Weather-resistant, flame retardant and impact-resistant polystyrene material, and preparation method

A polystyrene and polystyrene resin technology, applied in the field of polystyrene materials and preparation, can solve the problems of reducing the strength and toughness of the material, increasing the impact strength, increasing the molding of the material, etc., and achieves easy molding, high weather resistance, Production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

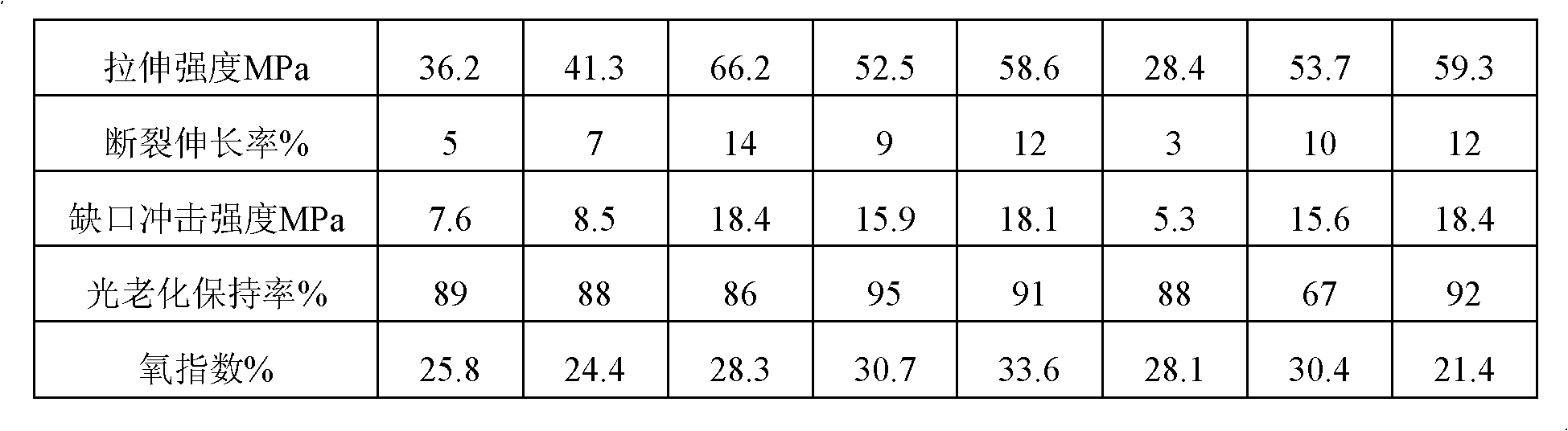

Embodiment 1

[0035] (1) Weigh 100 parts of polystyrene resin, 24 parts of styrene-butadiene-styrene copolymer, 8 parts of nano-calcium carbonate (average particle diameter is 60nm), 0.8 part of N-cyclohexylethanolamine and [β- (3,5 di-tert-butyl 4-hydroxyl-phenyl) propionic acid] pentaerythritol ester 0.6 part, 2-hydroxyl-4-methoxy benzophenone 0.5 part, epoxy resin coated ammonium polyphosphate 6 parts and 4 parts of melamine cyanurate, 1 part of zinc borate, and 2.8 parts of calcium stearate were placed in a reaction kettle, and stirred and mixed for 40 minutes at 85°C and normal pressure;

[0036] (2) After mixing, put the material into a screw extruder with a diameter of 54mm for granulation. The screw length-to-diameter ratio is 35, the rotation speed is 65r / min, and the segmented temperature of the barrel is: 170-180°C, 190-200°C, 200~210℃, head temperature 195~200℃;

[0037] (3) After granulation, dry the pellets at 85°C for 2 hours before injection molding. The injection molding t...

Embodiment 2

[0040] (1) Weigh 100 parts of polystyrene resin, 20 parts of EPDM rubber, 15 parts of nano-titanium dioxide (average particle diameter is 50nm), 1.0 parts of stearyl thiodipropionate and [β-(3,5 0.5 part of di-tert-butyl 4-hydroxy-phenyl) propionate] pentaerythritol ester, 0.2 part of tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite, polyphosphoric acid coated with polyurethane elastomer 5 parts of ammonium, 3 parts of melamine cyanurate, 2 parts of antimony trioxide, and 2.5 parts of zinc stearate were placed in a reaction kettle, and stirred and mixed at 90°C and normal pressure for 35 minutes;

[0041] (2) After mixing, put the material into a screw extruder with a diameter of 46mm to granulate. The screw length-to-diameter ratio is 32, the rotation speed is 80r / min, and the segmental temperature of the barrel is: 165-175°C, 180-190°C, 200~210℃, head temperature 190~195℃;

[0042] (3) After granulation, dry the pellets at 80°C for 2.5 hours before injection molding. The in...

Embodiment 3

[0045] (1) Take by weighing 100 parts of polystyrene resin, 32 parts of styrene-butadiene-styrene copolymer, 25 parts of nano barium sulfate (average particle diameter is 55nm), 0.6 part of dilauryl thiodipropionate and 0.4 parts of 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, 0.6 parts of 2-hydroxy-4-methoxybenzophenone, coated with epoxy resin Put 6 parts of ammonium polyphosphate, 6 parts of melamine octamolybdate, 4 parts of molybdenum oxide, and 3.5 parts of calcium stearate in a reaction kettle, and stir and mix at 80°C and normal pressure for 45 minutes;

[0046] (2) After mixing, put the material into a screw extruder with a diameter of 62mm to granulate. The length-to-diameter ratio of the screw is 40, the rotation speed is 55r / min, and the segmental temperature of the barrel is: 160-170°C, 180-190°C, 205~215℃, head temperature 185~190℃;

[0047] (3) After granulation, dry the pellets at 85°C for 2 hours before injection molding. The injection molding tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com