Patents

Literature

1662results about How to "Improve dispersion uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound and preparation method thereof as well as negative electrode prepared by adopting compound and lithium ion battery

ActiveCN106356508AImprove consistencyImprove dispersion uniformityCell electrodesSecondary cellsElectrical batterySilicon oxygen

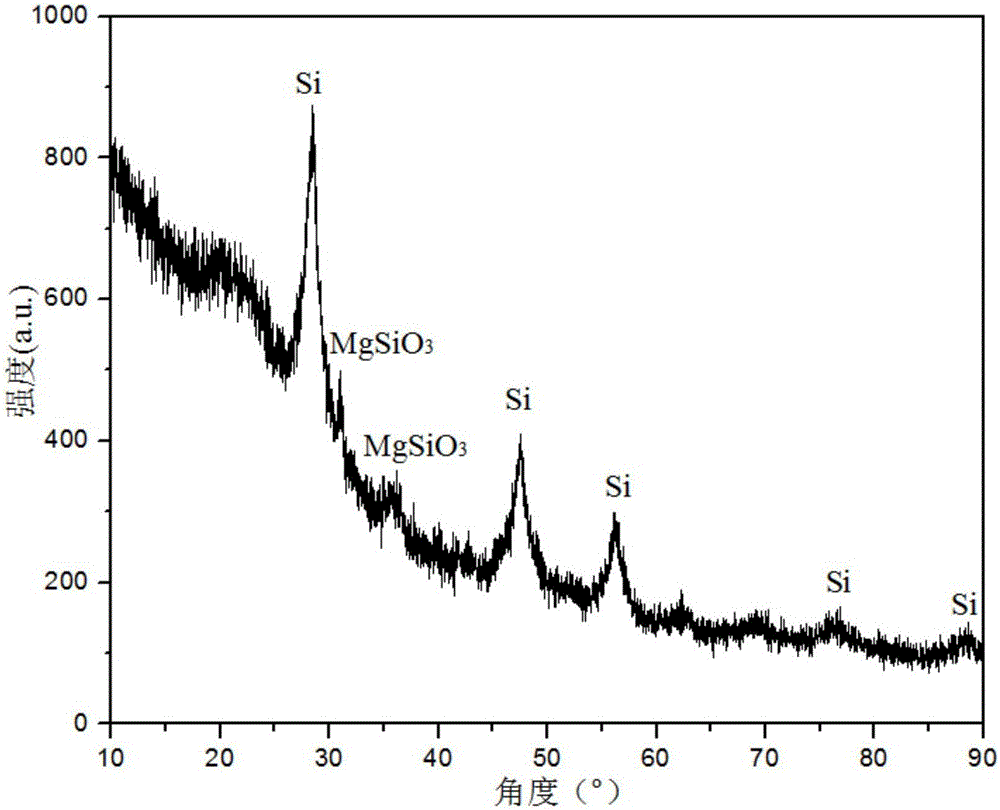

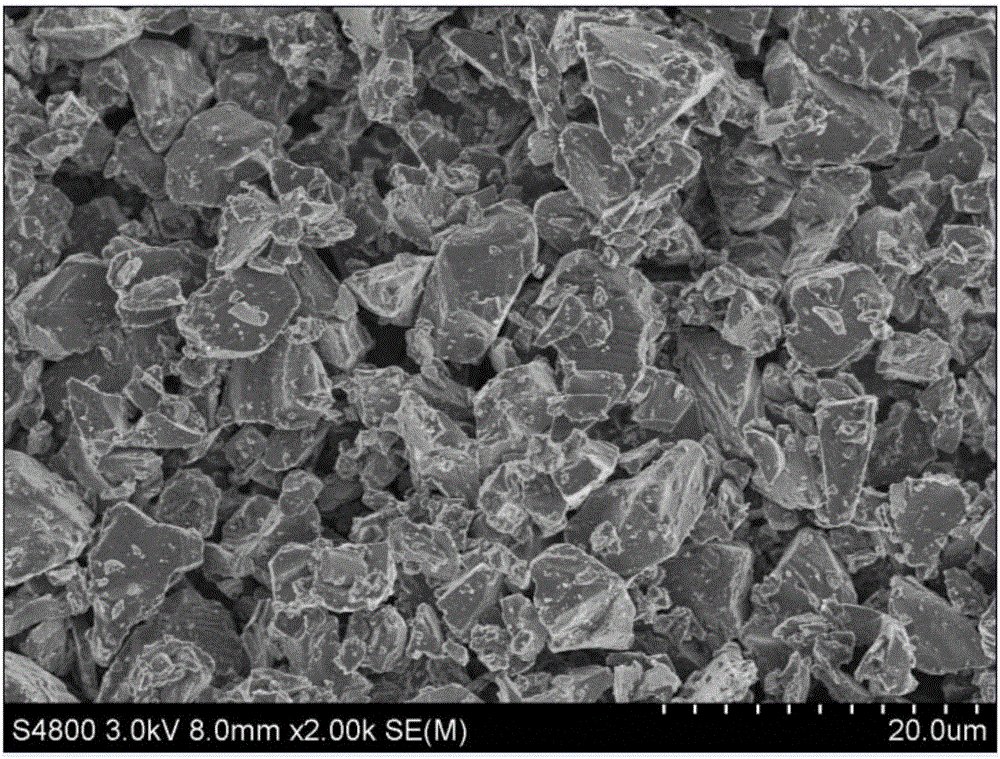

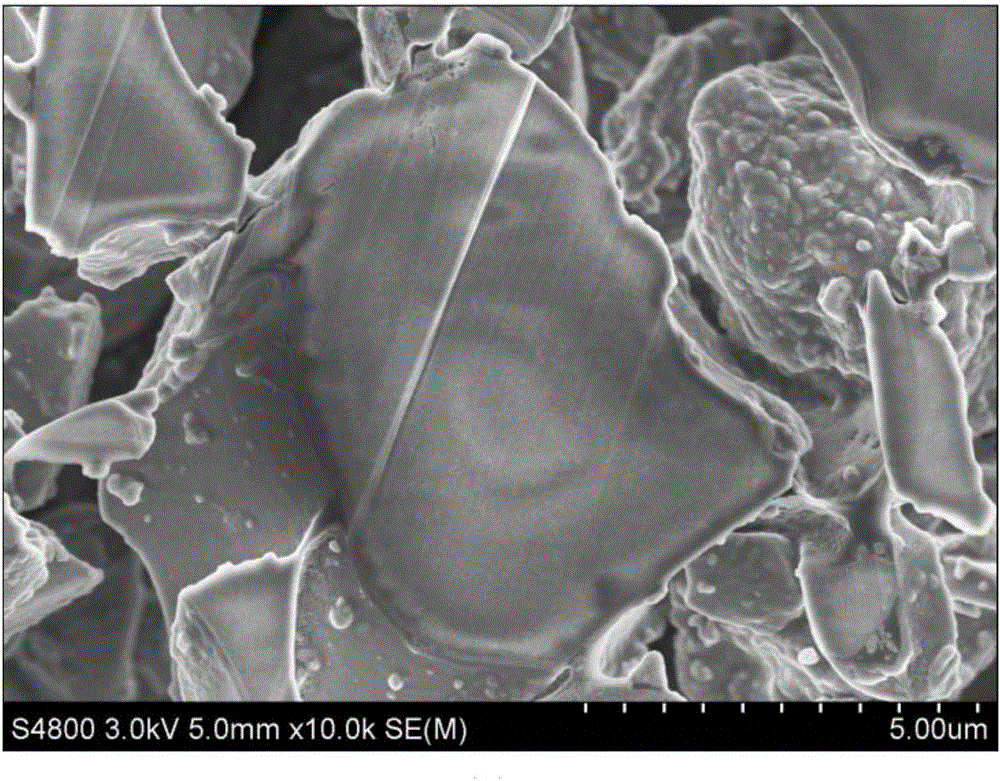

The invention relates to a compound and a preparation method thereof as well as a negative electrode prepared by adopting the compound and a lithium ion battery. The compound comprises silicon, silicon oxide SiOx (x is greater than 0 and is less than or equal to 2) and silicate, wherein positive ion elements of the silicate are reductant elements, and Si, O and the reductant elements in the compound are uniformly distributed. Reductants used in the compound are heated and insulated in the environment of negative pressure, so that SiO steam reacts with reductant steam in the form of a gas phase so as to condense to obtain the compound, and then the compound is further used as a raw material so as to prepare a modified silica negative electrode material. The negative electrode material is suitable for the lithium ion battery, the prepared lithium ion battery has high charge and discharge specific capacity and excellent first coulombic efficiency, the charge capacity is 1447 mAh / g or above, the discharge capacity is 1213 mAh / g or above, and the first coulombic efficiency is 83.8% or above.

Owner:BTR NEW MATERIAL GRP CO LTD

Water polyurethane electric conduction paint containing carbon nano-tube and preparation method thereof

InactiveCN101165127AImprove dispersion uniformityNo subsidencePolyurea/polyurethane coatingsEmulsion paintsPolyesterCarbon nanotube

The present invention belongs to the field of chemical technology, and is especially one kind of conducting water soluble polyurethane paint containing carbon nanotube and its preparation process. The conducting paint is prepared through the first modifying carbon nanotube chemically for the surface to carry hydroxyl group, carboxyl group or amino group; the subsequent introducing to polyester polyol or isocyanate terminated polyurethane pre-polymer through chemical bonding and self-emulsifying to prepare water soluble polyurethane dispersoid containing carbon nanotube; and final adding deionized water and assistants through high speed stirring to obtain the conducting paint. The conducting paint can form coating with volume resistivity of 1x10<-5>-4x10<-4. ohm.cm, surface resistivity of 1x10<-1>-2x10<2> ohm, adhesion of 0 grade, shielding effectiveness of 70-85 dB, and long term stability, and has wide application.

Owner:SHANGHAI SAFEGREEN TECH

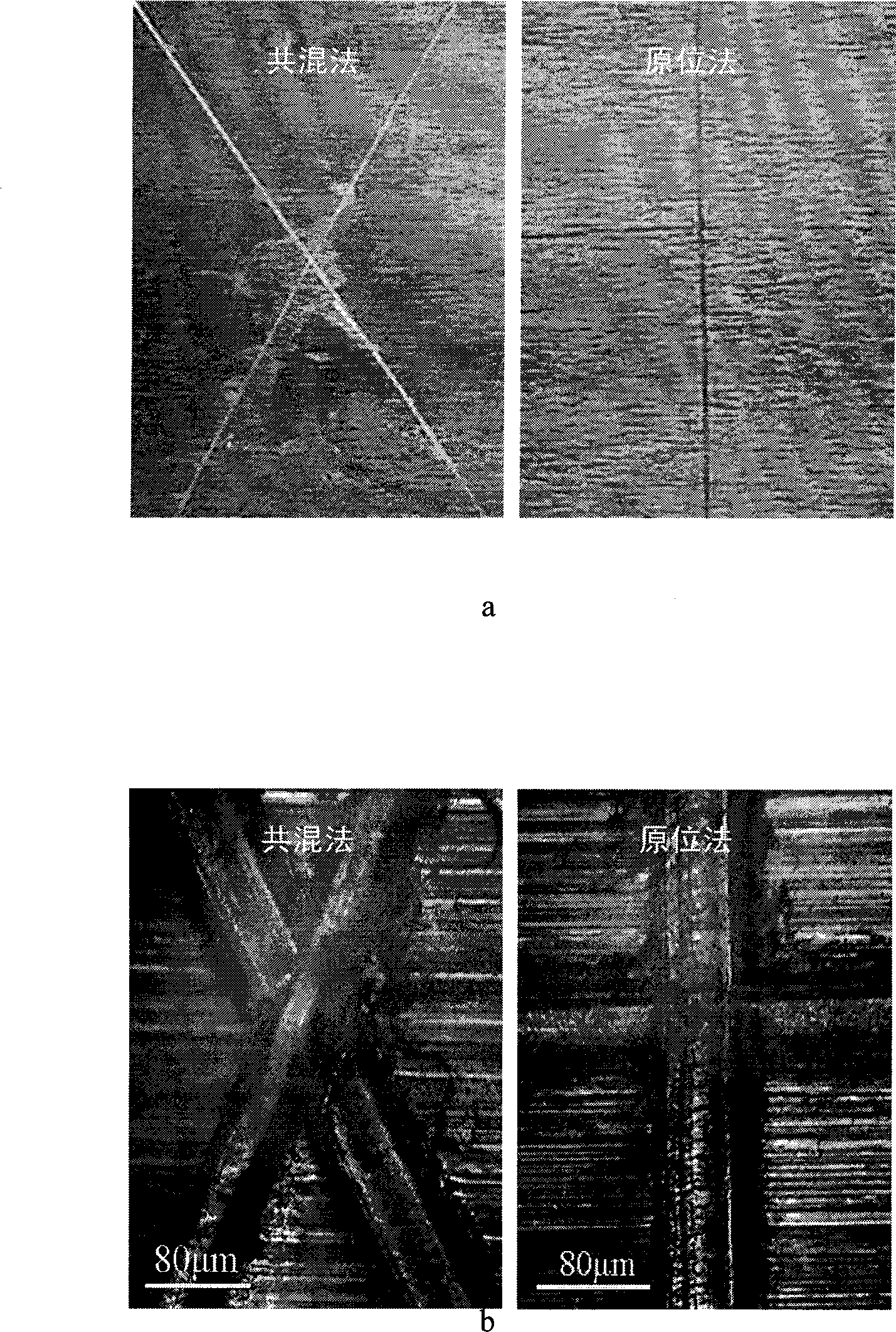

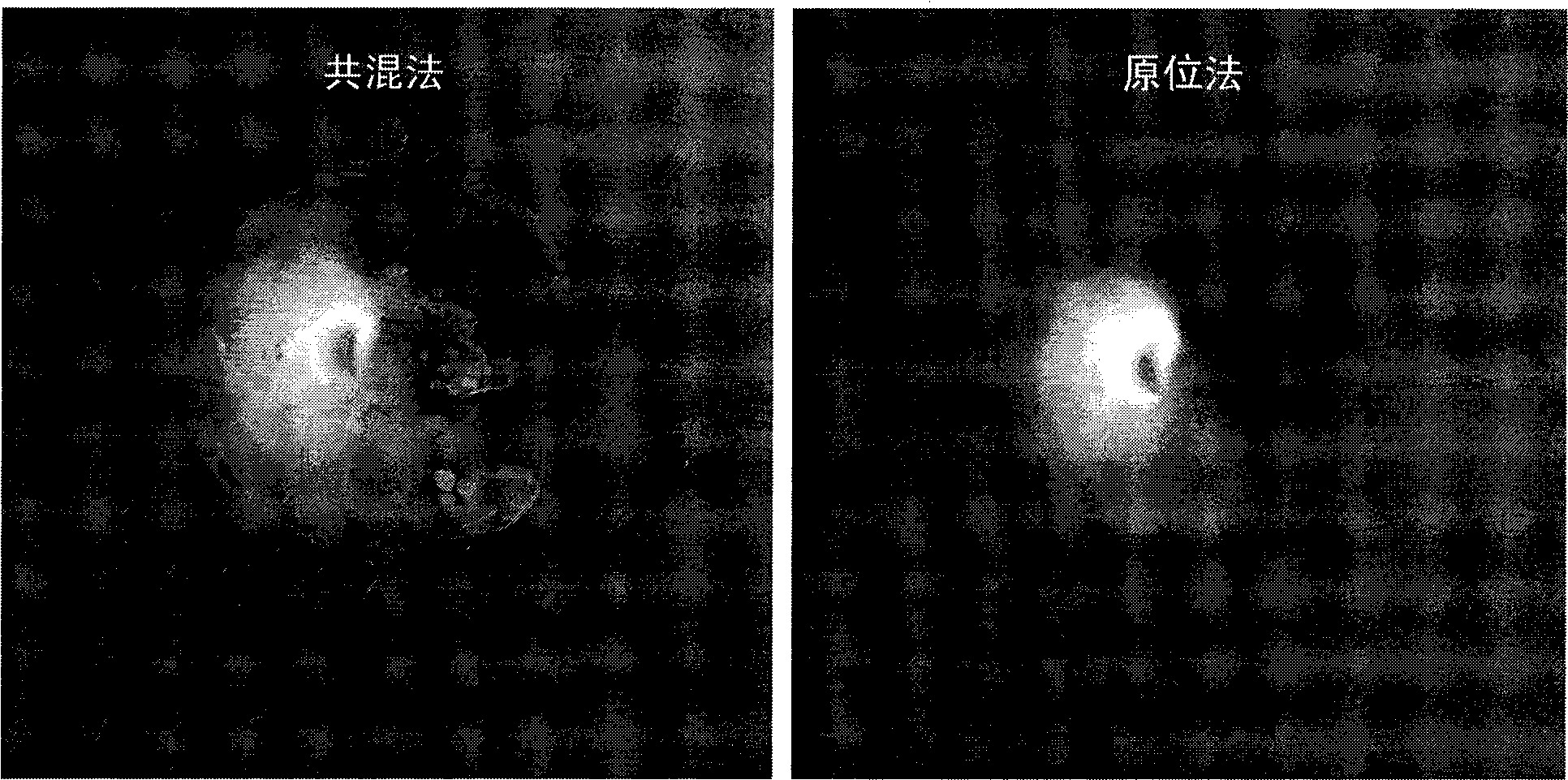

Preparation method of polyacrylonitrile/graphene composite-based carbon fiber

ActiveCN102560746AImprove thermal conductivityUniform deliveryElectroconductive/antistatic filament manufactureSynthetic polymer filament chemical after-treatmentCarbon fibersIn situ polymerization

The invention discloses a preparation method of polyacrylonitrile / graphene composite-based carbon fiber, which comprises the following steps: firstly preparing a polyacrylonitrile mixed solution uniformly dispersed with graphene through an in-situ polymerization method, and then employing the mixed solution as a spinning solution and obtaining a polyacrylonitrile / graphene composite protofilament by a wet spinning or dry-jet wet spinning process, and finally making the protofilament subject to a pre-oxidation treatment and a carbonization treatment to obtain the polyacrylonitrile / graphene composite-based carbon fiber. Compared with the existing polyacrylonitrile-based carbon fiber, the carbon fiber prepared by the method of the invention has a significantly increased mechanical property, and the carbonation yield in the preparation process is improved, therefore, the preparation method is an efficient and reliable preparation method with good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

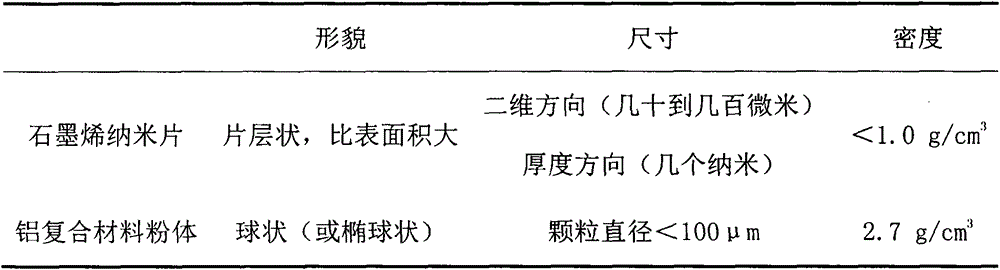

Preparation method of graphene/aluminum alloy composite material

The invention provides a preparation method of a graphene / aluminum alloy composite material. The addition quantity of graphene in the composite material accounts for 0.1wt.%-5.0wt.% of the total quantity of the composite material. Compared with tensile strength and electrical performance of an aluminum alloy without graphene, the mechanical properties and the electrical performance of the graphene / aluminum alloy composite material are improved to varied degrees. With the appearance of an intermediate alloy of the graphene / aluminum alloy composite material, the graphene can be added to molten aluminum in a form of a graphene / aluminum alloy intermediate alloy, and the dispersion uniformity of the graphene in the molten aluminum is improved to the greatest degree, so that industrial batch production of graphene modified aluminum conductor cables can be realized with a melt-casting method. The preparation method of the composite material comprises steps as follows: mechanical mixing, low-temperature ball milling, vacuum degassing, hot isostatic pressing and extrusion and the like, adopts simple and controllable technology, has lower production cost, is applicable to industrial production and has good market prospect.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for preparing Nano-composite material of poly lactic acid/montmorillonite

A nano-class polylactic acid-montmorillonie composition is prepared from polylactic acid, organically modified montmorillonite with different interlayer gaps, compatibilizer and antioxidizing agent through fusing and mixing polylactic acid with said montmorillonite to obtain mother material, and fusing and mixing the mother material with polylactic acid. Its advantages are high mechanical performance, resistance to high temp and biodegradability.

