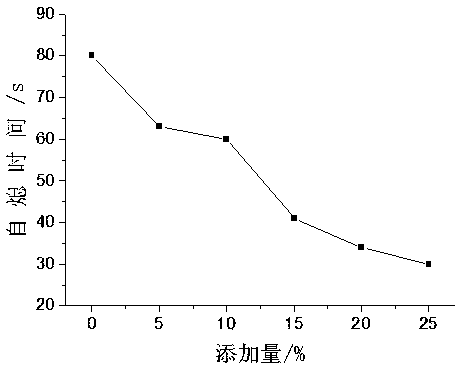

The invention belongs to the technical field of gel polymer electrolytes and particularly discloses a phosphorus-containing crosslinked gel polymer electrolyte and an on-site thermal-polymerization preparation method and application thereof. The preparation method comprises the steps of preparing the following raw materials, of which the total weight percent is 100%: 5-15% of polymerization monomers, 3-10% of crosslinker, 0.01-1.0% of thermal initiator and 75-90% of lithium-ion battery liquid electrolyte, uniformly mixing, and then, reacting for 20-100 minutes at the temperature of 75-150 DEG C under the protection of inert gas, thereby obtaining the phosphorus-containing crosslinked gel polymer electrolyte. The invention further discloses application of the phosphorus-containing crosslinked gel polymer electrolyte in the preparation of solid lithium-ion batteries. The invention provides novel phosphates and / or phosphonates, containing double bonds, which serve as monomers of the gel polymer electrolyte, and the phosphorus-containing crosslinked gel polymer electrolyte designed and synthesized from the monomers has the advantages of simple and convenient preparation method, high ionic conductivity, high thermal stability and good electrochemical stability, so that phosphorus-containing crosslinked gel polymer electrolytes with relatively good stability are provided for the practical application of the solid lithium-ion batteries and high-power lithium-ion batteries.

Owner:ZHENGZHOU UNIV

Modified silicone rubber cable material with high flame retardance and high wear resistance

InactiveCN104403318AGood flame retardancyImprove wear resistanceRubber insulatorsPlastic/resin/waxes insulatorsCarboxylationDicumyl peroxide

The invention discloses a modified silicone rubber cable material with high flame retardance and high wear resistance. The modified silicone rubber cable material is prepared from the following raw materials: silicone rubber, ethylene-propylene-diene monomer rubber, butyl rubber, ethylene-vinyl acetate rubber, polyurethane, modified alumina, nylon 6, 2,2,6,6-tetramethylpiperidinooxy, nanometer calcium carbonate, a carboxylation carbon nanotube, a coupling agent, dicumyl peroxide, modified enzymatic hydrolysis lignin, zinc oxide, stearic acid, ultra-fine aluminum hydroxide, ethyl glycol tetraethyl diphosphate, diethylene glycol tetraethyl diphosphate, a red phosphorus microcapsule, triallyl isocyanurate, acrylic acid, an accelerant, an anti-ageing agent, and a softener. The modified silicone rubber cable material with high flame retardance and high wear resistance disclosed by the invention is good in flame retardance, high in wear resistance, high in mechanical strength, and long in service life.

Owner:ANHUI DUJIANG CABLE GROUP

Highly-flame-retardant modified acrylate coating

InactiveCN104263182AGood flame retardancyStrong heat resistanceFireproof paintsPolyurea/polyurethane coatingsAmmonium polyphosphateEmulsion

The invention discloses a highly-flame-retardant modified acrylate coating. The raw materials for preparing the coating comprise the following ingredients: 65-80 parts of phosphate ester modified acrylic emulsion, 5-10 parts of polysiloxane, 3-10 parts of waterborne polyurethane emulsion, 2-6 parts of resorcinol bis(diphenyl) phosphate, 0.5-1.8 parts of tri-isopropylphenyl phosphate, 10-30 parts of nanometer aluminum hydroxide, 15-32 parts of titanium dioxide, 5-20 parts of nano-silica, 19-35 parts of ammonium polyphosphate, 5-10 parts of dipentaerythritol, 3-10 parts of beta-cyclodextrin, 3-8 parts of an organic solvent, 3-5 parts of a film-forming additive, 2-5 parts of an auxiliary, and 30-60 parts of water. The highly-flame-retardant modified acrylate coating disclosed by the invention is good in flame retardancy, high in heat resistance, high in strength, and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

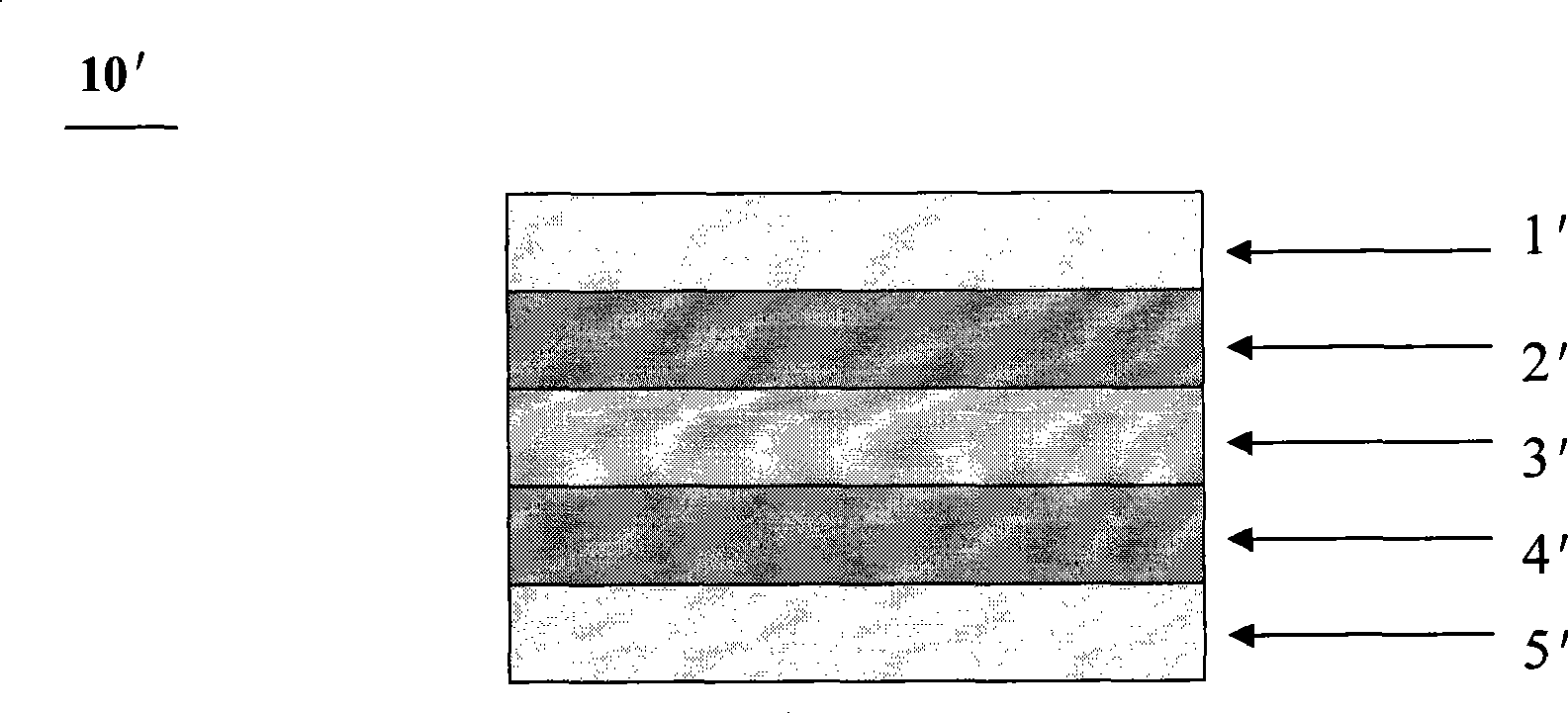

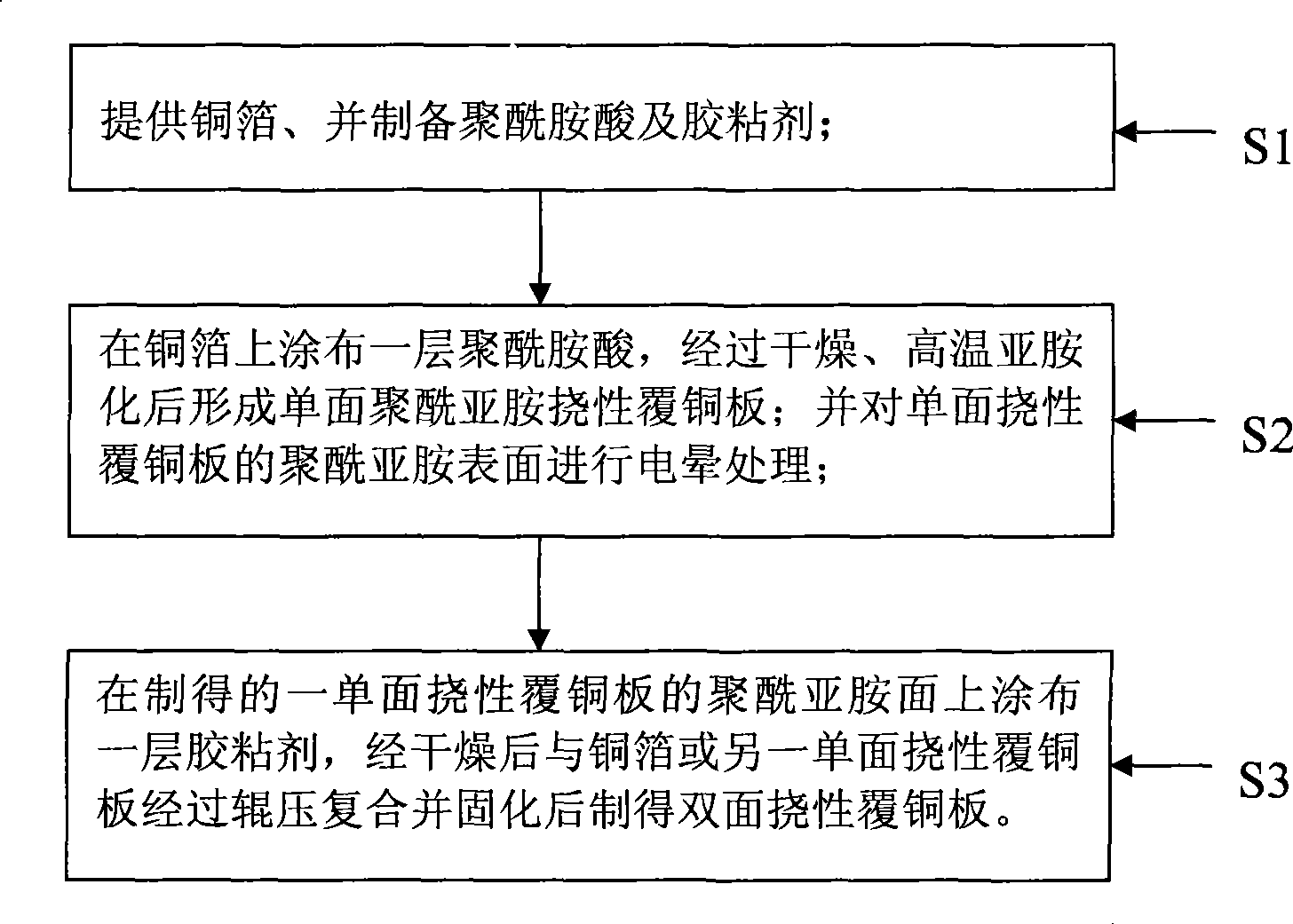

Double side flexible copper coated board and manufacturing method thereof

ActiveCN101420820AGood folding resistanceGood flame retardancyInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentAging propertyCopper foil

