Patents

Literature

355results about How to "Low degree of automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

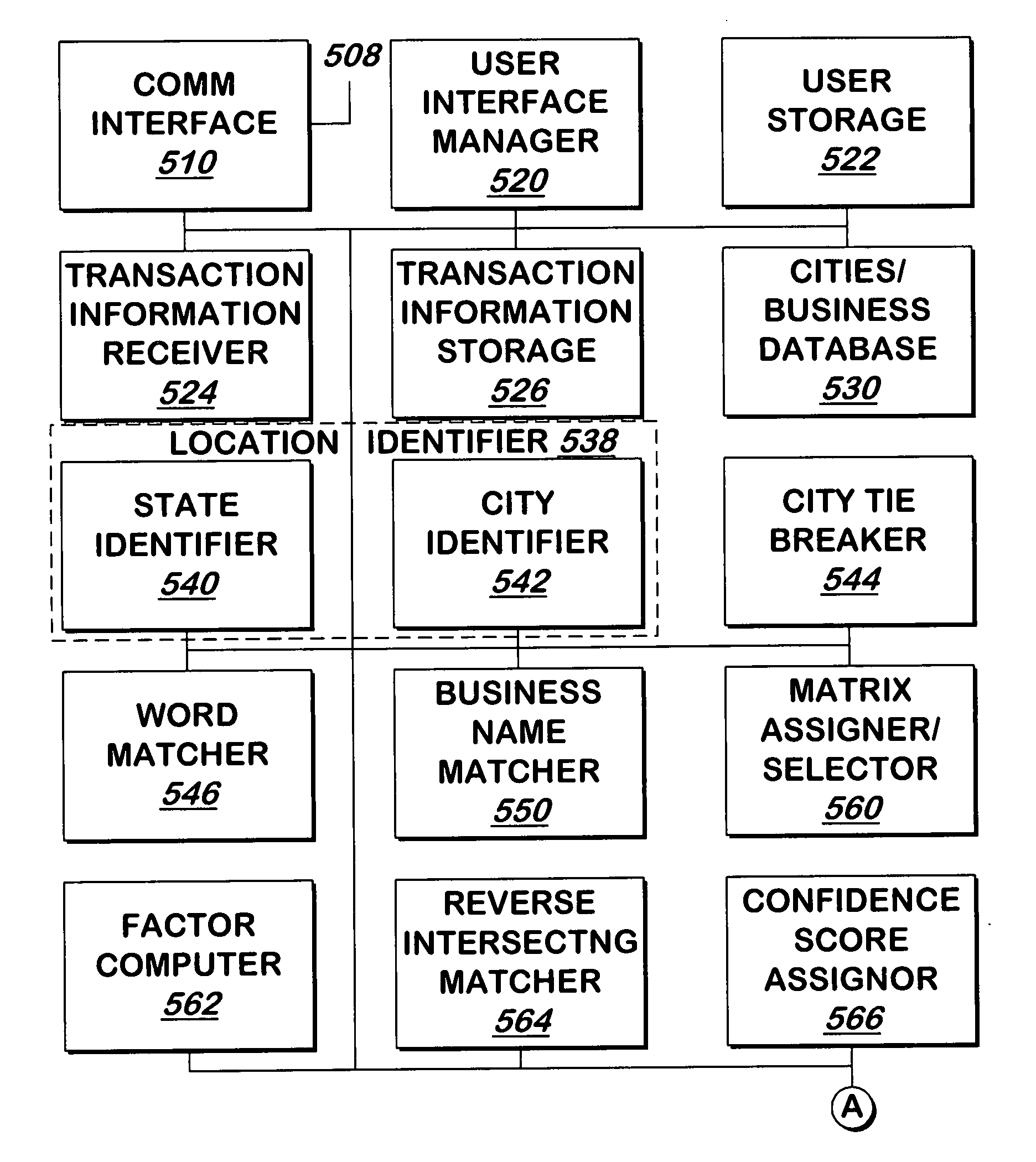

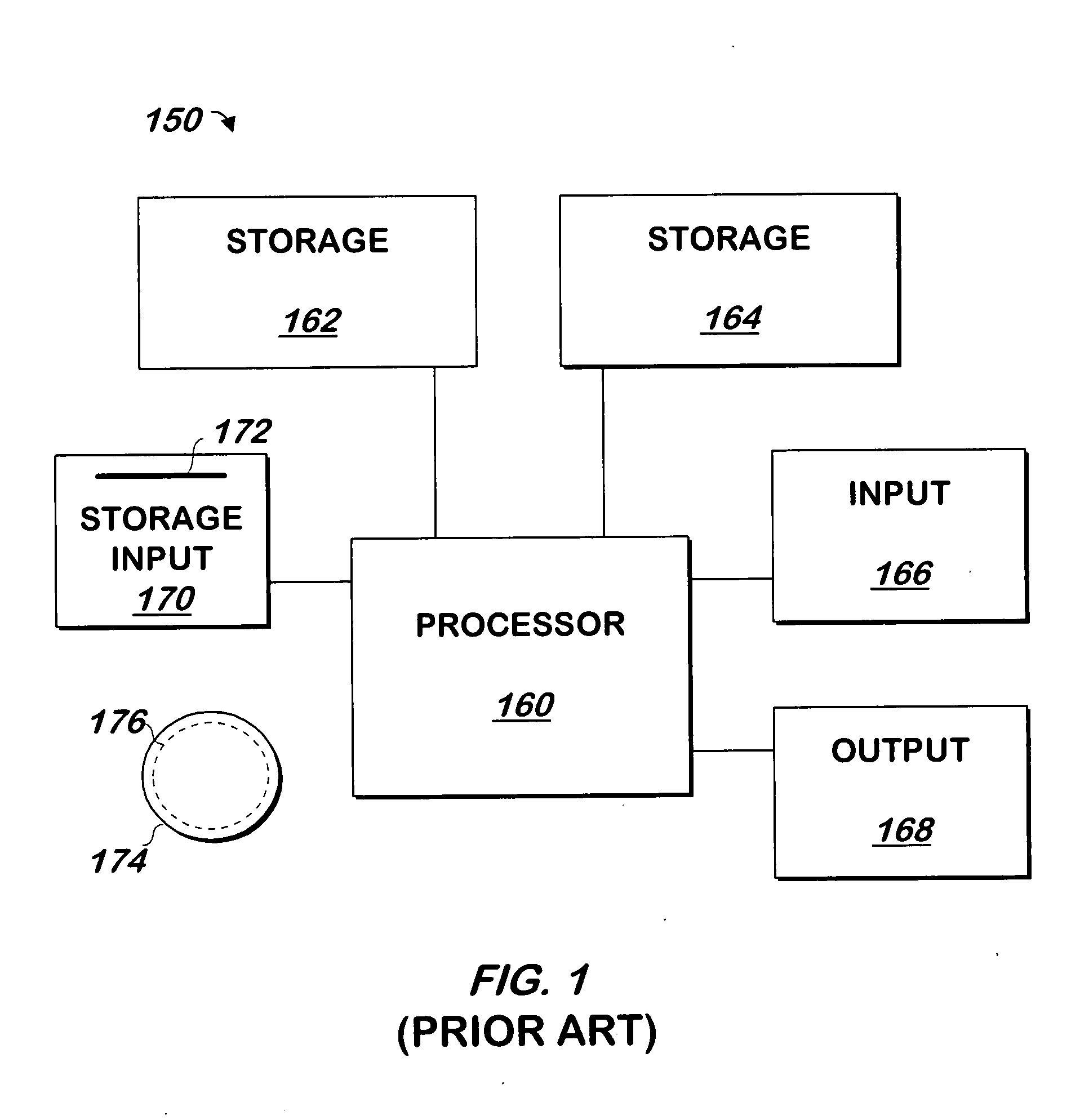

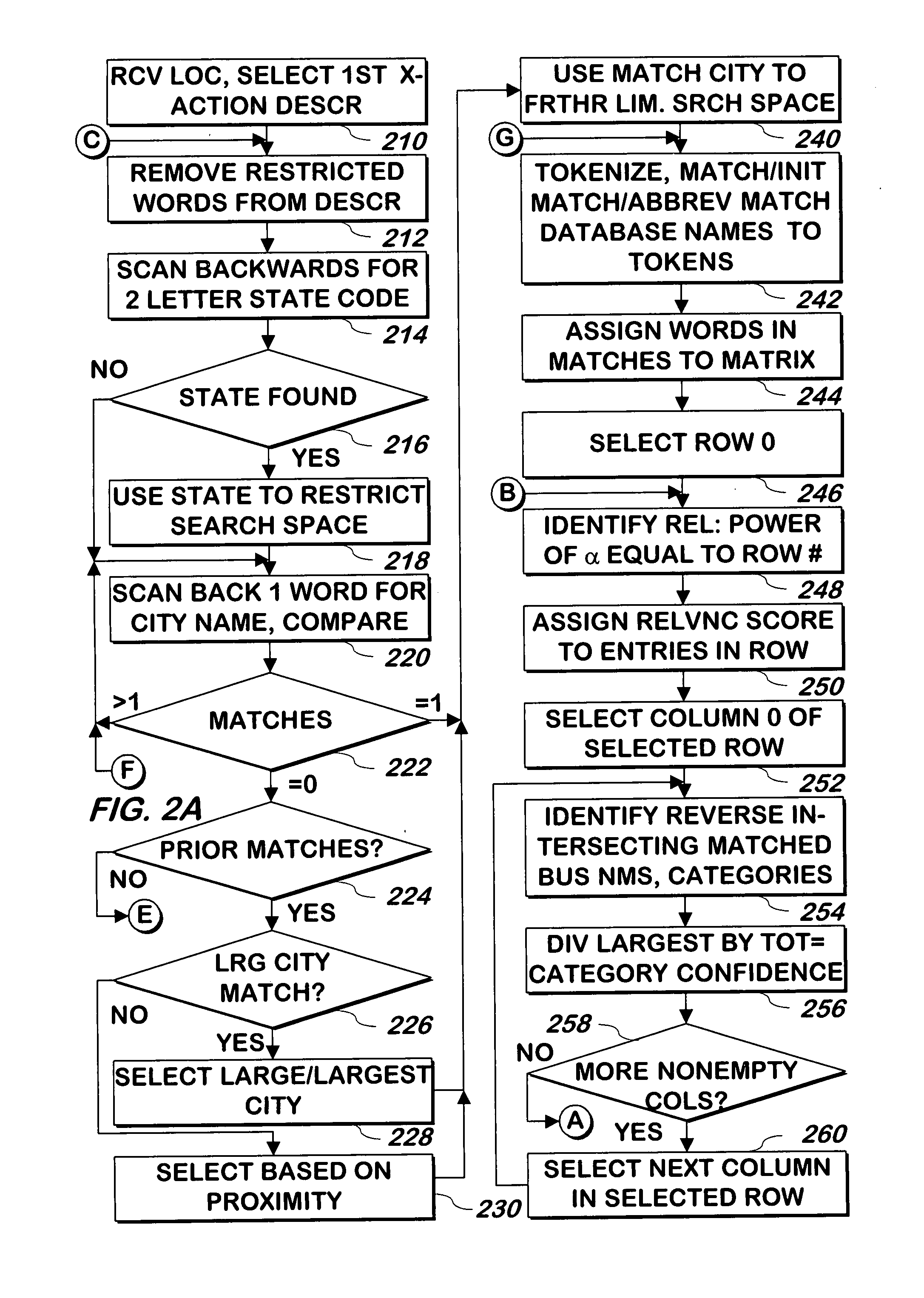

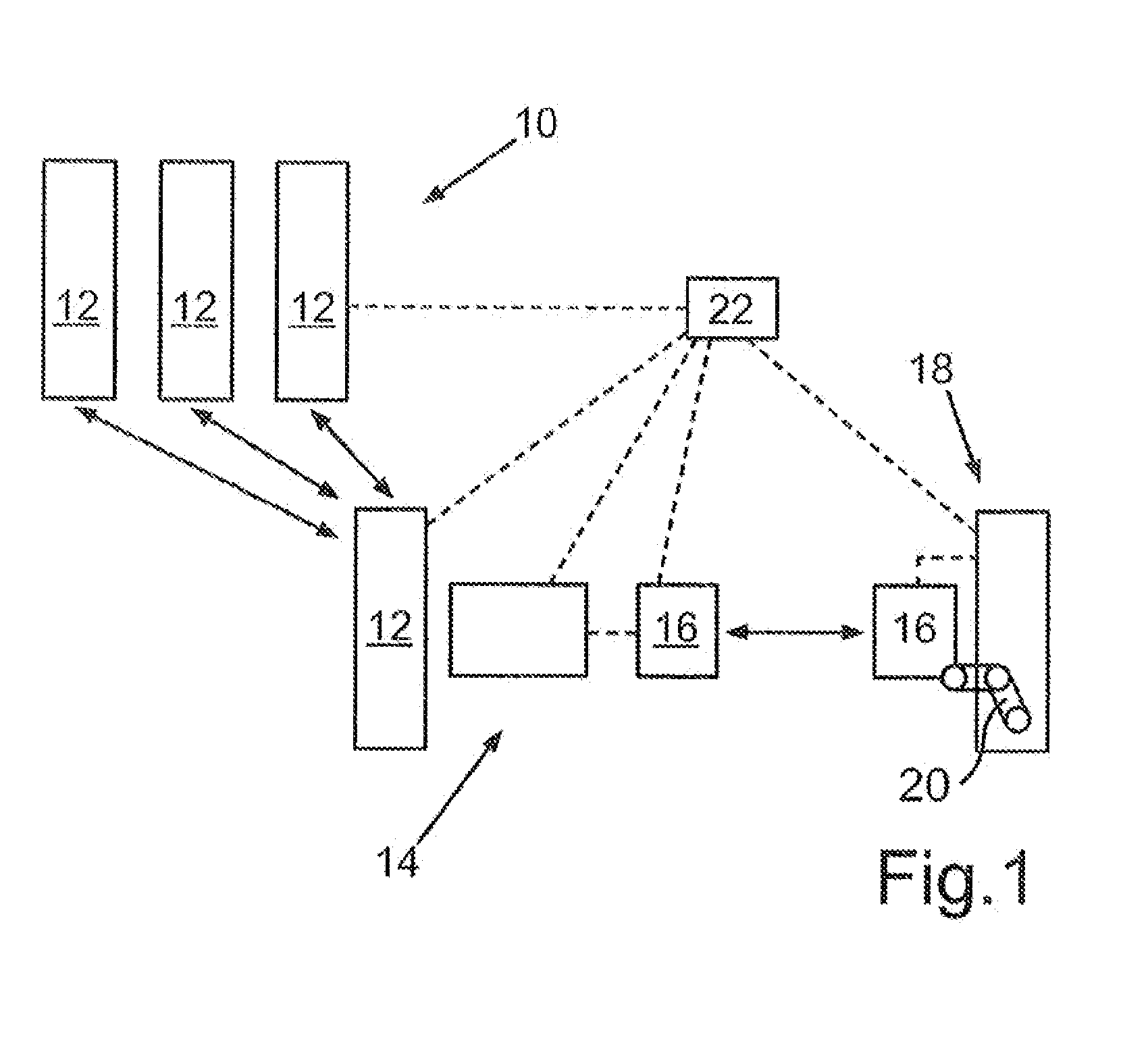

System and method for categorizing credit card transaction data

ActiveUS20080301042A1Low degree of automationProcessing speedComplete banking machinesFinanceCredit cardTransaction data

A system and method employs a categorized list of business names to identify a category corresponding to transaction information, such as credit card transaction data.

Owner:INTUIT INC

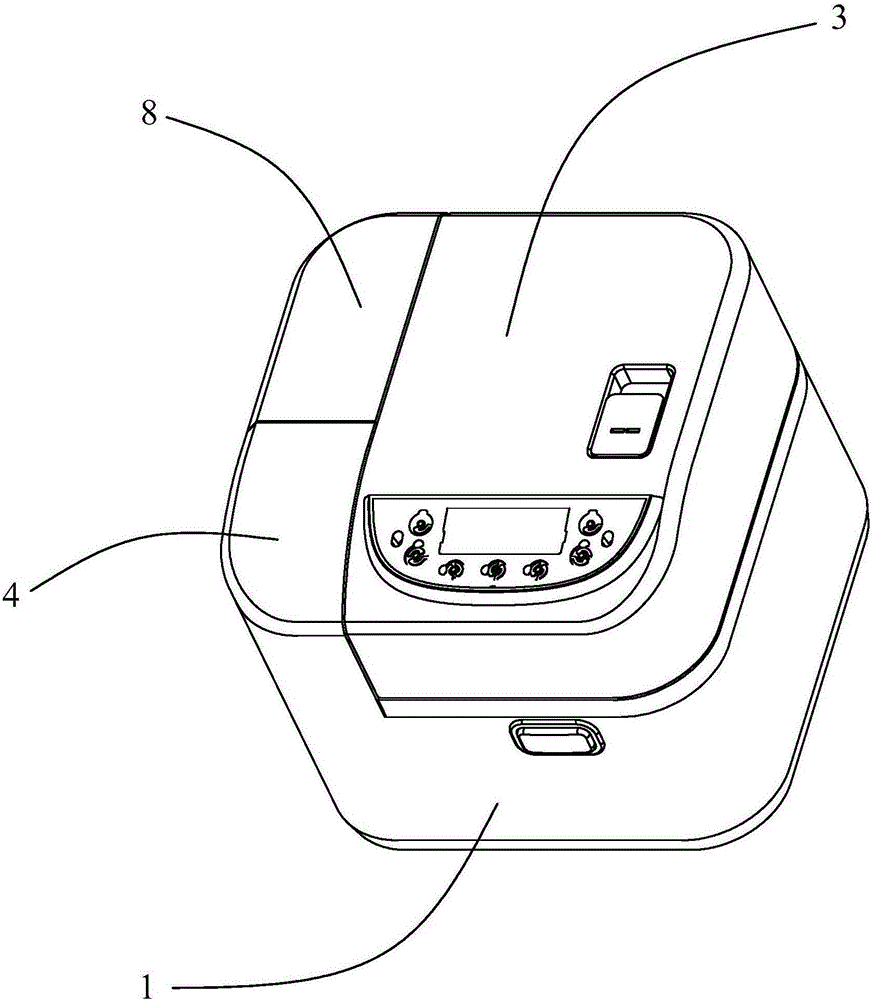

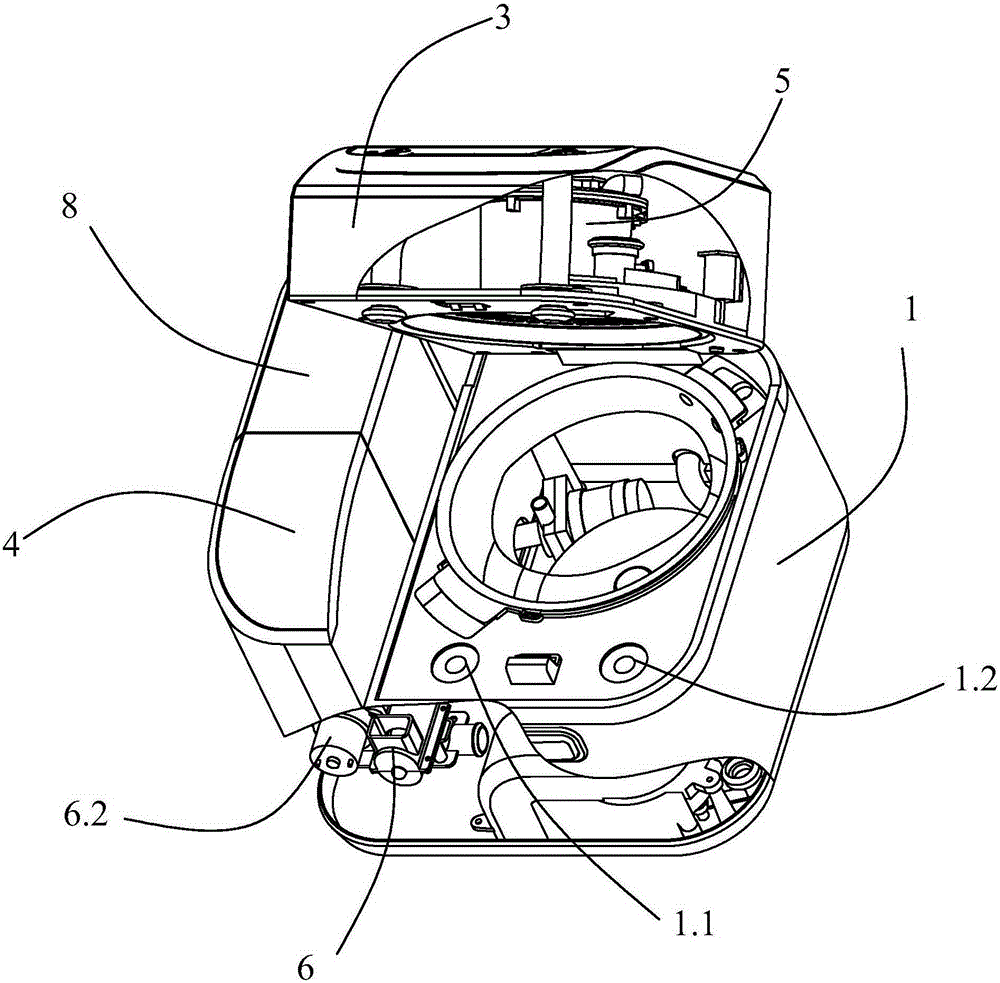

Automatic cooking appliance

The invention relates to an automatic cooking appliance capable of automatically adding water, feeding materials and washing the materials. The automatic cooking appliance comprises a pot body, an inner container disposed inside the pot body, a controller, and a pot cover buckled with the pot body. The automatic cooking appliance further comprises a material storage device provided with a material outlet arranged at the bottom and a washing device arranged on the pot cover. The washing device comprises a washing chamber and a stirring unit; the stirring unit comprises a washing rod and a driving motor; a water discharging port and a material discharging port communicated with the inner container are arranged on the lower part of the washing chamber; and the material outlet is communicated with the upper part of the washing chamber so that the materials can be conveyed. The invention also provides an automatic cooking method based on the structure mentioned above. According to the invention, a technical problem that a conventional rice cooker is of low automation degree is solved, and the automatic cooking appliance which can be used in common families, can automatically add water, and feed and wash the materials, and can be remotely controlled is provided.

Owner:JOYOUNG CO LTD

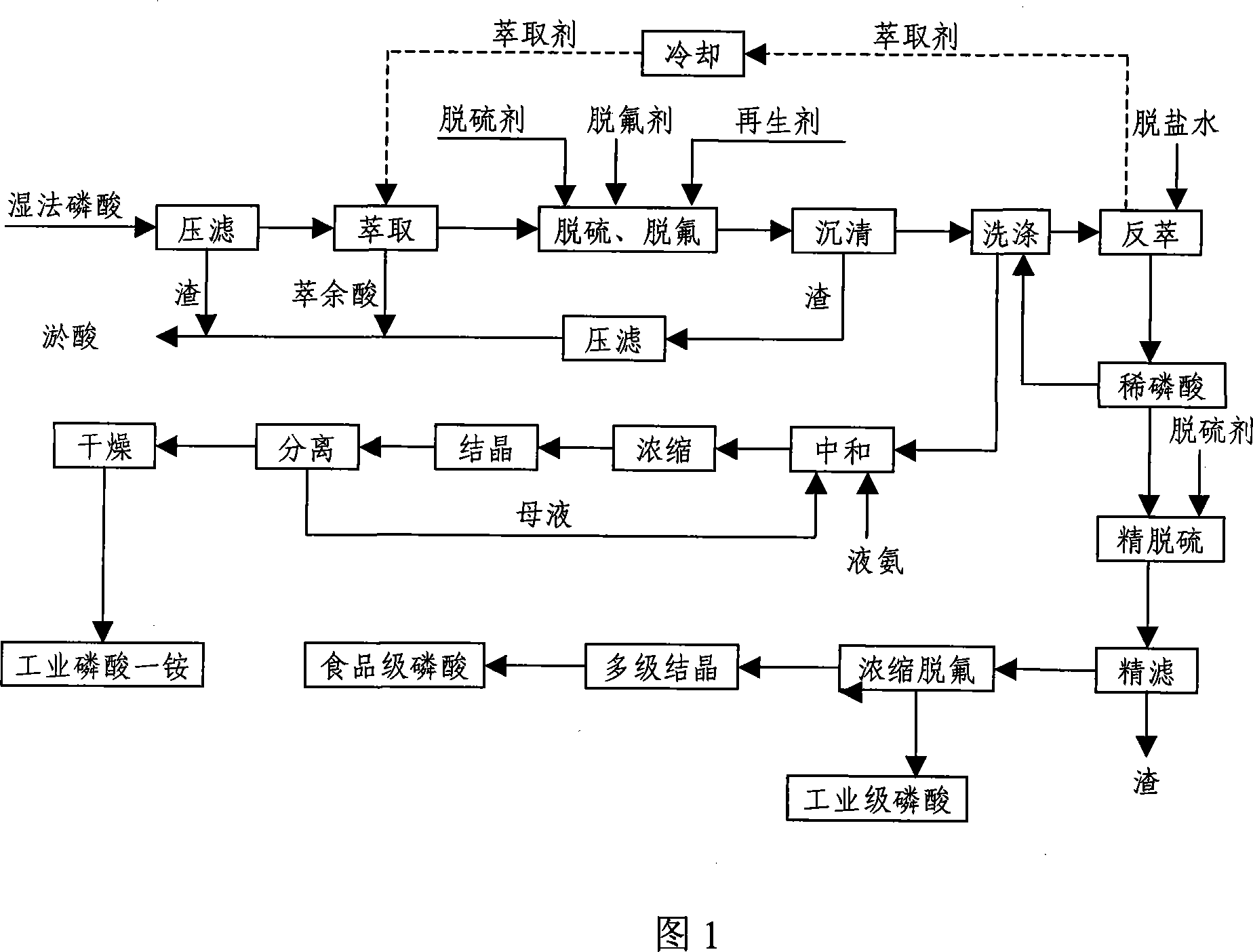

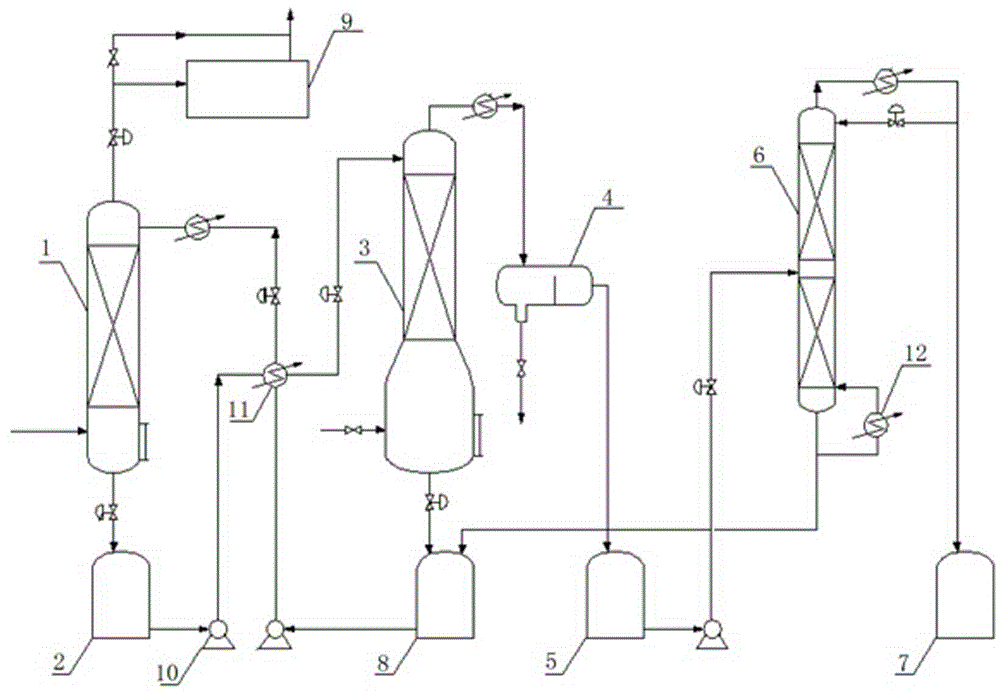

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method of using wet phosphoric acid to prepare industrial grade phosphoric acid, food grade phosphoric acid and industrial ammonium diacid phosphate, which is characterized in using wet phosphoric acid as the material, and preparing industrial grade phosphoric acid and food grade phosphoric acid respectively by using a series of compound purifying technologies such as chemical sedimentation and extracting by organic solvent and concentration and recrystallization and other technologies; meanwhile, the invention uses a part of purified diluted phosphoric acid to prepare industrial ammonium diacid phosphate. The invention has the advantages of reasonable cascade utilization of the wet phosphoric acid, high additional value of phosphorus, and further exploitation of the lower industrial and food grades phosphate.

