Patents

Literature

334 results about "Silumin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

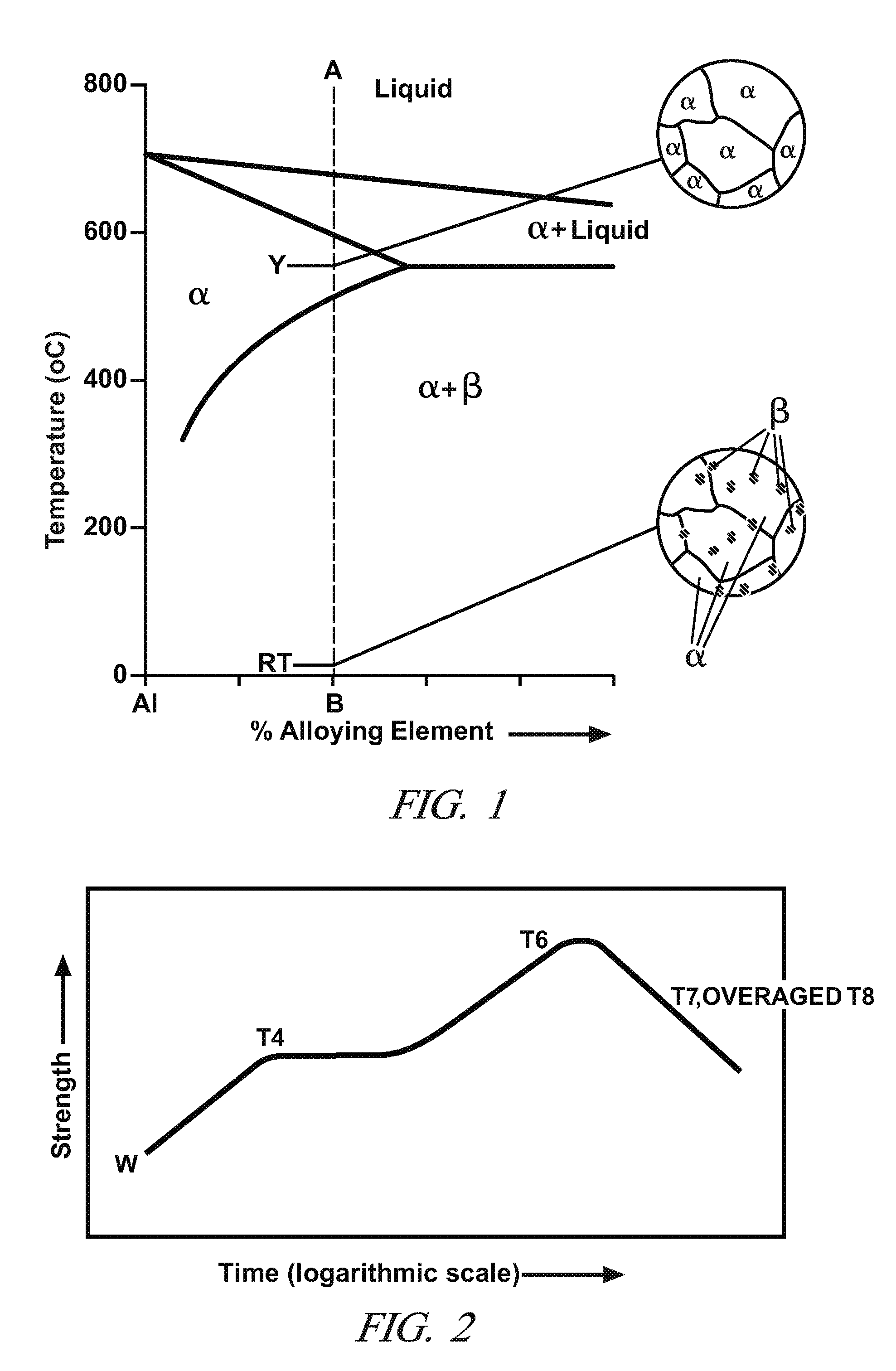

Silumin is a general name for a group of lightweight, high-strength aluminium alloys based on an aluminum–silicon system. Aluminium-silicon alloys typically contain 3 to 25% silicon content. Casting is the primary use of aluminum-silicon alloys, but they can also be utilized in rapid solidification processes and powder metallurgy. Alloys used by powder metallurgy, rather than casting, may contain even more silicon, up to 50%. Silumin has a high resistance to corrosion, making it useful in humid environments.

High strength aluminum alloy for high temperature applications

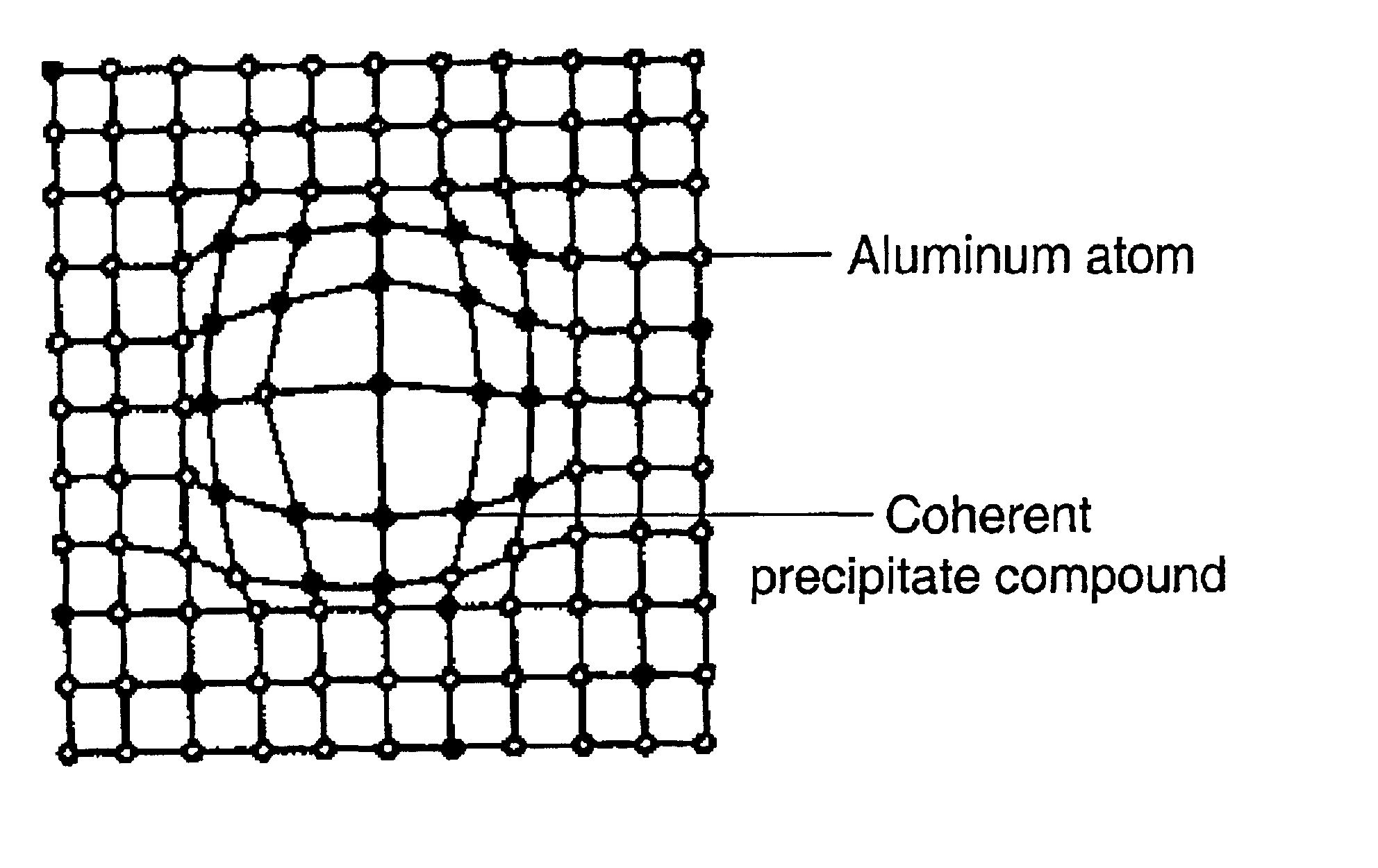

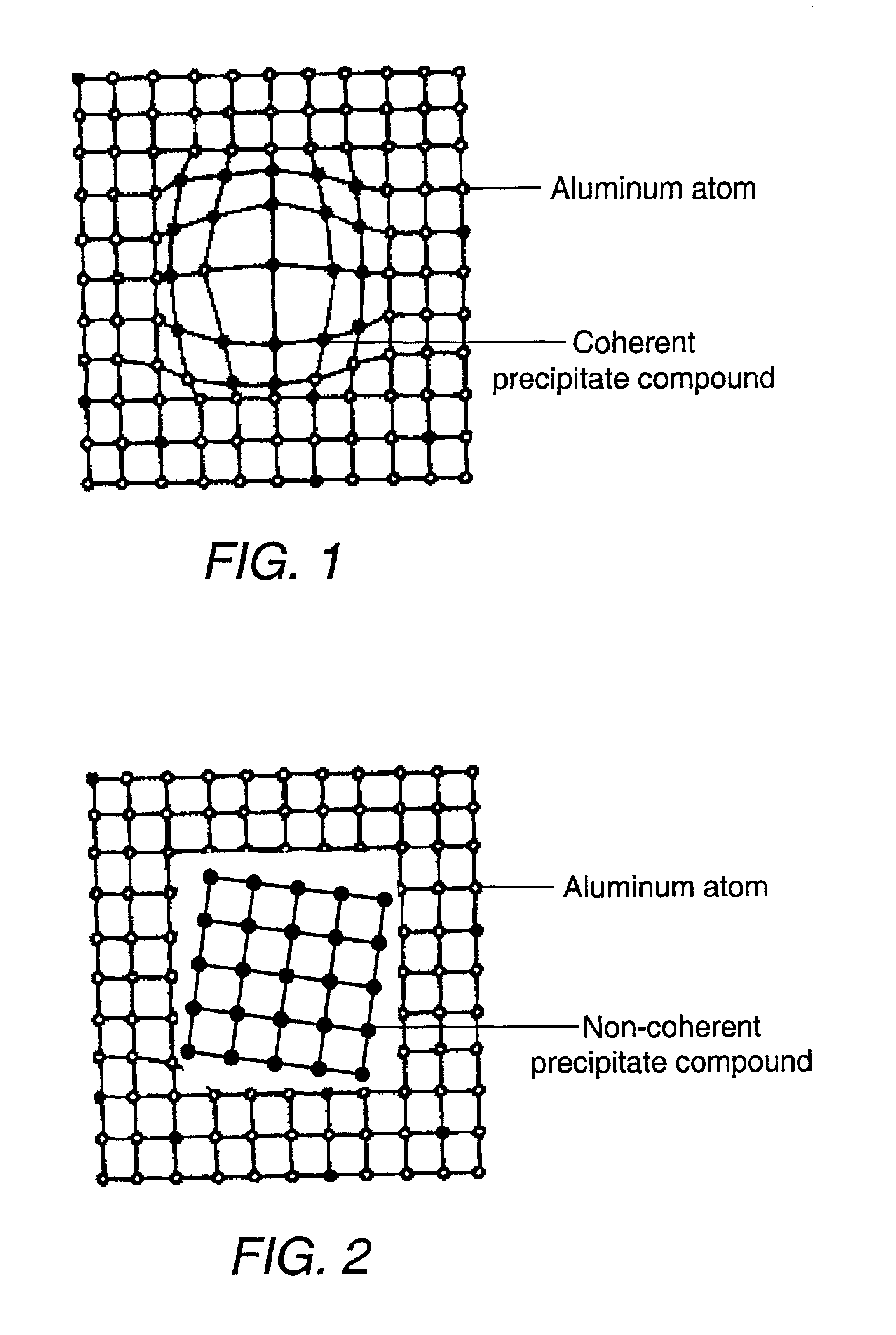

A cast article from an aluminum alloy has improved mechanical properties at elevated temperatures. The cast article has the following composition in weight percent: Silicon 6.0-25.0, Copper 5.0-8.0, Iron 0.05-1.2, Magnesium 0.5-1.5, Nickel 0.05-0.9, Manganese 0.05-1.2, Titanium 0.05-1.2, Zirconium 0.05-1.2, Vanadium 0.05-1.2, Zinc 0.05-0.9, Strontium 0.001-0.1, Phosphorus 0.001-0.1, and the balance is Aluminum, wherein the silicon-to-magnesium ratio is 10-25, and the copper-to-magnesium ratio is 4-15. The aluminum alloy contains a simultaneous dispersion of three types of Al3X compound particles (X=Ti, V, Zr) having a L12 crystal structure, and their lattice parameters are coherent to the aluminum matrix lattice. A process for producing this cast article is also disclosed, as well as a metal matrix composite, which includes the aluminum alloy serving as a matrix containing up to about 60% by volume of a secondary filler material.

Owner:NASA

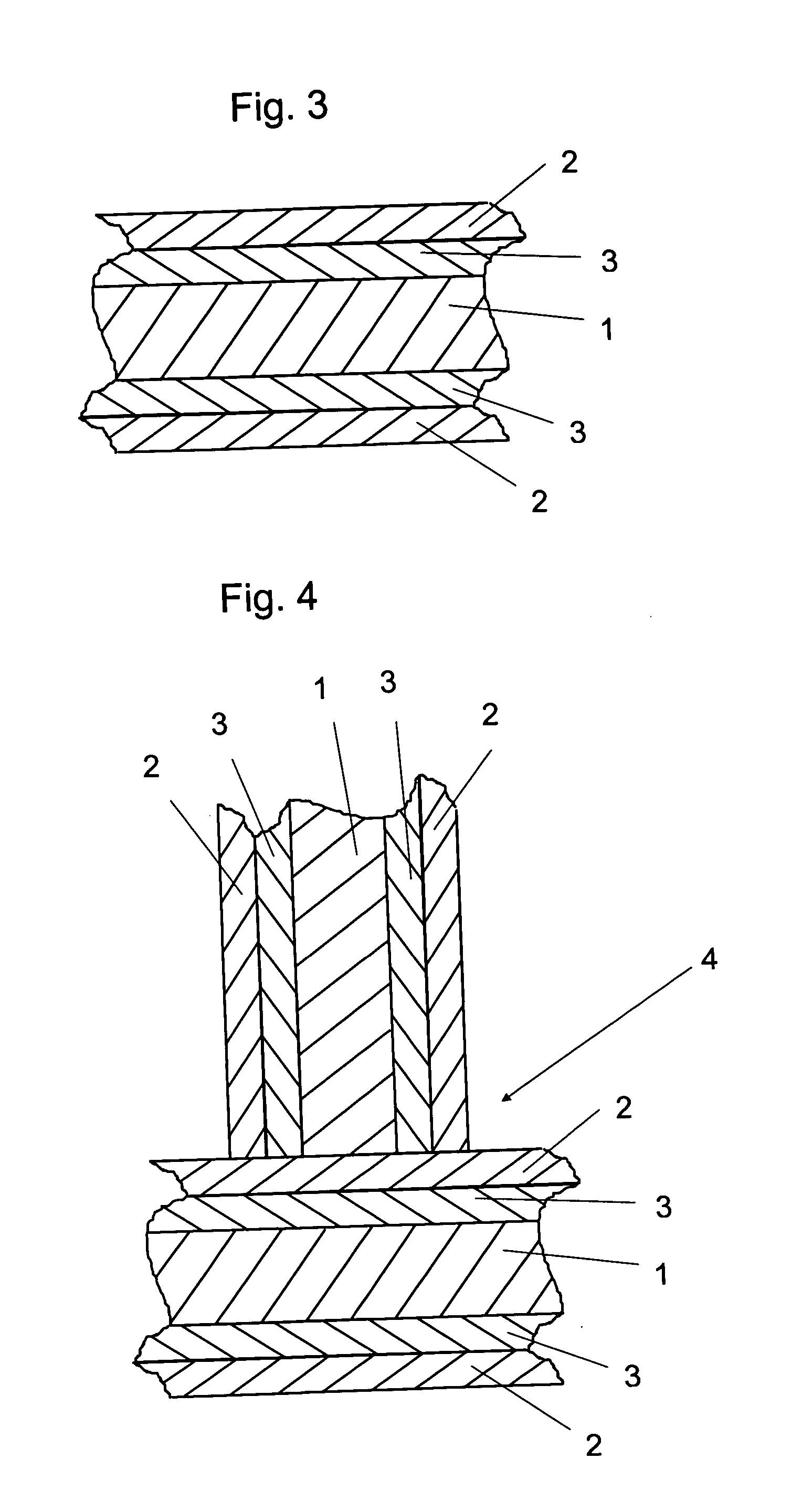

High strength aluminium alloy brazing sheet, brazed assembly and method for producing same

ActiveUS20050079376A1Good brazing propertyGood formability characteristicFurnace typesWelding/cutting media/materialsSiluminManganese

