Patents

Literature

201 results about "Metamorphism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metamorphism is the change of minerals or geologic texture (distinct arrangement of minerals) in pre-existing rocks (protoliths), without the protolith melting into liquid magma (a solid-state change). The change occurs primarily due to heat, pressure, and the introduction of chemically active fluids. The chemical components and crystal structures of the minerals making up the rock may change even though the rock remains a solid. Changes at or just beneath Earth's surface due to weathering or diagenesis are not classified as metamorphism. Metamorphism typically occurs between diagenesis (maximum 200°C), and melting (~850°C).

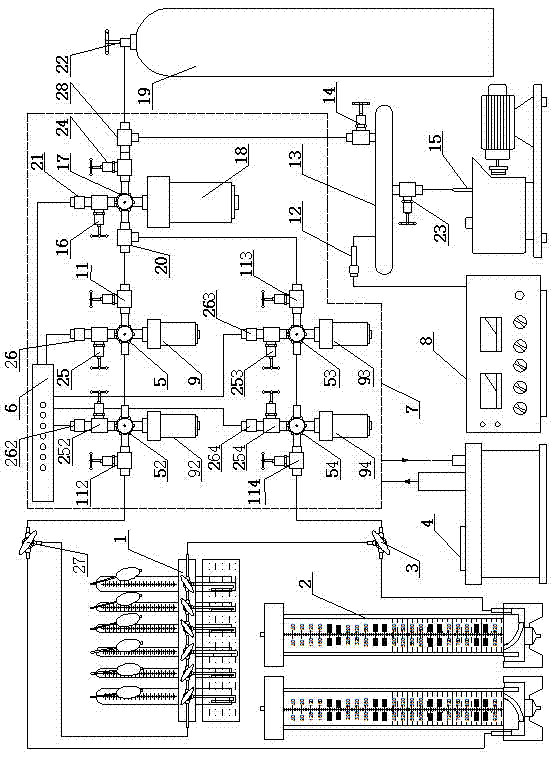

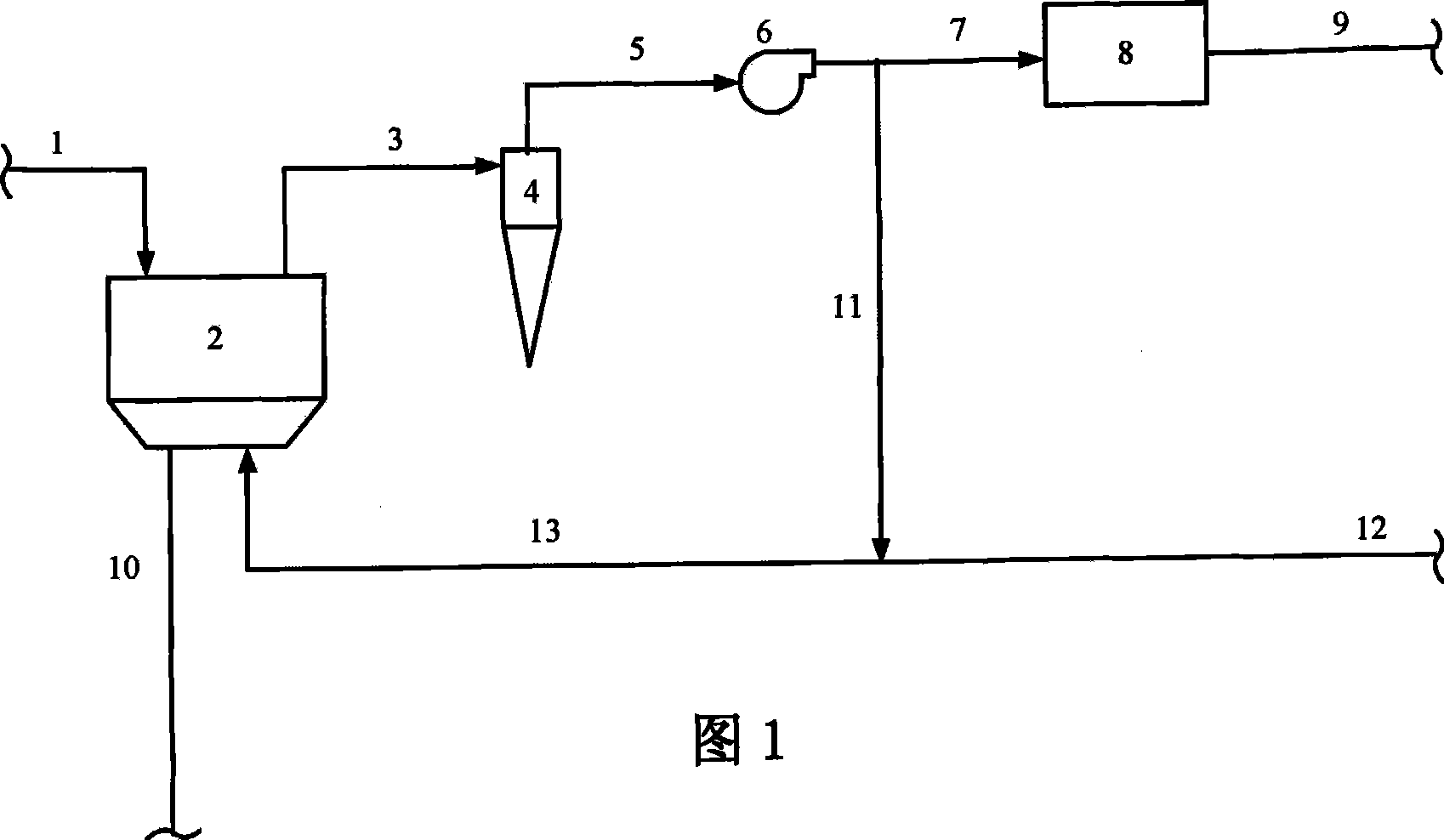

Gas adsorption and desorption test apparatus

ActiveCN103033442ASimple structureImprove experimental efficiencyMaterial analysisTest efficiencyTemperature control

The invention relates to a gas adsorption and desorption test apparatus, which comprises an inflation system, a degassing system, a gas adsorption and desorption system and a temperature control system. The gas adsorption and desorption test apparatus with a simple structure is used for determining the adsorption constant and the ultimate gas desorption quantity of coal, can determine the parameters such as the quantity of lost gas, the drilling cuttings desorption index, the diffusion coefficient and the like under the conditions of different temperature, different pressure, different degree of metamorphism and different particle sizes, and is suitable for a test of particles of coal gas adsorption and desorption laws. The gas adsorption and desorption test apparatus can simulate the underground reservoir environment, can simultaneously conduct gas adsorption and desorption tests of four groups of different particle sizes of cuttings coal samples at different temperatures, can conduct isothermal adsorption tests and gas diffusion tests, and can directly determine the gas adsorption loss amount and the ultimate gas desorption quantity. The gas adsorption and desorption test apparatus can simultaneously conduct multiple groups of gas adsorption and diffusion tests and effectively increase the test efficiency, and the determining precision is high.

Owner:HENAN POLYTECHNIC UNIV

Water-coal-slurry additive and preparation method thereof

ActiveCN101550369AImprove hydrophilicityReduce viscosityLiquid carbonaceous fuelsAlkylphenolMethyl group

The invention provides a water-coal-slurry additive and a preparation method thereof. The additive is compounded by anionic surfactant naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and non-ionic surfactant alkylphenol polyethenoxy ether (methyl) acrylic ester according to mass ratio of 8:1:1 to 1:8:1. The invention uses the naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and alkylphenol polyethenoxy ether (methyl) acrylic ester in the preparation technology of water-coal-slurry, and the additive has wide adaptability to coal, in particular to coal with low degree of metamorphism. When ternary compound additive reaches 0.1-1wt percent of the weight (dry basis) of the coal, the water-coal-slurry with the content of coal dust being 62-70wt percent can be prepared. The slurry has good fluidity, lower apparent viscosity and favorable steady state stability. The ternary compound additive is simple in production process, excellent in performance and wide in the range of applicable coal.

Owner:ENN XINNENG BEIJING TECH

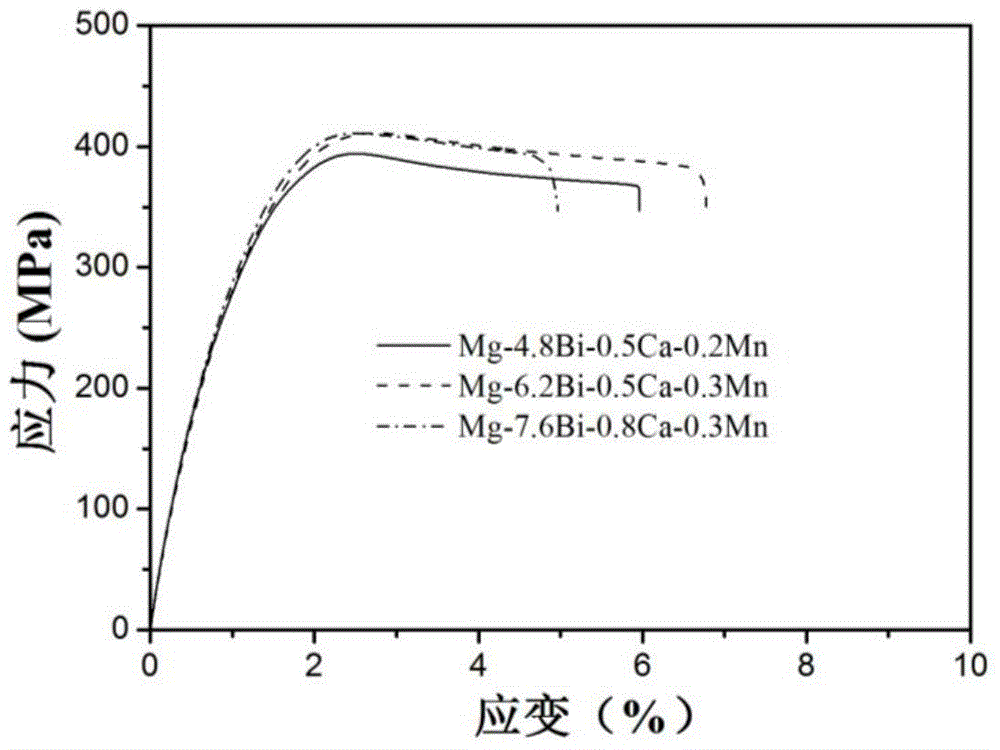

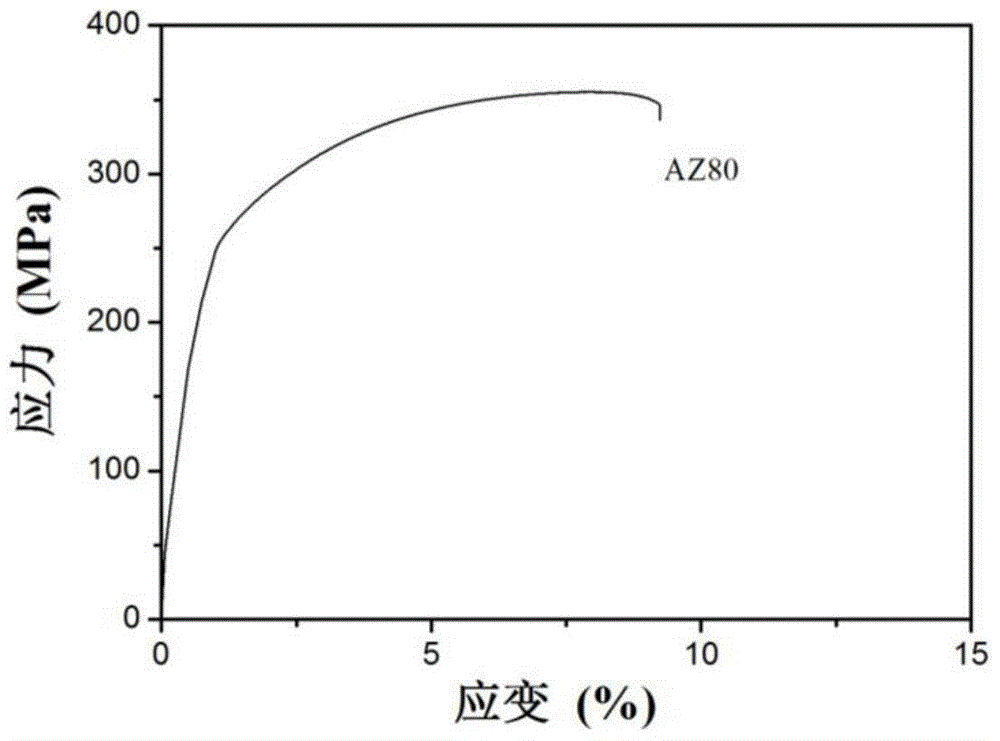

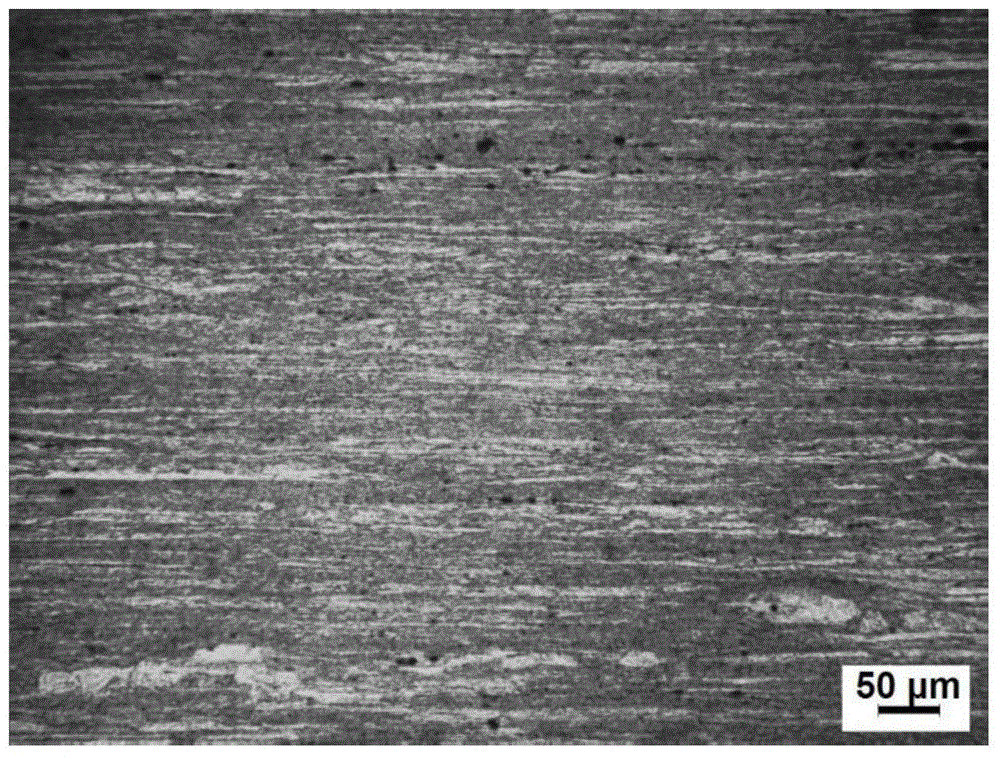

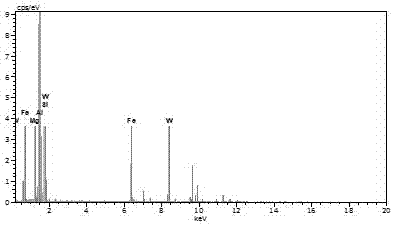

Low-cost non-rare-earth type high-strength magnesium alloy and preparing method thereof

The invention relates to low-cost non-rare-earth type high-strength magnesium alloy and a preparing method thereof. The alloy is Mg-Bi-Ca-Mn magnesium alloy, and is prepared from, by mass, 2-10% of Bi, 0.1-1.5% of Ca, 0.1-1.0% of Mn and the balance magnesium. The novel magnesium alloy is based on a Mg-Bi binary metal series, the element Bi serves as the main alloy element, and the Mg3Bi2 phase with high melting point is contained in the magnesium alloy. Furthermore, the magnesium alloy is evenly dispersed and distributed on a matrix through a simple alloying means, the metamorphism to a second phase by the element Ca and the element Mn and the combination of a plastic deformation processing means so that crystal boundary migration can be effectively pinned in the deformation process to hinder dislocated movement, grains are obviously refined, the strength of the alloy is greatly improved, and thus the ultra-high-strength magnesium alloy is developed in the alloy series.