Owner:中化重庆涪陵化工有限公司

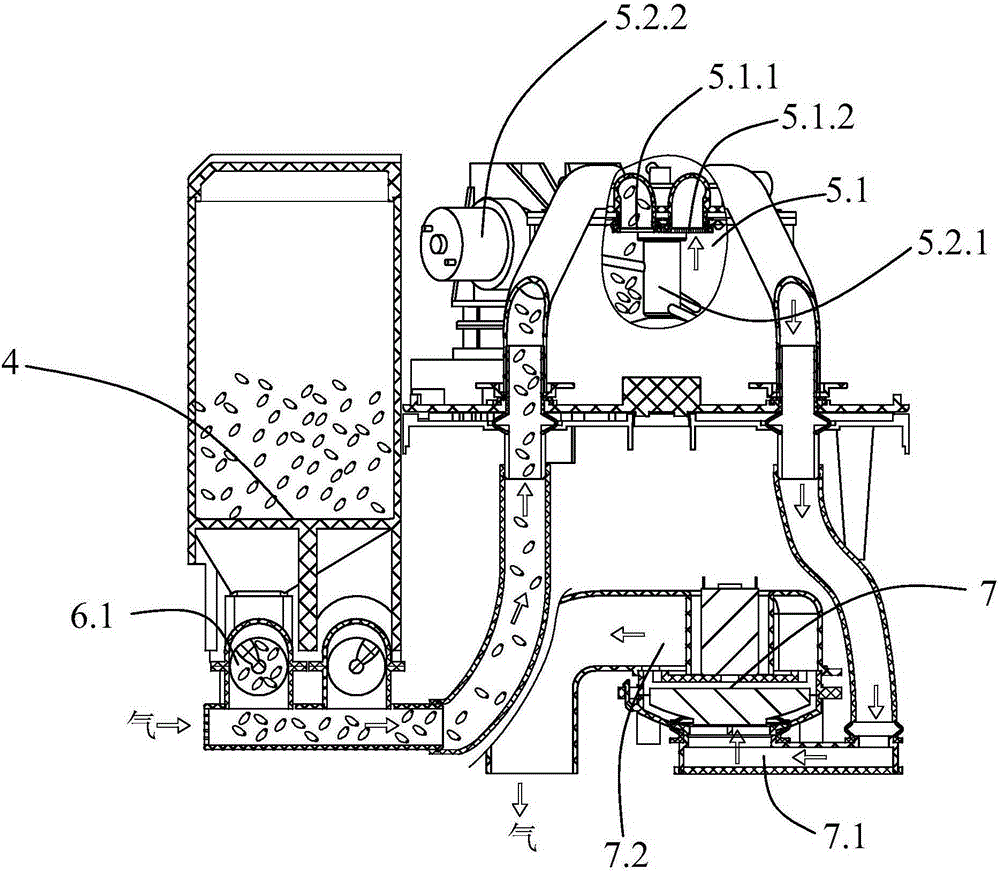

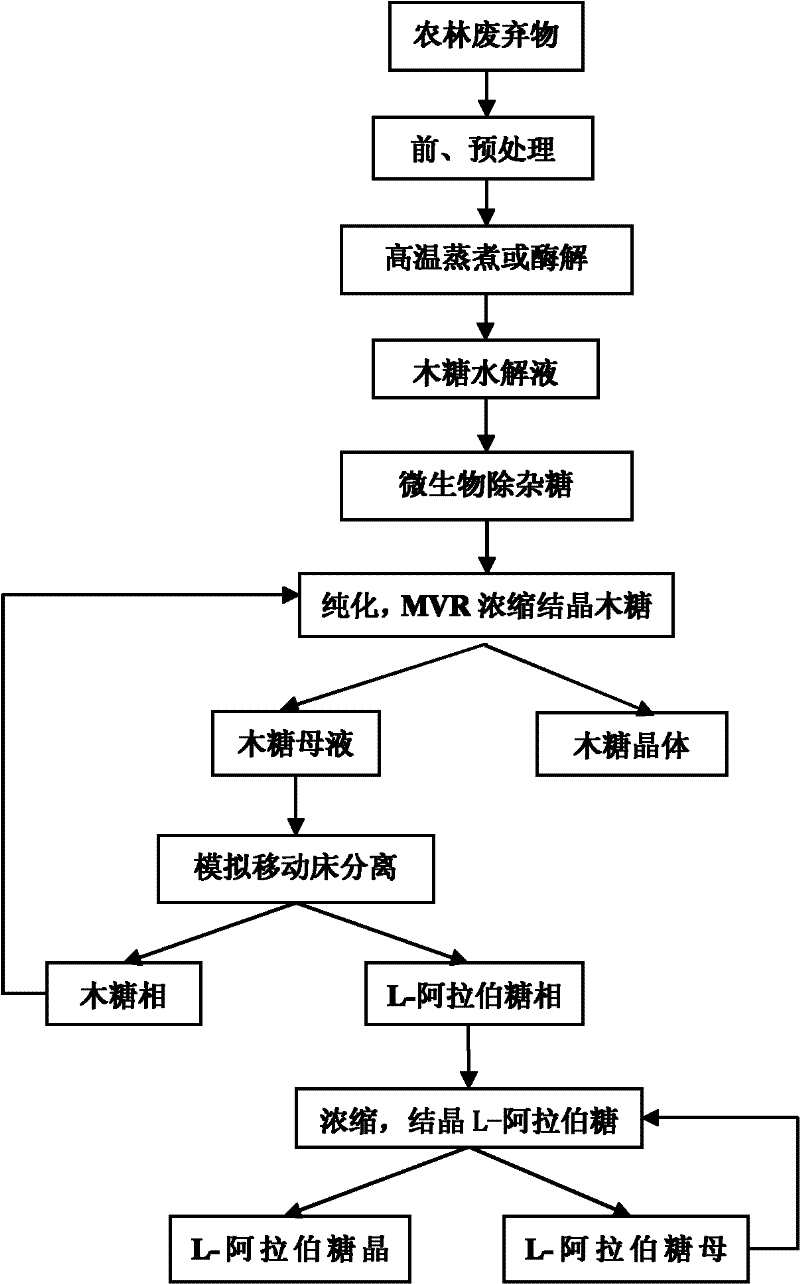

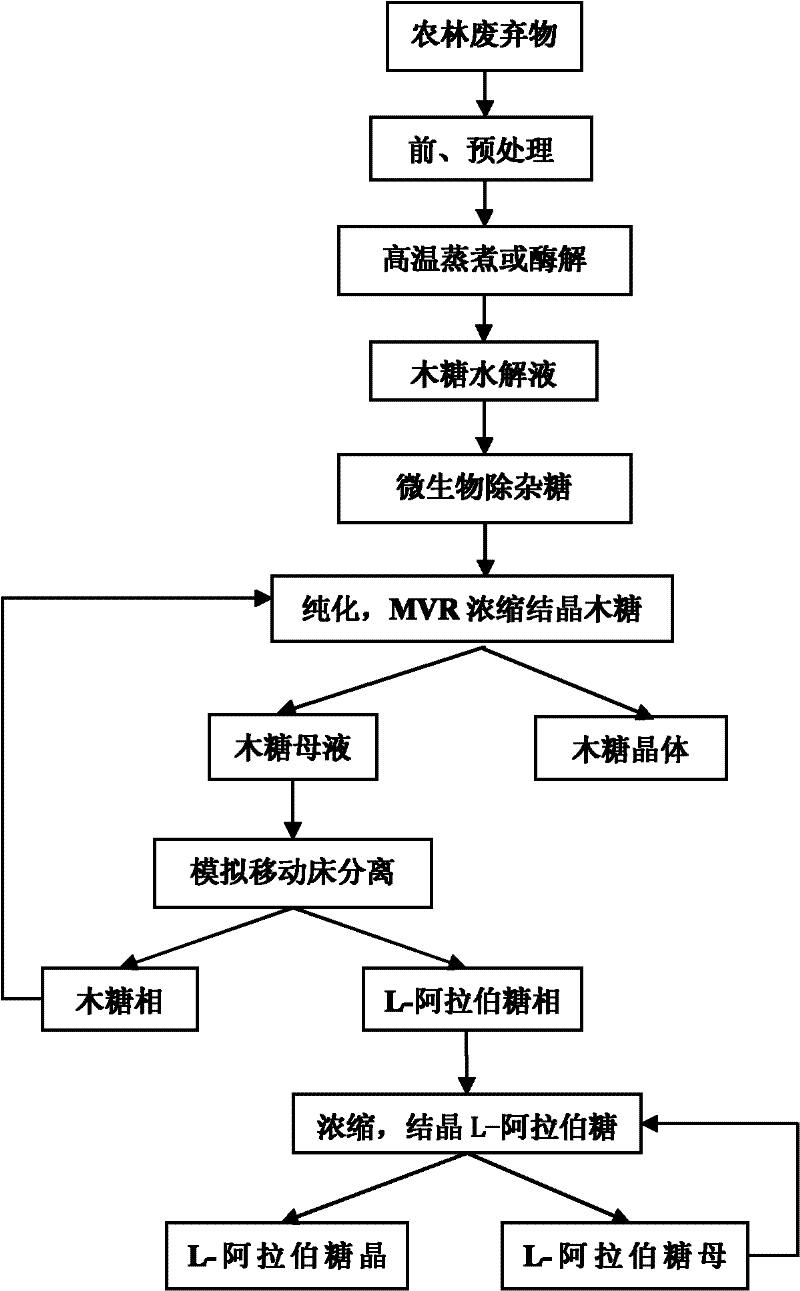

A clean and efficient production process for preparing xylose and l-arabinose

ActiveCN102286571AAddressing the effects of crystallizationHigh yieldSugar derivativesSugar derivatives preparationChromatographic separationYeast

The invention relates to a clean and high-efficiency production process for preparing xylose and L-arabinose and belongs to the field of application of wastes of agriculture and forestry. The production process comprises the following steps of: performing pretreatment on raw materials; hydrolyzing the raw materials in a high-temperature cooking mode; performing neutralizing treatment and performing centrifugal separation on solid slag to obtain xylose or xylooligosaccharide hydrolyzate; adding coarse enzyme solution into xylooligosaccharide solution to hydrolyze to obtain xylose solution; treating the hydrolyzate by Angle yeast; purifying by using active carbon and resin; performing recompression and concentration treatment on the purified hydrolyzate by using a mechanical vapor recompression (MVR) machine; crystallizing the concentrated solution in a gradient program cooling mode to obtain xylose products and xylose mother solution; separating the xylose mother solution by a simulated moving bed or a chromatographic separation technology to obtain a xylose phase and an L-arabinose phase; returning the xylose phase to the xylose solution to concentrate and recrystallize; reusing the xylose mother solution; performing MOVR concentration treatment on the L-arabinose phase and crystallizing in a gradient program cooling mode to obtain L-arabinose products; and reusing the L-arabinose mother solution.

Owner:BEIJING UNIV OF CHEM TECH

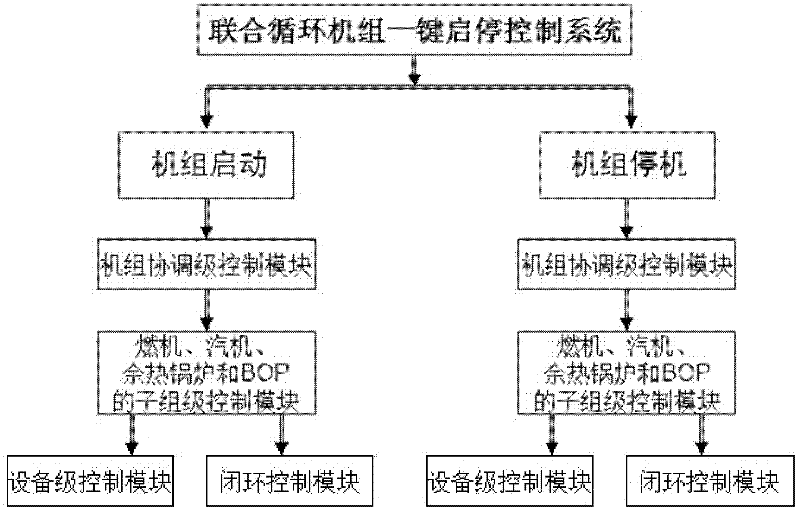

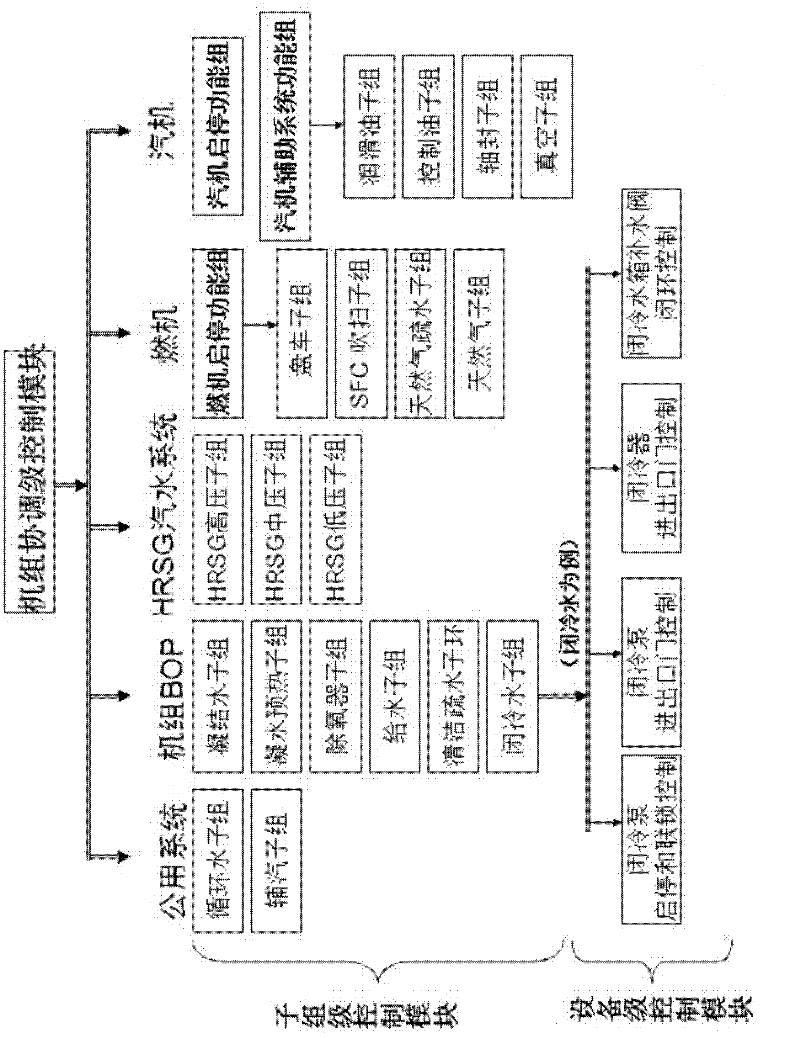

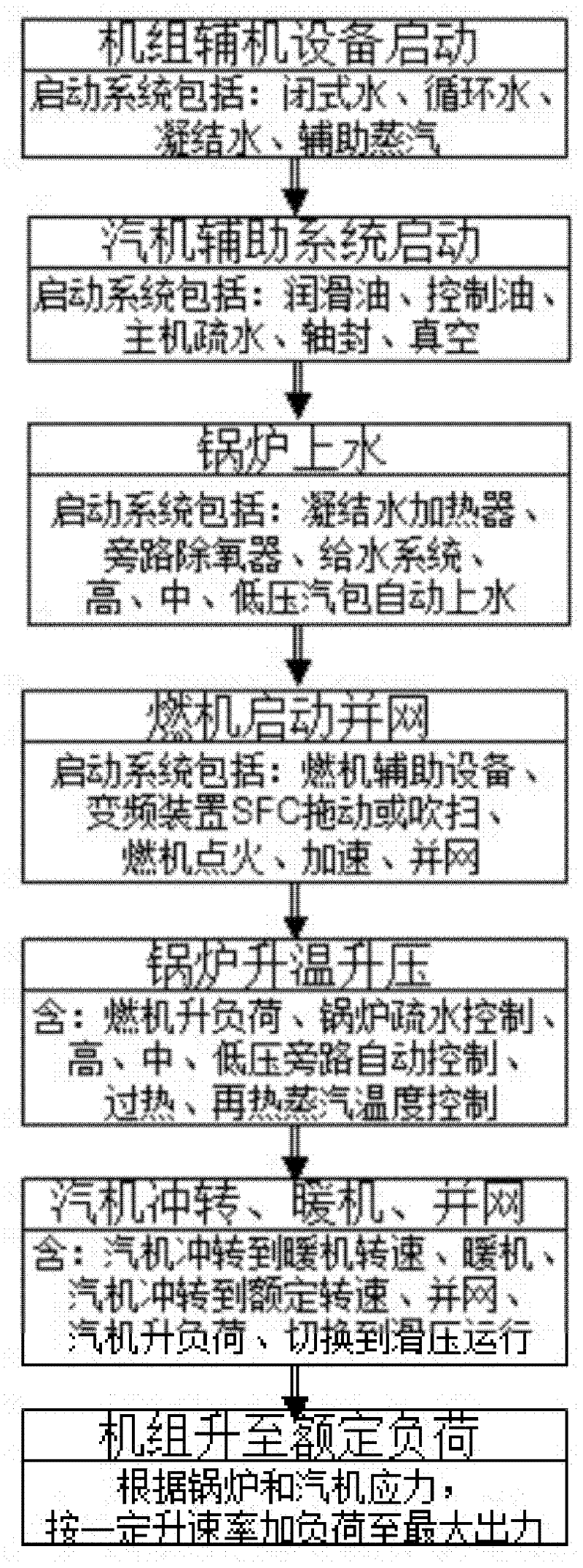

One-key start-stop control system for fuel gas and steam combined cycle unit

ActiveCN102393688ALow degree of automationHigh degree of automationTotal factory controlProgramme total factory controlStart stopControl system

The invention discloses a one-key start-stop control system for a fuel gas and steam combined cycle unit. The combined cycle unit at least comprises a combustion engine and a combustion engine auxiliary system, a steam turbine and a steam turbine auxiliary system, a waste heat boiler, a BOP (branch of plant) system and a common system; the one-key start-stop control system covers the combustion engine and combustion engine auxiliary system, the steam turbine and the steam turbine auxiliary system, the waste heat boiler, the BOP system and the common system; the one-key start-stop control system is a hierarchical control structure and comprises a unit coordinating level control module, a subgroup level control module and an equipment level control module from an upper layer to a lower layer in sequence. The system provided by the invention realizes safe and reliable start and stop of the combined cycle unit; the start-stop process of the unit is solidified to the control system, so that artificial error operation is prevented; artificial interference in the operation of the unit is greatly reduced, and the reliability of the unit is greatly improved.

Owner:上海申能临港燃机发电有限公司 +1

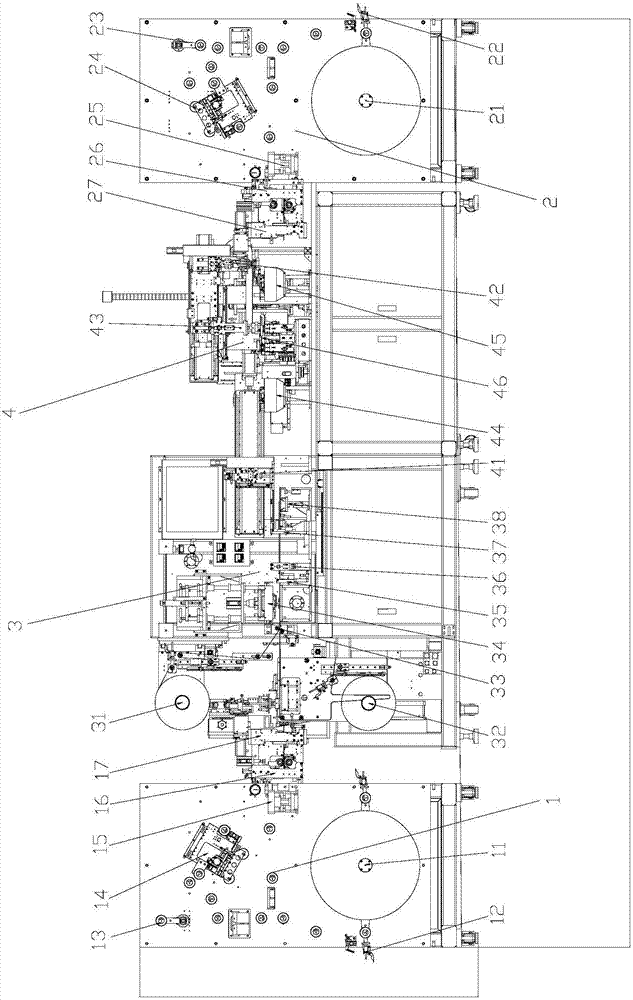

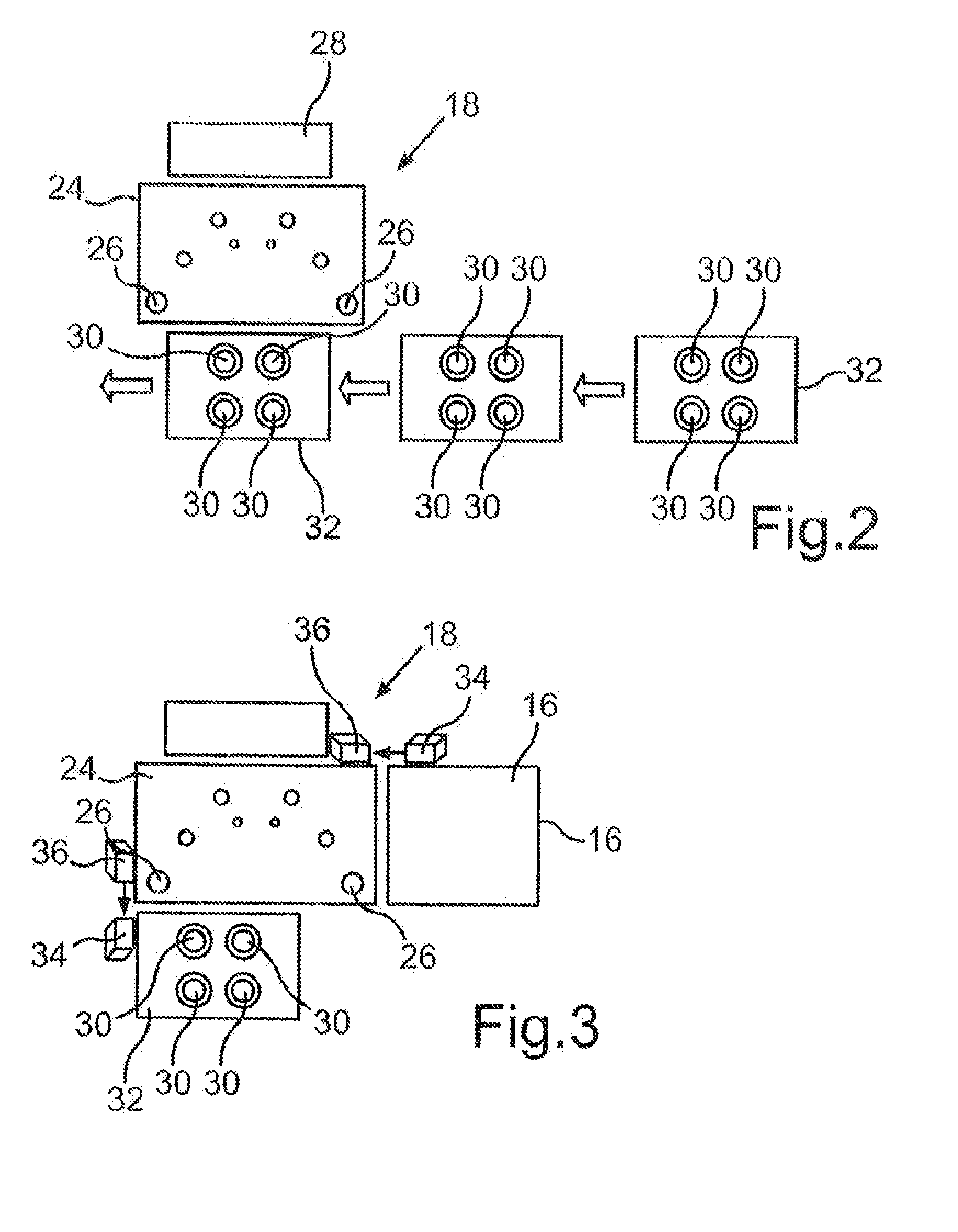

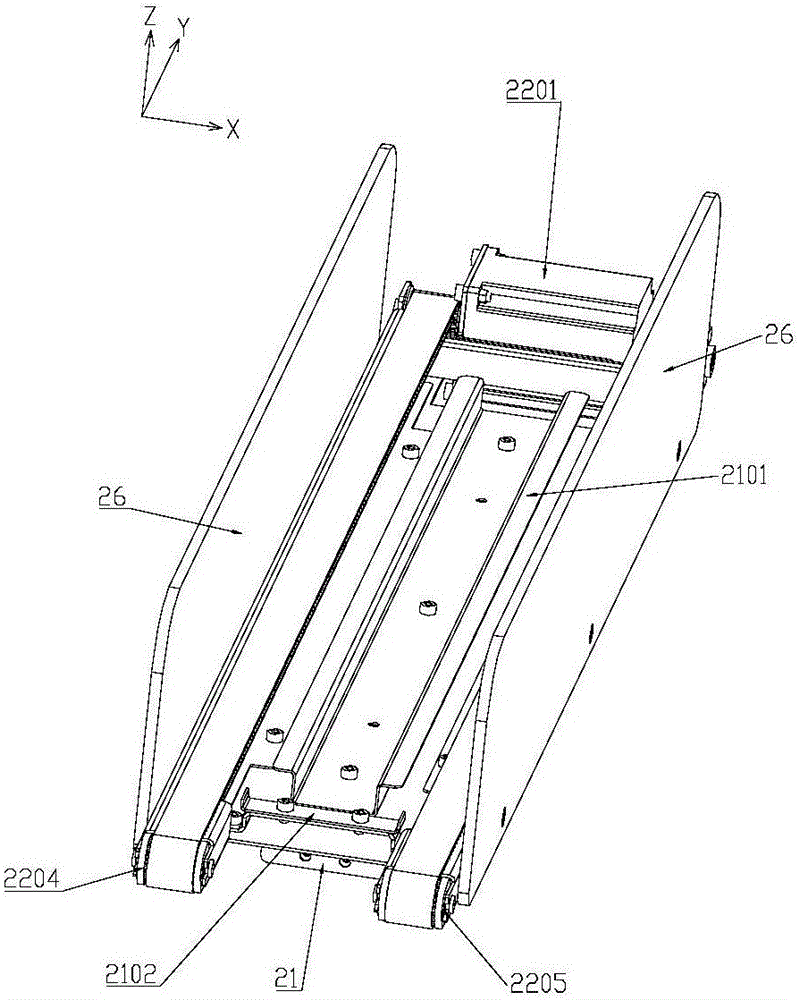

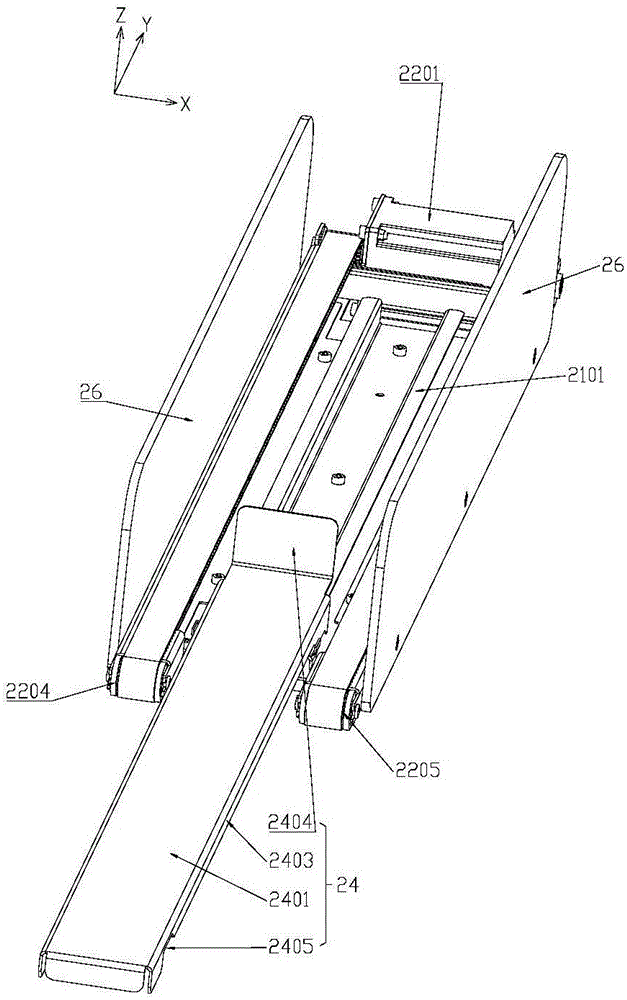

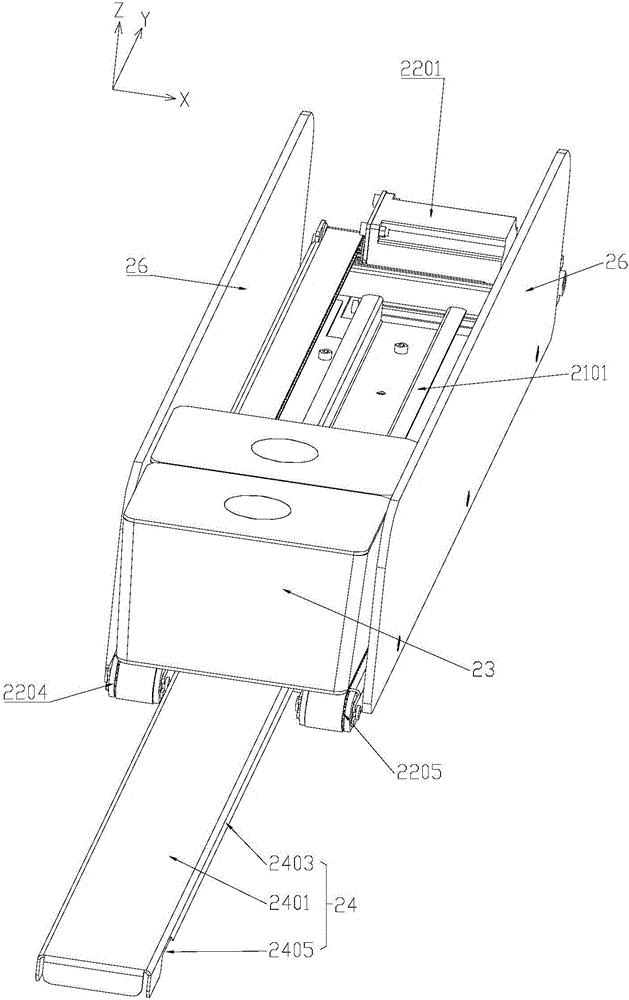

Die cutting, bag making and laminating integrated equipment for battery pole pieces

PendingCN107482171AHigh degree of automationImprove work efficiencyElectrode manufacturing processesState of artPole piece

The invention discloses die cutting, bag making and laminating integrated equipment for battery pole pieces. The equipment is characterized by comprising a positive pole piece die cutting mechanism, a negative pole piece die cutting mechanism, a composite bag making mechanism and a laminating mechanism, wherein the positive pole piece die cutting mechanism comprises a positive pole unwinding device, a positive pole correction sensor, a positive pole tension adjusting assembly, a positive pole correction assembly, a positive pole tab cutting die device, a positive pole pull belt drive device and a positive pole cutter assembly; the negative pole piece die cutting mechanism comprises a negative pole unwinding device, a negative pole correction sensor, a negative pole tension adjusting assembly, a negative pole correction assembly, a negative pole tab cutting die device, a negative pole pull belt drive device and a negative pole cutter assembly. The die cutting, bag making and laminating integrated equipment for the battery pole pieces has the advantages of simple structure, small occupied area, high automation degree, high production efficiency, low labor cost and the like which are absent in the prior art.

