Patents

Literature

920 results about "EPDM rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EPDM rubber (ethylene propylene diene monomer rubber), is a type of synthetic rubber, which can be used in a wide range of applications. This is an M-Class rubber where the 'M' in M-Class refers to its classification in ASTM standard D-1418; the M class comprises elastomers having a saturated chain of the polyethylene type (the M deriving from the more correct term polymethylene). EPDM is made from ethylene, propylene and a diene comonomer that enables crosslinking via sulphur vulcanisation systems. The earlier relative of EPDM is EPR, ethylene-propylene rubber, that contains no diene units and can only be crosslinked using radical methods such as peroxides. Dienes used in the manufacture of EPDM rubbers are ethylidene norbornene (ENB), dicyclopentadiene (DCPD), and vinyl norbornene (VNB).

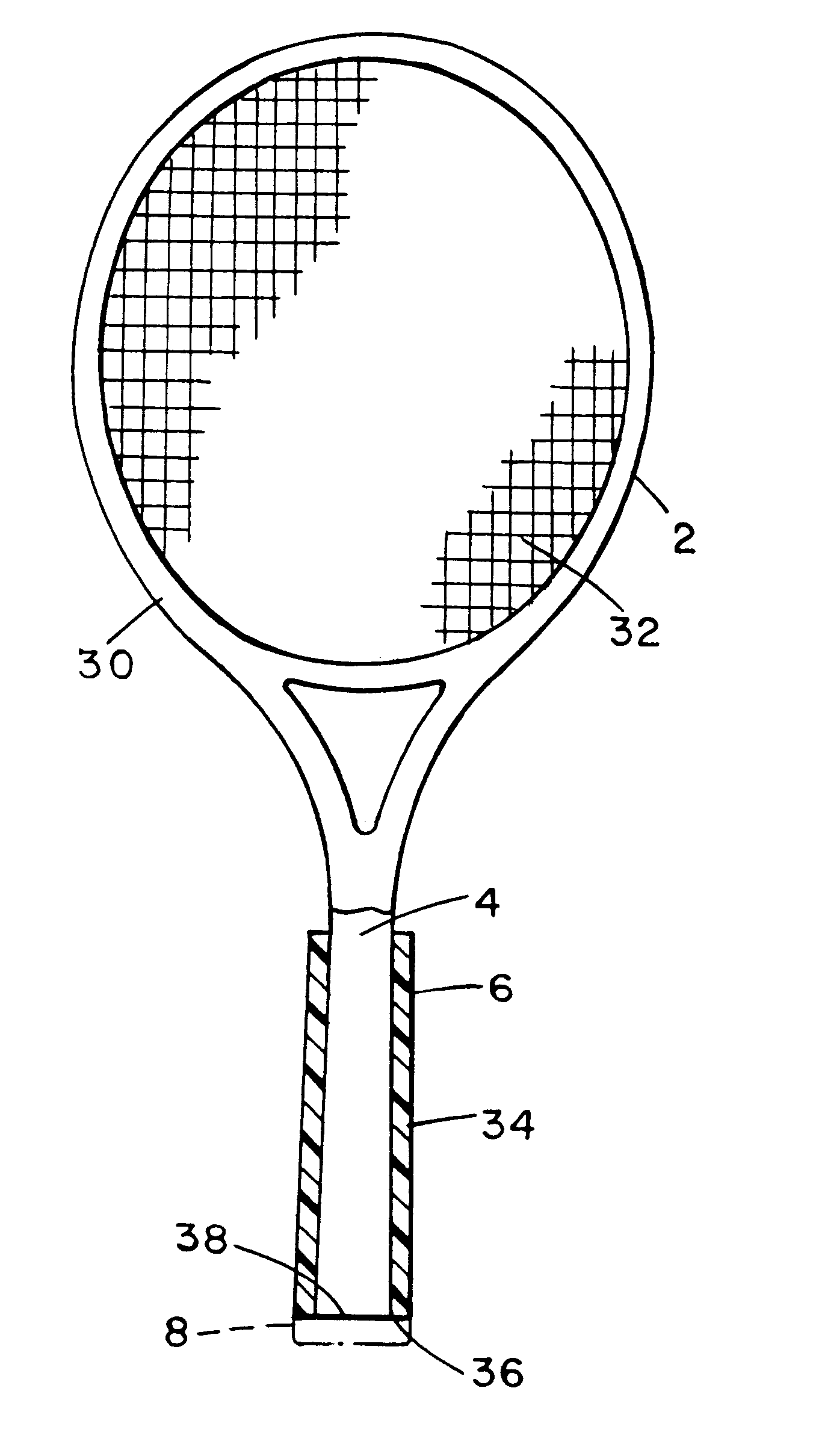

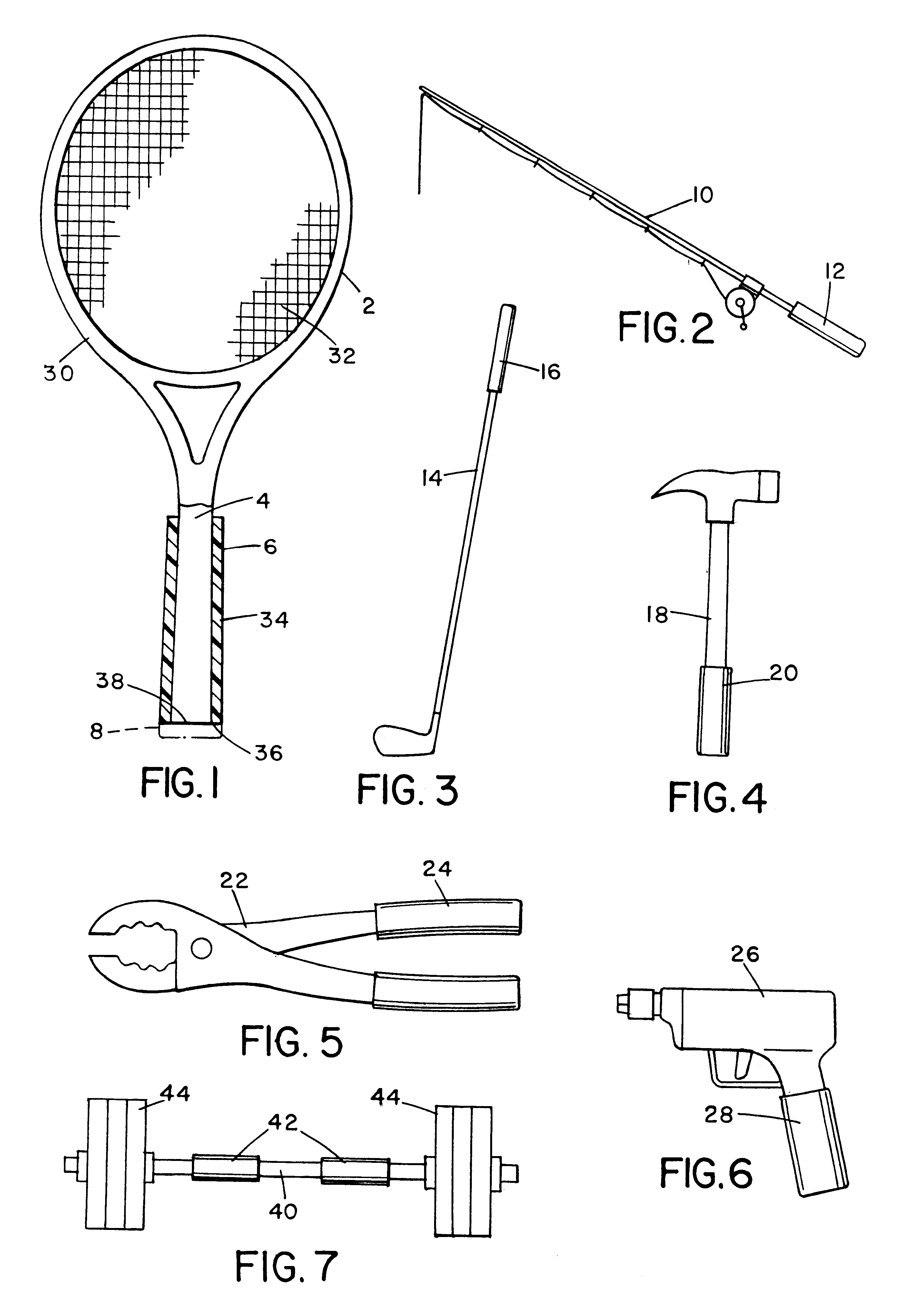

Low-odor single element equipment grip

A low odor grip is disclosed for a handle of a hand-held implement such as a sports implement or a manual or electric tool which is essentially free of disagreeable odors, which can be installed and quickly shrunk into a tight vapor resistant grip within a matter of a few minutes rather than requiring extended periods of time, and can be installed without the need for any application of heat or use of special tools, equipment or materials. The present device is therefore easy to install, merely sliding over the handle while in dilated state and then allowed to shrink and set by evaporation of the solvent, and thus can be satisfactorily installed in both fabrication facilities and in the field either as an original or replacement grip. The invention also includes an implement fitted with such grip. Representative implements include sports implements such as golf clubs, tennis racquets, weight bars and fishing poles, as well as tools such as hammers, drills, pliers, shovels, axes, and the like. The grip is preferable made of a swellable elastomeric material, preferably a natural or synthetic rubber. Suitable rubbers include EPDM rubber, neoprene or chlorosulfonate polyethylene (Hypalon(TM)) rubber, of which EPDM rubber is preferred.

Owner:JONES MICHAEL G

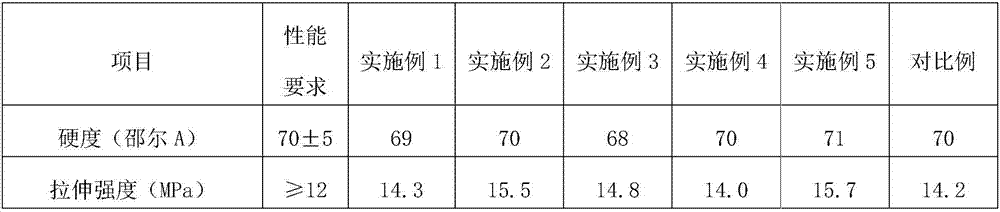

Sealing strip using epdm rubber as host material

ActiveCN101230248AReduce viscosityInhibitionEngine sealsOther chemical processesPolyethylene glycolEPDM rubber

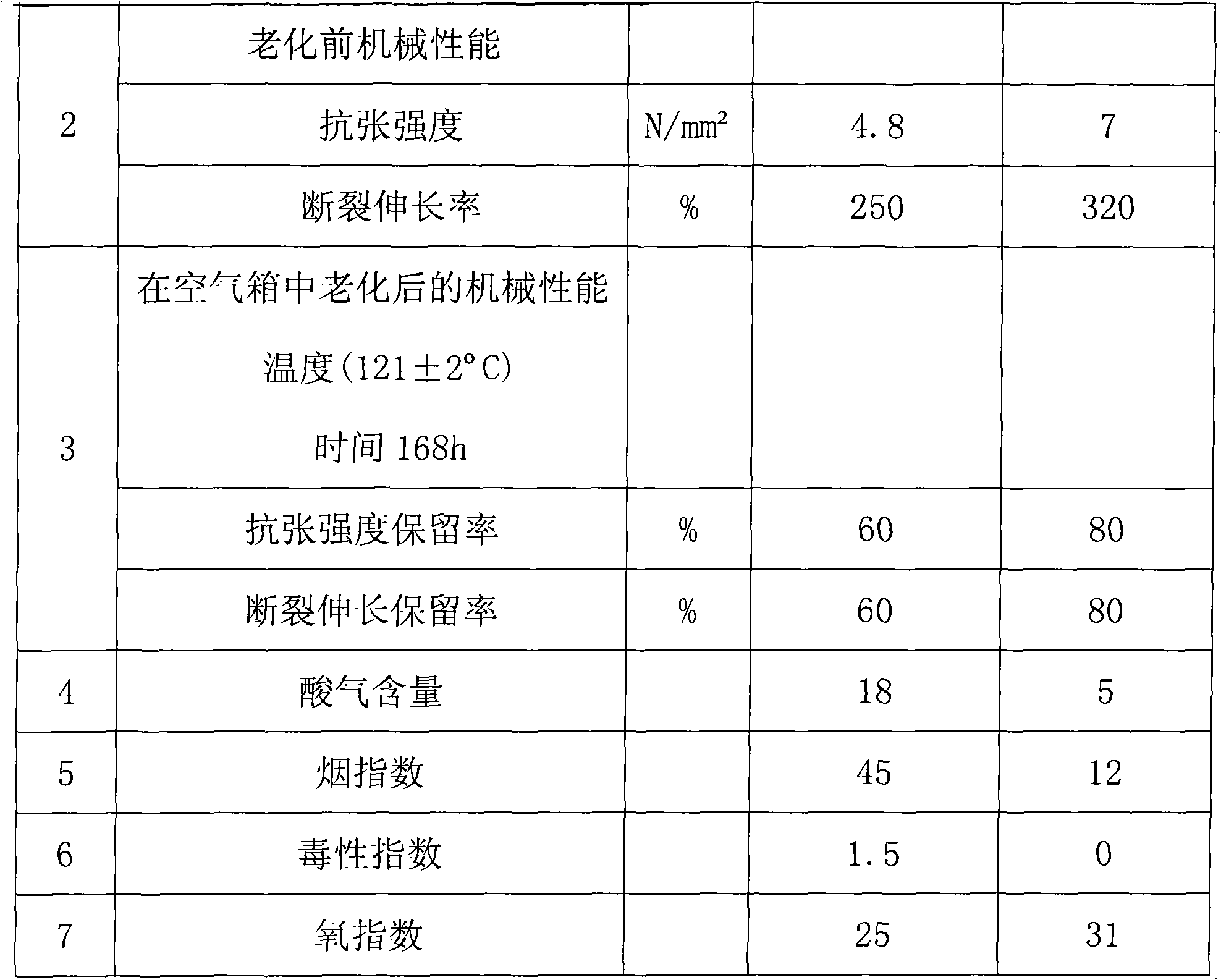

The invention discloses a sealing strip which takes EPDM as the host material and the preparing method, which is characterized in that the composition contains the following constituents (expressed by wt percent): EPDM 26 percent, zinc oxide 1-1.5 percent, stearic acid 1-6 percent, polyethyleneglycol 0.5-1.6 percent, hydrafil 10-32 percent, zinc borate 5-16 percent, orthophosphoric lipid 3-16 percent, black carbon 7-20 percent, paraffin oil 7-21 percent, calcium oxide 2-5 percent, sulfur 0.25-0.5 percent and accelerant 0.65-1.5 percent. The invention ensures the mechanical performance and extrusion performance, is convenient for extrusion, adopts the hydrafil, the zinc borate, and a inflaming retarding system; is the most realistic non-halogen inflaming retarding; can produce a lot of crystal water on the surface of the burning substance; can separate the burning substance from contacting oxygen, and then can perform the inflaming retarding effect; can inhibit the gases produced by the burning substance, accordingly does not produce smog.

