Patents

Literature

945results about How to "Low wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-lubricating sliding bearing material and its preparation method

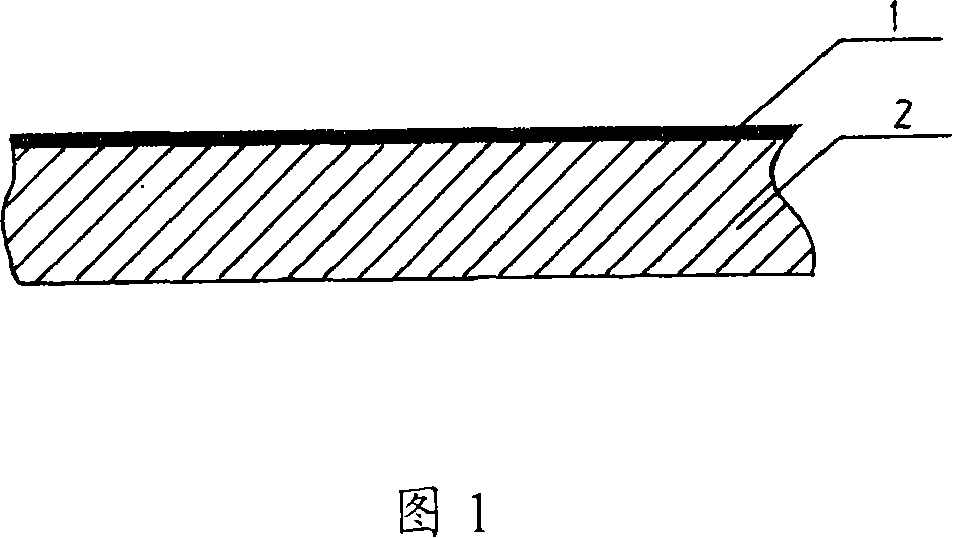

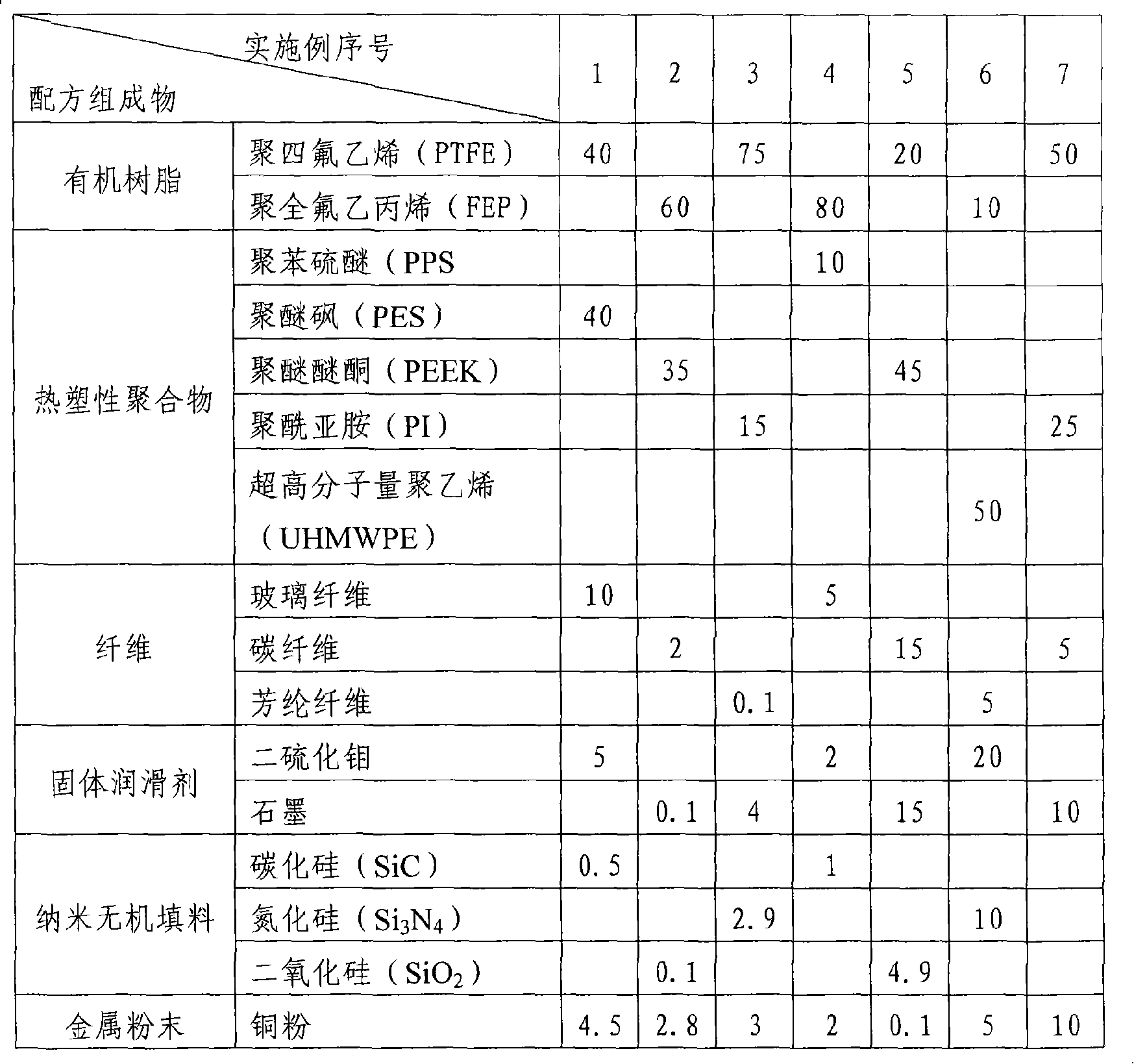

ActiveCN101126417AImprove carrying capacityReduce frictionBearing componentsCarrying capacityMetal sheet

The invention discloses a self-lubrication sliding bearing material and the preparation method, the self-lubrication sliding bearing material includes a self-lubrication sliding layer made of composite material which adopts the organic resin as the basis and a metal substrate, the sliding layer and the metal substrate are directly adhered together. During the preparation, the composite material for the self-lubrication sliding layer is blended proportionally and is laid on the metal sheet after being mixed mechanically, the surface of the metal sheet is treated, and then the metal sheet is sintered in a sintering furnace, then rolled immediately after the sintering process so that the surface coat is adhered on the metal substrate. The sliding bearing made of the material provided by the invention has the characteristics of higher carrying capacity and low friction and good wearing resistance, the metal substrate and the self-lubrication sliding layer can be stably adhered with each other, and is suitable for the dry friction and boundary or fluid friction conditions.

Owner:COB PRECISION PARTS

Cooking surface for cooking food having a glass ceramic surface with a glass coating thereon

InactiveUS6525300B1Reduction factorEasy to processCoil arrangementsHot plates heating arrangementsGlazeThermal expansion

The invention relates to lead- and cadmium-free glass for glazing, enamelling and decorating glasses or glass-ceramics which have a low coefficient of thermal expansion of less than 2x10-6 / K, having the composition (in % by weight) 0-6 Li2O, 0-5 Na2O, 0 to less than 2 K2O, where the sum Li2O+K2+Na2O is between 2 and 12, 0-4 MgO, 0-4 CaO, 0-4 SrO, 0-1 BaO, 0-4 ZnO, 3 to less than 10 Al2O3, 13-23 B2O3, 50-65 SiO2, 0-4 TiO2, 0-4 ZrO2 and 0-4 F, as replacement for oxygen and containing up to 30% by weight of a pigment which is resistant at the firing temperature, where the glass is suitable for glazing, enamelling and decoration in both primary and secondary firing, and both the full-area and sparse glaze, enamel or decoration layers have low abrasion susceptibility after firing, and it relates to processes for the production of a glass-ceramic coated therewith.

Owner:SCHOTT AG

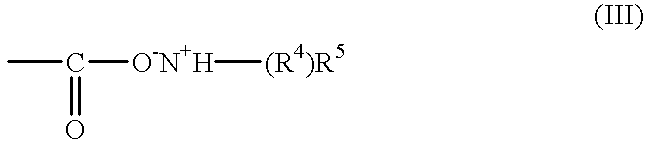

Polymer containing isobutylene as repeating unit and rubber composition containing the same

A modified polybutene(polyisobutylene) containing isobutylene repeating units and having, in the main chain, at the ends, and / or at the side chains of the polymer chain thereof, free radicals stable at a room temperature and in the presence of oxygen, or having a half-ester structure, amide structure, onium salt structure, or imide structure or acid anhydride residual group, as well as a rubber composition containing the same.

Owner:THE YOKOHAMA RUBBER CO LTD

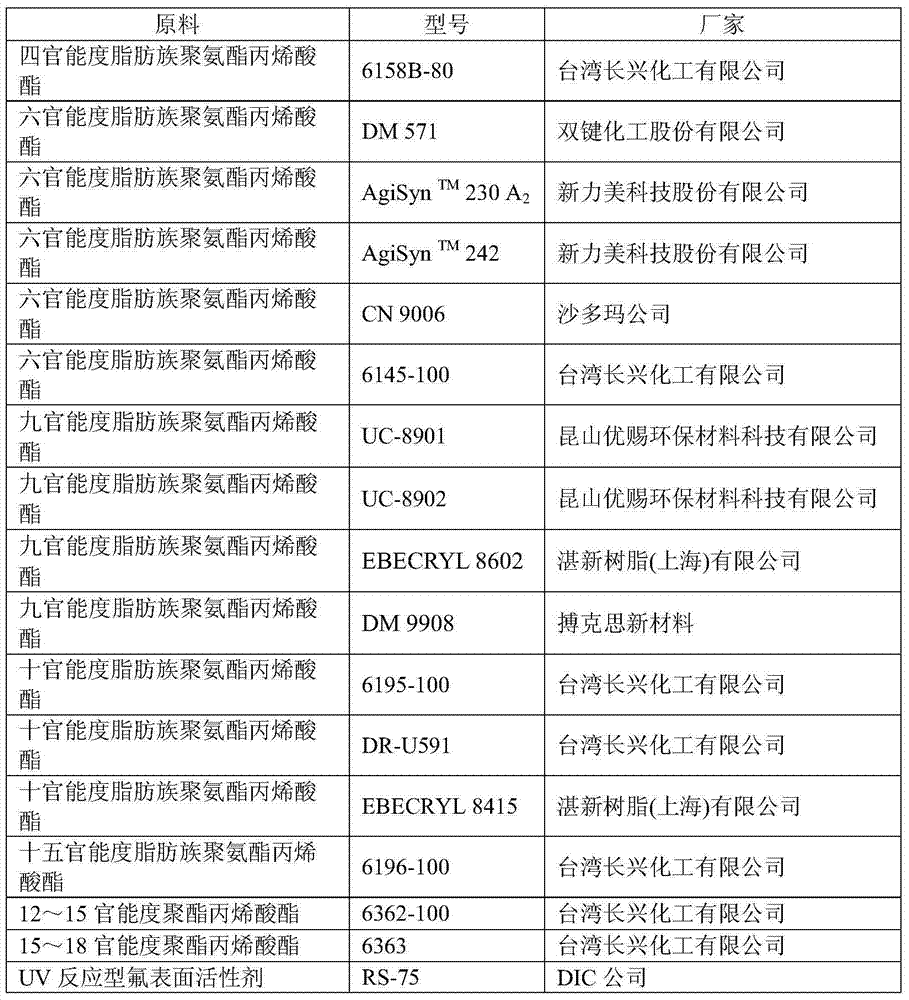

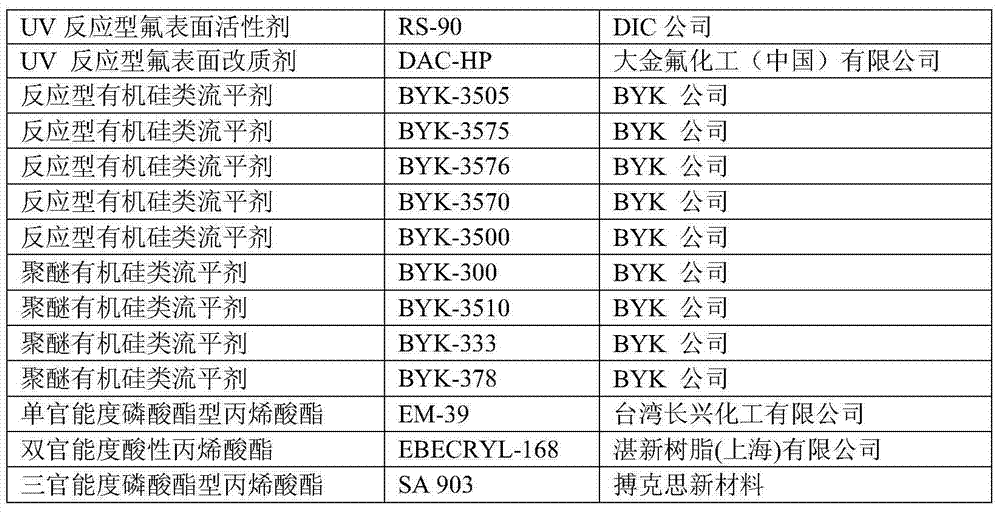

UV curing coating, wear-resistant and antifouling coating layer and mobile phone protection film containing wear-resistant and antifouling coating layer

ActiveCN104845521AHigh reactivityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesWear resistantPolysilazane

The invention provides an UV curing coating, a wear-resistant and antifouling coating layer and a mobile phone protection film containing the wear-resistant and antifouling coating layer. The coating comprises, in parts by weight, 10-95 parts of a first prepolymer, 5-60 parts of a second prepolymer, 0.05-8 parts of a polysilazane-based polymer, 0.05-8 parts of a fluorine-containing aid, 1-15 parts of a photoinitiator and 100-300 parts of a solvent, wherein the first prepolymer is a urethane acrylate prepolymer with a functionality degree of 4-8; the second prepolymer is an acrylate prepolymer with a functionality degree of 9-18. The wear resistance of the coating layer formed after curing the UV curing coating can be improved by the first prepolymer and the second prepolymer with high functionality degrees, improvement for the wear resistance of the coating layer and prolonging for the service life of the coating layer are benefited due to the adding of the polysilazane-based polymer and a polar compound, and the good antifouling performance of the coating layer can be ensured, and the reduction of the antifouling performance of the coating layer can be suppressed due to the fluorine-containing aid. The coating layer has both good antifouling performance and wear resistance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

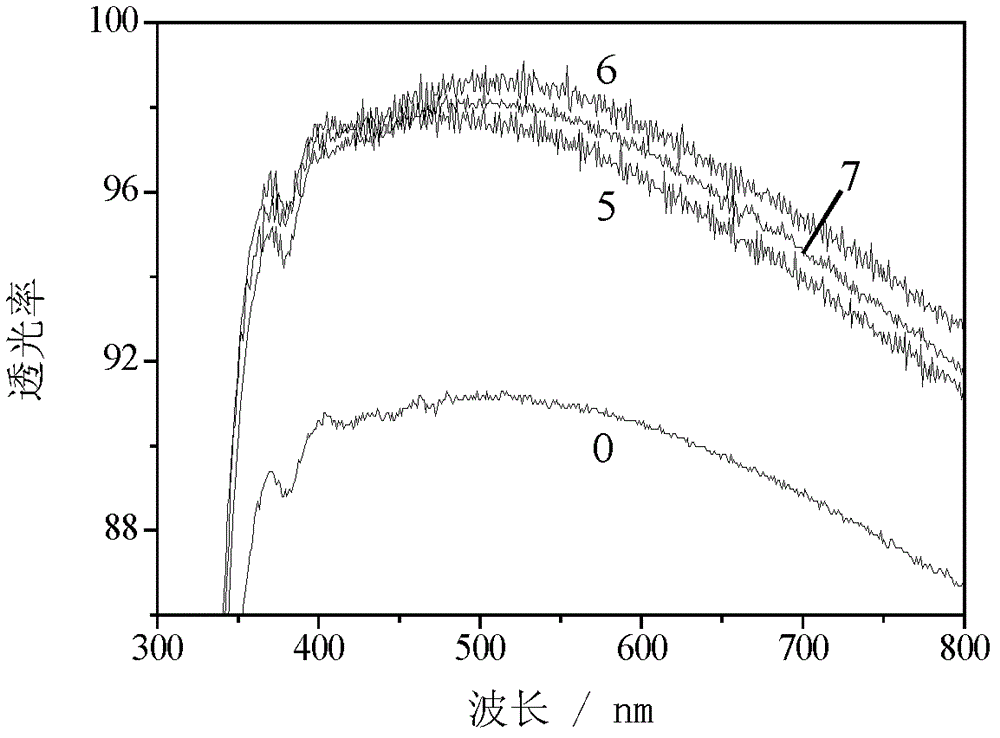

Anti-reflection coating and super-hydrophobic self-cleaning anti-reflection coating and preparation method thereof

The invention relates to an anti-reflection coating and a super-hydrophobic self-cleaning anti-reflection coating and a preparation method thereof. The anti-reflection coating is formed by a SiO2 ball-shaped nanoparticle layer with the particle size of 10-100 nm, and the surface of the coating has a rough structure. The super-hydrophobic self-cleaning anti-reflection coating is formed by providing a low surface energy substance on the surface of the anti-reflection coating, and the surface of the low surface energy substance has a rough structure. The coatings are obtained by using layer-by-layer electrostatic self-assembly technique. The light transmittance of the glass coated with the super-hydrophobic self-cleaning anti-reflection coating can increase to 99.1 from 91.3%, and the single-side reflectivity of the glass can reduce lowest to 0.3%. Compared with a solar cell coated with a common glass flake, a standard mono-silicon solar cell panel coated with a glass with the super-hydrophobic self-cleaning anti-reflection coating can utilize solar energy more effectively, and the efficiency can be improved to more than 6.6%.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