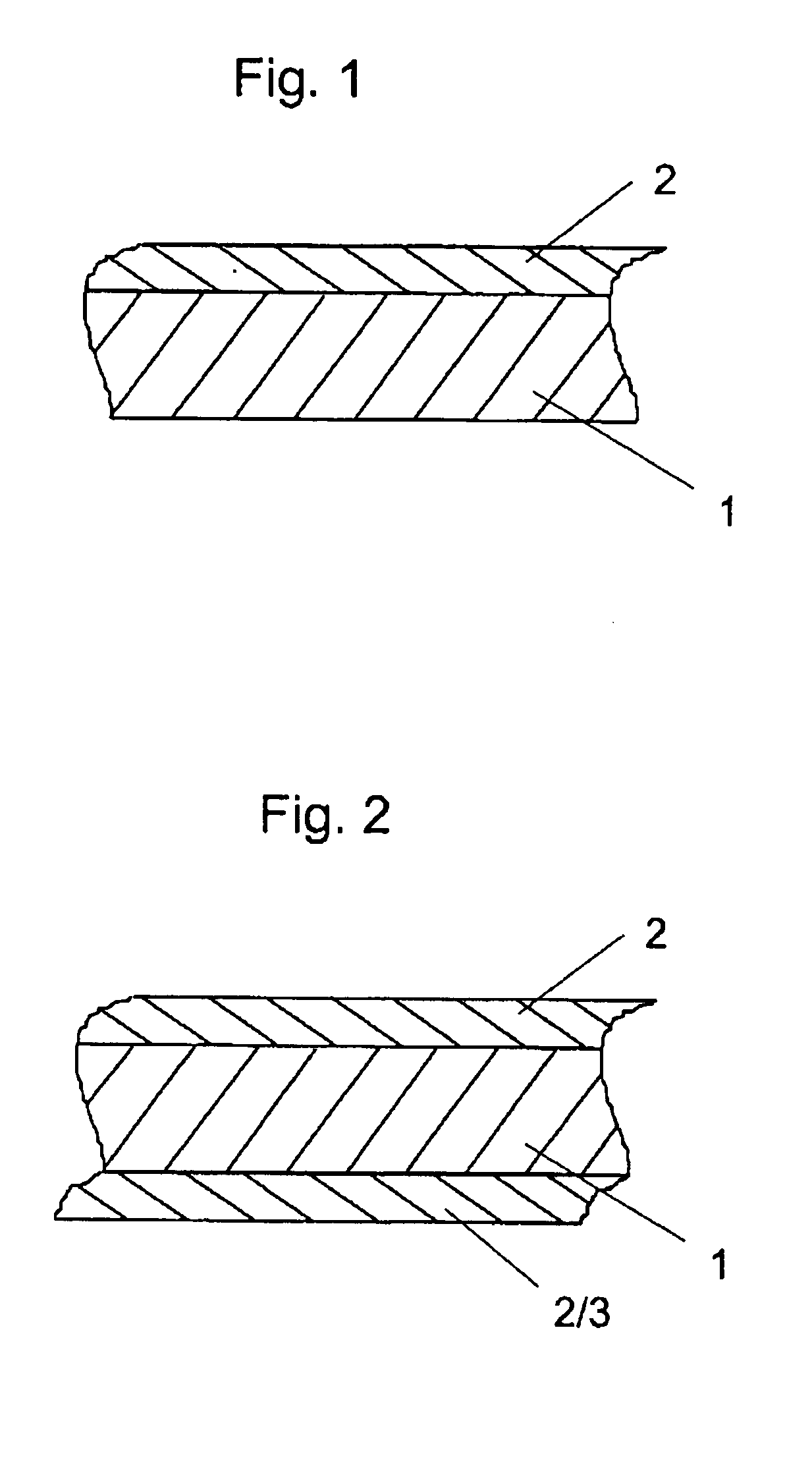

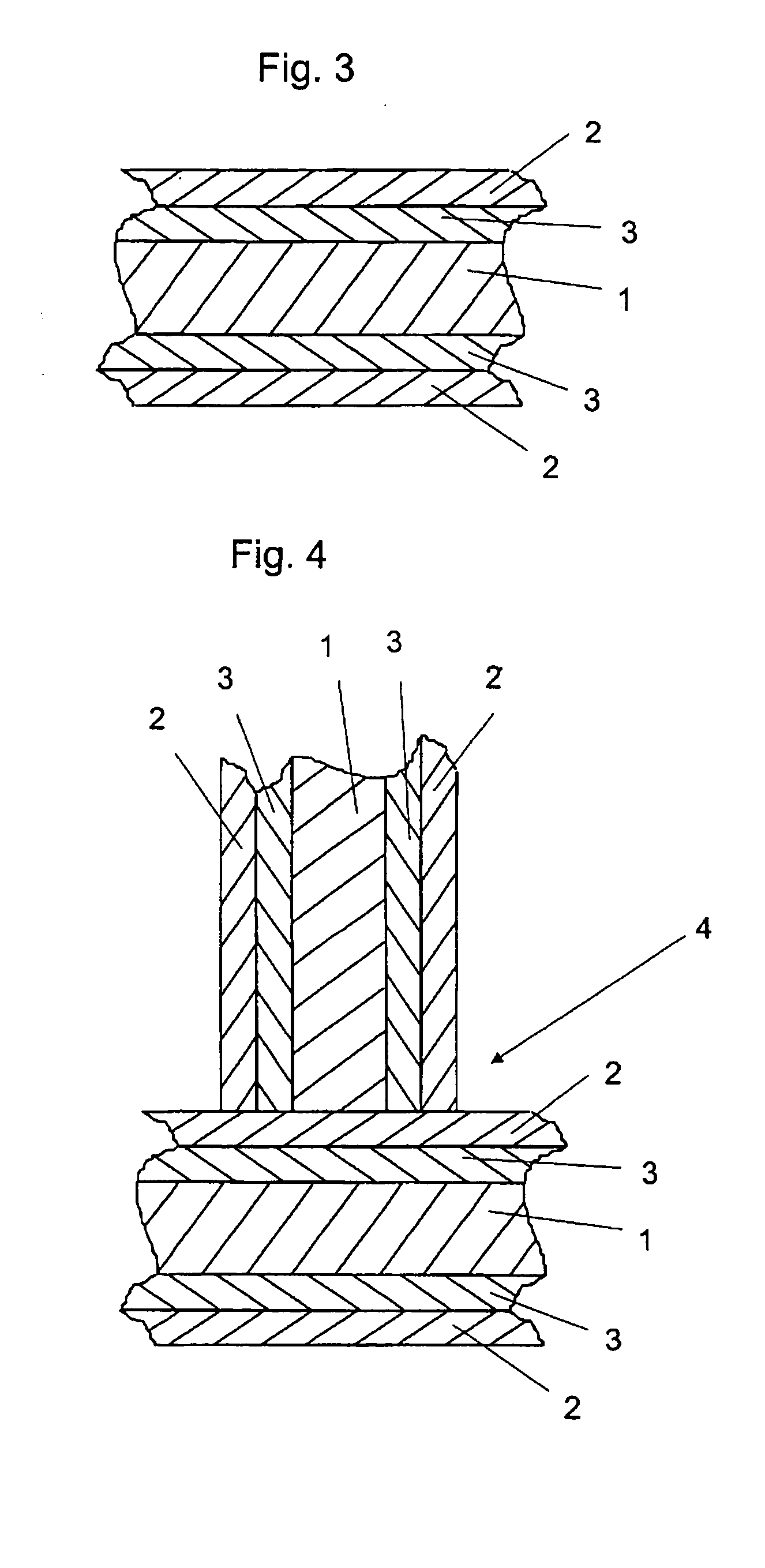

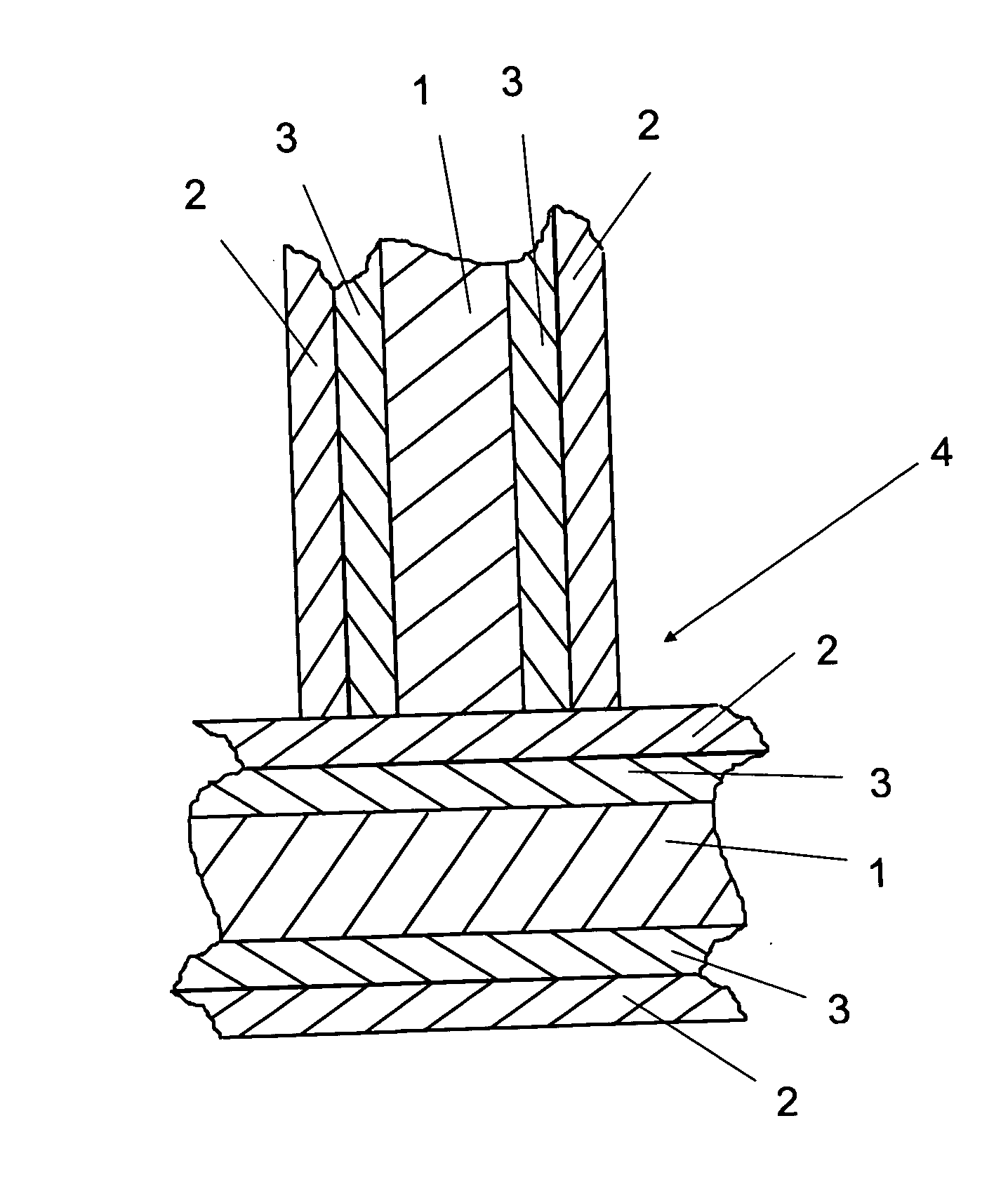

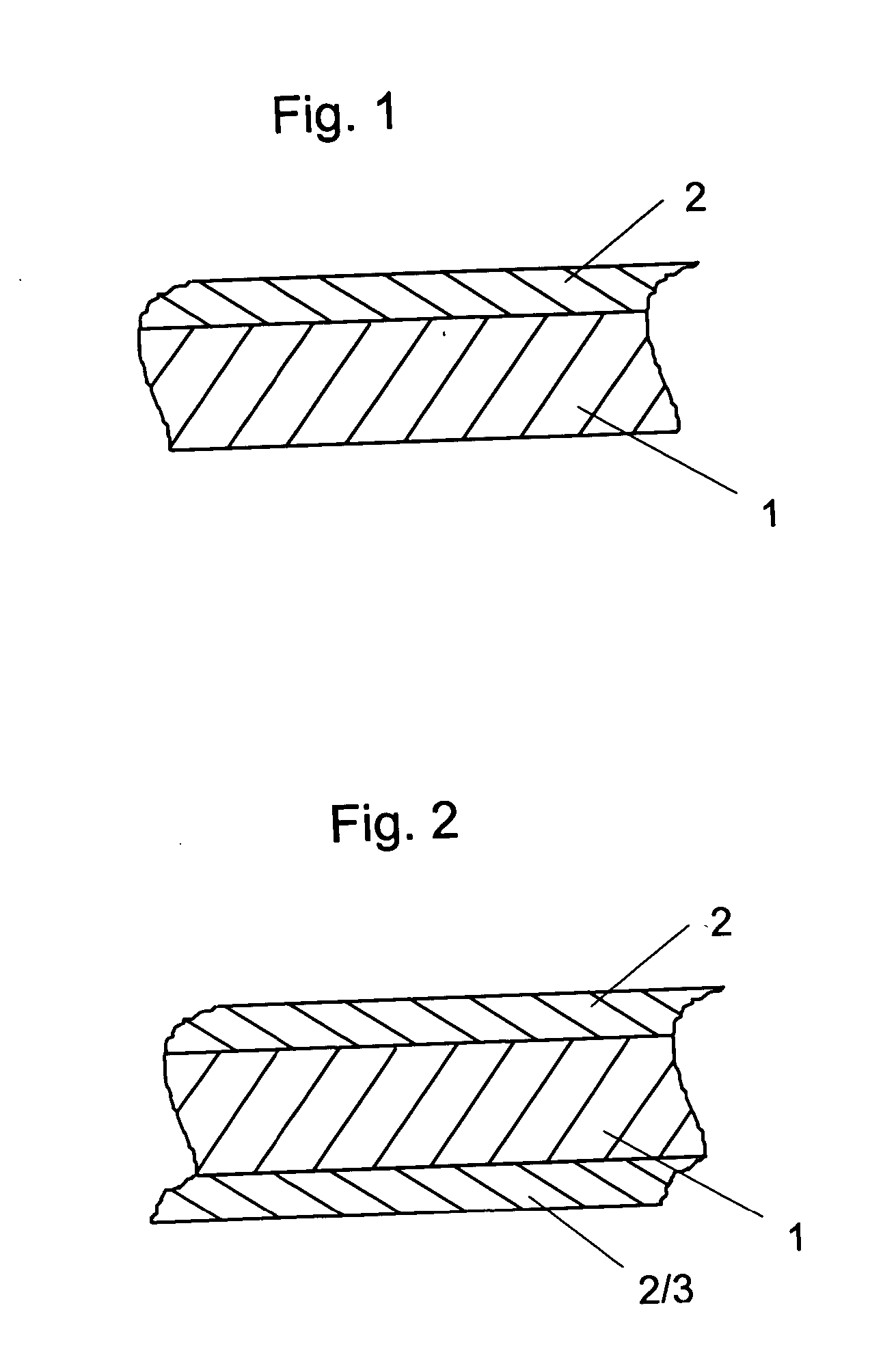

The present invention a high strength aluminium alloy brazing sheet, comprising an Al—Zn core layer and at least one clad layer, the core layer including the following composition (in weight percent): Zn1.2 to 5.5Mg0.8 to 3.0Mn0.1 to 1.0Cu<0.2Si <0.35Fe<0.5optionally one or more of: Zr<0.3Cr<0.3V<0.3Ti<0.2Hf<0.3Sc<0.5,the balance aluminium and incidental elements and impurities. The clad layer includes an Al—Si based filler alloy and is applied on at least one side of the core layer. The invention relates furthermore to a brazed assembly including such brazing sheet, to the use of such brazing sheet and to method for producing an aluminium alloy brazing sheet.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

High-strength aluminum alloy product and method of producing the same

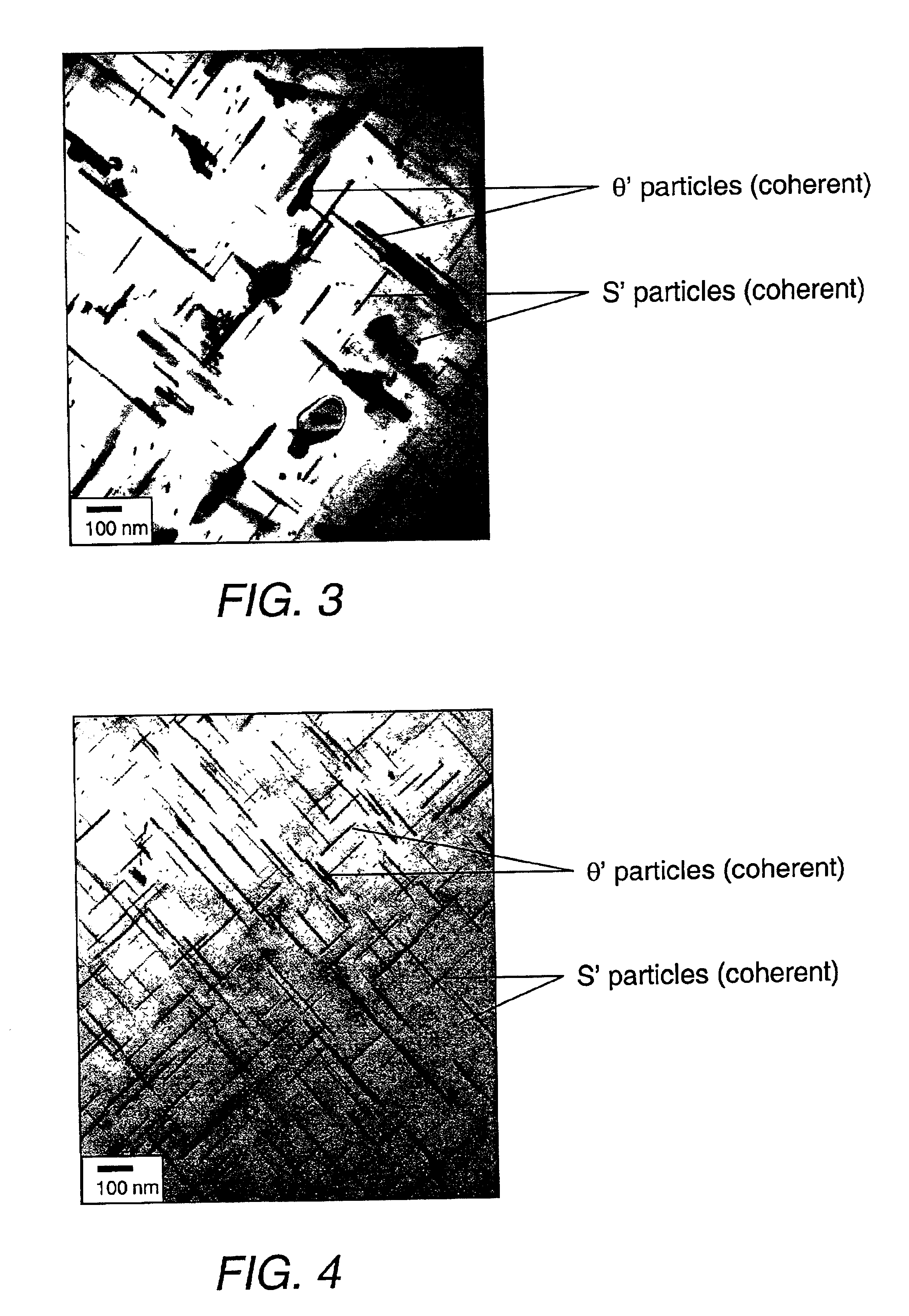

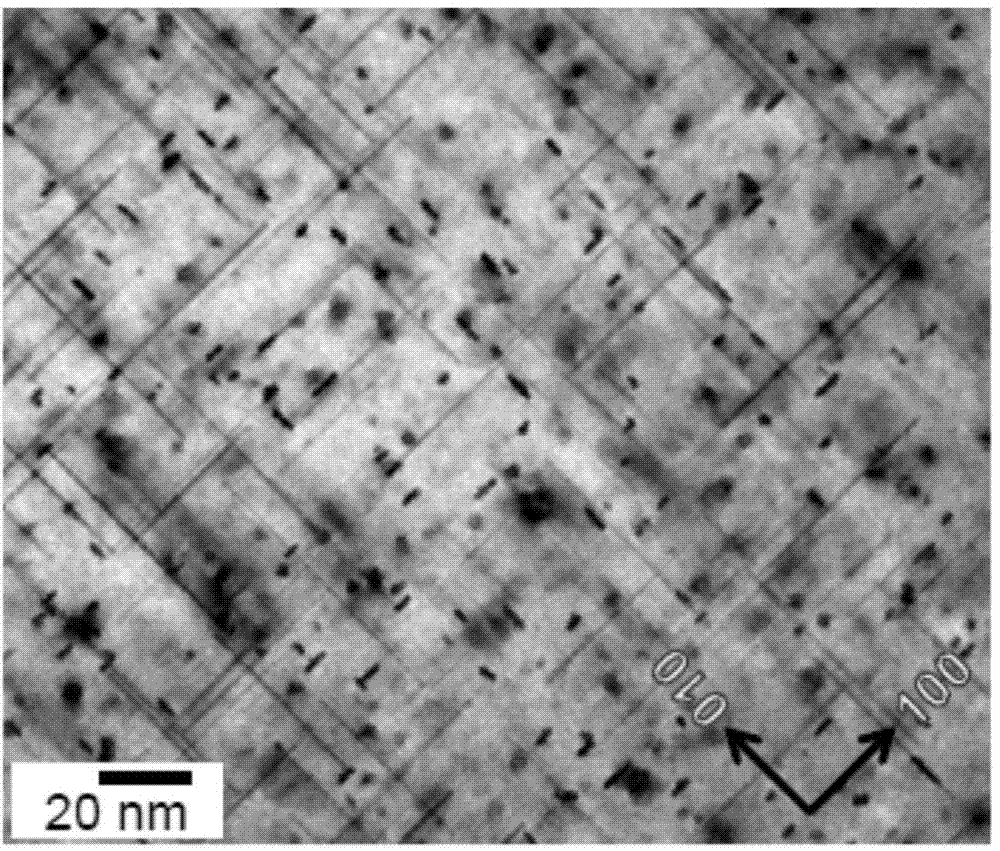

A heat-treated high-strength Al—Cu—Mg—Si aluminum alloy product exhibits excellent extrudability and high strength. The high-strength Al—Cu—Mg—Si aluminum alloy product obtained by extrusion is characterized in that the microstructure of the entire surface of the cross section of the aluminum alloy product is formed of recrystallized grains, the grains have an average aspect ratio (L / t) of 5.0 or less (wherein L is the average size of the grains in the extrusion direction, and t is the average thickness of the grains), and the orientation density of the grains in the microstructure, for which the normal direction to the {001} plane is parallel to the extrusion direction in comparison with the grains orientated to random orientations, is 50 or less. The high-strength Al—Cu—Mg—Si aluminum alloy product obtained by extrusion and cold working is characterized in that rod-shaped precipitates are arranged in the grains of the matrix in the <100> direction, the precipitates have an average length of 10 to 70 nm and a maximum length of 120 nm or less, and the number density of the precipitates in the [001] direction measured from the (001) plane is 500 or more per square micrometer.

Owner:SUMITOMO LIGHT METAL INDS LTD

High strength aluminium alloy brazing sheet

InactiveUS20050064226A1Good brazing propertyGood formability characteristicFurnace typesHigh frequency current welding apparatusSiluminHigh intensity

Disclosed is a high strength aluminium alloy brazing sheet, including an Al—Cu core layer and at least one clad layer, the core layer having the following composition (in weight percent): Cu: 1.2-4.0, Mn: 0.06-1.5, Mg: 0.06-1.5, Si: up to 0.5, Zn: <0.4, Zr: ≦0.25, Fe: ≦0.5, Ti: ≦0.25, Cr: ≦0.25; V≦0.25; the balance substantially aluminium and impurities, the clad layer including an Al—Si based filler alloy and being applied on at least one side of the core layer. Also disclosed is a brazed assembly including the brazing sheet and the use of the brazing sheet for a brazing application such as a heat exchanger.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

Heat resisting low expansion silumin and preparation thereof

The invention belongs to the field of non-ferrous materials and preparation and formation thereof, and relates to heat-resisting low-expansion high-silicon cast aluminum alloy. The alloy comprises the following compositions in percentage by mass: 18 to 25 percent of silicon, 1.0 to 2.5 percent of copper, 0.2 to 0.8 percent of magnesium, 0.5 to 2.5 percent of nickel, 0.3 to 0.6 percent of manganese, 0.3 to 1.0 percent of misch metal RE (the content of cerium is more than 40 percent), 0.006 to 0.04 percent of phosphorus, and the balance of aluminum. The production method comprises: firstly, melting raw materials of copper, nickel, silicon and aluminum into an aluminum silicon alloy fused mass; secondly, re-superheating the aluminum silicon alloy fused mass to the temperature of between 850 and 870 DEG C, adding manganese raw materials, and obtaining a mixed fused mass after uniform melting; thirdly, adjusting the temperature of the mixed fused mass to between 780 and 800 DEG C and adding the magnesium into the mixed fused mass; fourthly, adding rare earth raw materials into the mixed fused mass, maintaining at the temperature for 10 to 15 minutes, and raising the temperature to between 820 and 840 DEG C; fifthly, performing refining; and sixthly, raising the temperature of the refined mixed fused mass to between 830 and 850 DEG C, adding phosphorus raw materials into the mixed fused mass for modification, maintaining at the temperature for 15 to 20 minutes after modification, and performing casting, wherein the casting temperature is between 790 and 830 DEG C. Castings can well meet the performance requirements of peripheral materials of automobile engines after T6 heat treatment.

Owner:HUAZHONG UNIV OF SCI & TECH

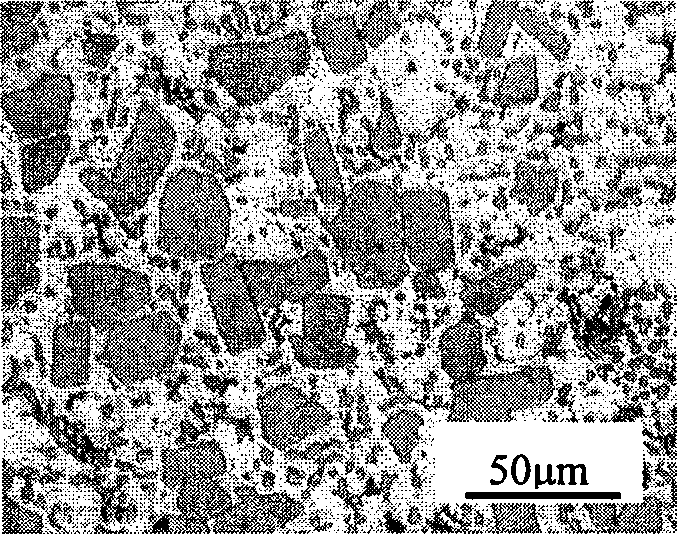

Method for manufacturing high-strength aluminum alloy material for vehicle heat exchanger

A method for producing a high tensile aluminum alloy for an auto heat exchanger, comprising: supplying molten aluminum alloy comprising: Si 0.3% to 1.2%, Fe 0.05% to 0.7%, Mn 0.8% to 2.0%, Zn 0.5% to 4.0%, and other part comprising aluminum and unavoidable impurity according to mass; processing the molten aluminum alloy into plates with thickness 2 to 12mm by continuous casting forging method; and curling the plates immediately; the temperature is 530 deg. C. or even lower of the aluminum alloy material to be curled; in addition, cooling the curled aluminum alloy material with an average cooling speed 15 deg. C / h or even higher, and then developing the aluminum alloy material; in addition, undergoing cold rolling at least two times and annealing at least two times so as to obtain finished plates with a thickness no more than 0.1mm.