Owner:HEBEI UNIV OF TECH

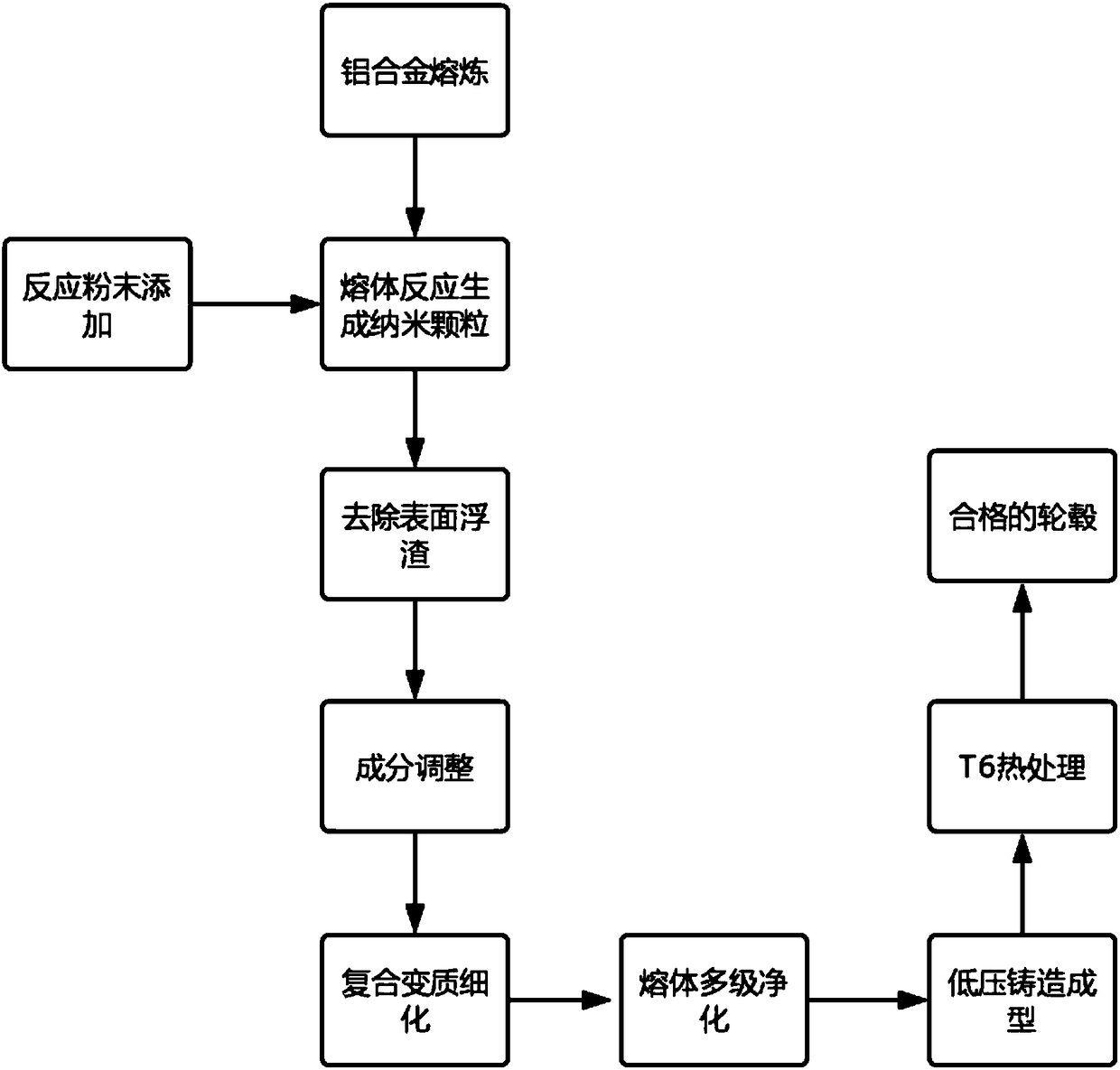

In-situ nanometer intensified aluminum alloy wheel hub for new energy automobile and manufacturing method thereof

ActiveCN108559864AReduce energy consumptionImprove battery lifeHubsWheelsChemical reactionNew energy

The invention relates to an in-situ nanometer intensified aluminum alloy wheel hub with light weight, high strength and fatigue resistance for a new energy automobile and a manufacturing method thereof. Through in-situ chemical reaction of a melted body, nanometer particle compound reinforcement is realized by Orowan reinforcement + refined crystalline reinforcement, long-term compound metamorphism and complex refinement are integrated, and the refined crystalline reinforcement is achieved. The purification technology of nitrogen and argon combined rotary air refining + aluminum-rear earth isadopted, multi-stage deep purification of aluminum melted body is realized, the characteristic that argon is greater than air in density is used for forming a protective layer on the surface of the melted body, and alloy is introduced between the aluminum-rear earth to produce intermediate compounds with the density greater than that of the particles, and therefore the deep high-efficiency purification is effectively achieved. A novel low pressure shaping technology of progressive solidification + rapid crystallization is adopted in the end, due to the fact that crystallization time is shortened, the space between secondary branch crystal arms in a casting microstructure is shortened, the structure is refined and the feeding effect is enhanced, the casting is denser in structure, and the wheel hub with high plasticity, high anti-fatigue performance and high density is obtained.

Owner:JIANGSU UNIV

Molten steel processing method of high-speed steel roller material

The invention relates to a molten steel processing method of a high-speed steel roller material, belonging to the technical field of metallurgy. The molten steel processing method comprises the following steps of: crushing the following materials containing metamorphic elements: rare earth magnesium-ferrosilicon alloy, ferrovanadium, ferrotitanium, ferroniobium, ferrozirconium, potassium oxide, silicon-calcium-barium alloy, nitrogenous ferrochrome, ferroboron and zinc into powder with a grain size of 60-100 meshes, and uniformly mixing the materials in percentage by mass; packaging the mixed materials by adopting a low-carbon steel strip with a thickness of 0.15-0.22 mm, and preparing a metal cored wire with a diameter phi of 5-8 mm by rolling; and adding the metal cored wire into molten steel for pouring high-speed steel rollers in a steel ladle by adopting a wire feeding method, wherein 8-10 kg of the metal cored wire is added into one ton of the molten steel. The molten steel processing method provided by the invention has the advantages of convenient and simple process, high yield of the metamorphic elements and stable metamorphism effect, so that the mechanical property and the operational performance of the high-speed steel roller are obviously improved; in addition, the molten steel processing method is easy to popularize and apply, and good in economic benefit.