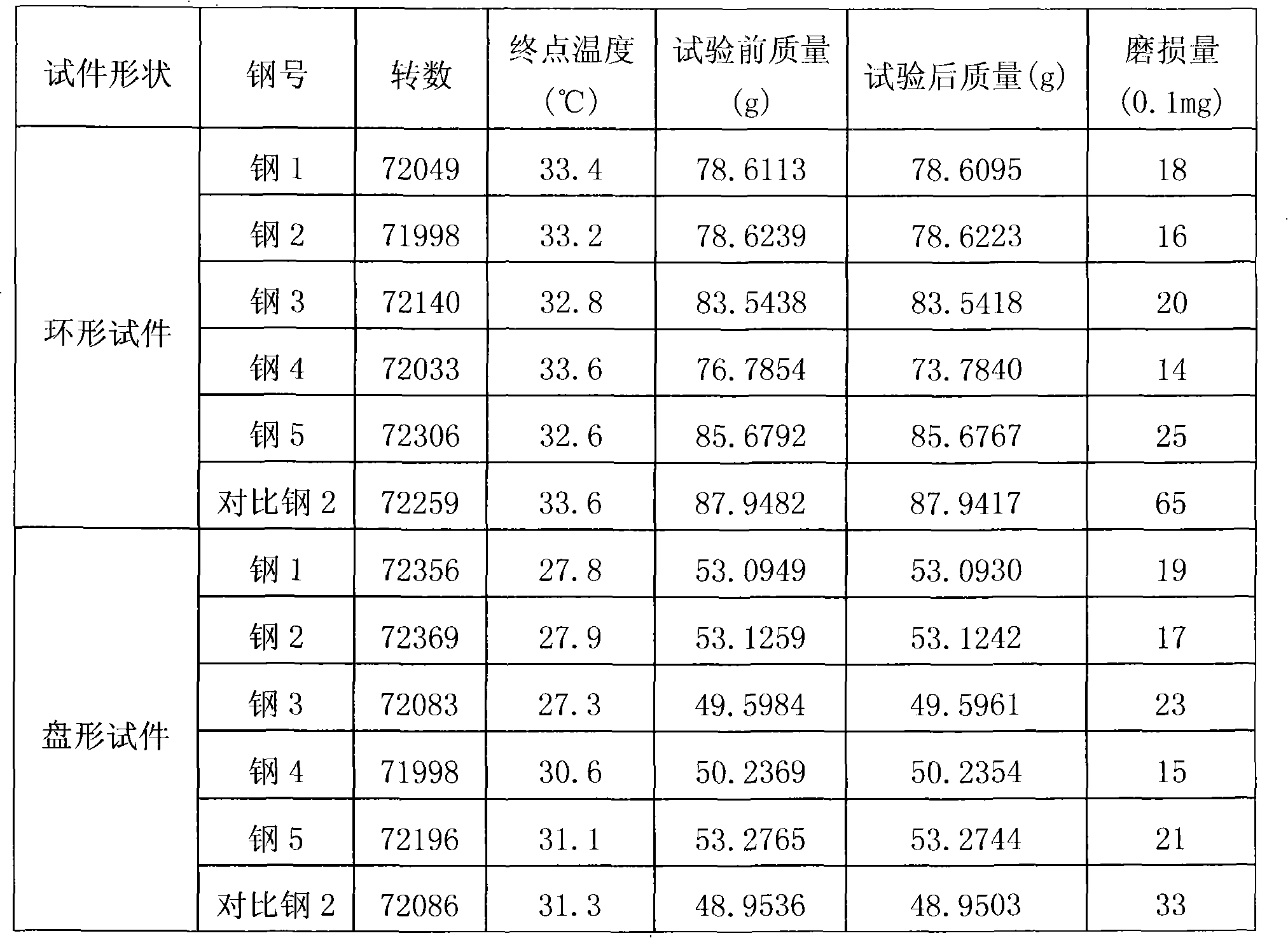

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

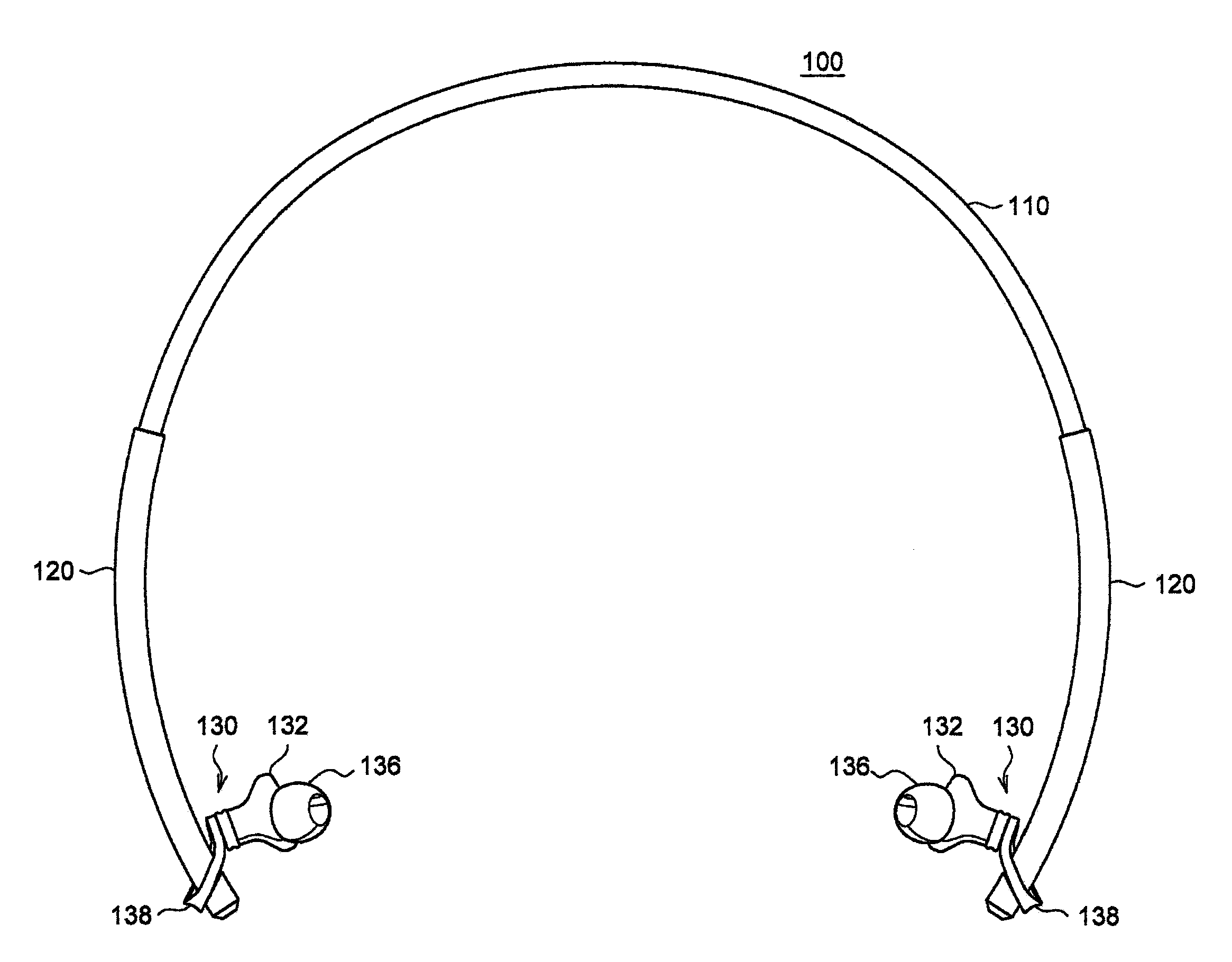

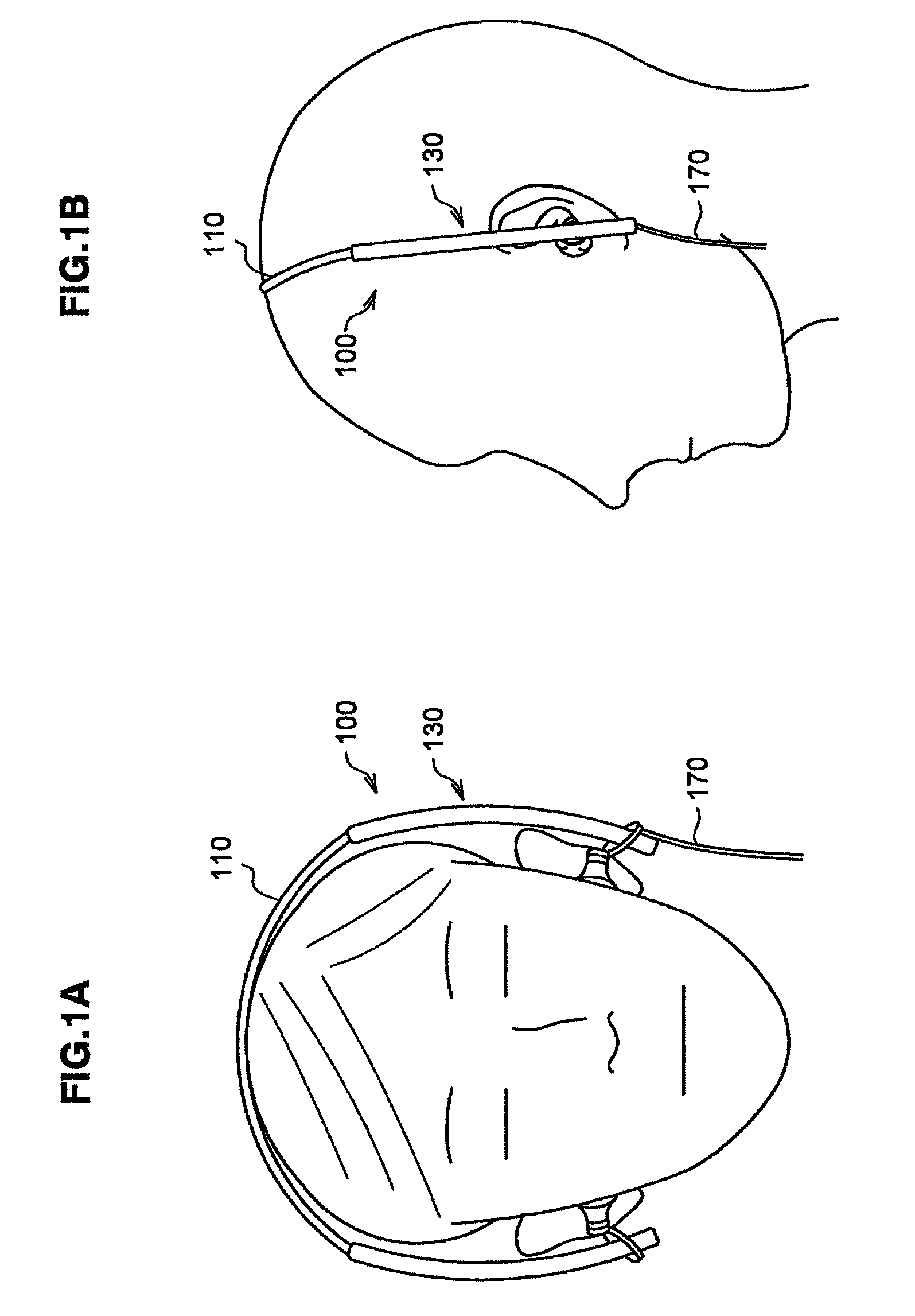

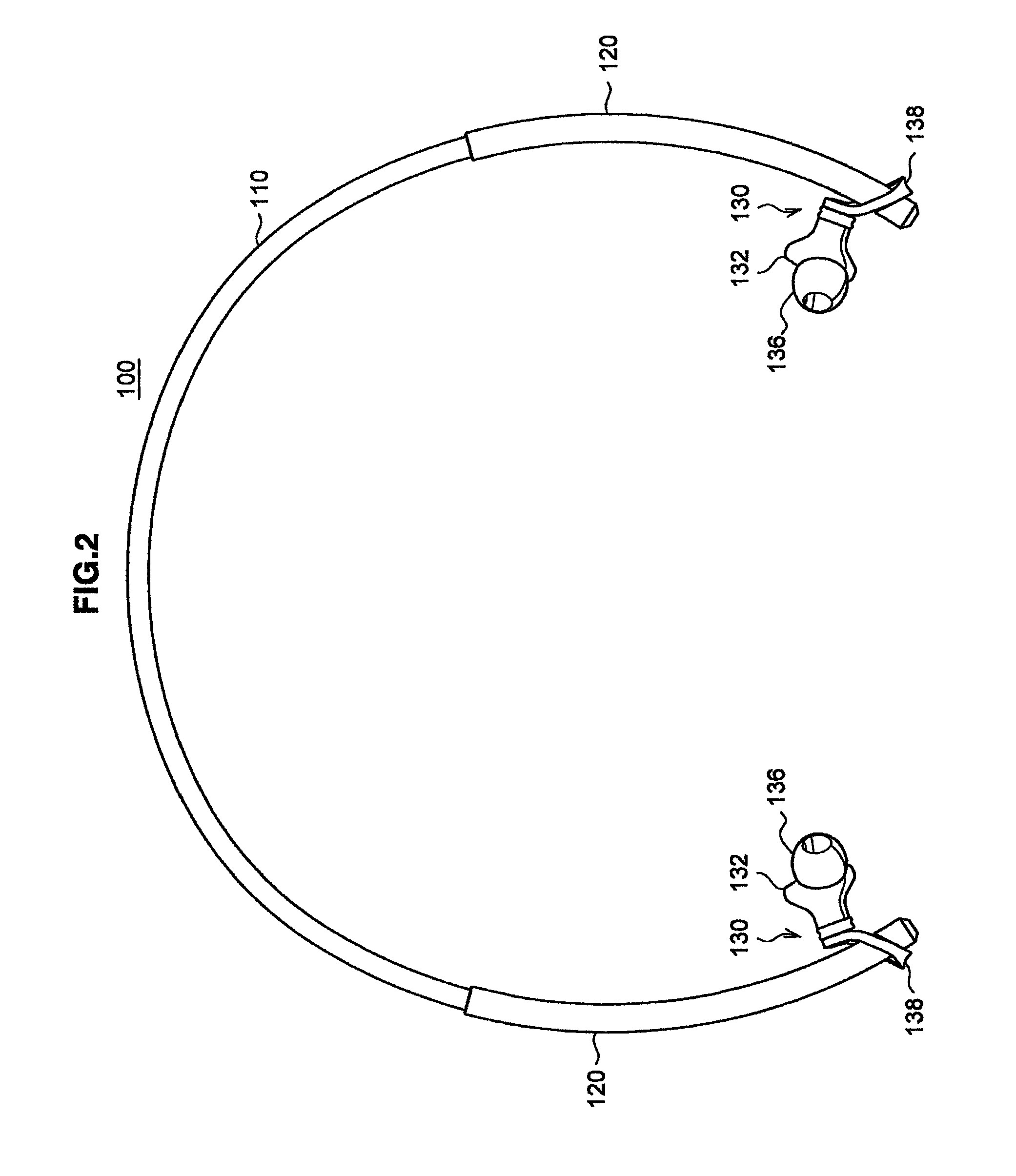

Headphone

InactiveUS8363875B2Low wear resistanceIncrease in sizeEarpiece/earphone cablesDeaf-aid setsEngineeringHeadphones

Owner:SONY CORP

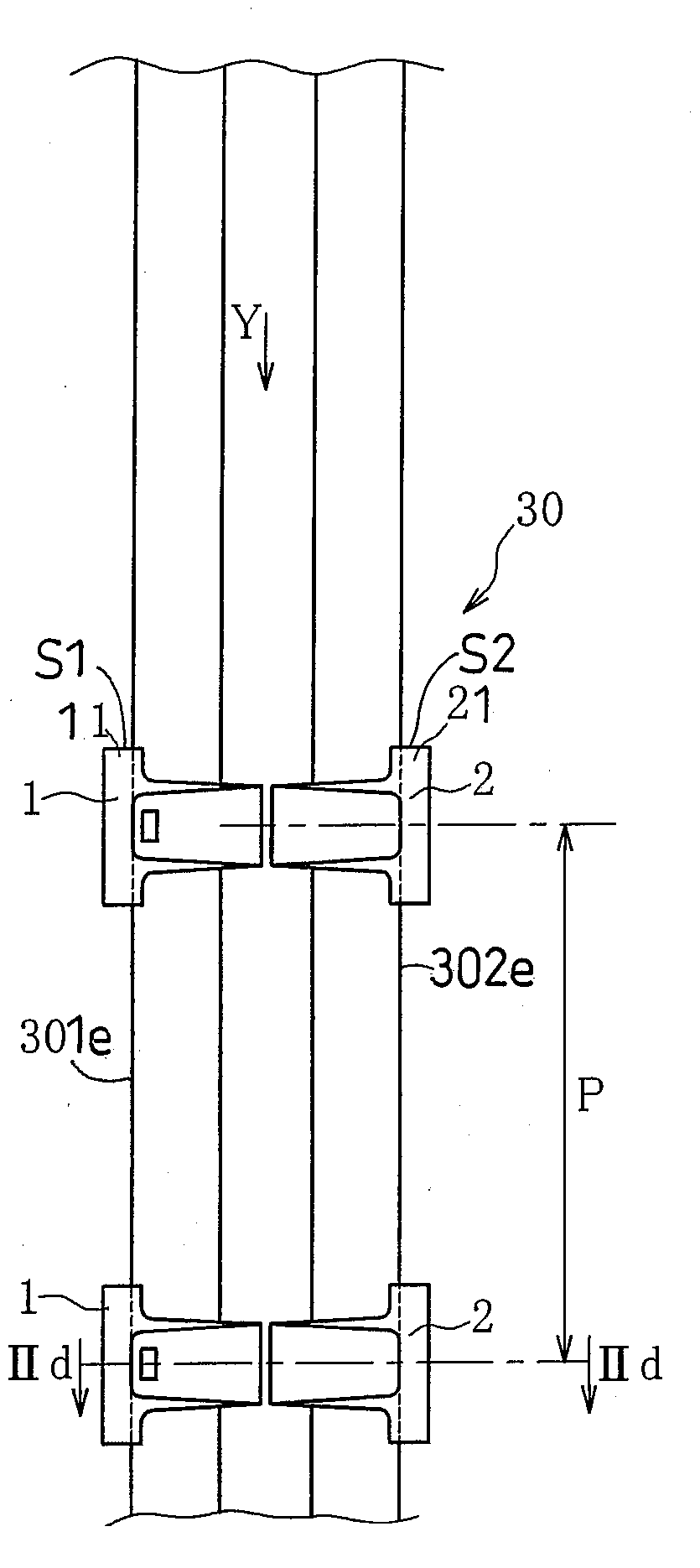

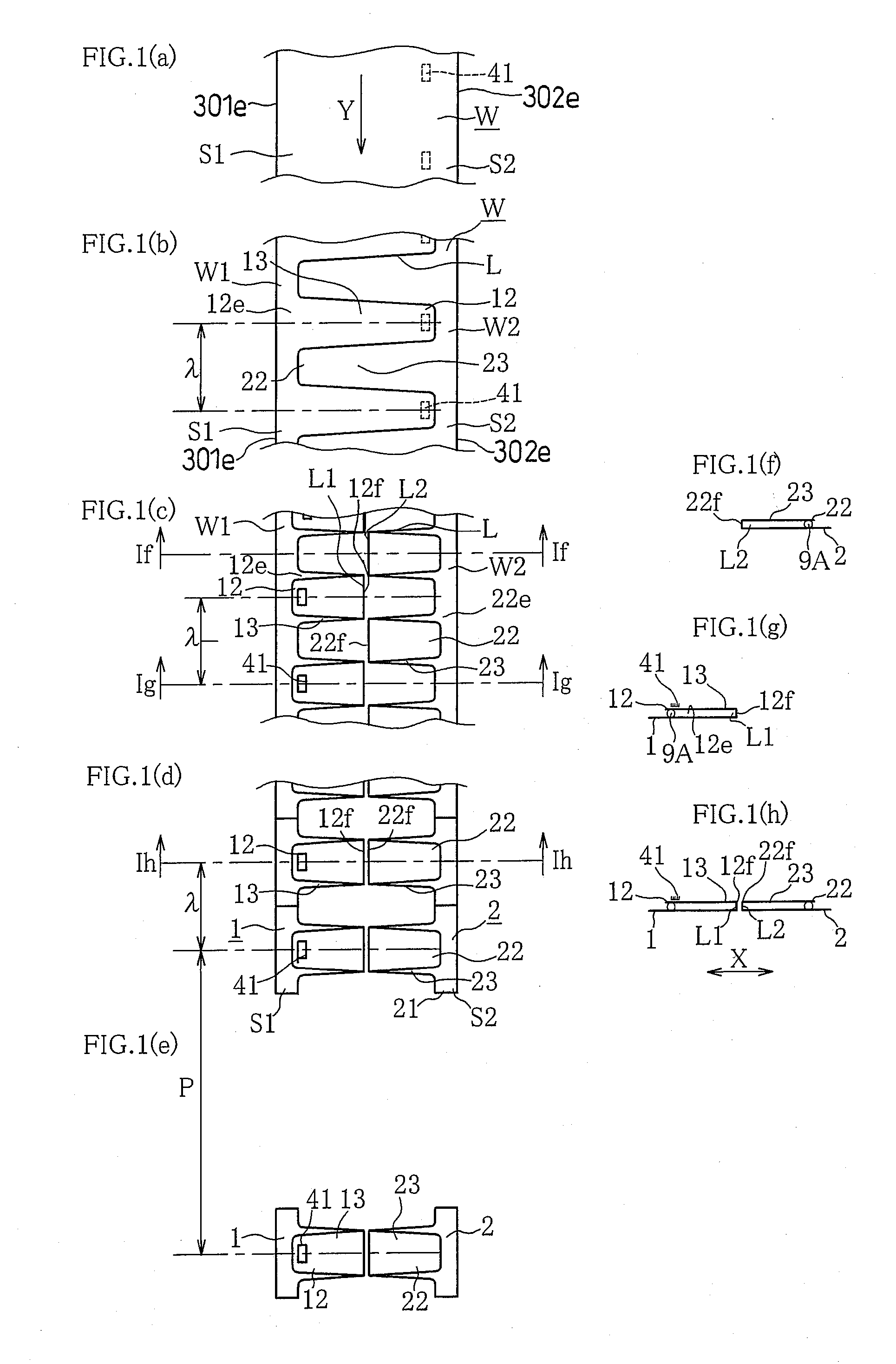

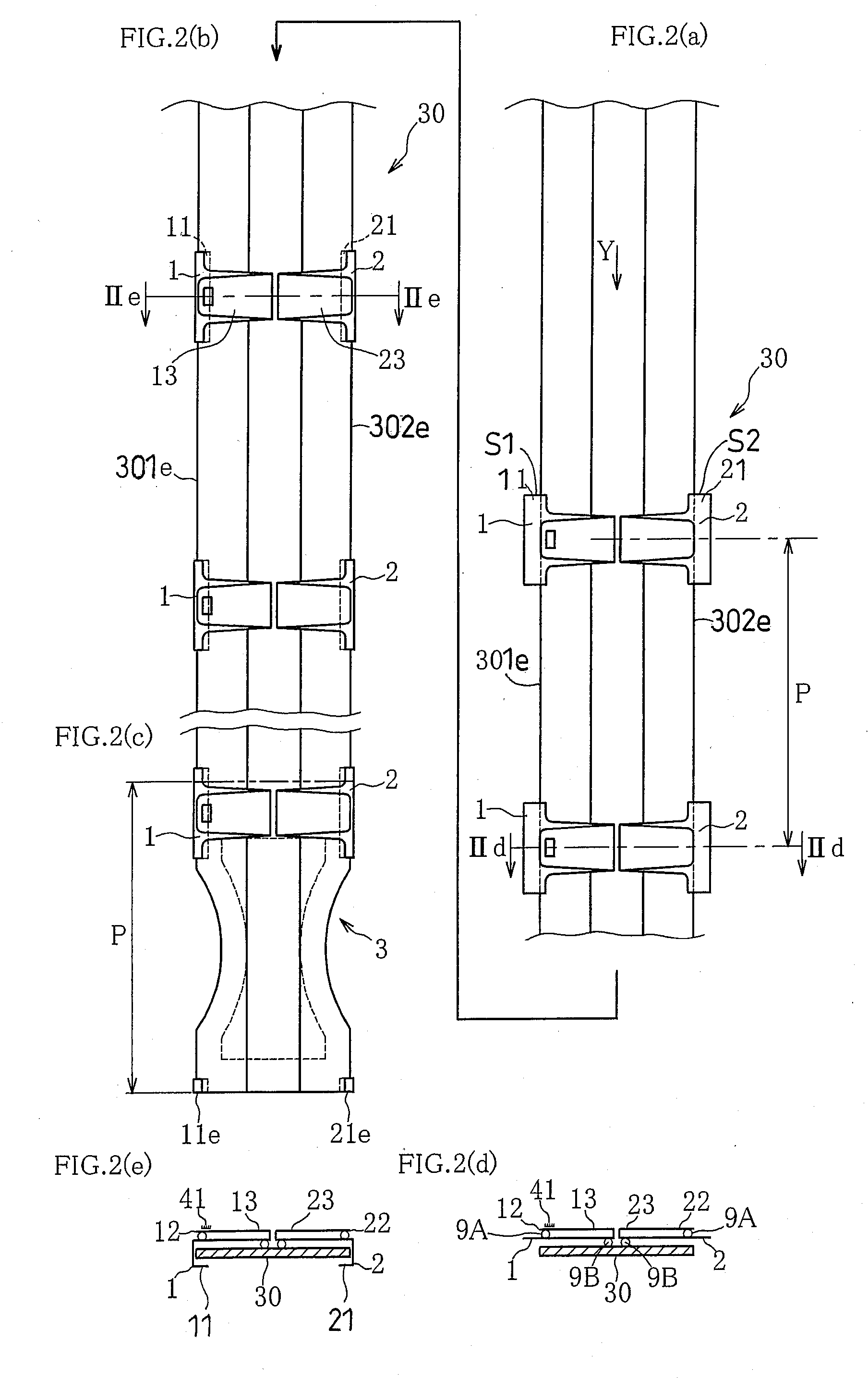

Method for producing diaper

InactiveUS20090126864A1Improve appearanceIncrease widthLayered productsAbsorbent padsEngineeringLeather belt

A method for producing a diaper of the present invention includes the steps of: folding back a first strip-shaped portion 13 and a second strip-shaped portion 23; successively forming pairs of first and second belts 1 and 2 by cutting first and second separate webs W1 and W2; placing pairs of the first and second belts 1 and 2 at a predetermined interval P in a carrying direction Y of a continuous piece; temporarily attaching the first and second belts 1 and 2 to a portion of the continuous piece to be a back portion; fixing the belts 1 and 2 to the continuous piece; and severing the continuous piece with the belts 1 and 2 fixed thereon at a predetermined pitch into individual diapers.

Owner:ZUIKO CORP

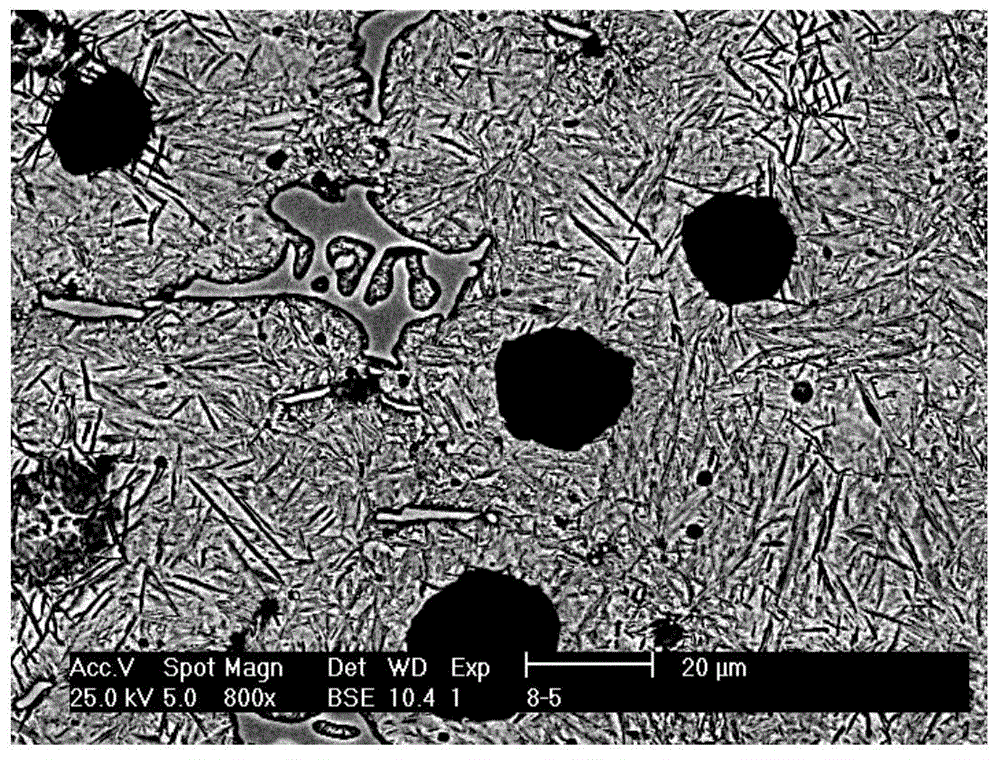

Ausferrite ductile cast iron grinding ball

ActiveCN104152792AHighlight substantive featuresImprove absorption rateGrain treatmentsAlloyDuctile iron

The invention discloses an Ausferrite ductile cast iron grinding ball, and relates to a spherulitic graphite-contained cast iron alloy. The Ausferrite ductile cast iron grinding ball comprises the following chemical elements in percentage by mass: 3.3-3.7% of C, 2.0-3.0% of Si, 1.0-2.5% of Mn, 0.7-3.0% of Cr, 0.1-1.0% of Mo, 0.1-1.0% of Cu, 0.04-0.08% of P, 0.01-0.020% of S, 0.03-0.05% of Mg, 0.02-0.04% of Ce, 0.03-0.07% of B, 0.06-0.12% of Ti, 0.03-0.2% of V, and the balance of Fe. The Ausferrite ductile cast iron grinding ball is prepared by the steps of preparation and smelting of raw materials, spheroidizing treatment, inoculation treatment and microalloying treatment, and isothermal quenching heat treatment. The Ausferrite ductile cast iron grinding ball overcomes the defects of low production efficiency and high consumption of electric energy of a ball mill due to easy surface stripping and crushing and shorter fatigue life of an existing grinding ball product in the service process.