Owner:MITSUBISHI ALUMINUM CO LTD

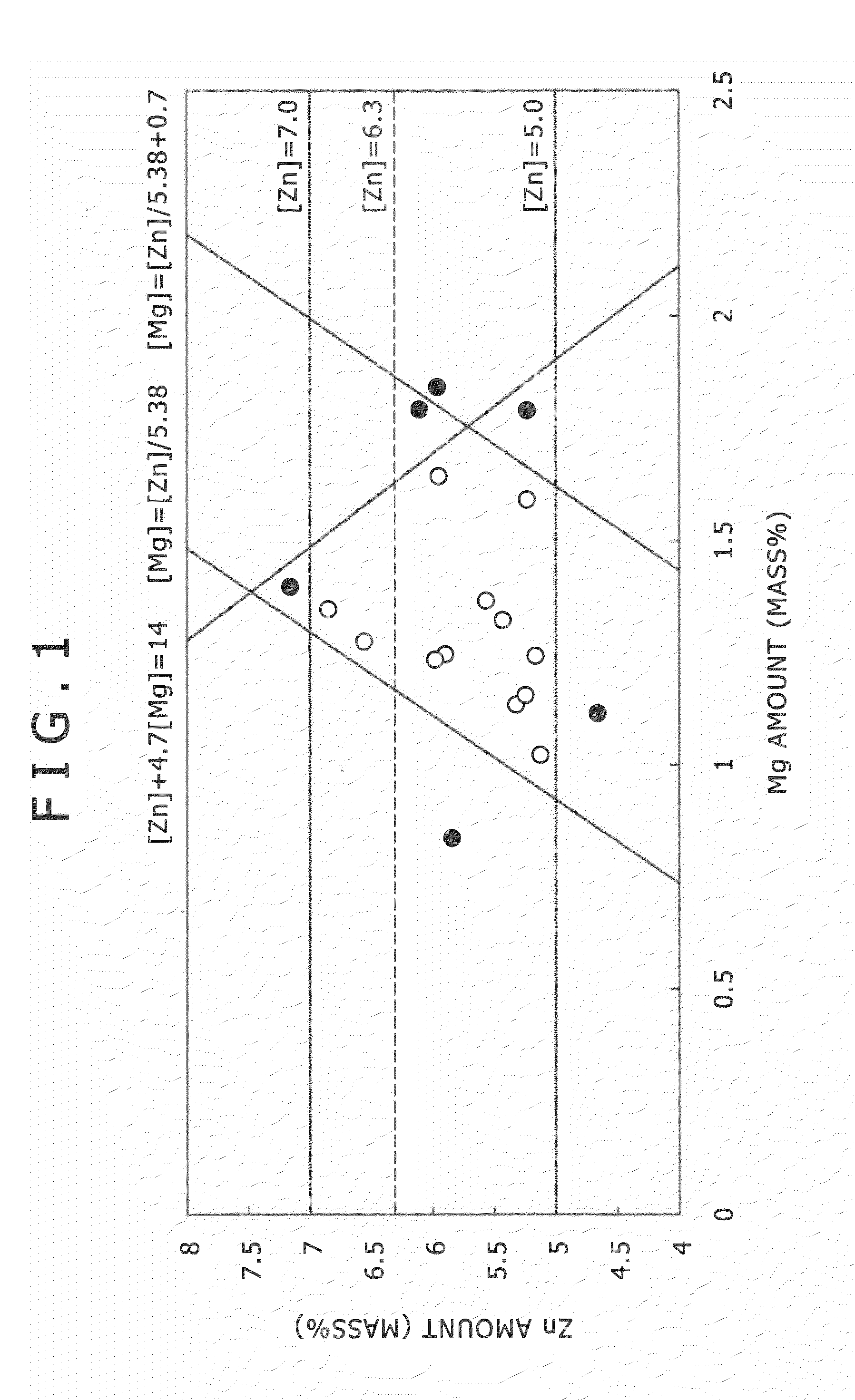

High strength aluminum alloy extruded material excellent in stress corrosion cracking resistance

An aluminum alloy extruded material in relation with the present invention is with high strength by die quench air cooling and excellent in SCC resistance. The aluminum alloy extruded material is an Al—Zn—Mg-based aluminum alloy extruded material for structural member for automobiles such as a bumper reinforce, a door guard bar and the like which satisfies three expressions of 5.0≦[Zn]7.0, [Zn] / 5.38<[Mg]≦[Zn] / 5.38+0.7, and [Zn]+4.7[Mg]≦14, where [Mg] represents mass % of Mg and [Zn] represents mass % of Zn, and contains at least either one element of Cu: 0.1-0.6 mass % and Ag: 0.01-0.15 mass %, Ti: 0.005-0.05 mass %, and at least one element out of Mn: 0.1-0.3 mass %, Cr: 0.05-0.2 mass %, Zr: 0.05-0.2 mass %.

Owner:KOBE STEEL LTD

High strength aluminum alloys and process for making the same

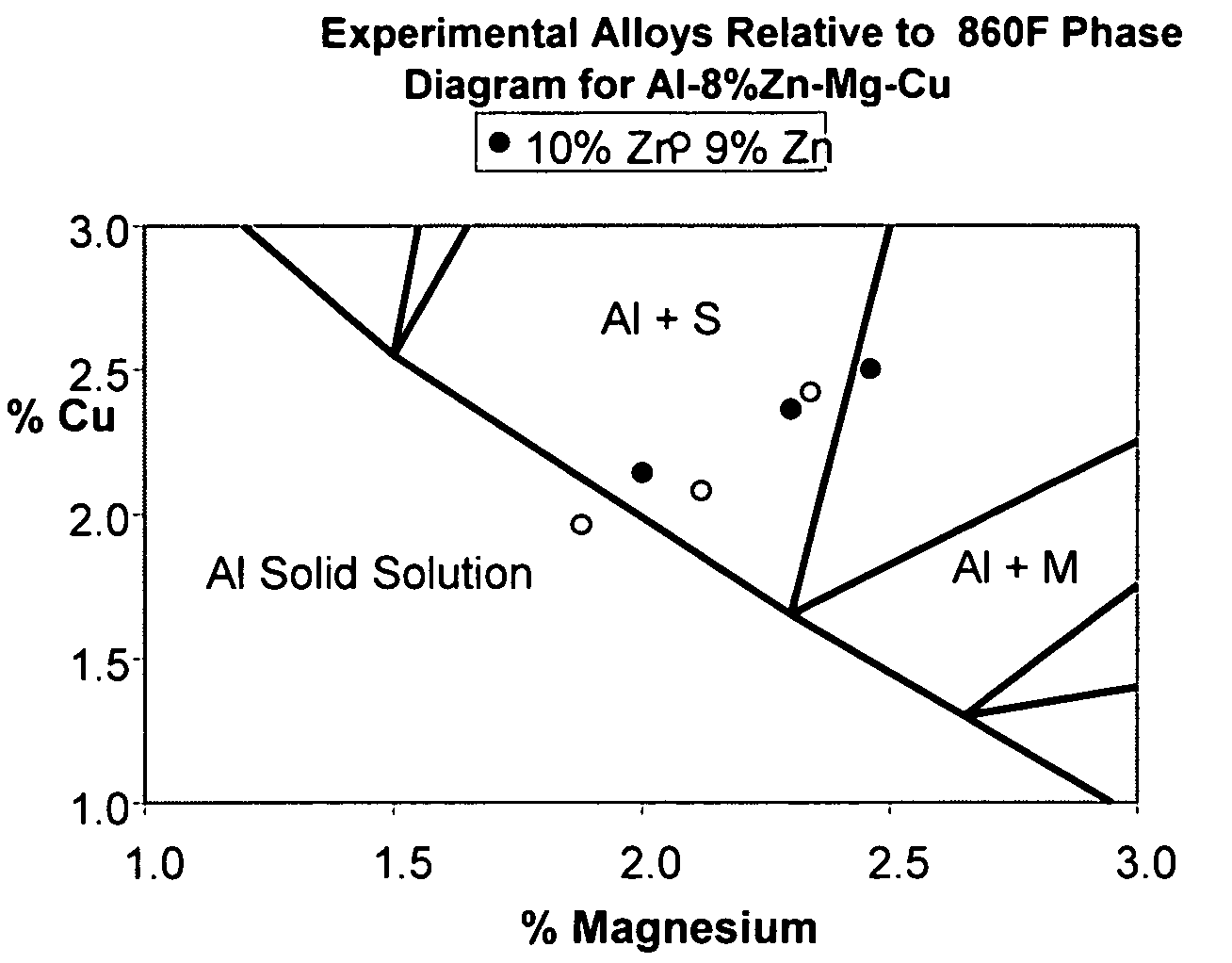

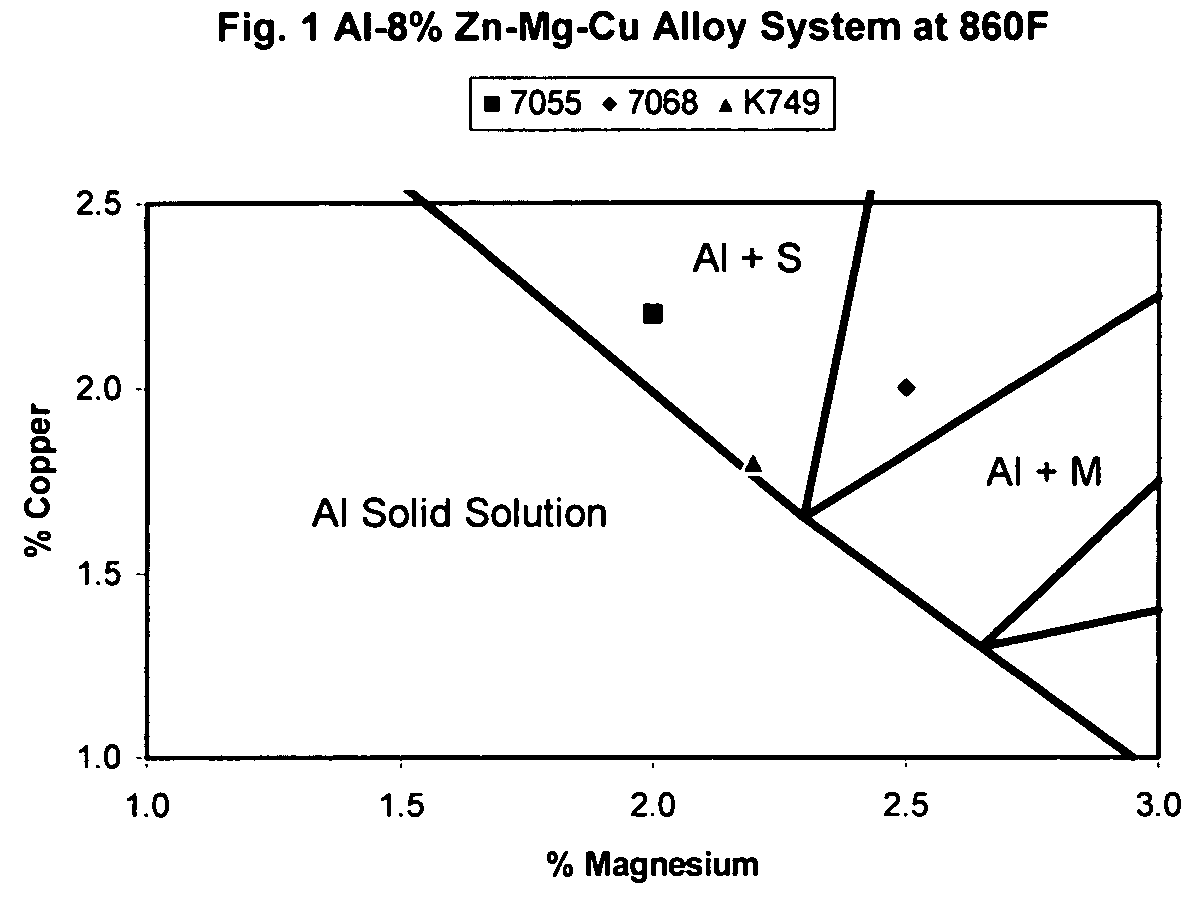

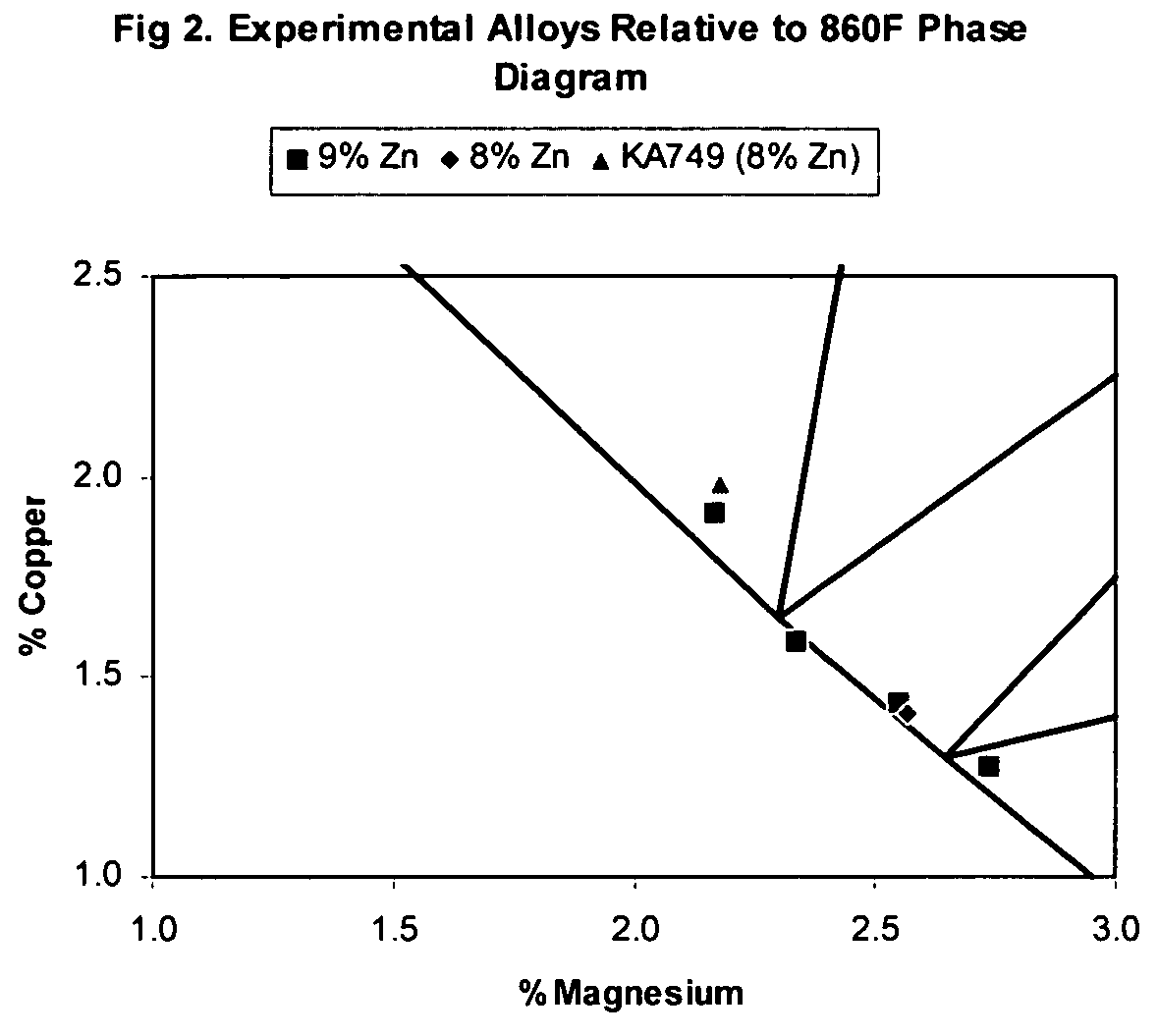

High strength aluminum alloys based on the Al—Zn—Mg—Cu alloy system preferably include high levels of zinc and copper to provide increased tensile strength without sacrificing toughness. In addition, small amounts of scandium are also preferably employed to prevent recrystalization. Preferred ranges of the elements include by weight, 8.5-11.0% Zn, 1.8-2.4% Mg, 1.8-2.6% Cu, 0.05-0.30% Sc and at least one element from the group Zr, V, or Hf not exceeding about 0.5%, the balance substantially aluminum and incidental impurities. During formation of the alloys, a homogenization process is preferably employed after alloy ingot casting in which a slow rate of temperature increase is employed as the alloy is heated as near as possible to its melting temperature. For the last 20-30 F below the melting temperature, the rate of increase is limited to 20 F / hr. or less to minimize the amount of low melting point eutectic phases and thereby further enhance fracture toughness of the alloy.

Owner:KAISER ALUMINUM FABTED PRODS

High-strenght aluminum alloy brazing sheet and method of manufacture

InactiveUS20120129003A1High strengthExcellent brazeabilityExhaust apparatusMachines/enginesFilling materialsImpurity

An aluminum alloy brazing sheet having a core material of an aluminum alloy, and a filler material cladded on the core is disclosed. The core material is an aluminum alloy having about 0.05 to about 1.2 mass Si, about 0.05-about 1.0 mass % Fe, about 0.05-about 1.2 mass % Cu, and about 0.6-about 1.8 mass % Mn, balance Al and the inevitable impurities. The filler material includes an aluminum alloy having about 2.5-about 13.0 mass % Si. Also, there is provided a method of manufacturing such an aluminum alloy brazing sheet.

Owner:FURUKAWA SKYALUMINUM

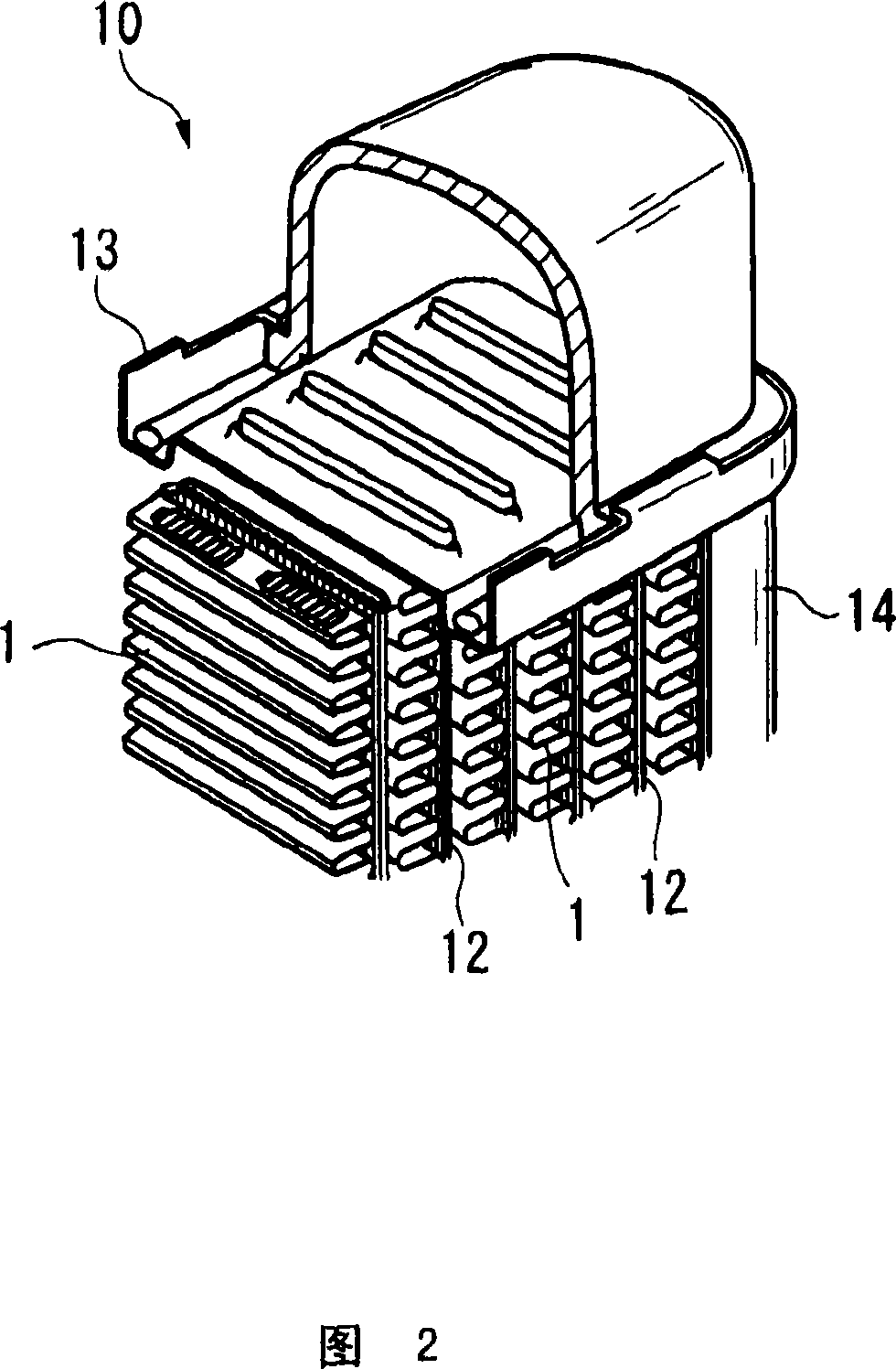

Process for preparing silumin electronic package materials

InactiveCN1877821AImprove featuresImprove performanceSemiconductor/solid-state device detailsSolid-state devicesSiluminMaterials processing

The invention discloses a making technology of high-silafont electronic packing material, which comprises the following steps: A) preparing powder: blending industrial pure aluminum and high-pure silicon at 6-8.8:4-1.2 percentage to prepare Al-Si alloy powder; B) proceeding ball grinding disposal for Al-Si alloy powder at 5-15:1 percentage for 8-32 h; C) loading oxide alloy powder in the pure aluminum; proceeding squeezing disposal on the 300-500 ton hydrostatic machine through forward squeezing pattern; keeping temperature at 400-520 deg.c for 0.5-2 h for Al-Si alloy powder before squeezing; placing each squeezing mould in the heat stove at 10-21 squeezing rate to preheat at 200-400 deg.c; squeezing to produce the product. The invention can improve heat conductivity, airtightness and tensile strength obviously, which keeps low expansion coefficient.