Owner:DANYANG WANBEN AUTOMOTIVE PARTS

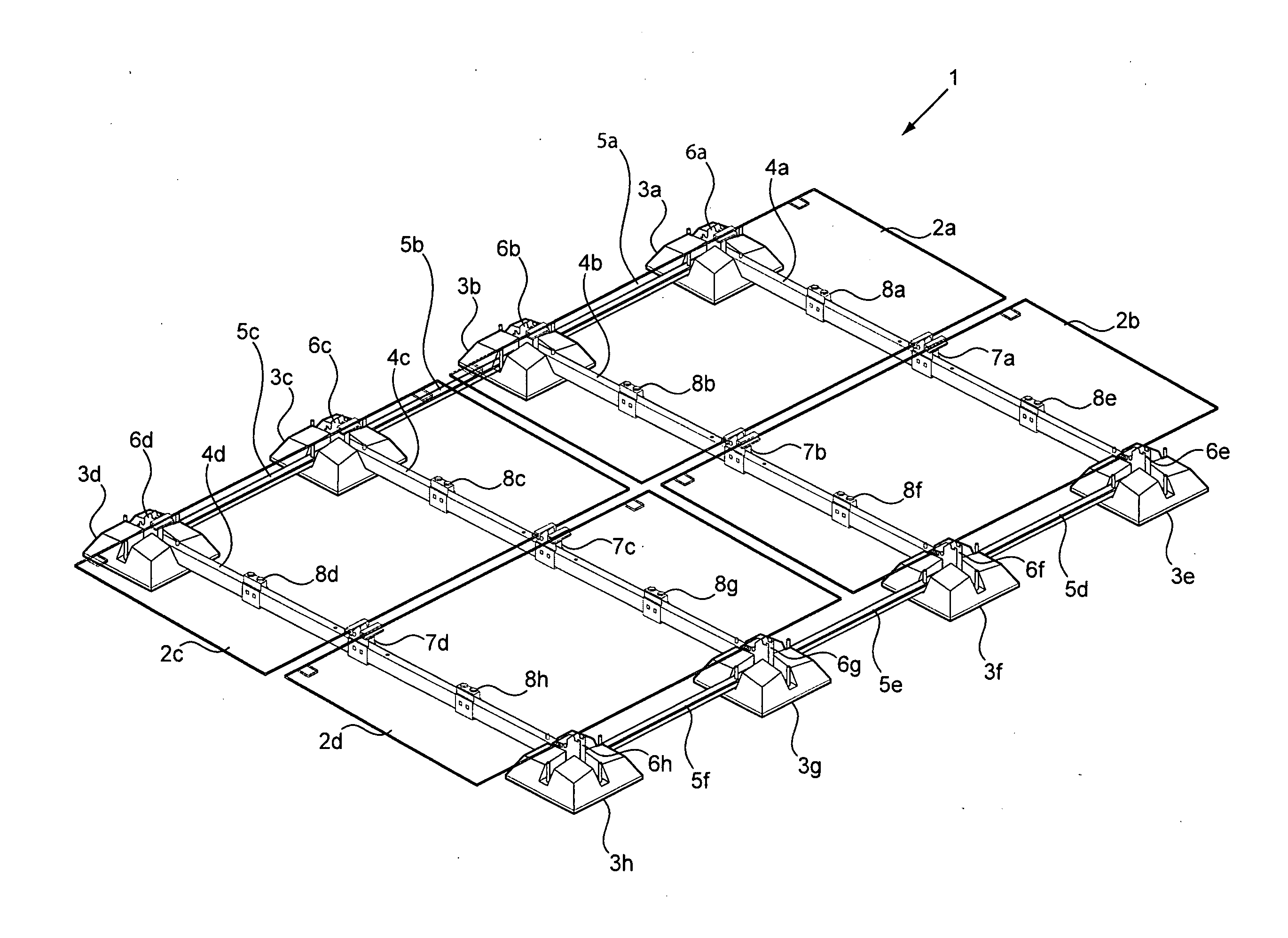

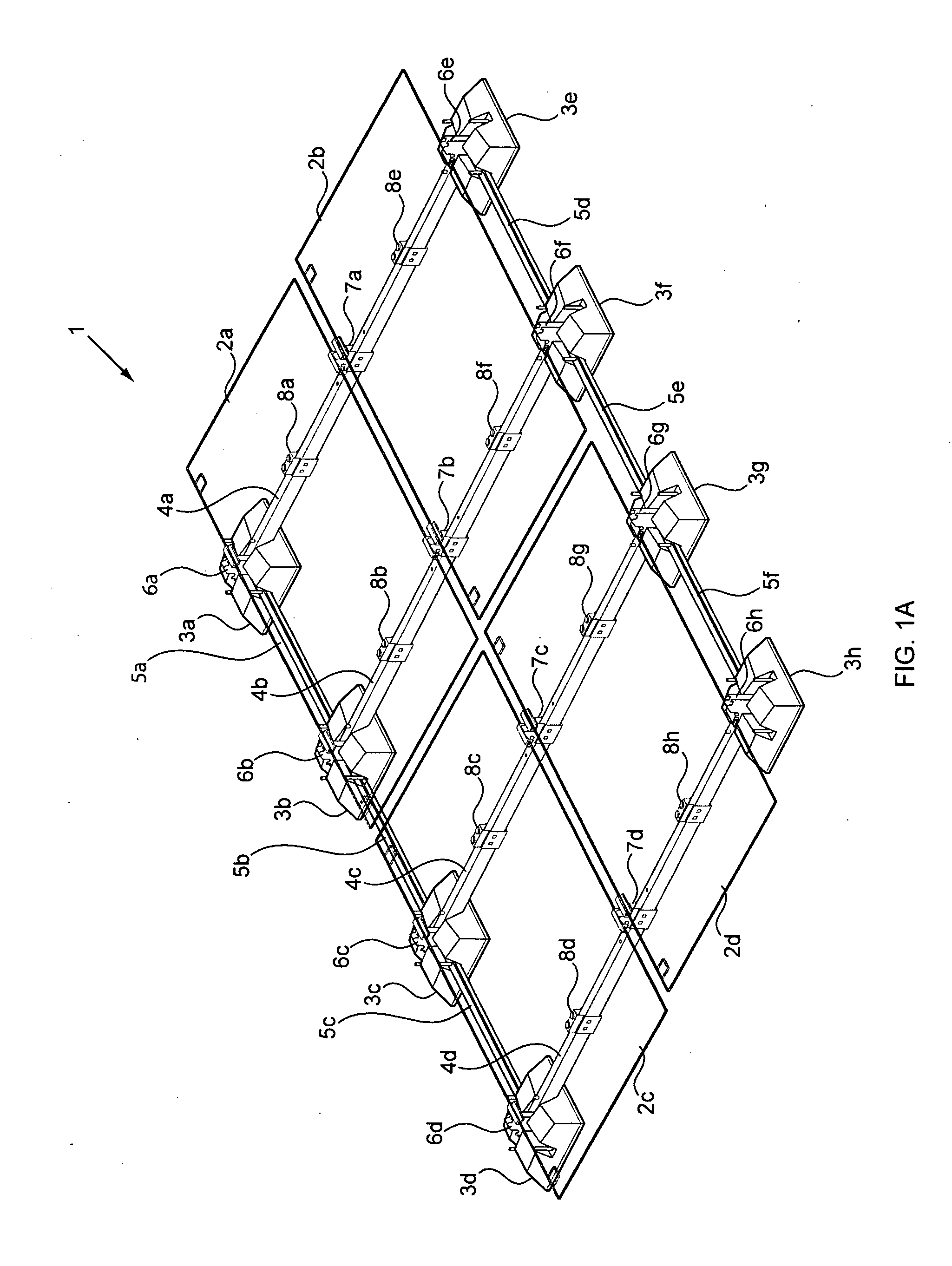

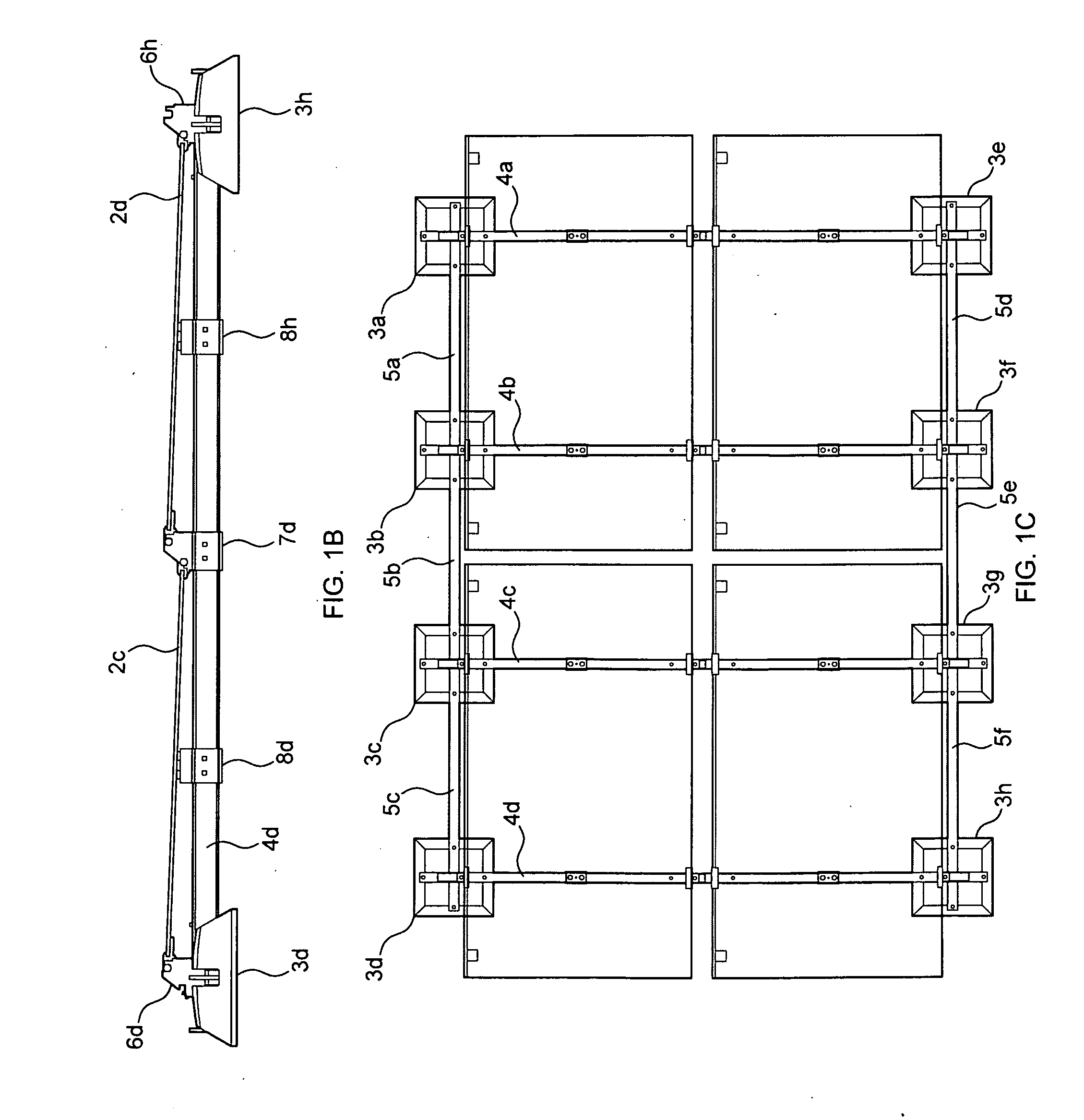

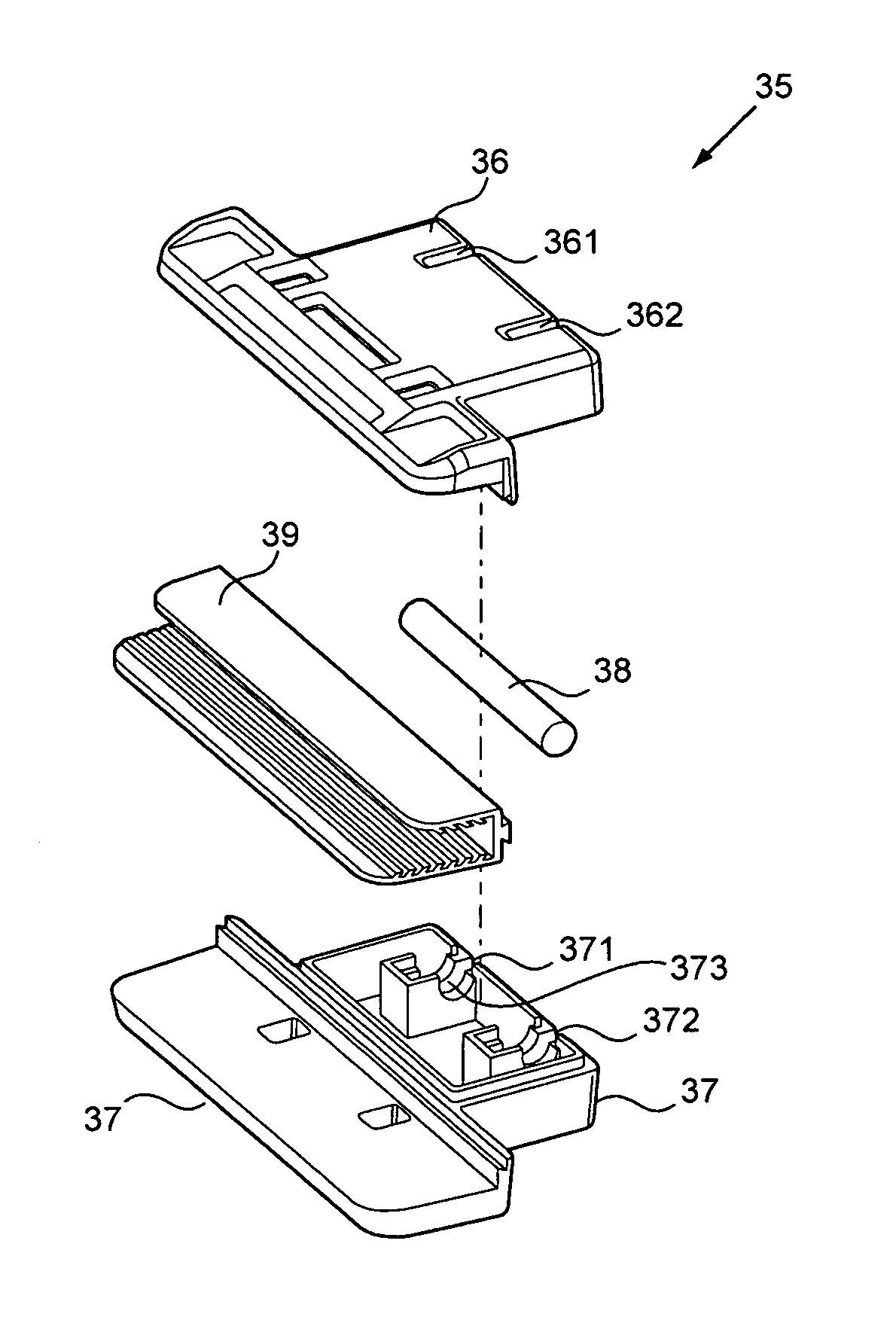

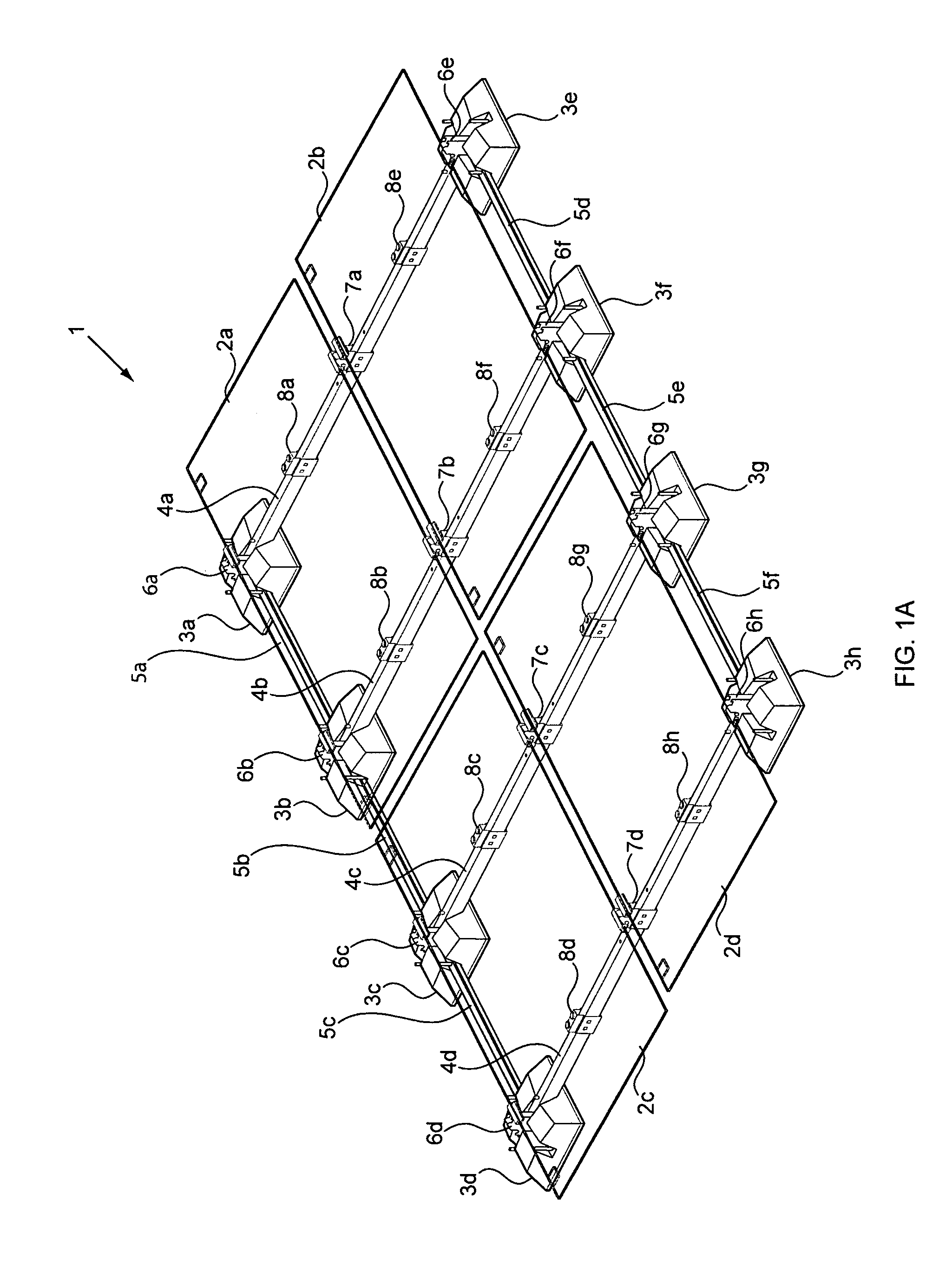

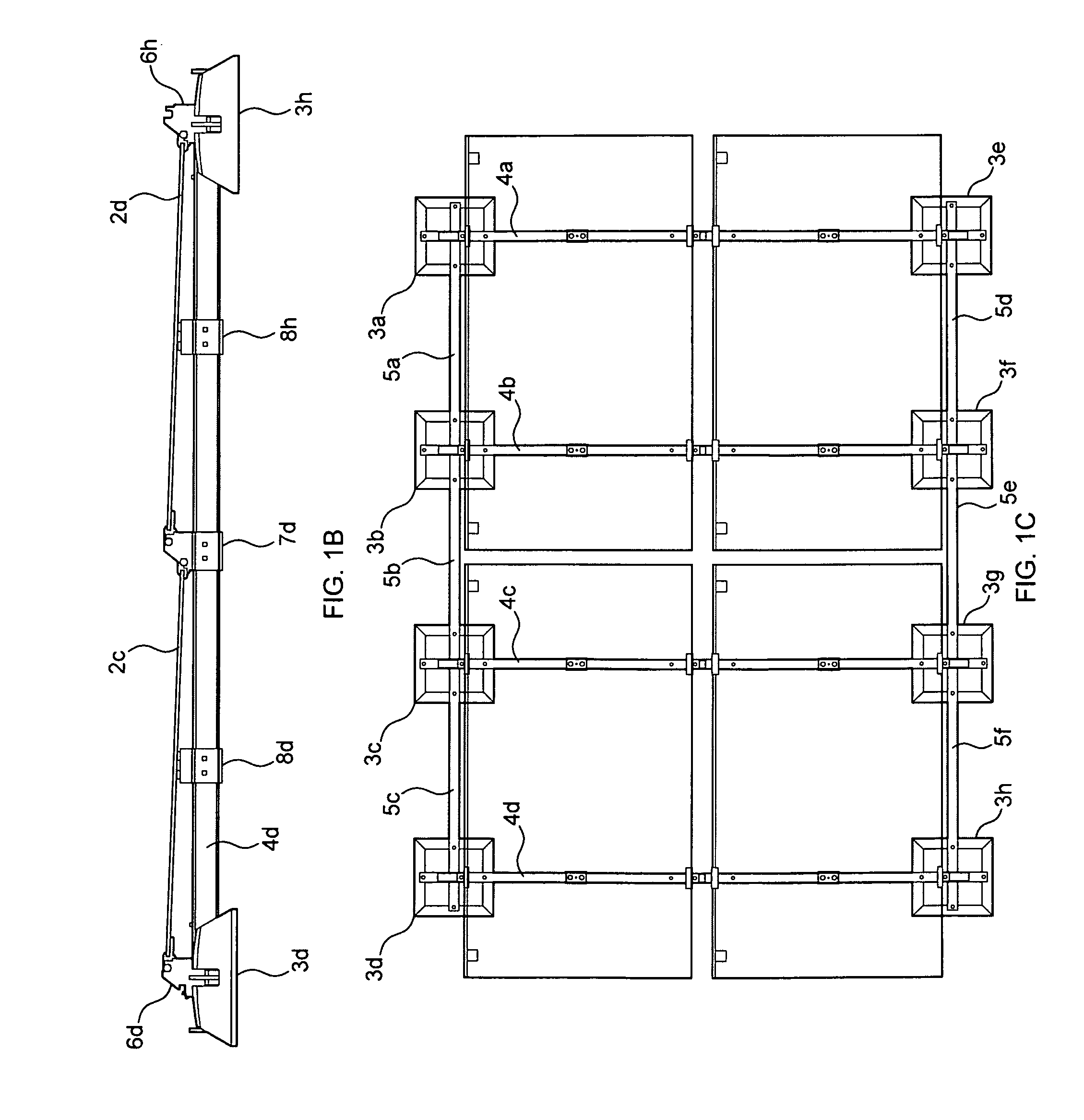

Photovoltaic panel clamp

ActiveUS20110088740A1Easy to insertAvoid easy removalPhotovoltaic supportsSolar heating energyEPDM rubberElectrical and Electronics engineering

A photovoltaic panel clamp includes an upper and lower section. The interface between the assembled clamp halves and the module edge is filled by a flexible gasket material, such as EPDM rubber. The gasket preferably has small, finger like protrusions that allow for easy insertion onto the module edge while being reversed makes it more difficult to remove them from the module once installed. The clamp includes mounting posts or an integral axle to engage a bracket. The clamp also may include a locking tongue to secure the clamp to a bracket.