Owner:SHENZHEN GREENSUN TECH CO LTD

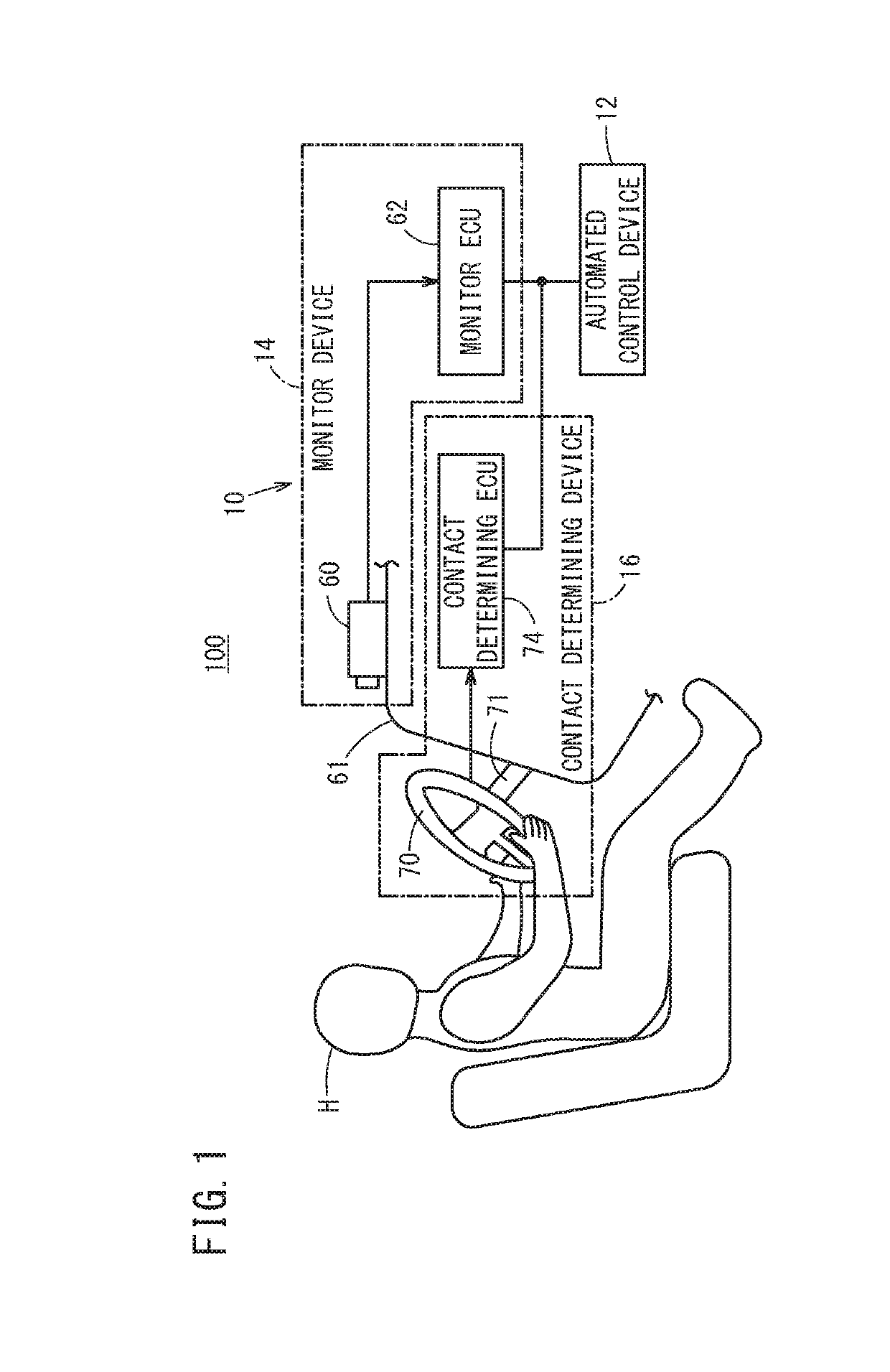

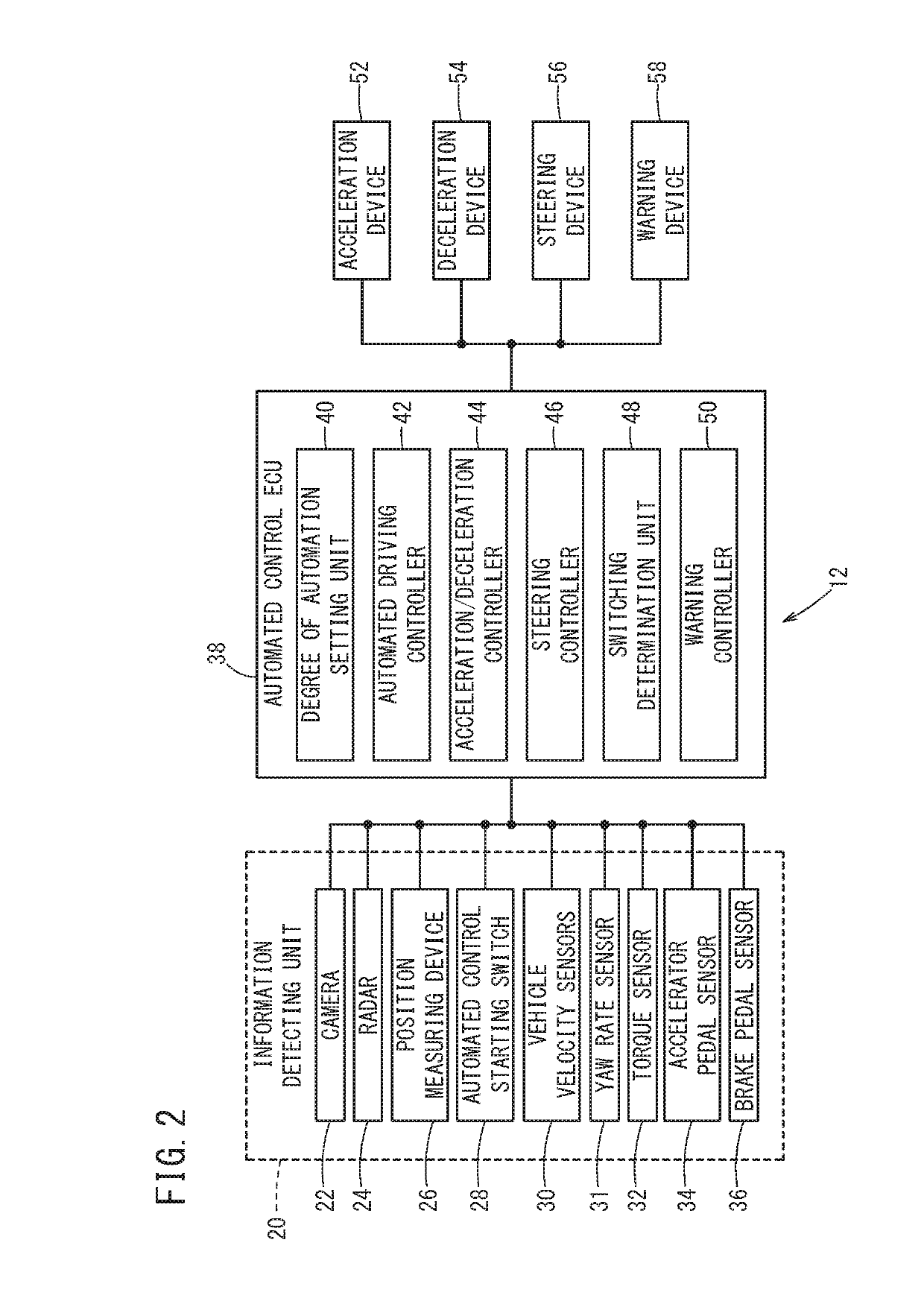

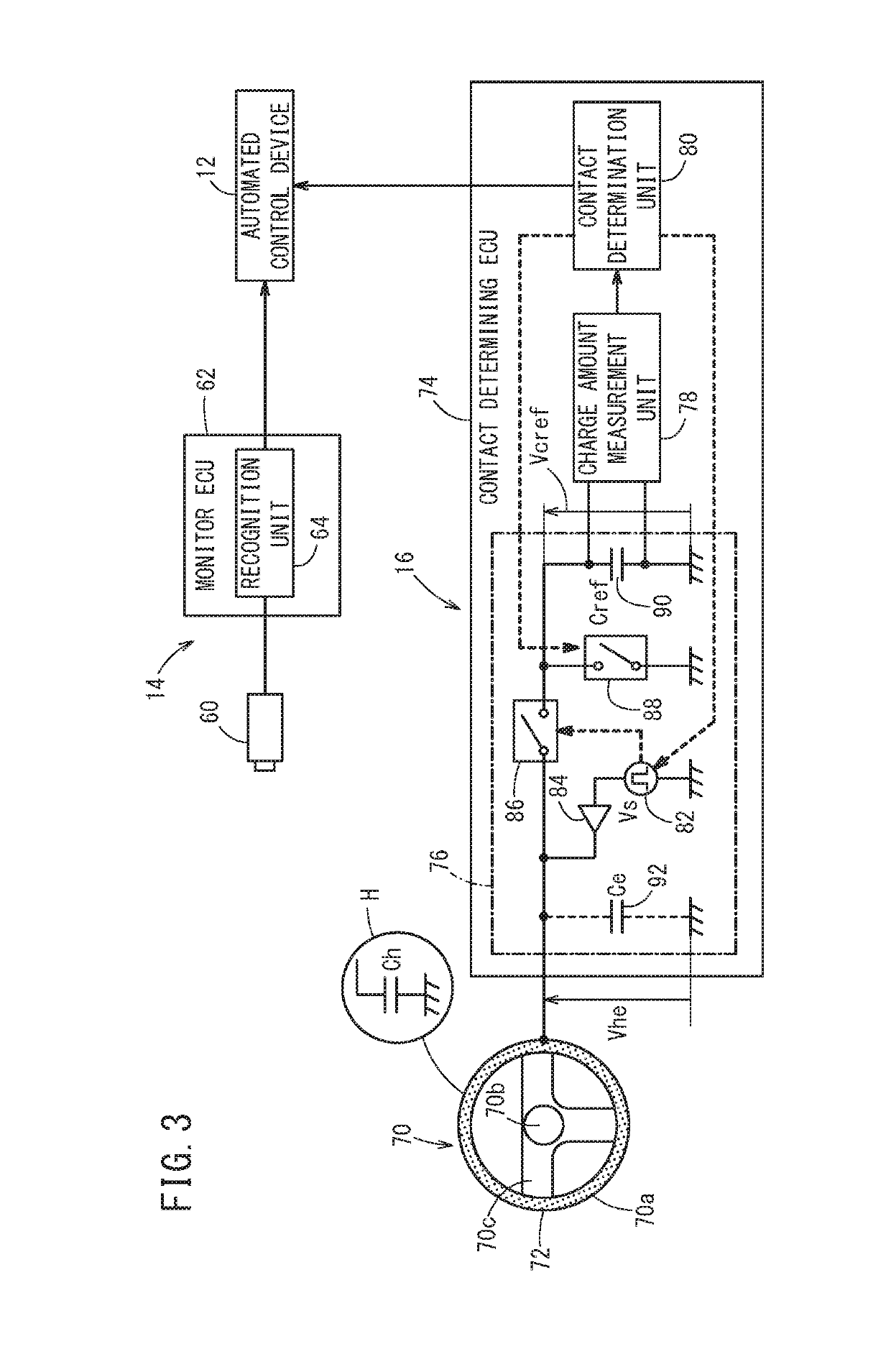

Automatic driving control device

ActiveUS20190092346A1Improve securityEnsure convenienceRoad vehicles traffic controlAutomatic steering controlAutomatic controlVehicle behavior

An automatic driving control device changes the degree of automation during an automatic control or the degree of change to the vehicle behavior during the automatic control, on the basis of the peripheral monitoring state of a driver, and on the basis of how easy it is to perform a switching operation for prioritizing manual control over automatic control. Thus, the automatic driving control device makes it possible to ensure the convenience of automatic control, by dynamically changing the degree of automation or the degree of change to the vehicle behavior, without uniformly stopping automatic control of steering and acceleration.

Owner:HONDA MOTOR CO LTD

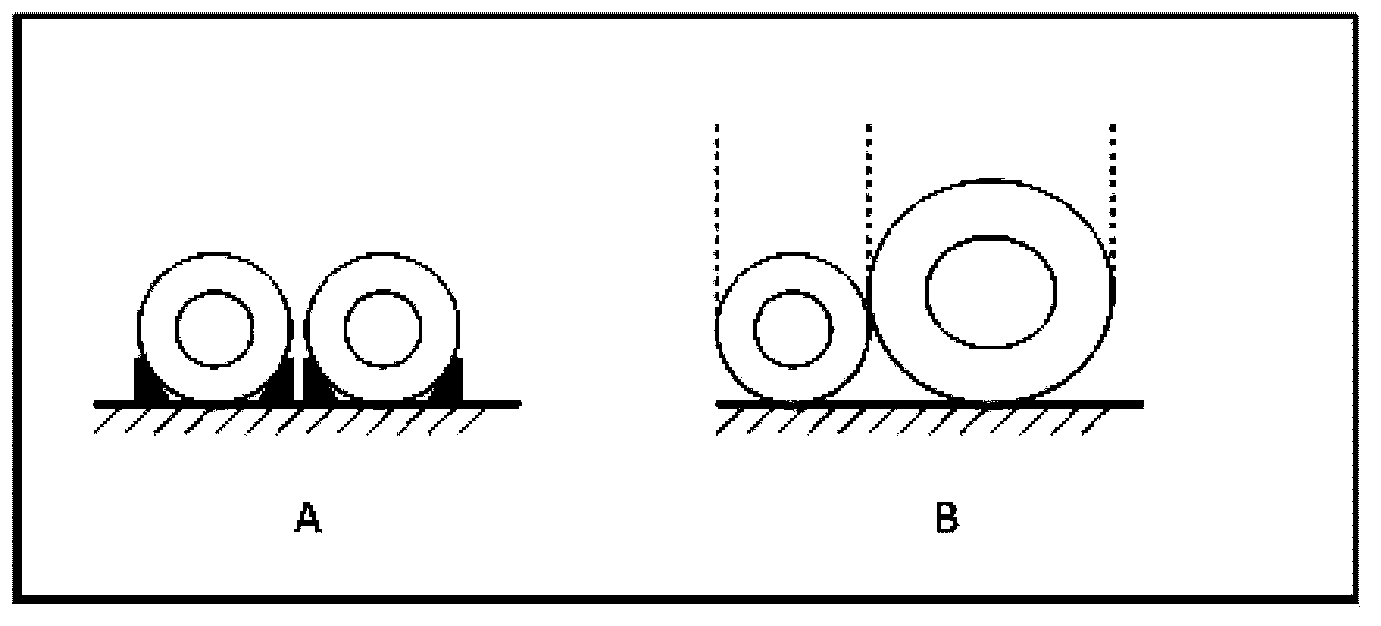

Steel coil storeroom position dynamic distribution method under position-data-reference-free condition

The invention discloses a steel coil storeroom position dynamic distribution method under a position-data-reference-free condition. The steel coil storeroom position dynamic distribution method includes the steps of dividing storeroom areas to form gridding structures, building a storeroom position distribution database in a management server of the storeroom areas, then determining a stacking rule of the storeroom areas, enabling each storeroom area to serve as a whole, carrying out stacking according to the same rule, carrying out stacking among the storeroom areas according to different demands and different user demand rules, dynamically modifying the user demand rule of the storeroom area to carry out stacking when the demands of the certain storeroom area are changed, and finally, after the steps are completed, carrying out management on steel coil storage, steel coil delivery, steel coil transferring and steel coil checking. According to the steel coil storeroom position dynamic distribution method, under the condition that a traveling positioning system is not provided, a dynamic storeroom position management mode is used for a steel coil storeroom, steel coils are reasonably and accurately stacked, the storeroom area use rate is improved, and the stack transferring quantity is reduced; meanwhile, the operation actual performance is collected, and therefore the position information of the steel coils inside the steel coil storeroom is accurate.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

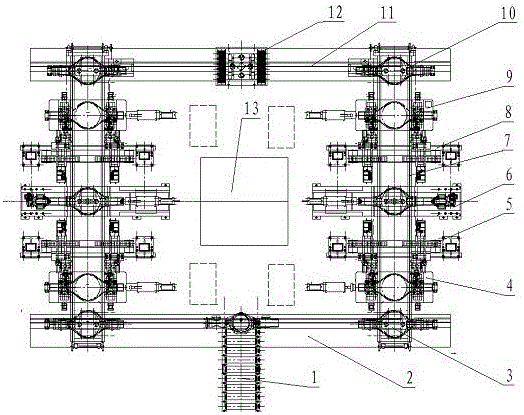

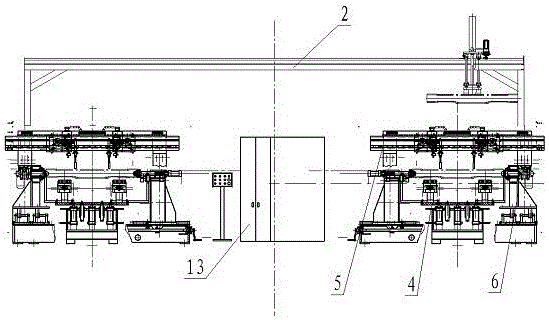

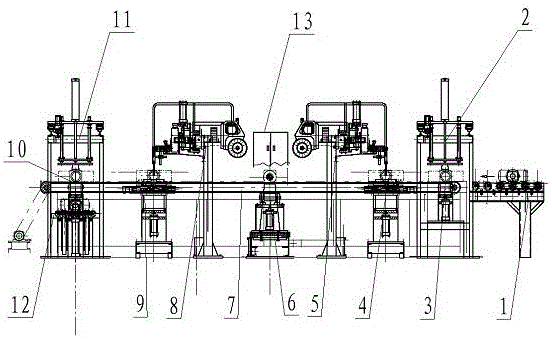

Axle housing body straight slit automatic welding production line and control method thereof

ActiveCN106334889AWith swing functionReliable structural lockingWelding/cutting auxillary devicesAuxillary welding devicesProduction lineElectrical control

The invention discloses an axle housing body straight slit automatic welding production line and a control method thereof. The production line is characterized by being composed of two welding lines, a feeding line and a discharging line. The production control method of the production line comprises the feeding line action, the welding action and the discharging line action. An aerial move loading magnetic attraction type automatic carrying feeding and discharging system is adopted in the whole production line, through automatic turnover, double-face welding of an axle housing straight slit can be completed, functions of welding slit automatic tracking, automatic gun clearing, wire shearing and silicon oil spraying are achieved, an electrical control system is arranged for achieving automatic running, program control and monitoring of actions of a whole production line device, line mixing production of varieties can be achieved, unmanned operation is achieved, the automation degree is high, and the production efficiency is high.

Owner:SHANDONG PENGXIANG AUTOMOBILE

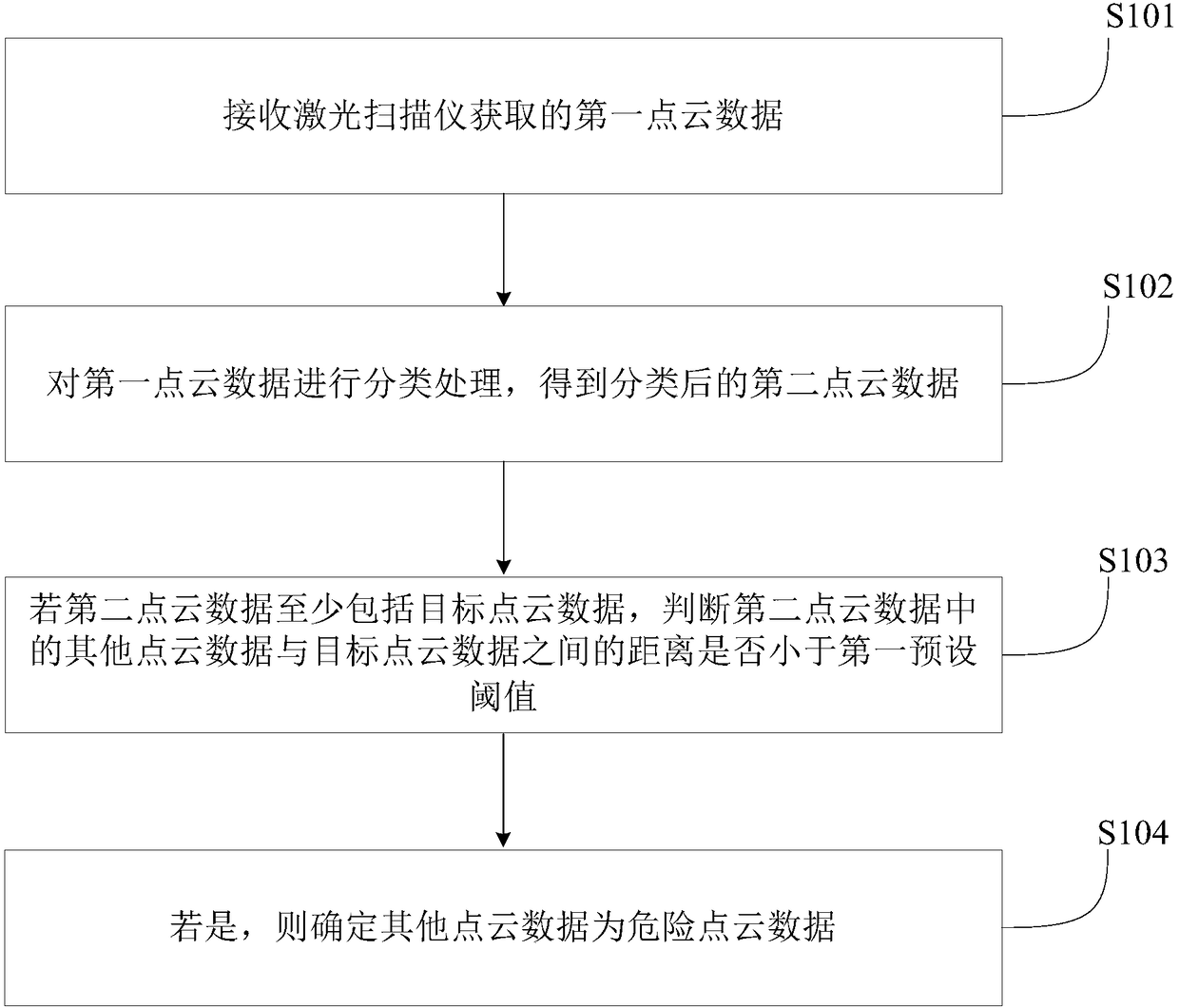

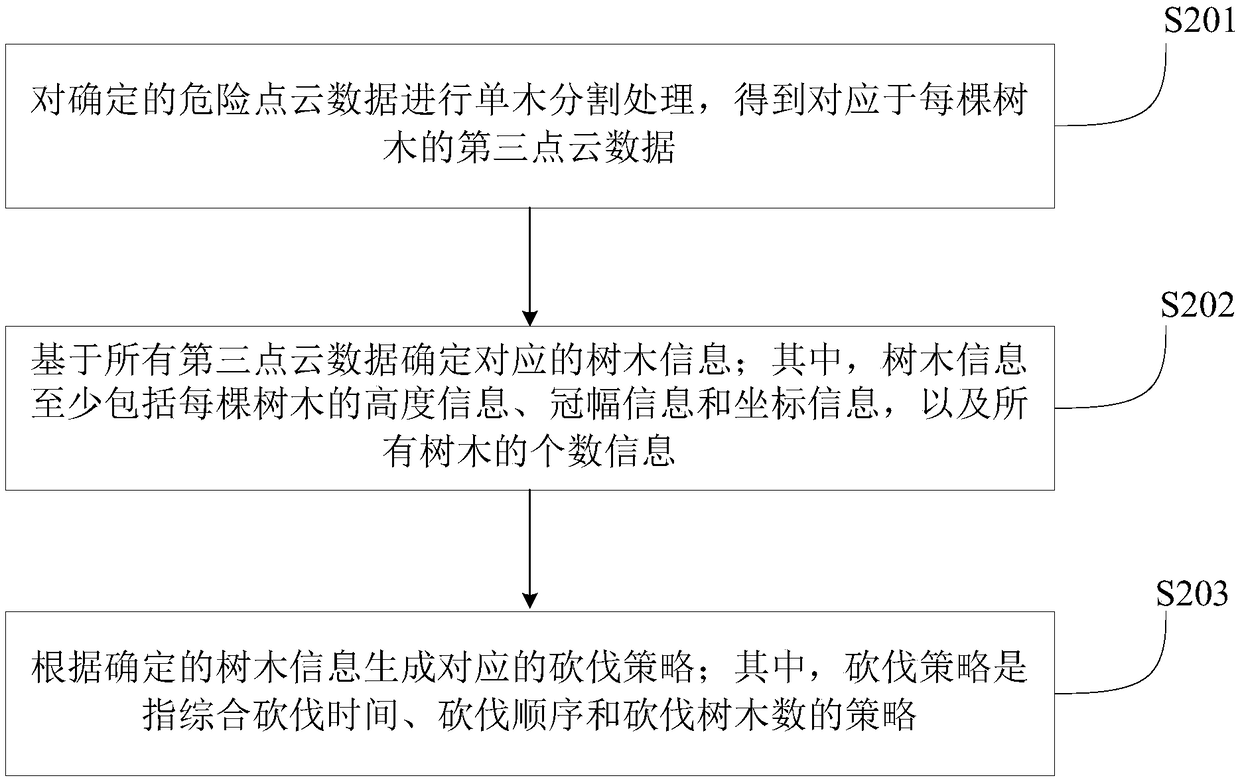

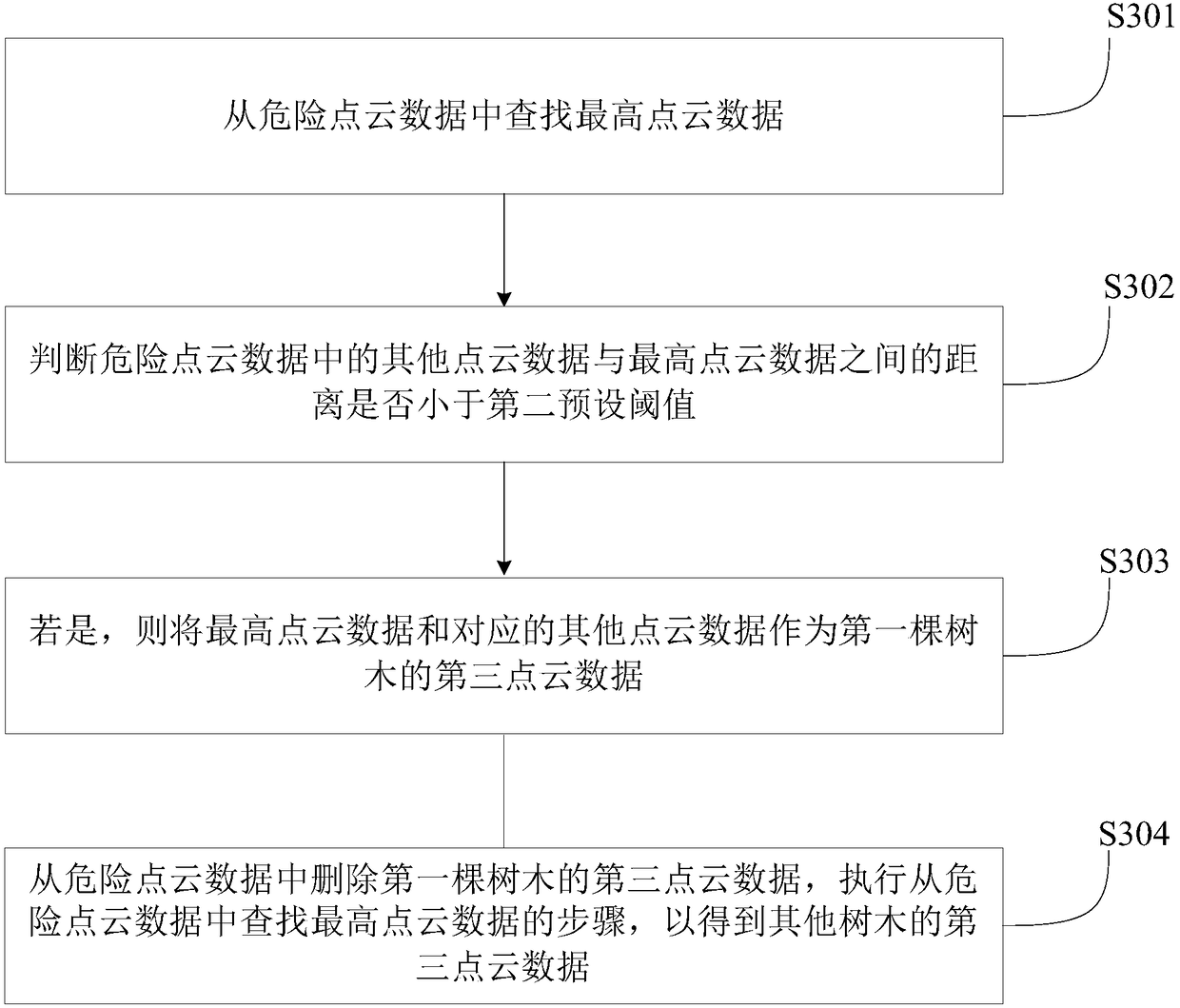

Point cloud data processing method and device

InactiveCN108226894AReduce human interventionIncrease costImage enhancementWave based measurement systemsPoint cloudLaser scanning

The invention provides a point cloud data processing method and a point cloud data processing device. The method comprises the following steps: receiving first point cloud data acquired by a laser scanner; performing classification processing on the first point cloud data to acquire classified second point cloud data; if the second point cloud data at least comprises target point cloud data, judging whether the distance between other point cloud data in the second point cloud data and the target point cloud data is less than a first preset threshold value or not; and if the distance between other point cloud data in the second point cloud data and the target point cloud data is less than the first preset threshold value, determining other point cloud data as dangerous point cloud data. Through the point cloud data processing method and the point cloud data processing device, which are provided by the invention, artificial intervention components in the point cloud judgment process aregreatly reduced, the automation degree and the accuracy degree are relatively high, the cost is relatively low and the practicability is excellent.