Owner:CENT SOUTH UNIV

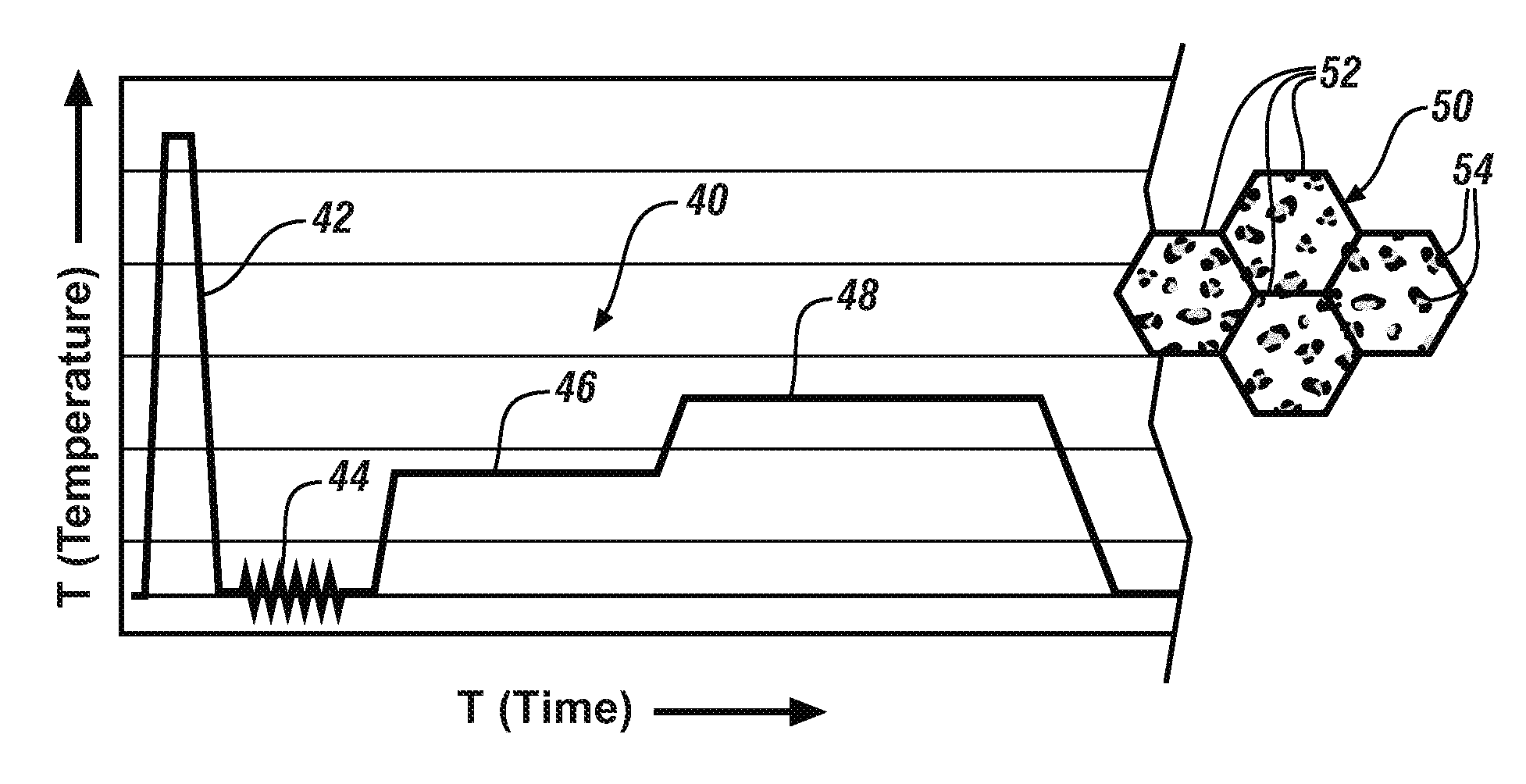

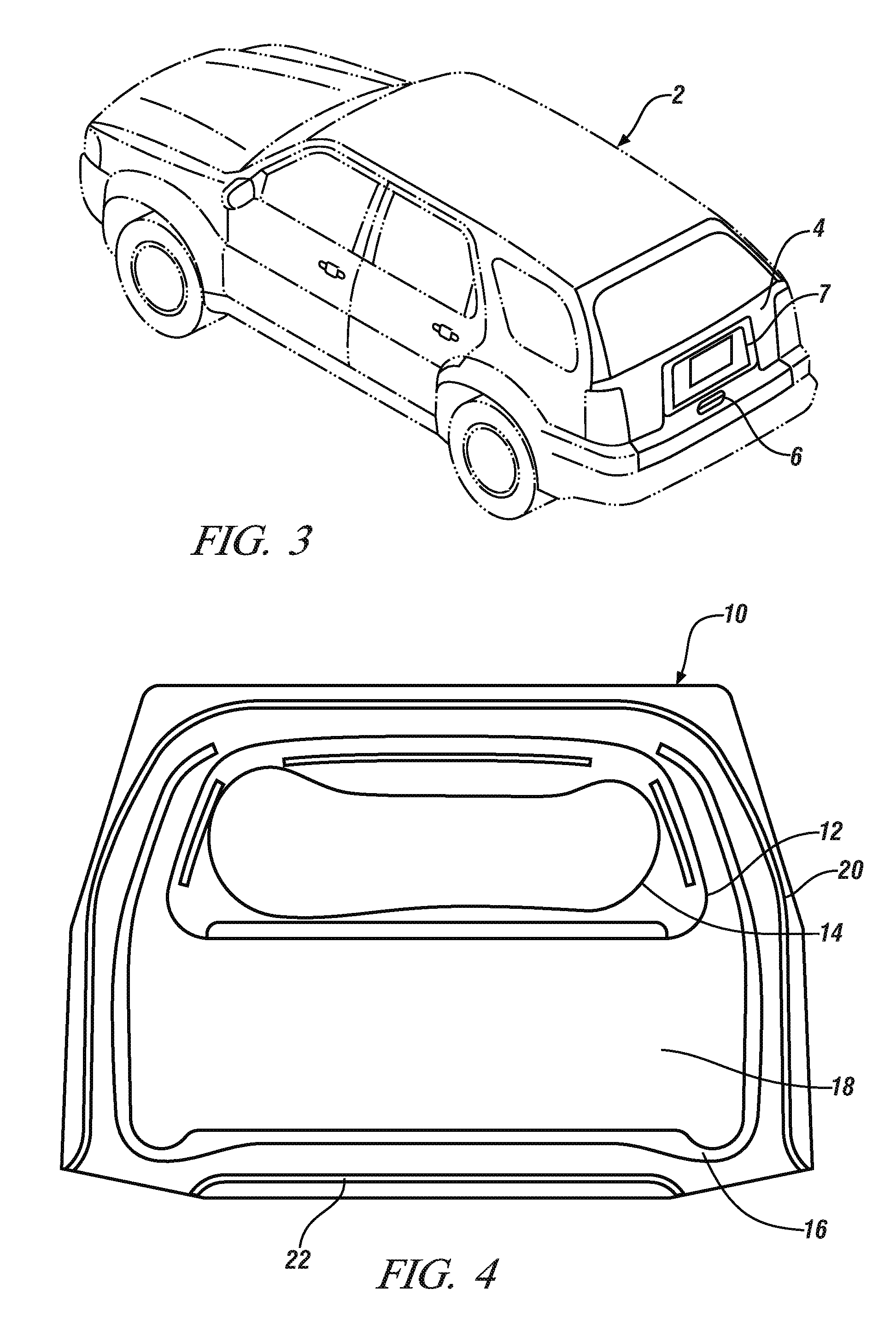

Stamping of age-hardenable aluminum alloy sheets

A method for enhancing the formability of press-formed high strength, age-hardenable aluminum alloy sheet is disclosed. The sheet is partially formed when in an overaged condition, for example in a T7 or T8 temper condition, to form a preform. After an annealing and solutionizing process the preform is promptly further deformed in a second forming operation and subsequently aged to develop high strength. The method may be employed to form components of more complex shape from higher strength aluminum alloys such as 6000 series and 7000 series alloys.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-strength aluminum alloy composite and resultant product

InactiveUS20050095447A1High post-braze strengthCorrosion resistanceRigid pipesHeat exchange apparatusSiluminAlloy composite

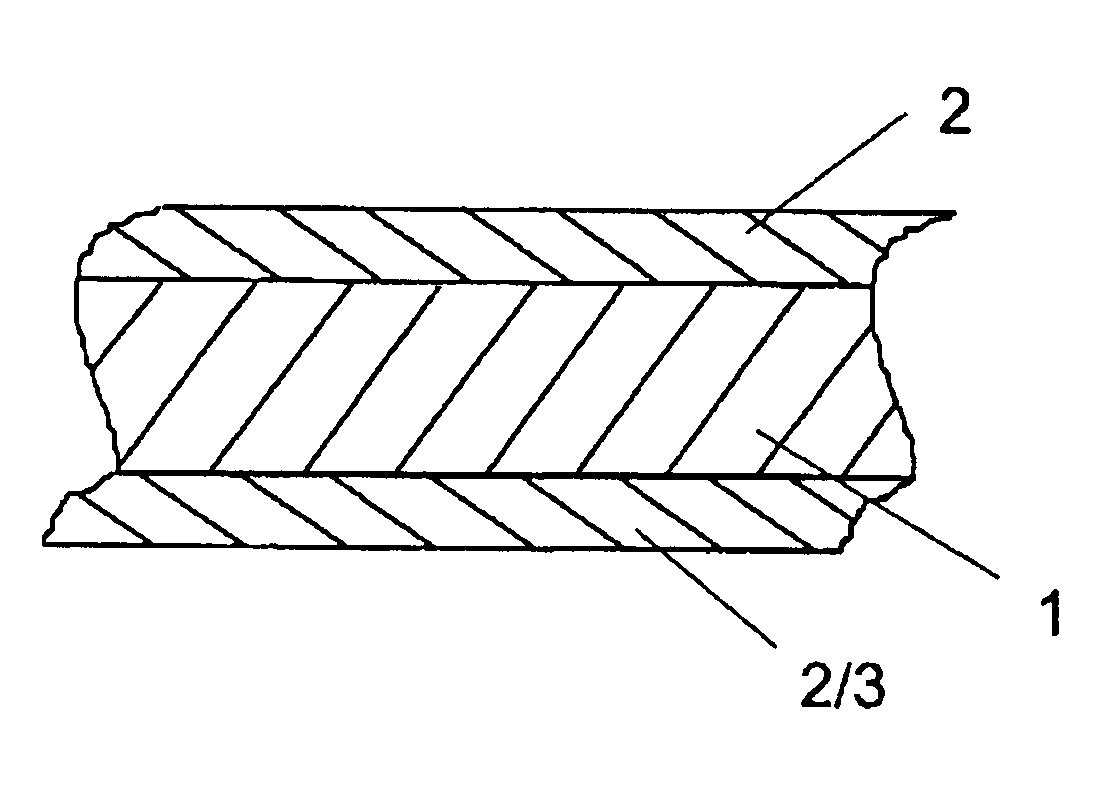

A high-strength aluminum alloy tubestock is for heat exchangers. The tubestock includes a core with low to moderate Si content to promote strengthening without excessively compromising corrosion resistance. A braze liner on the core exterior employs a Zn+Mg+Si water-side liner that will not experience undesirable melting during brazing. The water-side liner preferably comprises between about 0.2-0.5% Si, between about 2.5-5.0% Zn, between about 1.3-2.5% Mg, less than about 0.1% Cu, less than about 0.35% Fe and less than about 0.25% Mn, with the remainder comprising Al and tolerable impurities. The core preferably comprises between about 0.5-1.3% Mn, between about 0.1-0.3 Mg, between about 0.4-0.7% Cu, between about 0.15-0.5% Si, between about 0.01-0.25% Ti and less than about 0.5% Fe, with the remainder comprising Al and tolerable impurities. The braze liner preferably comprises an Al—Si-base alloy. A tubular member made from the foregoing tubestock is also disclosed.

