Curtain-wrapped pre-pressed drainage structure of a strip-shaped subgrade and its construction method

A technology of drainage structure and construction method, which is applied in infrastructure engineering, roads, roads, etc., can solve the problems of low foundation bearing capacity and uneven settlement of the site, so as to increase the pore water pressure, speed up the consolidation speed of soft soil, and speed up the The effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

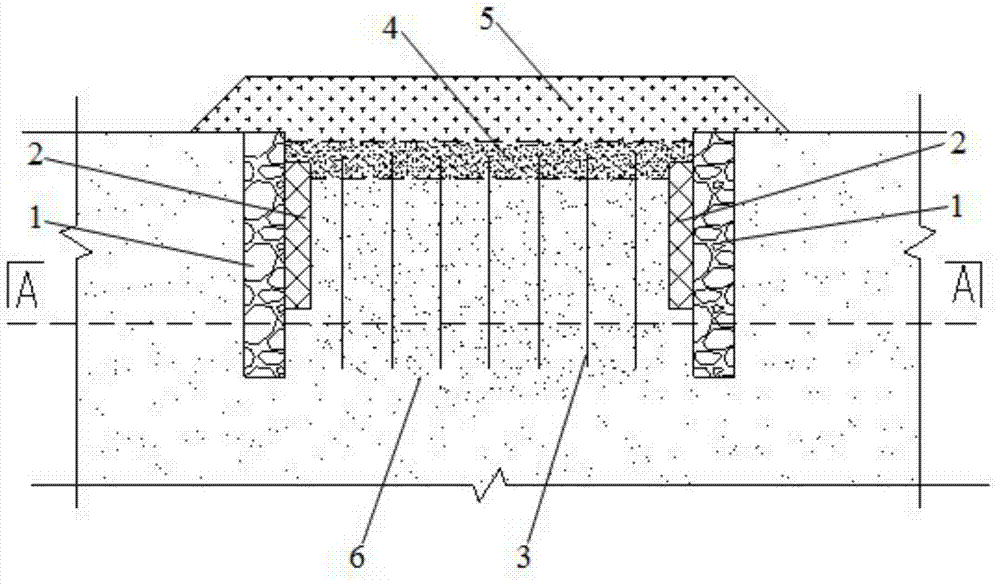

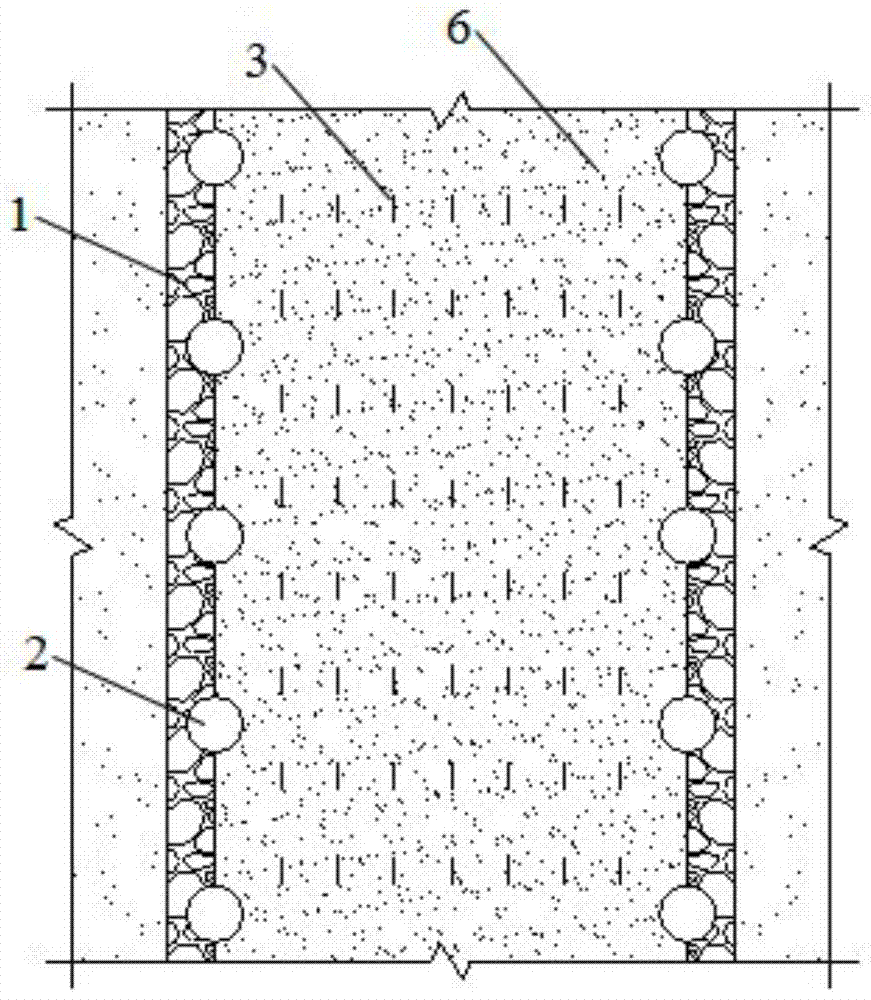

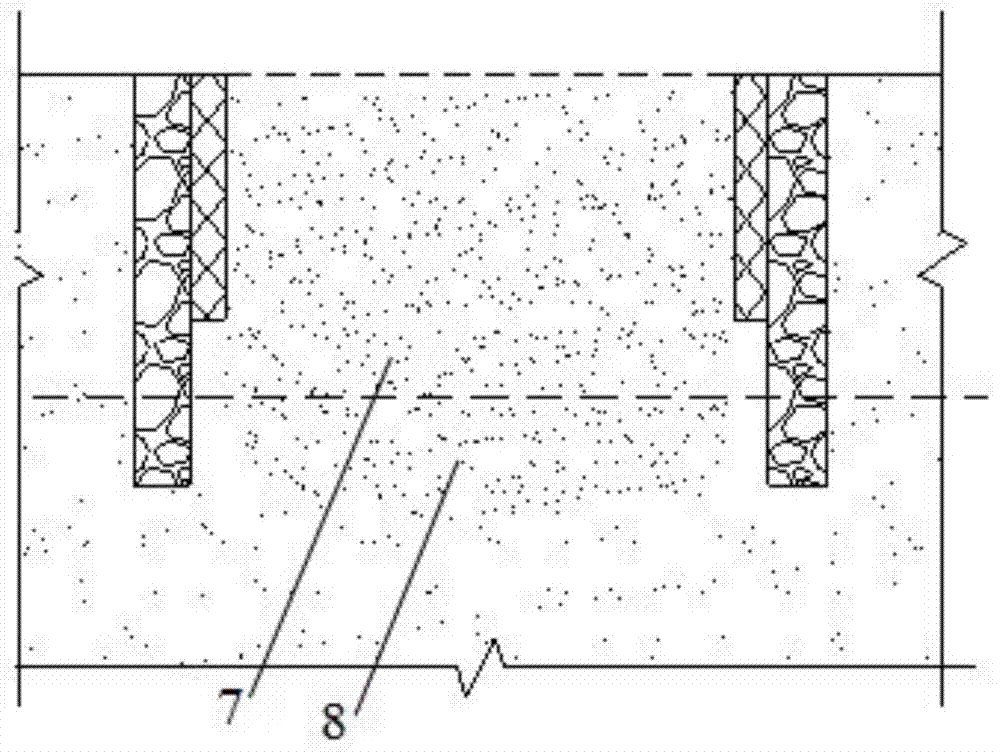

[0036] Such as Figure 1-2 As shown, the curtain-wrapped preloaded drainage structure of strip-shaped subgrade includes curtain structure 1, drainage pipe 2, drainage board 3, sand cushion layer 4 and surcharge layer 5, and the treatment area is divided into soft soil layer from top to bottom 7 and the impermeable layer 8, the soft soil layer 7 within the range of the strip roadbed 6 needs to be drained and consolidated.

[0037] The curtain structure 1 is arranged vertically and vertically on both sides of the subgrade 6. The curtain structure 1 is a concrete mixing pile, clay pile or steel sheet pile arranged longitudinally and continuously along the subgrade 6. The lower end of the curtain structure 1 passes through the soft soil layer 7 of the subgrade 6 to reach the The water-permeable layer 8 forms an airtight retaining wall in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com