Owner:TONGJI UNIV

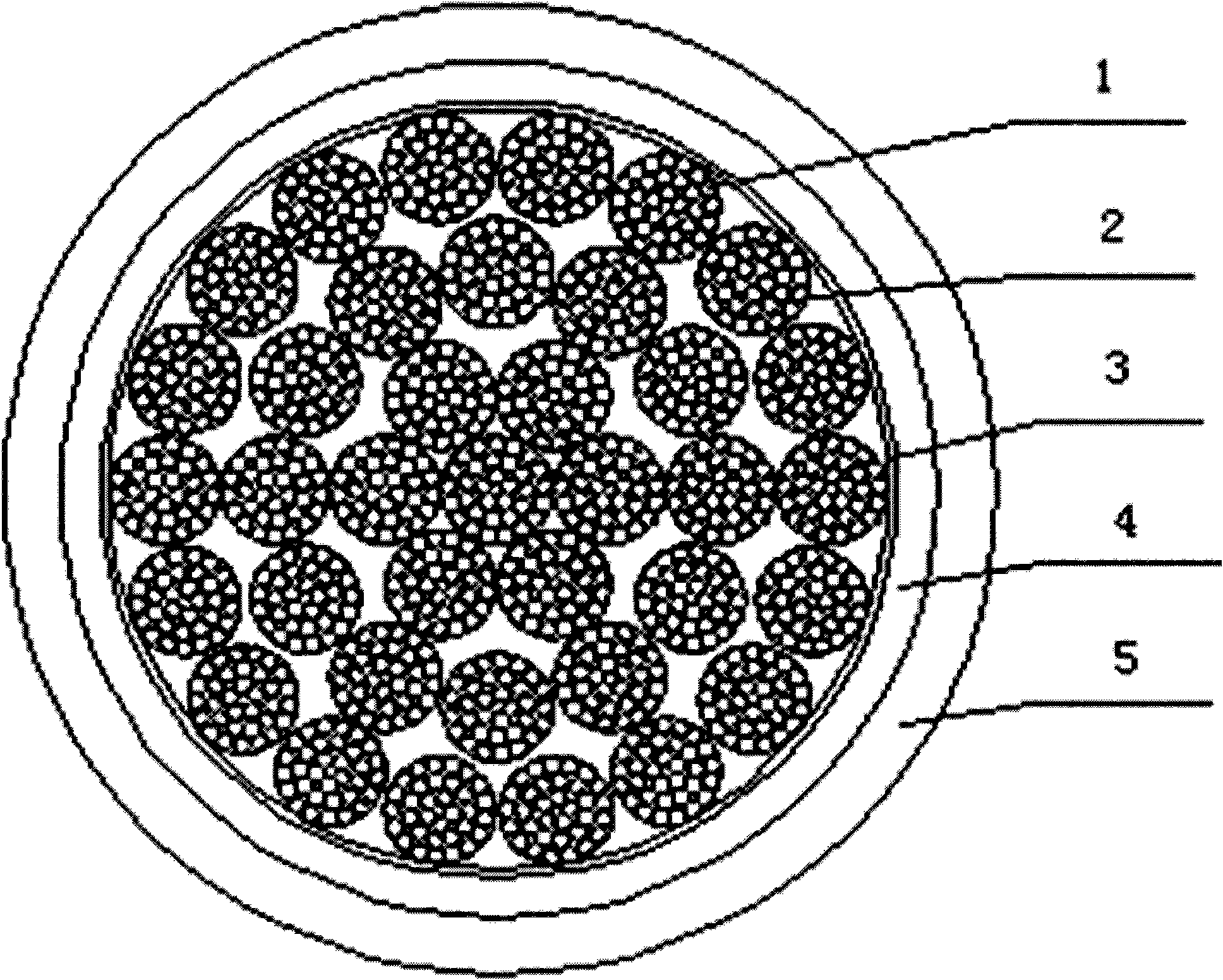

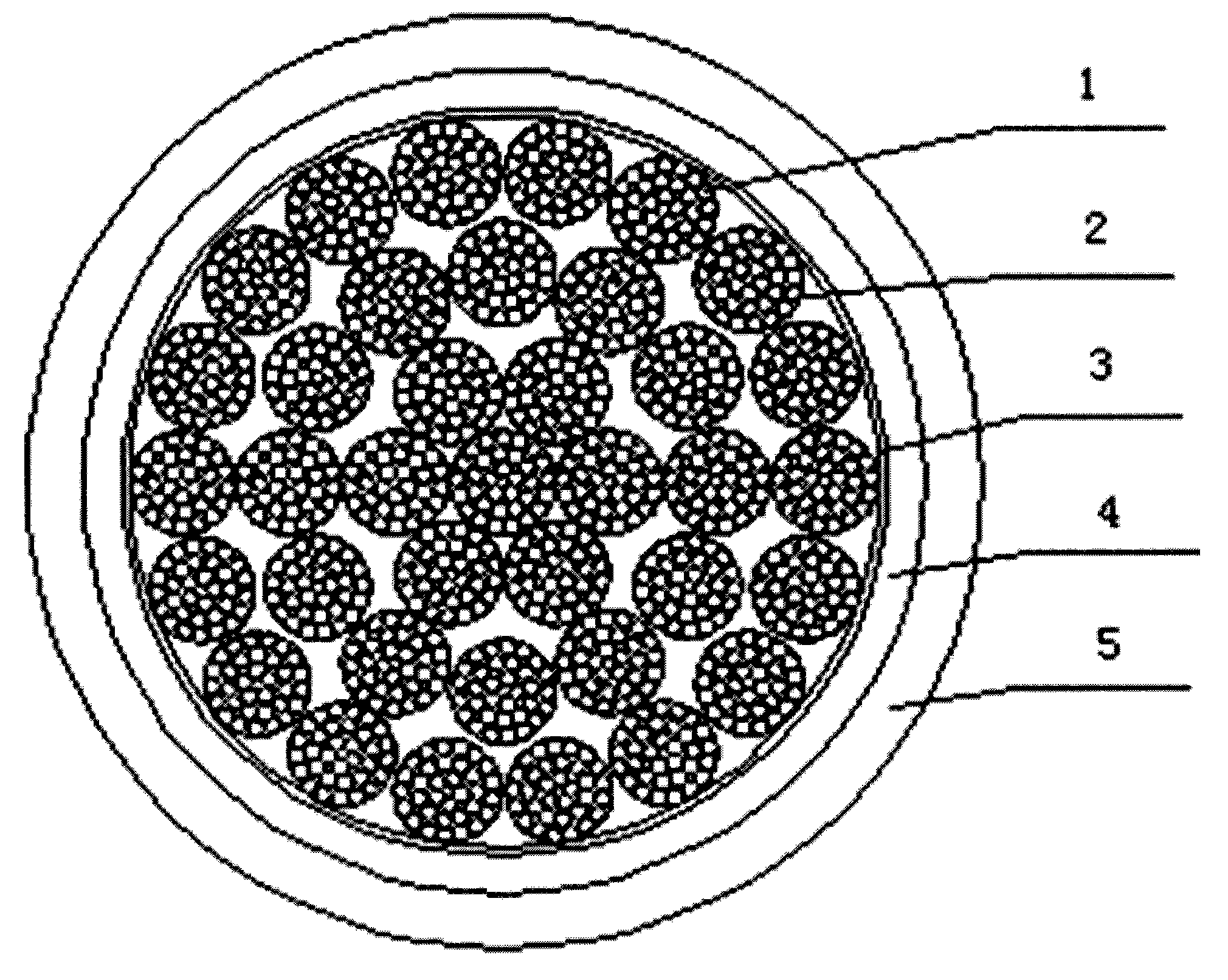

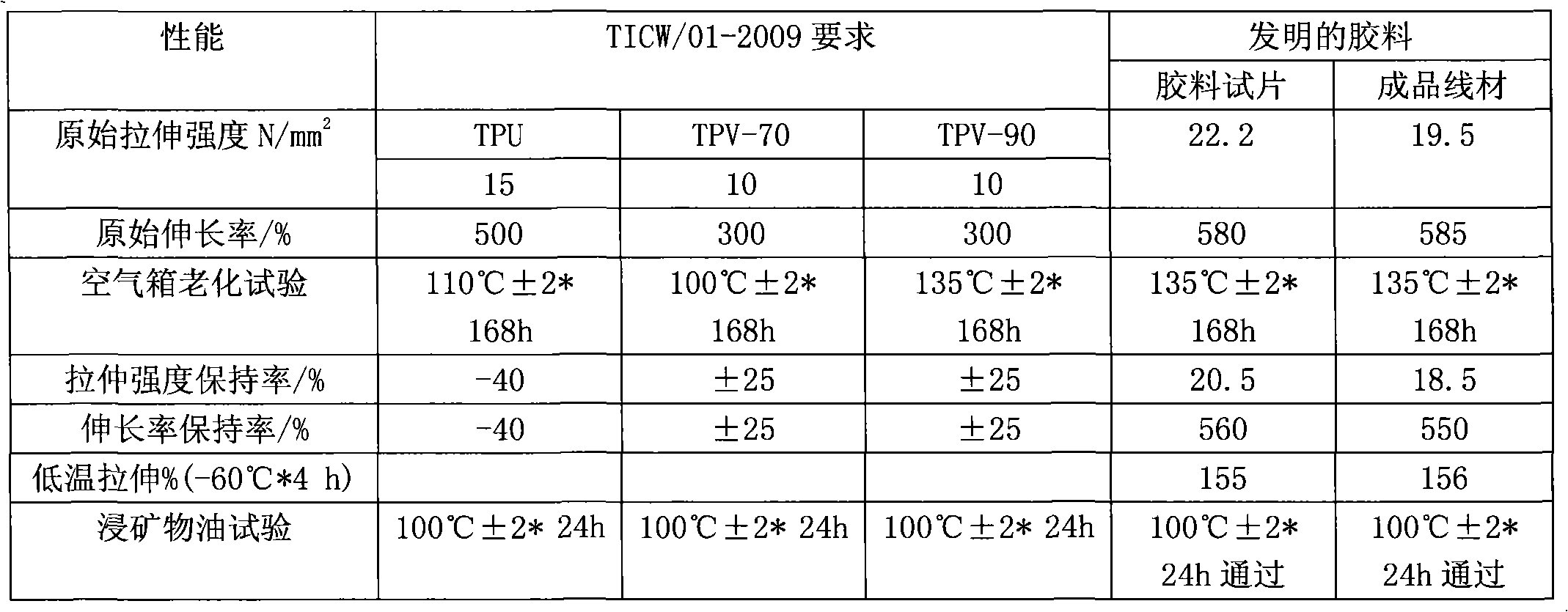

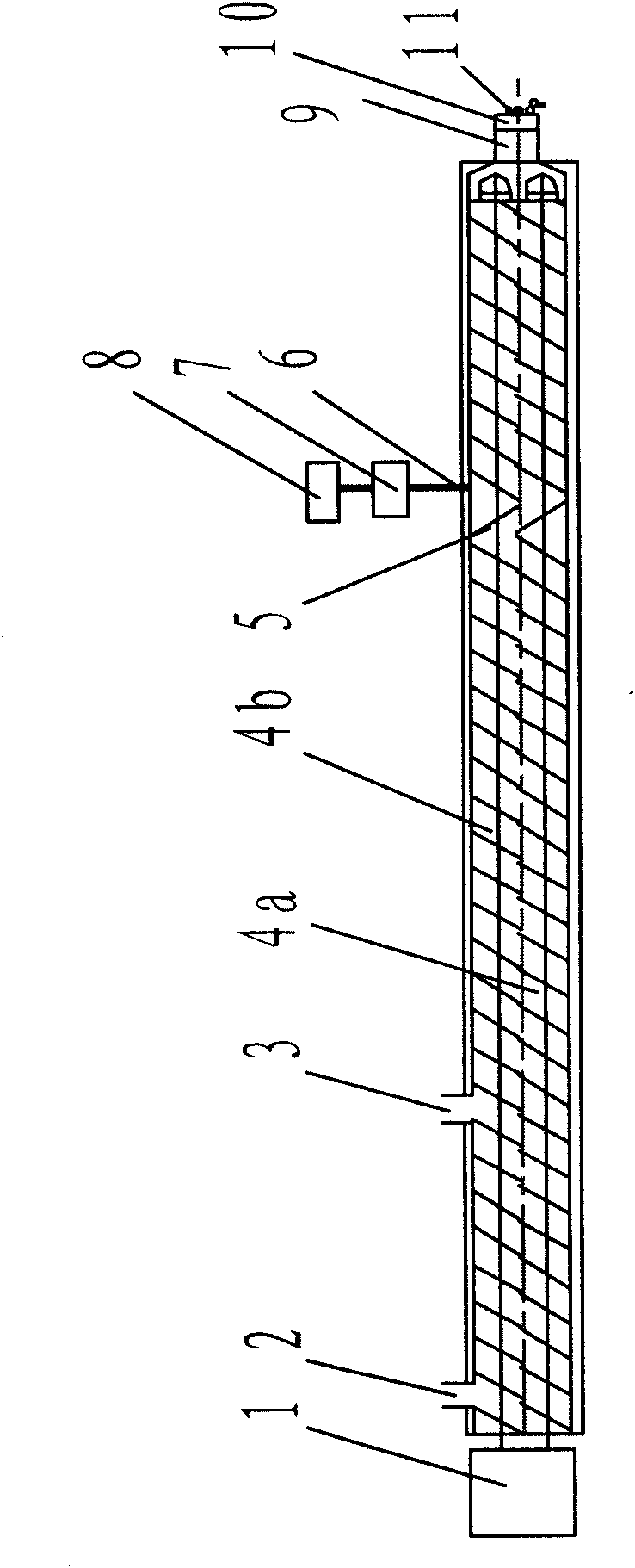

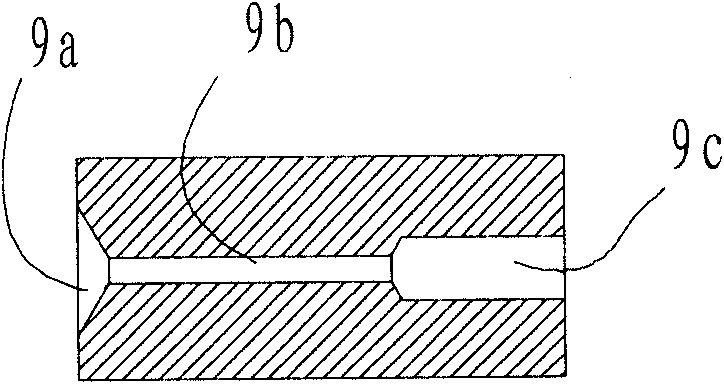

Distortion-resistance wind power generation cable sheath materials and cable

InactiveCN101838424AImproves UV resistanceFunction increasePlastic/resin/waxes insulatorsFlexible cablesElastomerCross-link

The invention discloses a distortion-resistance wind power generation cable sheath material and a cable. The cable material comprises the following components in weight parts: 100 parts of chlorinated polyethylene, 10-30 parts of amorphism copolymer, 10-20 parts of cold-resistant plasticizer, 40-80 parts of reinforcing filler, 5-15 parts of nanosacle inorganic active agent, 2.5-5 parts of cross-linking agent, 2-5 parts of cross-linking assistant agent, 1-2.5 parts of antioxidant antiager and 10-30 parts of inorganic fire retardant, wherein the amorphism copolymer is a mixture of amorphism polyolefin thermoplastic elastomer and chlorinated polyethylene elastic body; and the nanoscale inorganic active agent is nanoscale zinc oxide and magnesium oxide. The cable of the invention has low-temperature resistance (-60DEG C)and distortion resistance, excellent flexibility, improves the homogenisieren property of the other materials by adding the nanoscale inorganic active materials, improves the molecular structure, has better flexibility because of the uvio-resistance, and has the characteristics of distortion, cold, oil and corrosion resistance and the like.