Owner:COROSOLAR LLC +1

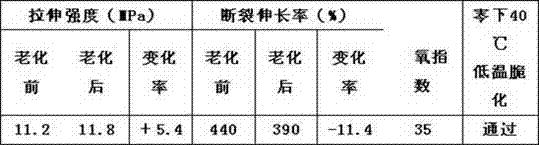

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

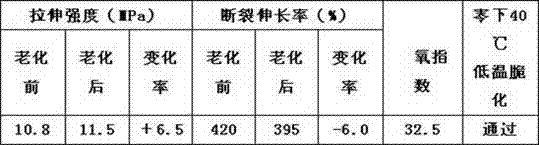

Ethylene propylene rubber insulation material for longitudinal high-voltage watertight cable of ships and warships and production method thereof

InactiveCN101831115AMeet the needs of useGuaranteed flexibilityRubber insulatorsParaffin waxPolymer science

The invention discloses an ethylene propylene rubber insulation material for longitudinal high-voltage watertight cables of ships and warships and a production method thereof. The method comprises the following steps: adding the ethylen e-propylene-diene mischpolymere, age resister and fire retardant into a banbury for banburying for 3.5min; adding argil, white carbon black and paraffin wax for continued banburying for 2min; adding active agent, and discharging after banburying for 1.5min; filtering the rubber compound with a three-layer filter screen (namely a 60 mesh filter screen, a 60 mesh filter screen and a 80 mesh filter screen) on a rubber filter; and beating into cornucopla on a double-roller mill, adding vulcanizer and co-crosslinker, then beating into cornucopla for 7 times, grinding and slicing after finishing the steps, and then cooling, wherein the materials are as follows in parts by weight: 100 parts of ethylen e-propylene-diene mischpolymere, 1-5 parts of vulcanizer, 1-4 parts of age resister, 15-70 parts of fire retardant, 0.5-10 parts of active agent, 10-20 parts of argil and 2-4 parts of paraffin. The prepared insulation material has the characteristics of low smoke, no halogen, fire resistance, high machinery strengthen, and high insulation resistance, good flexibility, elasticity and viscosity, and can be used for the ships and warships.

Owner:嘉兴君宏光学有限公司

Photovoltaic panel clamp

ActiveUS8191320B2Easy to insertAvoid easy removalPhotovoltaic supportsSnap fastenersEPDM rubberElectrical and Electronics engineering

A photovoltaic panel clamp includes an upper and lower section. The interface between the assembled clamp halves and the module edge is filled by a flexible gasket material, such as EPDM rubber. The gasket preferably has small, finger like protrusions that allow for easy insertion onto the module edge while being reversed makes it more difficult to remove them from the module once installed. The clamp includes mounting posts or an integral axle to engage a bracket. The clamp also may include a locking tongue to secure the clamp to a bracket.

Owner:COROSOLAR LLC +1

Nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket and preparation method thereof

The invention discloses a nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket. Raw materials for the nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket comprise, by weight, 135 to 145 parts of chlorosulfonated polyethylene rubber CSM2305, 10 to 15 parts of butyl rubber CBK139, 10 to 15 parts of Lanxess 2470 EPDM rubber, 2 to 5 parts of phthalate, 3 to 5 parts of propanediol sebacate polyester, 2 to 5 parts of n-butyl methacrylate, 3 to 4 parts of zinc oxide, etc. The gasket provided by the invention has the advantages of good high temperature resistance, sealing performance and flame resistance, excellent resistance to corrosion, small changes in its volume and hardness when working in mediums like an acid, an alkali and oil for a long time, no adherency onto the surface of a metal, a small friction coefficient, good wear resistance, flexibility of bonding with a sealing surface, good resistance to weathering ageing and ozone ageing, durability, etc.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Ultraviolet light crosslinked EPT rubber cable insulation material and preparation thereof

ActiveCN101434728AHigh volume resistivityIncrease productivityRubber insulatorsInsulated cablesCross-linkPolymer science

The invention discloses an ultraviolet cross-linking EPDM (ethylene propylene diene monomer) rubber cable insulation material and a preparation method thereof. The method is characterized in that: by weight, 100 portions of EPDM rubber, 100 portions to 120 portions of inorganic filling, 0.5 portion to 5.0 portions of ultrasonic initiator, 0.5 portion to 5.0 portions of polyfunctional cross-linking agent, 5.0 portions to 10.0 portions of softener, 0.8 portion to 1.2 portions of silane coupling agent and 0.01 portion to 1.0 portion of complex antioxidant are evenly mixed and extruded at the temperature of 100 DEG C to 150 DEG C, thereby obtaining the ultraviolet cross-linking EPDM rubber cable insulation material; then the wire core is fused and extruded coating to form an insulation layer or a protective coating; and ultraviolet cross linking is carried out under 200nm to 400nm of wave length and 400mW / cm<2> to 2000mW / cm<2> of light intensity. The cable insulation material has tensile strength of larger than 6.5MPa, elongation at break of higher than 300 percent and volume resistivity of higher 10<12>Omega question mark cm, and can pass a thermal aging test under the temperature of 135 DEG C for 168h.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Dynamic vulcanization of non-nitrile rubbers in fluoroplastic polymers

Processable rubber compositions contain a cured elastomer dispersed in a matrix comprising a thermoplastic material. The cured elastomer is present at a level of greater than or equal to 35% by weight based on the total weight of cured elastomer and thermoplastic material. The thermoplastic material comprises a fluorine containing thermoplastic polymer, and the cured elastomer comprises a non-nitrile rubber selected from the group consisting of acrylic rubber, EPDM rubber, butyl rubber, silicone rubber, butadiene rubber, isoprene rubber, and natural rubber. Methods for preparing the compositions involve dynamic vulcanization of the elastomer and thermoplastic components.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Hot melt pressure sensitive adhesive composition for providing water-tight joints in single-ply roofing membranes

InactiveUS20050043468A1Excellent tackExcellent quick stick propertyOrganic dyesAdhesivesThermoplasticPolymer science

An adhesive composition is provided for adhering together roofing materials such as EPDM rubber and thermoplastic polyolefin (TPO). The adhesive composition includes a rubbery polymer comprising a blend of a thermoplastic block copolymer and a polyisobutylene. The adhesive composition may further include a compatible tackifier and an amorphous polyolefin. The composition is a pressure sensitive adhesive which can be applied to roofing materials in a peel and stick manner and provides a long term, water-tight seal and high bond strength.

Owner:ADCO PROD INC

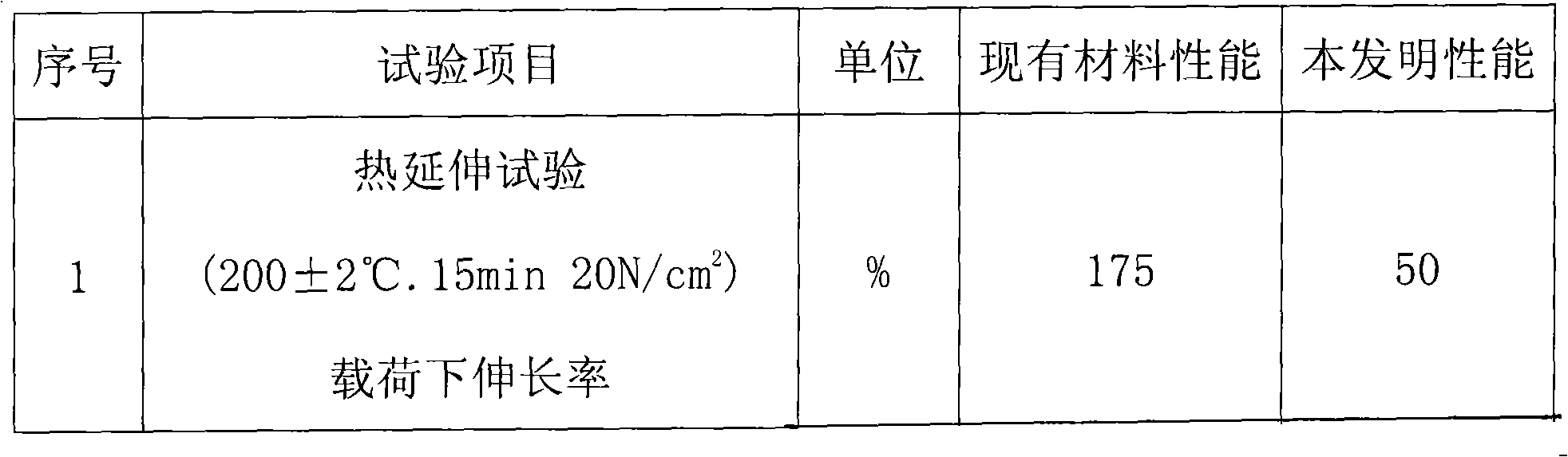

Polyolefine sheathing compound for coaxial cable and preparation method thereof

ActiveCN102153812AShorten the manufacturing cycleHarm reductionPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolyolefin

The invention discloses a polyolefine sheathing compound for a coaxial cable and a preparation method thereof. The sheathing compound consists of the following components in parts by weight: 60-90 parts of ethylene-propylene-diene rubber, 5-25 parts of high-density polyethylene, 5-15 parts of functional polyolefin resin, 180-200 parts of flame retardant, 1-3 parts of surface modifier, 0.01-0.05 part of crosslinking agent, 0.5-2 parts of antioxidant and 1.5-9 parts of processing aid. The preparation method comprises the following steps of: putting the flame retardant into a high-speed stirrer for stirring at a high speed at the temperature of not lower than 80 DEG C; adding organosilane and stirring for 3-5 minutes; putting the remaining materials into the high-speed stirrer for continually stirring for 3-5 minutes; adding into a double-screw mixing extruder set by using a feeder for pelletizing; and drying. The sheathing compound has the advantages of flame retardance, low smoke, freeness from halogen, low toxicity, freeness from harmful heavy metals such as lead, cadmium and the like, freeness from phosphorus, difficulty in burning and small smog harm in case of fire, environmental friendliness, high temperature resistance level of 105 DEG C, high extruding performance, excellent electric performance, no need of subsequent crosslinking after stranding, saving in a large amount of manpower and materials and great reduction in the manufacturing period of the cable.

Owner:KINGFA SCI & TECH CO LTD +2

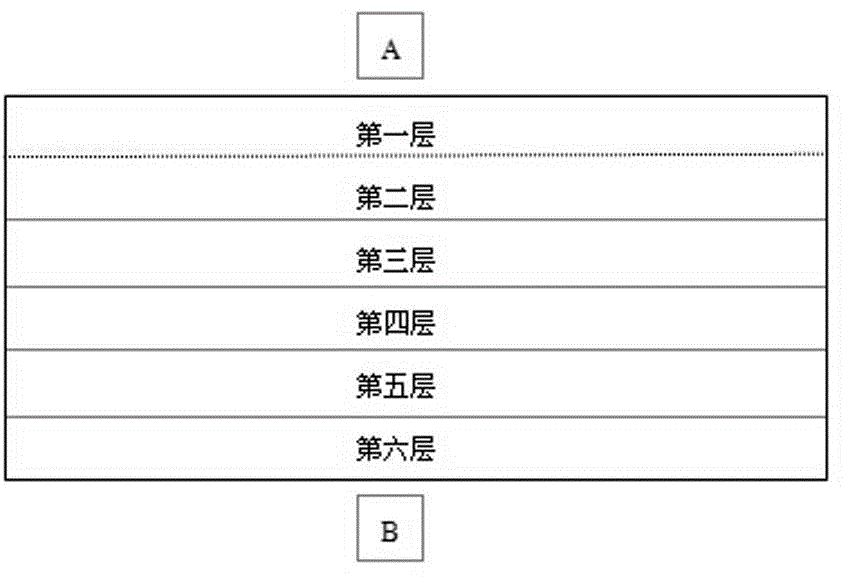

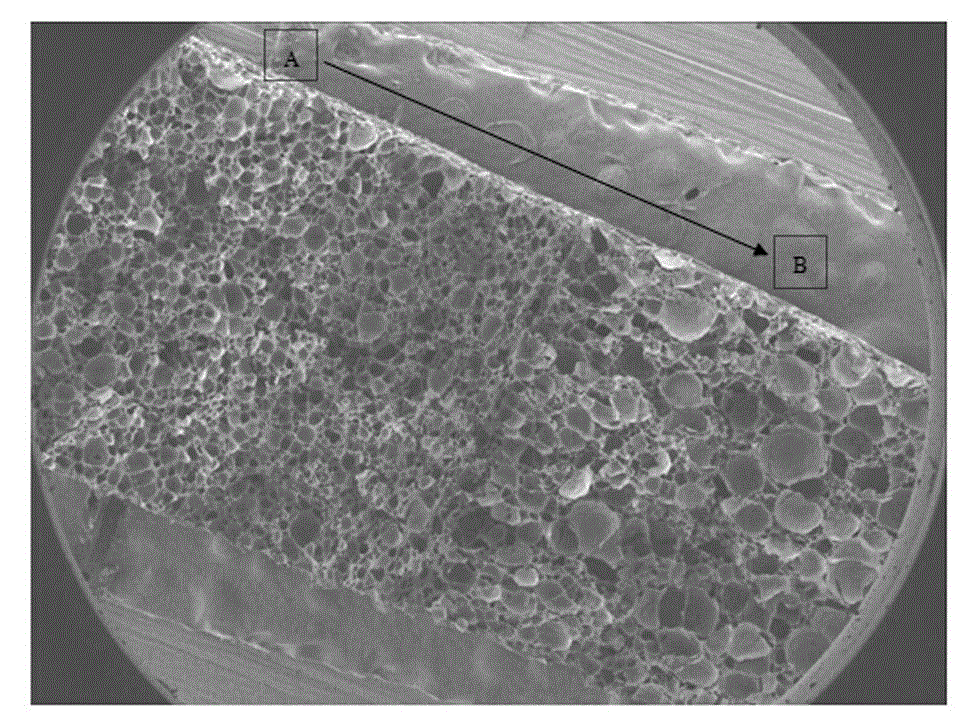

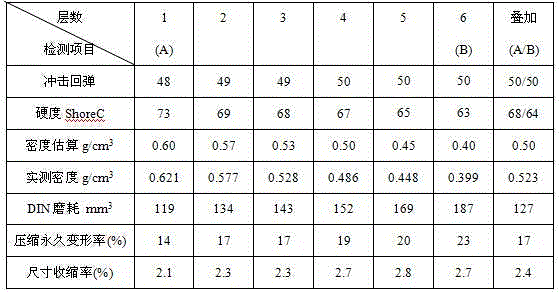

Lightweight wear-resistant density-gradient foamed sole material and preparation method thereof

The invention relates to a lightweight wear-resistant density-gradient foamed sole material and a preparation method thereof. The lightweight wear-resistant density-gradient foamed sole material is mainly composed of EPDM, ethylene-octene copolymer, low density polyethylene, a cross-linking agent, a filling material, a foaming agent and a foaming promoter. On the basis of foaming of EPDM, POE and LDPE and through control of a foaming ratio and density difference values of each layer of materials, a heterogeneous expandable rubber compound composed of a plurality of layers and having quasi-continuously changing performances in the thickness direction of the materials are subjected to one-shot mould pressing, foaming and moulding so as to prepare the foamed sole material, and function gradient differences of density, hardness and wear resistance are realized. Due to gradual change of density, stress concentration is mitigated, and the prepared foamed sole material does not warp. The foamed material has low density at one side close to the vola while the foamed material has high density at one side close to the outer sole, so the foamed sole material has good wear resistance, reduces the weight of the sole and has improved wearing comfortableness.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