Owner:HEBEI UNIV OF TECH

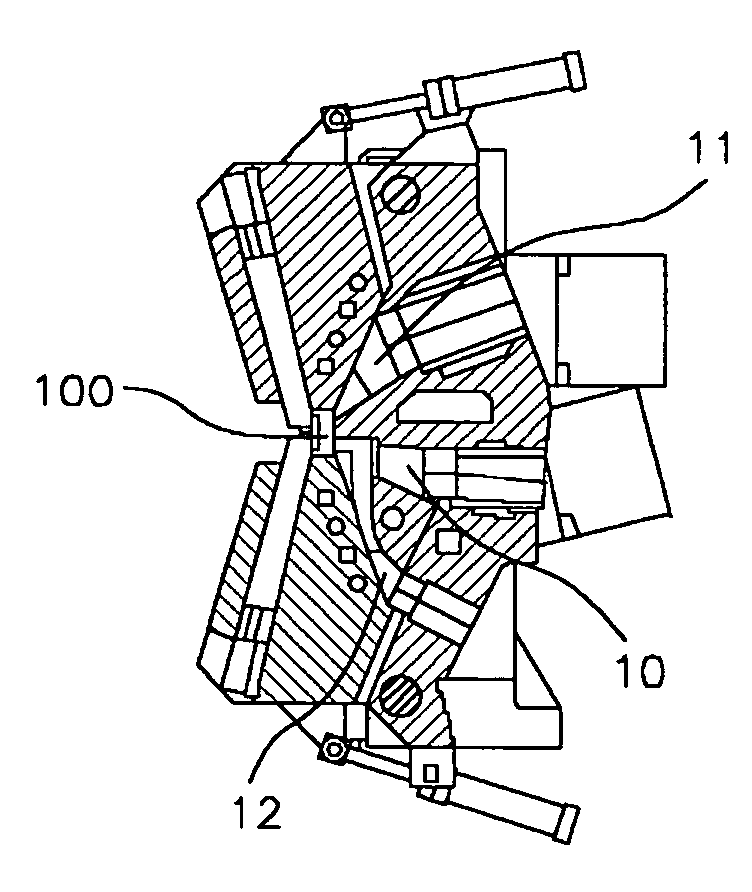

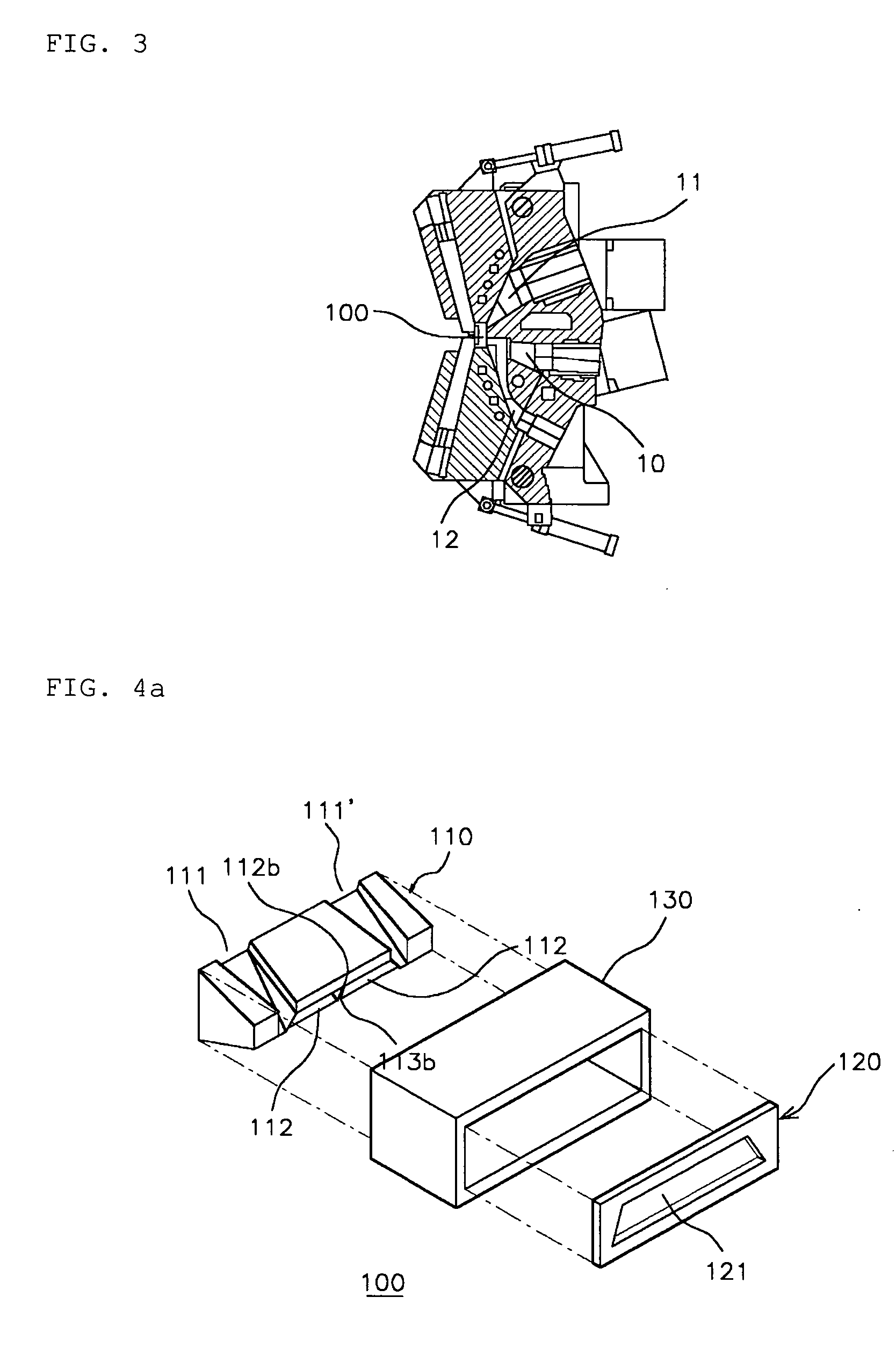

Die set of molding extruder for tire with slanted conductive ring

InactiveUS20050208167A1Improve productivityEfficient executionTyre partsConfectioneryEngineeringSilicon dioxide

A mold extruder for a tire with a highly electrically conductive ring and a manufacturing method using the same. The extruder solves the problem of static electricity caused by failure to discharge charges generated in a vehicle body, to the ground, but accumulating charges on the tire when a large amount of silica is used into the tread rubber composition of a tire. The mold extruding die for forming a conductive ring on the tread extrudes a cap tread, an under tread, and tread wings simultaneously, is installed to a head section of a mold extruder having a tri-extruder for extruding a tire tread, and includes a preform die, a final die, and a cassette. The extruding passages for the cap tread, the under tread, and the tread wings are formed by assembling the preform die, the final die, and the cassette. By designing a conductive ring passage for the extruding passage of the under tread to penetrate the extruding passage of the cap tread, the under tread rubber composition protrudes so as to divide a space of the cap tread extruding passage by the conductive ring passage penetrating the cap tread into a right-side space and a left-side space. For the purpose of easily protruding the under tread rubber composition to an upper end of the cap tread through the conductive ring passage, a triangular recess on a ceiling of the under tread extruding passage penetrates the cap tread extruding passage from a rear side to a front side is formed.

Owner:KUMHO TIRE CO INC

Large-diameter high-speed cutting and high-speed heavy load grinding resin wheel

InactiveCN101695827AHigh thermal conductivityImprove wear resistanceAbrasion apparatusGrinding devicesFilling materialsFilm coating

The invention discloses a large-diameter high-speed cutting and high-speed heavy load grinding resin wheel prepared from the following three components in percentage by weight: 60-72 percent of grinding materials, 18-25 percent of filling materials and 8-18 percent of resin, wherein the grinding materials in the wheel are film-coating calcined brown fused alumina, the filling materials comprise a heat conducting material and an active filling material, and the resin comprises a phenolic resin liquid and phenolic resin powder. The sand is produced by adopting the film-coating calcined brown fused alumina, which has good heat conduction property of metal plating, obviously strengthens the heat radiating effect of the wheel and prolongs the abrasive resistance and the service life of the wheel. In addition, the grinding materials have improved ball-milling flexibility after calcined, which enables the wheel to be durable and the property to be better. The wheel can be used for cutting hot-wire type steel with a diameter of over 100 mm or grinding the steel in a high-speed and heavy load way, and has long service life reaching 100-120min.

Owner:SAINT-GOBAIN ABRASIVES (SHANGHAI) CO LTD +2

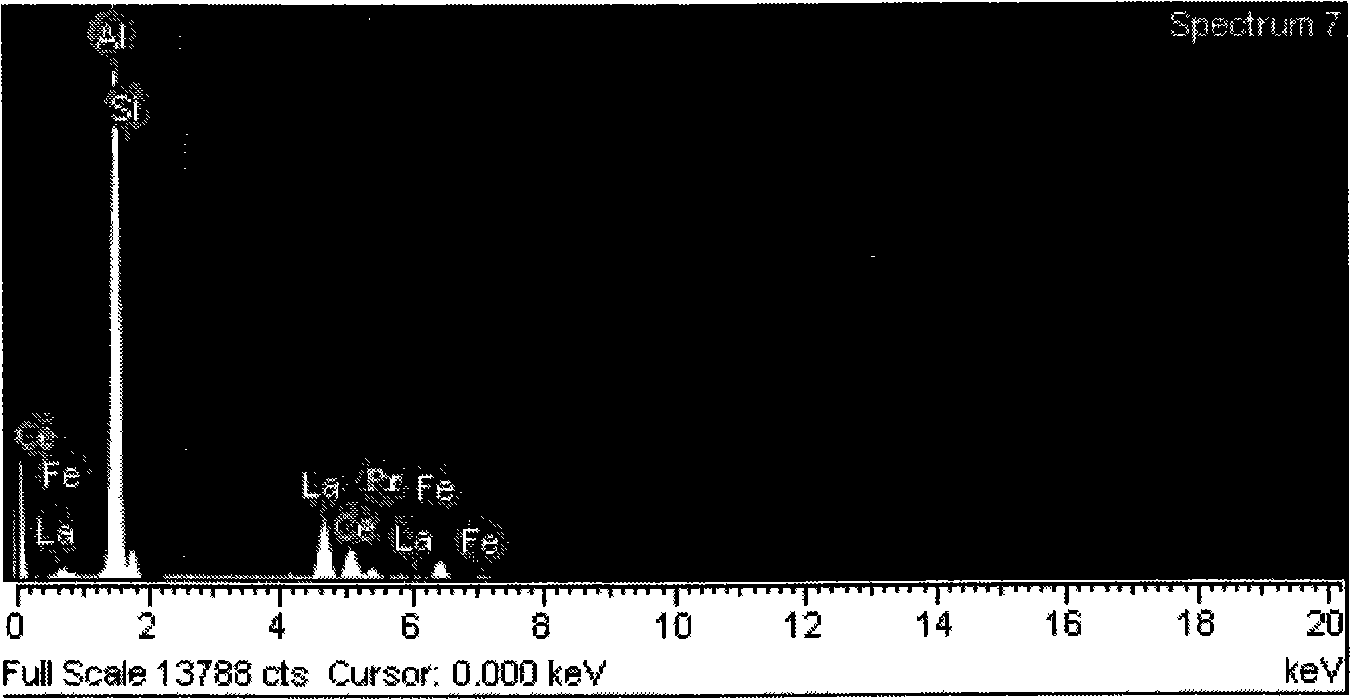

Cermet composition and method for preparing cermet coat on metal surface

A metal-ceramic composition and coating it on metal surface are both disclosed herewith. It consists both parts of mixed powders containing Cr, B, Si, Fe, Al, La rare-earth oxides and Ni, and carbide materials, TiC or WC. It is coated as following: mixing metal-ceramic composition with polyvinyl alcohol or ethyl estate as binding agent to be slurry, coating it onto metal surface, drying, and firing in gas protecting furnace or vacuum furnace to obtain metal-ceramic coated metal parts. It is available to various shaped parts with different materials, and reduces energy consumption.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Flame retardant polyurethane composite material and preparation method thereof

The invention relates to a flame retardant polyurethane composite material and a preparation method thereof. The traditional flame retardant polyurethane foamed material has a poor use effect. The flame retardant polyurethane composite material provided by the invention is a mixed system comprising 70-99wt% of flame retardant polyurethane and 1-30% of blending type fire retardant, wherein the blending type fire retardant is one or more than one of ammonium polyphosphate, melamine, melamine cyanurate acid, polysiloxane, graphine, a carbon nano tube and kaolin, the fire retardant polyurethane is a random copolymer consisting of a polycarbonate unit, a polyether and an isocyanate unit. The preparation method of the flame retardant polyurethane composite material comprises the following steps of: firstly, preparing fire retardant polyalcohol; then, mixing the fire retardant polyalcohol and the blending type fire retardant into a mixed system; and then adding polyisocyanates into the mixed system and reacting to finally obtain the flame retardant polyurethane composite material. The flame retardant polyurethane composite material prepared by using the preparation method disclosed by the invention has the advantages of excellent fire retardance, low-fogging performance and low-gas-releasing performance.

Owner:JIANGSU ZHONGKE JINLONG CHEM

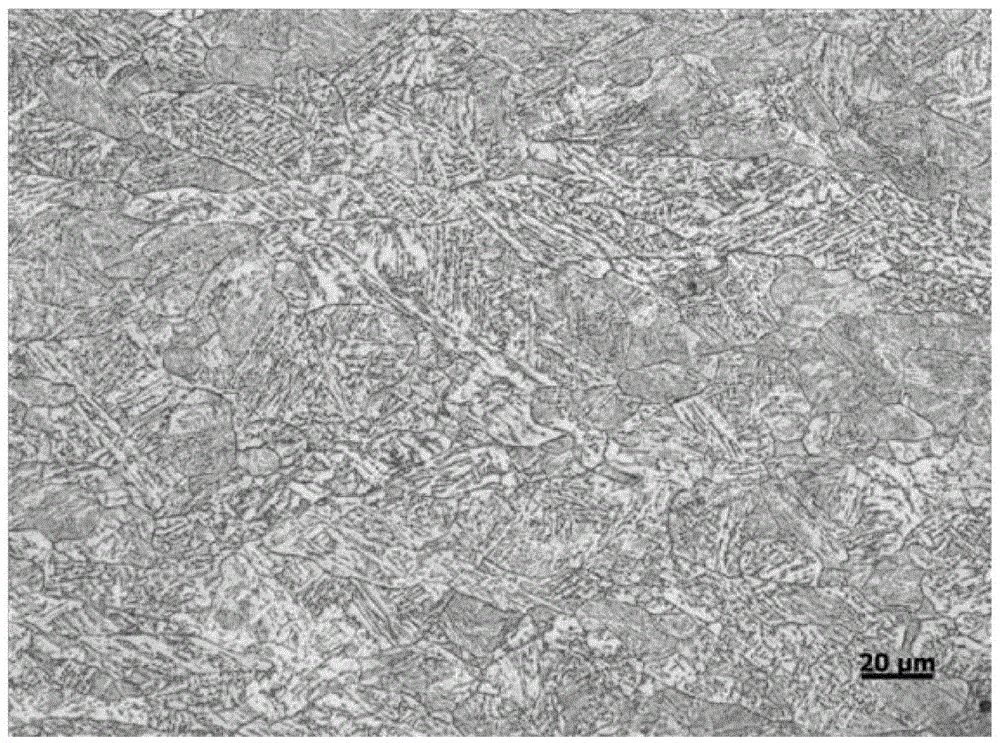

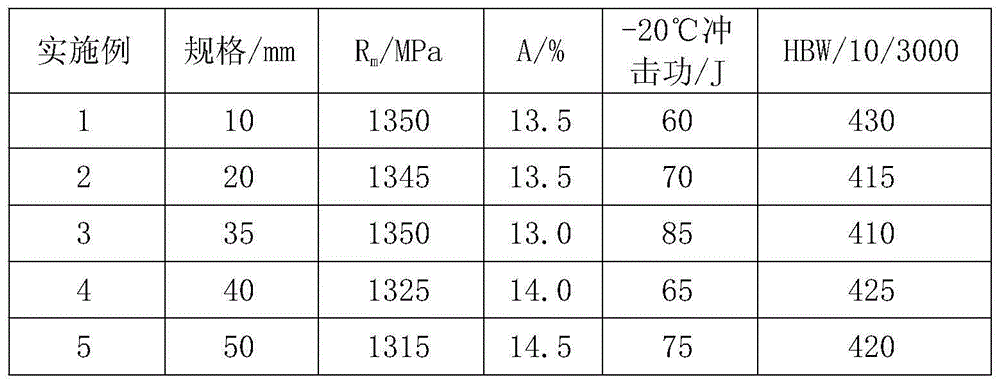

Low-cost HB400-grade wear-resisting steel and production method thereof

The invention discloses low-cost HB400-grade wear-resisting steel and a production method thereof. The low-cost HB400-grade wear-resisting steel comprises the following chemical components in percentage by weight: 0.08-0.19 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, smaller than or equal to 0.015 percent of P, smaller than or equal to 0.015 percent of S, 0.30-0.65 percent of Cr, 0.02-0.05 percent of Nb, 0.005-0.025 percent of Ti, 0.001-0.005 percent of B, 0.010-0.040 percent of Als and the balance of Fe and a trace amount of impurity elements. According to a steel plate, the thickness specification range is 10mm to 50mm; Rm is larger than or equal to 1300MPa; the percentage elongation is larger than or equal to 15%; the Akv is larger than or equal to 47J at -20 DEG C; the HBW / 10 / 3000 is larger than or equal to 400. The low-cost HB400-grade wear-resisting steel has the advantages that the manufacturing cost is greatly lowered, the problems of high strength and poor plasticity of wear-resisting martensite steel are solved, and the steel plate can be delivered directly. Therefore, the low-cost HB400-grade wear-resisting steel has quite high market competitiveness, wide application prospect and obvious economic benefits and social benefits.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Antistatic abrasion-resistant UV coating and preparation method thereof

InactiveCN101851466AReduce electrostatic adsorption capacityLow wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsUV coatingSodium hydroxide

The invention specifically relates to an antistatic abrasion-resistant UV coating and a preparation method thereof, and belongs to the field of materials. The antistatic abrasion-resistant UV coating comprises the following components in percentage by mass: 5 to 35 percent of multifunctional polyurethane acrylate, 15 to 45 percent of epoxy acrylate, 10 to 40 percent of reactive diluent, 2 to 12 percent of photoinitiator, 0.5 to 3 percent of other additives, 5 to 25 percent of conductive nano-attapulgite powder, and 0.05 to 0.5 percent of silane coupling agent. The coating of the invention has an appearance of white liquid or light yellow liquid; the surface resistance of a coat prepared by the coating of the invention is 4.8*10<6> to 6.5*10 <8> ohms; the 100-revolution weight loss in the Taber abrasion resistance test is 0.0045 to 0.0075 gram; and the surface hardness is more than or equal to 3 H; and the coating does not change after dipping in 5 percent sodium hydroxide for 24 hours. The antistatic abrasion-resistant UV coating of the invention has the advantages of simple preparation, low cost, convenient use, good effect and wide application prospect.

Owner:CHANGSHA HUALIANG COATING

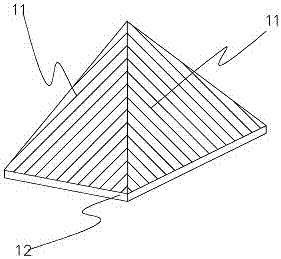

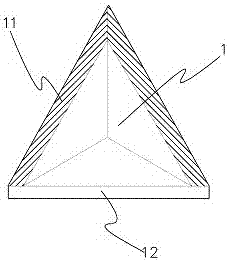

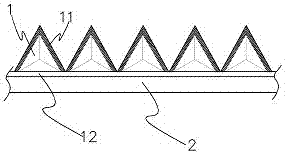

Micron order prism pyramid monomer and manufacturing method thereof

PendingCN107144903AAvoids the phenomenon of sedimentation at the bottom of the fluidImprove reflective effectOptical elementsMicron scalePolymer science

The invention relates to the light reflection material technology field and provides a micron order prism pyramid monomer and a manufacturing method thereof. The prism pyramid is capable of accommodating both the light flashing and light reflecting effects, and can exist independently without being attached to a carrier film. Only with adhesive glue, oil painting, hair glue and nail polishing oil and other colorless or colored transparent fluid or liquid media, it is possible to let the prism pyramid monomer to be attached on objects such as films, cloth, wires and plates requiring to be added with light or to realize light flash so that these materials can present the lighting effect. The monomer can be applied widely in great practical use, and the manufacturing method for the monomer is also simple and easy to implement. Therefore, with the method, batched monomer can be produced and used.

