Nucleating agent master batches used for foaming of thermoplastic resin

A thermoplastic resin, nucleating agent masterbatch technology, applied in the field of nucleating agents, can solve the problems of uneven dispersion, weak performance, uneven pores of materials or products, and achieve full peeling, enhanced dispersion uniformity, and reduced process effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

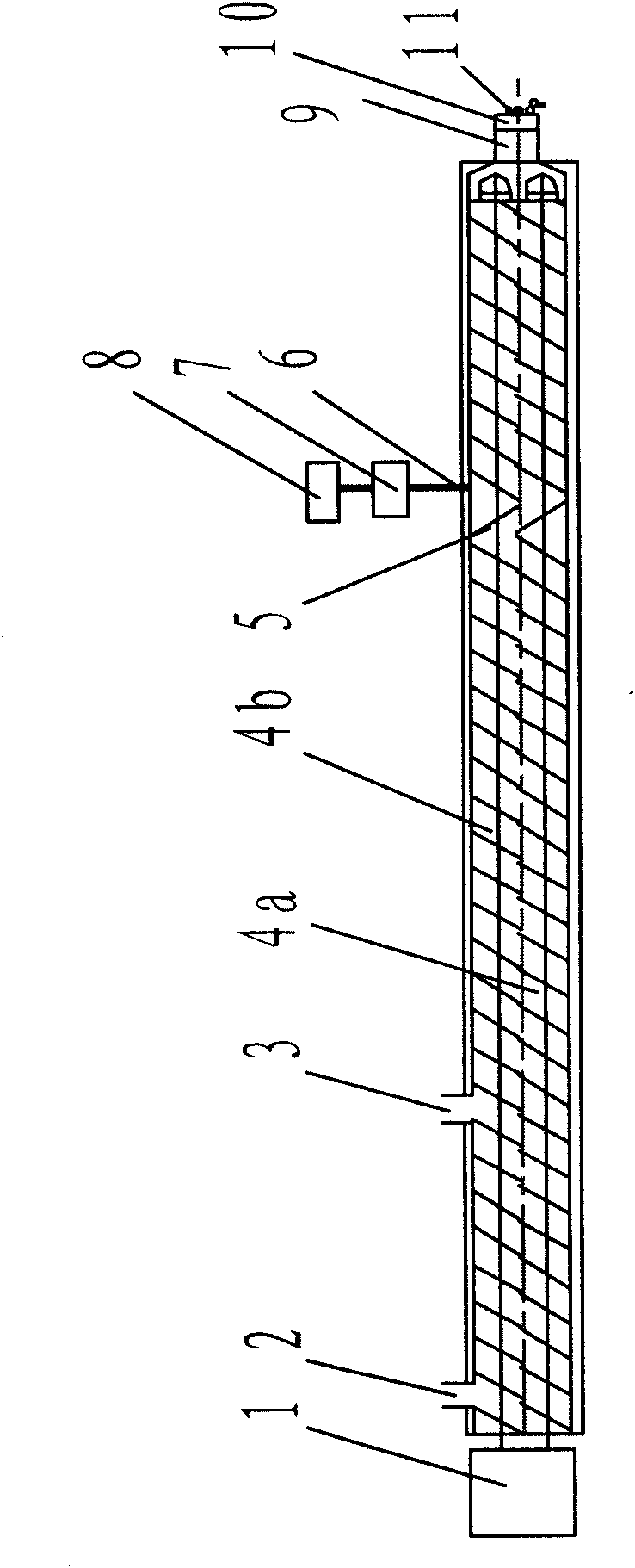

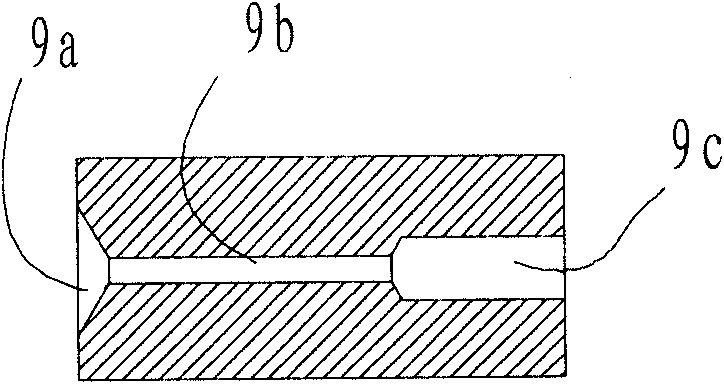

[0027] as attached figure 1 , 2 , 3, 4, where the labels represent: 1-extruder driving mechanism, 2-first feed port, 3-second feed port, 4a-the first screw assembly, 4b-the second Screw assembly, 5-reverse screw element on the screw, 6-third feed port, 7-supercritical fluid metering device, 8-supercritical fluid source, 9-die, 10-granulation device, 11-masterbatch Particles, 9a-melt glue inlet part, 9b-extrusion channel, 9c-setting channel;