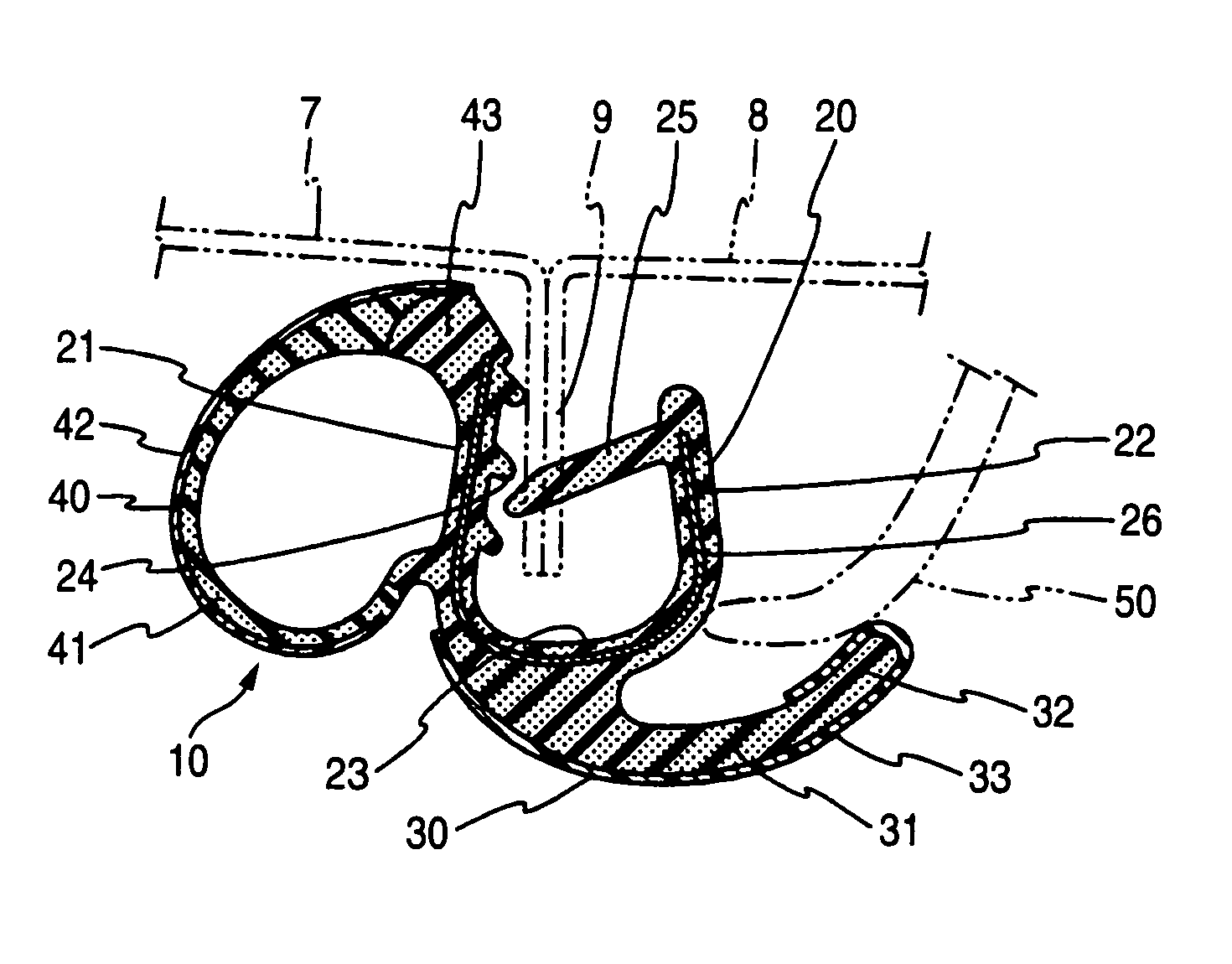

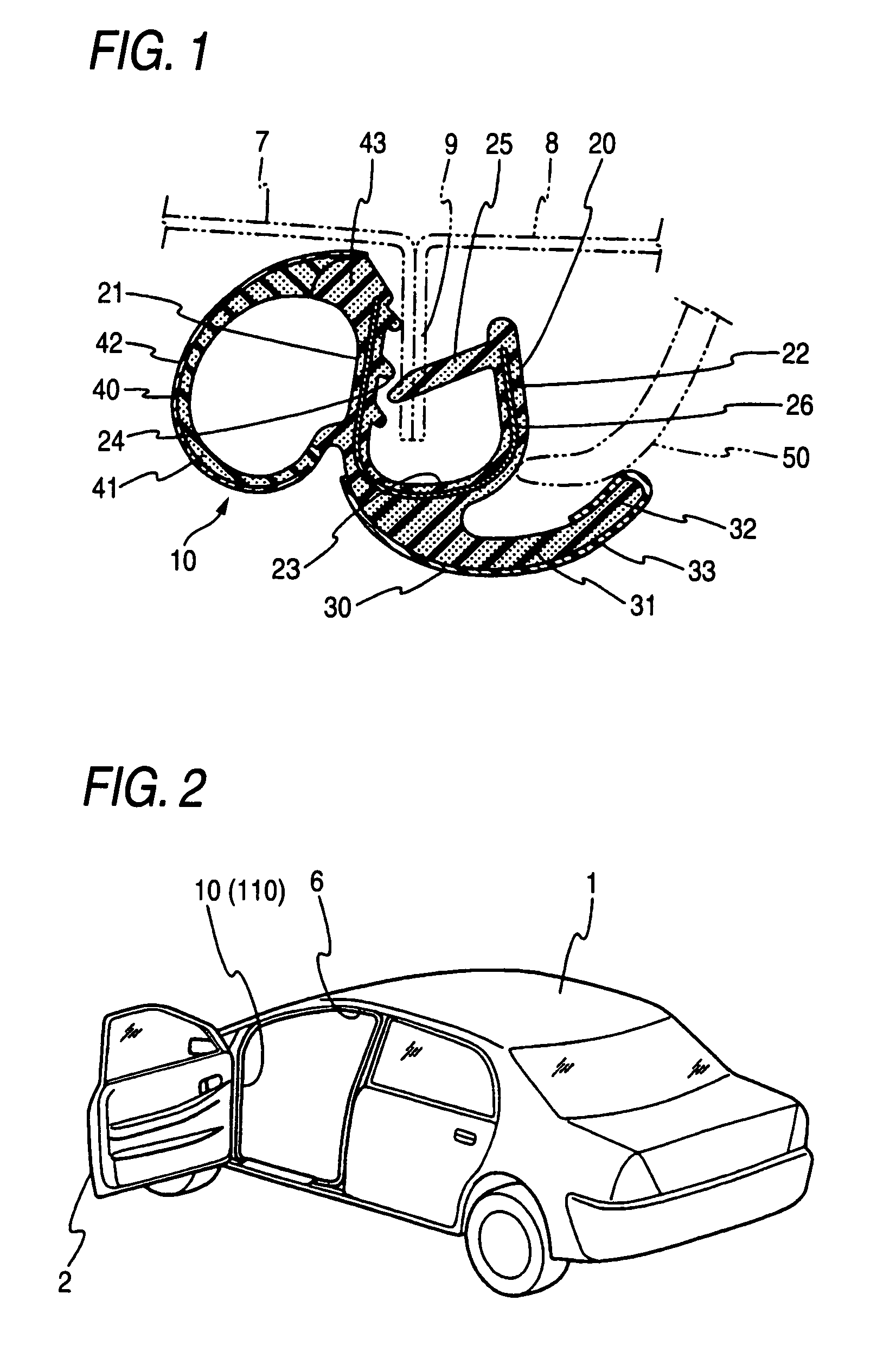

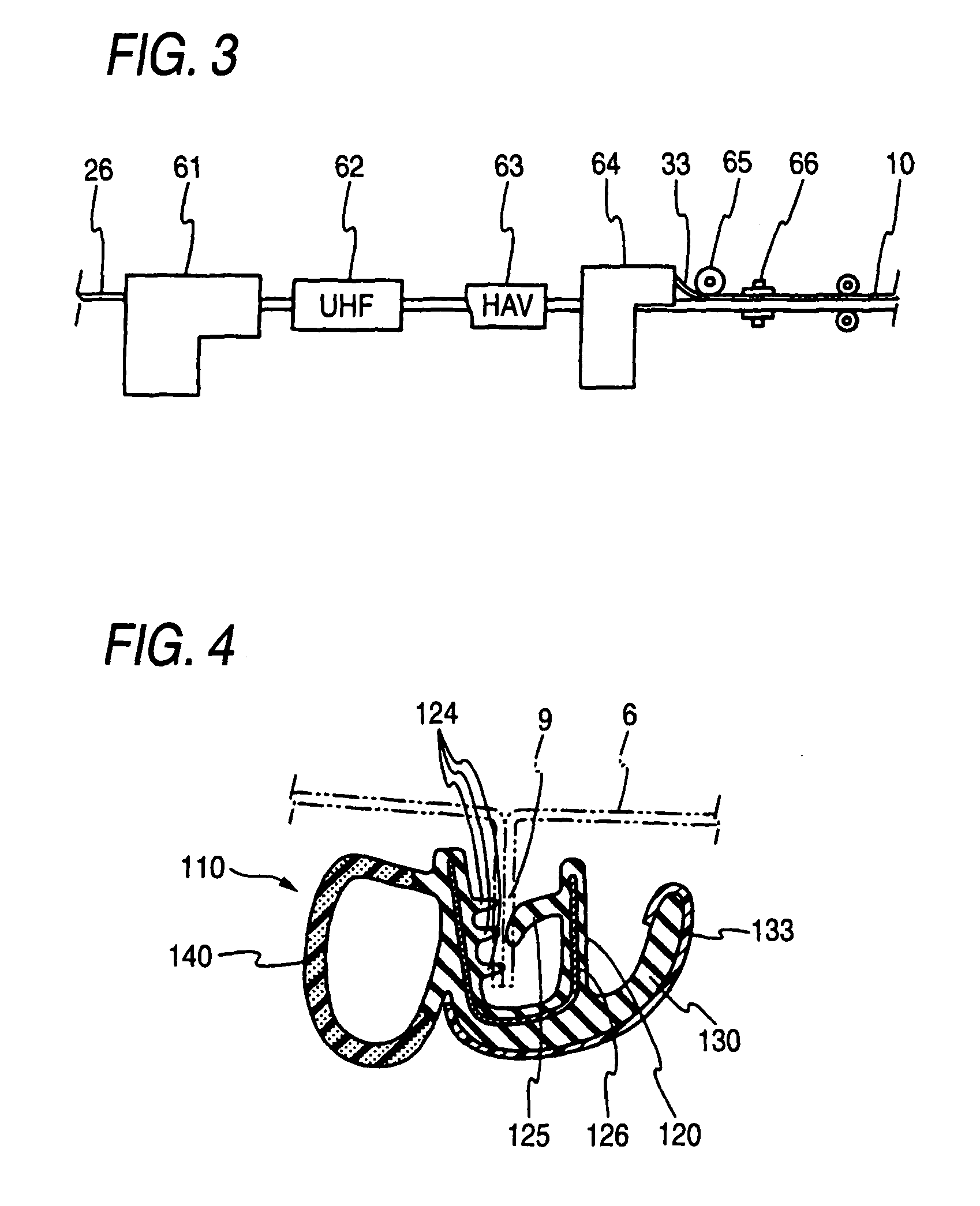

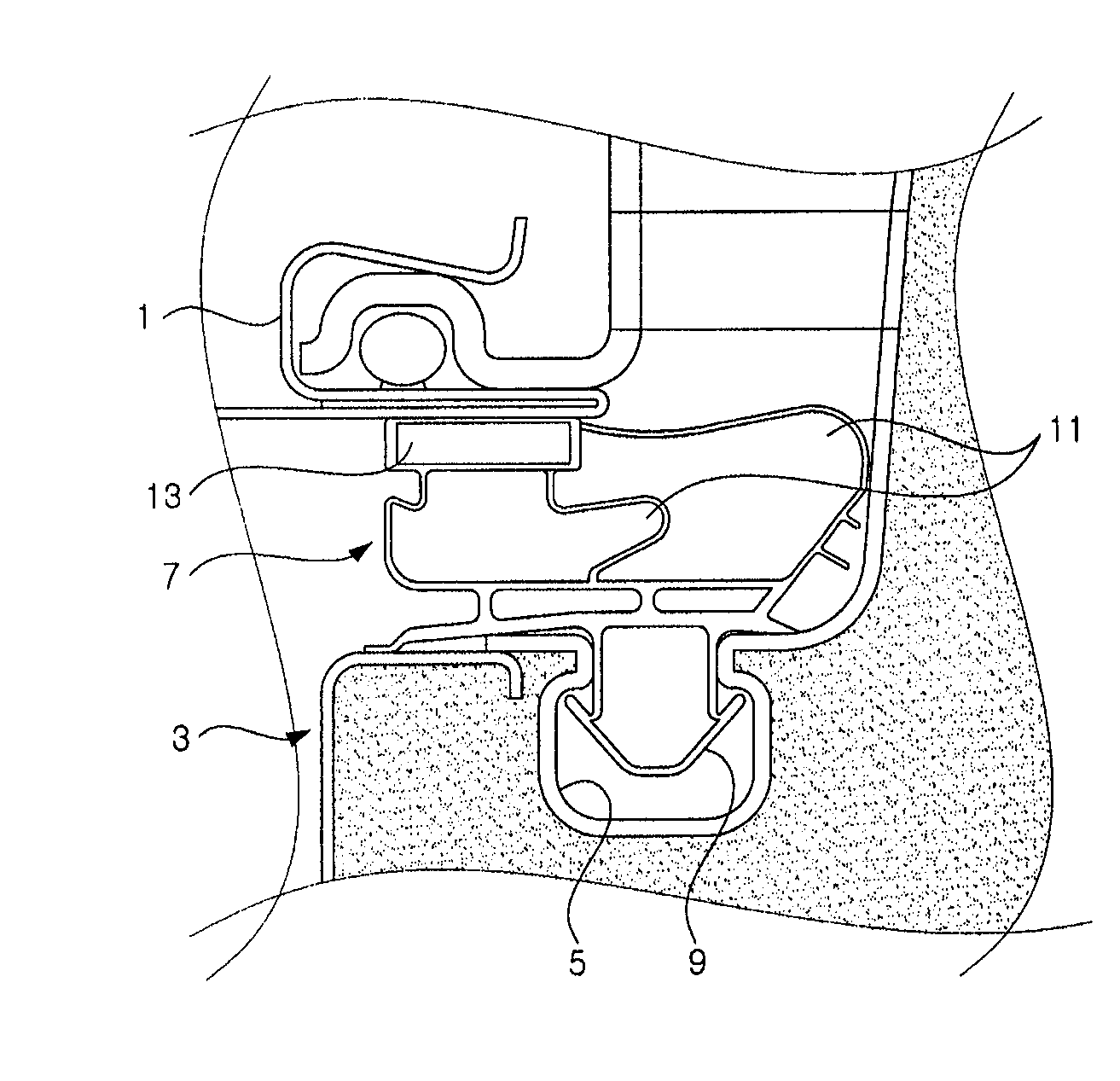

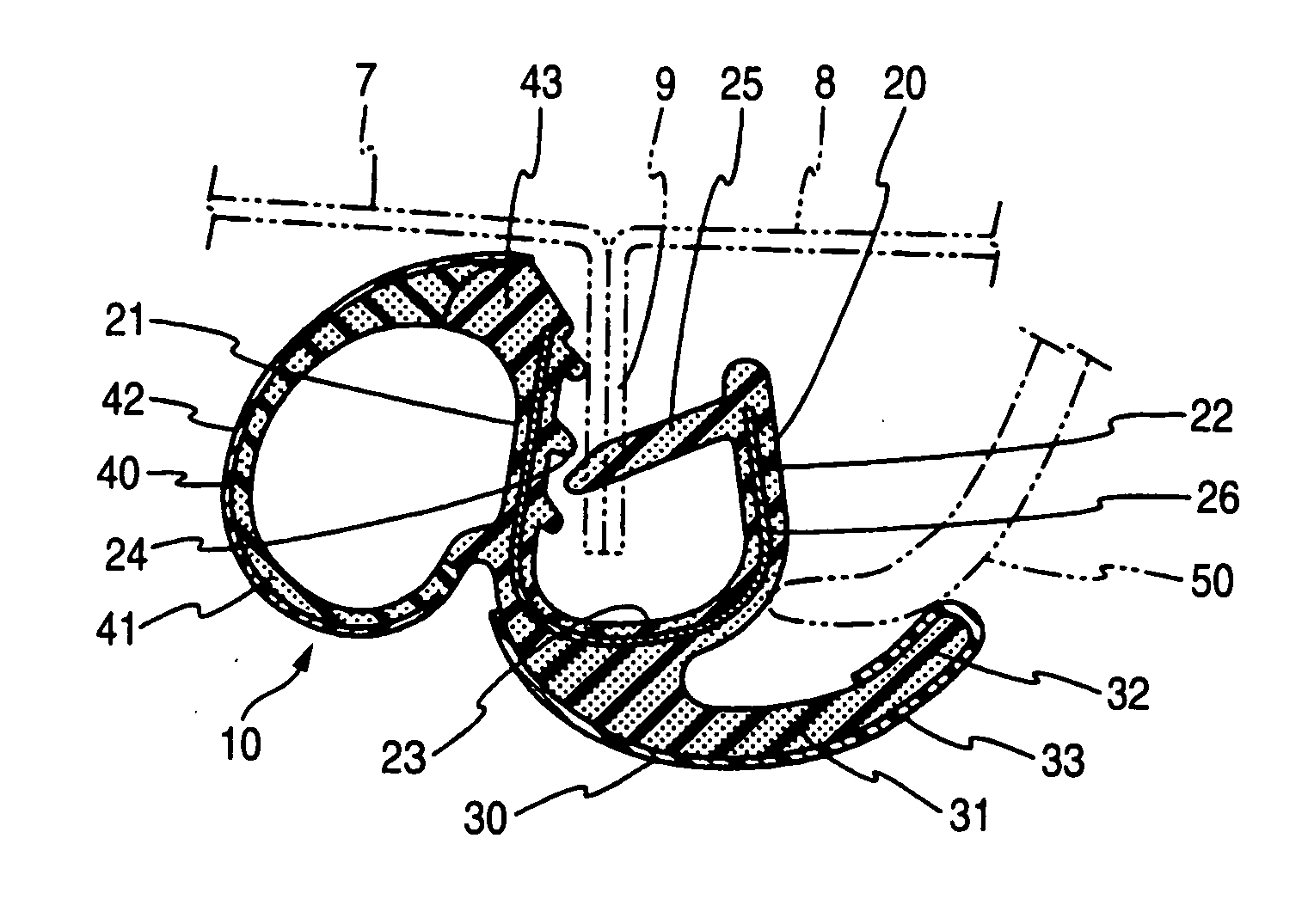

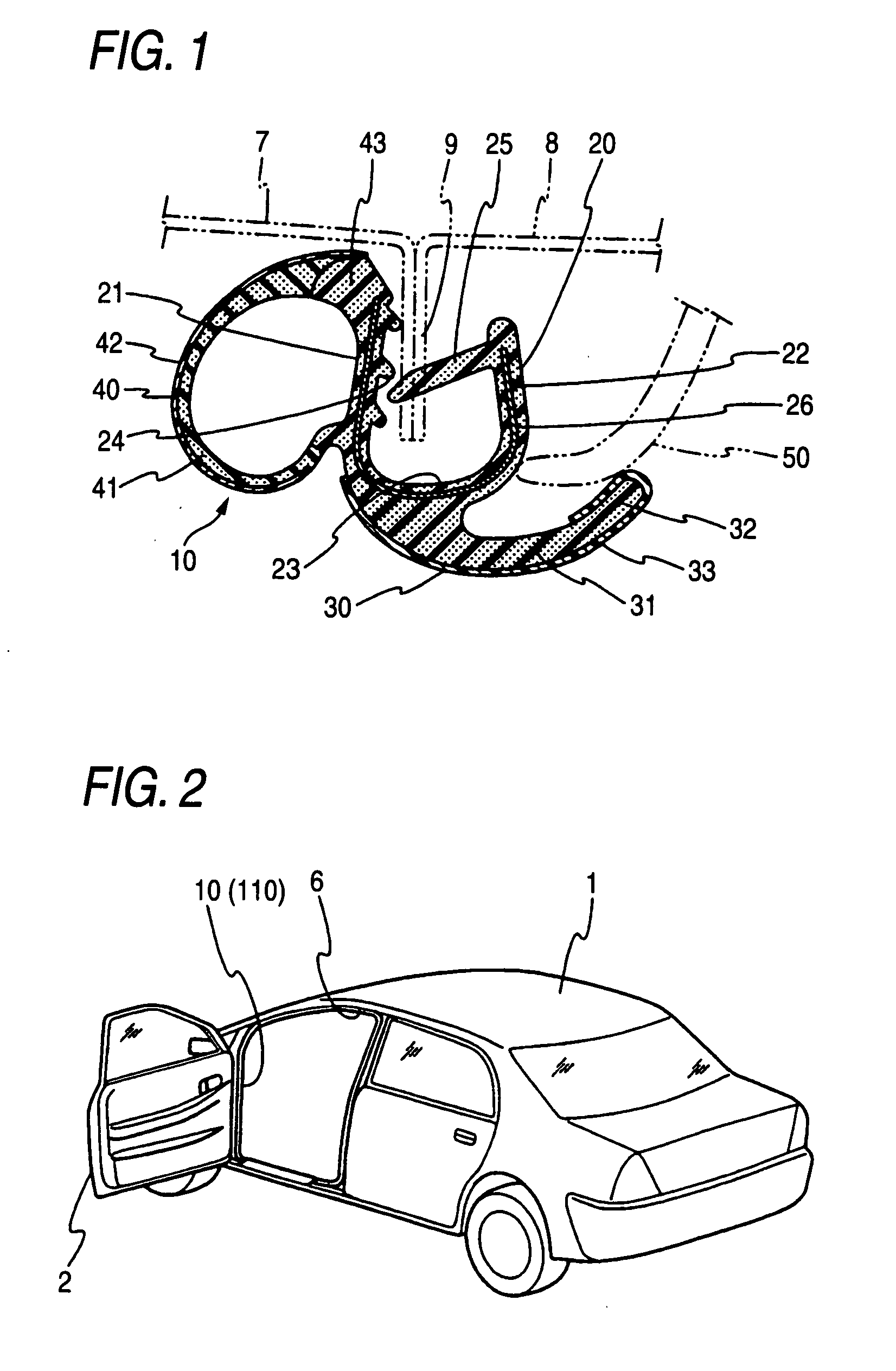

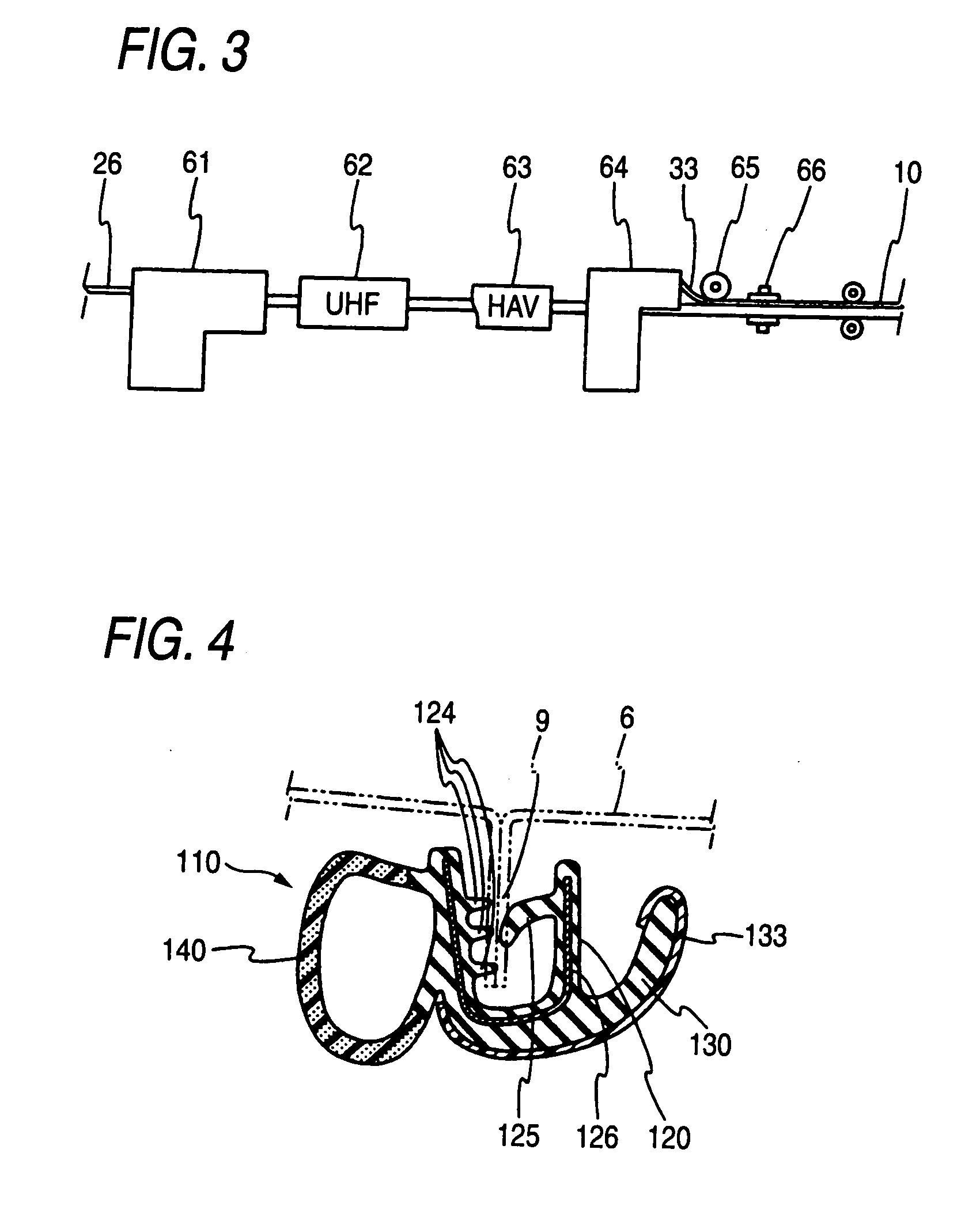

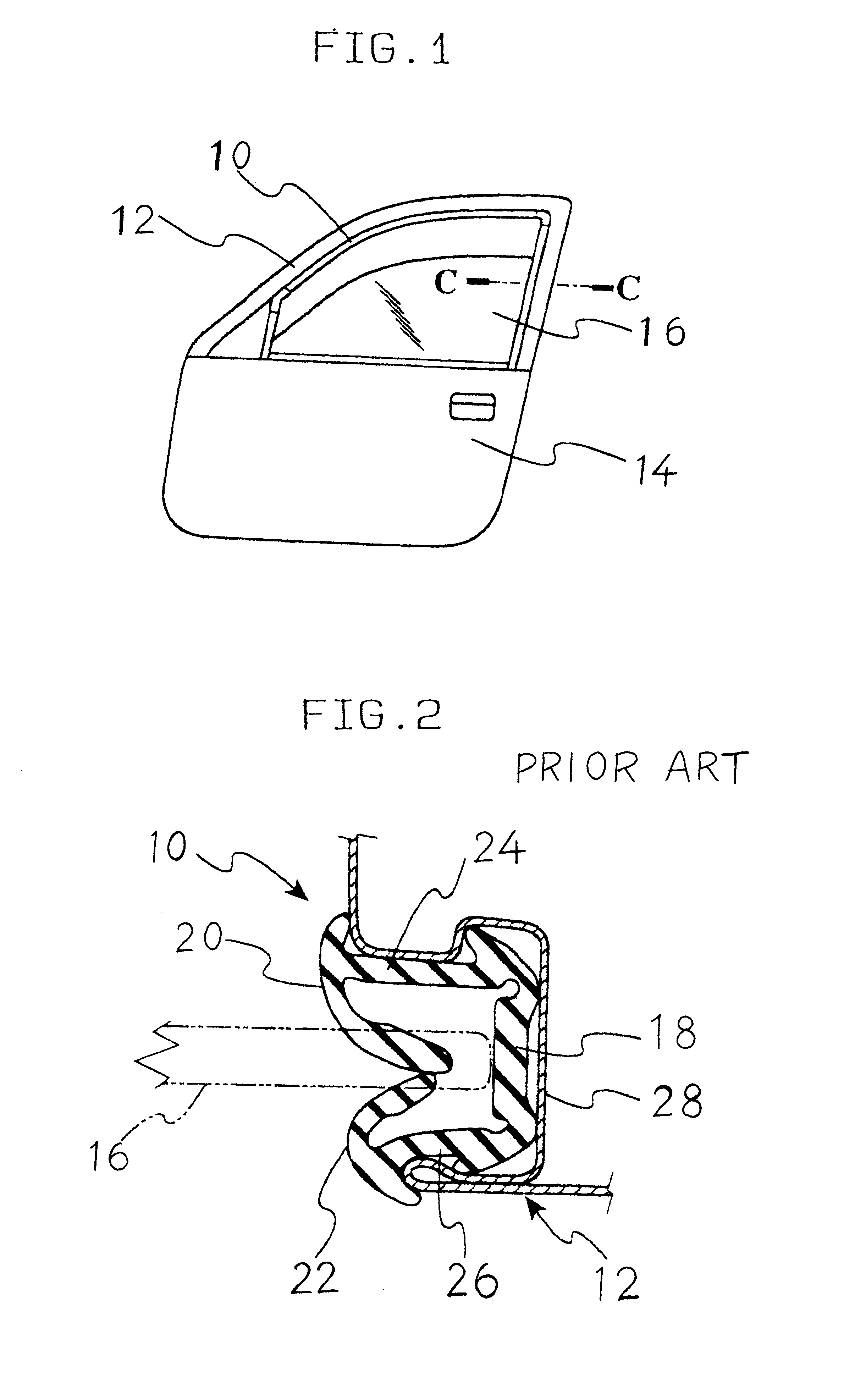

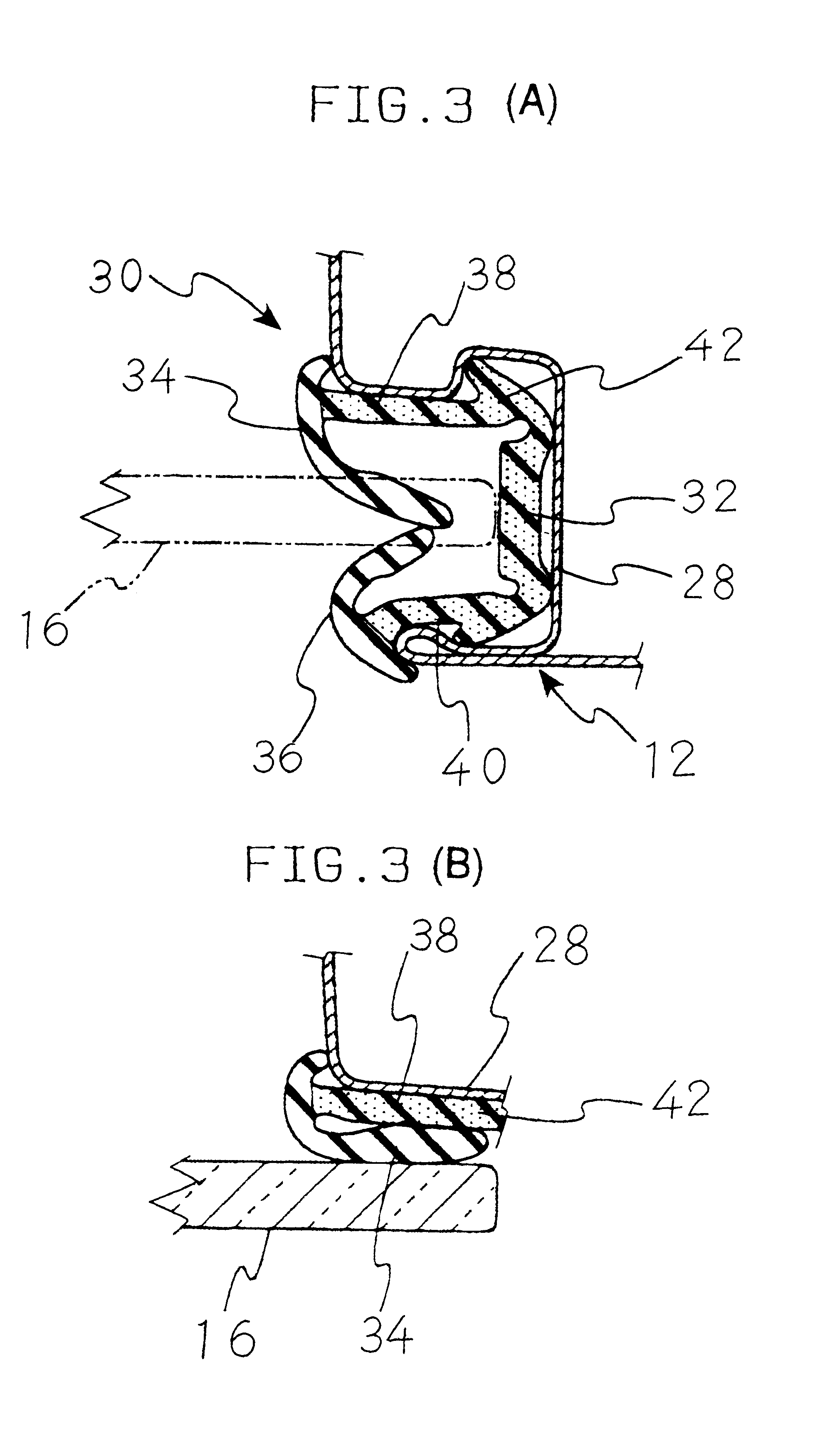

Automobile weather strip

ActiveUS8205391B2Firmly attachedInsert member is prevented from being corrodedSealing arrangementsVehicle sealing arrangementsEngineeringEPDM rubber

An automobile weather strip has a trim part having a substantially U-shaped section and a sealing part. The automobile weather strip is characterized in that: the trim part has an insert member and a covering material for covering the insert member; the covering member is provided with holding lips for holding a flange part on an inner surface of the trim part; a sponge material of a rubber formed by using a blend material of an EPDM rubber and an olefin-based thermoplastic synthetic resin and a sponge material of a rubber having physical properties of a specific gravity of 0.6 to 0.8 and a 25%-stretching stress of 500 KPa or more are used as the covering material.

Owner:TOYODA GOSEI CO LTD