Owner:江苏凯诺电缆集团有限公司

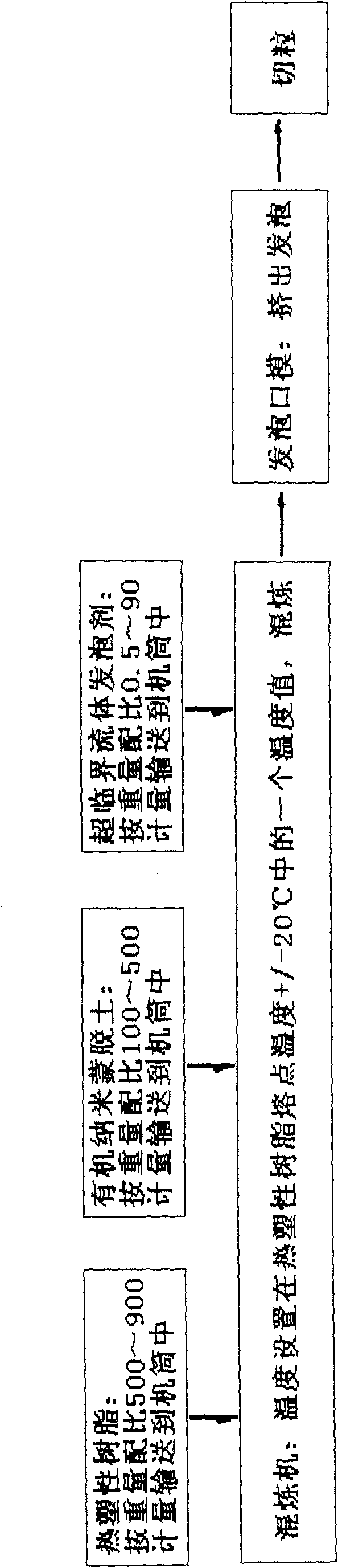

Nucleating agent master batches used for foaming of thermoplastic resin

ActiveCN101565550AConvenient injection foam moldingEasy extrusionVolumetric Mass DensityNitrogen gas

The invention relates to a nucleating agent and a method for preparing the nucleating agent, wherein the nucleating agent is used for reducing the dimension of the foaming hole and improving the density of the foaming hole when a supercritical fluid foaming agent (such as carbon dioxide or nitrogen) is used for producing thermoplastic foaming products. The raw materials of the nucleating agent mainly consists of an organic montmorillonite, a thermoplastic resin and a supercritical fluid foaming agent; the specific weight of the nucleating agent master batches is controlled within 100+ / -5% of that of the thermoplastic resin. The method has the advantages that a supercritical fluid foaming method is adopted to prepare the nucleating agent master batches which have approximate specific weights to the resin material adopted by the subsequent foam forming, thus facilitating the subsequent injection foam forming and extrusion foam forming; and the carbon dioxide or nitrogen in supercritical state is used for reducing the viscosity of the carrier resin during the mixing process, the dispersion uniformity of the peeled sandwich montmorillonite in the carrier resin is reinforced, the process temperature is reduced, the layer spacing of the sandwich nano-montmorillonite which may be not peeled is increased and the sufficient peeling is realized.

Owner:BEIJING CHN TOP MACHINERY

Conductive agent dispersion liquid, electrode slurry, electrode, battery, and preparation methods thereof

InactiveCN101752548AEvenly dispersedSmall diameterElectrode manufacturing processesActive material electrodesSolubilityCapacitance

The invention discloses a conductive agent dispersion liquid and a preparation method thereof. The conductive agent dispersion liquid contains a conductive agent, a solvent and a dispersion agent, wherein the dispersion agent contains aromatic rings and can be bound with the surface of the conductive agent by Van der Waals force among molecules and pi-pi action force between planes; and the solubility in the first solvent at the temperature of 25 DEG C is not smaller than 10wt%. The invention also discloses an electrode slurry and a preparation method thereof, and a battery electrode prepared from the electrode slurry and a battery. As using the matter which contains the aromatic rings and can be bound with the surface of the conductive agent by Van der Waals force among molecules and pi-pi action force between planes as the dispersion agent of the conductive agent, the battery capacitance, the charging and discharging capacitance and the rate discharge property are effectively enhanced.

Owner:BYD CO LTD

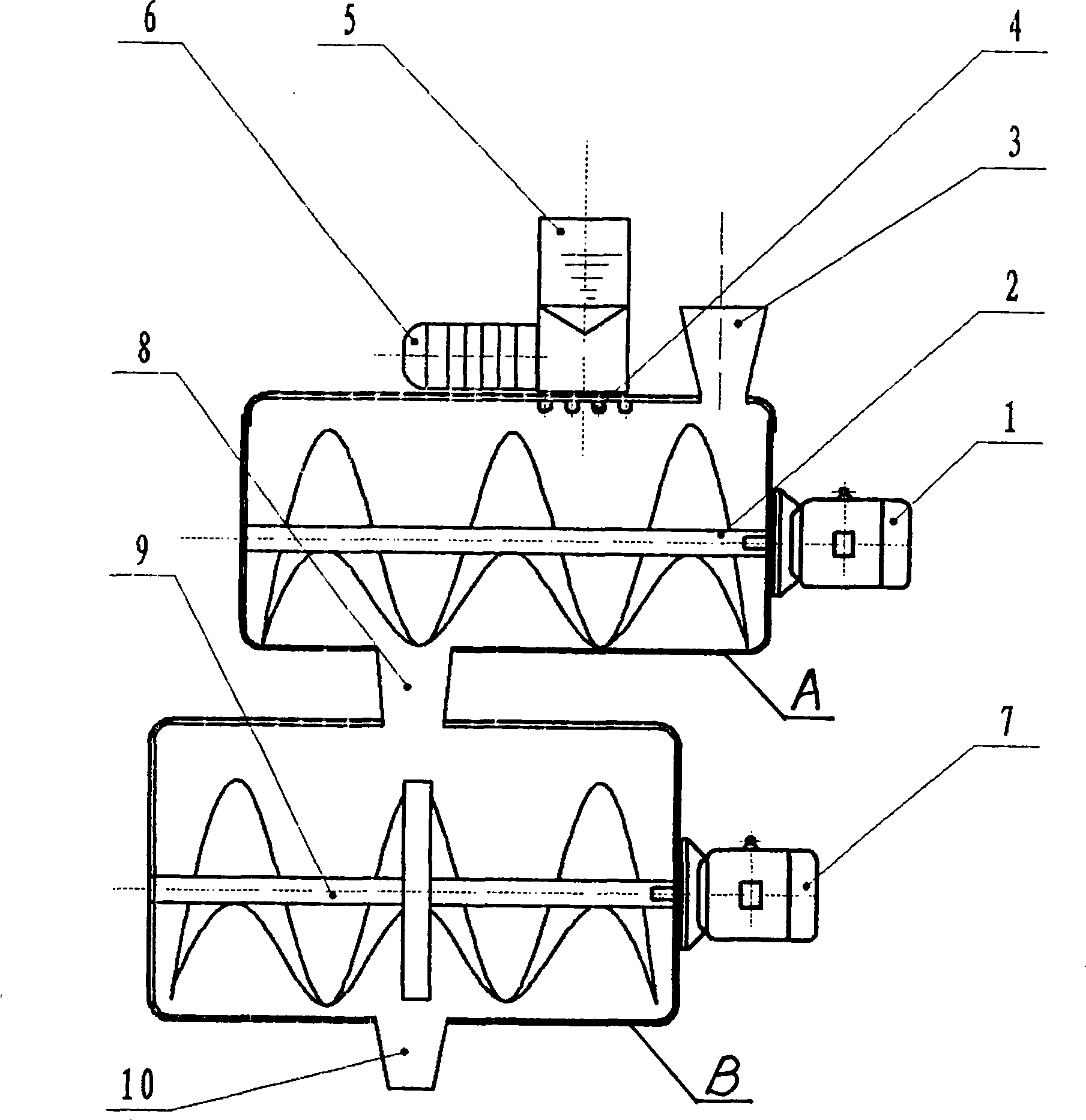

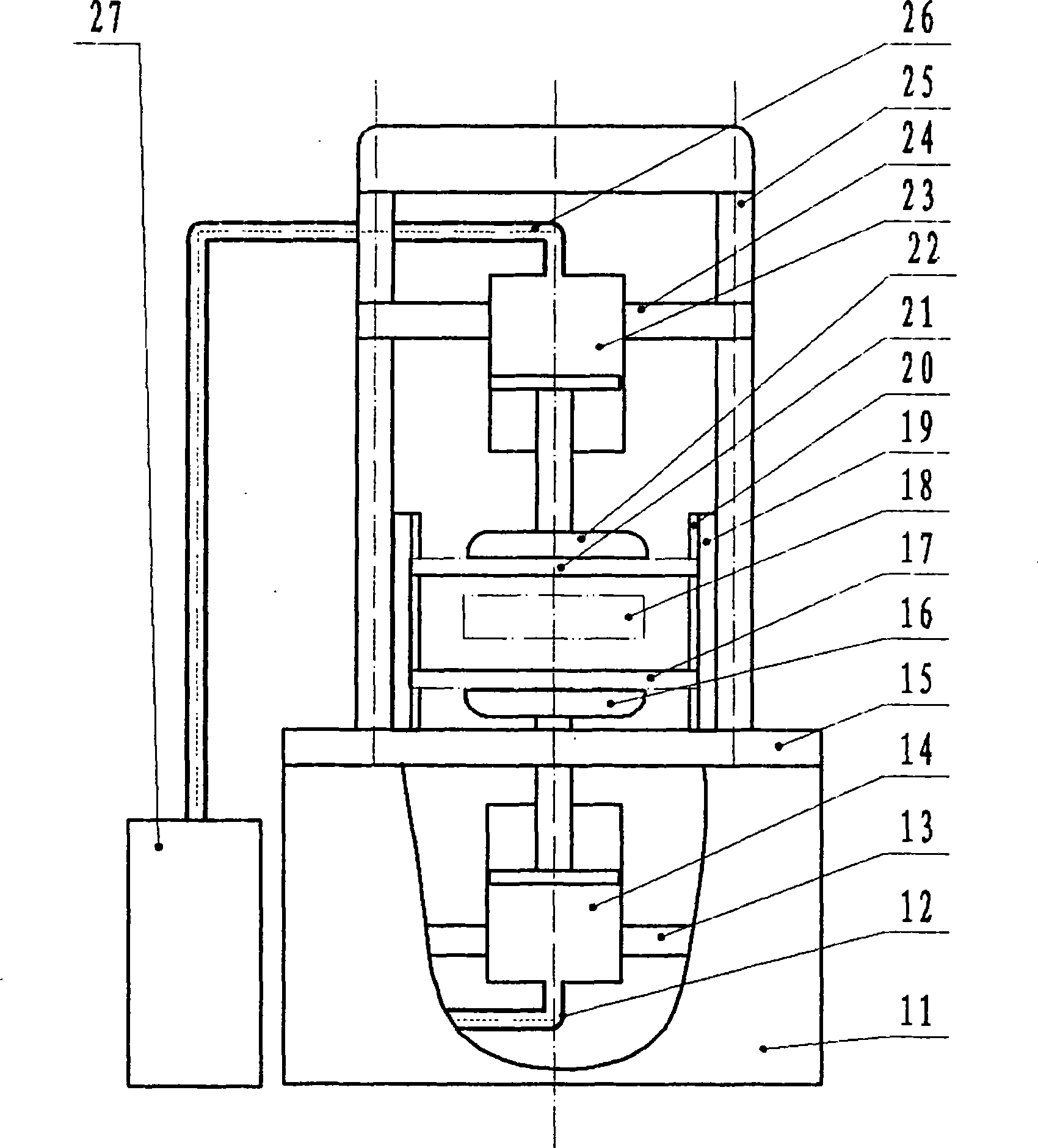

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

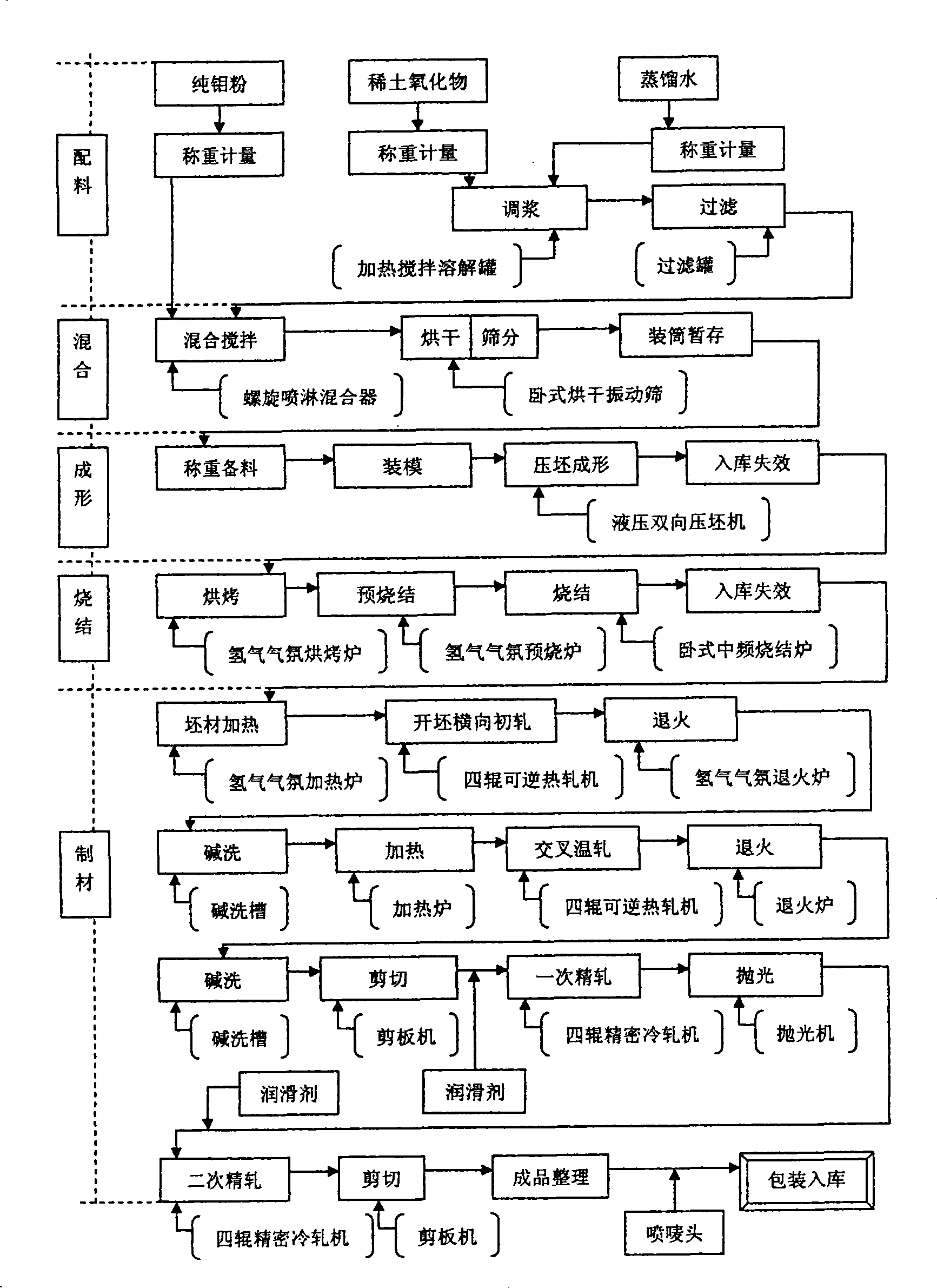

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

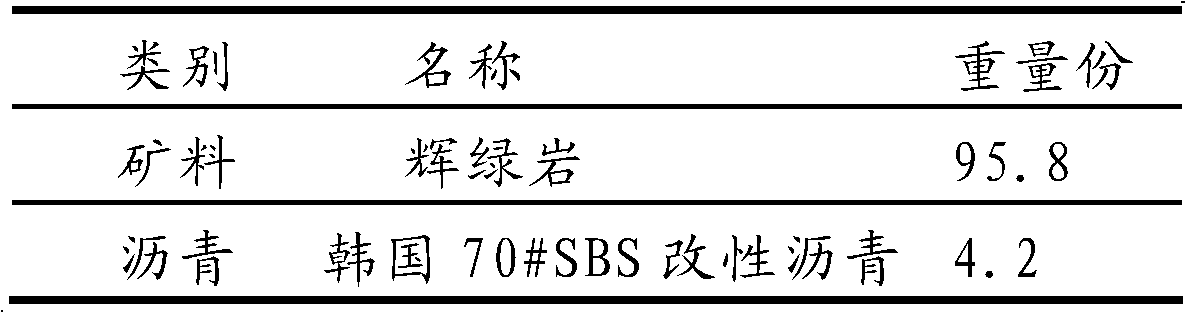

Direct-casting type anti-track agent and preparation method

ActiveCN102585522AImprove plasticityHigh modulus at room temperatureBuilding insulationsWaxPolyester

The invention discloses a direct-casting type anti-track agent, which is formed by the following components by weight in mixing mode: 20 to 40 parts of regenerative polyolefine plastic, 10 to 20 parts of regenerative polyester plastic, 2 to 10 parts of regenerative wax, 2 to 10 parts of organic powder body with small particle size and 5 to 10 parts of gilsonite. A preparation method of the direct-casting type anti-crack agent and a method for preparing asphalt mixture by adopting the direct-casting type anti-crack agent are further disclosed. Particles of the direct-casting type anti-crack agent can be directly cast in hot aggregate on construction sites to be mixed with the hot aggregate in drying mode, intermittent construction can be conducted, and the direct-casting type anti-track agent lowers or reduces probability of separation of modified asphalt in the cooling, transporting and storing processes, and break through limit and restraint brought by continuous production and construction.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

Reverse osmosis membrane and preparation method thereof

ActiveCN103071405AExcellent salt rejectionImprove uniformitySemi-permeable membranesGeneral water supply conservationDesalinationReverse osmosis

The invention discloses a reverse osmosis membrane and a preparation method thereof. The reverse osmosis membrane comprises a non-woven support layer, a polysulfone base membrane layer, a polyamide desalination layer and a transition layer, wherein the non-woven support layer is coated with the polysulfone base membrane layer; the transition layer is a hydrophilic membrane layer and is arranged between the polysulfone base membrane layer and the polyamide desalination layer. According to the reverse osmosis membrane, as the hydrophilic transition layer is inserted between the polysulfone base membrane layer and the polyamide desalination layer, the hydrophilic transition layer improves dispersion uniformity of a polyamine solution on the surface of the polysulfone base membrane layer, a binding force of the hydrophilic polyamide desalination layer with the polysulfone base membrane layer is increased greatly, the reverse osmosis membrane is high in desalinization ratio, uniformity and water flux, and long in service life, and can bear at least 0.5 MPa backpressure, and significantly lower engineering cost and manufacturing cost.

Owner:BEIJING ORIGIN WATER FILM TECH

Preparation of high performance metal protection nano coating

InactiveCN101486869AHigh coating hardnessImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyIn situ polymerization

A method for preparing a high-performance metal protection nanometer coating includes the following steps of: ball-milling diluter and nanometer oxide particles according to the weight ratio of 40-100:1 to obtain nanometer oxide suspension; measuring acrylic ester and remaining copolymerization monomers according to the weight ratio of 2-3:1 to obtain a mixed monomer, adding the nanometer oxide suspension accounting for 80 percent of the total weight of the mixed monomer and adding reaction additives to obtain a mixture which is stirred for 10min to obtain in-situ polymerization precursor liquid. Under nitrogen protection, 10 percent of the in-situ polymerization precursor liquid is added into a reaction container, within the reaction time of 1-8h, the rest 70-90 percent of the in-situ polymerization precursor liquid is dipped, and after the dripping is over, the temperature of the reaction system is raised to 90 DEG C and kept for 0.5-2h; and nanometer oxide-acrylics is obtained after adding pH regulator and stirring for 5-10min. With epoxy resin and assistant and the like added, the metal protection nanometer coating is prepared in a ball milling method.