Owner:ARCONIC INC

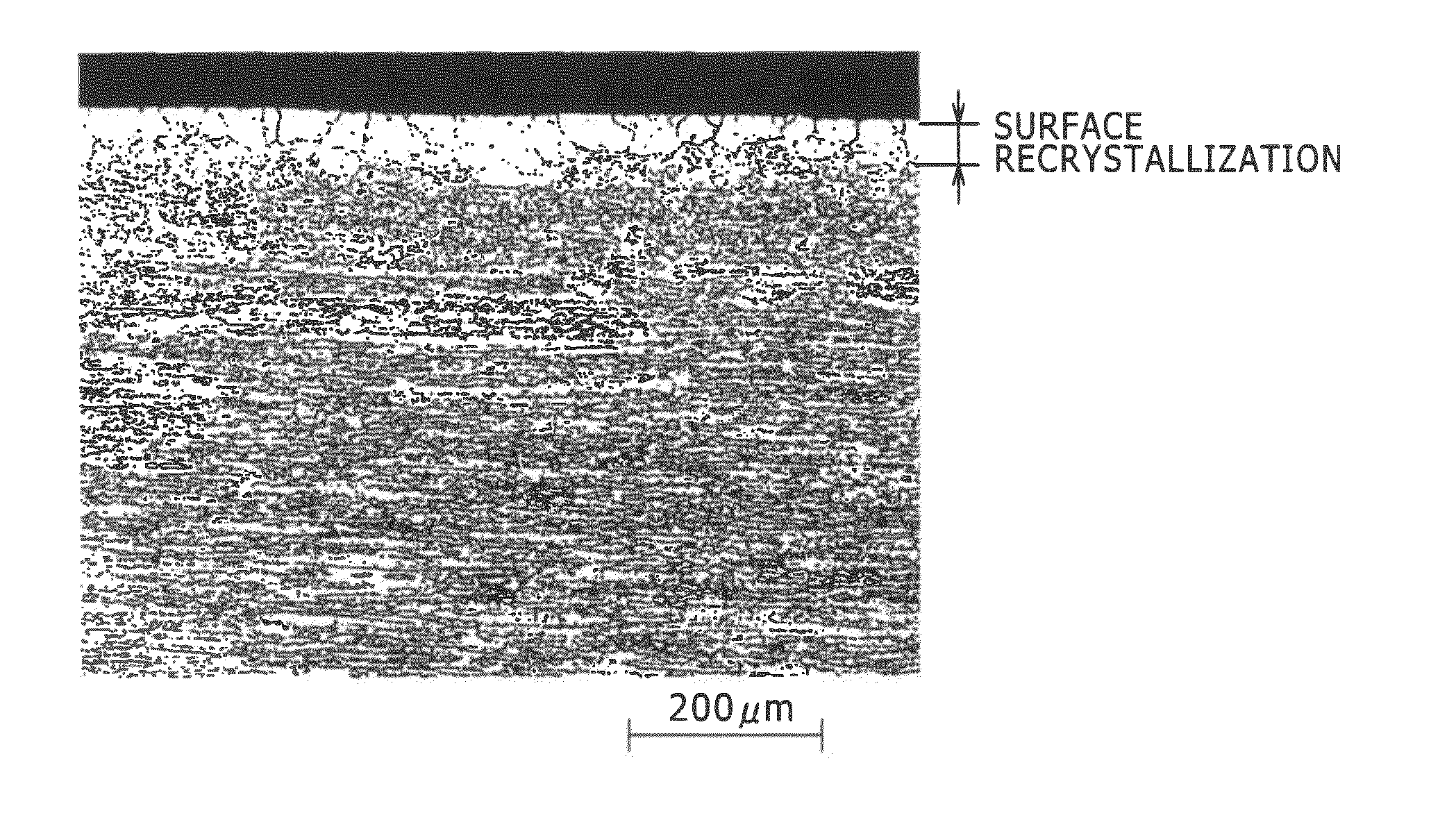

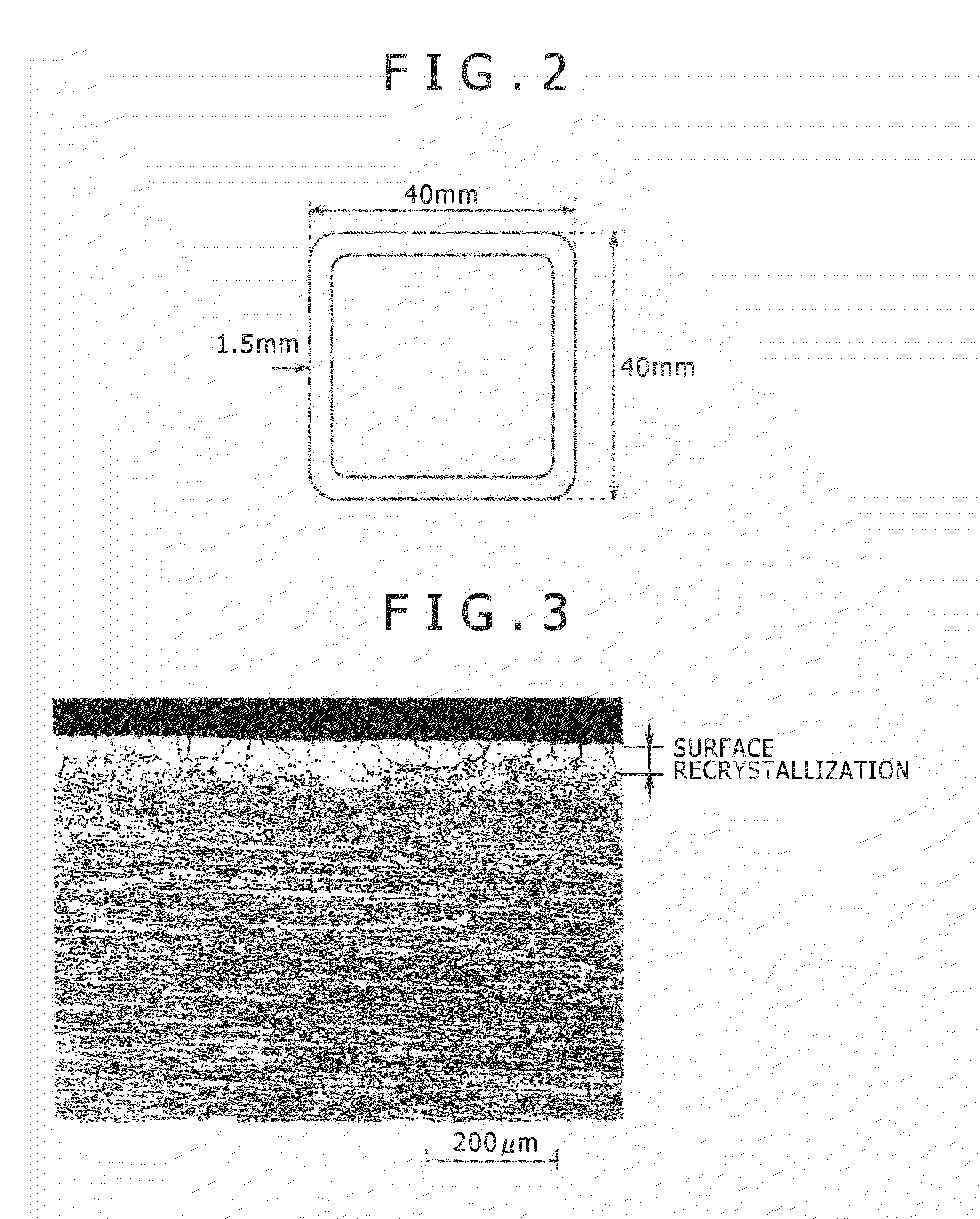

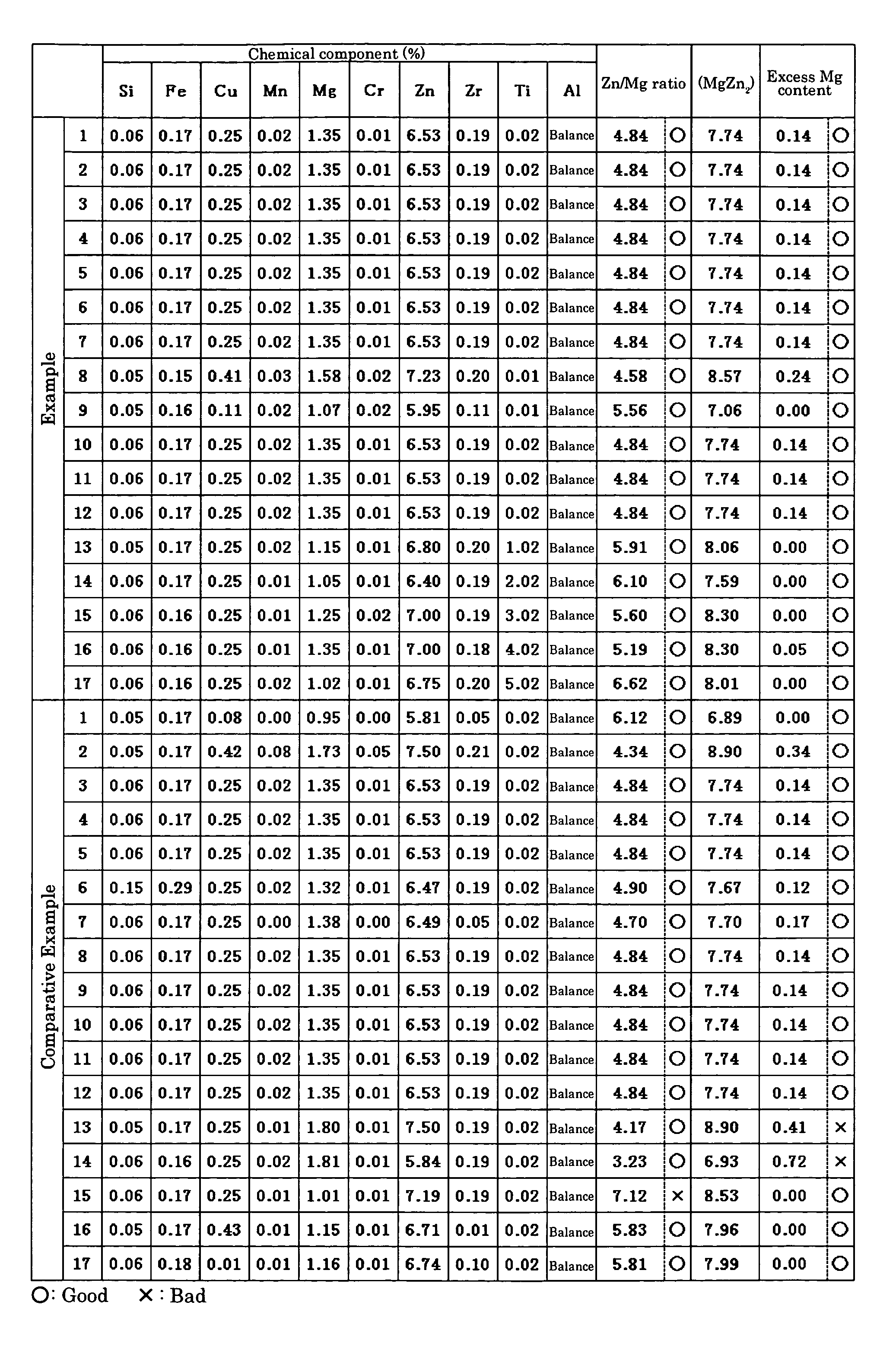

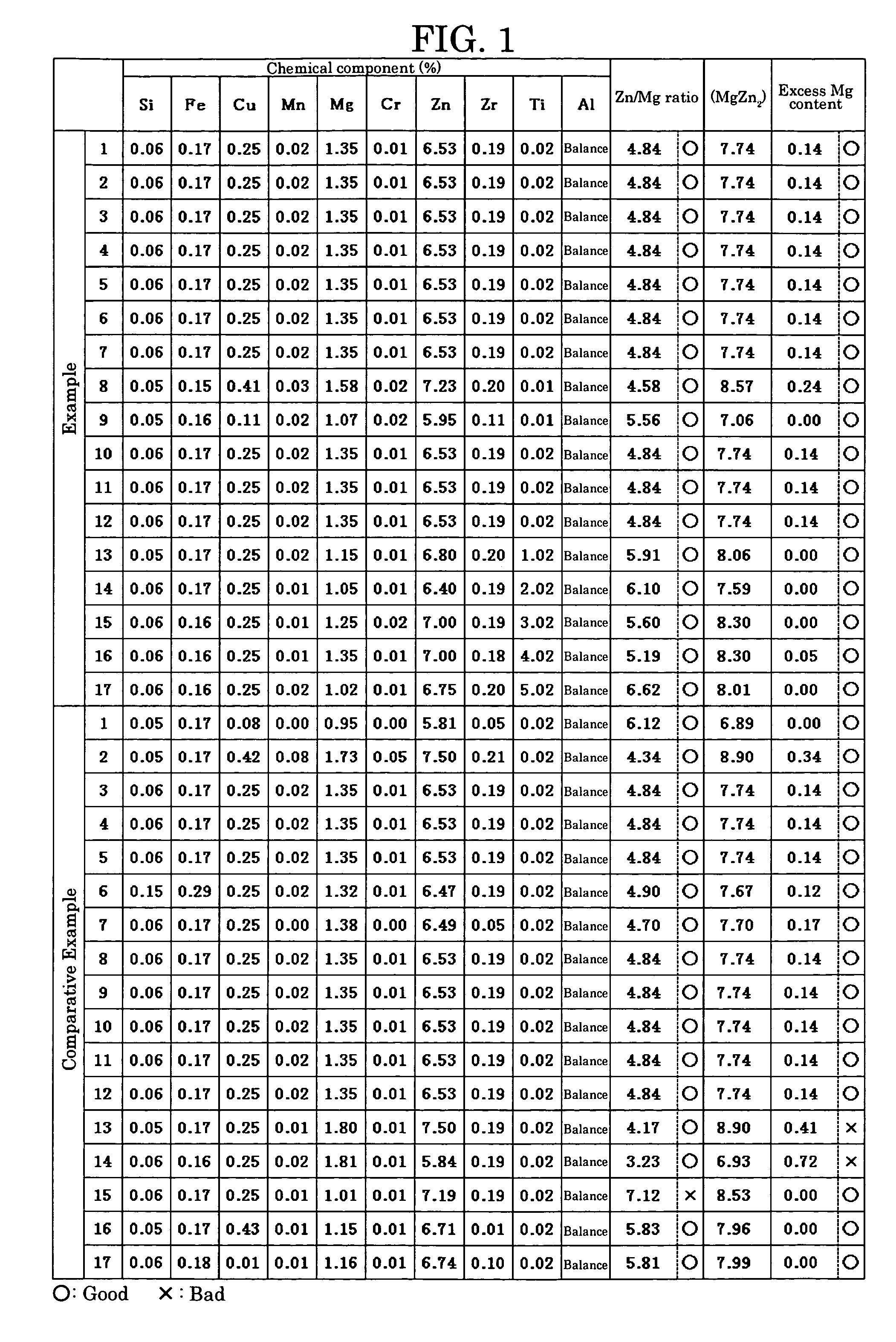

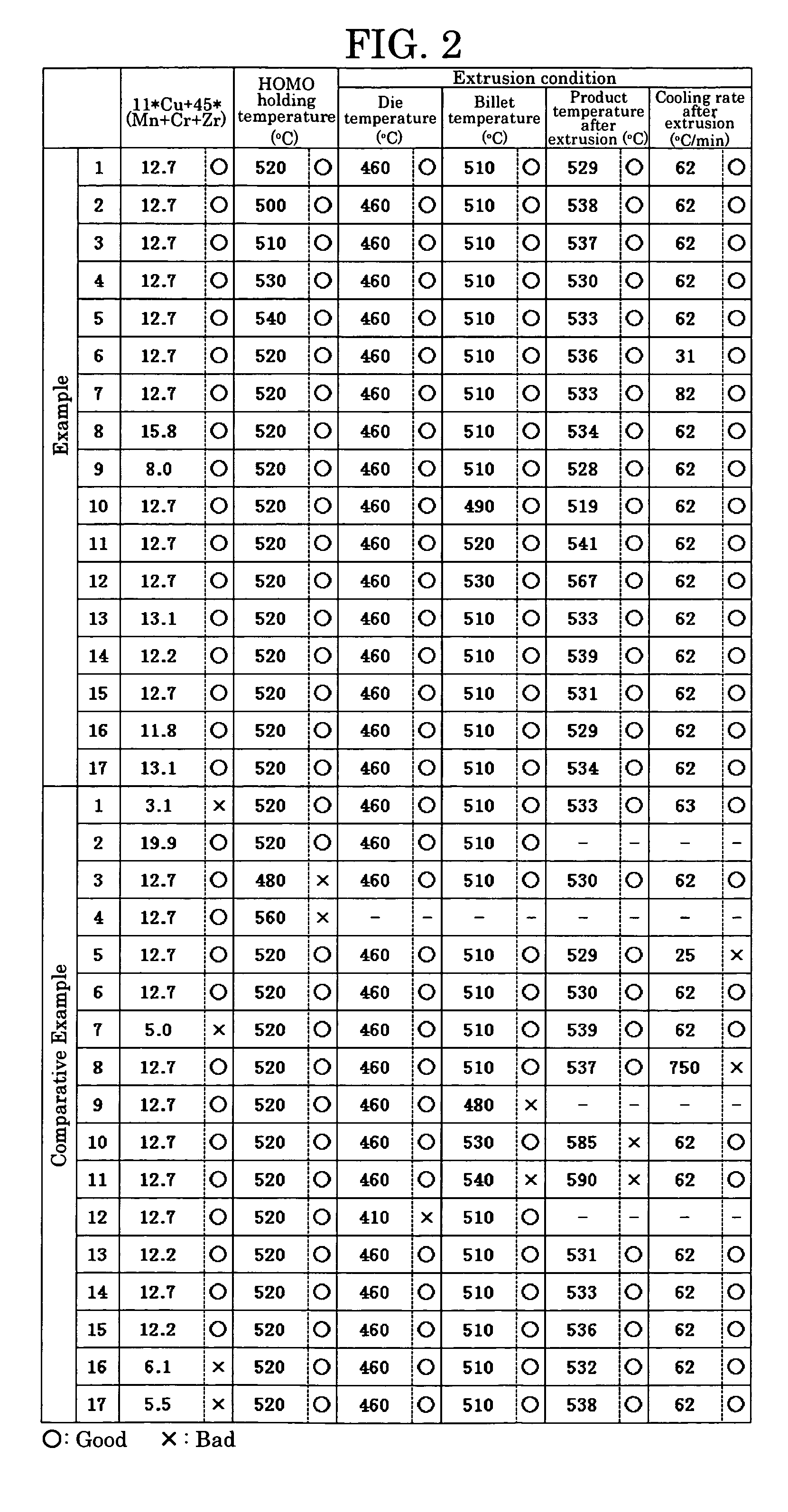

High-strength aluminum alloy extruded product with excellent impact absorption and stress corrosion cracking resistance and method of manufacturing the same

An aluminum alloy extruded product includes an aluminum alloy including 6.0 to 7.2 mass % of Zn, 1.0 to 1.6 mass % of Mg, 0.1 to 0.4 mass % of Cu, at least one component selected from the group consisting of Mn, Cr, and Zr in a respective amount of 0.25 mass % or less and a total amount of 0.15 to 0.25 mass %, 0.20 mass % or less of Fe, and 0.10 mass % or less of Si, with the balance substantially being aluminum, the aluminum alloy extruded product having a hollow cross-sectional shape, a recrystallization rate of 20% or less of a cross-sectional area of the extruded product, and a 0.2% proof stress of 370 to 450 MPa.

Owner:AISIN KEIKINZOKU CO LTD

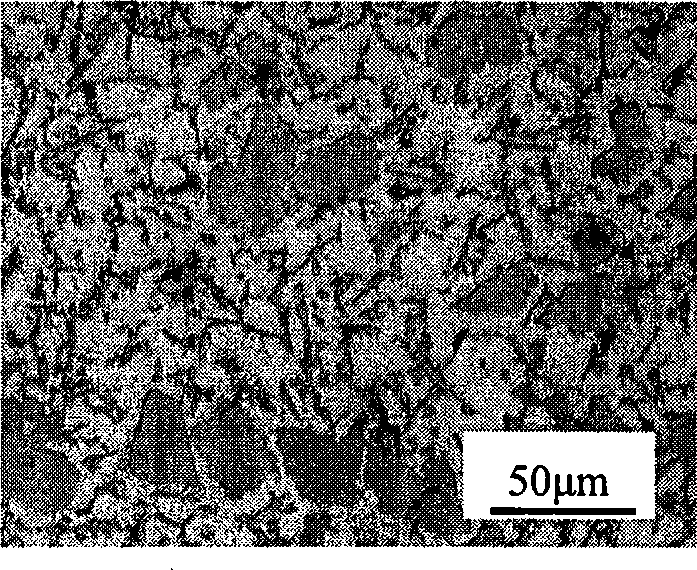

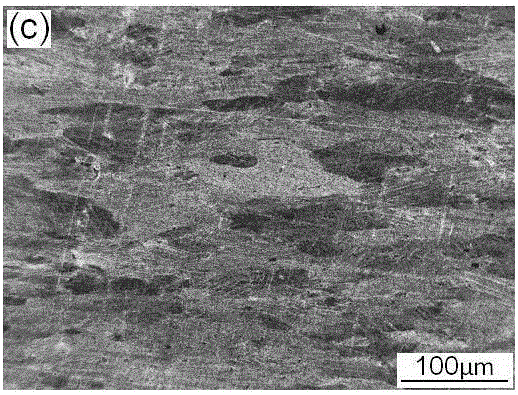

Structural material piece of magnesium-containing silumin and method for preparing same

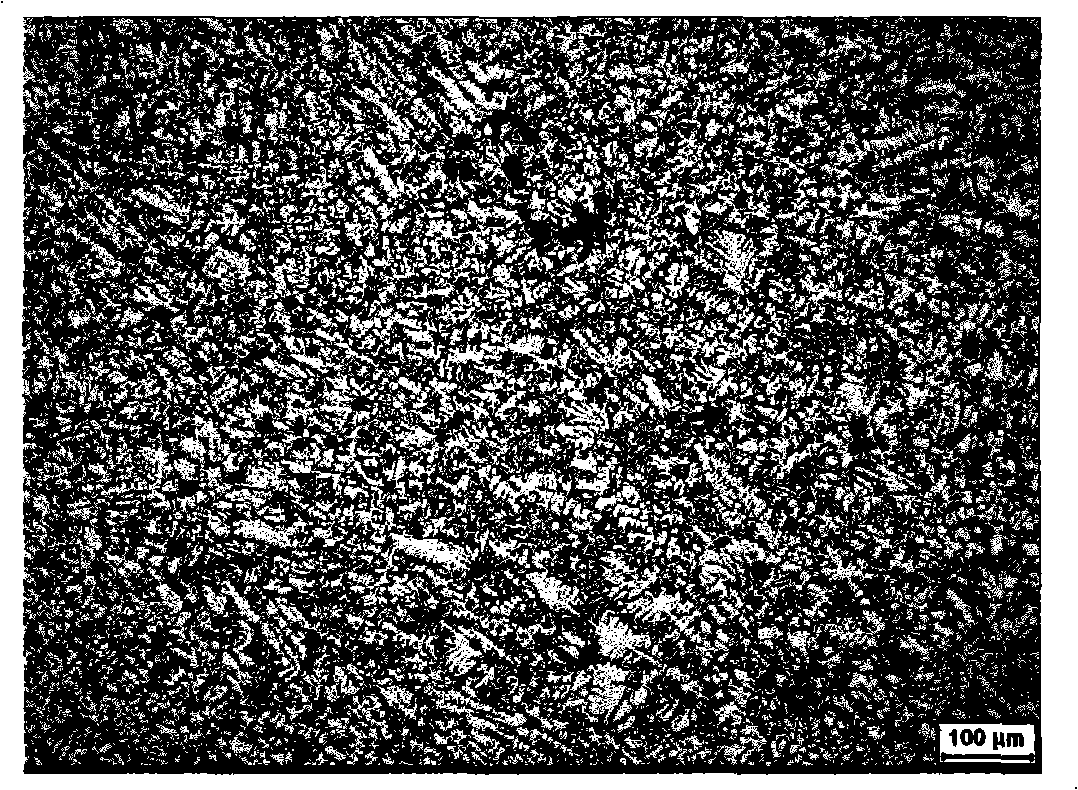

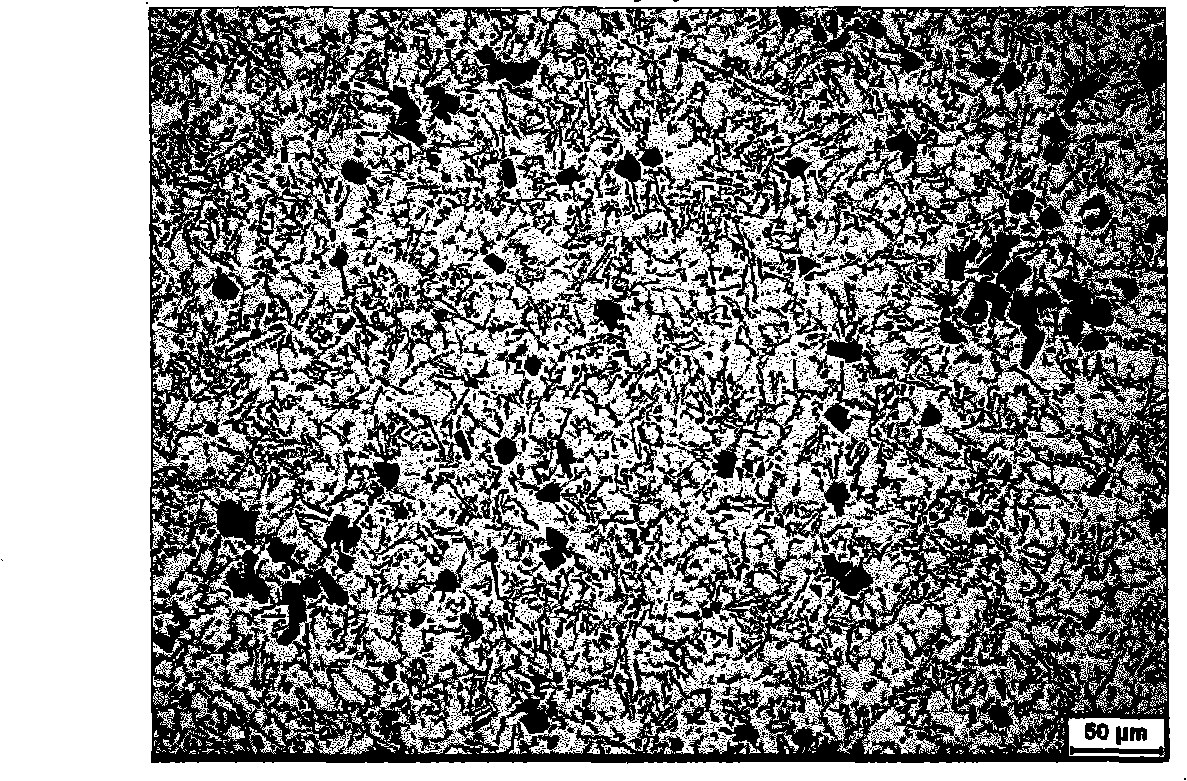

Disclosed is a structure material part containing magnesium and high-silicon aluminum alloy, which comprises a profile, a rod, a plate and a forged part. The structure material part is characterized in that an ingot is prepared by the method of semi-continuous casting, then phase particles of eutectic silicon are discretized by preheating treatment, and then the ultimate form and the microstructure are obtained by hot-deforming processing and heating treatment; the structure material part contains 0.2 to 2.0 weight percent of magnesium, and 8 to 18 weight percent of silicon; and the structure material part has even and refined microstructure, for the structure of aluminum matrix is of equiaxed grains whose average size is less than 6 microns, and the silicon and other second phase particles are dispersively distributed, and the average size of the second phase particles is less than 5 microns. The structure material part containing magnesium and high-silicon deformed aluminum alloy, which has good plasticity and higher strength, can be manufactured with low cost on the premise that no modifier is added in the casting process.

Owner:NORTHEASTERN UNIV LIAONING

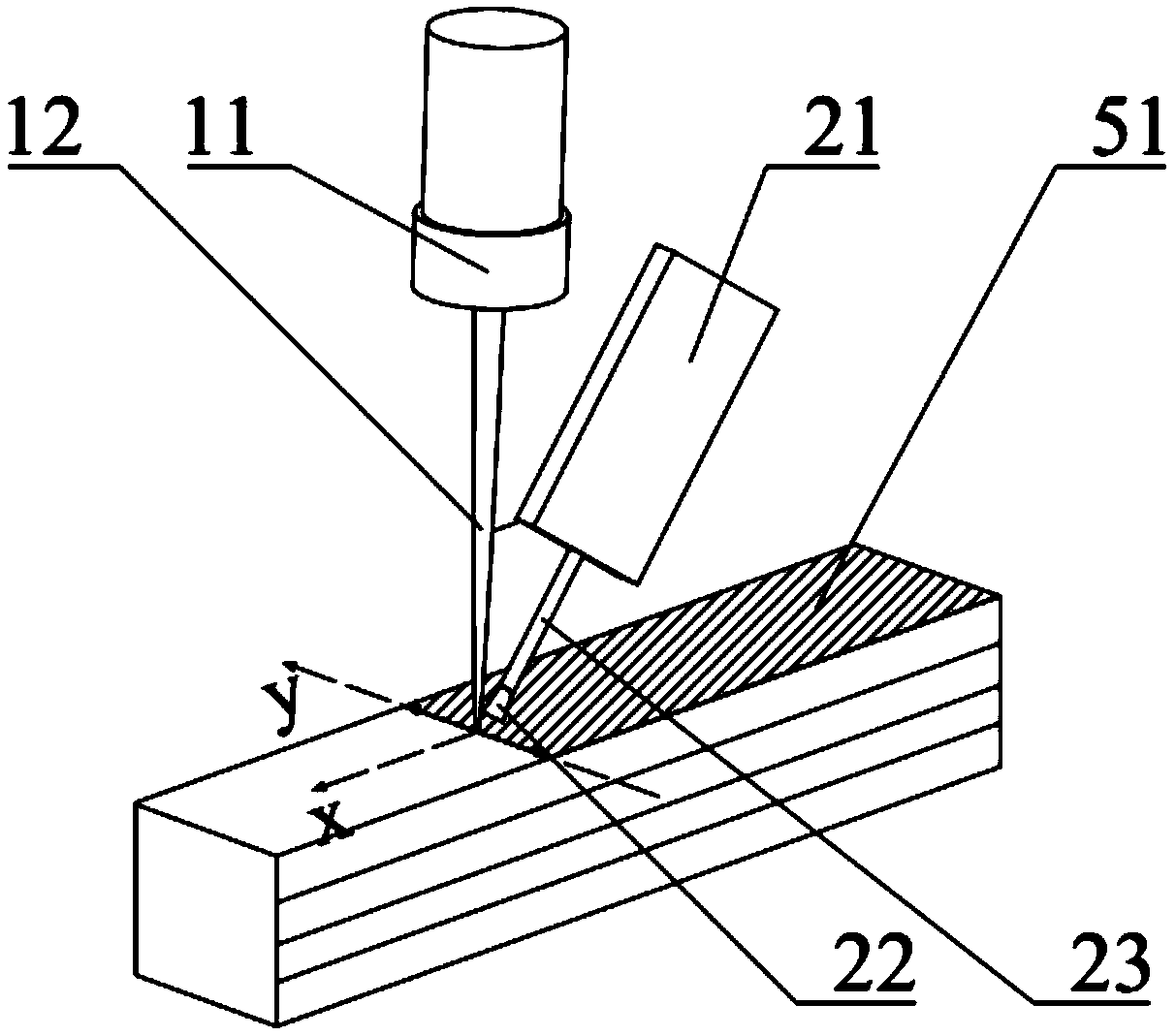

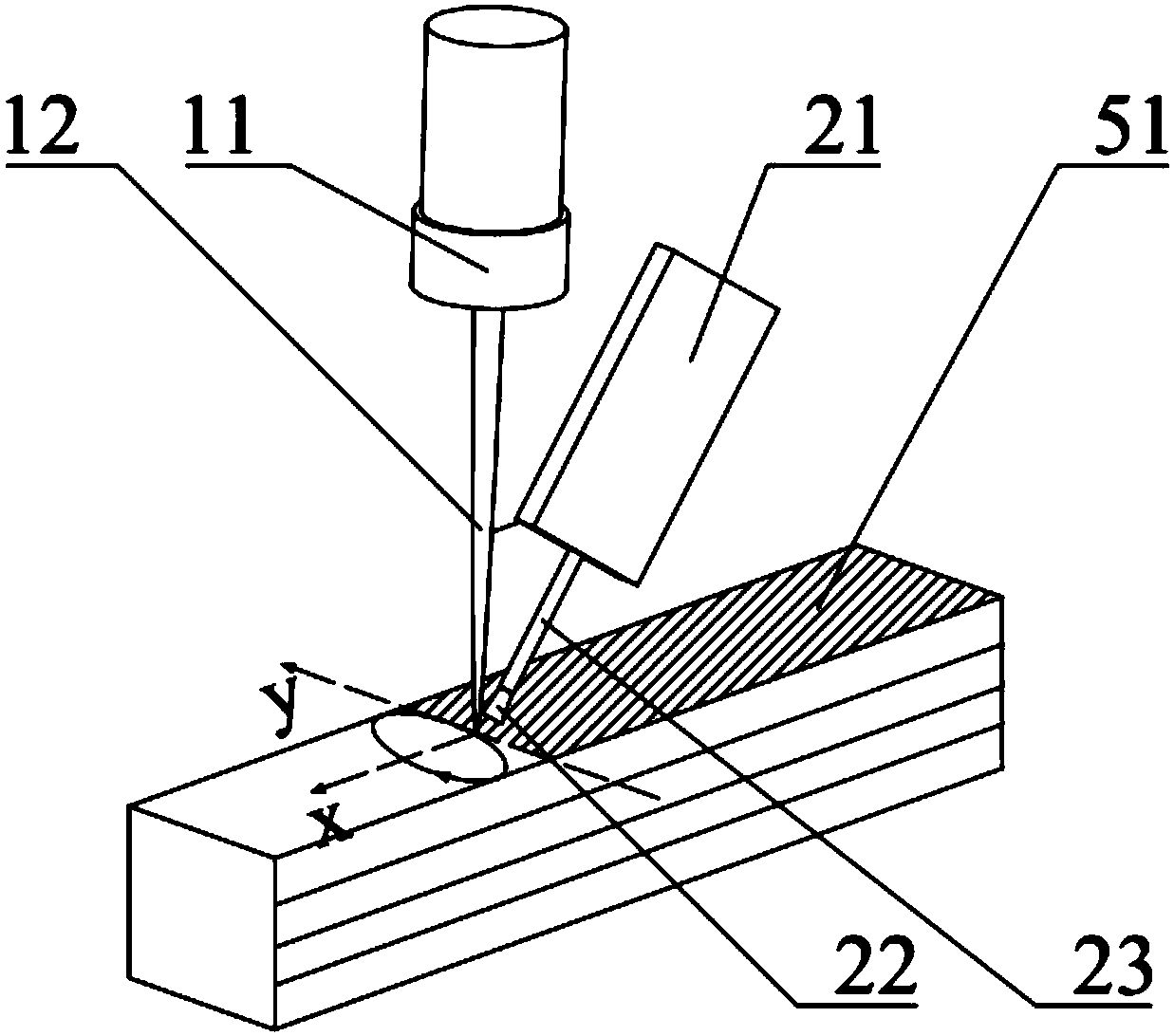

Metal powder for 3D printing of high-strength aluminum alloy and printing method and application thereof