Owner:BEIJING UNIV OF TECH +1

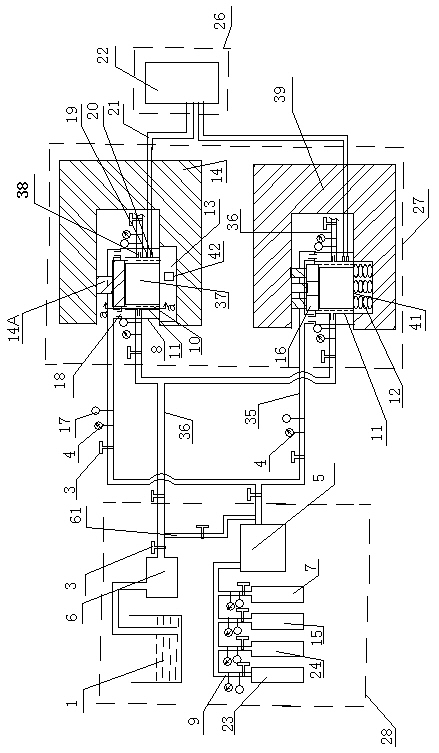

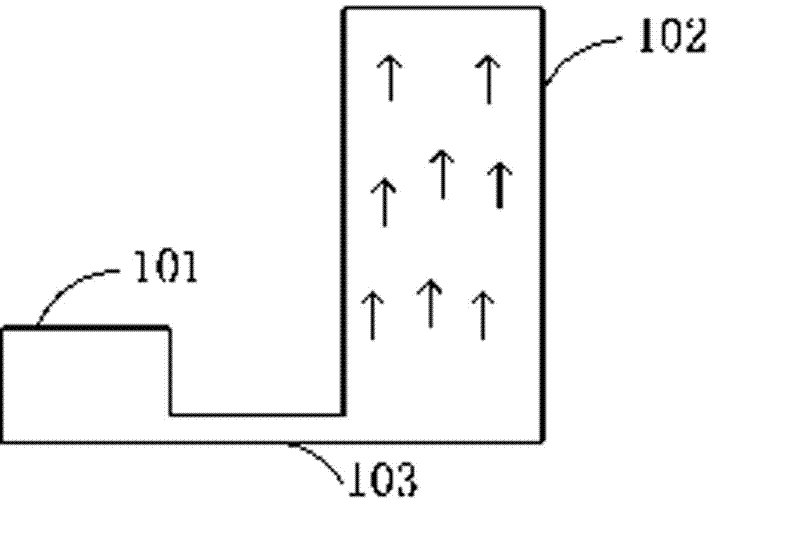

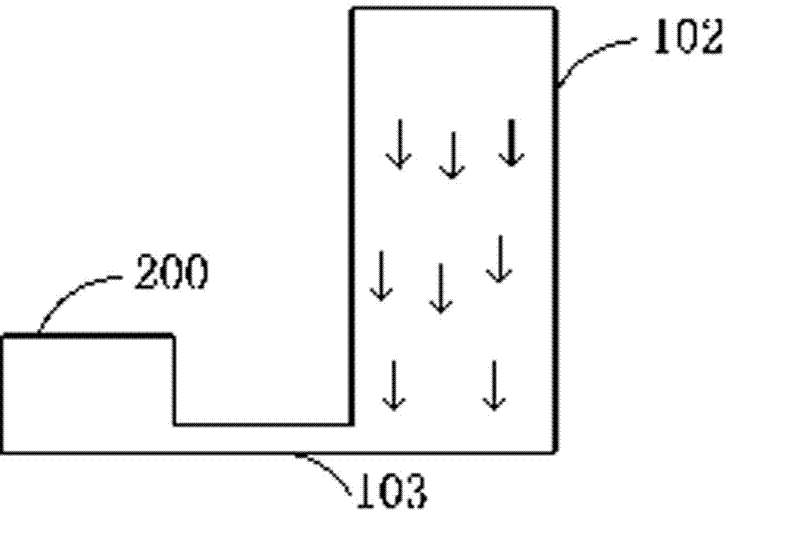

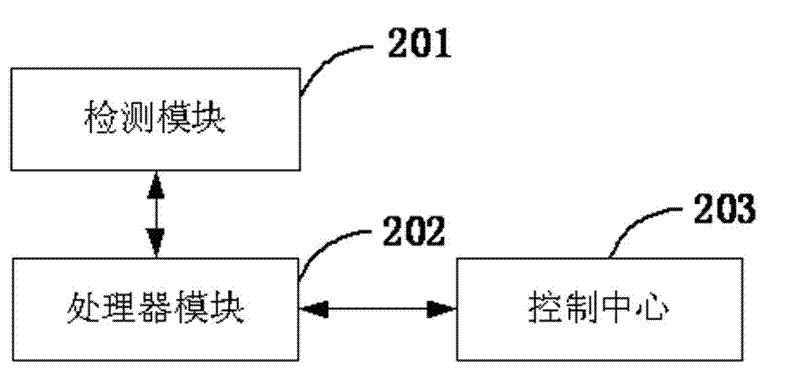

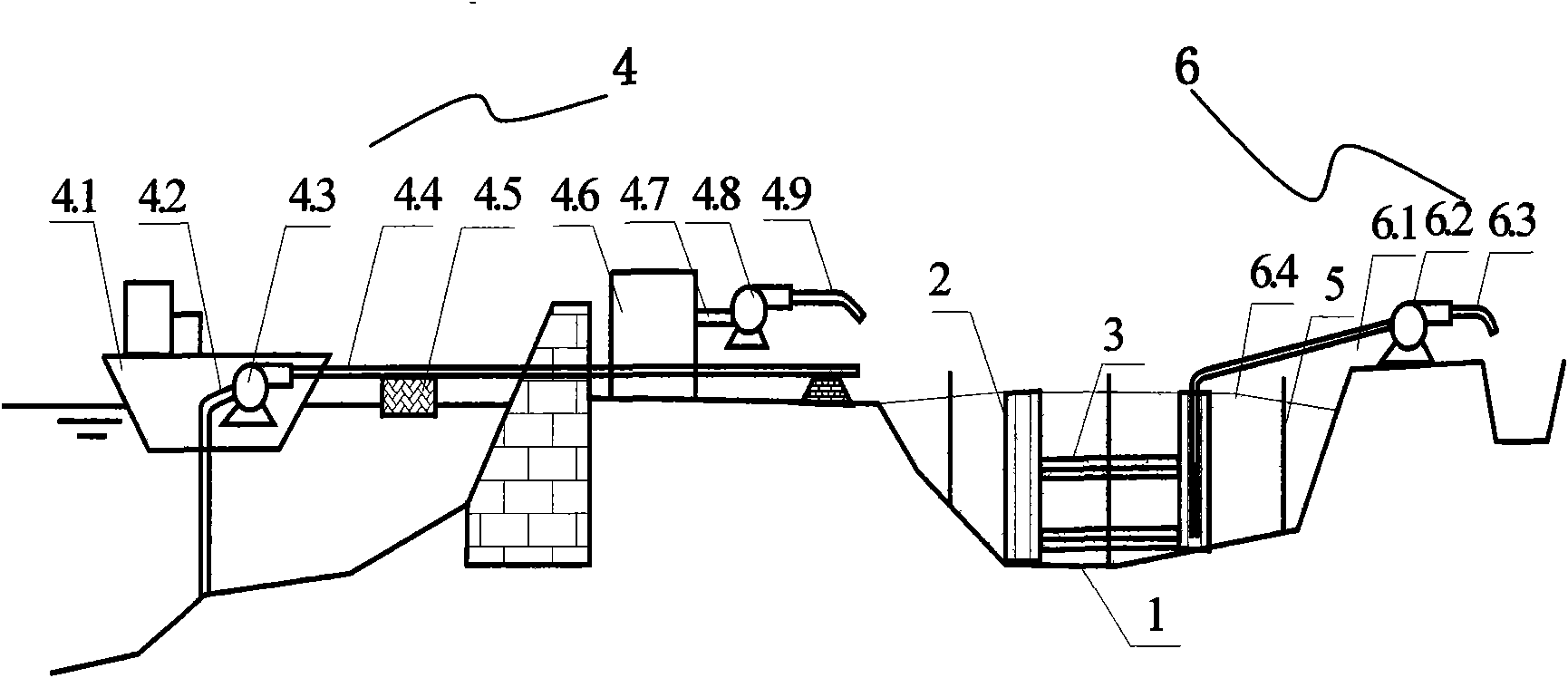

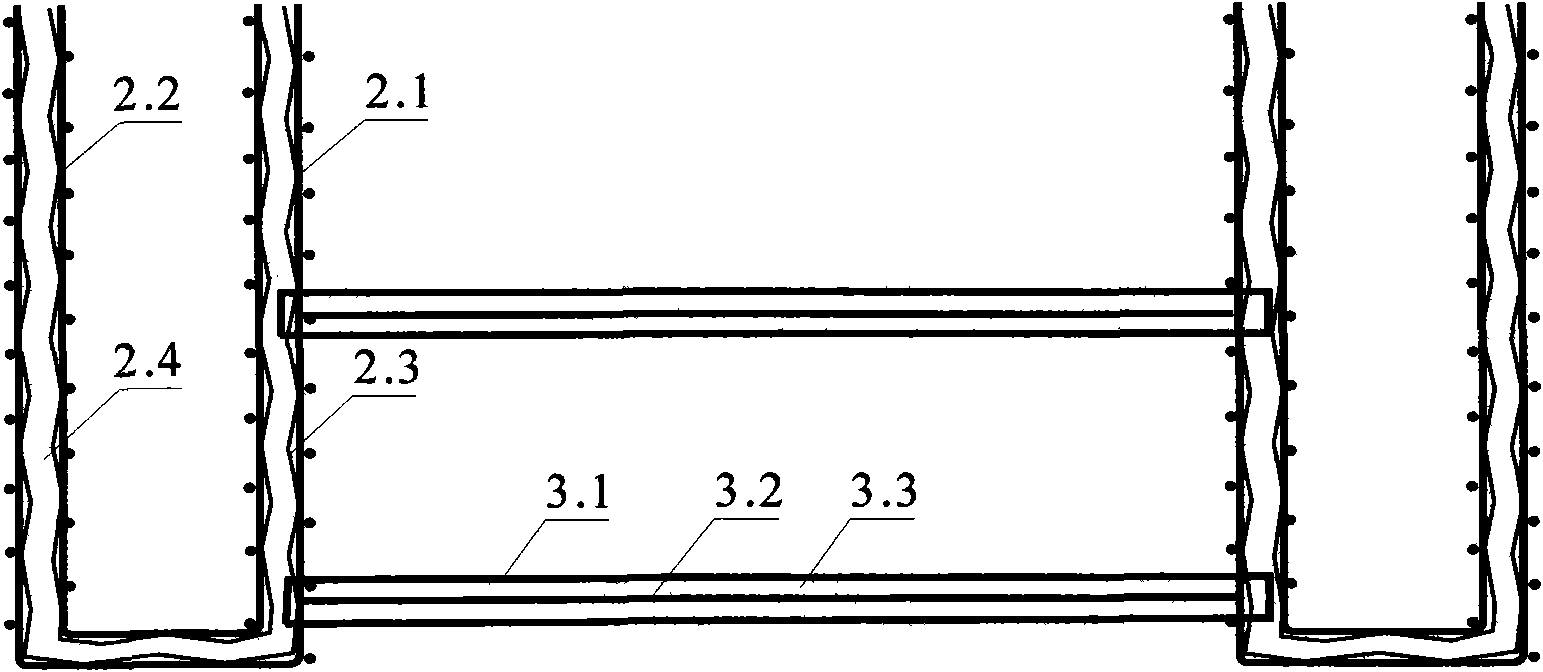

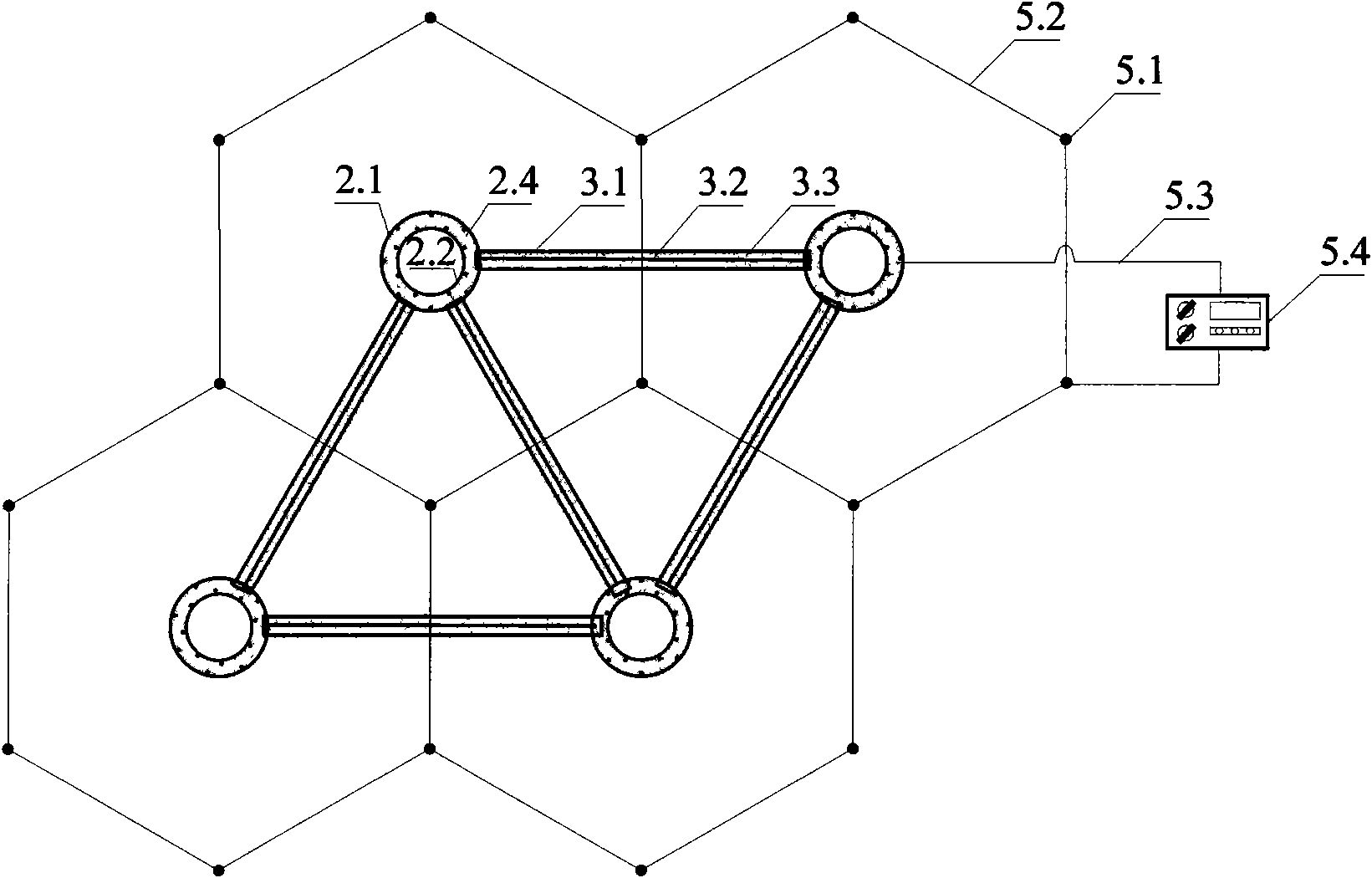

Coal Metamorphic Evolution Fracture System Development Simulation Test System

The invention discloses a development simulation test system of a coal metamorphism evolution fissure system. The development simulation test system comprises a power loading system, a coal rock fissure generation simulation system and a data display system. The power loading system comprises an air pressure apparatus and a hydraulic pressure apparatus. The coal rock fissure generation simulationsystem comprises an endogenic fissure generation simulation system and an exogenous fissure generation simulation system, wherein both the endogenic fissure generation simulation system and the exogenous fissure generation simulation system are provided with a set of confining pressure apparatus. The data display system comprises a sensing device and a data display device. The development simulation test system is simple in structure and convenient in use, endogenic fissure and the exogenous fissure formation processes in a metamorphism evolution process of coal at different temperature and pressure conditions can be simulated, permeability at different temperature and pressure conditions can be tested, quantification of a fissure growth system is carried out, and guidance for an economical evaluation system of coal layer and gas, correct selection and type selection of an exploitation technique is provided.

Owner:HENAN POLYTECHNIC UNIV

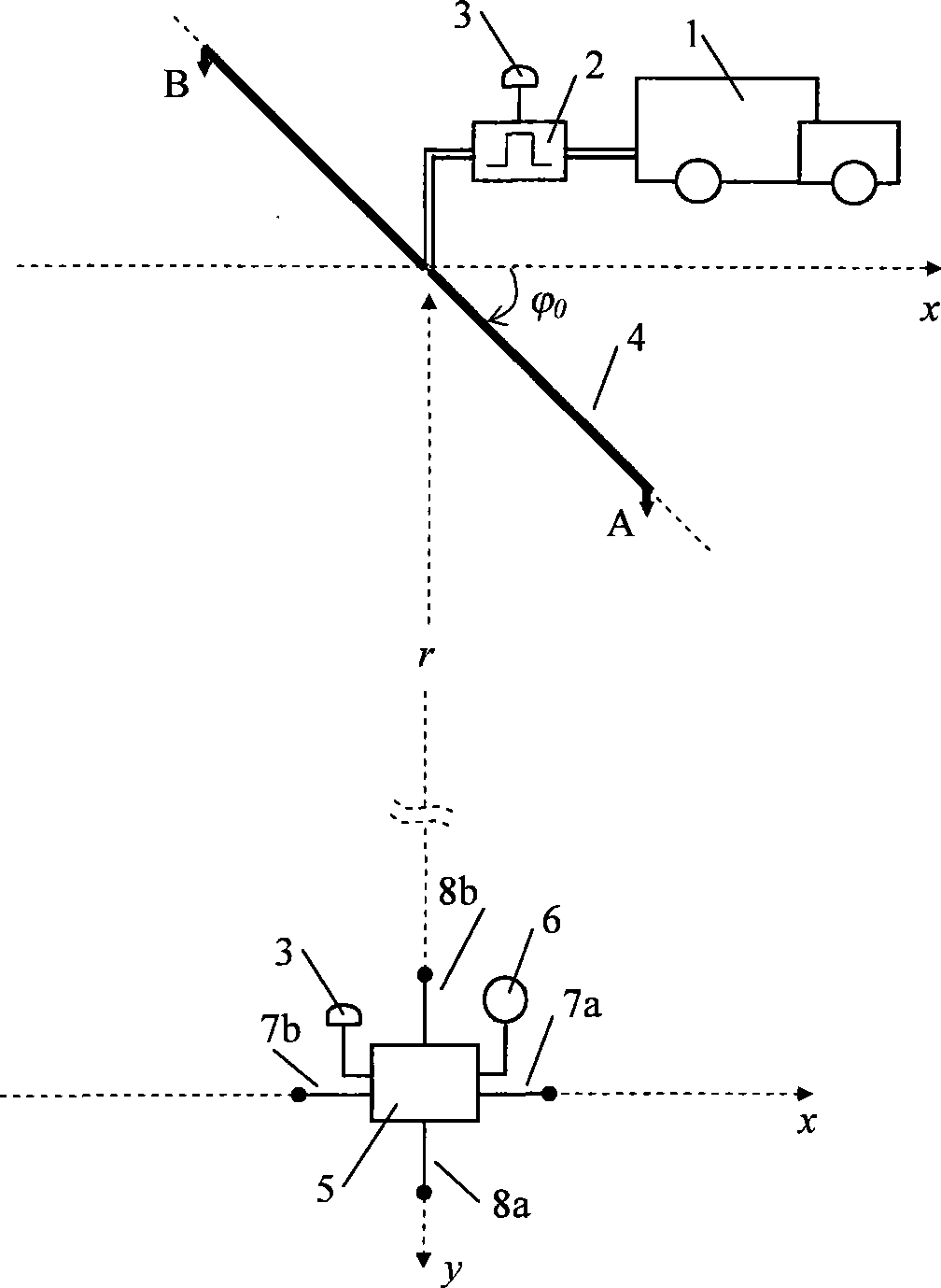

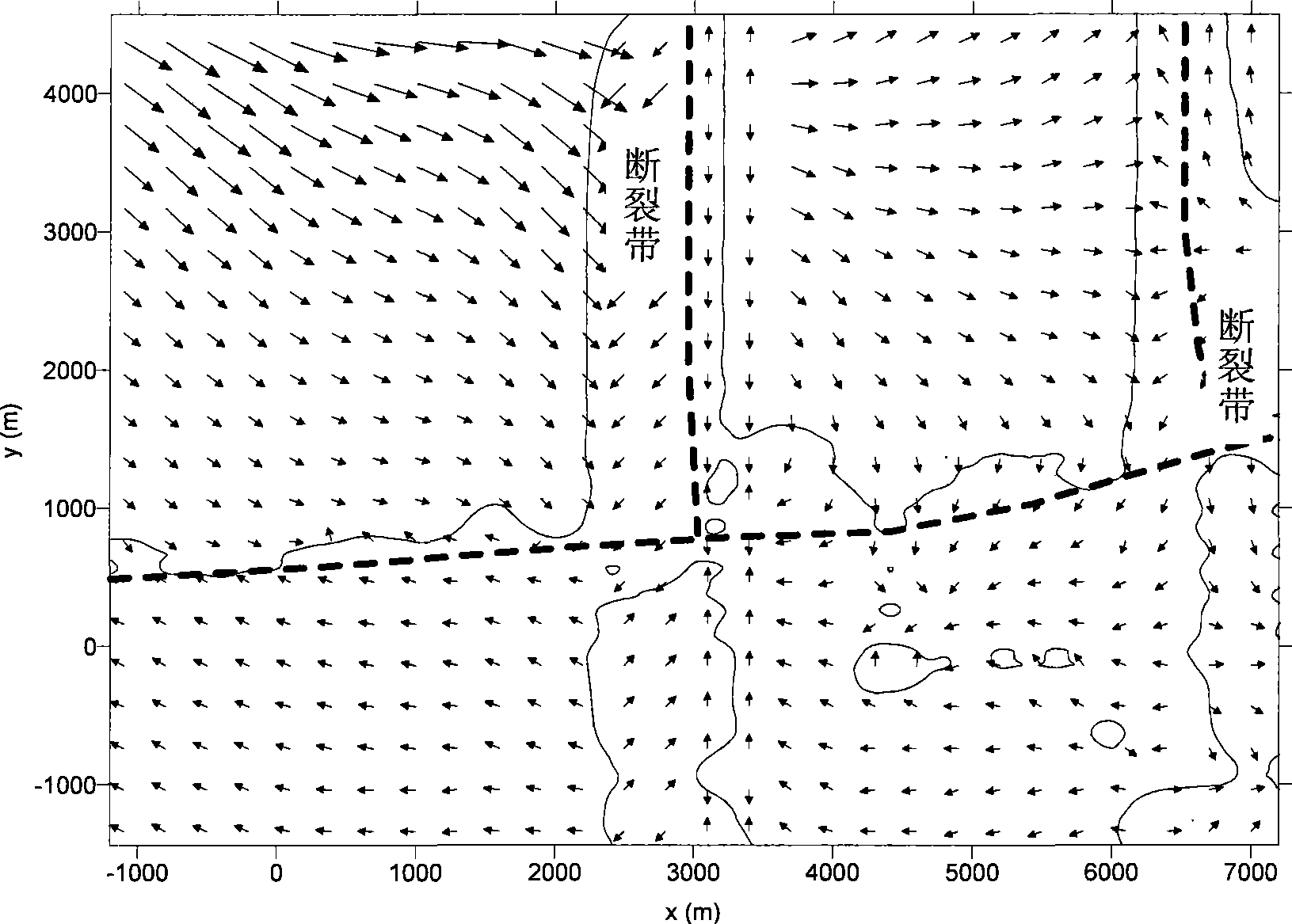

Transient electromagnetical method for reservoir pore space anisotropy

ActiveCN101382599AElectric/magnetic detection for well-loggingAcoustic wave reradiationLithologyPore distribution

The invention pertains to the field of geophysical exploration and oilfield development technology, is a transient electromagnetic method for determining the reservoir pore anisotropy and comprises the following steps: an earthing conductor is taken as a driving source which deviates from a measuring line x direction to form a deflection angle Phi0, and two electric field components Ex and Ey orthometric each other are measured and recorded; the formation resistivity of x direction and y direction at different depth are obtained by refutation; an amplitude value of the horizontal component of electric field total field vector, an electric field anisotropy coefficient and an azimuth of an electric field principal axis vector are counted; the formation porosity value on the direction of electric property principal axis is obtained by the resistivity value on the direction of electric property principal axis; a vector arrow diagram is drawn, the length of the arrow shows the magnitude of the formation porosity or the resistivity on the direction of electric property principal axis, the pointedness of the vector arrow and the azimuth of a source dipole are both formation porosity isotropic; and the vector arrow deviated from the electric property principal axis is formation porosity anisotropy. The invention can determine pore distribution, lithology changing, local anomaly and local metamorphism in the formation porosity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

System for monitoring ingredient change of insulating oil of transformer

InactiveCN102539283AReduce volumeExtend effective use timeFlow propertiesMaterial testing goodsTransformerLiquid state