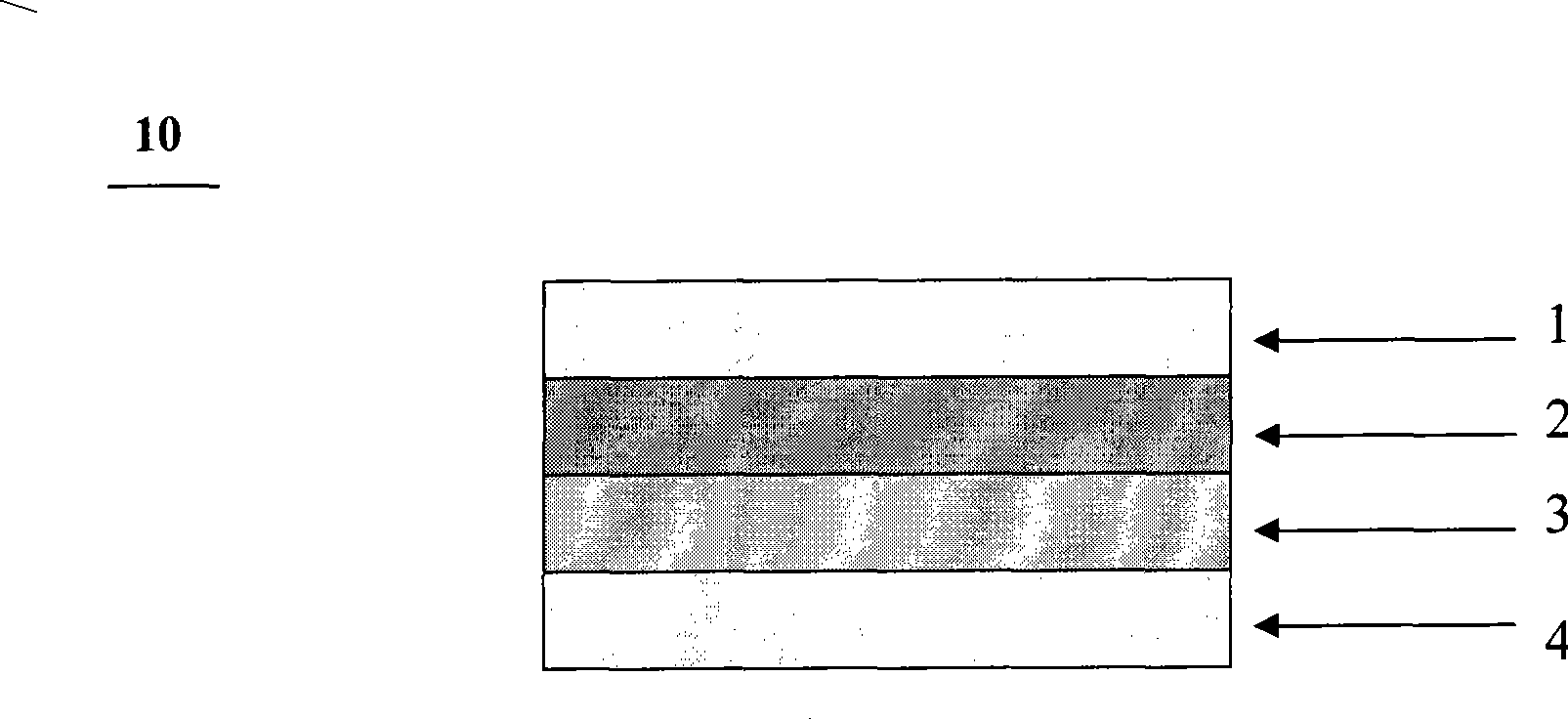

The invention relates to a double-sided flexible copper clad laminate and a production method thereof, the double-sided flexible copper clad laminate comprises a single-sided copper clad laminate, an adhesive layer which is coated on the single-sided copper clad laminate and the other copper foil or the other single-sided copper clad laminate which is coated on the adhesive layer by pressing, the single-sided copper clad laminate comprises one copper foil and a polyimide layer which is coated on the copper foil, wherein, the polyimide layer and the adhesive layer are adjacently arranged. The production method comprises the following steps: the copper foil is provided and polyamide acid and an adhesive are prepared; the polyamide acid is coated on the copper foil to prepare the single-sided copper clad laminate; the adhesive is coated between the single-sided copper clad laminate and the copper foil or the other single-sided copper clad laminate and carrying out the lamination to prepare the double-sided flexible copper clad laminate. The performances of size stability, folding resistance, anti-aging property, and the like of the double-sided flexible copper clad laminate are higher than the double-sided copper clad laminate which is produced by a traditional three-layer method, the appearance quality is better than the two-layer double-sided copper clad laminate produced by a lamination method, and the double-sided flexible copper clad laminate simultaneously has the low-cost advantage, thereby facilitating the mass production.

Owner:GUANGDONG SHENGYI SCI TECH

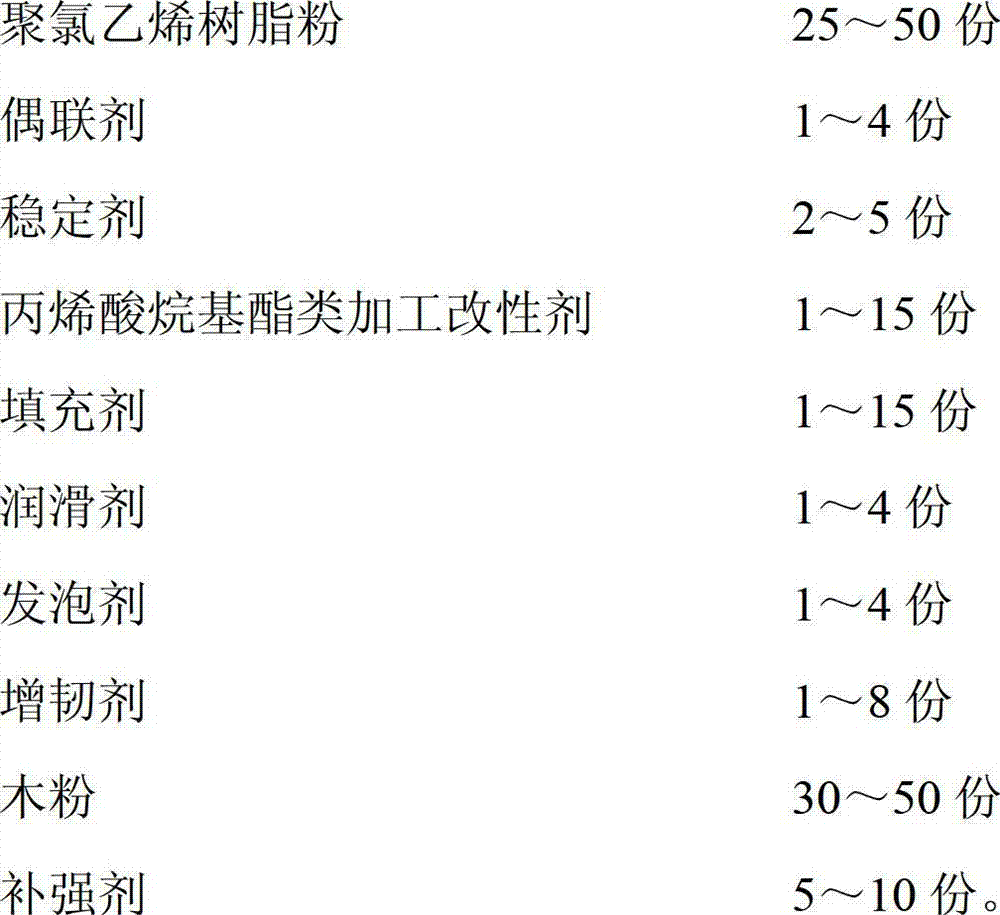

High-hardness wood-plastic building template and preparation method thereof

The invention relates to a high-hardness wood-plastic building template and a preparation method thereof, which belong to the technical field of polyvinyl chloride plates. The 100 parts by weight of high-hardness wood-plastic building template comprises the following raw materials in parts by weight: 20-50 parts of polyvinyl chloride resin powder, 1-4 parts of a coupling agent, 2-5 parts of a stabilizing agent, 1-15 parts of an acrylic alkyl ester processing modifier; 1-15 parts of a filling agent, 1-4 parts of a lubricant, 1-4 parts of a foaming agent, 1-8 parts of a toughening agent, 30-50 parts of wood flour, and 5-10 parts of a reinforcing agent. According to the invention, the plate stacking density is less than or equal to 700 kg / m<3>, so that the building template is good in flame retardancy and smoke suppression, meanwhile, the building template is high in hardness and strong in wood texture; and just like raw woods, the building template also has the properties that the template can be nailed, drilled, planed and adhered and the like, the surface of the template is smooth and fine, and the template is water-proof, corrosion-resistant, fireproof, mould-proof, moth-preventing, and pollution-free.