EPDM (ethylene propylene diene monomer) rubber insulated/jacketed cable with high strength, oil resistance and aging resistance

InactiveCN105255019AImprove heat resistanceGood weather resistanceRubber insulatorsInsulated cablesCarbon nanotubeEPDM rubber

The invention discloses an EPDM (ethylene propylene diene monomer) rubber insulated / jacketed cable with high strength, oil resistance and aging resistance. The EPDM rubber insulated / jacketed cable comprises following raw materials: EPDM rubber, nitrile butadiene rubber, maleic anhydride grafted polypropylene, an ethylene-vinyl acetate copolymer, diphenyl hexadiphthalein diamine, stearic acid, zinc oxide, superfine fully vulcanized powder nitrile butadiene rubber, tin(II) chloride dehydrate, bromo-octyl-phenolic curing resin, calcined kaolin, zinc methacrylate, carbon nano tubes, superfine silica, calcium sulfate whiskers, polyacrylonitrile fibers, a silane coupling agent, lanthanum glutamic dithiocarbamate, petroleum wax, naphthenic oil, an anti-aging agent and an accelerator. The EPDM rubber insulated / jacketed cable material with high strength, oil resistance and aging resistance serves as insulation and / or a jacket in a cable and has high strength, good oil resistance, aging resistance and combination properties and long service life.