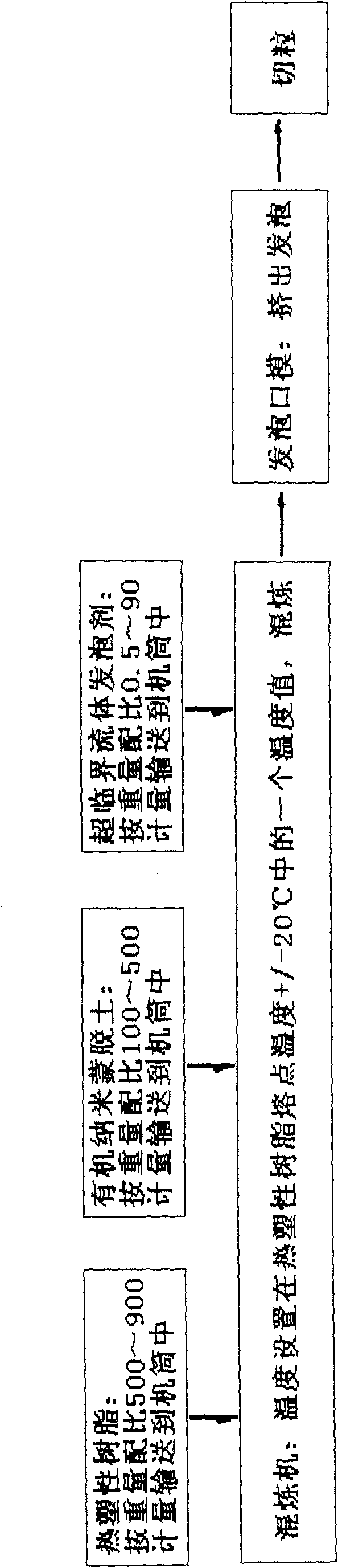

[0028] Set up a co-rotating twin-screw extruder, the length of which is between 38-40 times the diameter of the screw, and set three feeding ports on the extruder, which are respectively set at the starting position of the screw, about 9-10 times the screw diameter is the end of the plasticizing section, and about 28-29 times the screw diameter from the first feed inlet is the exhaust section. The thermoplastic resin particles, the organic montmorillonite particles and the supercritical foaming agent are introduced into the barrel of t...

Embodiment 2

[0049] Adopt the same co-rotating twin-screw extruder as in Example 1, but the thermoplastic resin adopts a mixture of polypropylene PP and maleic anhydride to improve polypropylene, and the specific gravity of the two materials is 0.9-0.91g / cm 3 Among them, the organic nano-montmorillonite adopts DK4 organic montmorillonite from Zhejiang Fenghong Clay Chemical Co., Ltd., and is screened with 400 mesh. The content of montmorillonite is 96%, and the specific gravity is 2.0g / cm 3 .

[0050] The weight parts of the mixture of polypropylene PP and maleic anhydride-modified polypropylene and DK4 nano-montmorillonite are 680g and 320g, wherein the weight of maleic anhydride-modified polypropylene in the 680g thermoplastic resin mixture is 120g. And the supercritical fluid adopts nitrogen, and the weight is 13.6g. The barrel temperature of the co-rotating twin-screw extruder is set between 170°C and 175°C, and the melting point of PP is 176°C.

[0051] In this embodiment, the struc...

Embodiment 3

[0053] Adopt identical co-rotating twin-screw extruder with embodiment 1, but thermoplastic resin adopts the mixture of nylon 6, polypropylene, maleic anhydride modified polypropylene resin, the total weight portion of this mixture is 650g, and wherein nylon 6 is 300g, polypropylene is 300g, and maleic anhydride-modified polypropylene is 50g; and organic montmorillonite adopts the DK4 product of Zhejiang Fenghong Clay Chemical Co., Ltd., the weight part is 350g, passes through 400 mesh sieve, specific gravity is 2.0g / cm 3 , the content of montmorillonite is 96%; the supercritical fluid foaming agent adopts carbon dioxide, and the weight part is 6g.

[0054] The mixture of three thermoplastic resins, organic montmorillonite powder, and supercritical carbon dioxide were added in the same way as in Example 1 and Example 2. The temperature of the kneader was set at 205°C.

[0055] According to this ratio, the specific gravity of the masterbatch is 1.1g / cm 3 . This masterbatch i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com