Owner:BEIJING GREEN VALLEY TECH CO LTD +1

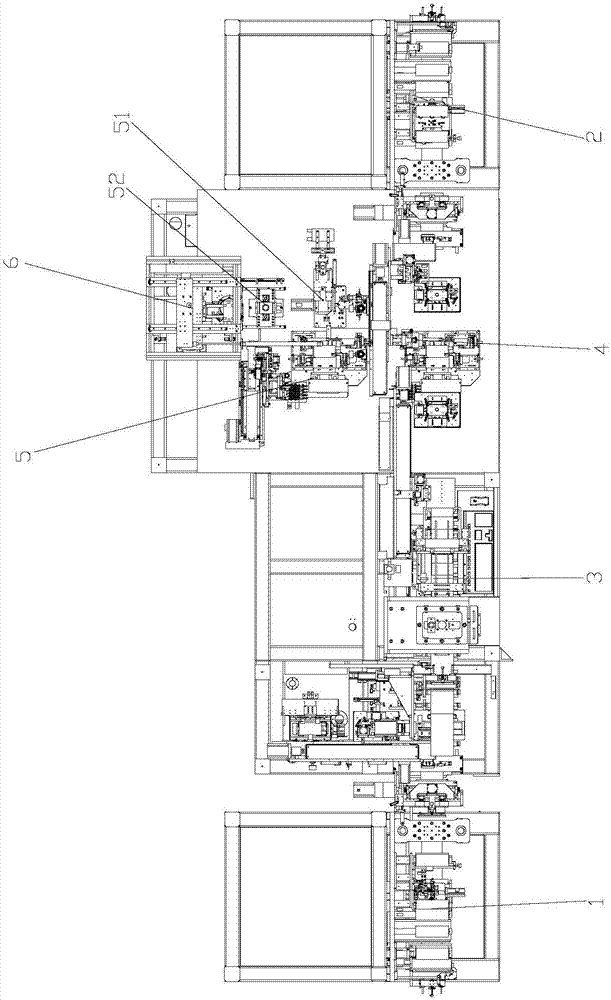

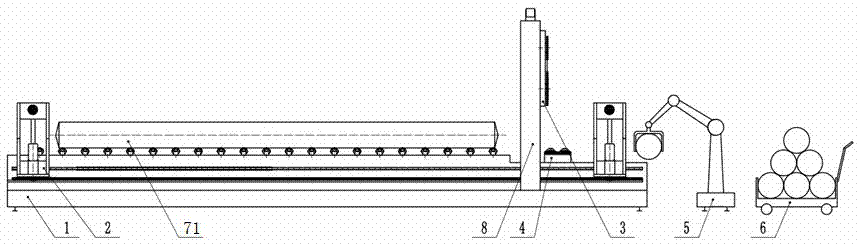

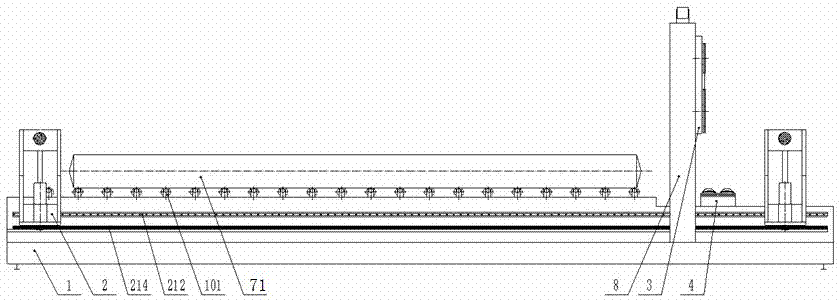

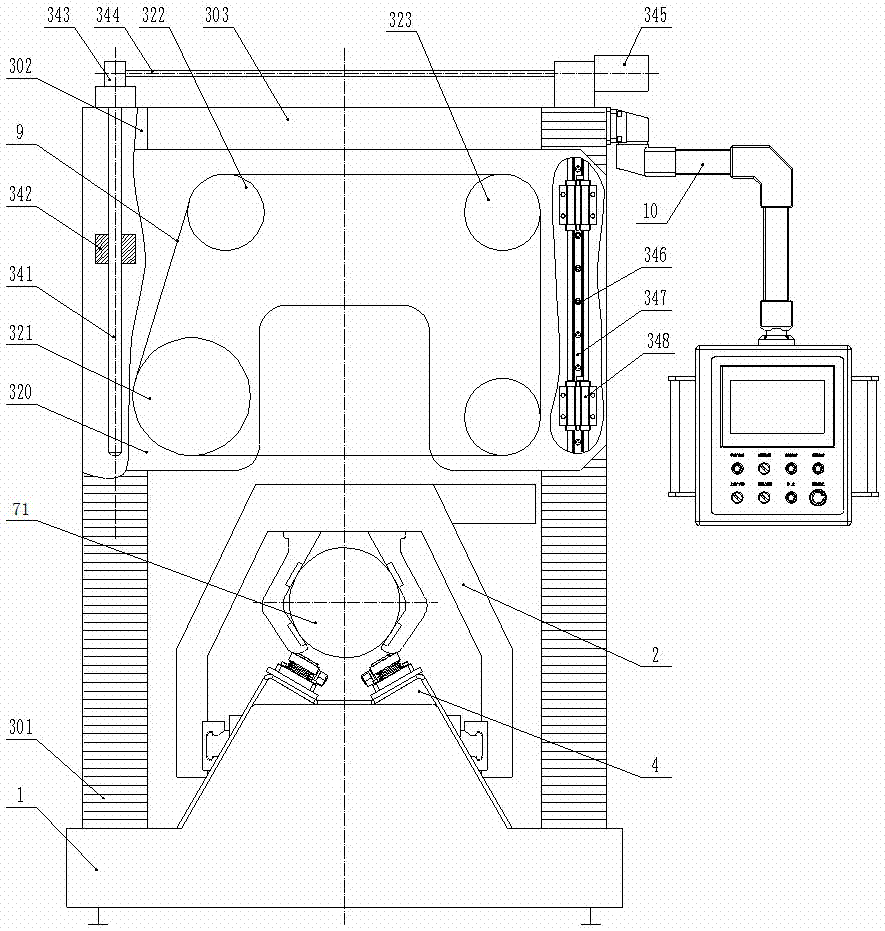

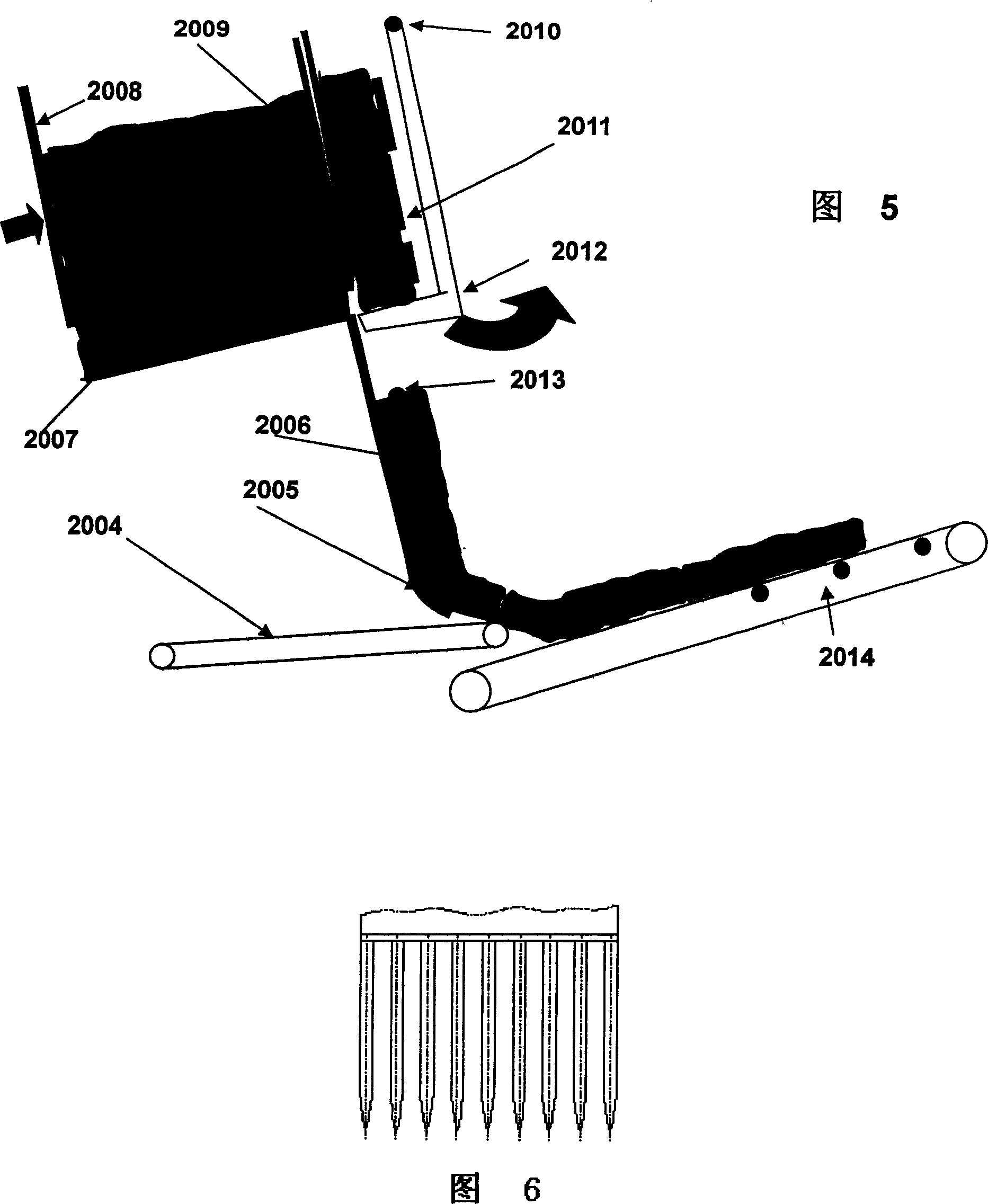

Single-crystal bar disconnection cutting equipment

PendingCN107443601AOperational securityReduce labor intensityWorking accessoriesGrinding machinesElectric machineryServo

The invention discloses single-crystal bar disconnection cutting equipment. The single-crystal bar disconnection cutting equipment comprises a machine frame, a single-crystal bar feeding device, a cutting machine frame, a wire saw cutting mechanism, a single-crystal bar jacking device, a material collecting and conveying robot and a skip car, wherein the single-crystal bar feeding device can slide on an undercarriage for operation; the cutting machine frame is installed on the undercarriage; the wire saw cutting mechanism is installed on the cutting machine frame; and the single-crystal bar jacking device, the material collecting and conveying robot and the skip car can slide on the undercarriage. The single-crystal bar disconnection cutting equipment is characterized in that supporting roller assemblies are fixed to a base; clamping jaws of two movable clamping units are located above supporting rollers, and the clamping units can penetrate through the space below the cutting machine frame; the wire saw cutting mechanism achieves single-section cutting; servo motors drive speed reducers to drive gears to be engaged with racks so that a bar flotation jacking device can move; and the material collecting robot is located on the side face of the bar flotation jacking device. The single-crystal bar disconnection cutting equipment has the advantages that the clamping units and the single-crystal bar jacking device can be driven to move automatically through matching of the motors, the gears and the racks, the labor intensity of operators is low and the degree of automation is high; and diamond wires can be replaced conveniently, wire breaking cannot happen easily and the failure rate is low.

Owner:福州天瑞线锯科技有限公司

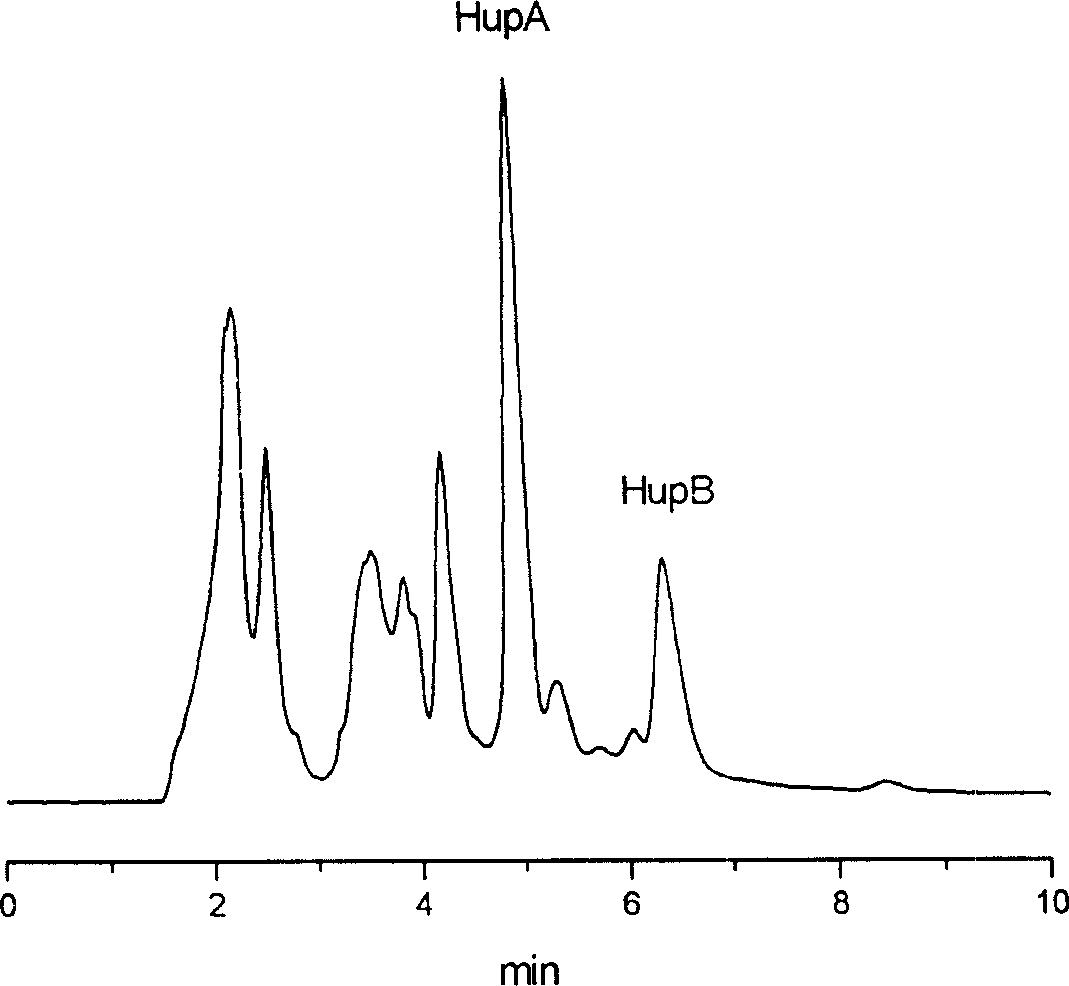

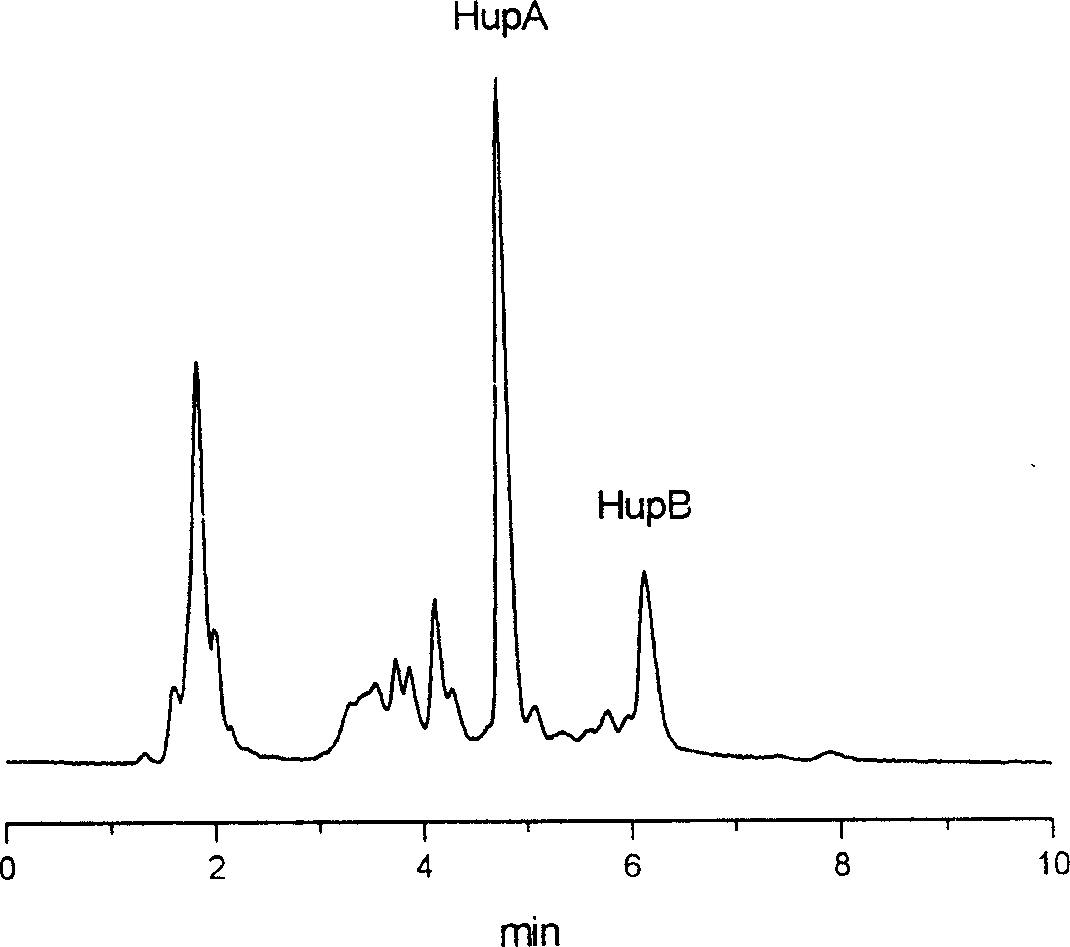

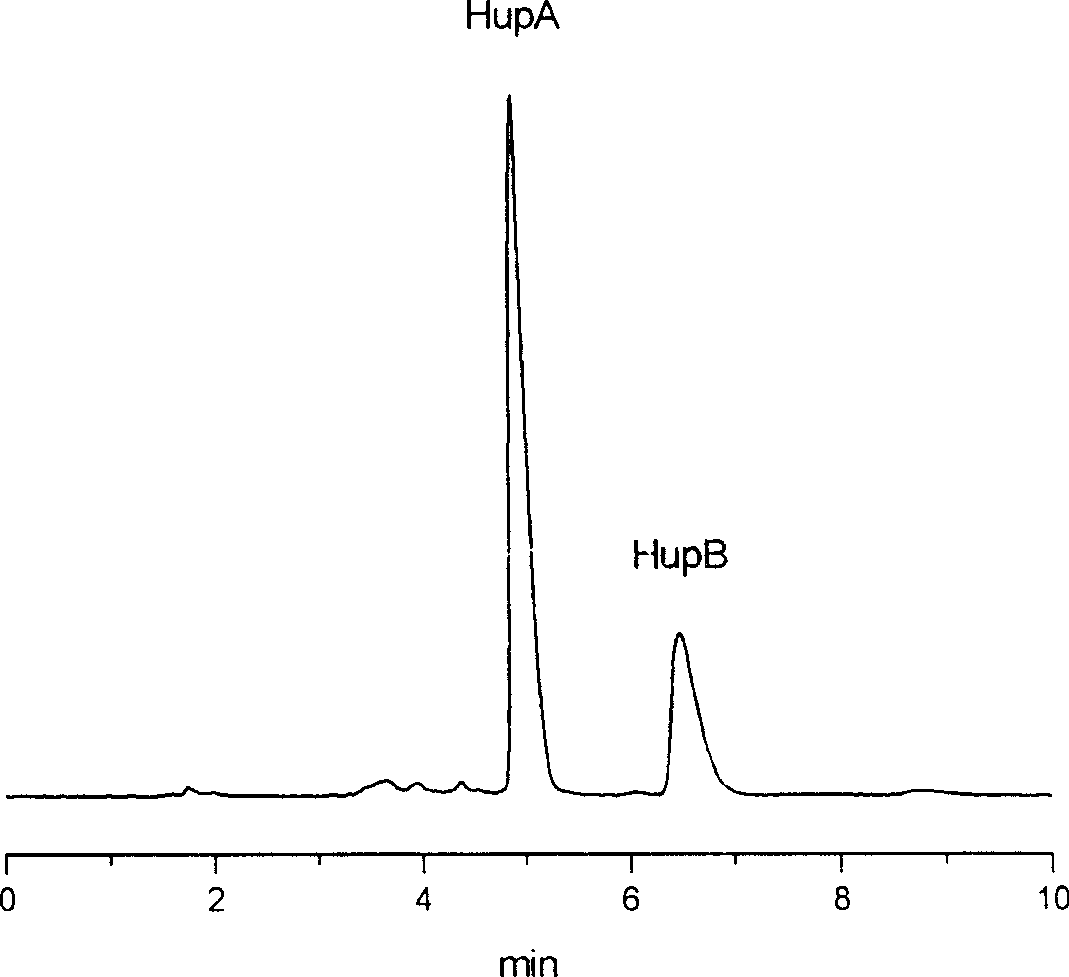

Method for analyzing and separating preparation of Huperzine A and Huperzine B

InactiveCN1704405AReduced resolutionEliminate distractionsOrganic chemistryTesting foodSilica gelAnalysis method

The invention relates to a process for analyzing and separating preparation of Huperzine A and Huperzine B, which comprises the steps of disintegrating and immersing raw material, enriching and concentrating with macroporous absorption resin, reversed phase column chromatography, non-alkyl bonded phase silica gel medium column chromatography, concentrating and crystallizing.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for Operating a Production Plant

InactiveUS20140303768A1Quick pickReduce investmentAssembly machinesVehicle position/course/altitude controlTransport systemEngineering

A method for operating a production plant having an unmanned transport system involves transporting a first parts carrier having a plurality of parts from a warehouse to a picking station by at least one industrial truck. At least one part, which is predetermined according to a parts list, is extracted from the parts carrier using a worker and deposition of the part on a further parts carrier. The further parts carrier is transported to a work station by a further industrial truck.

