Lightweight wear-resistant density-gradient foamed sole material and preparation method thereof

A technology of density gradient and sole material, applied in soles, footwear, applications, etc., can solve the problems of inconsistent foaming ratio and material warpage, and achieve the effect of shortening the molding cycle, saving labor costs, and wearing comfortably

Active Publication Date: 2015-09-09

CHINA LEATHER & FOOTWEAR IND RES INST +1

View PDF3 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Different densities will inevitably lead to inconsistent expansion ratios of materials. If they cannot be precisely controlled, the materials will warp to the side with larger expansion ratios.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0033] 1. Preparation of the first layer of materials:

[0034] The composition (mass ratio) is: EPDM rubber 70 parts, ethylene-octene copolymer 20 parts, low-density polyethylene 10 parts, dicumyl peroxide 2 parts, talcum powder 10 parts, white carbon black 5 parts , 1 part of azodicarbonamide, 2 parts of N, N'-dinitrosopentamethylenetetramine, 3 parts of zinc oxide, and 3 parts of zinc stearate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Abrasion | aaaaa | aaaaa |

| Abrasion | aaaaa | aaaaa |

Login to View More

Abstract

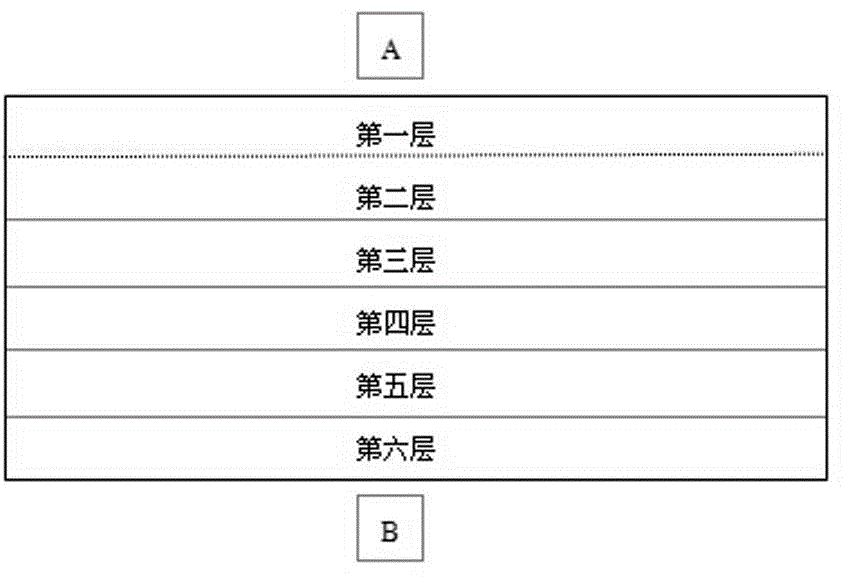

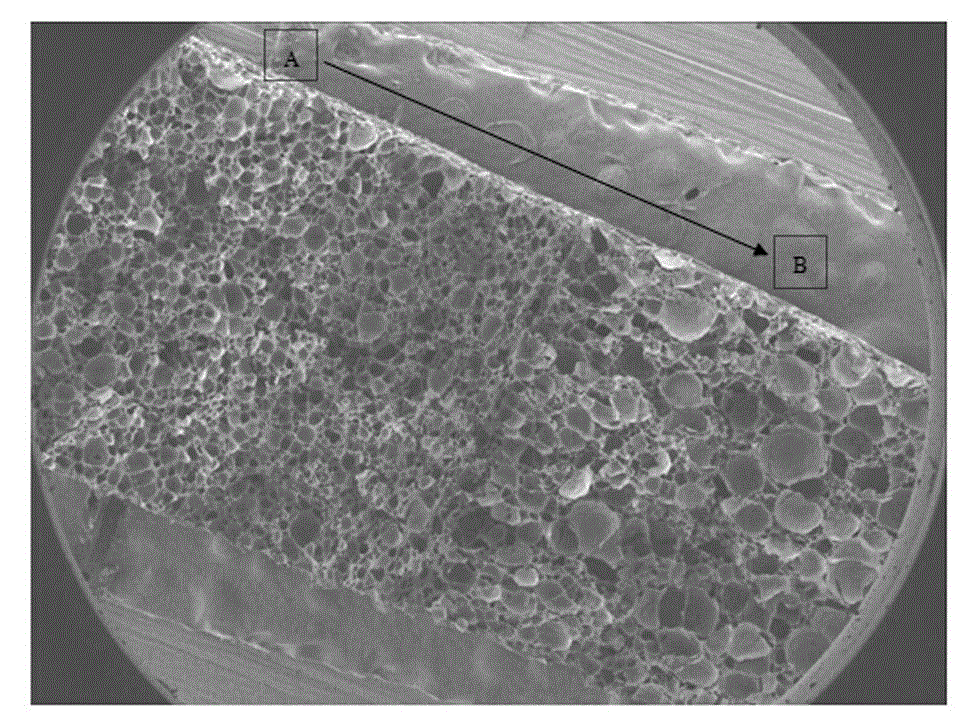

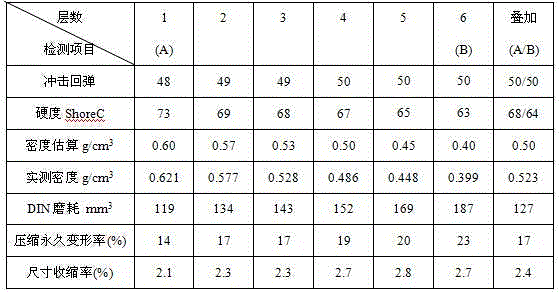

The invention relates to a lightweight wear-resistant density-gradient foamed sole material and a preparation method thereof. The lightweight wear-resistant density-gradient foamed sole material is mainly composed of EPDM, ethylene-octene copolymer, low density polyethylene, a cross-linking agent, a filling material, a foaming agent and a foaming promoter. On the basis of foaming of EPDM, POE and LDPE and through control of a foaming ratio and density difference values of each layer of materials, a heterogeneous expandable rubber compound composed of a plurality of layers and having quasi-continuously changing performances in the thickness direction of the materials are