ActiveCN109128150AImprove performanceShorten the setting timeAdditive manufacturing apparatusTransportation and packagingHigh intensityGraphene

The invention discloses a metal powder for 3D printing of a high-strength aluminum alloy, a printing method for 3D printing of the high-strength aluminum alloy with the metal powder and application ofthe 3D printing method. The metal powder for 3D printing of the high-strength aluminum alloy comprises aluminum alloy micro-particles. The metal powder is characterized in that the surface of the aluminum alloy micro-particles is modified with graphene and nano-reinforced particles from inside to outside; the addition amount of the graphene is 0.3-0.6% of the total mass of the metal powder, and the total addition amount of the nano-reinforced particles is 1-3% of the total mass of the metal powder; the particle size of the aluminum alloy micro-particles is 10[mu]m-60[mu]m; and the particle size of the nano-reinforced particles is 30nm-60nm. The metal powder can be used for printing the high-strength aluminum alloy and is widely applied in the manufacture of aluminum alloy parts.

Owner:SOUTHWEST JIAOTONG UNIV

Low-melting-point and high-intensity aluminum alloy powder brazing filler metal and preparing method of low-melting-point and high-intensity aluminum alloy powder brazing filler metal

ActiveCN104227263APrevent corrosionImprove performanceWelding/cutting media/materialsSoldering mediaSiluminSolidus

The invention discloses a high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C and a preparing method of the high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C, and belongs to the technical field of aluminum alloy brazing. The brazing filler metal comprises the following ingredients in parts by weight: 8.6 to 9.5 percent of Si, 16.5 to 17.5 percent of Cu, 8.5 to 9.5 percent of Ge, 4.5 to 5.0 percent of Ni, 4.0 to 5.0 percent of Zn, 0.70 to 0.75 percent of Sr, 0.35 to 0.40 percent of Bi, 0.40 to 0.45 percent of La, 0.40 to 0.55 percent of Ce, 0.10 to 0.20 percent of Yb and the balance Al. The brazing filler metal is prepared by adopting a flux rapid cooling-ball milling technology, the melting point is lower than 490 DEG C, the brazing temperature is 500 to 520 DEG C, and the brazing filler metal is applicable to aluminum alloy brazing with the solid phase line temperature higher than 500 DEG C, such as in-furnace brazing, vacuum brazing, induction brazing and flame brazing. The brazing filler metal is matched with QJ201 for brazing 3003 aluminum alloy, and the shearing intensity of a brazing joint is greater than 74MPa.

Owner:ZHEJIANG UNIV

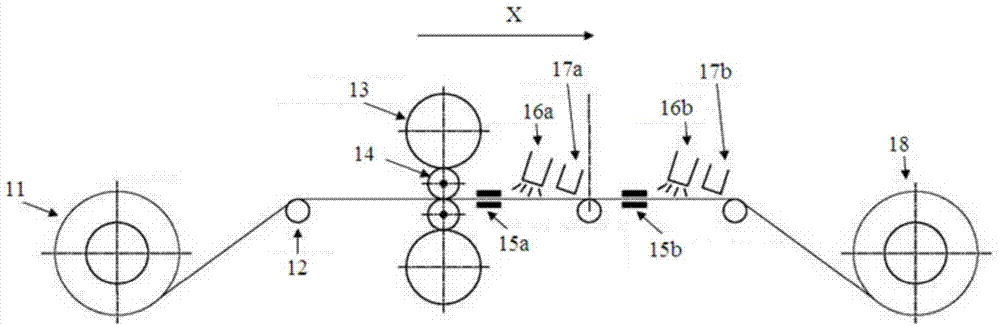

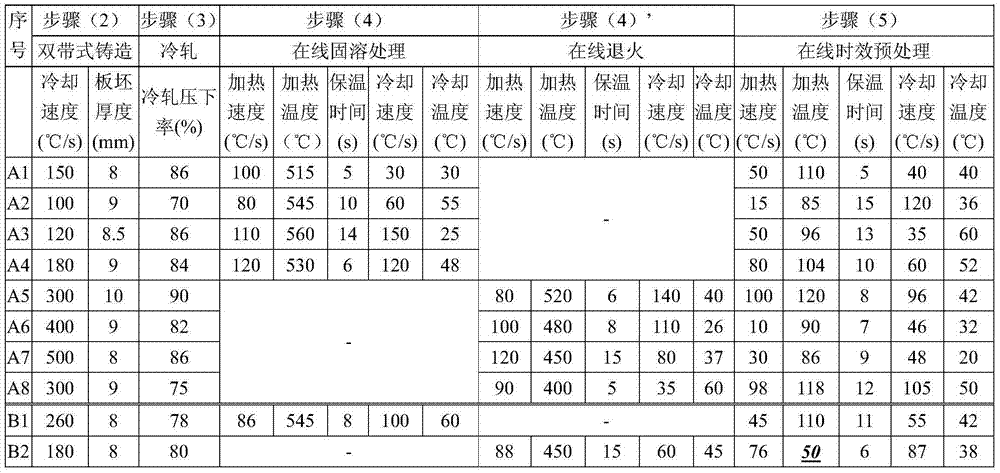

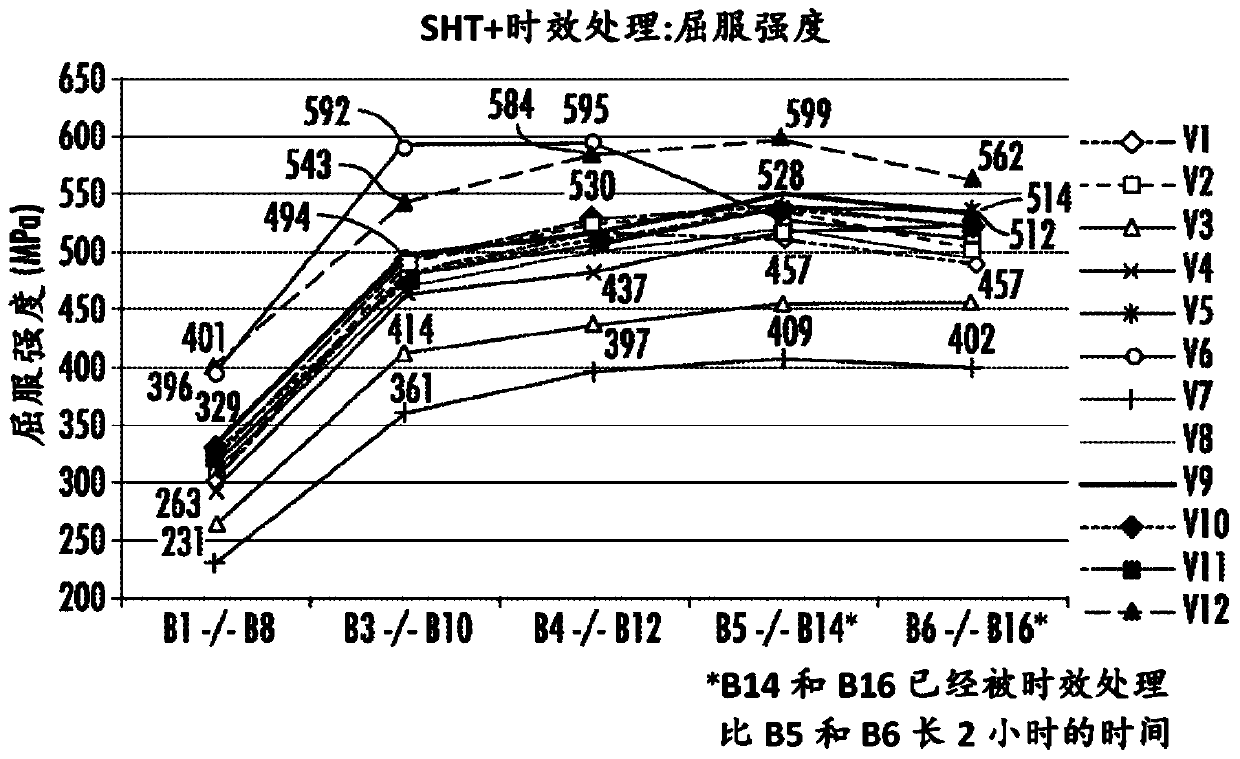

High-strength aluminum-alloy material, aluminum-alloy plate and manufacturing method thereof

The invention discloses a high-strength aluminum-alloy material. The high-strength aluminum-alloy material contains the chemical elements in percentage by mass: not lower than 1.5% and not higher than 3.0% of Mg, not lower than 0.05% and not higher than 0.2% of Si, not lower than 0.1% and not higher than 0.2% of Mn, not lower than 0.2% and not higher than 0.4% of Fe, higher than 0 and not higher than 0.03% of Cu, higher than 0 and not higher than 0.05% of Ti, either not lower than 0.05% and not higher than 0.15% of Ca or not lower than 0.05% and not higher than 0.15% of Sr and the balance of Al and other unavoidable impurities. The invention further discloses an aluminum-alloy plate manufactured from the aluminum-alloy material. The invention further discloses a manufacturing method of the aluminum-alloy plate, wherein the method comprises the steps of carrying out double-strip casting, carrying out cold rolling, carrying out online solid solution treatment and carrying out online aging pretreatment. The high-strength aluminum-alloy material and the aluminum-alloy plate, disclosed by the invention, have relatively high strength and good natural aging stability. After painting and baking, the yield strength of the high-strength aluminum-alloy material and the aluminum-alloy plate is higher than 300Mpa.

Owner:BAOSHAN IRON & STEEL CO LTD

High strength 7xxx aluminum alloys and methods of making the same

High strength 7xxx aluminum alloys and methods of making the same. Described herein are novel 7xxx series aluminum alloys. The alloys exhibit high strength. The alloys can be used in a variety of applications, including automotive, transportation, electronics, aerospace, and industrial applications. Also described herein are methods of making and processing the alloys. Further described herein aremethods of producing a metal sheet, which include casting an aluminum alloy as described herein to form an ingot, homogenizing the ingot, hot rolling the ingot to produce a hot band, and cold rollingthe hot band to a metal sheet of final gauge.

Owner:NOVELIS INC

Aluminum alloy extruded product for heat exchangers and method of manufacturing the same

InactiveUS20050189047A1Reduce resistanceReduce the amount requiredHeat exchange apparatusSiluminHigh intensity

A high-strength aluminum alloy extruded product for heat exchangers which excels in extrudability, allows a thin flat multi-cavity tube to be extruded at a high critical extrusion rate, and excel in intergranular corrosion resistance at a high temperature, and a method of manufacturing the same. The aluminum alloy extruded product includes an aluminum alloy including 0.2 to 1.8% of Mn and 0.1 to 1.2% of Si, having a ratio of Mn content to Si content (Mn % / Si %) of 0.7 to 2.5, and having a content of Cu as an impurity of 0.05% or less, with the balance being Al and impurities, the aluminum alloy extruded product having an electric conductivity of 50% IACS or more and an average particle size of intermetallic compounds precipitating in a matrix of 1 μm or less.

Owner:FURUKAWA SKY ALUMINUM CORP +2

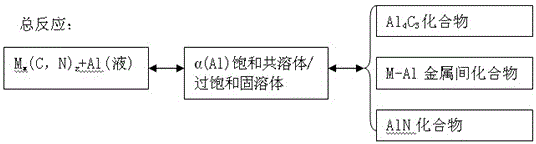

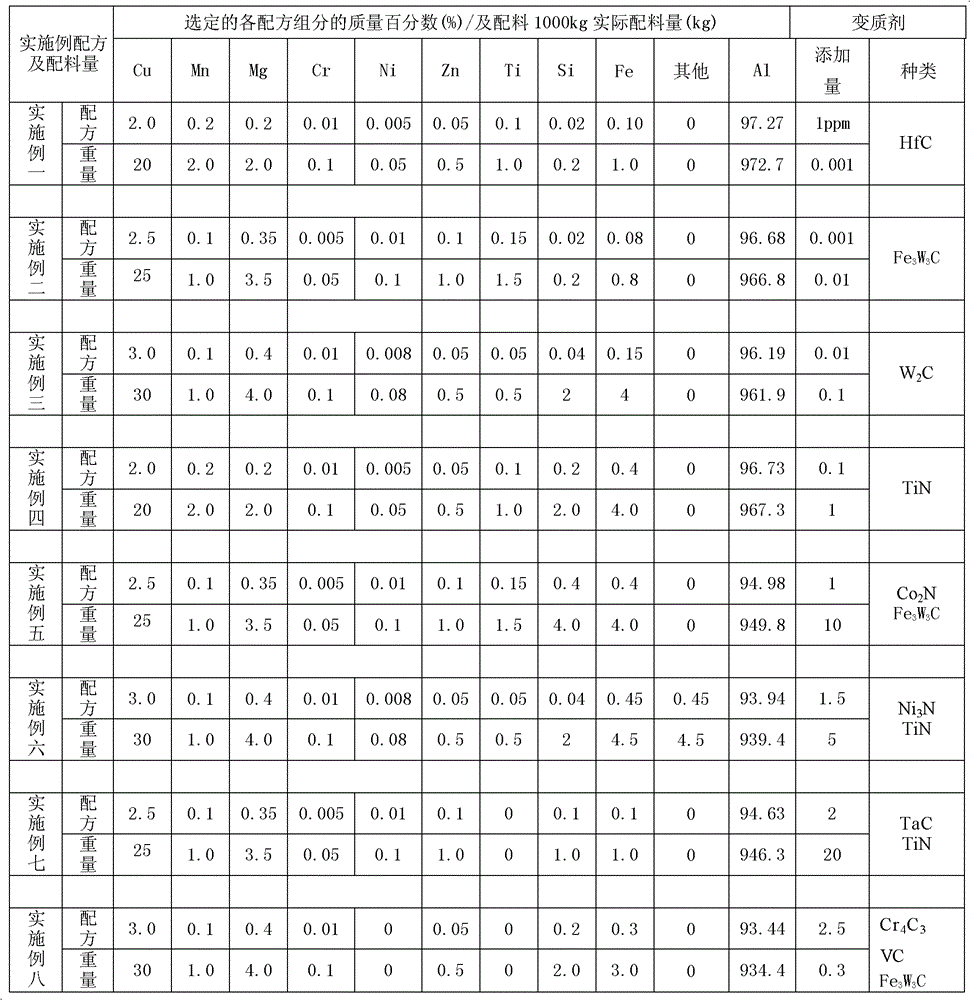

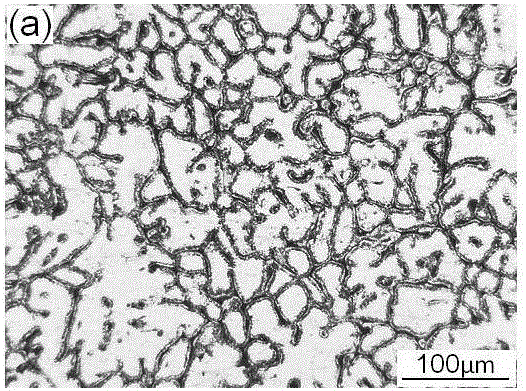

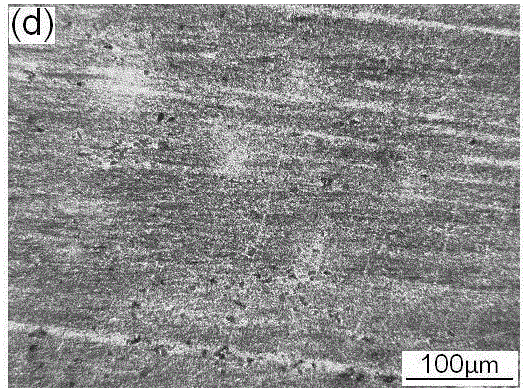

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Rolling method for ultrahigh-strength aluminum alloy plate

The invention discloses a rolling method for an ultrahigh-strength aluminum alloy plate. The rolling method comprises the following steps: A, a refined aluminum alloy ingot blank is annealed for 24-48 h uniformly at 450-550 DEG C; B, the annealing temperature is controlled to be 360-440 DEG C; single-pass 2-5% hot rolling pre-deformation is performed after inner temperature and outer temperature are uniform; temperature is continuously controlled to be 360-440 DEG C; then single-pass high reduction rolling deformation not less than 60% is performed, so that a thick plate blank is obtained; then water cooling or air cooling is performed; C, the cooled thick plate blank is subjected to 0.5-3h solid solution treatment at 450-550 DEG C, and then is subjected to water quenching; D, the water quenched thick plate blank is subjected to 6h of pre-aging treatment at 150-250 DEG C, and then is air-cooled to room temperature; and E, the thick plate blank which is air cooled to the room temperature is subjected to 40-60% of cold rolling deformation, and then is subjected to final-aging treatment at 120-200 DEG C. The plate made with the rolling method has ultrahigh strength, high damage-resistance and long service life.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Treatment method for alloying surface of superhigh-strength aluminum alloy

InactiveCN102691040AIncreased microhardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingSiluminMg alloys

The invention provides a treatment method for alloying the surface of a superhigh-strength aluminum alloy. The treatment method comprises the following steps: firstly, manufacturing a Cu-Cr alloy cast ingot of which the Cr content is 3-20 percent by using a vacuum induction smelting method; carrying out surface removal and grinding treatment and then fixedly mounting the Cu-Cr alloy cast ingot on a target device of vacuum magnetron sputtering equipment; mounting the aluminum alloy subjected to clean surface grinding treatment on a matched clamp and mounting the aluminum alloy into a vacuum chamber of the vacuum magnetron sputtering equipment; opening the vacuum magnetron sputtering equipment; plating a Cu-Cr alloy film with the thickness of 2-10mum on the surface of an aluminum alloy substrate; and feeding the surface-plated Ni-Cr alloy film into strong-current pulse electron beam equipment for carrying out surface alloying treatment on the electron beams. According to the method disclosed by the invention, a layer of Cu-Cr alloying layer with high microhardness and favorable wear resistance and corrosion resistance is formed on the surface of the aluminum alloy. The alloyed layer and an aluminum alloy matrix are better bonded; and the surface strength of the aluminum alloy can be effectively improved and the wear resistance and corrosion resistance of the surface of the aluminum alloy are improved.

Owner:CHONGQING UNIV OF TECH

High-strength aluminum alloy material formed through metamorphism of salt hexafluorosilicate

The invention discloses a high-strength aluminum alloy material formed through metamorphism of salt hexafluorosilicate. The high-strength aluminum alloy material formed through the metamorphism of the salt hexafluorosilicate comprises, by weight, 2.6-3.2% of Cu, 0.45-0.7% of Mn, 2.0-2.4% of Mg, not more than 0.1% of Zn, not more than 0.15% of Ti, not more than 0.3% of Si, and not more than 0.3% of Fe. Salt hexafluorosilicate alterant accounts for 0.1-1.0% of the total furnace burden, and the rest is Al and unavoidable trace impurities, and the trace impurities comprise, by weight, not more than 0.05% of a single and not more than 0.10% of a total. The high-strength aluminum alloy material formed through the metamorphism of the salt hexafluorosilicate is good in metamorphism refining effect, can purify a furnace body, and is high in strength.

Owner:GUIZHOU ACAD OF SCI

Directly extrusion cast high strength aluminium alloy

The present invention relates to aluminum alloy material, and is especially one kind of directly extrusion cast high strength aluminum alloy. The aluminum alloy consists of Cu 4.0-5.0 wt%, Mg 1.0-2.0 wt%, Mn 0.4-0.8 wt%, trace alloy elements including Ti 0.05-0.25 wt%, B 0.01-0.05 wt%, V 0.05-0.20 wt% and Zr 0.05-0.20 wt%, and mixed RE 0.05-0.15 wt% except Al and inevitable impurities, including Fe less than 0.2 wt% and Si less than 0.1 wt%. The aluminum alloy is prepared through direct extrusion casting, quenching and perfect artificially ageing process, has the features of capacity of being heat treated to reinforce, high strength, low cost, etc, and is suitable for use in making heavy bearing aluminum alloy structures.