Owner:SHANDONG BODO PLASTICS CO LTD

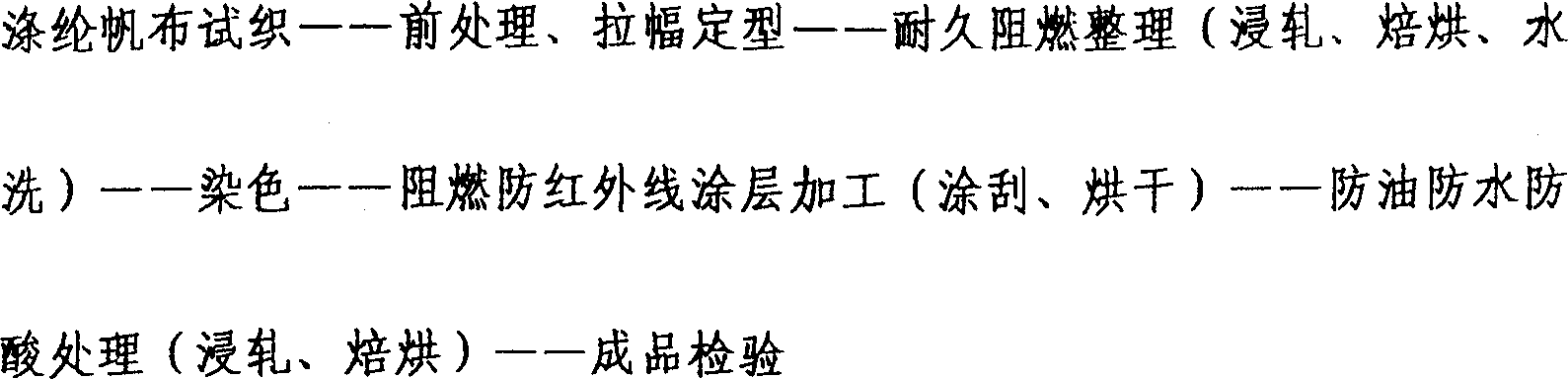

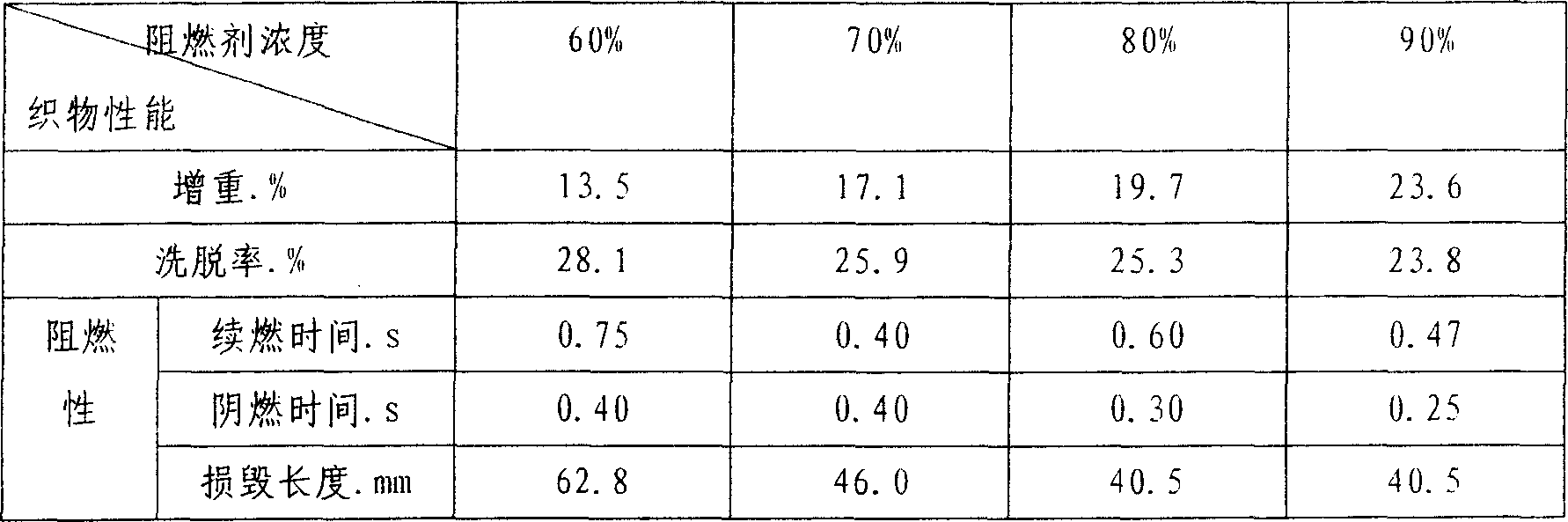

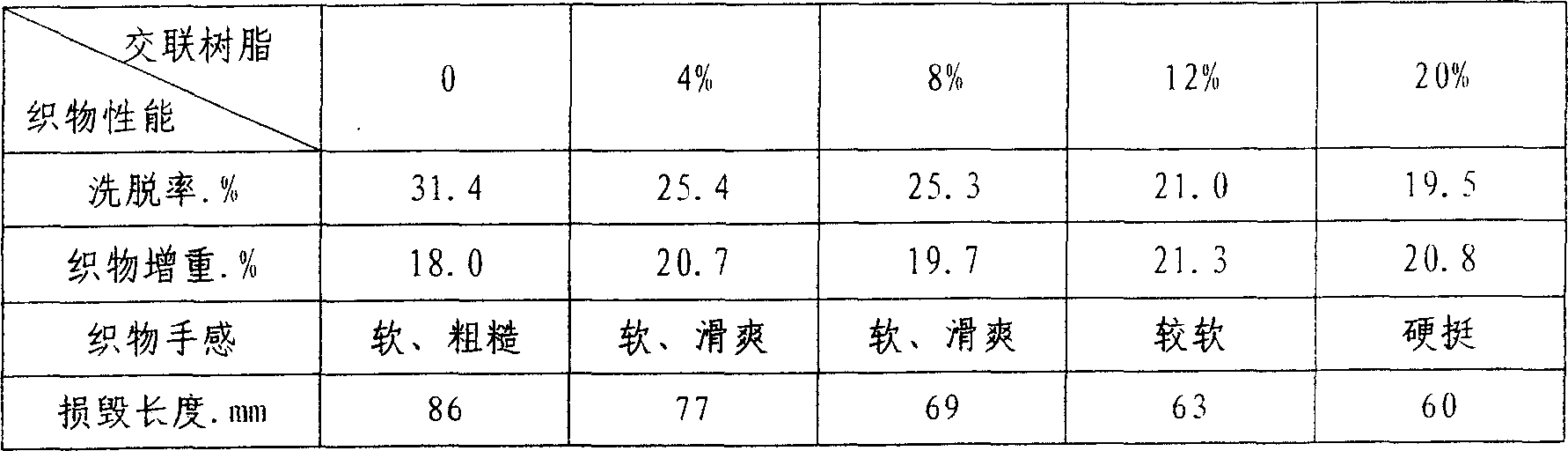

Production of ventilating, antiflame, oilproof, waterproof, acidproof, and antinear-infrared dacron tarpaulin

InactiveCN1888300AGood flame retardancyImprove low temperature performanceTextiles and paperPolyesterAdhesive

The present invention relates to a preparation process of breathable fire-retardant oil-proofing water-proofing acid-proofing and anti-near-infrared polyester sailcloth. Said preparation process includes the following several steps: firstly, making permanent flame retardant treatment of polyester sailcloth, said permanent flame retardant treatment includes padding and baking, baking temperature is 170 deg.C-200deg.C, baking time is 1-10 min, coating flame retardant PU coating adhesive, making water-proofing and acid-proofing treatment, drying and baking for 1-10 min, at 170-230 deg.C, then making permanent flame retardant of base cloth, dyeing, coating flame retardant PU coating adhesive, making water-proofing, oil-proofing and acid-proofing treatment.

Owner:南通东升艾克特种纺织防护面料有限公司

High-flame-retardance modified nitrile rubber cable material

InactiveCN104448434AGood flame retardancyHigh strengthRubber insulatorsAmmonium polyphosphateMaleic anhydride

The invention discloses a high-flame-retardance modified nitrile rubber cable material. The raw materials of the high-flame-retardance modified nitrile rubber cable material comprise the following components: nitrile rubber, natural rubber, fluorinated silicone rubber, attapulgite, nano-calcium carbonate, nano-zinc oxide, zinc methacrylate, modified ammonium polyphosphate, dipentaerythritol, aluminium hydroxide, hydrotalcite, polyethylene-graft-maleic anhydride, polydimethylsiloxane, benzoyl peroxide, 2,5-dimethyl-2,5-di(tert-butylperoxy) hexane, lignin, acrylate rubber, accelerant, plasticizer and antiager. The high-flame-retardance modified nitrile rubber cable material disclosed by the invention is good in flame retardance and high in strength, and the cable produced from the high-flame-retardance modified nitrile rubber cable material is long in service life.

Owner:ANHUI DUJIANG CABLE GROUP

Oxazolidone ring-containing epoxy resin, method for producing the thereof, epoxy resin composition, cured product and application thereof

ActiveCN105968321AGood flame retardancyExcellent dielectric propertiesSynthetic resin layered productsElectrical equipmentChemistryEpoxide

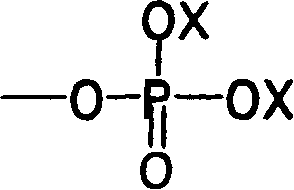

The invention provides an oazolidone ring-containing epoxy resin, a method for producing the thereof, an epoxy resin composition, a cured product and an application thereof. The oazolidone ring-containing epoxy resin is obtained by epoxy resin (a) of epoxy resin (a1) and an isocyanate compound represented by the following formula (3), the epoxide equivalent is 200-550g / eq.. The oazolidone ring-containing epoxy resin has good performances of heat resisting property, dielectric property, adhere property and the like and can be applied to purposes of stacking, moulding, casting, adhering and the like. The formula is as shown in the description. (X represents at least one selected from an alkyl group with carbon number of 1-4, an aryl group with carbon number of 6-10 and a cycloalkylene base with ring member number of 5-8 of substituent group of an aralkyl group with carbon number of 6-10. R represents a hydrogen atom, the alkyl group, a naphthene base, the aryl group or the aralkyl group, G represents a glycidyl group, and the average value of m is 0-5.).

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

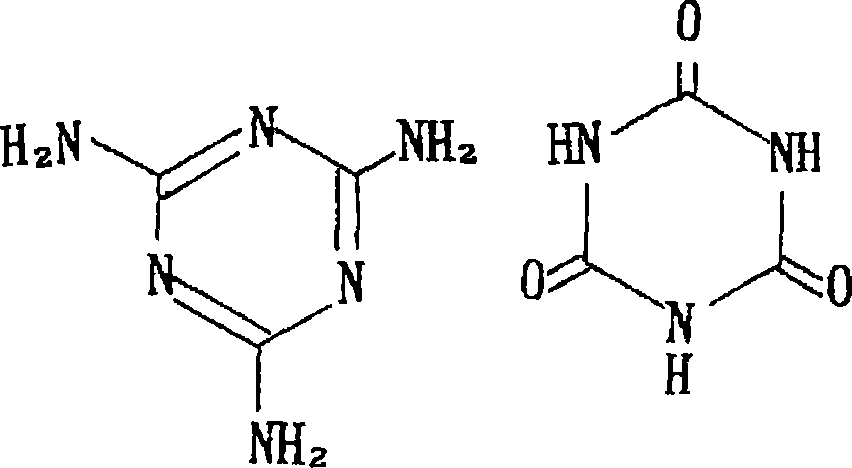

Halogen-free water resistant expansion type phosphor nitrogen combustion inhibitor for polyolefin and preparation thereof

The invention relates to a non-halogen, water resistant and expanding type phosphorus nitrogen flame retardant used for polyolefine. The phosphorus nitrogen flame retardant is characterized in that according to the weight percentage, the flame retardant comprises melamine phosphate which occupies 20 percent to 80 percent, triazine derivative which occupies 5 percent to 40 percent, nanometer compound material which occupies 1 percent to 15 percent, phosphonate ester which occupies 10 percent to 20 percent, padding which occupies 0.1 percent to 8 percent and antioxidant which occupies 0.1 percent to 5 percent. The flame retardant adopts the preparation method that the components are mixed, the mixture is coated through the polymer with barrier property, and the integrated modification of the flame retardant is realized. Compared with the prior general non-halogen and expanding type flame retardant, the non-halogen, water resistant and expanding type phosphorus nitrogen flame retardant used for polyolefine has the advantages that the flame retardance is better, the water resistance is greatly improved, the compatibility between the flame retardant and the plastic matrix is good, and the mechanical property and the processing property of the polyolefine are not affected.

Owner:SHANGHAI RES INST OF CHEM IND

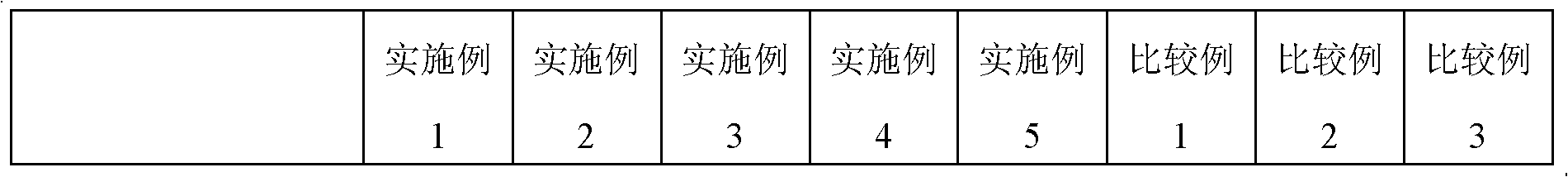

Weather-resistant, flame retardant and impact-resistant polystyrene material, and preparation method

InactiveCN103146090AGood flame retardancyImprove weather resistanceWeather resistanceFlame resistance

The invention belongs to the field of polymer material modification and processing technology, and relates to a polystyrene material and a preparation method. The polystyrene material is composed by the components of, by weight, 100 parts of a polystyrene resin, 20-35 parts of a toughening agent, 8-25 parts of a filler, 1-2.8 parts of an antioxidant, 0.2-1.0 parts of a light stabilizer, 8-15 parts of a flame retardant, 1-6 parts of a flame retardant synergist and 2.5-4 parts of a lubricant. The weather-resistant, flame retardant and impact-resistant polystyrene material provided by the invention has relatively high impact strength, relatively high tensile strength, good weather resistance and flame retardance, easy processing, stable performance and long service life, so that the application scope of the polystyrene material is expanded, and the polystyrene material can replace engineering plastics in some fields, can be used for electrical and mechanical parts, and has broad market application prospects.