Owner:NANJING UNIV

Preparation process of lithium ion battery negative paste, lithium ion battery negative pole plate and lithium ion battery

ActiveCN108305987AEvenly dispersedQuality improvementElectrode manufacturing processesElectrode carriers/collectorsPhysical chemistrySodium-ion battery

The invention belongs to the technical field of a lithium ion battery, and relates to a preparation process of lithium ion battery negative paste, a lithium ion battery negative pole plate and a lithium ion battery. The preparation process of the lithium ion battery negative paste comprises the following steps of (a) mixing a negative active substance, a conductive additive, a dispersion agent anda thickening agent in a dried way to obtain mixed powder; (b) adding a solvent, performing uniform mixing to obtain primary paste with solid content being 67-69wt%; (c) adding the solvent again, performing uniform mixing to obtain secondary paste with solid content being 58-62wt%; (d) adding the solvent again, performing uniform mixing to obtain third paste with solid content being 54-56wt%; and(e) adding a binding agent into the third paste, and performing uniform mixing to obtain the lithium ion battery negative paste. The process is simple and is easy to operate, the preparation time canbe remarkably prepared, the equipment utilization ratio is improved, meanwhile, the mixing is uniform, and the dispersion performance, the consistency and the fineness of the paste are improved.

Owner:BEIJING NAT BATTERY TECH

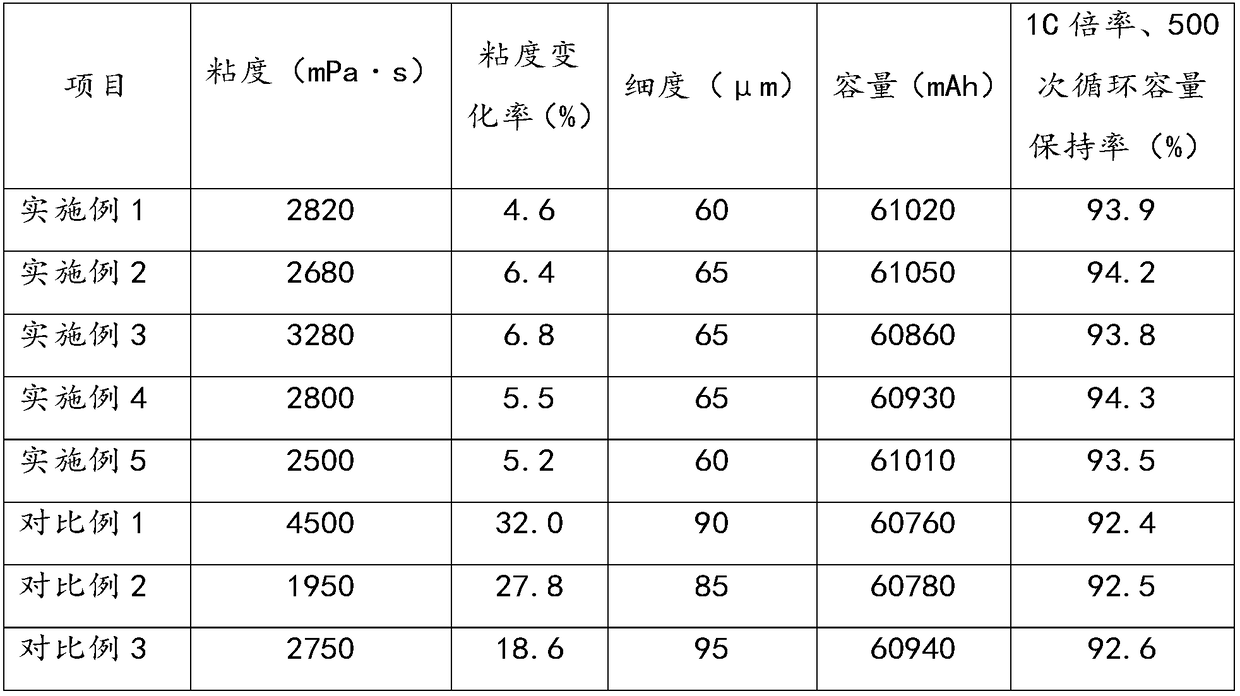

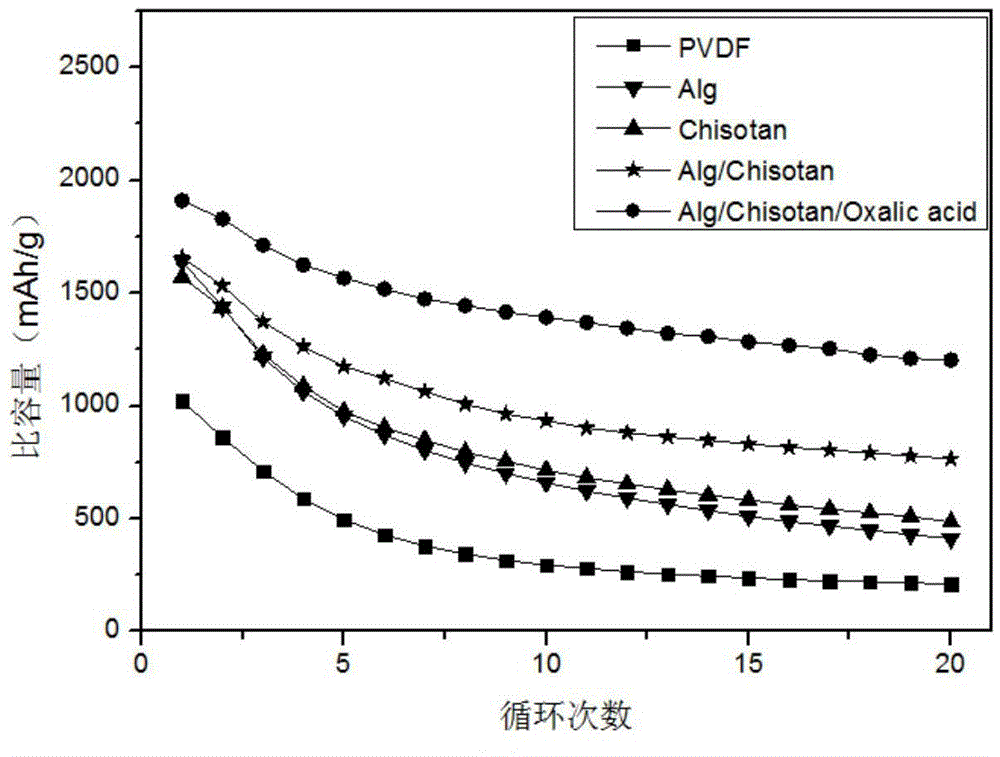

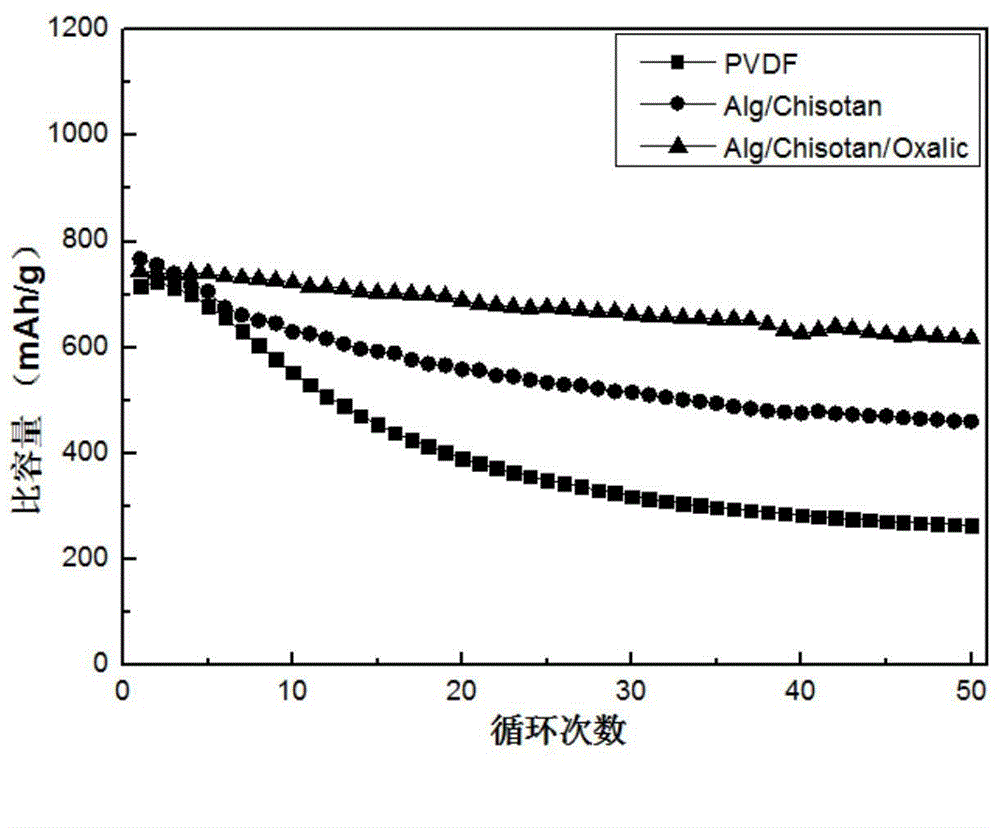

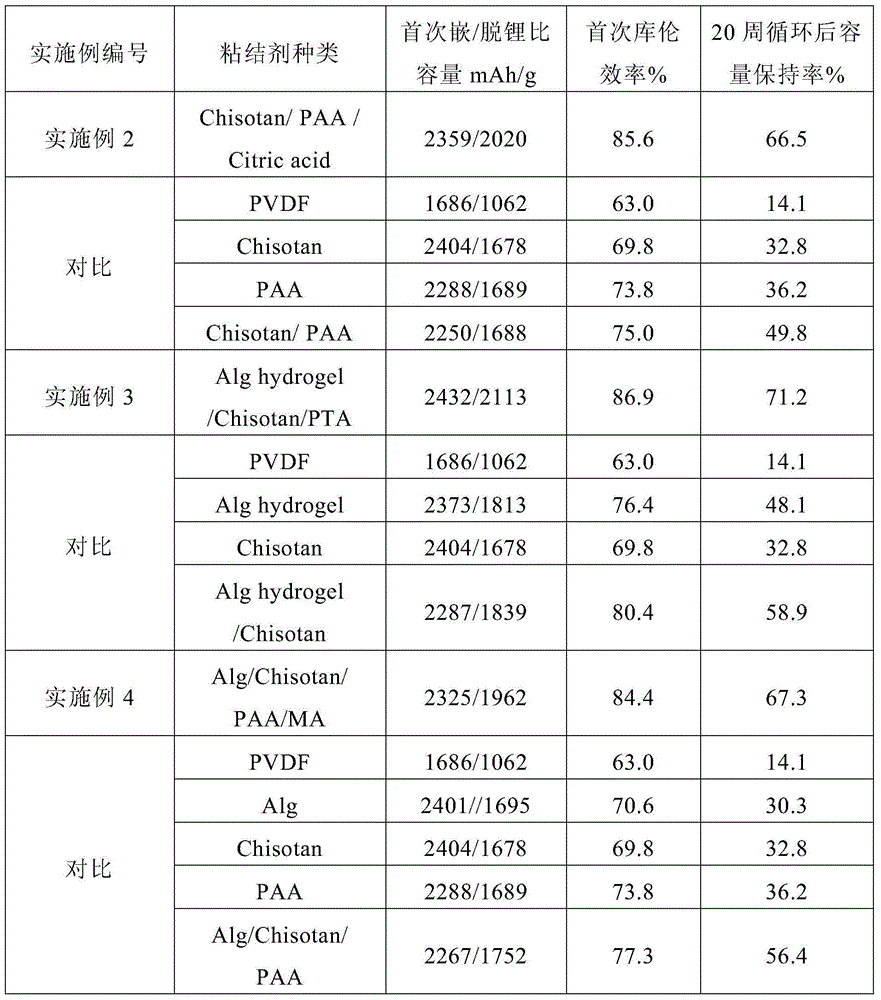

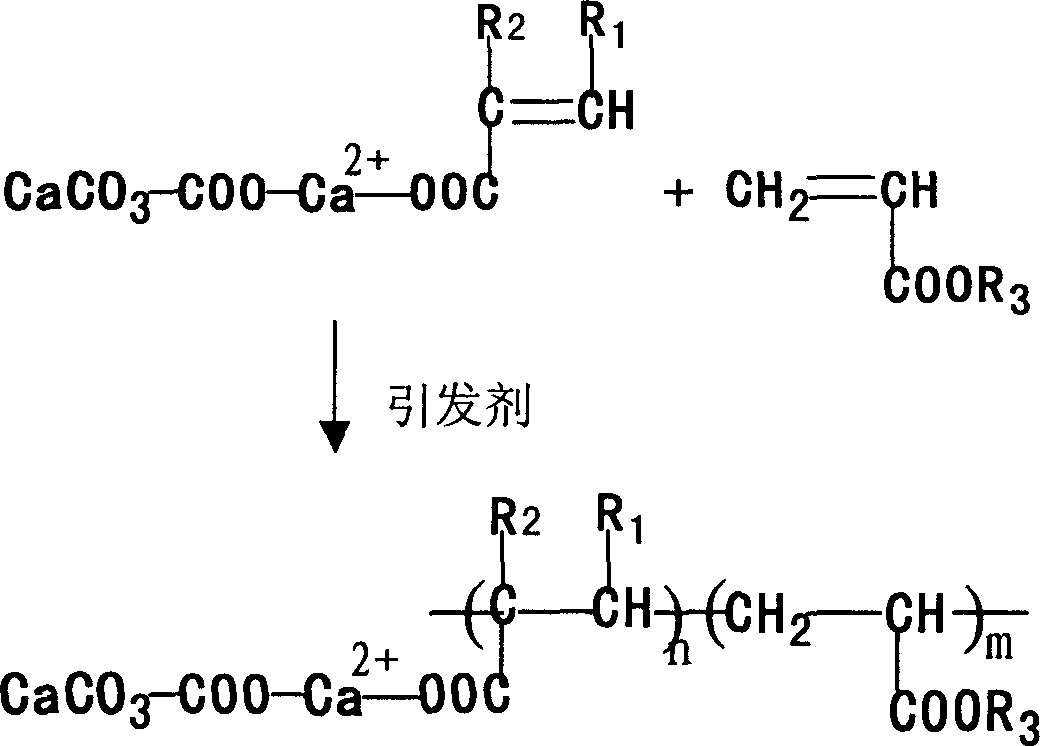

In-situ cross-linked polymer binding agent for lithium ion battery and electrode prepared from same

ActiveCN106159271AAvoid reunionImprove dispersion uniformitySecondary cellsNon-aqueous electrolyte accumulator electrodesCyclic processCross-link

The invention discloses an in-situ cross-linked polymer binding agent for a lithium ion battery and an electrode prepared from the in-situ cross-linked polymer binding agent. The polymer binding agent is of a three-dimensional network structure and is formed through in-situ polymerization of chitosan, at least one of polymers containing a carboxyl group or a carboxylate group, and at least one of micromolecule polybasic carboxylic acid and micromolecule polybasic carboxylate. An amidogen group on a chitosan molecular chain and a carboxyl group of the other polymer form a three-dimensional network structure in situ through electrostatic interaction at the room temperature, and dispersion uniformity of active materials in the electrode is improved. When the polymer binding agent is in use, a pole piece is subjected to further heat treatment, the cross-linking effect of the polymer chains is enhanced, and the stability of the electrode structure in the cycle process is improved. The electrochemical performance of the electrode of the lithium ion battery can be improved when the in-situ cross-linked polymer binding agent is used for preparing the electrode in situ, and particularly a more obvious improving effect is achieved on high specific capacity positive pole lithium-rich materials, a negative pole silicon substrate, tin-based materials and Li-S-based materials.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Light diffusion agent mother material used for light diffusion film, preparation method and application thereof

ActiveCN101812220AHigh light transmittanceHigh hazeFlat articlesNon-linear opticsLiquid-crystal displayMicrosphere

The invention provides a light diffusion agent mother material used for a light diffusion film, a preparation method and application thereof. A light diffusion agent is compounded from organic polymer cross linking microspheres with different refractive indexes and grain diameters, the light diffusion agent mother material is prepared from 100 weight parts of polyester resin, 60 to 100 weight parts of compounded light diffusion agents and 1 to 7 weight parts of diffusion resin through high-speed diffusion and fused extrusion grain cutting by a double-screw extruding machine. The invention also provides a high-transparency heat-resistance light diffusion film prepared by using the light diffusion agent mother materials as additives. The light diffusion layer of the light diffusion film is formed by mixing the light diffusion agent mother materials and polyester slices according to the mixture ratio of 40 to 60 weight percent of polyester slices and 40 to 60 weight percent of the light diffusion agent mother materials. The light diffusion film prepared by the invention has high light transmission rate, high mist degree, excellent heat resistance performance and excellent dimension stability, and is particularly suitable for being used as the light diffusion film in a back light module of a large-dimension liquid crystal display.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

Nano-wollastonite modified adhesive for packaging

InactiveCN102965036AHigh bonding strengthImprove water resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyvinyl chlorideEthyl acetate

The invention discloses a nano-wollastonite modified adhesive for packaging. The adhesive is prepared from the following raw materials in parts by weight: The adhesive is prepared from the following raw materials in parts by weight: 100-120 parts of styrene, 100-150 parts of ethyl acetate, 20-25 parts of duprene rubber CR121, 15-20 parts of xylene, 1-2 parts of 4,4'-diphenyl methane diisocyanate, 8-12 parts of polyisobutylene, 2-3 parts of (3-aminopropyl)trimethoxysilane, 2-3 parts of polytetramethylene ether glycol, 3-5 parts of SG-2 PVC (polyvinyl chloride) resin, 1-2 parts of ferrocene, 10-15 parts of 704 silicon rubber, 8-12 parts of butyl rubber CBK139, 3-5 parts of epoxidized soybean oil, and the like. The adhesive is excellent in heat resistance heat resistance and cold resistance, high in cohesive strength, water-resistant, moisture-proof, good in storage stability, good in environment friendliness, good in using effect and convenient.