Owner:SOUTH CHINA UNIV OF TECH

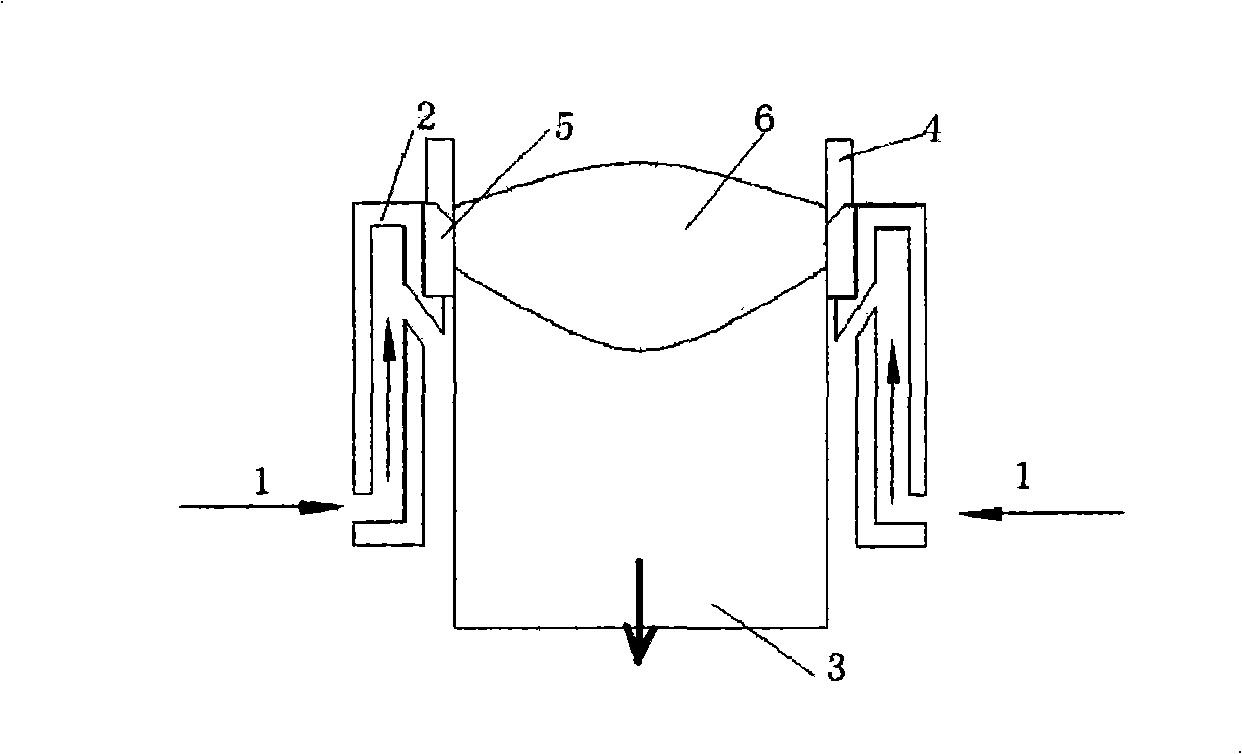

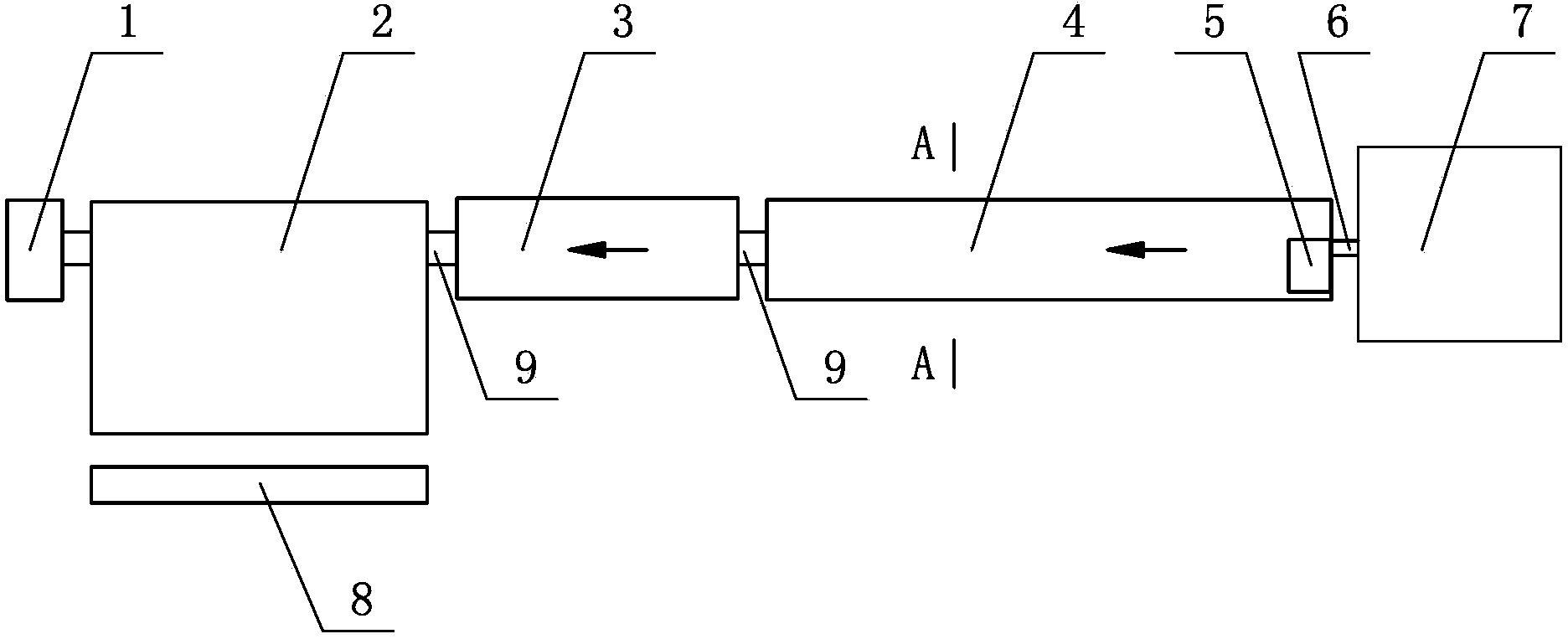

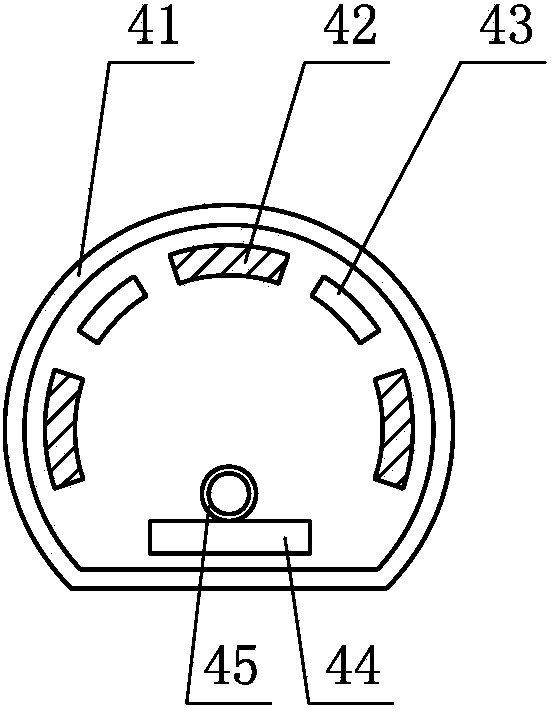

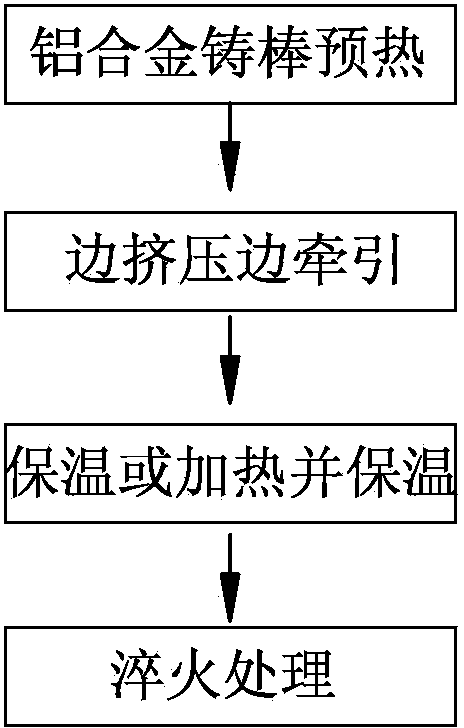

High-strength aluminum alloy online quenching system and online quenching technology

ActiveCN104060059APlay a stretching and straightening effectAvoid lostQuenching devicesEconomic benefitsHigh intensity

The invention discloses a high-strength aluminum alloy online quenching system and an online quenching technology of the high-strength aluminum alloy online quenching system. The high-strength aluminum alloy online quenching system comprises an extruding machine, a heat preservation furnace, a quenching device and a dragging machine. The online quenching technology includes the steps of preheating aluminum alloy cast rods, carrying out hot extrusion while dragging is carried out, carrying out heat preservation or heating for heat preservation, and carrying out quenching treatment. After the high-strength aluminum alloy online quenching system and the online quenching technology of the high-strength aluminum alloy online quenching system are adopted, the time of the whole transferring process that aluminum alloy profile leaves a profile outlet of the extruding machine to reach the quenching device for rapid cooling quenching treatment is quite short, immediate online quenching and continuous production after the process that the aluminum alloy profile is extruded to from product parts is completed are achieved, the production cycle is greatly shortened, and the coincidence of the product quality is guaranteed; in the production process, heat losses are few, energy consumption is low, energy is saved, the environment is improved, energy is saved by more than 80% compared with the vertical air furnace quenching technology, and the economic benefits are substantial.

Owner:SHANDONG HUAJIAN ALUMINUM GRP

High-strength aluminum alloy extruded material with excellent corrosion resistance and method of producing the same

InactiveUS20060243359A1Improve corrosion resistanceEasy extrusionExtrusion diesConditional expressionHigh intensity

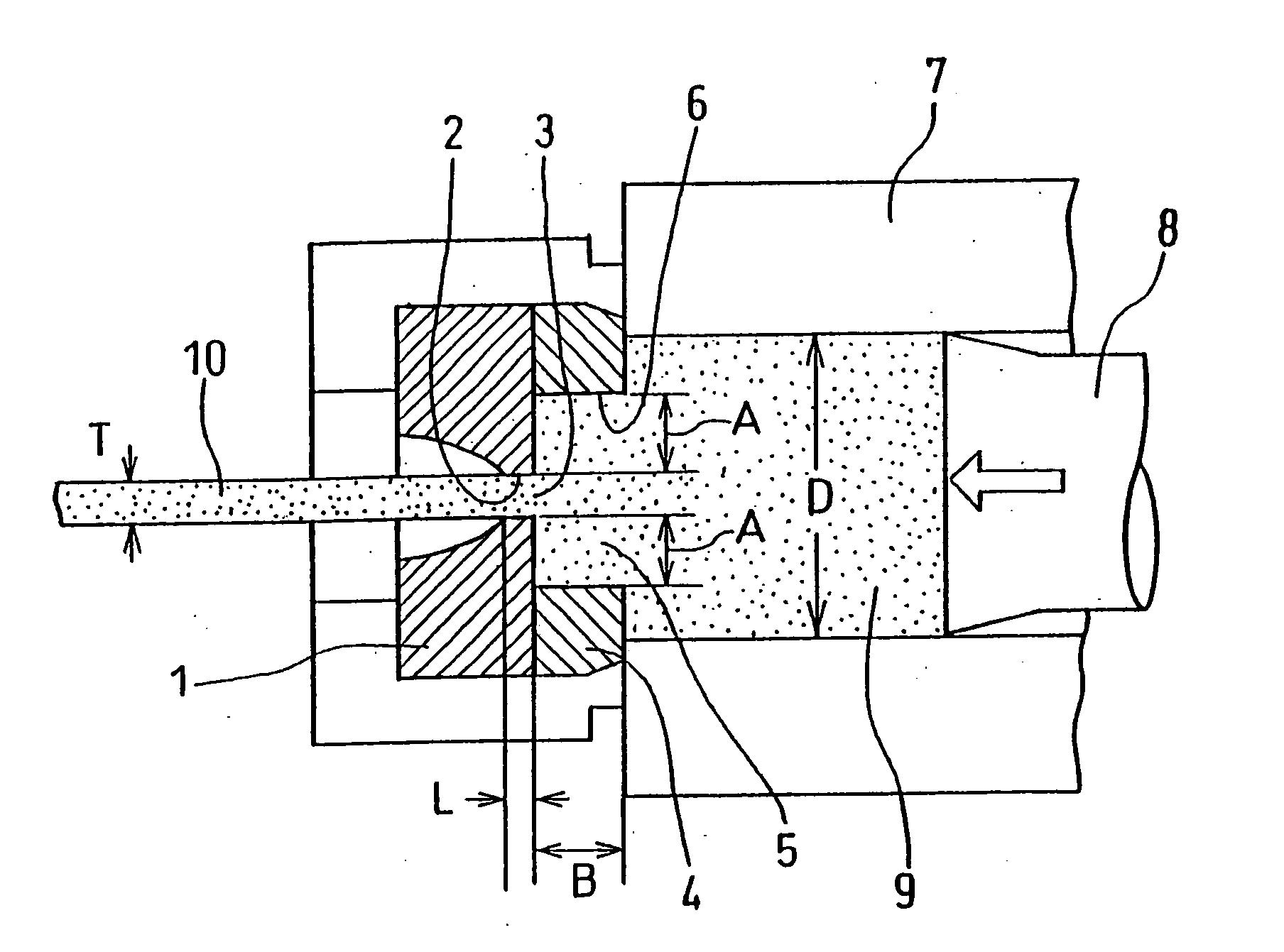

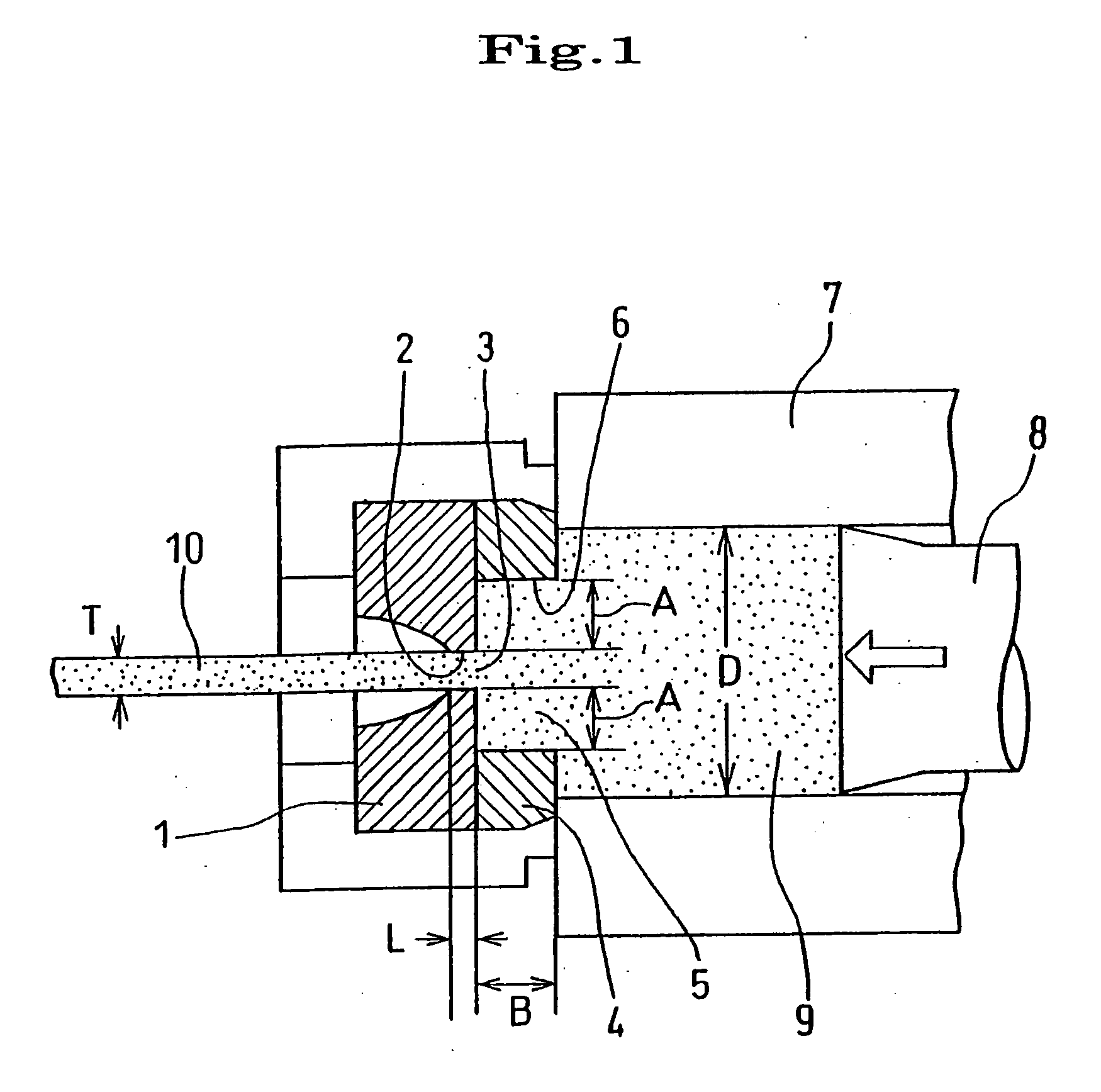

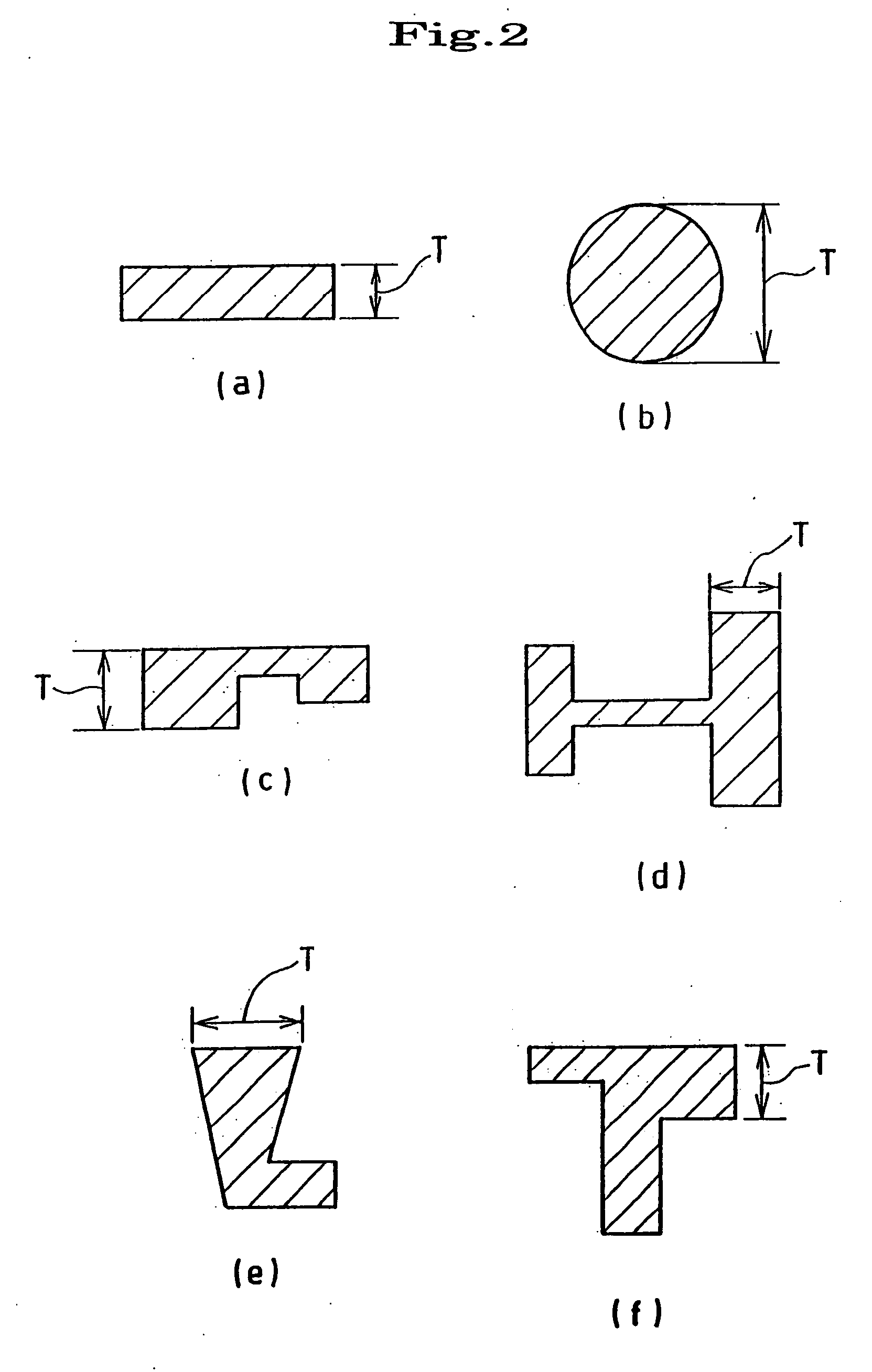

The present invention provides a high-strength aluminum alloy extruded product exhibiting excellent corrosion resistance and secondary workability and suitably used as a structural material for transportation equipment such as automobiles, railroad vehicles, and aircrafts, and a method of manufacturing the same. The aluminum alloy extruded product has a composition containing 0.6 to 1.2% of Si, 0.8 to 1.3% of Mg, and 1.3 to 2.1% of Cu while satisfying the following conditional expressions (1), (2), (3), and (4), 3%≦Si %+Mg %+Cu %≦4% (1) Mg %≦1.7×Si % (2) Mg %+Si %≦2.7% (3) Cu % / 2≦Mg %≦(Cu % / 2)+0.6% (4) and further containing 0.04 to 0.35% of Cr, and 0.05% or less of Mn as an impurity, with the balance being aluminum and unavoidable impurities. The cross section of the extruded product has a recrystallized structure with an average grain size of 500 μm or less. The manufacturing method includes, when extruding the aluminum alloy into a solid product by using a solid die, extruding the aluminum alloy by using a solid die in which a bearing length (L) is 0.5 mm or more and the bearing length (L) and the thickness (T) of the solid product have a relationship expressed as “L≦5 T”, and, when extruding the aluminum alloy into a hollow product by using a porthole die or a bridge die, extruding the aluminum alloy while setting the ratio of the flow speed of the aluminum alloy in a non-joining section to the flow speed of the aluminum alloy in a joining section in a chamber, where the billet reunites after entering a port section of the die in divided flows and subsequently encircling a mandrel, at 1.5 or less.