Owner:滁州格美特科技有限公司

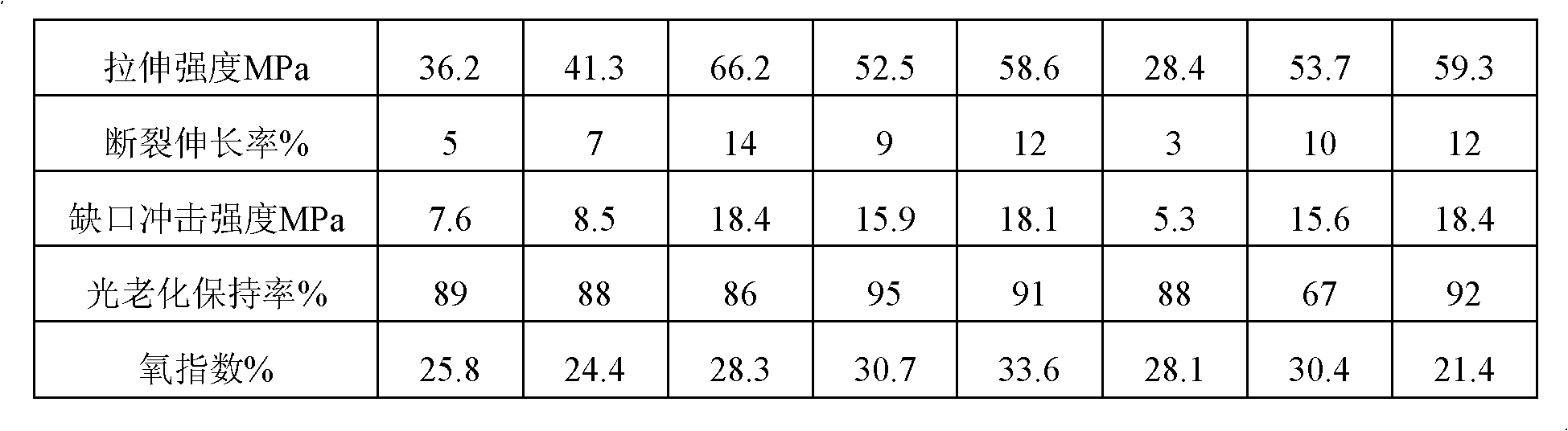

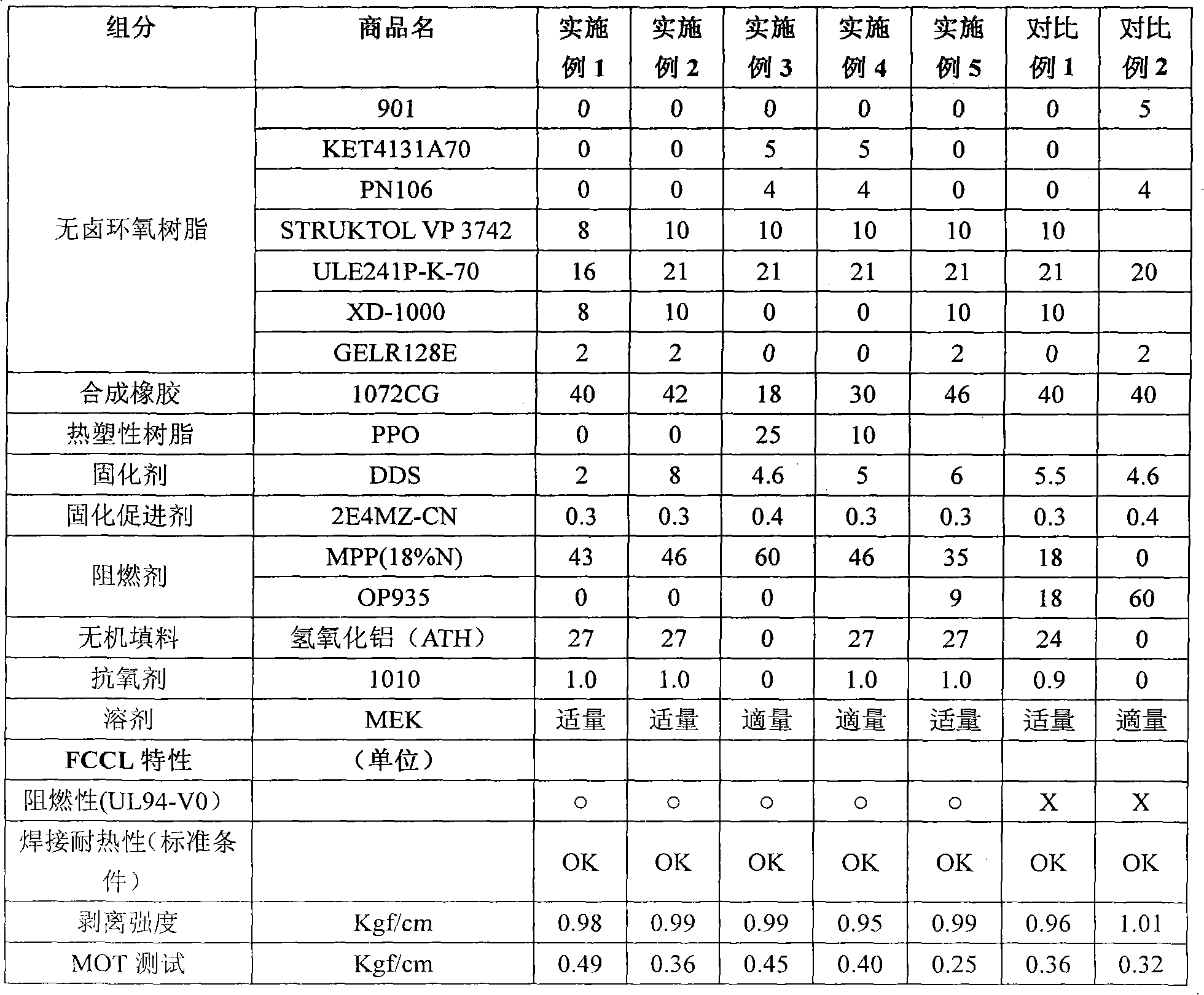

Halogen-free flame retardant adhesive composition and flexible copper-clad plate using same

ActiveCN101875825AReduce usageGood flame retardancyNon-macromolecular adhesive additivesPrinted circuit detailsCopper foilChemistry

The invention discloses a halogen-free flame retardant adhesive composition, which comprises the following components in parts by weight: 15 to 45 parts of halogen-free epoxy resin, 15 to 60 parts of thermoplastic resin and / or synthetic rubber, 0.1 to 8 parts of curing agent and 5 to 60 parts of nitrogen-containing flame retardant. The halogen-free flame retardant adhesive composition utilizes nitrogen-containing flame retardant, thus reducing the use of phosphonium flame retardant, in addition, the cured product shows good flame resistance, peel strength, electrical property and welding thermal resistance, does not contain elements of halogen, antimonide and other harmful substances and does not pollute the environment. The invention also discloses a flexible copper-clad plate, which is provided with an electrical insulating film, an adhesive coat and a copper foil, wherein the adhesive coat is prepared from the halogen-free flame retardant adhesive composition. The flame retardant rating of the flexible copper-clad plate is up to UL-94V0, thus the flexible copper-clad plate has good thermal resistance, adhesive force, soldering resistance and other performances.

Owner:ALLSTAE TECH ZHONGSHAN

Flame Retardant Thermoplastic Resin Composition

ActiveUS20070295946A1Good flame retardancyImprove flame retardant performanceGroup 5/15 element organic compoundsLiquid carbonaceous fuelsPolycarbonatePolyolefin

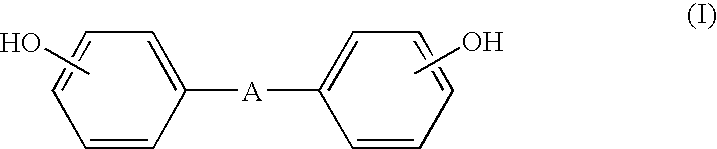

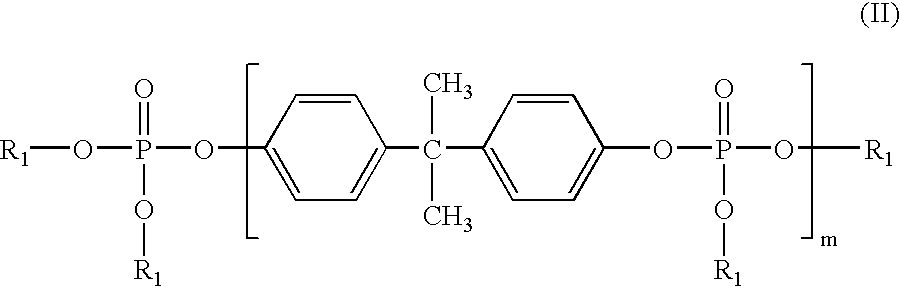

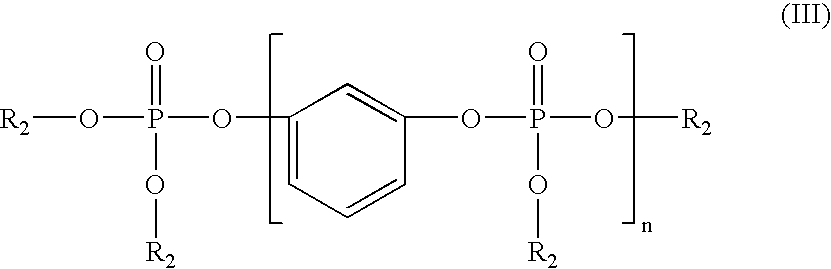

The flame retardant thermoplastic resin composition according to the present invention comprises (A) about 45 to 95 parts by weight of a polycarbonate resin; (B) about 1 to 50 parts by weight of a rubber modified vinyl graft copolymer; (C) about 0 to 50 parts by weight of a vinyl copolymer; (D) about 1 to 30 parts by weight of a mixture of oligomeric phosphoric acid ester compounds consisting of (d1) about 5 to 99 % by weight of an oligomeric phosphoric acid ester compound derived from bisphenol-A and (d2) about 1 to 95 % by weight of an oligomeric phosphoric acid ester compound derived from resorcinol, per 100 parts by weight of the sum of (A), (B) and (C); and (E) about 0.05˜5 parts by weight of a fluorinated polyolefin resin, per 100 parts by weight of the sum of (A), (B) and (C).

