A micro-splitting multi-layer high-vacuum layered pre-compression and compaction construction method

A construction method and high-vacuum technology, applied in infrastructure engineering, construction, soil protection, etc., can solve problems such as low permeability coefficient of coating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

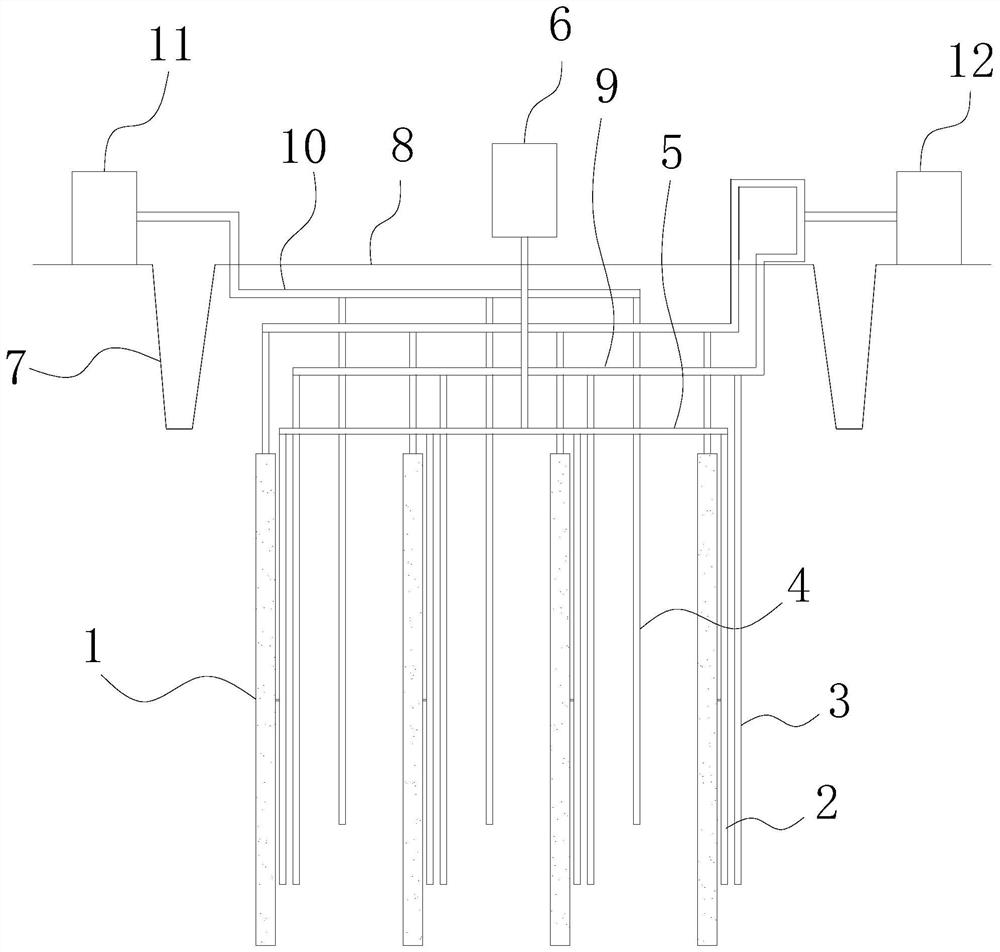

[0038] Attached to the following Figure 1-2 This application will be described in further detail.

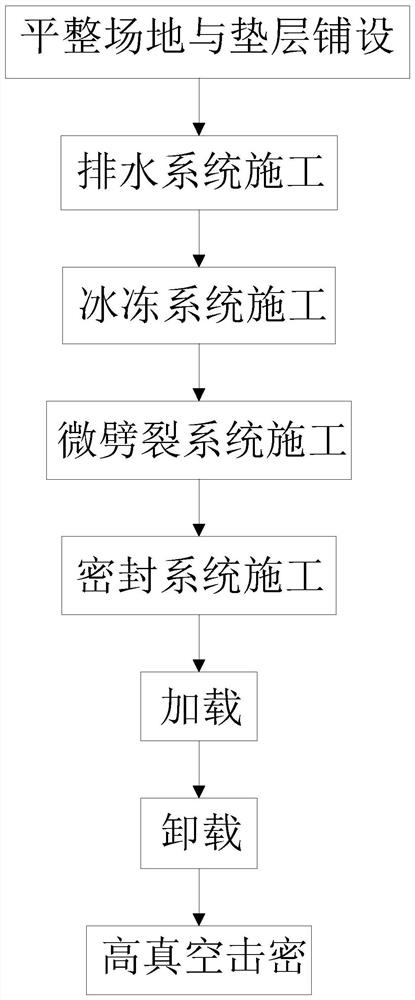

[0039] The embodiment of the present application discloses a micro-splitting multi-layer high-vacuum layered pre-compression and compaction construction method. refer to figure 1 and figure 2 , a micro-split multi-level high-vacuum layered pre-compression and compaction construction method comprises the following steps:

[0040] 1) Leveling the site and laying the cushion: Use the bulldozer to push the earthwork from the super high place on the construction site and push it to the low-lying part of the site to remove large stones and various impurities, so as not to affect the construction of the plastic drainage board 1. Part of it is replaced, and the replacement is made of plain soil without impurities, and it is leveled to meet the later construction needs. Then backfill a 30cm-thick sand cushion on the ground of the flat construction site. The mud content of the sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com