Owner:TONGLING XIANGYUN FIRE FIGHTING TECH

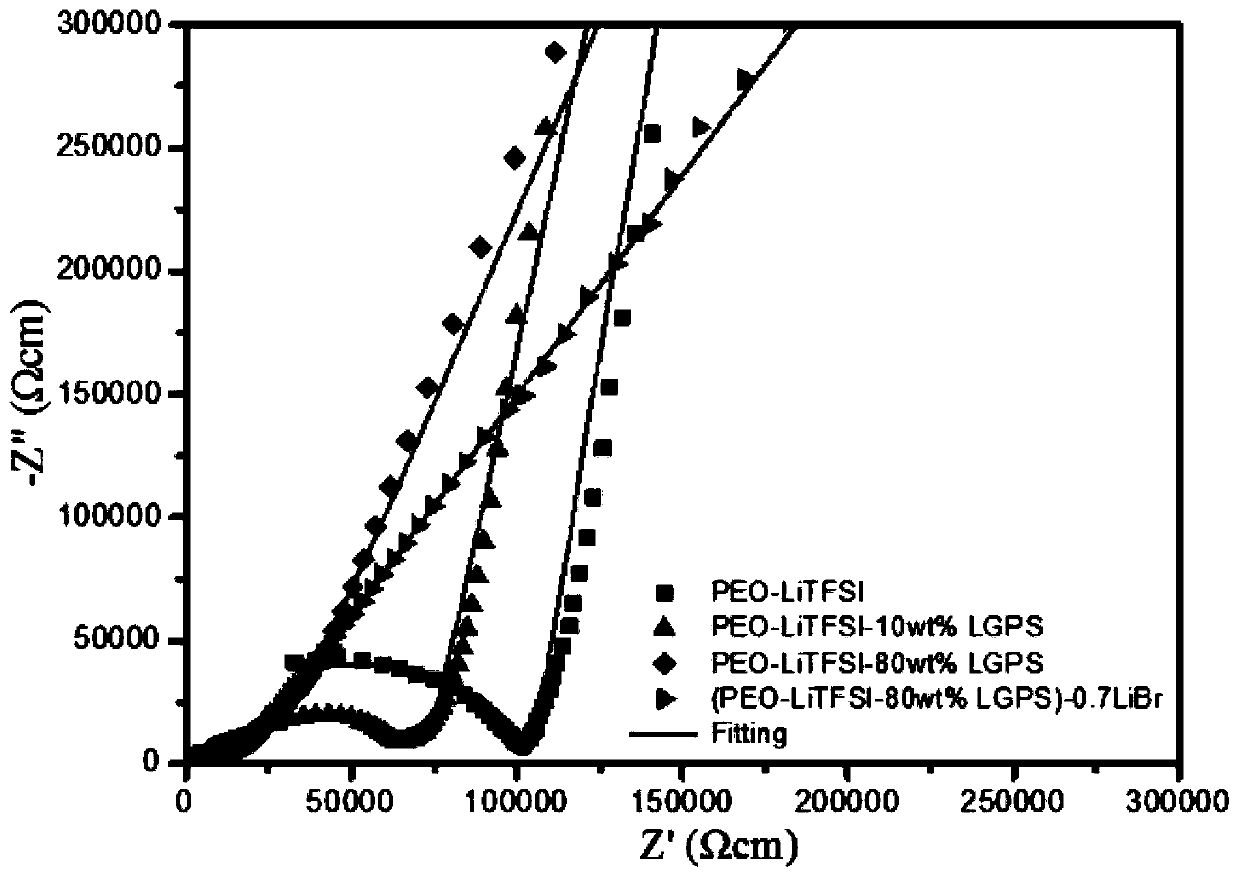

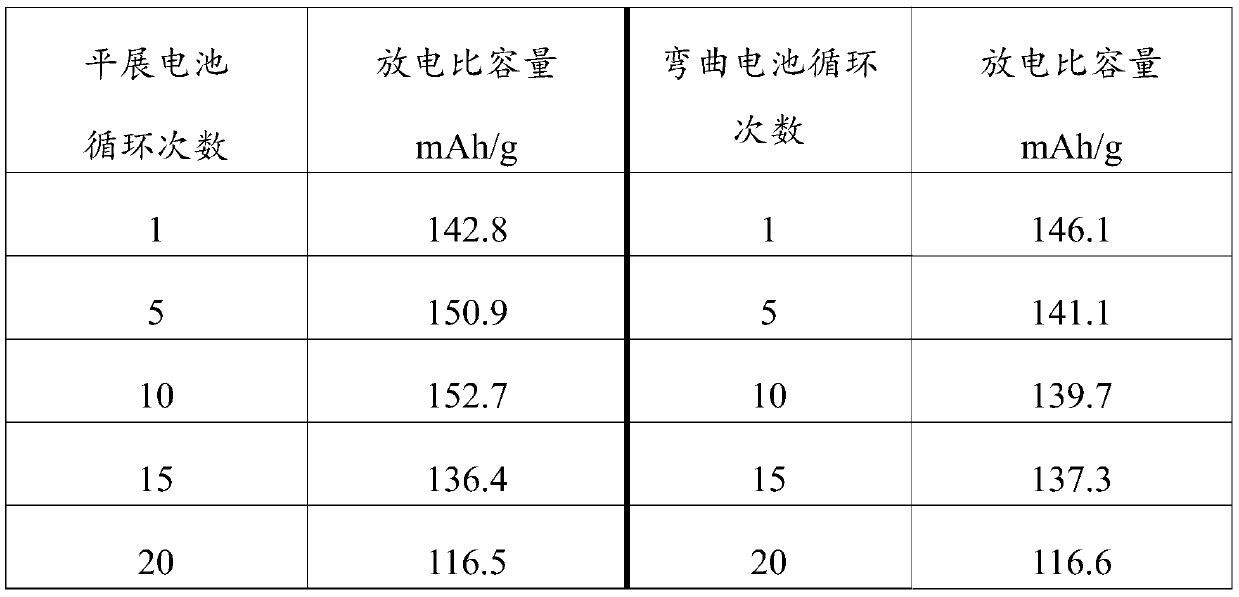

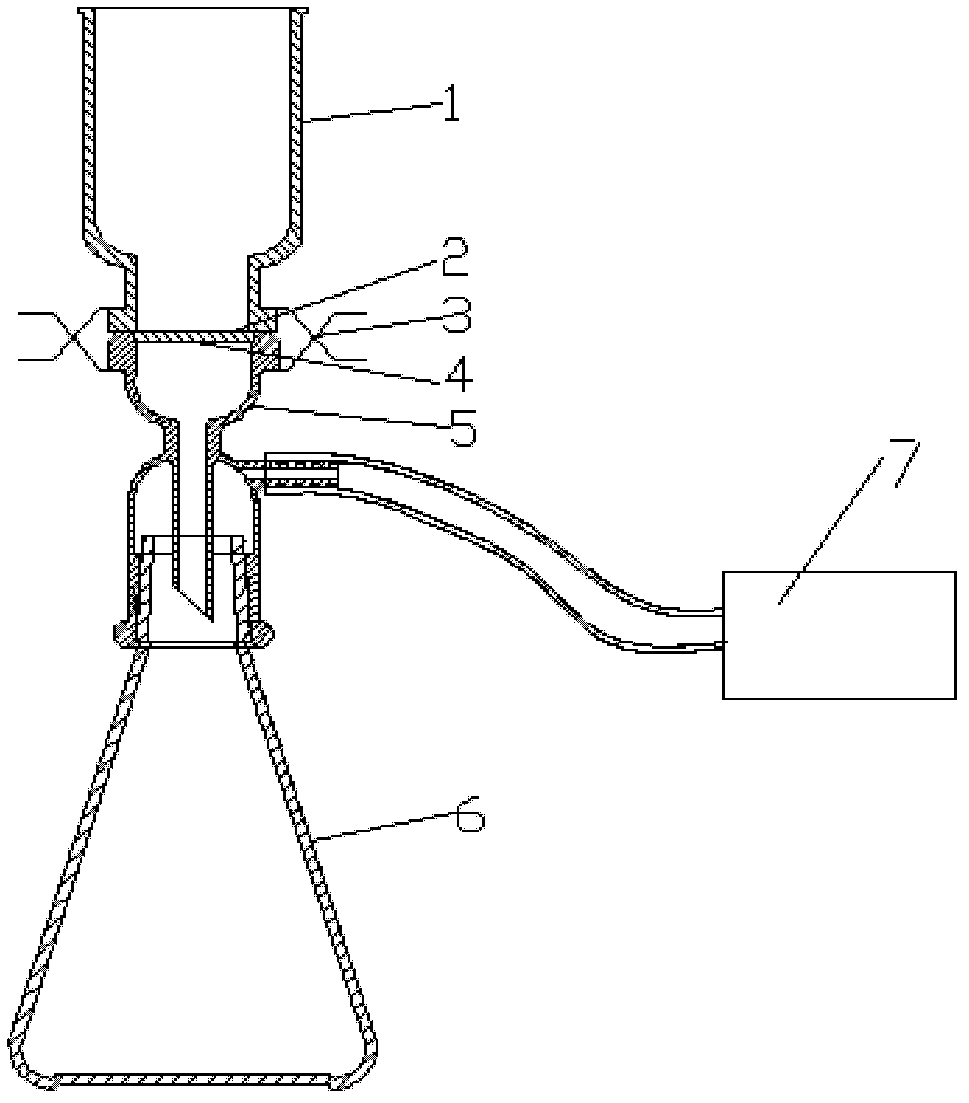

Flexible composite solid-state electrolyte, full-solid-state lithium-ion battery and preparation method thereof

ActiveCN110085904AGood flexibilityImprove dispersion uniformityFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteComposite electrolyte

The invention provides a flexible composite solid-state electrolyte, a full-solid-state lithium-ion battery and a preparation method thereof. The solid-phase mixing of a sulfide solid-state electrolyte or a modifier thereof, a thermoplastic polymer or a modifier thereof and lithium salt enables the composite solid-state electrolyte to have good flexibility while improving the dispersion uniformityand effective contact of each component. A halide, phosphate and / or an oxide are added to the sulfide material especially before the composition of the sulfide solid-state electrolyte and the polymersolid-state electrolyte, thereby providing a multi-dimensional channel for lithium ion transmission, increasing the disordered degree of lithium ion distribution, and being capable of further improving the lithium ion conductivity and electrochemical stability of the composite solid-state electrolyte. The flexible composite electrolyte has the advantages of high lithium conductivity at the room temperature, good electrochemical stability, easy preparation and processing, ability of being bent and cut and the like. The formed flexile full-solid-state battery has good mechanical performance andbending performance, and improves the cycle life and energy density.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Method for preparing carbon nanometer paper enhanced conductive polymer matrix composite material

The invention provides a method for preparing a carbon nanometer paper enhanced conductive polymer matrix composite material, which is intended to solves a problem that integral mechanical properties and electroconductivity of a current carbon nanotube composite material cannot completely reaches engineering application requirements. Multi-walled carbon nanotubes or single-walled carbon nanotubes and graphene oxide are dispersed in a plasma aqueous solution under action of supersonic waves by an anionic surfactant, after high speed centrifugation, a supernatant liquid of the carbon nanotubes and graphene oxide solution is obtained, and flexible carbon nanometer paper with thickness of 10-100mum can be prepared as an enhanced material by a vacuum filtration method. The carbon nanometer paper enhanced conductive polymer matrix composite materials can be prepared by an RTM forming or vacuum bag method, and conductivity can be raised by raising the content of the carbon nanotubes and dispersion uniformity of carbon nanotube grids in the composite material, wherein the conductivity of the nanocomposite can be raised in several orders of magnitude, and can reach 1-200S / m, thereby making the polymer matrix composite materials go into a semiconductor conductive material field from an insulator.

Owner:SHENYANG AEROSPACE UNIVERSITY

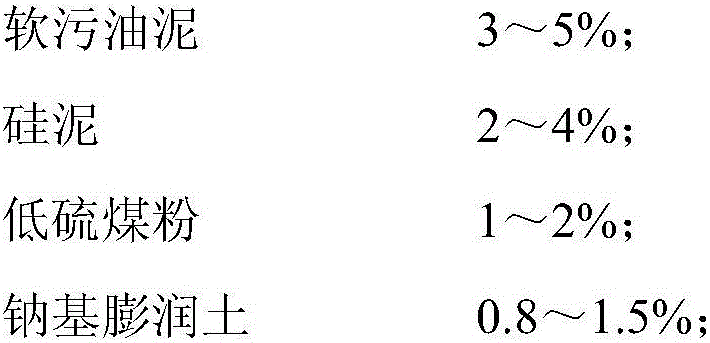

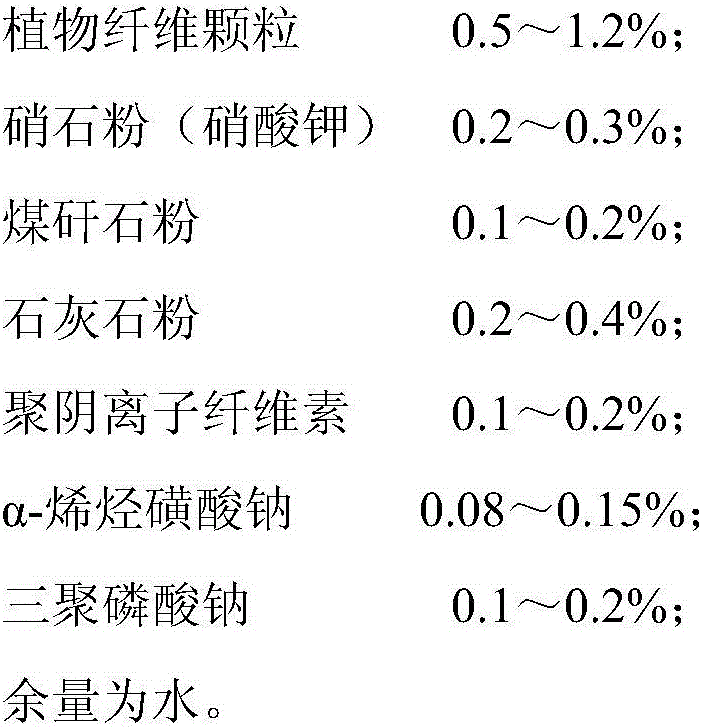

Sulfur-fixing combustion-supporting high-temperature profile control agent, and preparation method and application thereof

ActiveCN106833588AImprove temperature resistanceImprove seal strengthDrilling compositionFiberCellulose

The invention provides a sulfur-fixing combustion-supporting high-temperature profile control agent, and a preparation method and application thereof. By taking the total weight of the sulfur-fixing combustion-supporting high-temperature profile control agent as 100%, the profile control agent is prepared from the following raw materials in percentage by weight: 3-5% of soft oil sludge, 2-4% of silicon sludge, 1-2% of low sulfur coal powder, 0.8-1.5% of sodium bentonite, 0.5-1.2% of plant fiber particle, 0.2-0.3% of saltpetre powder, 0.1-0.2% of coal gangue powder, 0.2-0.4% of limestone powder, 0.1-0.2% of polyanionic cellulose, 0.08-0.15% of alpha-sodium olefinsulfonate, 0.1-0.2% of sodium tripolyphosphate and the balance of water. The profile control agent has favorable stratum compatibility, causes no damage to the oil reservoir, does not pollute the stratum, and has favorable temperature tolerance; and meanwhile, the profile control agent has sulfur-fixing and combustion-supporting functions, thereby being completely applicable to a profile control technology for a thick oil fireflood chemical profile control gas injection well.