Owner:ANHUI LAND GRP

Aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material

InactiveCN104610663AHigh strengthGood air aging resistanceRubber insulatorsPlastic/resin/waxes insulatorsCalcium silicateElastomer

The invention discloses an aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material. The material comprises raw materials as follows: EPDM rubber, natural rubber, an ethylene-butene elastomer, superfine talc powder, nano calcium carbonate, modified superfine desulfurization ash, active calcium silicate, zinc methacrylate modified nano silicon nitride, pre-dispersed hollow phenolic microspheres, reinforcing fibers, zinc oxide, stearic acid, dicumyl peroxide, sulfur, N,N'-meta phenylene bismaleimide, diphenylmethane bismaleimide, DIPDIS, coumarone-indene resin, APP (ammonium polyphosphate), ADP, an MPE (metallocene polyethylene) elastomer, N-(4-anilino phenyl maleimide and 2-mercapto benzimidazole. The aging-resistant and low-temperature-resistant EPDM rubber cable material is high in strength, good in aging resistance and low-temperature resistance, excellent in insulating property and flame retardation and long in service life.

Owner:无为县华祥电缆材料有限公司

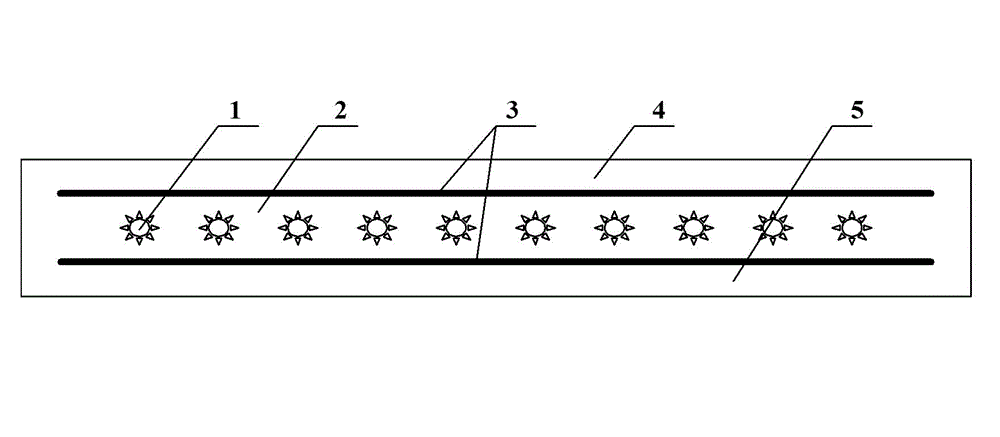

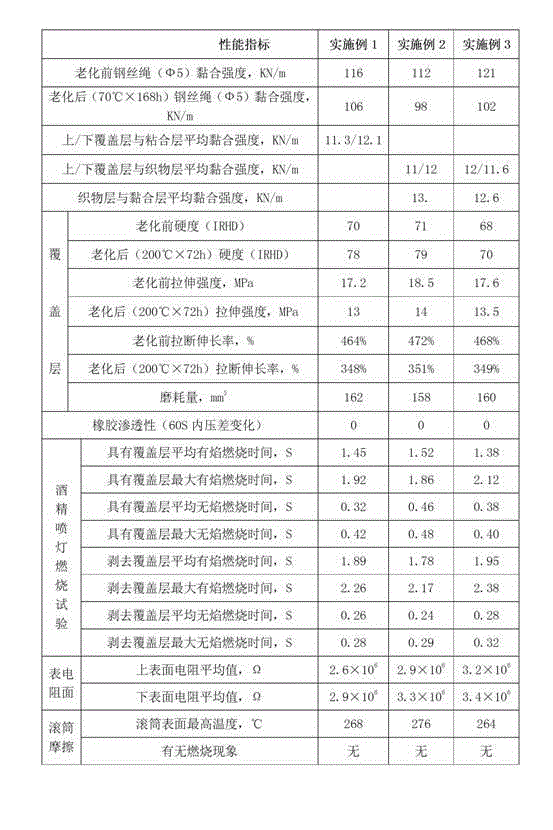

High temperature resistant wire rope core flame-retardant conveying belt

ActiveCN102718016AImprove high temperature resistanceHigh high temperature resistanceConveyorsEpoxyPolymer science

The invention discloses a high temperature resistant wire rope core flame-retardant conveying belt, and solves the problem that the conventional wire rope core flame-retardant conveying belt is not high temperature resistant. According to the invention, the sizing material of an upper covering bond layer as well as that of a lower covering bond layer comprise the following ingredients in part by weight: 30 to 50 parts of ethylene-propylene-diene rubber, 25 to 35 parts of chlorinated butyl rubber, chlorosulfonated polyethylene rubber or neoprene, 25 to 35 parts of chlorinated polyethylene rubber, 4 to 6 parts of dicumyl peroxide, 0.5 to 1.5 parts of sulfur, 0.5 to 1 part of tert-octylphenol-formaldehyde resin, 1 to 3 parts of epoxy resin, 8 to 12 parts of zinc oxide and / or magnesium oxide, 1 to 2 parts of stearic acid, 2 to 8 parts of accelerating agent, 2 to 4 parts of antiager, 8 to 15 parts of conductive carbon black, 25 to 45 parts of high abrasion resistant carbon black, 10 to 15 parts of active glass fiber powder, 20 to 50 parts of solid flame retardant, 10 to 20 parts of liquid flame retardant, and 3 to 8 parts of flame-retardant lubricant MB-202. Two glass fiber canvas thermal insulating layers are arranged between a middle bond layer and the upper covering bond layer and between the middle bond layer and the lower covering bond layer respectively. The high temperature resistant wire rope core flame-retardant conveying belt can be used for a long time at the temperature of 250 DEG C, and meets the conveying requirements of special high-temperature materials.

Owner:ANHUI ZHONGYI RUBBER BELTS

Flexographic printing precursors and methods of making

InactiveUS20110236705A1Easy to manufactureIncrease the lengthPigmenting treatmentPretreated surfacesPolymer sciencePlasticizer

A mixture of a high molecular weight EPDM rubber with a low molecular weight (liquid) EPDM rubber provides a highly useful laser-ablatable flexographic printing plate precursor formulation. This formulation is sensitive to infrared radiation by the incorporation of an IR absorbing compound such as a carbon black. The inclusion of the liquid EPDM rubber avoids the need for plasticizers such as process oils during manufacturing, and provides improved image sensitivity, print quality, and run length. Both flexographic printing plates and printing sleeves can be made using the mixture of EPDM rubbers.

Owner:EASTMAN KODAK CO

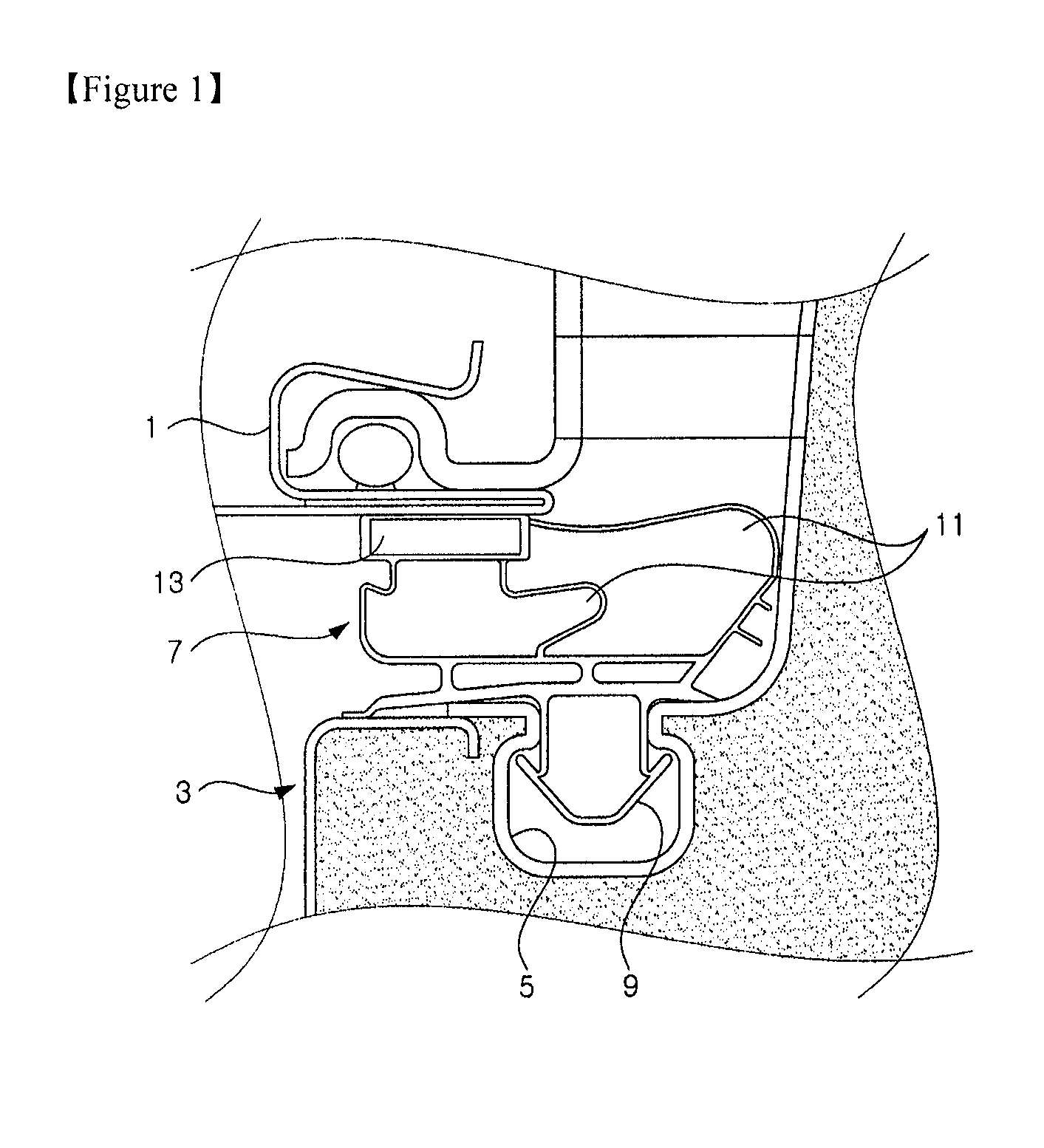

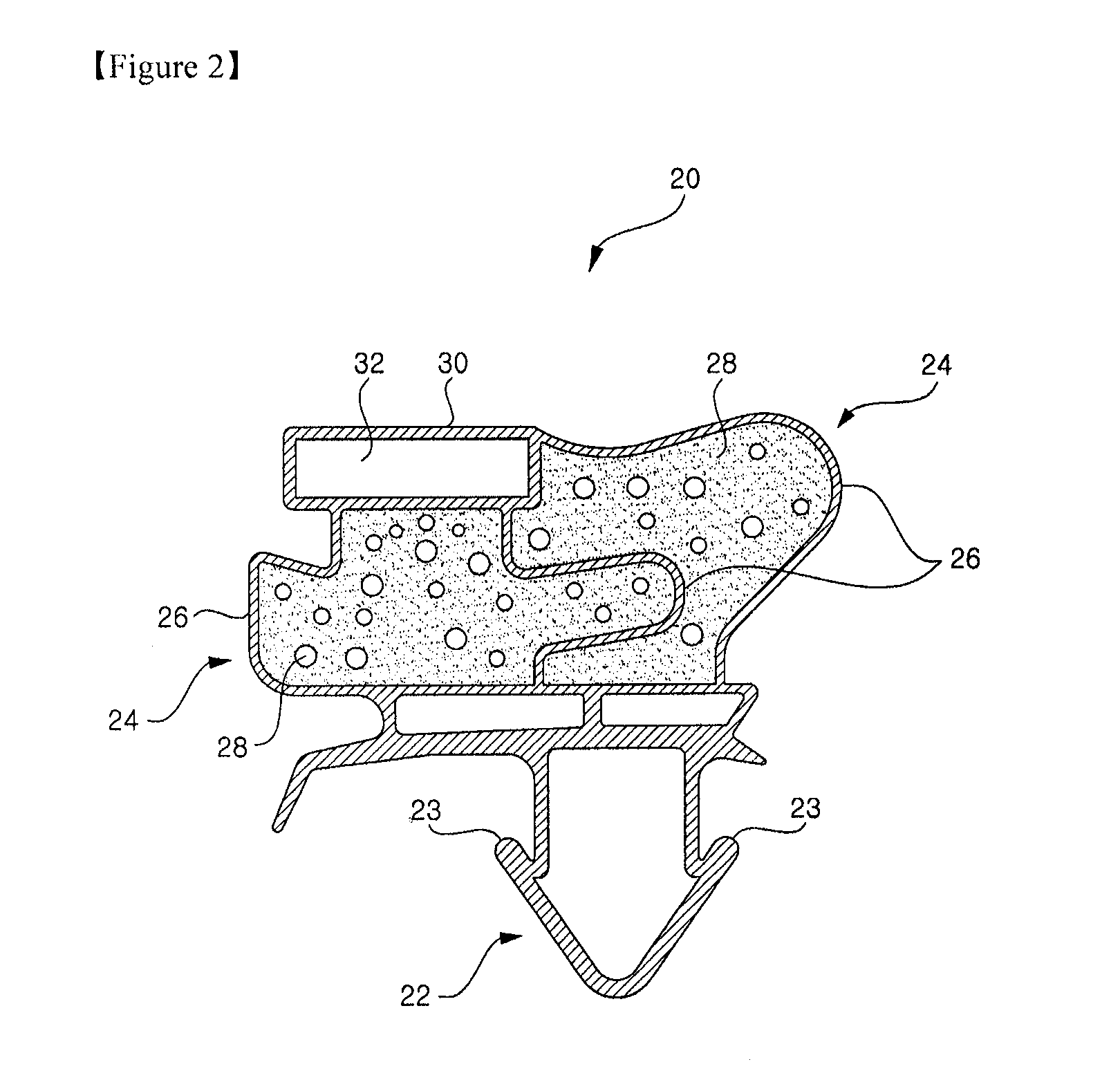

Gasket of Door for Refrigerator and Making Method the Same

InactiveUS20080276540A1Avoid conductionExcellent characteristicsDomestic cooling apparatusLighting and heating apparatusEPDM rubberEngineering

The present invention relates to a door gasket and a method of manufacturing the same. In the present invention, an expansible insulating portion (24) is formed integrally with an anchor portion (22) of a door gasket (20), and the interior of the expansible insulating portion (24) is filled with a soft foam (28). The soft foam (28) is made of a soft material with superior insulation property. Here, the anchor portion (22) may be made of synthetic resin or rubber, and the soft foam (28) may be made of any one of soft urethane, polyethylene, ethylene propylene diene monomer rubber (EPDM rubber), nitrile butadiene rubber (NBR), and styrene butadiene rubber (SBR), such as compressed sponge.

Owner:LG ELECTRONICS INC

Hydraulic brake hose with high antifatigue and production method

The invention discloses a high fatigue resistance hydraulic brake hose and the producing method thereof, playing the role of transferring brake pressure to drive arrester to make vehicle braking in automobile system, and comprising inner rubber layer, weaving layer, medium rubber layer, weaving layer, and outer rubber layer, where the inner, medium and outer rubber layers are made from EPDM rubber, butyl benzene and butyl EPDM rubber, and neoprene as main raw materials, respectively, and its producing method includes mixing, extruding, weaving, weaving, extruding, removing core after sulfuration and obtaining finished product. And it has characters of peculiar formula of raw materials, easy operation, excellent fatigue resistance, long service life and good use effect.