Owner:YEAGOOD INC

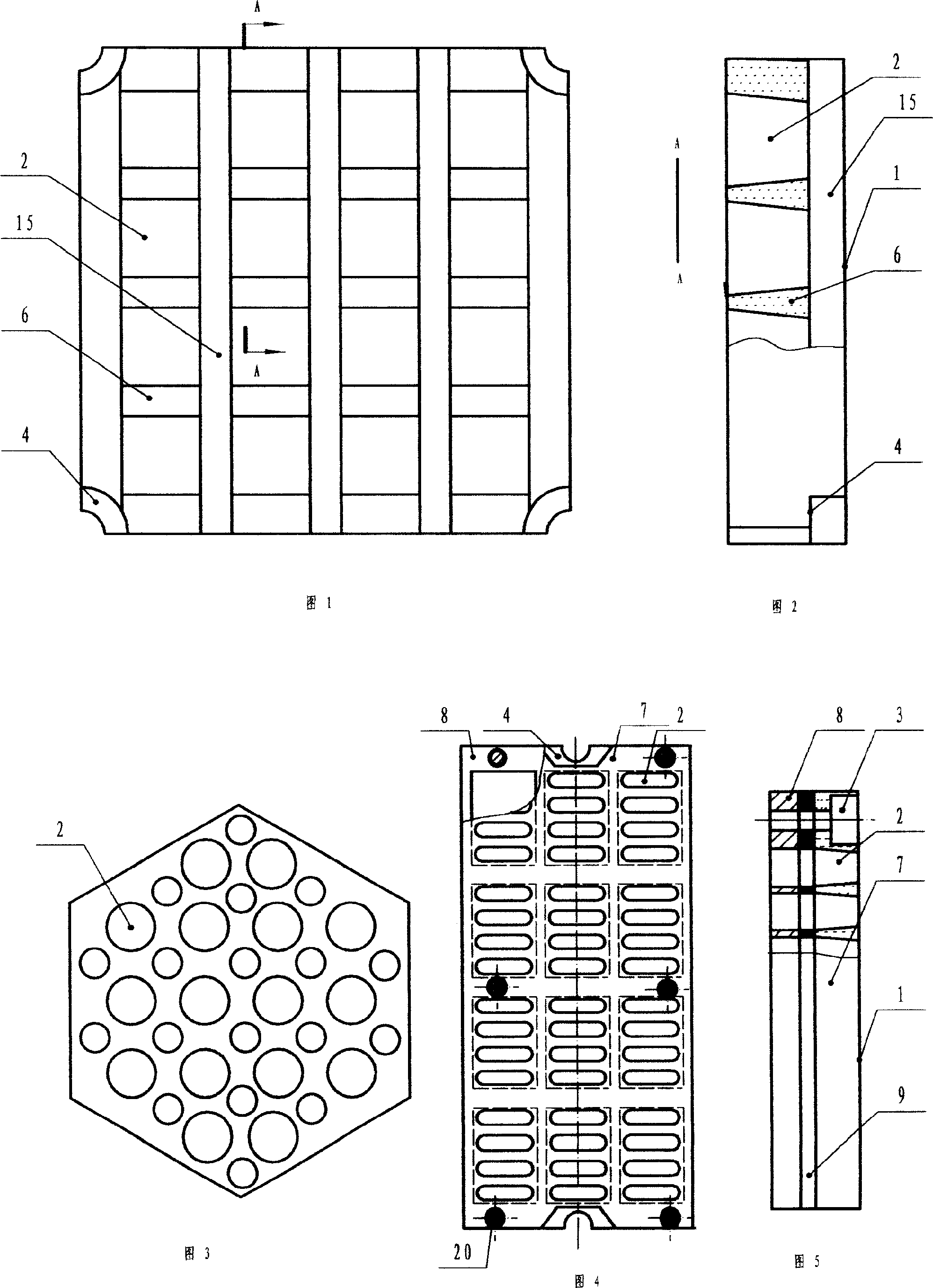

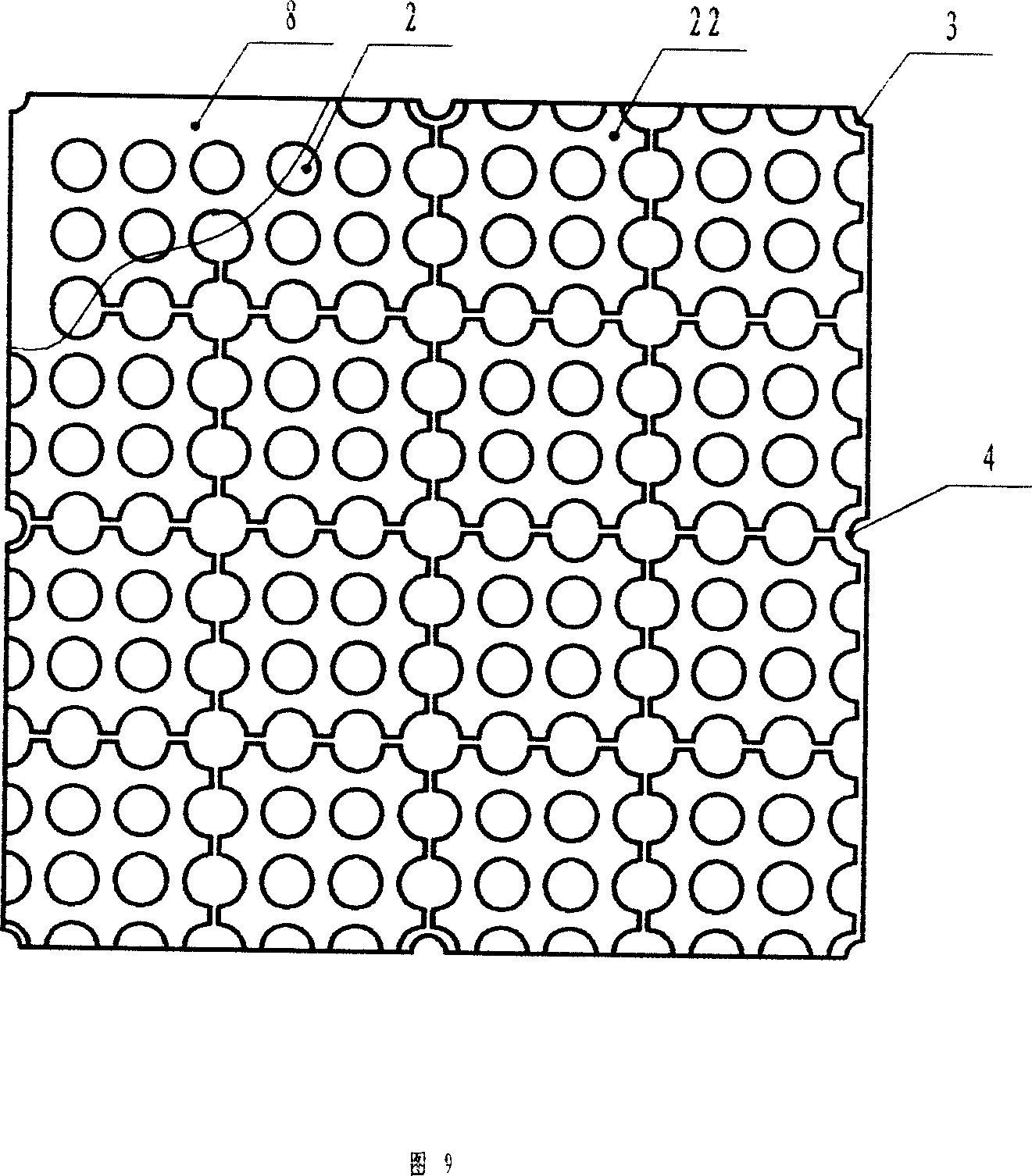

Screen deck and combined screen plate thereof

InactiveCN101020178AImprove wear resistanceReduce intensitySievingScreeningHigh resistanceSurface layer

The screen deck for sieving apparatus is made of ceramic material or comprises one ceramic surface layer and one bottom reinforcing layer. The screen deck has screen holes in certain geometric shape. The present invention also discloses one kind of combined screen plate with screen decks assembled onto the frame. The screen plate has high wear resistance, low cost, long service life and capacity of local replacement, and is used in different kinds of industrial sieving apparatus.

Owner:孙即杰

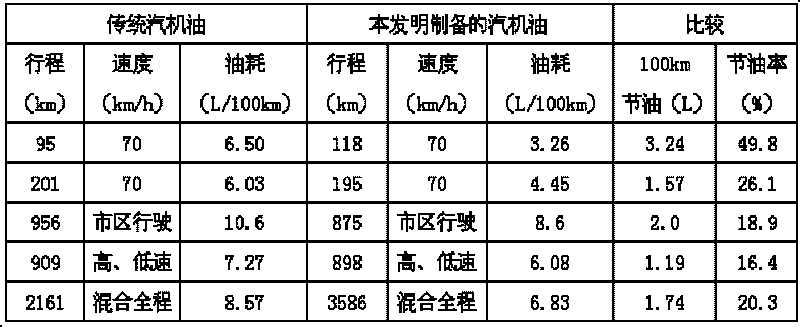

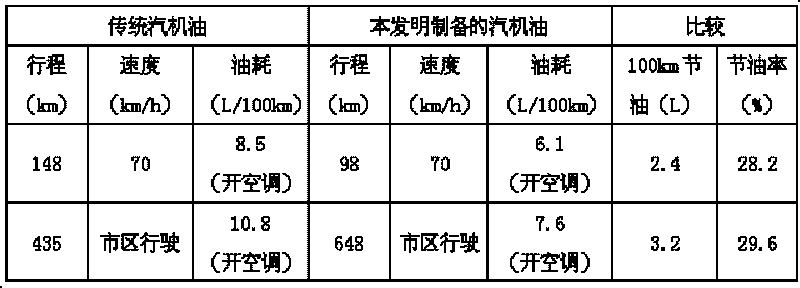

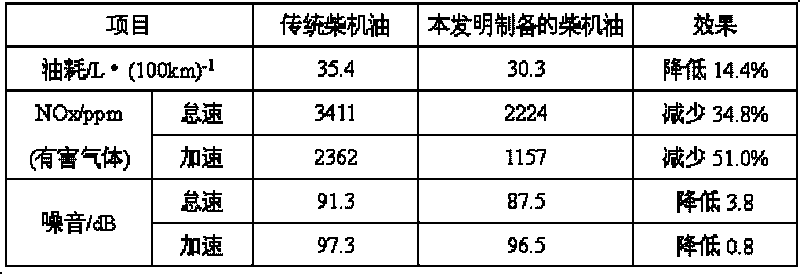

Vehicle engine oil additive and engine oil

The invention provides a vehicle engine oil additive and engine oil. The additive comprises the following components: 15 to 34 weight percent of nano WS2 powder, 0 to 24 weight percent of nano MoS2 powder, 20 to 20.5 weight percent of dispersant, 0 to 0.5 weight percent of antioxidant, 0 to 1 weight percent of metal passivant and the balance of base oil, wherein the kinematic viscosity of the base oil at 40 DEG C is 70 to 190mm2 / s, and the kinematic viscosity of the base oil at 100 DEG C is 12 to 20mm2 / s. The engine oil of the invention comprises 5 to 20 weight percent of additive and 80 to 95 weight percent of petrolic oil or comprises 15 to 25 weight percent of additive and 75 to 85 weight percent of diesel engine oil. The engine oil can improve the service life of engine, reduce oil consumption and has obvious energy-saving and emission-reducing effects and other effects.

Owner:CENT SOUTH UNIV

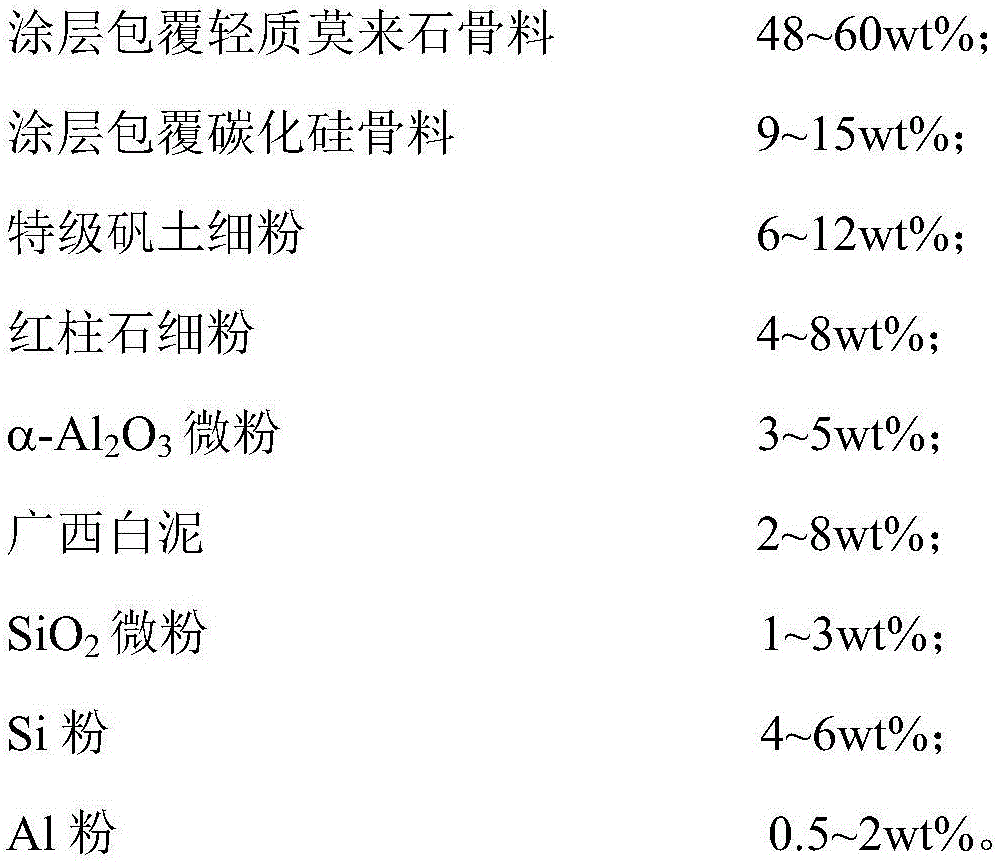

Mullite silicon carbide complex-phase fireproof material and preparation method thereof

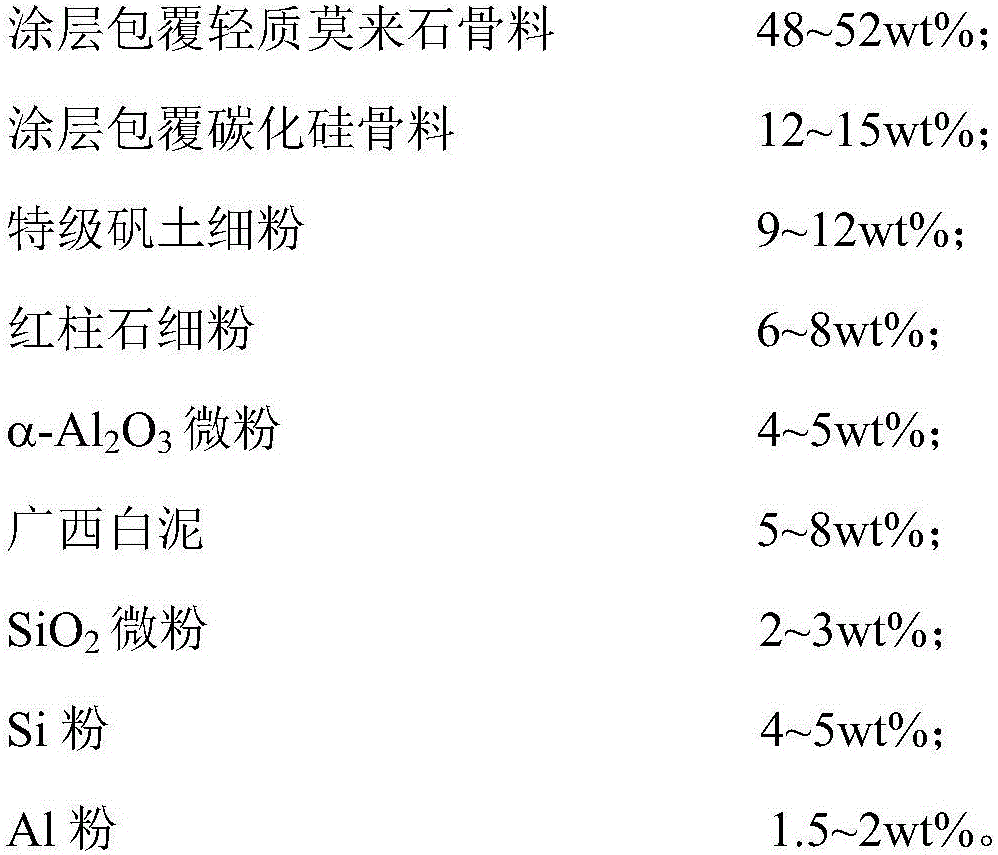

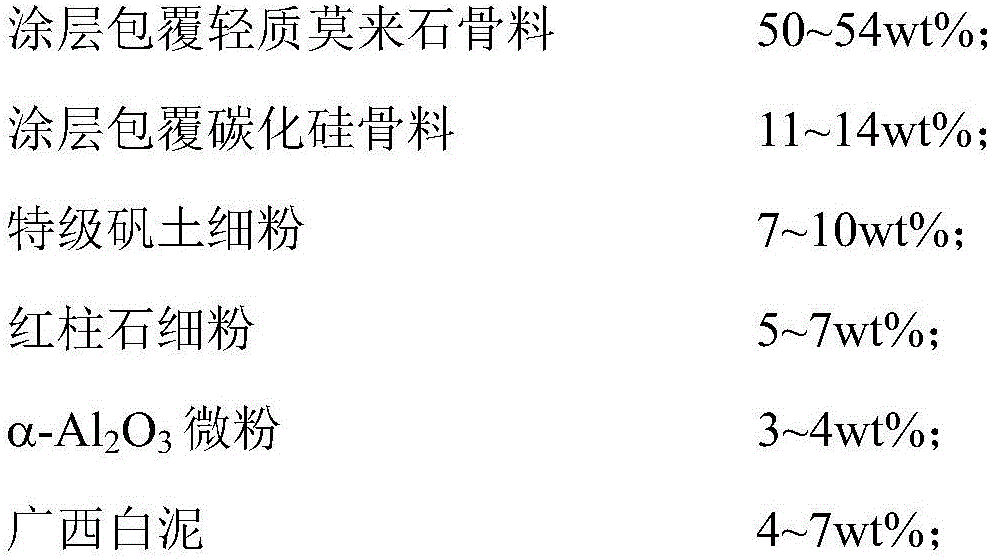

The invention relates to a mullite silicon carbide complex-phase fireproof material and a preparation method thereof. The mullite silicon carbide complex-phase fireproof material is characterized in that 48-60wt% of coating cladding mullite light aggregate, 9-15wt% of coating cladding silicon carbide aggregate, 6-12wt% of top-grade bauxite fine powder, 4-8wt% of andalusite fine powder, 3-5wt% of alpha-Al2O3 micro powder, 4-8wt% of Guangxi white clay, 1-3wt% of SiO2 micro powder, 4-6wt% of Si powder and 0.5-2wt% of Al powder are used as raw materials. The preparation method comprises the following steps of firstly mixing two kinds of the aggregate in the raw materials, adding a bonding agent, then performing mixed refining on the mixed aggregate, the bonding agent and other raw materials, performing material trapping, performing compression moulding, performing drying, and performing baking under the condition of 1250-1400 DEG C so as to obtain the mullite silicon carbide complex-phase fireproof material. The mullite silicon carbide complex-phase fireproof material prepared by the preparation method disclosed by the invention has the excellent characteristics of being low in heat conduction coefficients, good in erosion resistance, and high in intensity.

Owner:WUHAN UNIV OF SCI & TECH

High-performance electrophoresis aluminum alloy construction section bar and method for making same

InactiveCN101298644AUnique featuresReduce adhesionAnodisationElectrophoretic coatingsMisch metalElectrophoresis

The invention discloses an electrophoretic aluminum alloy building proximate matter with high performance and a preparation method thereof, and belongs to the technical field of aluminum alloy application. The electrophoretic aluminum alloy building proximate matter consists of following ingredients by mass: 0.5 to 0.54 percent of Mg, 0.4 to 0.44 percent of Si, 0.04 to 0.08 percent of RE, 0.01 to 0.02 percent of Ti, 0.002 to 0.004 percent of B, 0 to 0.2 percent of Fe and remaining aluminum. The preparation method of the electrophoretic aluminum alloy building proximate matter consists of following steps: a misch metal ingot, an alloy of Al, Ti and B, and a pure aluminum ingot are smelted into a refining and modifying agent of RE, Al, Ti and B; the refining and modifying agent is added during an alloy smelting process and cast into an aluminum rod; the electrophoretic proximate matter with high performance is prepared by techniques of squeeze aging and oxidizing electrophoresis, etc. By utilizing rare earth to subdivide second-phase particles, electrophoretic paint films of the proximate matter that are obtained by improving surface processing performance have higher uniformity, adhesive attraction, wear resistance, corrosion resistance and large film thickness than common proximate matters, and can be widely used for aluminum alloy doors and windows of buildings and curtain walls.