Owner:PETROCHINA CO LTD

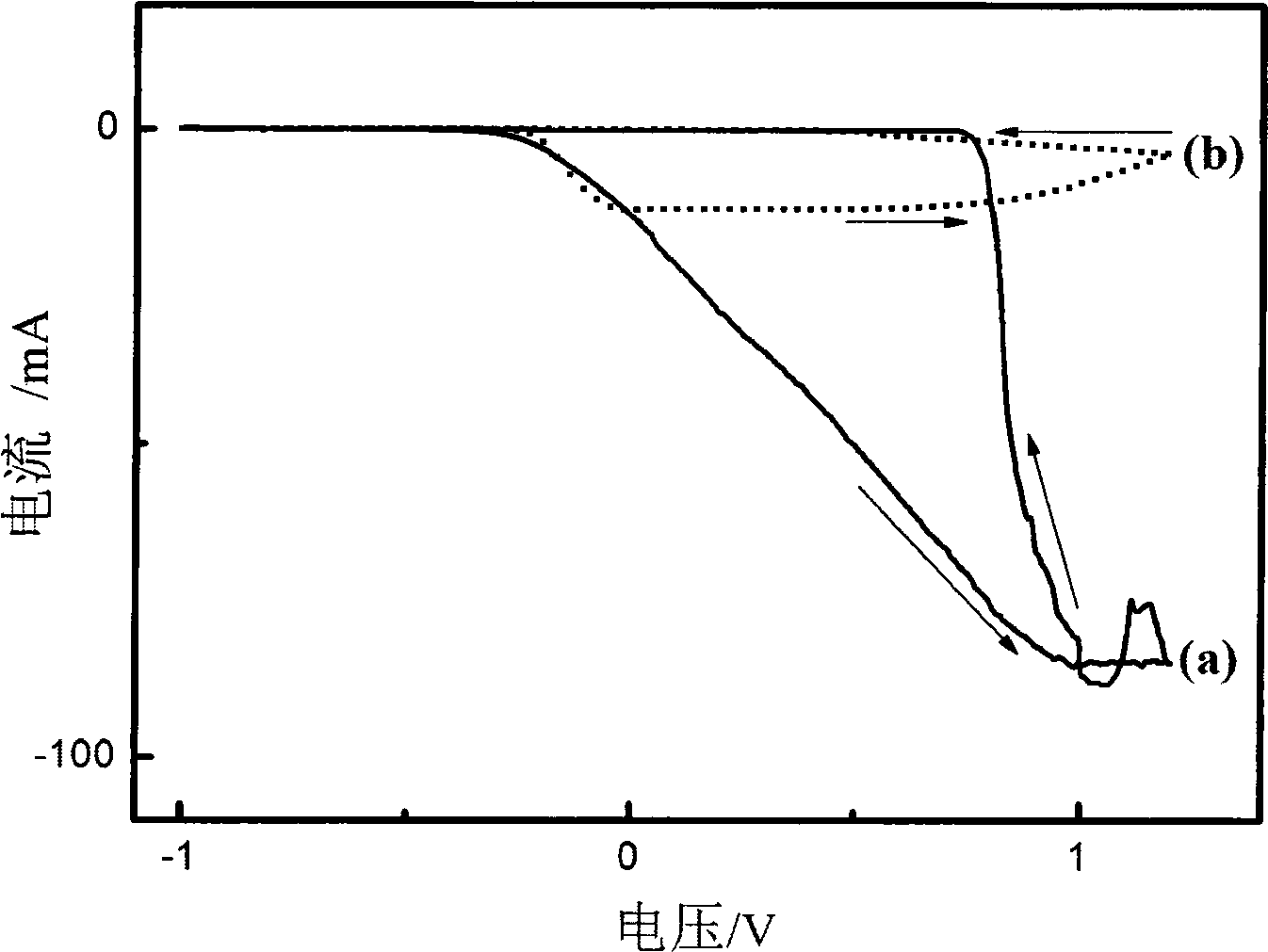

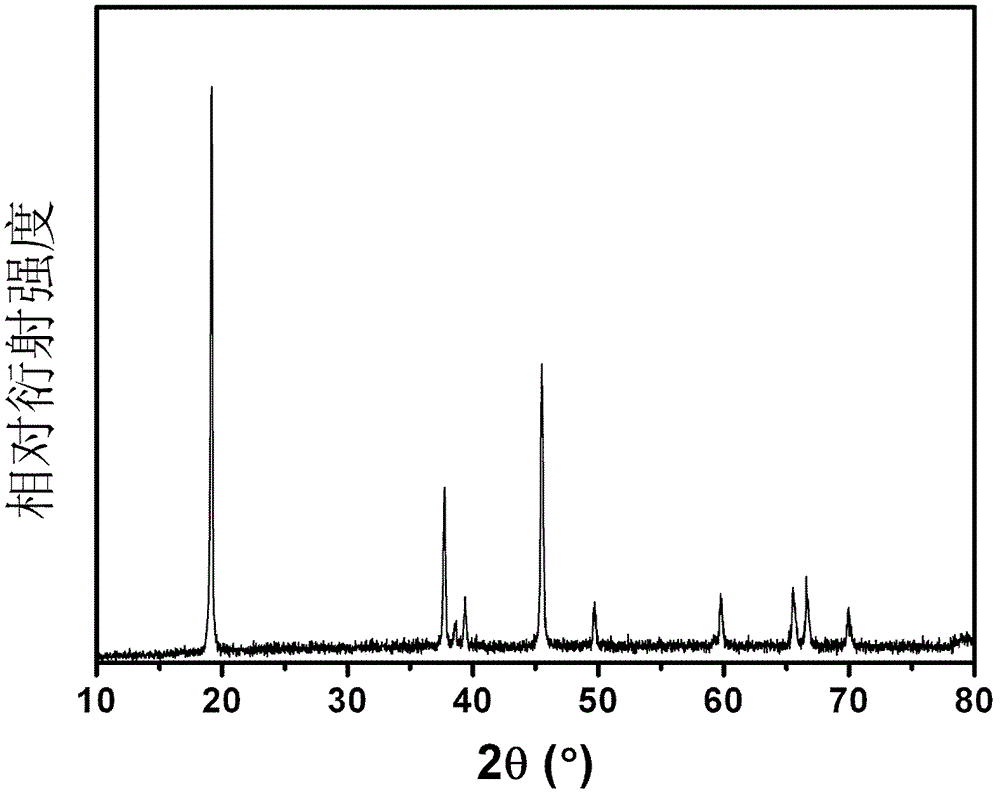

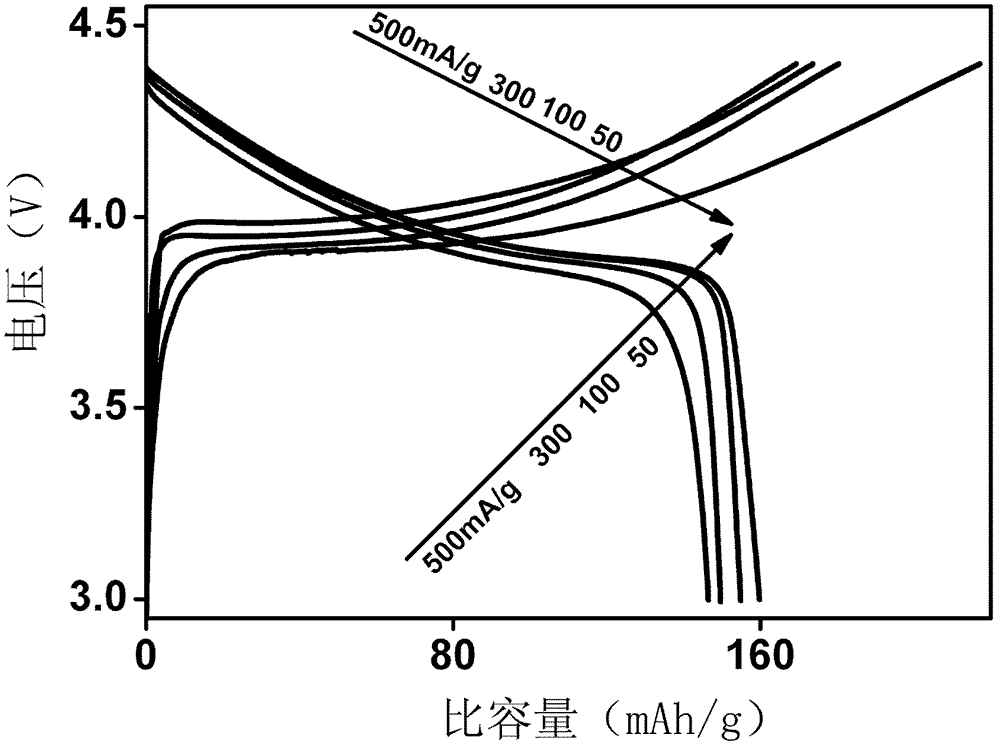

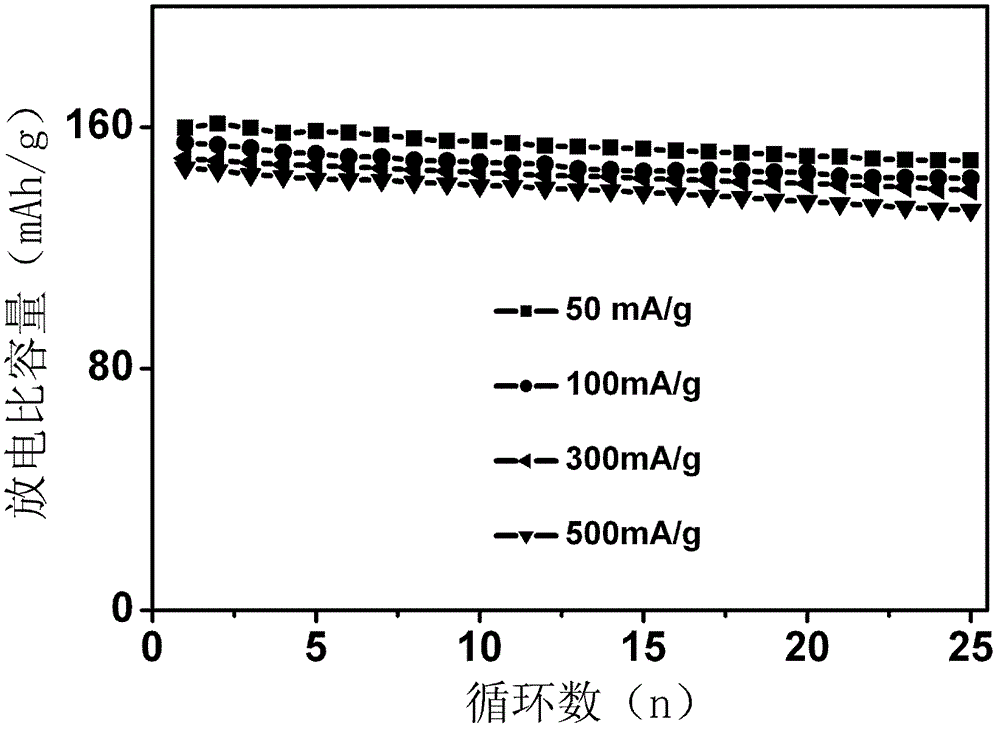

Li2MnO3 and LiCoO2 composite anode material

InactiveCN102751481AInhibition of phase transitionImprove electrochemical performanceCell electrodesHigh rateComposite oxide

The present invention discloses a Li2MnO3 and LiCoO2 composite anode material, which is a Li2MnO3 and LiCoO2 composite oxide meeting a stoichiometric ratio of xLi2MnO3.yLiCoO2, wherein x is more than or equal to 0.025 and is less than or equal to 0.15, and x plus y equals 1. The Li2MnO3 and LiCoO2 composite anode material of the present invention has characteristics of high specific capacity and high cycle life, and further has excellent performances under conditions of high rate, high temperature, low temperature, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

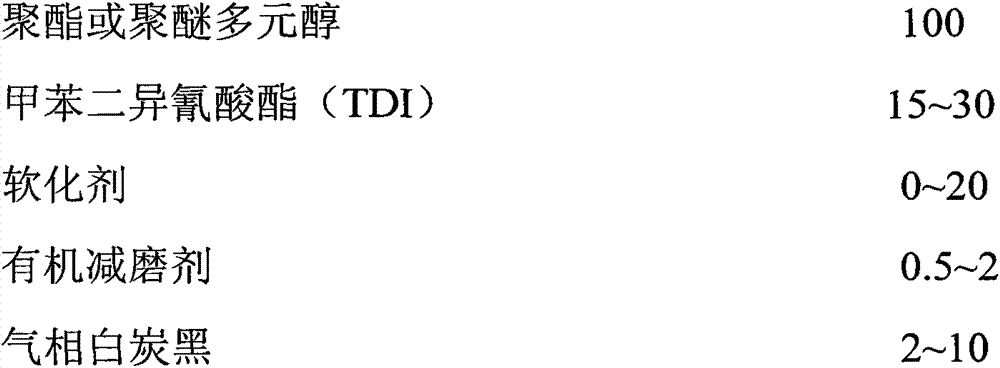

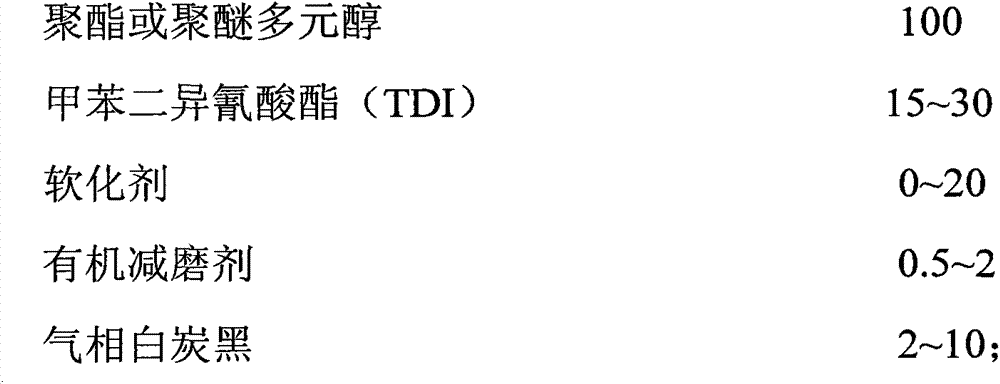

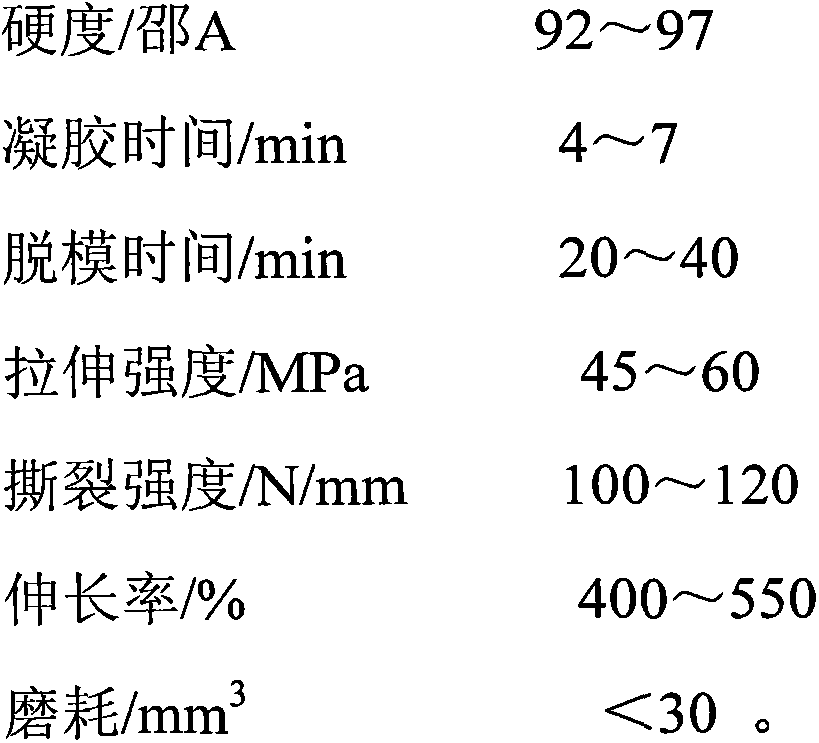

High abrasion-resistance polyurethane elastomer and preparation method thereof

ActiveCN103923457AImprove dispersion uniformityImprove wear resistancePolyurethane elastomerPolyester

The invention discloses a high abrasion-resistance polyurethane elastomer and a preparation method thereof. The high abrasion-resistance polyurethane elastomer comprises two parts, namely a prepolymer component (component A ) and a chain extender component (component B ), wherein the component A comprises the following substances in parts by weight: 100 parts of polyester or polyether glycol, 15-30 parts of TDI (Toluene Diisocynate), 0-20 parts of softening agents, 0.5-2 parts of organic anti-abrasive agents and 2-10 parts of gas-phase white carbon black; the component B is a mixed diamine chain extender and comprises methyl-bis(3-chlorine-2,6-diethyl-phenylamine) (MCDEA) and other diamine chain extender mixtures. The material disclosed by the invention has excellent abrasion-resistant property and mechanical property and can be used for preparing products in the field of preparation equipment, such as a polyurethane screen plate, a screen, a conveyer belt and the like.

Owner:珠海迈科思科技有限公司

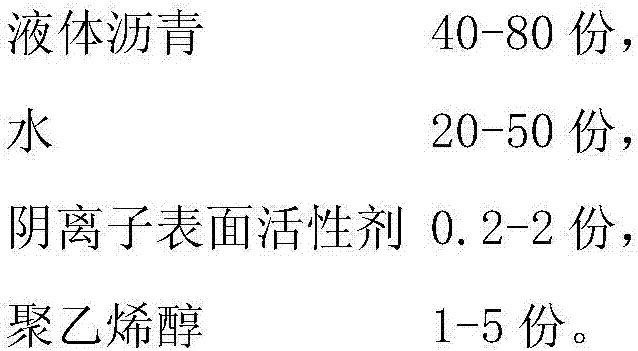

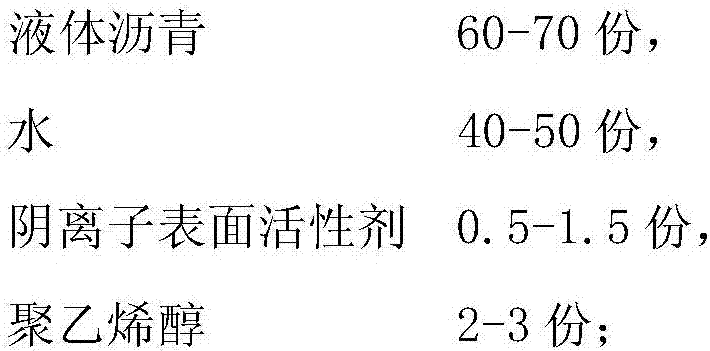

Modified asphalt waterproof coating, preparation method for modified asphalt waterproof coating and use method thereof

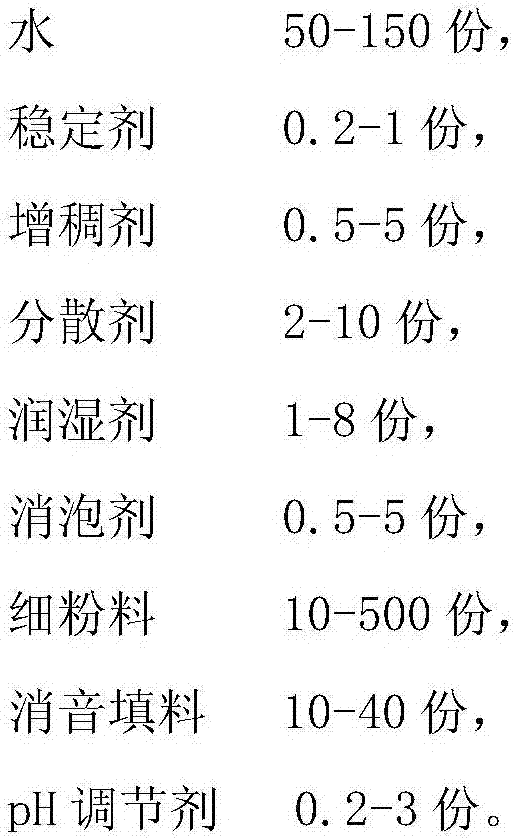

ActiveCN106957601AAvoid reunionTechnical effect of avoiding subsidenceBituminous coatingsBituminous waterproofingSlurry

The invention discloses a modified asphalt waterproof coating, a preparation method for the modified asphalt waterproof coating and a use method thereof and relates to the field of building materials. The problems of sound insulation and noise reduction of the waterproof coating film can be solved. The preparation method for the modified asphalt waterproof coating disclosed by the invention comprises the following steps: preparing the modified asphalt waterproof coating from a component A and a component B; mixing and uniformly stirring anion emulsified asphalt, polymer emulsion and slurry, thereby acquiring the component A; and uniformly mixing water with curing agent, thereby acquiring the component B, wherein the slurry is prepared according to the following steps: adding water, stabilizer, dispersing agent, wetting agent, de-foaming agent, fine powder and pH regulator into a dispersing device, dispersing for the first time, adding a silencing filling material soaked with a silane coupling agent solution after ending the dispersing for the first time, and then adding a thickening agent, dispersing for the second time and then ending the dispersing for the second time, thereby acquiring the slurry. The modified asphalt waterproof coating disclosed by the invention has excellent effects of sound insulation and noise reduction on the basis of excellent waterproof property.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