Owner:LOTTE ADVANCED MATERIALS CO LTD

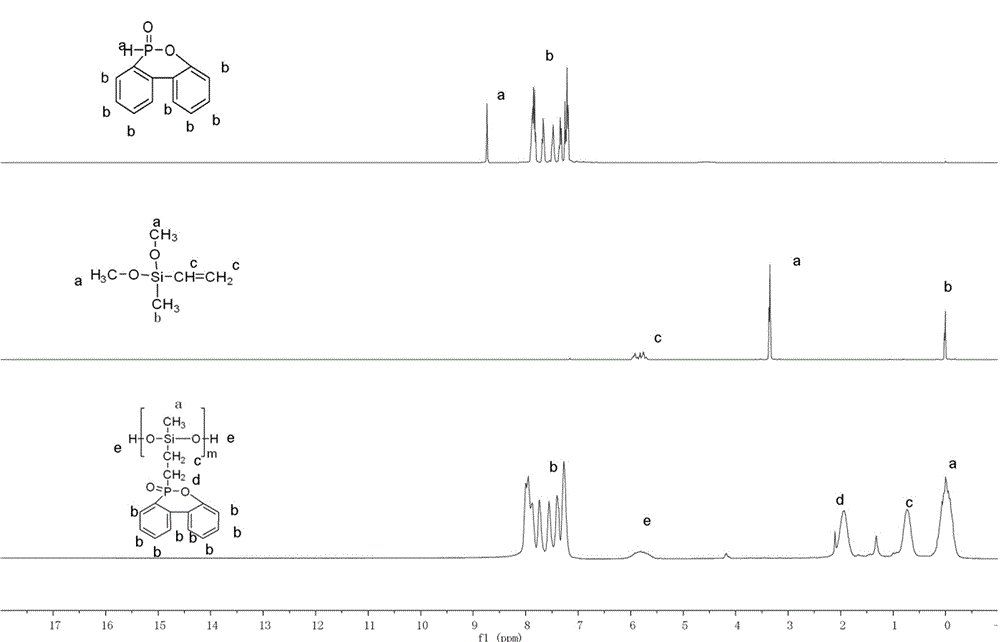

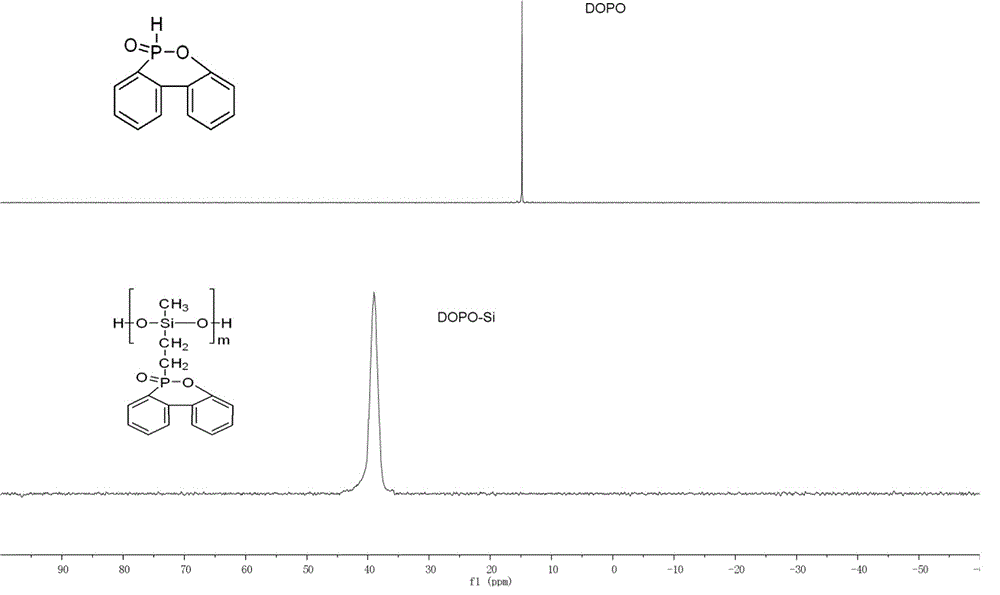

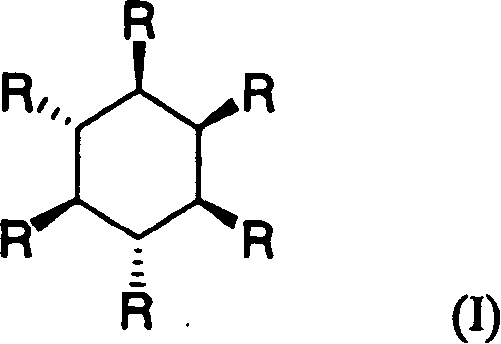

Phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber, preparation method therefor and application thereof

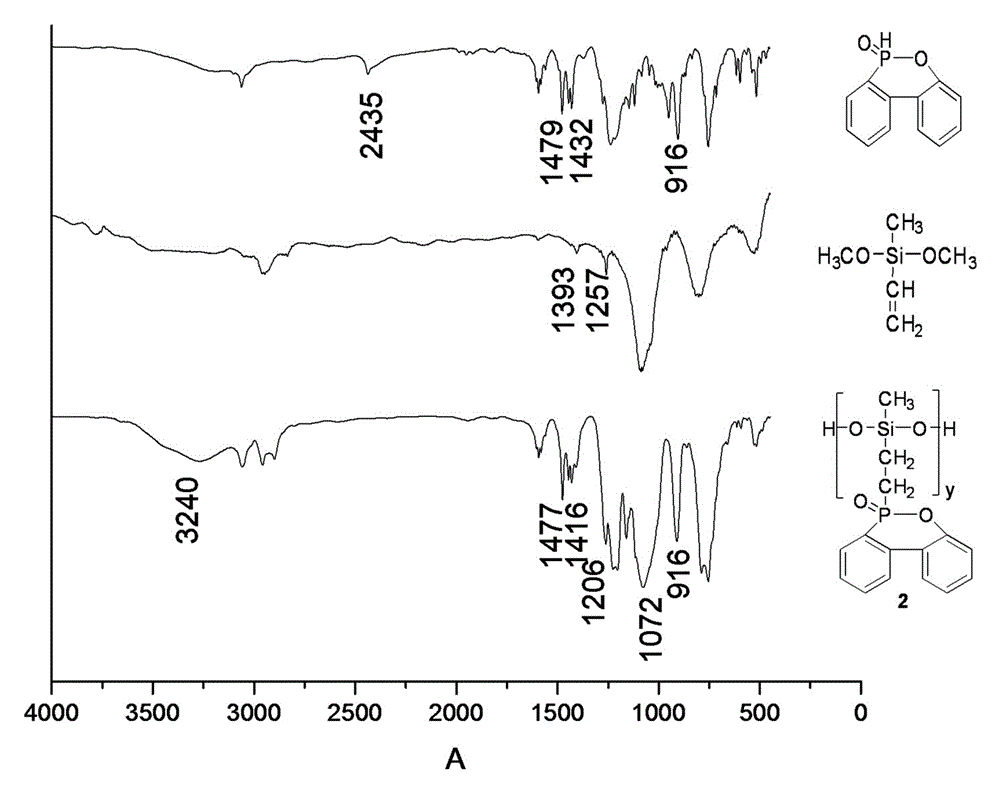

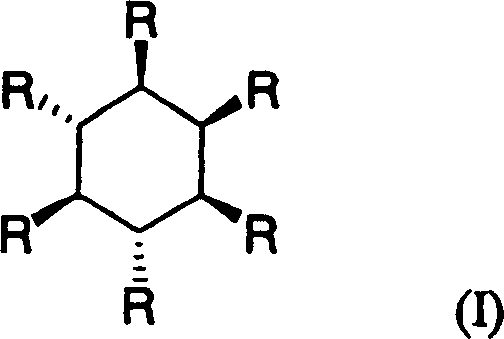

The invention discloses phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber, a preparation method therefor and an application thereof. The material has a following structural unit: FORMULA as shown in the specification, wherein X is 2-4, y is 3-6, z is 300-325 and Mw is equal to 18900-27600. The invention further discloses the preparation method for the phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber; linear methyl vinyl phosphorus-containing silicone rubber crude rubber with a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide structure in a side chain is obtained; compared with conventional addition methyl vinyl flame-retardant silicone rubber, the phosphorus-containing methyl vinyl flame-retardant silicone rubber crude rubber disclosed by the invention has better flame resistance; and problems of high filling volume and low flame resistance efficiency in a conventional flame-retardant rubber blending process are overcome; and physical characteristics such as good tensile strength, good impact strength and the like of the silicone rubber are kept.

Owner:湖北省兴发磷化工研究院有限公司 +1

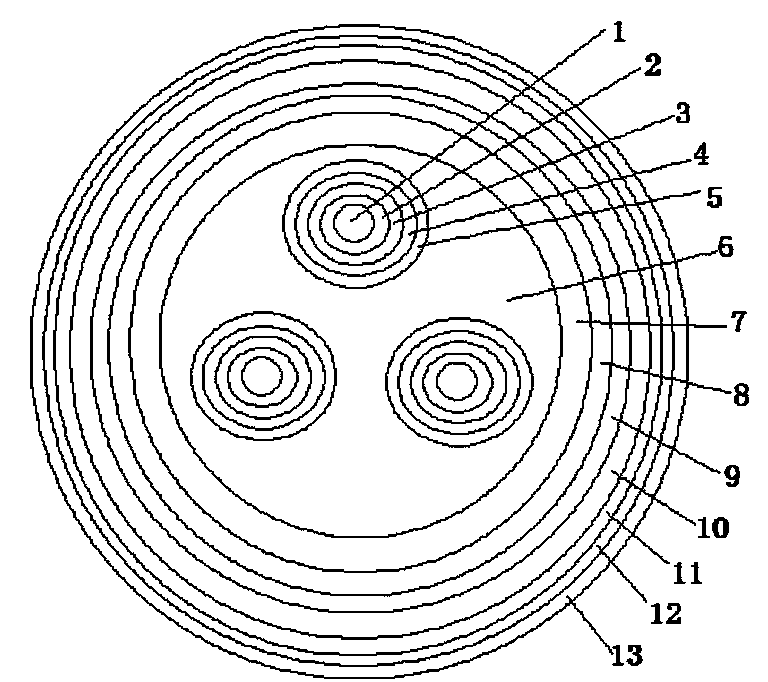

High-effect rat-proof and termite-proof electric wire and cable and preparation method thereof

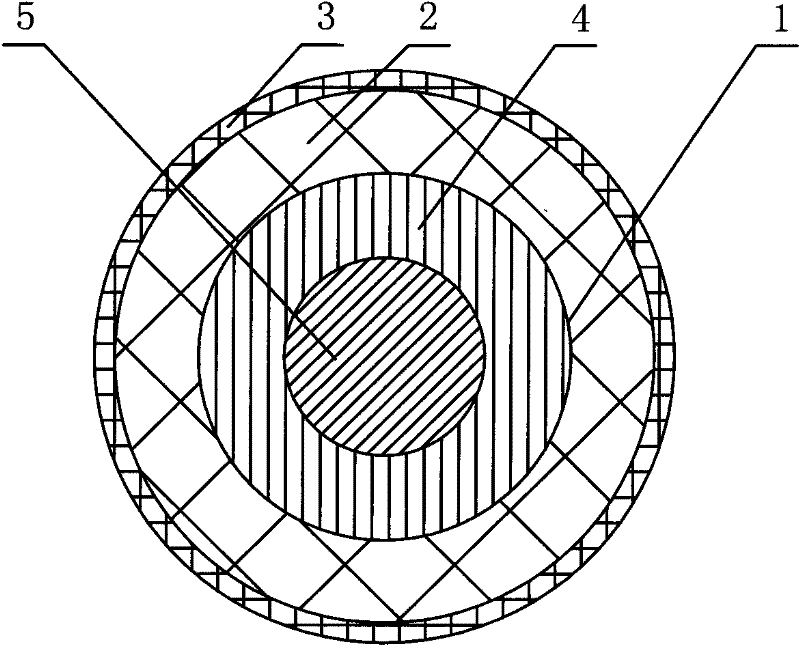

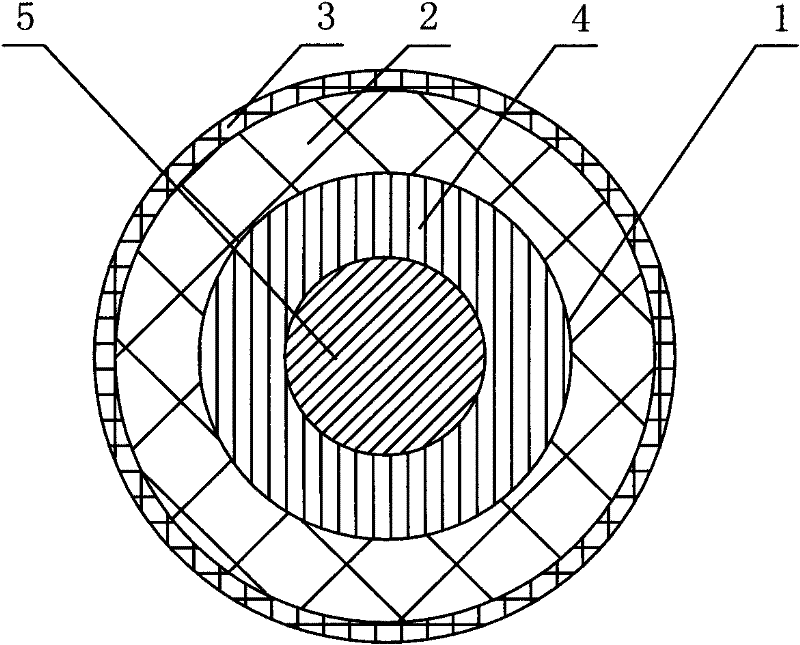

InactiveCN104200889AExcellent performance against rodents and antsGood flame retardancyInsulated cablesCable/conductor manufactureManufacturing engineeringElectrical conductor

The invention provides a high-effect rat-proof and termite-proof electric wire and cable which comprises conductors. A shielding layer is arranged outside each conductor, a flame-resistant PE (polyethylene) insulating layer is arranged outside each shielding layer, a ceramic silicone rubber layer is arranged outside each flame-resistant PE insulating layer, a waterproof layer is arranged outside each ceramic silicone rubber layer, the conductors are filled with a flame-resistant glass fiber filler rope, a flame-resistant belt is arranged outside the conductors and the flame-resistant glass fiber filled rope, a mica layer is arranged outside the flame-resistant belt, a flame-resistant PE protection layer is arranged outside the mica layer, an armor layer is arranged outside the flame-resistant PE protection layer, a nylon 12 sheath layer is arranged outside the armor layer, a carbon pipe is arranged outside the nylon 12 sheath layer, and a capsaicin rat-proof and termite-proof layer is arranged outside the carbon pipe. The invention further provides a preparation method of the electric wire and cable. The high-effect rat-proof and termite-proof electric wire and cable is provided with multiple rat-proof and termite-proof layers and multiple flame-resistant layers.