Owner:CHENGDU SUNSHINE ALUMINUM

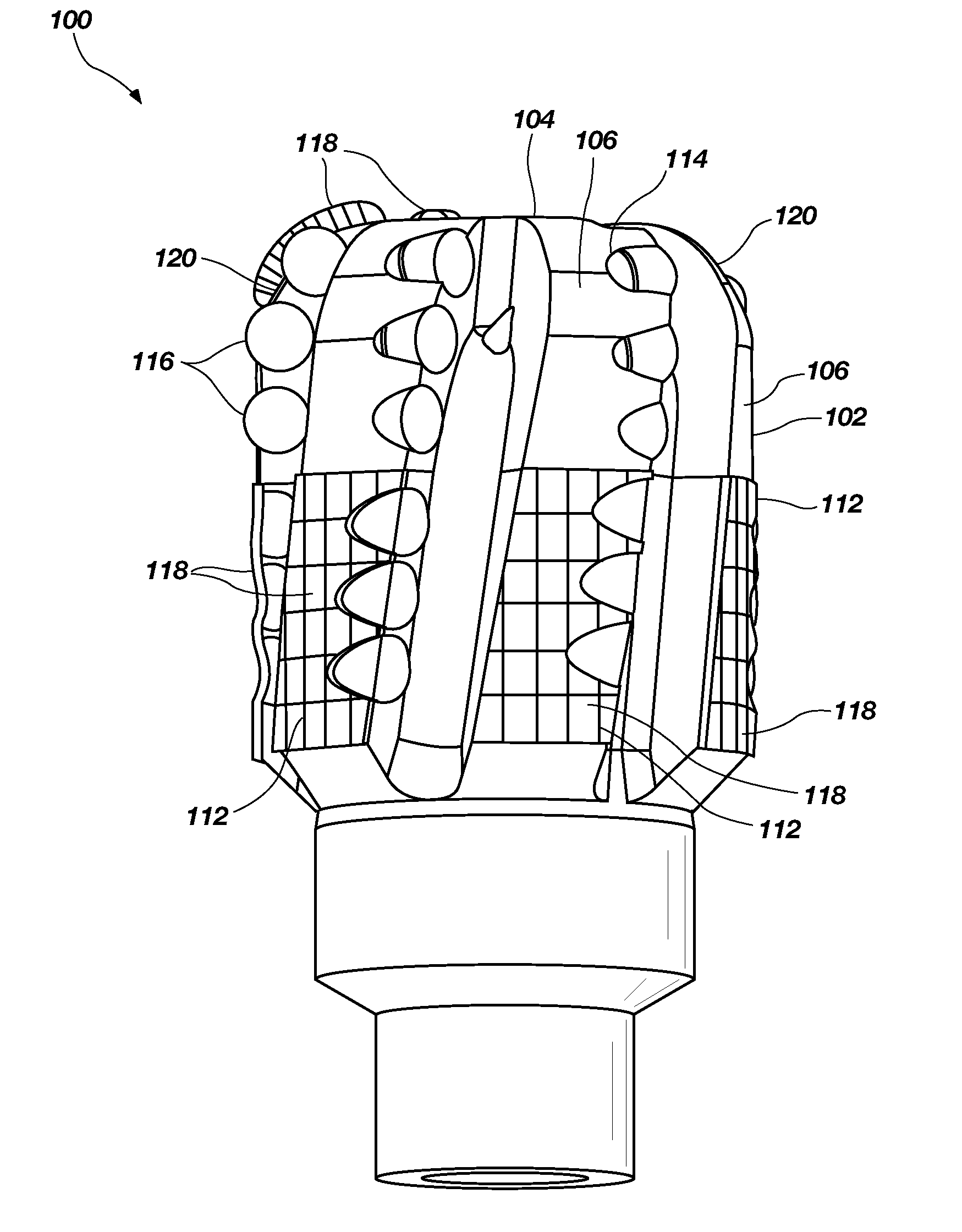

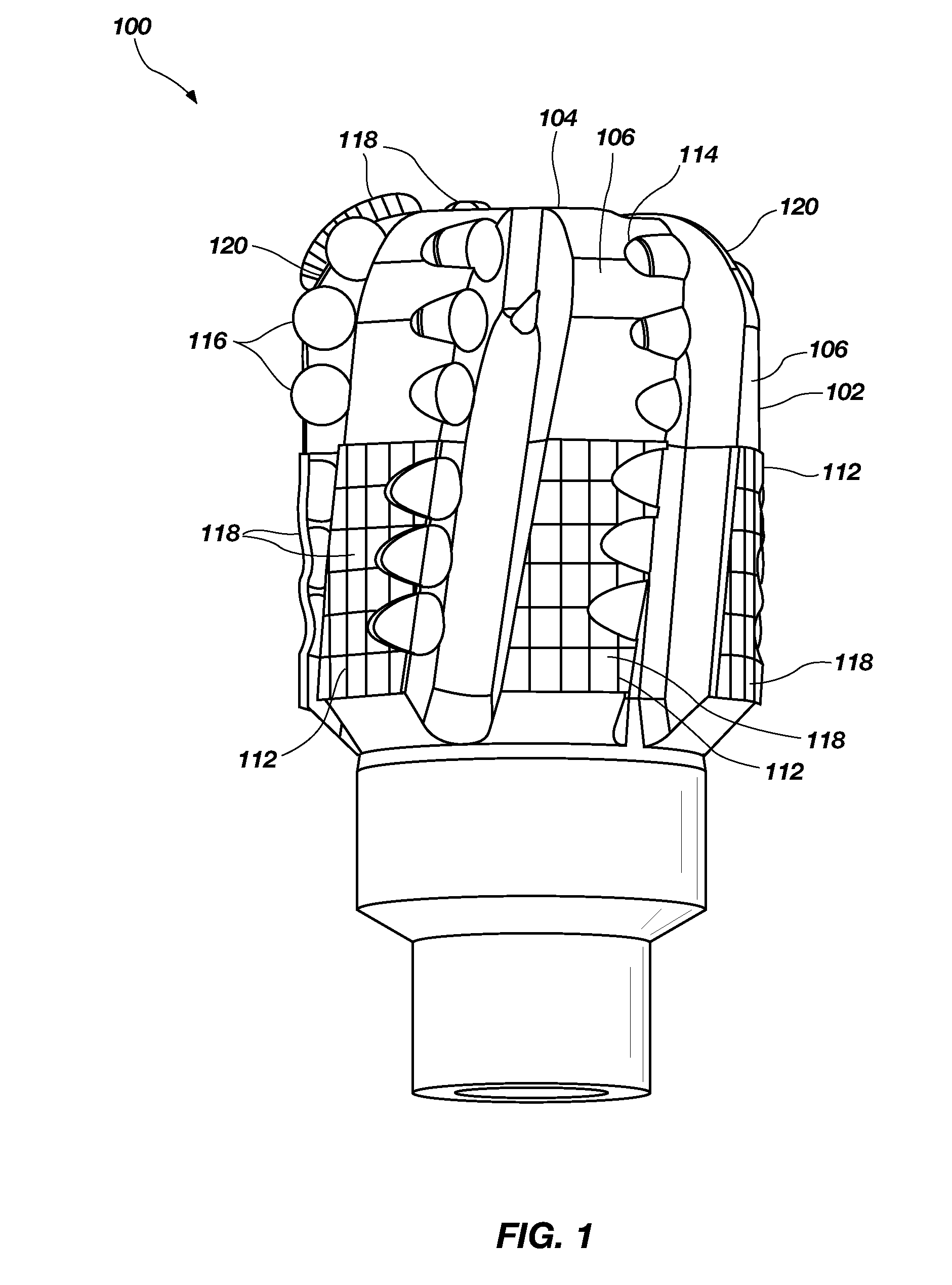

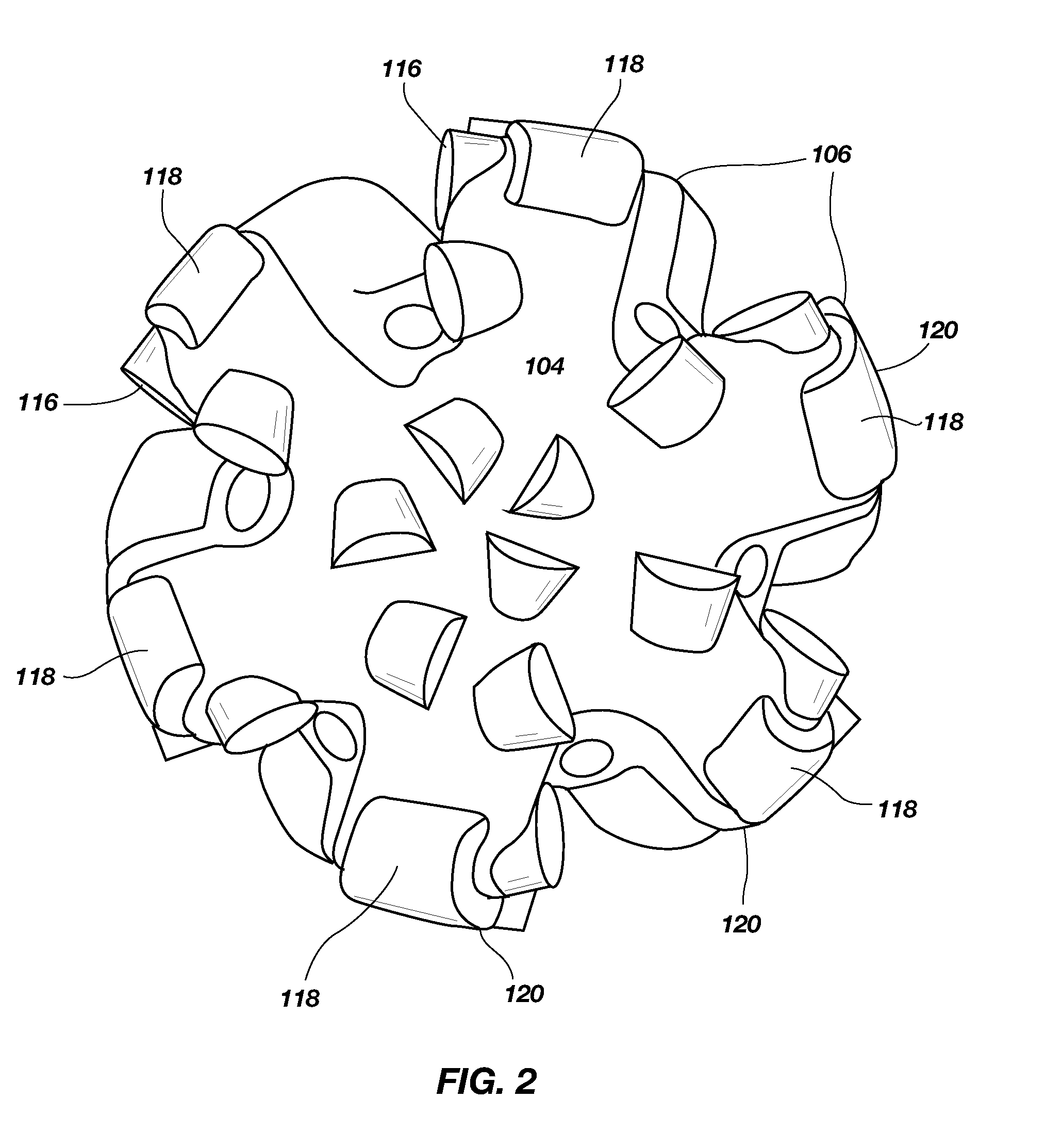

Earth-boring tools and methods of making earth-boring tools including an impact material, and methods of drilling through casing

Earth-boring tools comprise a face and a plurality of cutting elements disposed on at least a portion of the face. An impact material is positioned on at least one portion of the body and has a relative exposure equal to or greater than at least some of the cutting elements of the plurality of cutting elements. The impact material comprises a material having a lower abrasion resistance than the body. Methods of making and methods of using such earth-boring tools are also disclosed.

Owner:BAKER HUGHES INC

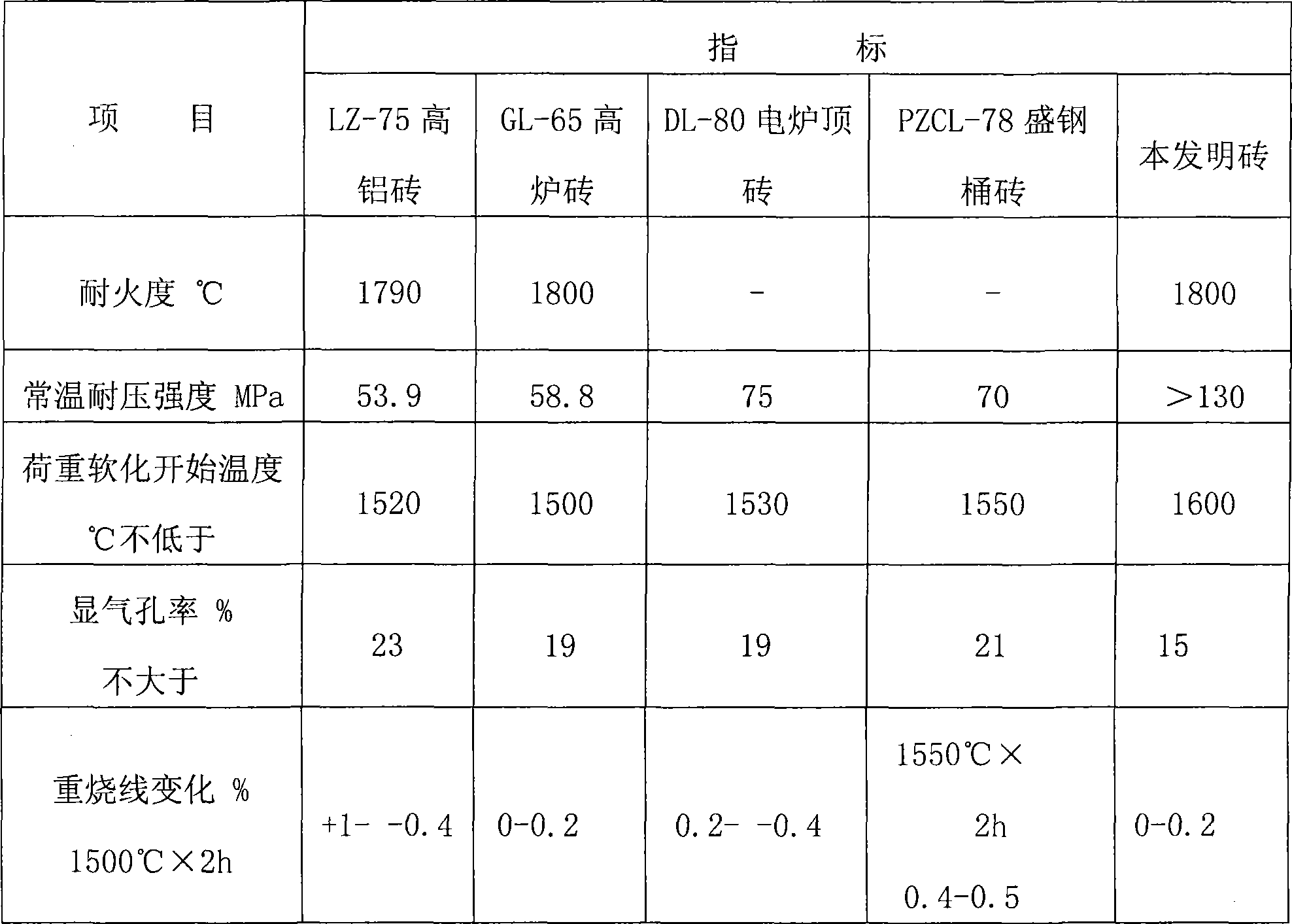

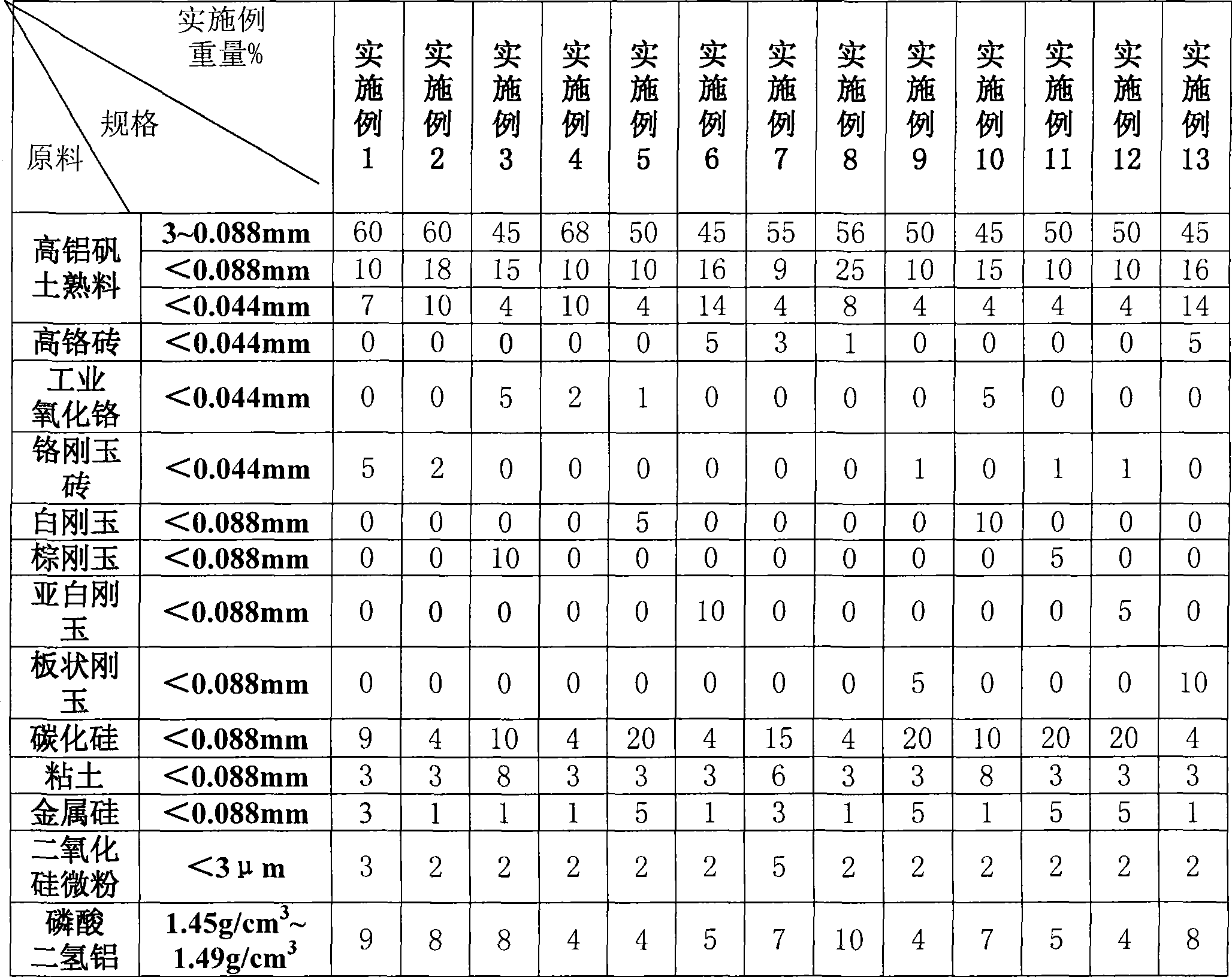

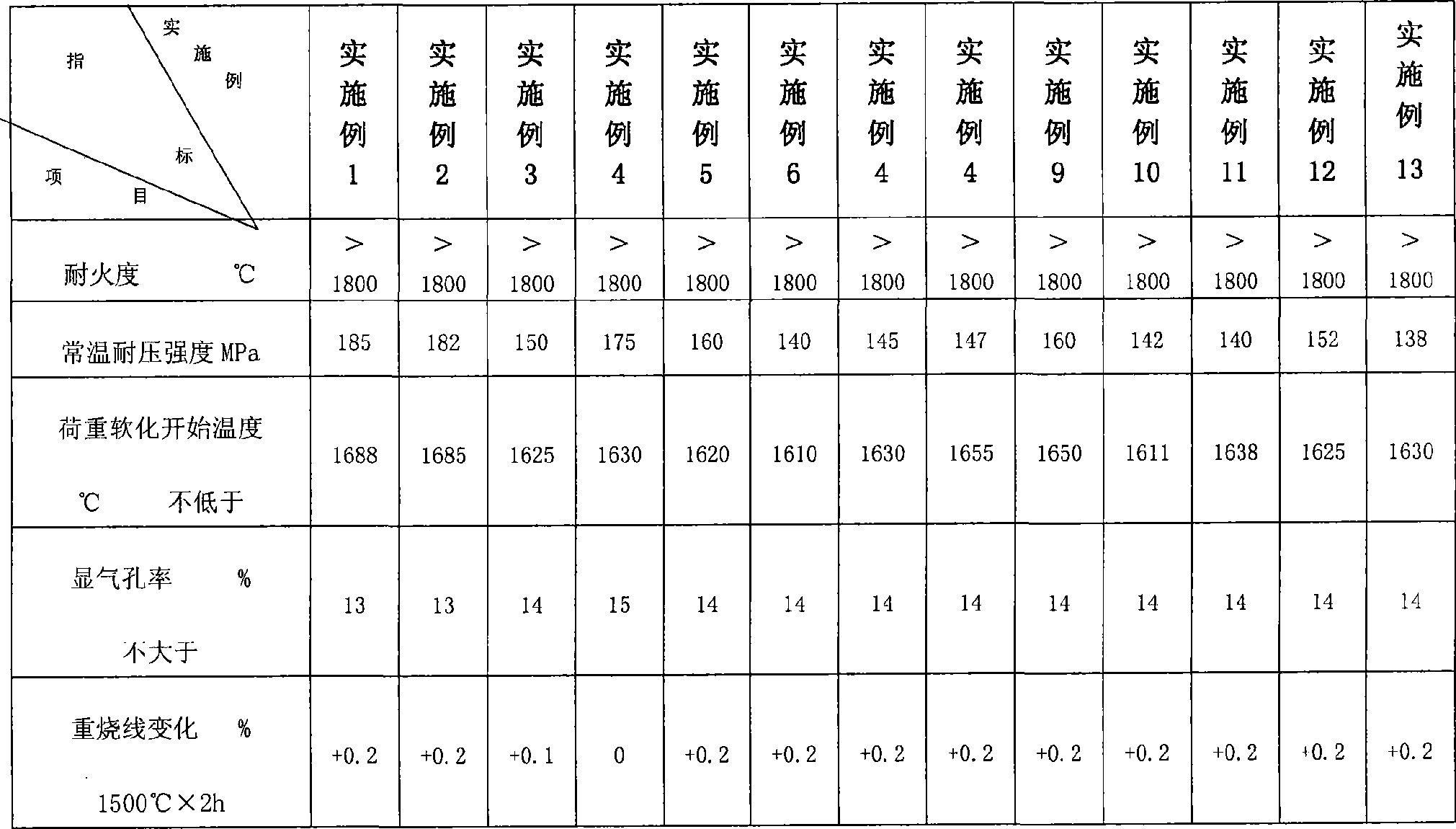

Phosphate-bonded aluminum silicon carbide brick and preparation method thereof

The invention discloses a phosphate-bonded aluminum silicon carbide brick, which is characterized by comprising main ingredients and a phosphate binder, wherein the main ingredients comprise the following raw materials by weight percentage: 45 to 68 percent of bauxite chamotte with a granularity of 3 to 0.088 mm, 10 to 25 percent of bauxite chamotte with a granularity of less than 0.088 mm, 4 to 14 percent of bauxite chamotte with a granularity of less than 0.044 mm, 0 to 10 percent of corundum, 1 to 5 percent of a chromic oxide-containing material, 4 to 20 percent of silicon carbide, 3 to 8 percent of clay, 2 to 5 percent of silicon dioxide micro powder, and 1 to 5 percent of metallic silicon; and the phosphate binder is added in an amount which is 4 to 10 percent of the weight of the main ingredients. The aluminum silicon carbide brick is made into high quality aluminum silicon carbide brick which has an apparent porosity of less than 15 percent, a cold crushing strength of more than 130MPa, a starting refractoriness under load of more than 1,600 DEG C and high inoxidability by ageing mixture, back rolling, forming, drying and baking.