Owner:DAIMLER AG

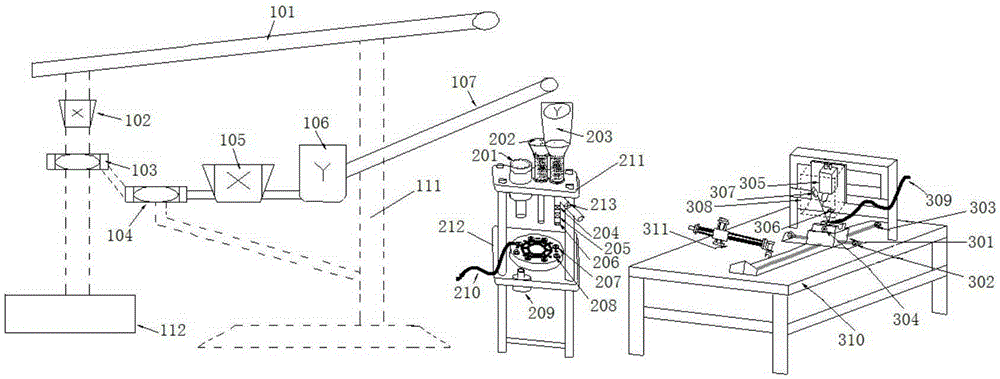

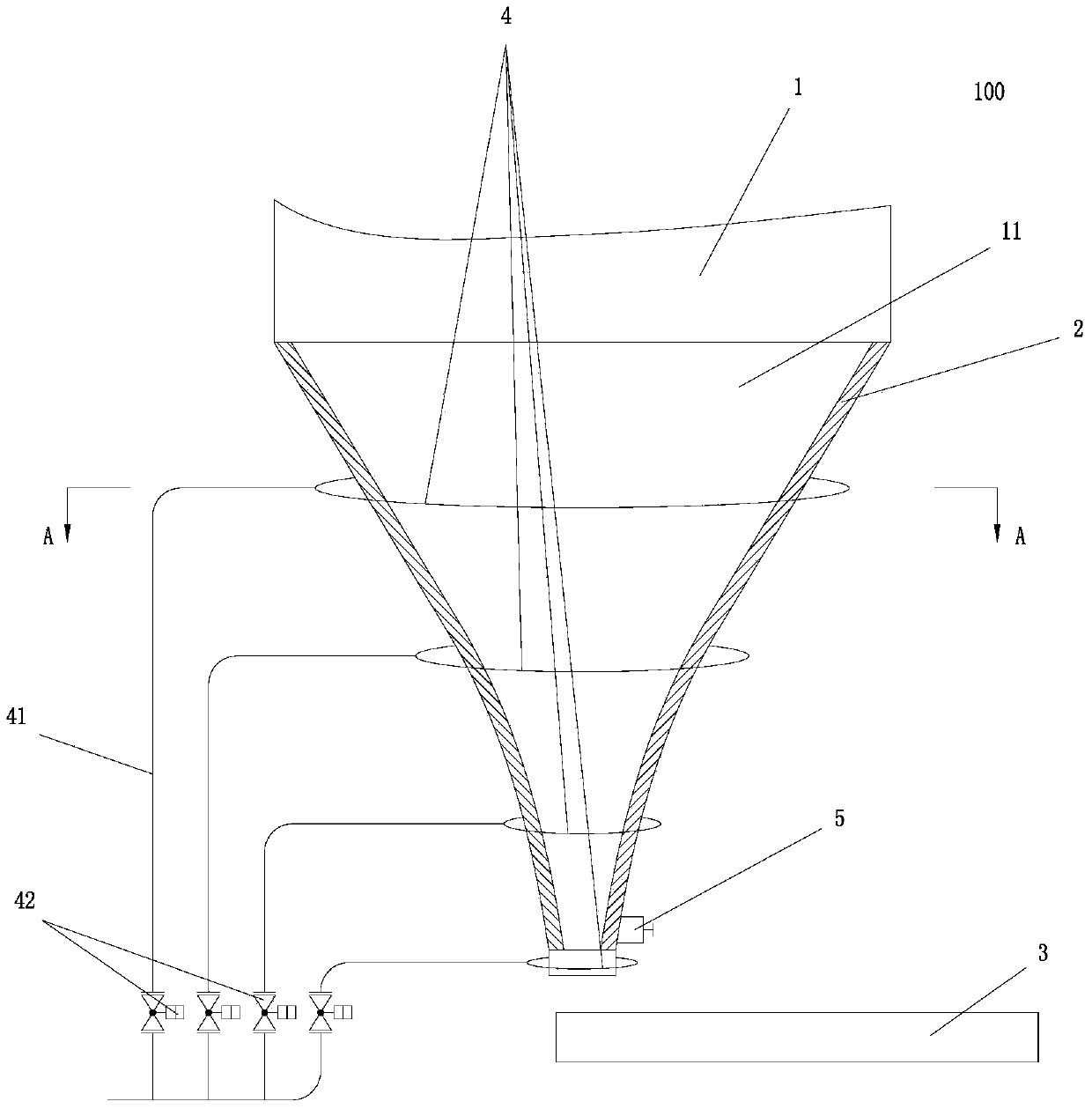

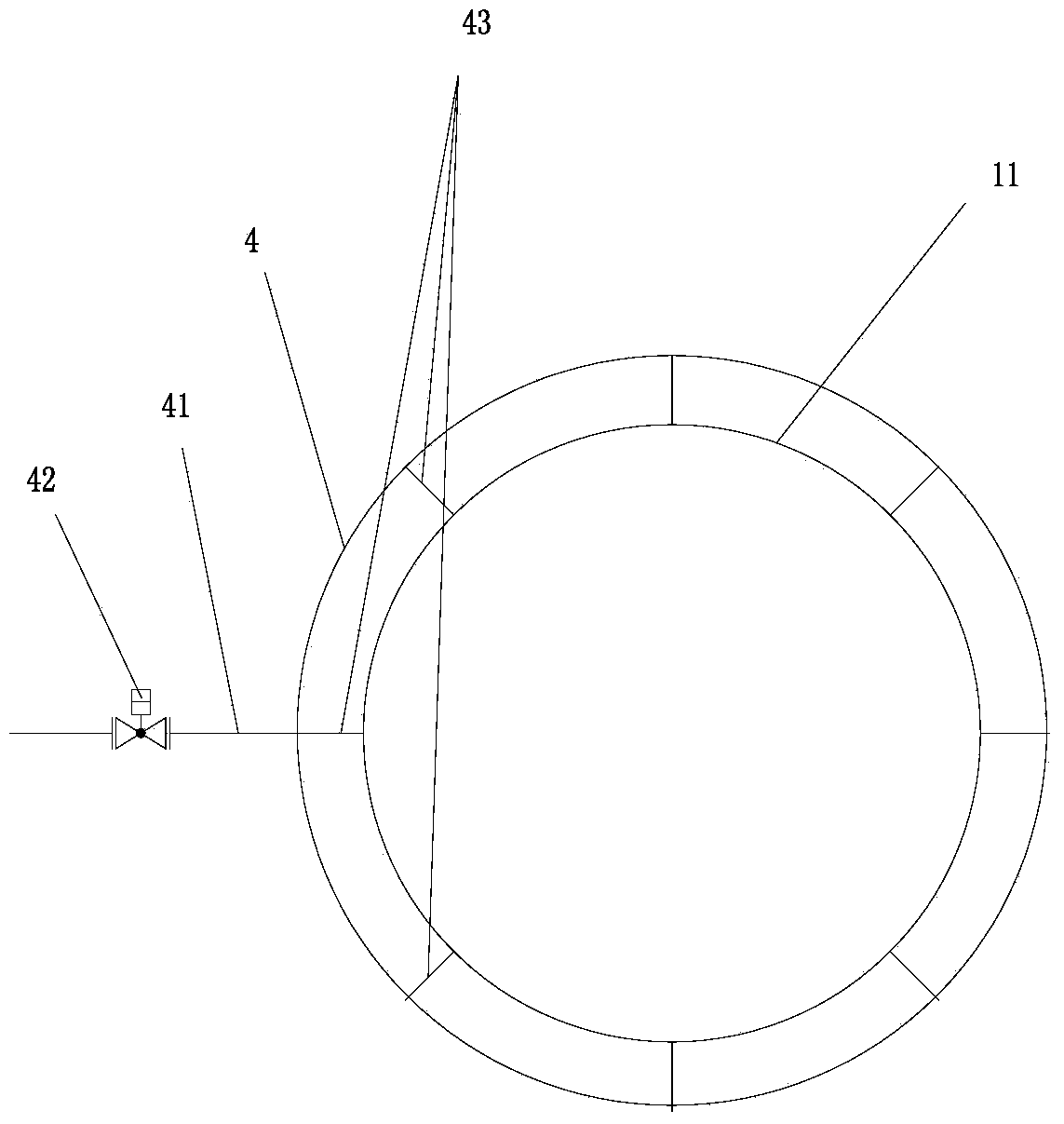

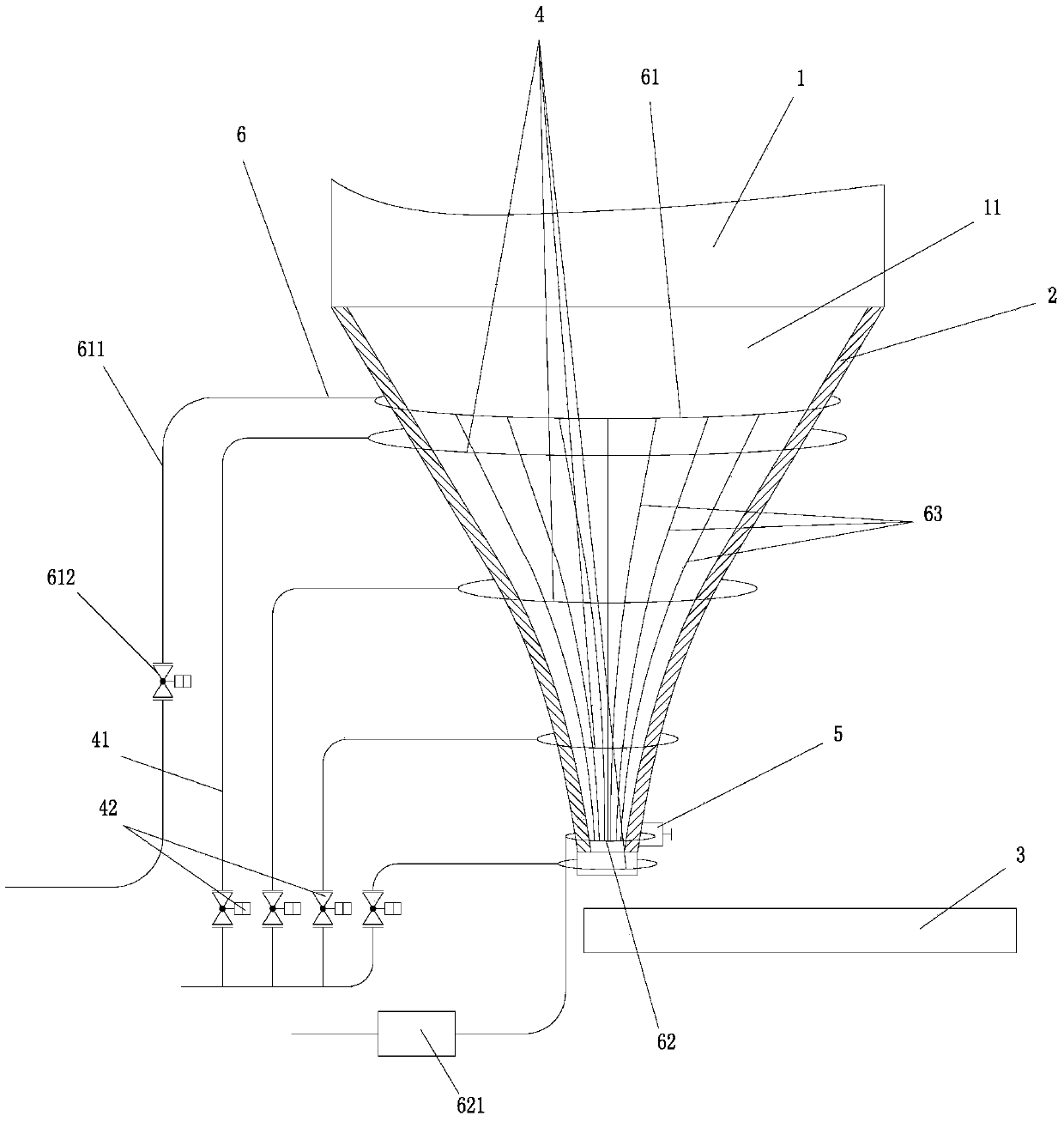

On-line coal quality laser detection and analysis system

PendingCN106680019AAnalysis and detection are accurateRapid Detection AnalysisWithdrawing sample devicesPreparing sample for investigationNumerical controlEngineering

The invention relates to an on-line coal quality laser detection and analysis system, which comprises an automatic coal-sampling unit, a continuous coal sample-tableting unit and a coal laser detection and analysis unit that are connected in sequence through cables, a conveyer belt and a manipulator; the conveyer belt connects the automatic coal-sampling unit with a pulverized coal sample bin of the continuous coal sample-tableting unit; the continuous coal sample-tableting unit comprises a sample-tableting disc, and a hydraulic head and a filling port are arranged on the top of the sample-tableting disc; a pulverized coal sample feed station and a filling station are arranged on the sample-tableting disc, and a pulverized coal tablet ejection station is arranged under the sample-tableting disc; the coal laser detection and analysis unit comprises a three-dimensional point location numerical control platform, a travelling unit is connected to the three-dimensional point location numerical control platform, and an optical focusing element, a pulsed laser and a laser detection and analysis instrument are arranged on the top of the three-dimensional point location numerical control platform. The on-line coal quality laser detection and analysis system can implement automatic sampling, automatic sample tableting and automatic laser detection and analysis in the process of coal transportation.

Owner:山东利普斯智慧能源科技有限公司

Device for recovery of carbon disulfide in viscose fiber production

InactiveCN103331078AInhibition releaseHigh ignition pointDispersed particle separationHigh absorptionVapor–liquid separator

The invention relates to the exhaust gas recovery field in the viscose fiber industry, and provides a device for recovery of carbon disulfide in viscose fiber production. The device is characterized in that: it comprises an alkali spray tower, an absorption tower, a heat exchanger, a desorption tower, a condenser and a gas-liquid separator. The spray tower is connected to the absorption tower, the absorption tower is in connection with the heat exchanger, the heat exchanger is connected to the desorption tower, the desorption tower is connected to the condenser, which is in connection with the gas-liquid separator. The device provided in the invention has the characteristics of simple structure, high absorption rate, low investment and operation cost, and suitability for industrialized application.

Owner:YIBIN HIEST FIBER +2

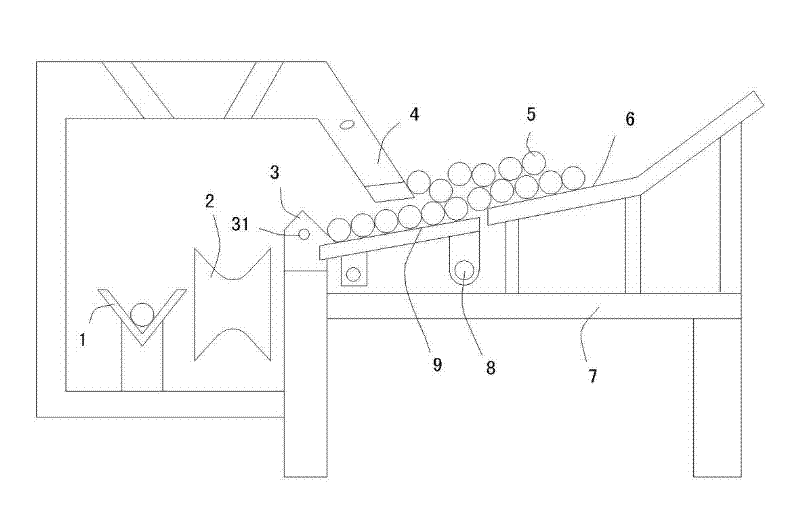

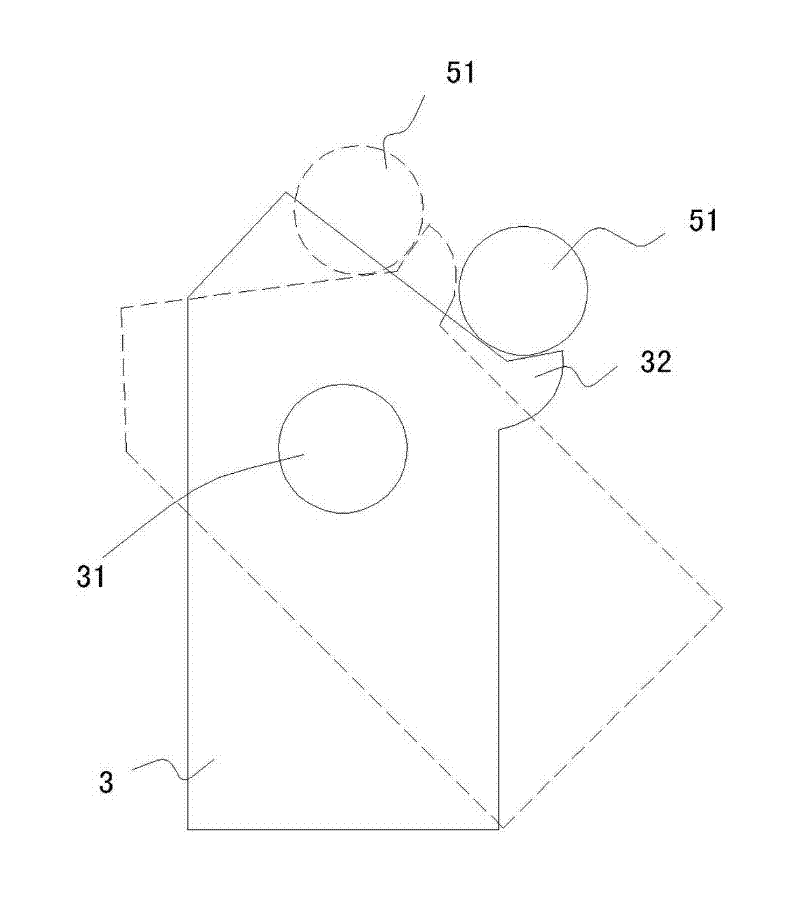

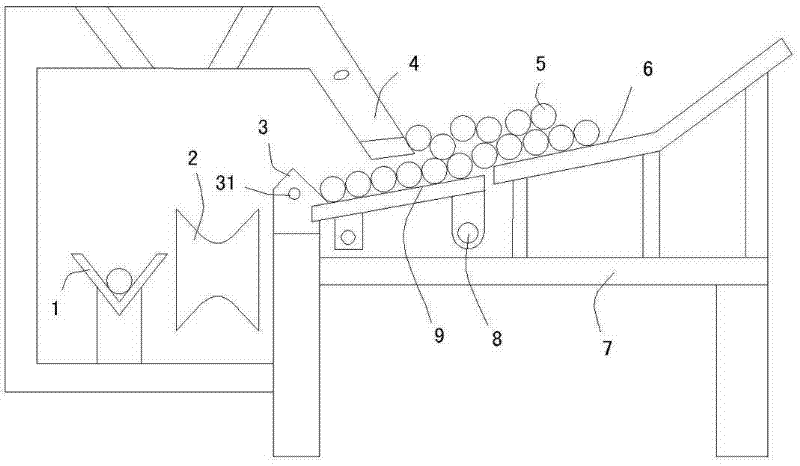

Automatic material distributing and conveying device of cold-drawn steel tubes

InactiveCN102527757AIncrease labor intensityHigh degree of automationEngineeringUltimate tensile strength

The invention relates to an automatic material distributing and conveying device of cold-drawn steel tubes. The automatic material distributing and conveying device comprises a frame, wherein the top surface of the frame is of a working face for stacking source steel tubes, and the automatic material distributing and conveying device is characterized in that the working face comprises two sections, namely a fixed inclined plane and a vibrating inclined plane, and the vibrating inclined plane is positioned at the downstream part of the fixed inclined plane; a flow limiting plate is arranged above an inlet of the vibrating inclined plane; a vertical turnover material stirring device and an axial feeding device are sequentially arranged on one side of the outlet end of the vibrating inclined plane; and the axial feeding device comprises a plurality of rolling wheels which are mounted axially relative to the source steel tubes and material turning rods arranged at the gaps between the rolling wheels. According to the automatic material distributing and conveying device, material distributing and conveying of the source steel tubes can be completed by utilizing the fixed inclined plane and the vibrating inclined plane, and the source steel tubes can be automatically conveyed to a V-shaped working groove under the action of the vertical turnover material stirring device and the axial feeding device, so that the automatic material distributing and conveying device has the advantages of low labor intensity, good operating environment, high degree of automation and continuous production, can realize the purpose of reliably ensuring quality and is further conductive to eliminating potential safety hazard.

Owner:浙江伦宝管业股份有限公司

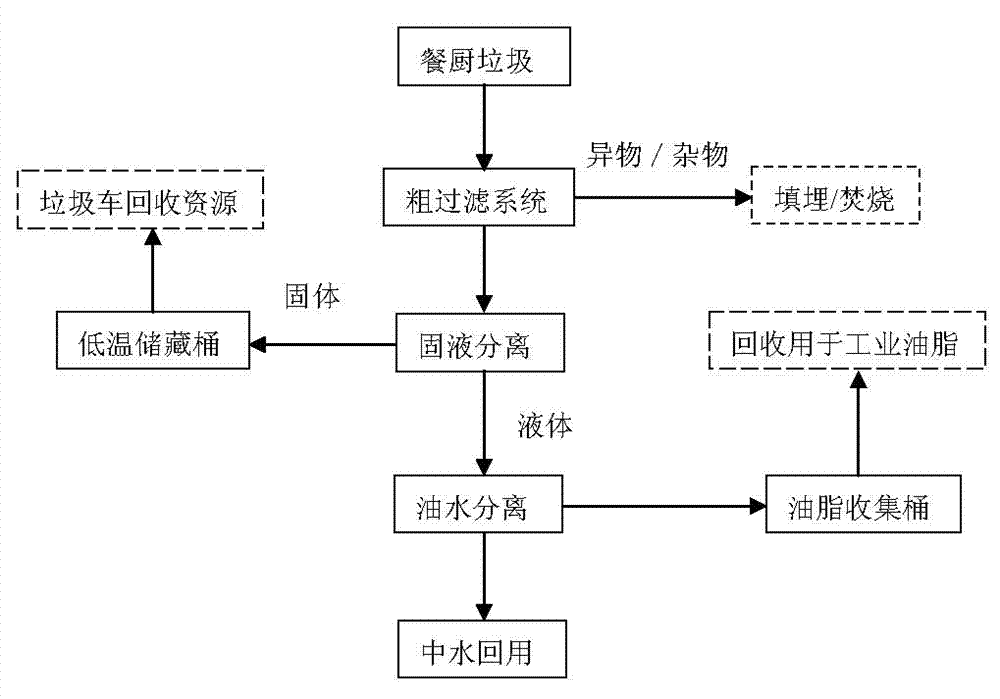

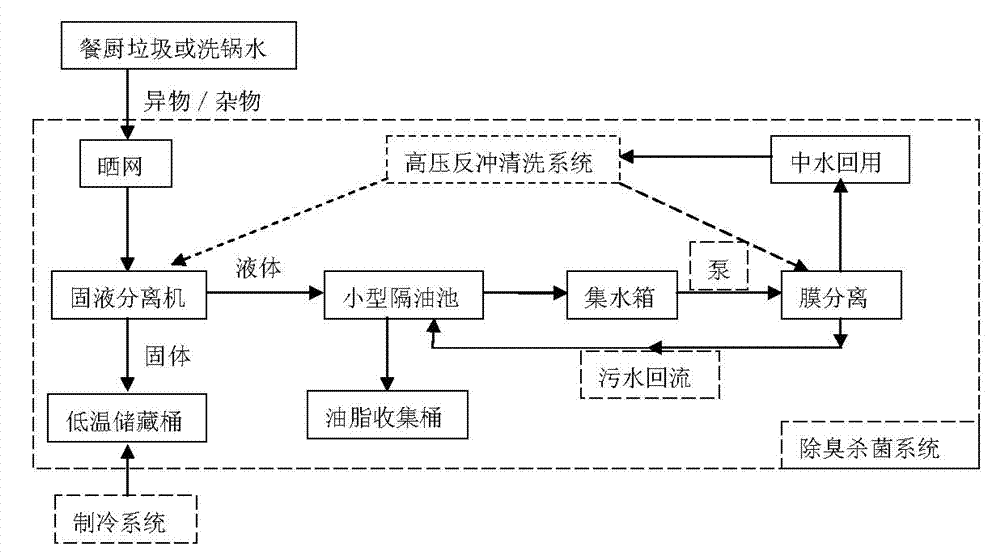

Recovery processing method of food waste

InactiveCN103111452ALow costEffective in situ reductionSolid waste disposalReclaimed waterWater resources

The invention discloses a recovery processing method of food waste. The recovery processing method of food waste comprises the following steps of: firstly screening the waste with a coarse filter system; filtering the food waste after being screened; conveying the waste into a low-temperature storage barrel for storage through screw extruding; and carrying out oil-water separation and advanced treatment by separated oil and water entering an oil-water separation device. The recovery processing method of food waste adopting the scheme has the characteristics of being simple in structure, convenient to realize, small in equipment volume, high in degree of automation, high in processing speed and low in cost, and is capable of efficiently carrying out in situ reducing, innoxious and resource processing on the food waste; sewage water can achieve the standard of reclaimed water reuse; and much water resource can be saved.

Owner:东莞市凯普精密机器有限公司

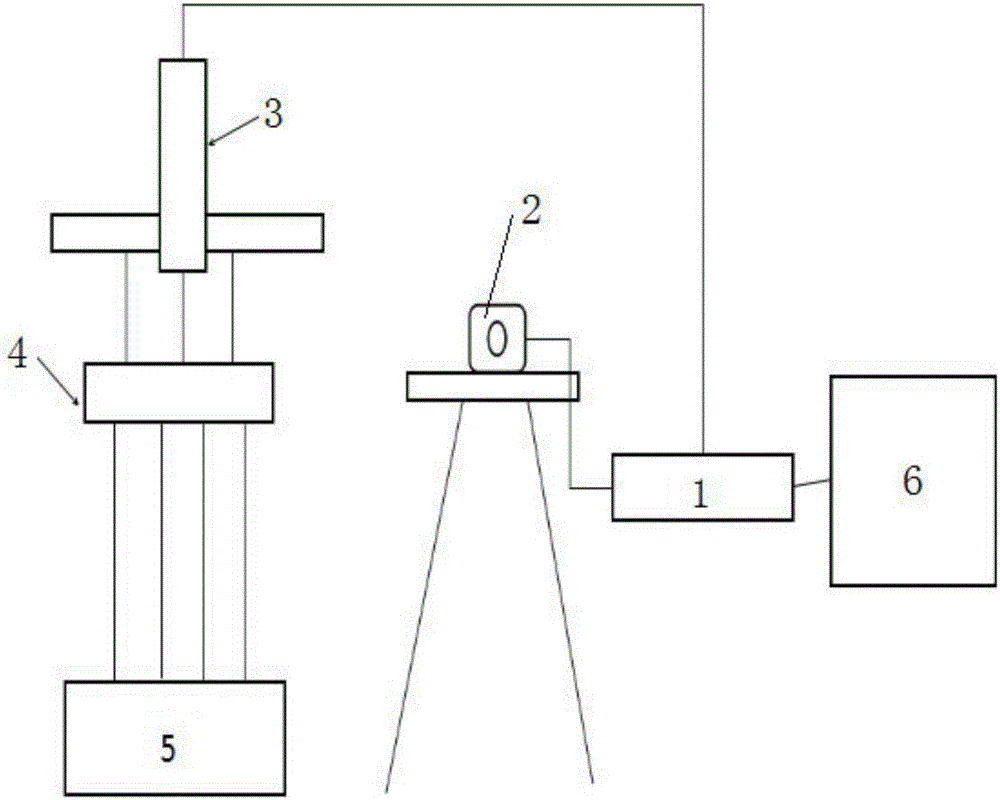

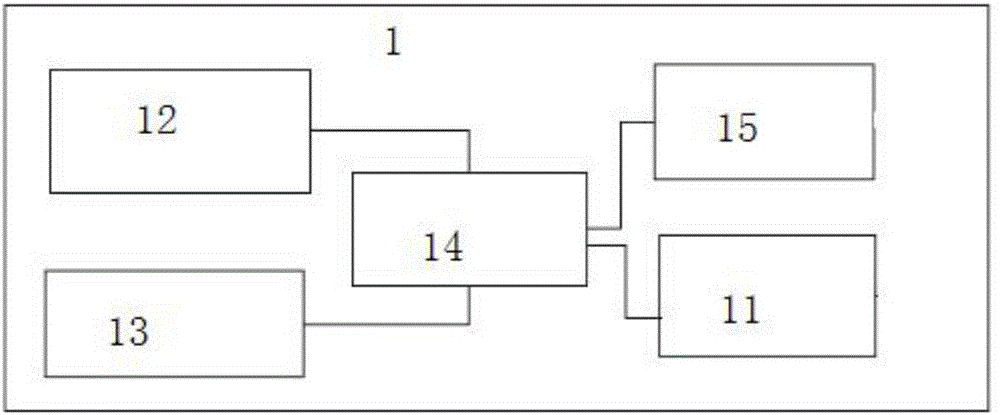

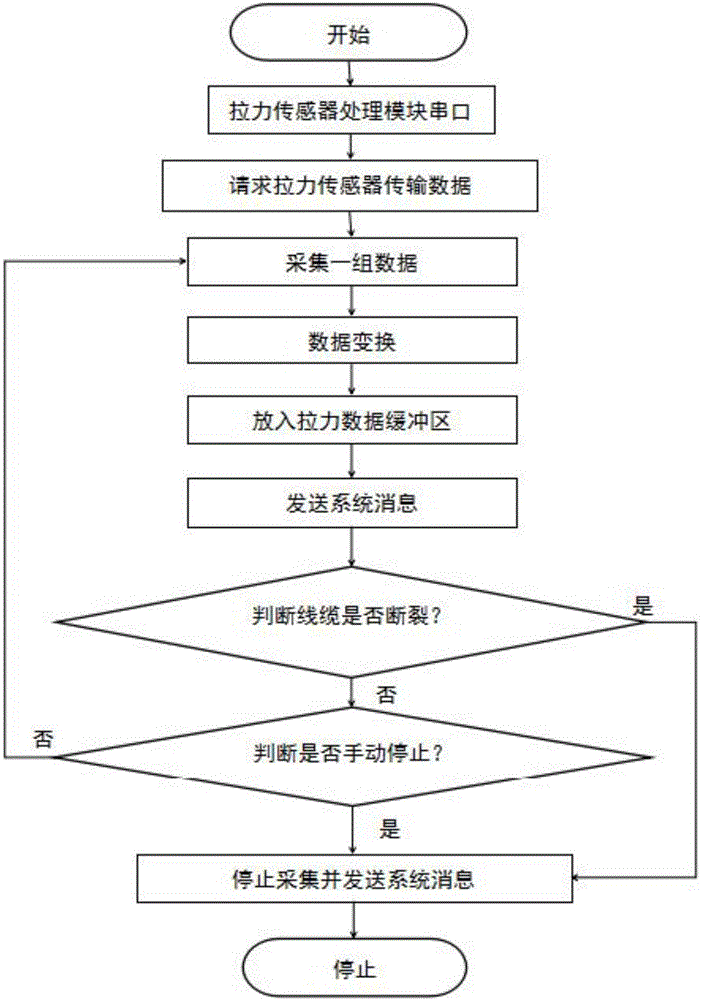

Cable sheath tensile length measuring device and cable sheath tensile length measuring method based on machine vision

InactiveCN105910539ABig errorLow efficiencyMaterial strength using tensile/compressive forcesUsing optical meansCamera imageMachine vision

The invention relates to a cable sheath tensile length measuring device and a cable sheath tensile length measuring method based on machine vision. The measuring device comprises a tension sensor, a tension transmission mechanism, and a servo motor, and is characterized by further comprising an upper computer, an embedded controller, and an industrial camera, wherein the embedded controller, the industrial camera, the tension sensor, the tension transmission mechanism and the servo motor constitute a lower computer. The embedded controller comprises a touch screen display module, a tension sensor processing module, a camera image processing module, a data processing module, and an upper computer communication module, wherein the input end of the touch screen display module, the output end of the camera image processing module and the input end of the upper computer communication module are connected with the data processing module, the data processing module is connected with the tension sensor through the tension sensor processing module, the input end of the camera image processing module is connected with the industrial camera through a USB cable, and the upper computer communication module is connected with the upper computer through a network cable.