Owner:TAICANG SUSHENG ELECTRICAL TECH

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveCN1847351AGood flame retardancyImprove flame retardant performanceNon-macromolecular adhesive additivesSynthetic resin layered productsCopper foilChemistry

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a phytate compound, and (E) a curing accelerator. Also provided are an adhesive sheet having a layer including the above composition, and a protective layer for covering the layer including the composition; a coverlay film having an electrically insulating film, and a layer including the above composition provided on top of the film; and a flexible copper-clad laminate having an electrically insulating film, a layer including the above composition provided on top of the film, and copper foil. Further provided are a process for producing the adhesive sheet, a process for producing the coverlay film, and a process for producing the flexible copper-clad laminate. The halogen-free adhesive composition yields a cured product, on curing, that exhibits excellent flame retardancy and electrical characteristics (anti-migration properties). The composition can be used for producing an adhesive sheet, a coverlay film, and a flexible copper-clad laminate.

Owner:SHIN ETSU CHEM IND CO LTD

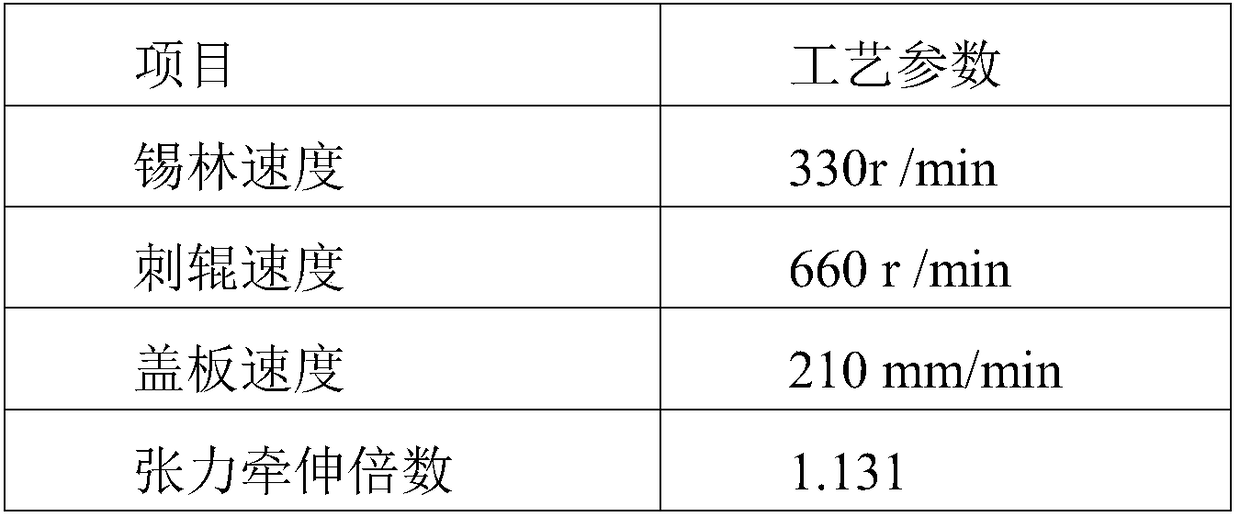

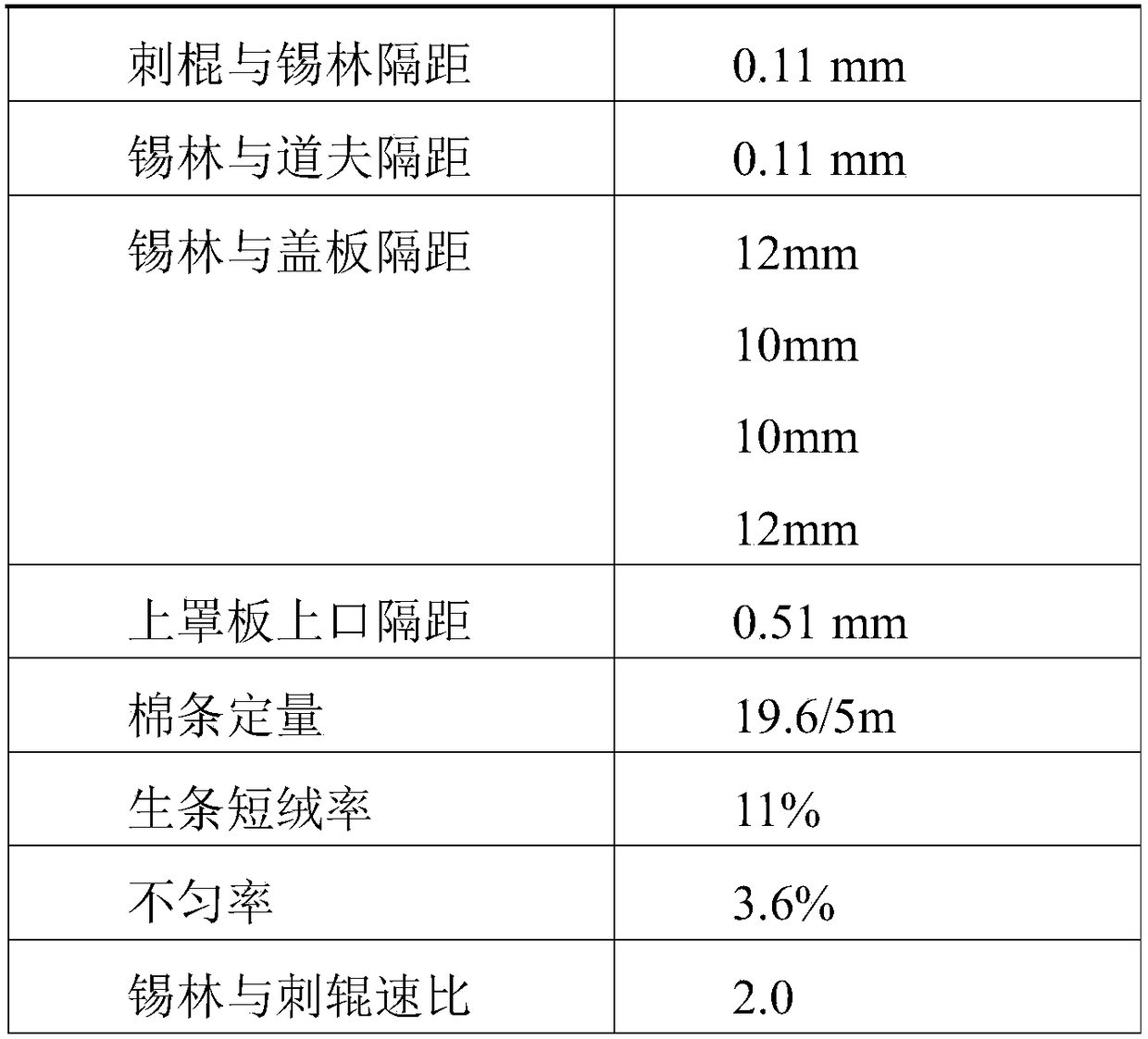

Flame retardant yarn, protective fabric and production process

The invention relates to flame retardant yarn, protective fabric and a production process of the flame retardant yarn. The flame retardant yarn is prepared by the following raw materials, by mass: 56%-64% of flame retardant viscose fibers, 23%-31% of para-aramid 1414, 6%-14% of polyamide and 2%-6% of aramid-based conductive fibers. The flame retardant yarn is blended by a specific proportion of the flame retardant viscose fibers, para-aramid 1414, polyamide and aramid-based conductive fibers, is excellent in flame retardancy and high in strength, and can be used to produce 32 flame retardant yarn with high wearability to meet performance requirements of finished garments.