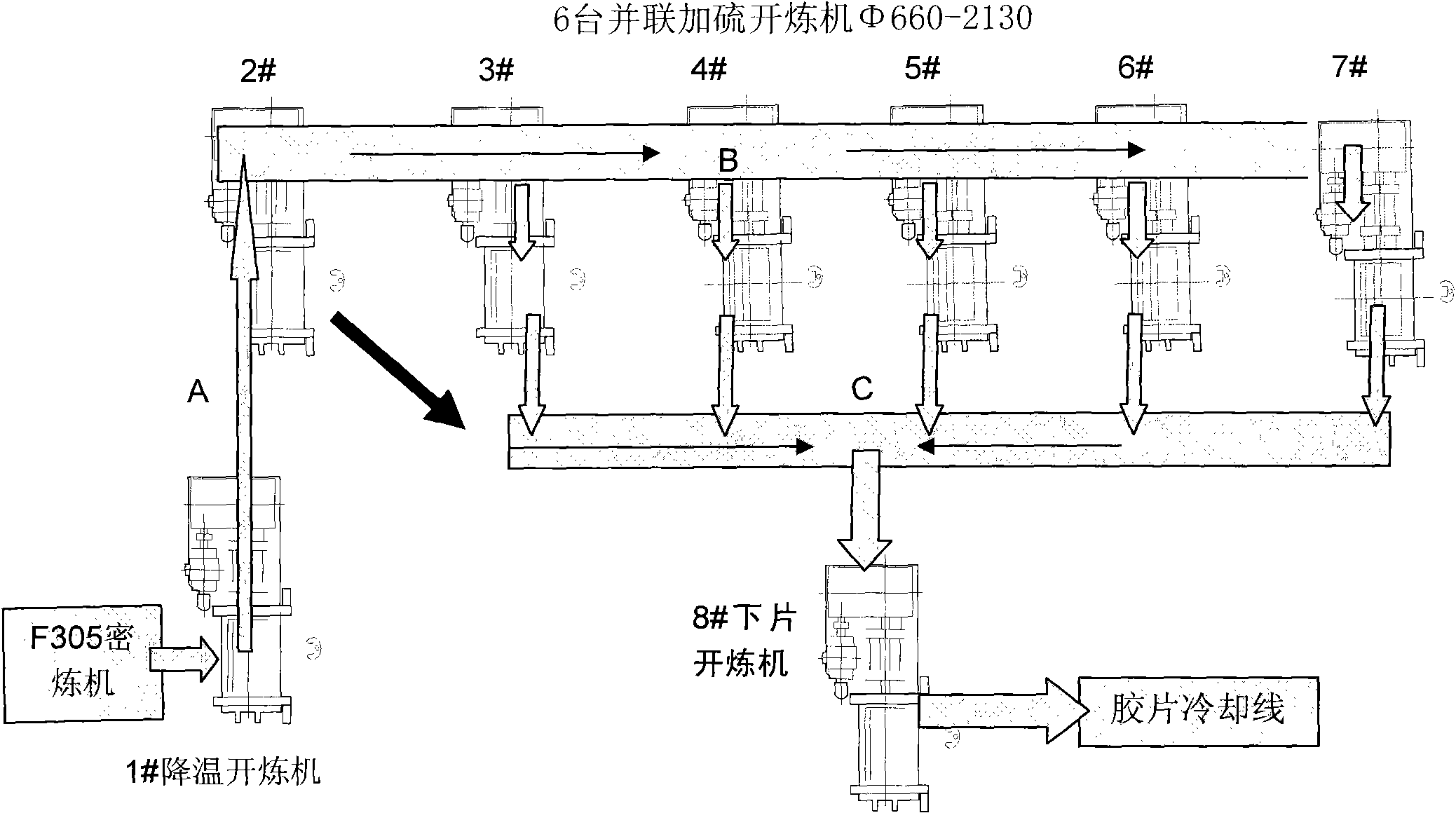

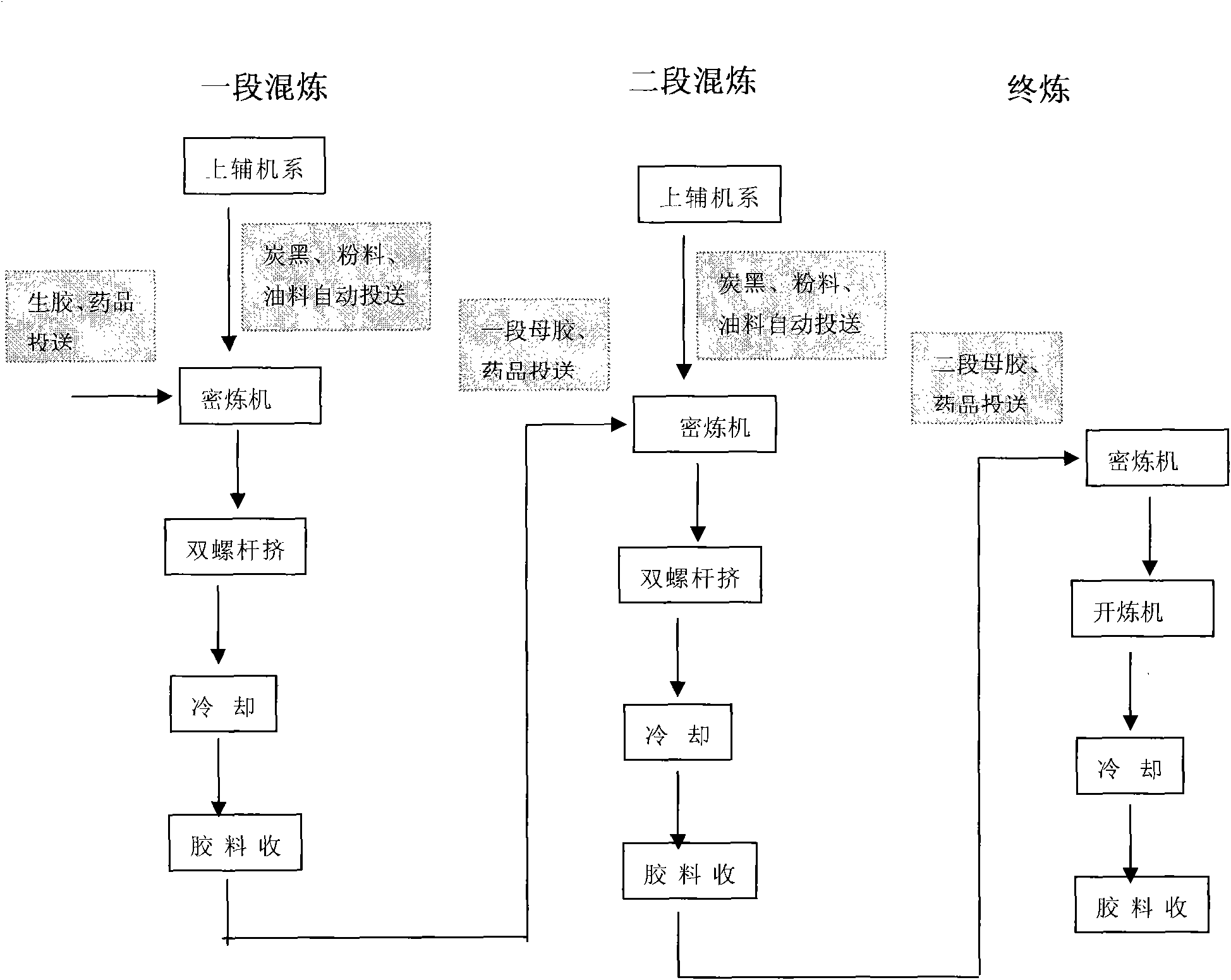

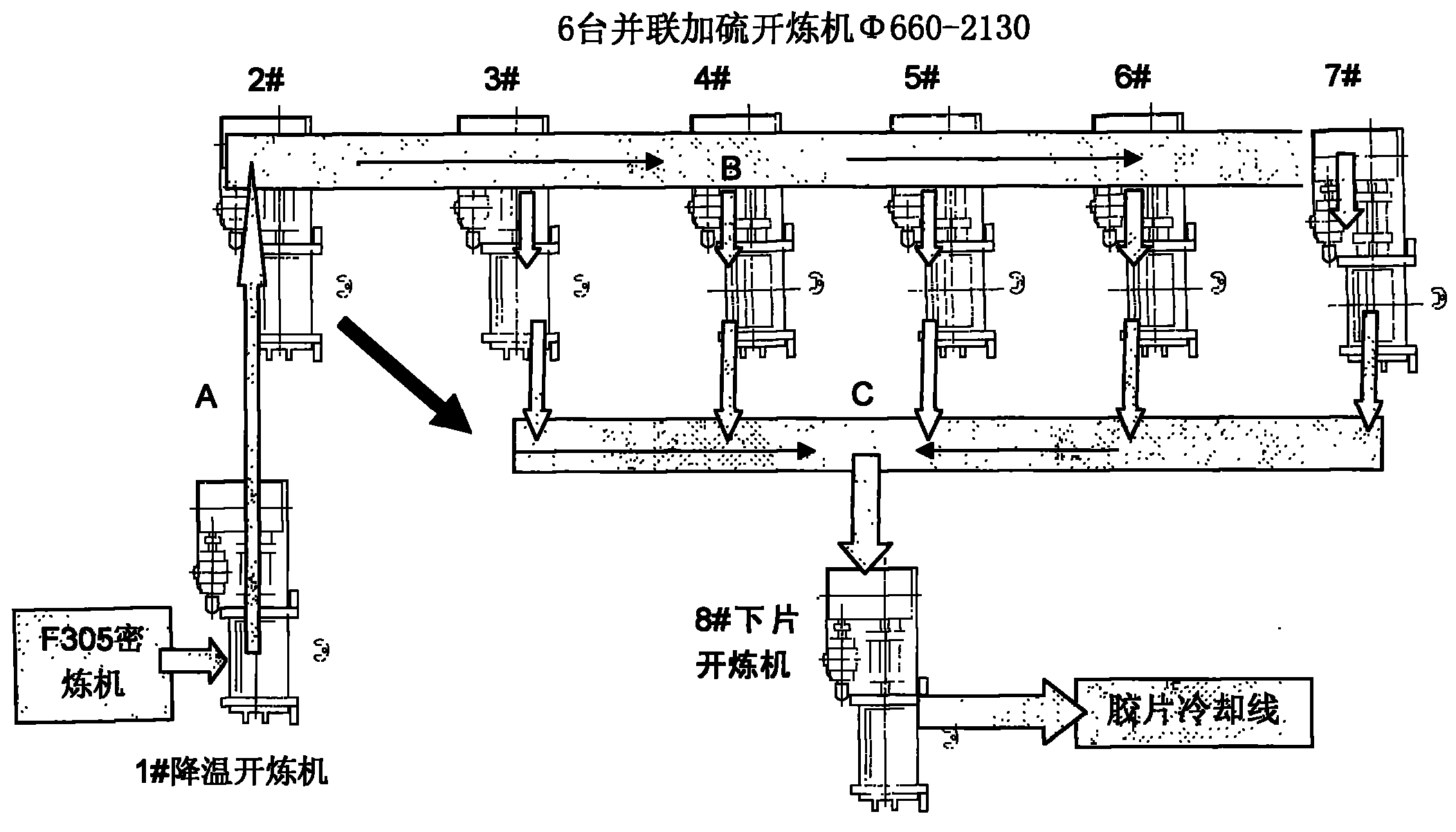

Production method for mixing rubber material at low temperature

A production method for mixing rubber material at a low temperature adopts a novel rubber mixing method improved on the basis of a low-temperature mixing principle so as to realize the high-quality and high-efficiency novel technology of mixed rubber production. An internal mixer is utilized and low-temperature mixing and low-temperature material discharge are taken as the objective function, a plurality of full automatic open mills are configured at the lower part of the internal mixer, supplementation mixing is carried out under low-temperature conditions so as to achieve automatic curing temperature, and the low-temperature mixing is ensured during the integral rubber material manufacturing process, and the purpose of high-quality and high-efficiency mixed rubber production can be achieved. The rubber material is put in the internal mixer so as to be mixed, the rubber material is discharged to an open mill number 1 after reaching the temperature reuquired by the technology and then rubber smashing and temperature reduction are carried out, then rubber material is conveyed to one of the open mills in an open mill set through a conveying device and the supplementation mixing is carried out, and the rubber material that is processed through the supplementation mixing is conveyed to an open mill number 8 and the piece unloading process can be carried out.

Owner:SAILUN GRP CO LTD

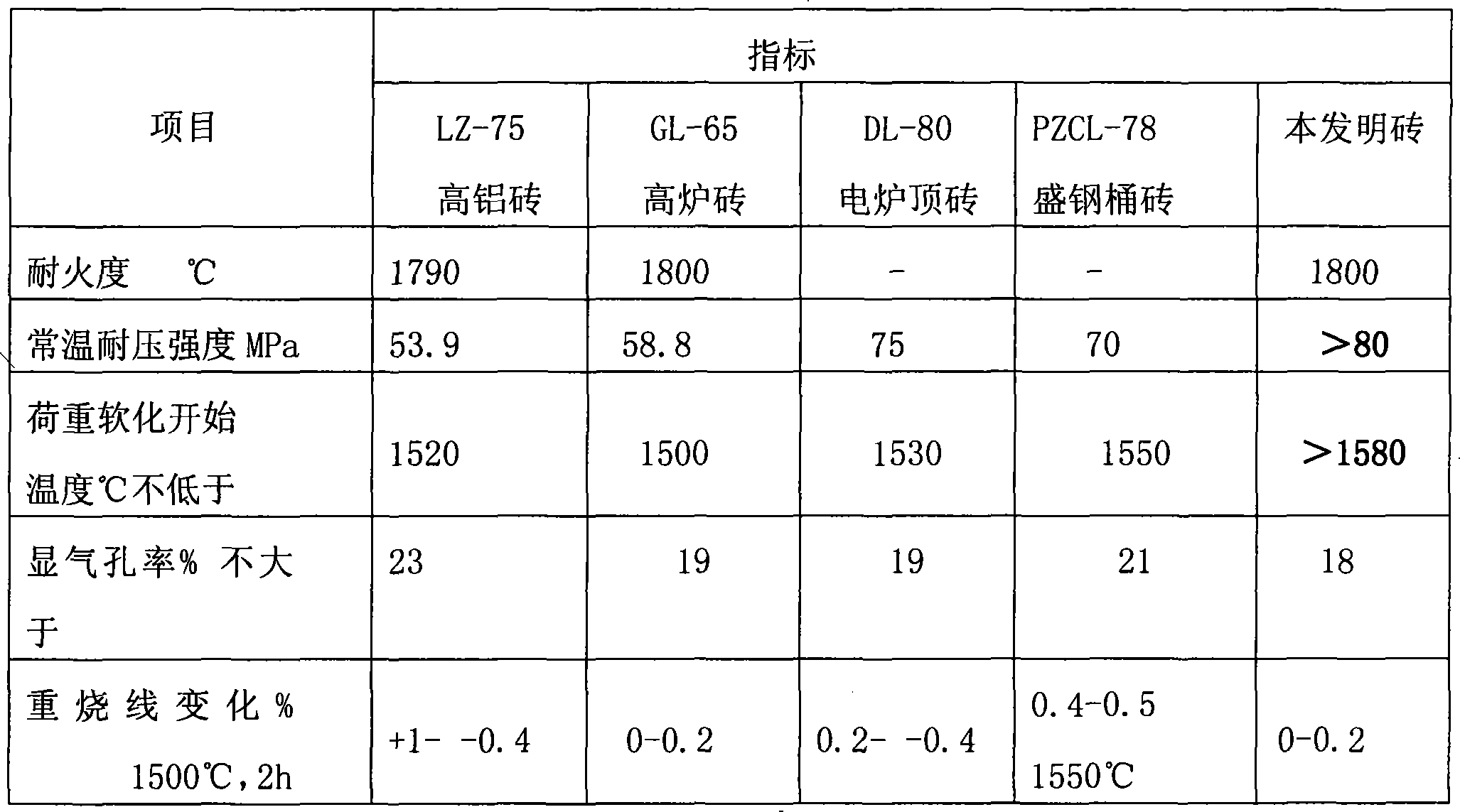

Low-temperature burning high-aluminum refractory brick and preparation method thereof

The present invention provides a low-temperature braking high-aluminum refractory brick and the preparing method thereof, and the invention is characterized in that the refractory brick is prepared by the following main raw material and bonding agent; wherein: the main material comprises the raw material with the following weight proportion: wherein the bauxite chamotte with granularity 3-0.088mm for 50-70%, bauxite chamotte with granularity less than 0.088 for 7-20%, emery with granularity less than 0.088 for 5-20%, dry powder shaped pyrophyllite for 2-10%, and dry powder shaped refractory clay for 5-20%; and the adding amount of the bonding agent is 10-20% of the weight of the raw material. The high-alumina brick is obtained using the low ore grade bauxite chamotte with low temperature 1250-1350 DEG C, and the high-quality refractory brick has the advantages of: ordinary-temperature compressive strength above 80MPa, and the load softening staring temperature above 1580 DEG C.

Owner:巩义市金岭耐火材料有限公司

High potential super capacitor electrode material and preparing method thereof

InactiveCN101373667AImprove dispersion uniformityReduce energy consumptionHybrid capacitor electrodesElectrolytic capacitorsHigh potentialAmount of substance

The invention relates to a high potential supercapacitor electrode material and a preparation method thereof, and belongs to the material and energy resource filed. The supercapacitor electrode material contains elements of C, Fe and P, the mass content of C is less than 10 percent, and other elements can be added as required. The working potential relative to LiLi can reach 4.3V and has good circulation stability. A matter containing C is added to a precursor, and the forming process of the material is utilized to synthesize and prepare the supercapacitor electrode material. The supercapacitor electrode material contains the elements of C, Fe and P, and can improve the compaction density of the C material and the working potential of the supercapacitor, thereby improving the capacity, the energy response and the power characteristics of the supercapacitor. Compared with the prior art, the method is convenient to operate, and the preparation process is simple and practical. The performance of the supercapacitor can be improved through the improvement of the compaction density and the working potential of the electrode material.