Owner:巩义市金岭耐火材料有限公司

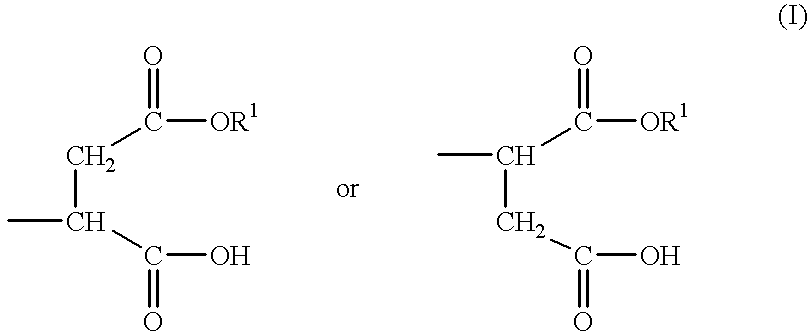

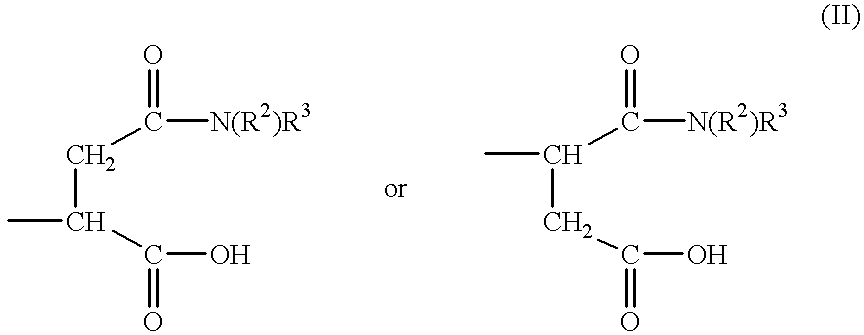

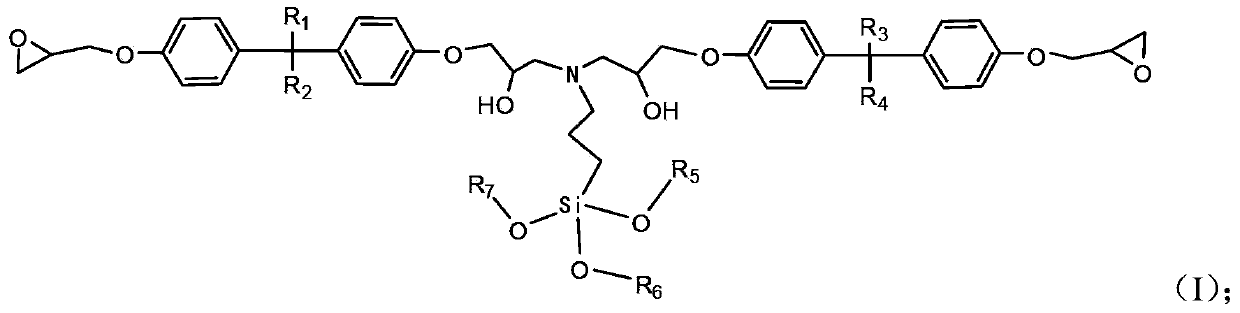

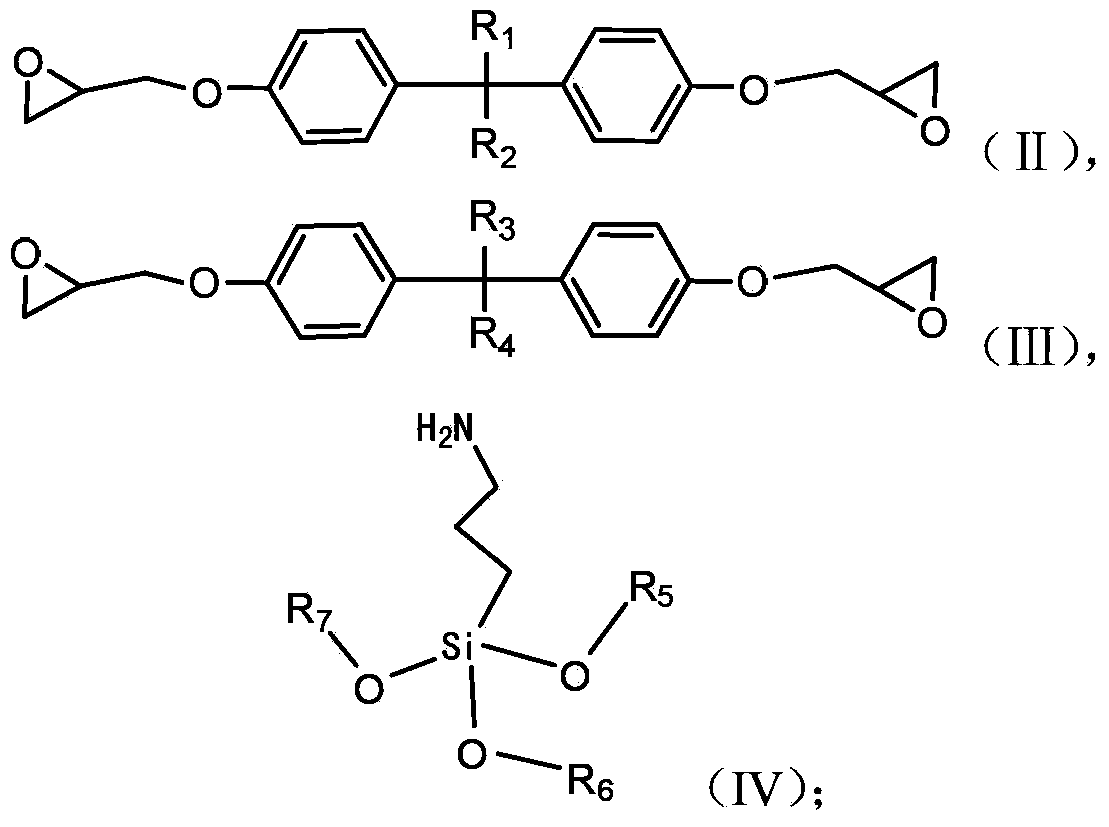

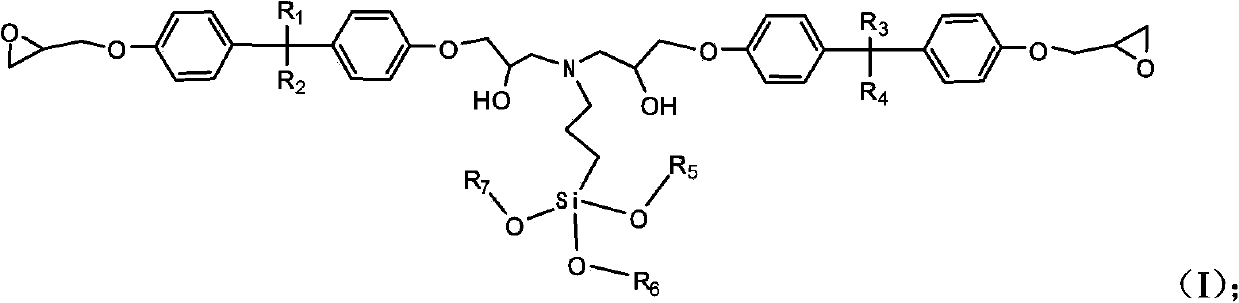

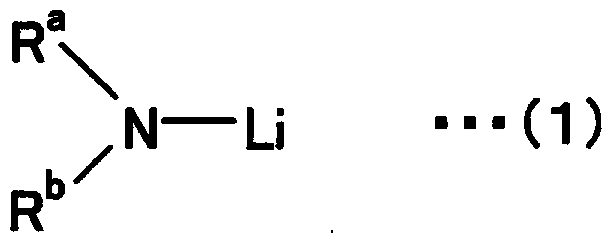

Silane coupling agent-modified epoxy resin, and preparation method and application thereof

ActiveCN103468095ASimple preparation processLow costAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

The invention provides a silane coupling agent-modified epoxy resin. The structural formula of the epoxy resin is represented by formula (I). The invention further provides an epoxy protective paint including the silane coupling agent-modified epoxy resin. A preparation method for the silane coupling agent-modified epoxy resin is simple; after a reaction of the silane coupling agent-modified epoxy resin with an amine curing agent, the structure of the molecular chain of the cured resin is stable, compatibility between the epoxy resin and the interface of a pigment is high, and the strength of the cured resin is slightly reduced; and the epoxy protective paint prepared from the silane coupling agent-modified epoxy resin has the advantages of good film glossiness, good toughness, high bonding strength on a substrate, good resistance to chemicals, environment friendliness, moderate cost, etc.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

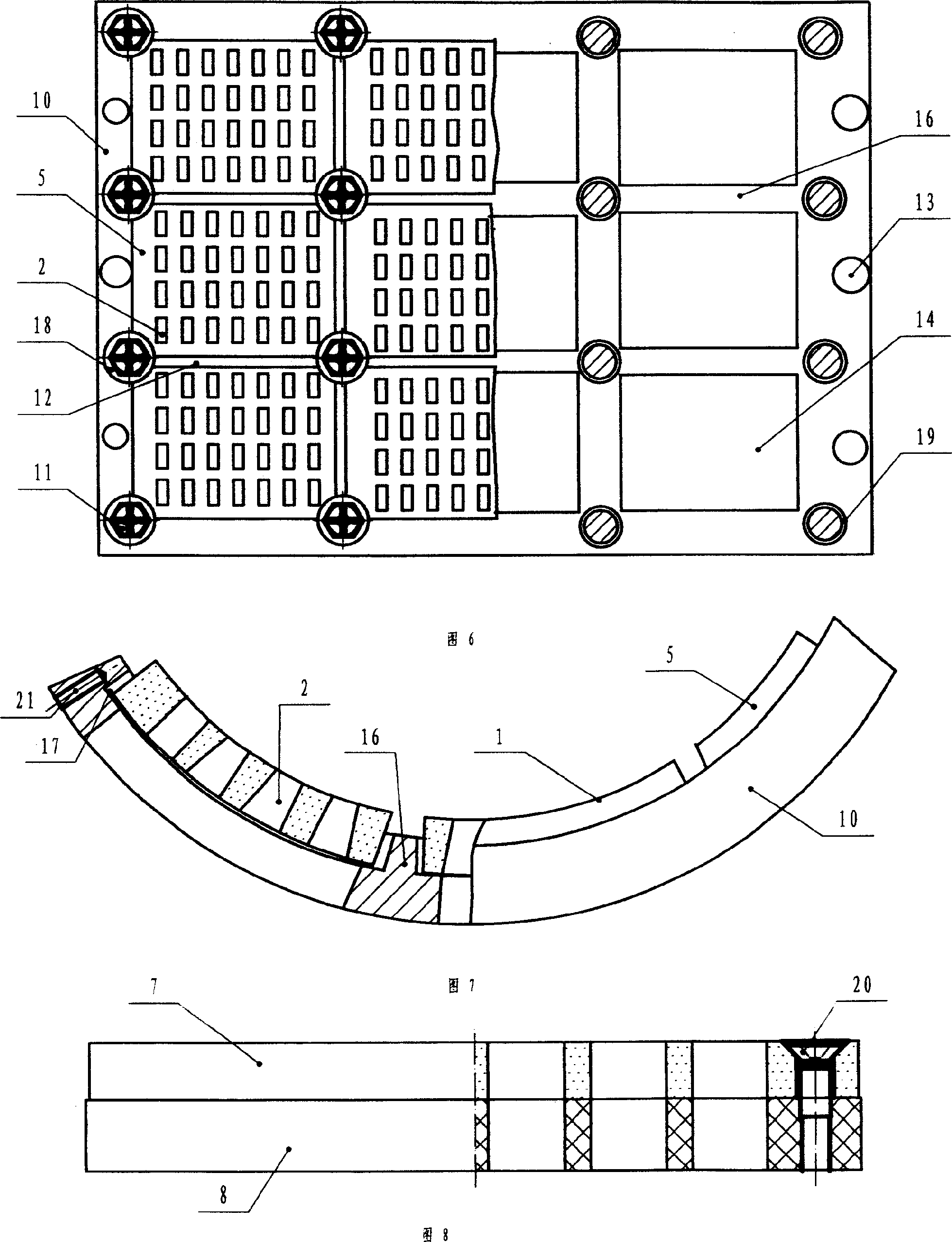

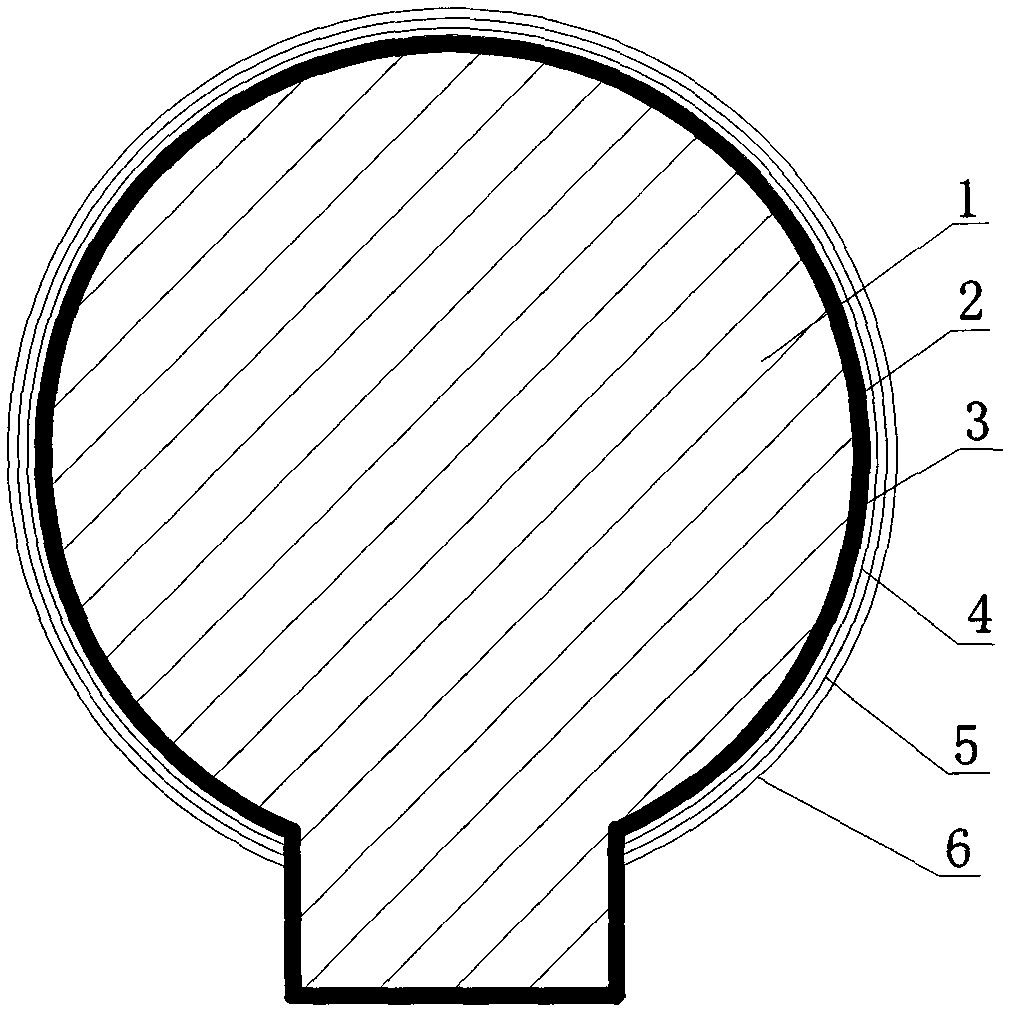

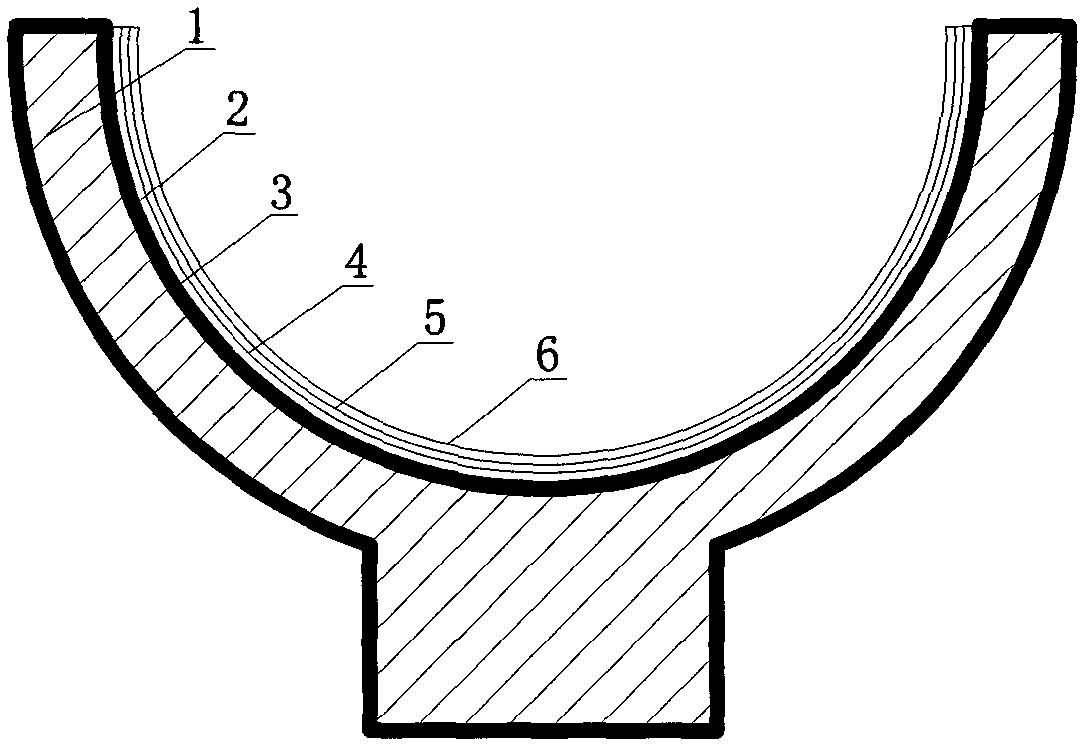

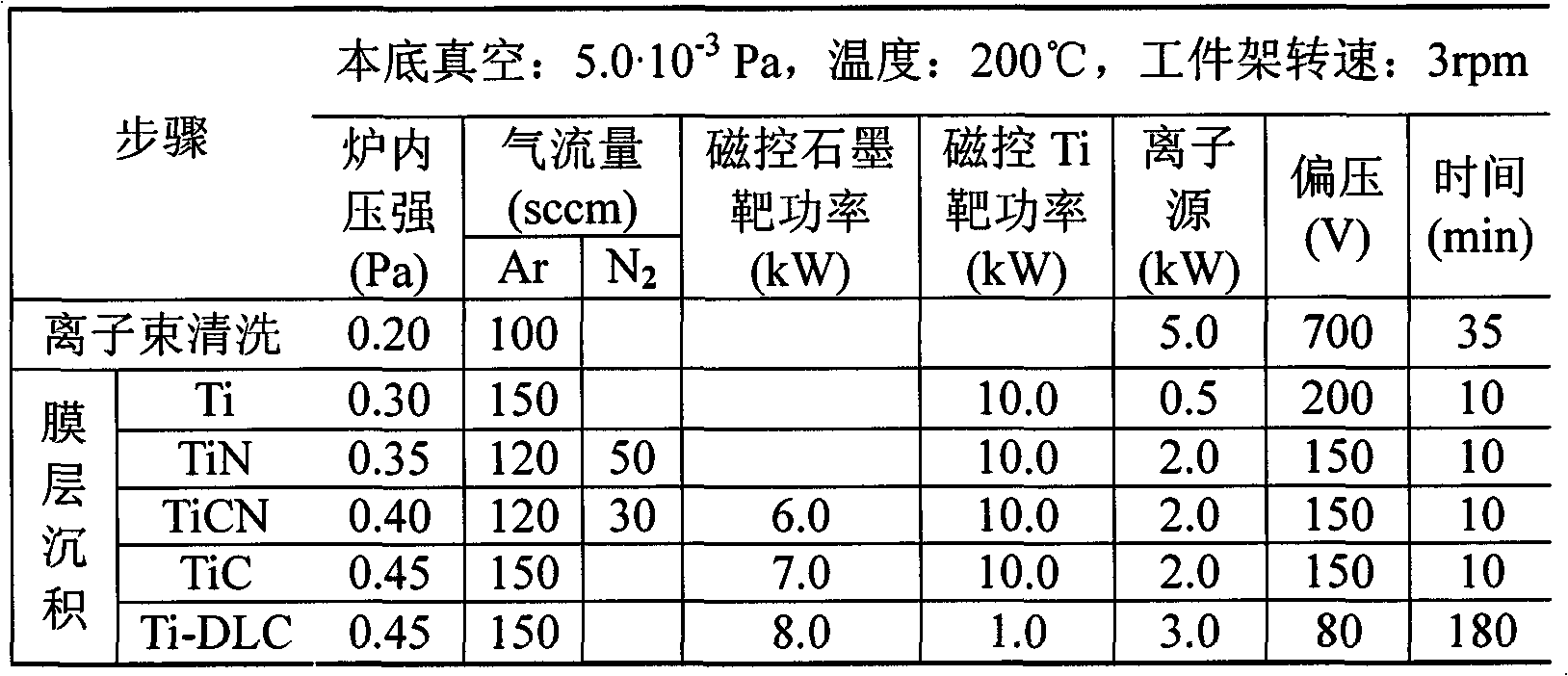

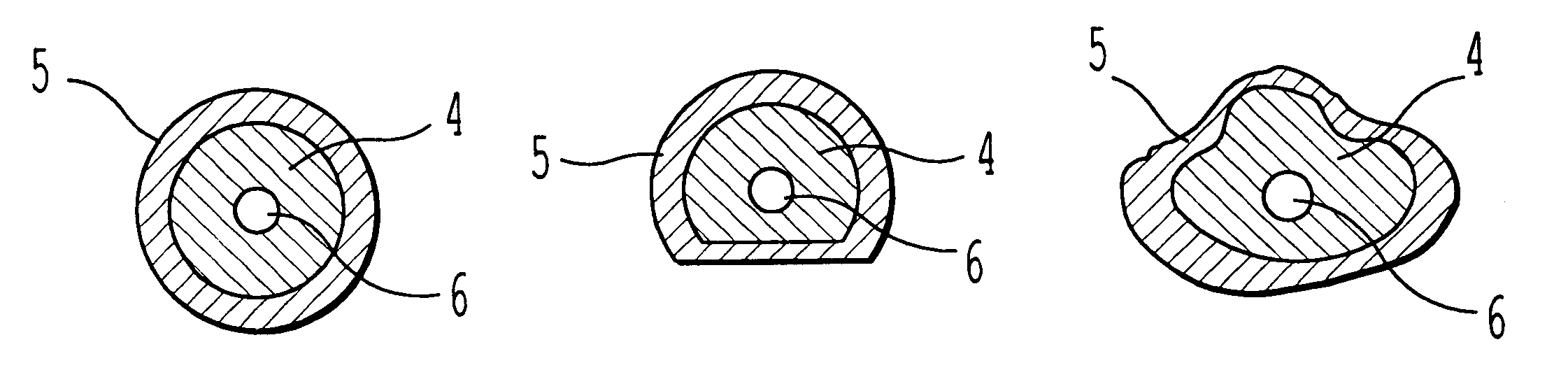

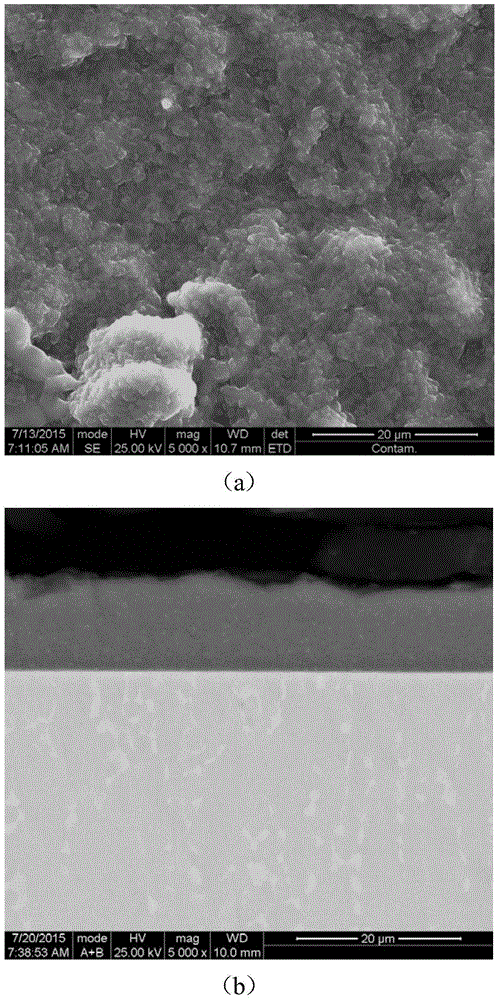

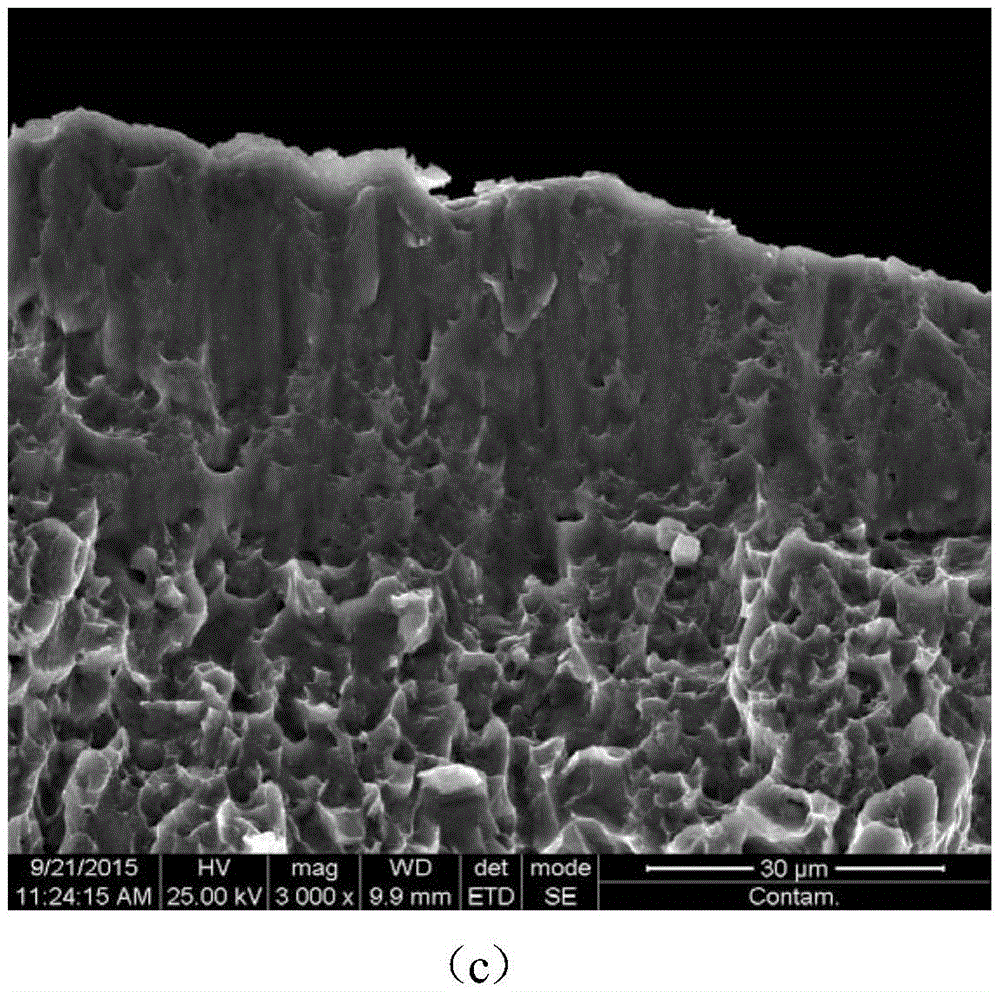

Artificial hip joint friction pair surface film layer and preparation method thereof