Owner:BEIJING ANSAIBO TECH

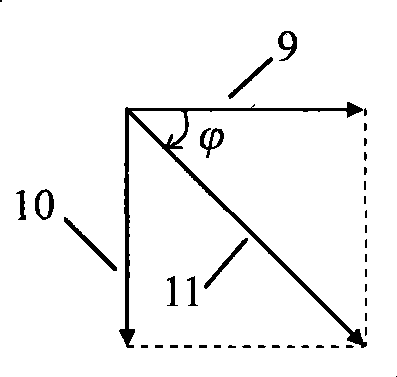

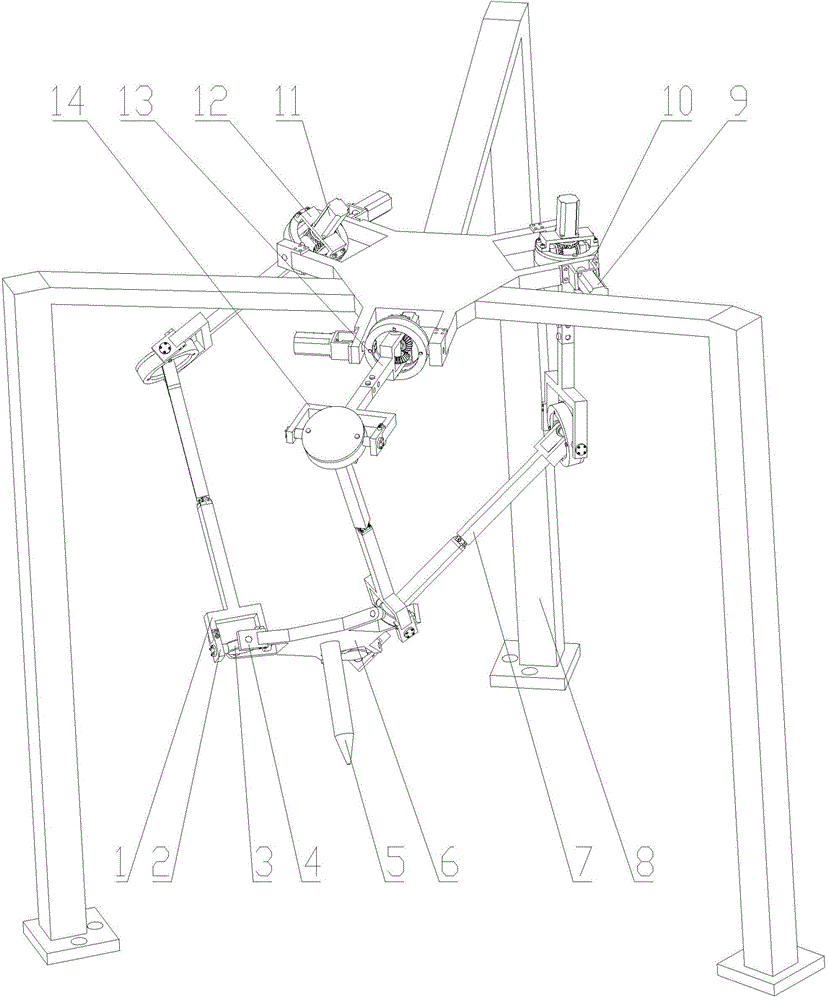

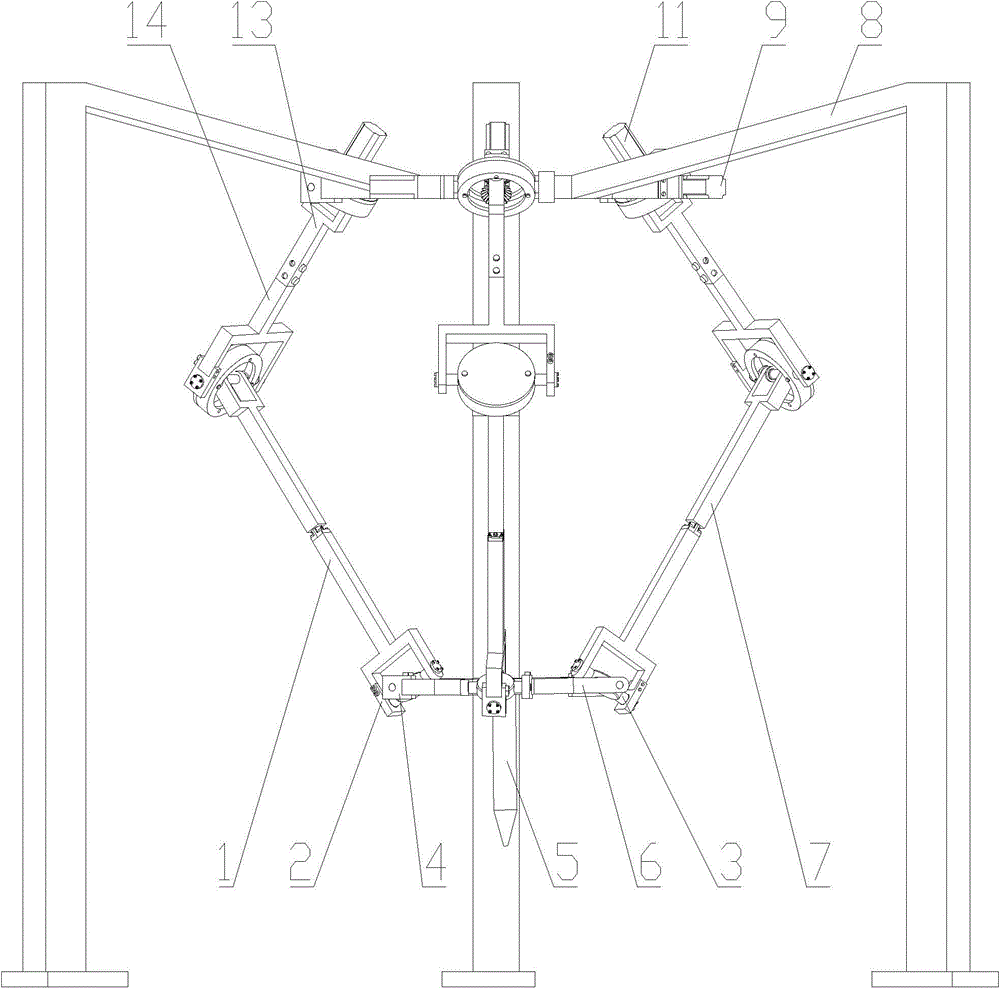

Parallel metamorphism platform with variable degree of freedom

InactiveCN103909519AProgramme-controlled manipulatorWork benchesThree degrees of freedomDegrees of freedom

The invention aims to provide a parallel metamorphism platform with variable degree of freedom. The parallel metamorphism platform consists of a frame, a workbench and three motion branch chains, wherein each motion branch chain is provided with two motors. The parallel metamorphism platform can be switched between three degrees of freedom and six degrees of freedom through a topological structure. Under the situation of three degrees of freedom, the workbench can be driven to move spatially in x, y and z directions through three horizontal motors. Under the situation of six degrees of freedom, the workbench can be driven to move and rotate spatially in x, y and z directions through horizontal and vertical motors. The state of the parallel platform can be switched freely according to different working conditions, thereby realizing needed motion locus through minimum driving. At present, most parallel mechanisms are of a single state, leading to redundancy of the degree of freedom. The parallel metamorphism platform is variable in the degree of freedom, has a very good market value, and the problem is well solved.

Owner:三亚哈尔滨工程大学南海创新发展基地

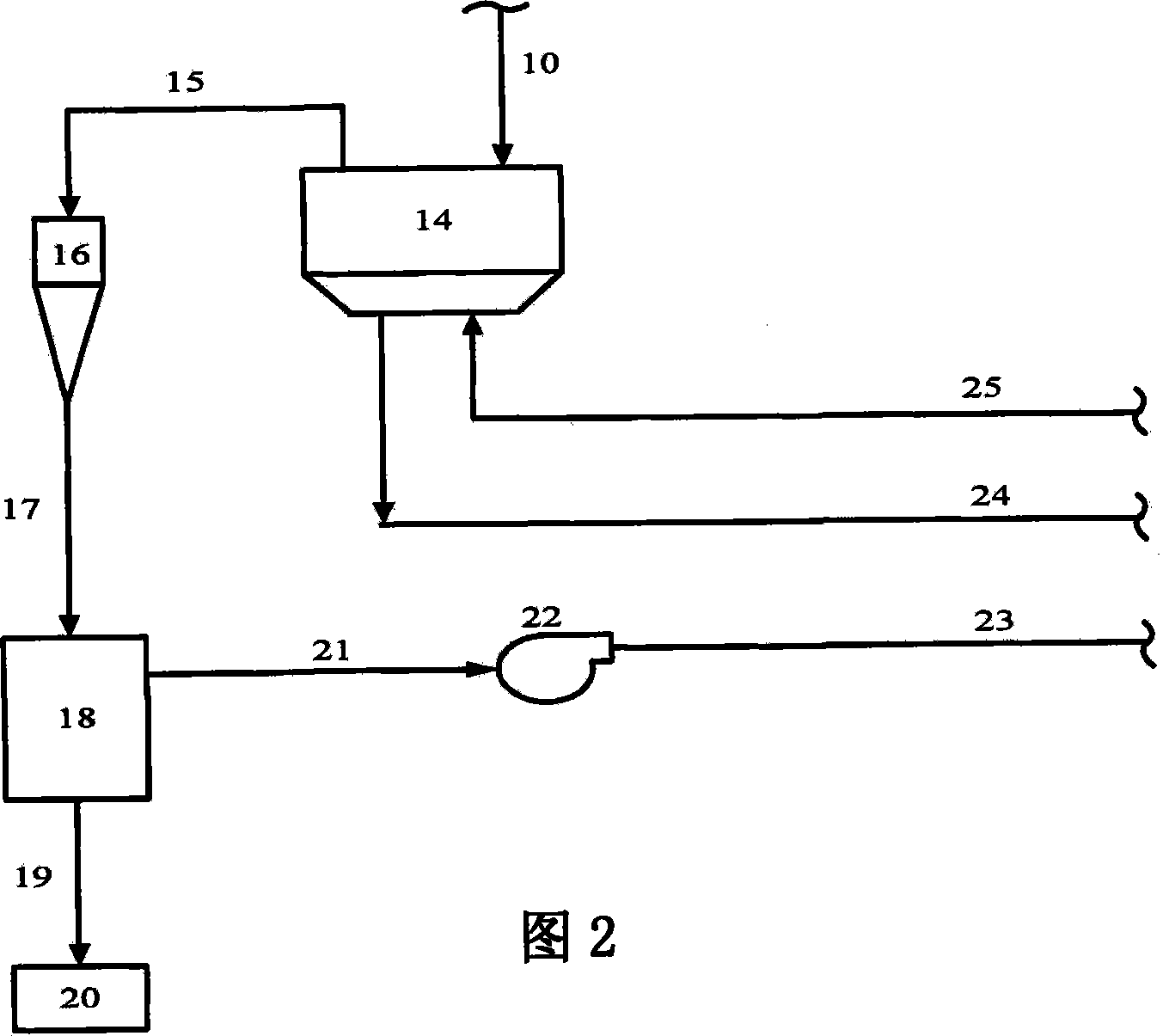

Process for processing coal with low degree of metamorphism

InactiveCN101429463AGood environmental protectionEmission reductionSolid fuelsEngineeringAtmospheric pollution

The invention provides a technique for processing coal with low metamorphism degree, which comprises the steps of crushing and sieving pretreatment. The technique is as follows: raw coal particles are sent into a drier, and subjected to anoxybiotic hot gas drying under normal pressure, wherein the drying condition is controlled to 10 to 50 cubic meters of hot gas required for each 1 kilogram of the coal, and the temperature of the raw coal particles is controlled to between 210 and 250 DEG C; the raw coal particles are sent into a pyrolysis apparatus, and high-temperature oxygen-poor hot gas is injected according to the flow ratio of 5 to 50 cubic meters per kilogram of coal, wherein the temperature of the oxygen-poor hot gas entering into a pyrolyzing furnace is controlled to between 400 and 950 DEG C, and the oxygen content is controlled to less than 6 percent of the volume; and the coal is fully mixed with the hot gas and heated to a temperature of between 530 and 580 DEG C. The technique has the advantages that the sulfur content is reduced compared with that in the raw coal, so that atmospheric pollution is reduced; solid products produced by the technique have high environment-friendly characteristic; the discharge amount of nitrogen oxide is obviously reduced; and atmospheric pollution is reduced.

Owner:HUNAN HUAYIN ENERGY TECH

Absorbent for deeply removing carbon dioxide

The invention provides an absorbent with deep removal of carbon dioxide, comprising water and alcohol amine; the improvement thereof is as follows, the alcohol amine is mixed solution of more than two types of alcohol amine, one of which is methyldiethanolamine (MDEA); the concentration by the weight percentage of the mixed alcohol amine solution is 45 percent to 50 percent; the concentration by the weight percentage of the methyldiethanolamine (MDEA) in the mixed alcohol amine solution is 30 percent to 40 percent; the absorbent is used in the deep removal technology of the carbon dioxide of natural gas, the content of the carbon dioxide in purified gas can be reduced to 50ppmv; the energy consumption of a reboiler of a regeneration tower can also be reduced, the degree of degradation and metamorphism of the absorbent can be reduced; the corrosion to a decarbonization system device and a pipeline can further be alleviated, the loss of the absorbent can be simultaneously reduced, the operation cost is low and the effect is satisfactory.

Owner:CHINA NAT OFFSHORE OIL CORP +1

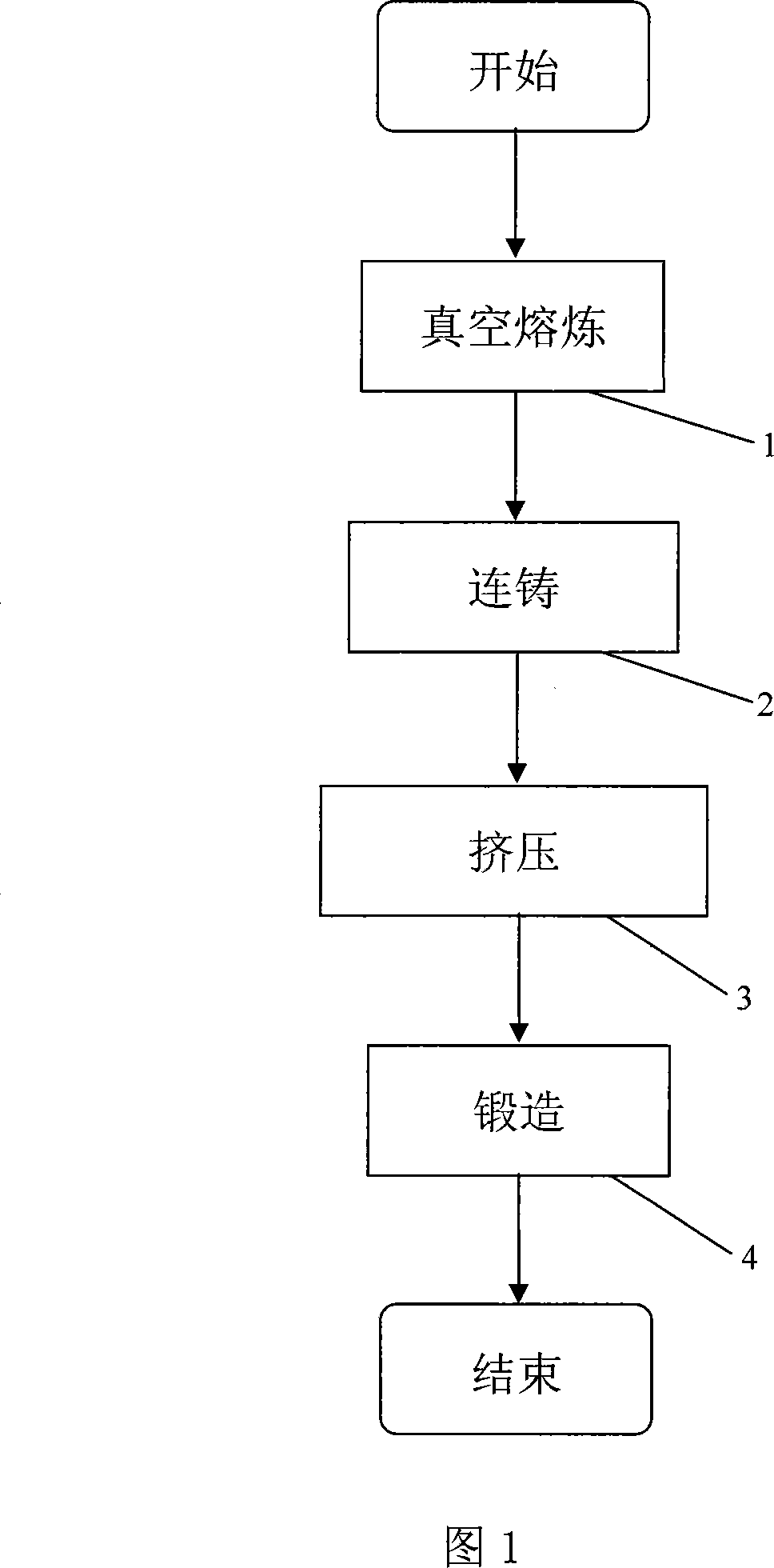

Technique for processing high-strength high-tractility magnesium alloy member

InactiveCN101121980AAvoid secondary oxidationGuarantee casting safetyExtrusion control devicesSteering controlElectromagnetic pump

The invention discloses a technology of processing a magnesium alloy with high intensity and flexibility, which subsequently includes vacuum melting, continuous casting, extrusion, forging and such procedures. The invention reasonably matches the solution body composition and the metamorphism liquid during casting process, and the grains are refined through the chilling action of a crystallizer at first; the magnesium alloy liquid is transmitted by an electromagnetic pump so as to prevent secondary oxidation and ensure safety in casting of the magnesium alloy; and then further refining the grains through electromagnetic mixing power, large ratio extrusion and heat treatment secondary crystallization, which effectively ensures tiny enough isometric crystals can be obtained from the alloy microstructure. The magnesium alloy elements of the automotive steering control arms, support elements of motorcycles and bicycles, can be obtained for the first time by the improvement, which are fully filled, good in surface quality, fine and even in grain size, reasonable in streamline distribution and without disordered streamline, vortexing and draining phenomena. The invention combines a plurality of technological processes into a production cycle, which reduces the turnover links, saves energy and reduces cost.