Owner:HEBEI UNIV OF TECH

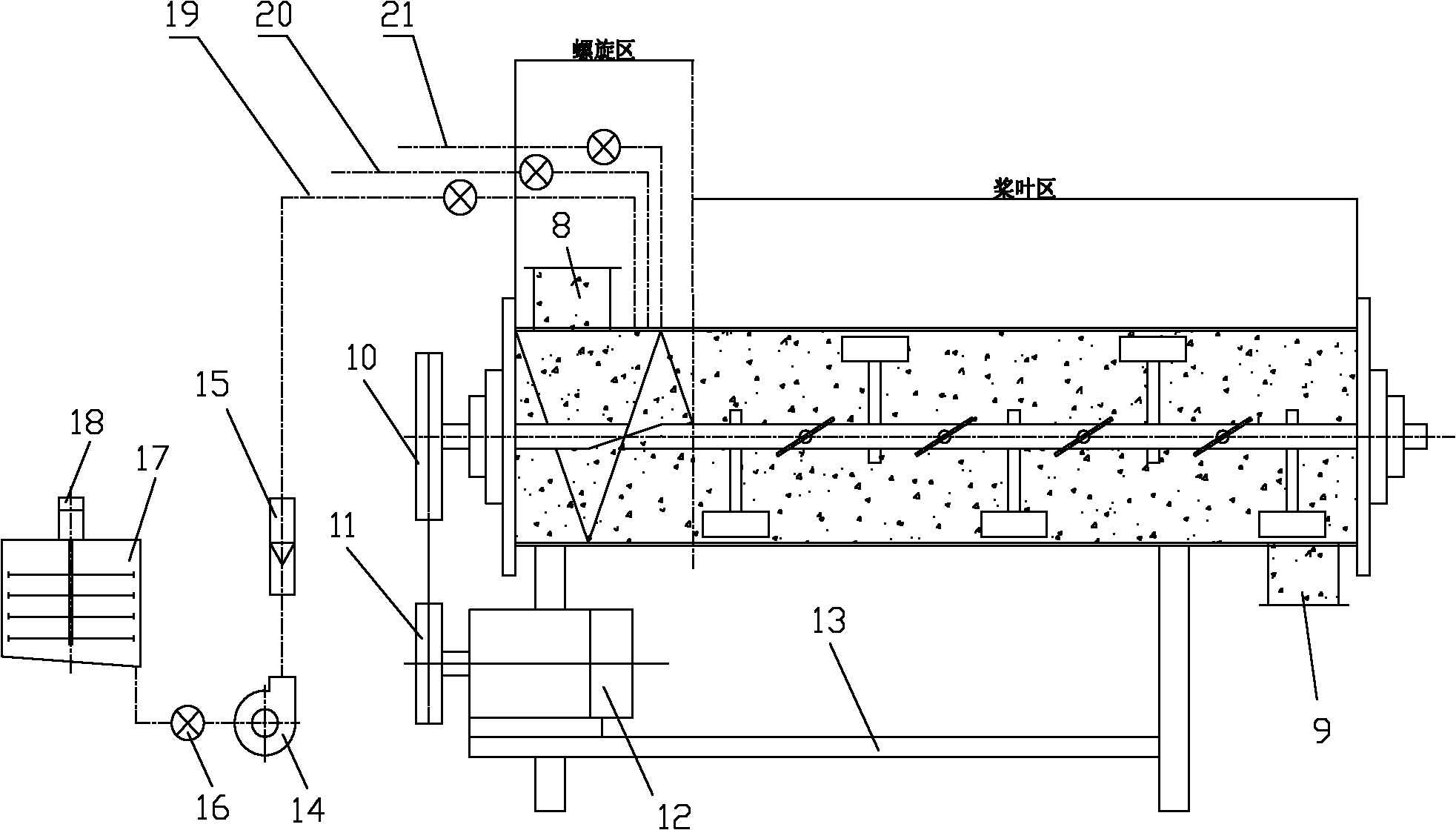

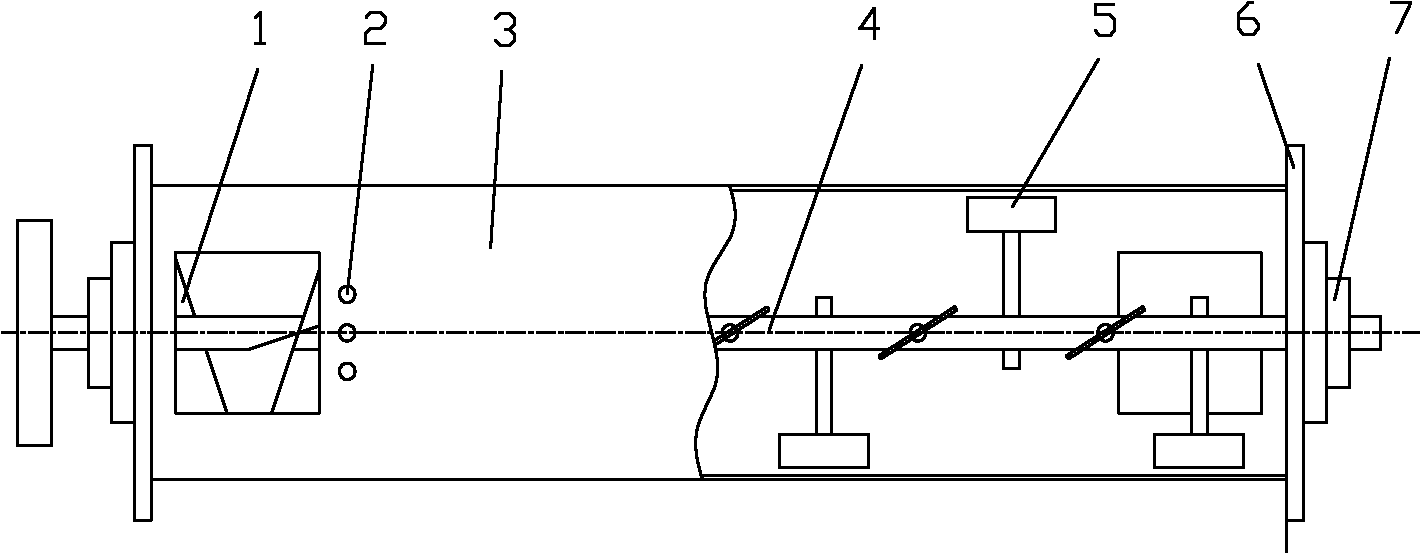

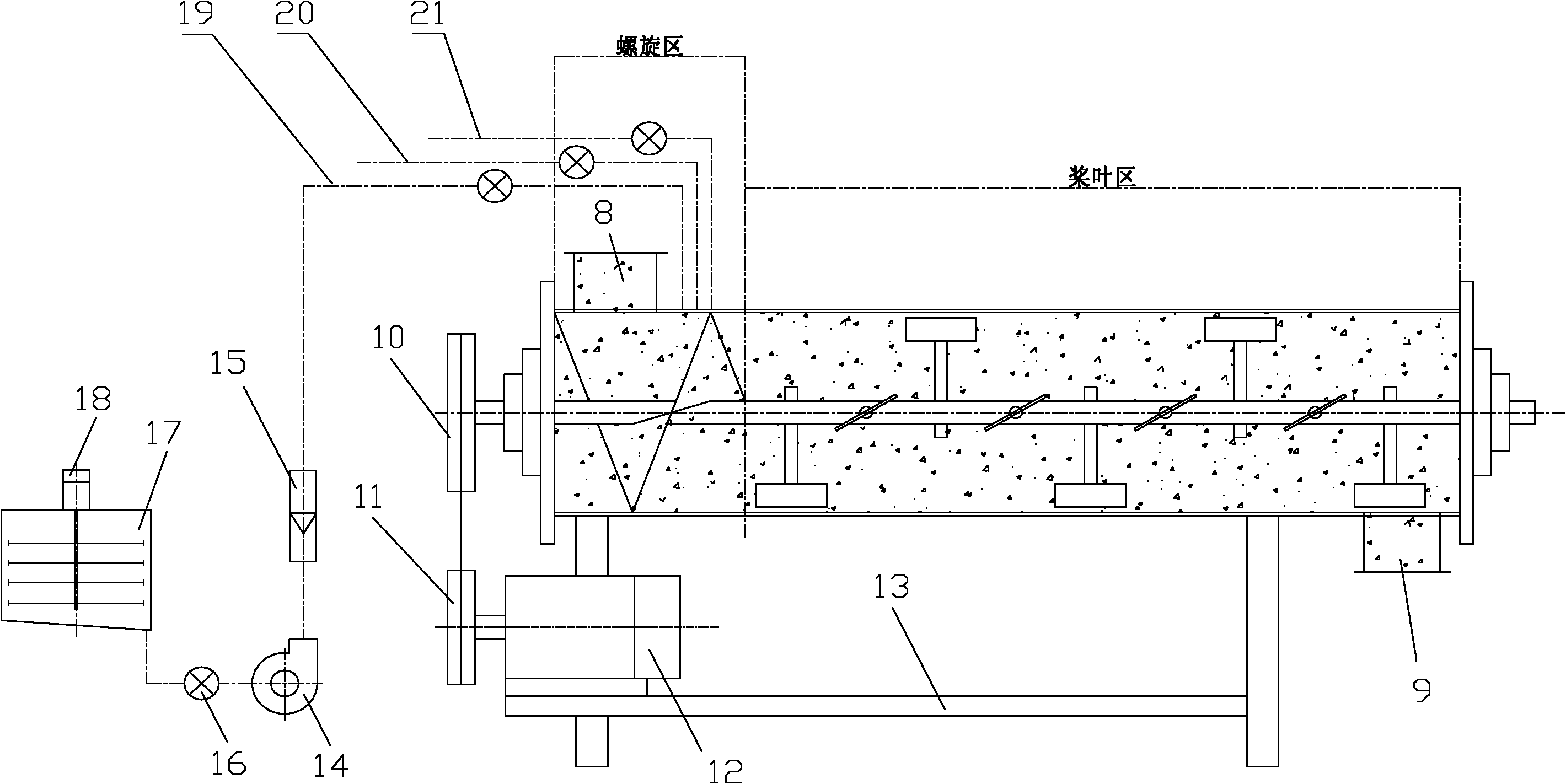

Equipment for preparing bean pulp solid-state fermentation substrate material and use method thereof

InactiveCN102178332ARealize continuous operationSimple production processFeeding-stuffSocial benefitsSpiral blade

The invention relates to a piece of equipment for processing a bean pulp solid-state fermentation substrate material and a use method thereof. In the equipment for preparing the bean pulp solid-state fermentation substrate material, flanges (6) are fixed at two ends of a barrel (3); a stirring shaft (4) is arranged at a centre of the barrel (3); and one end of the barrel (3) is provided with a feeding hole (8), and the other end of the barrel is provided with a discharging hole (9). A spiral blade (1) is arranged at the part of the stirring shaft (4), located at a spiral area; a plurality of radial paddle blades (5) are arranged at the part of the stirring shaft (4), located in a paddle blade area; a motor (12) is used for supplying power; a liquid stirrer (18) is arranged in a bacteria liquid tank (17), and bacteria liquid passes through a flow meter (15) and is fed into the spiral area of the barrel (3) via a bacteria liquid pipe (19) by a pump (14). The use method of the corresponding equipment mainly comprises the procedures of bacteria liquid preparation, inoculation and mixing. The invention provides a piece of continuous bean pulp inoculation and mixing equipment, which has high automation degree, is convenient to use, is beneficial to great reduction of labor intensity, and is about to produce large economic and social benefits.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

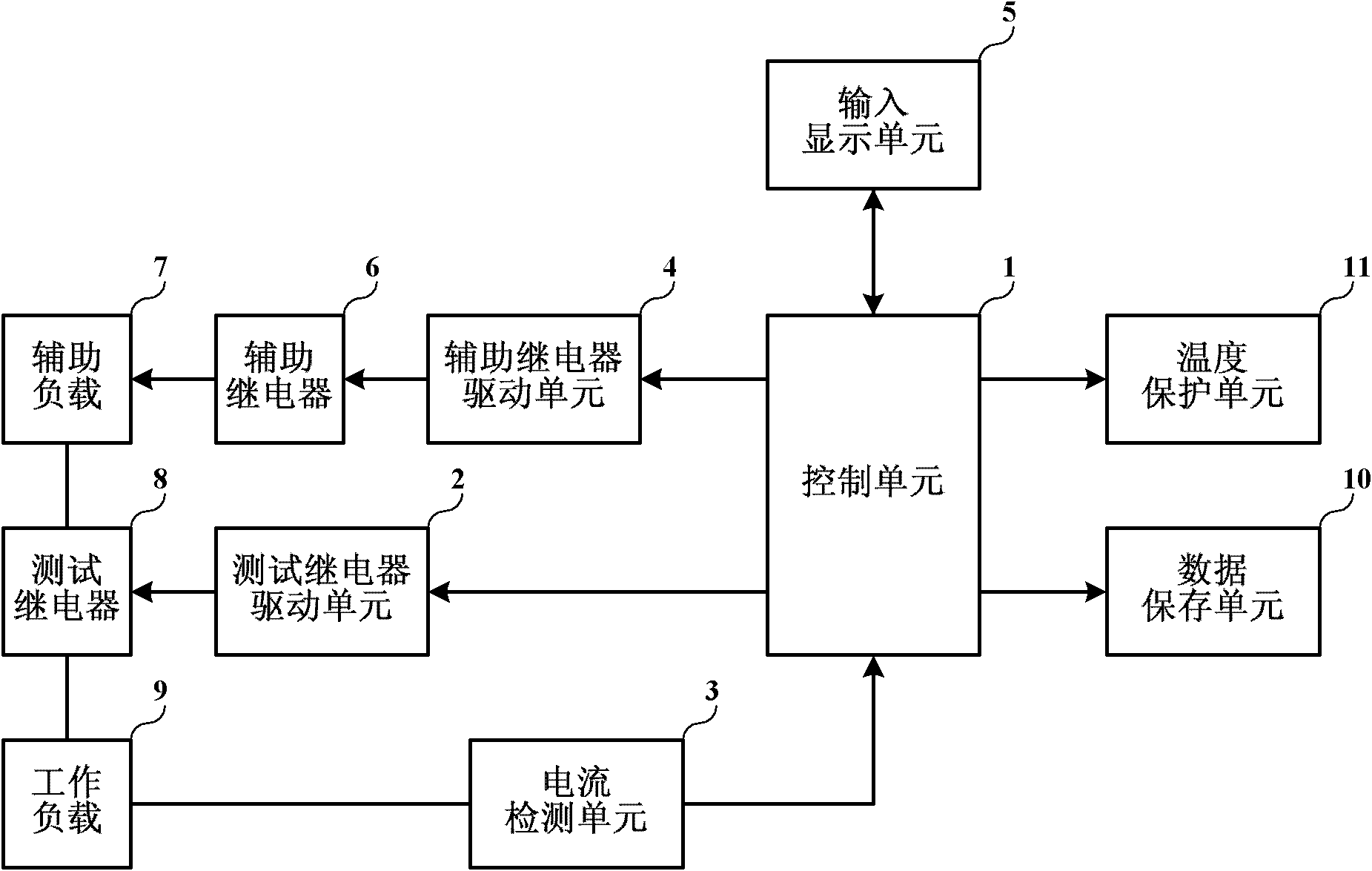

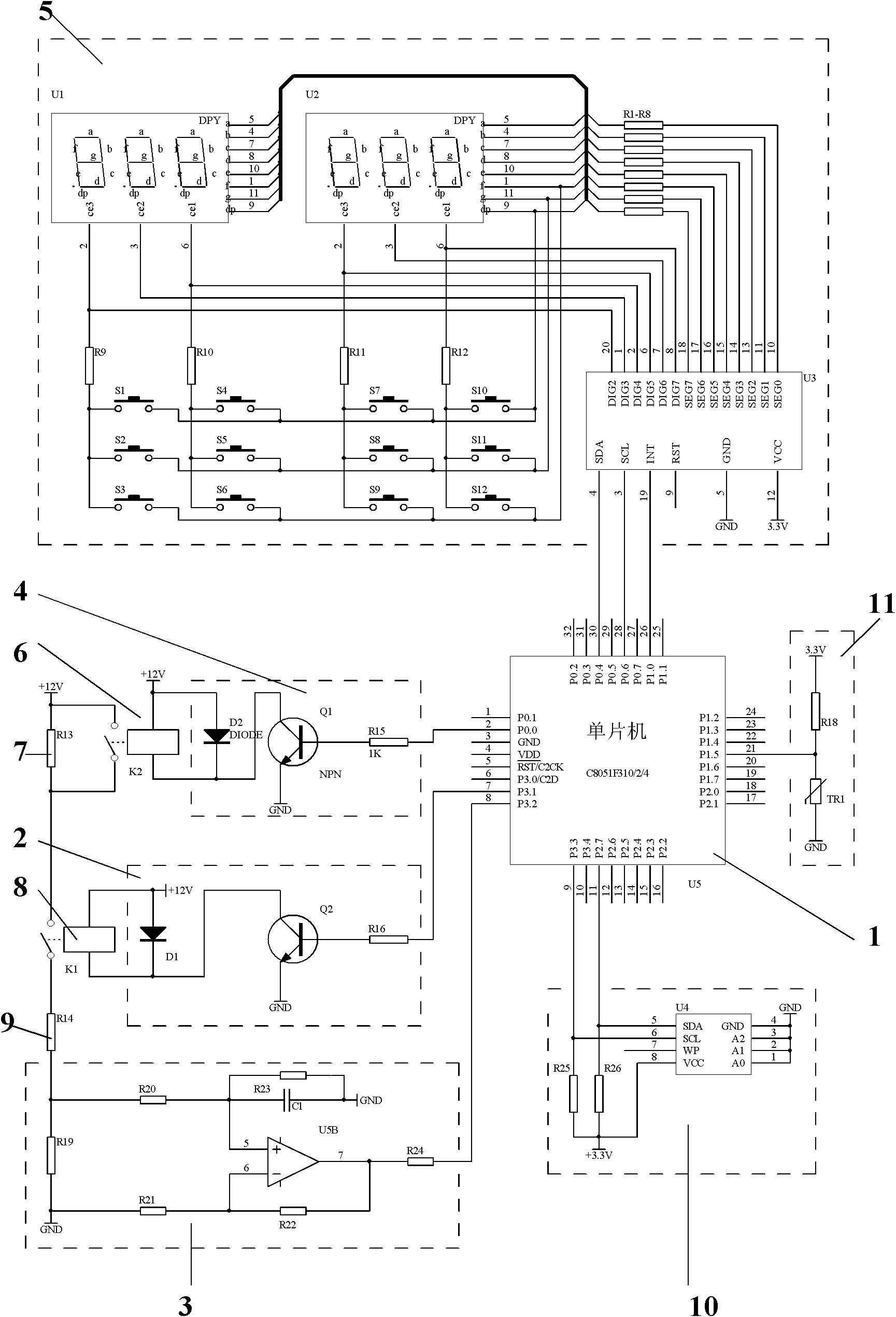

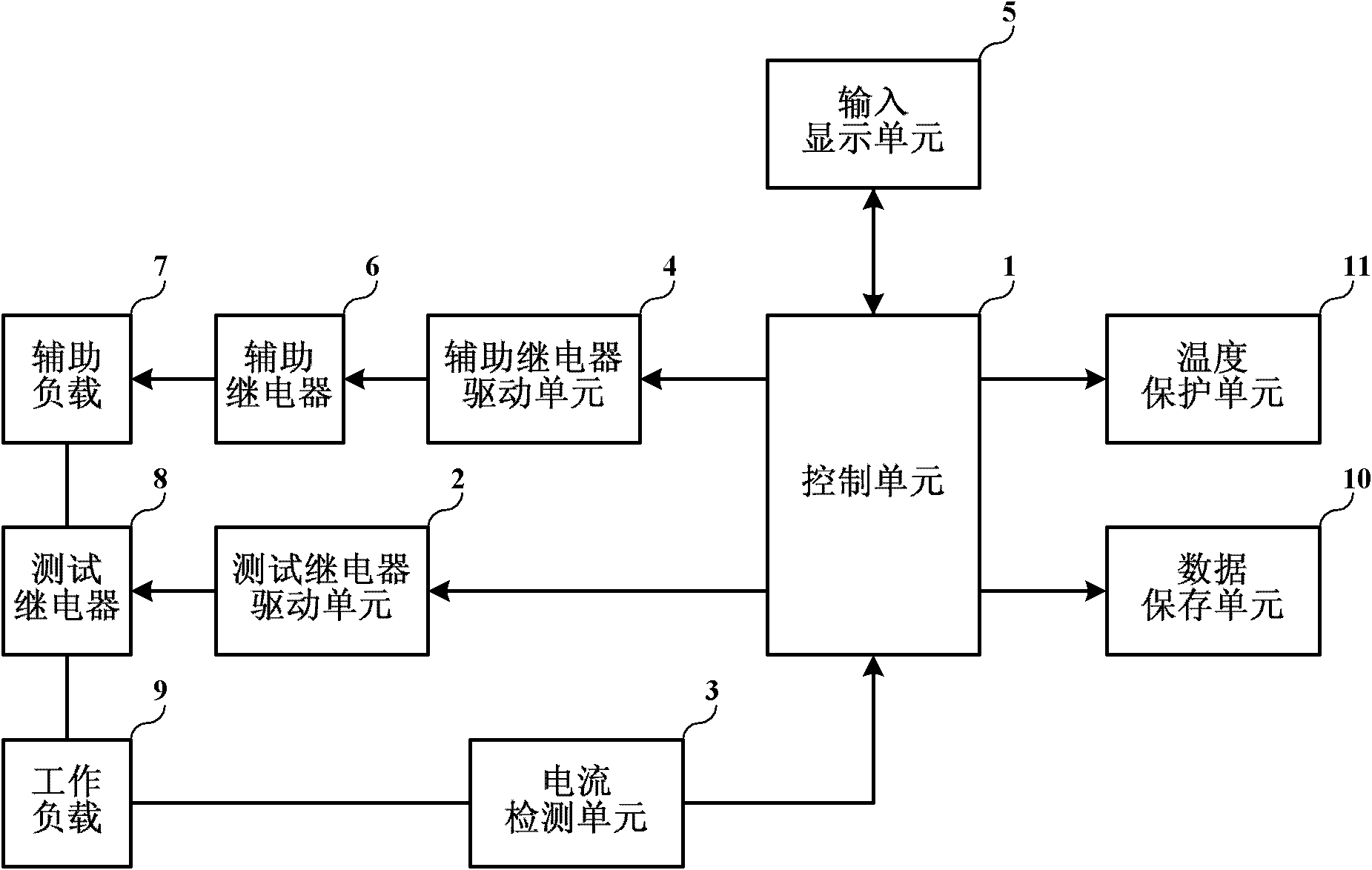

Device and method for testing durability of automobile relay

InactiveCN102135598ALow degree of automationSimple structureCircuit interrupters testingEngineeringElectrical current

The invention relates to a device for testing the durability of an automobile relay, which comprises a control unit, an auxiliary relay driving unit, an auxiliary relay, a testing relay driving unit, a testing relay, auxiliary loads, a current detecting unit and an inputting and displaying unit, wherein the control unit is used for judging various input signals and controlling various output signals; the auxiliary relay driving unit is used for controlling the on or off of the auxiliary relay; the two ends of the auxiliary relay are connected with auxiliary loads in parallel; the testing relay driving unit is used for controlling the on or off of the testing relay; the testing relay is connected with a working load in series; the auxiliary loads and the working load are mutually matched to provide impulse current and stationary working current for the contact circuit of the testing relay; the current detecting unit is used for detecting the current of the contact circuit of the testing relay; and the inputting and displaying unit is used for inputting various testing parameters and displaying various parameters. The testing method provided by the invention comprises the following steps of: providing impulse load current and stationary load current for a relay; and starting to stop circulation control and count the circulation times, thereby testing the durability of the automobile relay.

Owner:NINGBO TUOPU INTELLIGENT BRAKE SYST

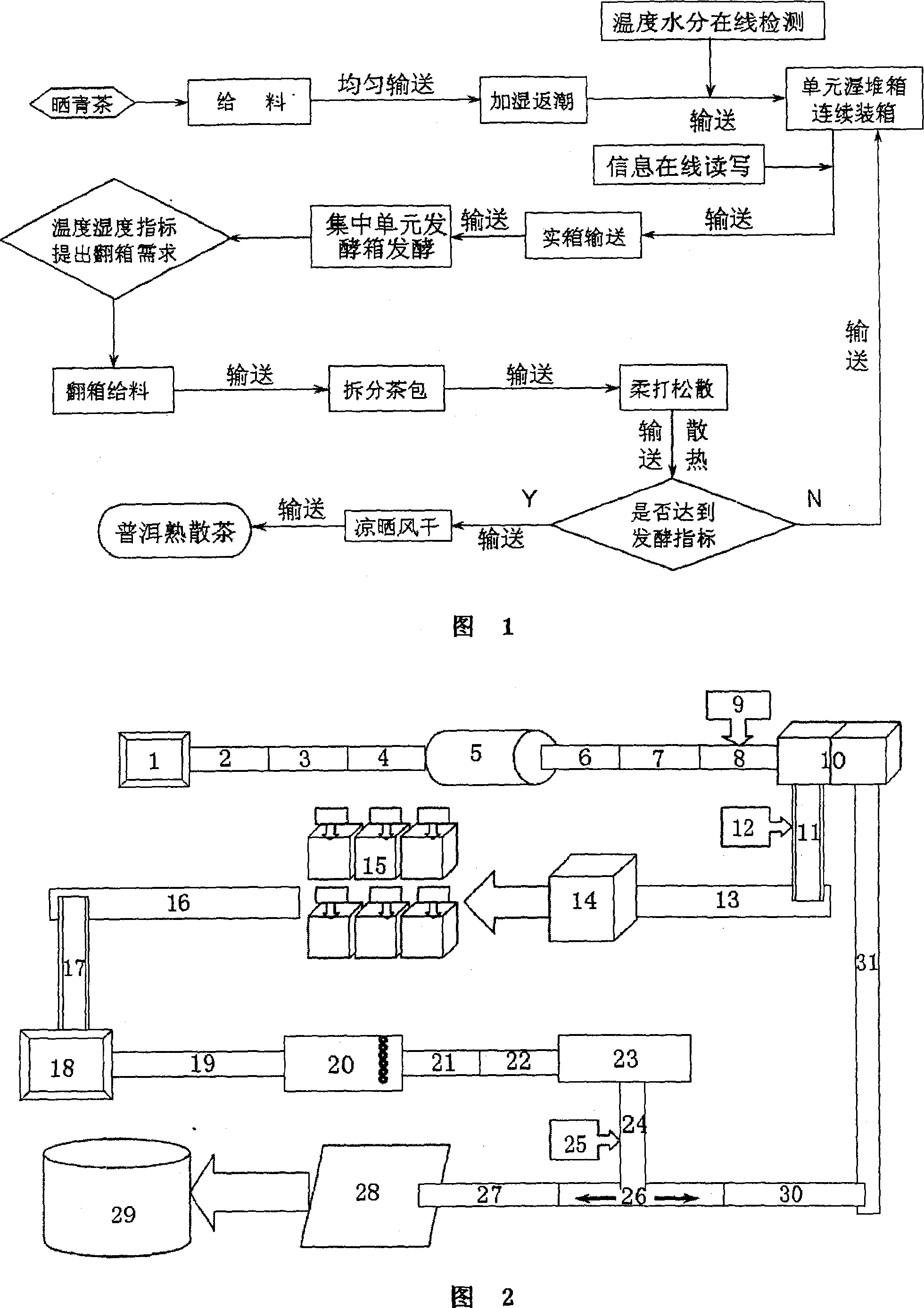

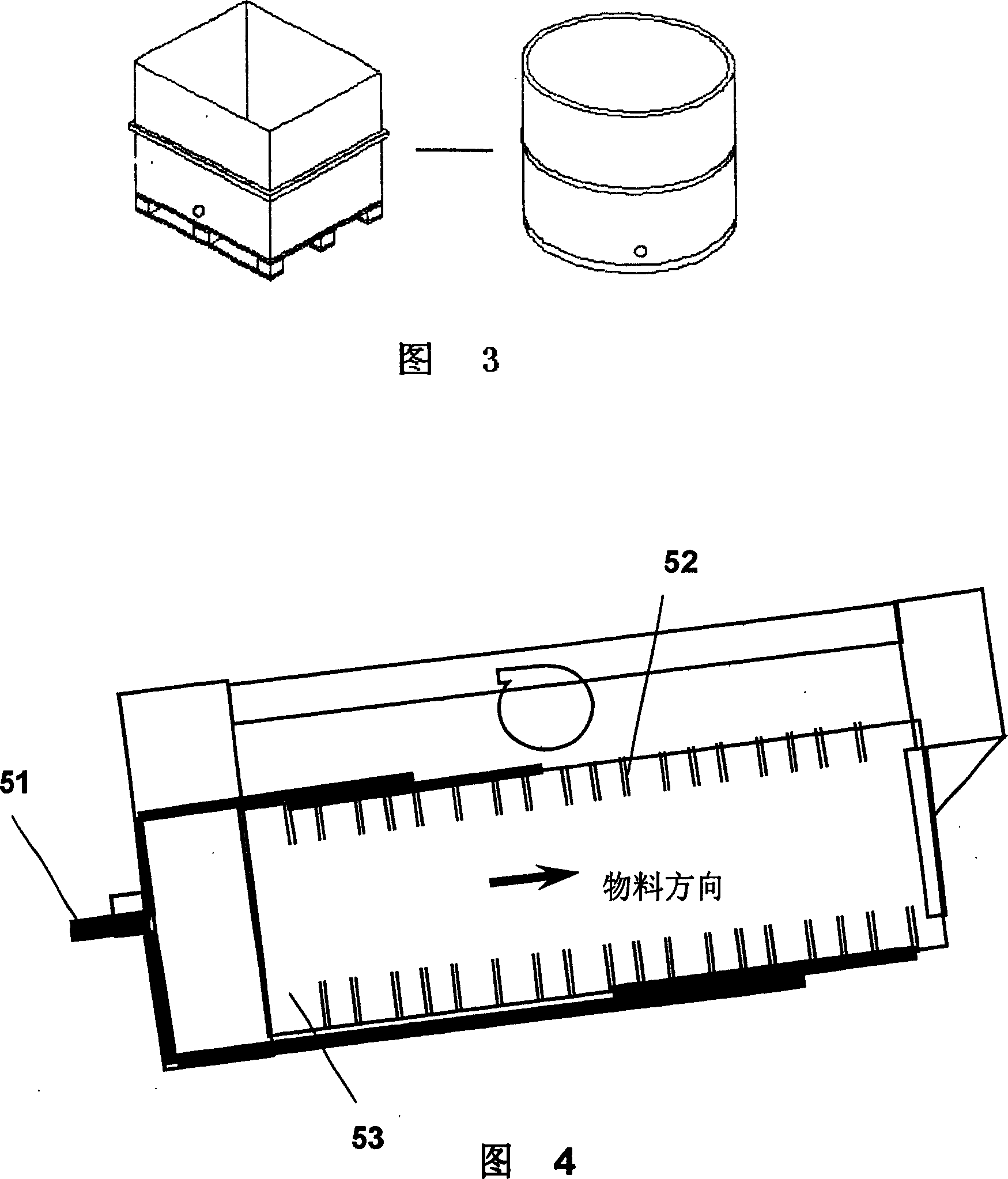

Automatic production technology for pu'er ripe tea

InactiveCN101142949AFlexible settingsAdapt to production requirementsPre-extraction tea treatmentClimate change adaptationAutomatic controlControl system

The invention discloses an automatic production process of pu-er ripe tea, which comprises the following procedures: material feeding, humidification moistening, packaging, real box transportation, fermentation, extraction and overturning box, resolution of tea package, flexible beating and loosening, sunning and air drying, loose pu-er ripe tea packaging, etc. the whole process of the invention can be automatically controlled by a central control system, index of each procedure can be set up flexibly and controlled effectively by the system, moreover, the invention has high degree of automation and can meet the manufacturing requirement of large-scale pu-er tea enterprise of information, digitalization, large scale and flexibility. Considering the cost, automation level of the invention can be reduced and the mainframe equipment can be used alone while supported by little manual work, therefore, the invention also can upgrade shortcoming of the prior pu-er tea production process and promote healthy and stable growth of the Yunnan pu-er tea industry.