Owner:JIHUA 3542 TEXTILE CO LTD

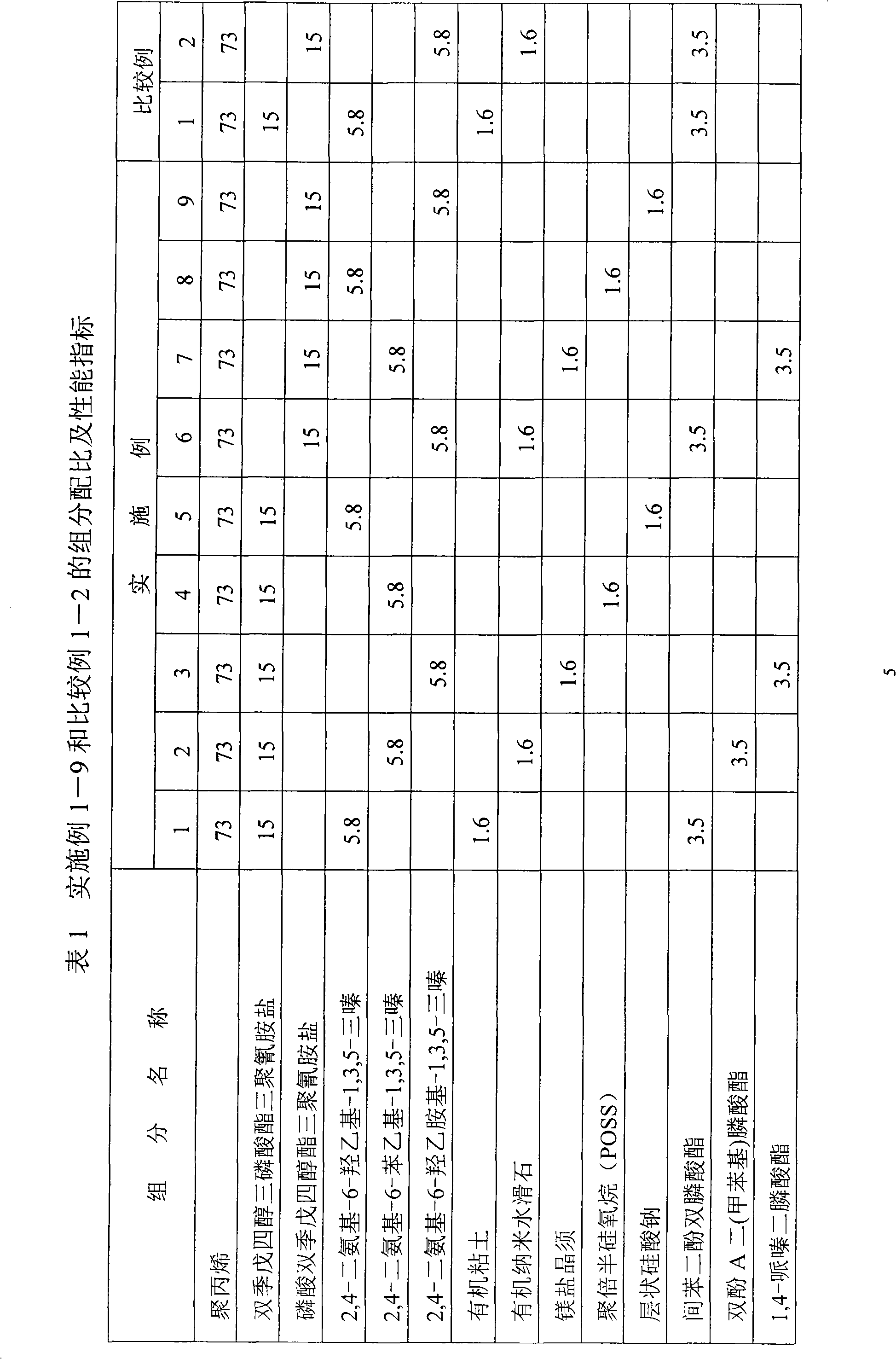

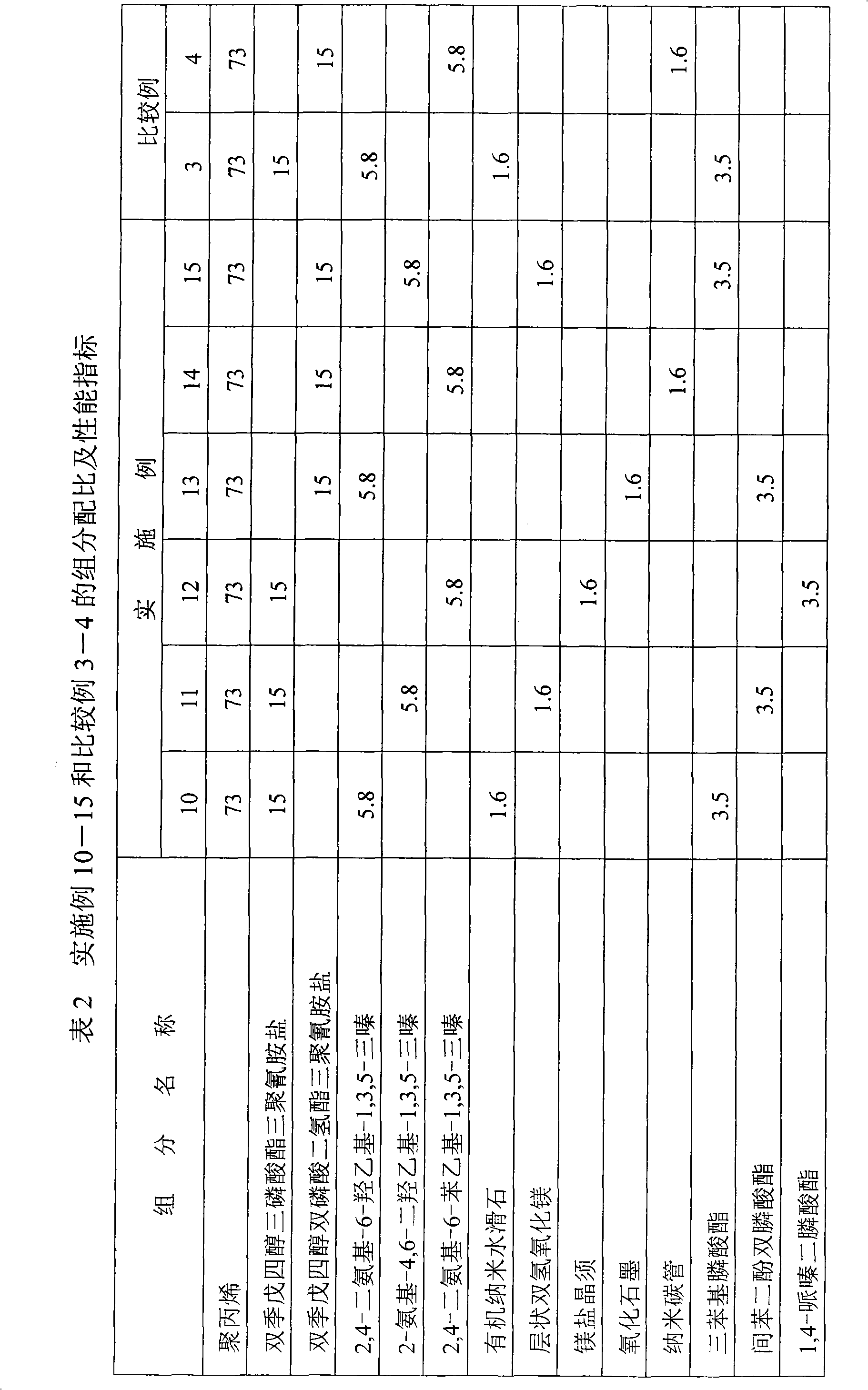

Preparation method of high-gloss high-rigidity no-precipitate environment-friendly flame-retardant polypropylene

The invention aims to provide a high-flame-retardancy high-gloss high-rigidity low-precipitate low-cost flame-retardant polypropylene which is easy to process and a preparation method thereof. The technical scheme adopted by the invention is as follows: the flame-retardant polypropylene is prepared from the following components in percentage by weight: 45% of polypropylene homopolymer, 45% of polypropylene copolymer, 4% of flame retardant, 2% of synergistic flame retardant, 8% of compatilizer, 0.5% of lubricant, 0.2% of antioxidant and other processing assistants. Compared with the prior art, the invention has the following effects: 1. the flame-retardant polypropylene has favorable flame retardancy, and can not produce precipitate; 2. the heat resistance of the flame retardant is good, the processability of the product is fine, and the influences on the mechanical properties of the flame-retardant polypropylene, such as toughness, strength and the like, are small due to the low addition amount of the flame retardant; 3. the flame-retardant polypropylene can not generate polybrominated dibenzodioxin (PBDD), polybrominated dibenzofuran (PBDF) and other carcinogenic substances, thereby being relatively environment-friendly; and 4. due to the adoption of the compatilizer, the flame-retardant polypropylene has high precipitation resistance and high surface gloss.

Owner:FOSHAN SHUNDE WHEELING PLASTIC

Flame-retardant thermal-insulating antistatic coating and preparation process thereof

InactiveCN102115629AGood flame retardancyImprove the thermal insulation performance of coatingsFireproof paintsAnti-corrosive paintsChemistryPlasticizer

The invention relates to a flame-retardant thermal-insulating antistatic two-component coating and a preparation process thereof. The flame-retardant thermal-insulating antistatic two-component coating comprises epoxy resin, rutile type titanium dioxide, hollow microspheres, decabromdiphenylethane, antimonous oxide, aluminum hydroxide, a plasticizer, an antistatic agent, an epoxy hardener, an aid and the like, and is prepared by the steps of dispersing in a high-speed dispersing kettle, mixing and the like. The coating has high adhesion, water resistance, acid and alkali resistance, and antistatic property, has obvious thermal-insulating and flame-retardant effects, is convenient to construct, and can be constructed under the condition of high humidity and cured at normal temperature. The coating is mainly used for thermal insulation of rock stratums at the bottoms of mines, and can slow down the heat transfer of high-temperature rock stratums so as to achieve the effect of reducing ambient temperature.

Owner:BEIJING UNIV OF CHEM TECH

Double-layer metal cladded flame-retardant electric cable

InactiveCN102254594ALow smoke productionGood flame retardancyPlastic/resin/waxes insulatorsInsulated cablesAluminiumCopper-clad steel

The invention relates to a double-layer metal cladded flame-retardant electric cable which is manufactured by cladding an insulation layer and a conductive core wire, wherein the conductive core wire is manufactured by cladding double layers of different metal materials; the insulation layer is made of a smokeless and flame-retardance nano modified polyvinyl hydrocarbon polymer insulation material; a flame-retardance jacket is cladded outside the insulation layer; and the conductive core wire is made of copper clad aluminum, copper clad steel or aluminum clad steel. The double-layer metal cladded flame-retardant electric cable is safe and reliable, has less smoke generation amount in a combustion environment when accidents happen, better flame retardance and no harmless gases or corrosivegases and can be used for effectively reducing accidental loss and reducing material cost.

Owner:贵州长江通信实业有限公司

Fine cell flexible polyurethane foam

Owner:BRIDGESTONE CORP

Dual blend-knitted flame-retardant fiber yarn

The invention discloses a dual blend-knitting flame-retardant fiber yarn. The dual blend-knitting flame-retardant fiber yarn is formed by blend-knitting flame-retardant yarn, anti-static yarn and high-temperature-resistant yarn. The flame-retardant yarn is formed by blend-knitting calcium alginate fiber and PMIA fiber, the anti-static yarn is formed by blend-knitting polyaniline conductive terylene fiber and conductive polyvinyl alcohol fiber, and the high-temperature-resistant yarn is formed by blend-knitting polyarylsulfone amide fiber and polyimide fiber. The dual blend-knitting flame-retardant fiber yarn is made from, by weight, 63 percent to 71 percent of the flame-retardant yarn, 11 percent to 15 percent of the anti-static yarn and 18 percent to 22 percent of the high-temperature-resistant yarn. The dual blend-knitting flame-retardant fiber yarn is formed through dual blend-knitting, and the knitted yarn has the advantages of being compact in texture, good in flame retardance, conductivity and anti-static performance, resistant to high temperature, firm and durable in material and long in service life.

Owner:淄博大洋阻燃制品有限公司

Wood/plastic composite floor board production process

InactiveCN103790338AGood flame retardancyStrong moisturizing performanceFlooringMoisture retentionWax

The invention relates to a wood / plastic composite floor board production process and belongs to the field of wood / plastic composite floor board processing. The production process includes the first step of carrying out drying and ungrease treatment on small wood angle materials, straw and other things and then carrying out smashing to enable the fineness degree to reach 70-100 meshes, the second step of getting and mixing fine powder raw materials, PVC, light calcium carbonate, calcium stearate, PVC processing agents, PVC foaming agents, PVC tensile modifying agents, compound stabilizers, plastic filling agents, soda, PE wax, stearic acid and PVC foaming modifiers at a high speed, wherein the mixing temperature is 100 DEG C to 130 DEG C, the rotation speed for mixing is 700 rounds per minute, the mixing time is 25 to 35 minutes, and the feeding speed of equipment is 100 to 800 rounds per minute, the third step of carrying out high-temperature extruding and forming on obtained wood / plastic mixed powder through a double-screw extruder and a shaping die, and making the wood / plastic mixed powder into basic plates, and the fourth step of enabling male grooves and female grooves to be cut in four faces of the basic plates through a double-end milling device, and carrying out printing on the basic plates through coating and curing process to form finished wood / plastic composite floor boards. The finished wood / plastic composite floor boards are friendly to environment, waterproof, resistant to corrosion, capable of preventing insects, high in mildew resistance, good in flame retarding performance, strong in moisture retention and convenient to install.

Owner:青岛德隆园木塑板业科技有限公司

Halogen-free flame retardant polyethylene-nylon heat shrinkable tube and preparation method thereof

The invention discloses a halogen-free flame retardant polyethylene-nylon heat shrinkable tube and a preparation method thereof. Specifically, the halogen-free flame retardant polyethylene-nylon heat shrinkable tube comprises the following components in parts by weight: 50-80 parts of polyethylene, 5-20 parts of nylon, 0.5-5 parts of segmented copolymer, 10-30 parts of phosphate retardant, 0.5-5 parts of active nano-calcium carbonate and 0.5-5 parts of nanosilicon dioxide. Compared with the prior art, the halogen-free flame retardant polyethylene-nylon heat shrinkable tube uses a physical crosslinking method, the polyethylene and the nylon do not form a covalent bond, the molecular structure is not broken, and the subsequent recovery is implemented; the materials do not contain hazardous substances like mercury, cadmium and hexavalent chromium, so that the requirements of the RoHS (Restriction of Hazardous Substances) directives of European Union are met, and the halogen-free flame retardant polyethylene-nylon heat shrinkable tube is harmless to the environment and human bodies; the halogen-free flame retardant polyethylene-nylon heat shrinkable tube is excellent in heat resistance, insulativity and fire resistance, and comparatively ideal in mechanical strength, and can be widely applied in various fields.