Owner:王仁辉

Method and device for pre-consolidating mixed hydraulically-filled soft soil foundation

InactiveCN101555689AAccelerate the rate of consolidationReduce processingSoil preservationDouble tubeCombined method

The invention discloses a method for pre-consolidating mixed hydraulically-filled soft soil foundation and a device thereof, relating to the field of pre-consolidation treatment technology of soft soil foundation. The method arranges a horizontal drainage passage in the mixed hydraulically-filled process, adopts a vacuum preloading and electroosmosis combined method for construction, carries out early intervention and consolidation of the ultra-soft soil actively during the hydraulically-filled process and the initial stage of the hydraulically-filled process, and creates a prophase condition for the subsequent foundation consolidation. The device arranges reinforcement cage sand bad collecting wells at the construction site and arranges a horizontally-communicated drainage sand bag between the reinforcement cage sand bag collecting wells; and a dual-pipe mixed hydraulically-filled equipment, the reinforcement cage sand bag collecting wells, a treatment equipment by the vacuum preloading and electroosmosis combined method and a collecting well pumping equipment are sequentially connected from left to right. The method and the device can cause the saturated soft soil to generate early consolidation and pre-settlement, leads the pre-treated foundation soil to meet the load metamorphism requirement better in the engineering usage stage and can greatly save engineering period and subsequent engineering treatment expense.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

Vitamin K micro-capsule preparation method

InactiveCN101422446AIncrease contentImprove thermal stabilityOrganic active ingredientsMetabolism disorderInstabilityGuar gum

The invention relates to a preparation method of a microcapsule of vitamin K. The vitamin K has the problems of instability and easy metamorphism. In the method, the salt of the vitamin K is used as core material, and xanthan or arabic gum or guar gum or isinglass is used as wall material to prepare the microcapsule of the vitamin K. The detailed preparation method is as follows: the aqueous liquid of the wall material and the aqueous liquid of the core material are respectively prepared; then the two are fully mixed; an the obtained mixture is pre-frozen, frozen, dried, crashed and screened in turn, thus being prepared into the product of the microcapsule of the vitamin K with excellent organoleptic attributes. The product has excellent thermal stability and optical stability, can be used as a food accessory to be applied to food processing to enhance the content of the vitamin K in the food.