Owner:THE SOC OF JAPANESE AEROSPACE +2

High-strength aluminum alloy

The invention discloses a high-strength aluminum alloy. The high-strength aluminum alloy comprises, by weight percent, 2.5%-6.5% of Zn, 2.3%-4.0% of Mg, 3.1%-5.5% of Cu, 0.01%-0.1% of Mn, 2.0%-6.2% of Zr, 3.0%-5.5% of Ti, 4.5%-6.0% of Nb, 2.5%-3.5% of Ta, 0.03%-0.06% of Be, 0.8%-1.2% of Co, 1.8%-3.0% of Ru, 0.05%-0.2% of Hf, 0.02%-0.1% of Re, not larger than 0.1% of Si, not larger than 0.3% of Fe, not larger than 0.005% of P, not larger than 0.005% of S, not larger than 0.08% of Y and the balance Al and inevitable microelements.

Owner:无棣向上机械设计服务有限公司

Method for controlling aldural stretch forming covering surface quality

InactiveCN101342556AAvoid uneven distribution of internal stressGood plasticityRoughcastHigh intensity

The present invention relates to a method for controlling the surface quality of the stretching forming coating of high-strength aluminum alloy, and comprises the steps that the stretching formed roughcast is correctly arranged on the stretching forming lathe and the work station; stable and middle stretching forming speed is adopted for the operation; the deformation volume of the pre-stretching forming is controlled within the range of 1 percent to 1.5 percent; the pre-stretching formed roughcast is undertaken the solid-melting processing, and is aged for 20 to 25 hours at the room temperature, and then is performed the second (final) stretching forming. Through the correct installation of the material on the work station and the device, the material stays at the uniform plastic deformation status during the stretching forming process, so that the appearance of the coating is obtained with the minimum extension rate; through the control of the pre-stretching forming deformation volume, the problems such as the large plastic deformation and large material crystal grain are prevented during the solid-melting processing heating process. The problems that the appearance accuracy is poor for large crystal grain appears on the surface or for the less stretching deformation volume are resolved during the stretching forming of the high-strength aluminum alloy coating.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

High strength aluminum alloy casting and method of production of same

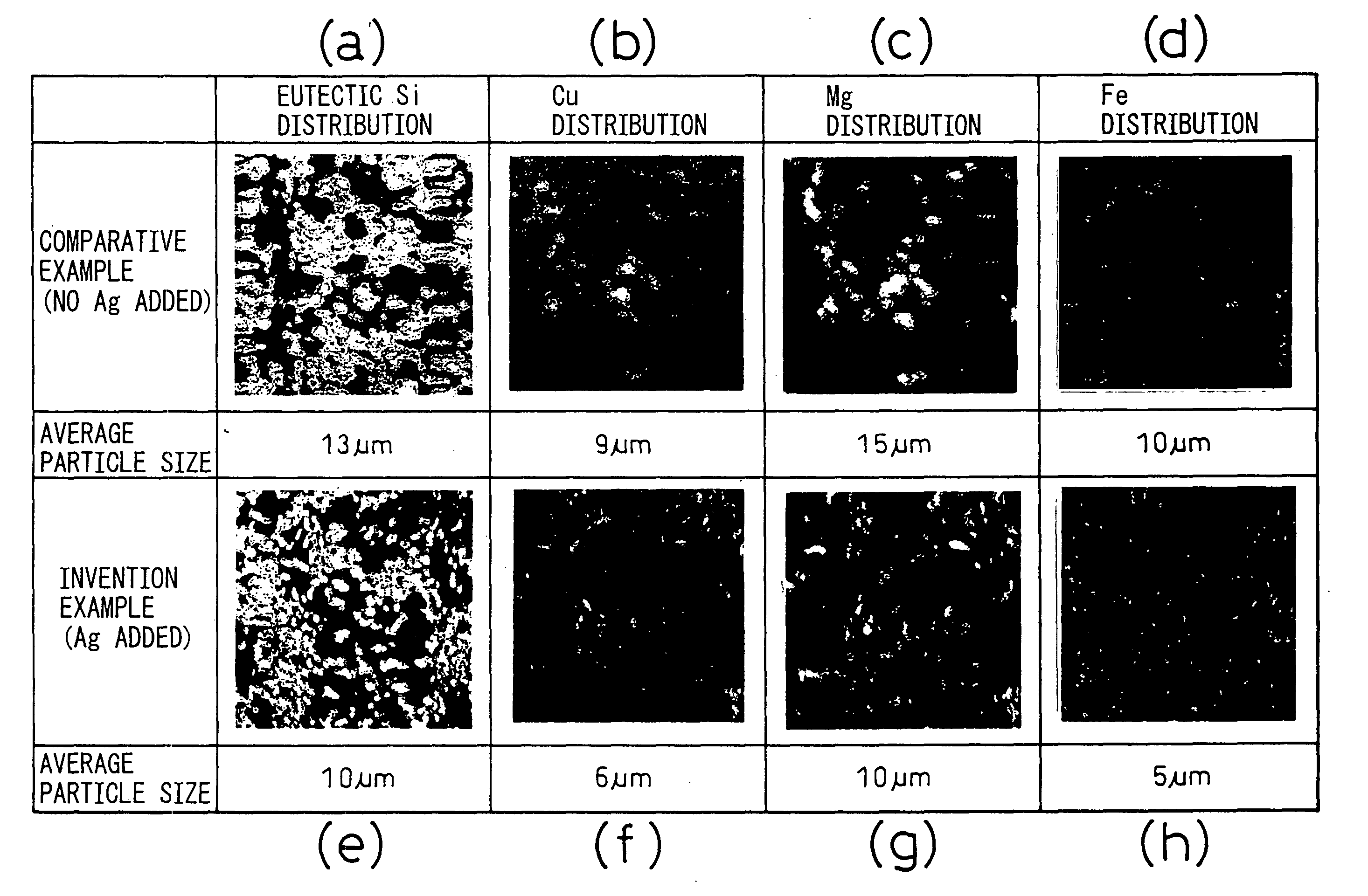

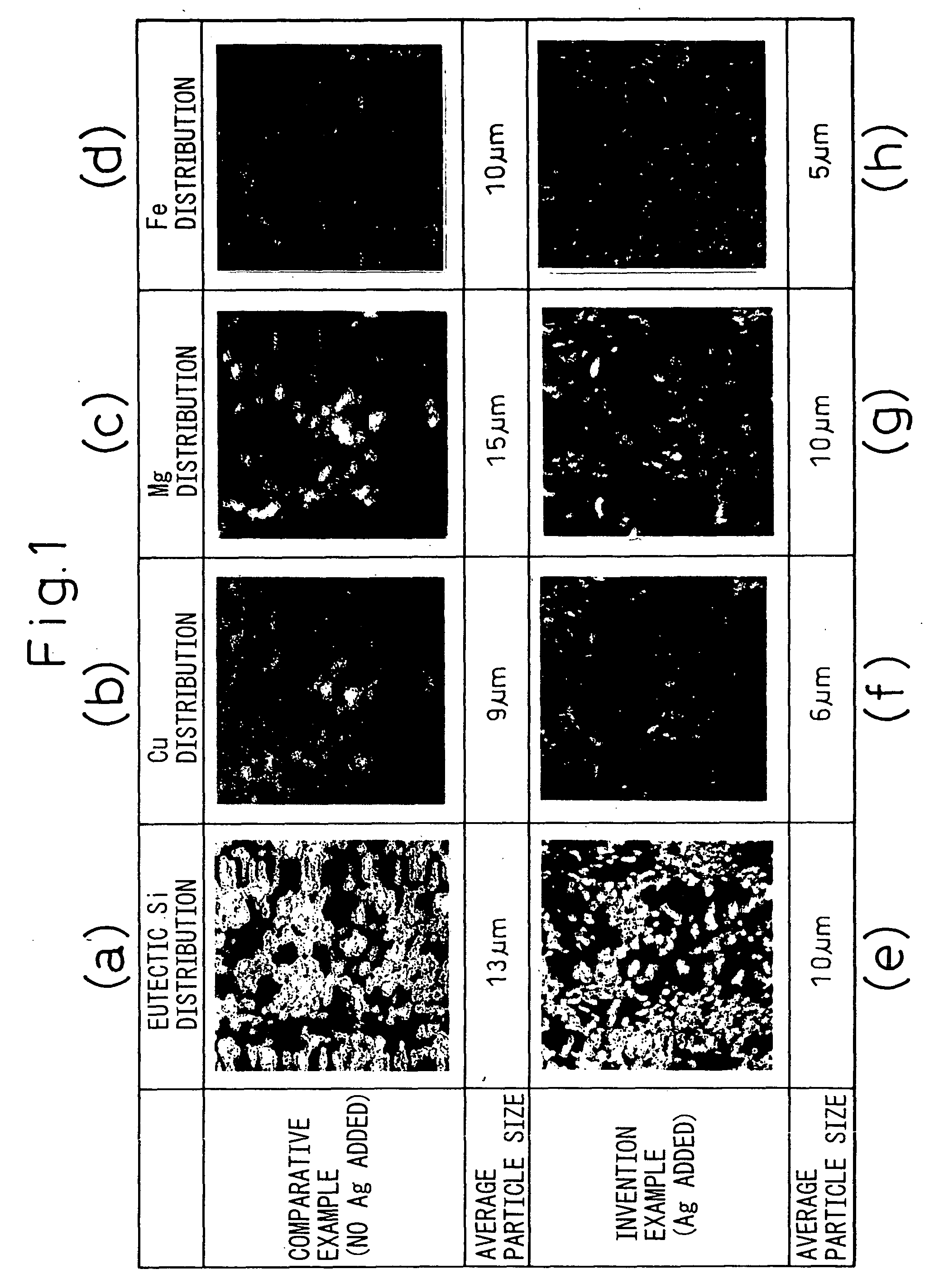

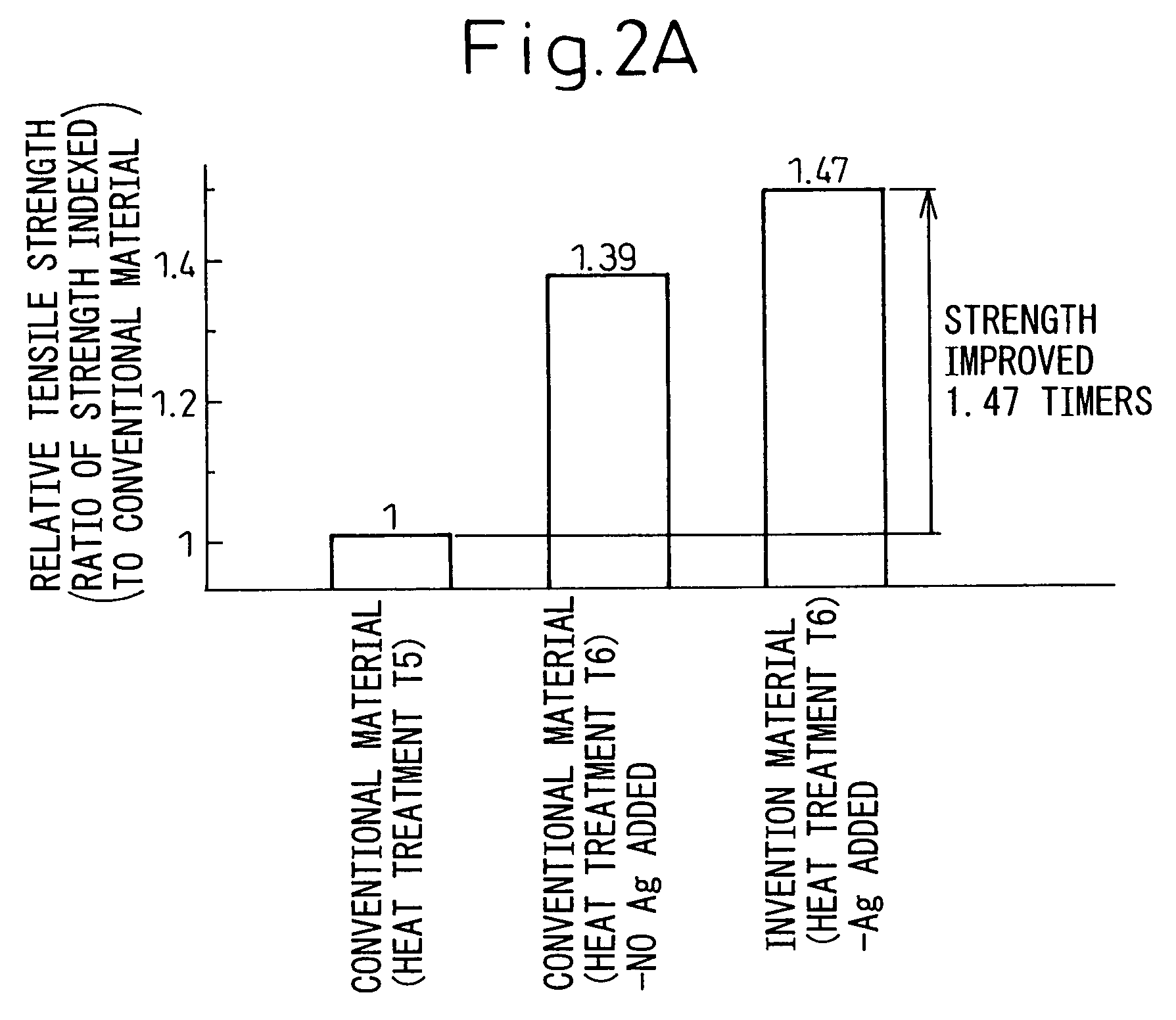

A high strength aluminum alloy casting obtained by casting an aluminum alloy comprised of 7.5 to 11.5 wt % of Si, 3.8 to 4.8 wt % of Cu, 0.45 to 0.65 wt % of Mg, 0.4 to 0.7 wt % of Fe, 0.35 to 0.45 wt % of Mn, and the balance of Al and not more than 0.2 wt % of unavoidable impurities, wherein this aluminum alloy has 0.1 to 0.3 wt % of Ag added to it or contains 0.1 to 1.0 wt % of at least one element selected from the group of second additive elements comprised of Rb, K, Ba, Sr, Zr, Nb, Ta, V, and Pd and rare earth elements, and a method of production of a high strength aluminum alloy casting comprising the steps of filling a melt of an aluminum alloy in a mold to obtain a casting, taking out the aluminum alloy casting from the mold, solubilizing the high strength aluminum alloy casting by heating in a temperature range of 495 to 505° C. for 2 to 6 hours, quenching the high strength aluminum alloy casting after the solubilization, and age hardening the high strength aluminum alloy casting by heating in a temperature range of 160 to 220° C. for 2 to 6 hours after quenching.

Owner:DENSO CORP +1

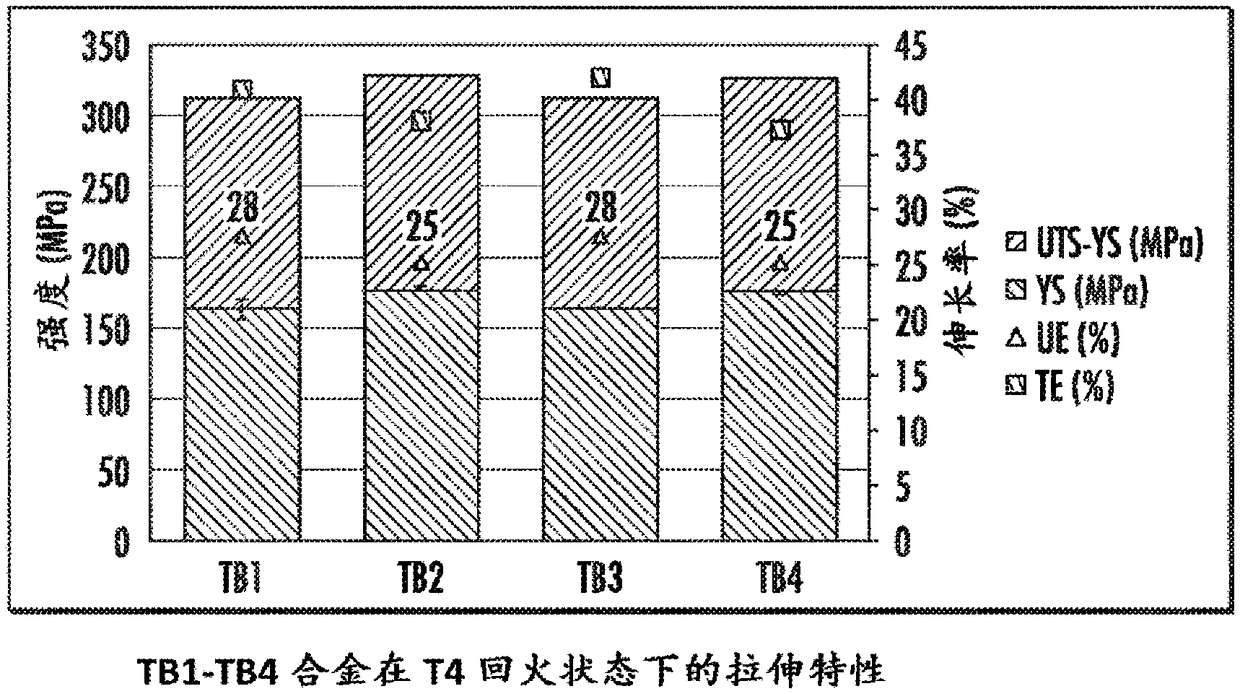

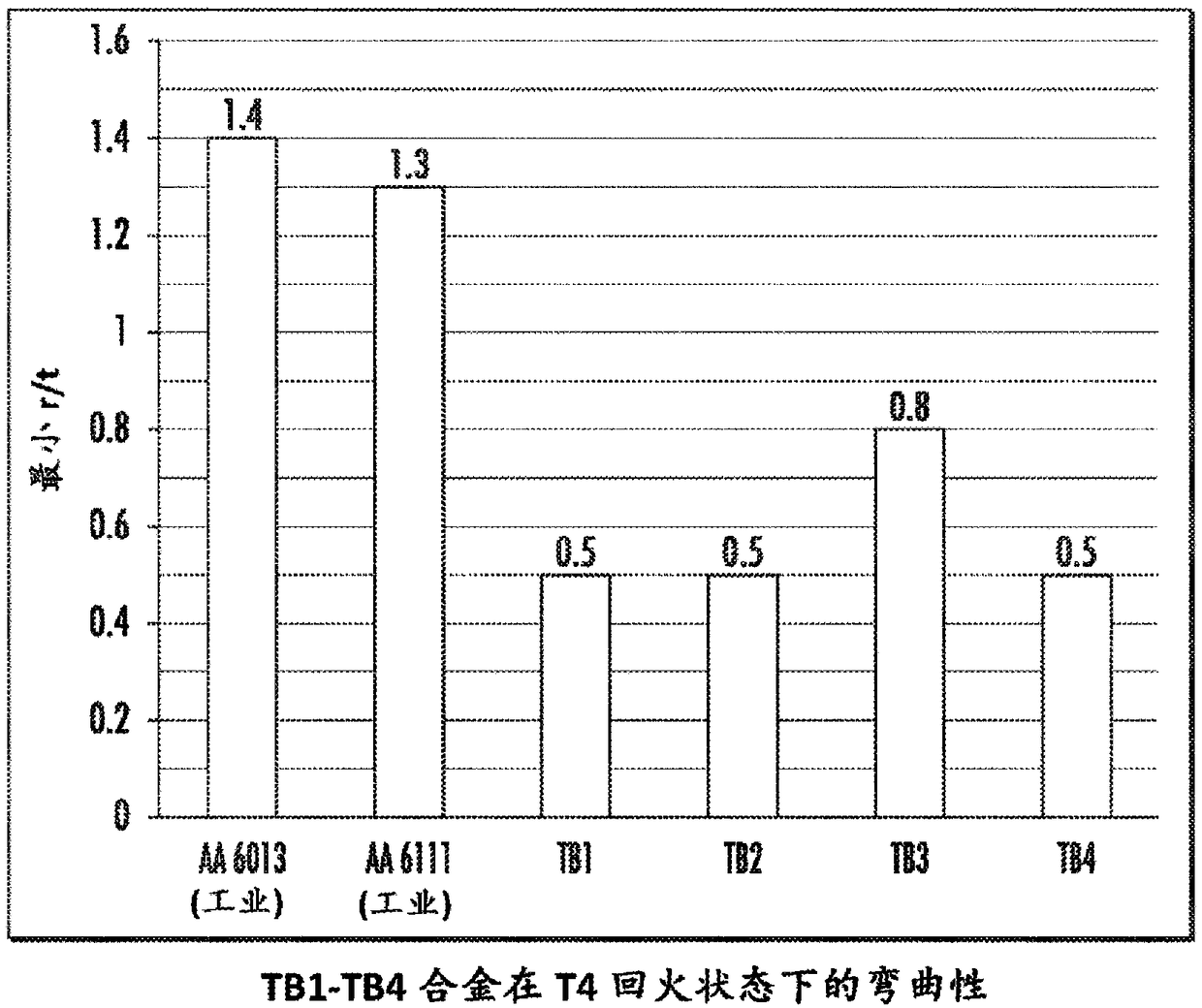

High-strength 6xxx aluminum alloys and methods of making same

The present invention discloses high-strength aluminum alloys and methods of making and processing such alloys. More particularly, the present invention discloses a 6XXX series aluminum alloy exhibiting improved mechanical strength, formability, corrosion resistance, and anodized qualities. An exemplary method includes homogenizing, hot rolling, solutionizing, and quenching. In some cases, the processing steps can further include annealing and / or cold rolling.

Owner:NOVELIS INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com