Owner:冉文学

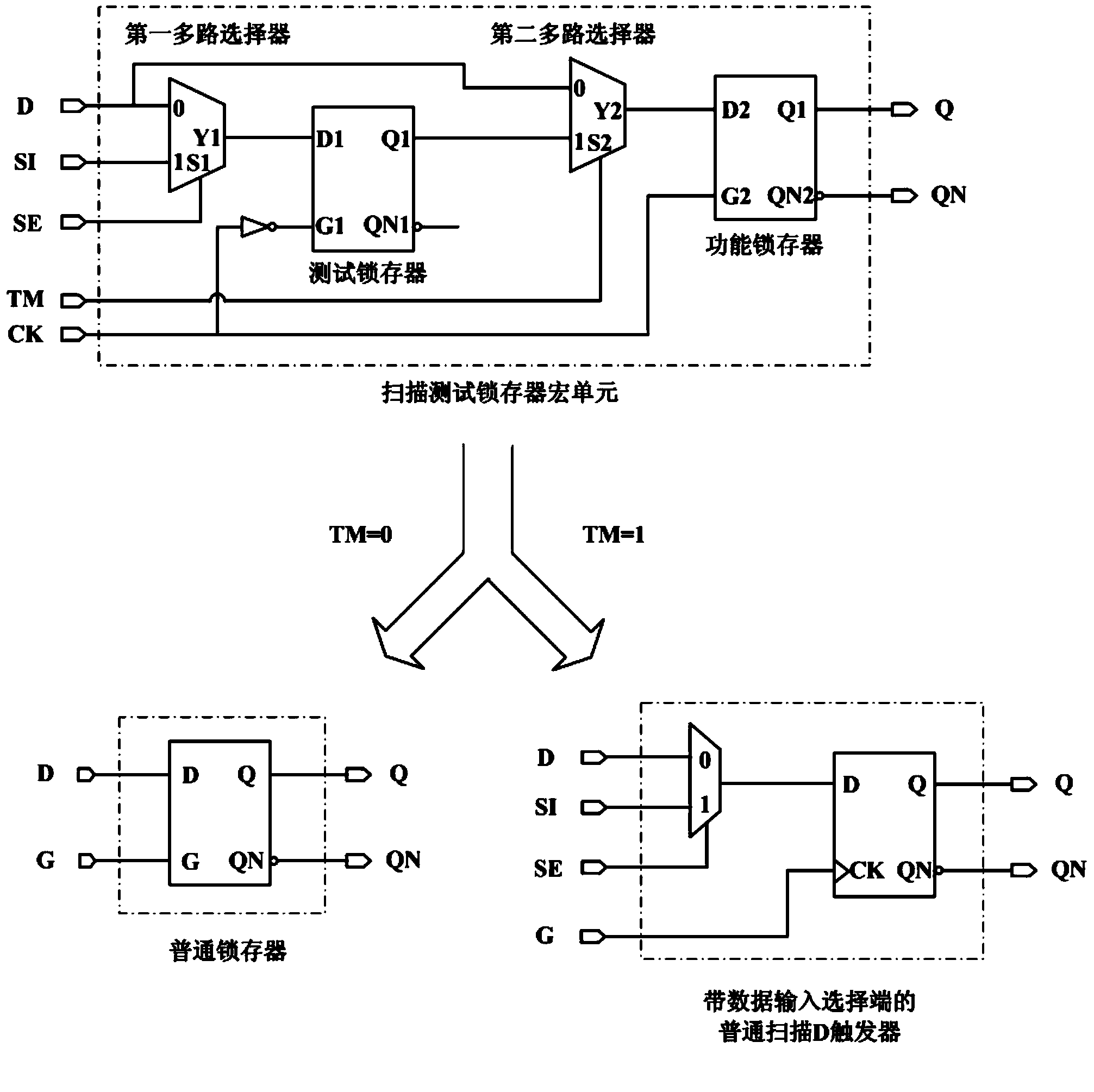

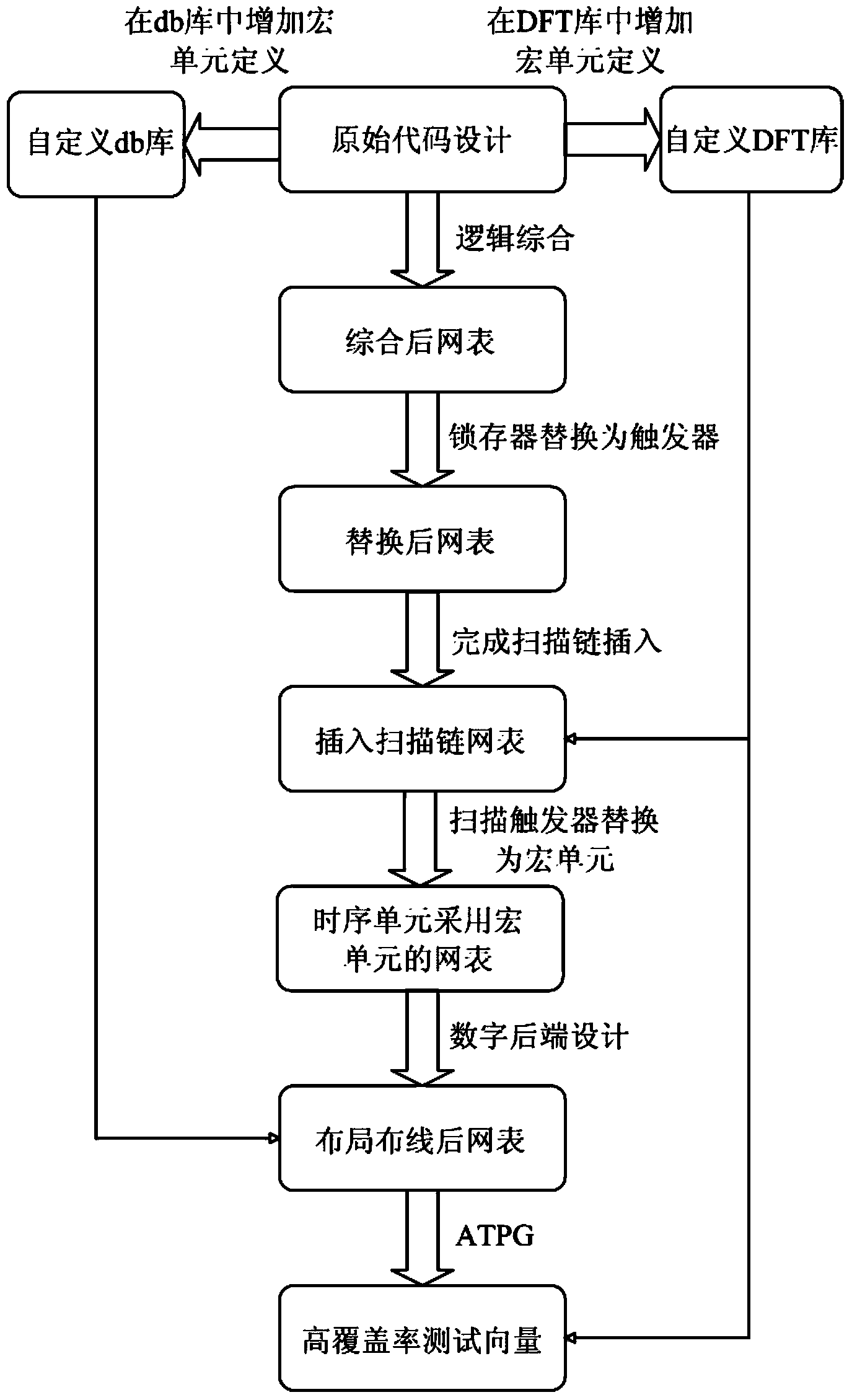

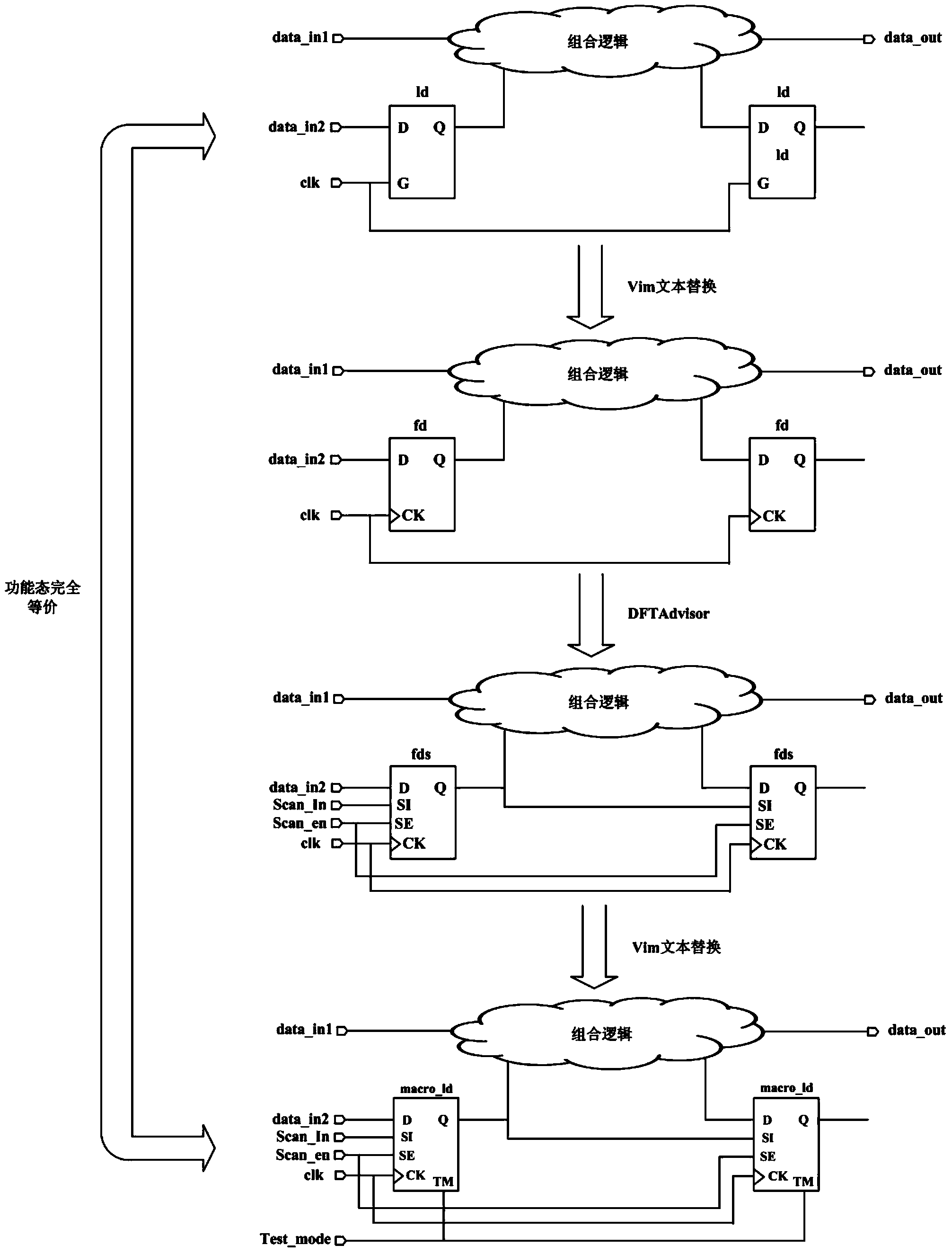

Scan test latch macrocell and scan test method

The invention provides a scan test latch macrocell and a scan test method. According to the scan test method, through a customized scan test macrocell, an ATPG test vector, based on a structure, used for a latch unit can be generated with a common scan test design method for a D trigger according to a special design process, the problems that testability design development cannot be easily performed on an existing digital special integrated circuit based on latch design, the fault coverage rate of the test vector is low, and time sequence analysis is complex are solved, the fault coverage rate of chip tests is substantially increased, the effectiveness and the completeness of the chip tests are guaranteed, and the method is mainly applied to the test vector development of the digital special integrated circuit based on latch design.

Owner:BEIJING MXTRONICS CORP +1

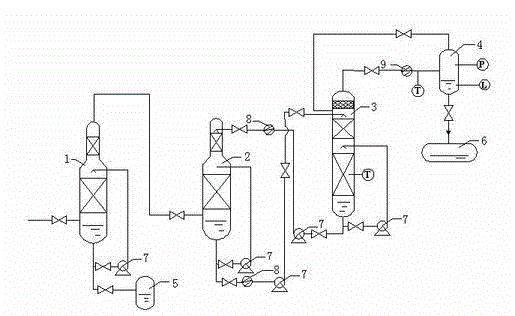

Method for recycling hydrogen peroxide oxidized tail gas

InactiveCN106139824AHigh recovery rateReduce dosageDispersed particle separationSteam distillationFiberCarbon fibers

The invention discloses a method for recycling hydrogen peroxide oxidized tail gas. The device comprises an absorption tower, a liquid-rich tank, a stripping tower, a separator, a recycling tank, a rectifying column and a refining tank which are sequentially connected through a pipeline. The device is further provided with a barren liquid tank, a discharging port of the barren liquid tank is connected to the absorption tower, the stripping tower and the rectifying column are provided with pipelines to be connected to a feeding port of the barren liquid tank, and an evacuation pipeline is arranged at the top of the absorption tower. An adsorption tank is arranged at the top of the absorption tower, and the adsorption tank is filled with carbon fibers. The method can be applied to the oxidized tail gas treatment process during hydrogen peroxide production, arene is recycled from the oxidized tail gas, the raw material consumption of the device is reduced, meanwhile, energy consumption can be reduced, and environmental protection can be achieved.

Owner:HUBEI SANNING CHEM

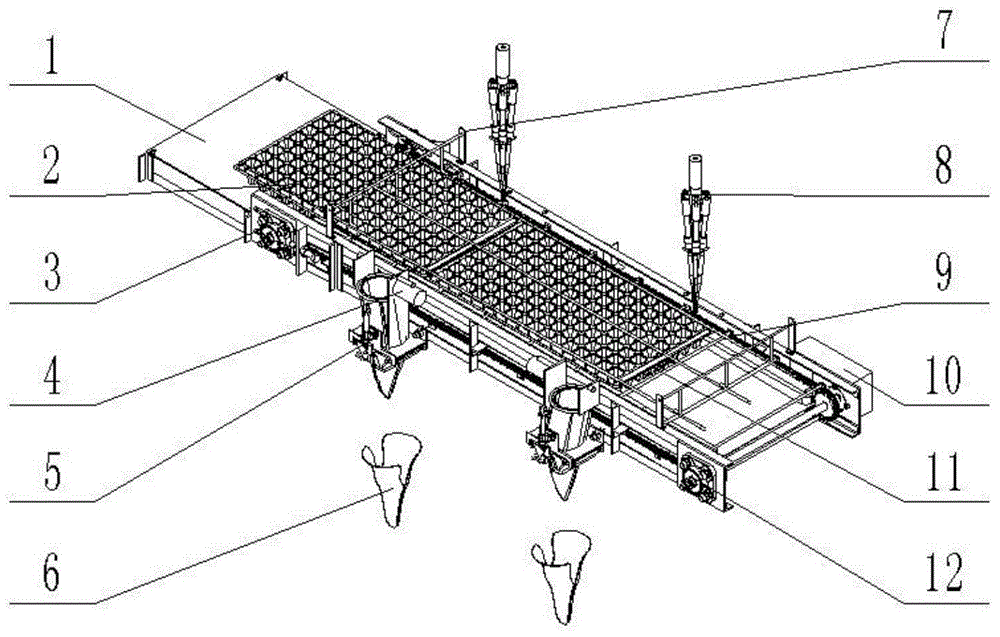

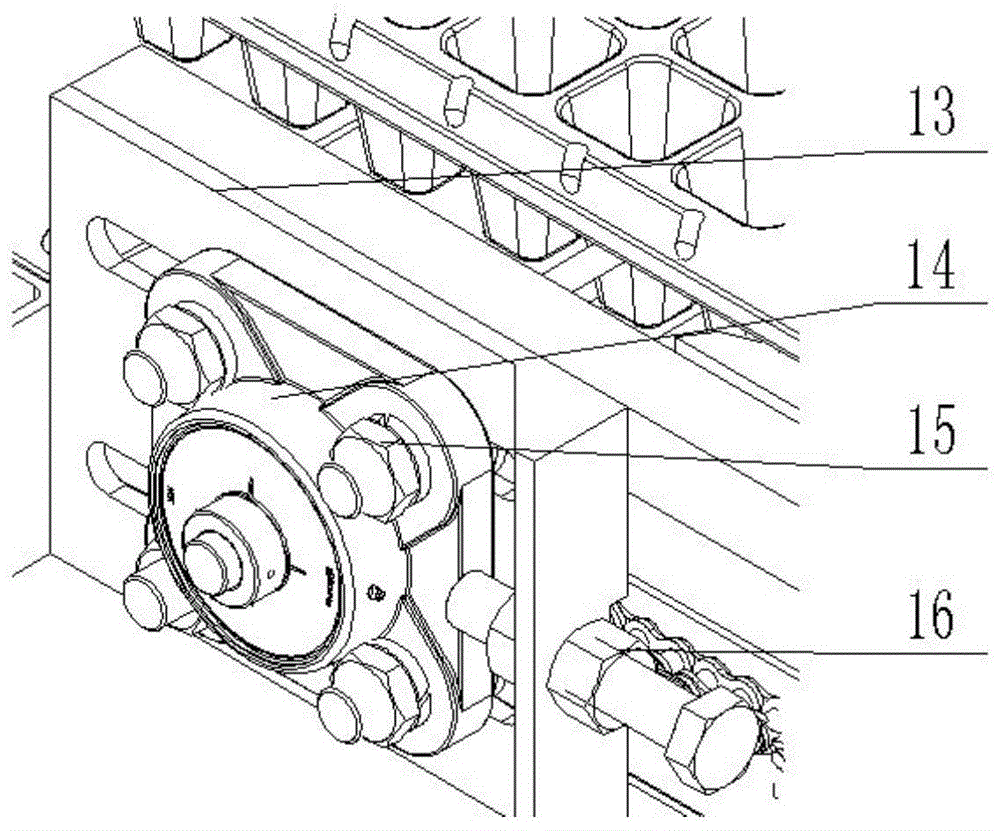

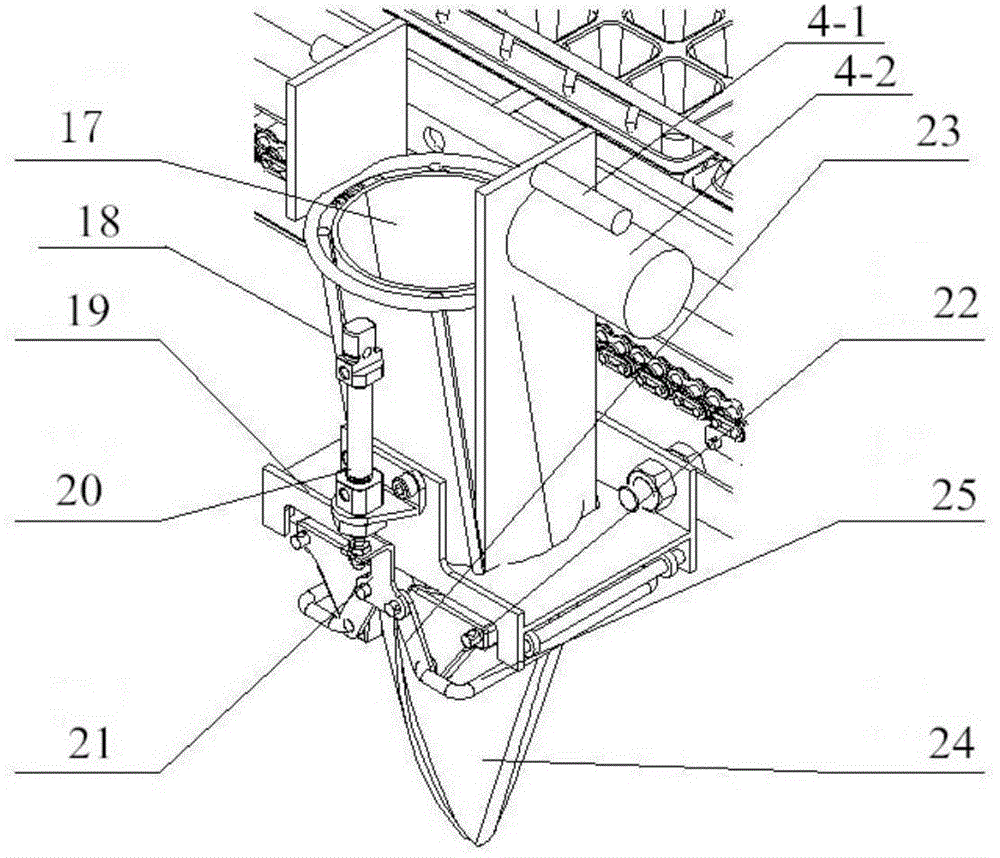

Tray seedling conveying, positioning and launching device for pot seedling transplanting machine

InactiveCN104813783ALow degree of automationLow transplanting efficiencyTransplantingBiologySeedling

The invention provides a tray seedling conveying, positioning and launching device for a pot seedling transplanting machine. The device can simultaneously convey, position, take and launch seedlings for two trays and is small in occupied space, simple in structure, low in manufacturing cost, easy to maintain and accurate in positioning and launching. The distance between the seedlings is adjusted by the aid of a seedling guide barrel, two seedling taking claws simultaneously work, so that seedling taking efficiency is high, the seedlings can be accurately launched by the aid of an independent opening and closing mechanism, an image recognition system can recognize good seedlings and bad seedlings, and the bad seedlings can be removed when discovered.

Owner:JIANGSU UNIV

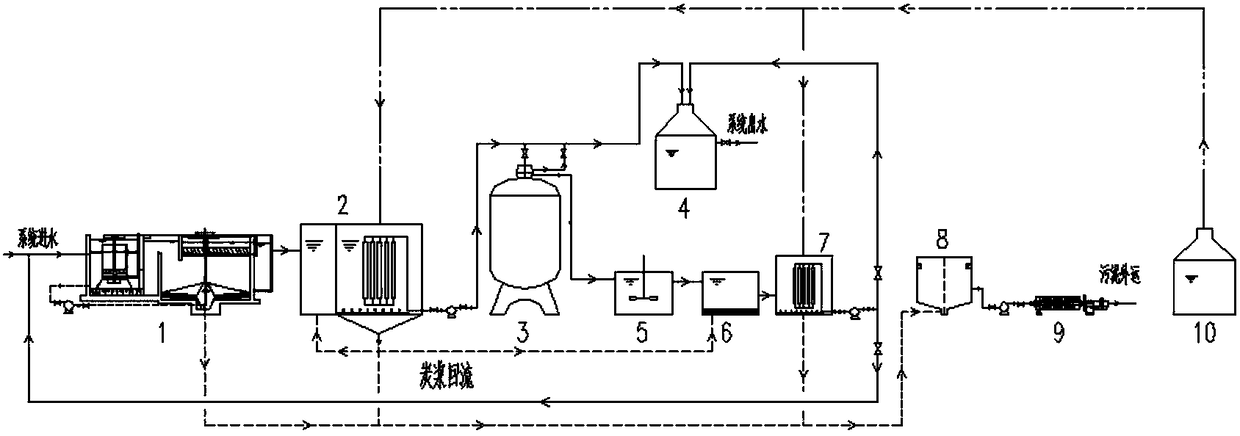

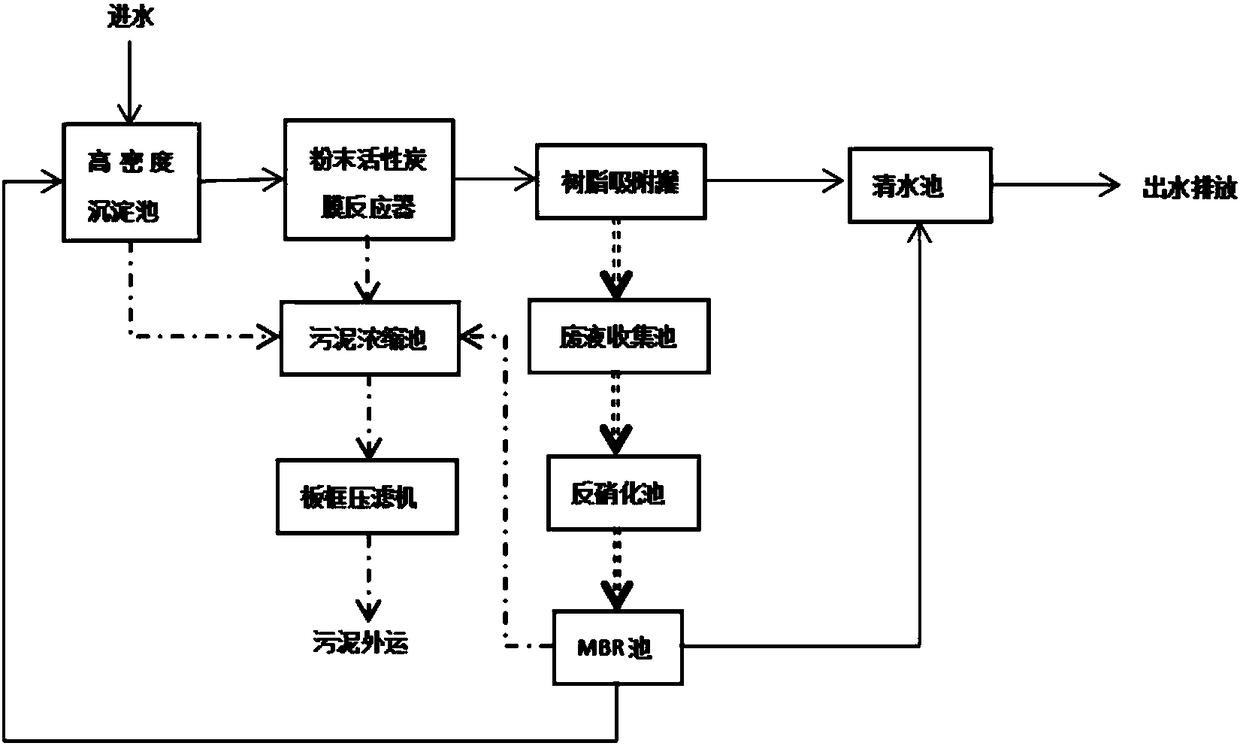

System and method for deeply treating tail water of sewage plant

PendingCN108218153AImprove removal efficiencyHigh degree of automationSludge treatment by de-watering/drying/thickeningWater treatment compoundsSludgeElectric control

The invention discloses a system and a method for deeply treating tail water of a sewage plant. The system comprises a high-density settlement tank, a powder activated carbon membrane reactor, a resinadsorption tank, a clear water tank, a waste liquid collection tank, a denitrification tank, an MBR tank, a sludge concentration tank, a plate and frame filter press, and an electric control system.Raw water enters the high-density settlement tank at first so as to remove total phosphorus, then the water is sent to the powder activated carbon membrane reactor, powder activated carbon is added toadsorb pollutants, the water is filtered through a membrane component so as to reduce CODcr, color scale and suspended matters of effluent water, then the effluent water is sent to the resin adsorption tank to remove nitrogen, the effluent water flows into the clear water tank, is sterilized and then is discharged, after being saturated through absorption, the resin is regenerated through a sodium chloride solution, the waste liquid is collected and then sent to the denitrification tank to remove nitrogen, some carbon paste in the powder activated carbon membrane reactor in the previous stageflows back to the denitrification tank, so as to enable pollutants to be further adsorbed to improve water quality, then the effluent water enters the MBR to separate sludge from water. Through adoption of the system, the water quality is stable, the effluent water contains low content of nitrogen and phosphorus; and the system occupies a small area and has high automation degree.