Owner:QINGDAO SUNSONG CO LTD

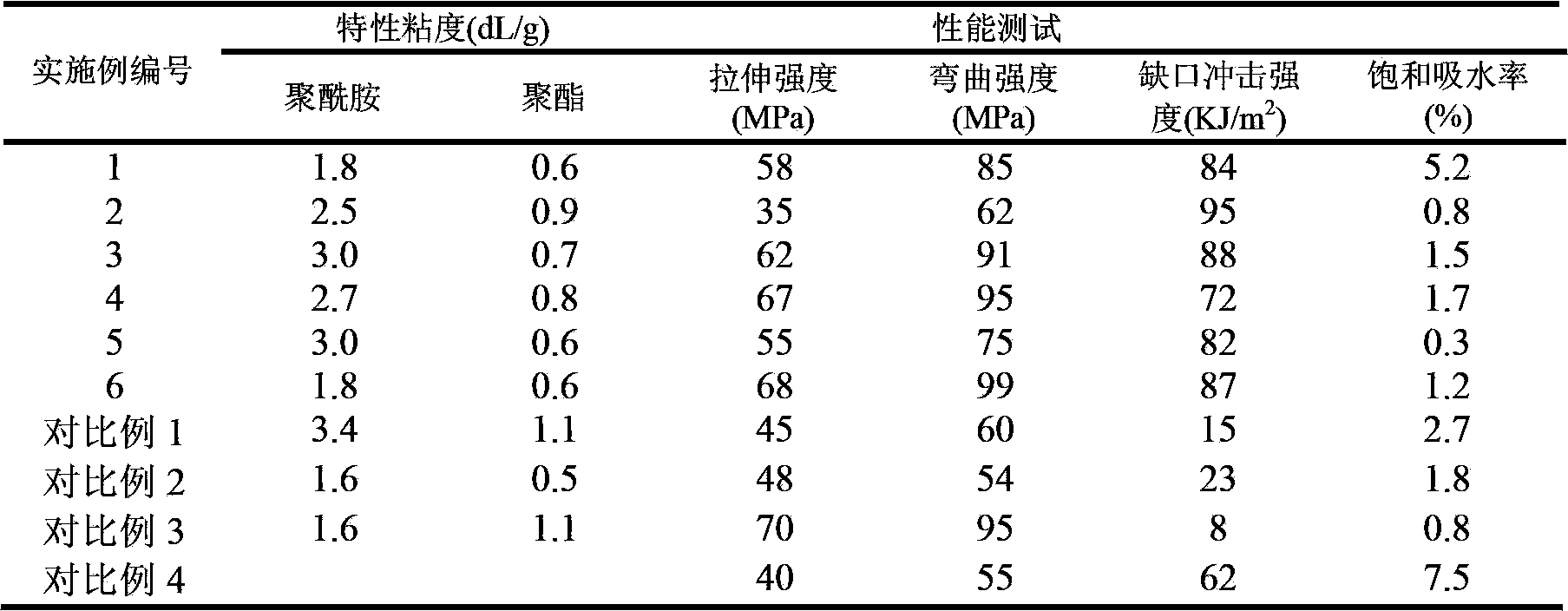

Super-tough polyamide alloy as well as preparation method and application thereof

The invention discloses a super-tough polyamide alloy as well as a preparation method and application thereof. The super-tough polyamide alloy comprises the following preparation materials: 2%-81.5% of polyamide, 2%-81.5% of polyester, 0.5%-5% of a compatilizer and 10%-35% of a toughening agent, wherein intrinsic viscosity of the polyamide is 1.8 dL / g-3.0 dL / g, and the intrinsic viscosity of the polyester is 0.6 dL / g-0.9 dL / g; the compatilizer is more than one of polymer ionomer, polyamide-polyester segmented copolymer, phenyl sulfonate, epoxy resin, maleic anhydride-grafted copolymer or rubber phase-containing elastomer; the toughing agent is one of maleic anhydride-grafted ethylene propylene terpolymer rubber, maleic anhydride-grafted ethylene-octylene copolymer or maleic anhydride-grafted hydrogenated styrene-butadiene-styrene terpolymer. Compared with the super-tough polyamide, the super-tough polyamide alloy disclosed by the invention has high notch impact strength, lower humidity absorption as well as resulting in good dimension stability.

Owner:KINGFA SCI & TECH CO LTD +1

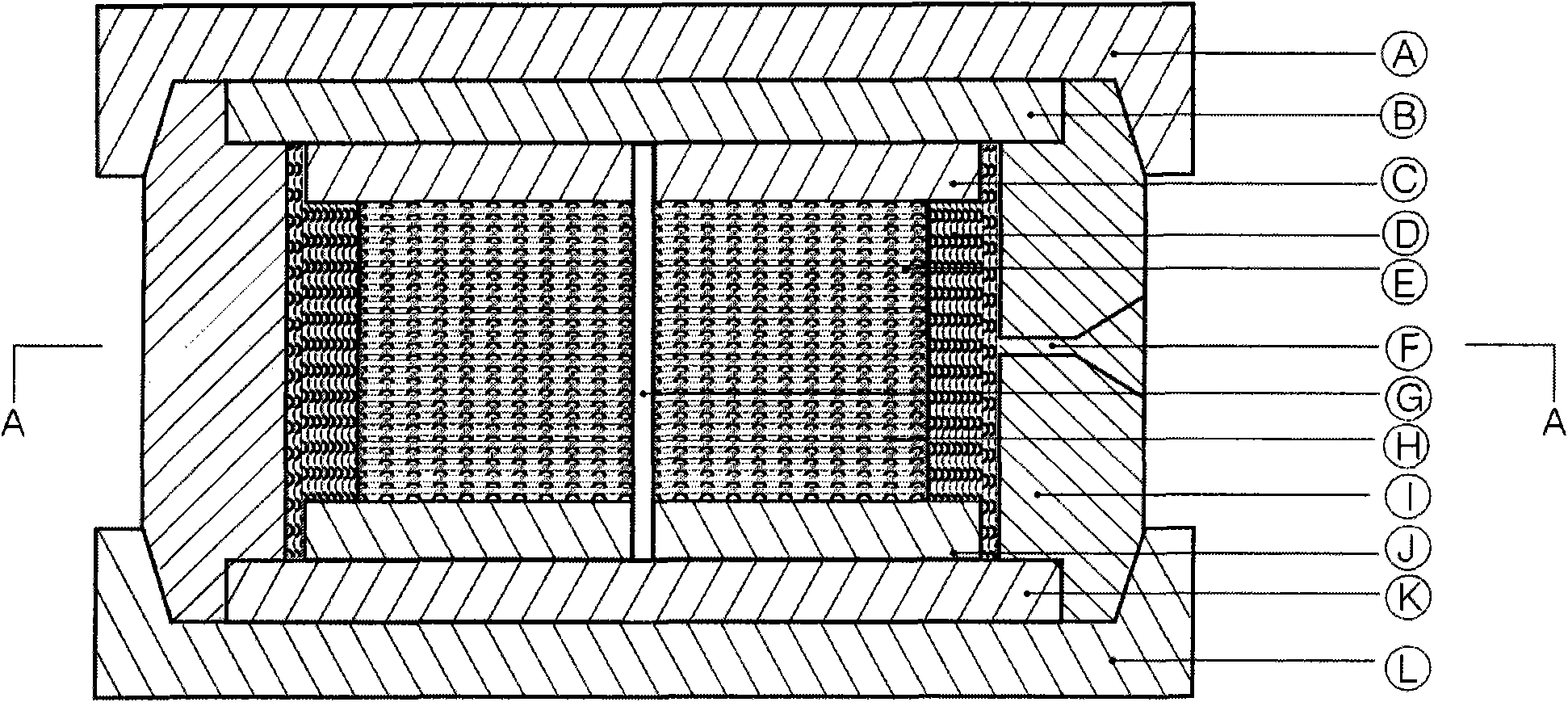

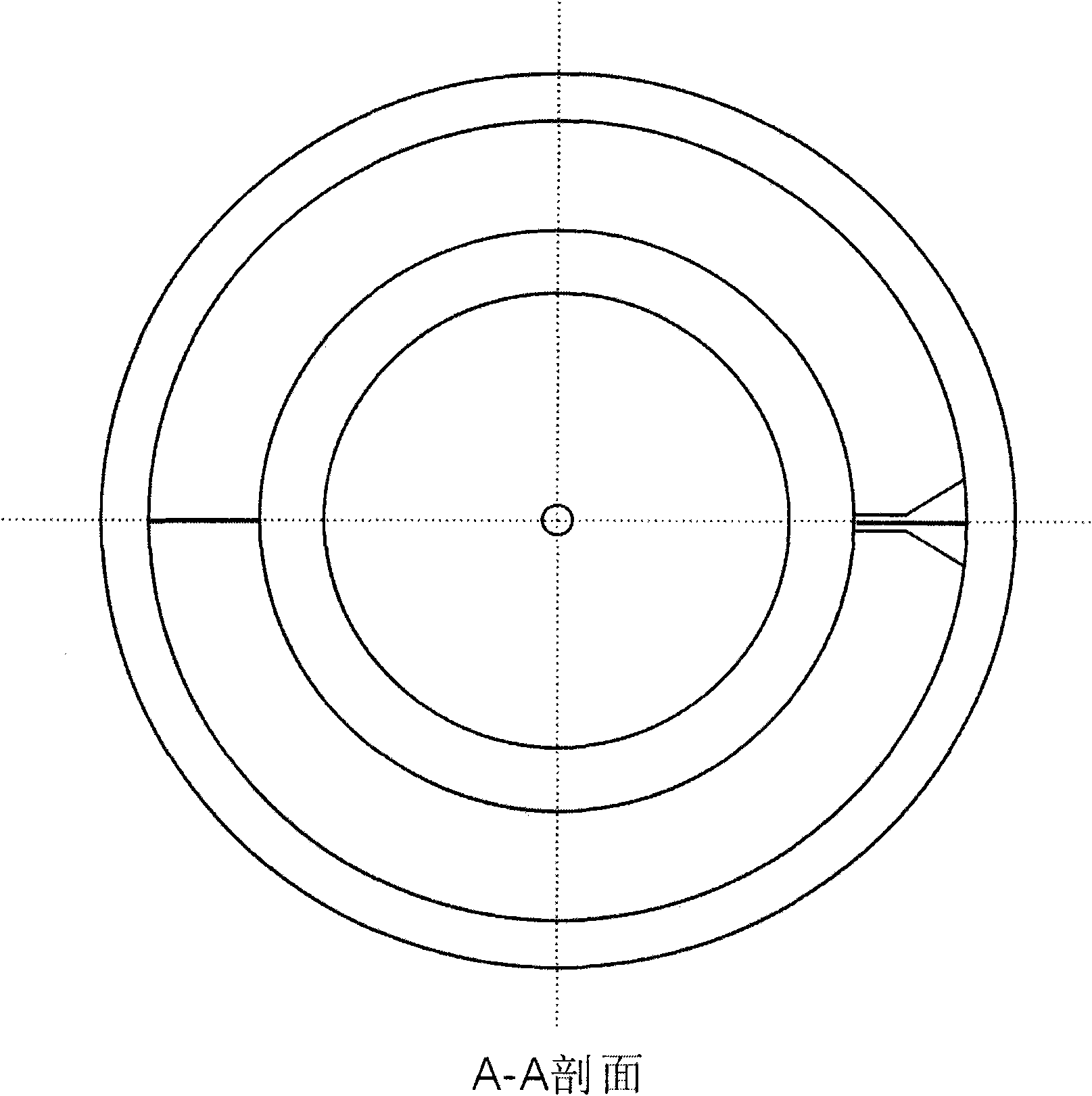

Vibration-isolating rubber bearing for building and manufacturing method thereof

InactiveCN101864807AResolve offsetQuality improvementBridge structural detailsShock proofingEngineeringEPDM rubber

The invention relates to a manufacturing method of a vibration-isolating rubber bearing for building, which adopts a mould to make internal steel plates and internal rubber by pressing to form an internal rubber and internal steel plate composite layer and an internal rubber, internal steel plate and internal rubber composite layer, and the size is precise and the thickness error is 0.05mm. The invention solves the offset problem of the internal steel plates, and simultaneously no residual rubber is removed; no air is generated in the process of curing mold, so no air needs to be exhausted. Since the rubber protective layer of the vibration-isolating rubber bearing for building adopts an injection rubber process, the rubber protective layer of the vibration-isolating rubber bearing for building can adopt more anti-aging special rubber different from the internal rubber, such as EPDM rubber, halogenated butyl rubber, mixing polyurethane rubber and the like, thereby improving the quality and service life of products.

Owner:武军

Tire curing bladder of EPDM rubber and use thereof

The invention relates to expandable rubber bladders comprised of EPDM rubber for shaping and curing articles of conjugated diene-based elastomers such as pneumatic tires. The bladders are of a rubber composition comprised of resin cured EPDM rubber composition as a terpolymer of ethylene / propylene and a minor amount of a non-conjugated diene. The bladder composition may also contain castor oil, corn oil and / or soya-bean oil. The bladder composition may also contain at least one of graphite and polytetrafluoroethylene powder. Alternately, the EPDM-based bladder rubber composition may also contain a minor amount of a butyl-type of rubber. The invention also relates to a method of curing pneumatic rubber tires by utilizing such EPDM-based expandable rubber tire curing bladder in a tire curing press.

Owner:SANDSTROM PAUL HARRY

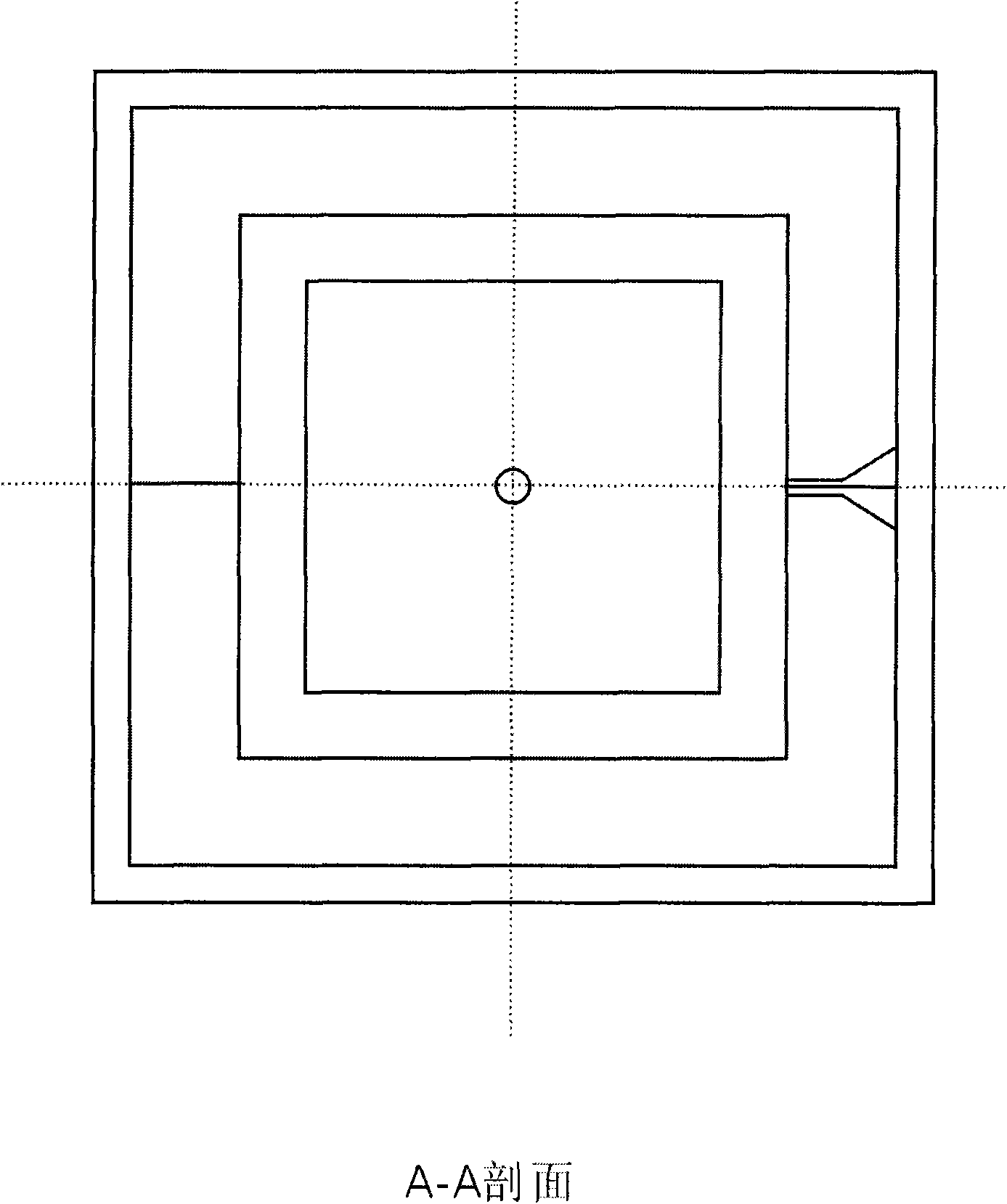

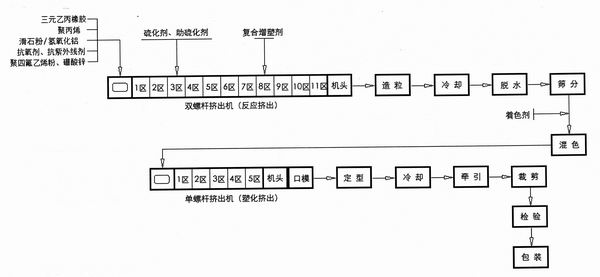

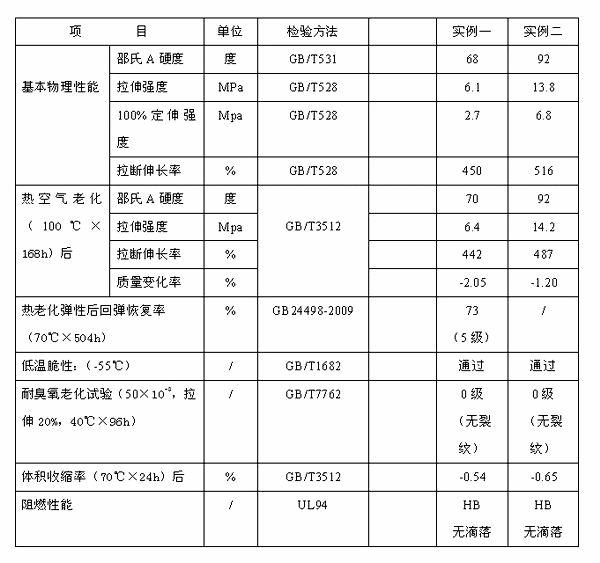

Building sealing strip based on thermoplastic ethylene-propylene-diene monomer (EPDM) rubber material and preparation method of building sealing strip

The invention discloses a building sealing strip based on a thermoplastic ethylene-propylene-diene monomer (EPDM) rubber material. The building sealing strip comprises the following components in part by weight: 30 to 50 parts of EPDM rubber, 15 to 40 parts of polypropylene, 2 to 10 parts of cycloalkane rubber oil, 2 to 10 parts of paraffin oil, 5 to 20 parts of phosphate, 2 to 10 parts of talcpowder, 5 to 20 parts of aluminum hydroxide, 0.2 to 1 part of antioxidant, 0.2 to 1 part of ultraviolet resisting agent, 0.5 to 2 parts of vulcanizing agent, 1 to 5 parts of auxiliary vulcanizing agent,5 to 10 parts of zinc borate, 2 to 5 parts of polytetrafluoroethylene powder and 0.5 to 5 parts of coloring agent. The other aim of the invention is to provide a preparation method of the building sealing strip based on the thermoplastic ethylene-propylene-diene monomer (EPDM) rubber material. The method comprises the following steps of: weighing raw materials, blending, reacting and extruding with a double-screw extruder, and plasticizing and extruding with a single-screw extruder. The performance requirements of the building sealing strip are met; and the building sealing strip has certain burning resistance, is low-smoke, halogen-free and environment-friendly, and can be recycled. The building sealing strip is suitable for a building door window curtain wall.