Owner:ZHEJIANG UNIV

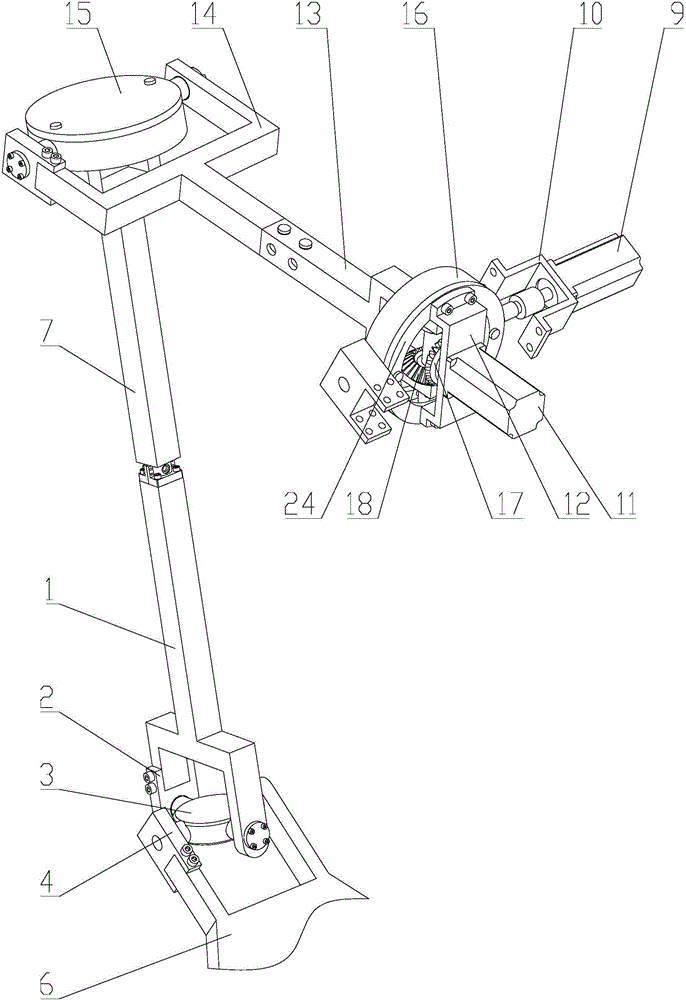

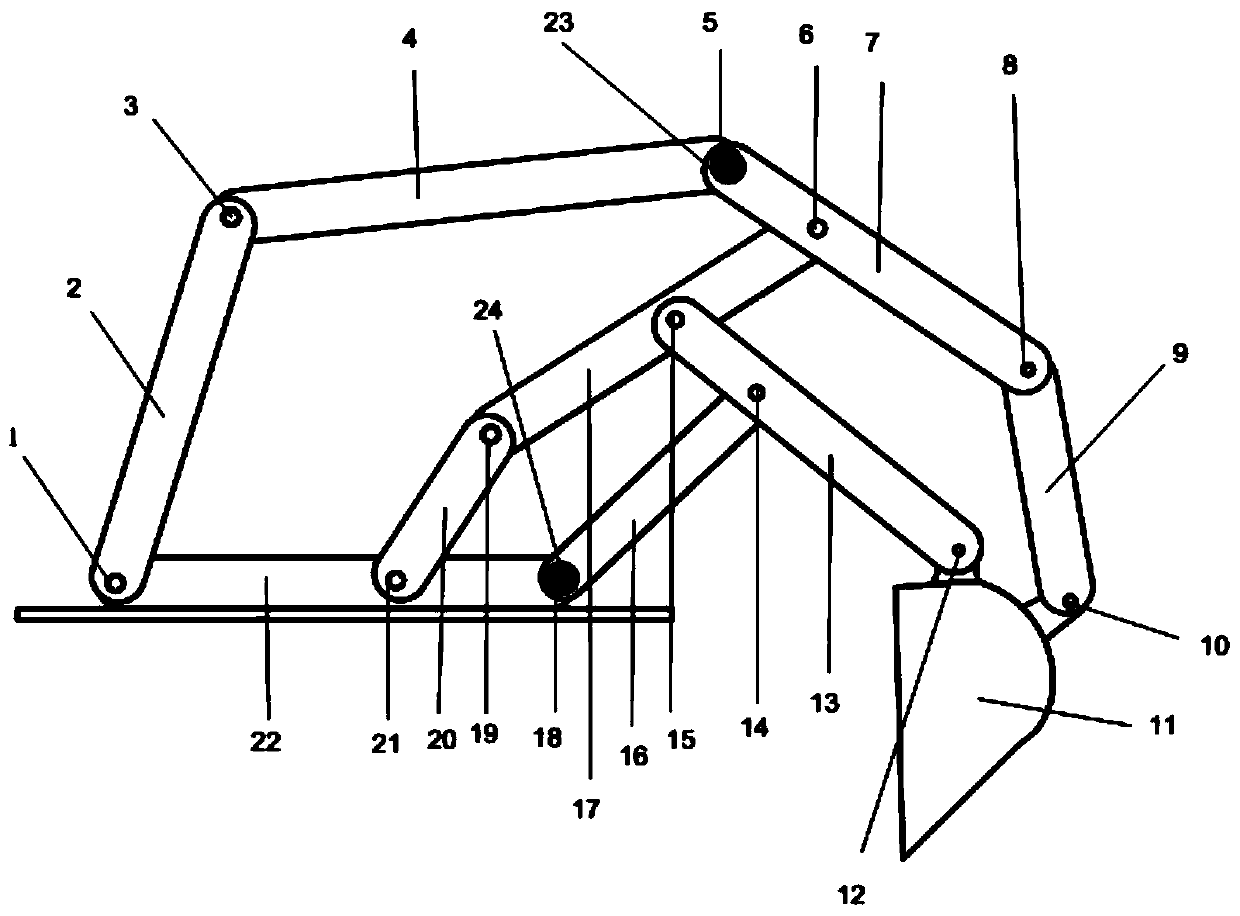

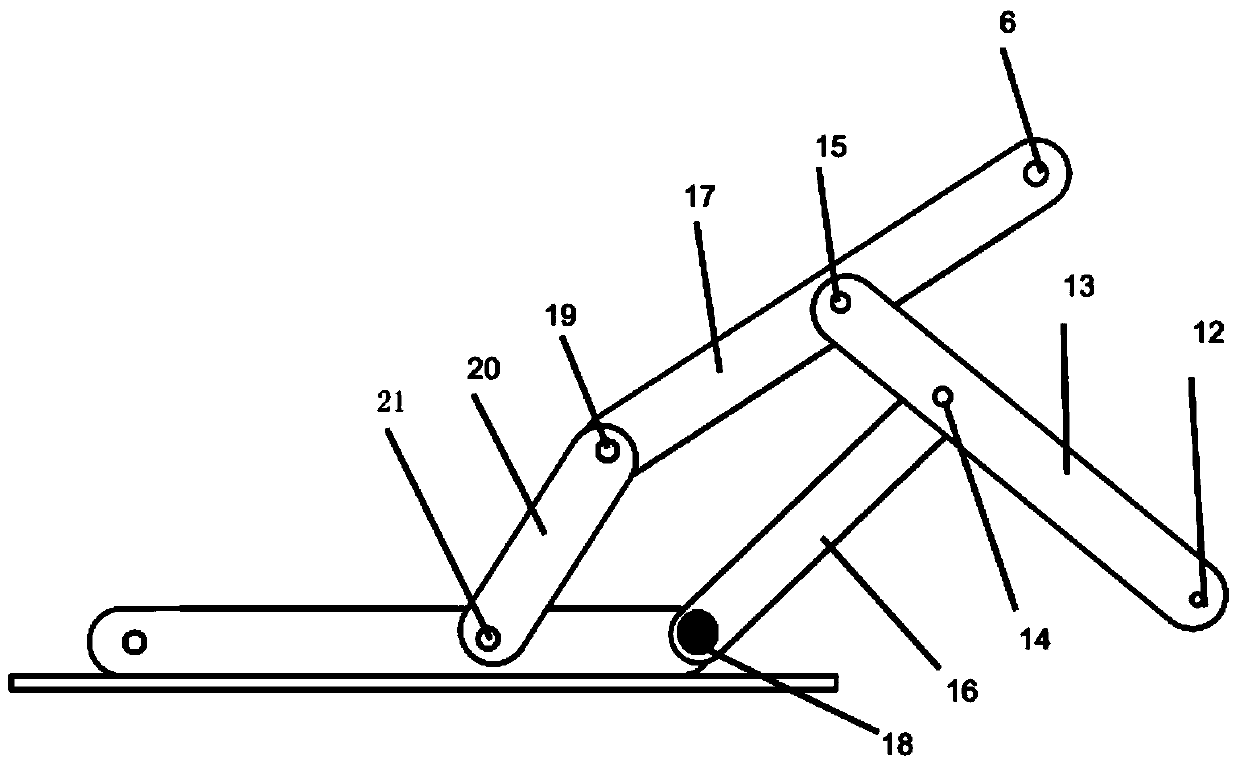

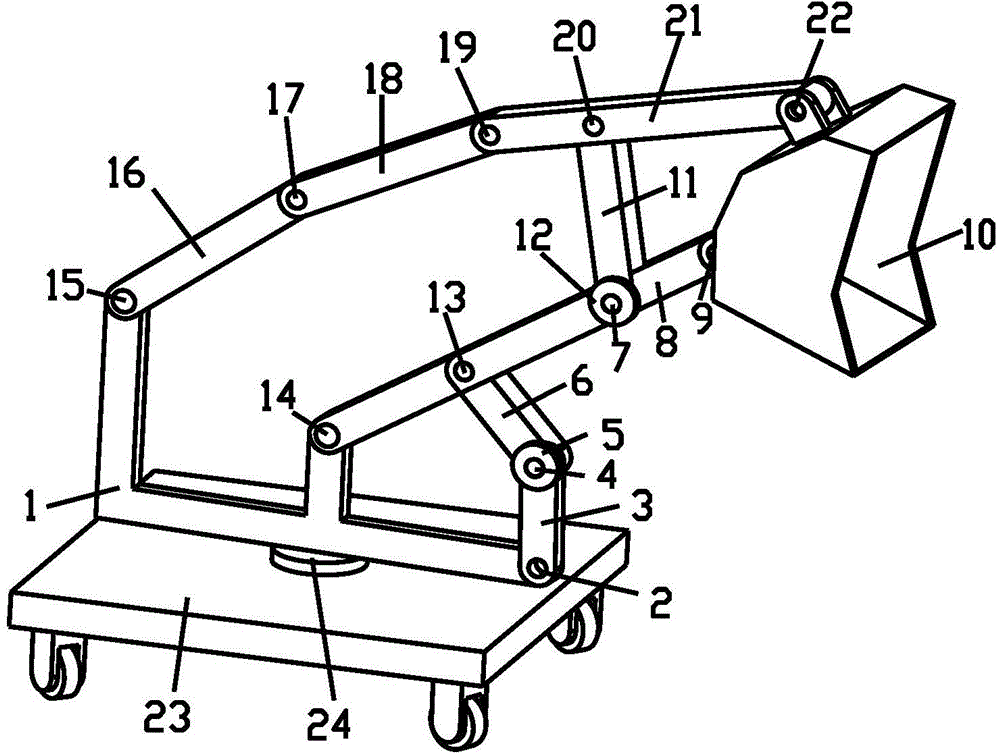

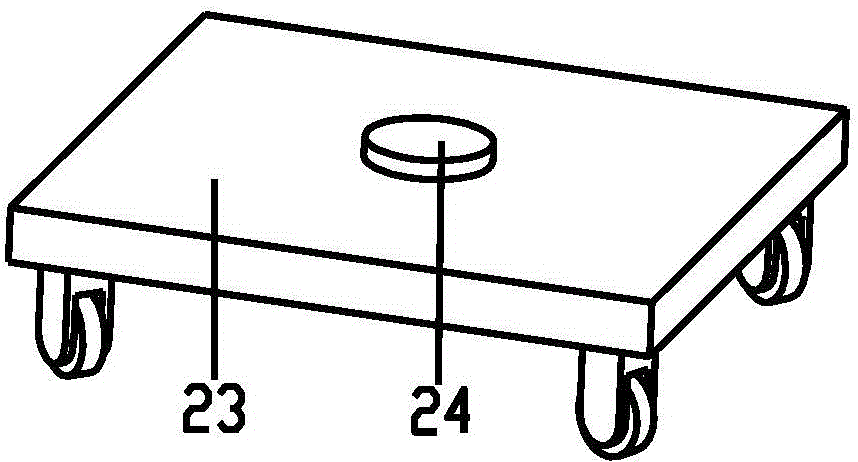

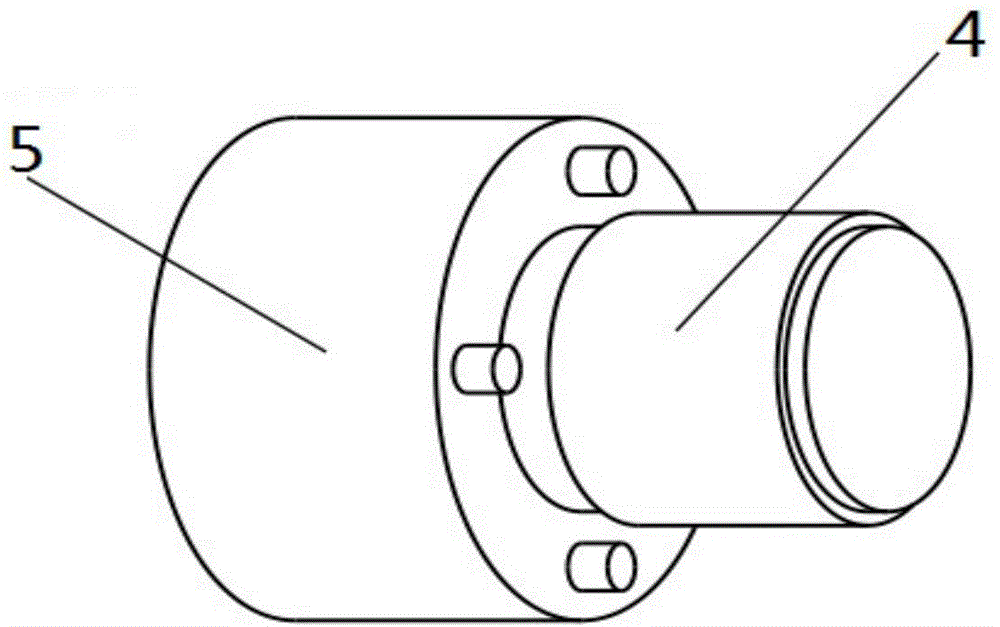

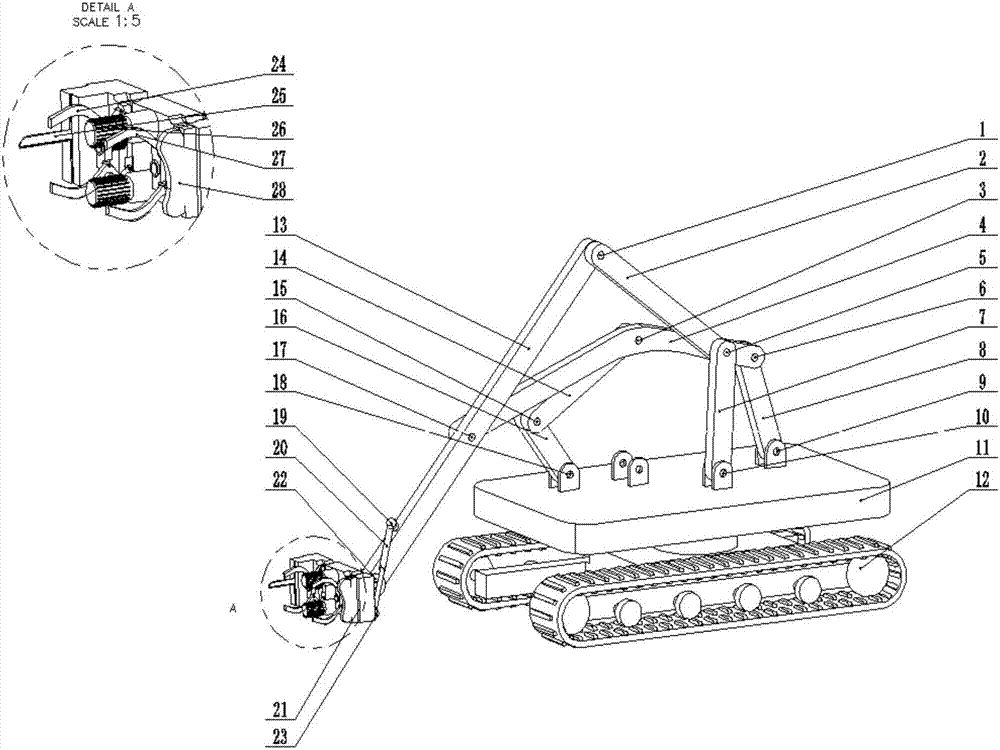

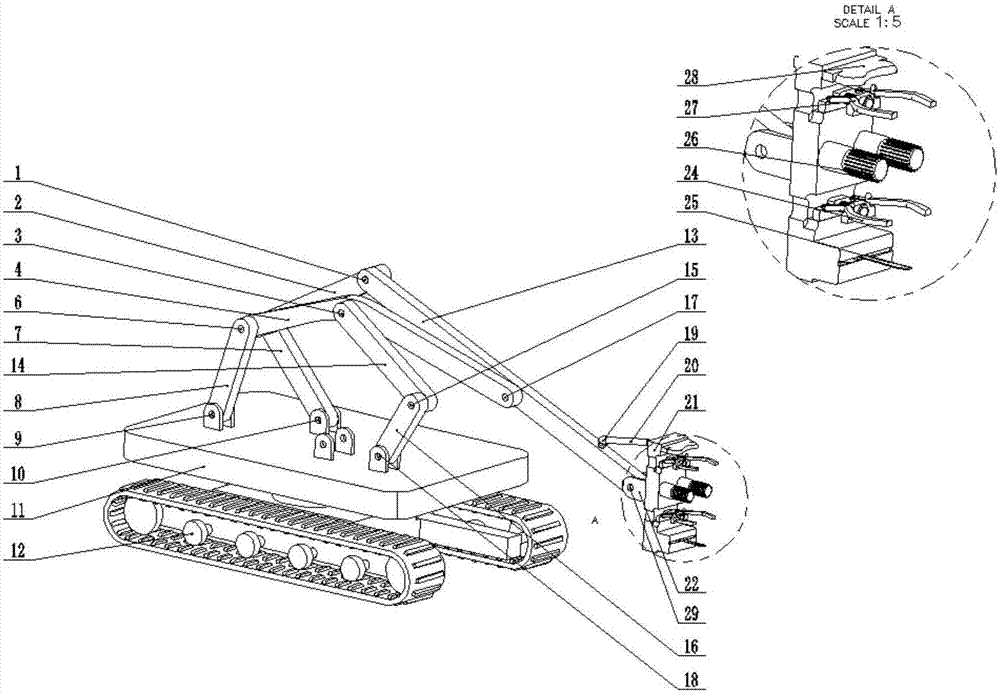

Multi-freedom-degree controllable excavating mechanism with driving metamorphism function

InactiveCN104047316ALess freedomLow costMechanical machines/dredgersMulti degree of freedomEngineering

The invention relates to a multi-freedom-degree controllable excavating mechanism with a driving metamorphism function. One end of a second driving part is connected to a rack, the other end of the second driving part is connected with a second connecting rod, the other end of the second connecting rod is connected with a third connecting rod through a tenth rotation pair, the other end of the third connecting rod is connected to a fourth connecting rod, and the other end of the fourth connecting rod is connected to a bucket. One end of a first driving part is connected to the rack, the other end of the first driving part is connected with a first connecting rod, and the other end of the first connecting rod is connected to the third connecting rod. One end of a bucket rod is connected with the bucket and the other end of the bucket rod is connected to the first connecting rod. One end of a big arm is connected to the rack through a first rotation pair and the other end of the big arm is connected with the bucket rod. Two electromagnetic locking devices are installed on the first rotation pair and the tenth rotation pair respectively. By the adoption of the two electromagnetic locking devices, driving metamorphism can be achieved according to different working conditions, flexibility of a hydraulic excavator is achieved, three-freedom-degree excavating operation can be achieved simply through the two driving parts, and manufacturing cost of the excavating mechanism is reduced.

Owner:GUANGXI UNIV

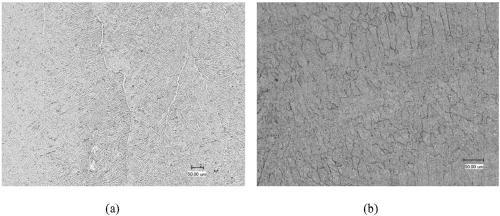

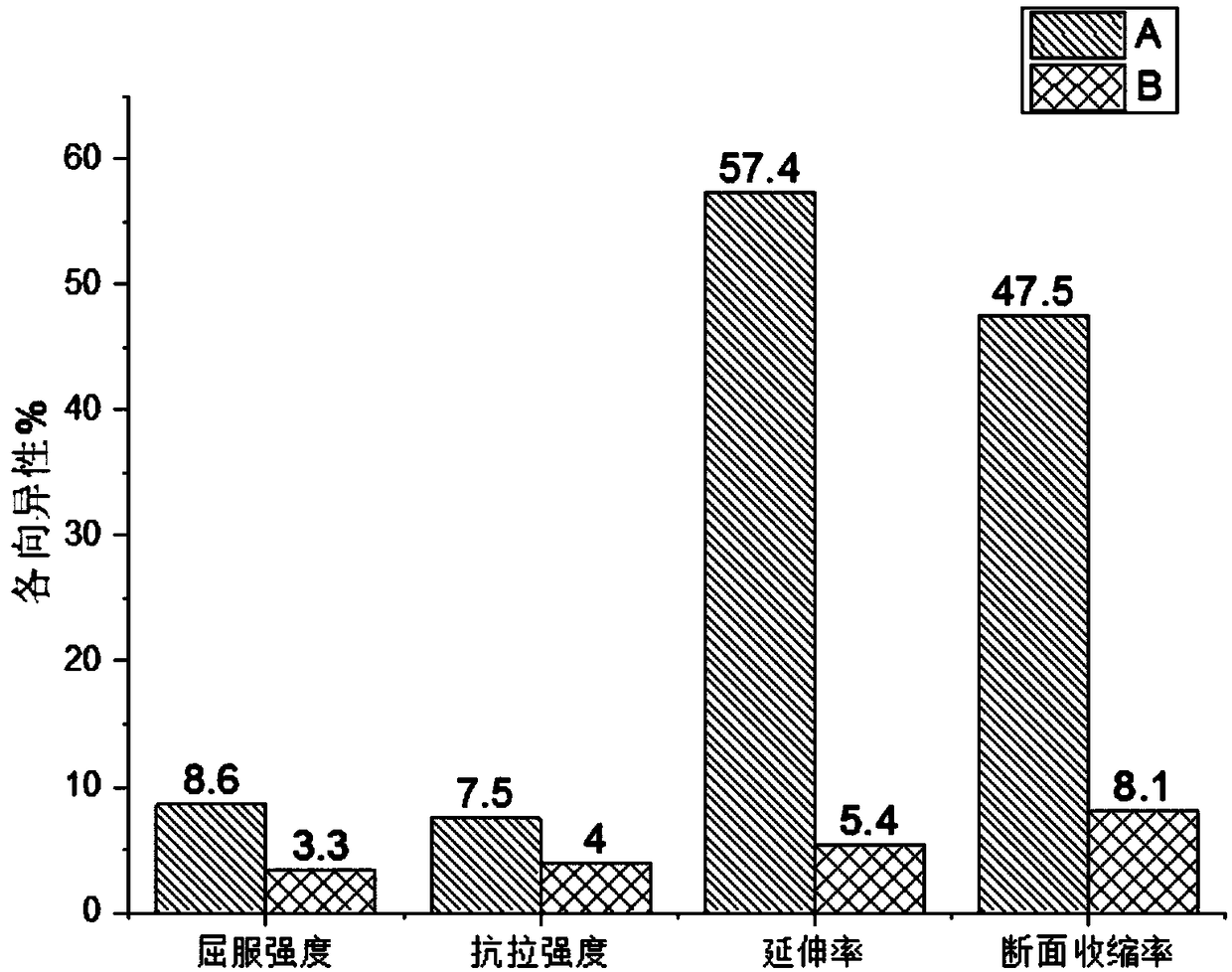

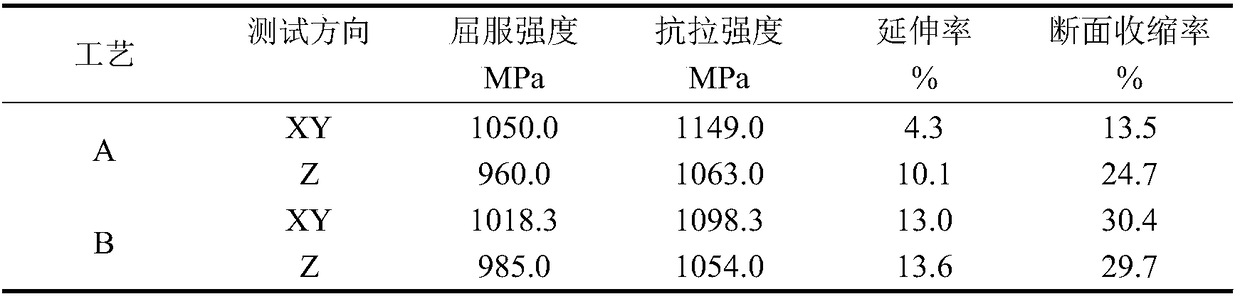

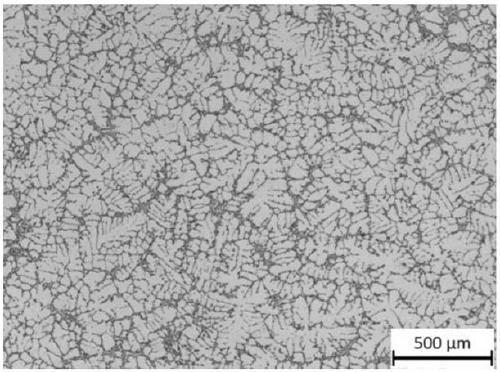

Method for utilizing boron alloying metamorphism to reduce anisotropy of TC4 additive manufacturing

InactiveCN109226743AGrain equiaxation and refinementReduce anisotropyAdditive manufacturing apparatusIncreasing energy efficiencyTi 6al 4vSedimentation

The invention discloses a method for utilizing boron alloying metamorphism to reduce anisotropy of TC4 additive manufacturing. The method includes the following steps of S1, drying Ti-6Al-4V-0.05B alloy powder under a vacuum environment at 120 DEG C for 8 hours; S2, using a laser additive manufacturing device for conducting laser melting, covering and forming on the alloy powder dried in step S1 under a protective atmosphere of inert gas to obtain a formed sample component; S3, conducting thermal dissolution and aging treatment on the formed component under argon protection of the inert gas. By using a new material obtained by alloying boron and TC4 in the method for laser melting, covering and sedimentation, boron effectively inhibits generation of thick preliminary cylindrical crystals in a TC4 titanium alloy during forming and facilitates isometry and refining of TC4 titanium alloy grains, the structure is more uniform, and the anisotropy of conventional mechanical performance is controlled within 10%. A new approach is provided for laser additive manufacturing of the TC4 titanium alloy.

Owner:XI AN JIAOTONG UNIV

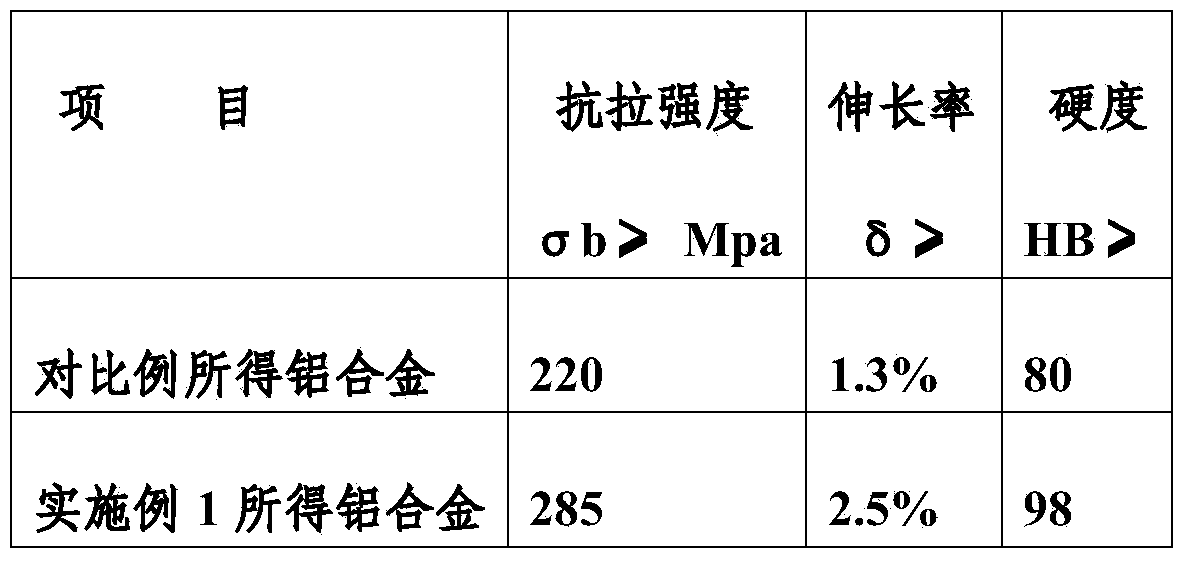

High-performance aluminium alloy material for automatic transmission and preparation method thereof

The invention discloses a high-performance aluminium alloy material. The high-performance aluminium alloy material is Al-Si-Cu aluminium alloy and also contains a rare earth element RE with the mass percentage of 0.25%-0.45%. The high-performance aluminium alloy material disclosed by the invention has the advantages that through purification of the rare earth element, metamorphism and microalloying, the porosity of the material is greatly reduced, and the mechanical performance of the material is improved. Compared with the air impermeability and mechanical performance of existing products, the air impermeability and mechanical performance of transmission oil pumps, valve plate components, valve core components or engine water pumps which are manufactured by using the material are obviously improved.