InactiveCN102626525AReduce the internal stress of the film layerPromote bone growth and developmentVacuum evaporation coatingSputtering coatingCotyloid CavitySacroiliac joint

Provided are an artificial hip joint friction pair surface film layer and a preparation method thereof. The artificial hip joint friction pair surface film layer is characterized by being sequentially composed of a substrate (1), a metal layer (2), a metal nitride layer (3), a metal carbonitride layer (4), a metal carbide layer (5) and a metal-mixed diamond layer (6). The preparation method sequentially includes the steps of washing the substrate with ion beams and depositing the metal layer, the metal nitride layer, the metal carbonitride layer, the metal carbide layer and the metal-mixed diamond layer. The artificial hip joint friction pair surface film layer greatly reduces friction coefficient of a friction pair bulb and the acetabulum, reduces abrasion of a metal base body and release of metal ions, prolongs service life of the artificial hip joint, and resolves the failure problem of joint implanting of the artificial hip joint caused by joint head mortar abrasion and abrasive dust. Tests for simulating the human environment show that the artificial hip joint has excellent chemical inertness and biocompatibility, and is free of harmful tissue reaction and allergic reaction and high in safety.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

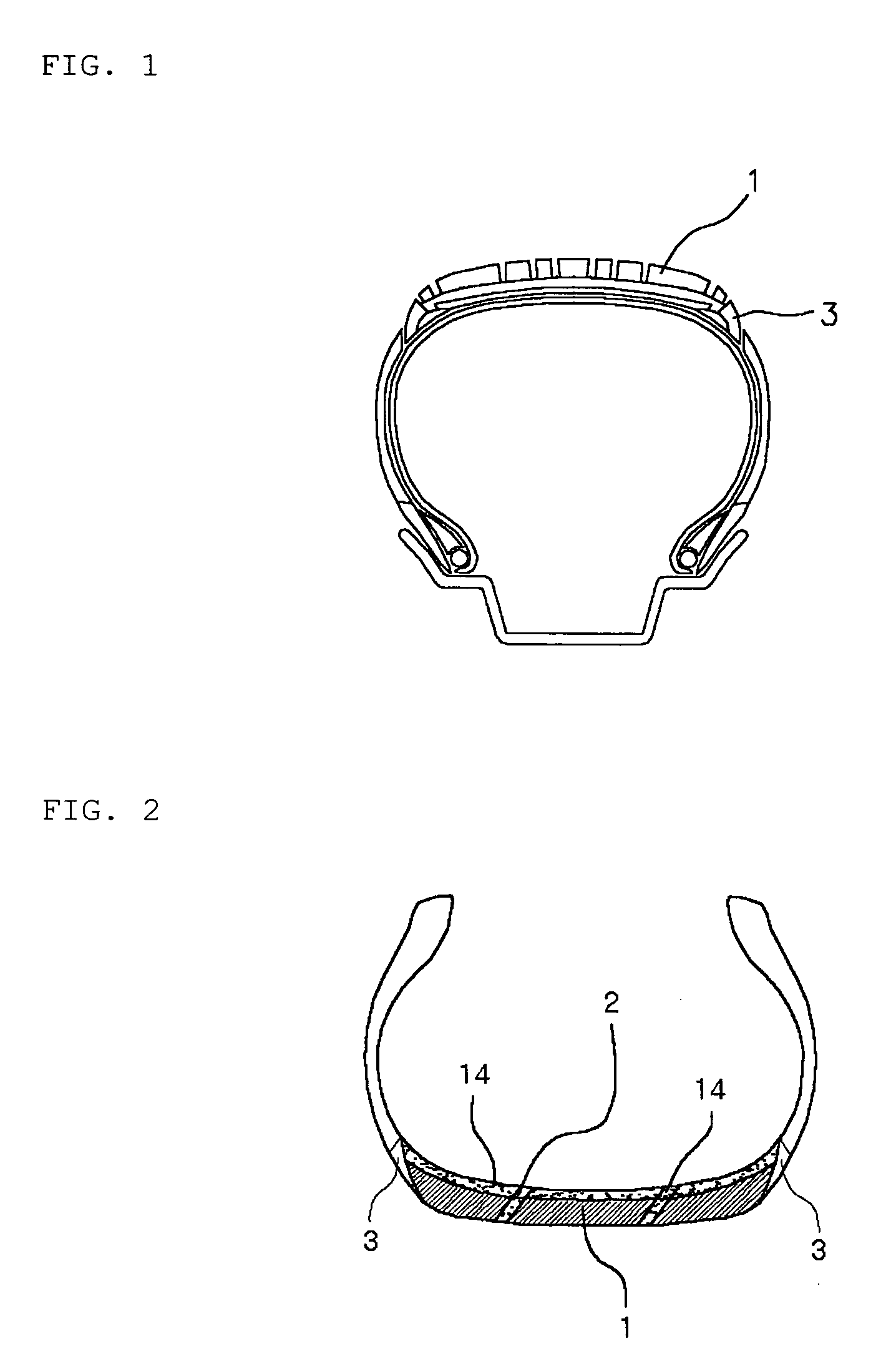

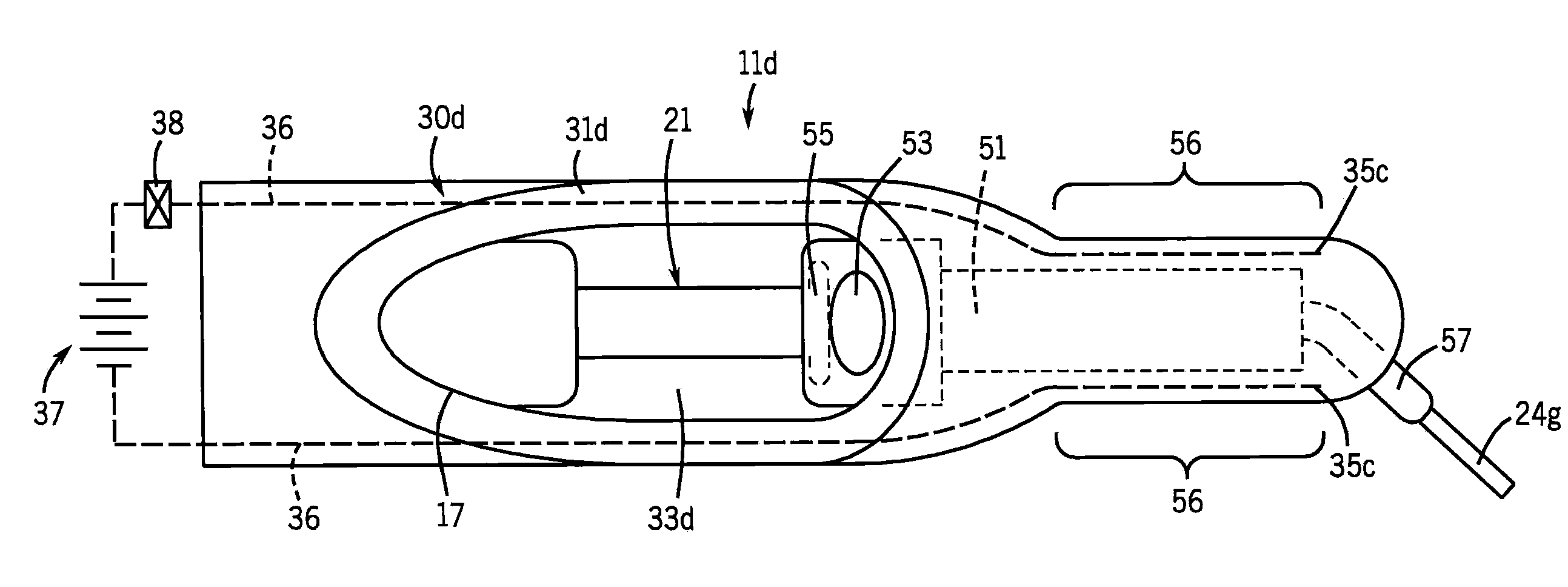

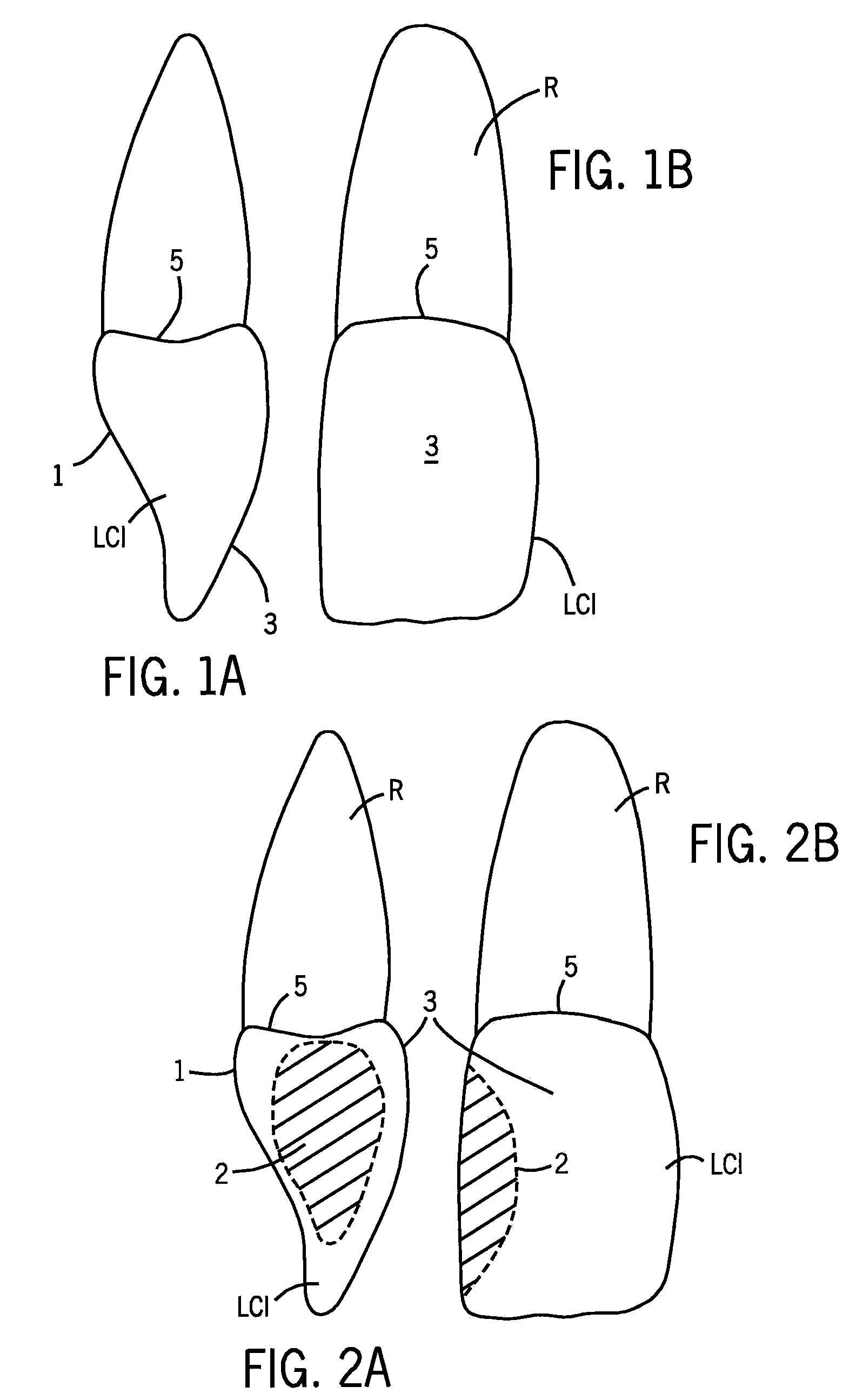

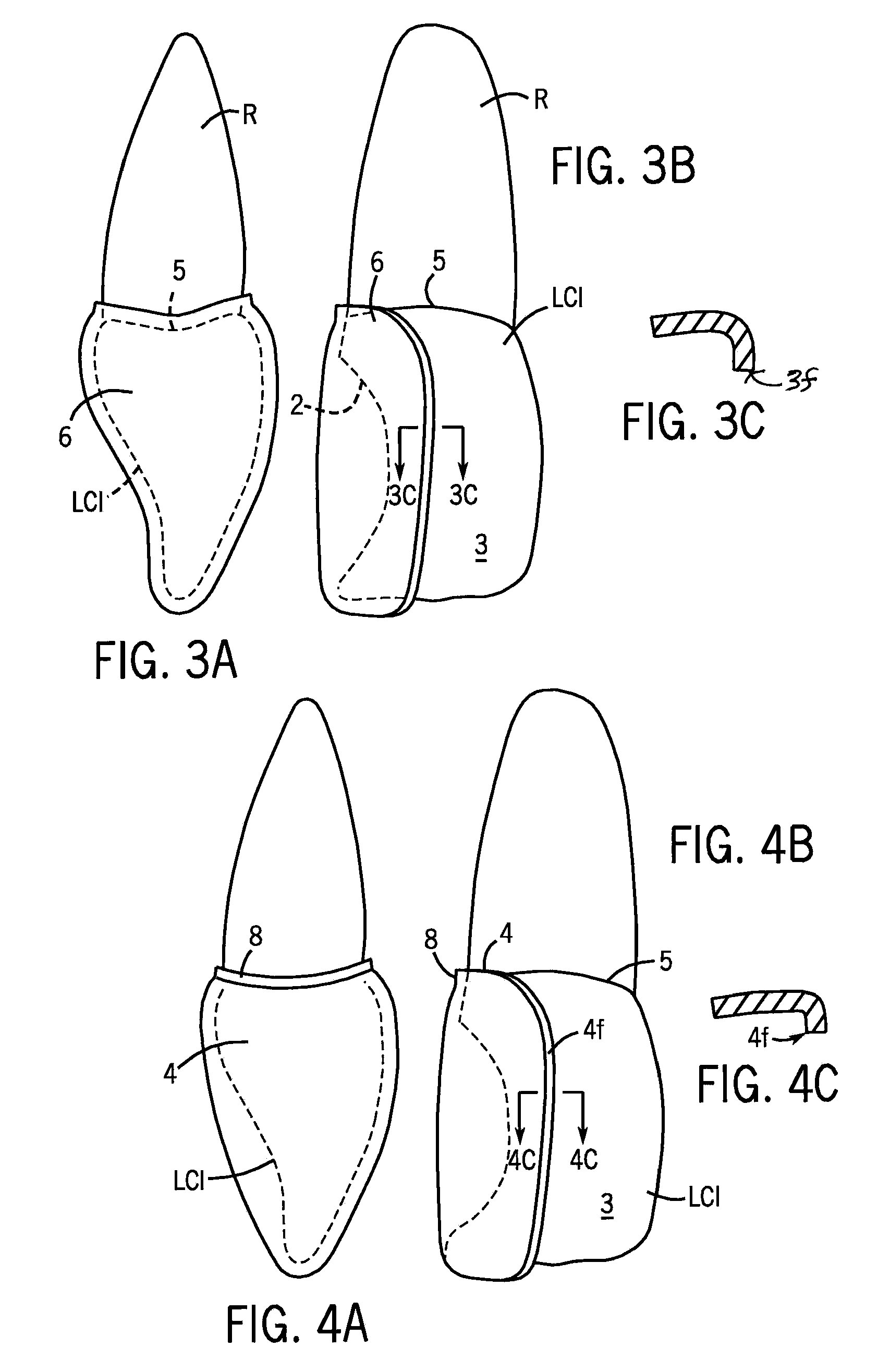

Dental Matrix Devices Specific To Anterior Teeth, and Injection Molded Filling Techniques and Devices

ActiveUS20090191505A1Easy to handleEasy to placeAmalgam presses/mixersDental aidsMold fillingResin-Based Composite

The present invention relates to methods for the restoration of a decayed portion of an anterior tooth or re-restoration of a previously filled anterior tooth, and to dental matrices and composite resin dispensers that may be used in the methods for the restoration of a decayed portion of an anterior tooth

Owner:CLARK DAVID J

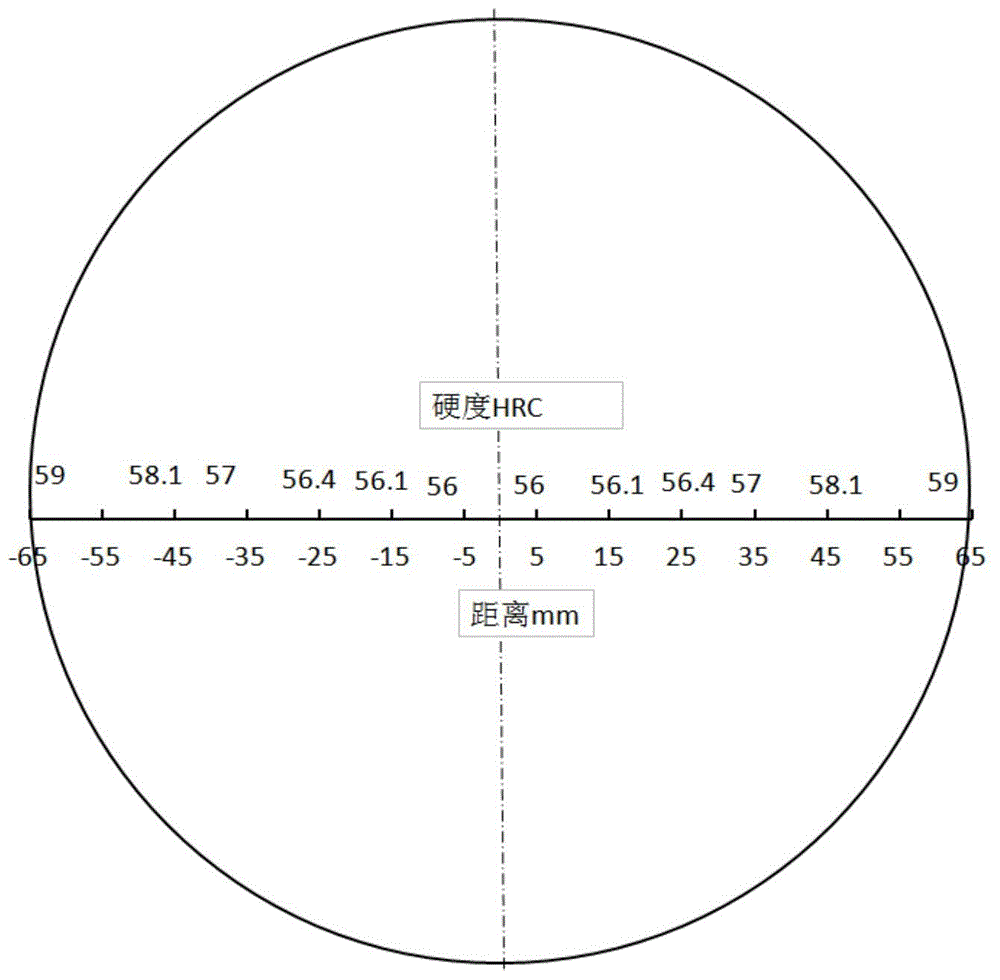

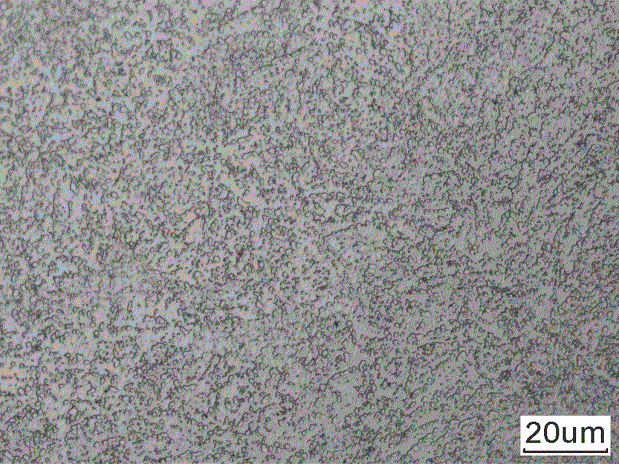

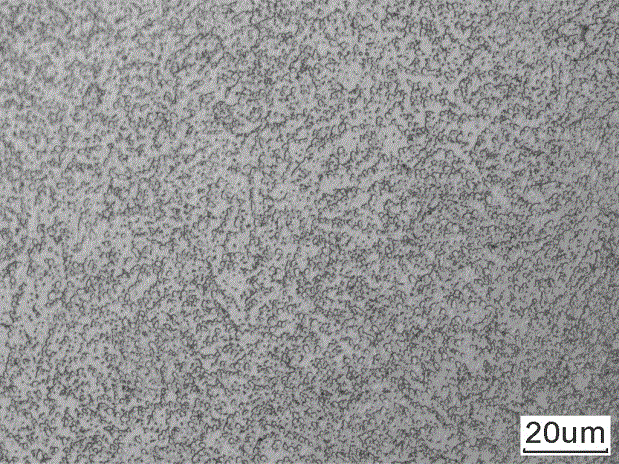

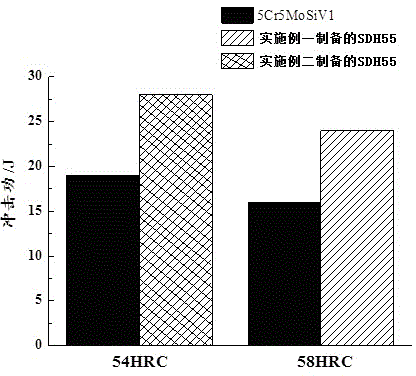

Alloy steel SDH55 for shield machine tools and production method thereof

The invention discloses alloy steel SDH55 for shield machine tools and a production method thereof. The alloy steel comprises, by weight, 0.4% to 0.55% of C, 0.10% to 0.40% of Si, 0.10% to 0.30% of Mn, 5.10% to 6.50% of Cr, 2.20% to 3.00% of Mo, 0.45% to 0.85% of V, the balance of Fe and unavoidable impurity elements, including not greater than 0.005% of S and not greater than 0.010% of P. The alloy steel high in wear resistance and high in toughness is made by means of matching, smelting, casting and electroslag remelting, by thermal feeding for high-temperature homogenous treatment after demolding, and by means of multidirectional forging, soft annealing and ultra-fining treatment; the problem that the current tools for shield machines are of short lives due to wear and failure and edges cracking caused by low toughness is solved; the alloy steel is of great significance to the development of the industry of special steels of shield machine tools.