Owner:上海东明橡塑制品有限公司

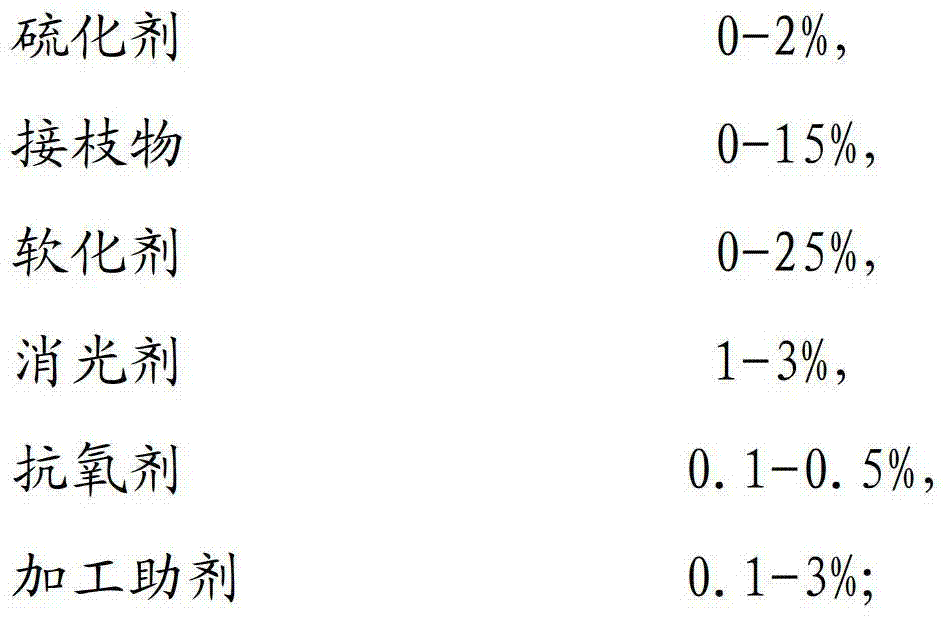

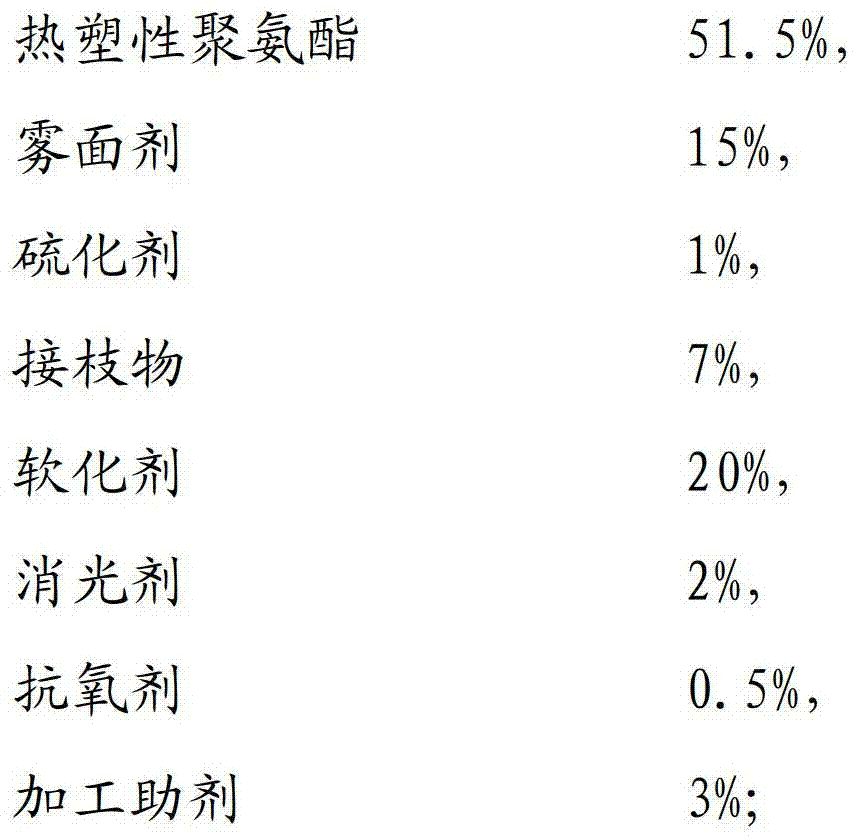

Halogen-free full fogging face polyurethane composition and preparation method thereof

InactiveCN103483803AFull fog maskFull-matte polyurethane composition is environmentally friendly and non-toxicThermoplastic polyurethaneEPDM rubber

The invention provides a halogen-free full fogging face polyurethane composition which comprises the following components in parts by weight: 30-60% of thermoplastic polyurethane, 5-25% of a fogging agent, 0-2% of a vulcanizing agent, 0-15% of a graft, 0-25% of a softener, 1-3% of a delustering agent, 0.1-0.5% of an antioxygen agent and 0.1-3% of a processing agent, wherein the fogging agent is one or a composition selected from SEBS, SEPS, crylic acid ester rubber, EPDM rubber, NBR or POE. The halogen-free full fogging face polyurethane composition has the excellent characteristics of environmental protection, innocuity, full, high temperature resistance and the like, and is suitable for preparing flexible electric wires.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Thermoplastic elastomer composition and method for preparing the same

Disclosed is a thermoplastic elastomer composition comprising 100 parts by weight of EPDM rubber, 5-1,000 parts by weight of styrenic thermoplastic elastomer, 50-3,000 parts by weight of paraffin oil, 10-200 parts by weight of a polyolefin resin as a curative, 1-15 parts by weight of a phenolic resin, and 0.5-5 parts by weight of a curing activator. The composition is superior in flowability, mechanical properties and oil resistance as well as being low in hardness, so that it can be applied for automobile parts.

Owner:HYUNDAI ENGINEERING PLASTICS CO LTD

Silicon resin filled EPDM heat insulation material

A silicon resin filled EPDM heat insulation material is prepared from, by weight, 100 parts of EPDM rubber, 20-60 parts of silicon resin, 3-20 parts of a metallic compound, 15-20 parts of a fortifier, 8-15 parts of organic fibers, 8-12 parts of tackifying resin and 3-12 parts of other auxiliaries.An appropriate amount of silicon resin and metallic compound are added into the EPDM heat insulation material, a molten silicate sticky liquid membrane is generated in situ by means of high-temperature pyrolysis and reaction, the molten silicate sticky liquid membrane is attached to the surface of a cracked solid residue, a solid network structure is formed by the solid residue in a physical crosslinking mode through adhesion action of the liquid membrane, self-supporting capacity and the function of resisting outer scouring of a heat insulation carbonizing layer are added, and scouring resistance and ablation resistance of the heat insulation material are effectively improved.The rubber type heat insulation material can be used in an engine, widely used for manufacturing porcelainized wire and cable materials and widely used in other fields needing fire prevention and flame retardance.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

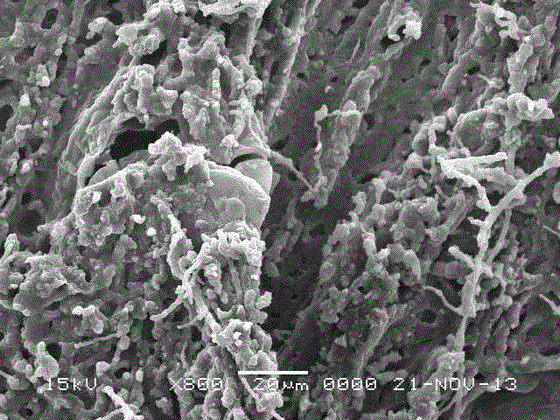

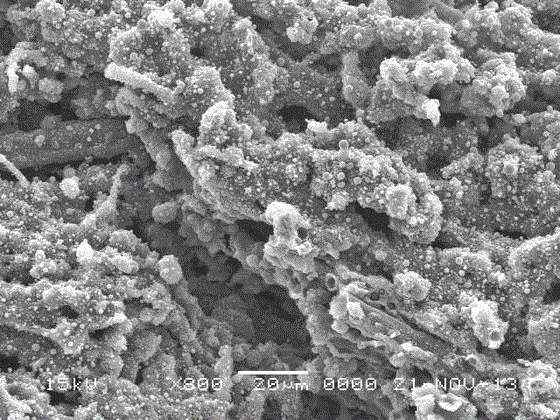

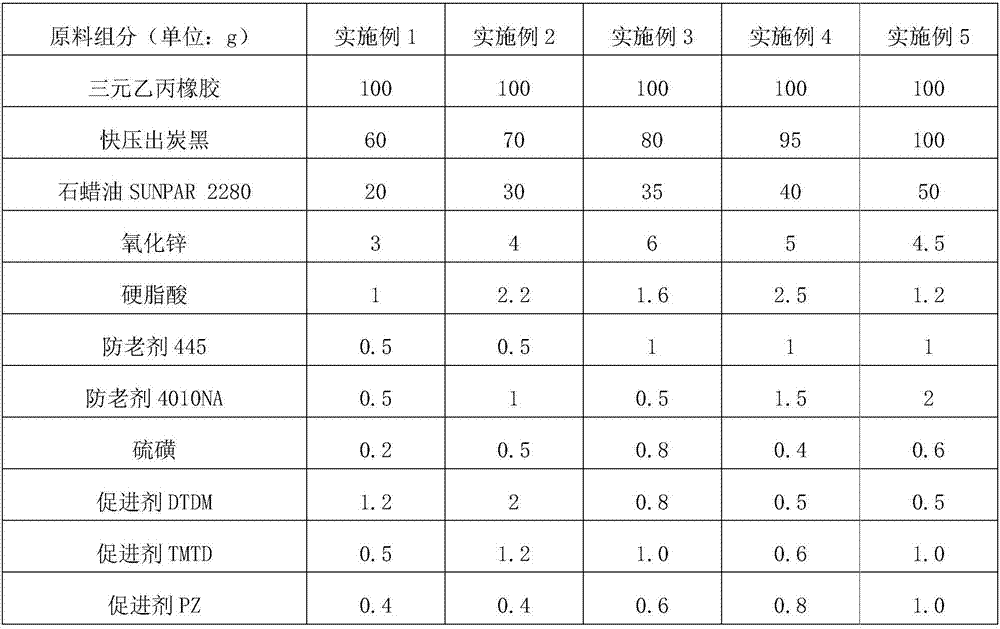

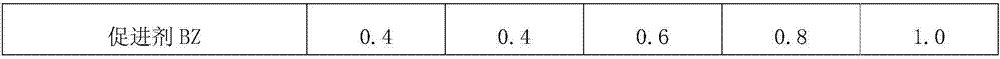

Heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, preparation method, application and application product thereof

ActiveCN107189236AImprove heat aging resistanceGood physical and mechanical propertiesVulcanizationPolymer science

The invention discloses a heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, a preparation method, application and an application product thereof. The composition is prepared from 100 parts of EPDM rubber, 50 to 130 parts of carbon black, 10 to 60 parts of paroline, 2 to 8 parts of zinc oxide, 0.5 to 3 parts of stearic acid, 1 to 6 parts of an anti-aging agent, 0.2 to 1 part of sulfur and 1 to 6 parts of an accelerator. Compared with a sulfur vulcanized EPDM rubber composition prepared in the prior art, the composition has the advantages that heat aging resistance and low compression set are remarkably increased, and the composition is applied to rubber products having the requirements on heat aging resistance and low pressure change, and is particularly applied to an outer adhesive layer of a rubber hose which adopts a poly-4-methyl-1-pentene (TPX) coating and vulcanizing technology; meanwhile, the preparation method of the composition is simple, the vulcanization temperature is lower, and the purpose of saving energy is achieved.

Owner:NANJING ORIENTLEADER TECH CO LTD

Automobile weather strip

ActiveUS20090120007A1Firmly attachedInsert member is prevented from being corrodedVehicle sealing arrangementsSealing arrangementsEngineeringEPDM rubber

An automobile weather strip has a trim part having a substantially U-shaped section and a sealing part. The automobile weather strip is characterized in that: the trim part has an insert member and a covering material for covering the insert member; the covering member is provided with holding lips for holding a flange part on an inner surface of the trim part; a sponge material of a rubber formed by using a blend material of an EPDM rubber and an olefin-based thermoplastic synthetic resin and a sponge material of a rubber having physical properties of a specific gravity of 0.6 to 0.8 and a 25%-stretching stress of 500 KPa or more are used as the covering material.

Owner:TOYODA GOSEI CO LTD

Silicon rubber/ethylene propylene terpolymer blending material and processing method

The invention discloses a silicon rubber / ethylene propylene terpolymer blending material and a processing method of the silicon rubber / ethylene propylene terpolymer blending material. The silicon rubber / ethylene propylene terpolymer blending material comprises silicon rubber raw rubber, ethylene propylene terpolymer raw rubber, diphenylmethane bismaleimide and an organic peroxide vulcanizing agent. In the silicon rubber / ethylene propylene terpolymer blending material vulcanized by peroxide, the vulcanizing speed of the ethylene propylene terpolymer component is improved by diphenylmethane bismaleimide, so that the vulcanizing speed of the ethylene propylene terpolymer component and the vulcanizing speed of the silicon rubber component trend to be close, and the purpose of co-vulcanization of all rubber components can be achieved. According to the invention, the silicon rubber / ethylene propylene terpolymer blending material is mixed and processed by an open two-roll rubber mixing mill and a sealed rubber mixing mill, and the rubber compound containing diphenylmethane bismaleimide is heated and vulcanized to obtain the silicon rubber / ethylene propylene terpolymer rubber compound with excellent properties.

Owner:SOUTH CHINA UNIV OF TECH

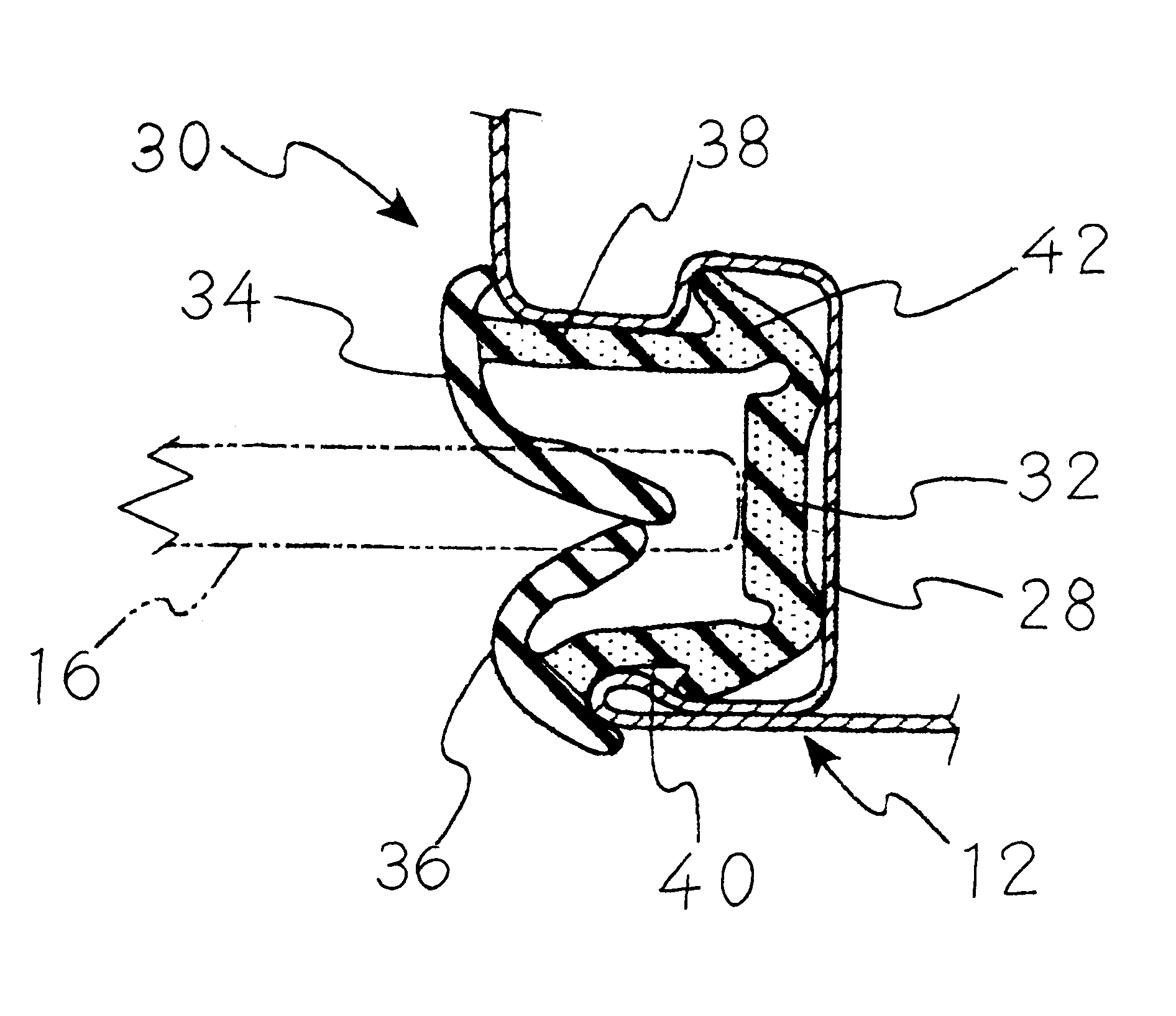

Glass run including fine lubricant powder for reducing noise

Owner:TOYODA GOSEI CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com