Owner:自贡市川力科技股份有限公司

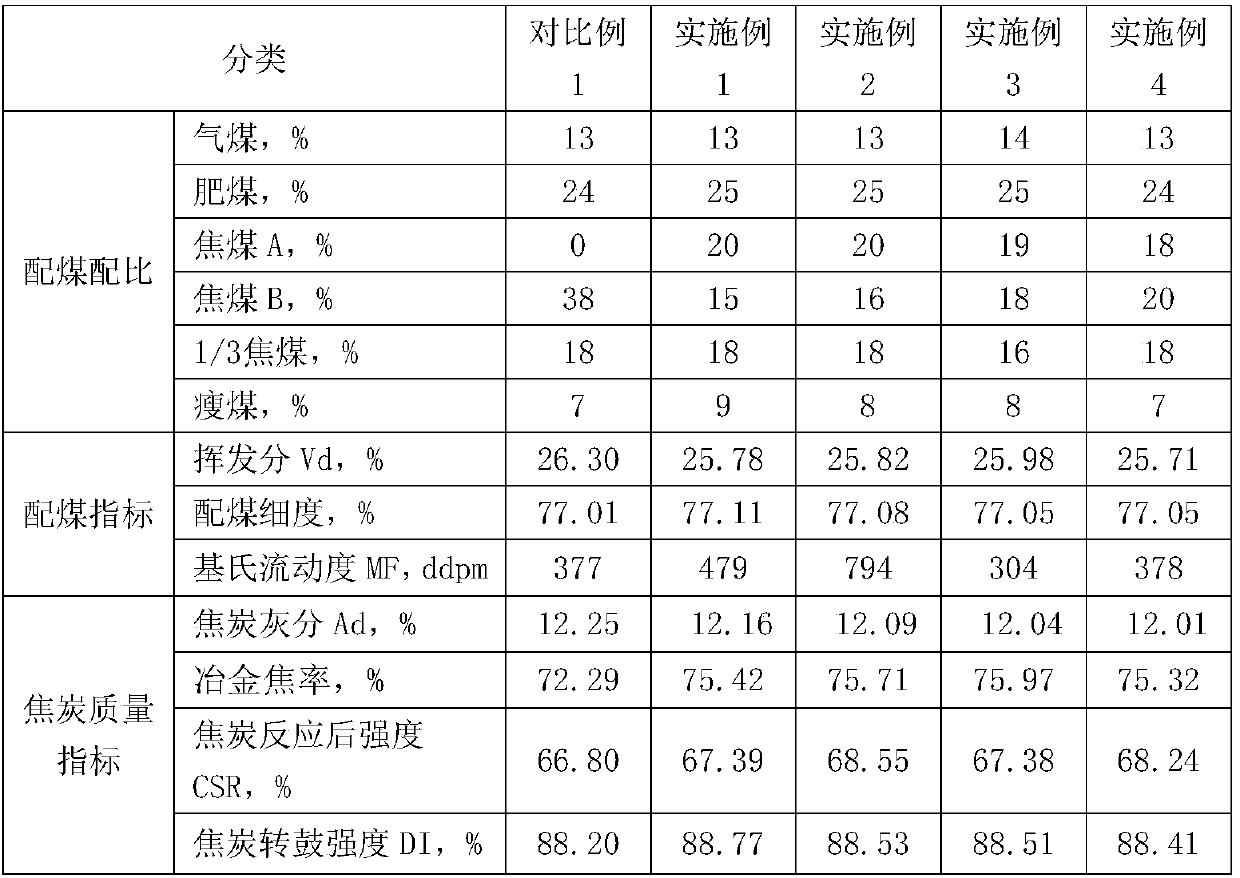

Coal blending method for coking chamber coke oven with width of 7.63 meters

InactiveCN101619224ASave resourcesReduce coal blending costsCoal charges mechanical treatmentCoke ovenProcess engineering

The invention relates to a coal blending method for a coking chamber coke oven with the width of 7.63 meters, which comprises the following steps: 1. selecting each single-species coking coal for participating in coal blending; 2. blending all the single-species coking coal comprising the following components in percentage by weight: 30-45 percent of coking coal, 5-10 percent of gas-fat coal, 30-45 percent of 1 / 3 coking coal and 8-15 percent of meager lean coal. Compared with the prior art, the invention breaks through a current high-cost coal blending structure mainly using high-quality coking coal with moderate degree of metamorphism, partial gas-fat coal and 1 / 3 coking coal with low degree of metamorphism are used for replacing fat-free coal, the meager lean coal is used for replacing lean coal, the coal blending cost is greatly reduced, and high-quality coking coal resources are saved. By the coal blending method, the acquired coke of the coke oven with the width of 7.63 meters comprises the following components in percentage by weight: 85-90 percent of M40 and 5.0-7.5 percent of M10, and the intensity after reaction is 63-70 percent, thereby satisfying the need of a blast furnace in more than 3,000 m<3>.

Owner:WUHAN IRON & STEEL (GROUP) CORP

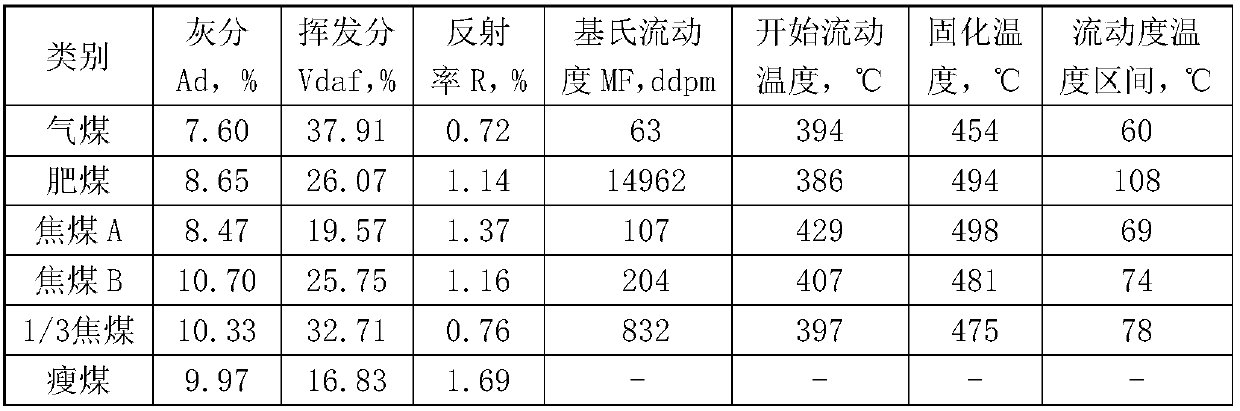

Coking method for improving coke granularity

The invention discloses a coking method for improving coke granularity. In the prior art, the coke granularity increase and the coking cost reducing cannot be simultaneously achieved in the top-loading coke oven. A purpose of the present invention is mainly to solve the problem in the prior art. The technical scheme comprises that the coking method comprises: detecting the coal rock reflectivity Rof coking coal is detected to screen high-metamorphism coking coal and low-metamorphism coking coal; detecting the Gieseler fluidity MF of the coking coal, and pre-breaking the coking coal with the Gieseler fluidity MF of less than or equal to 100 ddpm; carrying out coal blending, wherein the high-metamorphism coking coal, the low-metamorphism coking coal and other coking coal are blended according to a certain mass ratio; breaking the mixed coal; coking the blended coal, wherein the broken mixed coal is fed into a top-loading coke oven, and is subjected to coking at a coking temperature of 1000 + / -50 DEG C for 20+ / -2 h; and cooling after coke discharging, wherein a coke dry quenching process is adopted for coke cooling. According to the method of the invention, the coke granularity is improved, the coking process does not need to be changed, the technology is simple and feasible, and the coking cost is low.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

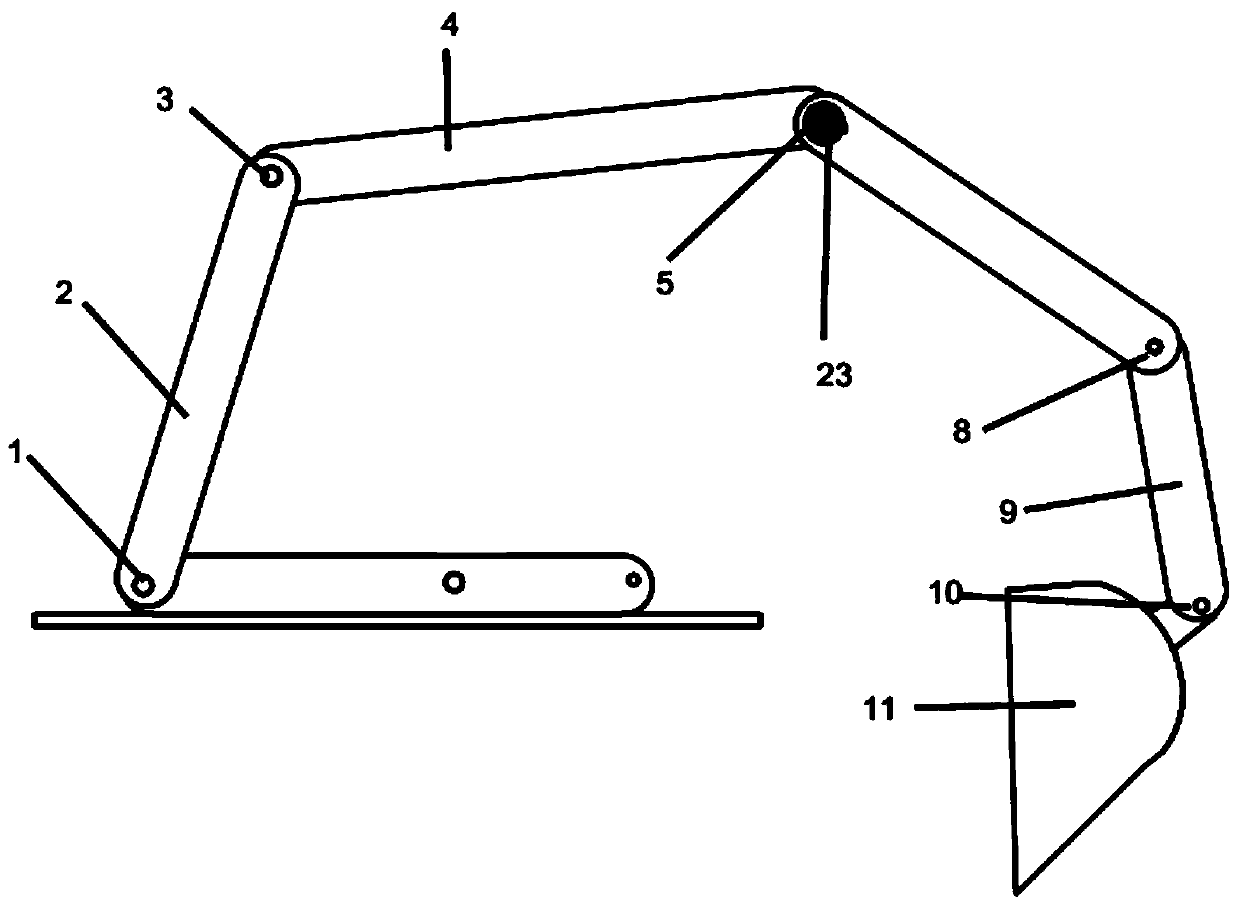

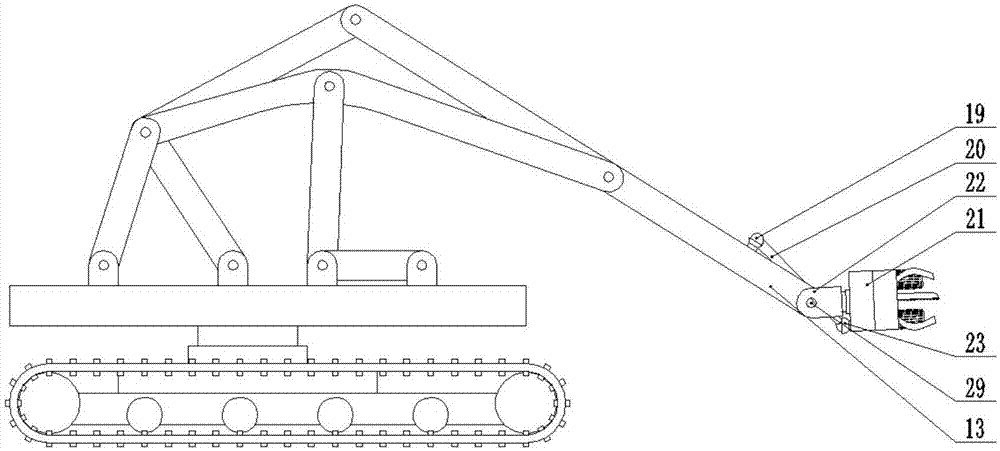

MDOF movable loading mechanism with initiative metamorphism function

InactiveCN104612191ALess freedomLow costMechanical machines/dredgersTwo degrees of freedomProcessing accuracy

The invention discloses an MDOF movable loading mechanism with an initiative metamorphism function. The MDOF movable loading mechanism comprises a movable platform, a rack, a big arm lifting mechanism, a bucket turnover mechanism and two locking devices. The big arm lifting mechanism comprises a big arm and a lifting mechanism body. The bucket turnover mechanism comprises a bucket and a turnover mechanism body. The locking devices are installed on a revolute pair, the initiative metamorphism function can be achieved by locking the revolute pair, and the movement function can be achieved through the movable platform. According to the MDOF movable loading mechanism, a traditional hydraulic transmission mechanism is replaced by a novel connecting rod transmission mechanism, so the defects that a hydraulic system of a hydraulic loading machine is complex, prone to oil leakage, high in requirement for machining precision and the like are overcome. Due to the fact that the locking devices are adopted in the revolute pair, the MDOF movable loading mechanism can perform initiative metamorphism according to different operation conditions, and not only has the flexibility of the hydraulic loading machine, but also can achieve loading operation of two degrees of freedom by utilizing one initiative rod; meanwhile, the MDOF movable loading mechanism has the movement function and an operation function, thereby being suitable for manufacturing various loading machines and other engineering machines.

Owner:GUANGXI UNIV

Smelting for ultra-large thick-wall spheroidal cast iron element and on site metamorphism treatment method thereof

The invention relates to a process of melting and field modification treatment of melting ductile iron castings, in particular to a process of melting and field modification treatment of super large ductile iron castings with thick walls, which is characterized in that the invention includes the steps of selecting melting devices, feeding to melt, heat preservation, spheroidization, inoculation and pouring. The processing method of the invention is unique and simple, thereby successfully and effectively resolving the melting of a small-tonnage electric induction furnace on large-tonnage molten iron and the modification treatment of large-tonnage spheroidal graphite cast-iron, which also solves the problems of inner decline of casings with inner walls, graphite segregation of the thick walls and the like.

Owner:KOCEL EQUIP

Composite metamorphic agent and composite metamorphic method of regenerative cast aluminum alloy

The invention discloses a composite metamorphic agent and a composite metamorphic method of a regenerative cast aluminum alloy, and relates to the technical field of metamorphism of cast aluminum alloys. The composite metamorphic agent is used for composite metamorphism of the regenerative cast aluminum alloy, and comprises a Mn agent, an Al-B intermediate alloy, and an Al-Sr intermediate alloy, wherein the Mn agent is an Al-Mn intermediate alloy or a Mn additive, and the appending proportion of the Mn agent is 30%-60% of the Fe content in the regenerative cast aluminum alloy; the additive amount of a B agent in the Al-B intermediate alloy is 0.01-0.05% of the melt mass of the regenerative cast aluminum alloy, and the additive amount of Sr in the Al-Sr intermediate alloy is 0.01-0.05% of the melt mass. According to the composite metamorphic agent, the purpose of synchronously refining three phases of alpha-Al, eutectic silicon, and an iron-rich phase can be achieved, thus the elongation of the alloy can be increased, and the composite metamorphic agent is especially suitable for composite metamorphism of a regenerative aluminum-silicon alloy with the high iron content.

Owner:GUANGDONG INST OF NEW MATERIALS

Composite metamorphic agent and composite metamorphic method of cast aluminum-silicon alloy

The invention discloses a composite metamorphic agent and a composite metamorphic method of a cast aluminum-silicon alloy, and relates to the technical field of metamorphism of cast aluminum alloys. The composite metamorphic method mainly uses the composite metamorphic agent for metamorphism. The composite metamorphic agent comprises an Al-Ti-B intermediate alloy, an Al-Sr intermediate alloy and an Al-RE intermediate alloy; the appending proportion of the Al-Ti-B intermediate alloy is 0.01%-0.04% of the melt mass of the cast aluminum-silicon alloy; the additive amount of Sr in the Al-Sr intermediate alloy is 0.01-0.05% of the melt mass; and the additive amount of RE in the Al-RE intermediate alloy is 0.01%-0.1% of the melt mass. According to the composite metamorphic method of the cast aluminum-silicon alloy, the cost is low, operation is easy, the purpose of synchronously refining alpha-Al crystalline grains and metamorphic eutectic silicon can be achieved through composite metamorphism, the additive amount of the Sr, and Al-Ti-B is decreased, thus the tensile strength and elongation of the alloy can be improved, and meanwhile, the strength and toughness of a cast aluminum alloy can be improved.