Owner:SICHUAN UNIV

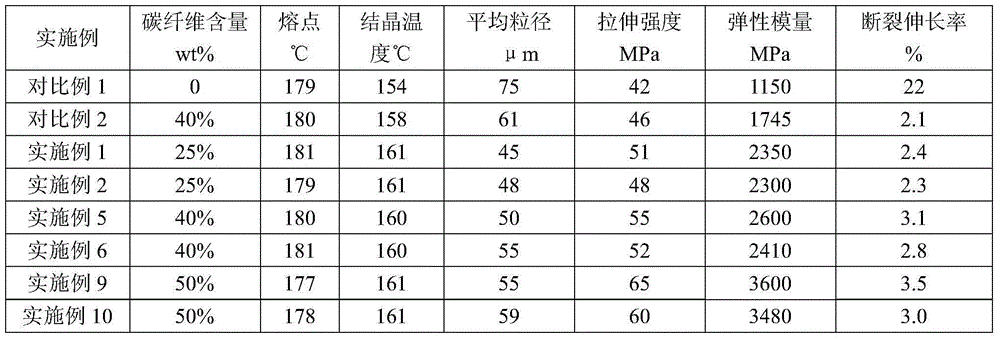

Preparation method of carbon fiber reinforced nylon composite micro-powder for selective laser sintering

The present invention discloses a preparation method of carbon fiber reinforced nylon composite micro-powder for selective laser sintering. The method comprises: carrying out surface pre-treatment on carbon fiber powder, adding the pre-treated carbon fiber powder and nylon particles into a polymer good solvent containing a dispersing agent, carrying out heating stirring to completely dissolve the polymer, adding a poor solvent of nylon to make the nylon gradually crystallize by adopting the carbon fibers as the crystal nucleus and be coated on the carbon fiber surface, carrying out suction filtration, drying, screening, and adding other auxiliary agents to obtain the carbon fiber reinforced nylon composite micro-powder for selective laser sintering. Compared to the method in the prior art, the method of the present invention has characteristics of no requirement of high-temperature and high-pressure equipment, simple process, economy, effectiveness, environmental protection, and easy performing; and the sintering performance of the prepared material is excellent, the carbon fiber content in the material is controllable, and the mechanical property of the obtained SLS molded member is substantially improved compared to the SLS molded member of the matrix resin material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

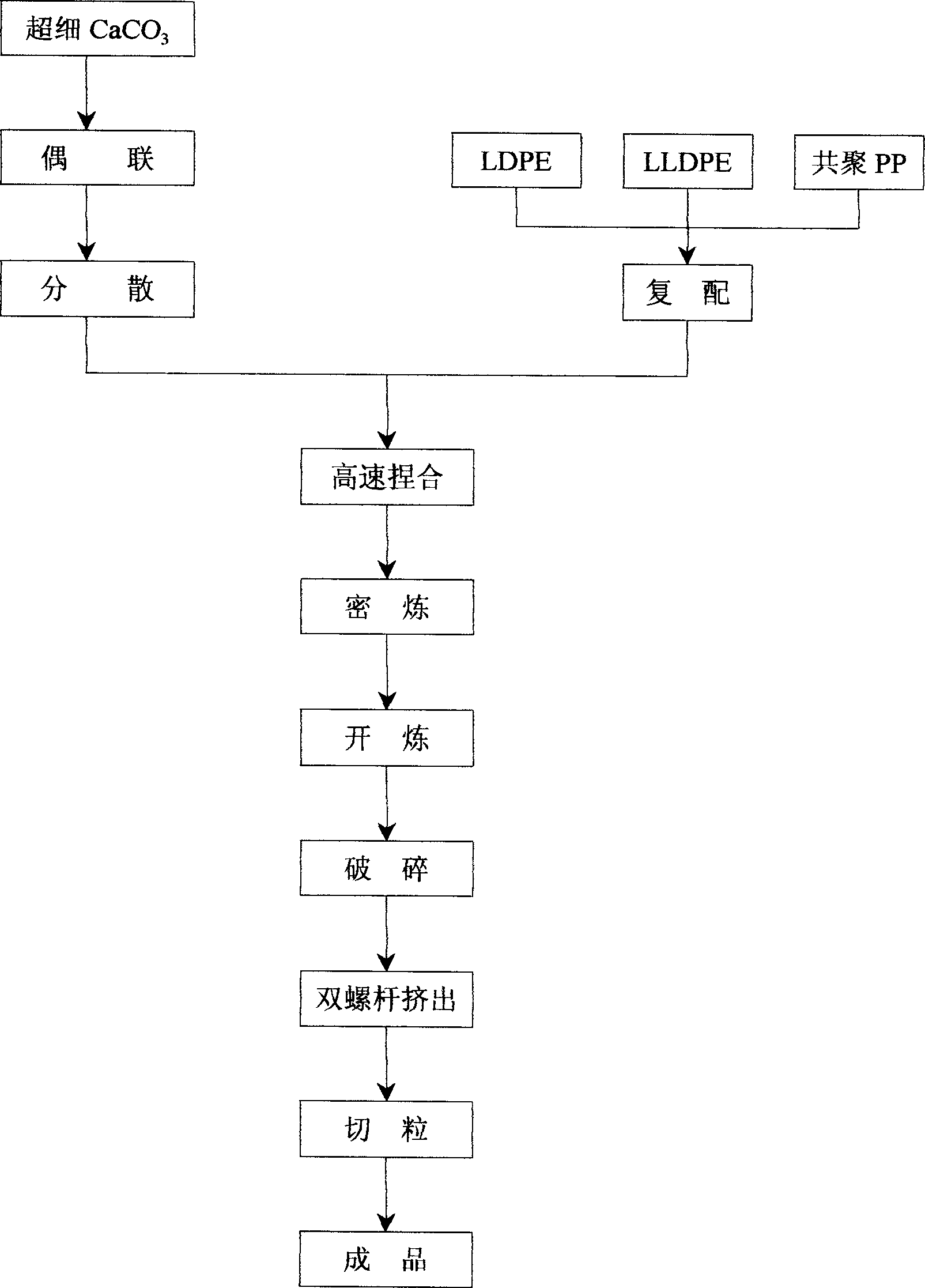

Prepn of polyolefine resin specially for permeating curtain coated film

InactiveCN1453305AImprove dispersion uniformityImprove mechanical propertiesPolyolefinFood packaging

The present invention is preparation of polyolefine resin specially for permeating curtain coated film. Polyolefine resin and superfine mineral filler as main material are added with Ti-Al composite coupling agent, POE modifier and OPE dispersant, and the mixture is further treated through coupling, dispersing, internally mixing, extruding and dicing to produce the special resin. The special resin is further treated through curtain coating and stretching to form fine and homogeneous pores between the mineral filler phase and the polyolefine phase in the film, and through cooling and crystallization permeating curtain coated polyolefine film is formed. The film has the features of being permeating, soft, high in stretching strength, easy degradation, etc, and may be used widely in medicine, food packing, daily used article and other fields.

Owner:南安长利塑胶有限公司 +1

Polishing solution for hard disk magnetic head and preparation method thereof

ActiveCN102174294AImprove suspension stabilityImprove dispersion uniformityOther chemical processesPolishing compositions with abrasivesHydrocarbon solventsMachined surface

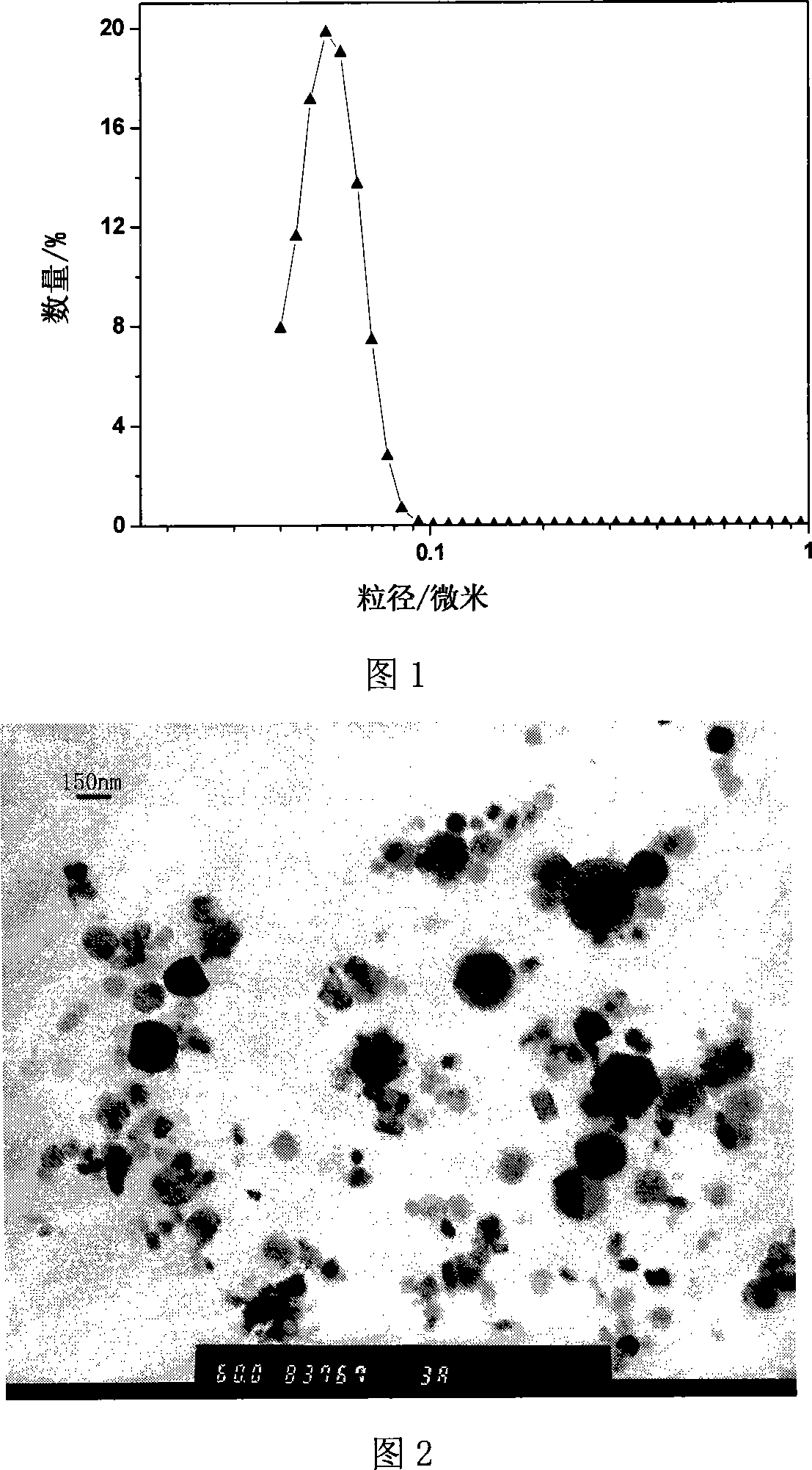

The invention discloses polishing solution for a hard disk magnetic head and a preparation method thereof. The polishing solution is mainly prepared from diamond abrasive particles, a dispersing agent, a corrosion inhibitor, a phase transfer solvent, an oil phase medium regulator and a hydrocarbon solvent, wherein the average particle size of the diamond abrasive particles is 30 to 150nm, the particle size distribution of the particles is 20 to 300nm, and the length-diameter ratio of the particles is 1.0 to 2.0. The preparation method comprises the following steps of: mixing diamond powder and a surface modifier, grinding, removing impurities, and grading to obtain suspension slurry; adding the phase transfer solvent into the suspension slurry, and stirring and dispersing the system; removing fine particles and coarse particles in the phase transfer solvent system by grading to ensure that the particle size distribution and concentration of the diamond abrasive particles meet the requirements; and transferring to the hydrocarbon solvent, adding the oil phase medium regulator, the dispersing agent and the corrosion inhibitor, and uniformly stirring to obtain the polishing solution for the hard disk magnetic head. The polishing solution prepared by the method has high suspension stability and dispersion uniformity, and high polishing efficiency during polishing, and a machined surface has high quality.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

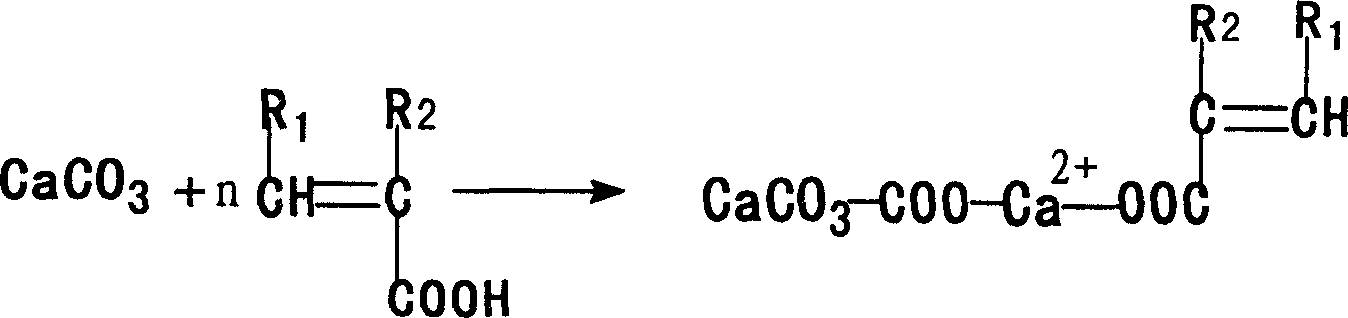

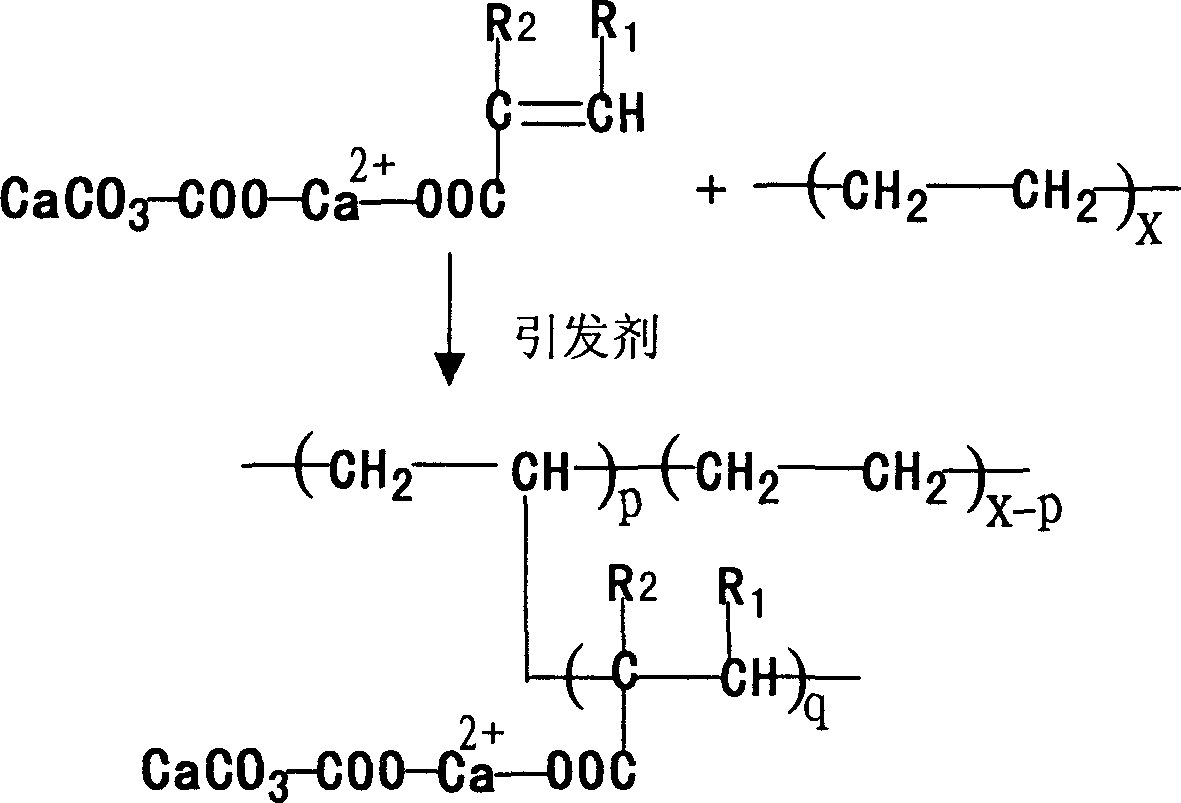

Process for preparing predispersed masterbatch of polyolefin and nano calcium carbonate

The invention relates to a method for preparation of predispersed master batch of polyolefin / nano-alcium carbonate, which includes: (1) adding nano-alcium carbonate into the kneading machine, afterwards, adding unsaturated acid monomer, long fatty chain monomer, initiating agent, polyethersulfonate, macromolecular coupling agent and polyolefin resin in turn, and kneading for 0.5-5 minutes; (2) discharging mixtures into the twin-screw extruder to perform squeezing, granulating and drying, then obtaining the predispersed master batch of polyolefin / nano-alcium carbonate, with a speed of host machine of twin-screw extruder of 50-600 revolutions per minute, a feeding speed of 20-400 revolutions per minute, a heating-up temperature of 80-220 DEG C; the invention is of few job steps, strong interaction between polyolefin and nano-alcium carbonate and is liable to disperse in the polymeric matrix. The said predispersed master batch of polyolefin / nano-alcium carbonate obtained by this invention can be widely used in enhancing, toughening and modifying various plastics, specially adapted for preparation of polyolefin permeability films and so on.

Owner:SOUTH CHINA UNIV OF TECH

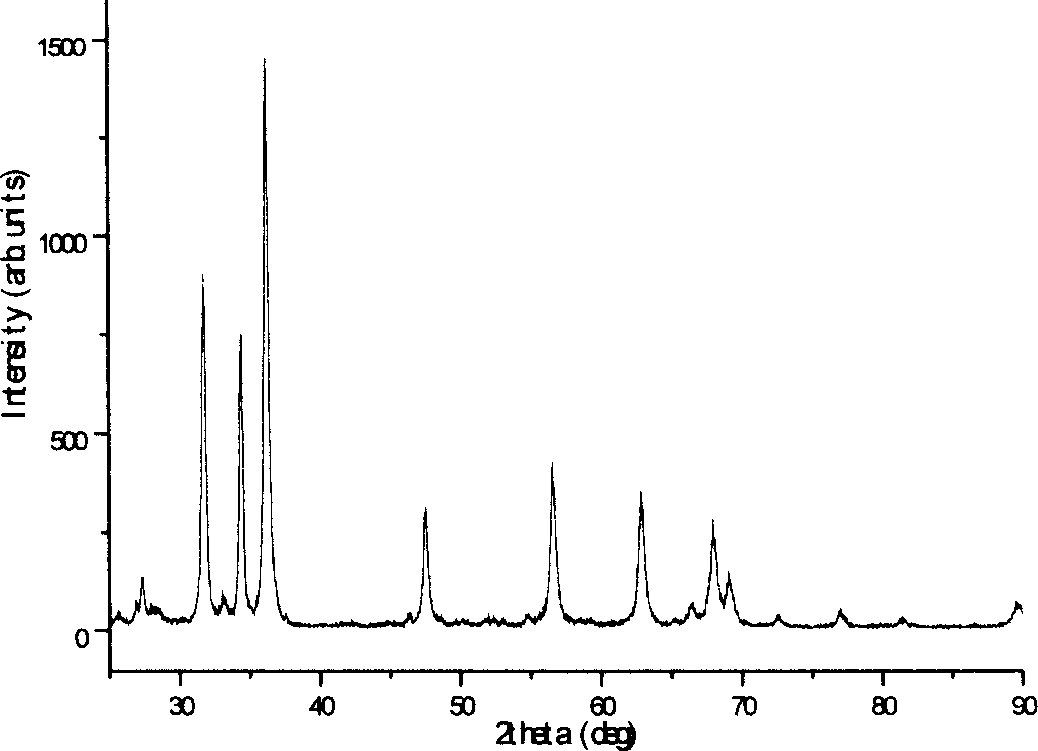

Preparation and application of high-potential gradient zinc oxide piezoresistor material

This invention relates to the preparation and application of a high potential gradient ZnO piezoresistive material including: mixing raw materials in the mol ratio of ZnO: Bi2O3:Sb2O3:Cr2O3:Co2O3:MnO2=96.5:0.7:1.0:0.5:0.8:0.5 to get the product by first and second time powerful fine grindings, low temperature sinter, which is taken as the raw material to be pressed to formation, sintered at low temperature, coated with electrode Ag pulp and welded with electrode lead to get the product of high potential gradient ZnO piezoresistors. This invention greatly refines the metal oxide mixed powder grain size by twice-powerful grindings, the sintered temperature is only 900deg.C and the grain is 1.5-3.5mum.

Owner:EAST CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com