Owner:SHANGHAI SHIJIN NEW MATERIAL TECH

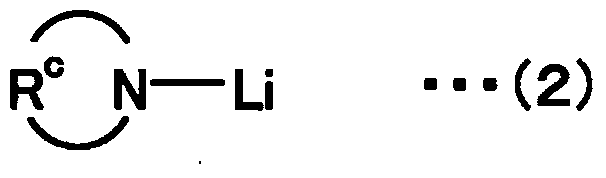

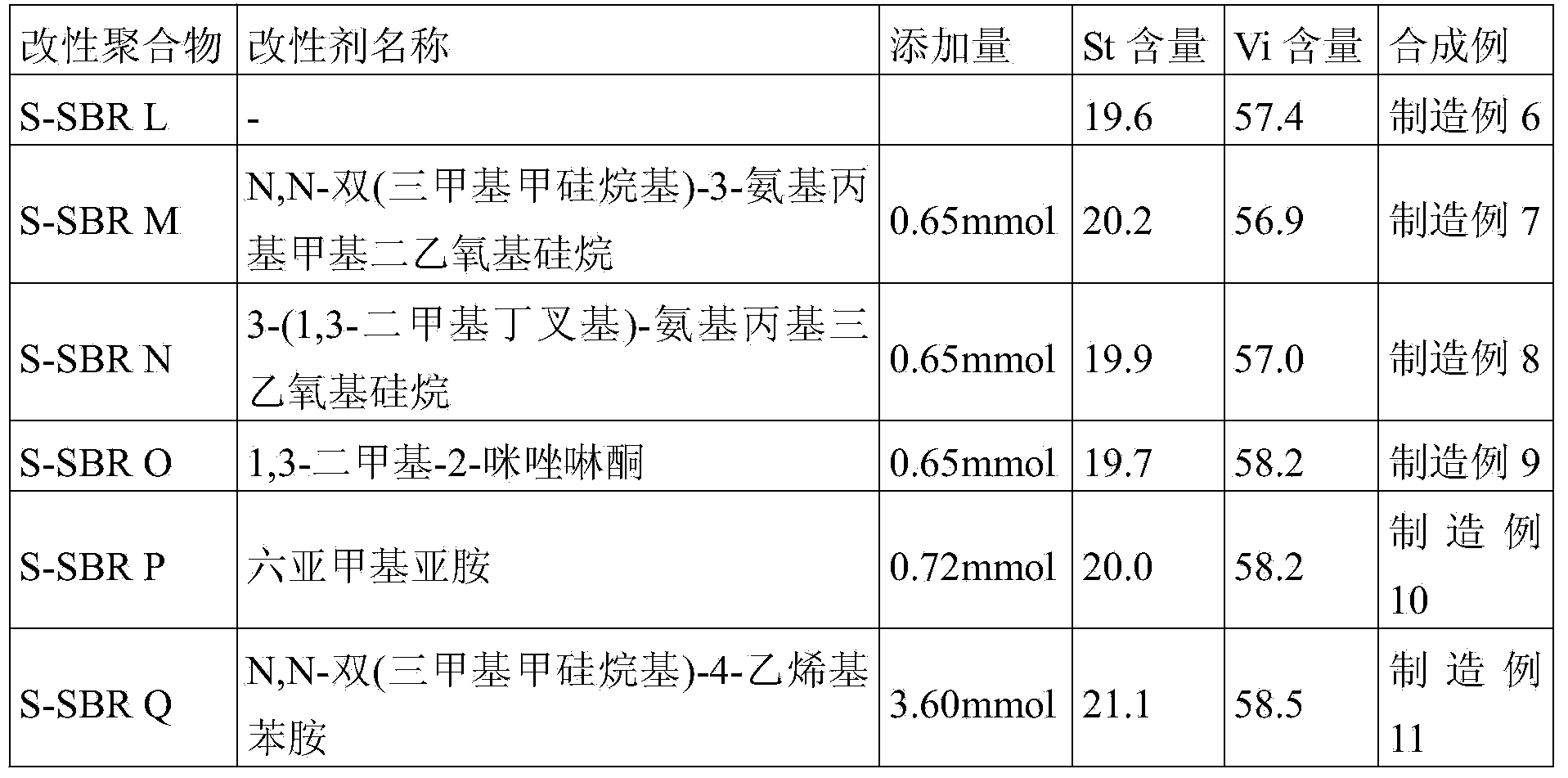

Rubber composition and tire produced using same, and process of producing rubber composition

ActiveCN103391967AImprove heating effectImprove wear resistanceSpecial tyresOrganic acidPolymer science

Owner:BRIDGESTONE CORP

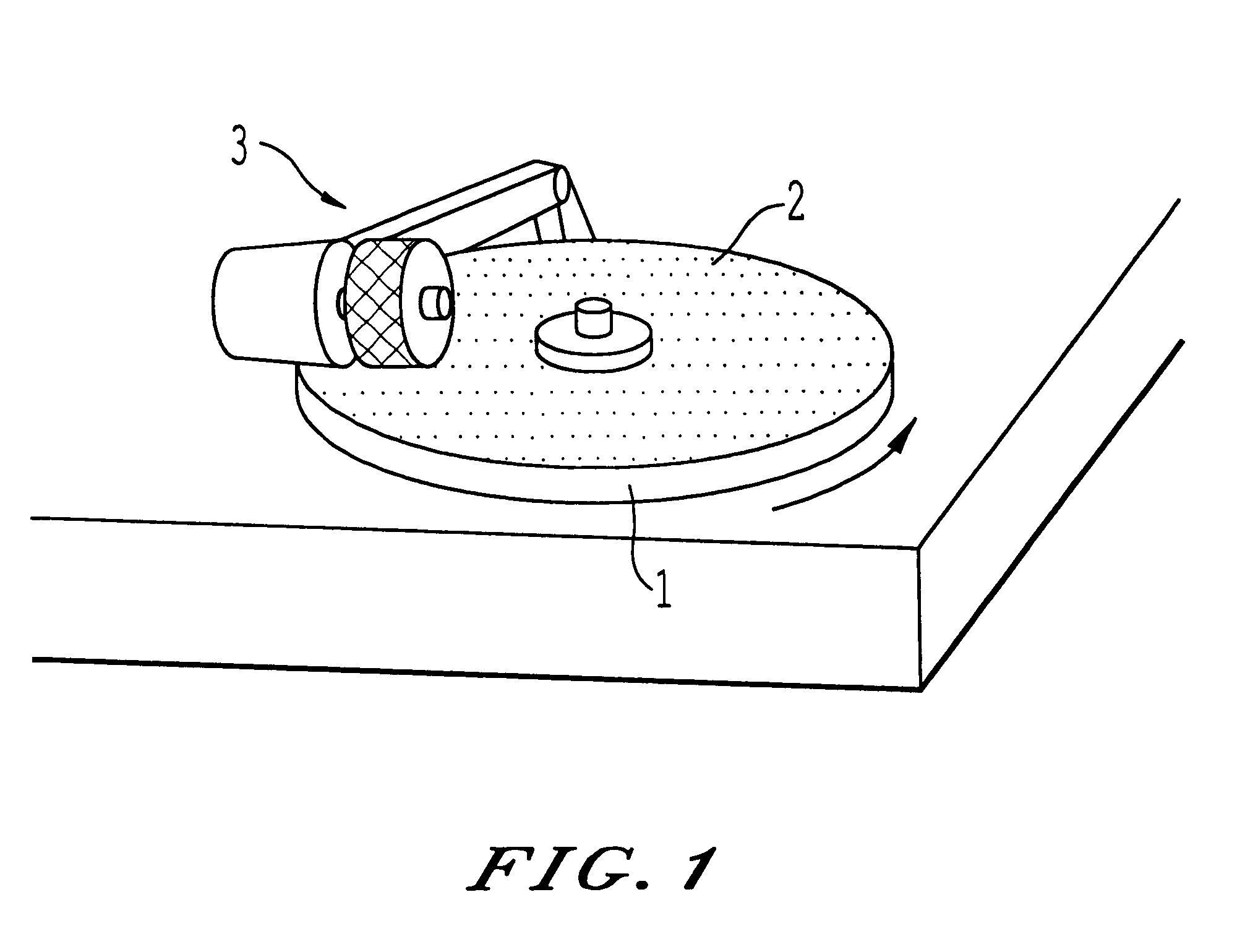

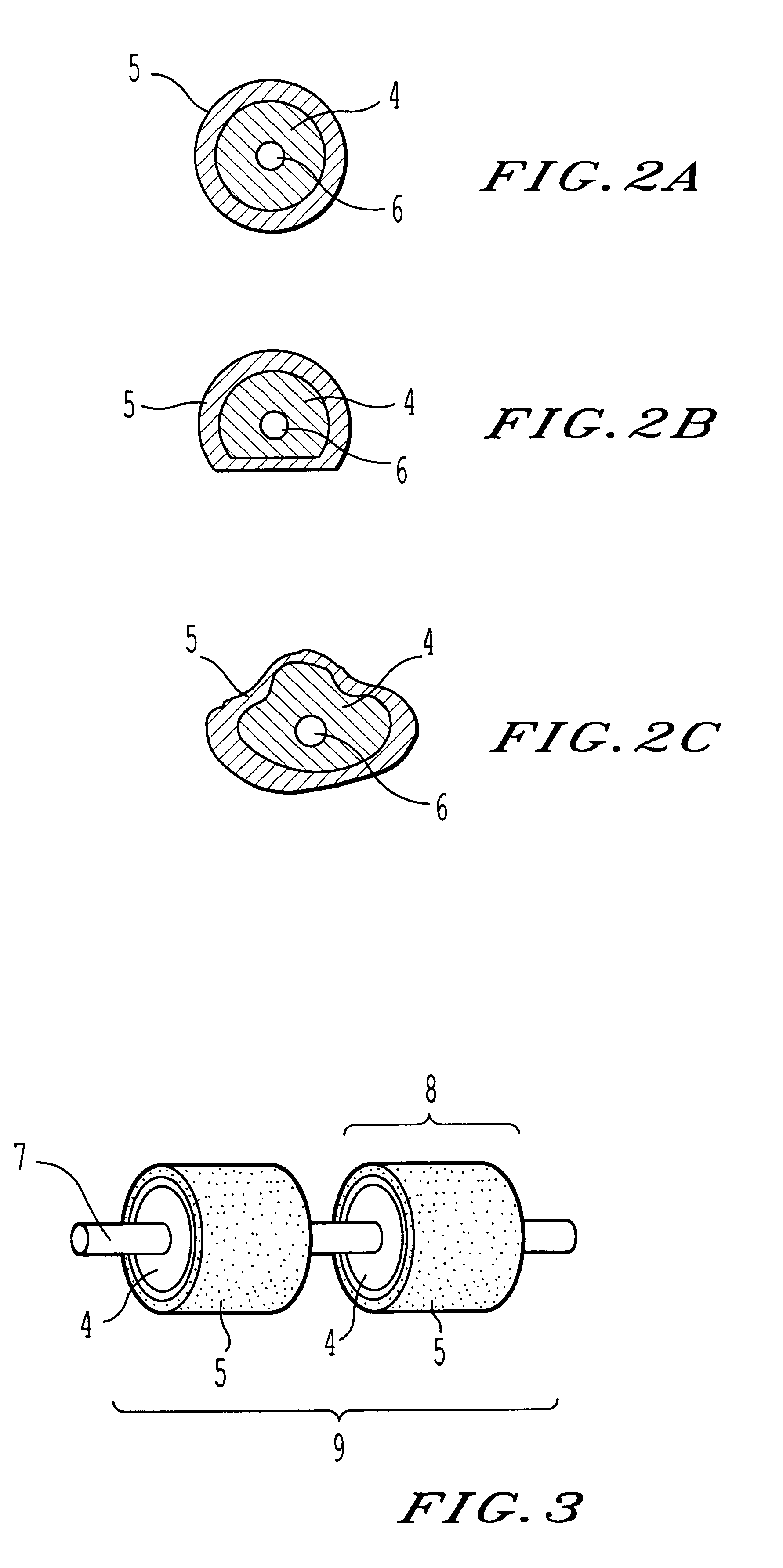

Member for office machines

InactiveUS6273415B1Process stabilityIncrease coefficient of frictionOther printing apparatusArticle feedersPaper sheetEngineering

There is disclosed a member for office machines which comprises a core body and an annular elastic body installed on the peripheral surface thereof, wherein the expansion rate of the annular elastic body E(%) falls within the range of 5 to 30%, when expressed by the formulawherein d1 in mm is the diameter of the core body, or a longest value in the cross-section of the core body in the shape of a roller or odd-shape; and d2 in mm is the inside diameter in mm of the annular elastic body before being installed on the peripheral surface of the core body. The member for office machines enables stable and steady paper sheet feeding, when used as a paper feeding member in electrophotographic equipment and electrostatic recording equipment, and equipment having a variety of paper feeding mechanisms such as ink-jet printers, automatic teller machines (ATM), money exchange machines, counting machines, automatic vending machines and cash dispensers (CD).

Owner:BRIDGESTONE CORP

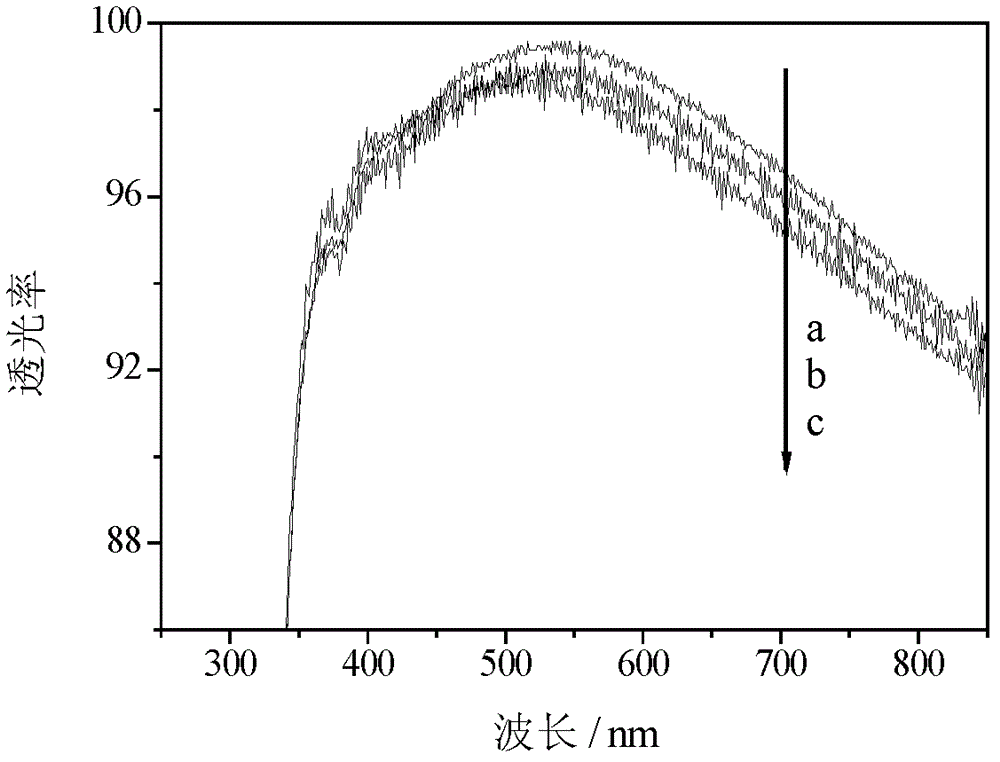

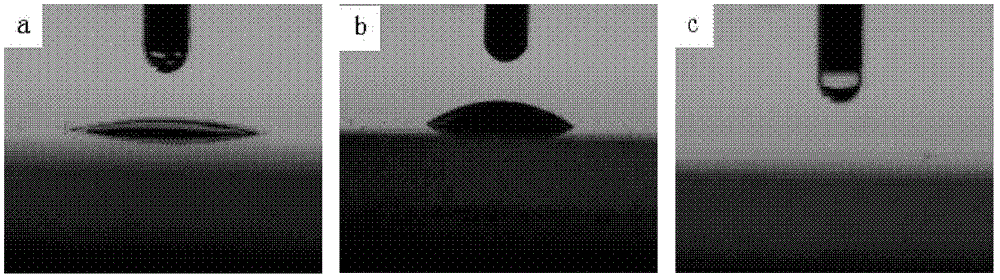

Wear-resistant super-hydrophilic anti-reflecting coating

The invention relates to a wear-resistant super-hydrophilic anti-reflecting coating. The wear-resistant super-hydrophilic anti-reflecting coating disclosed by the invention is characterized in that: by using the advantages that a SiO2 surface is good in hydrophilicity and a silica film is lower in reflectivity, high in light transmittance and good in wear-resisting performance and the like, a rough-structured surface structure is constructed through a SiO2 spherical nanoparticle layer consisting of nanoparticles with particle sizes of about 10-40 nm, and the coating has super-hydrophilicity. The contact angle of water on the glass surface of the coating is 0 degree, and the light transmittance of sheet glass coated with the coating is increased from 91.3% to 99.0%. When water drops on the surface of glass coated with the coating, a droplet is flattened rapidly and uniformly and then evaporated without leaving any spots. The wear-resistant super-hydrophilic anti-reflecting coating disclosed by the invention has the technical advantages of simple preparation process, low cost, obvious effect, wide applicable scope and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

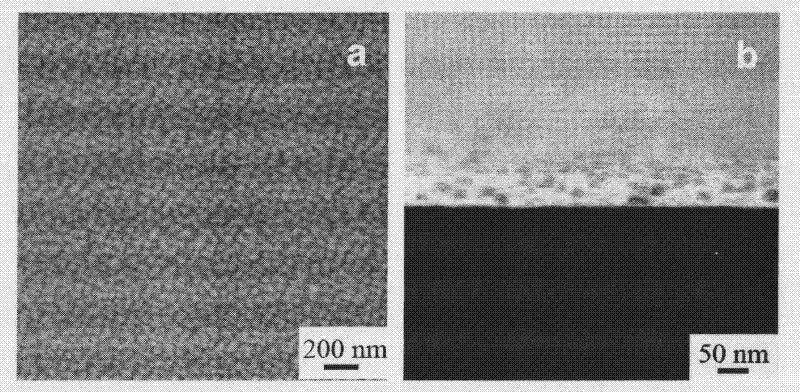

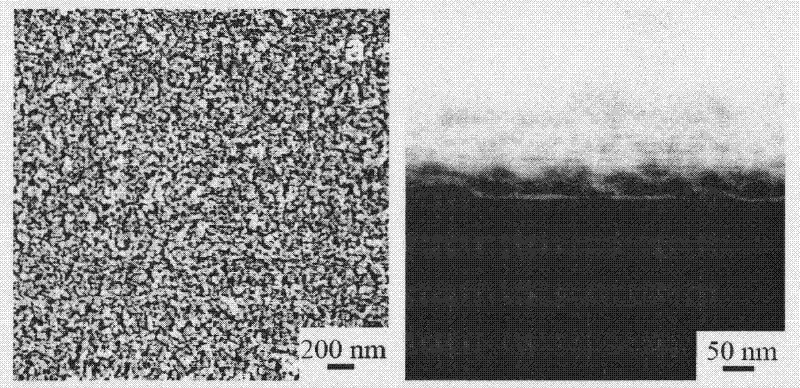

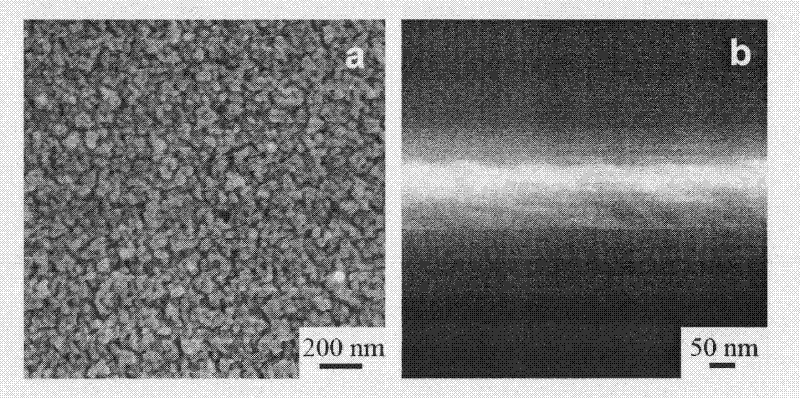

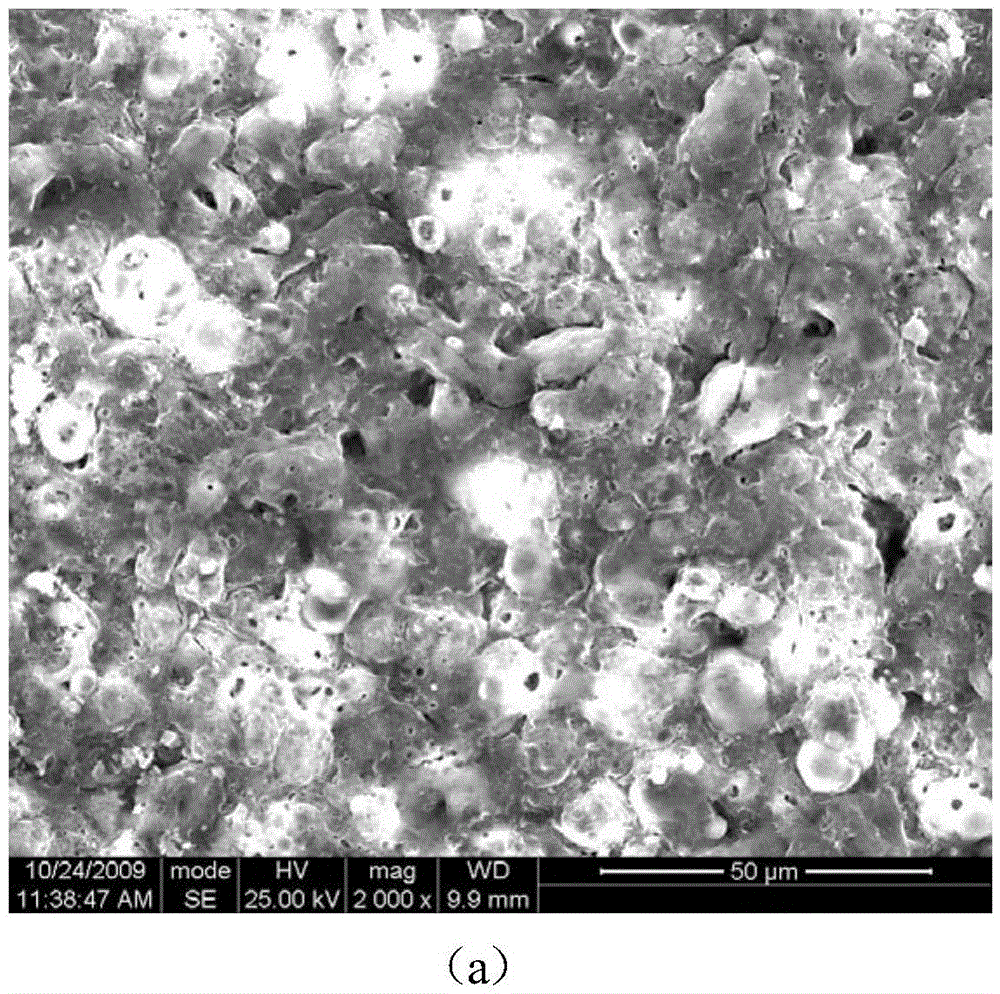

Carbon steel or stainless steel surface micro-arc oxidation ceramic coating based on aluminized coating, and preparation method thereof

InactiveCN106702330AHigh hardnessLow wear resistanceAnodisationVacuum evaporation coatingMicro arc oxidationCorrosion resistant

The invention discloses a carbon steel or stainless steel surface micro-arc oxidation ceramic coating based on an aluminized coating, and a preparation method thereof, and belongs to the technical field of metal surface treatment. A nanoscale pure aluminum coating is formed by performing multi-arc ion plating on the surface of a stainless steel matrix, the surface of the aluminized coating is subjected to single positive pulse micro-arc oxidation, and a ceramic coating with the main component being Al2O3 is formed on the surface of the stainless steel by controlling the components of an electrolyte and electrical parameters such as the frequency and the oxidation time, so that preparation of the stainless steel surface coating with a wear-resistant function is realized. The stainless steel surface ceramic coating prepared by the method has high corrosion resistance and scratching resistance and extremely high hardness, and solves the problem that the traditional stainless steel surface treatment technology (phosphorization, chemical plating and plasma spray-coating) cannot meet requirements such as high wear resistance, high hardness, high corrosion resistance and good binding force under the condition that the coating is thin (the thickness is less than 30 microns).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com