Method and device for pre-consolidating mixed hydraulically-filled soft soil foundation

A technology of soft soil foundation and treatment method, which is applied in the comprehensive utilization of dredging and filling soil, the pre-reinforcement treatment of mixed dredging and filling of soft soil foundation, and the pre-reinforcement treatment technology field of ultra-soft foundation, which can solve the problem of low bearing capacity and consolidation Large settlement and other problems, to achieve the effect of clear mechanism, simple process, saving construction period and subsequent engineering processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

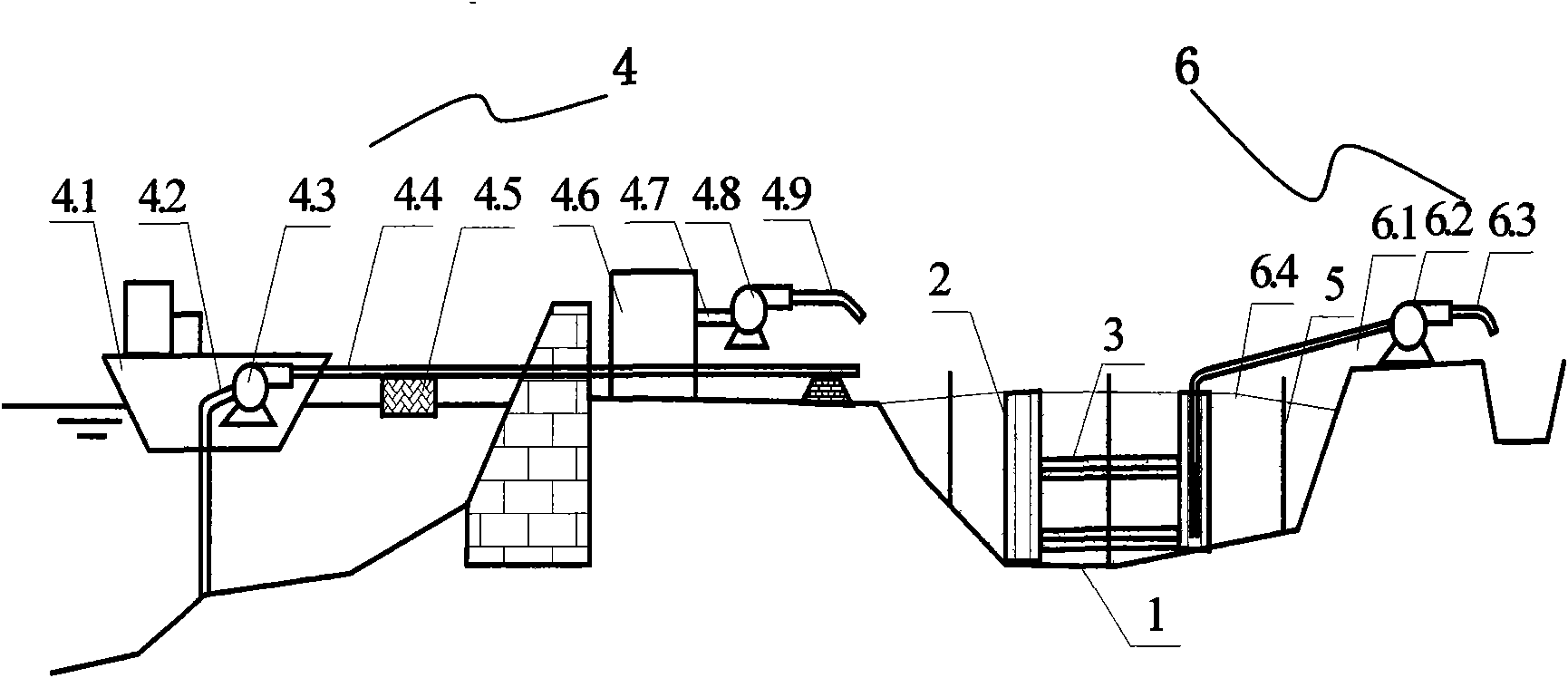

[0052] Below in conjunction with accompanying drawing, the present invention is further described:

[0053] 1. Pre-reinforcement treatment of mixed dredging soft soil foundation

[0054] 1. Step ①, determine the curing agent combination and its ratio with the filling material

[0055] In view of the characteristics of dredger fill soft soil, carry out indoor comparative tests on the sludge solidification effect of quicklime, cement, gypsum, fly ash, slag, etc., to screen and combine the curing agent materials and their formulations suitable for dredger fill sludge with the best early strength solidification effect. Compare.