subjected to one-shot mould pressing, foaming and moulding so as to prepare the foamed sole material, and function gradient differences of density, hardness and wear resistance are realized. Due to gradual change of density, stress concentration is mitigated, and the prepared foamed sole material does not warp. The foamed material has low density at one side close to the vola while the foamed material has high density at one side close to the outer sole, so the foamed sole material has good wear resistance, reduces the weight of the sole and has improved wearing comfortableness.

Description

technical field [0001] The invention relates to a sports and leisure shoe sole material and a preparation method thereof, in particular to a density gradient foam sole material and a preparation method thereof. Background technique [0002] Functional Gradient Materials (Functional Gradient Materials abbreviated as FGM) is to make the elements of the material (composition, structure, porosity, concentration) change continuously along the thickness direction from one side to the other during the manufacturing process, so that there is no obvious internal Interface, so that the properties and functions of the material are also a new material that changes continuously. Compared with composite materials, the composition of functionally graded materials changes gradually from one side to the other, and there is no specific interface, so that the properties of the material change smoothly, thus easing the stress between the surface layer and the bottom layer, resulting in better p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/16C08L23/08C08L23/06C08K13/02C08K3/22C08K5/098C08K5/14C08J9/10C08J9/08A43B13/04B29C51/14B29C51/42B29C35/02B29B7/38B29B7/88

CPCA43B13/04B29B7/38B29B7/88B29C35/02B29C51/14B29C51/42C08J9/103C08J9/107C08J2323/08C08J2323/16C08J2423/08C08J2423/16C08L23/0815C08L23/16C08L2203/14C08L2205/02C08L2205/03C08L2207/066C08L23/06C08K13/02C08K2003/2296C08K5/098C08K5/14

Inventor 王旭熊祖江梁纪宇贯丽华

Owner CHINA LEATHER & FOOTWEAR IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com