Owner:苏州泰斯拓伟机电设备有限公司

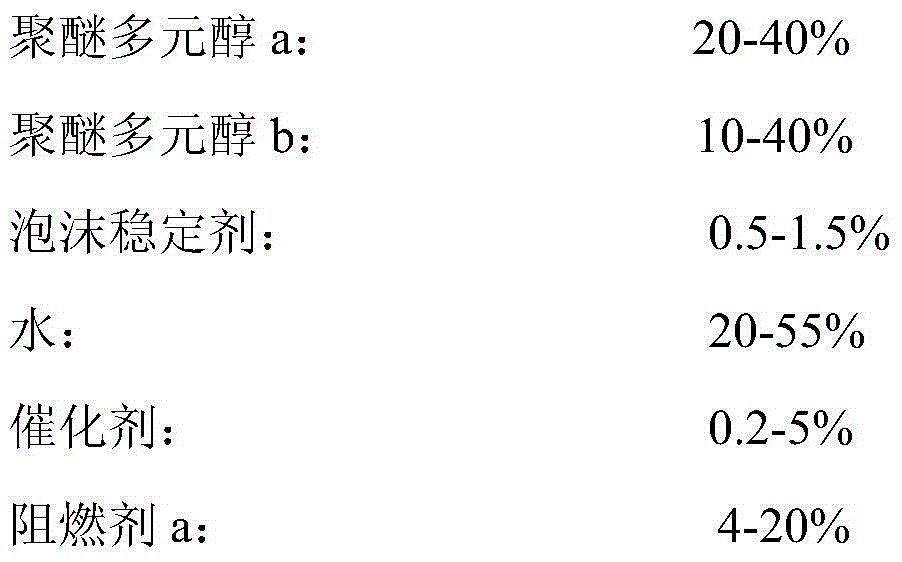

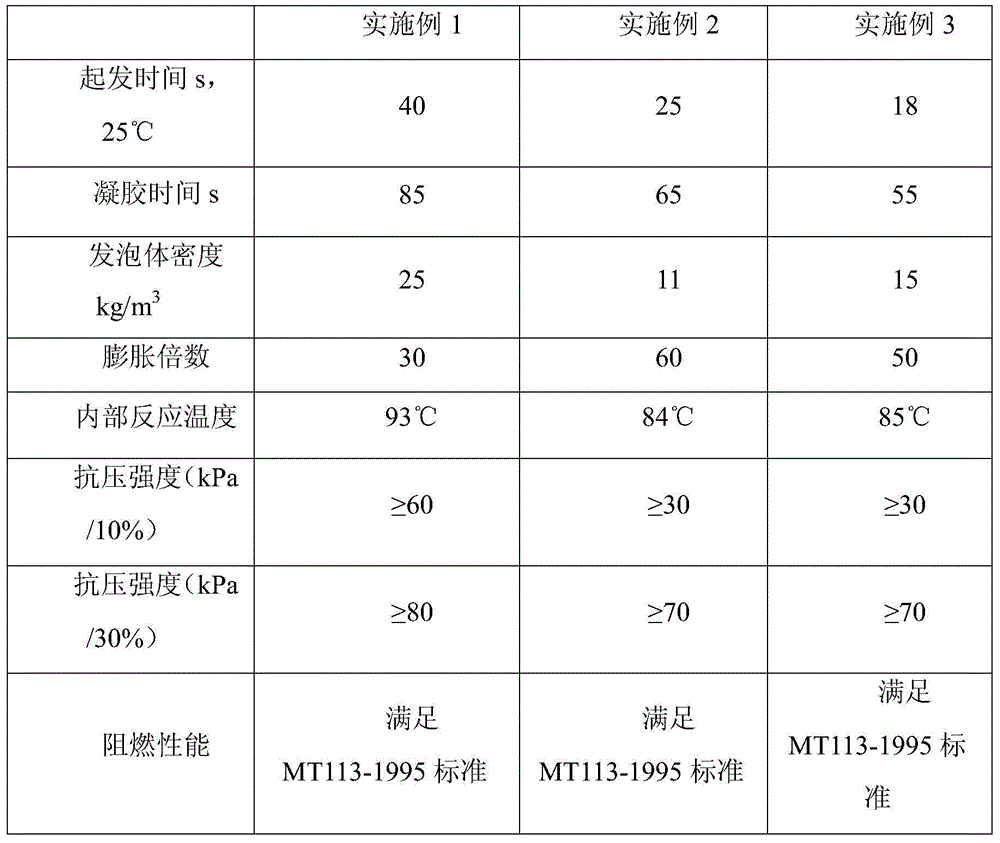

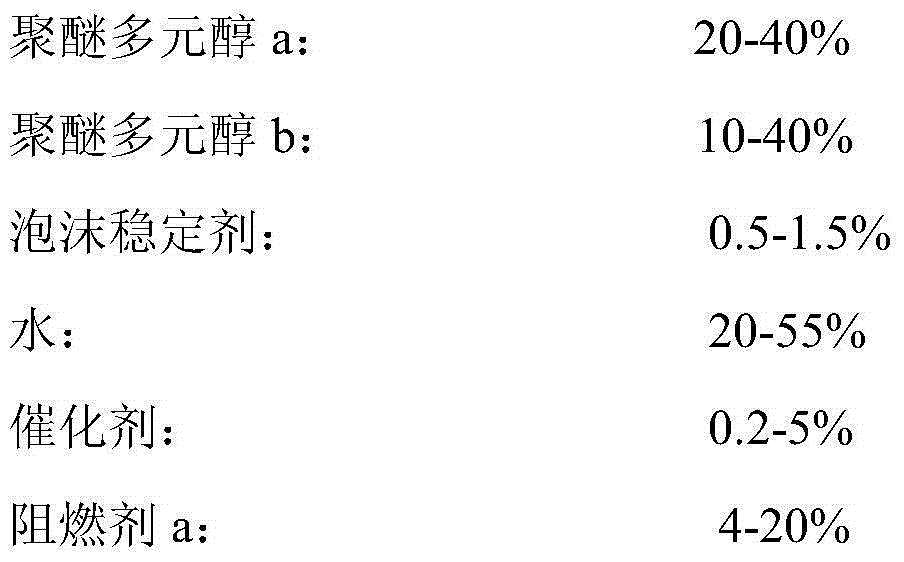

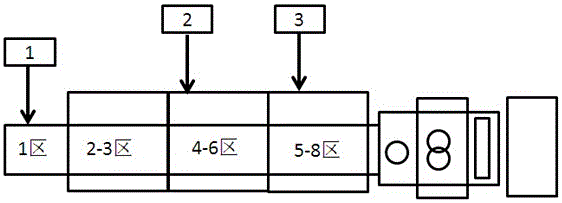

Polyurethane self-endothermic low-temperature filling material and preparation method thereof

The invention belongs to the technical field of preparation of polyurethane materials, and particularly relates to a polyurethane self-endothermic low-temperature filling material and a preparation method thereof. The polyurethane self-endothermic low-temperature filling material consists of a component A and a component B, wherein the component A consists of polyol, water, an auxiliary agent and a fire retardant; the component B consists of polyisocyanate and a fire retardant. The polyol, the auxiliary agent, the fire retardant and the polyisocyanate are selected, a large amounts of water is added into a reaction system, and heat generated by the reaction system is taken away through evaporation of the unreacted water, so that the internal reaction temperature is not higher than 95 DEG C and the problem of poor fire retardance is solved at a time; the polyurethane self-endothermic low-temperature filling material is good in fire retardance, and liquid raw material is convenient to transport, low in viscosity, good in fluidity and good in storage stability; the raw material is environment-friendly and pollution-free, does not contain a volatile solvent, does not produce any toxic gas, and is harmless to a human body; the preparation method is simple and easy to implement.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Liquid waterborne waterproof agent and preparation method thereof

The invention relates to a building material and particularly relates to a liquid waterborne waterproof agent and a preparation method thereof. The liquid waterborne waterproof agent disclosed by the invention contains aluminum silicate, an expanding agent, aluminum sulfate, sodium hydroxide and water. The liquid waterborne waterproof agent disclosed by the invention has the advantages of no organic solvent, no toxicity, no pollution to the environment, favorable flame-retardant performance, compact crystallization, water resistance, hydrophobility and aging resistance, capabilities of greatly improving the durability of a concrete structure and improving the compression strength and low cost; and the liquid waterborne waterproof agent is more ideal waterborne waterproof coating.

Owner:李鹏涛

Flame retardant rubber composition and obtained therefrom, rubber product and electric wire coating material

InactiveUS20090099293A1Good flame retardancySatisfactory mechanical strengthRubber insulatorsMonomerElectrical wiring

The present invention lies in a flame-retardant rubber composition comprising, as essential components, a synthetic rubber (a component A), a flame-retardant (a component B), sulfur (a component C) and a polyfunctional monomer la component D), wherein an amount of the component B is 10 to 200 parts by masse an amount of the component C is 0.1 to 15 parts by mass and an amount of the component D is 3 to 30 parts by mass, all relative to 100 parts by mass of the component A. It is a technical task of the present invention to provide a flame-retardant rubber composition which has excellent flame retardancy and can give a fully satisfactory mechanical strength (particularly, tensile strength at break) even when subjected to steam cure generally regarded to be difficult to impart a strength.

Owner:JSR CORPORATIOON

Polycarbonate composition and preparing method thereof

The invention discloses a polycarbonate composition. The polycarbonate composition is prepared from, by weight, 50-90 parts of polycarbonate, 5-50 parts of polysiloxane-polycarbonate copolymer, 5-50 parts of fibrous filler and 0-10 parts of other adjuvants, wherein the sum of the weight parts of the components is 100 parts. The fibrous filler comprises a component I and a component II, wherein the component I is composed of fibrous filler bodies with the length of 100-300 micrometers and accounts for 30-50 wt% of the fibrous filler, and the component II is composed of fibrous filler bodies with the length of 400-800 micrometers and accounts for 10-20 wt% of the fibrous filler. Moreover, based on the total weight of the polycarbonate composition, the content of polydimethylsiloxane (PDMS) in the composition is 0.05-30%. According to the polycarbonate composition, the fibrous filler is distributed in the polycarbonate composition in a bimodal mode, while rigidity of the polycarbonate composition is enhanced, the obtained polycarbonate composition has flame retardance and excellent toughness, especially low-temperature toughness, and rigidity and toughness are balanced.

Owner:KINGFA SCI & TECH CO LTD

Thermoplastic resin composition with excellent flame retardancy and impact resistance

The invention discloses a thermoplastic resin compound with outstanding flame- proof and anti- vibration property. The component proportions are as follows: panlite 60- 90, polyacryl-nitrile- butadiene- polystyrene 10- 40, additional compatiable agent 1- 10, additional phosphate compound 5- 15, additional polyorganosilicon oxidant 1- 10, additional metal oxidant or inorganic acidic metal salt 1- 5. The product is characterized by environmental protection, high- efficiency flame proof and good mechanical property.

Owner:浙江荣泰塑胶有限公司 +1

Flame-retardant resin composition and molded body using same

The present invention provides a flame retardant resin composition, characterized in that, with respect to 100 parts by mass of the resin component (A), it contains more than 100 parts by mass and not more than 300 parts by mass of magnesium hydroxide, and contains a specific amount of The resin of the propylene unit also contains a specified amount of acid and / or ester component, and the resin component (A) contains a specific content of ethylene-vinyl acetate copolymer and / or ethylene-(meth)acrylate copolymer, whether or not Polyolefin and / or ethylene-(meth)acrylic acid copolymer modified with saturated carboxylic acid or its derivative, acrylic rubber containing (meth)acrylic acid as a copolymerization component, polypropylene.

Owner:FURUKAWA ELECTRIC CO LTD

Environment-friendly low-smoke flame-retardant rubber cable material and preparation method thereof

InactiveCN104961928ALow smoke productionGood flame retardancyRubber insulatorsEnvironmental resistanceOxide

The invention relates to a cable material and a preparation method thereof, in particular to an environment-friendly low-smoke flame-retardant rubber cable material and a preparation method thereof. The environment-friendly low-smoke flame-retardant rubber cable material consists of, by weight, 40-100 parts of natural rubber, 40-80 parts of chloroprene rubber, 30-40 parts of butadiene-acrylonitrile rubber, 4-5 parts of stearic acid, 4-5 parts of coupling agent, 5-6 parts of zinc oxide, 4-5 parts of stabilizing agent, 5-6 parts of antioxidant BHT, 3-5 parts of accelerant, 100-120 parts of flame retardant and 60-100 parts of filling agent, wherein the main component of the natural rubber is polyisoprene, the natural rubber is one of air-dried rubber pieces and crepe, the accelerant is rubber accelerant TMTD, and the chloroprene rubber is an elastomer generated by using chloroprene as a main raw material through alpha-polymerization. The environment-friendly low-smoke flame-retardant rubber cable material has the advantages that the cable material has the advantages of low smoke, flame retarding and weather proofing and is environment-friendly and safe, the prepared cable materials is good in physical and mechanical performance and machining manufacturability and easy to machine, the raw materials are more environment-friendly and is low in toxicity, and popularization strength is large.

Owner:梁忠顺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com