[0056] 2. In step ⑤, determine the filling rate according to the test results

[0057] The mixing equipment is used to form the curing agent slurry on site, and the double-pipe mixed blowing and filling material equipment 4 is installed at the blowing and filling injection port. Mix well during blow-fill.

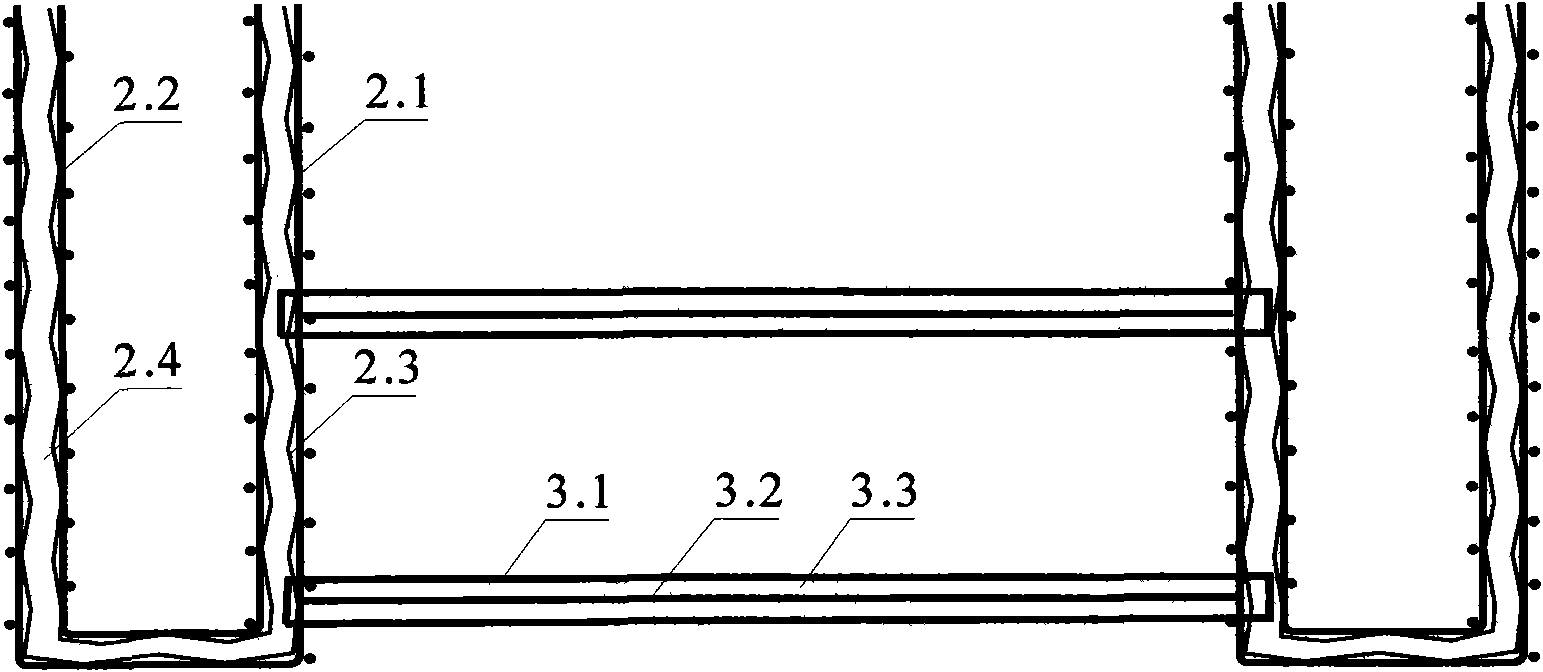

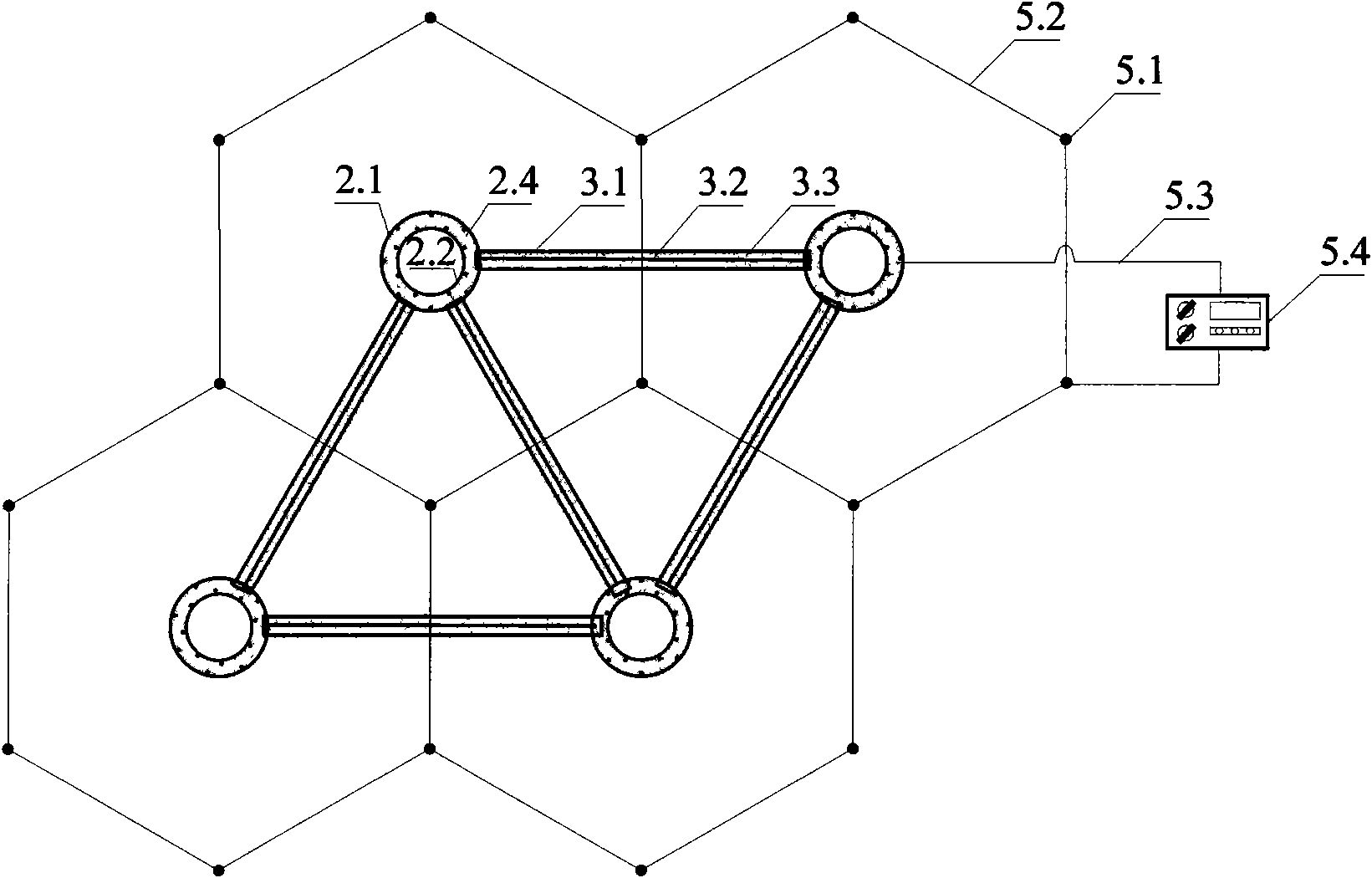

[0058] 2. Pre-reinforcement treatment device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com