Owner:GUANGDONG INST OF NEW MATERIALS

Method for renewable aluminum alloy iron-rich phase metamorphism

The invention discloses a method for renewable aluminum alloy iron-rich phase metamorphism. The invention adopts the technical scheme that the method comprises the steps of melting renewable aluminum alloy furnace burdens, and rising temperature to 740 to 800 DEG C; pressing W-containing intermediate alloy into a melt body, and then carrying out intensively stirring for 10 to 30 min, wherein the amount of W added into the melt body accounts for 0.05 to 0.3 weight percent of the mass of the melt body; after stirring, adding a refining agent at 730 to 760 DEG C, and then carrying out stirring, degassing, refining and slagging off; and carrying out stilling for 5 to 10 min with the temperature kept, and then carrying out discharging and casting. By utilizing the method, a form of an iron-rich phase can be improved, a needle-shaped iron-rich phase is eliminated, and a bone-shaped or Chinese script type iron-rich phase is refined, so that a renewable aluminum alloy structure is improved, a mechanical property and a processing property of the renewable aluminum alloy are improved, and the recovery rate of the aluminum alloy is remarkably improved.

Owner:ZHONGBEI UNIV

Waxberry preserving process based on ultra pressure technology

InactiveCN102028018APreserve the flavorRetain nutrientsFruit and vegetables preservationUltra high pressureHardness

The invention discloses a waxberry preserving process based on an ultra high pressure technology, which comprises the steps of: selecting a single fresh waxberry without insect pest damage for vacuum packaging, placing 6-10 vacuum packaging bags containing the single waxberry in a plastic bag, adding clear water, and plastically packaging; placing the plastically packaged plastic bag in ultra high pressure equipment, sealing, pressurizing to 400-600MPa, holding the pressure for 2-5 minutes, wherein the pressurized temperature is 20-60 DEG C; and releasing the pressure, taking the plastically packaged plastic bag from the ultra high pressure equipment and unpacking, and storing the taken vacuum packaging bags containing the single waxberry at a temperature of 4 DEG C or 20 DEG C. The invention has the advantages of good safety and low energy consumption, and belongs to an environment-friendly processing technology; the PH value change of the waxberry in a storage course is obviously decreased, enzyme activity is declined, the colour and the hardness of the waxberry are better kept, metamorphism is effectively restrained, and the shelf life of the waxberry is prolonged.

Owner:ZHEJIANG UNIV

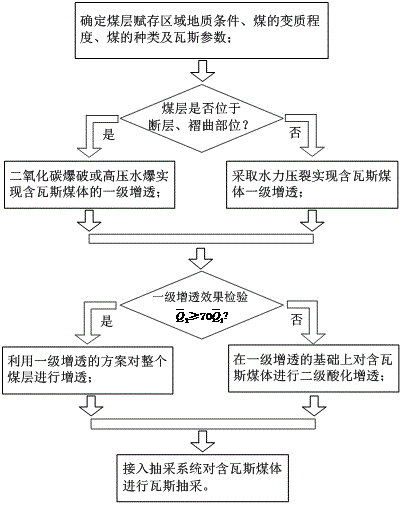

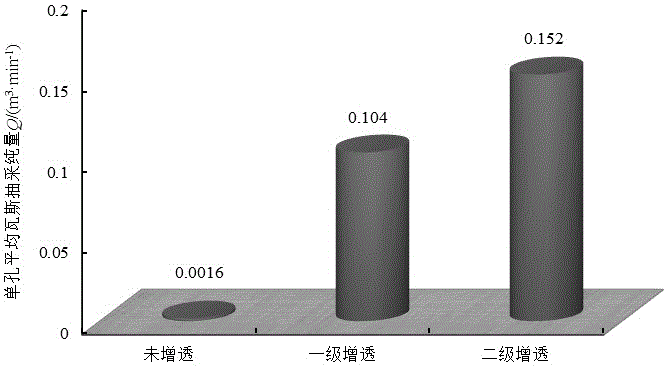

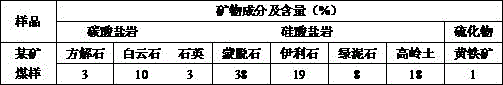

Gas-containing-coal multistage permeability increasing method

InactiveCN106437824AQuality improvementImprove use valueFluid removalGas removalINCREASED EFFECTCoal

The invention discloses a gas-containing-coal multistage permeability increasing method. The gas-containing-coal multistage permeability increasing method includes the steps that firstly, the geological conditions of a coal seam hosting region, the coal metamorphism degree, the coal class and gas parameters are determined; secondly, according to whether a coal seam is located at a fault portion or a fold portion, different schemes are adopted to achieve first-stage permeability increasing of gas containing coal and detect the permeability increasing effect, and if a preset effect is achieved, permeability increasing of the whole coal seam is carried out with the first-stage permeability increasing scheme; thirdly, if the preset effect is not achieved, on the basis of the first-stage permeability increasing, second-stage acidification permeability increasing is carried out on the gas containing coal; finally, after the second-stage acidification permeability increasing is completed, gas extraction is carried out on the gas containing coal. According to the gas-containing-coal multistage permeability increasing method, different permeability increasing schemes are formulated according to the geology of different coal-seam hosting regions, and high pertinence is achieved; meanwhile, after multistage permeability increasing is adopted, the gas permeability of the coal seam is greatly improved, and the gas extraction rate is increased.

Owner:田成林

Fast production of subsphaeroidal crystal tissue semi-solid aluminium alloy

A prepared method of semi-solid spherocrystal A-alloy is to treating the alloy fusant by the process of 'refining after metamorphism' or 'metamorphism after refining'; preparing the semi-solid by the reversible electromagnetic stirring; monitoring the temperature while stirring until the temperature is under the liquid phase 3-5 Deg C., then cooling and geting the product. The efficient of the process has been improved more greatly than the traditional one, and the alloy has been more available crystal nucleus.

Owner:TSINGHUA UNIV

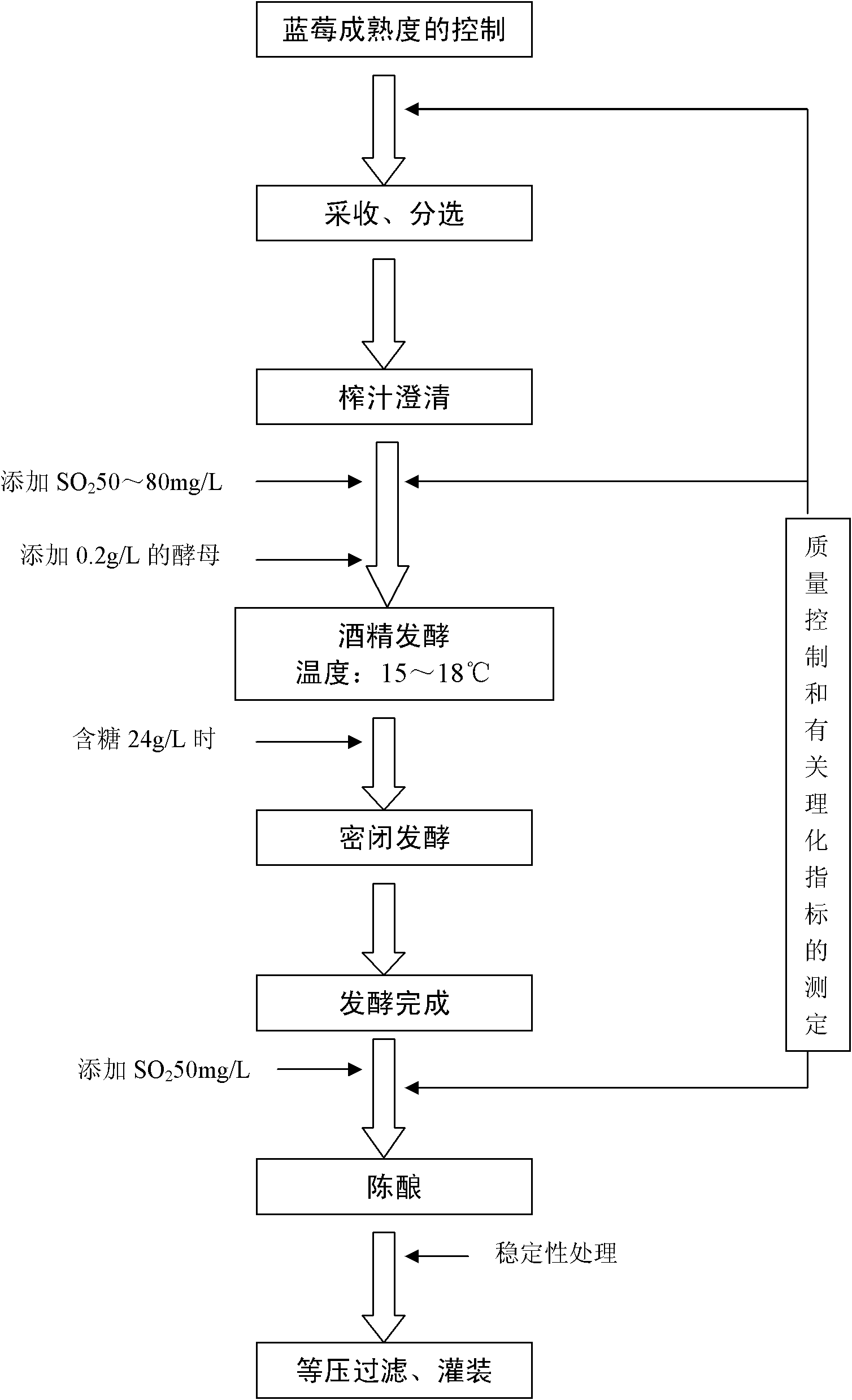

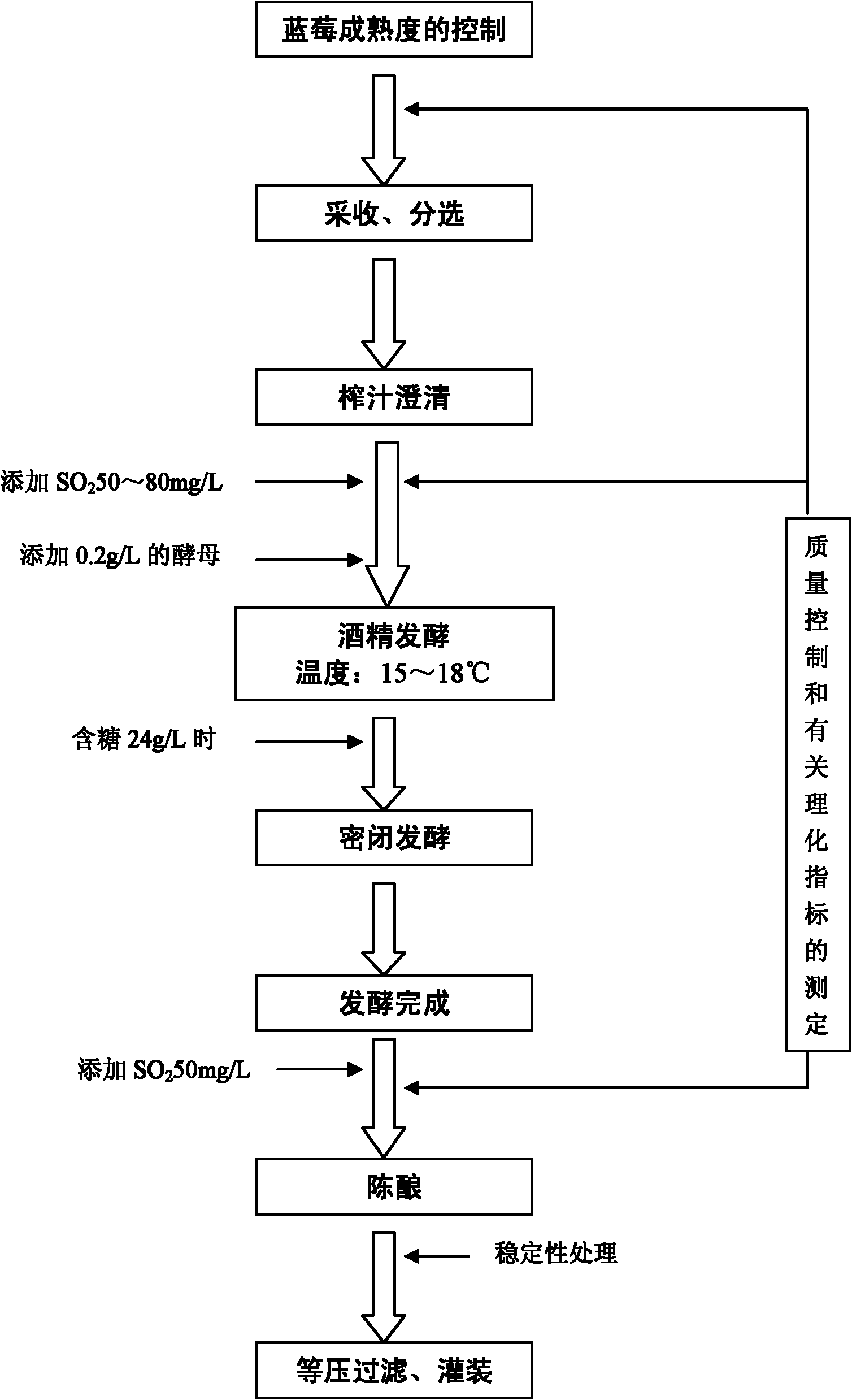

Making method of pure blueberry juice carbonated wine

InactiveCN101921688AQuality improvementRefreshing and comfortableMicroorganism based processesAlcoholic beverage preparationFruit wineProduct gas

The invention relates to a making method of wine, in particular to a making method of pure blueberry juice carbonated wine, which is characterized by comprising the following steps of: (1) controlling the maturity grade of raw materials; (2) picking up and sorting; (3) juicing and settling, and adding sulfur dioxide; (4) alcoholic fermentation; (5) tanking switching; (7) stopping fermentation and adding sulfur dioxide; (7) refrigeration and aging; and (8) filtering under constant pressure and filling. The invention uses the sugar of blueberry per se to ferment to generate carbon dioxide gas, thereby avoiding the damage to the taste of fruit wine caused by adding carbon dioxide manually, simplifying the brew process and preventing danger caused by the metamorphism of wine.

Owner:NORTHWEST A & F UNIV

Preparation method for low-alcohol physalis alkekengi beverage

The invention provides relates to a preparation method for a beverage, in particular to a preparation method for a low-alcohol physalis alkekengi beverage. The preparation method comprises the following steps: selecting ripe physalis alkekengi without mildew, rot and metamorphism for peeling and cleaning; adding clear water which is three times the quality of the physalis alkekengi for juicing to obtain two parts of physalis alkekengi juice and physalis alkekengi pomace; adding thermophilic streptococcus freeze-dried powders into the physalis alkekengi juice for fermentation; filtering after the fermentation to obtain a solution A; adding water into the physalis alkekengi pomace for boiling; adding glucose after filtering; adding aroma-producing active dry yeasts for fermentation; filtering after the fermentation to obtain a solution B; mixing the solution A with the solution B at a ratio of 2:1; blending, filtering, sterilizing and sterile filling the mixed solution to obtain a finished product. The preparation method provided by the invention effectively overcomes the deficiencies that the physalis alkekengi is difficult to store and is restricted by season when appearing on the market, and develops a novel path for the deep processing of the physalis alkekengi.

Owner:卜进锋 +1

Three-configuration metamorphic tree pruning and chopping machine with three-DOF (degree of freedom) transformation function

InactiveCN106954476AImprove motion stabilitySmall three-dimensional spaceCuttersCutting implementsHydraulic cylinderAgricultural engineering

A three-configuration metamorphic tree pruning and chopping machine with a three-DOF (degree of freedom) transformation function comprises a wood chopping combined mechanism, a crawler walking system, a rack, a driving linkage, a transmission linkage, an output connecting rod, pins, a hydraulic cylinder and a hook joint, wherein the rack is mounted on the crawler walking system, the driving linkage, the transmission linkage and the output connecting rod are mutually connected through the pins, the driving linkage and the transmission linkage are mounted on the rack, the wood chopping combined mechanism is mounted at one end of the output connecting rod through the hydraulic cylinder and the hook joint and comprises a saw mechanism, a lower clamping mechanism, rollers, an upper clamping mechanism and a branching knife. During working, flexible metamorphism of three-DOF and three-configuration transformation is realized, and large space operation is realized through overlaying of movement spaces; the tree pruning and chopping machine comprises full rod pieces and is lower in manufacturing cost, long in service life and simple to maintain. The tree pruning and chopping machine can prune, trim and chop trees and perform sectional wood cutting operation in severe and rugged forest.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com