Owner:HUBEI JUNJI WATER TREATMENT

Juice vending machine

InactiveCN106157452ALow degree of automationApparatus for dispensing fluids/granular materialsFlavorMechanical engineering

The invention discloses a juice vending machine. The vending machine comprises a feeding station, a juicing station and a packaging station. The juicing station is connected with the feeding station, and the packaging station is connected with the juicing station. The feeding station comprises a raw material conveying device and a material selecting device used for selecting material boxes on the raw material conveying device. The juicing station comprises a juicer. The packaging station comprises an automatic cup dropping device. The juice vending machine is used for solving the technical problem that an existing juicer can not squeeze juice with various flavors.

Owner:湖南果益智能科技有限公司

Program-controlled coal discharging device for raw coal bunker

The invention relates to a program-controlled coal discharging device for a raw coal bunker. The program-controlled coal discharging device comprises a raw coal bunker of which the lower part is of a conical section; a smooth lining plate is paved on the inner wall of the conical section; a coal feeder is correspondingly arranged below a discharge opening of the bottom end of the conical section; a plurality of hot nitrogen gas purging pipelines are arranged on the outer wall of the conical section at intervals from top to bottom; each hot nitrogen gas purging pipeline is formed by connecting a corresponding first pipeline and a first control valve arranged in the first pipeline to a hot nitrogen gas output pipeline of a coal injection station; a plurality of injection pipes are arranged around the circumference of the conical section of the outer wall of the conical section at intervals on each hot nitrogen gas purging pipeline; each injection pipe penetrates through the outer wall of the conical section and the lining plate and is conducted with the inside of the conical section; a quick-open hand hole is formed in the discharge opening of the bottom end of the conical section; a monitoring device for monitoring the flowing state of pulverized coal is arranged on the raw coal bunker; the monitoring device is electrically connected with a PLC (Program Logic Controller) automatic control device; when the discharging is unsmooth, the PLC automatic control device automatically controls valves of the hot nitrogen gas purging pipelines to be opened for purging the inside of the raw coal bunker to enable raw coal to be smoothly discharged.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

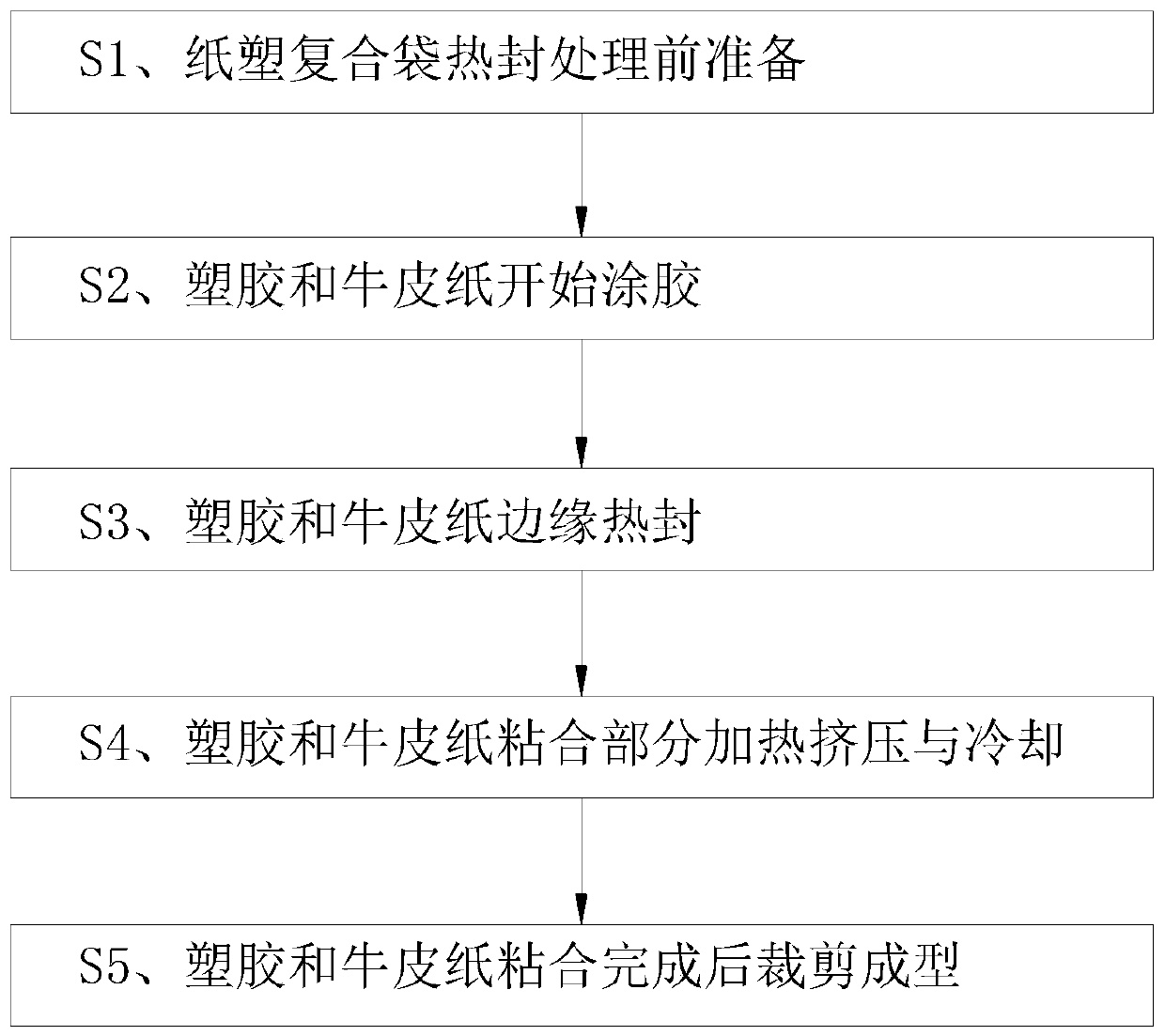

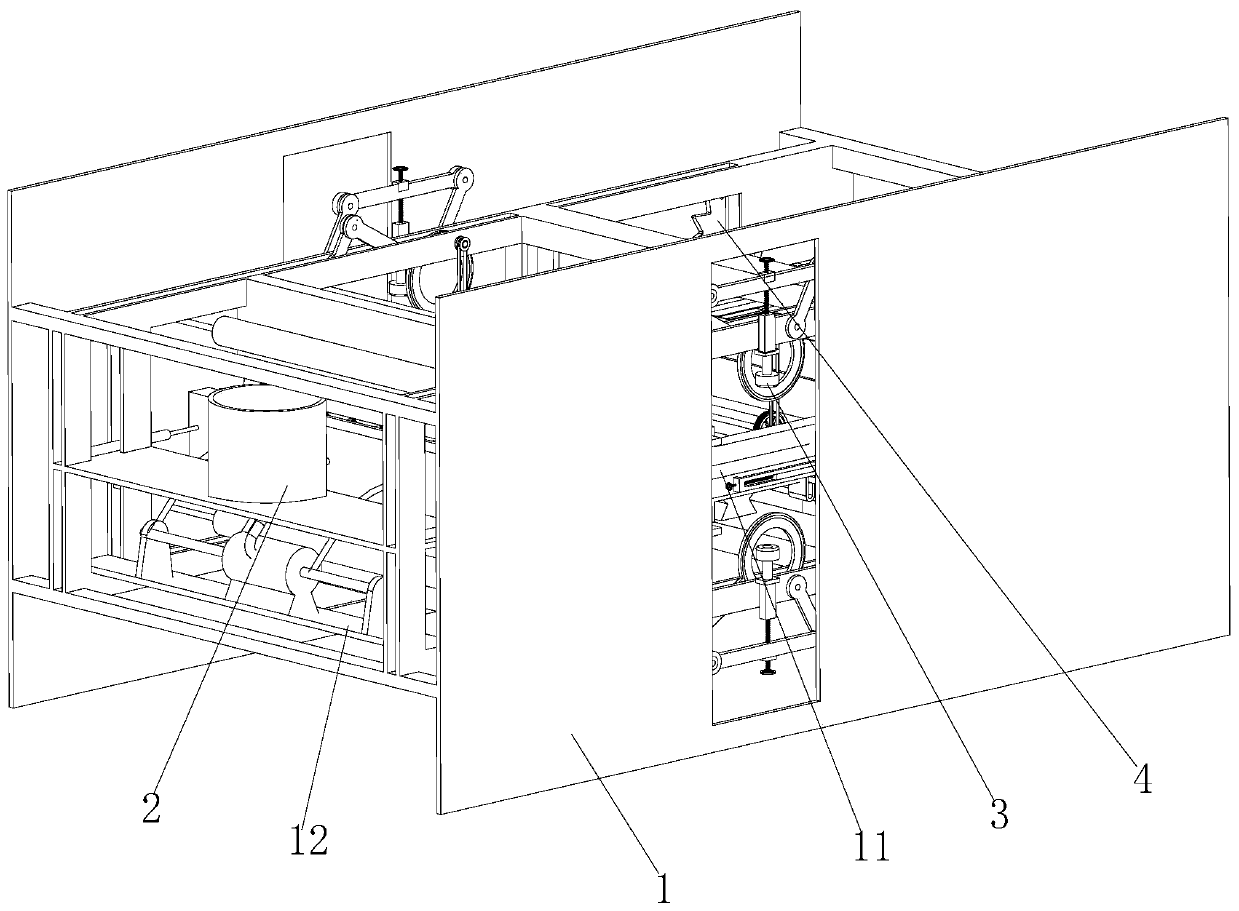

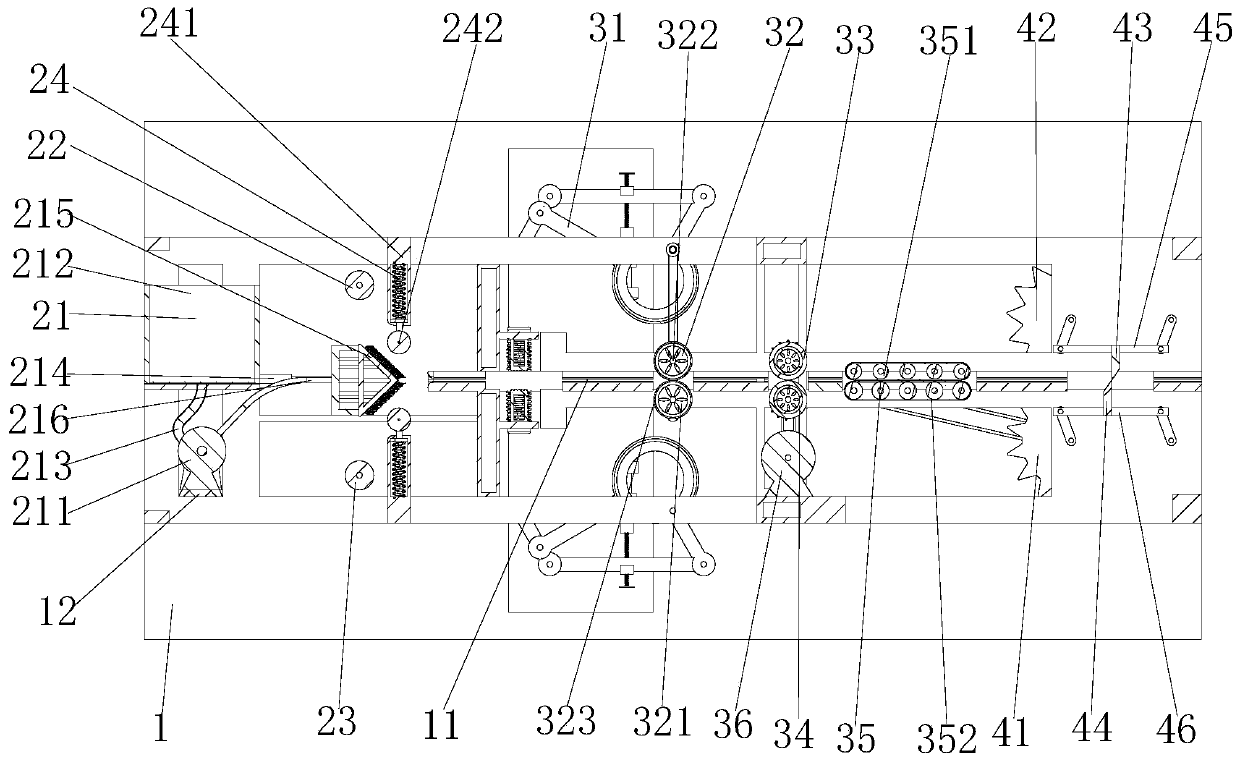

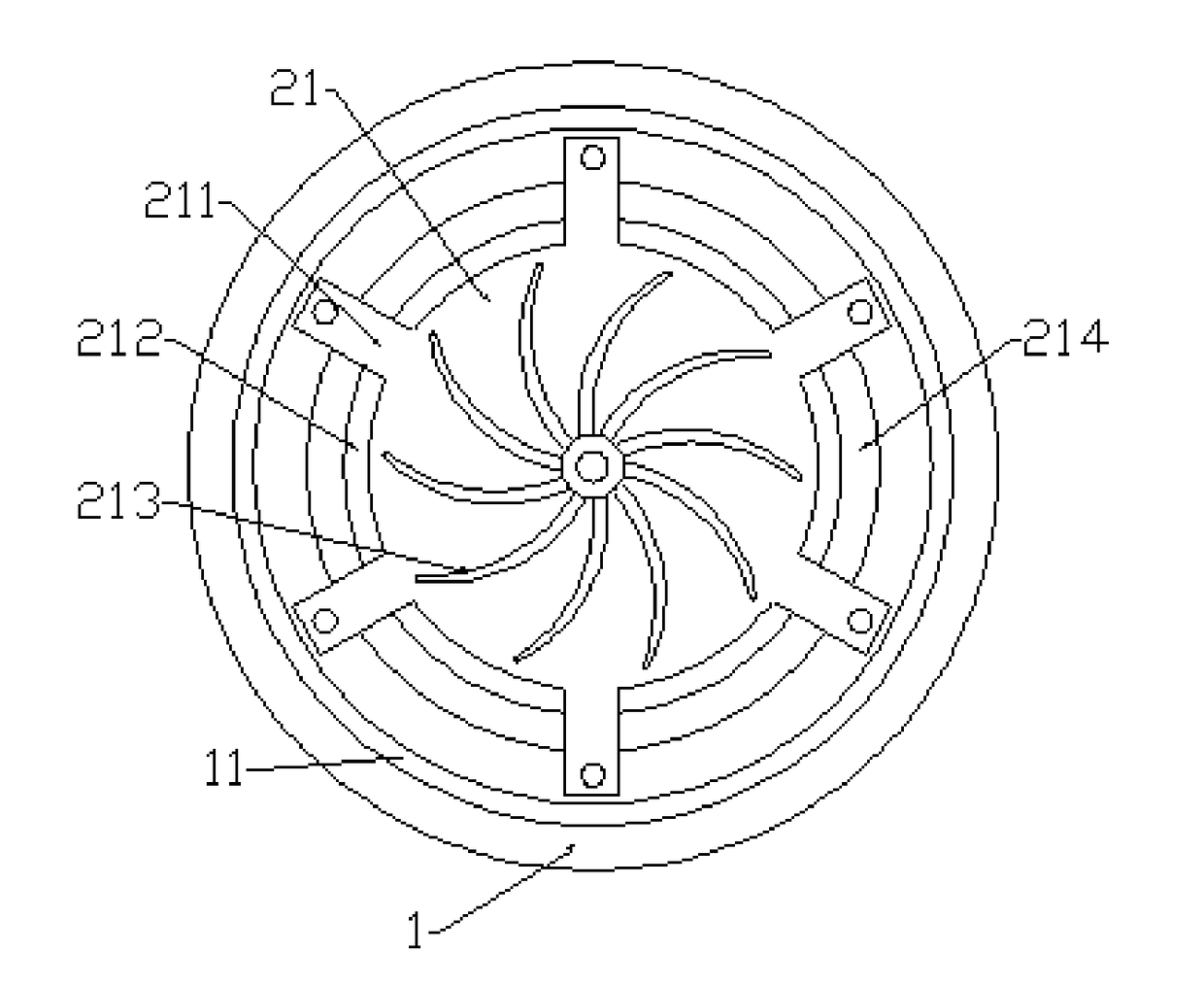

Heat-sealing treatment process for paper-plastic composite bag

ActiveCN111231420ALow degree of automationSave human effortBag making operationsPaper-makingProduction lineKraft paper

The invention relates to a heat-sealing treatment process for a paper-plastic composite bag. The process is characterized in that a heat-sealing treatment device for the paper-plastic composite bag isprovided, wherein the heat-sealing treatment device comprises an installation frame, a gluing device, a heat-sealing device and a cutting mechanism; a conveying channel is installed in the middle ofthe installation frame; the gluing device is installed at the left end of the installation frame; the heat-sealing device is installed in the middle of the installation frame; the cutting mechanism isinstalled at the right end of the installation frame; the conveying channel, the gluing device, the heat-sealing device and the cutting mechanism are positioned on the same horizontal line; and the heat-sealing device is in transmission connection with the cutting mechanism through a chain. The process can solve the problems that the existing composite paper which is used for manufacturing the paper-plastic composite bag and is compounded by plastic and kraft paper is finished by one production line in a plurality of steps in the production process including the processes of gluing, edge sealing, hot pressing, cooling, cutting, forming and the like, the process needs more manpower, the required production time is longer, the production efficiency is reduced, and the automatic production degree is low.

Owner:东营正宜包装股份有限公司

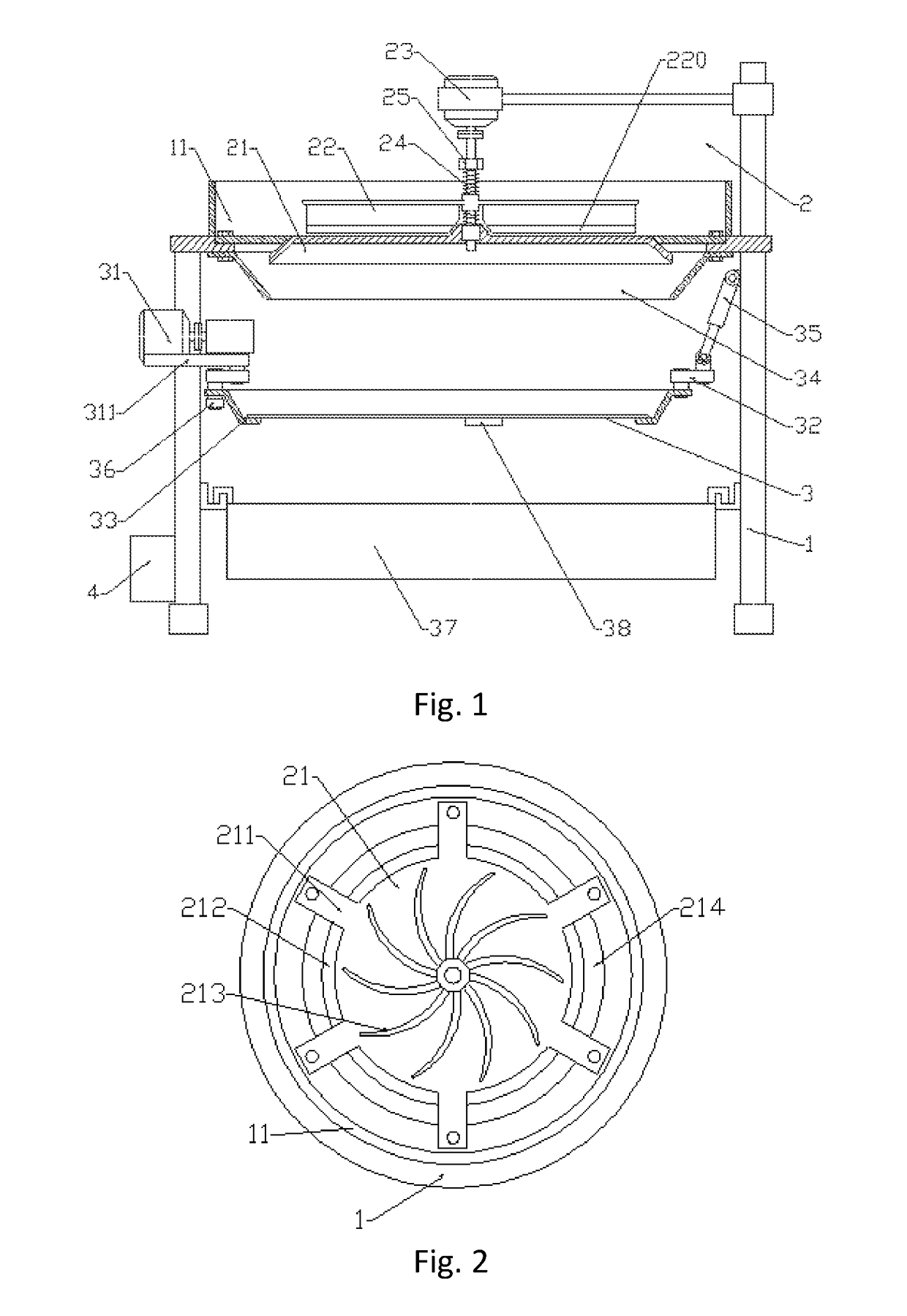

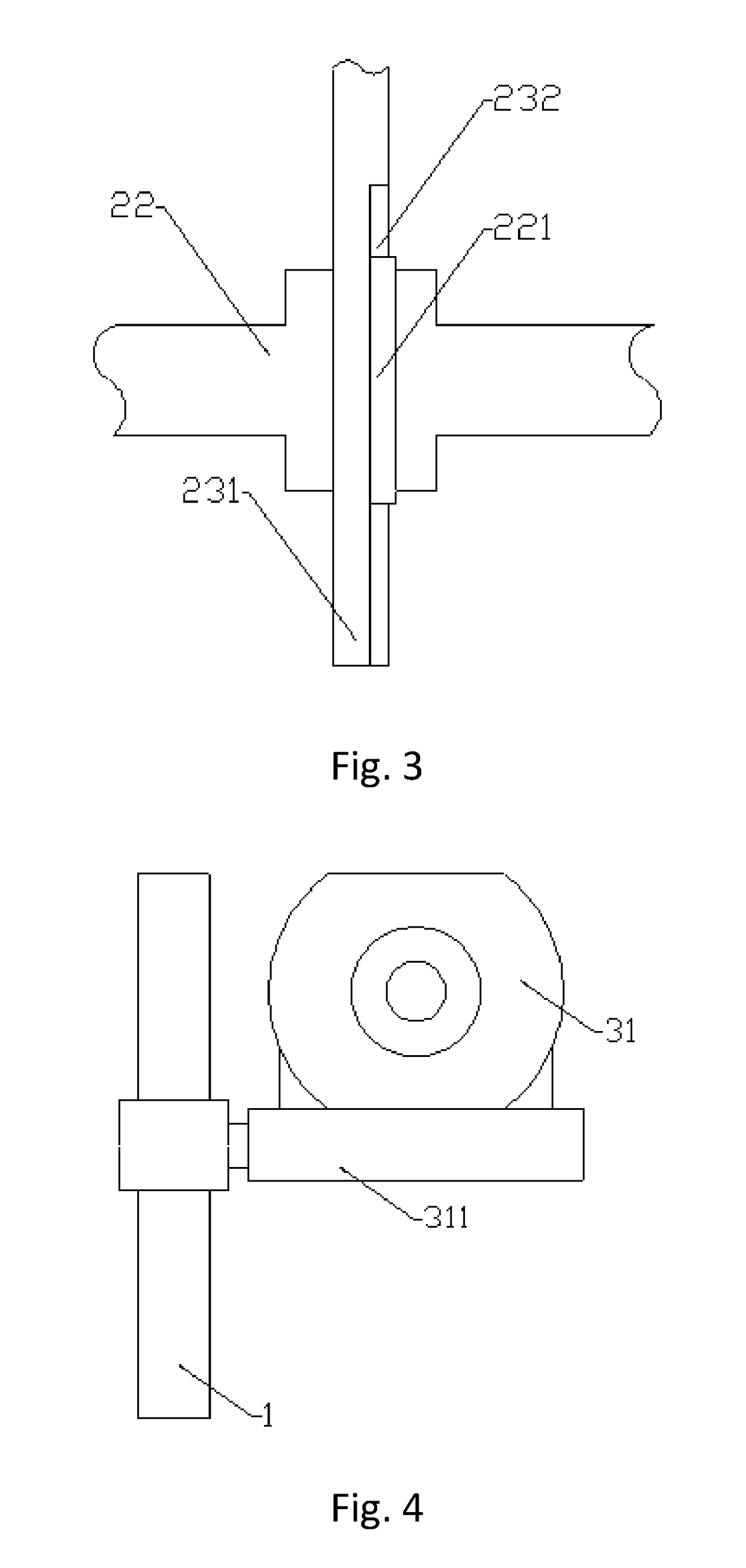

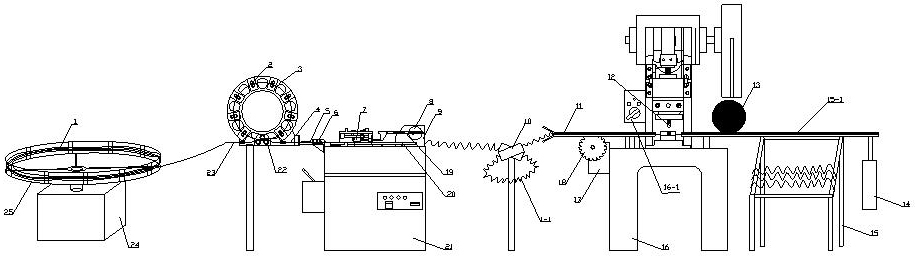

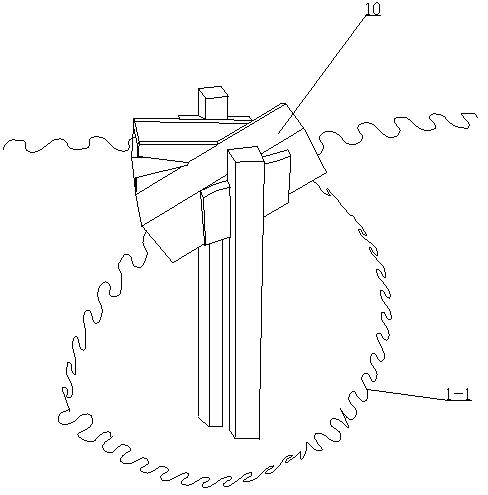

Weight sensing integrated bruising-sieving machine for automated tea processing

InactiveUS20180257086A1Increase profitIncrease the level of automationProgramme controlSievingEngineeringAutomation

The weight sensing integrated bruising-sieving machine for automated tea processing of the present invention comprises a frame, a bruiser device mounted on the frame, a sieving device and a PLC controller. The bruiser device comprises a bruiser disc, a number of bruiser blades, a first motor mounted on the frame, two pressure adjustment springs, and an adjustment bolt disposed on a first motor main axis. The bruiser disc is mounted on the frame through a number of supporter plates. The sieving device is disposed below the bruiser device. The sieving device comprises a second motor, a pair of crank mechanisms, a sieve, a sleeve for directing unloading of tea leaves, and an electrically actuated cylinder. An end of the sieve is interdrivably connected to the second motor through the crank mechanism, another end of the sieve is interconnected to an end of the electrically actuated cylinder through the crank mechanism. The structure of the weight sensing integrated bruising-sieving machine for automated tea processing of the present invention is sensible, simple, convenient to use, efficient and highly automated, effectively solving the problem of low efficiency and low degree of automation of traditional tea bruising machines

Owner:YEUNG CHI LAI

Multifunctional serpentine spring production device

ActiveCN102172746AQuality improvementLow degree of automationWire springsEngineeringMechanical engineering

The invention discloses a multifunctional serpentine spring production device comprising a payoff reel, a serpentine spring machine and a cutoff machine, wherein a straightener is arranged between the payoff reel and the serpentine spring machine, a buffer is arranged between the serpentine spring machine and the cutoff machine, and a blanking unit is connected to the rear part of the cutoff machine. The multifunctional serpentine spring production device has low degree of automation and manufacturing cost.

Owner:JIAXING TAIEN SPRINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com